Page 1

DS80C390

www.dalsemi.com

64-PIN QFP

PRELIMINARY

161910274360

68-PIN PLCC

Dual CAN High-Speed

Microprocessor

FEATURES

§ 80C52 compatible

− 8051 instruction-set compatible

− Four 8-bit I/O ports

− Three 16-bit timer/counters

− 256 bytes scratchpad RAM

§ High-Speed Architecture

− 4 clocks/machine cycle (8051=12)

− Runs DC to 40 MHz clock rates

− Frequency multiplier reduces EMI

− Single-cycle instruction in 100 ns

− 16/32-bit math coprocessor

§ 4 kB internal SRAM usable as

program/data/stack memory

§ Enhanced memory architecture

− Addresses up to 4 MB external

− Defaults to true 8051 memory compatibility

− User-enabled 22-bit program/data counter

− 16-Bit/22-bit paged/22-bit contiguous

modes

− User-selectable multiplexed / non-

multiplexed memory interface

− Optional 10 bit stack pointer

§ Two full-function CAN 2.0B controllers

− 15 message centers per controller

− Standard 11-bit or extended 29-bit

identification modes

− Supports DeviceNet, SDS, and higher layer

CAN protocols

− Disables transmitter during autobaud

− SIESTA low power mode

§ Two full-duplex hardware serial ports

§ Programmable IrDA clock

§ High integration controller includes

− Power-fail reset

− Early-warning power-fail interrupt

− Programmable watchdog timer

− Oscillator-fail detection

§ 16 total interrupt sources with 6 external

§ Available in 64-pin QFP, 68-pin PLCC

PIN ASSIGNMENT

48 33

49

64

32

DS80C390

17

161

DS80C390

1 of 58 110199

Page 2

DS80C390

DESCRIPTION

The DS80C390 is a fast 8051-compatible microprocessor. The redesigned processor core executes 8051

instructions up to 3 times faster than the original for the same crystal speed. The DS80C390 supports a

maximum crystal speed of 40 MHz, resulting in apparent execution speeds of 100 MHz (approximately

2.5X). An optional internal frequency multiplier allows the microprocessor to operate at full speed with a

reduced crystal frequency, reducing EMI. A hardware math accelerator further increases the speed of 32

and 16 bit multiply and divide operations, as well as high-speed shift, normalization and accumulate

functions.

The DS80C390 features two full-function Controller Area Network (CAN) 2.0B controllers. Status and

control registers are distributed between SFRs and 512 bytes of internal MOVX memory for maximum

flexibility. In addition to standard 11-bit or 29-extended message identifiers, the device supports two

separate 8-bit media masks and media arbitration fields to support the use of higher-level CAN protocols

such as DeviceNet and SDS.

All of the standard 8051 resources such as three timer/counters, serial port, and four 8-bit I/O ports (plus

two 8-bit ports dedicated to memory interfacing) are included in the DS80C390. In addition it includes a

second hardware serial port, seven additional interrupts, programmable watchdog timer, brown-out

monitor, power-fail reset, and a programmable output clock that supports an IRDA interface. The device

provides dual data pointers with increment/decrement features to speed block data memory moves. It

also can adjust the speed of MOVX data memory access from two to twelve machine cycles for flexibility

in addressing external memory and peripherals.

The device incorporates a 4kB SRAM, which can be configured as various combinations of MOVX

memory, program memory, and optional stack memory. A 22-bit program counter supports access to a

maximum of 4 MB of external program memory and 4 MB of external data memory. A 10-bit stack

pointer addresses up to 1kB of MOVX memory for increased code efficiency.

A new Power Management Mode (PMM) is useful for portable or power-conscious applications. This

feature allows software to switch from the standard machine cycle rate of 4 clocks per cycle to 1024

clocks per cycle. For example, at 12 MHz standard operation has a machine cycle rate of 3 MHz. In

Power Management Mode at the same external clock speed, software can select 11.7 kHz machine cycle

rate. There is a corresponding reduction in power consumption when the processor runs slower.

The EMI reduction feature allows software to select a reduced electromagnetic interference (EMI) mode

by disabling the ALE signal when it is unneeded. The device also incorporates active current control on

the address and data buses, reducing EMI by minimizing transients when interfacing to external circuitry.

