maximal FD80T, FD100T, FD50-70T MWF, FD50-70T MWH, FD50-70T MGH Maintenance Manual

...

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-1-

Introduction

This manual has mainly introduced the items related to performance, structure, operation,

maintenance, as well as service, and other aspects of M portfolio 5-10t forklift trucks, in order

for operators to understand the forklift trucks, and to use and maintain the trucks correctly.

During the application of forklift trucks, user’s operators and equipment management

personnel involved shall carefully observe the requirements and specifications for forklift

trucks in this manual, for the forklift trucks to regularly maintain a good technical condition.

Due to our continuous improvement of the forklift truck products, the items of this manual are

subject to alteration and may vary slightly from the real forklift trucks without prior notice,

for which your kind understanding is expected.

Note: The type code in this manual is different from the model on product data plate and

certificate of conformity. The type code of this series of trucks has covered engine and its

modification code.

Example:

FD50T — M W F

Isuzu 6BG1 Engine

Imported

Maximal

Model

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-2-

Table of Contents

Introduction............................................................................................................................................... 1

Table of Contents......................................................................................................................................1

I. Safety Rule for Drive and Operation of Forklift Truck.................................................................. 4

II. Main Technical Parameters for Forklift Truck..............................................................................12

III. Introduction for Main Parts of Forklift Truck .............................................................................15

IV. Structure, Principle, Adjustment, and Maintenance of Forklift Truck....................................17

1. Power System.......................................................................................................................................18

1.1 Overview............................................................................................................................................. 18

1.2 Engine Configuration ....................................................................................................................... 18

1.3 Fuel System ........................................................................................................................................21

1.3.1 Fuel Tank .........................................................................................................................................22

1.3.2 Fuel Sensor Device........................................................................................................................22

1.3.3 Fuel Filter ........................................................................................................................................23

1.4 Cooling System.................................................................................................................................. 23

1.5 Examination and Adjustment..........................................................................................................23

1.5.1 Air Filter...........................................................................................................................................24

1.5.2 Fuel Filter.........................................................................................................................................24

1.5.3 Engine Oil Filter.............................................................................................................................25

1.5.4 Cooling System .............................................................................................................................. 25

1.5.5 Fastening of Bolts for Engine Cylinder Head..........................................................................26

1.5.6 Adjustment of Valve Clearance................................................................................................... 27

1.5.7 Confirmation of Ignition Time for Fuel Injection ...................................................................28

1.5.8 Adjustment of Ignition Time for Fuel Injection....................................................................... 29

1.5.9 Determination of Compression Pressure...................................................................................29

1.5.10 Exhaust of Injection Pump.........................................................................................................29

2. Electrical System .................................................................................................................................30

2.1 Overview............................................................................................................................................. 30

2.2 Brief Introduction about Operation ...............................................................................................35

2.3 Battery..................................................................................................................................................38

2.4 Wire Harness ...................................................................................................................................... 38

3. Transmission Device........................................................................................................................... 39

3.1 Overview............................................................................................................................................. 41

3.2 Torque Converter............................................................................................................................... 41

3.3 Oil Feed Pump ................................................................................................................................... 43

3.4 Hydraulic Clutch ...............................................................................................................................43

3.5 Control Valve and Inching Valve....................................................................................................45

3.6 Oil Circult System for Torque Converter .....................................................................................46

3.7 Notices during Failure Occurrence with Forklift Truck............................................................48

3.8 Failure Removal ................................................................................................................................48

4. Drive Axle .............................................................................................................................................55

4.1 Overview............................................................................................................................................. 55

4.2 Speed Differential..............................................................................................................................55

4.3 Wheel-sided Reducer........................................................................................................................58

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-3-

4.4 Failure Removal ................................................................................................................................60

4.5 Maintenace Data................................................................................................................................ 61

5. Brake System........................................................................................................................................62

5.1 Overview............................................................................................................................................. 63

5.2 Power Brake .......................................................................................................................................64

5.2.1 Brake Pedal Device .......................................................................................................................64

5.2.2 Brake Valve .....................................................................................................................................67

5.2.3 Energy Accumulator......................................................................................................................68

5.3 Vacuum Power Brake .......................................................................................................................70

5.3.1 Vacuum Booster and Brake Master Cylinder........................................................................... 70

5.3.2 Method for Installation of Vacuum Booster and Brake Master Cylinder Assembly........73

5.3.3 User Notices....................................................................................................................................74

5.3.4 Failure and Cause Analysis..........................................................................................................74

5.4 Wheel Brake.......................................................................................................................................74

5.4.1 Wheel Brake (For 5-7t Trucks)................................................................................................... 75

5.4.2 Wheel Brake (For 8-10t Trucks).................................................................................................78

5.5 Parking Brake.....................................................................................................................................78

5.6 Failure Removal ................................................................................................................................81

6. Steering System....................................................................................................................................82

6.1 Steering Unit.......................................................................................................................................84

6.1.1 Overview..........................................................................................................................................84

6.1.2 Operating Principle........................................................................................................................85

6.1.3 Application Requirements............................................................................................................ 86

6.1.4 Examination and Maintenance of Steering Unit......................................................................87

6.1.5 Failure and Removal for Steering Unit...................................................................................... 89

6.2 Examination after Reassembly of Steering System: ..................................................................91

6.3 Failure Removal for Steering System ...........................................................................................93

6.4 Steering Axle ......................................................................................................................................93

6.4.1 Steering Axle Body........................................................................................................................93

6.4.2 Left-Right Steering Knuckle Assembly.....................................................................................93

6.4.3 Wheel Hub.......................................................................................................................................94

6.4.4 Steering Cylinder ...........................................................................................................................94

7. Hydraulic System ................................................................................................................................96

7.1 Overview............................................................................................................................................. 97

7.2 Oil Pump ............................................................................................................................................. 97

7.3 Multi-way Valve ................................................................................................................................ 97

7.4 Operation of Multi-way Valve ........................................................................................................98

7.5 Work of Main Safety Valve .............................................................................................................99

7.6 Work of Tilt Auto-locking Valve ..................................................................................................100

7.7 Control Device of Multi-way Valve ............................................................................................100

7.8 Oil Tank............................................................................................................................................. 100

7.9 Oil Circuit of Hydraulic System...................................................................................................101

7.10 Maintenance ...................................................................................................................................104

7.10.1 Disassembly of Multi-way Valve ...........................................................................................104

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-4-

7.10.2 Reassembly of Multi-way Valve.............................................................................................104

7.10.3 Notices ......................................................................................................................................... 105

8. Lift Cylinder and Tilt Cylinder .......................................................................................................105

8.1 Lift Cylinder.....................................................................................................................................105

8.2 Isolating Valve..................................................................................................................................108

8.3 Limiting Valve..................................................................................................................................108

8.4 Tilt Cylinder...................................................................................................................................... 110

9. Lifting System.................................................................................................................................... 111

9.1 Overview........................................................................................................................................... 112

9.2 Outer & Inner Mast......................................................................................................................... 112

9.3 Fork Carriage.................................................................................................................................... 112

9.4 Adjustment of Lifting System....................................................................................................... 112

9.4.1 Gasket Adjustment for Lift Cylinder Head............................................................................. 112

9.4.2 Height Adjustment for Fork Carriage ......................................................................................113

9.5 Mounting Positions of Rollers...................................................................................................... 114

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-5-

I. Safety Rule for Drive and Operation of Forklift Truck

I. The drivers and management personnel of forklift truck must bear in mind “Safety First”,

and conduct safety operation and standard operation according to the “Operation and

Maintenance Manual” for the forklift truck.

II. Conveyance of Forklift Truck

It is required to pay attention to the following items when motor vehicle is used to load and

convey the forklift truck.

1. Skid the parking brake.

2. Both the front and rear parts of mast and counterweight shall be properly fixed using steel

wire. The corresponding positions of front and rear tyres shall be firmly wedged up using

wedge blocks.

3. The forklift truck shall be listed according to the marked position on the “Lift Data Plate”

for forklift truck at the lifting time.

III. Storage of Forklift Truck

1. Drain the fuel completely (It is not to be drained if coolant is the antirust and antifreeze

fluid.)

2. Coat the surface of unpainted parts with antirust oil, and coat the lift chain with lubricating

oil.

3. Drop the mast to the lowest position.

4. Skid the parking brake.

5. Wedge up the front and rear tyres properly using wedge blocks.

IV. Preparation prior to Use

1. Avoid examining fuel, oil leak, oil level, and examining electrical instrument in a place

with an open fire, and avoid adding fuel during operation.

2. Examine the air pressure of tyres.

3. It is required to place the handle for forward/backward gear at the middle position (zero

gear position).

4. Don’t smoke when fuel system is working and when battery is being examined.

5. Examine the status of respective handles and pedals.

6. Get properly prepared for startup.

7. Loosen the parking brake.

8. Perform the test actions such as rise and fall of mast, forward and backward tip, steering,

and brake.

V. Operation of Forklift Truck

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-6-

1. Only the drivers who have been trained and hold driving license are allowed to drive the

truck.

2. The operators shall wear shoes, helmet, clothes, and gloves that can be used for safety

protection.

3. Examine respective controls and warning devices before truck is driven, and the truck shall

be operated after it has been repaired in the case when any damage or defect is found.

4. During conveyance, the load shall not exceed the specified value, the fork must be

completely inserted into the underside of cargo, and the cargo must be uniformly placed on

the fork. It is not allowed to pick up cargo using a single fork tip.

5. Smoothly perform start, steering, running, brake, and, and slow down at turning, on wet or

smooth pavements.

6. It is required to place cargo as low as possible, and to keep the mast tilt backwards, when

cargo is loaded for driving.

7. It is required to be careful during driving on a ramp. It is required to drive forward during

upgrade and drive reversely during downgrade, when the truck is driven on a ramp larger than

1/10. Turning shall be avoided by all means, and please never perform loading-unloading

operation when forklift truck is running downgrade.

8. It is required to pay attention to passengers, obstacles, and low-lying pavements, and pay

attention to the clearance above the forklift truck, during driving.

9. It is not allowed for anyone to stand on fork and it is not allowed for anyone to be carried

on truck.

10. It is not allowed for anyone to stand under the fork, or to walk under the fork.

11. It is not allowed to control the truck and attachments at any position other than the driver

seat.

12. It is required to pay attention to the fall of cargo from above, for any high lift forklift

trucks with a lifting height larger than 3m, and protective measures must be taken, when

necessary.

13. Try as much as possible to tip backward the mast for high-lift forklift trucks during work,

and it is required to perform front or back tip within the minimum range during

loading-unloading operation.

14. It is required to take a doubled care, and to drive slowly, during running on dock or on

temporary planks.

15. Driver shall not stay on the truck, when fuel is added, and the engine shall be turned off.

Ignition is to be avoided when battery or level of oil tank is examined.

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-7-

16. The forklift trucks with attachments shall be operated as loaded forklift trucks during

unloaded operation.

17. Don’t convey unfixed or loosely stacked cargo, and take care when cargo of relatively

large size is conveyed.

18. Drop the fork onto the ground, put the handle for gear position to neutral gear, and turn off

the engine or disconnect the power supply when driver leaves the truck. Pull the parking

brake device properly when truck is parked on a ramp, while wedge blocks must be used to

fill up the wheels when the truck is to be parked there for a long time.

19. It is not allowed to open radiator cover carelessly, under the condition when engine is very

hot.

20. The pressures of multi-way valve and safety valve have been properly adjusted before

delivery of forklift truck from factory, and users shall not adjust them at discretion during use,

to avoid damage of entire hydraulic system and hydraulic components due to excessively high

adjustment.

21. The value of air pressure specified on the label plate of “Tyre Air Pressure” shall be

followed for tyre air charge.

