Page 1

INSTALLATION INSTRUCTIONS

FOR

WHEELCHAIR LIFT MODEL NO.

• WL7-vers. C

• WL7-vers. C-1K

DOT-Public Use Lift

PATENTS PENDING

FOR INSIDE VEHICLE

INSTALLATION ONLY

© MAXON Lift Corp. 2009

MP-06-09

REV. A

APRIL 2009

Page 2

PATENTS PENDING

Page 3

THIS PAGE INTENTIONALLY LEFT BLANK

PATENTS PENDING

Page 4

TABLE OF CONTENTS

INTRODUCTION ...................................................................................................................6

SAFETY SUMMARY ............................................................................................................. 6

VEHICLE REQUIREMENTS ................................................................................................. 8

LIGHTING .............................................................................................................................. 9

WHEELCHAIR DOOR DIMENSIONS ................................................................................. 10

LIFT DIMENSIONS ..............................................................................................................11

LIFT COMPONENTS & TERMINOLOGY ............................................................................ 14

DECALS AND DECAL PLACEMENT .................................................................................. 16

DECALS FOR WL7-vers. C ................................................................................................. 17

DECALS FOR WL7-vers. C-1K ........................................................................................... 18

SERIAL PLATE & CONTROLLER ....................................................................................... 19

ANTI-SLIP & SAFETY STRIPING ....................................................................................... 20

LIFT INSTALLATION .......................................................................................................... 23

INSTALLATION KITS .......................................................................................................... 23

PREPARING AND POSITIONING THE LIFT ..................................................................... 23

USING TEMPLATE TO POSITION LIFT ............................................................................ 25

MOUNTING THE LIFT ........................................................................................................ 28

INSTALL MAIN CIRCUIT BREAKER ................................................................................... 29

ROUTE/CONNECT CABLES & HAND PENDANT ............................................................. 31

CHECKING HYDRAULIC FLUID LEVEL ............................................................................ 39

ADJUSTMENTS .................................................................................................................. 42

MAT SWITCH ADJUSTMENT (IF REQUIRED) ................................................................... 42

PLATFORM TILT ADJUSTMENT (MANDATORY) ............................................................. 44

INBOARD SWITCH ADJUSTMENT (IF REQUIRED) ......................................................... 46

CHANGING CONTROLLER TO SPANISH OR ENGLISH (IF REQUIRED) ....................... 48

Page 5

OUTBOARD ROLLSTOP TIME ADJUSTMENT (IF REQUIRED) ....................................... 50

FLOOR POSITION ADJUSTMENT (MANDATORY) .......................................................... 52

SYSTEM DIAGRAMS ......................................................................................................... 57

HYDRAULIC SYSTEM DIAGRAM ...................................................................................... 57

ELECTRICAL SYSTEM DIAGRAM ..................................................................................... 58

COMPLETED LIFT INSTALLATION CHECKLIST ............................................................. 59

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

5

PATENTS PENDING

Page 6

INTRODUCTION

This manual contains instructions for installing the MAXON MOBILITY Wheelchair Lift in a

transit vehicle. Please follow these instructions carefully and call us immediately if you need

assistance with the installation. Do not take shortcuts, skip over installation steps, or modify

the Lift. Correct installation is important to ensure the Lift operates correctly. If you have

questions that are not covered in this manual, please contact:

MAXON Lift Corp. - Customer Service

11921 Slauson Ave., Santa Fe Springs, CA 90670

Phone: (800) 227-4116 FAX: (888) 771-7713

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

After receiving the Wheelchair Lift, unpack the Lift and check it for freight damage. For

freight-damaged items, immediately submit a claim to the carrier.

Make sure installation kit contains all items on the packing list shipped with the kit. Please

report any missing items immediately to our Customer Service Department. The Warranty

Registration Card, shipped with the Lift, must be completed and returned to Maxon Lift

Corp. within 30 days after installation and/or receipt of the Lift.

E-mail: cservice@maxonlift.com

SAFETY SUMMARY

Comply with the following WARNINGS and safety precautions while maintaining the

Wheelchair Lift. See Operator’s Manual for operating safety requirements.

WARNING

!

1. Read and understand the instructions in this Installation Manual before installing Lift.

2. Before operating the Lift, read and understand the operating instructions contained in

the Operator’s Manual.

3. Comply with all WARNING and instruction decals attached to both the Lift and the ve-

hicle.

4. Keep decals clean and legible. If decals are illegible or missing, free replacement

decals are available from MAXON Lift Corp. Customer Service. Refer to DECALS &

DECAL PLACEMENT and the instructions for installing decals on vehicle in this manu-

al.

5. Consider the safety and location of bystanders and location of nearby objects when operating the Lift. Stand to one side of platform while operating the Lift.

6. Do not allow untrained persons to operate the Lift.

7. Do not stand, or allow obstructions, under the Platform when lowering the Lift. Be sure

your feet are clear of the Lift.

8. Keep fi ngers, hands, arms, legs, and feet clear of moving Lift parts (and platform

edges) when operating the Lift.

9. Make sure vehicle battery power is disconnected when installing Lift. Connect

vehicle power to the Lift only when instructed to connect power.

PATENTS PENDING

6

Page 7

1. Read and understand the instructions in this Installation Manual before installing Lift.

2. Before operating the Lift, read and understand the operating instructions contained in the

Operator’s Manual.

3. Comply with all WARNING and instruction decals attached to both the Lift and the ve-

hicle.

4. Keep decals clean and legible. If decals are illegible or missing, free replacement decals are available from MAXON Lift Corp. Customer Service. Refer to DECALS & DECAL PLACEMENT and the instructions for installing decals on vehicle in this manual.

5. Consider the safety and location of bystanders and location of nearby objects when op-

erating the Lift. Stand to one side of platform while operating the Lift.

6. Do not allow untrained persons to operate the Lift.

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

7

PATENTS PENDING

Page 8

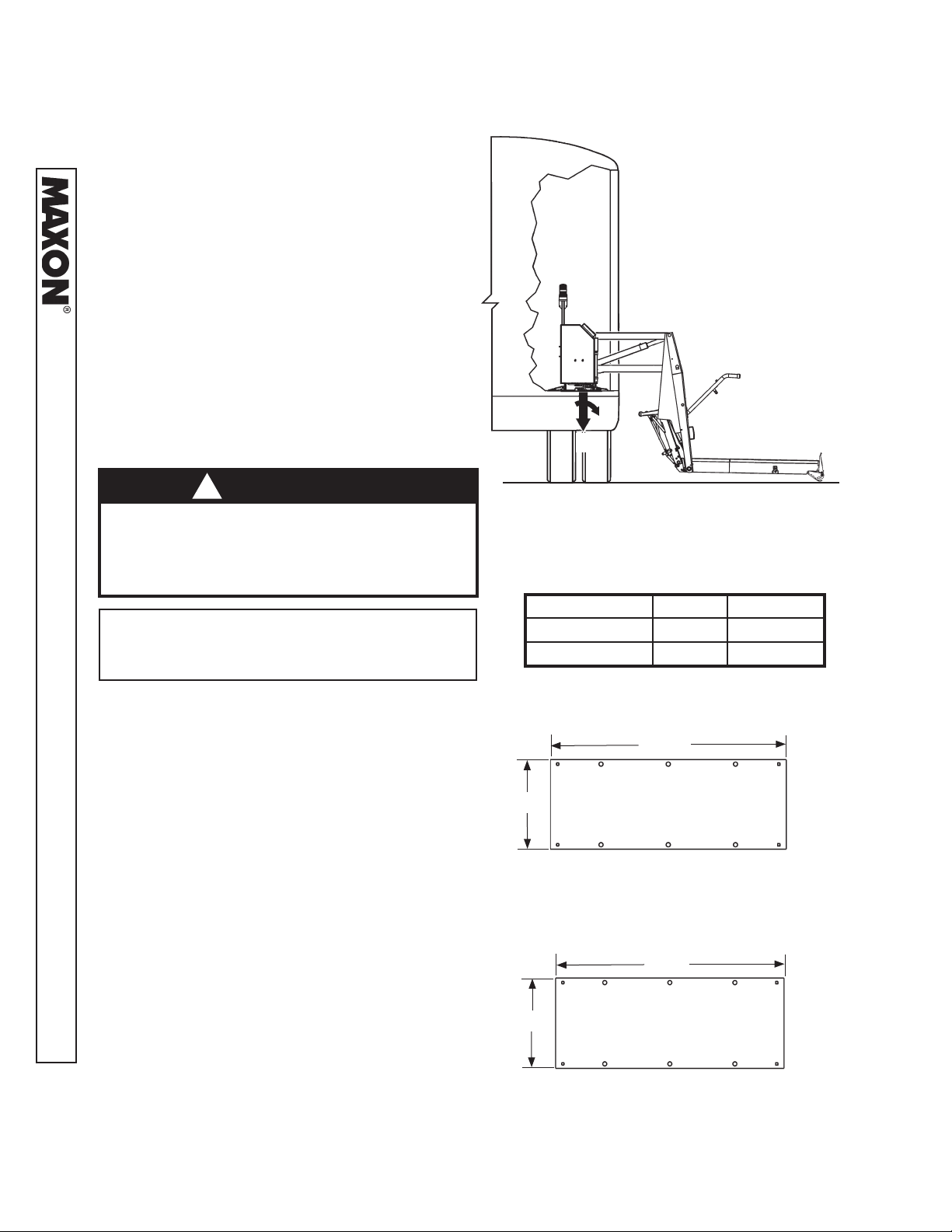

VEHICLE REQUIREMENTS

The minimum vehicle requirements

for installing the WL7 Wheelchair Lift

are described below. Installing the

Lift in accordance with the vehicle

requirements and the instructions in

this manual will result in an installation

that is compliant with Federal Motor

Vehicle Safety Standard (FMVSS) 403

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

and FMVSS 404.

BODY STRENGTH

WARNING

!

Consult body manufacturer for body

strength data. Make sure the forces

created by the Lift are within the limits

prescribed by body manufacturer.

NOTE: The Lift represents approximately

400 lbs. of “F” shown in the illustration.

The WL7 Lift must be bolted to the vehicle

body. Body must withstand the maximum

vertical force (“F”) and moment of force (“M”)

(FIG. 8-1 and TABLE 8-1 ) produced

by the Lift on the vehicle fl oor surface shown

in FIGS. 8-2 and 8-3.

M

F

FORCE & MOMENT PRODUCED

BY LIFT ON VEHICLE FLOOR

FIG. 8-1

MODEL “F” (LB) “M” (LB-IN)

WL7-vers. C 2800 154,000

WL7-vers. C-1K 3400 187,000

TABLE 8-1

42.5”

15”

PATENTS PENDING

LIFT FOOTPRINT ON VEHICLE FLOOR

(LIFT WITH 33” OR 34” PLATFORM)

FIG. 8-2

39.5”

15”

LIFT FOOTPRINT ON VEHICLE

FLOOR (LIFT WITH 30” PLATFORM)

8

FIG. 8-3

Page 9

ELECTRICAL POWER

Vehicle must have a 12 volt dc electrical

system capable of supplying 65 amperes

of electrical power to the Lift for each

operating cycle.

SAFETY INTERLOCK SYSTEM

Vehicle must have an FMVSS 403 compliant, onboard

Safety Interlock System that interfaces with the Wheelchair Lift interlock signal. Interlock signal may be V+ or

V-. The interlock system on a host vehicle must:

Prevent the Lift from deploying when vehicle is in

•

drive or reverse.

Prevent the vehicle from moving when the Lift is

•

deployed.

Prevent the Lift from disabling vehicle if the Lift

•

signals a deployed condition when the vehicle is

moving.

For the applicable interlock electrical connections on the Lift,

refer to the ELECTRICAL SYSTEM DIAGRAM in this manual. For more information about the interlock connections, call:

MAXON Lift Corp. Technical Service at (800) 227-4116

LIGHTING

Public use vehicle manufacturers are responsible for

complying with Lift lighting requirements stated in Federal Motor Vehicle Safety Standard No. 404, Platform

Lift Installations in Motor Vehicles (49 CFR 571.404).

