MC-2 SERIES

OPERATION MANUAL

MAXTHERMO

MAXTHERMO--

GITTA GROUP CORP.

GITTA GROUP CORP.

Version

Version

:

:

0711070001

0711070001

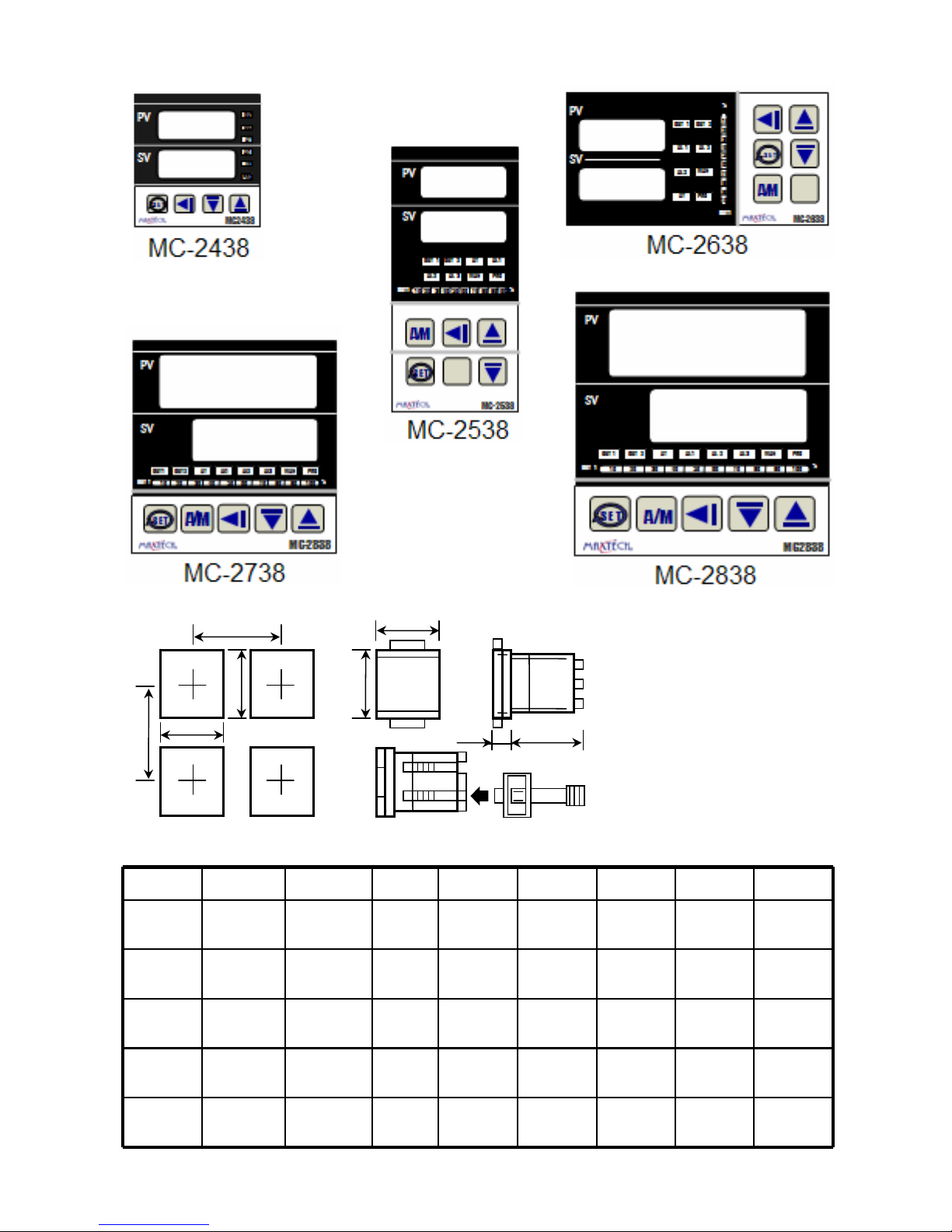

Dimension & Cut

Dimension & Cut--

out

out

…………………………………

…………………………………

Panel function

Panel function

…………………………………………

…………………………………………..

Operation flow

Operation flow

…………………………………………

…………………………………………..

How to set special function ....................................

How to set special function ......................................

Specification

Specification

……………………………………………

……………………………………………

Error information ..............................................

Error information ..............................................

........

........

Input selection table

Input selection table

…………………………………

…………………………………....

Alarm selection table

Alarm selection table

…………………………………

…………………………………..

P. 1

P. 2

P. 3

P. 7

P.11

P.11

P.12

P.17

Alarm action description

Alarm action description …………………………......

Order information

Order information …………………………………....... P.18

Hookup

Hookup

………………………………………………

………………………………………………

......

...... P.13

P.10

Available function for MC

Available function for MC--

2X38.

2X38.…………………..... P.19

CONTENT

CONTENT

Dimension & Cut

Dimension & Cut--

out

out

:

:

