Page 1

maxon motor

maxon motor control 4-Q-EC Servoamplifier DES 70/10

Order number 228597

Operating Instructions April 2006 Edition

The DES (Digital EC Servoamplifier) is a very efficient digital

servoamplifier with sinusoidal current commutation for

perfectly controlling EC (Electronic Commutation) motors.

The EC motors must be equipped with Hall sensors and a

digital encoder with line driver.

Control, monitoring and complete control algorithms are

carried out in a very fast digital signal processor.

As with classic, conventional automatic controllers, easy

trimming and adjustment of the servoamplifier is possible,

with just a few potentiometers.

As an alternative, configuration is also possible using a

PC (RS232 or CAN). This is particularly beneficial with

series application, as all adjustments and parameters can

be set quickly, numerically and easily reproduced.

The set value specification can be made conventionally

with an analogue input (0 ... 5 V or ±10 V), RS232 or CAN

bus interface.

The sinusoidal commutation causes minimal torque ripple

and low motor noise.

Table of Contents

1

Safety Instructions ...........................................................................................................................................2

2 Performance Data............................................................................................................................................3

3 Minimum External Wiring for Different Modes of Operation ............................................................................4

4 Operating Instructions......................................................................................................................................5

5 Functions..........................................................................................................................................................7

6 Error Messages..............................................................................................................................................15

7 EMC-compliant installation ............................................................................................................................16

8 Block Diagram................................................................................................................................................18

9 Dimension Drawing........................................................................................................................................18

The latest edition of these operating instructions, additional documentation and software to the DES 70/10 may also be found

on the Internet under

www.maxonmotor.com category «Service & Downloads», Order number 228597.

This document is valid for the HardwareVersion 4102.

Page 2

maxon motor

4-Q-EC Servoamplifier DES 70/10 Operating Instructions

1 Safety Instructions

Skilled Personnel

Installation and starting of the equipment shall only be performed by experienced,

skilled personnel.

Statutory Regulations

The user must ensure that the servoamplifier and the components belonging to it

are assembled and connected according to local statutory regulations.

Load Disconnected

For primary operation the motor should be free running, i. e. with the load disconnected.

Additional Safety Equipment

An electronic apparatus is, in principle, not fail-safe. Machines and apparatus must

therefore be fitted with independent monitoring and safety equipment. If the

equipment breaks down, if it is operated incorrectly, if the control unit breaks down

or if the cables break, etc., it must be ensured that the drive or the complete

apparatus is kept in a safe operating mode.

Repairs

Repairs may be made by authorised personnel only or by the manufacturer. It is

dangerous for the user to open the unit or make repairs to it.

Danger

Do ensure that during the installation of the DES 70/10 no apparatus is connected

to the electrical supply. After switching on, do not touch any live parts!

Max. Supply Voltage

Make sure that the supply voltage is between 24 and 70 VDC. Voltages higher than

75 VDC or of wrong polarity will destroy the unit.

Short circuit and earth fault

The DES 70/10 amplifier is not protected against winding short circuits against

ground safety earth and/or Gnd!

Electrostatic Sensitive Device (ESD)

2 maxon motor control April 2006 Edition / Subject to change

Page 3

maxon motor

Operating Instructions 4-Q-EC Servoamplifier DES 70/10

2 Performance Data

2.1 Electrical Data

Supply voltage VCC (Ripple < 5%)...............................................................................24 - 70 VDC

Max. output voltage.......................................................................................................... 0.9 · V

CC

Max. output current Imax ........................................................................................................30 A

Continuous output current Icont ..............................................................................................10 A

Switching frequency............................................................................................................50 kHz

Max. efficiency ....................................................................................................................... 92 %

Band width current controller ................................................................................................1 kHz

Max. speed (motor with 1 pole pair)............................................................................. 25 000 rpm

Minimum terminal inductance .............................................................................................400 µH

2.2 Inputs

“Set value”...................................... configured by DIP switch S9: -10 ... +10 V (R

i

= 80 kΩ)

0 ... +5 V (R

i

= 50 kΩ)

“Enable” .......................................................................................... +2.4 ... +50 VDC (Ri = 12 kΩ)

“Digital 1” (Switch “Monitor n” / “Monitor I”) ..................................... +2.4 ... +50 VDC (Ri = 17 kΩ)

“Digital 2” (Switch speed-/ current controller) .................................. +2.4 ... +50 VDC (Ri = 90 kΩ)

“STOP”............................................................................................ +2.4 ... +50 VDC (Ri = 17 kΩ)

Encoder signals ...............................................................................A, A\, B, B\, I, I\ ; max. 1 MHz

Hall sensor signals.......................................................Hall sensor 1, Hall sensor 2, Hall sensor 3

CAN ID (CAN identification) ........................................................configured by DIP switch S1 ... 7

ID = 1 ... 127 (binary coded)

2.3 Outputs

Monitor...........................configurable by DIP Switch 10: -10 ... +10 V (R0 = 1 kΩ, fg = 900 Hz)