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

9

PATENTS PENDING

Page 10

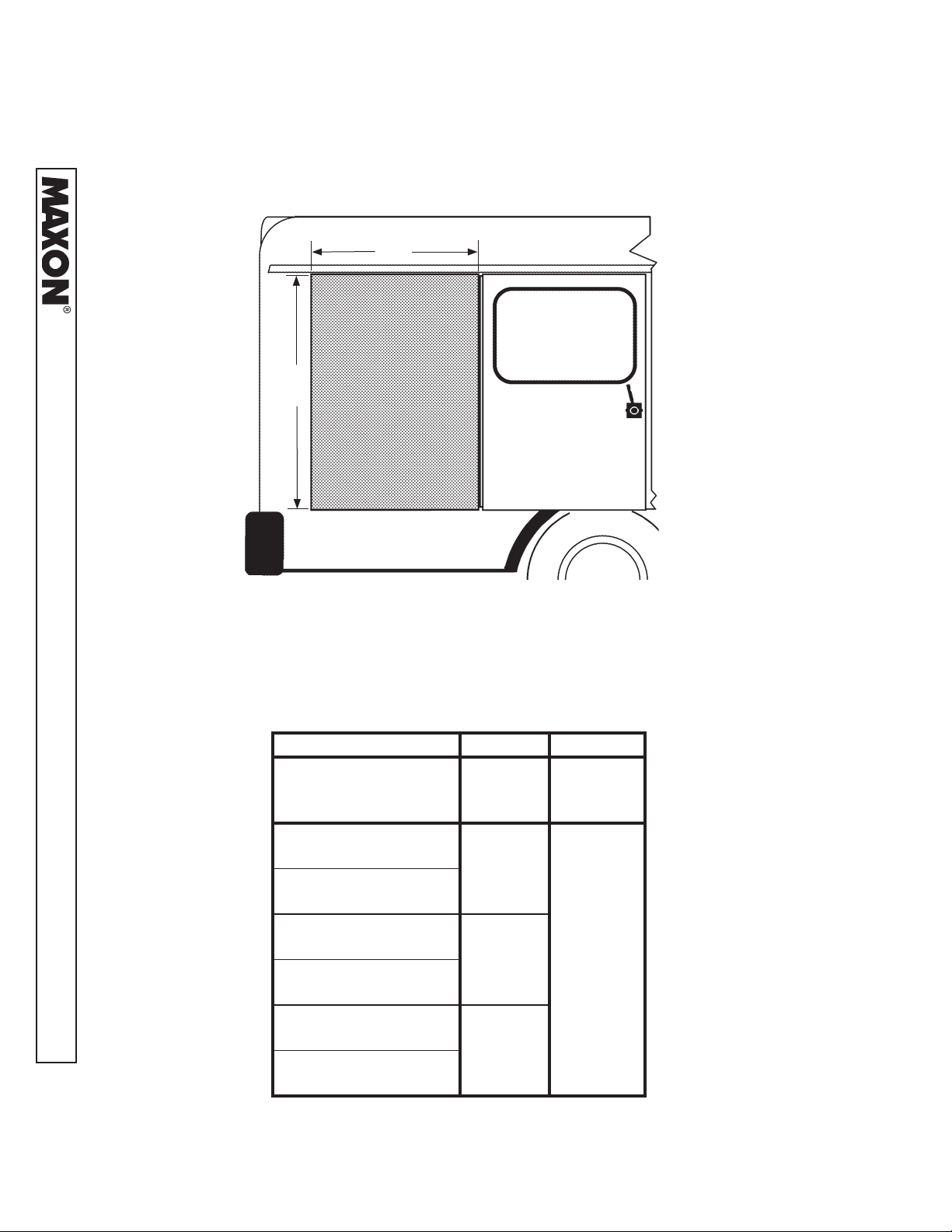

VEHICLE REQUIREMENTS - Continued

WHEELCHAIR DOOR DIMENSIONS

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

B

A

WHEELCHAIR DOOR DIMENSIONS ON

TYPICAL VEHICLE WITH SIDE DOOR

(SEE TABLE 10-1)

FIG. 10-1

AB

MODEL

DESCRIPTIONS

30” WIDE PLATFORM

RH PUMP

30” WIDE PLATFORM

LH PUMP

33” WIDE PLATFORM

RH PUMP

33” WIDE PLATFORM

LH PUMP

34” WIDE PLATFORM

RH PUMP

34” WIDE PLATFORM

LH PUMP

WHEELCHAIR

DOOR WIDTH

(MINIMUM)

39”

42”

43”

WHEELCHAIR

DOOR HEIGHT

(MINIMUM)

56”

PATENTS PENDING

TABLE 10-1

10

Page 11

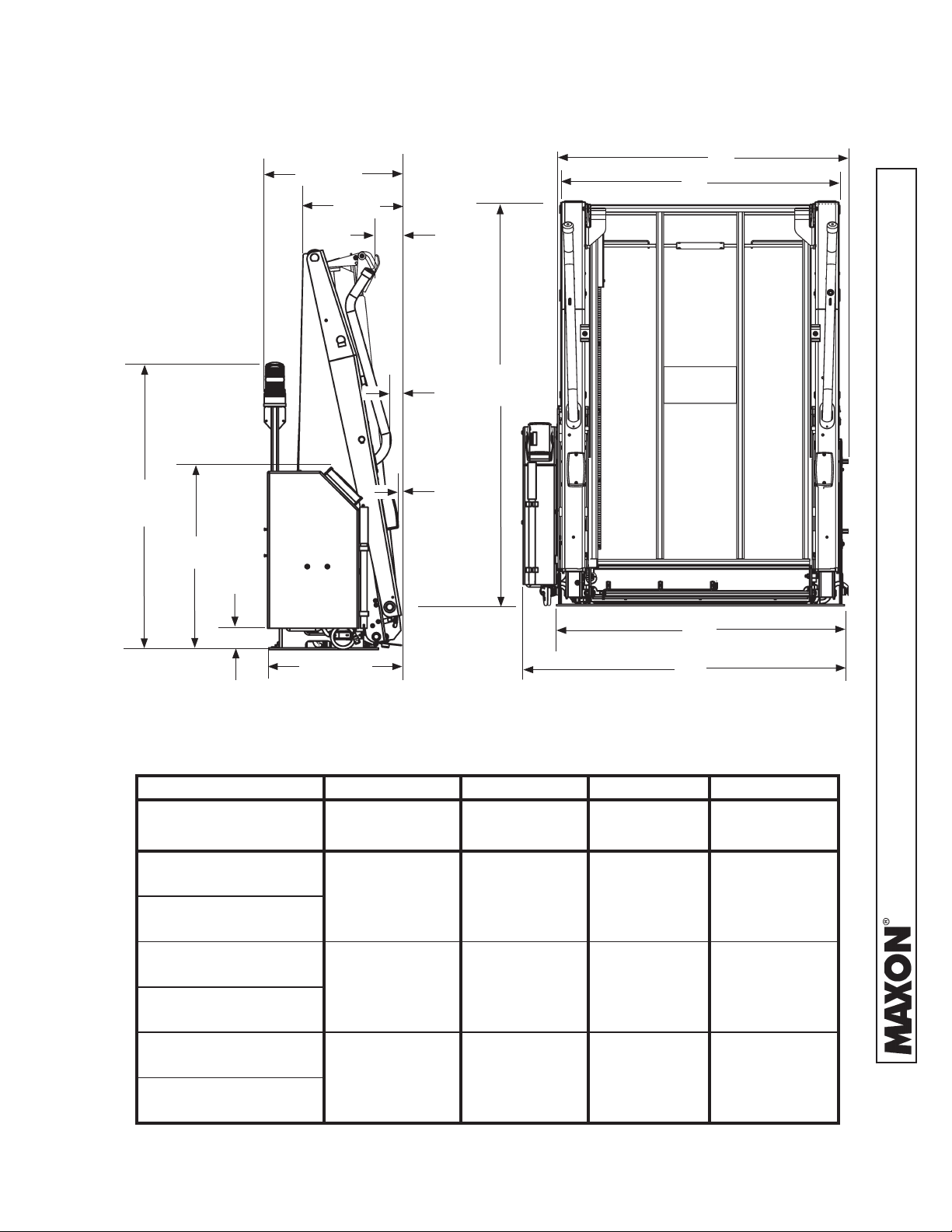

LIFT DIMENSIONS

18.9”

13.3”

2.9”

1.4”

C

D

55.13”

39”

25”

4.75”

SIDE VIEW OF STOWED LIFT

(LH PUMP MODEL SHOWN)

FIG. 11-1

MODEL

DESCRIPTIONS

30” WIDE PLATFORM

RH PUMP

30” WIDE PLATFORM

LH PUMP

33” WIDE PLATFORM

RH PUMP

33” WIDE PLATFORM

LH PUMP

34” WIDE PLATFORM

RH PUMP

34” WIDE PLATFORM

LH PUMP

18-3/4”

CDEF

LIFT WIDTH AT

WARNING BEACONS

40.25” 38” 39.5” 45.5”

43.25” 41” 42.5” 48.5”

44.25” 42” 43.5” 49.5”

0.5”

FRONT VIEW OF STOWED LIFT

LIFT WIDTH AT

HANDRAILS

E

F

(LH PUMP MODEL SHOWN)

(SEE TABLE 11-1)

FIG. 11-2

LIFT WIDTH AT

BASE PLATE

OVERALL LIFT

WIDTH (INCLUDING

PUMP COVER)

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

TABLE 11-1

11

PATENTS PENDING

Page 12

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

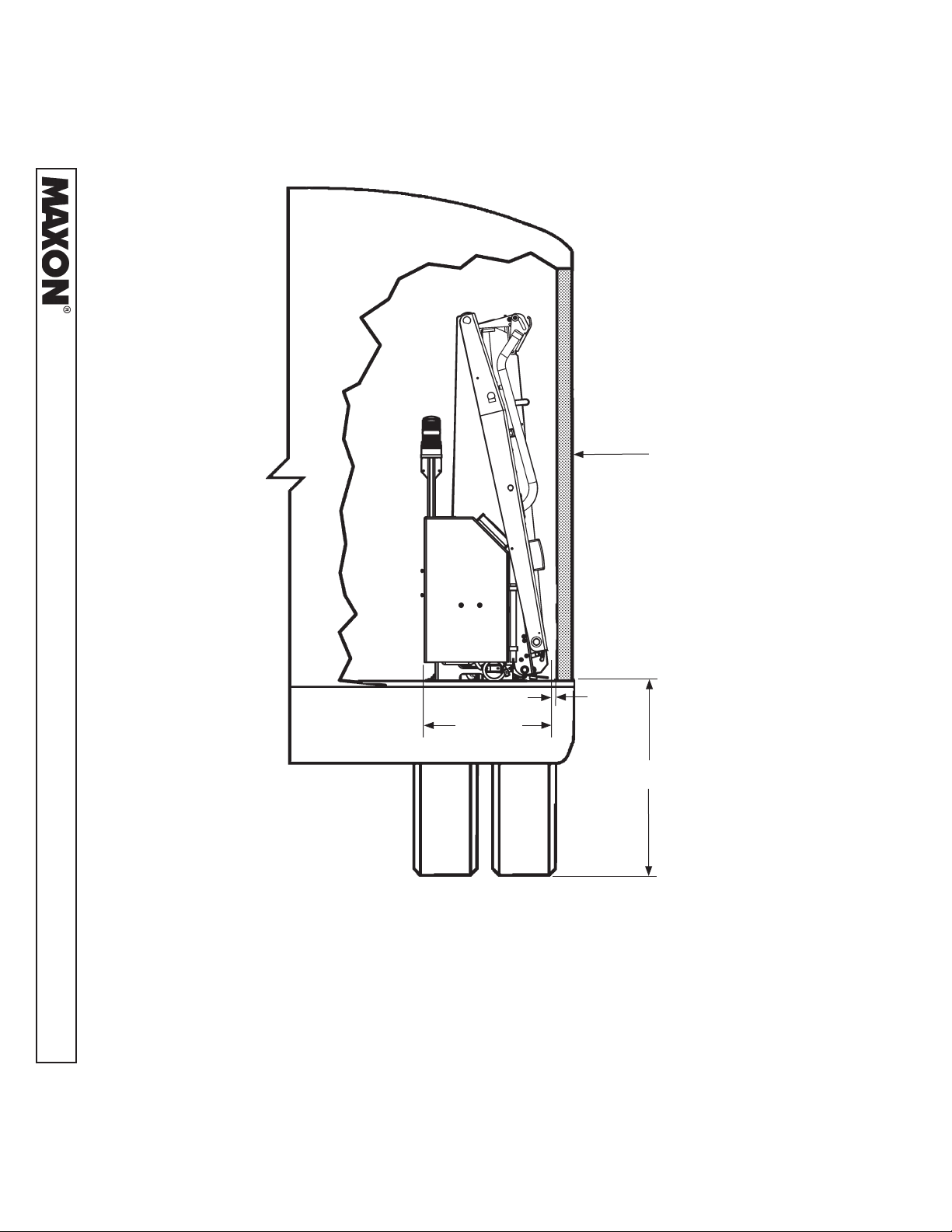

VEHICLE REQUIREMENTS - Continued

WHEELCHAIR

DOOR

0.75”

18-3/4”

(APPROX.)

