Page 1

MaxPac Single/Dual/Triple

Screen 8230 XRA1/2/3 Rev-A

Training and Maintenance Guide

Maintaining and Repairing Your MaxPac

Single/Dual/Triple-Screen 8230 XRA1/2/3 Rev-A

High-Performance Transportable Workstation

MaxVision Corporation

495 Production Avenue

Madison, AL 35758, USA

Part Number: 209-0054-0

Page 2

ii MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

Warranties and Liabilities

MaxVision Corporation warrants that the Product, in the course of its normal use, will conform to MaxVision's

specifications and be free from defects in material and workmanship for a period of twelve (12) months from the date of

the original sale. Such warranty commences on the purchase date appearing on the invoice. The original end user is

entitled to customer support through telecommunication during normal MaxVision business hours and email support to be

responded to as support staff are available. Such support shall be limited to hardware operations and the software

required operating such hardware. Upon written request and subject to the availability of MaxVision personnel, additional

support may be provided by MaxVision in its sole discretion on a time and materials basis.

Limited Warranty for Software. MaxVision warrants to the original end user only that the Software as delivered at the

time of purchase will perform in MaxVision hardware, and that the original diskettes or compact disks are free from

defects in material and workmanship under normal use, for a period of thirty (30) days from the date of original sale,

provided the Software is used with a MaxVision unit. MaxVision makes no warranty that the Software will work in

combination with any hardware or software products provided by third parties, that the operation of the Software will be

uninterrupted or error-free, or that all defects in the Software will be corrected. This limited warranty is void if failure of the

Software has resulted from accident, abuse, or misapplication. MaxVision's entire liability, and your sole and exclusive

remedy shall be, at MaxVision's option, either to (a) correct or help you work around or avoid a reproducible Error or (b)

replace defective diskettes or compact disks. Any replacement Software will be warranted for the remainder of the original

Limited Software Warranty Period.

Limited Warranty for the Product. MaxVision warrants to the original end user only that all Products sold by MaxVision

will be free from defects in material and workmanship and conform substantially to the applicable standards set forth in

the Documentation, under normal use, for a period of 365 days from the date of original sale. This limited warranty is void

if failure of the Product has resulted from accident, abuse, or misapplication. If MaxVision confirms a Product is defective

after you have obtained a Return Materials Allowance Number for such Product and, at your expense, have returned the

Product to MaxVision for inspection, MaxVision will, at its election, repair or replace such Product at no charge to you.

Replacement Product may be either new or remanufactured. In the event that the Product returned is not defective, you

will be responsible for freight costs for return shipment to you. The foregoing warranty shall not apply to Product that has

been (a) damaged by accident, Acts of God, shipment, improper installation, abnormal physical or electrical stress,

misuse or misapplication, as determined by MaxVision in its sole reasonable discretion, or (b) modified without

MaxVision's express written acceptance of such modification for warranty purposes. MaxVision reserves the right to

charge additional fees for repairs or replacements performed outside the Warranty Period. Any replaced or repaired

components, subassemblies or units as well as spare parts are warranted for thirty (30) days or the remainder of the

original warranty period, whichever is longer. MaxVision shall not be responsible for any software, firmware, information or

memory data of yours contained in, stored on, or integrated with any Products returned to MaxVision pursuant to any

warranty under this Agreement.

Disclaimer of Warranties. EXCEPT AS SPECIFICALLY PROVIDED ABOVE, NEITHER MAXVISION NOR ITS

LICENSORS OR SUPPLIERS PROVIDES ANY WARRANTY OF ANY KIND FOR THE SOFTWARE OR THE

PRODUCT, WHETHER EXPRESS, IMPLIED, STATUTORY OR OTHERWISE, INCLUDING BUT NOT LIMITED TO

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF

THIRD PARTY RIGHTS. EXCEPT AS SET FORTH IN THIS AGREEMENT, THE ENTIRE RISK AS TO THE QUALITY

AND PERFORMANCE OF THE SOFTWARE AND THE PRODUCT IS WITH YOU. If a disclaimer of implied warranties is

not permitted by law, the duration of any such implied warranty is limited to ninety (90) days from the date of purchase by

the original end user. Some jurisdictions do not allow the exclusion of implied warranties or limitations on how long an

implied warranty may last, so such limitations or exclusions may not apply to you. This limited warranty gives you specific

legal rights, and you may also have other rights which vary from jurisdiction to jurisdiction.

Liability Exclusions and Limitations. IN NO EVENT SHALL MAXVISION OR ITS LICENSORS OR SUPPLIERS BE

LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, EXEMPLARY OR CONSEQUENTIAL DAMAGES OF ANY KIND

(INCLUDING LOST PROFITS, LOSS OF USE OR INTERRUPTION OF BUSINESS), OR FOR LEGAL FEES, ARISING

OUT OF THE USE OF THE SOFTWARE OR THE PRODUCT, REGARDLESS OF THE FORM OF ACTION, WHETHER

IN CONTRACT, TORT (INCLUDING NEGLIGENCE), STRICT PRODUCT LIABILITY OR OTHERWISE, EVEN IF

MAXVISION OR ITS LICENSORS OR SUPPLIERS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES. IN NO EVENT WILL COMPANY'S AGGREGATE LIABILITY HEREUNDER EXCEED THE PURCHASE

PRICE PAID BY YOU. This limitation shall apply notwithstanding any failure or inability to provide the limited remedies set

forth above. Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation(s) or exclusion(s) may not apply to you.

Page 3

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide iii

Proprietary Rights-Contracts with Certain U.S. Government Agencies. If the Software is acquired under the terms of

a Department of Defense or civilian agency contract, the Software is "commercial item" as that term is defined at 48

C.F.R. 2.101 (Oct. 1995), consisting of "commercial computer software" and "commercial computer software

documentation" as such terms are used in 48 C.F.R. 12.212 of the Federal Acquisition Regulations and its successors

and 48 C.F.R. 227.7202-1 through 227.7202-4 (June 1995) of the DoD FAR Supplement and its successors. All U.S.

Government end users acquire the Software with only those rights set forth in this Agreement.

Export Restrictions. You acknowledge that the laws and regulations of the United States restrict the export and re-export

of certain commodities and technical data of United States origin, including the Product and the Software, in any medium.

You agree that you will not knowingly, without prior authorization if required, export or re-export the Software or the

Product in any medium without the appropriate United States and foreign government licenses.

Severability. You acknowledge and agree that each provision of this Agreement that provides for a disclaimer of

warranties or an exclusion or limitation of damages represents an express allocation of risk, and is part of the

consideration of this Agreement. Invalidity of any provision of this Agreement shall not affect the validity of the remaining

provisions of this Agreement.

General. This Agreement is the entire agreement between you and MaxVision relative to the Product and the Software,

and supersedes all prior written statements, proposals or agreements relative to its subject matter. It may be modified only

by a writing executed by an authorized representative of MaxVision. No MaxVision reseller or sales representative is

authorized to make any modifications, extensions or additions to this Agreement. This Agreement is governed by the laws

of the State of Alabama without application of the principles of conflicts or choice of laws. The application of the United

Nations Convention on Contracts for the International Sale of Goods to this Agreement is expressly excluded.

Copyright

The materials in this document are the copyrighted works of MaxVision Corporation, copyright © 2005-2006. All rights

reserved. Email sales@maxvision.com for permission to duplicate and otherwise re-use.

Trademarks

MaxVision, and MaxPac are registered trademarks, and MaxPro and TeraPac are trademarks, of MaxVision Corporation.

Microsoft and Windows are registered trademarks of Microsoft Corporation. Intel and Pentium are registered trademarks

and Xeon is a registered trademark of Intel Corporation. Other trademarks and registered trademarks are the property of

their respective owners.

Regulatory Approvals

EN60950, EN55024, EN55022, FCC, Part 15, EN61000-3-2 & EN61000-3-3.

Warnings

Changes or modifications to this device that are not approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

Each type of MaxPac system should be re-shipped only in the Pelican case and/or other packaging materials in

which the system was first delivered to the customer. Damage caused by shipping systems using unapproved

Pelican cases and/or other packaging materials is NOT covered by MaxVision's warranty.

To reduce the risk of electrical shock, do not attempt to open the device unless instructed to do so. Do not use any tool for

purposes other than instructed.

A Lithium Ion battery is included with the system motherboard. This battery is used for the Real Time Clock (RTC) circuit.

The expected lifetime of the battery is approximately 5 years. There is a danger of explosion if this battery is incorrectly

replaced. Replace only with the same or equivalent type recommended by the motherboard manufacturer. Dispose of

used batteries according to the manufacturer’s instructions.

Page 4

iv MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

Contents

Legal and Related Information

Warranties and Liabilities..................................................................................................................................... ii

Copyright............................................................................................................................................................. iii

Trademarks ......................................................................................................................................................... iii

Regulatory Approvals.......................................................................................................................................... iii

Warnings ............................................................................................................................................................. iii

Chapter 1: Troubleshooting Tips for 8230 XRA1/2/3 Systems ........................................................................... 1

Chapter 2: Motherboard Diagrams ........................................................................................................................ 3

Chapter 3: Setting-Up the Software/Devices/Network/RAID Array..................................................................... 5

Setting-Up the Network ....................................................................................................................................... 5

Setting-Up the Graphics...................................................................................................................................... 5

Adjusting the Screens ......................................................................................................................................... 6

Setting Up Video Input for Picture-in-Picture (Dual- and Triple-Screen Configurations Only) ........................... 6

Configuring the RAID Array (with Separate System Drive) ................................................................................ 8

Configuring the RAID Array (with Hot Spare and System Partition on RAID Array)......................................... 22

Chapter 4: Module Replacement and Upgrade Procedures for Single-Screen Systems............................... 33

Introduction ....................................................................................................................................................... 33

Required Tools and Techniques ....................................................................................................................... 33

Names and Types of Screws ............................................................................................................................ 33

Flat Panel Display Module ................................................................................................................................ 34

Opening the Display Assembly into its Service Position................................................................................... 40

Memory ............................................................................................................................................................. 43

PCI Cards (General) ......................................................................................................................................... 44

PCI Express Card (Primary).............................................................................................................................. 45

Power Distribution Assembly ............................................................................................................................ 47

Hard Drive Magazine (also Individual Hard Drives).......................................................................................... 50

Optical Drive (CD/DVD) .................................................................................................................................... 51

Optical Drive (CD/DVD) Backplane .................................................................................................................. 51

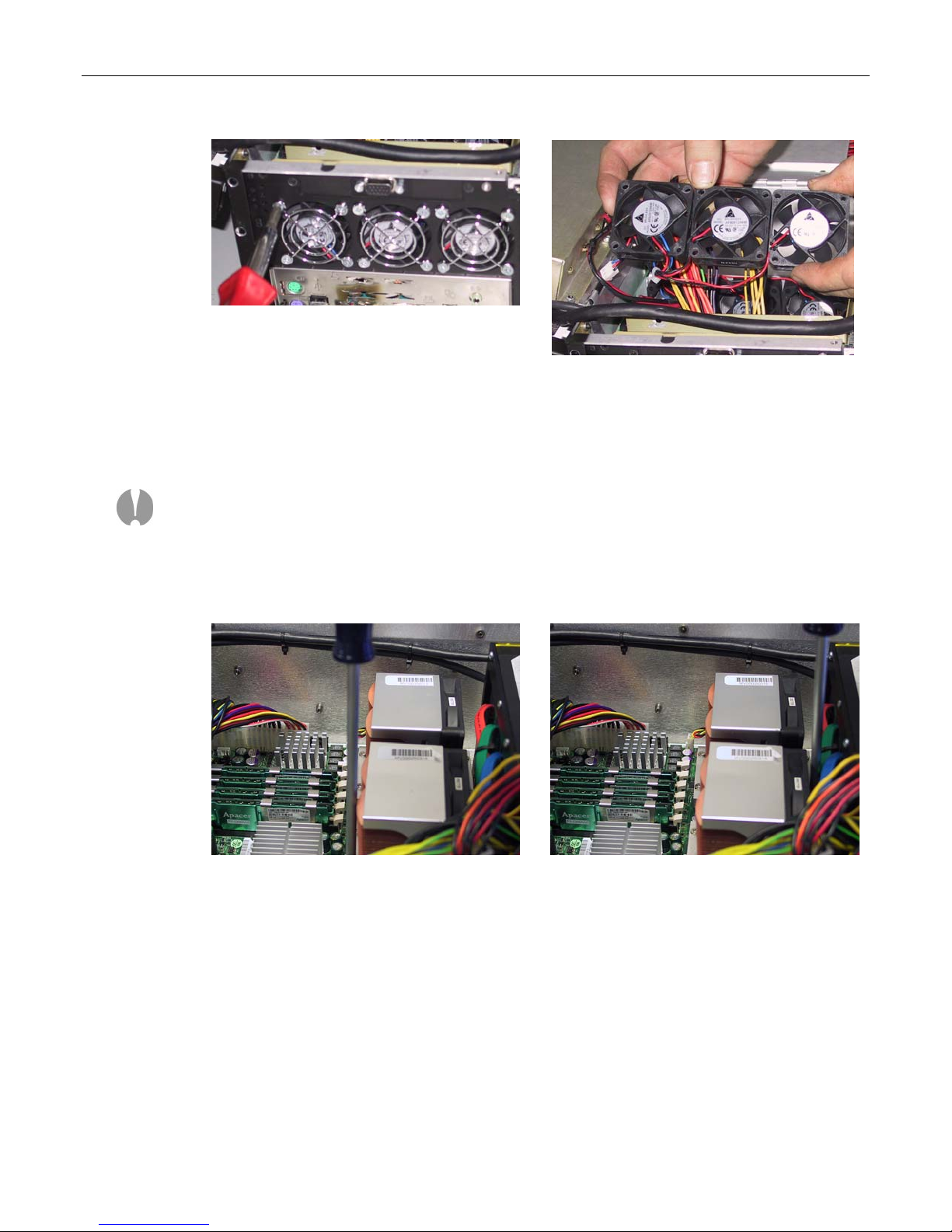

External Cooling Fan Assembly........................................................................................................................ 53

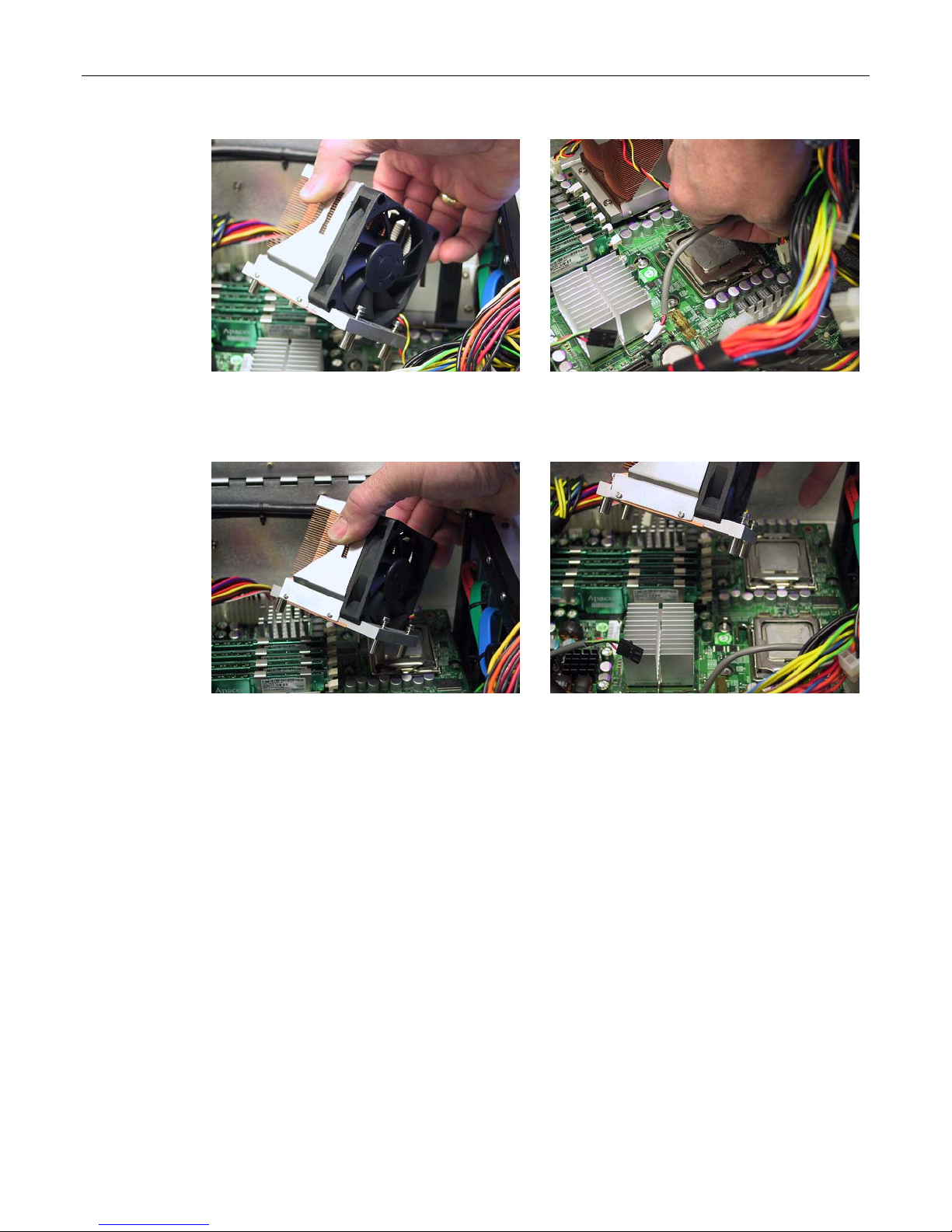

CPU Cooling Fans ............................................................................................................................................ 54

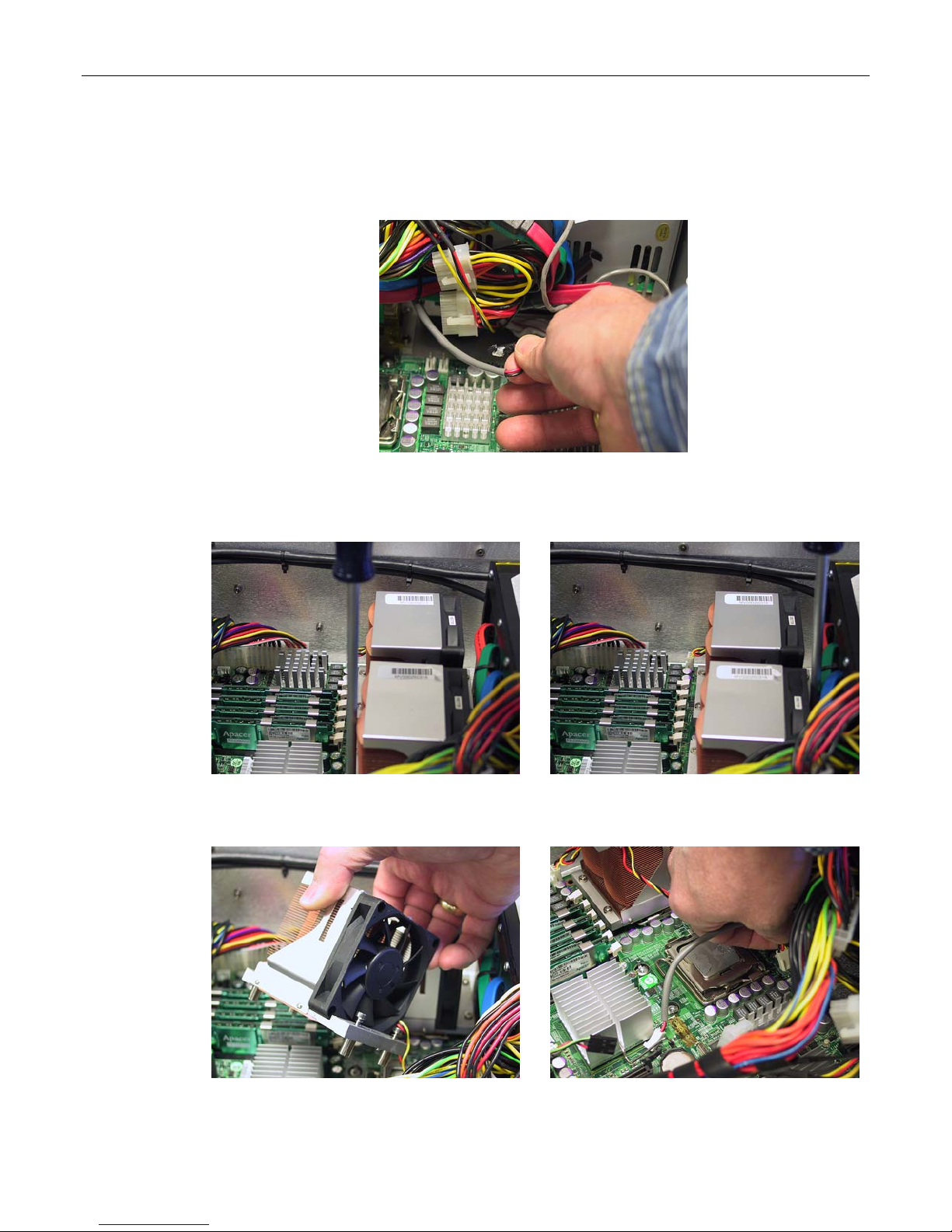

Main Power Supply Unit (PSU)......................................................................................................................... 55

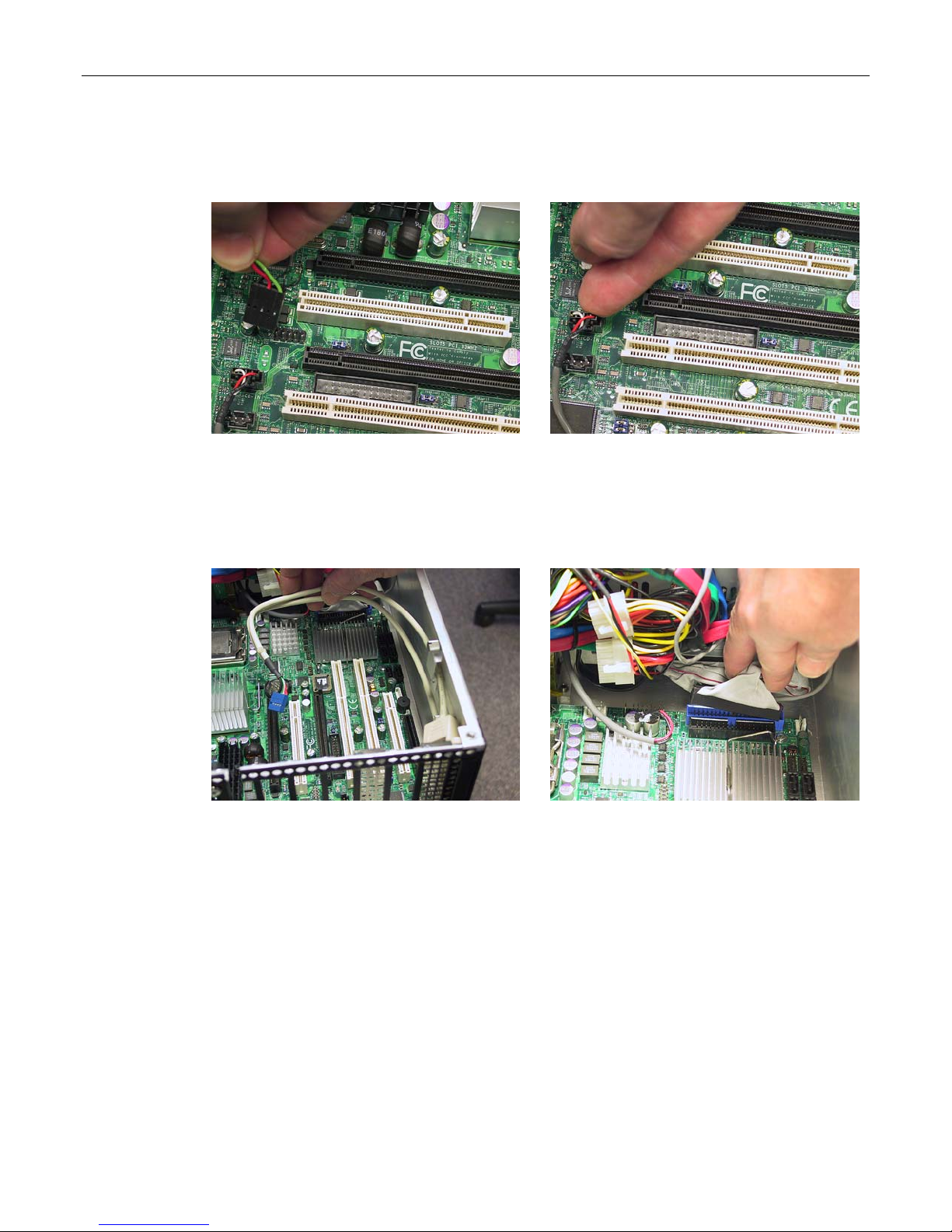

Motherboard...................................................................................................................................................... 57