0 ... +5 V (R

0

= 1 kΩ, fg = 900 Hz)

Status reading “Ready” .................................................open collector: max. 30 VDC (I

L

< 20 mA)

2.4 Voltage outputs

Encoder supply voltage...............................................................................+5 VDC, max. 100 mA

Hall sensors supply voltage ..........................................................................+5 VDC, max. 50 mA

Auxiliary supply voltage ................................................................................+5 VDC, max. 20 mA

2.5 Interfaces

RS232............................................................................................ RxD, TxD (max. 115 200 bit/s)

CAN ..............................................................................................CAN_H, CAN_L (max.1 Mbit/s)

2.6 Trim potentiometers

n

max

, Offset, I

max,

gain

2.7 LED indicator

Bi-colour LED .................................................................................................... READY / ERROR

green = READY, red = ERROR

2.8 Ambient temperature/ humidity range

Operating ................................................................................................................... -10 ... +45°C

Storage ......................................................................................................................-40 ... +85°C

non condensating.......................................................................................................... 20 ... 80 %

2.9 Mechanical data

Weight...................................................................................................................... approx. 400 g

Dimensions (L x W x H) ............................................................see dimension drawing,

chapter 9

Mounting plate .........................................................................................................for screws M4

2.10 Connections

PCB clamps ............................................................................. Power (6 poles), Signal (20 poles)

Pitch ..................................................................................... Power 5.08 mm, Signal 2.54 mm

suitable for wire cross section ........................................Power 0.14 ... 1.5 mm

2

(AWG 26-16)

Signal 0.14 ... 0.5 mm

2

(AWG 26-20)

Encoder ................................................................................................ Plug DIN41651 (10 poles)

