MAX Power COMPACT User Manual

English Manual: Compact Retract 12/24V, Version 2 14/04/2005

INSTALLATION GUIDE & MAINTENANCE OVERVIEW

MECHANICAL & ELECTRICAL

Serial N°: ----------------------------------------------------

Start up date: -----------------------------------------------

IT IS VERY IMPORTANT TO KEEP THIS MANUAL ON BOARD

TECHNOLOGY CENTER – 10 ALLEE FRANCOIS COLI – F 06210 CANNES-MANDELIEU FRANCE

TEL + 33 492 19 60 60 FAX + 33 492 19 60 61 www.max-power.com

e-mail: mp@max -power.com

1

English Manual: Compact Retract 12/24V, Version 2 14/04/2005

To ensure a proper installation, correct usage and long-lasting enjoyment of this

equipment, please take time to read this manual thoroughly.

TABLE OF CONTENTS

1 Positioning of Unit 4

2 Location of Auxiliary Equipment 4

3 Mechanical installation General 5

3.2 Determining & Marking up Position 6

3.3 Construction of the Hull Opening & Closing Plate 7

3.4 Final Fitting of the Mounting Base to the Hull 8

3.5 Final Fitting of the thruster Unit to the Mounting Base 8

3.6 Fitting of Hull Closing Plate 10

3.7 Final Adjustment and Set-Up of Thruster Unit 11

4 Electircal Installation (General) 11

4.2 Control Panel Installation 11

4.3 Control System 12

4.4 Control Panel & Thruster Control Box fucntions & Modes of Operation 13

a) General Remarks 13

b) Manual Mode 13

c) Automatic set-up Mode 14

d) Normal Operation Mode 14

4.5 Battery Requirements 16

4.6 Power Cable Sections (battery to Relay) 16

4.7 Power Fuse 17

5 Operation Limitations 17

6 Basic Maintenance 18

DIAGRAMS

1) Build Diagram 19

2) Wiring of Control Box 20

3) Control Wiring 21

4) Power Cable Connections 22

Your thruster is a highly technical product and should be treated as such. The employment of a

qualified marine personnel, with bow and stern thruster installation experience is strongly adviced.

Where possible, the boat manufacturers architect, design departments and/or shipyard should be

consulted, prior to installation taking place. For any boat requiring official classification, bodies of

approval should also be consulted at the earliest opportunity.

Your thruster should be delivered with the following parts:

Thruster assembly with integrated

thrusters motor, up / down motor,

motor coupling, leg and propellers

Control Panel (Grey) 25m Control Cable Manual

Plaque for closing

plate (kit)