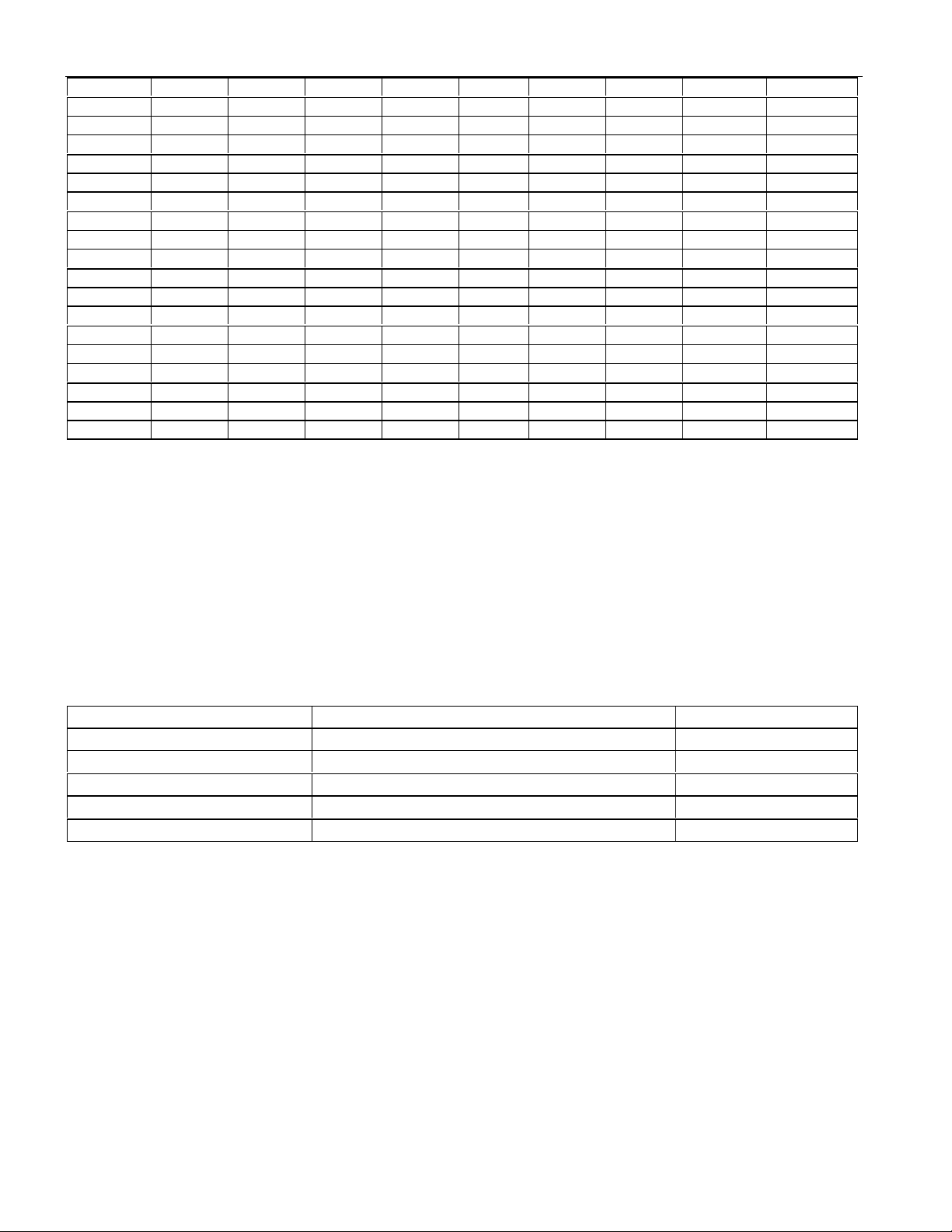

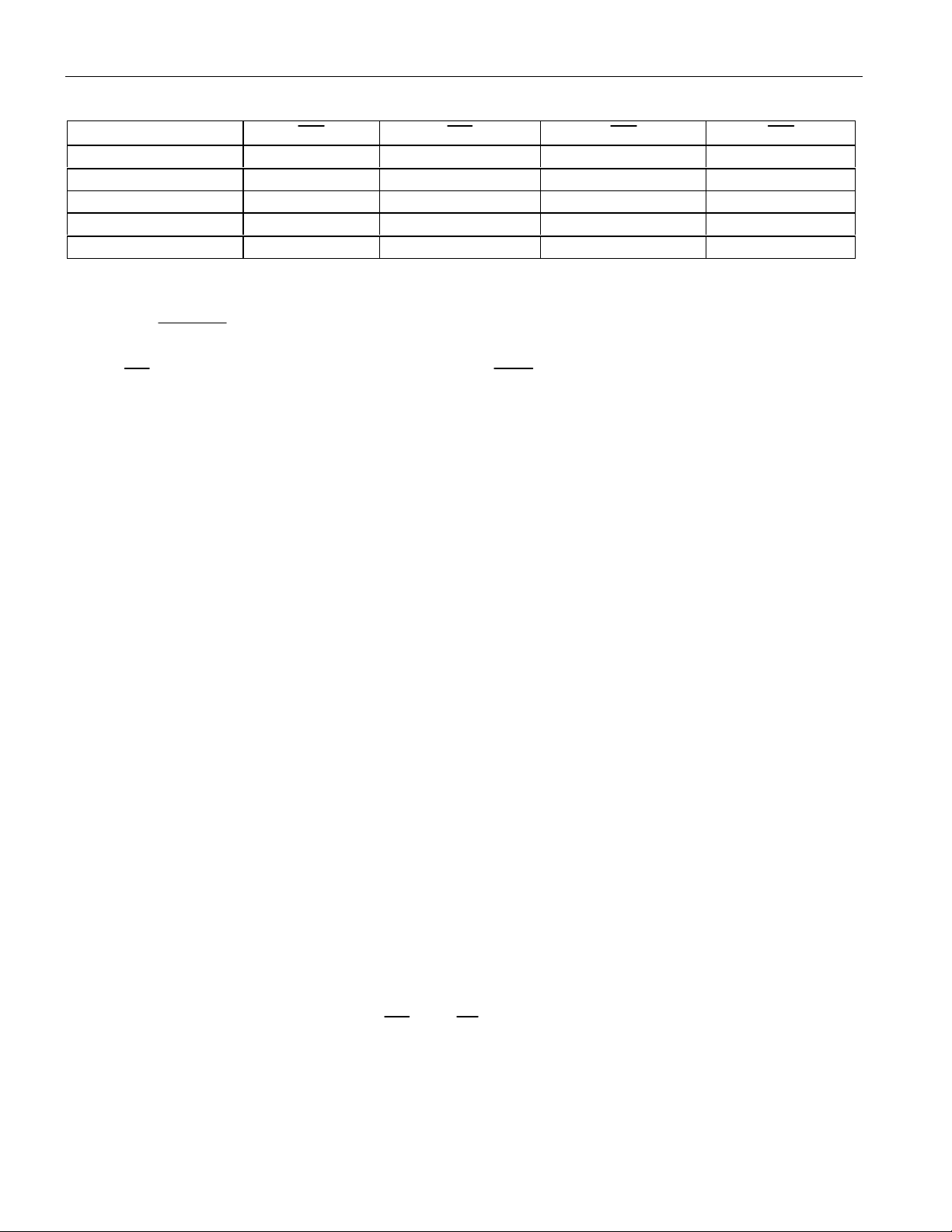

ORDERING INFORMATION

Part Number Package Max. Clock Speed Temperature Range

DS80C390-QCR 68-pin PLCC 40 MHz

DS80C390-FCR 64-pin LQFP 40 MHz

DS80C390-QNR 68-pin PLCC 40 MHz

DS80C390-FNR 64-pin LQFP 40 MHz

0°C to +70°C

0°C to +70°C

-40°C to +85°C

-40°C to +85°C

2 of 58 110199

Page 3

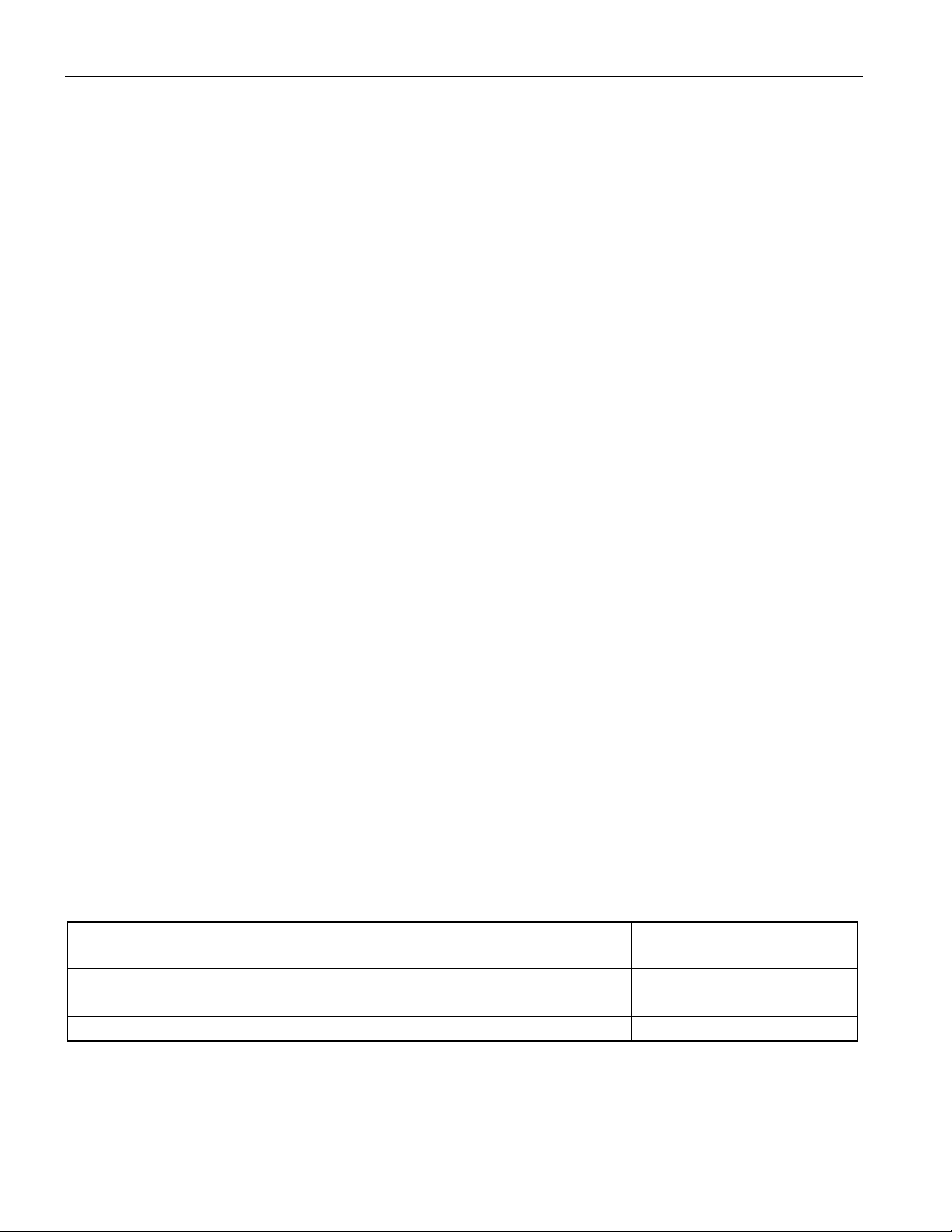

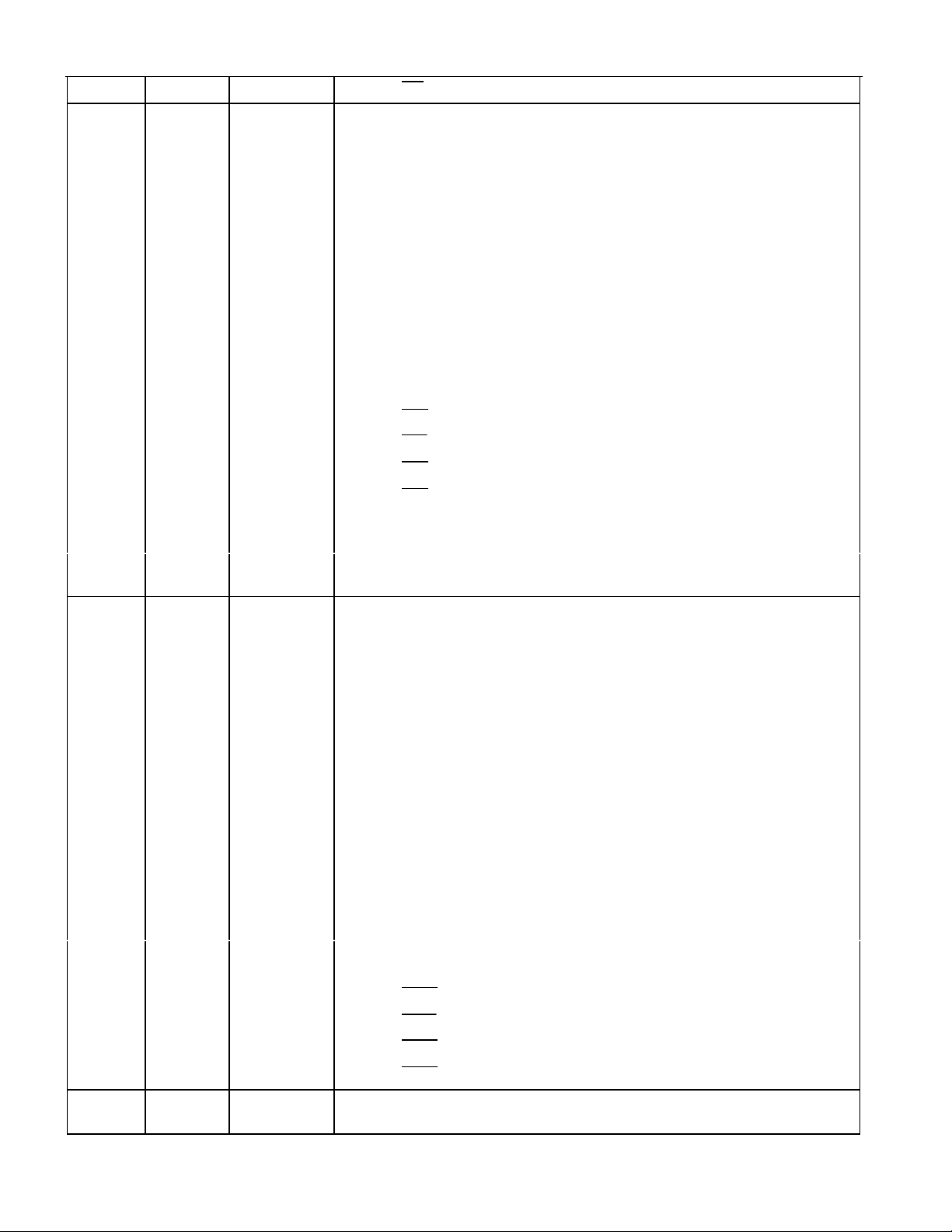

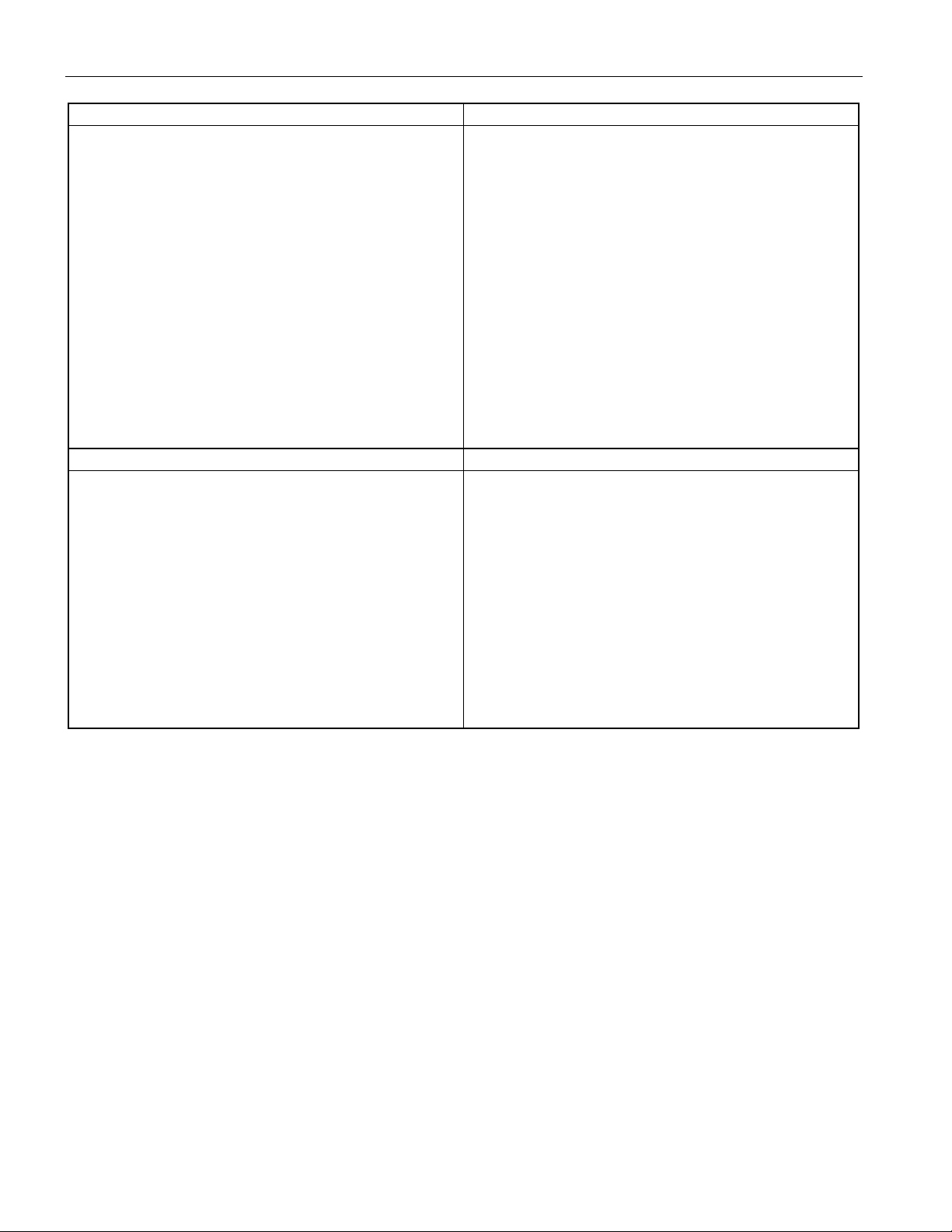

DS80C390 BLOCK DIAGRAM Figure 1

DS80C390

3 of 58 110199

Page 4

PIN DESCRIPTION Table 1

LQFP PLCC SIGNAL

NAME

8, 22,

40, 56

9, 25,

41, 57

46 57 ALE

17, 32,

51, 68

1, 18,

35, 52

V

CC

+5V

GND Digital Circuit Ground

Address Latch Enable - Output. When the MUX pin is low, this

pin outputs a clock to latch the external address LSB from the

multiplexed address/data bus on Port 0. This signal is commonly

connected to the latch enable of an external transparent latch. ALE

has a pulse width of 1.5 XTAL1 cycles and a period of four

XTAL1 cycles. When the MUX pin is high, the pin will toggle

continuously if the ALEOFF bit is cleared. ALE is forced high

when the device is in a Reset condition or if the ALEOFF bit is set

while the MUX pin is high.

45 56

PSEN

Program Store Enable - Output. This signal is the chip enable for

external ROM memory. PSEN provides an active low pulse and is

driven high when external ROM is not being accessed.

47 58

EA

External Access Enable - Input. This pin must be tied to GND for

proper operation.

26 36

MUX

Multiplex/Demultiplex Select - Input. This pin selects if the

address/data bus operates in multiplexed (MUX =0) or

demultiplexed ( MUX =1) mode.

2 11 RST Reset - Input. The RST input pin contains a Schmitt voltage input

to recognize external active high Reset inputs. The pin also

employs an internal pulldown resistor to allow for a combination of

wired OR external Reset sources. An RC circuit is not required for

power-up, as the device provides this function internally.

3 12

RSTOL

Reset Output Low - Output. This active low signal will be

asserted:

When the processor has entered reset via the RST pin,

During crystal warm-up period following power-on or Stop mode,

During a watchdog timer reset (2 cycles duration),

During an oscillator failure (if OFDE=1),

23,

24

33,

34

XTAL2,

XTAL1

Whenever V

XTAL1, XTAL2 - Crystal oscillator pins support fundamental

mode, parallel resonant, AT cut crystals. XTAL1 is the input if an

CC

≤ V

external clock source is used in place of a crystal. XTAL2 is the

output of the crystal amplifier.

55

54

53

52

51

50

49

48

67

66

65

64

63

62

61

59

AD0 / D0

AD1 / D1

AD2 / D2

AD3 / D3

AD4 / D4

AD5 / D5

AD6 / D6

AD7 / D7

AD0-7 (Port 0) - I/O. When the MUX pin is tied low, Port 0 is the

multiplexed address/data bus. While ALE is high, the LSB of a

memory address is presented. While ALE falls, the port transitions

to a bi-directional data bus. When the MUX pin is tied high, Port 0

functions as the bi-directional data bus. Port 0 cannot be modified

by software. The reset condition of Port 0 pins is high. No pullup

resistors are needed.

DESCRIPTION

RST

DS80C390

4 of 58 110199

Page 5

DS80C390

58-64,12-8, 10 P1.0-P1.7 Port 1 - I/O. Port 1 can function as an 8-bit bi-directional I/O port,

the non-multiplexed A0 - A7 signals (when the MUX pin =1), and

as an alternate interface for internal resources. Setting the SP1EC

bit relocates RXD1 and TXD1 to Port 5. The reset condition of Port

1 is all bits at logic 1 via a weak pullup. The logic 1 state also

serves as an input mode, since external circuits writing to the port

can overdrive the weak pullup. When software clears any port pin

to 0, a strong pulldown is activated that remains on until either a 1

is written to the port pin or a reset occurs. Writing a 1 after the port

has been at 0 will activate a strong transition driver, followed by a

weaker sustaining pullup. Once the momentary strong driver turns

off, the port once again becomes the output (and input) high state.

Port Alternate Function

58 2 A0 P1.0 T2 Exter nal I/O for Timer/Counter 2

59 3 A1 P1.1 T2EX Timer/Counter 2 Capture/Reload Trigger

60 4 A2 P1.2 RXD1 Serial Port 1 Input

61 5 A3 P1.3 TXD1 Serial Port 1 Output

62 6 A4 P1.4 INT2 External Interrupt 2 (Pos. Edge Detect)

63 7 A5 P1.5 INT3 External Interrupt 3 (Neg. Edge Detect)

64 8 A6 P1.6 INT4 External Interrupt 4 (Pos. Edge Detect)

1 10 A7

35

36

37

38

39

42

43

44

4-7,

10-13

46

47

48

49

50

53

54

55

13-16,

19-22

A10 (P2.2)

A11 (P2.3)

A12 (P2.4)

A13 (P2.5)

A14 (P2.6)

A15 (P2.7)

A8 (P2.0)

A9 (P2.1)

P3.0-P3.7 Port 3 - I/O. Port 3 functions as an 8-bit bi-directional I/O port,

P1.7

External Interrupt 5 (Neg. Edge Detect)

INT5

A15-A8 (Port 2) - Output. Port 2 serves as the MSB for external

addressing. The port automatically asserts the address MSB during

external ROM and RAM access. Although the Port 2 SFR exists,

the SFR value will never appear on the pins (due to memory

access). Therefore accessing the Port 2 SFR is only useful for

MOVX A, @Ri or MOVX @Ri, A instructions, which use the Port

2 SFR as the external address MSB.

and as an alternate interface for several resources found on the

traditional 8051. The reset condition of Port 1 is all bits at logic 1

via a weak pullup. The logic 1 state also serves as an input mode,

since external circuits writing to the port can overdrive the weak

pullup. When software clears any port pin to 0, the device activates

a strong pulldown that remains on until either a 1 is written to the

port pin or a reset occurs. Writing a 1 after the port has been at 0

will activate a strong transition driver, followed by a weaker

sustaining pullup. Once the momentary strong driver turns off, the

port once again becomes the output (and input) high state.

Port Alternate Function

4 13 P3.0 RXD0 Serial Port 0 Input

5 14 P3.1 TXD0 Serial Port 0 Output

6 15

7 16

P3.2 INT0 External Interrupt 0

P3.3 INT1 External Interrupt 1

10 19 P3.4 T0 Timer 0 External Input

11 20 P3.5 T1/XCLK Timer 1 External Input/External Clock Output

12 21

P3.6 WR External Data Memory Write Strobe

5 of 58 110199

Page 6

13 22

34-27 45, 44,

42-37

P4.0-P4.7 Port 4 - I/O. Port 4 can function as an 8-bit bi-directional I/O port,

P3.7 RD External Data Memory Read Strobe

and as the source for external address and chip enable signals for

program and data memory. Port pins are configured as I/O or

memory signals via the P4CNT register. The reset condition of

Port 1 is all bits at logic 1 via a weak pullup. The logic 1 state also

serves as an input mode, since external circuits writing to the port

can overdrive the weak pullup. When software clears any port pin

to 0, the device activates a strong pulldown that remains on until

either a 1 is written to the port pin or a reset occurs. Writing a 1

after the port has been at 0 will activate a strong transition driver,

followed by a weaker sustaining pullup. Once the momentary

strong driver turns off, the port once again becomes the output (and

input) high state.

Port Alternate Function

34 45

33 44

32 42

31 41

P4.0 CE0 Program Memory Chip Enable 0

P4.1 CE1 Program Memory Chip Enable 1

P4.2 CE2 Program Memory Chip Enable 2

P4.3 CE3 Program Memory Chip Enable 3

30 40 P4.4 A16 Program/Data Memory Address 16

29 39 P4.5 A17 Program/Data Memory Address 17

28 38 P4.6 A18 Program/Data Memory Address 18

27 37 P4.7 A19 Program/Data Memory Address 19

21-14 31-27,

25-23

P5.0-P5.7 Port 5 - I/O. Port 5 can function as an 8-bit bi-directional I/O port,

the CAN interface, or as peripheral enable signals. Setting the

SP1EC bit will relocate the RXD1 and TXD1 functions to P5.3-

P5.2 as described in the User’s Guide.

The reset condition of Port 1 is all bits at logic 1 via a weak pullup.

The logic 1 state also serves as an input mode, since external

circuits writing to the port can overdrive the weak pullup. When

software clears any port pin to 0, the device activates a strong

pulldown that remains on until either a 1 is written to the port pin or

a reset occurs. Writing a 1 after the port has been at 0 will activate

a strong transition driver, followed by a weaker sustaining pullup.

Once the momentary strong driver turns off, the port once again

becomes the output (and input) high state.

Port Alternate Function

21 31 P5.0 C0TX CAN0 Transmit Output

20 30 P5.1 C0RX CAN0 Receive Input

19 29 P5.2 C1RX CAN1 Receive Input (optional RXD1)

18 28 P5.3 C1TX CAN1 Transmit Output (optional TXD1)

17 27

16 25

15 24

14 23

9, 26,

43, 60

P5.4 PCE0 Peripheral Chip Enable 0

P5.5 PCE1 Peripheral Chip Enable 1

P5.6 PCE2 Peripheral Chip Enable 2

P5.7 PCE3 Peripheral Chip Enable 3

NC - Reserved. These pins are reserved for use with future

devices in this family and should not be connected.

DS80C390

6 of 58 110199

Page 7

DS80C390

80C32 COMPATIBILITY

The DS80C390 is a CMOS 80C32-compatible microcontroller designed for high performance. Every

effort has been made to keep the core device familiar to 80C32 users while adding many new features.

Because the device runs the standard 8051 instruction set, in general software written for existing 80C32based systems will work on the DS80C390. The primary exceptions are related to timing-critical issues,

since the high-performance core of the microcontroller executes instructions much faster than the

original. Memory interfacing is performed identically to the standard 80C32. The high-speed nature of

the DS80C390 core will slightly change the interface timing, and designers are advised to consult the

timing diagrams in this data sheet for more information.

The DS80C390 provides the same timer/counter resources, full duplex serial port, 256 bytes of scratchpad

RAM and I/O ports as the standard 80C32. Timers will default to a 12 clocks per machine cycle

operation to keep timing compatible with original 8051 systems, but can be programmed to run at the

faster 4 clocks per machine cycle if desired. New hardware functions are accessed using Special

Function Registers that do not overlap with standard 80C32 locations.

This data sheet provides only a summary and overview of the DS80C390. Detailed descriptions are

available in the corresponding user’s guide. This data sheet assumes a familiarity with the architecture of

the standard 80C32. In addition to the basic features of that device, the DS80C390 incorporates many

new features.

PERFORMANCE OVERVIEW

The DS80C390’s higher performance comes not just from increasing the clock frequency, but from a

more efficient design. This updated core removes the dummy memory cycles that are present in a

standard, 12 clocks per machine cycle 8051. In the DS80C390, the same machine cycle takes 4 clocks.