(MIN.)

48”(MAX.)

WHEELCHAIR DOOR CLEARANCE & FLOOR

HEIGHT ON TYPICAL VEHICLE WITH SIDE DOOR

FIG. 12-1

PATENTS PENDING

12

Page 13

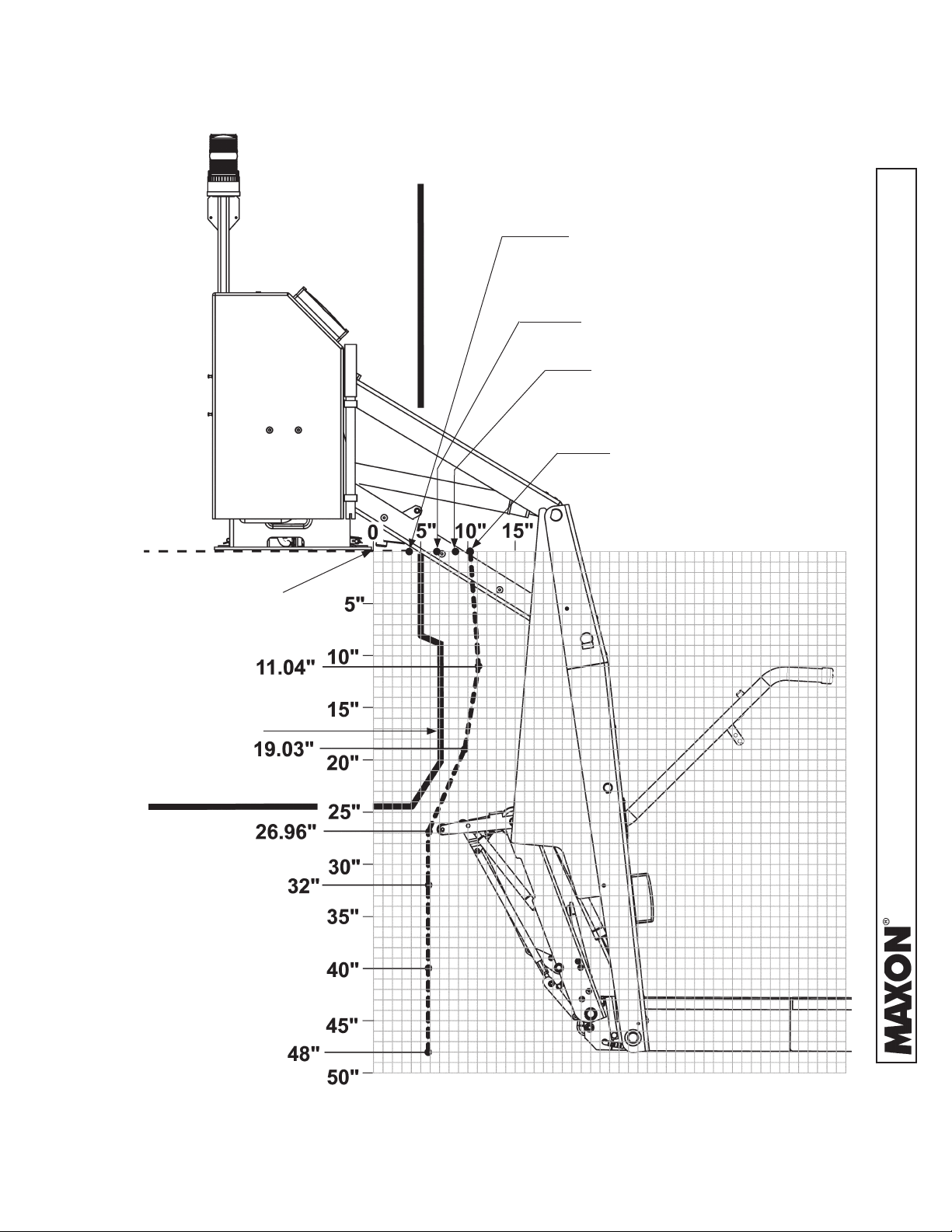

BASE PLATE

OUTBOARD

EDGE (REF)

3.75”

(48” FLOOR LEVEL - REF)

6.75”

(46” FLOOR LEVEL - REF)

8.75”

(44” FLOOR LEVEL - REF)

10.25”

(42” FLOOR LEVEL - REF)

TYPICAL

VEHICLE REAR

BUMPER

(VAN GND LVL)

(BUS GND LVL)

(BUS GND LVL)

BODY CLEARANCE POINTS: 32”, 40”, 42”, 46” & 48” FLOOR HEIGHTS

FIG. 13-1

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

13

PATENTS PENDING

Page 14

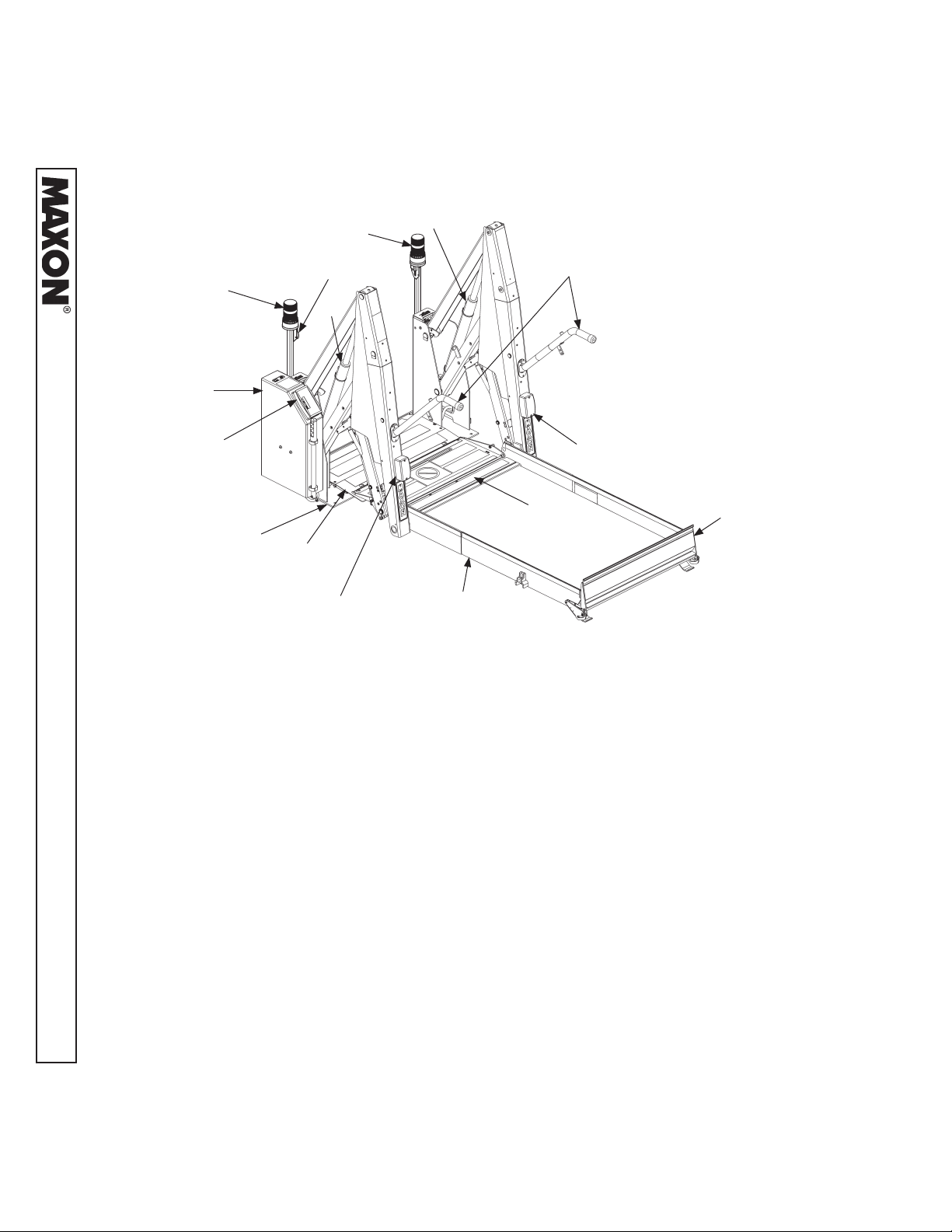

LIFT COMPONENTS & TERMINOLOGY

INBOARD

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

10

7

8

LEFT

10

11

6

9

1

12

6

RIGHT

4

12

5

3

OUTBOARD

2

LIFT COMPONENTS (SEE TABLE 13-1)

FIG. 14-1

PATENTS PENDING

14

Page 15

ITEM NAME DESCRIPTION

1. THRESHOLD PLATE Component that bridges the entry way, through the

Lift, into the vehicle. Detects if that portion of Lift is

occupied during “UP/DOWN” operation between

vehicle fl oor and the ground.

2. OUTBOARD ROLLSTOP Barrier to prevent the wheelchair from rolling off of

the platform. Provides entry/exit ramp for platform

on the ground.

3. PLATFORM Contains the wheelchair and occupant during “UP/

DOWN” operation between vehicle fl oor and the

ground.

4. HANDRAILS (Left/Right) Provides a hand hold for the Lift

occupant.

5. INBOARD ROLLSTOP Barrier to prevent the wheelchair from rolling off

inboard side of platform. Provides bridge between

platform and threshold.

6. HYDRAULIC CYLINDER (Left/Right) Telescoping steel tube and rod,

pressurized by hydraulic fl uid, that folds and unfolds

the Lift and moves the Lift up and down.

7. HYDRAULIC POWER

UNIT (COVER IS

SHOWN)

8. LIFT CONTROLLER

(BRAIN BOX)

Contains motorized hydraulic pump, manually

operated backup pump, fl uid lines, and controls that

operate the hydraulic cylinders.

Electronic device that controls and monitors Lift

operation and the interlock connection with the

vehicle.

9. BASE Structure that secures Lift to the vehicle fl oor.

10. THRESHOLD WARNING

BEACON

Flashing red light indicates threshold is occupied by

a person or object when the platform is below fl oor

level. Indicates outboard rollstop is open if platform

is at fl oor level.

11. THRESHOLD WARNING

ALARM

Audible alarm sounds when threshold is occupied

by a person or object when the platform is below

fl oor level. Also indicates outboard rollstop is open

if platform is at fl oor level.

12. PLATFORM LIGHTS Illuminates the platform when ready to load at fl oor

level and during “UP/DOWN” operation between

vehicle fl oor and the ground.

