Page 1

1

YAK 54

Aerobatic Model Aircraft

Assembly and Instruction Manual

Warning:

This radio controlled model is not a toy. It requires skill to fly and is not recommended for

the novice pilot. It should not be operated by children without the supervision of a suitably

experienced adult. Max-Thrust reserves the right to modify the specification of this model at

any time.

© Century UK Limited 2012. All rights reserved.

Page 2

2

1. Do not attempt to repair or modify this aircraft with non-factory parts.

2. Never fly this model over roads, railway lines, near to power lines, airports,

do not fly this model in excessively strong winds, in the rain, or thunderstorms.

3. Do not fly or launch the model towards people.

4. Keep hands and face away from rotating propeller at all times.

5. We strongly recommend that all fixings and fasteners used in the construction of this

model are checked regularly for integrity. Failure to do so could cause a crash or injury

to yourself or those around you.

6. We only recommend the use of 2.4GHz radio equipment with this model.

Disclaimer

Overview

Thank-you for purchasing this MAX-THRUST YAK 54 radio controlled model aircraft. The

YAK54 offers a stunning combination of terrific looks and sensational flight performance.

Manufactured from “EPOFLEXY” it is extremely robust, however, in the event of a “less than

perfect” arrival, we supply a range of spares to get you flying again in the shortest time. It is

capable of a wide range of amazing 3D aerobatic manoeuvres to thrill the experienced pilot,

but with reduced control throws it provides a solid and predictable flight performance,

perfect for the sports flyer. We are certain you will enjoy your new model, please take the

time to read this manual thoroughly and understand its contents completely prior to

commencing assembly.

Key Features

Powerful Brushless Motor

100A Brushless ESC

Efficient 2 Blade Propeller

Pre-Installed servos

“Live” Control Surface Hinging

Durable “EPOFLEXY” Construction

Steerable Tail Wheel

Superb Flight Performance

Specification

Wingspan: 1500mm

Length: 1210mm

Flying Weight: 2500g

Wing Loading: 57g/dm2

Motor: 4255 750KV Out-Runner

ESC: 100A

Servos: 5 x 17g Metal Geared

Battery: 3350mAh 14.8v Li-Po (Not Included, Power-Tech Recommended)

Safety Precautions

1. This radio controlled model is not a toy. Used incorrectly it is capable of inflicting serious

injury to persons or damage to property. The owner/pilot assumes all responsibility for any

damage to persons or property resulting from the use of this product.

2. The manufacturer and distributor decline all responsibility for any liability arising from use

of this product.

3. It is very important that you follow all instructions for assembling and setting up of this

model. Failure to do so could result in a loss of control and possibly a crash.

