1bios.ru

General Description

The MAX1908/MAX8724/MAX8765/MAX8765A highly

integrated, multichemistry battery-charger control ICs

simplify the construction of accurate and efficient chargers. These devices use analog inputs to control charge

current and voltage, and can be programmed by the host

or hardwired. The MAX1908/MAX8724/MAX8765/

MAX8765A achieve high efficiency using a buck topology

with synchronous rectification.

The MAX1908/MAX8724/MAX8765/MAX8765A feature

input current limiting. This feature reduces battery

charge current when the input current limit is reached

to avoid overloading the AC adapter when supplying

the load and the battery charger simultaneously. The

MAX1908/MAX8724/MAX8765/MAX8765A provide outputs to monitor current drawn from the AC adapter (DC

input source), battery-charging current, and the presence of an AC adapter. The MAX1908’s conditioning

charge feature provides 300mA to safely charge deeply

discharged lithium-ion (Li+) battery packs.

The MAX1908 includes a conditioning charge feature

while the MAX8724/MAX8765/MAX8765A do not.

The MAX1908/MAX8724/MAX8765/MAX8765A charge two

to four series Li+ cells, providing more than 5A, and are

available in a space-saving, 28-pin, thin QFN package (5mm

× 5mm). An evaluation kit is available to speed designs.

Applications

Notebook and Subnotebook Computers

Personal Digital Assistants

Handheld Terminals

Features

o ±0.5% Output Voltage Accuracy Using Internal

Reference (±0.4% for MAX8765A, 2-/3-Cell Only)

o ±4% Accurate Input Current Limiting

o ±5% Accurate Charge Current

o Analog Inputs Control Charge Current and

Charge Voltage

o Outputs for Monitoring

Current Drawn from AC Adapter

Charging Current

AC Adapter Presence

o Up to 17.6V Battery-Voltage Set Point

o Maximum 28V Input Voltage

o > 95% Efficiency

o Shutdown Control Input

o Charge Any Battery Chemistry

Li+, NiCd, NiMH, Lead Acid, etc.

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

________________________________________________________________

Maxim Integrated Products

1

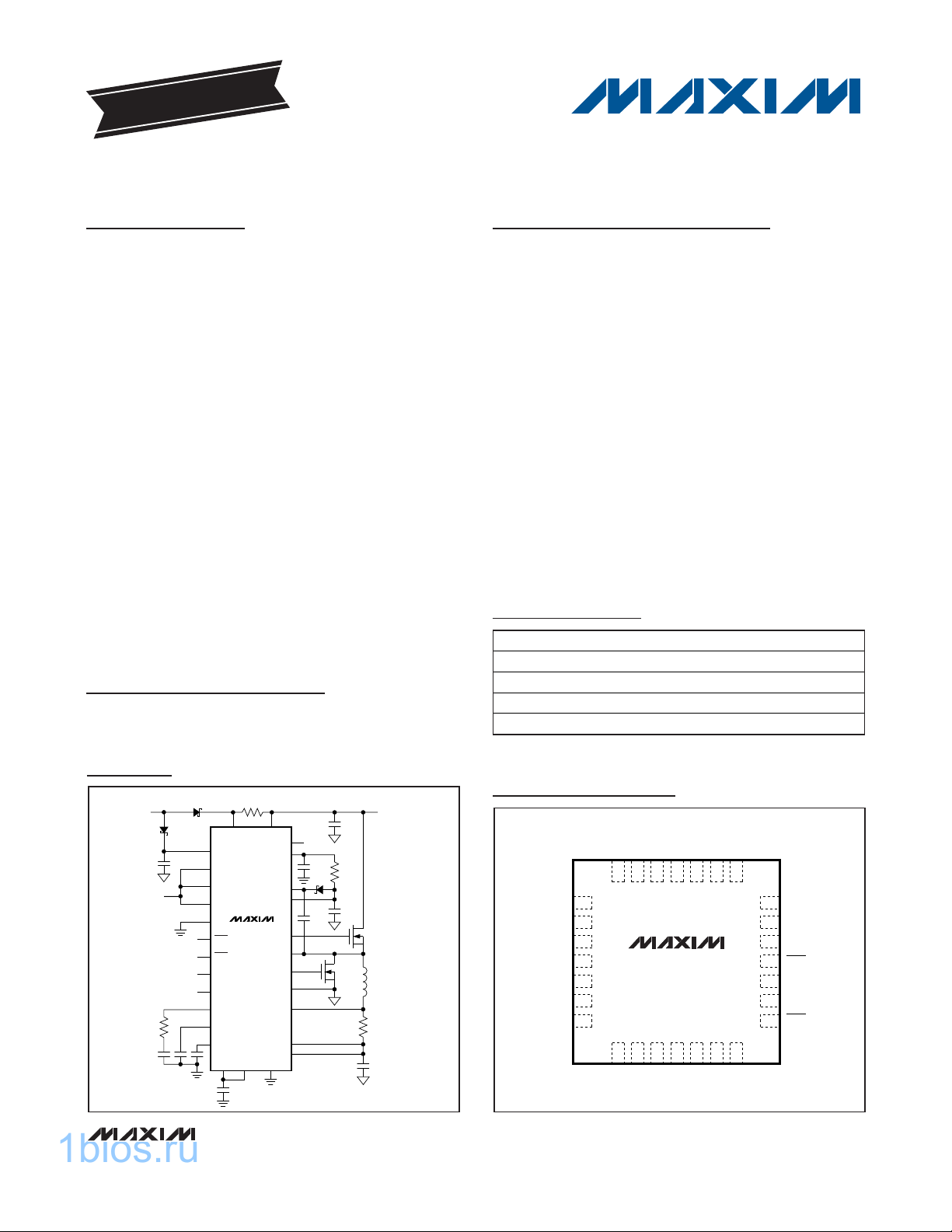

Pin Configuration

Ordering Information

MAX1908

MAX8724

MAX8765

MAX8765A

AC ADAPTER

INPUT

TO EXTERNAL

LOAD

LDO

FROM HOST µP

10µH

0.015Ω

BATT+

DCIN

REFIN

VCTL

ICTL

ACIN

ACOK

SHDN

ICHG

IINP

CCV

CCI

CCS

CELLS

LDO

BST

DLOV

DHI

LX

DLO

PGND

CSIP

CSIN

BATT

REF CLS

GND

CSSP CSSN

0.01Ω

Minimum Operating Circuit

19-2764; Rev 5; 11/09

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

+

Denotes a lead(Pb)-free/RoHS-compliant package.

*

EP = Exposed pad.

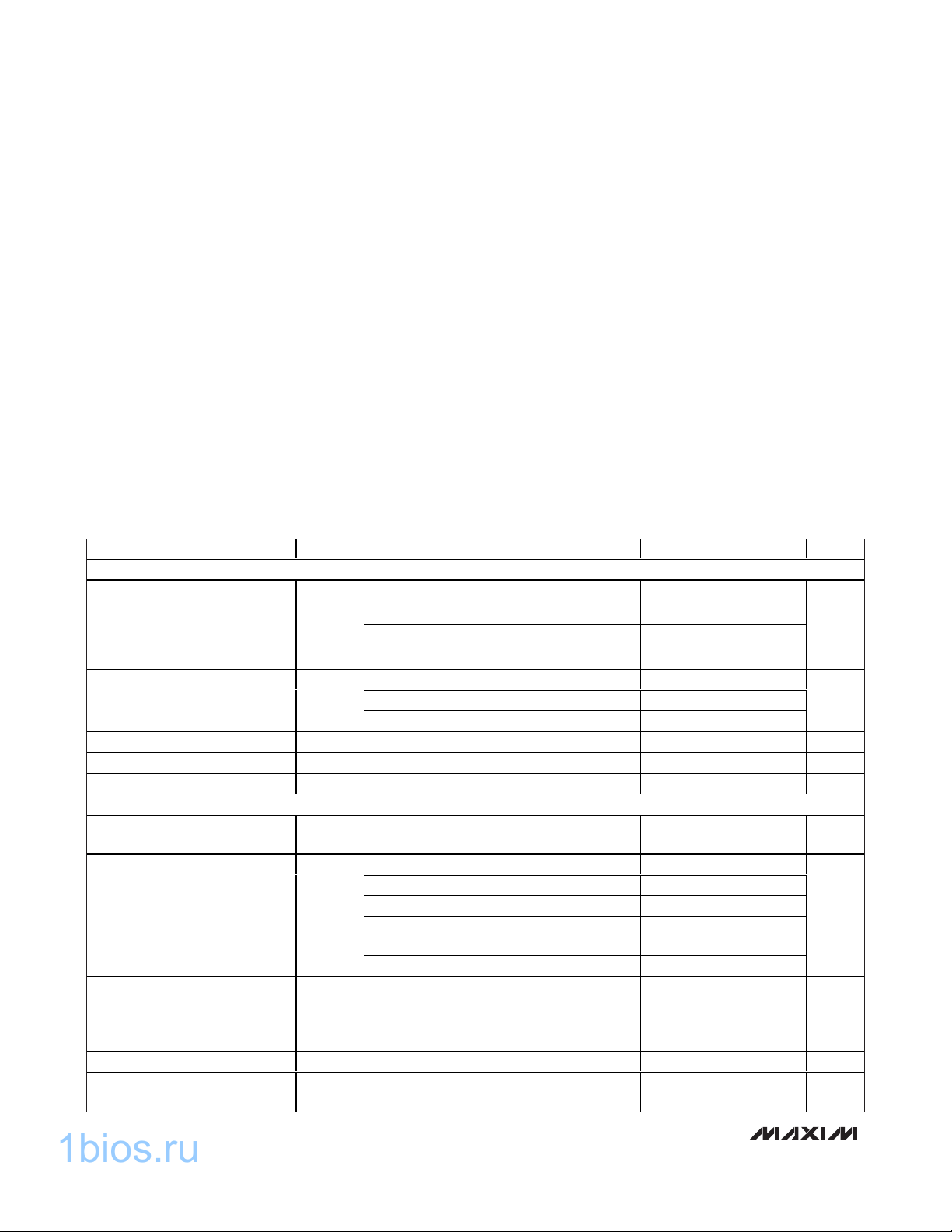

PART TEMP RANGE PIN-PACKAGE

MAX1908ETI+ -40°C to +85°C 28 Thin QFN-EP*

MAX8724ETI+ -40°C to +85°C 28 Thin QFN-EP*

MAX8765ETI+ -40°C to +85°C 28 Thin QFN-EP*

MAX8765AETI+ -40°C to +85°C 28 Thin QFN-EP*

TOP VIEW

VCTL

BATT

CELLS

CSIN

CSIP

PGND

DLO

15161718192021

22

DLOV

BST

DHI

CSSN

CSSP

IINP

23

LX

24

25

26

27

28

+

MAX1908

MAX8724

MAX8765

MAX8765A

7654321

CCI

REF

CLS

DCIN

LDO

THIN QFN

CCS

CCV

14

GND

13

ICTL

REFIN

12

11

ACOK

ACIN

10

9

ICHG

SHDN

8

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

2 _______________________________________________________________________________________