Model A B C D E F G H

MC 2438

44.5 44.5 65 70 50 50 80 17

MC 2538

44.5 90.5 111 116 50 96 80 17

MC 2638

90.5 44.5 65 70 96 50 80 17

MC 2738

68.5 68.5 89 94 74 74 80 17

MC 2838

90.5 90.5 111 116 96 96 80 17

A

C

D

B

F

E

HG

unit:mm

+ 0.5

-0

+ 0.5

-0

+ 0.5

-0

+ 0.5

-0

+ 0.5

-0

+ 0.5

-0

+ 0.5

-0

+ 0.5

-0

+ 0.5

-0

+ 0.5

-0

P.1

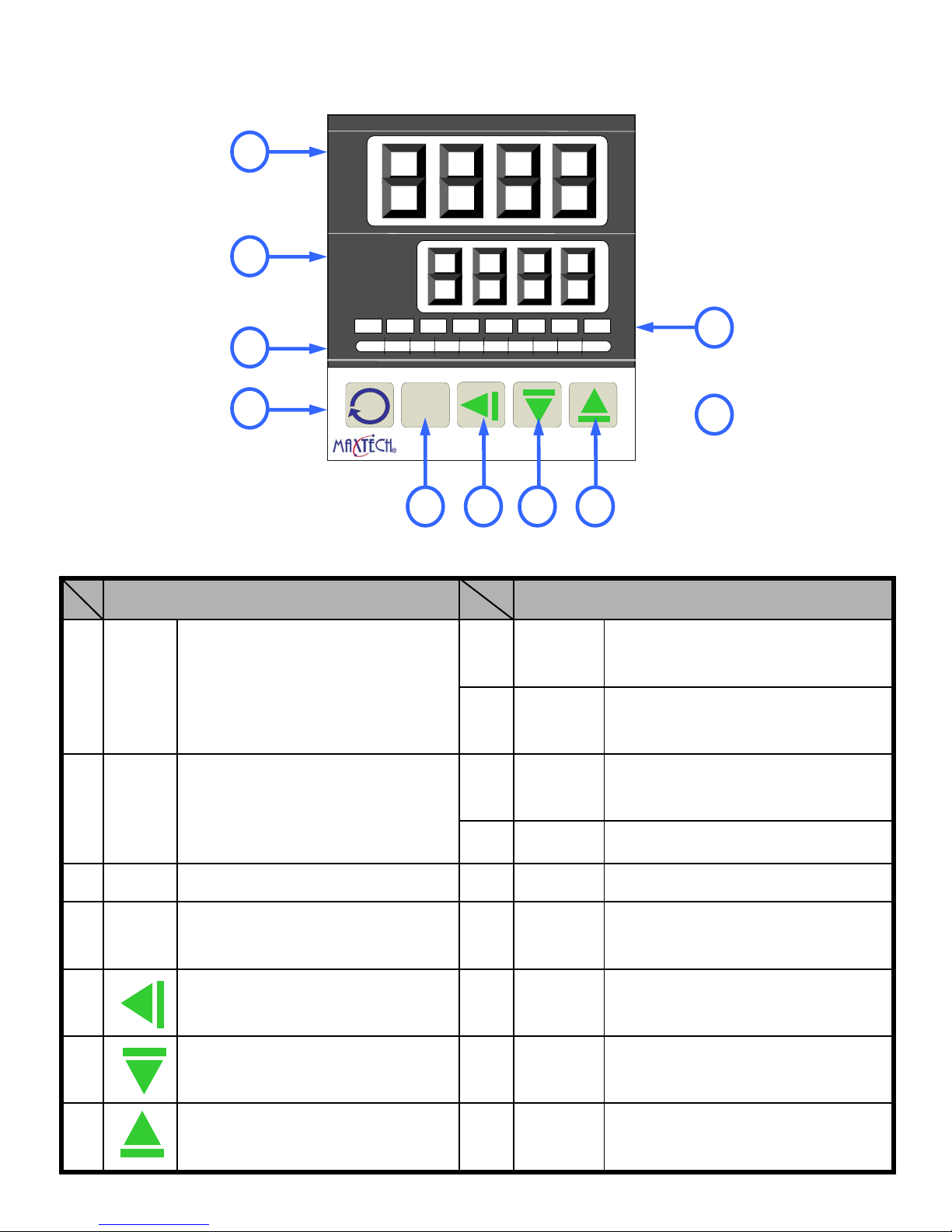

Panel function

Panel function

:

:

