Page 1

maxon motor

maxon motor control 4-Q-DC Servo Control LSC 30/2

Order number 250521

Operating Instructions June 2010 Edition

The LSC 30/2 (Linear Servo Controller) is a linear

4-Q-Servoamplifier used to control DC motors up to

approx. 50 W that are powered by permanent magnets.

It allows the following operating modes:

• IxR compensation

• Voltage regulator

• Digital encoder control

• DC tacho control

• Current control

The required operating mode is easily selected using a DIP

switch.

There are also several ways of choosing the set value input:

• ± 10 V to connect to layout systems, such as a positioning

controller

• auxiliary voltages ± 3.9 V are already provided by the LSC

for use with external potentiometer

• well suited for fixed speed adjustment using internal

potentiometer

Its wide input voltage, ranging from 12 – 30 VDC, makes the LSC very flexible for use with different voltage

sources. The modular-style aluminum housing offers several fastening options, notably plugging into a 19”

rack (3HE). Separable screw terminal strips and a robust controller design make the amplifier ideal for

immediate use.

Table of contents

1 Safety Instructions ...........................................................................................................................................2

2 Technical Data .................................................................................................................................................3

3 Minimum External Wiring .................................................................................................................................4

4 Start-up Procedure...........................................................................................................................................6

5 Inputs and Outputs...........................................................................................................................................8

6 Operating Status Display ...............................................................................................................................12

7 Error Handling................................................................................................................................................12

8 EMC-compliant installation ............................................................................................................................13

9 Block Diagram................................................................................................................................................13

10 Dimension Drawing........................................................................................................................................14

11 Spare Parts List .............................................................................................................................................14

The latest edition of these operating instructions may be downloaded from the Internet as a PDF-file under

www.maxonmotor.com category Service & Downloads, Order number 250521 or

in the e-shop

http://shop.maxonmotor.com.

Page 2

maxon motor

4-Q-DC Servo Control LSC 30/2 Operating Instructions

1 Safety Instructions

Skilled personnel

Only skilled, experienced personnel should install and start the equipment

Statutory regulations

The user must ensure that the amplifier and the components belonging to it

are assembled and connected according to local statutory regulations.

Load disconnected

For initial operation, the motor should be free running, i.e. with the load

disconnected.

Additional safety equipment

Any electronic equipment is, in principle, not fail-safe. Machines and

apparatus must therefore be fitted with independent monitoring and safety

equipment. If the equipment breaks down, if it is operated incorrectly, if the

control unit breaks down or if the cables break etc., it must be ensured that

the drive or the complete apparatus is kept in a safe operating mode.

Repairs

Repairs may only be carried out by authorized personnel or the

manufacturer. It is dangerous for the user to open the unit or carry out any

repairs.

Danger

Ensure that no apparatus is connected to the electrical supply during

installation of the LSC 30/2! After switching on, do not touch any live parts!

Max. supply voltage

Make sure that the supply voltage is between 12 and 30 VDC. Voltages

higher than 32 VDC or of the wrong polarity will destroy the unit.

Electrostatic sensitive device (ESD)

2 maxon motor control June 2010 Edition / Subject to change

Page 3

maxon motor

Operating Instructions 4-Q-DC Servo Control LSC 30/2

2 Technical Data

2.1 Electrical data

Supply voltage VCC.....................................................................................................12 – 30 VDC

Max. output voltage.................................................................................................................25 V

Max. output current I

max

.............................................................................................................2 A

Max. power output .................................................................................................................50 W

It is advisable to consider mounting on a heat sinking surface if ambient temperature is high and

there is a high power loss in the LSC !

2.2 Inputs

Set value “+Set / -Set”.......................... configurable .......................-10 ... +10 V or -3.9 ... +3.9 V

Disable “Dis IN”.................................... Disable....................................................... min. V

CC

- 1 V

Enable..................................................... max. Gnd + 1 V

DC tacho “+T / -T”.................................................................................min. 2 VDC, max. 50 VDC

Encoder signals “Ch A / Ch B” .................................................................max. 100 kHz, TTL level

2.3 Outputs

Status reading “Ready” ........................ Open collector......................... max. 30 VDC (IL < 20 mA)

Error .......................................... “Ready” = high impedant

Ready........................................................“Ready” = Gnd

2.4 Voltage output

Auxiliary voltages “+Vaux / -Vaux” ..........................+3.9 VDC, max. 2 mA / -3.9 VDC, max. 2 mA

