Page 1

A Maxim Integrated Products Brand

78M6612 M-API Library

User Guide

September 30, 2010

Rev. 1.00

UG_6612_036

Page 2

78M6612 M-API Library User Guide UG_6612_036

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit

patent licenses are implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Int egrated Products, 120 San Gabriel Drive, Sunnyvale, CA 9408 6 408-737-7600

2010 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products.

Page 3

UG_6612_036 78M6612 M-API Library User Guide

Table of Contents

1 Introduction ......................................................................................................................................... 5

1.1 Terminology .................................................................................................................................. 5

1.2 Library Measurement Equations ................................................................................................... 6

1.3 Library Parameters ....................................................................................................................... 7

1.3.1 Global Symbols ................................................................................................................. 7

1.3.2 Formulae for Scaled Parameters ...................................................................................... 7

1.3.3 Example Calculation of Sensor Parameters ..................................................................... 8

1.4 Reference Documentation ............................................................................................................ 8

2 Firmware Partitions ............................................................................................................................ 9

3 Build Environment and Software/Firmware Configurations ........................................................ 10

3.1 Firmware Library and CE Mem ory Configurations ..................................................................... 10

3.2 Program and RAM Memory ........................................................................................................ 10

3.2.1 Program Memory ............................................................................................................. 10

3.2.2 RAM/Data Memory .......................................................................................................... 11

3.3 Build Configuration...................................................................................................................... 11

3.3.1 Flash/Code and RAM Size .............................................................................................. 11

3.3.2 Flash/Code Space Assignment ....................................................................................... 12

3.3.3 Library Assignment .......................................................................................................... 13

3.3.4 Module’s Selection within a Library ................................................................................. 14

4 MAPI Libraries ................................................................................................................................... 17

4.1 Library Initialization and Operation ............................................................................................. 17

4.1.1 MAPI_Init() ....................................................................................................................... 17

4.1.2 MAPI_MeterRun() ........................................................................................................... 17

4.1.3 MAPI_MinMaxSetGet() ................................................................................................... 17

4.2 Library Inputs and Outputs ......................................................................................................... 18

4.2.1 MAPI_GetSetRegister() ................................................................................................... 18

4.3 CE and MPU Control .................................................................................................................. 23

4.3.1 MAPI_CEOn().................................................................................................................. 23

4.3.2 MAPI_CEOff().................................................................................................................. 23

4.3.3 MAPI_GetCEName() ....................................................................................................... 23

4.3.4 MAPI_SoftReset() ........................................................................................................... 23

4.3.5 MAPI_HardReset() .......................................................................................................... 24

4.3.6 MAPI_UpdateMPU() ........................................................................................................ 24

4.3.7 MAPI_UpdateCE() ........................................................................................................... 24

4.4 Calibration and Power Measurement ......................................................................................... 25

4.4.1 MAPI_CalSetGet() ........................................................................................................... 25

4.4.2 MAPI_Calibrate() ............................................................................................................. 27

4.4.3 MAPI_MeterStatus() ........................................................................................................ 28

4.4.4 MAPI_TimeToAverage() .................................................................................................. 30

4.4.5 MAPI_GetEnergyUsed() .................................................................................................. 30

4.4.6 MAPI_GetVoltageCurrent() ............................................................................................. 31

4.5 Zero Crossing and Relay Control ............................................................................................... 32

4.5.1 MAPI_RelayConfig() ........................................................................................................ 32

4.5.2 MAPI_RelayControl () ..................................................................................................... 33

4.5.3 MAPI_CloseCircuit_0X() ................................................................................................. 33

4.5.4 MAPI_OpenCircuit_0X() .................................................................................................. 33

4.6 Soft-Timers ................................................................................................................................. 34

4.6.1 MAPIstm_init() ................................................................................................................. 34

4.6.2 MAPIstm_fn_start() ......................................................................................................... 34

4.6.3 MAPIstm_run() ................................................................................................................ 34

4.6.4 MAPIstm_wait() ............................................................................................................... 34

Rev. 1.00 3

Page 4

78M6612 M-API Library User Guide UG_6612_036

4.7 DIO Configuration (future release) .............................................................................................. 35

4.7.1 MAPI_DIOConfig() .......................................................................................................... 35

4.7.2 MAPI_DIORW() ............................................................................................................... 36

4.8 Flash Management ..................................................................................................................... 37

4.8.1 Memcpy_rx() .................................................................................................................... 37

4.8.2 Memcpy_xr() .................................................................................................................... 38

4.8.3 Memcpy_xx() ................................................................................................................... 38

4.9 Serial/RS232 Interface ................................................................................................................ 39

4.9.1 MAPI_UARTInit() ............................................................................................................. 39

4.9.2 MAPI_UARTTx().............................................................................................................. 39

4.9.3 MAPI_TxLen() ................................................................................................................. 40

4.9.4 MAPI_UARTRx() ............................................................................................................. 40

4.9.5 MAPI_RxLen() ................................................................................................................. 40

5 Default Values ................................................................................................................................... 41

6 Contact Information .......................................................................................................................... 42

Revision History ........................................................................................................................................ 43

Figure

Figure 1: High Level Host/Firmware Interface Architecture

Tables

Table 1: CE Configuration ........................................................................................................................... 10

Table 2: Flash Memory Map ....................................................................................................................... 10

Table 3: Data RAM Shared by CE and MPU .............................................................................................. 11

Table 4: Flash and RAM Consumption by MAPI and Sample Application ................................................. 11

Table 5: Breakdown of M-API’s Flash Consumption .................................................................................. 11

Table 6: MAPI Feature/Module Selections ................................................................................................. 15

.......................................................................... 9

4 Rev. 1.00

Page 5

UG_6612_036 78M6612 M-API Library User Guide

1 Introduction

This document describes the Metrology Appl icat ion Pro gr am ming Interface (M-API) version 2.00 firmware

libraries available from Teridian for use with the 78M6612 IC. These libraries are specifically designed for

measurement and switch control of two (2) single-phase AC outlets (same phase).

The firmware delivery is a set of metrology libraries that configure and operate the measurement front

end (e.g. MUX, ADC, CE, etc.) and provides simplified access to measurement output data such as

Power, Voltage, Current, accumulated Energy and Line Frequency. All measurement calculations are

computed by the MAPI library every accumulation interval and mapped to a dedicated block of registers

reserved by the library.

Measurement data are made available to the user application via API calls. A demo application making

use of the M-API library set and serial UART interface is included as part of the 78M6612 OMU

Evaluation Kit.

Timer functions using the hardware RTC are also available and can be accessed directly by the

application. APIs specific to RTC are not available in the current library. Contact a Teridian

representative for more information on non-Volatile RTC operation (e.g. battery backup modes).

1.1 Terminology

The following terminology is used throughout this document:

• CREEP – Threshold value where meas urem ent outp ut s are sque lched t o zero.

• IMAX – External RMS current corresponding to 250 mVpk at the current input of the 78M6612. It should be set

IMAX= (Vpk/√2)/R

• VARs – Reactive Power (Q)

SENSE

.

• VAs – Apparent Power (S).

• Watts – Active Power (P).

• VMAX – External RMS voltage corresponding to 250 mVpk at the voltage input of the 78M6612 (VA, VB). It

must be set high enough to account for over-voltages.

• NB – Narrowband values.

• WB – Wideband values.

Rev. 1.00 5

Page 6

78M6612 M-API Library User Guide UG_6612_036

1.2 Library Measurement Equations

The integrated Compute Engine (CE) accumulates the raw samples from the ADC and provides to the

80515 MPU the critical *atomic measurements needed to derive all other data. This consists of RMS

Voltage, Voltage Sag Status , and AC Line Freq uency data as well as RMS Current, Active Po wer, and

Reactive Power for each outlet. The MAPI library provides the application developer with two equation

options for processing the atomic values before updating the libraries output data registers. One equation

option is defined as “Narrowband” (NB) and the other is defined as “Wideband” (WB).

When using NB equations; RMS Voltage, Active Power, and Reactive Power data is provided by

the CE and used to derive RMS Current, Apparent Power, and Power Factor in the MPU for each

outlet. Harmonic content is not included in the reported current measurement.

*Voltage (V

Current (I

) = √∑v(t)2

RMS

) = S/V

RMS

RMS

*Active Power (P) = ∑ (i(t) * v(t))

*Reactive Power (Q) = ∑ (i(t) * v(t) shift 90º)

Apparent Power (S) = √(P

2

+ Q2)

Power Factor (PF) = P/S

When using WB equations (recommended); RMS Voltage, RMS Current, and Active Power data

provided by the CE is used to derive Reactive Power, Apparent Power, and Power Factor in the

MPU for each outlet.

*Voltage (V

*Current (I

) = √∑v(t)2

RMS

) = √∑i(t)2

RMS

*Active Power (P) = ∑ (i(t) * v(t))

RMS

2

– P2)

* I

RMS

Reactive Power (Q) = √(S

Apparent Power (S) = V

Power Factor (PF) = P/S

6 Rev. 1.00

Page 7

UG_6612_036 78M6612 M-API Library User Guide

1.3 Library Parameters

This section describes critical constants and variable parameters of the MAPI library and their

recommended usage.

1.3.1 Global Symbols

The following symbols are fixed constants for the MAPI v2.00 firmware library:

Samples : 1806

FS : 3641

POWERSCALE : 2.3439E-06

VRMS_MSCALE : 9.6827E-05

IRMS_MSCALE : 2.4207E-05

The following variables are unique to the sensor configuration and represent the real world values

mapped to the upper range of the 78M6612 analog front end.

IMAX : 52 Amps for 4mOhm shunt

VMAX : 471.5 Volts

1.3.2 Formulae for Scaled Parameters

The measurement outputs (and respective alarm thresholds) for the M-API library are stored in a raw

format to preserve native resolution of the computed measurements. When using API calls to access or

fetch measurement data, the values are automatically scaled and converted according to the data types,

below.

I

rms

V

rms

Watts = float(Val)* POWERSCALE*IMAX*VMAX/1000

Frequency = integer(Val)/100

Val : library data

In some rare cases, when raw measurement data (Val) is directly accessed without going through the

library, which is not recommended, scaling to and from real world or usable values must be done using

the formulae above.

= float(Val)* IRMS_MSCALE* IMAX*√(FS/Sampl es)

= float(Val)* VRMS _MSCALE* VMAX*√(FS/Samples)

Rev. 1.00 7

Page 8

78M6612 M-API Library User Guide UG_6612_036

1.3.3 Exam pl e Calculati on of Sensor Parameters

This example demonstrates the calculation of IMAX and VMAX for the default sensor configuration. For

more information on sensor selection and configuration, refer to the 78M6612 Hardware Design

Guidelines.

IMAX Calculation:

IMAX = Imax (pk) / sqrt(2) = Imax (rms)

Max ADC input = 250 mV = IMax (pk) * R shunt

Example:

With a 4 MΩ current shunt, IMax (pk) = 62.5A

=> IMAX = 52 Amps.

