Page 1

maxon motor control

EPOS2 Positioning Controller

Hardware Reference

Edition May 2017

Positioning Controller

Hardware Reference

Document ID: rel7050

maxon motor ag Brünigstrasse 220 P.O.Box 263 CH-6072 Sachseln Phone +41 41 666 15 00 Fax +41 41 666 16 50 www.maxonmotor.com

Page 2

PLEASE READ THIS FIRST

These instructions are intended for qualified technical per sonnel. Prior commencing with any

activities …

• you must carefully read and understand this manual and

• you must follow the instructions given therein.

We have tried to provide you with all information necessary to install and commission the equipment in a

secure, safe and time-saving manner. Our main focus is …

• to familiarize you with all relevant technical aspects,

• to let you know the easiest way of doing,

• to alert you of any possibly dangerous situation you might encounter or that you might cause if

you do not follow the description,

•to write as little and to say as much as possible and

• not to bore you with things you already know.

Likewise, we tried to skip repetitive information! Thus, you will find things mentioned just once. If, for

example, an earlier mentioned action fits other occasions you then will be directed to that text passage

with a respective reference.

Follow any stated reference – observe respective information – the n go back and continue with

the task!

PREREQUISITES FOR PERMISSION TO COMMENCE INSTALLATION

The EPOS2 Module 36/2 is considered as partly completed machinery according to EU directive 2006/

42/EC, Article 2, Clause (g) and therefore is intended to be incorporated into or assembled with

other machinery or other partly completed machinery or equipment.

You must not put the device into service, …

• unless you have made completely sure that the other machinery – the surrounding system the device

is intended to be incorporated to – fully complies with the requirements stated in EU directive 2006/

42/EC!

• unless the surrounding system fulfills all relevant health and safety aspects!

• unless all respective interfaces have been established and fulfill the stated requirements!

maxon motor control

A-2 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 3

TABLE OF CONTENTS

1 About this Document 5

2 Introduction 9

2.1 Documentation Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Technical Data 11

3.1 Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Mechanical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.5 Order Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.6 Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Connections 17

4.1 Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Minimum external Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3 Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3.1 Determination of Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3.2 Use of separate Logic Supply (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3.3 Low Supply Voltage Operation (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4 Motor Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4.1 maxon EC motor (brushless) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4.2 maxon DC motor (brushed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.5 Hall Sensor Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.6 Encoder Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.7 Digital Input Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.7.1 Digital Inputs 1, 2, 3 and 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.7.2 Digital Inputs 7 and 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.8 Analog Input Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.8.1 Analog Inputs 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.9 Digital Output Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.9.1 Digital Outputs 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.9.2 Digital Output 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.10 RS232 Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.11 SCI Interface Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.12 CAN Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.13 CAN Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.13.1 CAN ID (Node Address). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.13.2 CAN automatic Bit Rate Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.14 Status LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

A-3

Page 4

5 Motherboard Design Guide 37

5.1 Requirements for external Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1.1 Card Edge Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1.2 Power Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1.3 Logic Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.1.4 Motor Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.1.5 Supplier Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.1.6 USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2 Design Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.2.1 Ground. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.2.2 Communication Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.2.3 I/Os . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.2.4 Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.3 Schematic Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.3.1 Minimum External Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.3.2 Separate Logic Supply Voltage and CAN Communication . . . . . . . . . . . . . . . . . . . . . . 42

5.3.3 USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.3.4 Wiring Example: Low Supply Voltage Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.3.5 Wiring Example: Two Axes with RS232 to CAN Gateway. . . . . . . . . . . . . . . . . . . . . . . 45

maxon motor control

A-4 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 5

1 About this Document

1.1 Intended Purpose

The purpose of the present document is to familiarize you with the described equipment and the tasks

on safe and adequate installation and/or commissioning.

Observing the described instructions in this document will help you …

• to avoid dangerous situations,

• to keep installation and/or commissioning time at a minimum and

• to increase reliability and service life of the described equipment.

Use for other and/or additional purposes is not permitted. maxon motor, the manufacturer of the equipment described, does not assume any liability for loss or damage that may arise from any other and/or

additional use than the intended purpose.

1.2 Target Audience

This document is meant for trained and skilled personnel working with the equipment described. It conveys information on how to understand and fulfill the respective work and duties.

This document is a reference book. It does require particular knowledge and expertise specific to the

equipment described.

1.3 How to use

Take note of the following notations and codes which will be used throughout the document.

Notation Explanation

(n) referring to an item (such as order number, list item, etc.)

denotes “see”, “see also”, “take note of” or “go to”

Table 1-1 Notations used in this Document

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

1-5

Page 6

About this Document

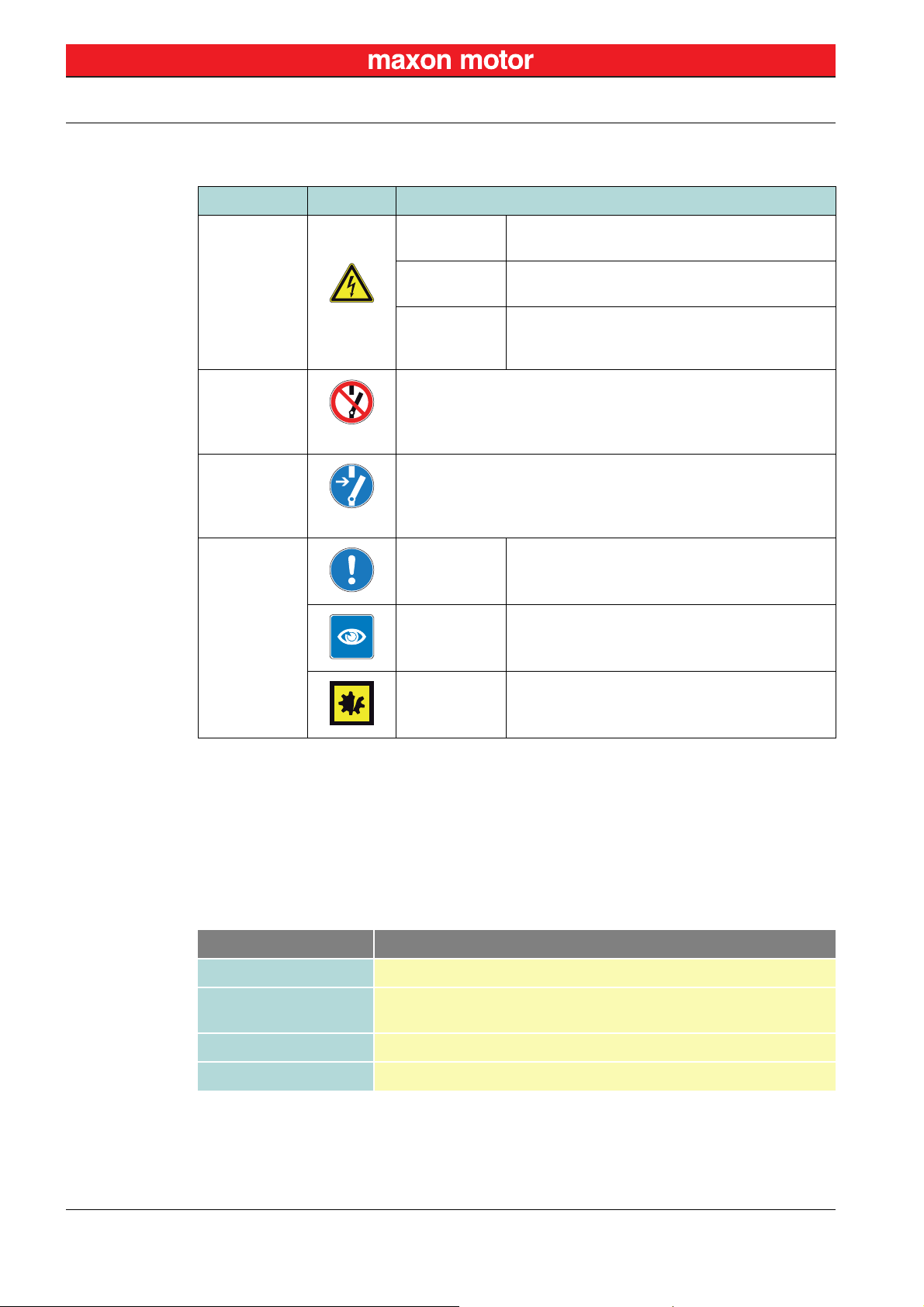

1.4 Symbols and Signs

In the course of the present document, the following symbols and sings will be used.

Type Symbol Meaning

Safety Alert

Prohibited

Action

Mandatory

Action

Information

(typical)

(typical)

(typical)

DANGER

WARNING

CAUTION

Indicates a dangerous action. Hence, you must not!