TABLE 15-1

15

PATENTS PENDING

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

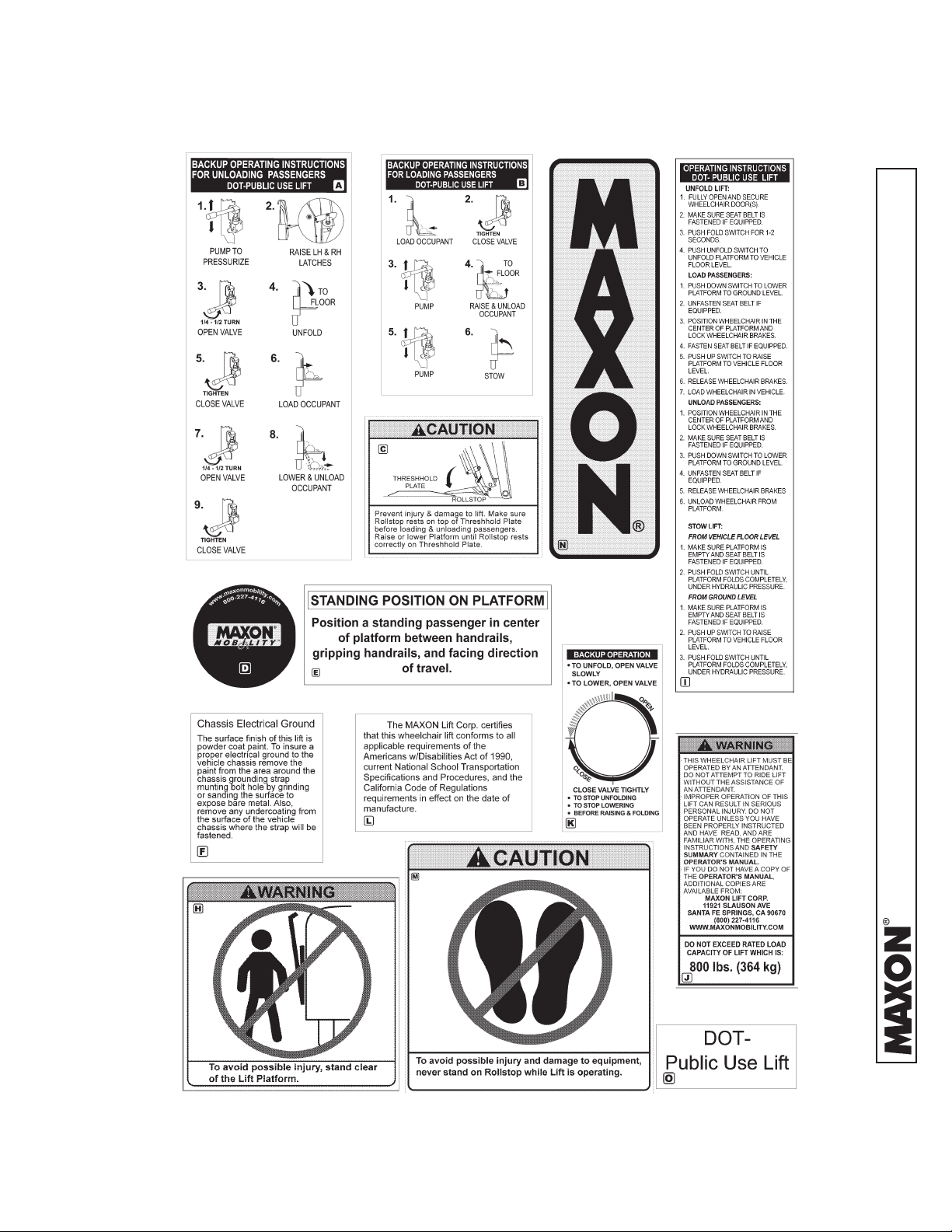

Page 16

DECALS AND DECAL PLACEMENT

DECAL ”D”

DECAL “O”

DECAL “K”

DECAL “A”

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

DECAL “B”

DECAL “F”

DECAL “L”

DECAL “M”

DECAL “I”

DECAL“J”

DECAL“N”

DECAL “C”

DECAL

“E”

DECAL“N”

DECAL “H”

PATENTS PENDING

FIG. 16-1

All WARNING, CAUTION, and OPERATION de-

cals provided with Wheelchair Lift must always be

in place on the Lift and vehicle (see FIG. 36-1), and

must always be legible. If decals are missing or illegible, get free replacement decals from:

