Page 1

78M6610+LMU Evaluation Kit

User Manual

July 2013

Rev. 1

Maxim Integrated cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim Integrated product. No circuit

patent licenses are implied. Maxim Integrated reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated 160 Rio Robles, San Jose, CA 95134 USA 1-408-601-1000

© 2013 Maxim Integrated Products, Inc. Maxim Integrated and the Maxim Integrated logo are trademarks of Maxim Integrated Products, Inc.

Page 2

78M6610+LMU Evaluation Kit User Manual

Table of Contents

1 Introduction ......................................................................................................................................... 4

1.1 Ordering Information .................................................................................................................. 4

1.2 Package Contents...................................................................................................................... 4

1.3 System Requirements ............................................................................................................... 4

1.4 Safety and ESD Notes ............................................................................................................... 5

1.5 Testing the 78M6610+LMU EV Board Prior to Shipping ........................................................... 5

2 USB Driver Installation ....................................................................................................................... 6

2.1.1 Confirm COM Port Mapping ............................................................................................. 6

2.1.2 FTDI COM Port Trouble Shooting .................................................................................... 6

3 Hardware Setup: Sensor Interface .................................................................................................... 7

3.1 Single-Phase Measurements using Shunts ............................................................................... 7

3.1.1 Jumper and Switch Descriptions ...................................................................................... 8

3.1.2 Device Configuration ........................................................................................................ 8

3.2 Single/Multiphase Measurements Using CTs ............................................................................ 9

3.2.1 Jumper Position Changes .............................................................................................. 10

3.2.2 Device Configuration ...................................................................................................... 10

3.3 Pseudo-Isolated Single-Phase Measurements Using CTs...................................................... 21

3.3.1 Jumper Position Changes .............................................................................................. 23

3.3.2 Device Configuration ...................................................................................................... 23

4 Hardware Setup: Digital Interface .................................................................................................... 11

4.1 USB Interface ........................................................................................................................... 11

4.2 RS-485 Interface ...................................................................................................................... 12

5 Graphical User Interface (GUI) ......................................................................................................... 13

5.1 GUI Initialization ....................................................................................................................... 13

5.1.1 SSI Tab .......................................................................................................................... 13

5.1.2 Device Tab ..................................................................................................................... 14

5.1.3 Direct Tab ....................................................................................................................... 14

5.1.4 Configuration Tab ........................................................................................................... 15

5.1.5 Command Register Tab ................................................................................................. 15

5.1.6 Calibration Tab ............................................................................................................... 16

5.1.7 Power Tab ...................................................................................................................... 16

5.1.8 Energy Tab ..................................................................................................................... 17

5.1.9 Fundamental Tab ........................................................................................................... 17

5.1.10 Min/Max Tab ................................................................................................................. 17

5.1.11 Alarms Tab ................................................................................................................... 18

5.1.12 Monitor Tab, .................................................................................................................. 19

6 Hardware Design Information .......................................................................................................... 24

6.1 Board Schematics .................................................................................................................... 24

6.2 Bill of Materials ......................................................................................................................... 28

6.3 PCB Layout .............................................................................................................................. 30

7 Contact Information .......................................................................................................................... 32

Revision History ........................................................................................................................................ 32

2 Rev 1

Page 3

78M6610+LMU Evaluation Kit User Manual

Figures

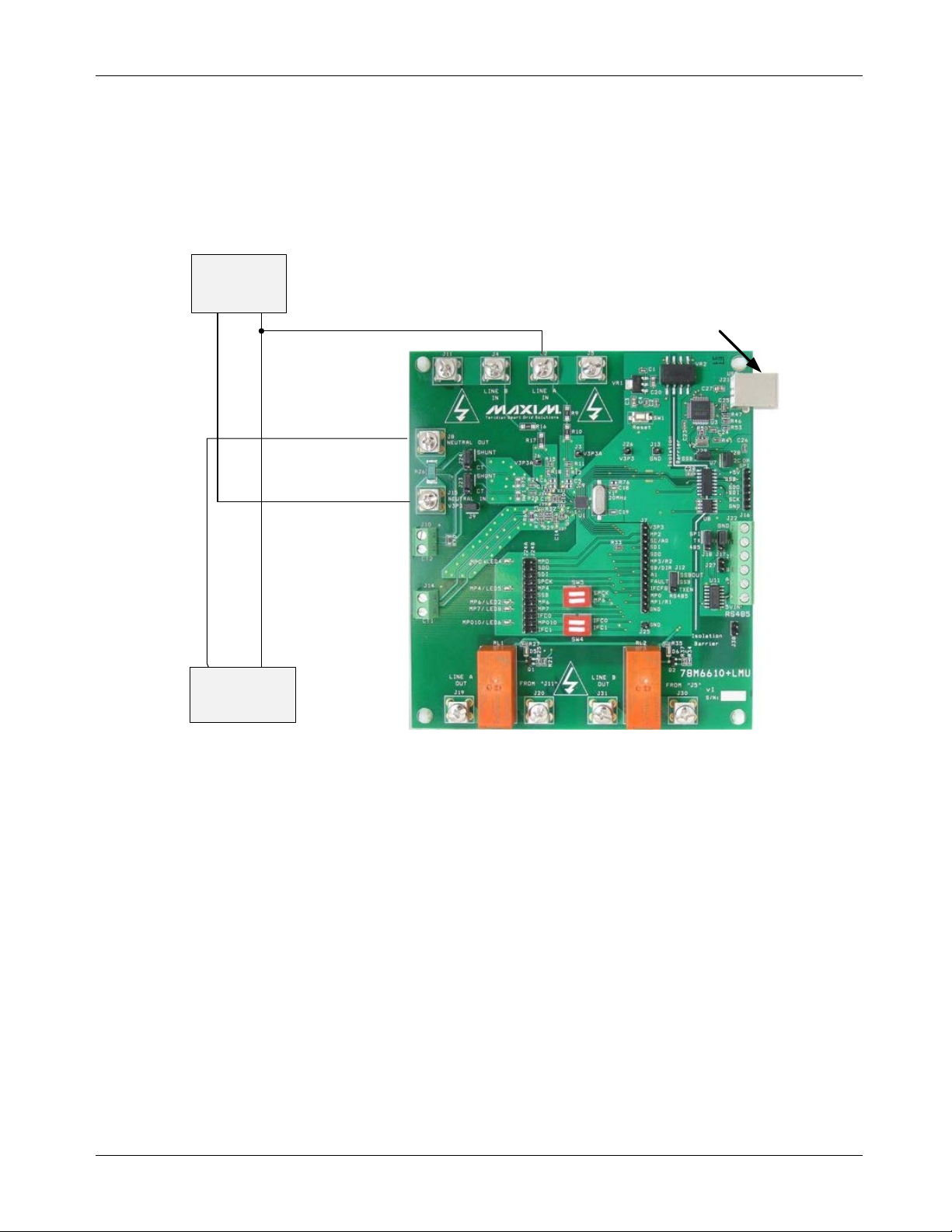

Figure 1: 78M6610+LMU Evaluation Board Con nections ..................................................................................... 7

