maxon motor MCD EPOS P 60 W Reference Manual

maxon motor

maxon motor control MCD EPOS P 60 W

Hardware Reference April 2009 Edition

60 W

Programmable Positioning Compact Drive

Documentation

Hardware Reference

maxon document number: 787218-04

maxon motor

Hardware Reference MCD EPOS P 60 W

1 Table of contents

1 Table of contents................................................................................................................... 2

2 Table of figures ..................................................................................................................... 2

3 Introduction ........................................................................................................................... 3

4 How to use this guide............................................................................................................ 3

5 Safety Instructions................................................................................................................. 4

6 Performance Data................................................................................................................. 5

6.1 Motor data ........................................................................................................................... 5

6.2 Electrical data...................................................................................................................... 5

6.3 Inputs .................................................................................................................................. 5

6.4 Outputs................................................................................................................................5

6.5 Interfaces ............................................................................................................................ 6

6.6 Memory Data....................................................................................................................... 6

6.7 LED indicator....................................................................................................................... 6

6.8 Ambient temperature- / Humidity range .............................................................................. 6

6.9 Mechanical data .................................................................................................................. 6

6.10 Connections ........................................................................................................................ 6

6.11 Order number...................................................................................................................... 6

7 Connections .......................................................................................................................... 7

7.1 Signal connector (J1) .......................................................................................................... 8

7.1.1 Digital input 7 “High Speed Command” ......................................................................... 9

7.1.2 Digital input 8 “High Speed Command” ....................................................................... 10

7.1.3 Digital input 1, 2, 3, 4 “General Purpose” .................................................................... 11

7.1.4 “+V Opto IN” external supply Input voltage for Digital Outputs.................................... 13

7.1.5 Digital output 3 and 4 “General Purpose” .................................................................... 14

7.2 Power / Communication connector (J2)............................................................................ 15

7.2.1 RS-232 communication ............................................................................................... 16

7.2.2 CAN communication .................................................................................................... 17

7.2.3 Logic supply (optional)................................................................................................. 18

7.2.4 Power supply ............................................................................................................... 19

8 LED status........................................................................................................................... 20

9 Dimension drawing.............................................................................................................. 20

2 Table of figures

Figure 1: MCD EPOS P 60 W ......................................................................................................... 3

Figure 2: EPOS documentation hierarchy....................................................................................... 3

Figure 3: Connector location ........................................................................................................... 7

Figure 4: Wiring diagram (overview) ............................................................................................... 7

Figure 5: Signal connector (J1) D-Sub connector High-Density 15 poles (female) ........................ 8

Figure 6: Digital input 7 “Differential” circuit .................................................................................... 9

Figure 7: Digital input 7 “Single-ended” circuit ................................................................................ 9

Figure 8: Digital input 8 “Differential” circuit .................................................................................. 10

Figure 9: Digital input 8 “Single-ended” circuit .............................................................................. 10

Figure 10: Logic level .................................................................................................................... 11

Figure 11: Digital input 1,2,3,4 ...................................................................................................... 11

Figure 12: Digital input 1,2,3,4 external wiring examples ............................................................. 12

Figure 13: Digital output 3 ............................................................................................................. 14

Figure 14: Power / Communication connector (J2) D-Sub connector 9 poles (male)................... 15

Figure 15: Dimensions MCD EPOS P 60 W ................................................................................. 20

April 2009 Edition / document number 787218-04 / subject to change maxon motor control 2

maxon motor

Hardware Reference MCD EPOS P 60 W

3 Introduction

This documentation “Hardware Reference” provides the hardware details of the maxon compact drive

MCD EPOS P 60 W. It contains performance data, connections, specification, pin assignment and

wiring examples.

