COMMISSIONING, OPERATING AND MAINTENANCE MANUAL

MODEL: MAXLOGIC SERIES

SUB MODEL: INTELLIGENT ANALOGUE ADDRESSABLE

FIRE ALARM CONTROL PANEL

ML-121X

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 2

CONTENTS

1- INTRODUCTION .................................................................................................................................... 3

2- WARNINGS ........................................................................................................................................... 4

3- MOUNTING........................................................................................................................................... 4

4- PANEL INPUTS....................................................................................................................................... 5

4.1 Mains power supply ........................................................................................................................ 5

4.2 Batteries ......................................................................................................................................... 5

4.3 Detection Devices Inputs (Loop Lines) ............................................................................................. 5

4.4 Panel PC Connection ....................................................................................................................... 6

5- PANEL OUTPUTS ................................................................................................................................... 6

5.1 Sounder Outputs (4 Units) ............................................................................................................... 6

5.2 Auxiliary Power Supply Output (24 V DC) ......................................................................................... 7

5.3 Relay Outputs (3 Units) .................................................................................................................... 7

6- PANEL BUTTONS AND INDICATORS ....................................................................................................... 8

6.1 Control Buttons ............................................................................................................................... 8

6.2 Front Panel Indicators ................................................................................................................... 10

6.3 Internal Indicators ......................................................................................................................... 11

7- PANEL FUSES ...................................................................................................................................... 11

8- POWERING THE PANEL ....................................................................................................................... 12

8.1. First Boot of Panel ........................................................................................................................ 12

8.2. Booting Previously Configured Panel ............................................................................................. 16

9- FIRE EVENT MESSAGE FORMAT on PANEL LCD SCREEN ....................................................................... 17

10- FAULT EVENT MESSAGE FORMAT ON LCD SCREEN ............................................................................ 18

11- PANEL MENU .................................................................................................................................... 18

12- NETWORKING PRINCIPLES................................................................................................................. 23

13- TECHNICAL SPECIFICATIONS.............................................................................................................. 26

14- PANEL MODELS ................................................................................................................................. 27

ANNEX-A PANEL DIMENSIONS AND MOUNTING HOLES .......................................................................... 28

ANNEX-B CONNECTION SCHEME ............................................................................................................. 29

ANNEX-C PANEL SPARE PARTS ................................................................................................................ 30

ANNEX-D SERIAL COMMUNICATION CABLE ............................................................................................. 31

ANNEX-E SCHEME OF MENU FUNCTIONS ................................................................................................ 32

ANNEX-F NETWORK CONNECTION SCHEME ............................................................................................ 36

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 3

Maxlogic ML-121X Series

Intelligent Analogue Addressable Fire Alarm Control Panels

1- INTRODUCTION

Maxlogic ML-121X series intelligent analogue addressable fire alarm control panels are

provided with 0, 1, 2 loop options and 1000 user-defined zone capacity. Up to 127 analogue

addressable devices per loop are allowed to be connected.

Devices operating with VIP protocol such as Photo-Electric Smoke Detectors, Heat Detectors,

Multi-Sensor Detectors, Switch Monitor Modules, Relay Controller Modules, Sounder

Controller Modules, Loop-powered Addressable Sounders and Zone Monitor Modules are

compatible with ML-121X series control panels.

The project planning must be made carefully, in order not to have any difficulties when

commissioning the system. Zone location text (up to 40 characters including blank spaces) for

each device should be predetermined. Then, the devices should be categorized in zones

depending on the physical specifications of the building. After these steps, the panel can be

configured via the software program called ‘Loop Manager’.

The panel is equipped with 4 programmable and fault monitored 24 V DC 500mA sounder

outputs. Panel also contains 3 volt-free 30 V DC 1A relay outputs (fire relay, alarm relay, fault

relay) and a 24V DC 500mA auxiliary power supply output. Furthermore, 4 remote control

inputs (alarm, silence/sound alarm, reset and fault) exist in the panel.

ML-121X series fire alarm control panels have the optional functions described in TS EN 54-2

standards;

Sounder outputs

ML-121X series fire alarm control panels have also the supporting functions described in TS

EN 54-2 standards;

Network: The supporting function used to communicate in network.

NOTE: This user manual is valid for the panel models indicated in 14

th

section.

Producer-manufacturer or importer firms’ title, address, and telephone number

Manufacturer Firm:

MAVILI ELEKTRONIK TICARET VE SANAYI A.S.

SERIFALI MAHALLESI, KUTUP SOKAK NO: 27/1-2-4 UMRANIYE / ISTANBUL / TURKEY

TEL: +90 216 466 45 05 - +90 216 466 45 10

Service stations’ communication information that related spare parts have been

provided

Authorized Services:

MAVILI ELEKTRONIK TICARET VE SANAYI A.S.

SERIFALI MAHALLESI, KUTUP SOKAK NO: 27/1-2-4 UMRANIYE / ISTANBUL / TURKEY

TEL: +90 216 466 45 05 - +90 216 466 45 10

TEKSIS TEKNIK ELEKTRONIK SIS.TIC. VE SAN. LTD. STI.

SERIFALI MAHALLESI, KUTUP SOKAK NO: 27/3 UMRANIYE / ISTANBUL / TURKEY

TEL: +90 216 313 60 60 - +90 216 313 47 49

Expected operation life which has been determined and announced by related ministry

This device’s expected operation life is 7 years.

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 4

2- WARNINGS

The panel contains static-sensitive high quality electronic control equipment. Do not use the

panel before reading this manual.

In case of any fault, only the technicians of the manufacturer or technicians authorized by the

manufacturer should repair or maintain the panel.

The person who will operate the system should be well trained on powering and operating the

system.

Two years of warranty is valid from the production date as long as the system is used with

regard of obeying the rules, instructions and recommendations provided by the manufacturer.

Use the recommended cable types defined in this manual for cabling of panel power supply,

sounder power supply and detector line. Do not remove any connections and do not make any

connections while mains power supply is connected. Panel’s earth connection must be made

definitely.

Do NEVER apply 230V AC 50Hz mains power into the detectors and manual call points input

terminals, sounder line outputs and battery connection inputs.

This panel has been designed to operate on 230 V AC 50 Hz power supply. The protective

earth connection must be made definitely and the mains power supply must be presented

through the device via a fuse assigned only to this device. If the earth connection is not made

appropriately, all the conductive parts in the device may result in electrical leakage and this

may create hazard.

‘Automatic Learning’ causes erasing of existing configuration data at the panel. Therefore, it is

recommended to download the configuration data to PC, before ‘Automatic Learning’.

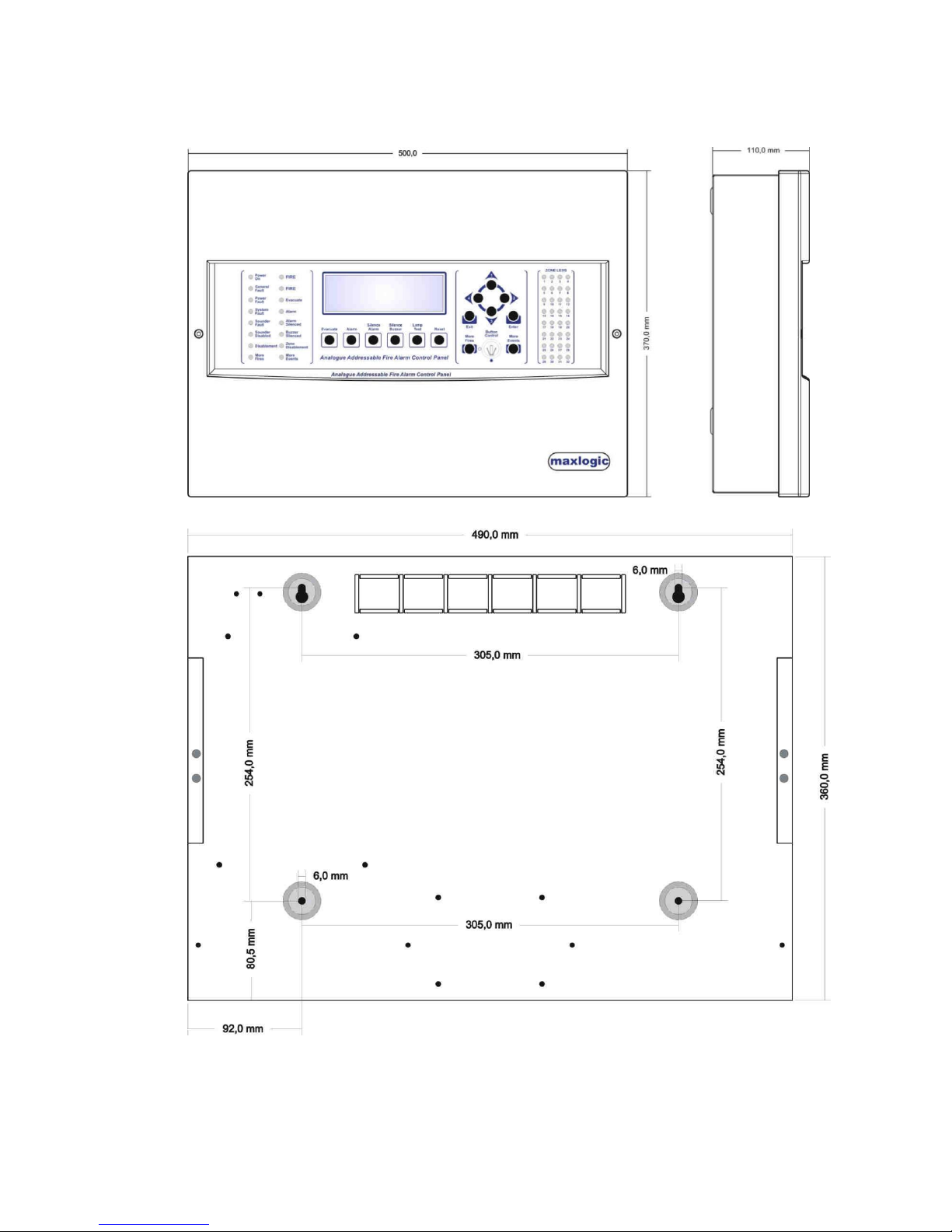

3- MOUNTING

The chosen mounting site of the panel must be clean, dry, not subject to shock or vibration

and easily accessible. The temperature must be in between the temperature range of

-5C° and +50C°. The relative humidity must not be m ore than 95%.

