Page 1

General Description

The MAX1416 evaluation kit (EV kit) is an assembled and

tested circuit board that demonstrates the MAX1416

multichannel, 16-bit, sigma-delta data-acquisition system.

Windows®98/2000/XP software provides a convenient

user interface to exercise the features of the MAX1416.

Order the complete evaluation system (EV system)

(MAX1416EVC16) for a comprehensive evaluation of the

MAX1416 using a personal computer. Order the EV kit

(MAX1416EVKIT) if the 68HC16MODULE-DIP has been

purchased with a previous Maxim EV system, or for custom use in other microcontroller (µC)-based systems.

To evaluate the MAX1415, request a free sample of the

MAX1415EUE. To evaluate the MX7705, request a free

sample of the MX7705EUE.

Features

♦ Proven PC Board Layout

♦ Complete Evaluation System

♦ Convenient On-Board Test Points

♦ Fully Assembled and Tested

Evaluates: MAX1416/MAX1415/MX7705

MAX1416 Evaluation Kit/

Evaluation System

________________________________________________________________ Maxim Integrated Products 1

19-3084; Rev 0; 12/03

MAX1416EVC16 System

Component List

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Ordering Information

MAX1416EVKIT Parts List

Windows is a registered trademark of Microsoft Corp.

PART

INTERFACE TYPE

MAX1416EVC16

Windows software

MAX1416EVKIT

User supplied

Note: The MAX1416 software is designed for use with the complete EV system (MAX1416EVC16). It includes a 68HC16MODULE-DIP module and a MAX1416EVKIT. If the MAX1416 evaluation software is not used, the MAX1416EVKIT board can be purchased by itself, without the µC.

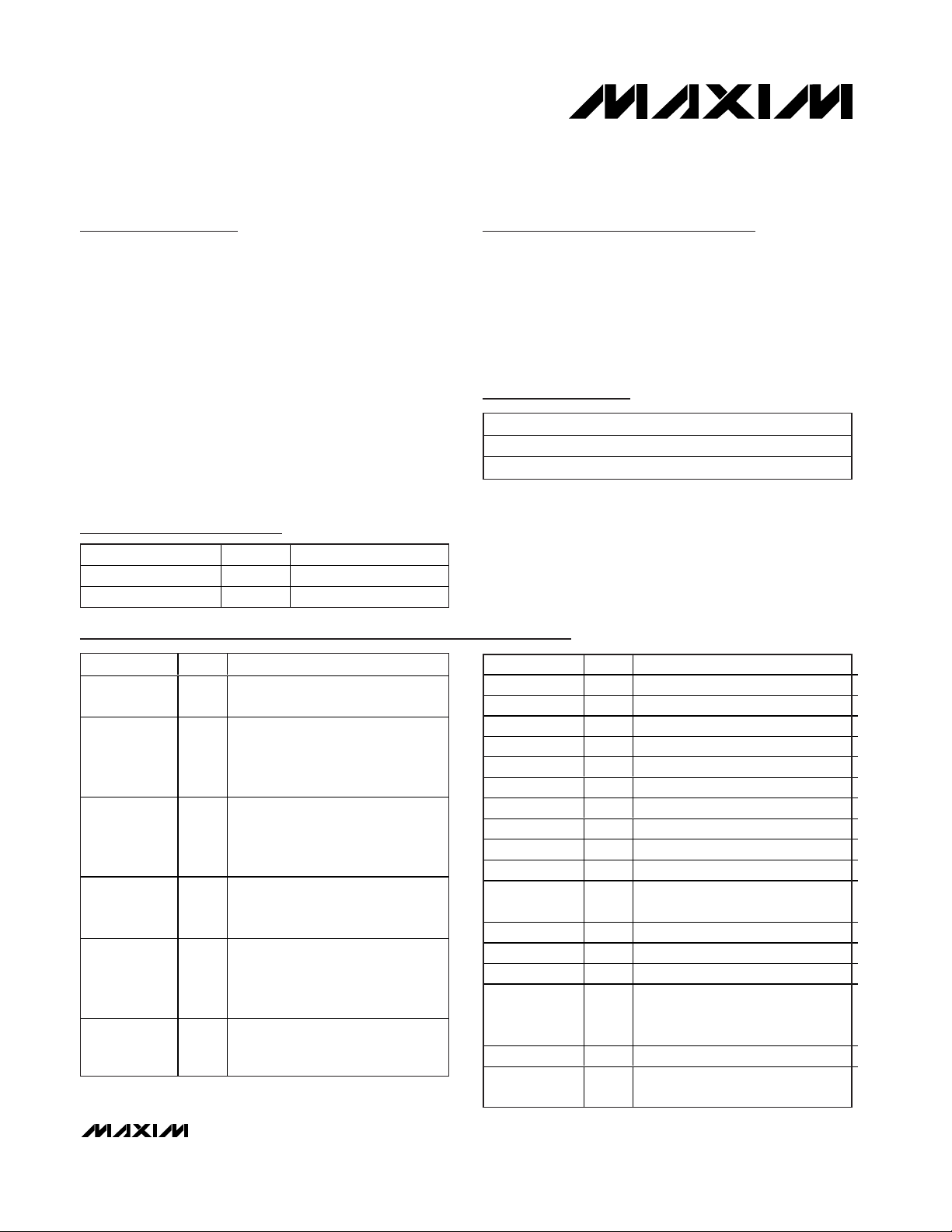

PART QTY DESCRIPTION

MAX1416EVKIT 1 MAX1416 evaluation kit

68HC16MODULE-DIP

1 68HC16 µC module

REFERENCE QTY DESCRIPTION

C1–C4, C10,

C11

C5 1

C6 1

C7, C8 2

C9, C12, C13 3

C14 1

0.01µF, 10V X7R ceramic capacitors

6

(radial leaded)

0.01µF ±10%, 50V X7R ceramic

capacitor (0603)

Taiyo Yuden UMK107B103KZ

TDK C1608X7R1H103KT

4.7µF ±20%, 10V X5R ceramic

capacitor (1206)

