Page 1

maxon motor

maxon motor control EPOS Positioning Controller

Hardware Reference December 2008 Edition

70/10

Positioning Controller

Documentation

Hardware Reference

maxon document number: 752380-04

Page 2

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

1 Table of contents

1

Table of contents................................................................................................................... 2

2 Table of figures ..................................................................................................................... 3

3 Introduction ........................................................................................................................... 4

4 How to use this guide............................................................................................................ 4

5 Safety Instructions................................................................................................................. 5

6 Performance Data ................................................................................................................. 6

6.1 Electrical data...................................................................................................................... 6

6.2 Inputs .................................................................................................................................. 6

6.3 Outputs................................................................................................................................ 6

6.4 Voltage outputs ................................................................................................................... 6

6.5 Motor connections...............................................................................................................6

6.6 Interfaces ............................................................................................................................ 7

6.7 LED indicator....................................................................................................................... 7

6.8 Ambient temperature- / Humidity range.............................................................................. 7

6.9 Mechanical data.................................................................................................................. 7

6.10 Connections ........................................................................................................................ 7

6.11 Order number...................................................................................................................... 7

7 Connections 300583 ............................................................................................................. 8

7.1 Power supply connector (J1) .............................................................................................. 9

7.2 Logic supply connector (J1A)............................................................................................ 10

7.3 Motor connector (J2)......................................................................................................... 11

7.3.1 maxon EC motor .......................................................................................................... 11

7.3.2 maxon DC motor with separated motor and encoder cable ........................................ 11

7.4 Hall sensor connector (J3) ................................................................................................ 12

7.5 Encoder connector (J4)..................................................................................................... 13

7.6 Signal 1 connector (J5) ..................................................................................................... 14

7.6.1 Digital input 1, 2, 3 “General Purpose“ ........................................................................ 15

7.6.2 Digital input 4, 5, 6 "Home Switch", "Positive and Negative Limit Switch" .................. 16

7.6.3 “+V Opto IN” external supply Input voltage for Digital Outputs.................................... 18

7.6.4 Digital output 1, 2, 3 “General Purpose“ ...................................................................... 19

7.6.5 Digital output 4 "Brake"................................................................................................ 20

7.7 Signal 2 connector (J5A)................................................................................................... 21

7.7.1 Reference Output voltage............................................................................................ 22

7.7.2 Analogue input 1 "General Purpose" ........................................................................... 23

7.7.3 Analogue input 2 "General Purpose" ........................................................................... 23

7.7.4 Digital input 7 "High Speed Command"....................................................................... 24

7.7.5 Digital input 8 "High Speed Command"....................................................................... 25

7.8 RS-232 connector (J6)...................................................................................................... 26

7.9 CAN connector (J7, J8)..................................................................................................... 27

7.10 CAN Node Identification (JP 1) ......................................................................................... 28

8 LED status........................................................................................................................... 29

9 Dimension drawing.............................................................................................................. 29

2 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 3

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

2 Table of figures

Figure 1: EPOS 70/10 photo ........................................................................................................... 4

Figure 2: EPOS documentation hierarchy....................................................................................... 4

