Page 1

19-0876; Rev 1; 5/96

CMOS, µP-Compatible, 5µs/10µs, 8-Bit ADCs

_______________General Description

Maxim’s MX7575/MX7576 are high-speed (5µs/10µs),

microprocessor (µP) compatible, 8-bit analog-to-digital

converters (ADCs). The MX7575 provides an on-chip

track/hold function that allows full-scale signals up to

50kHz (386mV/µs slew rate) to be acquired and digitized accurately. Both ADCs use a successive-approximation technique to achieve their fast conversions and

low power dissipation. The MX7575/MX7576 operate

with a +5V supply and a 1.23V external reference. They

accept input voltages ranging from 0V to 2V

REF

.

The MX7575/MX7576 are easily interfaced to all popular 8-bit µPs through standard CS and RD control signals. These signals control conversion start and data

access. A BUSY signal indicates the beginning and

end of a conversion. Since all the data outputs are

latched and three-state buffered, the MX7575/MX7576

can be directly tied to a µP data bus or system l/O port.

Maxim also makes the MAX165, a plug-in replacement

for the MX7575 with an internal 1.23V reference. For

applications that require a differential analog input and

an internal reference, the MAX166 is recommended.

________________________Applications

Digital Signal Processing

High-Speed Data Acquisition

Telecommunications

Audio Systems

High-Speed Servo Loops

Low-Power Data Loggers

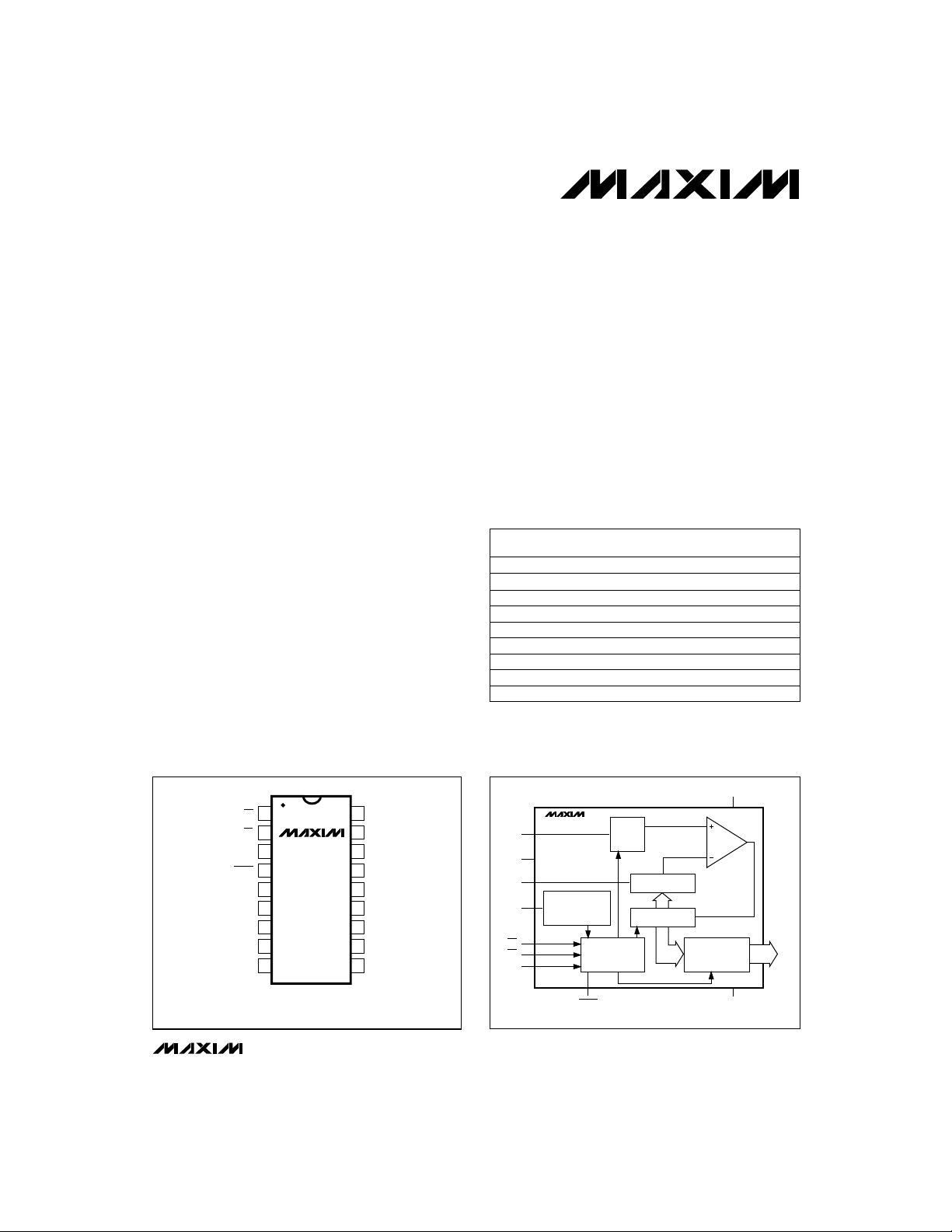

_________________Pin Configurations

____________________________Features

♦ Fast Conversion Time: 5µs (MX7575)

10µs (MX7576)

♦ Built-In Track/Hold Function (MX7575)

♦ Low Total Unadjusted Error (±1LSB max)

♦ 50kHz Full-Power Signal Bandwidth (MX7575)

♦ Single +5V Supply Operation

♦ 8-Bit µP Interface

♦ 100ns Data-Access Time

♦ Low Power: 15mW

♦ Small-Footprint Packages

______________Ordering Information

PART

MX7575JN

MX7575KN

MX7575JCWN 0°C to +70°C

MX7575KCWN 0°C to +70°C 18 Wide SO

MX7575JP 0°C to +70°C 20 PLCC

MX7575KP 0°C to +70°C 20 PLCC

MX7575J/D 0°C to +70°C Dice* ±1

MX7575AQ -25°C to +85°C 18 CERDIP**

MX7575BQ -25°C to +85°C 18 CERDIP**±1±1/2

TEMP. RANGE PIN-PACKAGE

0°C to +70°C

0°C to +70°C

18 Plastic DIP

18 Plastic DIP

18 Wide SO

Ordering Information continued at end of data sheet.

* Contact factory for dice specifications.

** Contact factory for availability.

INL

(LSB)

±1

±1/2

±1

±1/2

±1

±1/2

_______________Functional Diagrams

MX7575/MX7576

V

TOP VIEW

1

CS

2

RD

TP (MODE)

BUSY

CLK

D7 (MSB)

D6

D5

DGND

( ) ARE FOR MX7576 ONLY.