Chapter 5: Module Replacement and Upgrade Procedures for Dual/Triple-Screen Systems....................... 65

Introduction ....................................................................................................................................................... 65

Required Tools and Techniques ....................................................................................................................... 65

Names and Types of Screws ............................................................................................................................ 65

Flat Panel Display Module (Left-Hand Screen)................................................................................................. 66

Flat Panel Display Module (Right-Hand Screen) .............................................................................................. 67

Flat Panel Display Module (Center Screen)...................................................................................................... 68

Opening the Display Assembly into its Service Position................................................................................... 72

Memory ............................................................................................................................................................. 74

PCI Cards (General) ......................................................................................................................................... 75

PCI Express Card (Secondary card for third screen and Projector Port) ........................................................ 76

PCI Express Card (Primary).............................................................................................................................. 77

Power Distribution Assembly ............................................................................................................................ 79

Hard Drive Magazine (also Individual Hard Drives).......................................................................................... 82

Optical Drive (CD/DVD) .................................................................................................................................... 83

Optical Drive (CD/DVD) Backplane .................................................................................................................. 84

Page 5

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide v

External Cooling Fan Assembly........................................................................................................................ 85

CPU Cooling Fans ............................................................................................................................................ 86

Main Power Supply Unit (PSU)......................................................................................................................... 87

Motherboard...................................................................................................................................................... 89

Chapter 6: Installation of the optional UPS Power Management System........................................................ 98

Installing the UPS Hardware............................................................................................................................. 98

Installing the UPS Software ............................................................................................................................ 102

Using the UPS Software ................................................................................................................................. 104

Chapter 7: Optional TeraPac 3 Connection to the MaxPac8230..................................................................... 107

Using the TeraPac 3 with a MaxPac 8230...................................................................................................... 107

Appendix A: Creating and Using Backup Images (Including Restoring Your OS)....................................... 109

Introduction ..................................................................................................................................................... 109

Appendix B: Regular System Maintenance ...................................................................................................... 118

Cleaning Interior Dust ..................................................................................................................................... 118

Replacing the Lithium Battery ......................................................................................................................... 118

Maintaining (Cleaning) the "Baghdad Filters" ................................................................................................. 118

Resetting the Motherboard BIOS.................................................................................................................... 121

Appendix C: Screws and Required Tools ......................................................................................................... 123

Screws............................................................................................................................................................. 123

Required Tools................................................................................................................................................ 124

Appendix D: Contacting MaxVision Support (RMA and Serial Numbers) ..................................................... 125

Repairing/Replacing Products/Accessories .................................................................................................... 125

Contacting Technical Support and RMA Numbers ......................................................................................... 125

Page 6

Page 7

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 1

Chapter 1: Troubleshooting Tips for

8230 XRA1/2/3 Systems

1) The MaxPac8230 has both a hard power switch (at power supply itself ---O; --- for ON) and a soft power

momentary switch (on center monitor behind the display controls). If the optional UPS Power

Management System is installed and the 8230 is ON then removing the AC chord or switching the hard

power to O will not shut down the system. Instead the UPS system will beep and provide power through

the batteries. The system must be shut down via Windows or the soft power switch for a complete

shutdown to occur. Failing to do this step when packing up your system will drain your batteries.

2) When AC power is applied to the 8230 the motherboard goes into standby power mode. Some of the

motherboard circuitry is powered waiting on the soft power or other low level command. When the

motherboard first goes into standby (AC power applied with hard power switch ON) the 3 keyboard led’s

will flash green and then turn back off.

3) When the 8230 is powered on via soft power all of the display power LEDs should turn on with an orange

color. During initial startup the primary display will not light-up until a good portion of the POST (Power On

Self Test) sequence is complete. This time delay depends on the amount of memory present but for most

systems is about 10 seconds. Then all 3 of the keyboard LED’s should flash green. Usually the left

keyboard LED will remain lit. If you need to get into the motherboard BIOS depress the Delete key a few

times now. The BIOS will not be entered until initialization is complete including scanning of drives

attached to the RAID controller.

4) At this stage if any of the display LEDs are RED (instead of Orange or Green) then the display is off.

Depress the display power button (next to the display LED) to power up the display. It’s LED will change

from Red to Orange to Green and back to Orange if the display is not receiving a signal. The LED should

stay green if receiving video signals. Also note that each display must have its input set to DVI and NOT

RGB. To change the input source use the Input button on the display. The RGB input can be used if one

of the display’s PIP VGA inputs is connected from an external source (discussed later) and you wish to

display it’s data rather than the 8230 video data. Initial BIOS initialization data only will appear on the

Primary PCI Express graphics board’s displays. This is normally the Center and Right screens. The Left

screen (if present) will show “No signal DVI” until it has been enabled in Windows. Note that the power

state, input mode, etc of each display is saved for subsequent power-up cycles.

5) At this point depressing the Num Lock key (upper left of the numeric keypad) repeatedly will toggle the

left keyboard LED from green to off. This indicates that the CPU and motherboard is responding to

commands even if you see nothing on the displays. If nothing appears on the display(s) in order to further

debug the problem the 8230 must be put into its service position as documented in chapter 4 (8230XRA1)

or chapter 5 (8230XRA2/3).

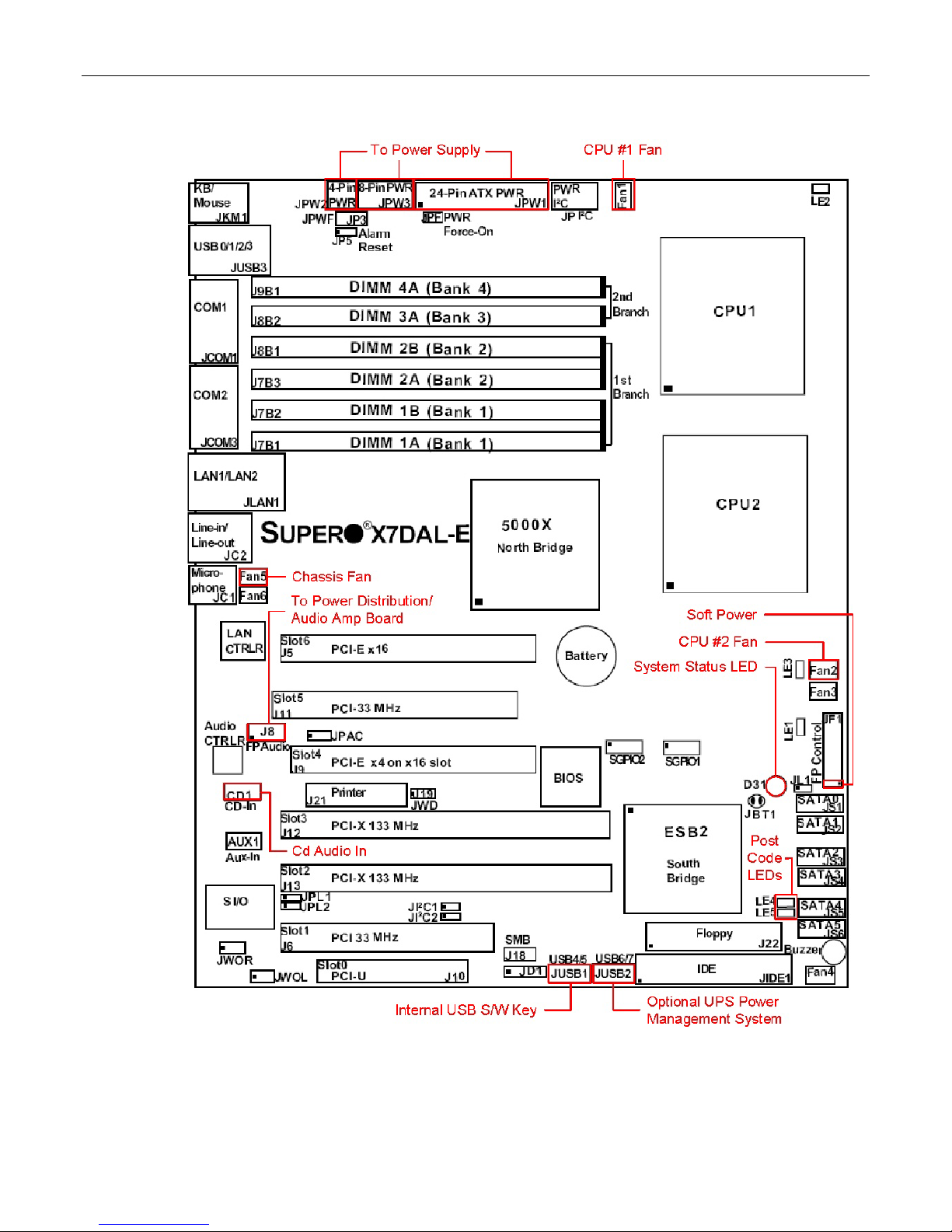

6) With the 8230 in its service position refer to Figure 2-2 and find the System Status LED and Post Code

LEDs. Check for proper seating of the PCI Express graphics boards (the 8230XRA3 requires a 2

graphics board for the left screen). Make sure the Poron is attached to the inside of the inner-chassis lid

as shown in Fig 5-33. Assuming the PCI-E boards are seated observe the LEDs in Figure 2-2. With the

motherboard in standby (after proper shutdown with AC applied) the System Status LED should be

yellow. Also both the yellow and green POST Code LEDs should be on.

7) Now depress the soft power button to turn on your 8230. The System Status LED should turn green. The

POST LEDs should sequence as follows: Yellow ON Green OFF during memory checks; Yellow OFF

Green ON during system shadowing checks; Yellow ON Green ON during final CPU checks; then Both

OFF just prior to the keyboard LED’s flashing.

nd

PCI-E

Page 8

2 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

8) If after system startup the POST LED stick at the Yellow ON Green OFF state then the FBDIMM memory

is not being seen. Refer to the Memory Section of chapter 4 or 5. Note that memory must be installed in

pairs starting with DIMM 1A/1B (Fig 2-2). This means that a bad (or poorly seated) FBDIMM in slot 1A or

1B could cause NONE of the memory to be seen (even in slots 2A and beyond). Note that slots 3A and

4A do not require population in pairs (but must be in order). Memory failures are sometimes just seating

problems so reseating is worth trying. If memory is still failing and you have 4 FBDIMM then try each set

in just slots 1A and 1B (1A/1B bank must be populated in all cases).

9) If you are still not getting video and both POST LEDs are off you could have several video related

problems. Unfortunately the motherboard will allow a boot all the way into Windows with the PCI-E

graphics not present or bad. Assuming neither the middle nor right displays are not getting valid video the

fault is probably with the primary PCI-E graphics card. For 8230XRA3 systems (assuming you do not

have a spare PCI-E board) you could temporarily remove the primary PCI-E graphics board. Now the

secondary PCI-E board (for the left display) should become the primary display for the BIOS and

Windows.

10) Assuming you now have video displaying on your middle and right screen you should see the 3ware

BIOS scan for the RAID array and then boot into Windows. If you are sure a valid image exists on the

RAID array (or individual system disk connected to the motherboard) and you still see “Operating System

not found” a Boot order problem likely exists.

11) Reboot your system and use the delete key to enter the BIOS. Use the arrow keys to go to the Boot

section. Now check your boot order. Make sure that your IDE CD is listed before the 3ware Storage

Controller in the upper part of the screen (listed 1-8). Note that if your system disk is connected directly to

the motherboard it should be listed before the 3ware. If you have connected a USB disk or memory stick

it may be listed ahead of your boot disk. Move it behind your boot disk in this case.

Page 9

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 3

Chapter 2: Motherboard Diagrams

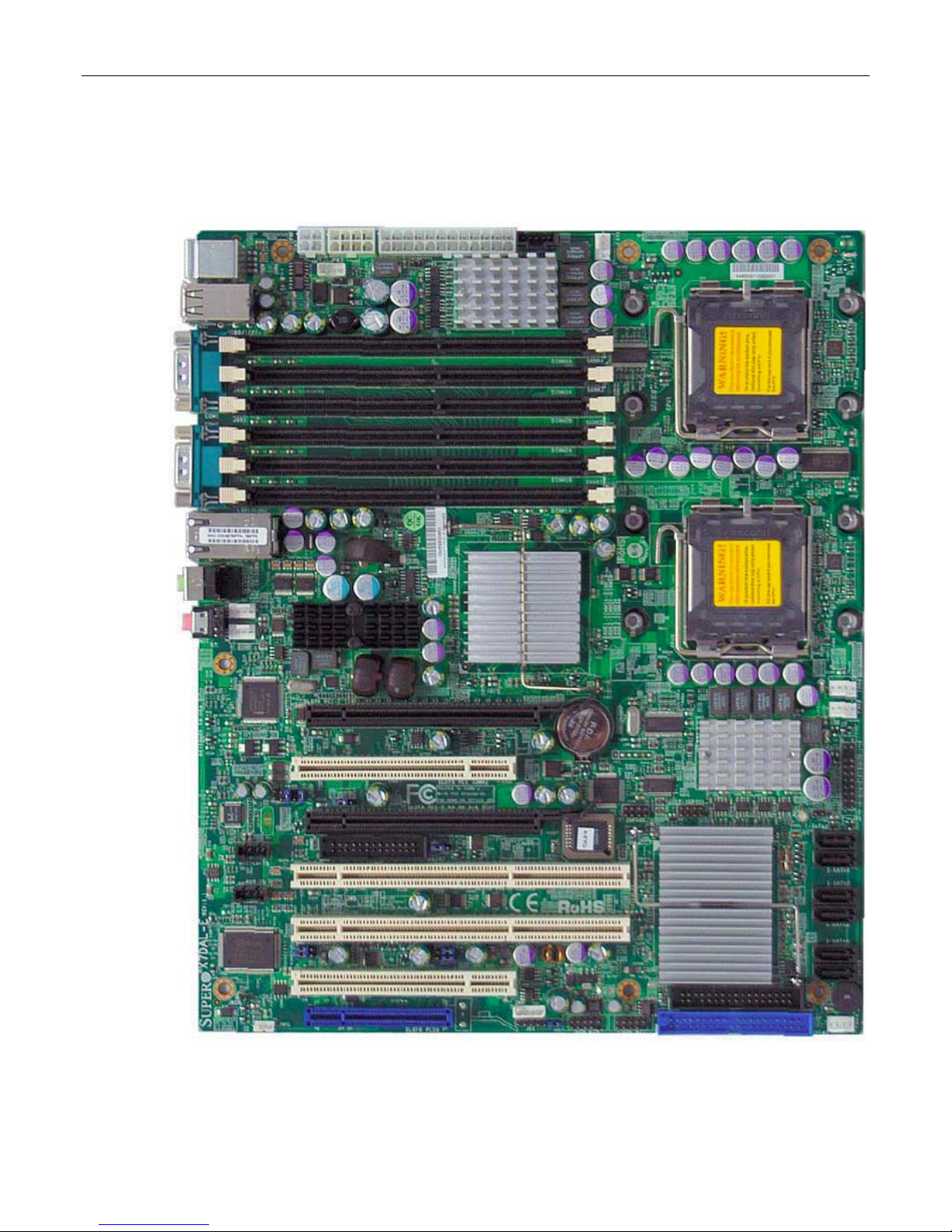

Figure 2-1. Top-down view of the X7DAL-E motherboard.

Page 10

4 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

Figure 2-2. Cable connections and LEDs on the X7DAL-E motherboard.

Page 11

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 5

Chapter 3: Setting-Up the

Software/Devices/Network/RAID Array

Setting-Up the Network

In the majority of environments, it is sufficient to use the Windows XP defaults for the network. Simply

connect the network cable (Figure 3-1) and the system should auto-detect the presence of the

network and the data/communications light next to the network cable connector should start to flash.

Figure 3-1. Connecting the network cable

The easiest way to test your network connection is to invoke your web browser and visit a website

such as www.MaxVision.com. In the event of any problems or special requirements, you should first

consult your on-site IT representative (if the problems persist, contact MaxVision support as

discussed in Appendix D).

Setting-Up the Graphics

When you receive your MacPac dual/triple-screen X-Class system, you will find that the graphics

subsystem has been pre-installed with the following (recommended) characteristics:

• Color Quality: Highest (32-bit)

• Resolution: 1, 2, or 3 x 20.1” displays: 1600 x 1200

Irrespective of the configuration, the graphics on your system will have been custom pre-configured to

suite your particular requirements.

MaxPac systems are available with a variety of different graphics cards depending on your unique

application. The standard configuration for a triple-screen system, for example, is to have the center

and right-hand displays controlled by a PCI Express-based NVIDIA Quadro FX4500 graphics card,

while the left-hand display and projector port are controlled by a second PCI Express-based NVIDIA

Quadro FX-series board.

Note: OpenGL™ acceleration is now available all displays controlled by the PCI Express-based

NVIDIA Quadro FX series controllers. This allows the user to run applications requiring OpenGL

acceleration on all displays as long as all are controlled by the same NVIDIA Graphics driver.

Page 12

6 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

If you do have a special graphics card, you may consult the manual associated with this card (this

manual will be included in your documentation package as discussed in Chapters 1 and 2) or contact

MaxVision support (as discussed in Appendix D) for more information.

Adjusting the Screens

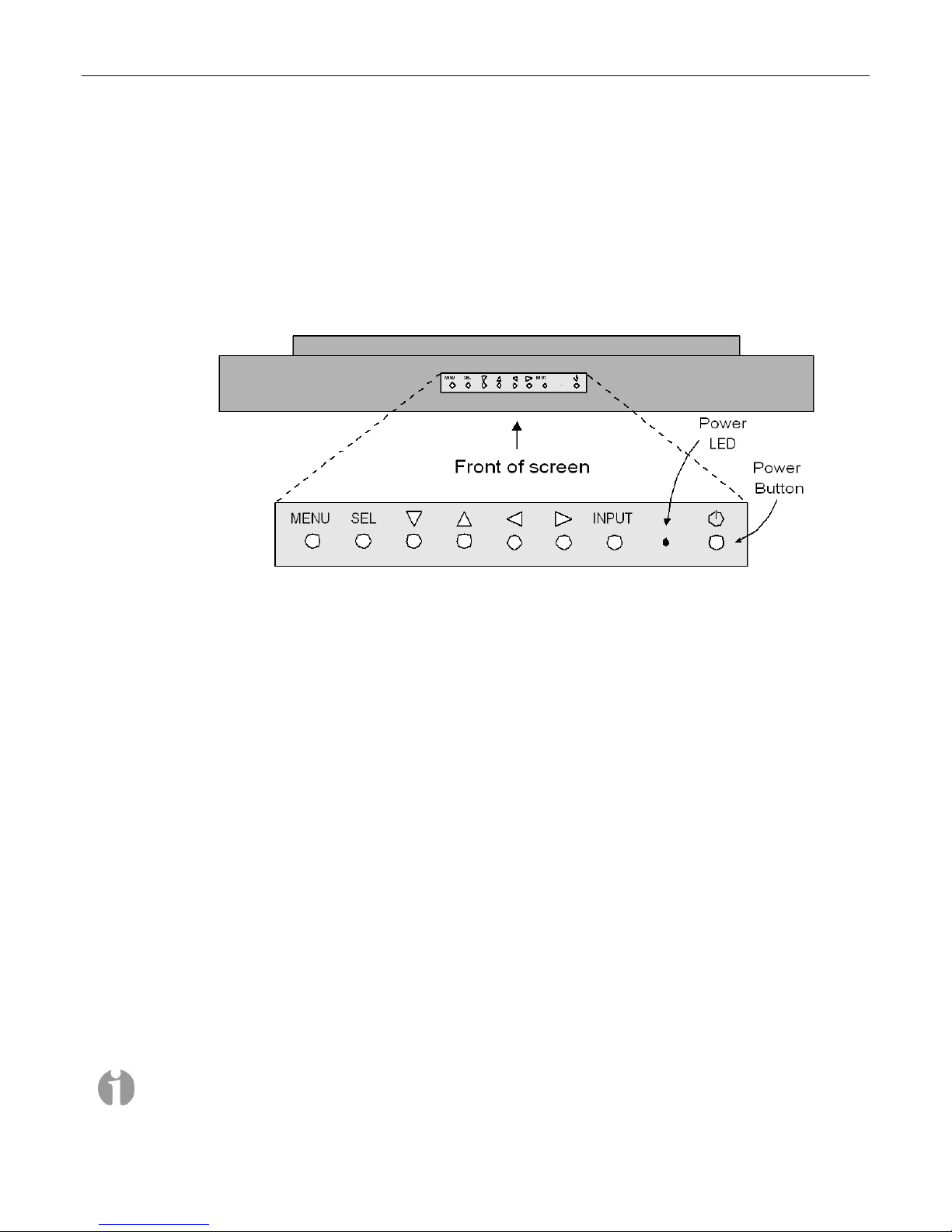

In the case of a dual-display or triple-display configuration, each screen has a set of controls mounted

on the top of the display (Figure 3-2). (In the case of a single-display system, these controls are

located on the left-hand side of the unit next to the CD/DVD optical drive.)

Figure 3-2. Top-down view of screen controls on dual- and triple-display systems

Observe the power button located to the right of the power light-emitting diode (LED). This is an

independent power button for the display/screen.

Pressing the MENU button will bring up a series of items on the screen. Use the up/down buttons to

move between these items; press and release the SEL button to select that item; and use the

right/left buttons to vary the settings.

Some custom configurations allow the display to be driven from multiple sources. In this case,

pressing the INPUT button selects between digital and analog inputs. These custom configurations

will come equipped with a special documentation addendum that details the actions of the INPUT

button; in the case of standard configurations, the source should always be set to “Digital.”