VMAX Calculation:

VMAX = Vmax (pk) / sqrt(2) = Vmax (rms)

Max ADC input = 250 mV = Vmax (pk) * Shunt R / (Series R - Shunt R)

Example:

With a Series R of 2 MΩ and a Shunt R of 750 ohms, VMax (pk) = 666.42 Volts.

=> VMAX = 471.23 Volts

1.4 Reference Documentation

• 78M6612 Data Sheet

• 78M6612 Hardware R efer e nce Manua l

• 78M6612 OMU Evaluat ion Boar d User Manua l (reference schematics)

• 78M6612 OMU Demo Application User Manual (CLI)

• 78M6612 OMU Firmware Description Document (register descriptions)

8 Rev. 1.00

Page 9

UG_6612_036 78M6612 M-API Library User Guide

UART/RS232 or I2C

Serial/I2C Host

Application

Host Controller

78M6612

CE

M-API

Application

2 Firmware Partitions

The 78M6612 firmware provided by Teridian is partitioned into three main components:

• The Compute Engine (CE) firmware, although a separate set of source code, is a component of the

MAPI libraries responsible for precision Voltage, Current, Watts, and VARs measurements handled

by a dedicated processor. The source code for the CE is not described in this document or made

available for user modification.

• The 80515-based M-API firmware, in combination with the CE firmware, completes the M-API librar y

set and provides all the necessary IC configuration, calibration sub-routines, scaling, data conversion,

and timing control. This set of libraries is to be linked to the application firmware specific to the

desired host interface.

• The Application firmware exercises the M-API library and manages the communication to the host

controller/application. Teridian provides an example Serial Driver to be used as sample code as well

as the application firmware that uses this Serial Driver to exercise the MAPI library. Refer to the

applicable Firmware Description Document for more information on the application firmware.

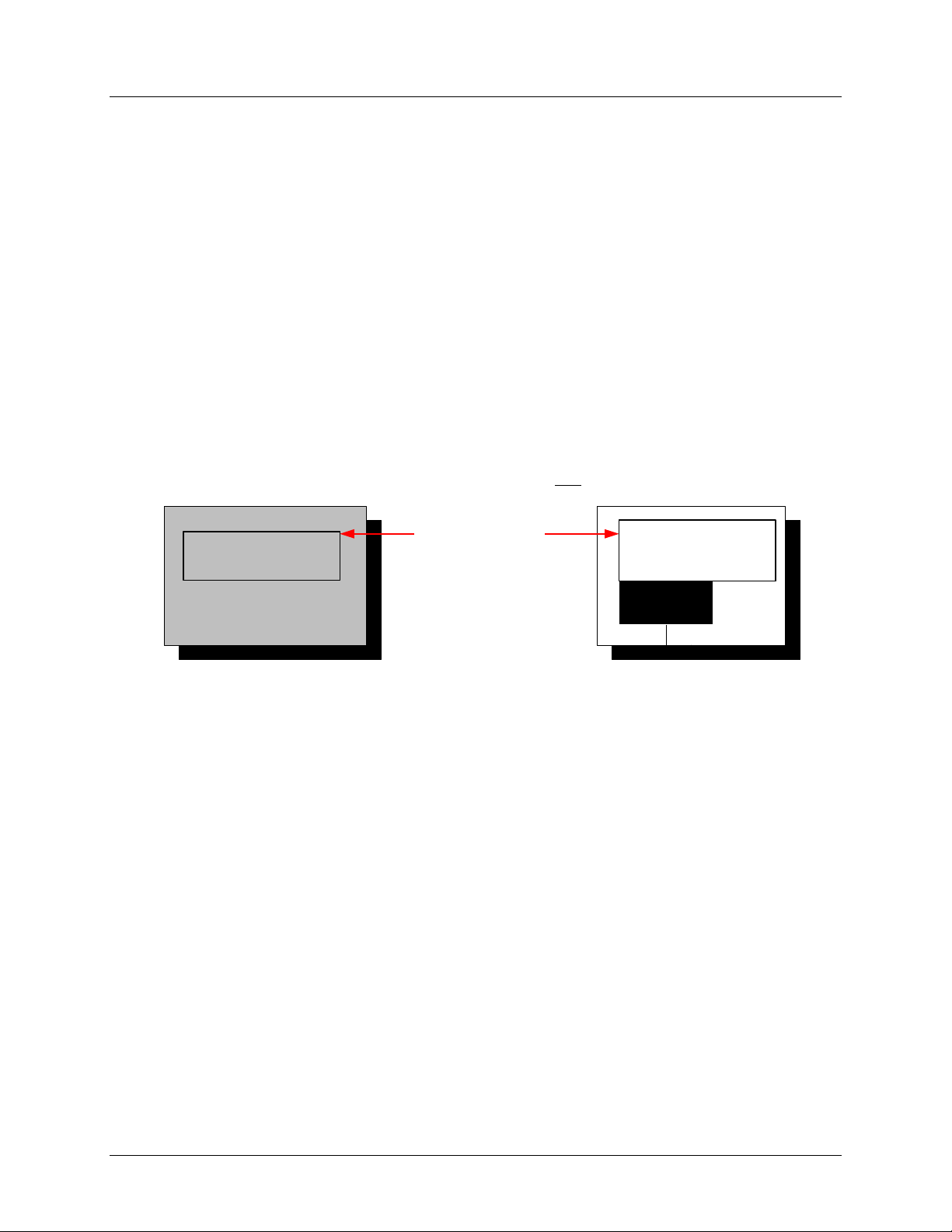

Figure 1 shows a high level partitioning of the firmware architecture. The black boxes indicate object

and

code to be provided by Teridian. The white box indicates object

source code provided by Teridian.

Figure 1: High Level Host/Firmware Interface Architecture

Rev. 1.00 9

Page 10

78M6612 M-API Library User Guide UG_6612_036

3 Build Environment and Software/Firmware Configurati ons

The Metrology Application Programming Interface (MAPI) is built using Keil Compiler version 8.02,

although any Keil version 7.00 or higher is also compatible.

The MAPI is built using specific default configuration as listed below.

3.1 Firmware Library and CE Memory Configurations

Processing of ADC inputs is done by the CE. The MAPI libraries are built to link to the specific CE code

according to the specific hardware conf ig urati on. The table below shows the different libraries as built

with specific CE code to support different configurations:

Table 1: CE Configuration

Library Name Default Accumulation Interval = 500ms

6612S22_WB_MAPI.lib Built for Wide-Band.

6612S22_NB_MAPI.lib Built for Narrow-Band.

3.2 Program and RAM Memory

The embedded 80515 MPU within the 78M6612 has separate program memory (32K bytes) and data

memory (2K bytes).

3.2.1 Pr ogr am Memory

The Flash program memory is non-volatile and is segmented into 512-byte pages. The last 2.5K (five

512-byte pages) of Flash space is reserved for CE data, CE code and default values used for Energy

Calibration and Measurement. The code for the Compute Engine program resides in the MPU program

memory (flash) and must begin on 1K-byte boundary.

Table 1 below shows the partitions of Flash memory.

Table 2: Flash Memory Map

Address (hex) Type Typical Usage

0000-75FF

7600-773E

777F-7FFF Non-volatile

Non-volatile

Non-volatile

Program and any non-volatile

data. Shared by the MAPI and

application layer.

Reserved for MAPI energy

measurement constants

(defaults).

Reserved for CE code and CE

data.

Wait States

(at 5 MHz)

0

0

0

Size (bytes)

29.5KB

< ~350B

2KB

10 Rev. 1.00

Page 11

UG_6612_036 78M6612 M-API Library User Guide

3.2.2 RAM/Data Memory

The 78M6612 has 2K bytes of Data Memory for exclusive use by the embedded 80515 MPU library and

application layers. In addition, there are 512 bytes reserved for the Compute Engine.

Table 3: Data RAM Shared by CE and MPU

Address (hex) Type Typical Usage Size (bytes)

0000-07FF Volatile MPU data XRAM, 2KB

1000-11FF Volatile CE data 512

2000-20FF Volatile

Miscellaneous I/O RAM

(configuration RAM)

256

3.3 Build Configuration

The accompanying example application source code has been set up to link to each library under specific

hardware configuration. Each configuration is defined under a different ‘Target’. However, for all ‘Targets’,

specific area of Flash is reserved for specific function as described below.

3.3.1 Flash/Code and RAM Size

The attached zipped file (78M6612MAPIv200.zip) contains a sample Application code, of which source

code is also included. The functions of this application are detailed in Section 6.

This sample applic at ion is taking up Flash/RAM usage according to the table below. It was written to

demonstrate the use of the MAPI libraries via two types of commands: the ‘M’ commands (as shown in

Section 6) to specifically address the MAPI calls; and the ‘CLI’, aka Command Line Interface, commands

for backward compatibility to support those who have evaluated, or are familiar with, Teridian OMU

products in the past.

The following tables show RAM and Flash consumptions by this sample application. They also show a

breakdown of Flash consumption by different features as implemented in the MAPI libraries.

Table 4: Flash and RAM Consumption by MAPI and Sample Application

Firmware Module

6612S22_WB_MAPI.lib

6612S22_NB_MAPI.lib

6612IVIV_50F0_v200WB.hex

6612IVIV_50F0_v200NB.hex

Table 5: Breakdown of M-API’s Flash Consumption

Library:

6612S22_WB_MAPI.lib

6612S22_NB_MAPI.lib

Calibration 5.7K Includes calibration for: Temperature, Current, Voltage,

Initialization, Default Settings 5.8K Initializes Defaults, Metering Constants Tables,

MAPI Interface (to App) 1.5K Direct interface to the library from application.

Flash Manager 2K Flash Read/Write management.

Rev. 1.00 11

RAM

Used

~ 26K The RAM usage is overlay-able. See the

1.7K 6K + 26K(lib) The app from this build uses every single API

Flash Used Features

Flash Used Note

breakdown of Flash usage in Table 5.

library call.

Watt and Phase.

Registers, etc.

Page 12

78M6612 M-API Library User Guide UG_6612_036

Metering 6K Metrology functions (alarms, power factor, RMS, etc.)

Measurement 2K Metrology computations

Serial Driver 1K Serial 0/RS232 I/O

Timer < 0.5K Timer 0 driver.

Relay Management/Misc . 2K Relay Control/On/Off, some math logic, IRQ.