22. The maximum noise outside the forklift truck is not to be larger than 89dB (A), and

JB/T3300 shall be followed as test method.

23. Get familiar with and pay attention to the functions of various data plates on the forklift

truck.

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-8-

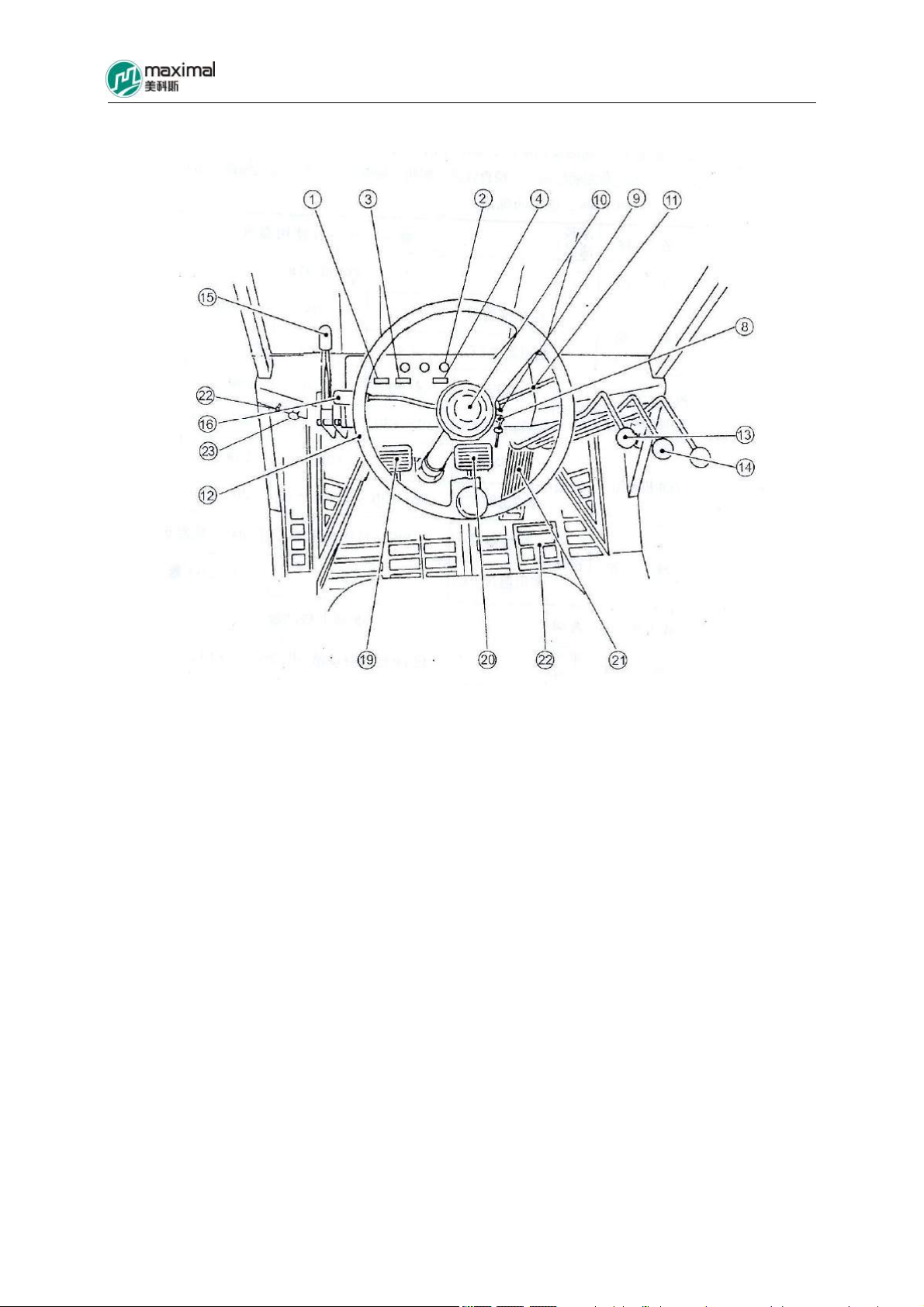

VI. Schematic Drawing of Instruments and Control Layout for Forklift Truck

1. Fuel Gage 13. Lift Handle

2. Indicator Light 14. Tilt Handle

3. Water Temperature Gauge 15. Parking Brake Handle

4. Hour Meter 16. Front-Rear-Gear Handle

8. Ignition Switch 19. Inching Pedal

9. Light Switch 20. Brake Pedal

10. Horn Pushbutton 21. Throttle Accelerator Pedal

11. Steering Light Switch 22. Engine Hood Stay Cable

12. Steering Wheel 23. Engine Stop Stay Cable

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-9-

Gasoline Engine

VII. Routine Maintenance of Forklift Truck

1. Key Points for Startup

1) Oil quantity and oil level of hydraulic oil shall be at the middle position of scale on oil

level indicator.

2) Examine whether or not leak or damage exists with pipe, joint, pump, and valve.

3) Examine wheel brake.

a) The idle stroke of brake pedal shall be 40mm.

b) The clearance between front bottom plate and pedal shall be larger than 20mm.

4) Examine the hand brake function: When hand brake handle is thoroughly pulled, it shall be

able to be skidded on a 20% ramp (no load).

5) Instruments and Illumination Light Fittings, etc: Examine whether or not the respective

parts including instruments, illumination, connection joints, switches, and electrical circuit are

working normally.

2. Oils, Greases, and Anti-freeze Fluids Used for Forklift Truck:

Original Oil

Name

Gasoline 93# or 97#

Diesel Oil

Oil (SF)

Electronic

Injection Type

(SG)

Diesel Engine

Oil (CD)

Product

Great Wall

Great Wall

Brand of Light

Diesel Oil

Application

Temperature (℃)

Viscosity Grade 5W/30 10W/40

Application

Temperature(℃)

Viscosity Grade 5W/30 10W/30

Application

Temperature(℃)

Brand, Code, and Temperature of Use

0# -10# -20# -35#

≥4 ≥-5 ≥-5~-14 ≥-14~-29

-30~

+40

-30~

+30

-25~

+40

-25~

+30

10W/30 15W/40

-25~+30 -25~+40

15W/40 20W/50

-20~+40 -15~+50

L-HM32 Antiwear

Viscosity Grade

Hydraulic Oil

Torque HAIPAI 6# Torque converter oil

Kunlun

Application

Temperature(℃)

Hydraulic Oil

>-19

L-HV32 Low Temperature

Antiwear Hydraulic oil

>-33(in Open Air in Cold

Regions)

-10-

converter oil

Brake Fluid

Lubricating

Grease

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

Chongqing

4604 Synthetic Brake Fluid GB12981HZY4

Yiping

Great Wall 3# General Lithium Base Lubricating Grease(-20℃~+120℃)

Viscosity Grade 85W/90GL-5 80W/90GL-5 Heavy-duty

Truck Gear

Oil

Anti-freeze

Fluid

HAIPAI

Jinbai

Application

-15~+49 -25~+49

Temperature(℃)

Code FD-1 FD-2 FD-2A FD-3

Application

≥-25 ≥-35 ≥-45 ≥-50

Temperature(℃)

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-11-

3. Notices for Operation of Cooling System

1) When forklift truck is being operated, in the case when radiator is overheated or

temperature of coolant is excessively high, don’t open the radiator cover immediately.

Examine the liquid level, in order to find the overheating cause. When cover has to be opened,

it is required to slow down the engine to a medium speed. Turn the radiator cover slowly and

loosen off the cover after waiting for a while, to avoid scald of operator by splash of coolant.

Make sure to screw the radiator cover properly in place, when it is tightened up, and

otherwise it is difficult to build up a specified pressure system.

2) There is a feeding tank on the left side of engine, with the marks of FULL and LOW

labeled in the upper and lower parts of the tank wall, and the level of anti-freeze fluid shall be

between these two countermarks during use. Antirust and anti-freeze fluid of the same model

shall be supplied after anti-freeze fluid is leaked out or evaporated. Anti-freezing fluid is

generally used both in winter and summer, not changed for four seasons. It shall be drained

out for filtration and purification treatment after use for one year in general, to be then further

used.

3)According to different work conditions, the smudge on the outer surface of radiator shall be

periodically cleaned and removed, either to be soak cleaned using detergent, or to be flushed

using compressed air or high-pressure water (pressure not larger than 4kg/cm).