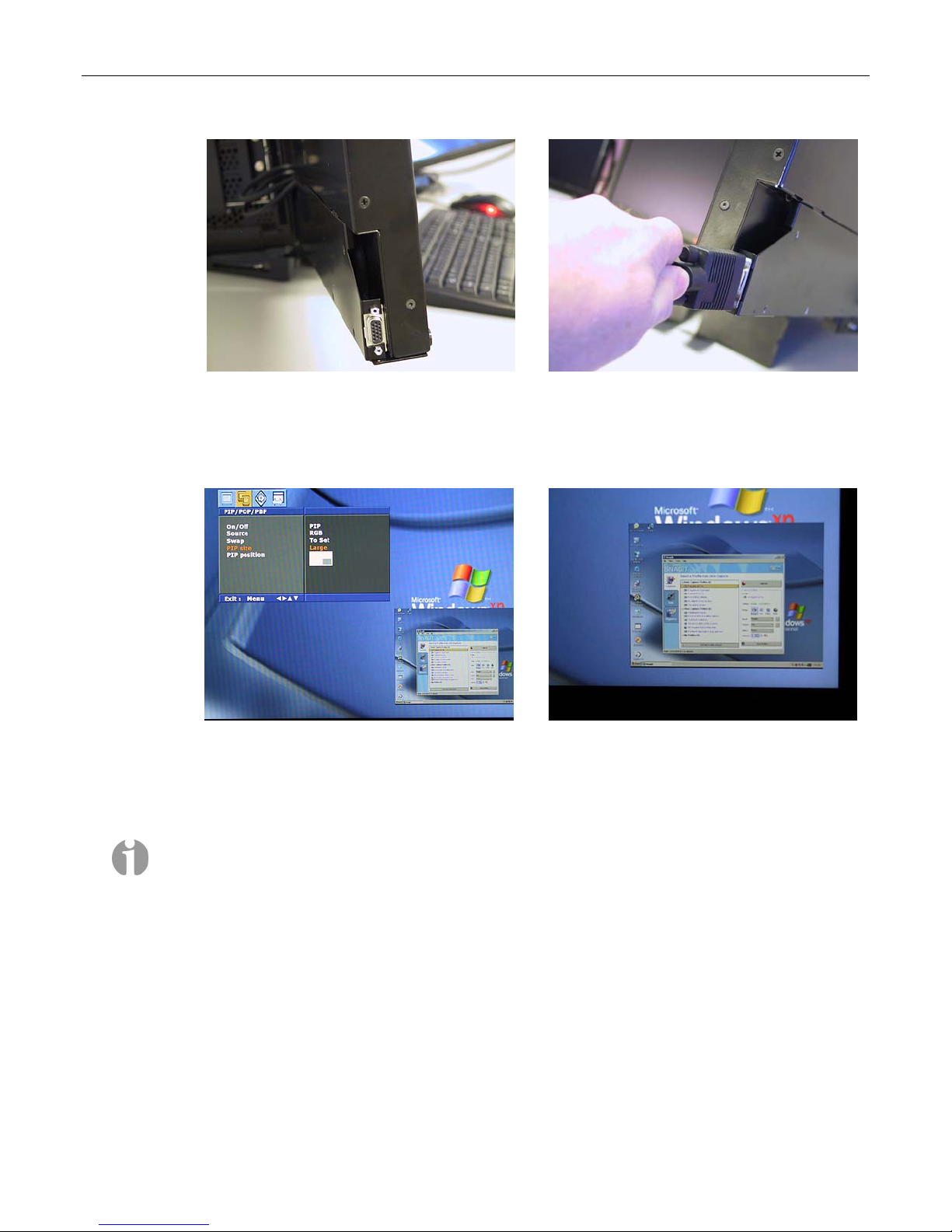

Setting Up Video Input for Picture-in-Picture

(Dual- and Triple-Screen Configurations Only)

In the case of a MaxPac 8230 XRA2 (dual-screen) system, the right-hand monitor supports multiple

inputs: the default DVI-I input from the system and an external VGA input that can be used for

picture-in-picture monitoring purposes. Similarly, in the case of a MaxPac 8230 XRA3 (triple-screen)

system, both the left- and right-hand monitors support this capability.

1) Observe the VGA connector associated with the left-hand screen (Figure 3-3). The external video

source would be fed into this connector as shown for the right-hand screen (Figure 3-4).

Note: For the purposes of this example, the video signal being used as input to the right-hand

screen originates from another PC. In reality, this input could come from any VGA video source

with a resolution no higher than 1024 x 768.

Page 13

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 7

Figure 3-3

Figure 3-4

2) In order to access the external video source, press the Menu button in the controls mounted on

the top of that display (Figure 3-2), and then use the left/right arrow buttons on this control panel

to access the Picture-in-Picture dialog (Figure 3-5)

Figure 3-5

Figure 3-6

3) Use this dialog to turn the Picture-and-Picture window On/Off and to specify characteristics such

as the size and position of the Picture-and-Picture window (located in the lower right-hand corner

of the screen in Figures 3-5 and 3-6.)

Note: The video source and the Picture-in-Picture window must be set to the same resolution,

which must be less-than or equal-to 1024 x 768.

Page 14

8 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

Configuring the RAID Array (with Separate System Drive)

Note: Your MaxPac8230 may be configured for connection to the optional TeraPac3 8 drive SATA

Expansion. In this case the MaxPac8230 will include a 12 or 16 port SATA RAID 5 controller. This

chapter illustrates and assumes a 4 port SATA RAID 5 controller so the photos may be somewhat

different. Refer to Chapter 7 for a brief section on the MaxPac8230 connection to the TeraPac3 and

to the TeraPac3 User Operation and Maintenance Guide for more details.

Note that these discussions reflect system configurations with a separate system drive as illustrated

in Figures 3-7 and 3-8). Configurations that have the system partition established on the RAID array

itself (leaving a hot-spare drive) are discussed later in this chapter.

When you take possession of your MaxPac 8230 system, the RAID system will already have been

established, initialized, and verified. The instructions in this section are intended to address those rare

situations where you need to replace a degraded/failed drive or you wish to rebuild the RAID system

from the ground up.

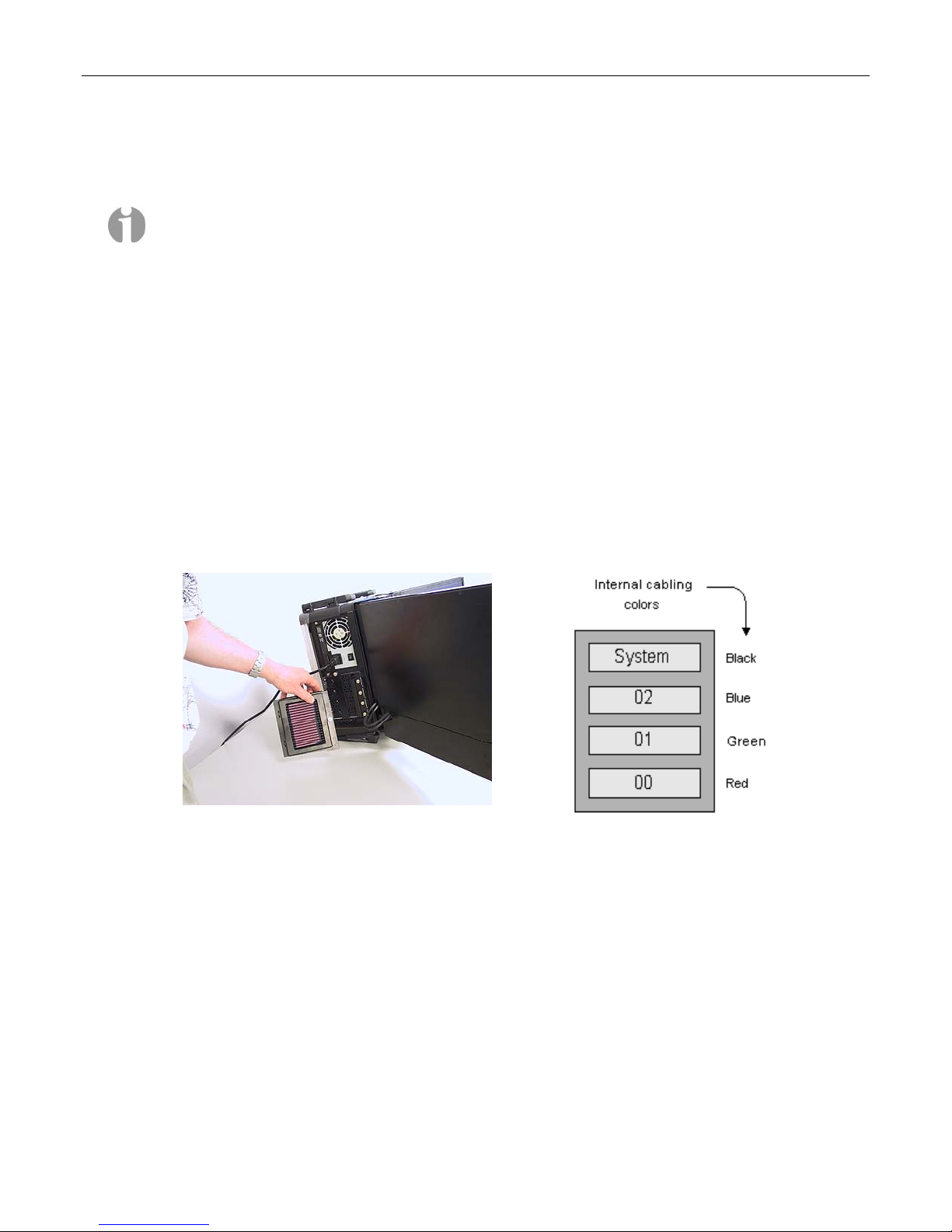

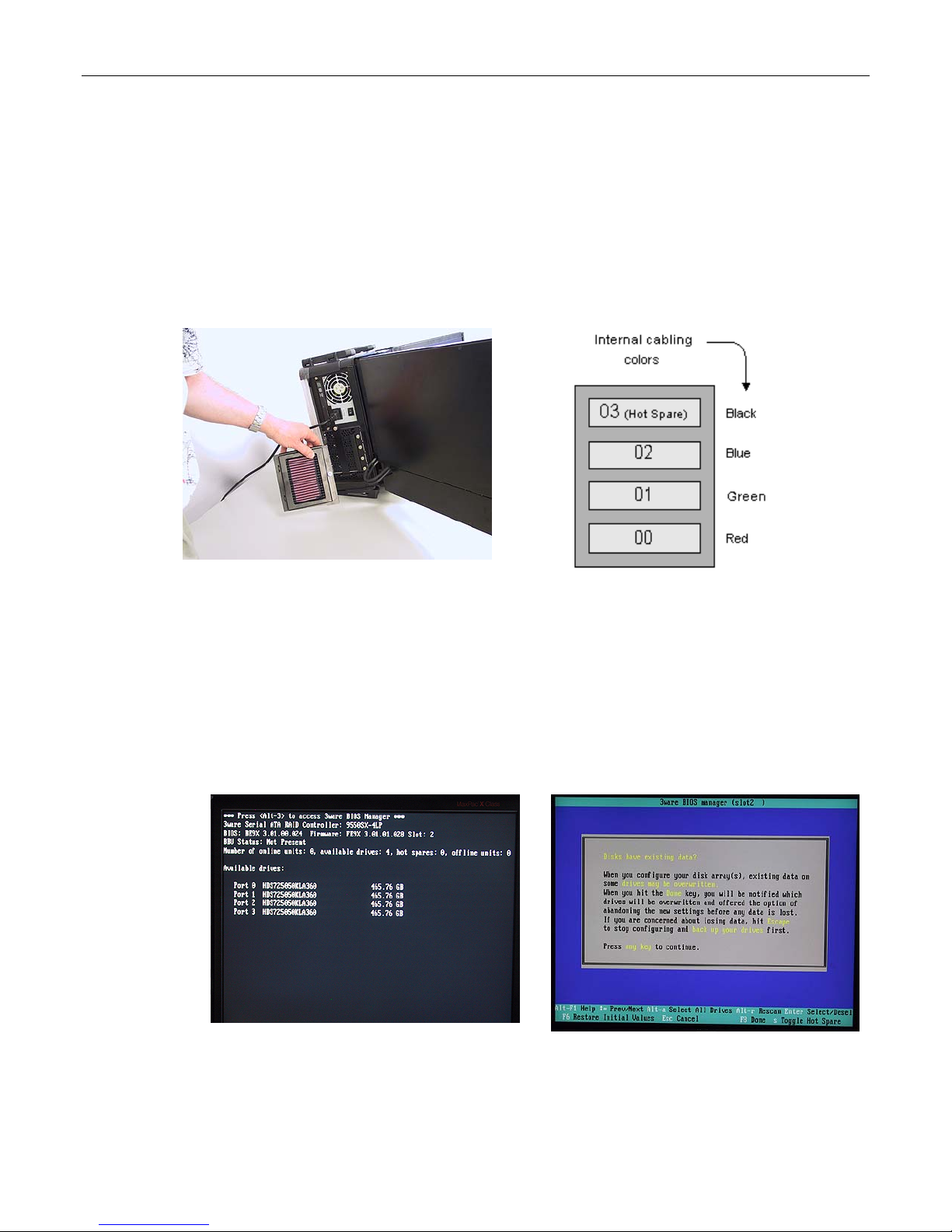

Your MaxPac system can contain up to four SATA hot-swappable hard disk drives presented in a

4-drive disk caddy. This caddy is located on the lower left-hand side of the main chassis under the

"Baghdad Filter" assembly as shown in Figure 3-7 (the numbering of the disks is as shown in

Figure 3-8). In the case of a typical RAID 5 system, the upper disk is the system disk, while the

lower three disks are used to implement the RAID data array.

Figure 3-7 Figure 3-8

Installing the Web-Based 3ware Software

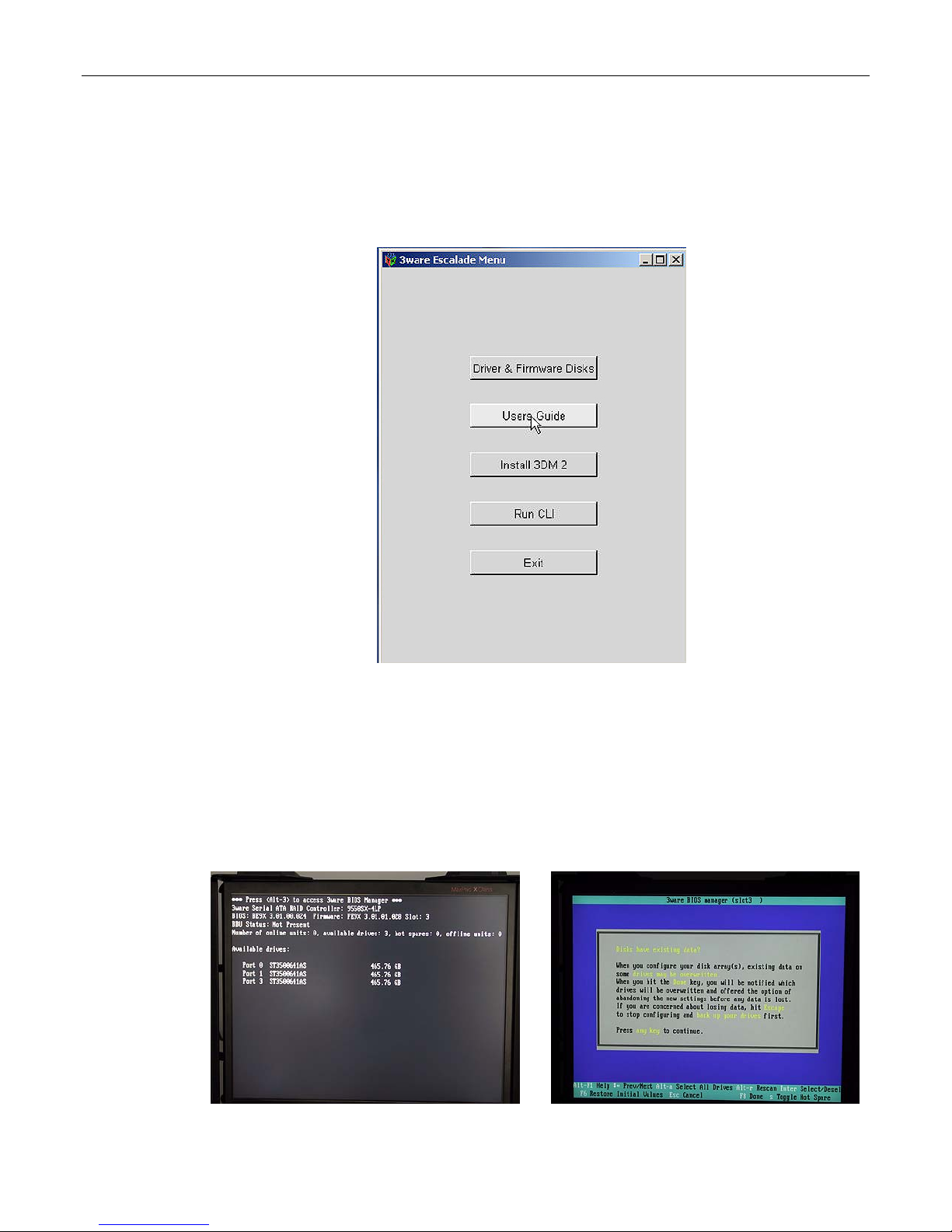

If you reload your operating system, then you will also need to reload the appropriate RAID driver

followed by 3ware's 3DM 2 web-based RAID management application as follows:

1) Power-up the system. The operating system will see the RAID controller as a new device and will

therefore prompt you to load the appropriate driver from the 3ware CD, which is provided with

your system.

2) Insert the 3ware CD. The auto-play function will bring up the 3ware Escalade Menu as shown in

Figure 3-9. Initially you should ignore this menu; don’t dismiss it, but instead use the operating

system's Device Manager utility to look for the 3ware driver on the CD and install it.

3) Once the 3ware driver has been loaded, return to the 3ware Escalade Menu and click the Install

3DM 2 button.

4) Approve the license agreement in the ensuing pop-up dialog.

Page 15

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 9

5) Following acceptance of the license agreement, you may be presented with the operating

system's standard Welcome to New Connection Wizard dialog. In this case, use this dialog to

setup your network connection.

6) Following this wizard, 3ware's 3DM 2 software will be installed (when prompted to do so, allow

the installation script to place a 3DM 2 icon on your desktop).

Figure 3-9

Building a New 3ware RAID 5 Array from Scratch

The discussions in this section assume that you have an existing system disk and – for one reason or

another – have installed three new/empty data disks.