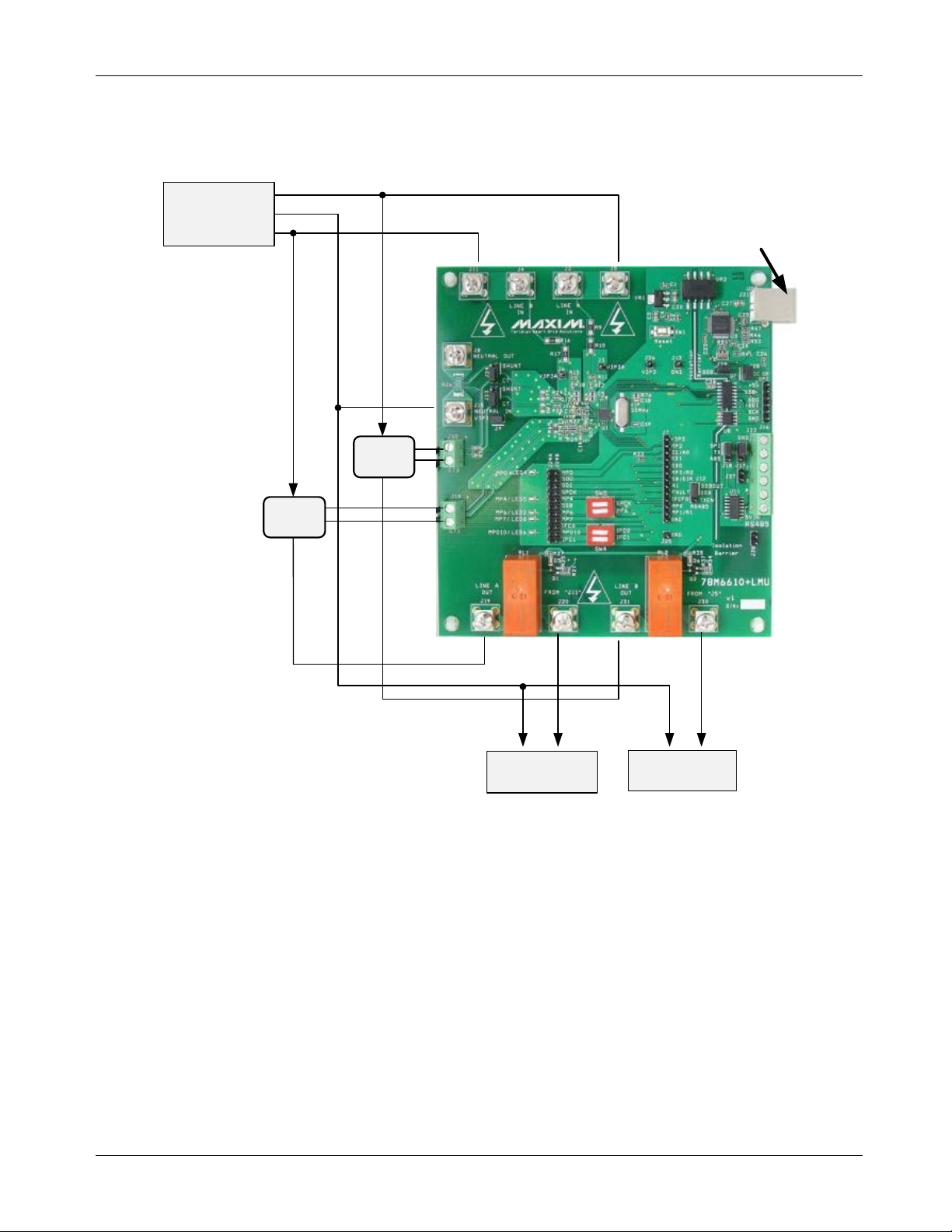

Figure 2: 78M6610+LMU Evaluation Board Con nections ..................................................................................... 9

Figure 2: 78M6610+LMU Evaluation Board Con nections ................................................................................... 22

Figure 3: 78M6610+LMU Evaluation Board Electrical Schematic (1 of 4) .......................................................... 24

Figure 4: 78M6610+LMU Evaluation Board Electrical Schematic (2 of 4) .......................................................... 25

Figure 5: 78M6610+LMU Evaluation Board Electrical Schematic (3 of 4) .......................................................... 26

Figure 6: 78M6610+LMU Evaluation Board Electrical Schematic (4 of 4) .......................................................... 27

Figure 7: 78M6610+LMU Evaluation Board PCB Top View ............................................................................... 30

Figure 8: 78M6610+LMU Evaluation Board P CB Bottom View .......................................................................... 31

Rev 1 3

Page 4

78M6610+LMU Evaluation Kit User Manual

PART

TYPE

78M6610+LMUEVK1#

Evaluation Kit

Windows and Windows XP are registered trademarks of Microsoft Corp.

1 Introduction

The 78M6610+LMU evaluation kit (EV kit) demonstrates the capability of the 78M6610+LMU for monitoring a

single-phase or split-phas e AC load using up to two voltages and two currents (sensors included). The EV kit

connects to a PC through a USB cable that provides both power and data communication to the board. A

Windows®-based graphical user interface (GUI) communicates with the device over a virtual for simplified

access to measurement data and controls.

1.1 Ordering Information

#Denotes a RoHS-compliant device that may include lead that is

exempt under the RoHS requirements.

1.2 Package Contents

The 78M6610+LMU EV kit includes the following:

• 78M6610+LMU Evaluation Board

• Two 20A Current Transformers

• USB Cable Assembly USB A-B 28/24 1.8M (Tyco/Amp 1487588-3)

• CD with Documentation, GUI Application, and USB Drivers

• Calibration Coefficients Document (Hardcopy Only)

1.3 System Requirements

In addition to an AC source and load for measuring, the EV kit requires a Windows PC with the following

features:

