Page 1

Page 2

MAXON

SD-125 RF LINK MODULE

i

i

TABLE OF CONTENTS…………………………………………………………………………………….…………. i

SPECIFICATIONS……………………………………………………………………………………………...……… i

UNPACKING……………………………………………………………………………………………………………. 7

INTRODUCTION………………………………………………………………………………………………………… 8

FEATURES ……………………………………………………………………………………………………………… 8

THEORY OF OPERATION ……………………………………………………………………………………………. 9

INTRODUCTION …………………………………………………………………………………………………………………

DIGITAL CIRCUITS ……………………………………………………………………………………………….. 9

RF CIRCUITS ……………………………………………………………………………………………………… 9

RF CIRCUITS PLL SYNTHESIZER …………………………………………………………………………….. 10

RECEIVER …………………………………………………………………………………………………………. 10

MAINTENANCE AND REPAIR ………………………………………………………………………………………. 12

GENERAL …………………………………………………………………………………………………………. 12

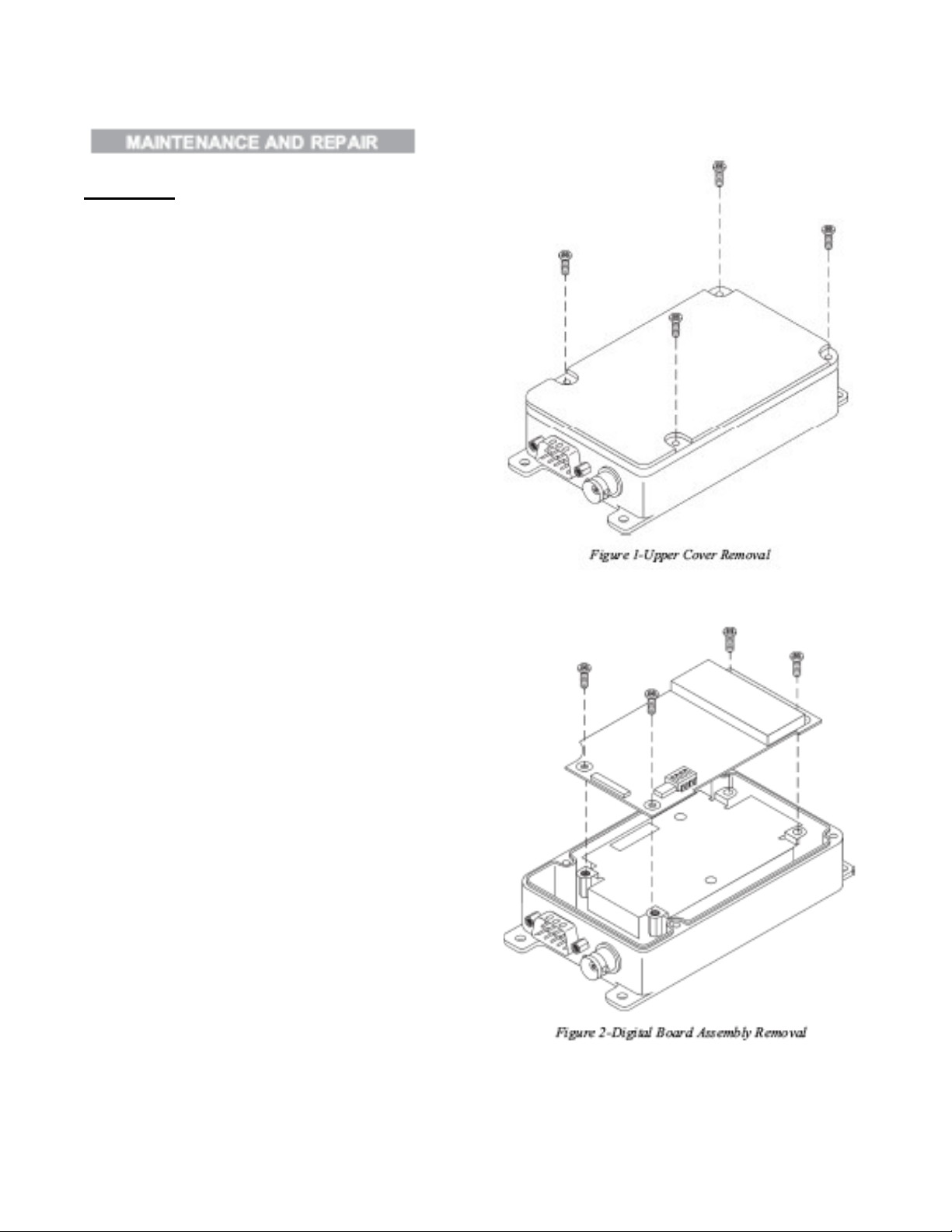

REMOVING & REPLACING THE UPPER COVER ………………………………………………………….. 12

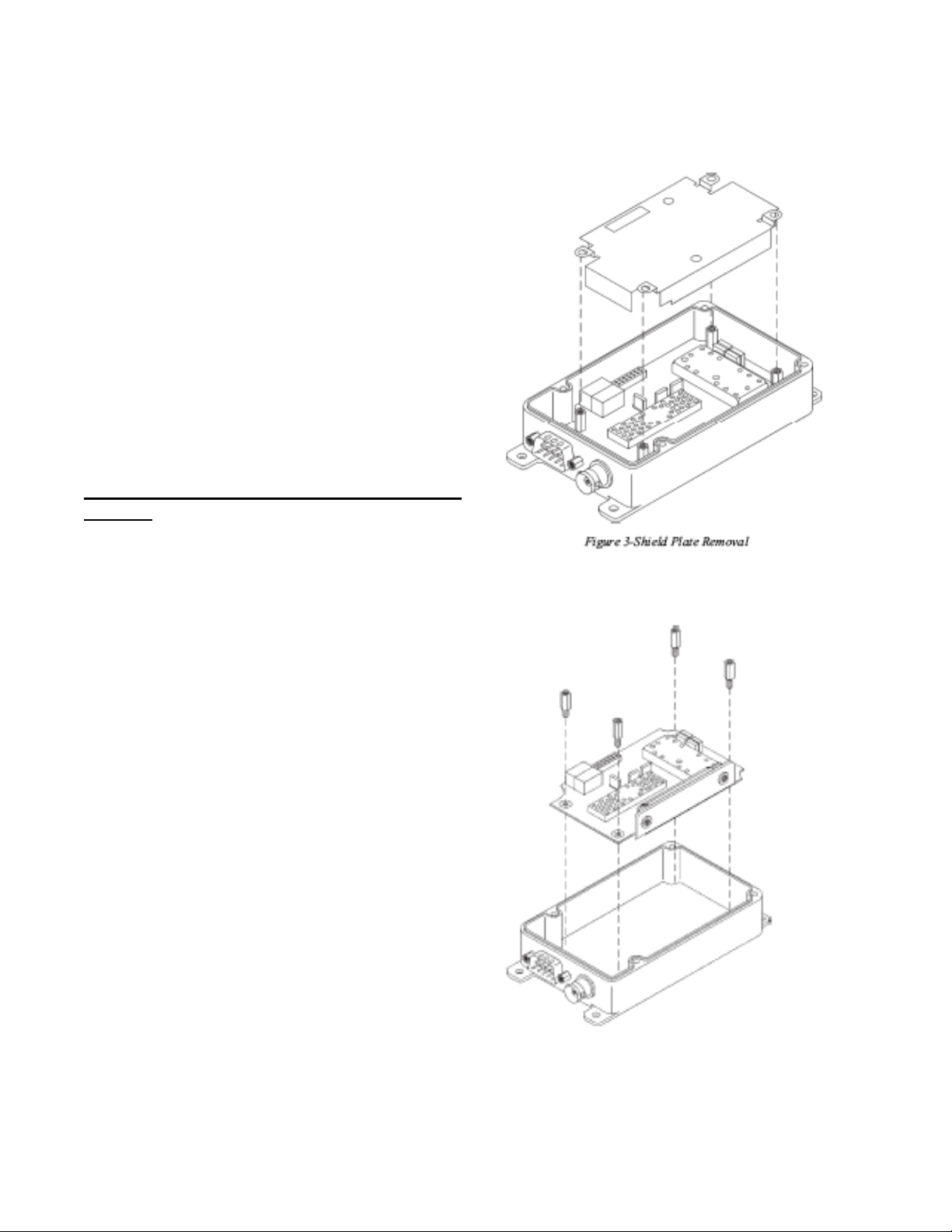

REMOVING 7 REPLACING THE DIGITAL BOARD 7 SHIELD PLATE …………………………………... 12

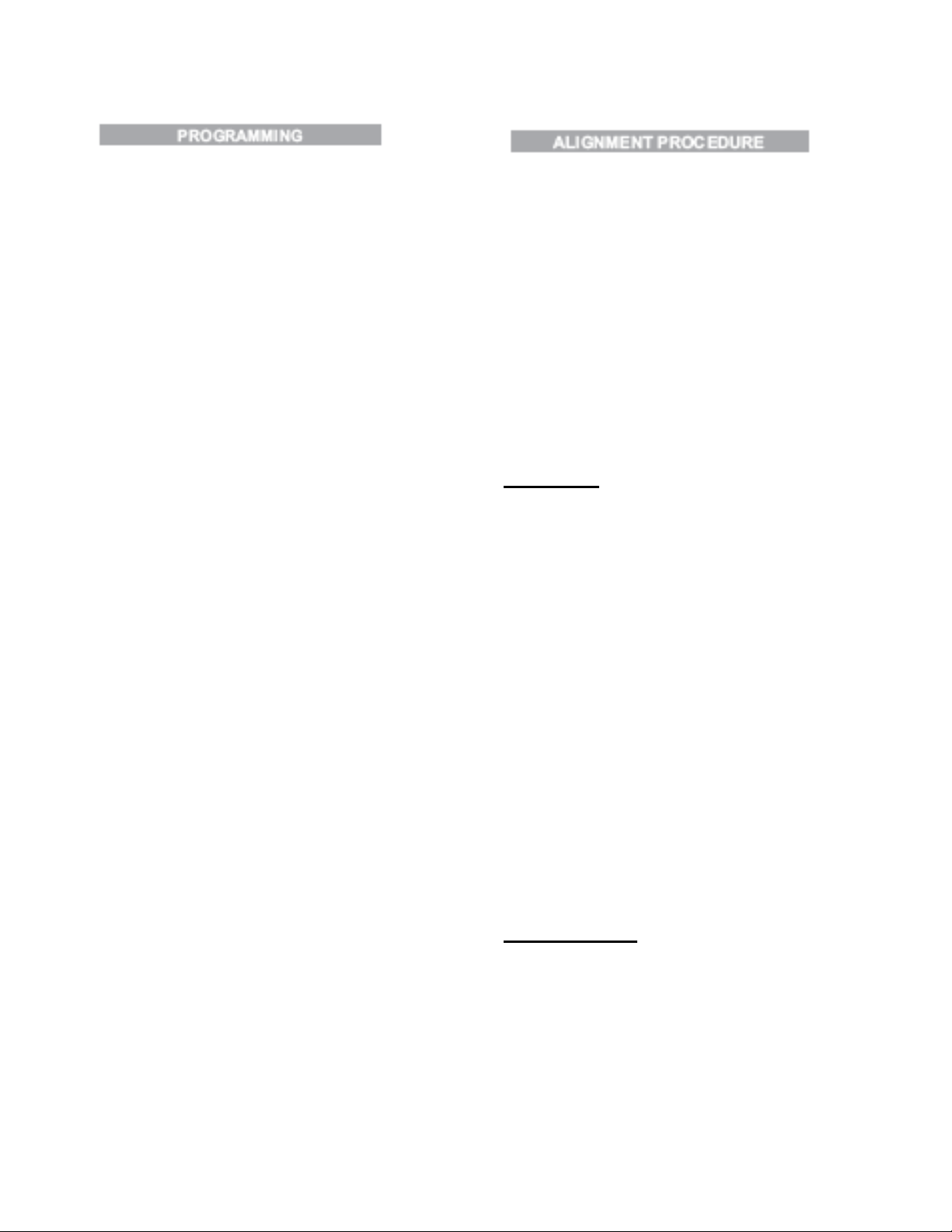

REMOVING 7 REPLACING THE RF BOARD ………………………………………………………………... 13

PROGRAMMING ……………………………………………………………………………………………………….. 14

ALIGNMENT PROCEDURE ………………………………………………………………………………………….. 14

RECEIVER ……………………………………………………………………………………………………….. 14

TRANSMITTER ………………………………………………………………………………………………….. 14

TEST EQUIPMENT SETUP …………………………………………………………………………………………… 17

ALIGNMENT POINTS DIAGRAM ………………………………………………………………………………………………….