Thus the fastest instruction, 1 machine cycle, executes 3 times faster for the same crystal frequency. The

majority of instructions on the DS80C390 will see the full 3 to 1 speed improvement, while a few will

execute between 1.5 and 2.4 times faster. Regardless of specific performance improvements, all

instructions are faster than the original 8051.

Improvement of individual programs will depend on the actual mix of instructions used. Speed sensitive

applications should make the most use of instructions that are 3 times faster. However, the large number

of 3 to 1 improved opcodes makes dramatic speed improvements likely for any arbitrary combination of

instructions. These architecture improvements and the sub-micron CMOS design produce a peak

instruction cycle in 100 ns (10 MIPs). The Dual Data Pointer feature also allows the user to eliminate

wasted instructions when moving blocks of memory.

INSTRUCTION SET SUMMARY

All instructions perform exactly the same functions as their 8051 counterparts. Their effect on bits, flags,

and other status functions is identical. However, the timing of instructions is different, both in absolute

and relative number of clocks. The absolute timing of software loops can be calculated using a table in

the user’s guide. However, counter/timers default to run at the traditional 12 clocks per increment. In

this way, timer-based events occur at the standard intervals with software executing at higher speed.

Timers optionally can run at the faster 4 clocks per increment to take advantage of faster processor

operation.

The relative time of two DS80C390 instructions might differ from the traditional 8051. For example, in

the original architecture the “MOVX A, @DPTR” instruction and the “MOV direct, direct” instruction

7 of 58 110199

Page 8

DS80C390

required the same amount of time: two machine cycles or 24 oscillator cycles. In the DS80C390, the

MOVX instruction takes as little as two machine cycles or 8 oscillator cycles but the “MOV direct,

direct” uses three machine cycles or 12 oscillator cycles. While both are faster than their original

counterparts, they now have different execution times. This is because the device usually uses one

instruction cycle for each instruction byte. Examine the timing of each instruction for familiarity with the

changes. Note that a machine cycle now requires just 4 clocks, and provides one ALE pulse per cycle.

Many instructions require only one cycle, but some require five. Refer to the user’s guide for details and

individual instruction timing.

SPECIAL FUNCTION REGISTERS

Special Function Registers (SFRs) control most special features of the microcontroller. This allows the

device to have many new features but use the same instruction set as the 8051. When writing software to

use a new feature, an equate statement defines the SFR to an assembler or compiler. This is the only

change needed to access the new function. The DS80C390 duplicates the SFRs contained in the standard

80C52. Table 2 shows the register addresses and bit locations. Many are standard 80C52 registers. The

user’s guide contains a full description of all SFRs.

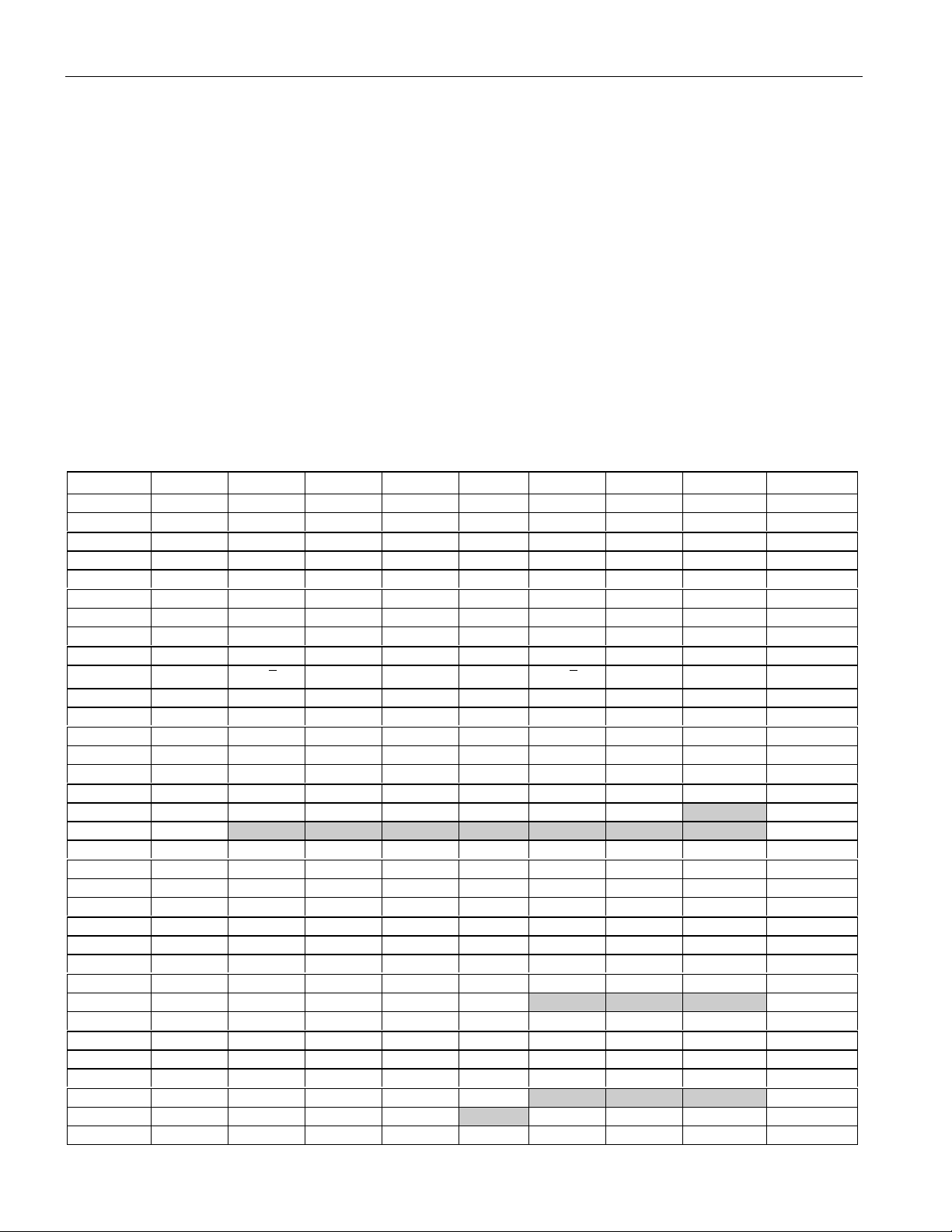

SPECIAL FUNCTION REGISTER LOCATION Table 2

Register Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0 ADDRESS

P4 P4.7 P4.6 P4.5 P4.4 P4.3 P4.2 P4.1 P4.0 80h

SP 81h

DPL 82h

DPH 83h

DPL1 84h

DPH1 85h

DPS ID1 ID0 TSL - - - - SEL 86h

PCON SMOD_0 SMOD0 OFDF OFDE GF1 GF0 STOP IDLE 87h

TCON TF1 TR1 TF0 TR0 IE1 IT1 IE0 IT0 88h

TMOD GATE

TL0 8Ah

TL1 8Bh

TH0 8Ch

TH1 8Dh

CKCON WD1 WD0 T2M T1M T0M MD2 MD1 MD0 8Eh

P1 INT5/P1.7 INT4/P1.6 INT3/P1.5 INT2/P1.4

EXIF IE5 IE4 IE3 IE2 CKRY RGMD RGSL BGS 91h

P4CNT - SBCAN P4CNT.5 P4CNT.4 P4CNT.3 P4CNT.2 P4CNT.1 P4CNT.0 92h

DPX 93h

DPX1 95h

C0RMS0 96h

C0RMS1 97h

SCON0 SM0/FE_0 SM1_0 SM2_0 REN_0 TB8_0 RB8_0 TI_0 RI_0 98h

SBUF0 99h

ESP - - - - - - ESP.1 ESP.0 9Bh

AP 9Ch

ACON - - - - - SA AM1 AM0 9Dh

C0TMA0 9Eh

C0TMA1 9Fh

P2 P2.7 P2.6 P2.5 P2.4 P2.3 P2.2 P2.1 P2.0 A0h

P5 P5.7 P5.6 P5.5 P5.4 P5.3 P5.2 P5.1 P5.0 A1h

P5CNT CAN1BA CAN0BA SP1EC C1_I/O C0_I/O P5CNT.2 P5CNT.1 P5CNT.0 A2h

C0C ERIE STIE PDE SIESTA CRST AUTOB ERCS SWINT A3h

C0S BSS EC96/128 WKS RXS TXS ER2 ER1 ER0 A4h

C/ T

M1 M0 GATE

TXD1/P1.3

C/ T

RXD1/P1.2 T2EX/P1.1 T2/P1.0 90h

M1 M0 89h

8 of 58 110199

Page 9

DS80C390

C0IR INTIN7 INTIN6 INTIN5 INTIN4 INTIN3 INTIN2 INTIN1 INTIN0 A5h

C0TE A6h

C0RE A7h

IE EA ES1 ET2 ES0 ET1 EX1 ET0 EX0 A8h

SADDR0 A9h

SADDR1 AAh

C0M1C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP ABh

C0M2C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP ACh

C0M3C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP ADh

C0M4C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP AEh

C0M5C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP AFh

P3 P3.7 P3.6 T1 T0 INT1 INT0 TXD0 RXD0 B0h

C0M6C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP B3h

C0M7C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP B4h

C0M8C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP B5h

C0M9C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP B6h

C0M10C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP B7h

IP - PS1 PT2 PS0 PT1 PX1 PT0 PX0 B8h

SADEN0 B9h

SADEN1 BAh

C0M11C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP BBh

C0M12C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP BCh

C0M13C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP BDh

C0M14C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP BEh

C0M15C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP BFh

SCON1 SM0/FE_1 SM1_1 SM2_1 REN_1 TB8_1 RB8_1 TI_1 RI_1 C0h

SBUF1 C1h

PMR CD1 CD0 SWB CTM

STATUS PIP HIP LIP - SPTA1 SPRA1 SPTA0 SPRA0 C5h

MCON IDM1 IDM0 CMA - PDCE3 PDCE2 PDCE1 PDCE0 C6h

TA C7h

T2CON TF2 EXF2 RCLK TCLK EXEN2 TR2

T2MOD - - - D13T1 D13T2 - T2OE DCEN C9h

RCAP2L CAh

RCAP2H CBh

TL2 CCh

TH2 CDh

COR IRDACK C1BPR7 C1BPR6 C0BPR7 C0BPR6 COD1 COD0 CLKOE CEh

PSW CY AC F0 RS1 RS0 OV F1 P D0h

MCNT0

MCNT1 MST MOF - CLM - - - - D2h

MA D3h

MB D4h

MC D5h

C1RMS0 D6h

C1RMS1 D7h

WDCON SMOD_1 POR EPFI PFI WDIF WTRF EWT RWT D8h

C1TMA0 DEh

C1TMA1 DFh

ACC E0h

C1C ERIE STIE PDE SIESTA CRST AUTOB ERCS SWINT E3h

C1S BSS CECE WKS RXS TXS ER2 ER1 ER0 E4h

C1IR INTIN7 INTIN6 INTIN5 INTIN4 INTIN3 INTIN2 INTIN1 INTIN0 E5h

C1TE E6h

C1RE E7h

LSHIFT

CSE SCB MAS4 MAS3 MAS2 MAS1 MAS0 D1h

4X/ 2X

ALEOFF - - C4h

C/ T2 CP/ RL2

C8h

9 of 58 110199

Page 10

DS80C390

EIE CANBIE C0IE C1IE EWDI EX5 EX4 EX3 EX2 E8h

MXAX EAh

C1M1C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP EBh

C1M2C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP ECh

C1M3C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP EDh

C1M4C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP EEh

C1M5C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP EFh

B F0h

C1M6C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP F3h

C1M7C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP F4h

C1M8C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP F5h

C1M9C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP F6h

C1M10C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP F7h

EIP CANBIP C0IP C1IP PWDI PX5 PX4 PX3 PX2 F8h

C1M11C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP FBh

C1M12C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP FCh

C1M13C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP FDh

C1M14C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP FEh

C1M15C MSRDY ETI ERI INTRQ EXTRQ MTRQ ROW/TIH DTUP FFh

*Shaded bits are Timed Access protected.

ON-CHIP ARITHMETIC ACCELERATOR

An on-chip math accelerator allows the microcontroller to perform 32- and 16-bit multiplication, division,

shifting, and normalization using dedicated hardware. Math operations are performed by sequentially

loading three special registers. The mathematical operation is determined by the sequence in which three

dedicated SFRs (MA, MB and MC) are accessed, eliminating the need for a special step to choose the

operation. The normalize function facilitates the conversion of 4-byte unsigned binary integers into

floating point format. The following table shows the operations supported by the math accelerator and

their time of execution.

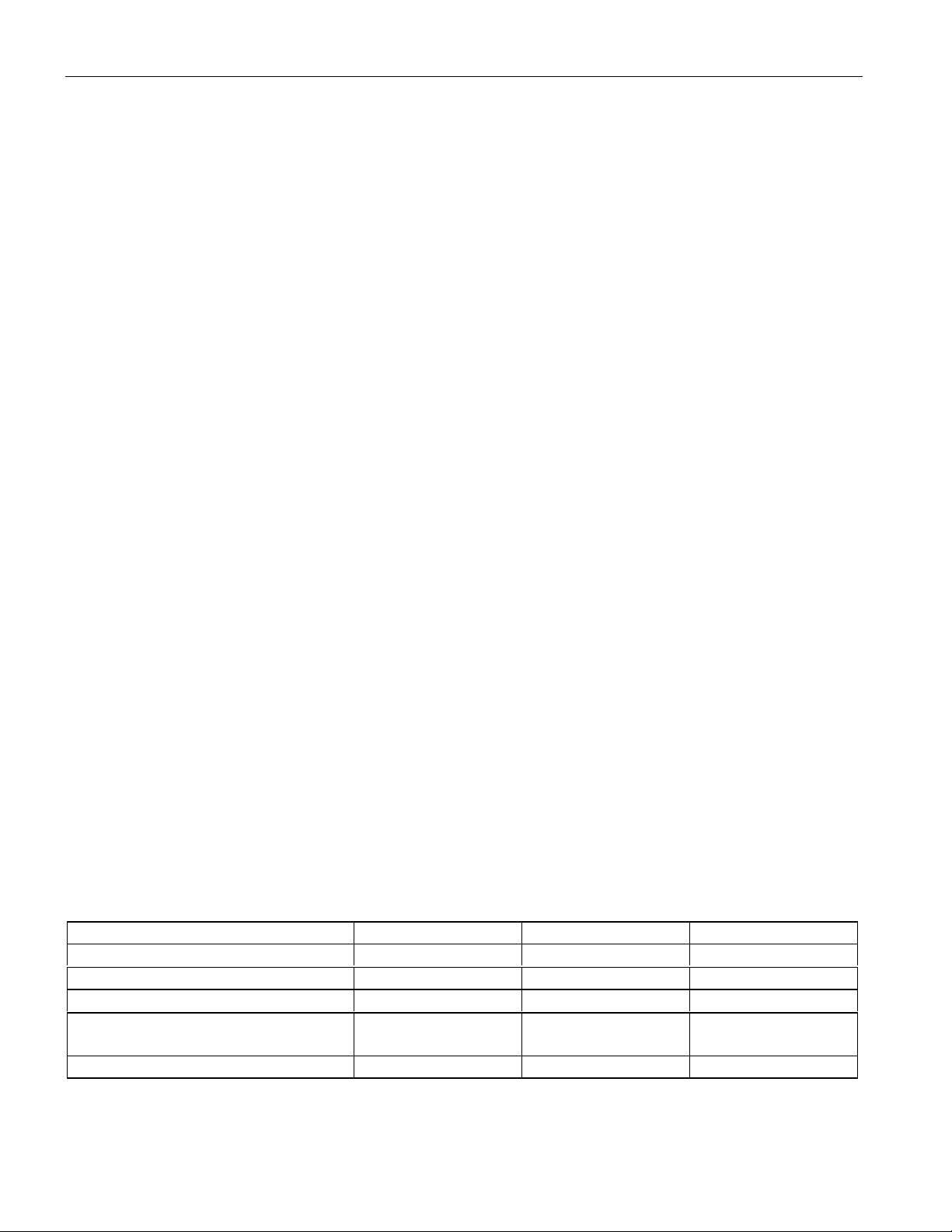

ARITHMETIC ACCELERATOR EXECUTION TIMES Table 3

Operation Result Execution Time

32-bit/16-bit divide 32-bit quotient, 16-bit remainder 36 t

16-bit/16-bit divide 16-bit quotient, 16-bit remainder 24 t

16-bit/16-bit multiply 32-bit product 24 t

32-bit shift left/right 32-bit result 36 t

32-bit normalize 32-bit mantissa, 5 bit exponent 36 t

The following table demonstrates the procedure to perform mathematical operations using the hardware

math accelerator. The MA and MB registers must be loaded and read in the order shown for proper

operation, although accesses to any other registers can be performed between access to the MA or MB

registers. An access to the MA, MB, or MC registers out of sequence will corrupt the operation, requiring

the software to clear the MST bit to restart the math accelerator state machine. Consult the description of

the MCNT0 SFR for details of how the shift and normalize functions operate.

