Page 1

DS4830

OpticalMicrocontroller

User’sGuide

Rev 0.3 8/2012

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are implied. Maxim reserves

the right to change the circuitry and specifications without notice at any time.

Maxim Integrated 160 Rio Robles, San Jose, CA 95134 USA 1-408-601-1000

© 2012 Maxim Integrated The Maxim logo and Maxim Integrated are trademarks of Maxim Integrated Products, Inc.

Page 2

DS4830 User’s Guide

Contents

SECTION 1 – OVERVIEW ...................................................................................................................................................... 9

SECTION 2 – ARCHITECTURE ........................................................................................................................................... 11

2.1 – Instruction Decoding ................................................................................................................................................. 11

2.2 – Register Space ......................................................................................................................................................... 12

2.3 – Memory Types .......................................................................................................................................................... 13

2.3.1 – Flash Memory .................................................................................................................................................... 13

2.3.2 – SRAM Memory ................................................................................................................................................... 13

2.3.3 – Utility ROM ......................................................................................................................................................... 13

2.3.4 – Stack Memory .................................................................................................................................................... 13

2.4 – Program and Data Memory Mapping and Access ................................................................................................... 14

2.4.1 – Program Memory Access .................................................................................................................................. 14

2.4.2 – Program Memory Mapping ................................................................................................................................ 15

2.4.3 – Data Memory Access ......................................................................................................................................... 15

2.4.4 – Data Memory Mapping ...................................................................................................................................... 16

2.5 – Data Alignment ......................................................................................................................................................... 20

2.6 – Reset Conditions ...................................................................................................................................................... 20

2.6.1 – Power-On/Brownout Reset ................................................................................................................................ 20

2.6.2 – Watchdog Timer Reset ...................................................................................................................................... 21

2.6.3 – External Reset ................................................................................................................................................... 21

2.6.4 – Internal System Resets ...................................................................................................................................... 22

2.7 – Clock Generation ...................................................................................................................................................... 22

SECTION 3 – SYSTEM REGISTER DESCRIPTIONS ......................................................................................................... 23

SECTION 4 – PERIPHERAL REGISTER DESCRIPTIONS ................................................................................................. 31

SECTION 5 – INTERRUPTS ................................................................................................................................................ 36

5.1 – Servicing Interrupts ................................................................................................................................................... 37

5.2 – Module Interrupt Identification Registers .................................................................................................................. 39

5.3 – Interrupt System Operation ...................................................................................................................................... 40

5.3.1 – Synchronous vs. Asynchronous Interrupt Sources ............................................................................................ 40

5.3.2 – Interrupt Prioritization by Software ..................................................................................................................... 40

5.3.3 – Interrupt Exception Window ............................................................................................................................... 40

SECTION 6 – DIGITAL-TO-ANALOG CONVERTER (DAC) ................................................................................................ 42

6.1 – Detailed Description ................................................................................................................................................. 42

6.1.1 – Reference Selection.......................................................................................................................................... 43

6.1.2 – Requirement for Enabled DACs ....................................................................................................................... 43

6.2 – DAC Register Descriptions ....................................................................................................................................... 43

6.3 –DAC Code Examples ................................................................................................................................................. 45

SECTION 7 – ANALOG-TO-DIGITAL CONVERTER (ADC) ................................................................................................ 46

7.1 – Detailed Description ................................................................................................................................................. 46

7.1.1 – ADC Controller ................................................................................................................................................... 46

7.1.2 – ADC Conversion Sequencing ............................................................................................................................ 47

2

Page 3

DS4830 User’s Guide

7.1.3 – Temperature Conversion ................................................................................................................................... 48

7.1.4 – Sample and Hold Conversion ............................................................................................................................ 48

7.1.5 – ADC Frame Sequence ....................................................................................................................................... 48

7.1.6 – ADC Conversion Time ....................................................................................................................................... 49

7.1.7 – Location Override............................................................................................................................................... 50

7.1.8 – ADC Data Reading ............................................................................................................................................ 50

7.1.9 – ADC Interrupts ................................................................................................................................................... 51

7.1.10 – ADC Internal Offset .......................................................................................................................................... 51

7.2 – ADC Register Descriptions ....................................................................................................................................... 52

7.3 –ADC Code Examples ................................................................................................................................................. 58

SECTION 8 – SAMPLE AND HOLD ..................................................................................................................................... 60

8.1 – Detailed Description ................................................................................................................................................. 60

8.1.1 – Operation ........................................................................................................................................................... 60

8.1.2 – Fast Mode Operation ......................................................................................................................................... 61

8.1.3 – Sampling Control ............................................................................................................................................... 61

8.1.4 – Pin Capacitance Discharge ............................................................................................................................... 63

8.1.5 – Sample and Hold Data Reading ........................................................................................................................ 64

8.1.6 – Sample and Hold Interrupts ............................................................................................................................... 64

8.2 – Sample and Hold Register Descriptions ................................................................................................................... 65

SECTION 9 – QUICK TRIP (FAST COMPARATOR) ........................................................................................................... 68

9.1 – Detailed Description ................................................................................................................................................. 68

9.1.1 – Quick Trip List Sequencing ................................................................................................................................ 69

9.1.2 – Operation ........................................................................................................................................................... 69

9.1.3 – Quick Trip Interrupts .......................................................................................................................................... 71

9.2 – Quick Trip Register Descriptions .............................................................................................................................. 72

SECTION 10 – I2C-COMPATIBLE MASTER INTERFACE .................................................................................................. 76

10.1 – Detailed Description .............................................................................................................................................. 76

10.1.1 – Description of Master I2C Interface ................................................................................................................. 76

10.1.2 – Default Operation ............................................................................................................................................. 76

10.1.3 – I2C Clock Generation ...................................................................................................................................... 76

10.1.4 – Timeout ............................................................................................................................................................ 77

10.1.5 – Generating a START ....................................................................................................................................... 78

10.1.6 – Generating a STOP ......................................................................................................................................... 79

10.1.7 – Transmitting a Slave Address .......................................................................................................................... 80

10.1.8 – Transmitting Data............................................................................................................................................. 80

10.1.9 – Receiving Data................................................................................................................................................. 81

10.1.10 – I2C Master Clock Stretching .......................................................................................................................... 83

10.1.11 – Resetting the I2C Master Controller .............................................................................................................. 83

10.1.12 – Operation as a Slave ..................................................................................................................................... 84

10.1.13 – GPIO .............................................................................................................................................................. 84

10.2 – I2C Master Controller Register Description ........................................................................................................... 85

SECTION 11 – I2C-COMPATIBLE SLAVE INTERFACE ...................................................................................................... 89

3

Page 4

DS4830 User’s Guide

11.1 – Detailed Description .............................................................................................................................................. 90

11.1.1 – Default Operation ............................................................................................................................................. 90

11.1.2 – Slave Address .................................................................................................................................................. 90

11.1.3 – I2C Start Detection........................................................................................................................................... 90

11.1.4 – I2C Stop Detection ........................................................................................................................................... 90

11.1.5 – Slave Address Matching .................................................................................................................................. 90

11.1.6 – Transmitting Data............................................................................................................................................. 91

11.1.7 – Receiving Data................................................................................................................................................. 92

11.1.8 – Clock Stretching ............................................................................................................................................... 93

11.1.9 – SMBus Timeout ............................................................................................................................................... 93

11.1.10 – Resetting the I2C Slave Controller ................................................................................................................ 94

11.1.11 – Operation as a Master ................................................................................................................................... 94

11.2 – I2C Slave Controller Register Description .............................................................................................................. 95

SECTION 12 – SERIAL PERIPHERAL INTERFACE (SPI) .................................................................................................. 99

12.1 – Serial Peripheral Interface (SPI) Detailed Description ........................................................................................... 99

12.1.1 – SPI Transfer Formats .......................................................................................................................................... 99

12.1.2 – SPI Character Lengths ...................................................................................................................................... 101

12.2 – SPI System Errors ................................................................................................................................................ 101

12.2.1 – Mode Fault ......................................................................................................................................................... 101

12.2.2 – Receive Overrun ................................................................................................................................................ 101

12.2.3 – Write Collision While Busy ................................................................................................................................ 102

12.3 – SPI Interrupts ........................................................................................................................................................ 102

12.4 – SPI Master ............................................................................................................................................................ 103

12.4.1 – SPI Transfer Baud Rates .................................................................................................................................. 103

12.4.2 – SPI Master Operation ........................................................................................................................................ 103

12.4.3 – SPI Master Register Descriptions ..................................................................................................................... 105

12.5 – SPI Slave .............................................................................................................................................................. 107

12.5.1 – SPI Slave Select ................................................................................................................................................ 107

12.5.2 – SPI Transfer Baud Rates .................................................................................................................................. 107

12.5.3 – SPI Slave Operation .......................................................................................................................................... 107

12.5.4 – SPI Slave Register Descriptions ....................................................................................................................... 108

SECTION 13 – 3-WIRE ....................................................................................................................................................... 110

13.1 – Detailed Description ............................................................................................................................................. 110

13.1.1 – Operation ....................................................................................................................................................... 110

13.2 – 3-Wire Register Descriptions ................................................................................................................................ 112

SECTION 14 – PWM .......................................................................................................................................................... 113

14.1 – Detailed Description ............................................................................................................................................. 113

14.1.1 – PWMCN and PWMDATA SFRs .................................................................................................................... 113

14.1.2 – PWMSYNC SFR ............................................................................................................................................ 114

14.2 – Individual PWM Channel Operation ..................................................................................................................... 115

14.2.1 – Duty Cycle Register (DCYCn) ....................................................................................................................... 115

14.2.2 – PWM Configuration Register (PWMCFGn) ................................................................................................... 116

4

Page 5

DS4830 User’s Guide

14.2.3 – Pulse Spreading............................................................................................................................................. 116

14.2.4 – Alternate PWM Output ................................................................................................................................... 119

14.2.5 – PWM DELAY Register (PWMDLYn).............................................................................................................. 119

14.3 – PWM Output Register Descriptions ...................................................................................................................... 120

14.4 – PWM Output Code Examples .............................................................................................................................. 125

SECTION 15 – GENERAL-PURPOSE INPUT/OUTPUT (GPIO) PINS ............................................................................. 126

15.1 – Overview ............................................................................................................................................................... 126

15.2 – GPIO Port 0 Register Descriptions ....................................................................................................................... 129

15.2.1 – GPIO Direction Register Port 0 (PD0) ........................................................................................................... 129

15.2.2 – GPIO Output Register Port 0 (PO0) .............................................................................................................. 129

15.2.3 – GPIO Input Register for Port 0 (PI0) .............................................................................................................. 129

15.2.4 – GPIO Port 0 External Interrupt Edge Select Register (EIES0) ..................................................................... 129

15.2.5 – GPIO Port 0 External Interrupt Flag Register (EIF0) ..................................................................................... 130

15.2.6 – GPIO Port 0 External Interrupt Enable Register (EIE0)................................................................................. 130

15.3 – GPIO Port 1 Register Descriptions ....................................................................................................................... 130

15.3.1 – GPIO Direction Register Port 1 (PD1) ........................................................................................................... 130

15.3.2 – GPIO Output Register Port 1 (PO1) .............................................................................................................. 130

15.3.3 – GPIO Input Register for Port 1 (PI1) .............................................................................................................. 131

15.3.4 – GPIO Port 1 External Interrupt Edge Select Register (EIES1) ..................................................................... 131

15.3.5 – GPIO Port 1 External Interrupt Flag Register (EIF1) ..................................................................................... 131

15.3.6 – GPIO Port 1 External Interrupt Enable Register (EIE1)................................................................................. 131

15.4 – GPIO Port 2 Register Descriptions ....................................................................................................................... 131

15.4.1 – GPIO Direction Register Port 2 (PD2) ........................................................................................................... 131