MAXON Lift Corp. - Customer Service

11921 Slauson Ave., Santa Fe Springs, CA 90670

Phone: (800) 227-4116 FAX: (888) 771-7713

E-mail: cservice@maxonlift.com

16

Page 17

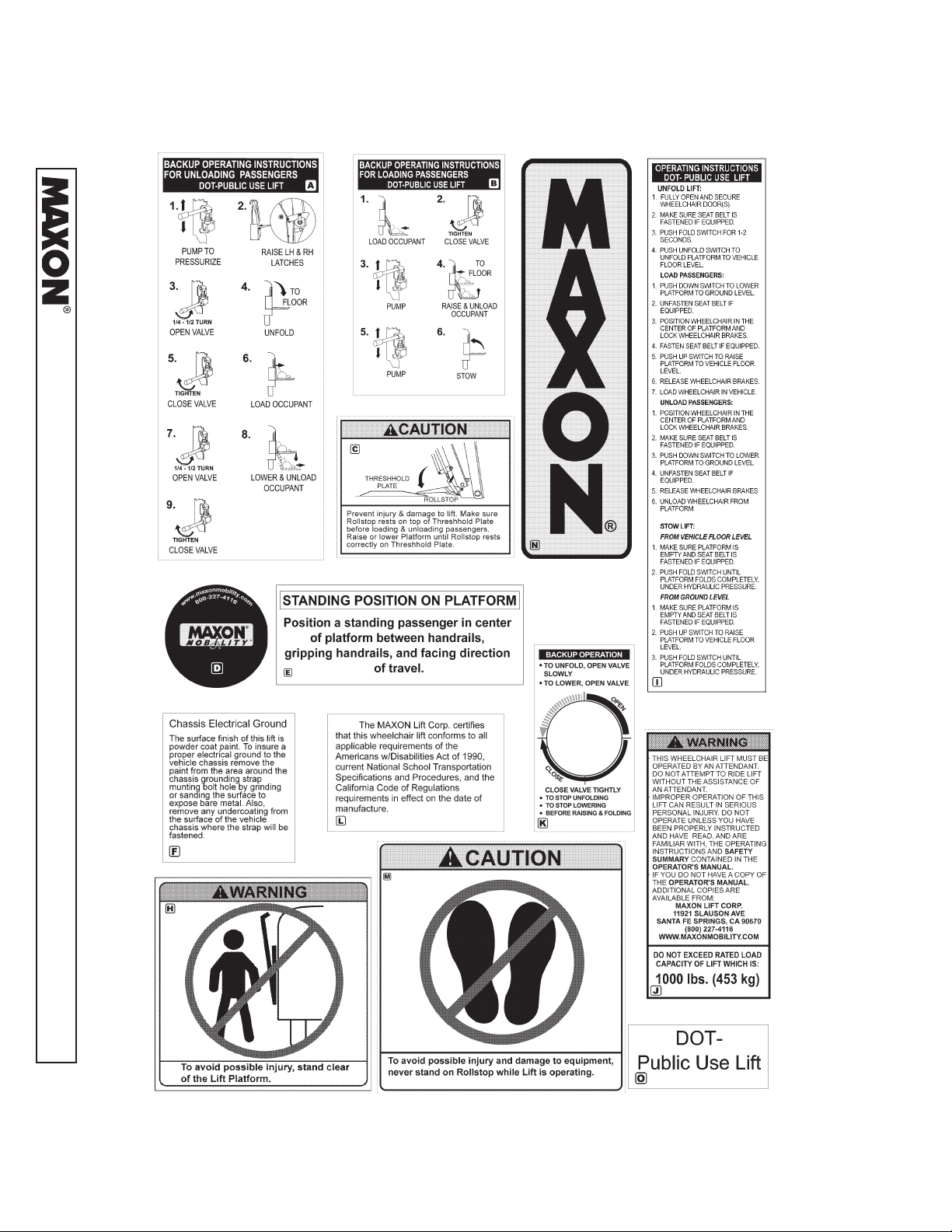

DECALS FOR WL7-vers. C

DECAL SET P/N 268302-01

FIG. 17-1

17

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

PATENTS PENDING

Page 18

DECALS AND DECAL PLACEMENT - Continued

DECALS FOR WL7-vers. C-1K

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

PATENTS PENDING

DECAL SET P/N 268302-03

FIG. 18-1

18

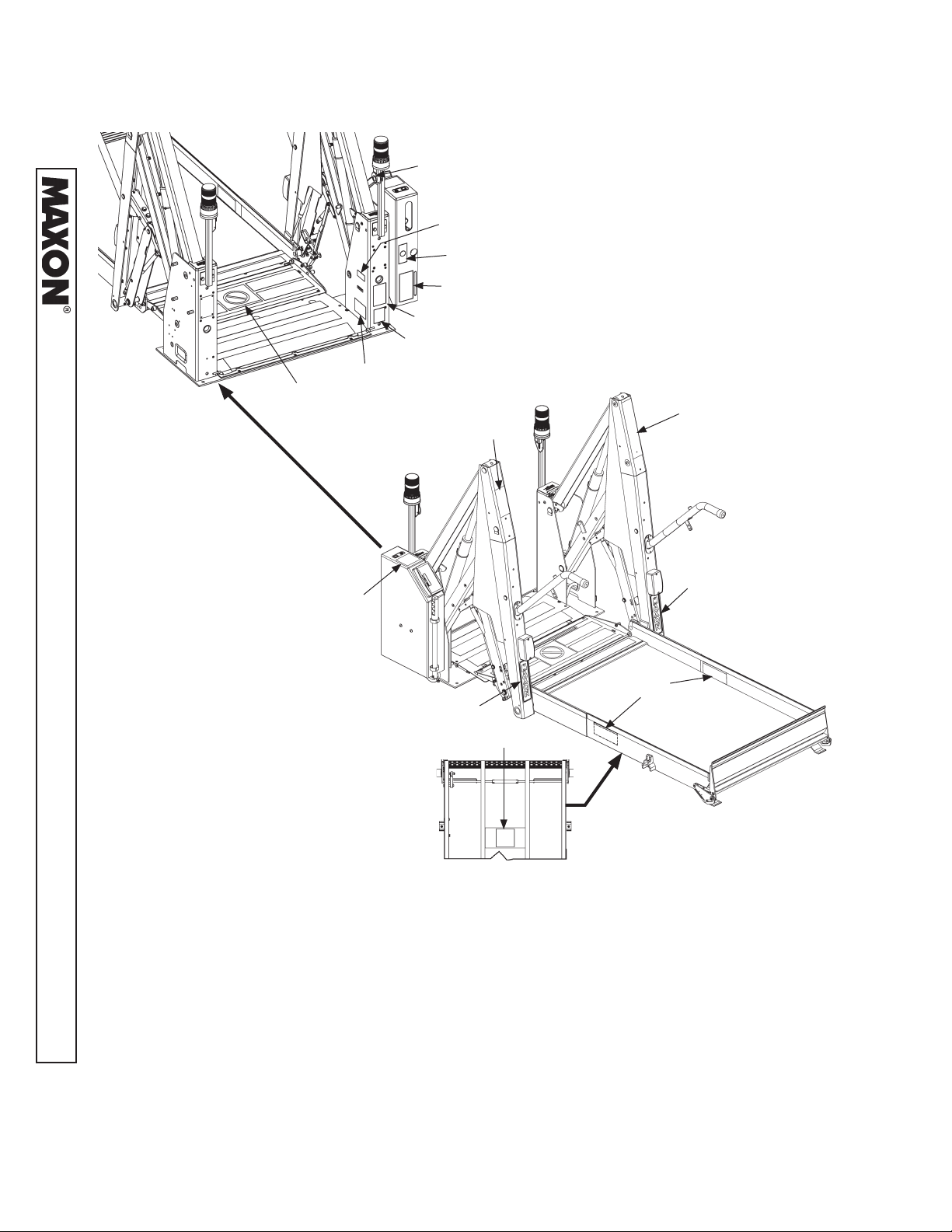

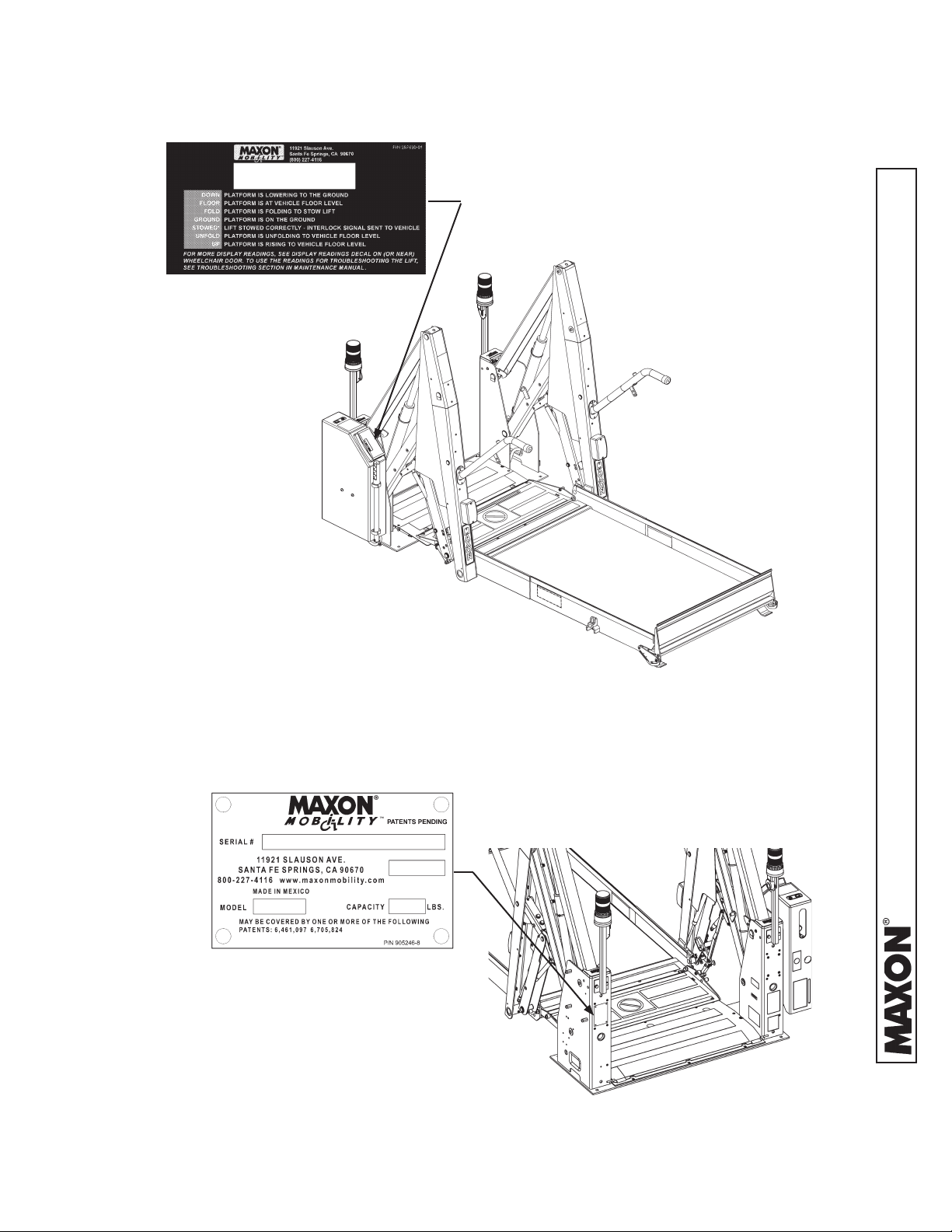

Page 19

SERIAL PLATE & CONTROLLER

CONTROLLER OVERLAY

P/N 2667630-01

SERIAL PLATE

P/N 905246-8

FIG. 19-1

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

FIG. 19-2

19

PATENTS PENDING

Page 20

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

ANTI-SLIP TAPE

P/N 096020-10

ANTI-SLIP & SAFETY STRIPING

(30” WIDE PLATFORM)

YELLOW TAPE

(BOTTOM-ROLLSTOP)

P/N 905293-17

ANTI-SLIP TAPE

(ROLLSTOP)

P/N 096020-13

ANTI-SLIP TAPE

P/N 096024-10

ANTI-SLIP TAPE

P/N 096013-10

ANTI-SLIP TAPE

(ROLLSTOP)

P/N 096020-13

YELLOW TAPE

P/N 905293-11

FIG. 20-1

YELLOW TAPE

P/N 905293-16

YELLOW TAPE

P/N 905293-14

YELLOW TAPE

(OUTBOARD)

P/N 905293-11

YELLOW TAPE

(OUTBOARD)

P/N 905293-14

(INBOARD)

YELLOW TAPE

(INBOARD & OUTBOARD)

P/N 905293-13

PATENTS PENDING

20

Page 21

ANTI-SLIP & SAFETY STRIPING - Continued

(33” WIDE PLATFORM)

YELLOW TAPE

(BOTTOM-ROLLSTOP)

P/N 905293-18

ANTI-SLIP TAPE

(ROLLSTOP)

P/N 096020-14

ANTI-SLIP TAPE

P/N 096024-11

ANTI-SLIP TAPE

P/N 096020-11

ANTI-SLIP TAPE

P/N 096013-11

ANTI-SLIP TAPE

(ROLLSTOP)

P/N 096020-14

YELLOW TAPE

P/N 905293-11

FIG. 21-1

YELLOW TAPE

P/N 905293-16

YELLOW TAPE

P/N 905293-14

(INBOARD)

YELLOW TAPE

(OUTBOARD)

P/N 905293-11

YELLOW TAPE

(OUTBOARD)

P/N 905293-14

YELLOW TAPE

(INBOARD & OUTBOARD)

P/N 905293-15

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

21

PATENTS PENDING

Page 22

ANTI-SLIP & SAFETY STRIPING - Continued

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

ANTI-SLIP TAPE

P/N 096020-12

(34” WIDE PLATFORM)

YELLOW TAPE

(BOTTOM-ROLLSTOP)

P/N 905293-18

ANTI-SLIP TAPE

(ROLLSTOP)

P/N 096020-15

ANTI-SLIP TAPE

P/N 096024-12

ANTI-SLIP TAPE

P/N 096013-11

ANTI-SLIP TAPE

(ROLLSTOP)

P/N 096020-15

YELLOW TAPE

P/N 905293-11

FIG. 22-1

YELLOW TAPE

P/N 905293-16

YELLOW TAPE

P/N 905293-14

YELLOW TAPE

(OUTBOARD)

P/N 905293-11

YELLOW TAPE

(OUTBOARD)

P/N 905293-14

(INBOARD)

YELLOW TAPE

(INBOARD & OUTBOARD)

P/N 905293-15

PATENTS PENDING

22

Page 23

LIFT INSTALLATION

INSTALLATION KITS

An installation kit is required to install Lift on your vehicle. Refer to the instruction sheet,

included with the installation kit, for specifi c instructions to fi t the Lift to your vehicle.

PREPARING AND POSITIONING THE LIFT

1. Make sure you have the correct model of Lift.

NOTE: Keep shipping straps on Lift until Lift is

bolted to vehicle and power is connected.

2. Unpack the Lift and check for damage. Report

damage to:

MAXON Lift Corp. - Customer Service

11921 Slauson Ave., Santa Fe Springs, CA 90670

Phone: (800) 227-4116 FAX: (888) 771-7713

E-mail: cservice@maxonlift.com

3. Open the wheelchair door on vehicle (FIG. 23-1) in

which Lift will be mounted. Secure door wide open.

4. Check the clearance dimensions of your vehicle

before beginning installation. Refer to VEHICLE

REQUIREMENTS section in this Installation Manual.

WHEELCHAIR

DOORWAY

DOOR

VEHICLE RH SIDE VIEW

FIG. 23-1

23

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

PATENTS PENDING

Page 24

PREPARING AND POSITIONING THE LIFT - Continued

NOTE: You may use a template instead of the

Lift for positioning the Lift on vehicle. To

use a template, refer to USING TEM

PLATE TO POSITION LIFT section in

this Installation Manual.

5. Using an appropriate lifting device that

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

can safely lift 500 pounds, raise Lift to the

wheelchair doorway. Place the Lift inside

doorway (FIG. 24-1). Align outboard

edge of Lift threshold plate parallel with

outboard edge of doorway. The decal on

the underside of the Lift platform must

face outboard (FIG. 24-1).

6. Position the Lift according to the clearance dimensions given in VEHICLE REQUIREMENTS

section in this Installation Manual.

7. Remove lifting device and close wheelchair door.

Enter the vehicle. Verify the wheelchair door

closes correctly and the minimum clearance is

3/4”. If door will not close correctly, reposition the

Lift.

DECAL (FACES

OUTBOARD)

WHEELCHAIR

LIFT

DOOR

VEHICLE RH SIDE VIEW

FIG. 24-1

8. Secure vehicle door wide open (FIG. 24-1).

9. Check under the vehicle fl oor for possible in-

terference between the Lift base plate mounting bolts and the vehicle underbody. For

example, check subframe members, wiring

harnesses, cables, and fl uid lines.

PATENTS PENDING

24

Page 25

USING TEMPLATE TO POSITION LIFT

1. Fabricate template for base plate hole pattern

according to the dimensions shown in FIGS.

25-1, 25-2, 26-1 and 26-2. Use a suitable

material that maintains correct shape and

dimensions.

BASE PLATE HOLE PATTERN FOR LIFTS

WITH 33” & 34” WIDE PLATFORMS & RH PUMP

FIG. 25-1

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

BASE PLATE HOLE PATTERN FOR LIFTS

WITH 33” & 34” WIDE PLATFORMS & LH PUMP

FIG. 25-2

25

PATENTS PENDING

Page 26

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

USING TEMPLATE TO POSITION LIFT - Continued

BASE PLATE HOLE PATTERN FOR LIFTS

WITH 30” WIDE PLATFORM & LH PUMP

FIG. 26-1

PATENTS PENDING

BASE PLATE HOLE PATTERN FOR LIFTS

WITH 30” WIDE PLATFORM & RH PUMP

FIG. 26-2

26

Page 27

CAUTION

For vehicles with 48” fl oor height:

If the front edge of Lift base plate is moved more than 3.75” (5” from outside of

body, as shown in FIG. 11-1) away from the inside of the wheelchair door, lower

Lift arms can hit vehicle body before platform reaches the ground. See the

vehicle fl oor levels plotted in FIG. 11-1 and maintain the clearance for the fl oor

level that applies to your Lift installation.

2. Center the template inside wheelchair door-

way (FIG. 27-1). Line up the outboard

edge of template parallel with inboard edge

of doorway. Maintain center and the clearance dimension shown.

VEHICLE BODY

(CUTAWAY)

BASE PLATE TEMPLATE

HOLE PATTERN

INSIDE

OF

DOOR

3.75”

BACK

1

5

23

6

CENTER

10

78

FRONT

BASE PLATE TEMPLATE CLEARANCE FROM WHEEL-

CHAIR DOOR (TOP VIEW, SIDE DOOR SHOWN)

FIG. 27-1

49

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

27

PATENTS PENDING

Page 28

MOUNTING THE LIFT

NOTE: MAXON recommends using all 10 carriage screws (Kit items) to bolt Lift to

vehicle. A minimum of 8 screws or bolts and use of holes 1, 2, 3, 4 & 9 are

required for correct installation. Also, the 3 front holes should be selected to

give a symmetrical bolt pattern (i.e. holes 5,10, & 8 or holes 6,10, & 7).

