Maximum Controls MAX MEGATRON 2500 Installation Manual

www.max.us.com

CONFORMS TO UL STD 325

UL CLASS - I, II, III, IV

CERTIFIED TO CAN/CSA STD

C22.2 NO. 247

High Traffic Commercial

Brushless DC High Profile

Swing Gate Operator

4009963

Made in USA

MAX megatron 2500

Installation and Owners Manual

Table of contents

© 2014 Maximum Controls LLC.

All rights reserved. No part of this

manual may be reproduced in any

means: graphics, electronics or

mechanical, including photocopying

without the expressed written

permission of the publisher. Materials

components and specifications are

subject to change without notice.

Magatron 2500 Specifications

Important Safety Information

UL 325 Model Classifications

UL 325 Required Entrapment Protection

UL 325 Compliant Installation Requirements

Intended Use of Swing Gate Operator

Installation

Gate Operator Position

Single Gate Operator

Dual Gate Operators

Arm Position Options

Arm Connection to Gate

Optional Remote Power Supply Kit - MAX Magic Box

Solar

Install Warning Signs

Entrapment Protection

In-Ground Loops

Wiring operator

Gate Operator System Overview

Input AC Power

Optional Remote Power Supply Kit - MAX Magic Box

Solar Power

Secondary Operator to Matrix 1

Turn ON / OFF Operator Power

matrix 1

Matrix 1 Overview

Wiring Overview

Primary Gate - Open Left / Open Right

Close Timer

Selectable Gate Speed Control

Battery Back-Up Mode

Anti-Tailgate

Single Pass Anti-Tailgate

Radio Receiver

Radio Safety Pause

Gate in Motion Alarms

OBD Port Black Box

Maglock

Plug-In Loop Detectors

In-Ground Loop Connection

ID Plug

Gate Tamper

UL Entrapment LEDs

Emergency Vehicle / Max Open Inputs

Gate Disable

Partial Open

UL Alarm / Alarm Reset Button

Gate Status Monitoring

OPEN / STOP / CLOSE Connection

CLOSING Photocell Connection

Gate Operators Communication LEDs

24V Power for Matrix 1

Battery in Use LED

Motor Motion LEDs

Optional External Open/Close Key Switch

Adjustments

Open and Close Limits

Release Handle Clamp

Reverse Sensor (ERD)

Maintenance

Qualified gate operator technician

End user/Home owner

Megatron 2500 Wiring Schematics

Manual Release

Audible Alarm

Replacement Parts List

Warranty

2

2

3

3

4

5

6

7

8

9

10

10

11

12

13

14

15-16

17

18

19

20

21

22

23

24

24

24

24

25

25

26

26

26

26

27

27

27

28

28

28

28

29

29

30

30

30

30

31

31

31

31

32

33

34

35

36

36

37

38

39

40

41

1

megatron 2500 specifications

UL 325 Class of Operation - Class I, II, II, IV

Gate Type - Vehicular Swing Gate

Max Gate Weight / Length - 2500lbs/15 ft or 2000 lbs/20 ft

90° Opening Time - 16 selectable speeds from approximately 11.5 sec to 20 sec depending on the weight and length of gate.

Cycles per Hour AC Input Power - Continuous

Battery Back-Up Cycles - 400 continuous cycles for a 2500 lbs gate

Input AC Power - Switchable: 115VAC or 230VAC single phase

Motor - 24VDC Brushless (equivalent to 1 HP AC motor)

Operating Temperature - -4°F to 158°F (-20°C to 70°C)

Entrapment Protection:

- UL 325 Type A Inherent (ERD sensor)

- Input for UL 325 Type B1 (photocell) and B2 (reverse edge)

important safety information

WARNING – To reduce the risk of injury or death:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. Never let children operate or play with gate controls. Keep the remote control away from children.

3. Always keep people and objects away from the gate. NO ONE SHOULD CROSS THE PATH OF THE MOVING GATE.

4. Test the gate operator monthly. The gate MUST reverse on contact with a rigid object or stop when an object activates the

non-contact sensors. After adjusting the force or the limit of travel, retest the gate operator. Failure to adjust and retest the

gate operator properly can increase the risk of injury or death.

5. Use the emergency release only when the gate is not moving.

6. KEEP GATES PROPERLY MAINTAINED. Read the owner’s manual. Have a qualified service person make repairs to gate

hardware.