15.4.2 – GPIO Output Register Port 2 (PO2) .............................................................................................................. 132

15.4.3 – GPIO Input Register for Port 2 (PI2) .............................................................................................................. 132

15.4.4 – GPIO Port 2 External Interrupt Edge Select Register (EIES2) ..................................................................... 132

15.4.5 – GPIO Port 2 External Interrupt Flag Register (EIF2) ..................................................................................... 132

15.4.6 – GPIO Port 2 External Interrupt Enable Register (EIE2)................................................................................. 132

15.5 – GPIO Port 6 Register Descriptions ....................................................................................................................... 133

15.5.1 – GPIO Direction Register Port 6 (PD6) ........................................................................................................... 133

15.5.2 – GPIO Output Register Port 6 (PO6) .............................................................................................................. 133

15.5.3 – GPIO Input Register for Port 6 (PI6) .............................................................................................................. 133

15.5.4 – GPIO Port 6 External Interrupt Edge Select Register (EIES6) ..................................................................... 133

15.5.5 – GPIO Port 6 External Interrupt Flag Register (EIF6) ..................................................................................... 134

15.5.6 – GPIO Port 6 External Interrupt Enable Register (EIE6)................................................................................. 134

SECTION 16 – GENERAL-PURPOSE TIMERS ................................................................................................................ 135

16.1 – Detailed Description ............................................................................................................................................. 135

16.1.1 – Timer Modes .................................................................................................................................................. 135

16.1.2 – Clock Selection .............................................................................................................................................. 136

16.1.3 – Timer Clock Prescaler ................................................................................................................................... 136

16.2 – Timer Register Descriptions ................................................................................................................................. 137

SECTION 17 – SUPPLY VOLTAGE MONITOR (SVM) ..................................................................................................... 139

5

Page 6

DS4830 User’s Guide

SECTION 18 – HARDWARE MULTIPLIER MODULE ....................................................................................................... 140

18.1 – Hardware Multiplier Organization ......................................................................................................................... 140

18.2 – Hardware Multiplier Controls ................................................................................................................................ 140

18.3 – Register Output Selection..................................................................................................................................... 141

18.3.1 – Signed-Unsigned Operand Selection ............................................................................................................ 141

18.3.2 – Operand Count Selection .............................................................................................................................. 141

18.4 – Hardware Multiplier Operations ............................................................................................................................ 141

18.4.1 – Accessing the Multiplier ................................................................................................................................. 141

18.5 – Hardware Multiplier Peripheral Registers ............................................................................................................. 142

18.6 – Hardware Multiplier Examples .............................................................................................................................. 145

SECTION 19 – WATCHDOG TIMER.................................................................................................................................. 146

19.1 - Overview ............................................................................................................................................................... 146

19.2 – Watchdog Timer Description ................................................................................................................................ 146

19.2.1 – Watchdog Timer Interrupt Operation ............................................................................................................. 147

19.2.2 – Watchdog Timer Reset Operation ................................................................................................................. 147

19.2.3 – Watchdog Timer Applications ........................................................................................................................ 147

SECTION 20 – TEST ACCESS PORT (TAP) ..................................................................................................................... 149

20.1 – TAP Controller ...................................................................................................................................................... 150

20.2 – TAP State Control ................................................................................................................................................. 151

20.2.1 – Test-Logic-Reset............................................................................................................................................ 151

20.2.2 – Run-Test-Idle ................................................................................................................................................. 151

20.2.3 – IR-Scan Sequence ......................................................................................................................................... 151

20.2.4 – DR-Scan Sequence ....................................................................................................................................... 152

20.3 – Communication via TAP ....................................................................................................................................... 152

20.3.1 - TAP Communication Examples – IR-Scan and DR-Scan .............................................................................. 153

SECTION 21 – IN-CIRCUIT DEBUG MODE ...................................................................................................................... 155

21.1 – Background Mode Operation ............................................................................................................................... 156

21.1.1 – Breakpoint Registers ..................................................................................................................................... 157

21.1.2 – Using Breakpoints .......................................................................................................................................... 159

21.2 – Debug Mode ......................................................................................................................................................... 160

21.2.1 – Debug Mode Commands ............................................................................................................................... 160

21.2.2 – Read Register Map Command Host-ROM Interaction .................................................................................. 162

21.2.3 – Single Step Operation (Trace) ....................................................................................................................... 163

21.2.4 – Return ............................................................................................................................................................ 164

21.2.5 – Debug Mode Special Considerations ............................................................................................................ 164

21.3 – In-Circuit Debug Peripheral Registers .................................................................................................................. 165

SECTION 22 – IN-SYSTEM PROGRAMMING .................................................................................................................. 169

22.1 – Detailed Description ............................................................................................................................................. 169

22.1.1 - Password Protection ....................................................................................................................................... 170

22.1.2 – Entering JTAG Bootloader ............................................................................................................................. 170

22.1.3 – Entering I2C Bootloader ................................................................................................................................ 171

22.2 – Bootloader Operation ........................................................................................................................................... 171

6

Page 7

DS4830 User’s Guide

22.2.1 – JTAG Bootloader Protocol ............................................................................................................................. 172

22.2.2 – I2C Bootloader Protocol ................................................................................................................................. 172

22.3 – Bootloader Commands ......................................................................................................................................... 173

22.3.1 - Command 00h – No Operation ....................................................................................................................... 173

22.3.2 - Command 01h – Exit Loader .......................................................................................................................... 173

22.3.3 - Command 02h – Master Erase ....................................................................................................................... 173

22.3.4 - Command 03h – Password Match ................................................................................................................. 174

22.3.5 - Command 04h – Get Status ........................................................................................................................... 174

22.3.6 - Command 05h – Get Supported Commands ................................................................................................. 175

22.3.7 - Command 06h – Get Code Size ..................................................................................................................... 175

22.3.8 - Command 07h – Get Data Size ...................................................................................................................... 175

22.3.9 - Command 08h – Get Loader Version ............................................................................................................. 175

22.3.10 - Command 09h – Get Utility ROM Version .................................................................................................... 175

22.3.11 - Command 10h – Load Code ........................................................................................................................ 176

22.3.12 - Command 11h – Load Data ......................................................................................................................... 176

22.3.13 - Command 20h – Dump Code ....................................................................................................................... 176

22.3.14 - Command 21h – Dump Data ........................................................................................................................ 177

22.3.15 - Command 30h – CRC Code ......................................................................................................................... 177

22.3.16 - Command 31h – CRC Data .......................................................................................................................... 177

22.3.17 - Command 40h – Verify Code ....................................................................................................................... 177

22.3.18 - Command 41h – Verify Data ........................................................................................................................ 177

22.3.19 - Command 50h – Load and Verify Code ....................................................................................................... 178

22.3.20 - Command 51h – Load and Verify Data ........................................................................................................ 178

22.3.21 - Command E0h – Code Page Erase ............................................................................................................. 178

SECTION 23 – PROGRAMMING ....................................................................................................................................... 179

23.1 – Addressing Modes ................................................................................................................................................ 179

23.2 – Prefixing Operations ............................................................................................................................................. 179

23.3 – Reading and Writing Registers ............................................................................................................................. 179

23.3.1 – Loading an 8-bit register with an immediate value ........................................................................................ 180

23.3.2 – Loading a 16-bit register with a 16-bit immediate value ................................................................................ 180

23.3.3 – Moving values between registers of the same size ....................................................................................... 180

23.3.4 – Moving values between registers of different sizes ....................................................................................... 180

23.4 – Reading and Writing Register Bits ....................................................................................................................... 181

23.5 – Using the Arithmetic and Logic Unit ..................................................................................................................... 182

23.5.1 – Selecting the active accumulator ................................................................................................................... 182

23.5.2 – Enabling auto-increment and auto-decrement .............................................................................................. 182

23.5.3 – ALU operations using the active accumulator and a source ......................................................................... 184

23.5.4 – ALU operations using only the active accumulator........................................................................................ 184

23.5.5 – ALU bit operations using only the active accumulator ................................................................................... 184

23.5.6 – Example: Adding two four-byte numbers using auto-increment .................................................................... 184

23.6 - Processor Status Flag Operations ........................................................................................................................ 184

23.6.1 - Sign Flag ......................................................................................................................................................... 184

7

Page 8

DS4830 User’s Guide

23.6.2 - Zero Flag ........................................................................................................................................................ 185

23.6.3 - Equals Flag ..................................................................................................................................................... 185

23.6.4 - Carry Flag ....................................................................................................................................................... 185

23.6.5 - Overflow Flag .................................................................................................................................................. 186

23.7 - Controlling Program Flow ...................................................................................................................................... 186

23.7.1 - Obtaining the next execution address ............................................................................................................ 186

23.7.2 - Unconditional jumps ....................................................................................................................................... 186

23.7.3 - Conditional jumps ........................................................................................................................................... 187

23.7.4 - Calling subroutines ......................................................................................................................................... 187

23.7.5 - Looping operations ......................................................................................................................................... 187

23.7.6 - Conditional returns.......................................................................................................................................... 188

23.8 - Handling Interrupts ................................................................................................................................................ 188

23.8.1 - Conditional return from interrupt ..................................................................................................................... 189

23.9 - Accessing the Stack .............................................................................................................................................. 189

23.10 - Accessing Data Memory ..................................................................................................................................... 190

SECTION 24 – INSTRUCTION SET................................................................................................................................... 192

SECTION 25 – UTILITY ROM ............................................................................................................................................ 220

25.1 – Overview ............................................................................................................................................................... 220

25.2 – In-Application Programming Functions ................................................................................................................ 221

25.2.1 – UROM_flashWrite .......................................................................................................................................... 221

25.2.2 – UROM_flashErasePage ................................................................................................................................ 221

25.3 – Data Transfer Functions ....................................................................................................................................... 222

25.3.1 – UROM_moveDP0 .......................................................................................................................................... 223

25.3.2 – UROM_moveDP0inc ..................................................................................................................................... 223

25.3.3 – UROM_moveDP0dec .................................................................................................................................... 223

25.3.4 – UROM_moveDP1 .......................................................................................................................................... 224

25.3.5 – UROM_moveDP1inc ..................................................................................................................................... 224

25.3.6 – UROM_moveDP1dec .................................................................................................................................... 224

25.3.7 – UROM_moveBP ............................................................................................................................................ 225

25.3.8 – UROM_moveBPinc ........................................................................................................................................ 225

25.3.9 – UROM_moveBPdec ...................................................................................................................................... 225

25.3.10 – UROM_copyBuffer ....................................................................................................................................... 226

25.4 – Utility ROM Examples ........................................................................................................................................... 227

25.4.1 – Reading Constant Word Data from Flash ...................................................................................................... 227

25.4.2 – Reading Constant Byte Data from Flash (Indirect Function Call) .................................................................. 227

8

Page 9

DS4830 User’s Guide

SECTION 1 – OVERVIEW

The DS4830 System Management Microcontroller provides a complete optical control, calibration, and monitor solution.

The IC is based on the high-performance 16-bit family of MAXQ

microcontrollers, and provides generous amounts of flash program memory and SRAM data memory.

