maxon motor ESCON 50/5, ESCON 70/10, 422969 Reference Manual

maxon motor ag Brünigstrasse 220 P.O.Box 263 CH-6072 Sachseln Phone +41 41 666 15 00 Fax +41 41 666 16 50 www.maxonmotor.com

Edition September 2013

ESCON Servo Controller

Hardware Reference

maxon motor control

ESCON 50/5

Servo Controller

P/N 409510

Hardware Reference

Document ID: rel4285

maxon motor control

A-2 Document ID: rel4285 ESCON Servo Controller

Edition: September 2013 ESCON 50/5 Hardware Reference

© 2013 maxon motor. Subject to change without prior notice.

1 About 3

1.1 About this Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 About the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 About the Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Specifications 7

2.1 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Setup 11

3.1 Generally applicable Rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Determination of Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4 Potentiometers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.5 Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4 Wiring 29

4.1 DC Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2 EC Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5Spare Parts 35

TABLE OF CONTENTS

READ THIS FIRST

These instructions are intended for qualified technical personnel. Prior comme ncing with any activities …

• you must carefully read and understand this manual and

• you must follow the instructions given therein.

The ESCON 50/5 is considered as partly completed machinery according to EU Directive 2006/42/EC, Article 2, Clause (g)

and is intended to be incorporated into or assembled with other machinery or other partly completed machinery or

equipment.

Therefore, you must not put the device into service, …

• unless you have made completely sure that the other ma chinery fully complies with the EU directive’s requirements!

• unless the other machinery fulfills all relevant health and safety aspects!

• unless all respective interfaces have been established and fulfill the herein stated requirements!

About

About this Document

maxon motor control

ESCON Servo Controller Document ID: rel4285

1-3

ESCON 50/5 Hardware Reference Edition: September 2013

© 2013 maxon motor. Subject to change without prior notice.

1 About

1.1 About this Document

1.1.1 Intended Purpose

The purpose of the present document is to familiarize you with the ESCON 50/5 Servo Controller. It will

highlight the tasks for safe and adequate installation and/or commissioning. Follow the described

instructions …

• to avoid dangerous situations,

• to keep installation and/or commissioning time at a minimum,

• to increase reliability and service life of the described equipment.

The document contains performance data and specifications, information on fulfilled standards, details

on connections and pin assignment, and wiring examples.

1.1.2 Target Audience

The present document is intended for trained and skilled personnel. It conveys information on how to

understand and fulfill the respective work and duties.

1.1.3 How to use

Take note of the following notations and codes which will be used throughout the document.

