Page 1

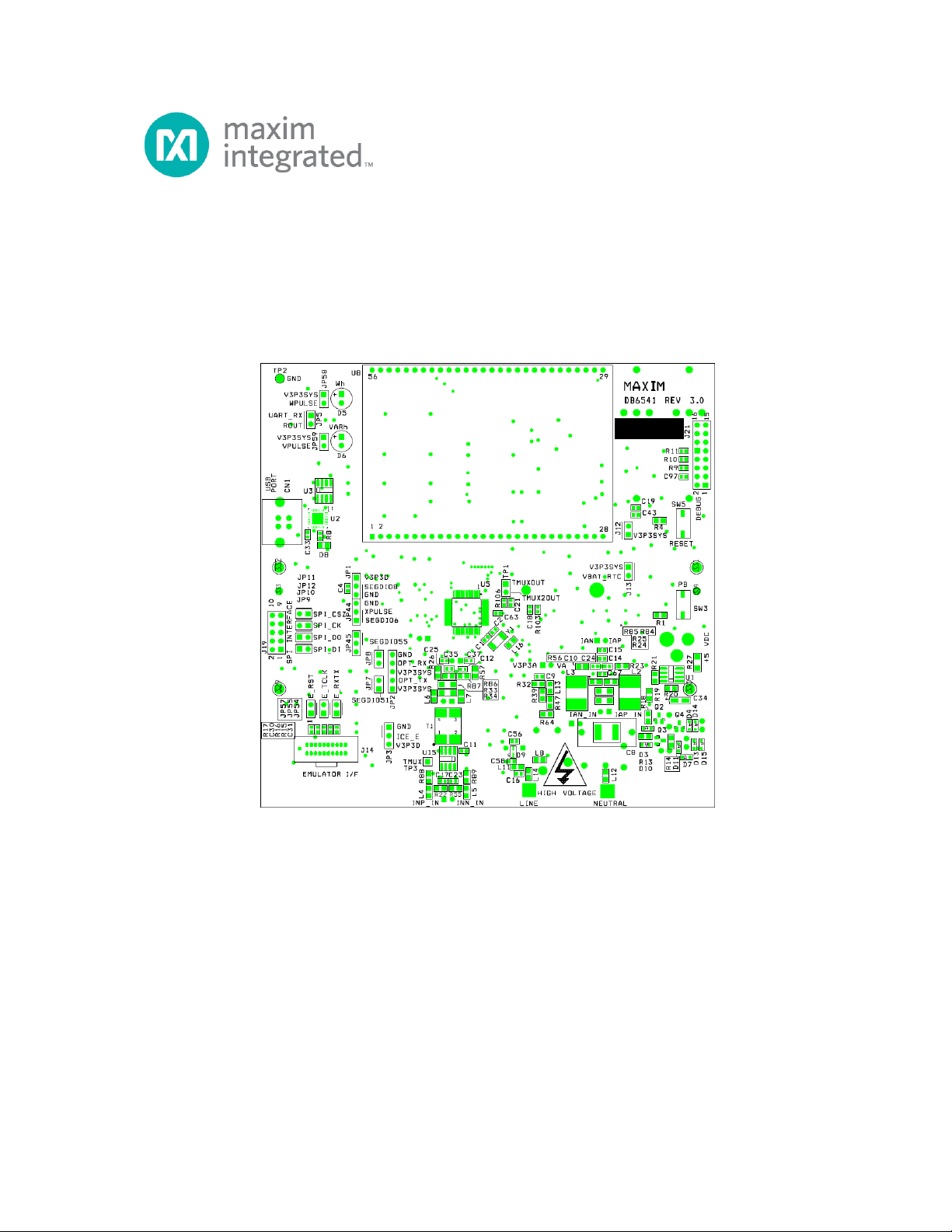

71M6541 Demo Board REV 3.0

User’s Manual

Rev 4.0; 12/12

Maxim Integrated cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim Integrated product. No circuit patent

licenses are implied. Maxim Integrated reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated 160 Rio Robles, San Jose, CA 95134 USA 1-408-601-1000

© 2012 Maxim Integrated Products, Inc. Maxim Integrated and the Maxim Integrated logo are trademarks of Maxim Integrated Products, Inc.

Page 2

71M6541 Demo Board REV 3.0 User’s Manual

Table of Contents

1 GETTING STARTED................................................................................................................................................ 5

1.1 General .................................................................................................................................................................... 5

1.2 Safety and ESD Notes ............................................................................................................................................ 5

1.3 Demo Kit Contents ................................................................................................................................................. 6

1.4 Demo Board Versions ............................................................................................................................................ 6

1.5 Compatibility ........................................................................................................................................................... 6

1.6 Suggested Equipment not Included ..................................................................................................................... 6

1.7 Demo Board Test Setup ......................................................................................................................................... 7

1.7.1 Power Supply Setup .......................................................................................................................................... 8

1.7.2 Cables for Serial Communication ...................................................................................................................... 8

1.7.3 Checking Operation ........................................................................................................................................... 9

1.7.4 Serial Connection Setup .................................................................................................................................... 9

1.8 Using the Demo Board ......................................................................................................................................... 10

1.8.1 Serial Command Language ............................................................................................................................. 11

1.8.2 Using the Demo Board for Energy Measur ements .......................................................................................... 17

1.8.3 Adjusting the Kh Factor for the Demo Board ................................................................................................... 17

1.8.4 Adjusting the Demo Boards to Different SHUNT Resistors ............................................................................. 17

1.8.5 Using the Pre-Amplifier ................................................................................................................................... 17

1.8.6 Using Current Transformers (CTs) .................................................................................................................. 17

1.8.7 Implementing a Single-Phase 3-Wire Meter (EQU 1) ...................................................................................... 17

1.8.8 Adjusting the Demo Boards to Different Voltage-Dividers ............................................................................... 17

1.9 Calibration Parameters ........................................................................................................................................ 18

1.9.1 General Calibration Procedur e ........................................................................................................................ 18

1.9.2 Calibration Macro File ..................................................................................................................................... 19

1.9.3 Updating the Demo Code (hex file) ................................................................................................................. 19

1.9.4 Updating Calibration Data in Flash or EEPROM ............................................................................................. 20

1.9.5 Loading the Code for the 71M6541 into the Demo Board ............................................................................... 20

1.9.6 The Programming Interface of the 71M65 41 ................................................................................................... 22

1.10 Demo Code ........................................................................................................................................................ 23

1.10.1 Demo Code Description ............................................................................................................................... 23

1.10.2 Important MPU Addresses ........................................................................................................................... 23

1.10.3 LSB Values in CE Registers ........................................................................................................................ 30

1.10.4 Calculating IMAX and Kh ............................................................................................................................. 30

1.10.5 Determining the Type of 71M6x0x ............................................................................................................... 31

1.10.6 Communicating with the 71M6X0X .............................................................................................................. 32

1.10.7 Bootloader Feature ...................................................................................................................................... 32

2 APPLICATION INFORMATION ............................................................................................................................. 34

2.1 Sensor Connections and Equations ................................................................................................................... 34

2.1.1 Sensor Wiring .................................................................................................................................................. 34

2.1.2 Single-phase two-wire (EQU 0) ....................................................................................................................... 35

2.1.3 Single-phase three-wire (EQU 1) .................................................................................................................... 36

2.2 Calibration Theory ................................................................................................................................................ 37

2.2.1 Calibration with Three Measurements ............................................................................................................. 37

2.2.2 Calibration with Five Measurements ............................................................................................................... 38

2.3 Calibration Procedures ........................................................................................................................................ 40

2.3.1 Calibration Equipment ..................................................................................................................................... 40

2.3.2 Phase-by-Phase Calibration ............................................................................................................................ 40

2.3.3 Detailed Calibration Procedures ...................................................................................................................... 40

2.3.4 Calibration Procedure with Three Measurements ........................................................................................... 41

2 Rev 4.0

Page 3

71M6541 Demo Board REV 3.0 User’s Manual

2.3.5 Calibration Procedure with Fiv e M easurements .............................................................................................. 42

2.3.6 Calibration Spreadsheets ................................................................................................................................ 42

2.3.7 Compensating for Non-Linearities ................................................................................................................... 45

2.4 Temperature Compensation ................................................................................................................................ 46

2.4.1 Error Sources .................................................................................................................................................. 46

2.4.2 Software Features for Temperatur e Compensation ........................................................................................ 47

2.4.3 Calculating Parameters for Compensation ...................................................................................................... 48

2.5 Testing the Demo Board ...................................................................................................................................... 51

2.5.1 Functional Meter Test ...................................................................................................................................... 51

2.6 Sensors and Sensor Placement .......................................................................................................................... 53

2.6.1 Self-Heating .................................................................................................................................................... 53

2.6.2 Placement of Sensors (ANSI) ......................................................................................................................... 54

2.6.3 Placement of Sensors (IEC) ............................................................................................................................ 55

2.6.4 Other Techniques for Avoiding Magnetic Crosstalk......................................................................................... 56

3 HARDWARE DESCRIPTION ................................................................................................................................. 58

3.1 71M6541-DB Description: Jumpers, Switches and Test Points ....................................................................... 58

3.2 Board Hardware Specifications .......................................................................................................................... 62

4 APPENDIX ............................................................................................................................................................. 64

4.1 71M6541-DB Electrical Schematic ...................................................................................................................... 65

4.2 71M6541-DB Bill of Material ................................................................................................................................. 67

4.3 71M6541-DB PCB Layout ..................................................................................................................................... 69

4.4 71M6541 Pinout Information ................................................................................................................................ 73

4.5 Revision History ................................................................................................................................................... 76

List of Figures

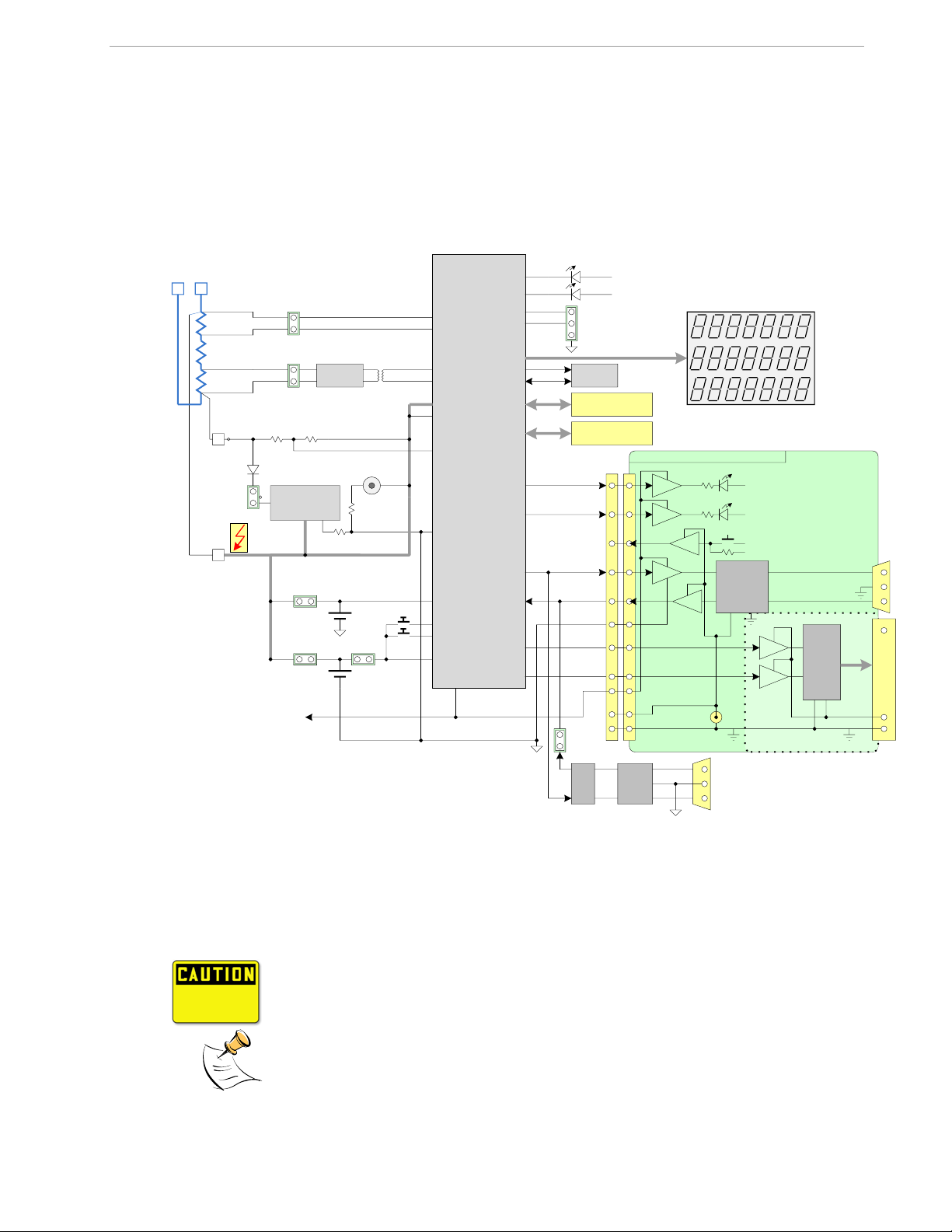

Figure 1-1: D6541 REV2.0 Demo Board with Debug Board: Basic Connections ................................................................ 7