COMPONENT REPLACEMENT …………………………………………………………………………………………………….

TROBLESHOOTING GUIDE ………………………………………………………………………………………………………..

VOLTAGE CHART ……………………………………………………………………………………………………………………

SD-125 DIGITAL BOARD (COMMON) PARTS LIST (650-010-0029) …………………………………………... 25

SD-125 (U1 400-430 MHz)RF BOARD PARTS LIST (650-020-0027) …………………………………………... 27

SD-125 (U2 440-470MHz) RF BOARD PARTS LIST (650-020-0026) ………………………………………….. 30

SD-125 (V2 148-174MHz) RF BOARD PARTS LIST (650-020-0029) ………………………………………….. 33

COMPONENT PINOUT ………………………………………………………………………………………………... 37

WRING DIAGRAM ……………………………………………………………………………………………………... 41

SCHEMATICS, BLOCK DIAGRAM & PCB´S ……………………………………………………………………… 43

BLOCK DIAGRAM …………………………………………………………………………………………….

DIGITAL BOARD SCHEMATIC………………………………………………………………………………

RF BOARD (148-174 MHz) SCHEMATIC ………………………………………………………………….. 45

RF BOARD (400-430 MHz) SCHEMATIC ………………………………………………………………….. 46

RF BOARD (440-470MHz) SCHEMATIC ………………………………………………………………….. 47

TCOX (148-174MHz) ………………………………………………………………………………………….. 48

VCO (148 -174MHz) ………………………………………………………………………………………... 48

PAGE-i-

October 98

9

18

19

20

21

43

44

Page 3

MAXON

SD-126 RF LINK MODULE

VCO (400-430 MHZ) ………………………………………………………………………………

VCO (440-470MHz) ……………………………………………………………………………….

FRONT-END (148-174MHz) ……………………………………………………………………..

FRONT-END (400-430 MHz) …………………………………………………………………….

FRONT-END (440-470MHz.) …………………………………………………………………….

POWER AMPLIFIER (148-174MHz) …………………………………………………………….

POWER AMPLIFIER (400-430MHz) …………………………………………………………….

POWER AMPLIFIER (440-470MHz) …………………………………………………………….

DIGITAL PCB ASSEMBLY………………………………………………………………………..

RF PCB ASSEMBLY (148-174MHz) …………………………………………………………….

RF PCB ASSEMBLY (400-430 MHz)…………………………………………………………….

RF PCB ASSEMBLY (440-470MHz)……………………………………………………………..

EXPLODED VIEW & PARTS LIST……………………………………………………………… 55

PAGE-ii-

October 98

49

49

50

50

50

51

51

51

52

53

54

54

Page 4

MAXON

SD-125 RF LINK MODULE

SPECIFICATIONS

GENERAL

Equipment Type............................................................................. Data Radio

Performance Specifications …………………………………………TIA / EIA-603 & ETS 300-113

Band………………………………………………………………………UHF / VHF

Channel Spacings………………………………………………………25 Khz, programmable

RF Output Power ……………………………………………………….5/1 watt

Modulation Type……………………………………………………….. F3D, F3E

Intermediate Frequency ……………………………………………….451 MHz & 455 MHz

Numbers of Channels…………………………………………………..16

Frequency Source……………………………………………………….SAynthesizer

Operation Rating…………………………………………………………Intermitent

90:5:5 (Standby: RXC:TX)

Power Supply…………………………………………………………….Ext.Power Supply (12 VDC Nominal Voltage)

9.0V – 15.0V DC EXTREME

TEMPERATURE RANGE

Storage……………………………………………... from-40ºC to + 80º C

Operating…………………………………………….from – 30º C to + 60ºC

Current Consumption

Standby (Muted)………………………………..< 65 mA

Transmit 5 Watts RF Power…………………..< 2.0 A

Transmit 5 Watts RF Power…………………..< 1.0 A

PAGE-1-

October 98

Page 5

Frequency Bands:

RX

VHF:V1

V2

UHF:U2

U1

U5

U3

U4

Dimensions……………………………………………………..(30 mm) H x (62mm)W x (118mm)D

Weight ..................................................................................250 grams

136.000 – 162.000 MHz

148.000 – 174.000 MHz

440.000 – 470.000 MHz 440.000 – 470.000 MHz

400.000 – 430.000 MHz 400.000 – 430.000 MHz

420.000 – 450.000 MHz 420.000 – 450.000 MHz

470.000 – 490.000 MHz 470.000 – 490.000 MHz

490.000 – 512.000 MHz 490.000 – 512.000 MHz

TRANSMITTER

Carrier Power........................................

HiI ....................................................

Low .................................................

Sustained Transmission …………………………Nominal conditions

Time:

Power:

Frequency Error

Frequency Deviation

25 Khz Channel Spacing ……………….

Audio Frequency Response ……………

@ 300 Hz to 3,0 Khz for 25 Khz C.S

Adjacent Channel Power

25 kHz …………………………………….

Conducted Spurious Emission………….

Nom Max Min

5W <6W >4,5 w

1W <1.5W >0.8 w

5 10 30 Sec

>90% >85% >80%

<0,5 Khz Nominal condition for VHF

<0,75 Khz Nominal condition for UHF

-3,0 ppm Extreme condition for UHF

Peak – 5.0, Min. – 3.8

Within + 1/-3dB of 6dB octave

< 70 dBc @ Nominal Condition

< 65 dBc @ extreme Condition

< 57 dBc

PAGE-2-

October 98

MAXON

Sd-125 RF LINK MODULE

TX

136.000 – 162.000 MHz

148.000 – 174.000 MHz

Page 6

MAXON

SD-125 RF LINK MODULE

Modulation Sensitivity …………………..

Hum & Noise:

25 Khz Channel Spacing………………..

Modulation Symmetry……………………

Load Stabilitty ……………………………….

Peak Deviation Range Adjustment @ 1

kHz,Nom. Dev + 20 dB :

25 kHz Channel Spacing …………………..

RECEIVER

Sensitivity (12dB Sinad)……………………...

Amplitude Characteristic……………………..

Adjacent Channel Selectivity ………………..

25 kHz Channel Spacing ……………….

Spurious Response Rejection ………………

Image Response Rejection…………………

IF Response …………………………………..

Others …………………………………………

Intermodulation Response Rejection:

± 25 kHz / 50 kHz ………………..…………

± 50 kHz / 100 kHz ………………..……….

Conducted Spurious Emiision @ Nominal

Conditions

9 kHz - 1 GHz …………………………..

1 Ghz – 4 GHz …………………………..

RX Spurious Emissions (Radiated) @

Nominal Conditions

9 kHz - 1 GHz …………………………..

1 Ghz – 12.75 GHz ………………………..

100mmV RMS @ 60% Peak Dev.

> 40 dB(with no PSOPH)

< 10% Peak Dev @ 1kHz input for nominal dev + 20db

No osc at ≥ 10:1 VSWR all phase angels and suitable

antena

No destroy at ≥ 20:1 all phase angle

Min. 3.5, Max. 6.0

UHF < - 117 dBm, VHF < - 118 dBm @ Nom.Condition

UHF < - 115 dBm, VHF < - 116 dBm @ Extreme

.Condition

< 3dB

> 60 dB @ Nom., > 55dB @ Extreme Condition

70 dB (100 kHz – 4 GHz)

>70

>70

>70

65 dB

65 dB

<- 57dBm

<- 47dBm

<- 57dBm

<- 47dBm

PAGE-3

October 98

Page 7

MAXON

Sd-125 RF LINK MODULE

AF Distortion…………………………………………...

25,0 kHz CP………………………………………….

Receiver Opening Range…………………………..

Squelch Opening Range:……………………………

Squelch Closing Range (Hysteresis)………………

Squelch Attack Time:

RF Level at Threshold …………………………..

RF Level at Threshold + 20 dB …………………..

Squelch Decay Time: ………………………………

Antenna Socket Input Match……………………….

L.O Frequency Temperature Stability…………….

L.O Frequency Aging Rate ………………………..

REFERENCE CRYSTAL

< 5% @ Nom., < 10% @ Extreme Condition

< 40 dB No PSOPH

< 16 mS

RF level for 6 to 14 dB Sinad

0 - 6 dB Sinad@ Nominal Condition

< 40 mS

< 30 mS

5 mS Min, 20 mS Max

> 10 dB Return Loss

1st - < 5ppm, 2nd < 15 ppm from – 30 to + 60 C

- 2 ppm / year

Frequency……………………………………………….

Holder Type…………………………………………….

Temperature Characteristics………………………..

Aging Rate ……………………………………………

Lock Time………………………………………………

TX to RX…………………………………………………

RX to TX ………………………………………………..

12,8 MHz

HC – 18

- 5.0 ppm fom -30 C to + 60 C

-

< 2 ppm / year in 1st year

< 1 ppm / year therafter

< 10 mS

< 20 (No Power Saving)

< 20

PAGE-4-

October

Page 8

ENVIRONMENTAL (performance without degradation unless stated)

Temperature……………………………………………….. Deg C

Operating …………………………………………………. - 30 to + 60 C Degradation Specified @ Extreme

Storage ……………………………………………………. - 40 to + 80 C

Recharging…………………………………………………. - 10 to + 55 C

ESD…………………………………………………………. 20 Kv (C – MIC ≥ 15 Kv)

PROGRAMMER

Programmer ( Interface Module) ………………………. ACC-2000

Programmer ( Interface Cable) …………………………. QPA-4000

MAXON

SD-125 RF LINK MODULE

Programmer ( Interface Software) …………………...… ACC-900

• Due to continuing research and development the company reserves the right to alter these

specifications without prior notice

PAGE – 5 –

October 98

Page 9

INTRODUCTION

The Maxon SD 125 Series of RF Link Modules From

Maxon utilizes the latest technology in its design and

manufacturing. Both he UHF and VHF models (Phase

Lock Loop Synthesizer) / microprocessor controlled,

And offer one to five watts of power with 16 channel

capability . Multiple functions including 1200 to 9600

baud rates, AC and/or DC audio coupling, GMSK and

FSK modulation are standard in these fully

programmable wide bandwidth RF Link Module units.

The radio is programmed using a IBM Personal

Computer, DOS based software, an interface module

and a programming cable. This allows the radio to be

tailored to meet the requirements of the individual user

and of the System (s) it is operating within.

PAGE-6-

October 98

MAXON

SD-125 RF LINK MODULE

FEATURES

• Busy Channel Lockout

• 16 Channels

• TX Time-out

• Power Save

• 1/5 Watt Programmable Output

• 15 kHz Programmable Spacing

Busy Channel Lockout

The Busy Channel Lockout feature , when

enabled, disables the transmitter when the

receiving channel is busy and the user

attempts to transmit.

16 Channels

The SD-125 Series radio can store up to

16channels within the same band

TX Time – Out

The TX Time-Out feature, when enabled,

limits the amount of time that the user can

continuously transmit. This time can be set in

increments of 10 seconds from 10 seconds to

990 seconds

Power Save

The Power Save feature is used when an

external battery is used as the power source.

When Power Save is enable, the receiver ON

and OFF time can be programmed into the

radio and allows the operator to set the length

of time the receiver is asleep.