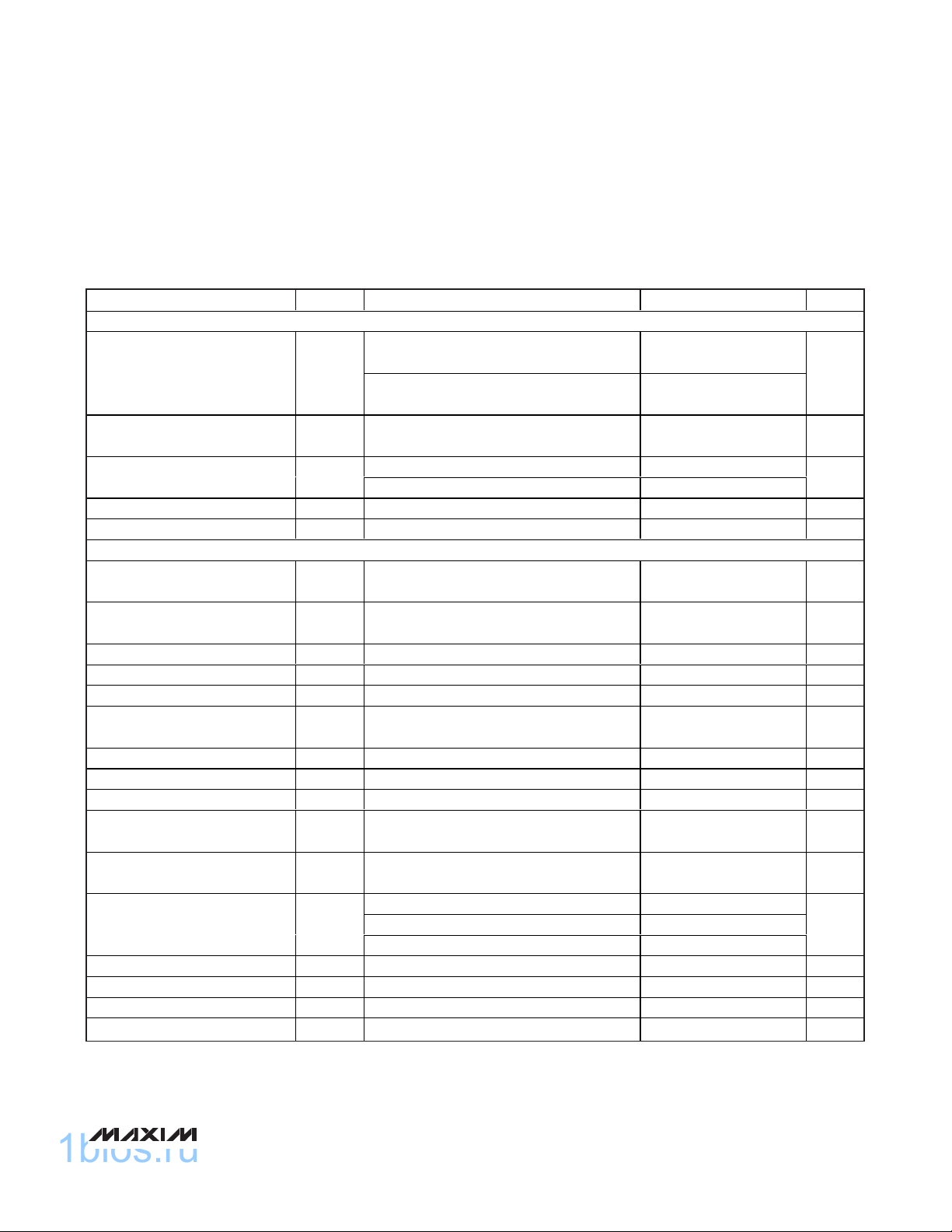

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(V

DCIN

= V

CSSP

= V

CSSN

= 18V, V

BATT

= V

CSIP

= V

CSIN

= 12V, V

REFIN

= 3V, V

VCTL

= V

ICTL

= 0.75 x V

REFIN

, CELLS = open, CLS =

REF, V

BST

- VLX= 4.5V, ACIN = GND = PGND = 0, C

LDO

= 1µF, LDO = DLOV, C

REF

= 1µF; CCI, CCS, and CCV are compensated

per Figure 1a; T

A

= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

DCIN, CSSP, CSSN, ACOK to GND.......................-0.3V to +30V

BST to GND ............................................................-0.3V to +36V

BST to LX..................................................................-0.3V to +6V

DHI to LX...................................................-0.3V to (V

BST

+ 0.3V)

LX to GND .................................................................-6V to +30V

BATT, CSIP, CSIN to GND .....................................-0.3V to +20V

CSIP to CSIN or CSSP to CSSN or

PGND to GND ....................................................-0.3V to +0.3V

CCI, CCS, CCV, DLO, ICHG,

IINP, ACIN, REF to GND.......................-0.3V to (V

LDO

+ 0.3V)

DLOV, VCTL, ICTL, REFIN, CELLS, CLS,

LDO, SHDN to GND .............................................-0.3V to +6V

DLOV to LDO.........................................................-0.3V to +0.3V

DLO to PGND .........................................-0.3V to (V

DLOV

+ 0.3V)

LDO Short-Circuit Current...................................................50mA

Continuous Power Dissipation (T

A

= +70°C)

28-Pin Thin QFN (5mm × 5mm)

(derate 20.8mW/°C above +70°C) .........................1666.7mW

Operating Temperature Range ..........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-60°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CHARGE-VOLTAGE REGULATION

V

Battery-Regulation Voltage

Accuracy

(MAX1908/MAX8724/MAX8765

(2, 3, or 4 Cells) and MAX8765A

(4 Cells Only))

Battery-Regulation Voltage

Accuracy (MAX8765A, 2 or 3

Cells Only)

VCTL Default Threshold V

= V

V

V

V

V

V

VCTL

VCTL

VCTL

VCTL

VCTL

VCTL

VCTL

REFIN

= V

REFIN

= V

LDO

= V

REFIN

= V

REFIN

= V

LDO

rising 4.0 4.1 4.2 V

REFIN Range (Note 1) 2.5 3.6 V

REFIN Undervoltage Lockout V

falling 1.20 1.92 V

REFIN

CHARGE-CURRENT REGULATION

CSIP-to-CSIN Full-Scale Current-

Sense Voltage

Charging-Current Accuracy

V

V

V

V

ICTL

ICTL

ICTL

ICTL

= V

= V

= V

= V

REFIN

REFIN

REFIN

LDO

MAX8765/MAX8765A only; V

0.036

MAX8724 only; V

Charge-Current Gain Error

(MAX8765/MAX8765A Only)

Charge-Current Offset

(MAX8765/MAX8765A Only)

ICTL Default Threshold V

BATT/CSIP/CSIN Input Voltage

Range

-2 +2 %

-2 +2 mV

rising 4.0 4.1 4.2 V

ICTL

0 19 V

-0.5 +0.5

/20 -0.5 +0.5

-0.5 +0.5

-0.4 +0.4

/20 -0.4

-0.4

+0.4

+0.4

71.25 75 78.75 mV

-5 +5

x 0.6 -5 +5

-6 +6

ICTL

= V

= V

ICTL

x 0.058 -33 +33

REFIN

REFIN

x

-45 +45

%

%

%

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

_______________________________________________________________________________________ 3

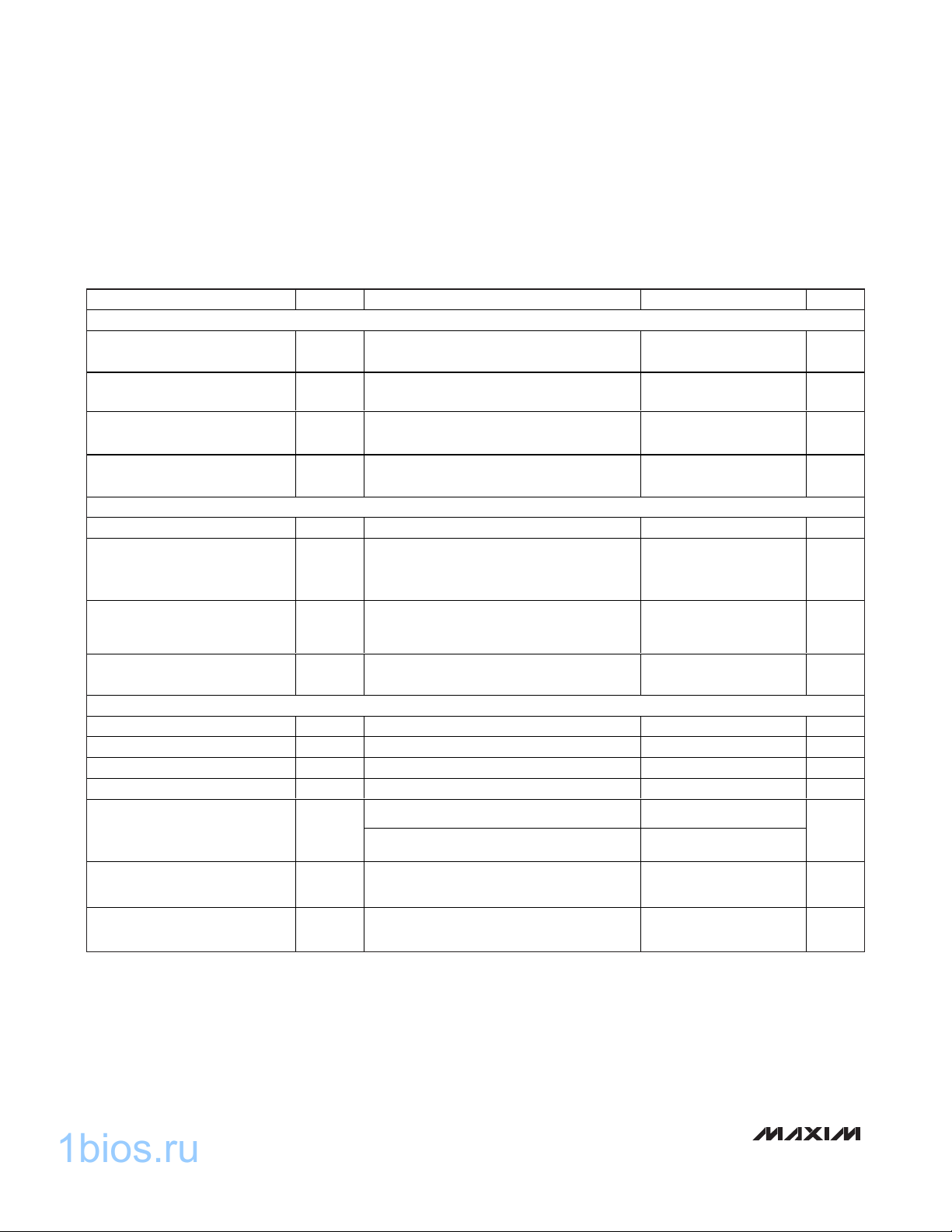

ELECTRICAL CHARACTERISTICS (continued)

(V

DCIN

= V

CSSP

= V

CSSN

= 18V, V

BATT

= V

CSIP

= V

CSIN

= 12V, V

REFIN

= 3V, V

VCTL

= V

ICTL

= 0.75 x V

REFIN

, CELLS = open, CLS =

REF, V

BST

- VLX= 4.5V, ACIN = GND = PGND = 0, C

LDO

= 1µF, LDO = DLOV, C

REF

= 1µF; CCI, CCS, and CCV are compensated

per Figure 1a; T

A

= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

CSIP/CSIN Input Current

Cycle-by-Cycle Maximum Current

Limit

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

Charging 400

DCIN

= 0V or V

ICTL

RS2 = 0.015mΩ 6.0 6.8 7.5

ICTL Power-Down Mode

Threshold Voltage

(MAX1908/MAX8724 Only)

V

ICTL, VCTL Input Bias Current

REFIN Input Bias Current

ICHG Transconductance

(MAX1908/MAX8724 Only)

ICHG Transconductance

(MAX8765/MAX8765A Only)

ICHG Transconductance Error

(MAX8765/MAX8765A Only)

ICHG Transconductance Offset

(MAX8765/MAX8765A Only)

G

ICHG VCSIP

G

ICHG VCSIP

-5 +5 %

-5 +5 µA

ICHG Output Current V

ICHG Output Voltage V

rising

VCTL

V

VCTL

V

DCIN

V

DCIN

V

REFIN

V

CSIP

V

CSIP

V

CSIP

CSIP

CSIP

= V

= 0V, V

= 5V, V

- V

- V

- V

- V

- V

- V

- V

= 0 or 3V -1 +1

ICTL

= V

VCTL

REFIN

= 5V -1 +1

= 45mV 2.7 3 3.3 µA/mV

CSIN

= 45mV 2.85 3 3.15 µA/mV

CSIN

= 75mV -6 +6

CSIN

= 45mV -5 +5 ICHG Accuracy

CSIN

= 5mV -40 +40

CSIN

= 150mV, V

CSIN

= 150mV, ICHG = open 3.5 V

CSIN

INPUT-CURRENT REGULATION

CSSP-to-CSSN Full-Scale

Current-Sense Voltage

Input Current-Limit Accuracy

Input Current-Limit Gain Error

(MAX8765/MAX8765A Only)

Input Current-Limit Offset

(MAX8765/MAX8765A Only)

CSSP, CSSN Input Voltage

Range

CSSP, CSSN Input Current

(MAX1908/MAX8724 Only)

CSSP Input Current

(MAX8765/MAX8765A Only)

72 75 78 mV

V

= V

CLS

REF

V

= V

/2 -7.5 +7.5

REF

= 1.1V (MAX8765/MAX8765A only) -10 +10

V

CLS

CLS

-2 +2 %

-2 +2 mV

8 28 V

V

= 0V 0.1 1

V

DCIN

V

CSSP

CSSP

= V

= V

CSSN

CSSN

= V

= 28V

= 0V or V

SHDN

= 0V

1

650

REFIN/

= V

ICTL

= 3V -1 +1

ICHG

= 5V -1 +1

REFIN

= 0V 350 µA

100

REFIN/55 REFIN/

33

-4 +4

> 8V 350 600

DCIN

V

= 0V 0.1 1

DCIN

V

DCIN

= 28V

400 650

µA

A

V

µA

µA

%

%

µA

µA

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

4 _______________________________________________________________________________________

