Page 1

Maxim > Design Support > Technical Documents > User Guides > APP 3917

Page 1 of 6

Keywords: sequencer, sequencing, monitor, eeprom, tracking,

USER GUIDE 3917

The MAX6876 Power -Supply Tracker/Sequencer User

Guide

By: Eric Schlaepfer, Applications Engineer

Sep 20, 2006

Abstract: This application note provides a step -by-step tutorial for configuring the MAX6876. The tutorial

describes how to set thresholds, timing delays, current measurements, and sequencing/tracking order.

Overview of the MAX6876's Key Features

Tracks and sequences up to four voltages

Closed- loop tracking control with programmable slew rate

Mixed tracking and sequencing

I²C programmable

Overcurrent sensing

Separate power-good (PG) outputs

Introduction

The MAX6876 tracks and sequences up to four voltages using parameters programmed over I²C and stored in

the internal EEPROM; these parameters include voltage thresholds, slew rates, timing delays, and the

sequencing order. The parameters are set within the user-friendly MAX6876 Evaluation Kit software. The part

may be programmed in-circuit using four wires: V

experimentation during prototyping very easy since no resistors or capacitors need to be replaced to change the

thresholds or timing delays. In this circuit, power during normal operation comes from IN1 (the highest of the

input voltages), and power during programming comes from V

power supplies on the board to remain off during programming.

