Page 1

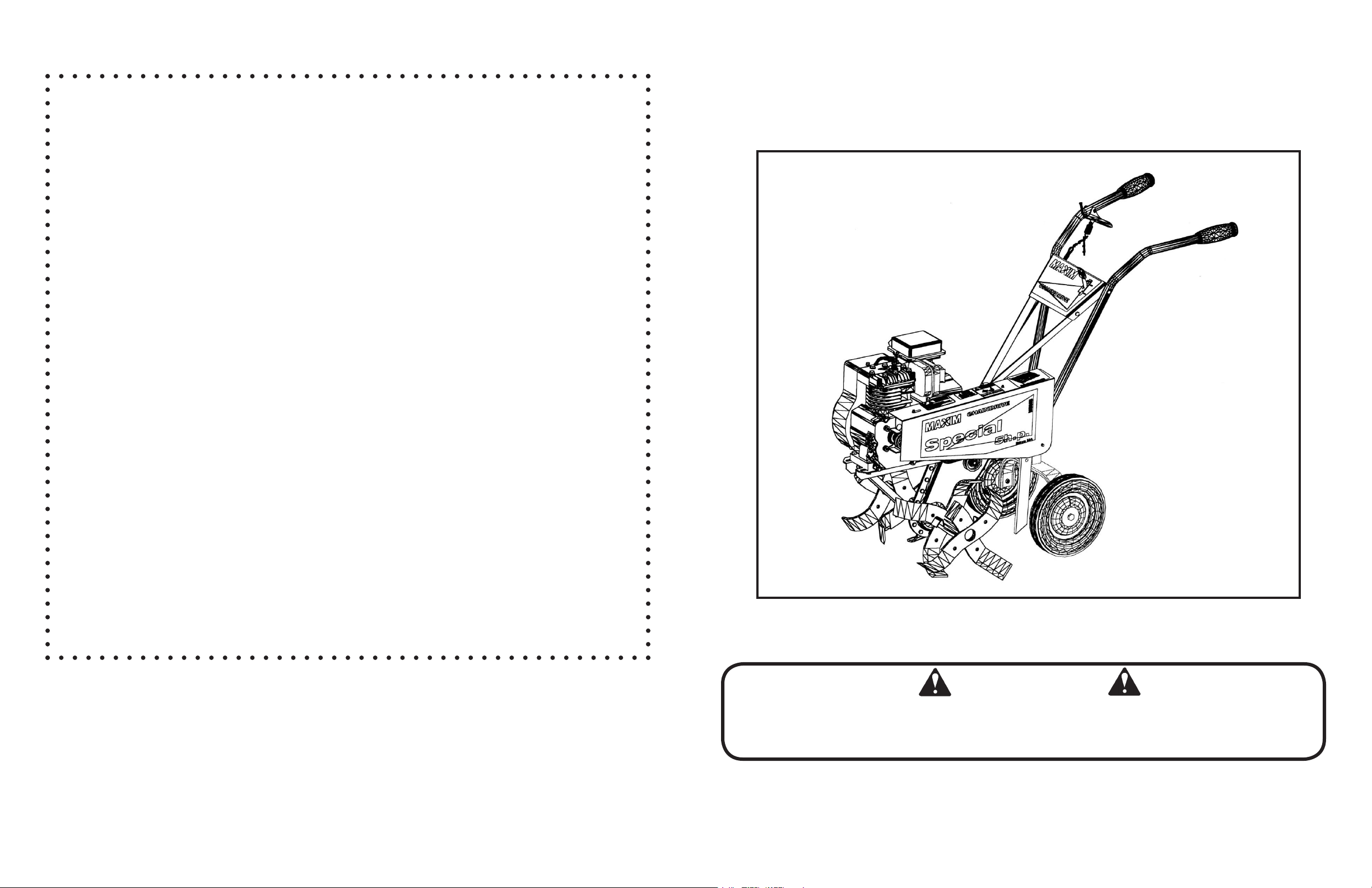

Maxim Chain Drive Tiller

Limited Warranty

Maxim Manufacturing Corporation, through its dealers will repair or replace any part, or parts

of the MS50B, MS30B, or MS50BR or handles that are defective in material or workmanship or

both. Transportation charges on parts submitted for repair or replacement under this

Warranty must be borne by the purchaser. The original sales receipt must be submitted as

proof of purchase date. The sales receipt will be returned. Maxim Manufacturing Corporation

assumes no liability for labor charges made in performance of this warranty.