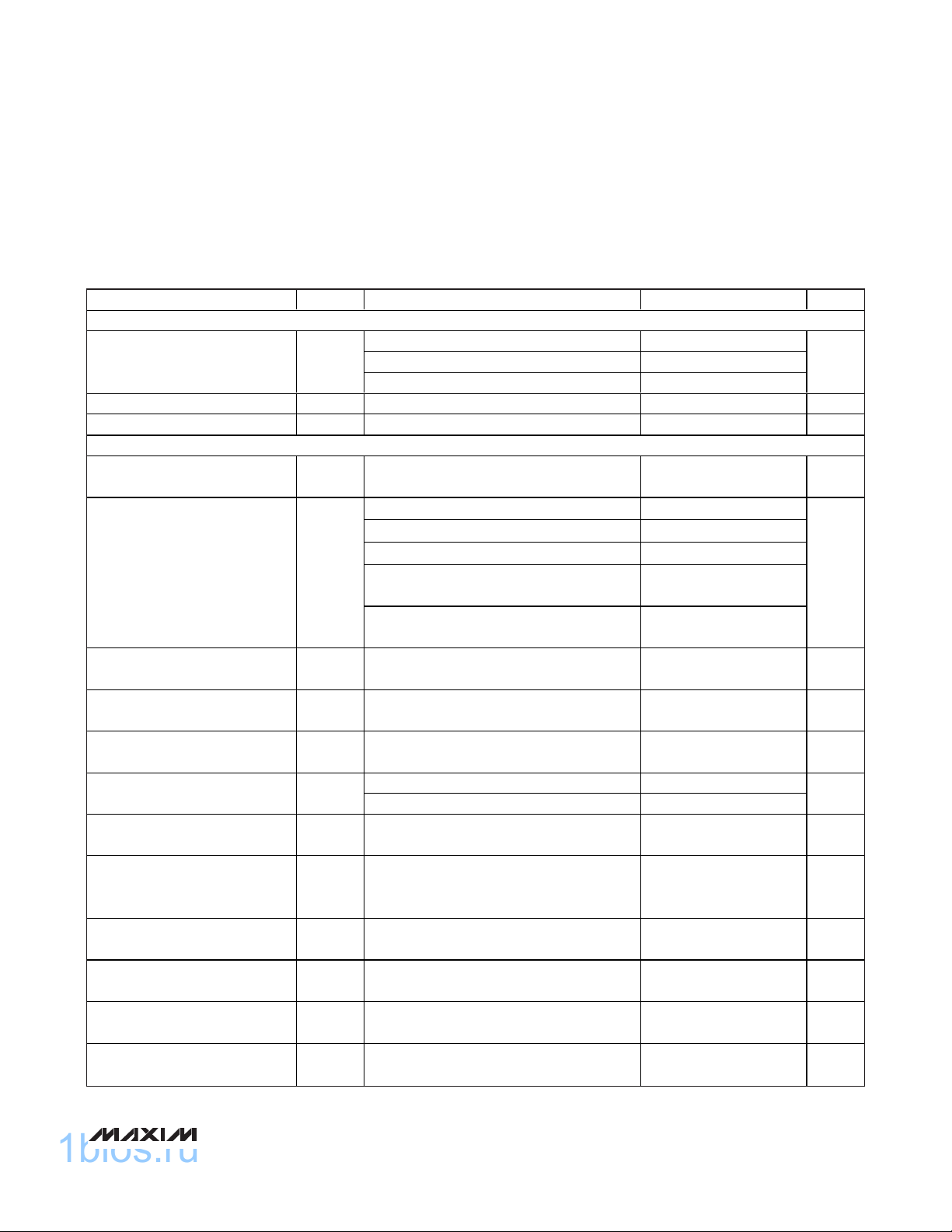

ELECTRICAL CHARACTERISTICS (continued)

(V

DCIN

= V

CSSP

= V

CSSN

= 18V, V

BATT

= V

CSIP

= V

CSIN

= 12V, V

REFIN

= 3V, V

VCTL

= V

ICTL

= 0.75 x V

REFIN

, CELLS = open, CLS =

REF, V

BST

- VLX= 4.5V, ACIN = GND = PGND = 0, C

LDO

= 1µF, LDO = DLOV, C

REF

= 1µF; CCI, CCS, and CCV are compensated

per Figure 1a; T

A

= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

CSSN Input Current

(MAX8765/MAX8765A Only)

CLS Input Range

(MAX1908/MAX8724 Only)

CLS Input Range

(MAX8765/MAX8765A Only)

CLS Input Bias Current V

IINP Transconductance

(MAX1908/MAX8724 Only)

IINP Accuracy

IINP Transconductance

(MAX8765/MAX8765A Only)

IINP Transconductance Error

(MAX8765/MAX8765A Only)

IINP Transconductance Offset

(MAX8765/MAX8765A Only)

IINP Output Current V

IINP Output Voltage V

SUPPLY AND LDO REGULATOR

DCIN Input Voltage Range V

DCIN Undervoltage-Lockout Trip

Point

DCIN Quiescent Current I

BATT Input Current I

LDO Output Voltage 8V < V

LDO Load Regulation 0 < I

LDO Undervoltage-Lockout Trip

Point

REFERENCE

REF Output Voltage 0 < I

REF Undervoltage-Lockout Trip

Point

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

CSSP

= V

= 28V

CSSN

V

= 0V 0.1 1

DCIN

V

= 28V 0.1 1

DCIN

1.6 REF V

1.1 REF V

= 2V -1 +1 µA

CLS

G

IINP VCSSP

G

IINP VCSSP

V

CSSP

V

CSSP

- V

- V

- V

- V

= 75mV 2.7 3 3.3 µA/mV

CSSN

= 75mV -5 +5

CSSN

= 37.5mV -7.5 +7.5

CSSN

= 75mV 2.82 3 3.18 µA/mV

CCSN

-6 +6 %

-10 +10 µA

- V

DCIN

DCIN

BATT

V

V

- V

CSSN

CSSN

= 150mV, V

= 150mV, V

CSSP

CSSP

8 28 V

V

falling 7 7.4

DCIN

V

rising 7.5 7.85

DCIN

8.0V < V

V

BATT

V

BATT

LDO

DCIN

REF

falling 3.1 3.9 V

REF

< 28V 3.2 6 mA

DCIN

= 19V, V

= 2V to 19V, V

< 28V, no load 5.25 5.4 5.55 V

DCIN

< 10mA 34 100 mV

= 8V 3.20 4 5.15 V

< 500µA 4.072 4.096 4.120 V

= 0V 1

DCIN

DCIN

= 0V 350 µA

IINP

= open 3.5 V

IINP

= 19.3V 200 500

µA

%

V

µA

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

_______________________________________________________________________________________ 5

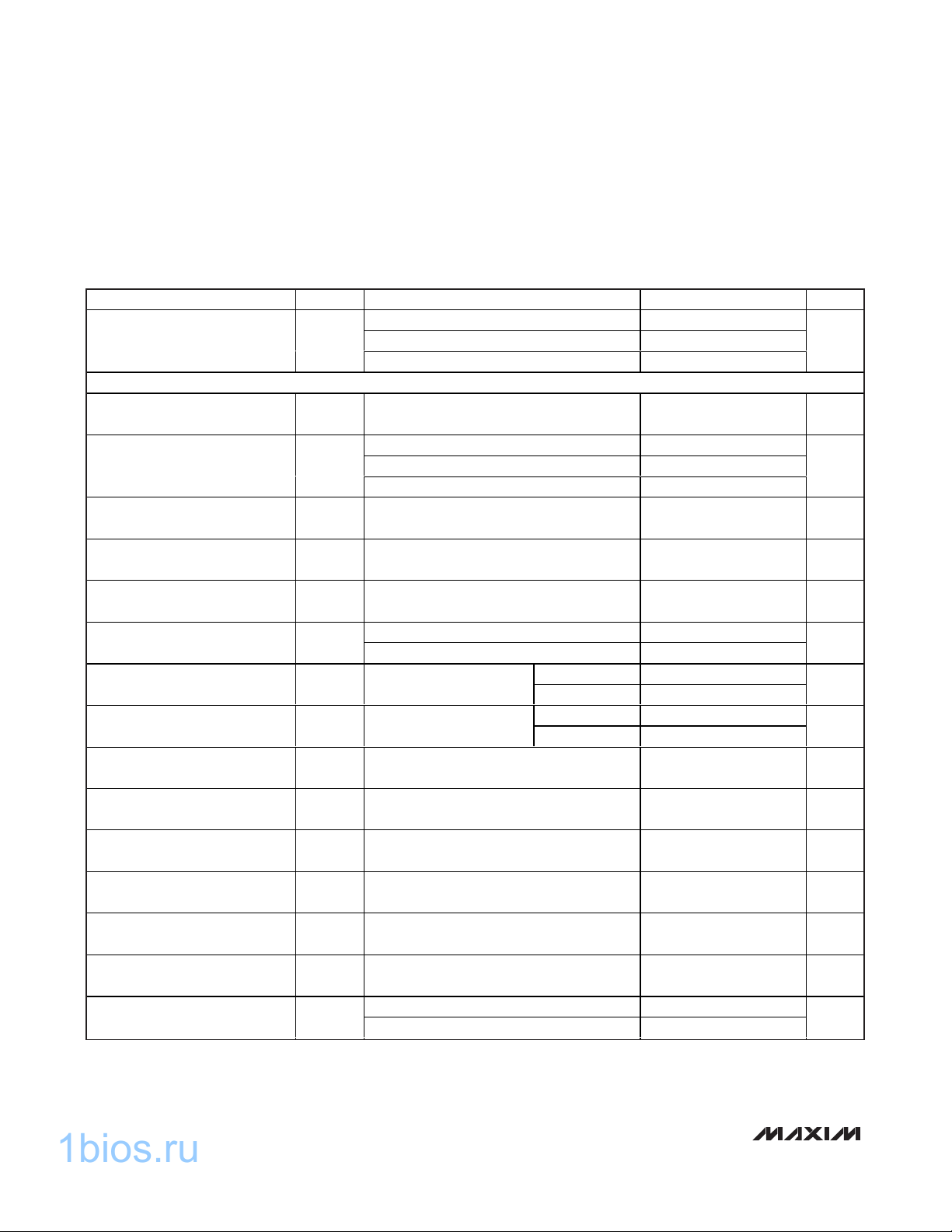

ELECTRICAL CHARACTERISTICS (continued)

(V

DCIN

= V

CSSP

= V

CSSN

= 18V, V

BATT

= V

CSIP

= V

CSIN

= 12V, V

REFIN

= 3V, V

VCTL

= V

ICTL

= 0.75 x V

REFIN

, CELLS = open, CLS =

REF, V

BST

- VLX= 4.5V, ACIN = GND = PGND = 0, C

LDO

= 1µF, LDO = DLOV, C

REF

= 1µF; CCI, CCS, and CCV are compensated

per Figure 1a; T

A

= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

TRIP POINTS

V

falling, referred to V

DCIN

(MAX1908/MAX8724 only)

CSIN

50 100 150

BATT Power-Fail Threshold

V

falling, referred to V

BATT Power-Fail Threshold

Hysteresis

ACIN Threshold

CSSP

(MAX8765/MAX8765A only)

