Page 1

MAX11300PMB1 Peripheral Module

and Munich (USB2PMB1) Adapter Board

Quick Start Guide

Rev 0; 7/14

For pricing, del ivery , and or der ing info r mation, p lea se co nta ct M axim D irect at 1-888-629-4642, or visit M axi m Inte grated ’s w ebs ite at ww w .maxi mintegra ted .com.

Maxim Integrate d cannot a ssume res ponsibi lity f or use of a ny circui try oth er than circuitry entirel y embodie d in a Maxim Inte grate d product. No circui t

patent licenses are implied. Maxim Integrated reserves the right to change the circuitry and specifications without notice at any time.

© 2014 Maxim Integrated Products, Inc. Ma xi m Integr at ed and the Maxim Integrate d logo ar e trad em arks of Maxim Integrate d Prod uc ts, Inc .

Page 2

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Table of Contents

1. Required Equipment ................................................................................................. 3

2. Overview ................................................................................................................... 3

3. Included Files............................................................................................................ 6

4. Procedure ................................................................................................................. 7

5. Munich GUI ............................................................................................................. 12

6. Examples ................................................................................................................ 17

7. References ............................................................................................................. 35

8. Trademarks............................................................................................................. 36

9. Revision History ...................................................................................................... 37

2

Page 3

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

1. Required Equipment

• PC with Windows® OS (Windows XP®, Windows Vista, Windows 7, Wind ows 8

and Windows 8.1) with one USB port

• MAX11300PMB1# board

• Munich (USB2PMB1#) board

• USB Type A to Mini B Cable

• Munich Software GUI

2. Overview

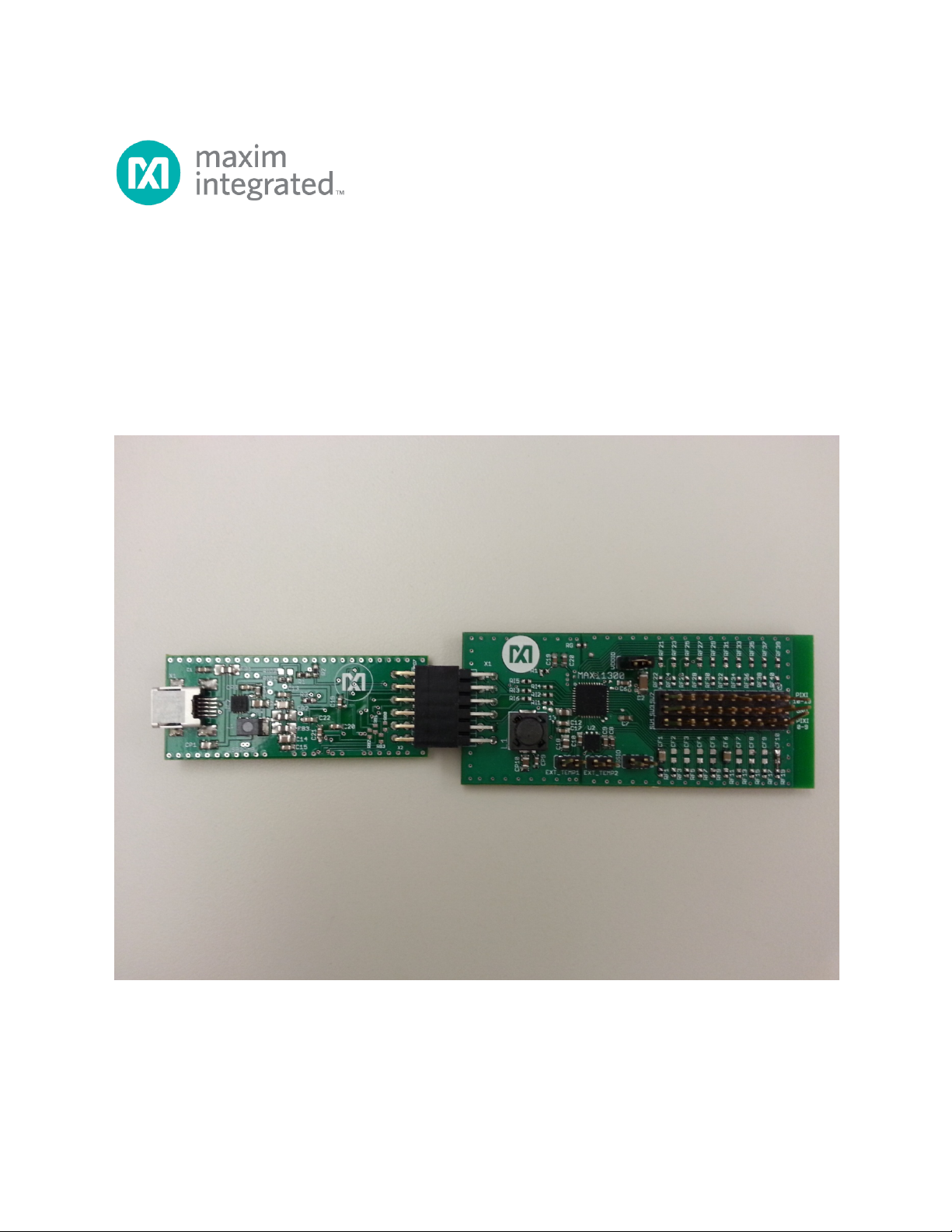

This document explains how the MAX11300PMB1 featuring the MAX11300 20-port

programmable mixed-signal I/O device interfaces with the Munich (USB2PMB1#)

adapter board and how to use the GUI.

The MAX11300PMB1 peripheral module provides the necessary hardware to interface

the MAX11300 20-port device to any system that utilizes Pmod™-compatible expansion

ports configurable for SPI communication (Figure 1). MAX11300 configura tion softwar e

is a design tool used to create the configuration bit stream that is downloaded to the

MAX11300 through the Munich adapter board (Figure 2

Refer to the MAX11300 IC data sheet for detailed information regarding operation of the

IC and to the USB2PMB1 adapter board data sheet for detailed information regarding

the Munich board and GUI. Refer to the MAX11300/MAX11301 PIXI™ Configuration

Software User Guide for detailed information using the design tool.

The Munich GUI and the USB2PMB1 adapter board are referred to as Munich

throughout this document.

).

3

Page 4

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

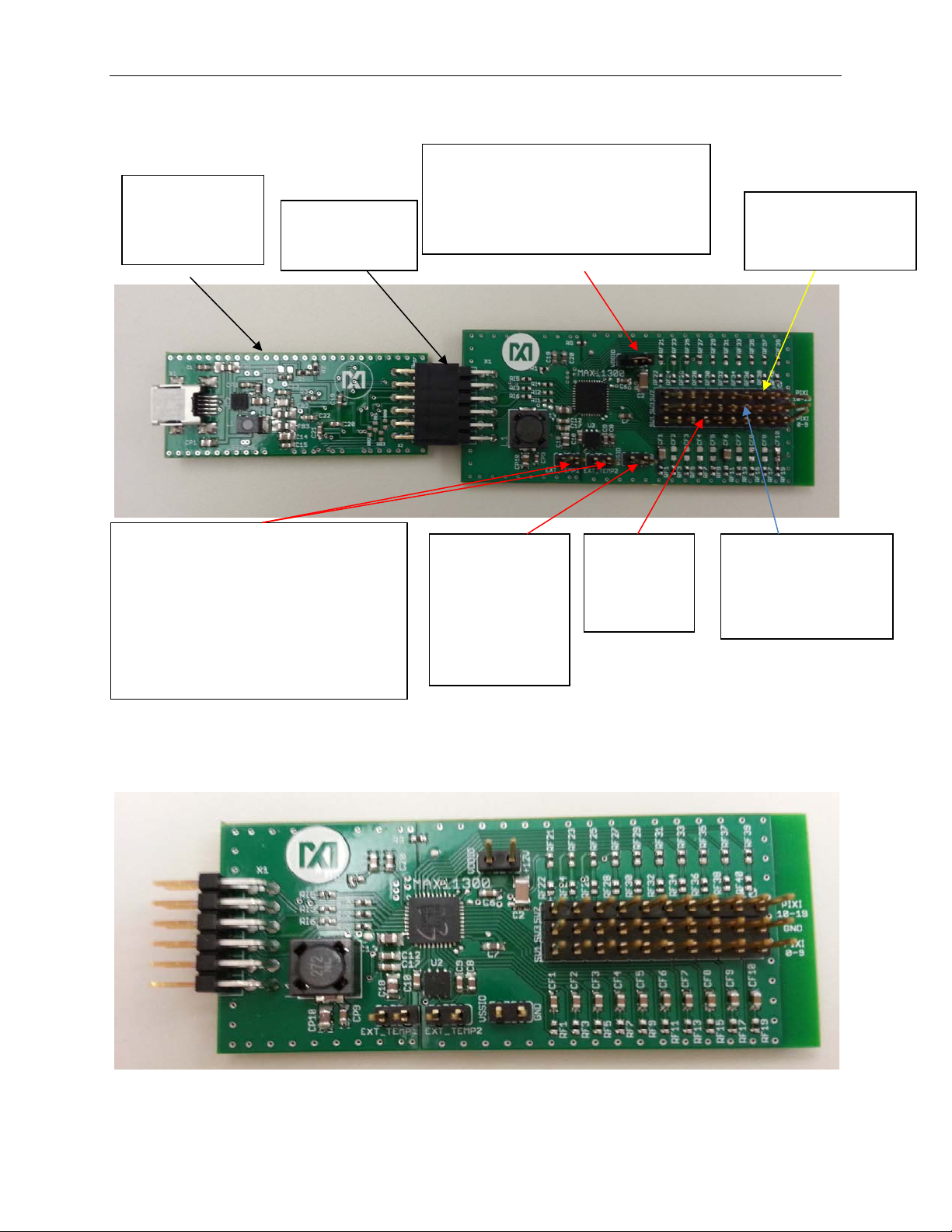

THE MUNICH

Pmod

VDDIO PROVIDES ON-BOARD +12 V

P10 TO P19 (FROM

VSSIO.