Pin Configurations continued at end of data sheet.

MX7575

3

MX7576

4

5

6

7

8

9

DIP/SO

________________________________________________________________

18

17

16

15

14

13

12

11

10

V

DD

REF

AIN

AGND

D0 (LSB)

D1

D2

D3

D4

MX7575

16

AIN

15

AGND

17

REF

CLOCK

5

CLK

Functional Diagrams continued at end of data sheet.

OSCILLATOR

1

CS

2

RD

3

TP

TRACK/

HOLD

CONTROL

LOGIC

49

BUSY DGND

Maxim Integrated Products

DAC

SAR

DD

18

COMP

LATCH AND

THREE-STATE

OUTPUT DRIVERS

6

D7

.

.

D0

14

1

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800

Page 2

CMOS, µP-Compatible, 5µs/10µs, 8-Bit ADCs

ABSOLUTE MAXIMUM RATINGS

VDDto AGND...............................................................-0.3V, +7V

to DGND ..............................................................-0.3V, +7V

V

DD

AGND to DGND...............................................-0.3V, V

Digital Input Voltage to DGND

(CS, RD, TP, MODE)......................................-0.3V, V

Digital Output Voltage to DGND

(BUSY, D0–D7)..............................................-0.3V, V

CLK Input Voltage to DGND............................-0.3V, V

REF to AGND...................................................-0.3V, V

AIN to AGND....................................................-0.3V, V

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

DD

DD

DD

DD

DD

DD

+ 0.3V

+ 0.3V

+ 0.3V

+ 0.3V

+ 0.3V

+ 0.3V

Continuous Power Dissipation (T

Plastic DIP (derate 11.11mW/°C above +70°C)...............889mW

= +70°C)

A

Wide SO (derate 9.52mW/°C above +70°C)..................762mW

CERDIP (derate 10.53mW/°C above +70°C).................842mW

PLCC (derate 10.00mW/°C above +70°C) ....................800mW

Operating Temperature Ranges

MX757_J/K............................................................0°C to +70°C

MX757_A/B........................................................-25°C to +85°C

MX757_JE/KE ....................................................-40°C to +85°C

MX757_S/T.......................................................-55°C to +125°C

Storage Temperature Range.............................-65°C to +160°C

Lead Temperature (soldering,10sec)..............................+300°C

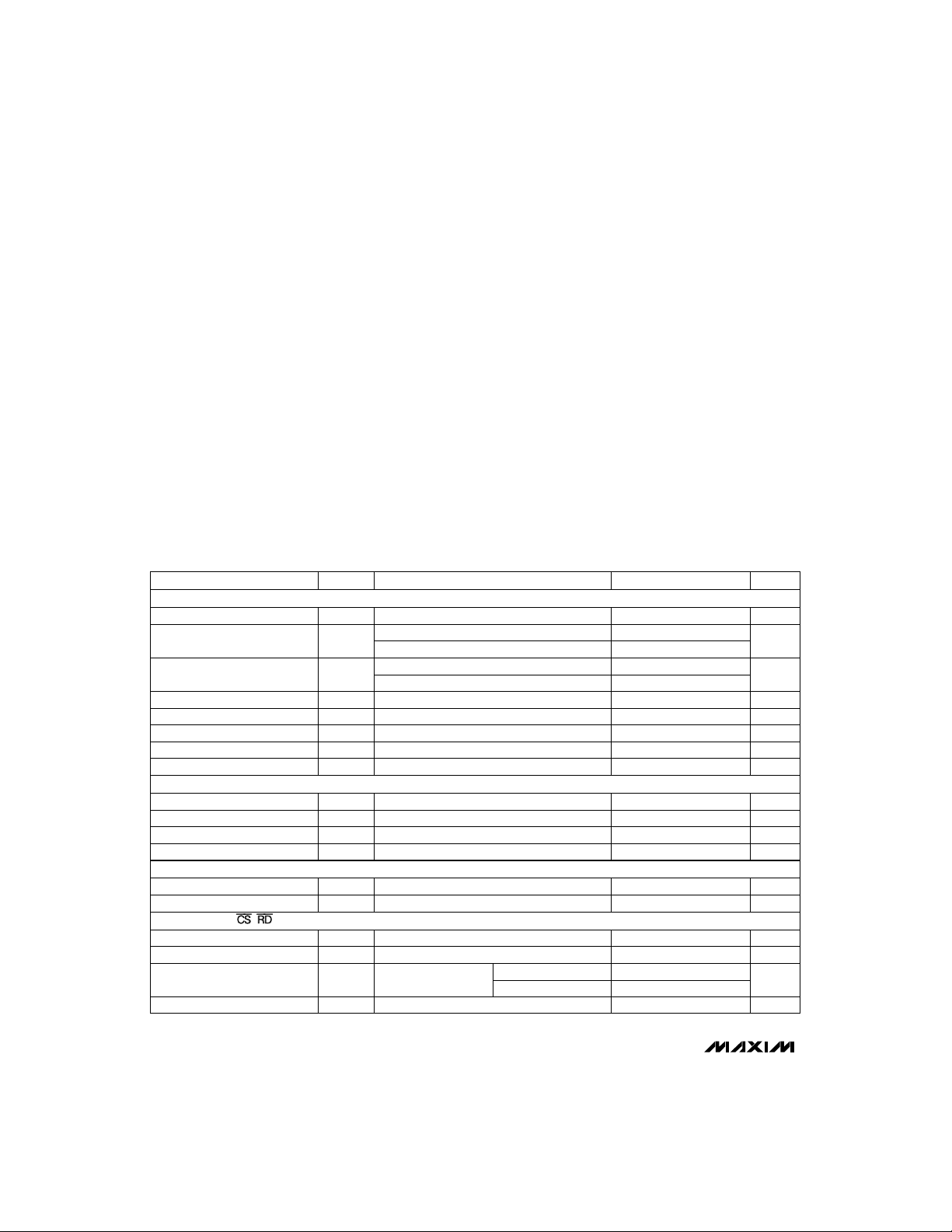

MX7575/MX7576

ELECTRICAL CHARACTERISTICS

(VDD= +5V; V

= T

T

to T

A

MIN

ACCURACY

ANALOG INPUT

Voltage Range

REFERENCE INPUT

Reference Voltage

Reference Current

LOGIC INPUTS CS, RD, MODE

Input Low Voltage

Input High Voltage

Input Current µA

Input Capacitance (Note 2)

= 1.23V; AGND = DGND = 0V; f

REF

, unless otherwise noted.)