Taiyo Yuden LMK316BJ475ML

TDK C3216X5R1A475MT

22pF ±5%, 50V C0G ceramic

capacitors (0603)

TDK C1608C0G1H220J

0.1µF ±10%, 50V X7R ceramic

capacitors (0805)

Taiyo Yuden UMK212BJ104KG

TDK C2012X7R1H104KT

1µF, 10V X7R ceramic capacitor

(0805)

TDK C2012X7R1A105K

TEMP RANGE

0°C to +70°C

0°C to +70°C

REFERENCE QTY DESCRIPTION

H1 1 8-pin header

J1 1 2 x 20 right-angle socket

JU1 1 2-pin header

JU2 1 2-pin header

JU3 1 3-pin header

JU4 1 2-pin header

JU1–JU4 4 Shunts

R1–R4 4 10Ω ±5% resistors (axial leaded)

R5, R6 2 10Ω ±5% resistors (1206)

TB1 1

TB2, TB3 2

U1 1 MAX1416EUE

U2 1 MAX873ACSA

U3, U4 2 MAX1840EUB

Y1 1

None 1 MAX1416 PC board

None 1

0.200in 2-circuit screw terminal

0.200in 3-circuit screw terminal

blocks

4.9152MHz crystal (HC49/US),

parallel resonant, 20pF load

ECS 49-20-4

Software disk, MAX1416

Evaluation Kit

Page 2

Evaluates: MAX1416/MAX1415/MX7705

MAX1416 Evaluation Kit/

Evaluation System

2 _______________________________________________________________________________________

Component Suppliers

SUPPLIER PHONE FAX WEBSITE

Taiyo Yuden 800-348-2496 847-925-0899 www.t-yuden.com

TDK 847-803-6100 847-390-4405 www.component.tdk.com

Note: Please indicate that you are using the MAX1416 when contacting these component suppliers.

Quick Start

Required Equipment

Before you begin, you need the following equipment:

• MAX1416EVC16 (contains a MAX1416EVKIT board

and a 68HC16MODULE-DIP)

• DC power supply, +7VDC to +12VDC at 0.25A

• DC power supply, +5VDC

• Windows 98/2000/XP computer with an available serial

(COM) port

• 9-pin I/O extension cable

Procedure

Do not turn on the power until all connections are

completed.

1) Ensure that JU1, JU2, and JU4 are closed, and that

JU3 is in the 1-2 position (see Table 1 for jumper

settings).

2) Carefully connect the boards by aligning the 40-pin

header of the MAX1416 EV kit with the 40-pin connector of the 68HC16MODULE-DIP module. Gently

press them together. The two boards should be

flush against one another.

3) Connect the +5VDC power source to the MAX1416

EV kit at terminal block TB1. Observe the polarity

marked on the board.

4) Connect the +7VDC to +20VDC power source to

the µC module at the terminal block located next to

the on/off switch, along the top edge of the µC

module. Observe the polarity marked on the board.

5) Connect a cable from the computer’s serial port to

the µC module. If using a 9-pin serial port, use a

straight-through, 9-pin female-to-male cable. If the

only available serial port uses a 25-pin connector, a

standard 25-pin to 9-pin adapter is required. The

EV kit software checks the modem status lines

(CTS, DSR, DCD) to confirm that the correct port

has been selected.

6) Install the evaluation software on your computer by

running the INSTALL.EXE program on the disk. The

program files are copied and icons are created for

them in the Windows Start menu.

7) Turn on the power supply.

8) Start the MAX1416 program by clicking on its icon

in the Start menu.

9) The program prompts you to connect the µC module and to turn on its power. Slide SW1 to the ON

position. Select the correct serial port, and click

OK. The program automatically downloads its software to the module.

10) When the main window appears (Figure 1), click

Initialize and then Calibrate.

11) Apply input signals between AIN1+ and AIN1-. Tie

the unused analog input AIN2+ and AIN2- to GND.

Click Read or check Auto Read. Observe the code

and voltage readout on the screen.