The Warranty Periods are as follows:

A. Frame for 1 year

B. Handles for 1 year

C. Transmissions for 1 year

The Throttle Cable, Tires, Fasteners, and belt are not warranted because during normal service

they are subject to wear.

The Warranty on the Frame is Void if:

A. Frame is broken or bent due to abuse.

Operator’s Manual and Parts List

B. Wheels are bent or broken due to impact.

C. Altering of engine or its components has occurred.

All warranties are voided if the Tiller has been altered, used under abnormal conditions,

or subject to abuse, misuse, neglect, improper maintenance, or rented.

The Engine is warranted by the engine manufacturer, not by Maxim Manufacturing Corporation.

See Engine Owner’s Manual for information regarding engine warranty.

Should you experience problems with your tiller take it back to your authorized Maxim

dealer or distributor to make warranty claims.

Maxim Manufacturing is not liable for any damage claim or liability claim, personal or otherwise, resulting from the operation of this tiller in any way.

MS50B • MS30B • MS50BR

WARNING

If incorrectly used this machine can cause severe injury. Those who use and maintain the

machine should be trained in its proper use, warned of its dangers, and should read the

entire manual before attempting to set up, operate, adjust or service the machine.

Maxim Manufacturing Corporation • Sebastopol, MS 39359 • (601) 625-7471 • 336745 • 2/2003

READ THIS MANUAL.

RETAIN IT FOR FUTURE REFERENCE.

Page 2

SAFE PRACTICES FOR GARDEN TILLERS

TRAINING

Regard your tiller as a piece of power equipment and teach

this respect to all who operate it.

Read the owner’s manual carefully. Be thoroughly familiar

with the controls and proper use of the equipment. Know

how to stop the unit and disengage the controls quickly.

Never allow children to operate equipment. Never allow

adults to operate equipment without proper instruction.

Keep the area of operation clear of all persons, especially

small children.

Exercise caution to avoid slipping and falling.

PREPARATION

Check the tiller to make certain it is in good operating condition.

Check tines to be sure they are free of any obstruction.

Check engine crankcase oil level.

Unless there is very good articial light operate during day-

light hours only.

Do not operate power tools in wet soil, which clogs the

cutter and increases the danger of your slipping and falling

and possibly coming into contact with the tines.

Thoroughly inspect the area where the equipment is to be

used and remove all large stones, boards, wires, and other

foreign objects.

Do not operate machine when barefoot or wearing open

sandals. Wear strong work-type footwear which will

improve footing and provide optimum protection. Provide

leg protection by means of long, heavy denim trousers and

brogues.

Check that clutch is disengaged before starting engine.

Handle fuel with care; it is highly ammable.

• Use approved fuel container.

• Never add fuel to a running engine or hot engine.

• Fill fuel tank outdoors with extreme care. Never ll fuel

tank while smoking.

• Replace gasoline cap securely and wipe up spilled fuel.

Never attempt to make any adjustments while engine is

running except carburetor mixture as instructed in the engine owner’s guide.

Allow engine sufcient warm-up period before tilling.

OPERATION

Give complete and undivided attention to the job at hand.

Familiarize yourself with the controls. Be sure you know

how to stop your machine quickly. Do not start engine until

you set machine on ground to be tilled.

Hold the handle with your left hand while pulling the starter

rope with your right. Be sure the machine will not tip or roll

during the starting operation.

Stay clear of the front of self-propelled machine during

and after starting. Do not put hands or feet near rotating

tines or belt when machine is operating. Once machine is

started stand behind it with hands on handles at all times.

