Page 1

maxon EC motor EC-i30 with integrated electronics

Document ID: rel8710

Operating Manual

The EC-i30 with integrated electronics is a brushless, speed-controlled

4-quadrant drive with four pole pairs. It is available as 55 Watt version

with two shaft ends:

Order

number

618864 5-wire, CW «Enable» 6’000 20

619301 5-wire, CW «Direction» 6’000 20

Var iant

Nominal

speed

[rpm]

Output

[W]

Functions

• Commutation with Hall sensors

• Digital speed control

• Speed range: 250…6’000 rpm

• Current limitation, non-adjustable

• Overvoltage and undervoltage switch-off

2

• Short-term overcurrent with I

• Temperature monitoring of electronics

• Protection against reverse polarity of supply voltage

• Set value speed via analog signal 0…10 V

• Speed monitor delivers speed-proportional frequency signal

• Parameter setting via power line communication (optional, by factory setting)

• Variants with control input «Enable» or «Direction»

T limitation possible

Edition March 2019

Contents

READ THIS FIRST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3 Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4 Protective Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

maxon motor ag Brünigstrasse 220 P.O.Box 263 CH-6072 Sachseln Phone +41 41 666 15 00 Fax +41 41 666 16 50 www.maxonmotor.com

Page 2

READ THIS FIRST

These instructions are intended for qualified technical personnel.

Prior commencing with any activities…

• you must carefully read and understand this manual and

• you must follow the instructions given therein.

The EC-i30 with integrated electronics is considered as partly completed machinery according to EU Directive 2006/42/

EC, Article 2, Clause (g) and is intended to be incorporated into or assembled with other machinery or other partly

completed machinery or equipment.

Therefore, you must not put the device into service,…

• unless you have made completely sure that the other machinery – the surrounding system the device is intended to

be incorporated to – fully complies with the requirements stated in the EU directive 2006/42/EC!

• unless the surrounding system fulfills all relevant health and safety aspects!

• unless all respective interfaces have been established and fulfill the stated requirements!

Safety Guidelines

Qualified

personnel

Legal

requirements

Additional safety

equipment

Repairs Be aware that you are not entitled to perform any repair on components supplied by maxon motor.

Danger to life Touching live wires causes death or serious injuries!

Max. supply

voltage

Electrostatic sensitive components

Temperature During operation, the temperature of housing, flange, or other components may exceed 60°C.

Do not engage with any work unless you possess the necessary skills.

Observe any regulation applicable in the country and/or at the site of implementation with regard to

health and safety/accident prevention and/or environmental protection.

Make sure that all associated devices and components are installed according to local regulations.

Be aware that, by principle, an electronic apparatus can not be considered fail-safe. Therefore, you must

make sure that any machine/apparatus has been fitted with independent monitoring and safety equipment. If the machine/apparatus should break down, if it is operated incorrectly, if the control unit breaks

down or if the cables break or get disconnected, etc., the complete drive system must return – and be

kept – in a safe operating mode.

• Consider any power cable as connected to live power, unless having proven the opposite!

• Make sure that neither end of cable is connected to live power!

• Make sure that power source cannot be engaged while work is in process!

• Obey lock-out/tag-out procedures!

• Make sure to securely lock any power engaging equipment against unintentional engagement

and tag it with your name!

The connected supply voltage must be between 8 VDC and 28 VDC. Permanently applied voltages

above 30 VDC will destroy the unit.

The built-in electronics can be destroyed by externally applied electronic discharges during transport,

installation, and during operation.

• Make sure to wear working cloth in compliance with ESD.

• Handle the device with extra care.

• Limit the voltage between flange and any live parts to 500 VDC

maxon EC motor

2 Document ID:: rel8710 EC-i30 IE

Edition: March 2019 Operating Manual

© 2019 maxon motor. Subject to change without prior notice.

Page 3

Terms used

4-Q speed

controller

Brake chopper Limits the operating voltage to a preset value as soon as its feed-in should rise above the threshold

Direction

CW/CCW

IP40 Protected against access to dangerous parts with a wire, tool, or similar ≥Ø 1 mm and against solid for-

Max. torque

[mNm]

M

max

Max. current

[A]

I

max

The motor produces positive torque in the selected or programmed direction. When the speed set value

is reduced or the direction changed (direction preselection version) the load is actively decelerated as to

the factory-set speed ramp.A load can be permanently decelerated.