Encoder supply voltage “+Venc” ...................................................................+5 VDC, max. 80 mA

2.5 Motor connections

Motor +; Motor -

2.6 Trim potentiometers

n

max

IxR compensation

Offset

I

max

gain

2.7 Protection

Heat monitoring of power stage .......................................................................................T > 85°C

2.8 LED indicator

green LED.......................................................................................................................... READY

red LED............................................................................................................................. ERROR

2.9 Ambient temperature / humidity range

Operation ........................................................................................................................ 0...+45°C

Storage ........................................................................................................................-40...+85°C

No condensation ............................................................................................................. 20...80 %

2.10 Mechanical data

Weight...................................................................................................................... approx. 330 g

Mounting plate ......................................................................................................for 4 screws M4

Dimensions .............................................................................see dimension drawing,

chapter 10

2.11 Terminals

separable PCB terminals ................................................................................................... 16-pole

Pitch ..................................................................... 3.5 mm

suitable for wire cross-section....................... AWG 28-18

0.14 ... 1 mm2 multiple-stranded; 0.14 ... 1.3 mm2 single wire

June 2010 Edition / Subject to change maxon motor control 3

Page 4

maxon motor

4-Q-DC Servo Control LSC 30/2 Operating Instructions

4 maxon motor control June 2010 Edition / Subject to change

3 Minimum External Wiring

Set

Dis +V

Dis I N

Sig Gnd

+

Vau x

Gnd

Set

Ready

T/ChA

T/ChB

Gnd

Ven c

1

234567890123456

11111

1

1

Motor

Motor+Vcc

+

Vau x

+

+

+

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

1

1

2

2

1

2

1313

1

2

1

2

12...30 VDC

IxR

Ta c h o

unten

Encoder

1234567 8910111213141516

1414

15

16

Ch ACh A

Ch BCh B

Gnd

+5 V

IxRTach oEncoderCurrent

Vol tag e

Regulator

Power

supply

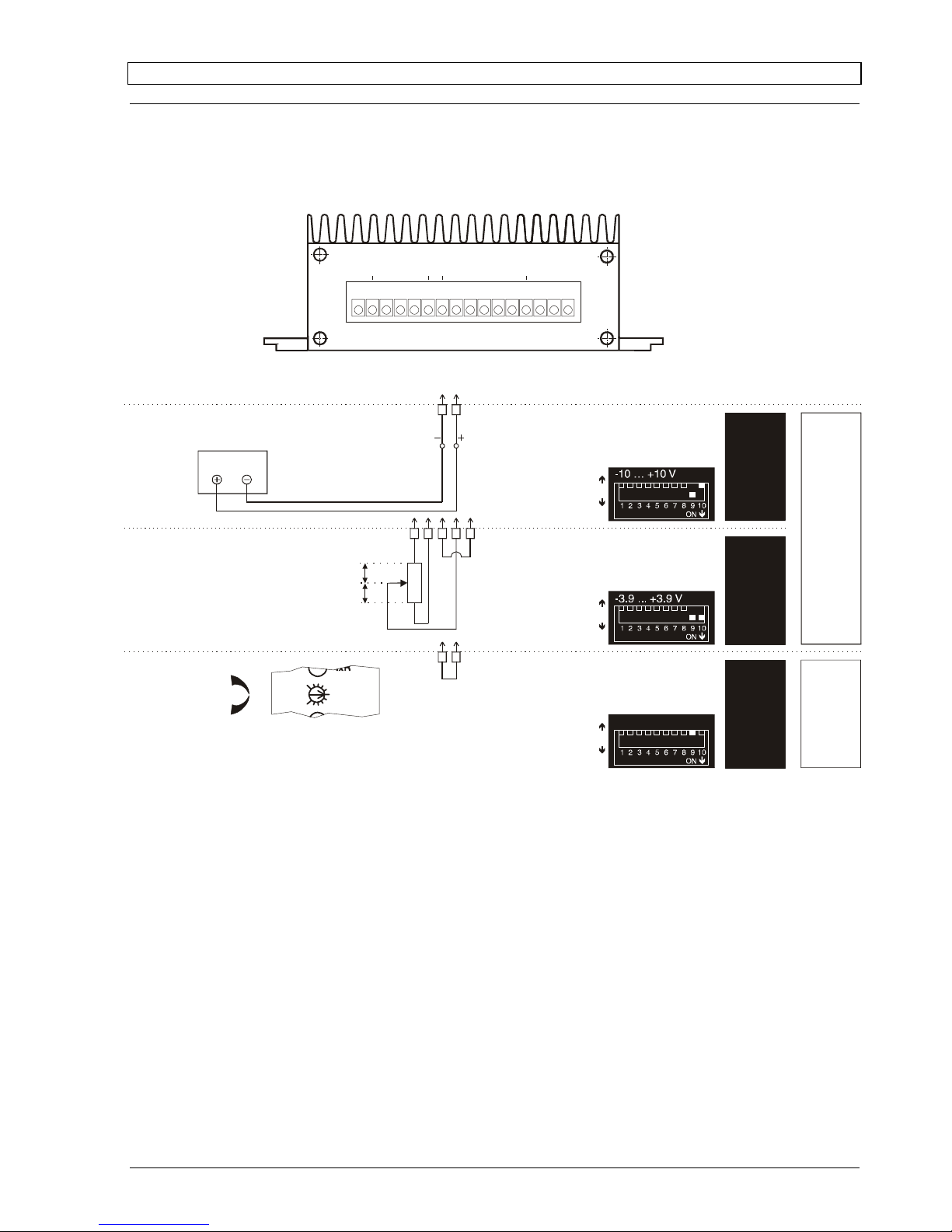

3.1 Operating mode

Page 5

maxon motor

