Page 1

SP200/210

Service Manual

Page 2

Published by Maxon Electronics Ltd

36a Gibson Avenue

Padstow Sydney

NSW Australia 2211

Tel: +61 (0) 2 9707 2000

Fax: +61 (0) 2 9707 3328

e-mail sales@maxon.com.au

Internet: www.maxon.com.au

Any queries regarding information in this manual, please contact the Technical Services Group Leader at the above address.

Information provided in this document is believed correct at time of printing but is subject to change without notic e.

Maxon will not accept liability for any loss, damage or costs howsoever caused as a result of the information provided.

Page 3

SM-SP200/210 Maxon SP200/210 Radio

AMENDMENT RECORD SHEET

All amendments to this manual should be incorporated as soon as they are received and recorded below:

Issue No. Effective Date Reason for Change Date Signature

All Engineering Bulletins relevant to this product should be placed at the rear of this binder. Please ensure

that this manual is updated with any replacement pages, which may accompany these Engineering Bulletins.

Always read all Engineering Bulletins before carrying out work on a radio.

Please read the WARNINGS on the next page before referring to subsequent sections.

Issue 1.0 AMENDMENT RECORD SHEET

03/01 Page i

Page 4

Maxon SP200/210 Radio SP200/210

WARNINGS

Components containing beryllium oxide are used in the equipment. Dust from this material is a

•

health hazard if inhaled or allowed to come into contact with the skin. Great care must be taken

when handling these components. They must not be broken or subjected to excessive heat.

Never operate the radio transmitter without the correct Maxon antenna, or a suitable artificial

•

load, connected.

Never modify a radio, or accessory, except as instructed in the Service Manual, Engineering

•

Bulletins or formal communication as this may invalidate any warranty, guarantee or type

approval.

Do not operate this equipment in environments containing explosive materials or vapour.

•

WARNINGS Issue 1.0

Page ii 03/01

Page 5

SP200/210 Maxon SP200/210 Radio

TABLE OF CONTENTS

Page Number

1 INTRODUCTION 1-1

1.1 Using this Manual 1-1

1.2 Amendments to this Manual 1-1

1.3 Contact Information 1-2

2 SPECIFICATIONS 2-1

2.1 General 2-1

3 ACCESSORIES & OPTIONS 3-1

3.1 Pre-Install Check 3-1

3.2 Accessories 3-1

3.3 Options 3-1

4 INSTALLATION, COMMISSIONING & ALIGNMENT 4-1

4.1 Installation 4-1

4.2 Connections 4-1

4.3 Commissioning 4-2

4.3.1 Test Equipment Connection 4-6

4.3.2 Transmitter Performance Tests 4-6

4.3.3 Receiver Performanc e T ests 4-6

4.4 Power Adjustment 4-7

4.5 Alignment 4-8

4.5.1 Preparation 4-8

4.5.2 Disassembly and Re-assembly of the Radio 4-9

4.5.3 PLL Alignment 4-10

4.5.4 Squelch Sensitivit y 4-11

4.5.5 Transmitter Alignment 4-11

4.5.6 Receiver Alignment 4-14

5 DETAILED FUNCTIONAL DESCRIPTION 5-1

5.1 Introduction 5-1

5.2 Common Circuits 5-1

5.3 Audio ASIC 5-2

5.3.1 Audio Signal Path 5-2

5.3.2 Sat Signal Path 5-3

5.3.3 Miscellaneous Signals and Controller 5-3

5.4 Audio/SAT Circuits 5-4

5.5 Common RF Circuits 5-5

5.6 Transmitter 5-7

5.7 Receiver 5-8

6 TROUBLESHOOTING 6-1

6.1 Diagnostic Function 6-1

6.2 Troubleshooting Chart 6-2

6.3 Voltage Charts 6-3

6.3.1 Transistors (Main Circuit) 6-3

6.3.2 Integrated Circuits 6-4

7 PROGRAMMING 7-1

7.1 SMP6100 7-1

7.1.1 Introduction 7-1

7.1.2 Getting Started 7-1

7.1.3 Programming 7-1

Issue 1.0 TABLE OF CONTENTS

03/01 Page iii

Page 6

Maxon SP200/210 Radio SP200/210

8 EXPLODED MECHANICAL DRAWINGS & PARTS LISTS 8-1

8.1 Parts List 8-1

8.2 Spare Parts 8-1

8.3 Mechanical Parts 8-3

8.4 SL100 VHF Parts List 8-8

8.4.1 V2 Control Circuit 8-8

8.4.2 V2 RF 8-10

8.4.3 TCXO Assembly 8-13

8.4.4 V2 VCO 8-14

8.4.5 V2 Front End 8-14

8.5 SL100 UHF Parts List 8-15

8.5.1 U2 Control Circuit 8-15

8.5.2 U2 RF 8-17

8.5.3 TCXO 8-20

8.5.4 VCO 8-21

9 CIRCUIT DIAGRAMS & PCB LAYOUTS 9-1

10 SPARE PARTS 10-1

10.1 Spare Parts 10-1

10.1.1 Component Replacement 10-2

11 APPENDIX – ACC-2003 ALIGNMENT BOX 11-1

11.1 Purpose 11-1

11.2 Test Equipment 11-1

11.3 Calibration Program 11-1

11.3.1 Operation 11-1

11.3.2 Adjustment of ASIC values 11-4

11.3.3 Transmit Adjustments 11-6

11.3.4 Receive Adjustments 11-7

11.4 Default Settings 11-8

11.4.1 V1 Band Default Settings 11-8

11.4.2 V2 Band Default Settings 11-9

11.4.3 U1 Band Default Settings 11-10

11.4.4 U2 Band Default Settings 11-11

LIST OF FIGURES

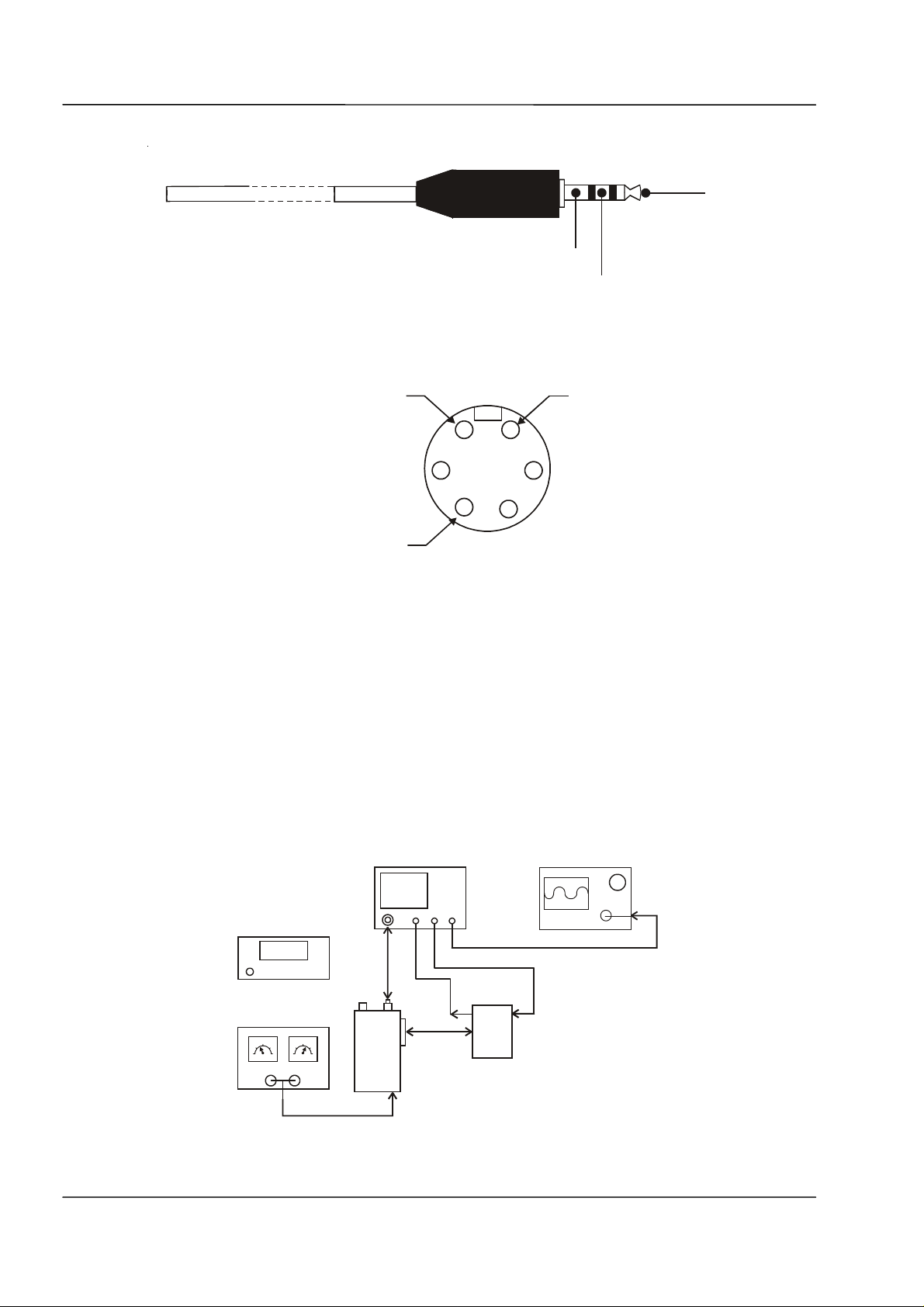

Figure 4-1 - Connections and controls............................................................................................................4-1

Figure 4-2 – Connections................................................................................................................................4-2

Figure 4-3 - Hirose connector .........................................................................................................................4-2

Figure 4-4 – Commissioning Test Setup using SK2055 Service Kit...............................................................4-2

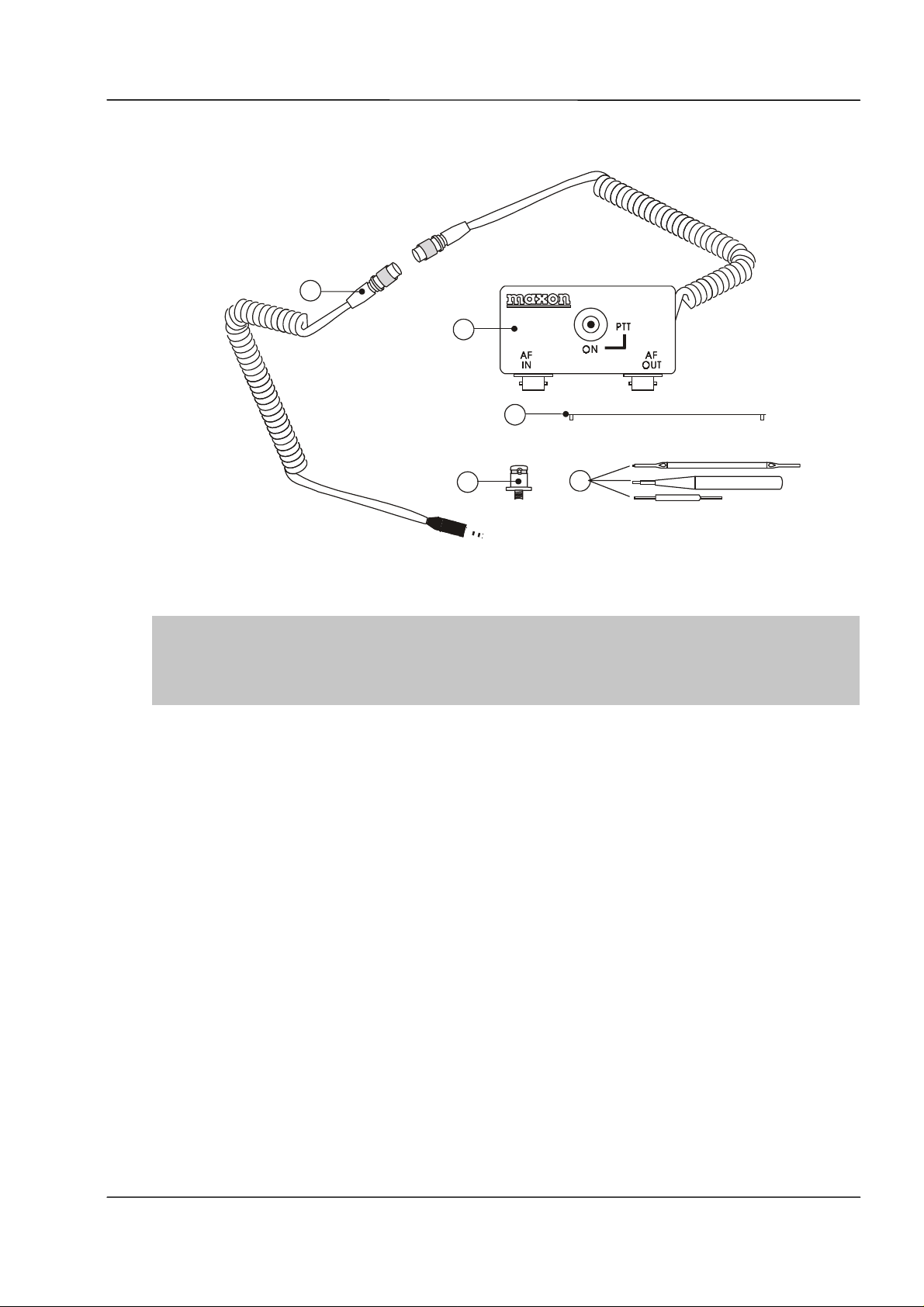

Figure 4-5 – Commissioning Kit......................................................................................................................4-3