Directional Relay Box Control Box

2

English Manual: Compact Retract 12/24V, Version 2 14/04/2005

y

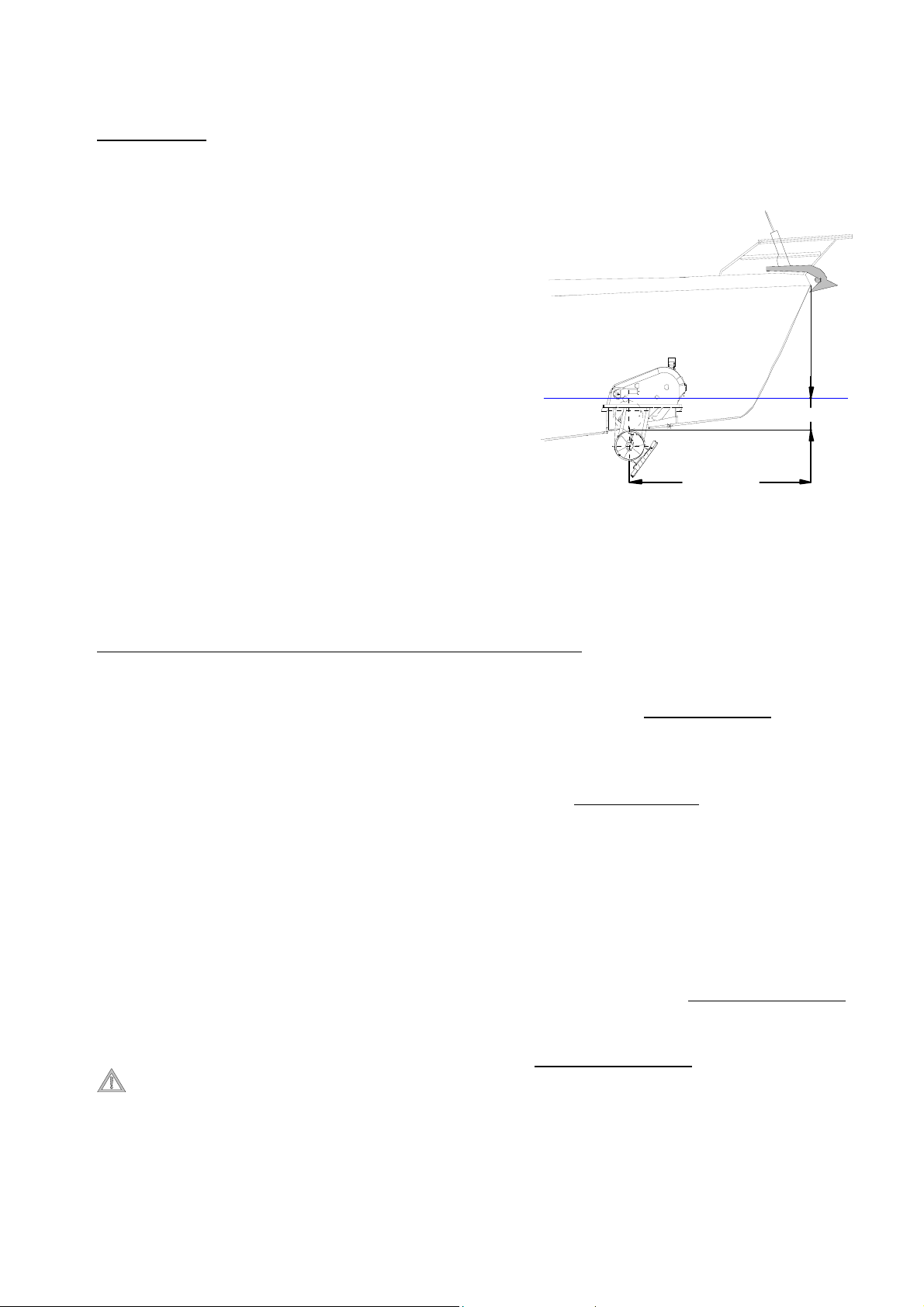

1. POSITIONING

WARNING: Correct positioning is essential for the correct operation of this unit.

Find the point the farthest forward

(or aft), while keeping in mind the

space available, given the vessel’s

fixtures, space and shape ensuring

ou respect the minimum immersion

depth of one full turbine diameter

(185 mm).

Water

Line

Minimum 185 mm

As far forward

as possible

Always check and make sure that there is enough room to allow for the complete removal of

the thruster unit and enough room for the connection of the electric cables.

To install a Compact Retract in the stern, make sure that the turbine flow is clear of all

obstacles, or select the best possible compromise.

2. DETERMINE THE LOCATION OF THE AUXILIARY EQUIPMENT

A power fuse, of the correct size

(see section 4.3),

must be installed in the positive supply cable,

as close as possible to the thruster’s battery bank and it must be easily accessible and clearly

marked.

A manual battery isolator, of the correct size, should be installed in the positive supply cable, as

close as possible to the thruster’s battery bank and must be easily accessible and clearly marked

An electrical battery isolator, as supplied by Max Power, should be installed in the positive supply

cable, as close as possible to the thruster’s battery bank, in order to benefit from all automatic

safety features of the electronic control system.

The thruster electronic control box should be installed in proximity of the thruster unit in a

completely dry and ventilated area.

The thruster relay box should be installed in proximity of the thruster unit, above the waterline in

a completely dry and ventilated area.

The thruster motor terminal busbar should be installed above the waterline.

Care should be taken to securely fix the opening of the black rubber hose, containing power

cables, above the vessel’s waterline.

The control panel(s) should be installed as desired at the helm station(s) in a protected and

waterproof manner.