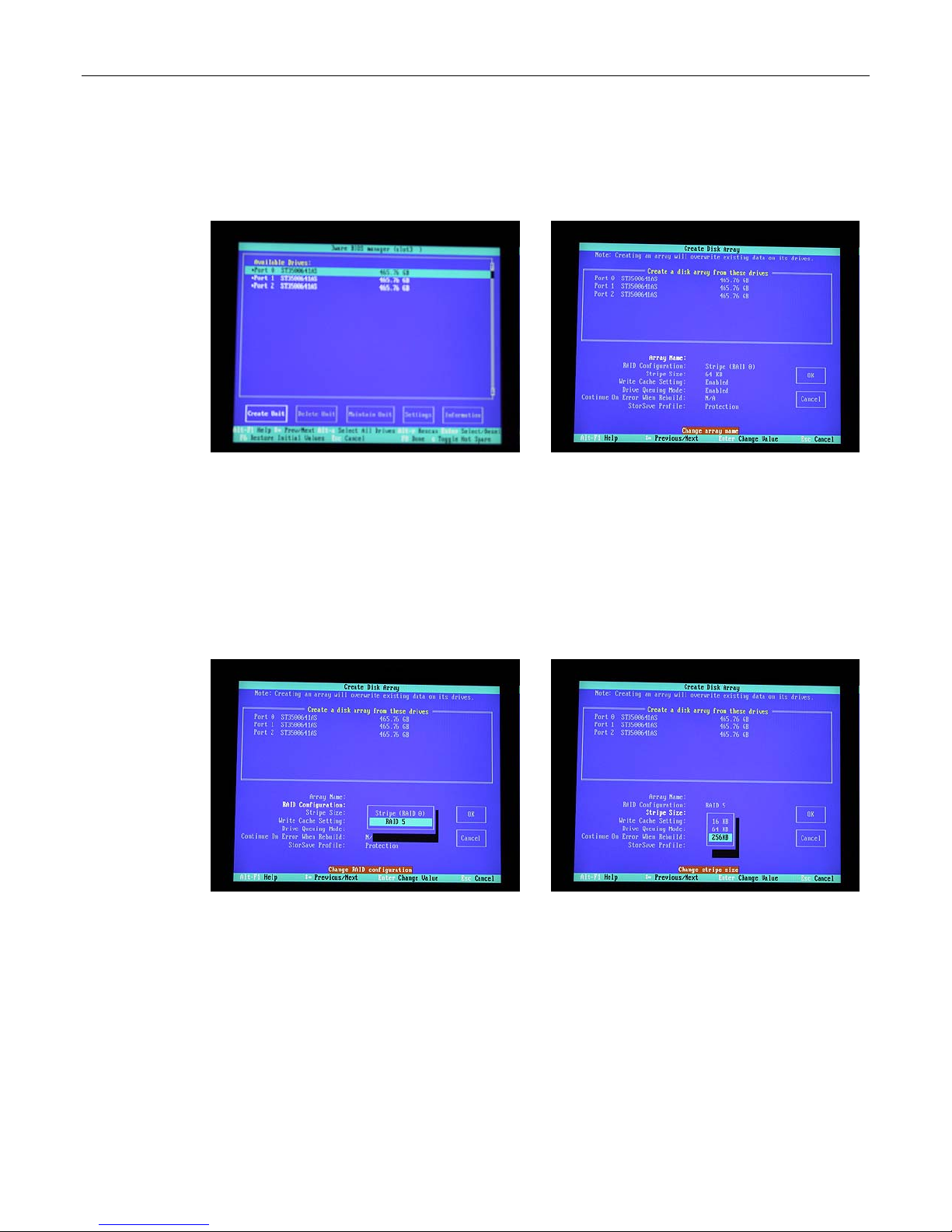

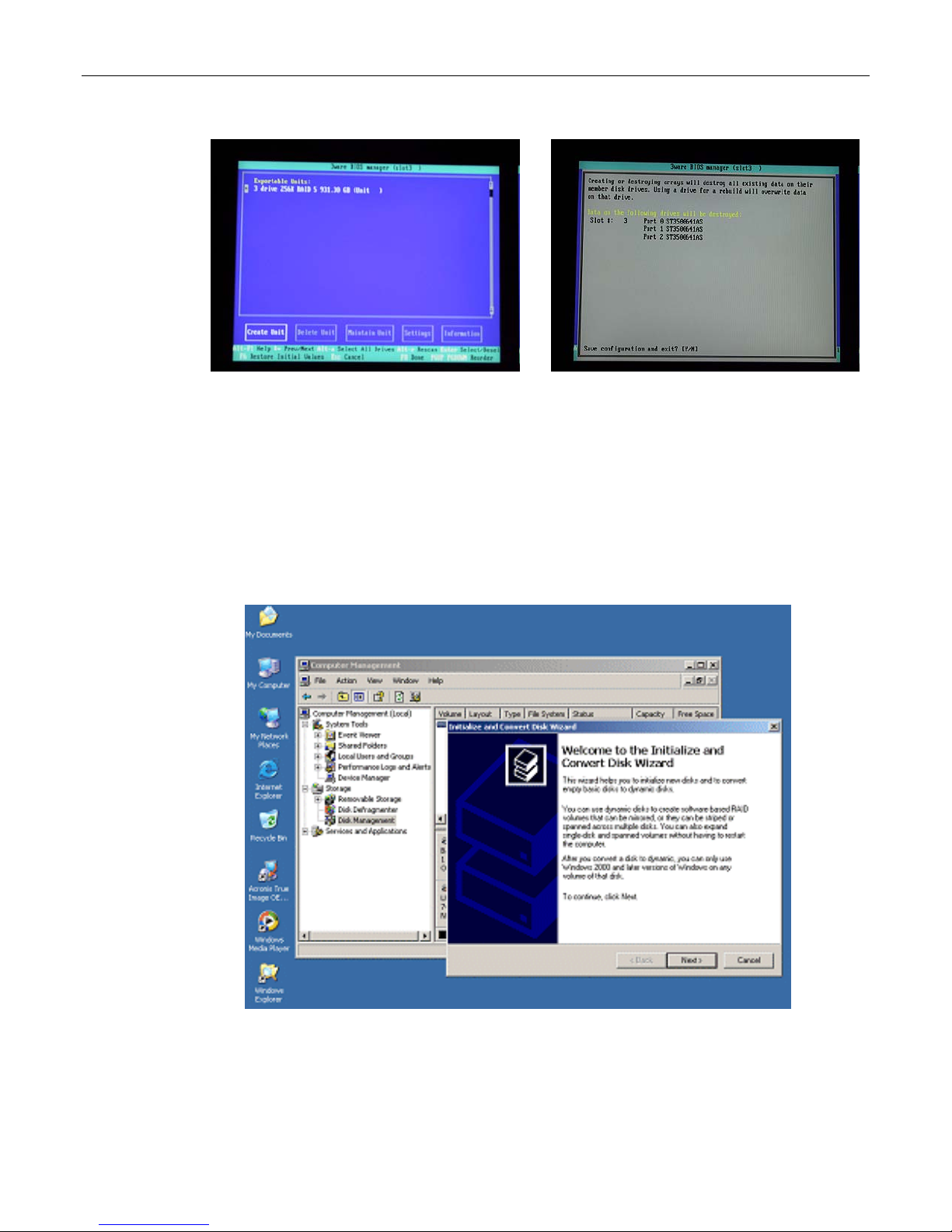

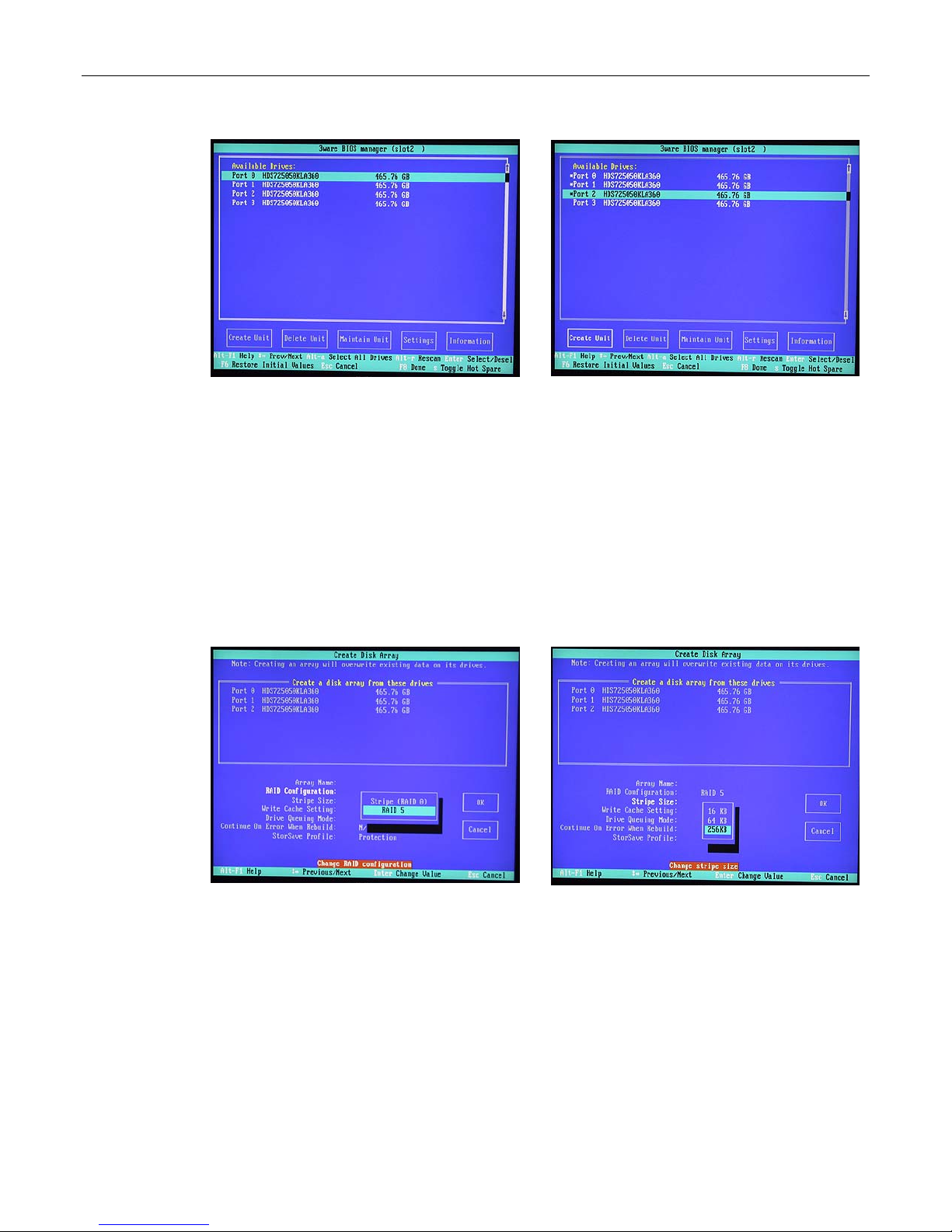

1) Start to power-up the system. When you see the BIOS message "<Alt-3> to access 3ware BIOS

Manager" (Figure 2-10) press and hold the <ALT> (alternate) key and – while still holding this key

– press the number "3" key. This will invoke the 3ware BIOS manager; in most cases, you will be

presented with a warning screen as shown in Figure 3-11.

Figure 3-10

Figure 3-11

Page 16

10 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

2) Press any key to continue, which will take you fully into the 3ware BIOS Manager. Observe that

the Create Unit option is selected by default. Use <Alt-A> to select all of the drives; asterisk "*"

characters appear to the left of each drive's port number to indicate that the drive has indeed

been selected (Figure 3-12)

Figure 3-12

Figure 3-13

3) Ensure that the Create Unit item is still selected (the white box shown to the bottom left of the

screen in Figure 2-12), and then press the <Enter> key to invoke the Create Disk Array screen

(Figure 3-13).

4) Use the up/down arrow keys to highlight the RAID Configuration item, and then press the

<Enter> key to access an associated pop-up dialog (Figure 3-14).

5) Use the up/down arrow keys to highlight the RAID 5 option, and then press the <Enter> key to

select this option.

Figure 3-14

Figure 3-15

6) Use the up/down arrow keys to highlight the Stripe Size item, and then press the <Enter> key to

access an associated pop-up dialog (Figure 3-15).

7) Use the up/down arrow keys to highlight the 256 KB option, and then press the <Enter> key to

select this option.

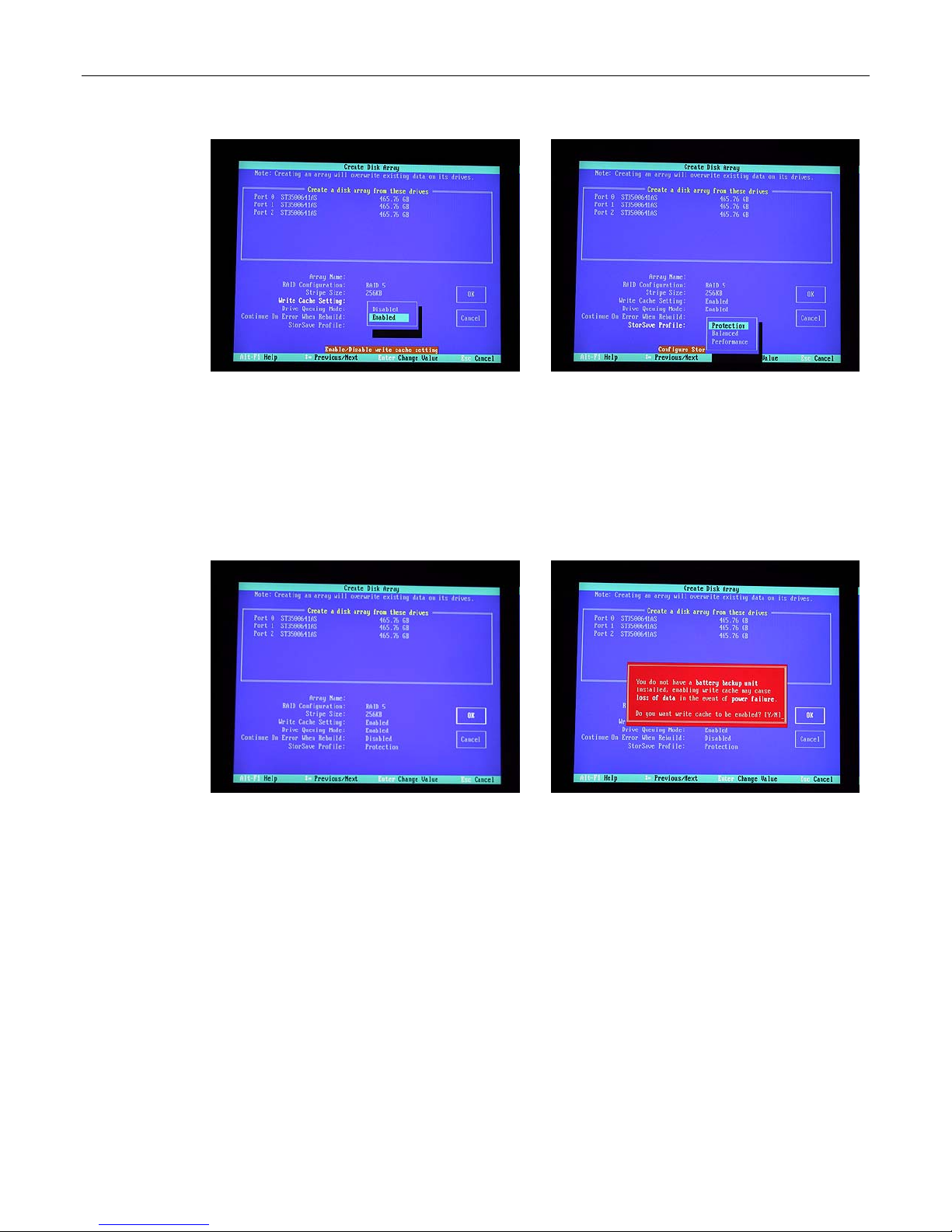

8) Use the up/down arrow keys to highlight the Write Cache Setting item, and then press the

<Enter> key to access an associated pop-up dialog (Figure 3-16).

9) Use the up/down arrow keys to highlight the Enabled option, and then press the <Enter> key to

select this option.

Page 17

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 11

Figure 3-16

Figure 3-17

10) Use the up/down arrow keys to highlight the StorSave Profile item, and then press the <Enter>

key to access an associated pop-up dialog (Figure 3-17).

11) Use the up/down arrow keys to highlight the Protection option, and then press the <Enter> key

to select this option.

12) Use the up/down/right/left arrow keys to highlight the OK item (Figure 3-18) and then press the

<Enter> key to save your changes.

Figure 3-18

Figure 3-19

13) You will be presented with a warning dialog as shown in Figure 3-19. Press the Y (yes) to allow

the write cache to be enabled (note that this mode significantly improves performance, but it can

result in a loss of data in the event of a power failure, so MaxVision STRONGLY recommends the

use of an uninterruptible power supply (UPS) with your system).

14) At this point, you will be presented with a summary description of the RAID array you have

defined (Figure 3-20).

15) Press the <F8> key to request that your array be established and to exit the 3ware BIOS

setup utility.

Page 18

12 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

Figure 3-20

Figure 3-21

16) You will be presented with a warning screen as shown in Figure 3-21. Press the Y (yes) key in

order to establish your array and exit the 3ware BIOS setup utility. The system will automatically

reboot itself in order to make your new RAID array available to the operating system. During the

boot process you will see the BIOS report the existence of your new RAID array.

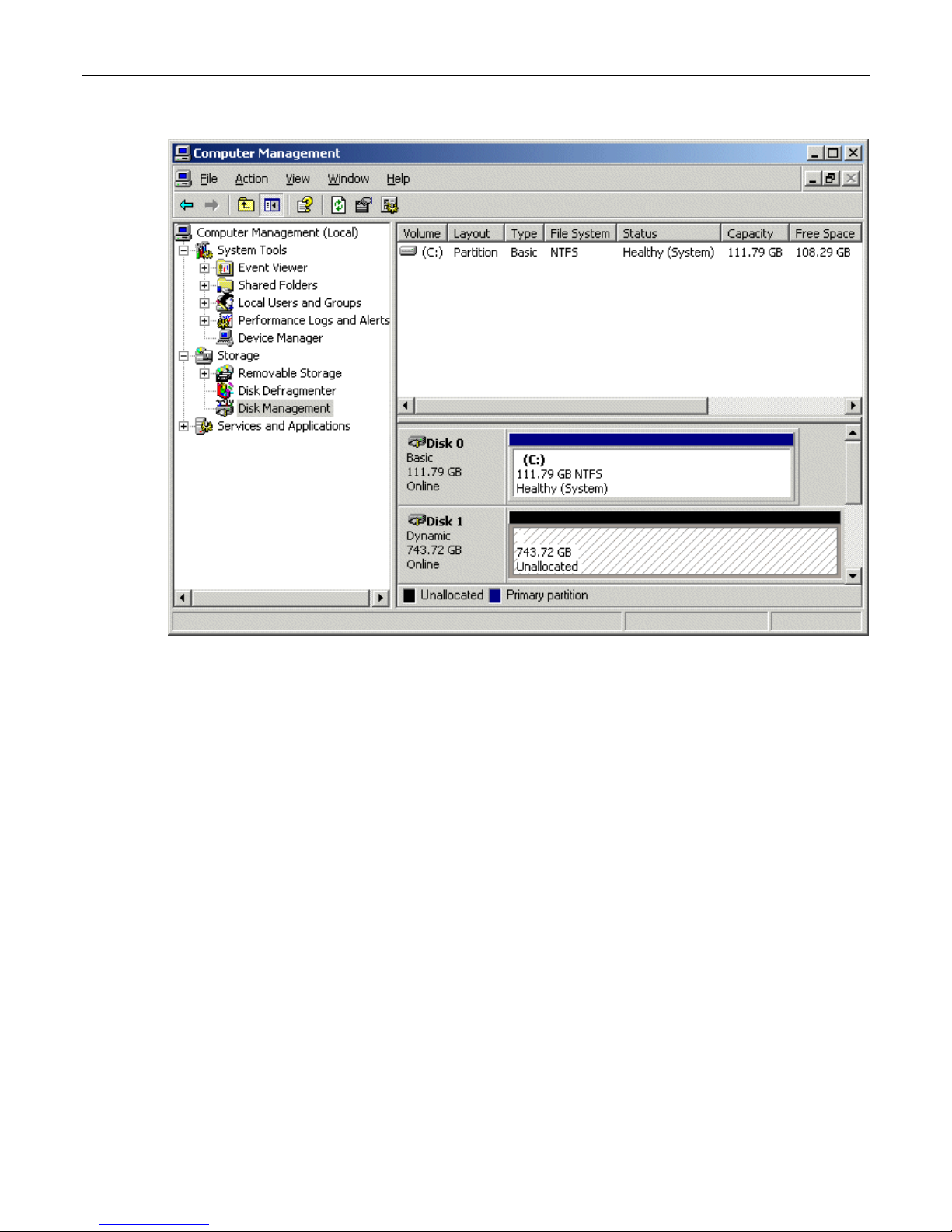

17) Once the system has booted up into Windows®, right-click on the My Computer icon and then

select the Manage option. In the ensuing Computer Management dialog, click on the Disk

Management item. As you have just created a new RAID array, this will automatically launch the

Initialize and Convert Disk Wizard as shown in Figure 3-22.

18) Click the Next button to be presented with the Select Disk to Initialize screen. Click the Disk 1

item as shown in Figure 3-23.

Figure 3-22. The Initialize and Convert Disk Wizard

Page 19

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 13

Figure 3-23

Figure 3-24

19) Click the Next button to be presented with the Select Disk to Convert screen. Click the Disk 1

item as shown in Figure 3-24.

20) Click the Next button to be presented with the Completing the Wizard screen as shown in

Figure 3-25, and then click the Finish button to perform the operations and exit the wizard.

21) Observe that the Disk Management area of the Computer Management dialog now shows Disk 1

as being a Dynamic disk that is – as yet – unallocated as shown in Figure 3-26.

Figure 3-25. The Completing the Wizard dialog

Page 20

14 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

Figure 3-26. Disk 1 is – as yet - unallocated

Note: In the case of the system used in this example, the system disk was 120 GB in size, while the

three data disks used to form the RAID array were each 400 GB in size.

Observe in Figure 3-26 that Disk 1 is shown as being approximately 800 GB in size, where 800 GB

equates to 2/3 of the 3 x 400 GB capacity of the data disks (the remaining 400 GB is used to provide

the RAID 5 redundancy).

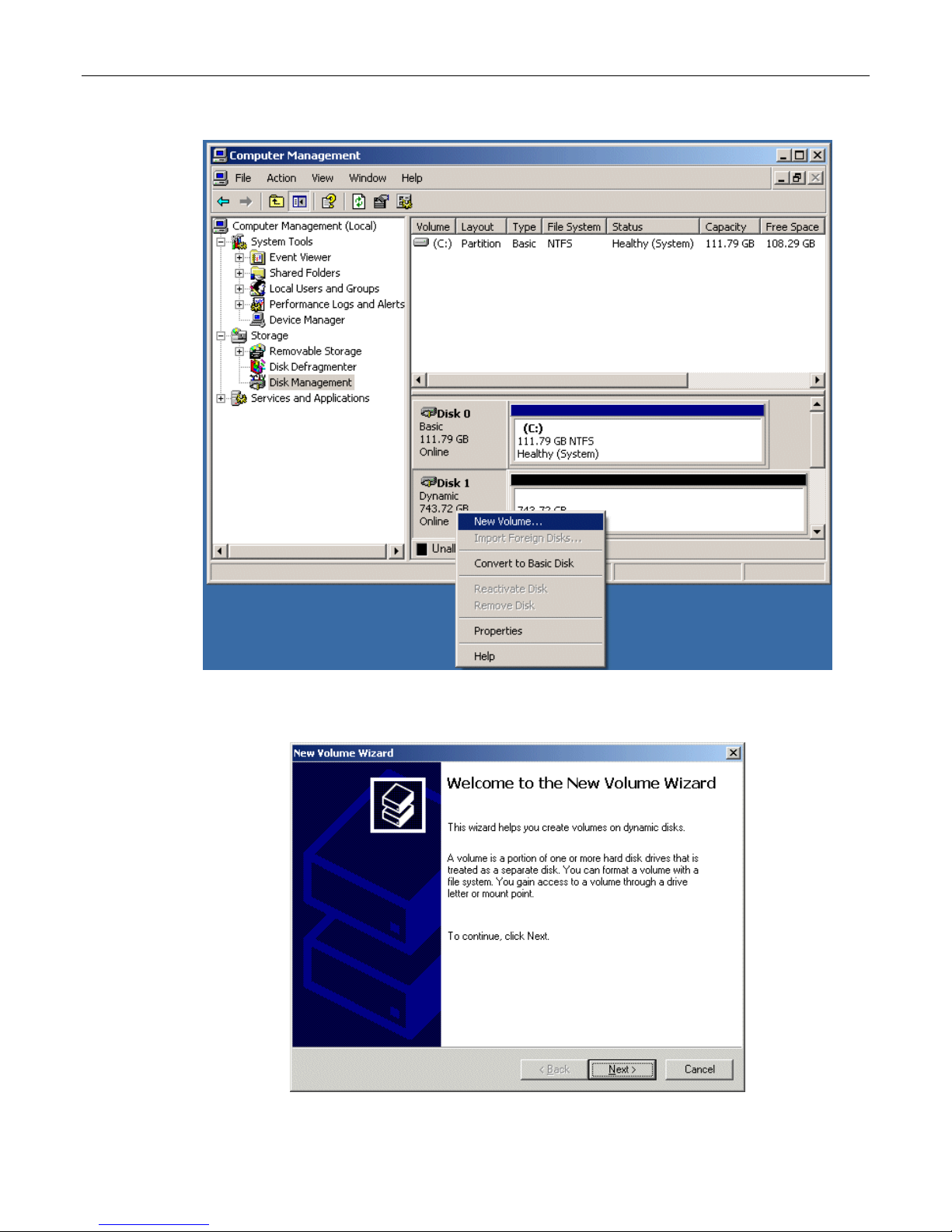

22) Now, right-click on the Disk 1 item in the lower-right-hand portion of the screen, and then select

the New Volume option from the ensuing pop-up menu as shown in Figure 3-27.

Page 21

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 15

Figure 3-27. Select the New Volume option

23) Observe the New Volume Wizard appear as shown in Figure 3-28.

Figure 3-28. The New Volume Wizard

Page 22

16 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

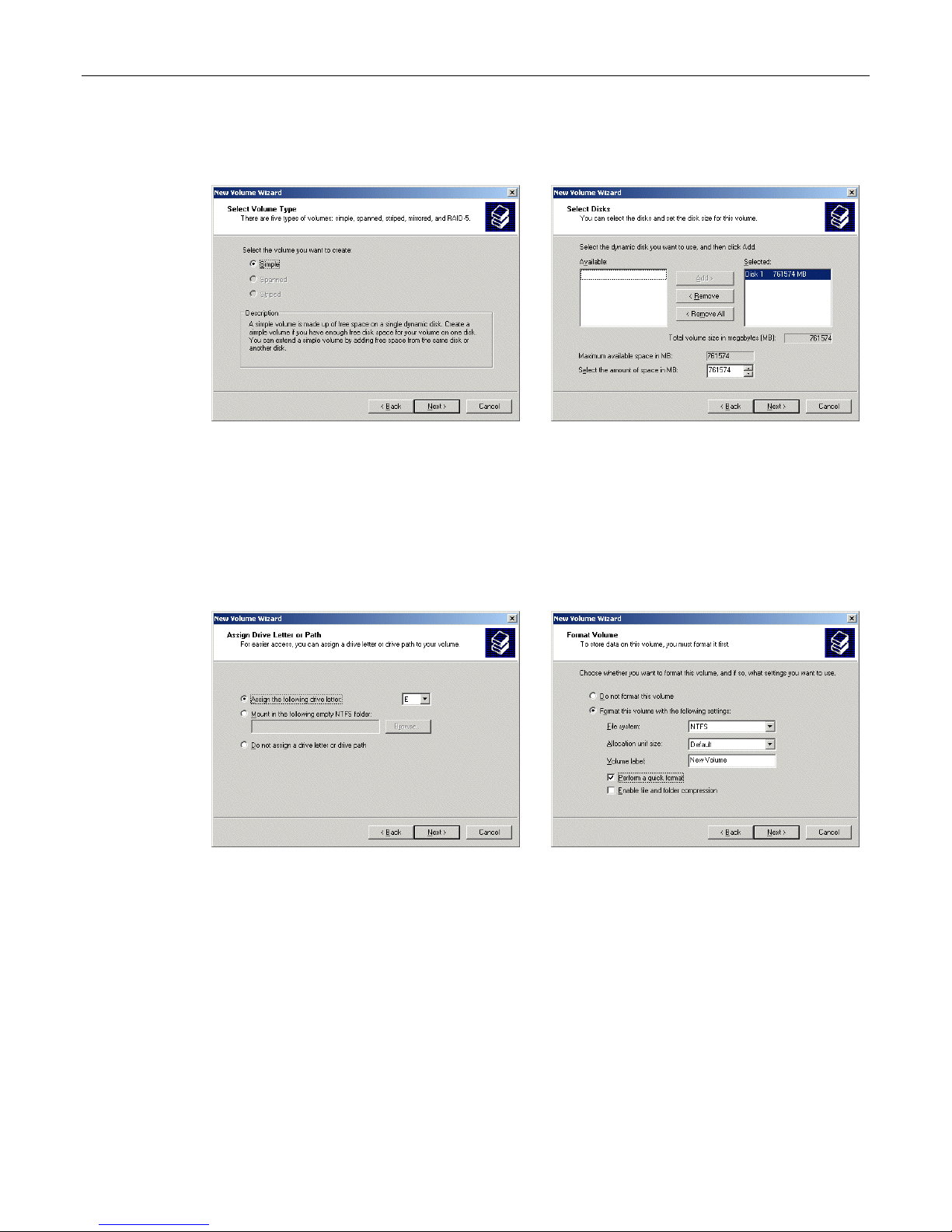

24) Click the Next button to be presented with the Select Volume Type screen. Click the Simple

option as shown in Figure 3-29.