Some of the resources and features that the DS4830 provides for monitoring and controlling an optical sy stem include the

following:

16-Bit MAXQ20 Low-Power Microcontroller

13-Bit ADC with a 26 Input Mux

Single and Differential Mode

4 User-Selectable Gains for Individual Channel

V

, Internal Reference and DAC External Reference Measurement

DD

40ksps with Fastest ADC Clock

10 PWM Channels

Normal and Pulse Spreading Operation Modes

PWM Output Synchronization

User-Selectable 7- to 12-Bit Resolution

1MHz Switching Using 133MHz External Clock

8-bit Fast Comparator with 16 Input Mux

Single and Differential Mode

Low and High Threshold Configurations

3.2s Conversion Time per Channel

Two Independent Sample and Hold

Single, Fast and Dual Mode Operation

Internal and External Trigger Option

Pin Discharge

Temperature Sensors

Internal Die Temperature Measurement

Remote Temperature Measurement of Two Diode Connected Transistors

8 Voltage DAC Channels having 12-Bit Resolution with Selectable Internal or External Reference Option

SPI or 400kHz I

SPI, 400kHz I

2

C-Compatible Slave Communication Interface

2

C-Compatible, or Maxim Integrated 3-Wire Laser Driver Master Communication Interface

Two 16-bit Timers with Synchronous and Compare modes

Watchdog Timer

Maskable Interrupt Sources

Hardware Multiplier Unit

Supply Voltage Monitoring

32KWords of Flash and 1KWords of SRAM Memory

Included ROM Routines that allow Bootloading and In-Application Programming of Flash Memory

In-System Debugging

®

reduced instruction set computing (RISC)

MAXQ is a registered trademark of Maxim Integrated Products, Inc.

9

Page 10

DS4830 User’s Guide

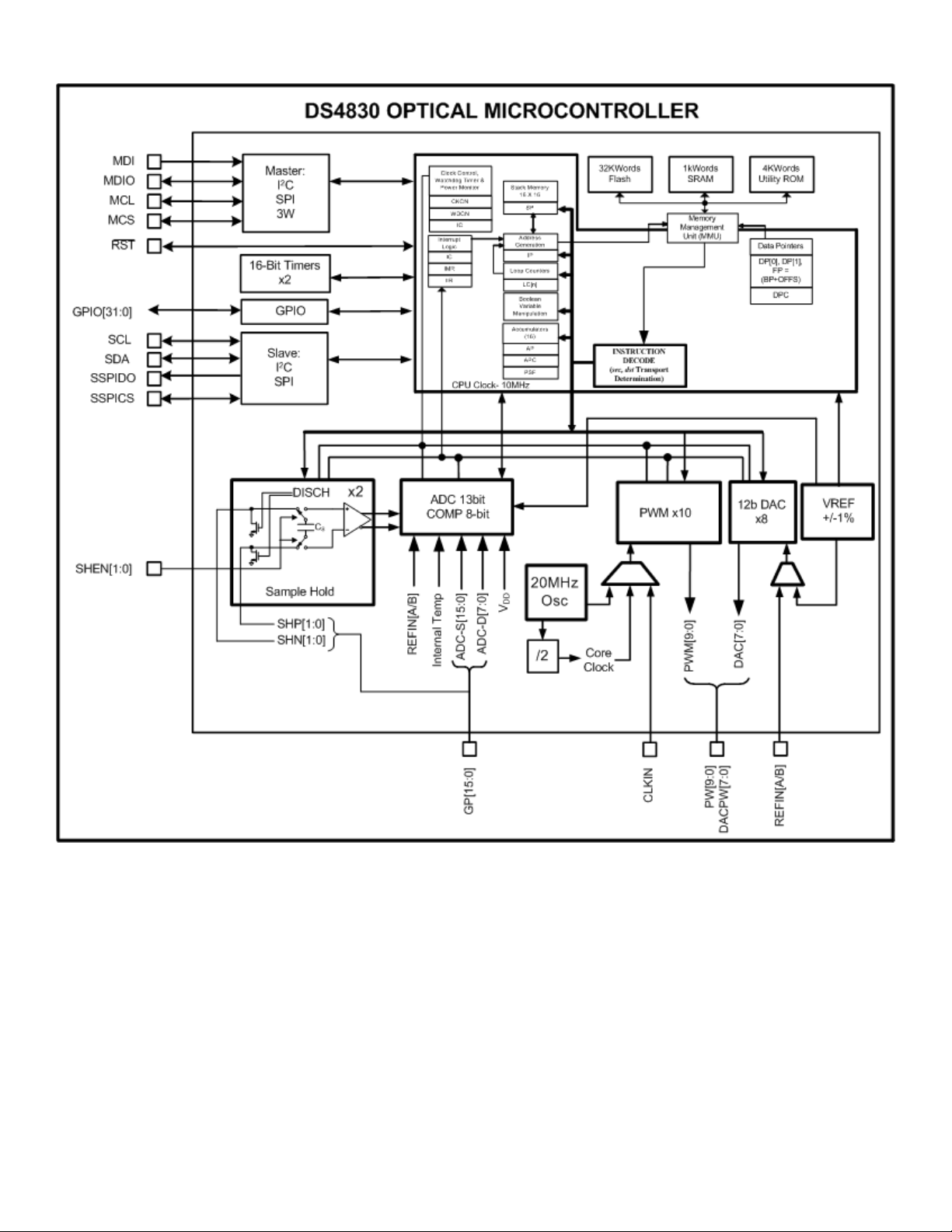

Figure 1-1 DS4830 Block Diagram

This document is provided as a supplement to the DS4830 IC data sheet. This user’s guide provides the information

necessary to develop applications using the DS4830. All electrical and timing specifications, pin descriptions, package

information, and ordering information can be found in the DS4830 IC data sheet.

10

Page 11

DS4830 User’s Guide

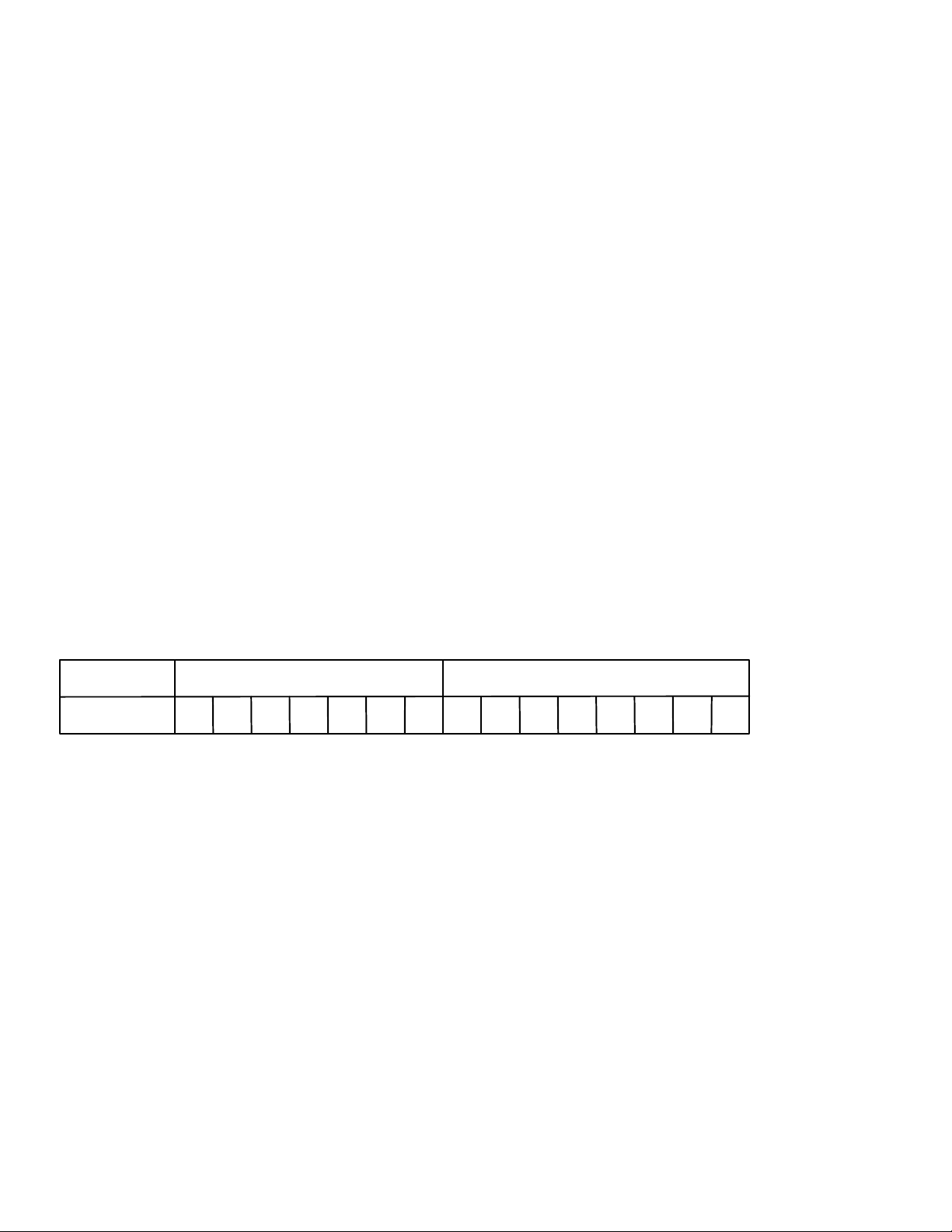

FORMAT DESTINATION SOURCE

s sd

f s s

s s s sd d d d

d d

SECTION 2 – ARCHITECTURE

The DS4830 contains a MAXQ20 low-cost, high-performance, CMOS, fully static microcontroller with flash memory. It is

structured on a highly advanced, 16-accumulator-based, 16-bit RISC architecture. Fetch and execution operations are

completed in one cycle without pipelining, since the instruction contains both the op code and data. The highly efficient

core is supported by 16 accumulators and a 16-level hardware stack, enabling fast subroutine calling and task switching.

Data can be quickly and efficiently manipulated with three internal data pointers. Two of these data pointers, DP0 and

DP1, are stand-alone 16-bit pointers. The third data pointer, Frame Pointer, is composed of a 16-bit base pointer (BP) and

an 8-bit offset register (OFFS). All three pointers support post-increment/decrement functionality for read operations and

pre-increment/decrement for write operations. For the Frame Pointer (FP=BP[OFFS]), the increment/decrement operation

is executed on the OFFS register and does not affect the base pointer. Multiple data pointers allow more than one

function to access data memory without having to save and restore data pointers each time.

Stack functionality is provided by dedicated memory with a 16-bit width and a depth of 16. An on-chip memory

management unit (MMU) allows logical remapping of the program and data spaces, and thus facilitates in-system

programming and fast access to data tables, arrays, and constants located in flash memory.

This section provides details on the following topics.

1. Instruction decoding

2. Register space

3. Memory types

4. Program and data memory mapping and access

5. Data alignment

6. Reset conditions

7. Clock generation

8. Power modes

2.1 – Instruction Decoding

The DS4830 uses the standard 16-bit MAXQ20 core instruction set, which is described in the Instruction Set section.

Every instruction is encoded as a single 16-bit word. The instruction word format is shown in Figure 2-1.

Figure 2-1: Instruction Word Format

Bit 15 (f) indicates the format for the source field of the instruction as follows:

o If f equals 0, the instruction is an immediate source instruction. The source field represents an immediate

8-bit value.

o If f equals 1, the instruction is a register source instruction. The source field represents the register that

the source value will be read from.

Bits 14 to 8 (ddddddd) represent the destination for the transfer. This value always represents a destination

register. The lower four bits contain the module specifier and the upper three bits contain the register index in

that module.

Bits 7 to 0 (ssssssss) represent the source for the transfer. Depending on the value of the format field, this can

either be an immediate value or a source register. If this field represents a register, the lower four bits contain the

module specifier and the upper four bits contain the register index in that module.

This instruction word format presents the following limitations.

1. There are 32 registers per register module, but only four bits are allocated to designate the source register and

only three bits are allocated to designate the destination register.

2. The source field only provides 8 bits of data for an immediate value; however a 16-bit immediate value may be

required.

The DS4830 uses a prefix register (PFX) to address these limitations. The prefix register provides the additional bits

required to access all 32 register within a module. The prefix register also provides the additional 8 bits of data required

to make a 16-bit immediate data source. The data that is written to the prefix register survives for only one clock cycle.

