Page 1

maxon motor

maxon EC motor EC 20 flat with integrated electronics

Doc. no. 903155

Operating Instructions Edition September 2010

Order Number: 350795, 350776, 350796, 350778, 350794, 349694, 370413, 370412, 350834, 350804,

350835, 350805, 350806, 349731, 370416, 370415

The EC 20 flat motor with integrated electronics is a brushless, speed-controlled 1-quadrant drive. The EC 20 flat

can be supplied in a 2 watt or 5 watt version.

Functions:

• Commutation with Hall sensors

• Digital speed control

• Speed range: 200 rpm – 7000 rpm (depends on version)

• Current restriction fixed

• Overvoltage and undervoltage switch-off

• Overvoltage protection

• Blockage protection, temperature monitoring

• Inverse polarity protection

2-wire version

• Speed proportional to input voltage

5-wire version

• Set value speed target through analog signal 0 ... 10 V

• 2-wire operation possible

• Versions: - «Enable» TTL level compatible

- Direction pre-selection «cw/ccw» TTL level compatible

• Speed monitor supplies frequency signal proportional to speed

Table of contents

1 Safety instructions ....................................................................................................................................... 2

2 Technical data .............................................................................................................................................. 3

3 Minimum external wiring .............................................................................................................................. 7

4 Description function of inputs and outputs 5-wire version ......................................................................... 10

5 Description function of 2-wire version ........................................................................................................ 13

6 Protective functions.................................................................................................................................... 14

7 Installation instructions .............................................................................................................................. 15

8 EMC-compliant installation ........................................................................................................................ 15

9 Trouble shooting ......................................................................................................................................... 16

10 Dimensions ................................................................................................................................................ 17

11 Glossary..................................................................................................................................................... 18

These instructions are available on the Internet as a PDF file at www.maxonmotor.com, under “Service & Downloads”. Doc. no. 903155_PDF_E.

Page 2

maxon motor

EC 20 flat with integrated electronics Operating Instructions

1 Safety instructions

Skilled personnel

Only skilled, experienced personnel should install and start the equipment.

Statutory regulations

The user must ensure that the EC 20 flat with integrated electronics and the

components belonging to it are assembled and connected according to local

statutory regulations.

Additional safety equipment

Any electronic equipment is, in principle, not fail-safe. Machinery and equipment should therefore be fitted with equipment-independent monitoring and

safety features. There must be guarantees that the drive or the entire piece of

equipment can be run safely if the equipment fails, if it is used incorrectly, if

the control unit fails, if the cable breaks etc.

Repairs

Repairs may only be carried out by authorised personnel or the manufacturer.

It is dangerous for users to open the unit or carry out any repairs.

Danger

Users must ensure that no apparatus is connected to the electrical supply

during installation of the EC 20 flat with integrated electronics! After switching

on, do not touch any live parts!

Max. supply voltage

Make sure that the supply voltage is between 10 VDC and 28 VDC. Permanently switched on voltages above 30 VDC destroy the unit.

Electrostatic sensitive components

During transportation, assembly and operation, contact of the EC 20 flat with

integrated electronics with electrostatically charged components or persons

must be avoided. The integrated electronics can be destroyed by electrostatic

discharges.

2 maxon EC motor

Temperature

The temperature of the housing, flange or components may exceed 60°C

during operation.

September 2010 Edition / document number 903155_PDF_E - 07 / subject to change

Page 3

maxon motor

Operating Instructions EC 20 flat with integrated electronics

2 Technical data

2.1 Order number

350795 (IP40), 350776 (IP00) 2-wire version, nominal speed 3000 rpm, 2 Watt

350796 (IP40), 350778 (IP00) 2-wire version, nominal speed 6000 rpm, 2 Watt

350794 (IP40), 349694 (IP00)

370413 (IP40), 370412 (IP00)

350834 (IP40), 350804 (IP00) 2-wire version, nominal speed 3000 rpm, 5 Watt

350835 (IP40), 350805 (IP00) 2-wire version, nominal speed 6000 rpm, 5 Watt

350806 (IP40), 349731 (IP00)

370416 (IP40), 370415 (IP00)