Operating Instructions 4-Q-DC Servo Control LSC 30/2

3.2 Set value input

Set

Dis +V

Dis I N

Sig Gnd

+

Vaux

Gnd

Set

Ready

T/ChA

T/ChB

Gnd

Venc

1

234567890123456

11111

1

1

Motor

Motor+Vcc

+

Vaux

+

+

+

1 2 3 4 5 6 7 8 9 10111213141516

87

+3.9V

87

50k

Ω

int ernal

OFF

OFF

OFF

ON

ON

ON

65 9

-3.9V

0V

87

P3 Offset

with external

set vallue

-10 ... +10 V

external

with external

potentiometer

-3.9 ... +3.9 V

with internal

potentiometer

P3

internal

negative set value: motor turns counterclockwise

positive set value: motor turns clockwise

Set value -10 ... +10V

Motor turns counterclockwise

Motor turns clockwise

Motor turns counterclockwise

Motor turns clockwise

June 2010 Edition / Subject to change maxon motor control 5

Page 6

maxon motor

4-Q-DC Servo Control LSC 30/2 Operating Instructions

4 Start-up Procedure

4.1 Power supply layout

Any available power supply can be used as long as it meets the minimum

requirements set out below.

During set-up and adjustment phases, we recommend separating the motor

mechanically from the machine to prevent damage from uncontrolled motion.

Power supply requirements

Output voltage VCC min. 12 VDC; VCC max. 30 VDC

Ripple < 5 %

Output current depending on load, continuous max. 2A

The required voltage can be calculated as follows:

Known values:

Ö Operating torque M

B

[mNm]

Ö Operating speed n

B

[rpm]

Ö Nominal motor voltage U

N

[V]

Ö Motor no-load speed at U

N

, n0 [rpm]

Ö Speed/torque gradient of motor ∆n/∆M [rpm/mNm]

Sought values:

Ö Supply voltage V

CC

[V]

Solution:

VM

M

n

n

n

U

V

BB

N

CC

5)(

0

+⋅

∆

∆

+⋅=

Choose a power supply capable of supplying this calculated voltage under load.

The formula takes into account a 5 V maximum voltage drop at the power

stage.

4.2 Function of potentiometers

Potentiometer

Function Turning direction

left right

P1 n

max

maximum speed

at maximum set value

Speed lower Speed higher

P2

IxR

IxR compensation

weak

compensation

strong

compensation

P3 Offset

1

Adjustment = 0 rpm

at 0 V set value

Motor turns

CCW

Motor turns

CW

P4 I

max

Current limit

lower

min. approx. 0 A

higher

max. approx. 2 A

P5

gain Speed control gain lower higher

P1

P2

P3

P4

P5

n

max

IxR

Offse t

I

max

gain

1

P3 can also be used for the set value input (see 5.1.1)

6 maxon motor control June 2010 Edition / Subject to change

Page 7

maxon motor

Operating Instructions 4-Q-DC Servo Control LSC 30/2

4.3 Adjusting the potentiometers

4.3.1 Pre-adjustment

With pre-adjustment, the potentiometers are set in a preferred position.

