Maximum Controls MAX 1500, MAX 2200, MAX F18 Installation Manual

Quick Install Guide for

MAX 1500 / MAX 2200

Slide Gate Operators

CONFORMS TO UL STD 325

UL CLASS - I, II, III, IV

CERTIFIED TO CAN/CSA STD

C22.2 NO. 247

SAFETY SENSORS REQUIRED

Version 8

Residential/Commercial

Brushless DC Slide Gate Operators

Made in USA

www.max.us.com

1

4009963

UL 325 2016 Standard-MAX Quick Install Rev 8

Table of Contents

Quick Install Guide

Installation Steps 1 thru 12

1 12

Gate Shut-Off Switch

Gate Tamper Feature

Dropping the Chain - Gate Tamper is Armed (ON)

Dual Gate Operators Wiring

Page

1-10

11

12

13

14

Troubleshooting

USB Black Box Port

Test Edge 1 Entrapment sensor

Gate Cycling Troubleshooting

Matrix 1 LED Troubleshooting

MC-200 LED Troubleshooting

BC-7 Module LED Troubleshooting

15

15

16

17-18

19

20

Commonly Used Safety Sensor Wiring

Omron E3K-R10K4

Omron IRB-RET

EMX IRB-MON Single Gate

EMX IRB-MON Dual Gates

Miller Gate Link

21

21

22

23

24

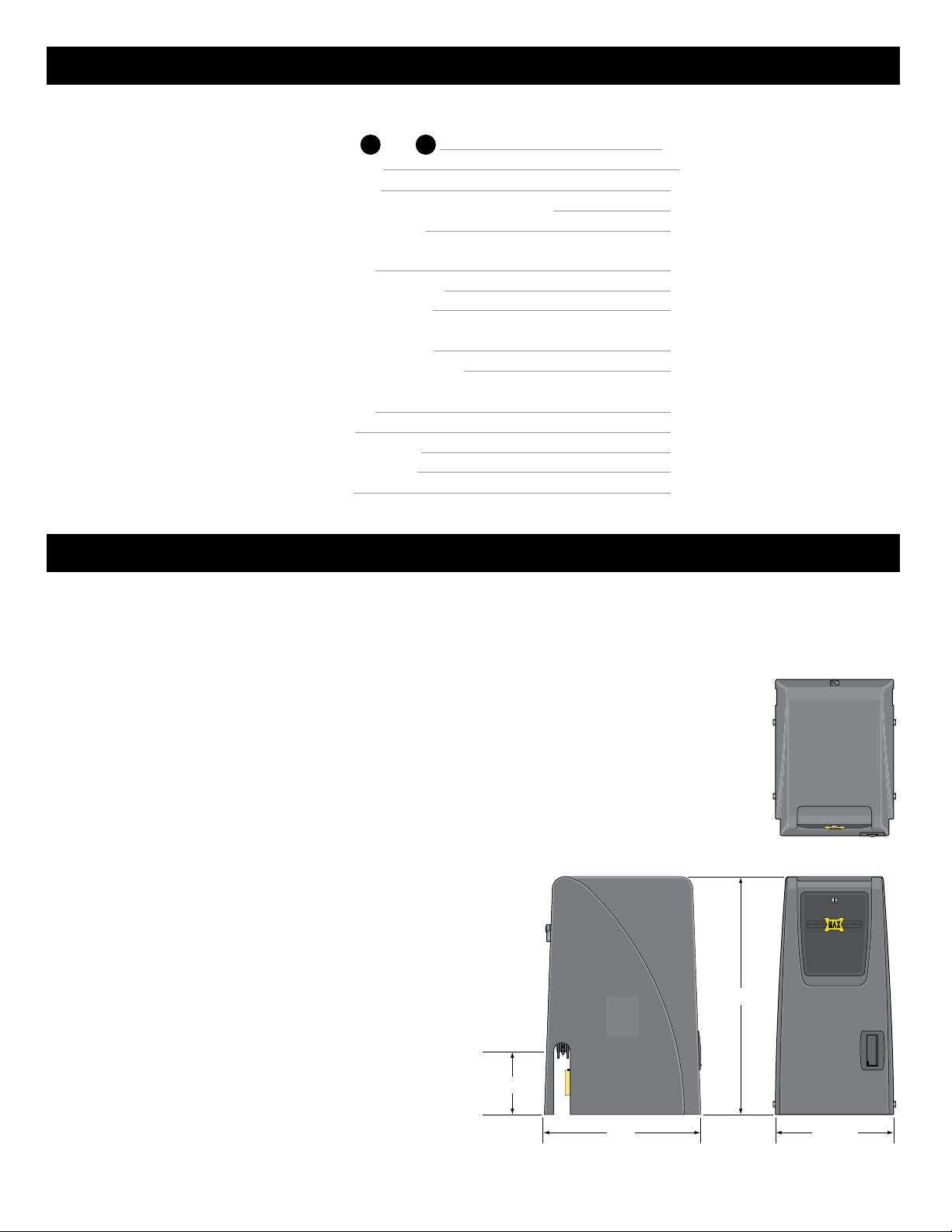

MAX 1500 / 2200 specifications

UL 325 Class of Operation - Class I, II, III, IV

Gate Type - Vehicular Slide Gate

Max Gate Length - 50 ft

Max Gate Weight:

• MAX 1500 - 1500 lbs Level Gate; 1000 lbs Uphill Gate - 5° Max

• MAX 2200 - 2200 lbs Level Gate; 1500 lbs Uphill Gate - 5° Max

Opening Time - Selectable speed control (MAX - 12 inch per second)

Cycles per Hour AC Power - Continuous

Battery Back-Up Cycles (Batteries fully charged):

• MAX 1500 - approximately 100 cycles

• MAX 2200 - approximately 100 cycles

NOTE: The number of gate cycles using ONLY battery back-up power will vary

depending on the weight of the gate, the gate length, the operating condition

of the gate, temperature and the amount of charge the batteries have at the

beginning of the battery power only operation.

Input AC Power/Amps - Switchable: 115VAC / 6 Amp, 1 phase

or 230VAC / 2 Amp, 1 phase

Motor:

• MAX 1500 - 1/2 HP 24VDC Brushless (6 million cycles)

• MAX 2200 - 1 HP 24VDC Brushless (6 million cycles)

Chain Size - #40

Operating Temperature: -4°F to 158°F (-20°C to 70°C)

Entrapment Protection:

- UL 325 Type A Inherent (ERD sensor)

- Inputs for NORMALLY CLOSED (N.C.)

UL 325 Type B1 (photo cell)

and Type B2 (sensing edge)

2

29”

7 1/2”

14 1/2”19”