Remark

When the load is decelerated, energy is fed back to the operating voltage supply. Thereby, the operating

voltage can undesirably increase and can damage in parallel connected consumers. Use an operating

voltage supply with feed-in possibility or a brake choppers to prevent excessive voltage surges.

value.

As seen towards the mounting flange:

• CW = shaft turns to the right (clockwise)

• CCW = shaft turns to the left (counterclockwise)

eign bodies ≥Ø 1 mm. No protection against water.

The maximum torque the motor can produce for a short term. It is limited by the overload protection of

the electronics.

Supply current with which the peak torque is generated at nominal voltage. With an active speed controller, the supply current is not proportional to the torque, but also depends on the supply voltage. As a

result, this value only applies at nominal voltage.

maxon EC motor

EC-i30 IE Document ID:: rel8710

Operating Manual Edition: March 2019

© 2019 maxon motor. Subject to change without prior notice.

3

Page 4

1 Technical Data

All data in the document are typical values.

For detailed information consult the data sheet at the end of this document.

Nominal voltage VDC 24

No load speed rpm 6’000

No load current mA 107

Nominal speed rpm 6’000

Nominal torque mNm 32.6

Nominal current A 1.19

Max. torque mNm 105

Max. current A 6.5

Max. efficiency % 75.4

Rotor inertia

Radial play — preloaded bearings

Max. axial load

Max. radial load 10 mm from flange N 30

Weight g 160

Motor Data

Mechanical Data

g·cm2

6.69

dynamic N 9

statistic N 48.8

supported N 2’510

Thermal Data

Thermal resistance housing/ambient air

Thermal resistance winding/housing

K/W-1

K/W-1

5.89

13

Thermal time constant winding s 34.1

Thermal time constant motor s 1’030

Max. winding temperature °C 155

Max. temperature of electronics °C 100

Connections

Operating voltage +VIN

Operating voltage GND

Speed setpoint «Set value speed»

Speed monitor «Monitor speed»

Control input «Enable» or «Direction»

red AWG 20 / 0.52 mm

black AWG 20 / 0.52 mm

white AWG 24 / 0.20 mm

green AWG 24 / 0.20 mm

grey AWG 24 / 0.20 mm

2

2

2

2

2

maxon EC motor

4 Document ID:: rel8710 EC-i30 IE

Edition: March 2019 Operating Manual

© 2019 maxon motor. Subject to change without prior notice.

Page 5

Controller Data

Operating voltage +VIN

Max. output voltage V

Output current, continuous I

Max. output current I

max

cont

Firmware A 6.5

Hardware A 8.0

VDC +8…+28

(+VIN x 0.97) − 0.5

A 4.5

Clock frequency of power stage kHz 50

Sampling rate of speed controller Hz 1’000

Velocity range rpm 250…6'000

Direction version «Enable» — CW

Direction version «Direction» — CCW / CW

Inputs

Speed set value «Set value speed»

Analog input 0…10.0 V (10.1 V); 101 kΩ

Resolution: 4’096 steps

Outputs

Speed monitor «Monitor speed» Digital output 3.3 V; 4.1 kΩ

Protective Functions

Inverse polarity protection

Undervoltage protection

Overvoltage protection

Temperature monitoring

cuts off at T >100 °C (typical)

engages at T <90 °C (typical)

up to max. −30 VDC

cuts off at VCC <7.5 VDC

engages at V

>7.7 VDC

CC

cuts off at VCC >29.5 VDC

engages at V

<28.5 VDC

CC

Overvoltage protection (transient) bipolar Transzorb diode 400 W·ms

Ambient Conditions

Operation °C

Temperature range

Operation with reduced

power output

Storage °C

Humidity (condensation not permitted) % 20…80

Voltage Supply

Ripple % <5

Load-dependent output current (recommended) A ≥3

Output current

min VDC 8.5

max VDC 28

Safe against forced supply if load is being decelerated.