BIPOLAR.

EXTERNAL TEMPERATURE-

EXTERNAL TEMPERATURE.

P0 TO P9

ALL PINS IN THE

TO AVDD OF THE MAX11300. FOR

BOARD

(USB2PMB1)

CONNECTORS

BEST PERFORMANCE, USE +12.5V

EXTERNAL POWER SUPPLY.

SENSOR HEADERS. CONNECT THE

BASE AND COLLECTOR OF DIODECONNECTED TRANSISTORS SUCH

AS THE 2N3906 TO TEMP1 OR

TEMP2 PIN AND THE EMI T T ER TO

EXT PIN TO MEASURE THE

CONNECT TO

GND (OR -12V

EXTERNAL

POWER

SUPPLY FOR

(FROM

LEFT TO

RIGHT)

LEFT TO RIGHT)

MIDDLE ROW ARE

CONNECTED TO

GND.

Figure 1. MAX11300PMB1 Connected to Munich Adapter Board

Figure 2. MAX11300PMB1 Board

4

Page 5

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

7

10

8

9

11

12

1

4

2

3

5

6

X1

SPI

CS

MOSI

MISO

SCLK

GND

3.3V3.3V

GND

X

INTB

CNVTB

The Munich adapter board is designed to supply power to external boards (i.e.,

MAX11300PMB1, Santa Fe, and many more) through the connector X2. It is i ntended to

provide power supply to the interface circuitry present in the connected board.

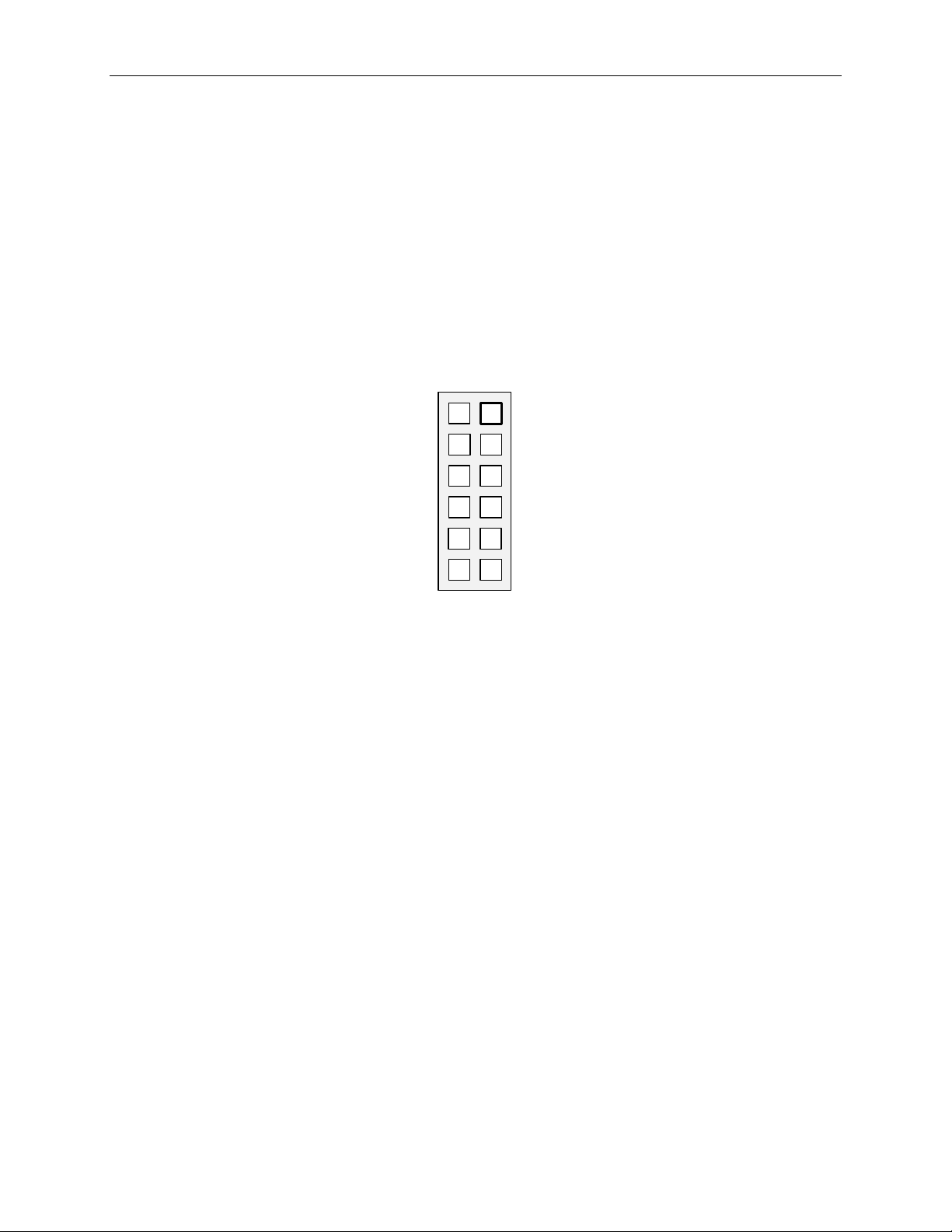

Figure 3 shows the pin configuration for the SPI-compatible connector at the

USB2PMB1 board. The MAX11300PMB1 board itself generates positive voltages from

3.3V on pins 6 and 12 with an on-board DC-DC converter. The 3.3V supply is limited to

~1.5W, limiting power available for the MAX11300PMB1 if a higher watt power supply is

required and external power supply is used. Refer to the MAX11300PMB1 data sheet

for details.

Figure 3. SPI Connector Inputs Found on the MAX11300PMB1

5

Page 6

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

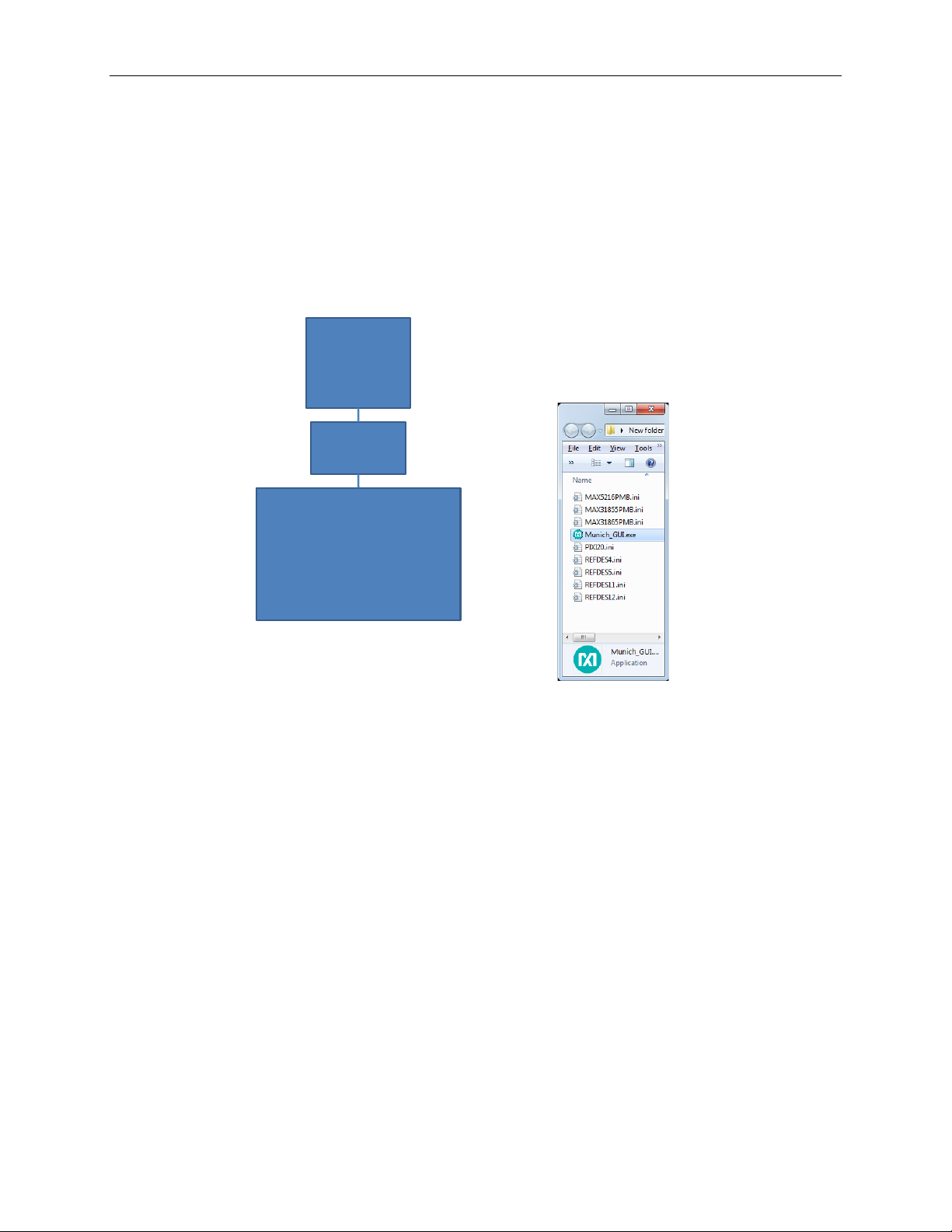

Munich

(USB2PMB)

PC

– USB-Port

(DUT) PMOD

MAX11300PMB1

Included Files:

GUI and the configuration-File

for each Tab.