for flat band cable, pitch 1.27 mm, AWG28

April 2006 Edition / Subject to change maxon motor control 3

Page 4

maxon motor

4-Q-EC Servoamplifier DES 70/10 Operating Instructions

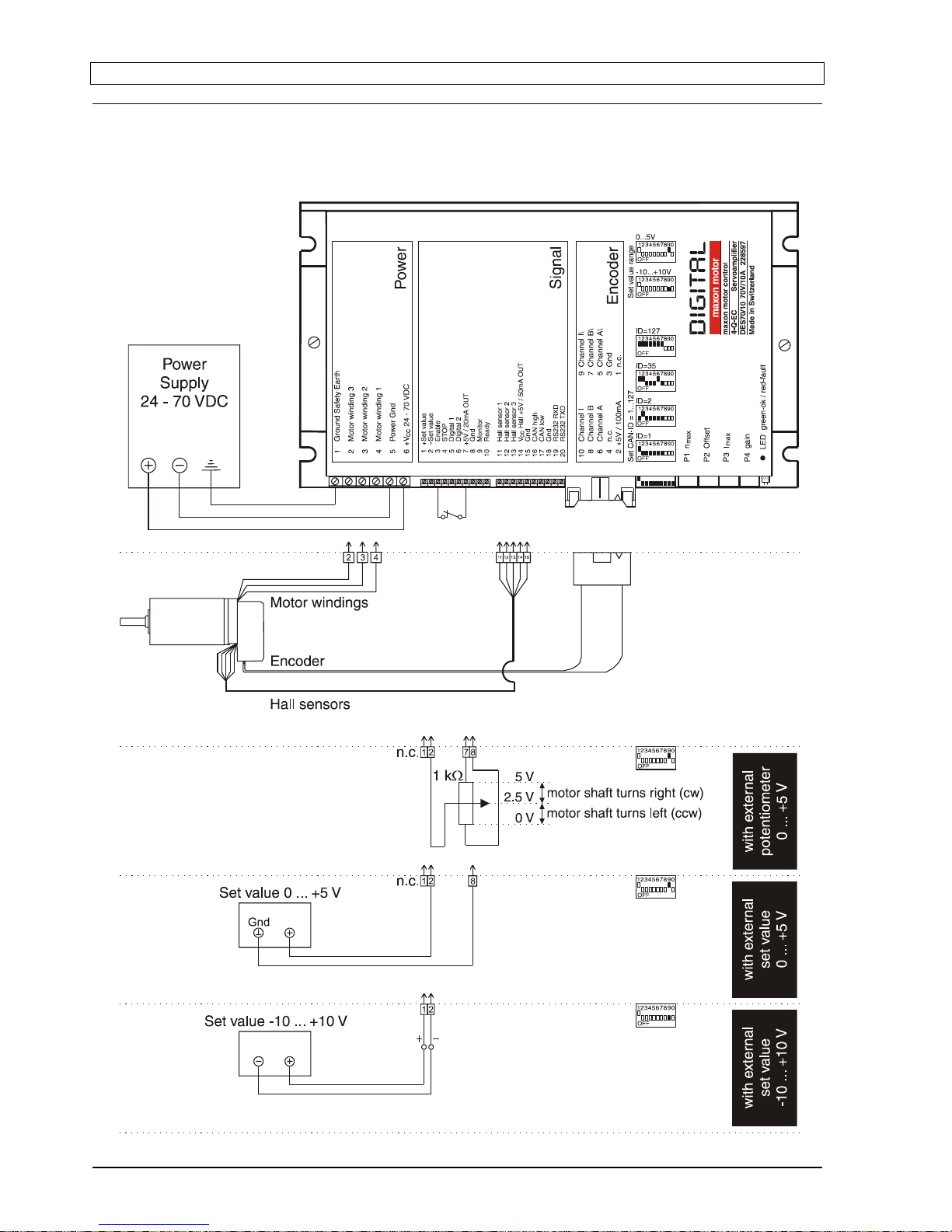

3 Minimum External Wiring for Different Modes of Operation

4 maxon motor control April 2006 Edition / Subject to change

Page 5

maxon motor

Operating Instructions 4-Q-EC Servoamplifier DES 70/10

4 Operating Instructions

4.1 Power supply layout

Any available power supply can be used, provided it meets the minimal requirements set out below.

During set up and adjustment phases, we recommend separating the motor

mechanically from the machine to prevent damage due to uncontrolled motion.

Power supply requirements

Output voltage VCC min. 24 VDC; VCC max. 70 VDC

Ripple < 5 %

Output current depending on load,

continuous max. 10 A

acceleration, short-time max. 30 A

The required voltage can be calculated as follows:

Known values

Ö Operating torque MB [mNm]

Ö Operating speed n

B

[rpm]

Ö Nominal motor voltage U

N

[V]

Ö Motor no-load speed at U

N

, n0 [rpm]

Ö Speed/torque gradient of the motor ∆n/∆M [rpm / mNm]

Sought value

Ö Supply voltage

V

CC

[V]

Solution

][2

9.0

1

)(

0

VM

M

n

n

n

U

V

BB

N

CC

+⋅⋅

∆

∆

+⋅=

Choose a power supply capable of supplying this calculated voltage under load.

The formula takes a max. PWM cycle of 90 % and a 2 volts max. voltage drop

at DES 70/10 into account.

Consider:

The power supply must be able to buffer the back-fed energy from brake operation e. g. in a condenser. With electronically stabilized power supply units, care

must be taken to ensure that the overcurrent protection responds in nonoperating condition.