1. Use template (FIG. 27-1) or the base plate on the

Lift (FIG. 28-1, holes 1-10) to mark eight (8) to

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

ten (10) 7/16” mounting holes through the vehicle

fl oor. Before drilling holes in the vehicle fl oor, make

sure no wires and fl uid lines are too close to hole

locations. Drill holes 1, 2, 9, 3, and 4.

NOTE: Vehicle fl oor must meet the requirements shown at the beginning of the

VEHICLE REQUIREMENTS section in this Installation Manual.

2. Position Lift so holes 1-10 in the base plate (FIG. 28-1)

are aligned with the correct holes drilled in vehicle fl oor.

3. Temporarily secure Lift to vehicle with two mounting

bolts (Kit items), inserted through base plate holes 1

and 4, or holes 2 and 3 (FIG. 28-1). Use two lock

nuts and correct under-vehicle supports (Kit items) to

secure the Lift. Use instructions supplied with vehicle

installation kit to select the correct bolts, nuts and supports. Alternately, tighten the two bolts and nuts to 20

to 30 LBS.-FT.

BACK

12

56

9

10

FRONT

BASE PLATE BOLT

HOLE PATTERN

FIG. 28-1

4

3

8

7

PATENTS PENDING

28

Page 29

INSTALL MAIN CIRCUIT BREAKER

WARNING

!

To prevent personal injury and equipment damage, make sure power is disconnected from Lift when installing electrical parts.

NOTE: Apply dielectric grease on all electrical connections after all electrical cables are

connected.

1. Attach 90 amp main circuit breaker (Kit item) to

vehicle so power cable (Kit item) is within reach

of the battery, as follows. Find a place to attach

bracket (FIG. 29-1). (Note: The power cable must

be able to reach between 90 amp circuit breaker

and (+) battery terminal without straining the connections.) Attach 90 amp circuit breaker to bracket. Next, attach bracket to vehicle with four (4) #12

self-drilling screws (Kit items).

1/4”-20

LOCK NUT

(2 PLACES)

1/4” FLAT

WASHER

(2 PLACES)

BATTERY

POWER UNIT

(REF)

2 AWG POWER

CABLE (SHORT CABLE)

90 AMP MAIN

CIRCUIT BREAKER

1/4”-20

CAP SCREW

(2 PLACES)

#12 SELF-DRILLING

SCREW (4 PLACES)

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

2 AWG POWER CABLE

(LONG CABLE CONNECTED

BETWEEN TERMINAL OF

STARTER SOLENOID AND MAIN

CIRCUIT BREAKER)

MAIN CIRCUIT BREAKER & CABLING

FIG. 29-1

29

PATENTS PENDING

Page 30

INSTALL MAIN CIRCUIT BREAKER - Continued

2. Connect one end of power cable to 90

amp main circuit breaker (FIG. 30-1).

Do not connect battery end until instructed

to connect the battery.

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

POWER UNIT

(REF)

1/4” FLAT

WASHER

(2 PLACES)

BATTERY

1/4”-20

LOCK NUT

(2 PLACES)

2 AWG POWER

CABLE (SHORT CABLE)

90 AMP MAIN

CIRCUIT BREAKER

1/4”-20

CAP SCREW

(2 PLACES)

#12 SELF-DRILLING

SCREW (4 PLACES)

3. Lastly, connect one end of long power

cable to 90 amp main circuit breaker

(FIG. 30-1).

2 AWG POWER CABLE

(LONG CABLE CONNECTED

BETWEEN TERMINAL OF

STARTER SOLENOID AND MAIN

CIRCUIT BREAKER)

MAIN CIRCUIT BREAKER & CABLING

FIG. 30-1

PATENTS PENDING

30

Page 31

ROUTE/CONNECT CABLES & HAND PENDANT

!

CAUTION

Never route an energized wire. Make sure the battery is disconnected. Always

route electrical wire clear of any moving parts, brake lines, sharp edges, and exhaust systems. Never route power cable next to a wiring harness on the vehicle.

Do not loop excess cable. Cut the cable to fi t and leave slack. Attach securely.

If drilling is necessary, be sure to check underside of vehicle before drilling so

you do not damage any fuel lines, vent lines, brake lines or wires. When routing

electrical wire through a hole in vehicle fl oor, use supplied grommet to protect

wires from chafi ng.

1. Locate and drill a 1-5/16” hole through

the vehicle fl oor (FIG. 31-1). Drill the

hole in a location that will be hidden

by the pump cover and that will allow

power cable to be routed to power input

bracket (FIG. 31-1). Since the interlock system wiring from the Lift also

branches out in that area, locate the

hole so the 3-conductor Interlock system

cable can be routed from the Lift through

the vehicle fl oor to the vehicle safety in-

terlock. Install the plastic grommet (FIG.

31-1) on the vehicle fl oor with 2 of the

#12 self-drilling screws.

BRACKET

POWER

INPUT

LONG

POWER

CABLE

2. Route the long power cable (Kit item)

from main circuit breaker (FIG. 31-2),

underneath vehicle fl oor to power input

bracket (FIG. 31-1).

3. Secure power cable every 8”-10”.

SELF-TAPPING

SCREWS

LONG POWER

31

GROMMET

FIG. 31-1

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

CABLE

90 AMP MAIN

CIRCUIT BREAKER

FIG. 31-2

PATENTS PENDING

Page 32

ROUTE/CONNECT CABLES & HAND PENDANT - Continued

4. Cut any excess wire from long power cable.

Strip 1/2” insulation from the cut end and

install 2 GA terminal lug and shrink tubing.

Next, insert the power cable through the

protective cover (FIG. 32-1). Connect the

cable terminal to the terminal stud on the

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

power input bracket as shown in FIG. 32-

1. Position the protective cover over the

power cable connection (FIG. 32-1).

5. Route the interlock cable from safety interlock

system on the vehicle, underneath vehicle fl oor

and through the grommet, and up to the Lift (FIG.

32-2). If possible, use the same cable routing as

the long power cable installed in previous steps. Secure the interlock cable

every 8”-10”.

TERMINAL

STUD

LONG

POWER

CABLE

POWER

INPUT

BRACKET

2 GA

TERMINAL

LUG

EXTERNAL

TOOTH LOCK

WASHER

HEX

NUT

PROTECTIVE

COVER

FIG. 32-1

6. Make sure interlock cable will reach

the white-red stripe wire (interlock

signal from vehicle) and the brown

wire (interlock signal to vehicle) on

the Lift (FIG. 32-2). Signal may

be ground or V+. Connect the interlock wires from the vehicle interlock

system to the white-red stripe wire

and brown wire on the Lift (FIG.

32-2).

PATENTS PENDING

INTERLOCK

CABLE

INTERLOCK WIRE

(SIGNAL FROM

VEHICLE)

INTERLOCK WIRE

(SIGNAL TO

VEHICLE)

BROWN WIRE

(FROM LIFT)

32

WHITE-RED STRIPE

WIRE (FROM LIFT)

FIG. 32-2

Page 33

7. Uncoil the ground cable from the bottom of

the pump cover. Route the ground cable

on the Lift through grommet in vehicle fl oor

(FIG. 33-1A & 33-1B).

GROUND

CABLE

GROMMET

NOTE: Clean the ground cable

connection point on the

frame down to bare metal.

NOTE: If there is a grounding

point on the frame, use it

to connect ground cable.

Skip step 8.

NOTE: Apply dielectric grease to

all electrical connections.

8. Extend the ground cable to reach

vehicle frame (FIG. 33-2). Connect to an existing grounding point

if available. If necessary, drill a

13/32” (0.406”) hole in vehicle

frame for bolting the ground cable

terminal lug (FIG. 33-2).

9. Bolt the ground cable terminal lug

to vehicle frame as shown in FIG.

33-2.

GROUND CABLE ROUTED FROM LIFT

FIG. 33-1A

TERMINAL LUG

3/8”-16 X 1” LG.

CAP SCREW

GROUND

CABLE

BOLTING GROUND CABLE

TO VEHICLE FRAME

FIG. 33-2

BARE

METAL

VEHICLE

FRAME

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

3/8”-16

HEX NUT

3/8” LOCK

WASHER

33

PATENTS PENDING

Page 34

ROUTE/CONNECT CABLES & HAND PENDANT - Continued

!

To prevent vehicle access door from pinching and damaging the hand pendant

cable, secure cable away from the door frame. Also, be sure that the hand

pendant cable does not interfere with or bind against moving parts.

10. Connect the hand pendant cable as follows.

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

Feed the cable through the hole located

in the main frame (FIG. 34-1). Secure cable

strain relief to main frame with plastic nut (FIG.

34-1). Next, connect hand pendant connector

to wiring harness (FIG. 34-1).

CONNECTOR

CAUTION

WIRING

HARNESS

MAIN

FRAME

HEX NUT

CONNECTOR

STRAIN

RELIEF

HAND

PENDANT

CONNECTING HAND PENDANT CABLE

(RH SIDE CONNECTION SHOWN)

FIG. 34-1

PATENTS PENDING

34

Page 35

11. Find accessible place on vehicle wall or

wheelchair door (near Lift) to place the

hand pendant hanger and cable hook (FIG.

35-1).

HAND PENDANT

& HANGER

CABLE HOOK

PUMP COVER

TYPICAL LOCATION (INSIDE VEHICLE)

FOR STOWING HAND PENDANT

FIG. 35-1

35

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

PATENTS PENDING

Page 36

ROUTE/CONNECT CABLES & HAND PENDANT - Continued

12. Place decals (from Parts Box) on the vehicle, near the hand pendant (typical placement shown in FIG. 36-1). Make sure decals are visible to operator when Lift is

being operated.

HAND PENDANT &

HANGER MOUNTING

DECAL “J”

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

DECALS AND HAND PENDANT

MOUNTING ON VEHICLE

DECAL “I”

DECAL “A”

DECAL “C”

DOOR

DECAL “B”

CABLE

HOOK

DECAL “A”

P/N 268303-01

FIG. 36-1

DECAL SET FOR WL7-vers.C

P/N 267620-02

PATENTS PENDING

FIG. 36-2

36

DECAL SET FOR WL7-vers.C-1K

P/N 267620-04

FIG. 36-3

Page 37

13. Connect short power cable to vehicle

battery as follows. Remove nut from

positive (+) battery terminal connector (FIG. 37-1). Connect the power

cable. Reinstall nut.

14. Turn ON power ON/OFF switch on

pump cover to power the Lift (FIG.

37-2). The POWER light on hand

pendant should be illuminated (FIG.

37-3). Briefl y press the FOLD button

on hand pendant (FIG. 37-3) to pressurize hydraulic system. Then, remove

remaining shipping straps.

POSITIVE (+) BATTERY

TERMINAL

NUT

SHORT POWER

BOLT

CABLE

CONNECTING POWER TO LIFT (TYPICAL)

FIG. 37-1

POWER ON/OFF

SWITCH

STOWED LIFT - LH SIDE SHOWN

FIG. 37-2

37

UP

FOLD

POWER

LIGHT

HAND PENDANT

FIG. 37-3

FOLD

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

UNFOLD

PATENTS PENDING

Page 38

ROUTE/CONNECT CABLES & HAND PENDANT - Continued

15. Press the UNFOLD button on hand

pendant to unfold Lift (FIG. 38-

1). Platform lights will turn on when

platform is at fl oor level.

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

16. Next, press DOWN button on hand

pendant. When the platform reaches

the ground, the outboard rollstop will

automatically open to ramp position

(FIG. 38-2).

PLATFORM LIGHT

(2 PLACES)

LIFT AT FLOOR LEVEL

FIG. 38-1

OUTBOARD

ROLLSTOP

GROUND

PLATFORM

PLATFORM LOWERED TO

GROUND LEVEL

FIG. 38-2

17. Install the remaining bolts, lock nuts, and

under-vehicle supports supplied with

your installation kit. Use the instruction

sheet (Kit item) for information to install

the remaining Kit items correctly.

NOTE: Lift installation is not complete until all the instructions in this manual,

your installation kit instructions, and the checks and adjustments that

follow (in this manual) are completed.

PATENTS PENDING

38

Page 39

CHECKING HYDRAULIC FLUID LEVEL

CAUTION

!