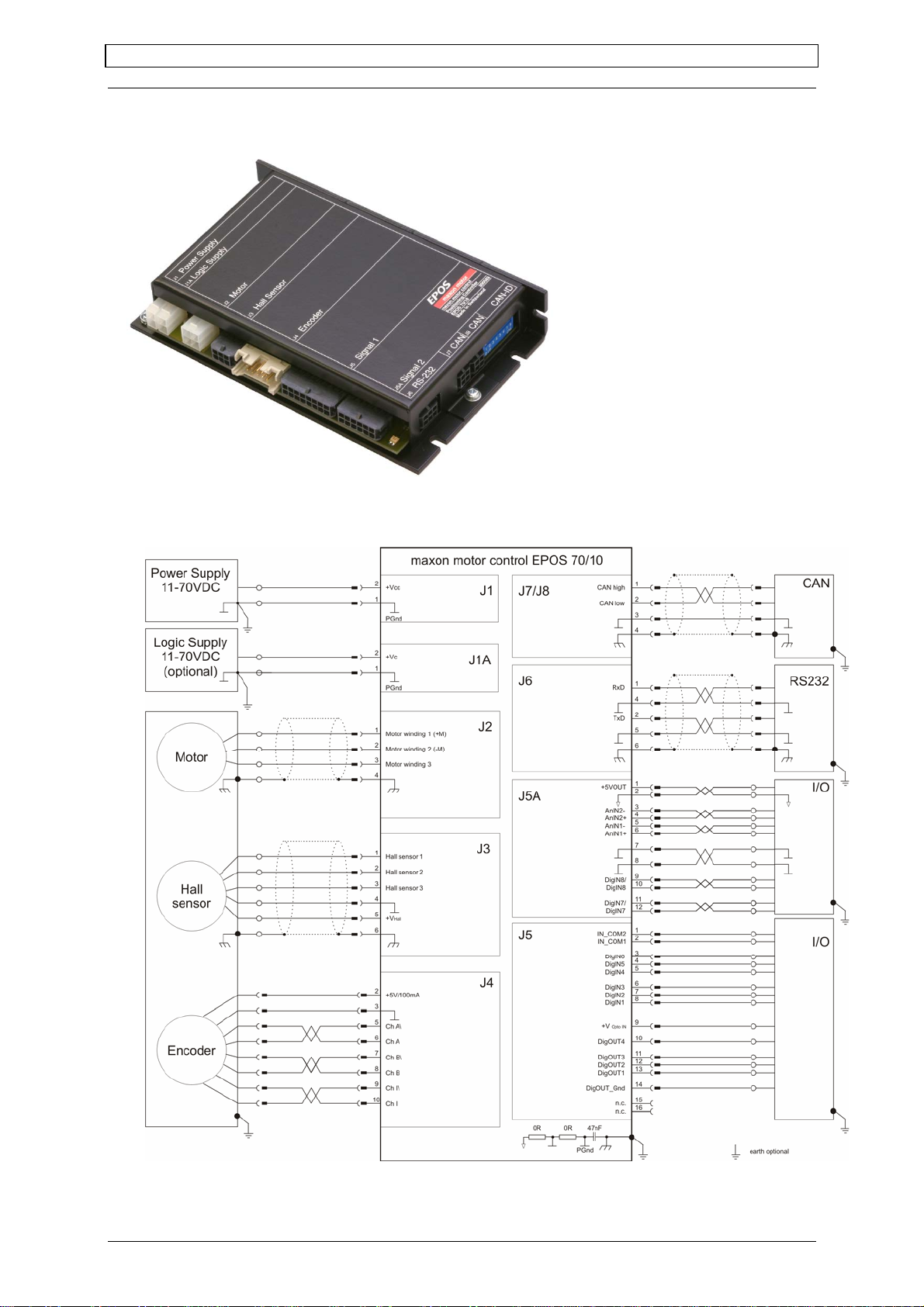

Figure 3: EPOS photo with connector description .......................................................................... 8

Figure 4: Wiring diagram (overview) ............................................................................................... 8

Figure 5: Power connector (J1)....................................................................................................... 9

Figure 6: Logic supply connector (J1A)......................................................................................... 10

Figure 7: Motor connector (J2)...................................................................................................... 11

Figure 8: Motor connector (J2)...................................................................................................... 11

Figure 9: Hall sensor input circuit.................................................................................................. 12

Figure 10: Hall sensor connector (J3) ...........................................................................................12

Figure 11: Encoder input circuit sketch .........................................................................................13

Figure 12: Encoder connector (J4)................................................................................................ 13

Figure 13: Signal connector (J5) ................................................................................................... 14

Figure 14: Logic level .................................................................................................................... 15

Figure 15: Digital input 1..3 ........................................................................................................... 15

Figure 16: Logic level .................................................................................................................... 16

Figure 17: Digital input 4…6.......................................................................................................... 16

Figure 18: Digital input 4,5,6 external wiring examples ................................................................ 17

Figure 19: Digital output 1, 2, 3 circuit........................................................................................... 19

Figure 20: Signal connector (J5A)................................................................................................. 21

Figure 21: Analogue input 1 circuit................................................................................................ 23

Figure 22: Analogue input 2 circuit................................................................................................ 23

Figure 23: Digital input 7 “Differential” circuit ................................................................................ 24

Figure 24: Digital input 7 “Single-ended” circuit ............................................................................ 24

Figure 25: Digital input 8 “Differential” circuit ................................................................................ 25

Figure 26: Digital input 8 “Single-ended” circuit ............................................................................ 25

Figure 27: RS232 cable connector (J6) ........................................................................................ 26

Figure 28: CAN connector (J7,J8)................................................................................................. 27

Figure 29: Table binary code value............................................................................................... 28

Figure 30: CAN ID examples ........................................................................................................ 28

Figure 31: Dimensions EPOS 70/10 ............................................................................................. 29

3 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 4

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

3 Introduction

This documentation “Hardware Reference” provides the hardware details of the EPOS 70/10

positioning controller. It contains performance data, connections, specification, pin assignment

and wiring examples.

The maxon motor EPOS 70/10 is a small-sized full digital

smart motion controller. Due to the flexible and high efficient

power stage the EPOS 70/10 drives brushed DC motors with

digital encoder as well as brushless EC motors with digital

Hall sensors and encoder.

Figure 1: EPOS 70/10 photo

control functionality allows sophisticated positioning applications. It is specially designed being

commanded and controlled as a slave node in the CANopen network. In addition the unit can be

operated through any RS-232 communication port.

The latest edition of these “Hardware Reference”, additional documentation and software to the

EPOS positioning controller may also be found on the internet in

category <Service>, subdirectory <Downloads>.

The sinusoidal current commutation by space vector control

offers to drive brushless EC motors with minimal torque ripple

and low noise. The integrated position-, velocity- and current

http://www.maxonmotor.com

4 How to use this guide

Setup

Getting Started

Installation Configuration Programming Application

• Cable Starting Set

• Hardware

Reference

• Graphical User

Interface

• Windows DLL

• IEC1131 libraries

• Application Notes

• Application

Samples

Figure 2: EPOS documentation hierarchy

4 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

• Firmware

Specification

• Communication

Guide

Page 5

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

5 Safety Instructions

Skilled Personnel

Installation and starting of the equipment shall only be performed by experienced,

skilled personnel.

Statutory Regulations

The user must ensure that the positioning controller and the components belonging

to it are assembled and connected according to local statutory regulations.

Load Disconnected

For primary operation the motor should be free running, i.e. with the load

disconnected.

