maxon motor 380200 Instructions Manual

maxon motor

maxon motor control 1-Q-EC Amplifier DEC Module 50/5

Order number 380200

Operating Instructions Edition April 2015

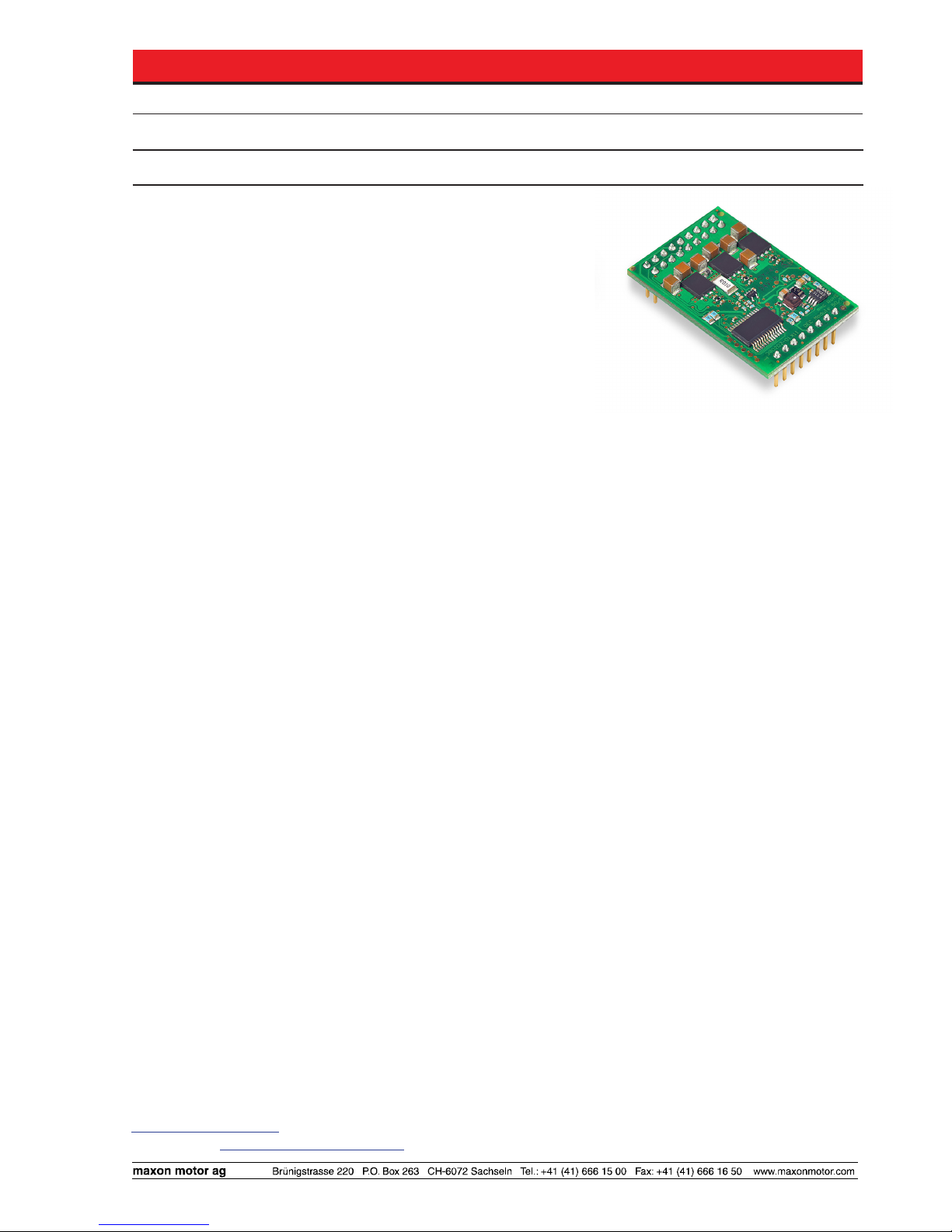

The DEC Module 50/5 (Digital EC Controller) is a small

1-quadrant digital controller for the control of brushless DC motors

(Electronic Commutated motors) up to 250 W.

The used EC motor must be equipped with digital Hall sensors.

