Page 1

www.max.us.com

CONFORMS TO UL STD 325

UL CLASS - I, II, III, IV

CERTIFIED TO CAN/CSA STD

C22.2 NO. 247

High Traffic Commercial

Brushless DC Low Profile

Swing Gate Operator

4009963

Made in USA

MAX Phantom 2000

Installation and Owners Manual

Page 2

Page 3

Table of contents

Phantom 2000 Specifications

Important Safety Information

UL 325 Model Classifications

UL 325 Required Entrapment Protection

UL 325 Compliant Installation Requirements

Intended Use of Swing Gate Operator

Installation

Gate Operator Position

Recommended Gate Operator Layout

Single Gate Operator

Dual Gate Operators

Arm Position Options

Arm Connection to Gate

Optional Remote Power Supply Kit - MAX Magic Box

Solar Optional

Install Warning Signs

Entrapment Protection

In-Ground Loops

Wiring operator

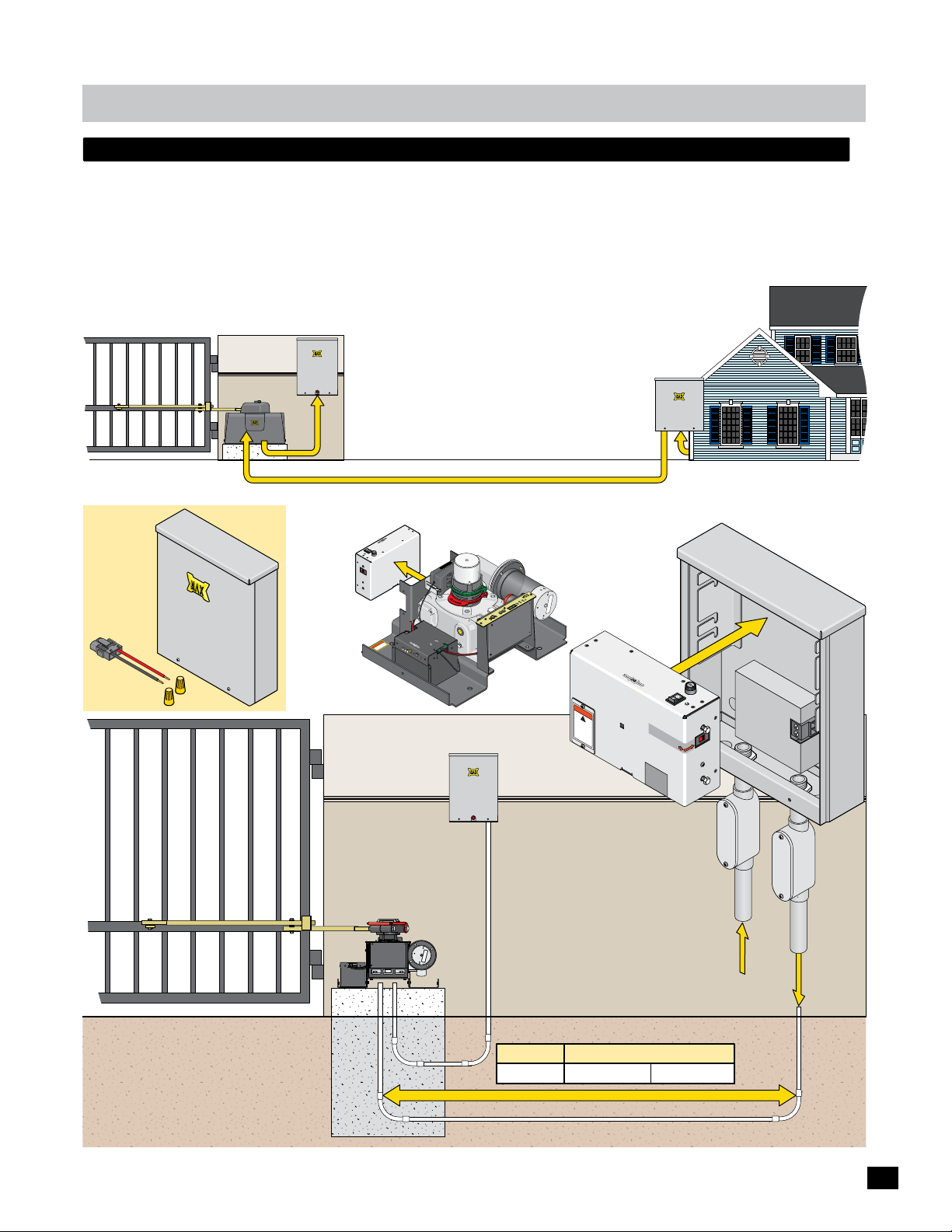

Gate Operator System Overview

Input AC Power

Optional Remote Power Supply Kit - MAX Magic Box

Solar Power Connection - Optional

Operators to Matrix 1

Optional Key Switch to Operator(s)

Turn ON / OFF Operator Power

matrix 1

Matrix 1 Overview

Wiring Overview

Primary Gate - Open Left / Open Right

Close Timer

Selectable Gate Speed Control

Battery Back-Up Mode

Anti-Tailgate

Single Pass Anti-Tailgate

Radio Receiver

Radio Safety Pause

Gate in Motion Alarms

OBD Port Black Box

Maglock

Loop Detectors

In-Ground Loop Connection

ID Plug

Gate Tamper

UL Entrapment LEDs

Emergency Vehicle / Max Open Inputs

Gate Disable

Partial Open

UL Alarm / Alarm Reset Button

Gate Status Monitoring

OPEN / STOP / CLOSE Connection

CLOSING Photocell Connection

Gate Operators Communication LEDs

24V Power for Matrix 1

Battery in Use LED

Motor Motion LEDs

10

10

11

12

13

14

15

16-17

18

19

20

21

22

23

24

25

26

26

26

26

27

27

28

28

28

28

29

29

29

30

30

30

30

31

31

32

32

32

32

33

33

33

33

2

2

3

3

4

5

6

7

8

9

Adjustments

Open and Close Limits

Release Handle Clamp

Reverse Sensor (ERD)

Maintenance

Qualified gate operator technician

End user/Home owner

Phantom 2000 Wiring Schematics

Manual Release

Electronic Gate Open / Close

Audible Alarm

Replacement Parts List

Warranty

Phantom options / unique features

Gate Tamper Feature

36 Amp/Hr Phantom Battery Module - Optional

Gate Disable Feature

Event History Download

© 2014 Maximum Controls LLC.

All rights reserved. No part of this manual may be reproduced in any

means: graphics, electronics or mechanical, including photocopying

without the expressed written permission of the publisher. Materials

components and specifications are subject to change without notice.

34

35

36

37

37

38

39

40

40

41

42

43

43

44

44

1

Page 4

phantom 2000 specifications

UL 325 Class of Operation - Class I, II, III, IV

Gate Type - Vehicular Swing Gate

Max Gate Weight / Length - 2000lbs @ 15 ft or 1500 lbs @ 20 ft

90° Opening Time - 16 selectable speeds from approximately 11.5 sec to 20 sec depending on the weight and length of gate.

Cycles per Hour AC Input Power - Continuous

Battery Back-Up Cycles (Batteries fully charged):

- BC-7 Battery Module-7 Amp/Hr Batteries, approximately 450 cycles

- BC-36 Phantom Battery Module-36 Amp/Hr Batteries, approximately 2000 cycles

NOTE: The number of gate cycles using ONLY battery back-up power will vary

depending on the weight of the gate, the gate length, the operating condition of the gate

hardware, temperature and the amount of charge the batteries have at the beginning of

the battery power only operation.

Input AC Power - Switchable: 115VAC or 230VAC single phase

Motor - 24VDC Brushless (equivalent to 1 HP AC motor)

Operating Temperature - -4°F to 158°F (-20°C to 70°C)

Entrapment Protection:

- UL 325 Type A Inherent (ERD sensor)

- Input for UL 325 Type B1 (photocell) and B2 (sensing edge)

12 5/8”

22”

important safety information

WARNING – To reduce the risk of injury or death:

1. READ AND FOLLOW ALL INSTRUCTIONS.

18 3/4”

14 5/8”

2. Never let children operate or play with gate controls. Keep the remote control away from children.

3. Always keep people and objects away from the gate. NO ONE SHOULD CROSS THE PATH OF THE MOVING GATE.

4. Test the gate operator monthly. The gate MUST reverse on contact with a rigid object or stop when an object activates the

non-contact sensors. After adjusting the force or the limit of travel, retest the gate operator. Failure to adjust and retest the

gate operator properly can increase the risk of injury or death.

5. Use the emergency release only when the gate is not moving.

6. KEEP GATES PROPERLY MAINTAINED. Read the owner’s manual. Have a qualified service person make repairs to gate

hardware.

7. The entrance is for vehicles only. Pedestrians must use separate entrance.

8. SAVE THESE INSTRUCTIONS

2

Page 5

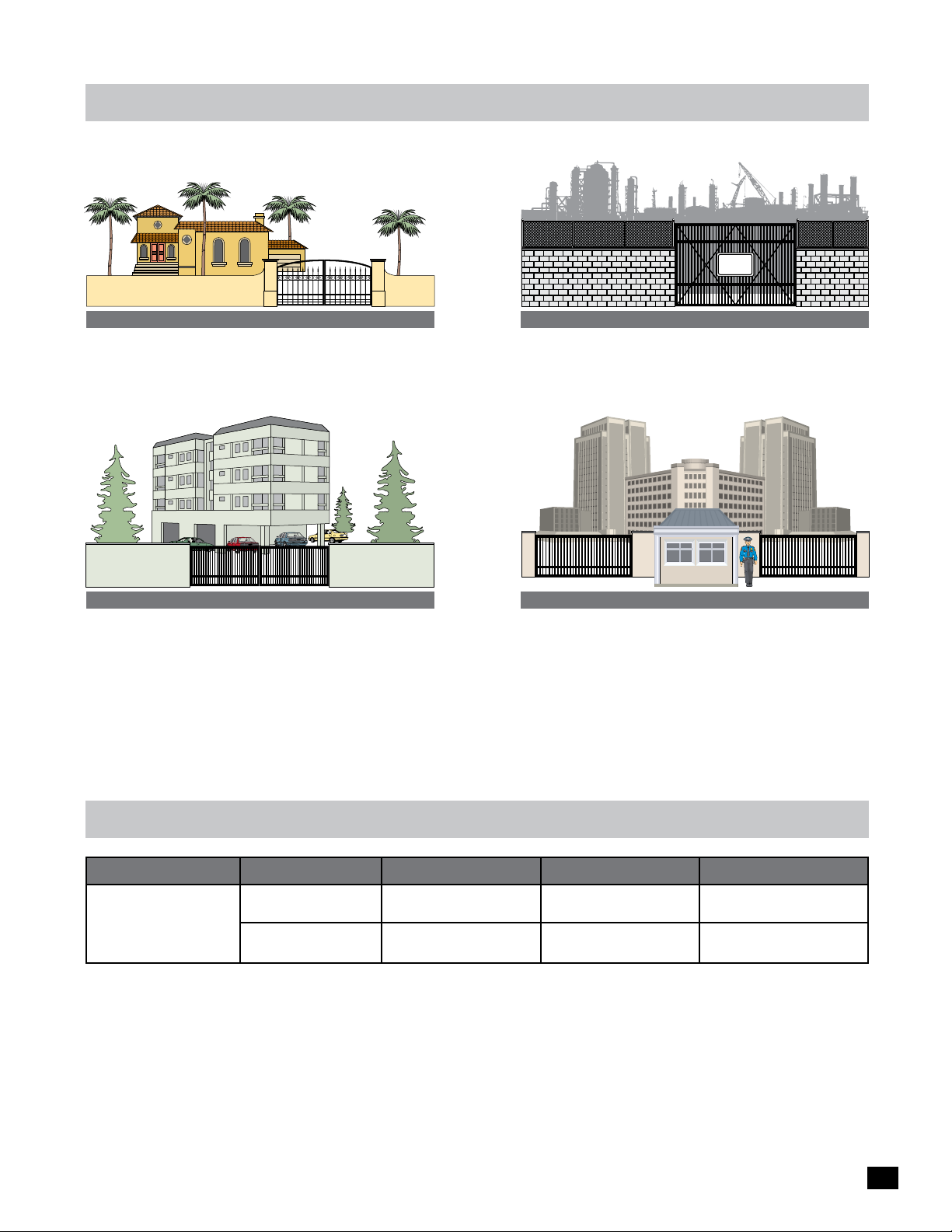

ul 325 model classifications

AUTHORIZED

PERSONNEL

ONLY

CLASS I

Residential Vehicular Gate Operator - A vehicular gate operator

(opener or system) intended for use in a home of one to four

single family dwellings, or a garage or parking area associated

therewith.