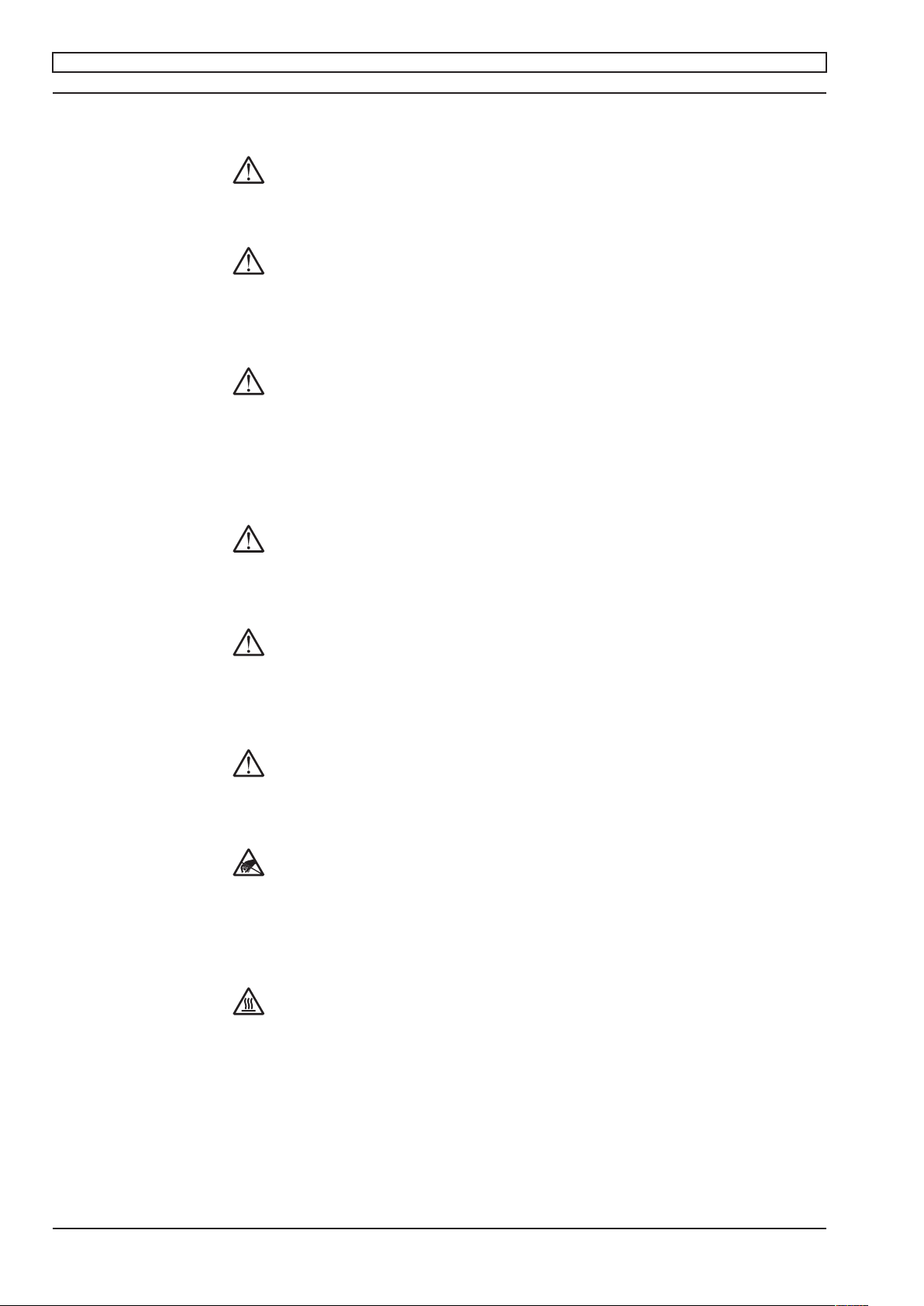

2.2 Motor data 2 Watt at 24VDC

Order number IP40 (with housing) 350795 350796 350794/370413

Order number IP00 (without housing) 350776 350778 350794/370412

Nominal voltage VDC 24 24 24

No load speed rpm 3000 6000 6000

No load current mA 14.5 19.8 19.8

Nominal speed rpm 3000 6000 6000

Nominal torque mNm 3.74 3.74 3.74

Nominal current mA 196 278 278

Max. torque mNm 5 5 5

Max. current mA 330 330 330

Max. efficiency % 25 37 37

-1

n [min

4000

3500

3000

2500

2000

1500

1000

500

]

Vcc = 28V

Vcc = 24V

Vcc = 18V

Vcc = 12V

Vcc = 10V

«Enable» 5-wire version, nominal speed 6000 rpm, 2 Watt

«cw/ccw» 5-wire version, nominal speed 6000 rpm, 2 Watt

«Enable» 5-wire version, nominal speed 6000 rpm, 5 Watt

«cw/ccw» 5-wire version, nominal speed 6000 rpm, 5 Watt

0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6

M [mNm]