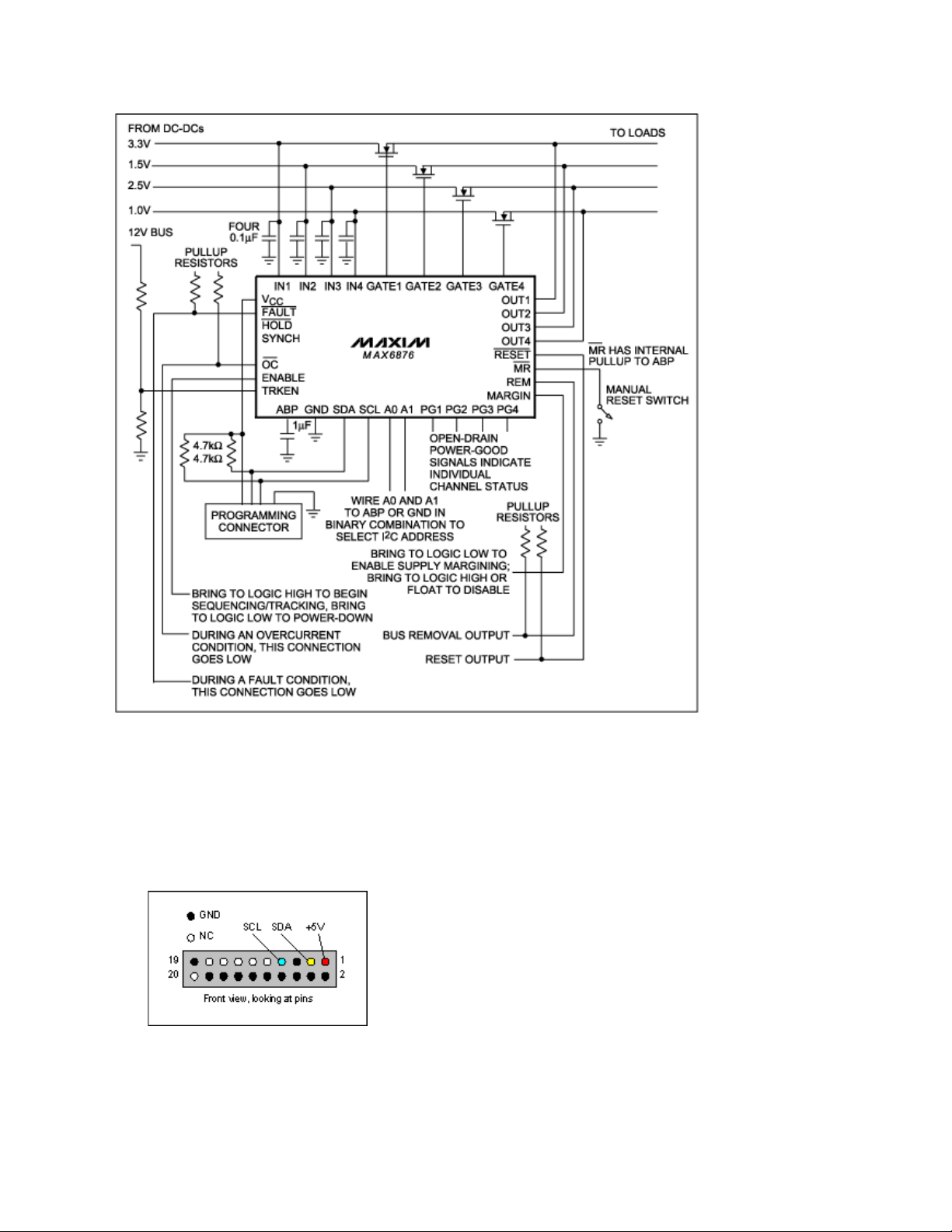

Several passive components are required for operation. The ABP connection needs to be connected to a 1µF

ceramic capacitor to filter the internal power supply. All of the status outputs are open drain and, accordingly,

require pullup resistors. These resistors can be connected to any power-supply voltage under +6V. To filter

noise on the IN_ connections, 0.1µF capacitors can be connected, but they are not absolutely necessary.

Figure 1 illustrates the basic connections and key features of the MAX6876.

, SDA, SCL, and GND. In - circuit programming makes

CC

. This configuration allows the main DC -DC

CC

Page 2

Figure 1. A diagram of the MAX6876's basic connections.

Page 2 of 6

To create a basic design with the MAX6876, use the following steps:

1. Download and install the MAX6876 Evaluation Kit software.

2. Connect a CMOD232 board (included in the Evaluation Kit) to the host computer using an RS232 cable

(not a "null modem" type cable). Note that the MAX6876 Evaluation Kit software does not yet support the

newer CMAXQUSB interface board.

3. Connect the CMOD232 board to either the MAX6876 Evaluation Kit or the application circuit board. The

pinout of the CMOD232 connector P3 is as follows:

Figure 2. The pinout of the CMOD232 connector P3.

4. To connect to the CMOD232 and the MAX6876, launch the Evaluation Kit software, select System-

Page 3

>Connect from the menu, and choose OK.