Driver installs automatically on

WinXP, Win7, Win8, and

Win8.1 if PC is connected to

the Internet.

3. Included Files

Included files are the MAX11300 configuration software and Munich GUI (Figure 4). The

Munich GUI evaluates this MAX11300PMB1 and other Pmod designs from Maxim

Integrated.

Figure 4. MAX11300PMB1/Munich Included Files

6

Page 7

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

4. Procedure

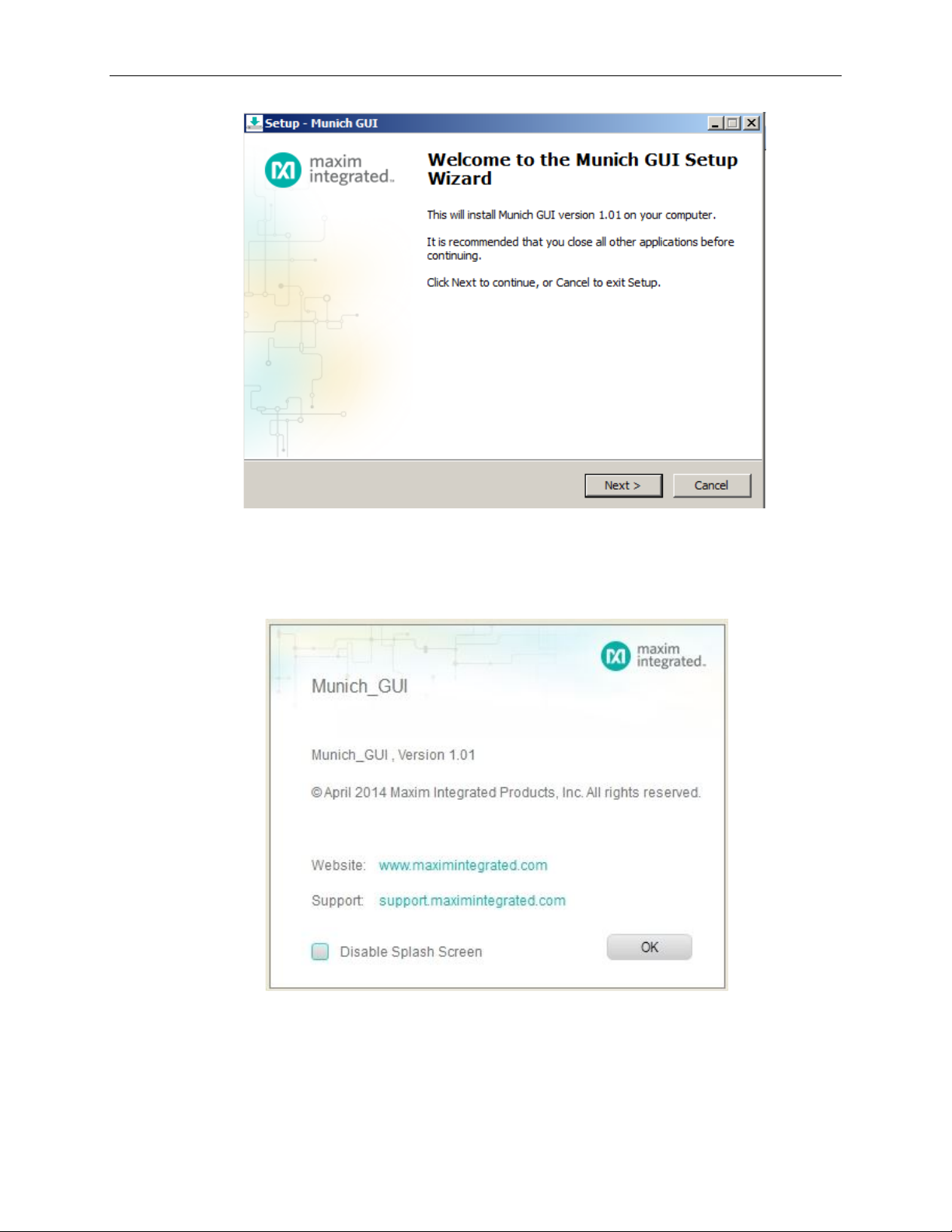

1) Go to www.maximintegrated.com/evkitsoftware to download the most recent

version of the Munich board software, Munich GUI. Double-click on the

installation file Munich GUISetupV1.0.exe to install the GUI.

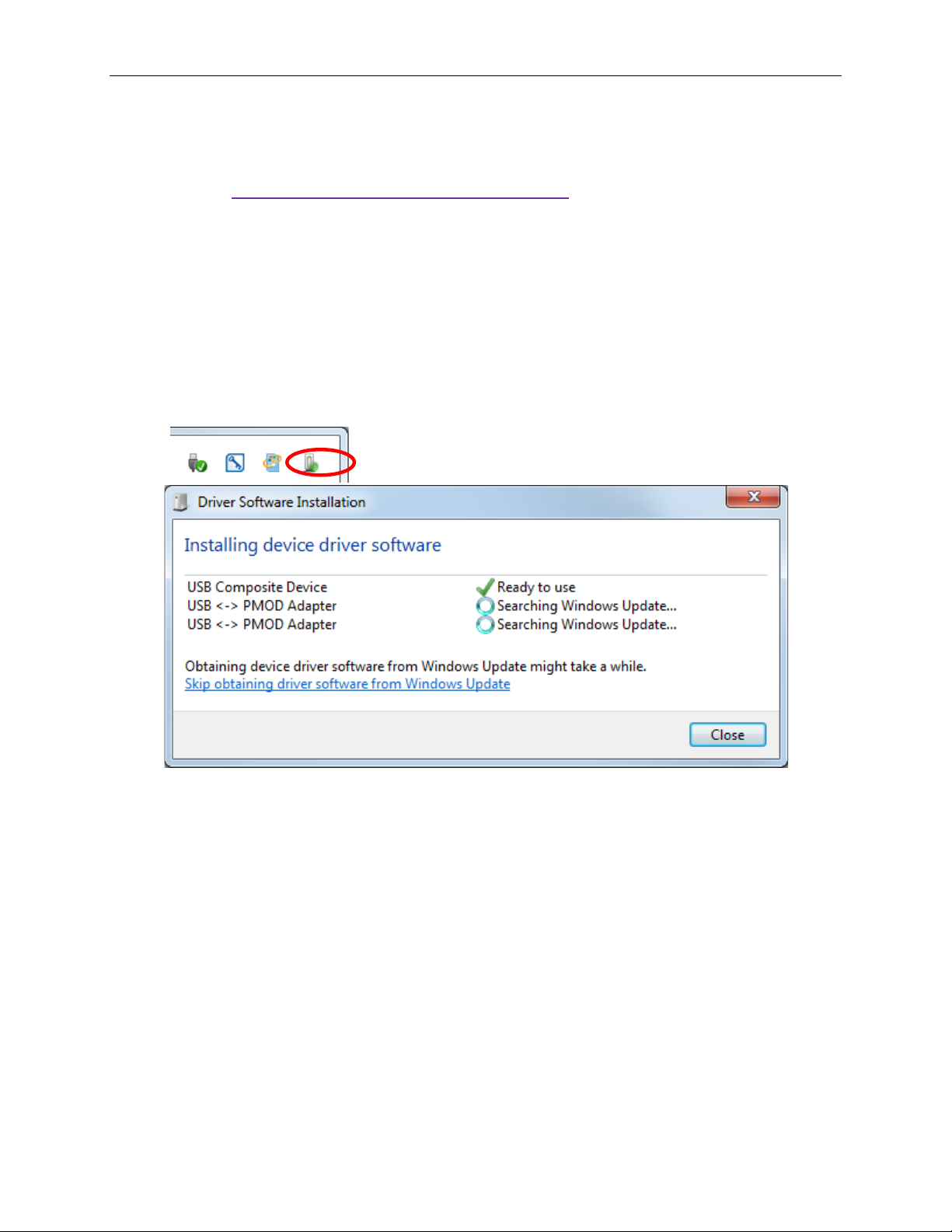

2) Connect the USB cable between the Munich board and the PC; the USB driver is

installed automatically (Internet connection required). Alternately, install the FTDI

driver by double-clicking on the CDM V2.08.30 WHQL Certified.exe application

file in the FTDI Driver.zip folder. See Figure 5, Figure 6, and Figure 7.

Figure 5. Driver Install ation for Munich Board

7

Page 8

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Figure 6. Munich GUI Setup Wizard

Figure 7. Munich GUI at Startup

8

Page 9

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

3) Ensure that the jumper settings for VSSIO and VSSIO power supplies are correct

(both closed). Refer to the MAX11300P MB 1 d ata sheet for further details.