The panel should be mounted on a flat surface in such a way that, the indicators should be at

the eye-level and must not be mounted near the sources of excessive heat or cold and inside

of any cabinet.

Uncover the panel via the allen key provided with the panel.

Panel cable entries from back and top of the panel are available for easy mounting. Mark the

position of the fixing holes according to the respective Annex-A, Figure-2; ensuring that the

wall is flat at the chosen location.

Screws or bolts of a minimum of 4mm diameter must be used to mount the cabinet in all four

mounting positions. Drill and plug the wall then fix the cabinet using all fixing points.

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 5

4- PANEL INPUTS

4.1 Mains power supply

The system is designed to operate with 230V AC 50Hz. Earth connections must be made to

earth terminal and earth resistor must be less than 10Ω. The mains supply of the panel must

be via an independent self-resetting fuse rated 230V AC 6A. This fuse must be separate from

the other fuses and a caution note should be written such as ‘ATTENTION! FIRE ALARM

CONTROL PANEL’S FUSE. DO NOT REMOVE’ to ensure safe operation of the panel.

Recommended cable types are 3x2,5 NYM or 3x2,5 NYA. Connections must be done

according to Annex- B, Figure-1.

Do not connect or disconnect loops, mains supply input and PCB connections while the panel

is energized, to avoid an electric shock.

4.2 Batteries

Batteries provide continuity of operation during a failure of the mains power supply. The panel

uses 2 units of 12 V DC 7Ah dry type batteries. Battery connection scheme can be seen from

Annex-B, Figure-14.

4.3 Detection Devices Inputs (Loop Lines)

ML-121X series panels are produced with 0, 1, 2 loop models. Panels with

0 loops (no-loop) are used as repeater panels. Each loop is capable of hosting up to 127

addressable devices. Connection of loop line to the control panel must be as like in Annex-B,

Figure-7. A 0Ω resistor must be connected to the unused loops. Each device in the loop must

be addressed via MG-8200 Address Programmer depending on the architectural project of the

site.

The semi-duplex two-wire digital serial synchronous communication between the devices

connected to the loop and the fire alarm control panel is established by the VIP

communication protocol.

Short circuit isolators must be placed in such a way that more than 20 detectors and/or

manual call points shall not be out of service in case of any short circuit occurrence in the

loop.

The devices should be connected to a one-pair cable to create a loop and should turn back to

the panel from the last device.

The loop is energized from the ‘out’ terminal of the panel and the turn back point toward the

panel is the ‘in’ terminal. In case of rupture or short circuit, the loop is energized from both the

‘in’ terminal and the ‘out’ terminal. Thanks to this functionality; it is provided that the devices,

except from the detectors / buttons which are in failure, go on functioning properly while the

part in failure is isolated.

It should be used the short circuit isolator for each ‘in’ and ‘out’ terminals. Thus, if any problem

occurs in between the part from any of the ‘in’ or ‘out’ terminals to the first short circuit isolator

location, this part is isolated and the rest of the loop can go on functioning properly.

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 6

1x2x1,5+0,8J-Y(st)Y, 1x2x0,8+0,8J-Y(st)Y or 1x2x1,5+0,8J-H(st)H, 1x2x0,8+0,8J-H(st)H

coded cables should be used. While cabling (starting from Loop + terminal), cable’s earth line

must be connected to appropriate earth terminal in the control panel (See Annex-B, Figure-2).

This earth line should be installed throughout all detectors and call points. Earthing cables

should be wired after placing detectors and/or call points and line should be ended. When a

return is performed to (Loop -), earthing line should be done as it is shown in Annex-B,

Figure-2 and line is ended.

4.4 Panel PC Connection

4.4.1 PC Port

Cable connection between panel and PC for data communication is plugged into the PC

Socket which found on front panel of (See Annex-B, Figure-11). The communication cable

shown in Annex-D must be used for communication with computer.

4.4.2 Write Enable Switch

Write enable switch has two positions as “ON” and “OFF”. (Annex-B, Figure-8) When the

panel is energized while the switch is OFF, the panel runs previously saved data. When the

panel is energized while the switch is ON, panel operation modes appears on the screen.

More details are provided in Section-8.

4.5 Remote Control Inputs

There are remote control inputs on the panel which are likely to control the panel remotely by

the help of any remote button. One terminal of the button is connected to the desired input

and other one is connected to GND. (See Annex-B, Figure-6). It should be used the cable with

this code; 2x1,5 N2XH or 2x1,5 NYY for remote control input line.

AL : Reactivates alarm condition, sounders and relays which was silenced and positioned

by Silence Alarm.

FLT : Activates fault condition.

RS : Resets the panel.

SIL : Silences sounders and returns the relays to their initial position.

5- PANEL OUTPUTS

5.1 Sounder Outputs (4 Units)

The panel has 4 sounder outputs rated 24 V DC 500mA. In order to monitor the line against to

open or short circuit conditions, normally 16 V DC reverse voltage is seen from the sounder

outputs. During fire alarm outputs are driven by 24 V DC (Annex-B, Figure-4). Current driven

more than 0.5A leads the panel into the fault condition.

2x1,5 N2XH or 2x1,5 NYY cable should be used for the sounder line. 10KOhm resistor,

located on sounder outputs from factory default is used as end-of-line resistor and must be

connected to the end of the sounder line. Otherwise, open circuit fault is monitored on the

sounder line of panel. In case of any open circuit or short circuit faults occurred, it can be

displayed on the screen of panel with the line number.

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 7

5.2 Auxiliary Power Supply Output (24 V DC)

The panel is equipped with an auxiliary 0.5А 24 V DC power supply output. Exceeding this

level causes fault condition. It can be used for supplying power to peripheral devices.

2x1,5 N2XH or 2x1,5 NYY cables should be used for external power supply line. In case of

mains power supply failure, the batteries provide power supply to the output (24 V DC).

(Annex-B, Figure-3).

5.3 Relay Outputs (3 Units)

The panel has 3 units of relay outputs with volt free changeover contacts rated 1A 30 V DC.

These volt-free outputs; fire relay (normally non-energized), alarm relay (normally nonenergized) and fault (normally energized). (Annex-B, Figure-5). 2x1,5 N2XH or 2x1,5 NYY

cable should be used for relay output line.

5.3.1 Fire Relay : The output is activated on any fire event and it can be used to trigger

any other system. The output is returned to its initial position only by pressing ‘Reset’ button

on panel.

5.3.2 Alarm Relay : The output is activated on any fire event and it can be used to activate

any other system. The output is returned to its initial position only by pressing ‘Alarm Silence’

button on panel. If a new alarm occurs, Alarm relay reactivates.

5.3.3 Fault Relay : The output is activated on any fault event, changes its contact in case

of mains failure. The output returns to its initial position, if fault condition is removed and the

‘Reset’ button on the panel is pressed.

Important notice : Fire alarm panel relays operate as signal-based relays. If these relays

will activate any other devices as like control relays, then a contactor should be used between

the relay and device. In case of high current driven applications, the relay outputs can get

damage if there is no contactor. This situation is not subjected to the warranty condition.

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 8

6- PANEL BUTTONS AND INDICATORS

6.1 Control Buttons

While control panel is in normal operating condition, it is in ‘Access Level 1’. In Access Level

1, the buttons; Silence Buzzer, Lamp Test, More Fires, More Events can be used.

The Silence Buzzer, Lamp Test, More Fires, More Events Buttons can be used in Access

Level 1.

Passing ‘Access Level 2’ enables to use other buttons. In order to pass ‘Access Level 2’

button control key is brought to enable position. To prevent unauthorized access, button

control key must always be kept as disable position while panel operating in normal condition.

Evacuate : Used for the purpose of evacuation. It requires to be programmed by

the Loop Manager Program.

Pressing this button:

- Buzzer sounds.

- Sounders ring.

- Alarm and fire relays get activated.

- Fire LEDs and Evacuation LEDs illuminate.

Alarm : Pressing Alarm button reactivates the sounders and relay outputs

which were silenced before.

Silence Alarm : This button is used to silence an alarm and bring relay outputs to their

old positions.

Silence Buzzer : This button is used to silence the internal buzzer which rings during fire

alarm or any fault condition occur in the system.

Lamp Test : It is used to check all the LEDs and LCD screen of the panel whether

they are operate normally or not.

Reset : Resets all existing fire and fault events in the system. Fire and Fault

relays are brought to normal position (if fire and fault condition is not proceeding).

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 9

More Fires : Among existing events, if there are more than one fire event, this

button is used to see fire events in the system.

The latest fire event remains at the bottom of the LCD screen. Pressing ‘More Fire’ button

shows all the fire events at the upper part of the LCD screen.