200 mV

ACIN rising (MAX8765/MAX8765A only) 2.028 2.048 2.068

ACIN rising (MAX1908/MAX8724 only) 2.007 2.048 2.089

CSIN

50 100 150

ACIN Threshold Hysteresis 0.5% of REF 20 mV

ACIN Input Bias Current V

= 2.048V -1 +1 µA

ACIN

SWITCHING REGULATOR

DHI Off-Time

DHI Minimum Off-Time

V

BATT

V

CELLS

V

BATT

V

CELLS

= 16V, V

= V

REFIN

= 16V, V

= V

REFIN

DCIN

DCIN

= 19V,

= 17V,

0.36 0.4 0.44 µs

0.24 0.28 0.33 µs

DHI Maximum On-Time 2.5 5 7.5 ms

DLOV Supply Current DLO low 5 10 µA

BST Supply Current DHI high 6 15 µA

BST Input Quiescent Current

LX Input Bias Current V

LX Input Quiescent Current V

DCIN

V

BATT

DCIN

DCIN

= 0V, V

= V

= 28V, V

= 0V, V

LX

BST

= 20V

BATT

BATT

= 24.5V,

= V

LX

= V

LX

0.3 1 µA

= 20V

= 20V 0.3 1 µA

150 500 µA

V

DHI Maximum Duty Cycle 99 99.9 %

Minimum Discontinuous-Mode

Ripple Current

Battery Undervoltage Charge

Current

Battery Undervoltage Current

Threshold

DHI On-Resistance High V

DHI On-Resistance Low V

DLO On-Resistance High V

DLO On-Resistance Low V

0.5 A

V

= 3V per cell (RS2 = 15mΩ),

BATT

MAX1908 only, V

BATT

rising

CELLS = GND, MAX1908 only, V

CELLS = open, MAX1908 only, V

CELLS = V

- VLX = 4.5V, I

BST

- V

BST

LX

= 4.5V, I

DLOV

= 4.5V, I

DLOV

, MAX1908 only, V

REFIN

DHI

= 4.5V, I

DHI

= +100mA 4 7 Ω

DLO

= -100mA 1 3.5 Ω

DLO

= +100mA 4 7 Ω

= -100mA 1 3.5 Ω

150 300 450 mA

rising 6.1 6.2 6.3

BATT

rising

BATT

rising 12.2 12.4 12.6

BATT

9.15 9.3 9.45

mV

V

V

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(V

DCIN

= V

CSSP

= V

CSSN

= 18V, V

BATT

= V

CSIP

= V

CSIN

= 12V, V

REFIN

= 3V, V

VCTL

= V

ICTL

= 0.75 x V

REFIN

, CELLS = open, CLS =

REF, V

BST

- VLX= 4.5V, ACIN = GND = PGND = 0, C

LDO

= 1µF, LDO = DLOV, C

REF

= 1µF; CCI, CCS, and CCV are compensated

per Figure 1a; T

A

= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

ERROR AMPLIFIERS

GMV Amplifier Transconductance GMV

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

= V

V C T L

C E LLS = V

, V

LD O

RE F IN

BAT T

= 16.8V ,

0.0625 0.125 0.2500 µA/mV

GMI Amplifier Transconductance GMI V

GMS Amplifier Transconductance GMS V

CCI, CCS, CCV Clamp Voltage 0.25V < V

ICTL

CLS

= V

RE F IN

= V

REF

CCV,CCS,CCI

, V

, V

CSIP

CSSP

- V

- V

= 75mV 0.5 1 2.0 µA/mV

CSIN

= 75mV 0.5 1 2.0 µA/mV

CSSN

< 2V 150 300 600 mV

LOGIC LEVELS

CELLS Input Low Voltage 0.4 V

CELLS Input Open Voltage CELLS = open

CELLS Input High Voltage

CELLS Input Bias Current CELLS = 0V or V

RE F IN

(V

REFIN

/2) -

0.2V

V

- 0.4V

V

REFIN

-2 +2 µA

( V

R E F IN

/

R E F IN

/2) +

2

0.2V

V

ACOK AND SHDN

ACOK Input Voltage Range 0 28 V

ACOK Sink Current V

ACOK Leakage Current V

A COK

A COK

= 0.4V, V

= 28V, V

= 3V 1 mA

ACIN

= 0V 1 µA

ACIN

SHDN Input Voltage Range 0 LDO V

V

SHDN

= 0V OR V

LDO

-1 +1

SHDN Input Bias Current

V

SHDN

= 0V OR V

= 5V -1 +1

SHDN

V

µA

SHDN Threshold V

SHDN Threshold Hysteresis 1

falling 22 23.5 25

S HDN

% of

V

REFIN

% of

V

REFIN

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

ELECTRICAL CHARACTERISTICS

(V

DCIN

= V

CSSP

= V

CSSN

= 18V, V

BATT

= V

CSIP

= V

CSIN

= 12V, V

REFIN

= 3V, V

VCTL

= V

ICTL

= 0.75 x V

REFIN

, CELLS = open, CLS =

REF, V

BST

- VLX= 4.5V, ACIN = GND = PGND = 0, C

LDO

= 1µF, LDO = DLOV, C

REF

= 1µF; CCI, CCS, and CCV are compensated

per Figure 1a; T

A

= -40°C to +85°C, unless otherwise noted.) (Note 2)

Low-Cost Multichemistry Battery Chargers

_______________________________________________________________________________________ 7

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

CHARGE-VOLTAGE REGULATION

Battery Regulation Voltage

Accuracy (2, 3, or 4 Cells)

= V

VCTL

V

V

VCTL

VCTL

= V

= V

REFIN

/20 -0.6 +0.6

REFIN

LDO

-0.6 +0.6

-0.6 +0.6

V

REFIN Range (Note 1) 2.5 3.6 V

REFIN Undervoltage Lockout V

falling 1.92 V

REFIN

CHARGE CURRENT REGULATION

CSIP-to-CSIN Full-Scale Current-

Sense Voltage

Charging-Current Accuracy

Charge-Current Gain Error

(MAX8765/MAX8765A Only)

Charge-Current Offset

(MAX8765/MAX8765A Only)

BATT/CSIP/CSIN Input Voltage

Range

CSIP/CSIN Input Current

Cycle-by-Cycle Maximum Current

Limit

ICTL Power-Down Mode

Threshold Voltage

(MAX1908/MAX8724 Only)

V

= V

V

V

V

ICTL

ICTL

ICTL

ICTL

= V

= V

= V

REFIN

REFIN

x 0.6 -7.5 +7.5

REFIN

LDO

MAX8765/MAX8765A only; V

0.036

MAX8724 only;

V

ICTL

= V

REFIN

x 0.058

ICTL

= V

REFIN

70.5 79.5 mV

-6 +6

-7.5 +7.5

x

-50 +50

-33 +33

-2 +2 %

-2 +2 mV

0 19 V

V

I

MAX

V

= 0V or V

DCIN

Charging 650

RS2 = 0.015Ω 6.0 7.5 A

rising

ICTL

ICTL

= 0V or V

= 0V 1

SHDN

REFIN/

100

REFIN/

33

%

%

µA

V

ICHG Transconductance

(MAX1908/MAX8724 Only)

ICHG Transconductance

(MAX8765/MAX8765A Only)

ICHG Transconductance Error

(MAX8765/MAX8765A Only)

ICHG Transconductance Offset

(MAX8765/MAX8765A Only)

G

ICHG VCSIP

G

ICHG VCSIP

- V

= 45mV 2.7 3.3 µA/mV

CSIN

- V

= 45mV 2.785 3.225 µA/mV

CSIN

-7.5 +7.5 %

-6.5 +6.5 µA

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

8 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(V

DCIN

= V

CSSP

= V

CSSN

= 18V, V

BATT

= V

CSIP

= V

CSIN

= 12V, V

REFIN

= 3V, V

VCTL

= V

ICTL

= 0.75 x V

REFIN

, CELLS = open, CLS =

REF, V

BST

- VLX= 4.5V, ACIN = GND = PGND = 0, C

LDO

= 1µF, LDO = DLOV, C

REF

= 1µF; CCI, CCS, and CCV are compensated

per Figure 1a; T

A

= -40°C to +85°C, unless otherwise noted.) (Note 2)

ICHG Accuracy

INPUT-CURRENT REGULATION

CSSP-to-CSSN Full-Scale

Current-Sense Voltage

Input Current-Limit Accuracy

Input Current-Limit Gain Error

(MAX8765/MAX8765A Only)

Input Current-Limit Offset

(MAX8765/MAX8765A Only)

CSSP, CSSN Input Voltage

Range

CSSP, CSSN Input Current

(MAX1908/MAX8724 Only)

CSSP Input Current

(MAX8765/MAX8765A Only)

CSSN Input Current

(MAX8765/MAX8765A Only)

CLS Input Range

(MAX1908/MAX8724 Only)

CLS Input Range

(MAX8765/MAX8765A Only)

IINP Transconductance

(MAX1908/MAX8724 Only)

IINP Transconductance

(MAX8765/MAX8765A Only)

IINP Transconductance Error

(MAX8765/MAX8765A Only)

IINP Transconductance Offset

(MAX8765/MAX8765A Only)

IINP Accuracy

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

V

V

CSIP

CSIP

CSIP

- V

- V

- V

= 75mV -7.5 +7.5

CSIN

= 45mV -7.5 +7.5

CSIN

= 5mV -40 +40

CSIN

71.25 78.75 mV

V

= V

CLS

REF

V

= V

/2 -7.5 +7.5

REF

= 1.1V (MAX8765/MAX8765A only) -10 +10

V

CLS

CLS

-5 +5

-2 +2 %

-2 +2 mV

8 28 V

V

= 0V 1

V

V

DCIN

V

CSSP

CSSP

CSSP

= V

= V

= V

CSSN

CSSN

CSSN

= V

DCIN

= 28V

= 28V

> 8V 600

V

= 0V 1

DCIN

V

= 28V 650

DCIN

V

= 0V 1

DCIN

V

= 28V 1

DCIN

1.6 REF V

1.1 REF V

G

IINP VCSSP

G

IINP VCSSP

- V

- V

= 75mV 2.7 3.3 µA/mV

CSSN

= 75mV 2.785 3.225 µA/mV

CCSN

-7.5 +7.5 %

-12 +12 µA

V

- V

CSSP

V

CSSP

= 75mV -7.5 +7.5

CSSN

- V

= 37.5mV -7.5 +7.5

CSSN

%

%

µA

µA

µA

%

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

_______________________________________________________________________________________ 9

ELECTRICAL CHARACTERISTICS (continued)

(V

DCIN

= V

CSSP

= V

CSSN

= 18V, V

BATT

= V

CSIP

= V

CSIN

= 12V, V

REFIN

= 3V, V

VCTL

= V

ICTL

= 0.75 x V

REFIN

, CELLS = open, CLS =

REF, V

BST

- VLX= 4.5V, ACIN = GND = PGND = 0, C

LDO

= 1µF, LDO = DLOV, C

REF

= 1µF; CCI, CCS, and CCV are compensated

per Figure 1a; T

A

= -40°C to +85°C, unless otherwise noted.) (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

SUPPLY AND LDO REGULATOR

DCIN Input Voltage Range V

DCIN Quiescent Current I

BATT Input Current I

DCIN

DCIN

BATT

LDO Output Voltage 8V < V

LDO Load Regulation 0 < I

8 28 V

8.0V < V

V

BATT

V

BATT

LDO

< 28V 6 mA

DCIN

= 19V, V

= 2V to 19V, V

< 28V, no load 5.25 5.55 V

DCIN

< 10mA 100 mV

= 0V 1

DCIN

= 19.3V 500

DCIN

REFERENCE

REF Output Voltage 0 < I

< 500µA 4.065 4.120 V

REF

TRIP POINTS

V

falling, referred to V

BATT Power-Fail Threshold

ACIN Threshold

DCIN

(MAX1908/MAX8724 only)

V

falling, referred to V

CSSP

(MAX8765/MAX8765A only)

ACIN rising (

ACIN rising (MAX1908/MAX8724 only) 2.007 2.089

MAX8765/MAX8765A

CSIN

CSIN

50 150

50 150

only) 2.028 2.068

SWITCHING REGULATOR

DHI Off-Time

DHI Minimum Off-Time

BATT

V

CELLS

V

BATT

V

CELLS

= 16V, V

= V

REFIN

= 16V, V

= V

REFIN

DCIN

DCIN

= 19V,

= 17V,

0.35 0.45 µs

0.24 0.33 µs

V

DHI Maximum On-Time 2.5 7.5 ms

DHI Maximum Duty Cycle 99 %

Battery Undervoltage Charge

Current

Battery Undervoltage Current

Threshold

DHI On-Resistance High V

DHI On-Resistance Low V

DLO On-Resistance High V

DLO On-Resistance Low V

V

= 3V per cell (RS2 = 15mΩ),

BATT

MAX1908 only, V

BATT

CELLS = GND, MAX1908 only, V

CELLS = open, MAX1908 only, V

CELLS = V

- VLX = 4.5V, I

BST

- VLX = 4.5V, I

BST

= 4.5V, I

DLOV

= 4.5V, I

DLOV

, MAX1908 only, V

REFIN

DLO

DLO

rising

rising 6.09 6.30

BATT

rising 9.12 9.45

BATT

rising 12.18 12.60

BATT

= +100mA 7 Ω

DHI

= -100mA 3.5 Ω

DHI

= +100mA 7 Ω

= -100mA 3.5 Ω

150 450 mA

µA

mV

V

V

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

10 ______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(V

DCIN

= V

CSSP

= V

CSSN

= 18V, V

BATT

= V

CSIP

= V

CSIN

= 12V, V

REFIN

= 3V, V

VCTL

= V

ICTL

= 0.75 x V

REFIN

, CELLS = open, CLS =

REF, V

BST

- VLX= 4.5V, ACIN = GND = PGND = 0, C

LDO

= 1µF, LDO = DLOV, C

REF

= 1µF; CCI, CCS, and CCV are compensated

per Figure 1a; T

A

= -40°C to +85°C, unless otherwise noted.) (Note 2)

Note 1: If both ICTL and VCTL use default mode (connected to LDO), REFIN is not used and can be connected to LDO.

