19-3880; Rev 2; 1/10

భᄋຶৰۇ

᎖ೡࣞMFEདࣅࡼ

ಭሣါĂED.ED!QXN఼ᒜ

``````````````````````````````````` গၤ

NBY27912B0C0NBY27913B0Cဵೡࣞ)IC* MFEདࣅ఼

ᒜJDLjดݝ۞೫ଐጙৈၒྜྷᆍMFEདࣅჅኊࡼ

ཝݝ࢟വLjးᄰᑍීመာ።ăNBY27912ޟး

ᄰၒྜྷ)96WBDᒗ376WBDᑳഗ࢟ኹၒྜྷ*! MFEདࣅLj

NBY27913း᎖ࢅၒྜྷ࢟ኹ)21/9WEDᒗ35WED*!MFEད

ࣅă

ኊገறමࢯஂMFE࢟ഗဟLjభಽຢࡼᇙތࡍጲૺ

றࣞᆐ2&ࡼᓰăᄰࢅຫQXNೡࣞࢯஂభဣሚ୷ࡼ

ೡࣞࢯஂᆍă

NBY279120NBY27913ᎌၒྜྷ་ኹჄࢾ)VWMP*ᄂቶLjభ

ᒙၒྜྷࣅ࢟ኹLj݀భཀྵۣᏴ࢟Ꮞࢰൢဟᑵޟᔫă

NBY27912ᎌ୷ᒣૄ࢟ኹࡼดݝᔈ་ኹჄࢾ࢟വLj

଼࠭છ೫ಭሣါMFEདࣅࡼଐăNBY27913ดݝ

ᎌᑚৈᔈ࢟വLjభᒇᎅ,23W࢟ኹᄋມᒙ࢟Ꮞă

ดݝᆈࢯࡼ373lI{ৼࢾఎຫൈᏤᎁછኡᐋࠟቶᏄୈ

݆ᏄୈLj࠭ဣሚஜĂቶଥ܈ࡼMFEདࣅă

NBY27912B0NBY27913Bࡼᔢࡍᐴహ܈ᆐ61&LjNBY27912C0

NBY27913Cࡼᔢࡍᐴహ܈ᆐ86&ăᑚቋୈݧ9୭

®

μNBY

ᓤLjభᔫᏴ.51°Dᒗ,96°Dᆨࣞᆍă

``````````````````````````````````` ።

ಭሣါED.ED! MFEདࣅ

SHC۳Lj᎖MDE!UW

ପ၁

μ

NBYဵNbyjn! Joufhsbufe! Qspevdut-!Jod/ࡼᓖݿܪă

ጓᎧጓᑍී

ᓤြᎧᓔᑍී

``````````````````````````````````` ᄂቶ

♦ းcvdlĂcpptuĂgmzcbdlĂTFQJDᅠແ

♦ ࡉ61Xৎࡼၒ߲ൈ

♦ ᄰಭሣၒྜྷ࢟ኹᆍǖ

ᑳഗઁࡼ96WBDᒗ376WBD! )NBY27912*

♦ JO୭ᒇᎅ21/9WEDᒗ35WEDၒྜྷདࣅ)NBY27913*

♦ ดݝࡒᎌᇙތࡍ2&றࣞࡼᓰLjభဣሚறමࡼ

MFE࢟ഗࢯஂ

♦ QXNሣቶೡࣞࢯஂ

♦ 373lI{ ±23&ࡼৼࢾఎຫൈ

♦ ེࣥ

♦ ၫᔊྟࣅ

♦ భܠ߈ၒྜྷࣅ࢟ኹ

♦ ᎌ୷ᒣૄ࢟ኹࡼดݝᔈVWMP! )NBY27912*

♦ 56μB!)࢜ቯᒋ*ࣅ࢟Ꮞ࢟ഗLj2/5nB! )࢜ቯᒋ*

ᔫ࢟Ꮞ࢟ഗ

♦ 61&!)NBY27912B0NBY27913B*86&

)NBY27912C0NBY27913C*ᔢࡍᐴహ܈

♦ ݧᆈቯ9୭μNBYᓤ

``````````````````````````````` ࢾ৪ቧᇦ

PART

MAX16801AEUA+ -40°C to +85°C 8 μMAX

MAX16801BEUA+ -40°C to +85°C 8 μMAX

MAX16802AEUA+ -40°C to +85°C 8 μMAX

MAX16802BEUA+ -40°C to +85°C 8 μMAX

,

ܭာᇄᓤă

TEMP

RANGE

PINPACKAGE

NBY27912B0C0NBY27913B0C

`````````````````````````````````````````````````````````````````````` ࢜ቯᔫ࢟വ

10.8VDC TO 24VDC

ENABLE

PWM

வসǖNBY279120NBY27913ଐᔫ᎖ኹሆLjᓖፀቃቦݷᔫă

________________________________________________________________ Maxim Integrated Products 1

۾ᆪဵ፞ᆪၫᓾ೯ࡼፉᆪLjᆪᒦభถࡀᏴፉࡼݙᓰཀྵࡇᇙăྙኊጙݛཀྵཱྀLj༿Ᏼิࡼଐᒦݬఠ፞ᆪᓾ೯ă

ᎌଥৃĂૡૺࢿ৪ቧᇦLj༿ೊNbyjnᒴሾ၉ᒦቦǖ21911!963!235:!)۱ᒦཌ*Lj21911!263!235:!)ฉᒦཌ*Lj

ᆰNbyjnࡼᒦᆪᆀᐶǖdijob/nbyjn.jd/dpnă

UVLO/EN IN

DIM/FB

MAX16802B

COMP

CS

GND

V

NDRV

GND

LEDs

L1

CC

Q1

C1 R1

C2

C3

D1

᎖ೡࣞMFEདࣅࡼ

ಭሣါĂED.ED!QXN఼ᒜ

ABSOLUTE MAXIMUM RATINGS

IN to GND

V

CC

..........................................................................

to GND

......................................................................

-0.3V to +30V

-0.3V to +13V

DIM/FB, COMP, UVLO/EN, CS to GND....................-0.3V to +6V

NDRV to GND.............................................-0.3V to (V

Continuous Power Dissipation (T

= +70°C)

A

CC

+ 0.3V)

8-Pin μMAX (derate 4.5mW/°C above +70°C) ..............362mW

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

ELECTRICAL CHARACTERISTICS

(VIN= +12V (MAX16801: VINmust first be brought up to +23.6V for startup), 10nF bypass capacitors at IN and VCC, C

V

UVLO/EN

are at T

UNDERVOLTAGE LOCKOUT/STARTUP

Bootstrap UVLO Wake-Up Level V

Bootstrap UVLO Shutdown Level V

UVLO/EN Wake-Up Threshold V

UVLO/EN Shutdown Threshold V

NBY27912B0C0NBY27913B0C

UVLO/EN Input Current I

UVLO/EN Hysteresis 50 mV

IN Supply Current In

Undervoltage Lockout

IN Voltage Range V

UVLO/EN Propagation Delay

Bootstrap UVLO Propagation

Delay

INTERNAL SUPPLY

VCC Regulator Set Point V

IN Supply Current After Startup I

Shutdown Supply Current UVLO/EN = low 90 μA

GATE DRIVER

Driver Output Impedance

Driver Peak Sink Current 1A

Driver Peak Source Current 0.65 A

PWM COMPARATOR

Comparator Offset Voltage VO

CS Input Bias Current I

Comparator Propagation Delay t

Minimum On-Time t

= +1.4V, V

= +25°C.) (Note 1)

A

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

= +1.0V, COMP = unconnected, VCS= 0V, TA= -40°C to +85°C, unless otherwise noted. Typical values

DIM/FB

SUVR

SUVF

ULR2

ULF2

UVLO

I

START

t

EXTR

t

EXTF

t

BUVR

t

BUVF

CCSP

IN

R

ON(LOW)

R

ON(HIGH)

PWMVCOMP

CS

PWM

ON(MIN)

VIN rising (MAX16801 only) 19.68 21.6 23.60 V

VIN falling (MAX16801 only) 9.05 9.74 10.43 V

UVLO/EN rising 1.188 1.28 1.371 V

UVLO/EN falling 1.168 1.23 1.291 V

TJ = +125°C 25 nA

VIN = +19V, for MAX16801 only when in

bootstrap UVLO

IN

UVLO/EN steps up from +1.1V to +1.4V 12

UVLO/EN steps down from +1.4V to +1.1V 1.8

VIN steps up from +9V to +24V 5

VIN steps down from +24V to +9V 1

VIN = +10.8V to +24V, sinking 1μA to 20mA

from V

CC

VIN = +24V 1.4 2.5 mA

Measured at NDRV sinking, 100mA 2 4

Measured at NDRV sourcing, 20mA 4 12

- V

CS

VCS = 0V -2 +2 μA

VCS = +0.1V 60 ns

Operating Temperature Range ...........................-40°C to +85°C

Storage Temperature Range ............................-65°C to +150°C

Junction Temperature......................................................+150°C

Lead Temperature (soldering, 10s) .................................+300°C

= 0μF,

NDRV

45 90 μA

10.8 24 V

μs

μs

7 10.5 V

Ω

1.15 1.38 1.70 V

150 ns

2 _______________________________________________________________________________________

᎖ೡࣞMFEདࣅࡼ

ಭሣါĂED.ED!QXN఼ᒜ

ELECTRICAL CHARACTERISTICS (continued)

(VIN= +12V (MAX16801: VINmust first be brought up to +23.6V for startup), 10nF bypass capacitors at IN and VCC, C

V

UVLO/EN

are at T

CURRENT-SENSE COMPARATOR

Current-Sense Trip Threshold V

CS Input Bias Current I

Propagation Delay From

Comparator Input to NDRV

Switching Frequency f

Maximum Duty Cycle D

IN CLAMP VOLTAGE

IN Clamp Voltage V

ERROR AMPLIFIER

Voltage Gain R

Unity-Gain Bandwidth R

Phase Margin R

DIM/FB Input Offset Voltage 3mV

COMP Clamp Voltage

Source Current 0.5 mA

Sink Current 0.5 mA

Reference Voltage V

Input Bias Current 50 nA

COMP Short-Circuit Current 8mA

THERMAL SHUTDOWN

Thermal-Shutdown Temperature 130 °C

Thermal Hysteresis 25 °C

DIGITAL SOFT-START

Soft-Start Duration 15,872

Reference Voltage Steps During

Soft-Start

Reference Voltage Step 40 mV

Note 1: All devices are 100% tested at TA= +85°C. All limits over temperature are guaranteed by characterization.

Note 2: V

Note 3: The MAX16801 is intended for use in universal input offline drivers. The internal clamp circuit is used to prevent the boot-

= +1.4V, V

= +25°C.) (Note 1)

A

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

is measured with DIM/FB connected to the COMP pin (see the Functional Diagram).

REF

strap capacitor (C1 in Figure 5) from charging to a voltage beyond the absolute maximum rating of the device when

UVLO/EN is low. The maximum current to IN (hence to clamp) when UVLO/EN is low (device in shutdown), must be externally limited to 2mA (max). Clamp currents higher than 2mA may result in clamp voltage higher than +30V, thus exceeding

the absolute maximum rating for IN. For the MAX16802, do not exceed the +24V maximum operating voltage of the device.

= +1.0V, COMP = unconnected, VCS= 0V, TA= -40°C to +85°C, unless otherwise noted. Typical values

DIM/FB

262 291 320 mV

230 262 290 kHz

31 Steps

CS

t

PWM

SW

MAX

INC

REF

CS

VCS = 0V -2 +2 μA

50mV overdrive 60 ns

MAX1680_A 50 50.5

MAX1680_B 75 76

2mA sink current, MAX16801 only (Note 3) 24.1 26.1 29.0 V

= 100kΩ 80 dB

LOAD

= 100kΩ, C

LOAD

= 100kΩ, C

LOAD

High 2.2 3.5

Low 0.4 1.1

(Note 2) 1.218 1.230 1.242 V

= 200pF 2 MHz

LOAD

= 200pF 65 D eg r ees

LOAD

NDRV

= 0μF,

%

V

Clock

cycles

NBY27912B0C0NBY27913B0C

_______________________________________________________________________________________ 3

᎖ೡࣞMFEདࣅࡼ

ಭሣါĂED.ED!QXN఼ᒜ

`````````````````````````````````````````````````````````````````````` ࢜ቯᔫᄂቶ

(V

UVLO/EN

= +1.4V, V

= +1V, COMP = unconnected, VCS= 0V, TA= +25°C, unless otherwise noted.)

DIM/FB

BOOTSTRAP UVLO WAKE-UP LEVEL

vs. TEMPERATURE

21.60

21.55

21.50

(V)

21.45

IN

V

21.40

21.35

21.30

-40 80

MAX16801 VIN RISING

MAX16801 toc01

6040200-20

TEMPERATURE (°C)

UVLO/EN SHUTDOWN THRESHOLD

vs. TEMPERATURE

1.30

NBY27912B0C0NBY27913B0C

1.25

1.20

UVLO/EN (V)

1.15

1.10

-40 80

TEMPERATURE (°C)

UVLO/EN FALLING

MAX16801 toc04

6040200-20

BOOTSTRAP UVLO SHUTDOWN LEVEL

vs. TEMPERATURE

10.1

10.0

(V)

9.9

IN

V

9.8

9.7

-40 80

TEMPERATURE (°C)

VIN SUPPLY CURRENT IN UNDERVOLTAGE

LOCKOUT vs. TEMPERATURE

52

VIN = 19V

51

MAX16801 WHEN IN BOOTSTRAP UVLO

MAX16802 WHEN UVLO/EN IS LOW

50

49

48

(μA)

47

START

I

46

45

44

43

42

-40 80

TEMPERATURE (°C)

MAX16801 VIN FALLING

6040200-20

6040200-20

MAX16801 toc02

MAX16801 toc05

UVLO/EN WAKE-UP THRESHOLD

vs. TEMPERATURE

1.280

1.275

1.270

1.265

UVLO/EN (V)

1.260

1.255

1.250

-40 80

TEMPERATURE (°C)

VIN SUPPLY CURRENT AFTER STARTUP

vs. TEMPERATURE

1.5

1.4

(mA)

1.3

IN

I

1.2

1.1

-40 80

TEMPERATURE (°C)

UVLO/EN RISING

MAX16801 toc03

6040200-20

VIN = 24V

MAX16801 toc06

6040200-20

VCC REGULATOR SET POINT

vs. TEMPERATURE

9.8

9.7

NDRV OUTPUT IS NOT

SWITCHING, V

9.6

(V)

9.5

CC

V

9.4

9.3

9.2

-40 80

NDRV OUTPUT IS

SWITCHING

= 1.5V

DIM/FB

TEMPERATURE (°C)

VIN = 19V

NO LOAD

6040200-20

MAX16801 toc07

(V)

V

VCC REGULATOR SET POINT

vs. TEMPERATURE

8.9

8.8

8.7

8.6

8.5

CC

8.4

8.3

8.2

8.1

-40 80

TEMPERATURE (°C)

VIN = 10.8V

10mA LOAD

20mA LOAD

6040200-20

310

305

MAX116801 toc08

300

295

290

285

280

CURRENT-SENSE THRESHOLD (mV)

275

270

CURRENT-SENSE THRESHOLD

vs. TEMPERATURE

+3σ

MEAN

-3σ

-40 80

TEMPERATURE (°C)

4 _______________________________________________________________________________________

TOTAL NUMBER OF

DEVICES = 100

6040200-20

MAX16801 toc09

᎖ೡࣞMFEདࣅࡼ

ಭሣါĂED.ED!QXN఼ᒜ

``````````````````````````````````````````````````````````````````````````` ࢜ቯᔫᄂቶ)ኚ*

(V

UVLO/EN

PERCENTAGE OF UNITS (%)

(ns)

PWM

t

= +1.4V, V

= +1V, COMP = unconnected, VCS= 0V, TA= +25°C, unless otherwise noted.)

DIM/FB

CURRENT-SENSE THRESHOLD

30

25

20

15

10

5

0

260 320

CURRENT-SENSE THRESHOLD (mV)

TOTAL NUMBER OF

DEVICES = 200

310300290280270

PROPAGATION DELAY FROM

CURRENT-SENSE COMPARATOR INPUT

TO NDRV vs. TEMPERATURE

75

70

65

60

55

50

-40 80

TEMPERATURE (°C)

6040200-20

280

+3σ

275

MAX16801 toc10

270

265

MEAN

260

255

250

SWITCHING FREQUENCY (kHz)

MAX16801 toc13

-3σ

245

240

-40 80

14

13

12

11

10

9

8

7

6

5

4

3

2

UNDERVOLTAGE LOCKOUT DELAY (μs)

1

0

-40 80

SWITCHING FREQUENCY

vs. TEMPERATURE

TOTAL NUMBER OF

DEVICES = 100

6040200-20

TEMPERATURE (°C)

UVLO/EN PROPAGATION DELAY

vs. TEMPERATURE

UVLO/EN RISING

UVLO/EN FALLING

6040200-20

TEMPERATURE (°C)

30

25

MAX16801 toc11

20

15

10

PERCENTAGE OF UNITS (%)

5

0

230 290

1.230

VIN = 12V

1.229

MAX16801 toc14

1.228

1.227

REFERENCE VOLTAGE (V)

1.226

1.225

-40 80

SWITCHING FREQUENCY

TOTAL NUMBER OF

DEVICES = 200

SWITCHING FREQUENCY (kHz)

REFERENCE VOLTAGE

vs. TEMPERATURE

TEMPERATURE (°C)

280270260250240

6040200-20

NBY27912B0C0NBY27913B0C

MAX16801 toc12

MAX16801 toc15

INPUT CURRENT

vs. INPUT VOLTAGE

10

9

8

7

6

5

4

INPUT CURRENT (mA)

3

2

1

0

10.0 30.0

INPUT VOLTAGE (V)

_______________________________________________________________________________________ 5

INPUT CLAMP VOLTAGE

vs. TEMPERATURE

27.0

26.8

MAX16801 toc16

26.6

26.4

26.2

26.0

25.8

25.6

INPUT CLAMP VOLTAGE (V)

25.4

25.2

27.525.020.0 22.515.0 17.512.5

25.0

-40 80

TEMPERATURE (°C)

IIN = 2mA

6040200-20

MAX16801 toc17

2.2

2.1

2.0

1.9

1.8

(Ω)

1.7

ON

R

1.6

1.5

1.4

1.3

1.2

NDRV OUTPUT IMPEDANCE

vs. TEMPERATURE

VIN = 24V

SINKING 100mA

-40 80

TEMPERATURE (°C)

6040200-20

MAX16801 toc18

᎖ೡࣞMFEདࣅࡼ

ಭሣါĂED.ED!QXN఼ᒜ

```````````````````````````````````````````````````````````````````````````` ࢜ቯᔫᄂቶ)ኚ*

(V

UVLO/EN

= +1.4V, V

= +1V, COMP = unconnected, VCS= 0V, TA= +25°C, unless otherwise noted.)