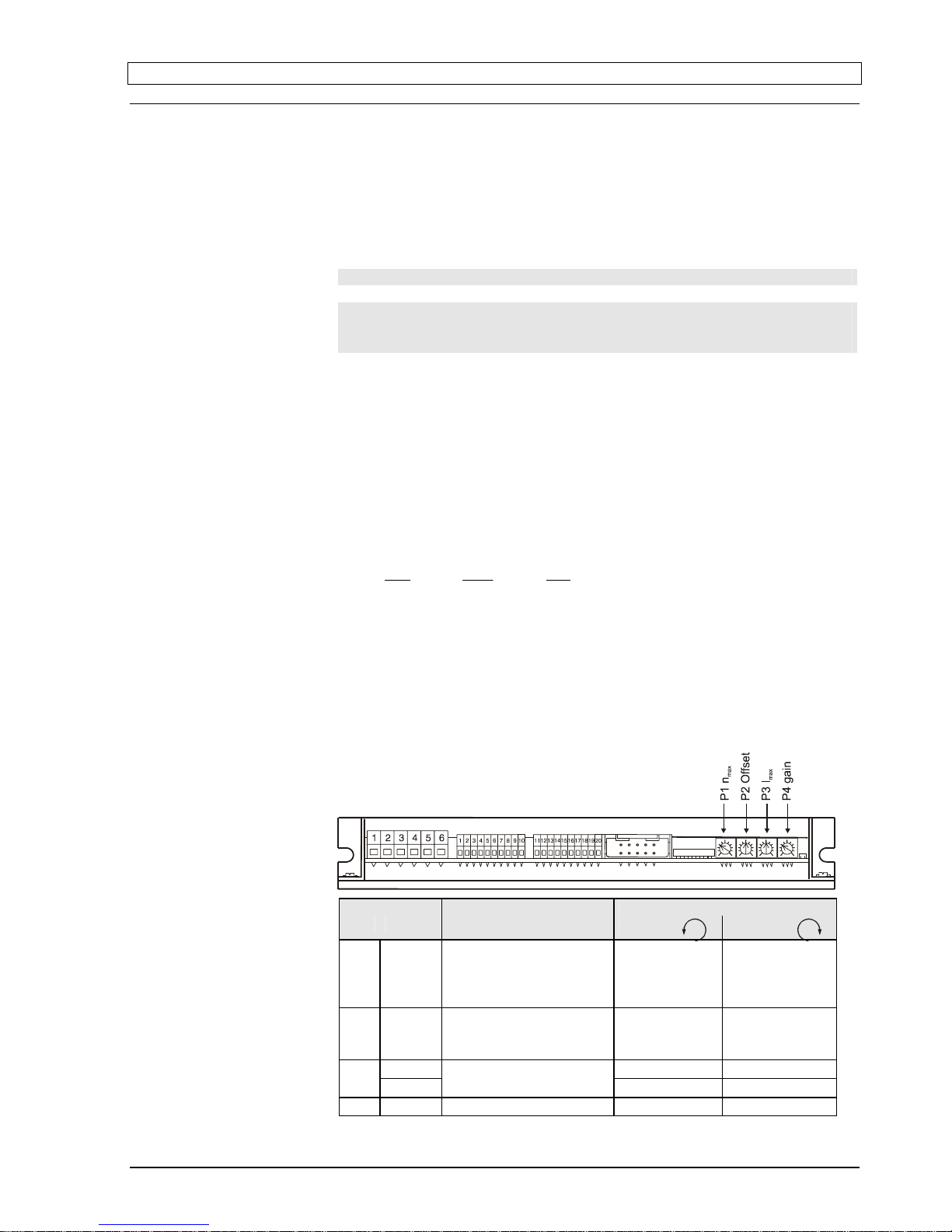

4.2 Function of the potentiometers

Potentiometer Function Turn to the

left right

P1

n

max

max. speed at

max. set value (e.g.

external potentiometer

fully clockwise; 5 V; 10 V)

slower

min. 0 rpm

faster

max.

25 000 rpm

P2

Offset

Adjustment: n = 0 rpm

(set value e. g. ext. potentiom. in centre pos.)

motor turns

CCW

motor turns CW

I

max

lower ≈ 0A higher ≈ 30A

P3

I

cont

current limit

lower ≈ 0A higher ≈ 10A

P4

gain amplification lower higher

April 2006 Edition / Subject to change maxon motor control 5

Page 6

maxon motor

4-Q-EC Servoamplifier DES 70/10 Operating Instructions

4.3 Adjustment of the potentiometer

4.3.1 Pre-adjustment

With the pre-adjustment, the potentiometers are set in a preferred position.

DES units in the original packing are preset.

Pre-adjustment potentiometers

P1 n

max

30 %

1)

P2 Offset 50 %

P3

I

max

50 %

2)

P4

gain

30 %

1) 30 % are equivalent to n

max

= approx 7500 rpm

2) 50 % are equivalent to I

cont

= approx. 5 A, I

max

= approx. 15 A

4.3.2 Adjustment

Digital speed control

(see also 5.1.6)

1. Give the max. set value (e.g. 10 V) and turn potentiometer P1 n

max

until

the required speed is achieved.

2. Set potentiometer P3 I

max

at the required limiting value.

Important: The limiting value I

cont

(= 1/3 I

max

) should be below the nominal

current (max. continuous current) as shown on the motor data sheet.

3. Increase potentiometer P4 gain slowly until amplification is set suffi-

ciently high.

Important: If the motor vibrates or becomes loud, the selected amplifica-

tion is too high and the potentiometer P4 must be readjusted until the

instability of the drive’s closed loop ceases under all loads.

4. Adjust set value to zero, e.g. by short-circuiting the set value. Then, with

the potentiometer P2 Offset, set the motor speed to zero.

Note: Step 4 is not necessary with external set value potentiometer.

Digital current control

(see also 5.1.6)

1. Set potentiometer P3 I

max

at the required limiting value.

Important: The limiting value I

cont

(= 1/3 I

max

) should be below the nominal

current (max. continuous current) as shown on the motor data sheet.

2. Adjust set value to zero, e.g. by short-circuiting the set value. Then, with

the potentiometer P2 Offset, set the motor speed to zero.

Note

Configured as a digital current controller, P1 n

max

und P4 gain are not activated.

6 maxon motor control April 2006 Edition / Subject to change

Page 7

maxon motor

Operating Instructions 4-Q-EC Servoamplifier DES 70/10

5 Functions

5.1 Inputs

5.1.1 “Set value”

Two different versions can be selected to give an analogue set value.

Versions are selected by setting the DIP switch S9 “Set value range”.

The “Set value” input is protected against overvoltage.

Set value range -10 ... +10 V

Input voltage range -10 ... +10 V

Input circuit differential

Input resistance

80 kΩ

Positive set value (+Set Value) > (-Set Value)

Negative set value (+Set Value) < (-Set Value)

DIP-Switch 9 OFF

Set value range 0 ... +5 V is selected, if the set value is given from an external

potentiometer.

Set value range 0 ... +5 V Input voltage range 0 ... +5 V

Input circuit against Gnd

Input resistance

50 kΩ

Positive set value (-Set Value) < 2.5 VDC

Negative set value (-Set Value) > 2.5 VDC

DIP-Switch 9

ON

Required external potentiometer

1 kΩ

Note on set value range 0 ... +5 V:

If using a set value range 0 ... +5 V, do not connect “+Set Value”

(Signal clamp pin 1).