UL 325 2016 Standard-MAX Quick Install Rev 8

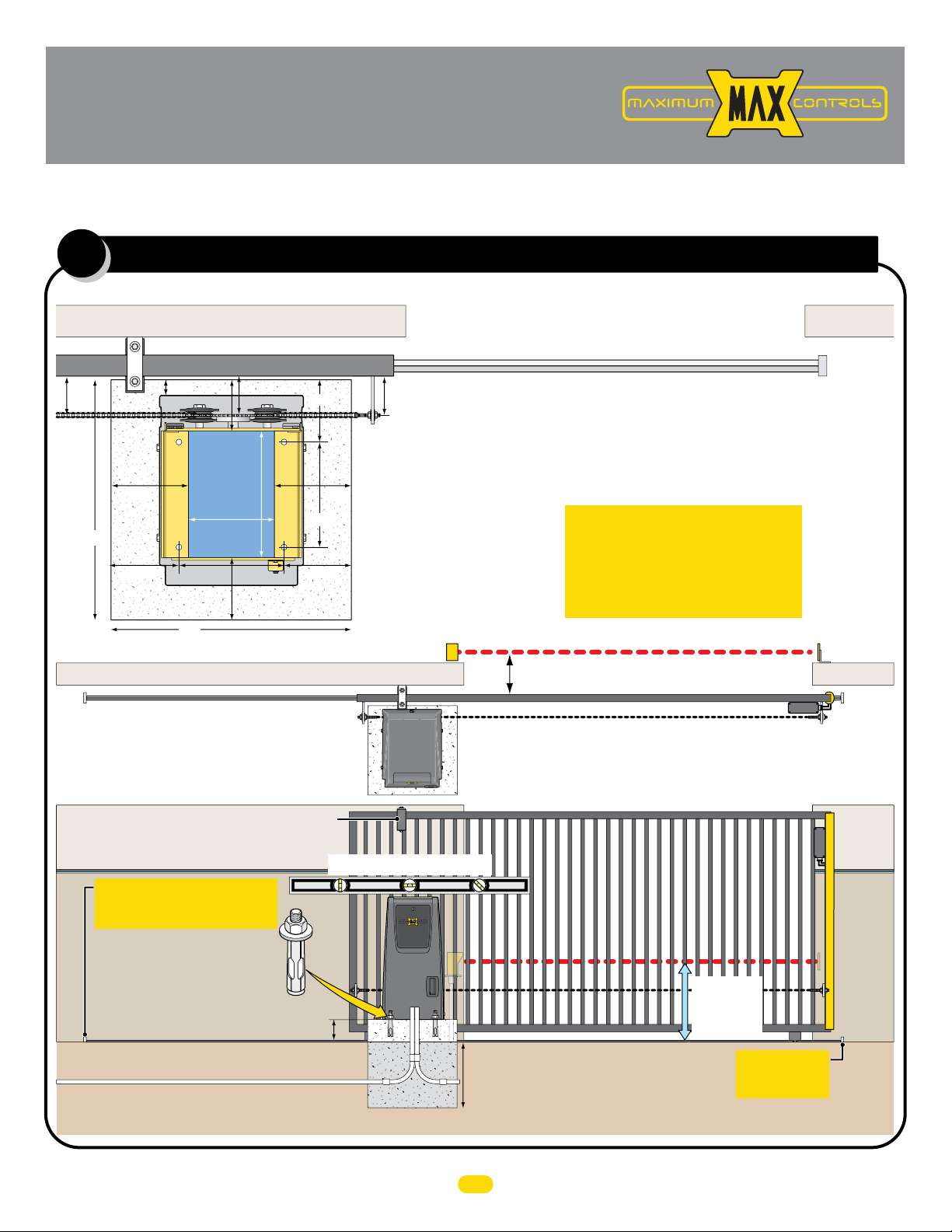

Quick Install Guide

www.max.us.com

For detailed installation instructions and COMPLETE information about ALL the available options & features for

the MAX 1500/2200/F18, please refer to the MAX 1500/2200/F18 Installation and Owners manuals.

Operator Placement (standard)

1

The gate must be properly installed and work freely in both directions prior to installation of the gate operator.

Guide Rollers

24”

6.75”

Outside Property

1.5”

24”

Conduit

8.625”

10.5”

12.75”

Area

2” Gate Frame

4”5”

Cover

6.5”

6.2”

7.5”7.5”

10.5”

6.75”

Concrete Pad

Photcell to MC-200 EDGE 1 Input

4”4”

Operator

Position on

Concrete Pad

V-Rail

Conduit Guidelines and Suggestions

• REQUIRED - AC input power wire.

• REQUIRED - Entrapment protection CLOSING photocell and/or

sensing edge - when not using Gate Link wireless transmitter.

• In-ground loop wires.

UL 325 2016 Standard

ONE Entrapment protection sensor

MUST installed or operator will NOT

function. It MUST be MONITORED

and NORMALLY CLOSED (N.C.).

CLOSING Photocell Beam can be 5” or less away from gate

Physical Stop

Reflector

Gate in Closed Position

Inside Property

Operator in Front Position (Standard)

Note: See manual when mounting operator in REAR Position.

Guide rollers MUST be Installed to keep gate upright.

Operator MUST be level.

IMPORTANT: Physical stops MUST

be installed on BOTH ends of rail to

keep gate from traveling off of rail.

Secure gate operator to

concrete pad with four

(4) 1/2” x 3” (min)

sleeve anchors.

6” above ground to avoid flooding.

Input Power

Concrete Depth Note: The heavier the gate, the deeper the concrete pad should be. At least two feet recommended for heavier gate.

1/2

Conduit Run

Concrete Pad

Check local building

codes in your area for

depth of concrete

before installation.

Photocell

Beam Height:

21” Normal

27.5” Max.

MUST be installed

Wireless

Module

IMPORTANT:

Physical Stop

CLOSING

Sensing

Edge with

Wireless

Module

Wireless

Module

CLOSING

Sensing

Edge with

Wireless

Module

UL 325 2016 Standard-MAX Quick Install Rev 8

1

2

YES

NO

YES

YES

NO

NO

NO

NO

NO

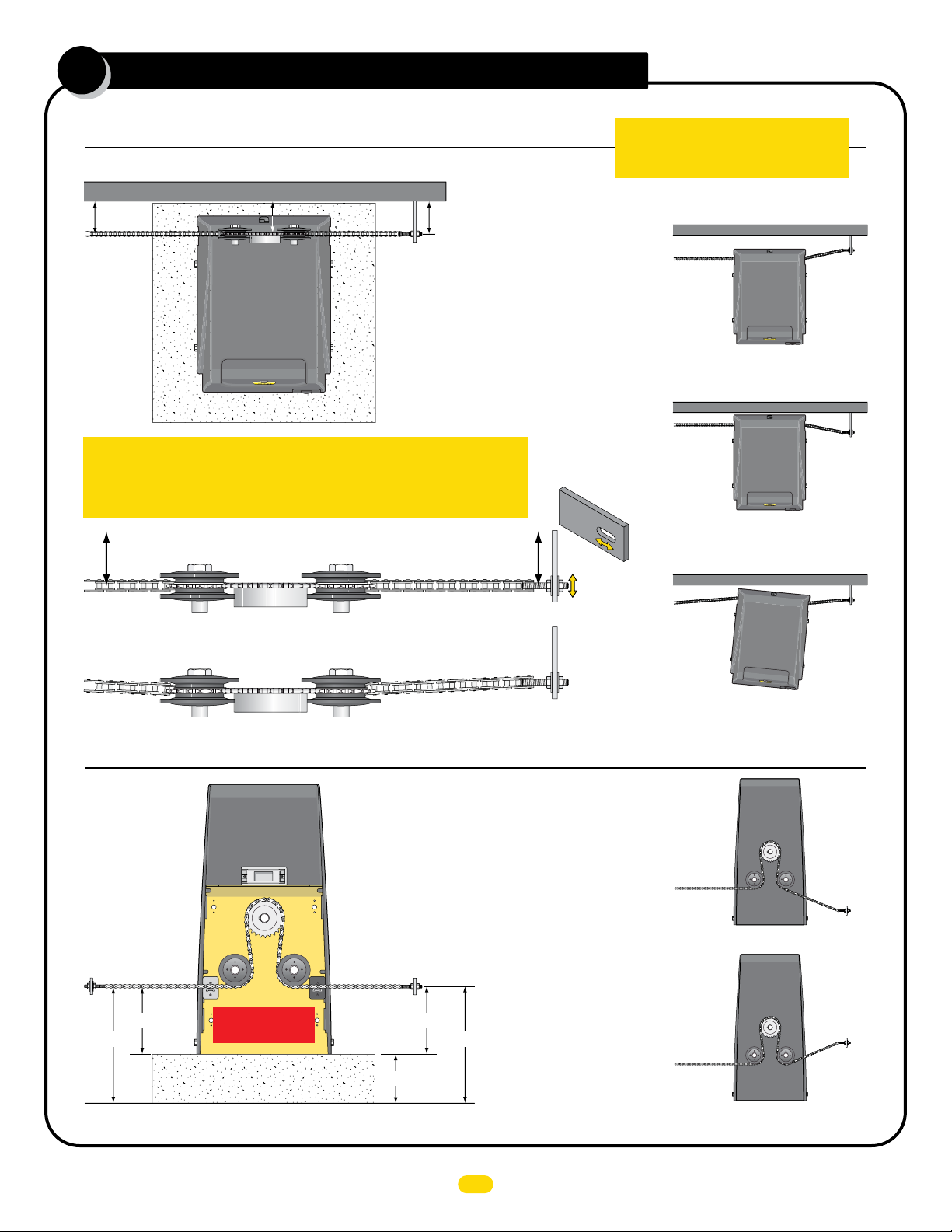

connect chain to gate

Top View of Operator

NOTE: 25 ft of #40 nickel plated chain included.