MAX

TUETotal Unadjusted Error

INLRelative Accuracy

REF

REF

INL

INH

I

IN

IN

= 4MHz external for MX7575; f

CLK

CONDITIONS

MX757_K/B/T

MX757_J/A/S

MX757_K/B/T

MX757_J/A/S

1LSB = 2V

REF

/256

MX7575

MX7575, VIN= 2.46V

at 10kHz, Figure 13

p-p

±5% variation for specified performance

V

IN

= 0V or V

DD

TA= +25°C

TA= T

MIN

to T

MAX

= 2MHz external for MX7576;

CLK

±1

±2

±1/2

±1

REF

±1

±10

UNITSMIN TYP MAXSYMBOLPARAMETER

ppm/°C±5Full-Scale Tempco

ppm/°C±5Offset Tempco

Bits8Resolution

LSB

LSB

Bits8No-Missing-Codes Resolution

LSB±1Full-Scale Error

LSB±1/2Offset Error (Note 1)

V02V

MΩ10DC Input Impedance

V/µs0.386Slew Rate, Tracking

dB45SNRSignal-to-Noise Ratio (Note 2)

V1.23V

µA500I

V0.8V

V2.4V

pF10C

2 _______________________________________________________________________________________

Page 3

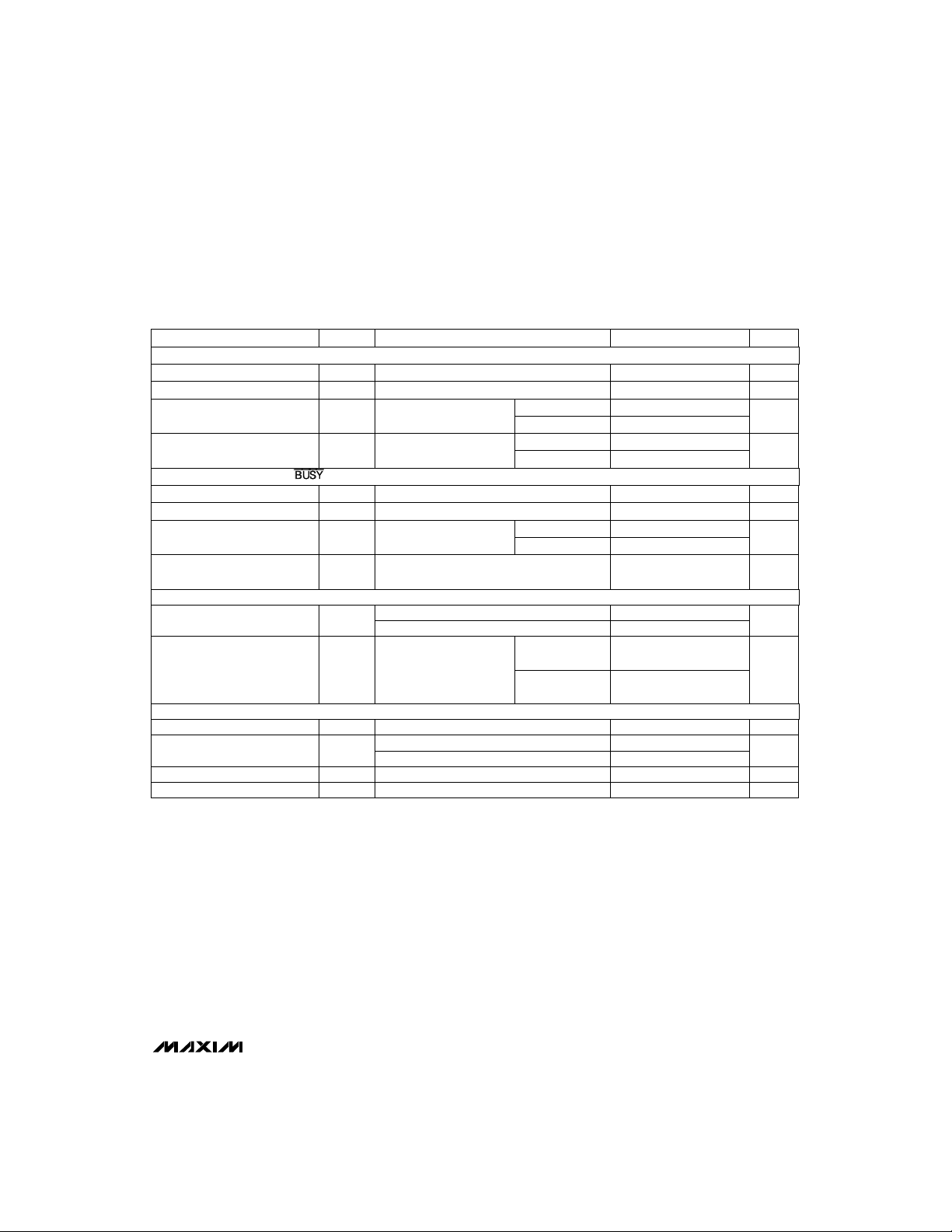

CMOS, µP-Compatible, 5µs/10µs, 8-Bit ADCs

BUSY

ELECTRICAL CHARACTERISTICS (continued)

(VDD= +5V; V

= T

T

to T

A

MIN

CLOCK

Input Low Voltage

Input High Voltage

Input Low Current

Input High Current

LOGIC OUTPUTS (D0–D7,

Output Low Voltage

Output High Voltage

Floating State Leakage Current

Floating State Output

Capacitance (Note 2)

CONVERSION TIME (Note 3)

Conversion Time with

External Clock

Conversion Time with

Internal Clock

POWER REQUIREMENTS (Note 4)

Supply Voltage

Supply Current

Note 1: Offset Error is measured with respect to an ideal first-code transition that occurs at 1/2LSB.

Note 2: Sample tested at +25°C to ensure compliance.

Note 3: Accuracy may degrade at conversion times other than those specified.

Note 4: Power-supply current is measured when MX7575/MX7576 are inactive, i.e.:

For MX7575 CS = RD = BUSY = high;

For MX7576 CS = RD = BUSY = MODE = high.

= 1.23V; AGND = DGND = 0V; f

REF

, unless otherwise noted.)