Page 3

3

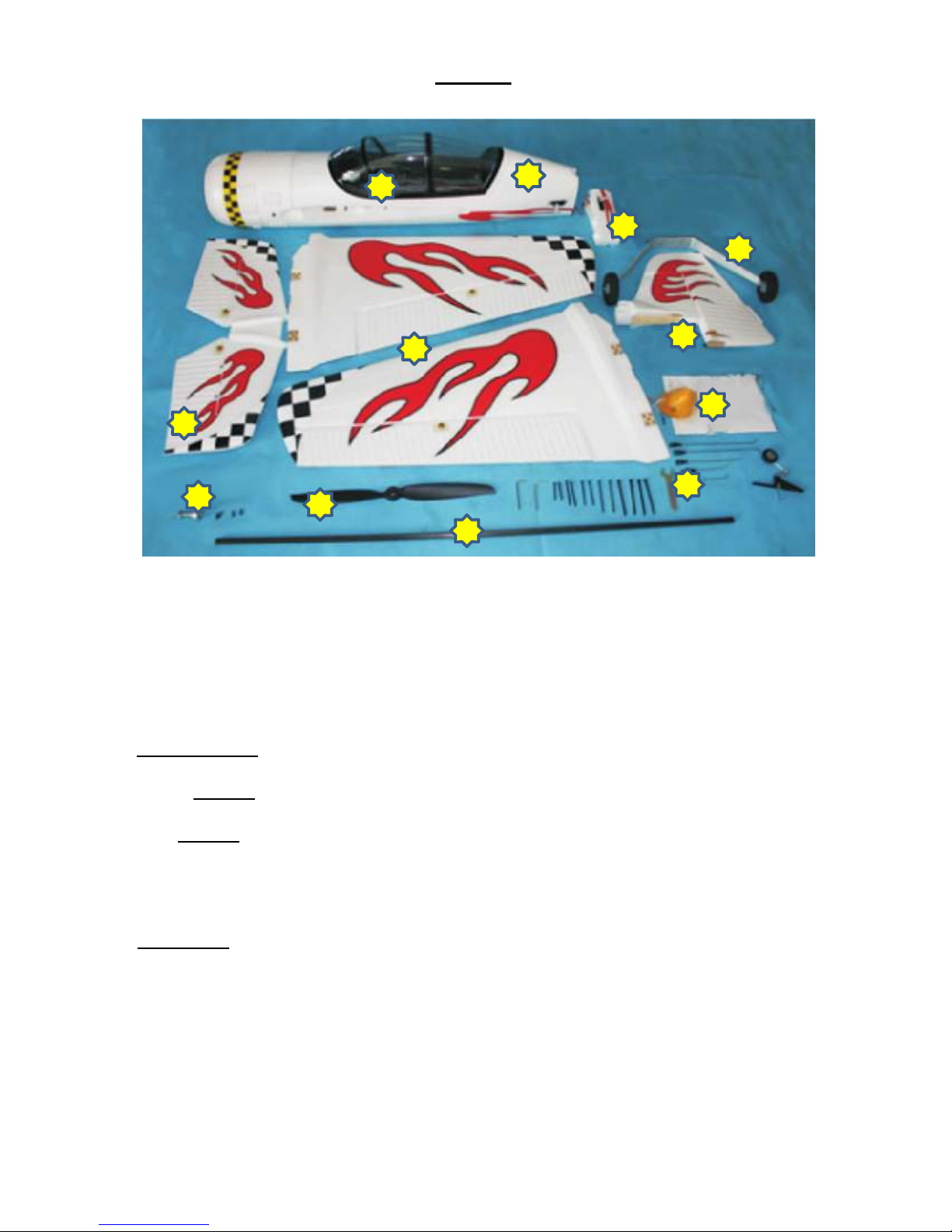

Parts List

.

1

2

3

4

5

6

7

8

9

10

11

12

1. Main Fuselage Section 7. Prop Adaptor

2. Tail Fuselage Section 8. Propeller

3. Wings 9. Wing Spar

4. Horizontal Tail Plane 10. Accessory Pack

5. Undercarriage 11. Spinner

6. Vertical Fin & Rudder 12. Clear Canopy

Note: Image shows model with all control horns fitted and decals applied.

Use of Adhesive:

Apply a thin film to one of the mating surfaces to be bonded. Applying light pressure, press the

two parts together and hold in position with masking tape until the adhesive has cured. Only

use a thin film of adhesive, excessive amounts do not provide any additional strength and add

unnecessary weight. Remove any paint from surfaces to be glued, as this could impair the

strength of the bond. Always check the fit and alignment of parts to be glued prior to the

application of adhesive.

Please Note:

“EPOFLEXY” is a very tough and durable material perfect for the manufacture of model aircraft.

When using screwed fixings with “EPOFLEXY” components it is important to tighten the screws

sufficiently to provide a firm fixing.

Excess tightening could result in the foam material becoming compressed, possibly damaging or

distorting the part. Take care to ensure that all screws are tightened sufficiently to provide a firm

fixing, but do-not over tighten. We recommend that all fixings are checked regularly for security

and safety purposes.

Page 4

4

Tools Required to Complete

1. Screwdrivers 4. Modelling Knife

2. Pliers 5. Measure or Rule

3. 10mm Spanner 6. Drill

Additional Items Required to Complete

3350mAh Li-Po 4S Battery Pack (Power-Tech Recommended)

Charger (Power-Tech C6, B606 or X-Drive 6 Recommended)

2.4GHz Transmitter (4 + Channel)

2.4GHz Receiver

Self-Adhesive Tape

Velcro Fastenings

Optional Pilot Figure (Dave Recommended. Part No. CUK-P-

DAVE)

Fuselage Assembly:

Glue the rear section of the fuselage to the main section with adhesive, (Image 1). Make certain

that both parts are lined up correctly, (Image 2). Hold in place with masking tape until the

adhesive has cured.

1

2

Horizontal & Vertical Stabiliser Assembly:

Offer up the horizontal and vertical stabilisers to the fuselage as shown in images 3, 4 & 5.

3

4

5

Page 5

5

Once you are certain that these

parts align correctly, apply adhesive

to the mating surfaces and secure

in position using two 3x60mm

screws, (Image 6). Use a thin film of

adhesive and remove any excess

carefully before the adhesive cures.