Z o n e s I n A l a r m : 1 A l a r m : 2 F a u l t : 1

* F I R E : M G 6 2 0 8 8 - W a y S w . M o n . Z o n e : 1 *

P : 0 L : 1 A : 2 8 M L - 1 2 X X R e - i n i t i a t e d

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

* F I R E : M G 6 2 0 8 8 - W a y S w . M o n . Z o n e : 1 *

P : 0 L : 1 A : 2 8 M L - 1 2 X X R e - i n i t i a t e d

More Events : If more than one event occurs, it is possible to see all other events by

pressing this button. Pressing this button categorizes the events. It is possible to check other

events by pressing ‘1(UP)’, ‘3(DOWN)’ buttons. To see the desired event category, press the

button with number ‘2 (RIGHT)’. To get back to the main category press ‘EXIT’ button.

Event categories as below ;

Fires

Tech. Alarms

Announce Event

Informations

Evacuates

Tech. Faults

FF Tel. Event

Disablements

Faults

Alerts

Analog Event

Test

Pre-Alarms

Securities

Internal Events

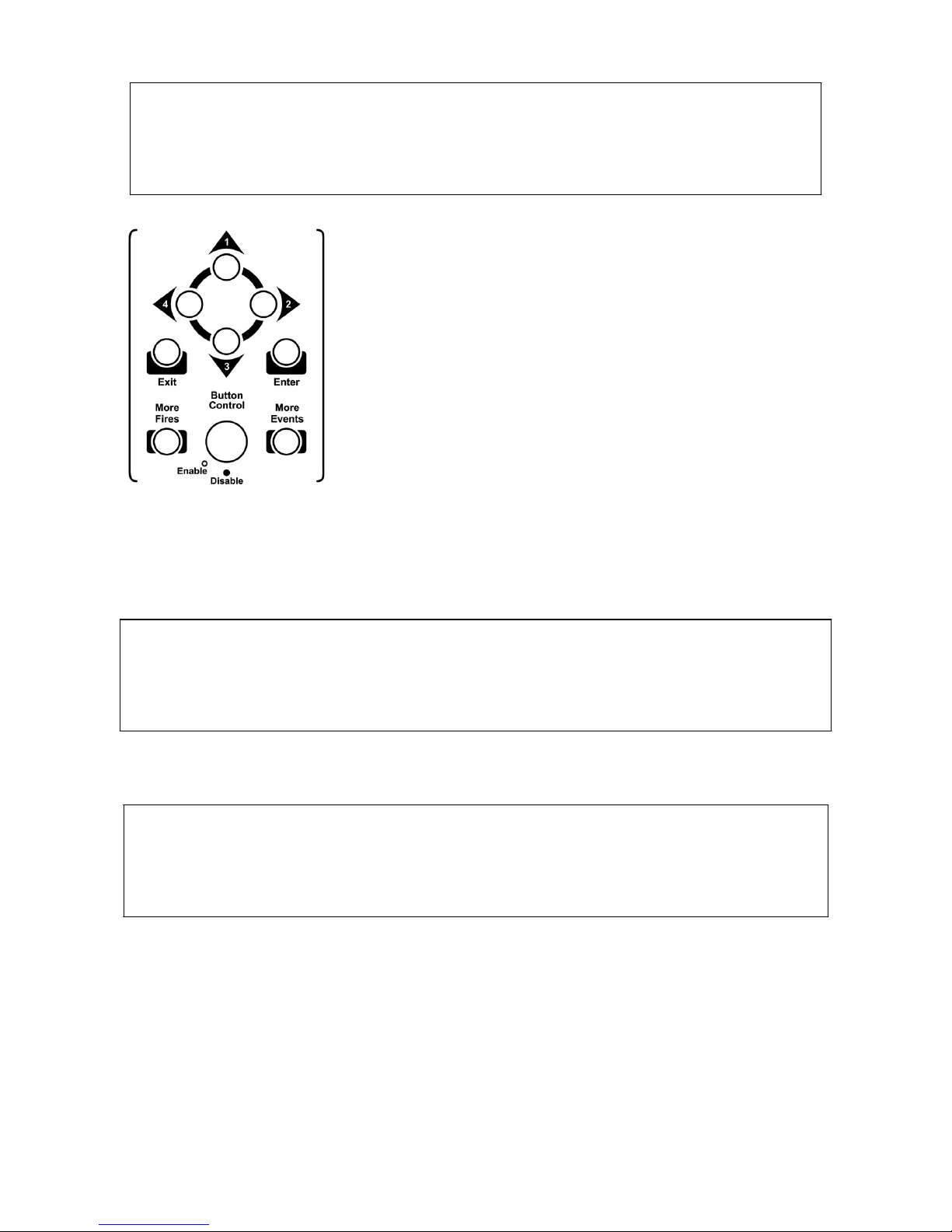

Direction buttons:

Button number ‘1’ : It is used to go upward in the panel’s main menu screen and in the

‘More Events’ menu.

Button number ‘2’ : It is used to select the desired feature in panel’s main menu and

desired category in ‘More Events’ screen and go to right direction.

Button number ‘3’ : It is used to go downward in the panel’s main menu screen and More

Events menu.

Button number ‘4’ : It is used to go back to previous menu and go to left direction.

Enter : Enter Button is used to see the menu screen and select the desired

feature inside the menu.

Exit : It is used to go back to previous menu when LCD screen shows main

panel menu or go back to categories menu from the selected category.

Note: Menu features are described in detail in the 11

th

section of Panel menu. To see the

transitions among menu features please check ANNEX-E Scheme of Menu Functions.

W/Dog Reset : Used for elimination error in case of ‘System Fault’ LED illuminates.

However, if the LED illuminates because of any fault in the central microprocessor preventing

the program to run; the button will be useless for this situation (ANNEX-B, Figure-9).

Microprocessor Reset: Microprocessor can be reset by pressing the ‘Microprocessor Reset’

button. (ANNEX-B, Figure-13)

LCD Lighting : Used to adjust the LCD display contrast with the aid of trimpot

(ANNEX-B, Figure-10).

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 10

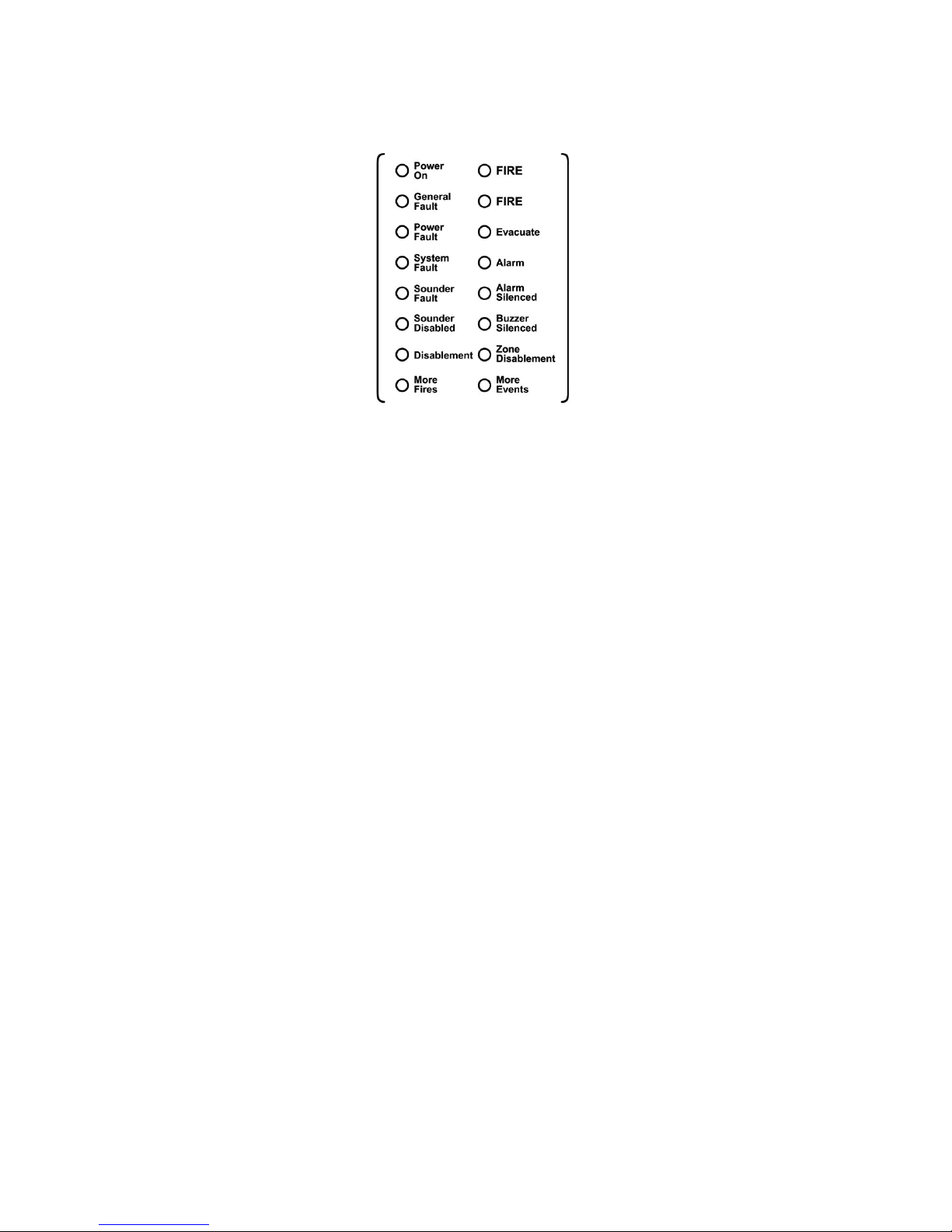

6.2 Front Panel Indicators

FIRE : Fire LEDs illuminate in two conditions; if there is a fire situation in the

system or in case of pressing Evacuate button. Each one of these conditions makes the LEDs

illuminate in ‘Red’ colour.