Additional Safety Equipment

An electronic apparatus is not fail-safe in principle. Machines and apparatus must

therefore be fitted with independent monitoring and safety equipment. If the

equipment breaks down, if it is operated incorrectly, if the control unit breaks down

or if the cables break, etc., it must be ensured that the drive or the complete

apparatus is kept in a safe operating mode.

Repairs

Repairs may be made by authorized personnel only or by the manufacturer. It is

dangerous for the user to open the unit or make repairs to it.

Danger

Do ensure that during the installation of the EPOS 70/10 no apparatus is

connected to the electrical supply. After switching on, do not touch any live parts!

Max. Supply Voltage

Make sure that the supply voltage is between 11 and 70 VDC. Voltages higher than

77 VDC or of wrong polarity will destroy the unit.

Electrostatic Sensitive Device (ESD)

5 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 6

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

6 Performance Data

6.1 Electrical data

Power supply voltage VCC (Ripple < 10%) .......................................... 11 … 70 VDC

Logic supply voltage V

Max. output voltage .................................................................................... 0.9 • V

Max. output current I

Continuous output current I

Switching frequency ....................................................................................... 50 kHz

Max. efficiency .................................................................................................. 93 %

Sample rate PI - current controller ................................................................. 10 kHz

Sample rate PI - speed controller .................................................................... 1 kHz

Sample rate PID - positioning controller .......................................................... 1 kHz

Max. speed (motors with 2 poles) ........................................................... 25 000 rpm

Built-in motor choke per phase ............................................................. 25 µH / 10 A

6.2 Inputs

Hall sensor signals ........................... Hall sensor 1, Hall sensor 2 and Hall sensor 3

...................... for Hall effect sensor IC's (Schmitt trigger with open collector output)

Encoder signals .......................................................... A, A\, B, B\, I, I\ (max. 1MHz)

................................................................ internal line receiver EIA standard RS-422

Digital input 1 (“General Purpose”) ......... opto-isolated +9 ... +24 VDC (Ri = 1.8kΩ)

Digital input 2 (“General Purpose”) ......... opto-isolated +9 ... +24 VDC (Ri = 1.8kΩ)

Digital input 3 (“General Purpose”) ......... opto-isolated +9 ... +24 VDC (Ri = 1.8kΩ)

Digital input 4 (“Home Switch”) ............... opto-isolated +9 ... +24 VDC (Ri = 1.8kΩ)

Digital input 5 (“Positive Limit Switch”) ... opto-isolated +9 ... +24 VDC (Ri = 1.8kΩ)

Digital input 6 (“Negative Limit Switch”) .. opto-isolated +9 ... +24 VDC (Ri = 1.8kΩ)

Digital input 7 (“High Speed Command”).internal line receiver EIA standard RS-422

Digital input 8 (“High Speed Command”).internal line receiver EIA standard RS-422

Analogue input 1 ...................................... resolution 10-bit 0 ... +5 V (differential)

Analogue input 2 ...................................... resolution 10-bit 0 ... +5 V (differential)

+V Opto IN ...................................................................................... +12 … +24 VDC

CAN-ID (CAN identification) ........... ID 1-127configured by DIP-Switch or Software

(Ripple < 10%) (optional) ............................. 11 … 70 VDC

C

(<1sec) ........................................................................ 25 A

max

........................................................................... 10 A

cont

CC

6.3 Outputs

Digital output 1 (“General Purpose”) ........ opto-isolated max. 24 VDC (IL < 20 mA)

Digital output 2 (“General Purpose”) ........ opto-isolated max. 24 VDC (I

Digital output 3 (“General Purpose”) ........ opto-isolated max. 24 VDC (I

Digital output 4 (“Brake”)……………………opto-isolated max. 24 VDC (I

6.4 Voltage outputs

Encoder supply voltage ........................................................ +5 VDC, max. 100 mA

Hall sensors supply voltage .................................................... +5 VDC, max. 30 mA

Reference Output voltage ........................................................... +5 VDC (Ri =1 kΩ)

6.5 Motor connections

maxon EC motor maxon DC motor

Motor winding 1 +Motor

Motor winding 2 -Motor

Motor winding 3

6 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

< 20 mA)

L

< 20 mA)

L

< 500 mA)

L

Page 7

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

6.6 Interfaces

RS-232 .............................. RxD; TxD ......................................... max. 115 200 bit/s

CAN (1) ............................. CAN_H (high); CAN_L (low) .................... max.1 MBit/s

CAN (2) ............................. CAN_H (high); CAN_L (low) .................... max.1 MBit/s

6.7 LED indicator

2 colours LED ............................................................................... ENABLE / FAULT

................................................................................. green = ENABLE, red = FAULT

6.8 Ambient temperature- / Humidity range

Operating .............................................................................................. -10 ... +45°C

Storage ................................................................................................. -40 ... +85°C

Non condensating .................................................................................... 20 ... 80 %

6.9 Mechanical data

Weight ................................................................................................. approx. 330 g

Dimensions (L x W x H) ................................................................ 150 x 93 x 27 mm

Mounting plate .................................................................................... for M3 screws

6.10 Connections

Power on board: .................. dual row male header (2 poles) Molex Mini-Fit Jr.TM

Supply

Suitable plug: .......... dual row female receptacle (2 poles) Molex Mini-Fit Jr.