3

English Manual: Compact Retract 12/24V, Version 2 14/04/2005

3. MECHANICAL INSTALLATION

(Please refer to “Build Drawing” at back of this document, see pg 18

):

3.1 GENERAL

MAX POWER can supply, either a steel reinforced G.R.P. mounting base or a 5086 aluminium

alloy-mounting flange. These bases save considerable shipyard time while assuring solid and

precise installation.

a) For GRP hulls the mounting base should be laminated into the hull. The base supplied is

only to help give the initial form; its strength will come from additional lamination (inside

and out) added when laminating the hull.

b) For alloy hulls the mounting flange should be welded onto the base, which has been

fabricated into the hull.

The method and materials used for making the mounting base must be adapted to the particular

hull material (laminated wood, GRP, sandwich, aluminium, or steel). Naval Architects,

Classification Societies or specialised firms should be consulted.

The thruster(s) mechanical stresses are spread over the hull by the mounting base. Its installation

reinforces the hull, if well calculated, but it might be necessary to attach it by gussets to frames

and stringers.

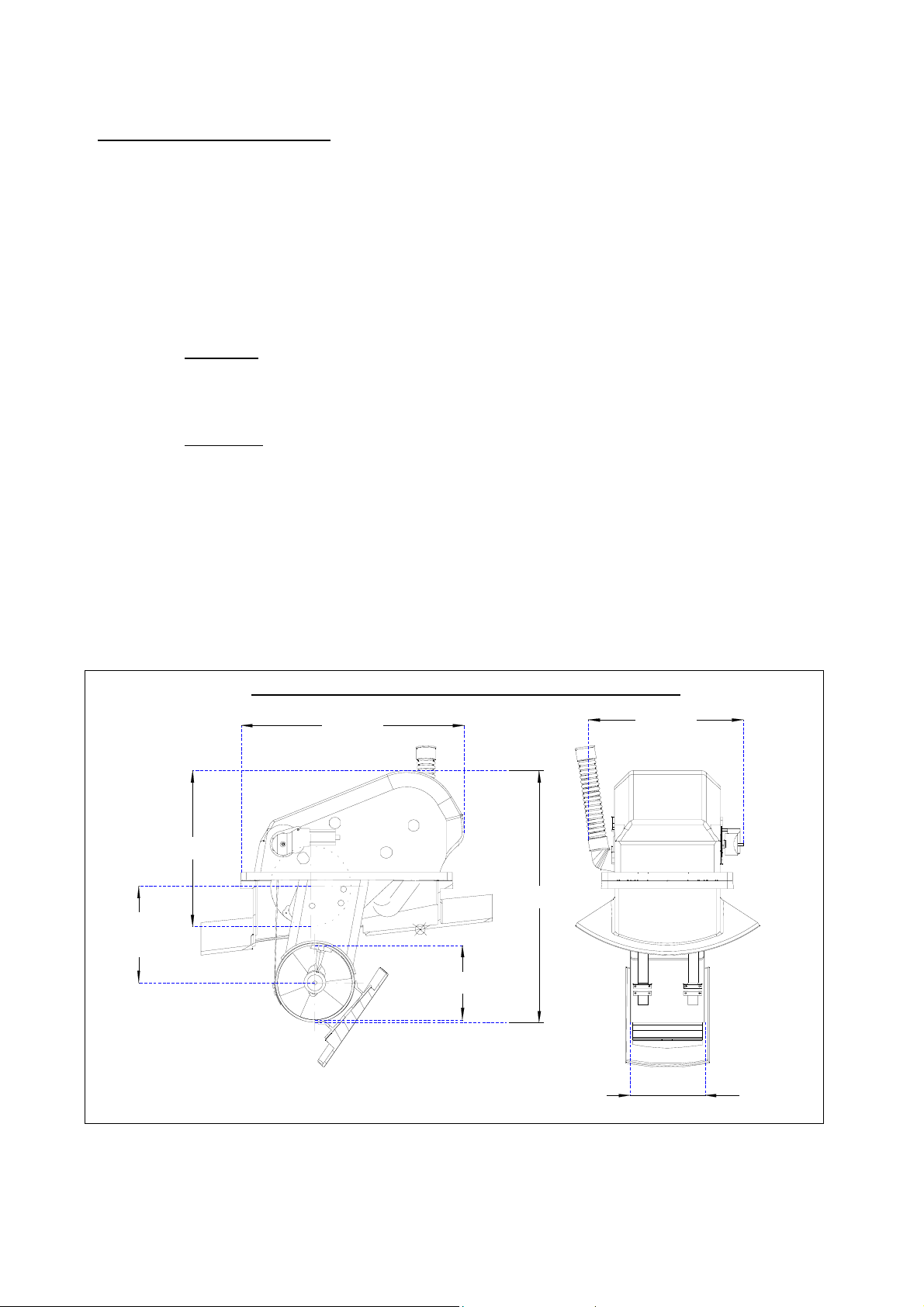

Compact Retract 12/24V Principal Dimensions

555mm

387mm

625mm

241mm

( Stroke )