• 1GHz processor and 1GB RAM

• Minimum 1024 x 768 video display resolution

• Available USB port

• Microsoft Windows 7 or Windows XP®

4 Rev 1

Page 5

78M6610+LMU Evaluation Kit User Manual

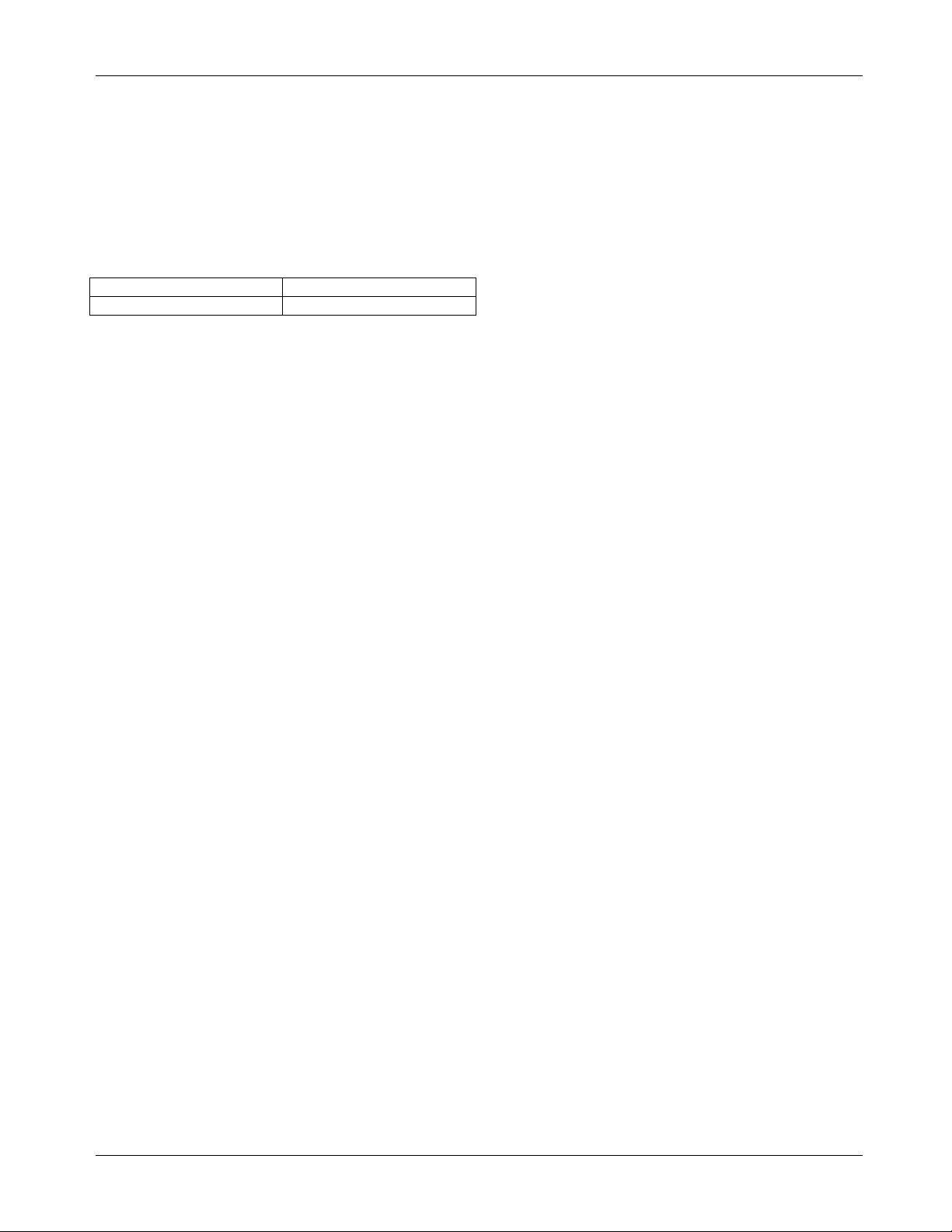

1.4 Safety and ESD Notes

EXERCISE CAUTION WHEN LIVE AC VOLTAGES ARE PRESENT!

Do not connect test equipment or external development boards directly to the nonisolated portion of the 78M6610 hardware. Damage to the 78M6610 and external

equipment will occur due to the 78M6610’s “high side” reference topology. The

78M6610’s V3P3 supply (i.e., “high side”) is connected directly to Neutral (Earth

Ground) creating a ground reference disparity with any properly grounded external

equipment.

The board components and firmware settings are designed to operate with the following nominal A C el ectrical

ranges:

Voltage Current Line Frequency

10-300 VAC 10 mA – 20A 46-64 Hz

1.5 Testing the 78M6610+LMU EV Board Prior to Shipping

Before every kit is shipped, the board (and sensors) undergo a single-load point calibration using precise

energy source equipment. The device temperature is also calibrated at the same time. Results printed out on

paper and included with the EV kit.

Rev 1 5

Page 6

78M6610+LMU Evaluation Kit User Manual

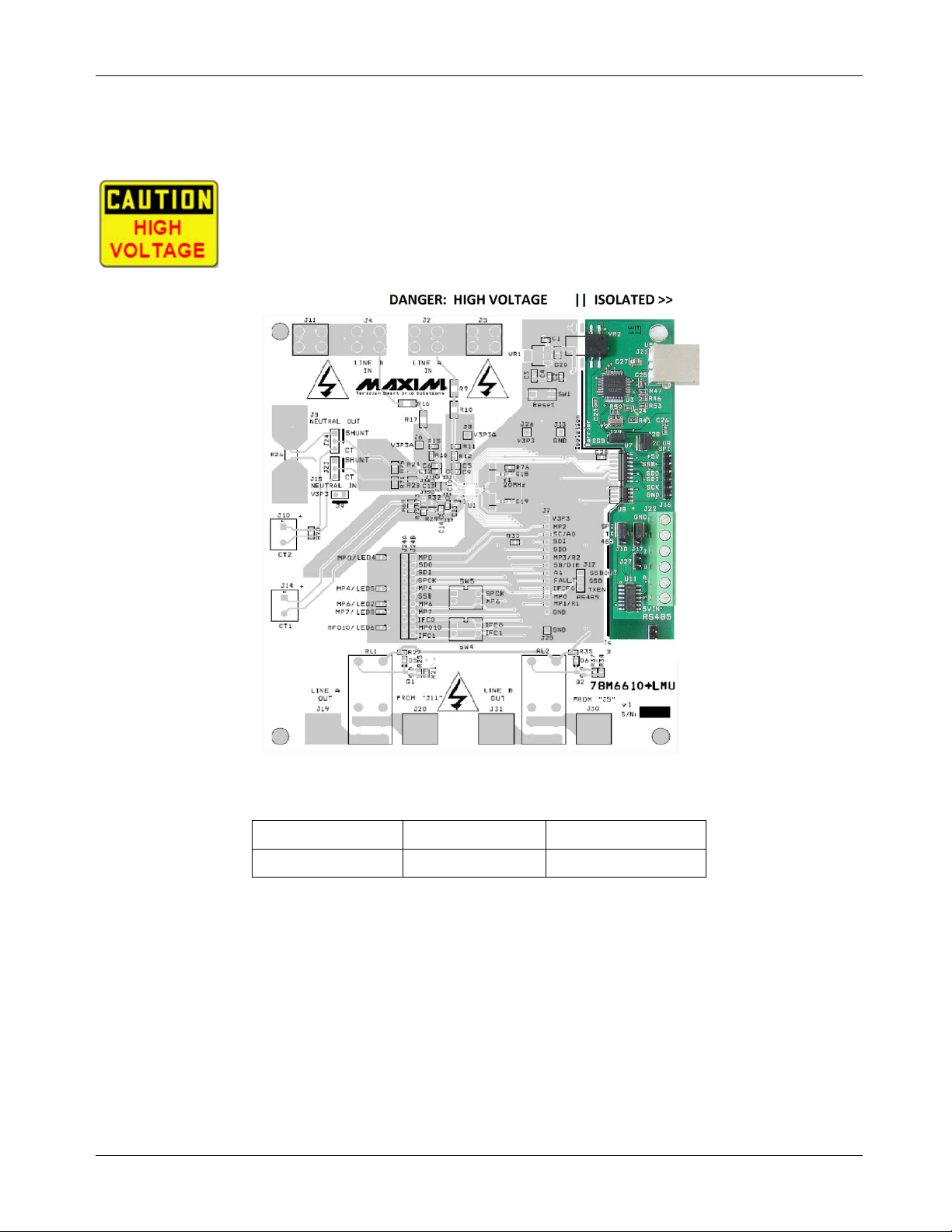

Two sequential COM

2 USB Driver Installation

This EV kit includes an isolated USB interface for serial communications with a PC. The FTDI USB controller

IC FT2232 performs the USB functions. The FTDI Windows d river presents a virtual COM port for enabling

serial communications. The FTDI Windows driver is a certified driver for Windows XP and Windows 7.

Upon attaching the 78M6610+LMU EV Board to the PC, the Found New Hardware Wizard automatically

launches and installs the appropriate driver files. I f your PC does not find the FTDI driver files on its local hard

disk drive, locate and reference the FTDI USB Driver and Utilities subdirectory on the CD. The FT2232

controller and 78M6610+LMU is powered from the USB cable and is active when no AC power is ap pl i ed to

the sensor interface of the 78M6610+LMU EV Kit.

Note: If an older FTDI driver has been previously installed, it is recommended to remove the older version

before installing this newer FTDI driver. Execute the ftdiClean.exe utility from the FTDI USB Driver and

Utilities subdirectory. For FTDI driver support on othe r operating sy stem s, refer t o the FTDI website at

www.ftdichip.com.

2.1.1 Confirm COM Port Mapping

• Launch the Control Panel and click on the System icon.

• The System Properties screen appears. Click on the Hardware tab. Click on Device Manager. Under

Ports (COM & LPT), look for the USB Serial Port assignment.

• Take note of the COM port assignment for the US B S eri al Port.