Suitable terminal: ..... female crimp terminal Molex Mini-Fit Jr.

TM

444-76-1111 (AWG 18-24)

Logic On board: ....................... dual row male header (2 poles) Molex Mini-Fit Jr.

Supply Suitable plug: ............. dual row female receptacle (2 poles) Molex Mini-Fit Jr.

Suitable terminal: ...... female crimp terminal Molex Mini-Fit Jr.

TM

444-76-1111 (AWG 18-24)

Motor On board: ....................... dual row male header (4 poles) Molex Mini-Fit Jr.

Suitable plug: ............. dual row female receptacle (4 poles) Molex Mini-Fit Jr.

Suitable terminal: ...... female crimp terminal Molex Mini-Fit Jr.

TM

444-76-1111 (AWG 18-24)

Hall On board: ................... dual row male header (6 poles) Molex Micro-Fit 3.0

Suitable plug: ........ dual row female receptacle (6 poles) Molex Micro-Fit 3.0

Suitable terminal: .... female crimp terminal Molex Micro-Fit 3.0

TM

430-30-0010 (AWG26-30)

Signal 1 On board: ................ dual row male header (16 poles) Molex Micro-Fit 3.0

Suitable plug: dual row female receptacle (16 poles) Molex Micro-Fit 3.0

Suitable terminal: ..... female crimp terminal Molex Micro-Fit 3.0

TM

430-30-0010(AWG26-30)

Signal 2 On board: ................ dual row male header (12 poles) Molex Micro-Fit 3.0

Suitable plug: ...... dual row female receptacle (12 poles) Molex Micro-Fit 3.0

Suitable terminal: ..... female crimp terminal Molex Micro-Fit 3.0

TM

430-30-0010(AWG26-30)

RS232 On board: ................... dual row male header (6 poles) Molex Micro-Fit 3.0

Suitable plug: ........ dual row female receptacle (6 poles) Molex Micro-Fit 3.0

Suitable terminal: ..... female crimp terminal Molex Micro-Fit 3.0

TM

430-30-0010(AWG26-30)

CAN 1 On board: ................... dual row male header (4 poles) Molex Micro-Fit 3.0

Suitable plug: ........ dual row female receptacle (4 poles) Molex Micro-Fit 3.0

Suitable terminal: ..... female crimp terminal Molex Micro-Fit 3.0

TM

430-30-0010(AWG26-30)

CAN 2 On board: ................... dual row male header (4 poles) Molex Micro-Fit 3.0

Suitable plug: ........ dual row female receptacle (4 poles) Molex Micro-Fit 3.0

Suitable terminal: ..... female crimp terminal Molex Micro-Fit 3.0

TM

430-30-0010(AWG26-30)

Encoder On board: ........................................... Plug DIN41651 (10 poles) for flat band cable

............................................................................................................... pitch 1.27mm, AWG 28

Suitable locking clip: .............................................................. Tyco C42334-A421-C42 (right)

.................................................................................................. Tyco C42334-A421-C52 (left)

TM

39-01-2020

TM

39-01-2020

TM

39-01-2040

TM

430-25-0600

TM

430-25-1600

TM

430-25-1200

TM

430-25-0600

TM

430-25-0400

TM

430-25-0400

TM

TM

TM

TM

TM

TM

TM

TM

6.11 Order number

EPOS 70/10 .................................................................................................. 300583

7 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 8

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7 Connections 300583

Figure 3: EPOS photo with connector description

Figure 4: Wiring diagram (overview)

8 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 9

maxon motor

∆

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.1 Power supply connector (J1)

Any available power supply can be used, provided it meets the

minimal requirements set out below.

During set up and adjustment phases, we recommend separating the

motor mechanically from the machine to prevent damage due to

uncontrolled motion.

Ripple < 10 %

Output current Depending on load,

Power supply requirements

Output voltage VCC min. 11 VDC; VCC max. 70 VDC

continuous min. 10 A

acceleration, short-time min. 25 A

The required voltage can be calculated as follows:

Known values:

• Operating torque M

• Operating speed n

• Nominal motor voltage U

• Motor no-load speed at U

• Speed/torque gradient of the motor ∆n/∆M [min

[mNm]

B

[min-1]

B

[Volt]

N

, n0 [min-1]

N

-1

mNm-1]

Sought value:

• Supply voltage

V

CC

[Volt]

Solution:

V

CC

U

N

n

n

0

n

+⋅=

M

∆

1

)(

BB

9.0

][1

VM

+⋅⋅

Choose a power supply capable of supplying this calculated voltage

under load. The formula takes a max. PWM cycle of 90 % and

a 1 volts max. voltage drop at EPOS 70/10 into account.

Consider:

During braking of the load, the power supply must be capable of

buffering the fed back energy, e.g. in a capacitor or shunt regulator

(235811).

When using an electronically stabilized power supply observe that the

over current protection shall not be activated in any operating state

Figure 5: Power connector (J1)

Pin

Signal Description

No.

1 Power_Gnd Ground of supply voltage

2 +VCC Power supply voltage

+11 ... +70 VDC

Accessories: EPOS power cable maxon order number: 275829

Notes: Suitable connector: Molex Mini-Fit Jr.

Suitable crimp terminals: Molex Mini-Fit Jr.

TM

2 poles (39-01-2020)

TM

female crimp

terminals (444-76-1111)

Suitable hand crimper: Molex hand crimper (69008-0724)

9 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 10

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.2 Logic supply connector (J1A)

Optionally, the logic supply voltage can be sourced separately.