CLASS II

Commercial/General Access Vehicular Gate Operator - A

vehicular gate operator (opener or system) intended for use in

a commercial location or building such as a multi-family

housing unit (five or more single family units) hotel, garages,

retail store or other building servicing the general public.

CLASS III

Industrial/Limited Access Vehicular Gate Operator - A

vehicular gate operator (opener or system) intended for uses

in an industrial location, loading dock area or other location

not intended to service the general public.

SECURITY

CLASS IV

Restricted Access Vehicular Gate Operator - A vehicular gate

operator (opener or system) intended for use in a guarded

industrial location or buildings such as airport security area or

other restricted access locations not servicing the general

public, in which unauthorized access is prevented via

supervision by security personnel.

ul 325 required entrapment protection

Gate Type Protection Type Class I & II Class III Class IV

Primary

A, C A, B1, B2, C

Swing Gate

Secondary

The same type of device shall not be utilized for both the primary and the secondary entrapment protection means. Use of a single device to

cover both the opening and closing directions is in accordance with the requirement; however, a single device is not required to cover both

directions. A combination of one Type B1 for one direction and one Type B2 for the other direction is the equivalent of one device for the

purpose of complying with the requirements of either the primary or secondary entrapment protection areas.

A - Inherent entrapment protection system.

B1 - Provision for connection of a non-contact sensor

(photoelectric sensor or the equivalent).

B2 - Provision for connection of a contact sensor

(edge device or the equivalent).

A, B1, B2, C, D

C - Inherent adjustable clutch or pressure relief device.

D - Provision for connection of an actuating device

requiring continuous pressure to maintain opening

or closing motion of the gate.

E - An audio alarm.

A, B1, B2, C, D, E A, B1, B2, C, D, E

A, B1, B2, C, D

3

Page 6

ul 325 compliant

installation requirements

A Install the gate operator only when:

1 The operator is appropriate for the construction of the gate and the usage Class of the gate,

2 All exposed pinch points are eliminated or guarded.

B The operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied with a separate access

opening. The pedestrian access opening shall be designed to promote pedestrian usage. Locate the gate such that persons

will not come in contact with the vehicular gate during the entire path of travel of the vehicular gate.

C The gate must be installed in a location so that enough clearance is supplied between the gate and adjacent structures when

opening and closing to reduce the risk of entrapment. Swinging gates shall not open into public access areas.

D The gate must be properly installed and work freely in both directions prior to the installation of the gate operator.

Do not over-tighten the operator clutch or pressure relief valve to compensate for a damaged gate.

E For gate operators utilizing Type D protection:

1 The gate operator controls must be placed so that the user has full view of the gate area when the gate is moving,

2 A gate operator shall additionally be provided with a placard that is marked in letters at least 1/4-in (6.4-mm) high with

the word “WARNING” and the following statement or the equivalent: “Moving Gate Has Potential of Inflicting Injury or

Death - Do Not Start Gate Unless Path is Clear”.

3 An automatic closing device (such as a timer, loop sensor, or similar device) shall not be employed, and

4 No other activation device shall be connected.

F Controls intended for user activation must be located at least ten feet (10’) away from any moving part of the gate and where

the user is prevented from reaching over, under, around or through the gate to operate the controls. Outdoor or easily

accessible controls shall have a security feature to prevent unauthorized use.

G The Stop and/or Reset button must be located in the line-of-sight of the gate. Activation of the reset control shall not cause

the operator to start.

H A minimum of two (2) WARNING SIGNS shall be installed, one on each side of the gate where easily visible.

I For gate operators utilizing a non-contact sensor:

1 See instructions on the placement of non-contact sensors for each Type of application,

2 Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle, trips the sensor while the gate is

still moving, and

3 One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the

perimeter reachable by a moving gate or barrier.

J For a gate operator utilizing a contact sensor:

1 One or more contact sensors shall be located where the risk of entrapment or obstruction exists, such as at the leading

edge, trailing edge, and post mounted both inside and outside of a vehicular horizontal slide gate.

2 One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

3 One or more contact sensors shall be located at the pinch point of a vehicular vertical pivot gate.

4 A hardwired contact sensor shall be located and its wiring arranged so that the communication between the sensor and

the gate operator is not subjected to mechanical damage.

5 A wireless device such as one that transmits radio frequency (RF) signals to the gate operator for entrapment protection

functions shall be located where the transmission of the signals are not obstructed or impeded by building structures

natural landscaping or similar obstruction. A wireless device shall function under the intended end-use conditions.

6 One or more contact sensors shall be located on the inside and outside leading edge of a swing gate. Additionally, if the

bottom edge of a swing gate is greater than 6 inches (152 mm) above the ground at any point in its arc of travel, one or

more contact sensors shall be located on the bottom edge.

7 One or more contact sensors shall be located at the bottom edge of a vertical barrier (arm).

4

Page 7

intended use of

swing gate operator

The operator is intended for use on a VEHICULAR swing gate ONLY. It is intended to be used WITH appropriate entrapment

protection safety devices and in-ground vehicle loop detection system.

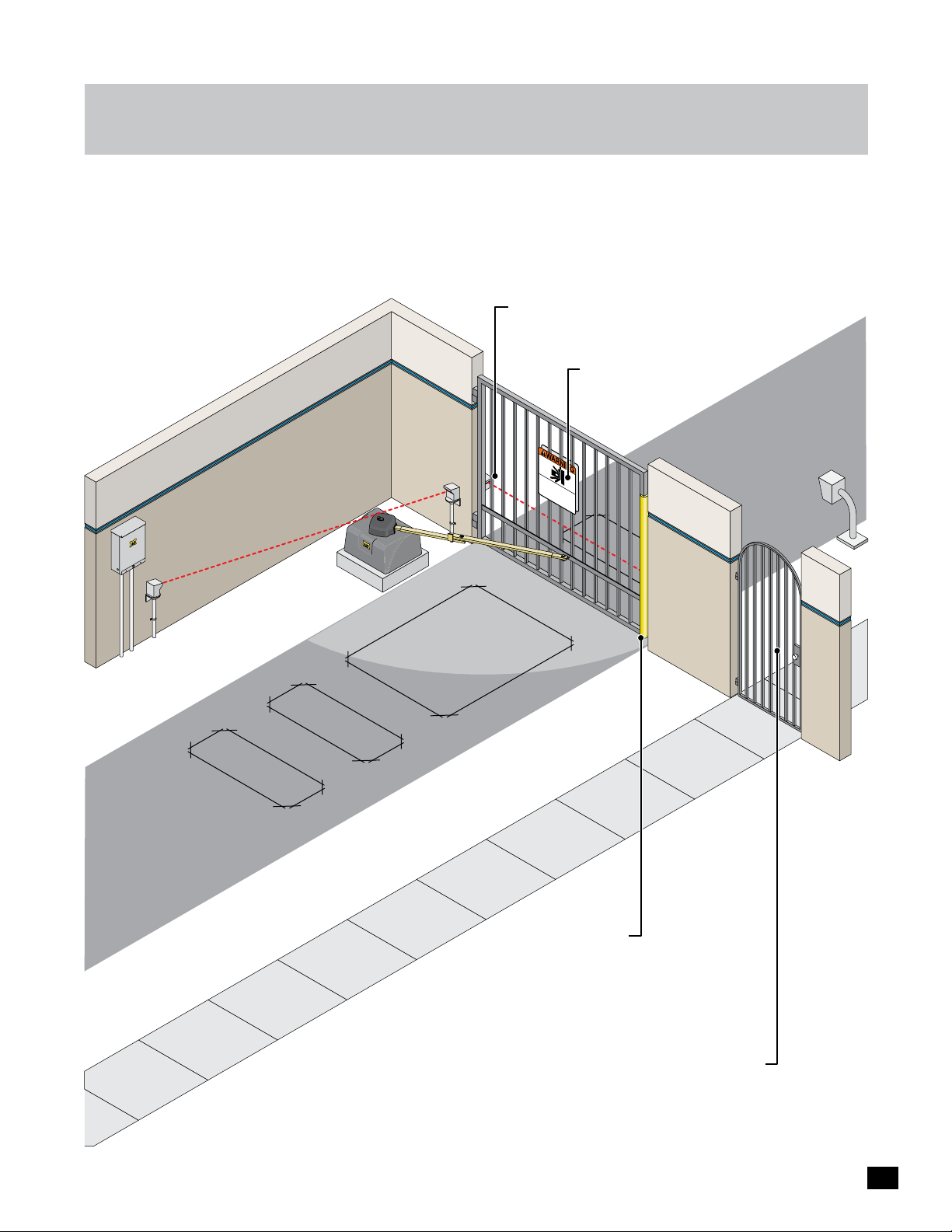

Closing Gate Protection Photocell: Helps protect the gate operator

from accidentally closing on vehicles in the gate’s closing path.

Warning Signs: Should be installed

on both sides of gate area and

easily visible.

Moving Gate Can

Seriou

KEEP

without

C

s Injury o

LE

D

AR!

prior warning.

o not

in

Ga

the gat

let

t

Cause

e ma

children operat

T

hi

r Death

e area.

s

y

Pedes

entranc

m

ov

e at any

trians

e is

e

the gat

f

must

or

t

ime

ve

hic

us

e or play

e

le

separat

s

Entrapment Protection Photocell:

Helps guard against the opening

gate from entrapment.

onl

y

.

e

entrance.

In-Ground Loops:

Help protect the gate

operator from accidentally

opening and/or closing on

vehicles in the gate’s path.

Entrapment Area

Sensing Edge: Helps

protect the gate operator

from accidentally opening

and/or closing on vehicles

in the gate’s path.

Pedestrians MUST use a separate entrance.

The gate operator IS NOT intended to be

used on a PEDESTRIAN gate.

5

Page 8

installation

Read and understand this entire manual before installation. Check with the local building department prior to installing this gate

operator to comply with local building code requirements. The gate must be installed in a location so that enough clearance is

supplied between the gate and adjacent structures when opening and closing to reduce the risk of entrapment. Swinging gates

should not open into public access areas.