Keep dirt, water and other contaminants from entering the hydraulic system. Before opening the hydraulic fl uid reservoir fi ller cap, drain plug and

hydraulic lines, wipe off contaminants that can get in the openings. Also,

protect the openings from accidental contamination.

1. Check the hydraulic fl uid level in reservoir as

follows. With Lift in STOWED position, fl uid

level should be as shown in FIG. 39-1.

INSPECTION

SLOT

PUMP

COVER

2. If needed, add fl uid to the reservoir

as follows. Unbolt the pump cover as

shown in FIG. 39-2.

RESERVOIR

2”

HYDRAULIC FLUID LEVEL

(LH PUMP SHOWN)

FIG. 39-1

PUMP COVER

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

SCREWS

UNBOLTING/BOLTING PUMP COVER

(LH PUMP SHOWN)

FIG. 39-2

39

PATENTS PENDING

Page 40

CHECKING HYDRAULIC FLUID LEVEL - Continued

3. Pull out fi ller cap (FIG. 40-1). Fill the

reservoir with hydraulic fl uid (TABLE

40-1) to level shown in FIG. 40-1.

Reinstall fi ller cap (FIG. 40-1).

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

RECOMMENDED HYDRAULIC FLUID

BRAND PART NUMBER

ROSEMEAD THS FLUID 17111

EXXON UNIVIS HVI 26

TABLE 40-1

NOTE: If the expected seasonal

temperatures are below

20°F, use MIL-H-5606G

hydraulic fl uid.

4. Bolt on the pump cover as shown

in FIG. 39-2. Tighten the 5/16”-18

cover screws until snug.

FILLER

CAP

RESERVOIR

2”

HYDRAULIC FLUID LEVEL

(LH PUMP SHOWN)

FIG. 40-1

PATENTS PENDING

40

Page 41

THIS PAGE INTENTIONALLY LEFT BLANK

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

41

PATENTS PENDING

Page 42

ADJUSTMENTS

MAT SWITCH ADJUSTMENT (IF REQUIRED)

1. Make sure power switch

(FIG. 42-1A) is turned

on. Lower Lift to the

ground (FIG. 42-

1A).

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

2. Measure the height of the

threshold plate as shown in FIG.

42-1B. If the height is 5/8”,

go to step 4 (skip step 3). If the

height is not 5/8”, go to step 3.

5/8”

HEIGHT MEASUREMENT

(RH SIDE SHOWN)

FIG. 42-1B

POWER SWITCH

LIFT AT GROUND LEVEL

FIG. 42-1A

3. Set edge of the threshold plate to

5/8” height by turning the adjustment screw on the RH side of

threshold plate (FIG. 42-2B).

Turn adjustment screw counterclockwise (FIG. 42-3) to raise

threshold plate or clockwise to

lower. Repeat for LH side of

threshold plate. Alternately measure height (see instruction 2).

Then, turn the adjustment screw

on RH side and LH side until the

entire edge of threshold plate is at

5/8” height.

LIFT THRESHOLD

FIG. 42-2A

ADJUSTMENT

SCREW

HEIGHT ADJUSTMENT SCREW

CCW - RAISE CW - LOWER

HEIGHT ADJUSTMENT SCREWS

(RH SIDE SHOWN)

FIG. 42-2B

FIG. 42-3

PATENTS PENDING

42

Page 43

4. Turn the MAT switch adjustment screw

(FIGS. 43-1B and 43-2) clockwise until

threshold warning alarm and beacons activate (FIG. 43-1A). Then, turn adjustment

screw counter-clockwise (FIG. 43-2) approximately 1-1/2 turn. Warning alarm and

beacons should turn off.

ADJUSTMENT

SCREW

THRESHOLD

PLATE

THRESHOLD

WARNING BEACON

THRESHOLD

WARNING ALARM

BASE

PLATE

ADJUSTING SWITCH

FIG. 43-1B

5. Step on threshold plate. Warning alarm

and beacons should activate. If the warning

alarm and beacons do not activate, slightly

turn adjustment screw (FIGS. 43-1B and

43-2) clockwise. Repeat until warning

alarm and beacons activate when stepping

on threshold plate and deactivate stepping

off threshold plate.

LH SIDE OF LIFT

FIG. 43-1A

CW - UNTIL ALARM &

BEACONS TURN ON

1-1/2 TURN CCW - ALARM

& BEACONS TURN OFF

MAT SWITCH ADJUSTMENT SCREWS

FIG. 43-2

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

43

PATENTS PENDING

Page 44

PLATFORM TILT ADJUSTMENT (MANDATORY)

NOTE: The platform tilt adjustment is important for operation of the outboard roll-

stop and for keeping platform level when it reaches the ground. Vehicle

fl oor height, Lift and stiffness of the vehicle suspension may change the

angle of platform on the ground.

1. Make sure power switch

(FIG. 44-1) is turned

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

on. Lower the platform

and stop approximately 4”

above ground.

2. Measure distance from

front of the platform (1) to

the ground (FIG. 44-2).

Next, measure the distance

from the bottom of the vertical

arm (2) to the ground

(FIG. 44-2).

POWER

SWITCH

GROUND

LEVEL

PLATFORM

4”

PLATFORM LOWERED TO GROUND LEVEL

FIG. 44-1

POWER

SWITCH

VERTICAL

ARM

GROUND

LEVEL

3. The measurement at the vertical

arm (2) must be 1/2” -1” more than

the measurement at the front of

platform (1). For example: If you

measure 4” at the front (1), then you

should measure from 4-1/2” to 5” at

the vertical arm (2). If there is not a

1/2” - 1” difference, go to step 4 to

obtain the correct measurement.

PATENTS PENDING

PLATFORM

(1)

(2)

PLATFORM LOWERED TO GROUND LEVEL

FIG. 44-2

44

Page 45

4. Manually lower the inboard

rollstop for access to the adjustment screws (FIG. 45-1).

To ensure proper leveling, turn

platform tilt adjustment screws

(FIG. 45-1) an equal amount

on both sides of platform. Turn

adjustment screws clockwise

(FIG. 45-2) to tilt the platform

up or counter-clockwise to tilt

platform down.

OUTBOARD ROLLSTOP

(REF)

INBOARD ROLLSTOP

PLATFORM TILT ADJUSTMENT SCREW

(BACK VIEW OF PLATFORM SHOWN)

ADJUSTMENT

SCREW

PLATFORM

FIG. 45-1

CW - PLATFORM

TILT UP

CCW - PLATFORM

TILT DOWN

PLATFORM TILT ADJUSTMENT SCREWS

FIG. 45-2

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

45

PATENTS PENDING

Page 46

INBOARD SWITCH ADJUSTMENT (IF REQUIRED)

NOTE: Do this procedure if the Controller reads “IBRS SW” when Inboard Rollstop is

locked in the up position.

The adjustment is done correctly if the Controller does not read “IBRS SW”

when the Inboard Rollstop is locked in the up position.

1. Position the platform at fl oor level

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

(FIG. 46-1).

2. Turn OFF power switch on pump

cover (FIG. 46-1).

POWER

SWITCH

PLATFORM AT FLOOR LEVEL

(LH SIDE SHOWN)

FIG. 46-1

3. Using the manual backup pump (FIG. 46-

2), lower the platform until inboard rollstop

(IBRS) is locked in the up position (FIG. 47-

1). Refer to Operation Manual for instruc-

tions to operate the manual pump.

PATENTS PENDING

46

RELEASE

VALVE

BACKUP PUMP

HANDLE

USING BACKUP PUMP TO UNFOLD

(LIFT WITH LH PUMP)

FIG. 46-2

Page 47

4. Push the inboard rollstop back

against the lock as if a wheelchair is pushing on the rollstop

FIG. 47-1).

PUSH IBRS

AGAINST LOCK

IBRS

5. On the inboard rollstop switch,

loosen screws (1) and (2) one-half

turn (FIG. 47-2B). Next, rotate

switch bracket clockwise until the

switch activates with an audible

“click”. Then tighten screws (1)

and (2) securely.

SWITCH

(REF)

SWITCH

BRACKET

PLATFORM BELOW FLOOR LEVEL,

WITH IBRS UP (LH SIDE SHOWN)

FIG. 47-1

SCREW (2)

SCREW (1)

POWER SWITCH

6. Turn ON power switch on pump

cover (FIG. 47-2A). Then raise

(UP) the platform to fl oor level

(FIG. 46-1). Verify that “INBD

SW” is not displayed on the lift

controller. If necessary repeat

this procedure.

CUT-AWAY VIEW OF

LH VERTICAL ARM

& IBRS SWITCH

FIG. 47-2B

PLATFORM BELOW FLOOR LEVEL,

WITH IBRS UP (LH SIDE SHOWN)

FIG. 47-2A

47

PATENTS PENDING

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

Page 48

CHANGING CONTROLLER TO SPANISH OR ENGLISH (IF REQUIRED)

NOTE: The power switch on the Lift

must be turned OFF before

entering SETUP.

1. Turn power switch OFF

(FIG. 48-2).

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

FOLD

UP

HAND PENDANT:

ENTERING SETUP

FIG. 48-1

POWER

SWITCH

CONTROLLER

(REF)

2. Enter SETUP by holding

both the UP and FOLD

switches on the hand

pendant (FIG. 48-1) and

turning the power switch

ON at the same time (FIG.

48-2). Controller will

read SETUP (FIG. 48-3).

TURNING POWER SWITCH ON/OFF

(LH PUMP SHOWN)

FIG. 48-2

SETUP

CONTROLLER:

ENTERING SETUP

FIG. 48-3

PATENTS PENDING

48

Page 49

3. Push and release the FOLD

switch (FIG. 49-1). Controller should be in the

LANGUAGE mode (FIG.

49-2).

FOLD

HAND PENDANT:

CHANGING SETUP MODE

FIG. 49-1

LANGUAGE: ENGLISH

NOTE: After you exit SETUP, the con-

troller readings will be displayed

in the language you selected.

4. Push the UP switch or DOWN

switch to change from ENGLISH

to SPANISH (or from SPANISH

to ENGLISH) (FIGS. 49-2 and

49-3).

5. Push and release the FOLD

switch (FIG. 49-1) three

times to exit SETUP (FIG.

49-4).

CONTROLLER: LANGUAGE

SETTING (ENGLISH OR SPANISH)

FIG. 49-2

UP

DOWN

HAND PENDANT:

CHANGING THE SETTING

FIG. 49-3

MAXON LIFT CORP.

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

49

CONTROLLER:

EXITING SETUP

FIG. 49-4

PATENTS PENDING

Page 50

OUTBOARD ROLLSTOP TIME ADJUSTMENT (IF REQUIRED)

NOTE: Call MAXON Technical Service

before doing this adjustment.

NOTE: The power switch on the Lift

must be turned OFF before

entering SETUP.

1. Turn power switch OFF

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

(FIG. 50-2).

FOLD

UP

HAND PENDANT:

ENTERING SETUP

FIG. 50-1

POWER

SWITCH

CONTROLLER

(REF)

2. Enter SETUP by holding

both the UP and FOLD

switches on the hand

pendant (FIG. 50-1) and

turning the power switch

ON at the same time (FIG.

50-2). Controller will

read SETUP (FIG. 50-3).

TURNING POWER SWITCH ON/OFF

(LH PUMP SHOWN)

FIG. 50-2

SETUP

CONTROLLER:

ENTERING SETUP

FIG. 50-3

PATENTS PENDING

50

Page 51

3. Push and release the FOLD

switch (FIG. 51-1) to access the OUTBD TIME setting (FIG. 51-2).

FOLD

HAND PENDANT:

CHANGING SETUP MODE

FIG. 51-1

NOTE: A larger number for the OUTBD

TIME setting allows more time

for the controller to sense the

outboard rollstop is closed. A

smaller number decreases the

time. Call MAXON Technical

Service to advise you about the

best setting for your vehicle.

4. Push the UP switch (FIG. 51-3) to

increase the OUTBD TIME from -7

to 10. Push the DOWN switch (FIG.