Power On : Panel is energized and operates normally. It illuminates as ‘Green’

continuously.

General Fault : If any fault occurs during operation. It illuminates with the specified

respective faults such as power fault. It illuminates as ‘Yellow’.

Power Fault : It indicates that there is a mains power failure or a problem of battery.

It illuminates as ‘yellow’ and related fault condition can be viewed on the LCD screen.

System Fault : Main microprocessor fault. It Illuminates as ‘Yellow’.

Sounder Disabled : It shows that the sounder outputs on the panel has been disabled and

illuminates as ‘yellow’.

Disablement : If any device or line disabled in the system this LED illuminates as

‘Yellow’.

More Fires : It indicates the presence of more than one fire in the existing event list

of the system. It illuminates as ‘Yellow’.

Evacuate : It indicates that the Evacuate button is pressed. The Evacuate button

must be programmed by Loop Manager Software Program. It illuminates as ‘Red’.

Alarm : It indicates that the alarm button is pressed, it illuminates as ‘Yellow’.

Alarm Silenced : This led shows that incoming alarms are silenced by pressing ‘Alarm

Silenced’ button. It illuminates as ‘Yellow’.

Buzzer Silenced : It indicates that the Buzzer Silenced button is pressed and it

illuminates as ‘Yellow’.

Zone Disablement : It indicates that one or more zones are disabled from the panel menu.

It illuminates as ‘Yellow’.

More Events : If there is more than one event in the system this LED illuminates as

‘Yellow’.

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 11

6.3 Internal Indicators

Internal Indicators on SLCU (Single Loop Card Unit) (Annex-B, Figure-16);

SEND LED: While sending communication signal to the devices in the loop, it blinks as RED.

RECEIVE LED: While receiving responses from the devices in the loop, it blinks as

GREEN.

7- PANEL FUSES

Fuses on the panel;

SLCU Fuse (FS1) is a self-resetting fuse and becomes active on 0.5А current overload at the

loop output line. The General fault LED illuminates and on LCD screen ‘Loop open or Short

circuit’ comment is seen. Panel’s loop output becomes unusable. In each single loop card this

fuse is present.

Sounder 1 Self-resetting fuse (FSO3)

Self-resetting and becomes active on 0.5А current overload. Sounder fault Led illuminates,

and on LCD screen ‘Sounder 1 open circuit’ message is seen. Panel’s sounder-1 output

becomes unusable.

Sounder 2 Self-resetting fuse (FSO4)

Self-resetting and becomes active on 0.5А current overload. Sounder fault Led illuminates,

and on LCD screen ‘Sounder 2 open circuit’ message is seen. Panel’s sounder-2 output

becomes unusable.

Sounder 3 Self-resetting fuse (FSO5)

Self-resetting and become active on 0.5А current overload. Sounder fault Led illuminates, and

on LCD screen ‘Sounder 3 open circuit’ message is seen. Panel’s sounder-3 output becomes

unusable.

Sounder 4 Self-resetting fuse (FSO1)

Self-resetting and becomes active on 0.5А current overload. Sounder fault Led illuminates,

and on LCD screen ‘Sounder 4 open circuit’ message is seen. Panel’s sounder-4 output

becomes unusable.

24 V DC Self-resetting Fuse (FSO2)

Self-resetting and becomes active on 0.5А current overload or wrong connection into the

output. The General fault LED illuminates and ‘24 V Fault’ comment is seen on LCD screen.

24 V DC output becomes unusable.

Internal Indicators on MLY-0502 Power Supply;

28 V input fuse (F1)

3 A self-resetting fuse becomes active in case the power supply becomes faulty.

Battery fuse (F2)

1.1 A self-resetting fuse becomes active upon any fault or short circuit at battery inputs.

28 V output fuse (F3)

3A self-resetting fuse becomes active upon short circuit in 28 V output of power supply. In this

case, the outputs of power supply become de-energized.

Note: the placement of the fuses is shown in Annex-B.

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 12

8- POWERING THE PANEL

8.1. First boot of panel

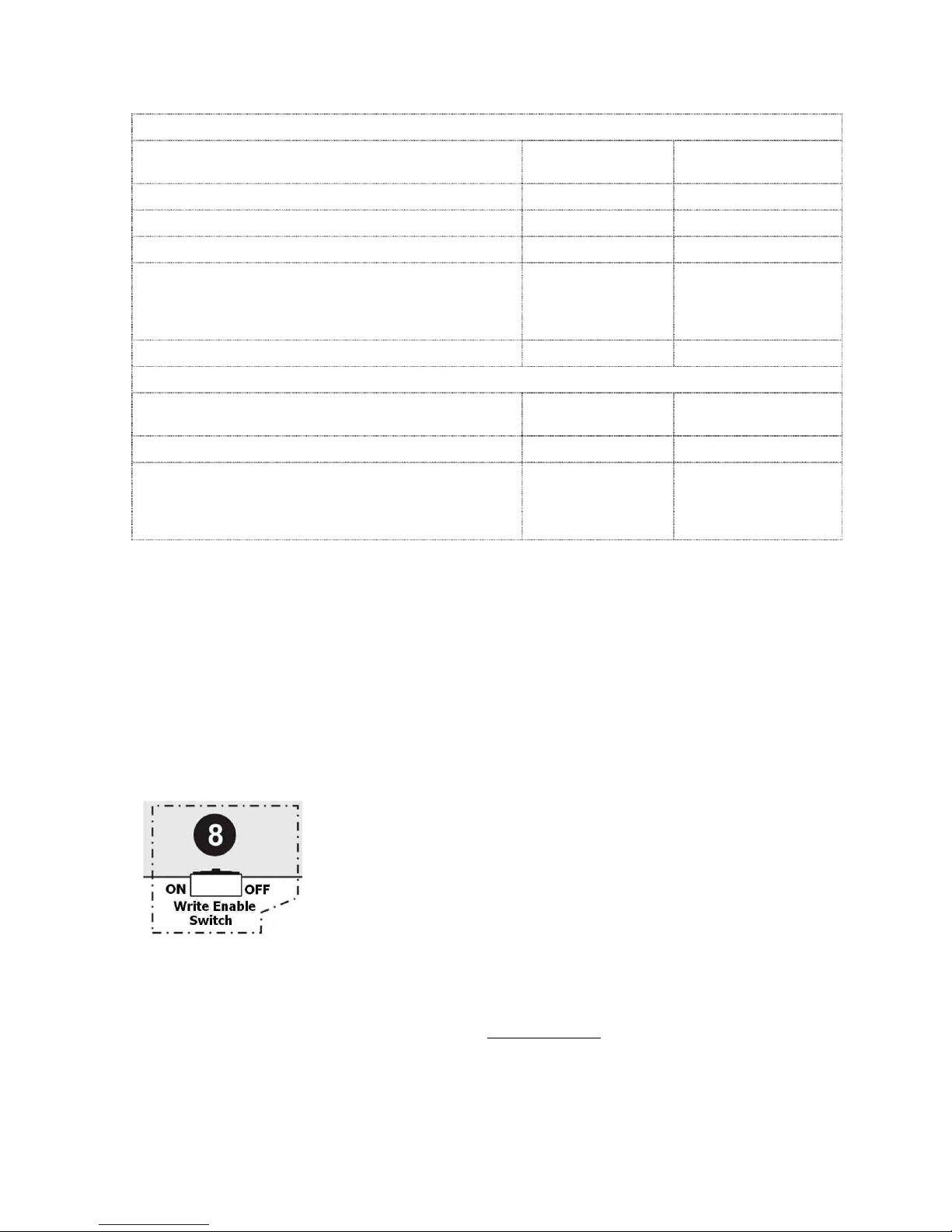

Operation Panel Status Write Enable Switch

Position

8.1.1. Cabling OFF (Not-energized) OFF (OFF Position)

8.1.2. Checking cabling OFF (Not-energized) OFF (OFF Position)

8.1.3. Addressing OFF (Not-energized) OFF (OFF Position)

8.1.4. Determining connected

devices

8.1.4.1. Re-Initiate System (Automatic Learning)

8.1.4.2. PC Program

ON (Energized) ON (ON Position)

8.1.5. Booting panel ON (Energized) OFF (OFF Position)

8.2. Booting Previously Configured Panel

Operation Panel Status Write Enable Switch

Position

8.2.1. Using updated data ON (Energized) OFF (OFF Position)

8.2.2. Reconfiguring the panel

8.2.2.1. Updating Panel Configuration File

8.2.2.2. Using Valid Data

ON (Energized) ON (ON Position)

8.1. First Boot of Panel

8.1.1. Cabling: Before powering the panel, all connections should be made properly

depending on the connection scheme in ANNEX-B.

8.1.2. Checking cabling: All the connected cables (sounder line, loop etc.) should be

checked for short circuit, open circuit (broken line) etc.

8.1.3. Addressing: All devices in the loop should be assigned to a unique address number

by ‘MG-8200 Address programmer’ device, with regard of architectural project of the site.

8.1.4. Determining connected devices: The devices connected to the panel loop lines

must be determined properly.

In order to determine connected devices, the panel is energized while

‘Write Enable Switch’ is ‘ON’.

(Annex-B, Figure-8)

The below screen appears. The operation shall be selected.

Re-Initiate System (Automatic Learning)

PC Program

Use Valid Data (In case the panel is energized for the first time, panel memory is empty and

this option cannot be selected at the first system boot.)

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 13

S e l e c t C o n f i g T y p e

R e - I n i t i a t e S y s t e m

P C P r o g r a m

U s e V a l i d D a t a

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

[ U p / D o w n ] : S c r o l l i n g [ E n t e r ] : A c c e p t

From the screen above, the configuration type is selected.