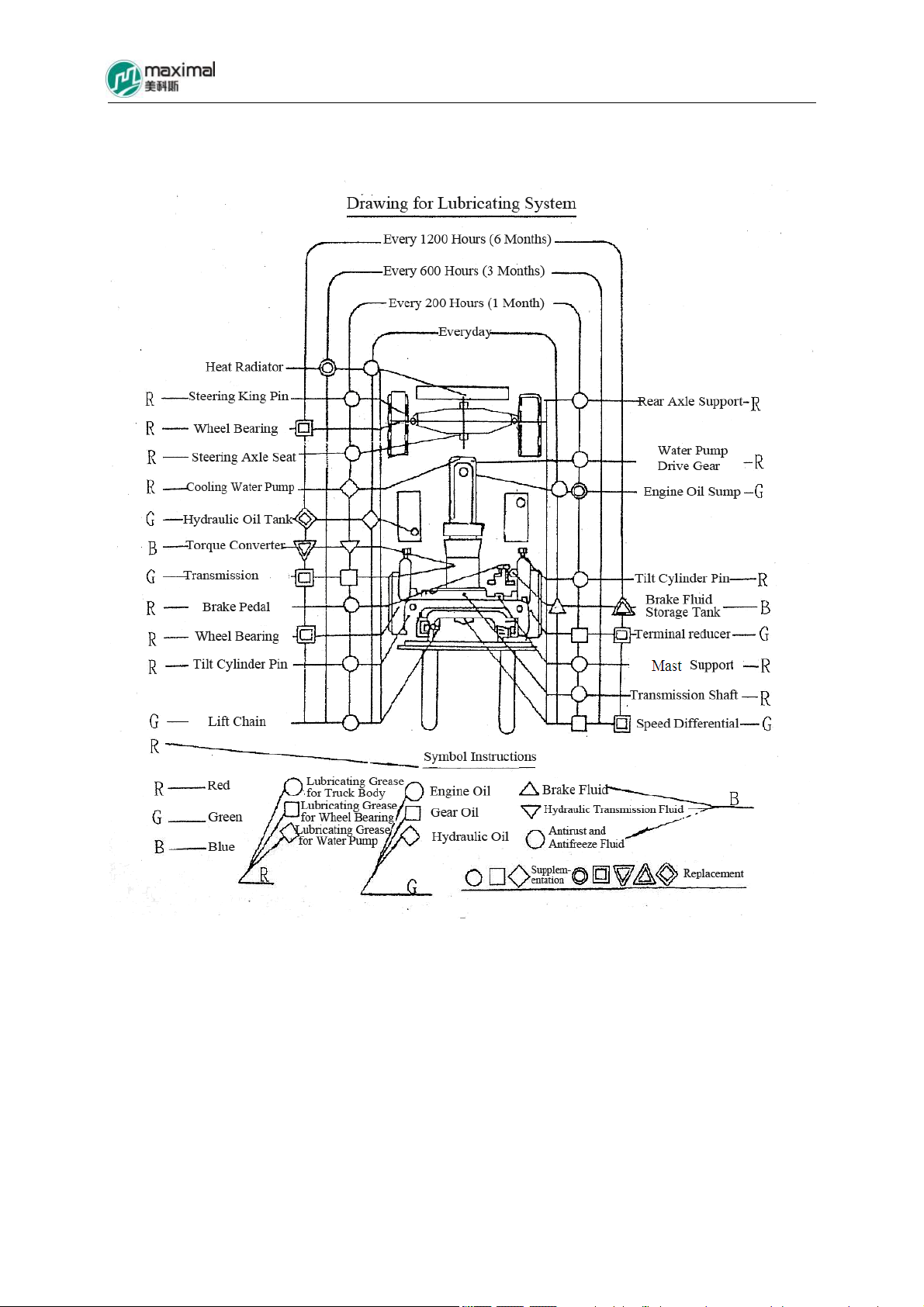

4. Drawing of Lubricating System

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-12-

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-13-

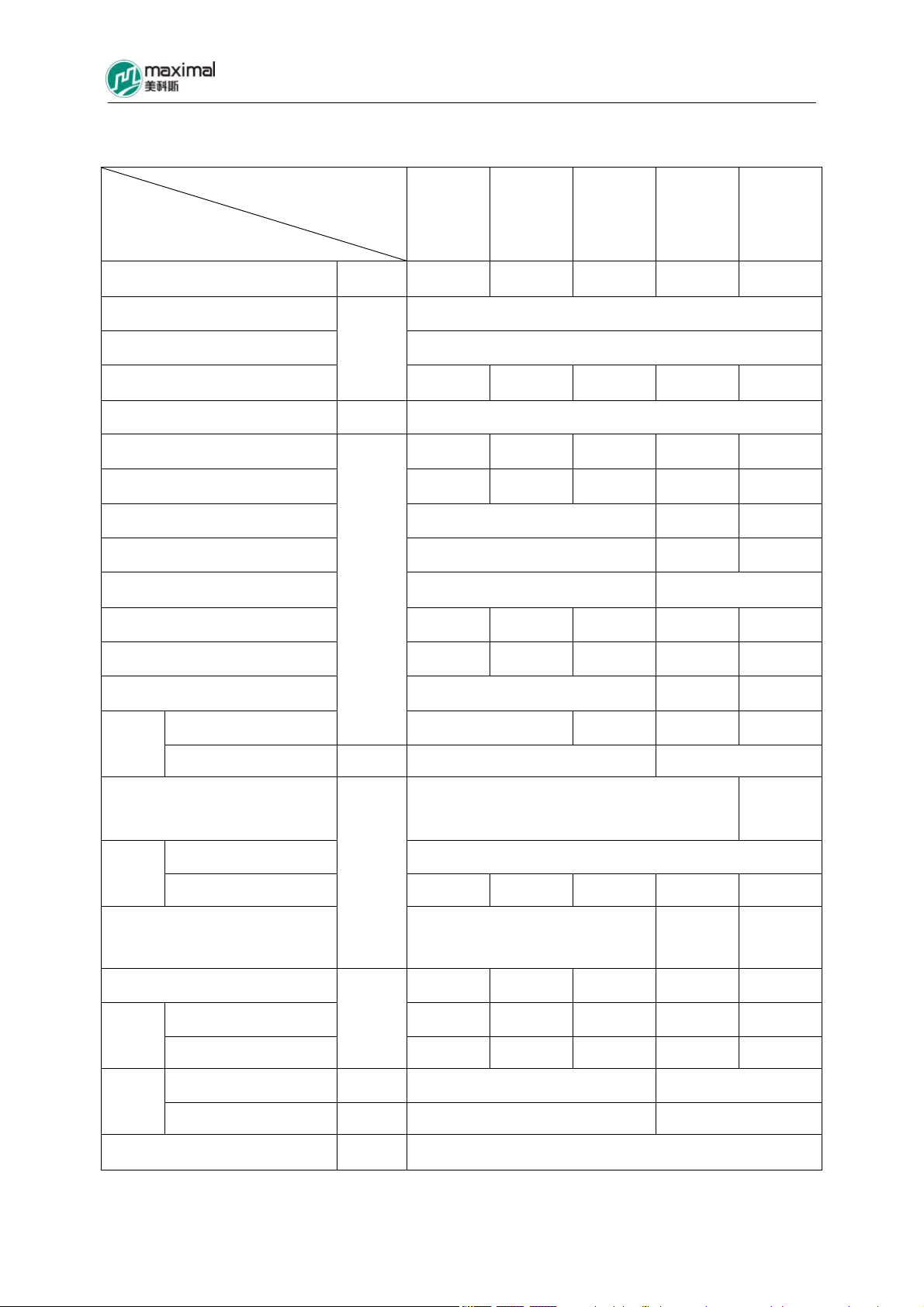

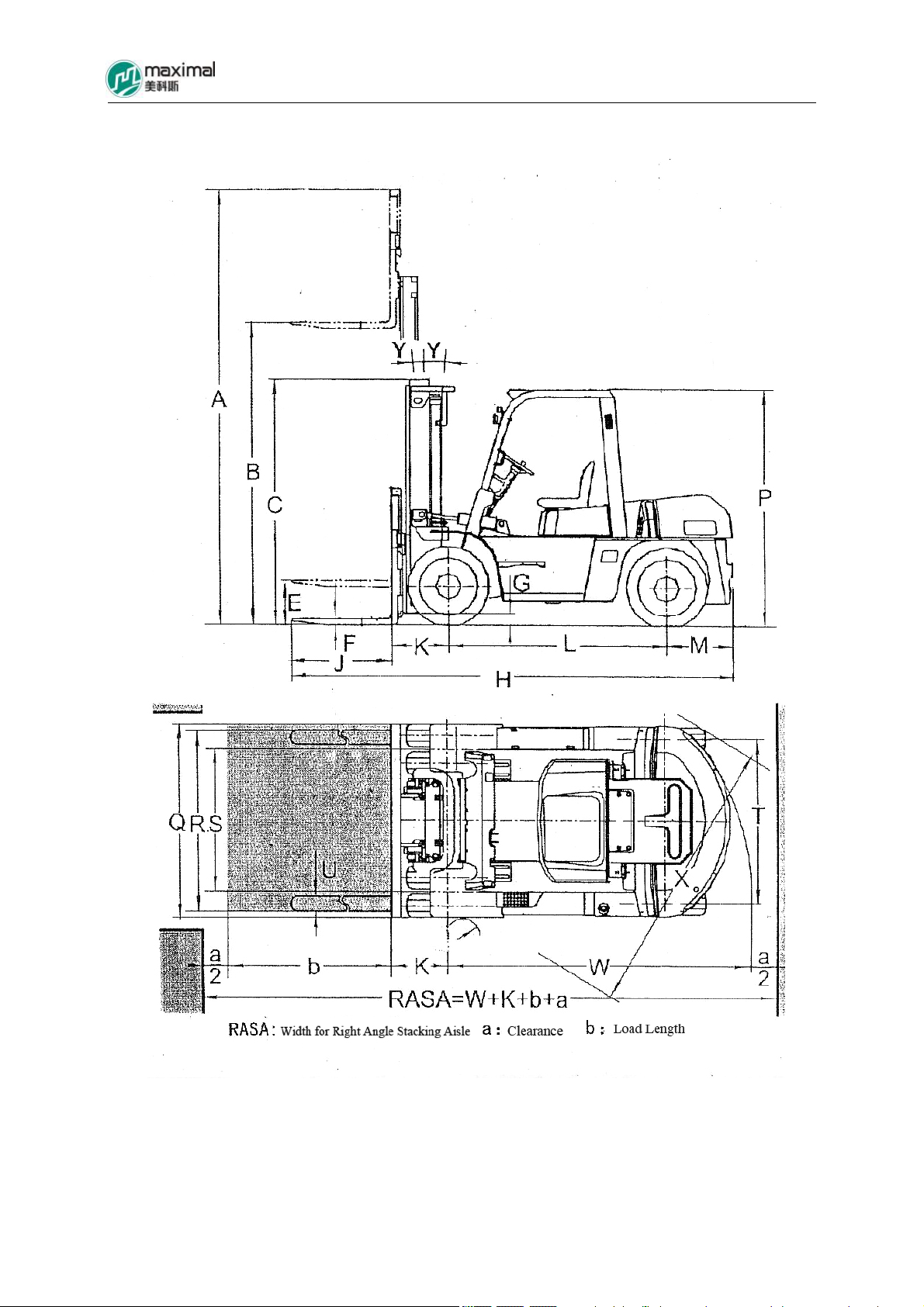

II. Main Technical Parameters for Forklift Truck

Forklift Truck

Lifting Capacity

5t 6t 7t 8t 10t

Parameter

Rated Load-lifting Capacity kg 5000 6000 7000 8000 10000

Load Center Distance 600

Max Lifting Height (Standard) B

Free Lifting Height (Standard) E

mm

195 200 205 200 210

3000

Mast Tip Angle Y/Y (º)/( º) 6/12

Min Turning Radius W 3250 3300 3370 3700 3900

Min Right Angle Aisle Width X 2960 3000 3040 3310 3540

Min Off-ground Clearance G 200 250 245

Wheelbase L 2250 2500 2800

Tread Front/Rear S/T 1470/1700 1600/1700

mm

Clearance Front/Rear K/M 590/600 590/675 590/740 700/740 718/740

Whole Length H 4660 4735 4800 5160 5480

Entire Length Q 1995 2165 2245

Height

Mast C

Overhead Guard P mm 2450 2585

2500 2625 2700 2850 Whole

Height at Rise of Fork (with Cargo

4420 4330

Stop Frame) A

Length J 1220

Fork

mm

Width×Thickness F 150×55 150×60 150×65 170×70 175×80

Fork Adjusting Range (Outer

300-1700 340-1944 410-2140

Side of Fork) R

Forklift Truck Dead Weight 8080 8740 9450 11660 12610

kg

4010/3970 3880/4760 3860/5490 4840/6120 5700/6810

Load

Full Load Front/Rear 11660/1320 13050/1590 14570/1780 17000/1950 20380/2130 Axle

No-Load Front/Rear

Front 4 8.25-15-14PR 9.00-20-14PR

Tyre

Rear 2 8.25-15-14PR 9.00-20-14PR

Batte4ry Voltage/Capacity V/Ah 24/80

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-14-

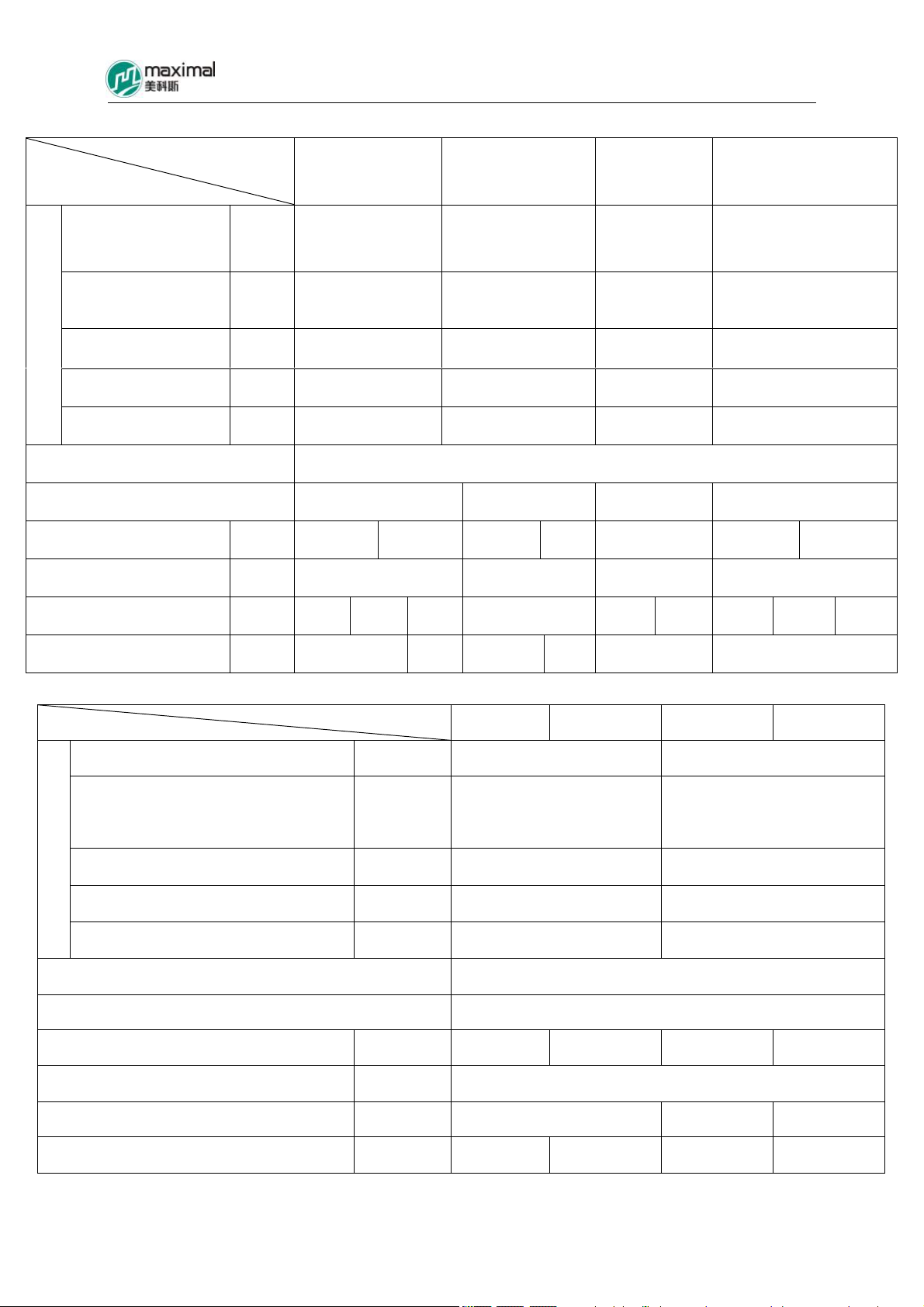

Vehicle Type

Parameter

Model

Number of Cylinders

Engine

–Diameter of Cylinder

mm 6-105×125 6-102×118 6-94×120 4-105×127

× Stroke

Rated Power/Rotating

Speed

Max Torque/Rotating

Speed

Min Fuel

Consumption Rate

Kw/rp

m

Nm/rp

m

g/kwh

Number of Transmission Shift Gears

Front/Rear

Wheel Brake Mode Power Brake

Lifting Speed Full

Load/No-Load

Max Running Speed Full

Load/No Load

Max Gradeability Full

Load/No Load

Max Traction Capacity Full

Load

Mm/s 460/500 380/420 400/600

Km/h

% 35/19 32/19 30/19

KN 54 53 53 52 45 54

FD50-70T

MWF

Isuzu (Diesel)

A-6BG1QC

FD50-70T

MGH

Chaochai

6102BG

FD50-60T

MWJ

Mitsubishi

(Diesel)

S6S-T

FD50-70T

MWH

Perkins

1104D-44TA

82.3/2000 81/2500 67.6/2300 83/2300

416/1400-1600 353/1650 293/1700 418/1400

233 231 265 245

2/2 Power Gear Shift

Vacuum Power or

Power Brake

400/6

00

Power Brake Power Brake

390/500 460/500 380/420

26/28 26/28 26/28 26/28

20/15 26/23 22/20 35/19 32/19 32/119

Vehicle Type

Parameter

Model Isuzu A-6BG1QC (Diesel)

Number of Cylinders – Diameter of

Engine

Cylinder x Stroke

mm 6-105×125 6-102×118

Rated Power/Rotating Speed Kw/rpm 82.3/2000 81/2500

Max Torque/Rotating Speed Nm/rpm 416/1400-1600 353/1650

Min Fuel Consumption Rate g/kwh 233 231

Number of Transmission Shift Gears Front/Rear 2/2 Power Gear Shift

Wheel Brake Mode Power Brake – Pedal Type

Lifting Speed Full Load/No-Load mm/s 380/410 310/350 390/480 310/390

Max Running Speed Full Load/No-Load km/h 26/30

Max Gradeability Full Load/No-Load % 21/21 21/21 20/15

FD80T FD100T FD80T FD100T

Chaochai 6102BG

Max Traction Capacity Full Load KN 63.2 58 51 57

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-15-

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-16-

III. Introduction for Main Parts of Forklift Truck

Refer to the following table for main parts of forklift truck.

S/N Name Item