Indicates a mandatory action. Hence, you must!

Requirement /

Note / Remark

Best Practice

Indicates an imminent hazardous situation. If not

avoided, it will result in death or serious in jury.

Indicates a potential hazardous situation. If not

avoided, it can result in death or serious injury.

Indicates a probable hazardous situation or calls

the attention to unsafe practices. If not avoided, it

may result in injury.

Indicates an activity you must perform prior

continuing, or gives information on a particular item

you need to observe.

Indicates an advice or recommendation on the

easiest and best way to further proceed.

Table 1-2 Symbols & Signs

1.5 Trademarks and Brand Names

For easier legibility, registered brand names are listed below and will not be further tagged with their

respective trademark. It must be understood that the brands (the below list is not necessarily concluding) are protected by copyright and/or other intellectual property rights even if their legal trademarks are

omitted in the later course of this document.

The brand name(s) … … is/are a registered trademark(s) of …

Adobe® Reader® © Adobe Systems Incorporated, USA-San Jose, CA

OMNI-BLOK®

SMD NANO2®

Pentium® © Intel Corporation, USA-Santa Clara, CA

Windows® © Microsoft Corporation, USA-Redmond, WA

Table 1-3 Brand Names and Trademark Owners

Material

Damage

© Littelfuse, USA-Chicago, IL

Indicates information particular to possible damage

of the equipment.

maxon motor control

1-6 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 7

1.6 Copyright

© 2017 maxon motor. All rights reserved.

The present document – including all parts thereof – is protected by copyright. Any use (including reproduction, translation, microfilming and other means of electronic data processing) beyond the narrow

restrictions of the copyright law without the prior approval of maxon motor ag, is not permitted and subject to persecution under the applicable law.

maxon motor ag

Brünigstrasse 220

P.O.Box 263

CH-6072 Sachseln

Switzerland

Phone +41 41 666 15 00

Fax +41 41 666 16 50

www.maxonmotor.com

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

1-7

Page 8

About this Document

••page intentionally left blank••

maxon motor control

1-8 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 9

2Introduction

The present document provides you with information on the EPOS2 Module 36/2 Positioning Controller’s hardware. It contains…

• performance data and specifications,

• information on connections and pin assignment and

• wiring examples.

maxon motor control’s EPOS2 Module 36/2 is a small-sized, full digital, smart motion controller. It is designated for the use as plug-in module in customer-specific motherboards for single axis or multi axes

motion control systems. Due to its flexible and high efficient power stage, the EPOS2 Module 36/2

drives brushed DC motors with digital encoder as well as brushless EC motors with digital Hall sensors

and encoder.

The sinusoidal current commutation by space vector control offers the possibility to drive brushless EC

motors with minimal torque ripple and low noise. The integrated position, velocity and current control

functionality allows sophisticated positioning applications. The EPOS2 Module 36/2 is especially

designed being commanded and controlled as a slave node in a CANopen network. In addition, the unit

can be operated via any USB (external transceiver necessary) or RS232 interface.

Find the latest edition of the present document, as well as additional documentation and software to the

EPOS2 Module 36/2 Positioning Controller also on the Internet: www.maxonmotor.com

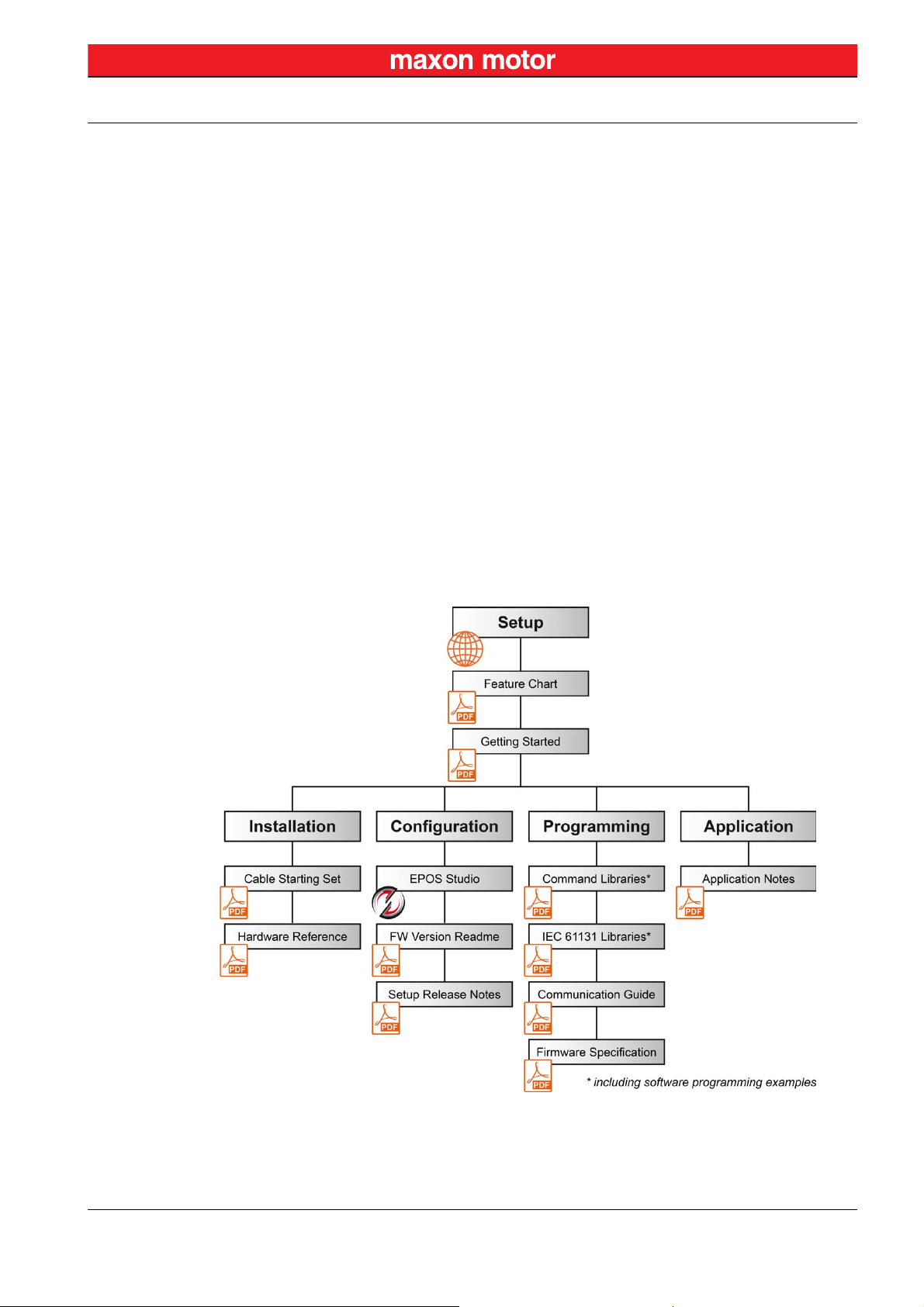

2.1 Documentation Structure

The present document is part of a documentation set. Please find below an overview on the documentation hierarchy and the interrelationship of its individual parts:

Figure 2-1 Documentation Structure

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

2-9

Page 10

Introduction

Safety Precautions

2.2 Safety Precautions

Prior continuing …

• make sure you have read and understood chapter “ PLEASE READ THIS FIRST” on page A-2,

• do not engage with any work unless you possess the stated skills (chapter “1.2 Target Audience” on page 1-5),

• refer to chapter “1.4 Symbols and Signs” on page 1-6 to understand the subsequently used

indicators,

• you must observe any regulation applicable in the country and/or at the site of implementation

with regard to health and safety/accident prevention and/or environmental protection,

• take note of the subsequently used indicators and follow them at all times.

DANGER

High Voltage and/or Electrical Shock

Touching live wires causes death or serious injuries!

• Consider any power cable as connected to live power, unless having proven the opposite!

• Make sure that neither end of cable is connected to live power!

• Make sure that power source cannot be engaged while work is in process!

• Obey lock-out/tag-out procedures!

• Make sure to securely lock any power engaging equipment against unintentional engagement and

tag with your name!

Requirements

• Make sure that all associated devices and components are installed according to local regulations.

• Be aware that, by principle, an electronic apparatus can not be considered fail-safe. Therefore, you

must make sure that any machine/apparatus has been fitted with independent monitoring and safety

equipment. If the machine/apparatus should break down, if it is operated incorrectly, if the control unit

breaks down or if the cables break or get disconnected, etc., the complete drive system must return –

and be kept – in a safe operating mode.

• Be aware that you are not entitled to perform any repair on components supplied by maxon motor.

Best Practice

• For initial operation, make sure that the motor is free running. If not the case, mechanically disconnect the motor from the load.