185mm

Total Unit Weight: 40 kg

When fixing the mounting base, do not forget to take into account the overall dimensions of the

Compact Retract

385mm

185mm

4

English Manual: Compact Retract 12/24V, Version 2 14/04/2005

tolerances

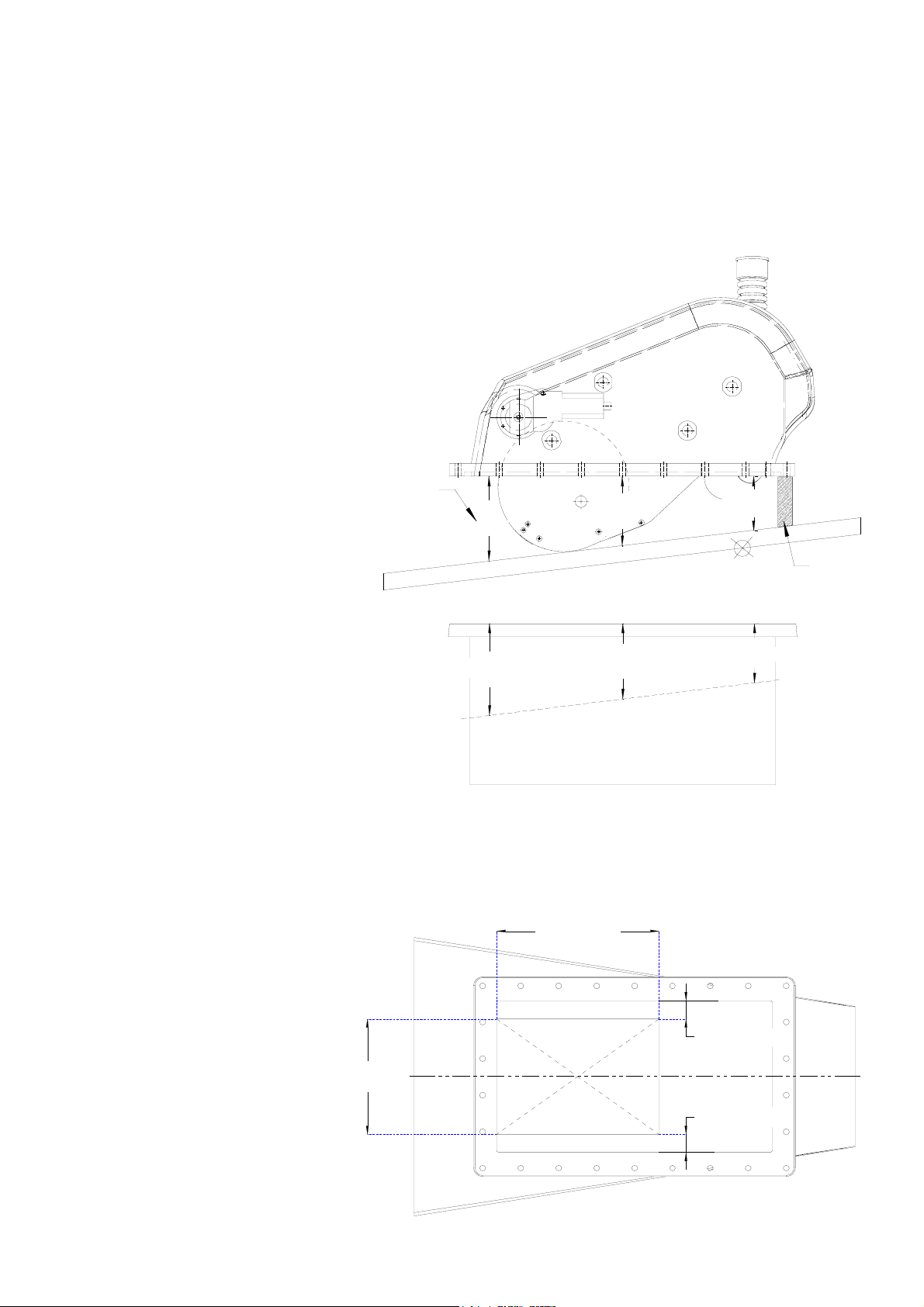