4) Connect the Munich board’s 2x6 pin right-angle connector to the

MAX11300PMB1’s 2x6 pin right-angle header.

5) Once the Munich board is connected with the MAX11300PMB1, open the

Munich GUI.exe (double-click) software.

6) Click on Device tab and select the MAX11300PMB as shown in Figure 8, the

Munich GUI.

Figure 8. The Munich GUI

9

Page 10

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Scans for

boards

Available Munich

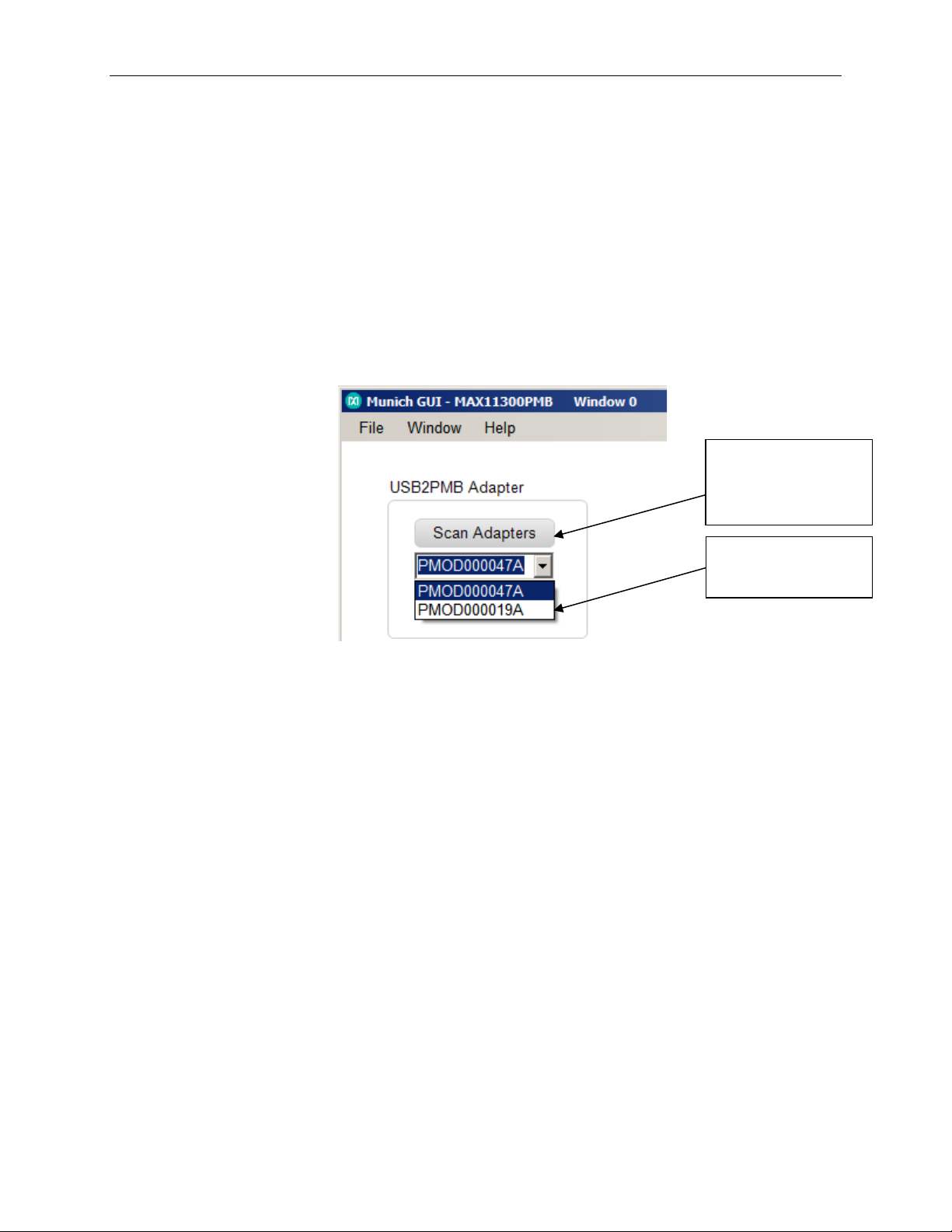

7) Press the Scan Adapters pushbutton to scan the available Munich boards

connected to the computer. This allows the user to test multiple companion driver

boards at the same time. Each Munich board has a unique ID that the software

determines.

Scan and Select:

Figure 9 depicts the scanning and available Munich devices connected.

The software has identified two devices:

1. PMOD000047A

2. PMOD000019A

connected

devices

Figure 9. Connect PMOD Adapter

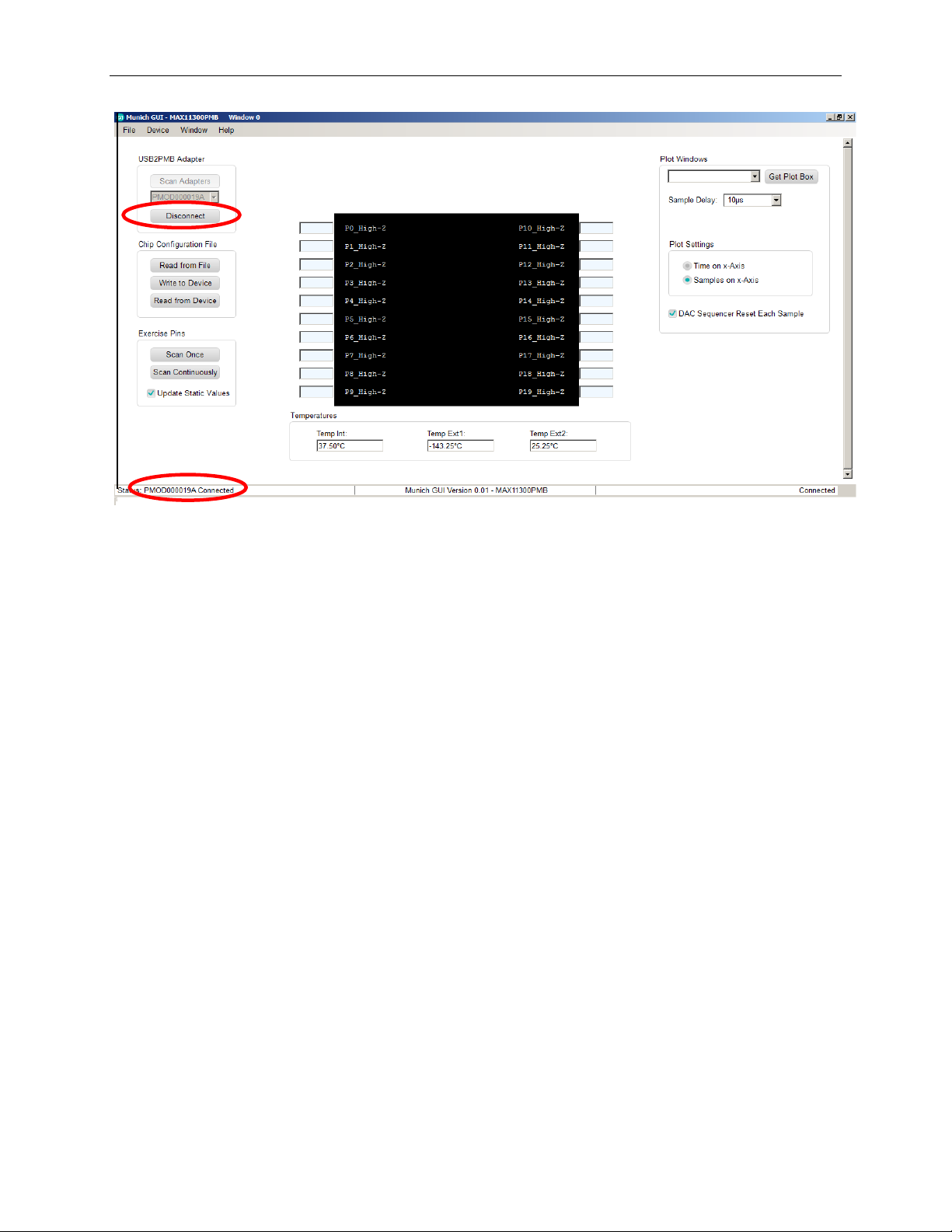

8) Within the tab sheet, press the Connect button and verify that the button

changes its text to Disconnect and the status bar at the bottom indicates that the

companion board is connected. See Figure 10.

10

Page 11

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Figure 10. MAX11300 Connected to Munich GUI

11

Page 12

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

5. Munich GUI

The Munich GUI contains the internal block diagram of the MAX11300 device

showing the 20 programmable I/Os with their programmed setting.