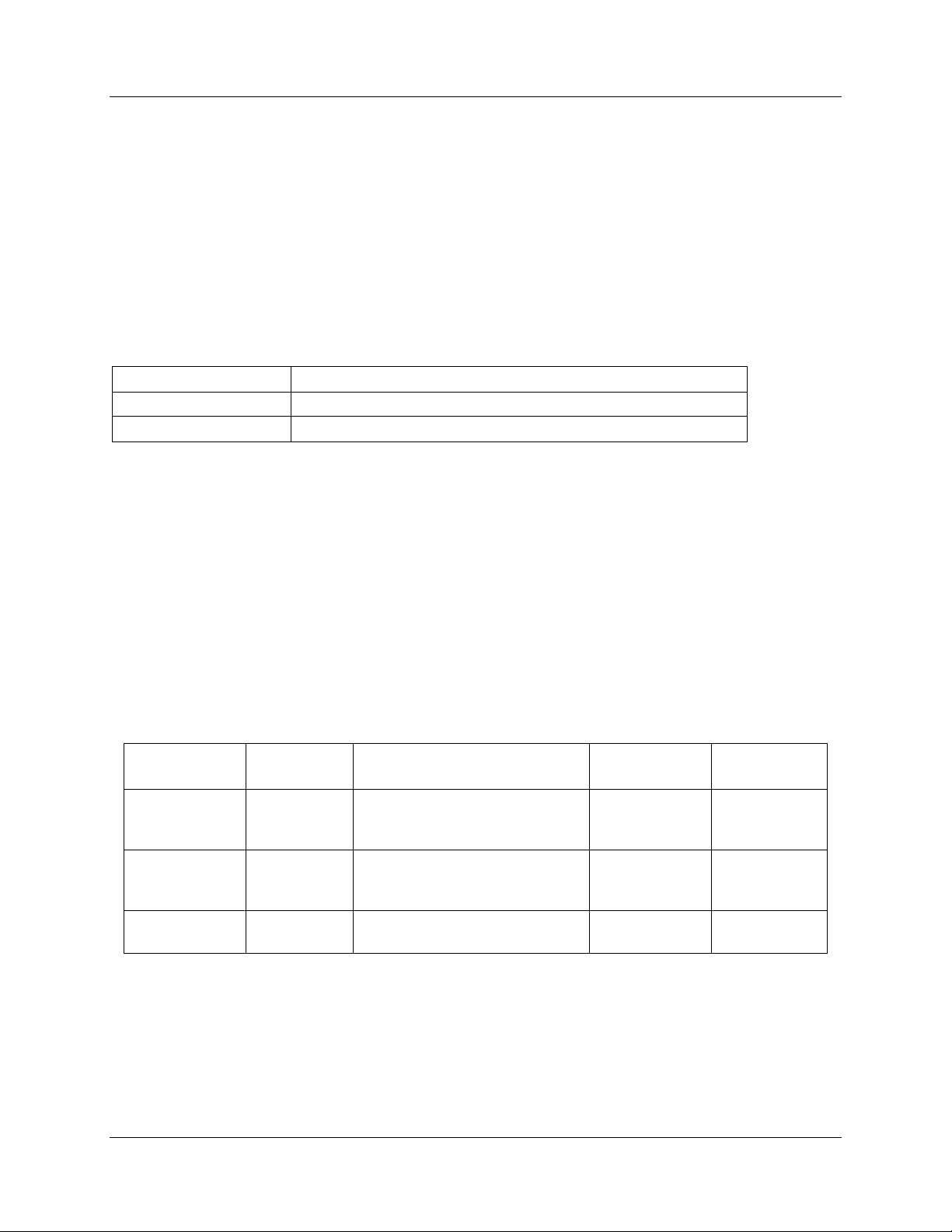

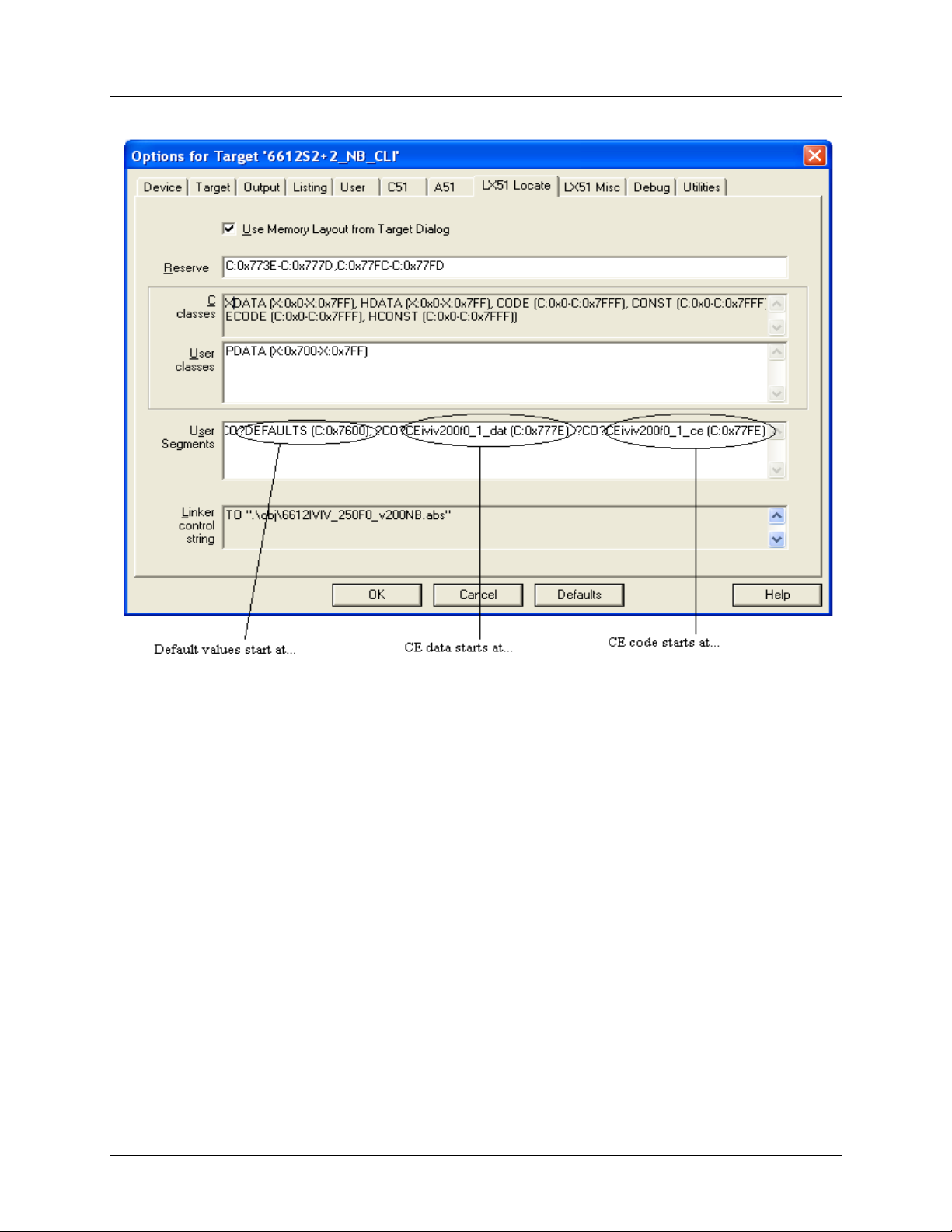

3.3.2 Flash/Code Space Assignment

As shown in Table 1, in order to reserve specific regions of Flash for specific MAPI default data, CE code

and CE data, the build file of the firmware application must be setup to specify where the modules will

reside. It is necessary to keep images of CE code/data and default data isolated at the application’s build

file. The accompanying application code has setup these assignments as follows: Default data is at

starting address 0x7600. CE Data is at starting address 0x777E. CE Code is at starting address

0x77FE.

This information is represented in the mapped file (.M51) as follows:

SEGMENTS (?CO?DEFAULTS(C:0X7600),

?CO?CEIVIV200F0_1_DAT(C:0X777E),

?CO?CEIVIV200F0_1_CE (C:0X77FE))

The following figures show how the setup is done.

12 Rev. 1.00

Page 13

UG_6612_036 78M6612 M-API Library User Guide

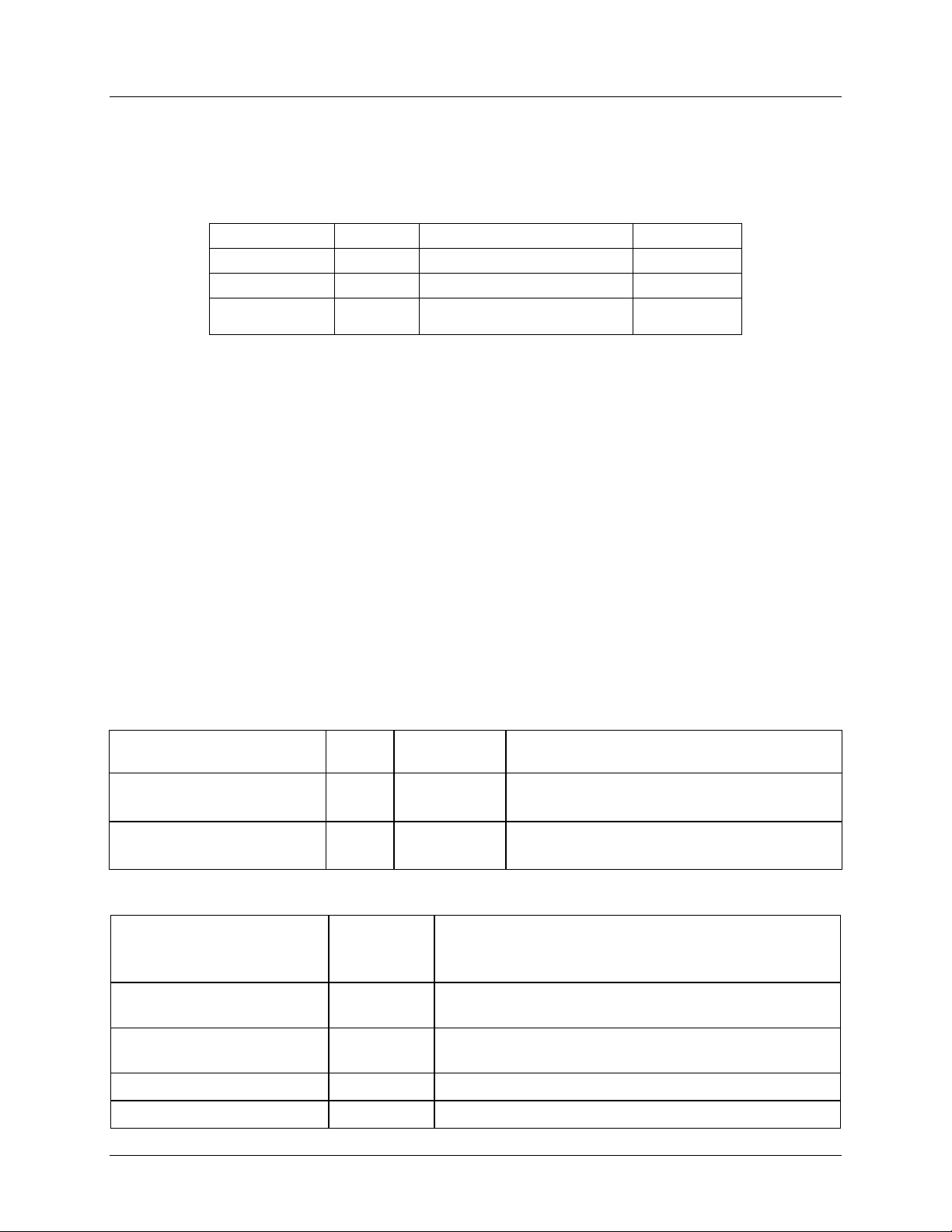

3.3.3 Library Assignment

The firmware application source code, as shipped with this document, is setup such that its project file

contains all the supported libraries as built for the specific CE code and data to support different

configuration options. As sho wn in the projec t, the libr ar ies built for Narrow-Band and Wide-Band are

included in the project but only one library shall be selected to be built with a specific ‘Target’ at a time.