Maximal permitted Supply Voltage

• Make sure that supply power is between 11…36 VDC.

• Supply voltages above 40 VDC will destroy the unit.

• Wrong polarity will destroy the unit.

Electrostatic Sensitive Device (ESD)

• Make sure to wear working cloth in compliance with ESD.

• Handle device with extra care.

Hot plugging the USB interface may cause hardware damage

If the USB interface is being hot-plugged (connecting while the power supply is on), the possibly high

potential differences of the two power supplies of controller and PC/Notebook can lead to damaged

hardware.

• Avoid potential differences between the power supply of controller and PC/Notebook or, if possible,

balance them.

• Insert the USB connector first, then switch on the power supply of the controller.

maxon motor control

2-10 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 11

3Technical Data

3.1 Electrical Data

Rating

Nominal power supply voltage V

Nominal logic supply voltage VC (optional)

Absolute minimum supply voltage 10 VDC

Absolute max. supply voltage 40 VDC

Max. output voltage

Max. output current I

Continuous output current I

Switching frequency 50 kHz

Max. efficiency 93%

Sample rate PI – current controller 10 kHz

Sample rate PI – speed controller 1 kHz

Sample rate PID – positioning controller 1 kHz

Max. speed @ sinusoidal commutation (motors with 1 pole pair) 25 000 rpm

Max. speed @ block commutation (motors with 1 pole pair) 100 000 rpm

Built-in motor choke per phase 10 μH / 2 A

Table 3-4 Electrical Data – Rating

max

(<1sec)

cont

CC

11…36 VDC

11…36 VDC

0.9 • V

CC

4 A

2 A

Inputs

Hall sensor 1, Hall sensor 2 and Hall sensor 3

Hall sensor signals

Encoder signals

Digital Input 1 (“General Purpose”) +3…+36 VDC (Ri = 12 kΩ)

Digital Input 2 (“General Purpose”) +3…+36 VDC (Ri = 12 kΩ)

Digital Input 3 (“General Purpose”) +3…+36 VDC (Ri = 12 kΩ)

Digital Input 4 (“General Purpose”) +3…+36 VDC (Ri = 12 kΩ)

Digital Input 7 (“High Speed Command”) internal line receiver EIA RS422 Standard

Digital Input 8 (“High Speed Command”) internal line receiver EIA RS422 Standard

Analog Input 1 resolution 11-bit 0…+5 V (Ri = 34 kΩ)

Analog Input 2 resolution 11-bit 0…+5 V (Ri = 34 kΩ)

CAN ID (CAN identification) ID 1…127 configurable by external wiring

for Hall effect sensor ICs (Schmitt trigger with

open collector output)

A, A\, B, B\, I, I\ (max. 5 MHz)

internal line receiver EIA RS422 Standard

Table 3-5 Electrical Data – Inputs

Outputs

Digital Output 1 (“General Purpose”), open collector

Digital Output 2 (“General Purpose”), open collector

Digital Output 5 (“High Speed Command”), push-pull

max. 36 VDC (IL <50 mA)

max. 36 VDC (IL <50 mA)

max. 3.3 VDC (IL <10 mA)

Table 3-6 Electrical Data – Outputs

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

3-11

Page 12

Technical Data

Mechanical Data

Voltage Outputs

Encoder supply voltage

Hall sensors supply voltage

+5 VDC (IL <100 mA)

+5 VDC (IL <30 mA)

Table 3-7 Electrical Data – Voltage Outputs

Motor Connections

maxon EC motor maxon DC motor

Motor winding 1 + Motor

Motor winding 2 − Motor

Motor winding 3

Table 3-8 Electrical Data – Motor Connections

Interfaces

RS232 RxD; TxD max. 115 200 bit/s

USB 2.0 /

USB 3.0

CAN CAN_H (high); CAN_L (low) max.1 Mbit/s

external transceiver necessary

Table 3-9 Electrical Data – Interfaces

Status Indicators

Operation green LED

Error red LED

Table 3-10 Electrical Data – LEDs

Connections

On board:

Suitable plug:

Suitable retainer:

Table 3-11 Electrical Data – Connections

3.2 Mechanical Data

Mechanical Data

Weight approx. 10 g

Dimensions (L x W x H) 54.5 x 28.2 x 9 mm

Mounting

Card edge connector

PCI Express (PCIe) Connector 2x32 Pin vertical or horizontal, 1 mm pitch

Tyco 2-1775801-1 (vertical) / Tyco 1761465-2 (horizontal)

FCI 10018783-11111TLF (vertical)

Meritec 983172-064-2MMF (horizontal)

FCI PCI express retainer, blue, 10042618-002LF

pluggable card edge connector

with optional PCB support brackets

Table 3-12 Mechanical Data

maxon motor control

3-12 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 13

3.3 Dimensional Drawings

VERTICAL CONNECTOR

Figure 3-2 Dimensional Drawing (with vertical Connector) [mm]

H

ORIZONTAL CONNECTOR

Figure 3-3 Dimensional Drawing (with horizontal connector Meritec 983172-064-2MMF) [mm]

ETAINER

R

Figure 3-4 Footprint of Retainer (Meritec 983172-064-2MMF connector) [mm]

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

3-13

Page 14

Technical Data

Environmental Conditions

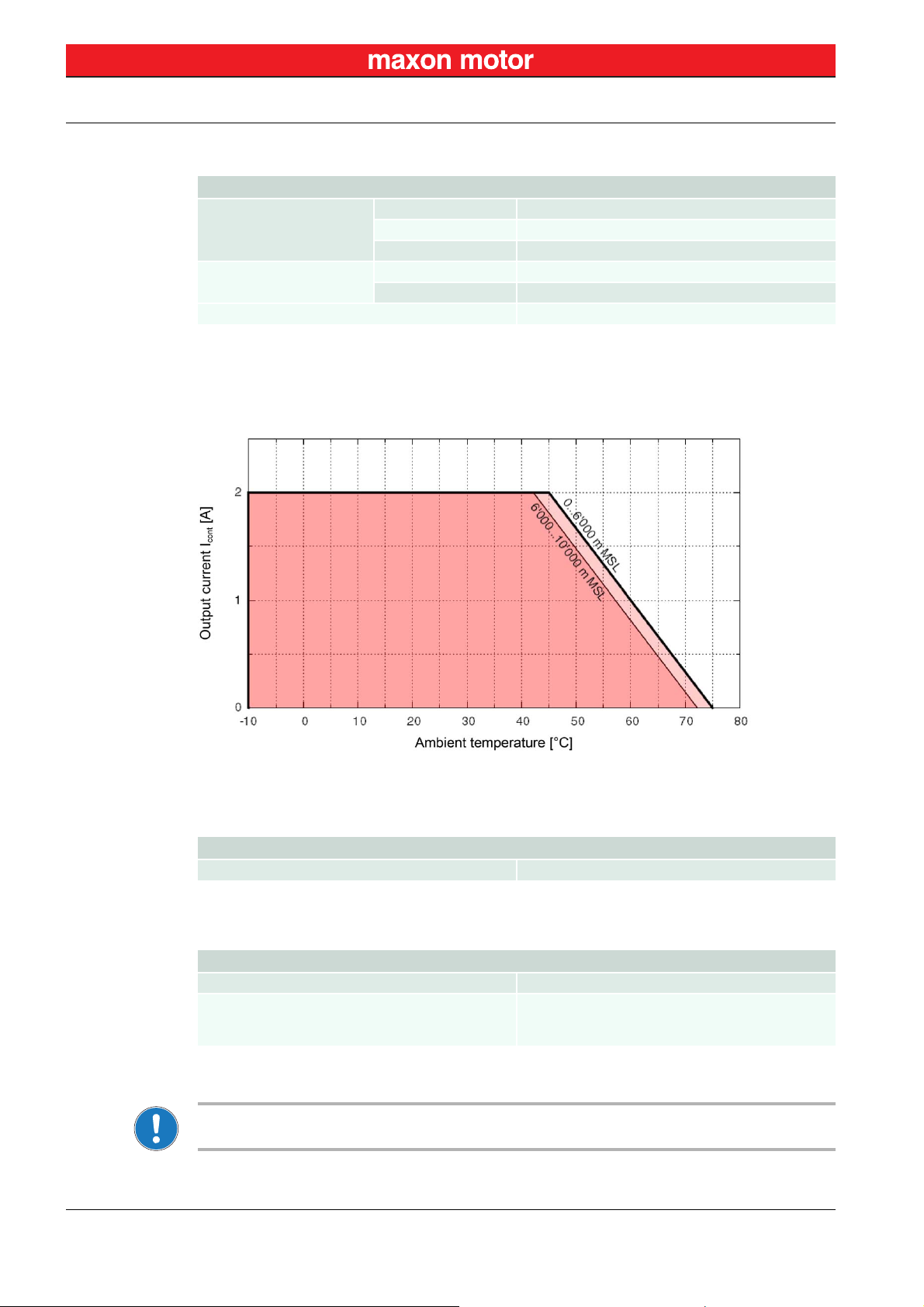

3.4 Environmental Conditions

Environmental Condition

Temperature

*2)

Altitude

Humidity 5…90% (condensation not permitted)

*1) Operation within the extended range (temperature and altitude) is permitted. However, a respective derating

*2) Operating altitude in meters above Mean Sea Level, MSL.