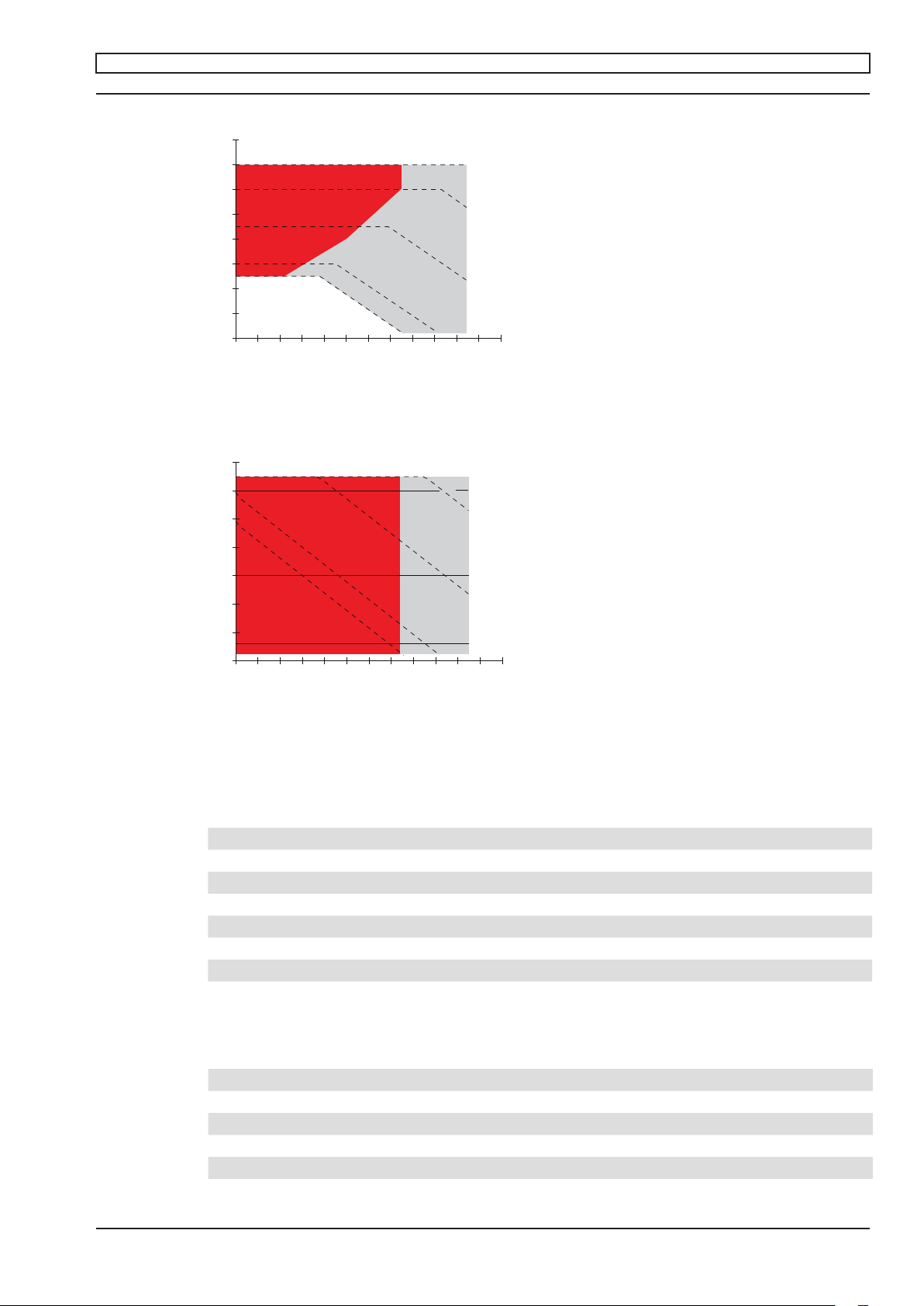

Picture 1: Operating range n = f (M)

2-wire version, nominal speed 3000 rpm, order number 350795, 350776

-1

n [min

8000

7000

6000

5000

4000

3000

2000

1000

]

Vcc = 28V

Vcc = 24V

Vcc = 18V

Vcc = 12V

Vcc = 10V

0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6

M [mNm]

Picture 2: Operating range n = f (M)

2-wire version, nominal speed 6000 rpm, order number 350796, 350778

September 2010 Edition / document number 903155_PDF_E - 07 / subject to change

maxon EC motor 3

Page 4

maxon motor

EC 20 flat with integrated electronics Operating Instructions

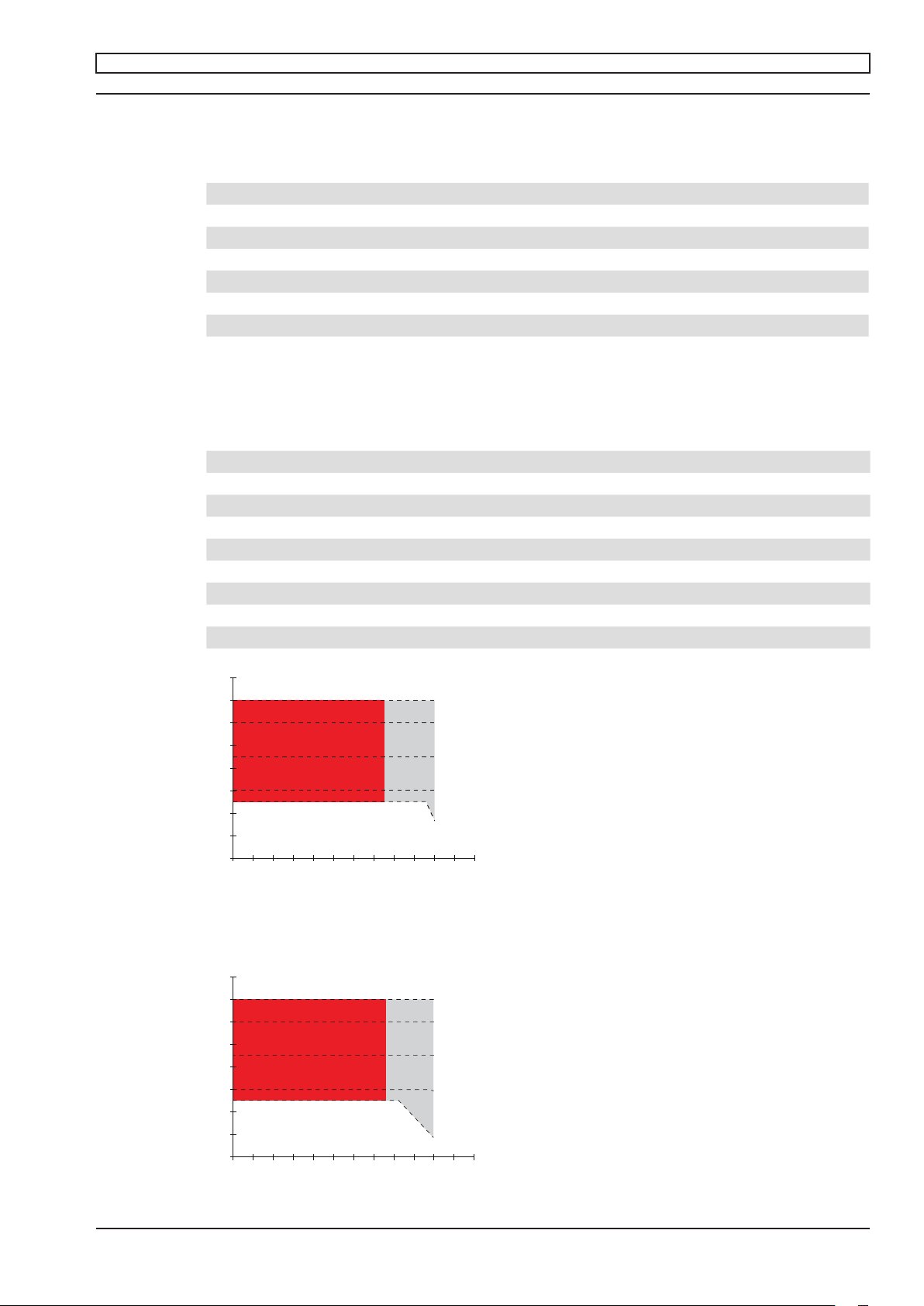

-1

]

n [min

7000

6000

set value = 10V

5000

4000

3000

2000

1000

set value = 5V

set value = 1V

0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6

Picture 3: Operating range n = f (M)

5-wire version, order number 350794 and 349694, 370413, 370412

If the supply voltage is reduced, the torque and/or speed may change.