PV

SV

OUT1 OUT2 AT AL1 AL2 AL3 MAN PRO

OUT 1

%

SET

A/M

10 20 30 40 50 60 70 80 90 100

1

1

2

2

3

3

16

16

4

4

5

5

6

6

7

7

8

8

~

~

15

15

MC

MC--

2438/MC

2438/MC--

2538/MC

2538/MC--

2638/MC

2638/MC--

2738/MC

2738/MC--

2838

2838

MARKS/

MARKS/

DESCRIPTION

DESCRIPTION

MARKS/

MARKS/

DESCRIPTION

DESCRIPTION

8

8OUT 1Output1 action indication

1

1PVProcess value display

9

9OUT 2Output2 action indication

10

10 AT Auto tuning action indication

2

2SVSet value

11

11 AL 1 Alarm1 action indication

3

3 SET Set key & enter key

12

12 AL 2 Alarm2 action indication

4

4 A/M

Manual/auto

exchange key

13

13 AL 3 Alarm3 action indication

5

5 Shift key

14

14 MAN

Manual action

Indication

6

6

Down key and program

suspending key

15

15 PRO

Programming action

indication

7

7

Up key and Program

starting key

16

16

OUT 1%

Output percentage of out1

P.2

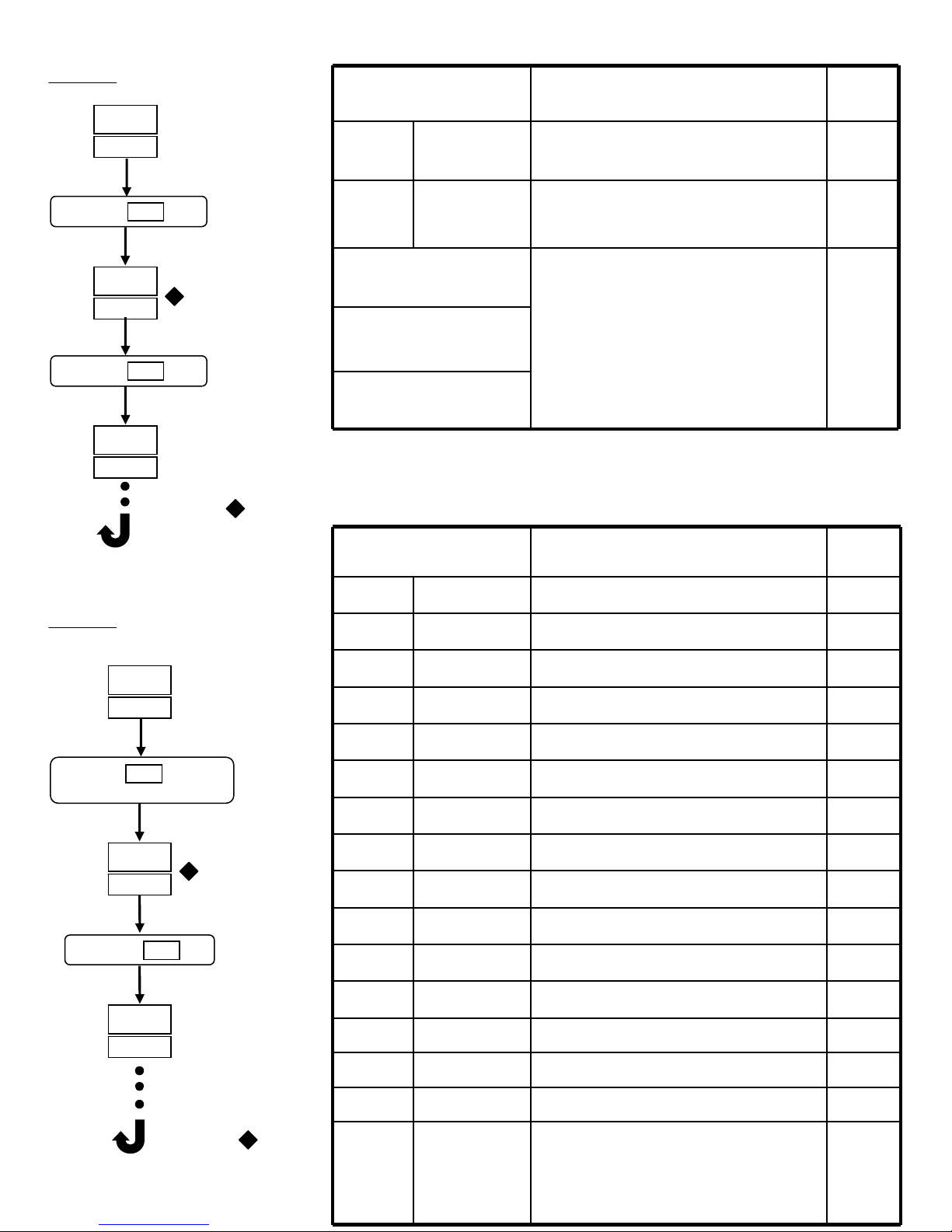

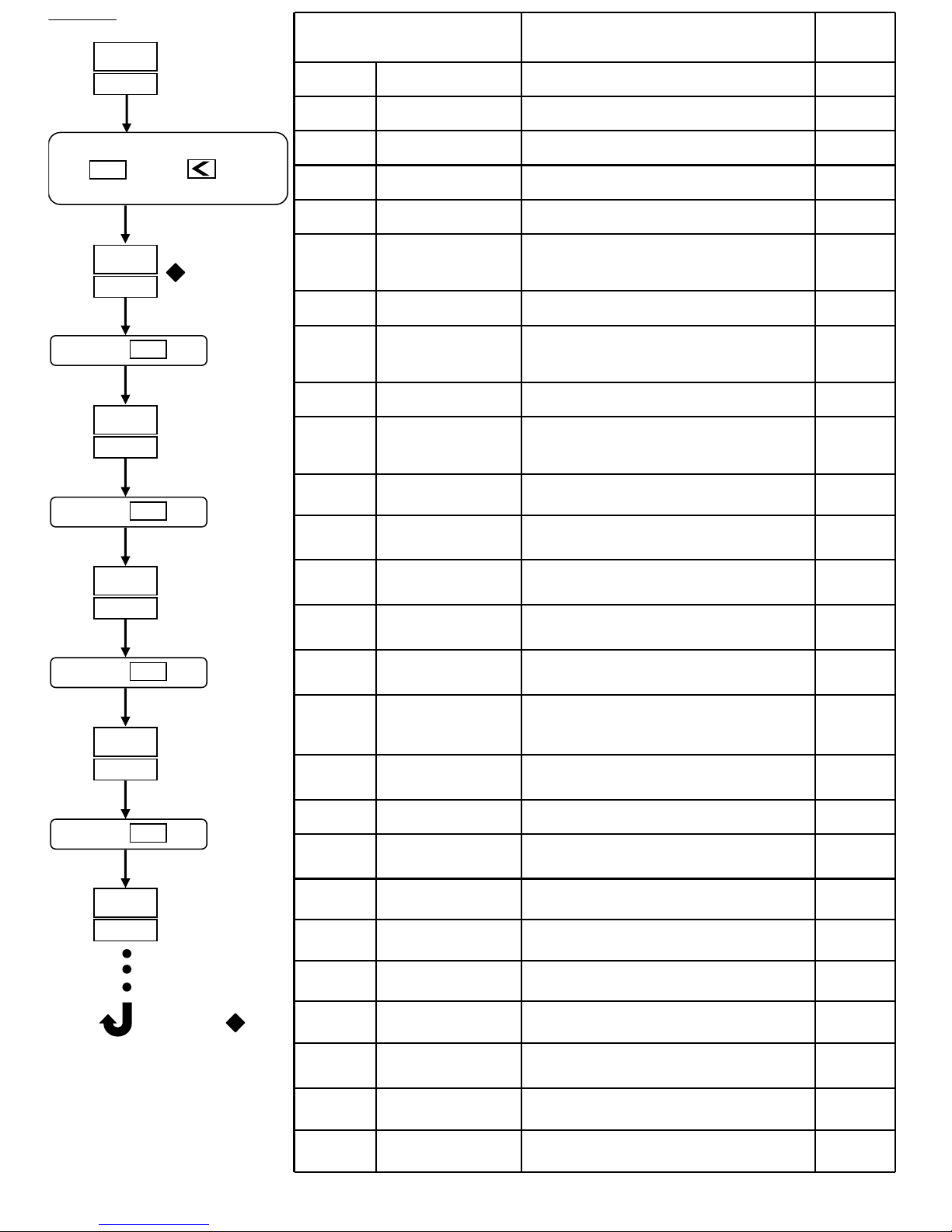

PV

SV

Repeat same steps

as above to display the

parameters listed at right.

Operating display

Level1 (User level)

press the key

for 4 seconds to level 2

SET

Level2 (PID level)

Press the key

27.5

27.5

PV

SV

Operating display

Name Description

Ex-

factory

OUTL

Output

percentage

Range of setting:0~100%

Skip

AT

Auto tuning

“RUN/NO”

to be used when setting PID

NO

AL1/RAMP/RATE

AL2/RAMP/RATE

AL3/RAMP/RATE

Alarm setting range: 0-100%F.S.

But if select ramp function, it will display ”rAmP”

setting range from 00.00 to 99.99℃ /min If

select soak function, it will display “AL1” setting

range from 00.00 to 99.99 min/sec or hour/min.

If select slaver function, it will display “rAtE”

setting range from 0 to 9999. If select program

segment ending alarm function, it will display

“AL1”, setting range from 1-8 or 1-16

(AL2 and AL3 are the same as above)

0

Name Description

Ex-

factory

P1

Main Control

Proportional Band

Range of setting:0-100%

ON/OFF at P=0

30

I1

Main Control

Integral Time

Range of setting:0-3600 Sec

Integral off at I=0

240

D1

Main Control

Derivative Time

Range of setting:0-3600 Sec

Derivative off at D=0

60

DB1

Main Control

Dead-band

Dead-band of main control

Range of setting:-10-+10

0

ATVL

Main Control

Auto tuning off-set

Range of setting:0-100% F.S.

0

CYT1

Main Control

Output cycle time

When output is SSR, it is set at 3, 4-20 mA is set at 1 but output

is relay usually it is set at 20. Range of setting:0-100 Sec

20

HYS1

Main Control

Hystersis

For ON/OFF control only

Range of setting :0.4-100

0.4

P2

Sub Control

Proportional Band

Range of setting:0-100%

ON/OFF at P=0

30

I2

Sub Control

Integral Time

Range of setting:0-3600 Sec

Integral off at I=0

240

D2

Sub Control

Derivative Time

Range of setting:0-3600 Sec

Derivative off at D=0

60

CYT2

Sub Control

Output cycle time

When output is SSR, it is set at 3, 4-20 mA is set at 1 but output

is relay usually it is set at 20. Range of setting:0-100 Sec

20

HYS2

Sub Control

Hystersis

For ON/OFF control only

Range of setting :0.4-100

0.4

RST1

Reset1

Adjust offset of output1 when I1 set at “0”

0

RST2

Reset2

Adjust offset of output2 when I2 set at “0”

0

AR

Anti- Integral

Setting range from 0-100 to limit integr al

100

LCK

Function Lock

LCK=0000, SV, level 1 & 2 open

LCK=0001, SV, open only

LCK=0010, SV, level 1 open

LCK=0011, lock all except LCK

LCK=0100, SV, level 1 & prog. open

LCK=0101, SV,level 1,2,3 open

LCK=1010, level 4 open only

0101

P1

30

PV

SV

SET

i1

240

Press the key

Repeat the same steps

as above to display the

parameters listed at right.