Table 3-13 Environmental Conditions

(declination of output current I

Operation −10…+45 °C

Extended Range

Storage −40…+85 °C

Operation 0…6’000 m MSL

Extended Range

) as to the stated values will apply.

cont

*1)

*1)

+45…+75 °C / Derating: Figure 3-5

6’000…10’000 m MSL / Derating: Figure 3-5

Figure 3-5 Derating Output Current

3.5 Order Details

Order Details

EPOS2 Module 36/2 Order number 360665

Table 3-14 Order Details

Accessories

EPOS2 Module Evaluation Board Order number 361435

EPOS2 Module Starter Kit

(including EPOS2 Module 36/2, EPOS2 Module

Evaluation Board and necessary cables)

Table 3-15 Accessories

Note

Accessories are not part of the delivery. You will need to order them separately.

Order number 363407

maxon motor control

3-14 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 15

3.6 Standards

The described device has been successfully tested for compliance with the below listed standards. In

practical terms, only the complete system (the fully operational equipment comprising all individual components, such as motor, servo controller, power supply unit, EMC filter, cabling etc.) can undergo an

EMC test to ensure interference-free operation.

Important Notice

The device’s compliance with the mentioned standards does not imply its compliance within the final,

ready to operate setup. In order to achieve compliance of your operational system, you must perform

EMC testing of the involved equipment as a whole.

Generic Standards

Electromagnetic Compatibility

IEC/EN 61000-6-2 Immunity for industrial environments

IEC/EN 61000-6-3

Emission standard for residential, commercial and lightindustrial environments

IEC/EN 61000-6-3

IEC/EN 55022

Radio disturbance characteristics / radio interference

(CISPR22)

IEC/EN 61000-4-3

Applied Standards

Radiated, radio-frequency, electromagnetic field immunity

test >10 V/m

IEC/EN 61000-4-4 Electrical fast transient/burst immunity test ±1 kV/±2 kV

IEC/EN 61000-4-6

Immunity to conducted disturbances, induced by radiofrequency fields 10 Vrms

IEC/EN 61000-4-8 Power frequency magnetic field 30 A/m

Others

Environmental

IEC/EN 60068-2-6

Environmental testing – Test Fc: Vibration (sinusoidal,

2

10…500 Hz, 20 m/s

)

Standards

MIL-STD-810F

Random transport (10…500 Hz up to 1.05 g

rms

)

Safety Standards UL File Number E172472 or E92481; unassembled printed circuit board

Reliability prediction of electronic equipment

Environment: Ground, benign

Reliability MIL-HDBK-217F

Ambient temperature: 298 K (25 °C)

Component stress: In accordance with circuit diagram and

nominal power

Mean Time Between Failures (MTBF): 610'435 hours

Table 3-16 Standards

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

3-15

Page 16

Technical Data

Standards

••page intentionally left blank••

maxon motor control

3-16 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 17

4 Connections

Figure 4-6 EPOS2 Module 36/2 – PCB with Connector Array

4.1 Pin Assignment

ARRAY A

Pin Signal Description

A1 Power_GND Ground of supply voltage

A2

A4

A5

A6 Power_GND Ground of supply voltage

A7 Hall sensor 1 Hall sensor 1 input

A8 Hall sensor 2 Hall sensor 2 input

A9 Hall sensor 3 Hall sensor 3 input

A10

A11 GND

A12 Channel A Encoder channel A

A13 Channel A\ Encoder channel A complement

A14 Channel B Encoder channel B

A15 Channel B\ Encoder channel B complement

A16 Channel I Encoder index

A17 Channel I\ Encoder index complement

A18 GND Ground of analog inputs

A19 AnIN1 Analog Input 1

A20 AnIN2 Analog Input 2

A21 GND Ground of digital output

A22 DigOUT5 Digital Output 5

A23 not connected

A24 EPOS SCI RTS Serial communication interface handshake

A25 EPOS SCI RxD Serial communication interface receive

A26 EPOS SCI TxD Serial communication interface transmit

A27 EPOS RxD EPOS RS232 receive

A28 EPOS TxD EPOS RS232 transmit

A29 GND Ground of SCI and RS232

V

V

V

V

+V

+V

CC

CC

CC

C

aux

DDin

Power supply voltage +0…+36 VDCA3

Logic supply voltage 11…36 VDC (optional)

Auxiliary voltage output +5 VDC

Auxiliary supply voltage input +5 VDC (optional)

Ground of Hall sensor supply and

Ground of encoder supply

*1)

*1)

*1)

*2)

*2)

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

4-17

Page 18

Connections

Pin Assignment

Pin Signal Description

A30 CAN low CAN low bus line

A31 CAN high CAN high bus line

A32 GND Ground of CAN bus

Note

*1) Voltage level “low” = 0V, “high” = 3.3V, connected directly to the DSP

*2) EIA RS232 Standard

Table 4-17 EPOS2 Module 36/2 – Pin Assignment Array A

RRAY B

A

Pin Signal Description

B1 Power_GND Ground of supply voltage

B2

B3

B4

B5

B6

B7

B8

B9

B10

EC: Motor winding 1

DC: Motor +

EC: Motor winding 1

DC: Motor +

EC: Motor winding 1

DC: Motor +

EC: Motor winding 2

DC: Motor −

EC: Motor winding 2

DC: Motor −

EC: Motor winding 2

DC: Motor −

EC: Motor winding 3

DC: not connected

EC: Motor winding 3

DC: not connected

EC: Motor winding 3

DC: not connected

EC motor: Motor winding 1

DC motor: Motor +

EC motor: Motor winding 2

DC motor: Motor −

EC motor: Motor winding 3

DC motor: not connected

B11 Power_GND Ground of supply voltage

B12 GND Ground of digital input

B13 DigIN1 Digital Input 1

B14 DigIN2 Digital Input 2

B15 DigIN3 Digital Input 3

B16 DigIN4 Digital Input 4

B17 GND Ground of digital input

B18 DigIN7 Digital Input 7 “High Speed Command”

B19 DigIN7\ Digital Input 7 “High Speed Command” complement

B20 DigIN8 Digital Input 8 “High Speed Command”

B21 DigIN8\ Digital Input 8 “High Speed Command” complement

B22 DigOUT1 Digital Output 1

B23 DigOUT2 Digital Output 2

B24 GND Ground of CAN ID setting

B25 CAN ID 1 CAN ID 1 (valence = 1)

B26 CAN ID 2 CAN ID 2 (valence = 2)

maxon motor control

4-18 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 19

Pin Signal Description

B27 CAN ID 3 CAN ID 3 (valence = 4)

B28 CAN ID 4 CAN ID 4 (valence = 8)

B29 CAN ID 5 CAN ID 5 (valence = 16)

B30 CAN ID 6 CAN ID 6 (valence = 32)

B31 CAN ID 7 CAN ID 7 (valence = 64)

B32 Auto bit rate Automatic bit rate detection of CAN bus

Table 4-18 EPOS2 Module 36/2 – Pin Assignment Array B

4.2 Minimum external Wiring

Figure 4-7 Minimum external Wiring

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

4-19

Page 20

Connections

V

CC

U

N

n

O

-------

n

B

Δn

ΔM

-------- -

MB⋅+

1

0.9

-------

⋅⋅ 1 V[]+=

Power Supply

4.3 Power Supply

Best Practice

Keep the motor mechanically disconnected during setup and adjustment phase.

External Protection

Supply voltages above 40 VDC will destroy the unit.

To prevent damage to the EPOS2 Module 36/2, we recommend to install two upstream fuses – a tran-

sient voltage suppressor diode (TVS diode) and a capacitor in the power supply voltage line (for details

chapter “5.1.2 Power Supply Voltage” on page 5-37).

4.3.1 Determination of Power Supply

Basically, any power supply may be used, provided it meets below stated minimal requirements.