The ‘Target’s as defin ed in the Keil proj ec t file for the sample application are shown below. When modify

this project’s targets, it is important that the correct library is selected:

Rev. 1.00 13

Page 14

78M6612 M-API Library User Guide UG_6612_036

3.3.4 Module’s Selection within a Library

The M-API libraries are organized into separate modules based on their functions so that code size and

RAM size can be easily optimized during Keil’s build/link time. Some of the modules are mandatory and

must be included while others can be de-selected to save Flash space if the functions/features are not

used. Typically, when an API is called directly, the Keil Linker would automatically include the module.

However, in some cases, a needed module used by the library would not be included as it is only called

within the library. In this case, the application would need to exclusively include the module. Table 6

shows the individual modules as built with the library and the selection criteria that an application is

recommended to follow.

14 Rev. 1.00

Page 15

UG_6612_036 78M6612 M-API Library User Guide

LIBRARY

modules

SET_DEFAULTS

Table 6: MAPI Feature/Module Selections

Module Optional (O)/Mandatory

Description

(M)

?C_STARTUP M 80515 Startup

CEIVIV200F0_1_CE

CEIVIV200F0_1_DAT

CALW (Watt cal)

CALP (Phase cal)

CALT (Temperature cal)

CALV (Volt cal)

CALI (Current cal)

REINIT_CALI (Current cal)

FLASH

TSC

ACCESS

DEFAULTS

MAPI

IOMAP

M

O

O

O

O

O

M (if any CALW/CALI is M)

M

M

M

O

CE data and code modules

If calib2ration is required, these modules are

needed based on the type of calibration is

required.

If Phase calibration is not needed, the

application can exclusively de-select it by

unchecking CALP.

Required by Meter, Measure, and calibration

Required for all initialization of Energy

measurement.

Interface layer between the librar y and the

app.

When a permanent change to any of the

initialization/default constant values for MPU

or CE is necessary.

MEASURE

Part of Energy Measurement function.

Rms

CE6612

CE

M

CE_ACCESS

IO6612

FREQ

Part of Metering function.

METER

PEAK_ALERTS

PHASE_ANGLE

POWER

PWRFACT

RMS_METER

M

VAH

VARH

WH

MATH

UPDATE

IRQ

SER0CLI O Serial UART/RS232 driver

TMR0

STM

M

Soft-Timer and Timer0 interrupt service

routine.

TRIP O Relay control

Rev. 1.00 15

Page 16

78M6612 M-API Library User Guide UG_6612_036

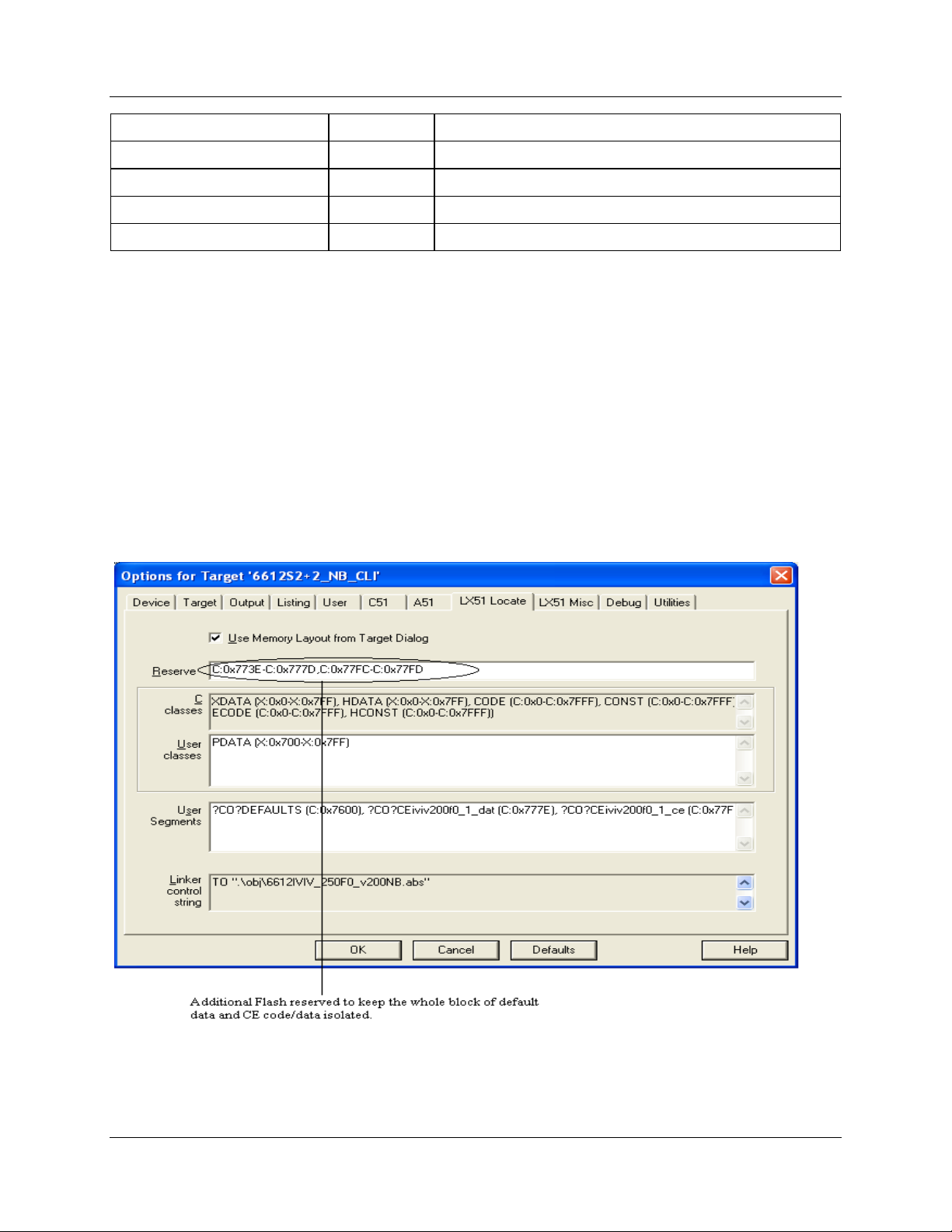

The following figure shows the Keil IDE/UV4 IDE menu where the module can be selected or de-selected.

To invoke this menu, left-click on a highlighted library and select ‘Options for File

‘6612S22_NB_MAPI.LIB or 6612S22_WB_MAPI.LIB’:

16 Rev. 1.00

Page 17

UG_6612_036 78M6612 M-API Library User Guide

4 MAPI Libraries

The following sections describe the available MAPI calls supported by these libraries.

4.1 Library Initialization and Opera ti on

4.1.1 MAPI_Init()

Purpose Initialize all critical variables, start the Compute Engine (CE) and its interrupts,

start the MPU timer, setup all default values. The application must first call this

API before any attempt to use other API s.

Synopsis Void MAPI_Init( void );

Parameters None.

Return Codes None.

4.1.2 MAPI_MeterRun()

Purpose Run this function in foreground mode periodically to reset the watchdog, update

all measurement outputs, and compare data to Min/Max thresholds. Once

MAPI_Init is called, the CE will update all atomic measurements periodically. It

is the task of the application to put this API into its main loop so that it can post-

process the data just imported from the CE. If this API is called more than once

within the same accumulation interval, no changes will be updated and a FALSE

will be returned. Typically, the application layer will then call

MAPI_MeterStatus() to check for any alarm conditions and call

MAPI_GetSetRegister()to get updated measurement data.

Synopsis Bool MAPI_MeterRun ( void );

Parameters None.

Return Codes TRUE (1) – New data has been updated.

FALSE(0) – No change from the last update run.

4.1.3 MAPI_MinMaxSetGet()

Purpose Start or Stop MinMax control.

Synopsis uint8_t MAPI_MinMaxSetGet( uint8_t SetData, uint8_t Op)

Parameters Op: input parameter.

Get = 0, Set = 1.

SetData: input parameter.

When Op = 1, set MinMax control register to SetData. MinMax control register is

defined as: Bit1=Start_MinMax, Bit0=Reset_MinMax. It is customary that when

Start_MinMax is set (Bit1 = 1), Reset_MinMax (Bit0 = 1) shall also be set.

Reset_MinMax is auto-cleared by the library.

Return Codes Current value of MinMax register.

Rev. 1.00 17

Page 18

78M6612 M-API Library User Guide UG_6612_036

4.2 Library Inputs and Outputs

4.2.1 MAPI_GetSetRegister()

Purpose Get or Set the value of a specific register location. An error will be returned if the

address is out of range or within the restricted location. Care must be taken when

calling this API to Set the value into a register. There are three types of registers:

MPU, CE and I/O Hardware Control. The range of address indicates the type of

0x0000 – 0x03FF: MPU Address

0x0400 – 0x07FF: CE Address

0x2001 – 0x2001: Hardware I/O Control registers. Only address 2001 is accessible.

CE_ADDRESS = 0x1000,

RI_ADDRESS = 0x2000};

MAPI_GetSetRegisters (READ, &Regt);

Synopsis enum MAPI_RC MAPI_GetSetRegister( bool Operation,

Where Reg_t is defined as:

registers as follows:

When calling this function, make sure the Reg.Address is OR’ed with the specific

type of register (CE or MPU or I/O RAM) defined such as:

enum REG_TYPE {

MPU_ADDRESS = 0x0000,

For example:

{ //example code to get different types of registers

Struct Reg_t xdata Regt;

//CE Address

//shift 2 to accommodate 4-byte increment. Get CE add 100E

Regt.Address = (unsigned long) (CE_ADDRESS | ( 0x01 << 2));

MAPI_GetSetRegister (READ, &Regt);

//Change CE contents at address 0x100E

Regt.Value = 0x6050; //Change SAG counts

MAPI_GetSetRegister (WRITE, &Regt);

//MPU Address

//Get MPU address 0x07 – Read-only

Regt.Address = (unsigned long) (MPU_ADDRESS | (0x07));

MAPI_GetSetRegister (READ, &Regt);

//RI address

Regt_Address = (unsigned long) ((RI_ADDRESS) | (0x01));

....