7. The entrance is for vehicles only. Pedestrians must use separate entrance.

8. SAVE THESE INSTRUCTIONS

2

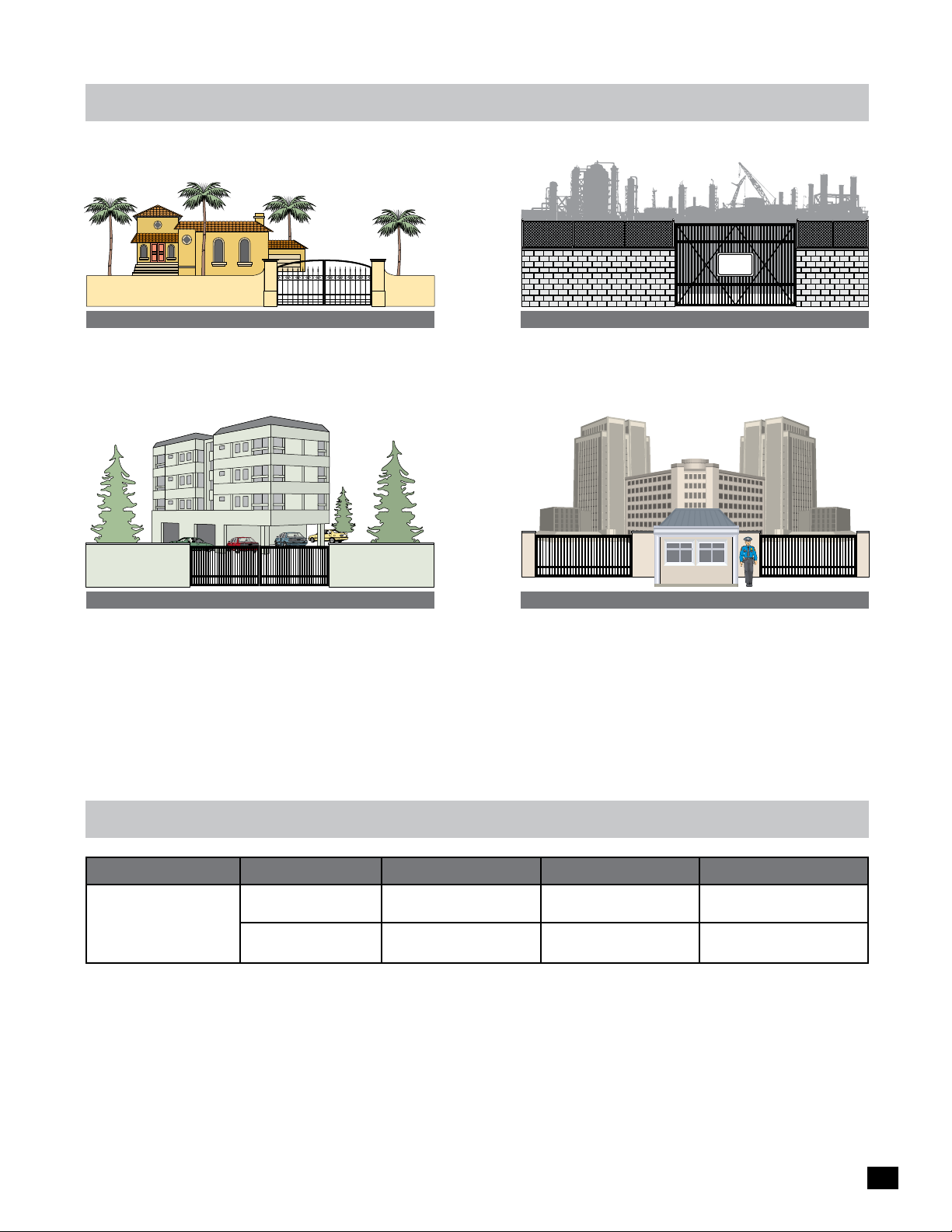

ul 325 model classifications

AUTHORIZED

PERSONNEL

ONLY

CLASS I

Residential Vehicular Gate Operator - A vehicular gate operator

(opener or system) intended for use in a home of one to four

single family dwellings, or a garage or parking area associated

therewith.

CLASS II

Commercial/General Access Vehicular Gate Operator - A

vehicular gate operator (opener or system) intended for use in

a commercial location or building such as a multi-family

housing unit (five or more single family units) hotel, garages,

retail store or other building servicing the general public.

CLASS III

Industrial/Limited Access Vehicular Gate Operator - A

vehicular gate operator (opener or system) intended for uses

in an industrial location, loading dock area or other location

not intended to service the general public.

SECURITY

CLASS IV

Restricted Access Vehicular Gate Operator - A vehicular gate

operator (opener or system) intended for use in a guarded

industrial location or buildings such as airport security area or

other restricted access locations not servicing the general

public, in which unauthorized access is prevented via

supervision by security personnel.

ul 325 required entrapment protection

Gate Type Protection Type Class I & II Class III Class IV

Primary

A, C A, B1, B2, C

Swing Gate

Secondary

The same type of device shall not be utilized for both the primary and the secondary entrapment protection means. Use of a single device to

cover both the opening and closing directions is in accordance with the requirement; however, a single device is not required to cover both

directions. A combination of one Type B1 for one direction and one Type B2 for the other direction is the equivalent of one device for the

purpose of complying with the requirements of either the primary or secondary entrapment protection areas.

A - Inherent entrapment protection system.

B1 - Provision for connection of a non-contact sensor

(photoelectric sensor or the equivalent).

B2 - Provision for connection of a contact sensor

(edge device or the equivalent).

A, B1, B2, C, D

C - Inherent adjustable clutch or pressure relief device.

D - Provision for connection of an actuating device

requiring continuous pressure to maintain opening

or closing motion of the gate.

E - An audio alarm.

A, B1, B2, C, D, E A, B1, B2, C, D, E

A, B1, B2, C, D

3

ul 325 compliant

installation requirements

A Install the gate operator only when:

1 The operator is appropriate for the construction of the gate and the usage Class of the gate,

2 All exposed pinch points are eliminated or guarded.

B The operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied with a separate access

opening. The pedestrian access opening shall be designed to promote pedestrian usage. Locate the gate such that persons

will not come in contact with the vehicular gate during the entire path of travel of the vehicular gate.

C The gate must be installed in a location so that enough clearance is supplied between the gate and adjacent structures when

opening and closing to reduce the risk of entrapment. Swinging gates shall not open into public access areas.

D The gate must be properly installed and work freely in both directions prior to the installation of the gate operator.

Do not over-tighten the operator clutch or pressure relief valve to compensate for a damaged gate.

E For gate operators utilizing Type D protection:

1 The gate operator controls must be placed so that the user has full view of the gate area when the gate is moving,

2 A gate operator shall additionally be provided with a placard that is marked in letters at least 1/4-in (6.4-mm) high with

the word “WARNING” and the following statement or the equivalent: “Moving Gate Has Potential of Inflicting Injury or

Death - Do Not Start Gate Unless Path is Clear”.