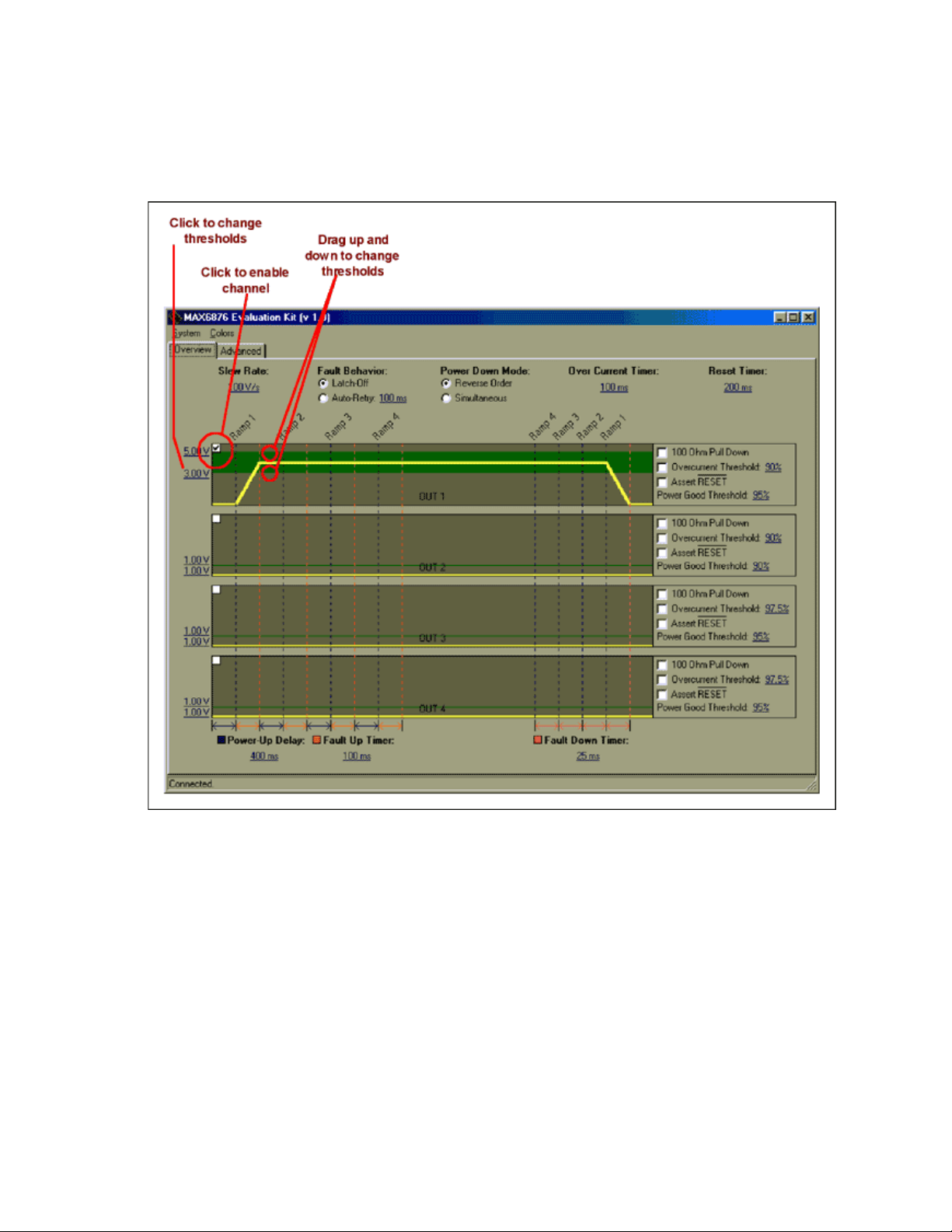

5. To enable a channel, click the checkbox in the upper left corner of each channel window; next, set the

Page 3 of 6

undervoltage and overvoltage thresholds by either clicking the voltage to the right of the window or

dragging the waveform.

Figure 3. This screen capture illustrates how to enable a channel and set the thresholds of the MAX6876

with the Evaluation Kit software.