}

struct Reg_t *Reg)

Struct Reg_t

{

Unsigned Integer Address;

Unsigned Long Value;

Unsigned Char TypeSize;

Unsigned Integer ScaleFactor;

};

18 Rev. 1.00

Page 19

UG_6612_036 78M6612 M-API Library User Guide

Parameters Operation Input parameter.

WRITE(1) – Set Operation, READ(0) – Get Operation.

Struct _Reg_t When Operation=READ, Output parameter.

When Operation=WRITE, Input parameter.

Address Four-byte address location.

Address where its content will be extracted

(Operation=READ) or stored (Operation = WRITE).

Value Four-byte value to be stored or retrieved. If

Content from Address to be extracted (Operation=READ) or

stored (Operation = WRITE).

TypeSize Type and Size of register’s content. Read-only.

This byte is defined as follows:

Bit 8 Bit 7…4 Bit 3…1

SIGNED: Register

value is a signed

value (1-negative,

0-positive).

TYPE: Register value is one

of the following types. Note

this is a

read-only field used

to determine the type of the

Register content that is

returned (see mapi_t.h):

SIZE

: Indicates

storage size (in

bytes) of register

where:

1 – Char, 1-byte

2 - Integer, 2-byte

4 - Word, 4-byte

INTEGER

FLOAT

IRMS_M

VRMS_M

CONTROL

CONFIG

POWER

ENERGY

FREQ

COUNT

TIMER

STATUS

STRING

0x00

0x10

0x40

0x50

0x60

0x70

0x18

0x28

0x38

0x48

0x58

0x68

0x78

Typically used for

power factor,

phase adjust.

ScaleFactor Output parameter.

This byte indicates presentation format of the register

content defined as follows:

10 – Tenth unit factor.

100 – Hundredth unit factor.

1000 – Thousandth unit factor.

Return Codes MAPI_OK – successful operation.

MAPI_RESTRICTED – specified address is restricted.

Rev. 1.00 19

Page 20

78M6612 M-API Library User Guide UG_6612_036

MAPI_MeterStatus() for

4.2.1.1 Auto-Scaling

When retrieving measurement data using the MAPI_GetSetRegister() call, the returned data value is

automatically converted to usable data according to the TypeSize of the register location. The

ScaleFactor is for information only.

When writing alarm thresholds to library input registers, usable data values are automatically converted to

raw values according to the TypeSize of the target register address.

4.2.1.2 Output Data Address Locations

The following output data is updated once per accumulation interval and available via the

MAPI_GetSetRegister() call.

MPU

Address

NB WB

00 20 Delta Temperature 0.1 °C FLOAT Temperature difference from 22 °C.

01 21 Line Frequency 0.01 Hz FREQ Line Frequency.

02 22

03 23

Name LSB Type Description

Alarm Status

(common)

OverCurrent Event

Count

STATUS

1

INTEGER

See Section 4.4.3 –

details.

Number of event counts where value

exceeded over current alarm thresh old.

04 24

05 25

06 26 Volts mVrms VRMS_M AC Line Voltage (RMS)

Under Voltage Event

Count

Over Voltage Event

Count

1 INTEGER

1 INTEGER

Number of event counts where value

exceeded under voltage alarm threshold.

Number of event counts where value

exceeded over voltage alarm threshold.

MPU Address

Name LSB Type Description Outlet 1 Outlet 2

NB WB NB WB

07 27 47 67

08 28 48 68 Energy mWh ENERGY

09 29 49 69 Cost mUnits FLOAT Accumulated Cost.

0A 2A 4A 6A Current mArms IRMS_M RMS Current.

0B 2B 4B 6B

0C 2C 4C 6C

0D 2D 4D 6D

Active

Power

Reactive

Power

Apparent

Power

Power

Factor

mW POWER Active Power (per accum inter v al).

Accumulated Energy.

mW POWER Reactive Power (per accum interval).

mW POWER Apparent Power (per accum interval).

– FLOAT

Power factor.

(output will be between -1.00 and 1.00)

20 Rev. 1.00

Page 21

UG_6612_036 78M6612 M-API Library User Guide

D0

D2

D6

Max Voltage (A) Alarm Threshold

DA

DC

E0

E2

Current -Outlet 1

A1

Imin(IA) - "creep" or squelch level

4.2.1.3 MPU Library Inputs

The following inputs can be modified (and saved to Flash) using API calls. For more information on

register descriptions, refer to the 6612_OMU Firmware Description Document.

Category

Common Alarm

Threshold

Name

Temperature

Frequency

Voltage (A)

LSB

MPU

Address

D1

D3

D4

D5

Description

Min Temperature Alarm Threshold

Max Temperature Alarm Threshold

Min Frequency Alarm Threshold

Max Frequency Alarm Threshold

SAG (A) Voltage Alarm Threshold

Min Voltage (A) Alarm Threshold

Outlet Specific

Alarm Thresholds

Alarm Mask

Alarm Mask

Sensor Scaling

Cost Factor Cost AA

Relay Control Relay Configuration AC

Calibration Calibration

Creep Threshold

Current - Outlet 1 D8 D9 Max Current Alarm Threshold

Power Factor - Outlet 1

Current - Outlet 2 DE DF Max Current Alarm Threshold

Power Factor - Outlet 2

Total Current E4 E5 Max Current Alarm Threshold

Alarm Mask for Status Registers E6

Alarm Mask for Alarm DIO4 E7

Voltage - V(A)

Current -Outlet 1

Current - Outlet 2

Configuration

Parameters

Current - Outlet 2

NB

DB

E1

A0

A2

A4

AB

AD

AE

AF

BF

C0

C1

C2

C3

C4

C5

C6

C7

C8

C9

CA

CB

CC

CD

CE

CF

A3

WB

Power Factor Alarm - Threshold

DD

Power Factor Alarm + Threshold

Power Factor Alarm - Threshold

E3

Power Factor Alarm + Threshold

32-BIT alarm mask (0=masked)

32-BIT alarm mask (0=masked)

VMAX A

IMAX Outlet 1 (IA)

IMAX Outlet 2 (IB)

Cost per KWh

Cost Unit string

Polarity, Latch type

Sequence Delay

Energize Delay

De-energize Delay

Tolerance on Phase Calibration

Calibration Type

Calibration Voltage (Target)

Calibration Current (Target)

Calibration Phase (Target)

Tolerance on Voltage Calibration

Tolerance on Current Calibration

Average Count for Voltage

Average Count for Current

Max Iterations for Voltage

Max Iterations for Current

Tolerance on Watts Calibration

Average Count for Watts

Max Iterations for Watts

Calibration WRATE

Calibration Temperature

Calibration Wattage (Target)

Imin(IB) - "creep" or squelch level

Rev. 1.00 21

Page 22

78M6612 M-API Library User Guide UG_6612_036

4.2.1.4 CE Library Inputs

The following inputs can

only

be modified (and saved to Flash) using API calls. For more information on

register descriptions, refer to the 6612 OMU Firmware Description Document.

CATEGORY CE Address Description

Calibration

0A-0B Calibration Gain VA, VB

Phase Adjust

CE Configuration

Pulse Rate

Quantization Corrections

Temperature Compensation

SAG Threshold

More Temperature

Compensation

08-09 Calibration Gain IA-IB (Outlet 1-2)

0C-0D Phase Adjust IA - IB

0E CE State

0F Wrate

12-13 Quantization offset Watt 1 to Watt 2

14-15 Quantization offset VAR A – VAR B

16-17 Quantization offset IA – IB

19 Temperature Gain Adjust

10 SAG Threshold on kVar

11 SAG Threshold

A6 Temperature Nominal

A7 Degree Scale

A8 ppm / ˚c

A9

ppm / ˚c2

22 Rev. 1.00

Page 23

UG_6612_036 78M6612 M-API Library User Guide

4.3 CE and MPU Control

4.3.1 MAPI_CEOn()

Purpose Turn CE on. After calling MAPI_Init(), CE is automatically turned on. This

API is provided as a convenience for the Application level to control the CE,

especially when reading/writing to Flash is necessary (writing to Flash is not

allowed when CE is on).

Synopsis void MAPI_CEOn ( void );

Parameters None.

Return Codes None.

4.3.2 MAPI_CEOff()

Purpose Turn CE off. When writing to flash, the CE must be turned off. This API is

necessary with MAPI_UpdateCE, MAPI_UpdateMPU or memcpy_rx calls.

Synopsis void MAPI_CEOff ( void );

Parameters None.

Return Codes None.

4.3.3 MAPI_GetCEName()

Purpose Get the CE name embedded as part of the CE data. The CE name size is 24

bytes and these exact 24 bytes will be returned in the XDATA string pointed to by

ptr.

Synopsis void MAPI_GetCEName ( unsigned char xdata *ptr );

Parameters ptr Output parameter.

The CE name will be returned at the xdata location pointed to by

ptr. For version 2.00 Library release, the string will look as follows:

CE6612_OMU_S2+2_A01_V1_4.

Return Codes None.

4.3.4 MAPI_SoftReset()

Purpose Reset the MPU, this includes stopping the CE, and setting all registers to

hardware Power-On Reset values.

Synopsis void MAPI_SoftReset ( Void );

Parameters None.

Return Codes None.

Rev. 1.00 23

Page 24

78M6612 M-API Library User Guide UG_6612_036

4.3.5 MAPI_HardReset()

Purpose Reset the MPU, this includes stopping the CE, and setting all registers to

hardware Power-On Reset values.

Synopsis void MAPI_HardReset ( Void );

Parameters None.

Return Codes None.

4.3.6 MAPI_UpdateMPU()

Purpose Update the MPU contents permanently into Flash. The MPU measurement input

and calibration default values are stored in Flash. During power up, its content is

copied to XRAM to be used as a working copy. The application can change

some of the registers’ values using the MAPI_SetGetRegister(). This

change only takes effect in the XRAM copy of the data. To permanently save the

new data into Flash, the application must exclusively call this function to perform

the permanent save. This function is not to, and should not, be called too often

as Flash Write does have a life-expectancy. It is typically used after the part is

calibrated successfully to save the coefficient values. See the

OMU_MAPICLI.uproj for sample usage of this API. In order for this function to

perform properly, the CE must be turned off by calling MAPI_CEOff().

Synopsis Bool MAPI_UpdateMPU ( void );

Parameters none

Return Codes TRUE – Successful write of MPU data to Flash.

FALSE – Write was not successful; perhaps CE is still running.