3 An automatic closing device (such as a timer, loop sensor, or similar device) shall not be employed, and

4 No other activation device shall be connected.

F Controls intended for user activation must be located at least ten feet (10’) away from any moving part of the gate and where

the user is prevented from reaching over, under, around or through the gate to operate the controls. Outdoor or easily

accessible controls shall have a security feature to prevent unauthorized use.

G The Stop and/or Reset button must be located in the line-of-sight of the gate. Activation of the reset control shall not cause

the operator to start.

H A minimum of two (2) WARNING SIGNS shall be installed, one on each side of the gate where easily visible.

I For gate operators utilizing a non-contact sensor:

1 See instructions on the placement of non-contact sensors for each Type of application,

2 Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle, trips the sensor while the gate is

still moving, and

3 One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the

perimeter reachable by a moving gate or barrier.

J For a gate operator utilizing a contact sensor:

1 One or more contact sensors shall be located where the risk of entrapment or obstruction exists, such as at the leading

edge, trailing edge, and post mounted both inside and outside of a vehicular horizontal slide gate.

2 One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

3 One or more contact sensors shall be located at the pinch point of a vehicular vertical pivot gate.

4 A hardwired contact sensor shall be located and its wiring arranged so that the communication between the sensor and

the gate operator is not subjected to mechanical damage.

5 A wireless device such as one that transmits radio frequency (RF) signals to the gate operator for entrapment protection

functions shall be located where the transmission of the signals are not obstructed or impeded by building structures

natural landscaping or similar obstruction. A wireless device shall function under the intended end-use conditions.

6 One or more contact sensors shall be located on the inside and outside leading edge of a swing gate. Additionally, if the

bottom edge of a swing gate is greater than 6 inches (152 mm) above the ground at any point in its arc of travel, one or

more contact sensors shall be located on the bottom edge.

7 One or more contact sensors shall be located at the bottom edge of a vertical barrier (arm).

4

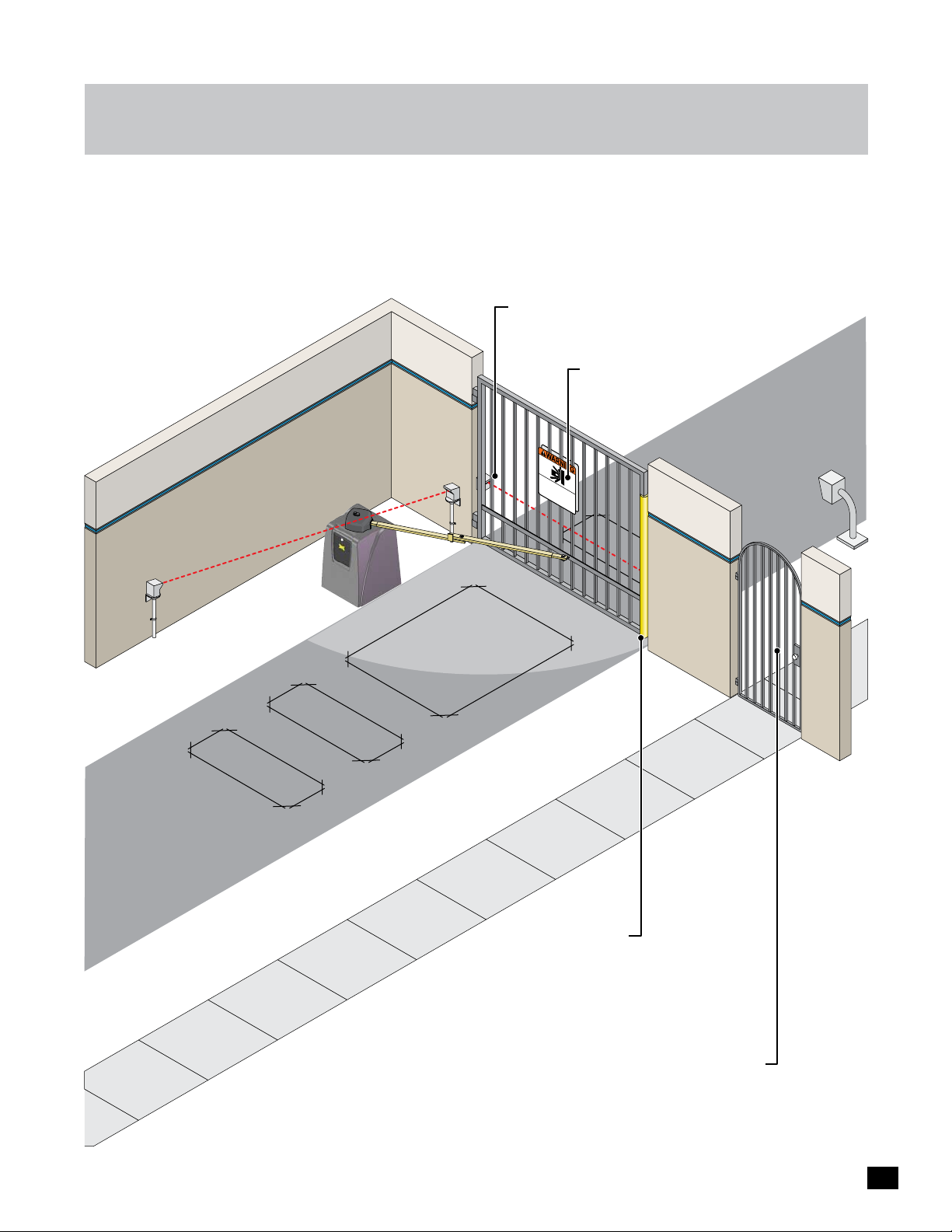

intended use of

swing gate operator

The operator is intended for use on a VEHICULAR swing gate ONLY. It is intended to be used WITH appropriate entrapment

protection safety devices and in-ground vehicle loop detection system.

Closing Gate Protection Photocell: Helps protect the gate operator

from accidentally closing on vehicles in the gate’s closing path.