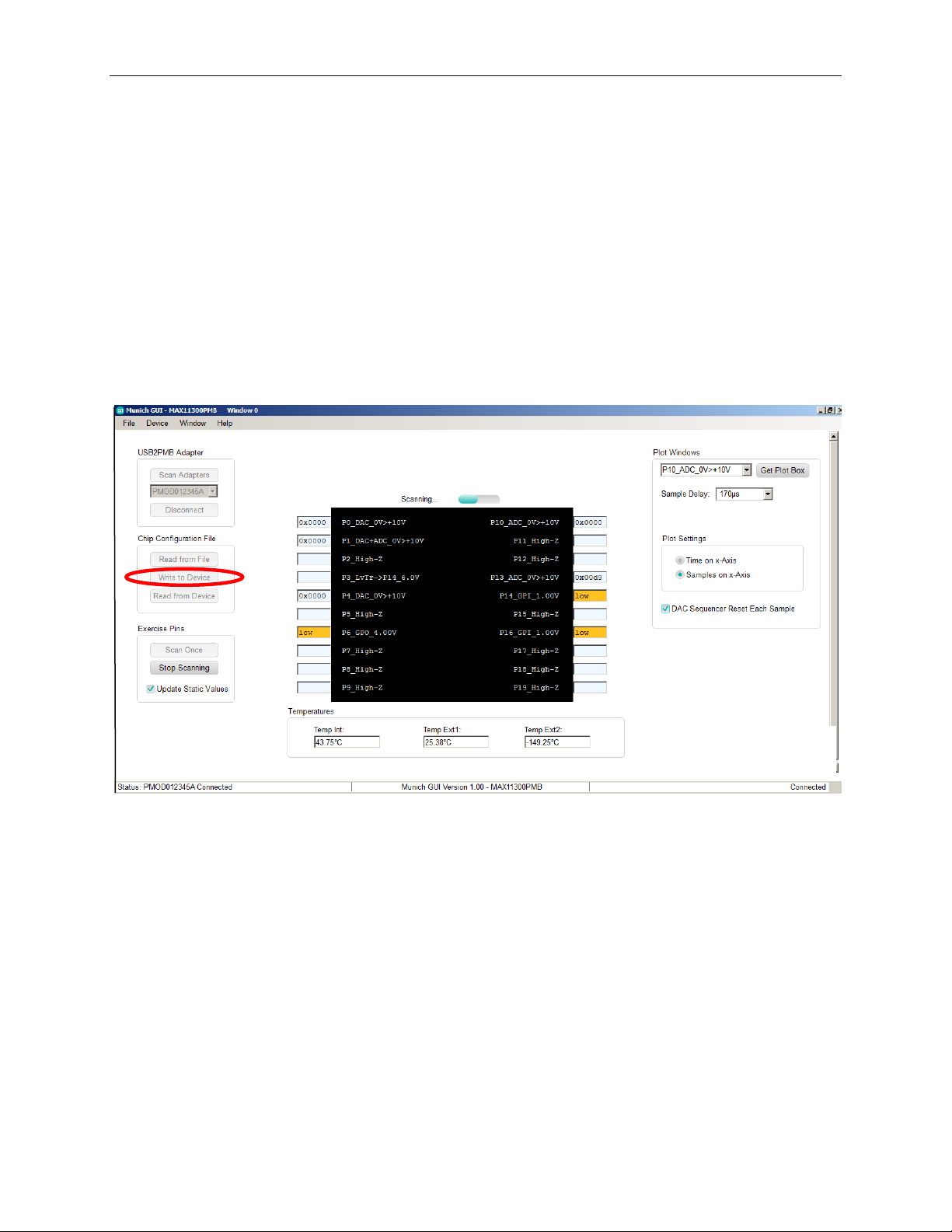

At startup, the MAX11300 device is not programmed. To program the device,

click on Chip Configuration File | Read from File and select a .csv file that was

created with the MAX11300 Configuration Software tool. In the example

provided, the MAX11300Register_Demo.csv is selected. Next, write this

configuration bitstream to the MAX11300 device by clicking on

Chip Configuration File | Write to Device as shown in Figure 11.

Figure 11. Configuration Example

5.1 Write to Device

Click this button to transfer the configuration bit stream to the MAX11300. After

updating the device, use the Scan command to read the status and the port

name is updated to reflect the configuration. In this case, P10_ADC shown in

Figure 11 denotes that Port 10 is configured as an ADC.

12

Page 13

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

The functions supported by the MAX11300 GUI are as follow s:

• Configuration

• Get predefined waveform files

• Choose sample delay and single or continue scan mode

• View/save plots

• Plot view options

Once the MAX11300 device is configured, click Scan Continuously. The GUI

then exercises each port with the programmed function.

5.2 Part Configuration

If the port is configu red as:

a. General-Purpose Input Port (GPI): The user-defined logic level is

read from the port and written to the appropri a t e port box.

b. General-Purpose Output Port (GPO): The user-defined logic level

defined in the port text box is written to the port (use either 0/1 or

high/low).

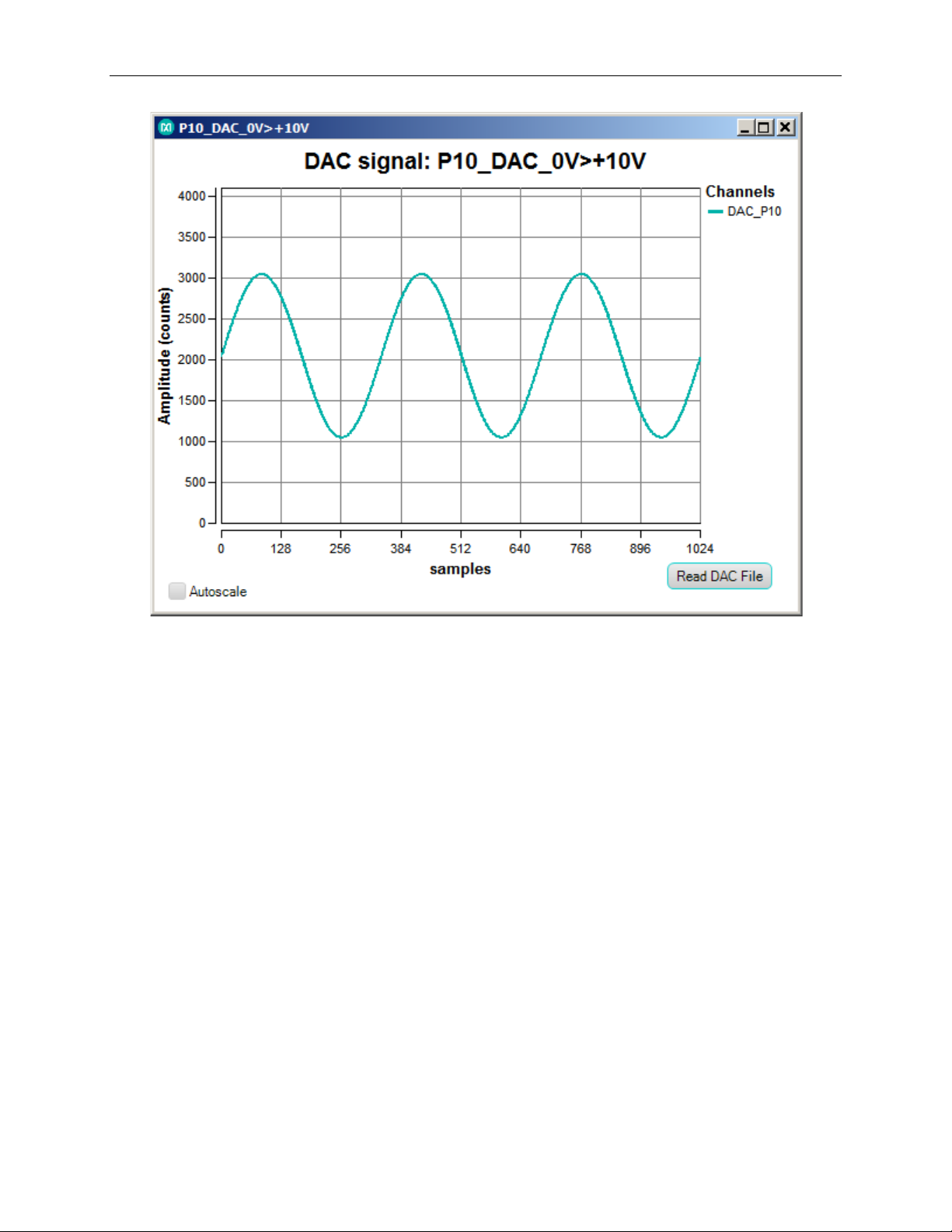

c. DAC Analog Output: The value written to the text box is applied to the

port. For DAC analog outputs, it is also possible to apply a complete

waveform. To do that, select a target DAC-port, and to apply a

waveform, click on Get Plot Box on the top right. A separate window

opens, and a comma separated file (.adc) that contains hex or decimal

numbers can be read with up to 1024 samples (Figure 12

). There are

a few waveform examples provided for sawtooth and sine and triangle

waveforms; these files have the suffix .adc*. Note that once a plot box

for the port is open, the text box in the GUI main window is ignored.

d. ADC Analog Input: the hexadecimal number in the text box

corresponds to the voltage applied to the pin. Note that the ADC input

type and the input range is selected in the configuration tool. As with

the DAC configuration, you can also open a plot box by selecting the

appropriate pin and clicking on Get Plot Box on the top right. If a plot

box is open, the plot box shows the waveform applied to the ADC input

pin.

e. Differential ADC Input: The MAX11300 can be configured for

differential ADC mode using two ports. The operation of the GUI is the

same as in step d.

f. Level Translator: The IC acts correctly, but the GUI shows only static

values for the input and the output.

*Although the files have suffix .adc, the content is a simple hex value that can either be a file saved from an

ADC analog input or as file that can be opened and written to a DAC to provide an analog output.