DIM/FB

NDRV OUTPUT IMPEDANCE

5.0

4.8

4.6

4.4

4.2

(Ω)

4.0

ON

R

3.8

3.6

3.4

3.2

3.0

-40 80

vs. TEMPERATURE

VIN = 24V

SOURCING 20mA

TEMPERATURE (°C)

MAX16801 toc19

6040200-20

ERROR-AMPLIFIER OPEN-LOOP GAIN

120

100

GAIN (dB)

-20

-40

-60

-80

-100

AND PHASE vs. FREQUENCY

80

60

40

20

0 -70

0.1 100M

GAIN

PHASE

FREQUENCY (Hz)

MAX16801 toc20

50

30

10

-10

-30

-50

-90

PHASE (DEGREES)

-110

-130

-150

-170

10M1M10k1k 100k10 1001

`````````````````````````````````````````````````````````````````````````` ୭ႁී

୭

NBY27912B0C0NBY27913B0C

1 UVLO/EN

2 DIM/FB

3 COMP

߂ ถ

ᅪݝభܠ߈་ኹჄࢾăVWMPᒙၒྜྷࣅ࢟ኹăVWMPೌᒗHOEభணᒏୈᔫă

ࢅຫQXNೡࣞࢯஂၒྜྷ0ᇙތࡍሤၒྜྷ࣡ă

ᇙތࡍၒ߲ăᏴறࣞMFE࢟ഗࢯஂ።ᒦLjݗޡᏄୈೌᏴEJN0GCDPNQᒄମă

4CS

5 GND

6 NDRV

7V

CC

࢟ഗঢ።ቧೌ࣡Lj᎖࢟ഗࢯஂăᒗଶഗ࢟ᔜ࣡ăభጲSD݆߹བྷ༄ዘࡼඇࠦă

࢟Ꮞă

ᅪݝoࡸNPTGFUᐜೌ࣡ă

ᐜདࣅ࢟ᏎăดݝᎅJOଢ଼ኹࡻࡵăW

ᎧHOEମጙᒑ21oGྏᒋৎࡼབྷẮ࢟ྏă

DD

JD࢟ᏎăJOᎧHOEମጙᒑ21oGྏᒋৎࡼབྷẮ࢟ྏăᔈᔫෝါ)NBY27912*ሆLjభᏴၒྜྷ࢟Ꮞ

8IN

JOᒄମጙৈࣅ࢟ᔜăມᒙླྀᔝ࢟Ꮞೌᒗক࢛)ݬᅄ6*ă࣪᎖NBY27913LjJOᒇ,21/9Wᒗ,35W

࢟Ꮞă

``````````````````````````````` ሮᇼႁී

NBY279120NBY27913ᇹୈ᎖ೡࣞ)IC*! MFEࡼ

ഗདࣅLjးᄰᑍීመာ።ăকᇹୈᓜᆐ

ಭಭ࢟വᅠແଐLjྙcvdlĂcpptuĂgmzcbdl

TFQJDࢀLjᔫᏴೌኚೌኚෝါăఎຫൈᏴดݝᆈ

ࢯᆐ373lI{ৼࢾᒋLjభဣሚ࢟ഗෝါ఼ᒜăᎌ୷ᒣ

ૄ࢟ኹ)22/:W*ࡼᔈVWMP࢟വĂިࢅࣅ࢟ഗጲૺࢅ

ᔫ࢟ഗᄂቶLjభဣሚࡼᄰၒྜྷMFEདࣅăকᇹ

ୈ߹ดᒙᔈVWMPᅪLjથถᄰVWMP0FO୭࣪ၒྜྷ

ࣅ࢟ኹቲܠ߈ᒙăNBY27912ޟးᄰୣഗၒ

ྜྷ)96WBDᒗ376WBDᑳഗ࢟ኹၒྜྷ* དࣅăNBY27913

ޟးࢅၒྜྷ࢟ኹ)21/9WEDᒗ35WED*።ă

NBY279120NBY27913ᓆᒲ໐ପ၁ഗᅪݝNPTGFUࡼ࢟

ഗLj࠭ဣሚ࣪MFE࢟ഗࡼࢯஂă

6 _______________________________________________________________________________________

᎖ೡࣞMFEདࣅࡼ

ಭሣါĂED.ED!QXN఼ᒜ

ࡩᔫᏴࡒᎌܤኹࡼᔈෝါဟ)ᅄ6*Ljক࢟വથభᄋ

ࡍࣶၫവ৺ᑇۣઐăࡩ߲ሚവ৺ᑇဟLjྯླྀᔝ

࢟ኹଢ଼ᒗ,21WጲሆLjᒘဧVWMP࢟വܕᅪݝ

NPTGFUࡼᐜདࣅቧăᑚ્ᒮቤ߿ጙࠨྟࣅ߈ă

ྦኊገறමࢯஂMFE࢟ഗLjభಽຢᇙތࡍጲૺற

ࣞᆐ2&ࡼᓰ)ᅄ:*ăᑚጙᅪౣభࡍࡍଢ଼ࢅᎅ᎖ᇄᏎ

ᏄୈܤછມތჅޘညࡼ፬ሰLj݀༦ᒑኊᔢࡼᅪᆍᏄ

ୈ૾భဣሚă

ࢅຫQXNೡࣞࢯஂቧᒇౣྜྷEJN0GC୭భဣሚ

ᆍࡼೡࣞࢯஂă

᎖NBY27912ଐࡼMFEདࣅ࢟വݧጙৈᒋࣅ࢟

ᔜS2ᆐถ࢟ྏD2ߠ࢟)ᅄ6ᅄ:*ăᏴ߱ဪࣤLjߠ࢟

࢟ኹࢅ᎖ดݝᔈVWMPඡሢ࢟ኹLjୈሿࡼஸზ࢟ഗ

ஞᆐ56μB )࢜ቯᒋ*ăࢅࣅ࢟ഗ୷ᒣૄ࢟ኹࡼᔈ

VWMPభࡍࡍଢ଼ࢅS2ࡼLj૾ܣဵᏴᄰୣഗၒྜྷ࢟ኹ

ᆡ᎖࣡ဟጐቃă

ࡩበຢஉᆨި,241°D )࢜ቯᒋ*ဟLjดᒙࡼࣥ࢟വభ

ࣅۣઐถă

ೡࣞࢯஂ

ሣቶೡࣞࢯஂဵᄰᏴDTࡼጙৈཇஂ࢛ဣሚࡼLj

ྙᅄ7ᅄ8Ⴥာă

ࢅຫQXN )࢟ഗᐮ݆*ೡࣞࢯஂᐌᄰᏴୈࡼEJN0GC

୭ဗଝጙৈሤ൝QXNቧဣሚ)ᅄ9*ăᑚᒬ

࣪᎖กቋገཇࢯஂೡࣞဟዏৃۣߒໍݙܤࡼ።ޝ

ጐ્ဵ၅ኡښăဵᄰ࣪ࢾࣞࡼMFE࢟ഗቲ

ᐮ݆ဣሚࢯࡼă

NBY279120NBY27913ࡼມᒙ

ࡩܤኹࡀᏴဟLjᎅܤኹဣሚᔈ)ᅄ6*ăݧಭ

ါᅠແဟጐభᒇᎅMFEޘညມᒙ)ᅄ2*ă

NBY27912B0C0NBY27913B0C

R1

V

CC

IN GND

AC

IN

BRIDGE

RECTIFIER

COMP

C1

C2 C3

DIM/FB

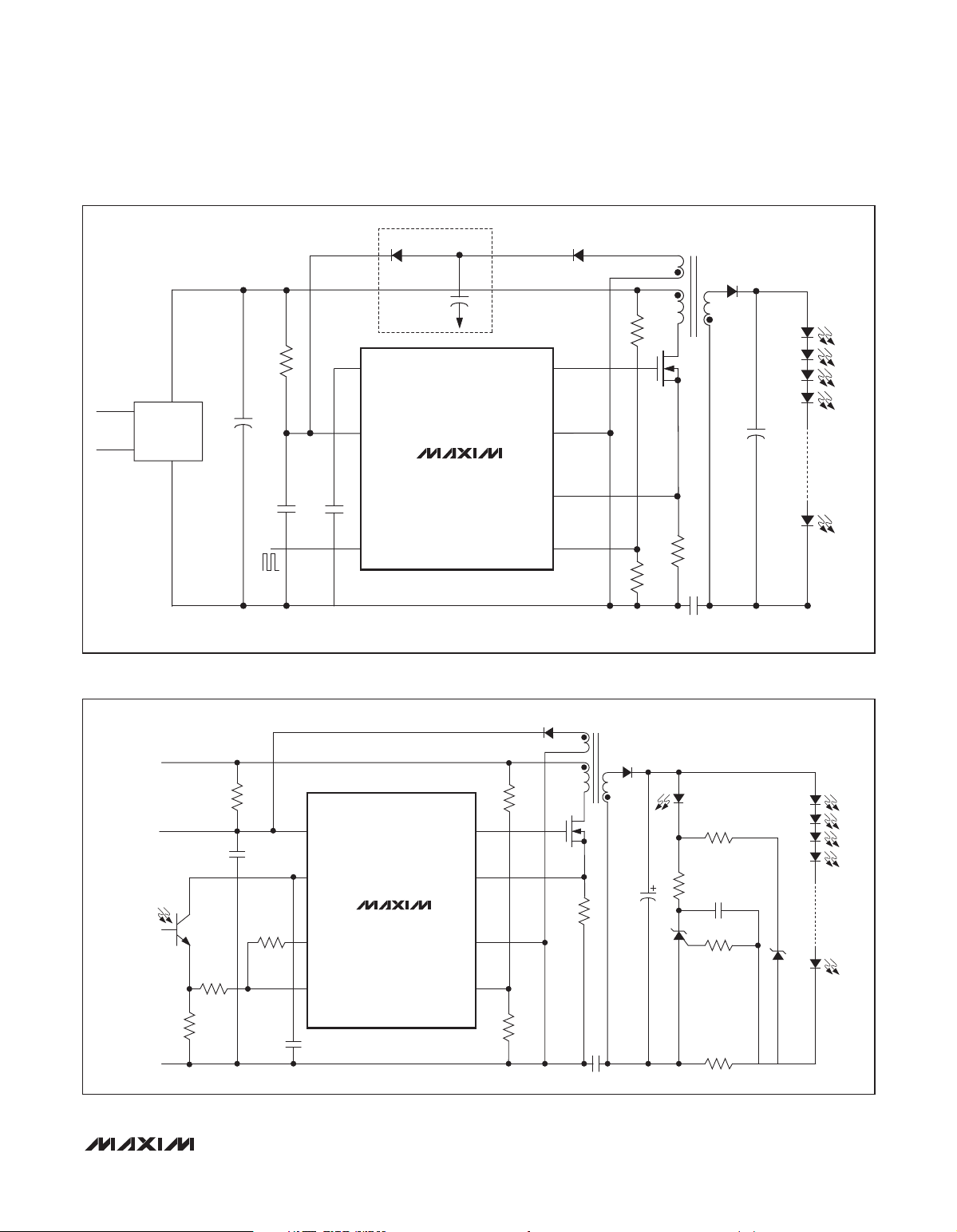

ᅄ2/! ᏴಭቯgmzcbdlདࣅᒦಽMFEᆐJDᄋມᒙ

MAX16801B

NDRV

UVLO/EN

R5

R2

CS

R6

Q1

R3

R4

L1

C4

D3

TOTAL LED VOLTAGE:

11V TO 23V

_______________________________________________________________________________________ 7

᎖ೡࣞMFEདࣅࡼ

ಭሣါĂED.ED!QXN఼ᒜ

VDC

VDC

R

IN

D

(a)

ᅄ3/! )b*࢟ᔜ.ฃ)c*ᄏ.ฃ.࢟ᔜມᒙ࢟വ

MAX16802A

NBY27913భᒇᎅ21/9WEDᒗ35WEDၒྜྷ࢟ኹቲມᒙă

ಽ࢟ᔜ.ฃ)ᅄ3b*ᄏ.ฃ.࢟ᔜ

ມᒙ࢟വ)ᅄ3c*LjNBY27913ጐభᏴৎᒇഗၒྜྷ࢟

ኹࡼޝă

NBY279120NBY27913་ኹჄࢾ

NBY27912B0C0NBY27913B0C

NBY279120NBY27913ᎌጙৈၒྜྷ࢟ኹVWMP0FO୭ă

VWMPඡሢ࢟ኹᆐ,2/39WăᒑᎌᏴক୭࢟ኹࡍ᎖,2/39W

ઁ࢟വݣఎဪᔫăVWMP࢟വభဧDQXN܈୷ĂJMJN

܈୷Ăᑩጲૺၒ߲དࣅࠀ᎖ࣥᓨზLjጲି

࢟ഗሿ)ݬ

ࣅ࢟ኹăኹ࢟ᔜS3S4 )ᅄ6*ᔜᒋࡼଐႯါྙሆǖ

ถౖᅄ

*ăಽকVWMPถభᒙၒྜྷ

R

Q

IN

DC

(b)

MAX16802A

NBY27912ᔈ་ኹჄࢾ

߹೫NBY279120NBY27913ᎌࡼᅪݝభܠ߈VWMPᅪLj

NBY27912થดᒙጙৈᅪࡼᔈVWMPLjᏴଐኹ

MFEདࣅဟޟᎌ)ݬ

߱ဪ࢟ဟᔈቲࣅăࡩW

,34/7WဟLjNBY27912ఎဪࣅăࣅ໐ମLjVWMP࢟വ

ۣߒDQXN܈୷ĂJMJN܈୷Ăᑩጲૺၒ߲དࣅ

ࠀ᎖ࣥᓨზLjጲିቃ࢟ഗሿăጙࡡW

VWMP࢟വࣅDQXN܈୷ĂJMJN܈୷ᑩLj݀

Ꮴၒ߲དࣅఎဪఎݷᔫăྙW

VWMP࢟വᐌࣥDQXN܈୷ĂJMJN܈୷Ăᑩጲ

ૺၒ߲དࣅLj࠭ဧNBY27912ૄᒗࣅෝါă

ถౖᅄ

JO

*ăᑚዹᏤୈᏴ

᎖ᔈVWMPඡሢ࢟ኹ

ࡉࡵ,34/7WLj

JO

ଢ଼ᒗ,:/8WጲሆLj

JO

VV

R

3

≅

500

ULR IN

IVV

×

UVLO IN ULR

ኡᐋS4ᔜᒋဟLj።ဧVWMP0FOၒྜྷມᒙ࢟ഗᏴS3ࡼኹ

ଢ଼ჅޘညࡼᇙތᔢࢅăW

)ᔢࡍᒋ*LjW

ဵ࢟Ꮞࣅဟࡼၒྜྷ࢟Ꮞ࢟ኹᒋă

JO

VV

IN ULR

R

23

=×

×

2

−

()

> ,2/39WLjJ

VMS3

−

2

V

ULR

2

2

> 61oB

VWMP

R

NBY27912ࣅᔫෝါ

ᏴಭါMFEདࣅ።ᒦLjWJOནᔈܤኹࡼྯླྀᔝă

Ljࣅဟܤኹᒦᎌ࢟ถᄋăፐࠥLjኊገᄂࢾ

ࡼᔈ߈ăᅄ4ჅာᆐࣅဟJOW

ఎဪLjW

JOWDD

S2D2ߠᒗ෭ৈᒦମ࢟ኹăࠥဟLjดݝᆮኹఎဪሶD3

ߠ࢟ )ݬᅄ6*ăᏴᎅS2ᄋࡼ࢟ഗࡩᒦLjNBY27912ஞ

56μBLjၒྜྷ࢟ഗᐌᆐD2D3ߠ࢟ăࡩW

ᆐ1Wăဗଝ࢟Ꮞ࢟ኹᒄઁLjࣅ࢟ᔜ

႒ᆐ,:/6WဟLjᄫᒏ࣪D3ߠ࢟LjD2ೝ࣡ࡼ࢟ኹଖኚဍLj

ᒦJ

ဵVWMP0FO୭ࡼၒྜྷ࢟ഗLjW

VWMP

ဵVWMP0FO

VMS3

ታඡሢă

8 _______________________________________________________________________________________