The maxon MCD EPOS P 60 W is a small-sized free

programmable compact drive. It contains a brushless EC motor

with Hall-sensors, digital Encoder and a digital position control

unit. The optimized commutation by space vector control offers to

drive the integrated brushless EC motor with minimal torque

ripple and low noise. The integrated position-, velocity- and

current control functionality allows sophisticated positioning

applications. The MCD EPOS P 60 W is programmable with a

very efficient software tool. The programming languages are

according to IEC 61131-3 standard. The built-in CANopen

interface allows the design of an easy-to-use standalone multiple

axis system, particularly with standard maxon MCD EPOS controllers or standard maxon EPOS

controllers. In addition the unit can be operated through any RS-232 communication port.

The latest edition of these “Hardware Reference”, additional documentation and software to the MCD

EPOS compact drive may also be found on the internet under

<Service & Downloads> or in the maxon motor e-shop http://shop.maxonmotor.com.

Figure 1: MCD EPOS P 60 W

http://www.maxonmotor.com category

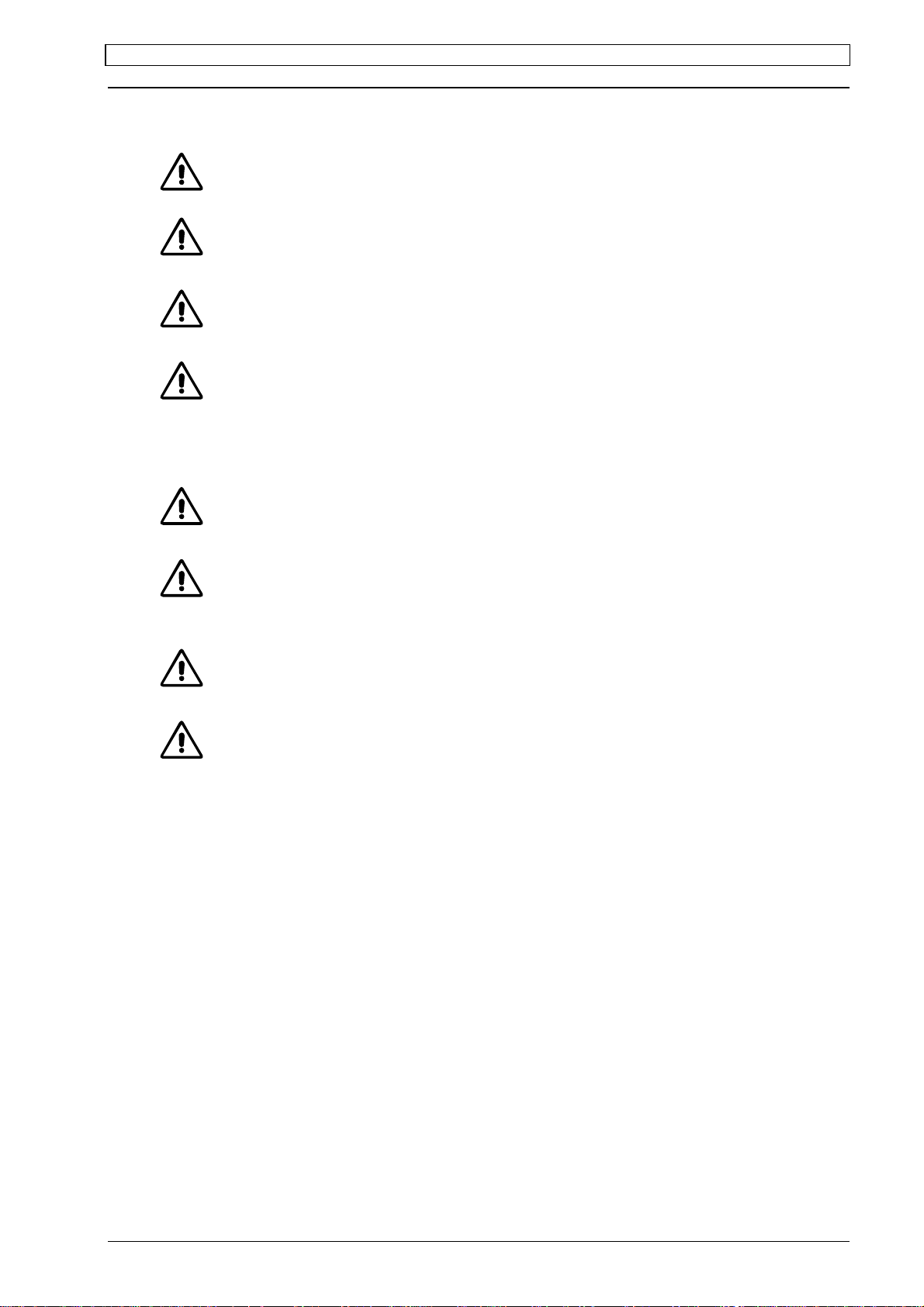

4 How to use this guide

Setup

Getting Started

Installation Configuration Programming Application

Cable Starting Set

Hardware Reference

EPOS Studio

EPOS Studio

Programming

Reference

Application Notes

Application Samples

Firmware

Specification

Figure 2: EPOS documentation hierarchy

April 2009 Edition / document number 787218-04 / subject to change maxon motor control 3

maxon motor

Hardware Reference MCD EPOS P 60 W

5 Safety Instructions

Skilled Personnel

Installation and starting of the equipment shall only be performed by experienced,

skilled personnel.

Statutory Regulations

The user must ensure that the compact drive and the components belonging to it

are assembled and connected according to local statutory regulations.

Load Disconnected

For primary operation the compact drive should be free running, i.e. with the load

disconnected.

Additional Safety Equipment

Any electronic apparatus is, in principle, not fail-safe. Machines and apparatus

must therefore be fitted with independent monitoring and safety equipment. If the

equipment breaks down, if it is operated incorrectly, if the control unit breaks down

or if the cables break, etc., it must be ensured that the drive or the complete

apparatus is kept in a safe operating mode.

Repairs

Repairs may be made by authorized personnel only or by the manufacturer.

Improper repairs can result in substantial dangers for the user.

Danger

During installation of the MCD EPOS P 60 W, make sure to disconnect all