13

Page 14

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Figure 12. DAC Plot Box

The GUI also displays the three temperature-sensor measurements in degrees

Celsius (°C). The internal device temperature measures the IC die temperature.

For the external temperature measurements, add diode-connected transistors

sensors such as a 2N3906 to each channel. If the pins are left open, then the

temperature typically shows ~380°C. This is normal.

5.3 Sampling

The flexibility of the MAX11300 supports different modes of operation, including

different sampling schemes:

a. Scan Once: In this mode, the software reads the status of each input port a

single time and displays the value of each port.

b. Scan Continuously: In this mode, the software continually loops, reading all

input ports and updating the display to show the value of each port.

c. Sample Delay: This drop-down menu allows the user to select up to 1030µs

delay. This delay is enabled by the GUI between each complete sequence of

ADC read. See Figure 13.

14

Page 15

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Figure 13. Sample Delay Drop-Down Menu

5.4 DAC Sequencer Reset Each Sample

The DAC ports can be updated in different ways, either following a default sequence, or

as soon as new data is received, or using one of two data values that can be

programmed to all DAC ports. This button when selected enables the DAC to be

updated as soon as new data is received at the DAC Data register. See Figure 14.

15

Page 16

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Figure 14. DAC Sequencer Reset

16

Page 17

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

6. Examples

The MAX11300PMB1 software includes a number of waveform plots and examples

for configuring and testing the MAX11300.

Figure 15 lists the files provided with the software tool. The files with suffix .ADC are

predefined waveform plots that can be used as input values to ports configured in

DAC mode. The files with suffix .csv are example configurations showing different

ways the MAX11300 can be configured. The files with suffix .mpix are design files

from MAX11300 configuration software.

Figure 15. MAX11300PMB1 Files

The Munich GUI is provided with an example configuration file for the examples in

Figure 15. To create a configuration file, a separate tool is needed: MAX11300

Configuration Software.

A step-by-step guide to use example register file is as follows:

1. Ensure the Munich board is connected to the MAX11300PMB1 board and the

USB is connected to a PC through a USB Type A to Mini B Cable as shown in

Figure 16.

2. Ensure the MAX11300PMB tab is opened in the Munich GUI and the adapter

number is shown in top-left corner. If you have multiple USB2PMB adapters,

verify the serial numbers.

17

Page 18

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

HIGH-Z AT STARTUP

Figure 16. MAX11300PMB1/Munich Connected to PC Through a USB Cable

Figure 17. Munich GUI at Startup

3. Click the Connect button. The Munich GUI then reads the current

configuration from the connected MAX11300PMB and displays the pin

description for each pin. If the device is powered up, every pin is high-Z (high

impedance) as shown in Figure 17.

4. Under Configuration, click on Read from File and select the register file

MAX11300Register_Demo.csv as shown in Figure 18.

18

Page 19

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Figure 18. Register Files

5. The Munich GUI now shows all pin descriptions in the GUI according to the register

file. But the GUI does not immediately write it to the device, allowing the user

opportunity to double-check. This step is only important if something is already

connected to the MAX11300 ports as a DAC can provide up to ±10V and potentially

destroy the external circuitry. Also, do not connect 2-DAC ports together (shorted)

and set to different voltage levels. In addition, GPI ports can only support

levels between 0V and 5V. Therefore, do not connect a DAC to a GPI with a

voltage outside of the allowed range. A Confirmation window appears as depicted

in Figure 19.

19

Page 20

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Figure 19. Confirmation Window

Select Yes to write the new configuration to the MAX11300. If No is chosen, the GUI

does not write to the device, but reads the configuration from the device and displays

that again.

6. After the Example Register File is written, the screen on the GUI appears as shown in

Figure 20.

Figure 20. Pin Configuration

20

Page 21

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Pin configurations in this example are as follows:

P0:DAC Range 0V to +10V

P1:DAC + ADC Monitoring Range 0V to +10V

P2, P5, P7, P8, P9, P11, P12, P15, P18, P19: High-Z (not used)

P3: Unidirectional Level Translator Input from P14, Output Level 5.0V

P6: GPO General Purpose Digital Output, Level 4.0V

P10: ADC (Single-Ended ADC) Range 0V to +10V

P13: ADC (Single-Ended ADC) Range 0V to +10V

P14: GPI General-Purpose Digital Input, Threshold 1.0V

P16: GPI General-Purpose Digital Input, Threshold 1.0V

7. Hover the mouse cursor over the abbreviated pin description to obtain the detailed

description as shown in Figure 21.

Figure 21. Detailed Port Description

8. Select the Scan Once button under Exercise Pins. The Munich GUI then scans

through all 20 PIXI ports and executes its function. For DAC, it writes the value in the

port box to the DAC; for ADC, it reads the ADC and displays the received value into the

port box, similar to the GPIs and GPOs. Only switches and level translators are

independent, and the Munich GUI does not make any changes to them. The Scan

continuously button performs the same function as the Scan Once button, but it

repeats the scanning process until Stop Scanning is pressed.

To see results in real time, click on Scan Continuously. The Scan Continuously

button then changes to the Stop Scanning button, and the Scanning Progress bar

appears. All inputs are continuously updated (i.e., GPIs, ADCs, temperature sensors).

See Figure 22.

21

Page 22

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Figure 22. Continuous Scanning Mode

The following examples illustrate step-by-step instructions to:

• Write a waveform to a DAC and sample it back with an ADC.

• Demonstrate the behavior of a DAC with ADC monitoring.

• Generate PWM with potentiometer-adjustable pulse width.

6.1 Writing a Waveform to a DAC and Sampling It Back with an ADC

1.

Under Plot Windows in the drop-down menu at the top right, select

P0_DAC_0V>+10V and Get plot box. A small plot window appears on the screen as

shown in Figure 23

. Click Read DAC File and select an analog data point file called

ideal_sine_1000_3x.adc.

22

Page 23

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Figure 23. P0_DAC_0V>+10V Plot Window

The plot window now shows a sine wave, and the entire plot has 1024 data points.

While Continuous Scan is in progress, this waveform is written to the DAC and the

speed depends on how many DAC and ADC pins are available and how many plot

windows are open.

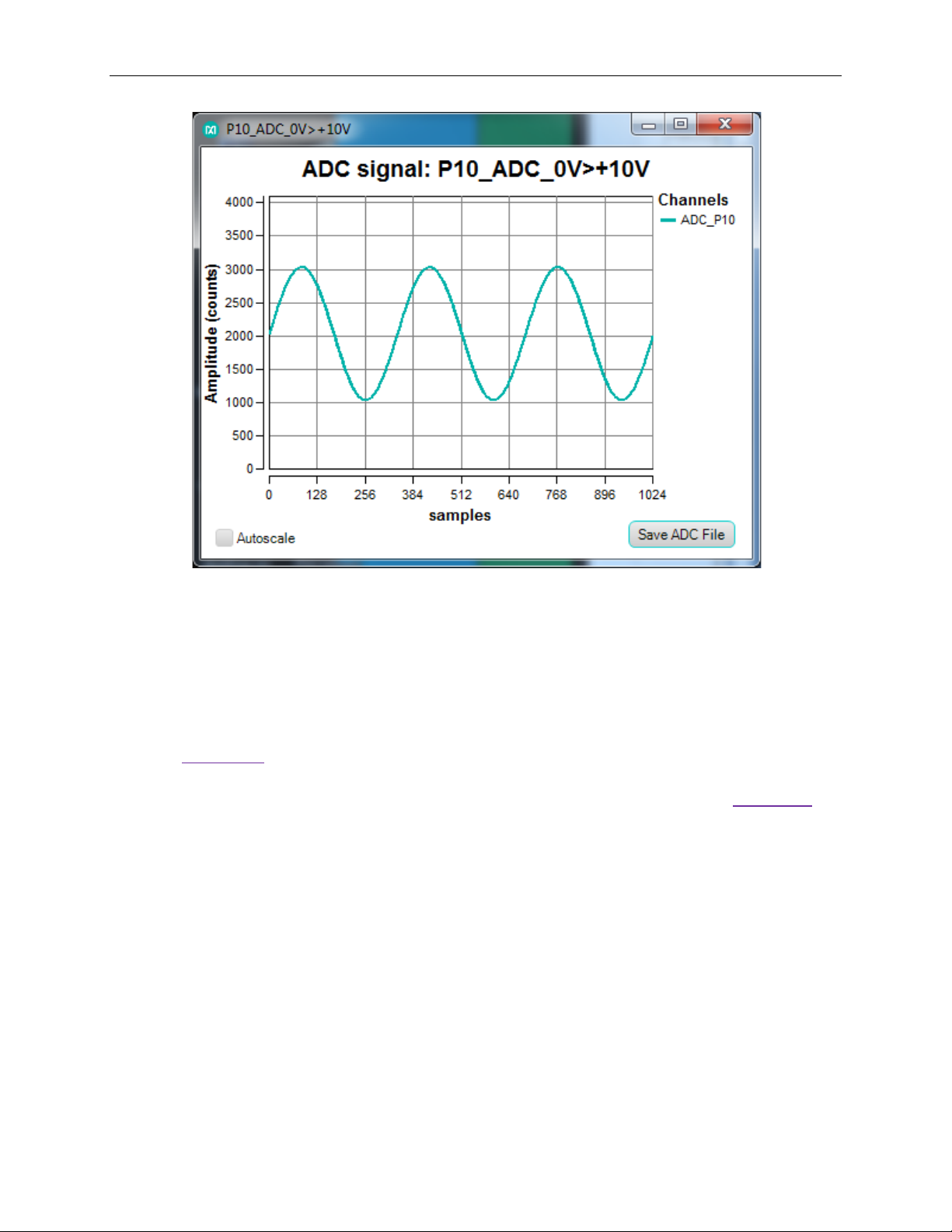

2. In the drop-down menu at the t op right, select P10_ADC_0>+10V and click the Get

plot box button. A plot window opens and shows the analog level on the ADC as shown

in Figure 24.