MAX

INL

INH

I

INL

I

INH

)

OL

OH

DD

I

DD

= 4MHz external for MX7575; f

CLK

CONDITIONS

VIN= 0V

VIN= V

DD

I

= 1.6mA

SINK

I

= 40µA

SOURCE

V

= 0V to VDD, D0–D7

OUT

MX757_J/A/K/B

MX757_S/T

MX757_J/A/K/B

MX757_S/T

TA= +25°C

TA= T

D0–D7

MX7575: f

MX7576: f

CLK

CLK

= 4MHz

= 2MHz

Using recommended

clock components:

= 100kΩ,

R

CLK

= 100pF;

C

CLK

= +25°C

T

A

±5% for specified performance

MX757_J/A/K/B

MX757_S/T

4.75V < VDD< 5.25V LSB±1/4Power-Supply Rejection

MIN

MX7575

MX7576

to T

CLK

MAX

= 2MHz external for MX7576;

UNITSMIN TYP MAXSYMBOLPARAMETER

V0.8V

V2.4V

700

800

700

800

µA

µA

V0.4V

V4.0V

±1

±10

µA

pF10

5

10

µs

515

µs

10 30

V5V

36

mA

7

mW15Power Dissipation

MX7575/MX7576

_______________________________________________________________________________________ 3

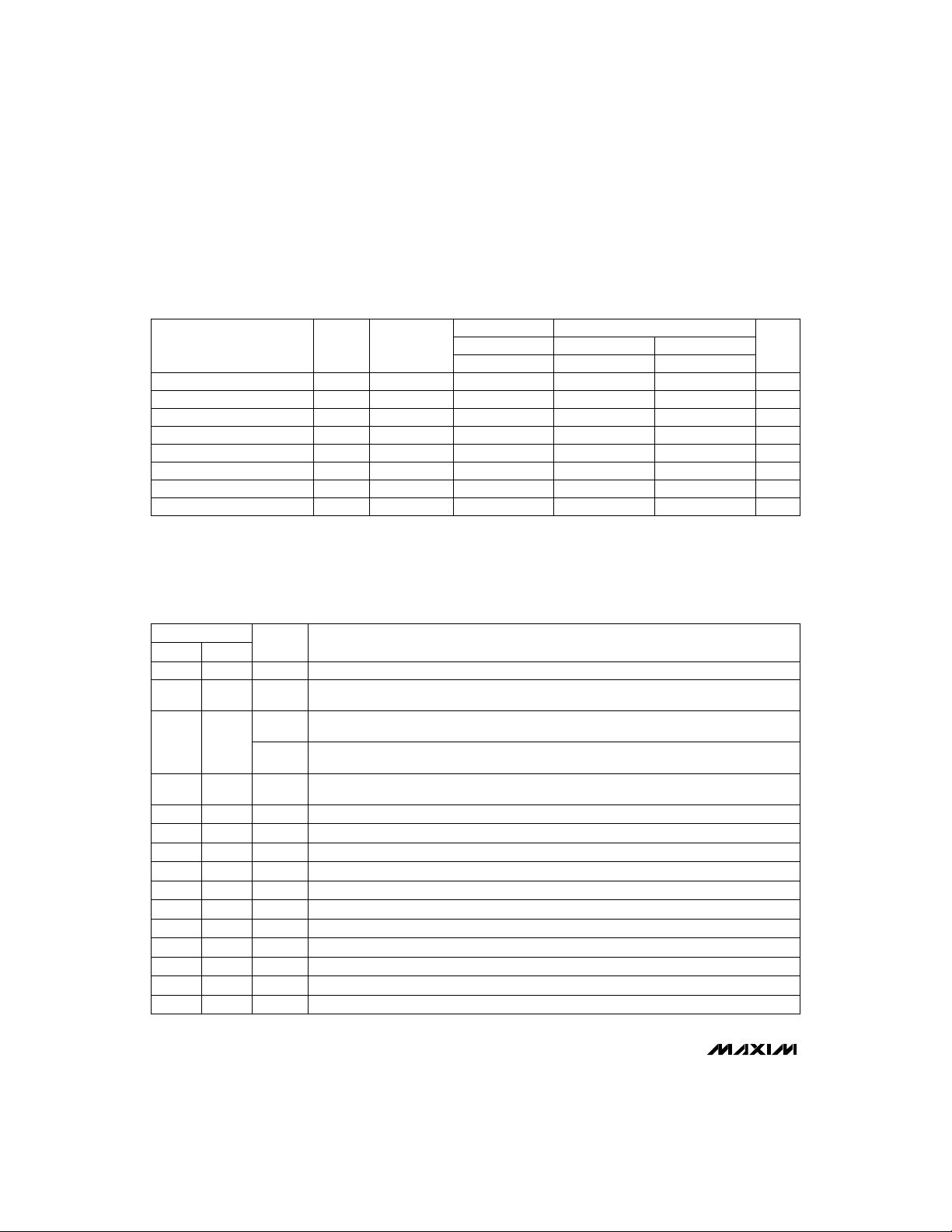

Page 4

CMOS, µP-Compatible, 5µs/10µs, 8-Bit ADCs

TIMING CHARACTERISTICS (Note 5)

(VDD= +5V, V

CS to RD Setup Time

RD to BUSY Propagation Time

Data-Access Time after RD

RD Pulse Width

CS to RD Hold Time

Data-Access Time after BUSY

Data-Hold Time t

MX7575/MX7576

BUSY to CS Delay

Note 5: Timing specifications are sample tested at +25°C to ensure compliance. All input control signals are specified with

Note 6: t3and t6are measured with the load circuits of Figure 1 and defined as the time required for an output to cross 0.8V or 2.4V.

Note 7: t

______________________________________________________________Pin Description

= 1.23V, AGND = DGND = 0V.)

REF

TA= +25°C TA= T

PARAMETER SYMBOL CONDITIONS

t

1

t

2

t

(Note 6) 100 100 120 ns

3

t

4

t

5

t

(Note 6) 80 80 100 ns

6

(Note 7) 10 80 10 80 10 100 ns

7

t

8

t

= tf= 20ns (10% to 90% of +5V) and timed from a voltage level of 1.6V.

r

is defined as the time required for the data lines to change 0.5V when loaded with the circuits of Figure 2.

7

ALL J/K/A/B S/T

MIN MAX MIN MAX MIN MAX

0 0 0 ns

100 100 120 ns

100 100 120 ns

0 0 0 ns

0 0 0 ns

MIN

to T

MAX

UNITS

PIN

DIP/SO

10–13 D4–D1 Three-State Data Outputs, bits 4–1

4 _______________________________________________________________________________________

PLCC

1

2

3

4

5 CLK External Clock Input/Internal Oscillator Pin for frequency setting RC components.

6 D7 Three-State Data Output, bit 7 (MSB)

7, 8 D6, D5 Three-State Data Outputs, bits 6 and 5

9 DGND Digital Ground

12–15

14 D0 Three-State Data Output, bit 0 (LSB)

15 AGND Analog Ground

16 AIN Analog Input. 0V to 2V

17 REF Reference Input. +1.23V nominal.

18 V

— N.C. No Connect

1, 11

NAME FUNCTION

2

3

4

5

6

7

8, 9

10

16

17

19

20

CS Chip Select Input. CS must be low for the device to be selected or to recognize the RD input.

Read Input. RD must be low to access data. RD is also used to start conversions. See the

RD

TP

(MX7575)

MODE

(MX7576)

BUSY

DD

Microprocessor Interface

Test Point. Connect to VDD.