2.1.2 FTDI COM Port Trouble Shooting

If the FTDI device driver did not install properly, there would be no assigned COM port number for the FTDI

controller. Repeat the USB Driver Installation, see

Microsoft Windows may associate a Ball Point device to the FTDI USB controller. When this occurs a FTDI

device COM port assignment is available via HyperTerminal but there is no communications data. Verify if a

Ball Point device has been added to the “Human Interface Devices” via the Device manager. See

for access to the Device Manager. If a Ball Point device exists, delete it and unplug and replug the EV Kit’s

USB cable.

ports are associated

with the kit. Use the

second COM port

Port numbers may

differ on each PC.

Section 2.1.

Section 2.1.1

6 Rev 1

Page 7

78M6610+LMU Evaluation Kit User Manual

Connect

USB port

to PC

Line

Neutral

Load

AC source

3 Hardware Setup: Sensor Interface

The 78M6610+LMU EV board can be provisioned in multiple configurations. This manual covers common

setups for using a shunt, shunt with CT, or two CTs. The board is provisioned and calibrated for the following

configuration to retrieve the gain value of the shunt (printed on a label located on the bottom of the board).

3.1 Simple 2-Wire Single-Phase Measurements Using Shunts

Figure 1: 78M6610+LMU Evaluation Board Connections

1. Connect the AC source Neutral output to J15.

2. Connect J8 to Load’s Neutral input.

3. Connect the AC source Line 1 output to J2 and to Load’s Line 1 input.

Rev 1 7

Page 8

78M6610+LMU Evaluation Kit User Manual

J24 Pins

Description

Jumper

Voltage

Current

VA

S0 0 IA

S1 0 VB

IB

VC

Pre-Amp

1X S1

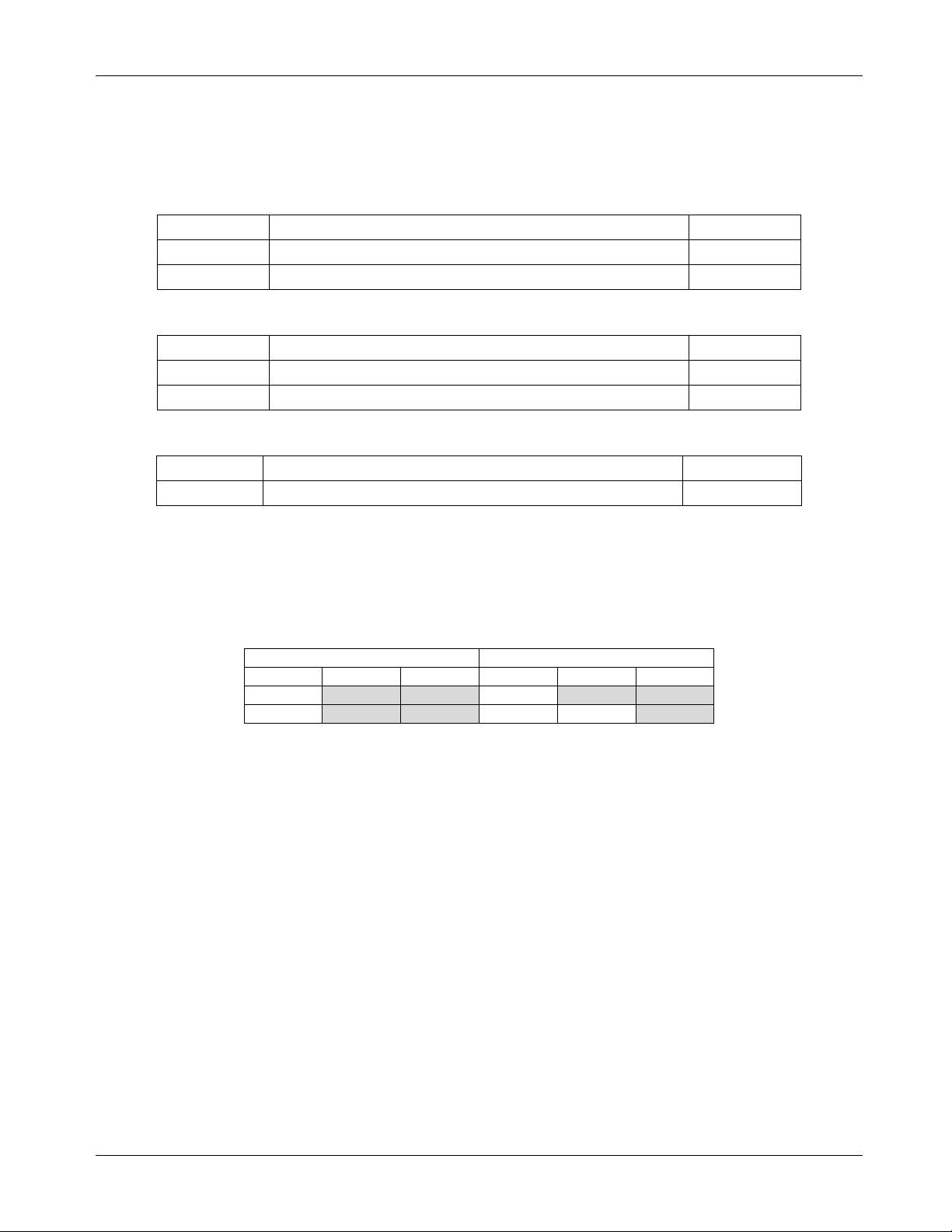

3.1.1 Jumper and Switch Descriptions

The following tables describe the default position of the EV board jumpers and switches for using the on-board

shunt current sensor at sensor slot S1.

J23 Jumper Description

J23 Pins Description Jumper

1/2 Connect J15 SHUNT to 78M6610+LMU Sensor Slot 1 Installed

2/3 Connect J10 CT2+ to 78M6610+LMU Sensor Slot 1 -

J24 Jumper Description

1/2 Connects J8 SHUNT to 78M6610+LMU Sensor Slot 1 Installed

2/3 Connects J10 CT2- to 78M6610+LMU Sensor Slot 1 -

J9 Jumper Description

J9 Pins Description Jumper

1/2 Connect AC Neutral to V3P3A (chip reference) Installed

3.1.2 Device Configuration

Use the Configuration tab to map the sensors as shown in the table below. Re-enter the gain value, as

needed, for the shunt resistor into the S1_GAI N register.

8 Rev 1

Page 9

78M6610+LMU Evaluation Kit User Manual

Connect

USB port

to PC

CT1

CT2

Line 1 Load

Line 2 Load

N

L1

N

L2

Line 1

Neutral

Line 2

+

+

AC source

3.2 Single/Multiphase Measurements Using CTs

In this diagram, the on-board relays are also wired in series to demonstrate load control.