With additional brake chopper if operating voltage rises too high due to active feed-in.

maxon EC motor

EC-i30 IE Document ID:: rel8710

Operating Manual Edition: March 2019

© 2019 maxon motor. Subject to change without prior notice.

−40…+40

°C +40…+85

−40…+35

5

Page 6

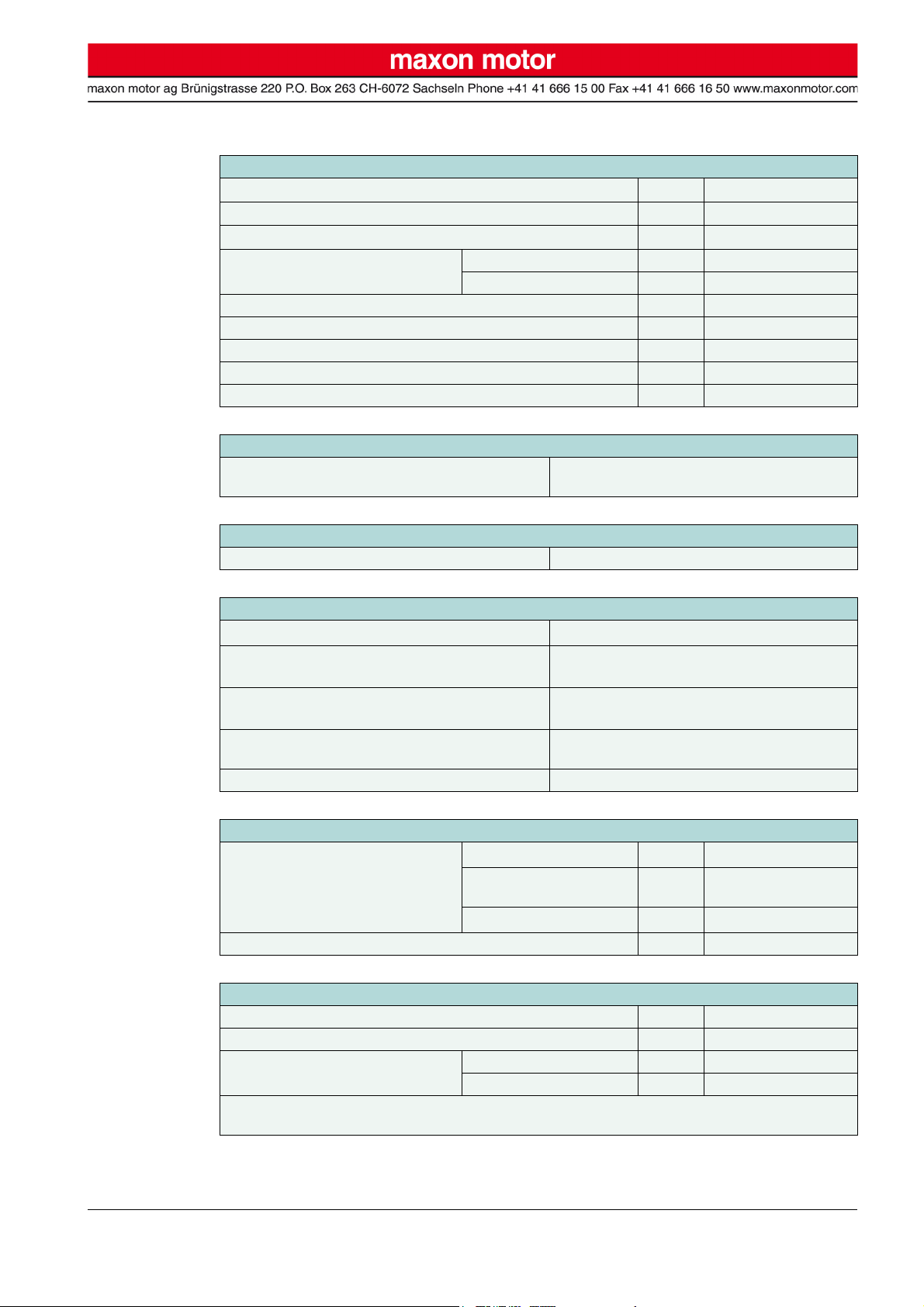

1.1 Speed / Torque / Operating Voltage Diagram

Provisional, calculated data. Measurement pending.