Mode Input. MODE = low puts the ADC into its asynchronous conversion mode. MODE has to be

tied high for the synchronous conversion mode and the ROM interface mode.

BUSY Output. BUSY going low indicates the start of a conversion. BUSY going high indicates the

end of a conversion.

Power-Supply Voltage. +5V nominal.

REF

section.

input range.18

Page 5

CMOS, µP-Compatible, 5µs/10µs, 8-Bit ADCs

+5V

3k

D_ D_

100pF

DGND DGND

a) HIGH-Z TO V

NOTE: D_ REPRESENTS ANY OF THE DATA OUTPUTS

Figure 1. Load Circuits for Data-Access Time Test

OH

b) HIGH-Z TO V

100pF3k

OL

_______________Detailed Description

The MX7575 and MX7576 use the successive-approximation technique to convert an unknown analog input

voltage to an 8-bit digital output code (see

Diagrams

). The MX7575 samples the input voltage on

an internal capacitor once (at the beginning of the conversion), while the MX7576 samples the input signal

eight times during the conversion (see

Track/Hold

and

MX7576 Analog Input

internal DAC is initially set to half scale, and the comparator determines whether the input signal is larger

than or smaller than half scale. If it is larger than half

scale, the DAC MSB is kept. But if it is smaller, the MSB

is dropped. At the end of each comparison phase, the

SAR (successive-approximation register) stores the

results of the previous decision and determines the

next trial bit. This information is then loaded into the

DAC after each decision. As the conversion proceeds,

the analog input is approximated more closely by comparing it to the combination of the previous DAC bits

and a new DAC trial bit. After eight comparison cycles,

the eight bits stored in the SAR are latched into the output latches. At the end of the conversion, the BUSY signal goes high, and the data in the output latches is

ready for microprocessor (µP) access. Furthermore, the

DAC is reset to half scale in preparation for the next

conversion.

The CS and RD logic inputs are used to initiate conversions and to access data from the devices. The MX7575

and MX7576 have two common interface modes: slowmemory interface mode and ROM interface mode. In

addition, the MX7576 has an asynchronous conversion

mode (MODE pin = low) where continuous conversions

Converter Operation

Functional

MX7575

sections). The

Microprocessor Interface

+5V

3k

D_ D_

10pF

DGND DGND

a) VOH TO HIGH-Z b) VOL TO HIGH-Z

NOTE: D_ REPRESENTS ANY OF THE DATA OUTPUTS

Figure 2. Load Circuits for Data-Hold Time Test

10pF3k

are performed. In the slow-memory interface mode, CS

and RD are taken low to start a conversion and they

remain low until the conversion ends, at which time the

conversion result is latched. This mode is designed for

µPs that can be forced into a wait state. In the ROM

interface mode, however, the µP is not forced into a wait

state. A conversion is started by taking CS and RD low,

and data from the previous conversion is read. At the

end of the most recent conversion, the µP executes a

read instruction and starts another conversion.

For the MX7575, TP should be hard-wired to V

DD

ensure proper operation of the device. Spurious signals

may occur on TP, or excessive currents may be drawn

from VDDif TP is left open or tied to a voltage other than

VDD.

Slow-Memory Mode

Figure 3 shows the timing diagram for slow-memory

interface mode. This is used with µPs that have a waitstate capability of at least 10µs (such as the 8085A),

where a read instruction is extended to accommodate

slow-memory devices. A conversion is started by executing a memory read to the device (taking CS and RD

low). The BUSY signal (which is connected to the µP

READY input) then goes low and forces the µP into a

wait state. The MX7575 track/hold, which had been

tracking the analog input signal, holds the signal on the

third falling clock edge after RD goes low (Figure 12).

The MX7576, however, samples the analog input eight

times during a conversion (once before each comparator decision). At the end of the conversion, BUSY

returns high, the output latches and buffers are updated with the new conversion result, and the µP completes the memory read by acquiring this new data.

The fast conversion time of the MX7575/MX7576

ensures that the µP is not forced into a wait state for an

excessive amount of time. Faster versions of many µPs,

MX7575/MX7576

to

_______________________________________________________________________________________ 5

Page 6

CMOS, µP-Compatible, 5µs/10µs, 8-Bit ADCs

BUSY

DATA

CS

RD

HIGH-

IMPEDANCE

BUS

t

1

t

2

t

CONV

t

3

OLD DATA

t

6

NEW

DATA

t

7

t

5

IMPEDANCE

Figure 3. Slow-Memory Interface Timing Diagram

A8–A15

MX7575/MX7576

8085A-2

S0 RD

ALE

AD0–AD7

READY

* SOME CIRCUITRY OMITTED FOR CLARITY

S0 IS LOW FOR READ CYCLES

ADDRESS

LATCH

ADDRESS BUS

ADDRESS

DECODE

DATA BUS

+5V

TP/MODE

CS

MX7576

BUSY

D0–D7

MX7575*

Figure 4. MX7575/MX7576 to 8085A-2 Slow-Memory Interface

including the 8085A-2, test the status of the READY

input immediately after the start of an instruction cycle.

Therefore, if the MX7575/MX7576 are to be effective in

placing the µP in a wait state, their BUSY output should

go low very early in the cycle. When using the 8085A-2,

the earliest possible indication of an upcoming read

operation is provided by the S0 status signal. Thus, S0,

which is low for a read cycle, should be connected to

the RD input of the MX7575/MX7576. Figure 4 shows

the connection diagram for the 8085A-2 to the

MX7575/MX7576 in slow-memory interface mode.

ROM Interface Mode

Figure 5 shows the timing diagram for ROM interface

mode. In this mode, the µP does not need to be placed

in a wait state. A conversion is started with a read

instruction (RD and CS go low), and old data is

accessed. The BUSY signal then goes low to indicate

the start of a conversion. As before, the MX7575

track/hold acquires the signal on the third falling clock

edge after RD goes low, while the MX7576 samples it

eight times during a conversion. At the end of a conversion (BUSY going high), another read instruction always

accesses the new data and normally starts a second

conversion. However, if RD and CS go low within one

HIGH-

BUS

CS

BUSY

DATA

RD

IMPEDANCE

t

1

HIGH-

BUS

t

2

t

3

t

4

OLD

DATA

t

5

t

8

t

7

HIGH-IMPEDANCE BUS

t

3

NEW

DATA

t

7

IMPEDANCE

HIGH-

BUS

Figure 5. ROM Interface Timing Diagram

A0–A15

6502-6809

R/W

Φ2 OR E

D0–D7

* SOME CIRCUITRY OMITTED FOR CLARITY

ADDRESS BUS

ADDRESS

EN

DECODE

DATA BUS

+5V

TP/MODE

CS

RD

D0–D7

MX7575*

MX7576

Figure 6. MX7575/MX7576 to 6502/6809 ROM Interface

external clock period of BUSY going high, then the second conversion is not started. Furthermore, for correct

operation in this mode, RD and CS should not go low

before BUSY returns high.