Figure 24. P10_ADC_0>+10V Plot Window

23

Page 24

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

3. Use a jumper wire to connect P0 to P10 as shown in Figure 25.

Figure 25. P0 Connected to P10

4. After connecting the DAC to the ADC, observe a sine-wave-like-shaped waveform in

the ADC plot window as shown in Figure 26

.

24

Page 25

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Figure 26. Sine-Wave-Like Waveform Without Sample Delay

The waveform does not appear as smooth as the waveform applied in the DAC window.

The reason is that the DAC can sample 20ksps only, but the ADC can sample 400ksps.

Therefore, multiple data points are written to the DAC before the DAC can accept a new

data point. To allow ample time for the DAC to settle before writing a new value, insert a

sample delay between each sample by selecting 10μs or more in the Sample delay

drop-down menu.

5. After adding 170μs sample delay, the ADC shows the same waveform as we apply

to the DAC. See Figure 27

.

6. Keep the plot windows open.

25

Page 26

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Figure 27. Sine Wave with 170µs Sample Delay

6.2 Demonstrate the Behavior of a DAC with ADC Monitoring

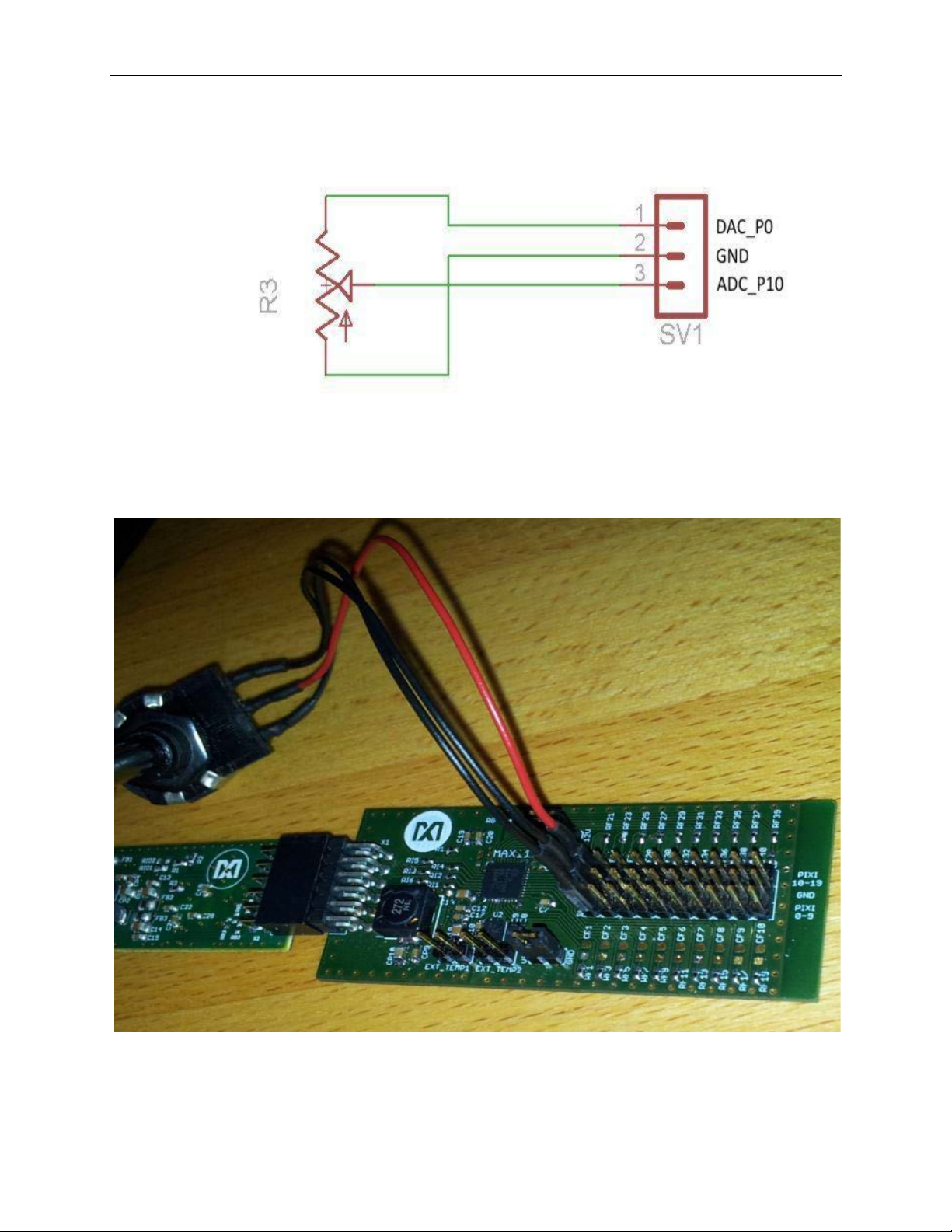

In this example, a potentiometer is connected between ADC and DAC to adjust the

amplitude.

1. See Figure 28 for the potentiometer schematic connection. Make sure that (1) is

connected to the DAC output of the MAX11300 Port 0, (2) is connected to GND

(middle row), and (3) is connected to the ADC MAX11300 Port 10. See

Figure 29 for

the setup.

26

Page 27

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Figure 28. Potentiometer Schematic Connection

to MAX11300PMB Ports

Figure 29. Potentiometer Setup for Demonstrating the

Behavior of a DAC with ADC Monitoring

27

Page 28

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

2. Adjust the potentiometer and observe the amplitude received at the ADC changes

as the potentiometer is varied.

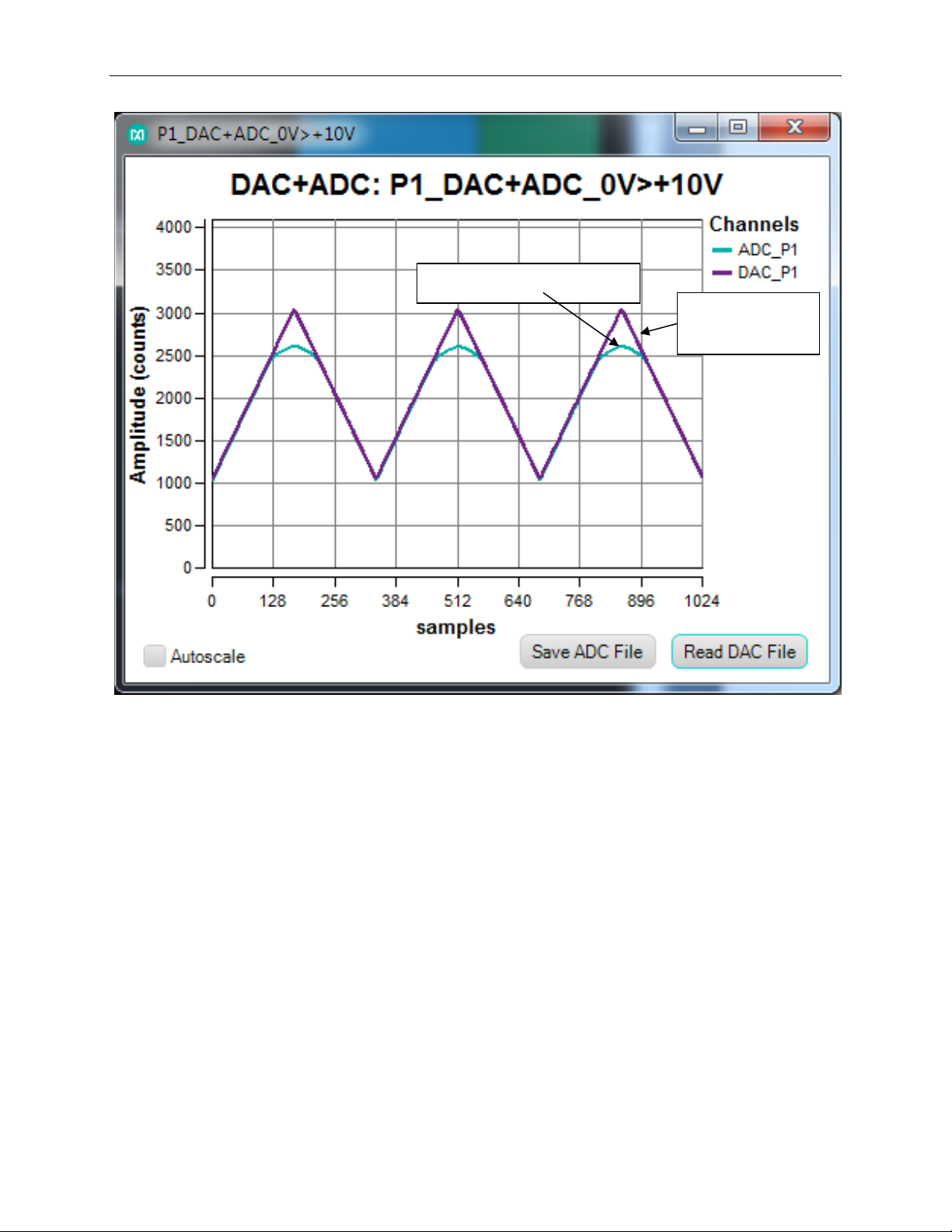

3. In drop-down menu at the top right, select P1_DAC+ADC_0>+10V and select the

Get plot box button. Another plot window opens and displays two waveforms: one

in teal and one in purple. The teal waveform is for A DC, and the purple waveform is

for DAC. Click on Read DAC File and open the ideal_triangle_1000_3x.adc file.