Figure 2: 78M6610+LMU Evaluation Board Connections

1. Connect the AC source Neutral to J1 5 and the load(s).

2. Connect the AC source Line 1 to J2 and to J19 (Relay1) through the Line 1 CT.

3. Connect J20 (Relay1) to Line 1 load.

4. Connect Line 1 CT’s secondary to J14 (burden resistor).

5. Connect the AC source Line 2 to J4 and to J31 (Relay2) through the Line 2 CT.

6. Connect J30 (Relay1) to Line 1 load.

7. Connect Line 2 CT’s secondary to J10 (burden resistor).

Rev 1 9

Page 10

78M6610+LMU Evaluation Kit User Manual

J23 Pins

Description

Jumper

J9 Pins

Description

Jumper

Voltage

Current

VA

S0 IA

S1 0 VB 0 S2

IB 0 S3

VC

S0

-S2

Pre-Amp

1X S1

1X S3

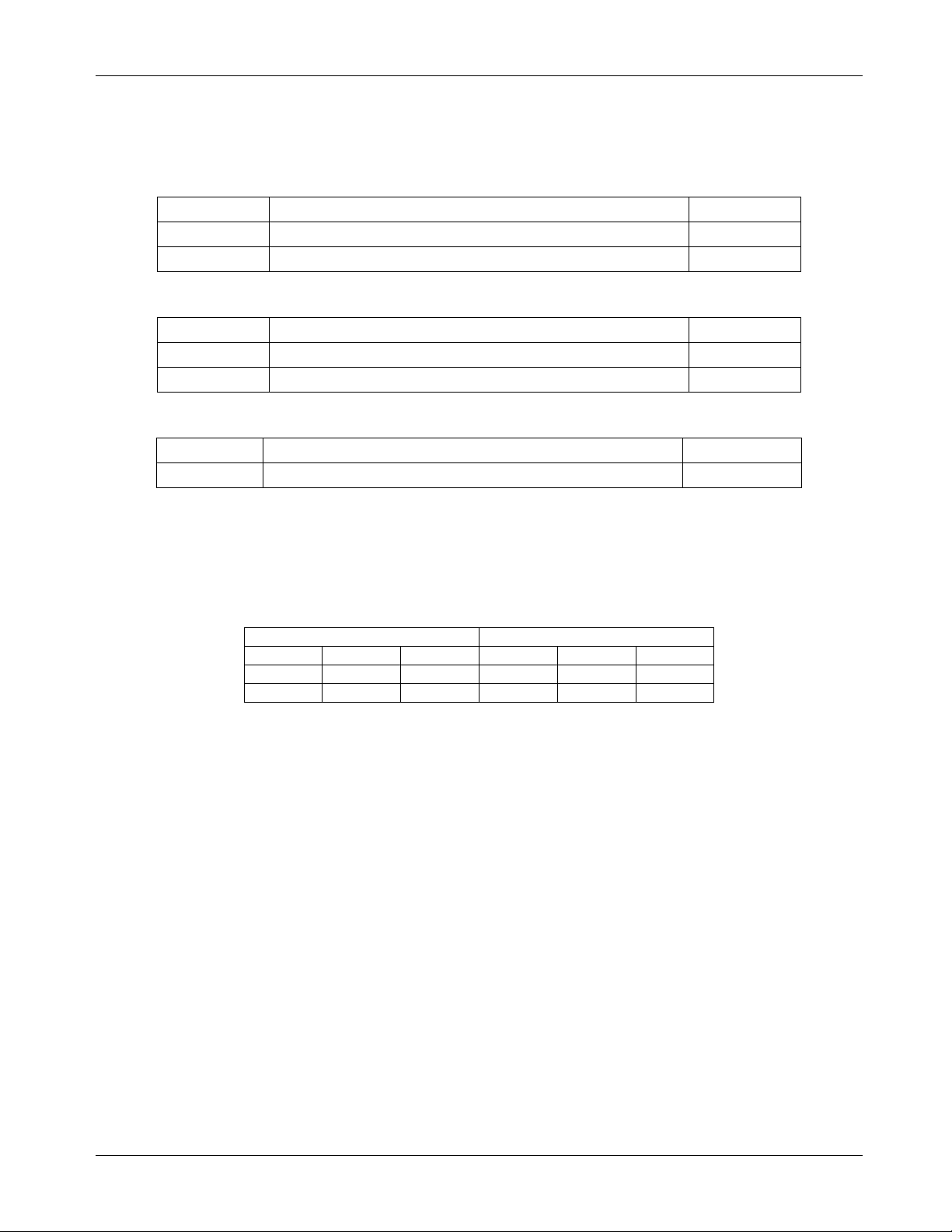

3.2.1 Jumper Position Changes

Move J23 and J24 jumpers to position CT to use CT2 for sensor slot S1.

J23 Jumper Description

1/2 Connect J15 SHUNT to 78M6610+LMU Sensor Slot 1 2/3 Connect J10 CT2+ to 78M6610+LMU Sensor Slot 1 Installed

J24 Jumper Description

J24 Pins Description Jumper

1/2 Connects J8 SHUNT to 78M6610+LMU Sensor Slot 1 2/3 Connects J10 CT2- to 78M6610+LMU Sensor Slot 1 Installed

J9 Jumper Description

1/2 Connect AC Neutral to V3P3A (chip reference) Installed

3.2.2 Device Configuration

Use the Configuration tab to map the sensors as shown in the table below. Re-enter the gain value as needed

for CT2 into the S1_GAIN register.

Note: The values for VC will not be displayed correctly on the Power tab of the provided GUI due to the

increased full-scale value of VC. Reported results for measurements derived from VC will be one-half the

expected magnitude.

10 Rev 1

Page 11

78M6610+LMU Evaluation Kit User Manual

Description

Default

J12 Pins

Description

Default

J18 Pins

Description

Default

J24A/B Pins

Description

Default

4 Hardware Setup: Digital Interface

4.1 Isolated USB Interface

Switch Description

SW4 Sets host interface mode upon reset

SW5 Sets device address upon reset (UART/I2C modes) Both Closed

J12 Jumper Description

1/2 Connect 78M6610+LMU to USB Controller (U3) Installed

2/3 Connect 78M6610+LMU to RS485 transceiver (U11) -

J17 Jumper Description

J17 Pins Description Default

1/2 Connect USB Controller to isolation IC (U7) Installed

2/3 Connect RS485 transceiver to isolation IC (U7) -

J18 Jumper Description

1/2 Connect USB Controller to isolation IC (U7) Installed

2/3 Connect RS485 transceiver to isolation IC (U7) -

J24A, J24B Jumper Description

IFC0 Open

IFC1 Closed

1/1 Connects MP0 to LED4 Installed

2/2 SDO/TXD/SDAo 3/3 SDI/RXD/SDAi 4/4 SPCK/ADDR0 5/5 Connects MP4 to LED5 Installed

6/6 SSB/DIR/SCL 7/7 Connects MP6/ADDR1 connection t o LED2 Installed

8/8 Connects MP7 connection to LED8 Installed

9/9 IFC0 10/10 Connects MP10 connection to LED6 Installed

11/11 IFC1 -

Rev 1 11

Page 12

78M6610+LMU Evaluation Kit User Manual

J27 Pins

Description

Default

J28 Pins

Description

Default

J29 Pins

Description

Default

J38 Pins

Description

Default

1/2

Enable on-board RS485 termination resist or

-

J22 Pin Number

Pin Name

Pin Description

J27 Jumper Description

1/2 Enable on-board RS485 termination resist or -

J28 Jumper Description

1/2 Connect USB Controller to isolation IC (U7) Installed

J29 Jumper Description

1/2 Connect USB Controller to isolation IC (U7) Installed

J38 Jumper Description

4.2 Isolated RS-485 Interface

The board also includes an isolated RS-485 interface as an alternative to the USB interface. The

78M6610+LMU serial UART is connected to the RS-485 transceiver. Refer to the IC data sheet for details on

the serial protocol.

Move J12, J17, and J18 jumpers from position 1-2 to position 2-3 to connect the RS-485 transceiver

instead of the USB controller.

The USB cable provides power to the EV board when connected to the PC. If the USB cable not being used

+5VDC power must be provided at J16, pins 1 and 6 (+5V and ground, respectively). D o not supply power to

JJ16, pin1 AND connect the USB cable to the PC.

J22 RS-485 Connector Pin Assignment

1 +5VDC Connect to external source

2 Data - P Tri-state, Bi-directional

3 Data - N Tri-state, Bi-directional

4 GND Connect to external source

4.3 Isolated UART, I2C, SPI Interfaces

The native host interfaces of the 78M6610+LMU are made available on the isolated side of the barrier at J16.