1 Air Filter and Installation Including air filter, air filter support plate, air inlet pipe, and air outlet pipe

2 Battery and Installation Including battery, cross beam, and support bar

Including radiator and standby tank, water supply and drain pipes, rubber

3 Radiator and Installation

gasket, and bolts for radiator

Fuel Device and

4

Installation

5 Muffler and Installation

6 Electrical System

Drive Axle and

7

Installation

8 Front Wheel Assembly Including tyre, front wheel rim assembly, and air valve bracket

9 Rear Wheel Assembly Including tyre, and rear-wheel rim assembly

Engine and Transmission

10

Installation

Including cover plate assembly, cover plate gasket, air plug, oil quantity

sensor, oil tank cover, oil-water separator, diesel oil filter, and oil delivery

hose

Including muffler, front vent pipe, rubber gasket, connecting pipe, vent

pipe, and U-bolt for block plate

Mainly including light fittings, instruments, wire harnesses, and electrical

components

Mainly including axle housing, transmission, speed differential,

wheel-sided reducer, half shaft, and brake

Including drive transmission, engine, transmission bracket, and

transmission support

Including bracket for control rod, pin shaft, rocking arm, and connecting

11 Transmission Control

rod

Steering Device and

12

Installation

Steering Axle and

13

Installation

Including steering column, universal joint, connecting shaft, steering

wheel, and handle

Including steering axle, and steering cylinder

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-17-

S/N Name Item

Torque Converter Oil

14

Cooling System

Overhead Guard and

15

Installation

16 Throttle Control Including pedal, connecting shaft, bracket, and stay wire

17 Hand Brake Control Including hand brake assembly

Including articulating bolts, oil filter, oil pipe, and bracket for oil filter

Including overhead guard, handle, light bracket, and air intake window

Brake and Inching

18

Control

19 Truck Frame

Counterweight and

20

Installation

Instrument Bracket and

21

Hook Installation

22 Seat and Installation Including seats, and rubber gaskets for seats

Multi-way Reversing

23

Valve Control

Mainly including brake and inching control, oil pipe, joint, energy

accumulator (or vacuum tank and vacuum booster), brake valve, and

safety valve

Including front plate, left/right truck frames, rear truck frame,

transmission bracket, bracket for tilt cylinder, engine bracket, and battery

cover plate

Including counterweight, traction bolt, and netting guard

Including instrument bracket, internal combustion engine hood, floor,

articulation, cross beam, radiator cover plate, and air spring

Including control rod, bent plate, connecting shaft, and pull rod

Working Oil Tank and

24

Installation

25 Hydraulic System

26 Working Device

Including oil suction pipe assembly, edge filter, and breathing apparatus

Mainly including gear pump, multi-way valve, hydraulic steering unit, HP

oil pipe, and joint

Mainly including mast, fork, fork carriage, cargo stop frame, lift cylinder,

tilt cylinder, lift chain, mast sprocket, and roller, etc

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-18-

IV. Structure, Principle, Adjustment, and Maintenance of Forklift Truck

1. Power System

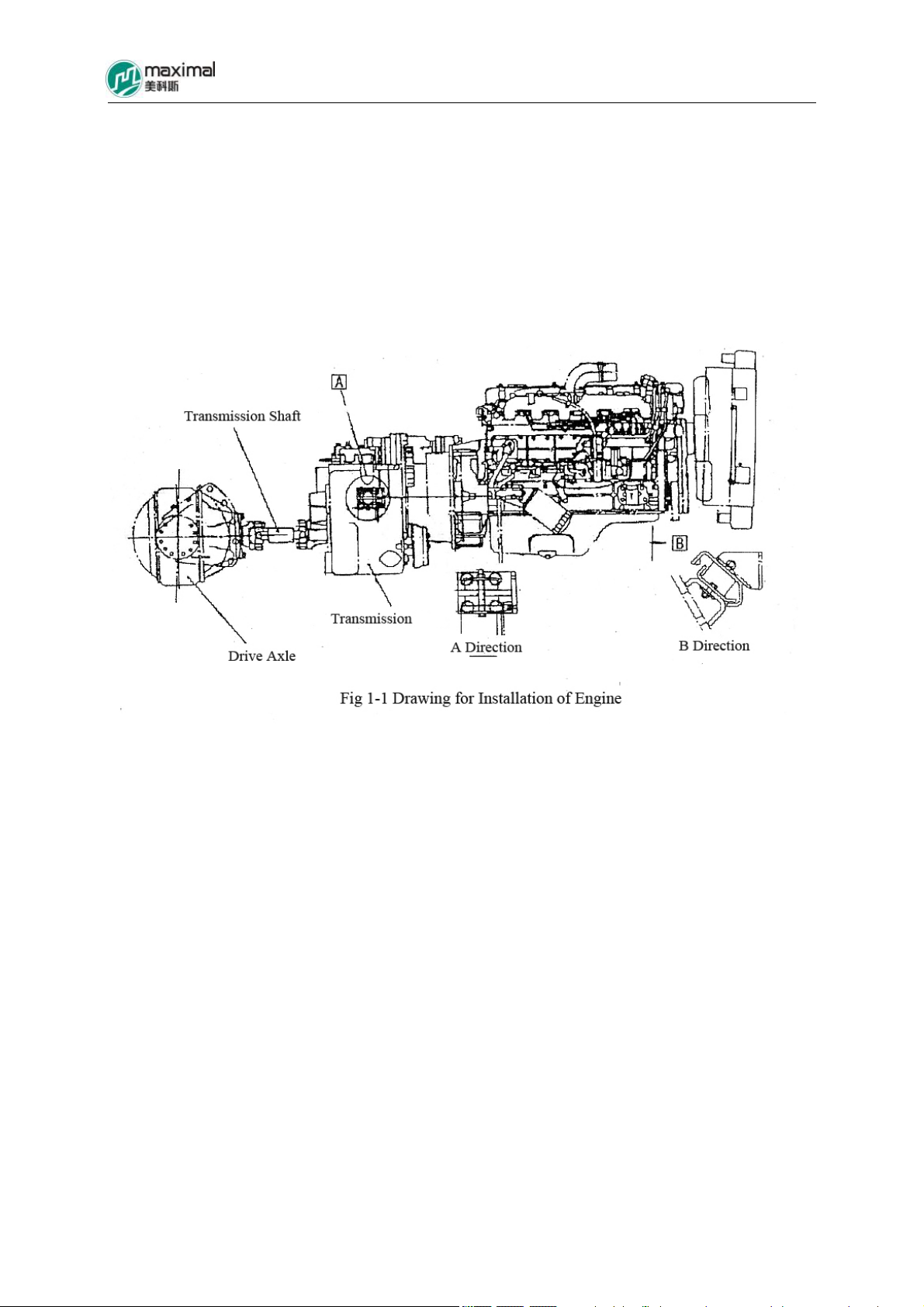

1.1 Overview

Power system mainly includes engine, fuel system, cooling system, and exhaust system.

Engine is installed on truck frame through rubber pads, to reduce vibration. Engine, torque

converter, transmission, transmission shaft, and drive axle are formed into a unit. Refer to Fig

1-1.