5.1.2 “Enable”

If a voltage is given at “Enable”, the servoamplifier switches the motor voltage to

the winding connections. If the “Enable” input is not switched on (floating) or is

connected to Gnd, the power stage will be high-impedance and therefore disabled.

The “Enable” input is protected against overvoltage.

Input resistance

12 kΩ (+5 V)

7 kΩ (+24 V)

“Enable”

Minimum input voltage +2.4 VDC

Maximum input voltage +50 VDC

Switching time nominal 3 ms (at 5 V)

“Disable” Minimum input voltage 0 VDC

Maximum input voltage +0.8 VDC

Switching time nominal 4 ms (at 5 V)

April 2006 Edition / Subject to change maxon motor control 7

Page 8

maxon motor

4-Q-EC Servoamplifier DES 70/10 Operating Instructions

5.1.3 “Hall sensor 1”, “Hall sensor 2”, “Hall sensor 3”

On one hand the Hall sensors detect the rotor position during start-up and on

the other hand monitor the rotor position during operation.

The “Hall sensor“ inputs are protected against overvoltage.

Voltage value “low” max. 0.8 V

Voltage value “high” min. 2.4 V

Internal pull-up resistance

2.7 kΩ against +5 VDC

Suitable for Hall effect sensors IC using Schmitt trigger with open collector output.

5.1.4 “STOP”

If a voltage is given at “STOP”, the motor speed will be stopped with maximum

deceleration (adjusted value at potentiometer P3 I

max

) until motor shaft stands

still.

If the “STOP” input is not switched off (floating) or is connected to Gnd, the motor speed is not affected.

The “STOP” input is protected against overvoltage.

Input resistance

17 kΩ (+5 V)

12 kΩ (+24 V)

“STOP” disabled

Minimum input voltage 0 VDC

Maximum input voltage +0.8 VDC

“STOP” enabled Minimum input voltage +2.4 VDC

Maximum input voltage +50 VDC

5.1.5 Toggle monitor signal “Digital 1”

If the “Digital 1” input is not switched on (floating) or is connected to Gnd, the

actual motor speed n is given at the “Monitor” output.

If a voltage is given at “Digital 1”, the actual motor current l is given at the

“Monitor” output.

The “Digital 1” input is protected against overvoltage.

Input resistance

17 kΩ (+5 V)

12 kΩ (+24 V)

“Monitor n” enabled

Minimum input voltage 0 VDC

Maximum input voltage +0.8 VDC

“Monitor I” enabled

Minimum input voltage +2.4 VDC

Maximum input voltage +50 VDC

8 maxon motor control April 2006 Edition / Subject to change

Page 9

maxon motor

Operating Instructions 4-Q-EC Servoamplifier DES 70/10

5.1.6 Toggle controller mode (speed/current control) “Digital 2”

If the “Digital 2” input is not switched on (floating) or is connected to a voltage

higher than 2.4 VDC, the servoamplifier is configured to speed controller mode.

If the “Digital 2” input is connected to Gnd, the servoamplifier is configured to

current (torque) mode.

The “Digital 2” input is protected against overvoltage.

Input resistance

92 kΩ (+5 V)

13 kΩ (+24 V)

Internal pull-up resistance

22 kΩ against +5 VDC

Speed control enabled

Minimum input voltage +2.4 VDC

Maximum input voltage +50 VDC

Current control enabled

Minimum input voltage +0 VDC

Maximum input voltage +0.8 VDC

Note

If the controller mode has been changed, a disable-enable process (refer to

5.1.2, “Enable”) must be carried out to activate the new mode.

5.1.7 Encoder

Encoder supply voltage +5 VDC max. 100 mA

Maximum encoder frequency 1 MHz

Voltage value TTL

Low max. 0.8 V

High min. 2.0 V

Internal Line Receiver EIA standard RS-422

It is recommended to use an encoder with built-in line driver.

Male connector (front view)

Pin configuration at “Encoder” input:

1 n.c. Not connected

2 +5 V +5 VDC max. 100 mA

3 Gnd Ground

4 n.c. Not connected

5 A\ Inverted channel A

6 A Channel A

7 B\ Inverted channel B

8 B Channel B

9 I\ Inverted channel I

10 I Channel I

This pin configuration is compatible with the flat cable plugs of the HEDL 55xx

encoder (with line driver) and the MR encoders with line driver, type ML and L.

Note

The standard encoder adjustment (original packing) refers to a 500-counts per

turn encoder. For other encoders, the adjustment must be modified with the software (GUI).

April 2006 Edition / Subject to change maxon motor control 9

Page 10

maxon motor

4-Q-EC Servoamplifier DES 70/10 Operating Instructions

5.2 Outputs

5.2.1 Auxiliary voltage “VCC Hall +5 V / 50 mA OUT”

An internal auxiliary voltage of +5 V is provided for powering the Hall sensors.

The output is protected against overload.

Output voltage +5 VDC

Maximum output current 50 mA

5.2.2 Auxiliary voltage “+5 V / 20 mA OUT”

An internal auxiliary voltage of +5 V is provided:

• Control of inputs: “Enable”, “Digital 1” and “Digital 2”

• Supplying external potentiometer 1 kΩ

The output is protected against overload.