Features:

• Digital speed control

operates as «closed loop» or as «open loop» speed controller

• Maximum speed 80 000 rpm (motor with 1 pole pair)

• Set value input through external analogue voltage (0 ... +5 V)

• 3 different speed ranges selectable

• Direction of rotation preset by a digital signal

• The output stage can be enabled or disabled

• Maximum output current limit adjustable up to 10 A

• Motor speed can be monitored with the «Monitor n» output

• Status indication via «Ready»output

• Blockage protection (current limit for blocked motor)

• Protective functions: undervoltage, overvoltage and thermal overload

• Standardized connector strip, pitch 2.54 mm

Thanks to the wide input power supply range of 6...50 VDC (optional 5 VDC operation possible), the DEC Module

50/5 is very versatile and can be used with various power supplies.

A sturdy PI speed controller design is an ideal premise for immediate operation.

The well-priced and miniaturized OEM module seamlessly integrates into applications. Now the customer can

fully focus on developing his/hers own device - while being able to make use of maxon motor‘s vast drive knowhow. For start-up maxon motor offers a comprehensive Evaluation Board.

The latest edition of these operating instructions may be downloaded from the internet as a PDF-file under

www.maxonmotor.com, category «Service & Downloads», order number 380200 or

in the e-shop http://shop.maxonmotor.com.

Table of Contents

1 Safety Instructions ............................................................................................................................................. 2

2 Technical Data ................................................................................................................................................... 3

3 Pin assignment DEC Module 50/5 ..................................................................................................................... 5

4 Commissioning Instructions............................................................................................................................... 6

5 Functional Description of Inputs and Outputs.................................................................................................... 7

6 Protective functions ......................................................................................................................................... 14

7 Block Diagram ................................................................................................................................................. 15

8 Dimensional Drawing ....................................................................................................................................... 16

9 Accessories (not included in delivery) ............................................................................................................. 16

10 Appendix «Motherboard Design Guide» ....................................................................................................... 16

maxon motor

2 maxon motor control

1-Q-EC Amplifier DEC Module 50/5 Operating Instructions

April 2015 Edition / document number 1094861_PDF_E - 05 / subject to change

1 Safety Instructions

Skilled Personnel

Installation and commissioning of the equipment shall only be performed by

experienced, skilled personnel.

Statutory Regulations

The user must ensure that the amplifier and the components belonging to it

are assembled and connected according to local statutory regulations.

Disconnect Load

For primary operation the motor should be free running, i.e. with load disconnected.

Additional Safety Equipment

Any electronic apparatus is, in principle, not fail-safe. Machines and apparatus must therefore be fitted with independent monitoring and safety equipment. If the equipment breaks down, if it is operated incorrectly, if the control

unit breaks down or if the cables break, etc., it must be ensured that the drive

or the complete apparatus is kept in a safe operating mode.

Repairs

Repairs may be made by authorized personnel only or by the manufacturer.

Improper repairs can result in substantial dangers for the user

Danger

During installation of the DEC Module, make sure to disconnect all apparatus

from the electrical supply.

After switch-on, do not touch any life parts!

Wiring Procedure

All electrical connections should only be connected or disconnected when the

power is switched off.

Max. Supply voltage

Make sure that the supply voltage is between 6 and 55 VDC. Voltage higher

than 56 VDC or wrong polarity will destroy the unit.

Short Circuit and Earth Fault

The amplifier is not protected against winding short circuits against ground

safety earth and/or GND!

Electrostatic sensitive device (ESD)

a

a

a

a

a

a

a

a

a

a

maxon motor control 3

maxon motor

Operating Instructions 1-Q-EC Amplifier DEC Module 50/5

April 2015 Edition / document number 1094861_PDF_E - 05 / subject to change

2 Technical Data

2.1 Electrical data

Nominal supply voltage +VCC ..................................................................... 6 … 50 VDC (optional 5 VDC1)

Absolute minimum supply voltage +V

cc min

........................................................... 6 VDC (optional 5 VDC1)

Absolute maximum supply voltage +V

cc max

.................................................................................... 55 VDC

Max. output voltage ...................................................................................................................... 0.95 • V