This allows a safe and economical power backup feature.

In case no separate Logic supply is applied, the Logic supply will be

sourced by the Power supply voltage automatically.

Any available power supply can be used, provided it meets the

minimal requirements set out below.

Ripple < 10 %

Logic supply requirements

Output voltage VCC min. 11 VDC; VCC max. 70 VDC

Min. Output power PCC min. 5W

Figure 6: Logic supply connector (J1A)

Pin

Signal Description

No.

1 Power_Gnd Ground of supply voltage

2 +VC Logic supply voltage

+11 ... +70 VDC

Accessories: EPOS power cable maxon order number: 275829

Notes: Suitable connector: Molex Mini-Fit Jr.

Suitable crimp terminals: Molex Mini-Fit Jr.

TM

2 poles (39-01-2020)

TM

female crimp

terminals (444-76-1111)

Suitable hand crimper: Molex hand crimper (69008-0724)

10 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 11

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.3 Motor connector (J2)

7.3.1 maxon EC motor

Connect the maxon EC motor (brushless) motor windings on motor

connector (J2).

Figure 7: Motor connector (J2)

Pin

Signal Description

No.

1 Motor winding 1 EC motor: Winding 1

2 Motor winding 2 EC motor: Winding 2

3 Motor winding 3 EC motor: Winding 3

4 Motor shield Cable shield

Accessories: EPOS motor cable maxon order number: 275851

Notes: Suitable connector: Molex Mini-Fit Jr.

(39-01-2040)

Suitable crimp terminals: Molex Mini-Fit Jr.

terminals (444-76-1111)

Suitable hand crimper: Molex hand crimper (69008-0724)

7.3.2 maxon DC motor with separated motor and encoder cable

Connect the maxon DC motor (brush) on motor connector (J2).

Figure 8: Motor connector (J2)

TM

4 poles

TM

female crimp

11 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Pin

Signal Description

No.

1 Motor (+M) DC motor: Motor +

2 Motor (-M) DC motor: Motor 3 Do not connect Do not connect

4 Motor shield Cable shield

Accessories: EPOS motor cable maxon order number: 275851

Notes: Suitable connector: Molex Mini-Fit Jr.

(39-01-2040)

Suitable crimp terminals: Molex Mini-Fit Jr.

TM

4 poles

TM

female crimp

terminals (444-76-1111)

Suitable hand crimper: Molex hand crimper (69008-0724)

Page 12

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.4 Hall sensor connector (J3)

Hall sensors are needed for detecting rotor position of maxon EC

motors (brushless).

Suitable for Hall Effect sensors IC using Schmitt-trigger with open

collector output.

Hall sensor supply voltage +5 VDC

Input voltage 0…+10 VDC

Logic 1 typical > 2.4 VDC

Max. Hall sensor supply current 30 mA

Logic 0 typical < 0.8 VDC

Internal pull-up resistor

2.7 kΩ (against +5 VDC)

Figure 9: Hall sensor input circuit

Figure 10: Hall sensor connector (J3)

Pin

Signal Description

No.

1 Hall sensor 1 Hall sensor 1 Input

2 Hall sensor 2 Hall sensor 2 Input

3 Hall sensor 3 Hall sensor 3 Input

4 GND Ground of Hall sensor supply

5 +V

Hall sensor supply voltage

Hall

+5 VDC / 30 mA

6 Hall shield Cable shield

Accessories: EPOS Hall sensor cable maxon order number: 275878

Notes: Suitable connector: Molex Micro-Fit 3.0

(430-25-0600)

Suitable crimp terminals: Molex Micro-Fit 3.0

TM

6 poles

TM

female crimp

terminals (430-30-0010)

Suitable hand crimper: Molex hand crimper (69008-0983)

12 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 13

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.5 Encoder connector (J4)

It is necessary that an encoder with a built-in line driver is used

(3-channel recommended).

The standard encoder adjustment (original packing) refers to a

500-count per turn encoder. For other encoders the adjustment must

be modified with the software.

Max. encoder supply current 100 mA

Line receiver (internal) EIA standard RS-422

Encoder supply voltage +5 VDC

Min. differential Input voltage ± 200 mV

Max. encoder input frequency 1 MHz

1 n.c. Not connected

2 +5 VDC / 100 mA Encoder supply voltage

3 GND Ground

4 n.c. Not connected

5 Channel A\ Channel A complement

6 Channel A Channel A

7 Channel B\ Channel B complement

8 Channel B Channel B

9 Channel I\ Index complement

10 Channel I Index

Accessories: EPOS encoder cable maxon order number: 275934

Notes: Suitable connector: DIN 41651 Plug, pitch 2.54 mm,

Figure 11: Encoder input circuit sketch

Figure 12: Encoder connector (J4)

Pin

No.

Encoder pin out suits for example to:

- maxon digital MR-Encoder type ML, L all with Line Driver

- maxon digital encoder HEDL 55__ with Line Driver RS 422

Signal Description

10 poles, plug strain relief

13 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 14

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.6 Signal 1 connector (J5)

Signal connector contains smart multi-purpose digital I/O’s

configurable as: “Positive- and Negative Limit Switches”, “Home

Switch” and “Brake Output”.

Additionally “General Purpose” digital I/O’s are provided.