It is possible to scroll up and down in the menu by using ‘1’

and ‘3’ buttons, to confirm the selection press ‘Enter’ button.

8.1.4.1. Re-Initiate System (Automatic Learning)

Automatic learning is the operation that the panel scans and saves all devices connected to

the loop lines one by one.

Auto learning is activated by pressing ‘ENTER’ button. Below screen is displayed:

S e l e c t C o n f i g T y p e

C l e a r V a l i d D a t a ?

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

[ E x i t ] : C a n c e l [ E n t e r ] : A c c e p t

Activating this option will erase the panel memory and re-configure the system by scanning all

devices.

S e l e c t C o n f i g T y p e

D i s a b l e P r o g r a m E n a b l e S w i t c h

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

[ E x i t ] : M a i n M e n u

When program enable switch is OFF, Automatic Learning starts. As a result, new

configuration data is created depending on the currently connected devices and the previous

configuration data is erased. The new data is saved to the memory of panel.

8.1.4.2. PC Program

A special software program called ‘Loop Manager’ is used for programming the panel.

Creating zone location texts, creating cause-effect scenarios, device settings etc. are all done

through ‘Loop Manager’ Software.

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 14

The communication between panel and computer is established while the panel is in normal

operating mode or while ‘Write Enable Switch’ is ‘ON’.

The serial communication cable is connected to the PC socket which found on the panel front

cover. (For the cable connection, see Annex-D)

The selection of ‘Download from Panel’ or ‘Upload to Panel’ operations is made through the

‘Loop Manager’ Software as shown on the below screen.

Data transfer can be initiated through the Loop Manager; there is no need to follow any

procedure on the panel. It is sufficient to click on ‘Start Downloading’ Button.

When data transfer completed, the following comment is displayed on the program;

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 15

In case any communication fault occurs, the below screen appears:

In this case, the panel should be deenergized, the connection cables should be checked and

all the above steps should be repeated after debugging the problem.

8.1.5. Booting panel:

At the end of automatic learning or computer/panel communication, system boots in normal

operation mode.

On the LCD screen of the panel following comment is seen;

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 16

L I N E I

N

I

T

I A T I N

G

P l e a s e W

a

i t .

After uploading or downloading, panel gets back to its normal condition as below;

M a v i l i E l

e k t r o n

i k A . S . 0

2 1 6 4 6 6 4 5 0 5

V e r s i o

n : 1 . 0 .

2 2

M L - 1 2 X X R e - i n i t i a t e d

A c c e s s L e v e l 2

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

[ E n t e

r

] : M e n u

8.2. Booting Previously Configured Panel

8.2.1. Using updated data:

If the panel is turned OFF for some reasons, the rebooting should be while ‘Write Enable

Switch’ is ON in order to start with actual data.

Upon energizing the panel, the internal units are checked and results are reported.

The internal units which are checked during the system start-up:

Supervisor

Port (1)

XNCU

SLCU (loop)

Panel Status

General Leds Driver

TCP/IP

Pcus

LCD

Power Unit

Zone Leds (1..32)

Printer

Port (0)

I/O Driver

Zone Leds (33..64)

Network

Status information format of checked units in the panel is as like OK/Fault. In case the internal

device has version number, then this number appears on the screen.

Panel automatically starts to load the information after 10 seconds countdown and go over to

normal operating condition. During 10 seconds countdown, report results of the internal units

can be seen by using ‘1’ and ‘3’ buttons or ‘write enable switch’ position can be changed.

After panel displays all detected units on to screen, the data is loaded automatically and panel

pass to normal operating mode.

M a v i l i E l

e k t r o n

i k A . S . 0

2 1 6 4 6 6 4 5 0 5

V e r s i o

n : 1 . 0 .

2 2

M L - 1 2 X X R e - i n i t i a t e d

A c c e s s L e v e l 2

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

[ E n t e r ] : M e n u

8.2.2. Reconfiguring the panel:

Reconfiguring of an already existing panel may be necessary for some reasons like adding

new device(s), removing device(s), updating zone location text information and changing

device settings etc.

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 17

Panel is energized while ‘Write Enable Switch’ is in ‘ON’ position. The screen to select

operating mode appears:

Re-Initiate System (Automatic learning results in erasing the already existing data (such as

zone location texts etc.). For this reason this information must be well noted.)

PC Program (It is also possible to update data in normal operating mode.)

Use Valid Data

8.2.2.1. Updating panel configuration file:

Previously created (if it exists) configuration file (*.hrz) is open through Loop Manager

software or the data is downloaded from the panel. The desired changes are made and finally,

the file is uploaded to panel. (See, Section 8.1.4.2. PC Program)

8.2.2.2. Using valid data:

In order to select ‘Use Valid Data’ option, panel is energized while ‘Write Enable Switch’ is

‘ON’. In this configuration type; the latest data is reloaded to the panel and activated. If there

is no correct data kept in the panel memory, then this option will not be avail able to be

selected. (It is also possible to load automatically the data saved to panel by turning ON the

panel while ‘Write Enable Switch’ is ‘ON’.)

To keep the previous data in panel memory is provided by the battery. If the battery detaches

or broken then all the data kept in the panel get lost.

9- FIRE EVENT MESSAGE FORMAT on PANEL LCD SCREEN

On fire event, the panel displays a message in 4 lines as shown below; alarm relays and fire

relays get activated, buzzer and sounders ring.

Z o n e s I n A l a r m : 1 D i s . : 2 F a u l t : 1

* F I R E : M G 6 2 0 8 8 - W a y S W . M o n . Z o n e : 1 *

P : 0

L

: 1 A : 2 8 M L - 1 2 X X R e - i n i t i a t e d

F L O O R C O R R I D O R

1. In the 1

st

row following information is displayed;

Zone In Alarm: Number of Alarm at the zones

Disablements: Total number of disablements

Fault: Total number of faults

2. In the 2

nd

row; the device model and zone number in which fire alarm comes is

dispalyed.

3. In the 3

rd

row; panel, loop, address number, and panel name of the device in which fire

alarm comes is displayed.

4. In the 4

th

row; zone name of the device where fire alarm comes is displayed.

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 18

10- FAULT EVENT MESSAGE FORMAT ON LCD SCREEN

On fault event, the panel displays a message in 6 lines as shown below; fault relays get

activated and buzzer rings.

Z o n e s I n A l a r m : 0 D i s . : 0 F a u l t : 1

* F A U L T - M G 9 4 0 0 M u l t i s e n s o r Z o n e : 1 *

P : 0 L : 1 A : 2 8 M L - 1 2 X X A u t o - l e a r n e d

M E E T I N G R O O M

D i s c o n n e c t e d D e v i c e

1. In the 1

st

row following information is displayed;

Zone In Alarm: Number of Alarm at the zones.

Disablements: Total number of disablements

Fault: Total number of faults

2. 2

nd

row is empty.

3. In the 3

rd

row; the device model and zone information is displayed.

4. In the 4

th

row; location information of the faulty device is displayed. (Panel No., the

faulty device (like SLCU, PCU, NCU), address information if the device is addressable,

panel name)

5. In the 5

th

row; zone location text of the faulty device is displayed.

6. In the 6

th

row; fault type is displayed.

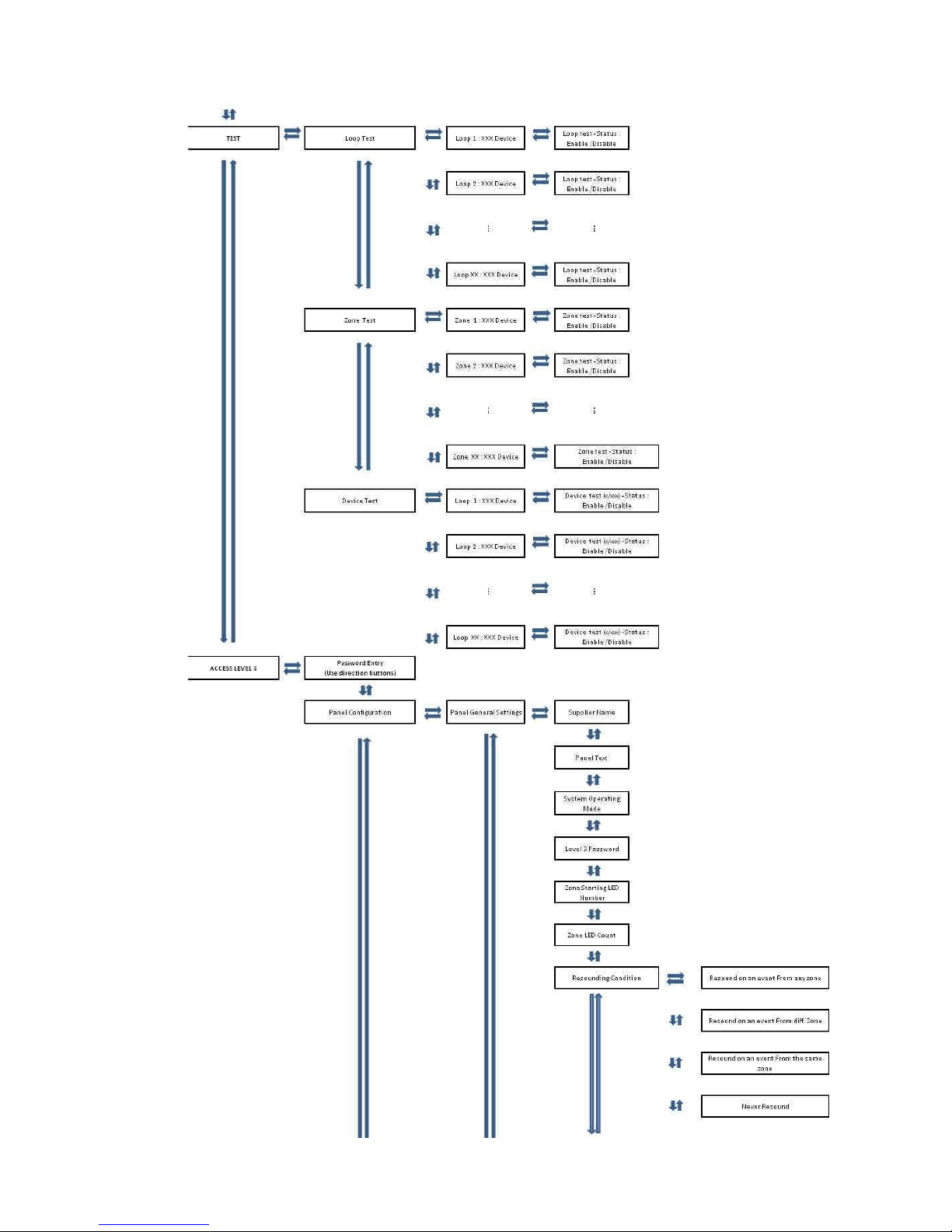

11- PANEL MENU

There are 3 access levels in order to prevent unauthorized access.