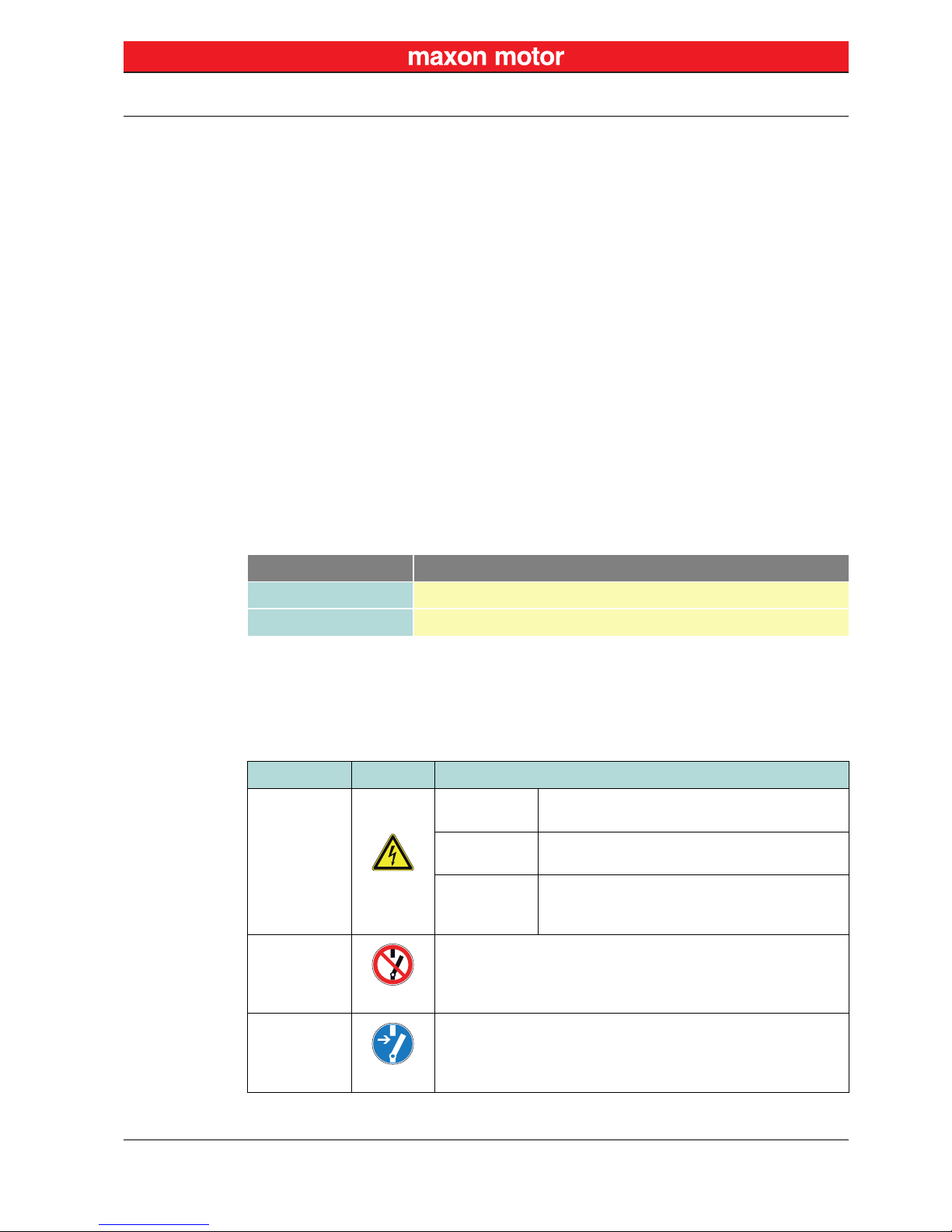

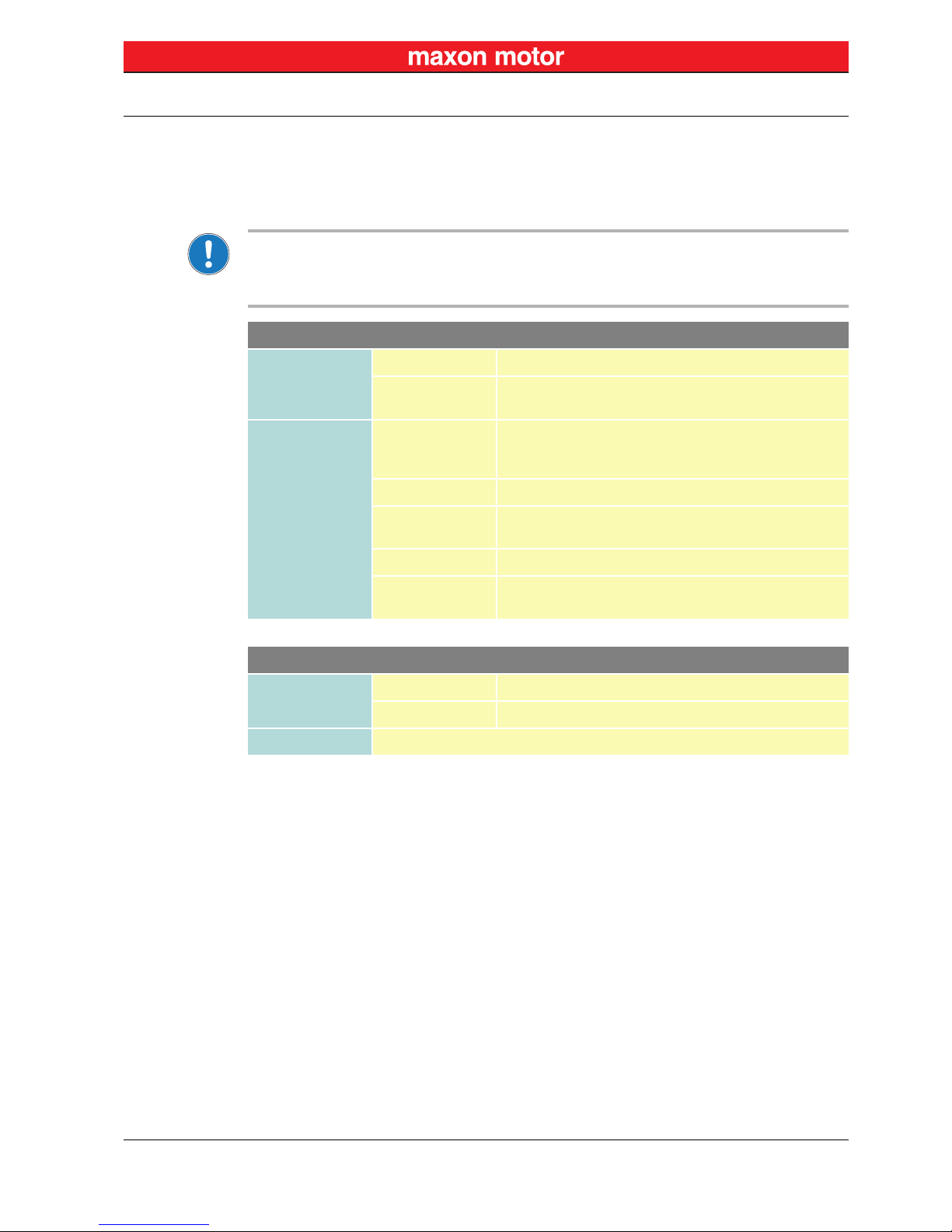

Table 1-1 Notation used

1.1.4 Symbols & Signs

In the course of the present document, the following symbols and sings will be used.