This means the write to the prefix register must occur immediately prior to the instruction requiring the prefix register. The

11

Page 12

DS4830 User’s Guide

prefix register is cleared to zero after one cycle so it will not affect any other instructions. The write to the prefix register is

done automatically by the assembler and requires one additional execution cycle. So, while most instructions execute in

a single cycle, two cycles are needed for instructions that require the prefix register.

The architecture of the DS4830 is transport-triggered. This means that writing to or reading from certain register locations

will also cause side effects to occur. These side effects form the basis of the DS4830’s higher level op codes, such as

ADDC, OR, and JUMP. While these op codes are actually implemented as MOVE instructions between certain register

locations, the encoding is handled by the assembler and need not be a concern to the programmer. The unused "empty"

locations in the System Register Modules are used for these higher level op codes.

The instruction set is designed to be highly orthogonal. All arithmetic and logical operations that use two registers can use

any register along with the accumulator. Data can be transferred between any two registers in a single instruction.

2.2 – Register Space

The DS4830 provides a total of 13 register modules broken up into two different groups. These groupings are descriptive

only, as there is no difference between accessing the two register groups from a programming perspective. The two

groups are:

1. Peripheral Registers: These are the lower six modules (Modules 0h through 5h). The Peripheral Registers in the

DS4830 are used for functionalities such as ADC, PWM Outputs, Sample and Hold, 3Wire, I2C Master and Slave,

SPI Master and Slave, GPIO, etc. The Peripheral Registers are not used to implement op codes.

2. System Registers: These are modules 8h, 9h, and Bh through Fh. The System Registers in the DS4830 are used

to implement higher level op codes as well as the following common system features.

16-bit ALU and associated status flags (zero, equals, carry, sign, overflow)

16 working accumulator registers, each 16-bit, along with associated control registers

Instruction pointer

Registers for interrupt control, handling, and identification

Auto-decrementing Loop Counters for fast, compact looping

Two Data Pointer registers and a Frame Pointer for data memory access

Each System Register module has 16 registers, while each Peripheral Register module has 32 registers. The number of

cycles required to access a particular register depends upon the register’s index within the module. The access times

based upon the register index are grouped as follows:

The first eight registers (index 0h to 7h) in each module may be read from or written to in a single cycle

The second eight registers (index 8h to 0Fh) may be read from in a single cycle and written to in two cycles (by

using the prefix register PFX).

The last sixteen registers (10h to 1Fh) in Peripheral Register modules may be read or written in two cycles

(always requiring use of the prefix register PFX).

Registers may be 8 or 16 bits in length. Some registers may contain reserved bits. The user should not write to any

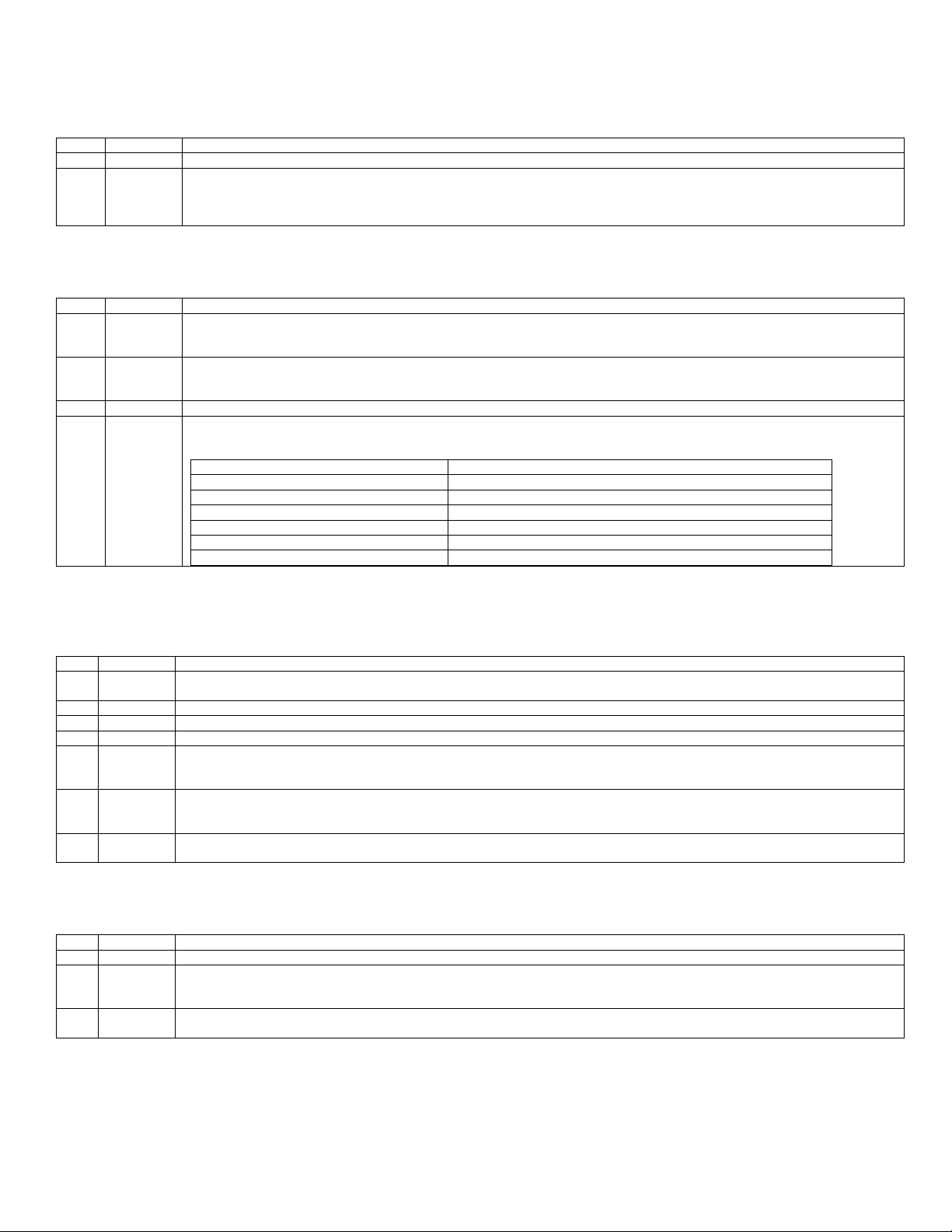

reserved bits. Data transfers between registers of different sizes are handled as shown in Table 2-1.

If the source and destination registers are both 8 bits wide, data is copied bit to bit.

If the source register is 8 bits wide and the destination register is 16 bits wide, the data from the source register is

transferred into the lower 8 bits of the destination register. The upper 8 bits of the destination register are set to

the current value of the prefix register; this value is normally zero, but it can be set to a different value by the

previous instruction if needed. The prefix register reverts back to zero after one cycle, so this must be done by the

instruction immediately before the one that will be using the value.

If the source register is 16 bits wide and the destination register is 8 bits wide, the lower 8 bits of the source are

transferred to the destination register.

If both registers are 16 bits wide, data is copied bit to bit.

The above rules apply to all data movements between defined registers. Data transfer to/from undefined register locations

has the following behavior:

If the destination is an undefined register, the MOVE is a dummy operation but may trigger an underlying

operation according to the source register (e.g., @DPn--).

If the destination is a defined register and the source is undefined, the source data for the transfer will depend

upon the source module width. If the source is from a module containing 8-bit or 8-bit and 16-bit source registers,

the source data will be equal to the prefix data as the upper 8 bits and 00h as the lower 8 bits. If the source is

from a module containing only 16-bit source registers, 0000h source data is used for the transfer.