Keep in step with machine. Do not lag behind or let it pull

you so you will not be in full command of the machine.

Control the direction of the machine by hand pressure on

the handle, not by foot pressure on the machine housing.

Stay alert for hidden hazards.

When operating over uneven terrain and slopes, use

extreme care and make sure of solid and rm footing at all

times.

Exercise special care when operating around objects to

prevent the tines from striking them and never deliberately

operate over any object.

After striking a foreign object, stop the engine, remove wire

from spark plug, thoroughly inspect the tiller for any damage and repair the damage before restarting and operating

the tiller.

If the unit should start to vibrate abnormally, stop the

engine and check immediately for the cause. Vibration is

generally a warning of trouble.

Stop operation when another person approaches.

Stop the engine whenever you leave the operating position

before making any repairs, adjustment, or inspections.

Stop the engine whenever leaving the tiller unattended.

When cleaning, repairing, or inspecting make certain tines

and all moving parts have stopped. Disconnect spark plug

wire and keep wire away from plug to prevent accidental

starting.

Do not run engine indoors.

Exercise extreme caution when changing direction on

slopes. Do not attempt to till steep slopes.

Never operate tiller without guards, plates, or other safety

protective devices in place.

Never operate tiller near glass enclosure, automobiles,

window wells, drop-offs, or bystanders. Keep children and

pets away.

Do not over load machine capacity by attempting to till

ground at too fast a rate.

Use care when backing.

Never allow anyone in front of unit. Disengage clutch,

when someone approaches, when transporting or when not

in use.

Use only attachments and accessories approved by manufacturer of tiller.

Never operate tiller without good visibility or light. Always

be sure of your footing and keep a rm hold on the handles

and walk, never run.

MAINTENANCE AND STORAGE

Follow the recommendations for maintenance described in

this manual and engine literature.

Have a competent service man make a thorough inspection

of the tiller before the season begins.

Check shear bolts and engine mounting bolts at frequent

intervals for proper tightness to be sure equipment is in

safe working condition. Check that the engine stop circuit

is intact.