Notation Meaning

(n) refers to an item (such as order number, list item, etc.)

denotes “see”, “see also”, “take note of” or “go to”

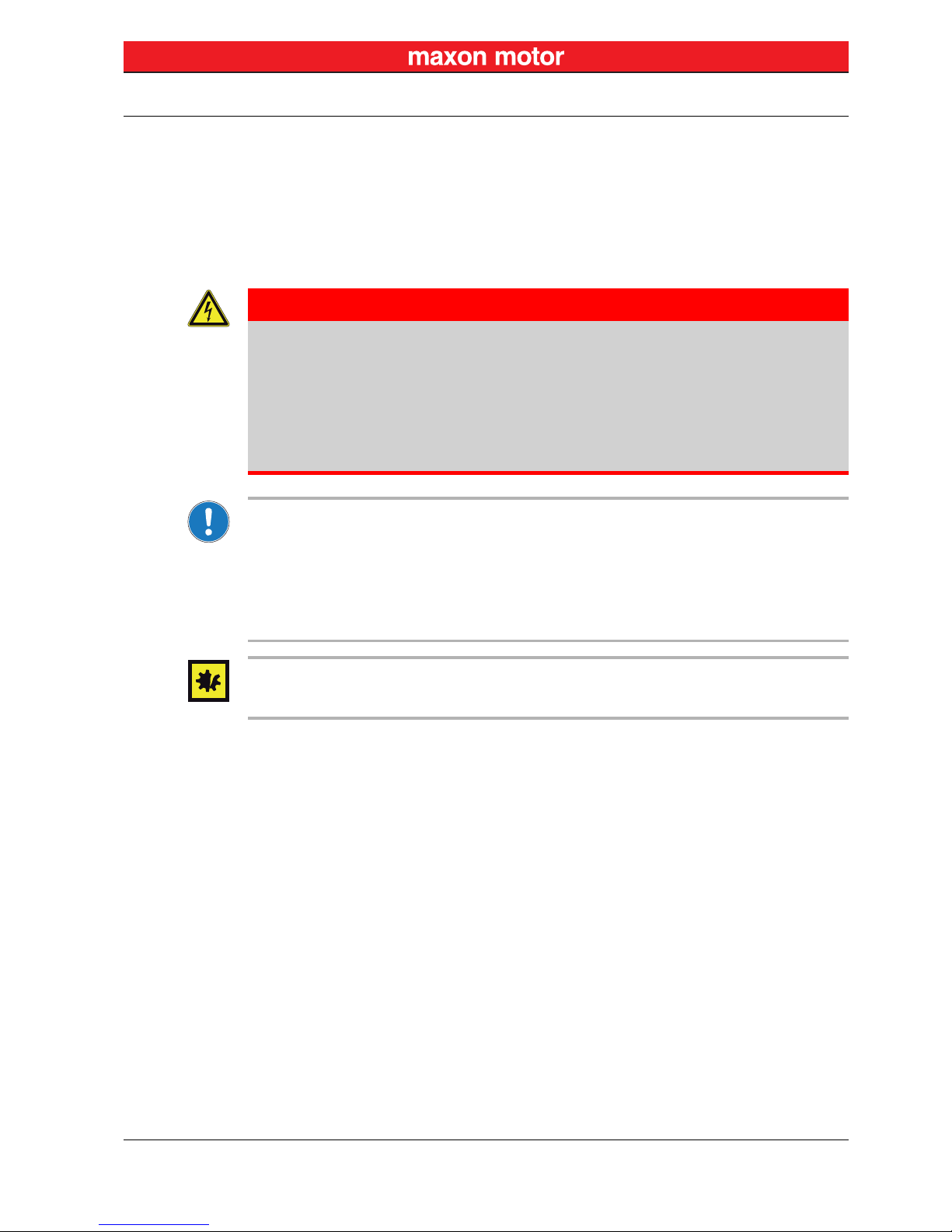

Type Symbol Meaning

Safety Alert

(typical)

DANGER

Indicates an imminent hazardous situation. If not

avoided, it will result in death or serious injury.

WARNING

Indicates a potential hazardous situation. If not

avoided, it can result in death or serious injury.