Minimum distance between the drive gear and gate is 4”.

4” Min4” Min

Drive

Gear

Chain

Bracket

YES

IMPORTANT: Operator and chain MUST be parallel to gate or the idler

wheels could fail. Use the “Fine Tune” adjustment on the gate bracket

connection bolt and make sure the chain runs through the idler wheels

without binding on the side chain guides.

YES

Side Chain Guide

Side Chain Guide

Idler Wheel

4” Min4” Min

NO

Gate Bracket

Fine Tune

Adjustment

IMPORTANT: Physical stops MUST be

installed on BOTH ends of gate rail to

keep gate from traveling off of rail.

NO

Operator is too far from gate.

Chain is NOT parallel to gate.

NO

Operator is too close to gate.

Chain is NOT parallel to gate.

NO

Operator is NOT parallel to gate.

Chain is NOT parallel to gate.

Back View of Operator

YES

Chain brackets MUST

remain same height as

idler wheels.

Chain

Bracket

Idler Wheels

Factory installed

position

Concrete Pad

Operator in Front Position (Standard)

Chain

Bracket

7.5”7.5”

6”

Note: See manual when Connecting chain

with operator mounted in REAR Position.

NOTE: The chain should

sag no more than one (1)

inch per 10 feet of travel.

Do not over tighten the

chain.

13.5”13.5”

2

NO

Chain

Bracket

DO NOT mount chain bracket too low on gate.

NO

Chain

Bracket

DO NOT mount chain

bracket too high on gate.

UL 325 2016 Standard-MAX Quick Install Rev 8

ac input power

W

A

RN

IN

G

HIGH

V

O

L

T

AG

E

A

T

T

E

NT

ION!

H

I

G

H

VO

LT

A

G

E

W

ARNING

HIGH

V

O

LT

A

G

E

3

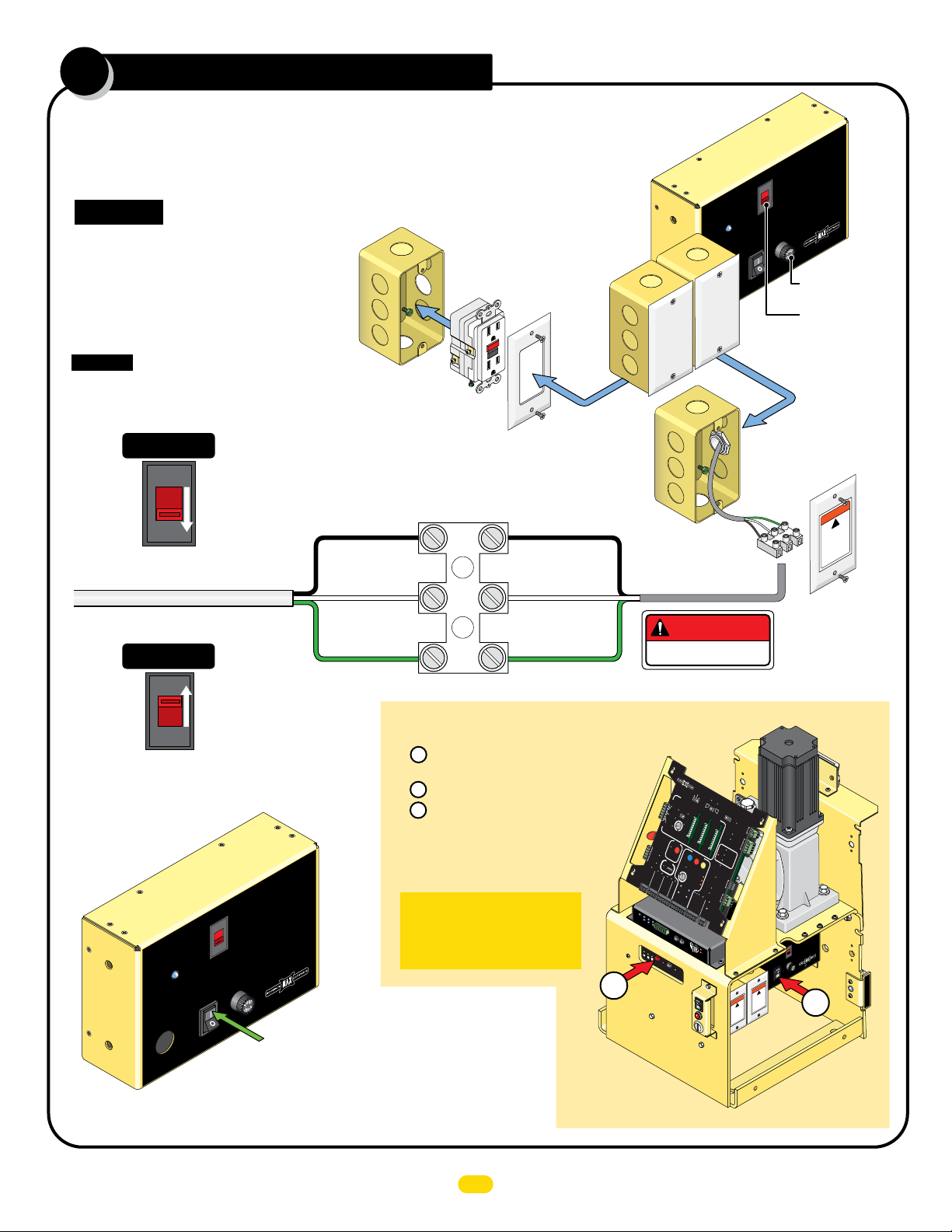

Choose either 115V or 230V setting on input AC power selector switch.

Wire desired input AC power wire to power terminal. A additional single gang box is provided to

install power outlets if desired. GFCI outlet type is recommended.

CAUTION: Make sure circuit

breaker is OFF from incoming

AC input wire BEFORE wiring!

Additional single gang box

provided. Wire GFCI outlet

to the input AC wire

BEFORE connecting to

operator power terminal if

power outlets are desired.

Input AC Power Options

CAUTION: If input AC power selector

switch is set for 115V but input power

is actually 230 V, 7 Amp Fuse will blow.

Single Phase 115VAC Only

115VAC

115V

Set to 115V

115 OR 230VAC

Power Wire

Single Phase 230VAC Only

230VAC

IMPORTANT: Make sure there are NO exposed bare

wires at the power terminal connection.

Chassis (Green)

Additional

Gang Box

Line (Black)

Neutral (White)

GFCI Outlet

NOT provided

Power Terminal

Line (Black)

Neutral (White)

Chassis (Green)

MAX

Toroid Box

AC

IN

Additional

AC

Power

Bo

Box

x

DANGER

HIGH VOLTAGE!

11

5

V

ER

OW

P

On

To

Off

AX

M

AC Power

Gang Box

Power

Terminal

Input

t

Selec

tage

Vol

AC or

5V

AC

11

230V

www.Max.US.com

FUSE

Amp

7

roid 15 Amp

7 Amp Fuse

Input AC Power

Selector Switch

WARNING

!

HIGH

LT

VO

sconn

di

power

icing unit

v

ser

E

AG

t

ec

before

Set to 230V

230V

Turn Power

ON

MAX

Toroid Box

AC

N

I

LEDs should light up on operator.

Battery power automatically turns ON.

Turn ALL Power OFF

1 Turn OFF POWER Switch on MAX Toroid Box.

Battery power will remain ON.

2 WAIT for 15 seconds.

3 Press and HOLD (approx. 5 seconds)

the RED ON/OFF BATTERY button until

MAX BC-7 LEDs turn ON,

then release button. LEDs will

turn OFF. (Up to 30 sec.)

t

pu

n

lect I

e

Se

g

or

Volta

AC

115V

5V

C

11

230VA

om

c

S.

.U

x

Ma

www.

FUSE

OWER

P

p

p

Am

7

MAX Toro

id 15

Am

n

O

Off

Turn Power ON

IMPORTANT: This procedure

must be followed whenever

ALL power must be turned

OFF on operator.

DO NOT

CYCLE

MC

Mo

3

OPERATOR!