Page 10

INTRODUCTION

The VHF and UHF radios are comprised of two PCB's (an

RF PC Band a digital PCB). These boards are connected

with an 18 pin female and male connector. The digital board

is interfaced with external data equipment through the 9 pin

d-sub male connector, which controls the radio and data

receiving and sending.

DIGITAL CIRCUITS

The Digital circuit contains the CPU, the channel select

switch, and associated digital circuits.

TX-SIGNAL CIRCUIT

The TX data signal comes from Pin 2 of Con 401, and goes

through U404D. The TX-signal is amplified by U406C. The

TX-signal is filtered by U405A & B which is a 4’Th order low

pass filter, the output of U405A is then fed to the RF board

for TX modulation.

RX-SIGNAL CIRCUIT

The RX- data signal comes from the RF board, which is

connected with pin 10 of Con 403. The RX-signal is switched

by U404A and adjusted by RV403 and amplified by U407.

The amplified signal goes to pin10 of Con 401.

RSSI DETECTOR

From the RF board, the RSSI (Received Signal Strength

Indicator) signal flows to U403A&Bthrough R461. The pulse

is injected from pin 5 of U403B every 1 mS and C451 is

discharged. It is then charged by R464. The RSSI signal is

simultaneously input to pin 7 of U403A and those signals are

compared. The compared signal is output from U403A. Pin 1

of U403A and the CPU detects the pulse width. The pulse

width is varied by RSSI DC voltage; therefore, the carrier

detection is controlled by the CPU.

EEPROM

RX / TX channel and RSSI detection level as well as other

data from the programmer are stored in the EEPROM. The

data stored is retained without power supplied. This is a nonvolatile memory. The EEPROM may have information reprogrammed or erased. U402 is an EEPROM with 2048 (8 x

256) capacity and data is written and read serially.

PAGE-7-

October 98

MAXON

SD-125 RF LINK MODULE

CHANNEL SELECTOR

One of 16 channels may be selected using the Dip Switch

(SW401). SW401 encodes the channel number, selected

into 4-bit binary code. The binary code plus one equals the

channel number. The binary code is decoded by the CPU

enabling the appropriate RX or TX frequency and

associated data to be selected from the EEPROM.

DC TO DC CONVERTER

The main DC power is injected to the DC to DC converter.

The DC to DC converter regulates the various input power

supply voltage and outputs a constant voltage of 7.5 Volts.

It is a source for all of the RF and digital circuits.

The DC to DC converter is formed by U801, Q801, Q802,

L801 and R804. U801 is a switch mode DC to DC

Converter IC.

Input DC various appears as a voltage various through

R804.

U801 detects the voltage and controls the switching pulse.

As the switching pulses, Q801and Q802 switches the input

DC of various supply voltages and generates the constant

DC of supply voltage.

RF CIRCUITS

TRANSMITTER

The transmitter is comprised of:

1. Buffer

2. P.A. Module

3. Low Pass Filter

4. Antenna Switch

5. A.P.C. Circuits

BUFFER

VCO output level is -6dBm and amplified to +10dBm

(UHF), +6dBm (VHF). The buffer consists of Q16 and Q17

for isolation and gain.

P.A. MODULE

The P.A. Module contains Q501, Q502, and Q503. Three

stage amplifiers Q501 amplify the TX signal from +10 dBm

to 100 mW. Q502 is amplified to 0.5W. Q503 amplifies to

3W and then matched to 50 Ohms using the L.C. network,

thereby reducing the harmonics by -30 dB.

LOW PASS FILTER

L7, L8, L11, C72, C73, C74 and C75 are the 7th order

Chebyshev low pass filter. Unwanted harmonics are

reduced by -70 dBc.

Page 11

ANTENNA SWITCH

When transmitting, the diodes D5 and D6 are forward biased

enabling the RF signal passage to the antenna. D6 is

shorted to ground inhibiting the RF signal to front end. In

receive the diodes D5 and D6 are reversed biased passing

the signal from the antenna through L13 and C83 to the front

end without signal loss.

AUTOMATIC CURRENT CONTROL (ACC)

CIRCUITS

The ACC circuit consists of R109, variable resistor RV1,

IC3(B) and transistors Q21 and Q22. The supply current is

monitored by the difference voltage on R109 (0.1 Ohm). If

the current varies by RF power output or other reasons, it

produces some bias voltage by IC3A and Q19. The

differential signal at the output of IC3 is passed to Q21 and

Q22 that produces a constant power output to the antenna.

RV1 is used to adjust the RF power level.

RF CIRCUITS PLL SYNTHESIZER

12.8 MHz TCXO

The TCXO contains the 3-stage thermistor network

compensation and crystal oscillator and modulation ports.

Compensation is ±5 PPM or less from -30c to +60c.

PLL IC DUAL MODULES PRESCALER

Input frequency of 12.8 MHz to IC2 MC14519 pin 20 is

divided to 6.25 kHz or 5 kHz by the reference counter, and

then supplied to the comparator. RF signal input from VCO is

divided to 1/64 at the prescaler in IC2, divided by A and N

counter in IC2 to determine frequency steps, and then

supplied to the comparator. PLL comparison frequency is

6.25/5kHz so that minimum programmable frequency step is

5/6.25 kHz.

The A and N counter is programmed to obtain the desired

frequency by serial data in the CPU. In the comparator, the

phase difference between reference and VCO signal is

compared. When the phase of the reference frequency is

leading , Fv is the output, but when VCO frequency is

leading, Fr is the output. When Fv = Fr, phase detector out is

a very small pulse. 64/65 modulus prescaler is comprised in

IC2, and has two output ports:

• Port A pin 16: TX enable 2

• Port B pin 15: prescaler power save control in PLL

IC Pin 13 labeled test2 allows the technician to see

the output of the dual modulus prescaler for trouble

shooting purposes, no connection should be made

to this pin.

PAGE- 8-

October 98

MAXON

SD-125 RF LINK MODULE

LEVEL SHIFTER & CHARGE PUMP

The charge pump is used for changing output signals Fr,

Fv at PLL IC from 0-5v to 0-12v necessary for controlling

the VCO.

REFERENCE FREQUENCY LPF

The Loop Filter contains R12, C21 and C22. LPF settling

time is 12mS with 1 kHz frequency. This also reduces the

residual side-band noise for the best signal-to-noise ratio.

DC TO DC CONVERTER

The DC to DC converter convert the 5v to 14-16v to supply

the necessary voltage for wide range frequency in the

VCO.

VCO

The VCO consist of an RX VCO and a TX VCO. It is

switched TX/RX by the power source. It is configured as a

colpits oscillator and connected to the buffer as a cascade

bias in order to save power. The varicap diode D201/D301

are low-resistance elements and produce a change in

frequency with a change in reverse bias voltage (2-11v).

L203/L303 are resonant coils, which changes the control

voltage by the tuning core. D202 modulation diode,

modulates the audio signal.

C204 compensates for the non-linearity of the VCO due to

modulation diode, and maintains a constant modulation

regardless of frequency.

RECEIVER

FRONT-END

The receive signal is routed backward through the low

pass filter, then onward to Pin 1 of the Hybrid Receiver

Front End Module to a bandpass filter consisting of (VHF

C622 through C608, L607 through L604 ) and (UHF

C601through C610, L601 through L603 ) is coupled to the

base of Q601 which serves as an RF amplifier. Diode

D601 serves as protection from static RF overload from

nearby transmitters. The output of Q601 is then coupled to

a second bandpass filter consisting of (VHF C607 through

C623 and L604 through L607).The output of Pin 6 is then

coupled to the doubly balanced mixer D9. The receiver

front end module is factory pre-tuned and requires no

adjustment. Repair is effected by replacement of the entire

module of the proper banded module. These are VHF

148MHz to 174 MHz and UHF 440 MHz to 470 MHz. The

receiver front end module signal pins are as follows:

1. RF Input

2. Input Ground

3. N/A

4. Receive +5V

5. Ground

6. Output

Page 12

FIRST MIXER

D9, T2 and T3 are double balanced mixers which provide the

45.1 MHz intermediate frequency output. The filtered

frequency from the front end module is coupled to T2 . The

45.1 MHz IF output is matched to the input of the 2-pole

monolithic filter by L14, L31, C69 and C97. The crystal filter

provides a bandwidth of ±7.2 kHz from the operating

frequency providing a high degree of spurious and

intermodulation protection.

Additionally, a 90 MHz trap (XF1) is also placed at the filter

output to provide additional attenuation of the second order

IMD. The output of the filter is impedance matched by C97

and C69 to the base of the post of filter IF amplifier Q25.

SECOND OSCILLATOR MIXER LIMITER AND

FM DETECTOR

The output of the post filter amplifier, Q25, is coupled via

C98 to the input of IC5 ( MC3371). IC5 is a monolithic single

conversion FM transceiver, containing a mixer, the second

local oscillator, limiter and quadrature detector. Crystal X1

44.645 MHz is used to provide resultant 455kHz signal from

the output of the second mixer. The mixer output is then

routed to CF1 (455F). These ceramic filters provide the

adjacent channel selectivity of 25 kHz bandwidth .

RSSI ( RECEIVER SIGNAL STRENGTH

INDICATOR )

The RSSI signal is output from IC5 on pin 13. As the receiver

signals the output, DC voltage is varied as much as receiver

signal strength. Also, the DC signal is temperature

compensated with a thermistor (TH1).

PAGE- 9-

October 98

MAXON

SD-125 RF LINK MODULE

Page 13

GENERAL

When removing or fitting, use the Exploded View and Parts

List, located on page 55 in conjunction with the following

procedures:

• WARNING: Disconnect the SD-125 from all

external equipment at the D-Sub connector prior to

disassembly.

REMOVING & REPLACING THE UPPER

COVER

Removing the Upper Cover:

1. Unscrew the four upper cover mounting screws

located on the upper cover of the radio.

To replace the Upper Cover:

1. Reverse the steps taken to remove the Upper

Cover.

REMOVING & REPLACING THE DIGITAL

BOARD & SHIELD PLATE

Removing the Digital Board Assembly & Shield

Plate:

1. Remove the Upper Cover (refer to Removing &

Replacing the Upper Cover).

2. Disconnect the DB9 pin connector on CON401.

3. Unscrew the 4 mounting screws.

4. Remove the Digital Board Assembly.

5. Remove the Shield Plate.

To replace the Digital Board Assembly:

1. Reverse the steps taken to remove the Digital

Board Assembly & Shield Plate.

PAGE-10-

October 98

MAXON

SD-125 RF LINK MODULE

Page 14

REMOVING & REPLACING THE RF

BOARD

Removing the RF Board Assembly:

1. Remove the Upper Cover (refer to Removing &

Replacing the Upper Cover).

2. Remove the Digital Board Assembly and Shield

Plate (refer to Removing & Replacing the Digital

Board Assembly & Shield Plate).

3. Unscrew the 4 mounting standoffs.

4. Unsolder the antenna connector cable.

5. Remove the RF Board Assembly.

To replace the RF Board Assembly:

1. Reverse the steps taken to remove the RF Board

Assembly.

PAGE-11-

October 98

MAXON

SD-125 RF LINK MODULE

Figure 4-RF Board Removal

Page 15

MAXON

SD-125 RF LINK MODULE

The SD-125 Series radio requires the ACC-900

Programming Software, ACC-2000 Interface Module,

9-15 VDC 200mA Power Supply and QPA-4000

Programmer Interface Cable.

Refer to the ACC-900 Programming Manual (P/N: 680110-0032) for detailed information on programming the

SD-125 Series radio.

PAGE-12-

October 98

The SD-125 UHF/VHF Receiver is by design, broad

band covering UHF(400-430 MHz & 440-470 MHz)

and VHF(148-174 MHz) and should require no

special alignment, unless repairs are performed on

the receiver portion.

Should repairs be necessary, use the "Test

Equipment Diagram" on page 17 & the "Alignment

Points Diagram" on page 18, in conjunction with the

following procedures:

• An Extender Board (P/N: 650-060-0016) is

required in order to separate the Digital and

RF PCB.s to allow access to the alignment

points. Installation instructions are provided

with the Extender Board Assembly.

