Page 1

19-5449; Rev 0; 7/10

MAX17127 Evaluation Kit

General Description

The MAX17127 evaluation kit (EV kit) is a fully assembled

and tested surface-mount PCB that evaluates the highefficiency MAX17127 white LED (WLED) driver. The EV

kit utilizes a step-up DC-DC converter to generate the

voltage required to drive up to six strings of 10 surfacemount WLEDs. The EV kit uses a 5V to 26V input power

supply and can be configured to provide an adjustable

10mA to 30mA full-scale LED current.

Evaluates: MAX17127

Features

S 5V to 26V Input Range

S WLED Drives Up to 30mA/String

S Drives Six Strings of 10 WLEDs

S Full-Scale LED Current Adjustable from 10mA to

30mA

S 1MHz PWM Switching Frequency Adjustable from

250kHz to 1MHz (Component Change Required)

S All Components < 1mm Height

S Fully Assembled and Tested

Ordering Information

PART TYPE

MAX17127EVKIT+ EV Kit

+Denotes lead(Pb)-free and RoHS compliant.

Component List

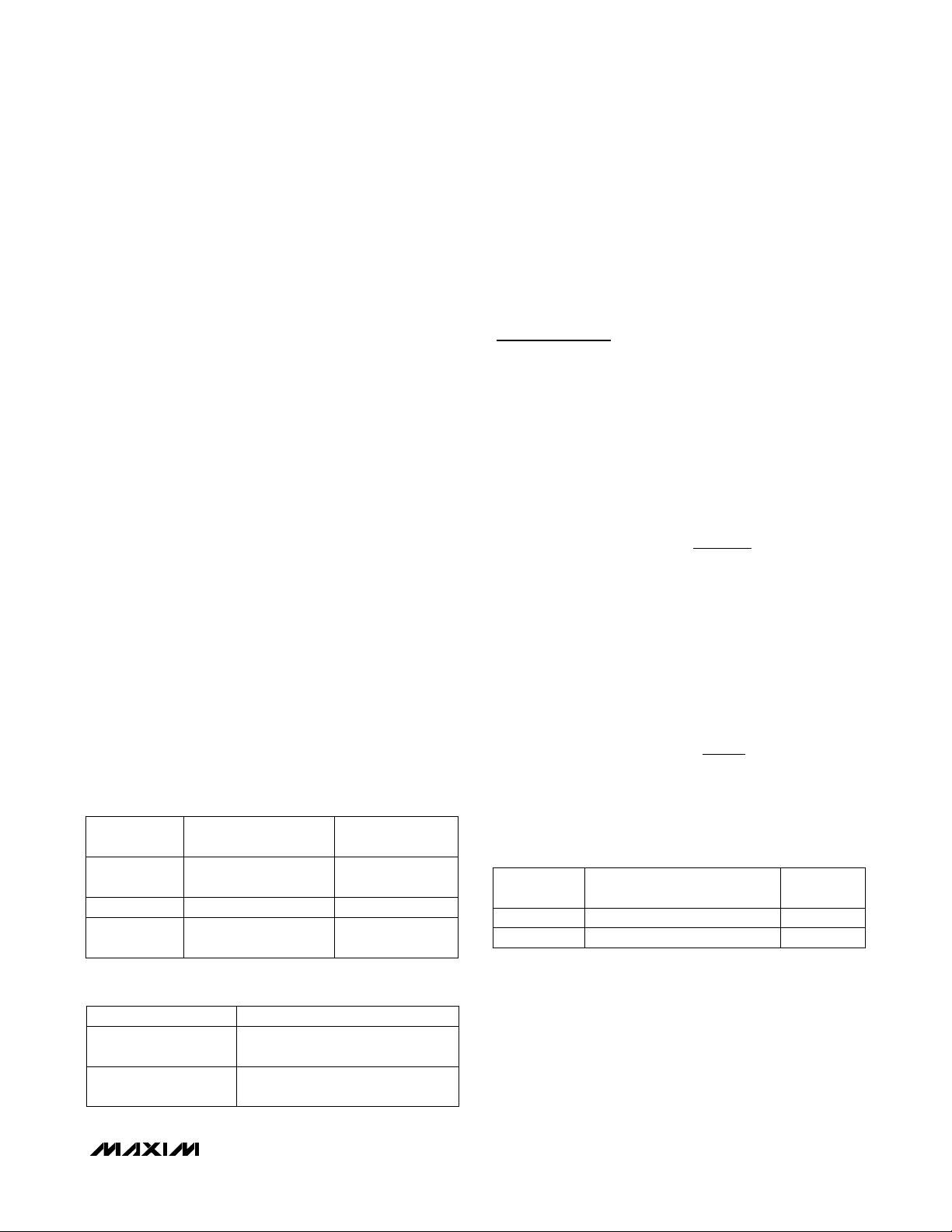

DESIGNATION QTY DESCRIPTION

0.1FF Q10%, 50V X7R ceramic

C1 1

C2–C8,

C10–C16, C24

C9 1

C17 1

C18, C22, C23 0

C19, C21 2

C20 1

capacitor (0603)