2.3 Motor data 5 Watt at 24VDC

Order number IP40 (with housing) 350834 350835 350806/370416

Order number IP00 (without housing) 350804 350805 349731/370415

Nominal voltage VDC 24 24 24

No load speed rpm 3000 6000 6000

No load current mA 18.8 23.1 23.1

Nominal speed rpm 3000 6000 6000

Nominal torque mNm 7.5 7.5 7.5

Nominal current mA 258 394 394

Max. torque mNm 10.3 10.3 10.3

Max. current mA 458 580 580

Max. efficiency % 42 55 55

Vcc = 12V

Vcc = 10V

M [mNm]

-1

]

n [min

4000

3500

3000

2500

2000

1500

1000

Vcc = 28V

Vcc = 24V

Vcc = 18V

Vcc = 12V

Vcc = 10V

500

1 2 3 4 5 6 7 8 9 10 11 12

M [mNm]

Picture 4: Operating range n = f (M)

2-wire version, nominal speed 3000 rpm, order number 350834, 350804

4 maxon EC motor

September 2010 Edition / document number 903155_PDF_E - 07 / subject to change

Page 5

maxon motor

Operating Instructions EC 20 flat with integrated electronics

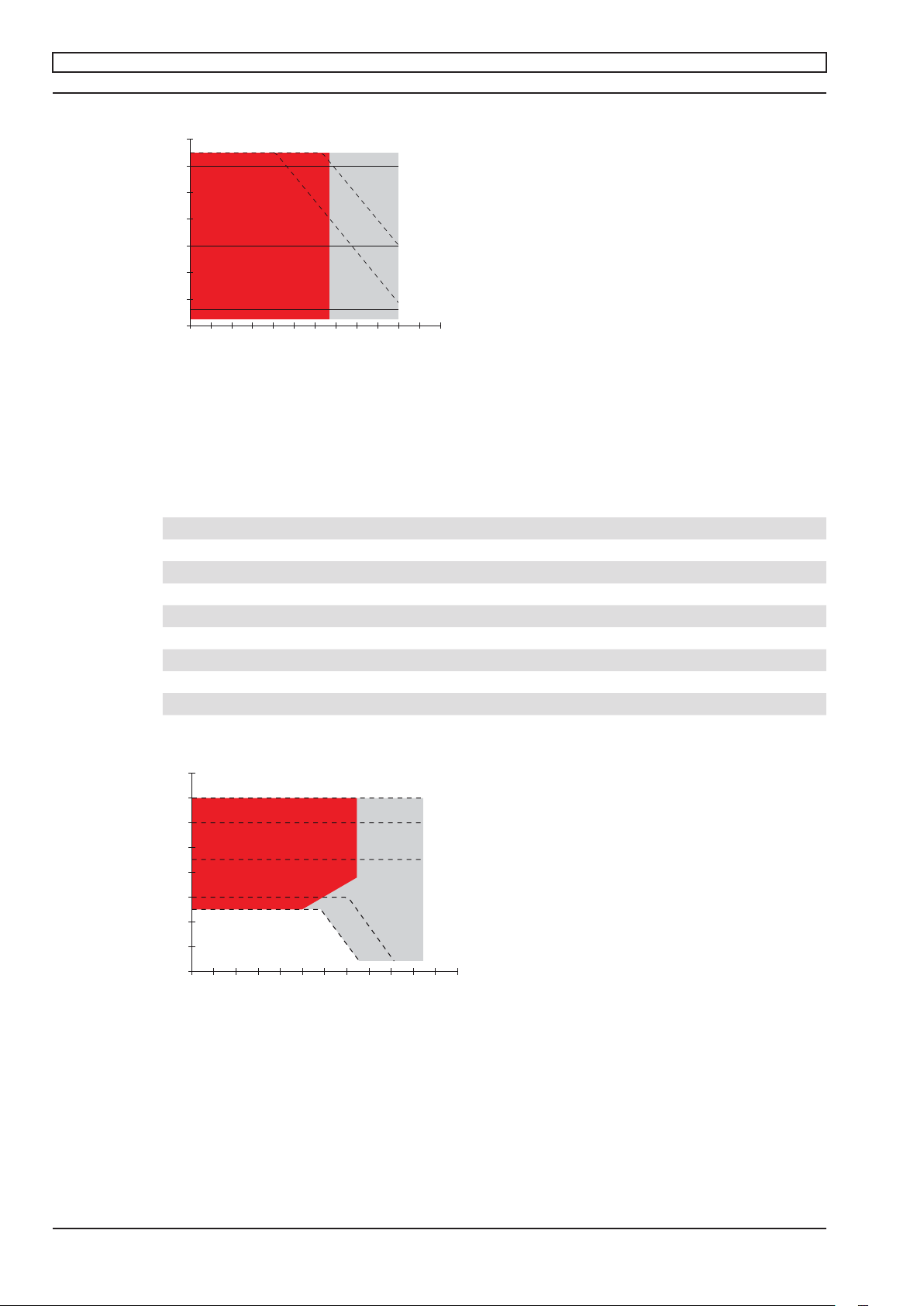

-1

]

n [min

8000

7000

6000

5000

4000

3000

2000

1000

Vcc = 28V

Vcc = 24V

Vcc = 18V

Vcc = 12V

Vcc = 10V

Picture 5: Operating range n = f (M)

2-wire version, nominal speed 6000 rpm, order number 350835, 350805

n [min

7000

6000

5000

4000

3000

2000

1000

Picture 6: Operating range n = f (M)

5-wire version, order number 350806, 349731, 370416, 370415

If the supply voltage is reduced, the torque and/or speed may change.