CLCL

CLCL

CLCL

CLCL

CLCL

10 of 58 110199

Page 11

ARITHMETIC ACCELERATOR SEQUENCING

Divide (32/16 or 16/16) Multiply (16x16)

Load MA with dividend LSB.

Load MA with dividendLSB+1*

Load MA with dividend LSB+2*

Load MA with dividend MSB.

Load MB with divisor LSB.

Load MB with divisor MSB.

Poll the MST bit until cleared

(9 machine cycles).

Read MA to retrieve the quotient MSB.

Read MA to retrieve the quotient LSB+2.

Read MA to retrieve the quotient LSB+1.

Read MA to retrieve the quotient LSB.

Read MB to retrieve the remainder MSB.

Read MB to retrieve the remainder LSB.

*Not performed for 16 bit numerator.

Shift Right/Left Normalize

Load MA with data LSB.

Load MA with data LSB+1.

Load MA with data LSB+2.

Load MA with data MSB.

Configure MCNT0 register as required

Poll the MST bit until cleared.

(9 machine cycles)

Read MA for result MSB.

Read MA for result LSB+2.

Read MA for result LSB+1.

Read MA for result LSB.

Load MB with multiplier LSB.

Load MB with multiplier MSB.

Load MA with multiplicand LSB.

Load MA with multiplicand MSB.

Poll the MST bit until cleared

Read MA for product MSB.

Read MA for product LSB+2.

Read MA for product LSB+1.

Read MA for product LSB.

Load MA with data LSB.

Load MA with data LSB+1.

Load MA with data LSB+2.

Load MA with data MSB.

Configure MCNT0 register as required.

Poll the MST bit until cleared

Read MA for mantissa MSB.

Read MA for mantissa LSB+2.

Read MA for mantissa LSB+1.

Read MA for mantissa LSB.

Read MCNT0.4-MCNT0.0 for exponent.

DS80C390

(6 machine cycles).

(9 machine cycles).

40-BIT ACCUMULATOR

The accelerator also incorporates an automatic accumulator function, permitting the implementation of

multiply-and-accumulate and divide-and-accumulate functions without any additional delay. Each time

the accelerator is used for a multiply or divide operation, the result is transparently added to a 40-bit

accumulator. This can greatly increase speed of DSP and other high-level math operations.

The accumulator can be accessed any time the Multiply/Accumulate Status Flag (MCNT1;D2h) is

cleared. The accumulator is initialized by performing five writes to the Multiplier C Register (MC;D5h),

LSB first. The 40-bit accumulator can be read by performing five reads of the Multiplier C Register,

MSB first.

11 of 58 110199

Page 12

DS80C390

MEMORY ADDRESSING

The DS80C390 incorporates three internal memory areas:

§ 256 bytes of scratchpad (or direct) RAM

§ 4 KB of SRAM configurable as various combinations of MOVX data memory, stack memory, and

MOVC program memory

§ 512 bytes of RAM reserved for the CAN message centers.

Up to 4 MB of external memory is addressed via a multiplexed or demultiplexed 20-bit address bus/8-bit

data bus and four chip enable (active during program memory access) or four peripheral enable (active

during data memory access) signals.

Three different addressing modes are supported, as selected by the AM1, AM0 bits in the ACON SFR.

16-bit address mode

16-bit address mode accesses memory similarly to the traditional 8051. It is opcode compatible with the

8051 microprocessor and identical to the byte and cycle count of the Dallas Semiconductor High-Speed

Microcontroller family. A device operating in this mode can access up to 64 KB of program and data

memory. The device defaults to this mode following any reset.

22-bit paged address mode

The 22-bit paged address mode retains binary code compatibility with the 8051 instruction set, but adds

one machine cycle to the ACALL, LCALL, RET and RETI instructions with respect to the Dallas

Semiconductor High-Speed Microcontroller family timing. This is transparent to standard 8051

compilers. Interrupt latency is also increased by one machine cycle. In this mode, interrupt vectors are

fetched from 0000xxh.

22-bit contiguous address mode

The 22-bit contiguous addressing mode uses a full 22-bit program counter, and all modified branching

instructions automatically save and restore the entire program counter. The 22-bit branching instructions

such as ACALL, AJMP, LCALL, LJMP, MOV DPTR, RET and RETI instructions require an assembler,

compiler and linker that specifically supports these features. The INC DPTR is lengthened by one cycle

but remains byte count compatible with the standard 8051 instruction set.

Internally, the device uses a 22-bit program counter. The lowest order 22 bits are used for memory

addressing, with a special 23rd bit used to map the 4KB SRAM above the 4 MB memory space in

bootstrap loader applications. Address bits 16-23 for the 22-bit addressing modes are generated via

additional SFRs dependent on the type of instruction as shown below.

EXTENDED ADDRESS GENERATION: Table 2

Address bits 23-16 Address bits 15-8 Address bits 7-0

MOVX instructions using DPTR DPX;93h DPH;83h DPL;82h

MOVX instructions using DPTR1 DPX1;95h DPH1;85h DPL1;84h

MOVX instructions using @Ri MXAX;EAh P2;A0h Ri

Addressing program memory in

22-bit paged mode

10-bit stack pointer mode -- ESP;9Bh SP;81h

AP;9Ch -- --

12 of 58 110199

Page 13

DS80C390

INTERNAL MOVX SRAM

The DS80C390 contains 4kB of SRAM that can be configured as user accessible MOVX memory,

program memory, or optional stack memory. The specific configuration and locations are governed by the

Internal Data Memory Configuration bits (IDM1, IDM0) in the Memory Control Register (MCON;C6h).

Note that when the SA bit (ACON.2) is set, the first 1kB of the MOVX data memory is reserved for use

by the 10-bit expanded stack. Internal memory accesses will not generate WR , RD , or PSEN strobes.

The DS80C390 can configure its 4kB of internal SRAM as combined program and data memory. This

allows the application software to execute self-modifiable code. The technique loads the 4kB SRAM

with bootstrap loader software, and then modifies the IDM1 and IDM0 bits to map the 4kB starting at

memory location 40000h. This allows the system to run the bootstrap loader without disturbing the 4 MB

external memory bus, making the device in-system reprogrammable for Flash or NV RAM.

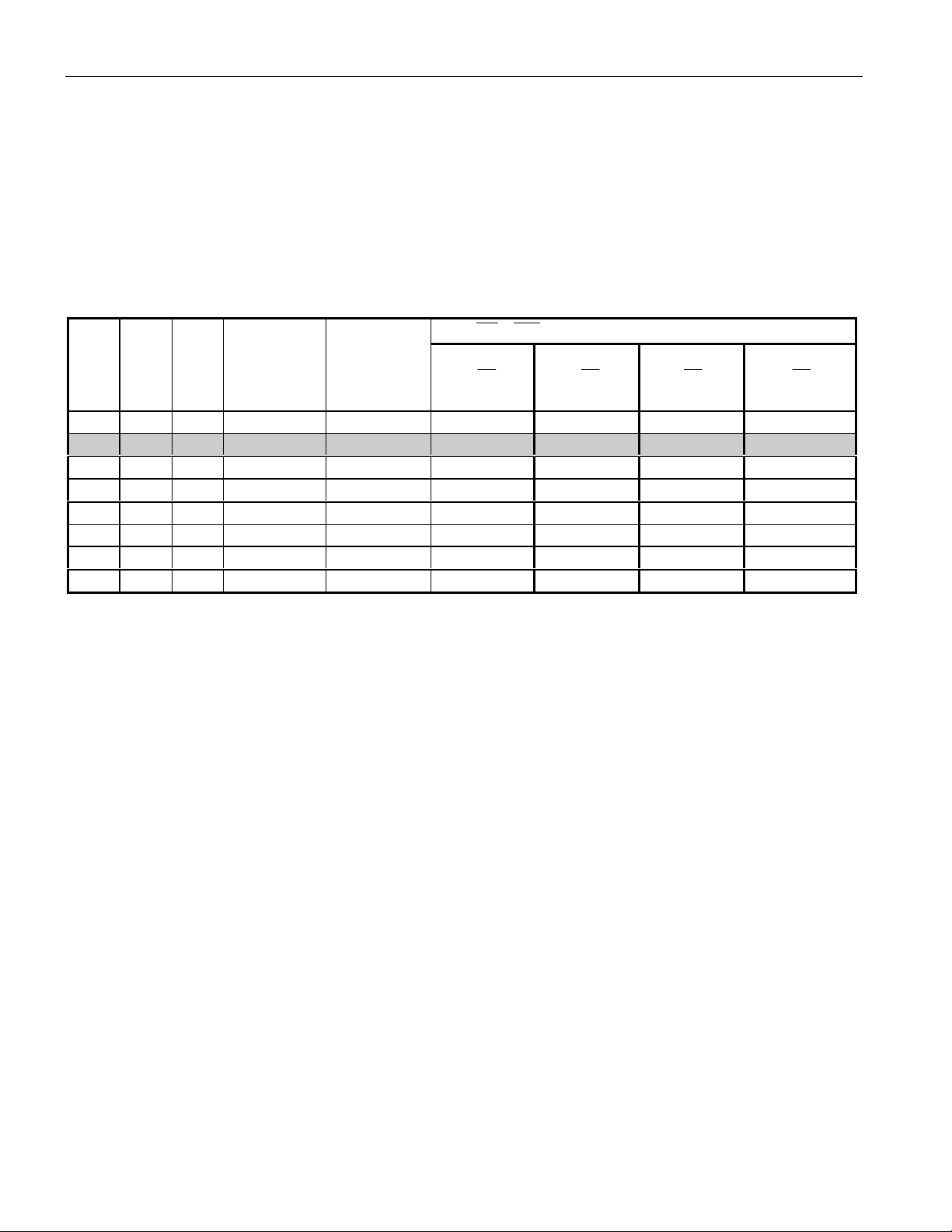

INTERNAL MOVX SRAM CONFIGURATION Table 4

IDM1 IDM0 CMA MOVX Data Memory CAN Message

Memory

0 0 0 00F000h-00FFFFh 00EE00h-00EFFFh - 0 0 1 00F000h-00FFFFh 401000h-4011FFh - 0 1 0 000000h-000FFFh 00EE00h-00EFFFh - 0 1 1 000000h-000FFFh 401000h-4011FFh - 1 0 0 400000h-400FFFh 00EE00h-00EFFFh - 1 0 1 400000h-400FFFh 401000h-4011FFh - 1 1 0 - - 00EE00h-00EFFFh 400000h-400FFFh*

1 1 1 - - 401000h-4011FFh 400000h-400FFFh*

*10-bit expanded stack not available in Shared Program /Data Memory mode.

Shared Program /Data

Memory

EXTERNAL MEMORY ADDRESSING

The enabling and mapping of the chip enable signals is done via the Port 4 Control Register (P4CNT;92h)

and Memory Control Register (MCON; 96h); The Extended Address and Chip Enable Generation Table

shows which chip enable and address line signals are active on Port 4. Following reset, the device will be

configured with P4.7-P4.4 as address lines and P4.3-P4.0 configured as 0-CE3 , with the first program

fetch being performed from 00000h with CE0 active. The following tables illustrate which memory

ranges are controlled by each chip enable as a function of which address lines are enabled.

EXTERNAL MEMORY ADDRESSING PIN ASSIGNMENTS Table 5

Address/Data Bus

CE3 -CE0 PCE3 - PCE0

Multiplexed P4.3-P4.0 P5.7-P5.4 P4.7-P4.4 P2 P0 P0

Demultiplexed P4.3-P4.0 P5.7-P5.4 P4.7-P4.4 P2 P1 P0

Addr 19-16 Addr 15-8 Addr 7-0 Data Bus

EXTENDED ADDRESS AND CHIP ENABLE GENERATION Table 6

Port 4 Pin Function Port 4 Pin Function

P4CNT.5-3 P4.7 P4.6 P4.5 P4.4 P4CNT.2-0 P4.3 P4.2 P4.1 P4.0

000 I/O I/O I/O I/O 000 I/O I/O I/O I/O

100 I/O I/O I/O A16 100 I/O I/O I/O

101 I/O I/O A17 A16 101 I/O I/O

110 I/O A18 A17 A16 110 I/O

111(default) A19 A18 A17 A16 111(default)

CE3 CE2 CE1 CE0

CE2 CE1 CE0

13 of 58 110199

CE1 CE0

CE0

Page 14

DS80C390

PROGRAM MEMORY CHIP ENABLE BOUNDARIES Table 7

P4CNT.5-3

000 0h-7FFFh 8000h-FFFFh 10000h-17FFFh 18000h-1FFFFh

100 0h-1FFFFh 20000h-3FFFFh 40000h-5FFFFh 60000h-7FFFFh

101 0h-3FFFFh 40000h-7FFFFh 80000h-BFFFFh C0000h-FFFFFh

110 0h-7FFFFh 80000h-FFFFFh 100000h-17FFFFh 180000h-1FFFFFh

111(default) 0-FFFFFh 100000h-1FFFFFh 200000h-2FFFFFh 300000h-3FFFFFh

The DS80C390 incorporates a feature allowing PCE and CE signals to be combined. This is useful when

incorporating modifiable code memory as part of a bootstrap loader or for in-system reprogrammability.

Setting the 0PDCE3 − (MCON.3-0) bits causes the corresponding chip enable signal to function for both

MOVC and MOVX operations. Write access to combined program and data memory blocks is controlled

by the WR signal, and read access is controlled by the PSEN signal. This feature is especially useful if

the design achieves in-system reprogrammability via external Flash memory, in which a single device is

accessed via both MOVC instructions (program fetch) and MOVX Write operations (updates to code

memory). In this case, the internal SRAM is placed in the program/data configuration and loaded with a

small bootstrap loader program stored in the external Flash memory. The device then executes the

internal bootstrap loader routine to modify/update the program memory located in the external Flash

memory.