RECEIVER

1. Apply a standard test signal to the receiver

antenna terminals.

2. Adjust T1 for maximum sensitivity and audio

output with minimum audio distortion.

3. Adjust RV403 for the specific audio output

level.

RX VCO

1. Set the unit to the highest receive frequency,

470MHz(UHF), 174MHz(VHF) and adjust

the VCO L303 to 8 volts.

2. Set the unit to the lowest receive frequency

440MHz(UHF), 148(VHF) and check that the

VCO voltage is above 2.0 volts. If voltage is

below 2.0 volts, adjust L303 for 2.0 volts or

more.

• Note: Use TP1 to measure the voltage.

TRANSMITTER

Connect the unit to a Service Monitor with the power

meter setting to the 10 W scale (or autorange)

TCXO

Set the channel selector to the mid-range frequency

460 MHz, adjust TCX01 for a reading of 460 MHz

±200Hz (155 MHz VHF models).

Page 16

TX VCO

1. Set the unit to the highest transmit frequency,

470MHz(UHF), 174MHz(VHF) key the

transmitter and adjust the VCO L203 to 8

volts.

2. Set the unit to the lowest transmit frequency

440 MHz(UHF), 148(VHF) key the transmitter

and check that the VCO voltage is above 2.0

volts. If voltage is below 2.0 volts, adjust L203

for 2.0 volts or more.

Note: use TP1 to measure the voltage.

TX Deviation and Balance Adjustment

1. Set the unit to a mid-frequency and input the

TX data with 400 Hz standard audio level.

2. Increase the signal level to 20 dB from

standard level.

3. Monitor the demodulated signal from service

monitor. Adjust RV3 to make the monitored

signal to be a balanced square wave.

4. Reduce input signal to the standard level and

adjust RV2 for the standard deviation.

APC

1. Adjust RV1 for High Power (5W)

2. Adjust RV6 for Low Power (1W)

3. This completes the transmitter alignment

procedures.

SD-125 Squelch setting using the ACC-2000

Interface Module

Maxon.s wide range of data radio products since the

crystal control module (DM-0500 series) had their

squelch level setting by hardware touch up. With the

new SD-125 series, the squelch level to open or close

(unmute or mute) is set up by software control.

The RSSI utilizes the A/D conversion that will be fed to

the microprocessor, which in turn will use this input to

determine the squelch level setting to control the mute

and unmute of the receiver.

Default setting of squelch level for all the SD-125 from

our manufacture and workshop is approximately set at:

PAGE-13-

October 98

MAXON

SD-125 RF LINK MODULE

1. Squelch open (unmute) at -114dBm to 113dBm (0.45 - 0.5mV of the RX signal

strength)

2. Squelch close (mute) at -117dBm to 116dBm (0.3 - 0.35mV of the RX signal

strength)

Changing the default squelch settings requires use

of the programming adaptor box. This box is

designed for use not only as part of the

programming kit but also as a tool of squelch level

setting.

The minimum equipment required for squelch level

setting is a RF signal generator. Radio

communication test equipment is recommended.

1. Power up the programming adaptor box (use the

DC supply of 9 - 15 Volts 200mA).

2. Hook up the SD-125 unit to the programming

adaptor box, and its antenna connector to the RF

input port of the RF signal generator.

3. With the adaptor box turned "off., simultaneously

press and hold both "ON/OFF" and "WRITE" buttons

down.

4. Release the "ON/OFF" button first then the

"WRITE" button next. (LED indicator on the box will

flash twice after that it may stay on / off, this is of no

concern , because depending on the signal strength

of the RF generator as well as the pre-set level of

squelch the SD125 may be in standby mode (LED

OFF) or in receiving mode (LED ON)

5. Adjust the RF signal generator for the desired

signal strength to OPEN squelch (e.g. default setting

is -113dBm, that is equivalent to 0.5mV)

6. Press and release "READ" button, LED indicator

will flash 3 times then it will be ON.

7. Adjust the RF signal generator for the desired

signal strength to CLOSE squelch (e.g. default

setting is -116dBm, that is equivalent to 0.35mV)

8. Press and release "READ" button, LED indicator

will flash 1 time then it will be OFF.

9. Press and release "WRITE" button, LED indicator

will flash twice.

10. Squelch level is now set. Test for desired level

by increasing or decreasing the RF signal to levels

set

Page 17

for open and close squelch (mute LED will be OFF &

unmute LED will be ON).

NOTE: The difference of RF signal strength

between the unmute and mute levels must be

greater than or at least equal to 0.15mV (i.e. at

least -123.5dBm) for the squelch setting to

work properly. If they are too close to one

another, RSSI through the A/D conversion can

not differentiate between the mute and unmute

level properly. As a result, it would cause the

CD (Carrier Detect) to act intermittently.

PAGE-14-

October 98

MAXON

SD-125 RF LINK MODULE

Page 18

MAXON

SD-125 RF LINK MODULE

PAGE-15-

October 98

Page 19

MAXON

SD-125 RF LINK MODULE

PAGE-16-

October 98

Page 20

COMPONENT REPLACEMENT

COMPONENT REPLACEMENT

Surface Mount Components

Surface mount components should always be replaced using

a temperature controlled soldering system. The soldering

tools may be either a temperature controlled soldering iron or

a temperature controlled hot-air soldering station. A hot-air

system is recommended for the removal of components on

these boards. With either soldering system, a temperature

of 700 F (371 C) should be maintained.

The following procedures outline the removal and

replacement of surface mount components. If a hot-air

soldering system is employed, see the manufacturer s

operating instructions for detailed information on the use of

your system.

CAUTION: Avoid applying heat to the body of any

surface mount component using standard soldering

methods. Heat should be applied only to the

metalized terminals of the components. Hot-air

systems do not damage the components since the

heat is quickly and evenly distributed to the external

surface of the component

CAUTION: The CMOS Integrated Circuit devices

used in this equipment can be destroyed by static

discharges. Before handling one of these devices,

service technicians should discharge themselves by

touching the case of a bench test instrument that

has a 3-prong power cord connected to an outlet

with a known good earth ground. When soldering

or desoldering a CMOS device, the soldering

equipment should have a known good earth

ground.

Surface Mount Removal

1 . Grip the component with tweezers or small needle

nose pliers.

2. Alternately heat the metalized terminal ends of

the surface mount component with the soldering

iron. If a bot-air system is used, direct the heat to

the terminals of the component Use extreme care

with the soldering equipment to prevent damage

to the printed circuit board (PCB) and the

surrounding components.

3. When the solder on all terminals is liquefied,

gently remove the component Excessive force

may cause the PCB pads to separate from the

board if all solder is not completely liquefied.

4. lt may be necessary to remove excess solder

using a vacuum de-soldering tool or Solder wick.

Again, use great care when de-soldering or

soldering on the printed circuit boards. It may also

be necessary to remove the epoxy adhesive that

was under the

PAGE - 17

October 98

MAXON

SD-125 RF LINK MODULE

surface mount component and any flux on the printed

circuit board.

Surface Mount Component Replacement

1 . Tin one terminal end of the new component and

the corresponding pad of the PCB. Use as little

solder as possible.

2. Place the component on the PCB pads,

observing proper polarity for capacitors, diodes,

transistors, etc.

3. Simultaneously touch the tinned terminal end

and the tinned pad with the soldering iron.

Slightly press the component down on the

board as the solder liquefies. Solder all

terminals, allowing the component time to cool

between each application of heat. Do not apply

heat for an excessive length of time and do not

use excessive solder.

With a hot-air system, apply hot air until all tinned areas

are melted and the component is seated in place. lt may

be necessary to slightly press the component down on the

board. Touch up the soldered connections with a standard

soldering iron if needed. Do not use excessive solder.

• CAUTION: Some chemicals may damage the

internal and external plastic parts of the radio.

4. Allow the component and the board to cool and

then remove all flux from the area using alcohol

or another approved flux remover.

Surface Mounted Integrated Circuit

Replacement

Soldering and de-soldering techniques of the surface

mounted IC s are similar to the above outlined procedures

for the surface mounted chip components. Use extreme

care and observe static precautions when removing or

replacing the defective (or suspect) IC s. This will prevent

any damage to the printed circuit board or the surrounding

circuitry.

The hot-air soldering system is the best method of

replacing surface mount IC s. The IC s can easily be

removed and installed using the bot-air system. See the

manufacturer s instructions for complete details on tip

selection and other operating instructions unique to your

system. If a hot-air system is not available, the service

technician may wish to clip the pins near the body of the

defective IC and remove it. The pins can then be removed

from the PCB with a standard soldering iron and tweezers,

and the new IC installed following the Surface Mount

Component Replacement procedures. it may not be

necessary to tin all (or any) of the IC pins before the

installation process.

Page 21

MAXON

SD-125 RF LINK MODULE

SIMPTOMS CAUSES COUNTERMEASURES

Unit does not work

Bad RX Sensitivity

(-10 to -60d B)

Defective RX

1. lncomplete connection

2. Defective DC/DC VCC

3. Sv voltage source

4. PLL error

5. Filtering error

6. EEPROM fail

1. Defective ANT Switch

2. Defective Front-End

3. Defective dBm

4. IF IC

5. VCO levei drop

6. Change of 1 St local f requency

1. VCO frequency change or level drop

2. Defective voltage source

1. Check CON401 connection

2. Check U801

3. 1C1 (Sv -0.2v)

4. Check TCXOIVCO/PLL IC

5. Check LPF (IC407)

6. Re-programming

1. Check D5, D6

2. Check Q601

3. Check D9, T2, T3

4. Replace 1C5

5. RX VCO level.2dBm

6. Re-Tune TCXO

1. Repair RX VCO

2. Defective IF IC (ICS)

3. [Cl, Ql, Q3

PLL Error

Low TX Power

No TX Power

No Modulation

No Programming

• An Extender Bard, P/N: 650-060-0016, is required in order to separate the Digital and RF PCB s for

troubleshooting purposes.

1. Defective 12.8 MHz TCXO

2. Voltage source for RX VCPITX VCO

3. Defective PLL IC

1. APC 1. Re-adjust Rvi

1. TX Buffer

2. Power Module

3. APC controf

1. SW IC & Mic Amp [C 1. Check U404, 405, 406

1. Short protector VCC 1. Defective programming lead

PAGE-18-

October 98

1. Replace TCXO

2. Check RX VCO/TX VCO

3. Replace 1C2

1. Check Ql 6, 17

2. Check Q501, 502, 503

3. Check Q22, D4

Page 22

SD-125 RF LINK MODULE

CONTROL CIRCUIT TRANSISTOR

RX TX

REF# B C E B C E

Q401 5,0 0,0 5,0

5,0 0,0 5,0

Q402 5,0 GND 5,0 5,0 0.0 5,0

Q403 4.7 0,0 5,0 4.7 0,0 5,0

Q404 4.8 0,0 GND - 0,0 GND

Q405 4.6 1.8 1.8 4.6 1.8 1.8

Q406 4.8 0,0 0.0 0.0 5,0 0.0

Q407 7.5 4,0 7.5 7.5 4,0 7.5

Q408 0.0 7.5 0.0 0.0 7.5 0.0

RF BOARD TRANSISTOR

RX TX

REF# B C E B C E

Q2

Q3 0.0 4.7 5.0 4.7 0.0 5.0

Q4 0.0 5.0 5.0 0.0 5.0 5.0

Q5 5.0 0.0 5.0 5.0 0.0 5.0

Q6 4.0 18.0 5.0 4.2 18.0 5.0

Q7 18.0 6.3 18.0 18.0 6.3 18.0

Q8 5.0 0.0 5.0 5.0 0.0 5.0

Q11 0.0 6.3 0.0 0.0 6.3 0.0

Q12 2.0 4.7 1.2 0.0 0.0 0.0

Q13

Q14 0.0 0.0 0.0 4.6 4.6 4.6

Q16 0.0 0.0 0.0 1.6 4.8 0.8

Q17 0.0 0.0 0.0 0.6 3.0 GND

Q18 0.0 0.0 0.0 5.0 0.2 GND

Q19 1.0 7.5 0.5 1.6 7.5 1.0

Q21 0.0 7.5 0.0 1.6 6.6 1.2

Q22 7.5 0.0 7.5 6.8 5.0 7.5

Q25 0.7 4.0 GND

4.7 0.0 5.0 0.0 4.7 5.0

4.6 4.6 4.0 0.0 0.0 0.0

0.0 0.0 GND

PAGE-19-

October 98

MAXON

Page 23

SD-125 RF LINK MODULE

RF BOARD IC´S

RECEIVE MODE

Pin # IC1 IC2 IC3(OFF) IC5 IC7(OFF) IC8(OFF)