3

MA

T

R

I

X

1

MA

B

AT

D

BACK-

E

i

T

n

E

USA

RY

U

P

M

ODE

LE

LE

AV

A

C

E

V

LO

E

O

SE

P

EN

D

P

RIM

OP

A

R

EN

G

Y

1

AT

A

TI

M

UT

E

E

OM

OP

EN

A

L

E

TI

F

T

C

OP

OP

AN

EN

R

EX

I

T

GH

TA

I

I

T

EN

T

IL

GA

M

/

AG

TE

C

L

L

O

OSE

O

CE

NT

E

R

SA

F

ET

Y

M

I

N

O

M

F

A

F

X

C

L

O

S

E

T

IME

ID

R

P

L

U

G

PA

RT

I

AL

O

P

E

N

12

V

D

C

G

N

D

P

O

SI

R

T

I

E

O

CO

24

N

V

R

D

C

DE

R

G

N

D

OBD

P

B

ORT

L

A

C

K

MAX

B

OX

G

M

IN

M

A

X

D

EPT

D

RADIO SIG.

R

RADIO GN

RE

D

I

F

E

L

/ RD

AX OPEN

D

GN

M

RIK

GN

D

PAD

Y

ST

M

GN

O

KE

P

N

R

I

GND

M

A

RY

GA

PHOTOCEL

T

E

GND

)

D

(+

GN

(-)

P

h

ot

oCe

P

OW

l

l

E

d

g

ER

e

Li

mi

t

-2

SW

2

00

t

o

UL

r

C

E

n

1

o

t

Ed

ra

n

p

t

g

ro

e

l

l

MA

e

r

TR

ON

I

X

-

L

I

NE

Cell

Photo

Edge 2

Edge 1

Jog RT

GND

Jog LT

J

OG

L

E

F

J

T

RI

E

1/

2

F

O

N

/O

F

Ba

F

Battery

t

Re

te

ry

pl

a

c

Ba

M

e

o

tt

d

e

u

ry

l

TEST

e

Ba

tte

PWR IN

ry

E

rro

r

D

N

OF

F

O

AT

E

SPE

LIMIT

SW

IT

O

C

N

L

INE

O

TO

R

LIN

E

SE

C

G

ATE

D

+)

(

GN

-)

(

MAX

LE

OG

GH

T

CK

E

OF

L

A

E

F

Y

X

C

IT

1.

ONTROL

5S

e

c

2S

e

c

MA

CEN

G

S

T

LO

E

R

CK

SAF

E

CO

TY

M

N

C

G

AT

E

TA

M

T

a

PE

m

p

R

e

r

N

O

CO

M

G

T

N

a

D

m

p

e

r

IN

PH

UL

MO

O

T

OCEL

T

O

R

MO

L

T

E

I

NT

O

N

R

E

AP

D

G

E

1

P

E

E

D

N

G

E

2

S

T

O

PCL

ID

PL

U

RE

G

E

O

VE

RROR

S

R

E

E

S

E

D

S

E

N

SITI

U

M

L

VI

OT

AL

T

O

Y

R

A

O

R

VER

ALAR

M

1

L

NO

O

2

A

LI

D

V

M

M

M

C

I

R

T

LAMP

OTOR

S

E

W

T

R

I

TC

E

S

S

LI

H

E

PP

/

T

I

NG

G

N

D

GAT

P

E

ower

S

T

A

H

TU

In

S

M

O

OT

I

P

N

OR

E

P

N

U

TS

C

O

B

A

M

T

T

CL

P

ER

A

C

OSE

Y

K

L

IM

S

W

IT

I

TCH

E

BA

A

L

T

A

T

R

E

M

R

Y

E

P

IN

U

SE

OPEN

M

STO

CLOS

PO

CO

GATE DISABL

D

O

1

1

5

N

6

14

1

3

1

2

3

4

5

E

R

ER

Se

Mot

D

n

si

Ov

ti

vi

ty

e

r

W

-

)

E

R

+

-

(

)

-

-

(

D

4V

2

GN

D

o

r

L

o

a

d

D

485

-

485

S-

V

GN

4

R

S-

2

R

M

R

A

W

T

B

R

P

O

I

ARD

X

put

t In

Selec

tage

or

l

C

Vo

A

1

1

5

V

5V

m

11

0VAC

.co

23

x.US

a

M

.

w

w

w

SE

U

F

ER

W

AC

O

P

IN

mp

n

p

A

O

7

m

A

5

1

ff

oroid

O

T

X

A

M

G

IN

RN

A

W

!

E

HIGH

N!

AG

O

I

T

t

L

O

e

r

V

TENT

onnec

fo

c

AT

is

it

be

d

un

!

g

in

power

ic

H

v

er

E

s

HIG

AG

T

r

he

nc

VOL

ra

nt

'b

a

en

e

i

t

d

av

e

r

t

n

'e

l

1

L

I

M

I

T

S

E

N

S

O

R

UL 325 2016 Standard-MAX Quick Install Rev 8

L

ground operator

WARNING

W

A

RN

I

N

G

4

Operator MUST be Properly GROUNDED

IMPORTANT: Operator MUST be grounded in lightning

prone areas or warranty will be VOIDED!

WARNING

connect chassis

to ground rod for

lightning protection

Proper grounding of this gate operator is a requirement for

LIGHTNING PROTECTION in lightning prone areas. To be effective,

ground connections should be made with a minimum 12 AWG, 600

volt insulated wire to a ground point within 3 feet of the gate

operator. The ground point must be at an electrical panel, a

metallic cold water pipe that runs in the earth, or a grounding rod.

Ground

within 3 ft

of operator.

Chassis

Grounding Rod

Ground

M

CO

AG

M

NC

OCK

LOCK

AGL

Y

A

M

ec

L

S

Y

2

DE

c

AR

e

S

5

IM

.

1

E

PR

T

F

F

O

GA

r NO

e

N

p

PE

M

m

T

a

O

T

H

CO

IG

Y

R

N

R

E

E

E

P

GND

O

OD

TT

T

BA

LEF

P M

U

E

V

N

A

E

E

BACK-

D

L

P

E

O

1

S

M

O

I

T

CL

1

IX

TR

A

VE

A

M

E

L

PEN

O

A

US

n

i

E

D

A

M

O

IC

T

A

M

TO

U

A

E

ANTI

T

A

G

TAIL

FF

O

N

O

T

XI

E

R

E

T

EN

C

Y

T

E

F

A

S

ID

G

U

PL

T

T

A

B

R

O

S

T

OT

U

P

M

N

I

n

I

r

e

w

o

WARNING

c

o

t

li

n

o

n

g

g

e

h

r

c

t

o

n

t c

u

in

nd

h

g

a

p

r

s

o

r

s

o

d

i

t

for

s

e

c

t

io

n

1

2

3

L

I

M

I

T

S

E

N

S

O

R

P

R

OTO

M

IN

r

e

ATE

LS

G

amp

T

R

O

E

PE

TR

AM

T

N

O

C

TY

E

E

L

F

S

SA

OCEL

LO

OT

/C

PH

N

E

P

XIT

E

N

I

F

F

M

O

OSE

CL

C

D

V

2

1

D

N

G

LIM

W

S

RY

V

E

4

2

K

C

A

P

G

1

R

E

DG

NTE

E

CE

2

GE

D

E

L

U

G

U

AP

PL

R

T

R

ID

N

O

E

ERR

V

2

1

T

E

ARM

R

AL

M

T

E

AR

UL

ES

AL

R

ND

G

N

O

I

T

O

M

R

O

T

O

M

AX

M

ER

IM

T

AL

I

T

R

N

PA

E

OP

SITIO

PO

ECOR

R

M

R

A

L

A

T

I

H

C

T

I

C

D

D

N

D

.