ᒇࡵক࢟ྏࡼ࢟ኹࡉࡵታ࢟ኹ,34/7WᆐᒏăጙࡡW

ࡍ᎖ᔈVWMPඡሢ࢟ኹLjOESWఎဪఎNPTGFULj݀

୭ࡼ࢟ኹă

DD

࢟ኹத

DD

JO

᎖ೡࣞMFEདࣅࡼ

ಭሣါĂED.ED!QXN఼ᒜ

V

CC

2V/div

MAX16801

PIN

V

IN

5V/div

0

100ms/div

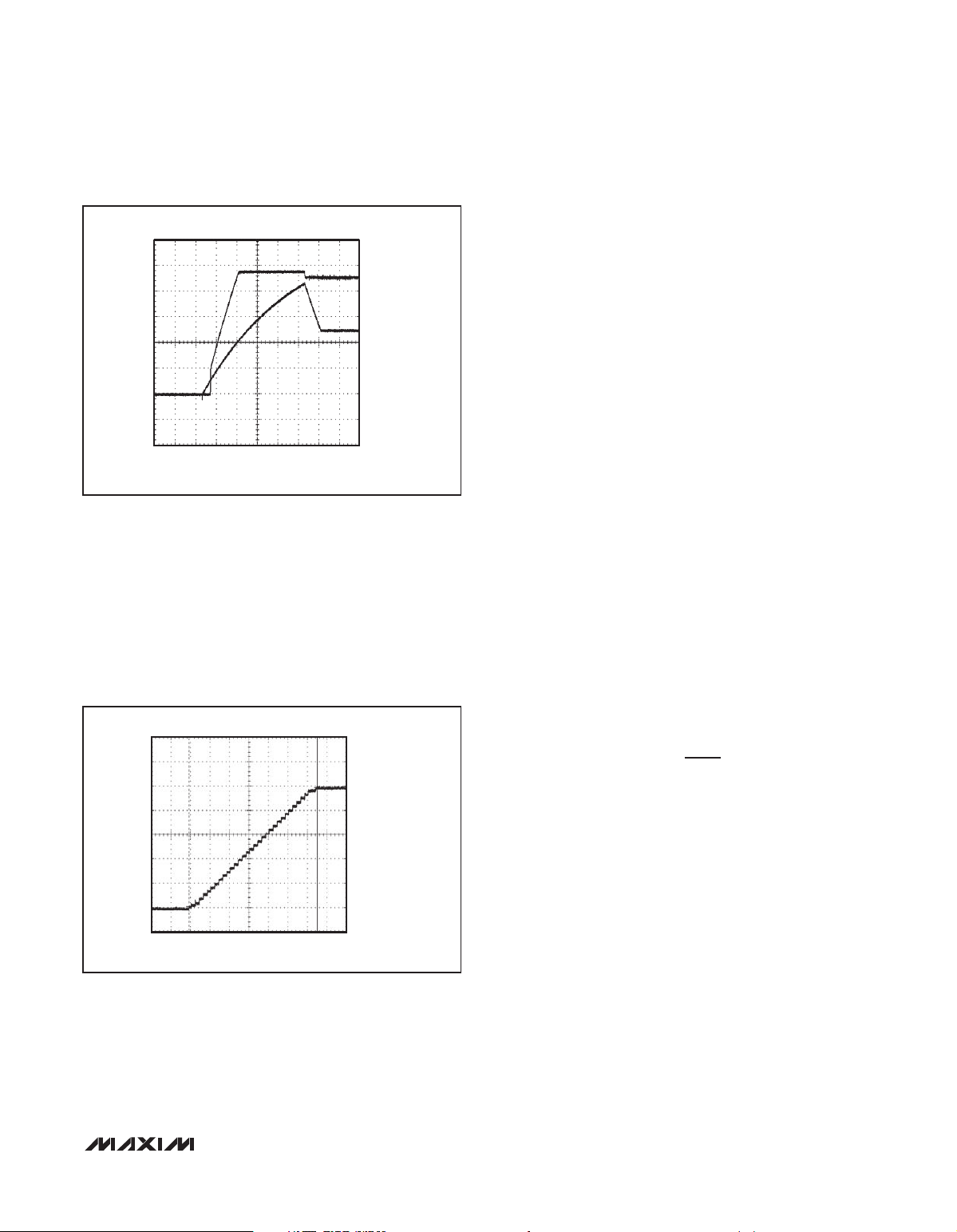

ᅄ4/! ࡩNBY27912ࠀ᎖ᔈෝါሆLjࣅဟࡼWJOW

DD

ሶླྀᔝྯླྀᔝࠅၒ࢟ถăྙྯླྀᔝၒ߲

ೂ࢟ኹ᎖,:/8W )ᔈVWMPࢅ࣡ඡሢ*Ljᐌࣅ߈ᅲ

߅Ljఎဪೌኚᔫă

ྙᏴࣅᅲ߅ᒄ༄W

ଢ଼ᒗ,:/8WጲሆLjᐌୈૄᒗ

JO

ࢅ࢟ഗVWMPᓨზăᑚᒬ༽ౚሆLjభᐐࡍD2ࡀᔗ৫ࡼ

࢟ถLjጲܣྯླྀᔝೂᔗ৫ࡼ࢟ኹă

````````````````````````````````` ྟࣅ

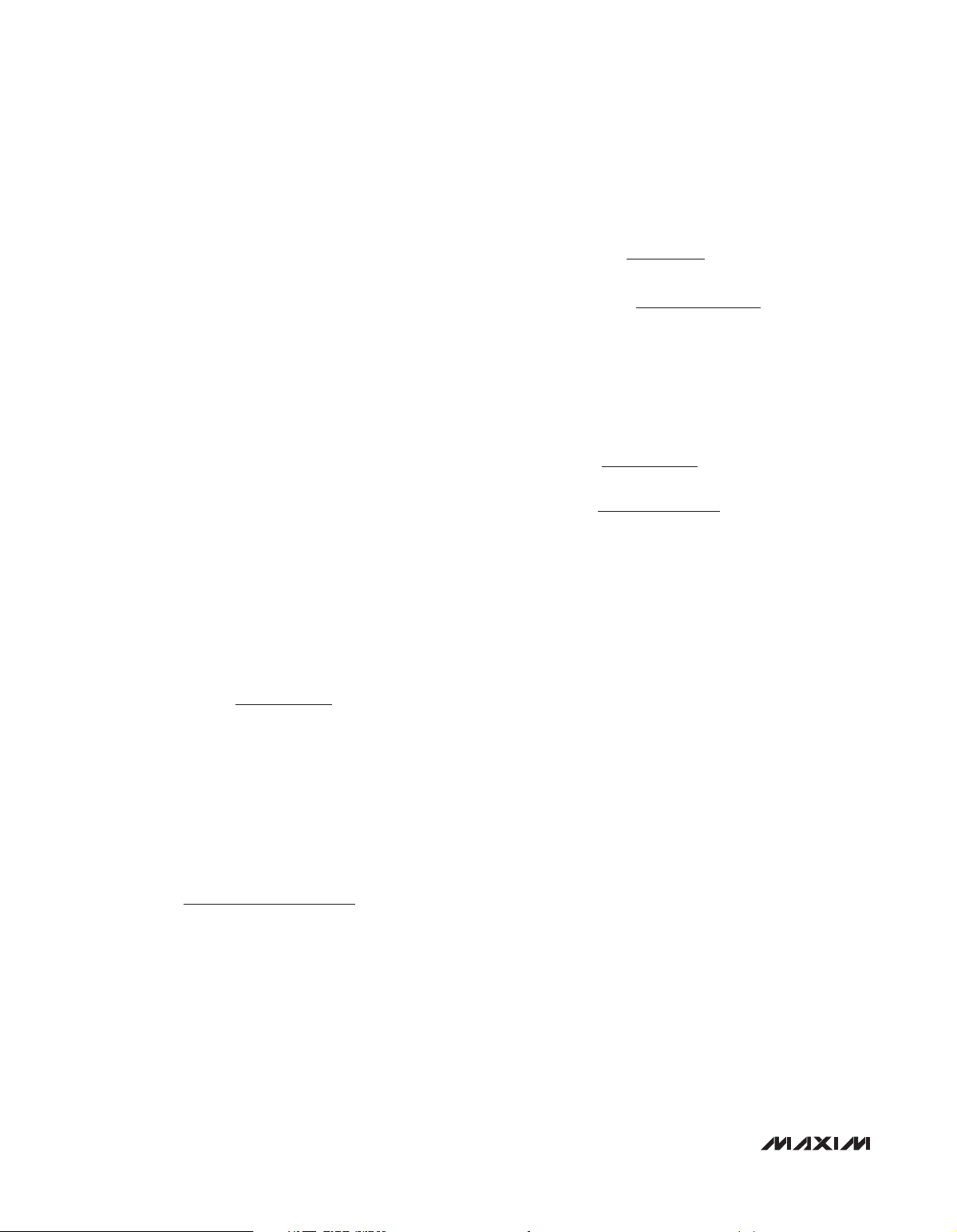

NBY279120NBY27913ࡼྟࣅᄂቶభဧMFE࢟ഗᏴ၊఼

ෝါሆዘቓຸဍăࡩᅙಭVWMPᓨზઁఎဪྟࣅ߈ă

ଝᒗࡍᄴሤஂ࢛ࡼ࢟ኹᏴ71ntࡼྟࣅဟମด࠭1ᒇ

ሣဍᒗ,2/34Wăᅄ5መာ೫1/6Bࡼ࢜ቯၒ߲࢟ഗᏴࣅ

߈ᒦࡼܤછ༽ౚăభᓖፀࡵMFE࢟ഗጲᄇါဍă

ᑚဵᎅ᎖ݧ೫ၫᔊྟࣅଆၣăᎧୈݙᄴࡼဵLj

ดᒙࡍࡼᓰ࢟ኹဵྟࣅࡼăᑚᒬถ୷

఼ᒜMFE࢟ഗă

oࡸNPTGFUఎདࣅ

OESW୭ถདࣅᅪݝoࡸNPTGFUăOESWၒ߲ᎅดݝ

ᆮኹ)W

࣪᎖ᄰၒྜྷ࢟ኹࡒᎌܤኹࡼ።ዔLjჅݧࡼ

NPTGFUܘኍถߌ၊࢟Ꮞ࢟ኹᔢဟࡼᒇഗ࢟ຳᎧܤኹ

߱ࡼ࢟ኹᒄă࣪᎖ࡍࣶၫݧೌኚgmzcbdlᅠແ

ࡼಭሣါ።ዔLjኊገࢾ࢟ኹᆐ711WࡼNPTGFUă

OESWถᏎ߲0ᇢྜྷި761nB02111nBᒋ࢟ഗăჅኡᐋ

ࡼNPTGFUޘညࡼࡴᄰႼఎႼܘኍᏴభ၊ࡼ

ᆍดă

NBY279120NBY27913۞౪ጙৈดݝᇙތࡍLjభ

ޟறཀྵࢯஂMFE࢟ഗăಿྙLjᅄ6Ⴥာࡼಭါ࢟

ᏎăMFE࢟ഗࡼଐႯါྙሆǖ

*࢟LjকดݝᆮኹᏴดݝᒙᆐᏖ,:/6Wă

DD

ดݝᇙތࡍ

NBY27912B0C0NBY27913B0C

0

10ms/div

ᅄ5/! ߱ဪࣅဟࡼ࢜ቯྟࣅ࢟ഗ

_______________________________________________________________________________________ 9

100mA/div

V

REF

=

R

7

ᒦW

I

LED

> ,2/34Wăࡍࡼᄴሤၒྜྷ࣡ᎅดݝೌᒗ

SFG

ၫᔊྟࣅ࢟വLjཀྵۣࣅ߈ᒦᓰ࢟ኹદൻဍLj

݀কᓰ࢟ኹဗଝᒗক୭ăᑚዹభ༓ᒜMFE࢟ഗᏴჅ

ᎌᓨზሆ࣒ږᑍᎾࢾࡼါᎌኔဍă

᎖ೡࣞMFEདࣅࡼ

ಭሣါĂED.ED!QXN఼ᒜ

``````````````````````````````` ።ቧᇦ

NBY27912᎖ೡࣞMFEདࣅ

ࡼࣅဟମఠ

JOവ࢟ྏD2᎖Ᏼ࢟വধধታဟኸႥᄋᔫ࢟ഗ

)ᅄ6*ăD2ࡼߛࡁྯླྀᔝࡼೌါࢾ೫భ᎖

ࣅࡼᒲ໐ၫăࡍྏᒋD2ዓޠ೫ࣅဟମLjࡣถᏴ߱ဪ

ࣅࣤᄋৎࣶ࢟ጲᑽߒৎࣶࡼఎᒲ໐ăྙD2ࡼ

ྏᒋვቃLjกඐOESWᎌᔗ৫ࡼဟମఎNPTGFULj

࠭ݙถᏴྯླྀᔝೂᔗ৫ࡼ࢟ኹᆐୈᄋ࢟ᏎLj

ᒘဧW

D2D3ኊݧࢅቛധ࢟ྏă

ଣࢾᏴࢅ࢟Ꮞ࢟ኹᓨზሆ )96WBDၒྜྷࡼᄰಭሣါ።*

ಭሣါMFEདࣅ྆ገᆒߒቃ᎖611ntࡼࣅဟମLjࣅ

࢟ᔜS2።ถᄴဟᄋୈჅኊࡼᔢࡍࣅມᒙ࢟ഗ)ᔢތ

ᓨზሆ:1μ B*ᆐD2ĂD3ߠ࢟Ⴥኊࡼ࢟ഗăᏴᎾ໐ࡼ

611ntࣅဟମดLjവ࢟ྏD3ܘኍۻߠ࢟ࡵ,:/6WLj

D2ܘኍߠ࢟ࡵ,35Wă

ᎅ᎖NBY27912ดݝᎌ71ntࡼྟࣅဟମLjD2ܘኍࡀᔗ

NBY27912B0C0NBY27913B0C

৫ࡼ࢟LjጲܣᒗᏴᑚࣤဟମดሶୈ።࢟ഗă

ጲሆါத႒ଐႯჅኊࡼ࢟ྏᒋǖ

ᒦJ

ဵR2ࡼᔐᐜ࢟LjgTXဵNBY27912ࡼఎຫൈ)373lI{*Lj

W

ମ)71nt*ă

ಿྙǖ

ଢ଼ᒗ,:/8WጲሆăୈૄVWMPᓨზݙถࣅă

JO

IQ f

=×

g gtot SW

C

=

1

ဵࣅઁNBY27912ࡼดݝ࢟Ꮞ࢟ഗ)2/5nB*LjR

JO

ဵᔈVWMPᒣૄ࢟ኹ)22/:W*LjuTTဵดݝྟࣅဟ

IZTU

8 262 2 1

Ig nC kHz mA

()( ) .

=× =

14 21 60

mA mA ms

..

()

1

C

=

IIt

+

()

IN g SS

+

()

V

HYST

×

()

12

V

()

=μ

17 5

.

hupu

F

ଣ D2 ? D3LjᐌږጲሆါଐႯS2ǖ

×

VC

SUVR

=

I

C

1

500

()

VV

IN MIN SUVR

1

=

R

ᒦW

VWMPታ࢟ຳ)ᔢࡍᒋ,34/7W*LjJ

Ꮞ࢟ഗ)ᔢࡍᒋ:1μB*ă

ಿྙLjୣഗၒྜྷ࢟ኹནᔢቃᒋ96WဟLjᎌǖ

࢟ᔜནܪᓰᒋ231lΩă

ྙᏤৎޠࡼࣅဟମLjᐌS2ᔜᒋభኡནࡻ܈ၤଐ

ႯᒋৎࡍጙቋLjᑚዹభጲଢ଼ࢅক࢟ᔜࡼă

ၤࣅښభ᎖ಢ႒᎖ᅄ6ࡼ࢟വăক࢟വᒦྯླྀ

ᔝᎧၒ߲ླྀᔝᄴሤăፐྀဟମྯླྀᔝࡼ࢟ኹᎧၒ

߲࢟ኹᔐ߅ᑵ܈Lj݀ၒ߲࢟ኹள಼ሤᄴࡼྟࣅ߈ă

D2࠭,33W࢟ᒗ,21Wࡼᔢ࢟ဟମܘኍࡍ᎖71ntࡼྟ

ࣅဟମă

ဣሚᔈࡼጙৈဵᏴࢯஂၒ߲࢟ኹࡼླྀᔝᒄᅪݧ

ጙৈࣖೂࡼມᒙླྀᔝLj݀ဧມᒙླྀᔝᎧNPTGFUࡴᄰဟ

ମᄴሤ)ݬᅄ:*ăᏴࠥ༽ౚሆLjჅኊࡼ࢟ྏᒋቃࣶ೫ă

LjᏴᑚᒬါሆLjၒྜྷ࢟ኹᆍܘኍቃ᎖3;2ăᏴ

ࢾມᒙླྀᔝဵᎧၒ߲ᄴሤဟLjથᎌጙৈኊገఠࡼ

ᆰᄌăྙᄴሤLjᐌMFEདࣅ࢟വ્Ᏼၒ߲വᓨზሆࡌ

ᡅྟࣅăࡣဵLjྙມᒙླྀᔝᎧNPTGFUࡴᄰဟମᄴ

ሤLjݙᎌকᄂቶă

ဵ።ᒦࡼᔢቃၒྜྷ࢟ኹLjW

JO)NJO*

24 15

×

VμF

()

I

=

C1

1

R

500

()

120

=

V

072 90

mA A

.()+μ

()

1

ms

−

()

+

II

C START

1

TUBSU

()

ms

−

224

072

=

.

V

=Ω

ဵᔈ

TVWS

ဵࣅဟJOࡼ࢟

mA

119

k

࢟ྏᒋནܪᓰᒋ26μGă

10 ______________________________________________________________________________________