Detailed Description

of Software

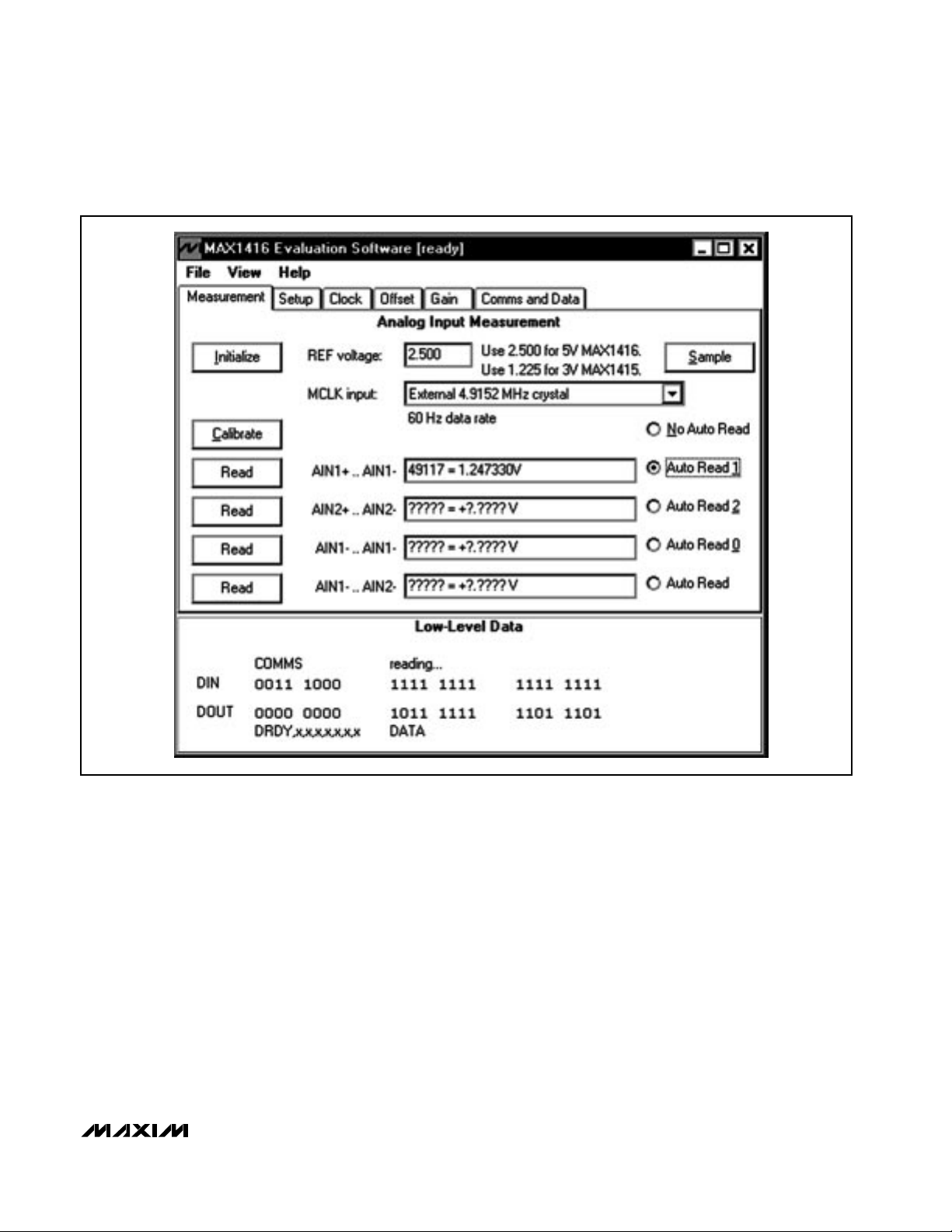

The main window of the evaluation software controls the

features of the MAX1416. The Measurement tab sheet is

used to initialize, calibrate, and read data. Prior to reading the MAX1416, select the appropriate MCLK masterclock input source and click Initialize. The FS1 and FS0

bits in the clock register determine the data rate.

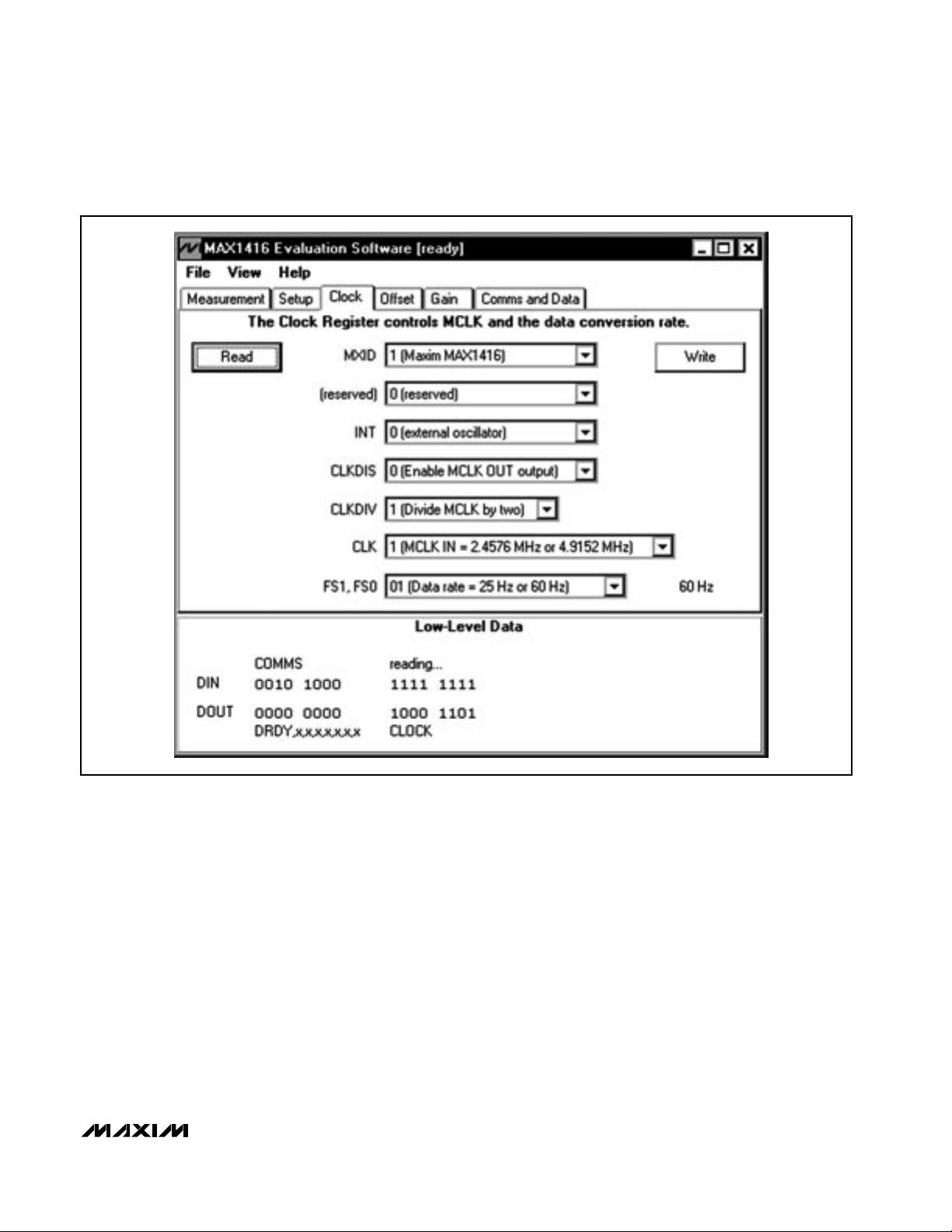

The Initialize button writes the clock register INT,

CLKDIS, CLKDIV, CLK, and FS bits, and then writes to

the setup register with FSYNC = 1. The exact value

written to the clock register depends on the MCLK

input setting, and can be viewed by bringing up the

Clock tab sheet after initialization.