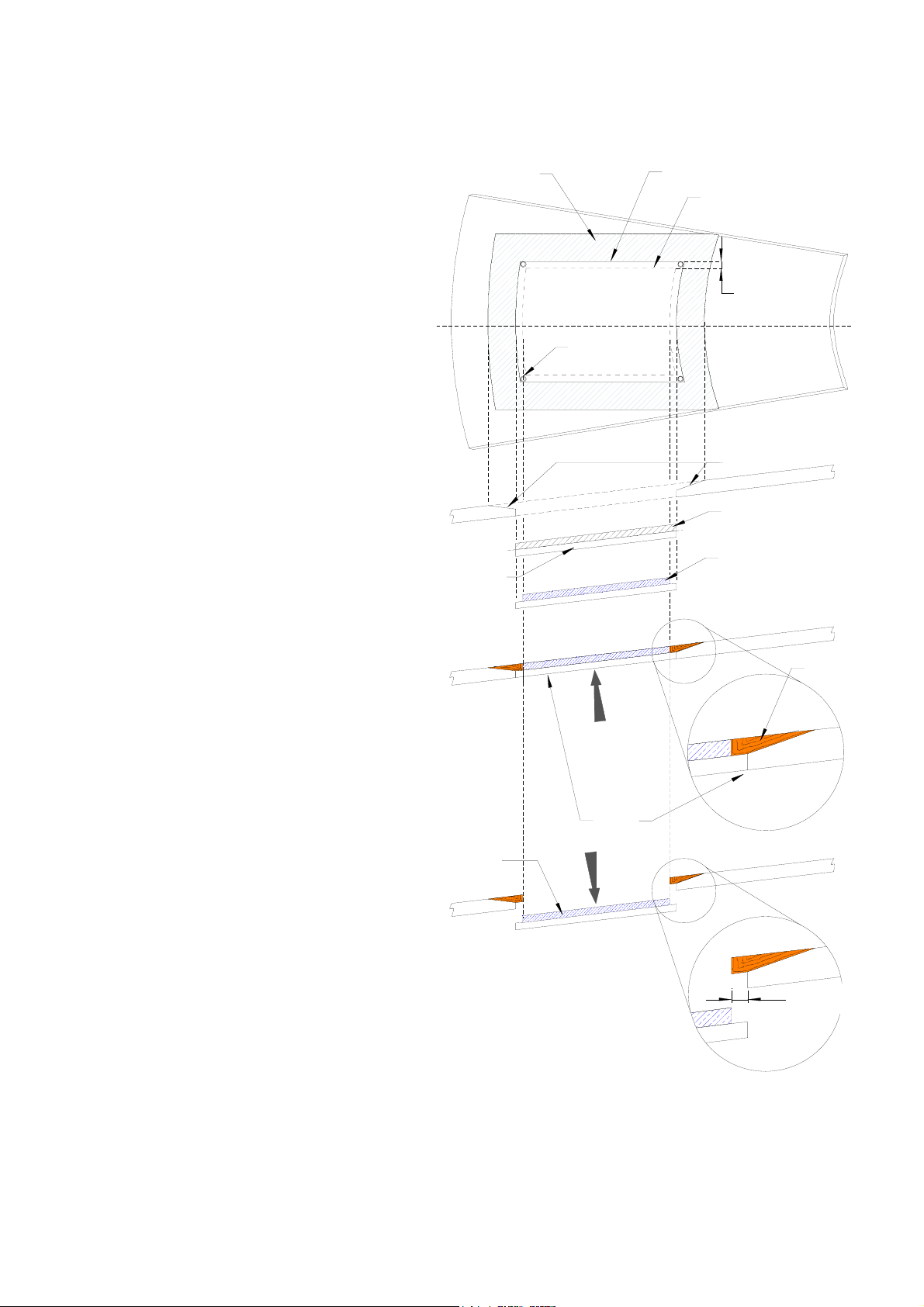

3.2 DETERMINING & MARKING UP POSITION

a) Remove the counter-mould on the inside of the hull ,in area where thruster will be installed,

allowing at least 15 cm on the outside of mounting base position for stratifying the mounting

base to the hull.