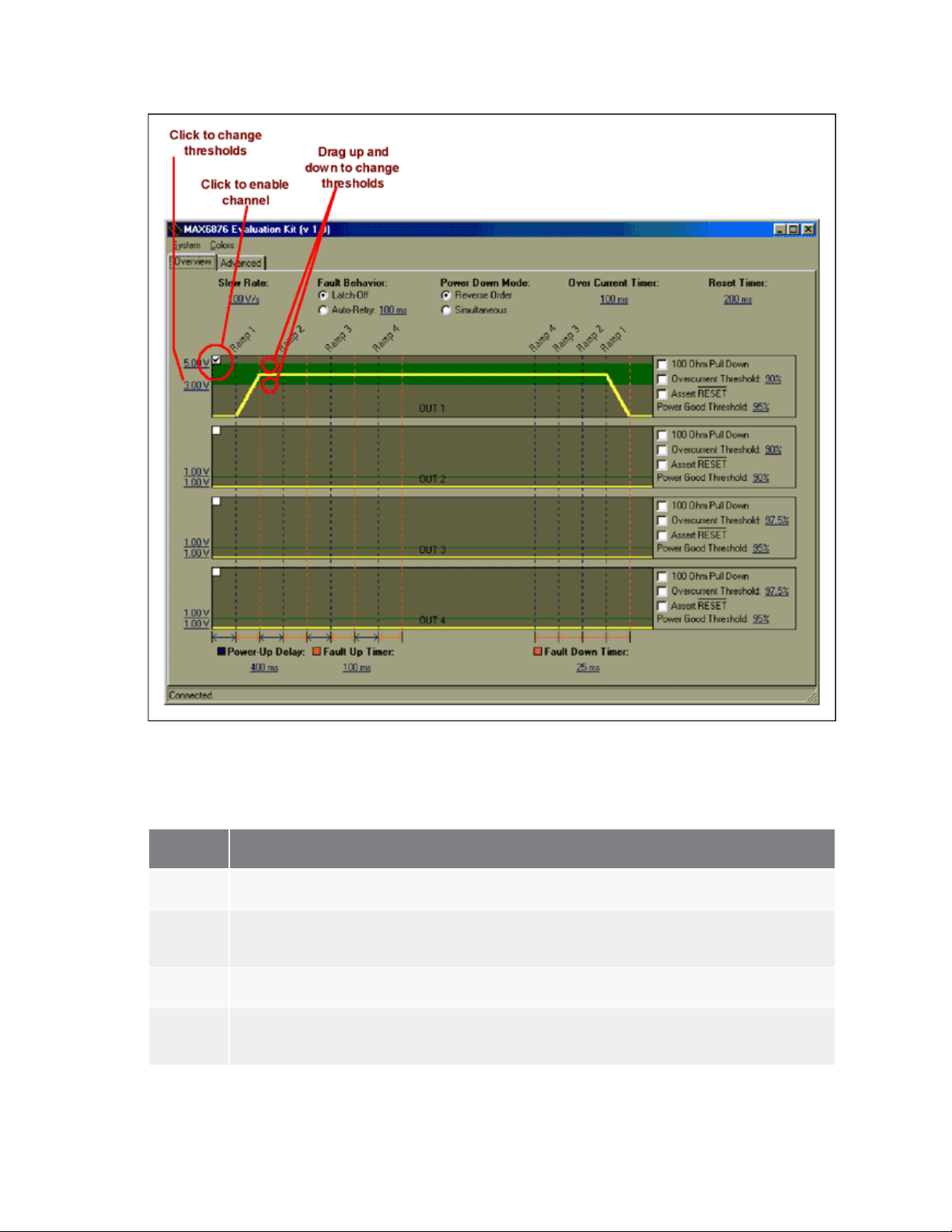

6. Select the sequence for each channel by dragging the base of each ramp. Reverse sequencing can be

turned-on using the Power Down Mode option buttons.

Page 4

Figure 4. This screen capture illustrates how to configure the MAX6876 for mixed -mode

Page 4 of 6

tracking/sequencing.

7. Consult Table 1 and select the appropriate options for each channel.

Table 1. Channel-Control Options.

Option

Name

100 Ohm

Pull Down

Overcurrent

Threshold

Assert

RESET

Power

Good

Threshold

Function

Activates a 100Ω pulldown resistor on the channel's OUT connection during shutdown only.

Activates overcurrent monitoring on the channel. This compares the IN_ voltage to the OUT_

voltage. When OUT_ falls below a percentage of IN_, Overcurrent Threshold asserts the OC

output (bringing it low).

Activates this channel's control over the RESET line. If this channel falls below its powergood threshold, RESET asserts low.

When the channel's OUT voltage is within this percentage of the IN voltage, the

corresponding PG pin asserts (goes high impedance).

Page 5

8. To set the slew rate, click the Slew Rate selection on the upper left portion of the screen.

9. Set the power- up delay by clicking Power - Up Delay in the lower left portion of the screen. The power- up

assert the OC output. Set the Over Current timer to a value that will not cause glitches to prematurely

Page 5 of 6

delay is the amount of time it takes for a channel to track up after another channel goes into power- good

mode.