CC

Continuous output current I

cont

................................................................................................................5 A

Max. output current I

max

.........................................................................................................................10 A

Switching frequency.......................................................................................................................46.8 kHz

Max. speed (motor with 1 pole pair) ......................................................................................... 80 000 rpm

2.2 Inputs

«Set value speed» ........................................................Analogue input (0 ... 5 V); Resolution: 1024 steps

«Enable» ......................................................................+2.4 … +55 V (Ri = 100 kΩ) or switch against V

CC

«Direction» ...................................................................+2.4 … +55 V (Ri = 100 kΩ) or switch against V

CC

Speed range «DigIN1 » ...............................+2.4 … +55 V (R

pull-up

= 47 kΩ at 5 V) or switch against Gnd

Speed range «DigIN2 » ...............................+2.4 … +55 V (R

pull-up

= 47 kΩ at 5 V) or switch against Gnd

«Set current limit» .............................................................................external resistor (1/16 W) against Gnd

Hall sensors ................................................................ «Hall sensor 1», «Hall sensor 2», «Hall sensor 3»

2.3 Output

Motor speed «Monitor n» ............................................................... Digital output signal, 5 V (Ro = 47 kΩ)

Status indication «Ready» .............................................................. Digital output signal, 5 V (Ro = 47 kΩ)

2.4 Voltage output

+5 VDC output voltage «VCC Hall» ............................................................................+5 VDC, max. 35 mA

2.5 Motor connections

Motor connections ...................................... «Motor winding 1», « Motor winding 2», « Motor winding 3»

2.6 Ambient temperature

Operation .................................................................................................................................-10 ... +45°C

Storage .....................................................................................................................................-40 ... +85°C

2.7 Humidity range

Non condensating .......................................................................................................................20 ... 80 %

2.8 Protective functions

Current limitation (cycle-by-cycle) ........................................................... adjustable up to maximum 10 A

Blockage ........................................................................Motor current limitation if motor shaft is blocked

Undervoltage shutdown ....................................................................................... shutdown if VCC < 6 VDC

Overvoltage shutdown ....................................................................................... shutdown if VCC > 56 VDC

Thermal overload protection of power stage ..............................................shutdown if T

power stage

> 100°C

2.9 Mechanical data

Weight ........................................................................................................................................ approx. 9 g

Dimensions (LxWxH). ......................................................................................... 43.18 x 27.94 x 12.7 mm

....................................................................................................................................... 1.7 x 1.1 x 0.5 Inch

2.10 Terminals

Pin header 1 ..................................................................................................................................2 x 9 pins

.......................................................................................................... double-row, pitch 2.54 mm (0.1 Inch)

Pin header 2 ....................................................................................................................................... 8 pins

............................................................................................................ single row, pitch 2.54 mm (0.1 Inch)

1 5V operating see chapter «10.8.2 Low Voltage +5V operation»