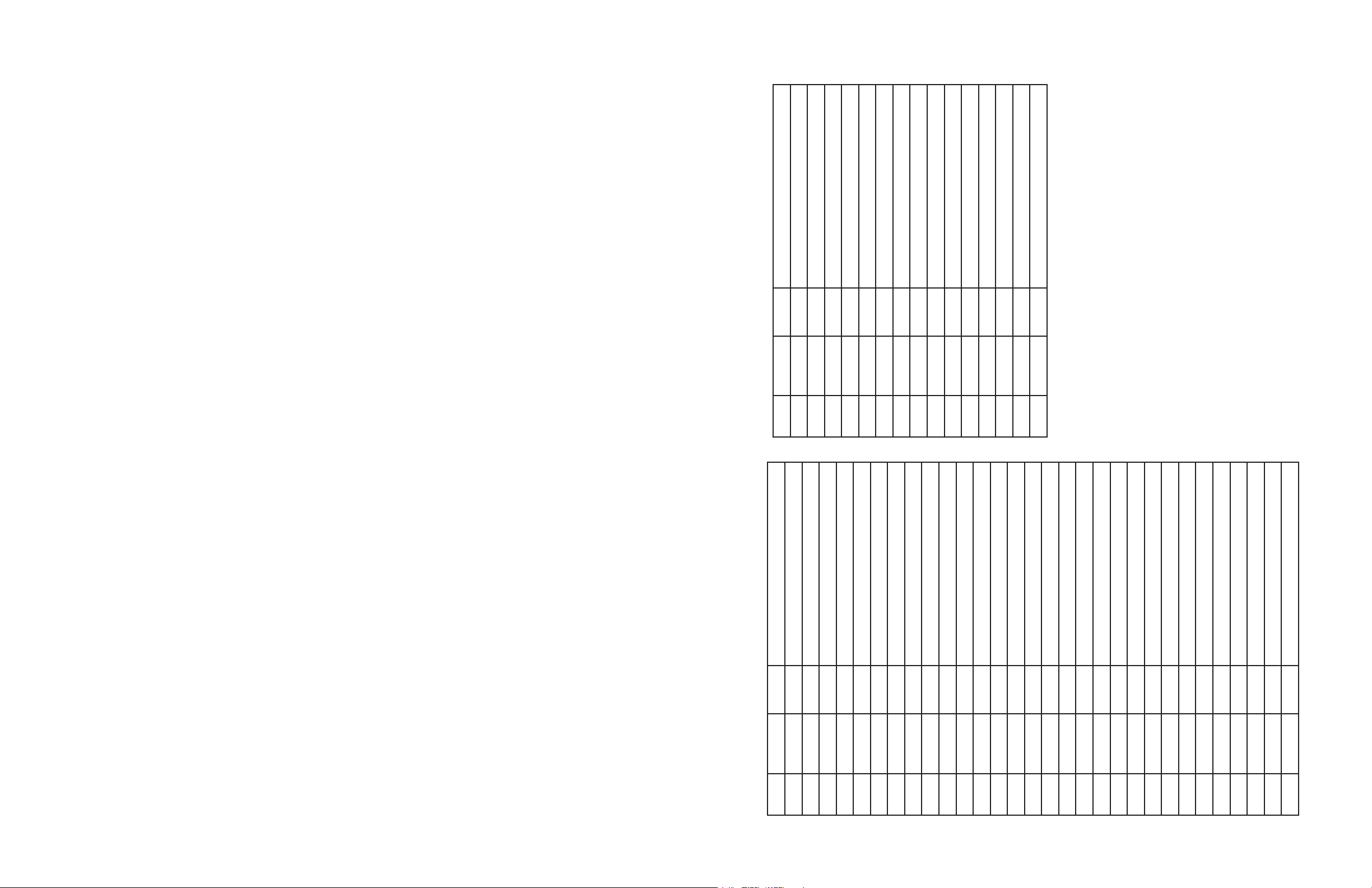

Ref. Part QTY Description

32 336680 1 Support RH

33 162027 1 LH Support Assembly

Ref. Part QTY Description

1 162039 1 Shaft & Sprocket Assembly

2 359350 1 Spacer

3 359293 2 Bushing

34 359311 4 Frame Spacer

36 359339 2 Brace

37 400108 3 Screw, 1/4-20 x 3/4 Hex

38 455768 3 Flanged Nut, 1/4 - 20

5 359295 1 Chain

6 162024 1 Sprocket Cluster Assembly

7 359297 2 Bearing, Needle

45 130715 1 LH Inner Tine Assembly

46 130716 1 RH Inner Tine Assembly

8 359298 1 Bushing

9 359299 2 Washer

47 130711 1 LH Outer Tine Assembly

48 130712 1 RH Outer Tine Assembly

10 359300 1 Chain

11 162025 1 Shaft & Sprocket Assembly

130717 Slasher Tine Set Complete

49 461466 4 Pin, 3/8 x 2 - 1/8 Clevis

50 460312 4 Hairpin, Lhcot #2

12 359303 1 Spacer

13 359313 AR Washer

14 359314 AR Shim, .03

130500 1 Transmission Complete

52 463017 1 Key, 3/16 x 3/4 Wooddruff #9

15 359315 AR Shim, .02

16 359304 2 Bearing, Needle

17 359305 2 Seal, Oil

18 359306 2 Shield

19 130696 1 RH Case Assembly

20 130697 1 LH Case Assembly

21 336674 1 Gasket

22 400104 21 Screw, 1/4-20 x 1/2 Hex

23 445768 21 Flanged Nut, 1/4 - 20

24 400179 4 Screw, 5/16-18 x 2 1/2 Hex

25 445765 4 Flanged Nut, 5/16 - 18 Hex

26 400200 3 Screw, 5/16 - 18 x 1/2 H

27 443106 3 Nut, 5/16 - 18 Hex

28 359312 1 Cap Plug

29 408883 1 Screw, 1/4 x 1/2 Hex Wash

30 359336 1 Washer, Rubber Seal

31 359310 1 Plug

112

Page 3

Transmission Assembly

Illustration 4

Continued from page 2

Never adjust the machine or change attachments until the

engine has been turned off and the spark plug wire disconnected. It is possible that the engine could start while making an adjustment or repair.