27.5

27.5

PV

SV

Out L

100.0

PV

SV

SET

At

no

PV

SV

Press the key

SET

Return to “ “

Return to “ “

Operation flow

Operation flow

:

:

P.3

Change LCK to 0101 then press

the key and key for

4 seconds to level 3

Operating display

Level3 (Input level)

Name Description

Ex-

factory

Inp1

Main input selections Select the input range, refer to input selection

K1

dP

Decimal point Set the position of decimal point

000.0

LSPL

Lower set point limit Set lower point within INP1

0.0

USPL

Upper set point limit Set highest point within INP1

400

ALd1

Alarm mode of AL1 Range of setting; oo~19

11

ALt1

Alarm 1 time set

It is used in program function. Range:

00~99.59mm, 0=flicker alarm, 99.59=continued

alarm, others=on delay time

99.59

ALd2

Alarm mode of AL2 Range of setting: 00~19

11

ALt2

Alarm 2 time set

It is used in program function. Range:

00~99.59mm, 0=flicker alarm. 99.59=continued

alarm, others=on delay time.

99.59

ALd3

Alarm mode of AL3 Range of setting: 00~19

11

ALt3

Alarm 3 time set

It is used in program function Range

00~99.59mm 0=flicker alarm 99.59=continued

alarm, others=on delay time

99.59

HYSA

Hystersis of alarm Range of setting: 0.4~100.0

0.4

CLO1

Output1 zero set

Calibrate the low value of output1

Range of setting: 0-2000( current output only )

400

CHO1

Output1 span set

Calibrate the high value of output1

Range of setting; 0-2000( current output only )

2000

OPrL

Transmitter zero set

Calibrate the low value of transmitter

Range of setting; 0-2000

400

OPrH

Transmitter span set

Calibrate the high value of transmitter

Range of setting; 0-2000

2000

rUCY

The time from open

to close of motor

Full run time of proportional motor, Range of

setting: 0~150Sec

5

WAit

Use in program for

SV wait PV

0=No wait

Other=Wait Volume

0.0

idNO

ID number Communication ID number

1

bAUd

Baud-rate

UART baud rate selection

Range of setting:110-38.4K BIT/sec

2.4k

SVOS

Compensate SV Range of setting:-100.0~100.0

0.0

PVOS

Compensate PV Range of setting:-100.0~100.0

0.0

Unit

Unit of PV ﹠SV Range of setting: C,F,A (analog)

℃

SOFt

Soft filter

Adjust the response time of PV, the little the

faster Range of setting:0~254

200

CASC

Cluster control

(don’t care)

Range of setting:0~1000

0.0

TOH

The time for loop

open

Range of setting:0~120 sec.

60

TsH

The time for loop

short

Range of setting:0~120 sec.

20

Press the key

Repeat the same

steps as above to

display the parameters

listed at right.

27.5

27.5

PV

SV

InP1

K1

PV

SV

SET

dP

000.0

PV

SV

SET

Press the key

SET

LSPL

000.0

PV

SV

Press the key

SET

USPL

400.0

PV

SV

Press the key

SET

ALd1

000.0

PV

SV

Return to “ “

P.4

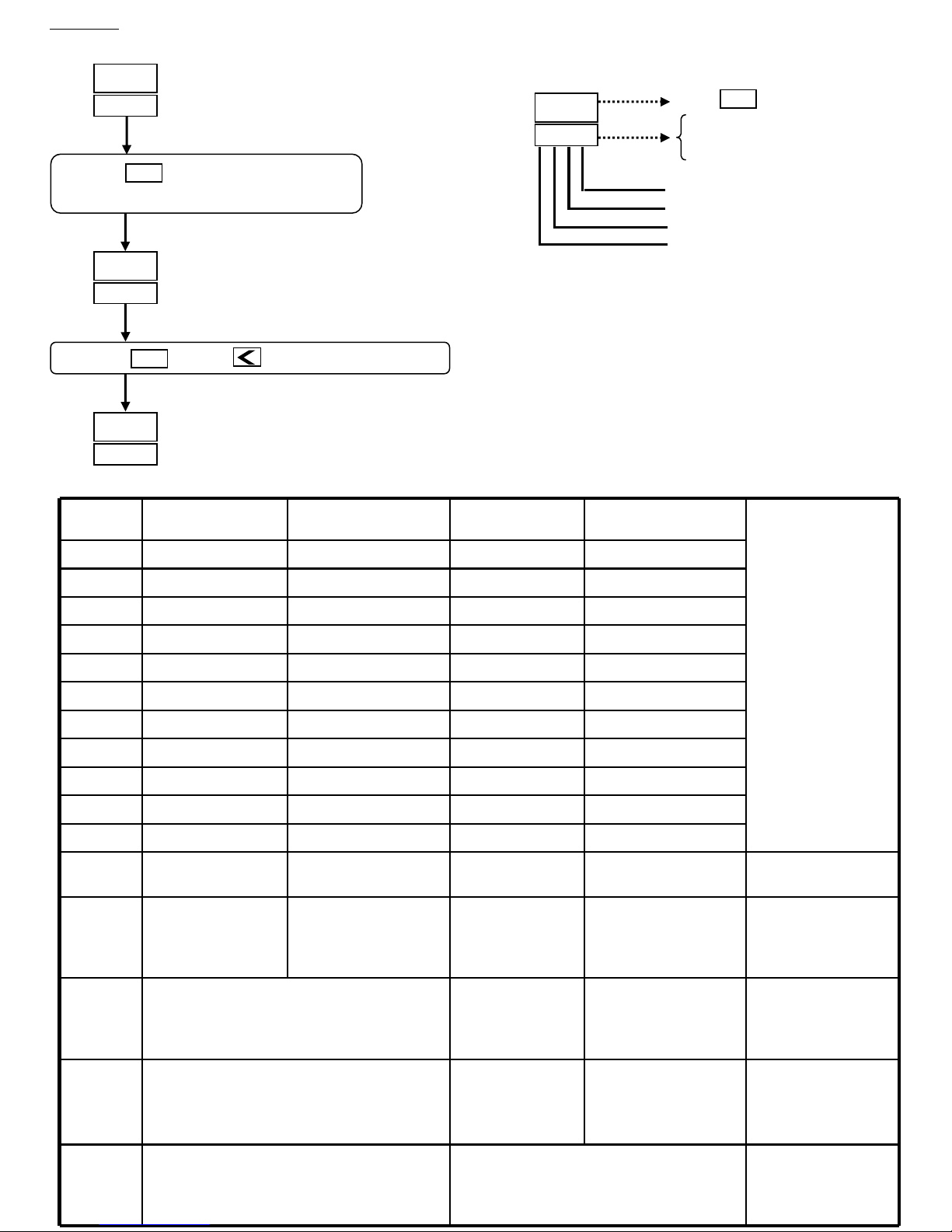

SET. 3 Third digit

Operating display

Level4 (Set level)

Press the key and key for 4 seconds to level 4

27.5

27.5

PV

SV

LCK

1010

PV

SV

SET

SEtl

0101

PV

SV

Press the key for 4 seconds

to level 2 and set “1010” in “LCK”

SET

Repeat same steps

as above to display the

parameters listed at below.