2.4 Controller data

Version 2-wire 2-wire 5-wire

Nominal speed 3000 rpm 6000 rpm 6000 rpm

Control variable speed speed speed

Supply voltage V

Set value speed input V = VCC = VCC 0.33 … 10.8

Scale set value speed input rpm/V 125 250 600

Speed range rpm 1250 … 3500 2500 … 7000 200 … 6480

Max. acceleration rpm/s 3000 6000 6000

Direction of rotation (CW = clockwise) cw cw cw

Direction of rotation presetting «cw/ccw» cw/ccw

1 2 3 4 5 6 7 8 9 10 11 12

-1

]

set value = 10V

Vcc = 18V

set value = 5V

set value = 1V

1 2 3 4 5 6 7 8 9 10 11 12

Vcc = 12V

Vcc = 10V

CC

M [mNm]

Vcc = 24V

M [mNm]

V 10 … 28 10 … 28 10 … 28

2.5 Thermal data

Version 2 Watt 5 Watt

Thermal resistance housing-ambient K/W

Thermal resistance winding-housing K/W

Thermal time constant winding s 2.38 10.3

Thermal time constant motor s 133 72.6

Max. permissible winding temperature °C +125 +125

Max. temperature of electronics °C +105 +105

September 2010 Edition / document number 903155_PDF_E - 07 / subject to change

-1

-1

13 13

10 7.5

maxon EC motor 5

Page 6

maxon motor

EC 20 flat with integrated electronics Operating Instructions

2.6 Mechanical data (preloaded ball bearings)

Version 2 Watt 5 Watt

Rotor inertia gcm

2

3.2 5.1

Axial play at axial load < 2 N mm 0 0

> 2 N mm 0.14 0.14

Radial play preloaded preloaded

Max. axial load (dynamic) N 1.8 1.8

Max. axial load (static) N 20 20

static, shaft supported) N 200 200

Max. radial load 5 mm from flange N 11 12

Weight of motor gr 30 37

2.7 Connection (input/output)

Cable Description Connection Value

Red Supply voltage VCC Supply 10 … 28 VDC

Black Gnd Supply Ground

White (only 5-wire operation) Set value speed input Input 0.33 … 10.8 VDC

Green (only 5-wire operation) Monitor speed n Output 6 counts per turn

Version Enable

grey (only 5-wire operation) «Enable» Input 2.4 … 28 VDC

Version Direction

grey (only 5-wire operation) «cw/ccw» Input 2.4 … 28 VDC

Wire size AWG28 =ˆ 0.09 mm

2

2.8 Protective functions

Inverse-polarity protection up to max. 30 VDC

Blockage protection cut off with blocked motor shaft after 2 s

Low voltage protection cut off at V

High voltage protection cut off at V

Thermal control of the power stage cut off at T > 100 °C typ.

High voltage protection (transient) 150 mWs

2.9 Ambient conditions

Temperature range -40 ... +40 °C

Range with reduced performance +40 ... +85 °C

Temperature range bearing -40 ... +85 °C

Humidity range not condensing 20 … 80 %

2.10 Voltage supply

Ripple < 5%

Output current depending on the load, recommendation >_ 1 A

Max. output voltage 29 VDC

Min. output voltage 9.5 VDC

< 8.5 V

CC

> 29.5 V

CC

6 maxon EC motor

September 2010 Edition / document number 903155_PDF_E - 07 / subject to change

Page 7

maxon motor

Supply

voltage

10 ... 28 VDC

Set value

Speed

0 ... 10 VDC

red

black

white

green

grey

«Enable» or «cw»

2.4 ... 28 VDC

«Disable» or «ccw»

0.0 ... 0.8 VDC

Supply

voltage

10 ... 28 VDC

red

black

white

green

grey

Supply

voltage

10 ... 28 VDC

red

black

white

green

grey

«Enable» or «cw»

2.4 ... 28 VDC

«Disable» or «ccw»

0.0 ... 0.8 VDC

«Enable» or «cw» if closed

«Disable» or «ccw» if open

Operating Instructions EC 20 flat with integrated electronics

3 Minimum external wiring

3.1 5-wire version

Supply

voltage

10 ... 28 VDC

Set value

Speed

0 ... 10 VDC

green

grey

white

black

red

«Enable» or «cw»

2.4 ... 28 VDC

«Disable» or «ccw»

0.0 ... 0.8 VDC

Picture 7: Example for speed set value and release «Enable» or direction «cw/ccw» (depending

on the variant) through external power source.

Supply

voltage

10 ... 28 VDC

Set value

Speed

green

grey

white

black

red

0 ... 10 VDC

«Enable» or «cw» if closed

«Disable» or «ccw» if open

Picture 8: Example for speed set value with external power source and release «Enable» or

direction «cw/ccw» (depending on the variant) with potentional-free contact.