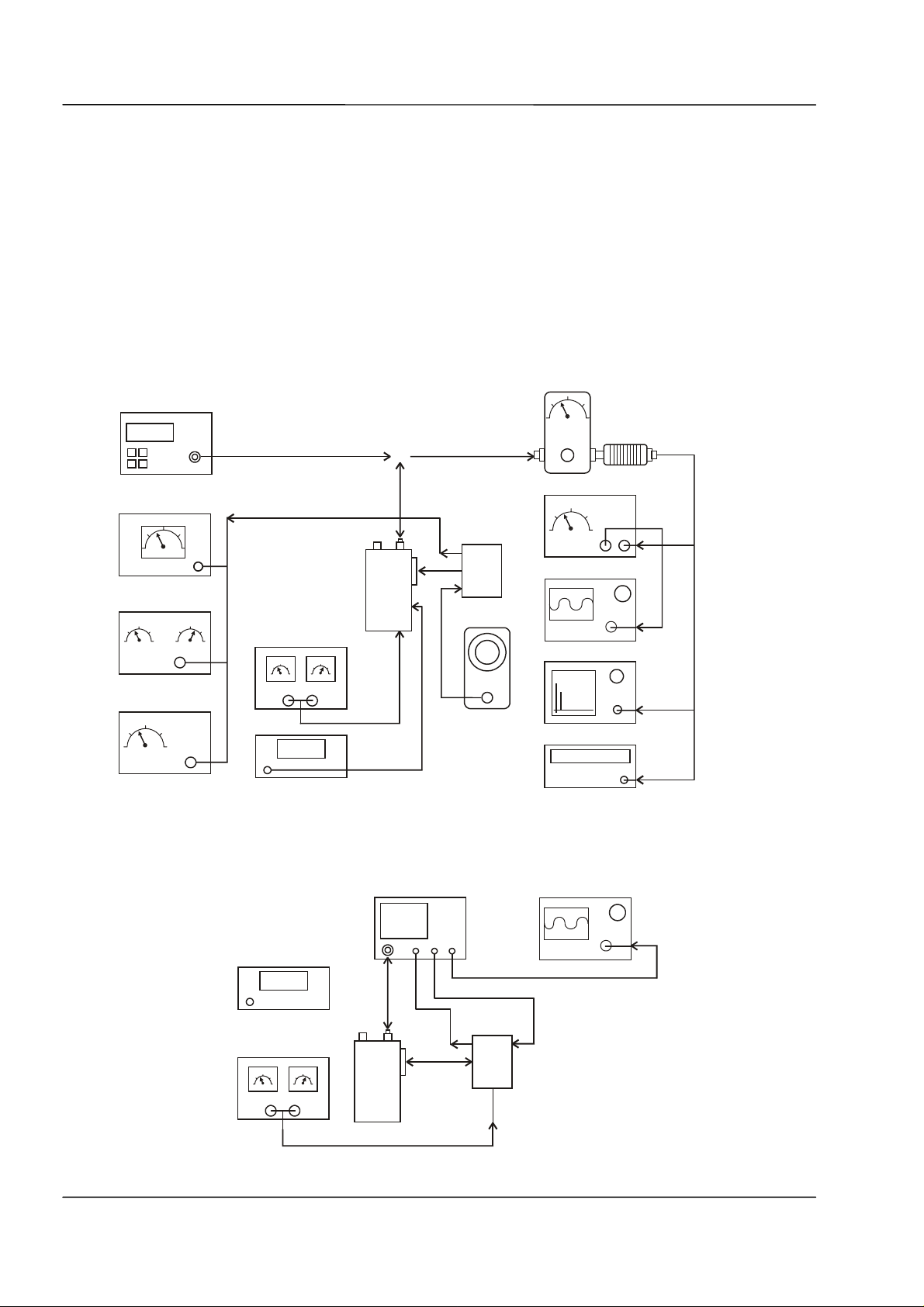

Figure 4-6 – Test Equipment Set-up using Discrete Test Equipment ............................................................4-4

Figure 4-7 – Test Equipment Set-up using a Communications Test Set........................................................4-4

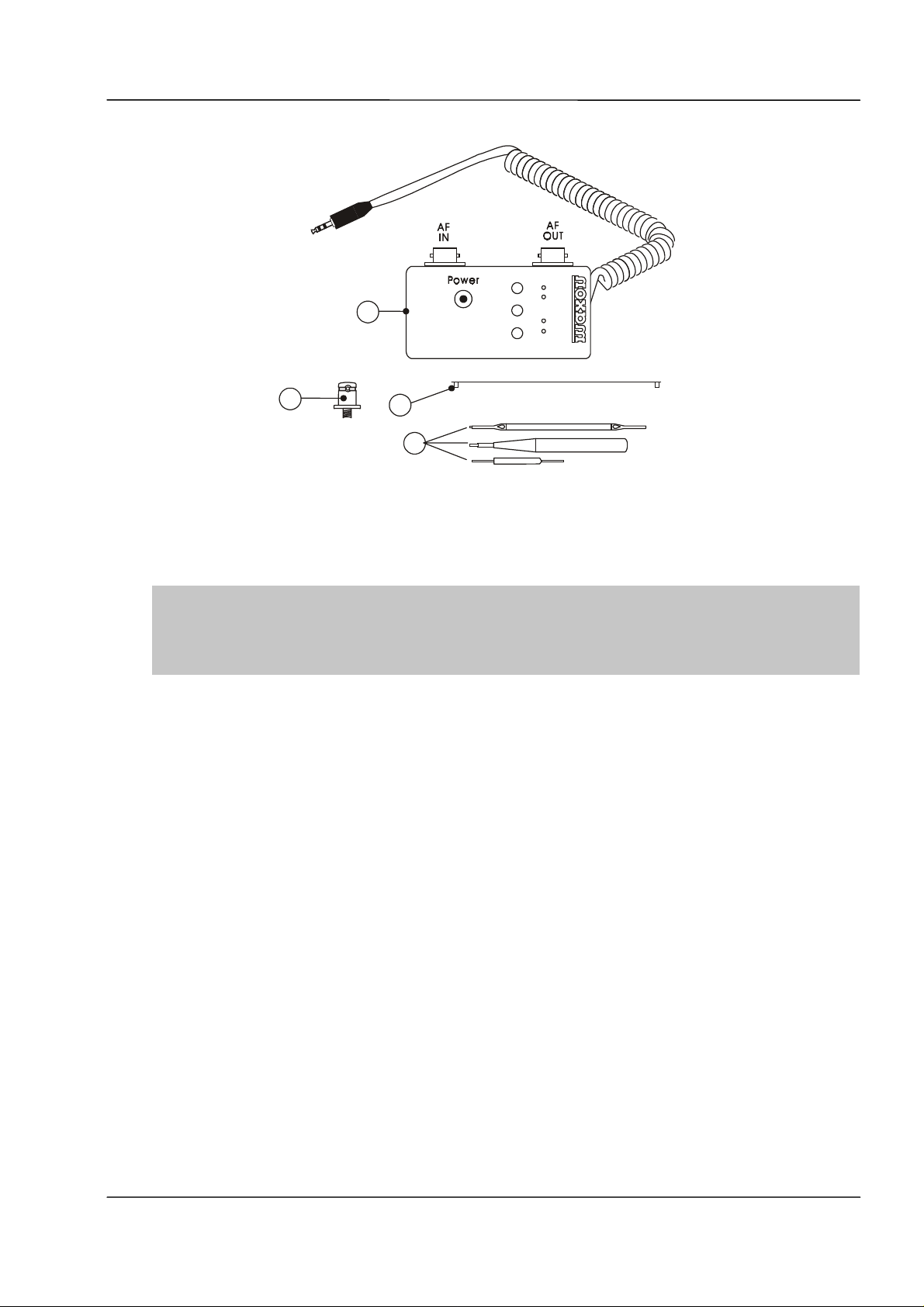

Figure 4-8 - SK 3100 Service Kit.....................................................................................................................4-5

Figure 4-9 - Back Panel Adjusters ..................................................................................................................4-7

Figure 4-10 - Removal of battery ....................................................................................................................4-9

Figure 4-11 - Replacing the battery.................................................................................................................4-9

Figure 4-12 – Replacing the battery................................................................................................................4-9

Figure 4-13 – Removing the belt clip ..............................................................................................................4-9

Figure 4-14 – Adjustment Points...................................................................................................................4-10

Figure 4-15 – ACC-2003 Alignment Box Test Setup....................................................................................4-12

Figure 5-1 – ASIC Block Diagram...................................................................................................................5-3

Figure 5-2 – Synthesiser Block Diagram ........................................................................................................5-5

Figure 5-3 - Transmitter Block Diagram..........................................................................................................5-7

Figure 5-4 - Receiver Block Diagram..............................................................................................................5-8

WARNINGS Issue 1.0

Page iv 03/01

Page 7

SP200/210 Maxon SP200/210 Radio

Figure 6-1 – Legend Layout for Top Side of Digital PCB ...............................................................................6-5

Figure 6-2 - Legend Layout for Bottom Side of Digital PCB...........................................................................6-6

Figure 6-3 - Legend Layout for Top Side of RF PCB .....................................................................................6-7

Figure 6-4 - Legend Layout for Bottom Side of RF PCB................................................................................6-8

Figure 8-1 - Exploded Mechanical Drawing 1.................................................................................................8-3

Figure 8-2 - Exploded Mechanical Drawing 2.................................................................................................8-5

Figure 8-3 – Exploded Mechanical Drawin g 3................................................................................................8-6

Figure 9-1 – Digital Board Layout Top Side....................................................................................................9-3

Figure 9-2 - Digital Board Layout Bottom Side...............................................................................................9-4

Figure 9-3 - RF Board Layout Top Side..........................................................................................................9-5

Figure 9-4 - RF Board Layout Bottom Side ....................................................................................................9-6

Figure 9-5 – Front-End Board Layout.............................................................................................................9-7

Figure 9-6 – VCO Board Layout .....................................................................................................................9-7

Figure 9-7 – TCXO Board Layout...................................................................................................................9-8

Figure 11-1 – Calibration Program Initial Screen .........................................................................................11-1

Figure 11-2 - Calibration Program Primary Screen ......................................................................................11-2

Figure 11-3 - ASIC Control Screen (Rx).......................................................................................................11-3

Figure 11-4 - ASIC Control Screen (Tx) .......................................................................................................11-4

Figure 11-5 - ASIC Control Screen (Rx).......................................................................................................11-5

Figure 11-6 - Modulation wave shape ..........................................................................................................11-6

LIST OF TABLES

Table 6-1 – Diagnostics ..................................................................................................................................6-1

Table 6-2 – Troubleshooting chart..................................................................................................................6-2

Table 6-3 - Main Circuit Transistor Voltages ..................................................................................................6-3

Table 6-4 - Integrated Circuit Voltages (Receive) ..........................................................................................6-4

Table 6-5 - Integrated Circuit Voltages (Transmit) .........................................................................................6-4

Table 8-1 - Parts List for Exploded Mechanical Drawing 1.............................................................................8-4

Table 8-2 - Parts List for Exploded Mechanical Drawing 2.............................................................................8-6

Table 3 – V1 Default Frequency Table.........................................................................................................11-8

Table 4 – V1 Default ASIC Settings..............................................................................................................11-8

Table 5 – V2 Default Frequency Table.........................................................................................................11-9

Table 6 – V2 Default ASIC Settings..............................................................................................................11-9

Table 7 - U1 Default Frequency Table........................................................................................................11-10

Table 8 - U1 Default ASIC Settings ............................................................................................................11-10

Table 9 – U2 Default Frequency Table.......................................................................................................11-11

Table 10 – U2 Default ASIC Settings .........................................................................................................11-11

Issue 1.0 TABLE OF CONTENTS

03/01 Page v

Page 8

Maxon SP200/210 Radio SP200/210

WARNINGS Issue 1.0

Page vi 03/01

Page 9

SP200 /210 Maxon SP200/210 Radio

1 INTRODUCTION

This Maxon Service Manual is a comprehensive guide to the maintenance and field repair of this

equipment. It covers a number of versions of the SP200/210 radio and its accessories. Differences

between the versions are indicat ed, as appropr iate, in the tex t.

Before using this manual please read the whole of this introductory chapter, this will help you to make

the best use of it. If you have not done so already, please also read the warnings on page ii before

proceeding any further.

The range of SP200/210 radios is as follows:

SP200/210 199 fixed channel, (V2) VHF or (U2) UHF radio.