Output voltage +5 VDC

Maximum output current 20 mA

5.2.3 “Monitor“

Speed monitor “Monitor n“ “Digital 1“ input 0 ... +0.8 VDC (or not connected)

The speed monitor is primarily intended for the qualitative estimation of the dynamics. The absolute speed is determined by the properties of the speed sensors and by the setting of the n

max

potentiometer. The signal is proportional to

the speed.

DIP-Switch S10 Ð OFF

DIP-Switch S10 Ï ON

Output voltage range 0 ... +5 VDC -10 ... +10 VDC

Ripple max. 0.02 V max. 0.08 V

Resolution approx. 0.0125 V

(400 Steps)

approx. 0.05 V

(400 Steps)

Output resistance R

O

1 kΩ 1 kΩ

Cutoff frequency f

g

900 Hz 900 Hz

Example:

-n

max

corresponding to 0 V -10 V

0 rpm corresponding to 2.5 V 0 V

+n

max

corresponding to 5 V +10 V

Current monitor “Monitor I“ “Digital 1“ input +2.4 ... +50 VDC

The servoamplifier makes a current actual value available for monitoring purposes. The signal is proportional to the mean value of the motor current.

DIP switch S10 Ð OFF

DIP switch S10 Ï ON

Output voltage range 0 ... +5 VDC -10 ... +10 VDC

Ripple max. 0.02 V max. 0.08 V

Resolution approx. 0.0125 V

(400 Steps)

approx. 0.0500 V

(400 Steps)

Output resistance R

O

1 kΩ 1 kΩ

Cutoff frequency f

g

900 Hz 900 Hz

Gradient ≈ 12 A/V ≈ 3 A/V

Example:

-30 A corresponding to 0 V -10 V

0 A corresponding to 2.5 V 0 V

+30 A corresponding to 5 V +10 V

The “Monitor“ output is protected against overload.

10 maxon motor control April 2006 Edition / Subject to change

Page 11

maxon motor

Operating Instructions 4-Q-EC Servoamplifier DES 70/10

5.2.4 Status reading “Ready”

The “Ready” signal can be used to report operational readiness or a fault condition on a master control unit. The fault condition is stored. In order to reset the

fault condition, the servoamplifier must be re-released (Enable). If the cause of

the fault situation cannot be eliminated, the error will occur again immediately.

Additional external voltage is required:

10

max. 30 V

Gnd

“Ready”

I

max

≤

20mA

Input voltage range max. 30 VDC

Load current < 20 mA

Caution:

The load current must be limited by an external barrier resistance up to 20 mA

maximum!

off

1111111111

Version 1:

Standard (pre-adjusted)

Error output

J403 short-circuited (0 Ω)

J404 not mounted (open)

The open collector output is, in normal cases, i.e. no faults, switched to Gnd.

In case of a fault, the error output is not conducting (see also 6.2).

Version 2:

Special (customized)

Inverted error output J403 not mounted (open)

J404 short-circuited (0 Ω)

The open collector output is, in normal cases, i.e. no faults, not conducting (high

resistance).

In case of a fault, the error output is switched to Gnd (see also 6.2).

April 2006 Edition / Subject to change maxon motor control 11

Page 12

maxon motor

4-Q-EC Servoamplifier DES 70/10 Operating Instructions

5.3 Interfaces

5.3.1 Serial Interface “RS232 RxD”, “RS232 TxD”

Maximum input voltage

± 30 V

Maximum output voltage

± 30 V

Maximum bit rate 115 200 bit/s

Data line protection ESD protected

internal RS232 driver/receiver EIA RS232 standard

Baud rate (can be configured) up to max. 115 200 bit/s

Note

• Please bear in mind your PC’s serial port maximal baud rate.

• The standard baud rate setting (original packing) is 38 600 bauds. If a differ-

ent rate is required, the setting must be changed using the software (GUI).

Data bits 8

Parity none

Stop bit 1

Protocol none

Connection DES - PC

Servoamplifier DES 70/10 PC Interface (RS232), DIN41652

Signal clamp pin 18 Gnd Pin 5 Gnd

Signal clamp pin 19 RS232 RxD Pin 3 TxD

Signal clamp pin 20 RS232 TxD Pin 2 RxD

5.3.2 CAN Interface “CAN high”, “CAN low”

Standard type CAN high-speed

ISO 11898 compatible

Maximum bit rate 1 Mbit/s

Max. number of CAN nodes (fan out) 127

Protocol CAN 2.0B

CAN frame type Standard (11 bit identifier)

Identifier setting by DIP Switch or

software using CAN or RS232 (only

temporary setting with software)

Connection DES - CAN

bus line CiA DS-102

Servoamplifier DES 70/10 CAN 9 pin D-Sub (DIN41652)

Signal clamp pin 16 CAN high Pin 7 CAN_H

Signal clamp pin 17 CAN low Pin 2 CAN_L

Signal clamp pin 18 Gnd Pin 3 CAN_GND

12 maxon motor control April 2006 Edition / Subject to change

Page 13

maxon motor

Operating Instructions 4-Q-EC Servoamplifier DES 70/10

5.3.3 CAN ID (CAN Identification)

The CAN-ID (node address) is set at DIP switch S1 ... 7.