Figure 1 Speed / Torque / Operating voltage diagram

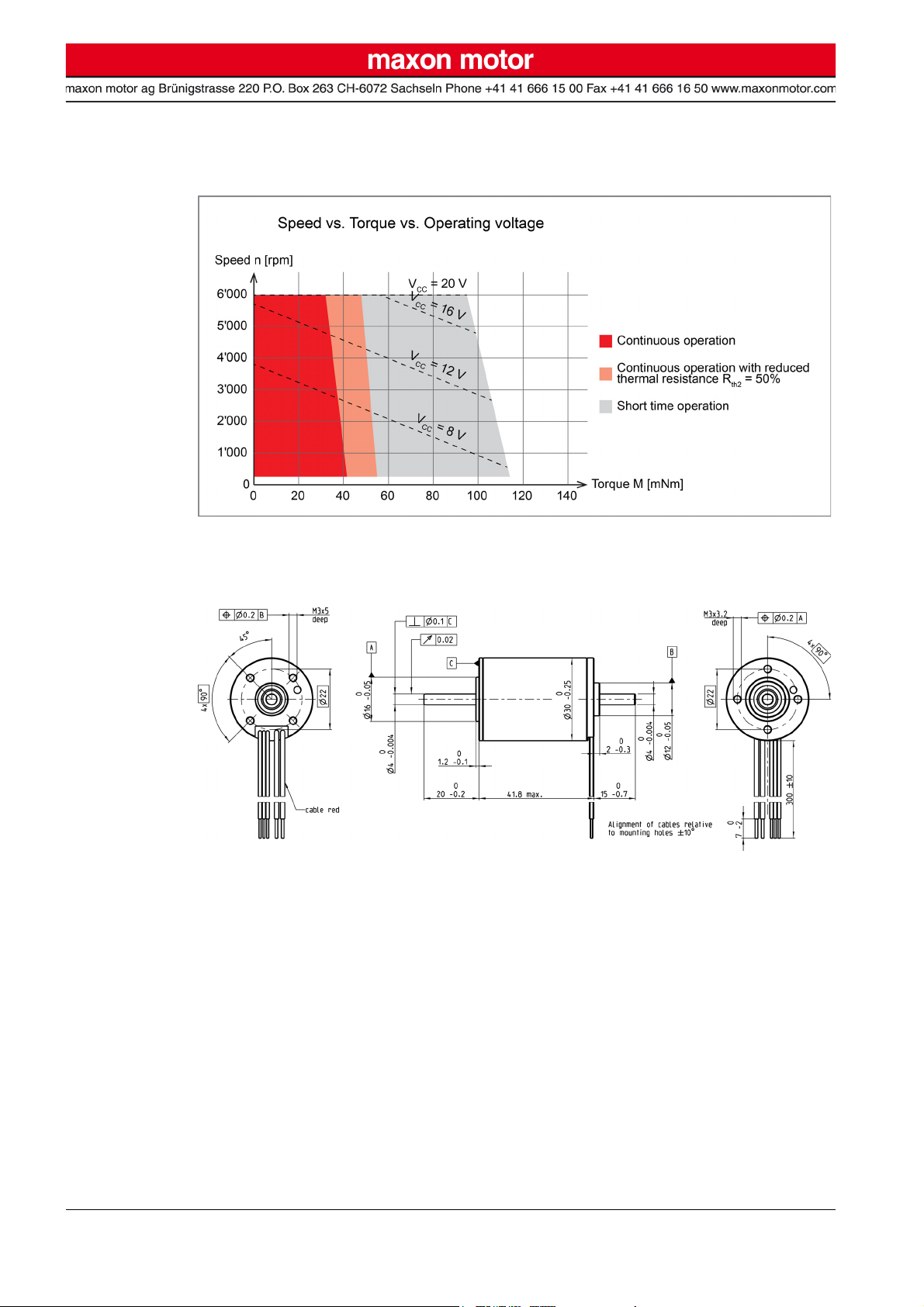

1.2 Dimensional Drawing

Figure 2 Dimensional drawing [mm]

maxon EC motor

6 Document ID:: rel8710 EC-i30 IE

Edition: March 2019 Operating Manual

© 2019 maxon motor. Subject to change without prior notice.