a) Access level 1: ‘Button Control’ key is ‘Disabled’. In this case; ‘Silence Buzzer’, ‘Lamp

Test’, ‘More Fires’, ‘More Events’ buttons can be used. ‘Button Control’ key must be switched

ON in order to unlock other buttons.

b) Access level 2: Some menu functions are active in this access level. Press ‘Enter’ while

‘Button Control’ key is enabled to access panel menu.

The button number ‘1’ is used to move ‘up’, and the button number ‘3’ is used to move

downward. To confirm the selected option press ‘enter’ button or press the button number ‘2’.

In order to get back to previous menu, press ‘Exit’ or press the button number ‘4’.

ACCESS LEVEL 2 MENU

+DEVICES

+DISABLEMENTS

+SET SYSTEM TIME

+FIRE ALARM COUNTER

+DELAY CONFIGURATION

+TEST

+ACCESS LEVEL 3

ACCESS LEVEL 2 MENU INSTRUCTIONS

+DEVICES: The following information for the devices connected to every single loop can be

displayed: Address information, zone location texts, device models, analogue values, status of

devices (Enabled/Disabled).

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 19

+DISABLEMENTS: It is possible to temporarily disable loop(s), zone(s), device(s), and

sounder(s). This option would typically be necessary during maintenance of the system or

painting, construction workings, etc. on the site, where the fire alarm system is installed, to

avoid faulty alarms.

+Disable Loop: It is possible to disable desired loop(s).

+Disable Zone: It is possible to disable desired zone(s).

+Disable Device: It is possible to disable desired device(s).

+Disable Sounder: By selecting this option, it is possible to disable all sounders

connected to the sounder line outputs, all addressable sounders connected to the loop line

and all sounders connected to the sounder controller module.

+SET SYSTEM TIME: It is possible to make the adjustments of Year, Month, Day, Hour and

Minute. (The correct system time is vital in proper registration of events.)

+FIRE ALARM COUNTER: Total number of fire events, which occur after installation of the

fire alarm system, can be displayed.

+DELAY CONFIGURATION: It is possible to activate or deactivate all delay values which are

assigned to output devices through ‘Loop Manager’ software.

+TEST: It is possible to test the system by activating loop(s), zone(s) and device(s) for a while

(Access level 3 – Test Reset Delay). This allows the system to be tested by only one single

person.

+Loop Test: It is possible to test desired loop(s).

+Zone Test: It is possible to test desired zone(s).

+Device Test: It is possible to test desired device(s).

+ACCESS LEVEL 3:

c) Access level 3:

Special settings can be made from this menu. ‘Access Level 3’ option must be selected to get

access to ‘Access Level 3 Menu’. “1,3,4,2” Password must be entered to Password Entry

field by using direction buttons. (This password can be personalized through Loop Manager

(Panel Settings - > Level 3 Password).)

ACCESS LEVEL 3 MENU

+Password Entry (Use direction buttons)

+Panel Configuration

+Event Logs

-Print Configuration

+Edit Event

+SLCU App. Software

+Contamination Control

-Analog Update

ACCESS LEVEL 3 MENU INSTRUCTIONS

+Password Entry (Use direction buttons):

+Panel Configuration: By selecting this option, special settings can be made

for the panel. The followings are available settings to be made.

-Panel General Settings:

-Supplier Name: The company name (and contact information)

information which will be displayed on panel screen in normal operating mode can be

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 20

modified. (The text to be entered should be max. 40 characters length.)

-Panel Text: A special desired name can be assigned to the

panel. (Site name, block na me in which the panel is installed can be chosen as Panel Name.

(The text to be entered should be max. 20 characters length.)

-System Operating Mode: Two different modes exist: “Common

Operating Mode” and “Zonal Operating Mode”.

In case “Common Operating Mode” is selected; all output devices (sounders, relay outputs

etc.) activate upon any fire alarm from any input devices (detectors, manual call points etc.).

In case “Zonal Operating Mode” is selected; upon any fire alarm from any zone, all output

devices (sounders, relay outputs etc.) only in the same zone get active.

-Level 3 Password: Level 3 password is displayed here to

authorize any user to access level 3 menu.

-Zone Starting LED Number: The system devices can be

assigned to a zone (Total amount of Zones is 1000). 64 units of LED exist on the panel front

cover. The first LED number of the interval (64/1000) to be monitored by LEDs is indicated

here.

-Zone LED Count: Total amount of LEDs on panel front cover is

indicated here. (32 or 64 depending on model type)

+Resounding Condition: If the devices, which activated upon a

fire event, are silenced by pressing ‘Silence Alarm’; the reactivation condition of these related

devices is selected here.

-Resound on an event From any zone

-Resound on an event From diff zone

-Resound on an event From the same zone

-Never resound

-Bypassing Condition: Delay value, which is assigned to output

devices (sounders, relays) through ‘Loop Manager’, can be canceled under some conditions.

These conditions are displayed here.

-Bypassing CE delays: Delay value of output devices

(sounders, relays) which are involved in a scenario (which created through ‘Loop Manager’)

can be canceled under some conditions. These conditions are displayed here.

** The Cause Effect (CE) Scenario(s) is created through ‘Loop Manager’ Software. The Cause

Effect Scenario indicates which output devices will be activated upon activation of which input

devices.

-Resounding Scenario Events: Upon activation of any

scenario, the output devices involved in scenario become active. If these output devices

(sounders, relays) are silenced by pressing “Silence Alarm”, the reactivation condition is

displayed here.

-Resetting Scenario Triggered Events: The resetting condition

of the created scenario is displayed here.

-Scenario Activation: The condition, which will affect the

activation of scenario, is displayed here.

-Programming Switch Usage: Write Enable Switch is to be

ON, before erasing event logs. By this way, it is possible to prevent unauthorized pe rsons to

access the panel.

-Global Silence: When selected as active; all outputs can be

silenced by pressing ‘Silence Alarm’ button. When selected as passive; only devices, which

are marked as “Yes” for “Is silenceable Output?” parameter to be accessed through Loop

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 21

Manager in “Device Settings” section, can be silenced by pressing ‘Silence Alarm’ button.

+Automatic Reset Delay Configuration:

+Test Reset Delay:

-Test Reset Delay: 6-30 sec.: This indicates the

‘TEST’ duration, which is enabled from Access Level 2 Menu. After the selected value of time,

the output devices get back to its normal statuses without need of any further manipulation.

+Type A Dependency Reset Delay: In case of any fire

alarm from any device in defined zone, the panel goes into ‘PRE-ALARM’ mode. Sounders do

not ring; pre-alarm message is displayed on screen. In case of any other fire alarm from the

same zone within the adjusted time, the panel goes into ‘ALARM’ mode.

-Type A Reset Delay: 30-1800 sec.: In type A

dependency; in case of any fire alarm from the previously defined zone, countdown duration

starts. During this time, a second fire alarm is expected. If a second fire alarm is not received

from the same zone within the adjusted time (30-1800sec.), then the first alarm state is reset

and pre-alarm message on panel screen disappears.

+Type B Dependency Reset Delay: In case of any fire

alarm from any device in defined zone, the panel goes into ‘PRE-ALARM’ Mode. Sounders do

not ring; the pre-alarm message appears on screen. In case of any other fire alarm from any

zone (the same or different zone) within the adjusted time, the panel goes into ‘ALARM’ mode

and sounders ring.

-Type B Reset Delay: 30-1800 sec.: In type B

dependency; in case of any fire alarm from the previously defined zone, countdown duration

starts. During this time, a second fire alarm is expected. If a second fire alarm is not received

from the same or different zone within the adjusted time (30-1800sec.), then the first alarm

state is reset and pre-alarm message on panel screen disappears.

-Panel Time Settings: It is possible to set system time as year, month,

day, hour and minute. (The correct system time is vital in terms of proper registration of

events.)

+Panel Version Information: This feature is used to display the version

information of panel internal cards.

(xMCU, sLCU, xNCU, cPCU)

XMCU: 1.0.XX-0.0.0

SLCU: 1.0.XX-0.0.0

NCU: 1.0.XX-0.0.0

PCU: 1.0.XX-0.0.0

-Network Status: This feature is used to display other panel address

information in the network. (If there is a network)

+Event Logs: All events are saved to the memory of panel. It is possible to

display and print-out all events from due to the installation time of panel.

+View by Category: The event logs are displayed as being categorized

depending on the event types.

Fires: x

Evacuates: x

Faults: x

Pre-Alarms: x

-View by list: All events are sorted.

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 22

+Print by Category: The event logs are printed-out as being

categorized depending on the event types.