Figure 3-29

Figure 3-30

25) Click the Next button to be presented with the Select Disk screen. Ensure that the Disk 1

item is selected and appears in the Selected column on the right-hand side of the dialog as

shown in Figure 3-30.

26) Click the Next button to be presented with the Assign Drive Letter or Path screen. Ensure

that the Assign the Following Drive Letter item is selected and accept the default letter

presented by the system (or enter a different letter if you require) as shown in Figure 3-31.

Figure 3-31

Figure 3-32

27) Click the Next button to be presented with the Format Volume screen. Click the Format this

volume with the following settings item as shown in Figure 3-32. Ensure that the settings

are File system = NTFS, Allocation unit size = Default, and Volume Label = user defined

(the default is "New Volume"). Also ensure that the Perform a quick format item is selected.

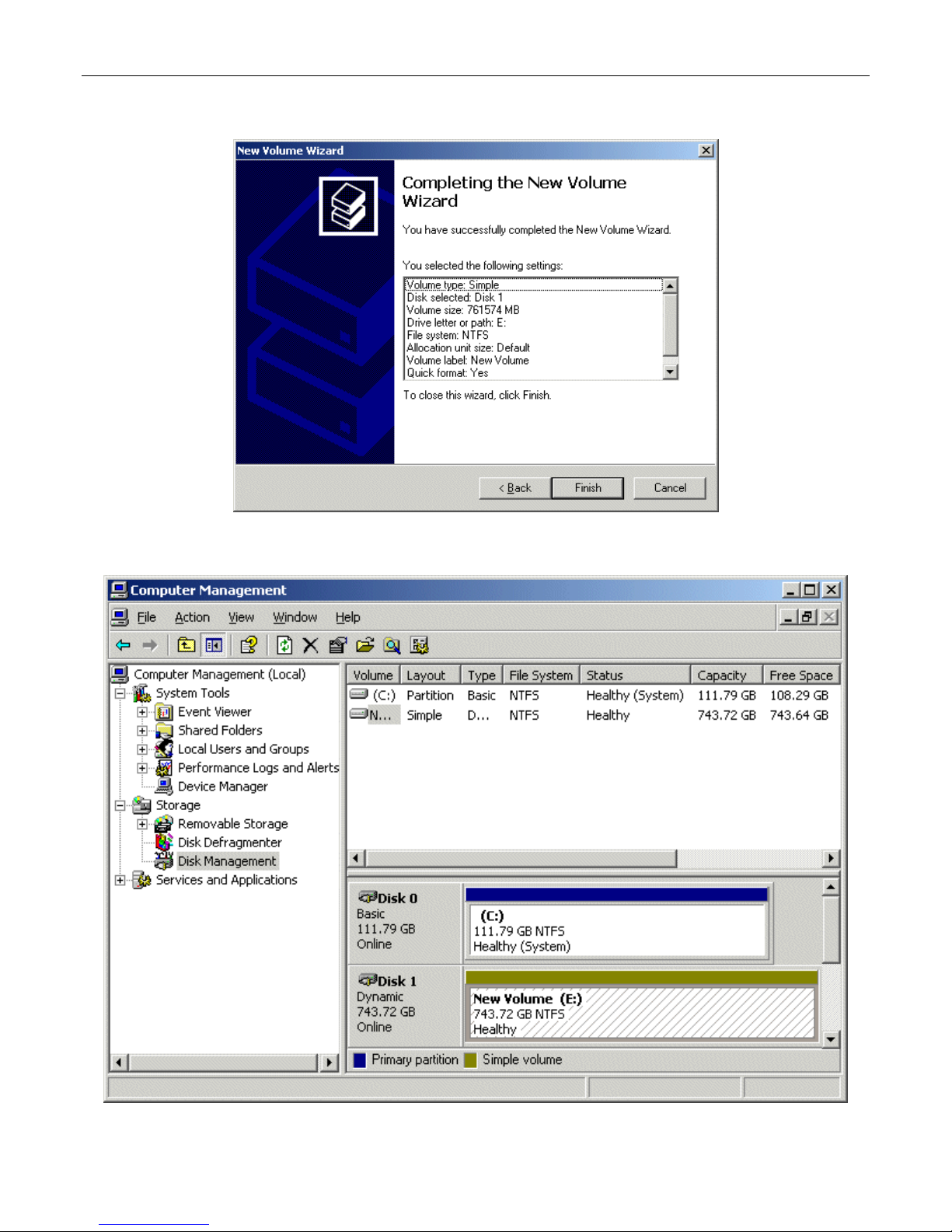

28) Click the Next button to be presented with the Completing the New Volume Wizard screen

as shown in Figure 3-33.

29) Click the Finish button to perform all of the operations and exit the wizard.

30) Observe that the Disk Management area of the Computer Management dialog now

shows Disk 1 as being Dynamic, Online, and Healthy as illustrated in Figure 3-34.

Page 23

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 17

Figure 3-33. The Completing the Wizard dialog

Figure 3-34. Disk 1 is now shown as being Dynamic, Online, and Healthy

Page 24

18 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

Rebuilding an Existing (Failed) 3ware RAID 5 Array

The discussions in this section assume that you originally have a good, working RAID 5 array. In this

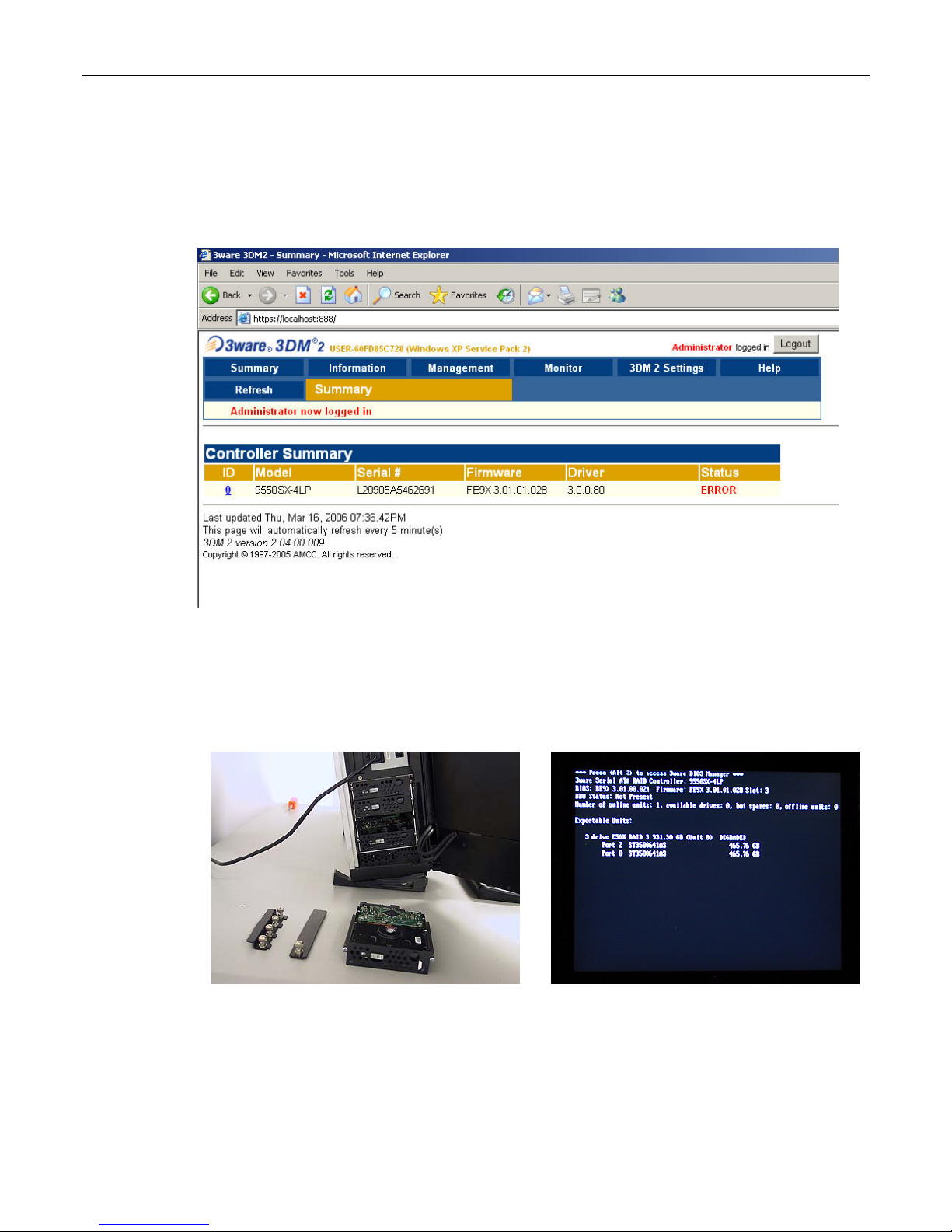

case, if you double-click the Connect to 3DM 2 icon on your desktop and login to the ensuing

webpage using the default password (which is 3ware), you will see that the status of your array looks

something like that shown in Figure 3-35.

Figure 3-35

Once you have observed this good array, exit out of the 3DM 2 web interface. At some stage, one of

the disks in the array may start to degrade or go completely off-line. For the purposes of these

discussions, we are going to power down the system, physically remove Disk 01 from the array

(thereby simulating a catastrophic failure on this disk) and power up the system back up again.

1) Power down the system and remove the center data disk (Disk 01) as shown in Figure 3-36.

Figure 3-36

Figure 3-37

2) Power the system back up again. The BIOS detects the fact that there is a problem with the RAID

array and displays an appropriate message (Figure 3-37). Press the <Pause Break> key to freeze

the display; from this (and Figure 3-8) you will be able to determine which drive has failed.

3) Press and hold the soft power key in order to power the system down.

Page 25

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 19

4) Remove the failed drive and replace it with a good drive of the same type and capacity

(remember that we only removed the drive above in order to simulate a catastrophic failure

scenario).

5) Power the system up again all the way into windows.

6) Double-click the Connect to 3DM 2 icon on your desktop and login to the ensuing webpage

using your administrator password (note that you may need to contact your IT department in

order to obtain this password).

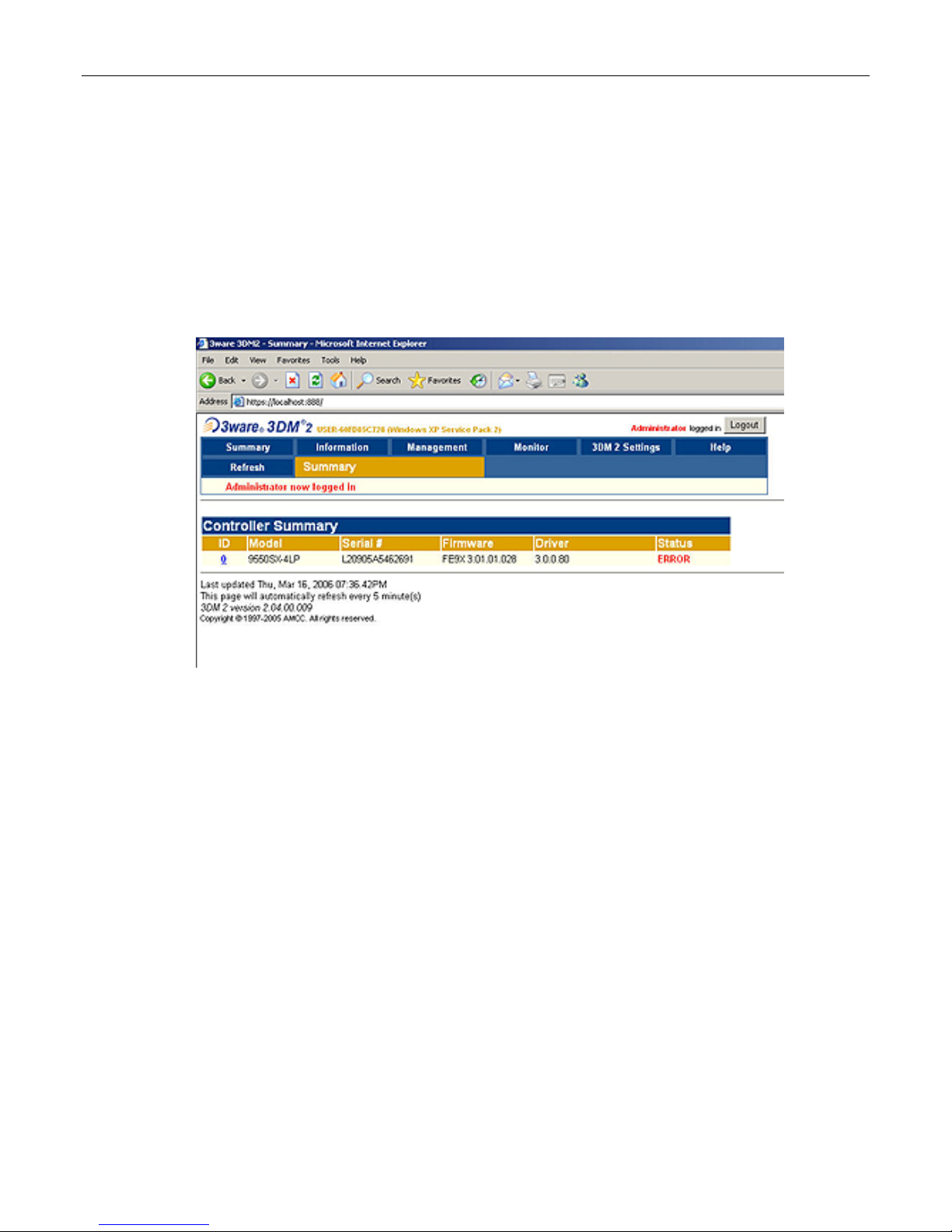

7) After you have logged in as the administrator, you will see a status of ERROR in the 3DM 2

interface (Figure 3-38).

Figure 3-38.

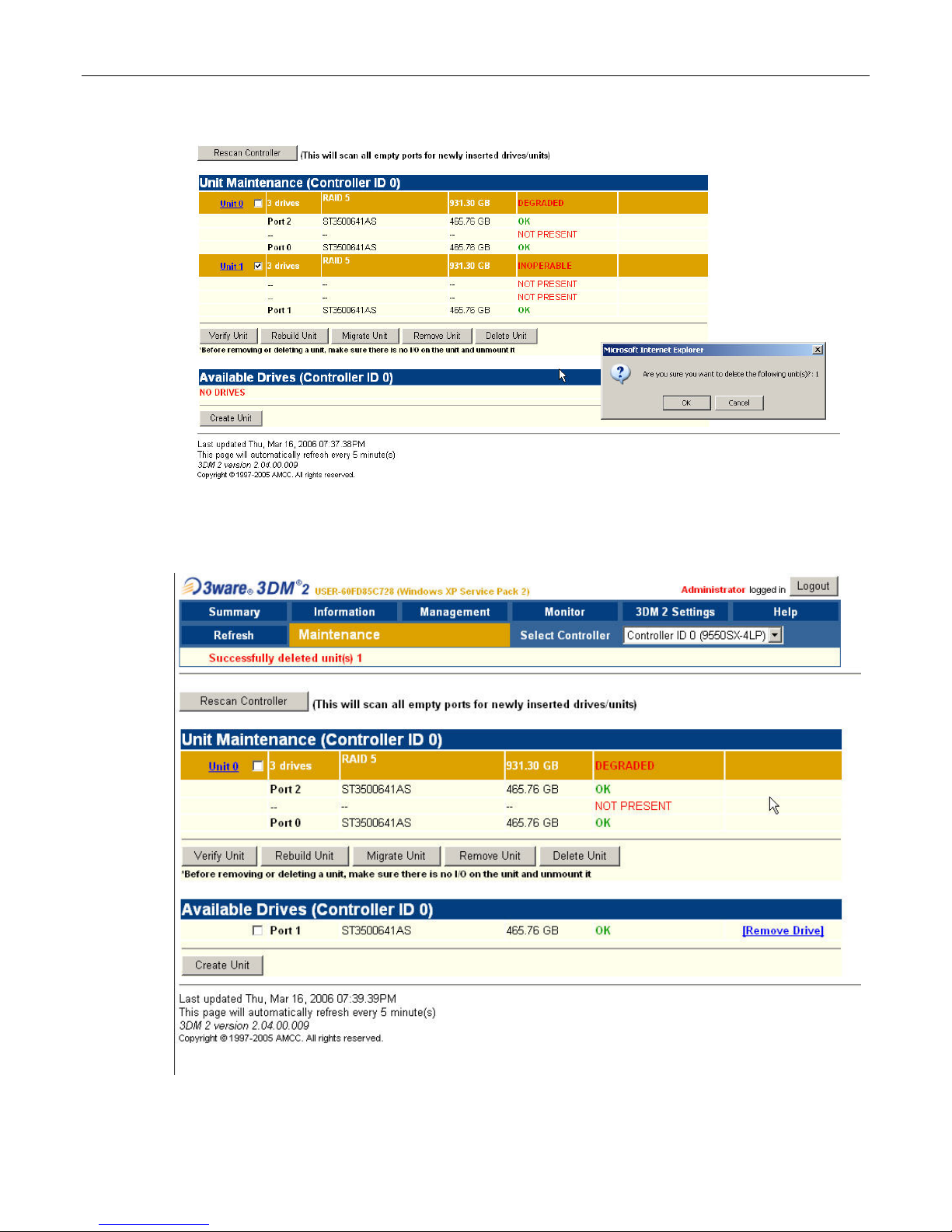

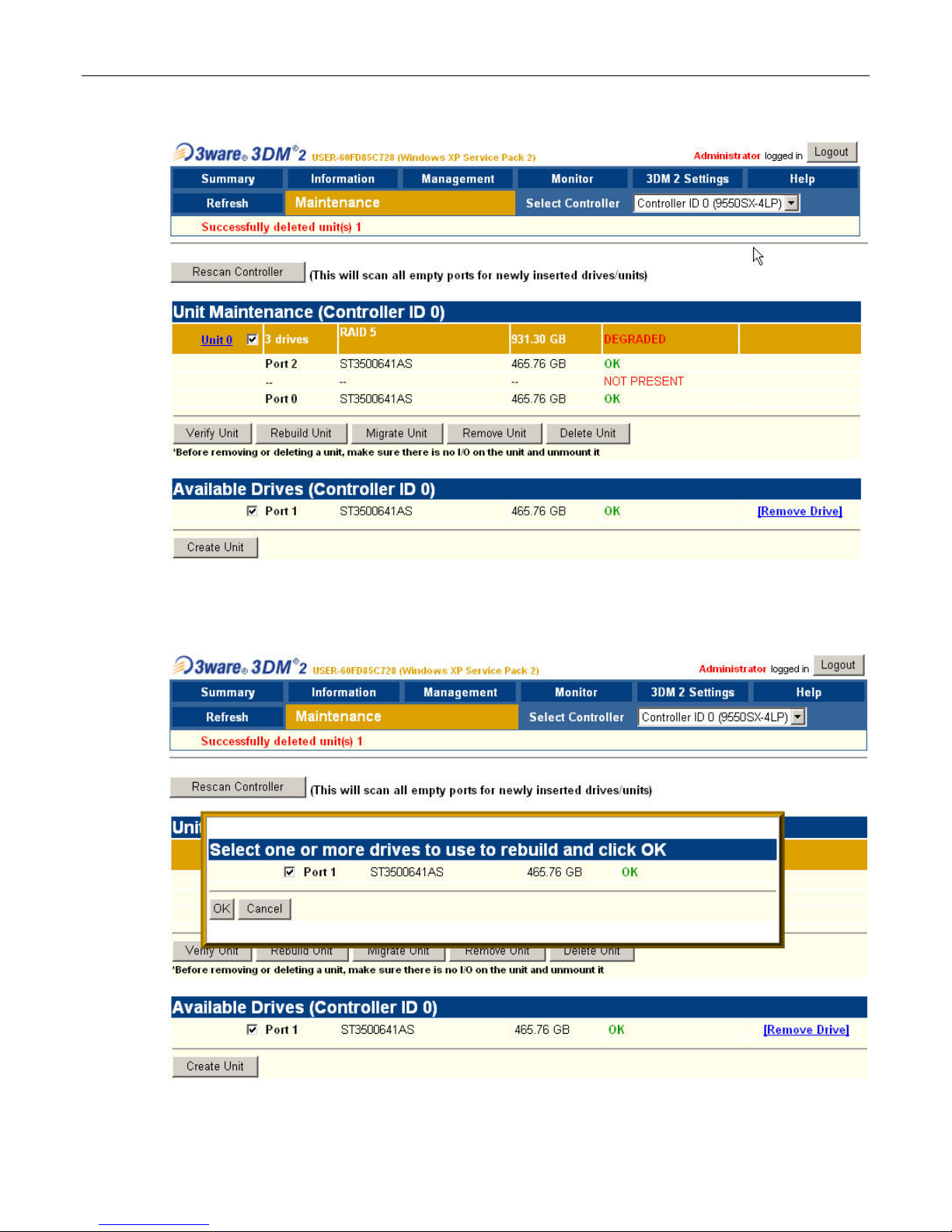

8) Observe that the system reports the two good drives as being in a DEGRADED unit as shown

in Figure 3-39.

9) Depending on the past history of the disk (whether or not it was previously part of a 3ware RAID

array) the system may report that the new disk is INOPERABLE as illustrated in Figure 3-39.

Alternatively, the system may report the new disk as being AVAILABLE as illustrated in Figure 3-40.

Assuming that the new disk is reported as being INOPERABLE, click the checkbox associated with

that unit (Unit 1 in this example) and then click the Delete Unit button. Observe that the system will

present you with a confirmation dialog as shown in Figure 3-39. Click the OK button, and observe

that the new disk is now reported as being AVAILABLE as illustrated in Figure 3-40.

10) Click the checkbox associated with the two good drives (shown as Unit 0 in this example) and also

click the checkbox associated the new replacement drive (shown as Port 1 in this example) and

then click the Rebuild Unit button associated with the two good drives as illustrated in Figure 3-41.

11) Observe the ensuing pop-up dialog box as shown in Figure 3-42. Click the checkbox associated

with the new drive, and then click the OK button.