1 GND NC

2 GND 5.0

3 GND 5.0

4

5.0

5.0

5 GND 5.0

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

7.5

-

-

-

-

-

-

-

-

-

-

-

-

-

-

NC

GND

NC

NC

AUDIO

AUDIO

5.0

NC

5.0

0.0

0.0

4.6

0.0

4.7

0SC1

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

OSC1

0SC2

-

4.7

3.3

3.3

3.3

4.7

AUDIO

NC

NC

NC

-

NC

GND

1.8

-

-

-

-

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

RF BOARD IC’S

TRANSMIT MODE

Pin # IC1 IC2 IC3(OFF) IC5(OFF) IC7 IC8(OFF)

1 GND NC

2 GND 5.0

3 GND 5.0

4

5.0

5 GND 5.0

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

7.5

-

-

-

-

-

-

-

-

-

-

-

-

-

-

5.0

NC

GND

NC

NC

AUDIO

AUDIO

5.0

NC

5.0

0.0

5.0

4.6

0.0

4.7

0SC1

1.6 - 1.8

3.0 - 1.8

3.0 - 1.8

GND - GND

0.8 - 1.8

0.3 - 1.8

4.0 - 1.8

5.0 - 5.0

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

PAGE-20-

October 98

MAXON

0.7

0.3

0.3

GND

1.88

1.88

1.88

5.0

Page 24

SD-125 RF LINK MODULE

CONTROL CIRCUIT IC’S

RECEIVE MODE

PIN #

1 0.0 1.3 - - 1.8 AUDIO

2 0.0 0.0 - - 1.8 GND

3 0.7 5.0 - - 1.8 AUDIO

4 5.0 1.8 - - 5.0 GND

5 GND 2.0 GND - AUDIO AUDIO

6 4.7 5.0 0.0 - 1.8 7.5

7 4.7 0.3 1.8 - AUDIO 4.0

8 4.7 0.0 1.8 AUDIO - AUDIO

9 - 1.8 - AUDIO -

10 - AUDIO 0.0 1.8 -

11 - AUDIO 0.0 AUDIO -

12 - GND 5.0 AUDIO -

13 - - - - -

14 - - - - -

15 - - - - -

16 - - - - -

17 - - - - -

18 - - - - -

19 - - - - -

20 - - - - -

PIN #

1 4.63 23 4.7

2 4.63 24 4.7

3 0.0 25 4.7

4 5.0 26 0.0

5 0.0 27 5.0

6 0.0 28 4.6

7 2.0 29 GND

8 4.6 30 4.6

9 4.6 31 0.0

10 4.6 32 4.6

11 0.0 33 0.0

12 0.0 34 0.0

13 0.0 35 0.9

14 4.6 36 OSC2

15 4.7 37 OSC1

16 NC 38 7.5

17 GND 39 NC

18 5.0 40 NC

19 0.0 41 4.6

20 0.0 42 4.6

21

22 N.C

IC402 IC403 IC404 IC405 IC406 IC407 IC408

IC401

0.0

PIN #

43

44 0.0

PAGE-21-

October 98

IC401

GND

MAXON

Page 25

CONTROL CIRCUIT IC’S

TRANSMIT MODE

PIN #

1 0.0

2 0.0

3 4.7

4

5 GND

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

PIN #

1 0.0 23 4.7

2 0.0 24 4.7

3 4.6 25 4.7

4 5.0 26 0.0

5 0.0 27 5.0

6 0.0 28 4.6

7 4.6 29 GND

8 4.6 30 4.6

9 4.6 31 0.0

10 0.0 32 4.6

11 0.0 33 0.0

12 0.0 34 0.0

13 4.6 35 0.0

14 0.4 36 OSC2

15 0.4 37 OSC1

16 NC 38 4.6

17 GND 39 NC

18 5.0 40 NC

19 0.0 41 4.6

20 0.0 42 4.6

21

22 0.0

IC402 IC403 IC404 IC405 IC406 IC407 IC408

- - AUDIO 1.8 -

- - AUDIO 1.8 -

- AUDIO AUDIO 1.8 -

5.0 - AUDIO 5.0 5.0 -

- 0.0 AUDIO - -

4.7 - - AUDIO - -

4.7 - GND AUDIO - -

4.7 - - 1.8 AUDIO -

-

-

-

-

- - - 1.8 AUDIO -

- - - 1.8 AUDIO -

- - - - - -

- - - - - -

- - - - - -

- - - - - -

- - - - - -

- - - - - -

IC401

-

-

-

-

- 1.8 AUDIO

AUDIO 1.8 1.8

AUDIO GND GND

4.6 0.0 1.8

PIN #

4.7

43

44 0.0

PAGE-22-

October 98

MAXON

SD-125 RF LINK MODULE

-

-

-

-

IC401

GND

Page 26

SD-125 RF LINK MODULE

MAXON

REF # DESCRIPTION _________ PART #

C401 CAP, CER,1UF,+80-20%,16V,Y5V,0805 100-803-2105

C402 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C403 CAP, CER,0.022UF,10%,50V,X7R,0603 100-621-1223

C404 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C405 CAP, CER,47PF,5%,50V,COG,0603 100-520-1470

C406 CAP, CER,0.022UF,10%,50V,X7R,0603 100-621-1223

C407 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C408 CAP, CER,47PF,5%,50V,COG,0603 100-520-1470

C409 CAP, CER,0.047UF,+20-80%,25V,Y5V,0603 100-813-1473

C410 CAP, CER,0.0056UF,10%,50V,X7R,0603 100-621-1562

C411 CAP, CER,0.0027UF,5%,50V,X7R,0603 100-521-1272

C412 CAP, CER,0.0047UF,10%,50V,X7R,0603 100-621-1472

C413 CAP, CER,150PF,10%,50V,X7R,0603 100-621-1151

C414 CAP, CER,0.0039UF,10%,50V,X7R,0603 100-621-1392

C415 CAP, CER,47PF,5%,50V,COG,0603 100-520-1470

C416 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C417 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C422 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C423 CAP, CER,0.047UF,+20-80%,25V,Y5V,0603 100-813-1473

C424 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C425 CAP, TA,10UF,20%,6.3V,3216,A 102-013-0106

C426 CAP, CER,0.047UF,+20-80%,25V,Y5V,0603 100-813-1473

C427 CAP, TA,100UF,20%,6.3V,D 102-013-3107

C428 CAP, TA,47UF,20%,16V,7343H 102-033-5476

C429 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C430 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C431 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C432 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C433 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C434 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C435 CAP, TA,4.7UF,20%,10V,A 102-023-0475

C436 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C437 CAP, CER,39PF,5%,50V,COG,0603 100-520-1390

C438 CAP, CER,39PF,5%,50V,COG,0603 100-520-1390

C439 CAP, TA,1UF,20%,25V,3216 102-053-0105

C440 CAP, TA,10UF,20%,6.3V,3216,A 102-013-0106

C441 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C442 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C443 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C444 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C445 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C446 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C447 CAP, TA, 22UF,20%,35V,7343 102-063-3226

C449 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C450 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C451 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C452 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C453 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C454 CAP, TA,4.7UF,20%,10V,A 102-023-0475

C455 CAP, TA,4.7UF,20%,10V,A 102-023-0475

C456 CAP, TA,4.7UF,20%,10V,A 102-023-0475

C457 CAP, TA,4.7UF,20%,10V,A 102-023-0475

C458 CAP, CER,47PF,5%,50V,COG,0603 100-520-1470

C459 CAP, CER,47PF,5%,50V,COG,0603 100-520-1470

C460 CAP, TA,10UF,20%,6.3V,3216,A 102-013-0106

C461 CAP, TA,1UF,20%,25V,3216 102-053-0105

REF # DESCRIPTION ________________ ____PART #

C463 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C464 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C465 CAP, CER,0.0033UF,10%,50V,X7R,0603 100-621-1332

C466 CAP, CER,0.0027UF,5%,50V,X7R,0603 100-521-1272

C801 CAP, CER,51PF,5%,50V,COG,0603 100-520-1510

C802 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C803 CAP, CER,330PF,5%,50V,COG,0603 100-520-1331

C804 CAP, CER,51PF,5%,50V,COG,0603 100-520-1510

C805 CAP, CER,100PF,+/-5%,50V,COG,0603 100-520-1101

C806 CAP, CER,100PF,+/-5%,50V,COG,0603 100-520-1101

C807 CAP, TA, 22UF,20%,35V,7343 102-063-3226

C808 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C810 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C811 CAP, TA,100UF,20%,16V,E,7343 102-033-3107

C812 CAP, CER,100PF,+/-5%,50V,COG,0603 100-520-1101

C813 CAP, TA,4.7UF,20%,10V,A 102-023-0475

C815 CAP, TA,100UF,20%,16V,E,7343 102-033-3107

CON401 CONN,PLUG,15P,1.25MM,RT,SMT 140-081-0015

CON403 CONN, SKT,18P/DIP,2.0MMST,SMT 140-020-0056

D401 DIODE, ZNR,Z02W5.6V-Y,5.6V,0.2W,SOT-23 221-020-0056

D402 DIODE, ZNR,Z02W5.6V-Y,5.6V,0.2W,SOT-23 221-020-0056

D403 DIODE, ZNR,Z02W5.6V-Y,5.6V,0.2W,SOT-23 221-020-0056

D404 DIODE, ZNR,Z02W5.6V-Y,5.6V,0.2W,SOT-23 221-020-0056

D405 DIODE, ZNR,Z02W5.6V-Y,5.6V,0.2W,SOT-23 221-020-0056

D406 DIODE, SW ,KDS193,SOT-23 220-010-0003

D407 DIODE, ZNR,Z02W5.6V-Y,5.6V,0.2W,SOT-23 221-020-0056

D408 DIODE, ZNR,Z02W5.6V-Y,5.6V,0.2W,SOT-23 221-020-0056

D409 DIODE, ZNR,Z02W5.6V-Y,5.6V,0.2W,SOT-23 221-020-0056

D410 DIODE, ZNR,Z02W5.6V-Y,5.6V,0.2W,SOT-23 221-020-0056

D801 DIODE, SW ,KDS160,6V,2PIN USC 220-010-0017

D802 DIODE, SCHOTTKY,MBRS140T3,SMB 220-040-0012

L801 COIL, CHIP,12UH, A814AY-120M=P3 355-010-0120

L802 COIL, CHIP,3.3UH, 636CY-3R3M=P3 355-010-0335

Q401 TRANS, PNP,KRA104S,SOT-23,SW,(PD) 870-010-0005

Q402 TRANS, PNP,KRA104S,SOT-23,SW,(PD) 870-010-0005

Q403 TRANS, PNP,KRA104S,SOT-23,SW,(PD) 870-010-0005

Q404 TRANS, NPN,KRC104SND,SOT-23,SW,ND 870-020-0001

Q405 TRANS, PNP,KRA104S,SOT-23,SW,(PD) 870-010-0005

Q406 TRANS, NPN,KRC104SND,SOT-23,SW,ND 0-020-0001

Q407 TRANS, PNP,KTA1504(Y),SOT-23,SW 870-100-0004

Q408 TRANS, NPN,KRC104SND,SOT-23,SW,ND 870-020-0001

Q801 TRANS, SI4412DY,SO-8,MOSFET,N-CH 870-070-0006

Q802 TRANS, SI4412DY,SO-8,MOSFET,N-CH 870-070-0006

R403 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R404 RES, TF,47K,5%,1/16W,+/-200,0603 741-102-1473