G

I

S

O

I

D

A

R

P

MC

ot

M

OPEN

SE

COM

O

CL

Y

T

P

CLOSE

I

V

E

O

T

TI

I

ST

S

N

GA

E

S

US

E

D

A

Y

N

RS

O

E

R

L

V

R

E

STAT

E

E

T

R

V

OPE

T

O

R

BA

/

O

T

H

O

C

T

M

IN USE

NG

I

SWI

P

T

P

D

I

L

MI

I

S

EE

L

AX

R

O

M

E

MP

N

SP

A

L

W

E

C

T

N

ER

D

T

OR

P

BD

BO

O

K

BLAC

PT

E

N

D

G

O

I

D

A

R

P

R

E

W

O

0

tr

20

n

-

r Co

o

PO

GA

E

L

-

B

V

N

-

4

MI

2

D

-

D

SA

R

N

)

I

-

G

W

(

-

N

P

V

)

AX

D

+

85

M

X

MIT

(

G

I

4

4

H

L

-

C

S

85

E

2

IT

4

X

R

E

I

-

W

N

T

S

S

R

D

LI

R

M

R

A

SE

AT

A

ON-

M

O

P

G

O

B

N

CO

O

OR

T

E

CL

NE

MO

P

C

LI

ST

-

SE

N

O

O

E

T

A

G

)

D

Y

L

(-

N

R

R

)

L

G

MA

I

R

D

E

E

P

(+

T

A

G

C

)

D

-

/ R

(

O

N

)

T

G

D

+

(

O

N

AD

D

G

PH

N

YP

KE

D

I

G

PEN

N

R

KE

O

T

G

D

S

X

N

A

D

G

E

N

M

R

G

I

F

Li

e

dg

E

ell

2

oC

hot

1

M

N

dge

O

E

L

U

ap

r

t

En

r

e

oll

D

R

E

3

2

1

1

4

1

r

5

o

1

ot

6

d

1

M

a

o

L

er

v

O

X

3

A

4

N

5

M

O

D

E

L

D

y

t

R

i

v

E

i

t

si

n

e

S

G

O

T

J

H

G

I

G

R

JO

T

F

E

L

Jog LT

Jog RT

W

S

t

i

m

Edge 1

GND

Edge 2

Photo

Cell

X

RI

T

E

A

N

I

L

-

e

l

odu

M

y

er

tt

Ba

N

I

y

r

e

t

t

a

B

or

r

r

E

T

S

TE

y

r

e

t

t

e

c

Ba

a

l

p

e

y

F

R

r

e

F

F

O

Batt

/

N

1/2

y

O

r

te

t

E

Ba

NOTE: Consult city codes for AC line wiring.

Beware of existing underground services.

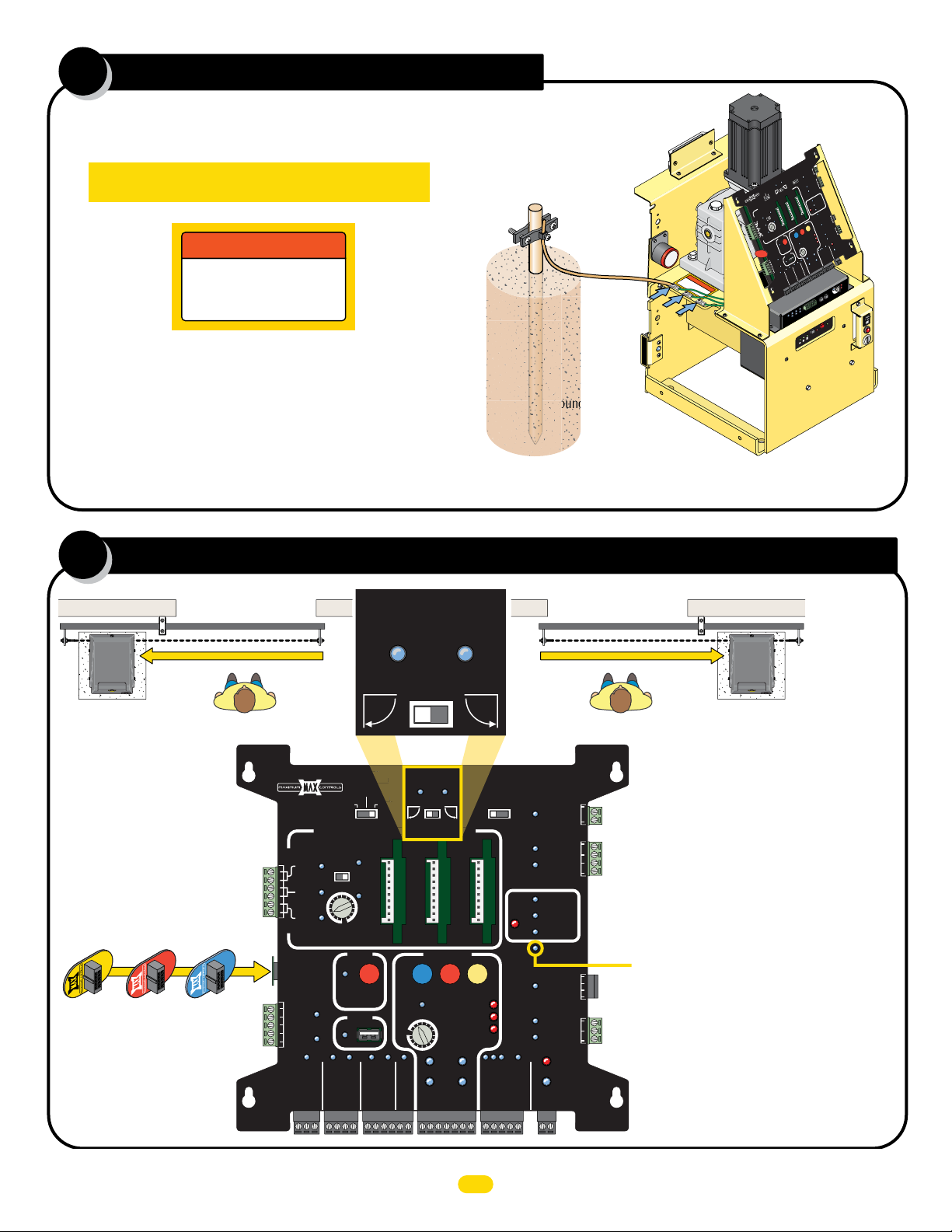

set opening direction and id plug

5

ID plug MUST be plugged in.

00

MAX 22

ID Plug

MAX 1500

ID Plug

MAX 1500

MAX 2200

MAX F18

ID Plug

Any of the THREE Chassis Grounds can be used. They are located next

to the gear reducer. DO NOT remove any existing green ground wires.

PRIMARY

GATE

OPEN

LEFT

OPEN

RIGHT

OPEN RIGHTOPEN LEFT

Set the desired opening direction.

MATRIX 1

MADE in USA

EXIT

CENTER

SAFETY

F18

MAX

PLUG

ID

12VDC

GND

24VDC

GND

RADIO SIG.

BATTERY

BACK-UP MODE

LEAVE

CLOSED

LEAVE

OPEN

OPEN

1 TIME

PRIMARY

OPEN

LEFT

GATE

OPEN

RIGHT

AUTOMATIC OPEN/CLOSE CONTROLS

ANTI

TAILGATE

OFFON

MAX

MIN

OFF

CLOSE TIMER

FIRE DEPT

RADIO GND

PARTIAL

OPEN

POSITION

RECORDER

OBD PORT

BLACK BOX

GND

MAX OPEN

STRIKE

GND

GND

MIN

MAX

KEYPAD / RDR

GND

OPEN

MAX

GATE SPEED

PHOTOCELL

GND

MOTOR MOTION

STOP CLOSE

REVERSE SENSITIVITY

LIMIT

SWITCH

ON-LINE

MOTOR

ON-LINE

PRIMARY

GATE

(+)

GND

(-)

SAFETYCENTEREXIT

MOTOR OVERLOAD

NO LIMIT SWITCH /

CLAMP SLIPPING

SEC

GATE

(+)

GND

(-)

MAGLOCK

OFF

OPEN

DELAY

STOP

2Sec1.5Sec

GATE

TAMPER

UL

ENTRAP

GATE

STATUS

CLOSE

COM

MAG

LOCK

PHOTOCELL

UL ALARM 12V

GATE DISABLE

COM

Tamper NO

COM

GND

Tamper IN

EDGE 1

EDGE 2

ID PLUG

ERROR

ALARM RET

RESET

GND

OPEN

CLOSE

BATTERY

IN USE

POWER

24V

GND

COM

NC

Dual Gate Operators NOTE: Secondary

operator will automatically be set to

the opposite opening direction as the

primary gate operator.

ID Plug Error: If ID plug is NOT plugged in,

board will constantly beep and operator will

NOT function.

NOTE: See manual for more

information about Matrix 1 settings.