apparatus from the electrical supply.

After switch-on, do not touch any life parts!

Max. Supply Voltage

Make sure that the supply voltage is between 12 and 50 VDC. Voltages higher than

55 VDC or of wrong polarity will destroy the unit.

Electrostatic Sensitive Device (ESD)

April 2009 Edition / document number 787218-04 / subject to change maxon motor control 4

maxon motor

Hardware Reference MCD EPOS P 60 W

6 Performance Data

6.1 Motor data

Nominal torque (max. continuous torque) .............. 54 mNm (Ta=25°C, 5000 rpm)

Max. torque ................................................................................................ 218 mNm

Max. permissible speed (restricted by Encoder) ..................................... 12000 rpm

Max. efficiency .................................................................................................. 70 %

Torque constant .................................................................................... 24.3 mNm/A

Speed constant ......................................................................................... 393 rpm/V

Speed / Torque gradient .................................................................... 20.6 rpm/mNm

Rotor inertia .............................................................................................. 21.9 gcm

Axial play at axial load < 6 N ....................................................................... 0 mm

> 6 N .................................................................. 0.14 mm

Radial play ................................................................................................ preloaded

Max. axial load (dynamic) ................................................................................. 5.5 N

Max. force for press fits (static) ....................................................................... 100 N

Max. radial loading, 5 mm from flange .............................................................. 25 N

6.2 Electrical data

Power supply voltage VCC (Ripple < 10%) .......................................... 12 … 50 VDC

Logic supply voltage V

Max. output voltage ..................................................................................... 0.9 · V

Max. output current I

Continuous output current I

Switching frequency ....................................................................................... 50 kHz

Max. efficiency .................................................................................................. 93 %

Sample rate PI - current controller ................................................................. 10 kHz

Sample rate PI - speed controller .................................................................... 1 kHz