b) Position the thruster inside

the hull. Cut a piece of

wood( length = 121mm –

hull thickness) to use as a

spacer. Place this spacer

between the thruster’s

flange and hull. This will

give the installation height

and position of the unit.

c) When satisfied with the

initial position of the unit,

take measurements at

various points between the

flange and the bottom of

the hull. Mark these

measurements onto the

mounting base to determine

the initial shape to which

the base should be cut. To

allow sufficient tolerance,

add 5 mm to all the above

measurements to allow for

.

( c )

x

l

l

u

H

x + 5mm

Thruster Unit

y + 5mm

Mounting Base

y

z

z + 5mm

BOWSTERN

u

H

( b )

l

l

d) Mark-up the thrusters initial position on the inside of the hull before removing unit.

e) The thruster unit can now be removed and once the mounting base has been cut, using the

above measurements, the base can be temporarily fixed in place in its marked position.

f) Place the thruster unit in the temporarily fixed mounting base to verify dimensions.

g) Once satisfied

clearly mark the

final position of the

inside of the

mounting base and

remove base.

h) Measure and mark

the hull opening

using the

dimensions noted

on the diagram

opposite. Also see

“Build Drawing”.

195mm

STERN

267mm

29.5mm

Final Hull

Opening

29.5mm

Mounting Base

BOW

Hull

Inside

5

English Manual: Compact Retract 12/24V, Version 2 14/04/2005

3.3 CONSTRUCTION OF THE HULL OPENING AND CLOSING PLATE

a) Measure & mark the hull opening

as mentioned before.

( c )

( b )

( a )

b) Trace a parallel line, 10 – 15 mm

away from marked-up hull

opening, to allow for position of

rebate.

c) Trace a parallel line, 100 – 150

mm away from marked-up

( d )

10 - 15mm

Hull

Inside

position of rebate, to allow for

area to be shaved down to allow

for the construction of the

rebate.

( e )

d) Drill holes in the corners of lines

marking the rebate position and

( f )

cut out this piece of the hull.

e) Shave down the marked up area

Hull-cut out

( g )

for construction of rebate ( see

“c” above ). Make sure when

grading the hull not to exceed ½

the hull thickness.

f) Shave down hull-cut out to half

its original thickness.

g) Use piece of wood (195 x 267

mm) to make male mould for

rebate construction. Position &

( h )

temporarily fix this on shaved

down hull cut-out, allowing 10 –

( j )

15 mm all-round. Make sure all

lines are smooth and liberally wax

this mould.

h) Position & secure this in hull

opening, making sure outside hull

lines are smooth.

i) Build the rebate, using matt &

roving on the inside of the hull.

Do not exceed the original

thickness and shape of the hull.

j) Once rebate is set, remove the male plug. Now remove temporarily fixed piece of wood from

shaved down hull cut-out and keep the hull cut-out to use as closing plate.

l

l

u

H

l

l

u

H

( i )