1 IN_COM 2 Common signal 2 for DigIN 4…6

2 IN_COM 1 Common signal 1 for DigIN 1…3

3 DigIN 6 Digital input 6 “Negative Limit Switch”

4 DigIN 5 Digital input 5 “Positive Limit Switch”

5 DigIN 4 Digital input 4 “Home Switch”

6 DigIN 3 Digital input 3 “General Purpose”

7 DigIN 2 Digital input 2 “General Purpose”

8 DigIN 1 Digital input 1 “General Purpose”

9 +V Opto IN External supply Input voltage for

10 DigOUT 4 Digital output 4 “Brake”

11 DigOUT 3 Digital output 3 “General Purpose”

12 DigOUT 2 Digital output 2 “General Purpose”

13 DigOUT 1 Digital output 1 “General Purpose”

14 DigOUT_Gnd Digital OUT Ground

15 n.c. Not connected

16 n.c. Not connected

Accessories: EPOS signal cable maxon order number: 275932

Notes: Suitable connector: Molex Micro-Fit 3.0

Suitable crimp terminals: Molex Micro-Fit 3.0

Suitable hand crimper: Molex hand crimper (69008-0983)

Figure 13: Signal connector (J5)

Pin

Signal Description

No.

Digital Outputs (+12 … 24VDC)

referred to “+V Opto IN”

TM

16 poles

(430-25-1600)

TM

female crimp

terminals (430-30-0010)

14 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 15

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.6.1 Digital input 1, 2, 3 “General Purpose“

These opto-isolated inputs are defined as “General Purpose” by

default and can be configured via software setting.

Digital input 2 [DigIN2] Connector [J5] Pin number [7]

Common signal [IN_COM1] Connector [J5] Pin number [2]

Type of Input

Max. input voltage ± 30 VDC

Logic 1

Digital input 1 [DigIN1] Connector [J5] Pin number [8]

Digital input 3 [DigIN3] Connector [J5] Pin number [6]

Optical isolated

Single ended, Bipolar

Input voltage ±24 VDC

Logic 0

| Iin | < 1 mA

| Uin | < 5 VDC

| > 3 mA

| I

in

| U

| > 9 VDC

in

Input current at logic 1 typical 13.2 mA

Figure 14: Logic level

Input resistance

Switching delay

typical 1.8 kΩ

@ 24 VDC

< 300 µs @ 24 VDC

15 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Figure 15: Digital input 1..3

Page 16

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.6.2 Digital input 4, 5, 6 "Home Switch", "Positive and Negative Limit Switch"

These opto-isolated inputs are defined as:

Digital input 4: “Home Switch”

Digital input 5: “Positive Limit Switch“

Digital input 6: “Negative Limit Switch“

by default and can be configured via software setting.

Digital input 5 [DigIN5] Connector [J5] Pin number [4]

Common signal [IN_COM2] Connector [J5] Pin number [1]

Type of Input

Max. input voltage ± 30 VDC

Logic 1

Digital input 4 [DigIN4] Connector [J5] Pin number [5]

Digital input 6 [DigIN6] Connector [J5] Pin number [3]

Optical isolated

Single ended, Bipolar

Input voltage ±24 VDC

Logic 0

| Iin | < 1 mA

| Uin | < 5 VDC

| > 3 mA

| I

in

| > 9 VDC

| U

in

Input current at logic 1 typical 13.2 mA

Figure 16: Logic level

Input resistance

Switching delay

typical 1.8 kΩ

@ 24 VDC

< 300 µs @ 24 VDC

16 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Figure 17: Digital input 4…6

Page 17

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

Wiring examples:

Different types of proximity switches

Figure 18: Digital input 4,5, external wiring examples

6

Notes:

• Use of 3-wire PNP proximity switches is preferred.

• Use of 3-wire NPN proximity switches needs an additional

external pull-up resistor

(12V) = 560 Ω (300mW)

R

ext

(24V) = 3 kΩ (200mW)

R

ext

• Use of 2-wire proximity switches is possible.

17 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 18

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.6.3 “+V Opto IN” external supply Input voltage for Digital Outputs

An external supply voltage has to be applied for supplying the EPOS

70/10 digital optical-isolated outputs.

Digital OUT Ground [DigOUT_Gnd] Connector [J5] Pin number [14]

Supply voltage +12…+24 VDC

+V Opto IN [+V Opto IN] Connector [J5] Pin number [9]

Any available power supply can be used, provided it meets the

minimal requirements set below.

Min. current 560 mA

18 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 19

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.6.4 Digital output 1, 2, 3 “General Purpose“

These opto-isolated outputs are defined as “General Purpose” by

default and can be configured via software setting.

Digital output 2 [DigOUT2] Connector [J5] Pin number [12]

+V Opto IN [+V Opto IN] Connector [J5] Pin number [9]

Output voltage

Leakage current

Digital output 1 [DigOUT1] Connector [J5] Pin number [13]

Digital output 3 [DigOUT3] Connector [J5] Pin number [11]

Type of Output

Max. load current

Optical isolated

Open-Emitter

≥ + V Opto IN – 3V

U

out

I

≤ 20 mA

load

≤ 20 µA

I

leak

Switching delay < 500 µs @ 24 VDC

Figure 19: Digital output 1, 2, 3 circuit

19 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 20

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.6.5 Digital output 4 "Brake"

Apply permanent magnet brake for DC voltage.