Press key to change SET 0-9

SEtl

0 1 0 1

a. Example:

PV

SV

SET

0=lock (skip)

1=open (display)

SET. 1 First digit

SET. 2 Second digit

SET. 4 Fourth digit

Parameter

Display

4thdigit 3rddigit 2nddigit 1stdigit

SEt1

AL2 AL1 AT OUTL

SEt2

D1 I1 PI AL3

SEt3

HYS1 CYT1 ATVL DB1

SEt4

CYT2 D2 I2 P2

SEt5

AR REST2 REST1 HYS2

SEt6

ALT1 ALD1 LSPL/HSPL DP

SEt7

ALT3 ALD3 ALT2 ALD2

SEt8

RUCY OPRL/OPRH CL01/CH01 HYSA

SEt9

PVOS SVOS IDN0/BAUD WAIT

SEtA

TSH CASC SOFT UNIT

SEtb

TOH

If the digit set at

“0’ the parameter

is skipped.

If the digit set at

“1” the parameter

is opened

.

PrOG

0:Program no repeat

1:Program repeat

0:Without power failure

1:With power failure

0:Start from “0”

1:Start from “PV”

0:Alarm during program

1:Program ending alarm

For Program

function only

FUNC

0:50Hz

1:60Hz

0:Without loop alarm

1:With loop alarm

0:Without master-

slaver function

1:With master-

slaver function

0:With RS485

1:With TTL

(use for master-slaver)

TIm2

00:Others (Relay & SSR Output)

01:Current output or PWM output

10:Transmission output

11:Communication output

0:PV transmission

1:SV transmission

0:Without hold function

1:With hold function

mOdE

00:PV/SV display

01:Program function

10:Ramp and soak

11:Remote SV

0:Hour/min for time

1:Min/sec. for time

0:Without input2

1:with input2

Outy

00:Nomal output

01:Motor valve

10:Single phase PWM output

11:Three phase PWM output

00:non

01:heat

10:cool

11:dual output

b. Function of set:

Password

This level is for the distributor use only

Name Description

PtN

Set program Pattern

Set pattern “1” at first for 8 segments then set pattern

“2’” for other 8 segments, pattern 1 & 2 can be

performed separately or be linked to make total 16

segments (steps). If it needs to link, set “PIN” to “0”

after pattern 1& 2 be set. Range of setting : 0-2

SEG

Program segment display Range of setting : (1-0)~(2-8)

tMEr

Program timer display Process time display only

SV-1

Set volume for seg.1 Range of setting : LSPL -USPL

tM-1

Set time for seg.1 Range of setting : 0~99 hours 59 min

OUT1

Set output for Seg.1 Range : 0~100%

SV-2

Set volume for seg.2 Range of setting : LSPL -USPL

tM-2

Set time for seg.2 Range of setting : 0~99 hours 59 min

OUT2

Set output for Seg.2 Range : 0~100%

SV-3

Set volume for seg.3 Range of setting : LSPL -USPL

tM-3

Set time for seg.3 Range of setting : 0~99 hours 59 min

OUT3

Set output for Seg.3 Range : 0~100%

SV-4

Set volume for seg.4 Range of setting : LSPL -USPL

tM-4

Set time for seg.4 Range of setting : 0~99 hours 59 min

OUT4

Set output for Seg.4 Range : 0~100%

SV-5

Set volume for seg.5 Range of setting : LSPL -USPL

tM-5

Set time for seg.5 Range of setting : 0~99 hours 59 min

OUT5

Set output for Seg.5 Range : 0~100%

SV-6

Set volume for seg.6 Range of setting : LSPL -USPL

tM-6

Set output for Seg.6 Range of setting : 0~99 hours 59 min

OUT6

Compensate PV Range : 0~100%

SV-7

Set volume for seg.7 Range of setting : LSPL -USPL

tM-7

Set time for seg.7 Range of setting : 0~99 hours 59 min

OUT7

Set output for Seg.7 Range : 0~100%

SV-8

Set volume for seg.8 Range of setting : LSPL -USPL

tM-8

Set time for seg.8 Range of setting : 0~99 hours 59 min

OUT8

Set output for Seg.8 Range : 0~100%

Operating display

Program level :

Press the key

Repeat the same steps

as above to display the

parameters listed at right.

27.5

27.5

PV

SV

OUTL

100.0

PV

SV

SET

At

no

PV

SV

Press the key

SET

AL1

0.0

PV

SV

Press the key

SET

AL2

0.0

PV

SV

Press the key

SET

AL3

0.0

PV

SV

Return to “ “

Ptn

1

PV

SV

Press the key

SET

SEG

1

PV

SV

Press the key

SET

P.6

Press the key

SET

1.Dual output :

It needs installing hardware then enter level 4 (set level) and set “OUTY. 1st& 2nddigit” to “11”. Output 1 is for heating

and output 2 is for cooling in the meantime. If it needs a gap, DB1 is for setting.

2.Loop broken alarm (loop short or loop open alarm):

It doesn’t need installing hardware but has to modify software as following steps.

a. Set “ALD1/ALD2/ALD3” to “18” in level 3 and enter level 4 to set “FUNC. 3

rd

digit” to “1”

b. Open “’AL1/AL2/AL3” in level 3 and set high/low/ alarm value.

c. Open “TOH, TSH” in level 3 and set the time of loop short and loop open.

Principal:

※ When PV is lower 2 ℃ than low alarm set value within TSH time or PV is higher

2 ℃ than high alarm set value

within TSH time, it is loop short.

※When PV is higher than high alarm set value, but it doesn’t drop 0.5

℃ in TOH time or PV is lower than low alarm

set value but it doesn’t raise 0.5

℃ in TOH time, it is loop open.

3.Program:

It doesn’t need installing hardware but has to modify software as following steps.

a. Open “MODE” in level 4 and set “mode. 3

rd

& 4thdigit” to “01” then the parameter of process will be displayed in

window.

b. Change “LCK” to “0100” then it can set program parameter. The program has 2 patterns, each pattern contains 8

segments. 2 patterns can be linked together to 16 segments.

c. The “PTN” parameter set to “1”, it will display first section of 8 segments. The “PTN”parameter set to “2” it will

display second section of 8 segments. If “PTN” is changed to “0” after setting PTN1 & PTN2, the program will be

linked together to 16 segments.

d. Each segment can be arranged as ramp or soak; ramp is for changing SV with time while soak is for keeping SV

with time.