CAUTION

Indicates a probable hazardous situation or calls

the attention to unsafe practices. If not avoided, it

may result in injury.

Prohibited

Action

(typical)

Indicates a dangerous action. Hence, you must not!

Mandatory

Action

(typical)

Indicates a mandatory action. Hence, you must!

About

About the Device

maxon motor control

1-4 Document ID: rel4285 ESCON Servo Controller

Edition: September 2013 ESCON 50/5 Hardware Reference

© 2013 maxon motor. Subject to change without prior notice.

Table 1-2 Symbols & Signs

1.1.5 Trademarks and Brand Names

For easier legibility, registered brand names are listed below and will not be further tagged with their

respective trademark. It must be understood that the brands (the list below is not necessarily concluding) are protected by copyright and/or other intellectual property rights even if their legal trademarks are

omitted in the later course of this document.

Table 1-3 Brand Names and Trademark Owners

1.1.6 Copyright

© 2013 maxon motor. All rights reserved.

The present document – including all parts thereof – is protected by copyright. Any use (including repro-

duction, translation, microfilming, and other means of electronic data processing) beyond the narrow

restrictions of the copyright law without the prior approval of maxon motor ag, is not permitted and subject to prosecution under the applicable law.

1.2 About the Device

The ESCON 50/5 is a small-sized, powerful 4-quadrant PWM servo controller for the highly efficient control of permanent magnet-activated brushed DC motors or brushless EC motors up to approximately

250 Watts.

The featured operating modes – speed control (closed loop), speed control (open loop), and current

control – meet the highest requirements. The ESCON 50/5 is designed being commanded by an analog

set value and features extensive analog and digital I/O functionality.

The device is designed to be configured via USB interface using the graphical user interface «ESCON

Studio» for Windows PCs.

You can download the latest ESCON software version (as well as the latest edition of the documentation) from the internet under http://escon.maxonmotor.com.

Information

Requirement /

Note / Remark

Indicates an activity you must perform prior

continuing, or gives information on a particular item

you need to observe.

Best Practice

Indicates an advice or recommendation on the

easiest and best way to further proceed.

Material

Damage

Indicates information particular to possible damage

of the equipment.

Brand Name Trademark Owner

Windows® © Microsoft Corporation, USA-Redmond, WA

maxon motor ag

Brünigstrasse 220

P.O.Box 263

CH-6072 Sachseln

Phone

Fax

Web

+41 41 666 15 00

+41 41 666 16 50

www.maxonmotor.com

Type Symbol Meaning

About

About the Safety Precautions

maxon motor control

ESCON Servo Controller Document ID: rel4285

1-5

ESCON 50/5 Hardware Reference Edition: September 2013

© 2013 maxon motor. Subject to change without prior notice.

1.3 About the Safety Precautions

• Make sure that you have read and understood the note “READ THIS FIRST” on page A-2!

• Do not engage with any work unless you possess the stated skills (chapter “1.1.2 Target

Audience” on page 1-3)!

• Refer to chapter “1.1.4 Symbols & Signs” on page 1-3 to understand the subsequently used

indicators!

• You must observe any regulation applicable in the country and/or at the site of implementation

with regard to health and safety/accident prevention and/or environmental protection!

Requirements

• Make sure that all associated devices and components are installed according to local regulations.

• Be aware that, by principle, an electronic apparatus can not be considered fail-safe. Therefore, you

must make sure that any machine/apparatus has been fitted with independent monitoring and safety

equipment. If the machine/apparatus should break down, if it is operated incorrectly, if the control unit

breaks down or if the cables break or get disconnected, etc., the complete drive system must return –

and be kept – in a safe operating mode.

• Be aware that you are not entitled to perform any repair on components supplied by maxon motor.