1.1 Using this Manual

At any one time you will need to refer to only a small part of the manual. It has been organised as

follows to make this as easy and as quick as possible.

Chapter 2 - Specification, gives the detailed specification.

Chapter 3 - Accessories and Options. Lists the Accessories and Options that are available.

Chapter 4 - Installation, Commissioning & Alignment. Describes connections to the radio, how to

commission it and how to Align the radio should this becomes necessary. You will also

find it helpful to read the operating instructions in the User Manual and Chapter 7 on

Programming.

Chapter 5 - Detailed Functional Description.

Chapter 6 - Troubleshooting and PCB Drawings.

Chapter 7 - Programming.

Chapter 8 - Exploded Mechanical Drawings and Parts Lists.

Chapter 9 - Circuit Diagrams and PCB Layouts.

Chapter 10 - Spare Parts & Maintenance Policy.

Chapter 11 – ACC-2003 Alignm ent Box

1.2 Amendments to this Manual

From time to time during its lifetime this product will be changed and improved. To cover such

changes, amendments to this manual will be issued in the form of replacement and/or additional

pages. It is important that anyone working on a product has all the relevant information. Therefore you

should incorporate amendments to this manual on receipt. Please follow the instructions

accompanying the amendment (in the form of an Engineering Bulletin) and be sure to complete the

amendment record at the front of this manual.

On occasion it may be necessary to issue product information more quickly than can be achieved with

an amendment. In this case the information will be distributed as an Engineering Bulletin. Engineering

Bulletin numbers are prefixed with a category letter – A, B or C. e.g.,

CATEGORY C - ENGINEERING BULLETIN 120

Issue 1.0 INTRODUCTION

03/01 Page 1-1

Page 10

Maxon SP200/210 Radio SP200/210

Category definitions are:

‘A’

Category A Engineering Bulletins will only be released if, by using the equipment manufactured

by Maxon or its subcontractors, a risk to operator safety or an infringement of Type Approval is

probable.

All units affected should be returned for modification to Maxon Europe Works Department on

receipt of such a Bulletin.

‘B’

Category B Engineering Bulletins are for equipment manufactured by Maxon that may have

component batch problem s .

All equipment’s affected, that are in service, are to be returned to the Distributor or Dealer

workshop for modification. Maxon will supply replacement components free of charge.

‘C’

Category C Engineering Bulletins are for improvement or modification to equipment

manufactured by Maxon.

Dealer/Distributor to modify affected units in the field on the next service call. Maxon will supply

components free of charge.

Please place these at the back of this manual and refer to them before carrying out any work. This

Service Manual should be updated with any accompanying replacement pages. You may wish to

retain the previous issue pages for future reference.

1.3 Contact Information

Should you have any queries regarding this manual, or the information within it, please contact:

The Technical Support Group

Maxon Electronics Australia.

36a Gibson Aveune

Padstow Sydeny

NSW Australia 2211

Telephone: +61 (0) 2 97072000 Fax: +61 (0) 2 97073328

Technical Support e-mail: engineering@maxon.com.au

Internet: www.maxon.com.au

INTRODUCTION Issue 1.0

Page 1-2 03/01

Page 11

SP200/210 Maxon SP200/210 Radio

2 SPECIFICATIONS

2.1 General

Performance Specifications

R&TTE Appendix IV CE 168

ETS 300.086 Jan 91

I-ETS 300 219 Oct 93

ETS 300 279 Feb 96

TIA/EIA-603

Band

Channel Spacing

RF Output Power

Modulation Type

Audio Power

Intermediate Frequencies

Number of Channels

Switching Range

Frequency Source

(without retuning)

VHF 146 – 174MHz (V2)

UHF 440 – 470MHz (U2)

12.5kHz or 25kHz

Channel spacing is programmable.

1W / 5W (programmable and variable)

G3E

1W (Internal 4 Ω speaker)

500mW (External 8Ω speaker),

45.1MHz First I.F.,

455kHz Second I.F.

199

V2 146 to 174MHz Rx

146 to 174MHz Tx

U2 440 to 470MHz Rx

440 to 470MHz Tx

Synthesiser

Operation Rating

Power Supply

Current Consumption

Battery Life

All figures stated with Power Save On

Issue 1.0 DRAFT SPECIFICATIONS

03/01 Page 2-1

(minimum)

Intermittent 90:5:5 (STBY:RX:TX)

7.5Vdc nominal

Standby (muted) with battery save on <40mA

Standby (muted) with battery save off <80mA

Unmuted with 100% AF power <250mA

Transmit @ 5W RF output <2.4A

1350mAH >8.5Hrs

Page 12

Maxon SP200/210 Radio SP200/210

Environmental

Operating Temperature Range

Storage Temperature Range -40 to +80°C (storage)

Charging Temperature Range 0 to +30°C

Humidity EIA/TIA 603 (95%)

Protection against ingress of IEC 529 IP54

dust and water

-15 to +35°C (nominal)

-20 to +55°C (extreme),

Vibration

Robustness Mil Std 810 C Procedures I, II & V

ESD

EMC

Physical Dimensions

Synthesiser

Reference Crystal

Frequency: 12.8MHz

Holder: HC-18

Accuracy:

Ageing Rate: < 2ppm / Year in the first year

Synthesiser Lock Time: < 10mS

Switching Times

Tx to Rx, same frequency < 20mS

Rx to Tx, same frequency < 20mS

Rx to Rx < 20mS

(over switching bandwidth)

Rx to Tx / Tx to Rx < 20mS

(over switching bandwidth)

BS2011 : Part 2.1Fc IEC 68-2-6

Part 2.1Fd IEC 68-2-34

20kV (C-MIC >= 15kV)

EMC Directive 89/336/EEC May 89

112 x 61 x 40mm

(Excluding antenna and with QPA1350 pack)

±

3ppm over –30 to +60°C

< 1ppm / Year in subsequent years

Receiver Sensitivity

Squelch Sensitivity

Adjacent Channel Selectivity

Sub Audio Tones – CTCSS / DCS

Decode Sensitivity

All tones <=9dB SINAD

CTCSS Tone Range 67 – 250Hz @ 0.3% accuracy

DCS Tone Standard Standard & Inverted

Programmer

SPECIFICATIONS DRAFT Issue 1.0

Page 2-2 03/01

Method (decrease signal level @ 10% peak deviation)

<-118dBm (VHF), <-117dBm (UHF)

7 – 12dB SINAD

Better than 70dB

50 – 260Hz @ 0.3% accuracy (non-standard tones)

SMP 6100

Page 13

SP200/210 Maxon SP200/210 Radio

3 ACCESSORIES & OPTIONS

3.1 Pre-Install Check

The SP200/210, as purchased, is supplied with an Antenna, charger and power supply, belt clip and User

Manual.

3.2 Accessories

A wide range of accessories are available for the SP200/210. The list below represents a summary of

accessories available at the time this manual was published. For up-to-date listings, and for price and

availability, please refer to the current Price Book.

Order Code Description

Batteries

QPA-1350 1350mAh NimH battery.

Chargers

QPA-1185-2 2-pin (European) Intelligent fast charger with mains adapter

QPA-1185-3 3-pin (UK) Intelligent fast charger with mains adapter

QPA-1185 Spare cup for the above chargers (No PSU)

QPA-1195-2 6 + 6 Intelligent fast charger (Euro)

QPA-1195-3 6 + 6 Intelligent fast charger (UK)

CA1246 In-car charger

Speaker / Microphone accessories

MA100-01 Small Remote speaker mic.

MA100-02 Standard Remote speaker mic.

Headset Accessories

HS100-02 Lightweight headset

QPA1432 Lightweight headset

QPA1433 Two-way covert kit

QPA1455 Earbud

HS100-01 Earbud with Earhanger

Cases

CA1487 Lightweight Nylon case.

CA1475 Soft Leather case

CA1476 Soft Leather case with window

CA-7059 Belt Clip

Programmer

SMP6100 SP200/210 Programming Kit

3.3 Options

None

Issue 1.0 ACCESSORIES & OPTIONS

03/01 Page 3-1

Page 14

Maxon SP200/210 Radio SP200/210

ACCESSORIES & OPTIONS Issue 1.0

Page 3-2 03/01

Page 15

SP200/210 Maxon SP200/210 Radio

4 INSTALLATION, COMMISSIONING & ALIGNMENT

4.1 Installation

The SP200/210 is a hand-held radio and thus requires no installation.

The User should ensure that the batteries are charged before commencing commissioning tests.

4.2 Connections

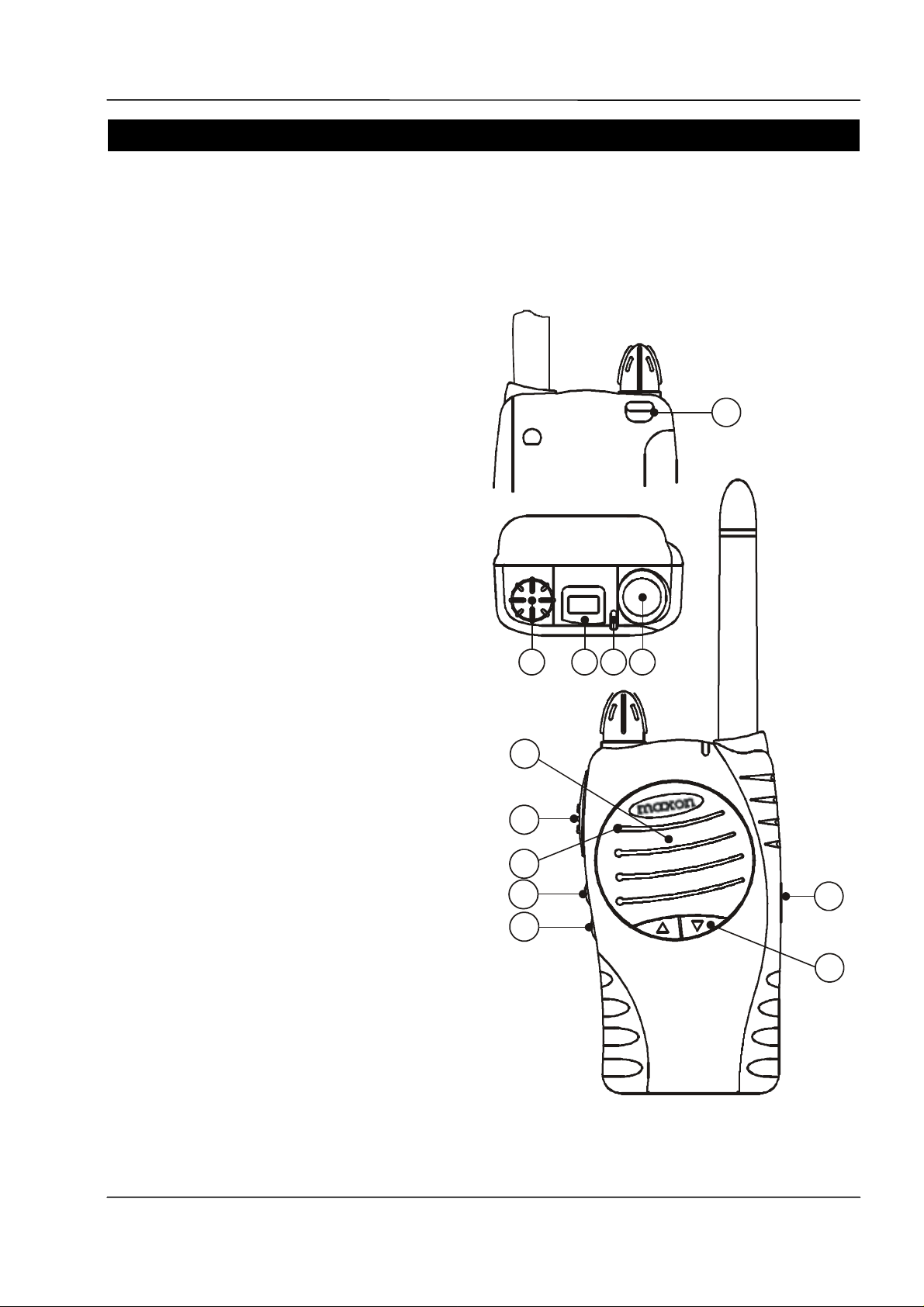

1. Antenna connector: socket.

2. Channel Busy / Talk tri-colour LED.

3. Display

4. Main Power switch and volume

control. Fully anti-clockwise is the

OFF position.

5. Battery Release Catch.

6. Speaker.

7. Push To Talk (PTT) button.

8. Microphone.

9. Scan button.

10. Monitor button (unmutes the radio).

11. Channel select keys: Up / Down

keys, used to select channels.