Power Supply Requirements

Output voltage

Absolute output voltage

Output current Depending on load (continuous max. 2 A / acceleration, short-time max. 4 A <1 s)

VCC min. 11 VDC; VCC max. 36 VDC

min. 0 V (VCC below 11 V is only possible with separate logic supply voltage!) /

max. 40 VDC

1) Calculate required voltage under load using following scheme (the formula takes a max. PWM

cycle of 90% and a max. voltage drop of −1 V at EPOS2 Module 36/2 into account):

NOWN VALUES:

K

• Operating torque MB [mNm]

• Operating speed n

• Nominal motor voltage U

• Motor no-load speed at U

• Speed/torque gradient of the motor Δn/ΔM [min

OUGHT VALUE:

S

• Supply voltage V

S

OLUTION:

2) Choose power supply capable as to above calculation. Thereby consider:

a) During braking of the load, the power supply must be capable of buffering the fed back

energy, e.g. in a capacitor or shunt regulator (309687).

b) When using an electronically stabilized power supply, observe that the overcurrent protec-

tion must not be activated in any operating state.

[min−1]

B

[Volt]

CC

[Volt]

N

, n0 [min−1]

N

−1

mNm−1]

Pin Signal Description

A1/6

B1/11

A2/3/4

Limited Current Rating per Pin

Due to the limited current rating per pin (1.1 A), you must connect all pins!

Power_Gnd Ground of supply voltage

V

CC

Power supply voltage +11…+36 VDC

maxon motor control

4-20 Document ID: rel7050 EPOS2 Positioning Controller

© 2017 maxon motor. Subject to change without prior notice.

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

Page 21

4.3.2 Use of separate Logic Supply (optional)

By default, the logic must be powered by (connected to) the regular supply voltage. Optionally, you may

wish to feed the logic supply voltage separately, permitting a safe and economical power backup feature. For connection chapter “4.2 Minimum external Wiring” on page 4-19).

External Protection

Supply voltages above 40 VDC will destroy the unit.

To prevent damage to the EPOS2 Module 36/2, we recommend to install two upstream fuses – a tran-

sient voltage suppressor diode (TVS diode) and a capacitor in the power supply voltage line (for details

chapter “5.1.2 Power Supply Voltage” on page 5-37).

Basically, any power supply may be used, provided it meets below stated minimal requirements.

Logic Power Supply Requirements

Output voltage

Absolute output voltage min. 9 VDC; max. 40 VDC

Min. output power

Pin Signal Description

A1/6

B1/11

A5

Power_Gnd Ground of supply voltage

V

C

VC min. 11 VDC; VC max. 36 VDC

PC min. 3 W

Logic supply voltage +11…+36 VDC

4.3.3 Low Supply Voltage Operation (optional)

For low voltage applications, you may supply the power stage separately with voltages lower than +11V.

PPLICATION EXAMPLE:

A

Operation with a Li-Ion battery 3.6 V:

• Power supply voltage direct via accumulator.

• An external step-up converter produces 5 V for logic supply voltage.

The low supply voltage operation for logic and power supply is possible, as long as the following conditions are met (for further details chapter “5.3.4 Wiring Example: Low Supply Voltage Operation” on

page 5-44):

• Supply the logic part via +V

• Supply the power part via V

(pin A10). The voltage range must be 4.75…5.25 V.

DDin

(pins A2, A3 and A4). The voltage range must be 0…40 V.

CC

• Deactivate undervoltage control using «EPOS Studio». Do so by opening the Object Dictionary

and set the object with Index 0x2008 (Miscellaneous Configuration) to 32 (decimal format).

Best Practice

We strongly recommend to use separate voltage supplies for logic part and power part.

• Using a common supply, it will be very difficult to maintain the logic voltage range condition

(4.75…5.25 V).

• Voltage drops during acceleration, as well as the fed back energy during breaking may cause signifi-

cant voltage variations on the power supply voltage.

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

4-21

Page 22

Connections

Motor Connection

Following requirements must be met:

Supply Voltage Requirements

Output voltage

Absolute output voltage min. 4.75 VDC; max. 5.25 VDC

Power Supply Requirements

Output voltage

Absolute output voltage min. 0 V / max. 40 VDC

Pin Signal Description

A1/6

B1/11

A2/3/4

A10

Power_Gnd Ground of supply voltage

V

CC

+V

DD

VDD +5 VDC

VCC min. 0 VDC; max. 36 VDC

Power supply voltage 0…+36 VDC

+5 V voltage supply

Limited Current Rating per Pin

Due to the limited current rating per pin (1.1 A), you must connect all pins!

4.4 Motor Connection

Limited Current Rating per Pin

Due to the limited current rating per pin (1.1 A), you must connect all pins!

4.4.1 maxon EC motor (brushless)

Pin Signal Description

B2/3/4 Motor winding 1 EC motor: Winding 1

B5/6/7 Motor winding 2 EC motor: Winding 2

B8/9/10 Motor winding 3 EC motor: Winding 3

4.4.2 maxon DC motor (brushed)

Pin Signal Description

B2/3/4 Motor (+M) DC motor: Motor +

B5/6/7 Motor (−M) DC motor: Motor −

maxon motor control

4-22 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 23

4.5 Hall Sensor Connection

Hall sensors are required to detect the rotor position of maxon EC motors (brushless).

Suitable Hall effect sensors IC use «Schmitt trigger» with open collector output.

Hall sensor supply voltage +5 VDC

Max. Hall sensor supply current 30 mA

Input voltage 0…+24 VDC

Logic 0 typical <0.8 VDC

Logic 1 typical >2.4 VDC

Internal pull-up resistor 2.7 kΩ (against +5 VDC)

Figure 4-8 Hall Sensor Input Circuit

Pin Signal Description

A7 Hall sensor 1 Hall sensor 1 Input

A8 Hall sensor 2 Hall sensor 2 Input

A9 Hall sensor 3 Hall sensor 3 Input

A10

A11 GND Ground of Hall sensor/encoder supply

+V

aux

Auxiliary output voltage for Hall sensors and encoder +5 VDC

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

4-23

Page 24

Connections

Encoder Connection

4.6 Encoder Connection

Best Practice

The use of encoder with built-in line driver is mandatory.

Even though 2-channel will do, we strongly recommend to use only 3-channel versions!

By default, the controller is set for a 500 count per turn encoder. For other encoders, you will need to

adjust respective settings via software.

Encoder supply voltage +5 VDC

Max. encoder supply current 100 mA

Min. differential Input voltage ± 200 mV

Line receiver (internal) EIA RS422 Standard

Max. encoder input frequency 5 MHz

Figure 4-9 Encoder Input Circuit

Pin Signal Description

A10

A11 GND Ground of Hall sensor/encoder supply

A12 Channel A Channel A

A13 Channel A\ Channel A complement

A14 Channel B Channel B

A15 Channel B\ Channel B complement

A16 Channel I Index

A17 Channel I\ Index complement

+V

aux

Auxiliary output voltage for Hall sensors and encoder +5 VDC

maxon motor control

4-24 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 25

4.7 Digital Input Connection

Contains four smart multi-purpose digital inputs configurable as “Positive Limit Switch”, “Negative Limit

Switch”, “Home Switch” and “General Purpose”.

Additionally offered are two “High Speed Command” inputs.

4.7.1 Digital Inputs 1, 2, 3 and 4

By default, the digital input is defined as “General Purpose” and may be configured via software.

DigIN1 “General Purpose”

DigIN2 “Home Switch”

DigIN3 “Positive Limit Switch”

DigIN4 “Negative Limit Switch”

GND

Type of input single-ended

Input voltage 0…36 VDC

Max. input voltage ±36 VDC

Logic 0

Logic 1

Input resistance

Input current at logic 1 typical 270 µA @ 5 VDC

Switching delay <300 µs

Pin [B13]

Pin [B14]

Pin [B15]

Pin [B16]

Pin [B12]

Uin <0.8 VDC

Uin >2.0 VDC

typical 22 kΩ (<3.3 V)

typical 18 kΩ (@ 5 V)

typical 12 kΩ (@ 24 V)

Figure 4-10 DigIN1 Circuit (analogously valid also for DigIN2…4)

For wiring examples page 4-26.

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

4-25

Page 26

Connections

R

ext

RINVSVIN–()⋅

V

IN

-------------------------------------- -

=

Digital Input Connection

WIRING EXAMPLE: “PROXIMITY SWITCH TYPE PNP 3-WIRE MODEL”

Figure 4-11 DigIN2 – Wiring Example for Type PNP Proximity Switch

W

IRING EXAMPLE: “SLOTTED OPTICAL SENSOR”

Figure 4-12 DigIN2 – Wiring Example for slotted optical Sensor

Note

Logic level threshold VIN assumed to be 5 V.

maxon motor control

4-26 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 27

4.7.2 Digital Inputs 7 and 8

The “High Speed Command” differential inputs are set by default and may be configured via software.