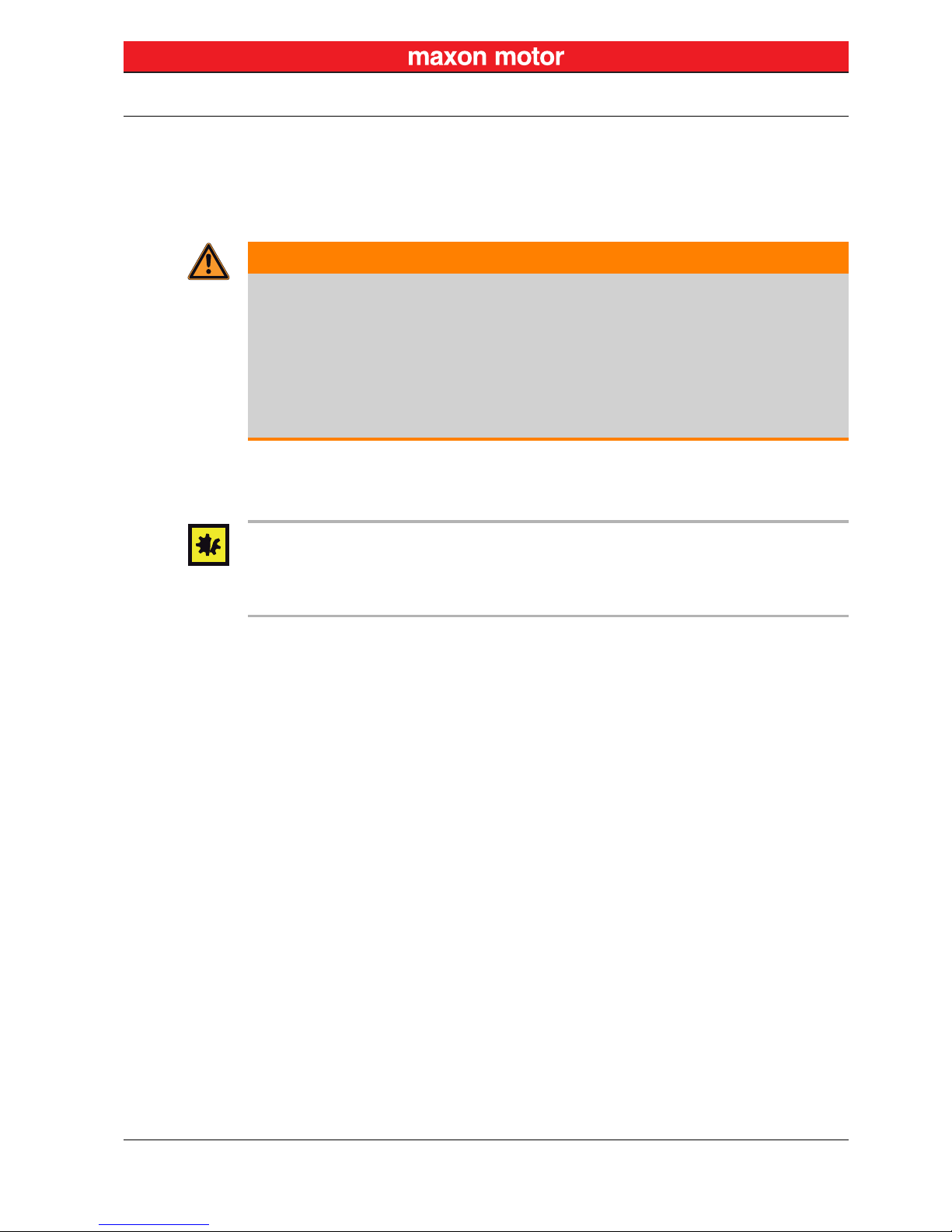

Electrostatic Sensitive Device (ESD)

• Make sure to wear working cloth in compliance with ESD.

• Handle device with extra care.

DANGER

High Voltage and/or Electrical Shock

Touching live wires causes death or serious injuries!

• Consider any power cable as connected to life power, unless having proven the opposite!

• Make sure that neither end of cable is connected to life power!

• Make sure that power source cannot be engaged while work is in process!

• Obey lock-out/tag-out procedures!

• Make sure to securely lock any power engaging equipment against unintentional engagement and

tag it with your name!

About

About the Safety Precautions

maxon motor control

1-6 Document ID: rel4285 ESCON Servo Controller

Edition: September 2013 ESCON 50/5 Hardware Reference

© 2013 maxon motor. Subject to change without prior notice.

••page intentionally left blank••

Specifications

Technical Data

maxon motor control

ESCON Servo Controller Document ID: rel4285

2-7

ESCON 50/5 Hardware Reference Edition: September 2013

© 2013 maxon motor. Subject to change without prior notice.