30 Min 30 Min 20 Min 30 Min 20 Min 40 Min 30 Min 20 Min

(℃) 500

400

300

200

100

0

30 Min

TM-1 TM-2 TM-3 TM-4 TM-5 TM-6 TM-7 TM-8 TM-1

SV-1 SV-2

SV-3

SV-4

SV-5 SV-6

SV-7 SV-8

SV-1

Ramp

Soak

How to set special function

How to set special function

:

:

Pattern 1 Pattern 2

db

SV

100%

0%

coolingheating

0

P.7

e. If next segment’s “OUT” set to “0”, the program will end at this segment. If the program needs repeat, it has to

enter level 4 and set “PROG. 4th digit” to “1”.

f . Function key for program:

In the intial window status, pushing ”up” key for 4 sec., the program start and “pro” LED flickers, pushing

“down” key for 4 sec., the program pause and “PRO” LED keeps light.

If pushing “UP” key first then pushing key again, the program will jump to next segment, but if pushing

“down” key first then pushing key again, the program will end immediately and “PRO” LED is “off”.

g. Alarm function for program:

1).Segment ending alarm

“AL1/AL2/AL3” & “ALD1/ALD2/ALD3” in level 3 must be set.

example: Set “ALD1” to “07”

Set “AL1” to “2”, the alarm function will perform in segment 2

Set “ALT1” to “00.20 M/S.” the alarm will perform 20 sec., 00.20 H/M. the alarm will perform 20 MIN If set

it to “0” the alarm is in flicker but if set it to “99.59” the alarm is in continuance.

2).Program ending alarm:

“ALD1/ALD2/ALD3” in level 3 must be set.

example: Set “ALD2” to “17”, if the “PROG. 1

st

digit in level 4” set “1”, the alarm2 will perform when the program

end, but if the “PROG. 1

st

digit” set “0”, the alarm2 will perform during program process then it stops

when the program end.

h. Other functions:

1).Power failure function:

If the “PROG. 1

st

digit” set “1”, it has power failure function the program will perform again from stopped

segment when the power is recovered. On the contrary, if the “PROG. 1

st

digit ” set “0”, it hasn’t power failure

function, the program always perform again from first segment when the power is recovered.

2).When the program start from first segment, if “the PROG. 2

nd

digit” set “1”, it will start according to “PV” but if

the “PROG. 2

nd

digit” set “0”, it will start according to “0”, if it is set to start from PV, the controller will check PV

& SV-1 which is small if PV is small it will start from PV but if SV-1 is small it will start from SV-1.

3).Wait function:

If the “WAIT” parameter in level3 set “0”, it has not wait function, but if it sets other volume the SV will wait the

PV when the PV exceed the SV over the set volume.

4.Remote SV function:

a. It needs modifying hardware (contact the distributor)

b. Set the “MODE. 1

st

digit” to “1” and the “MODE. 4th& 3rddigit” to “11” in level 4.

5.Master and slaver function:

a. Both master and slaver need installing TTL communication hardware.

b. The master unit must be with program function, then setting its “TIM2. 4

th

& 3rd” to “11” and “FUNC. 1

st

digit” to “1” in level4. in addition to set “IDNO” parameter to “0” and “BAUD” parameter with ideal volume in level3.

c. The slaver unit must be without program function, then setting “TIM2. 4

th

& 3rddigit” to “11”, “FUNC. 2nddigit” to

“1” “MODE. 4

th

& 3rddigit” to “11” and “MODE. 1stdigit” to “0” in level4 in addition to set among

“ALD1/ALD2/ALD3” to “0” in level3. In this case one among “AL1/AL2/AL3” will convert to “RATE” function.

SET

SET

P.8

d. The “RATE” parameter is for setting how many percentage of SV in Slaver unit according with master unit. For

example, if the master SV is “1000” then we set “RATE” to “90” in slaver, the SV of slaver will be “900”.

e. One set of alarm can be used for “RATE” only.

6.Ramp and Soak function:

It doesn’t need installing hardware but has to modify software as following steps.

a. Set “MODE. 4

th

& 3rddigit” to “10” in level4.

b. For ramp function , it needs setting one among “ALD1/ALD2/ALD3” to “9” then one among “AL1/AL2/AL3” will

convert to “ramp” function. Setting unit for “RAMP” is “xx.xx

℃/MIN.”, and the PV will raise according to setting

volume until it finishes.

c. For soak function, it needs setting “MODE. 1

st

digit” to “0” for H/M or “1” for M/S, and one among “ALD1/ALD2

/ALD3” must be set to “19”, then one among “AL1/AL2/AL3” will convert to “soak” function and a time can be set

among “AL1/AL2/AL3”. When the PV reach the SV, it starts time counting, in the meantime one among “AL1/AL2

/AL3” and time will display alternately. When the time reach setting volume, the alarm perform and the control

output stop.

d. One set of alarm can be used for ramp and one set of alarm can be used for soak only.

7.Motor valve control function:

a. It needs installing hardware. (contact the distributor).

b. Set “MODE. 1

st

digit” to “1” in level4 to open second input.

c. Set “OUTY. 4

th

& 3rddigit” to “01” in level4 to open motor valve control function.

d. Set “CYT1” to open/close cycle time of motor valve in level2 and “RUCY” to time from open to close of motor valve

in level3.

e. The LED bar on the panel will display the position of motor valve.

f . Second input is for feedback use, it has 4~20mA,0~10mA,0~10VDC,2~10VDC,0~5VDC,1~5VDC or potentiometer.

8.SCR control output (resistance load only):

a. It needs installing hardware (contact the distributor).

b. Set “TIM2. 4

th

and 3rddigit” to “01” in level4 to open PWM output function.

c. Set “OUTY. 4

th

and 3rddigit” to “10” in level4 to open single phase function or “11” to open three phase function.

9.Analogue output function:

a. It needs modifying hardware, there are 4~20mA, 0~20mA, 0~5VDC, 0~10VDC, 1~5VDC, 2~10VDC. (contact

the distributor).

b. Set “CLO1” to lowest limit in level3. For exam ple, if lowest output is 4mA, then set it to “400”.

c. Set “CHO1” to highest limit in level3. For example, if highest output is 20mA, then set it to “2000”.

d. Set “TIM2. 4

th

and 3rddigit” to “01” in level4 to open PWM function. (Relay & SSR Output set “00”)

e. Set “OUTY. 4

th

and 3rddigit” to “00” in level4.

10.Analogue input (Input 1 only):

a. It needs modifying hardware, there are 0~10mA,4~20mA,0~1VDC,0~5VDC,0~10VDC (contact the distributor).

b. Set “INP 1” to “AN1~4” in level3, and set “LSPL” to lowest range, “USPL” to highest range in level3.

c. Set “LCK” to “0111” in level 2.

d. Push key and key for 4 sec. until “INPL” is displayed on upper window.

e. Send input signal for lowest range until display is stable, then push key to enter.

SET

SET

P.9

f . Send input signal for highest range when upper window displays “INPH”.

g. Push key when “INPH” is stable.