Units in the original packing are already pre-set.

Pre-adjustment of potentiometers

P1

n

max

50 %

P2 IxR 0 %

P3

Offset

50 %

P4

I

max

50 %

P5

gain

10 %

P1

P2

P3

P4

P5

n

max

IxR

Offse t

I

max

gain

4.3.2 Adjustment

1.

Apply max. set value (10 V or 3.9 V) and turn potentiometer P1 n

max

until

required max. speed is reached.

Encoder operation

DC tacho operation

Voltage regulator

IxR compensation

2.

Adjust potentiometer P4 I

max

to required limit value.

Limited current in the 0…2 A range can be adjusted in linear fashion with

the P4 potentiometer.

Important: The limit value I

max

should be below the nominal current

(max. permissible continuous current) as per motor data sheet.

3.

Slowly increase potentiometer P5 gain until the gain is set sufficiently

high.

Important: If the motor is unsteady, vibrates or makes noises, the

selected amplification is too high.

4.

Apply 0 V set value and adjust the motor to speed 0 rpm with

potentiometer P3 Offset.

Important: DIP switch S9 must be set in the “ON

Д position for offset

adjustment.

Applicable to IxR compensation only:

5.

Slowly increase potentiometer P2 IxR until compensation is set

sufficiently high so that the motor speed does not drop or only drops very

slightly at higher motor load.

Important: If the motor is unsteady, vibrates or makes noises, the

selected compensation is too high.

Current regulator

1.

Adjust potentiometer P4 I

max

to required limit value.

Limited current in the 0…2 A range can be adjusted in linear fashion with

the P4 potentiometer.

Important: The limit value I

max

should be below the nominal current

(max. permissible continuous current) as per motor data sheet.

2.

Apply 0 V set value and adjust the motor to current 0 A with

potentiometer P3 Offset.

Important: DIP switch S9 must be set in the “ON

Д position for offset

adjustment.

Note:

• DIP switch

S10 in position:

“ON

Д: Set value range -3.9 ... +3.9 V equivalent to approx. -2 ... +2 A

motor current

“OFF

Ï”: Set value range -10 ... +10 V equivalent to approx. -2 ... +2 A

motor current

• In current regulator operation, potentiometers P1 n

max

, P2 IxR and P5 gain

are not active.

June 2010 Edition / Subject to change maxon motor control 7

Page 8

maxon motor

4-Q-DC Servo Control LSC 30/2 Operating Instructions

5 Inputs and Outputs

5.1 Inputs

5.1.1 Set value “Set”

The set value can be applied externally via an analogue voltage or internally

using potentiometer P3.

If the set value is applied externally using the “+Set” and “-Set” connections,

DIP switch S9 must be in the “ON

Д position.

Two different ranges can be selected to apply an external analogue set value.

The required range is determined by the position of DIP switch S10.

Set value range -10 ... +10 V

Input voltage range -10 ... +10V

Input wiring differential

Input impedance

200 kΩ (differential)

positive set value (+Set) > (-Set)

positive motor voltage or current

negative set value (+Set) < (-Set)

negative motor voltage or current

DIP switch S10 OFF

Ï

DIP switch S9 ONÐ

Use of external potentiometer

Set value range -3.9 ... +3.9 V

Input voltage range -3.9 ... +3.9 V

Input wiring differential

Input impedance

200 kΩ (differential)

positive set value (+Set) > (-Set)

positive motor voltage or current

negative set value (+Set) < (-Set)

negative motor voltage or current

DIP switch S10 ON

Ð

DIP switch S9 ONÐ

recommended potentiometer

50 kΩ (linear)

Use of internal potentiometer P3

If the set value is adjusted internally via potentiometer P3, DIP switch S9 must

be in the “OFF

Ï” position.