12. Accessories socket (microphone &

speaker)

Note: Socket 12 is the Accessories

Connector, which may be used to

connect the radio to the following:

5

BACK

3

124

6

7

8

9

12

An optional remote speaker / microphone

An optional headset

A PC for programming using

SMP6100software

Issue 1.0 INSTALLATION, COMMISSIONING & ALIGNMENT

03/01 Page 4-1

10

11

Figure 4-1 - Connections and controls

Page 16

Maxon SP200/210 Radio SP200/210

The Accessory connector is wired as follows:

PTT / Mic

Ground

Speaker

Figure 4-2 – Connections

The small multi-pin connector, which is connected

to the other end of the test lead, is wired

as follows:

PTT / Mic

1

View from

2

connector

3

6

rear of

4

Screen

5

Speaker

Figure 4-3 - Hirose connector

4.3 Commissioning

This section covers the tests, which should be undertaken prior to handover of the radio to the end

user. All of the following tests can be carried out without having to gain access to the interior of the

radio.

Recommended Test Equipment

The alignment and performance test procedures assume the use of the following equipment. The

functions of most of the equipment may be found in a “Communications Test Set”. This type of

equipment is available from a number of test equipment manufacturers.

Throughout this book reference will be made to the use of the Communications Test Set. Where

applicable, the equivalent discrete item of test equipment may be used.

COMMUNICATION TEST SET

VOLT METER

DC POWER SUPPLY

RF

..

DEMOD

AF OUT

OSCILLOSCOPE

AF IN

TEST BOX

S2055K

RADIO

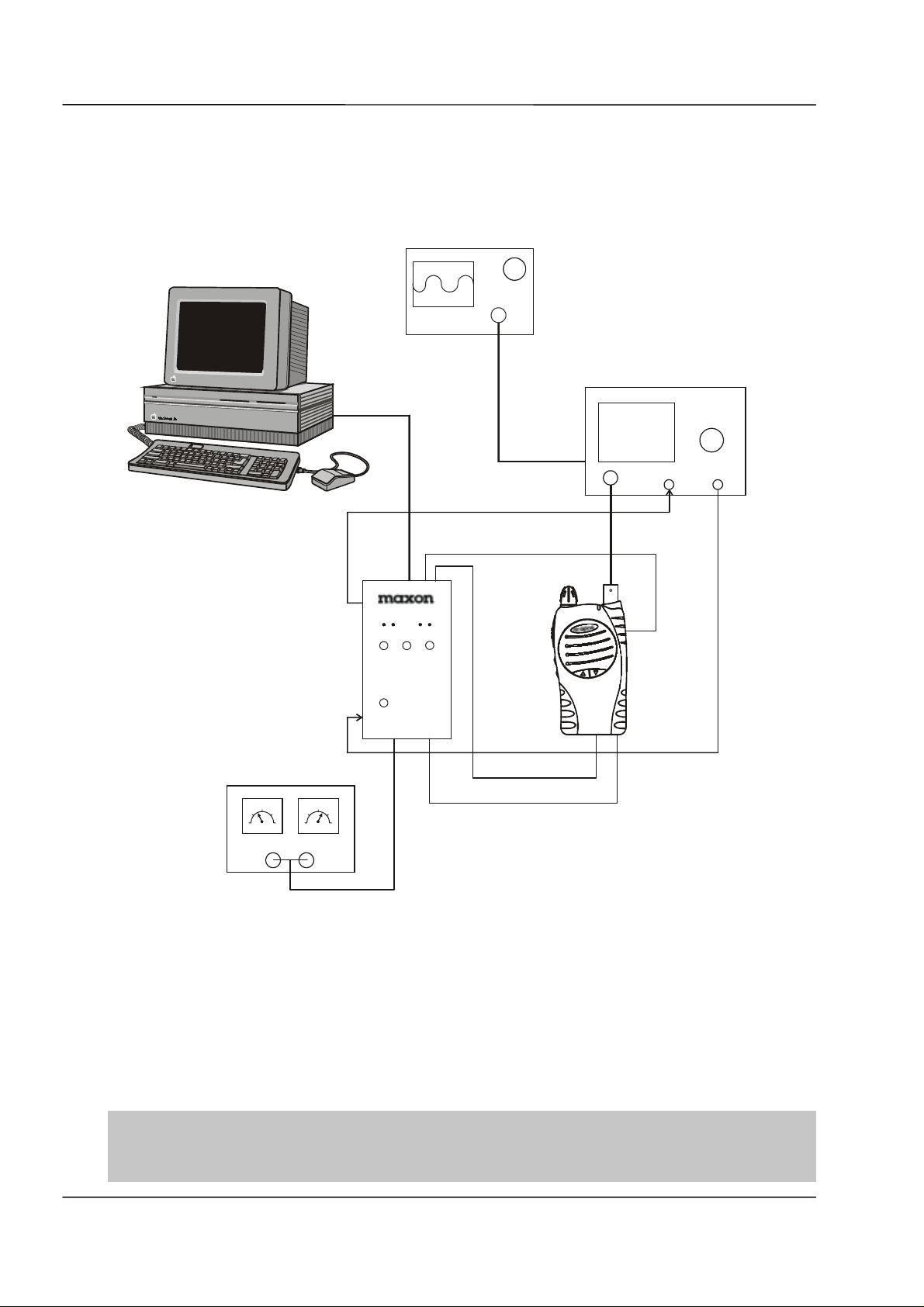

Figure 4-4 – Commissioning Test Setup using SK2055 Service Kit

INSTALLATION, COMMISSIONING & ALIGNMENT - Issue 1.0

Page 4-2 03/01

Page 17

SP200/210 Maxon SP200/210 Radio

Commissioning Equipment

2

1

3

5

4

Figure 4-5 – Commissioning Kit

Note

: For those dealers who already have the SK2055 Service Kit (SL25/55) the audio cable (2),

CA8700, may be purchased. This interfaces the Service Kit to the SP200/210 and allows all simple,

commissioning audio measurements to be made. SMA adapter (5), ME210089 will also be required.

Flexi-pcb (3), ME110016 may be required if simple internal adjustments are to be made.

Note

: The equipment shown in Figure 4-5 allows only VCO and power adjustments to be made to the

SP200/210. The full Service Kit, SK3100, is required for setting deviation.

Please refer to Figure 4-6 for the set-up using discrete test equipment and Figure 4-4 for the set-up

using the Communications Test Set. If the ACC-2003 Interface Box is used, please refer to

Figure 4-7.

Issue 1.0 INSTALLATION, COMMISSIONING & ALIGNMENT

03/01 Page 4-3

Page 18

Maxon SP200/210 Radio SP200/210

(op

Discrete Test Equipment

RF Signal Generator (with CTCSS/1kHz

tone)

RF Power Meter

RF Frequency Counter

Spectrum Analyser and notch filter

(optional)

Audio Signal Generator

Audio Power Meter

SINAD Meter

Modulation Meter

Oscilloscope

Voltmeter

DC Power Su pply, 0 - 10V 3A min.

RF SIGNAL GENERATOR

AUDIO POWER METER

Combined Equipment

Communications Test Set (e.g. Marconi

TF2955, Stabilock 4015 or similar).

Accessories

ME210089 SMA to BNC Adapter.

CA8700 Audio Lead for use with SK2055

Service Kit to perform audio

measurements.

SK3100 Service Kit

ACC-2002 SL100 Programming Lead

WA TT METER WITH

20dB ATTENUATOR

AUDIO

MODULATION- METER

DISTORTION METER

SINAD METER

Figure 4-6 – Test Equipment Set-up using Discrete Test Equipment

DC POWER SUPPLY

VOLT METER

VOLT METER

DC POWER SUPPLY

TEST BOX

RADIO

AUDIO GENERATOR

COMMUNICATION TEST SET

RF

..

DEMOD

AF OUT

2055SK

OSCILLOSCOPE

SPECTRUM ANALYZER

154.625

FREQUENCY COUNTER

OSCILLOSCOPE

AF IN

INTERFACE BOX

ACC-2003

tional)

RADIO

Figure 4-7 – Test Equipment Set-up using a Communications Test Set

INSTALLATION, COMMISSIONING & ALIGNMENT - Issue 1.0

Page 4-4 03/01

Page 19

SP200/210 Maxon SP200/210 Radio

SK 3100 Service Kit

1

2

4

3

Figure 4-8 - SK 3100 Service Kit

This kit can be used for commissioning in the same way as the SK2055 (ignoring computer

connections). The above kit also includes a battery eliminator.

Note

: If the Interface Box is used, ensure that it is set to manual, Audio enable is off and PTT is off

before powering up.

If programming the radio with the Battery eliminator connected, the curly cord must be disconnected

from the Interface Box.

The SK 3100 service kit is used with the

SP200/210 radio and provides most of the

interface cables and tools which will be required

for test and alignment of the SP200/210.

Prerequisites

For the following tests, signal generator

modulation level should be set to Average

System Deviation, i.e. 60% of maximum

system deviation.

The SK 3100 Service Kit

programming cable, ACC-2002. This is

does not

provide the

The level should therefore be set to:

available as part of the SMP6100

Programming Kit (see Section 3).

1.5 kHz for 12.5 kHz channel spacing

2.4 kHz for 20 kHz channel spacing

1. ACC-2003 Radio Interface Test Box. This

3.0 kHz for 25 kHz channel spacing

provides an audio interface, a battery

eliminator / programming interface and a

PTT switch.

2. ME210089 SMA to BNC Adapter

3. Trimmer Tools. These are used to adjust

the trimmers and ferrite cores within the

radio.

If the radio has had components installed to

change the channel spacing and/or operating

band from those installed at the factory,

ensure that the correct components are

installed in the receiver and transmitter stages

prior to testing.

4. ME110016 Flexi-PCB. Used to

interconnect the Digital and RF pcbs for

servicing.

Refer to the appropriate Electrical Parts List if

necessary.

Issue 1.0 INSTALLATION, COMMISSIONING & ALIGNMENT

03/01 Page 4-5

Page 20

Maxon SP200/210 Radio SP200/210

EEPROM programming

Ensure that the radio has the required

customer parameters programmed, otherwise

ensure that the radio is programmed with at

least the lowest, middle and highest Rx/Tx

frequencies prior to aligning the VHF and UHF

scanning handheld series radio.

Ensure that High and Low power are

programmed.

When CTCSS and DCS performance checks

are also required, ensure that the lowest,

middle and highest Rx/Tx frequencies include:

Lowest Rx/Tx freq. ch. 67.0 Hz CTCSS

Middle Rx/Tx freq. ch. DCS Code 072

Highest Rx/Tx freq. ch. 250.3 Hz CTCSS

The middle Rx/Tx frequencies should be

halfway between the lowest and the highest

frequencies.

Programming details are given in Section 7.

4.3.1 Test Equipment Connection

Use a battery or connect the power supply

leads from the battery eliminator to the power

supply. The red, positive, lead connects to

+7.5Vdc. The black, negative, lead connects

to the negative, terminal of the power supply.

A connection diagrams are given in

Figures 4-4, 4-6 or 4-7.

Set the radio to a channel with High power.

4.3.2 Transmitter Performance Tests

Power Output

This test is only possible using the battery

eliminator.

a. Connect the transmitter to the

Communications Test Set (CTS).

b. Set the power supply to 7.5Vdc and

connect a dc voltmeter across the

power supply to monitor the supply

voltage.

e. Switch to a channel with a low power

and ensure that the nominal power is

1W ± 1.5dB.

Frequency Error

a. Check that the transmit frequency is within

+/- 500Hz (VHF) or +/- 750Hz (UHF) of

the frequency which is program med

into the radio.

Deviation and Distortion

a. Set the radio to the middle Tx

frequency.

b. Set the audio signal generator to 1kHz

tone, low output impedance PTT and

adjust the AF generator level for 60%

system deviation:

12.5kHz channel spacing 1.5kHz dev.

20kHz channel spacing 2.4kHz dev.

25kHz channel spacing 3kHz dev.

c. Measure the audio distortion. This

should be less than 5%.

d. Increase the audio signal generator

level by 20dB (10x voltage). The peak

deviation should be:

12.5kHz channel spacing <= 2.25kHz dev.

20kHz channel spacing <= 3.6kHz dev.

25kHz channel spacing <= 4.5kHz dev.

4.3.3 Receiver Performance Tests

Sensitivity

The SINAD performance test may be used to

test the sensitivity of the receiver.

a. Connect the Communications Test Set,

modulated with a 1kHz tone, to the

radio.

b. Set the frequency to correspond to the

Rx frequency of one of the channels

programmed into the radio.

c. Using the Test Box, ensure that the AF

output from the Interface Box is connected

to the CTS SINAD meter.

c. Set the CTS to the same frequency as

the radio. Activate PTT. Check and

record the power output. The nominal

power output is 5W ± 1.5dB (3.5 to 7W)

d. Reduce the power suppl y voltage to

6.0Vdc and PTT. The output power

should be greater than 50% of the level

measured above.

INSTALLATION, COMMISSIONING & ALIGNMENT - Issue 1.0

Page 4-6 03/01

d. Set the volume control to mid-range.

e. Set the Test Set deviation to:

12.5kHz channel spacing 1.5kHz dev.

20kHz channel spacing 2.4kHz dev.

25kHz channel spacing 3kHz dev.

f. Adjust the RF signal generator level

until the SINAD meter reads 12dB.

Page 21

SP200/210 Maxon SP200/210 Radio

This section is included here as it is not

g. Check that the signal generator RF

level is < -117dBm (UHF) or

< -118dBm (VHF).