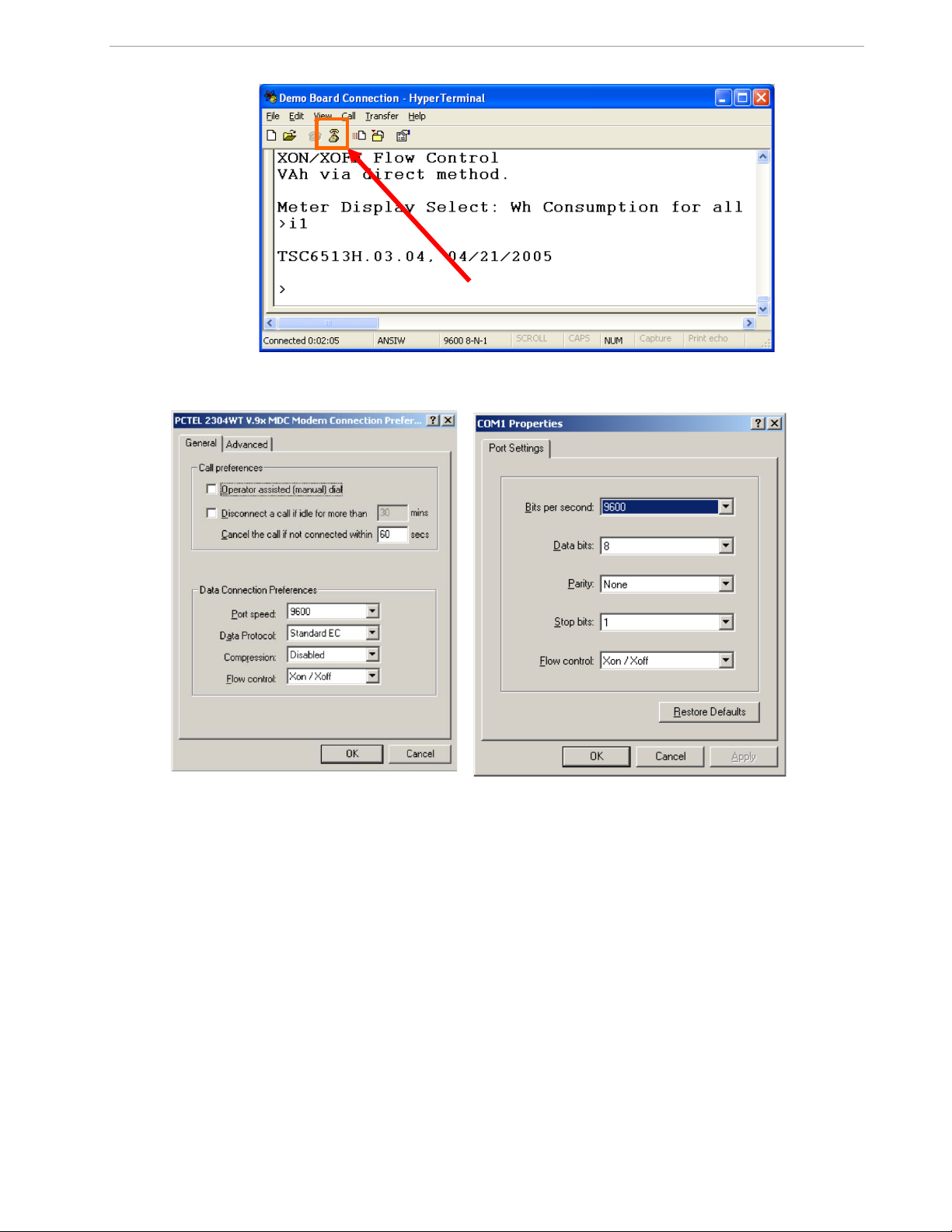

Figure 1-2: HyperTerminal Sample W indow with Disconnect Button (Ar r ow) ................................................................... 10

Figure 1-3: Port Speed and Handshake S etup (left) and Port Bit setup (r i ght) .................................................................. 10

Figure 1-4: Typical Calibration Macro File ......................................................................................................................... 19

Figure 1-5: Emulator Window Showing Reset and Erase Buttons (see Arro ws) ............................................................... 21

Figure 1-6: Emulator Window Showing Erased Flash Memory and File Loa d M enu ......................................................... 21

Figure 2-1: Shunt Connections.......................................................................................................................................... 34

Figure 2-2: Single-Phase Two-Wire M eter with Shunt Sensor .......................................................................................... 35

Figure 2-3: Single-Phase Two-Wire M eter with two Shunt Sensors .................................................................................. 35

Figure 2-4: Single-Phase Three-Wire M eter with two Shunt Sensors ............................................................................... 36

Figure 2-4: Watt Meter with Gain and Phase Errors. ......................................................................................................... 37

Figure 2-5: Phase Angle Definitio ns .................................................................................................................................. 40

Figure 2-7: Calibration Spreadsheet for Three Measurements ......................................................................................... 43

Figure 2-8: Calibration Spreadsheet for Five Measurements ............................................................................................ 44

Figure 2-9: Non-Linearity Caused by Quantification Noise ............................................................................................... 45

Figure 2-10: GAIN_ADJ over Temperature ........................................................................................................................ 49

Figure 2-11: GAIN_ADJ and GAIN_ADJ’ over Temperature .............................................................................................. 49

Figure 2-12: Meter with Calibration System ...................................................................................................................... 52

Figure 2-13: Calibration System S creen ........................................................................................................................... 52

Figure 2-14: Wh Load Lines at Room T em perature with 71M6201 and 50 µΩ Shunts ..................................................... 53

Figure 2-15: Typical Sensor Arrangement (left), Recommended Arrangement (right) ...................................................... 55

Figure 2-16: Improved Sensor Arrang ement ..................................................................................................................... 55

Figure 2-17: Loop Formed by Shunt and Sen sor Wire ...................................................................................................... 56

Figure 2-18: Shunt with Compensation Loop .................................................................................................................... 56

3 Rev 4.0

Page 4

71M6541 Demo Board REV 3.0 User’s Manual

Figure 2-19: Shunt with Center Drill H ol es ........................................................................................................................ 56

Figure 3-1: 71M6541-DB REV 3.0 - Boar d Description ..................................................................................................... 61

Figure 4-1: 71M6541-DB REV 3.0 Demo Board: Electrical Schematic 1/2 ....................................................................... 65

Figure 4-2: 71M6541-DB REV 3.0 Demo Board: Electrical Schematic 2/2 ....................................................................... 66

Figure 4-3: 71M6541-DB REV 3.0: T op View ................................................................................................................... 69

Figure 4-4: 71M6541-DB REV 3.0: T op C opper ............................................................................................................... 70

Figure 4-5: 71M6541-DB REV 3.0: Bottom View .............................................................................................................. 71

Figure 4-6: 71M6541-DB REV 3.0: Bottom Copper .......................................................................................................... 72

Figure 4-14: 71M6541, LQFP64: Pinout (Top View) ......................................................................................................... 75