12 Rev 1

Page 13

78M6610+LMU Evaluation Kit User Manual

5 Graphical User Interface (GUI)

A graphical user interface (GUI) is included on the 78M6610+LMU EV kit CD to facilitate quick evaluation of

the 78M6610+LMU energy measurement device. The GUI requires Microsoft.NET Framework 4 on the PC for

which the GUI is to execute on. Upon invoking the GUI executable file, an installation wizard may appear if

Microsoft.NET Framework 4 is not installed on the PC. Follow the installation wizard instructions, or download

Microsoft.NET Framework 4 from the Micro sof t website prior to launching the GUI.

5.1 GUI Initialization

The GUI is self-explanatory when used with the 78M6610+LMU Dat a Sheet. The user, however, should note

the following about the EV kit hardware:

• Serial COM Port:

Following the installation instructions in Section 2, launch the G UI executable. Click the

Connection pull-down menu and select Connect.

The COM Port / Baud Rate box appears. Select the COM port assigned to the EV kit and

5.1.1 SSI Tab

• SSI ID:

Click the SSI tab. Use the SSI ID number set by DIP switch 5 (1 and 2 are closed by default)

leave the baud rate set to 38400 (default). Click the Connect button.

and click Set Target. Upon successful communication with the EV kit, a message appears in

the message box.

Rev 1 13

Page 14

78M6610+LMU Evaluation Kit User Manual

5.1.2 Device Tab

The Device tab shows to current firmware build as well as the temperature and line frequency being

measured.

5.1.3 Direct Tab

The Direct tab allows read and write access to all the byte-addressable registers documented in the data

sheet. The data can be displayed with the scale factor and units applied for convenience. In the example

below, the voltage register is being read, so the volts option is used to display the data.

14 Rev 1

Page 15

78M6610+LMU Evaluation Kit User Manual

5.1.4 Configuration Tab

The Configuration tab is used to set up the sensor interface. Once this is done it can be saved to NVRAM for

future use, or programmed to a user-defined configuration and saved. See the Calibration tab for saving the

settings.

5.1.5 Command Register Tab

The Command Register tab is a read/write control tab for manual operation of the command register (0x00).

Hex and decimal formats are supported.

Rev 1 15

Page 16

78M6610+LMU Evaluation Kit User Manual

5.1.6 Calibration Tab

The Calibration tab is used to configure and execute calibration commands. The calibration targets can be

viewed and changed and the scaling parameters are also displayed for convenience.

The calibration and NVRAM are also saved using the provided button.

5.1.7 Power Tab

The Power tab displays the current power being consumed by the loads. P (active power), Q (reactive power),

and S (apparent power) are displayed along with the voltage, current, crest factor, and power factor are also

displayed.

16 Rev 1

Page 17

78M6610+LMU Evaluation Kit User Manual

5.1.8 Energy Tab

The Energy tab displays the accumulated power both into and out of the load. The pull-down menu is used to

select the channel that is being displayed; A, B , or C, and update is used to update the displayed data

5.1.9 Fundamental Tab

The Fundamental tab is used to display the fundamental and harmonic measurements for voltage, current,

and power. The harmonics displayed can be selected with the get/set harmonic buttons.

5.1.10 Min/Max Tab

The Min/Max tab is used to display the minimum and maximum measurements for the parameters selected in

the Word Addr column. The units can be selected with the provided pull-down menu and the most recent

measurements are updated using the get buttons. All the measurements are reset with the re set button.

Rev 1 17

Page 18

78M6610+LMU Evaluation Kit User Manual

5.1.11 Alarms Tab

The Alarms tab is a user-definable display of whatever parameters are required in a particular application. The

alarms are described in detail in Sections 2.11 and 2.12 of the 78M6610+LMU Data Sheet.

18 Rev 1

Page 19

78M6610+LMU Evaluation Kit User Manual

5.1.12 Monitor Tab

The Monitor tab is a running record of all the communications between the GUI and the target

78M6610+LMU. A log file can be generated to sav e the transactions for later analysis.

Rev 1 19

Page 20

78M6610+LMU Evaluation Kit User Manual

Connect

USB port

to PC

AC source

Line 1

Neutral

Line 2

Load

Line 1

CT

+

6 Alternate Sensor Configurations

6.1 Split-Phase Using Shunt (On Neutral) and One CT (On Line)

In this configuration, neutral is measured instead of Line 2. Results for Line 2 are indirectly calculated from the

measurements on Line 1 and Neutral.

1. Connect the AC source Neutral output to J15.

2. Connect J8 to Load’s Neutral input.

3. Connect the AC source Line 1 output to J2 and to Load’s Line 1 input.

4. Feed Line 1 through the CT.

5. Connect Line 1 CT’s secondary to J14 (burden resistor).

6. Connect the AC source Line 2 output to J4 and the Load’s Line 2 input.

20 Rev 1

Page 21

78M6610+LMU Evaluation Kit User Manual

J23 Pins

Description

Jumper

J9 Pins

Description

Jumper

Voltage

Current

VA

S0

0

IA 0 S3

VB 0 S2

IB

-S1

-S3

VC

S0

-S2

Pre-Amp

1X S1

1X S3

6.1.1 Jumper Position Changes

Move J23 and J24 jumpers to position CT to use CT2 and remove jumper at J9.

J23 Jumper Description

1/2 Connect J15 SHUNT to 78M6610+LMU Sensor Slot 1 Installed

2/3 Connect J10 CT2+ to 78M6610+LMU Sensor Slot 1 -

J24 Jumper Description

J24 Pins Description Jumper

1/2 Connects J8 SHUNT to 78M6610+LMU Sensor Slot 1 Installed

2/3 Connects J10 CT2- to 78M6610+LMU Sensor Slot 1 -

J9 Jumper Description

1/2 Connect AC Neutral to V3P3A (chip reference) Installed

6.1.2 Device Configuration

Use the Configuration tab to map the sensors as shown in the table below. Re-enter the gain value for CT2

(located on bottom of board) into the S1_GAIN register if needed.

Note: The values for VC and IB will not be displayed correctly on the Power tab of the provided GUI due to the

increased full-scale values of VC and IB. Reported results for measurements derived from VC and IB will be

one-half the expected magnitude.

Rev 1 21

Page 22

78M6610+LMU Evaluation Kit User Manual

Connect

USB port

to PC

CT

1

CT2

Load 1

Load

2

N

Line

N

Line

Line

Neutral

+

+

AC source

6.2 Pseudo-Isolated Single-Phase Measurements Using CTs

In this diagram, the two voltage inputs are used to measure a single 2-wire interface for a high-impedance

resistive isolation between AC and the 78M6610+LMU.

Figure 3: 78M6610+LMU Evaluation Board Connections

1. Connect the AC source Neutral to J4 and the load(s).

2. Connect the AC source Line to J2 an d to J19 (Relay1) through the Line 1 CT.

3. Connect J20 (Relay1) to Line 1 load.

4. Connect Line 1 CT’s secondary to J14 (burden resistor).

If measuring a second load:

5. Connect the AC source Line to J31 (Relay2) through the Line 2 CT.

6. Connect J30 (Relay1) to Line 1 load.

7. Connect Line 2 CT’s secondary to J10 (burden resistor).

22 Rev 1

Page 23

78M6610+LMU Evaluation Kit User Manual

J23 Pins

Description

Jumper

J9 Pins

Description

Jumper

Voltage

Current

VA

S0

-S2

IA 0 S3

VB

S0

-S2

IB

S1

0

VC

Pre-Amp

1X S1

1X S3

6.2.1 Jumper Position Changes

Move J23 and J24 jumpers to position CT to use CT2 and remove jumper at J9.