maxon motor

4 maxon motor control

1-Q-EC Amplifier DEC Module 50/5 Operating Instructions

April 2015 Edition / document number 1094861_PDF_E - 05 / subject to change

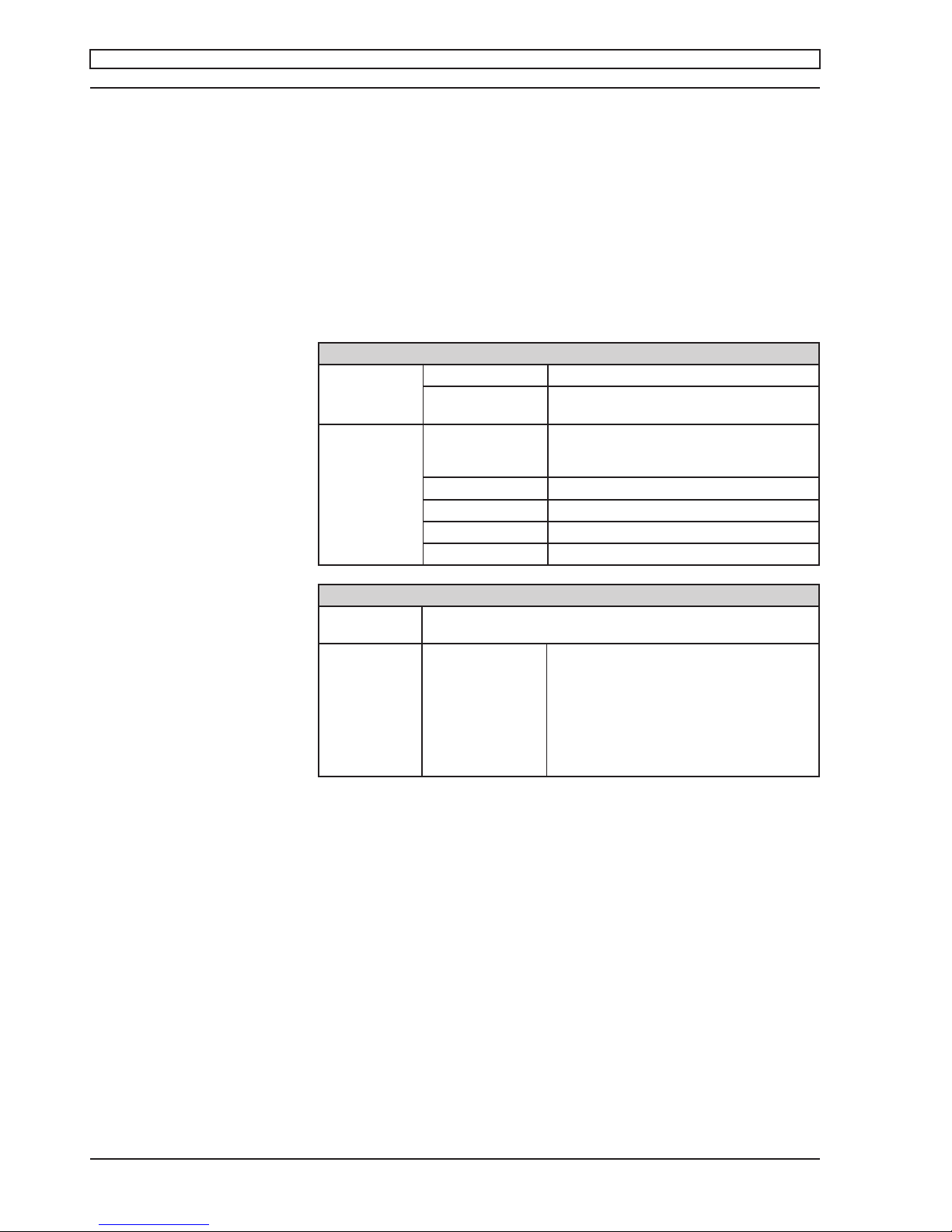

2.11 Standards

The described device has been successfully tested for compliance with the

below listed standards. In practical terms, only the complete system (the fully

operational equipment comprising all individual components, such as motor,

servo controller, power supply unit, EMC filter, cabling etc.) can undergo an

EMC test to ensure interference-free operation.

Important Notice

a The device’s compliance with the mentioned standards does not im-

ply its compliance within the final, ready to operate setup. In order to

achieve compliance of your operational system, you must perform EMC

testing of the involved equipment as a whole.

Electromagnetic compatibility

Generic

standards

IEC/EN 61000-6-2 Immunity for industrial environments

IEC/EN 61000-6-4

Emission standard for industrial environments

Applied

standards

IEC/EN 61000-6-4

EN 55011

(CISPR11)

RF disturbances

IEC/EN 61000-4-3 Radiated electromagnetic field > 10V/m

IEC/EN 61000-4-4 Electrical fast transient burst +/- 2 kV

IEC/EN 61000-4-6 RF conducted disturbances 10Vrms

IEC/EN 61000-4-8 Power frequency magnetic field 30A/m

Others

Safety

standards

UL File Number E172472, E92481 or E76251; unassembled

printed circuit board

Reliability MIL-HDBK-217F

Reliability prediction of electronic equipment

Environment: Ground, benign (GB)

Ambient temperature: 298 K (25°C)

Component stress: In accordance with circuit diagram and nominal power

Mean Time Between Failures (MTBF):