List of Tables

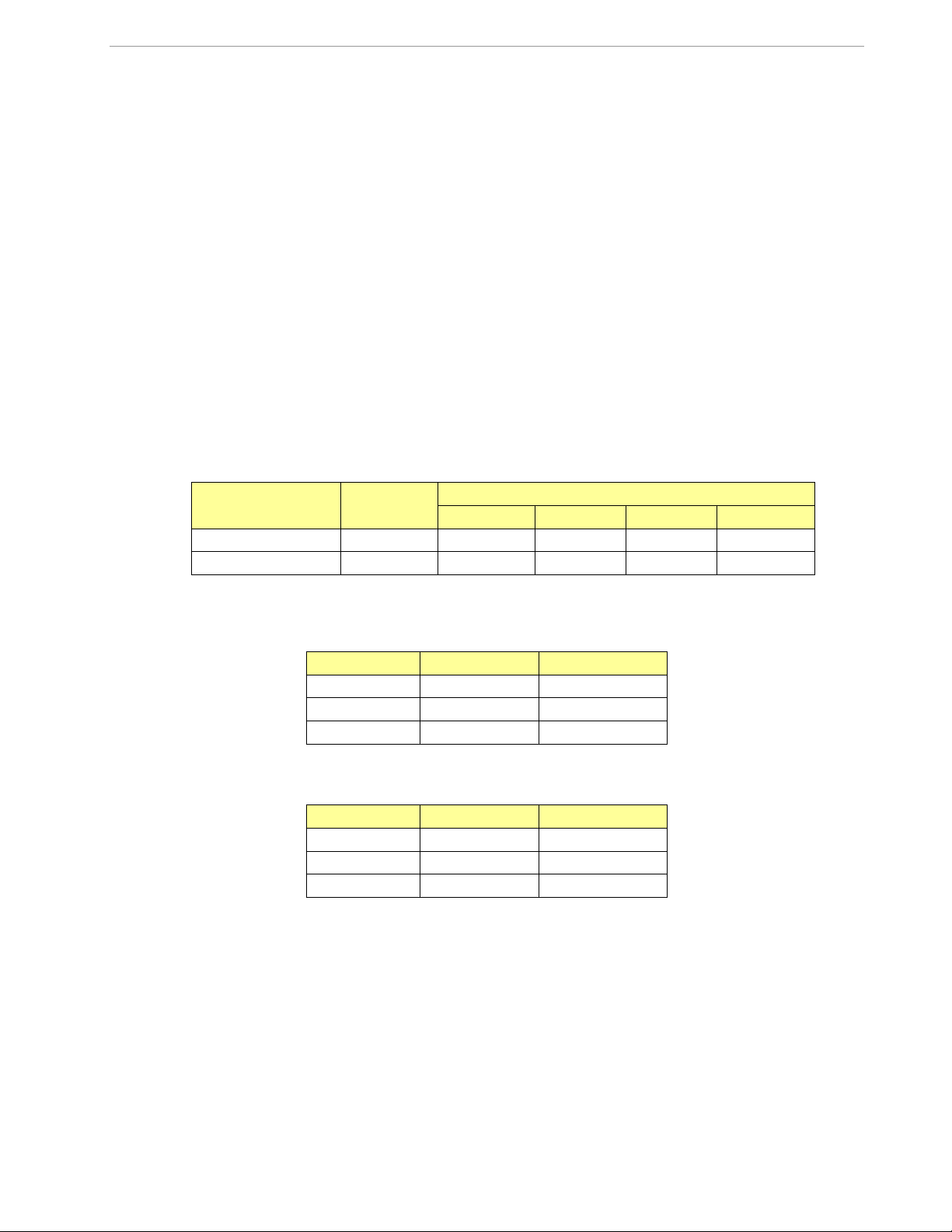

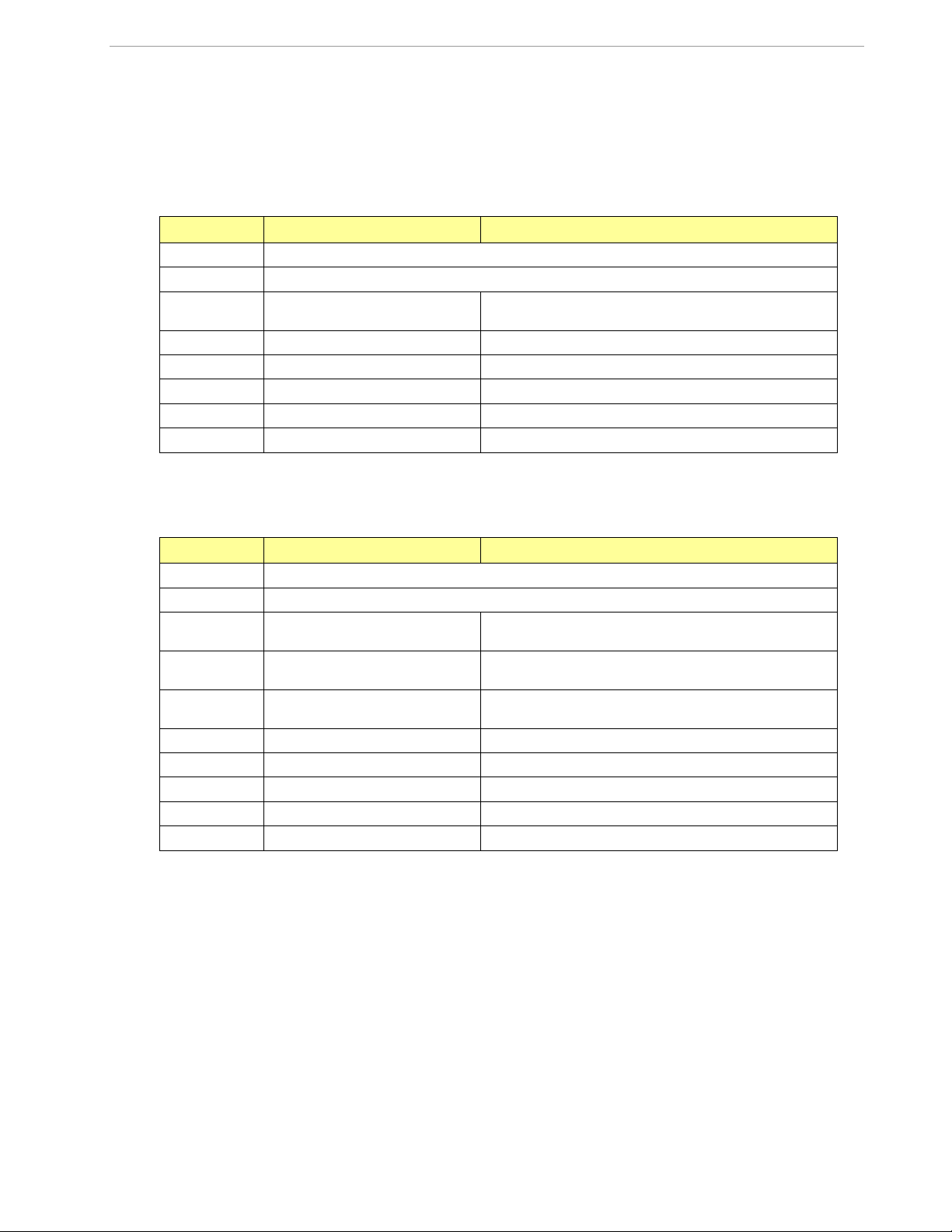

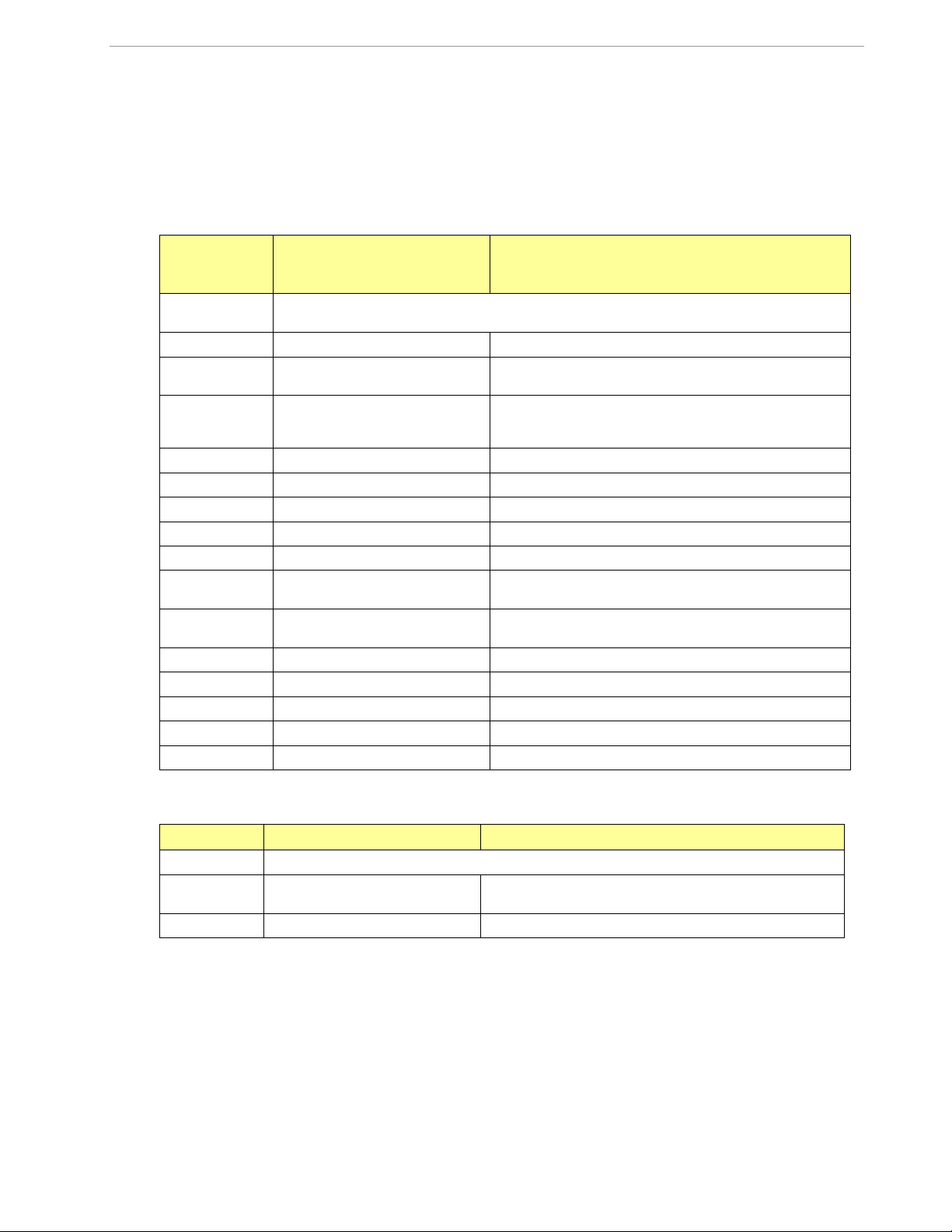

Table 1-1: Jumper Settings on Debug Board ...................................................................................................................... 8

Table 1-2: Straight Cable Connectio ns ............................................................................................................................... 8

Table 1-3: Null-modem Cable Connect ions ........................................................................................................................ 8

Table 1-4: CE RAM Locations for Calibr ation Constants .................................................................................................. 19

Table 1-5: Flash Programming Interf ac e Signals .............................................................................................................. 22

Table 1-6: MPU XRAM Locations ..................................................................................................................................... 24

Table 1-7: Bits in the MPU Status Word ............................................................................................................................ 29

Table 1-8: CE Registers and Associated LSB Values ....................................................................................................... 30

Table 1-9: IMAX for Various Shunt Resistance Values and Remote Sensor Types.......................................................... 31

Table 1-10: Identification of 71M6X 0X Remote Sensor Types .......................................................................................... 32

Table 2-1: Temperature-Related Er ror Sources ................................................................................................................ 46

Table 2-2: Temperature-Related Er ror Sources ................................................................................................................ 50

Table 3-1: 71M6541-DB REV 3.0 Description ................................................................................................................... 60

Table 4-1: 71M6541-DB REV 3.0: Bill of Material ............................................................................................................. 67

Table 4-3: 71M6541 Pin Description Table 1/3 ................................................................................................................. 73

Table 4-4: 71M6541 Pin Description Table 2/3 ................................................................................................................. 73

Table 4-5: 71M6541 Pin Description Table 3/3 ................................................................................................................. 74

4 Rev 4.0

Page 5

1

1 GETTING STARTED

1.1 GENERAL

The Maxim Integrated 71M6541-DB REV 3.0 Demo Bo ar d is a demonstration board for evaluating the 71M6541

device for single-phase electronic energy metering applications in conjunction with the Remote Sensor Interface. It incorporates a 71M6541 integrated circuit, a 71M6601 Remote Interface IC, peri pheral circuitry such as

a serial EEPROM, emulator port, and on-board power supply. A serial to USB converter allows communication

to a PC through a USB port. The Demo Board al lows the evaluation of the 71M6541 energy meter chip for

measurement accuracy and overall system use.

The board is pre-programmed with a Demo Program (Demo Code) in the FLAS H memory of the 71M6541F IC.

This embedded application is developed to exercise all low-level func tion calls to directly manage the p eripherals, flash programming, and CPU (clock, timing, power savings, etc.).

The 71M6541F IC on the Demo Board is pre-programmed and pre-calibrat ed for the 50 µΩ or 120 µΩ shunt

shipped with the board. The Demo Board may also be used for operation with a CT after hardware modifications that can be easily performed by the user. This configuration will require a different version of the Demo

Code.

71M6541 Demo Board REV 3.0 User’s Manual

1.2 SAFETY AND ESD NOTE S

Connecting live voltages to the demo boar d system will result in potentially hazardous voltages on t he demo

board.

THE DEMO SYSTEM IS ESD SENSITIVE! ESD PRECAUTIONS SHOULD BE TAKEN

WHEN HANDLING THE DEMO BOA RD!

EXTREME CAUTION SHOULD BE TAKEN WHEN HANDLING THE DEM O BOARD

ONCE IT IS CONNECTED TO LIVE VOLTAGES! BOARD GROUND IS CLOSE TO LIVE

VOLTAGE!

CAUTION: THE PHASE A CONNEC T ION OF THE DEMO BOARD IS CONNECTED TO

THE LIVE VOLTAGE SHUNT. THE NEUTRAL SHUNT IS ISOLATED VIA THE

71M6X0X REMOTE SENSOR INTE RFACE AND CONNECTED TO THE PHASE B INPUT. EXTREME CARE MUST BE TAKEN WHEN CHANGING SHUNT AND VOLTAGE

CONNECTIONS!

5 Rev 4.0

Page 6

1.3 DEMO KIT CONTENTS

• Demo Board D6541 REV 3.0 containing one 71M6601 or 71M6201 Remote Sensor Int erface and one

71M6541F IC with pre-loaded demo program

• 5VDC/1,000mA universal wall t r ansformer with 2.5mm plug (Switchcraft 712A compatible)

• Serial-USB converter

• USB cable

• ANSI base with 50 μΩ shunt resistor (optional, for ANSI kits only) or two 120 μΩ shunt resistors

1.4 DEMO BOARD VERSIONS

This manual applies to D6541 REV 3.0 only.

1.5 COMPATIBILITY

This manual applies to the following hardware and software revisions:

• 71M6541 chip revision B02

• Demo Kit firmware revision 5.4G or later

• Demo Board D6541 REV 3.0

71M6541 Demo Board REV 3.0 User’s Manual

1.6 SUGGESTED EQUIPMENT NOT INCLUDED

For functional demonstration:

• PC with Windows® 2000, Windows XP®, or Windows 7 operating system, equipped with USB port.

For the use of the optional Debug Board, a serial interface (COM port) is required.

For software development (MPU code) :

• Signum

• Keil 8051 “C” Compiler

Windows and Windows XP are registered trademarks of Microsoft Corp.

Systems In-Circuit Emulator (ICE): ADM-51

Signum WEMU51 version 3.11.09 or later should be used.

o

Kit: CA51

6 Rev 4.0

Page 7

1.7 DEMO BOARD TEST SETUP

DEMONSTRATION METER

IA

IB

NEUTRAL

IAP

IBP

V3P3A

VA

LINE

GND

V3P3

GND

5.0 VDC

Input

EEPROM

ICE Connector

SEGDIO52

SEGDIO10

TX

RX

DB9

to PC

COM Port

6541

Single Chip Meter

TMUXOUT

TMUX2OUT

3.3V or 5V

LCD

SDCK

SDATA

IAN

IBN

V3P3SYS

Wh

VARh

SEGDIO0/WPULSE

SEGDIO1/VPULSE

PULSE OUTPUTS

SEGDIO7/YPULSE

SEGDIO6/XPULSE

V3P3SYS

V3P3D

VBAT

Battery 2

(optional)

J13

PB

On-board components

powered by V3P3D

OPTO

OPTO

OPTO

OPTO

OPTO

5V DC

V5_DBG

GND_DBG

V5_DBG

V5_DBG

RS-232

INTERFACE

GND_DBG

V5_DBG

OPTO

OPTO

FPGA

06/03/2010

V5_NI

CE HEARTBEAT (1Hz)

MPU HEARTBEAT (5Hz)

DEBUG BOARD (OPTIONAL)

RTM INTERFACE

JP21

J21

4

15, 16

13, 14

6

6

8

12

10

3

1

2

5, 7,

9, 11

GND

V3P3SYS

JP6

J1

PULSE A

PULSE B

Power Supply

J5

68 Pin

Connector

VBAT_RTC

Battery 1

(optional)

RESET

JP56J12

JP20

SPI Connector

J14

J19

JP5

CN1

Isolator

RESET

PB

USB

Interface

External

Shunts

6601

J5

J3

Serial/USB

Converter

Iso-

GND

Load

LN

Figure 1-1 shows the basic connectio ns of the Demo Board plus optional Debug Board with the external equipment. The PC can be connected via the USB Interface (CN1). For stand-alone testing (without AC voltage) the

Demo Board maybe powered via the 5.0 VDC input (J20). The optional Debug Board must be powered with its

own 5 VDC power supply.