Page 26

20 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

Figure 3-39.

Figure 3-40.

Page 27

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 21

Figure 3-41.

Figure 3-42.

Page 28

22 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

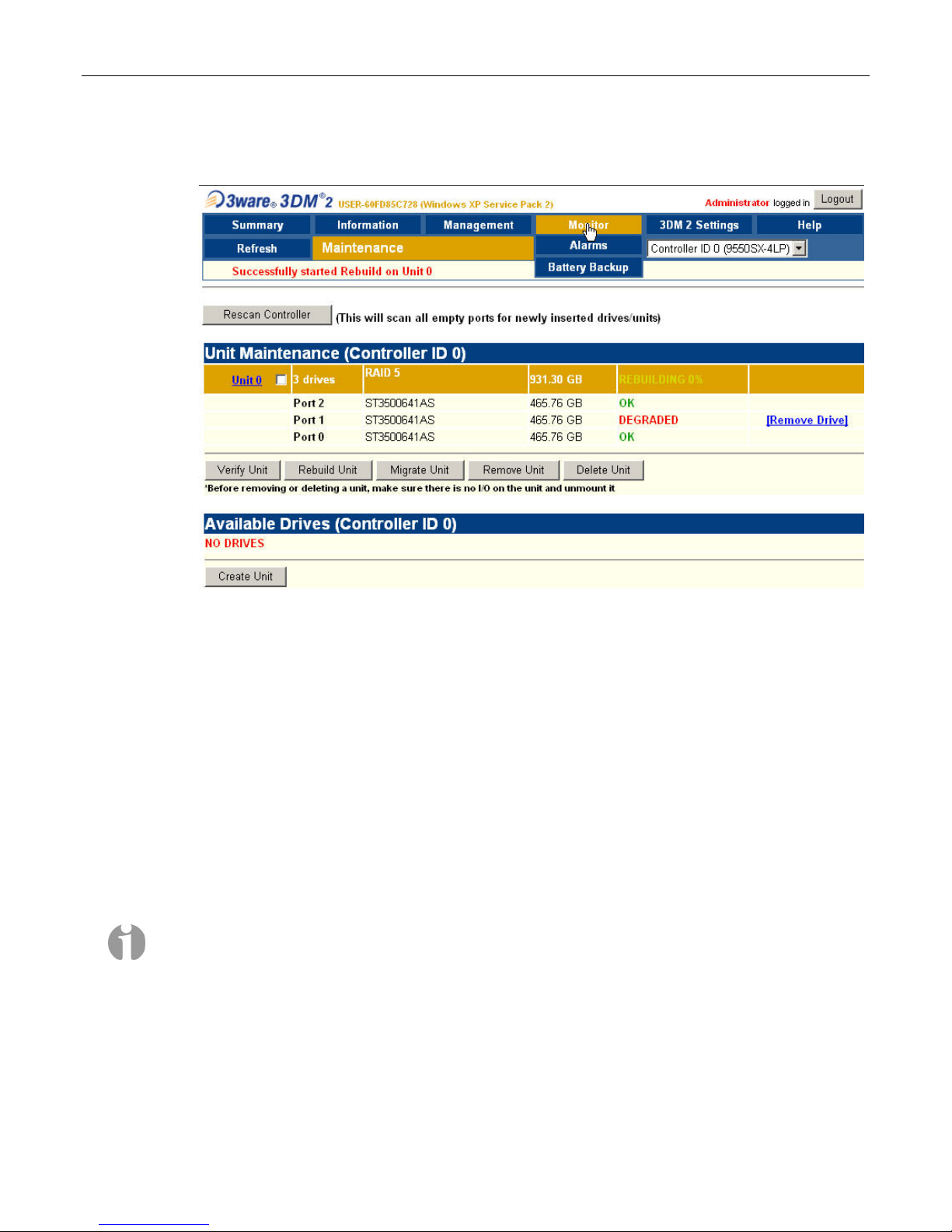

12) Observe that the replacement drive has now been incorporated into the RAID 5 array as

illustrated in Figure 3-43 (note that this array is still shown as being DEGRADED).

Figure 3-43.

When the new disk has been fully integrated into the array, the interface will reflect the

completion of the rebuild.

Note: This rebuild process can take a significant amount of time (14 hours in the case of our

example using 400 GB disks).

Note: The rebuild process is performed in the background, so you can continue to use your

system while the rebuild is taking place.

Configuring the RAID Array

(with Hot Spare and System Partition on RAID Array)

Note: Your MaxPac8230 may be configured for connection to the optional TeraPac3 8 drive SATA

Expansion. In this case the MaxPac8230 will include a 12 or 16 port SATA RAID 5 controller. This

chapter illustrates and assumes a 4 port SATA RAID 5 controller so the photos may be somewhat

different. Refer to Chapter 7 for a brief section on the MaxPac8230 connection to the TeraPac3 and

to the TeraPac3 User Operation and Maintenance Guide for more details.

Note that these discussions reflect system configurations that have the system partition established

on the RAID array itself (leaving a hot-spare drive) as illustrated in Figure 3-44. Configurations with a

separate system drive are discussed earlier in this chapter.

When you take possession of your MaxPac 8230 system, the RAID system will already have been

established, initialized, and verified. The instructions in this section are intended to address those rare

Page 29

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 23

situations where you need to replace a degraded/failed drive or you wish to rebuild the RAID system

from the ground up.

Your MaxPac system can contain up to four SATA hot-swappable hard disk drives presented in a

4-drive disk caddy. This caddy is located on the lower left-hand side of the main chassis under the

"Baghdad Filter" assembly as shown to the left of Figure 3-44 (the numbering of the disks is as shown

to the right of Figure 3-44). The main array – including the system partition – occupies disks 00, 01,

and 02, leaving disk 03 as the hot-spare (note that this is the initial/default configuration; once the hotspare disk has been deployed as discussed below, the failed-and-replaced disk will assume the role

of the new hot-spare).

Figure 3-44

Establishing the Array and Reloading the System Image

These discussions assume that you are reestablishing a system from the ground up, and that you

have four new disks in your disk caddy.

1) Start to power-up the system. When you see the BIOS message "<Alt-3> to access 3ware BIOS

Manager" (Figure 3-45) press and hold the <ALT> (alternate) key and – while still holding this key

– press the number "3" key. This will invoke the 3ware BIOS manager; in most cases, you will be

presented with a warning screen as shown in Figure 3-46.

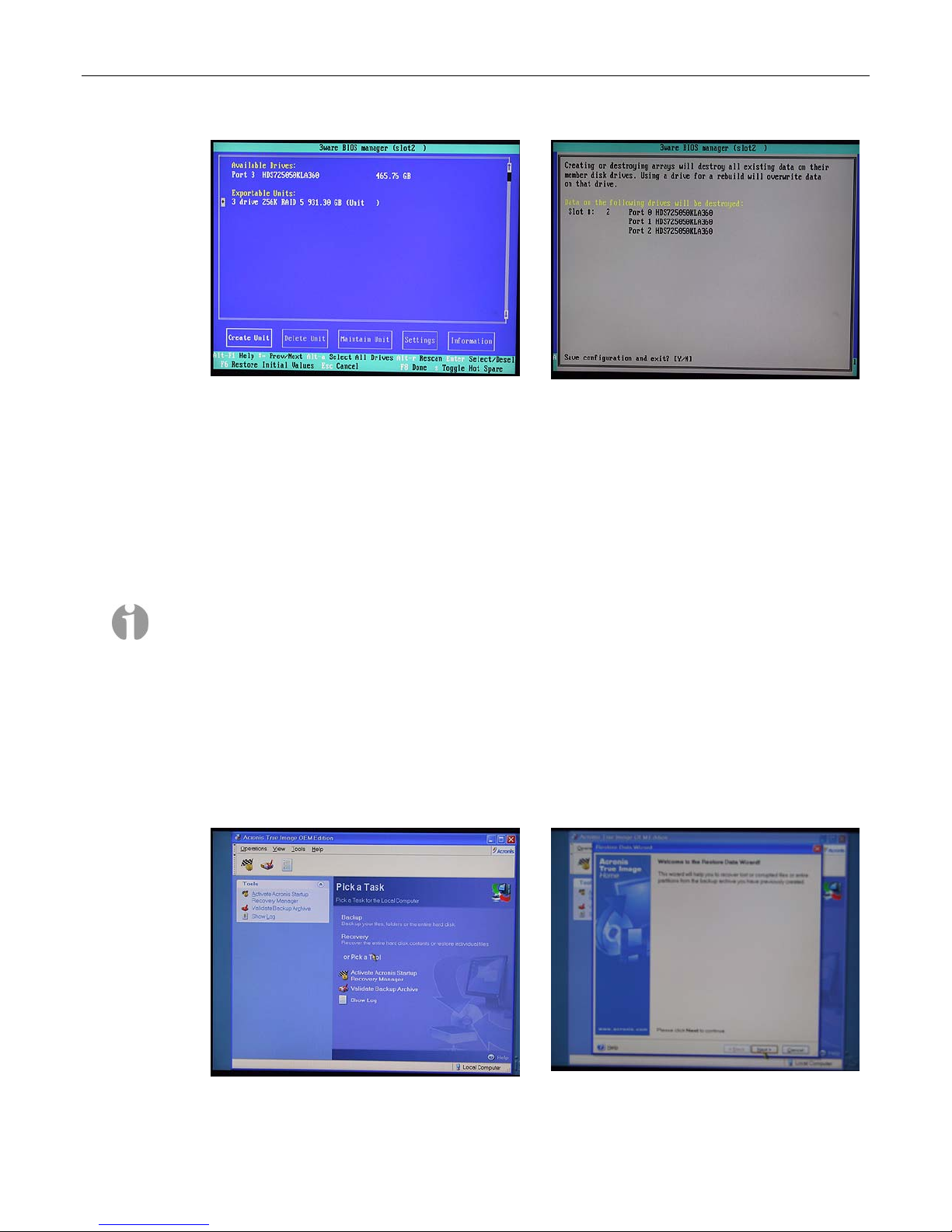

2) Press any key to continue, which will take you fully into the 3ware BIOS Manager. Observe that

the four disks are shown on the screen, but no drives are initially selected (Figure 3-47).

Figure 3-45

Figure 3-46

Page 30

24 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

Figure 3-47

Figure 3-48

3) Use the up/down arrow keys to highlight disks 00, 01, and 02 in turn; as each disk is highlighted,

press the <Enter> key to select it (selected disks are indicated with an asterisk '*' character as

shown in Figure 3-48). (Note that the reason disk 03 is not selected is that this is being reserved

as the hot-spare.)

4) Use the <Tab> key to highlight the Create Unit option (Figure 3-48), then press the <Enter> key

to key to invoke the Create Disk Array screen.

5) Use the up/down arrow keys to highlight the RAID Configuration item, and then press the

<Enter> key to access an associated pop-up dialog (Figure 3-49).

6) Now use the up/down keys to highlight the RAID 5 option and then press the <Enter> key to

select this option.

7) Next, use the up/down arrow keys to highlight the Stripe Size item, and then press the <Enter>

key to access an associated pop-up dialog (Figure 3-50).

8) Use the up/down arrow keys to highlight the 256 KB option, and then press the <Enter> key to

select this option.

9) Use the up/down arrow keys to highlight the Write Cache Setting item, and then press the

<Enter> key to access an associated pop-up dialog (Figure 3-51).

10) Use the up/down arrow keys to highlight the Enabled option, and then press the <Enter> key to

select this option.

Figure 3-49

Figure 3-50

Page 31

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 25

Figure 3-51

Figure 3-52

11) Use the up/down arrow keys to highlight the StorSave Profile item, and then press the <Enter>

key to access an associated pop-up dialog (Figure 3-52).

12) Use the up/down arrow keys to highlight the Protection option, and then press the <Enter> key

to select this option.

13) Use the up/down/right/left arrow keys to highlight the OK item (Figure 3-53) and then press the

<Enter> key to save your changes.

Figure 3-53

Figure 3-54

14) You will be presented with a warning dialog as shown in Figure 3-54. Press the Y (yes) key to

allow the write cache to be enabled [note that this mode significantly improves performance, but it

can result in a loss of data in the event of a power failure, so MaxVision STRONGLY

recommends the use of an uninterruptible power supply (UPS) with your system.

15) At this point, you will be presented with a summary description of the RAID array you have

defined (Figure 3-55).

16) Observe that this screen shows the array (3 drives) and the remaining uncommitted drive. Use

the up/down arrow keys to highlight the uncommitted drive and press the <Enter> key to select it

(the fact this has been selected will be indicated with an asterisk '*' character).

17) Now press the 'S' key to designate this selected drive as being the hot-spare (an annotation will

appear next to the drive confirming this status).

Page 32

26 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

Figure 3-55

Figure 3-56

18) Press the <F8> key to request that your array be committed and to exit the 3ware BIOS

setup utility.

19) You will be presented with a warning screen as shown in Figure 3-56. Before you do anything

else, ensure that the bootable recovery DVD supplied in the accessory pack is in the system's

CD/DVD drive. In the case of a multiple DVD image, ensure Disk #1 is in the drive. Then press

the Y (yes) key in order to establish your array, exit the 3ware BIOS setup utility, and

automatically reboot the machine.

Note: If you are using an image CD/DVD you've created yourself as discussed in Appendix A,

and if that CD/DVD (or the first CD/DVD in a set) has the Acronis Bootable Rescue Media

software on it, then simply insert this disk in the drive and proceed to point 20 below.

Alternatively, if your CD/DVD does not have the Acronis Bootable Rescue Media software on it,

then first insert the bootable recovery DVD supplied by MaxVision in the drive and reboot as

discussed in point 20 below. However, before proceeding to point 21, remove the bootable

recovery DVD supplied by MaxVision from the drive and replace it with the first disk from your

own image.

20) The system will automatically reboot itself from the recovery disk in the DVD drive. Following

the Acronis splash, you will be presented with the Pick a Task page in the Acronis True Image

application (Figure 3-57).

Figure 3-57

Figure 3-58

Page 33

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 27

21) Click the Recovery item to be presented with the first page from the Restore Data Wizard

(Figure 3-58).

22) Click the Next button to be presented with the Archive Selection screen (Figure 3-59).

Figure 3-59

Figure 3-60

23) Ensure that the CD Drive item in the left-hand selection pane is expanded (if not, click the '+'

icon next to this item) and then use the mouse to click on the image (*.tib) file you will see there

(Figure 3-59).

Note: In the case of a multi-CD/DVD image set, the system will present you with a message

saying that this is not the last created volume in the archive and requesting you to insert the

last created volume. In this case, replace the current CD/DVD with the last disk from the set,

click on the *.tib file on this disk, and proceed to point 24 (at some stage you will be prompted

to return to the first disk).

24) Click the Next button to be presented with the Restoration Type Selection page (Figure 3-60).

25) Select the Restore Disks or Partition item and then click the Next button to be presented with

the Partition or Disk to Restore page (Figure 3-61).

26) Select the NTFS (C) option (a tick-mark indicates that the option has been selected) and then

click the NEXT button to be presented with the Restored Partition Location page (Figure 3-62).

Figure 3-61

Figure 3-62

Page 34

28 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

27) Select the Unallocated (Disk 1) item and then click the Next button to be presented with the

Restored Partition Type page (Figure 3-63).

Figure 3-63

Figure 3-64

28) Select the Active item and then click the Next button to be presented with the Restored

Partition Size page (Figure 3-64).

29) We have chosen to establish a 200 GB system partition in this example; the remaining "Free

Space" will automatically be allocated to the data portion of the RAID 5 array. Click the Next

button to be presented with the Next Selection window (Figure 3-65)

Figure 3-65

Figure 3-66

30) Select the No, I Do Not option and then click the Next button to be presented with the Restore

Operation options page (Figure 3-66).

31) Simply click the Next button to be presented with the Restore Data Wizard summary screen

(Figure 3-67)

Page 35

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 29

Figure 3-67

Figure 3-68

32) Click the Proceed button to initiate the restoration, at which time you will be presented with the

Operation Progress dialog (Figure 3-68), which will reflect the status of the restoration. (In the

case of a multi-DVD image, the system will inform you as and when to insert subsequent

DVDs).

33) Once the restoration process has been completed, eject the DVD from the CD/DVD drive,

power-down the system by holding the Soft-Power button on top of the center display for

approximately five seconds, and then power-up the machine using the Soft Power button to

boot-up into Windows.

Note: Once you have re-loaded the original MaxVision-supplied image, you will also have to rerun the initialization procedures – including re-activating/re-registering your OS license – as

described earlier in this manual.

34) After the system has booted up into Windows (and you've re-run the initialization procedures as

noted above), right-click on the My Computer icon and then select the Manage option. In the

ensuing Computer Management dialog, click on the Disk Management item (Figure 3-69).

35) Right-mouse-click in the Unallocated area and select the New Partition item in order to be

presented with the New Partition Wizard as shown in Figure 3-70.

36) Click the Next button, then select the Perform a Quick Format option (ensure the File System

type is set to NTFS), and then click the OK button. The Computer Management window will

reflect your newly formatted partition (Figure 3-71).

Page 36

30 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

Figure 3-69

Figure 3-70

Figure 3-71

Page 37

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 31

Rebuilding an Existing (Failed) 3ware RAID 5 Array

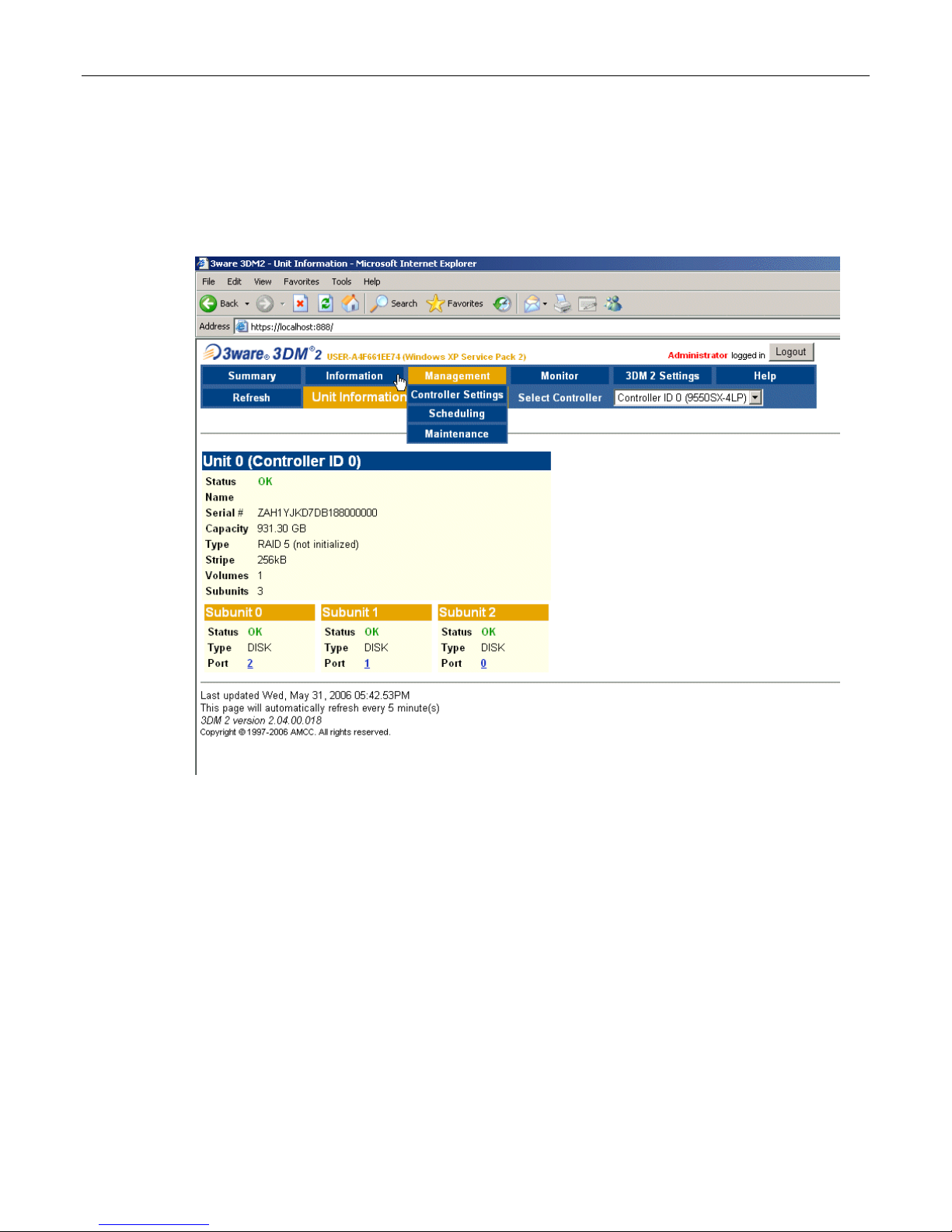

The discussions in this section assume that you originally have a good, working RAID 5 array

(consisting of 3 drives for the array and 1 Hot Spare). In this case, if you double-click the Connect to

3DM 2 icon on your desktop and login to the ensuing webpage using the default password (which is

3ware), you will see that the status of your array looks something like that shown in Figure 3-72.

Once you have observed this good array, exit out of the 3DM 2 web interface. At some stage, one of

the disks in the array may start to degrade or go completely off-line. For the purposes of these

discussions, we are going to power down the system, physically remove Disk 01 from the array

(thereby simulating a catastrophic failure on this disk) and power up the system back up again.

1) Power down the system and remove the center data disk (Disk 01) as shown in Figure 3-73.

2) Power the system back up again. The BIOS detects the fact that there is a problem with the RAID

array and displays an appropriate message (Figure 3-74). Press the <Pause Break> key to freeze

the display; from this (and Figure 3-44) you will be able to determine which drive has failed. (In

the case of our example, the RAID array is shown as being "Degraded" and only Ports 0 and 2

are shown as being available.)

3) Press the <Pause Break> key again to un-freeze the display. The system will automatically bring

the hot-spare drive online and integrate it into the array.

4) As soon as possible after the array has been reconstructed as discussed in point 3, power down

the system, remove the failed drive (in this case it was previously removed to simulate the

failure), and replace it with a good drive of the same type and capacity.

Figure 3-72

Page 38

32 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

Figure 3-73

Figure 3-74

5) Start to power-up the system. When you see the BIOS message "<Alt-3> to access 3ware BIOS

Manager", press and hold the <ALT> (alternate) key and – while still holding this key – press the

number "3" key. This will invoke the 3ware BIOS manager; in most cases, you will be presented

with a warning screen; press any key to continue, which will take you fully into the 3ware BIOS

Manager.

6) Observe that this screen shows the array (3 drives) and the remaining uncommitted drive (the

new drive you've just added to the system). Use the up/down arrow keys to highlight the

uncommitted drive and press the <Enter> key to select it (the fact this has been selected will be

indicated with an asterisk '*' character).

Note: If this drive was ever part of a previous 3ware RAID array, it will show up as a "Failed

Array" comprising only a single drive. In this case, use the <Tab> key to select the Delete Unit

option and then press the <Enter> key to select this option and delete the drive as an array.

7) Now press the 'S' key to designate this selected drive as being the new hot-spare (an annotation

will appear next to the drive confirming this status).

8) Press the <F8> key to exit the 3ware BIOS utility and automatically reboot the system.

9) Power the system up all the way into Windows.

Page 39

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 33

Chapter 4: Module Replacement and

Upgrade Procedures for Single-Screen

Systems

Introduction

The instructions in this chapter describe how to replace and upgrade various modules in your

MaxPac unit.