᎖ೡࣞMFEདࣅࡼ

ಭሣါĂED.ED!QXN఼ᒜ

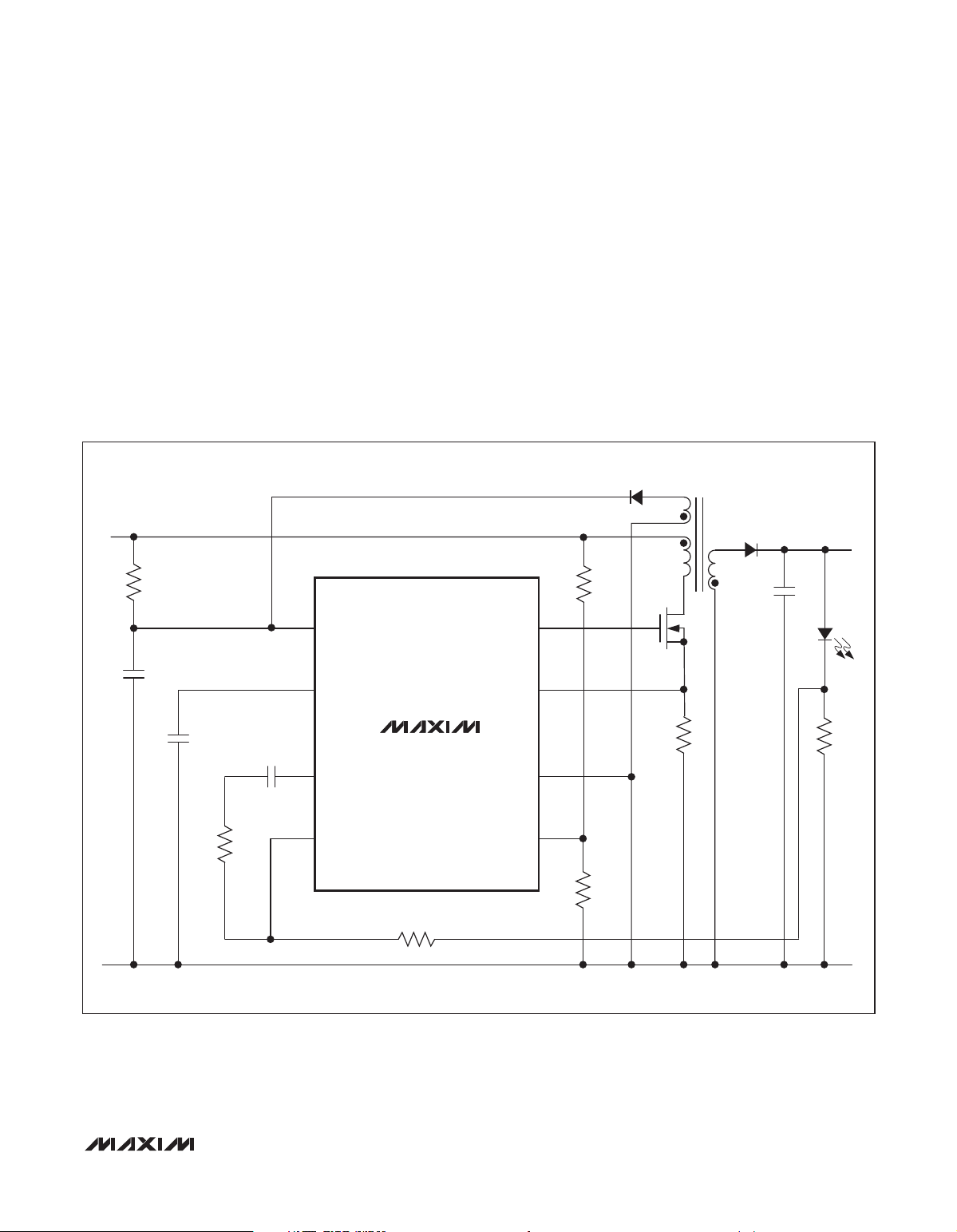

።࢟വ

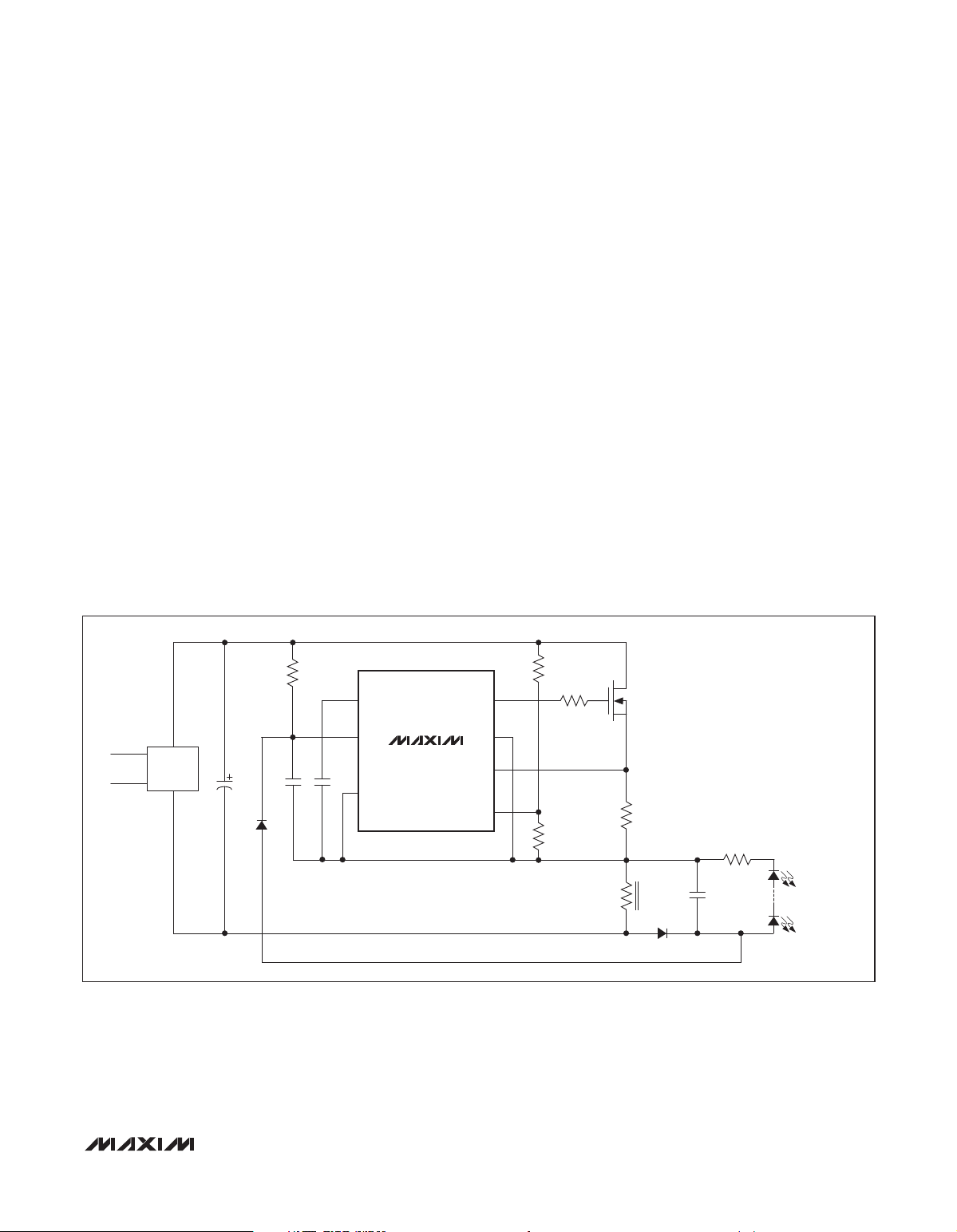

ᅄ6߲೫ጙৈ᎖NBY27912ࡼಭሣါIC! MFEདࣅ።

࢟വăܤኹU2భࡍࡍᄋଐࡼഉቶăดݝᇙތ

ࡍభဣሚޟறཀྵࡼMFE࢟ഗ఼ᒜă

ᅄ7߲೫ጙৈᎌሣቶೡࣞࢯஂถࡼೌኚgmzcbdl

MFEདࣅăMFEᔐ࢟ኹభࢅ᎖᎖ၒྜྷ࢟ኹă

V

SUPPLY

R1

IN

ᅄ8߲೫ጙৈೌኚࡴᄰෝါࡼIC! MFE! cvdlདࣅLj

ᎌሣቶࢯLjᒑኊࡼᅪݝᏄୈă

ᅄ9߲೫ጙৈ᎖NBY27912ĂݧࢅຫQXNါࢯ

ࡼಭሣါಭgmzcbdl IC MFEདࣅăQXNቧኊገሤ

)ݬ

ถౖᅄ

*ăܤኹU2ᄋڔཝಭLjᔫ᎖ᄰୣ

ഗ࢟Ꮞ)96WBDᒗ376WBD*ă

D1

R2

NDRV

T1

D2

C4

Q1

V

OUT

LEDs

NBY27912B0C0NBY27913B0C

C1

V

CC

C2

C3

COMP GND

R6

GND

ᅄ6/! ಭሣါĂಭĂgmzcbdl!MFEདࣅLjᎌభܠ߈ၒྜྷࣅ࢟ኹ

DIM/FB UVLO/EN

MAX16801

R5

CS

R7R4

R3

______________________________________________________________________________________ 11

᎖ೡࣞMFEདࣅࡼ

ಭሣါĂED.ED!QXN఼ᒜ

V

IN

10.8V TO 24V

R1

R2

DIMMING

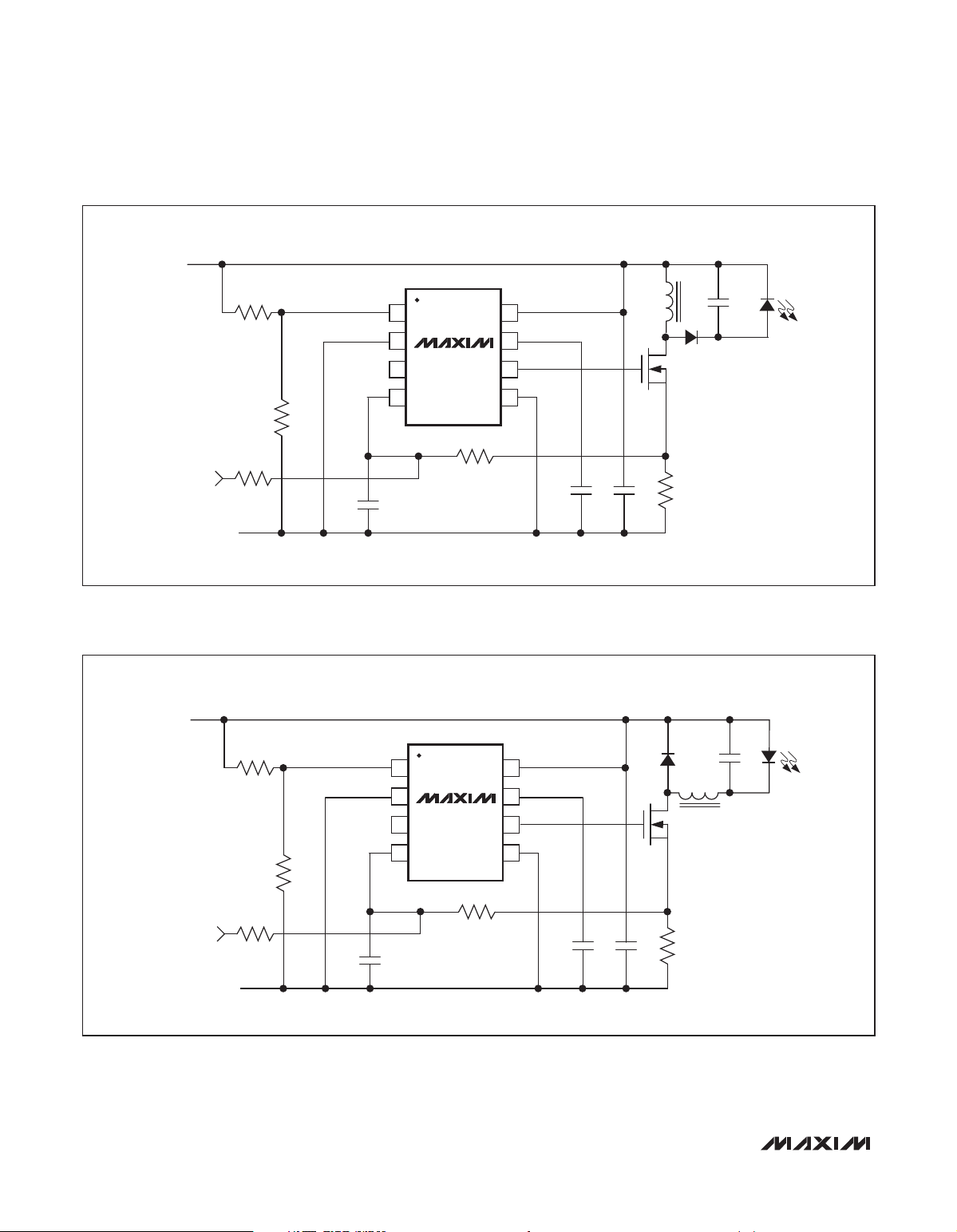

ᅄ7/! ᎌೡࣞࢯஂถࡼNBY27913! gmzcbdl!IC! MFEདࣅLjၒྜྷ࢟ኹᆍ21/9Wᒗ35W

NBY27912B0C0NBY27913B0C

10.8V TO 24V

R3

GND

V

IN

R1

R2

UVLO/EN

DIM/FB

COMP

UVLO/EN

DIM/FB

COMP

1

2

MAX16802B

3

CS

4

R4

C1

1

2

MAX16802B

3

CS

4

IN

8

V

CC

7

NDRV

6

GND

5

IN

8

V

CC

7

NDRV

6

GND

5

C2 C3

L1

C4

D1

Q1

R5

D1

C4

L1

Q1

LED(s)

LED(s)

R3

DIMMING

C1

GND

R4

C2 C3

R5

ᅄ8/! ᎌೡࣞࢯஂถࡼNBY27913! cvdl!IC! MFEདࣅLjၒྜྷ࢟ኹᆍ21/9Wᒗ35W

12 ______________________________________________________________________________________

᎖ೡࣞMFEདࣅࡼ

ಭሣါĂED.ED!QXN఼ᒜ

UNIVERSAL

AC INPUT

BRIDGE

RECTIFIER

OPTIONAL ONLY WHEN PWM DIMMING IS USED

C4

R1

C3

V

CC

IN

MAX16801B

C1

*PWM

*WARNING: PWM DIMMING SIGNAL IS SHOWN AT THE PRIMARY SIDE.

USE AN OPTOCOUPLER FOR SAFETY ISOLATION OF THE PWM SIGNAL.

C2

DIM/FB UVLO/EN

NDRV

GND

NBY27912B0C0NBY27913B0C

D1D3

R2

CS

R3

T1

D2

Q1

LEDs

C6

R4

C5

ᅄ9/! ᄰୣഗၒྜྷĂಭሣါĂಭቯgmzcbdl! IC!MFEདࣅLjݧࢅຫQXNࢯ

D1

+V

IN

U2

OPTO TRANS

GND

R1

IN

C1

V

CC

R7

COMP GND

R5

R6

DIM/FB UVLO/EN

C2

MAX16801

R2

NDRV

CS

R3

ᅄ:/! ᄰၒྜྷĂಭሣါĂಭቯgmzcbdl! IC!MFEདࣅLjᎌறࣞ࢟ഗࢯஂᄂቶ

T1

D3

Q1

C4

R4

C5

V

OUT

OPTO LED

R11

U3

TLV431

U2

R8

C3

R9

R10

Z1

______________________________________________________________________________________ 13

᎖ೡࣞMFEདࣅࡼ

ಭሣါĂED.ED!QXN఼ᒜ

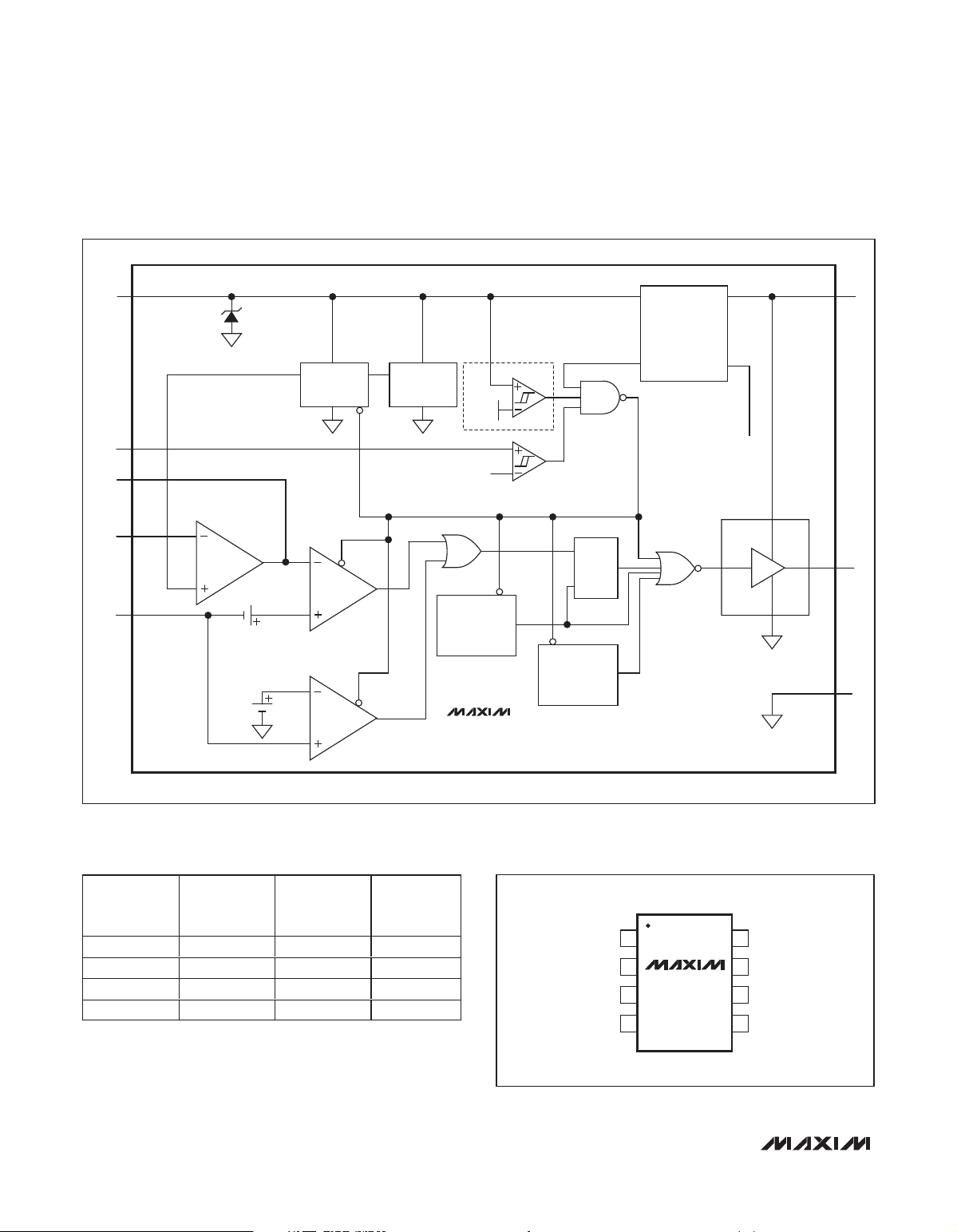

`````````````````````````````````````````````````````````````````````````` ถౖᅄ

V

CC

UVLO/EN

COMP

IN

IN

CLAMP

26.1V

BOOTSTRAP UVLO**

DIGITAL

SOFT-START

REFERENCE

1.23V

21.6V

9.74V

1.28V

1.23V

UVLO

IN

REGULATOR

REG_OK

V

CC

V

L

(INTERNAL 5.25V SUPPLY)

DIM/FB

ERROR

AMP

CPWM

LIM

*OSCILLATOR

262kHz

MAX16801

V

0.3V

1.38V

CS

V

OPWM

NBY27912B0C0NBY27913B0C

CS

MAX16802

``````````````````````````````` ኡቯᒎฉ

STARTUP

VOLTAGE

(V)

PART

BOOTSTRAP

UVLO

MAX16801A Yes 22 50

MAX16801B Yes 22 75

MAX16802A No 10.8* 50

MAX16802B No 10.8* 75

*

NBY27913ᎌดݝᔈVWMPă

୭࢟ኹ᎖,8W )JO୭࢟ኹᆐ,21/9Wဟࡼۣᑺၒ߲*Lj

W

DD

݀༦VWMP0FO୭ᆐ࢟ຳဟNBY27913ఎဪᔫă

MAX DUTY

CYCLE (%)

DRIVER

S

Q

R

THERMAL

SHUTDOWN

*MAX16801A/MAX16802A: 50% MAXIMUM DUTY CYCLE

MAX16801B/MAX16802B: 75% MAXIMUM DUTY CYCLE

**MAX16801 ONLY

NDRV

GND

``````````````````````````````` ୭ᒙ

TOP VIEW

UVLO/EN

DIM/FB

COMP

1

2

MAX16801

3

MAX16802

CS

4

μMAX

IN

8

V

7

CC

6

NDRV

GND

5

14 ______________________________________________________________________________________

᎖ೡࣞMFEདࣅࡼ

ಭሣါĂED.ED!QXN఼ᒜ