J23 Jumper Description

1/2 Connect J15 SHUNT to 78M6610+LMU Sensor Slot 1 2/3 Connect J10 CT2+ to 78M6610+LMU Sensor Slot 1 Installed

J24 Jumper Description

J24 Pins Description Jumper

1/2 Connects J8 SHUNT to 78M6610+LMU Sensor Slot 1 2/3 Connects J10 CT2- to 78M6610+LMU Sensor Slot 1 Installed

J9 Jumper Description

1/2 Connect AC Neutral to V3P3A (chip reference) -

6.2.2 Device Configuration

Use the Configuration tab to map the sensors as shown i n the table below. Re-enter the gain value for C T2

(located on bottom of board) into the S1_GAIN register if needed.

Note: The values will not be displayed correctly on the Power tab of the provided GUI due to the increased

full-scale value of the voltages. Reported results for measurements will be one-half the expected magnitude.

Rev 1 23

Page 24

C7

0.

1uF

0603

J10

1

2

R32

750 1%

0603

J

3

CON

1

1

C

12

1000

pF

0603

J8

CON

4

1

2

3

4

R

12

0

0603

J14

1

2

R

79

1

K

J

13

CON

1

1

R73

10K

R

18

0

0603

J

32

CON

1

1

R9

1

M

0.

1

%

1206

W

U

1

78

M6610+LMU

TQFN

24

V

3P

3

A

21

MP10

16

A0

19

XOUT

10

GNDA

2

A

1

20

MP

6

/ADDR

1

5

A3

23

A

4

24

XIN

9

A2

22

SSB/

DIR

/SCL

6

SPCK

/

ADDR0

14

MP

4

7

IFC

1

17

RESET

18

SDI

/

RX/

SDAo

13

A5

1

MP

7

4

IFC0

3

GNDD

11

MP0

15

SDO/

TX/

SDAi

12

V

3

P

3

D

8

J

7

CON

13

1

2

3

4

5

6

7

8

9

10

11

12

13

R26

0

.004 1

%

2.

5W

2512

P

R71

10K

C

3

10

uF

0805

SW4

SW DIP-

2

J35

CON1

1

J11

CON

4

1

2

3

4

J

4

CON4

1

2

3

4

J36

CON1

1

R

70

Rburden

R

11

750 0.

1%

0603

C

8

0

.1

uF

0603

VR1

+3

.

3

V

500

mA

511

-

LD

1117

S

33

C

SOT

223

VOUT

2

VIN

3

TAB

4

GND

1

J15

CON4

1

2

3

4

J34

CON1

1

R75

10

K

R

3

10

K

0603

R33

10

K

0603

J

26

CON

1

1

R69

Rburden

C13

1000

pF

0603

Y

1

20.

00MHz

1 2

R80

1K

C18

18pF

0603

R29

750 1

%

0603

R

16

1

M 0

.1

%

1206W

J

37

CON

1

1

J

25

CON

1

1

R

19

0

0603

R

10

1

M

0

.

1

%

1206W

C

5

NC

0603

J

2

CON4

1

2

3

4

C

9

1000pF

0603

C

10

1000

pF

0603

J

33

CON

1

1

C

1

0

.1

uF

0603

C

2

0.

1

uF

0603

C6

NC

0603

R78

1K

R

76

0

(NC

)

C

4

1000

pF

0603

SW

1

J

5

CON

4

1

2

3

4

J

23

CON

3

1

2

3

J9

CON

2

SIP

100P

2

1

2

R

24

750 1

%

0603

R15

750 0.

1%

0603

R39

10

K

0603

R38

10K

0603

R36

10

K

0603

J

6

CON1

1

C

14

1000pF

0603

SW5

SW DIP-

2

J

24

CON3

1

2

3

R17

1

M 0

.

1%

1206

W

R77

1K

C15

1000pF

0603

C19

18pF

0603

C11

0

.

1

uF

0603

R28

750 1

%

0603

R72

10

K

GND

GND

GND

V

3P

3

A

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

+

5

VISO

V

3

P3

V

3P

3

V3

P3

V

3

P

3

A

V

3

P3

A

V

3P

3

V3

P

3A

V3P

3A

GND

V3

P3

V

3P3

A

V3

P

3A

V3

P

3

V

3P

3

V3

P3

A

V3P

3A

SPCK

SDO

SSB

SDI

MP0

MP4

MP

6

MP7

IFC

0

MP

10

IFC

1

+5

VISO

S

2

S

0

MP

0

SPCK

/ADDR

0

SDI

/RX

/SDAo

SDO/

TX

/SDAi

SSB

/

DIR/

SCL

MP6

/ADDR1

MP

7

IFC

0

MP10

IFC1

CT2

CT1

GPIO ACCESS

For

int.

OSC

MP

0

SDO

/

TX

/

SDAi

SDI

/

RX

/

SDAo

SPCK

/

ADDR

0

MP

4

MP4

SSB

/

DIR

/

SCL

MP

7

IFC

0

MP

6

/

ADDR

1

MP

010

IFC

1

MP0

IFCF1

SSB

LINE A IN

LINE B IN

NEUTRAL OUT

NEUTRAL IN

S1

S

3

78M6610+LMU Evaluation Kit User Manual

7 Hardware Design Information

This section includes the schematics, bill of materials, and PCB layouts for the 78M6610+LMU EV board.

7.1 Board Schematics

24 Rev 1

Figure 4: 78M6610+LMU Evaluation Board Electrical Schematic (1 of 4)

Page 25

MP4L

R8

470

0603

R14

470

0603

LED5

0603

RED

1

2

LED4

0603

RED

1

2

LED8

0603

YELLOW

1

2

LED2

0603

AMBER

1

2

R6

470

0603

LED6

0603

BLUE

1

2

R2

470

0603

R7

470

0603

V3P3

V3P3

V3P3

V3P3

V3P3

J24A

CON11

1

2

3

4

5

6

7

8

9

10

11

J24B

CON11

1

2

3

4

5

6

7

8

9

10

11

J24A

SPCK

SDI

MP4

SSB

J24B

SDO

MP0

MP6

MP7

IFC0

MP10

IFC1

2x11

Jumper

Matrix

MP0

SDO

SDI

SPCK

MP4

SSB

MP6

MP7

IFC0

MP10

IFC1

MP010L

MP7L

MP0L

MP6L

78M6610+LMU Evaluation Kit User Manual

Rev 1 25

Figure 5: 78M6610+LMU Evaluation Board Electrical Schematic (2 of 4)

Page 26

78M6610+LMU Evaluation Kit User Manual

D7

BAS16W/SOT323

GND

GND

D8

BAS16W/SOT323

R37

10K

0603

D6

Green LED

0603

R34

1K

0603

Q2

MMBTA13/SOT

R35

2K

0603

MP0

RL2

16A 5V SPDT

ALZ

3

5

4

1

2

6

7

8

J19

1

2

3

4

+5VISO

J30

1

2

3

4

R25

10K

0603

D5

Green LED

0603

R21

1K

0603

Q1

MMBTA13/SOT

R27

2K

0603

MP10

RL1

16A 5V SPDT

ALZ

3

5

4

1

2

6

7

8

J20

1

2

3

4

J31

1

2

3

4

+5VISO

RLY1

RLY2

Remove R21 and R34 if the relay s are not needed

and DIO0 and DIO10 are used for other purposes

26 Rev 1

Figure 6: 78M6610+LMU Evaluation Board Electrical Schematic (3 of 4)