R406 RES, TF,22K,5%,1/16W,+/-200,0603 741-102-1223

R407 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R409 RES, TF,100K,5%,1/16W,+/-200,0603 741-102-1104

R410 RES, TF,220K,5%,1/16W,+/-200,0603 741-102-1224

R411 RES, TF,100K,5%,1/16W,+/-200,0603 741-102-1104

R412 RES, TF,3.3K,5%,1/16W,+/-200,0603 741-102-1332

R413 RES, TF,180K,5%,1/16W,+/-200,0603 741-102-1184

R414 RES, TF,100K,5%,1/16W,+/-200,0603 741-102-1104

R415 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R416 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R417 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

PAGE-23-

October 98

Page 27

REF # DESCRIPTION PART #

R418 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R419 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R420 RES, TF,9.1K,5%,1/16W,+/-200,0603 741-102-1912

R421 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R422 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R423 RES, TF,1K,5%,1/16W,+/-200,0603 741-102-1102

R424 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R425 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R426 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R428 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R429 RES, TF,47K,5%,1/16W,+/-200,0603 741-102-1473

R430 RES, TF,1M,5%,1/16W,+/-200,0603 741-102-1105

R431 RES, TF,47K,5%,1/16W,+/-200,0603 741-102-1473

R432 RES, TF,47K,5%,1/16W,+/-200,0603 741-102-1473

R433 RES, TF,4.7K,5%,1/16W,+/-200,0603 741-102-1472

R434 RES, TF,4.7K,5%,1/16W,+/-200,0603 741-102-1472

R435 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R436 RES, TF,4.7K,5%,1/16W,+/-200,0603 741-102-1472

R437 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R438 RES, TF,2.2K,5%,1/16W,+/-200,0603 741-102-1222

R439 RES, TF,4.7K,5%,1/16W,+/-200,0603 741-102-1472

R440 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R441 RES, TF,47K,5%,1/16W,+/-200,0603 741-102-1473

R442 RES, TF,47K,5%,1/16W,+/-200,0603 741-102-1473

R443 RES, TF,47K,5%,1/16W,+/-200,0603 741-102-1473

R444 RES, TF,47K,5%,1/16W,+/-200,0603 741-102-1473

R445 RES, TF,100K,5%,1/16W,+/-200,0603 741-102-1104

R446 RES, TF,100,5%,1/16W,+/-200,0603 741-102-1101

R447 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R448 RES, TF,1M,5%,1/16W,+/-200,0603 741-102-1105

R449 RES, TF,20K,5%,1/16W,+/-200,0603 741-102-1203

R450 RES, TF,33K,5%,1/16W,+/-200,0603 741-102-1333

R451 RES, TF,100K,5%,1/16W,+/-200,0603 741-102-1104

R452 RES, TF,100K,5%,1/16W,+/-200,0603 741-102-1104

R454 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R455 RES, TF,22K,5%,1/16W,+/-200,0603 741-102-1223

R456 RES, TF,470,5%,1/16W,+/-200,0603 741-102-1471

R457 RES, TF,22K,5%,1/16W,+/-200,0603 741-102-1223

R458 RES, TF,100K,5%,1/16W,+/-200,0603 741-102-1104

R460 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R461 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R463 RES, TF,1.8M,5%,1/10W,+/-200,0805 741-112-2185

R464 RES, TF,47K,5%,1/16W,+/-200,0603 741-102-1473

R465 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R466 RES, TF,47K,5%,1/16W,+/-200,0603 741-102-1473

R467 RES, TF,47K,5%,1/16W,+/-200,0603 741-102-1473

R468 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R469 RES, TF,100K,5%,1/16W,+/-200,0603 741-102-1104

R470 RES, TF,100K,5%,1/16W,+/-200,0603 741-102-1104

R471 RES, TF,220K,5%,1/16W,+/-200,0603 741-102-1224

R472 RES, TF,120K,5%,1/16W,+/-200,0603 741-102-1124

R473 RES., TF,68K, 5%, 1/16W,+/-200, 0603 741-102-1683

R474 RES, TF,100,5%,1/16W,+/-200,0603 741-102-1101

R475 RES, TF,100,5%,1/16W,+/-200,0603 741-102-1101

R476 RES, TF,100,5%,1/16W,+/-200,0603 741-102-1101

R477 RES, TF,100,5%,1/16W,+/-200,0603 741-102-1101

R478 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R480 RES, TF,100K,5%,1/16W,+/-200,0603 741-102-1104

R481 RES, TF,1K,5%,1/16W,+/-200,0603 741-102-1102

PAGE-24-

October 98

MAXON

SD-125 RF LINK MODULE

REF # DESCRIPTION PART #

R482 RES, TF,1K,5%,1/16W,+/-200,0603 741-102-1102

R483 RES, TF,1K,5%,1/16W,+/-200,0603 741-102-1102

R484 RES, TF,1K,5%,1/16W,+/-200,0603 741-102-1102

R485(LK2.10) RES, TF, 0, 5%,1/16W, +/-200,0603 741-102-1000

R486 RES., TF,68K, 5%, 1/16W,+/-200, 0603 741-102-1683

R487 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R488 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R489 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R490 RES, TF,10,5%,1/16W,+/-200,0603 741-102-1100

R491 RES, TF,56K,5%,1/16W,+/-200,0603 741-102-1563

R492 RES, TF,100K,5%,1/16W,+/-200,0603 741-102-1104

R493 RES, TF,100K,5%,1/16W,+/-200,0603 741-102-1104

R494 RES, TF,100K,5%,1/16W,+/-200,0603 741-102-1104

R495 RES, TF,100K,5%,1/16W,+/-200,0603 741-102-1104

R496 RES, TF,0,5%,1/8W,TC250,1206 741-127-3000

R801 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R802 RES, TF,36K,5%,1/16W,+/-200,0603 741-102-1363

R804 RES, TF,0.033,1%,1/10W,+/-100, 0805 740-112-R033

R805 RES, TF,68K,1%,1/16W,+/-100,0603 740-211-1683

R806 RES, TF,20K,5%,1/16W,+/-200,0603 741-102-1203

RV402 RES, TF,0, +/-5%,1/10W,+/-250,0805 741-117-2000

RV403 POT, VRES,22K,+/-25%,TOP ADJ 901-120-0223

RV404 RES, TF,0, +/-5%,1/10W,+/-250,0805 741-117-2000

SW401 SW, DIP8P,4 POS,KSD-04,SPST 830-130-0004

U401 IC, CPU, OPT, MC68HC705C8FB,44-QFP 443-100-0010

U402 IC, EEPROM,AT93C56-10SI,SO-8,2K,2-5V 442-010-0003

U403 IC, QUAD CMPTR,LM339,SO14 441-110-0003

U404 IC, SW/MUX,MC14066BDR2,SO-14,A-SW 444-050-0001

U405 IC, OP AMP,KIA324F,SO-14,QUAD 441-030-0002

U406 IC, OP AMP,KIA324F,SO-14,QUAD 441-030-0002

U407 IC, AUDIO AMP,LM386M-1,0.33W,SO-8 441-040-0002

U408 IC, V DET,KIA7042P,4.2V,SOT-89 441-020-0005

U801 IC, DC/DC CONV, LTC1435CS,SO-16 441-011-0005

X401 RESONATOR, CER,CSAC3.58MGC 310-020-0004

Page 28

SD-125 RF LINK MODULE

MAXON

REF # DESCRIPTION PART #

REPLACEMENT MODULES

ASSY, PCB,FRONT END,UHF,400-430MHZ 650-110-0019

ASSY, PCB,PWR AMP,UHF,400-430MHZ 650-230-0017

ASSY, PCB,TCXO 650-100-0002

ASSY, PCB,VCO TX/RX,UHF,400-430MHZ 650-030-0026

C1 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C2 CAP, TA,10UF,20%,6.3V,3216,A 102-013-0106

C3 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C4 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C5 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C6 CAP, TA,4.7UF,20%,10V,A 102-023-0475

C7 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C8 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C9 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C11 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C12 CAP, TA,10UF,20%,6.3V,3216,A 102-013-0106

C13 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C14 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C15 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C16 CAP, CER,2PF,0.25PF,50V,COG,0603 100-020-1020

C17 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C18 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C19 CAP, CER,220PF,5%,50V,COG,0603 100-520-1221

C21 CAP, METAL,POLY,0.33UF,63V BOX 083-013-2334

C22 CAP, METAL POLY,0.022UF,10%,63V BOX 083-013-2223

C23 CAP, METAL POLY,0.01UF,10%,63V KBOX 083-014-2103

C24 CAP, METAL POLY,0.01UF,10%,63V KBOX 083-014-2103

C25 CAP, CER,1UF,+80-20%,16V,Y5V,0805 100-803-2105

C26 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C34 CAP, CER,220PF,5%,50V,COG,0603 100-520-1221

C35 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C36 CAP, CER,7PF,0.5PF,50V,COG,0805 100-110-2070

C37 CAP, CER,5.6PF,0.25PF,50V,COG,0603 100-020-15R6

C38 CAP, CER,15PF,5%,50V,COG,0805 100-520-2150

C39 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C41 CAP, CER,6PF,0.5PF,50V,COG,0805 100-120-2060

C42 CAP, CER,27PF,5%,50V,COG,0805 100-520-2270

C43 CAP, CER,5PF,0.25PF,50V,COG,0603 100-020-1050

C44 CAP, CER,1UF,+80-20%,16V,Y5V,0805 100-803-2105

C45 CAP, CER,220PF,5%,50V,COG,0603 100-520-1221

C46 CAP, CER,3PF,0.25PF,50V,COG,0603 100-020-1030

C47 CAP, CER,220PF,5%,50V,COG,0603 100-520-1221

C49 CAP, CER,4.7PF,0.5PF,50V,COG,0805 100-120-24R7

C50 CAP, CER,12PF,5%,50V,COG,0603 100-520-1120

C51 CAP, CER,6.8PF,0.5PF,50V,COG,0603 100-120-16R8

C53 CAP, CER,1UF,+80-20%,16V,Y5V,0805 100-803-2105

C54 CAP, CER,220PF,5%,50V,COG,0603 100-520-1221

C55 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C56 CAP, CER,6.8PF,0.5PF,50V,COG,0603 100-120-16R8

C57 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C58 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C59 CAP, CER,0.47UF,+20-80%,16V,Y5V,0805 100-803-2474

C60 Cap, TA,4.7uF,20%,10V,A 102-023-0475

NOTES:

1. Components are not available, assembly is non-repairable.

REF # DESCRIPTION _______ PART #

C61 CAP, TA,10UF,20%,6.3V,3216,A 102-013-0106

C62 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C63 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C64 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C65 CAP, TA,10UF,20%,10V,B,3528 102-023-1106

C66 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C67 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C68 CAP, CER,470PF,10%,50V,X7R,0805 100-621-2471

C73 CAP, CER,9PF,0.25PF,50V,COG,0805 100-020-2090

C74 CAP, CER,18PF,5%,50V,COG,0805 100-520-2180

C75 CAP, CER,4PF,0.25PF,50V,COG,0805 100-020-2040

C76 CAP, CER,1PF,0.25PF,50V,COG,0805 100-020-2010

C77 CAP, CER,470PF,10%,50V,X7R,0805 100-621-2471

C78 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C79 CAP, CER,0.1UF,10%,25V,X7R,0805 100-611-2104

C80 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C81 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C82 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C83 CAP, CER,7PF,0.5PF,50V,COG,0603 100-120-1070

C84 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C87 CAP, CER,9PF,0.5PF,50V,COG,0603 100-120-1090