Murata GRM188R71H104K

TDK C1608X7R1H104K

Not installed, ceramic capacitors

0

(0603)

510pF Q5%, 50V C0G ceramic

capacitor (0603)

Murata GRM1885C1H511J

AVX 06035A511JA12A

1FF Q10%, 10V X7R ceramic

capacitor (0603)

Taiyo Yuden LMK107BJ105KA

Murata GRM188R71A105K

Not installed, ceramic capacitors

(1206)

2.2FF Q20%, 50V X7R ceramic

capacitors (1206)

Murata GRM31CR71H225K

4.7FF Q10%, 25V X5R ceramic

capacitor (1206)

Murata GRM319R61E475K

DESIGNATION QTY DESCRIPTION

0.7A, 60V Schottky diode

D1 1

D2–D61 60

JU1, JU6,

JU8–JU12

JU2 0

JU7 0

JU4,

JU13–JU19,

JU20, JU21

L1 1

R1, R8, R10 3

R2 1

R3 1

R4 1

(US Flat)

Toshiba CUS04

White LEDs

Nichia NSSW008CT-P1

OPTEK OVSRWACR6

7 3-pin headers

Not installed, 2-pin header—

short PC trace

Not installed, 3-pin header

(pins 2-3—short PC trace)

10 2-pin headers

10FH, 1.2A power inductor

Sumida CR6D09HPNP-100MC

TDK VLP6810T-100M1R2

100kI Q5% resistors (0603)

1MI Q5% resistor (0603)

0I Q5% resistor (0603)

10kI Q5% resistor (0603)

_______________________________________________________________ Maxim Integrated Products 1

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Page 2

MAX17127 Evaluation Kit

Component List (continued)

DESIGNATION QTY DESCRIPTION

R5 1

R6 1

R7 1

R11 0 Not installed, resistor (0603)

R12 0

R14 2

82.5kI Q1% resistor (0603)

2.21MI Q1% resistor (0603)

71.5kI Q1% resistor (0603)

Not installed, multiturn

potentiometer

500kI multiturn potentiometer

DESIGNATION QTY DESCRIPTION

Six-string WLED driver

U1 1

— 17 Shunts

— 1

*EP = Exposed pad.

(20 TQFN-EP*)

Maxim MAX17127ETP+

PCB: MAX17127 EVALUATION

KIT+

Component Suppliers

SUPPLIER PHONE WEBSITE

AVX Corporation 843-946-0238 www.avxcorp.com

Murata Electronics North America, Inc. 770-436-1300 www.murata-northamerica.com

Nichia Corp. 248-352-6575 www.nichia.com

OPTEK Technologies 972-323-2200 www.optekinc.com

Evaluates: MAX17127

Sumida Corp. 847-545-6700 www.sumida.com

Taiyo Yuden 800-348-2496 www.t-yuden.com

TDK Corp. 847-803-6100 www.component.tdk.com

Toshiba America Electronic Components, Inc. 949-623-2900 www.toshiba.com/taec

Note: Indicate that you are using the MAX17127 when contacting these component suppliers.

Quick Start

Recommended Equipment

• MAX17127 EV kit

• 5V to 26V power supply (VIN)

Procedure

The EV kit is fully assembled and tested. Follow the

steps below to verify board operation. Caution: Do not

turn on the power supply until all connections are

completed.

1) On the EV kit, verify that the shunts are installed, as

shown in Table 1.

2) Connect the positive terminal of the VIN power

supply to the VIN pad. Connect the ground terminal

of the VIN power supply to the PGND pad.

3) Set the VIN power supply to 12V and enable its output.

4) Verify that the six strings of WLEDs are on.

Table 1. Default Shunt Positions

JUMPER SHUNT POSITION

JU1, JU6, JU8–JU12 1-2

JU4, JU14, JU15,

JU17–JU20, JU21

JU13, JU16 Installed

Not installed

Detailed Description of Hardware

The MAX17127 evaluation kit (EV kit) operates on a 5V

to 26V wide-input voltage range and provides adjustable 10mA to 30mA full-scale LED current. The EV kit

utilizes a step-up DC-DC converter to generate the

voltage required to drive up to six strings of 10 surfacemount WLEDs.

2 ______________________________________________________________________________________

Page 3

MAX17127 Evaluation Kit

White LED String Configuration

As configured, the EV kit is assembled with six strings of

10 WLEDs. Each string has an associated 3-pin header

(JU1, JU8–JU12) and feedback pin (FB1–FB6). The

function of the 3-pin jumpers is summarized in Table 2.

To evaluate the EV kit with off-board WLED strings, see

the Off-Board WLED String Configuration section.