Squelch

a. Ensure that both the radio and the

Test Set are set to the

appropriate channel spacing.

b. With the above setting, reduce the RF

level to –130dBm. The radio should be

mute.

c. Adjust the RF level until the SINAD

meter reads 10dB. The radio should

unmute. (

press and hold the monitor button to read

< 10dB SINAD).

Audio Output

a. Set the RF signal generator to 1mV pd

(-47.0dBm) and the tone and deviation

as above.

b. Connect the audio power meter to the

external accessories socket on the

radio, via the test box.

Note

: it will be necessary to

necessary to disassemble the radio in order to

set the power output.

A stable power source is required and

therefore the ACC-2003 Interface Box should

be used as this contains a battery eliminator.

For squelch adjustments, see Section 4.5.6.

20/25kHz

12.5kHz

High

Low

PowerSquelch

Figure 4-9 - Back Panel Adjusters

a. Select a mid-frequency channel with

High Power.

b. Set the PTT switch to on.

c. Adjust the volume control on the radio

under test to maximum (fully clockwise).

The voltmeter should indicate >= 1.55V.

The audio power meter should read

>= 300mW.

d. Decrease the volume control on the radio

so that the voltmeter reads 1.0V. Check

that the audio distortion is <5%.

Note:

The audio power meter should be set to

8Ω.

This concludes the Performance Tests.

If the Radio should fail any of these tests it will

be necessary to turn to the next section on

Alignment.

4.4 Power Adjustment

Note:

Any power adjustments made should be

within R&TTE parameters.

Transmit periods longer than 5 minutes are to

be avoided.

Power setting potentiometers are located

underneath the upper label on the back of

the radio.

with every radio.

A replacement label is shipped

c. Adjust RV1 (High) to give 5W ± 0.1W.

d. Set the PTT switch to off.

e. Select a mid-frequency channel with

Low Power.

f. Set the PTT switch to on.

g. Adjust RV3 (Low) to give 1W ± 0.1W.

h. Set the PTT switch to off.

i. Repeat steps a to h until switching

between the two channels gives Low

Power of 1W and High Power of 5W.

j. Switch to a low frequency, low power

channel.

k. Set the PTT switch to on.

l. Check that the power output is

1W ± 1.5dB (0.7 to 1.41W).

m. Set the PTT switch to off.

n. Repeat steps k to m for a low power,

high frequency channel.

Issue 1.0 INSTALLATION, COMMISSIONING & ALIGNMENT

03/01 Page 4-7

Page 22

Maxon SP200/210 Radio SP200/210

4.5 Alignment

CAUTION

This radio contains static sensitive devices.

Static safe precautions should be observed, in

particular we would recommend the use of a

suitable floor mat, table mat, bonding cords

and a wrist strap. The soldering iron should

have an earthed tip.

Care should be exercised in the handling of

static sensitive components and they should

always be transported in the correct

containers.

Never remove, or insert, static sensitive

devices with the power applied.

4.5.1 Preparation

To perform the following tests it is necessary

to program the radio as follows:

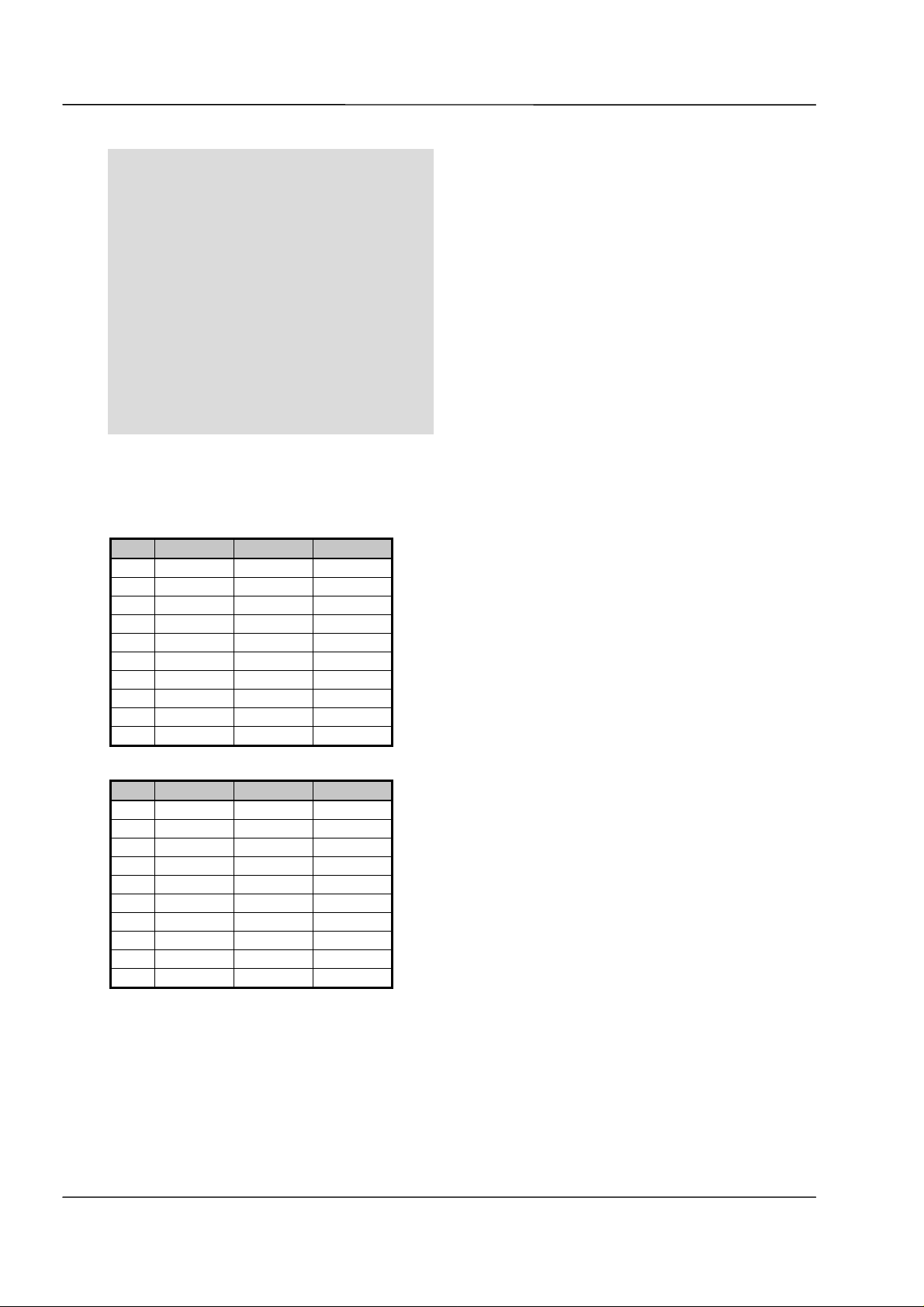

VHF

Ch. Tx(MHz) Rx(MHz) CTCSS

1 146.025 146.025 None

2 160.025 160.025 None

3 173.975 173.975 None

4 173.975 173.975 67Hz

5 173.975 173.975 250.3

6 146.025 146.025 None

7 160.025 160.025 None

8 173.975 173.975 None

9 173.975 173.975 67Hz

10 173.975 173.975 250.3

Tests without Disassembly

Power Output, Deviation, Balance and

Squelch adjustment do not require the radio to

be disassembled.

UHF

Ch. Tx(MHz) Rx(MHz) CTCSS

1 440.025 440.025 None

2 455.025 455.025 None

3 469.975 469.975 None

4 469.975 469.975 67Hz

5 469.975 469.975 250.3

6 440.025 440.025 None

7 455.025 455.025 None

8 469.975 469.975 None

9 469.975 469.975 67Hz

10 469.975 469.975 250.3

Channel spacing as required. Channels 1 to 5

should be set to Low Power and channels 6 to

10 set to High Power.

Ensure that the Power Save is OFF.

INSTALLATION, COMMISSIONING & ALIGNMENT - Issue 1.0

Page 4-8 03/01

Page 23

SP200/210 Maxon SP200/210 Radio

4.5.2 Disassembly and Re-assembly of

the Radio

Radio

In order to carry out the following PLL and

Alignment procedures it will be nec es sary to

gain access to the inside of the radio.

Care should be exercised when opening up

the radio for maintenance or repair.

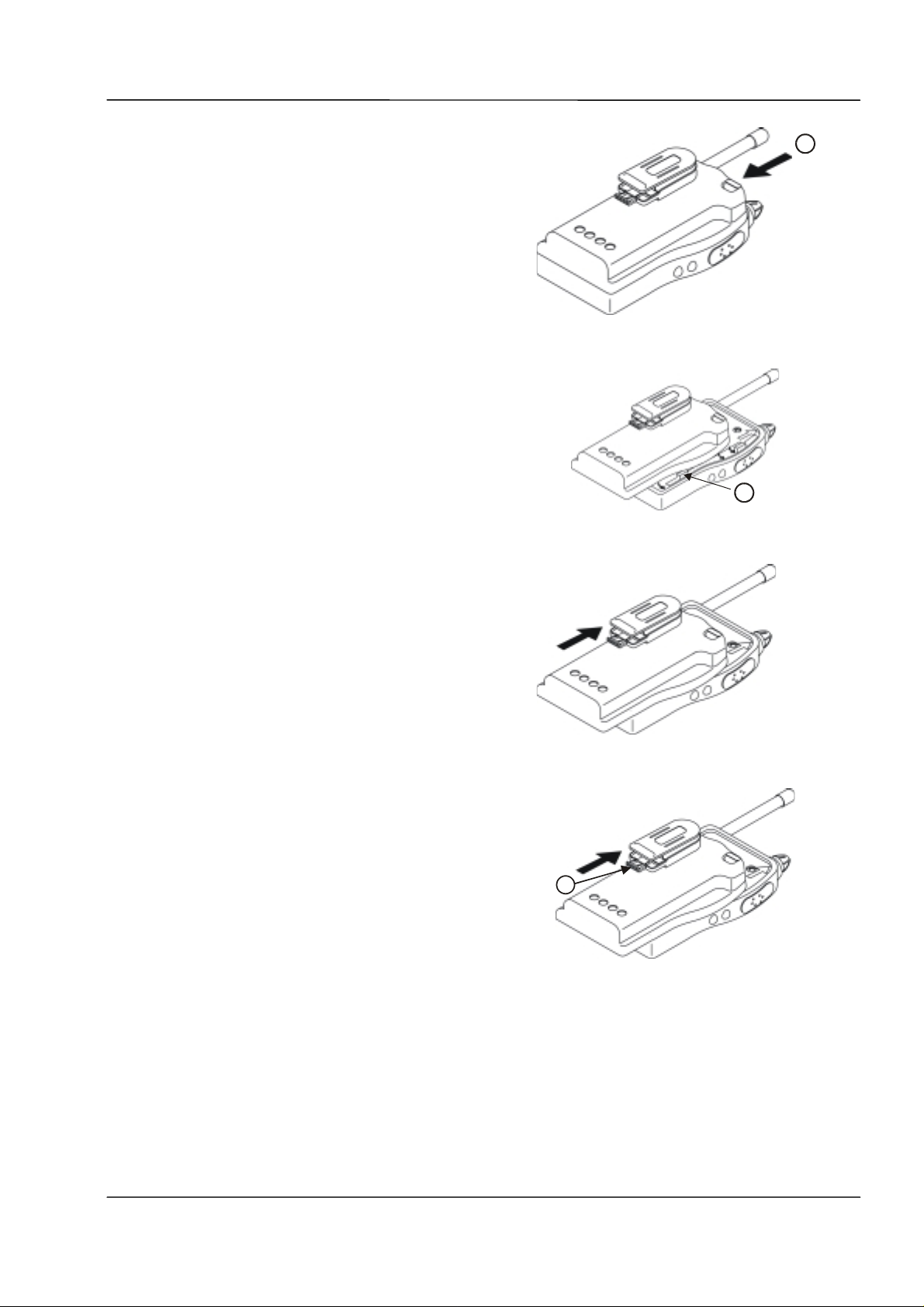

REMOVING AND REPLACING THE

BATTERY

Removal

Holding the radio chassis in one hand, press

and hold the battery release catch (1) on the

top of the battery pack.

Using the other hand, slide the battery down,

towards the bottom of the radio and off the

battery guide rail (2).

Replacement

With the slides of the battery positioned in line

with the radio battery rail guides, slide the

battery into position until a click is heard.

1

Figure 4-10 - Removal of battery

2

Figure 4-11 - Replacing the battery

REMOVING AND REPLACING THE BELT

CLIP

Removal

Lift the locking lever (3) located on the top of

the belt clip with one hand and pull the belt clip

out of the belt clip rail towards the battery /

radio top.

Replacement

With the slides of the belt clip positioned in line

with the belt clip rail guides, slide the belt clip

into position until a click is heard.