71M6541 Demo Board REV 3.0 User’s Manual

7 Rev 4.0

Figure 1-1: 71M6541-DB REV3.0 Demo Board with optional Debug Board: Basic Connections

The Demo Board contains all circuits necessary for operation as a meter , including display, calibration LEDs,

and internal power supply. Communication with a PC USB port is provided v i a c onnector CN1. The optional

Debug Board uses a separate power supply, and is optically isolate d from the Demo Board. It interfaces to a PC

through the USB connector.

It is recommended to set up the demo board with no live AC voltage connected, and to

connect live AC voltages only after the user is familiar with the demo system.

All input signals are referenced to the V3P3A (3.3V power supply to the chip).

Page 8

71M6541 Demo Board REV 3.0 User’s Manual

1.7.1 POWER SUPPLY SETUP

There are several choices for the meter power supply:

o Internal (using the AC line voltage). The internal power supply is only suitable when the voltage ex-

ceeds 100V RMS. To enable the internal s upply, a jumper needs to be inst all ed across JP6 on the top

of the board.

o External 5.0VDC connector (J20) on the Demo Board.

1.7.2 CABLES FOR SERIAL COMMUNICATION

1.7.2.1 USB Connection (Recommended)

A standard USB cable can be used to connec t the Demo Board to a PC running HyperTer minal or a similar serial interface program. A suitable driver, e.g., the FTDI CDM Driver Pac kage, must be installed on the PC to enable the USB port to be mapped as a virtual COM port. The driver can be found on the FTDI web site

(www.ftdichip.com).

See Table 3-1 for correct placement of j um per JP5 depending on whether the USB c onnection or the serial

connection via the Debug Board is used.

1.7.2.2 Serial Connection (via Optional Debug Board)

For connection of the DB9 serial port of the Debug Board to a PC serial port ( C OM port), either a straight or a

so-called “null-modem” cable may be used. JP1 and JP2 are plugged in for the straight cable, and JP3/JP4 are

empty. The jumper configuration is r ev ersed for the null-modem cable, as shown in Table 1-1.

Cable Configura-

tion

Straight Cable

Null-Modem Cable Alternative -- -- Installed Installed

JP1 through JP4 can also be used to alter the connection when the PC is not configured as a DCE device. Table 1-2 shows the connections necessary for the straight DB9 cable and t he pi n definitions.

Table 1-3 shows the connections neces sary for the null-modem DB9 cable and t he pin definitions.

See Table 3-1 for correct placement of j um per JP5 on the Demo Board depending on whether the USB connection or the serial connection via the Debug Board is used.

Mode

Default

Table 1-1: Jumper Settings on Debug Board

PC Pin

2 TX 2

3 RX 3

5 Signal Ground 5

Table 1-2: Straight Cable Connections

PC Pin Function Demo Board Pin

2 TX 3

3 RX 2

5 Signal Ground 5

Table 1-3: Null-modem Cable Connections

JP1 JP2 JP3 JP4

Installed Installed -- --

Function Demo Board Pin

Jumpers on Debug Board

8 Rev 4.0

Page 9

1.7.3 CHECKING OPERATION

H E L L 0

5. 4 G

0. 0 0 Wh SYS

0 3

Unit

A few seconds after power up, the LCD display on the Demo Board should display a brief greeting in the top

row and the demo code revision in the bottom row:

The “HELLO” message should be foll owed by the display of accumulated energy:

The “SYS” symbol will be blinking, indic ating activity of the MPU inside t he 71M6541.

In general, the fields of the LCD are us ed as shown below:

Command number

71M6541 Demo Board REV 3.0 User’s Manual

Measured value

(Phase)

1.7.4 SERIAL CONNECTION SETUP

After connecting the USB cable from the Demo Board to the PC, or after c onnecting the serial cable from the

optional Debug Board to the PC, s tart the HyperTerminal application and create a session using the following

parameters:

Port Speed: 9600 bd

Data Bits: 8

Parity: None

Stop Bits: 1

Flow Control: XON/XOFF

When using the USB connection, you may have to define a new port in HyperTerminal after selecting File

Properties and then clicking on the “Connect Using“ dialog box. If the U S B-to-serial driver is installed (see s ection 1.7.2.1) a port with a number not corresponding to an actual serial port, e.g., COM5, will appear in the dialog box. This port should be selected for the USB connection.

HyperTerminal can be found by selecting Programs Accessories Communicati ons from the Windows

menu. The connection parameters ar e configured by selecting File Properties and then by pressing the Configure button. Port speed and flow control are configured under the General tab (Figure 1-3, left), bit settings are

configured by pressing the Configur e button (Figure 1-3, right), as s hown below. A setup file (file name “Demo

Board Connection.ht”) for Hyper Terminal that can be loaded with Fil e Open is also provided with the to ols

and utilities.

Port parameters can only be adjusted when the connection is not active. The disconnect

button, as shown in Figure 1-2 must be clicked in order to disconnect the port.

start

9 Rev 4.0

Page 10

71M6541 Demo Board REV 3.0 User’s Manual

Figure 1-2: HyperTerminal Sample Window with Disconnect Button (Arr ow)

Figure 1-3: Port Speed and Handshake Setup (left) and Port Bit setup (right)

Once, the connection to the demo board is established, press <CR> and the command prompt,

pear. Type

>? to see the Demo Code help menu. Type >i to ver ify the demo code revision.

>, should ap-

1.8 USING THE DEMO BOARD

The 71M6541 Demo Board is a ready-to-use meter prepared for use with external sh unt resistors.

Demo Code versions for single-phase two-wire operation (EQU 0, with secondary tamper sensor) and for sin-

gle-phase three-wire operation ( A N S I configuration, EQU 1) are provided by Maxim Integrated. Demo Boards in

ANSI configuration are preloaded with Demo Code for EQU 1, Demo Boards in IEC configuration are preloade d

with Demo Code for EQU 0.

Using the Demo Board involves communicating with the Demo Code via the com mand line interface (CLI). The

CLI allows all sorts of manipulations to the metering parameters, ac c ess to the EEPROM, selection of the displayed parameters, changing calibration factors and many more operations.

Before evaluating the 71M6541 on the Demo B oard, users should get familiar with the commands and responses of the CLI. A complete descriptio n of the CLI is provided in section 1.8.1.

10 Rev 4.0

Page 11

1.8.1 SERIAL COMMAND LANGUAGE

The Demo Code residing in the flash memory of the 71M6541 provides a convenie nt way of examining a nd

modifying key meter parameters via its command line interface (CLI).

The tables in this chapter describe the commands in detail.

Commands for CE Data Access:

] CE D ATA ACCESS Comment

Description: Allows user to read from and write to CE data space.

Usage: ] [Starting CE Data Address] [option]…[option]

Command

combinations:

]A$$$ Read consecutive 16-bit words in Hex, starting at address A

]A=n=n Write consecutive memory values, starting at address A

Example: ]40$$$ Reads CE data words 0x40, 0x41 and 0x42.

]7E=1AD2=9A23 Writes two hexadecimal words starting @ 0x7E

]10=+16384 Writes one decimal word starting @ 0x10

All CE data words are in 4-byte (32-bit) format. Typing ]A? will access the 32-bit word located at the b yte address 0x0000 + 4 * A = 0x1028.

]A??? Read consecutive 16-bit words in Decimal, starting at ad-

71M6541 Demo Board REV 3.0 User’s Manual

dress A

Commands for MPU/XDATA Access:

) MPU DATA ACCESS Comment

Description: Allows user to read from and write to MPU data space.

Usage: ) [Starting MPU Data Address] [option]…[option]

Command

combinations:

)A$$$ Read three consecutive 32-bit words in Hex, starting at ad-

)A=n=m Write the values n and m to two consecutive addresses start-

?) Display useful RAM addresses.

Example: )08$$$$ Reads data words 0x08, 0x0C, 0x10, 0x14

)04=FFFFAD2=9A23 Writes two hexadecimal words starting @ 0x04

)04=+1000 Writes decimal 1,000 to address 0x04

)04=-1000 Writes decimal -1,000 to address 0x04

MPU or XDATA space is the address range for the MPU XRAM (0x0000 to 0xFFF). All MPU data words are in 4-byte (32-bit)

format. Typing ]A? will access the 32-bit word located at the byte address 4 * A = 0x28. The energy accumulation registers of

the Demo Code can be accessed by typing two Dollar signs (“$$”), typing question marks will display negative decimal values

if the most significant bit is set.

)A??? Read three consecutive 32-bit words in Decimal, starting at

address A

dress A

ing at address A

11 Rev 4.0

Page 12

71M6541 Demo Board REV 3.0 User’s Manual

Command

Command

combinations:

Command

combinations:

Commands for I/O RAM (Configuration RAM) and SFR Control:

R I/O RAM AND SF R CONTROL Comment

Description: Allows the user to read from and write to DIO RAM and special function registers (SFRs).

Usage: R [option] [register] … [option]

combinations:

Rx… Select internal SFR at address x

Ra???... Read consecutive SFR registers in Decimal, starting at ad-

Ra$$$... Read consecutive registers in Hex, starting at address a

Ra=n=m… Set values of consecutive registers to n and m starting at

Example: RI2$$$ Read DIO RAM registers 2, 3, and 4 in Hex.

The SFRs (special function registers) are located in internal RAM of the 80515 core, starting at address 0x80.

Commands for EEPROM Control:

EE EEPROM CONTROL Comment

Description: Allows user to enable read from and write to EEPROM.

Usage: EE [option] [arguments]

RIx… Select I/O RAM location x (0x2000 offset is automatically

added)

dress a

address a

EECn EEPROM Access (1 Enable, 0 Disable)

EERa.b Read EEPROM at address 'a' for 'b' bytes.

EESabc..xyz Write characters to buffer (sets Write length)

EETa Transmit buffer to EEPROM at address 'a'.

EEWa.b...z Write values to buffer

CLS Saves calibration to EEPROM

Example: EEShello

EET$0210

Due to buffer size restrictions, the maximum number of bytes handled by the EEPROM command is 0x40.

Writes 'hello' to buffer, then transmits buffer to EEPROM starting at address 0x210.

Commands for Flash Memory Control:

F FLASH CONTROL Comment

Description: Allows user to enable read from and write to Flash memory.

Usage: F [option] [arguments]

FRa.b Read Flash at address 'a' for 'b' bytes.

FSabc..xyz Write characters to buffer (sets Write length)

FTa Transmit buffer to Flash memory at address 'a'.

FWa.b...z Write string of bytes to buffer

Example: FShello

FT$FE10

Writes 'hello' to buffer, then transmits buffer to EEPROM starting at address 0xFE10.

12 Rev 4.0

Page 13

71M6541 Demo Board REV 3.0 User’s Manual

Auxiliary Commands:

Typing a comma (“,”) repeats the comman d issued from the previous command line. This is very helpful when

examining the value at a certain addres s over time, such as the CE DRAM addr ess for the temperature (0x40).

The slash (“/”) is useful to separate comments from commands when sending macro text files via the s erial interface. All characters in a line af ter the slash are ignored.

Commands controlling the CE, TMUX and the RTM:

C COMPUTE ENGINE,

Comment

MEMORY, AND CALIBRATION CONTROL

Description: Allows the user to enable and configure the compute engine, store and recall configurations, and

Usage: C [option] [argument]

Command

combinations:

CTn.m Selects the signal for the TMUX output pins (n = 1 for

CREn RTM output control (1 Enable, 0 Disable)

CRSa.b.c.d Selects CE addresses for RTM output

CLS Stores calibration and other settings to EEPROM.

CLR Restores calibration and other settings from EEPROM.

CLD Restores calibration and other settings to defaults.

CLB Start auto-calibration based on voltage (MPU address 0x17,

CLC Apply machine-readable calibration control (Intel Hex-

CPA Start the accumulating periodic pulse counters.

CPC Clear the pulse counters

CPDn Activate pulse counters for n seconds

Example: CE0 Disables CE, (“SYS will stop blinking on the LCD).