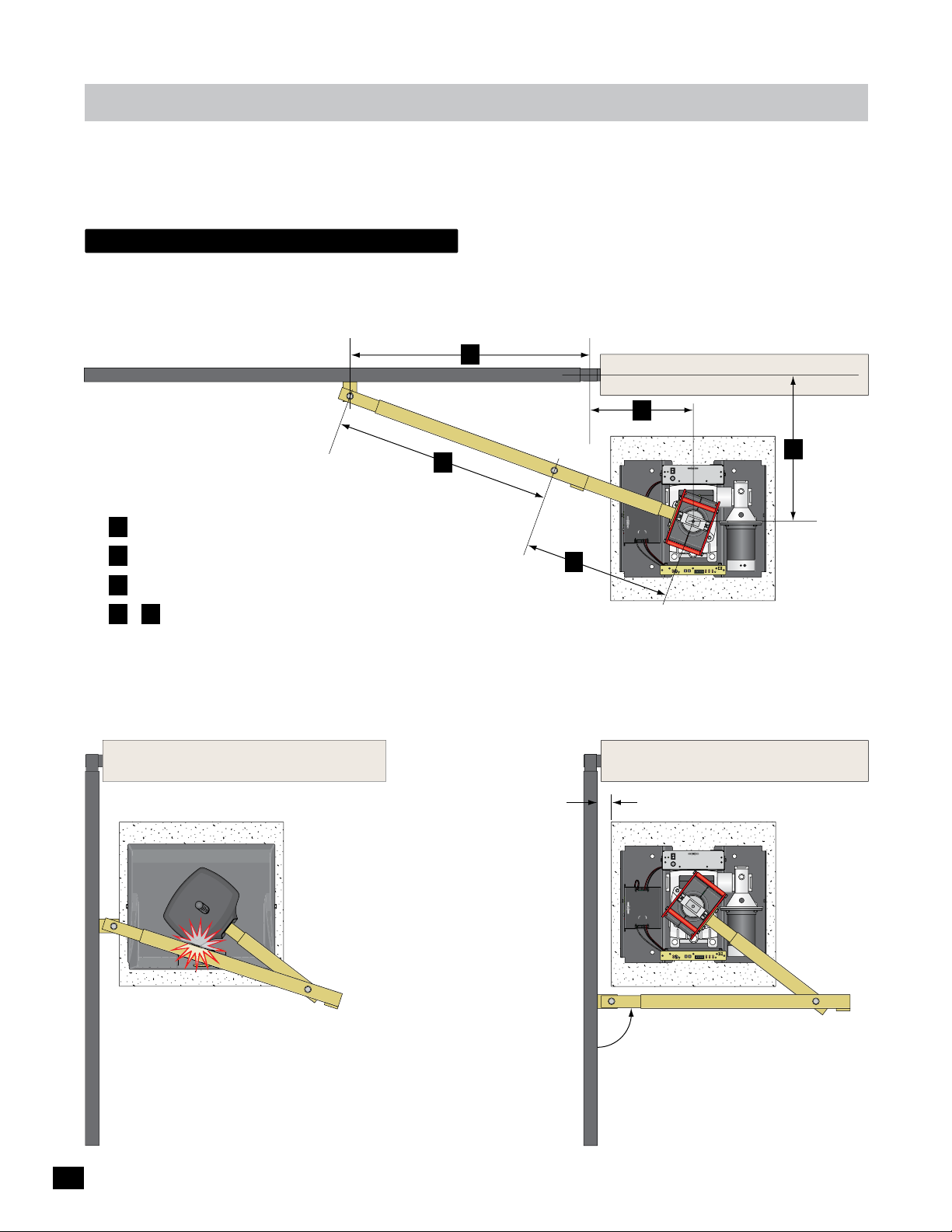

Gate Operator position

The gate must be properly installed and work freely in both directions prior to installation of the gate operator.

Closed Position

Gate Bracket Pivot Point

A

Hinge Pivot Point

Illustrations not to scale

Measurement Guidelines

than “E”

A Should be at least 1/4 the gate length.

B 15” minimum for open gate clearance (2” thick gate).

C Distance “A” minus 17 inches (A - 17 = C).

D & E Arm should be 90° from gate when OPEN

and in the straight “locked” position when CLOSED.

Open Position

Hood

Locked Position

Long Arm

D

Longer

Arm

Pivot

Point

E

Shorter

than “D”

15” Min

Short Arm

www.max.us.com

Made in USA

www.max.us.com

Made in USA

B

AC

IN

POWER/SOLAR

BATTERY

IN

IN

CONTROLLER

TO MOTOR

BATTERY

POWER

PACK

IN

MC-100

Motor Controller

Sensitivity

MOTOR OVERLOAD

ERD

Min

2” Min

AC

IN

POWER/SOLAR

BATTERY

IN

IN

CONTROLLER

TO MOTOR

BATTERY

POWER

PACK

IN

ON

Made in USA

POWER

OFF

FUSE

7 AMP

GND

JOG

JOG

ERD

Photo

Cell

Matrix

Jog LT

Edge 1

Edge 2

Jog RT

RIGHT

LEFT

Edge 1

On Line

Limit SW

Edge 2

Max

INPUTS

On Line

Concrete Pad

ON

Made in USA

POWER

OFF

FUSE

7 AMP

MAX PS-24

POWER SUPPLY

UL

Entrap

Power

Photo

Cell

24” x 24”

MAX PS-24

POWER SUPPLY

C

Operator

Pivot

Point

Outside Property

Inside Property

MC-100

JOG

JOG

GND

ERD

Photo

Cell

DO NOT allow arm to touch

hood in gate’s OPEN position.

TOO MUCH STRESS is put on

the arm in this position during

gate operation.

Motor Controller

MOTOR OVERLOAD

2” Gate Frame

Preferred arm position is 90°

from open gate. See page 10

for arm position options and

connection to gate.

UL

Matrix

Jog LT

Edge 1

Edge 2

Jog RT

RIGHT

LEFT

Sensitivity

Edge 1

Entrap

On Line

Power

ERD

Photo

Limit SW

Edge 2

Max

Min

INPUTS

Cell

On Line

6

Page 9

W

A

R

N

I

N

G

installation

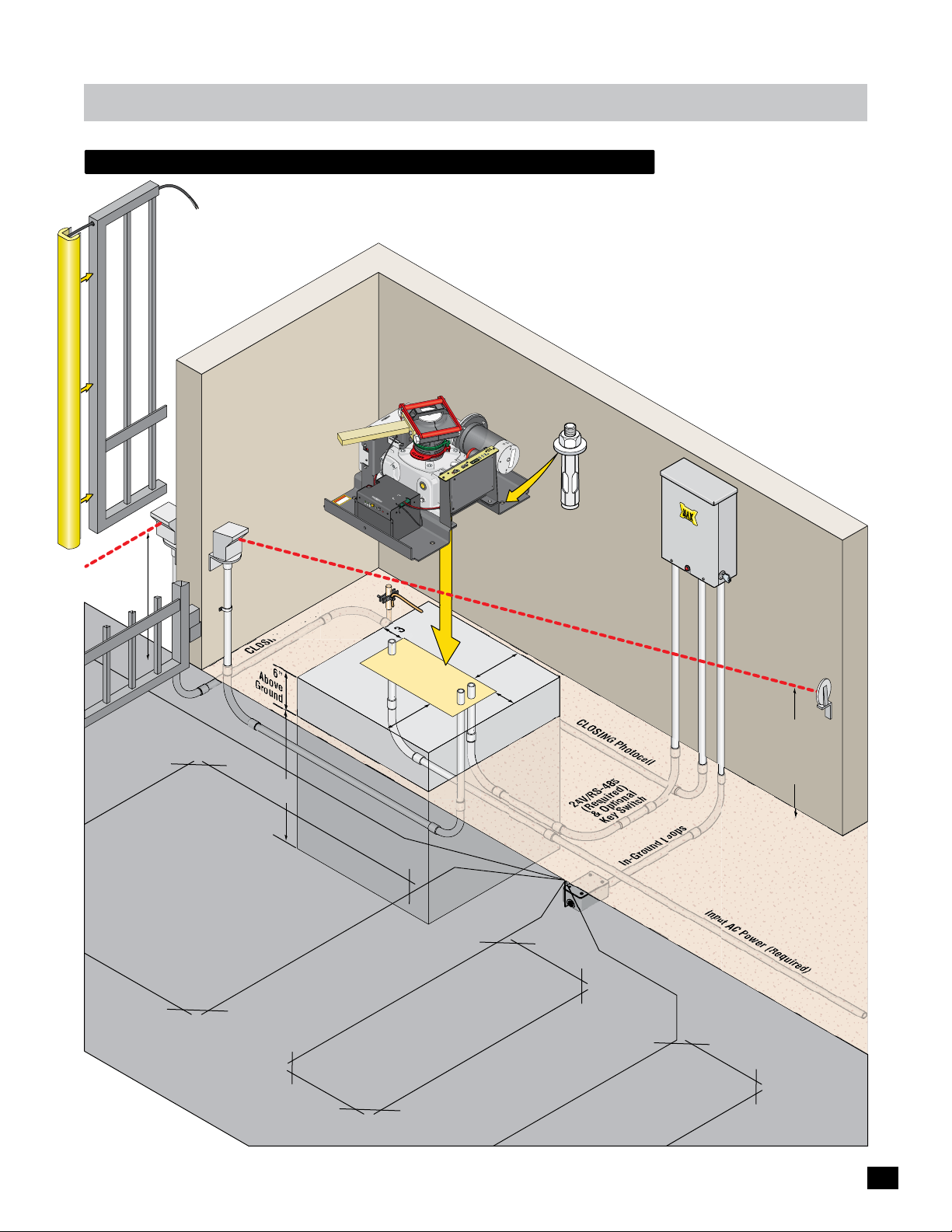

recommended Gate Operator layout

Use for VEHICULAR traffic ONLY. Pedestrians MUST use a separate entrance.

Install appropriate entrapment protection safety devices for the OPENING

direction and CLOSING direction of gate cycling. Install in-ground SAFETY

and CENTER loops. Install a GROUNDING ROD within 10 ft of

operator. An “Optional” EXIT loop can be installed if desired.

4

Y

L

P

P

U

S

X PS-2

A

R

E

M

W

PO

T

I

PEN

A

O

M

US

LI

in

e

d

a

D

M

T

I

M

CLOSE

LI

N

R

O

E

F

OW

OF

P

SE

P

U

F

M

A

7

C

A

N

I

V

5

1

1

o

r

t

n

o

100

C

C-

r

o

M

t

o

P

O

W

E

R

/

S

I

O

N

LA

R

B

A

TTE

RY

I

N

w

w

w

.

m

a

x

.

us

.

c

om

C

O

N

NG

r

o

ssis

f

NI

a

ti

h

d

R

c

c

ro

e

A

t

t

c

d

e

ro

n

W

n

p

u

n

o

g

r

o

n

g

c

i

o

tn

t

h

g

i

l

TR

B

n

M

a

o

t

a

t

e

de

ry

i

V

n

E

o

U

l

t

S

a

A

g

1

e

/2

F

O

N

/

O

MA

F

B

F

a

B

t

X

te

R

a

e

t

r

te

B

p

y

l

r

C

ac

y

B

-

M

e

a

7

o

t

t

d

e

u

r

l

y

T

e

E

S

T

B

a

t

B

t

e

a

ry

t

te

r

y

I

E

N

r

r

o

r

M

TO

M

P

O

O

TO

W

O

R

E

LL

I

R

N

ER

B

A

T

TERY

P

A

CK

r

e

w

Po

L

p

U

a

r

t

n

E

1

e

g

d

to

E

o

l

h

l

x

i

e

P

e

tr

C

n

a

i

l

L

o

M

l

2

t

n

o

e

O

Ce

g

2

d

Ph

e

E

g

1

d

W

e

E

S

g

e

D

d

it

n

i

N

E

L

m

i

G

T

L

n

R

O

g

o

LT

J

g

o

J

S

UT

P

N

I

OG

J

RIGHT

OG

T

J

F

E

L

y

D

x

it

a

R

iv

M

t

E

i

s

y

n

it

e

v

i

t

S

i

s

n

e

S

n

i

D

M

A

O

r

L

D

e

R

l

R

l

E

E

V

O

R

O

T

O

M

1/2

Support

un

R

ATE OPERATOR.

G

Sensing Edge

ount

M

Bar

wiring to

on end of gate.

I

l

lustration no

t

to s

cale

CLOSING

21” High

Photocell Beam

Support Bar

From Safety Loop

Center Loop

CLOSING Ph

6”

Above

G

round

24”

Min

otocell

24”x 24” Pad

OPENING Photocell

Secure gate operator

to concrete pad with

four

leeve anchors

ound

r

G

Rod

s

OPENING Photocell Beam

.