All addresses can be coded from 1 ... 127 using the binary code.

Switch Binary code Valence

1 2

0

1

2 2

1

2

3 2

2

4

4 2

3

8

5 2

4

16

6 2

5

32

7 2

6

64

If the valences of all switches set at ON are added together, this gives the set

CAN-ID (node address).

Examples:

The following table can be used as a guide, but is not comprehensive.

Switch 1 2 3 4 5 6 7

Valence 1 2 4 8 16 32 64

CAN-ID Switch setting Calculation

1 1 0 0 0 0 0 0 1

2 0 1 0 0 0 0 0 2

32 0 0 0 0 0 1 0 32

35 1 1 0 0 0 1 0 1 + 2 + 32

127 1 1 1 1 1 1 1

1 + 2 + 4 + 8 +

16 + 32 + 64

Note

• CAN-ID = 0 is invalid and overwritten with CAN-ID = 1.

• DIP-Switches 8 to 10 have no impact on the CAN-ID.

April 2006 Edition / Subject to change maxon motor control 13

Page 14

maxon motor

4-Q-EC Servoamplifier DES 70/10 Operating Instructions

5.4 Current limit

Brushless maxon EC motors are particularly well suited for use in servodrives.

Very fast acceleration times and thermal overload protection are required.

The digital servoamplifier DES 70/10 operates with I

max

- and I

cont

-current limita-

tion, which satisfies both requirements.

Maximum output current I

max

< 30 A

Continuous output current I

cont

< 10 A

Ratio I

max

: I

cont

3:1

The continuous output current Icont (0 ... 10 A), adjusted with the potentiometer,

is available on an unlimited basis.

A higher current is also permitted for a short time (Imax = 3 • Icont), whereby

the length of time is dependent on the previous history of the current path.

Example 1:

a) b)

During the time t

a

1

a higher current is permitted for motor acceleration. The cur-

rent is then limited to the continuous output current I

cont

.

If the motor is operated long-term with the continuous output current I

cont

, no

higher current is permitted (thus t

a

= 0 s).

Example 2: (cyclical mode)

a) b)

In cyclical mode, the max. output current I

max

is available after a break of

approx. 10 s, provided that the current between the acceleration processes is

zero, otherwise time ta is reduced.

1

The length of time depends on the current value and the motor’s previous current load.

14 maxon motor control April 2006 Edition / Subject to change

Page 15

maxon motor

Operating Instructions 4-Q-EC Servoamplifier DES 70/10

6 Error Messages

6.1 Faultless condition

The green LED shows the operating status (“Enable” or “Disable”) of DES.

DES in “Disable” status (DES ready): green LED flashes (flash frequency approx. 1 Hz), red LED does not shine.

DES in “Enable” status (power stage of DES is enabled): green LED shines

continually, red LED does not shine.

6.2 Faulty condition

Error conditions are detected by DES.

The red LED shines continually in the event of error condition.

Depending on error, the green LED flashes at varying intervals.

Example: Error 5

green LED on

123 546

Number of

flashing pulses

of green LED

possible errors

1

Error 0 => Hall sensor error

• Hall sensors incorrectly wired

• Hall sensor supply voltage incorrectly wired

• Damaged Hall sensor in the motor

2

Error 1 => Index processing error

• Encoder without working index channel

• System parameter “Encoder Resolution” set incorrectly

• Input frequency of encoder signal too high

3

Error 2 => Wrong setting of encoder resolution

• system parameter (“encoder resolution”) set incorrectly

4

Error 3 => Hall sensor 3 not found

• Hall sensor 3 incorrectly wired

• Damaged Hall sensor 3 in the motor

• System parameter “Encoder Resolution” set too low

5

Error 4 => Over current error

• Short circuit in the motor winding

• Power supply cannot supply enough acceleration current

• Gain regulation loop is too high; speed regulation gains must be reduced

• System parameter ‘’Acceleration’’ too high

• Damaged power stage

6

Error 5 => Over voltage error

• power supply voltage too high

• voltage in generation mode too high

7

Error 6 => Over speed error

• Speed in current control mode too high (> 30 000 rpm)

8

Error 7 => Supply voltage too low for operation

• supply voltage is too low for operation

9

Error 8 => Angle detection error

• The difference of the angle between the encoder and Hall sensors is out

of tolerance

• interference on encoder and Hall sensor signals

12

Error 11 => Overtemperature

• The temperature of the power stage is too high

April 2006 Edition / Subject to change maxon motor control 15

Page 16

maxon motor

4-Q-EC Servoamplifier DES 70/10 Operating Instructions

7 EMC-compliant installation

Power supply (+V

CC

- Power Gnd)

• No shielding normally required

• Star point-shaped wiring if several amplifiers are supplied by the same power

supply

Motor cable (> 30 cm)

• Shielded cable highly recommended.