The Calibrate button first writes the setup register with

FSYNC = 1, then writes setup with MD = 01 (self-calibration mode) and FSYNC = 0. After DRDY returns low,

the MAX1416 setup register automatically returns to

MD = 00 and FSYNC = 0.

Page 3

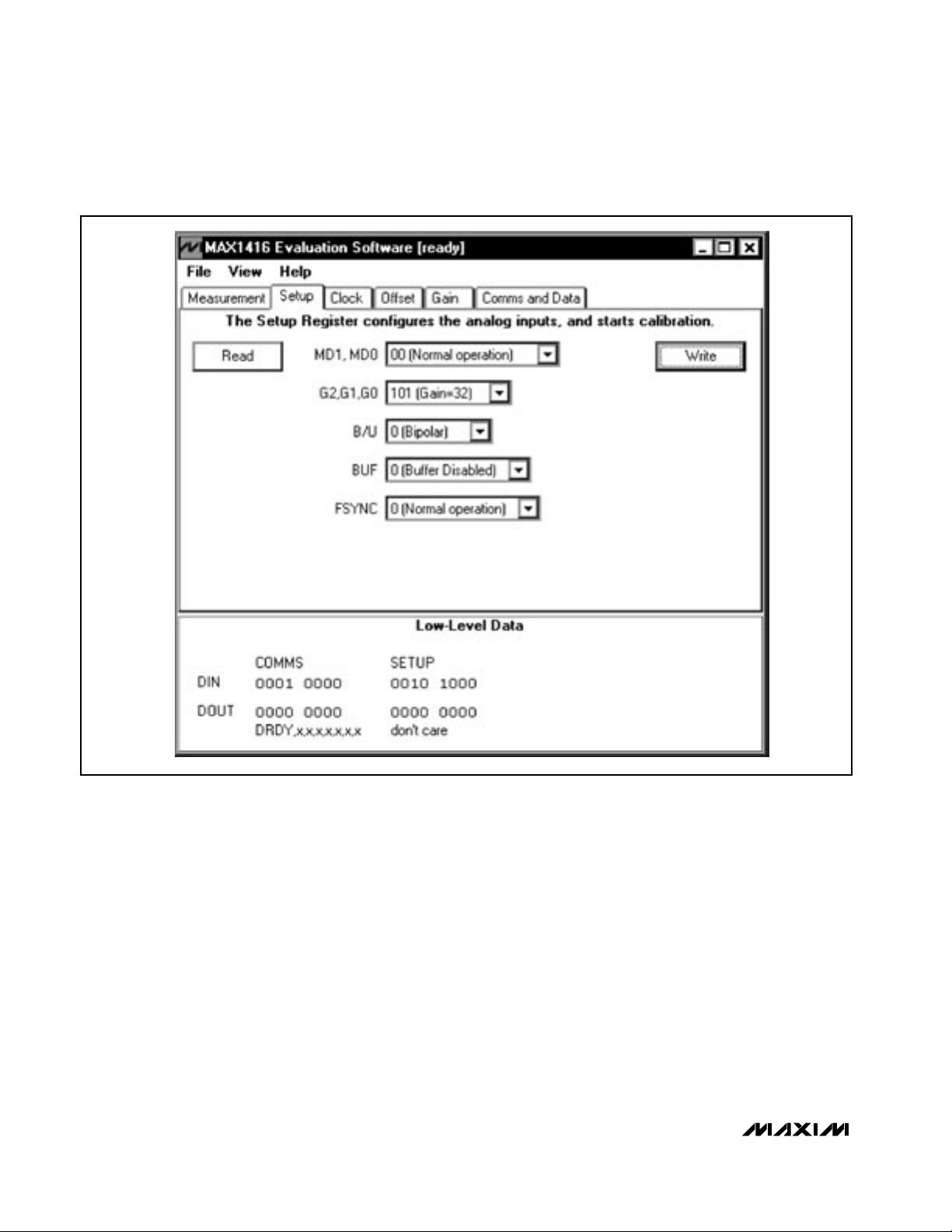

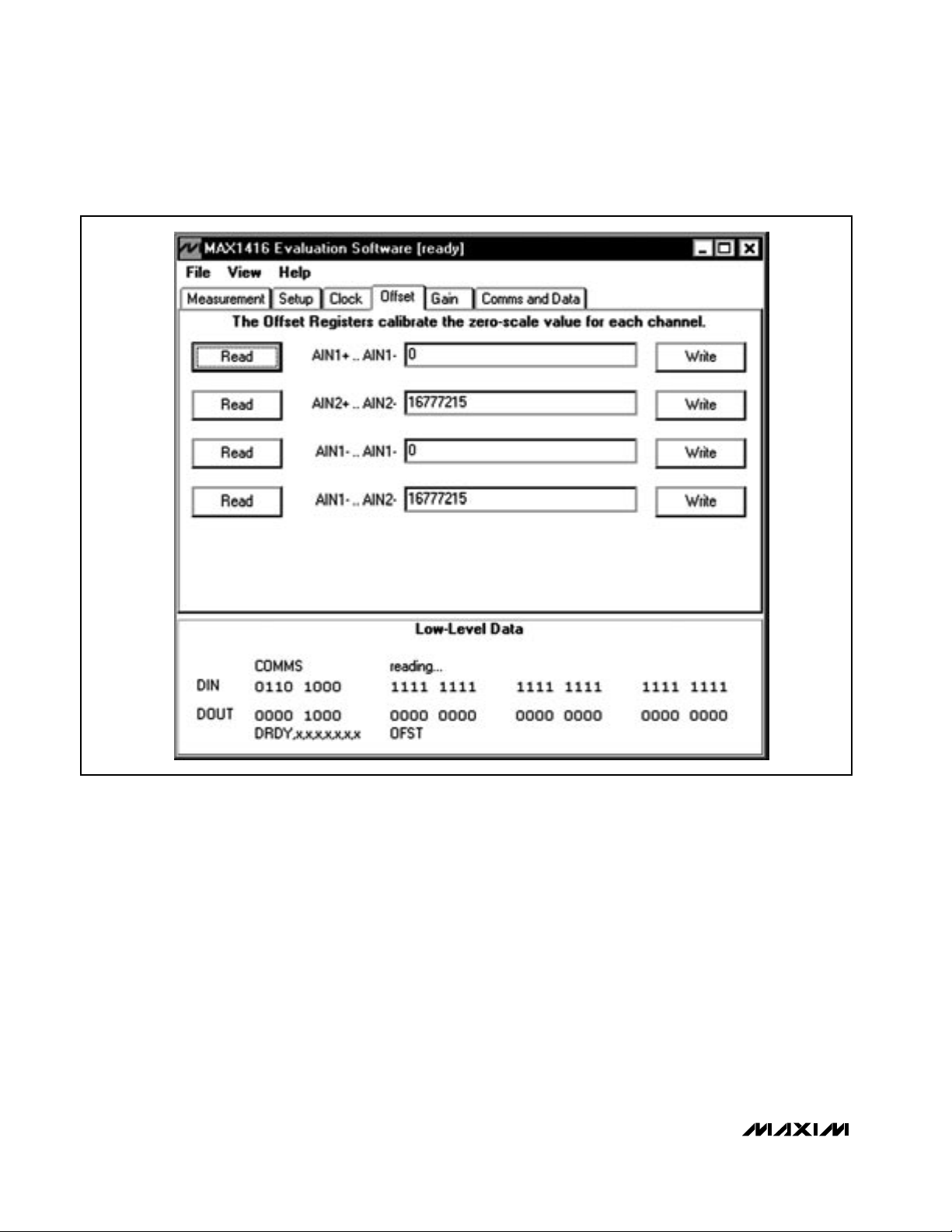

The Setup, Clock, Offset, and Gain tab sheets provide

read/ write access to each of the registers. See

Figures 2–5.

The Comms and Data (Figure 6) tab sheet provides

access to the Standby bit. The comms registers RS2,

RS1, RS0, and R/W bits are automatically set by each

register’s read and write buttons. The channel select