Page 7

2 Installation

Electrostatic Sensitive Devices (ESD)

The built-in electronics can be destroyed by externally applied electronic discharges during transport,

installation, and during operation.

• Make sure to wear working cloth in compliance with ESD.

• Handle the device with extra care.

• Limit the voltage between flange and any live parts to 500 VDC.

Possible irreversible Damage of Motor

• Until completion of the installation, individual components can be permanently damaged by improper

handling. Therefore, handle the components with particular care.

• Max. torque of flange screws is 1.1 Nm (grade 8.8 screws).

• A high heat dissipation by mounting to a large-scale metallic structural element permits higher power

output of the motor. However, in turn, the circuit board temperature protection can no longer adequately protect the winding.

• Cable outlet preferably downwards.

2.1 EMC-compliant Installation

Cable length ≤300 mm:

• Usually, no shielding is required.

• Star wiring recommended if several EC-i30 with integrated electronics are supplied by a common power supply.

Cable length >300 mm:

• The voltage drop in the connection cable must be minimized by choosing a sufficiently large

wire cross section.

• In electromagnetically harsh environments, use of shielded cables connected to ground at both

ends can improve immunity against interferences.

• Release cable shielding on one side if 50/60 Hz interference problems occur.

• The incidence surface for interferences can be reduced by shortening the unshielded original

connection cable.

• Immunity against interferences and speed stability in case of fluctuating loads can be accomplished by routing the set speed value signal separately in a shielded cable that is put to ground

on both sides. In addition to the set speed value signal, a second ground (GND) line must also

be carried in this separate cable, but only connected on the motor side. The external set value

speed signal must be potential-free.

maxon EC motor

EC-i30 IE Document ID:: rel8710

Operating Manual Edition: March 2019

© 2019 maxon motor. Subject to change without prior notice.

7

Page 8

2.2 Minimal Wiring

Figure 3 Set point «Set value speed» and (depending on version) activation «Enable» or direction

Figure 4 Set point «Set value speed» from external power supply and (depending on version)

preselection «Direction» from external power supply

activation «Enable» or direction preselection «Direction» with potential-free contact

maxon EC motor

8 Document ID:: rel8710 EC-i30 IE

Edition: March 2019 Operating Manual

© 2019 maxon motor. Subject to change without prior notice.

Page 9

Figure 5 Set point «Set value speed» via external potentiometer and (depending on version)

activation «Enable» or direction preselection «Direction» from external power supply

Figure 6 Set point «Set value speed» via external potentiometer and (depending on version)

activation «Enable» or direction preselection «Direction» with potential-free contact

maxon EC motor

EC-i30 IE Document ID:: rel8710

Operating Manual Edition: March 2019

© 2019 maxon motor. Subject to change without prior notice.

9

Page 10

3 Functional Description

3.1 Inputs

3.1.1 Set point «Set value speed»

The motor speed is set with the analog input «Set value speed». The input is protected against overvoltage up to the maximum operating voltage.

Pin assignment Connection wire «Set value speed», white

Input voltage range 0…+10.1 V (referenced to GND)

Input impedance

Continuous overvoltage protection −30…+30 V

Nominal design point 10.0 VDC equals 6'000 rpm

101 kΩ (in range of 0…+11.1 V)

68 kΩ (in range of +11.1 V…+VIN)

Figure 7 «Set value speed» – Input circuitry

The speed set value is set with the voltage at the set value input. The set speed is controlled by the controller. Changes to speed set value are executed by a delayed internal speed ramp.

A set value smaller a predefined minimum voltage (Table 1) disables the power stage, the motor shaft

coasts.

Set Value Function Remarks

0.00…0.21 V IDLE mode Motor not engaged or coasts

0.21…0.42 V Operation at minimal speed (250 rpm)

0.42…10.0 V

10.0…10.1 V

Table 1 «Set value speed» – Setpoint range

Linear speed setting between 250 rpm

and 6‘000 rpm

Linear speed setting between 6‘000 rpm

and 6‘060 rpm

maxon EC motor

10 Document ID:: rel8710 EC-i30 IE

Edition: March 2019 Operating Manual

© 2019 maxon motor. Subject to change without prior notice.