CT1.3 Selects the VBIAS signal for the TMUX output pin

initiate calibration.

CEn Compute Engine Enable (1 Enable,

0 Disable)

TMUXOUT, n = 2 for TMUX2OUT). m is interpreted as a dec-

imal number.

current (MPU 0x18), and duration (MPU 0x16) in seconds.

Records).

Commands for Identification and Information:

I INFORMATION MESSAGES Comment

Description: Allows the user to read information messages.

Usage: I Sends complete demo code version information on serial inter-

M0 Displays meter ID on LCD.

The I command is mainly used to identify the revisions of Demo Code and the contained CE code.

face.

13 Rev 4.0

Page 14

71M6541 Demo Board REV 3.0 User’s Manual

Command

combinations:

Commands for Battery Mode Control and Battery Test:

B I NFO RMATION MESSAGES Comment

Description: Allows the user to control battery modes and to test the battery.

Usage: BL Enters LCD mode when in brownout mode (B> prompt).

BS Enters sleep mode when in brownout mode (B> prompt).

BT Starts a battery test – when in mission mode (> prompt).

BWSn Set wake timer to n seconds for automatic return to brownout

mode.

BWMn Set wake timer to n minutes for automatic return to brownout

mode.

Commands for Controlling the RTC:

RT REAL-TIME CLOCK CON-

Comment

TROL

Description: Allows the user to read and set the real time clock.

Usage: RT [option] [value] … [value]

Command

combinations:

RTR Read Real Time Clock.

RTTh.m.s Time of day: (hr, min, sec).

RTAs.t Real Time Adjust: (start, trim). Allows trimming of the RTC.

> Access look-up table for RTC compensation.

Example: RTD05.03.17.5 Programs the RTC to Thursday, 3/17/2005

RTA1.+1234 Speeds up the RTC by 1234 PPB.

>0???? Read the first four bytes in the look-up table.

RTDy.m.d.w: Day of week (year, month, day, weekday [1 = Sunday]). If the weekday is

omitted it is set automatically.

If s > 0, the speed of the clock will be adjusted by ‘t’ parts per

billion (PPB). If the CE is on, the value entered with 't' will be

changing with temperature, based on Y_CAL, Y_CALC and

Y_CALC2.

The “Military Time Format” is used for the RTC, i.e., 15:00 is 3:00 PM.

Commands for Accessing the Trim Control Registers:

T TRIM CONTROL Comment

Description: Allows user to read trim and fuse values.

Usage: T [option]

T4 Read fuse 4 (TRIMM).

T5 Read fuse 5 (TRIMBGA)

T6 Read fuse 6 (TRIMBGB).

Example: T4 Reads the TRIMM fuse.

These commands are only accessible for the 71M6541H (0.1%) parts. When used on a 71M6541 (0.5%) part,

the results will be displayed as zero.

14 Rev 4.0

Page 15

71M6541 Demo Board REV 3.0 User’s Manual

Reset Commands:

W RESET Comment

Description: Watchdog control

Usage: W Halts the Demo Code program, thus suppressing the trigger-

Commands for the 71M6X0X Remote Sensor Interface:

6 71M6X0X Interface Comment

Description: Commands for control of the Re-

mote Sensor Interface IC.

Usage: 6En Remote sensor Enable (1 Enable, 0 Disable)

6Ra.b Read Remote Sensor IC number a with command b.

6Ca.b Write command b to Remote Sensor IC number a.

6Ta.b Send command b to Remote Sensor IC number a in a loop

6T2 Send temp command to 6000 number 2 in a loop forever.

6R1.20 Reads the temperature from Remote Sensor IC number 1.

ing of the hardware watchdog timer. This will cause a reset, if

the watchdog timer is enabled.

forever.

15 Rev 4.0

Page 16

71M6541 Demo Board REV 3.0 User’s Manual

1.04 Whr

04

2.21 VARhr

05

0.95 VARhr

06

07

0.7 hr

08

01:43:59

09

01.01.01

10

1

120

13

14

24.10 A

15

241.27 V

16

3.34 V

17

1

50400 W

19

88.88.88

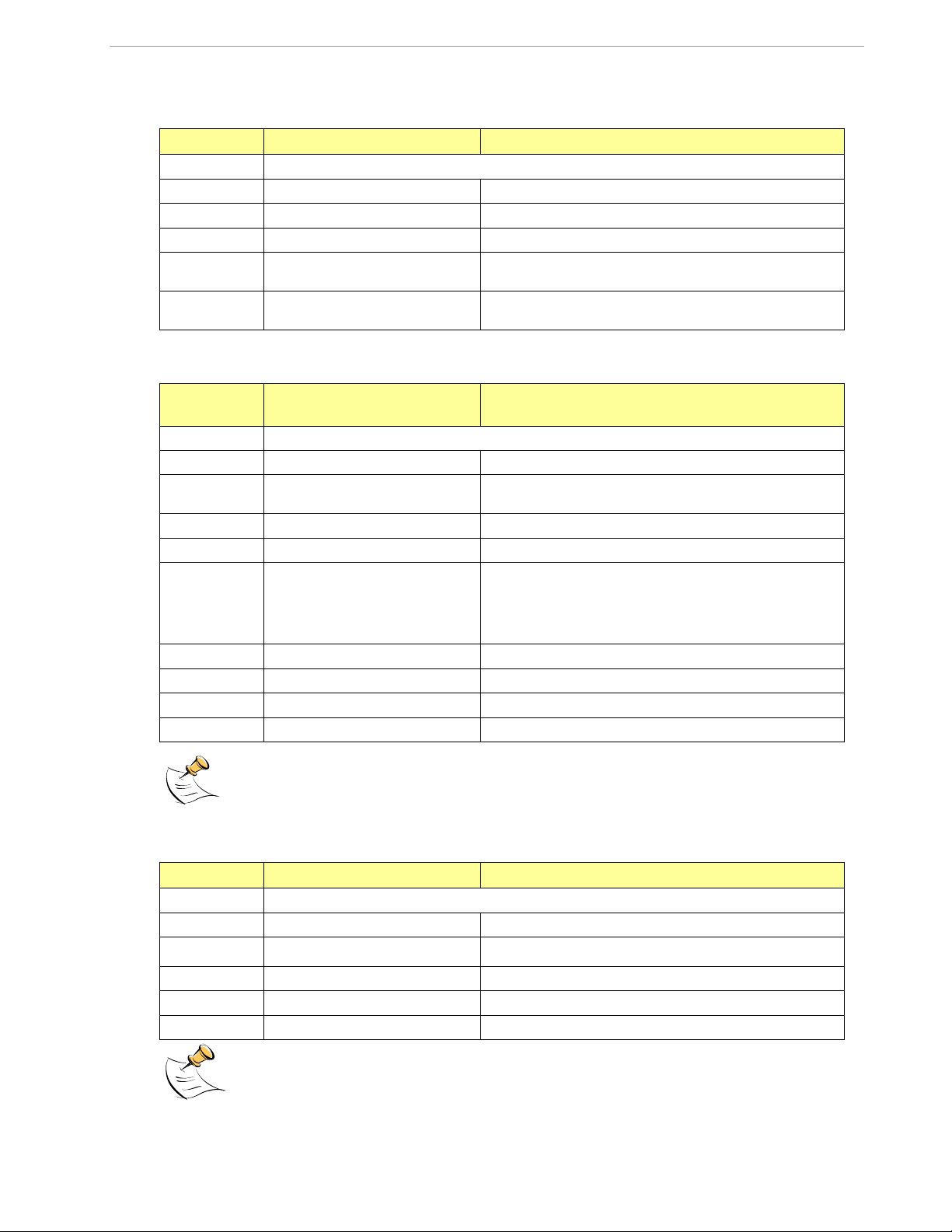

Commands for Controlling the Metering Values Shown on the LCD Display:

Step

0

1

2

3

4

5

6

7

8

9

Text or Nu-

merical Dis-

play

10000

00

24.5 °C

01

59.9

02

3.27 Whr

03

4.11 VAhr

CLI

command

M0

M1

M2

M3

M4

M5

M6

M7

M8

M9

Displayed Parameter(s)

Meter ID

Temperature difference from calibr ation temperature.

Frequency at the VA_IN input [Hz]

Accumulated imported real energy [Wh]. The default display setting

after power-up or reset.

Accumulated exported real energy [Wh].

Accumulated reactive energy [V ARh].

Accumulated exported reactive energy [VARh].

Accumulated apparent energy [V A h].

Elapsed time since last reset or power up.

Time of day (hh.mm.ss)

10

11

12

13

14

15

16

17

18

19

20

0.62

11

0

48

241.34 W

18

88.88.88

88.88.88

M10

M11.P

M12

M13

M14

M15.P

M16

M17

M18

M19

M20

Date (yy.mm.dd)

Power factor (P = phase)

Not used in the 71M6541

Zero crossings of the mains voltage

Duration of sag or neutral current [s]

RMS current (P = phase)

RMS voltage

Battery voltage

Momentary power in W (P = phase)

Demand

LCD Test

Displays for total consumption wrap around at 999.999Wh (or VARh, VAh) due to the limited number of available display digits. Internal registers (counters) of the Demo Code are 64 bits wide and do not wrap around.

16 Rev 4.0

Page 17

71M6541 Demo Board REV 3.0 User’s Manual

1.8.2 USING THE DEMO BOARD FOR ENERGY MEASUREMENTS

The 71M6541 Demo Board was designed for use with shunt resistors connected directly t o the IAP/IAN pins of

the 71M6541 and via the Remote Sensor I nterface and it is shipped in this configuration.

The Demo Board may immediately be used with a 50 µΩ shunt resistor (ANSI) or a 120 µΩ shunt resistor (IEC).

It is programmed for a kh factor of 1.0 (see Section 1.8.4 for adjusting the Demo Board for shunts with different

resistance).

Once, voltage is applied and load current is flowing, the red LED D5 will f l ash each time an energy sum of 1.0

Wh is collected. The LCD display wil l show the accumulated energy in Wh whe n s et to display mode 3 (com-

>M3 via the serial interface).

mand

Similarly, the red LED D6 will flas h each time an energy sum of 1.0 VARh is collected. The LCD display will

show the accumulated energy in VARh when set to display mode 5 (command

>M5 via the serial interface).

1.8.3 ADJUSTING THE KH FACTOR FOR THE DEMO BOARD

The 71M6541F Demo Board is shipped with a pre-programmed scaling factor Kh of 1.0, i.e., 1.0 Wh per pulse.

In order to be used with a calibrated loa d or a meter calibration system, the boar d should be connected to the

AC power source using the spade terminals on the bottom of the board. The shunt resistor should be connected

to the dual-pin header labeled J3 on the bottom of the board.

The Kh value can be derived by reading the values for IMAX and VMAX (i.e., the RMS current and voltage values that correspond to the 250mV maximum input signal to the IC), and insert i ng them in the following equation

for Kh:

Kh = 109.1587*

See the explanation in section 1.10.4 for an exact definition of the constants and variables involv ed i n the equation above.

VMAX*IMAX / (SUM_SAMPS*WRATE*X),

1.8.4 ADJUSTING THE DEMO BOARDS TO DIFFERENT SHUNT RESISTORS

The Demo Board is prepared for use with 120 µΩ or 50 µΩ (ANSI option) shunt resistors in both current channels. For the Demo Board, a certain current flowing through the 120 µΩ shunt resistor will result in the maximum

voltage drop at the ADC of the 71M6541. This current is defined as IMAX.

IMAX will change when different values are used for the shunt r es i s tor(s) which will require that

be updated as shown in section 1.10.4.

WRATE has to

1.8.5 USING THE PRE-AMPLIFIER

In its default setting, the 71M6541 is applies a gain of 1 to the current input for phase A (IAP/IAN pins). This

gain is controlled with the PRE_E bit in I/O RAM (r efer to the IC data sheet). The command line interface (RI

command) can be used to set or reset this bit. It is recommended to maintain the gain of setting of 1

(RI2704=0x90).

1.8.6 USING CURRENT TRANSFORMERS (CTs)

Phase B of the 71M6541 Demo Board can be equipped with a CT that may be connected at header J8. A burden resistor of 1.7 Ω, or any other value m ay be installed at the R33 and R34 locations. With a 2000:1 ratio CT,

the maximum current fort phase B will be 208 A.

Note: The CT configuration will require a different version of the Demo Code.

Current measurements can be displa ye d for phase B by the demo code, and the corr esponding currents can be

extracted by the MPU from the CE register s for tamper detection when using the Demo Code for EQU 0.