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-19-

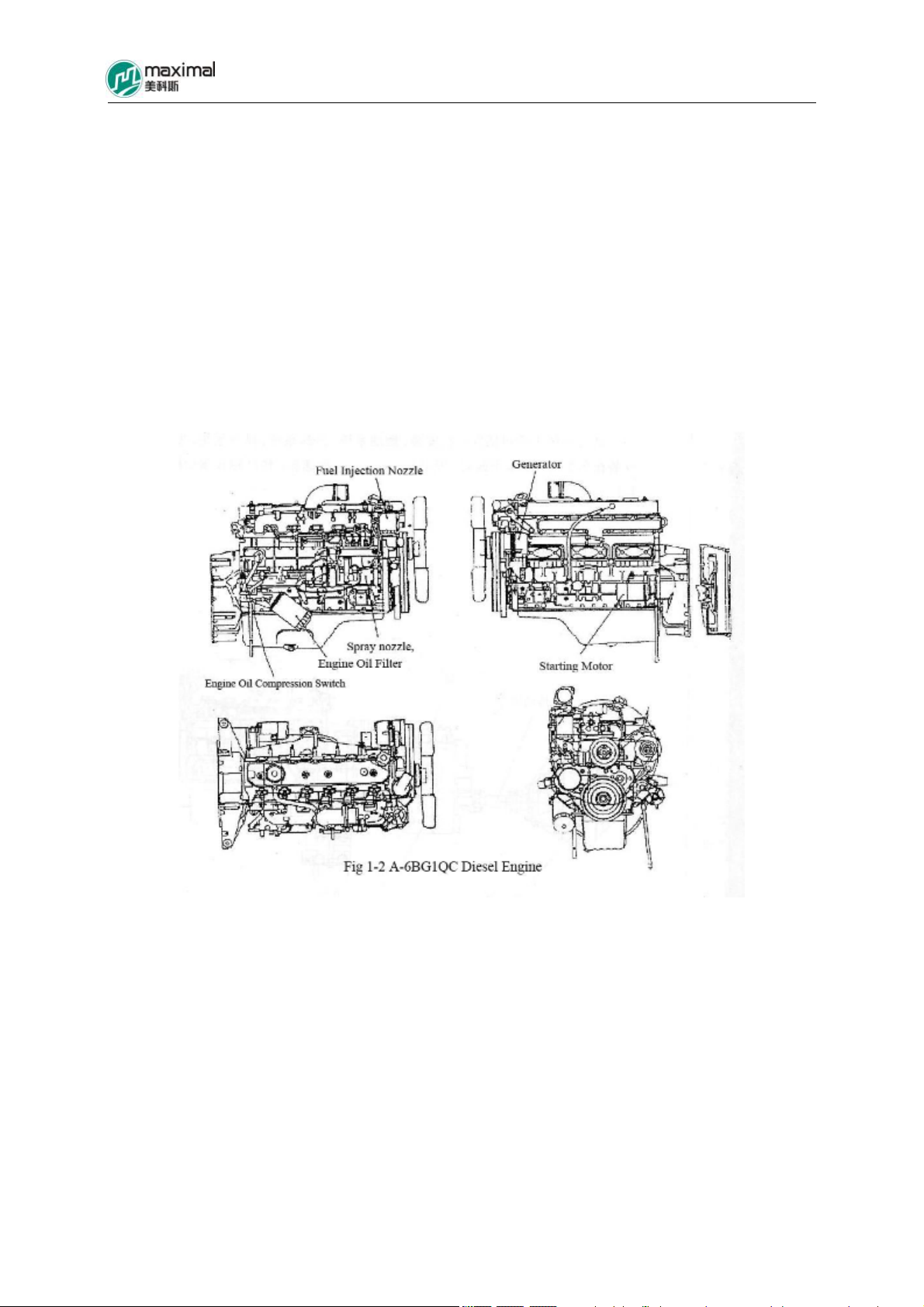

1.2 Engine Configuration

Engines for 5-7t forklift trucks mainly include imported diesel engines such as Isuzu 6BG1,

Mitsubishi S6S-T, and Perkins, and homemade diesel engines such as Chaoyang 6102BG-38.

Engines for 8-10t forklift trucks include imported diesel engine Isuzu 6BG1 and homemade

diesel engine Chaoyang 6102BG. The imported Isuzu 6BG1-model diesel engine is mainly

described here, and the others will not be described here as user may refer to the attached

operation manual for engines.

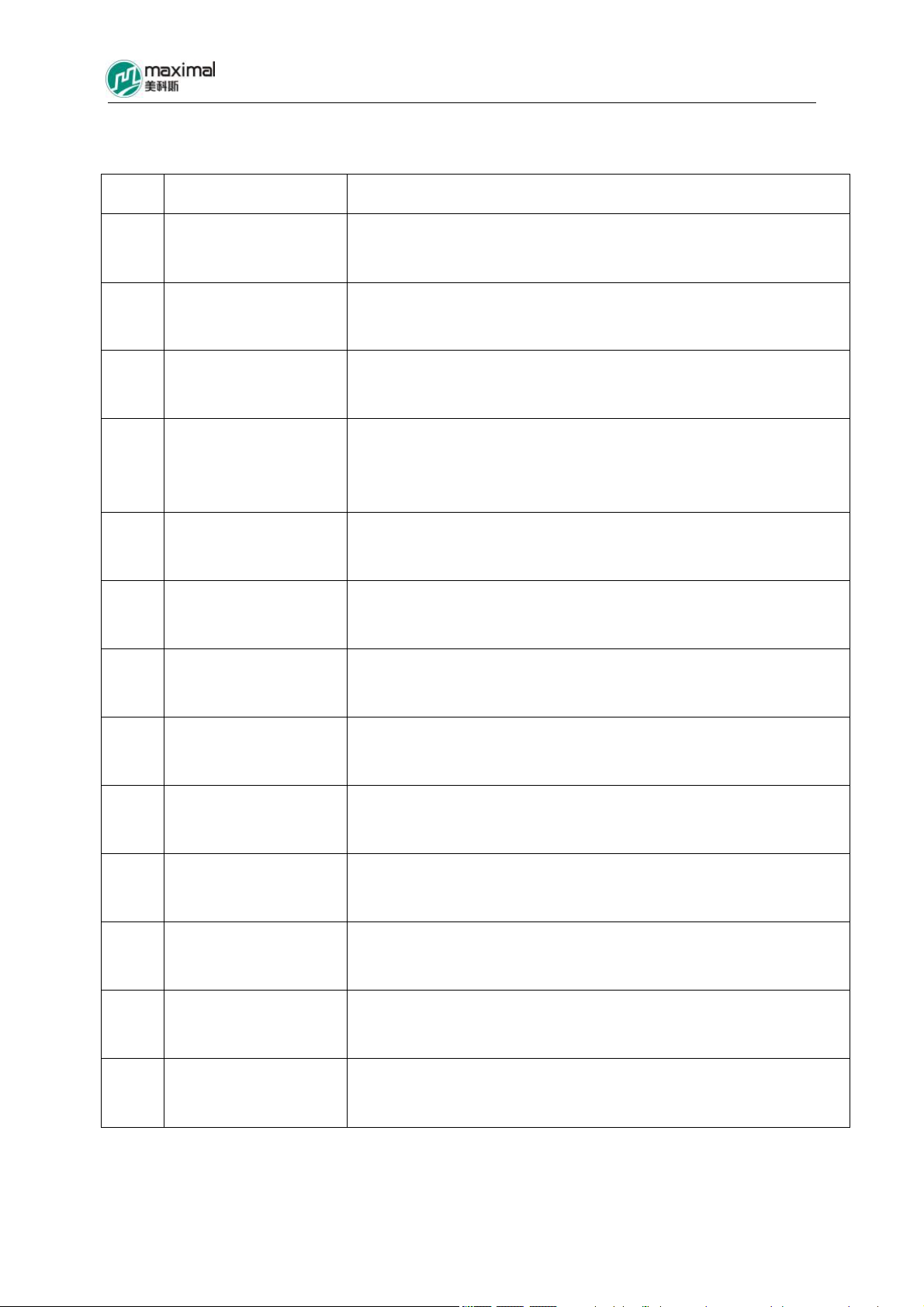

Refer to Fig 1-2 for the outside structural drawing for 6BG1, and refer to the attached Table 1

for its main performance parameters for structure and configuration.

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-20-

Name

Type

Numberof Cylinders – Cylinder Diameter ×

Stroke

Total Displacement (I)

Compression Ratio

Performance

Rated Speed(rpm)

Rated Power(kw)

Max Torque(N-m/rpm)

Fuel Consumption for Total Load (g/kwh)

Idle Speed(rpm)

Weight(㎏)

Dimension(㎜)

Ignition Sequence

Rotating Direction

Valve Gear

A-6BG1QC

4-stroke, Water-cooling, Straight-line, and top Diesel

Engine

6-105 ㎜×125 ㎜

6.494

17

2000

82.3

416/1400-1600

233

700

450

1129.5×672.0×860.0

1-5-3-6-2-4

Looking from the end of fan in clockwise direction

Top Mounted

Fuel Device

Injection Pump

Plunger Diameter x Stroke

Injection Nozzle

Oil Feed Pump

Fuel Filter

Speed Regulator

Mode of Speed Control

Lubrication Mode

Lubricating Device

Pump Type

Drive Type

Oil Pressure Adjusting Device

Oil Pressure Indicating Device

Filter Mode

Cooler

Cooling Device

Boshing Type

9.5 ㎜×8 ㎜

Multi-porous Type

Plunger Type

Paper Core of Filter Type

Centrifugal, and Full Speed Control

Forced Circulation Type

Gear Type

Camshaft Drive

Piston and Spring Type

Switch Type(0.3 ㎏/㎝2)

Full Flow and Filter Paper Type

Embedded Water Cooling Type

Cooling Mode

Cooling Fan

Drive Mode

Water Cooling

Exhaust Type, 7 Fan Blades, and Outer Diameter 550mm

Belt Drive

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-21-

Table 1 Continued

Pump Type

Drive Mode

Water Temperature Adjusting Device

Mode

Thermostat Opening Temperature

Thermostat Full Opening Temperature

Starting Motor

Mode

Voltage

Rated Power

Flameout Device

Preheating Device

Charging Generator

Mode

Voltage

Output

Vortex Type

Belt Drive

Wax Pellet Type

82℃

95℃

Magnetic Engagement Type

24V

4.5KW

Disconnecting Fuel Passage

Available

AC Generation, and Diode Rectification

24V

25A

Drive Mode

Charging Automatic Regulator

Referential Parameters

Oil Quantity in Oil Pan

Cooling Water Quantity

Valve Clearance

Suction Valve

Exhaust Valve

Valve On/Off Time

Suction Valve (Open)

(Close)

Exhaust Valve (Open)

(Close)

Injection Period

Injection Starting Pressure

Compression Pressure

Belt Drive

IC Type (Embedded in Generator

Max: 13L Min: 10L

12L

0.4 ㎜(in Cold Status)

0.4 ㎜(in Cold Status)

BTDC 19°

ABDC 47°

BBDC 57°

ATDC 15°

14° BTDC 14°

185 ㎏/㎝2

31 ㎏/㎝2(200rpm)

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-22-

1.3 Fuel System

Fuel system consists of fuel tank, filter, and fuel sensor device.