(4) 1/2” x 3” (min)

3.5”

8”x 17”

Conduit

8”

Area

8”

3.5”

CLOSING Photocell

ired)

24V/RS-485

(Requ

& Optional

Key Switch

In-Ground Loop

s

I

nput AC Power (Required)

Beam

Height

Just

Above

Gate

Operato

r

Safety Loop

Exit Loop

(Optional)

7

Page 10

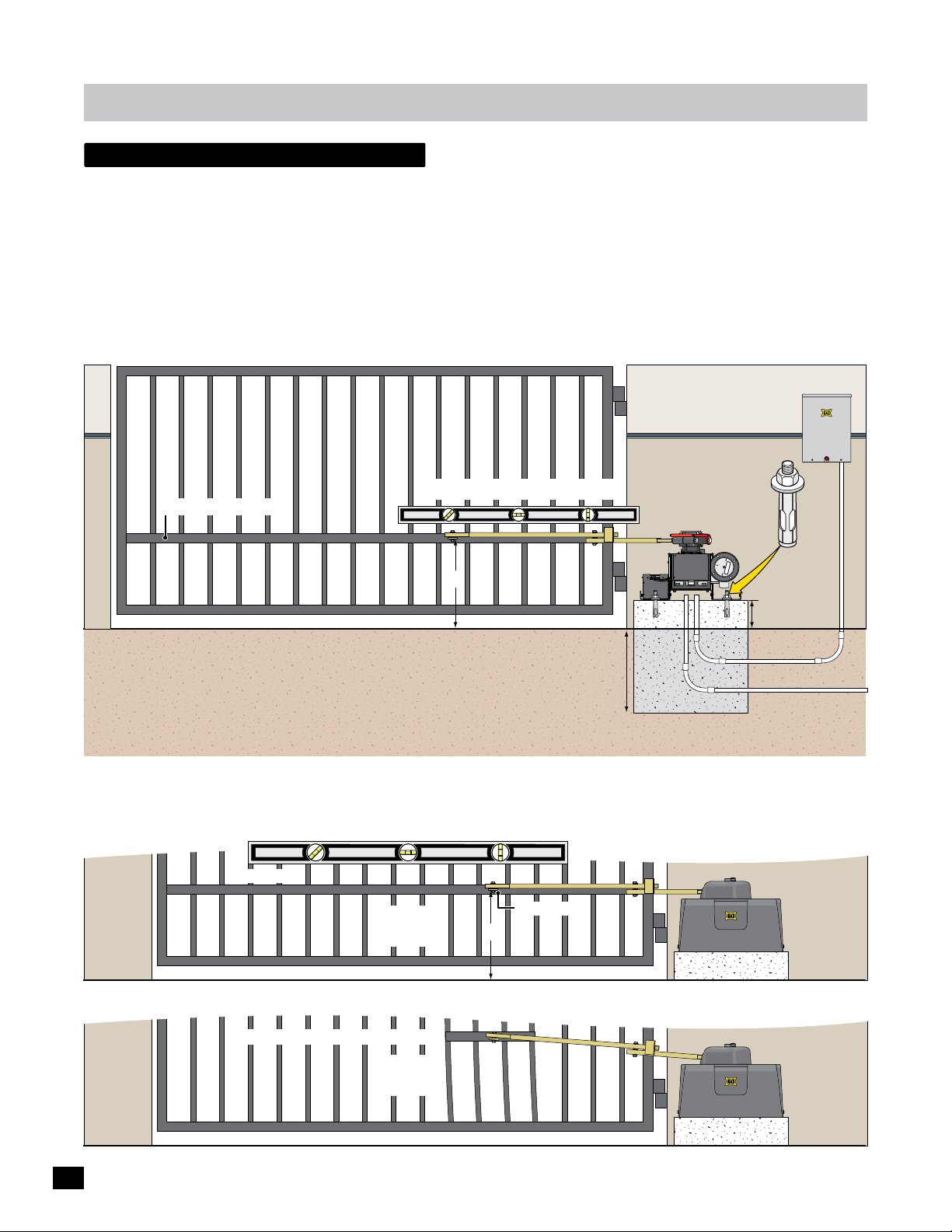

installation

YES

NO

single Gate Operator

The gate must be properly installed and work freely in both directions prior to the installation of the gate operator.

See “Gate Operator Position” on page 6 for operator position.

Conduit Guidelines and Suggestions (See page 7)

• REQUIRED - AC input power wire to the GATE OPERATOR.

• REQUIRED - 24VDC/RS-485/Optional Key Switch wires from CONTROL BOX to GATE OPERATOR.

• OPENING cycle protection device wires (photocells) to the GATE OPERATOR. See page 14.

• CLOSING cycle protection device wires (photocells) to the CONTROL BOX. See page 14.

• In-ground loop wires to the CONTROL BOX. See page 15.

Control Box

Secure gate operator

to concrete pad with

Arm MUST be installed level.

Support Bar: See below

four (4) 1/2” x 3”

(min) sleeve anchors.

Illustration not to scale

1/2

19”

6” Above Ground

Ground Level

“Optional” Input Power Note:

24VDC low voltage power wires can be run

from a remote power supply (MAX Magic

Box) to power the gate operator if desired.

See page 11 for more information.

Check local building

codes in your area for

depth of concrete

before installation.

Concrete Depth Note: The heavier the gate, the deeper the concrete

pad should be. At least two feet recommended for heavier gate.

Concrete Pad

24VDC/RS-485/

Key Switch

Conduit

Input Power

Support Bar

A support bar should be installed at the gate bracket height across the ENTIRE gate to keep the gate pickets from bending.

Support Bar

Gate Bracket

YES

Support Bar Too High & Not Long Enough

19”

NO

8

Page 11

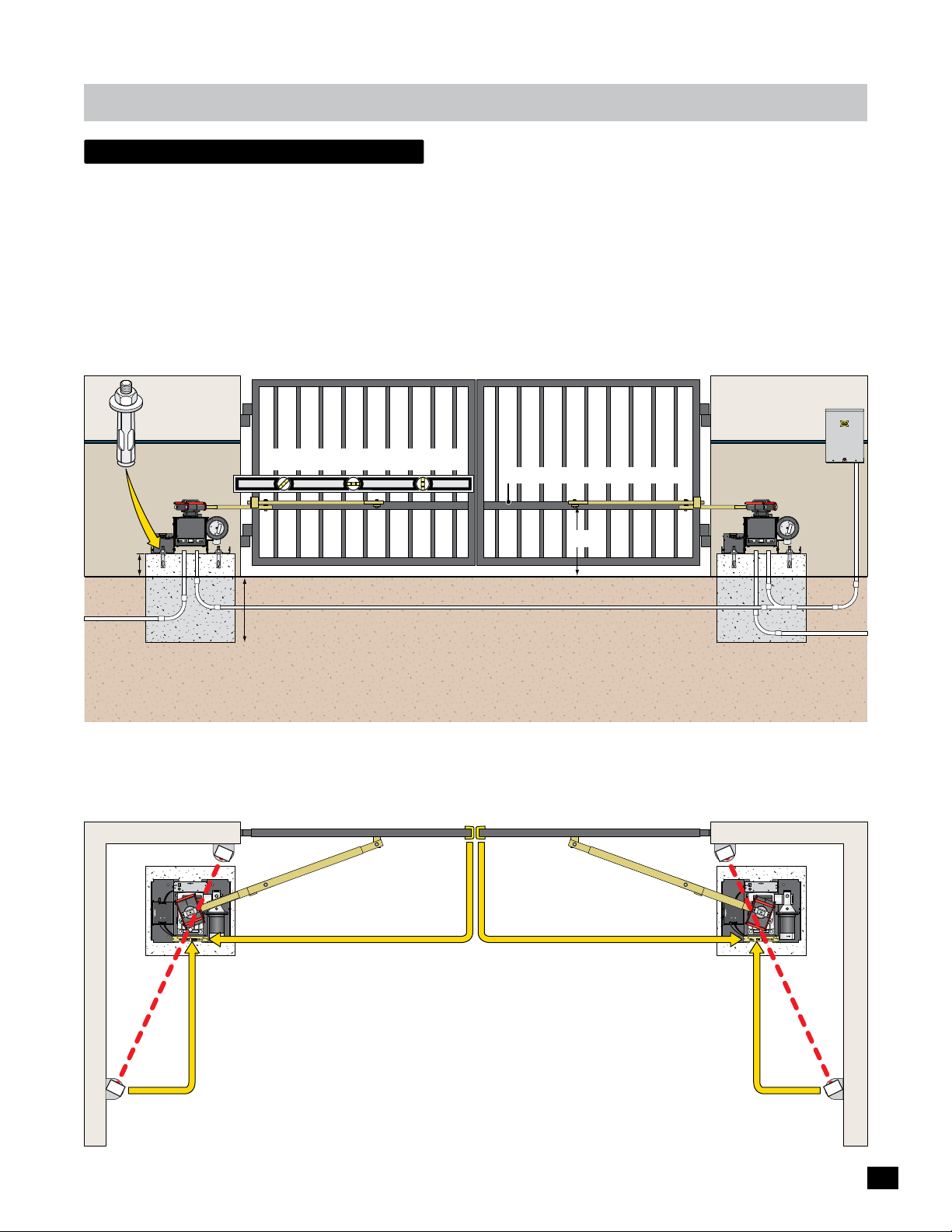

installation

dual Gate Operators

The gates must be properly installed and work freely in both directions prior to the installation of the dual gate operators.

See “Gate Operator Position” on page 6 for operator positions.

Conduit Guidelines and Suggestions

• REQUIRED - Run AC input power wire to EACH gate operator.

• REQUIRED - Run 24VDC/RS-485/Optional Key Switch wires from PRIMARY operator to the CONTROL BOX.

Secure EACH gate

operator to concrete

pad with four (4)

1/2” x 3” (min)

sleeve anchors.

• REQUIRED - Run RS-485/Optional Key Switch wires from SECONDARY operator to the CONTROL BOX.

• Run UL 325 entrapment protection device conduits to EACH Corresponding GATE OPERATOR. (see below & page 14)

• Run the CLOSING cycle protection device conduit (photocells) to the CONTROL BOX. (page 14)

• Run in-ground loop wires to the CONTROL BOX. (page 15)

Illustration not to scale

1/2

Control Box

Arms MUST be installed level.

6” Above

Ground

Input

Power

Secondary

Support Bars: See bottom of page 8.

RS-485/Optional Key Switch to Control Box

Check local building codes in your area for

depth of concrete before installation.

Concrete Depth Note: The heavier the gates, the deeper the concrete

pads should be. At least two feet recommended for heavier gates.

19”

“Optional” Input Power Note:

24VDC low voltage power wires can be run from a remote

power supply (MAX Magic Boxes) to power the gate

operators if desired. See page 11 for more information.

Primary

24VDC/RS-485/

Key Switch

Conduit

Input

Power

Each entrapment protection device MUST be connected to corresponding gate operator.

Outside Property

Sensing Edges

Illustrations not to scale

www.max.us.com

BATTERY

IN

Made in USA

CONTROLLER

BATTERY

PACK

Primary

ON

AC

POWER

OFF

IN

FUSE

7 AMP

POWER/SOLAR

IN

TO MOTOR

POWER

IN

MC-100

ERD

Motor Controller

Sensitivity

MOTOR OVERLOAD

ERD

Max

Min

MAX PS-24

POWER SUPPLY

Made in USA

JOG

JOG

GND

Photo

Cell

UL

Matrix

Jog LT

Edge 1

Edge 2

Jog RT

RIGHT

LEFT

Edge 1

Entrap

On Line

Power

Photo

Limit SW

Edge 2

INPUTS

Cell

On Line

Entrapment Area

Secondary

ON

AC

Made in USA

POWER

OFF

IN

FUSE

7 AMP

www.max.us.com

POWER/SOLAR

BATTERY

IN

IN

Made in USA

CONTROLLER

TO MOTOR

BATTERY

POWER

PACK

IN

MC-100

JOG

JOG

GND

ERD

Motor Controller

Jog LT

Jog RT

RIGHT

LEFT

Sensitivity

MOTOR OVERLOAD

ERD

Max

Min

INPUTS

MAX PS-24

POWER SUPPLY

Photo

Cell

UL

Matrix

Edge 1

Edge 2

Edge 1

Entrap

On Line

Power

Photo

Limit SW

Edge 2

Cell

On Line

to Secondary Operator

to Secondary Operator

to Primary Operator

Entrapment Area

Photocell

(OPENING Cycle

ONLY)

Inside Property

to Primary Operator

Photocell

(OPENING Cycle

ONLY)