Figures 6 and 7 show the connection diagrams for

interfacing the MX7575/MX7576 in the ROM interface

mode. Figure 6 shows the connection diagram for the

6502/6809 µPs, and Figure 7 shows the connections for

the Z-80.

Due to their fast interface timing, the MX7575/MX7576

will interface to the TMS32010 running at up to 18MHz.

Figure 8 shows the connection diagram for the

TMS32010. In this example, the MX7575/MX7576 are

mapped as a port address. A conversion is initiated by

using an IN A and a PA instruction, and the conversion

result is placed in the TMS32010 accumulator.

Asynchronous Conversion Mode (MX7576)

Tying the MODE pin low places the MX7576 into a continuous conversion mode. The RD and CS inputs are

only used for reading data from the converter. Figure 9

shows the timing diagram for this mode of operation,

and Figure 10 shows the connection diagram for the

8085A. In this mode, the MX7576 looks like a ROM to

6 _______________________________________________________________________________________

Page 7

CMOS, µP-Compatible, 5µs/10µs, 8-Bit ADCs

Z-80

MREQ

RD

DB7

DB0

* SOME CIRCUITRY OMITTED FOR CLARITY

Figure 7. MX7575/MX7576 to Z-80 ROM Interface

ADDRESS BUS

ADDRESS

EN

DECODE

DATA BUS

+5V

TP/MODE

CS

RD

D7

D0

MX7575*

MX7576

BUSY

DATA

CS

RD

t

1

t

3

HIGH-

IMPEDANCE

BUS

t

4

VALID

DATA

UPDATE

LATCH

t

5

t

7

HIGH-IMPEDANCE BUS

VALID

DATA

DEFER

UPDATING

HIGH-

IMPEDANCE

BUS

Figure 9. MX7576 Asynchronous Conversion Mode Timing

Diagram

MX7575/MX7576

PA2

PA0

TMS32010

MEN

DEN

DB7

DB0

* SOME CIRCUITRY OMITTED FOR CLARITY

ADDRESS BUS

ADDRESS

EN

DECODE

DATA BUS

+5V

TP/MODE

CS

RD

D7

D0

MX7575*

MX7576

Figure 8. MX7575/MX7576 to TMS32010 ROM Interface

the µP, in that data can be accessed independently of

the clock. The output latches are normally updated on

the rising edge of BUSY. But if CS and RD are low

when BUSY goes high, the data latches are not updated until one of these inputs returns high. Additionally,

the MX7576 stops converting and BUSY stays high until

RD or CS goes high. This mode of operation allows a

simple interface to the µP.

Processor Interface for Signal Acquisition (MX7575)

In many applications, it is necessary to sample the

input signal at exactly equal intervals to minimize errors

due to sampling uncertainty or jitter. In order to achieve

this objective with the previously discussed interfaces,

the user must match software delays or count the number of elapsed clock cycles. This becomes difficult in

interrupt-driven systems where the uncertainty in interrupt servicing delays is another complicating factor.

The solution is to use a real-time clock to control the

start of a conversion. This should be synchronous with

ADDRESS

LATCH

ADDRESS BUS

ADDRESS

ENCODE

DATA BUS

MODE

CS

D0–D7

MX7576*

A0–A15

8085A

RD RD

ALE

AD0–AD7

* SOME CIRCUITRY OMITTED FOR CLARITY

Figure 10. MX7576 to 8085A Asynchronous Conversion Mode

Interface

the CLK input to the ADC (both should be derived from

the same source), because the sampling instants occur

three clock cycles after CS and RD go low. Therefore,

the sampling instants occur at exactly equal intervals if

the conversions are started at equal intervals. In this

scheme, the output data is fed into a FIFO latch, which

allows the µP to access data at its own rate. This guarantees that data is not read from the ADC in the middle

of a conversion. If data is read from the ADC during a

conversion, the conversion in progress may be disturbed, but the accessed data that belonged to the previous conversion will be correct.

The track/hold starts holding the input on the third

falling edge of the clock after CS and RD go low. If CS

and RD go low within 20ns of a falling clock edge, the

ADC may or may not consider this falling edge as the

first of the three edges that determine the sampling

instant. Therefore, the CS and RD should not be

allowed to go low within this period when sampling

accuracy is required.

_______________________________________________________________________________________ 7

Page 8

CMOS, µP-Compatible, 5µs/10µs, 8-Bit ADCs

The track/hold consists of a sampling capacitor and a

MX7575 Track/Hold

switch to capture the input signal. The simplified diagram of this block is shown in Figure 11. At the beginning of the conversion, switch S1 is closed, and the

input signal is tracked. The input signal is held (switch

S1 opens) on the third falling edge of clock after CS

and RD go low (Figure 12). This allows a minimum of

two clock cycles for the input capacitor to be charged

to the input voltage through the switch resistance. The

time required for the hold capacitor to settle to ±1/4LSB

is typically 7ns. Therefore, the input signal is allowed

ample time to settle before it is acquired by the

track/hold. When a conversion ends, switch S1 closes,

and the input signal is tracked.

The track/hold is capable of acquiring signals with slew

MX7575/MX7576

rates of up to 386mV/µs (or equivalently a 50kHz sine

wave with 2.46Vp-p amplitude). Figure 13 shows the

signal-to-noise ratio (SNR) versus input frequency for

the ADC. The SNR plot is generated at a sampling rate

of 200kHz using sinusoidal inputs with a peak-to-peak

amplitude of 2.46V. The reconstructed sine wave is

passed through a 50kHz 8th-order Chebychev filter.

The improvement in SNR at high frequencies is due to

the filter cutoff.

The switching nature of the analog input results in transient currents that charge the input capacitance of the

track/hold. Keep the driving source impedance low

(below 2kΩ), so that the settling characteristics of the

track/hold are not degraded. A low driving impedance

also minimizes undesirable noise pickup and reduces

DC errors caused by transient currents at the analog

input. As with any ADC, it is important to keep external

sources of noise to a minimum during a conversion.

Therefore, keep the data bus as quiet as possible during a conversion, especially when the track/hold is

making the transition to the hold mode.

For conversion times that are significantly longer than

5µs, the device’s accuracy may degrade slightly, as

shown in Figure 14. This degradation is due to the

charge that is lost from the hold capacitor in the presence of small on-chip leakage currents.