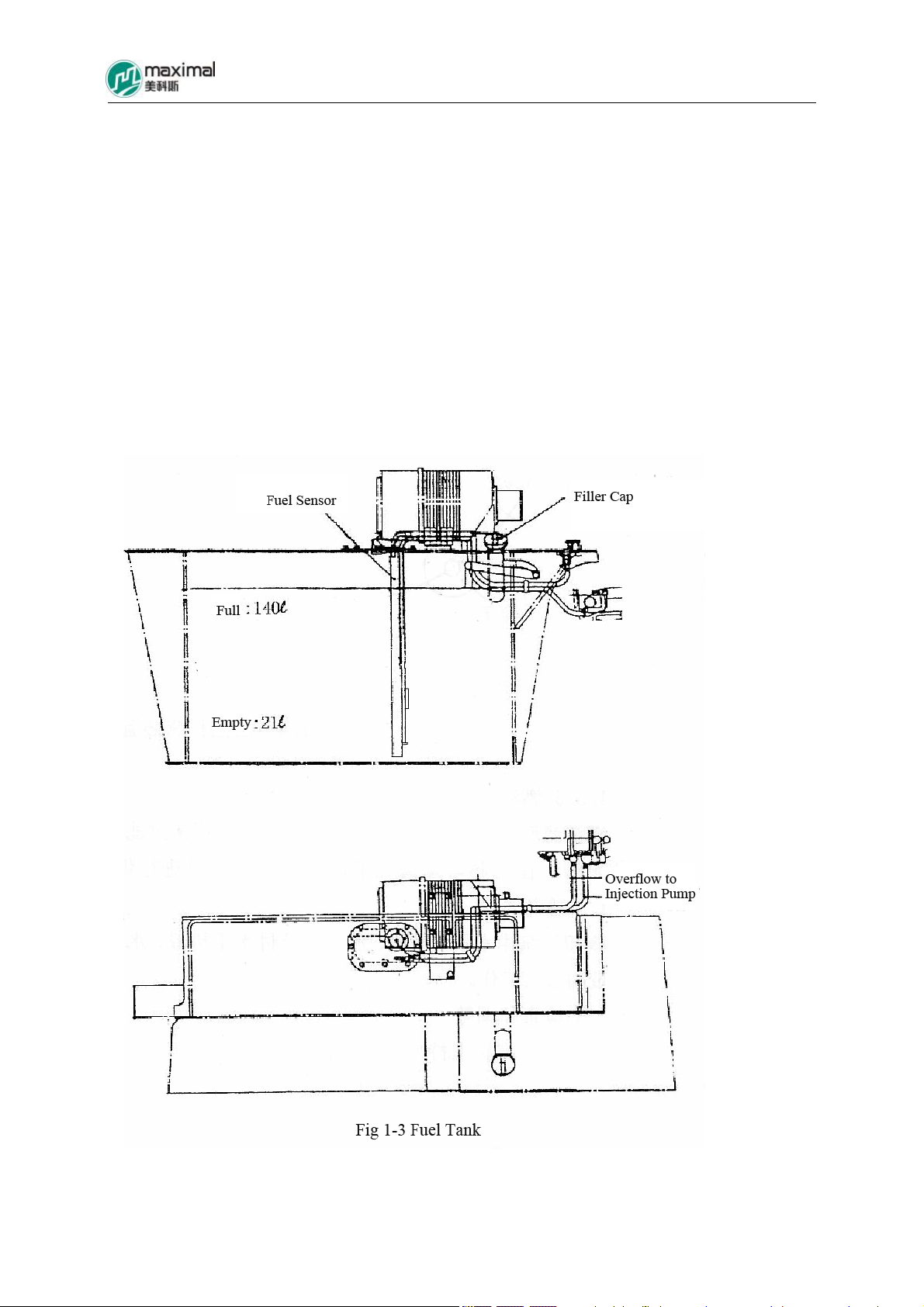

1.3.1 Fuel Tank

Fuel tank is a welded structure, connected with truck frame into a whole, mounted on the left

side of the truck frame, with fuel tank cover plate on top, and fuel sensor mounted on the plate.

Refer to Fig 1-3.

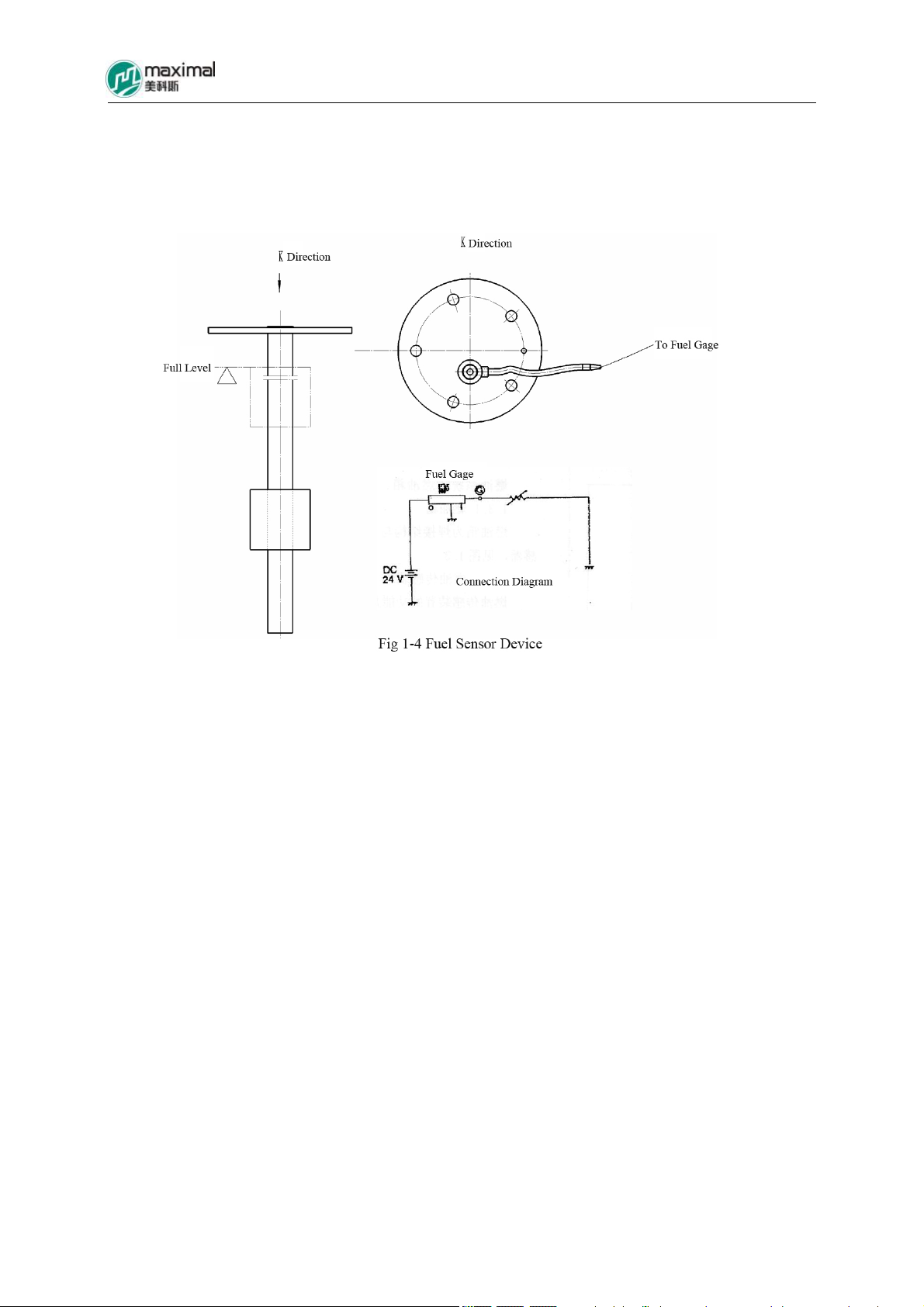

1.3.2 Fuel Sensor Device

The function of fuel sensor device is to transform the oil quantity stored in fuel tank into

current through up and down movement of float, to be ultimately responded to the fuel gage

on instrument panel, to allow people to visually understand the fuel quantity inside the fuel

tank. Refer to Fig 1-4.

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-23-

1.3.3 Fuel Filter

Fuel filter is mounted on the oil inlet manifold of engine, used to filter fuel to be supplied to

engine. Bypass valve is also mounted inside the filter, able to supply fuel to engine as well,

under the condition when core of filter is blocked.

1.4 Cooling System

Cooling system is composed of water pump, fan, radiator, and assistant radiator. Water pump

is installed on engine, and the crankshaft actuates the work of water pump through V-shaped

rubber belt.

1.5 Examination and Adjustment

In order for engine to maintain a good work status, it is required to carry out regular

examinations and adjustment to engine. The key points are given as follows:

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-24-

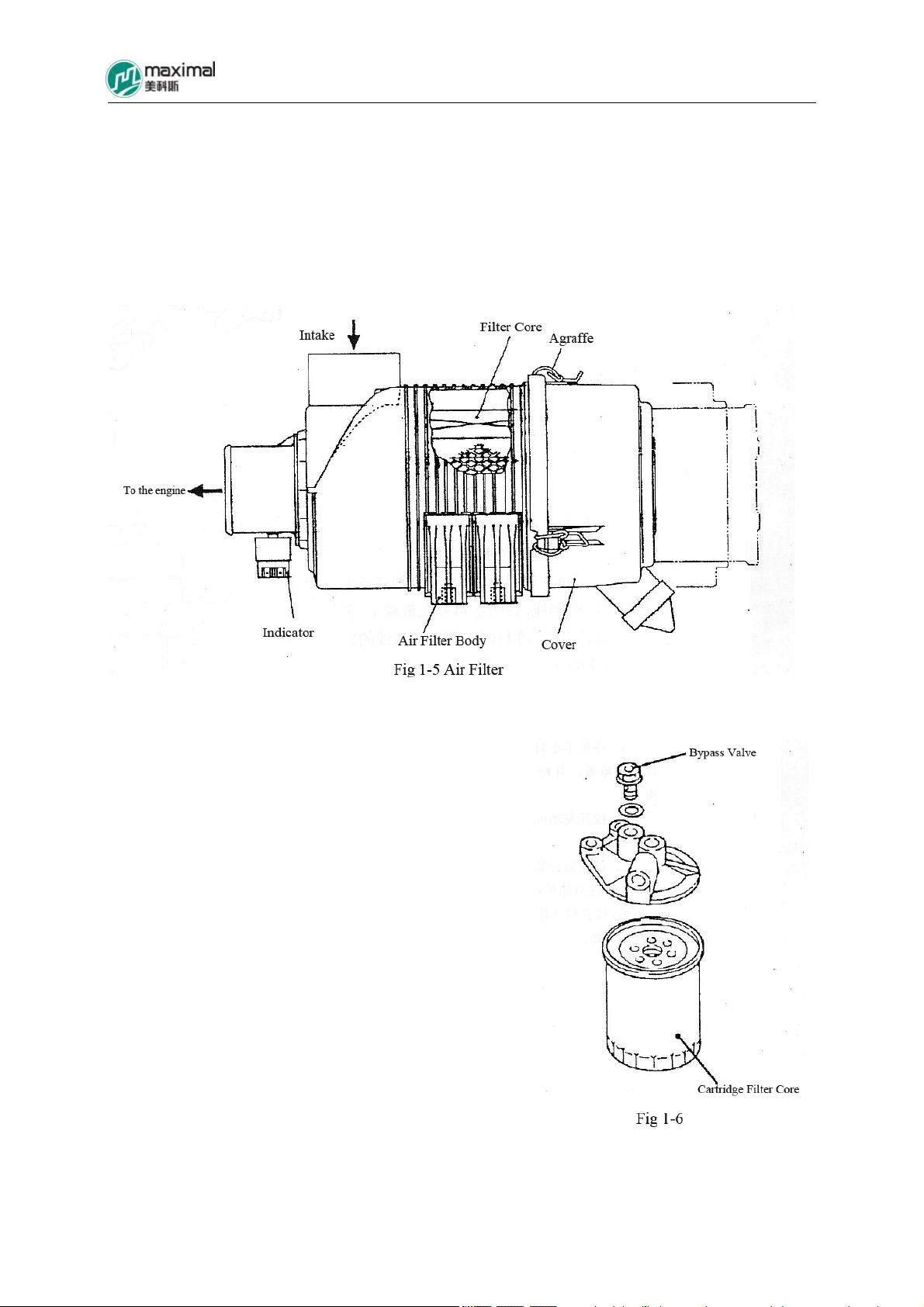

1.5.1 Refer to Fig 1-5 for air filter.

(1)Take out the core of filter.