1.8.7 IMPLEMENTING A SINGLE-PHASE 3-WIRE METE R (EQU 1)

This application will require two identical current sensors for eac h phase. The simplest approach is to use identical shunt resistors for each channel .

1.8.8 ADJUSTING THE DEMO BOARDS TO DIFFERENT VOLTAGE-DIVIDERS

The 71M6541 Demo Board comes equipped with its own network of resist or dividers for voltage measurement

mounted on the PCB. The resistor values (for the D6541 REV 3.0 Demo Board) are 2.5 477MΩ (R15-R21, R26R31 combined) and 750Ω (R32), resulti ng in a ratio of 1:3,393.933. Thi s means that

176.78mV*3,393.933 = 600V. A large value for VMAX has been selected in order t o have headroom for

17 Rev 4.0

VMAX equals

Page 18

71M6541 Demo Board REV 3.0 User’s Manual

overvoltages. This choice need not be of concern, since the ADC in the 71M6541 has enough resolution, even

when operating at 120Vrms or 240Vrms.

If a different set of voltage-dividers or an external voltage transformer (potential transformer) is to be used,

scaling techniques should be used.

In the following example we assume that the line voltage is not applied t o the resistor divider for VA formed b y

R15-R21, R26-R31, and R32, but to a volt age transformer with a ratio N of 20:1, followed by a simple resistor

divider. We also assume that we want t o m aintain the value for

voltage excursions.

VMAX at 600V to provide headroom for large

When applying

is scaled by the resistor divider rat i o RR. When the input voltage to the voltage channel of the 71M6541 is the

V

s

desired 177mV, V

VMAX at the primary side of the transformer, the secondary voltage V

= VMAX / N

V

s

is then given by:

s

V

= RR * 177mV

s

Resolving for RR, we get:

= (VMAX / N) / 177mV = (600V / 30) / 177mV = 170.45

R

R

This divider ratio can be implemented, for example, with a combination of one 16.95 kΩ and one 100 Ω resistor.

If potential transformers (PT s ) are used instead of resistor dividers, phase shifts will be introduced that will re-

quire negative phase angle compens ation. Maxim Integrated Demo C ode accepts negative calibration f ac tors

for phase.

1.9 CALIBRATION PARAMETERS

1.9.1 GENERAL CALIBRATION PROCEDURE

Any calibration method can be used with the 71M6541F chips. This Demo Board User’s Manual present s calibration methods with three or fiv e measurements as recommended methods, because they work with most

manual calibration systems based on counting "pulses" (emitted by LEDs on the meter).

Naturally, a meter in mass production will be equipped with special calibration code offering capabilities beyond

those of the 71M6541 Demo Code. It is basically possible to calibrate using voltage and current readings, with

or without pulses involved. For this purpose, the MPU Demo Code can be modif ied to display averaged voltage

and current values (as opposed to momentary values). Also, automate d c al ibration equipment can communicate with the Demo Boards via the serial interface and extract voltage and current readings. This is possible

even with the unmodified Demo Code.

Complete calibration procedur es are given in section 2.3 of this manual.

Regardless of the calibration proc edure used, parameters (calibration factors) will result that will have to be ap-

plied to the 71M6541F chip in order to make the chip apply the modified gains and phase shifts necessary for

accurate operation. Table 1-4 s hows the names of the calibration factors, their function, and their location in the

CE RAM.

Again, the command line interface can be used to store the calibration factors in their respective CE RAM addresses. For example, the command

>]10=+16302

is:

s

stores the decimal value 16302 in the CE RAM location controlling the gain of the current channel (

CAL_IA).

The command

>]11=4005

stores the hexadecimal value 0x4005 (decimal 16389) in the CE RAM loc ation controlling the gain of the voltage channel (

CAL_VA).

The internal power supply generat es a ripple on the supply and ground nets that is 90° phase shifted with respect to the AC supply voltage. This affects the accuracy of the VARh measurements. If optimization of the

VARh accuracy is required, this can be done by writing a value into the QUANT_VAR regist er of the CE (see

section 2.3.7).

18 Rev 4.0

Page 19

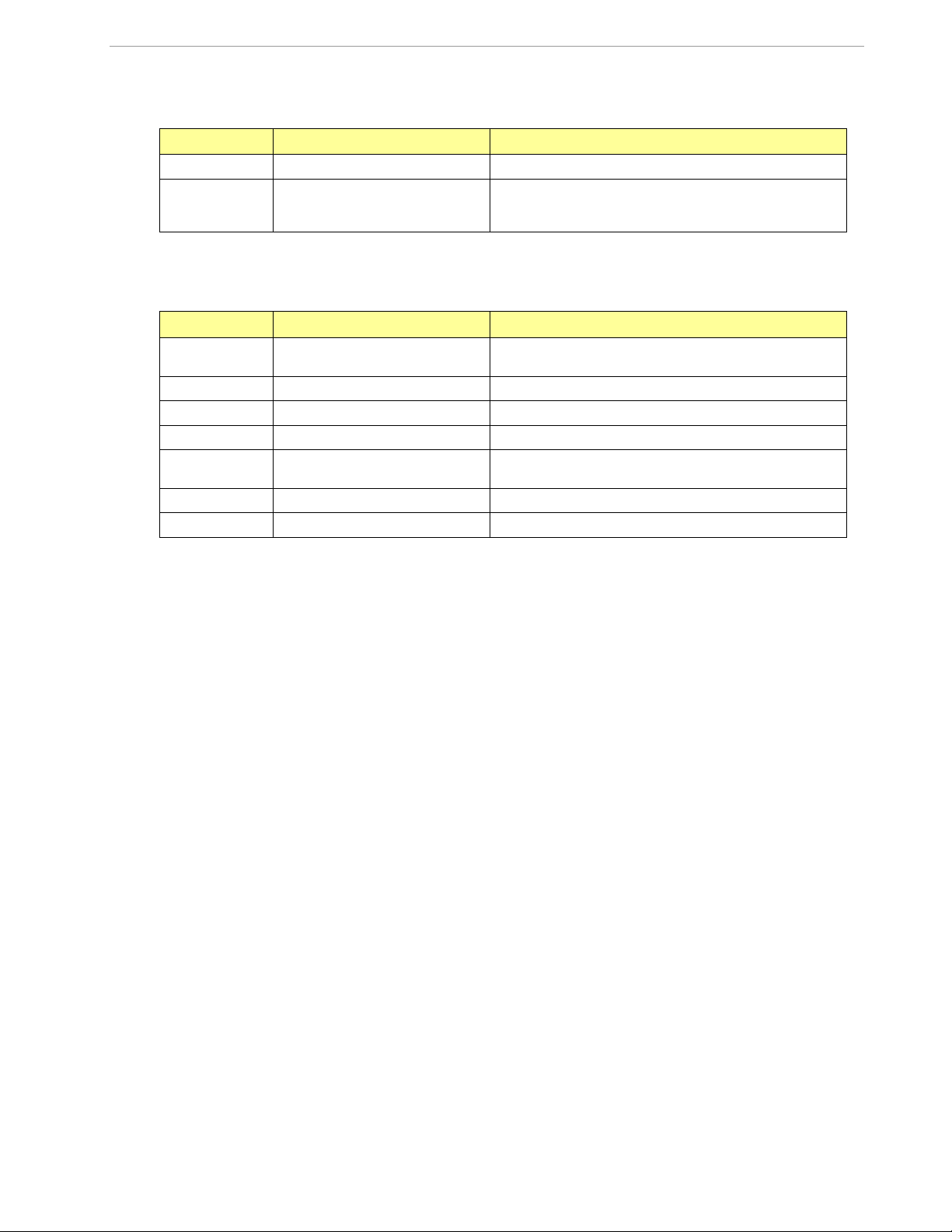

Table 1-4: CE RAM Locations for Calibration Constants

CE0 /disable CE

CE1 /enable CE

CE Ad-

Coefficient

CAL_VA

CAL_IA

CAL_IB

PHADJ_A

LCOMP2_B

dress

(hex)

0x11

0x10

0x13

0x12

0x15

Description

Adjusts the gain of the voltage chan nels. +16384 is the typical value. The

gain is directly proportional to the CAL parameter. Allowed range is 0 to

32767. If the gain is 1% slow, CAL should be increased by 1%.

Adjusts the gain of the current chann el s . +16384 is the typical value. The

gain is directly proportional to the CAL parameter. Allowed range is 0 to

32767. If the gain is 1% slow, CAL should be increased by 1%.

This constant controls the phase compensation. No compensation occurs

in a phase when PHADJ_A = 0 or when LCOMP2_n = 16384. As

LCOMP2_n is increased, more compensation is introduced.

CE codes for CT configuration do not use delay adjustment. These codes

use phase adjustment (

1.9.2 CALIBRATION MACRO FILE

The macro file in Figure 1-4 contains a sequence of the serial interface commands. It is a simple text file and

can be created with Notepad or an equivalent ASCII editor program. The file is executed with HyperTerminal’s

Transfer->Send Text File command.

71M6541 Demo Board REV 3.0 User’s Manual

PHADJ_n).

]10=+16022 /CAL_IA (gain=CAL_IA/16384)

]11=+16381 /CAL_VA (gain=CAL_VA/16384)

]12=+115 /PHADJ_A (default 0)

Figure 1-4: Typical Calibration Macro File

It is possible to send the calibration mac ro file to the 71M6541F for “temporary” calibration. This will temporaril y

change the CE data values. Upon power up, these values are refreshed back to the default values stored in

flash memory. Thus, until the flash memory is updated, the macro file must be loaded each time the part is

powered up. The macro file is run by sending it with the transfer

Use the Transfer Send Text File command!

1.9.3 UPDATING THE DEMO CODE (HEX FILE)

The d_merge program updates t he hex file (usually named 6541_1p2b_19jan09.hex or similar) with th e values

contained in the macro file. This pro gram is executed from a DOS command line window. Executing the

d_merge program with no arguments will display the syntax description. To merge macro.txt and

old_6541_demo.hex into new_6541_demo.hex, use the command:

d_merge old_6541_demo.hex macro.txt new_6541_demo.hex

The new hex file can be written to the 71M6541F/71M6541H through the ICE port using the ADM-51 in-circuit

emulator or the TFP-2 flash programmer.

send text file procedure of HyperTerminal.

19 Rev 4.0

Page 20

71M6541 Demo Board REV 3.0 User’s Manual

1.9.4 UPDATING CALIBRATION DATA IN FLASH O R EEPROM

It is possible to make data permanent that had been entered temporarily into the CE RAM. The transfer t o

EEPROM memory is done using the following serial interface command:

>]CLS

Thus, after transferring calibration data with manual serial int er face commands or with a macro file, all that has

to be done is invoking the U command.

Similarly, calibration data can be restored to default values using the CLD command.

After reset, calibration data is cop ied from the EEPROM, if present. Otherwise, calibration

data is copied from the flash memory. Writing 0xFF into the first few bytes of the EEPROM

deactivates any calibration data p r eviously stored to the EEPROM.

1.9.5 LOADING THE CODE FOR THE 71M6541 INTO THE DEM O BOARD

Hardware Interface for Programming: The 71M6541F IC provides an interface for loading code into the inter-

nal flash memory. This interface consi s ts of the following signals:

E_RXTX (data), E_TCLK (clock), E_RST (reset), ICE_E (ICE enable)

These signals, along with V3P3D an d GND are available on the emulator h eaders J14.

Programming of the flash memory requires a specific in-circuit emulator, the ADM-51 by Signum Systems

(www.signum.com) or the Flash Programmer (T FP2) available through Digi-Key (www.digikey.com) or Mouser

Electronics (www.mouser.com).

Chips may also be programmed before t hey are soldered to the board. Gang programmers suitable for highvolume production are availab le from BPM Microsystems (www.bpmmicro.com).