Note 2: Specifications to T

A

= -40°C are guaranteed by design and not production tested.

LOAD-TRANSIENT RESPONSE

(BATTERY INSERTION AND REMOVAL)

MAX1908 toc01

1ms/div

I

BATT

2A/div

V

BATT

5V/div

V

CCI

500mV/div

V

CCV

500mV/div

ICTL = LDO

VCTL = LDO

CCV

CCI

LOAD-TRANSIENT RESPONSE

(STEP IN-LOAD CURRENT)

MAX1908 toc02

1ms/div

V

BATT

2V/div

V

CCI

500mV/div

V

CCS

500mV/div

16.8V

0

0

LOAD

CURRENT

5A/div

ADAPTER

CURRENT

5A/div

ICTL = LDO

CHARGING CURRENT = 3A

V

BATT

= 16.8V

LOAD STEP = 0 TO 4A

I

SOURCE

LIMIT = 5A

CCS

CCS

CCI

CCI

V

BATT

2V/div

0

0

0

CHARGE

CURRENT

2A/div

LOAD

CURRENT

5A/div

ADAPTER

CURRENT

5A/div

LOAD-TRANSIENT RESPONSE

(STEP IN-LOAD CURRENT)

MAX1908 toc03

1ms/div

ICTL = LDO

CHARGING CURRENT = 3A

V

BATT

= 16.8V

LOAD STEP = 0 TO 4A

I

SOURCE

LIMIT = 5A

Typical Operating Characteristics

(Circuit of Figure 1, V

DCIN

= 20V, TA= +25°C, unless otherwise noted.)

ERROR AMPLIFIERS

GMV Amplifier Transconductance GMV

GMI Amplifier Transconductance GMI V

GMS Amplifier Transconductance GMS V

CCI, CCS, CCV Clamp Voltage 0.25V < V

LOGIC LEVELS

CELLS Input Low Voltage 0.4 V

CELLS Input Open Voltage CELLS = open

CELLS Input High Voltage

ACOK AND SHDN

ACOK Input Voltage Range 0 28 V

ACOK Sink Current V

SHDN Input Voltage Range 0 LDO V

SHDN Threshold V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

= V

, V

, V

= 16.8V ,

BAT T

, V

CSSP

CSIP

- V

- V

= 75mV 0.5 2.0 µA/mV

CSIN

= 75mV 0.5 2.0 µA/mV

CSSN

0.0625 0.250 µA/mV

< 2V 150 600 mV

(V

REFIN

/2) -

0.2V

V

REFIN

- 0.4V

= 3V 1 mA

ACIN

V

( V

/2) +

0.2V

R E F IN

V C T L

C E LLS = V

ICTL

CLS

ACOK

SHDN

LD O

RE F IN

= V

RE F IN

= V

REF

CCV,CCS,CCI

= 0.4V, V

falling 22 25

% of

V

REFIN

V

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

______________________________________________________________________________________

11

Typical Operating Characteristics (continued)

(Circuit of Figure 1, V

DCIN

= 20V, TA= +25°C, unless otherwise noted.)

LINE-TRANSIENT RESPONSE

V

DCIN

10V/div

V

BATT

500mV/div

INDUCTOR

CURRENT

500mA/div

ICTL = LDO

VCTL = LDO

= 3A

I

CHARGE

LINE STEP 18.5V TO 27.5V

REF VOLTAGE LOAD REGULATION

0

-0.01

-0.02

-0.03

-0.04

-0.05

ERROR (%)

-0.06

REF

V

-0.07

-0.08

-0.09

-0.10

0 200100 300 400 500

MAX1908 toc04

10ms/div

REF CURRENT (µA)

0

-0.1

-0.2

-0.3

-0.4

-0.5

ERROR (%)

-0.6

LDO

V

-0.7

-0.8

V

LDO

-0.9

-1.0

0 2341 567 9810

REF VOLTAGE ERROR vs. TEMPERATURE

0.10

0.08

MAX1908 toc07

0.06

0.04

0.02

0

ERROR (%)

-0.02

REF

V

-0.04

-0.06

-0.08

-0.10

-40 10-15 35 60 85

LDO LOAD REGULATION

= 5.4V

LDO CURRENT (mA)

TEMPERATURE (°C)

MAX1908 toc05

MAX1908 toc08

0.05

I

0.04

0.03

0.02

0.01

0

ERROR (%)

-0.01

LDO

V

-0.02

-0.03

-0.04

-0.05

= 0

LDO

= 5.4V

V

LDO

8 12141610 18 20 22 2624 28

VIN (V)

EFFICIENCY vs. CHARGE CURRENT

100

90

80

V

= 16V

LDO LINE REGULATION

70

60

50

40

EFFICIENCY (%)

30

20

10

0

0.01 1010.1

CHARGE CURRENT (A)

BATT

V

= 12V

BATT

V

= 8V

BATT

MAX1908 toc06

MAX1908 toc09

500

450

400

350

300

250

200

FREQUENCY (kHz)

150

100

50

0

FREQUENCY vs. VIN - V

4 CELLS

0462 8 10 12 14 16 18 20 22

(VIN - V

BATT

BATT

3 CELLS

I

= 3A

CHARGE

VCTL = ICTL = LDO

) (V)

OUTPUT V/I CHARACTERISTICS

0.5

0.4

MAX1908 toc10

0.3

0.2

0.1

0

-0.1

-0.2

BATT VOLTAGE ERROR (%)

-0.3

-0.4

-0.5

01234

3 CELLS

4 CELLS

BATT CURRENT (A)

2 CELLS

0.08

0.07

MAX1908 toc11

0.06

0.05

0.04

0.03

BATT VOLTAGE ERROR (%)

0.02

0.01

0

0 0.2 0.3 0.4 0.50.1 0.6 0.7 0.8 0.9

BATT VOLTAGE ERROR vs. VCTL

4 CELLS

REFIN = 3.3V

NO LOAD

VCTL/REFIN (%)

MAX1908 toc12

1.0

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

12 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(Circuit of Figure 1, V

DCIN

= 20V, TA= +25°C, unless otherwise noted.)

CURRENT-SETTING ERROR vs. ICTL

5

4

3

2

1

CURRENT-SETTING ERROR (%)

0

-1

01.00.5 1.5 2.0

V

REFIN

= 3.3V

V

ICTL

(V)

IINP ERROR vs. SYSTEM LOAD CURRENT

40

30

20

10

0

IINP ERROR (%)

-10

-20

-30

-40

01234

I

= 0

BATT

SYSTEM LOAD CURRENT (A)

MAX1908 toc13

MAX1908 toc15

ICHG ERROR vs. CHARGE CURRENT

5.0

4.5

4.0

3.5

3.0

2.5

ICHG (%)

2.0

1.5

1.0

0.5

0

01.00.5 1.5 2.0 2.5 3.0

V

= 3.3V

REFIN

V

= 16V

BATT

V

= 12V

BATT

V

= 8V

BATT

I

(A)

BATT

IINP ERROR vs. INPUT CURRENT

80

60

40

20

0

IINP ERROR (%)

-20

-40

-60

-80

ERROR DUE TO SWITCHING NOISE

SYSTEM LOAD = 0

0 0.5 1.0 1.5 2.0

INPUT CURRENT (A)

MAX1908 toc14

MAX1908 toc16

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

______________________________________________________________________________________ 13

Pin Description

PIN NAME FUNCTION

1 DCIN Charging Voltage Input. Bypass DCIN with a 1µF capacitor to PGND.

2 LDO D evi ce P ow er S up p l y. Outp ut of the 5.4V l i near r eg ul ator sup p l i ed fr om D C IN . Byp ass w i th a 1µF cap aci tor to GN D .

3 CLS Source Current-Limit Input. Voltage input for setting the current limit of the input source.

4 REF 4.096V Voltage Reference. Bypass REF with a 1µF capacitor to GND.

5 CCS Input-Current Regulation Loop-Compensation Point. Connect a 0.01µF capacitor to GND.

6 CCI Output-Current Regulation Loop-Compensation Point. Connect a 0.01µF capacitor to GND.

7 CCV Voltage Regulation Loop-Compensation Point. Connect 1kΩ in series with a 0.1µF capacitor to GND.

8 SHDN

9 ICHG

10 ACIN AC Detect Input. Input to an uncommitted comparator. ACIN can be used to detect AC-adapter presence.

11 ACOK AC Detect Output. High-voltage open-drain output is high impedance when V

12 REFIN Reference Input. Allows the ICTL and VCTL inputs to have ratiometric ranges for increased accuracy.

13 ICTL

14 GND Analog Ground

15 VCTL

16 BATT Battery Voltage Input

17 CELLS Cell Count Input. Tri-level input for setting number of cells. GND = 2 cells, open = 3 cells, REFIN = 4 cells.

18 CSIN Output Current-Sense Negative Input

19 CSIP Output Current-Sense Positive Input. Connect a current-sense resistor from CSIP to CSIN.

20 PGND Power Ground

21 DLO Low-Side Power MOSFET Driver Output. Connect to low-side nMOS gate.

22 DLOV Low-Side Driver Supply. Bypass DLOV with a 1µF capacitor to GND.

23 LX High-Side Power MOSFET Driver Power-Return Connection. Connect to the source of the high-side nMOS.

24 BST High-Side Power MOSFET Driver Power-Supply Connection. Connect a 0.1µF capacitor from LX to BST.

25 DHI High-Side Power MOSFET Driver Output. Connect to high-side nMOS gate.

26 CSSN Input Current-Sense Negative Input

27 CSSP Input Current-Sense Positive Input. Connect a current-sense resistor from CSSP to CSSN.

28 IINP

Shutdown Control Input. Drive SHDN logic low to shut down the MAX1908/MAX8724/MAX8765 MAX8765A.

Use with a thermistor to detect a hot battery and suspend charging.

Charge-Current Monitor Output. ICHG is a scaled-down replica of the charger output current. Use ICHG to

monitor the charging current and detect when the chip changes from constant-current mode to constantvoltage mode. The transconductance of (CSIP - CSIN) to ICHG is 3µA/mV.

Output Current-Limit Set Input. ICTL input voltage range is V

down if ICTL is forced below V

LDO, the set point for CSIP - CSIN is 45mV.

/100 while the MAX8765/MAX8765A does not. When ICTL is equal to

REFIN

REFIN

Output Voltage-Limit Set Input. VCTL input voltage range is 0 to V

point is (4.2 x CELLS)V.

is less than V

ACIN

/32 to V

REFIN

. The MAX1908/MAX8724 shut

REFIN

. When VCTL is equal to LDO, the set

REF

/2.

Input-Current Monitor Output. IINP is a scaled-down replica of the input current. IINP monitors the total

system current. The transconductance of (CSSP - CSSN) to IINP is 3µA/mV.

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

14 ______________________________________________________________________________________

Detailed Description

The MAX1908/MAX8724/MAX8765/MAX8765A include

all the functions necessary to charge Li+ batteries. A

high-efficiency synchronous-rectified step-down DC-DC

converter controls charging voltage and current. The

device also includes input-source current limiting and

analog inputs for setting the charge current and charge

voltage. Control charge current and voltage using the

ICTL and VCTL inputs, respectively. Both ICTL and

VCTL are ratiometric with respect to REFIN, allowing

compatibility with DACs or microcontrollers (µCs).

Ratiometric ICTL and VCTL improve the accuracy of the

charge current and voltage set point by matching V

RE-

FIN

to the reference of the host. For standard applications, internal set points for ICTL and VCTL provide 3A

charge current (with 0.015Ω sense resistor), and 4.2V

(per cell) charge voltage. Connect ICTL and VCTL to

LDO to select the internal set points. The MAX1908

safely conditions overdischarged cells with 300mA (with

0.015Ω sense resistor) until the battery-pack voltage

exceeds 3.1V × number of series-connected cells. The

SHDN input allows shutdown from a microcontroller or

thermistor.