12

Page 13

DS4830 User’s Guide

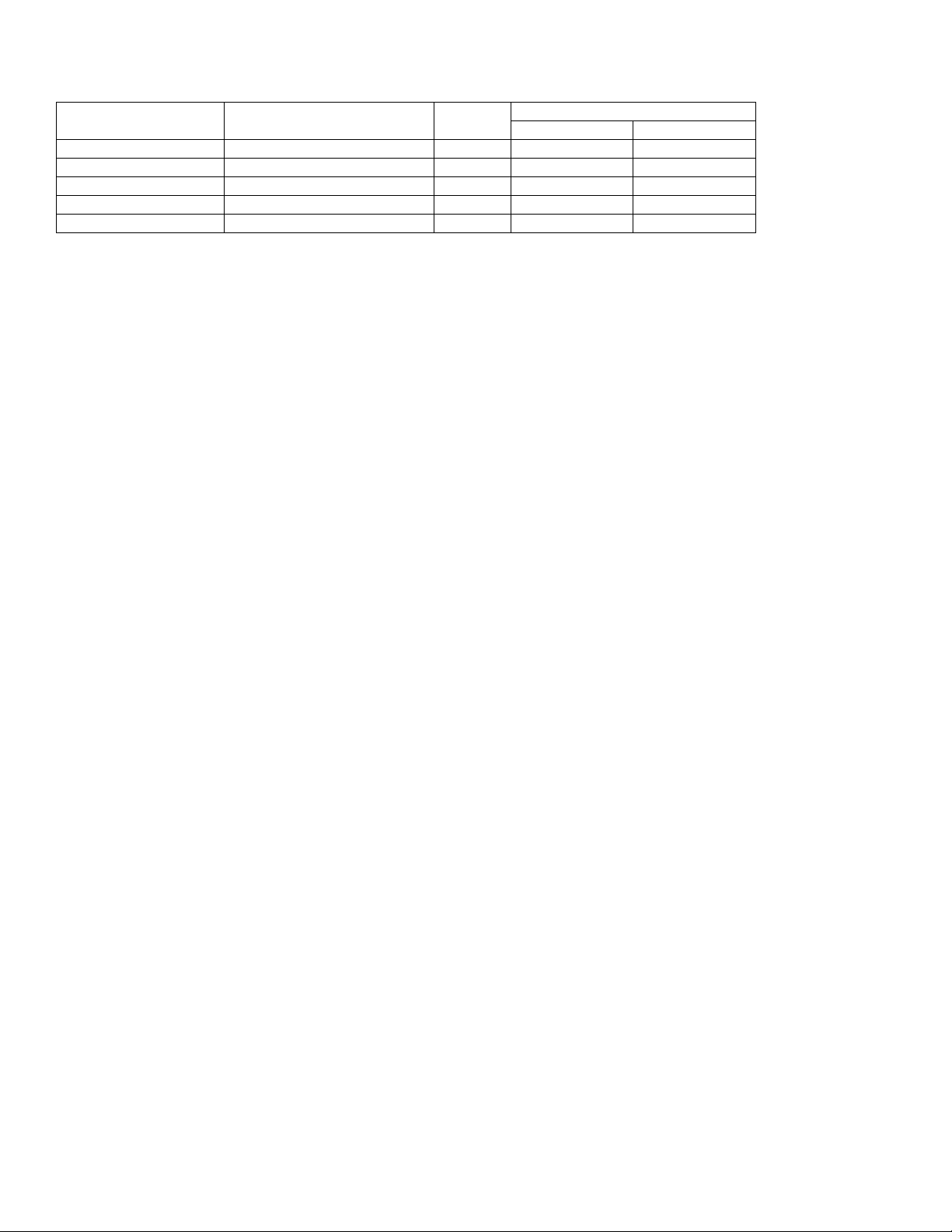

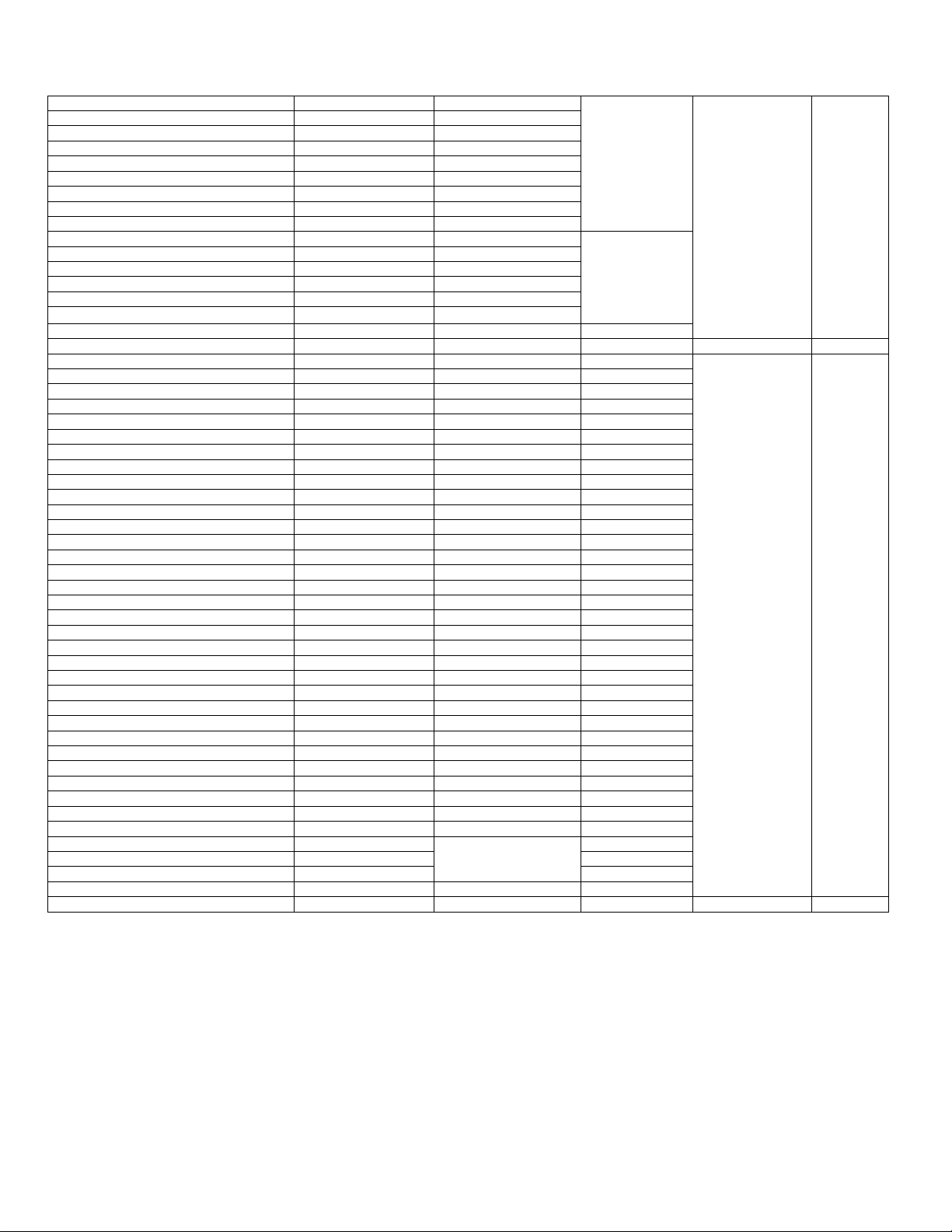

SOURCE REGISTER

SIZE (BITS)

DESTINATION REGISTER

SIZE (BITS)

PREFIX

SET?

DESTINATION SET TO VALUE

HIGH 8 BITS

LOW 8 BITS

8

8

X — Source [7:0] 8 16

No

00h

Source [7:0] 8 16

Yes

PFX [7:0]

Source [7:0]

16

8

X — Source [7:0]

16

16

X

Source [15:8]

Source [7:0]

Table 2-1. Register-to-Register Transfer Operations

2.3 – Memory Types

In addition to the internal register space, the DS4830 incorporates the following memory types:

32KWords of flash memory

4KWords of utility ROM contain a debugger and program loader

1KWords of SRAM

16-level stack memory for storage of program return addresses

The memory on the DS4830 is organized according to a Harvard architecture. This means that there are separate busses

for both program and data memory. Stack memory is also separate and is accessed through a dedicated register set.

2.3.1 – Flash Memory The DS4830 contains 32KWords (32K x 16) of flash memory. The flash memory begins at address 0000h and is contiguous through word address 7FFFh. The flash memory can also be used for storing lookup tables and other nonvolatile data.

The incorporation of flash memory allows the contents of the flash memory to be upgraded in the field, either by the

application or by one of the bootloaders (JTAG or I2C). Writing to flash memory must be done indirectly by using routines

that are provided by the utility ROM. See the Utility ROM and In-System Programming sections for more details.

2.3.2 – SRAM Memory

The DS4830 contains 1KWords (1K x 16) of SRAM memory. The SRAM memory address begins at address 0000h and

is contiguous through word address 03FFh. The contents of the SRAM are indeterminate after power-on reset, but are

maintained during non-POR resets.

When using the in-circuit debugging features, the highest 19 bytes of the SRAM must be reserved for saved state storage

and working space for the debugging routines. If in-circuit debug is not used, the entire 1KWords of SRAM is available for

application use.

2.3.3 – Utility ROM

The utility ROM is a 4kWord segment of memory. The utility ROM memory address begins at word address 8000h and is

contiguous through word address 8FFFh. The utility ROM is programmed at the factory and cannot be modified. The

utility ROM provides the following system utility functions:

Reset vector (not user code reset vector)

In-system programming (bootstrap loader) over JTAG or I2C-compatible interfaces

In-circuit debug routines

Routines for in-application flash programming

Following any reset, the DS4830 automatically starts execution at the Reset Vector which is address 8000h in the utility

ROM. The ROM code determines whether the program execution should immediately jump to the start of application code

(flash address 0000h), or to one of the special routines mentioned. Routines within the utility ROM are firmwareaccessible and can be called as subroutines by the application software. See the Utility ROM, In-System Programming,

and In-Circuit Debug sections for more information on the routines provided by the utility ROM.

2.3.4 – Stack Memory

A 16-bit, 16-level on-chip stack provides storage for program return addresses and temporary storage of system registers.

The stack is used automatically by the processor when the CALL, RET, and RETI instructions are executed, and when an

interrupt is serviced. The stack can also be used explicitly to store and retrieve data by using the @SP- - source, @++SP

destination, or the PUSH, POP, and POPI instructions. The POPI instruction acts identically to the POP instruction except

that it additionally clears the INS bit.

13

Page 14

DS4830 User’s Guide

The width of the stack is 16 bits to accommodate the instruction pointer size. On reset, the stack pointer SP initializes to

the top of the stack (0Fh). The CALL, PUSH, and interrupt vectoring operations first increment SP and then store a value

at @SP. The RET, RETI, POP, and POPI operations first retrieve the value at @SP and then decrement SP.

The stack memory is initialized to indeterminate values upon reset or power-up. Stack memory is dedicated for stack

operations only and cannot be accessed by the DS4830 program or data busses.

When using the in-circuit debugging features, one word of the stack must be reserved for the debugging routines. If incircuit debug is not used, the entire stack is available for application use.

2.4 – Program and Data Memory Mapping and Access

The memory on the DS4830 is implemented using a Harvard architecture, with separate busses for program and data

memory. The Memory Management Unit (MMU) allows the DS4830 to also support a pseudo-Von Neumann memory

map. The pseudo Von Neumann memory map allows each of the memory segments (flash, SRAM, and utility ROM) to

be logically mapped into a single contiguous memory map. This allows all of the memory segments to be accessed as

both program and memory data. The advantages the pseudo-Von Neumann memory map provides are:

Program execution can occur from the flash, SRAM, or utility ROM memory segments

The SRAM and flash memory segments can both be used for data memory.

Using the pseudo-Von Neumann memory map does have one restriction. This restriction is that a particular memory

segment cannot be simultaneously accessed as both program and data memory.

2.4.1 – Program Memory Access

The instructions that the DS4830 is executing reside in what is defined as the program memory. The MMU fetches the

instructions using the program bus. The Instruction Pointer (IP) register designates the program memory address of the

next instruction to fetch. The Instruction Pointer is read/write accessible by the user software. A write to the Instruction

Pointer will force program flow to the new address on the next cycle following the write. The content of the Instruction

Pointer will be incremented by 1 automatically after each fetch operation. From an implementation perspective, system

interrupts and branching instructions simply change the contents of the Instruction Pointer and force the op code to fetch

from a new program location.