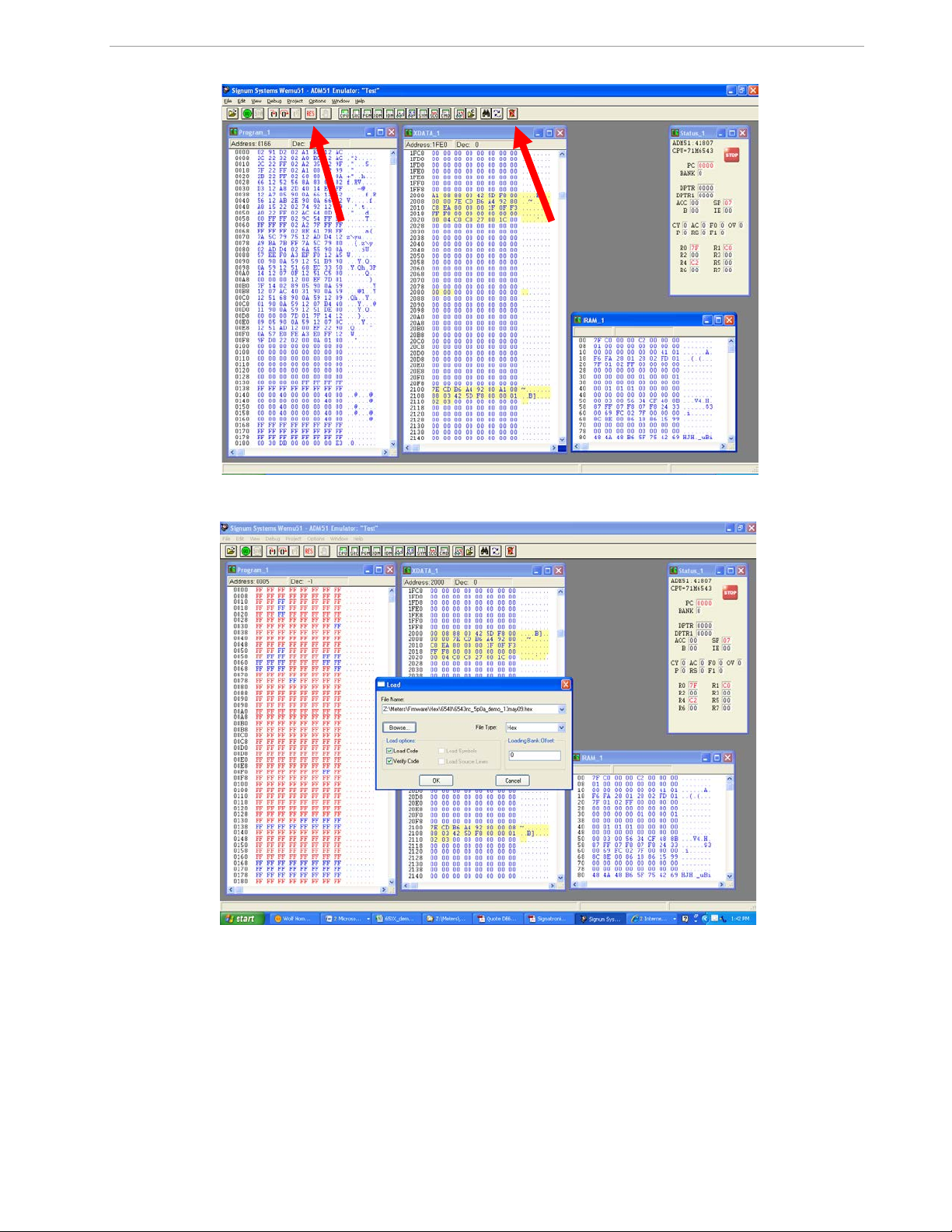

In-Circuit Emulator: If firmware exists in the 71M6541F flash memory; it has t o be erased before loading a new

file into memory. Figure 1-5 and Figure 1-6 show the emulator software active. In order to erase the flash

memory, the RESET button of the emulator software has to be clicked followed by the ERASE button.

To successfully erase the flash memory, the following steps have to be taken :

1) Disable the CE by writing 0x00 to addres s 0x2000

2) Write 0x20 to address 0x2702 (

3) Reset the demo board (RESET button or power cycle)

4) Activate the ERASE button in the WEMU51 user interface

5) Now, new code can be loaded into the flash memory

Once the flash memory is erased, the new file can be loaded using the comm ands File followed by Load. The

dialog box shown in Figure 1-6 will then appear making it possible to select the file to be loaded by clicking the

Browse button. Once the file is sel ec ted, pressing the OK button will loa d the file into the flash memory of t he

71M6541F IC.

At this point, the emulator probe (cab le) can be removed. Once the 71M6541F IC is reset using the reset button

on the Demo Board, the new code starts executing.

FLSH_UNLOCK[ ] register in I/O RAM)

20 Rev 4.0

Page 21

71M6541 Demo Board REV 3.0 User’s Manual

Figure 1-5: Emulator Window Showing Reset and Erase Buttons (see Arrows)

Figure 1-6: Emulator Window Showing Erased Flash Memory and File Load Menu

Flash Programmer Module (TFP-2): The operational firmware of the T FP 2 will have to be upgraded to revision

1.53. Follow the instructions given in the User Manual for the TFP-2.

21 Rev 4.0

Page 22

71M6541 Demo Board REV 3.0 User’s Manual

Signal

Direction

Function

ICE_E

Input to the 71M6541

ICE interface is enabled when ICE _E is

pulled high

E_TCLK

Output from 71M6541

Data clock

E_RXTX

Bi-directional

Data input/output

E_RST

Bi-directional

Flash Downloader Reset (active low)

1.9.6 THE PROGRAMMING INTERFACE OF THE 71M6541

Flash Downloader/ICE Interface Signals

The signals listed in Table 1-5 are neces sary for communication between the Flash Downloader or ICE and the

71M6541.

Table 1-5: Flash Programming Interface Signals

The E_RST signal should only be driven by the Flash Downloader when enabli ng these interface

signals. The Flash Downloader mus t release E_RST at all other times.

22 Rev 4.0

Page 23

1.10 DEMO CODE

1.10.1 DEMO CODE DESCRIPTION

The Demo Board is shipped preloade d with Demo Code in the 71M6541F chip. The code r ev i s i on can easily be

verified by entering the command >i v i a the serial interface (see sectio n 1.8.1). Check with your local Maxim Integrated representative or FAE for the latest revision.

The Demo Code is provided in two diff er ent versions:

• Single-phase two-wire operation (EQU 0, with secondary tamper sensor). Energy measurement and

Wh/VARh pulses are based solely on VA (phase A voltage) and IA (phase A current). Energy and current values for IB (secondary phase) are available as CE outputs to the MPU f or processing of tampering events.

• Single-phase three-wire operation ( ANSI configuration, EQU 1). E ner gy measurements and Wh/VARh

pulses are based on VA (IA – IB) / 2.

71M6541 Demo Board REV 3.0 User’s Manual

Both Demo Code versions use the same CE code, but with different settings of the

The Demo Code offers the following features:

• It provides basic metering functions such as pulse generation, display of accumulated energy, fre-

quency, date/time, and enables the user to evaluate the parameters of the metering IC such as accuracy, harmonic performance, etc .

• It maintains and provides access to basi c household functions such as the real-time clock (RTC).

• It provides access to control and dis pl ay functions via the serial interface, enabling the user to vie w

and modify a variety of meter parameters such as Kh, calibration coefficients, temperature compensation etc.

• It provides libraries for access of low-level IC functions to serve as building blocks for code de-

velopment.

A detailed description of the Demo C ode can be found in the Software User’s G uide (SUG). In addition, the

comments contained in the librar y prov ided with the Demo Kit can serve as usef ul documentation.

The Software User’s Guide contains the following information:

• Design guide

• Design reference for routines

• Tool Installation Guide

• List of library functions

• 80515 MPU Reference (hardware, instruction set, memory, register s)

1.10.2 IMPORTANT MPU ADDRESSES

In the demo code, certain MPU XRAM para m eters have been given addresses in order to permit easy external

access. These variables can be read via the command line interface (if available), with the )n$ com mand and

written with the )n=xx command where n is the word address. Note that accumulat ion variables are 64 bits long

and are accessed with )n$$ (read) and )n=hh=ll (write) in the case of accumulat ion variables.

The first part of the table, the addr esses )00..)1F, contains adjustments, i.e., numbers that may need adjustment in a demonstration meter, and so are par t of the calibration for demo code. In a r eference meter, these

may be in an unchanging table in code space.

The second part, )20..)2F, pertains to calibration, i.e., variables that are likely to need indivi dual adjustments for

quality production meters.

The third part, )30…, pertains to meas ur ements, i.e., variables and regi s ters that may need to be read in a

demonstration meter.

EQU register.

23 Rev 4.0

Page 24

71M6541 Demo Board REV 3.0 User’s Manual

Table 1-6: MPU XRAM Locations

Name Purpose LSB Default )? Signed? Bits

Metering element

enters creep mode

if current is below

this value.

i_min

cfg

v_min

i_max

v_max

i_limit

If 0, creep logic is

disabled. In creep

Same units as CE’s i0sqsum. 0.08A )0 signed 32

mode, on each metering element, Wh,

VARh, i0sqsum,

and other items are

zeroed.

bit0: 1=Display KWh.

bit1: 1=clear accumulators, er-

rors, etc. (e.g., “)1=2”)

bit2: 1=Reset demand. (e.g.,

“)1=4”)

bit3: 1=CE Raw mode. MPU

does not change CE values with

creep or small current calcula-

tions.

bit5: 1= Send a message once

Configure meter

operation on the fly.

per second for IEC 62056-217

Mode D on UART 1, at 2400

BAUD, even parity. The meter’s

serial number and current Wh

display are sent as data. UART

1 is routed to an IR LED if pos-

sible. Mode D data fields are

prefaced with OBIS codes in

legacy format.

7,1

bit6: 1=Auto calibration mode

bit7: 1=Enable Tamper Detect

2,1

error if below. Also

creep.*

Below this, low voltage seconds are

counted. Voltage,

Same units as CE’s v0sqsum. 40V )2 signed 32

Wh, VARh, Frequency, and other

voltage-dependent

items are zeroed.

Scaling Maximum

Amps for standard

0.1A

sensor.

Scaling Maximum

Volts for PCB

0.1V

Error if exceeded. Same units as CE’s i0sqsum.

0

Do nothing special.

1

110.5 for 200

μΩ shunt with

8x preamp.

884.0 A for 200

μΩ shunt,

442.0A for 400

μΩ shunt.

600 V, for the

6541 REV 3.0

Demo Board.

50.9A =

30A*sqrt(2)

*120%

)1 N/A 8

)3 signed 16

)4 signed 16

)5 signed 32

24 Rev 4.0

Page 25

v_limit

wrate_mpu

interval

mains_hz

temp_cal1

mtr_cal1

[0..3]

mtr_cal2

[0..3]

9

9

y_datum

y_cal1 5

y_cal2 5

s_cal 1

v_cal 1

i_cal 1

71M6541 Demo Board REV 3.0 User’s Manual

Error if exceeded.* Same units as CE’s v0sqsum.

CE’s w0sum units per pulse,

Convert from CE

counts to pulses.

The number of

minutes of a demand interval.

Expected number of

cycles per second

of mains. 0 disables

the software RTC

run from mains.

Machine-readable

units per 0.1C

Linear temperature

calibration for meter

elements A..D.

Squared temperature calibration for

meter elements

A..D.

Center temperature

of the crystal.

RTC adjust, linear

by temp.

RTC adjust,

squared by temp.

Accumulation intervals of

Autocalibration

Volts of

Autocalibration

Amps of

Autocalibration

rounded up to next largest CE

count so Wh accumulation and

display is always rounded down.

Count of minutes.

(60/interval)*interval = 60.

Hz 0 )9 unsigned 8

Refer to the IC data sheet.

Temperature is calculated as

temp = (measured_temp –

temp_datum)/temp_cal1 +

temp_cal0

ppm*(T - mtr_datum), in 0.1˚C 150 )B..E signed 16

ppm2*(T - mtr_datum)2, in 0.1˚C -392

0.1C 25C )13 signed 16

10ppb*(T - y_datum), in 0.1˚C 0 )14 signed 16

1ppb*(T - y_datum)2, in 0.1˚C 38 )15 signed 16

Count of accumulation intervals

of calibration.

0.1V rms of AC signal applied to

all elements during calibration.

0.1A rms of AC signal applied to

all elements during calibration.

Power factor of calibration sig nal

must be 1.

407.3V =

240V*sqrt(2)

)6 signed 32

*120%

3.2 Wh for 3phase

1.0 Wh for 1-

)7 signed 32

phase

2 minutes. )8 unsigned 8

Refer to the IC

data sheet.

)A signed 32

)F..1

2

signed 16

accumulation

intervals cover

both chop polar-

)16 signed 16

ities.

2400

240 V is a

standard full-

)17 signed 16

scale setup for

meter test.

300

30 A is a stand-

ard full-scale

)18 signed 16

setup for meter

test.

25 Rev 4.0

Page 26

lcd_idx

lcd_bit

mfr_id 6

Selects LCD’s current display.

Defines sequence

of LCD displays.

Manufacturer’s ID

text string of the

meter

71M6541 Demo Board REV 3.0 User’s Manual

0: Meter identification. (“#”)

1: Display variation from calibra-

tion temperature, 0.1C

2: Display mains Hz, 0.1 Hz

3: mWh, total

4: mWh total exported.