Fires: x

Evacuates: x

Faults: x

Pre-Alarms: x

+Print by List: All events are printed-out.

-Start to Print

-Clear Event Logs: All event logs are erased.

-Print Configuration: This feature is used to print-out panel settings.

+Edit Event: This feature allows determining for how the panel will give

warning in case of ‘New Device’ and ‘Disconnected Device’ states.

-Disconnected device: (Fault/Warning): The message is displayed in

case the panel cannot communicate with any device. In this case, the panel will give ‘Fault’ or

‘Warning’. It is possible to select the panel behavior upon disconnected device by this feature.

-New device: (Fault/Warning): The message displayed when detecting

a new device, which is not included in the configuration file. In this case, the panel will give

‘Fault’ or ‘Warning’. It is possible to select the panel behavior upon newly added device by this

feature.

+SLCU App. Software: Version update of panel loop cards can be done with

the aid of this feature. Version update can only be done by the manufacturer.

-LCU 1 – B.V. (1.0.0) /A.P.P.V. (1.0.12)

+Contamination Control: The system devices may be contaminated in time

because of the environmental reasons. These devices can cause “FALSE ALARMS”. In order

to prevent this issue, a regular maintenance must be made periodically. Panel is able to

display contamination level of connected devices. Devices contamination levels can be

checked for one loop or for all loops.

+General:

+Automatic Control: In case this option is selected, devices

connected to the system are continuously checked for any contamination. Interrogation count

can be selected as (8, 16, 64, 255). The contamination control is done depending on the

selected value. An analogue value greater than 75 is considered as the contamination

threshold by the panel. Upon detecting any contaminated device, a message appears on the

screen. This message disappears after cleaning or replacing the device with the new one and

resetting the panel.

+Interrogation Count: x

-Measuring contamination status

C o n t a m i n a t i o n C o n t r o

l

M e a s u r i n g c o n t a m i n a t i o n s t a t u s

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

[ E x i t / L e f t ] : B a c k

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 23

+Manual Control: When this option is selected, all system

devices are checked instantaneously for contamination. Interrogation count for measuring

contamination status is selected between 8-255. The interrogation count represents the

amount of measurements. An analogue value greater than 75 is considered as the

contamination threshold by the panel. Upon detecting any contaminated device, device(s)

listed. After cleaning devices the contamination control should be repeated.

Loop: n

+Measure

-Interrogation Count: x

-List Results

-Print Results

+Automatic Control

+Interrogation Count: x

-Measuring Contamination Status

+Manual Control

-Measure

-Interrogation Count: x

+List Results

+Print Results

C o n t a m i n a t i o n C o n t r o l

M G 9 1 0 0 O p t

.

S m o k

e D e

t . Z o n

e :

1

P :

1

L : 1 A

: 4 3

C o n t a m i n a t e d d e v i c e

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

[ U p / D o w n ] : S c r o l l [ E n t e r ] : U p d a t e

-Analog Update: Due to this feature, the analogue values of system devices

can periodically be followed.

Note: See, Annex-E Menu Functions Scheme for switch between menu functions.

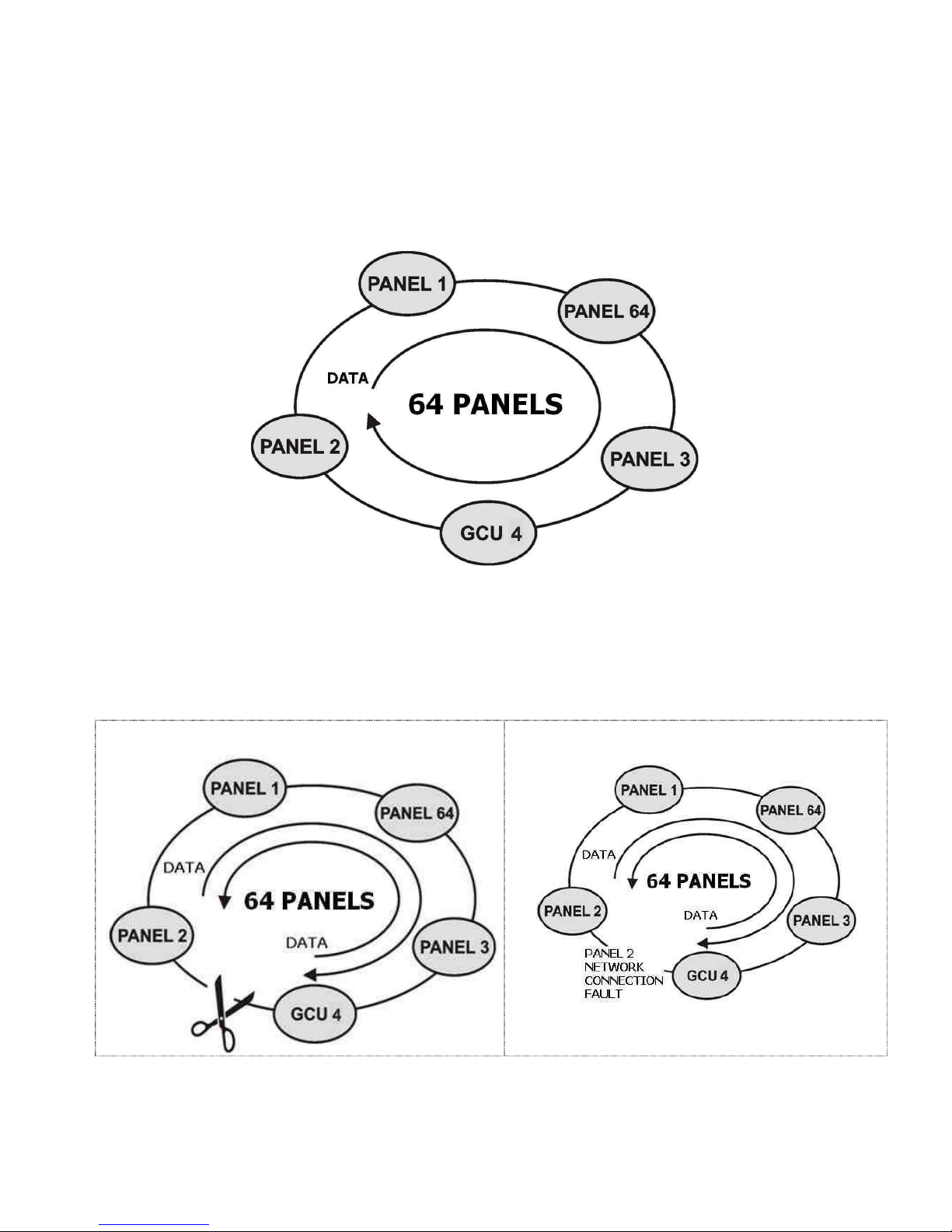

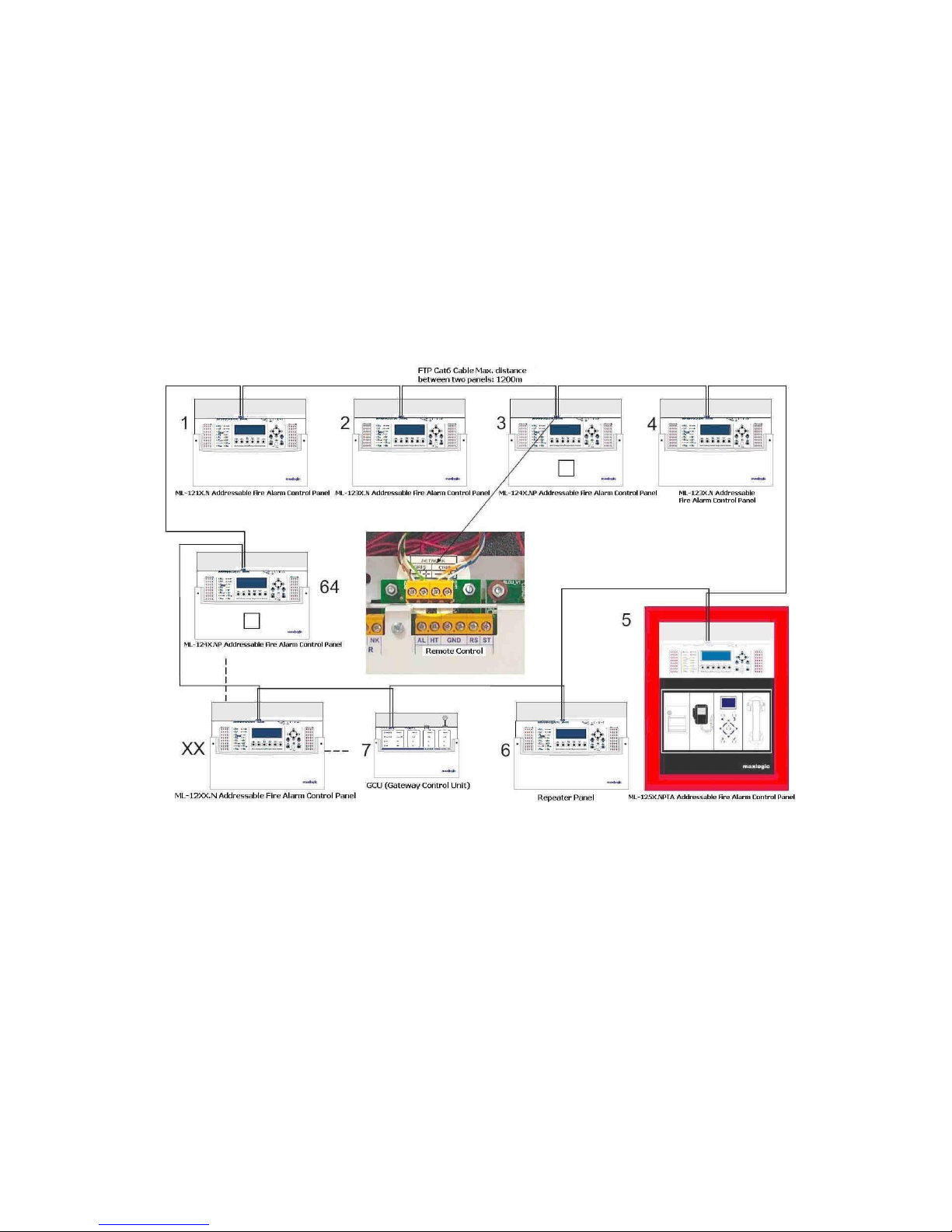

12- NETWORKING PRINCIPLES

So that Maxlogic series fire alarm control panels can operate in network, each panel must contain 1 unit

of ML-1201 Network Module.