Off-Board WLED String Configuration

The EV kit can also be used to drive off-board WLED

strings. To evaluate external WLED strings, reconfigure

shunts from jumpers JU1 and JU8–JU12. See Table 2

for jumpers JU1 and JU8–JU12 configuration and Table

3 for jumper JU13 configuration. Removing these jumpers effectively disconnects the on-board WLED strings

between the output and feedback pins, allowing the

connection of external WLED strings. For each external

WLED string, connect the cathode terminal of the string to

the corresponding feedback pad (FB1–FB6) and connect

the anode terminal of the string to the VOUT pad. Once the

external WLED strings are connected between the VOUT

pad and the FB1–FB6 pins, the EV kit can be evaluated in

the same manner as the on-board WLED strings. Evaluating

more than 10 WLEDs per string may require component changes. Refer to the MAX17127 IC data sheet for

component selections.

Enable (EN)

The EV kit features 2-pin jumper JU16 to control the activelow shutdown input. Drive EN high to place the device in

normal operation. If the JU16 shunt is removed, an internal

200kI (typ) pulldown resistor places the device in disabled

mode. See Table 4 for shunt positions.

Table 2. Jumper Function (JU1, JU8–JU12)

SHUNT

POSITION

1-2*

2-3 Connected to AGND Disabled

Not installed

*Default position.

FB_ PIN STRING_

Connected to cathode

of WLED string

Connect to an external

WLED string

Enabled

On-board WLED

string not used

Table 3. Jumper Function (JU13)

SHUNT POSITION VOUT

Installed*

Not installed

*Default position.

Connected to anodes of on-board

WLED strings

Connect to anodes of off-board

WLED strings

Brightness Control by PWM

Signal Input (PWM)

The EV kit features 2-pin jumper JU20 to implement

brightness control through the PWM signal input. See

Table 5 for shunt positions.

LED String Capacitance

In some LCD panel applications, a 0.1FF (typ) capacitor (C

) is placed in parallel with each LED string to

LED

improve ESD immunity. As such, the EV kit provides a

footprint across each LED string for optional C

LED

.

Full-Scale LED Current Adjustment (ISET)

The EV kit features 3-pin jumper JU6, along with R8 and

R14, to set the full-scale LED current. The resistance

from ISET to AGND controls the full-scale current in each

LED string according to the following equation:

I 20 mA

LED(MAX)

= ×

R8 R14

+

Ω

180k

where R8 is a 100kI resistor and R14 is a 500kI potentiometer. See Table 6 for jumper JU6 settings.

Switching-Frequency Selection (FSLCT)

The EV kit is configured to operate at 1MHz, but provides

the option to set the switching frequency of the step-up

DC-DC converter from 250kHz to 1MHz. The switching

frequency is set by adjusting the resistance from FSLCT

to AGND according to the following equation:

100k

Ω

f 1 MHz

= ×

SW

R10

Changing the switching frequency might require different converter components (refer to the MAX17127 IC

data sheet for proper component selections).

Table 4. Jumper Function (JU16)

SHUNT

POSITION

Installed* Connected to VDDIO Enabled

Not installed Internally connected to AGND Disabled

*Default position.

EN PIN MAX17127

Evaluates: MAX17127

_______________________________________________________________________________________ 3

Page 4

MAX17127 Evaluation Kit

Table 5. Jumper Function (JU20)

SHUNT

POSITION

Installed Connected to AGND Zero

Not

installed*

Not

installed

*Default position.

PWM PIN

Connected to VDDIO

through R2

Connect to an exter-

nal PWM signal

(0.1kHz to 25kHz)

Evaluates: MAX17127

PWM DUTY CYCLE

OF LED CURRENT

Maximum (100%)

Follows the signal

applied at PWM pad

Table 6. Jumper Function (JU6)

SHUNT

POSITION

1-2*

2-3 Connected to AGND 0.3mA (typ)

*Default position.

ISET PIN I

Connected to AGND

through R8 and R14

Adjustable from

10mA to 30mA

LED(MAX)

4 ______________________________________________________________________________________

Page 5

MAX17127 Evaluation Kit

Evaluates: MAX17127

Figure 1. MAX17127 EV Kit Schematic

_______________________________________________________________________________________ 5

Page 6

MAX17127 Evaluation Kit

Evaluates: MAX17127

1.0’’

Figure 2. MAX17127 EV Kit Component Placement Guide—Component Side

6 ______________________________________________________________________________________

Page 7

MAX17127 Evaluation Kit

Evaluates: MAX17127

Figure 3. MAX17127 EV Kit PCB Layout—Component Side

_______________________________________________________________________________________ 7

1.0’’

Page 8

MAX17127 Evaluation Kit

Evaluates: MAX17127

1.0’’

Figure 4. MAX17127 EV Kit PCB Layout—Solder Side

8 ______________________________________________________________________________________

Page 9

MAX17127 Evaluation Kit

Revision History

Evaluates: MAX17127

REVISION

NUMBER

0 7/10 Initial release —

REVISION

DATE

DESCRIPTION

PAGES

CHANGED

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are implied.

Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 9

©

2010 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Loading...

Loading...