Differential

DigIN7 “High Speed Command”

DigIN8 “High Speed Command”

Min. differential input voltage ±200 mV

Line receiver (internal) EIA RS422 Standard

Max. input frequency 5 MHz

Pins [B18] / [B19]

Pins [B20] / [B21]

Figure 4-13 DigIN7 “Differential” Circuit (analogously valid also for DigIN8)

Single-ended

DigIN7 “High Speed Command”

DigIN8 “High Speed Command”

Input voltage 0…5 VDC

Max. input voltage −7.5…+12.5 VDC

Logic 0 <0.8 V

Logic 1 >2.0 V

Input resistance typical 20 kΩ (referenced to D_GND)

Max. input frequency 2.5 MHz

Pins [B18]

Pins [B20]

Note

Do not connect DigIN’s complements!

Figure 4-14 DigIN7 “Single-ended” Circuit (analogously valid also for DigIN8)

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

4-27

Page 28

Connections

Analog Input Connection

4.8 Analog Input Connection

4.8.1 Analog Inputs 1 and 2

By default, the analog inputs are defined as “General Purpose” and may be configured via software.

AnIN1 “General Purpose”

AnIN2 “General Purpose”

GND

Input voltage 0…5 VDC

Max. input voltage 0…10 VDC

Input resistance typical 34 kΩ (referenced to GND)

Resolution 2.49 mV

Bandwidth 250 Hz

Pin [A19]

Pin [A20]

Pin [A18]

Figure 4-15 AnIN1 Circuit (analogously valid also for AnIN2)

maxon motor control

4-28 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 29

4.9 Digital Output Connection

Contains two “General Purpose” open collector (5 V) and one “High speed” push-pull (3.3 V) digital outputs.

4.9.1 Digital Outputs 1 and 2

By default, the digital outputs are defined as “General Purpose” and may be configured via software.

DigOUT1

DigOUT2

GND

Circuit

Switching delay <3 µs

Pin [B22]

Pin [B23]

Pin [A21]

Open collector (internal pull-up resistor 2k2 and

diode to +5 VDC

Figure 4-16 DigOUT1 Circuit (analogously valid also for DigOUT2)

DigOUT “Sinks”

Max. input voltage +36 VDC

Max. load current 50 mA

Max. voltage drop <1.0 V @ 50 mA

Figure 4-17 DigOUT1 “Sinks” Circuit (analogously valid also for DigOUT2)

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

4-29

Page 30

Connections

Digital Output Connection

Output voltage

Max. load current

Figure 4-18 DigOUT1 “Source” Circuit (analogously valid also for DigOUT2)

DigOUT “Source”

U

≈5 V − 0.75 V − (I

out

I

≤2 mA

load

× 2200 Ω)

load

maxon motor control

4-30 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 31

4.9.2 Digital Output 5

The digital output is defined as “High Speed” and may be configured via software.

DigOUT5

GND

Pin [A22]

Pin [A21]

Circuit Push-pull stage

Switching delay <10 ns

Figure 4-19 DigOUT5 Circuit

DigOUT “Sinks”

Max. input voltage

Max. load current

Max. voltage drop

Uin ≤3.3 VDC

I

≤24 mA

max

U

<0.55 V + (I

drop

x 100 Ω)

max

Figure 4-20 DigOUT5 “Sinks” Circuit

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

4-31

Page 32

Connections

RS232 Connection

Output voltage

Max. load current

Figure 4-21 DigOUT5 “Source” Circuit

4.10 RS232 Connection

The EPOS2 Module 36/2 can be configured via RS232 communication port. The software «EPOS Studio» provides a graphical user interface to setup all features via the PC’s serial port.

DigOUT “Source”

U

≈3.3 V − 0.75 V − (I

out

I

≤24 mA

load

× 100 Ω)

load

Max. input voltage ±30 V

Output voltage typical ±9 V @ 3 kΩ to Ground

Max. bit rate 115 200 bit/s

Internal RS232 driver/receiver EIA RS232 Standard

Note

• Consider your PC's serial port maximal baud rate.

• The standard baud rate setting (factory setting) is 115'200 bauds.

ONNECTION OF POSITIONING CONTROLLER TO PC

C

EPOS2 Module 36/2 PC Interface (RS232), DIN41652

Pin [A27] “EPOS RxD” Pin 3 “PC TxD”

Pin [A28] “EPOS TxD” Pin 2 “PC RxD”

Pin [A29] “GND” Pin 5 “GND”

maxon motor control

4-32 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 33

4.11 SCI Interface Connection

The serial communications interface (SCI) is a two-wire asynchronous serial port, commonly known as a

UART. The SCI modules support digital communication between the CPU and other asynchronous

peripherals that use the standard non-return-to-zero (NRZ) format.

As a common application for EPOS2 Module 36/2’s SCI interface, it can be wired to an USB-to-UART

converter to built an USB interface. For further details chapter “5.1.6 USB” on page 5-40.

Max. input voltage 3.3 VDC

High-level input voltage >2.0 VDC

Low-level input voltage <0.8 VDC

High-level output voltage >2.4 VDC

Low-level output voltage <0.4 VDC

Bit rate 1 Mbit/s

Data format NRZ (non-return-to-zero)

Pin Signal Description

A24 DSP_RTS2 Serial communication interface handshake

A25 DSP_RxD2 Serial communication interface receive

A26 DSP_TxD2 Serial communication interface transmit

A29 GND Ground

4.12 CAN Connection

The EPOS2 Module 36/2 is specially designed being commanded and controlled via a Controller Area

Network (CAN), an highly efficient data bus, very common in all fields of automation and motion control.

The EPOS2 Module 36/2 is preferably used as a slave node in the CANopen network.

Standard ISO 11898-2:2003

Max. bit rate 1 Mbit/s

Max. number of CAN nodes 127

Protocol CANopen DS-301 V4.02

Identifier setting by external wiring or software

Pin Signal Description

A30 CAN_L CAN low bus line

A31 CAN_H CAN high bus line

A32 GND Ground

Note

• Consider CAN Master’s maximal baud rate.

• The standard baud rate setting (factory setting) is “Auto Bit Rate”.

• Use 120

• For detailed CAN information separate document «EPOS2 Communication Guide».

Ω

termination resistor at both ends of the CAN bus.

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

4-33

Page 34

Connections

CAN Configuration

4.13 CAN Configuration

4.13.1 CAN ID (Node Address)

The CAN ID is set with input lines CAN ID1…CAN ID7. Addresses (1…127) may be coded using binary

code.

Logic 1 typical <0.8 VDC

Logic 0 typical >2.4 VDC

Internal pull-up resistor 4.7 kΩ (against +3.3 VDC)

Figure 4-22 CAN ID Input Circuit

Pin Signal Description Binary Code Valence

B24 GND Ground for CAN ID settings – –

B25 CANID1 CAN ID 1 2

B26 CANID2 CAN ID 2 2

B27 CANID3 CAN ID 3 2

B28 CANID4 CAN ID 4 2

B29 CANID5 CAN ID 5 2

B30 CANID6 CAN ID 6 2

B31 CANID7 CAN ID 7 2

0

1

2

3

4

5

6

1

2

4

8

16

32

64

Table 4-19 CAN ID – Binary Code Values

The set CAN ID (node address) can be observed by adding the valences of all inputs connected externally to GND.

XAMPLES:

E

Use following table as a (non-concluding) guide:

CAN ID/Switch 1234567

Valence 1 2 4 8 16 32 64

CAN ID Calculation

1 1*0**00000 1

2 0100000 2

32 0000010 32

35 1100010 1 + 2 + 32

127 1 1 1 1 1 1 1 1 + 2 + 4 + 8 + 16 + 32 + 64

Legend:

* 1 = CAN ID input line externally connected to GND

** 0 = CAN ID input line open or externally connected to +3.3 VDC

Table 4-20 CAN ID – Examples

maxon motor control

4-34 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 35

Note

The Node ID set by software is valid, if CAN ID is set “0” (all CAN ID input lines open or externally connected to +3.3 VDC).

4.13.2 CAN automatic Bit Rate Detection

By using this function, the CANopen interface can be put in a “listen only” mode. For further details

separate document «EPOS2 Firmware Specification».

The automatic bit rate detection is activated when the input line is connected externally to GND.

Auto Bit Rate

GND

Logic 0 typical <0.8 VDC

Logic 1 typical >2.4 VDC

Internal pull-up resistor 4.7 kΩ (against +3.3 VDC)

Pin [B32]

Pin [B24]

Figure 4-23 CAN automatic Bit Rate Detection Circuit

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

4-35

Page 36

Connections

Status LEDs

4.14 Status LEDs

The LEDs display the current status of the EPOS2 Module 36/2, as well as possible errors:

For detailed information separate document «EPOS2 Firmware Specification».