14

Page 15

DS4830 User’s Guide

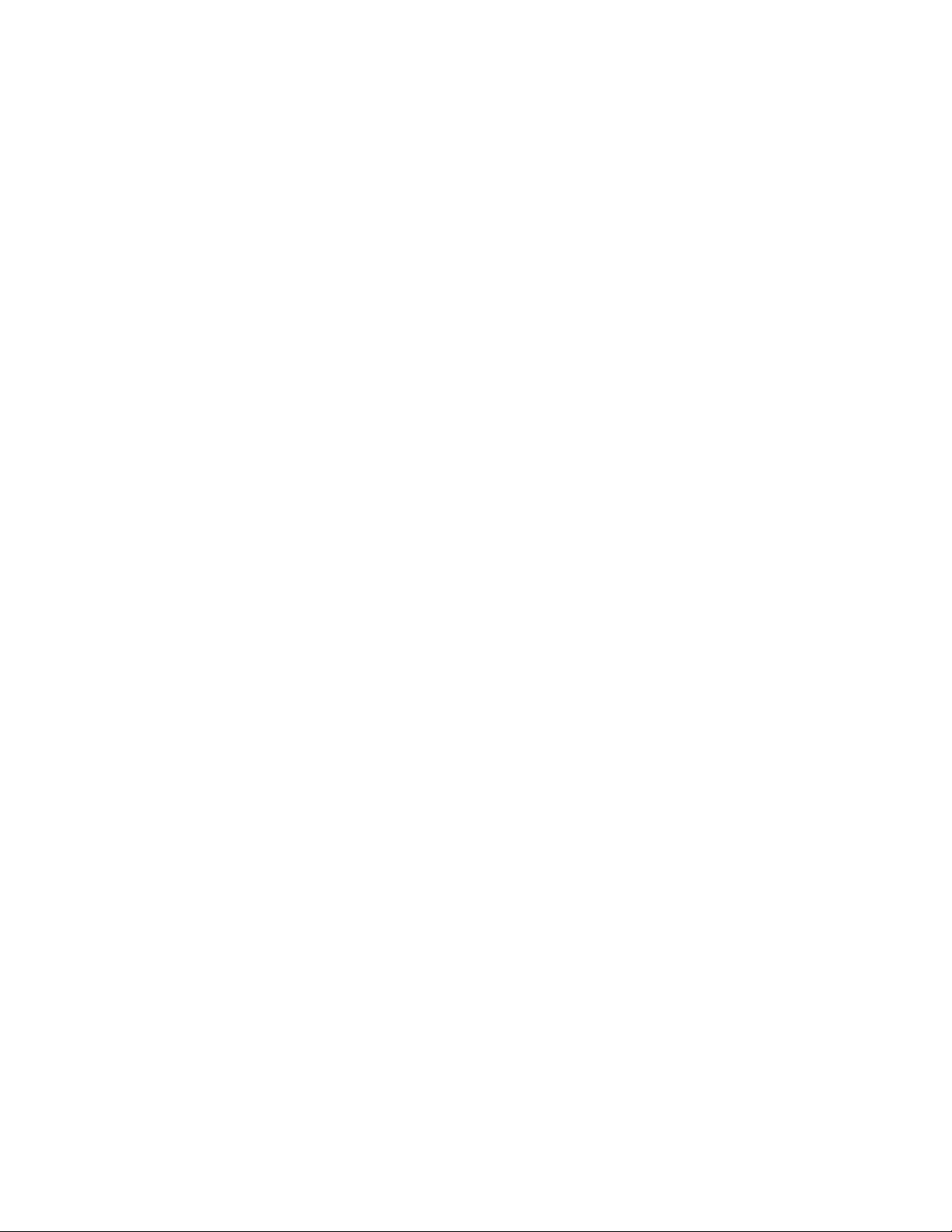

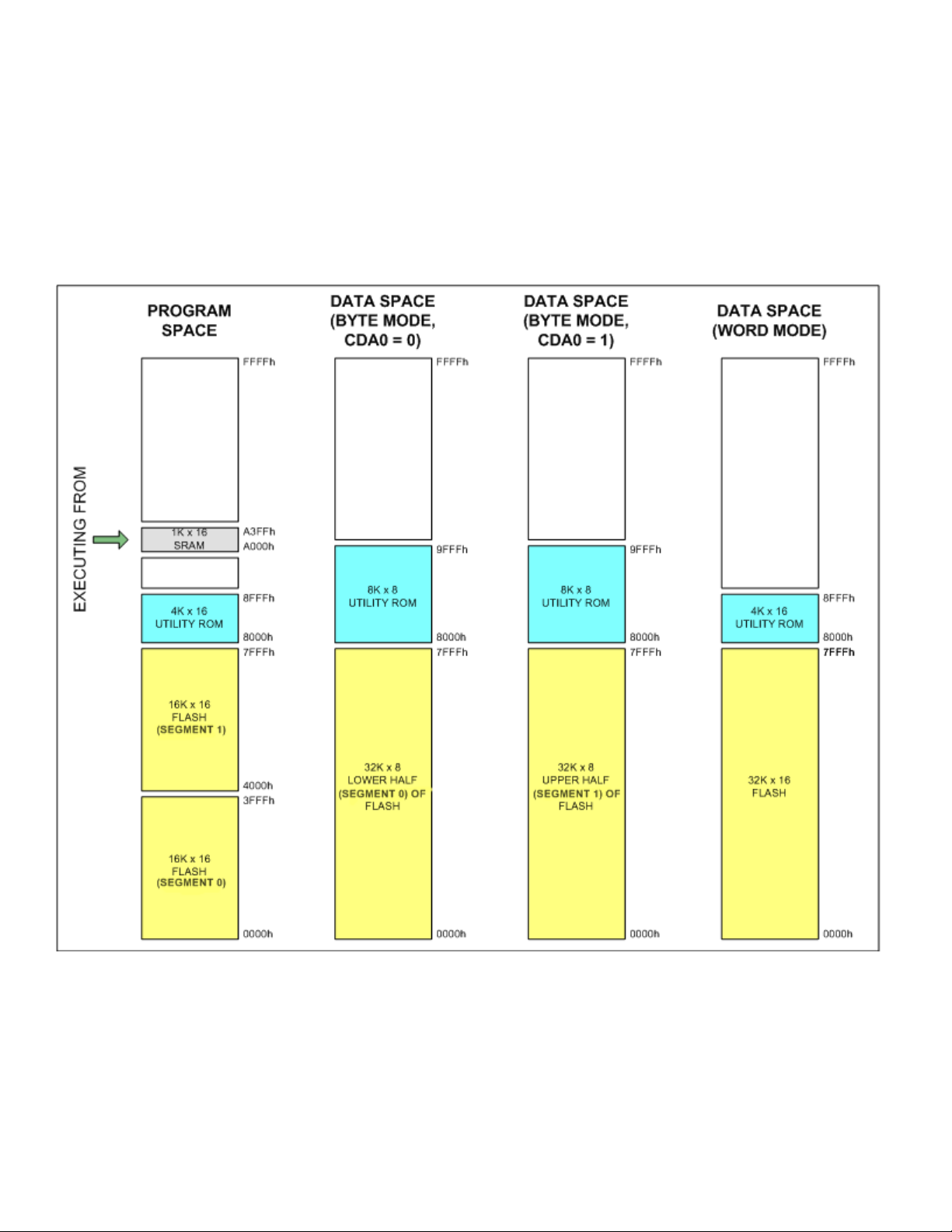

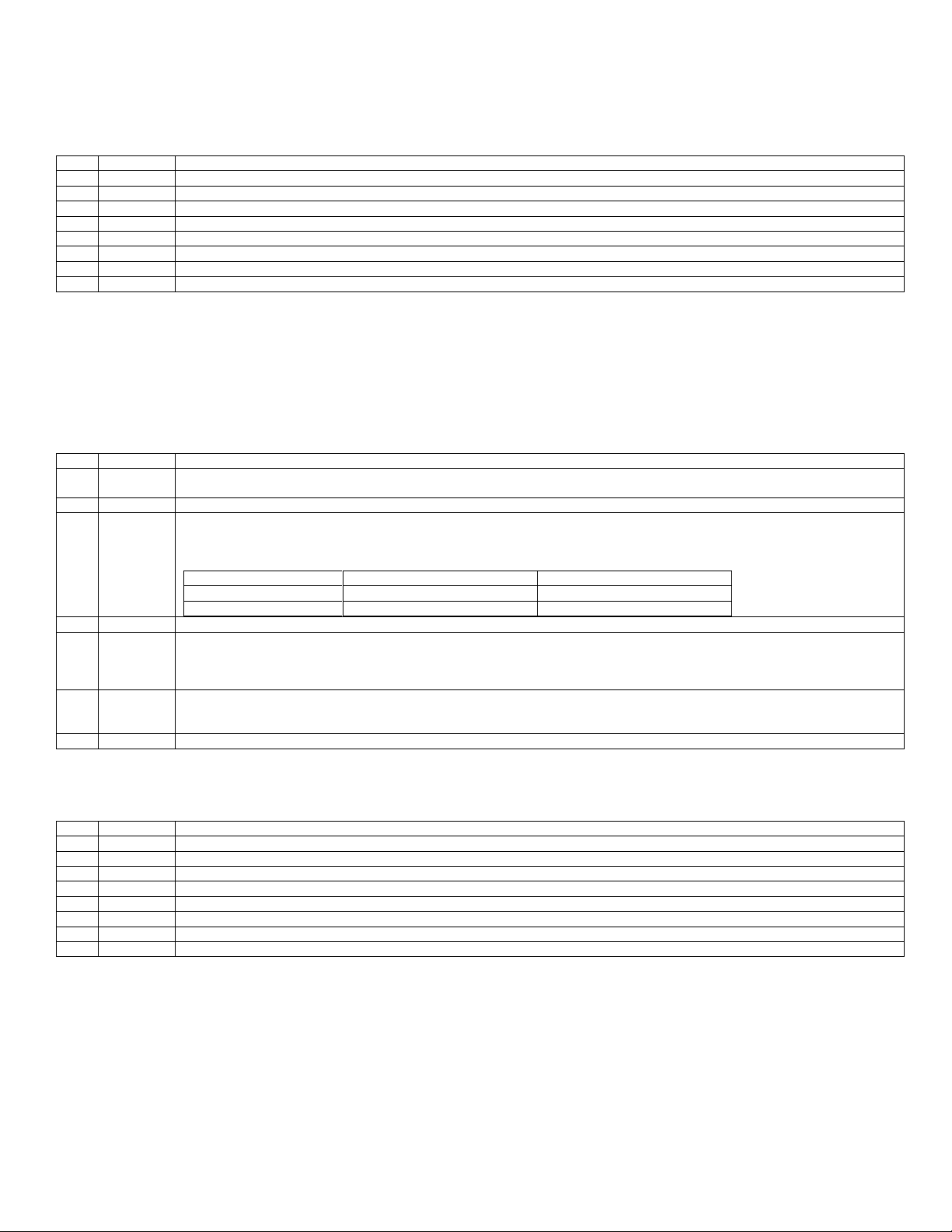

2.4.2 – Program Memory Mapping

The DS4830’s mapping of the three memory segments (flash, SRAM, and utility ROM) as program memory is shown in

Figure 2-2. The mapping of memory segments into program space is always the same. When referring to memory as

program memory, all addresses are given as word addresses. The 32KWord flash memory segment is located at

memory location 0000h through 7FFFh and is logically divided into two pages, each containing 16KWords. The utility

ROM is located from location 8000h through 8FFFh, followed by the SRAM memory segment at location A000h through

A3FFh. The user code reset vector, which is the first instruction of user program code that is executed, is located at flash

memory address 0000h. User program code should always begin at this address.

Figure 2-2: Program Memory Mapping

2.4.3 – Data Memory Access

Data memory mapping and access control are handled by the memory management unit (MMU). Read/write access to

data memory can be in word or in byte mode. The DS4830 provides three pointers that can be used for indirect

accessing of data memory. The DS4830 has two data pointers (@DPn) and one frame pointer (@BP[OFFS]). These

pointers are implemented as registers that can be directly accessed by user software. A data memory access requires

only one system clock period.

2.4.3.1 – Data Pointers

To access data memory, the data pointers are used as one of the operands in a MOVE instruction. If the data pointer is

used as a source, the core performs a load operation that reads data from the memory location addressed by the data

15

Page 16

DS4830 User’s Guide

CDA0

Selected Page in Byte Mode

Selected Page in Word Mode

0

P0

P0 and P1

1

P1

P0 and P1

pointer. If the data pointer is used as destination, the core performs a store operation that writes data to the memory

location addressed by the data pointer. Following are some examples of setting and using a data pointer.

move DP[0], #0100h ; set pointer DP[0] to address 100h

move Acc, @DP[0] ; read data from location 100h

move @DP[0], Acc ; write to location 100h

The address pointed to by the data pointers can be automatically incremented or decremented. If the data pointer is used

as a source, the pointer can be incremented or decremented after the data access. If the data pointer is used as a

destination, the increment or decrement can occur prior to the data access. Following are examples of using the data

pointers increment/decrement features.

move Acc, @DP[0]++ ; increment DP[0] after read

move Acc, @DP[1]-- ; decrement DP[1] after read

move @++DP[0], Acc ; increment DP[0] before write

move @--DP[1], Acc ; decrement DP[0] before write

2.4.3.2 – Frame Pointer

The frame pointer (BP[OFFS]) is formed by the 16-bit unsigned addition of the 16-bit Frame Pointer Base Register (BP)

and the 8-bit Frame Pointer Offset Register (OFFS). The method the DS4830 uses to access data using the frame

pointer is similar to the data pointers. When increments or decrements are used, only the value of OFFS is incremented

or decremented. The base pointer (BP) will remain unaffected by increments or decrements of the OFFS register,

including when the OFFS register rolls over from FFh to 00h or from 00h to FFh. Following are examples of how to use

the frame pointer.

move BP, #0100h ; set base pointer to address 100h

move OFFS, #10h ; set the offset to 10h,

move Acc, @BP[OFFS] ; read data from location 0110h

move @BP[OFFS], Acc ; write data to location 0110h

move Acc, @BP[OFFS++] ; increment OFFS after read

move Acc, @BP[OFFS++] ; decrement OFFS after read

move @BP[++OFFS], Acc ; increment OFFS before write

move @BP[--OFFS], Acc ; decrement OFFS before write

2.4.4 – Data Memory Mapping

The DS4830’s pseudo-Von Neumann memory map allows the MMU to read data from each of the three memory

segments (flash, SRAM, utility ROM). The MMU can also write data directly to the SRAM memory segment. Data

memory can be written to the flash memory segment, but because writing to flash requires the use of the utility ROM

routines, this is not a direct access. The logical mapping of the three memory segments as data memory varies

depending upon:

which memory segment instructions are currently being executed from

if data memory is being accessed in word or byte mode

In all cases, whichever memory segment is currently being used as program memory cannot be accessed as data

memory.

When the program is currently executing instructions from either the SRAM or utility ROM memory segments, the flash

memory will be mapped to half of the data memory space. If word access mode is selected, both pages (32KWords) can

be logically mapped to data memory space. If byte access mode is selected, only one page (32KBytes) can be logically

mapped to half of the data memory space. When operating in byte access mode, the selection of which flash page is

mapped into data memory space is determined by the Code Data Access bit (CDA0):

The next three sections detail the mapping of the different memory segments as data memory depending upon which

memory segment instructions are currently being executed from.