CE0 CE1 CE2 CE3

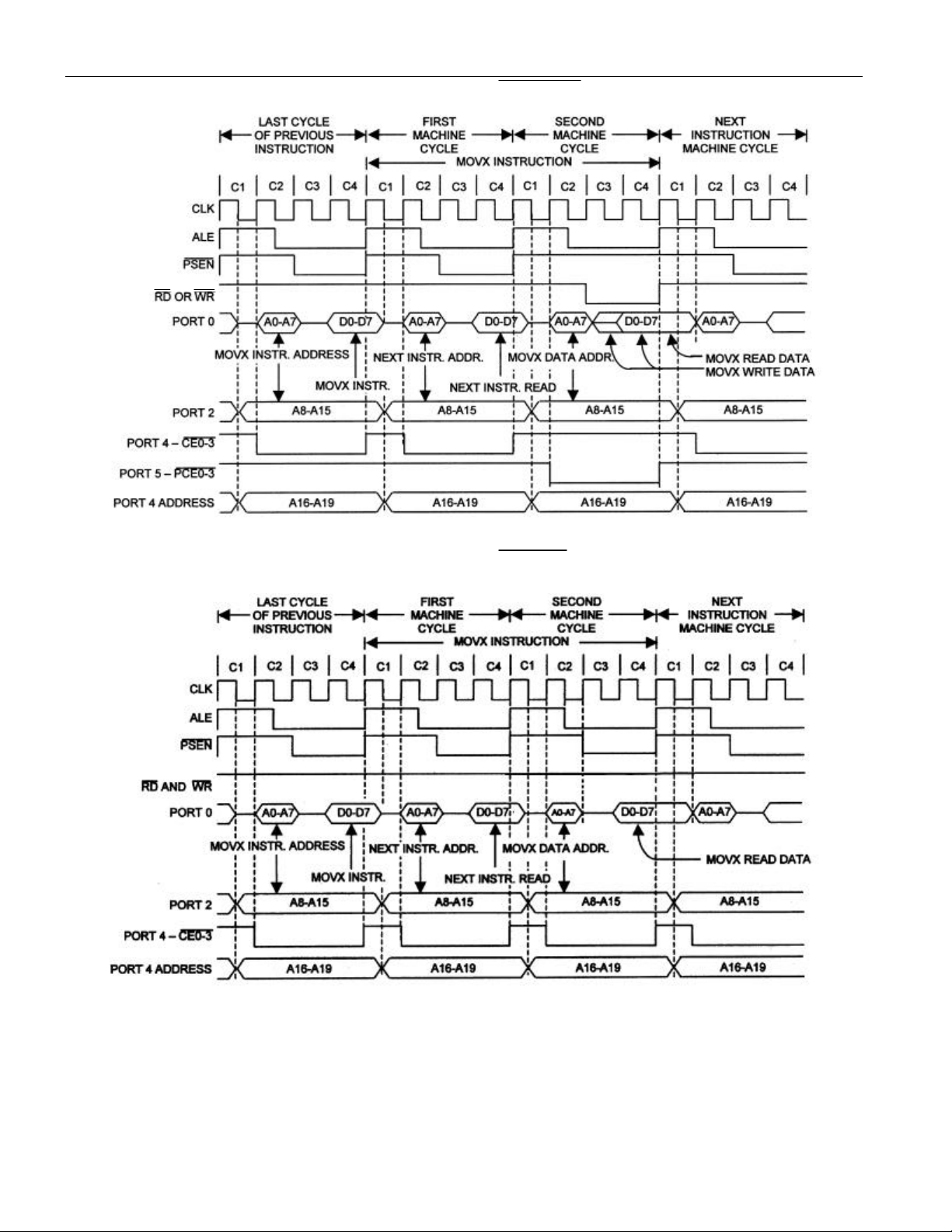

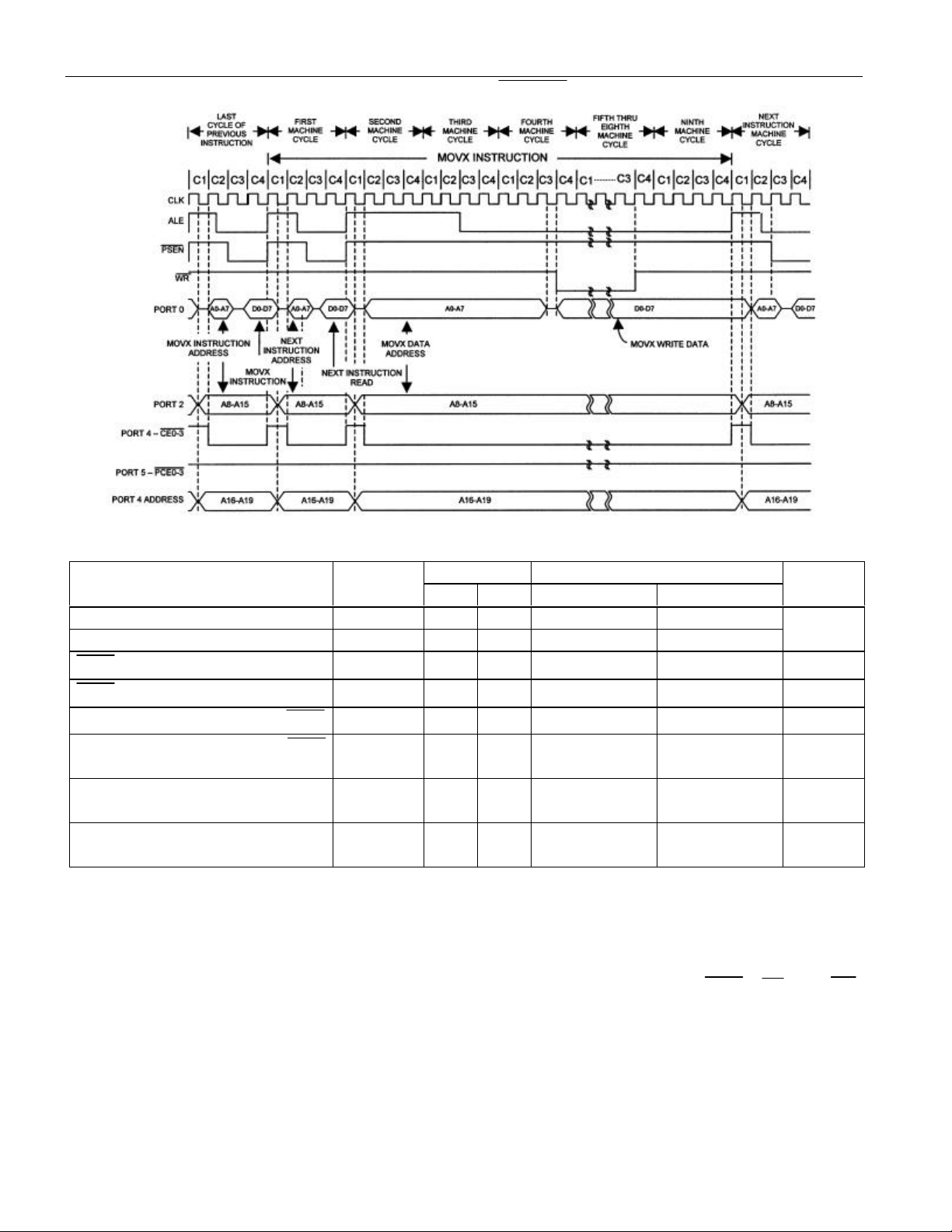

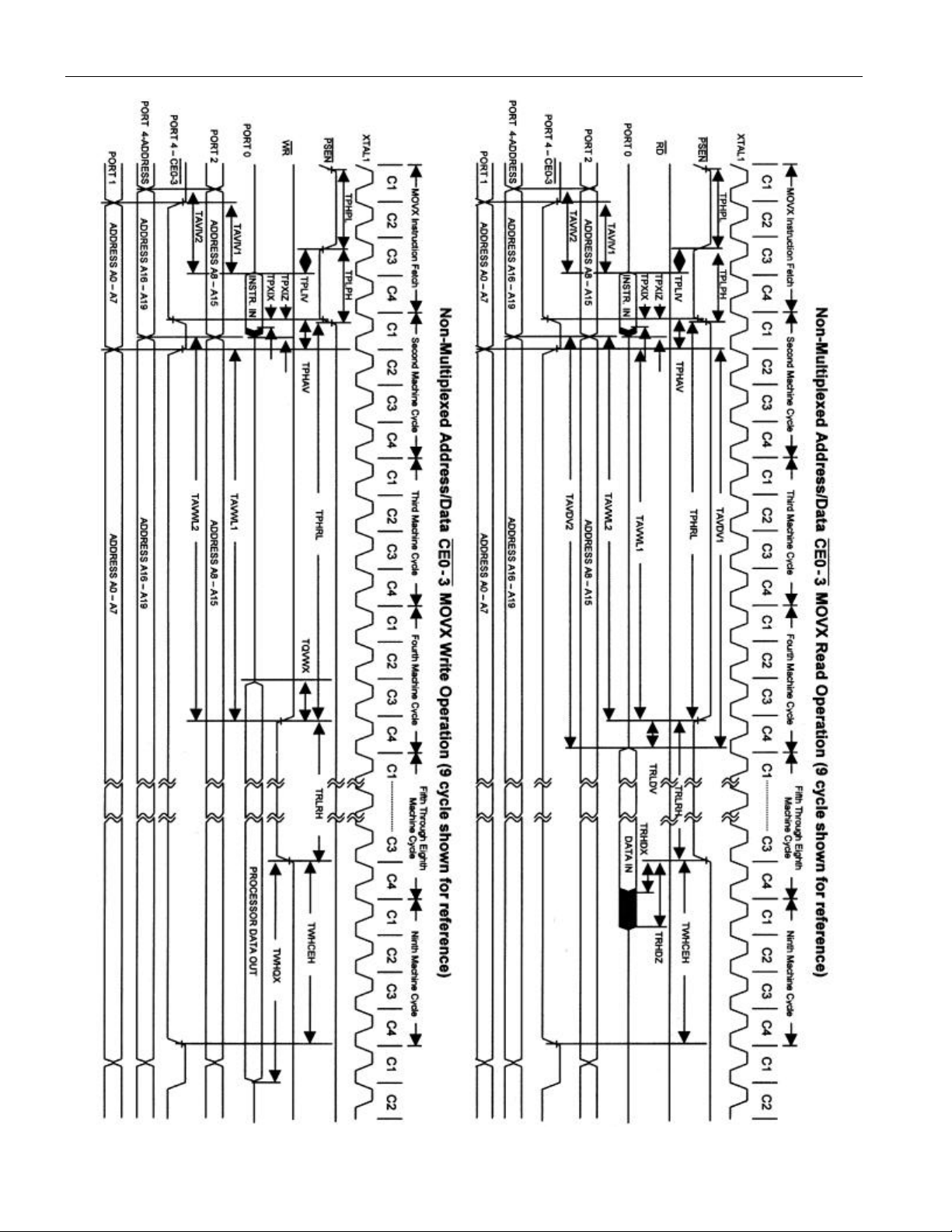

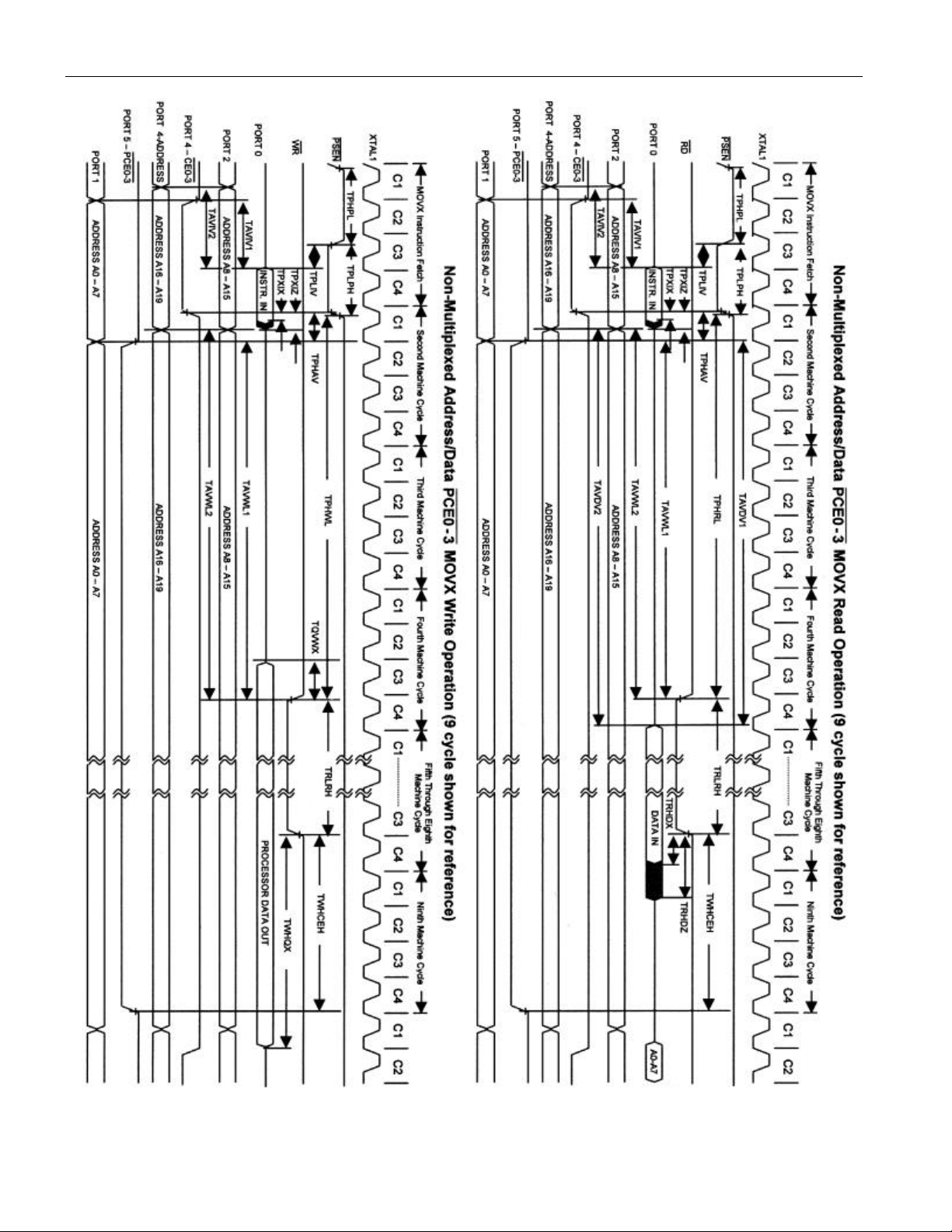

STRETCH MEMORY CYCLES

The DS80C390 allows user application software to select the number of machine cycles it takes to

execute a MOVX instruction, allowing access to both fast and slow off-chip data memory and/or

peripherals without glue logic. High-speed systems often include memory-mapped peripherals such as

LCDs or UARTs with slow access times, so it may not be necessary or desirable to access external

devices at full speed. The microprocessor can perform a MOVX instruction in as little as two machine

cycles or as many as twelve machine cycles. Accesses to internal MOVX SRAM always use two cycles.

Note that stretch cycle settings affect external MOVX memory operations only and that there is no way to

slow the accesses to program memory other than to use a slower crystal (or external clock).

External MOVX timing is governed by the selection of 0 to 7 Stretch cycles, controlled by the MD2-MD0

SFR bits in the Clock Control Register (CKCON.2-0). A Stretch of zero will result in a two-machine

cycle MOVX instruction. A Stretch of seven will result in a MOVX of twelve machine cycles. Software

can dynamically change the Stretch value depending on the particular memory or peripheral being

accessed. The default of one Stretch cycle allows the use of commonly available SRAMs without

dramatically lengthening the memory access times.

Stretch cycle settings affect external MOVX timing in three gradations. Changing the Stretch value from

0 to 1 adds an additional clock cycle each to the data setup and hold times. When a Stretch value of 4 or

above is selected, the interface timing changes dramatically to allow for very slow peripherals. First, the

ALE signal is lengthened by 1 machine cycle. This increases the address setup time into the peripheral

by this amount. Next, the address is held on the bus for one additional machine cycle increasing the

address hold time by this amount. The WR and RD signals are then lengthened by a machine cycle.

Finally, during a MOVX write the data is held on the bus for one additional machine cycle, thereby

increasing the data hold time by this amount. For every Stretch value greater than 4, the setup and hold

times remain constant, and only the width of the read or write signal is increased. These three gradations

are reflected in the AC Electrical characteristics, where the eight MOVX timing specifications are

represented by only three timing diagrams.

14 of 58 110199

Page 15

DS80C390

The reset default of one Stretch cycle results in a three cycle MOVX for any external access. Therefore,

the default off-chip RAM access is not at full speed. This is a convenience to existing designs that utilize

slower RAM. When maximum speed is desired, software should select a Stretch value of zero. When

using very slow RAM or peripherals, the application software can select a larger Stretch value.

The specific timing of MOVX instructions as a function of Stretch settings is provided in the Electrical

Specifications section of this data sheet. As an example, Table 8 shows the read and write strobe widths

corresponding to each Stretch value.