• Green LED shows the operating status

• Red LED indicates errors

LED

Red Green

OFF Slow

OFF ON

ON OFF

ON ON

ON Flash No valid firmware or firmware download in progress.

Flash = Flashing (≈0.9 s OFF/≈0.1 s ON)

Slow = Slow blinking (≈1 Hz)

Table 4-21 LEDs – Interpretation of Condition

Status / Error

Power stage is disabled. Device is in status…

• “Switch ON Disabled”

• “Ready to Switch ON”

• “Switched ON”

Power stage is enabled. Device is in status…

• “Operation Enable”

• “Quick Stop Active”

FAULT state. Device is in status…

• “Fault”

Power stage is enabled. Device is in temporary status…

• “Fault Reaction Active”

maxon motor control

4-36 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 37

5 Motherboard Design Guide

The «Motherboard Design Guide» provides helpful information on the implementation of the EPOS2

Module 36/2 into an electronics board. It contains external component requirements, routing instructions, pin assignment, mechanical dimensions and wiring examples.

CAUTION

Hazardous

Incorrect Design can lead to serious injuries!

• Do not further proceed if you are not familiar with electronic design!

• Designing an electronic board requires specific skills and must only be performed by experienced

electronic engineers!

• This short guide must only be considered as a help and does not by itself lead to a working design!

Get assistance:

If you are not familiar with electronic design, you might wish to seek assistance.

maxon motor ag’s specialists will be glad to offer you a customized motherboard design that suits your

particular application.

5.1 Requirements for external Components

For correct and save function of the EPOS2 Module 36/2, the following external components will be

required. Function and key data of each component is noted and completed with examples.

5.1.1 Card Edge Connector

The EPOS2 Module 36/2 is designed to plug into a card edge connector that is mounted on an application-specific PCB. This connector must be a 2x32 way vertical or horizontal type with at rated current per

pin of at least 1 A. In case of high vibration in your application, the EPOS2 Module 36/2 must be locked

with an additional PCB retainer (for details and references “Connections” on page 3-12.

5.1.2 Power Supply Voltage

Due to limited current rating of 1.1 A per pin, all pins of the power supply voltage V

To protect the module from damage, two fuses – a transient voltage suppressor diode (TVS diode) and

a capacitor in the power supply voltage line – are recommended.

Figure 5-24 Recommended Protection for Power Supply

must be connected.

CC

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

5-37

Page 38

Motherboard Design Guide

Requirements for external Components

5.1.2.1 Capacitor C1

An external capacitor is not mandatory for the function of the module, but – during braking of the load –

the power supply must be capable to buffer the fed back energy. Hence, connect an electrolytic capacitor to the power supply voltage. The capacity needed depends on the following items:

• Power supply voltage

• Speed at the beginning of the braking

• Total mass inertia

• Deceleration rate

• Number of modules

For recommended types (supplying one EPOS2 Module 36/2) “Supplier Reference” on page 5-39.

5.1.2.2 Fuse FU1

Place a fuse at the power supply’s entry to protect against reverse polarity. Together with the TVS

diode, the fuse breaks an occurring reverse current. The continuous current of the fuse depends on the

number of modules supplied and how much current each module needs. For recommended types

“Supplier Reference” on page 5-39.

5.1.2.3 Fuse FU2

For protection against short circuit of the motor winding connections, it is recommended to place additionally one fuse per module. The fuse must withstand 2 A continuously and 4 A during 5 seconds with a

2

typical melt I

t smaller than 0.05 A2s. For recommended types “Supplier Reference” on page 5-39.

5.1.2.4 TVS Diode D1

To protect against overvoltage due to supply transients or the braking energy, connect a transient voltage suppressor diode to the power supply voltage. For recommended types “Supplier Reference” on

page 5-39.

5.1.3 Logic Supply Voltage

The EPOS2 Module 36/2 features a logic supply voltage input and a +V

output. The logic supply volt-

aux

age input has a voltage range of 9…40 V and can be sourced separately or by the power supply voltage

(chapter “4.2 Minimum external Wiring” on page 4-19).

• If the logic supply voltage is sourced, the +V

can be used as +5 VDC supply output for Hall

aux

sensors and encoder.

• If the logic supply voltage is sourced separately, a transient voltage suppressor diode at the

logic supply voltage input can be connected to protect the module against overvoltage. For references on the TVS diode “Supplier Reference” on page 5-39.

maxon motor control

5-38 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 39

5.1.4 Motor Phase

L

ext

V

cc

6 INf

pwm

⋅⋅

----------------------------

L

int

0.3 L

mot

⋅()–()–=

L

extVcc

INf

pwmLint

L

mot

L

ext

0≤

L

ext

0>

The EPOS2 Module 36/2 features a built-in choke of 10 μH per phase. For most motors and applications

this will be sufficient. In case of high power supply voltage and for motors with very low inductance, the

current ripple will become too high thus, requiring additional chokes on the motherboard.

The minimum inductance of each choke can be calculated as to below formula.

• If the result is negative, no additional chokes will be needed.

• If the result is positive, additional chokes will be required.

The chokes must have an electromagnetic shield, high saturation current, low losses and a

rated current higher than the continuous motor current. For recommended types “Supplier

Reference” on page 5-39.

[H]

[V]

[A]

[Hz]

[H]

[H]

External inductance per phase

Power supply voltage

Nominal motor current (consult maxon catalog for applicable data)

PWM frequency = 50000 Hz

EPOS2 Module 36/2’s built-in inductance per phase = 10

Terminal inductance phase to phases of the motor

No additional motor choke necessary

Additional motor choke recommended

5.1.5 Supplier Reference Recommended Components

Panasonic (EEUFC1H221)

C=220 uF / UDC=50 V / IAC=1030 mA @ 100kHz, low impedance /

T=−55…105 °C

Capacitor C1

Rubicon (50ZL220M10X16)

C=220 uF / U

T=−55…105 °C

Littelfuse, 154 Series OMNI-BLOK fuse holder with SMD NANO2 fuse installed.

Fuse FU1

– 3 A very fast-acting (154003) when employing 1 EPOS2 Module 36/2

– 5 A very fast-acting (154005) when employing 2 EPOS2 Module 36/2

– 10 A very fast-acting (154010) when employing 4 EPOS2 Module 36/2

Fuse FU2

Bussmann, 3216FF Series (3216FF-2A), fast-acting, 2 A

Wickmann, SMD 0805 Series (FCD081200), quick-acting, 2 A

Vishay (SMBJ43A)

TVS diode D1

Motor choke

Diotec(P6KE51A)

=43 V / UBR=47.8…52.8 V @ 1 m A / UC=69.4 V @ 8.6 A

U

R

Würth Elektronik, WE-PD-XXL (7447709101)

LN=100 μH / RDC=100 mΩ / IDC=2.5 A / I

−5

H

=50 V / IAC=1370 mA @ 100kHz, low impedance /

DC

= 3.1A, shielded

sat

Table 5-22 Recommended Components

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

5-39

Page 40

Motherboard Design Guide

Requirements for external Components

5.1.6 USB

5.1.6.1 General Requirements

USB offers an easy way to configure and command the EPOS2 Module 36/2. The module itself does not

possess an USB interface, but an USB to UART converter placed on the motherboard can be wired to

the module’s SCI interface pins. It will be sufficient to place only one USB converter on the motherboard.

The modules among themselves communicate via the CAN bus. For a schematic example of the USB to

UART converter chapter “5.3.3 USB Interface” on page 5-43.

5.1.6.2 USB to UART Converter Configuration

1) Connect the USB cable to an USB port of a PC.

2) Install and start the «EPOS Studio» software.

The provided USB driver supports only the USB to UART converter “FT232RQ” by FTDI. It

must be configured with FTDI’s utility software «MProg» before communication between

«EPOS Studio» and the EPOS2 Module 36/2 will be available.

3) Download and install «D2XX drivers» from www.ftdichip.com – category «Drivers» / category

«D2XX» / column «Comments» / link «setup executable».

4) Download and install «MProg» from www.ftdichip.com – category «Resources» / category «Util-

ities» / heading «MProg - EEPROM Programming Utility».

5) Connect FT232RQ with an USB cable to your computer. The FT232RQ will be powered via

USB.

6) Start the software utility «MProg» and click in menu “Tools” / “Read and Parse”. The default

configuration will be read-out and displayed.

7) Change values as follows:

Name Change from… …to

USB VID/PID FTDI Default FTDI Supplied PID

Product ID 6001 A8B0

Manufacturer FTDI maxon motor ag

Description FT232R USB UART maxon motor EPOS2

Check box “Load D2XX driver” ticked

Table 5-23 USB to UART Converter Configuration – Settings

8) Select menu “File” / “Save As…” and assign a name.