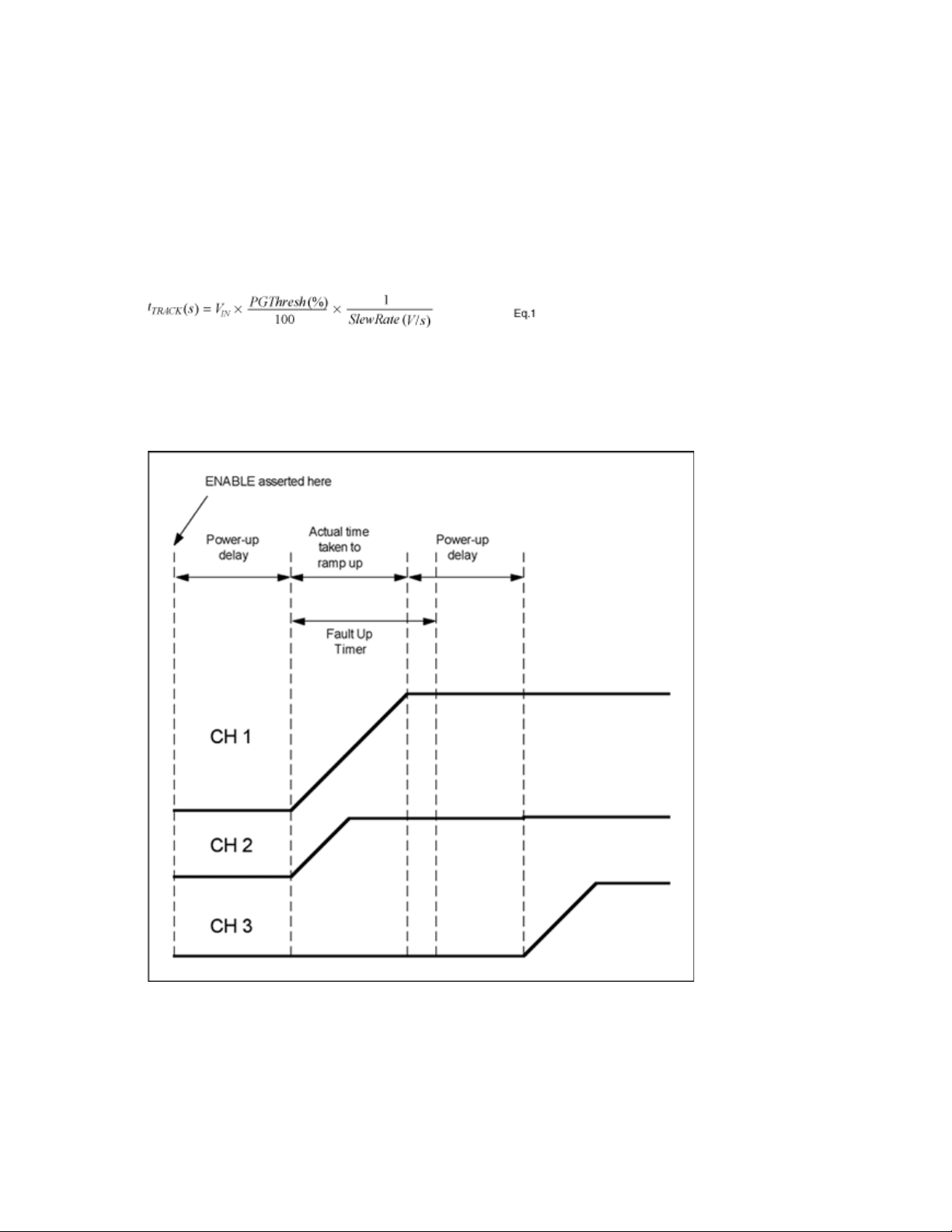

10. Set the Fault Up Timer and the Fault Down Timer. These are the maximum allowable times for a channel

output to ramp from zero volts to the channel input voltage, or from the channel input voltage to zero volts.

Be very careful when setting the fault timers: it is possible to generate an unnecessary fault by using slow

slew rates and fast fault timers. The time for a single voltage to track up from zero volts can be calculated

with the following formula:

For example, with a VIN of 3.3V, a Power Good Threshold of 95%, and a Slew Rate of 100V/s, the time

required to ramp-up/-down is 31.35ms. Therefore, the Fault Up Timer and Fault Down Timer must be set

to at least 50ms—the 25ms option would cause FAULT to be asserted. If more than one channel is

ramping-up/-down at the same time, the two voltages will track; it is, therefore, possible for the ramp - up/down time period to be longer than the theoretical calculation.

Figure 5. Power- Up and Fault Timings for the MAX6876.

11. Set the Fault Behavior option. In Latch - Off mode, the device shuts off after a fault and waits for ENABLE

to be toggled before trying again. In Auto-Retry mode, the device tries again at the specified interval.

12. The Over Current Timer setting determines how long an overcurrent condition must be present in order to

Page 6

assert the OC output.

13. The Reset Timer setting determines the RESET pulse width. Set the Reset Timer to a value that is

Page 6 of 6

guaranteed to reset the microprocessor connected to the pin.

14. Once all parameters are set, write them to the MAX6876 EEPROM by selecting System→Commit

Configuration to EEPROM.

15. The configuration can be saved to a file by selecting System→Save Configuration. All of the registers are

written to this configuration file.

Multiple MAX6876 devices can be connected together for more than 4 channels, but this multiple-device

configuration only operates in tracking mode, in which all channels ramp- up at once. See the datasheet for

more information and an application circuit for connecting multiple MAX6876 devices.

Related Parts

MAX6876 EEPROM-Programmable, Quad, Power- Supply

More Information

For Technical Support: http://www.maximintegrated.com/support

For Samples: http://www.maximintegrated.com/samples

Other Questions

Application Note

USER GUIDE 3917, AN3917, AN 3917, APP3917, Appnote3917, Appnote 3917

Copyright © by Maxim Integrated Products

Additional Legal Notices:

Tracker/Sequencer Circuit

and Comments:

http://www.maximintegrated.com/contact

3917: http://www.maximintegrated.com/an3917

http://www.maximintegrated.com/legal

Free Samples

Loading...

Loading...