4.3.7 MAPI_UpdateCE()

Purpose Update the CE Data contents permanently into Flash. The CE Data Image is

programmed into Flash, starting at address 0x775E. During power up, its

content is copied to XRAM to be used as a working copy. Thou gh it is NOT

recommended to change any CE Data, occasionally such needs arise, such as

changing the IMAX, VMAX or WRATE values. The application can change some

of the registers’ values using the MAPI_SetGetRegister(). This change only

takes effect in the XRAM copy of the data. To permanently save the data into

Flash, the application must exclusively call this function to perform the permanent

save into its specific location of Flash. This function is not, and should not, be

called too often as Flash Write does have a life-expectancy. See the

OMU_MAPICLI.uproj for sample usage of this API. In order for this function to

perform properly, the CE must be turned off by calling MAPI_CEOff().

Synopsis Bool MAPI_UpdateCE ( void );

Parameters None.

Return Codes TRUE – Successful write of MPU data to Flash.

FALSE – Write was not successful; perhaps CE is still running.

24 Rev. 1.00

Page 25

UG_6612_036 78M6612 M-API Library User Guide

4.4 Calibration and Power Measurement

4.4.1 MAPI_CalSetGet()

Purpose Set or Get Calibration referenced and tolerance parameters as specified in the

MPU_CParms_t structure. New values are kept in RAM only. When all

calibration data is setup and calibrated correctly, it shall be kept and recorded,

permanently in Flash by calling MAPI_UpdateCE() and MAPI_UpdateMPU().

A typical calibration of the part proceeds as follows:

1. Call MAPI_CalSetGet (FALSE, ….) to get current calibration data.

2. If necessary, call MAPI_SetGetCal (TRUE,…) to set new calibration data

(tolerance values, referenced values, etc.).

3. Call MAPI_Calibrate() to start the calibration. If calibration passes,

continue to step 4. If calibration fails, repeat step 1.

4. Call MAPI_UpdateCE() and MAPI_UpdateMPU() to permanently update

the new values in Flash.

5. Call MAPI_CalSetGet (FALSE,…) to make sure the new data is written,

preserved and correct.

Synopsis Bool MAPI_CalSetGet(IN unsigned char SetData,

Struct MPU_CParms_t *MAPI_CParams);

Struct MPU_CParms_t

{

uint8_t C_Tcal; // Type calibration. Read-Only.

float C_Wcal; // Wattage calibration value (Watts).

float C_Vcal; // Voltage calibration value (Vrms).

float C_Ical // Current calibration value (Arms).

int16_t C_Pcal; // Phase calibration value (Degrees).

float C_Wtolerance; // Watts Tolerance (Watts).

float C_Vtolerance; // Voltage Tolerance (Vrms).

float C_Itolerance; // Current Tolerance (Arms).

float C_Ptolerance; // Phase Tolerance (degrees).

uint8_t C_Vavg_cnt; // Voltage Average count.

uint8_t C_Iavg_cnt; // Current Average count.

uint8_t C_Wavg_cnt; // Watts Average count.

uint16_t C_Vmax_cnt; // Voltage Max count.

uint16_t C_Imax_cnt; // Current Max count.

uint16_t C_Wmax_cnt; // Watts Max count.

uint16_t C_Wrate_cal; // Wrate during calibration

(~.32Kh). Read-Only

uint16_t C_Tempcal; // Calibration temperature (0.1

degree).

};

Rev. 1.00 25

Page 26

78M6612 M-API Library User Guide UG_6612_036

Parameters SetData Input parameter.

TRUE(1) – Set calibration data as specified in MPU_CParms_t.

FALSE(0) – Get current calibration data and return values in MPU_CParms_t.

MAPI_CParams:

C_Tcal Input parameter – read-only. Calibration type. None(0x00).

C_Wcal Output parameter (SetData = FALSE), Input parameter (SetData = TRUE)

Referenced Wattage calibration value (in Watts). Default = 120W.

C_Vcal Output parameter (SetData = FALSE), Input parameter (SetData = TRUE)

Referenced Voltage calibration value (Vrms) . Default = 120V.

C_Ical Output parameter (SetData = FALSE), Input parameter (SetData = TRUE)

Referenced Current calibration value (Arms). Default = 1A.

C_Pcal Output parameter (SetData = FALSE), Input parameter (SetData = TRUE)

Referenced Phase calibration value (in 0.1 C Degrees). Default = 0 degree.

C_Wtolerance Output parameter (SetData = FALSE), Input parameter (SetData = TRUE).

Watts Tolerance (Watts). Default = 0.01W or 10mW.

C_Vtolerance Output parameter (SetData = FALSE), Input parameter (SetData = TRUE)

Voltage Tolerance (Vrms). Default = 10mV.

C_Itolerance Output parameter (SetData = FALSE), Input parameter (SetData = TRUE)

Current Tolerance (Arms). Default = 10mA.

C_Ptolerance Output parameter (SetData = FALSE), Input parameter (SetData = TRUE)

Phase Tolerance (degrees). Default = 0.1 Degree.

C_Vavg_cnt Output parameter (SetData = FALSE), Input parameter (SetData = TRUE)

Voltage Average count. Default = 3.

C_Iavg_cnt Output parameter (SetData = FALSE), Input parameter (SetData = TRUE)

Current Average count. Default = 3.

C_Wavg_cnt Output parameter (SetData = FALSE), Input parameter (SetData = TRUE)

Watts Average count. Default = 3.

C_Vmax_cnt Output parameter (SetData = FALSE), Input parameter (SetData = TRUE)

Maximum number of voltage reads to test for pass/fail result. Default = 10.

C_Imax_cnt Output parameter (SetData = FALSE), Input parameter (SetData = TRUE)

Maximum number of current reads to test for pass/fail result. Default = 10.

C_Wmax_cnt Output parameter (SetData = FALSE), Input parameter (SetData = TRUE)

Maximum number of Watts reads to test for pass/fail result. Default = 10.

C_Wrate_cal Output parameter.

Wrate use during calibration (~.32kh). Read-only.

C_Tempcal Output parameter (SetData = FALSE), Input parameter (SetData = TRUE).

Calibration temperature. In 0.1 degree unit.

Return Codes MAPI_OK //Calibration succeeded.

MAPI_ERROR //Calibration failed.

//For more detailed descriptions of the failure, call MAPI_CALStatus().

26 Rev. 1.00

Page 27

UG_6612_036 78M6612 M-API Library User Guide

4.4.2 MAPI_Calibrate()

Purpose Calibrate the part using referenced meter values and tolerance values as

specified in the MPU_CParms_t data structure (see the MAPI_CalSetGet API

for more information).

1. Call MAPI_CalSetGet (FALSE, ….) to get current calibration data.

2. If necessary, call MAPI_CalGetSet (TRUE,…) to set new calibration data

(tolerance values, referenced values, average count, maximum count, etc.).

3. Call MAPI_Calibrate() to start the calibration.

4. Call MAPI_UpdateCE() and MAPI_UpdateMPU() to permanently update

the new values in Flash.

5. Call MAPI_CalSetGet (FALSE,…) to make sure the new data is

written/preserved.

It is up to the application level to select the CAL_TYPE appropriately. It is

recommended that temperature calibration (CTYPE = C_TEMP) shall always be

part of CAL_TYPE; thus, C_TEMP shall always be OR’ing with c_type. When

this API is called with multiple CAL_TYPEs, calibration will be done in the

following order:

A typical application shall use this API as follows:

Temperature,

Phase,

Voltage,

Current,

Wattage.

Make sure the referenced values are setup correctly, using MAP_CalSetGet();

otherwise, calibration will not pass. See Section 4 for default valu es .

When the return code is not MAPI_OK, call MAPI_CalStatus() to get detailed

descriptions of the calibration error(s). If an error occurs during this call, the part

is NOT calibrated. It is the task of the application to call this API again if

recalibration of the part is necessary.

Synopsis MAPI_RC MAPI_Calibrate(IN enum CAL_TYPE c_type,

IN Unsigned Char Outlets);

Parameters c_type Input parameter.

The following types are acceptable:

Enum CAL_TYPE {

C_WATT = 0x01 – Calibrate Wattage.

C_VOLT = 0x02 – Calibrate Voltage.

C_CURRENT = 0x04 – Calibrate Current.

C_PHASE = 0x08 – Calibrate Phase Adjust.

C_TEMP = 0x10 – Calibrate Temperature.

}

Calibration source. The values can be OR’ing. For example: C_WATT | C_VOLT

indicate calibration to be done on Voltage first, then Wattage; C_TEMP | C_VOLT

indicate calibration to be done on Temperature then Voltage.

Rev. 1.00 27

Page 28

78M6612 M-API Library User Guide UG_6612_036

Outlets Input parameter

Bit representations of outlet # to be calibrated. For example: 0x03

represents outlet #1 and 2 to be calibrated.

Return Codes MAPI_OK //Calibration passed.

MAPI_ERROR //Calibration failed. Call MAPI_CalStatus() for specifics.

4.4.3 MAPI_MeterStatus()

Purpose Run this function after a failed calibration or per io dica ll y to detect any

error/warning. Any non-zero value returned indicates some failure/w arn ing has

occurred. MPU Output Threshold levels and mask settings for the alarms can be

read, modified, and saved using the MAPI_GetSetRegister() API call.

Synopsis void MAPI_MeterStatus ( unsigned long Status);

Parameters Status Output parameter.

Min Temperature exceeded Bit 0 = 1 //0000 0001

Max Temperature exceeded Bit 1 = 1 //0000 0002

Min Frequency exceeded Bit 2 = 1 //0000 0004

Max Frequency exceeded Bit 3 = 1 //0000 0008

SAG A detected Bit 4 = 1 //0000 0010

Under Min VA on A Bit 5 = 1 //0000 0020

Over Max Voltage on A Bit 6 = 1 //0000 0040

Over Max I on A – narro w Band Bit 7 = 1 //0000 0080

Over Max I on A – wide Ba nd Bit 8 = 1 //0000 0100

Min Power Factor exceeded on A -NB Bit 9 = 1 //0000 0200

Max Power Factor exceeded on A-NB Bit 10 = 1 //0000 0400

Min Power Factor exceeded on A -WB Bit 11 = 1 //0000 08 00

Max Power Factor exceeded on A-WB Bit 12 = 1 //0000 1000

Max Current exceeded on B - NB Bit 1 3 = 1 //0000 2000

Max Current exceeded on B - WB Bit 14 = 1 //0000 4000

Min Power Factor exceeded on B -NB Bit 15 = 1 //0000 8000

Max Power Factor exceeded on B-NB Bit 16 = 1 //0001 0000

Min Power Factor exceeded on B -WB Bit 17 = 1 //0002 0000

Max Power Factor exceeded on B-WB Bit 18 = 1 //0004 0000

Max Current Total exceeded - NB Bit 19 = 1 //0008 0000

Max Current Total exceeded - WB Bit 20 = 1 //0010 0000

Creep on A Bit 21 = 1 //0020 0000

Creep on B Bit 22 = 1 //0040 0000

_FAULT – Neutral/Line reversal Bit 23 = 1 //0080 0000

Power Register Not Accurate Bit 27 = 1 //0800 0000

Return Codes None.