Horizontal & Vertical Stabiliser Assembly (continued):

6

Tail Wheel Assembly:

Position the tail wheel assembly as shown, ensuring the locating pin on the rudder passes

through the slot in the plastic horn of the assembly, (Image 7). Secure in position using two

3x30mm screws. (Image 8).

7 8

Control Horn Installation (Tail):

Position the rudder control horn as shown and

secure with 3x30mm screw, (Image 9+10). Be

careful not to over-tighten. Repeat the process

for the elevator control horns using two 3x25mm

screws, (Image 9 +11).

9

10

11

Page 6

6

Rudder & Elevator Control Rods:

Pass the “Z” bend of the rudder control rod through the hole in the rudder servo arm. Then

connect the plastic clevis to the rudder control arm as shown, (Image 12). Repeat the process

connecting the elevators to the elevator servos, (Image 12+13).

12 13

Main Landing Gear Installation:

Position the main landing gear on the fuselage, ensuring that the holes in the landing gear lineup correctly with the holes in the wood mount. Fix the gear in position using four 3x45mm

screws, (Image 14). Do not over-tighten.

Place the foam landing gear cover in position to ensure correct alignment, then remove the

paper backing from the self-adhesive tape, (Image 15). Secure the cover in position on the

fuselage, (Image 16).

14

15

16

Page 7

7

Cowl Assembly:

Referring to images 17, 18 + 19, use the adhesive to glue the scale exhaust stacks and

additional scale detailing in position.

17 18 19

Ensure that the cowl is correctly aligned, then fix

in position with the 2 x screws provided. The cowl

must be firmly secured, but be careful not to over

tighten, (Image 20).

20

Propeller:

Attach the aluminium prop adaptor to the brushless motor using the four screws provided,

(Image 21).

Mount the spinner back-plate on to the adaptor shaft, (Image 22), then slide the propeller

onto the shaft and secure in position with the washer and nut, (Images 23+24). Attach the

main spinner body to the back plate using the two fixing screws, (Image 25).

Please note: It is extremely important to regularly check the tightness of these fixings.

Failure to do so could result in a serious accident.

21

22

23

24

25

Page 8

8

Canopy:

A pilot figure is not included with this model. However if you wish to fit one we recommend

“Dave”, Part No. CUK-P-DAVE, (Image 27). Your choice of pilot should be fixed in position with

double sided self-adhesive tape prior to securing the canopy with the supplied fixing screws,

(Image 26).

26 27

Wing Assembly:

Position the aileron control horn as

shown and secure with 3x25mm screw,

(Image 28). Repeat the process for the

other wing panel.

28

Page 9

9

Aileron Control Rods:

Pass the “Z” bend of the aileron

control rod through the hole in the

aileron servo arm. Connect the

plastic clevis to the control arm as

shown, (Image 29). Fix the aileron

servo cover in position as shown

using adhesive, (Image 30 + 31).

Repeat the process for the other

wing panel.

29

30

31

Final assembly:

Pass the fibreglass tube through the fuselage as shown, (Image 32).

32

Slide a wing panel onto the fibreglass tube, (Image 33). Connect the aileron servo

plug to the aileron “Y” lead. Repeat the process for the other wing panel. Fix the

wings to the fuselage with the screws provided, (Image 34).

33

34

Then connect the two elevator servo plugs to the “Y” lead extension.

Page 10

10

Plug all the servo leads into your receiver (not

included). Ensure that you have the correct servo

plugged into the appropriate channel of your

receiver. Fix the receiver to the fuselage using

double sided tape, (Image 35). Be certain to

comply with any instructions from the

manufacturer of the receiver regarding aerial

positioning.

Final assembly (continued):

35

Battery Installation:

Check the position of your battery in the front of

the fuselage, secure using your preferred

retaining method, (Image 36).

36

Canopy Installation:

Fit the cockpit/canopy assembly as shown. This is retained with a magnetic catch,

however always use the elastic retaining band for additional in-flight security, (Image

37 + 38).

37 38

Page 11

11

IMPORTANT:

Check before flight:

Check that all control surfaces move in the correct directions without binding.

We recommend the following control surface deflections for initial flight testing:

Ailerons: 10mm deflection each way.

Elevator: 10mm deflection each way.

Rudder: 10mm deflection each way.

These values can be altered after initial test flights to suit the pilot’s personal preference.

Centre of Gravity:

328mm – 335mm back from front of cowling.

Loading...

Loading...