Warning Signs: Should be installed

on both sides of gate area and

easily visible.

Moving Gate Can

Seriou

KEEP

without

C

s Injury o

LE

D

AR!

prior warning.

o not

in

Ga

the gat

let

t

Cause

e ma

children operat

T

hi

r Death

e area.

s

y

Pedes

entranc

m

ov

e at any

trians

e is

e

the gat

f

must

or

t

ime

ve

hic

us

e or play

e

le

separat

s

onl

y

.

e

Entrapment Protection Photocell:

Helps guard against the opening

gate from entrapment.

entrance.

Entrapment Area

In-Ground Loops:

Help protect the gate

operator from accidentally

opening and/or closing on

vehicles in the gate’s path.

Sensing Edge: Helps

protect the gate operator

from accidentally opening

and/or closing on vehicles

in the gate’s path.

Pedestrians MUST use a separate entrance.

The gate operator IS NOT intended to be

used on a PEDESTRIAN gate.

5

installation

Read and understand this entire manual before installation. Check with the local building department prior to installing this gate

operator to comply with local building code requirements. The gate must be installed in a location so that enough clearance is

supplied between the gate and adjacent structures when opening and closing to reduce the risk of entrapment. Swinging gates

should not open into public access areas.

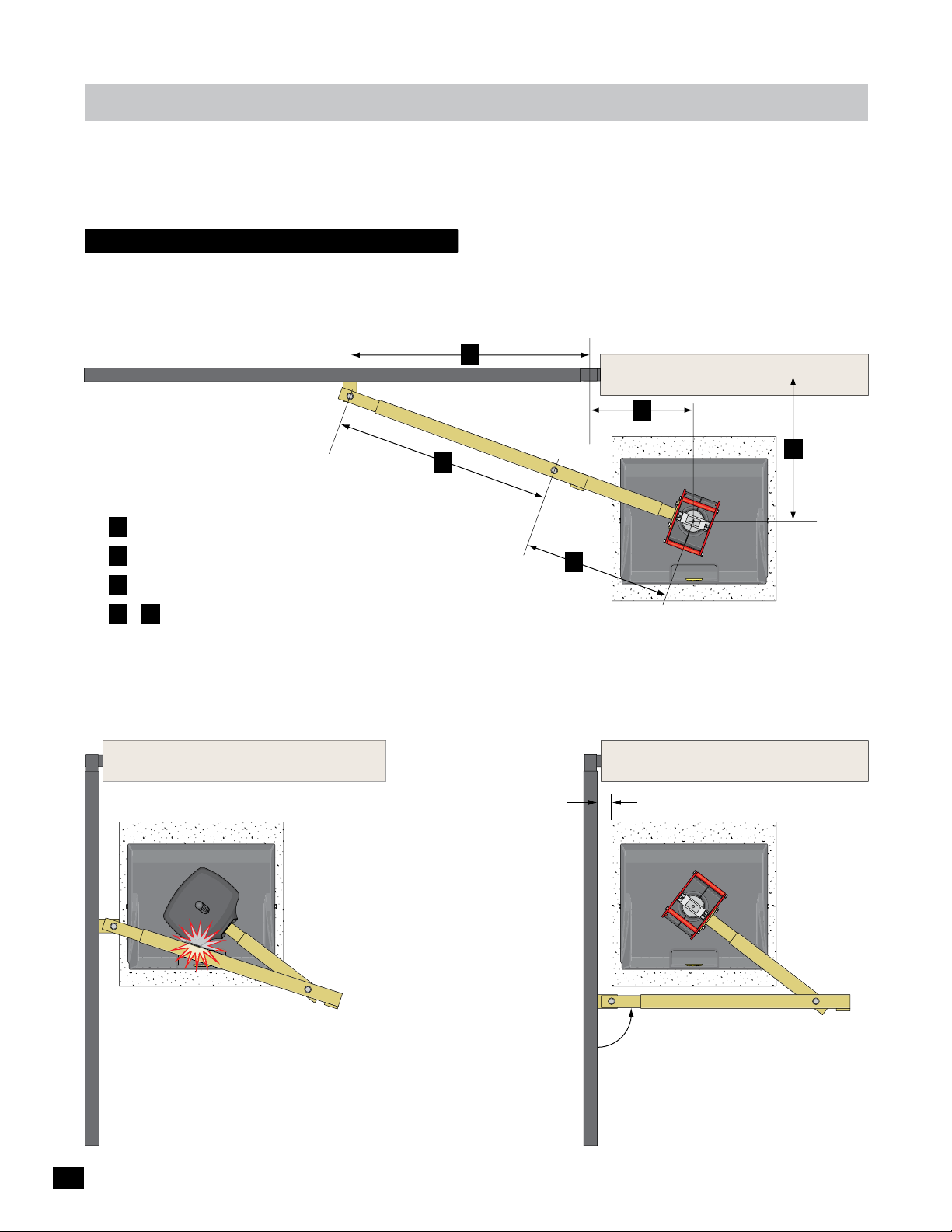

Gate Operator position

The gate must be properly installed and work freely in both directions prior to installation of the gate operator.

Closed Position

Gate Bracket Pivot Point

A

Hinge Pivot Point

Illustrations not to scale

Measurement Guidelines

A Should be at least 1/4 the gate length.

B 15” minimum for open gate clearance (2” thick gate).

C Distance “A” minus 8 inches (A - 8 = C).

D & E Arm should be 90° from gate when OPEN

and in the straight “locked” position when CLOSED.

Open Position

Locked Position

Long Arm

D

Longer

than “E”

Arm

Pivot

Point

E

Shorter

than “D”

15” Min

Short Arm

B

2” Min

C

Operator

Pivot

Point

Concrete Pad

24” x 24”

Outside Property

Inside Property

Hood

DO NOT allow arm to touch

hood in gate’s OPEN position.