Note: Generally speaking, you should only access the MaxPac internals under the direction of

MaxVision support. In some cases, performing unauthorized procedures or using components that

have not been tested and approved by MaxVision may invalidate your warranty.

Note: Power-down your MaxPac system (shut down Windows® and then turn the hard power switch

to its Off position) and then remove the power cable before performing any of the procedures

discussed in this chapter. Also please be aware of static discharge when working on your MaxPac. In

General, touch the metal part of the chassis to discharge any static prior to handling any delicate

electronic parts.

Note: When accessing the system internals and/or performing module upgrade procedures, you are

quickly going to end up with a lot of screws and other small items. In order to keep track of things and

to prevent misplacing any parts, it is strongly recommended to have a plastic container divided into

small compartments and to label these compartments as you work.

Required Tools and Techniques

Most of the module replacement and upgrade procedures discussed in this chapter can be performed

using only a pair of #1 (small tip) and #2 (regular tip) Phillips screwdrivers. However, some

procedures will require additional tools as discussed in Appendix C.

Note: It is extremely important that you use only high-quality tools so as to avoid any slippage and

stripping of screw heads and threads. Furthermore, in order to avoid any slippage, it is VERY

important to apply adequate force in the form of firm and steady pressure. See Appendix C for

details on the tools required to service the system.

Note: It is highly recommended that you use magnetized screwdrivers so as to prevent screws from

dropping inside the case and/or aiding in retrieving them if they do drop inside the case. (If your

screwdriver isn’t already magnetized, you can make it so by repeatedly “stroking” the blade with a

permanent magnet.

Names and Types of Screws

MaxPac X-Class systems use a variety of different screw types. In order to help you follow the

instructions in this chapter, details on these screws are provided in Appendix C.

Page 40

34 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

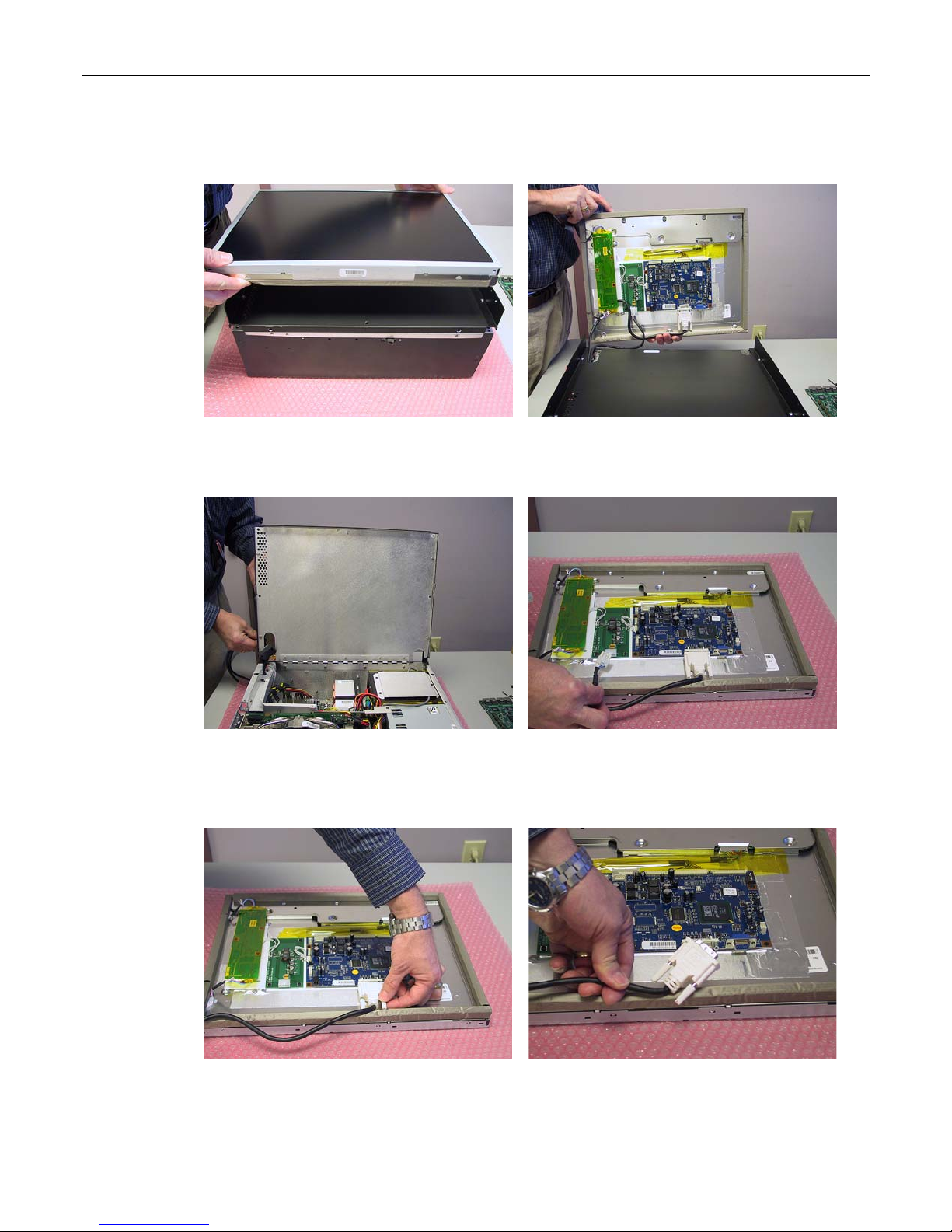

Flat Panel Display Module

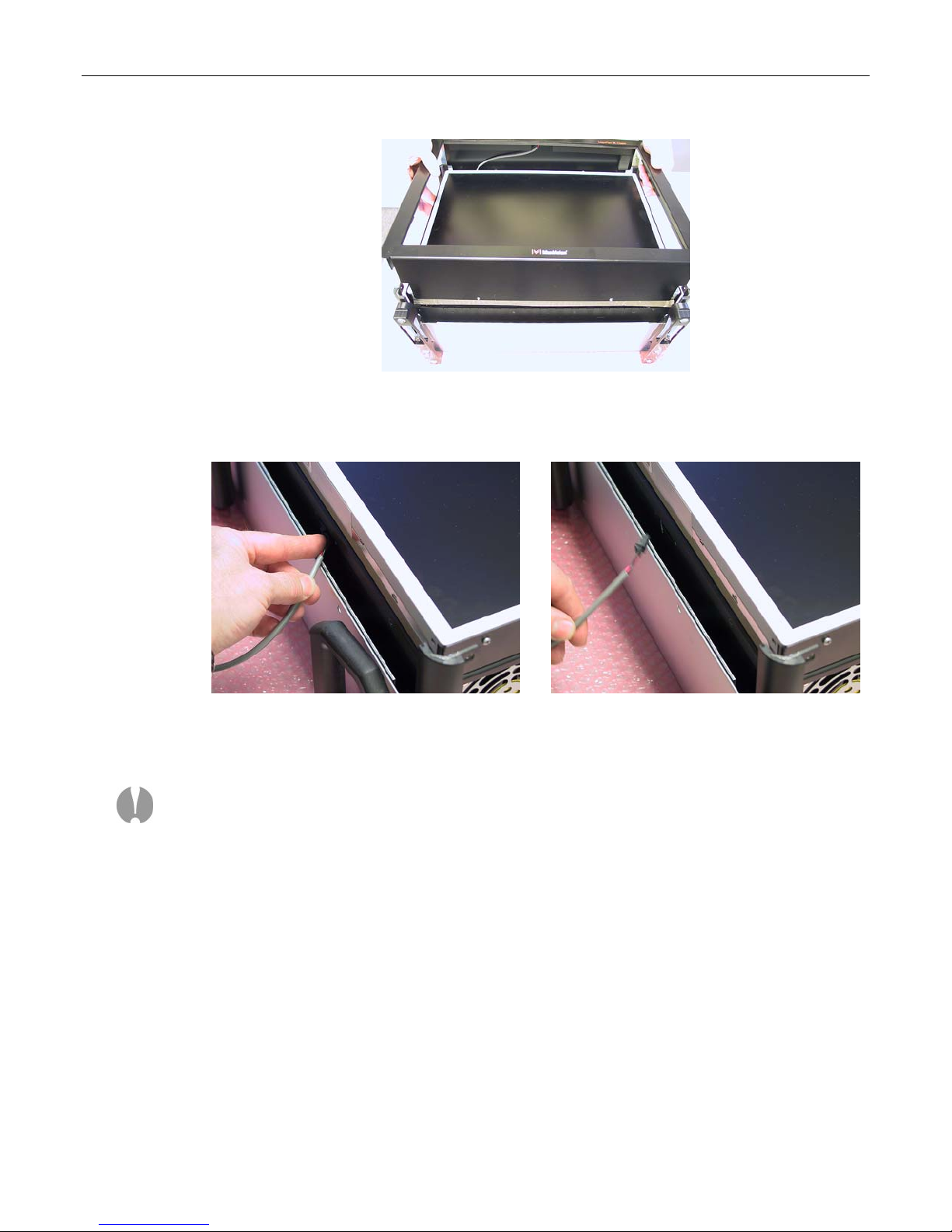

1) Lay the system flat on the table with the display facing upwards (it is recommended that you lay

the system on bubble wrap in order to protect the finish).

2) Use a Phillips #1 screwdriver to remove the four 4-40 3/16" black countersunk screws – two on

each side – holding the monitor bezel to the main chassis (Figures 4-1 and 4-2).

Figure 4-1

3) Use a Phillips #2 screwdriver to remove the four silver screws – two on the top and two on the

bottom holding the main chassis to the monitor bezel (Figures 4-3 and 4-4).

Figure 4-3

4) Gently lift the monitor bezel away from the main chassis. Observe the soft power cable as

illustrated in Figure 4-5.

Figure 4-2

Figure 4-4

Page 41

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 35

Figure 4-5

5) Disconnect the soft power cable as illustrated in Figures 4-6 and 4-7.

Figure 4-6

Figure 4-7

6) Gently lift the inner chassis – including the monitor assembly – away from the outer chassis as

illustrated in Figures 4-8 and 4-9.

Figure 4-8

Figure 4-9

Page 42

36 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

7) Use a Phillips #2 screwdriver to remove the four black countersunk screws holding the screen

assembly to the chassis – two on the top (Figure 4-10) and one on each side (Figure 4-11 and

Figure 4-12).

Figure 4-10

Figure 4-11

8) Observe that the monitor assemble is hinged. Gently lift the display on the side opposite the

hinge (Figure 4-13) until it is in its fully open position).

Figure 4-12

Figure 4-13

Note: The display folds all of the way over until it's horizontal. In fact, it will open further until it

touches the table, but this may strain the hinge. For this reason, it is strongly recommended that

you place some object under the monitor to support it (this object should be covered by some soft

material so as to protect the screen).

9) Use a screwdriver to disengage the latch on the monitor's power cable (Figure 4-14) and then

disconnect this cable (Figure 4-15).

Page 43

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 37

Figure 4-14

Figure 4-15

10) Use a Philips #1 screwdriver to remove the two screws attaching the over-molded DVI data cable

connector to the graphics board (Figure 4-16) and gently pull the connector a little way from the

system (Figure 4-17).

Figure 4-16

Figure 4-17

11) Use a Phillips #2 screwdriver to remove the two 6-32 screws attaching the access plate – and the

special linking bracket – to the inner chassis (Figure 4-18).

Figure 4-18

12) Lift the linking bracket away from the system (Figure 4-19) then lift the access plate away from

the chassis (Figure 4-20).

Figure 4-19

Page 44

38 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

Figure 4-20

Figure 4-21

13) Carefully cut the cable ties as illustrated in (Figure 4-21).

14) Gently lift the monitor power and data cables out of the slot as illustrated in (Figure 4-22).

Figure 4-22

15) Place the monitor power and data cables inside the chassis out of the way while you close the

display and remove the four screws – two on each side – holding the LCD panel to the main

monitor display assembly (Figures 4-23 and 4-24).

Figure 4-23

Figure 4-24

Page 45

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 39

16) Observe that the LCD panel can now be lifted away from the main display assembly (Figures 4-25

and 4-26). However, this step should not be performed just yet, instead proceed to step (18).

Figure 4-25

Figure 4-26

17) While carefully supporting the LCD panel, gently raise the main monitor assembly and "snake"

the cables through the slot as illustrated in Figure 4-27.

Figure 4-27

Figure 4-28

18) Gently lift the LCD away from the inner chassis and lay it face down on a protective surface.

Disconnect the power cable from the LCD (Figure 4-28). Unscrew the jack screws attaching the

data cable to the LCD (Figure 4-29) and detach this cable (Figure 4-30).

Figure 4-29

19) Take the replacement LCD provided by MaxVision support and incorporate it into the system by

performing the steps described above in reverse order.

Figure 4-30

Page 46

40 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

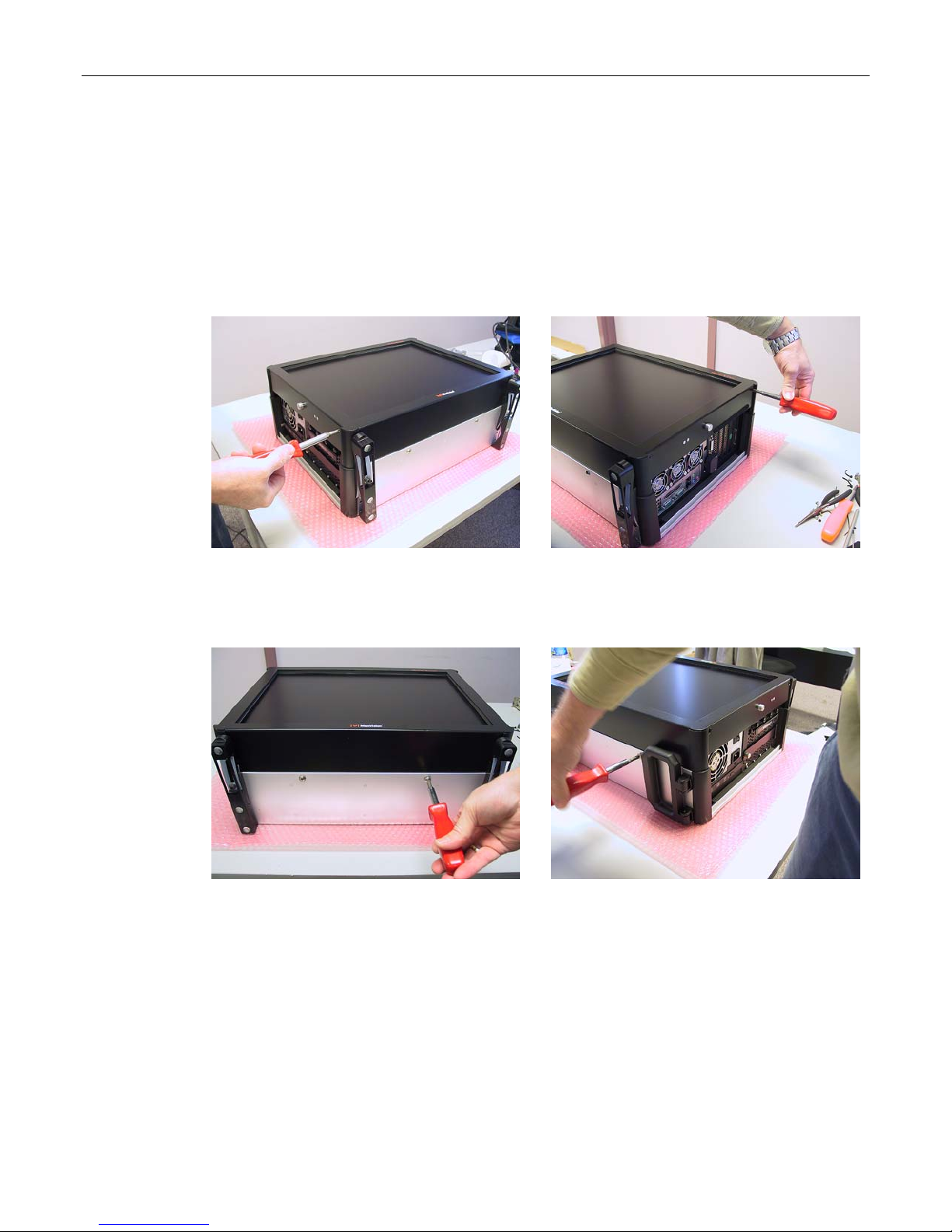

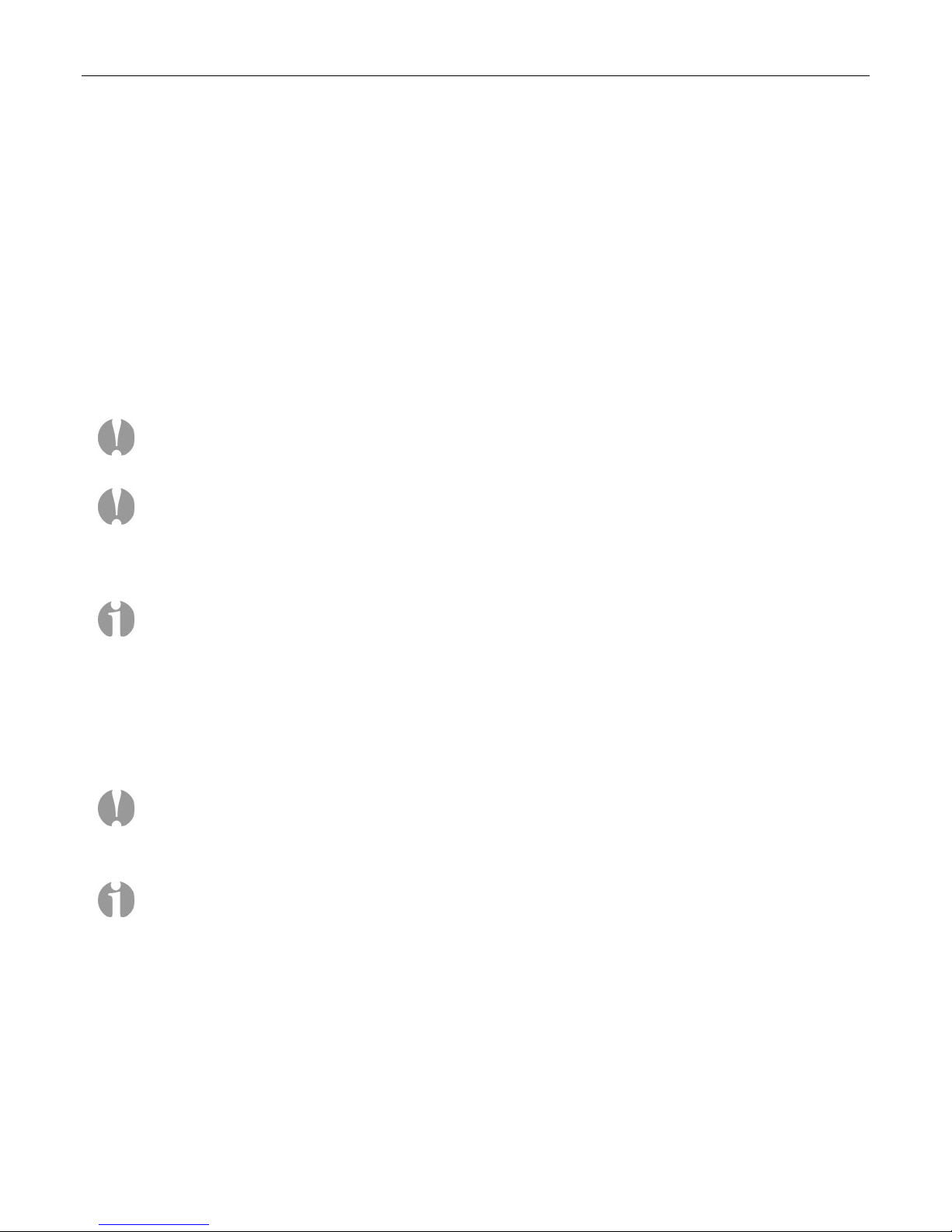

Opening the Display Assembly into its Service Position

In order to replace and/or upgrade modules inside the MaxPac system, it is necessary to open the

display assembly into its service position as discussed below.

1) Lay the system flat on the table with the display facing upwards (it is recommended that you lay

the system on bubble wrap in order to protect the finish).

2) Use a Phillips #1 screwdriver to remove the four 4-40 3/16" black countersunk screws – two on

each side – holding the monitor bezel to the main chassis (Figures 4-31 and 4-32).

Figure 4-31

3) Use a Phillips #2 screwdriver to remove the four silver screws – two on the top and two on the

bottom holding the main chassis to the monitor bezel (Figures 4-33 and 4-34).

Figure 4-33

4) Gently lift the monitor bezel away from the main chassis. Observe the soft power cable as

illustrated in Figure 4-35.

Figure 4-32

Figure 4-34

Page 47

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 41

Figure 4-35

5) Disconnect the soft power cable as illustrated in Figures 4-36 and 4-37.

Figure 4-36

Figure 4-37

Note: Certain components can be replaced without removing the inner chassis from the outer

chassis. Some of these components include memory, main power supply, PCI and PCI Express

boards. While it is fairly easy to remove the inner chassis for the Single-Display XRA1 it is more

difficult for the Dual/Triple-Display XRA2/3. Some photos will include the outer chassis while

others will not.

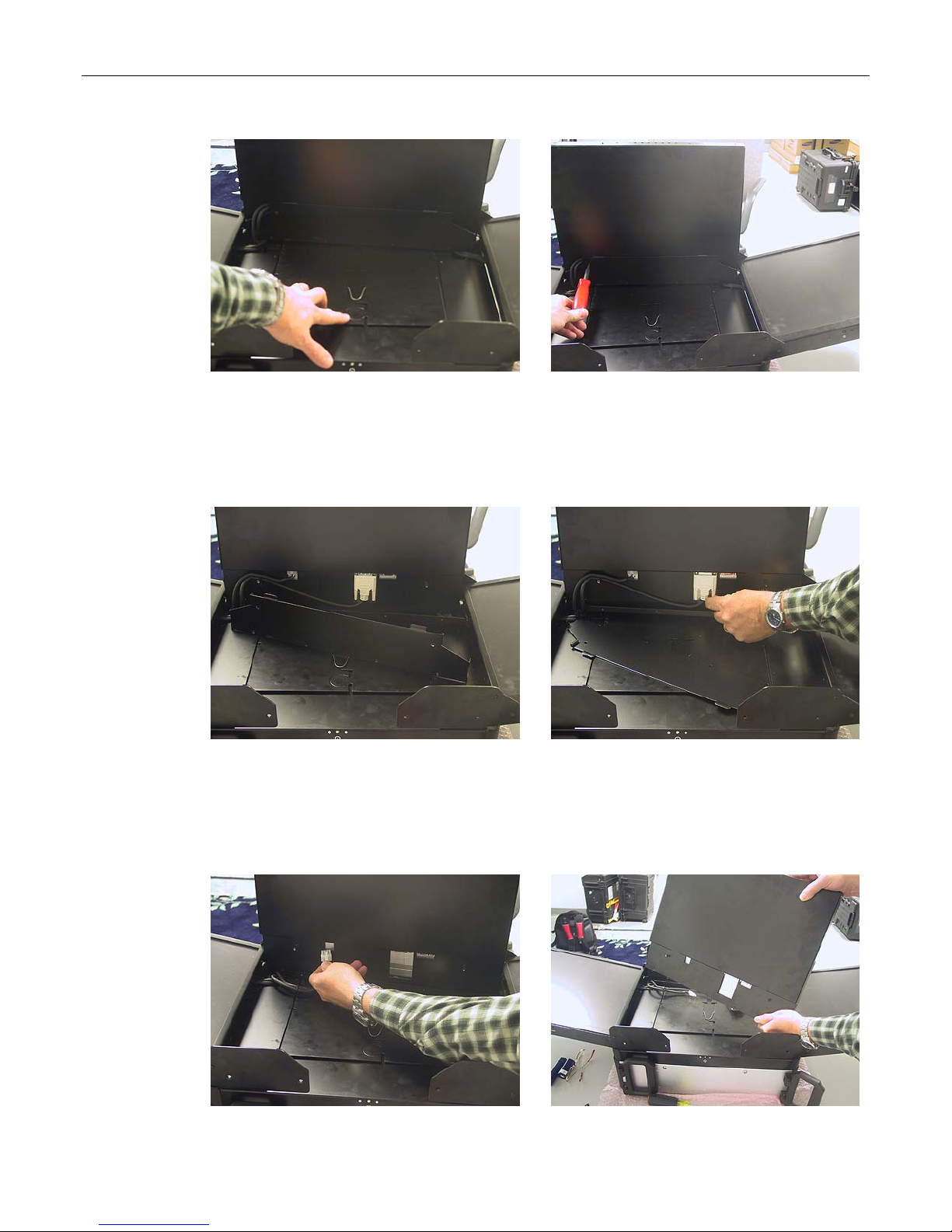

6) Gently lift the inner chassis – including the monitor assembly – away from the outer chassis as

illustrated in Figures 4-38 and 4-39.