The purple DAC waveform shows a triangle as driven into the DAC. The teal plot

shows the waveform as sampled with the ADC on that same pin. Zoom in or make

the plot window full screen to see the difference between the ADC and DAC plots,

which is mostly due to timing. DAC allows current up to ~20mA; if more current is

drawn, the DAC voltage drops. This happens if the DAC has an output voltage of

10V with a load resistor of 500Ω or less. On the MAX11300PMB1 board, an RC filter

is installed on every port as shown in Figure 30.

Figure 30. RC Filters Are Installed on the MAX11300PMB1 Ports (P0–P19)

This filter is not necessary to use the device, but it provides short-circuit protection. On

this board, it is acceptable to connect a jumper between P1 and the middle row (GND).

Connect a jumper between P1 and GND and observe that the DAC does not reach the

peak of the triangle waveform that is driven into the DAC as shown in Figure 31.

28

Page 29

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Purple (signal

Teal (signal at ADC)

at DAC)

Figure 31. DAC Waveform Does Not Reach the Peak When the Port

Is Connected to Ground

4. The purple waveform is the signal driven into the DAC. The teal waveform is the

voltage the ADC sees on the DAC pin. Since there is resistance between MAX11300

pin and board pin, the voltage observed by the ADC is not equal to the voltage on

the board output pin.

5. Remove the jumper wire between P1 and GND.

6. Keep the plot windows open.

29

Page 30

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Threshold

6.3. Generate PWM with Potentiometer-Adjustable Pulse-Width

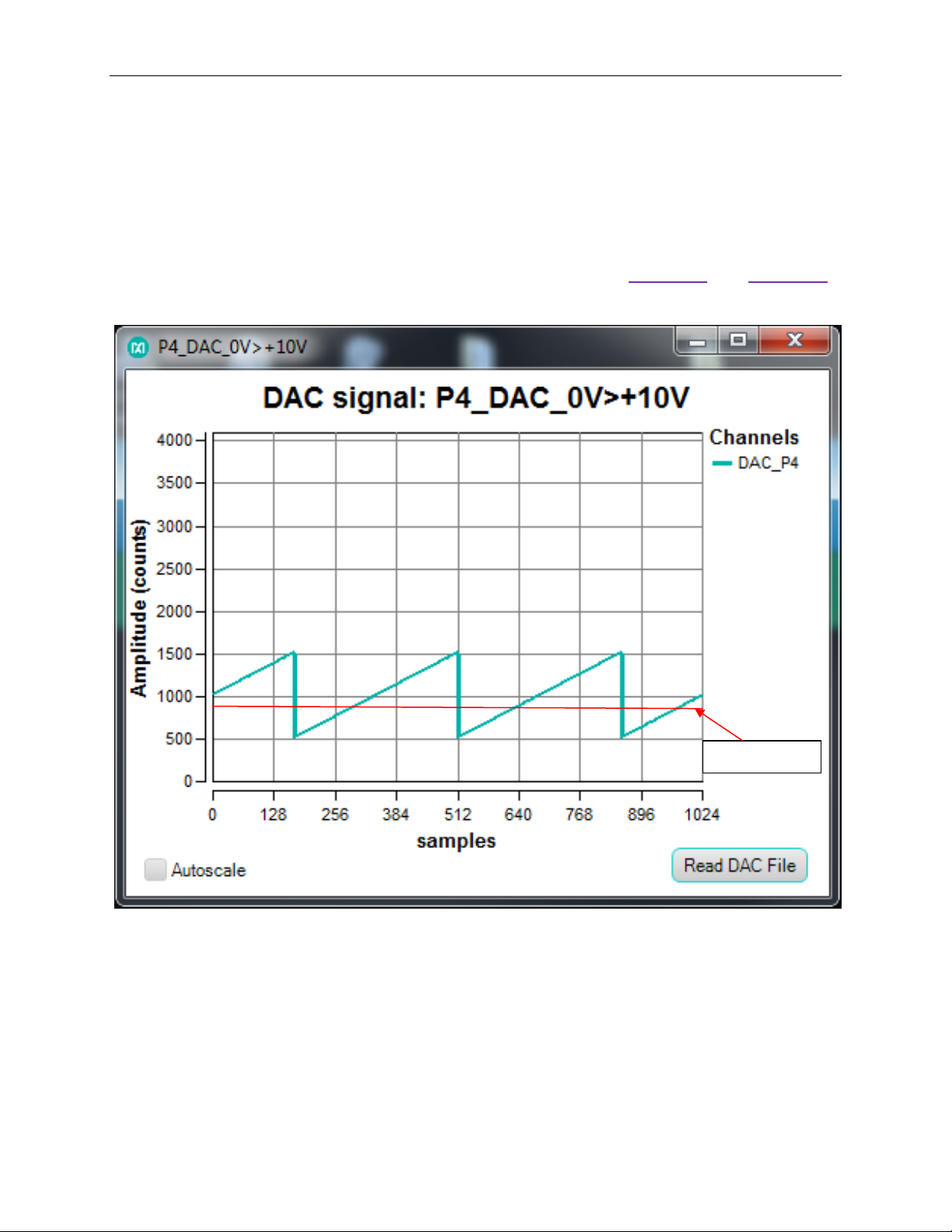

In this example, a sawtooth waveform is generated and fed to a comparator (i.e., a level

translator). The output of the comparator is high if the signal is above the threshold or

low if the signal is below the threshold (same case for a level translator). As the position

of the sawtooth waveform is moved up or down when the potentiometer is adjusted, the

width of the curve above the threshold is wider or thinner. See Figure 32 and Figure 33.

Figure 32. A Sawtooth Waveform Shown Is Generated and Applied to a Level

Translator, Resulting in a PWM as Depicted in Figure 33

30

Page 31

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Figure 33. The Width of a PWM Is Adjusted by a Potentiometer

1. In the drop-down menu at the top right, select P4_DAC_0V>+10V and click the Get plot

box button. Another plot window opens for DAC on P4. Click on Read DAC File in the

newly opened P4_DAC window and open the analog data point

file ideal_sawtooth_right_1000_3x.adc.

2. Connect a potentiometer cable assembly to Port 4 (black jumper wire), Port 14 (red

jumper wire), and GND (black jumper wire). Connect Port 3 to Port 13 (yellow

jumper wire) as shown in Figure 34 and Figure 35.

31

Page 32

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Figure 34. A Potentiometer Is Connected to Ports 4, 14, and GND

32

Page 33

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Figure 35. A Potentiometer Is Connected to Ports 4, 14, and GND

3. In the drop-down menu on the top right, select P13_ADC_0V>+10V and click the

Get plot box button. Another plot window opens for ADC on P13. Observe PWM

signal in the ADC plot window. Adjust the pulse width by turning the

potentiometer to the low and high positions and observe the width of the PWM

waveform as shown in Figure 36 and Figure 37.

Note that the input of the level translator can handle up to 5V only. T he provided

configuration file is set to deliver a max of 5V in 0V to 10V mode. If other files are

used, be sure not to apply more than 5V at any digital inputs.

33

Page 34

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Figure 36. PWM Width as the Potentiometer Set to a Low Position (~20%)

34

Page 35

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

Figure 37. PWM Width as the Potentiometer Set to a High Position (~80%)

7. References

For further detailed information, refer to the following documents available online:

• MAX11300 IC Data Sheet:

www.maximintegrated.com/datasheet/index.mvp/id/8175

• MAX11300PMB1 EV Kit Data Sheet:

www.maximintegrated.com/datasheet/index.mvp/id/8396

• MAX11300 EV Kit Dat a Sheet:

www.maximintegrated.com/MAX11300EVKIT

• MAX11300 EV Kit GUI:

www.maximintegrated.com/en/design/tools/applications/evkitsoftware/index.mvp?id=1171

• MAX11300 Configuration Software:

www.maximintegrated.com/en/design/tools/applications/evkitsoftware/index.mvp?id=1171

• USB2PMB1 Adapter Board (Munich) EV Kit Data Sheet:

www.maximintegrated.com/datasheet/index.mvp/id/8207

35

Page 36

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

• USB2PMB1 (Munich) Adapter Board GUI :

www.maximintegrated.com/design/tools/applications/evkitsoftware/index.mvp?id=1161

8. Trademarks

PIXI is a trademark of Maxim Integrated Products, Inc.

Pmod is a trademark of Digilent Inc.

Windows is a registered trademark and registered service mark and Windows XP is a

registered trademark of Microsoft Corporation.

36

Page 37

MAX11300PMB1 Peripheral Module and Munich (USB2PMB1) Adapter Board Quick Start Guide

9. Revision Histor y

REVISION

NUMBER

REVISION

DATE

DESCRIPTION

0 7/14 Initial release —

PAGES

CHANGED

37

Loading...

Loading...