9) Select menu “Device” / “Program”.

10) The “Programmed Serial Number: …” will now be displayed in the text box at the bottom. Leave

this number unchanged.

11) Close «MProg» utility and disconnect the USB cable.

Now, the converter is configured and the communication between «EPOS Studio» and the EPOS2 Module 36/2 via USB is established.

maxon motor control

5-40 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 41

5.2 Design Rules

Follow below rules to design your application-specific motherboard and to provide correct and save

function of the EPOS2 Module 36/2.

Before continuing, make sure to consult the following sections:

5.2.1 Ground

The ground pins (GND) are internally connected, but each ground pin is assigned to a functional block.

It is common practice to place a ground plane on the motherboard and will be required to connect pins

A1, A6, B1 and B11 with thick tracks to the power supply voltage ground.The ground pins of each functional block are as follows:

Use Pin(s)… …to connect this Functional Block to Ground:

A1/6

B1/11

A11 Encoder

A18 Analog inputs

A21

B12/17

A29 USB and RS232

A32 CAN bus

B24 CAN ID settings

•For Pin Description chapter “4.1 Pin Assignment” on page 4-17.

•For Performance Data chapter “3 Technical Data” on page 3-11 and chapter “4.3.3 Low

Supply Voltage Operation (optional)” on page 4-21.

•For Dimensional Drawings chapter “3.3 Dimensional Drawings” on page 3-13.

Power supply voltage

Digital inputs and outputs

Table 5-24 Functional Blocks – Ground Connections

If ground safety earth is available, connect the ground plane over some parallel capacitors to the ground

safety earth. We recommend the use of capacitors with 47 nF and 100 V.

5.2.2 Communication Interfaces

•For RS232 chapter “4.10 RS232 Connection” on page 4-32.

•For CAN chapter “4.12 CAN Connection” on page 4-33.

5.2.3 I/Os

•For Digital inputs chapter “4.7 Digital Input Connection” on page 4-25.

•For Analog Inputs chapter “4.8 Analog Input Connection” on page 4-28.

•For Digital Outputs chapter “4.9 Digital Output Connection” on page 4-29.

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

5-41

Page 42

Motherboard Design Guide

Schematic Examples

5.2.4 Layout

Follow these rules:

• Connect pins A2, A3 and A4 (power supply voltage V

• Connect pins A1, A6, B1 and B11 (Power_GND) with thick tracks to the ground of supply voltage.

• Copper plating’s width and thickness of traces for power supply voltage and motor winding

depend on the maximum current expected in the application. We recommend a minimum width

of 50 mil at a thickness of 35 µm.

• Route fast signal wire pairs (encoder, differential inputs, CAN, USB) close to the return wire in

order to minimize the area of the loop enclosed by the corresponding current.

5.3 Schematic Examples

5.3.1 Minimum External Wiring

Logic supply is sourced by the power supply voltage. The EPOS2 Module 36/2 is configured by RS232.

For details chapter “4.2 Minimum external Wiring” on page 4-19.

5.3.2 Separate Logic Supply Voltage and CAN Communication

Power and logic supply voltage are sourced separately. The EPOS2 Module 36/2 is configured and

commanded by CAN.

) with a thick track to the fuse.

CC

Figure 5-25 Separate Logic Supply Voltage and CAN Communication – Wiring Diagram

maxon motor control

5-42 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 43

5.3.3 USB Interface

If an external USB to UART converter is connected to the EPOS SCI, the module can be configured and

commanded by a PC through USB.

Figure 5-26 USB Interface – Wiring Diagram

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

5-43

Page 44

Motherboard Design Guide

Schematic Examples

5.3.4 Wiring Example: Low Supply Voltage Operation

The power stage is powered separately with a voltage between 0 and 36 VDC. The logic part must be

supplied with +5 VDC connected to V

supply voltage by an appropriate voltage converter (step-up-converter or step-down-converter).

It is recommended to use this operation mode only with power supply voltages below 11 VDC.

. As a possibility, this voltage can be produced out of the power

DDin

Figure 5-27 Low Supply Voltage Operation – Wiring Diagram

maxon motor control

5-44 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 45

5.3.5 Wiring Example: Two Axes with RS232 to CAN Gateway

The logic supply is sourced by the power supply voltage and the module is configured by RS232.

Both modules are configured and commanded by a PC via RS232. The upper module is used as RS232

to CAN gateway. Further modules can be connected and commanded to the CAN bus accordingly.

Figure 5-28 Two Axes with RS232 to CAN Gateway – Wiring Diagram

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

5-45

Page 46

Motherboard Design Guide

Schematic Examples

••page intentionally left blank••

maxon motor control

5-46 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 47

LIST OF FIGURES

Figure 2-1 Documentation Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Figure 3-2 Dimensional Drawing (with vertical Connector) [mm] . . . . . . . . . . . . . . . . . . . . . . . . . .13

Figure 3-3 Dimensional Drawing (with horizontal connector Meritec 983172-064-2MMF) [mm] . .13

Figure 3-4 Footprint of Retainer (Meritec 983172-064-2MMF connector) [mm] . . . . . . . . . . . . . .13

Figure 3-5 Derating Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Figure 4-6 EPOS2 Module 36/2 – PCB with Connector Array . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Figure 4-7 Minimum external Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Figure 4-8 Hall Sensor Input Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Figure 4-9 Encoder Input Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Figure 4-10 DigIN1 Circuit (analogously valid also for DigIN2…4) . . . . . . . . . . . . . . . . . . . . . . . . .25

Figure 4-11 DigIN2 – Wiring Example for Type PNP Proximity Switch . . . . . . . . . . . . . . . . . . . . . .26

Figure 4-12 DigIN2 – Wiring Example for slotted optical Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Figure 4-13 DigIN7 “Differential” Circuit (analogously valid also for DigIN8) . . . . . . . . . . . . . . . . . .27

Figure 4-14 DigIN7 “Single-ended” Circuit (analogously valid also for DigIN8) . . . . . . . . . . . . . . . .27

Figure 4-15 AnIN1 Circuit (analogously valid also for AnIN2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Figure 4-16 DigOUT1 Circuit (analogously valid also for DigOUT2) . . . . . . . . . . . . . . . . . . . . . . . .29

Figure 4-17 DigOUT1 “Sinks” Circuit (analogously valid also for DigOUT2) . . . . . . . . . . . . . . . . . .29

Figure 4-18 DigOUT1 “Source” Circuit (analogously valid also for DigOUT2) . . . . . . . . . . . . . . . . .30

Figure 4-19 DigOUT5 Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Figure 4-20 DigOUT5 “Sinks” Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Figure 4-21 DigOUT5 “Source” Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Figure 4-22 CAN ID Input Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Figure 4-23 CAN automatic Bit Rate Detection Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Figure 5-24 Recommended Protection for Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Figure 5-25 Separate Logic Supply Voltage and CAN Communication – Wiring Diagram . . . . . . .42

Figure 5-26 USB Interface – Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Figure 5-27 Low Supply Voltage Operation – Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Figure 5-28 Two Axes with RS232 to CAN Gateway – Wiring Diagram . . . . . . . . . . . . . . . . . . . . .45

maxon motor control

EPOS2 Positioning Controller Document ID: rel7050

EPOS2 Module 36/2 Hardware Reference Edition: May 2017

© 2017 maxon motor. Subject to change without prior notice.

Z-47

Page 48

LIST OF TABLES

Table 1-1 Notations used in this Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 1-2 Symbols & Signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 1-3 Brand Names and Trademark Owners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 3-4 Electrical Data – Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Table 3-5 Electrical Data – Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Table 3-6 Electrical Data – Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Table 3-7 Electrical Data – Voltage Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 3-8 Electrical Data – Motor Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 3-9 Electrical Data – Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Table 3-10 Electrical Data – LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Table 3-11 Electrical Data – Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 3-12 Mechanical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Table 3-13 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Table 3-14 Order Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 3-15 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Table 3-16 Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Table 4-17 EPOS2 Module 36/2 – Pin Assignment Array A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Table 4-18 EPOS2 Module 36/2 – Pin Assignment Array B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Table 4-19 CAN ID – Binary Code Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Table 4-20 CAN ID – Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Table 4-21 LEDs – Interpretation of Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 5-22 Recommended Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Table 5-23 USB to UART Converter Configuration – Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Table 5-24 Functional Blocks – Ground Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

maxon motor control

Z-48 Document ID: rel7050 EPOS2 Positioning Controller

Edition: May 2017 EPOS2 Module 36/2 Hardware Reference

© 2017 maxon motor. Subject to change without prior notice.

Page 49

INDEX

A

additionally applicable regulations 10

alerts