TOO MUCH STRESS is put on

the arm in this position during

gate operation.

6

2” Gate Frame

Preferred arm position is 90°

from open gate. See page 10

for arm position options and

connection to gate.

installation

YES

NO

single Gate Operator

The gate must be properly installed and work freely in both directions prior to the installation of the gate operator.

See “Gate Operator Position” on page 6 for operator position.

Conduit Guidelines and Suggestions

• REQUIRED - AC input power wire to the GATE OPERATOR.

• OPENING cycle protection device wires (photocells) to the GATE OPERATOR. See page 13.

• CLOSING cycle protection device wires (photocells) to the GATE OPERATOR. See page 13.

• In-ground loop wires to the GATE OPERATOR. See page 14.

Secure gate operator to concrete

pad with four (4) 1/2” x 3” (min)

sleeve anchors.

Support Bar: See below

Arm MUST be installed level.

Illustration not to scale

1/2

6” Above Ground

Ground Level

“Optional” Input Power Note:

24VDC low voltage power wires can be run

from a remote power supply (MAX Magic

Box) to power the gate operator if desired.

See page 10 for more information.

Concrete Depth Note: The heavier the gate, the deeper the concrete

pad should be. At least two feet recommended for heavier gate.

Check local building

codes in your area for

depth of concrete

before installation.

Concrete Pad

Conduit

Input Power

Support Bar

A support bar should be installed at the gate bracket height across the ENTIRE gate to keep the gate pickets from bending.

Support Bar

Gate Bracket

YES

Support Bar Too High & Not Long Enough

NO

7

installation

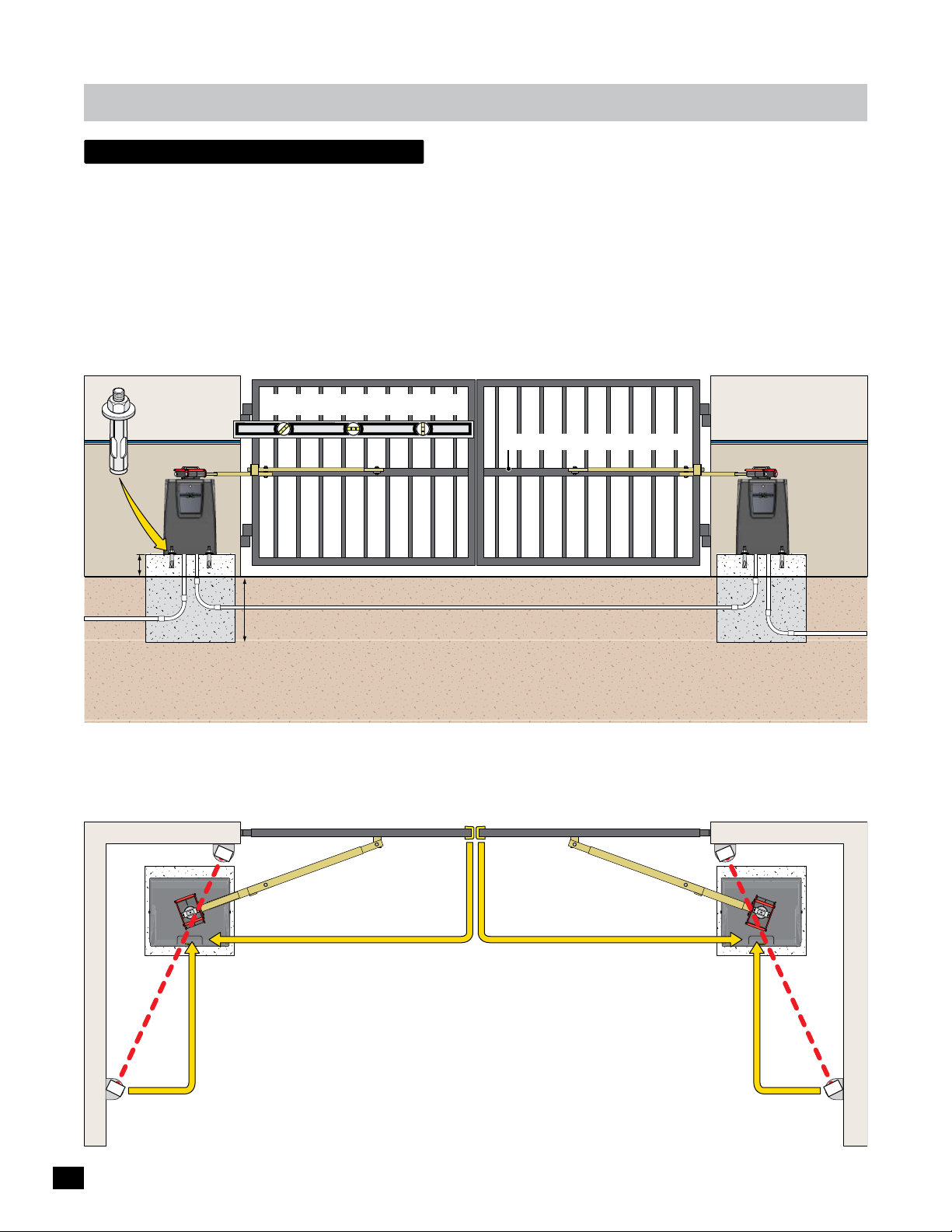

dual Gate Operators

The gates must be properly installed and work freely in both directions prior to the installation of the dual gate operators.

See “Gate Operator Position” on page 6 for operator positions.

Conduit Guidelines and Suggestions

• REQUIRED - Run AC input power wire to EACH gate operator.

• REQUIRED - Run RS-485 wires from SECONDARY operator to the PRIMARY OPERATOR.