R

ON

S1

CH

2pF

V

IN

Figure 11. Equivalent Input Circuit

CS

0.5pF

500Ω

The MX7576 analog input can also be modeled with the

MX7576 Analog Input

switch and capacitor as shown in Figure 11. However,

unlike the MX7575, the MX7576 samples the input voltage eight times during a conversion (once before each

comparator decision). Therefore, the precautions that

apply to the MX7575 also apply to the MX7576. These

include minimizing the analog source impedance and

reducing noise coupling from the digital circuitry during

a conversion, especially near a sampling instant.

Reference Input

The high speed of this ADC can be partially attributed to

the “inverted voltage output” topology of the DAC that it

uses. This topology provides low offset and gain errors

and fast settling times. The input current to the DAC,

however, is not constant. During a conversion, as different DAC codes are tried, the DC impedance of the DAC

can vary between 6kΩ and 18kΩ. Furthermore, when

the DAC codes change, small amounts of transient current are drawn from the reference input. These characteristics require a low DC and AC driving impedance for

the reference circuitry to minimize conversion errors.

Figure 15 shows the reference circuitry recommended

to drive the reference input of the MX7575/MX7576.

CS

RD

BUSY

EXTERNAL

CLOCK

a) WITH EXTERNAL CLOCK

CS

RD

BUSY

INTERNAL

CLOCK

b) WITH INTERNAL CLOCK

Figure 12. MX7575 Track/Hold (Slow-Memory Interface)

Timing Diagrams

INPUT SIGNAL HELD HERE

INPUT SIGNAL HELD HERE

8 _______________________________________________________________________________________

Page 9

CMOS, µP-Compatible, 5µs/10µs, 8-Bit ADCs

40

TA = +25°C

42

44

46

48

SNR (dB)

50

52

54

100 1k 100k

INPUT FREQUENCY (Hz)

Figure 13. MX7575 SNR vs. Input Frequency

2.5

A: TA = +125°C

= +85°C

B: T

A

= +25°C

C: T

A

2.0

1.5

1.0

RELATIVE ACCURACY (LSB)

0.5

0

10 100 10000

CONVERSION TIME (µs)

Figure 14. MX7575 Accuracy vs. Conversion Time

+5V

3.3k

ICL8069

Figure 15. External Reference Circuit

+

_

1.23V

+

10k

A B C

1000

0.1µF47µF

MX7575/6 FIG13

MX7575/6 FIG14

REF

The decoupling capacitors are necessary to provide a

low AC source impedance.

Internal/External Clock

The MX7575/MX7576 can be run with either an externally applied clock or their internal clock. In either case,

the signal appearing at the clock pin is internally divided by two to provide an internal clock signal that is relatively insensitive to the input clock duty cycle.

Therefore, a single conversion takes 20 input clock

cycles, which corresponds to 10 internal clock cycles.

Internal Clock

The internal oscillator frequency is set by an external

capacitor, C

, and an external resistor, R

CLK

CLK

, which

are connected as shown in Figure 16a. During a conversion, a sawtooth waveform is generated on the CLK

pin by charging C

CLK

through R

and discharging it

CLK

through an internal switch. At the end of a conversion,

the internal oscillator is shut down by clamping the CLK

pin to VDDthrough an internal switch. The circuit for the

internal oscillator can easily be overdriven with an

external clock source.

The internal oscillator provides a convenient clock

source for the MX7575. Figure 17 shows typical conversion times versus temperature for the recommended

R

and C

CLK

tions, the oscillation frequency for this R

combination. Due to process varia-

CLK

CLK/CCLK

combination may vary by as much as ±50% from the

nominal value shown in Figure 17. Therefore, an external clock should be used in the following situations:

1) Applications that require the conversion time to be

within 50% of the minimum conversion time for the

specified accuracy (5µs MX7575/10µs MX7576).

2) Applications in which time-related software con-

straints cannot accommodate conversion-time differences that may occur from unit to unit or over

temperature for a given device.

External Clock

The CLK input of the MX7575/MX7576 may be driven

directly by a 74HC or 4000B series buffer (e g., 4049),

or by an LS TTL output with a 5.6kΩ pull-up resistor. At

the end of a conversion, the device ignores the clock

input and disables its internal clock signal. Therefore,

the external clock may continue to run between conversions without being disabled. The duty cycle of the

external clock may vary from 30% to 70%. As discussed previously, in order to maintain accuracy, clock

rates significantly lower than the data sheet limits

(4MHz for MX7575 and 2MHz for MX7576) should not

be used.

MX7575/MX7576

_______________________________________________________________________________________ 9

Page 10

CMOS, µP-Compatible, 5µs/10µs, 8-Bit ADCs

+5V

47µF

+5V

3.3k

+

47µF

-

MX7575/MX7576

2.46V(max)

+1.23V

0.1µF

0.1µF

18

V

DD

16

17

15

AIN

REF

AGND

MX7575

MX7576

CLK

BUSY

CS

RD

TP/

MODE

9

+5V

5

4

1

2

3

R

CLK

100k, 2%

C

CLK

100pF, 1%

CONTROL INPUTS

D7–D0

DATA OUT

OUTPUT

CODE

1111 1111

1111 1110

1111 1101

0000 0011

0000 0010

0000 0001

0000 0000

1LSB

3LSBs0

2LSBs

AIN, INPUT VOLTAGE (IN TERMS OF LSBs)

FULL-SCALE

TRANSITION

(FS - 3/2LSB)

FS = 2V

REF

2FS

1LSB = –––

256

FS - 1LSB

Figure 16a. Unipolar Configuration Figure 16b. Nominal Transfer Characteristic for Unipolar

Operation

______________ Typical Applications

Unipolar Operation

Figure 16a shows the analog circuit connections for

unipolar operation, and Figure 16b shows the nominal

accurate enough that calibration will not be necessary. If

calibration is not needed, resistors R1–R7 should have a

0.1% tolerance, with R4 and R5 replaced by one 10kΩ

resistor, and R2 and R3 with one 1kΩ resistor. If calibra-

tion is required, follow the steps in the sections below.

transfer characteristic for unipolar operation. Since the

offset and full-scale errors of the MX7575/MX7576 are

very small, it is not necessary to null these errors in

most cases. If calibration is required, follow the steps in

the sections below.

Offset Adjust

The offset error can be adjusted by using the offset trim

capability of an op amp (when it is used as a voltage follower) to drive the analog input, AIN. The op amp should

have a common-mode input range that includes 0V. Set

its initial input to 4.8mV (1/2LSB), while varying its offset

until the ADC output code flickers between 0000 0000

and 0000 0001.

Full-Scale Adjustment

Make the full-scale adjustment by forcing the analog

input, AIN, to 2.445V (FS - 3/2LSB). Then vary the reference input voltage until the ADC output code flickers

between 1111 1110 and 1111 1111.