bits CH1 and CH0 are determined by which channel is

selected on the Measurement tab sheet.

Sampling

To collect data, go to the Measurement tab sheet and

click Sample. Select the sample size and click Begin

Sampling. After the samples have been collected, the

data is automatically uploaded to the host and is

graphed. Once displayed, the data can be saved to a

file (optional).

Saving Graphs to Disk

Data in the real-time graph and in the sampled data

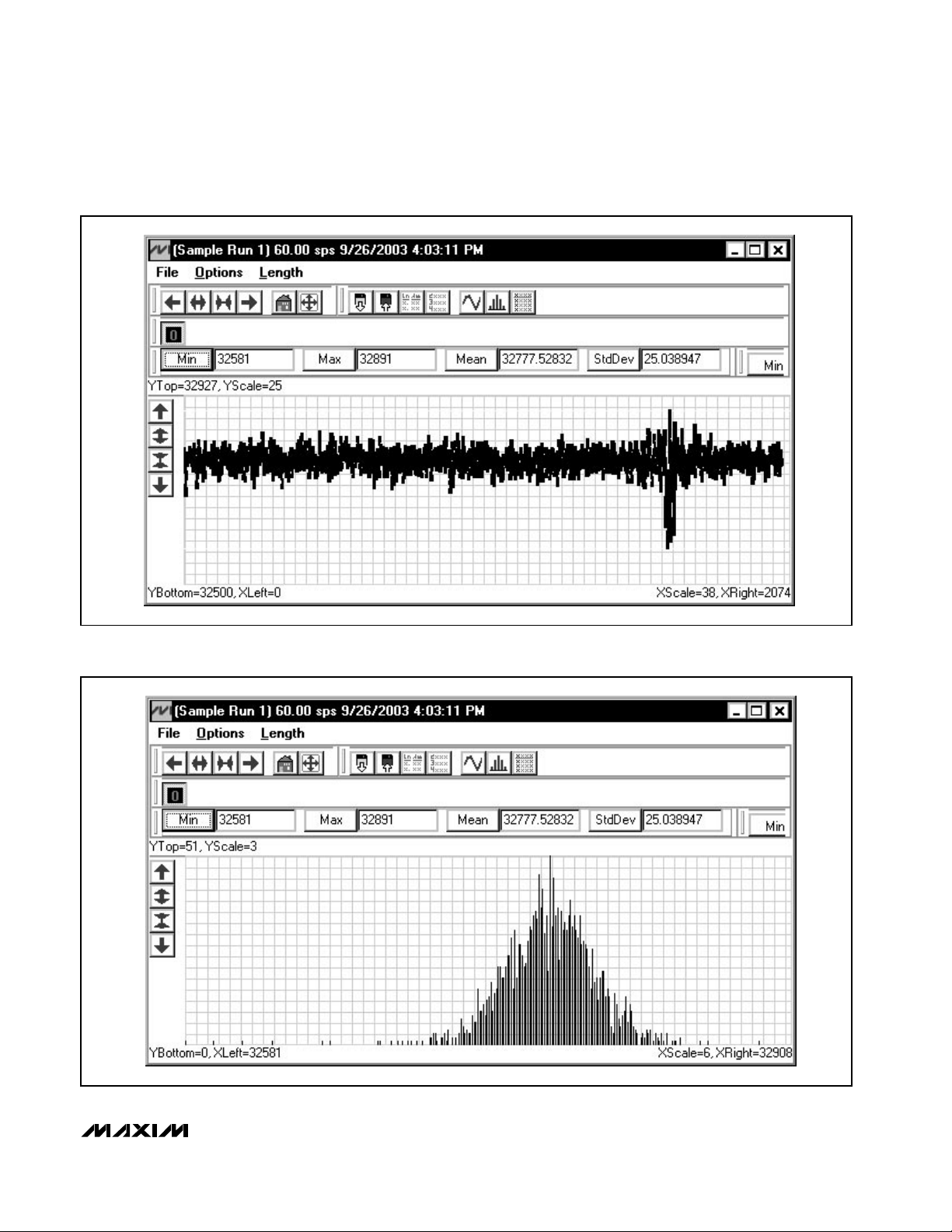

graphs can be saved to a file (Figures 7–8). Only the

raw output codes are saved, but voltages can be

inferred based on the reference voltage and the maximum code value.