UL 325 2016 Standard-MAX Quick Install Rev 8

4

install and adjust limit sensors

6

The limit sensor activators MUST be

installed on BOTH ends of chain to

indicate the OPEN and CLOSE positions

of the gate or DAMAGE will occur. They

will activate the corresponding LIMIT

SENSOR (Gray or Black) when they

move within range, stopping the gate at

the desired positions.

Back

View

Bracket

Plu

g

GRAY

Limit Sensor

Gate

LED lights when

sensing a limit

sensor activator

(Magnet).

Limit Sensor

Activator

(Magnet)

IMPORTANT: LEDs MUST light up when gate

reaches OPEN and CLOSE positions or operator

WILL NOT learn gate positions. If gate positions

are not learned, gate cycling speed will remain

slow during normal operation.

Limit Sensor

Activator installation

Gate

Plu

g

Plug

BLACK

Limit Sensor

IMPORTANT: Limit Sensor Activators

MUST be installed on BOTTOM of chain

Bracket

as shown.

Factory Installed

GRAY Limit Sensor

Limit Sensor

Activator

Note: See manual when installing limit sensors

with operator mounted in REAR Position.

JOG Left/Right Buttons on MC-200

PhotoCell

POWER

MC-200

Motor Controller

Push and HOLD the JOG LEFT or JOG RIGHT buttons

accordingly to move the gate (release the button to stop gate).

Operator in Front Position

(Standard)

Limit SW

UL

Entrap

Edge

2

1

Edge

MATRIX

ON-LINE

Jog RT

Edge 2

Edge 1

Jog LT

Photo

Cell

GND

JOG

LEFT

JOG

RIGHT

MAX

LED ON

Sensitivity

Factory Installed

BLACK Limit Sensor

Limit Sensor

Activator

14

15

13

16

12

ERD

3

Motor

4

5

OverLoad

ERD

Install Limit Sensors:

Use JOG Left/Right Buttons on MC-200 for installation

1. JOG gate to CLOSE position.

2. Mark magnet position on chain.

3. JOG gate open slightly and install magnet.

4. JOG gate to OPEN position.

5. Mark magnet position on chain.

6. JOG gate closed slightly and install magnet.

7. Gate positions can now be learned AFTER at least

ONE entrapment protection device has been installed

(see & ).

Breather Pin

7 8

CAUTION

OVE

EM

R

BEFORE

ATION

OPER

IMPORTANT:

Remove breather pin

from gear reducer

BEFORE cycling

operator.

UL 325 2016 Standard-MAX Quick Install Rev 8

5

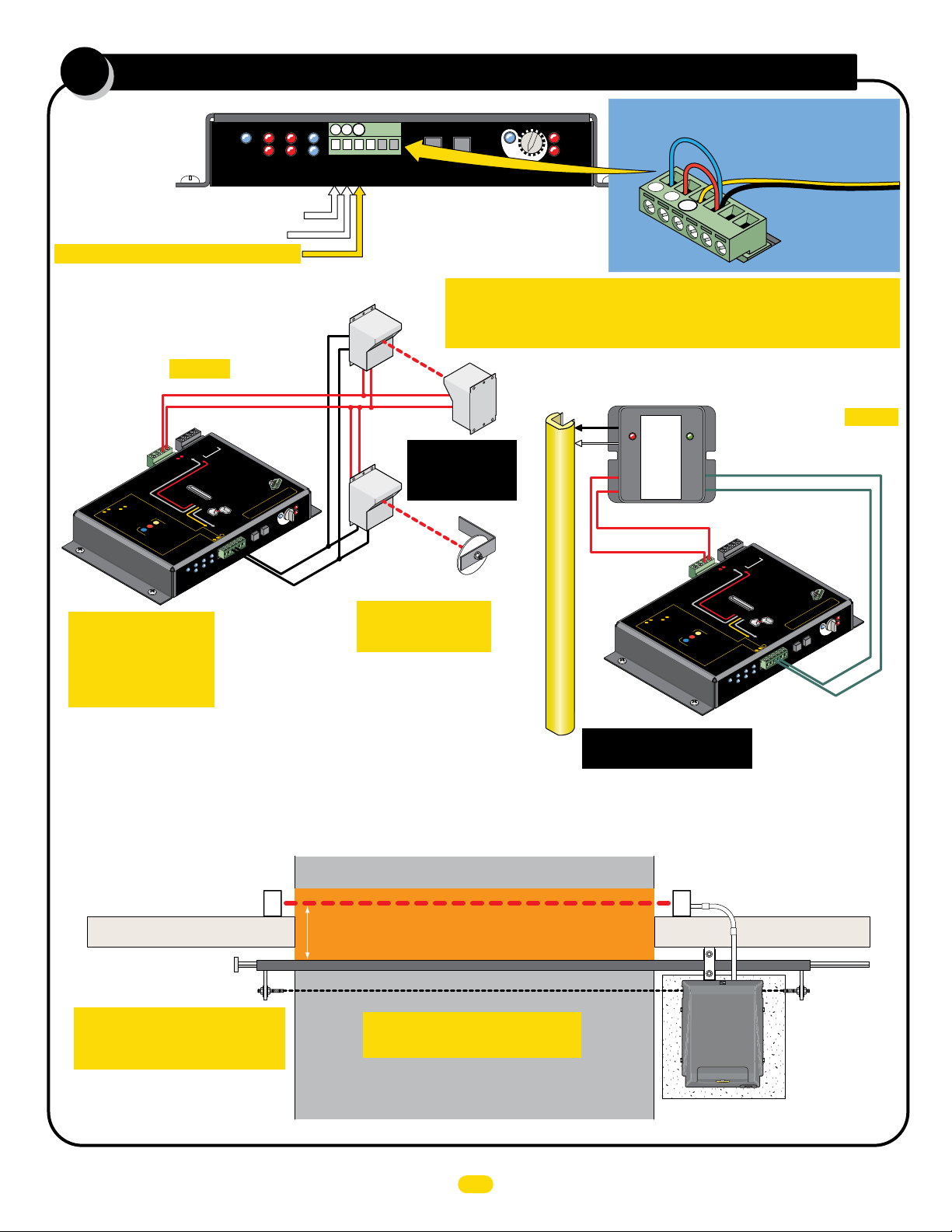

entrapment protection wiring

G

N

D

1

2

3

GN

D

1

2

3

7

PhotoCell

Edge

POWER

MC-200

Motor Controller

UL

Entrap

Edge

Photo Cell: LEARNED MONITORED OPEN/CLOSE

Edge 2: LEARNED MONITORED OPEN/CLOSE

EDGE 1: MONITORED CLOSE ONLY

Typical Wiring For:

Normally Closed (N.C.)

Photo Cell to EDGE 1

NOTE:

Matrix 1 MUST be

removed to wire

MC-200.

Power In

OR

be “

MOT

nsors

3

MUST

se

ts

&

R

2

O

s

IT

inpu

t

N

N

RED

npu

I

MO

nput

TO

i

to

o

t

o LEAR

T

d

d.

MONI

e

re

.

i

1

w

earn

l

umper

j

Rev

.

2

ALARM

CH

LIMIT

IT

SW

RY

E

T

K

t

C

AT

B

PA

w

er en

w

R

TO

sors

po

Y

L

MO

sen

N

INPUTS

O

MC-200 P

”

D

NE

R

EA

L

be

e

b

n

:

be

.

a

T

c

3

S

n

UST

&

ey

ca

M

h

t

MU

l

l

2

rs

s

e

o

C

P

s

n

o

O

nput

1

e

.

i

FORE

T

.

s

S

x

3

d

S

in

e

Phot

BE

tri

g

&

s

or

s

a

e

u

or

2

b

M

t

d/

EN

un

u

n

on

a

OP

np

i

e

Any

mode

ge

he

er

im

.

d

t

t

h

d

E

arn

e

eit

N

le

O

ng

,

o

ame

t

s

OTI

rd

HOLD

d

M

ersi

a

c

SE

he

re

i

t

O

di

nd

OR

he

t

n

a

w

CL

i

OT

s

a

i

.

s

e

M

s

p

b

re

ons

ee

t

min

P

t

b

TOP

5

u

3.

S

r

il

c

b

t

a

fo

n

e

u

s

t

r

s

o

f

la

ED

OPEN

L

.