11.Transmitter output:

a. It needs installing hardware (contact the distributor).

b. Set “TIM2. 4

th

and 3rddigit” to “10” in level4 to open transmitter function.

c. Set “TIM2. 2

nd

digit” to “0” in level4 for PV transmitter or to “1” for SV transmitter.

d. Set “OPRL” to lowest range and “OPRH” to highest range in level3.

12.Communication function:

a. It needs installing hardware (contact the distributor).

b. Set “FUNC. 1

st

digit” to “0” to RS485 function.

c. Set “TIM2. 4

th

& 3rddigit” to “11” to open communication function.

d. Set “IDNO” parameter to address and “BAUD” parameter to ideal volume in level3.

e. Refer to communication protocol.

13. Auto/manual switch function:

a. It doesn’t need installing hardware.

b. Push key for 4 sec. under auto status, it converts to manual control function. In this case, the “MAN” LED

light and the volume of output will be controlled by “OUTL” which can be adjusted with or key to increase

or decrease. For example, set “OUTL” to “50”, the output volume always keep 50% until “OUTL” is changed.

c. Push key for 4 sec. under manual status, it converts to auto control function.

d. MC-2438 series don’t have this function.

SET

A / M

A / M

P.10

1).I

1).I

nput (Main)

nput (Main)

:

:

1.T/C Thermocouple S, B, R, K, E, J, W, N, Cu or

PT100,selectable.

2.DC V : -10~10mV, 0~10mV, 0~20mV, 0~50mV,

0~1V, 0~5V, 0~10V selectable.

3.DC mA : 0~20mA, 4~20mA, selectable or others to

be ordered.

4.Input (Sub) :

Remote set: -4~20mA, 0~10V to be ordered.

2).Output

2).Output

:

:

1.Relay output : SPST, SPDT, 5A/240VAC.

2.SSR drive : 20mA/20VDC.

3.Current proportioning output : 4~20mA adjustable

(Load max 800Ω).

4.3 wire system motor valve control 5A/240VAC

(with feed back)

5.Alarm : SPST 5A/240VAC for MC-2438, 2738

SPDT 5A/240VAC for other models.

3).Control mode

3).Control mode

:

:

1.ON/OFF : sensitivity adjustable

2.P (Proportional) : 0~100% adjustable

3.I (Integral) : 0~3600 sec adjustable

4.D (Derivative) : 0~3600 sec adjustable

5.Proportioning cycle time : 0~100 sec adjustable

(mA=1, SSR=3, RY>=20)

Specification

Specification

:

:

4).Electrical characteristics

4).Electrical characteristics

:

:

1.Working voltage : AC85~265V, DC15~50V

2.Power consumption : 2VA

3.Isolated resistance : 20MΩup

4.Dielectricity strength : AC2000V/50/60Hz

1min

5.Sampling time : 250m sec

6.Accuracy : +-0.2% of full range +-1 digit

5).Mechanical characteristics

5).Mechanical characteristics

:

:

1.Working temperature : -10~+50°C

2.Storage temperature : -10~+70°C

3.Working humidity : 50~+85%RH

4.Weight: :

MC-2438 about 190g

MC-2538 about 310g

MC-2638 about 310g

MC-2738 about 310g

MC-2838 about 410g

Parameter

Display Code

Description

ln1E Open circuit of main control sensor

* AdCF A/D convector failed.

* CJCE Cold junction compensation failed.

ln2E Open circuit of sub control sensor.

uuu1 PV exceeds USPL

nnn1 PV und er LS PL

uuu2 Input signal of sub control exceeds the upper limit.

nnn2 Input signal of sub control under the upper limit.

* rAmF RAM failed.

lntF Interface failed.

AutF Auto tuning failed.

NOTE: If the “* ”marked error occurs, the Temperature Controller need repair.

Please send it to the nearest sales office or retail dealer.

Error information:

Error information:

Type Code Range

S S 0~1600℃

B b 0~1800℃

R r 0~1700℃

k1 0.0~400.0℃

K

k2 0~1300 ℃

E1 0.0~300.0℃

E

E2 0~600℃

T t 0.0~400.0℃

J1 0.0~400.0℃

J

J2 0~800℃

WU3-RE25 w 0~2000℃

n n 0~1300 ℃

Pt1 -199.9~199.9 ℃

PT

Pt2 -200~800 ℃

CU50 CU50 -50.0~150.0 ℃

AN1 An1 0~20MV/-1999~9999

AN2 An2 0~50MV/-1999~9999

AN3 An3 0~5V/-1999~9999

AN4 An4 4~20MA/-1999~9999

Input

Input

selection table:

selection table:

P.11

Code Description Inhibit

00 None or master & solver function use. -

10 Deviation high limit alarm -

01 Deviation high limit alarm YES

11 Deviation high limit alarm NO

02 Deviation low limit alarm YES

12 Deviation low limit alarm NO

03 Deviation high / low limit alarm YES

13 Deviation high / low limit alarm NO

04 / 14 Dand alarm NO

05 Absolute value high limit alarm YES

15 Absolute value high limit alarm NO

06 Absolute value low limit alarm YES

16 Absolute value low limit alarm NO

07 Segment end alarm (use for program model only ) -

17 Segment run alarm (use for program model only ) -

08 System error alarm-(on) -

18 System error alarm-(off) or loop broken alarm -

09 Ramp -

19 Soak (On delay timer alarm) -

Alarm selection table:

Alarm selection table:

P.12

Hookup

Hookup

:

:

6

7

8

9

10

1

2

3

4

5

11

12

13

14

4

5

+

-

+

-

2

3

+

-

2

3

4

5

7

8

9

10

7

8

9

10

7

8

9

10

+

-

+

-

A

B

B

2

3

13

14

13

14

11

12

13

11

12

11

12

13

MC-2438

AC 85~265V

DC 15~50V(Option)

A. Power Supply

B. Control Output

C. Input

D. Alarm

F. Communication

Relay,SSR,mA,V Relay,SSR

(Proportional MotorValve Control)

OUT1

(Option)

CLOSE

OPEN

COM

AL1 AL2

OUT1

OUT2

mA , V

RTD TC, mV

(Use OUT1 & OUT2)

(Proportional Motor

Valve Control)

RS232 RS485 TTL

RD

SD

SG

RD

SD

SG

Dx+

Dx-

AL1

11

12

+

-

Remote SV

G. Remote

11

12

AL2

11

12

+

-

E. Retransmission

TRS

11

12

+

-

Feed back

P.13

8

9

10

11

12

13

14

15

16

17

18

19

20

21

1

2

3

4

5

6

7

6

7

+-+

-

3

4

+

-

4

5

6

7

11

12

13

14

+

-

+

-

A

B

B

3

4

9

10

18

19

15

16

17

15

16

15

16

17

5

3

11

12

13

14

11

12

13

14

8

+

-

8

9

+

-

MC-2738

AC 85~265V

DC 15~50V(Option)