The DC-DC converter uses external n-channel

MOSFETs as the buck switch and synchronous rectifier

to convert the input voltage to the required charging

current and voltage. The

Typical Application Circuit

shown in Figure 1 uses a µC to control charging current, while Figure 2 shows a typical application with

charging voltage and current fixed to specific values

for the application. The voltage at ICTL and the value of

RS2 set the charging current. The DC-DC converter

generates the control signals for the external MOSFETs

to regulate the voltage and the current set by the VCTL,

ICTL, and CELLS inputs.

The MAX1908/MAX8724/MAX8765/MAX8765A feature

a voltage regulation loop (CCV) and two current regulation loops (CCI and CCS). The CCV voltage regulation

loop monitors BATT to ensure that its voltage does not

exceed the voltage set by VCTL. The CCI battery current regulation loop monitors current delivered to BATT

to ensure that it does not exceed the current limit set by

ICTL. A third loop (CCS) takes control and reduces the

battery-charging current when the sum of the system

load and the battery-charging input current exceeds

the input current limit set by CLS.

Setting the Battery-Regulation Voltage

The MAX1908/MAX8724/MAX8765/MAX8765A use a

high-accuracy voltage regulator for charging voltage.

The VCTL input adjusts the charger output voltage.

VCTL control voltage can vary from 0 to V

REFIN

, provid-

ing a 10% adjustment range on the V

BATT

regulation

voltage. By limiting the adjust range to 10% of the regulation voltage, the external resistor mismatch error is

reduced from 1% to 0.05% of the regulation voltage.

Therefore, an overall voltage accuracy of better than

0.7% is maintained while using 1% resistors. The percell battery termination voltage is a function of the battery chemistry. Consult the battery manufacturer to

determine this voltage. Connect VCTL to LDO to select

the internal default setting V

BATT

= 4.2V × number of

cells, or program the battery voltage with the following

equation:

CELLS is the programming input for selecting cell count.

Connect CELLS as shown in Table 2 to charge 2, 3, or 4

Li+ cells. When charging other cell chemistries, use

CELLS to select an output voltage range for the charger.

The internal error amplifier (GMV) maintains voltage

regulation (Figure 3). The voltage error amplifier is

compensated at CCV. The component values shown in

Figures 1 and 2 provide suitable performance for most

applications. Individual compensation of the voltage regulation and current regulation loops allows for optimal

compensation (see the

Compensation

section).

Table 2. Cell-Count Programming

Table 1. Versions Comparison

V CELLS V

=×+×

BATT

⎛

⎛

404.

⎜

⎜

⎝

⎝

DESCRIPTION MAX1908 MAX8724

Conditioning

Charge Feature

ICTL Shutdown

Mode

ACOK Enable

Condition

Yes No No

Yes Yes No

REFIN must

be ready

REFIN must

be ready

CELLS CELL COUNT

GND 2

Open 3

V

REFIN

⎞

⎞

V

VCTL

⎟

V

REFIN

⎟

⎠

⎠

MAX8765/

MAX8765A

Independent

of REFIN

4

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

______________________________________________________________________________________ 15

MAX1908/MAX8724/MAX8765/MAX8765A

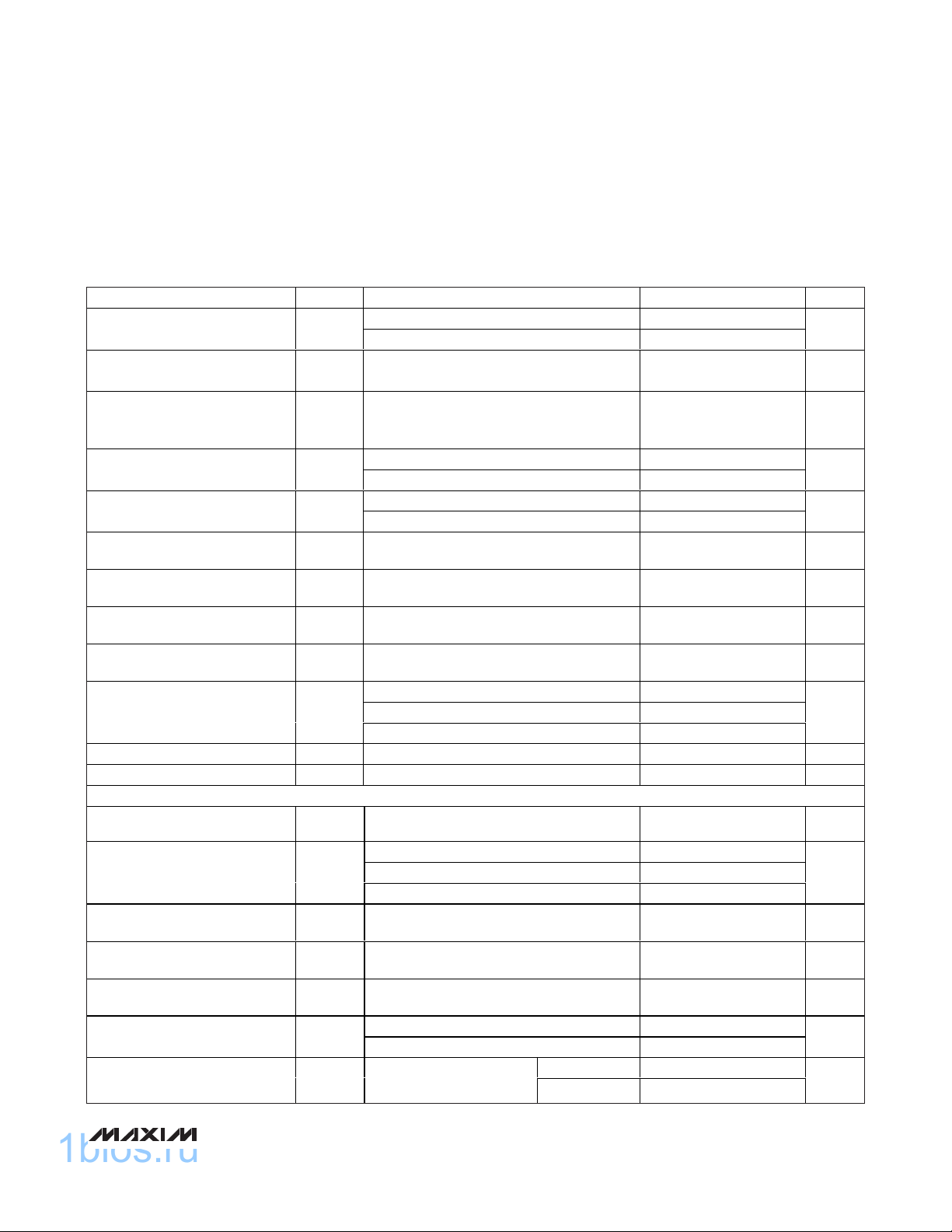

Figure 1. µC-Controlled Typical Application Circuit

Typical Application Circuits

AC ADAPTER INPUT

8.5V TO 28V

DAC OUTPUT

V

CC

OUTPUT

ADC INPUT

ADC INPUT

HOST

AVDD/REF

C14

0.1µF

R6

59kΩ

1%

R8

1MΩ

R9

20kΩ

R19, R20, R21

10kΩ

D2

R7

19.6kΩ

1%

12.6V OUTPUT VOLTAGE

C20

0.1µF

0.01µF

C5

1µF

R10

10kΩ

C9

D1

R5

1kΩ

C11

0.1µF

C10

0.01µF

0.01Ω

0.1µF

CSSP CSSN

DCIN

LDO

VCTL

ICTL

REFIN

ACIN

ACOK

SHDN

ICHG

MAX1908

MAX8724

C12

1µF

MAX8765

MAX8765A

IINP

CCV

CCI

CCS

RS1

0.1µF

CELLS

CLSREF

7.5A INPUT

CURRENT LIMIT

LDO

BST

DLOV

DHI

DLO

PGND

CSIP

CSIN

BATT

GND

LX

OPEN (3 CELLS SELECT)

C13

1µF

D3

C15

0.1µF

N1b

R13

33Ω

C16

1µF

N1a

C4

22µF

L1

10µH

RS2

0.015Ω

BATT

TO EXTERNAL

C1

2 × 10µF

+

SMART

BATTERY

LOAD

SCL

SDA

ADC INPUT

GND

SCL

SDA

TEMP

BATT-

PGND GND

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

16 ______________________________________________________________________________________

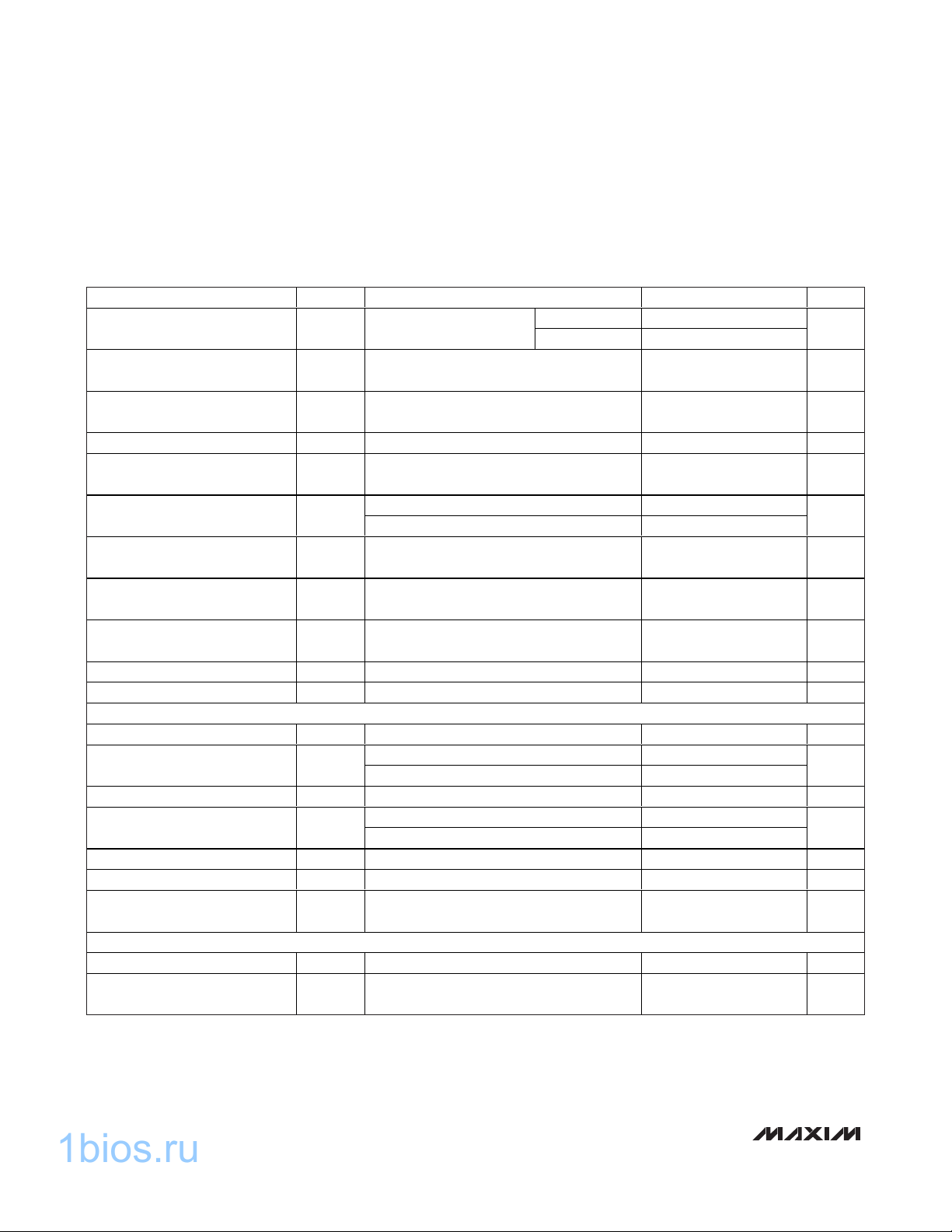

Figure 2. Typical Application Circuit with Fixed Charging Parameters

Typical Application Circuits (continued)

AC ADAPTER

INPUT

8.5V TO 28V

R6

59kΩ

LDO

R14

10.5kΩ

1%

R15

8.25kΩ

1%

R16

8.25kΩ

1%

FROM HOST µP

(SHUTDOWN)

1%

19.6kΩ

N

1%

R7

R19

10kΩ

1%

0.01µF

P1

R11

15kΩ

R12

12kΩ

D2

C5

1µF

LDO

16.8V OUTPUT VOLTAGE

2.5A CHARGE LIMIT

C12

1.5nF

R20

10kΩ

1%

R5

1kΩ

C11

0.1µF

C9

C10

0.01µF

CSSP CSSN

ACOK

DCIN

VCTL

REFIN

ICTL

ACIN

SHDN

ICHG

IINP

CCV

CCI

CCS

C12

1µF

RS1

0.01Ω

0.01µF

0.01µF

MAX1908

MAX8724

MAX8765

MAX8765A

R17

19.1kΩ

1%

REFIN (4 CELLS SELECT)