Evaluating Power-Down Mode

To enter standby mode, first make sure that Auto Read

is not checked in the Measurement tab sheet. Then go

to the Comms and Data tab sheet and check power-

down, then click write.

Reference Voltage

The evaluation software assumes a 2.500V reference

voltage, unless otherwise specified. To override this

value, go to the Measurement tab sheet and type the

new reference voltage next to REF voltage.

Software Listing

The EV kit software disk contains the driver source and

header file. Refer to DRV1416.cpp and DRV1416.h.

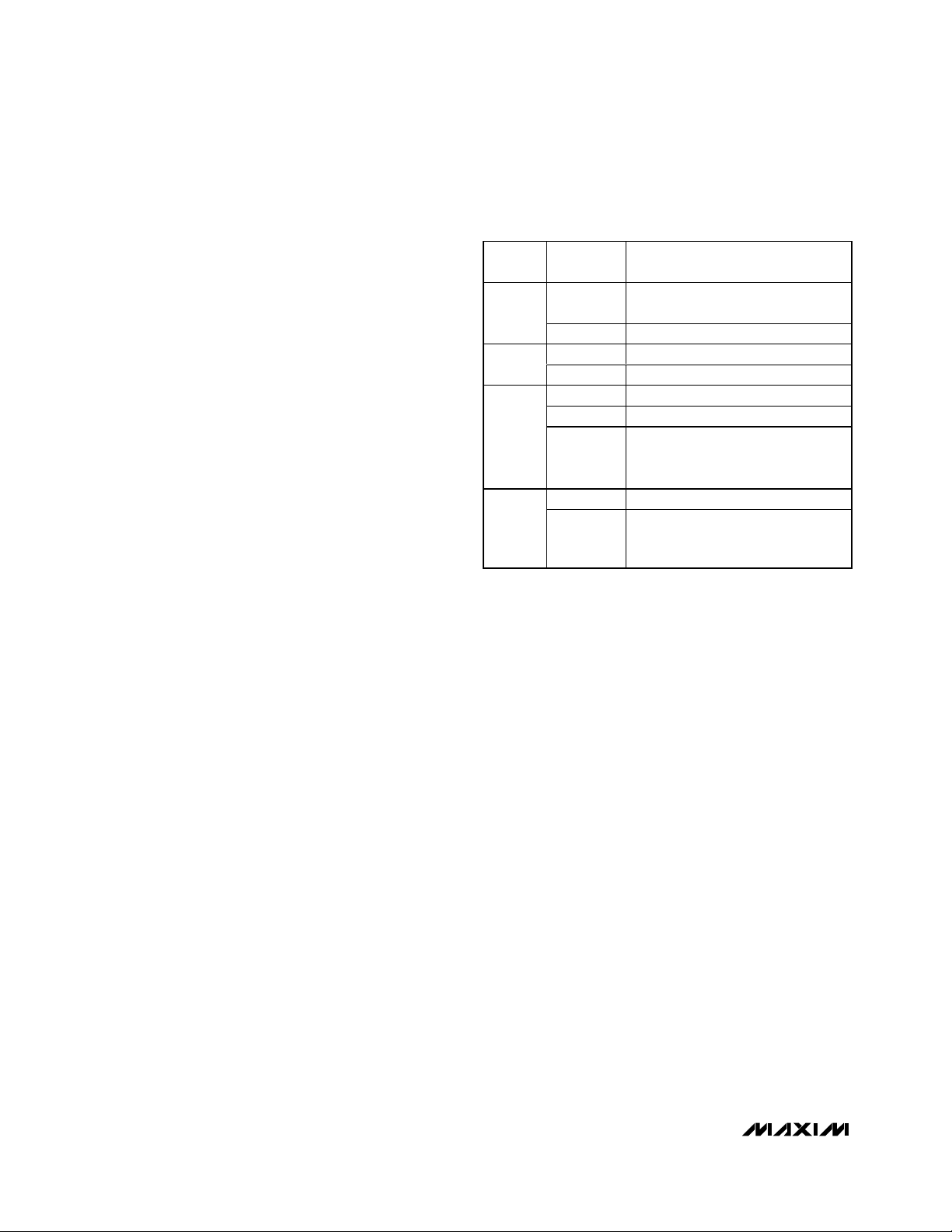

Detailed Description

of Hardware

The MAX1416 (U1) is a multichannel, 16-bit, sigmadelta data-acquisition system. Resistors R1–R4 and

C1–C4 act as anti-aliasing filters. The MAX873 (U2) is a

2.5V reference. C14 ensures the MAX873’s stability for

arbitrary values of input capacitor C11. Level translators U3 and U4 allow the kit to support the 3V

MAX1415, as well as the 5V MAX1416. The input signal

can be applied directly to terminal blocks TB2 and TB3.

C5 and C6 bypass the analog-to-digital converter’s

power supply. See Figure 9, and refer to the MAX1416

data sheet.

Evaluating the MAX1415

To evaluate the MAX1415, request a free sample of the

MAX1415EUE and replace U1. Follow the Quick Start

procedure, with the following exceptions:

• In step 1, leave JU1 and JU2 open.

• In step 3, apply a +3VDC power supply (instead of

+5V) to TB1. Apply an external +1.225VDC differential reference between TB3 pins 3 and 2.

• After step 10, go to the software’s Measurement tab

sheet and type the new reference voltage of 1.225

next to REF voltage.

Evaluating the MX7705

To evaluate the MX7705, request a free sample of the

MX7705EUE and replace U1. The MX7705 is similar to

the MAX1415/1416 except it does not support internal

clock mode (INT must always be zero).

Using an External Reference

To use an external reference, remove the shunts from

JU1 and JU2, and connect a differential reference

between TB3 pins 3 and 2. The evaluation software

assumes a 2.500V reference voltage, unless otherwise

specified. To override this value, go to the Measurement

tab sheet and type the new reference voltage next to

REF voltage.