16

Page 17

DS4830 User’s Guide

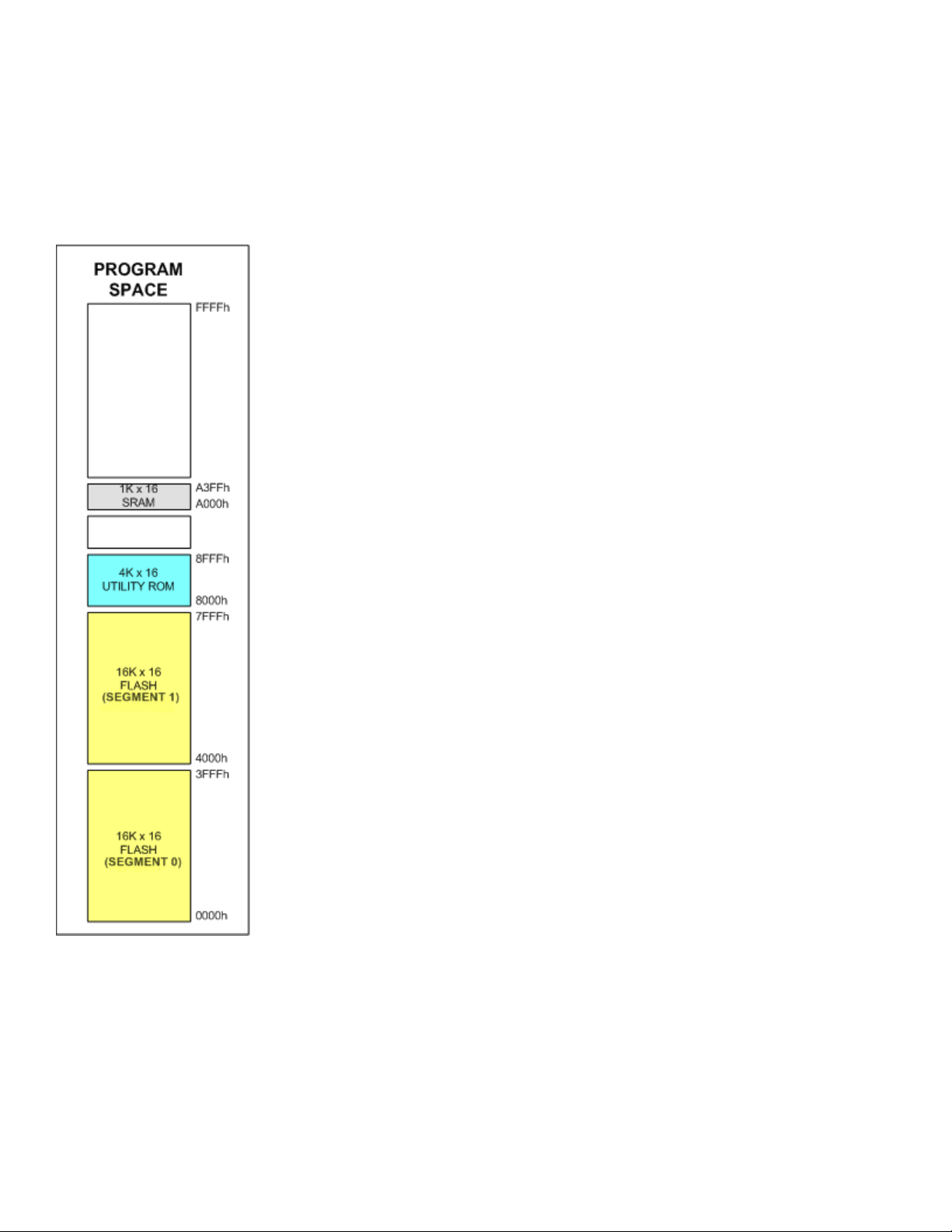

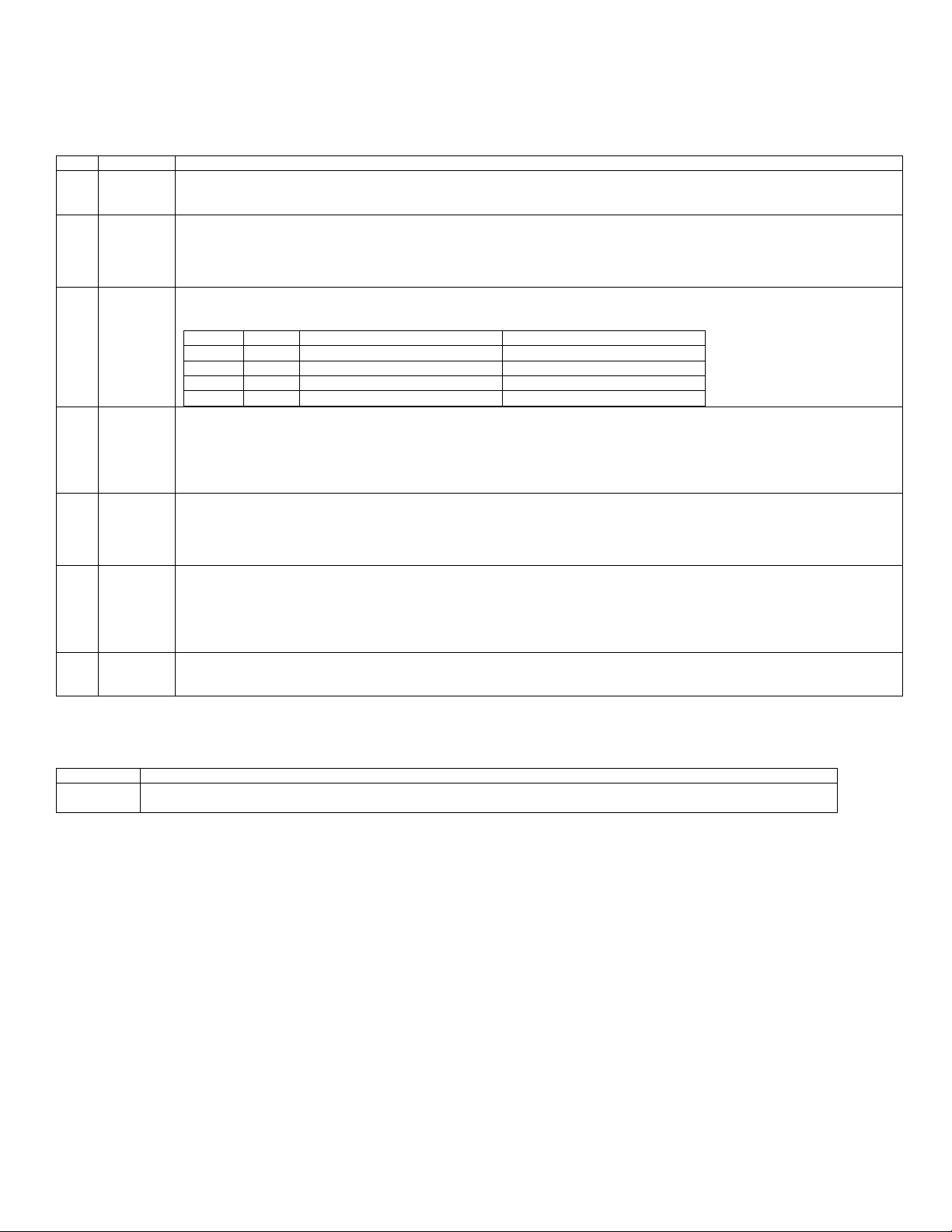

2.4.4.1 – Memory Map When Executing from Flash Memory

When executing from the flash memory:

Read and write operations of SRAM memory are executed normally.

The utility ROM can be read as data, starting at 8000h of the data space. The utility ROM cannot be written.

Figure 2-3 illustrates the mapping of the SRAM and utility ROM memory segments into data memory space when code is

executing from the flash memory segment.