• Connect shielding on both sides:

DES 70/10 side: Terminal 1 “Ground Safety Earth” and/or bottom of housing.

Motor side: Motor housing or with motor housing mechanical design with

low resistive connection.

• Use separate cable.

Hall sensor cable (> 30 cm)

• Shielded cable highly recommended.

• Connect shielding on both sides:

DES 70/10 side: Terminal 1 “Ground Safety Earth” and/or bottom of housing.

Motor side: Motor housing or with motor housing mechanical design with

low resistive connection.

• Use separate cable.

Direct connection motor/Hall cable (≤ 30 cm) on DES 70/10

• Shield casing over motor/Hall connection cable (expecting EC 45/EC 60).

• Connect shielding on both sides.

or

• Lowest resistive connection of motor housing and “Ground Safety Earth”

terminal 1 and/or bottom of DES 70/10 housing

• Cable design of motor/Hall connection cable as close as possible with aforemen-

tioned connection

Encoder cable

• Encoder with line driver recommended.

• Channel A, A\; channel B, B\; channel I, I\; twisted pair.

• No shielding normally required.

• Use separate cable.

RS-232

• Twisted pair shielded cable recommended.

• Use separate cable.

16 maxon motor control April 2006 Edition / Subject to change

Page 17

maxon motor

Operating Instructions 4-Q-EC Servoamplifier DES 70/10

CAN

• See CiA DS-102 (twisted and / or shielded two-wire circuit closed with the cir-

cuit’s impedance with common return circuit).

• Closure with impedance through external circuit.

• No galvanic separation on DES 70/10.

Analogue signals (Set value, Monitor)

• No shielding normally required.

• Use cable shielding with analogue signals with small signal level and electro-

magnetically harsh environment.

• Normally connect shielding on both sides. Place shielding on one side if there are

50/60 Hz interference problems.

Digital signals (Enable, Stop, Digital 1, Digital 2, Ready)

• No shielding necessary.

See also block diagram in

chapter 8.

In practical terms, only the complete equipment, comprising all individual components (motor, amplifier, power supply unit, EMC filter, cabling etc.) can undergo an

EMC test to ensure interference-free CE-approved operation.

April 2006 Edition / Subject to change maxon motor control 17

Page 18

maxon motor

4-Q-EC Servoamplifier DES 70/10 Operating Instructions

8 Block Diagram

+5V

CAN

Transceiver

RS232

Transceiver

Line

Receiver

Current

detect

Power

Driver

MOSFET

Full

Bridge

Current

detect

Supply

Monitor

J403

Ready

AA\BB\I

I\

+Set va lue

-Set value

Enable

STOP

Digital 1

Digital 2

+V Hall +5V / 50mA

CC

Gnd

+V 24 - 70VDC

CC

Power Gnd

+5V (1)

+5V (2)

+5V

+3.3V

+3.3V

+3.3V

+3.3V

P1 n

max

P2 Offset

P3 I

max

P4 gain

+5V (2)

D

S

P

igital

ignal

rocessor

+3.3V

+3.3V

+3.3V

DIP1..DIP7 (CAN ID)

DIP9

+3.3V

+12V

-12V

+12V

+12V

-12V

-12V

+3.3V

+3.3V

+3.3V+5V

+5V

+5V

+5V

DIP10

+5V / 10 0m AGnd

+5V (1)

J404

+5V

+5V

green

LED

red

LED

Current

detect

+5V / 20mA OUT

Gnd

CAN high

CAN low

Gnd

1

RXD

TXD

Gnd

1

Motor winding 1

Motor winding 2

Motor winding 3

1

1

0R

Hall sensor 1

Hall sensor 2

Hall sensor 3

1

123456

1 2 3 4 5 6 7 8 9 10 1112131415 16171819

20

76

103

12

29

13.2

180

174

maxon motor

LED green-ok / red-fault

gain

P4

I

max

P3

OffsetP2

n

max

P1

maxon motor control

4-Q-EC Servoamplifier

22859770V/10ADES70/10

Made in Switzerland

Power

+Set value

Enable

Hall sensor 1

Hall sensor 2

Hall sensor 3

+5V / 20mA OUT

Gnd

Monitor

Ready

STOP

Digital 1

Digital 2

CAN high

CAN low

Gnd

RS232 RXD

RS232 TXD

1

2

3

11

12

13

7

8

9

10

4

5

6

16

17

18

19

20

Signal

14

Gnd15

Vcc Hall +5V / 50mA OUT

Set value

Encoder

Set value range

0...5V

Set CAN-ID = 1...127

ID=1

ID=2

ID=35

ID=127

9 Dimension Drawing

Dimensions in [mm]

18 maxon motor control April 2006 Edition / Subject to change

Loading...

Loading...