9

Page 12

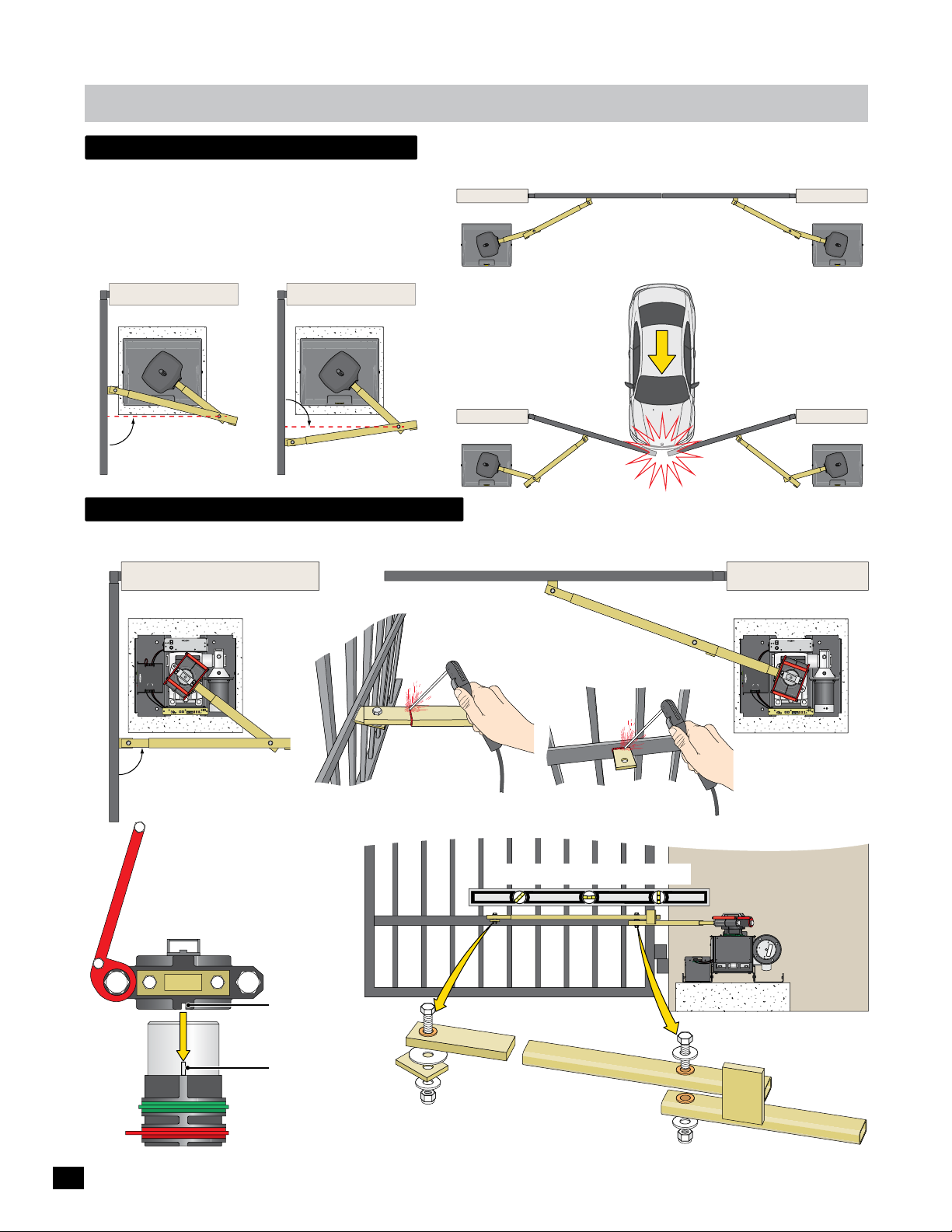

installation

arm position options

Retro-Fit Arm Option

When replacing an existing gate operator, the arm may not be able

to conform to the preferred arm position (90° from gate in open

position). The positions illustrated below can be acceptable as long

as the gate operator cycles smoothly and there is NO gate hesitation

when gate starts cycling in either direction.

90°

Gate in Opened Position

arm connection to gate

After you’re satisfied testing the arm in the FULL OPEN and FULL CLOSED positions, weld gate bracket and arm.

90°

Gate in Opened Position

High Traffic Arm Option

Gates in Closed Position

Arms are NOT installed in LOCKED position.

If a vehicle tries to push gates

open, arms will give when NOT

in the locked position and allow

gates to move without damaging

the gate operators.

The tamper relay will be

activated for a few seconds

which will trigger a camera or

alarm system if desired.

Illustrations not to scale

MAX PS-24

ON

POWER SUPPLY

AC

Made in USA

POWER

OFF

IN

FUSE

7 AMP

www.max.us.com

POWER/SOLAR

BATTERY

IN

IN

Made in USA

CONTROLLER

TO MOTOR

BATTERY

POWER

PACK

IN

MC-100

JOG

JOG

GND

ERD

Photo

Cell

Motor Controller

UL

Matrix

Jog LT

Edge 1

Edge 2

Jog RT

RIGHT

LEFT

Sensitivity

Edge 1

Entrap

On Line

MOTOR OVERLOAD

Power

ERD

Photo

Limit SW

Edge 2

Max

Min

INPUTS

Cell

On Line

Full Open

Preferred arm position

is 90° from open gate.

Re-Attach Arm to Operator:

Limit pin MUST fit into slot in

bottom of release handle clamp

directly under the arm when

re-attaching arm to operator.

Release Handle Clamp

Arm

Slot

Full Closed

Locked Position

weld completely around arm tubing and gate bracket.

Arm MUST be installed level.

MAX PS-24

ON

POWER SUPPLY

AC

Made in USA

POWER

OFF

IN

FUSE

7 AMP

www.max.us.com

POWER/SOLAR

BATTERY

IN

IN

Made in USA

CONTROLLER

TO MOTOR

BATTERY

POWER

PACK

IN

MC-100

GND

JOG

JOG

ERD

Photo

Cell

Motor Controller

UL

Matrix

Jog LT

Edge 1

Edge 2

Jog RT

RIGHT

LEFT

Sensitivity

Edge 1

Entrap

On Line

MOTOR OVERLOAD

Power

ERD

Photo

Limit SW

Edge 2

Max

Min

INPUTS

Cell

On Line

10

Limit Tabs

Limit Pin

Gate Bracket

Assembly

Arm Elbow

Assembly

Page 13

installation

W

A

R

N

I

N

G

H

IGH

VOL

T

AG

E

W

A

R

N

I

N

G

optional remote power supply kit - max magic box

A remote power supply is for installations where it is too costly or difficult to trench a 115/230 VAC power line to the operator

but instead run a low voltage power line to the operator. A MAX Magic Box Kit (sold separately) is required to remotely install

the MAX PS-24 power supply.

Install the MAX Magic Box near the 115 VAC or 230 VAC input AC power source, up to 1000 ft away from gate operator.

Remove MAX PS-24 power supply from gate operator and place in MAX Magic Box. See page 19 for MAX Magic Box wiring

instructions.

NOTE: A MAX Magic Box kit is required for EACH gate operator when using dual gate operators.

Control Box

(Matrix 1)

MAX

Magic

Box Kit

Power/

Connector

S

o

la

r In

W

Nuts

Operator

MAX Magic Box

Near Power Source

Distance - See table below

2-Wires, 24VDC Low Voltage Power

4

Y

-2

L

S

P

P

UP

S

X

ER

MA

OW

P

A

US

n

i

e

d

Ma

ON

F

OWER

F

O

P

E

S

P

U

F

M

A

7

C

A

IN

V

5

1

1

w

w

w

.

m

a

x

.

u

G

s

i

N

r

s

I

n

o

s

f

o

N

a

i

t

h

d

R

c

c

o

r

e

A

t

t

d

o

ec

r

n

W

n

p

u

o

g

r

on

n

g

c

i

n

o

t

t

h

g

i

l

EN

T

I

OP

IM

L

D

E

S

T

I

O

L

IM

C

L

e

g

d

E

ix

r

e

t

a

in

l

L

o

M

l

t

n

Ce

O

ho

2

P

e

g

1

d

e

E

D

dg

N

E

im

G

L

RT

g

o

LT

J

g

o

J

S

UT

NP

I

G

O

J

RIGHT

G

O

J

FT

E

L

y

x

it

a

v

RD

M

ti

E

i

s

y

n

it

e

v

i

t

S

i

s

n

Se

in

D

M

A

O

D

RL

ler

R

l

E

E

o

r

OV

0

t

n

R

o

10

O

-

C

OT

r

o

M

MC

t

o

P

OW

E

R

/

S

I

O

N

L

AR

B

A

T

T

E

R

I

N

Y

s

.

c

o

m

C

O

Ba

M

tter

a

d

e

y

i

V

n

E

olta

U

S

g

A

1/

e

2

F

O

N/

OF

M

B

F

A

a

B

t

X

t

Re

a

e

t

r

t

B

p

y

e

l

r

C

a

y

ce

B

-

M

a

7

o

t

t

d

e

u

r

l

y

T

e

E

S

T

B

a

t

B

t

e

a

r

t

t

y

e

r

y

I

E

N

rro

r

M

T

O

M

N

P

O

T

OW

T

RO

O

R

E

L

I

R

N

L

E

R

B

A

T

T

P

E

A

R

C

Y

K

ire

Control Box

At MAX Magic Box

MAX PS-24

Power Supply

Removed from

r

e

w

o

P

L

p

U

tra

n

E

1

o

t

o

h

ll

e

P

C

2

e

g

d

E

W

e

it S

in

L

n

O

Operator

Y

PL

P

SU

S-24

P

OWER

MAX

WARNIN

G

!

HIG

VO

H

L

TA

disconnec

GE

power

se

t

before

rvicing

u

nit

P

A

S

U

in

e

d

Ma

Se

l

e

ct

115V

w

a

rra

VOID

i

f la

b

R

el is

E

MOVED

(Matrix 1)

At Gate

115/230 VAC Power Source

AMP

SE

7

FU

F

ER

OF

W

PO

ON

IN

AC

Input Vo

A

C

o

230V

r

ltage:

230VAC

nty

E

D

r

e

ut Pow

Inp

Conduit

not suppl

ied

Operator

24 VDC

To

Low Voltage

Operator

Ground Level

Conduit

Concrete Pad

24VDC/RS-485/

Optional Key Switch

Gate Weight Max Wire Distance - Wire Gauge

500 ft - 10AWG2000 lbs 1000 ft - 8AWG

24VDC Low Voltage Power

Input AC

Power

24VDC Low

Vo

ltage

Power

11

Page 14

installation

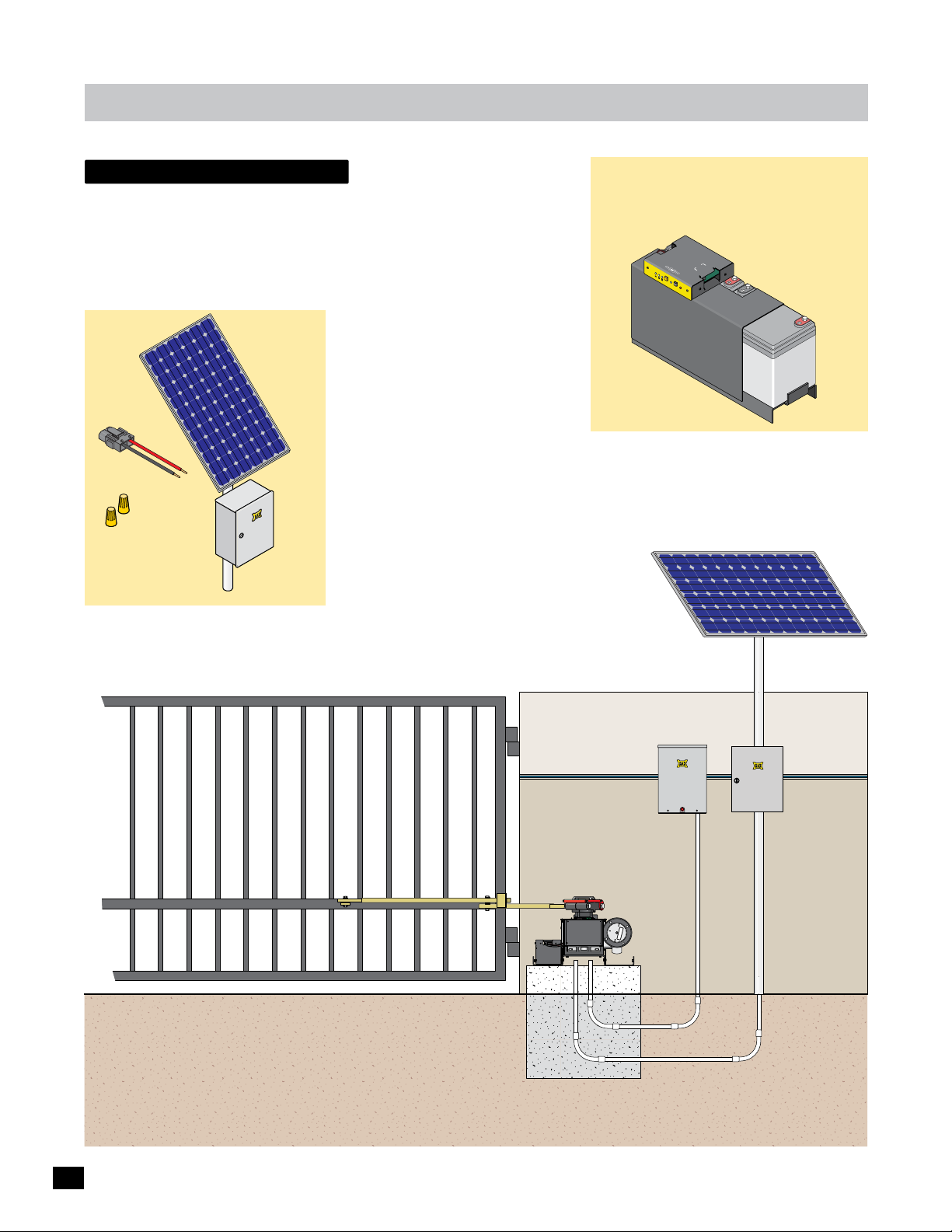

solar - Optional

Refer to Solar application guide.