Please, see Section “15- Panel Models” which includes ML-121X.N models having network module by

default. ML-1201 Network Module should NOT be added for those panels which have a network

module by default.

ML-1201 Network Module is compatible with all Maxlogic Series Intelligent Analogue Addressable Fire

Alarm Control Panels.

Up to 64 Maxlogic Series Intelligent Analogue Addressable Fire Alarm Control Panels can operate in a

network structure. “16 loops x 127 devices x 64 panels = 130.048 devices” can operate in a network.

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 24

All panels in the same network can communicate with each others. An event, which occurs in a panel,

can be seen from every panel in the network. Furthermore, one panel can control other panels (Reset,

Silence Sounder etc.)

All models of Maxlogic Series Fire Alarm Control Panels can operate in the same network.

(ML-121X.N, ML-123X.N, ML-124X.N, ML-125X.N)

** GCU (Gateway Controller) allows the network to be monitored graphically and controlled remotely

from a distant place. GCU connect to the network line as a control panel. The panels must be

connected to each other with FTP Cat6 Network Cable.

(See, Annex-F Network Connection Scheme.)

In case of open circuit (broken line), network continues

operating.

In case of open circuit fault of the network line, the

system can detect the exact point of problem.

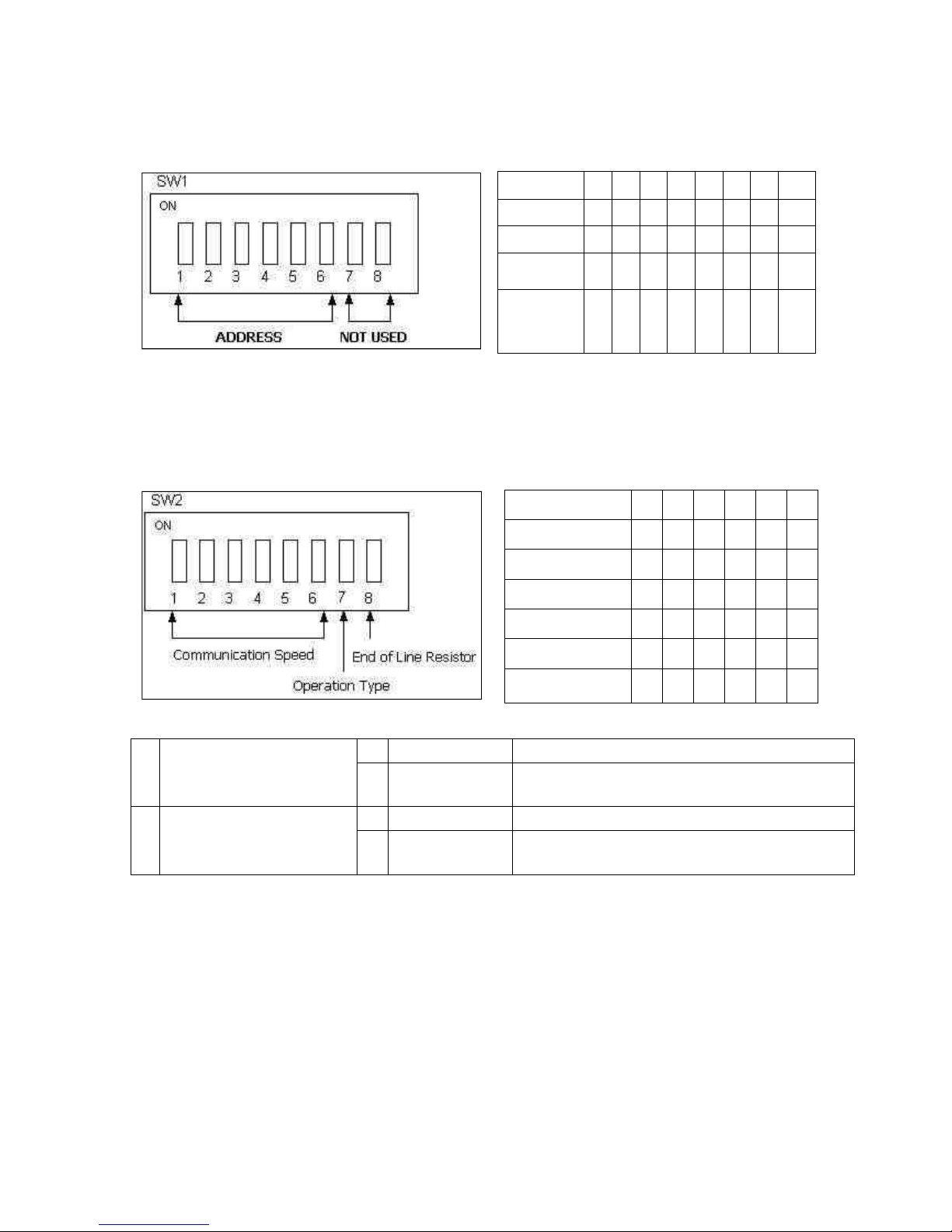

Switch Settings on Network Card:

ML-1201 Network Module has 2 switches related to the networking.

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 25

SWITCH 1- Used to set the address of panel in network.

1

0 0 0 0 0 0 0 0

11

0 1 0 1 0 0 0 0 23

0 1 1 0 1 0 0 0

54

1

0

1

0

1

1

0

0

Panel

Address

1

2

3

4

5

6

7

8

SWITCH 2- Used to set the communication speed, operation type and end of line

resistor of Panel which will operate in the network.

250 Kbps

1 0 0 0 0 0

100 Kbps

0 1 0 0 0 0

50 Kbps

0 0 1 0 0 0

20 Kbps

0 0 0 1 0 0 10 Kbps

0 0 0 0 1 0

5 Kbps

0 0 0 0 0 1

Communication

Speed

1

2

3

4

5

6

7

Operation Type

0 Normal Mode

Used for panels and repeater panels

1

Transparent

Mode

Used for signal amplifying distance extender

modules

8

End-of-Line

Resistor

Setting

0 120R disabled

-

1

120R enabled

Used to activate 120R which is the end-of-line

resistor. Always, it must be at this position

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 26

13- TECHNICAL SPECIFICATIONS

Loop capacity

:

Sounder outputs

:

Fire alarm relay

:

Alarm relay

:

Fault relay :

Remote controls

:

Operating ambient humidity

:

Auxilary supply output

:

Operating ambient temperature

:

Main power supply :

Operating voltage

:

System fuse

:

Batteries

:

Construction

:

Finish

:

Mounting

:

Standard color

:

Dimensions

:

Weight :

1 to 2 loops

4 x (24 V DC 500 mA), programmable,

Supervised, self –resetting fuse protected,

10 kOhm end-of-line resistor

30 V DC 1 A volt-free contact, programmable

30 V DC 1 A volt-free contact, programmable

30 V DC 1 A volt-free contact, programmable

4 units of programmable inputs

%0-95 (non-condensing)

24 V DC 500 mA self-resetting fuse protected

(-5ºC) - (+50ºC)

230 V AC 50 Hz (5 A glass type fuse) 83 Watt

24 V DC

5 A, glass type fuse

2 x (12 V 7 Ah)

1mm DKP

Epoxy paint

Surface or flush mount

Grey (RAL 7015), white panel front cover

500 x 370 x 110 mm

max. 7.650 kg

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 27

14- PANEL MODELS

ML-1210.N

Maxlogic intelligent analogue addressable fire alarm panel, 0 Loop, Network, 230V AC, 50 Hz, 83 Watt, IP30

ML-1211

Maxlogic intelligent analogue addressable fire alarm panel, 1 Loop, 127 Address, 230V AC, 50 Hz, 83 Watt, IP30

ML-1211.N

Maxlogic intelligent analogue addressable fire alarm panel, 1 Loop, 127 Address, Network, 230V AC, 50 Hz,

83 Watt, IP30

ML-1212

Maxlogic intelligent analogue addressable fire alarm panel, 2 Loop, 254 Address, 230V AC, 50 Hz, 83 Watt, IP30

ML-1212.N

Maxlogic intelligent analogue addressable fire alarm panel, 2 Loop, 254 Address, Network, 230V AC, 50 Hz,

83 Watt, IP30

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 28

ANNEX-A PANEL DIMENSIONS AND MOUNTING HOLES

Figure 1- Panel Dimensions

Figure 2- Mounting Holes

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 29

ANNEX-B CONNECTION SCHEME

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 30

ANNEX-C PANEL SPARE PARTS

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 31

ANNEX-D SERIAL COMMUNICATION CABLE

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 32

ANNEX-E SCHEME OF MENU FUNCTIONS

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 33

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 34

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 35

ANNEX-F NETWORK CONNECTION SCHEME

KK-641.002 Rev.No:1 01.08.12 ML-121X User Manual Page | 36

Loading...

Loading...