If carburetor adjustment is necessary, stand to one side

and keep feet and hands in the clear while making adjustments.

Keep engine free from accumulations of grass, leaves, or

excessive grease. An accumulation of these combustible

materials may result in a re.

Store gasoline in a safe container. Store the container in

a cool, dry place, not in the house or near heating appliances.

Never store machine with fuel in the fuel tank inside a building where open ame or sparks are present. Allow engine

to cool before storing in any enclosure.

Keep the machine and fuel container in locked storage to

prevent children from playing and tampering with them.

Maximum operating results and safety can only be expected if the machine is maintained and operated correctly.

Always refer to operator’s manual for important details if

tiller is to be stored for extended period.

IMPORTANT: THIS UNIT IS EQUIPPED WITH AN INTERNAL COMBUSTION ENGINE, AND SHOULD

NOT BE USED ON OR NEAR ANY UNIMPROVED FOREST-COVERED, BRUSH COVERED OR GRASS

COVERED LAND UNLESS THE ENGINE’S EXHAUST SYSTEM IS EQUIPPED WITH A SPARK ARRESTER MEETING APPLICABLE LOCAL LAWS (IF ANY). IF A SPARK ARRESTER IS USED, IF SHOULD BE

MAINTAINED IN EFFECTIVE WORKING ORDER BY THE OPERATOR.

IN THE STATE OF CALIFORNIA A SPARK ARRESTER IS REQUIRED BY LAW (SECTION 4442 OF

THE CALIFORNIA PUBLIC RESOURCES CODE). OTHER STATES MAY HAVE SIMILAR LAWS. FEDERAL LAWS APPLY ON FEDERAL LANDS. SEE YOUR AUTHORIZED SERVICE CENTER FOR A

SPARK ARRESTER.

WARNING

The engine exhaust from this product contains chemicals know to the State of

California to cause cancer, birth defects, or other reproductive harm.

Specications

Engine: Briggs & Stratton 4 cycle

5.5 Intek, 1264120226E1C1032 -- Horiz.

3.5HP #91202 Type 1264

Air Cleaner: Replaceable Paper Element

Fuel Tank: 3 Quarts

Throttle: On Handle Panel

Transmission: Roller chain and sprocket,

sealed and running in oil.

Tines: 14” slasher, self-sharpening

Tine Speed: Approximately 78 RPM maximum

Tilling Width: 14” to 26” standard

Tilling Depth: Up to 12”

Handle: 14 gauge seamless tubular steel with

braces

Clutch: Hand controlled belt tightener

Frame: All steel, welded and braced

Wheels: 10 x 1.75

Approximate Shipping Weight:

5hp -- 134 lbs.

3hp -- 125 lbs.

Safe Practices for Garden Tillers 2-3

Specications 3

Set-Up Instructions 4-5

General Information 5

Operation 6

Adjustments 7

Maintenance 7

Parts Lists 8-11

Warranty 12

Contents

10 3

Page 4

UNPACKING

SET UP INSTRUCTIONS

Do not attempt to lift the tiller from the carton.

After opening the top, cut all four corners and lay

the sides at on the oor or working space. Take

out all unassembled parts, bag of parts, and protective packing. Be careful not to kink the control

cables.

DEFINITION OF DIRECTIONS

As used throughout this manual, the following

denitions apply: “Right” and “Left” refer to the

operator’s right and left when standing behind the

machine in the normal operating position. “Forward” and “Rearward” likewise to directions from

the viewpoint of the operator.