ON

de

0

.

o

wh

e

0

s

g

b

m

0

-2

in

0

p

C

rn

d

LL

e

-2

e

I

M

s

ea

W

be

n

u

L

MC

o

s

y

r

re

u

b

D

H

o

a

b

T

LE

ns

rs

.

e

o

4

OP

s

BO

t

s

T

n

r

ra

e

o

S

e

s

s

p

f

s

st

o

rn

a

Pre

le

ing

.

p

5

o

t

e

s

t

e

u

b

p

n

I

IMPORTANT Sensing

devices MUST be

powered by MC-200

or they will NOT be

MONITORED.

me

p

ra

MC-200

h

it

d

e

t

a

c

e

t

de

h

LL

I

W

s

du

n

e

.

g

a

on

d

t

t

n

a

rs

o

.

s

p

w M

o

o

n

re

a

E

-

-

-

ectio

t

ro

WR

p

P

nt

MU

12V

WR

Monito

Rever

d

e

t

ON

e

b

l

min

a

5

in

h

mo

t

i

w

rn

n

i

a

lea

d

n

e

ORED

T

I

N

O

me

put

rap

n

I

nt

POWE

MC-200

Motor Controller

V -

-) -

GND -

(

5

48

-

RS

2V

1

RS-485 (+) -

ND

R

G

MATRIX

PW

n

12V

nt

ed

me

r

o

ap

be us

ns

T

ntr

e

S

E

S

MU

WILL

sensor

ator

A

N

•

oper

Wire

•

MO

operator

d

e

r

g

n

i

s

ed

Edge

r

OR

P

Monito

Edge

GN

.

Ph

Edge

,

e

d

oto

2

C

e

ll

.

n

o

3

er

p

cti

s

t

e

pu

jum

T

in

S

U

nt Prot

sed

M

:

nu

s

u

SW

t

Limi

ge

d

E

2

otoCell

h

X

P

1

ATRI

M

N-LINE

O

Edge

R

UL

trap

n

E

GND

PWR 12V

Polarity does NOT matter

PWR 24

1

or

1

E

s

ection

ot

ne

DG

i

E

.)

Pr

n.

idel

o

N.C

(

Gu

ncti

D

wired to

E

an

fu

T

be

c

NLY, to each

OS

O

L

ST

s

C

NO

MA

R

O

RE

TO

NI

are used.

Reversing

•

o

hot

Cel

Jog

Jog R

D

1

2

Photo

Cell

r

Y

hen dual operators

so

L

oto Cell

n

w

L

D

N

puts.

G

E

-2

ow

p

•

-

dge and/or Ph

ANY

P

00

MO

er

NUS

U

JU

Jog LT

Jog RT

1

In

2

3

be used to

T

n

of the 3

r.

MUS

sensors.

emai

cu

r

D

E

oc

o

12V

ST

R

OR

ucti

W

IT

N

install

on instr

or fault will

inputs MU

D

lati

E

ce d’

l

ED

i

R

nsta

i

MPE

ee

oir la not

S

V

:

:

15

ON

ON

16

TI

UTI

A

EN

C

TT

A

3

4

N

5

MAX

O

LED

ER

Sensitivit

JOG

RIGHT

JOG

LEFT

se

200

D

-

MC

’s

ired to

w

e

b

MC

•

l

L

T

T

-

-

1

Edge 1

GND

Edge 2

CLOSING Direction ONLY

NOTE: See manual for more information about

photcell and sensing edges installation and wiring.

Limit SW

23

2

1

MATRIX

ON-LINE

Cell

Edge 2

Photo

Recr

M

C-

2

00

Sl

i

d

e

ns.

ation.

ERD

3

2

1

1

14

d

Motor

Loa

Over

D

y

ND (C)

G

EDGE 1 (N.C.)

1

Jog RT

Edge 1

GND

Jog LT

JOG

LEFT

JOG

RIGHT

NOTE: See manual for more

information about learned

monitored inputs.

ONE Entrapment protection sensor MUST be installed or operator will

Thru-Beam

Power

Power

NOT function. It MUST be MONITORED and NORMALLY CLOSED (N.C.).

Power

Trans

See pages 21-23

for specific

photocell wiring.

Reflective

Beam

Reflector

IMPORTANT: Photocells

MUST be in alignment

or fault will occur.

MAX

LED ON

14

15

16

3

4

5

ERD

Sensitivity

13

12

ERD

Motor

OverLoad

Jumper UNUSED Entrapment Protection

3

2

1

hoto

P

Edge 2

EDGE 1

UL 325 2016 Standard

Typical HARDWiring For:

10K Edge

Normally

Closed

GEM - 104

ON = Obstruction

BLINKING = Fault

MON.

PWR

SAFETY

INPUT

GEM-104 MUST be used.

PWR 12V

Polarity does NOT matter

GND

R

TO

O

M

INPUTS

Power In

”

ED

RN

EA

OR

L

e

b

e

b

n

:

MOT

a

T

c

3

rs.

ST

&

ey

so

MUST be “

MUS

h

t

n

MU

2

3

rs

s

o

se

ts

s

&

put

u

R

n

t

n

p

2

e

i

FORE

O

S

d

s

IT

in

e

Pho

Sensing Edge

See page 24 to wire a Gate

Link wireless transmitter.

BE

D

N

s

N

r

u

ts

put

R

2

RE

t

d/o

In

MO

un

u

n

npu

TO

i

p

a

to

OP

n

i

o

e

t

Any

o LEA

e

r

g

.

T

d

h

e

.

d

d

t

h

d

MONI

e

E

re

.

it

i

e

1

r

e

g

w

e

o

p

t

earn

l

same

rsin

rd

HOLD

d

e

a

um

j

d

e

he

re

i

t

n

t

a

w

Rev

a

.

is h

s

e

M

2

s

s

p

b

n

e

re

o

e

t

P

t

b

.

u

3

il

b

t

n

u

Inputs to GND or a fault will occur.

Sensor Wire

GND

Example: Inputs 2 & 3

are NOT used and MUST

be jumpered to GND.

Normally Closed (N.C.)

Sensing Edge to EDGE 1

(CLOSING Direction ONLY)

V -

-) -

GND -

(

PWR 24

5

48

-

RS

1

-

2V

1

RS-485 (+) -

-

ND

R

-

G

MATRIX

PW

n

io

ALARM

ect

12V

IT

WR

H

P

IM

L

nt prot

ITC

me

SW

RY

E

T

rap

K

t

MC-200

C

AT

h

B

it

PA

be us

w

er en

ST

rs

so

MU

pow

Y

L

sen

N

12V

O

WR

P

MC-200

d

e

r

s

Monito

Rever

e

b

can

l

l

e

C

o

1

.

.

s

x

3

STOP

i

in

r

tr

g

&

o

e

b

Ma

EN

e

n

d

o

e

mo

im

t

rn

a

N

le

d

O

I

,

e

t

OT

a

M

c

SE

O

d

di

e

n

CL

i

t

OTOR

c

ON

.

e

n

t

e

b

mi

de

5

.

h

LL

r

n

I

c

i

l

o

a

f

W

m

,

e

s

e

s

t

5

r

dua

d

o

PEN STOP

f

in

n

ED

O

las

h

mo

L

e

it

.

ON

d

w

whe

0

rn

.

e

0

n

g

s

i

b

mo

0

lea

-2

a

in

.

0

g

p

.

C

d

rn

d

LL

a

e

n

-2

a

e

I

e

M

s

e

e

W

b

n

u

L

on

d

t

MC

o

t

s

y

n

r

ORED

re

u

b

D

a

H

o

a

T

b

I

E

s

rs

L

N

n

rs

.

o

e

o

4

OP

s

BOT

t

n

r

s.

ra

MO

e

s

o

ST

p

e

s

w

o

s

t

p

Prot

f

o

s

s

o

rn

n

a

re

g

P

re

le

nt

in

.

M

p

5

o

t

e

s a

t

e

u

me

b

p

n

I

puts:

rap

In

nt

E

h

P

R

E

POWE

MC-200

Motor Controller

or

on

1

cti

E

s

e

G

ne

D

i

rot

E

P

.)

n.