2 Specifications

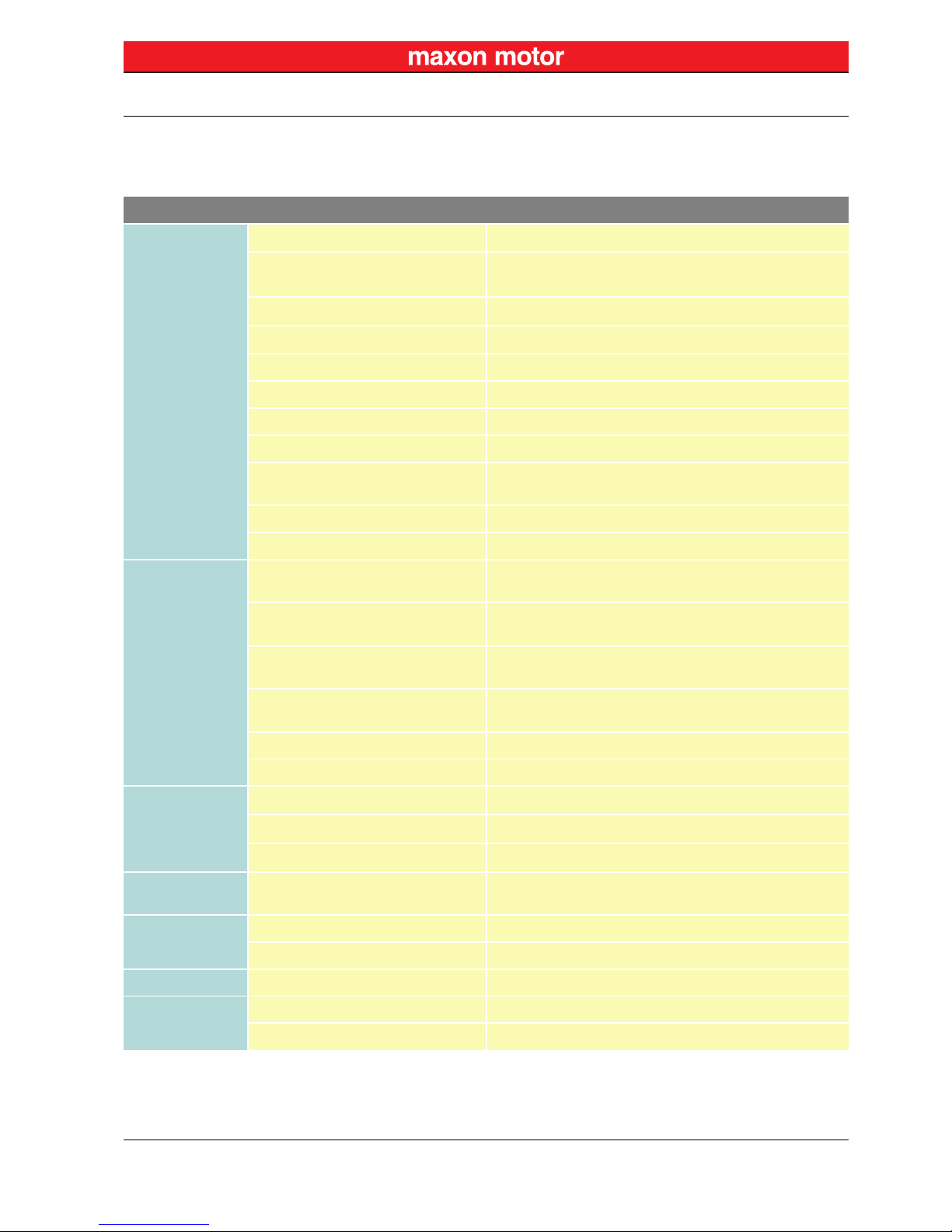

2.1 Technical Data

ESCON 50/5 (409510)

Electrical Rating

Nominal operating voltage +V

CC

10…50 VDC

Absolute operating voltage

+V

CC min

/ +V

CC max

8 VDC / 56 VDC

Output voltage (max.)

0.98 x +V

CC

Output current I

cont

/ I

max

(<20 s)

5 A / 15 A

Pulse Width Modulation frequency 53.6 kHz

Sampling rate PI current controller 53.6 kHz

Sampling rate PI speed controller 5.36 kHz

Max. efficiency 95%

Max. speed DC motor

limited by max. permissible speed (motor) and max. output

voltage (controller)

Max. speed EC motor 150’000 rpm (1 pole pair)

Built-in motor choke 3 x 30 μH; 5 A

Inputs & Outputs

Analog Input 1

Analog Input 2

resolution 12-bit; –10…+10 V; differential

Analog Output 1

Analog Output 2

resolution 12-bit; –4…+4 V; referenced to GND

Digital Input 1

Digital Input 2

+2.4…+36 VDC (Ri = 38.5 kΩ)

Digital Input/Output 3

Digital Input/Output 4

+2.4…+36 VDC (Ri = 38.5 kΩ) / max. 36 VDC (IL <500 mA)

Hall sensor signals H1, H2, H3

Encoder signals A, A\, B, B\, (max. 1 MHz)

Voltage Outputs

Auxiliary output voltage

+5 VDC (IL ≤10 mA)

Hall sensor supply voltage

+5 VDC (IL ≤30 mA)

Encoder supply voltage

+5 VDC (IL ≤70 mA)

Potentiometers

Potentiometer P1 (on board)

Potentiometer P2 (on board)

240°; linear

Motor

Connections

DC motor + Motor, – Motor

EC motor Motor winding 1, Motor winding 2, Motor winding 3

Interface USB 2.0 full speed (12 Mbit/s)

Status Indicators

Operation green LED

Error red LED

Specifications

Technical Data

maxon motor control

2-8 Document ID: rel4285 ESCON Servo Controller

Edition: September 2013 ESCON 50/5 Hardware Reference

© 2013 maxon motor. Subject to change without prior notice.