C88 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C90 CAP, CER,7PF,0.5PF,50V,COG,0603 100-120-1070

C92 CAP, CER,24PF,5%,50V,COG,0603 100-520-1240

C93 CAP, CER,82PF,5%,50V,COG,0603 100-520-1820

C94 CAP, CER,1UF,+80-20%,16V,Y5V,0805 100-803-2105

C96 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C97 CAP, CER,30PF,5%,50V,COG,0603 100-520-1300

C98 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C100 CAP, TA,10UF,20%,6.3V,3216,A 102-013-0106

C101 CAP, TA,10UF,20%,6.3V,3216,A 102-013-0106

C102 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C103 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C104 CAP, TA,1UF,20%,25V,3216 102-053-0105

C111 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C117 CAP, CER,47PF,5%,50V,COG,0603 100-520-1470

C118 CAP, CER,33PF,5%,50V,COG,0603 100-520-1330

C121 CAP, CER,20PF,5%,50V,COG,0603 100-520-1200

C122 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C123 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C124 CAP, CER,0.1UF,10%,25V,X7R,0805 100-611-2104

C125 CAP, CER,0.1UF,10%,25V,X7R,0805 100-611-2104

C126 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C127 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C128 CAP, TA,4.7UF,20%,10V,A 102-023-0475

C129 CAP, ELE,10UF,16V,20%,3X5,5.0PT 081-032-3106

C131 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C133 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C152 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C901 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C902 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C904 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C905 CAP, CER,68PF,5%,50V,COG,0603 100-520-1680

C906 CAP, CER,220PF,5%,50V,COG,0603 100-520-1221

C907 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

PAGE-25October 98

Page 29

REF # DESCRIPTION PART #

C909 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

CF1 FILTER, CER, LT-455FW,455KHZ 310-101-0010

CF2 FILTER, CER,CF455HT,455KHZ 310-010-0013

CON1 CONN, SKT,18P/DIP,2.0MMST,SMT 140-020-0056

D5 DIODE, PIN,UPP9401,(T&R)50V,2.5W 220-020-0001

D6 DIODE, PIN,UPP9401,(T&R)50V,2.5W 220-020-0001

D9 DIODE, SCHOTTKY,CHIP,HSMS-2817#L31 220-040-0009

D12 DIODE, SW,KDS193,SOT-23 220-010-0003

D13 DIODE, SW,KDS181S,SOT-23 220-010-0004

D14 DIODE, SW,KDS181S,SOT-23 220-010-0004

D903 DIODE, SW,KDS226,SOT-23 220-010-0005

D904 DIODE, SW,KDS226,SOT-23 220-010-0005

H3 SCRW, MACH,STL,M2X6,FLH,PHL,ZN 330-110-0142

H4 SCRW, MACH,STL,M2X6,FLH,PHL,ZN 330-110-0142

IC1 IC, VREG,TK11450MTR,+5V,SOT-23L,(R5) 441-010-0002

IC2 IC, PLL,MC145191FR2,SO-20,RS-440 440-050-0011

IC3 IC, OP AMP,LM358MX,SO-8,DUAL 441-030-0006

IC5 IC, VHF RCVR,MC3371D,SO-16,NWRBAND 441-060-0007

IC7 IC, OP AMP,LM358MX,SO-8,DUAL 441-030-0006

IC8 IC, OP AMP,DUAL,TL062CDR,SO-8 441-030-0012

L1 COIL, CHIP,18NH,20%,LL2012-F18NM 371-010-5180

L2 COIL, CHIP,18NH,20%,LL2012-F18NM 371-010-5180

L3 COIL, CHIP,18NH,20%,LL2012-F18NM 371-010-5180

L4 COIL, CHIP,18NH,20%,LL2012-F18NM 371-010-5180

L5 COIL, CHIP,18NH,20%,LL2012-F18NM 371-010-5180

L6 COIL, CHIP,0.82UH:NL252018T-R82J 371-804-3R82

L7 COIL, SPRG, 2X0.75X3T:L SMD 350-000-0103

L8 COIL, SPRG, 2X0.75X3T:L SMD 350-000-0103

L11 COIL, SPRG, 2X0.75X3T:L SMD 350-000-0103

L12 COIL, CHIP,1.2UH,5%,NL252018T-1R2J 371-004-31R2

L13 COIL, SPRG, 1.0X0.35X7T;R, 350-000-0095

L14 COIL, CHIP,0.47UH:NL252018T-R47J 371-804-3R47

L15 COIL, CHIP,0.15UH,5%,NL252018T-R15J 371-004-3R15

L18 COIL, CHIP,1UH,5%,NL252018T-1R0J 371-017-3102

L19 COIL CHIP,10UH,CYLNDRCL,+/-10%,1206 371-005-3103

Q2 TRANS, PNP,KRA110SPK,SOT-23,SW,PK 870-010-0010

Q3 TRANS, PNP,KRA110SPK,SOT-23,SW,PK 870-010-0010

Q4 TRANS, PNP,KRA110SPK,SOT-23,SW,PK 870-010-0010

Q5 TRANS, PNP,KRA104S,SOT-23,SW,(PD) 870-010-0005

Q6 TRANS, NPN,KTC3875(BL),SOT-23, 870-200-0006

Q7 TRANS, PNP,KTA1504(Y),SOT-23,SW 870-100-0004

Q8 TRANS, PNP,KTA1504(Y),SOT-23,SW 870-100-0004

Q11 TRANS, NPN,KTC3875(BL),SOT-23, 870-200-0006

Q12 TRANS, NPN,BFR92A,SOT-23 870-200-0020

Q13 TRANS, NPN,KTC3875(BL),SOT-23, 870-200-0006

Q14 TRANS, NPN,KTC3875(BL),SOT-23, 870-200-0006

Q16 TRANS, NPN,BFR92A,SOT-23 870-200-0020

Q17 TRANS, 900MHZ AMP,MMBR951,SOT-23 870-200-0026

Q18 TRANS, NPN,KRC104SND,SOT-23,SW,ND 870-020-0001

Q19 Trans, NPN,KTC3875(BL),SOT-23, 870-200-0006

Q21 TRANS, NPN,KTC3875(BL),SOT-23, 870-200-0006

Q22 TRANS, PNP,KTA1663(Y),SOT-89,HC/SW,H(Y) 870-150-0002

Q25 TRANS, NPN,BFR92A,SOT-23 870-200-0020

Q31 TRANS, NPN,KRC104SND,SOT-23,SW,ND 870-020-0001

Q32 TRANS, NPN,KRC104SND,SOT-23,SW,ND 870-020-0001

Q34 TRANS, NPN,KRC104SND,SOT-23,SW,ND 870-020-0001

Q901 TRANS, NPN,KTC4075,UMT3 870-200-0031

Q902 TRANS, PNP,KTA2014, USM 870-100-0018

Q903 TRANS, NPN,KTC4075,UMT3 870-200-0031

MAXON

SD-125 RF LINK MODULE

REF # DESCRIPTION PART #

Q904 TRANS, NPN,KTC4075,UMT3 870-200-0031

Q905 TRANS, NPN,KTC4075,UMT3 870-200-0031

R1 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R2 RES, TF,100K,5%,1/16W,+/-200,0603 741-102-1104

R3 RES, TF,2.2K,5%,1/16W,+/-200,0603 741-102-1222

R4 RES, TF,1.8K,5%,1/16W,+/-200,0603 741-102-1182

R5 RES, TF,1.8K,5%,1/16W,+/-200,0603 741-102-1182

R6 RES, TF,2K,5%,1/16W,+/-200,0603 741-102-1202

R7 RES, TF,1.8K,5%,1/16W,+/-200,0603 741-102-1182

R8 RES, TF,910,5%,1/10W,TC250,0805 741-117-2911

R11 RES, TF,100,5%,1/16W,+/-200,0603 741-102-1101

R12 RES, TF,5.6K,5%,1/16W,+/-200,0603 741-102-1562

R13 RES, TF,2.7K,5%,1/16W,+/-200,0603 741-102-1272

R14 RES, TF,2.7K,5%,1/16W,+/-200,0603 741-102-1272

R15 RES, TF,100,5%,1/16W,+/-200,0603 741-102-1101

R16 RES, TF,910,5%,1/10W,TC250,0805 741-117-2911

R17 RES, TF,12K,5%,1/16W,+/-200,0603 741-102-1123

R21 RES, TF,33,5%,1/16W,+/-200,0603 741-102-1330

R22 RES, TF,4.7K,5%,1/16W,+/-200,0603 741-102-1472

R23 RES, TF,100,5%,1/16W,+/-200,0603 741-102-1101

R24 RES, TF,5.6K,5%,1/16W,+/-200,0603 741-102-1562

R25 RES, TF,4.7K,5%,1/16W,+/-200,0603 741-102-1472

R26 RES, TF,18,5%,1/16W,+/-200,0603 741-102-1180

R27 RES, TF,4.7K,5%,1/16W,+/-200,0603 741-102-1472

R28 RES, TF,220,5%,1/16W,+/-200,0603 741-102-1221

R31 RES, TF,300,5%,1/16W,+/-200,0603 741-102-1301

R32 RES, TF,300,5%,1/16W,+/-200,0603 741-102-1301

R33 RES., TF,6.8K, 5%, 1/16W,+/-200, 0603 741-102-1682

R34 RES, TF,18,5%,1/16W,+/-200,0603 741-102-1180

R35 RES, TF,5.6K,5%,1/16W,+/-200,0603 741-102-1562

R36 RES, TF, 0, 5%,1/16W, +/-200,0603 741-102-1000

R37 RES, TF,1.2K,5%,1/16W, +/-200,060 3 741-102-1122

R41 RES, TF,100,5%,1/16W,+/-200,0603 741-102-1101

R42 RES, TF,12K,5%,1/16W,+/-200,0603 741-102-1123

R43 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R45 RES, TF,12K,5%,1/16W,+/-200,0603 741-102-1123

R46 RES, TF,2.2K,5%,1/16W,+/-200,0603 741-102-1222

R47 RES, TF,2.2,5%,1/10W,TC250,0805 741-117-2229

R48 RES, TF,2.2,5%,1/10W,TC250,0805 741-117-2229

R49 RES, TF, 0, 5%,1/16W, +/-200,0603 741-102-1000

R50 RES, TF,1M,5%,1/16W,+/-200,0603 741-102-1105

R51 RES, TF,2.2,5%,1/10W,TC250,0805 741-117-2229

R52 RES, TF,3.3K,5%,1/16W,+/-200,0603 741-102-1332

R53 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R54 RES, TF,1K,5%,1/16W,+/-200,0603 741-102-1102

R55 RES, TF,1.5K,5%,1/16W,+/-200,0603 741-102-1152

R56 RES, TF,120 5%,1/16W,+/-200,0603 741-102-1121

R57 RES, TF,100K,1%,1/16W,0603 740-211-1003

R58 RES, TF,470K,5%,1/16W,+/-200,060 3 741-102-1474

R59 RES, TF,39,5%,1/16W,+/-200,0603 741-102-1390

R61 RES, TF,68K,1%,1/16W,+/-100,0603 740-211-1683

R64 RES, TF,22,5%,1/16W,+/-200,0603 741-102-1220

R65 RES, TF,51,5%,1/16W,+/-200,0603 741-102-1510

R66 RES, TF,100,5%,1/16W,+/-200,0603 741-102-1101

R68 RES, TF,680K,5%,1/16W,+/-200,0603 741-102-1684

R69 RES, TF,470K,5%,1/16W,+/-200,0603 741-102-1474

R70 RES, TF,470K,5%,1/16W,+/-200,0603 741-102-1474

R71 RES, TF,1K,5%,1/16W,+/-200,0603 741-102-1102

R72 RES, TF,470K,5%,1/16W,+/-200,0603 741-102-1474

PAGE-26SEPTEMBER 98

Page 30

REF # DESCRIPTION PART #

R74 RES, TF,22K,5%,1/16W,+/-200,0603 741-102-1223

R75 RES, TF,18K,5%,1/16W,+/-200,0603 741-102-1183

R76 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R77 RES, TF,1.2K,5%,1/16W, +/-200,0603 741-102-1122