Troubleshooting

Problem: No output measurement. System seems to

report zero voltage, or fails to make a measurement.

Check VDD supply voltage at TB1. The EV kit requires

a separate supply in addition to the supply on the

microcontroller module. Check the reference voltage

using a digital voltmeter. Use an oscilloscope to verify

that the CS, SCLK, and DIN waveforms are correct. If

the DRDY signal is pulsing, then the software has successfully initialized the MAX1416 and conversions have

been triggered.

Problem: Cannot see MCLK waveform on oscilloscope.

When using an external crystal, the MCLKIN and

MCLKOUT nodes are very sensitive to extra load

capacitance. Connecting a typical 10x scope probe

effectively doubles the load capacitance from 20pF to

40pF, which can slow down or even halt oscillation.

When using the internal oscillator (clock register INT =

1 and CLKDIS = 0), the oscillator signal is visible on the

MCLKOUT pin. In this mode, MCLKOUT can be measured using a typical 10x scope probe.

Evaluates: MAX1416/MAX1415/MX7705

MAX1416 Evaluation Kit/

Evaluation System

_______________________________________________________________________________________ 3

Page 4

Evaluates: MAX1416/MAX1415/MX7705

Problem: Internal oscillator does not work.

The internal-oscillator mode is a feature of the

MAX1416/MAX1415 only, and is not supported on the

MX7705. The MX7705 requires an external clock, and

can only be used with INT = 0. To observe the internal

oscillator driving the MCLKOUT pin, U1 must be a

MAX1416 or MAX1415, and the clock register must

have INT = 1 and CLKDIS = 0.

Problem: Measurements are erratic or unstable or

there is poor accuracy.

Check the reference voltage using a digital voltmeter.

Use an oscilloscope to check for noise. When probing

for noise, keep the oscilloscope ground-return lead as

short as possible, preferably less than 1/2 in (10mm).

Problem: Unacceptable errors when measuring a

transducer.

Although most signal sources can be connected directly to the MAX1416’s analog input, some high-impedance signal sources may require using the internal

input buffer (BUF = 1).

Problem: PDA hot-sync software or other device software interferes with EV kit software.

COM ports can only be used by one device at a time.

Disable PDA hot-sync manager.

MAX1416 Evaluation Kit/

Evaluation System

4 _______________________________________________________________________________________

QSPI is a trademark of Motorola, Inc.

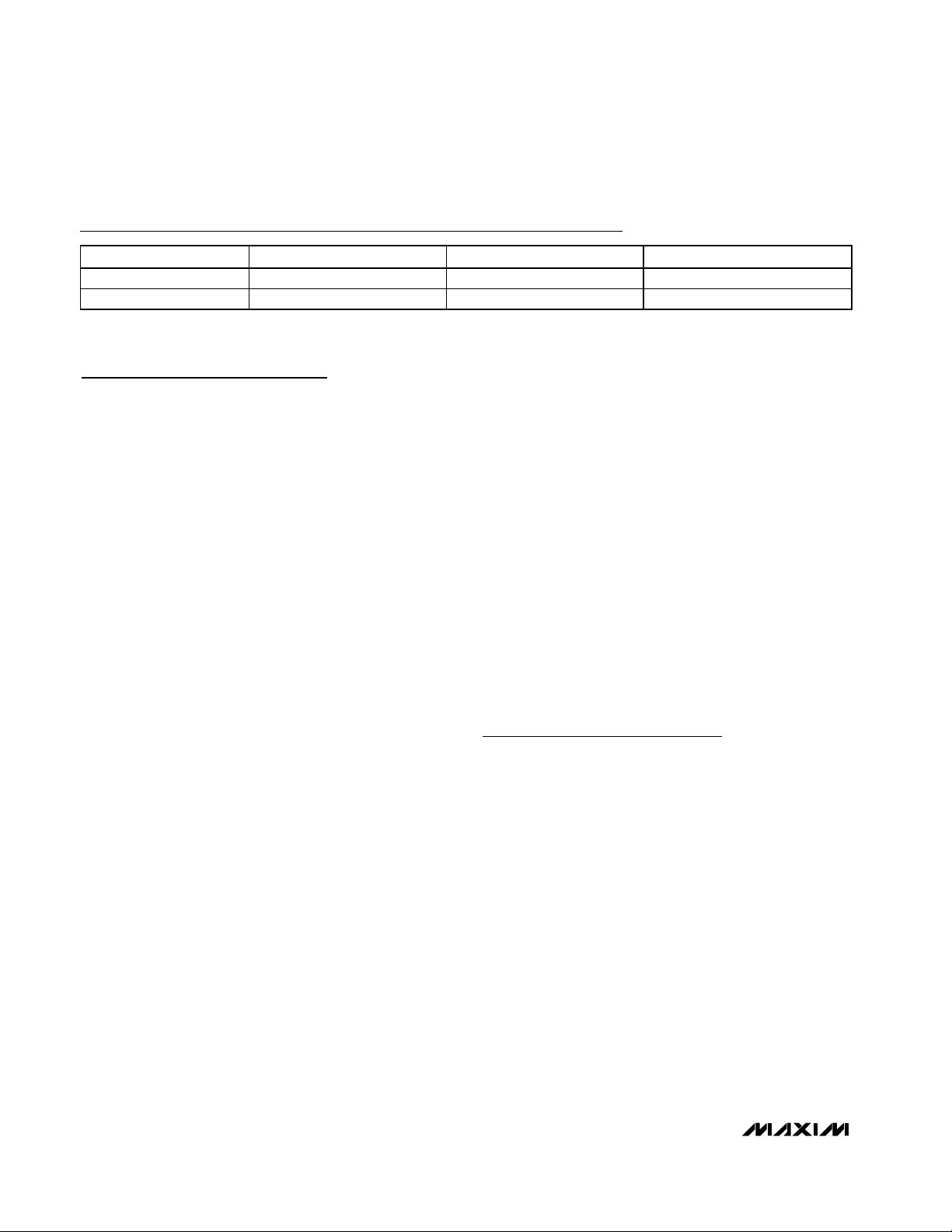

Table 1. Jumper Functions

JUMPER

SHUNT

FUNCTION

Closed*

U2 (MAX873) supplies REF+

reference voltage

JU1

Open REF+ must be externally connected

Closed* REF- connects to ground at U2

JU2

Open REF- must be externally connected

1-2* MCLKIN connects to crystal Y1

Open MCLKIN is not connected

JU3

2-3

MCLKIN connects to ground

(MAX1416/MAX1415 internaloscillator mode only)