Table 2-4 Technical Data

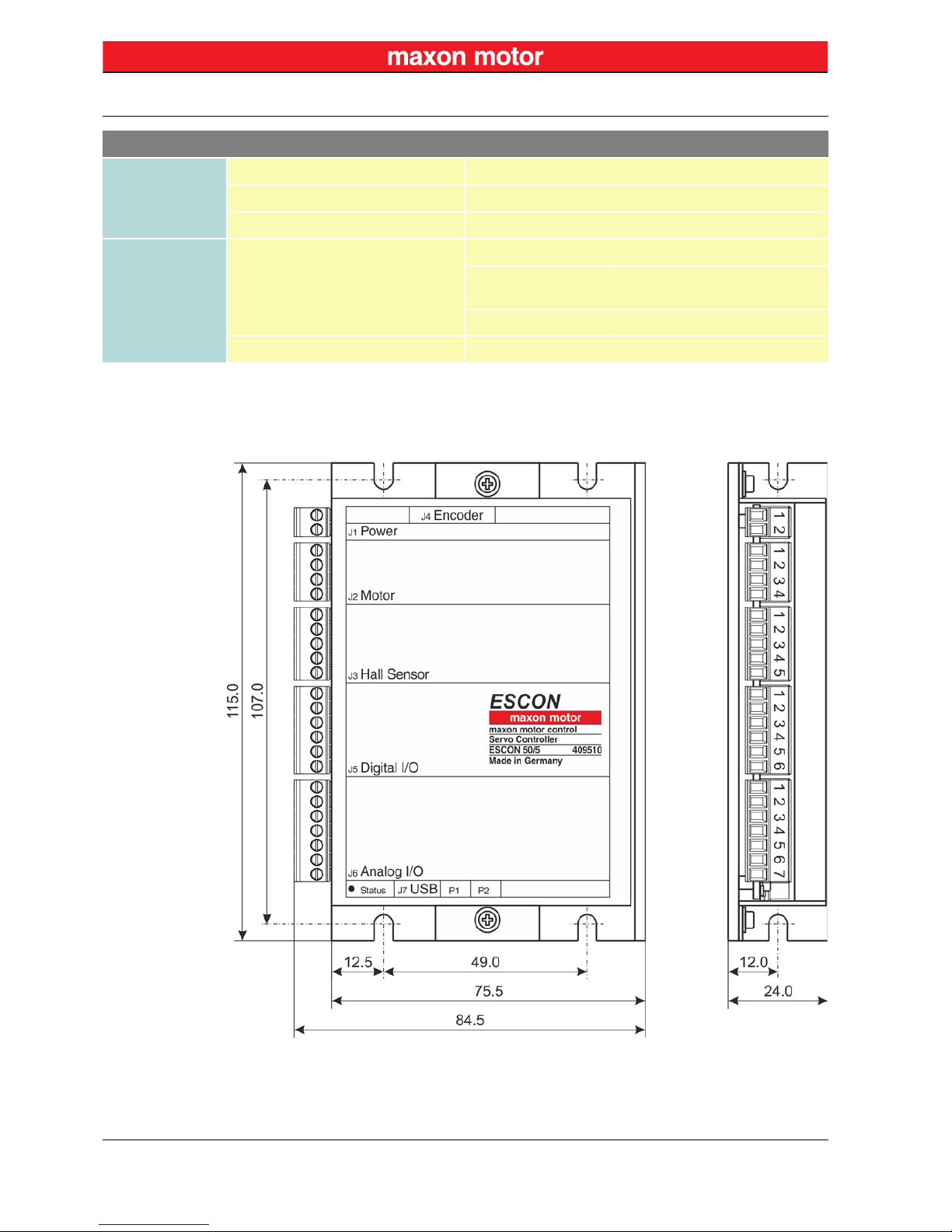

Figure 2-1 Dimensional Drawing [mm]

Physical

Weight approx. 204 g

Dimensions (L x W x H) 115 x 75.5 x 24 mm

Mounting holes for M4 screws

Environmental

Conditions

Temperature

Operation –30…+45°C

Extended range

*1)

+45…+85°C

Derating: –0.113 A/°C

Storage –40…+85°C

Humidity 20…80% (condensation not permitted)

Remark: *1) Operation within the extended temperature range is permitted. However, a respective derating (declination of

max. output current) as to the stated value will apply.

ESCON 50/5 (409510)

Specifications

Standards

maxon motor control

ESCON Servo Controller Document ID: rel4285

2-9

ESCON 50/5 Hardware Reference Edition: September 2013

© 2013 maxon motor. Subject to change without prior notice.