+V Opto IN [+V Opto IN] Connector [J5] Pin number [9]

Output voltage

Leakage current

Max. inductive load 2 H @ 24VDC; 500mA

Digital output 4 [DigOUT4] Connector [J5] Pin number [10]

Digital OUT Ground [DigOUT_Gnd] Connector [J5] Pin number [14]

Type of Output

Max. load current

Optical isolated

Open-Emitter

≥ +V Opto IN – 1V

U

out

I

≤ 500 mA

load

≤ 50 µA

I

leak

Switching delay < 300 µs @ 24 VDC

Wiring example:

Permanent magnet brake

20 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 21

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.7 Signal 2 connector (J5A)

Signal 2 connector contains differential “High Speed Command” digital

I/O’s and additionally differential analogue inputs are provided.

1 +5VOUT Reference Output voltage +5V

2 A_Gnd Analogue signal ground

3 AnIN2 - Negative analogue signal input 2

4 AnIN2 + Positive analogue signal input 2

5 AnIN1 - Negative analogue signal input 1

6 AnIN1 + Positive analogue signal input 1

7 D_Gnd Digital signal ground

8 D_Gnd Digital signal ground

9 DigIN 8/ Digital input 8 “High Speed

10 DigIN 8 Digital input 8 “High Speed

11 DigIN 7/ Digital input 7 “High Speed

12 DigIN 7 Digital input 7 “High Speed

Accessories: EPOS signal 2 cable maxon order number: 300586

Notes: Suitable connector: Molex Micro-Fit 3.0

Suitable crimp terminals: Molex Micro-Fit 3.0

Suitable hand crimper: Molex hand crimper (69008-0983)

Figure 20: Signal connector (J5A)

Pin

Signal Description

No.

Command” complement signal

Command”

Command” complement signal

Command” complement signal

TM

12 poles

(430-25-1200)

TM

female crimp

terminals (430-30-0010)

21 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 22

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.7.1 Reference Output voltage

Reference Output voltage can be used as supply voltage for external

loads connected to EPOS 70/10 analogue inputs.

Output voltage +5 VDC

Connector No. and Pin No. Connector [J5A] Pin number [1]

Output resistance

1.0 kΩ

22 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 23

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.7.2 Analogue input 1 "General Purpose"

“General Purpose” differential analogue input by default. Not

configurable via software setting.

Input voltage range 0 ... 5 VDC (differential)

Common-mode voltage range - 5 ... + 10 VDC (referenced to AGnd)

A/D converter 10-bit

Bandwidth 2 KHz

Connector No. and Pin No.

Max. input voltage - 30 ... + 30 VDC

Input resistance

Resolution 0.005 V

Connector [J5A] Pin number [5]

Connector [J5A] Pin number [6]

30.2 kΩ (differential)

25.1 kΩ (referenced to AGnd)

Figure 21: Analogue input 1 circuit

7.7.3 Analogue input 2 "General Purpose"

“General Purpose” differential analogue input by default. Not

configurable via software setting.

Input voltage range 0 ... 5 VDC (differential)

Common-mode voltage range - 5 ... + 10 VDC (referenced to AGnd)

A/D converter 10-bit

Bandwidth 2 KHz

Connector No. and Pin No.

Max. input voltage - 30 ... + 30 VDC

Input resistance

Resolution 0.005 V

Connector [J5A] Pin number [3]

Connector [J5A] Pin number [4]

30.2 kΩ (differential)

25.1 kΩ (referenced to AGnd)

23 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Figure 22: Analogue input 2 circuit

Page 24

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.7.4 Digital input 7 "High Speed Command"

“High Speed Command” differential input by default and can be

configured via software setting.

Differential

Min. differential input voltage ±200 mV

Max. input frequency 1 MHz

Connector No. and Pin No.

Line receiver (internal) EIA standards RS-422

Connector [J5A] Pin number [11]

Connector [J5A] Pin number [12]

Single-ended DigIN7 Connector No. and Pin No. Connector [J5A] Pin number [12]

Max. input voltage ± 24 VDC

Logic 1 > 3.0 V

Figure 23: Digital input 7 “Differential” circuit

Input voltage 0…5 VDC

Logic 0 < 2.0 V

Input resistance

Figure 24: Digital input 7 “Single-ended” circuit

typical 48 kΩ

(referenced to D_Gnd)

24 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Notes: Connect signal to DigIN7 [J5A/12] and do not connect DigIN7/ [J5A/11]

Page 25

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.7.5 Digital input 8 "High Speed Command"

“High Speed Command” differential input by default and can be

configured via software setting.

Min. differential Input voltage ±200 mV

Max. input frequency 1 MHz

Connector No. and Pin No.

Line receiver (internal) EIA standards RS-422

Connector [J5A] Pin number [9]

Connector [J5A] Pin number [10]

Single-ended DigIN8 Connector No. and Pin No. Connector [J5A] Pin number [10]

Max. input voltage ± 24 VDC

Logic 1 > 3.0 V

Figure 25: Digital input 8 “Differential” circuit

Input voltage 0…5 VDC

Logic 0 < 2.0 V

Input resistance

Figure 26: Digital input 8 “Single-ended” circuit

typical 48 kΩ

(referenced to D_Gnd)

25 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Notes: Connect signal to DigIN8 [J5A/10] and do not connect DigIN8/ [J5A/9]

Page 26

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.8 RS-232 connector (J6)

Output voltage

Internal RS232 driver/receiver EIA RS232 standard

Connection EPOS - PC

Connector J6 pin 4 + 5 “GND” Pin 5 “GND”

Connector J6 pin 2 “EPOS TxD” Pin 2 “PC RxD”

Maximum input voltage

± 30 V

typical ± 9 V

@ 3kΩ to Ground

Maximum bit rate 115 200 bit/s

Note:

• Please consider your PC’s serial port maximal baud rate.