Secure EACH gate

operator to concrete

pad with four (4)

1/2” x 3” (min)

sleeve anchors.

1/2

Secondary

6” Above

Ground

• Run UL 325 entrapment protection device conduits to EACH Corresponding GATE OPERATOR. (see below & page 13)

• Run the CLOSING cycle protection device conduit (photocells) to the PRIMARY OPERATOR. (page 13)

• Run in-ground loop wires to the PRIMARY OPERATOR. (page 14)

Illustration not to scale

Arms MUST be installed level.

Support Bars: See bottom of page 8.

Primary

RS-485

Input

Power

Concrete Depth Note: The heavier the gates, the deeper the concrete

pads should be. At least two feet recommended for heavier gates.

Check local building codes in your area for

depth of concrete before installation.

Input

“Optional” Input Power Note:

24VDC low voltage power wires can be run from a remote

power supply (MAX Magic Boxes) to power the gate

operators if desired. See page 10 for more information.

Power

Each entrapment protection device MUST be connected to corresponding gate operator.

Outside Property

Sensing Edges

Illustrations not to scale

Secondary

to Secondary Operator

Entrapment Area

to Secondary Operator

to Primary Operator

Inside Property

Primary

Entrapment Area

8

Photocell

(OPENING Cycle

ONLY)

to Primary Operator

Photocell

(OPENING Cycle

ONLY)

installation

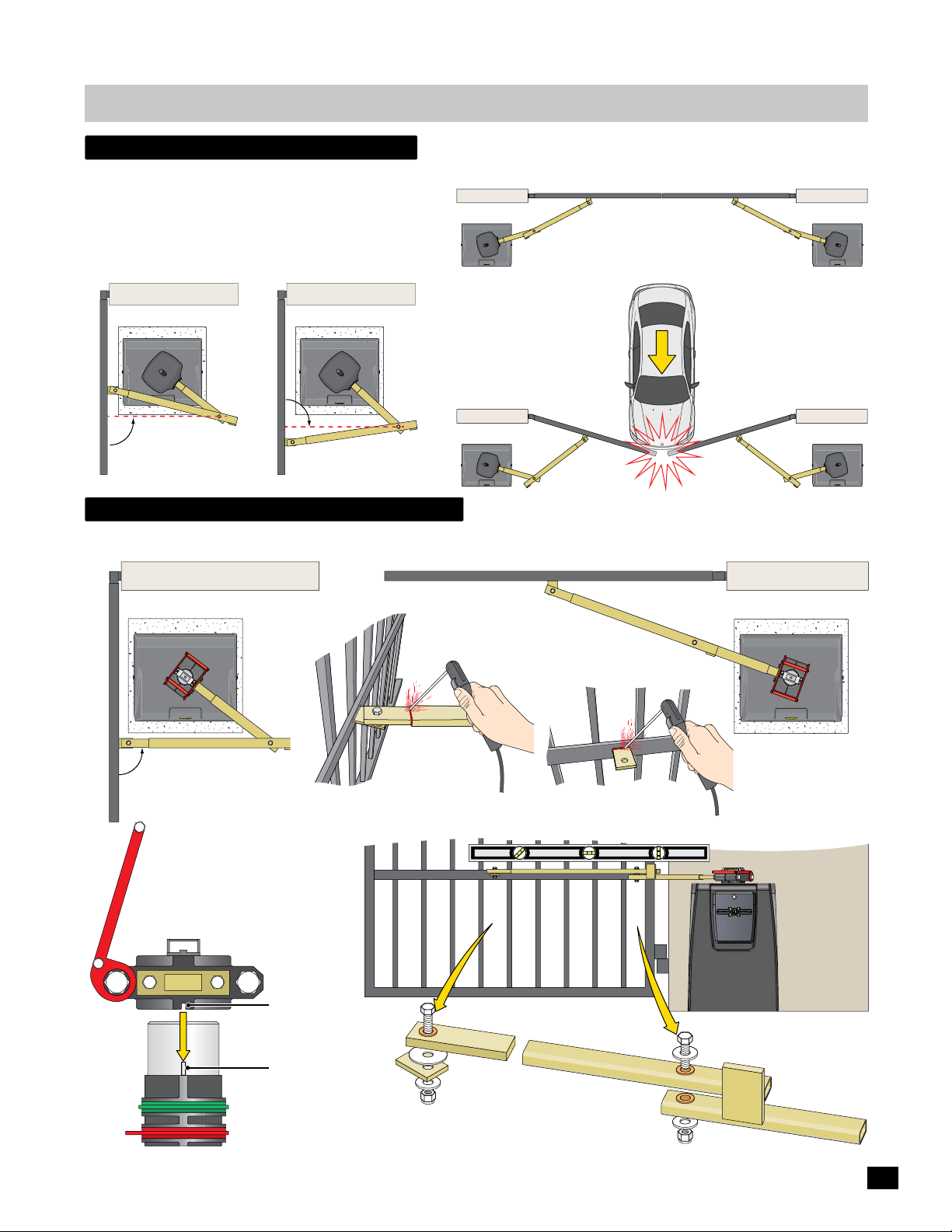

arm position options

Retro-Fit Arm Option

When replacing an existing gate operator, the arm may not be able

to conform to the preferred arm position (90° from gate in open

position). The positions illustrated below can be acceptable as long

as the gate operator cycles smoothly and there is NO gate hesitation

when gate starts cycling in either direction.

90°

Gate in Opened Position

arm connection to gate

After you’re satisfied testing the arm in the FULL OPEN and FULL CLOSED positions, weld gate bracket and arm.

90°

Gate in Opened Position

High Traffic Arm Option

Gates in Closed Position

Arms are NOT installed in LOCKED position.

If a vehicle tries to push gates

open, arms will give when NOT

in the locked position and allow

gates to move without damaging

the gate operators.