1‘434‘315 hours

maxon motor control 5

maxon motor

Operating Instructions 1-Q-EC Amplifier DEC Module 50/5

April 2015 Edition / document number 1094861_PDF_E - 05 / subject to change

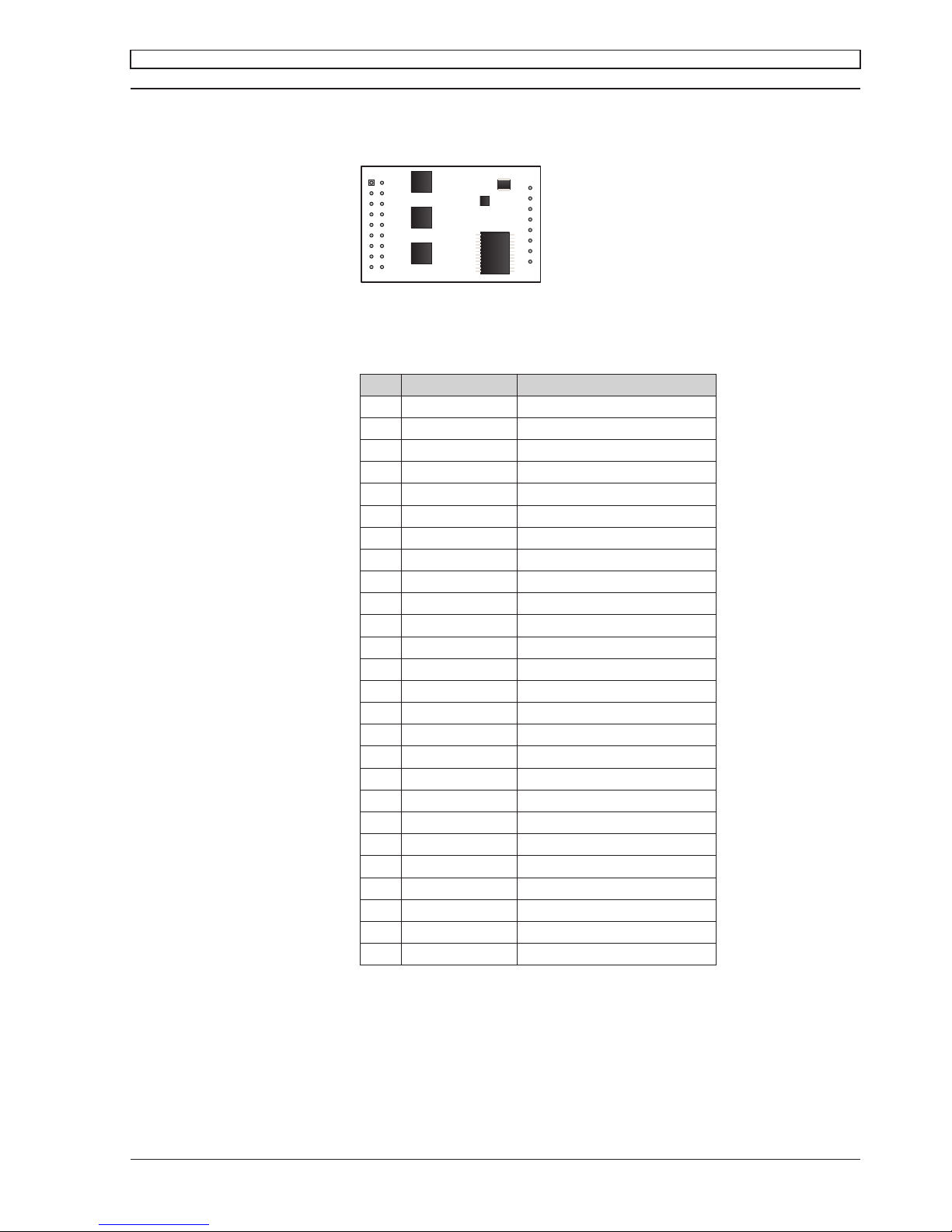

3 Pin assignment DEC Module 50/5

Top view

3.1 Pin assignment

Pin Signal Description

1 W1 Motor winding 1

2 W1 Motor winding 1

3 W2 Motor winding 2

4 W2 Motor winding 2

5 W3 Motor winding 3

6 W3 Motor winding 3

7 +V

cc

Supply voltage 6...50 VDC

8 +V

cc

Supply voltage 6...50 VDC

9 Gnd Ground

10 Gnd Ground

11 Vcc Hall +5 VDC output voltage

12 n.c. do not connect

13 H1 Hall sensor 1

14 Gnd Ground

15 H2 Hall sensor 2

16 Gnd Ground

17 H3 Hall sensor 3

18 Monitor n Speed monitor output

19 Ready Status indication output

20 DigIN1 Digital input 1

21 DigIN2 Digital input 2

22 Enable Enable input

23 Direction Direction input

24 Gnd Ground

25 Set current limit Set current limit input

26 Set value speed Set value speed input

1

2

17 18

19

26

DEC Module 50/5

maxon motor

6 maxon motor control

1-Q-EC Amplifier DEC Module 50/5 Operating Instructions

April 2015 Edition / document number 1094861_PDF_E - 05 / subject to change

4 Commissioning Instructions

4.1 Power supply layout

Any available power supply can be used, as long as it meets the minimum

requirements shown below.