Figure 4-12 – Replacing the battery

3

Figure 4-13 – Removing the belt clip

Issue 1.0 INSTALLATION, COMMISSIONING & ALIGNMENT

03/01 Page 4-9

Page 24

Maxon SP200/210 Radio SP200/210

REMOVING AND REPLACING THE MAIN ASSEMBLY

Removal

With the battery pack removed, there are four,

black, cross-head screws visible.

These can now be removed along with the

black, cross head screw holding the

accessories socket dust cover.

Unscrew the antenna and slide off the volume

control knob.

Replace the battery

but do not

push all of the

way home. Gripping the lower sides of the

battery, and the lower sides of the radio lever

the two apart at the bottom of the radio to

separate the two.

Withdraw the module from the case.

Remove the battery from the module.

This level of disassembly will be enough for

test purposes.

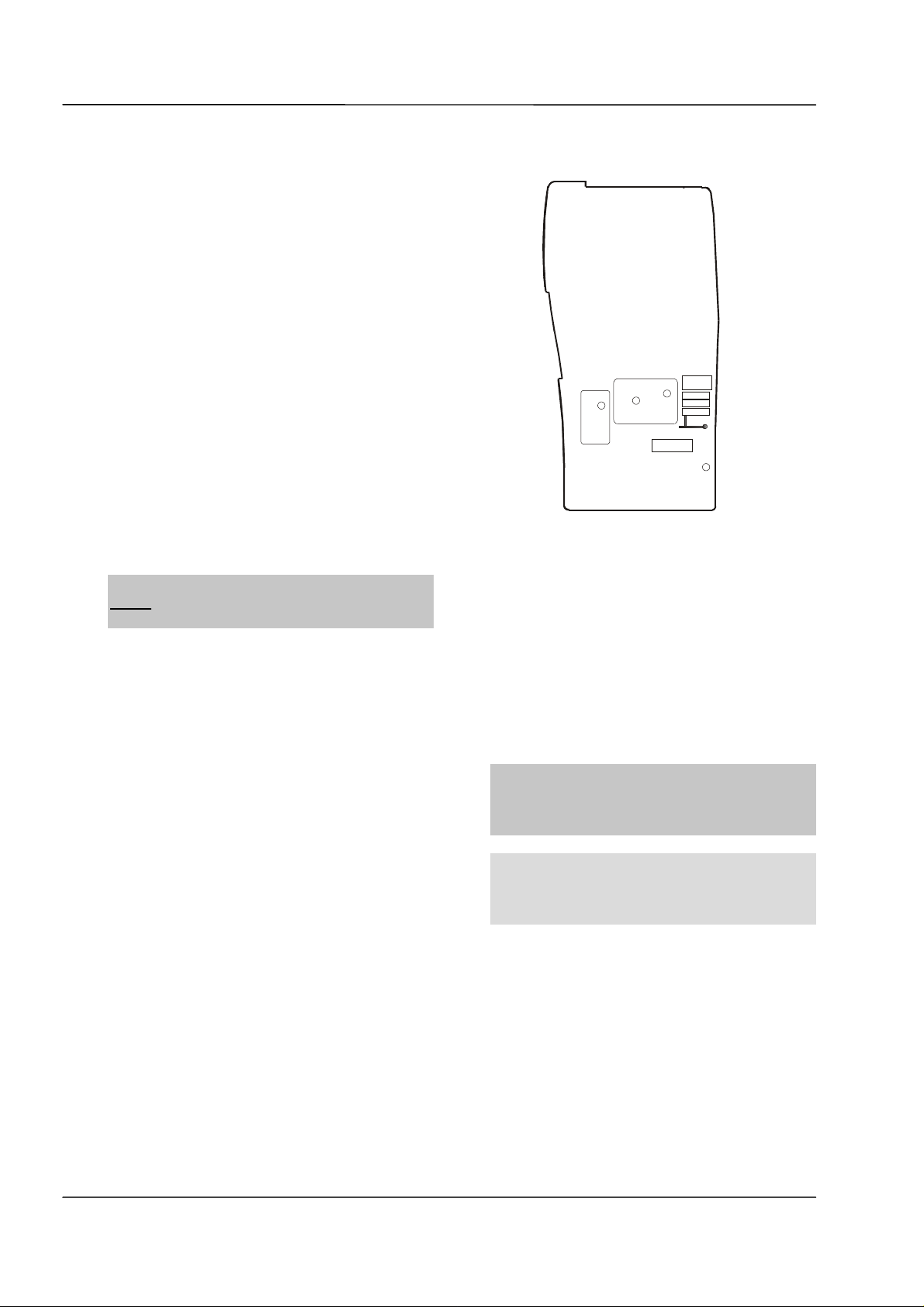

LOCATION OF ADJUSTMENT POINTS

L203

C208

TCXO

TP1

RF PCB

Figure 4-14 – Adjustment Points

Note

: A screwdriver, or similar object, should

never

be used to force open the radio as the

sealing gasket is likely to be damaged.

To reassemble the radio, carry out the above

instructions in reverse, ensuring that the seal

is pushed down into the cover. Take care not

to damage the sealing gasket.

With the two parts of the radio separated, for

servicing, it will be necessary to link the two

pcbs using the flexi-pcb ME110016, which is

part of the Service Kit.

4.5.3 PLL Alignment

Before any alignment is carried out to the

transmitter, or receiver, it is necessary to align

the Phase Locked Loop (PLL). The PLL

consists of the Rx VCO, Tx VCO and TCXO.

If the PLL is out of lock, an audible warning

will be heard UL will appear on the LCD

display.

Note:

This alert will also be heard when a

channel is programmed out of the range of

operation of the radio, or it is not programmed

at all.

Note

: If the power save parameter is

programmed there will be a periodic change at

TP1. Measurement should be based on the

steady state voltage, with power save off.

In order to carry out repairs, the two halves of

the radio may need to be linked using the flexipcb, ME110016.

This is part of the Service Kit and the Interface

Box and leads will also be required for some

of the tests.

Connect the radio under test to the Test

Equipment.

INSTALLATION, COMMISSIONING & ALIGNMENT - Issue 1.0

Page 4-10 03/01

Page 25

SP200/210 Maxon SP200/210 Radio

Rx VCO

a. Select Channel 1.

b. Check that the VCO tuning voltage at

TP1 is >5.7V +/- 0.25V (VHF) or >1.0V

+/- 0.25V (UHF).

c. Select Channel 3

d. Check that the voltage at TP1 is <12.5V.

Tx VCO

a. Select Channel 1.

b. Set the PTT switch to on and check that

the voltage at TP1 is 1.0V +/- 0.25V

(VHF) or 2.0V +/- 0.25V (UHF).

c. Select Channel 3.

d. Check that the voltage at TP1 is <12.5V.

e. Set the PTT switch to off.

Note

: If TP1 is below 0.6V or above 12.5V, in

any of the above tests, L203 may be adjusted.

L203 is covered in wax and therefore great

care will need to be taken when removing the

wax.

4.5.4 Squelch Sensitivity

The RF input level to open the squelch is

usually set in the range –123.5 to –117dBm

(0.15 to 0.3mV). The squelch should open at

a SINAD between 7 and 12dB (no CCITT).

The squelch should close between 2 and 4dB

of the value at which it opens.

RV2 sets the squelch level for 12.5kHz

channel spacing and RV4 sets the squelch

level for 20/25kHz channel spacing.

Note

: RV2

MUST

be set before RV4.

4.5.5 Transmitter Alignment

Power Adjustment

See Section 4.4.

TCXO

a. Select Channel 2.

b. Set the PTT switch to on.

c. Using the frequency counter, adjust the

TCXO control, so that the transmit

frequency is within +/- 200Hz of the

required frequency.

d. Set the PTT switch to off.

If no further alignment is to be carried out, it

may be necessary to check the squelch

setting.

Issue 1.0 INSTALLATION, COMMISSIONING & ALIGNMENT

03/01 Page 4-11

Page 26

Maxon SP200/210 Radio SP20/210

All further adjustments require the use of the ACC-2003 Alignment Box.

Refer to the ACC-2003 User Manual (on floppy disk) for operational information.

OSCILLOSCOPE

RADIOCOMMUNICATIONS

TEST SET

SERIAL DATA

DEMOD

AF IN AF OUT

AUDIO

AUDIO IN

ACC-2003

INTERFACE

BOX

AUDIO OUT

DC POWER SUPPLY

Power ATE TXD RXD

ATE AUDIO PTT

Power

SERIAL DATA

7.5VDC @ 2.4A max.

Figure 4-15 – ACC-2003 Alignment Box Test Setup

Please refer to the ACC-2003 Interface Test Jig User Guide for details on how to use the ACC-2003

Interface Box.

The radio should remain programmed as Section 4.5.1 with ASIC values being read as per the

instructions.

Note

: The ASIC programmer

DOES NOT

read frequency data, so only default frequencies will be

displayed even though the actual radio is programmed and operational on different frequencies.

Any adjustments to deviation and balance must be carried out in accordance to the R&TTE directive.

INSTALLATION, COMMISSIONING & ALIGNMENT - Issue 1.0

Page 4-12 03/01

Page 27

SP200/210 Maxon SP200/210 Radio

Balance Adjustment

a. Select Channel 3 (using software).

b. Set the audio generator to a 310H z tone,

low output impedance, at a level of

400mV.

c. Press Shift + T on the keyboard to

transmit.

d. Adjust TXTRIM2/TXTRIM3 to give a

square wave on the oscilloscope

(check that audio enable is ON on the

Interface Box.

e. Press Shift + R to turn off the transmitter.

Audio deviation adjustment

a. Select Channel 3 and press Shift + T to

turn on the transmitter.

b. Set the audio generator to 1kHz and

adjust its level for 60% peak system

deviation. Ensure that, depending upon

the channel spacing of channel 3, the

deviation is either:

12.5kHz channel spacing 1.5kHz dev.

or 20kHz channel spacing2.4kHz dev.

or 25kHz channel spacing3kHz dev.

c. Measure the audio distortion. This

should be less than 5%.

If necessary, adjust TXTRIM1 to keep within

the system deviation.

h. Press Shift + R to return to receive.

CTCSS / DCS deviation

a. Select Channel 4.

b. Turn off the audio signal generator so

that the RF signal generator is not

modulated.

c. Press Shift + T on the keyboard.

d. Adjust SATRIM2 for the desired CTCSS

tone peak deviation (± 50Hz) which is:

12.5kHz channel spacing 0.25kHz dev.

or 20kHz channel spacing0.4kHz dev.

or 25kHz channel spacing0.5kHz dev.

e. Press Shift + R to return to receive.

f. Select Channel 5.

g. Press Shift + T and check that

the deviation is the same as above.

If the deviation is greater than above,

adjust SATTRIM2.

h. Press Shift + R to return to receive.

i. Select Channel 4.

d. Increase the audio level by 20dB (10x

voltage).

e. Adjust TXTRIM1. to set the deviation to:

12.5kHz channel spacing 2.25kHz dev.

or 20kHz channel spacing3.6kHz dev.

or 25kHz channel spacing4.5kHz dev.

f. Slowly sweep the audio signal generator

between 300Hz and 3kHz. Record the

peak deviation. The peak deviation

should be:

12.5kHz channel spacing <= 2.5kHz dev.

or 20kHz channel spacing<= 4kHz dev.

or 25kHz channel spacing<= 5kHz dev.

If necessary, adjust TXTRIM1 to keep within

the system deviation.

g. Repeat para. f with the radio set to

Channel 1.

j. Press Shift + T to transmit.

k. Turn the audio generator back on so that

the RF signal generator is modulated

with a 310Hz tone.

12.5kHz channel spacing 2.5kHz dev.

or 20kHz channel spacing4.0kHz dev.

or 25kHz channel spacing5.0kHz dev.

l. Press Shift + R to return to receive.

Select Channel 5 and press Shift + T.

Check that the peak deviation is less than:

12.5kHz channel spacing <= 2.5kHz dev.

or 20kHz channel spacing<= 4.0kHz dev.

or 25kHz channel spacing<= 5.0kHz dev.

If necessary, adjust TXTRIM to keep within the

system deviation.

m. Press Shift + R to return to receive.

n. Write the changes to the radio.

Issue 1.0 INSTALLATION, COMMISSIONING & ALIGNMENT

03/01 Page 4-13

Page 28

Maxon SP200/210 Radio SP200/210

This completes the transmitter alignment

process.

4.5.6 Receiver Alignment

Audio Volume Level

a. Set the test set to the appropriate

frequency at –47dBm with 1kHz tone

modulation at 60% system deviation:

12.5kHz channel spacing 1.5kHz dev.

or 20kHz channel spacing2.4kHz dev.

or 25kHz channel spacing3kHz dev.

b. Select Channel 1.

c. With the calibration program running on

the PC, select Rx_Vol.

d. Turn the volume control to maximum.

e. Using the PageUp and PageDown keys,

press until the desired maximum volume

level is achieved.

Note:

-17.5dB corresponds to 2.10V (+/-0.2V)

into 4 ohm speaker.

At maximum volume, nominal distortion is

10%.

f. Write the changes to the radio.

It may be necessary to carry out adjustment of

the squelch setting, see Section 4.5.4.

This completes the receiver alignment

process.