CELLS

LDO

C13

1µF

BST

DLOV

C15

0.1µF

DHI

LX

DLO

PGND

CSIP

CSIN

BATT

GND

CLSREF

N1b

R13

33Ω

D3

C16

1µF

N1a

L1

10µH

RS2

0.015Ω

C4

22µF

GNDPGND

TO EXTERNAL

C1

2 × 10µF

+

BATT

BATTERY

THM

BATT-

LOAD

R18

22kΩ

1%

4A INPUT CURRENT LIMIT

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

______________________________________________________________________________________ 17

MAX1908/MAX8724/MAX8765/MAX8765A

Figure 3. Functional Diagram

Functional Diagram

SHDN

GND

CCS

CLS

CSSP

CSSN

CSIP

CSIN

ICTL

CCI

BATT

23.5%

REFIN

REFIN

GND

DCIN

75mV

x

LEVEL

SHIFTER

LEVEL

SHIFTER

75mV

x

REFIN

REF

R1

3.1V/CELL

MAX1908

MAX8724

MAX8765

MAX8765A

GMS

GMI

MAX1908 ONLY

BAT_UV

SRDY

LOGIC

BLOCK

CSI

LVC

LVC

RDY

5.4V

LINEAR

REGULATOR

REF/2

CONVERTER

MAX1908/MAX8724 ONLY

GM

GM

LEVEL

SHIFTER

DC-DC

4.096V

REFERENCE

1/55

ICTL

DRIVER

DCIN

LDO

REF

REFIN

ACIN

ACOK

N

IINP

ICHG

BST

DHI

LX

CELLS

CCV

VCTL

CELL

SELECT

LOGIC

x

400mV

REFIN

4V

GMV

DRIVER

DLOV

DLO

PGND

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

18 ______________________________________________________________________________________

Setting the Charging-Current Limit

The ICTL input sets the maximum charging current. The

current is set by current-sense resistor RS2, connected

between CSIP and CSIN. The full-scale differential

voltage between CSIP and CSIN is 75mV; thus, for a

0.015Ω sense resistor, the maximum charging current

is 5A. Battery-charging current is programmed with

ICTL using the equation:

The input voltage range for ICTL is V

REFIN

/32 to V

REFIN

.

The MAX1908/MAX8724 shut down if ICTL is forced

below V

REFIN

/100 (min), while the MAX8765/MAX8765A

does not.

Connect ICTL to LDO to select the internal default fullscale, charge-current sense voltage of 45mV. The

charge current when ICTL = LDO is:

where RS2 is 0.015Ω, providing a charge-current set

point of 3A.

The current at the ICHG output is a scaled-down replica

of the battery output current being sensed across CSIP

and CSIN (see the

Current Measurement

section).

When choosing the current-sense resistor, note that the

voltage drop across this resistor causes further power

loss, reducing efficiency. However, adjusting ICTL to

reduce the voltage across the current-sense resistor

can degrade accuracy due to the smaller signal to the

input of the current-sense amplifier. The chargingcurrent-error amplifier (GMI) is compensated at CCI

(see the

Compensation

section).

Setting the Input Current Limit

The total input current (from an AC adapter or other DC

source) is a function of the system supply current and

the battery-charging current. The input current regulator

limits the input current by reducing the charging

current when the input current exceeds the input

current-limit set point. System current normally fluctuates as portions of the system are powered up or

down. Without input current regulation, the source must

be able to supply the maximum system current and the

maximum charger input current simultaneously. By using

the input current limiter, the current capability of the AC

adapter can be lowered, reducing system cost.

The MAX1908/MAX8724/MAX8765/MAX8765A limit the

battery charge current when the input current-limit

threshold is exceeded, ensuring the battery charger

does not load down the AC adapter voltage. An internal

amplifier compares the voltage between CSSP and

CSSN to the voltage at CLS. V

CLS

can be set by a

resistive divider between REF and GND. Connect CLS

to REF for the full-scale input current limit. The CLS voltage range for the MAX1908/MAX8724 is from 1.6V to

REF, while the MAX8765/MAX8765A CLS voltage is

from 1.1V to REF.

The input current is the sum of the device current, the

charger input current, and the load current. The device

current is minimal (3.8mA) in comparison to the charge

and load currents. Determine the actual input current

required as follows:

where η is the efficiency of the DC-DC converter.

V

CLS

determines the reference voltage of the GMS

error amplifier. Sense resistor RS1 and V

CLS

determine

the maximum allowable input current. Calculate the

input current limit as follows:

Once the input current limit is reached, the charging

current is reduced until the input current is at the

desired threshold.

When choosing the current-sense resistor, note that the

voltage drop across this resistor causes further power

loss, reducing efficiency. Choose the smallest value for

RS1 that achieves the accuracy requirement for the

input current-limit set point.

Conditioning Charge

The MAX1908 includes a battery-voltage comparator

that allows a conditioning charge of overdischarged Li+

battery packs. If the battery-pack voltage is less than

3.1V × number of cells programmed by CELLS, the

MAX1908 charges the battery with 300mA current when

using sense resistor RS2 = 0.015Ω. After the

battery voltage exceeds the conditioning charge threshold, the MAX1908 resumes full-charge mode, charging

to the programmed voltage and current limits. The

MAX8724/MAX8765/MAX8765A do not offer this feature.

AC Adapter Detection

Connect the AC adapter voltage through a resistive

divider to ACIN to detect when AC power is available,

as shown in Figure 1. ACIN voltage rising trip point is

V

REF

/2 with 20mV hysteresis. ACOK is an open-drain

output and is high impedance when ACIN is less than

V

I

CHG

ICTL

=×

VRS

REFIN

I

=

CHG

0 0452.

RS

0 0752.

V

II

=+

INPUT LOAD

I

INPUT

V

=×

VRS

⎛

IV

CHG BATT

⎜

V

⎝

IN

0 0751.

CLS

REF

×

⎞

⎟

×

η

⎠

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

______________________________________________________________________________________ 19

V

REF

/2. Since ACOK can withstand 30V (max), ACOK

can drive a p-channel MOSFET directly at the charger

input, providing a lower dropout voltage than a

Schottky diode (Figure 2). In the MAX1908/MAX8724

the ACOK comparator is enabled after REFIN is ready.

In the MAX8765/MAX8765A, the ACOK comparator is

independent of REFIN.

Current Measurement

Use ICHG to monitor the battery-charging current being

sensed across CSIP and CSIN. The ICHG voltage is

proportional to the output current by the equation:

V

ICHG

= ICHG x RS2 x G

ICHG

x R9

where I

CHG

is the battery-charging current, G

ICHG

is

the transconductance of ICHG (3µA/mV typ), and R9 is

the resistor connected between ICHG and ground.

Leave ICHG unconnected if not used.

Use IINP to monitor the system input current being

sensed across CSSP and CSSN. The voltage of IINP is

proportional to the input current by the equation:

V

IINP

= I

INPUT

x RS1 x G

IINP

x R10

where I

INPUT

is the DC current being supplied by the AC

adapter power, G

IINP

is the transconductance of IINP

(3µA/mV typ), and R10 is the resistor connected between

IINP and ground. ICHG and IINP have a 0 to 3.5V output

voltage range. Leave IINP unconnected if not used.

LDO Regulator

LDO provides a 5.4V supply derived from DCIN and

can deliver up to 10mA of load current. The MOSFET

drivers are powered by DLOV and BST, which must be

connected to LDO as shown in Figure 1. LDO supplies

the 4.096V reference (REF) and most of the control circuitry. Bypass LDO with a 1µF capacitor to GND.

Shutdown

The MAX1908/MAX8724/MAX8765/MAX8765A feature

a low-power shutdown mode. Driving SHDN low shuts

down the MAX1908/MAX8724/MAX8765/MAX8765A. In

shutdown, the DC-DC converter is disabled and CCI,

CCS, and CCV are pulled to ground. The IINP and

ACOK outputs continue to function.

SHDN can be driven by a thermistor to allow automatic

shutdown of the MAX1908/MAX8724/MAX8765/

MAX8765A when the battery pack is hot. The shutdown

falling threshold is 23.5% (typ) of V

REFIN

with 1%

V

REFIN

hysteresis to provide smooth shutdown when

driven by a thermistor.

DC-DC Converter

The MAX1908/MAX8724/MAX8765/MAX8765A employ

a buck regulator with a bootstrapped nMOS high-side

switch and a low-side nMOS synchronous rectifier.

CCV, CCI, CCS, and LVC Control Blocks

The MAX1908/MAX8724/MAX8765/MAX8765A control

input current (CCS control loop), charge current (CCI

control loop), or charge voltage (CCV control loop),

depending on the operating condition.

The three control loops, CCV, CCI, and CCS are brought

together internally at the LVC amplifier (lowest voltage

clamp). The output of the LVC amplifier is the feedback

control signal for the DC-DC controller. The output of the

GMamplifier that is the lowest sets the output of the LVC

amplifier and also clamps the other two control loops to

within 0.3V above the control point. Clamping the other

two control loops close to the lowest control loop ensures

fast transition with minimal overshoot when switching

between different control loops.

DC-DC Controller

The MAX1908/MAX8724/MAX8765/MAX8765A feature a

variable off-time, cycle-by-cycle current-mode control

scheme. Depending upon the conditions, the MAX1908/

MAX8724/MAX8765/MAX8765A work in continuous or

discontinuous-conduction mode.

Continuous-Conduction Mode

With sufficient charger loading, the MAX1908/MAX8724/

MAX8765/MAX8765A operate in continuous-conduction

mode (inductor current never reaches zero) switching at

400kHz if the BATT voltage is within the following range:

3.1V x (number of cells) < V

BATT

< (0.88 x V

DCIN

)

The operation of the DC-DC controller is controlled by

the following four comparators as shown in Figure 4:

• IMIN—Compares the control point (LVC) against

0.15V (typ). If IMIN output is low, then a new cycle

cannot begin.

• CCMP—Compares the control point (LVC) against the

charging current (CSI). The high-side MOSFET ontime is terminated if the CCMP output is high.

• IMAX—Compares the charging current (CSI) to 6A

(RS2 = 0.015Ω). The high-side MOSFET on-time is

terminated if the IMAX output is high and a new cycle

cannot begin until IMAX goes low.

• ZCMP—Compares the charging current (CSI) to

333mA (RS2 = 0.015Ω). If ZCMP output is high, then

both MOSFETs are turned off.

MAX1908/MAX8724/MAX8765/MAX8765A

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

20 ______________________________________________________________________________________

Figure 4. DC-DC Functional Diagram

DC-DC Functional Diagram

5ms

RESET

1.8V

0.15V

0.1V

IMAX

CCMP

IMIN

ZCMP

S

BST

RQ

LVC

MAX1908

MAX8724

MAX8765

MAX8765A

RQ

CHG

S

Q

t

OFF

GENERATOR

GMS

GMI

GMV

DHI

DLO

CSS

X20

CSI

X20

CSSP

CSSN

BST

DHI

LX

DLO

CSIP

CSIN

BATT

AC ADAPTER

RS1

N1a

N1b

C

OUT

BATTERY

D3

L1

RS2

LDO

C

BST

SETV

CONTROL

CCVCCICCS

SETI

CLS

CELLS

CELL

SELECT

LOGIC

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

______________________________________________________________________________________ 21

In normal operation, the controller starts a new cycle by

turning on the high-side n-channel MOSFET and

turning off the low-side n-channel MOSFET. When the

charge current is greater than the control point (LVC),

CCMP goes high and the off-time is started. The

off-time turns off the high-side n-channel MOSFET and

turns on the low-side n-channel MOSFET. The operational frequency is governed by the off-time and is

dependent upon V

DCIN

and V

BATT

. The off-time is set

by the following equations:

where:

These equations result in fixed-frequency operation

over the most common operating conditions.

At the end of the fixed off-time, another cycle begins if

the control point (LVC) is greater than 0.15V, IMIN =

high, and the peak charge current is less than 6A (RS2

= 0.015Ω), IMAX = high. If the charge current exceeds

IMAX, the on-time is terminated by the IMAX comparator. IMAX governs the maximum cycle-by-cycle current

limit and is internally set to 6A (RS2 = 0.015Ω). IMAX

protects against sudden overcurrent faults.

If, during the off-time, the inductor current goes to zero,

ZCMP = high, both the high- and low-side MOSFETs

are turned off until another cycle is ready to begin.