During commissioning and adjustment phases, we recommend to mechanically separate the motor from the machine to prevent damage due to uncontrolled motion!

Power supply requirements

Nominal output voltage 6 VDC < V

CC

< 50 VDC

Absolute minimum output voltage 6 VDC

Absolute maximum output voltage 55 VDC

Output current depending on load, continuous max. 5 A

acceleration, short-time max. 10 A

The required supply voltage can be calculated as follows:

Known values

Ö Operating torque MB [mNm]

Ö Operating speed nB [rpm]

Ö Nominal motor voltage UN [V]

Ö Motor no-load speed at UN, n0 [rpm]

Ö Speed/torque gradient of the motor Dn/DM [rpm/mNm]

Sought value

Ö Supply voltage VCC [V]

Solution

VM

M

n

n

n

U

V

BB

o

N

cc

3.0

95.0

1

¸

¹

·

¨

©

§

'

'

Select a power supply capable of supplying this calculated voltage under

load. The formula takes into account a maximum PWM duty cycle of 95%

and a 0.3 V maximum voltage drop (at maximum output current) of the power

stage.

What speed can be reached with a given power supply:

»

¼

º

«

¬

ª

'

'

»

¼

º

«

¬

ª

B

N

ccB

M

M

n

U

n

VVn

0

3.095.0

Note

Ö During controlled deceleration, the power supply must be able to buffer

the back-fed energy e.g. in a capacitor.

Ö The under voltage protection switches off the DEC Module 50/5, as soon

as the supply voltage VCC drops below 6 V. Therefore, at low supply voltage VCC attention has to be payed to the voltage drop over the supplying

cables.