The tamper relay will be

activated for a few seconds

which will trigger a camera or

alarm system if desired.

Illustrations not to scale

Full Open

Preferred arm position

is 90° from open gate.

Re-Attach Arm to Operator:

Limit pin MUST fit into slot in

bottom of release handle clamp

directly under the arm when

re-attaching arm to operator.

Release Handle Clamp

Arm

Slot

Full Closed

weld completely around arm tubing and gate bracket.

Locked Position

Arm MUST be installed level.

Limit Tabs

Limit Pin

Gate Bracket

Assembly

Arm Elbow

Assembly

9

installation

W

A

R

N

I

N

G

H

IGH

VOL

T

AG

E

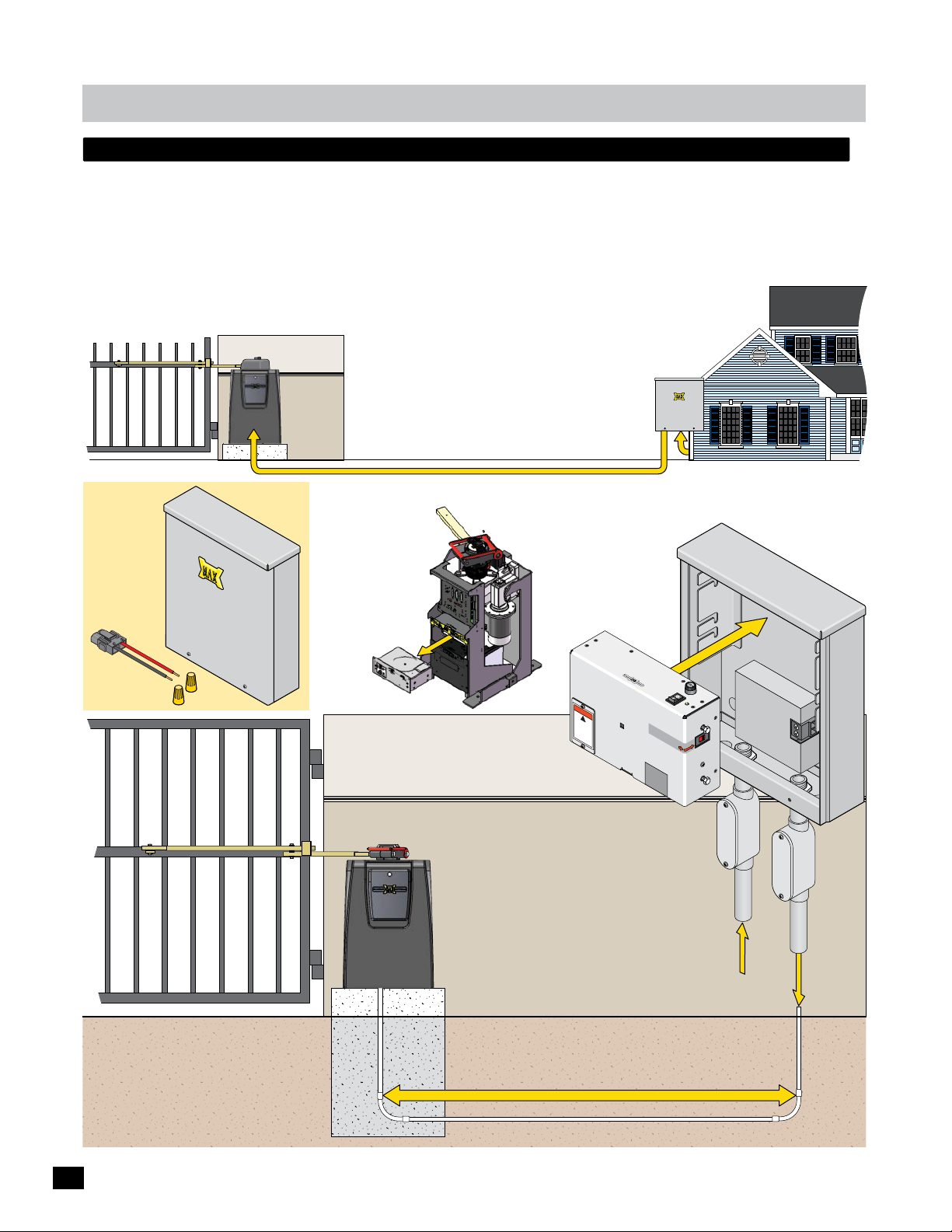

optional remote power supply kit - max magic box

A remote power supply is for installations where it is too costly or difficult to trench a 115/230 VAC power line to the operator

but instead run a low voltage power line to the operator. A MAX Magic Box Kit (sold separately) is required to remotely install

the MAX PS-24 power supply.

Install the MAX Magic Box near the 115 VAC or 230 VAC input AC power source, up to 500 ft away from gate operator.

Remove MAX PS-24 power supply from gate operator and place in MAX Magic Box. See page 18 for MAX Magic Box wiring

instructions.

NOTE: A MAX Magic Box kit is required for EACH gate operator when using dual gate operators.

Operator

MAX Magic Box

Near Power Source

500 ft MAX

115/230 VAC Power Source

MAX

Magic

Box Kit

2-Wires - 10 AWG Min.

24VDC Low Voltage Power

At MAX Magic Box

MAX PS-24

Power Supply

Removed from

Operator

Power/Solar

Connecto

r

Ground Level

Y

PL

P

SU

S-24

P

OWER

P

MAX

A

S

U

in

e

d

In

Wire

Nuts

WARNIN

G

!