A 32-bit word status that indicates statuses as follows:

28 Rev. 1.00

Page 29

UG_6612_036 78M6612 M-API Library User Guide

Rev. 1.00 29

Page 30

78M6612 M-API Library User Guide UG_6612_036

4.4.4 MAPI_TimeToAverage()

Purpose Set/Get the time increment (in seconds) in which the power (in Watts) is to be

averaged. If a Time Interval has been set previously, it will be reset from this

point forward and the accumulator’s value will also be reset. Default value will be

10 seconds if this API is not called or if it is called with TimeInterval = 0. This

time is global time that is applicable to both channels.

Synopsis Void MAPI_TimeToAverage ( IN Bool SetTIME,

IN unsigned int TimeInterval);

Parameters SetTIME Input parameter.

TRUE (1) will set the time to TimeInterval seconds.

FALSE(0) will return the current Time Increment Query to

TimeInterval.

TimeInterval Input parameter (SetTIME = TRUE), Output parameter

(SetTIME = FALSE). Time in units of seconds, used to

average the Watts used.

Return Codes None.

4.4.5 MAPI_GetEnergyUsed()

Purpose Get the energy used per time increment query. This API will return the current

values as recorded according to Index and the Time Increment Interval.

Synopsis Void MAPI_GetEnergyUsed(OUT struct E_Query_t *EQuery);

Where E_Query_t is defined as:

struct E_Query_t

{

Unsigned char Chan; //Channel/Outlet number

float mWattsUsed;

float WattHrsUsed;

Unsigned char Index;

Unsigned int cLineFreq;

}

Parameters Chan Input parameter.

Channel/Outlet number to get the energy information from.

mWattsUsed Output param eter .

Instantaneous Power used in milli-Watts.

WattHrsUsed Output param eter .

WattHour used over the past hour as pointed to by Index.

Index Output parameter.

Number of hours past since power up. This value will reset to

0 (wrap-around) once the maximum is reached, i.e. 255 hours.

cLineFreq Output: Current line frequency value in ##.##Hz format.

Return Codes None.

30 Rev. 1.00

Page 31

UG_6612_036 78M6612 M-API Library User Guide

4.4.6 MAPI_GetVoltageCurrent()

Purpose Get the current values of Voltage and Current . This function can be useful for

determining referenced voltage and current values for calibration. Follow the

steps below for a sample usage of this API:

1. Call MAPI_CalSetGet() to get default calibration values.

2. Call MAPI_GetVoltageCurrent() to get current Voltage and Current.

3. Set new parameters with call to MAPI_CalSetGet().

4. Call MAPI_Calibrate() to start the calibration.

5. As a check call MAPI_GetVoltageCurrent() to confirm new calibrated

values.

Synopsis void MAPI_GetVoltageCurrent( OUT struct VIT_t *VIT_Params);

Where VIT_t is defined as:

struct VIT_t

{

Unsigned char Channel;

float Current_I;

float Current_V;

};

Parameters Channel Input parameter.

Channel/outlet number (1 or 2) where present Current va lue will be

read.

Current_I Output parameter.

Present value of Current (in mAmps) for the specified outlet.

Current_V Output parameter

Present value of Voltage for Voltage A (in mVolts).

Return Codes None.

Rev. 1.00 31

Page 32

78M6612 M-API Library User Guide UG_6612_036

4.5 Zero Crossing and Rel ay Control

4.5.1 MAPI_RelayConfig()

Purpose Read/Write relay configuration values. Relay configuration is applicable to all

channels/outlets.

Synopsis void MAPI_RelayControl( IN Bool Operation, OUT/IN struct

Relay_Config_t Relay_Config);

Where Relay_Config_t is defined as:

struct Relay_Config_t

{

Unsigned Char Relay_CTL;

Unsigned Integer SeqDlyTime;

Unsigned Integer DeEnergizedTime;

Unsigned Integer EnergizedTime;

Unsigned Char InvertPNonLatch;

};

Parameters Operation Input parameter.

TRUE (1) = set operation. FALSE (0) = get operation,

Relay_Config will all be output parameter.

When Operation = TRUE:

Relay_CTL Output parameter.

This parameter is output only. It is set via

MAPI_RelayControl().

SeqDlyTime Input parameter.

Set the new Sequence Delay Time in 10ms

units. Delay time is time between turning

Relays ON (close circuit). Default value is 10

100ms.

DeEngergizedTime Input parameter.

Time in mseconds + 1msecond to delay after

open circuit.

EngergizedTime Input parameter.

Time in msecond + 1msecond to delay after

close circuit.

InvertPolarity Input parameter.

Bit 1 = Polarity (0 = non-inverted). Bit 0 =

Latch type (0 = non-latched).

Notes:

Sequence Delay Time will be used between turning relays ON.

Energized Delay Time is used as the delay time to wait

immediately after a zero-crossing before close circuit.

DeEnergized Delay Time is used as delay time to wait

immediately after a zero-crossing before open circuit.

Return Codes None.

32 Rev. 1.00

Page 33

UG_6612_036 78M6612 M-API Library User Guide

4.5.2 MAPI_RelayControl ()

Purpose Turning Relay ON/OFF (close/open circuit) on all channels.

Synopsis void MAPI_RelayControl( IN unsigned char Channels);

Parameters Channels Input parameter.

Each bit indicates turning ON(1) or OFF(0). The bit’s position

represents the specific channel/outlet number. For example:

0x01h – Turn relay ON on channel 1/A. Turn relays OFF on channel 2/B.

0x02h – Turn relay ON on channel 2/B. Turn relays OFF on channel 1/A.

Both channels can be turned ON with a single call to this API by setting 1 at the

bits representing the channels. For example:

0x03h – Turn relay ON on both channels.

Note: in the library code, channel 1 relay is mapped to DIO7 and channel 2 to

DIO19. But all other evaluation boards (6612, 6613, etc) are setup such that

DIO19 to TP4 and DIO7 is grounded. This means relay control doesn’t mean

much since only DIO19 would be suitable to be controlled in this case but since

there is only one channel, there is no point of having a control.

Return Codes None.

4.5.3 MAPI_CloseCircuit_0X()

Purpose Get zero-crossing status when positioning from open circuit to close circuit. The

value returned TRUE/FALSE indicates whether

occurred. The usage of this API is intended to be for when the circuit is

transitioning from open to close. This API uses the hardware Timer 1 in the case

when zero crossing does not take place. A delay of 12ms is set for such break.

Synopsis bool MAPI_CloseCircuit_0X( void );

Parameters None.

Return Codes TRUE – Zero crossing occurs.

FALSE – Zero crossing does not occur.

4.5.4 MAPI_OpenCircuit_0X()

Purpose Get zero-crossing status when transitioning from close circuit to open circuit.

The value returned TRUE/FALSE indicates whether

occurred for a specific channel. There is no indication of either direction

(falling/rising). The usage of this API is intended to be for when the circuit is

transitioning from close to open. This API uses the hardware Timer 1 in the case

when zero crossing does not take place. A delay of 10ms is set for such break.

Synopsis bool MAPI_OpenCircuit_0X( unsigned char Channel );

Parameters Channel Input parameter.

Channel/outlet number (1 or 2) where zero crossing will be

detected.

Return Codes TRUE – Zero crossing occurs.

FALSE – Zero crossing does not occur.

Voltage

Current

zero-crossing has

zero-crossing has

Rev. 1.00 33

Page 34

78M6612 M-API Library User Guide UG_6612_036

4.6 Soft-Timers

There are eight soft-timers in the 8051 Timer 0. Only six of these timers are available to application level

as two are used internally by the library. The timer is a fixed 10-milisecond time increment. When

TSC_Init() is called, the timer will be started and setup. It also calls MAPIstm_init() so the

application layer does NOT need to call MAPIstm_init().

4.6.1 MAPIstm_init()

Purpose Initialize soft-timers variables and structures.

Synopsis void MAPIstm_init ( void );

Parameters None.

Return Codes None.

4.6.2 MAPIstm_fn_start()

Purpose Start a soft-timer with a call-back function pointer. Upon expiration of the timer,

execute the function then remove/free the timer.

Synopsis unsigned integer *MAPIstm_fn_start (unsigned integer tenms_count,

Parameters tenms _count Input parameter.

Number of counts (in 10ms units) passed to execute the call

*fn_ptr Input parameter.

Return Codes NULL_PTR: if there is no more soft-timer available. Or,

The address of where tenms_count value is stored, and counted down, is returned.

This is useful when the application needs to stop the timer at any time before it is expired.

4.6.3 MAPIstm_run()

void (code *fn_ptr) (void))

back function fn_ptr.

Pointer to the call-back function to execute when the

tenms_count has expired. The function should be a reentrant.

Purpose Keep the soft-timers updated and current. This API shall be called in the

application’s main loop after MAPIstm_fn_start() is used. This is where

fn_ptr (in MAPIstm_fn_start() above) is processed.

Synopsis void MAPIstm_run ( void );

Parameters None.

Return Codes None.

4.6.4 MAPIstm_wait()

Purpose Delay processing for a fixed time (in 10ms increment). Typically use when it is

Synopsis void MAPIstm_wait ( IN unsigned integer DelayTime );

Parameters DelayTime Input parameter

Wait (hold up CPU processing) for DelayTime * 10ms.

Return Codes None.

34 Rev. 1.00

necessary to wait for something to stabilize.

Page 35

UG_6612_036 78M6612 M-API Library User Guide

4.7 DIO Configuration (future release)

4.7.1 MAPI_DIOConfig()

Purpose Configure the DIOs to be a specific function. Note: DIO 1 – 8 are part of 80515

USER0 SFR (0x80). DIO8-15 are part of 80515 USER1 SFR (0x90). And

DIO16-21 are part of 80515 USER2 SFR (0xA0). These are all bit-addressable

SFR. An application shall call this API either right before or right after calling

MAPI_Init() to setup all the signals properly. Each member of the Signals_t

structure shall be assigned the appropriate DIO pin as defined in the enum type

DIO_NO. The library is built with specific default assignments as follows: ActiveB

= DIO20, FaultB = DIO21, ReadyB = DIO11, Relay1 = DIO7, Relay2 = DIO19.

When unsure, it’s best to call this API with a Get Operation (OP=1) to get current

settings prior to changing any DIO assignments.