(2)Examine the dust and damage status of core of filter. Firstly use low-pressure air to blow

from the inner side to the outer side, for cleaning, and the core of filter shall be replaced, if it

is severely block and cannot be cleaned or it has been damaged.

(3)Clean the dust inside the cover.

1.5.2 Refer to Fig 1-6 for fuel filter.

(1)Demount the fuel filter using special wrench, and it

shall be replaced, if damaged or blocked.

(2)Add several drips of fuel around the seal ring along

the new fuel filter and then mount it on. Further screw

it in for 2/3 circles, after seal ring has touched the

main body of fuel filter.

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-25-

1.5.3 Refer to Fig 1-7 for engine oil

filter.

(1)Detach the fuel filter using special

wrench and replace it.

(2)Fill several drips of lubricating oil

around the seal ring along the new

engine oil filter and then mount it on.

Further screw it in for 2/3 circles

after the seal ring has touched the

main body of the filter.

C

1.5.4 Cooling System

(1)Examine the coolant in the assistant radiator.

Refer to Fig 1-8 for assistant radiator, and it

indicates that the supply of radiator is reduced and

it is required to add coolant, when the level of

coolant is lower than the scale line of “LOW, and

it shall be added up to the place of 2/3 scale

between the upper and lower countermarks.

(2)Replace the coolant.

A. Open the radiator cover, after shutdown for

more than half an hour and until it has been

cooled down, and loosen the water drain valve on

the underside of radiator.

B. Loosen the water drain valve of engine, and

drain the coolant completely.

C. Tighten up the abovementioned two water

Fig 1-8

drain valves after coolant is completely drained.

D. Add the specified coolant, and examine that the liquid level of assistant radiator shall be in

the place 2/3 that of the upper and lower scale lines, after idle-speed operation for a while.

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-26-

(3)Adjust the fan belt.

The fan belt shall be tightened, if it gets loose. Refer

to Fig 1-9.

Procedure: Firstly loosen the fixed bolts B and C for

generator, and move the generator outwards. Press the

belt in the place of A with finger using a 10kg force,

and its deflection is at about 10mm. Then tighten the

bolts B and C in order.

Fig 1-9

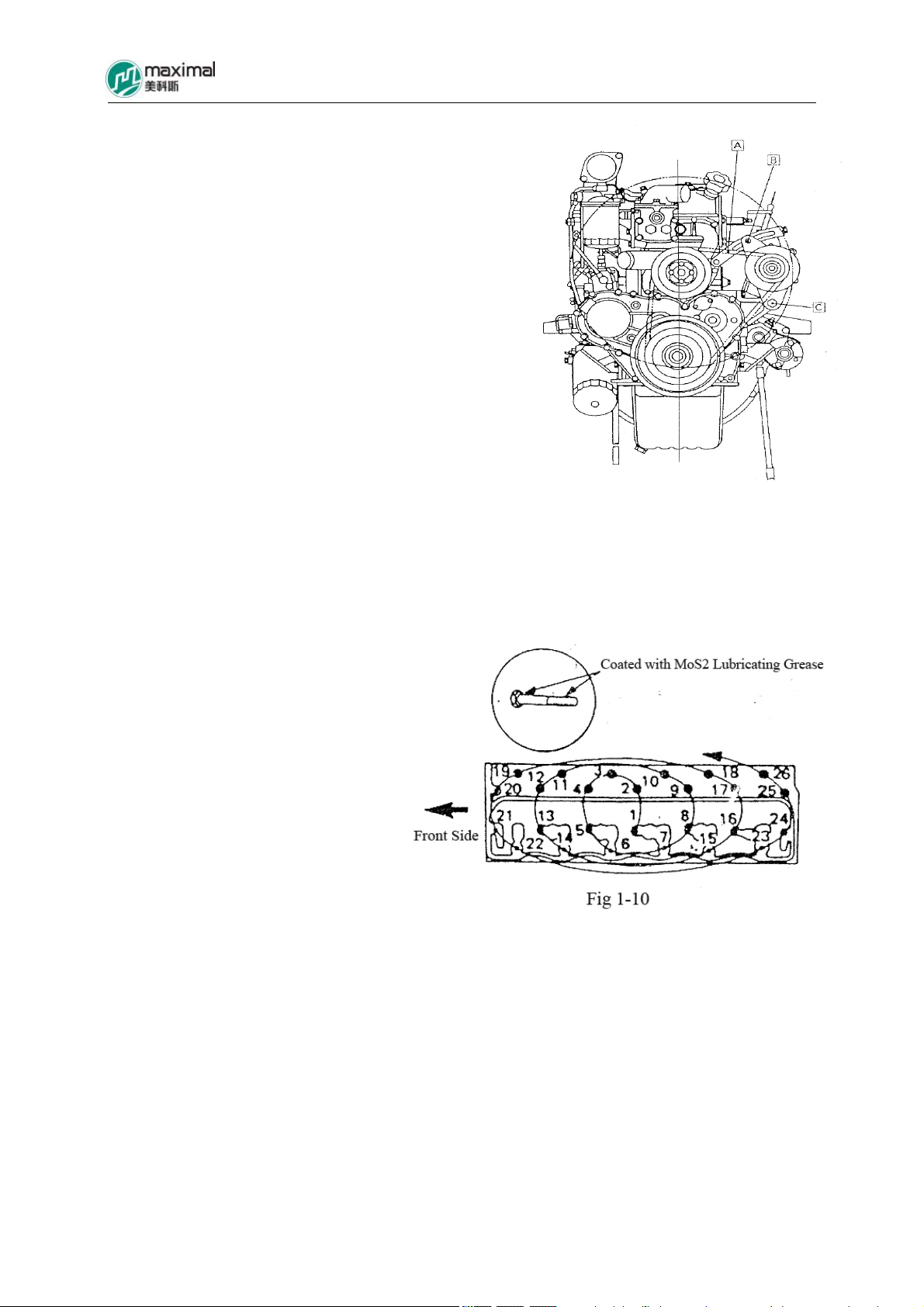

1.5.5 Fastening of Bolts for Engine

Cylinder Head

(1)Tighten the bolts for cylinder head

one by one at a 68Nm torque,

following the sequence as indicated

in Fig 1-10.

(2)Further increase the tightening

torque to 93Nm, and tighten

respective bolts one by one.

(3)Then turn respective bolts by 90°

and screw them down.

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-27-

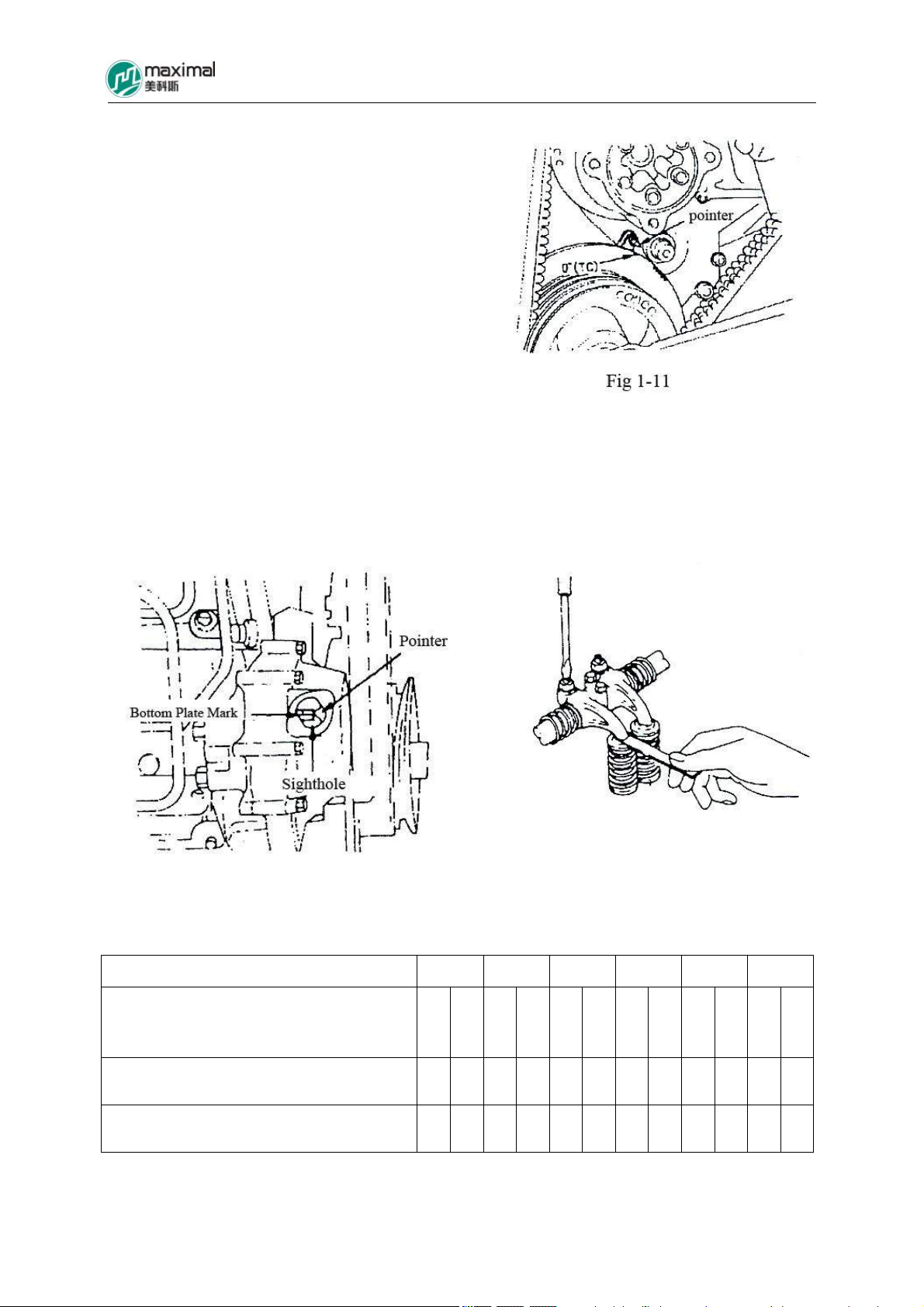

1.5.6 Adjustment of Valve Clearance

(1)Turn the crankshaft in the clockwise direction,

for the “TC” mark of belt pulley shock absorber

and the pointer to be superposed with each other.

(2)Open the inspection cover, and confirm the

positions of bottom plate mark and the pointer.

If the positions of bottom plate mark and the

pointer are consistent, it indicates upper dead

center of compression stroke for the 1st cylinder.

Adjust the valve clearance of “ ”△ countermark,

and adjust the valve clearance of “ ”※ countermark as well.

Valve Clearance Value: 0.4mm (the same value for both suction and exhaust, under the cold

status)

Refer to Figs 1-11, 1-12, and 1-13 for details.

Fig 1-12 Fig 1-13

Refer to Table 1-2 for specific adjustment.