.C

idel

nt

o

N

(

ed

, to each

ncti

Gu

D

me

wired to

r

an

fu

o

SE

ap

be

c

NLY

O

tr

OT

ns

O

L

ST

n

N

e

s

C

E

S

MU

WILL

MA

tor

R

sensor

a

r

O

RE

A

N

•

ope

TO

NI

Wire

•

MO

operato

are used

g

n

•

i

dge

ed

E

r

o

hot

OR

P

Cel

Monito

Jog R

Edge

GN

D

Phot

Ed

1

ge

o

2

C

e

ll

2

n

3

er

p

ctio

ts

e

pu

jum

T

in

US

nused

u

SW

t

Limi

ge

d

E

ll

Photo

e

2

otoC

Cell

X

1

ATRI

M

N-LINE

O

Edge

UL

trap

n

r

.

Y

hen dual operators

so

L

oto Cell

n

w

L

D

N

puts

G

E

ow

p

-

dge and/or Ph

ANY

00

er

NUS

U

•

JU

Jog RT

1

In

M

2

3

C-

3

2

T be used to

0

0

n

of the

r.

MUS

sensors.

emai

cu

r

V

D

ns.

E

oc

o

12

ST

OR

ucti

ation.

MU

IT

PWR

N

MO

on instr

or fault will

inputs

D

lati

E

ce d’install

l

ED

R

E

nsta

i

MP

Jog LT

3

2

1

oir la noti

See

1

V

14

:

N:

15

O

ON

16

TI

UTI

Moto

EN

CA

TT

A

Over

3

4

N

5

MAX

O

LED

D

y

ER

Sensitivit

JOG

RIGHT

JOG

LEFT

ND (C)

G

se

200

D

-

MC

s

r’

.

ired to

w

Reversing

e

b

MC-2

•

l

Jog

L

T

T

-

-

1

Edge 1

GND

Edge 2

EDGE 1 (N.C.)

CLOSING Direction ONLY

Sl

i

d

e

ERD

r

d

Loa

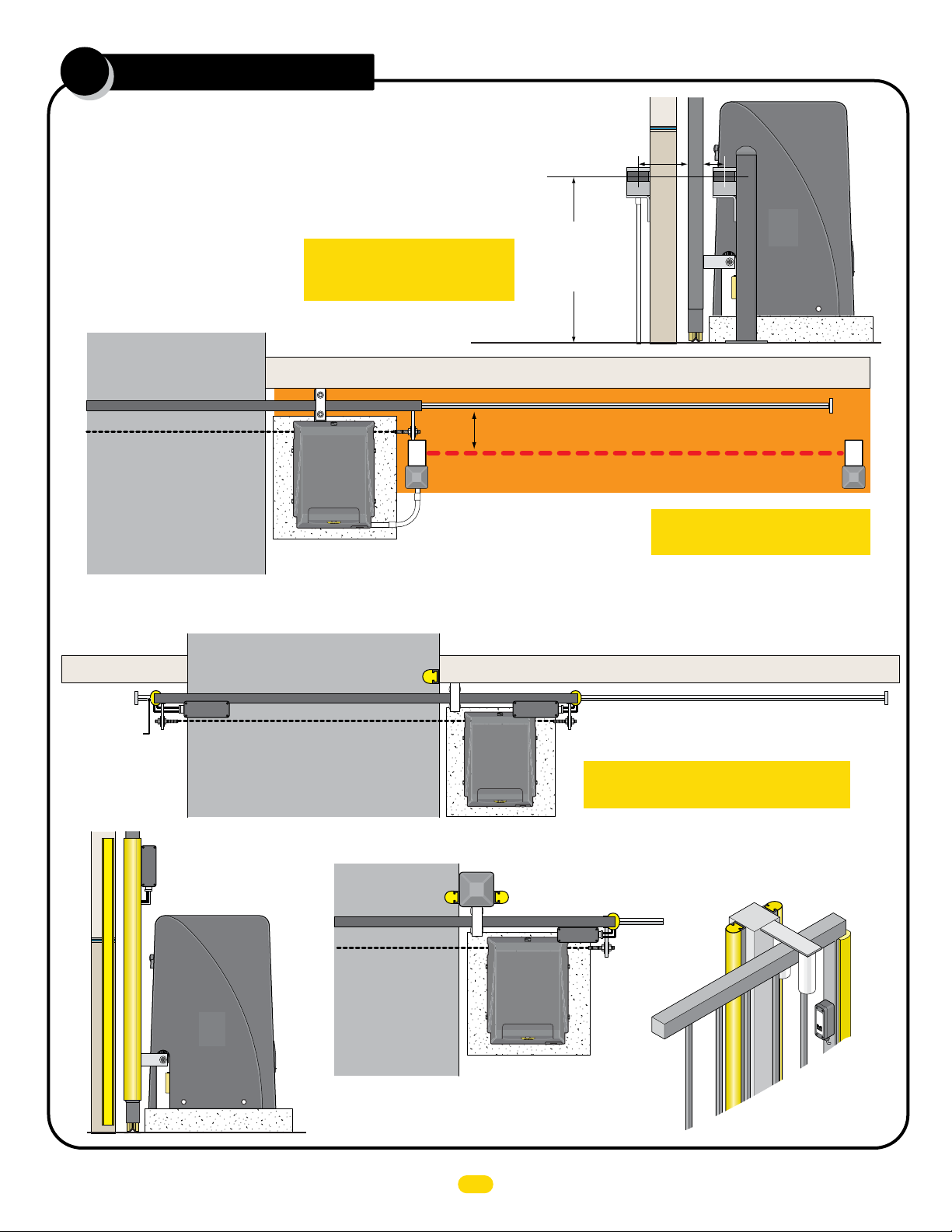

Entrapment Protection Device Locations:

CLOSING Direction

Photocell

IMPORTANT: Entrapment

Protection Photocells MUST be

Monitored Normally Closed Type.

NOTE: Photo input on Matrix 1 is NOT

MONITORED (Normally OPEN) and is

NOT UL 325 entrapment protection.

Beam: 5” or LESS

from CLOSED gate.

IMPORTANT: Photocells MUST

be in alignment or fault will occur.

Outside Property

Entrapment Area

Gate Closed

Inside Property

Continued on next page.

6

CLOSING direction photocell

to MC-200 EDGE 1 input.

Run conduit to operator

Wall

UL 325 2016 Standard-MAX Quick Install Rev 8

continued

7

Entrapment Protection Device

Locations:

Photocell Beam Height

Install photocells on either side of

gate, as close as practical to the

gate but no further away than 5”.

Less

5”

or

Less

5”

or

OPENING Direction

Photocell

Outside Property

Gate Closed

Inside Property

Sensing Edges

Outside

Property

IMPORTANT: Entrapment

Protection Photocells MUST be

Monitored Normally Closed Type.

Beam: 5” or LESS from OPEN gate.

Run conduit to operator

OPENING direction photocell to MC-200

motor controller, Monitored. Normally

CLOSED (N.C.)

NOTE: Connect to Photo Cell input on MC-200.

Beam Height:

21” for most

installations but No

higher than 27.5”

above ground.

Wall

Entrapment Area

Inside

Property

Gate

Wall

Illustrations not to scale

Photo Beam

IMPORTANT: Photocells MUST

be in alignment or fault will occur.

CLOSING direction

10K NORMALLY CLOSED

Sensing Edge Wirelessly

Module

Wireless

Wall

NORMALLY CLOSED Sensing Edge

Wireless

Wireless Module

Module

WIRELESS NOTE: Refer to the

instruction sheet that comes

with the wireless module for

wiring and mounting instructions

when using wireless option.

OPENING direction 10K

Gate Closed

Wireless

Module

OPENING direction10K NORMALLY CLOSED Sensing Edge Wirelessly

IMPORTANT: Sensing edges MUST be

Monitored 10K Normally Closed Type.

Self-Supporting Post

OPENING direction

Sensing Edge

Gate Closed

If a self-supporting post is being used, then sensing edges need to

be installed on EACH side of the post to protect against entrapment

in the OPENING and CLOSING direction of gate travel.

CLOSING direction Sensing Edge

Wireless

Module

OPENING

direction

Sensing

Edge

Wall

OPENING

direction

Sensing

Edge

CLOSING direction

Sensing Edge

MGL-TX

M

on

2

0

ito

G

re

a

te

d

L

in

k

M

i

l

l

e

r

Ed

g

e

OPENING

direction

Sensing

Edge

(Wireless)

UL 325 2016 Standard-MAX Quick Install Rev 8

7

Loading...

Loading...