• The standard baud rate setting (factory setting) is 38’400 bauds.

Positioning Controller EPOS 70/10

PC Interface (RS232),

DIN41652

Connector J6 pin 1 “EPOS RxD” Pin 3 “PC TxD”

Figure 27: RS232 cable connector (J6)

Pin

Signal Description

No.

1 EPOS RxD EPOS RS232 receive

2 EPOS TxD EPOS RS232 transmit

3

4 GND RS232_Ground

5 GND RS232_Ground

6 Shield Cable shield

Accessories: EPOS RS232-COM cable maxon order number: 275900

Notes: Suitable connector: Molex Micro-Fit 3.0

(430-25-0600)

Suitable crimp terminals: Molex Micro-Fit 3.0

TM

6 poles

TM

female crimp

terminals (430-30-0010)

Suitable hand crimper: Molex hand crimper (69008-0983)

26 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 27

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.9 CAN connector (J7, J8)

ISO 11898 compatible

Max. number of CAN nodes 127

Identifier setting by DIP-Switch or software

Connection EPOS - CAN

bus line CiA DS-102

Connector J7 (J8) pin 1 “CAN high” Pin 7 “CAN_H” high bus line

Connector J7 (J8) pin 3 “CAN GND” Pin 3 “CAN_GND” Ground

Standard type CAN high-speed

Maximum bit rate 1 MBit/s

Protocol CANopen DS-301 V4.02

Positioning Controller EPOS 70/10

CAN 9 pin D-Sub

(DIN41652)

Connector J7 (J8) pin 2 “CAN low” Pin 2 “CAN_L” low bus line

Connector J7 (J8) pin 4 “CAN shield” Pin 5 “CAN_Shield” Cable

shield

Note:

• Please consider your CAN Master port maximal baud rate.

• The standard baud rate setting (factory setting) is 1 MBit/s.

• Further CAN information may be found in the “Communication

Guide” documentation.

• Use termination resistor on both ends of the CAN bus.

Figure 28: CAN connector (J7,J8)

Pin

Signal Description

No.

1 CAN high CAN high bus line

2 CAN low CAN low bus line

3 CAN GND CAN Ground

4 CAN shield Cable shield

Accessories: EPOS CAN-COM cable maxon order number: 275908

EPOS CAN-CAN cable maxon order number: 275926

EPOS CAN termination plug maxon order number: 275937

Notes: Suitable connector: Molex Micro-Fit 3.0

(430-25-0400)

Suitable crimp terminals: Molex Micro-Fit 3.0

terminals (430-30-0010)

TM

4 poles

TM

female crimp

Suitable hand crimper: Molex hand crimper (69008-0983)

27 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 28

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

7.10 CAN Node Identification (JP 1)

The CAN-ID (node address) is set at DIP-Switch 1 ... 7.

All addresses can be coded from 1 ... 127 using the binary code.

Switch

Binary

Value

1 20 1

2 21 2

3 22 4

4 23 8

5 24 16

6 25 32

7 26 64

Figure 29: Table binary code value

If the value of all switches set at “ON” are added together, this gives

the set CAN-ID (node address).

Examples:

The following table can be used as a guide, but is not comprehensive.

Switch 1 2 3 4 5 6 7

Value 1 2 4 8 16 32 64

CAN-ID Switch setting

Calculation

1

2

32

35

127

1 0 0 0 0 0 0 1

0 1 0 0 0 0 0 2

0 0 0 0 0 1 0 32

1 1 0 0 0 1 0 1 + 2 + 32

1 1 1 1 1 1 1

1 + 2 + 4 + 8 +

16 + 32 + 64

Figure 30: CAN ID examples

Notes:

• The Node ID set by software is valid, if DIP-Switch is set to value

0.

• DIP-Switch 8 has no impact on the CAN-ID.

28 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Page 29

maxon motor

EPOS Positioning Controller EPOS 70/10 Hardware Reference

8 LED status

The green LED shows the operating status and the red LED indicates

an error of the positioning controller EPOS 70/10. Detailed information

may be found in the Firmware Specification document.

Red LED Green LED Description

OFF Slow blinking

(≈ 1Hz)

OFF

ON

ON ON

ON

ON

OFF The EPOS is in state

Flashing There is no valid firmware on the

The EPOS is in state:

Switch ON Disabled

Ready to Switch ON

Switched ON

-

The power stage is disabled

The EPOS is in state:

- Operation Enable

- Quick St p Active

The power stage is enabled

- Fault

The EPOS is in temporary state

- Fault Reaction Active

The power stage is enabled

EPOS (due to a failed firmware

download)

o

9 Dimension drawing

Dimensions in [mm]

Figure 31: Dimensions EPOS 70/10

29 maxon motor control December 2008 Edition / document number 752380-04 / subject to change

Loading...

Loading...