MAX

Solar

Volt

Solar Panel

24

Power/Solar

Connector

In

Wire

Nut

s

MAX Solar Power Kit: MUST be used

when using solar power. Sold separately.

Power

c

ni

ro

Solar Panel

lect

E

Box

Kit

s

MAX BC-36 Phantom

w

w

w

.

m

ax

.

us

.

c

om

B

M

a

t

t

e

ry

V

E

o

l

t

a

g

1

e

/

2

F

O

N

/

O

B

a

t

t

e

MAX BC-36 Phantom

Battery Module

(36 Amp/Hr)

This OPTIONAL module replaces the MAX

BC-7 Battery Module in the operator. It can

be used when the operator is in a high traffic

cycling area (Approximately 2000 cycles

using only battery power). Sold separately.

Solar Panel: must be mounted facing

south. It must get full sunlight throughout

the day, NO shadow obstructions.

OPTIONAL

Battery Module

PO

WE

R/

B

S

A

TTER

IN

O

LA

I

N

Y

R

TO

C

O

M

N

POW

O

TR

TO

O

R

ER

LL

I

N

ER

ade

B

A

T

TERY

i

n U

P

A

CK

SA

M

FF

A

X

R

e

B

r

P

p

y

B

h

C

lac

a

at

-3

ntom

B

te

e

a

r

6

t

y

t

er

Modu

y

TE

S

l

T

e

B

at

B

t

e

at

r

t

y

er

y

I

Er

N

r

o

r

Operator

Control Box

MAX Solar Kit

Solar Panel

Electronics

Box

12

Page 15

installation

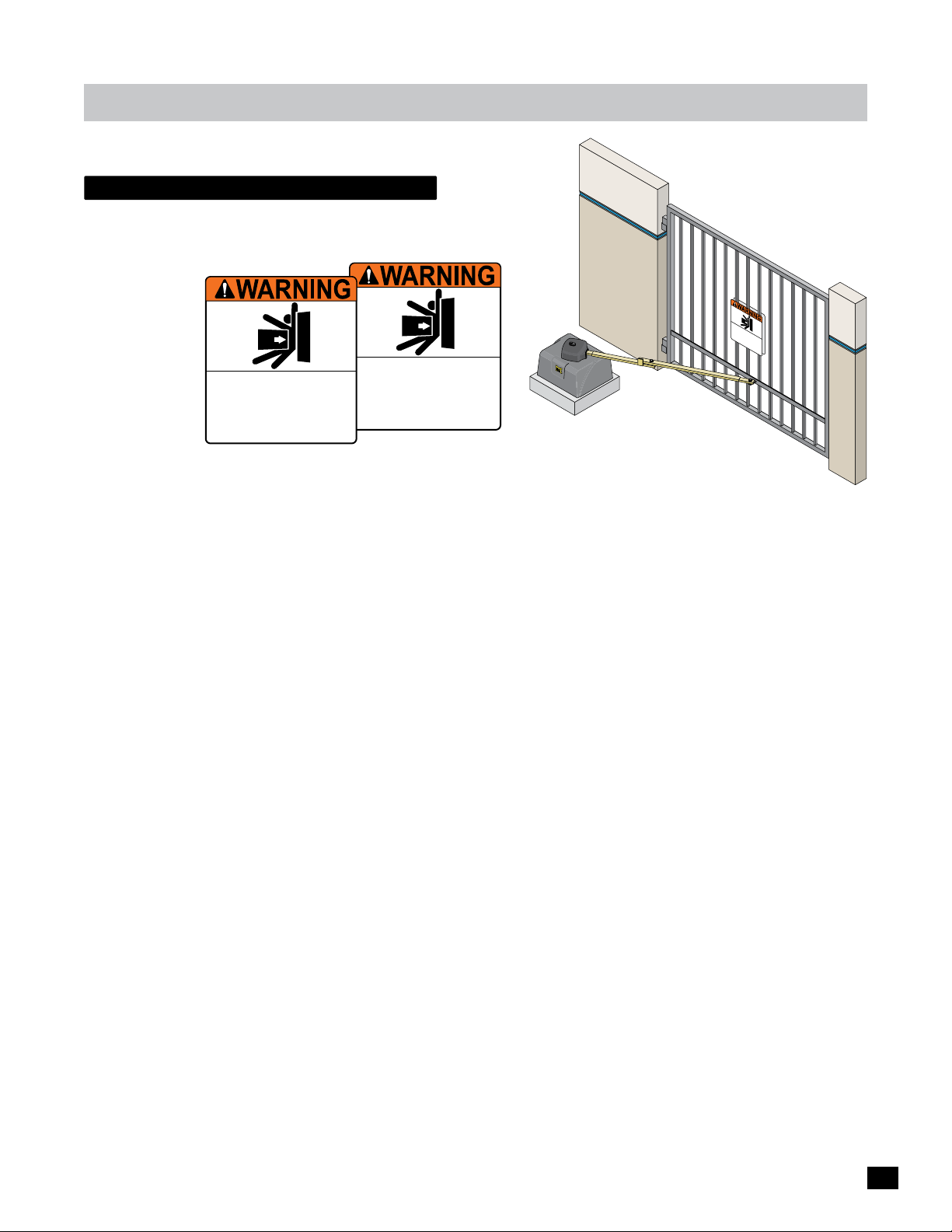

install warning signs

A minimum of two (2) WARNING SIGNS shall be installed,

one on each side of the gate where easily visible.

Moving Gate Can Cause

Moving Gate Can Cause

Serious Injury or Death

KEEP CLEAR! Gate may move at any time

without prior warning.

Do not let children operate the gate or play

in the gate area.

This entrance is for vehicles only.

Pedestrians must use separate entrance.

Serious Injury or Death

KEEP CLEAR! Gate may move at any time

without prior warning.

Do not let children operate the gate or play

in the gate area.

This entrance is for vehicles only.

Pedestrians must use separate entrance.

M

o

vi

Seri

ng

KEE

ou

G

w

P

at

i

t

C

s

ho

L

I

e Can Caus

EAR

u

D

t

n

p

o

j

r

!

n

i

u

o

in

o

r

Ga

t

w

ry or

t

l

h

e

a

t

e

e

t

r

c

n

g

Th

m

h

in

a

il

a

t

g

is

d

e

y

.

r

Pe

e

a

e

m

De

n

r

n

o

e

d

t

o

r

v

a

e

e

a

e

pe

.

s

n

a

t

a

c

r

r

ia

t

e

t

a

an

h

t

n

is

e

s

y

t

f

he

m

o

ti

r

us

me

ve

g

t

a

h

u

t

e

i

s

c

e

l

o

e

r

s

s

p

e

o

l

p

a

n

a

y

l

y

r

a

.

t

e

e

n

t

r

a

nc

e.

13

Page 16

installation

entrapment protection

Install photocells to help protect against entrapment during the OPENING cycle of the gate (secondary entrapment protection).

Install photocells to help protect vehicles during the CLOSING cycle of the gate.

Install sensing edge to help protect vehicles from a moving gate. See pages 17 & 25 for wiring instructions.

Top View

Photocell (CLOSING Cycle)

Beam: 5” or LESS from CLOSED gate.

SENSING EDGE

Mount on end of gate.

Dual Gate Operators NOTE: Run

EACH OPENING Cycle Photocells

conduit to each corresponding

GATE OPERATOR. See page 9.

Gate Closed

Outside Property

Inside Property

SENSING EDGE

Run wire to

GATE OPERATOR.

Run CLOSING Cycle conduit to CONTROL BOX.

Conduit

Gate OpenGate Open

If this dimension is less

than 16”, then secondary

entrapment protection is

REQUIRED in this area.

Illustrations not to scale

Run OPENING Cycle

photocell conduit to

GATE OPERATOR.

Area

Entrapment

Control Box

Side View

14

OPENING Cycle NOTE: Additional OPENING Cycle Photocells

can be installed anywhere needed. Run all additional

OPENING Cycle photocell’s conduit to the GATE OPERATOR.

CLOSING Cycle NOTE: Additional CLOSING Cycle Photocells

can be installed anywhere needed. Run all additional CLOSING

Cycle photocell’s conduit to the CONTROL BOX.

Photocell (CLOSING Cycle)

Beam Height:

21” Normal

27.5” Max.

Photocell

(OPENING Cycle)

Control Box

Photocell (OPENING Cycle)

Install just above gate operator.

Page 17

in-ground loops

T

Install in-ground loops to help

protect vehicles from a moving

gate. See pages 25 & 29 for

wiring instructions.

Outside Property

Illustration not to scale

Inside Property

Side View of

Saw Cut

Sealant

Backer Rod

1 1/2”

Typical

installation

4 ft

Safety

Loop

4 ft

4 ft

Center

Loop

4 ft

Refer to loop maunufacturer’s

instructions to determine specific

loop dimensions.

It is recommended that a

licenced installer perform

this work.

Control Box

Run in-ground

loops conduit to

CONTROL BOX.

Loop Wire

1/4” Saw Cut

Pavement

Safety Loops

Are placed on each side of the gate to prevent

the gate from closing on a vehicle in it’s path.

They will stop or reverse the cycling of the

gate while a vehicle is in or near the gate’s

pathway.

Center Loop

Will ONLY HOLD the gate in the Full Open

Position when a vehicle is on the center loop.

However, it WILL NOT stop or reverse the

gate once it starts to close.

Exit Loop

Automatically opens the gate for exiting

vehicles without having to use a radio

transmitter (remote control). The exit loop

can be placed a minimum of 4 feet away from

the safety loop or far enough away from the

gate so it has opened by the time the vehicle

approaches it.

Inside Property

Saw Cut

4 ft

EXIT LOOP

Lead Wires

SAFETY LOOP

4 ft

Safety

Loop

4 ft min.

Exit

Loop

CENTER LOOP

Safety loops need

to be wired in series.

Outside Property

SAFETY LOOP

4 ft

EXIT

CENTER

SAFETY

Loop lead wires are

twisted 6 twists per

foot minimum inside

conduit.

Matrix 1 Wiring

BATTERY

MATRIX 1

MADE in USA

AUTOMATIC OPEN/CLOSE CONTROLS

EXIT

CENTER

SAFETY

ID

PLUG

12VDC

GND

24VDC

GND

RADIO SIG.

RADIO GND

TAILGATE

MIN

CLOSE TIMER

FIRE DEPT

ANTI

OFF

BACK-UP MODE

LEAVE

OPEN

OFFON

MAX

PARTIAL

OPEN

POSITION

RECORDER

OBD PORT

BLACK BOX

GND

MAX OPEN

GND

PRIMARY

GATE

LEAVE

CLOSED

OPEN

OPEN

OPEN

RIGHT

LEFT

1 TIME

STRIKE

GND

OFF

SAFETYCENTEREXIT

MOTOR MOTION

OPEN

STOP CLOSE

REVERSE SENSITIVITY

MAX

GATE SPEED

MOTOR OVERLOAD

MIN

NO LIMIT SWITCH /

CLAMP SLIPPING

MAX

LIMIT

SWITCH

ON-LINE

MOTOR

ON-LINE

PRIMARY

SEC

GATE

GATE

PHOTOCELL

GND

KEYPAD / RDR

GND

(+)

GND

(-)

(+)

GND

(-)

MAGLOCK

DELAY

MAG

2Sec1.5Sec

LOCK

COM

NC

Tamper NO

GATE

COM

TAMPER

GND

Tamper IN

PHOTOCELL

UL

EDGE 1

ENTRAP

EDGE 2

ID PLUG

ERROR

UL ALARM 12V

ALARM RET

RESET

GND

OPEN

GATE

COM

STATUS

CLOSE

BATTERY

IN USE

POWER

24V

GND

OPEN

STOP

CLOSE

COM

GATE DISABLE

15

Page 18

W

A

R

N

I

N

G

Wiring operator

Check with local building department prior to installing any permanent wiring on this gate operator. Make sure all wiring

complies with local code requirements.