ASSEMBLY OF HANDLE BARS (Figures 2 & 3)

1. Attach the lower end of the handle bars to the

rear of the chassis using four bolts, lock washers, and nuts supplied. Assemble nuts but do not

tighten. Note that the lower belt cover bracket

goes under the chassis on the left rear handle

bar bolt.

Figure 2

Handle Bar Assembly -- Illustration 2

Ref. Part Qty Description

1 162007 1 Throttle Control Assembly

2 336677 1 Support LH

3 336676 1 Support RH

4 130698 1 RH Handle Assembly

5 313786 2 Grip

6 130699 1 LH Handle Assembly

7 130731 1 Handle Cross Brace

8 400186 2 Screw 5/16 - 18 x 1” Hex

9 446136 4 Lockwasher 5/16 Heavy

10 443106 4 Nut, 5/16 - 18 Hex

11 402014 2 #10 x 3/8” Slot Tapping Scr.

14 162029 1 Cable and Chain Assembly

15 359346 1 Clutch Locking Pin

16 359359 1 Spring

17 359327 1 Spring

18 359326 1 Clip

19 359345 1 Pin

20 336683 1 Lever

21 400208 2 5/16 x 18 x 1 3/4 Hex Cap

2. Assemble the handle bar support brackets to

the transmission. Note the location of the clutch

cable guide. Assemble nuts but do not tighten.

3. Assemble the Handle Panel to the handle bars

and supports. Note the location of the clutch

cable guide.

4. Tighten all bolts and nuts.

5. Assemble the throttle control to the underside

of the panel. Secure the cable to the left handle

bar with the clip supplied.

6. Assemble the clutch spring to the clutch lever on the handle bar. Crimp lightly so it cannot

come off.

7. Route the loop in the end of the clutch cable

down through the two cable guides and attach it

level on the idler arm weldment. Attach the chain

on the other end to the spring on the clutch lever.

Select a loop that will stretch the spring slightly

when the clutch lever is pulled against the handle

bar.

8. With the throttle control in the “OFF” position

and the clutch lever released, pull the engine

starter rope several times to be sure that the tines

do not turn.

Hitch Assembly

Illustration 2

Figure 3

IMPORTANT

ENGINE IS SHIPPED FROM

FACTORY WITHOUT OIL. DO

NOT START ENGINE WITHOUT

ADDING OIL.

4 9

Ref Part Qty Description

1 130670 1 Rear Support Assembly

3 400265 1 Screw, 3/8” - 16 x 1 1/2

8 162034 1 Wheel Yoke Assembly

13 162031 2 Wheel

14 359330 2 Bolt, Wheel

16 444721 3 3/8” Center Locknut

18 460312 2 Hairpin

19 461466 2 Pin, 3/8” x 2 1/8” Clevis

21 336685 1 Drag Stake

Page 5

Drive Assembly

Illustration 1

SET UP INSTRUCTIONS CONTINUED

TINE ASSEMBLY (Figure 4)

Assemble the inner tine assemblies to the transmission. Secure with clevis and hair pins. The

short end of the tube goes next to the transmission. Be sure the cutting edge of the blade faces

the direction of rotation. Assemble the out tines

to the inner tine tubes and secure with hair pins

and clevis pins.

FINAL SETUP (Figure 5)

1. Remove the oil ll plug from the engine. With

the unit sitting level, ll the crankcase with oil.

See the engine instruction manual for type and

further directions (Figure 5).

2. Fill the gas tank with clean, fresh, regular

grade gasoline. Do not mix oil and gas.

3. When cranking the unit, be sure no one is

standing in front or near the unit. Check for

proper operation of the clutch lever (see page 7).

Figure 4

Figure 5

Ref. Part Qty Description Ref. Part Qty Description

1 359328 1 Belt, V-Drive

2 408883 3 Screw, 1/4” - 20 x 1/2” Hex Cap 15 443109 3 Nut 3/8” - NF5 Hex

3 130733 1 Guard 16 359325 1 Lever

4 359383 1 Key, Pulley Mtg. 17 359326 1 Clip

5 271686 1 Pulley, Crankshaft (5 hp) 18 445768 3 Flange Nut, 1/4” - 20 Hex Cap

6 415562 2 Screw, 5/16” - 18 x 5/16”

Socket Head Cap Pt.