Cylinder Sequence Number

Valve Sequence Number

I: Suction Valve

E: Exhaust Valve

Upper Center for 1st Cylinder Compression

Stroke

Upper Center for 6th Cylinder Compression

Stroke

1 2 3 4 5 6

I E I E I E I E I E I E

△ △ △ △ △ △ △

※ ※ ※ ※ ※

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-28-

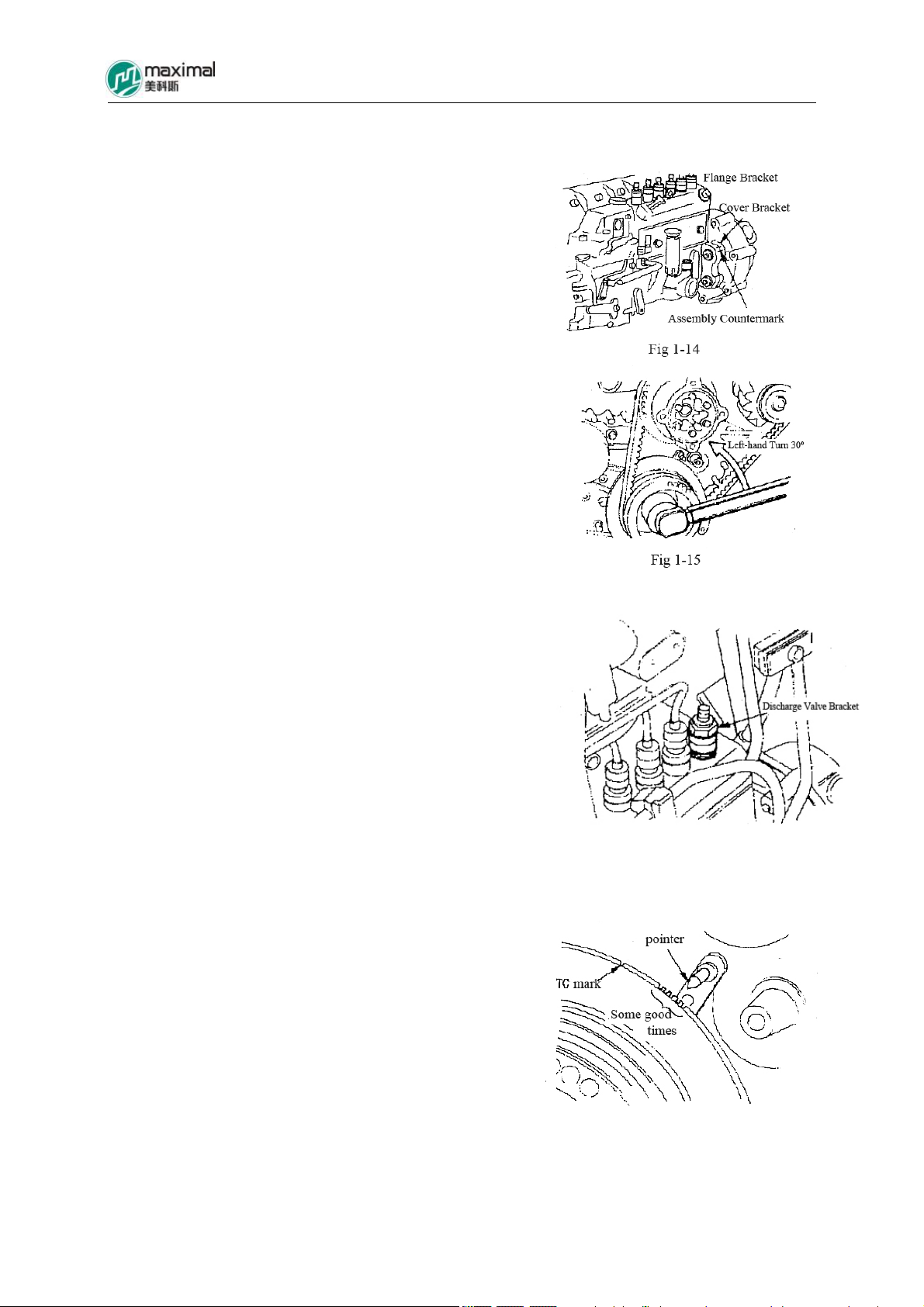

1.5.7 Confirmation of Ignition Time for Fuel Injection

(1)Firstly confirm whether or not the “Assembly

Countermark” in the place of flange for the injection

pump is consistent. Refer to Fig 1-14.

(2)Put the 1st cylinder at the position of upper dead

center for compression stroke, and turn the crankshaft

from this position in clockwise direction by about 30°.

Refer to Fig 1-15

(3)Loosen the injection pipe of the 1st cylinder, then

detach the spring and discharge valve on the bracket of

discharge valve, and then mount the bracket for

discharge valve on the fuel injection pump. Refer to Fig

1-16

(4)Slow turn the crankshaft in the clockwise direction,

at the same time while fuel feed pump is compressing

and delivering fuel, and stop turning the crankshaft

Fig 1-16

when the level of the first end for bracket of discharge

valve has risen to the stop position. Confirm the mark

of pointer symbol. Refer to Fig 1-17.

Fig 1-17

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-29-

1.5.8 Adjustment of Ignition Time for Fuel Injection

(1)Dismantle the pipe mounted on the injection pump (fuel and lubricating oil).

(2)Loosen the mounting bolts for the injection pump.

(3)Adjust towards the direction far away from engine in the “Advance” case, and adjust

towards the direction near to engine in the “Delay” case, at the same time while ignition time

is being confirmed according to the key points of 1.5.7.

(4)Tighten all the bolts assembled for injection pump, and confirm the ignition time again,

after adjustment is completed.

(5)Assemble the oil drain valve used for the first cylinder, and assemble the respective pipes

at their original separate positions.

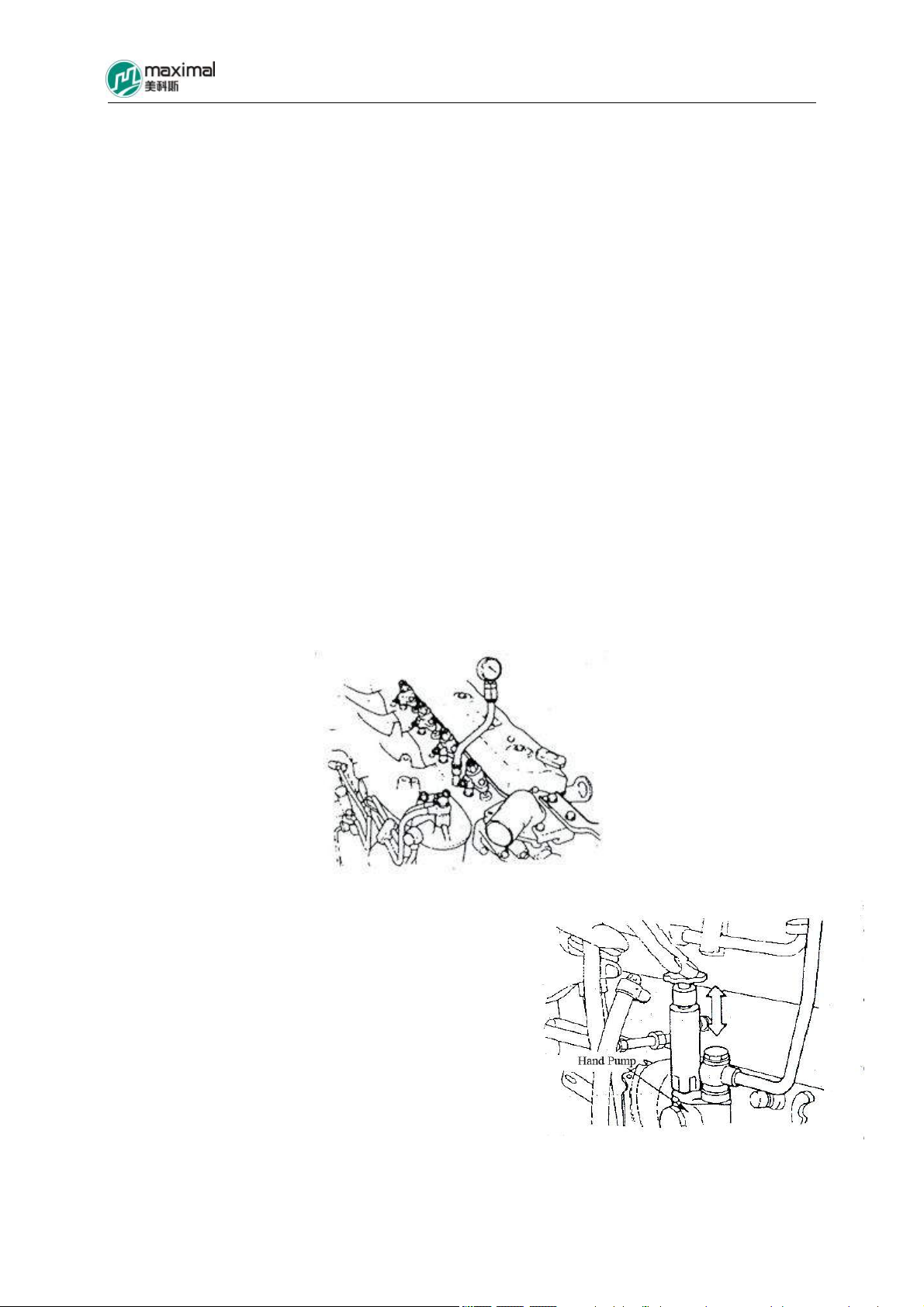

1.5.9 Determination of Compression Pressure (Refer to Fig 1-18.)

(1)Detach the heating spark plug and injection pipes totally.

(2)Fit on the pressure gauge in the assembling part for heating spark plug of the first cylinder

(calibrated value as 500N/㎝2).

(3)Use fully charged battery to allow the rotation of starting device, and measure the pressure

at this point.

(4)Measure up to the 6th cylinder with the same method, and measure for more than two times,

respectively. Then figure out their respective average values, Compression Pressure: 304N/㎝

2

(Limit Value 255N/㎝2)

Fig 1-18

1.5.10 Exhaust of Injection Pump (Refer to Fig

1-19.)

(1)Loosen the exhaust plug for injection pump.

(2)Operate the hand pump slowly, until no air

bubble appears in the place of exhaust plug.

(3)Then tighten the exhaust plug.

Fig 1-19

5-10t Internal Combustion Counterbalance Forklift Truck Operation & Maintenance Manual

-30-

2. Electrical System

2.1 Overview

Electrical system is a negative earthed single-wire circuit. It is compared to the “Nervous

System” of forklift trucks. The electrical system is mainly composed of several units as

follows (Electrical Schematic Diagram as indicated in Fig 2-1).

1) Charging System

It is composed of generator, battery, and charging indicator light, etc, to provide the forklift

trucks with power supply for power consumers, Voltage: DC24V.

2) Starting System

It is mainly comprised of preheating system, start switch, start protective circuit, and starter,

etc, and its function is to start engine.

3) Shutdown Control System

Shutdown control system mainly consists of start switch, flameout relay, and flameout stay

wire/flameout solenoid valve, etc.

4) Instrument System

It mainly includes hour meter, and oil quantity gage, as well as charging indicator light, oil

pressure indicator light, neutral position indicator light, air filter blockage warning light, and

oil-water separator indicator light, etc, as the test equipment on forklift truck.

5) Lighting and Signal Equipment

It includes various illuminations, signal lights and horn, as well as buzzer, etc.

Front Headlight: 70W

Front Combination Light (Steering/Width) 21W/8W

Rear Combination Light (Steering/Width/Reversing/Brake): 21W(Yellow) /8W(Yellow)

/10W(White) /21W(Red)

Caution Light (Optional Part): 21W

Rear Headlight (Optional Part): 70W

License Plate Light (Optional Part): 10W

Loading...

Loading...