The following parameters would NOT normally

be adjusted unless specific environmental

conditions necessitate a change:

INTRIM on the receiver (Audio from IF IC.)

SATRIM on the receiver (gain received – sub

audible tone)

Refer to the ACC-2003 User Guide for details.

INSTALLATION, COMMISSIONING & ALIGNMENT - Issue 1.0

Page 4-14 03/01

Page 29

SP200/210 Maxon SP200/210 Radio

5 DETAILED FUNCTIONAL DESCRIPTION

5.1 Introduction

This section provides a detailed description of the operation of the radio.

5.2 Common Circuits

Power Circuits

Battery voltage, or external voltage through the accessories connector, is applied via a 4A fuse (plus

diode protection) directly to the RF power module and, after the on/off switch, to the dc to dc converter

and voltage regulator. The majority of the circuitry is powered via IC1, which regulates the +7.5V dc

supply down to +5V.

Transistors Q2 and Q32, in conjunction with the Tx Enable and Rx Enable lines from the

microcontroller, apply +5V Tx or +5V Rx to the relevant circuitry during receive or transmit. Thus, for

instance, the receive front end amplifier is only powered during receive and the power control IC is

only powered during transmit.

It is possible to program the radio for power saving. This mode causes the microcontroller to pulse the

Rx Enable line high and low for periods between 100 and 300mS. The time may be selected when

programming the radio. As soon as the radio detects a signal it switches into normal mode.

Microcontroller

The microcontroller (IC403) is a One Time Programmed Processor chip based on the Hitachi HD3837

processor with onboard ROM and RAM.

It controls all functions performed by the radio, in conjunction with control signals from push buttons,

switches etc. It controls the data to/from the EEPROM and to the PLL IC, Audio ASIC as well as

controlling external data from the programmer and alignment interface. The microcontroller generates

the enable lines, controlling routing of signals and the indicators (LED,LCD and bleeps).

The microcontroller also generates and decodes the SAT tones (filtered by the ASIC).

EEPROM

Relevant channel information, such as Rx / Tx frequencies and CTCSS / DCS codes, is stored in the

EEPROM (IC404) which is a X25330. This information may be programmed and erased via the

accessories socket. Certain parameters can also be altered via the pushbuttons and keys on the

radio, i.e. scan channels and priority channel. The EEPROM has 32768 (8x4096) capacity and data is

written serially.

Channel Select Circuit

Up to 199 channels may be selected, using the channel keys on the front panel. Pressing the channel

keys earths pins 40 and 41 of the microcontroller, so enabling the decoding for the appropriate Rx and

Tx frequencies, and associated data, to be selected from the EEPROM.

Issue 1.0 DETAILED FUNCTIONAL DESCRIPTION

03/01 Page 5-1

Page 30

Maxon SP200/210 Radio SP200/210

5.3 Audio ASIC

The audio ASIC (IC406) processes both the audio signal and the sub-audible tones, including filtering,

amplifying, setting attenuations levels etc. It is a programmable device, controlled by the

microcontroller, hence alteration of deviation levels is achieved by the ACC-2003 Alignment Software.

The internal block diagram is shown in Figure 5-1. The audio and SAT routes within the ASIC will be

described separately.

5.3.1 Audio Signal Path

A1 Buffers discriminator audio input from Pin 30 (INI) and passes it to

Analogue Switch 1 (ASW1). It has a gain of x1.

A2 Amplifies the analogue signal from the mic input terminal (IN2) and

passes this signal to Analogue Switch 1. It has a gain of 10dB.

ASW1 This is a two-way analogue switch. It is controlled by the serial control

interface. Default value is 0, which is Rx (A1).

INTRIM Sets the deviation for the input analogue signal sensitivity. The control

range of this device is –3.5 to +4dB controllable in 16 steps. The

control is a 4 bit signal where the default value is 1000, which

corresponds to 0dB.

300Hz HPF Comprises an 8

Attenuation of the unwanted is at least 30d B.

ASW2 This is a four-way analogue switch, controlled by the serial control

interface. It passes the received audio to the de-emphasis circuit or

the transmit audio to the pre-emphasis circuit. Alternatively, the preemphasis or de-emphasis can be bypassed. The control signal is a 2

bit signal with 00 as the default, which is de-em phas is .

DE-EMPHASIS Applies de-emphasis to the received audio at 6dB/octave. At 1kHz, the

gain is x1.

PRE-EMPHASIS Applies pre-emphasis to the transmit audio at 6dB/octave. At 1kHz,

the gain is x1.

RXVOL Controls the magnitude of the Rx audio signal which is passed, via the

volume control (VR5) to the speaker in 16 steps from 0dB attenuation

up to 37.5dB attenuation, to Rxout on pin 28.

AMP This amplifier provides gain, to the Tx audio, in 8 steps from +20dB to

+41dB.

LIMITER Applies limiting at 0dB (2.8V p-p). The output of this stage is controlled

in 4 steps from 0dB to –5.4dB attenuation by a 2 bit control signal.

ASW3 This is a two-way analogue switch, controlled by the serial control

interface. It passes the Tx audio, or the SAT to the low-pass filter.

VLPF This is a 6

control interface. The cut-off point is switched between 2.55kHz and

3kHz.

TXTRIM1 Provides deviation adjustment of Tx audio in 16 steps from +3.5dB

gain to –4dB attenuation. Uses a 4 bit control signal.

TXSUM Mixes (Adds) the signal from TXTRIM1 with the SAT signals from

COMPIN+, or selects one or other of the signals. Can also apply 50dB

muting. Controlled by the serial control interface.

ATTN Attenuates the signal from TXSUM by either 0dB or 6dB.

TXTRIM2/3 Signal follows two routes (to VCO & TCXO) for final deviation

adjustment in 32 stages from +3.75dB to –4dB. Controlled by 5 bit

signal.

A3/A4/INV Final output buffer amplifier for Tx analogue signal. Gain is 0dB. A3

output (modout 1 on pin 1) goes to the VCO and A4 (modout 2 on pin

2) goes to TCXO, are non-inverting outputs. The inverting output (INV)

from A4 is not used.

th

order filter with a cut-off frequency of 300Hz.

th

order low pass filter, which is controlled by the serial

DETAILED FUNCTIONAL DESCRIPTION Issue 1.0

Page 5-2 03/01

Page 31

SP200/210 Maxon SP200/210 Radio

5.3.2 Sat Signal Path

ASW4 ASW4 switches between RxSAT (RDIN) and Tx SAT (TXIN) and

routes to the filter.

VSCLPF Seventh order Elliptic Variable Switched Capacitor Low Pass Filter.

Cut-off frequency is variable from 50Hz to 300Hz. Level adjustable in

0.5dB steps from –3dB to +2.5dB. Output is on pin 23 FLT OUT.

SATRIM1 Not used.

SATRIM2 SAT level adjustment. Amplitude is controlled in 0.5dB steps from –

3dB to +2.5dB. Output is on pin 23 FLTOUT.

COM Compares the external reference voltage (COMPPIN-) with the applied

SAT signal which is from FLTOUT to COMPIN+ and it goes to Logic

High and Logic Low at this point. The output COMPOUT (pin 21) goes

to the microcontroller IC406. NB in transmit the SAT is switched into

TXSUM.

5.3.3 Miscellaneous Signals and Controller

ADC / DAC ADC is not used. DACs are 8 bit devices.

CONTROL Control serial interface for control lines.

DATA Operates as output line for a READ instruction and as input line for a

WRITE instruction, Pin 18.

CLOCK This is the synchronous input terminal for communication with the

microcontroller, pin 12.

ENBL With an active low, data read and write is enabled.

AGND.DGND Reference analogue and digital grounds.

Figure 5-1 – ASIC Block Diagram

Issue 1.0 DETAILED FUNCTIONAL DESCRIPTION

03/01 Page 5-3

Page 32

Maxon SP200/210 Radio SP200/210

5.4 Audio/SAT Circuits

CTCSS / DCS Decoder Circuits

Discriminator audio from pin 9 IC5 is applied, via IC408D, to pin 3 of the audio ASIC. The audio

frequencies of the signal are filterecd out by the 7

audio tones. The level is then set by the ASIC and is routed via IC407A back to the ASIC for

comparison with a reference voltage. This produces the logic data signal. This logic signal on pin 21

(IC406) is fed into the microcontroller (IC403) where it is matched with a programmed frequency. If

there is a successful match, decode occurs, which is shown by a green LED on the top of the radio

and audio is heard. If there is an invalid decode, the LED will light yellow (BUSY)

CTCSS / DCS Encoder Circuits

During TX encode the tone squelch digital signal is produced as a 3-bit parallel word at pins 48, 49

and 50 of the micro controller (IC403). The 3-bit digital signal is converted to an analogue signal by

resistors R420, 421 and 423. The analogue signal is fed into IC406 pin 4 where it is filtered and its

deviation level is set.

The filtered encode output from pin 23 (IC406) is fed back into pin 22 (IC406) via IC407a (LM358).

The filtered encode signal is mixed with the audio signal from TXTRIM1 by TXSUM. Via ATTN, the

mixed signals are applied to TXTRIM2/TXTRIM3, which controls the modulation to the VCO and

TCXO respectively (see RF description).

th

order Elliptic Low Pass Filter, leaving only the SAT

External Mic / PTT Control Circuit

The external microphone is connected via a 3.5 mm stereo jack socket on the right-hand side of the

radio. The internal mic and speaker are disabled when the external connector is plugged the

SPK/MIC jack socket.

When the external PTT is depressed, a low impedance is presented to the base of Q403 (below 20k

ohm). Q402 and Q403 switch on and so Q402 collector is low (normally tied high). This point is

connected to IC403 (microcontroller) pin 43 (PTT). The same point is connected to the normal PTT

button, SW403, which is earthed when depr es s ed.

The mic audio itself is switched through IC401A by the Tx enable line to IC408D amplifier stage and

through to the audio ASIC for filtering and deviation level setting. As described previously, this audio

signal is added to the SAT and routed to the TCXO and VCO.

Rx Audio

The discriminator audio is fed directly into the audio ASIC from the RF section (see later). The ASIC

sets the gain and filters out any SAT. The output is fed to the volume control (VR5). The alert tones

and switch on melody is routed from the microcontroller via link LK27 to the same point to the volume

control.

The AF from the volume control is fed to the audio amplifier, a TDA7233, which is activated by the

mute circuit. The output is then fed to the internal or external speaker.

Mute Circuit

The microcontroller (IC403) has a mute circuit which is output on pin 13 (7233EN). The operation of

the mute depends upon a number of factors, such as is the demodulator receiving a mute signal from

the FM detector and does the signal have the correct CTCSS / DCS. The microcontroller will also

change the state of the mute if the monitor button is depressed (SW402), assuming that this function

has been enabled in the programming

Pin 13 is connected to Q414, Q415 via R446, which mutes the TDA7233IC.

DETAILED FUNCTIONAL DESCRIPTION Issue 1.0

Page 5-4 03/01

Page 33

SP200/210 Maxon SP200/210 Radio

Battery Low Indicator Circuit

When the battery voltage drops below 5.6 VDC a Battery Low indication is given. Due to the volts drop

across D403, a voltage below 5.6V on the battery gives a voltage less than 5V on the base of Q405. ,

Q405 switches on its when base is below 5v (current flow through R413), which switches on Q404, so

driving pin 52 of the microcontroller low (normally tied high). The micro controller disables the

transmitter and at the same time enables the red LED and sends an alert tone to warn the user. The

battery should be replaced or recharged at this time (one transmission is allowed after the low battery

warning).

LEDs and indicators

The red and green LEDs are switched on, via Q407and Q411, by control lines from the

microcontroller. Both the red and green LEDs being lit indicate the condition ‘busy’ i.e. orange. Both

the LCD and backlight are driven from the microcontroller.

The alert tones are generated in the microcontroller and are fed through a filter to the volume control

via link 27. There is an option of routing the tones directly to the audio amp via link28.

5.5 Common RF Circuits

PLL Synthesiser

The PLL synthesiser circuit is common to both the transmitter and receiver.

The synthesiser comprises:

Data

TCXO

IC 2

PLL

Tx or Rx

VCO

~

RF Out

DC - DC

Converter

Charge Pump

Loop Filter

Figure 5-2 – Synthesiser Block Diagram

12.8 MHz TCXO

The TCXO contains a crystal oscillator, which has 2-stage thermistor network compensation, and a

modulation port. Accuracy is +/-2.5 PPM from -30°C to +60°C. Frequency adjustment is provided by

TC701.

VCO

The VCO is configured as a Colpitts oscillator using transistor Q202, varactor diodes D201 / 202,

frequency setting inductor L203 and associated components. Cascade bias is provided by Q201.

The frequency of operation is controlled by reverse biasing D201 in the range of 1 to 12 V dc (from the

PLL). During receive Q9 is switched on by the Rx enable (active low), so switching D203 in circuit (via

Q203), which puts C208 (variable capacitor) in parallel with the varactor diodes and adjustable

inductor.