```````````````````````````````````````````````````````````````````````````` ᓤቧᇦ

ྙኊᔢதࡼᓤᅪተቧᇦݚLj༿އኯ china.maxim-ic.com/packagesă༿ᓖፀLjᓤܠ൩ᒦࡼĐ,đĂĐ$đĐ.đஞܭာSpITᓨზă

ᓤᅄᒦభถ۞ݙᄴࡼᆘᓮᔊLjࡣᓤᅄᒑᎧᓤᎌLjᎧSpITᓨზᇄă

ᓤಢቯ

8 μMAX — 21-0036

ᓤܠ൩

ᆪܠ

NBY27912B0C0NBY27913B0C

______________________________________________________________________________________ 15

᎖ೡࣞMFEདࣅࡼ

ಭሣါĂED.ED!QXN఼ᒜ

```````````````````````````````````````````````````````````````````````````` ኀࢿ಼ဥ

ኀࢿ ኀࢿ྇໐ ႁී ኀখ

0 10/05 —

1 1/06 1

2 1/10 1, 2, 3, 6–15

ᔢ߱ۈ۾ă

ᐐଝ೫NBY27913BFVB,ୈă

ৎᑵ೫ଐႯါLjৎቤ೫ሆܪLj݀࿎߹೫ᓤᅄă

NBY27912B0C0NBY27913B0C

Nbyjn۱யێူࠀ

۱ய 9439ቧረ ᎆᑶܠ൩211194

࢟જǖ911!921!1421

࢟જǖ121.7322 62::

ࠅᑞǖ121.7322 63::

Nbyjnݙ࣪Nbyjnޘອጲᅪࡼྀ࢟വဧঌᐊLjጐݙᄋᓜಽభăNbyjnۣഔᏴྀဟମĂᎌྀᄰۨࡼ༄ᄋሆኀখޘອᓾ೯ৃࡼཚಽă

16 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2010 Maxim Integrated Products

NbyjnဵNbyjn!Joufhsbufe!Qspevdut-!Jod/

ࡼᓖݿܪă

MAX16801, MAX16801A, MAX16801B, MAX16802, MAX16802A, MAX16802B 离线式、DC-DC PWM控制器,用于高亮度LED驱动器 - 概述

ENGLISH • 简体中文 • 日本語 • 한국어

Login | Register

请输入关键词或器件型号

最新内容 产品 方案 设计 应用 技术支持 销售联络 公司简介 我的Maxim

Maxim > 产品 > 汽车电子产品 > MAX16801, MAX16801A, ...

Maxim > 产品 > 电源和电池管理 > MAX16801, MAX16801A, ...

MAX16801, MAX16801A, MAX16801B, MAX16802, MAX16802A, MAX16802B

离线式、DC-DC PWM 控制器,用于高亮度LED驱动器

具有宽工作范围、高电流精度的LED驱动方案

概述 技术文档 定购信息 用户说明 (0) 所有内容

状况

状况:生产中。

概述

MAX16801A/B/MAX16802A/B高亮度(HB) LED驱动控制器IC含有设计宽输入电压范围LED驱动

器所需的全部电路,适用于通用照明和显示器应用。MAX16801非常适用于通用输

入(85VAC至265VAC整流电压输入) LED驱动器,MAX16802适用于低输入电

压(10.8VDC至24VDC) LED驱动器。

需要精密调节LED电流时,可利用板上误差放大器以及精度为1%的基准。通过低频PWM亮度调

节可实现较宽的亮度调节范围。

完整的数据资料

英文

中文

下载

下载

Rev. 2 (PDF, 212kB)

Rev. 2 (PDF, 700kB)

MAX16801/MAX16802具有输入欠压锁定(UVLO)特性,可设置输入启动电压,并可确保在电源跌落时正常工作。MAX16801具有大滞

回的内部自举欠压锁定电路,从而简化了离线LED驱动器的设计。MAX16802没有这个内部自举电路,可直接由+12V电压偏置。

内部微调的262kHz固定开关频率允许优化选择磁性元件和滤波元件,从而实现紧凑、高性价比的LED驱动

器。MAX16801A/MAX16802A的最大占空比为50%,MAX16801B/MAX16802B的最大占空比为75%。这些器件均采用8引脚µMAX®封

装,可工作在-40°C至+85°C温度范围内。

现备有评估板:MAX16802BEVKIT

关键特性 应用/使用

适合buck、boost、flyback、SEPIC和其它拓扑

高达50W或更高的输出功率

通用离线输入电压范围:85VAC至265VAC整流电压(MAX16801)

IN引脚直接由10.8V至24V直流输入驱动(MAX16802)

商用与工业照明

装饰灯与建筑照明

离线式DC-DC LED驱动器

RGB背光,用于LCD TV 和监视器

内部带有误差放大器和1%精度的基准,可实现精密的LED电流调节

PWM或线性亮度调节

262kHz ±12%固定开关频率

热关断

数字软启动

可编程输入启动电压

大滞回内部自举UVLO (MAX16801)

45µA ( 典型值)启动电源电流,1.4mA (典型值)工作电源电流

50% (MAX16801A/MAX16802A)或75% (MAX16801B/MAX16802B) 最大占空比

采用微型8引脚µMAX封装

Key Specifications: High Brightness LED Drivers

Device

Part

http://china.maxim-ic.com/datasheet/index.mvp/id/5001[2010-8-12 8:16:37]

Topology

V

(V)

IN

Device

V

IN

(V)

Application

V

IN

(V)

LED

per

I

LED

Channel

(A)

LED

String

Volt.

Internal

Pwr.

Freq.

(kHz)

PWM

Dimming

Freq.

PWM

Dimming

Ratio

EV

Price

MAX16801, MAX16801A, MAX16801B, MAX16802, MAX16802A, MAX16802B 离线式、DC-DC PWM控制器,用于高亮度LED驱动器 - 概述

(V)

(kHz)

Number Channels

max min max max max max max max

MAX16801

MAX16802

Boost/SEPIC

Flyback

Boost/SEPIC

Buck

Flyback

24 10.8

400

1

24 Yes

1

查看所有High Brightness LED Drivers (23)

图表

MOSFETs

3 250 No 262 2 3000

Kit

No

See

Notes

$0.66

@1k

$0.66

@1k

典型工作电路

相关产品

MAX16802BEVKIT MAX16802B评估板

类似产品:浏览其它类似产品线

查看所有High Brightness LED Drivers (25产品)

更多信息

新品发布 [ 2005-11-14 ]

没有找到你需要的产品吗?

应用工程师帮助选型,下个工作日回复

参数搜索

应用帮助

概述 技术文档 定购信息

概述

关键特性

应用/使用

关键指标

图表

注释、注解

相关产品

数据资料

应用笔记

评估板

设计指南

可靠性报告

软件/模型

价格与供货

样品

在线订购

封装信息

无铅信息

参考文献: 19-3880 Rev. 2; 2010-04-01

本页最后一次更新: 2010-04-01

联络我们:信息反馈、提出问题 • 对该网页的评价 • 发送本网页 • 隐私权政策 • 法律声明

© 2010 Maxim Integrated Products 版权所有

http://china.maxim-ic.com/datasheet/index.mvp/id/5001[2010-8-12 8:16:37]

``````````````````````````````````` গၤ

NBY27913Cຶৰۇ)FW lju*ዝာ᎖NBY27913Cࡼ࢟

ഗ఼ᒜĂࡍ࢟ഗၒ߲MFEདࣅăຶৰۇభᄋᆮࢾࡼ

861nBၒ߲࢟ഗLjᔫᏴ21/9W ᒗ41W࢟Ꮞ࢟ኹᒄମLj

ᔫᆨࣞᆍᆐ.51°Dᒗ,96°Dă

NBY27913Cຶৰۇᎌೝᒬݙᄴಢቯࡼೡ఼ࣞᒜါǖ

ಽෝผၒྜྷ࢟ኹQXNၒྜྷቧ఼ᒜ MFEೡࣞăকຶ

ৰۇથᎌVWMPถLjᏴၒྜྷ࢟Ꮞ࢟ኹࢅဟܕຶৰ

ۇLj݀༦భጲᏴMFEఎവဟᆐຶৰۇᄋኹۣઐă

NBY27913Cຶৰۇဵᅲཝڔᓤ݀ளހ၂ࡼ࢟വۇă

வসǖࡩ߲ሚዏᒮ৺ᑇပᓨზဟLj۾ຶৰۇభถሿ

ࡍถLjᐆ߅ᏄୈᏄୈႵຢࡼႥă༿டဇ

ݷᔫ۾ຶৰۇLjጲܜభถࡼཽă

``````````````````````````````````` ᄂቶ

♦ 21/9Wᒗ41W࢟Ꮞ࢟ኹᆍ

♦ ࢟ഗ఼ᒜၒ߲

♦ 23Wၒ߲ဟ࢟ഗభࡉ861nB

♦ ሣቶQXNೡ఼ࣞᒜ

♦ ൸Ᏺဟൈࡉ91&

♦ ࢟Ꮞ࢟ኹ་ኹჄࢾ

♦ ၒ߲ኹۣઐ

ຶৰۇǖNBY27913C

NBY27913Cຶৰۇ

________________________________________________________________ Maxim Integrated Products 1

19-0560; Rev 0; 5/06

`````````````````````````````````````````````````````````````````````````` Ꮔୈܭ

``````````````````````````````` ࢾ৪ቧᇦ

μ

NBYဵ Nbyjn! Joufhsbufe! Qspevdut-! Jod/ࡼᓖݿܪă

۾ᆪဵNbyjn ᑵါ፞ᆪᓾ೯ࡼፉᆪLjNbyjnݙ࣪ፉᒦࡀᏴࡼތፊᎅࠥޘညࡼࡇᇙঌᐊă༿ᓖፀፉᆪᒦభถࡀᏴᆪᔊᔝᒅ

ፉࡇᇙLjྙኊཀྵཱྀྀࠤᎫࡼᓰཀྵቶLj༿ݬఠ Nbyjnᄋࡼ፞ᆪۈᓾ೯ă

Ⴣནዹອᔢቤۈࡼၫᓾ೯Lj༿ᆰNbyjnࡼᓍǖxxx/nbyjn.jd/dpn/doă

PART TEMP RANGE IC PACKAGE

MAX16802BEVKIT -40°C to +85°C 8 μMAX

®

DESIGNATION QTY DESCRIPTION

C1, C2, C5, C6 4

C3, C4, C7 3

C8 1

C9 1

D1 1

D2 1

D3 1

J1, J2 2

4.7μF, 50V X7R ceramic capacitors

Murata GRM32ER71H475KA88L

0.1μF, 50V X7R SMD ceramic

capacitors

Murata GRM188R71H104KA93D or

TDK C1608X7R1H104K

470pF, 50V X7R ceramic capacitor

Murata GRM188R71H471KA01D or

TDK C1608X7R1H471K

1nF, 50V X7R ceramic capacitor

Murata GRM188R71H102KA01D or

TDK C1608X7R1H102K

22V, 1.5W zener diode

Vishay SMZG3797B

60V, 1A Schottky diode

Central Semiconductor CMSH1-60M

or Diodes Inc. B160

20V, small-signal Schottky diode

Vishay SD103CWS or

Diodes Inc. SD103CWS

0.1in, 2-pin hole headers

(through hole)

DESIGNATION QTY DESCRIPTION

L1 1

Q1 1

R1 1 392kΩ ±1%, 1/8W resistor (0603)

R2 1 11kΩ ±1%, 1/8W resistor (0603)

R3 1 499kΩ ±1%, 1/8W resistor (0603)

R4 1 73.2kΩ ±1%, 1/8W resistor (0603)

R5, R7 2 1kΩ ±1%, 1/8W resistors (0603)

R6 1 330Ω ±1%, 1/4W resistor (1206)

R8 1 220Ω ±1%, 1/8W resistor (0603)

R9 1

R10 1 1Ω ±5%, 1/8W resistor (0603)

U1 1 MAX16802B (8-pin μMAX)

VIN, VLED,

PWM_IN,

LIN_IN

— 1 MAX16802B PC board

4.7μH, 4.2A peak SMD inductor

Coilcraft DO3308P-472ML

60V, 3.2A n-channel MOSFET

Vishay Si3458DV

0.10Ω ±1%, 1/2W resistor (1206)

Susumu RL1632R-R100-F

0.1in, 2-pin male connectors

4

(through hole)

ຶৰۇǖNBY27913C

NBY27913Cຶৰۇ

2 _______________________________________________________________________________________

``````````````````````````````` Ⴅྜྷඡ

NBY27913Cຶৰۇဵᅲཝᓤ݀ளހ၂ࡼ࢟വۇăږ

ᑍሆݛᒾዩᑺᔫ༽ౚăᏴᅲ߅Ⴥᎌೌᒄ༄Ljݙ

ገᄰ࢟Ꮞă

2* ᒇഗ࢟Ꮞ)1ᒗ41WৎLj2B*ೌᒗ,WJOHOEă

3* ࢟ኹܭာ݆MFEᑫ)ࠈቲೌLj861nBᑵሶ

࢟ഗሆኹଢ଼Ꮦᆐ23W*ೌᒗ,WMFE .WMFE࣡Ǘዴ

,WMFELjፓ.WMFEă

4* ᄰᄢሣK2K3ጲணᒏೡࣞࢯஂă

5* ࡌఎ࢟ᏎLj݀ၒྜྷ࢟ኹᐐଝࡵ21/9Wጲăၒ߲࢟ኹ

ᐐࡍࡵMFEᑫᑵሶມᒙ࢟ኹLj݀ᄋࡍᏖ 861nB

ᆮࢾࡼMFEຳ࢟ഗăၒྜྷ࢟ኹᐐᒗ 41WLjຳၒ߲

࢟ഗᏴᑳৈ࢟Ꮞ࢟ኹᆍดۣߒᆮࢾă

6* ࣥఎവK2Lj݀ᏴQXN`JOଝᏲQXNቧ)ຫൈᆐ

311I{-!ࣞᆐ1ᒗ3W*ă࠭1ᒗ211&খܤᐴహ܈LjMFE

ೡࣞႲᒄܤછLjሤ።࠭211&ܤછᒗ1&ăࡩ QXNቧ

ᐴహ܈ᆐ1&ဟLjMFEೡࣞᆐ 211&ă

7* ᄰK2݀ࣥఎK3ăೌጙৈభܤ࢟ኹᏎᒗMJO`JOLj

Ᏼ1ᒗ 2/7Wᒄମࢯஂ࢟ኹăMFEೡࣞᏴ211&Ꭷ1&ᒄ

ମܤછăၒྜྷMJO`JO࢟ኹᆐ 1WဟLjMFEೡࣞᆐ211&ă

வসǖݙঌᏲဟ༿ᇖຶৰۇ࢟ă

``````````````````````````````` ሮᇼႁී

NBY27913Cຶৰۇ)FW lju*ဵ࢟ഗ఼ᒜቯĂࡍ࢟ഗၒ߲

MFEདࣅLjభᄋࡉ861nB ࡼᆮࢾ࢟ഗLj༦ݙ၊࢟Ꮞ

࢟ኹܤછ፬ሰă

কຶৰۇ᎖ᔫᏴ373lI{Ăೌኚ࢟ഗෝါ)EDN*ࡼ

cvdl.cpptuᓞધLjඛৈᒲ໐ᆐၒ߲ᄋጙࢾถLjᄏࡼ

ถᒋᓍገན᎖࢟ঢઓభܠ߈ࡼᒋ࢟ঢ࢟ഗLjᎧ

ၒྜྷ࢟ኹᇄăږᑍᑚጙᒙLjຶৰۇࡼၒ߲࢟ኹᏴ

ࢾMFEᔫ࢟ኹሆ MFEࡼၒ߲࢟ഗᎧ࢟Ꮞ࢟ኹᇄă

কຶৰۇଐ᎖དࣅMFEঌᏲLj23W ᔫ࢟ኹሆభᄋ

ࡉ861nBࡼᔢࡍ࢟ഗăྙ MFEࡼᔫ࢟ኹ୷ࢅLjกඐ

ᔢࡍၒ߲࢟ഗږ܈ಿᐐଝLjభۣߒᆮࢾࡼၒ߲ൈă

ᆐདࣅݙᄴᔫ࢟ኹࡼMFEᑫLjኊገখܤଶഗ࢟ᔜăሆ

ෂ߲೫ݙᄴᔫ࢟ኹሆଶഗ࢟ᔜଐႯࡼሮᇼႁීă

ၒྜྷ࢟ᏎVWMP

ၒྜྷ࢟ᏎVWMP࢟വᎅ S4ĂS5ᔝ߅ࡼ࢟ᔜᆀဣሚăক

࢟ᔜᆀଶހၒྜྷ࢟Ꮞ࢟ኹLj݀Ᏼၒྜྷ࢟ኹ᎖21/9Wဟ

ᄰFO୭ࣅ࢟വăࡩ FO୭ࡼ࢟ኹဍဟLjታ

࢟ኹඡሢᆐ2/34WLjᎌ61nW ᒣૄăୈጙࡡఎဪᔫLj

ᒑᏴၒྜྷ࢟Ꮞ࢟ኹࢅ᎖21/5W )ఠࡵᒣૄ࢟ኹ*ဟݣ્

ࣥă

VWMPඡሢభږᑍሆါᄰ࢟ᔜS2 S3ቲࢯஂǖ

ᒦLjW

VWMP

ᆐჅገཇࡼVWMPඡሢăᆐۣߒඡሢறࣞLj

S5።ቃ᎖211lΩă

```````````````````````````````````````````````````````````````````````` Ꮔୈ።

ᓖǖᎧၤᏄୈ።ೊᇹဟLj༿ႁීิᑵᏴဧࡼဵNBY27913Că

V

⎛

R

UVLO

3

⎜

⎝

123

.