Page 48

42 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

Figure 4-38

Figure 4-39

7) Use a Phillips #2 screwdriver to remove the four black countersunk screws holding the screen

assembly to the chassis – two on the top (Figure 4-40) and one on each side (Figure 4-41 and

Figure 4-42).

Figure 4-40

Figure 4-41

8) Observe that the monitor assemble is hinged. Gently lift the display on the side opposite the

hinge (Figure 4-13) until it is in its fully open position.

Figure 4-42

Figure 4-43

Page 49

MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide 43

Note: The display folds all of the way over until it's horizontal. In fact, it will open further until it

touches the table, but this may strain the hinge. For this reason, it is strongly recommended that

you place some object under the monitor to support it (this object should be covered by some soft

material so as to protect the screen).

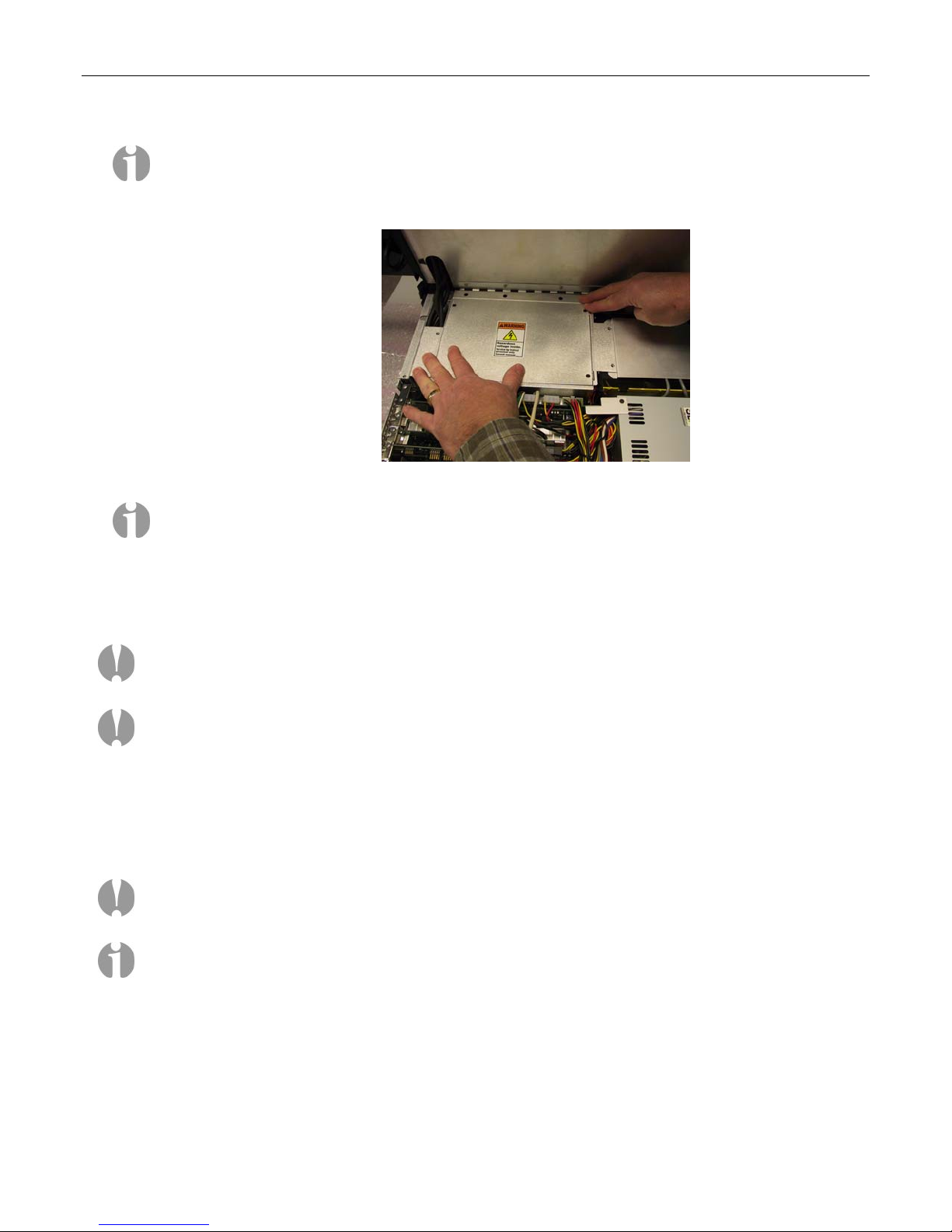

Note: Your MaxPac8230 may contain the optional UPS Power Management System. In this case

the inside of the inner chassis will look similar to the photo above. Please refer to Chapter 6 for

details of the installation and removal of the UPS System. The UPS System must be removed to

gain access to the memory and CPUs.

Memory

Note: Due to the fact that high-end computer systems can experience a host of memory compatibility

issues and problems, you should only use replacement and/or additional memory sticks supplied by

MaxVision.

Note: The MaxPac 8230 uses a Fully Buffered DDR2 memory (FB-DIMM or FBD). Specifically the

MaxPac 8230 uses FBD DDR2 667MHz. What separates FBD from regular DDR2 is a chip on each

module called the AMB (Advanced Memory Buffer), which buffers all data/address/command

requests to the DRAM devices. This buffering allows up to 12GB of memory to be installed in the

MaxPac 8230. FB-DIMMs REQUIRE that memory sticks be used in pairs, with each pair having the

same size/capacity/speed. Population of the first pair of FBD occupies the first and second DIMM

slots (labeled DIMM1A and DIMM1B on the motherboard). Population of the second pair of FBD

occupies the third and fourth DIMM slots (labeled DIMM2A and DIMM2B).

Note: In the event that you begin to experience problems with the memory that is already resident in

your MaxPac, you must first determine which stick has failed under the direction of MaxVision

support.

Note: The BIOS will always report the true amount of physical memory that is present in the system.

This may be as much as 12 GB. However, the actual amount of memory that can be seen by the

system is determined by the main operating system (OS). With regard to the 32-bit Windows® XP

Professional operating system, for example, in the case of a MaxPac 8230 XRA2 (dual-screen)

configuration, the maximum amount of memory reported in the System Information dialog is 3 GB;

by comparison, in the case of a MaxPac 8230 XRA3 (triple-screen) configuration, the maximum

amount of memory reported in the system information dialog is 2 GB. (Further note that even when

the OS reports 3 GB for the dual-screen configuration, the maximum amount of shared user space is

actually only 2 GB.) However, with regard to the 64-bit Windows XP Professional x64 Edition of the

operating system, the System Information dialog will accurately report the true amount of physical

Page 50

44 MaxPac Single/Dual/Triple-Screen 8230 Training and Maintenance Guide

memory (which can theoretically be up to 128 GB) and all of this memory will be available to the

applications.

1) Open the display assembly into its service position as discussed earlier in this chapter.

2) In order to remove and replace a memory stick, gently press down-and-out on the two plastic

“rabbit-ears” at either side of the stick which will cause it to pop out (Figure 4-44), and then

remove the stick from the system (Figure 4-45).

Figure 4-44

3) Observe that the memory sticks are keyed such that they can only be inserted one way. Take the

new (replacement) memory stick sent to you by MaxVision support and gently press it down into

the original slot on the motherboard.

4) Return the system to its initial condition by reversing the order of the operations discussed at the

beginning of this section.

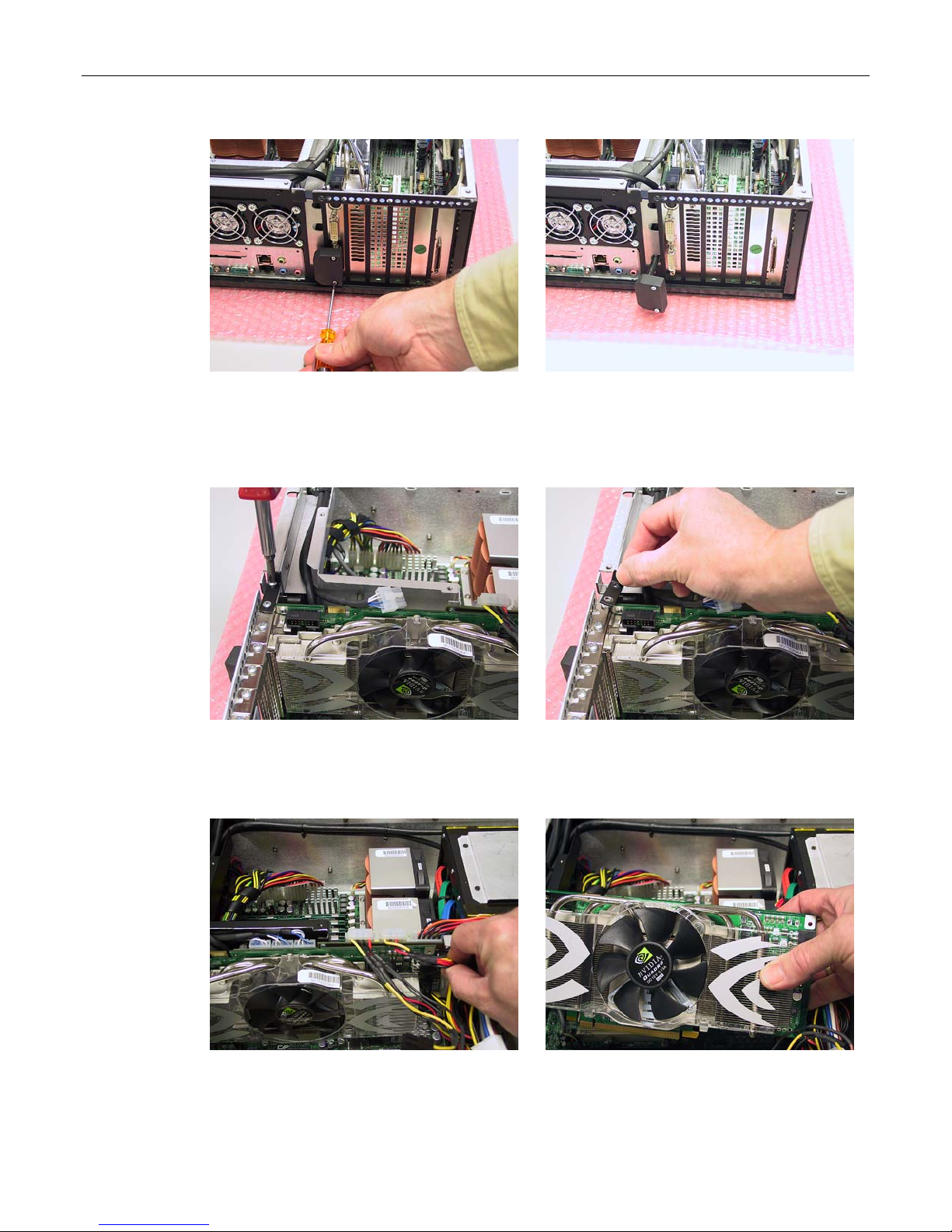

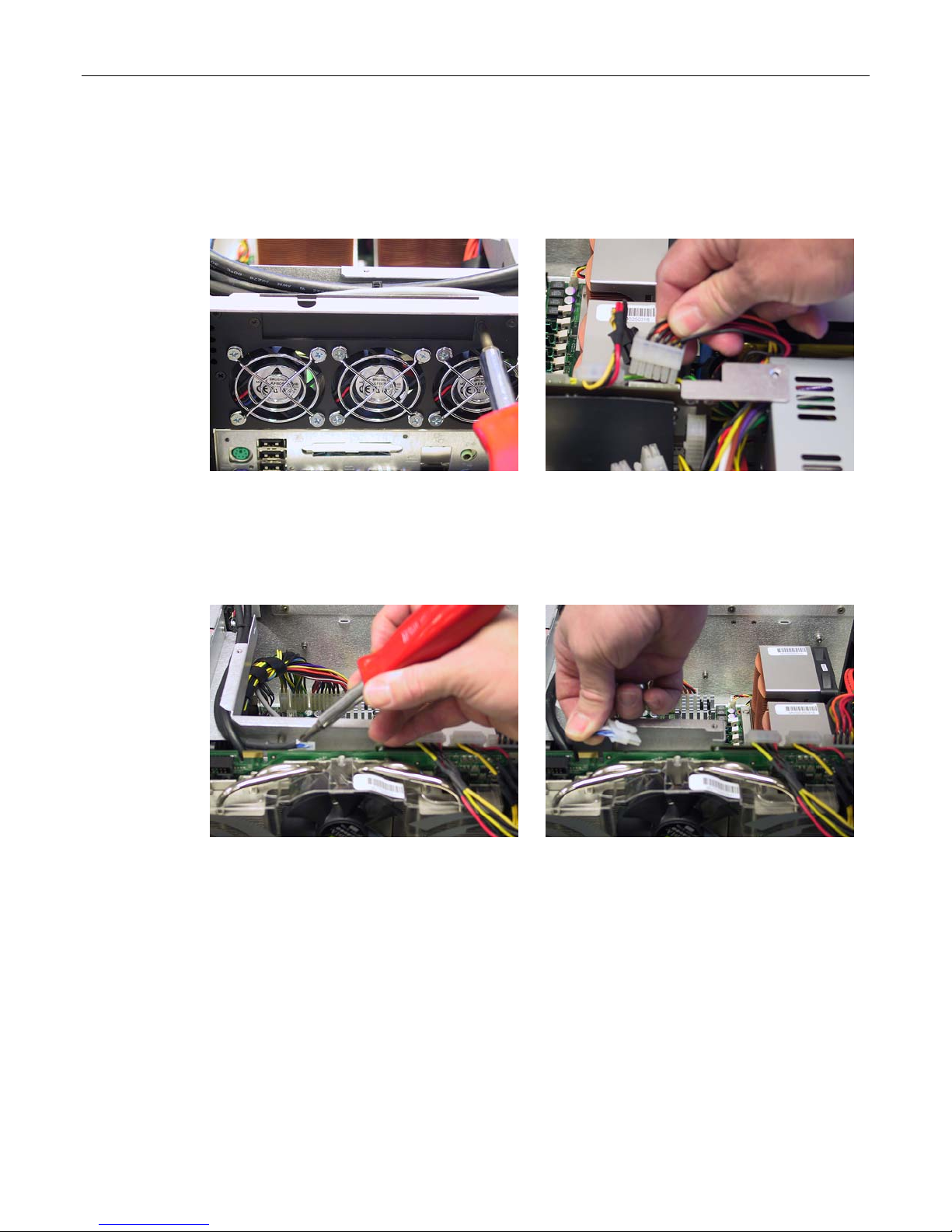

PCI Cards (General)

1) Open the display assembly into its service position as discussed earlier in this chapter.

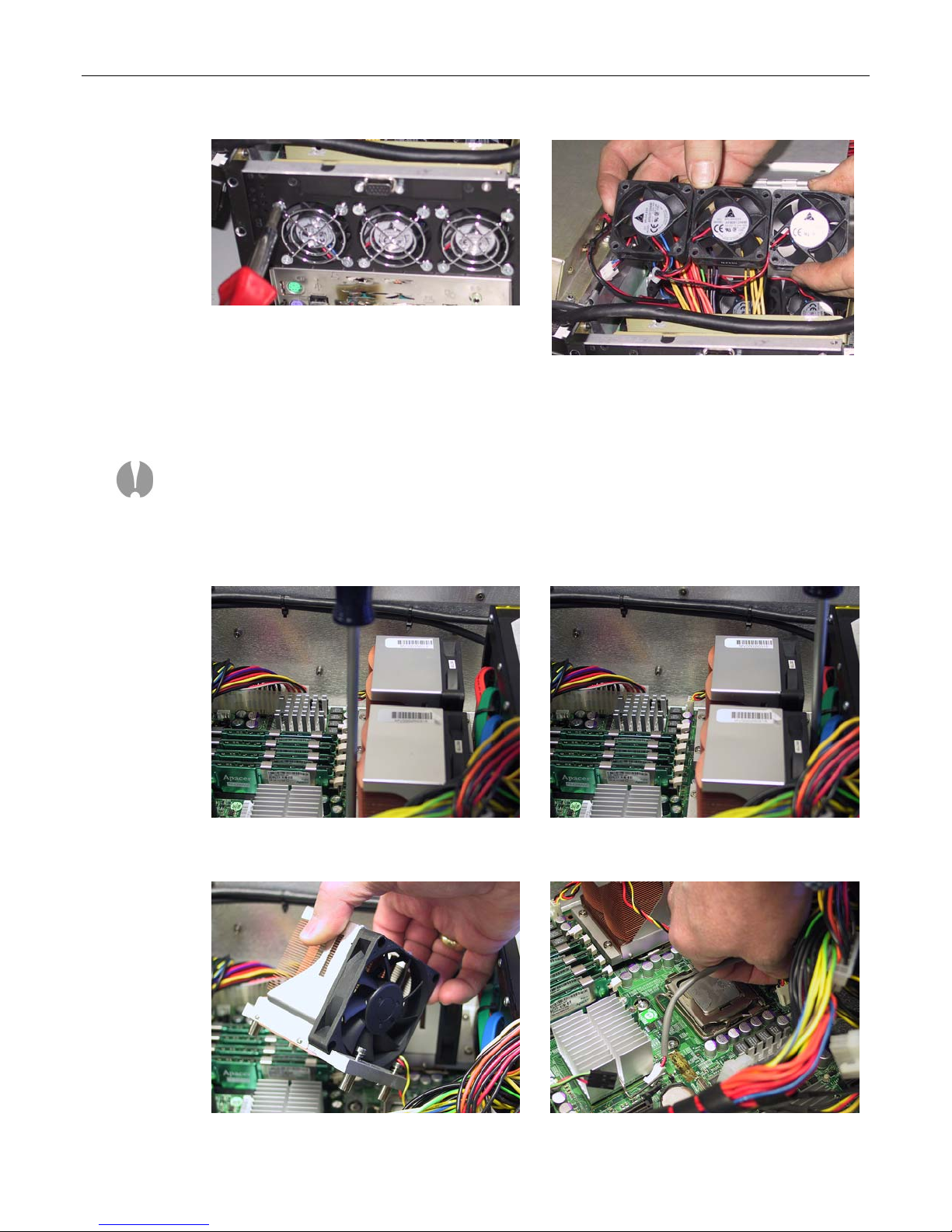

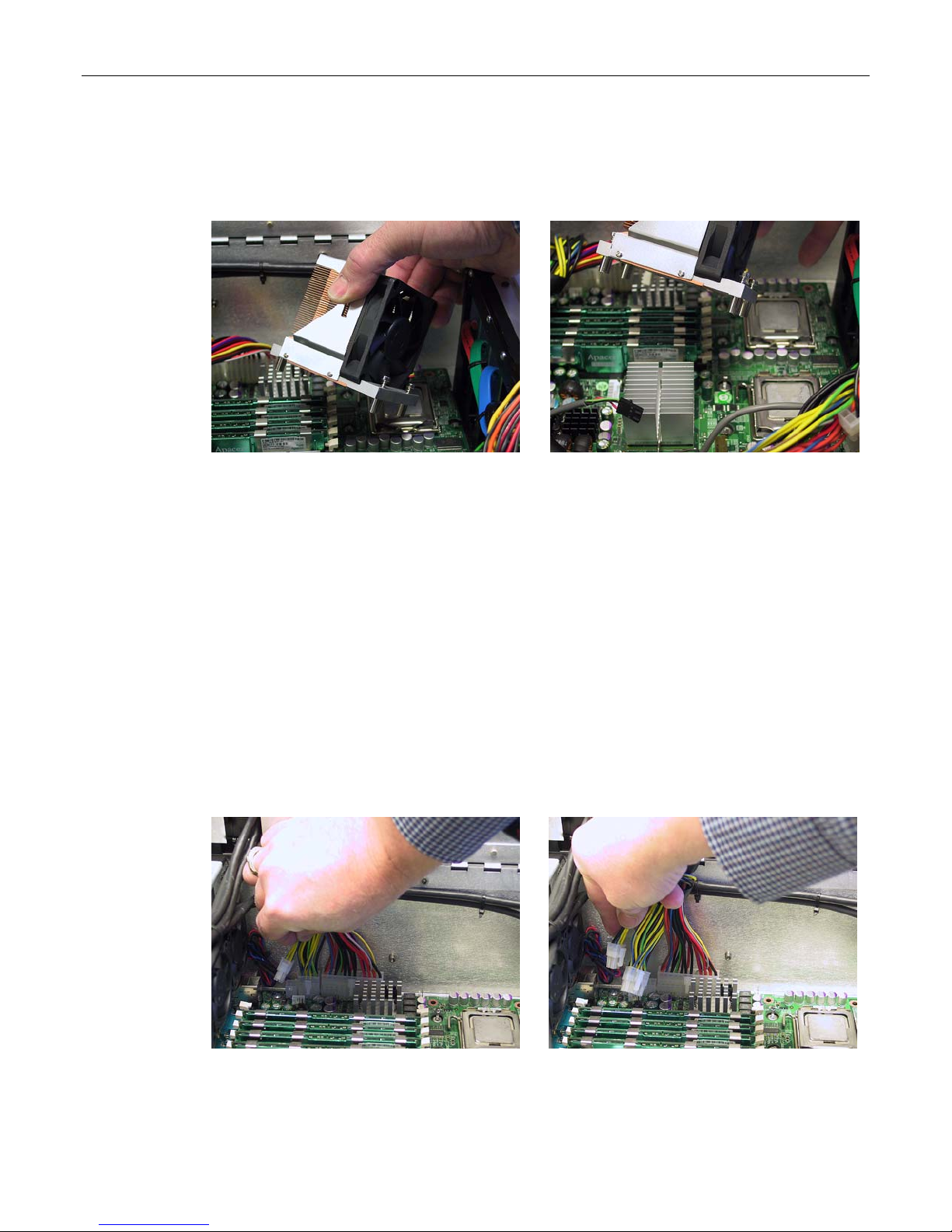

2) If you are replacing an existing PCI card, use a Phillips #2 screwdriver to remove the 6-32 screw