Sample rate PID - positioning controller .......................................................... 1 kHz

Position resolution ............................................................................................ 0.09°

Position accuracy...................................................................................... typical ± 1°

Position reproducibility......................................................................... typical ± 0.09°

Hall sensor signals ................................. Hall sensor 1, Hall sensor 2, Hall sensor 3

Encoder signals .............................................................................. 1000 Increments

A, A\, B, B\, I, I\ (max. 200 KHz)

(Ripple < 10%) (optional) ............................. 12 … 50 VDC

C

....................................................................................... 9 A

max

...................................... 2.6 A (Ta=25°C, 5000 rpm)

cont

1)

2

CC

1)

6.3 Inputs

Digital input 1 (“General Purpose”) ............. opto-isolated ................ +9 ... +24 VDC

Digital input 2 (“Home Switch”) ................... opto-isolated ................ +9 ... +24 VDC

Digital input 3 (“Positive Limit Switch”) ....... opto-isolated ................ +9 ... +24 VDC

Digital input 4 (“Negative Limit Switch”) ...... opto-isolated ................ +9 ... +24 VDC

Digital input 7 (“High Speed Command”) ............ line receiver EIA standard RS-422

Digital input 8 (“High Speed Command”) ............ line receiver EIA standard RS-422

+V Opto IN ...................................................................................... +12 … +24 VDC

6.4 Outputs

Digital output 3 (“General Purpose”) ...... opto-isolated max. 24 VDC (IL < 350 mA)

Digital output 4 (“General Purpose”) ...... opto-isolated max. 24 VDC (I

1)

Valid at Ta =25°C, thermally isolated, no convection and 5000 rpm

Higher value (I

max.3A) possible with better ambient conditions for example:

cont

- free convection or forced air cooling

- thermal coupling

- lower speed

April 2009 Edition / document number 787218-04 / subject to change maxon motor control 5

< 350 mA)

L

maxon motor

Hardware Reference MCD EPOS P 60 W

6.5 Interfaces

RS-232 .............................. RxD; TxD ......................................... max. 115 200 bit/s

CAN (high speed) ............. CAN_H (high); CAN_L (low) .................... max.1 MBit/s

CAN-ID, no mechanical switch, configured according to ............ LSS CiA DSP-305

6.6 Memory Data

Total memory.............................................................................................. 512 kByte

Application memory (free programmable) ......................................... 256 kByte

Non-volatile memory ............................................................................ 512 Byte

6.7 LED indicator

Bi-colour LED .......................................................... green = ENABLE, red = FAULT

Blue LED .................................................................................. PROGRAM STATUS

6.8 Ambient temperature- / Humidity range

Protection class ......................................................................... IP42 (optional IP54)

Operating .............................................................................................. -20 ... +85°C

................................................................... power derating 1.4%/K above T

a

Storage ................................................................................................. -40 ... +85°C

Non condensating .................................................................................... 20 ... 80 %

Max. case temperature ................................................................................ < 100°C

=25°C

1)

6.9 Mechanical data

Weight ................................................................................................. approx. 495 g

Dimensions (L x W x H) ................................................................ 120 x 33 x 53 mm

Mounting plate ............................................................................. for M3x4.5 screws

6.10 Connections

J1 Signal ...................................... D-Sub connector High-Density 15 poles (female)

J2 Power / Communication .................................... D-Sub connector 9 poles (male)

6.11 Order number

MCD EPOS P 60 W ...................................................................................... 315665

Suitable plug: ............................................... D-Sub connector High-Density 15 poles (male)

Suitable plug: .................................................................... D-Sub connector 9 poles (female)

1)

Valid at Ta =25°C, thermally isolated, no convection and 5000 rpm

Higher value (I

max.3A) possible with better ambient conditions for example:

cont

- free convection or forced air cooling

- thermal coupling

- lower speed

April 2009 Edition / document number 787218-04 / subject to change maxon motor control 6

Loading...

Loading...