maxon motor control 7

maxon motor

Operating Instructions 1-Q-EC Amplifier DEC Module 50/5

April 2015 Edition / document number 1094861_PDF_E - 05 / subject to change

5 Functional Description of Inputs and Outputs

5.1 Inputs

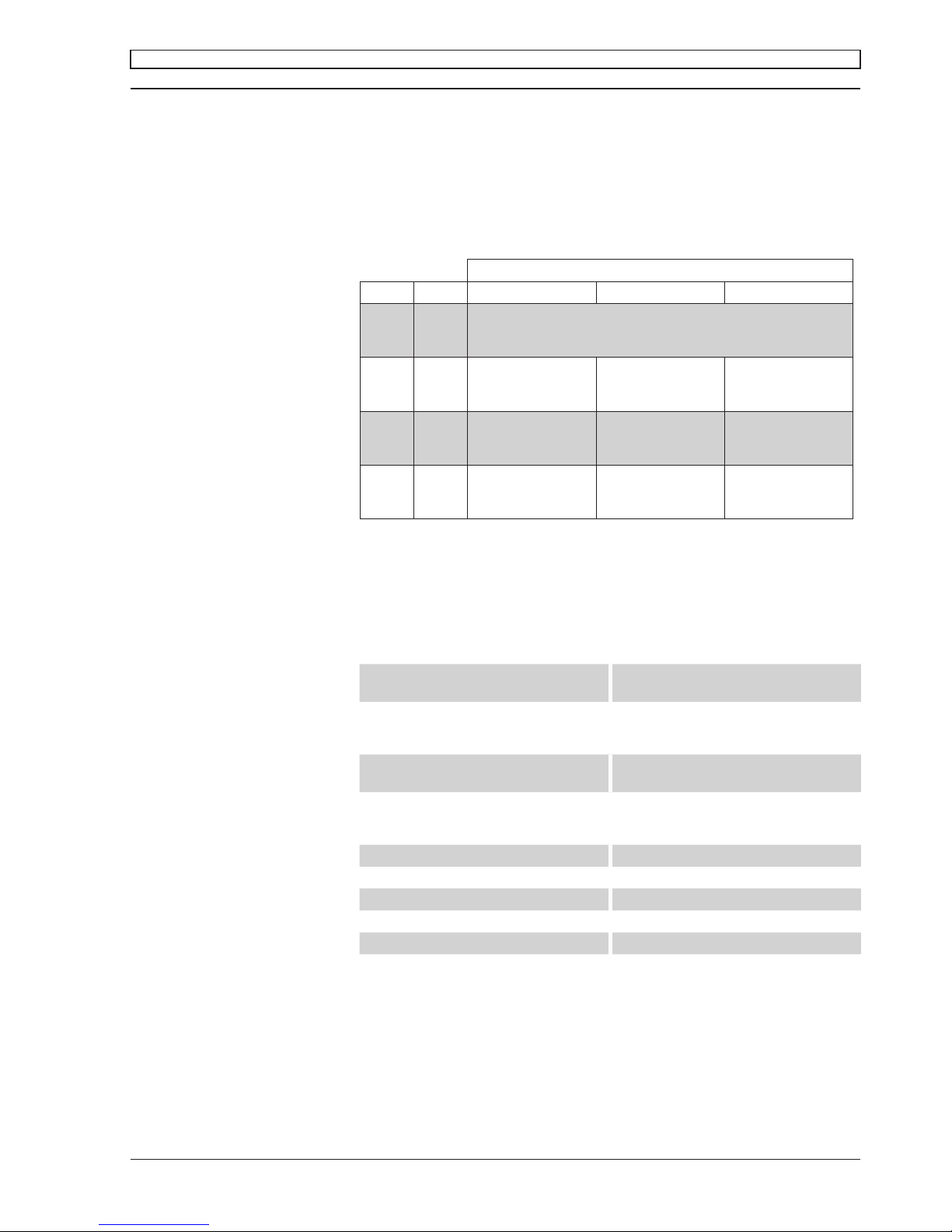

5.1.1 Speed range and mode selection with «DigIN1» and «DigIN2»

The digital inputs «DigIN1» [20] and «DigIN2» [21] determine both, the operation mode (digital speed controller or digital speed actuator) and the speed

range in speed set value mode.

Motor type

DigIN1 DigIN2 1 pole pair 4 pole pair 8 pole pair

0 0

Open loop speed control, 0...95 % PWM

depending on the «Set value speed» input voltage

1 0

500...5 000 rpm 125...1 250 rpm 62...625 rpm

0 1

500...20 000 rpm 125... 5 000 rpm 62...2 500 rpm

1 1

500...80 000 rpm 125...20 000 rpm 62...10 000 rpm

Please note

Ö If the signal level of the digital inputs DigIN1 [20] and DigIN2 [21] are

changed, the new levels are adopted by a disable-enable procedure.

If the input «DigIN» is not connected (floating) or a voltage higher than 2.4 V

is applied, the input is active.

Logic 1

Input not connected (floating)

Input voltage > 2.4 V

Input active

If the input «DigIN» is set to ground potential or a voltage smaller than 0.8 V

is applied, the digital input is inactive

Logic 0 Input set to Gnd

Input voltage < 0.8 V

Input inactive

The inputs «DigIN1»and «DigIN2» are protected against overvoltage.

Digital input 1 Pin number [20] «DigIN1»

Digital input 2 Pin number [21] «DigIN2»

Input voltage range 0 ... +5 V

Input impedance 47 kΩ pull-up resistor against 5 V

Continuous overvoltage protection -55 ... +55 V

Loading...

Loading...