Supply

voltage

10 ... 28 VDC

14k / 0.1 W

Values for 24 VDC operating voltage

10k / 0.1 W

Picture 9: Example for speed set value with external potentiometer and release «Enable» or

direction «cw/ccw» (depending on the variant) with external power source.

September 2010 Edition / document number 903155_PDF_E - 07 / subject to change

green

grey

white

black

red

«Enable» or «cw»

2.4 ... 28 VDC

«Disable» or «ccw»

0.0 ... 0.8 VDC

maxon EC motor 7

Page 8

maxon motor

Supply

voltage

10 ... 28 VDC

red

black

white

green

grey

Supply

voltage

10 ... 28 VDC

Supply

voltage

10 ... 28 VDC

14k / 0.1 W

10k / 0.1 W

Values for 24 VDC operating voltage

red

black

white

green

grey

red

black

white

green

grey

«Enable» or «cw»

2.4 ... 28 VDC

«Disable» or «ccw»

0.0 ... 0.8 VDC

«Enable» or «cw» if closed

«Disable» or «ccw» if open

«Enable» or «cw»

2.4 ... 28 VDC

«Disable» or «ccw»

0.0 ... 0.8 VDC

Supply

voltage

10 ... 28 VDC

red

black

white

green

grey

Supply

voltage

10 ... 28 VDC

red

black

EC 20 flat with integrated electronics Operating Instructions

Supply

voltage

10 ... 28 VDC

14k / 0.1 W

Values for 24 VDC operating voltage

Picture 10: Example for speed set value with external potentiometer and release «Enable» or

direction «cw/ccw» (depending on the variant) with potentional-free contact.

3.2 5-wire version in 2-wire operating mode

2-wire operating mode can be simulated by short-circuiting the terminals set

value speed input and speed monitor output. Speed is proportional to the

supply voltage (see picture 17).

Supply

voltage

10 ... 28 VDC

10k / 0.1 W

green

grey

white

black

red

«Enable» or «cw» if closed

«Disable» or «ccw» if open

green

grey

white

black

red

Picture 11: Example for 5-wire version in 2-wire operating mode

Version direction «cw/ccw»: the direction of rotation can be selected at the

grey wire.

Supply

voltage

10 ... 28 VDC

«cw»

2.4 ... 28 VDC

green

grey

white

black

red

«ccw»

0.0 ... 0.8 VDC

Picture 12: Example for 5-wire version direction «cw/ccw» in 2-wire operating mode.

8 maxon EC motor

September 2010 Edition / document number 903155_PDF_E - 07 / subject to change

Page 9

maxon motor

Supply

voltage

10 ... 28 VDC

red

black

white

green

grey

Supply

voltage

10 ... 28 VDC

red

black

Supply

voltage

10 ... 28 VDC

red

black

white

green

grey

«cw»

2.4 ... 28 VDC

«ccw»

0.0 ... 0.8 VDC

Supply

voltage

10 ... 28 VDC

red

black

white

green

grey

Operating Instructions EC 20 flat with integrated electronics

Version direction «cw/ccw»: the direction of rotation can be selected at the

grey wire.

Supply

voltage

3.3 2-wire version

10 ... 28 VDC

green

grey

white

black

red

«cw» if closed

«ccw» if open

Picture 13: Example for 5-wire version direction «cw/ccw» in 2-wire operating mode.

Supply

voltage

10 ... 28 VDC

black

red

Picture 14: Example for 2-wire version

September 2010 Edition / document number 903155_PDF_E - 07 / subject to change

maxon EC motor 9

Page 10

maxon motor

12k

100k

grey

Enable

12k

grey

Direction «cw/ccw»

f

n

10

10

Monitor n

actual

actual Monitor n

$

=

=

EC 20 flat with integrated electronics Operating Instructions

4 Description function of inputs and outputs 5-wire version

4.1 Set value speed input

Motor speed is set with an analog voltage at the set value speed input.

The set value speed input is protected against overvoltage.

Pin allocation Cable white

Input voltage range 0 ... +10.8 V (based on GND)

Input impedance 62 kW (range 0 ... +21.9 V)

47 kW (range 21.9 V... +30 V)

Continuous overvoltage protection -30 V ... +30 V

set value speed

47k

white

15k

Picture 15: Wiring set value speed

1µF

The speed set value is set with the voltage at the speed set value input. The

set speed is controlled by the amplifier. Changes to speed set value are restricted by the maximum acceleration (see section 2.4).

To activate the output stage in the «enable» version, the voltage at the enable

input must be higher than 2.4 V, while the speed set value must be above

0.17 V.

With the «cw/ccw» direction pre-selection version, the output stage is activated when the speed set value is higher 0.17 V.

Set value input area Function Comments

0 V … 0.17 V «Disable» Power stage switched off.

0.17 V … 0.33 V Operation at minimum speed

(200 rpm)

0.33 V … 10.8 V Linear speed setting between

200 rpm and 6480 rpm

If «enable» higher than 2.4 V for version

«Enable».

If «enable» higher than 2.4 V. In speed

range between 200 rpm and 300 rpm,

control accuracy of the speed controller

n

=

target

600

V

target

is restricted. The speed can vary from

the specified set value depending on the

load and supply voltage.

10 maxon EC motor

= Set value voltage

V

target

n

= Desired speed

target

September 2010 Edition / document number 903155_PDF_E - 07 / subject to change

Page 11

maxon motor

47k

15k

1µF

white

set value speed

12k

100k

grey

7’000

Speed

[rpm]

0

0

28

2’500

10

6’000

24

Enable

3’500

3’000

Operating voltage [V]

Speed

[rpm]

12k

grey

Direction «cw/ccw»

12k

100k

grey

Direction «cw/ccw»

Operating Instructions EC 20 flat with integrated electronics

Speed

[rpm]

6’480

6’000

3’000

4.2 «Enable»

200

0

0

0.17 0.33

5

10.0

Operating voltage [V]

10.8

Picture 16: Speed as function of specified set value voltage.