Closed* MCLKOUT drives crystal Y1

JU4

Open

MCLKOUT is not connected

(MAX1416/MAX1415 internaloscillator mode only)

*Default configuration

POSITION

Page 5

Evaluates: MAX1416/MAX1415/MX7705

MAX1416 Evaluation Kit/

Evaluation System

_______________________________________________________________________________________ 5

Figure 1. MAX1416—Main Window of the Evaluation Software—Measurement Tab Sheet

Page 6

Evaluates: MAX1416/MAX1415/MX7705

MAX1416 Evaluation Kit/

Evaluation System

6 _______________________________________________________________________________________

Figure 2. MAX1416—Main Window of the Evaluation Software—Setup Tab Sheet

Page 7

Evaluates: MAX1416/MAX1415/MX7705

MAX1416 Evaluation Kit/

Evaluation System

_______________________________________________________________________________________ 7

Figure 3. MAX1416—Main Window of the Evaluation Software—Clock Tab Sheet

Page 8

Evaluates: MAX1416/MAX1415/MX7705

MAX1416 Evaluation Kit/

Evaluation System

8 _______________________________________________________________________________________

Figure 4. MAX1416—Main Window of the Evaluation Software—Offset Tab Sheet

Page 9

Evaluates: MAX1416/MAX1415/MX7705

MAX1416 Evaluation Kit/

Evaluation System

_______________________________________________________________________________________ 9

Figure 5. MAX1416—Main Window of the Evaluation Software—Gain Tab Sheet

Page 10

Evaluates: MAX1416/MAX1415/MX7705

MAX1416 Evaluation Kit/

Evaluation System

10 ______________________________________________________________________________________

Figure 6. MAX1416 —Main Window of the Evaluation Software—Comms and Data Tab Sheet

Page 11

Evaluates: MAX1416/MAX1415/MX7705

MAX1416 Evaluation Kit/

Evaluation System

______________________________________________________________________________________ 11

Figure 7. MAX1416—Saving Graphs to Disk

Figure 8. MAX1416—Saving Graphs to Disk

Page 12

Evaluates: MAX1416/MAX1415/MX7705

MAX1416 Evaluation Kit/

Evaluation System

12 ______________________________________________________________________________________

Figure 9. MAX1416 EV Kit Schematic

J1

CONNECTOR

J1-9

N.C.

J1-10

N.C.

J1-11

N.C.

J1-12

N.C.

J1-13

N.C.

J1-14

N.C.

J1-15

N.C.

J1-16

N.C.

J1-17

N.C.

J1-18

N.C.

J1-5

J1-6

J1-29

J1-34

J1-39

J1-40

J1-1

J1-2

J1-3

J1-4

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

J1-19

N.C.

J1-20

N.C.

J1-21

N.C.

J1-22

N.C.

J1-38

J1-7

J1-8

J1-23

N.C.

J1-24

N.C.

J1-37

J1-36

J1-25

N.C.

J1-26

N.C.

J1-28

N.C.

J1-30

N.C.

J1-32

N.C.

J1-27

J1-35

J1-33

N.C.

J1-31

1

2

3

4

C5

0.01µF

C6

4.7µF

16

15

14

11

GND

V

DD

DIN

AIN2-

10

REF-

SCLK

MCLKIN

MCLKOUT

CS

MAX1416

U1

MAX1840

U3

MAX873

U2

H1-7

Y1

4.9152MHz

C8

22pF

C7

22pF

SCLK

H1-8

CS

5

RESET6AIN2+

H1-6

R3

10Ω

RESET

JU3

JU4

123

TB2-1

TERMINAL

BLOCK

TB2

TERMINAL

BLOCK

TB1

7

AIN1+

R1

10Ω

C3

0.01µF

C4

0.01µF

C10

0.01µF

C14

1µF

C9

0.1µF

JU2

JU1

C1

0.01µF

C2

0.01µF

TB2-2

8

AIN1-

R2

10Ω

R4

10Ω

R6

10Ω

R5

10Ω

TB2-3

TB1-1

H1-2

H1-1

TB1-2

TEST

1

TEST

VIN N.C.

TEMP VOUT

GND TRIM

2

3

4

8

7

6

5

H1-3

DIN

13

DOUT

H1-4

DOUT

12

DRDY

H1-5

DRDY

TERMINAL

BLOCK

TB3

TB3-1

TB3-2

9

REF+

C11

0.01µF

TB3-3

DATA

1

I/O

DV

CC

V

CC

CIN CLK

RIN

RST

2

3

4

10

CS

SCLK

DIN

DRDY

DOUT

RESET

9

8

7

SHDN GND

56

MAX1840

U4

GND

6

SHDN

RST RIN

CLK CIN

V

CC

DV

CC

7

8

9

5

4

3

2

I/O DATA

10 1

C13

0.1µF

C12

0.1µF

+5V

+5V

+5V

Page 13

Evaluates: MAX1416/MAX1415/MX7705

MAX1416 Evaluation Kit/

Evaluation System

______________________________________________________________________________________ 13

Figure 10. MAX1416 EV Kit Component Placement Guide—Component Side

Figure 11. MAX1416 EV Kit PC Board Layout—Component Side

Page 14

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

14 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2003 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Evaluates: MAX1416/MAX1415/MX7705

MAX1416 Evaluation Kit/

Evaluation System

Figure 12. MAX1416 EV Kit PC Board Layout —Solder Side

Loading...

Loading...