Page 27

78M6610+LMU Evaluation Kit User Manual

J12

CON3

1

2

3

R45

0

0603

C24

0.1uF

0603

R52

120

0805

R57

1K

0603

U3

FT2232C

TQFP48

USBDM

8

3V3OUT

6

USBDP

7

AD0

24

RSTOUTB

5

TEST

47

AVCC

46

AGND

45

RESETB

4

XTIN

43

XTOUT

44

EECS

48

EESK

1

EEDATA

2

VCC1

3

VCC2

42

VCCIOA

14

VCCIOB

31

GND1

9

GND2

18

GND3

25

GND4

34

AD1

23

AD2

22

AD3

21

AD4

20

AD5

19

AD6

17

AD7

16

AC0

15

AC1

13

AC2

12

AC3

11

S1/WUA

10

BD0

40

BD1

39

BD2

38

BD3

37

BD4

36

BD5

35

BD6

33

BD7

32

BC0

30

BC1

29

BC2

28

BC3

27

SI/WUB

26

PWREN

41

Y2

CSTCRG6M00

CSTCR

2

3 1

U7

IL516-3E

GND1

2

IN2

4

OUT4

6

NC

10

IN4

11

OUT1

14

VDD1

1

GND2

15

IN1

3

OUT3

5

NC

7

GND2

9

OUT2

13

IN3

12

GND1

8

VDD2

16

R56 1K

0603

J38

CON2

SIP100P2

1

2

J17

CON3

1

2

3

C28

0.1uF

0603

J28

CON2

SIP100P2

1

2

R55

NC

0603

C23

0.1uF

0603

U11

MAX13433EESD+

VL

1

RO

2

DE

3

RE

4

DI

5

GND

6

NC

7

GND

8

Y

9

Z

10

B

11

A

12

NC

13

VCC

14

C27

10uF

0805

445-3458-1-ND

R59

120

0805

R58

1K

0603

C31

0.1uF

0603

R47

2.2K

0603

C29

0.1uF

0603

J18

CON3

1

2

3

U8

IL510-3E

VDD1

2

IN1

1

GND1

4

OUT1

8

VDD2

7

GND2

5

OUT2

3

IN2

6

J21

CON6

USBB

1

2

3

4

5

6

R40

0

0603

C25

0.033uF

0603

C21

10uF

0805

445-3458-1-ND

R50

1M

0603

VR2

VBT1-5V

NC1

3

VOUT

5

VIN

2

VGND

4

GND

1

NC2

6

NC3

7

NC4

8

R41

470

0603

J27

CON2

SIP100P2

1

2

C20

10uF

R49

0

0603

R46

2.2K

0603

C30

1uF

0603

R43

10K

0603

R54

10K

0603

J16

CON6

SIP100P6

1

2

3

4

5

6

J29 CON2

SIP100P2

1

2

R53

10K

0603

C26

0.1uF

0603

J22

CON4

1

2

3

4

5

6

R42

10K

0603

C22

0.1uF

0603

GND

GND

+5VISO

5VIN

GND

5VIN

UGND

SSBin

MOSIin

SSB

SCKin

5VIN

RS485RX

RS485Y

GND

5VIN

MISOout

RS485TXEN

UGND

SPCK

SSBout

MOSIF

SDI

5VIN

SDO

GND

UGND

GND

GND

USBDM

USB3

UGND

UGND

RSTOB

UGND

UGND

AVCC

XTI

XTO

UGND

UGND

UGND

USBDP

RXFTDI

MISOF

SSBF

5VUSB

RS485TXENout RS485TXENout

RS485Z

RS485B

RS485A

V3P3

V3P3

V3P3

SDI

SSB

+5VISO

SDO

SPCK

MOSI

SSB/TXEN

Isolation

Optional External I2C or SPI

Do NOT apply +5VDC to

J22-1 when USB cable is

attached to J21.

RS485

MISO

SCK

RS485/SPI

Select

RS485/SPI

Select

RS485

TXen/

SSB

Select

SCKout

MISOin

USB

SPI &

UART

500 ma Max

1K

RE-WORK

0603

Figure 7: 78M6610+LMU Evaluation Board Electrical Schematic (4 of 4)

Rev 1 27

Page 28

78M6610+LMU Evaluation Kit User Manual

11

5

J3,J6,J13,J25,J26

CON1

SIP100P1

13

5

J9,J27,J28,J29,J38

CON2

SIP100P2

15

5

J12,J17,J18,J23,J24

CON3

SIP100P3

17

1

J21

CON6

USBB

19

2

J24B,J24A

CON11

SIP100P11

20

6

J32,J33,J34,J35,J36,J37

CON1

sm pad

22

2

LED4,LED5

RED

0603

24

1

LED8

YELLOW

0603

26

2

RL1,RL2

16A 5V SPDT

ALZ

R3,R25,R33,R36,R37,R38,R39,R42,R43,R

30

2

R11,R15

750 0.1%

0603

34

1

R26

0.004 1% 2.5W

2512P

36

2

R46,R47

2.2K

0603

7.2 Bill of Materials

Item

1 12

2 4 C3,C20,C21,C27 10uF 0805

3 7 C4,C9,C12,C10,C13,C14,C15 1000pF 0603

4 4 C5,C6 NC 0603

5 2 C18,C19 18pF 0603

6 1 C25 0.033uF 0603

7 1 C30 1uF 0603

8 2 D5,D6 Green LED 0603

9 2 D7,D8 BAS16W/SOT323 SOT-323 AC

10 10 J2,J4,J5,J8,J11,J15,J19,J20,J30,J31 CON4 STERM

12 1 J7 CON13 SIP100P13

Quantity Reference Part PCB Footprint

C1,C2,C7,C8,C11,C22,C23,C24,C26,C28,

C29,C31

0.1uF 0603

14 2 J10,J14 TERM BLK 200-2 TERM BLK 200-2

16 1 J16 CON6 SIP100P6

18 1 J22 CON4 TERM BLK 200-6

21 1 LED2 AMBER 0603

23 1 LED6 BLUE 0603

25 2 Q1,Q2 MMBTA13/SOT SOT-23

27 6 R2,R6,R7,R8,R14,R41 470 0603

28 13

53,R54,R72,R73

10K 0603

29 4 R9,R10,R16,R17 1M 0.1% 1206W

31 6 R12,R18,R19,R40,R45,R49 0 0603

32 9 R21,R34,R56,R57,R58,R77,R78,R79,R80 1K 0603

33 4 R24,R28,R29,R32 750 1% 0603

35 2 R27,R35 2K 0603

28 Rev 1

Page 29

78M6610+LMU Evaluation Kit User Manual

37

1

R50

1M

0603

41

2

R55,R76

0(NC)

0603

43

2

SW4,SW5

SW DIP-2

DIP4

47

1

U8

IL612A

IL611A

49

1

VR1

+3.3V 500mA

SOT223

Item

Quantity Reference Part PCB Footprint

38 2 R52,R59 120 0805

39 2 R69,R70 Rburden 0805

40 2 R71,R75 10K

42 1 SW1 PUSHBUTTON SMD (SMT) Tab

44 1 U1 78M6610+LMU/B TQFN24

45 1 U3 FT2232C TQFP48

46 1 U7 IL516-3E SO-16 NARROW

48 1 U11 MAX13433EESD+ SO-14 NARROW

50 1 VR2 VBT1-5V VBT1

51 1 Y1 20.00MHz ABLS

52 1 Y2 CSTCRG6M00 CSTCR

Rev 1

Page 30

78M6610+LMU Evaluation Kit User Manual

7.3 PCB Layout

Figure 8: 78M6610+LMU Evaluation Board PCB Top View

30 Rev 1

Page 31

78M6610+LMU Evaluation Kit User Manual

Figure 9: 78M6610+LMU Evaluation Board PCB Bottom View

Rev 1

Page 32

78M6610+LMU Evaluation Kit User Manual

8 Contact Information

For more information about Maxim Integrated products or to check the availability of the 78M6610+LMU,

contact technical support at

Revision History

www.maximintegrated.com/support.

REVISION

NUMBER

0 2/13 Initial release —

1 7/13 Updated ordering part number

REVISION

DATE

DESCRIPTION

PAGES

CHANGED

4

32 Rev 1

Loading...

Loading...