Option

By connecting (short-circuiting) the two wires speed monitor (green wire) and

set speed value (white wire), control is set into 2-wire operating mode. It has

to be connected before the supply voltage is switched on.

The power stage is activated with the digital input enable.

The input enable is protected against overvoltage.

Pin allocation Cable grey

Input voltage range 0 ...+5.0 V (based on GND)

Input impedance 112 kW (range 0 ... +5.9 V)

12 kW (range 5.9 V... +30 V)

Continuous overvoltage protection -30 V ... +30 V

Input voltage range Function Comments

0 V … 0.8 V «Disable» Power stage switched off

2.4 V … 5.0 V «Enable» Power stage switched on if set value

September 2010 Edition / document number 903155_PDF_E - 07 / subject to change

Enable

12k

grey

100k

Picture 17: Enable wiring.

The power stage is activated by a voltage of more than 2.4 V. Speed is dependent on the connected voltage at the set value speed input. The power

stage is switched off by a voltage of less than 0.8 V, the motor gradually slows

down, irrespective of the connected voltage at the set value speed input.

higher than 0.17 V.

maxon EC motor 11

Page 12

maxon motor

EC 20 flat with integrated electronics Operating Instructions

4.3 «Enable» and direction version «cw/ccw»

The output stage is activated with the speed set value input. The output

stage is activated if the speed set value is higher than 0.17 V. The «cw/ccw»

direction is determined with the direction pre-selection digital input.

Pin allocation Cable grey

Input voltage range 0 … +5.0 V (based on GND)

Input impedance 112 kW (range 0 ... +5.9 V)

12 kW (range 5.9 V ... +30 V)

Continous overvoltage protection -30 V ... +30 V

Direction «cw/ccw»

grey

Picture 18: Direction wiring

12k

100k

The «cw» direction is activated by a voltage of more than 2.4 V. Speed is

dependent on the applied voltage at the speed set value input. If the direction

is changed during operation, the motor will run down to minimum speed and

then accelerates in requested direction.

Input Voltage range Function Comments

0 V … 0.8 V Sense of rotation «ccw» Motor turns direction «ccw»

2.4 V … 5.0 V Sense of rotation «cw» Motor turns direction «cw»

4.4 Monitor speed «Monitor n»

12 maxon EC motor

The actual speed of the motor shaft can be monitored at the speed monitor

output of the electronics. The actual speed is available as a digital signal

(high/low) and supplies 6 output pulses per mechanical revolution.

Pin allocation Cable green

Output voltage range 0 or +5 V (based on GND)

Output resistance 4.1 kW

Low level max. 0.5 V

High level max. 4.2 V

Duty cycle 50%

Continous overvoltage protection -30 V ... +30 V

September 2010 Edition / document number 903155_PDF_E - 07 / subject to change

Page 13

maxon motor

f

n

10

Monitor n

actual

=

7’000

Speed

[rpm]

0

0

28

2’500

10

6’000

24

Operating voltage [V]

Speed

12k

100k

grey

Direction «cw/ccw»

Speed

12k

100k

grey

Direction «cw/ccw»

Operating Instructions EC 20 flat with integrated electronics

Frequency at speed monitor output

n

f

Monitor n

f

= Frequency at speed monitor output [Hz]

Monitor n

n

= speed [rpm]

actual

=

actual

10

10

=

$

actual Monitor n

Note:

The speed monitor output also works in «disable» mode.

5 Description of function 2-wire version

5.1 Speed proportional to supply voltage V

– Motor speed is proportional to the supply voltage, independant of torque.

– Supply voltage can be varied within the permitted range.

– Speed at 24V supply voltage is:

3000 rpm for versions 350795 and 350776

6000 rpm for versions 350796 and 350778

3’500

3’000

1’250

[rpm]

0

0

10

Operating voltage [V]

28

24

Picture 19: 3000 rpm as function of the supplied voltage.

Picture 20: 6000 rpm as function of the supplied voltage.

CC

7’000

6’000

2’500

[rpm]

0

0

10

24

Operating voltage [V]

28

September 2010 Edition / document number 903155_PDF_E - 07 / subject to change

maxon EC motor 13

Page 14

maxon motor

EC 20 flat with integrated electronics Operating Instructions

6 Protective functions

6.1 Inverse polarity protection

The EC 20 flat with integrated electronics is protected against polarity reversal of the supply voltage VCC. This means that the negative input voltage must

not exceed the maximum permitted supply voltage VCC.

6.2 Undervoltage switch-off

The power stage is switched off if the supply voltage VCC falls below approx.

8.5 V to prevent the EC 20 flat with integrated electronics operating off the

specification.

As soon as the supply voltage exceeds the restart threshold of approx. 9 V,

the EC 20 flat with integrated electronics is ready for operation.

6.3 Overvoltage switch-off

The power stage is switched off if the supply voltage VCC exceeds approx.

29.5 V to prevent the EC 20 flat with integrated electronics operating of the

specification.

As soon as the supply voltage falls below the restart threshold of approx. 28.5 V,

the EC 20 flat with integrated electronics is ready for operation.

6.4 Blockage protection

6.5 Temperature monitoring

6.6 Current limiting

6.7 Overvoltage protection

The power stage is switched off if the rotor is blocked continiously for more

than 2 seconds.

The EC 20 flat with integrated electronics automatically attempts to restart

after 4 seconds.

The power stage is switched off if the PCB temperature exceeds approx. 100°C.