Bipolar Operation

Figure 18a shows an example of the circuit connection

for bipolar operation, and Figure 18b shows the nominal

transfer characteristic for bipolar operation. The output

code provided by the MX7575 is offset binary. The analog input range for this circuit is ±2.46V (1LSB =

19.22mV), even though the voltage appearing at AIN is

in the 0V to 2.46V range. In most cases, the MX7575 is

Adjust the offset error by applying an analog input volt-

age of 2.43V (+FS - 3/2LSB). Then adjust resistor R5

until the output code flickers between 1111 1110 and

1111 1111.

Full-Scale Adjust

Null the full-scale error by applying an analog input

voltage of -2.45V (-FS + 1/2LSB). Then adjust resistor

R3 until the output code flickers between 0000 0000

and 0000 0001.

14

13

12

11

10

CONVERSION TIME (µs)

Figure 17. Typical Conversion Times vs. Temperature Using

Internal Clock

MX7576

9

8

7

-55 -25 25 75

0 12510050

AMBIENT TEMPERATURE (°C)

MX7575

R

C

CLK

CLK

= 100kΩ

= 100pF

Offset Adjust

10 ______________________________________________________________________________________

Page 11

CMOS, µP-Compatible, 5µs/10µs, 8-Bit ADCs

+5V

47µF

+5V

TLC271

R5

5k

R4

8.2k

R7

10k

0.1µF

47µF

+

+5V

R6

3.3k

ICL8069

1.2V

REFERENCE

Figure 18a. MX7575 Bipolar Configuration

0.1µF

17

R1

1k

16

R2

820Ω

R3

500Ω

INPUT VOLTAGE

18

V

DD

REF

MX7575

AIN

AGND DGND

15

MX7575/MX7576

+5V

R

CLK

5

CLK

9

C

100pF

2%

D7–D0

DATA OUT

L

Figure 18b. Nominal Transfer Characteristic for Bipolar

Operation

111...111

111...110

100...010

100...001

100...000

011...111

011...110

000...001

000...000

OUTPUT

CODE

-FS

-1/2LSB

2

1/2LSB

FS

2

FS = 2V

1LSB =

-1LSB

REF

2FS

256

AIN

__________Applications Information

Noise

To minimize noise coupling, keep both the input signal

lead to AIN and the signal return lead from AGND as

short as possible. If this is not possible, a shielded

cable or a twisted-pair transmission line is recommended. Additionally, potential differences between the ADC

ground and the signal-source ground should be minimized, since these voltage differences appear as

errors superimposed on the input signal. To minimize

system noise pickup, keep the driving source resistance below 2kΩ.

Proper Layout

For PC board layouts, take care to keep digital lines

well separated from any analog lines. Establish a single-point, analog ground (separate from the digital system ground) near the MX7575/MX7576. This analog

ground point should be connected to the digital system

ground through a single-track connection only. Any

supply or reference bypass capacitors, analog input filter capacitors, or input signal shielding should be

returned to the analog ground point.

__Functional Diagrams (continued)

V

DD

18

16

AIN

AGND

REF

CLK

MODE

MX7576

15

17

CLOCK

5

OSCILLATOR

1

CS

2

RD

3

CONTROL

LOGIC

49

BUSY DGND

DAC

SAR

COMP

LATCH AND

THREE-STATE

OUTPUT DRIVERS

6

D7

.

.

D0

14

______________________________________________________________________________________ 11

Page 12

CMOS, µP-Compatible, 5µs/10µs, 8-Bit ADCs

____Pin Configurations (continued)

TOP VIEW

TP (MODE)

D7 (MSB)

BUSY

CLK

RD

3

2 1

4

5

6

7

D6

8

CS

MX7575

MX7576

N.C.

DD

V

20 19

REF

18

17

16

15

14

MX7575/MX7576

9

10

11

12

13

( ) ARE FOR MX7576 ONLY.

D5

DGND

PLCC

N.C.

D4

D3

AIN

AGND

D0 (LSB)

D1

D2

_Ordering Information (continued)

PART

MX7575JEWN

MX7575KEWN

MX7575JEQP -40°C to +85°C

MX7575KEQP -40°C to +85°C 20 PLCC

MX7575SQ -55°C to +125°C 18 CERDIP**

MX7575TQ -55°C to +125°C 18 CERDIP**

MX7576JN

MX7576KN

MX7576JCWN 0°C to +70°C

MX7576KCWN 0°C to +70°C 18 Wide SO

MX7576JP 0°C to +70°C 20 PLCC

MX7576KP 0°C to +70°C 20 PLCC

MX7576J/D 0°C to +70°C Dice* ±1

MX7576AQ -25°C to +85°C 18 CERDIP**

MX7576BQ -25°C to +85°C 18 CERDIP**±1±1/2

MX7576JEWN

MX7576KEWN

MX7576JEQP -40°C to +85°C

TEMP. RANGE PIN-PACKAGE

-40°C to +85°C

-40°C to +85°C

18 Wide SO

18 Wide SO

20 PLCC

0°C to +70°C 18 Plastic DIP

0°C to +70°C

18 Plastic DIP

18 Wide SO

-40°C to +85°C 18 Wide SO

-40°C to +85°C

18 Wide SO

20 PLCC

MX7576KEQP -40°C to +85°C 20 PLCC

MX7576SQ -55°C to +125°C 18 CERDIP**

MX7576TQ -55°C to +125°C 18 CERDIP**

* Contact factory for dice specifications.

** Contact factory for availability.

__________________________________________________________Chip Topographies

INL

(LSB)

±1

±1/2

±1

±1/2

±1

±1/2

±1

±1/2

±1

±1/2

±1

±1/2

±1

±1/2

±1

±1/2

±1

±1/2

MX7575

D7

D6

D5

DGND

D4

0.081"

(2.057mm)

D3

D2 D1

*The two AGND pads must both be used (bonded together).

TRANSISTOR COUNT: 768

SUBSTRATE CONNECTED TO V

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

12

__________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 (408) 737-7600

CLK

BUSY

D0 AGND* AGND*

0.130"

(3.302mm)

DD

N.C.

D5

TP

RD

CS

V

DD

REF

AIN

DGND

D4

0.081"

(2.057mm)

D3

*The two AGND pads must both be used (bonded together).

TRANSISTOR COUNT: 768

SUBSTRATE CONNECTED TO VDD

D6

D2 D1

MX7576

D7

(MSB)

D0

(LSB)

0.130"

(3.302mm)

CLK

MODE

BUSY

AGND* AGND*

N.C.

RD

CS

V

DD

REF

AIN

© 1996 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Loading...

Loading...