7 400235 1 Screw, 1/2” x 3/4” Hex Head 20 162069 1 Idler Shaft

8 446145 1 Lock washer, 1/2 Heavy 21 446136 4 Lock washer, 5/16” Heavy

9 162035 1 Belt Guide (Honda 162067) 22 443106 8 Nut, 5/16” - 18 Hex

10 400194 4 Screw, 5/16” x 1 1/2” Hex Cap 23 400112 3 1/4” - 20 x 1 1/4” Hex Head

11 359343 1 Bracket Upper 24 446136 4 Lock washer, 5/16” Heavy

13 336672 1 Pulley 25 443106 1 Nut, 5/16” - Hex

14 359340 1 Bracket Lower 26 400208 4 Screw, 1/4” - 20 x 1 1/4” Hex

19 359321 1 Idler

8 5

GENERAL INFORMATION

The Maxim Chain Drive is the most versatile power unit ever developed for the home gardener and

does a soil preparation job second to none, so a few minutes spent in studying the following instructions will pay many dividends.

The tiller will dig deeper and move forward slower by pushing down on the handles, and it will go

ahead faster but at a shallower depth by raising up on the handles. The speed of the rotors is controlled by the use of the throttle.

To control the depth of tilling, the tiller must be operated with both the proper throttle speed and correct up and down hand pressure on the handles. Raising up means going forward. This action

releases the grip of the drag stake in the soil, allowing the tiller to progress ahead. Pushing down

means slowing down or even standing still. This directs the drag stake into the soil, thus holding the

tiller back. Adjust throttle for desired speed of rotors.

When a person is rst learning the proper use of the tiller, it is not unlikely that he will encounter an

uneven or “buckling” action in the operation of this machine. A little practice will accustom the operator on how to overcome this. Never push on the machine if it has dug itself into a depth of six or more

inches in order to get it to move forward. This is accomplished by slightly raising up on the handles

and tilting the machine slowly from on side to the other.

Your tiller has been carefully designed in both workmanship and material. However, by the very nature of its operation, common sense and caution must be employed at all times. Read carefully and

abide by the safety suggestions stated in this operators guide.

Page 6

OPERATION

DANGER

For safe operation, the tine drive must disengage immediately when

clutch lever is released. If it does not, adjust belt and cable tension as described in “ADJUSTMENT” section of this manual.

Never leave the tiller unattended with the engine running because children might be attracted to a running tiller and could be injured if struck by the

rotating tines.

OPERATION OF CHAIN DRIVE TILLER

1. When ground is hard (especially during spring and fall

plowing), place wheels in up position by removing the clevis

pin from the wheel clevis, and repositioning the wheel

frame bar. Replace the clevis pin and the pin clip (Figure

6). For weeding or cultivating, wheels may be left down if

you prefer.

2. Adjust the drag stake for comfortable operation. This

is done by removing the pin clip from the drag stake clevis

pin, removing the clevis pin, and sliding the drag stake up

or down. The drag stake should be set so that when it is

rmly in the ground, and your hands are on the tiller handle,

your arms hang comfortably with the elbows slightly bent.

3. Move the throttle control to center position. Start the engine and allow it to warm up, then set the throttle at about

half speed. After you have become familiar with the tiller,

you may want to run the engine a little faster.

4. Press down rmly on the handles, and then squeeze the

clutch lever. The tines will begin to turn, but the tiller should

not move forward. If it does, don’t pull backwards -- merely

press down harder on the handles. When you nd the right

amount of downward pressure so that the tines are digging

and the tiller is not moving forward, release the pressure

slightly. As you release it you’ll notice the tiller beginning to

move forward.