Synopsis void MAPI_DIOConfig (struct Signals_t *Signals, uint8_t OP)

Where:

//all possible DIO signals

struct Signals_t {

uint8_t Act ive B;

uint8_t Al arm;

uint8_t FaultB;

uint8_t Rea d yB;

uint8_t Rel a y1;

uint8_t Rel a y2;

uint8_t SAG_sign;

uint8_t WPulse;

uint8_t RFU; //Customer’s specific –delete?

uint8_t RFU; //Customer’s specific –delete?

uint8_t RFU; //Customer’s specific –delete?

uint8_t RFU; //Customer’s specific –delete?

uint8_t RFU; //Customer’s specific –delete?

uint8_t Unus e d1;

uint8_t Unus e d2;

uint8_t Unus e d3;

};

enum DIO_NO { DIO0=0x00, DIO1, DIO2, DIO3, DIO4, DIO5, DIO6, DIO7,

DIO8, DIO9, DIO10, DIO11, DIO12, DIO13, DIO14, DIO15,

DIO16, DIO17, DIO18, DIO19, DIO20, DIO21, DIO22, DIO23};

Parameters OP - Input parameter

Get (1) or Set DIO assignments.

Signals - Input parameter (OP = 1)/ Output parameter (OP = 0)

When OP = 1, return the current DIO pin assignments.

When OP = 0, set all DIO pin assignment according to the value assigned to

Signals..

Return Codes None.

Note: care must be taken when assigning the same DIO to be used for different functions as

there is no checking in the library for any conflict that may arise. For example, DIO6 may be used

to drive a LED and to be used as part of the I2C function. The library does NOT check for this

conflict of usage.

Rev. 1.00 35

Page 36

78M6612 M-API Library User Guide UG_6612_036

4.7.2 MAPI_DIORW()

Purpose Perform the Read/Write operation of/to the DIO.

Synopsis void MAPI_DIORW ( enum SIGNAL_TYPE Signal,

unsigned char *Value,

uint8_t OP );

Where:

enum SIGNAL_TYPE {ACTIVEB, ALARM, FAULTB, READYB, RELAY1B,

RELAY2B, SAG, WATTPULSE,

AC_OK, PFC_CTRL, PFC_OK, PFC_ON, Q183_ON,

UNUSED1, UNUSED2, UNUSED3};

Also where OP = (READ/ 0, WRITE = 1

Parameters OP: Input parameter.

0 = read, 1 = write.

Value: Input parameter (OP=0)/ Output parameter (OP=1)..

Read the value of the specified signal (OP=0) or write (OP=1) to it (assuming pin

direction is output). There is no checking of pin direction.

Signal: Input parameter

Value is one of: ACTIVEB, ALARM, FAULTB, READYB, RELAY1B,

RELAY2B, SAG, WATTPULSE,

AC_OK, PFC_CTRL, PFC_OK, PFC_ON, Q183_ON,

UNUSED1, UNUSED2, UNUSED3

Return Codes None.

36 Rev. 1.00

Page 37

UG_6612_036 78M6612 M-API Library User Guide

4.8 Flash Management

4.8.1 Memcpy_rx()

Purpose Write to Flash the content data from a specific RAM location. If the length of the

source and the starting ROM location cause the write operation to span more than

one 512-byte Flash page, the Read/Erase/Verify/Write will take place on all the

pages involved. An erase operation will result in the Flash contents being set to

0xFF. CE will be disabled during execution of this API. After the write, this API will

validate the write by comparing the Flash content against the RAM content and the

return code is reflected from this comparison.

Note1: When calling this API, CE must be turned off. See MAPI_CEOff and

MAPI_CEOn APIs in the sections above.

Note2: it is the task of the application to setup the specific Flash bank before calling

Synopsis Bool memcpy_rx ( Unsigned char code *dst,

Unsigned char xdata *src,

Unsigned integer len );

Parameters dst Input parameter.

Return Codes TRUE if the Write was successful.

FALSE if the Write was not completed.

Note: To avoid accidental write to Flash, this function requires a ‘flash write’ confirmation from the

application layer. This confirmation is done such as follows: there shall be a function called

get_buff(), at application level, which returns a pointer of Xdata whose content is checked as

the following:

uint8x_t xdata *bptr;

bptr = get_buff ();

if ((']' == toupper (*(bptr + 0)) && 'U' == toupper (*(bptr + 1))) ||

(')' == toupper (*(bptr + 0)) && 'U' == toupper (*(bptr + 1))) ||

('C' == toupper (*(bptr + 0)) && 'A' == toupper (*(bptr + 1))) ||

('C' == toupper (*(bptr + 0)) && 'L' == toupper (*(bptr + 1))) ||

('C' == toupper (*(bptr + 1)) && 'C' == toupper (*(bptr + 2))) ||

('U' == toupper (*(bptr + 1)) && 'C' == toupper (*(bptr + 2))) ||

('U' == toupper (*(bptr + 1)) && 'M' == toupper (*(bptr + 2)))

uint8x_t *get_buff (void)

{

return Bufptr;

}

this API. An example use of this API is as follows:

ok = memcpy_rx ((int8r_t *) ROMData, (int8x_t *) RAMData, ROMSIZE);

Specifies starting ROM address of Flash to be written (destination).

src Input parameter.

Use contents at this RAM address location as the source data.

len Input parameter.

Length (in bytes) of data to write to Flash.

)

Rev. 1.00 37

Page 38

78M6612 M-API Library User Guide UG_6612_036

4.8.2 Memcpy_xr()

Purpose Use to write to Flash the content data to a speci fic RAM loca tion. An example use

of this API is as follows:

memcpy_xr (RAMData, ROMData, ROMSIZE);

Synopsis Void memcpy_xr ( Unsigned char xdata *dst,

Unsigned char code *src,

Unsigned integer len );

Parameters dst Input parameter

Specifies starting RAM address to be written (destination).

src Input parameter

Use contents at this ROM/Flash address location as the source data.

len Input parameter

Length (in bytes) of data to write to RAM.

Return Codes TRUE if the Write was successful.

FALSE if the Write was not completed.

4.8.3 Memcpy_xx()

Purpose Use to copy data from an xdata location to another xdata location.

Synopsis Void memcpy_xx ( Unsigned char xdata *dst,

Unsigned char xdata *src,

Unsigned integer len );

Parameters dst Input parameter

Specifies starting RAM address to be written (destination).

src Input parameter

Use contents at this RAM address location as the source data.

len Input parameter

Length (in bytes) of data to write to RAM.

Return Codes None.

38 Rev. 1.00

Page 39

UG_6612_036 78M6612 M-API Library User Guide

4.9 Serial/RS232 Interface

4.9.1 MAPI_UARTInit()

Purpose Configure the communication speed, flow control, character parity and number of

stop bits. The serial interrupt service routine is NOT maskable, the interrupt

vector is set internally. Xon/Xoff will always be enabled. Non-parity, 8 data bit, 1

stop bit is the only supported configuration. The only thing the application can

change is the baud rate.

Synopsis Bool MAPI_UARTInit ( IN enum SERIAL_SPD speed, Bool XOnOff)

Parameters speed: Input parameter

This selects the communication speed. Possible values are:

_RATE_300 0

_RATE_600, 1

_RATE_1200, 2

_RATE_2400, 3

_RATE_4800, 4

_RATE_9600, 5

_RATE_19200, 6

_RATE_38400, 7 (default)

Return Codes None.

4.9.2 MAPI_UARTTx()

Purpose Setup the Tx buffer before sending data to the PC UART. Subsequent call to this

API will append the buffer to the existing transmittal buffer. An application should

call this API immediately after calling MAPI_UARTInit(). This is a non-

blocking call so always call MAPI_TxLen to make sure the transmission is

completed successfully.

Synopsis enum SERIAL_RC data MAPI_UARTTx ( U08x xdata *buffer, U16 len )

Parameters buffer Input parameter.

Specifies a pointer to the data buffer containing data to send to the

PC UART.

Len Input parameter.

Specifies the current number of bytes to be sent.

Return Codes: S_EMPTY Successful transmission.

S_PENDING, Successful transmission thus far but not yet finished.

Where return code SERIAL_RC is defined as: Enum SERIAL_RC.

After calling this API, an applica tion can m ake sure all bytes were transm itted by

checking that MAPI_TxLen() returns a 0.

Rev. 1.00 39

Page 40

78M6612 M-API Library User Guide UG_6612_036

4.9.3 MAPI_TxLen()

Purpose Number of bytes transmitted thus far.

Synopsis Unsigned integer MAPI_ TxLen ( void )

Parameters None.

Return Value Unsigned integer specifying the number of bytes left in the Tx buffer, i.e. the

remaining bytes to be sent.

4.9.4 MAPI_UARTRx()

Purpose Setup the receive buffer and start receiving. Always call this function after

MAPI_UARTInit() to make sure the receive buffer is available. Subsequent

call to this API will append the data to the existing buffer queue, if data is being

received. This is a non-blocking call so always check for completion of the

reception by calling MAPI_RxLen().

Synopsis uint16_t MAPI_UARTRx ( U08x xdata *buffer, U16 len )

Parameters buffer Input parameter.

Specifies a pointer to the data buffer to store the data received from

the PC UART.

len Input parameter.

Specifies the maximum number of bytes to receive at any one time.

Return Codes Unsigned integer specifying the number of bytes fetched thus far. Use

MAPI_RxLen() to keep track of the remaining number of bytes unfetched in the

Rx buffer.

4.9.5 MAPI_RxLen()

Purpose Number of bytes received thus far.

Synopsis Unsigned Integer MAPI_ RxLen ( void )

Parameters None.

Return Value Unsigned integer specifying the number of bytes in the queued buffer.

40 Rev. 1.00

Page 41

UG_6612_036 78M6612 M-API Library User Guide

5 Default Values

The following default values are used to build the MAPI library:

struct MPU_CParms_t MPU_CParams =

{

Unsigned Char Channels = 0

float C_Wcal = 120W

float C_Vcal = 120V

float C_Ical = 1A

Unsigned Integer t C_Pcal = 0

float C_Wtolerance = 10mA

float C_Vtolerance = 10mV

float C_Itolerance = 10mA

float C_Ptolerance = 0.1 degree

Unsigned Char C_Vavg_cnt = 3

Unsigned Char C_Iavg_cnt = 3

Unsigned Char C_Wavg_cnt = 3

Unsigned Integer C_Vmax_cnt = 10

Unsigned Integer C_Imax_cnt = 10

Unsigned Integer C_Wmax_cnt = 10

Unsigned Integer C_Wrate_cal = 4860 (shall not change)

Unsigned Integer C_Tempcal (read-only)

};

#define DefaultTIQ 10 //Default Time Increment Query

struct VIT_t xdata mapi_tVIT =

{

0x01, //Channel 1

0.00, //Current_I;

0.00, //Current_V;

};

struct Relay_Config_t xdata RlyConfig =

{

0x00, //unsigned char Relay_CTL;

0x64, //unsigned int SeqDlyTime;

0x01, //unsigned int DeEnergizedTime;

0x01, //unsigned int EnergizedTime;

0x00, //InvertPNonLatch

};

Rev. 1.00 41

Page 42

78M6612 M-API Library User Guide UG_6612_036

6 Contact Information

For more information about Maxim products or to check the availability of the 78M6612, contact technical

support at

www.maxim-ic.com/support.

42 Rev. 1.00

Loading...

Loading...