Gate Operator System Overview

1

MAX PS-24 Power Supply: AC power management for the

AC input power to the gate operator. See pages 18, 19 & 23.

Gate Operator

MAX PS

1

USA

in

e

d

Ma

N

O

OWER

FF

O

P

SE

FU

7 AMP

C

A

N

I

V

5

1

1

BA

IN

www.m

a

x

.u

s

.com

s

i

r

B

o

ss

f

ion

ha

ct

c

ct

ote

nd rod

WARNING

u

pr

nne

o

g

o

c

in

gr

o

tn

t

h

lig

M

att

ade

er

y

i

V

E

oltage

1/2

F

O

N

/

O

F

B

F

a

t

R

t

e

ry

B

8

POWE

R/

SOLAR

I

N

T

TER

Y

T

O

CONT

M

PO

OT

6

R

WE

OR

OLL

IN

ER

BATT

n USA

PACK

E

RY

MAX

B

a

e

ttery

B

p

lac

C-

M

e

a

7

o

t

t

d

e

u

r

l

y

T

e

E

S

T

B

a

tt

B

e

a

r

t

tery

y

I

E

N

rro

r

2

-24

LY

PP

U

S

OWER

P

4

3

er

Pow

L

p

U

a

r

t

n

E

1

e

g

o

t

Ed

l

ho

x

i

el

P

r

e

t

C

n

i

l

L

Ma

l

2

to

e

Ce

On

g

2

d

Pho

e

E

g

1

d

W

e

E

S

g

e

t

d

n

i

ND

E

L

mi

i

G

L

n

RT

O

g

LT

Jo

g

Jo

S

7

y

D

it

v

R

i

t

E

si

en

S

AD

O

er

RL

l

RD

l

E

o

r

OVE

t

00

n

OR

-1

T

Co

C

r

o

MO

M

t

o

M

R

T

U

P

IN

G

JO

5

RIGHT

G

T

JO

EF

L

x

a

M

ty

i

v

i

t

i

s

Sen

Min

2

Release Handle Clamp: Manually move the gate when

handle is raised. See page 35.

3

Audible Alarm: Sounds when there is a problem with cycling

the gate. Push the alarm reset button on the control box to

shut off alarm (see below). Alarm can sound every time

operator is cycled using ONLY battery back-up power when

turned ON, See page 32.

4

24VDC Brushless Motor (6 million cycles)

5

MAX MC-100 Motor Controller: Manages UL entrapment

protection devices and operator motor reversing ERD

sensitivity adjustment. See pages 17, 21, 22 & 25.

6

MAX BC-7 Battery Module: Battery Back-Up and DC power

management for the gate operator. See page 17.

7

Limit Tabs: Adjusts the OPEN and CLOSE gate positions.

See page 34.

8

Limit Switch Box: Contains the limit switches. Gate operator

will NOT function when limit switch box is not connected.

See page 34.

Control Box

16

M

A

TRI

X

1

MA

DE

B

in

AT

B

A

USA

T

C

E

K

R

-UP MO

Y

L

L

E

EA

A

DE

VE

V

C

E

LO

OPEN

S

ED

P

RI

O

M

P

AU

EN

A

1

R

GAT

TI

Y

T

M

E

O

E

M

OPE

A

T

N

LE

IC

F

T

A

E

NT

XI

O

O

TA

T

CE

NT

E

R

SA

FE

T

Y

ID

P

LU

G

1

2

V

DC

GN

D

A

2

4

V

DC

G

ND

RADIO SIG.

RADIO GND

P

I

P

E

ILGA

RIGH

N

E

N/

T

T

E

C

O

N

O

FF

MI

N

O

MAX

FF

C

L

OSE

T

IM

E

R

PAR

T

IA

O

PE

N

P

OSITIO

RE

C

ORDER

O

BD

B

P

LA

O

CK

FIRE DEPT

GND

MAX OPEN

GND

MA

LO

GL

S

O

DEL

E

XIT

L

N

RT

B

O

X

STRIKE

GND

C

OF

K

CO

F

AY

.

NTROL

5

Sec

C

2

Sec1

E

NTERE

MA

S

G

LOCK

S

A

FE

T

Y

COM

NC

GATE

T

A

M

Tamp

P

ER

e

r

NO

C

OM

GN

Tam

D

p

er

M

OTOR

MO

OP

E

N

MA

X

S

T

GAT

E

SP

R

MIN

EV

E

E

D

MA

X

LI

M

SW

IT

IT

O

N-LI

MO

KEYPAD / RDR

TO

O

PRI

N-LI

GND

MA

PHOTOCELL

R

G

Y

A

T

GND

E

(+)

GND

(-)

IN

P

UL

HO

T

OC

EL

TI

L

O

ENTR

N

AP

E

DG

E 1

E

DG

E

OP

2

I

D

C

P

L

L

OS

ER

UG

S

E

E

E

RR

SE

NSIT

OR

MOT

I

VI

U

O

T

L

R

Y

A

OV

L

E

A

R

NO

RM

LO

AL

L

AD

I

MI

ARM R

1

C

T

L

2

SWITC

AM

V

P

SL

ET

H

RESET

I

P

/

PI

NG

GN

GAT

D

E

CH

S

T

AT

N

E

US

R

OP

N

E

E

N

C

OM

C

S

E

L

C

OS

G

A

TE

E

(+)

B

AT

GND

T

(-)

E

RY

IN

USE

OPEN

STOP

CLOSE

P

COM

OWE

GATE DISABLE

R

24V

GND

A

Matrix 1: Manages control panel operations. Manages

inputs/outputs, loops and reports problems with gate

operator. See Matrix 1 Section starting on page 24.

B

Alarm Reset Button: Push to shut off alarm and/or reset

Matrix 1. See pages 25, 32 & 38.

C

Optional Electronic Gate Open/Close Key Switch:

Electronically move the gate open or closed by turning

removable key in the key switch if connected to operator(s).

See pages 22 & 40.

B

C

Page 19

Wiring operator

Gate Operator System Overview continued

MAX BC-7 Battery Module

R

POWE

IN

TTER

BA

TO MOTOR

NTROLLER

CO

OLAR

/S

IN

OWER

P

Y

TTER

IN

BA

www.max.us.com

Battery

E1

de in

Ma

4

ltage

Vo

F

/2

ON/OFF

Batte

3

IMPORTANT

connect to

before use

“BATTERY IN”

2

1

MAX MC-100 Motor Controller

MC-100

Motor Controller

MOTOR OVERLOAD

A

ERD

B

Optional Electronic

Open/Close

Key Switch,

See page 22.

OPENING Cycle

Entrapment

Photocells

ONLY.

24V

Power.

24V

PWR 24V -

ERD

Sensitivity

D

Max

Min

Sensitivity

C

Photocell (N.O.)

GND

24V

GND -

RS-485 (-) -

RS-485 (+) -

JOG

JOG

RIGHT

LEFT

E

GND

To Matrix 1

RS-485

ALARM

LIMIT

SWITCH

Jog LT

Jog RT

INPUTS

GND

F

BATTERY

PACK

Edge 1

Edge 2

MOTOR

INPUTS

Photo

G I K

Cell

Matrix

On Line

Limit SW

On Line

H J L

Edge 1

Y

ACK

P

MAX BC-7

Battery

6

USA

ry IN

Batte

Error

T

TES

ry

e

Batte

7

Replac

Battery

ry

5

UL

Edge 1

Entrap

Power

Photo

Edge 2

Cell

M

(N.O.)

GND

Edge 2

(N.O.)

Sensing Edges

POWER IN MOTOR

Modul

GND

1

BATTERY Plug: MUST be plugged into BATTERY IN port Before use.

POWER/SOLAR IN Port: MAX PS-24 Power Supply connection.

2

3

Battery Voltage LEDs: Show amount of battery power available.

LEDs are always ON when using AC power. Test battery button must be

pressed to show battery power when using battery power ONLY.

4

e

ON/OFF Battery Button:

IMPORTANT: Battery power automatically turns ON when MAX PS-24 Power

Supply AC POWER Switch is turned ON.

To turn OFF ALL POWER to operator:

1. Turn OFF AC POWER Switch on MAX PS-24 Power Supply.

Battery power remains ON.

2. WAIT for 15 seconds.

3. Press and HOLD (approx. 5 seconds) the YELLOW ON/OFF BATTERY

button until MAX BC-7 LEDs turn ON, then release button.

LEDs will turn OFF.

5

Replace Battery LED: Replace battery when lit.

6

TEST Battery Button: Press to show amount of battery power available when

using battery power ONLY (Battery voltage LEDs will light respectively).

Battery IN Error LED: Lights when there is a battery connection problem.

7

Make sure battery plug #1 is plugged into BATTERY IN port or there is no

damaged or loose wires.

A

MOTOR OVERLOAD LED: Excessive current being drawn by motor when lit.

B

ERD LED: ERD sensor has been activated when lit.

C

ERD Sensitivity Knob: 16 selectable sensitivity settings of ERD sensor.

D

ERD Sensitivity LED: MAX sensitivity reached when lit.

E

Jog LEFT/RIGHT Buttons:

Push and HOLD buttons accordingly to move the gate (release the button to

stop gate). WARNING: Avoid moving arm while using Jog buttons.

INPUTS:

F

Jog LT/RT: Connects to optional key switch on Control Box.

GND: Low Voltage Common connection.

Edge 1: Connects to a Sensing Edge. Multiple sensing edges can be

connected.

Edge 2: Connects to a second Sensing Edge. Multiple sensing edges can be

connected.

PHOTOCELL: Connects to a UL 325 Standard OPENING Cycle photocell

ONLY. Multiple OPENING Cycle photocells can be connected.

G

Matrix On Line LED: Gate operator is successfully communicating with

Matrix 1 when lit.

H

Limit SW On Line LED: Limit Switch Box is successfully communicating

with MC-100 Motor Controller when lit.

I

Edge 1 LED: Reversing Edge 1 input has been activated when lit.

Edge 2 LED: Reversing Edge 2 input has been activated when lit.

J

UL Entrap LED: Edge1/Edge2/Photocell input has been activated when lit.

K

Photocell LED: Photocell input has been activated when lit.

L

Power LED: Low voltage power is connected when lit.

M

www.max.us.com

DUAL GATE OPERATORS NOTE: Connect EACH photocell/reverse

edge to the corresponding gate operator. See page 9.

17

Page 20

WARNI

N

G

H

I

G

H

VO

LT

A

G

E

Wiring operator

WARNING

W

A

R

N

I

N

G

input ac power

Wire input AC power wire to the MAX PS-24 power supply as shown.

Choose either 115V or 230V setting on input AC power selector switch.

NOTE: AC power wire is required for EACH gate operator

when using dual gate operators.

CAUTION: MAKE SURE CIRCUIT

BREAKER IS OFF BEFORE WIRING

LY

PP

-24

MAX PS

MAX PS-24 Power Supply

POWER SU

DO NOT TURN POWER

ON AT THIS TIME.

A

US

in

e

ad

M

7 AMP

FUSE

F

ER

OF

OW

N

P

O

N

I

AC

7 Amp Fuse

Input AC Power Options

Single Phase 115VAC Only

115VAC

115V

Set to 115V

115 OR 230VAC

Power Wire

Single Phase 230VAC Only

230VAC

230V

Set to 230V

NOTE: Consult city codes for AC line wiring.

Beware of existing underground services.

DANGER

HIGH VOLTAGE!

Line (Black)

Neutral (White)

Chassis (Green)

IMPORTANT NOTE: Make sure there are NO exposed

bare wires at the power terminal connection.