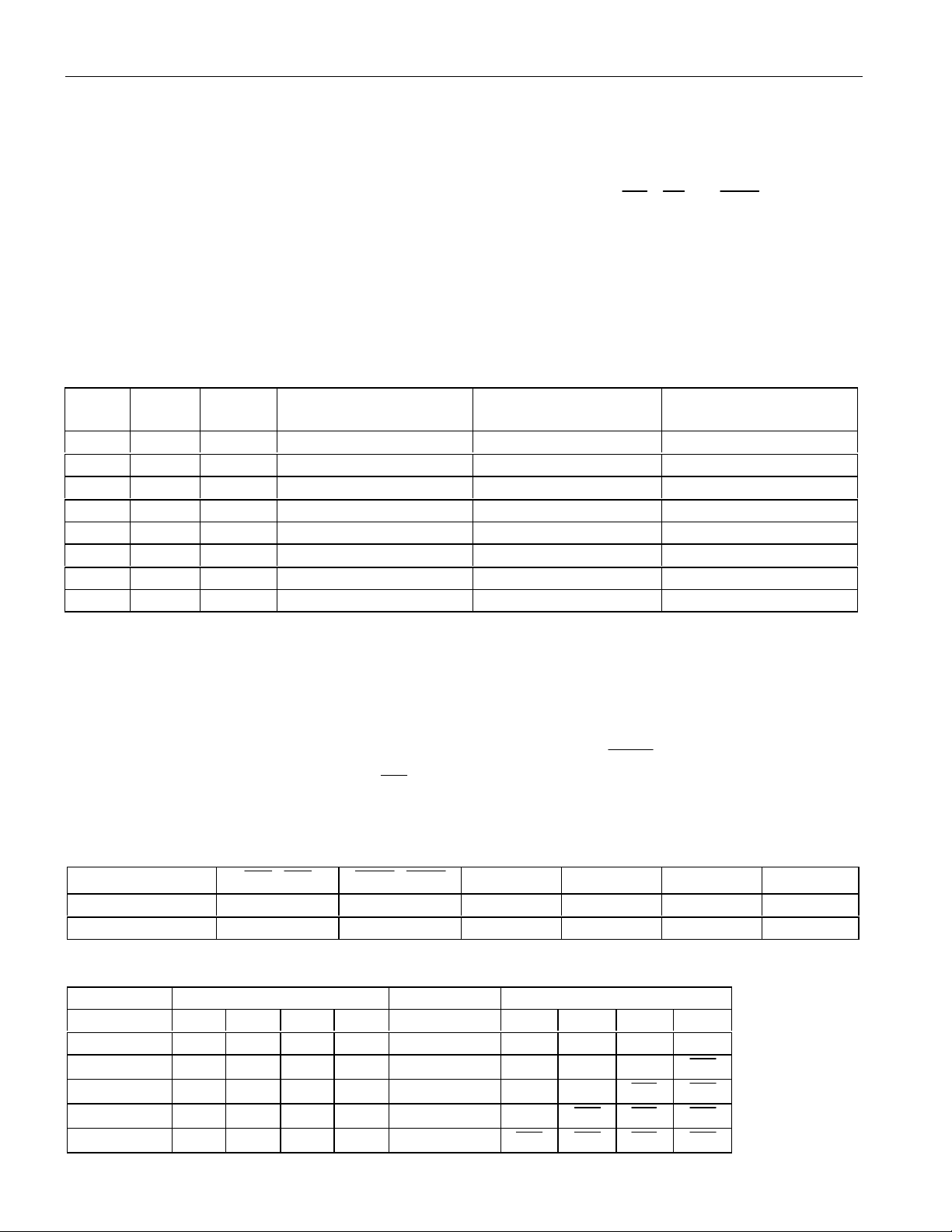

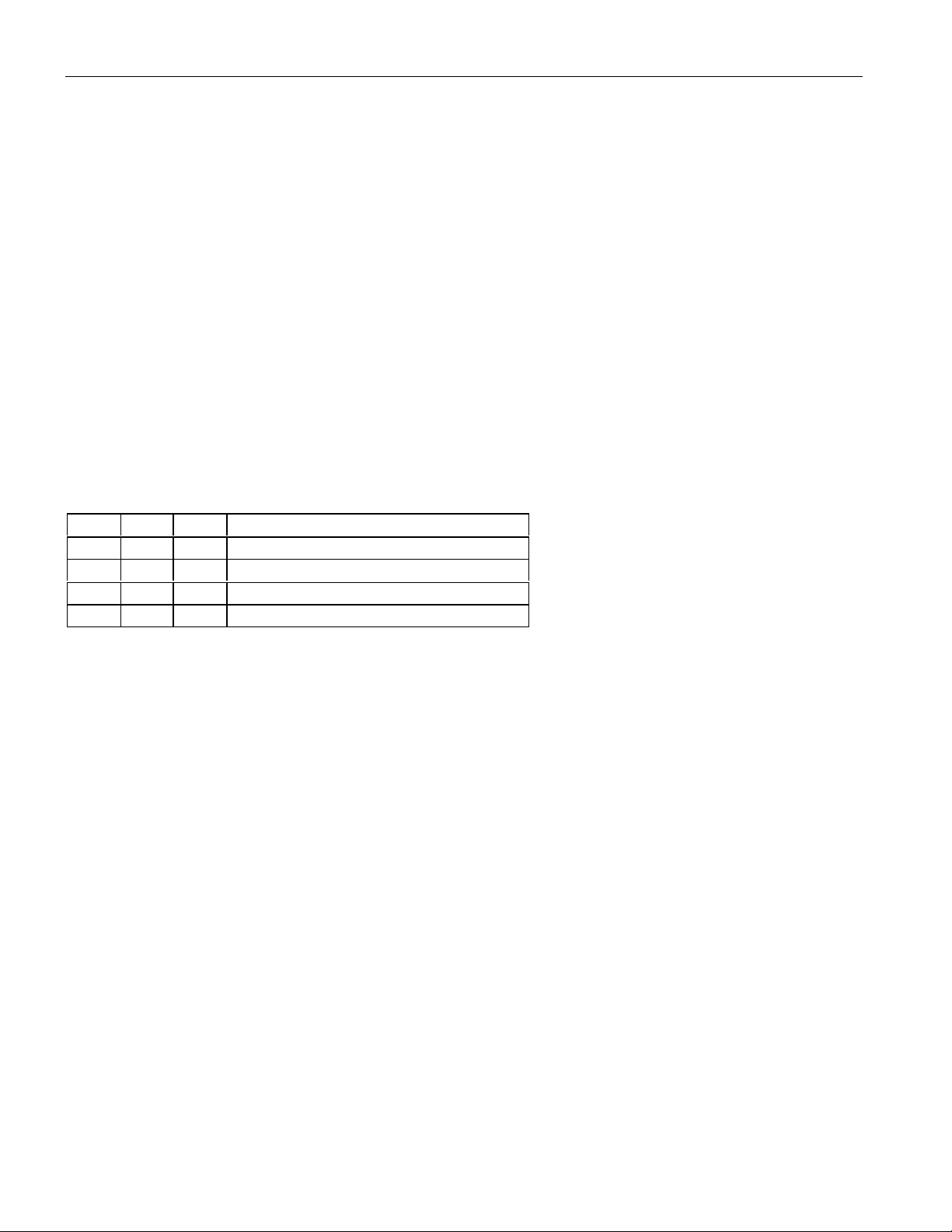

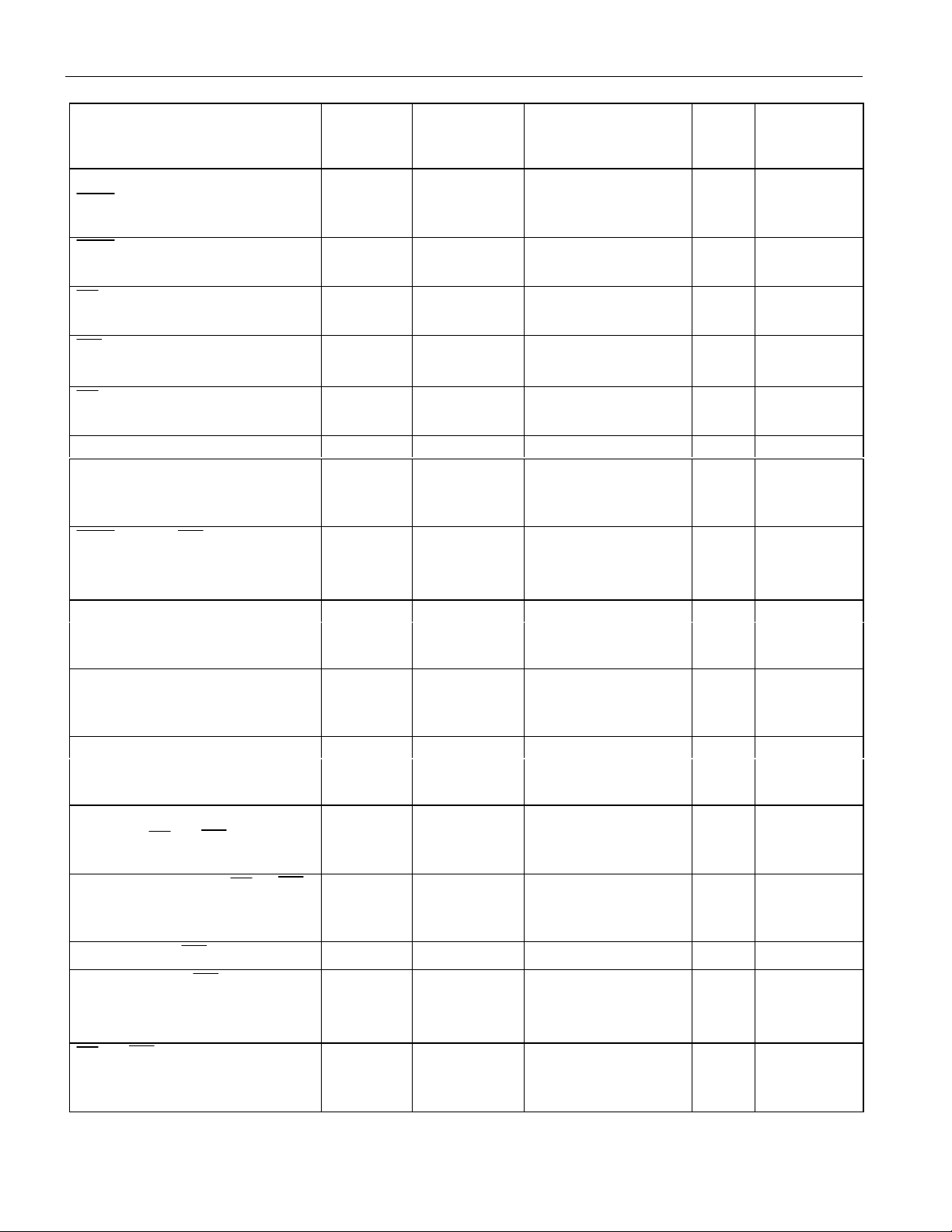

DATA MEMORY CYCLE STRETCH VALUES Table 8

MD2 MD1 MD0 Stretch

Cycle

Count

0 0 0 0* 2 0.5 t

0 0 1 1** 3 t

0 1 0 2 4 2 t

0 1 1 3 5 3 t

1 0 0 4 9 4 t

1 0 1 5 10 5 t

1 1 0 6 11 6 t

1 1 1 7 12 7 t

*All internal MOVX operations execute at the 0 Stretch setting.

** Default Stretch setting for external MOVX operations following reset.

MOVX

Machine

Cycles

RD, WR Pulse Width (in oscillator clocks)

t

MCS

(4X/ 2X = 1

CD1:0 = 00)

CLCL

CLCL

CLCL

CLCL

CLCL

CLCL

CLCL

CLCL

t

MCS

(4X/ 2X = 0

CD1:0 = 00)

1 t

CLCL

2 t

CLCL

4 t

CLCL

6 t

CLCL

8 t

CLCL

10 t

CLCL

12 t

CLCL

14 t

CLCL

t

MCS

(4X/ 2X = X

CD1:0 = 10)

2 t

CLCL

4 t

CLCL

8 t

CLCL

12 t

CLCL

16 t

CLCL

20 t

CLCL

24 t

CLCL

28 t

CLCL

t

MCS

(4X/ 2X = X

CD1:0 = 11)

2048 t

CLCL

4096 t

CLCL

8192 t

CLCL

12288 t

16384 t

20480 t

24576 t

28672 t

CLCL

CLCL

CLCL

CLCL

CLCL

EXTENDED STACK POINTER

The DS80C390 supports both the traditional 8-bit and an extended 10-bit stack pointer that improves the

performance of large programs written in high-level languages such as C. The 10-bit stack pointer

feature is enabled by setting the Stack Address Mode bit, SA (ACON.2). The bit is cleared following a

reset, forcing the device to use an 8-bit stack located in the Scratchpad RAM area. When the SA bit is

set, the device will address up to 1kB of stack memory in the first 1kB of the internal MOVX memory.

The 10-bit stack pointer address is generated by concatenating the lower two bits of the Extended Stack

Pointer (ESP;9Bh) and the traditional 8051 Stack Pointer (SP;81h). The 10-bit stack pointer cannot be

enabled when the 4kB of SRAM is mapped as both program and data memory.

15 of 58 110199

Page 16

DS80C390

ENHANCED DUAL DATA POINTERS

The DS80C390 contains two data pointers, DPTR0 and DPTR1, designed to improve performance in

applications that require high data throughput. Incorporating a second data pointer allows the software to

greatly speed up block data (MOVX) moves by using one data pointer as a source register and the other

as the destination register.

DPTR0 is located at the same address as the original 8051 data pointer, allowing the DS80C390 to

execute standard 8051 code with no modifications. The second data pointer, DPTR1, is split between the

DPH1 and DPL1 SFRs, similar to the DPTR0 configuration. The active data pointer is selected with the

data pointer select bit SEL (DPS.0). Any instructions that reference the DPTR (i.e., MOVX A, @DPTR),

will select DPTR0 if SEL=0, and DPTR1 if SEL=1. Because the bits adjacent to SEL are not

implemented, the state of SEL (and thus the active data pointer) can be quickly toggled by the INC DPS

instruction without disturbing other bits in the DPS register.

Unlike the standard 8051, the DS80C390 has the ability to decrement as well as increment the data

pointers without additional instructions. When the INC DPTR instruction is executed, the active DPTR

increments or decrements according to the ID1, ID0 (DPS.7-6), and SEL (DPS.0) bits as shown. The

inactive DPTR is not affected.

DATA POINTER AUTOINCREMENT/DECREMENT CONFIGURATION Table 9

ID1 ID0 SEL Result of INC DPTR

X 0 0 Increment DPTR0

X 1 0 Decrement DPTR0

0 X 1 Increment DPTR1

1 X 1 Decrement DPTR1

Another useful feature of the device is its ability to automatically switch the active data pointer after a

DPTR-based instruction is executed. This feature can greatly reduce the software overhead associated

with data memory block moves, which toggle between the source and destination registers. When the

Toggle Select bit (TSL;DPS.5) is set to 1, the SEL bit (DPS.0) is automatically toggled every time one of

the following DPTR related instructions is executed.

INC DPTR

MOV DPTR, #data16

MOVC A, @A+DPTR

MOVX A, @DPTR

MOVX @DPTR, A

As a brief example, if TSL is set to 1, then both data pointers can be updated with two INC DPTR

instructions. Assume that SEL=0, making DPTR the active data pointer. The first INC DPTR increments

DPTR and toggles SEL to 1. The second instruction increments DPTR1 and toggles SEL back to 0.

INC DPTR

INC DPTR

CLOCK CONTROL AND POWER MANAGEMENT

The DS80C390 includes a number of unique features that allow flexibility in selecting system clock

sources and operating frequencies. To support the use of inexpensive crystals while allowing full speed

operation, a clock multiplier is included in the processor’s clock circuit. Also, in addition to the standard

16 of 58 110199

Page 17

DS80C390

80C32 Idle and power down (Stop) modes, the DS80C390 provides a new Power Management Mode.

This mode allows the processor to continue instruction execution, yet at a very low speed to significantly

reduce power consumption (below even Idle mode). The DS80C390 also features several enhancements

to Stop mode that make this extremely low power mode more useful. Each of these features is discussed

in detail below.

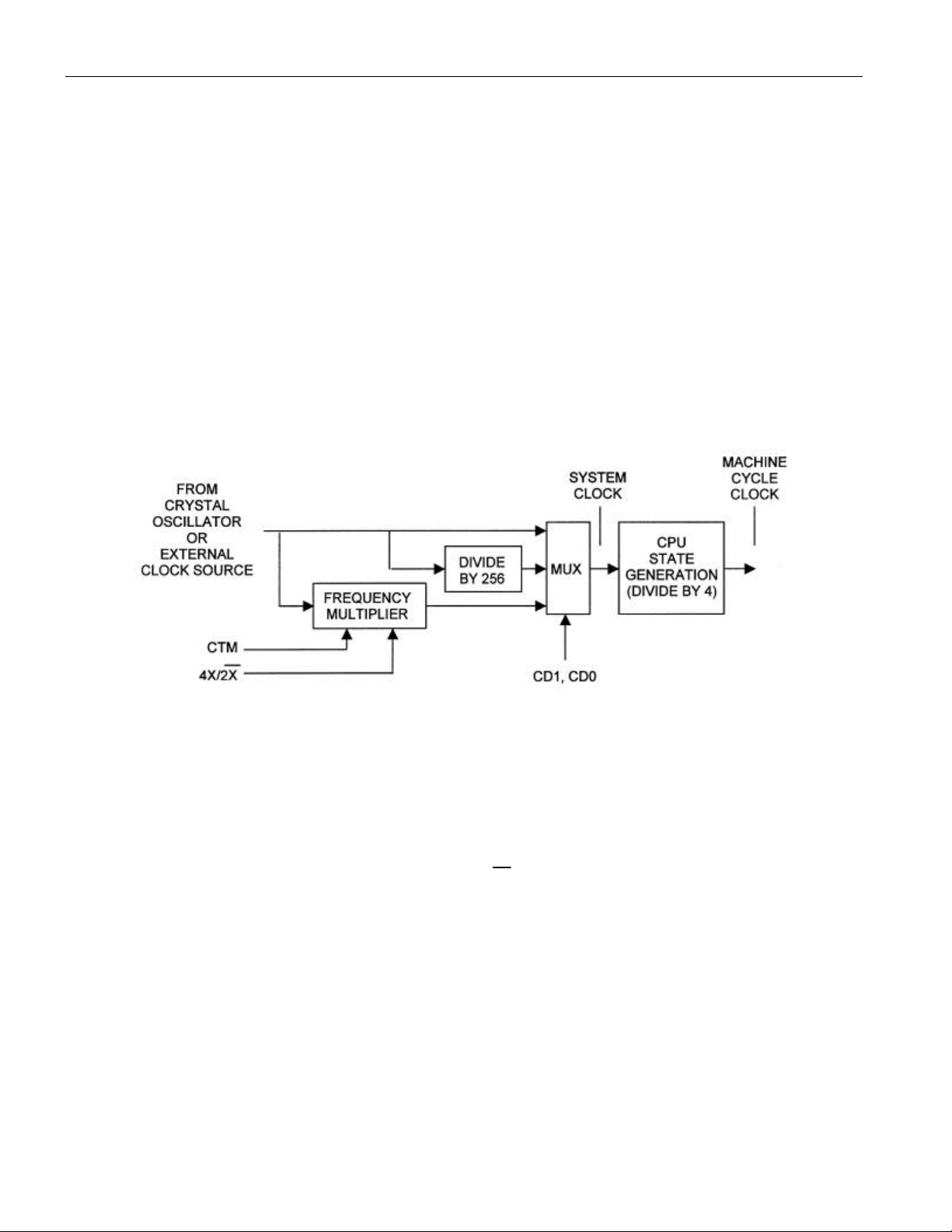

SYSTEM CLOCK CONTROL

As mentioned previously, the microcontroller contains special clock control circuitry that simultaneously

provides maximum timing flexibility and maximum availability and economy in crystal selection. The

logical operation of the system clock divide control function is shown in Figure 2. A 3:1 multiplexer,

controlled by CD1, CD0 (PMR.7-6), selects one of three sources for the internal system clock:

§ Crystal oscillator or external clock source

§ (Crystal oscillator or external clock source) divided by 256

§ (Crystal oscillator or external clock source) frequency multiplied by 2 or 4 times.