⎞

R

14=−

×

⎟

⎠

SUPPLIER PHONE FAX WEBSITE

Central Semiconductor 631-435-1110 631-435-3388 www.centralsemi.com

Coilcraft 847-639-6400 847-639-1469 www.coilcraft.com

Diodes Inc. 805-446-4800 805-446-4850 www.diodes.com

Murata 770-436-1300 770-436-3030 www.murata.com

Susumu Co Ltd. 208-328-0307 208-328-0308 www.susumu-usa.com

TDK 847-390-4373 847-390-4428 www.component.tdk.com

Vishay 402-563-6866 402-563-6296 www.vishay.com

ၒ߲ኹۣઐ

WMFEᑵ୭ሤ࣪᎖HOE ࡼᔢࡍ࢟ኹᎅS2ĂS3ᔝ߅ࡼ

ౣᆀሢᒜᏴ56WLjকᆀೌᒗNBY27913C ࡼGC

୭ăྙຶৰۇᏴᎌঌᏲဟఎMFEఎവLjᐌ

WMFEᑵ࢟ኹభถ્ဍࡵݙڔཝࡼ࢟ኹăดݝᇙތ

ࡍ્ଶހᑚᒬ༽ౚLj࠭ଢ଼ࢅ࢟ঢࡼᒋ࢟ഗLj

WMFEᑵ୭ࡼ࢟ኹሢᒜᏴ56W ጲดă૾ܣဧ೫ᑚᒬ

ۣઐLj྆ፇᏴຶৰۇ࢟ᒄ༄ᒎࢾࡼঌᏲă

QXNೡࣞࢯஂ

ᄰࢯஂೌᏴQXO`JOၒྜྷ࣡ࡼ QXNቧᐴహ܈఼

ᒜMFEೡࣞăQXN`JO ၒྜྷᆐ࢟ຳဟࣥMFE࢟ഗǗၒ

ྜྷᆐࢅ࢟ຳဟఎMFE࢟ഗăቧᒋᏴ 2/6Wᒗ6/1WĂຫ

ൈᆐ211I{ᒗ 2111I{Ljᄰখܤᐴహ܈ࢯஂMFEೡࣞăຫ

ൈࢅ᎖211I{ࡼቧభถ્ࡴᒘၒ߲࿑ႄăᐐࡍᐴహ܈ဟLj

MFEೡࣞିྦྷLjᒄጾăQXNᐴహ܈ᆐ 1&ဟLjMFEೡ

ࣞࡉࡵ211&ă

ሣቶೡࣞࢯஂ

ሣቶೡࣞࢯஂဵᄰখܤMJO`JOၒྜྷ࢟ኹࡼ఼ࣞᒜ

MFEೡࣞăMJO`JOၒྜྷࢯᒜଶഗቧLjᏴݙᄴࡼ࢟ഗሆ

߿NPTGFUăᑚጙ߈્ጙݛ఼ᒜၒ߲࢟ഗLj࠭ࡉ

ࡵ఼ᒜMFEೡࣞࡼࡼăፐᆐᏴྀೡࣞࢀ MFEဪᒫۣ

ߒࡴᄰᓨზLjሣቶೡࣞࢯஂݙ્ޘည࿑ႄሚሷăᏴ1ᒗ

2/7WᆍดࢯஂMJO`JO ࢟ኹLjభဧMFEೡࣞᏴ211&ᒗ1&

ମܤછăMJO`JO࢟ኹᐐࡍဟLjMFEೡࣞିྦྷLjᒄጾă

MJO`JO࢟ኹᆐ1W ဟLjMFEೡࣞᆐ211&ă

ࢯஂၒ߲ൈ

োሆါࢯஂଶഗ࢟ᔜS:Ljభጲখܤຶৰۇࡼᔢࡍ

ၒ߲ൈǖ23WĂ861nBăᓖፀǖຶৰۇᔢࡍၒ߲࢟ഗሢ

ᒜᏴ861nBĂᔢࡍၒ߲࢟ኹሢᒜᏴ26WLj༦ᔢࡍၒ߲ൈ

ሢᒜᏴ9/36Xă

၅ሌଐႯᔢቃၒྜྷ࢟ኹሆࡼᔢଛࡴᄰᐴహ܈ǖ

ᒦLjW

JONJO

ᆐᔢቃၒྜྷ࢟ኹLjW

MFE

ᆐMFEᔫ࢟ኹLj

J

MFE

ᆐჅገཇࡼMFE࢟ഗLjWEᆐE3ࡼᑵሶ࢟ኹă

ଐႯჅገཇࡼᒋ࢟ঢ࢟ഗǖ

ᒦLjl

g

ᆐĐኀᑵፐᔇđ)ஏᇹၫ*Ljক࢟വᒦ

ᒙᆐ2/2ă

ଐႯჅኊࡼ࢟ঢᒋLj݀ኡᐋᔢதܪᓰᒋࡣቃ᎖ଐႯᒋ

ࡼ࢟ঢǖ

ᒦLjMᆐ࢟ঢM2ࡼ࢟ঢᒋǗgTXᆐఎຫൈLjࢀ᎖373lI{ă

ᄰ૮ෝါᄋၒ߲࢟വࡼൈᆐǖ

ၒ߲࢟വሿࡼൈᆐǖ

োถ၆ࢾേLjၤೝৈࢀါሤࢀLj࠭ཇ߲ጙৈ

ৎறཀྵࡼᒋ࢟ঢ࢟ഗǖ

োཇࡻࡼJ

QFBL

LjಽሆါଐႯଶഗ࢟ᔜS:ǖ

ᒦLj1/3:3Wᆐଶഗඡሢ࢟ኹăS8ĂS9ᔝ߅ጙৈ࢟ᔜ

ኹLjถ৫Ᏼୈଶഗ୭ᒄ༄ږ܈ಿଢ଼ࢅଶഗ࢟ᔜ

ࡼኹଢ଼ă

ᄢሣኡᐋ

ݙဧQXNೡࣞࢯஂဟᄢሣ K2ᄰǗݙဧሣቶೡࣞ

ࢯஂဟᄢሣK3ᄰă

ຶৰۇǖNBY27913C

NBY27913Cຶৰۇ

_______________________________________________________________________________________ 3

VV

+

D

=

ON

LED D

VVV

++

INMIN LED D

kI

××

f LED

I

=

P

D

−21

ON

DV

×

ON INMIN

L

=

fI

×

SW P

1

PLIf

=×× ×

IN P SW

2

2

PVIVI

=×+×

OUT LED LED D LED

×+×

⎛

2( )VVI

IP=

R

LED D LED

⎜

⎝

0 292 8 7

.( )

9

=

×

fL

SW

RR

×+

IR

×

PEAK

7

⎞

⎟

⎠

ຶৰۇǖNBY27913C

NBY27913Cຶৰۇ

4 _______________________________________________________________________________________

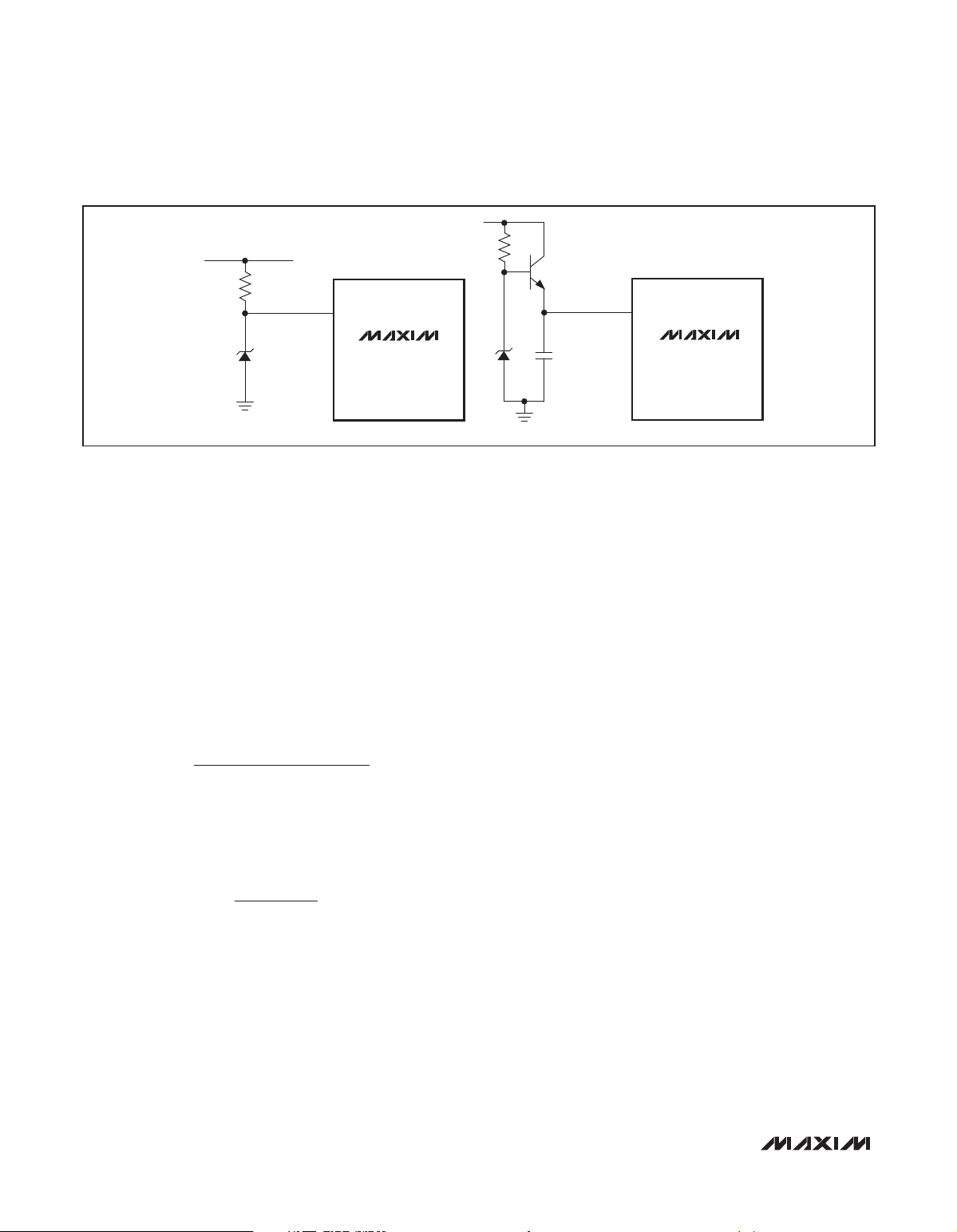

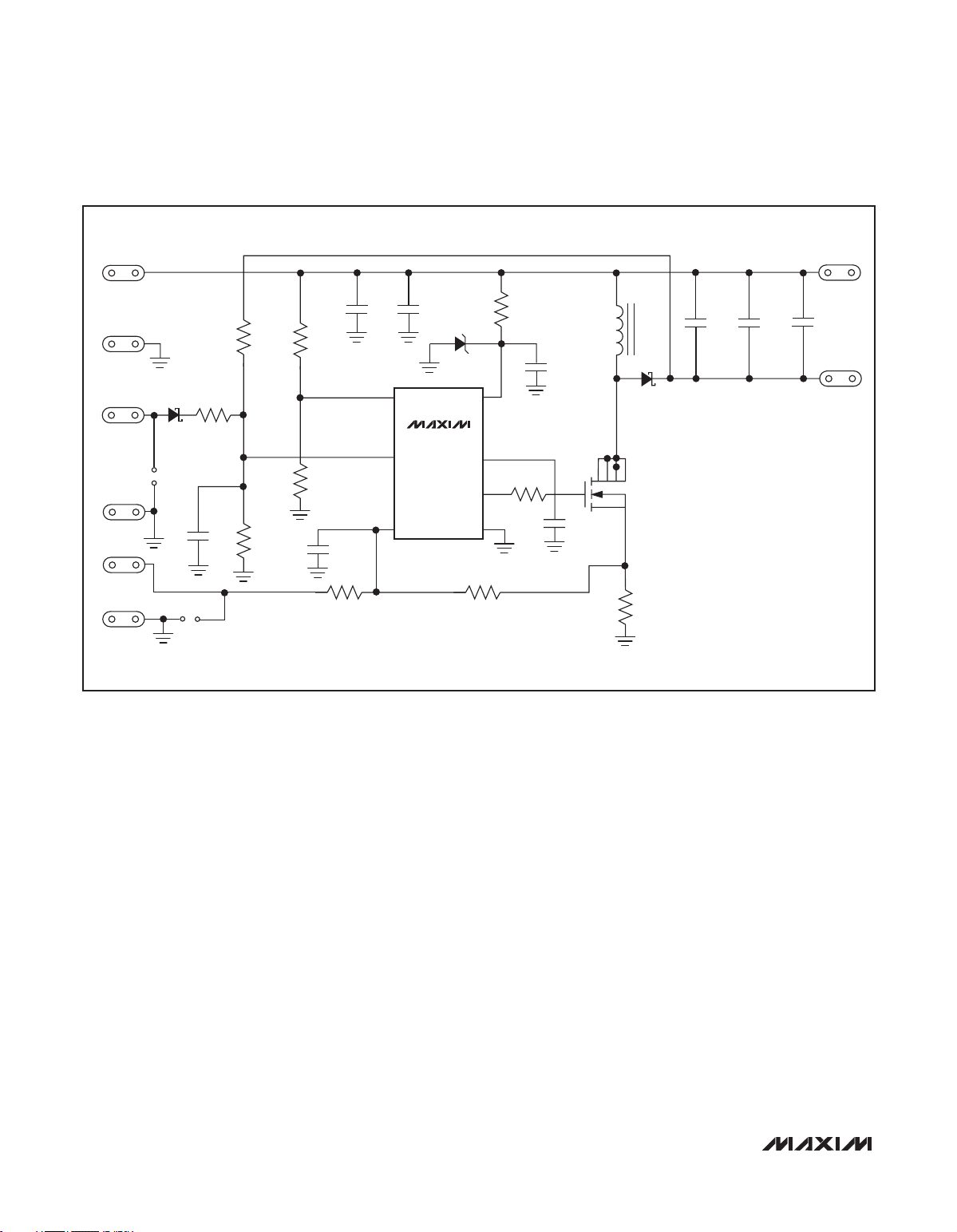

ᅄ2/! NBY27913CຶৰۇᏇಯᅄ

+VIN

1%

R1

392kΩ

1%

R5

C9

R2

1nF

11kΩ

50V

1%

GND

D3

SD103CWS

J2

1kΩ

PWM_IN

J1

PWM_GND

LIN_IN

LIN_GND

R3

499kΩ

1%

R4

73.2kΩ

1%

C8

470pF

50V

R7

1kΩ

1%

C1

4.7μF

50V

1

2

3

4

UVLO/EN

MAX16802B

DIM/FB

COMP

CS

C2

4.7μF

50V

-VLED

R6

330Ω

D1

1%

22V

C3

0.1μF

R10

1Ω

50V

3

C7

0.1μF

50V

8

IN

U1

7

V

CC

6

NDRV

5

GND

R8

220Ω

1%

12

56

L1

4.7μH

CMSH1-60M

Q1

Si3458DV

4

R9

0.10Ω

1%

C4

0.1μF

50V

D2

C5

4.7μF

50V

C6

4.7μF

50V

+VLED

ຶৰۇǖNBY27913C

NBY27913Cຶৰۇ

ᅄ3/! NBY27913CຶৰۇᏄୈݚ—Ꮔୈށ ᅄ4/! NBY27913CຶৰۇQDCݚ—Ꮔୈށ

ᅄ5/! NBY27913CຶৰۇQDCݚ—ށ

Nbyjnݙ࣪ Nbyjnޘອጲᅪࡼྀ࢟വဧঌᐊLjጐݙᄋᓜಽభăNbyjnۣഔᏴྀဟମĂᎌྀᄰۨࡼ༄ᄋሆኀখޘອᓾ೯ৃࡼཚಽă

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ______________________5

© 2006 Maxim Integrated Products Printed USA

ဵ

Nbyjn!Joufhsbufe!Qspevdut-!Jod/

ࡼᓖݿܪă

MAX16802BEVKIT MAX16802B评估板 - 概述

ENGLISH • 简体中文 • 日本語 • 한국어

Login | Register

请输入关键词或器件型号

最新内容 产品 方案 设计 应用 技术支持 销售联络 公司简介 我的Maxim

Maxim > 产品 > 电源和电池管理 > MAX16802BEVKIT

MAX16802BEVKIT

MAX16802B评估板

概述 技术文档 定购信息 用户说明 (0) 所有内容

状况

状况:生产中。

概述

MAX16802B评估板(EV kit) 用来演示基于MAX16802B的电流控制型、大电

流LED驱动器。该评估板具备高达750mA的稳定电流供给能力,并可运行

在10.8V至30V电源电压之间,工作温度范围为-40°C至+85°C。

MAX16802B评估板具有两种不同类型的亮度控制方式:使用模拟输入电压

或PWM输入信号来控制LED亮度。该评估板还具有UVLO功能,可以在输入电源

电压过低时关闭评估板,并且可以在LED开路时为评估板提供过压保

护。MAX16802B评估板是一块经过完全安装与测试的电路板。

完整的数据资料

英文

中文

下载

下载

Rev. 0 (PDF, 132kB)

Rev. 0 (PDF, 640kB)

警告:当出现严重故障或失效状态时,本评估板有巨大能量耗散,可能会造成元件或元件碎片的高速溅射。请小心操作本

评估板,以避免可能的人身伤害。

关键特性 应用/使用

10.8V至30V电源电压范围

电流控制型输出

12V输出时,电流可高达750mA

线性或PWM亮度控制

满载时效率高达80%

商用与工业照明

装饰灯与建筑照明

离线式DC- DC LED驱动器

RGB背光,用于LCD TV和监视

器

电源电压欠压锁定

输出过压保护

相关产品

MAX16801,

离线式、DC- DC PWM 控制器,用于高亮度LED驱动器

MAX16801A,

MAX16801B,

MAX16802,

MAX16802A,

MAX16802B

没有找到你需要的产品吗?

应用工程师帮助选型,下个工作日回复

参数搜索

应用帮助

概述 技术文档 定购信息

概述 数据资料 价格与供货

http://china.maxim-ic.com/datasheet/index.mvp/id/5209[2010-8-12 8:16:14]

MAX16802BEVKIT MAX16802B评估板 - 概述

关键特性

应用/使用

关键指标

图表

注释、注解

相关产品

联络我们:信息反馈、提出问题 • 对该网页的评价 • 发送本网页 • 隐私权政策 • 法律声明

© 2010 Maxim Integrated Products 版权所有

应用笔记

评估板

设计指南

可靠性报告

软件/模型

参考文献: 19-0560 Rev. 0; 2006-05-30

本页最后一次更新: 2006-07-20

样品

在线订购

封装信息

无铅信息

http://china.maxim-ic.com/datasheet/index.mvp/id/5209[2010-8-12 8:16:14]

General Description

The MAX16802B evaluation kit (EV kit) demonstrates a

current-controlled, high-output-current LED driver

based on the MAX16802B. This EV kit is capable of

supplying stable output currents of up to 750mA, can

run at supply voltages between 10.8V and 30V, and can

operate at temperatures ranging from -40°C to +85°C.

The MAX16802B EV kit features two different types of

dimming controls using either a linear input voltage or a

PWM input signal to control the LED brightness. This EV

kit also has a UVLO feature to turn off the EV kit operation during low input supply voltage and an overvoltage

protection to protect the EV kit under an open-LED condition. The MAX16802B EV kit is a fully assembled and

tested board.

Warning: Under severe fault or failure conditions, this

EV kit may dissipate large amounts of power, which

could result in the mechanical ejection of a component

or of component debris at high velocity. Operate this

EV kit with care to avoid possible personal injury.

Features

♦ 10.8V to 30V Wide Supply Voltage Range

♦ Current-Controlled Output

♦ Up to 750mA LED Current at 12V Output

♦ Linear and PWM Dimming Control

♦ Over 80% Efficiency at Full Load

♦ Supply Undervoltage Lockout

♦ Output Overvoltage Protection

Evaluates: MAX16802B

MAX16802B Evaluation Kit

________________________________________________________________ Maxim Integrated Products 1

19-0560; Rev 0; 5/06

Component List

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Ordering Information

µMAX is a registered trademark of Maxim Integrated Products, Inc.