Page 11

Figure 8 Speed as function of set value voltage

Figure 9 Speed as function of set value voltage – «Enable»

maxon EC motor

EC-i30 IE Document ID:: rel8710

Operating Manual Edition: March 2019

© 2019 maxon motor. Subject to change without prior notice.

11

Page 12

Setting Speed Set Value by PWM Signal

The speed set value can be preset by fixed frequency and amplitude.

The desired set speed value change is obtained by variation of the duty cycle in range of 0…100%.

Both, amplitude and duty cycle thereby have an effect on the resulting speed. The average of the

applied PWM voltage corresponds to the analog input signal of the speed set value.

Remark

Depending on load and type of installation, low PWM frequencies can cause audible speed fluctuations.

Nominal value amplitude PWM set value 0…+10.1 VDC (referenced to GND)

Max. value amplitude PWM set value −30…+30 VDC (referenced to GND)

Frequency range PWM set value 500 Hz…20 kHz

Modulation PWM set value 0…100%

Continuous overvoltage protection −30…+30 V

Figure 10 Examples for possible PWM activation for the input «Set value speed»

maxon EC motor

12 Document ID:: rel8710 EC-i30 IE

Edition: March 2019 Operating Manual

© 2019 maxon motor. Subject to change without prior notice.

Page 13

3.1.2 Version Power Stage Activation: Control Input «Enable»

The power stage is activated with digital input «Enable». The input is protected against overvoltage up

to the maximum operating voltage.

Pin assignment Connection wire «Enable», grey

Input voltage range 0…+3.3 V (referenced to GND)

Input impedance

130 kΩ (in range of 0…+4.4 V)

10 kΩ (in range of +4.4 V…+VIN)

Continuous overvoltage protection −30…+30 V

Figure 11 «Enable» – Input circuitry

The power stage is activated by a voltage above 2.1 V, the speed is dependent on the voltage applied

on the input «Set value speed». The power stage is deactivated by voltage below 1.1 V, the motor shaft

coasts independent on the voltage applied on the input «Set value speed».

Set Value Function Remarks

0.0…1.1 V IDLE mode Power stage not activated

2.1…3.3 V RUN mode

Power stage activated if «Set value

speed» higher than 0.21 V

Table 2 «Enable» – Setpoint range

maxon EC motor

EC-i30 IE Document ID:: rel8710

Operating Manual Edition: March 2019

© 2019 maxon motor. Subject to change without prior notice.

13

Page 14

3.1.3 Version Direction Preselection: Control Input «Direction»

The motor’s rotational direction is set with digital input «Direction». The input is protected against overvoltage up to the maximum operating voltage.

Pin assignment Connection wire «Direction», grey

Input voltage range 0…+3.3 V (referenced to GND)

Input impedance

130 kΩ (in range of 0…+4.4 V)

10 kΩ (in range of +4.4 V…+VIN)

Continuous overvoltage protection −30…+30 V

Figure 12 «Direction» – Input circuitry

The activation of the power stage is solely dependent on the setpoint voltage «Set value speed». Upon

reversal of the direction with a rotating motor shaft, the internal set value is decreased by a preset ramp

until the minimal speed is reached. The power stage is briefly deactivated until the motor shaft accelerates (with the set ramp) in the newly commanded direction up to the preset speed.

Set Value Function Remarks

0.0…1.1 V CCW Motor shaft turns counterclockwise

2.1…3.3 V CW Motor shaft turns clockwise

Table 3 «Direction» – Setpoint range

maxon EC motor

14 Document ID:: rel8710 EC-i30 IE

Edition: March 2019 Operating Manual

© 2019 maxon motor. Subject to change without prior notice.

Page 15

3.2 Outputs

f

MonitorSpeed

n

actualZPolepairs

2⋅⋅

80

-----------------------------------------------------= Hz[]

n

actual

f

MonitorSpeed

80⋅

Z

Polepairs

2⋅

------------------------------------------= rpm[]

n

actual

Z

Polepairs

f

MonitorSpeed

3.2.1 Speed monitor «Monitor speed»

The actual motor velocity can be monitored using the output «Monitor speed» of the electronics.