SYSTEM CLOCK CONTROL DIAGRAM Figure 2

The system clock control circuitry generates two clock signals that are used by the microcontroller. The

internal system clock provides the timebase for timers and internal peripherals. The system clock is run

through a divide by 4 circuit to generate the machine cycle clock that provides the timebase for CPU

operations. All instructions execute in one to five machine cycles. It is important to note the distinction

between these two clock signals, as they are sometimes confused, creating errors in timing calculations.

Setting CD1, CD0 to 0 enables the frequency multiplier, either doubling or quadrupling the frequency of

the crystal oscillator or external clock source. The 2X4X/ bit controls the multiplying factor, selecting

twice or four times the frequency when set to 0 or 1, respectively. Enabling the frequency multiplier

results in apparent instruction execution speeds of 2 or 1 clocks. Regardless of the configuration of the

frequency multiplier, the system clock of the microcontroller can never be operated faster than 40 MHz.

This means that the maximum crystal oscillator or external clock source is 10 MHz when using the 4X

setting, and 20 MHz when using the 2X setting.

The primary advantage of the clock multiplier is that it allows the microcontroller to use slower crystals

to achieve the same performance level. This reduces EMI and cost, as slower crystals are generally more

available and thus less expensive.

17 of 58 110199

Page 18

DS80C390

SYSTEM CLOCK CONFIGURATION Table 10

CD1 CD0

0 0 0 Frequency Multiplier (2X) 2 20 MHz

0 0 1 Frequency Multiplier (4X) 1 10 MHz

0 1 N/A Reserved

1 0 N/A Divide-by-four (Default) 4 40 MHz

1 1 N/A Power Management Mode 1024 40 MHz

The system clock and machine cycle rate changes one machine cycle after the instruction changing the

control bits. Note that the change will affect all aspects of system operation, including timers and baud

rates. The use of the switchback feature, described later, can eliminate many of the problems associated

with the Power Management Mode.

Changing the system clock/machine cycle clock frequency

The microcontroller incorporates a special locking sequence to ensure “glitch-free” switching of the

internal clock signals. All changes to the CD1, CD0 bits must pass through the 10 (divide-by-four) state.

For example, to change from 00 (frequency multiplier) to 11 (PMM), the software must change the bits in

the following sequence: 00 -> 10 -> 11. Attempts to switch between invalid states will fail, leaving the

CD1, CD0 bits unchanged.

The following sequence must be followed when switching to the frequency multiplier as the internal time

source. This sequence can only be performed when the device is in divide-by-four operation. The steps

must be followed in this order, although it is possible to have other instructions between them. Any

deviation from this order will cause the CD1, CD0 bits to remain unchanged. Switching from frequency

multiplier to non-multiplier mode requires no steps other than the changing of the CD1, CD0 bits.

2X4X/

Name Clocks/MC Max. External Frequency

1. Ensure that the CD1, CD0 bits are set to 10, and the RGMD (EXIF.2) bit = 0.

2. Clear the CTM (Crystal Multiplier Enable) bit.

3. Set the 2X4X/ bit to the appropriate state.

4. Set the CTM (Crystal Multiplier Enable) bit.

5. Poll the CKRDY bit (EXIF.4), waiting until it is set to 1. This will take approximately 65536 cycles

of the external crystal or clock source.

6. Set CD1, CD0 to 00. The frequency multiplier will be engaged on the machine cycle following the

write to these bits.

OSCILLATOR FAIL DETECT

The microprocessor contains a safety mechanism called an on-chip Oscillator Fail Detect circuit. When

enabled, this circuit causes the processor to be held in reset if the oscillator frequency falls below TBD

kHz. In operation, this circuit complements the Watchdog timer. Normally, the watchdog timer is

initialized so that it will time-out and will cause a processor reset in the event that the processor loses

control. In the event of a crystal or external oscillator failure, however, the watchdog timer will not

function and there is the potential for the processor to fail in an uncontrolled state. The use of the

oscillator fail detect circuit forces the processor to a known state (i.e., reset) even if the oscillator stops.

The oscillator fail detect circuitry is enabled when software sets the enable bit OFDE (PCON.4) to a 1.

Please note that software must use a “Timed Access” procedure (described later) to write this bit. The

OFDF (PCON.5) bit will also be set to a 1 when the circuitry detects an oscillator failure, and the

processor is forced into a reset state. This bit can only be cleared to a 0 by a power fail reset or by

software. The oscillator fail detect circuitry will not be activated when the oscillator is stopped due to the

processor entering Stop mode.

18 of 58 110199

Page 19

DS80C390

POWER MANAGEMENT MODE (PMM)

Machine Cycle Rate Operating Current Estimates

Full Operation

Crystal Speed

11.0592 MHz 2.765 MHz 10.8 kHz 13.1 ma 4.8 ma

16 MHz 4.0 MHz 15.6 kHz 17.2 ma 5.6 ma

25 MHz 6.25 MHz 24.4 kHz 25.7 ma 7.0 ma

33 MHz 8.25 MHz 32.2 kHz 32.8 ma 8.2 ma

40 MHz 10.0 MHz 39.1 kHz TBD TBD

Note that power consumption in PMM is less than Idle mode. While both modes leave the power-hungry

internal timers running, PMM runs all clocked functions such as timers at the rate of crystal divided by

1024, rather than crystal divided by 4. Even though instruction execution continues in PMM (albeit at a

reduced speed), it still consumes less power than Idle mode. As a result there is little reason to use Idle

mode in new designs.

(4 clocks per

machine cycle)

PMM

(1024 clocks per

machine cycle)

Full Operation

(4 clocks per

machine cycle)

PMM

(1024 clocks per

machine cycle)

SWITCHBACK

When enabled, the Switchback feature allows serial ports and interrupts to automatically switch back

from divide by 1024 (PMM) to divide by 4 (standard speed) operation. This feature makes it very

convenient to use the Power Management Mode in real-time applications. Software can simply set the

CD1 and CD0 clock control bits to the 4 clocks per cycle mode to exit PMM. However, the

microcontroller provides hardware alternatives for automatic Switchback to standard speed (divide by 4)

operation.

The Switchback feature is enabled by setting the SFR bit SWB (PMR.5) to a 1. Once it is enabled, and

when PMM is selected, two possible events can cause an automatic Switchback to divide by four mode.

First, if an interrupt occurs and is acknowledged, the system clock will revert from PMM to divide by

four mode. For example, if INT0 is enabled and the CPU is not servicing a higher priority interrupt, then

Switchback will occur on INT0 . However, if INT0 is not enabled or the CPU is servicing a higher

priority interrupt, then activity on INT0 will not cause Switchback to occur.

A Switchback can also occur when an enabled UART detects the start bit indicating the beginning of an

incoming serial character or when the SBUF register is loaded initiating a serial transmission. Note that a

serial character’s start bit does not generate an interrupt. The interrupt occurs only on reception of a

complete serial word. The automatic Switchback on detection of a start bit allows timer hardware to

return to divide by 4 operation (and the correct baud rate) in time for a proper serial reception or

transmission. So with Switchback enabled and a serial port enabled, the automatic switch to divide by 4

operation occurs in time to receive or transmit a complete serial character as if nothing special had

happened.

STATUS

The Status register (STATUS ;C5h) provides information about interrupt and serial port activity to assist

in determining if it is possible to enter PMM. The microprocessor supports three levels of interrupt

priority: Power-fail, High, and Low. The PIP (Power-fail Priority Interrupt Status; STATUS.7), HIP

(High Priority Interrupt Status; STATUS.6), and LIP (Low Priority Interrupt Status; STATUS.5) status

bits, when set to a logic one, indicate the corresponding level is in service.

19 of 58 110199

Page 20

DS80C390

Software should not rely on a lower-priority level interrupt source to remove PMM (Switchback) when a

higher level is in service. Check the current priority service level before entering PMM. If the current

service level locks out a desired Switchback source, then it would be advisable to wait until this condition

clears before entering PMM. Alternately, software can prevent an undesired exit from PMM by

intentionally entering a low priority interrupt service level before entering PMM. This will prevent other

low priority interrupts from causing a Switchback.

Entering PMM during an ongoing serial port transmission or reception can corrupt the serial port activity.

To prevent this, a hardware lockout feature ignores changes to the clock divisor bits while the serial ports

are active. Serial port activity can be monitored via the Serial Port Activity bits located in the Status

register.

IDLE MODE

Setting the IDLE bit (PCON.0) invokes the Idle mode. Idle will leave internal clocks, serial ports and

timers running. Power consumption drops because memory is not being accessed and instructions are not

being executed. Since clocks are running, the Idle power consumption is a function of crystal frequency.

It should be approximately ½ of the operational power at a given frequency. The CPU can exit Idle mode

with any interrupt or a reset. Because Power Management Mode (PMM) consumes less power than Idle

mode, as well as leaving timers and CPU operating, Idle mode is no longer recommended for new

designs, and is included for backward software compatibility only.

STOP MODE

Setting the STOP bit of the Power Control register (PCON.1) invokes Stop mode. Stop mode is the

lowest power state (besides power off) since it turns off all internal clocking. The ICC of a standard Stop

mode is approximately 1 µA (consult the Electrical Specifications section for full details). All processor

operation ceases at the end of the instruction that sets the STOP bit. The CPU can exit Stop mode via an

external interrupt, if enabled, or a reset condition. Internally generated interrupts (timer, serial port,

watchdog) cannot cause an exit from Stop mode because internal clocks are not active in Stop mode.

BAND-GAP SELECT

The DS80C390 provides two enhancements to Stop mode. As described below, the device provides a

band-gap reference to determine Power-fail Interrupt and Reset thresholds. The band-gap reference is

controlled by the Band-Gap Select bit, BGS (RCON.0). Setting BGS to a 1 will keep the band-gap

reference enabled during Stop mode. The default or reset condition of the bit is logic 0, which disables

the band-gap during Stop mode. This bit has no control of the reference during full power, PMM, or Idle

modes.

With the band-gap reference enabled, the Power-fail reset and interrupt are valid means for leaving Stop

mode. This allows software to detect and compensate for a power supply sag or brownout, even when in

Stop mode. In Stop mode with the band-gap enabled, ICC will be approximately 100 µA compared with 1

µA with the band-gap disabled. If a user does not require a Power-fail Reset or Interrupt while in Stop

mode, the band-gap can remain disabled. Only the most power sensitive applications should disable the

band-gap reference in Stop mode, as this results in an uncontrolled power down condition.

RING OSCILLATOR

The second enhancement to Stop mode reduces power consumption and allows the device to restart

instantly when exiting Stop mode. The ring oscillator is an internal clock that can optionally provide the

clock source to the microcontroller when exiting Stop mode in response to an interrupt.

20 of 58 110199

Page 21

DS80C390

During Stop mode the crystal oscillator is halted to maximize power savings. Typically 4 - 10 ms are

required for an external crystal to begin oscillating again once the device receives the exit stimulus. The

ring oscillator, by contrast, is a free-running digital oscillator that has no startup delay. The ring oscillator

feature is enabled by setting the Ring Oscillator Select bit, RGSL (EXIF.1). If enabled, the

microcontroller uses the ring oscillator as the clock source to exit Stop mode, resuming operation in less

than 100 ns. After 65536 oscillations of the external clock source (not the ring oscillator), the device will

clear the Ring Oscillator Mode bit, RGMD (EXIF.2) to indicate that the device has switched from the

ring oscillator to the external clock source.

The ring oscillator runs at approximately 10 MHz, but varies over temperature and voltage. As a result,

no serial communication or precision timing should be attempted while running from the ring oscillator

since the operating frequency is not precise. The default state exits Stop mode without using the ring

oscillator.

TIMED ACCESS PROTECTION

Selected SFR bits are critical to operation, making it desirable to protect them against an accidental write

operation. The Timed Access procedure prevents an errant processor from accidentally altering bits that

would seriously affect processor operation. The Timed Access procedure requires that the write of a

protected bit be immediately preceded by the following two instructions:

MOV 0C7h, #0AAh

MOV 0C7h, #55h

Writing an AAh followed by a 55h to the Timed Access register (location C7h), opens a three-cycle

window that allows software to modify one of the protected bits. If the instruction that seeks to modify

the protected bit is not immediately preceded by these instructions, the write will be ignored. The

protected bits are:

WDCON.6 POR Power-On Reset Flag

WDCON.3 WDIF Watchdog Interrupt Flag

WDCON.1 EWT Watchdog Reset Enable

WDCON.0 RWT Reset Watchdog Timer

RCON.0 BGS Band-Gap Select

ACON.2 SA Stack Address Mode

ACON.1-0 AM1-AM0 Address Mode Select bits

MCON.7-6 IDM1-IDM0 Internal Memory Configuration and Location bits

MCON.5 CMA CAN Data Memory Assignment

MCON.3-0 PDCE3-PDCE.0 Program/Data Chip Enables

C0C.3 CRST CAN 0 Reset

C1C.3 CRST CAN 1 Reset

P4CNT.6 SBCAN Single Bus CAN

P4CNT.5-0 Port 4 Pin Configuration Control Bits

P5CNT.2-0 P5.7-P5.5 Configuration Control Bits

COR.7 IRDACK IRDA Clock Output Enable

COR.6-5 C1BPR7-C1BPR6 CAN 1 Baud Rate Pre-scale Bits

COR.4-3 C0BPR7-C0BPR6 CAN 0 Baud Rate Pre-scale Bits

COR.2-1 COD1-COD0 CAN Clock Output Divide Bit 1 and Bit 0

COR.0 CLKOE CAN Clock Output Enable

21 of 58 110199

Page 22

DS80C390

EMI REDUCTION

One of the major contributors to radiated noise in an 8051-based system is the toggling of ALE. The

microcontroller allows software to disable ALE when not used by setting the ALEOFF (PMR.2) bit to a

1. When ALEOFF = 1, ALE will automatically toggle during an off-chip MOVX. However, ALE will

remain static when performing on-chip memory access. The default state of ALEOFF is 0 so ALE

normally toggles at a frequency of XTAL/4.

PERIPHERAL OVERVIEW

The DS80C390 provides several of the most commonly needed peripheral functions in microcomputerbased systems. New functions include a second serial port, power-fail reset, power-fail interrupt flag, and

a programmable watchdog timer. In addition, the microcontroller contains two Controller Area Network

(CAN) modules for industrial communication applications. Each of these peripherals is described below,

and more details are available in the User’s Guide.

SERIAL PORTS

The microcontroller provides a serial port (UART) that is identical to the 80C52. In addition it includes a

second hardware serial port that is a full duplicate of the standard one. This second port optionally uses

pins P1.2 (RXD1) and P1.3 (TXD1). It has duplicate control functions included in new SFR locations.

The second serial port can alternately be mapped to P5.2 and P5.3 to allow use of both serial ports in nonmultiplexed mode.

Both ports can operate simultaneously but can be at different baud rates or even in different modes. The

second serial port has similar control registers (SCON1, SBUF1) to the original. The new serial port can

only use Timer 1 for baud rate generation.

The SCON0 register provides control for serial port 0 while its I/O buffer is SBUF0. The registers

SCON1 and SBUF1 provide the same functions for the second serial port. A full description on the use

and operation of both serial ports may be found in the User’s Guide.

WATCHDOG TIMER

The Watchdog is a free running, programmable timer that can set a flag, cause an interrupt, and/or reset

the microcontroller if allowed to reach a preselected time-out. It can be restarted by software.

A typical application uses the watchdog timer as a reset source to prevent software from losing control.