5: mVARh, total.

6: mVARh, total exported.

7:mVAh, total

8: Operating hours.

9: Time of day

10: Calendar date

11: Power factor, total

12: Angle between phase 0 & 1

13: Main edge count, last accu-

mulation.

14: KW, instantaneous total

15: V, instantaneous max of all

phases.

16: A, total

17: V, Battery (“VB”)

18: Seconds, bad power (“BPS”)

19: Seconds, tamper (- = tamper

in progress) (“TS”)

20: LCD Test

Scrolling not standard for these:

111: PF, phase 0

112: Angle, phase 0 & 1

114: KW, phase 0

115: V, phase 0

116: A, phase 0

211: PF, phase 1

212: Angle, phase 0 & 2

214: KW, phase 1

215: V, phase 1

216: A, phase 1

311: PF, phase 2

312: Angle, phase 2.0

314: KW, phase 2

315: V, phase 2

316: A, phase 2

416: A, neutral (measured)

The value is a bit mask that describes a scrolling display sequence. Each set bit permits a

display with an lcd_idx value

from 0..31. Each is displayed for

7 seconds. Ordered by increasing bit number. If value is zero,

display does not change.

3 ASCII bytes, in MSB of 32-bit

number. Least significant byte

should be zero. For AMR

demonstrations, sent as the

manufacturer’s ID of the meter.

3 )19 signed 16

0 )1A unsigned 32

“TSC”,

0x54534300

)1B unsigned 32

26 Rev 4.0

Page 27

71M6541 Demo Board REV 3.0 User’s Manual

Like i_max, except

for the 2nd current

sensor.

i_max2 4

in_limit 3

in_wait 3

Reserved )1F

meter_id 8

temp_datum 8

mtr_datum[0.

.3]8

rtca_adj 8

y_cal0 5,8

v_bat_min 8

cal_cnt

ver_hash

data_ok_cal

Reserved

Currents, Wh etc.

using currents from

the second sensor

are rescaled into the

same units as the

first current sensor.

Maximum valid neutral current.

The time that neutral current can exceed n_max before

the neutral error is

asserted.

Identification number of meter.

Count of temperature sensor at calibration.

Center temperature

of a meter element’s

temperature curve.

Default value for

RTCA_ADJ, the

crystal’s capacitor

adjustment.

RTC offset rate adjust

Minimum valid battery voltage.

Count of calibrations. In demo code,

it also checks adjustments.

Checked to prevent

old calibration data

from being used by

new code. Value

that changes with

the banner text, and

therefore with the

version, date and

time.

Checks calibrations.

In demo code, it

also checks adjustments.

0.1 Amps 208 A (2080) )1C signed 16

Same units as CE’s i3sqsum. 0.1A )1D signed 32

Count of accumulation intervals. 10 secs. )1E signed 16

32 bit unsigned number. For

AMR demonstrations, this is

sent in decimal as the identification number of the meter.

Refer to the IC data sheet.

Temperature is calculated as

temp = (measured_temp –

temp_datum)/temp_cal1 +

temp_cal0

0.1C 22C

Refer to the IC data sheet. Set

from hardware value when

hardware is changed.

100ppb 0 )27 signed 16

Units of hardware’s battery

measurement register.

Counts number of times calibration is saved, to a maximum of

255.

Uses data_ok() to calculate a

value from the string.

Checked by data_ok() of calibr ation value.

100000000 )20 signed 32

n/a )21 signed 32

)22..

25

Hardware default (refer to

the IC data

sheet).

2V on a real

PCB; should be

adjusted for

battery and

chip.

0 )29 unsigned 8

n/a )2A unsigned 8

n/a )2B unsigned 16

)26 unsigned 8

)28 signed 32

)2C.

)2F

signed 16

27 Rev 4.0

Page 28

71M6541 Demo Board REV 3.0 User’s Manual

data_ok_reg

state_bit_ar

y

Status of meter.

Nonvolatile.

Bits:

See table below.

0 = no errors )30 unsigned 32

First 32-bit number is a count of

wh_im

Wh energy register.

Nonvolatile.

pulses, =3.2 Wh in 3-phase meters, or 1 in 1-phase. A fractional

pulse is present in the CE data,

n/a )31 64

but not preserved.

Wh exported energy

wh_ex

register. Nonvola-

Like wh_im n/a )32 64

tile.

varh_im

varh_ex

dmd_max

dmd_max_rtc

VARh register.

Nonvolatile.

VARh exported register. Nonvolatile.

Maximum demand,

W

Time of maximum

demand.

Like wh_im n/a )33 64

Like wh_im n/a )34 64

Units of w0sum n/a )35 signed 32

Standard time and date struc-

ture.

year, month,

date, hour, min

)36..

3A

unsigned 7x8

Battery voltage at

v_bat

last measurement.

Volatile; not saved

0.1V n/a )3B signed 8

on power failure.

Count of accumula-

tion intervals since

reset, or last clear.

acc_cnt

Cleared with )1=2 or

count n/a )3C signed 32

meter read. Volatile;

not saved on power

failure.

Counts seconds

that tamper errors

tamper_sec

were asserted.

Cleared with )1=2 or

This is a tamper measurement. n/a )3D signed 32

meter read. Nonvol-

atile.

Counts seconds

sag_sec

that voltage low

error occurred. or

meter read. Nonvol-

This is a power quality meas-

urement.

n/a )3E signed 32

atile.

Counts seconds

that neutral current

in_sec 3

error was asserted.

Cleared with )1=2 or

This is a power quality meas-

urement.

n/a )3F signed 32

meter read. Nonvolatile.

rtc_copy

save_cnt

Clock time and date

when data was last

read from the RTC.

Number of power

register saves.

Standard time and date struc-

ture. year, month, date, hour,

min, sec

n/a

)40..

45

unsigned 8*7

n/a n/a )46 unsigned 16

Checks data. n/a n/a )47 unsigned 16

1

Valid only when autocalibration is int egrated. Meters with metering equations with differential cur rents or voltages do not

normally support autocalibration.

2

Requires features not in some demo PCBs .

28 Rev 4.0

Page 29

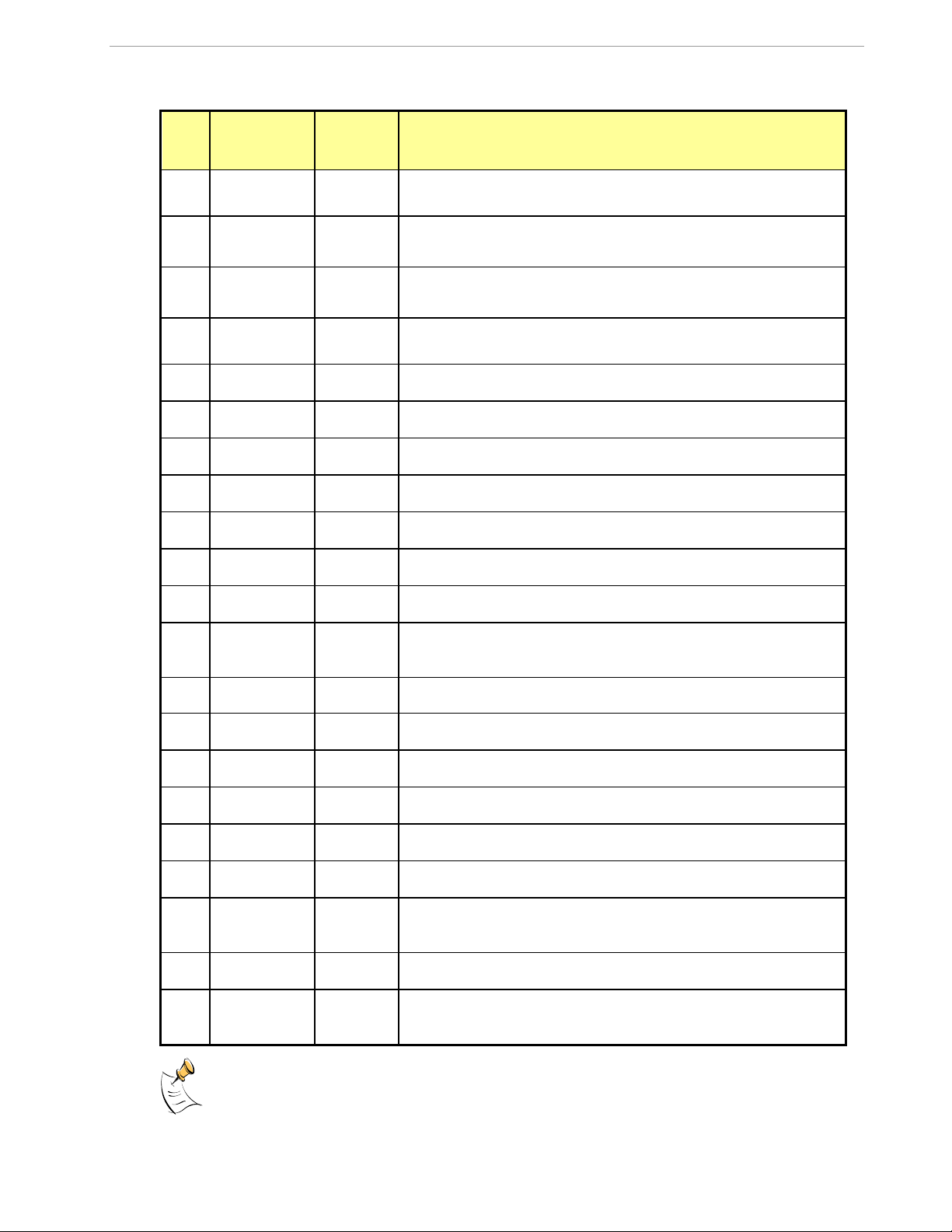

71M6541 Demo Board REV 3.0 User’s Manual

No.

MINIA

0

IA is below IThrshld. Current for this phase is in creep.

MINIB

MINIC

2

IC is below IThrshld. Current for this phase is in creep.

MINVA

3

VA is below VThrshld. Voltage for this phase is in creep.

MINVB

4

VB is below VThrshld. Voltage for this phase is in creep.

MINVC

5

VC is below VThrshld. Voltage f or this phase is in creep.

CREEPV

6

All voltages are below VThrshld.

CREEP

7

There is no combination of current and vo ltage on any phase.

SOFTWARE

8

A software defect was detected. error_software() was called. For example: An impossible value

occurred in a selection, or the tim ers ran out.

NEUTRAL

9

Neutral current was above in_limit for more than in_wait seconds.

SPURIOUS

SAG

11

Voltage was below VThrshld for more than in_wait seconds

DEMAND

12

Demand was too big (too many watts) to be credible.

CALIBRATION

13

Set after reset if the read of the calibrat i on data has a bad checksum, or is from an earlier version of software. The default values should be present.

RTC_UNSET

14

Set when the clock’s current reading is A ) Obtained after a cold start, indic ating that there was

time is preserved, but the clock can’t be trusted.

HARDWARE

15

An impossible hardware condition was detected. For example, the software times out waiting

for RTC_RD to become zero.

BATTERY_BAD

16

Just after midnight, the demo code sets this bit if VBat < VBatMin. The read is infrequent to

read occurs every second, for up to 20 sec onds.

REGISTER_BAD

17

Set after reset when the read of the power register data has a bad longitudi nal r edundancy

check or bad software version in all 5 copies. Unlikely to be an accident.

RTC_TAMPER

18

Clock set to a new value more than two hour s from the previous value.

TAMPER

19

Tamper was detected. Normally this i s a power tamper detected in the creep l ogi c . For example, current detected with no voltage.

3

Three-phase ICs only. Some CE codes calculate neutral current rather than measuring it. Consult the CE documenta-

tion.

4

Only in systems with two current sensors.

5

High accuracy use of this feature may require a calibrated clock.

6

IEC 62056 Manufacturers’ IDs are al located by the FLAG Association Limited. Maxim Integrated does not own or profit

from the FLAG association. Maxim Integrated’s default id may not confor m, and is for demonstration purposes only.

7

Nothing in the document should be interpreted as a guarantee of conformance to a third-party software specification.

Conformance testing is the respons ibility of a meter manufacturer.

8

May require calibration for best accuracy.

9

Calibration item in high-precision “H” series meters (71M6541H only).

Table 1-7: Bits in the MPU Status Word

Bit

Name

Explanation

1 I B i s bel ow IThrshld. Current for this phase is in creep.

10 An unexpected interrupt was detected.

no battery power, and therefore the clock has to be invalid. B) More than a year after the previously saved reading, or C) Earlier than the previously saved reading. In this case, the clock’s

reduce battery loading to very low values. When the battery voltage is being displayed, the