HIG

VO

H

L

TA

disconnec

GE

power

se

t

before

rvicing

u

nit

Ma

AMP

SE

7

FU

F

ER

OF

W

PO

ON

IN

AC

Se

l

e

ct

115V

Input Vo

A

C

o

230V

r

ltage:

230VAC

w

a

rra

VOID

nty

i

f la

E

D

b

R

el is

E

MOVED

Conduit not supplied

r

e

ut Pow

Inp

Operator

24 VDC

To

In

put AC Power

At Gate Operator

24VDC Low

Vo

ltage

Power

Conduit

500 ft MAX

10

24VDC Low Voltage Power

Concrete Pad

solar

Refer to Solar application guide.

installation

MAX Solar

Panel

Approx. 45°

11

installation

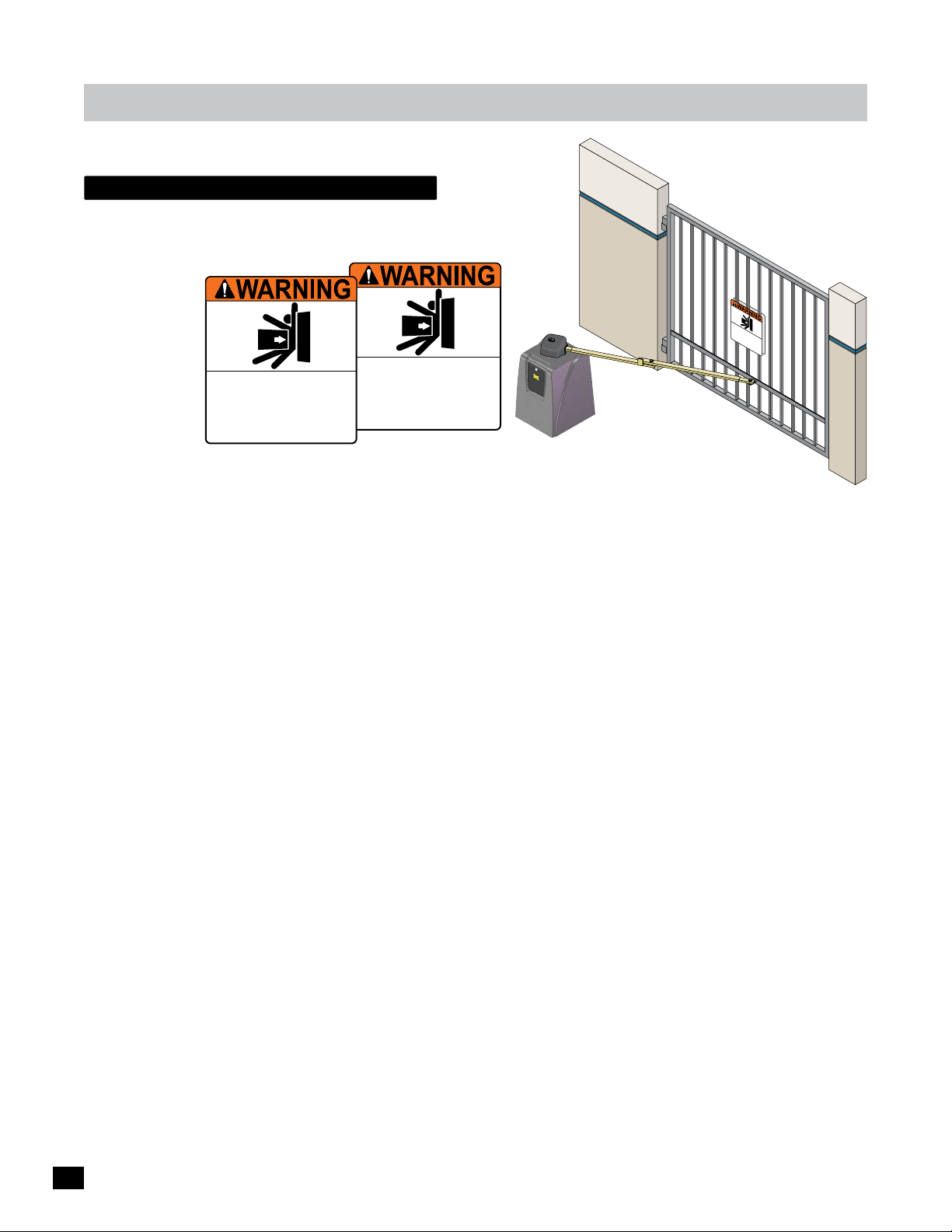

install warning signs

A minimum of two (2) WARNING SIGNS shall be installed,

one on each side of the gate where easily visible.

Moving Gate Can Cause

Moving Gate Can Cause

Serious Injury or Death

KEEP CLEAR! Gate may move at any time

without prior warning.

Do not let children operate the gate or play

in the gate area.

This entrance is for vehicles only.

Pedestrians must use separate entrance.

Serious Injury or Death

KEEP CLEAR! Gate may move at any time

without prior warning.

Do not let children operate the gate or play

in the gate area.

This entrance is for vehicles only.

Pedestrians must use separate entrance.

M

o

vi

Seri

ng

KEE

ou

G

w

P

at

it

C

s

h

L

o

I

e Can Caus

EAR

u

D

t

nj

p

o

r

!

n

io

ury

in

o

r

Ga

t

w

t

le

h

a

t

e

e

t

r

or De

c

n

g

Th

m

hildr

in

a

a

t

g

is

e

y

.

Pe

e

a

e

m

n

r

n

o

e

d

t

r

o

v

a

e

e

a

e

p

.

s

n

at

e

t

a

c

r

r

ia

t

e

a

an

h

t

n

is

e

s

y

t

f

h

m

o

tim

e

r

us

v

g

e

e

t

a

h

u

t

e

i

s

c

e

le

o

r

s

s

p

e

o

la

p

nly.

a

y

r

a

te

e

n

tr

a

nc

e.

12

Loading...

Loading...