l

l

u

H

Rebate

10 - 15 mm

6

English Manual: Compact Retract 12/24V, Version 2 14/04/2005

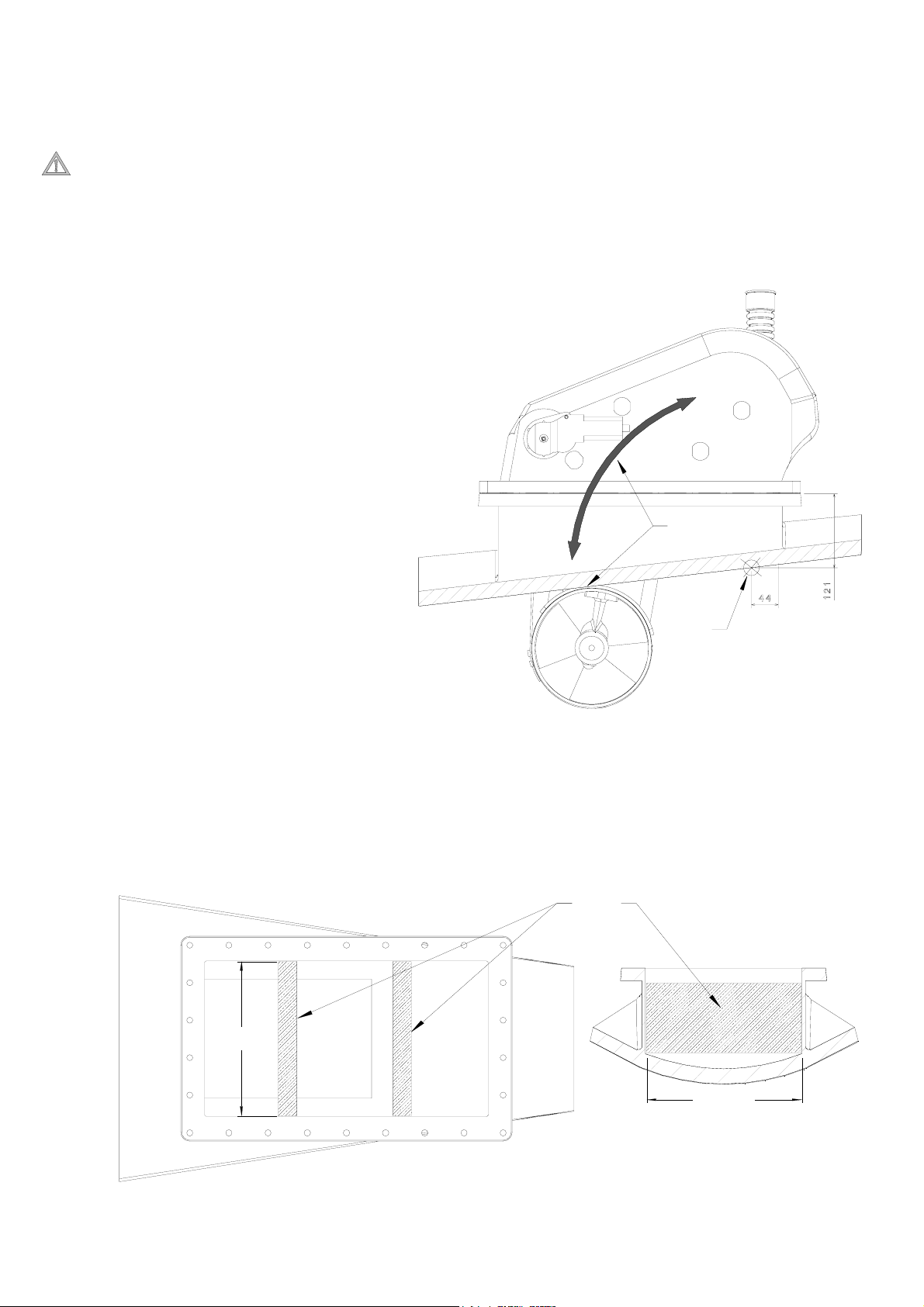

3.4 FINAL FITTING OF THE MOUNTING BASE TO HULL

WARNING : Please keep in mind that thruster unit will automatically retract after 10 minutes,

when in “Normal Operation Mode”. Thus before doing any work on the turbine, please ensure

that thruster is in “Manual Mode”. When in doubt remove fuse in supply of the electronic

control box.

a) Once the hull opening has

been cut and rebate

constructed, you need to

temporarily fix the mounting

STERN

BOW

base in its marked position.

Install the thruster in

position, fixing it with four

bolts at the corners, raise

and lower the unit, making

sure that the unit is not

being obstructed by

anything and that the

( a )

turbine completely clears the

hull when fully down;

b) IMPORTANT verify that the

( b )

construction point, as

shown on “Build Drawing”

has been respected.

c) Once completely satisfied with the position and height of the mounting base, the base can be

permanently stratified and fixed into the hull while respecting the inside dimensions of the

mounting base. In order to ensure that the mounting base keeps its initial form during the

stratification process, one can use some wooden spacers ( length = 249 mm) on the inside of

the mounting base.

( c )

STERN

BOW

249mm

Mounting Base

Hull

Inside

Mounting Base

249mm

7

Loading...

Loading...