DESIGNATION QTY DESCRIPTION

C1, C2, C5, C6 4

C3, C4, C7 3

C8 1

C9 1

D1 1

D2 1

D3 1

J1, J2 2

4.7µF, 50V X7R ceramic capacitors

Murata GRM32ER71H475KA88L

0.1µF, 50V X7R SMD ceramic

capacitors

Murata GRM188R71H104KA93D or

TDK C1608X7R1H104K

470pF, 50V X7R ceramic capacitor

Murata GRM188R71H471KA01D or

TDK C1608X7R1H471K

1nF, 50V X7R ceramic capacitor

Murata GRM188R71H102KA01D or

TDK C1608X7R1H102K

22V, 1.5W zener diode

Vishay SMZG3797B

60V, 1A Schottky diode

Central Semiconductor CMSH1-60M

or Diodes Inc. B160

20V, small-signal Schottky diode

Vishay SD103CWS or

Diodes Inc. SD103CWS

0.1in, 2-pin hole headers

(through hole)

PART TEMP RANGE IC PACKAGE

MAX16802BEVKIT -40°C to +85°C 8 µMAX

®

DESIGNATION QTY DESCRIPTION

L1 1

Q1 1

R1 1 392kΩ ±1%, 1/8W resistor (0603)

R2 1 11kΩ ±1%, 1/8W resistor (0603)

R3 1 499kΩ ±1%, 1/8W resistor (0603)

R4 1 73.2kΩ ±1%, 1/8W resistor (0603)

R5, R7 2 1kΩ ±1%, 1/8W resistors (0603)

R6 1 330Ω ±1%, 1/4W resistor (1206)

R8 1 220Ω ±1%, 1/8W resistor (0603)

R9 1

R10 1 1Ω ±5%, 1/8W resistor (0603)

U1 1 MAX16802B (8-pin µMAX)

VIN, VLED,

PWM_IN,

LIN_IN

— 1 MAX16802B PC board

4.7µH, 4.2A peak SMD inductor

Coilcraft DO3308P-472ML

60V, 3.2A n-channel MOSFET

Vishay Si3458DV

0.10Ω ±1%, 1/2W resistor (1206)

Susumu RL1632R-R100-F

0.1in, 2-pin male connectors

4

(through hole)

Evaluates: MAX16802B

MAX16802B Evaluation Kit

2 _______________________________________________________________________________________

Quick Start

The MAX16802B EV kit is fully assembled and tested.

Follow these steps to verify operation. Do not turn on

the power supply until all connections are completed.

1) Connect a DC power supply (0 to 30V or above, 1A)

to +VIN and GND.

2) Connect a voltmeter or oscilloscope and the LED

array (connected in series to drop about 12V at

750mA forward current) to +VLED and -VLED with

anode connected to +VLED and cathode to -VLED.

3) Close the jumpers J1 and J2 to disable dimming.

4) Turn on the power supply and increase the input

voltage to above 10.8V. The output voltage increases to forward bias the LED array and delivers

approximately 750mA regulated average LED current. Increase the supply further up to 30V and the

output average current will be regulated throughout

the range.

5) Open shunt J1 and apply a PWM signal to PWM_IN

with a frequency of 200Hz and 0 to 2V amplitude.

Vary the duty cycle from 0 to 100% and the LED

brightness varies from 100% to 0%. When the PWM

duty cycle is 0%, the LED brightness is 100%.

6) Close J1, and then open J2. Connect a variable voltage source to LIN_IN and vary the voltage between

0 and 1.6V. The LED brightness varies from 100% to

0%. When the voltage input at LIN_IN is 0V, the LED

brightness is 100%.

Caution: Avoid powering up the EV kit without connecting load.

Detailed Description

The MAX16802B evaluation kit is a current-controlled,

high-output-current LED driver capable of supplying

constant currents up to 750mA, irrespective of supply

voltage variations.

This EV kit is based on a discontinuous current mode

(DCM) buck-boost converter operating at 262kHz to

deliver a finite amount of energy to the output every

cycle. The amount of this energy depends primarily on

the value of the inductor and the user-programmable

peak inductor current and does not depend on the supply voltage. Due to this configuration, the power output

of the EV kit, and thus the output current supplied to the

LED at a given LED operating voltage, becomes independent of the supply voltage.

This EV kit is designed to drive LED loads capable of

taking up to 750mA of maximum current at a 12V operating voltage. If an LED load with lower operating voltage

is used, then the maximum output current will increase

by the same ratio to maintain the output power constant.

To drive an LED array with a different operating voltage,

the value of the current-sense resistor needs to be

adjusted. Calculation of the current-sense resistor for a

different output operating voltage is explained in later

sections.

Input Supply UVLO

Input supply UVLO is implemented by using a resistor

network that combines R3 and R4, which senses the

input supply voltage and uses the EN pin to turn on the

circuit when the input supply voltage goes above

10.8V. The wake-up threshold of EN is 1.23V when the

voltage at EN is rising, and it has a hysteresis of 50mV.

Once the device is turned on, due to the hysteresis, the

device turns off only if the input supply voltage goes

below 10.4V.

The UVLO threshold can be adjusted by varying R1 or

R2 using the equation below:

where V

UVLO

is the desired UVLO threshold. To main-

tain threshold accuracy, keep the value of R4 less than

100kΩ.

Component Suppliers

Note: Indicate you are using the MAX16802B when contacting these manufacturers.

V

⎛

R

UVLO

3

⎜

⎝

123

.

⎞

R

14=−

×

⎟

⎠

SUPPLIER PHONE FAX WEBSITE

Central Semiconductor 631-435-1110 631-435-3388 www.centralsemi.com

Coilcraft 847-639-6400 847-639-1469 www.coilcraft.com

Diodes Inc. 805-446-4800 805-446-4850 www.diodes.com

Murata 770-436-1300 770-436-3030 www.murata.com

Susumu Co Ltd. 208-328-0307 208-328-0308 www.susumu-usa.com

TDK 847-390-4373 847-390-4428 www.component.tdk.com

Vishay 402-563-6866 402-563-6296 www.vishay.com

Output Overvoltage Protection

The maximum voltage at the positive pin of VLED with

respect to GND is limited to 45V by a feedback network

formed by R1 and R2, which is connected to the FB pin

of the MAX16802B. If the EV kit is turned on with no load

or if the LED connection opens, the voltage at the positive pin of VLED may rise to unsafe levels. This condition

is sensed by the internal error amplifier, which reduces

the peak inductor current to limit the voltage at the positive pin of VLED to 45V. Even if this protection is present,

it is recommended to connect the specified load before

powering up the EV kit.

PWM Dimming

The PWM dimming is for controlling the LED brightness

by adjusting the duty cycle of the PWM input signal

connected to the PWM_IN input. A HIGH at PWM_IN

input turns off the LED current and LOW turns on the

LED current. Connect a signal with peak amplitude

between 1.5V to 5.0V and with frequency between

100Hz to 1000Hz and vary the duty cycle to adjust the

LED brightness. Frequencies lower than 100Hz can

introduce flickering in the light output. LED brightness

reduces when duty cycle is increased and vice-versa.

When the PWM duty cycle is 0%, the LED brightness

will be 100%.

Linear Dimming

The linear dimming is for controlling the LED brightness

by varying the amplitude of the voltage connected to

the LIN_IN input. The voltage at the LIN_IN input modulates the current-sense signal and makes the MOSFET

trip at a different current level. This process, in turn,

changes the output current and thus controls the LED

brightness. Since the LED is continuously on at all

brightness levels, flickering effect is not present with

linear dimming. Vary the LIN_IN voltage between 0 and

1.6V to adjust LED brightness from 100% to 0%. LED

brightness reduces when the voltage at LIN_IN is

increased and vice-versa. When the voltage at LIN_IN

is 0V the LED brightness is 100%.

Adjusting the Output Power

To change the maximum output power of the EV kit

from 12V at 750mA to a different level, adjust the value

of the current-sense resistor, R9, using the following

equations. Note that the maximum output current of the

EV kit is limited to 750mA, the maximum output voltage

is limited to 15V, and the maximum output power is limited to 8.25W.

Initially calculate the approximate optimum ON duty

cycle required at the minimum input voltage:

where V

INMIN

is the minimum input supply voltage,

V

LED

is the LED operating voltage, I

LED

is the desired

LED current and VDis the forward voltage of D2.

Calculate the approximate required peak inductor current:

where kfis a noncritical “fudge factor” set equal to 1.1

for this circuit.

Calculate the approximate required inductor value and

choose the closest standard value smaller than the calculated value:

where L is the inductance value of inductor L1, and f

SW

is the switching frequency equal to 262kHz.

Power transferred to the output circuit by the flyback

process is:

Power consumed by the output circuit is:

Conservation of power requires that the above two

equations can be equated and solved for a more precise value of the required peak inductor current.

Set the value of the current-sense resistor, R9, based

on the I

PEAK

value using the following equation:

where 0.292V is the current-sense trip threshold voltage. R7 and R8 form a voltage-divider, which scales

down the voltage across the current-sense resistor

before reaching the current-sense pin of the device.

Jumper Selection

Keep jumper J1 closed when PWM dimming is not

used. Keep jumper J2 closed when linear dimming is

not used.

Evaluates: MAX16802B

MAX16802B Evaluation Kit

_______________________________________________________________________________________ 3

VV

+

D

=

ON

LED D

VVV

++

INMIN LED D

kI

××

f LED

I

=

P

D

−21

ON

DV

×

ON INMIN

L

=

fI

×

SW P

1

PLIf

=×× ×

IN P SW

2

2

PVIVI

=×+×

OUT LED LED D LED

×+×

⎛

2( )VVI

IP=

LED D LED

⎜

⎝

×

fL

SW

⎞

⎟

⎠

0 292 8 7

R

9

=

RR

×+

.( )

IR

PEAK

7

×

Evaluates: MAX16802B

MAX16802B Evaluation Kit

4 _______________________________________________________________________________________

Figure 1. MAX16802B EV Kit Schematic

+VIN

1

2

3

4

UVLO/EN

MAX16802B

DIM/FB

COMP

CS

C2

4.7µF

50V

C1

4.7µF

C8

470pF

50V

R7

1kΩ

1%

50V

R5

1%

C9

1nF

50V

R1

392kΩ

1%

R2

11kΩ

1%

GND

D3

SD103CWS

J2

1kΩ

PWM_IN

J1

PWM_GND

LIN_IN

LIN_GND

R3

499kΩ

1%

R4

73.2kΩ

1%

-VLED

R6

330Ω

D1

1%

22V

C3

0.1µF

R10

1Ω

50V

3

C7

0.1µF

50V

8

IN

U1

7

V

CC

6

NDRV

5

GND

R8

220Ω

1%

12

56

L1

4.7µH

CMSH1-60M

Q1

Si3458DV

4

R9

0.10Ω

1%

C4

0.1µF

50V

D2

C5

4.7µF

50V

C6

4.7µF

50V

+VLED

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 _____________________ 5

© 2006 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products, Inc.

Evaluates: MAX16802B

MAX16802B Evaluation Kit

Boblet

Figure 2. MAX16802B EV Kit Component Placement Guide—

Component Side

Figure 3. MAX16802B EV Kit PC Board Layout—Component

Side

Figure 4. MAX16802B EV Kit PC Board Layout—Solder Side

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

General Description

The MAX16801A/B/MAX16802A/B high-brightness (HB)

LED driver-control ICs contain all the circuitry required

for the design of wide-input-voltage-range LED drivers

for general lighting and display applications. The

MAX16801 is well suited for universal input (rectified

85VAC to 265VAC) LED drivers, while the MAX16802 is

intended for low-input-voltage (10.8VDC to 24VDC) LED

drivers.

When the LED current needs to be tightly regulated, an

additional on-board error amplifier with 1% accurate reference can be utilized. A wide dimming range can be

implemented by using low-frequency PWM dimming.

The MAX16801/MAX16802 feature an input undervoltage

lockout (UVLO) for programming the input-supply start

voltage, and to ensure proper operation during brownout

conditions. The MAX16801 has an internal-bootstrap

undervoltage lockout circuit with a large hysteresis that

simplifies offline LED driver designs. The MAX16802 does

not have this internal bootstrap circuit and can be biased

directly from a +12V rail.

The 262kHz fixed switching frequency is internally

trimmed, allowing for optimization of the magnetic and filter components, resulting in a compact, cost-effective

LED driver. The MAX16801A/MAX16802A are offered with

50% maximum duty cycle. The MAX16801B/MAX16802B

are offered with 75% maximum duty cycle. These devices

are available in an 8-pin µMAX

®

package and operate

over the -40°C to +85°C temperature range.

Applications

Features

♦ Suitable for Buck, Boost, Flyback, SEPIC, and

Other Topologies

♦ Up to 50W or Higher Output Power

♦ Universal Offline Input Voltage Range: Rectified

85VAC to 265VAC (MAX16801)

♦ IN Pin Directly Driven From 10.8VDC to 24VDC

Input (MAX16802)

♦ Internal Error Amplifier with 1% Accurate

Reference for Precise LED Current Regulation

♦ PWM or Linear Dimming

♦ Fixed Switching Frequency of 262kHz ±12%

♦ Thermal Shutdown

♦ Digital Soft-Start

♦ Programmable Input Startup Voltage

♦ Internal Bootstrap UVLO with Large Hysteresis

(MAX16801)

♦ 45µA (typ) Startup Supply Current, 1.4mA (typ)

Operating Supply Current

♦ 50% (MAX16801A/MAX16802A) or 75%

(MAX16801B/MAX16802B) Maximum Duty Cycle

♦ Available in a Tiny 8-Pin µMAX Package

MAX16801A/B/MAX16802A/B

Offline and DC-DC PWM Controllers for

High-Brightness LED Drivers

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

19-3880; Rev 2; 1/10

PART

TEMP

RANGE

PINPACKAGE

MAX16801AEUA+ -40°C to +85°C 8 µMAX

MAX16801BEUA+ -40°C to +85°C 8 µMAX

MAX16802AEUA+ -40°C to +85°C 8 µMAX

MAX16802BEUA+ -40°C to +85°C 8 µMAX

+Denotes lead-free package.

Offline and DC-DC LED

Drivers

RGB Back Light for LCD

TVs and Monitors

Commercial and

Industrial Lighting

Decorative and

Architectural Lighting

EVALUATION KIT

AVAILABLE

Q1

MAX16802B

10.8VDC TO 24VDC

PWM

GND

C1 R1

L1

D1

C2

C3

LEDs

CS

COMP

DIM/FB

UVLO/EN IN

V

CC

NDRV

GND

ENABLE

Typical Operating Circuit

Warning: The MAX16801/MAX16802 are designed to work with high voltages. Exercise caution.

µMAX is a registered trademark of Maxim Integrated Products, Inc.

MAX16801A/B/MAX16802A/B

Offline and DC-DC PWM Controllers for

High-Brightness LED Drivers

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VIN= +12V (MAX16801: VINmust first be brought up to +23.6V for startup), 10nF bypass capacitors at IN and VCC, C

NDRV

= 0µF,

V

UVLO

= +1.4V, V

DIM/FB

= +1.0V, COMP = unconnected, VCS= 0V, TA= -40°C to +85°C, unless otherwise noted. Typical values are

at T

A

= +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

IN to GND

..........................................................................

-0.3V to +30V

V

CC

to GND

......................................................................

-0.3V to +13V

DIM/FB, COMP, UVLO, CS to GND..........................-0.3V to +6V

NDRV to GND.............................................-0.3V to (V

CC

+ 0.3V)

Continuous Power Dissipation (TA = +70°C)

8-Pin µMAX (derate 4.5mW/°C above +70°C) ..............362mW

Operating Temperature Range ...........................-40°C to +85°C

Storage Temperature Range ............................-65°C to +150°C

Junction Temperature......................................................+150°C

Lead Temperature (soldering, 10s) .................................+300°C

PARAMETER

CONDITIONS

UNDERVOLTAGE LOCKOUT/STARTUP

Bootstrap UVLO Wake-Up Level

V

SUVR

VIN rising (MAX16801 only)

V

Bootstrap UVLO Shutdown Level

V

SUVF

VIN falling (MAX16801 only)

V

UVLO/EN Wake-Up Threshold V

ULR2

UVLO/EN rising

V

UVLO/EN Shutdown Threshold V

ULF2

UVLO/EN falling

V

UVLO/EN Input Current I

UVLO

TJ = +125°C 25 nA

UVLO/EN Hysteresis 50 mV

IN Supply Current In

Undervoltage Lockout

I

START

VIN = +19V, for MAX16801 only when in

bootstrap UVLO

45 90 µA

IN Voltage Range V

IN

24 V

t

EXTR

UVLO/EN steps up from +1.1V to +1.4V 12

UVLO/EN Propagation Delay

t

EXTF

UVLO/EN steps down from +1.4V to +1.1V 1.8

µs

t

BUVR

VIN steps up from +9V to +24V 5

Bootstrap UVLO Propagation

Delay

t

BUVF

VIN steps down from +24V to +9V 1

µs

INTERNAL SUPPLY

VCC Regulator Set Point V

CCSP

VIN = +10.8V to +24V, sinking 1µA to 20mA

from V

CC

7

V

IN Supply Current After Startup I

IN

VIN = +24V 1.4 2.5 mA

Shutdown Supply Current UVLO/EN = low 90 µA

GATE DRIVER

)

Measured at NDRV sinking, 100mA 2 4

Driver Output Impedance

)

Measured at NDRV sourcing, 20mA 4 12

Ω

Driver Peak Sink Current 1A

Driver Peak Source Current

A

PWM COMPARATOR

Comparator Offset Voltage

V

COMP

- V

CS

V

CS Input Bias Current I

CS

VCS = 0V -2 +2 µA

Comparator Propagation Delay t

PWM

VCS = +0.1V 60 ns

Minimum On-Time

)

ns

SYMBOL

MIN TYP MAX UNITS

19.68 21.6 23.60

9.05 9.74 10.43

1.188 1.28 1.371

1.168 1.23 1.291

10.8

R

ON(LOW

R

ON(HIGH

VO

PWM

1.15 1.38 1.70

t

ON(MIN

0.65

150

10.5

MAX16801A/B/MAX16802A/B

Offline and DC-DC PWM Controllers for

High-Brightness LED Drivers

_______________________________________________________________________________________ 3

Note 1: All devices are 100% tested at TA= +85°C. All limits over temperature are guaranteed by characterization.

Note 2: V

REF

is measured with DIM/FB connected to the COMP pin (see the Functional Diagram).