2.2 Standards

The described device has been successfully tested for compliance with the below listed standards. In

practical terms, only the complete system (the fully operational equipment comprising all individual components, such as motor, servo controller, power supply unit, EMC filter, cabling etc.) can undergo an

EMC test to ensure interference-free operation.

Important Notice

The device’s compliance with the mentioned standards does not imply its compliance within the final,

ready to operate setup. In order to achieve compliance of your operational system, you must perform

EMC testing of the involved equipment as a whole.

Table 2-5 Standards

Electromagnetic Compatibility

Generic Standards

IEC/EN 61000-6-2 Immunity for industrial environments

IEC/EN 61000-6-3

Emission standard for residential, commercial and lightindustrial environments

Applied Standards

IEC/EN 61000-6-3

IEC/EN 55022

(CISPR22)

Radio disturbance characteristics / radio interference

IEC/EN 61000-4-2 Electrostatic discharge immunity test 8 kV/6 kV

IEC/EN 61000-4-3

Radiated, radio-frequency, electromagnetic field immunity

test >10 V/m

IEC/EN 61000-4-4 Electrical fast transient/burst immunity test ±2 kV

IEC/EN 61000-4-6

Immunity to conducted disturbances, induced by radiofrequency fields 10 Vrms

Others

Environmental

Standards

IEC/EN 60068-2-6 Environmental testing – Test Fc: Vibration (sinusoidal)

MIL-STD-810F Random transport

Safety Standards UL File Number E207844; unassembled printed circuit board

Specifications

Standards

maxon motor control

2-10 Document ID: rel4285 ESCON Servo Controller

Edition: September 2013 ESCON 50/5 Hardware Reference

© 2013 maxon motor. Subject to change without prior notice.

••page intentionally left blank••

Setup

Generally applicable Rules

maxon motor control

ESCON Servo Controller Document ID: rel4285

3-11

ESCON 50/5 Hardware Reference Edition: September 2013

© 2013 maxon motor. Subject to change without prior notice.

3Setup

IMPORTANT NOTICE: PREREQUISITES FOR PERMISSION TO COMMENCE INSTALLATION

The ESCON 50/5 is considered as partly completed machinery according to EU Directive 2006/42/EC,

Article 2, Clause (g) and is intended to be incorporated into or assembled with other machinery or

other partly completed machinery or equipment.

3.1 Generally applicable Rules

Maximal permitted Supply Voltage

• Make sure that supply power is between 10…50 VDC.

• Supply voltages above 56 VDC, or wrong polarity will destroy the unit.

• Note that the necessary output current is depending on the load torque. Yet, the output current limits

of the ESCON 50/5 are as follows; continuous max. 5 A / short-time (acceleration) max. 15 A.

WARNING

Risk of Injury

Operating the device without the full compliance of the surrounding system with the EU Directive 2006/42/EC may cause serious injuries!

• Do not operate the device, unless you have made completely sure that the other machinery fully

complies with the EU directive’s requirements!

• Do not operate the device, unless the other machinery fulfills all relevant health and safety

aspects!

• Do not operate the device, unless all respective interfaces have been established and fulfill the

requirements stated in this document!

Setup

Determination of Power Supply

maxon motor control

3-12 Document ID: rel4285 ESCON Servo Controller

Edition: September 2013 ESCON 50/5 Hardware Reference

© 2013 maxon motor. Subject to change without prior notice.

3.2 Determination of Power Supply

Basically, any power supply may be used, provided it meets the minimal requirements stated below.

1) Use the formula below to calculate the required voltage under load.

2) Choose a power supply according to the calculated voltage. Thereby consider:

a) During braking of the load, the power supply must be capable of buffering the recovered

kinetic energy (for example, in a capacitor).

b) If you are using an electronically stabilized power supply, make sure that the overcurrent

protection circuit is configured inoperative within the operating range.

Note

The formula already takes the following into account:

• Maximum PWM duty cycle of 98%

• Controller’s max. voltage drop of 1 V @ 5 A

K

NOWN VALUES:

• Operating torque M [mNm]

• Operating speed n [rpm]

• Nominal motor voltage U

N

[Volt]

• Motor no-load speed at U

N

, n0 [rpm]

• Speed/torque gradient of the motor Δn/ΔM [rpm/mNm]

S

OUGHT VALUE:

• Supply voltage +V

CC

[Volt]

S

OLUTION:

Power Supply Requirements

Output voltage

+VCC 10…50 VDC

Absolute output voltage min. 8 VDC; max. 56 VDC

Output current

Depending on load

(continuous max. 5 A; short-time (acceleration) max. 15 A (<20 s)

V

CC

U

N

n

O

-------

n

Δn

ΔM

-------- -

M⋅+

1

0.98

----------

⋅⋅1 V[]+≥

Loading...

Loading...