P3 = 50 ... 100 % (right end stop) positive motor voltage or current

P3 = 50 ... 0 % (left end stop) negative motor voltage or current

Input wiring (+Set) = (-Set)

short-circuited

DIP switch S10 optional

DIP switch S9 OFFÏ

8 maxon motor control June 2010 Edition / Subject to change

Page 9

maxon motor

Operating Instructions 4-Q-DC Servo Control LSC 30/2

5.1.2 “Disable”

Enabling or disabling the power stage.

If the “Dis IN” connection is not connected or at Gnd potential,

the power stage is activated (Enable).

Release “Enable”

minimum input voltage Gnd

maximum input voltage +1 VDC referenced to Gnd

maximum input current 2 mA

If the “Dis IN” terminal is connected with “Dis+V” or

the voltage is higher than V

CC

-1V, the power stage becomes high impedant and

the motor shaft freewheels and slows down (Disable).

Block “Disable”

minimum input voltage VCC - 1 VDC

maximum input voltage

V

CC

maximum input current

2 mA

Wiring examples:

a) Switch open = “Disable”; switch closed = “Enable”

4

“Gnd”

10

“Dis IN”

3

“+Vcc”

4k7

0.25W

4k7

0.25W

4k7

0.25W

4k7

0.25W

b) Switch open = “Enable”; switch closed = “Disable”

10

“Dis IN”

“Dis+V” terminal [11] or “+Vcc” terminal [3]

5.1.3 DC tacho

+T

positive tacho voltage terminal [14]

-T

negative tacho voltage terminal [13]

minimum input voltage 2.0 V

maximum input voltage 50.0 V

Input impedance

approx. 20 kΩ

Speed control range:

The speed range is set using Potentiometer P1 n

max

(max. speed at maximum

set value).

For full speed control with ± 10 V or ± 3.9 V, the tacho input voltage range must

be at least ± 2 V.

Example for a DC-tacho with 0.52 V / 1000 rpm:

2.0 V tacho voltage is equivalent to a speed of approx 3850 rpm. If the full set

value range has been used, the lowest adjustable speed with the n

max

potentiometer is 3850 rpm.

Lower speed ranges can be reached through a reduced set value range or by

using a DC tacho with a higher output voltage, such as 5 V / 1000 rpm.

June 2010 Edition / Subject to change maxon motor control 9

Page 10

maxon motor

4-Q-DC Servo Control LSC 30/2 Operating Instructions

5.1.4 Encoder

ChA

Channel A terminal [13]

ChB

Channel B terminal [14]

Encoder supply voltage +Venc +5 VDC, max. 80 mA

max. encoder input frequency DIP switch S8 OFF

Ï: 100 kHz

DIP switch S8 ONÐ: 6 kHz

Voltage level

TTL

low max. 0.8 V

high min. 2.0 V

The maximum encoder input frequency can be selected with DIP switch S8.

Standard adjustment is max. encoder frequency of 100 kHz.

DIP switch S8 OFFÏ: “high"

DIP switch S8 ONÐ: “low"

Max. input frequency is 100 kHz Max. input frequency is 6 kHz

Encoder pulses

per revolution

maximum motor

speed

Encoder pulses

per revolution

maximum motor

speed

1000

6 000 rpm

128 2 812 rpm

512 11 719 rpm 64 5 625 rpm

500 12 000 rpm 32 11 250 rpm

256 23 437 rpm 16 22 500 rpm

128 46 874 rpm

Note:

To achieve good control characteristics, encoders should be operated at a small

number of pulses per revolution with the DIP switch S8 in position ON

Ð “low”.

10 maxon motor control June 2010 Edition / Subject to change

Page 11

maxon motor

Operating Instructions 4-Q-DC Servo Control LSC 30/2

5.2 Outputs

5.2.1 Auxiliary voltage “+Vaux” and “-Vaux”

Auxiliary voltage for supplying an external potentiometer (50 kΩ).

+Vaux

positive auxiliary voltage terminal [5]

Output voltage +3.9 VDC referenced to Sig_Gnd

Max. output current 2 mA

-Vaux

negative auxiliary voltage terminal [6]

Output voltage -3.9 VDC referenced to Sig_Gnd

Max. output current 2 mA

5.2.2 Encoder supply “+Venc”

Auxiliary voltage for supplying the encoder

+Venc

Encoder supply voltage terminal [16]

Output voltage +5.0 VDC referenced to Gnd

Max. output current 80 mA

5.2.3 Status reading “Ready”

The readiness or error status can be reported to a higher level control through

the “Ready signal”. In normal circumstances, i.e. with no errors, the “Open

Collector” output is switched to Gnd.