Note 3: The MAX16801 is intended for use in universal input offline drivers. The internal clamp circuit is used to prevent the boot-

strap capacitor (C1 in Figure 5) from charging to a voltage beyond the absolute maximum rating of the device when

EN/UVLO is low. The maximum current to IN (hence to clamp) when UVLO is low (device in shutdown), must be externally

limited to 2mA (max). Clamp currents higher than 2mA may result in clamp voltage higher than +30V, thus exceeding the

absolute maximum rating for IN. For the MAX16802, do not exceed the +24V maximum operating voltage of the device.

ELECTRICAL CHARACTERISTICS (continued)

(VIN= +12V (MAX16801: VINmust first be brought up to +23.6V for startup), 10nF bypass capacitors at IN and VCC, C

NDRV

= 0µF,

V

UVLO

= +1.4V, V

DIM/FB

= +1.0V, COMP = unconnected, VCS= 0V, TA= -40°C to +85°C, unless otherwise noted. Typical values are

at T

A

= +25°C.) (Note 1)

PARAMETER

CONDITIONS

CURRENT-SENSE COMPARATOR

Current-Sense Trip Threshold V

CS

320 mV

CS Input Bias Current I

CS

VCS = 0V -2 +2 µA

Propagation Delay From

Comparator Input to NDRV

t

PWM

50mV overdrive 60 ns

Switching Frequency f

SW

290 kHz

MAX1680_A 50

Maximum Duty Cycle D

MAX

MAX1680_B 75 76

%

IN CLAMP VOLTAGE

IN Clamp Voltage V

INC

2mA sink current, MAX16801 only (Note 3)

V

ERROR AMPLIFIER

Voltage Gain R

LOAD

= 100kΩ 80 dB

Unity-Gain Bandwidth R

LOAD

= 100kΩ, C

LOAD

= 200pF 2

Phase Margin R

LOAD

= 100kΩ, C

LOAD

= 200pF 65

DIM/FB Input Offset Voltage 3mV

High 2.2 3.5

COMP Clamp Voltage

Low 0.4 1.1

V

Source Current 0.5 mA

Sink Current 0.5 mA

Reference Voltage V

REF

(Note 2)

V

Input Bias Current 50 nA

COMP Short-Circuit Current 8mA

THERMAL SHUTDOWN

Thermal-Shutdown Temperature

°C

Thermal Hysteresis 25 °C

DIGITAL SOFT-START

Soft-Start Duration

Clock

Reference Voltage Steps During

Soft-Start

31

Reference Voltage Step 40 mV

SYMBOL

MIN TYP MAX UNITS

262 291

230 262

24.1 26.1 29.0

1.218 1.230 1.242

130

15,872

50.5

MHz

D eg r ees

cycles

Steps

MAX16801A/B/MAX16802A/B

Offline and DC-DC PWM Controllers for

High-Brightness LED Drivers

4 _______________________________________________________________________________________

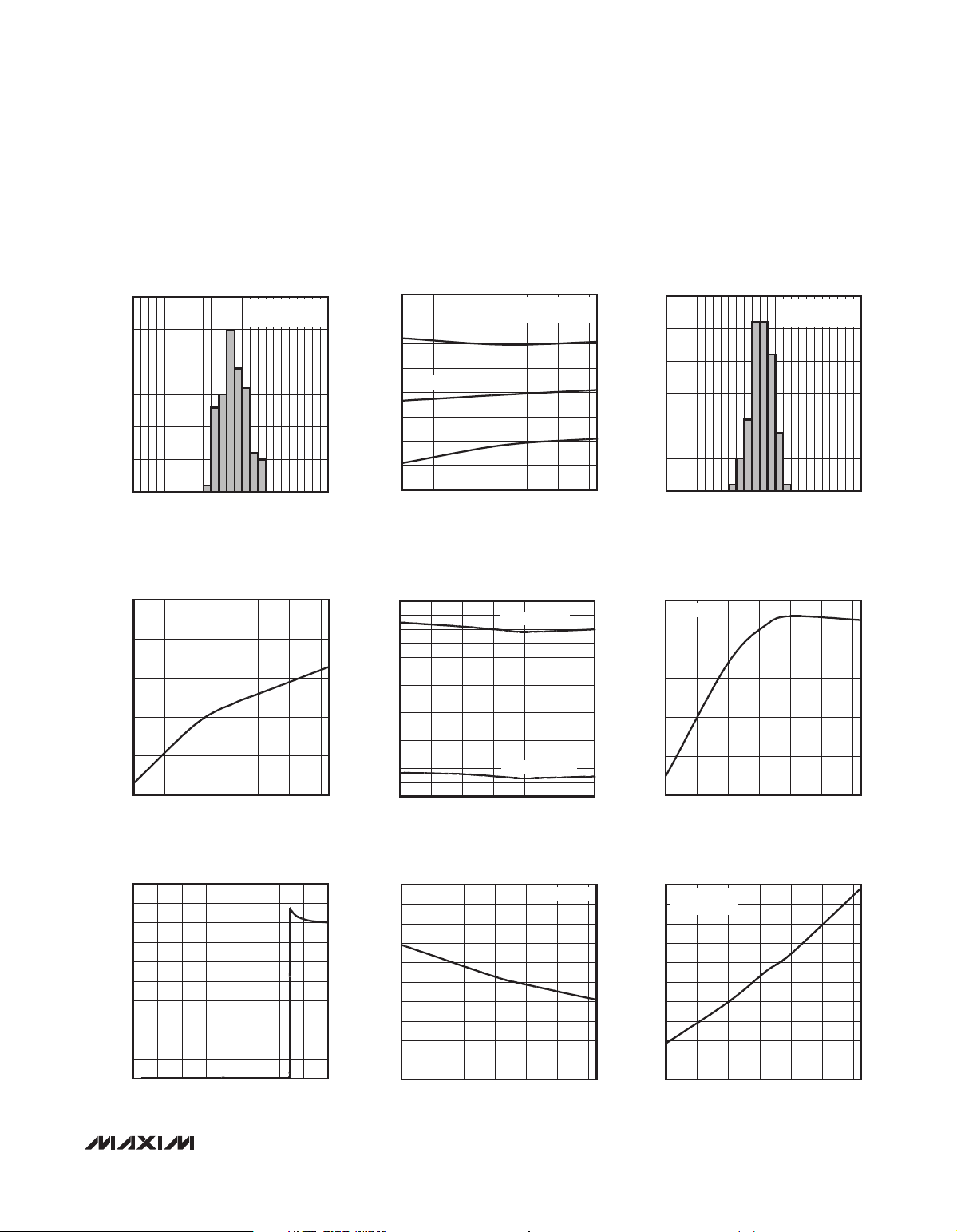

Typical Operating Characteristics

(V

UVLO/EN

= +1.4V, VFB= +1V, COMP = unconnected, VCS= 0V, TA= +25°C, unless otherwise noted.)

BOOTSTRAP UVLO WAKE-UP LEVEL

vs. TEMPERATURE

MAX16801 toc01

TEMPERATURE (°C)

V

IN

(V)

6040200-20

21.35

21.40

21.45

21.50

21.55

21.60

21.30

-40 80

MAX16801 VIN RISING

BOOTSTRAP UVLO SHUTDOWN LEVEL

vs. TEMPERATURE

MAX16801 toc02

TEMPERATURE (°C)

V

IN

(V)

6040200-20

9.8

9.9

10.0

10.1

9.7

-40 80

MAX16801 VIN FALLING

UVLO/EN WAKE-UP THRESHOLD

vs. TEMPERATURE

MAX16801 toc03

TEMPERATURE (°C)

UVLO/EN (V)

6040200-20

1.255

1.260

1.265

1.270

1.275

1.280

1.250

-40 80

UVLO/EN RISING

UVLO/EN SHUTDOWN THRESHOLD

vs. TEMPERATURE

MAX16801 toc04

TEMPERATURE (°C)

UVLO/EN (V)

6040200-20

1.15

1.20

1.25

1.30

1.10

-40 80

UVLO/EN FALLING

VIN SUPPLY CURRENT IN UNDERVOLTAGE

LOCKOUT vs. TEMPERATURE

MAX16801 toc05

TEMPERATURE (°C)

I

START

(µA)

6040200-20

43

44

45

46

47

48

49

50

51

52

42

-40 80

VIN = 19V

MAX16801 WHEN IN BOOTSTRAP UVLO

MAX16802 WHEN UVLO/EN IS LOW

VIN SUPPLY CURRENT AFTER STARTUP

vs. TEMPERATURE

MAX16801 toc06

TEMPERATURE (°C)

I

IN

(mA)

6040200-20

1.2

1.3

1.4

1.5

1.1

-40 80

VIN = 24V

VCC REGULATOR SET POINT

vs. TEMPERATURE

MAX16801 toc07

TEMPERATURE (°C)

V

CC

(V)

6040200-20

9.3

9.5

9.4

9.7

9.6

9.8

9.2

-40 80

VIN = 19V

NO LOAD

NDRV OUTPUT IS NOT

SWITCHING, V

FB

= 1.5V

NDRV OUTPUT IS

SWITCHING

VCC REGULATOR SET POINT

vs. TEMPERATURE

MAX116801 toc08

TEMPERATURE (°C)

V

CC

(V)

6040200-20

8.2

8.5

8.6

8.4

8.3

8.8

8.7

8.9

8.1

-40 80

VIN = 10.8V

10mA LOAD

20mA LOAD

CURRENT-SENSE THRESHOLD

vs. TEMPERATURE

MAX16801 toc09

TEMPERATURE (°C)

CURRENT-SENSE THRESHOLD (µV)

6040200-20

275

290

295

285

280

305

300

310

270

-40 80

+3σ

-3σ

MEAN

TOTAL NUMBER OF

DEVICES = 100

MAX16801A/B/MAX16802A/B

Offline and DC-DC PWM Controllers for

High-Brightness LED Drivers

_______________________________________________________________________________________ 5

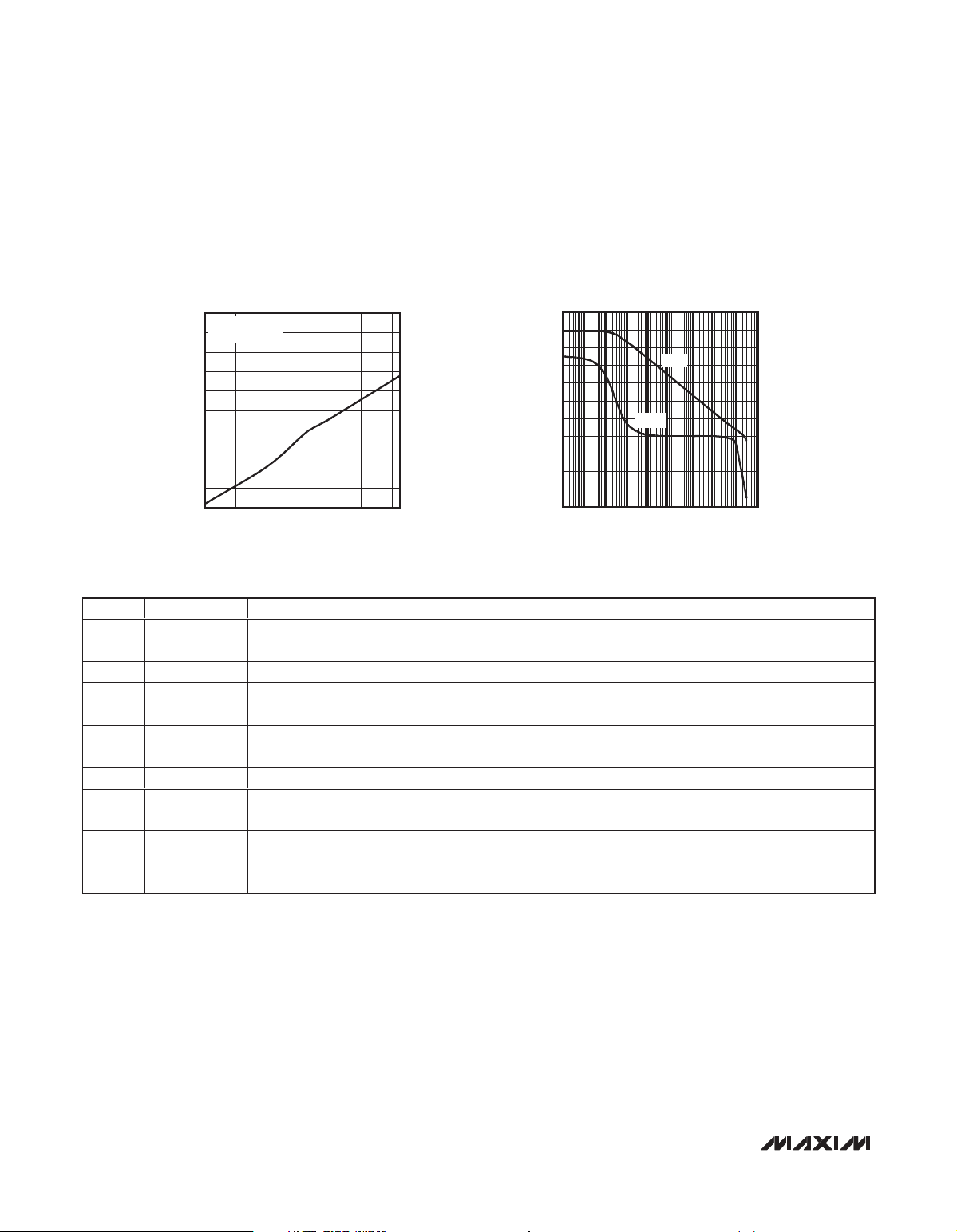

CURRENT-SENSE THRESHOLD

MAX16801 toc10

CURRENT-SENSE THRESHOLD (mV)

PERCENTAGE OF UNITS (%)

310300290280270

5

10

15

20

25

30

0

260 320

TOTAL NUMBER OF

DEVICES = 200

SWITCHING FREQUENCY

vs. TEMPERATURE

MAX16801 toc11

TEMPERATURE (°C)

SWITCHING FREQUENCY (kHz)

6040200-20

245

260

265

255

250

275

270

280

240

-40 80

+3σ

-3σ

MEAN

TOTAL NUMBER OF

DEVICES = 100

SWITCHING FREQUENCY

MAX16801 toc12

SWITCHING FREQUENCY (kHz)

PERCENTAGE OF UNITS (%)

280270260250240

5

10

15

20

25

30

0

230 290

TOTAL NUMBER OF

DEVICES = 200

PROPAGATION DELAY FROM

CURRENT-SENSE COMPARATOR INPUT

TO NDRV vs. TEMPERATURE

MAX16801 toc13

TEMPERATURE (°C)

t

PWM

(ns)

6040200-20

55

60

65

70

75

50

-40 80

UVLO/EN PROPAGATION DELAY

vs. TEMPERATURE

MAX16801 toc14

TEMPERATURE (°C)

UNDERVOLTAGE LOCKOUT DELAY (µs)

6040200-20

4

3

2

1

7

6

5

13

12

11

10

9

8

14

0

-40 80

UVLO/EN RISING

UVLO/EN FALLING

REFERENCE VOLTAGE

vs. TEMPERATURE

MAX16801 toc15

TEMPERATURE (°C)

REFERENCE VOLTAGE (V)

6040200-20

1.226

1.227

1.228

1.229

1.230

1.225

-40 80

VIN = 12V

INPUT CURRENT

vs. INPUT CLAMP VOLTAGE

MAX16801 toc16

INPUT VOLTAGE (V)

INPUT CURRENT (mA)

27.525.020.0 22.515.0 17.512.5

1

2

3

4

5

6

7

8

9

10

0

10.0 30.0

INPUT CLAMP VOLTAGE

vs. TEMPERATURE

MAX16801 toc17

TEMPERATURE (°C)

INPUT CLAMP VOLTAGE (V)

6040200-20

25.2

25.4

25.6

25.8

26.0

26.2

26.4

26.6

26.8

27.0

25.0

-40 80

IIN = 2mA

NDRV OUTPUT IMPEDANCE

vs. TEMPERATURE

MAX16801 toc18

TEMPERATURE (°C)

R

ON

(Ω)

6040200-20

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2.0

2.1

2.2

1.2

-40 80

VIN = 24V

SINKING 100mA

Typical Operating Characteristics (continued)

(V

UVLO/EN

= +1.4V, VFB= +1V, COMP = unconnected, VCS= 0V, TA= +25°C, unless otherwise noted.)

MAX16801A/B/MAX16802A/B

Detailed Description

The MAX16801/MAX16802 family of devices is intended for constant current drive of high-brightness (HB)

LEDs used in general lighting and display applications.

They are specifically designed for use in isolated and

nonisolated circuit topologies such as buck, boost, flyback, and SEPIC, operating in continuous or discontinuous mode. Current mode control is implemented with

an internally trimmed, fixed 262kHz switching frequency. A bootstrap UVLO with a large hysteresis (11.9V),

very low startup current, and low operating current

result in an efficient universal-input LED driver. In addition to the internal bootstrap UVLO, these devices also

offer programmable input startup voltage programmed

through the UVLO/EN pin. The MAX16801 is well suited

for universal AC input (rectified 85VAC to 265VAC) drivers. The MAX16802 is well suited for low input voltage

(10.8VDC to 24VDC) applications.

The MAX16801/MAX16802 regulate the LED current by

monitoring current through the external MOSFET cycle

by cycle.

Offline and DC-DC PWM Controllers for

High-Brightness LED Drivers

6 _______________________________________________________________________________________

Pin Description

NDRV OUTPUT IMPEDANCE

vs. TEMPERATURE

MAX16801 toc19

TEMPERATURE (°C)

R

ON

(Ω)

6040200-20

3.2

3.4

3.6

3.8

4.0

4.2

4.4

4.6

4.8

5.0

3.0

-40 80

VIN = 24V

SOURCING 20mA

ERROR-AMPLIFIER OPEN-LOOP GAIN

AND PHASE vs. FREQUENCY

MAX16801 toc20

FREQUENCY (Hz)

GAIN (dB)

10M1M10k1k 100k10 1001

-80

-60

-20

-40

0 -70

20

60

40

80

100

120

-100

PHASE (DEGREES)

-150

-130

-90

-110

-50

-10

-30

10

30

50

-170

0.1 100M

GAIN

PHASE

Typical Operating Characteristics (continued)

(V

UVLO/EN

= +1.4V, VFB= +1V, COMP = unconnected, VCS= 0V, TA= +25°C, unless otherwise noted.)

PIN NAME FUNCTION

1 UVLO/EN

Externally Programmable Undervoltage Lockout. UVLO programs the input start voltage. Connect

UVLO to GND to disable the device.

2 DIM/FB Low-Frequency PWM Dimming Input/Error-Amplifier Inverting Input

3 COMP

Error-Amplifier Output. Connect the compensation components between DIM/FB and COMP in highaccuracy LED current regulation.

4CS