Issue 1.0 DETAILED FUNCTIONAL DESCRIPTION

03/01 Page 5-5

Page 34

Maxon SP200/210 Radio SP200/210

In transmit the VCO has modulation from the audio processing circuitry applied to D202. C204 is used

to provide compensation for non-linearity caused by the modulation diode and maintains a constant

modulation regardless of the frequency of operation.

PLL IC

The reference frequency from the TCXO, at 12.8 MHz, is connected to pin 20 of IC2 (MC145191).

The appropriate VCO is connected to pin 11.

The external reference frequency, TCXO input, is divided by the reference divider (REFDIV), which is

set to divide by 2048 for 12.5kHz or 25kHz channels (6.25kHz) or to divide by 2560 for 20kHz

channels (5kHz). This is known as the reference frequency, Fr.

The comparison frequency is determined by the settings which are stored within the EEPROM

(IC404). Choice of these comparison frequencies means that the minimum step size of the synthesiser

is either 5kHz or 6.25kHz and therefore, 12.5kHz, 20kHz and 25kHz channel spacings can be

accommodated.

IC2 is programmed on pin 19, to obtain the desired frequency, by serial data from the microcontroller

(IC403 pin 21). IC2 Pin 19 is the data input and pin 18 is the clock input and pin 17 is the PLL enable

line.

The VCO frequency, Fin, is divided down by the programmable divider (64/65 prescaler VARDIV) to,

again, produce 5kHz or 6.25kHz. This frequency is known as the variable frequency, Fv.

In the phase/frequency comparator, the phase difference between the reference frequency, Fr, and

the VCO signal, Fv, is compared.

When Fv = Fr, the phase detector output (pins 3 and 4, IC2) produces narrow negative pulses and Fv

and Fr pulse widths are identical. When Fv > Fr, pin 4 (V) pulses negative, with pin 3 (R) remaining

high. When Fv < Fr, pin 3 (R) pulses negative with pin 4 (V) remaining high. The signal at pins 3 and

4 is smoothed by the loop filter and applied to the VCO.

Out-of-Lock Detector

The out-of-lock detector output remains essentially high with narrow low-going pulses when in lock.

The output pulses low when Fr and Fv are out of phase or at a different frequency (results in wider

pulses). These pulses at pin 2 are buffered by Q5 and then integrated by R1 and C11. The resultant

voltage is fed to the microcontroller, IC403, pin 53.

IC2 has two output ports:

Port A pin 16 Configurable digital port, which is used as tx enable 2, which controls the application

of volts to the PA stage.

Port B pin 15 Open drain digital output, which is used as a power save control.

Pin 13 labelled test2 allows the technician to see the output of the dual modules prescaler for trouble

shooting purposes, no connect ion shou ld be m ade to this pin .

Charge Pump and Loop Filter

Transistors Q6 to Q8 and Q11, and associated components, form the charge pump. The phase

detector output from IC2 pins 3 and 4 are combined by the charge pump to produce a 0 to 12V tuning

voltage.

The voltage signal is filtered by the loop filter (R12 – R14, C21 - C24) to remove harmonics of the

reference frequency.

DC to DC Converter

The DC to DC converter, converts the +7.5 V to a 16 V suppy. This is used to provide the tuning

voltage for the VCO. A wide voltage range is required to allow for the wideband operation of the radio.

Q904, Q905 and associated components, form a 200kHz oscillator. The output of the oscillator is

rectified (voltage tripled) by D901, D902 and D903. C901, C902 and C916 provide filtering. The

resultant 16Vdc is passed to R909 and then becomes the supply rail for the charge pump.

DETAILED FUNCTIONAL DESCRIPTION Issue 1.0

Page 5-6 03/01

Page 35

SP200/210 Maxon SP200/210 Radio

5.6 Transmitter

The transmitter comprises:

Figure 5-3 - Transmitter Block Diagram

Buffer

The RF output level from the VCO is 0dBm. This is amplified to +17dBm by the buffer amplifier

consisting of Q16, Q17, Q3 and associated components. All stages are simple common-emitter

amplifiers with resistive biasing and tuned collectors. A pi-type attenuator (R31, 32 and 34) is used

between the two stages.

PA module

The PA module consists of a hybrid amplifier. Pin 3 is permanently connected to the battery voltage

and pin 2 is connected to the supply when switched by Q22, which is controlled via the power control

circit by the Tx enable line. The RF input is on pin 1 and the output is on pin 4.

Low pass filter

L7, L8, L11, C73, C74, C75 and C76 form a 7th order Chebyshev low pass filter. Unwanted

harmonics are reduced by 65dB.

Antenna Switch

When transmitting, the diodes D5 and D6 are forward biased, allowing the RF to pass to the antenna.

D6 is shorted to ground which makes L13 look open circuit (1/4 wave tuned stub). This prevents the

Tx signal from passing to the receiver stage.

In receive, the diodes D5 and D6 are reverse biased. L13 is now in circuit, passing the signal from the

antenna to the front end without signal loss.

Automatic power control (APC) circuits

The APC circuit consists of IC3B, Q19, Q21, Q22 and associated components. The PA supply current

passes through R109. Variations in power output, produce variations in supply current, which is

amplified by IC3A and Q19.

The voltage on the wiper of RV1 is passed to IC3B and compared with the fixed reference voltage

developed by the potential divider R45 and R46. The output of IC3B, pin 7, controls Q21 and Q22 to

provide supply voltage to the PA driver transistors Q501 and Q502. RV3 controls the low power

setting and is switched into circuit by Q23.

A change in PA output will result in an inverse change in driver supply voltage maintaining a constant

RF output.

Issue 1.0 DETAILED FUNCTIONAL DESCRIPTION

03/01 Page 5-7

Page 36

Maxon SP200/210 Radio SP200/210

5.7 Receiver

The receiver comprises:

VCO

~

Rx

Audio

Audio

Amplifier

Filter

Local

Oscillator

~

FM Limiter-

Discriminator

Squelch

Circuit

Figure 5-4 - Receiver Block Diagram

Antenna Switch

In receive, the diodes D5 and D6 are reverse biased. L13 is now in circuit, passing the signal from the

antenna to the front end without signal loss.

Front End

The receive signal is routed to the RF Front End module, pin 1. It passes through a matching circuit

consisting of C601 to C603 / L601 & L602.

Diode D601 serves as protection from RF overload from nearby transmitters.

The input signal is coupled to the base of Q601 which serves as an RF amplifier. The output of Q601

is then coupled to a bandpass filter consisting of C604 to C620 / L603 to L607.

The output of the front end module, pin 6, is then coupled to the double-balanced mixer D9.

The receiver front end module is factory pre-tuned and requires no adjustment. Repair is effected by

replacement of the entire module.

The modules are:

VHF 146 MHz to 174 MHz

UHF 440 MHz to 470 MHz.

DETAILED FUNCTIONAL DESCRIPTION Issue 1.0

Page 5-8 03/01

Page 37

SP200/210 Maxon SP200/210 Radio

First Mixer

D9, T1 and T2 form a double balanced mixer which provides the 45.1MHz intermediate frequency

output. The filtered frequency from the front end module is coupled to T1.

The Local oscillator input from the VCO is coupled to T2.

The output of the mixer is taken from the tap on transformer T1 and fed to the single pole diplexer,

comprising L15 / C93 and R65 (High-pass terminating filter) and L14 / C92 (Low-pass coupling filter)

The 45.1MHz crystal filter provides a bandwidth of +/-7.2 kHz. This filter provides a high degree of

protection from spurious and intermodulation products. Additionally, a 90 MHz trap (C93 / L15) is

placed at the filter input.

The output of the filter is coupled by C43 to the base of the post filter IF amplifier Q25.

Second mixer, Second IF, FM detector

The output of the IF amplifier is fed into the narrowband FM IF Integrated Circuit, IC5 (MC3372). This

is a single conversion FM receiver which contains the second mixer, second IF amplifier, and FM

detector.

The second local oscillator frequency is determined by the crystal X1 connected to pin 1 of IC5. In this

case the crystal has a frequency of 44.645MHz. The first IF signal is applied to the mixer and the

resultant frequency of 455KHz, is the difference between the IF signal and second local oscillator.

The 455KHz IF signal is output from pin 3 and is applied to a 455KHz band-pass filter, CF1 (20/25 kHz

channel spacing) or CF2 (12.5 kHz channel spacing). The selection of the filters is accomplished by

diodes D13 (input) and D14 (output) whose bias is controlled by the N/S SW line on the

microcontroller (IC403, pin 25).

The microcontroller takes the relevant channel spacing data from the EEPROM. A High on the N/S

SW line switches the 455kHz signal to CF1, a low switches the signal to CF2.

The output of the relevant IF filter is passed to pin 5, which is the input to the limiting amplifier.

The limiting amplif ier is biased ex ter na ll y by R19 & R95 and conn ec ted b y C52 to the quadratur e

detector (X2). The output connects to pin 8. The quadrature circuitry provides a 90° phase shift at the

IF centre frequency, which enables audio to be recovered. Any detected signal is produced at pin 9 of

IC5 and applied to the Receiver Audio Circuit and the Mute (Squelch) Circuit.

Squelch (Mute) Circuit

The mute circuit switches off the audio amplifier when no audio signal is present. The squelch circuit

consists of IC5 and RV2 (RV4) and their associated components. The noise signal from pin 9 of IC5

is amplified by an internal amplifier in IC5 and fed to the 16kHz bandpass filter.

16kHz Band Pass Filter

The audio signal from pin 9 of IC5 is filtered by a 16 kHz band pass filter consisting of L16, L17 / C111

to C113. The noise in the IF passband is accepted and voice frequencies and their products are

rejected.

Any noise present at the output of the filter is applied to the noise detector circuit via RV2 (RV4). RV2

(RV4) is used to adjust the squelch circuit sensitivity and is normally adjusted to produce a noise

squelch opening sensitivity of 10 to 12 dB SINAD.

For 12.5 kHz channel spacing, RV4 is switched in, by the microcontroller and Q28, to attenuate signal

at RV2 for 25 kHz channels. A High on the N/S SW line switches in RV4.

The output from the band pass filter is applied to the filter amplifier input on pin 10 of IC5.

Issue 1.0 DETAILED FUNCTIONAL DESCRIPTION

03/01 Page 5-9

Page 38

Maxon SP200/210 Radio SP200/210

Noise detector circuit

The noise detector circuit, in conjunction with IC5, consists of transistors Q26, Q27, thermistor TH1

and diode D11. Any noise signal present is applied to Q27 from pin 11 of IC5. The signal is amplified

by Q27, rectified by D11 and then buffered by Q26. The buffered signal is applied to pin 12 of IC5

(Squelch input).

The squelch trigger output (pin 14, IC5) is applied to the microcontroller BUSY input on pin 54 of

IC403. The actual audio mute is from the microcontroller.

When noise is present, the voltage at pin 12 of IC5 (Squelch input) exceeds 0.7V. This causes the

squelch trigger output to go open circuit, which turns on Q24 and the busy line goes low, which mutes

the receiver audio circuit.

When no noise is present, the voltage at pin 12 of IC5 is less than 0.7 V and pin 14 of IC5 is

grounded, which switches Q24 off, so the busy line goes high, unmuting the receiver audio circuit.

Resistor R74 is used to provide hysteresis of 3 to 6 dB.

AF Output Low Pass Filter

A low pass filter formed by C115, C116 and R91 removes any extraneous 455 kHz energy from the

AF output of the FM receiver chip.

Speaker Audio Amplifier

After signal detection and audio filtering the signal is passed to the digital board, to the audio ASIC

(via IC408 for SAT). ). After the audio ASIC (see previous description) the signal is then routed, via

the volume control (VR5), to pin 8 of IC402. IC402 is a TDA7233 audio amplifier, which is enabled by

the control line from the microcontroller via Q415 and Q414.

DETAILED FUNCTIONAL DESCRIPTION Issue 1.0

Page 5-10 03/01

Page 39

SP200/210 Maxon SP200/210 Radio

6 TROUBLESHOOTING

This section includes voltage and troubleshooting charts which should assist the engineer to isolate

and repair the fault. Voltage measurements should be made using a high-impedance voltmeter and

the values given are with respect to ground.

Obvious checks, such as battery performance on load, should be made before pulling the radio apart.

Substitution of another set of batteries, or the use of a power supply, isolates this cause.

The alignment procedures, given in Section 5, list how standard tests such as SINAD measurements

can be made. These can be used to check the performance of the receiver.

Careful alignment, using suitable test equipment, and quality interface cables should ensure that the

radios meet their specified performance.

6.1 Diagnostic Function

The diagnostic function is designed to inform the user about the operational status of the radio.

The possible audible and visual warnings are:

Status Description LED Colour LCD Indication Audible Tone

Normal Power On Ready N/A 188 Melody

Busy Yellow Channel Number N/A

Correct S.A. Tone Green N/A

Transmit Red N/A

Transmit Not Allowed Red Flashing Alternating UL

with Channel No.

Scanning Scan Flashing Green N/A

Priority Scan Mode Green Flashing N/A N/A

Priority Lookback Green Flashing Lb/Ch annel

Number

Priority

Edit