Thereby, the actual motor velocity is available as digital signal (High/Low) and delivers 6 output pulses

per mechanical turn of a motor with 4 pole pairs.

Remark

The output «Monitor speed» is also available in condition «Disable».

Pin assignment Connection wire «Monitor speed», green

Output voltage range 0…+3.3 VDC

Output resistance 4.1 kΩ

Low level, no load max. 0.5 VDC

High level, no load min. 2.8 VDC

Duty cycle 50%

Continuous overvoltage protection −30…+30 V

Figure 13 «Monitor speed» – Output circuitry

Sought: Frequency at output «Monitor speed»

Sought: Speed of motor shaft

Speed [rpm]

Number of magnetic pole pairs of motor (4 for the maxon EC-i 30)

Frequency at output «Monitor speed» [Hz]

maxon EC motor

EC-i30 IE Document ID:: rel8710

Operating Manual Edition: March 2019

© 2019 maxon motor. Subject to change without prior notice.

15

Page 16

4 Protective Functions

Inverse polarity

protection

Undervoltage

switch-off

Overvoltage

switch-off

Overvoltage

protection

Temperature

monitoring

Current limiting The winding current is electronically limited to approx. 2.56 A (short-term 8.0 A). Thereby, the maximum

The amplifier is protected against polarity reversal of the supply voltage +VIN is protected. Thereby, the

negative input voltage must not exceed the maximum permitted supply voltage +V

The motor is switched off when the supply voltage +VIN drops below approx. 7.5 V to prevent operation

beyond the specified range.

If the supply voltage +V

for operation.

The motor is switched off when the supply voltage +VIN exceeds approx. 29.5 V to prevent operation

beyond the specified range.

If the supply voltage +V

ready for operation.

The overvoltage protection comprises a bidirectional Transzorb diode (overvoltage protection diode)

capable of receiving a maximum peak energy of 400 mWs. Threshold voltage is a minimum of 31.1 V,

independent of polarity.

The motor is switched off if the PCB temperature exceeds approx. 100°C. As soon as the PCB temperature has dropped below approx. 90°C, the amplifier will be again ready for operation.

load torque is limited accordingly.

exceeds the restart threshold of approx. 7.7V, the amplifier will be again ready

IN

drops below the restart threshold of approx. 28.5 V, the amplifier will be again

IN

.

IN

5 Troubleshooting

• Is the supply voltage +VIN between 8.0 VDC and 28.0 VDC?

• Is the supply voltage +V

• Is the voltage at the red motor connection positive compared to black connection?

• Is the speed set value voltage between 0.42 VDC and 10.0 VDC

• Is the speed set value voltage connected to white and black wires and switched on

• Is the voltage at the white motor connection positive compared to black connection?

• Is the power source not in current limiting?

• Is the motor not mechanically blocked? Can it turn freely?

• The green wire does not have to be connected.

connected to red and black wires and switched on?

IN

maxon EC motor

16 Document ID:: rel8710 EC-i30 IE

Edition: March 2019 Operating Manual

© 2019 maxon motor. Subject to change without prior notice.

Page 17

••page intentionally left blank••

maxon EC motor

EC-i30 IE Document ID:: rel8710

Operating Manual Edition: March 2019

© 2019 maxon motor. Subject to change without prior notice.

17

Page 18

© 2019 maxon motor. All rights reserved.

The present document – including all parts thereof – is protected by copyright. Any use (including reproduction, translation,

microfilming, and other means of electronic data processing) beyond the narrow restrictions of the copyright law without the

prior approval of maxon motor ag, is not permitted and subject to prosecution under the applicable law.

maxon motor ag

Brünigstrasse 220

P.O.Box 263

CH-6072 Sachseln

Switzerland

Phone +41 41 666 15 00

Fax +41 41 666 16 50

www.maxonmotor.com

maxon EC motor

18 Document ID:: rel8710 EC-i30 with integrated electronics EC-i30

Edition: March 2019 EC-i30 with integrated electronics IE Operating Manual

© 2019 maxon motor. Subject to change without prior notice.

Loading...

Loading...