The watchdog timer is initialized, selecting the time-out period and enabling the reset and/or interrupt

functions. After enabling the reset function, software must then restart the timer before its expiration or

hardware will reset the CPU. In this way if the code execution goes awry and software does not reset the

watchdog as scheduled, the processor is put in a known good state: reset.

Software can select one of four time-out values as controlled by the WD1 and WD0 bits. Time-out

values are precise since they are a function of the crystal frequency. When the Watchdog times out, it

sets the Watchdog Timer Reset Flag (WTRF=WDCON.2) which generates a reset if enabled by the

Enable Watchdog Timer Reset (EWT=WDCON.1) bit. Both the Enable Watchdog Timer Reset and the

Reset Watchdog Timer control bits are protected by Timed Access circuitry. This prevents errant

software from accidentally clearing or disabling the Watchdog.

The Watchdog interrupt is useful for systems that do not require a reset circuit. It will set the WDIF

(Watchdog interrupt) flag 512 clocks before setting the reset flag. Software can optionally enable this

interrupt source, which is independent of the watchdog reset function. The interrupt is common used

22 of 58 110199

Page 23

DS80C390

during the debug process to determine where watchdog reset commands must be located in the

application software. The interrupt also can serve as a convenient time-base generator or can wake-up the

processor from power saving modes.

The Watchdog timer is controlled by the Clock Control (CKCON) and the Watchdog Control (WDCON)

SFRs. CKCON.7 and CKCON.6 are WD1 and WD0 respectively, and they select the Watchdog time-out

period. Of course, the 2X4X/ (PMR.3) and CD1:0 (PMR.7:6) system clock control bits also affect the

time-out period. Selection of time-out is shown below.

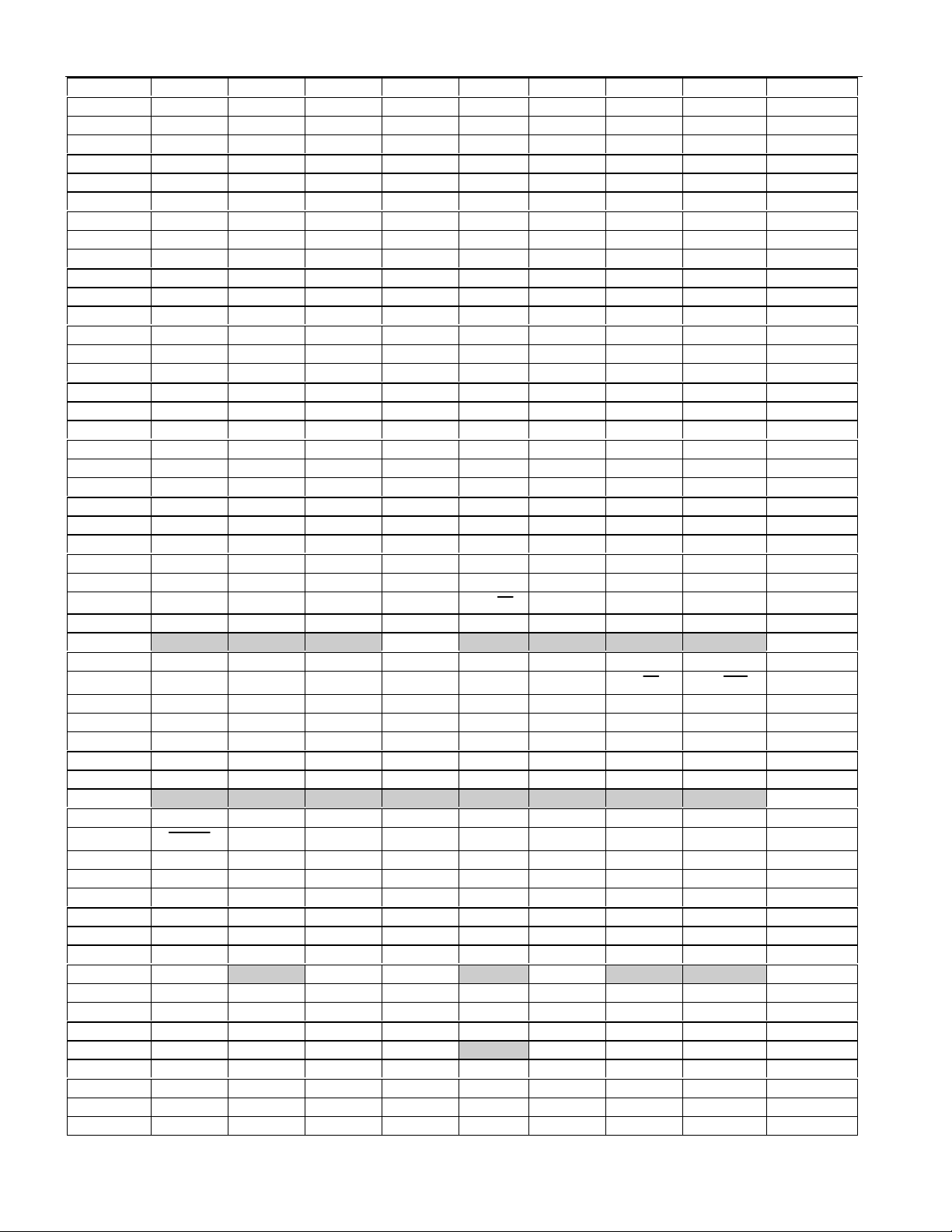

WATCHDOG TIME-OUT VALUES Table 11

WATCHDOG INTERRUPT TIME-OUT WATCHDOG RESET TIME-OUT

CD1:0 WD1:0=00 WD1:0=01 WD1:0=10 WD1:0=11 WD1:0=00 WD1:0=01 WD1:0=10 WD1:0=11

2X4X/

1 00 2

0 00 2

x 01 2

x 10 2

x 11 2

The table demonstrates that for a 33 MHz crystal frequency the Watchdog timer is capable of producing

time-out periods from 3.97 ms (217 * 1/33 MHz) to over two seconds (2.034 = 226 * 1/33 MHz) with the

default setting of CD1:0 (=10). This wide variation in time-out periods allows very flexible system

implementation.

15

16

17

17

25

18

2

19

2

20

2

20

2

28

2

21

2

22

2

23

2

23

2

31

2

24

2

25

2

26

2

26

2

34

2

215+512 218+512 221+512 224+512

216+512 219+512 222+512 225+512

217+512 220+512 223+512 226+512

217+512 220+512 223+512 226+512

225+512 228+512 231+512 234+512

In a typical initialization, the user selects one of the possible counter values to determine the time-out.

Once the counter chain has completed a full count, hardware will set the interrupt flag

(WDIF=WDCON.3). Regardless of whether the software makes use of this flag, there are then 512 clocks

left until the reset flag (WTRF=WDCON.2) is set. Software can enable (1) or disable (0) the reset using

the Enable Watchdog Timer Reset (EWT=WDCON.1) bit.

POWER FAIL RESET

The microcontroller incorporates an internal precision band-gap voltage reference and comparator circuit

which provide a power-on and power-fail reset function. This circuit monitors the processor’s incoming

power supply voltage (VCC), and holds the processor in reset while VCC is below the minimum voltage

level. When power exceeds the reset threshold, a full power-on reset will be performed. In this way, this

internal voltage monitoring circuitry handles both power-up and power-down conditions without the need

for additional external components.

Once VCC has risen above V

, the device will automatically restart the oscillator for the external crystal

RST

and count 65,536 clock cycles before program execution begins at location 0000h. This helps the system

maintain reliable operation by only permitting processor operation when the supply voltage is in a known

good state. Software can determine that a power-on reset has occurred by checking the Power-On Reset

flag (POR;WDCON.6). Software should clear the POR bit after reading it.

POWER FAIL INTERRUPT

The band-gap voltage reference that sets a precise reset threshold also generates an optional early warning

Power-fail Interrupt (PFI). When enabled by software, the processor will vector to ROM address 0033h

if VCC drops below V

(EPFI;WDCON.5). Setting this bit to logic 1 will enable the PFI. Application software can also read the

PFI flag at WDCON.4. A PFI condition sets this bit to a 1. The flag is independent of the interrupt

enable and must be cleared by software.

. PFI has the highest priority. The PFI enable is in the Watchdog Control SFR

PFW

23 of 58 110199

Page 24

DS80C390

EXTERNAL RESET PINS

The DS80C390 has both reset input (RST) and reset output ( RSTOL ) pins. The RSTOL pin supplies an

active low Reset when the microprocessor is issued a Reset from either a high on the RST pin, a time out

of the watchdog timer, a crystal oscillator fail, or an internally detected power-fail. The timing of the

RSTOL pin is dependent on the source of the reset.

Reset Type/Source

Power-on reset 65536 t

RSTOL Duration

(as described in Power Cycle Timing Characteristics)

CLCL

External reset < 1.25 machine cycles

Power fail 65536 t

(as described in Power Cycle Timing Characteristics)

CLCL

Watchdog timer reset 2 machine cycles

Oscillator fail detect 65536 t

(as described in Power Cycle Timing Characteristics)

CLCL

INTERRUPTS

The microcontroller provides 16 interrupt sources with three priority levels. All interrupts, with the

exception of the Power Fail interrupt, are controlled by a series combination of individual enable bits and

a global interrupt enable EA (IE.7). Setting EA to a 1 allows individual interrupts to be enabled.

Clearing EA disables all interrupts regardless of their individual enable settings.

The three available priority levels are low, high, and highest. The highest priority level is reserved for the

Power Fail Interrupt only. All other interrupt priority levels have individual priority bits that when set to

a 1 establish the particular interrupt as high priority. In addition to the user-selectable priorities, each

interrupt also has an inherent natural priority, used to determine the priority of simultaneously occurring

interrupts. The available interrupt sources, their flags, their enables, their natural priority, and their

available priority selection bits are identified in the following table.

INTERRUPT SUMMARY Table 12

NAME DESCRIPTION VECTOR NATURAL

PRIORITY

PFI Power Fail Interrupt 33h 0 PFI(WDCON.4) EPFI(WDCON.5) N/A

INT0 External Interrupt 0 03h 1 IE0(TCON.1)** EX0(IE.0) PX0(IP.0)

TF0 Timer 0 0Bh 2 TF0(TCON.5)* ET0(IE.1) PT0(IP.1)

INT1 External Interrupt 1 13h 3 IE1(TCON.3)** EX1(IE.2) PX1(IP.2)

TF1 Timer 1 1Bh 4 TF1(TCON.7)* ET1(IE.3) PT1(IP.3)

SCON0 TI0 or RI0 from serial

port 0

TF2 Timer 2 2Bh 6 TF2(T2CON.7) ET2(IE.5) PT2(IP.7)

SCON1 TI1 or RI1 from serial

port 1

INT2 External Interrupt 2 43h 8 IE2 (EXIF.4) EX2 (EIE.0) PX2 (EIP.0)

INT3 External Interrupt 3 4Bh 9 IE3 (EXIF.5) EX3 (EIE.1) PX3 (EIP.1)

INT4 External Interrupt 4 53h 10 IE4 (EXIF.6) EX4 (EIE.2) PX4 (EIP.2)

INT5 External Interrupt 5 5Bh 11 IE5 (EXIF.7) EX5 (EIE.3) PX5 (EIP.3)

C0I CAN0 Interrupt 6Bh 12 various C0IE (EIE.6) C0IP (EIP.6)

C1I CAN1 Interrupt 73h 13 various C1IE (EIE.5) C1IP (EIP.5)

WDTI Watchdog Timer 63h 14 WDIF (WDCON.3) EWDI (EIE.4) PWDI (EIP.4)

CANBUS CAN0/1 Bus Activity 7Bh 15 various CANBIE (EIE.7) CANBIP (EIP.7)

23h 5 RI_0(SCON0.0)

3Bh 7 RI_1(SCON1.0)

Unless marked, all flags must be cleared by the application software.

* Cleared automatically by hardware when the service routine is entered.

** If edge triggered, flag is cleared automatically by hardware when the service routine is entered. If

level triggered, flag follows the state of the interrupt pin.

FLAG BIT ENABLE BIT PRIORITY

CONTROL BIT

ES0(IE.4) PS0(IP.4)

TI_0(SCON0.1)

ES1(IE.6) PS1(IP.6)

TI_1(SCON1.1)

24 of 58 110199

Page 25

DS80C390

CONTROLLER AREA NETWORK (CAN) MODULE

The DS80C390 incorporates two CAN controllers that are fully compliant with the CAN 2.0B

specification. CAN is a highly robust, high-performance communication protocol for serial

communications. Popular in a wide range of applications including automotive, medical, heating,

ventilation, and industrial control, the CAN architecture allows for the construction of sophisticated

networks with a minimum of external hardware.

The CAN controllers support the use of 11-bit standard or 29-bit extended acceptance identifiers for up to

15 messages, with the standard 8 byte data field, in each message. Fourteen of the fifteen message

centers are programmable in either transmit or receive modes, with the fifteenth designated as a FIFObuffered, receive-only message center to help prevent data overruns. All message centers support two

separate 8-bit media masks and media arbitration fields for incoming message verification. This feature

supports the use of higher level protocols which make use of the first and/or second byte of data as a part

of the acceptance layer for storing incoming messages. Each message center can also be programmed

independently to test incoming data with or without the use of the global masks.

Global controls and status registers in each CAN unit allow the microcontroller to evaluate error

messages, generate interrupts, locate and validate new data, establish the CAN Bus timing, establish

identification mask bits, and verify the source of individual messages. Each message center is

individually equipped with the necessary status and control bits to establish direction, identification mode

(standard or extended), data field size, data status, automatic remote frame request and acknowledgment,

and perform masked or non-masked identification acceptance testing.

COMMUNICATING WITH THE CAN MODULE

The microcontroller interface to the CAN modules is divided into two groups of registers. All of the

global CAN status and control bits as well as the individual message center control/status registers are

located in the Special Function Register map. The remaining registers associated with the message

centers (data identification, identification/arbitration masks, format and data) are located in MOVX data

space. The CMA bit (MCON.5) allows the message centers to be mapped to either 00EE00h-00EEFFh

(CMA=0 or 401000h-4011FFh (CMA=1), reducing the possibility of a memory conflict with application

software. Note that setting the CMA bit employs a special twenty-third address bit that is only used for

addressing CAN MOVX memory. The internal architecture of the DS80C390 requires that the device be

in one of the two 22-bit addressing modes when the CMA bit is set to correctly utilize the twenty-third bit

and access the CAN MOVX memory. A special lockout feature prevents the accidental software

corruption of the control, status and mask registers while a CAN operation is in progress. Each CAN

processor utilizes a total of 15 message centers. Each message center is composed of four specific areas.

These include:

1. Four arbitration registers (C0MxAR0-3 and C1MxAR0-3) which store either the 11-bit or 29-bit

arbitration value. These registers are located in the MOVX memory map.

2. A Format Register (C0MxF and C1MxF) which informs the CAN processor as to the direction

(transmit or receive), the number of data bytes in the message, the Identification Format (standard or

extended), and the optional use of the Identification Mask or Media Mask during message evaluation.

This register is located in the MOVX memory map.

3. Eight data bytes for storage of 0 - 8 bytes of data (C0MxD0-7 and C1MxD0-7) are located in the

MOVX memory map.

4. Message Control Registers (C0MxC and C1MxC) are located in the SFR memory for fast access.

25 of 58 110199

Page 26

DS80C390

R

Each of the message centers is identical with the exception of message center 15. Message center 15 has

been designed as a receive only center and is also buffered through the use of a two message FIFO to help

prevent message loss in a message overrun situation. The receipt of a third message before either of the

first two are read will overwrite the second message, leaving the first message undisturbed.

Modification of the CAN registers located in MOVX memory is protected via the SWINT bits, with one

bit protecting each respective CAN module. Consult the description of this bit in the User’s Guide for

more information. Each CAN Module contains a block of Control/Status/Mask registers, 14 functionally

identical message centers, plus a fifteenth message center which is receive only and incorporates a

buffered FIFO. The following tables describe the organization of the message centers located in MOVX

space.

MOVX MESSAGE CENTERS FOR CAN 0

CAN 0 CONTROL/STATUS/MASK REGISTERS

MOVX Data

Register 7 6 5 4 3 2 1 0

Address

C0MID0 MID07 MID06 MID05 MID04 MID03 MID02 MID01 MID00 xxxx00h

C0MA0 M0AA7 M0AA6 M0AA5 M0AA4 M0AA3 M0AA2 M0AA1 M0AA0 xxxx01h

C0MID1 MID17 MID16 MID15 MID14 MID13 MID12 MID11 MID10 xxxx02h

C0MA1 M1AA7 M1AA6 M1AA5 M1AA4 M1AA3 M1AA2 M1AA1 M1AA0 xxxx03h

C0BT0 SJW1 SJW0 BPR5 BPR4 BPR3 BPR2 BPR1 BPR0 xxxx04h