OPERATING TIPS

To acquire the knack of letting the tiller do the work without

effort on the part of the operator, we offer the following suggestions:

1. Adjust drag stake so the handles are at such a height

that your arms hang straight down to contact them. Rear

wheels should be in up position for deep tillage or ease of

turning in conned areas.

2. Operate the tiller at about three fourths (3/4) throttle.

3. Don’t hurry the job -- proceed at a slow walk -- give the

IMPORTANT!

KEEP HANDS CLEAR OF BELT AND

TINES WHILE ENGINE IS RUNNING.

Figure 6

machine time to do its job.

4. Concentrate on keeping your arms relaxed (There is a

natural tendency for any beginner to tense up.). Operating

the tiller actually takes very little effort. Let the tiller do the

work.

5. When tilling on sloping ground, turn the front of the

machine uphill to sufciently counteract the tendency to run

downhill.

6. For best results, operate at reduced throttle settings

when ground is extremely hard or rough.

7. When cultivating, raise drag stake until the handles are

the proper height as described in Item 1 or set rear wheels

in position. Proceed at a slow walk, watching the rotor as it

tills along the row.

8. Tighten all nuts and bolts periodically.

TILLING PATTERN

Whenever possible till the soil in the direction in which the

planting or rows will run. If the soil is extremely hard and

dry, it may be advisable to till across the plot on the rst

digging and then obtain the depth you want by tilling in the

direction the planting will be done.

TRANSPORT

To transport tiller from garden to storage area, lift the

handles until the drag stake is above ground level, set

the engine throttle at slow speed and walk the tiller on the

tines.

6 7

ADJUSTMENTS and MAINTENANCE

CLUTCH ADJUSTMENT (Figure 7)

Proper clutch adjustment is very important. Minor adjustment, if needed, can be made by using the links on the

clutch cable chain only. However, the friction type clutch

may need further adjustments as the “V” belt stretches. Adjust as follows:

1. Remove belt guard.

2. Loosen 4 engine mount bolts. Slide engine forward or

backwards as required.

3. Unhook clutch cable from load spring.

4. Push upward on idler pulley to take all slack from the

drive belt. Distance between the inside of belt at the idler

pulley should be between 2 7/8 and 3 1/8 of an inch.

5. Retighten engine mounting bolts.

6. Remove all the slack from clutch cable and hook spring

in proper chain link.

7. Check your adjustment by starting the tiller and holding the tines off the ground. If the tines turn without any

hand pressure on the clutch lever, the adjustment is too

tight. Unhook the clutch load and hook into next chain link

to lengthen clutch cable. If the cable spring on the clutch

handle doesn’t stretch when you hold the clutch handle all

the way in, the adjustment is too loose. Unhook spring end

from chain and hook next link to shorten clutch cable.

CHECK TRANSMISSION OIL

Check transmission oil by removing oil level check plug

(See Figure 8). If you cannot see oil from the check plug.

Ret plug and add 90 weight gear oil from the oil ll plug.

Do not overll. This will cause leakage. Recheck level. Oil

should just ooze from Oil level check plug.

CLEAN COOLING SYSTEM (Figure 9)

Grass or chaff may clog cooling system after prolonged

service. Continued operation with a clogged cooling system causes severe overheating and possible engine damage. Remove blower housing and clean regularly.

BELT REPLACEMENT

The drive belt is located on the left side of the machine. To replace a worn or slipping belt proceed as follows:

1. Remove belt guard.

2. Make sure clutch lever is in disengaged position.

3. Start at the top of 10” pulley and begin removing belt in clockwise direction (facing tiller from left side). If tension on

belt is too great the idler pulley may be pulled downward to relieve pressure on belt.

4. Once belt is off 10” pulley, remove it from smaller pulley.

5. Replace belt by reversing sequence of steps above.

6. Replace belt guard with screws.

DANGER

To avoid possible serious bodily injury, when performing any adjustments other than carburetor

adjustment on engine, remove the spark plug wire and place the wire away from the plug to prevent

accidental starting.

Figure 7

Figure 8

Figure 9

Loading...

Loading...