R78 RES, TF,22K,5%,1/16W,+/-200,0603 741-102-1223

R79 RES, TF,10,5%,1/16W,+/-200,0603 741-102-1100

R82 RES, TF,33K,5%,1/16W,+/-200,0603 741-102-1333

R83 RES, TF,20K,5%,1/16W,+/-200,0603 741-102-1203

R92 RES, TF,4.7M,5%,1/16W,+/-200,0603 741-102-1475

R94 RES, TF,1K,5%,1/16W,+/-200,0603 741-102-1102

R95 RES, TF,82K,5%,1/16W,+/-200,0603 741-102-1823

R96 RES, TF,39K,5%,1/16W,+/-200,0603 741-102-1393

R97 RES, TF,100,5%,1/16W,+/-200,0603 741-102-1101

R98 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R99 RES, TF,100K,1%,1/16W,0603 740-211-1003

R100 RES, TF,68K,1%,1/16W,+/-100,0603 740-211-1683

R102 RES, TF,22K,5%,1/16W,+/-200,0603 741-102-1223

R103 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R104 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R105 RES, TF,22K,5%,1/16W,+/-200,0603 741-102-1223

R106 RES, TF,22K,5%,1/16W,+/-200,0603 741-102-1223

R108 RES, TF,56K,5%,1/16W,+/-200,0603 741-102-1563

R109 RES, TF,0.1,1%,1W, +/-100,0603 740-521-0R10

R110 RES, TF,330,5%,1/16W,+/-200,0603 741-102-1331

R111 RES, TF,10K,5%,1/16W,+/-200,0603 741-102-1103

R112 RES, TF,22K,5%,1/16W,+/-200,0603 741-102-1223

R115 RES, TF,47K,5%,1/16W,+/-200,0603 741-102-1473

R116 RES, TF, 0, 5%,1/16W, +/-200,0603 741-102-1000

R118 RES, TF,680,5%,1/16W,+/-200,0603 741-102-1681

R124 RES, TF,100,5%,1/16W,+/-200,0603 741-102-1101

R125 RES, TF,47,5%,1/16W,+/-200,0603 741-102-1470

R129 RES, TF, 0, 5%,1/16W, +/-200,0603 741-102-1000

R901 RES, TF,2.2K,5%,1/16W,+/-200,0603 741-102-1222

R902 RES, TF,2.2K,5%,1/16W,+/-200,0603 741-102-1222

R903 RES, TF,4.7K,5%,1/16W,+/-200,0603 741-102-1472

R904 RES, TF,7.5K,5%,1/16W,+/-200,0603 741-102-1752

R905 RES, TF,27K,5%,1/16W,+/-200,0603 741-102-1273

R906 RES, TF,7.5K,5%,1/16W,+/-200,0603 741-102-1752

R907 RES, TF,27K,5%,1/16W,+/-200,0603 741-102-1273

R908 RES, TF,47,5%,1/16W,+/-200,0603 741-102-1470

R909 RES, TF,470,5%,1/16W,+/-200,0603 741-102-1471

RV1 POT,VRES,10K,+/-25%,TOP ADJ, 901-120-0103

RV2 POT,VRES,100K,+/-25%,TOP ADJ, 901-120-0104

RV3 POT,VRES,47K,+/-25%,TOP ADJ, 901-120-0473

RV6 POT,VRES,10K,+/-25%,TOP ADJ, 901-120-0103

T1 COIL, VAR,455KHZ QUAD,IFT,SMD 353-012-0001

T2 XFMR, B4F, FREQ.MIXER,617PT-1019,SMT 840-010-0002

T3 XFMR, B4F, FREQ.MIXER,617PT-1019,SMT 840-010-0002

X1 XTAL, 44.645M -30 15PM,32P,RX 3RD,HC-45 168-044-6450

XF1 FILTER, XTAL,KFN1045AA,45.1M 310-030-0015

MAXON

SD-125 RF LINK MODULE

PAGE-27October 98

Page 31

MAXON

SD-125 RF LINK MODULE

REF # DESCRIPTION PART #

REPLACEMENT MODULES

ASSY, PCB,FRONT END,UHF,440-470MHZ 650-110-0017

ASSY, PCB,PWR AMP,UHF,440-470MHZ 650-230-0016

ASSY, PCB,TCXO 650-100-0002

ASSY, PCB,VCO TX/RX,UHF,440-470MHZ 650-030-0023

C1 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C2 CAP, TA,10UF,20%,6.3V,3216,A 102-013-0106

C3 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C4 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C5 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C6 CAP, TA,4.7UF,20%,10V,A 102-023-0475

C7 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C8 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C9 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C11 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C12 CAP, TA,10UF,20%,6.3V,3216,A 102-013-0106

C13 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C14 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C15 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C16 CAP, CER,2PF,0.25PF,50V,COG,0603 100-020-1020

C17 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C18 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C19 CAP, CER,220PF,5%,50V,COG,0603 100-520-1221

C21 CAP, METAL,POLY,0.33UF,63V BOX 083-013-2334

C22 CAP, METAL POLY,0.022UF,10%,63V BOX 083-013-2223

C23 CAP, METAL POLY,0.01UF,10%,63V KBOX 083-014-2103

C24 CAP, METAL POLY,0.01UF,10%,63V KBOX 083-014-2103

C25 CAP, CER,1UF,+80-20%,16V,Y5V,0805 100-803-2105

C26 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C34 CAP, CER,220PF,5%,50V,COG,0603 100-520-1221

C35 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C36 CAP, CER,7PF,0.5PF,50V,COG,0805 100-110-2070

C37 CAP, CER,5.6PF,0.25PF,50V,COG,0603 100-020-15R6

C38 CAP, CER,15PF,5%,50V,COG,0805 100-520-2150

C39 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C41 CAP, CER,6PF,0.5PF,50V,COG,0805 100-120-2060

C42 CAP, CER,27PF,5%,50V,COG,0805 100-520-2270

C43 CAP, CER,5PF,0.25PF,50V,COG,0603 100-020-1050

C44 CAP, CER,1UF,+80-20%,16V,Y5V,0805 100-803-2105

C45 CAP, CER,220PF,5%,50V,COG,0603 100-520-1221

C46 CAP, CER,3PF,0.25PF,50V,COG,0603 100-020-1030

C47 CAP, CER,220PF,5%,50V,COG,0603 100-520-1221

C49 CAP, CER,4.7PF,0.5PF,50V,COG,0805 100-120-24R7

C50 CAP, CER,12PF,5%,50V,COG,0603 100-520-1120

C51 CAP, CER,6.8PF,0.5PF,50V,COG,0603 100-120-16R8

C53 CAP, CER,1UF,+80-20%,16V,Y5V,0805 100-803-2105

C54 CAP, CER,220PF,5%,50V,COG,0603 100-520-1221

C55 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C56 CAP, CER,6.8PF,0.5PF,50V,COG,0603 100-120-16R8

C57 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C58 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C59 CAP, CER,0.47UF,+20-80%,16V,Y5V,0805 100-803-2474

NOTES:

1. Components are not available, assembly is non-repairable.

October 98

REF # DESCRIPTION PART #

C60 CAP, TA,4.7UF,20%,10V,A 102-023-0475

C61 CAP, TA,10UF,20%,6.3V,3216,A 102-013-0106

C62 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C63 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C64 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C65 CAP, TA,10UF,20%,10V,B,3528 102-023-1106

C66 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C67 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C68 CAP, CER,470PF,5%,50V,COG,0805 100-520-2471

C73 CAP, CER,10PF,0.25PF,COG,50V,0805 100-020-2100

C74 CAP, CER,16PF,5%,50V,COG,0805 100-520-2160

C75 CAP, CER,5PF,0.25PF,50V,COG,0805 100-020-2050

C76 CAP, CER,1PF,0.25PF,50V,COG,0805 100-020-2010

C77 CAP, CER,470PF,5%,50V,COG,0805 100-520-2471

C78 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C79 CAP, CER,0.1UF,10%,25V,X7R,0805 100-611-2104

C80 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C81 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C82 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C83 CAP, CER,7PF,0.5PF,50V,COG,0603 100-120-1070

C84 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C87 CAP, CER,22PF,5%,50V,COG,0603 100-520-1220

C87 CAP, CER,9PF,0.5PF,50V,COG,0603 100-120-1090

C88 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C90 CAP, CER,7PF,0.5PF,50V,COG,0603 100-120-1070

C92 CAP, CER,24PF,5%,50V,COG,0603 100-520-1240

C93 CAP, CER,82PF,5%,50V,COG,0603 100-520-1820

C94 CAP, CER,1UF,+80-20%,16V,Y5V,0805 100-803-2105

C96 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C97 CAP, CER,30PF,5%,50V,COG,0603 100-520-1300

C98 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C100 CAP, TA,10UF,20%,6.3V,3216,A 102-013-0106

C101 CAP, TA,10UF,20%,6.3V,3216,A 102-013-0106

C102 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C103 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C104 CAP, TA,1UF,20%,25V,3216 102-053-0105

C111 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C117 CAP, CER,47PF,5%,50V,COG,0603 100-520-1470

C118 CAP, CER,33PF,5%,50V,COG,0603 100-520-1330

C121 CAP, CER,20PF,5%,50V,COG,0603 100-520-1200

C122 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C123 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C124 CAP, CER,0.1UF,10%,25V,X7R,0805 100-611-2104

C125 CAP, CER,0.1UF,10%,25V,X7R,0805 100-611-2104

C126 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C127 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C128 CAP, TA,4.7UF,20%,10V,A 102-023-0475

C129 CAP, ELE,10UF,16V,20%,3X5,5.0PT 081-032-3106

C131 CAP, CER,0.001UF,10%,50V,X7R,0603 100-621-1102

C133 CAP, CER,0.1UF,+80-20%,25V,Y5V,0603 100-813-1104

C152 CAP, CER,470PF,10%,50V,X7R,0603 100-621-1471

C901 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C902 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C904 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C905 CAP, CER,68PF,5%,50V,COG,0603 100-520-1680

C906 CAP, CER,220PF,5%,50V,COG,0603 100-520-1222

PAGE-28-

Page 32

REF # DESCRIPTION PART #

C907 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

C909 CAP, CER,0.01UF,10%,25V,X7R,0603 100-611-1103

CF1 FILTER, CER, LT-455FW,455KHZ 310-101-0010

CF2 FILTER, CER,CF455HT,455KHZ 310-010-0013

CON1 CONN, SKT,18P/DIP,2.0MMST,SMT 140-020-0056

D5 DIODE, PIN,UPP9401,(T&R)50V,2.5W 220-020-0001

D6 DIODE, PIN,UPP9401,(T&R)50V,2.5W 220-020-0001

D9 DIODE, SCHOTTKY,CHIP,HSMS-2817#L31 220-040-0009

D12 DIODE, SW,KDS193,SOT-23 220-010-0003

D13 DIODE, SW,KDS181S,SOT-23 220-010-0004

D14 DIODE, SW,KDS181S,SOT-23 220-010-0004

D903 DIODE, SW,KDS226,SOT-23 220-010-0005

D904 DIODE, SW,KDS226,SOT-23 220-010-0005

H3 SCRW, MACH,STL,M2X6,FLH,PHL,ZN 330-110-0142

H4 SCRW, MACH,STL,M2X6,FLH,PHL,ZN 330-110-0142

IC1 IC, VREG,TK11450MTR,+5V,SOT-23L,(R5) 441-010-0002

IC2 IC, PLL,MC145191FR2,SO-20,RS-440 440-050-0011

IC3 IC, OP AMP,LM358MX,SO-8,DUAL 441-030-0006

IC5 IC, VHF RCVR,MC3371D,SO-16,NWRBAND 441-060-0007

IC7 IC, OP AMP,LM358MX,SO-8,DUAL 441-030-0006