51-3) to decrease the number

from 10 to -7.

OUTBD TIME: 0

CONTROLLER: SETTING

OUTBOARD RAMP TIME

(RANGE IS -7 TO 10)

FIG. 51-2

UP

DOWN

HAND PENDANT:

CHANGING THE SETTING

FIG. 51-3

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

5. Push and release the FOLD

switch (FIG. 51-1) two

times to exit SETUP (FIG.

51-4).

51

MAXON LIFT CORP.

CONTROLLER:

EXITING SETUP

FIG. 51-4

PATENTS PENDING

Page 52

FLOOR POSITION ADJUSTMENT (MANDATORY)

NOTE: Do the following procedure to ensure the inboard rollstop rests on threshold

plate and lines up approximately with edge of base plate.

1. Unfold the platform until the

lights illuminate at fl oor level or

raise the platform to fl oor level

as shown in FIG. 52-1A.

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

PLATFORM

LIGHT

THRESHOLD

EDGE OF

BASE PLATE

INBOARD ROLLSTOP LINES

EDGE OF

INBOARD

PLATE

ROLLSTOP

UP WITH BASE PLATE

FIG. 52-1B

PLATFORM AT FLOOR LEVEL

(LH SIDE SHOWN)

FIG. 52-1A

2. Inspect the threshold plate. The

edge of the inboard rollstop should

line up with the edge of the base

plate as shown in FIG.

52-1B.

PATENTS PENDING

52

Page 53

3. If the inboard rollstop does not line up

correctly with the edge of the base plate

(FIGS. 53-1 and 53-2), go to INSTRUCTION 4.

THRESHOLD

PLATE

EDGE OF

BASE PLATE

EDGE OF

INBOARD

ROLLSTOP

INBOARD ROLLSTOP OVERLAPS

EDGE OF BASE PLATE

FIG. 53-1

NOTE: The power switch on the Lift

must be turned OFF before

entering SETUP.

4. Turn power switch OFF (FIG.

53-3).

THRESHOLD

PLATE

EDGE OF

BASE PLATE

EDGE OF

INBOARD

ROLLSTOP

INBOARD ROLLSTOP WITH GAP

BETWEEN BASE PLATE

FIG. 53-2

POWER

SWITCH

CONTROLLER

(REF)

TURNING POWER SWITCH ON/OFF

(LH PUMP SHOWN)

FIG. 53-3

53

PATENTS PENDING

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

Page 54

FLOOR POSITION ADJUSTMENT - Continued

5. Enter SETUP by holding both

the UP and FOLD switches on

the hand pendant (FIG.

and turning the power switch

ON at the same time (FIG. 53-

3). Controller will read SETUP

(FIG. 54-2).

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

54-1)

UP

FOLD

HAND PENDANT:

ENTERING SETUP

FIG. 54-1

SETUP

CONTROLLER:

ENTERING SETUP

FIG. 54-2

6. Push and release the FOLD

switch (FIG. 54-3) two

times to access the FLOOR

POS setting (FIG. 54-4).

FOLD

HAND PENDANT:

CHANGING SETUP MODE

FIG. 54-3

FLOOR POS: 345

CONTROLLER:

SETTING FLOOR POSITION

(EXAMPLE READING SHOWN)

FIG. 54-4

PATENTS PENDING

54

Page 55

7. To decrease overlap, push the UP

switch from 1 to 5 times (FIG. 55-1).

The FLOOR POS number displayed on

the controller (FIG. 55-2) will increase

by 1 each time you push the UP button. To close the gap, push the DOWN

switch from 1 to 5 times (FIG. 55-1).

The FLOOR POS number displayed on

the controller (FIG. 55-2) will decrease

by 1 each time you push the DOWN

button.

UP

DOWN

(-)

HAND PENDANT:

CHANGING THE SETTING

FIG. 55-1

FLOOR POS: 350

CONTROLLER:

SETTING FLOOR POSITION

(EXAMPLE READING SHOWN)

FIG. 55-2

8. Push and release the FOLD

switch (FIG. 55-3) to exit

SETUP (FIG. 55-4).

FOLD

HAND PENDANT:

CHANGING SETUP MODE

FIG. 55-3

MAXON LIFT CORP.

CONTROLLER:

EXITING SETUP

FIG. 55-4

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

55

PATENTS PENDING

Page 56

FLOOR POSITION ADJUSTMENT - Continued

9. Lower the platform until the inboard

rollstop is in the up and locked position. Next, raise the platform to fl oor

level (FIG. 56-1A). Verify that the

inboard rollstop lines up with the

edge of the base plate as shown in

FIG 56-1B. If necessary, repeat

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

this entire procedure.

PLATFORM AT FLOOR LEVEL

(LH SIDE SHOWN)

FIG. 56-1A

PLATFORM

LIGHT

THRESHOLD

EDGE OF

BASE PLATE

INBOARD

ROLLSTOP

PLATE

INBOARD ROLLSTOP LINES

UP WITH BASE PLATE

FIG. 56-1B

PATENTS PENDING

56

Page 57

SYSTEM DIAGRAMS

HYDRAULIC SYSTEM DIAGRAM

CYLINDER

FLOW CONTROL

VALVE - .5 GPM

PRESSURE PORT

RELEASE VALVE

MANUAL

BACK-UP

FLOW CONTROL

VALVE - .5 GPM

PRESSURE

TRANSDUCER

CYLINDER

PRESSURE PORT

MANUAL

S.V.1

.018 DIA.

S.V.2

RETURN

PUMP

RETURN

GEAR

PUMP

FIG. 57-1

57

R.V.

SET @

1550 PSI

FILLER BREATHER

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

PATENTS PENDING

Page 58

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

SYSTEM DIAGRAMS - Continued

ELECTRICAL SYSTEM DIAGRAM

PATENTS PENDING

FIG. 58-1

58

Page 59

COMPLETED LIFT INSTALLATION CHECKLIST

1. Make sure vehicle is still parked on level ground. If vehicle is equipped with a parking brake, set the

parking brake. If equipped with locking service brake, set the service brake and make sure vehicle is

in park or neutral.

Start vehicle engine.

Turn on Wheelchair Lift power switch (if equipped) at the vehicle driver’s station.

If equipped, make sure occupant restraint belt is buckled on Lift.

Make sure Lift is stowed.

2. Turn ON power switch at the Lift. Record CYCLE COUNT _________ and LIFT COUNT _________

indicated on Lift controller.

!

WARNING

The following procedure requires checking equipment on the vehicle while the vehicle is in drive

and parking brake is released. A qualifi ed vehicle operator is needed inside the vehicle at the

driver’s station. A second qualifi ed operator is required outside the vehicle to operate the Wheel-

chair Lift. To prevent accidental injury and equipment damage, chock the vehicle wheels and get a

second qualifi ed vehicle operator to help you do the procedure.

Chock the vehicle wheels.

Check Vehicle Safety Interlocks:

3. Make sure the interlock system prevents Lift from being deployed when vehicle is set to move under

its own power. Release the vehicle brakes and/or shift vehicle to a drive gear (DRIVE or REVERSE).

Controller on the Lift should display LOCKED. Try to unfold Lift with the UNFOLD button on hand

pendant. Lift must not unfold from stowed position when vehicle is set to move under its own power.

4. Make sure the interlock system prevents vehicle from moving under its own power when the Lift is

deployed. Shift vehicle to PARK or NEUTRAL, and/or set parking brake/service brake as required for

your vehicle interlock system. Lift controller should display STOWED *. Use the UNFOLD button on

hand pendant to unfold the Lift. Release the UNFOLD button when the controller displays UNFOLD.

Try to move vehicle under its own power by shifting into DRIVE and/or releasing parking brake/service brake. Vehicle must not be able to shift into DRIVE and/or parking brake/service brake must not

release when Lift is deployed. Make sure vehicle is in PARK or NEUTRAL, and/or parking brake/ser-

vice brake is set as required for your vehicle interlock system. Use the FOLD button to stow the Lift.

The Lift controller displays STOWED * when Lift is stowed and interlock is working correctly.

Check Lift Operation:

NOTE: Keep off the threshold plate until instructed to stand on it.

5. Make sure the Lift unfolds all the way to vehicle fl oor level. Press the UNFOLD button on hand pen-

dant to unfold Lift. Release the UNFOLD button when:

• Platform stops unfolding at vehicle fl oor level

• Inboard rollstop is lowered to the threshold plate

• Platform lights are illuminated.

The Lift controller displays UNFOLD & FLOOR as Lift moves from stowed position to vehicle fl oor

level.

6. Make sure the occupant restraint belt works correctly on the Lift, if equipped. Unbuckle the belt. Then

press the DOWN button on the hand pendant. Lift must not move. Buckle the occcupant restraint belt

before proceeding to the next check.

7. Make sure the threshold warning beacons light up and the alarm sounds when:

• Threshold plate is occupied

• Lift is moving down

Stand on the threshold plate and press the DOWN button on the hand pendant. The controller dis-

plays DOWN as the Lift starts lowering. After the platform is lowered approximately 1” (25mm) below

fl oor level:

• Threshold warning beacons must light up

• Alarm must sound

• Controller must display MAT ERR

Move off the threshold plate into the vehicle before proceeding to the next check.

59

PATENTS PENDING

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

Page 60

8. Make sure platform lowers all the way to the ground and platform lights are illuminated while platform

is lowering. Press DOWN button on the hand pendant to lower platform to the ground. As the platform is lowering:

• Controller must display DOWN

• Platform lights must be illuminated

When the platform reaches the ground:

• Controller must display GROUND

• Outboard rollstop must lower to the ground

9. Make sure platform will not raise more than 3” above the ground if the outboard rollstop is not up all

11921 Slauson Ave. Santa Fe Springs, CA. 90670 (800) 227-4116 FAX (888) 771-7713

the way. Stand on the outboard rollstop to keep it from moving to the up position. Press UP button

on hand pendant to raise platform. As the platform is raising:

• Controller must display OUTBD SW

• Platform must stop raising at no more than 3” above the ground

Press the DOWN button on the hand pendant to lower platform to the ground. Move off the outboard

rollstop before proceeding to the next check.

10. Make sure platform raises from the ground all the way to vehicle fl oor level and platform lights are il-

luminated while platform is raising. Press UP button on the hand pendant to raise platform to vehicle

fl oor level. As the platform is raising:

• Controller must display UP

• Platform lights must be illuminated

When the platform reaches vehicle fl oor level:

• Controller must display FLOOR

• Platform lights must still be illuminated

11. Make sure platform cannot be folded if occupied. Place a 50 pound weight on the platform, on the end

closest to the inboard rollstop. Press FOLD button on the hand pendant.

• Platform must not fold

• Controller must display OCCUPIED

Remove the 50 pound weight from the platform before proceeding to the next check.

12. Make sure Lift folds into the stowed position and platform lights turn off. Press FOLD button on the

hand pendant until the Lift is in stowed position and stops folding.

• Controller must display FOLD

• Platform lights must be turned off

• Controller must display STOWED * when Lift is stowed

13. Turn the power switch on the Lift controller OFF and then ON again. Check and record CYCLE

COUNT ________ and LIFT COUNT ________ indicated on Lift controller. Both counters must indicate one more count than recorded at the beginning of CHECKLIST.

Check manuals and decals supplied with the Lift:

14. All decals are correctly affi xed to Lift and on the vehicle. Refer to the DECALS & DECALS PLACE-

MENT section in this manual for decal placement location instructions.

15. Lift Operation Manual and Maintenance Schedule are inserted in the vehicle owners manual.

VEHICLE I.D. (VIN)# _______________________________________

WHEELCHAIR LIFT SERIAL# ________________________________

CHECKED BY & DATE: _____________________________________

MAXON LIFT CORP.

11921 SLAUSON AVE. SANTA FE SPRINGS, CA 90670

(562) 464-0099 (800) 227-4116 FAX (888) 771-7713 Internet: www.maxonlift.com

PATENTS PENDING

60

Page 61

Loading...

Loading...