There is a minimum 0.3µs off-time when the (V

DCIN

-

V

BATT

) differential becomes too small. If V

BATT

≥ 0.88 ×

V

DCIN

, then the threshold for minimum off-time is

reached and the t

OFF

is fixed at 0.3µs. A maximum ontime of 5ms allows the controller to achieve > 99% duty

cycle in continuous-conduction mode. The switching

frequency in this mode varies according to the equation:

Discontinuous Conduction

The MAX1908/MAX8724/MAX8765/MAX8765A enter discontinuous-conduction mode when the output of the LVC

control point falls below 0.15V. For RS2 = 0.015Ω, this

corresponds to 0.5A:

for RS2 = 0.015Ω.

In discontinuous mode, a new cycle is not started until

the LVC voltage rises above 0.15V. Discontinuousmode operation can occur during conditioning charge

of overdischarged battery packs, when the charge current has been reduced sufficiently by the CCS control

loop, or when the battery pack is near full charge (constant-voltage-charging mode).

MOSFET Drivers

The low-side driver output DLO switches between

PGND and DLOV. DLOV is usually connected through

a filter to LDO. The high-side driver output DHI is bootstrapped off LX and switches between VLXand V

BST

.

When the low-side driver turns on, BST rises to one

diode voltage below DLOV.

Filter DLOV with a lowpass filter whose cutoff frequency

is approximately 5kHz (Figure 1):

Dropout Operation

The MAX1908/MAX8724/MAX8765/MAX8765A have 99%

duty-cycle capability with a 5ms (max) on-time and 0.3µs

(min) off-time. This allows the charger to achieve dropout

performance limited only by resistive losses in the DC-DC

converter components (D1, N1, RS1, and RS2, Figure 1).

Replacing diode D1 with a p-channel MOSFET driven by

ACOK improves dropout performance (Figure 2). The

dropout voltage is set by the difference between DCIN

and CSIN. When the dropout voltage falls below 100mV,

the charger is disabled; 200mV hysteresis ensures that

the charger does not turn back on until the dropout voltage rises to 300mV.

Compensation

Each of the three regulation loops—input current limit,

charging current limit, and charging voltage limit—are

compensated separately using CCS, CCI, and CCV,

respectively.

MAX1908/MAX8724/MAX8765/MAX8765A

ts

OFF

t

I

RIPPLE

f

=

=×

25. µ

ON

f

VV

()

CSSN BATT

VV

LI

×

=

VV

CSSN BATT

Vt

BATT OFF

=

=

tt

ON OFF

LI

×

RIPPLE

−

−

DCIN BATT

V

DCIN

RIPPLE

−

×

L

1

+

+103. µ

s

V

IMIN

015

RSA=×

20 2

=

05..

1

f

==

C

RC F

2

ππ µΩ

1

××

2331

=

48

.

kHz

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

22 ______________________________________________________________________________________

CCV Loop Definitions

Compensation of the CCV loop depends on the parameters and components shown in Figure 5. CCVand

RCVare the CCV loop compensation capacitor and

series resistor. R

ESR

is the equivalent series resistance

(ESR) of the charger output capacitor (C

OUT

). RLis the

equivalent charger output load, where RL= V

BATT

/

I

CHG

. The equivalent output impedance of the GMV

amplifier, R

OGMV

≥ 10MΩ . The voltage amplifier

transconductance, GMV = 0.125µA/mV. The DC-DC

converter transconductance, GM

OUT

= 3.33A/V:

where A

CSI

= 20, and RS2 is the charging current-

sense resistor in the

Typical Application Circuits

.

The compensation pole is given by:

The compensation zero is given by:

The output pole is given by:

where R

L

varies with load according to RL= V

BATT/ICHG.

Output zero due to output capacitor ESR:

The loop transfer function is given by:

Assuming the compensation pole is a very low

frequency, and the output zero is a much higher frequency, the crossover frequency is given by:

To calculate R

CV

and CCVvalues of the circuit of Figure 2:

Cells = 4

C

OUT

= 22µF

V

BATT

= 16.8V

I

CHG

= 2.5A

GMV = 0.125µA/mV

GM

OUT

= 3.33A/V

R

OGMV

= 10MΩ

f = 400kHz

Choose crossover frequency to be 1/5th the

MAX1908’s 400kHz switching frequency:

Solving yields RCV= 26kΩ.

Conservatively set RCV= 1kΩ, which sets the crossover

frequency at:

f

CO_CV

= 3kHz

Choose the output-capacitor ESR so the output-capacitor

zero is 10 times the crossover frequency:

Figure 5. CCV Loop Diagram

CCV

REF

BATT

R

C

ESR

OUT

R

L

GM

OUT

GMV

R

C

R

CV

CV

OGMV

f

Z ESR

LTF GM R GMV R

=××××

11

()

11

()

=

_

OUT L OGMV

+×

sC R sC R

+×

2π

sC R sC R

OUT ESR CV CV

CV OGMV OUT L

1

RC

×

ESR OUT

()

()

GMV R GM

××

f

CO CV

GM

OUT

=

ARS

×12

CSI

f

PCV

_

=

2π

1

RC

×

OGMV CV

f

CO CV

_

=

_

GMV R GM

=

××

CV OUT

C

2π

OUT

CV OUT

C

π

OUT

f

ZCV

_

=

1

RC

2π

×

CV CV

R

ESR

=

×× ×

210

π

1

fC

CO CV OUT

_

+×

+×

kHz

=280

=

. Ω

024

f

P OUT

_

=

2π

1

RC

×

L OUT

f

Z ESR

_

1

RC

2

×

π

ESR OUT

=

2 412

MHz

.=

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

______________________________________________________________________________________ 23

The 22µF ceramic capacitor has a typical ESR of

0.003Ω, which sets the output zero at 2.412MHz.

The output pole is set at:

where:

Set the compensation zero (f

Z_CV

) so it is equivalent to

the output pole (f

P_OUT

= 1.08kHz), effectively producing a pole-zero cancellation and maintaining a singlepole system response:

Choose CCV= 100nF, which sets the compensation

zero (f

Z_CV

) at 1.6kHz. This sets the compensation pole:

CCI Loop Definitions

Compensation of the CCI loop depends on the parameters and components shown in Figure 7. CCIis the CCI

loop compensation capacitor. A

CSI

is the internal gain

of the current-sense amplifier. RS2 is the charge current-sense resistor, RS2 = 15mΩ. R

OGMI

is the equivalent output impedance of the GMI amplifier ≥ 10MΩ.

GMI is the charge-current amplifier transconductance

= 1µA/mV. GM

OUT

is the DC-DC converter transconductance = 3.3A/V. The CCI loop is a single-pole system with a dominant pole compensation set by f

P_CI

:

The loop transfer function is given by:

Since:

The loop transfer function simplifies to:

MAX1908/MAX8724/MAX8765/MAX8765A

Figure 6. CCV Loop Gain/Phase vs. Frequency

f

P OUT

_

∆

R

==

L

∆

f

ZCV

_

RC

2

π

L OUT

V

BATT

I

CHG

1

×

Battery ESR

=

.=

108

kHz

=

1

RC

2π

×

CV CV

f

=

PCI

_

RC

2π

OGMI CI

LTF GM A RS GMI

=×××

OUT CSI

2

1

×

R

OGMI

+×

1

sR C

OGMI CI

C

=

CV

2108

1

R kHz

×

π .

CV

=

147

nF

f

PCV

_

80

60

40

20

GAIN (dB)

0

-20

-40

2

1

RC

π

OGMV CV

CCV LOOP GAIN

vs. FREQUENCY

=

×

.=

016

Hz

GM

OUT

=

ARS

×12

CSI

R

OGMI

+×1

sR C

OGMI CI

-45

-60

-75

-90

PHASE (DEGREES)

-105

-120

LTF GMI

=×

CCV LOOP PHASE

vs. FREQUENCY

-60

11M

FREQUENCY (Hz)

100k10k1k10010

-135

11M

FREQUENCY (Hz)

100k10k1k10010

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

24 ______________________________________________________________________________________

The crossover frequency is given by:

The CCI loop dominant compensation pole:

where the GMI amplifier output impedance, R

OGMI

=

10MΩ.

To calculate the CCI loop compensation pole, C

CI

:

GMI = 1µA/mV

GM

OUT

= 3.33A/V

R

OGMI

= 10MΩ

f = 400kHz

Choose crossover frequency f

CO_

CI

to be 1/5th the

MAX1908/MAX8724/MAX8765/MAX8765A switching

frequency:

Solving for C

CI

, CCI= 2nF.

To be conservative, set CCI= 10nF, which sets the

crossover frequency at:

The compensation pole, f

P_CI

is set at:

CCS Loop Definitions

Compensation of the CCS loop depends on the parameters and components shown in Figure 9. CCSis the CCS

loop compensation capacitor. A

CSS

is the internal gain of

the current-sense amplifier. RS1 is the input currentsense resistor, RS1 = 10mΩ. R

OGMS

is the equivalent

output impedance of the GMS amplifier ≥ 10MΩ. GMS is

Figure 7. CCI Loop Diagram

GM

CCI

R

C

CI

OGMI

OUT

GMI

CSIP CSIN

RS2

CSI

ICTL

f

CO CICI_

GMI

=

2π

C

f

PCI

_

=

2π

1

RC

×

OGMI CI

GMI

==

280π

C

kHz

f

CO CICI_

f

CO CI_

f

PCI

_

GMI

==

210

π

GMI

π

RC

OGMI CI

×

nF

16

=20 0016

kHz

.=

Hz

CCI LOOP GAIN

vs. FREQUENCY

100

80

60

40

20

GAIN (dB)

0

-20

-40

-60

0.1 1M

FREQUENCY (Hz)

CCI LOOP PHASE

vs. FREQUENCY

0

-15

-30

-45

-60

PHASE (DEGREES)

-75

-90

100k10k1 10 100 1k

-105

0.1 1M

FREQUENCY (Hz)

100k10k1k100101

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

______________________________________________________________________________________ 25

the charge-current amplifier transconductance = 1µA/mV.

GMINis the DC-DC converter transconductance =

3.3A/V. The CCS loop is a single-pole system with a dominant pole compensation set by f

P_CS

:

The loop transfer function is given by:

Since:

Then, the loop transfer function simplifies to:

The crossover frequency is given by:

The CCS loop dominant compensation pole:

where the GMS amplifier output impedance, R

OGMS

=

10MΩ.

To calculate the CCI loop compensation pole, CCS:

GMS = 1µA/mV

GMIN= 3.33A/V

R

OGMS

= 10MΩ

f = 400kHz

MAX1908/MAX8724/MAX8765/MAX8765A

Figure 9. CCS Loop Diagram

Figure 10. CCS Loop Gain/Phase vs. Frequency

f

=

PCS

_

RC

2π

OGMS CS

LTF GM A RS GMS

=××××

IN CSS

1

GM

=

IN

ARS

CSS

1

×

R

OGMS

+×

1

sR C

OGMS CS

×11

CCS

GM

IN

GMS

R

C

CS

OGMS

CSSP CSSN

RS1

CSS

CLS

R

LTF GMS

=×

OGMS

+×1

sR C

OGMS CS

f

CO CSCS_

100

80

60

40

20

GAIN (dB)

0

-20

-40

-60

0.1 1M

GMS

=

2π

C

CCS LOOP GAIN

vs. FREQUENCY

FREQUENCY (Hz)

f

=

PCS

_

2π

1

RC

×

OGMS CS

CCS LOOP PHASE

vs. FREQUENCY

0

-15

-30

-45

-60

PHASE (DEGREES)

-75

-90

100k10k1 10 100 1k

-105

0.1 1M

FREQUENCY (Hz)

100k10k1k100101

1bios.ru

MAX1908/MAX8724/MAX8765/MAX8765A

Low-Cost Multichemistry Battery Chargers

26 ______________________________________________________________________________________

Choose crossover frequency f

CO_CS

to be 1/5th the

MAX1908/MAX8724/MAX8765/MAX8765A switching

frequency:

Solving for CCS, CCS= 2nF.

To be conservative, set C

CS

= 10nF, which sets the

crossover frequency at:

The compensation pole, f

P_CS

is set at:

Component Selection

Table 3 lists the recommended components and refers

to the circuit of Figure 2. The following sections

describe how to select these components.

Inductor Selection

Inductor L1 provides power to the battery while it is

being charged. It must have a saturation current of at

least the charge current (I

CHG

), plus 1/2 the current rip-

ple I

RIPPLE

:

I

SAT

= I

CHG

+ (1/2) I

RIPPLE