Figure 2-3: Memory Map When Executing from Flash Memory

17

Page 18

DS4830 User’s Guide

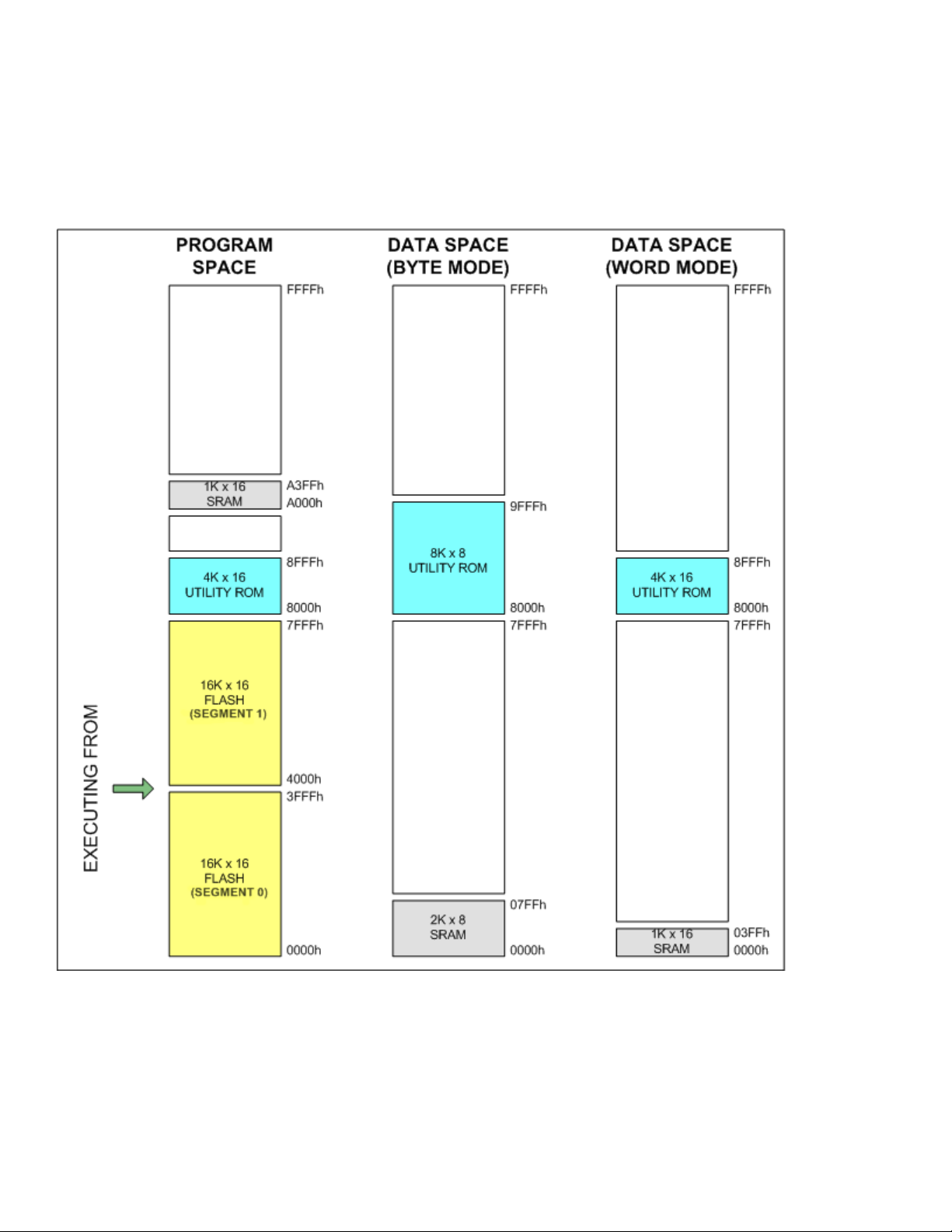

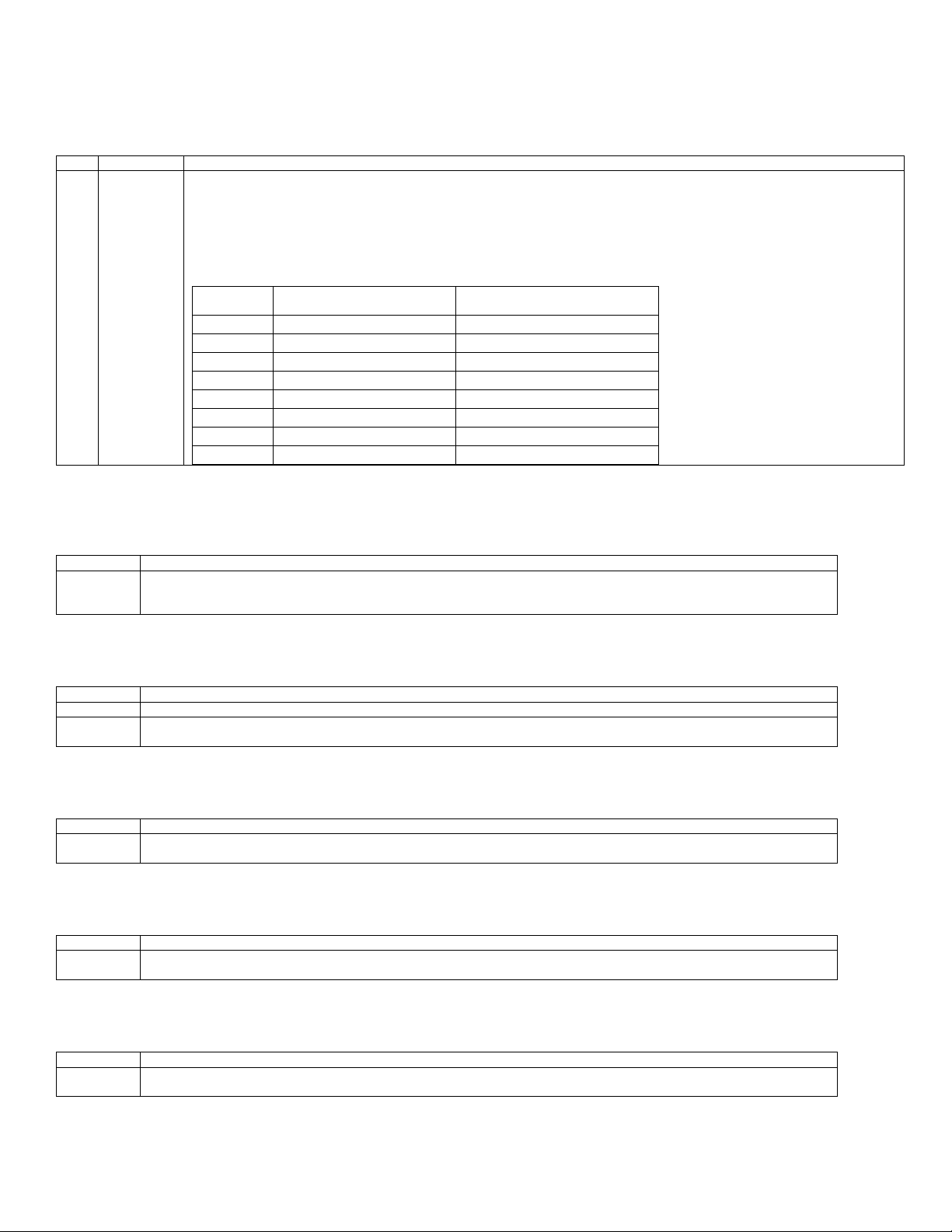

2.4.4.2 – Memory Map When Executing from Utility ROM

When executing from the utility ROM:

Read and write operations of SRAM memory are executed normally.

Reading of flash memory is executed normally. Writing to flash memory requires the use of the utility ROM

routines.

One page (byte access mode) or both pages (word access mode) of the flash memory can be accessed as data

with an offset of 8000h as determined by the CDA0 bit.

Figure 2-4 illustrates the mapping of the SRAM and flash memory segments into data memory space when code is

executing from the utility ROM memory segment.

Figure 2-4: Memory Map When Executing from Utility ROM

18

Page 19

DS4830 User’s Guide

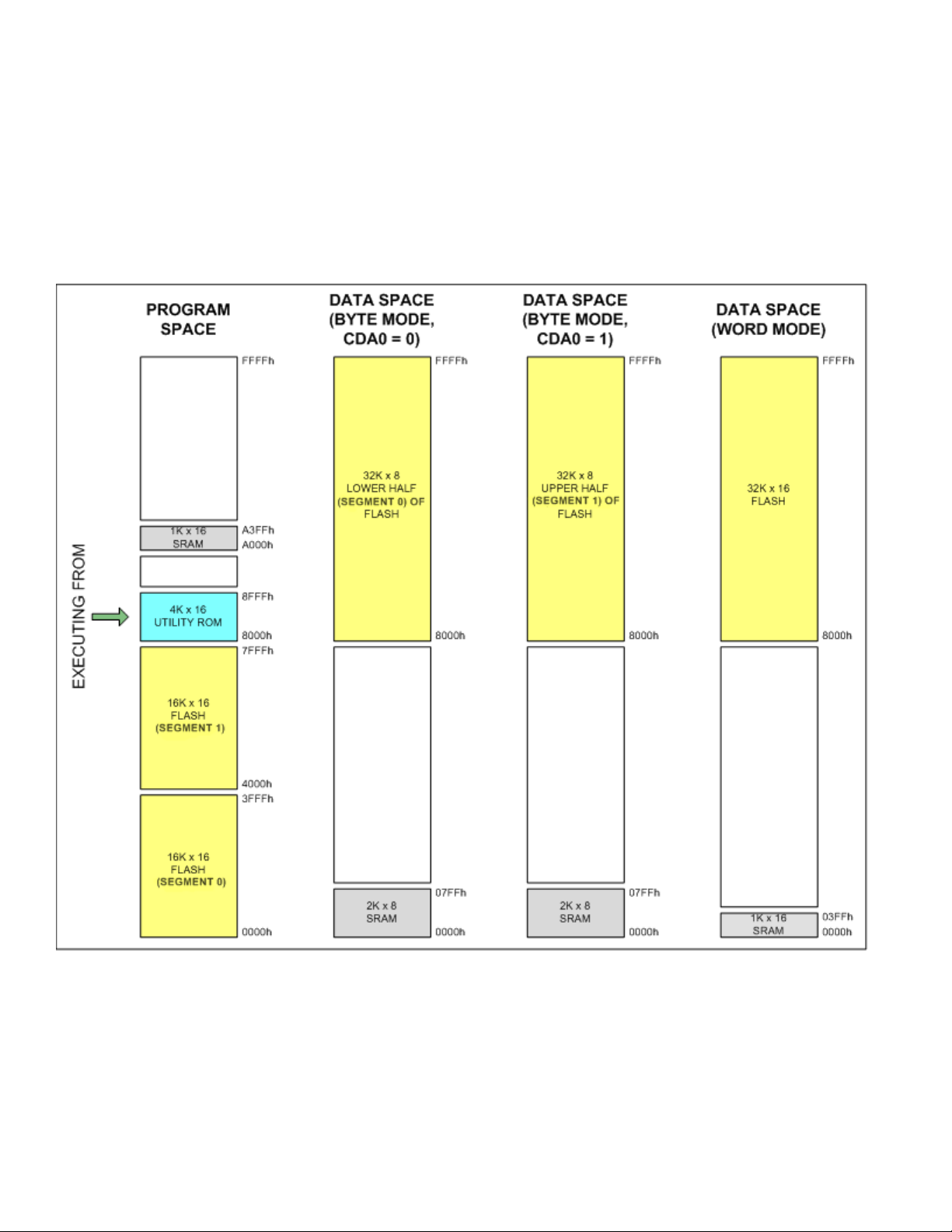

2.4.4.3 – Memory Map When Executing from SRAM

When executing from the SRAM:

The utility ROM can be read as data, starting at 8000h of the data space. The utility ROM cannot be written.

Reading of flash memory is executed normally. Writing to flash memory requires the use of the utility ROM

routines.

One page (byte access mode) or both pages (word access mode) of the flash memory can be accessed as data

with an offset of 0000h. For byte access mode, the page of flash accessed is determined by the CDA0 bit.

Figure 2-5 illustrates the mapping of the flash and utility ROM memory segments into data memory space when code is

executing from the SRAM memory segment.

Figure 2-5: Memory Map When Executing from SRAM

19

Page 20

DS4830 User’s Guide

2.5 – Data Alignment

To support merged program and data memory operation while maintaining efficient memory space usage, the data

memory must be able to support both byte and word mode accessing. Data is aligned in data memory as words, but the

effective data address is resolved to bytes. This data alignment allows program instruction fetching in words while

maintaining data accessibility at the byte level. It is important to realize that this accessibility requires strict word

alignment. All executable or data words must align to an even address in byte mode. Care must be taken when updating

a code segment as misalignment of words will likely result in loss of program execution control.

Memory will always be read as a complete word, whether for program fetch or data access. The program decoder always

uses a full 16-bit word. The data access can utilize a word or an individual byte. Data memory is organized as two bytewide memory banks with common word address decode but two 8-bit data buses. In byte mode, data pointer hardware

reads out the full word containing the selected byte using the effective data word address pointer (the least significant bit

of the byte data pointer is not initially used). Then, the least significant data pointer bit functions as the byte select that is

used to place the correct byte on the data bus. For write access, data pointer hardware addresses a particular word using

the effective data word address while the least significant bit selects the corresponding data bank for write. The contents

of the other byte are left unaffected.

2.6 – Reset Conditions

The DS4830 has several possible sources of reset.

Power-On/Brownout Reset

Watchdog Timer Reset

External Reset

Internal System Reset

Once a reset condition has completed or been removed, code execution begins at the beginning of utility ROM, which is

address 8000h. The utility ROM code interrogates the I2C_SPE, JTAG_SPE, and PWL bits to determine if bootloading is

necessary. If bootloading is not required, execution will jump to the user code reset vector, which is at flash memory

address 0000h.

The /RST\ pin is an output as well as an input. If a reset condition is generated by one of the DS4830’s internal reset

sources (brownout, watchdog timer, or internal reset), an output reset pulse is generated on the /RST\ pin while the

DS4830 remains in reset.

2.6.1 – Power-On/Brownout Reset

The DS4830 provides a power-on reset (POR) circuit to ensure proper initialization of internal device states and analog

circuits. The POR voltage threshold range is between approximately 1.1V and 1.7V. When VDD is below the POR level,

the state of all the DS4830 pins, including /RST\, is weak pull up.

The DS4830 also includes brownout detection capability. This is an on-chip precision reference and comparator that

monitors the supply voltage, VDD, to ensure that it is within acceptable limits. If VDD is below the brownout level (VBO), the

power monitor generates a reset. This can occur when:

The DS4830 is being powered up and VDD is above the POR level but still less than VBO.

VDD drops from an acceptable level to less than VBO.

Once VDD exceeds VBO, the DS4830 exits the reset condition and the internal oscillator starts up. After approximately 1ms

(t

The transition between POR, Brownout, and normal operation is detailed in Figure 2-6: DS4830 State Diagram.

Note: If VDD is below VBO, there is a chance that the SRAM was corrupted. If the POR flag in WDCN is set, all data in

SRAM should be re-initialized.

) the DS4830 performs the following tasks.

SU:MOSC

All registers and circuits enter their reset state

The POR flag in the Watchdog Control Register is set to indicate the source of the reset

The DS4830 begins normal operation (CPU State)

Code execution begins at utility ROM location 8000h

20

Page 21