WARN

V

di

power be

s

er

HIGH

O

LTAGE

sc

onnect

vicing uni

ING

!

f

or

e

t

S

el

ect

115VA

Inp

C

or 230V

ut Volta

ge:

A

C

230V

Input AC Power

Selector Switch

CAUTION: If power

selector switch is set

warranty

Power Terminal

VOIDED

if label is

REMOVED

Line (Black)

Neutral (White)

Chassis (Green)

for 115V but input

power is actually 230 V,

7 Amp Fuse will blow.

Operator MUST be Properly GROUNDED

LY

S-24

P

P

UP

X

A

R S

E

M

OW

P

A

S

U

n

i

e

d

a

M

R

ON

E

W

OFF

PO

E

US

F

MP

A

7

C

A

N

I

V

5

1

1

D

ER

nsi

e

S

D

A

O

r

L

D

e

R

l

R

l

E

E

V

o

r

O

t

00

n

R

o

O

-1

T

C

C

r

o

MO

M

t

o

P

O

W

E

R

/

S

IN

O

L

A

R

B

A

T

T

E

RY

IN

w

w

w

.

m

a

x

.

u

s

.

c

o

m

T

O

C

O

M

N

P

O

T

O

T

R

W

O

O

R

LLE

I

s

i

NG

r

s

I

n

o

f

o

as

i

t

h

RN

c

c

od

r

e

A

t

t

c

d

o

n

W

pr

u

nne

o

g

r

o

n

g

c

i

n

o

t

t

h

g

i

l

N

R

Ba

M

t

a

t

B

e

d

A

r

e

y

T

T

i

V

n

E

P

E

ol

A

RY

U

t

CK

S

a

A

ge

1/

2

F

O

N

/

O

M

F

Ba

F

A

Batte

t

X

t

R

e

e

ry

B

p

la

r

C

y

c

Ba

-7

M

e

od

tt

e

u

r

l

y

TE

e

ST

Ba

t

Batte

t

e

r

y

r

y

I

Er

N

r

o

r

M

E

R

OG

T

J

F

E

L

y

t

x

i

a

v

M

ti

ty

i

v

i

t

i

s

n

Se

n

i

M

RT

LT

g

o

J

OG

J

GHT

RI

Ground

er

ow

P

L

p

U

ra

t

n

E

1

Edge

l

hoto

l

x

e

P

tri

C

ne

a

l

Li

o

M

l

2

t

e

o

On

C

h

2

P

e

Edge

g

1

d

W

e

E

S

g

D

t

d

i

ne

i

N

E

L

m

G

Li

On

g

o

J

S

T

U

INP

Conduit Tunnel

Chassis

Proper grounding of this gate operator is a

requirement for LIGHTNING PROTECTION in

lightning prone areas. To be effective, ground

connections should be made with a minimum

12 AWG, 600 volt insulated wire to a ground

point within 10 feet of the gate operator. The

Ground Rod

within 10 ft

of operator

ground point must be at an electrical panel, a metallic cold water pipe that

runs in the earth, or a grounding rod.

Chassis Ground

TWO Chassis

Grounds are located

inside either end of

the conduit tunnel.

WARNING

connect chassis

to ground rod for

lightning protection

18

Page 21

Wiring operator

W

AR

N

I

NG

HI

G

H

VO

LT

AG

E

optional remote power supply kit - max magic box

A MAX Magic Box Kit (sold separately) is required to remotely install the MAX PS-24 Power Supply from the gate operator.

Remove MAX PS-24 power supply from gate operator and install in MAX Magic Box, plug in power supply to PS-24 connector.

Wire input AC power to the MAX PS-24 Power Supply (See page 18 for wiring).

Choose either 115V or 230V setting on input AC power selector switch. Run 24V low voltage wires (not included) from the MAX

Magic Box connection and wire to POWER/SOLAR IN connector (Polarity Matters!). Plug connector into POWER/SOLAR IN

port on the gate operator’s MAX BC-7 battery module.

NOTE: A MAX Magic Box kit is required for EACH gate operator

At MAX Magic Box

when using dual gate operators.

DO NOT TURN POWER

ON AT THIS TIME.

Y

L

PP

SU

ER

W

PO

MAX PS-24

MAX PS-24 Power Supply

removed from operator

WAR

NI

NG

!

HI

G

VOLTAG

H

dis

conn

p

E

owe

ect

s

r

e

b

r

vic

ef

o

in

re

g

uni

t

Connect Input

AC Power wire

(See page 18 for

wiring)

USA

n

i

e

d

Ma

R

E

N

O

Sel

ect I

115VAC or 230V

nput

V

warrant

VOIDED

y

i

f

l

abel i

REMOV

s

Input AC Power

ED

MP

A

7

FUSE

F

F

O

OW

P

IN

AC

230V

ol

ta

ge

:

AC

Input AC Power Selector Switch

CAUTION: If power selector switch is

set for 115V but input power is actually

230 V, 7 Amp Fuse will blow.

PS-24

Connector

Ground

Power In

From

PS-24

Input Power

GND

Pos +

24 VDC

To Operator

Low Voltage

24V

Wires

10 AWG

Minim

MAX Magic Box MUST

be Properly GROUNDED

um

IMPORTANT: MAX Magic Box and Gate

Operator MUST EACH be Properly GROUNDED.

Proper grounding is a requirement for

LIGHTNING PROTECTION in lightning prone

areas. To be effective, ground connections

should be made with a minimum 12 AWG, 600

volt insulated wire to a ground point within 10

feet of the MAX Magic Box and gate operator.

Ground Rod

within 10 ft

of Box

The ground point must be at an electrical panel,

DANGER

HIGH VOLTAGE!

115 VAC or

230 VAC

Input AC Power

NOTE: Consult city codes

for AC line wiring.

CAUTION: MAKE SURE CIRCUIT

BREAKER IS OFF BEFORE WIRING

POWER/SOLAR IN

a metallic cold water pipe that runs in the earth,

or a grounding rod.

NOTE: Beware of existing underground

services.

POWER/SOLAR IN

Connector

(Included in kit).

Port

LA

SO

/

R

E

IN

W

PO

MO

TO

CO

R

Y

R

E

T

IN

BAT

com

s.

u

.

.max

www

Ba

E1/2

R

WE

N

PO

I

Y

R

O

R

ER

T

LE

TT

L

O

ACK

BA

R

P

T

N

e

l

BC-7

u

d

Mo

AX

ry

M

e

t

t

Ba

A

S

U

in

Made

IN

y

r

e

Batt

or

Err

ST

TE

ry

e

t

t

age

Ba

ace

Volt

pl

e

y

F

r

R

ry

e

e

t

t

t

t

a

B

N/OFF

y

O

r

e

t

t

Ba

IMPORTANT NOTE: Maximum Control’s

remote power supply technology does NOT

utilize the battery power from the MAX BC-7 Battery

24V Low Voltage Wire in Conduit

Module during NORMAL gate operation. Battery power is

reserved for back-up power ONLY when an AC power failure

occurs. As a result, battery life is NOT shortened.

This low voltage system can CONTINUOUSLY cycle the gate during

NORMAL gate operation, perfect for high traffic gate applications.

Pos +

Polarity Matters!

GND

MAX BC-7

Battery Module

At Gate Operator

19

Page 22

Wiring operator

W

A

R

N

I

N

G

solar power connection - optional

Refer to Solar application guide.

NOTE: Cover solar panel from

sunlight BEFORE wiring plug to

solar panel to prevent a shock

from occurring.

Max Solar

Power Kit

(Sold separately)

Pos + Red

Polarity Matters!

GND Black

To MAX Solar

Power Kit

Connect to

POWER/SOLAR

IN

STANDARD MAX BC-7 Battery Module

(Approximately 450 cycles using only battery power)

IMPORTANT

connect to

before use

“BATTERY IN”

IN

POWER/SOLAR

IN

BATTERY

R

POWE

IN

TTERY

CK

BA

PA

TO MOTOR

NTROLLER

CO

MAX BC-7

Battery Module

USA

de in

Ma

om

Voltage

.max.us.c

www

F

Battery

1/2

ON/OFF

ry

E

Batte

IN

ry

Batte

Error

T

TES

ry

e

Batte

Replac

Battery

Connect to

POWER/SOLAR

OPTIONAL MAX BC-36 Phantom Battery Module

The OPTIONAL MAX BC-36 Phantom Battery Module is for high

traffic cycling areas (Approximately 2000 cycles using only

battery power). A BC-36 phantom module is needed for each

solar power kit used (One per gate operator when dual gate

operators have been installed).

It replaces the MAX BC-7 Battery module in the operator’s battery

position (see page 43). Operator cables reconnect to the same

plugs on the BC-36 as they did on the BC-7 battery module.

POW

E

R/SOLA

B

A

TTER

IN

I

N

Y

R

w

w

w

.

m

ax

.

us

.

com

TO

C

O

MO

N

P

TR

O

TO

W

O

R

ER

LLER

I

B

a

t

t

e

ry

IN

E

1/

MAX BC-36 Phantom

N

M

ade

B

A

TTER

i

Vo

n U

P

A

l

ta

CK

Y

SA

g

e

2

F

O

N

M

/

O

F

A

B

F

at

X

R

t

e

eplace

B

r

P

y

B

h

C

antom

at

-

B

ter

36

a

t

y

ter

Module

y

TES

T

B

at

B

t

er

at

t

y

e

r

y

I

E

N

r

r

o

r

Battery Module

(36 Amp/Hr)

Y

L

P

P

PS-24

U

S

R

E

MAX

W

O

P

SA

U

in

e

d

a

M

N

O

ER

F

OW

F

O

P

E

S

P

U

F

M

A

7

C

A

N

I

V

5

1

1

O

J

E

L

ty

D

i

ax

v

R

i

M

t

E

i

s

n

e

S

si

n

e

S

n

i

M

AD

O

r

D

RL

le

R

l

E

E

V

o

r

O

0

t

n

o

10

OR

-

T

C

C

O

r

o

M

M

t

o

M

is

NG

s

I

n

for

o

N

as

ti

h

d

R

c

c

ro

A

t

te

c

d

e

ro

n

W

n

n

g p

rou

o

n

g

c

i

tn

to

gh

i

l

er

w

o

P

p

UL

a

r

t

n

E

1

e

dg

o

E

l

hot

l

e

P

rix

e

C

n

at

i

L

o

M

ll

2

t

e

n

o

e

O

C

g

2

Ph

Ed

ge

1

d

W

E

S

ge

e

D

t

d

i

n

i

N

E

L

m

G

T

Li

n

R

O

g

LT

Jo

g

o

J

S

T

U

P

N

I

G

T

O

H

J

RIG

G

T

F

ty

i

v

i

t

20

Page 23

MA

GATE SP

N

CLA

MIN

ID

PLUG

Wiring operator

P

rimary/

Single

Operato

r

Primary/Single

Operator

Secondary

Operator

Bi-Parting Gates

operators to matrix 1

Unscrew MAX MC-100 motor controller from operator

to gain access to RS-485 connector. Schematics on page

38 of manual shows where all plugs are located to

re-install MAX MC-100 motor controller.

4

Y

-2

L

S

P

P

P

U

S

X

A

R

M

POWE

SA

U

n

i

de

a

M

R

ON

WE

F

O

F

O

P

E

S

P

U

F

M

A

7

C

A

N

I

V

5

1

1

24V

GND

BATTERY

MATRIX 1

BACK-UP MODE

LEAVE

MADE in USA

OPEN

AUTOMATIC OPEN/CLOSE CONTROLS

ANTI

TAILGATE

EXIT

OFFON

CENTER

SAFETY

MAX

MIN

OFF

CLOSE TIMER

PARTIAL

OPEN

ID

PLUG

BLACK BOX

PRIMARY

GATE

LEAVE

CLOSED

OPEN

1 TIME

MAX

MAX

GATE SPEED

MIN

PHOTOCELL

MAGLOCK

DELAY

OPEN

OPEN

LEFT

MOTOR MOTION

OPEN

PRIMARY

GATE

(+)

RIGHT

MOTOR

ON-LINE

GND

(-)

SAFETYCENTEREXIT

STOP CLOSE

REVERSE SENSITIVITY

MOTOR OVERLOAD

NO LIMIT SWITCH /

CLAMP SLIPPING

SEC

GATE

(+)

MAG

OFF

2Sec1.5Sec

LOCK

COM

NC

Tamper NO

GATE

COM

TAMPER

GND