In the event of an error (overheating), the output transistor is blocked.

12

max. 30V

Gnd

“Ready”

I

ma x

≤

20 mA

Input voltage range max. 30 VDC

max. load current 20 mA

June 2010 Edition / Subject to change maxon motor control 11

Page 12

maxon motor

4-Q-DC Servo Control LSC 30/2 Operating Instructions

6 Operating Status Display

A red and green LED shows the operating mode.

6.1 No LED

Reason:

• No supply voltage

• Fuse faulty

• Wrong polarity of supply voltage

6.2 Green LED

• Supply voltage applied

• No error status (overheating)

6.3 Red LED

If the power stage temperature exceeds a limit of approx. 85°C,

the power stage is switched off. (Disable - status).

The red LED comes on and the green LED goes out.

If the power stage temperature falls below approx. 60°C, the motor is restarted.

(Enable - status)

The red LED goes out and the green LED comes on.

Reason:

• High ambient temperature

• High power loss in the LSC

• Bad convection

• Heat sinking surface too small

7 Error Handling

Error Possible cause of error Action

Motor does not turn Supply voltage VCC< 12 VDC Check terminal [3] voltage “VCC”

Disable not activated Check terminal [10] “Dis IN”

Overheating disconnection active

Loss output in the LSC too high

Set value input 0 V Check terminal [7] “-Set” and [8] “+Set”

Incorrect operating mode selected Check adjustments at DIP switch

Bad contact Check terminals

Incorrect wiring Check wiring

Current limit too low Check adjustment Potentiometer P4 I

max

Speed not controlled Encoder mode: encoder signals Check “ChA” [13] “ChB” [14] sequence

Tacho mode: tacho signals Check polarity “-T” [13] and “+T” [14]

IxR mode: compensation incorrect Check adjustment Potentiometer P2 IxR

12 maxon motor control June 2010 Edition / Subject to change

Page 13

maxon motor

Operating Instructions 4-Q-DC Servo Control LSC 30/2

8 EMC-compliant installation

Power supply (+VCC - Power Gnd)

• No shielding normally required.

• Star point-shaped wiring if several amplifiers are supplied by the same power supply.

Motor cable

• No shielding normally required.

Encoder cable

• Although the LSC 30/2 does not have a line receiver, using an encoder with a line driver is

recommended as this improves interference resistance.

• Use cable shielding in electromagnetically harsh environment.

• Connect shielding on both sides (LSC housing).

• Use separate cable.

Analogue signals (Set, Tacho, Vaux)

• No shielding normally required.

• Use cable shielding with analogue signals with small signal level and electromagnetically

harsh environment.

• Normally connect shielding on both sides (LSC housing). Place shielding on one side if

there are 50/60 Hz interference problems.

Digital signals (Disable, Ready)

• No shielding necessary.

In practical terms, only the complete equipment, comprising all individual components

(motor, amplifier, power supply unit, EMC filter, cabling etc.) can undergo an EMC test to

ensure interference-free CE-approved operation.

9 Block Diagram

Linear

Power

Stag e

+Motor

-Motor

Gnd

+Vcc 12-30VDC

Current

Detector

Volt age

Detector

DIP6

+5V

+3.9V

-3.9V

Supply

Dis IN

Ready

F/V Converter

+Venc

Gnd

Ch A

Ch B

DIP8

+5V/80mA

DIP2

DIP3

+Vcc

Dis +V

Control &

Protection

Logic

+Vaux-Vaux Sig Gnd

+3.9V/2mA-3.9V/2mA

P2 IxR

P4 I max

Current

Limit

P3 Offset

DIP7

PI

Speed Control

DIP9

P5 gain

PI

Current

Control

-Set value

+Set val ue

DIP10

P1 n max

+Tacho

DIP5

DIP4

-Tacho

DIP1

June 2010 Edition / Subject to change maxon motor control 13

Page 14

maxon motor

4-Q-DC Servo Control LSC 30/2 Operating Instructions

10 Dimension Drawing

Dimensions in [mm]

11 Spare Parts List

maxon motor order number Designation

282310

16 poles pluggable PCB connector

pitch 3.5 mm

14 maxon motor control June 2010 Edition / Subject to change

Loading...

Loading...