As soon as the PCB temperature has fallen below approx. 90°C, the EC 20

flat with integrated electronics is ready for operation.

The winding current is limited electronically to approx. 650 mA. The maximum

load torque is also limited accordingly.

If the motor shaft slows down completely due to current limitation, the blockage protection switches off after 2 s.

The overvoltage protection comprises a bi-directional transzorb diode (overvoltage protection diode) that can take a maximum peak energy of 150 mWs.

Continuous power loss is 1W. Threshold voltage is 36 V, independant of

polarity.

14 maxon EC motor

September 2010 Edition / document number 903155_PDF_E - 07 / subject to change

Page 15

maxon motor

Operating Instructions EC 20 flat with integrated electronics

7 Installation instructions

– Max. torque of flange screws is 0.3 Nm (screw strength category 8.8).

– Cooling improvement through mounting a large metallic part.

– Cable outlet preferably downwards.

8 EMC compliant installation

8.1 Cable length <_ 300 mm

– Normally no shielding is required.

– Star wiring recomended if several EC 20 flat with integrated electronics

are supplied by a common supply voltage.

8.2 Cable length > 300 mm

– The voltage drop in the connection cable must be minimised by choosing

a large enough wire cross section.

– The use of shielded cables connected to ground can improve immunity

against interference in electromagnetically harsh environments.

– Release cable shielding on one side if 50/60 Hz interference problems

occur.

– The irradiance surface for interference can be reduced by shortening the

unshielded original connection cable.

– Immunity against interference and speed stability when loads fluctua-

te can be achieved by routing the set speed value signal separately in

a shielded cable that is put to ground both sides. In addition to the set

speed value signal, a second ground (GND) line must also be carried in

this separate cable, but only connected on the motor side. The external

set value speed signal must be potential-free.

September 2010 Edition / document number 903155_PDF_E - 07 / subject to change

maxon EC motor 15

Page 16

maxon motor

EC 20 flat with integrated electronics Operating Instructions

9 Trouble shooting

9.1 2-wire version

– Is the supply voltage set between 10.0 and 28.0 VDC?

– Is the supply voltage connected to the red and black wire and switched

on?

– Is the voltage at the red motor wire positive compared to voltage at the

black wire?

– Is the power supply source in the current limitation?

– Is the motor blocked mechanically?

9.2 5-wire version

– Is the supply voltage set between 10.0 and 28.0 V?

– Is the supply voltage connected to the red and black wire and switched

on?

– Is the voltage at the red motor wire positive compared to voltage at the

black wire?

– Is the set value speed voltage set between 0.33 and 10.0 V?

– Is the set value speed voltage connected and set at the white and black

wire?

– Is the voltage at the white motor wire positive compared to voltage at the

black wire?

– «Enable» through power supply (only for version «Enable»)

– Is the enable voltage set between 2.4 and 28.0 VDC?

– Is the enable voltage connected to the grey and black wire and

switched on?

– Is the voltage at the grey motor wire positive compared to voltage at

the black wire?

– «Enable» through potential-free contact (only for version «Enable»)

– Is the grey enable connected directly to the red supply voltage wire?

– Is the grey enable wire connected through a switch with the red

supply voltage wire?

– Is the switch or loop closed?

– is the power supply source in the current limitation?

– Is the motor blocked mechanically?

– The green wire does not have to be connected!

9.3 5-wire version, 2-wire operating mode

– Is the white and green wire directly connected together?

– Was there a direct connection between the white and green wire before

the supply voltage has been connected?

– Are there any more connections to the green or white wire?

– Is the supply voltage set between 10.0 and 28.0 VDC?

– Is the supply voltage connected and switched on?

– Is the voltage at the red motor wire positive compared to the voltage at

the black wire?

– In «enable» version, the grey cable does not require to be connected.

– In «cw/ccw» direction pre-selection version, the grey cable can be used

to define the direction (see 3.2).

– Is the power supply source in the current limitation?

– Is the motor blocked mechanically?

16 maxon EC motor

September 2010 Edition / document number 903155_PDF_E - 07 / subject to change

Page 17

maxon motor

Operating Instructions EC 20 flat with integrated electronics

10 Dimensions

10.1 2 Watt Version

IP 40 IP 00

Picture 21: Dimensional drawing 2 Watt Version

10.2 5 Watt Version

IP 40 IP 00

Picture 22: Dimensional drawing 5 Watt Version

September 2010 Edition / document number 903155_PDF_E - 07 / subject to change

maxon EC motor 17

Page 18

maxon motor

EC 20 flat with integrated electronics Operating Instructions

11 Glossary

1-Q speed controller

Max. torque [mNm]

Max. current [A]

IP 00

IP 40

Rotation CW/CCW

The motor produces positive torque in the selected or

programmed direction. The load is not actively decelerated when the speed set value is reduced or the

direction changed (direction pre-selection version). The

speed control enters again as soon as the load has

reduced its speed through friction to the level specified

by the set value speed.

The peak torque the motor can deliver intermittently. It

is restricted by the electronics overload protection.

Supply current with which the peak torque is generated

at nominal voltage. With an active speed controller,

the supply current is not proportional to the torque, but

also depends on the supply voltage. As a result, this

value only applies at nominal voltage.

No protection against access to dangerous parts. No

protection against water.

Protected against access to dangerous parts with a

wire, tool or similar >_ Ø1 mm.

Protected against fixed foreign objects >_ Ø1 mm.

No protection against water.

cw = clockwise

ccw = counter-clockwise

(seen on the flange side)

18 maxon EC motor

September 2010 Edition / document number 903155_PDF_E - 07 / subject to change

Loading...

Loading...