A. Power Supply

B. Control Output

C. Input

D. Alarm

E. Retransmission

F. RemoteG. Communication

Relay,SSR,mA,V

Relay SSR

OUT1

OUT2

NO

NC

COM

mA , V RTD TC, mV

TRS

NO

COM

NC

AL1 AL2

OUT1

(Option)

(Proportional MotorValve Control)

RD

SD

SG

Dx+

Dx-

RD

SD

SG

RS232 RS485 TTL

Remote SV

CLOSE

OPEN

COM

20

21

AL3

8

9

+

-

Feed back

Hookup

Hookup

:

:

P.14

Hookup

Hookup

:

:

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

9

10

+-+

-

6

7

+

-

7

8

9

10

17

18

19

20

+

-

+

-

A

B

B

14

15

14

15

16

14

15

14

15

16

8

6

17

18

19

20

17

18

19

20

12

13

11

+

-

4

5

3

6

7

MC-2538

MC-2638

AC 85~265V

DC 15~50V(Option)

A. Power Supply

B. Control Output C. Input

D. Alarm

E. Retransmission

G. Communication

F. Remote

Relay,SSR,mA,V

Relay,SSR

OUT1 OUT2

OUT1

(Option)

(Proportional MotorValve Control)

CLOSE

OPEN

COM

NO

NC

COM

mA , V RTD TC, mV

TRS

AL1 AL2

AL3

RD

SD

SG

14

15

+

-

Remote SV

RS232 RS485 TTL

NO

COM

NC NC

NO

COM

Dx+

Dx-

RD

SD

SG

12

13

+

TRS

-

(Use R-SV)

Feed back

14

15

+

-

P.15

Hookup

Hookup

:

:

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

31

32

33

34

35

36

37

38

39

40

28

29

30

21

22

23

24

25

26

27

9

10

+-+

-

6

7

+

-

7

8

9

10

17

18

19

20

+

-

+

-

A

B

B

14

15

16

14

15

14

15

16

8

6

17

18

19

20

17

18

19

20

12

13

11

4

5

3

6

7

14

15

+

-

MC-2838

AC 85~265V

DC 15~50V(Option)

A. Power Supply

B. Control Output C. Input

D. Alarm

G. Communication

F. Remote

OUT1

OUT2

Relay,SSR,mA,V

Relay,SSR

(Proportional MotorValve Control)

OUT1

CLOSE

OPEN

COM

Remote SV

RS232 RS485 TTL

RD

SD

SG

RD

SD

SG

Dx+

Dx-

AL1 AL2

AL3

NO

COM

NC

NO

COM

NC

mA , V RTD TC, mV

14

15

+

-

E. Retransmission

TRS

12

13

+

TRS

-

(Use R-SV)

14

15

+

-

Feed back

(Option)

P.16

: SV

: Alarm set value

(Inhibit means alarm doesn’t work at first time)

00

10

Non

01

Deviation high alarm inhibit

11

Deviation high alarm no inhibit

02

Deviation low alarm inhibit

12

Deviation low alarm no inhibit

03

High low alarm inhibit

13

High low alarm no inhibit

04

14

Band alarm

05

Absolute high alarm inhibit

15

Absolute high alarm no inhibit

OFF

LOW HIGH

ON

OFF

LOW HIGH

ON

OFF

LOW HIGH

ON

OFF

LOW HIGH

ON

OFF

LOW HIGH

ON ON

OFF

LOW HIGH

ON ON

LOW HIGH

ONOFF

OFF

LOW

HIGH

OFF ON

LOW

HIGH

OFF ON

LOW

HIGH

OFFON

06

Absolute low alarm inhibit

16

Absolute low alarm no inhibit

07

Segment end alarm

(use for Program Model only)

(1) ALD1~3, set 07

(2) AL1~3 = alarm segment No.set

(3) ALT1~3 if set 0 = flicker alarm

ALT1~3 if set 99.59 = continued alarm

ALT1~3 if set others = ON delay time

17

Program Run alarm (Refer to SETA4, P.23)

(use for Program Model only)

08

System error alarm – ON

18

System error alarm - O FF

09 Ramp

19

On delay timer

When PV= alarm SV , it keeps a certain

period (set time) before alarm action

Range:00H00M~99H59M

LOW

HIGH

OFFON

RUN END

ON OFF

AL

Normal

Error

ONOFF

AL

RUN END

ON OFF

AL

Alarm action description:

Alarm action description:

P.17

MC - 2438 - 101 - 001

A BCD EFG

AA--Model NO:

Model NO:

MC-2438 with size 48x48mm(DIN 1/16)

MC-2538 with size 48x96mm(DIN1/8)

MC-2638 with size 96x48mm(DIN1/8)

MC-2738 with size 72x72mm

MC-2838 with size 96x96mm(DIN1/4)

BB--Out 1 control output mode for heating

Out 1 control output mode for heating

or cooling:

or cooling:

0-None

1-Relay contact, SPDT 5A/240VAC

2-SSR Voltage pulse,20VDC/20mA

3-Current, 4-20mA

4-3 wire system motor valve control 1a contact

5A/240VAC(with feed back)

5-1 phase zero cross SCR

6-3 phase zero cross SCR

8-1 phase SCR

9-3 phase SCR

A-0~5V

B-0~10V

C-1~5V

CC--Out 2 control output mode for cooling:

Out 2 control output mode for cooling:

0-None

1-Relay contact, SPDT 5A/240VAC

2-SSR Voltage pulse,20VDC/20mA

3-Current, 4-20mA

A-0~5V

B-0~10V

C-1~5V

D-2~10V

DD--Alarm:

Alarm:

0-None

1-One set alarm

2-Two set alarm

3-Three set alarm

*(except MC-2438)

EE--Transmitter:

Transmitter:

0-None

1-4~20mA (Adjustable)

2-0~20mA (Adjustable)

A-0~5V

B-0~10V

C-1~5V

D-2~10V

FF--Second Input:

Second Input:

0-None

1-4~20mA remote set point

2-0~20mA remote set point

A-0~5V remote set point

B-0~10V remote set point

C-1~5V remote set point

D-2~10V remote set point

GG--Communication:

Communication:

0-None

1-RS232

2-RS485

3-TTL communication

(Master & Slave)

Order information

Order information

:

:

P.18

P.19

Available Function For MC-2X38

NO.

123456 7 8

Functions OUT2 ALM2 ALM3 R-SV TRS

MOTOR

VALVE

RS485 MASTER & SLAVE

MC-2438 V V V V V V V

MC-2538 V V V V V V V V

MC-2638 V V V V V V V V

MC-2738 V V V V V V V

MC-2838 V V V V V V V V

MC-2438 1 6 select 1

4 6 select 1

2 5 7 8 select 1

MC-2738 1 6 select 1

2 4 select 1

5 7 8 select 1

46 select1

MC-2538 while use 4 or 6 , 2 5 7 select 1

MC-2638

MC-2838 1 3 6 select 1

46 8 select 1

Loading...

Loading...