General Description

The MAXQ3100 microcontroller is a low-power, 16-bit

RISC device that incorporates an integrated liquid-crystal

display (LCD) interface that can drive up to 160 segments, two analog comparators with precision internal

1.25V reference voltage, and a real-time clock (RTC)

module with a dedicated battery-backup supply. An internal temperature sensor allows software to monitor device

temperature and optionally interrupt to alert when a temperature conversion is complete. The MAXQ3100 is

uniquely suited for single-phase electricity metering applications that require an external analog front-end, but can

be used in any application that requires high-performance operation. The device operates at a fixed

4.194MHz, generated from the 32.76kHz RTC crystal. The

device has 8kWords of EEPROM, 512 words of RAM,

three 16-bit timers, and two universal synchronous/asynchronous receiver/transmitters (USARTs). The microcontroller core and I/O are powered by a single 3.3V supply,

and an additional battery supply keeps the RTC running

during power outages.

Features

♦ High-Performance, Low-Power, 16-Bit RISC Core

4.194MHz Operation, Approaching 1MIPS

per MHz

3.3V Core and I/O

33 Instructions, Most Single-Cycle

Three Independent Data Pointers Accelerate

Data Movement with Automatic Increment/

Decrement

16-Level Hardware Stack

16-Bit Instruction Word, 16-Bit Data Bus

16 x 16-Bit, General-Purpose Working Registers

Optimized for C-Compiler (High-Speed/Density

Code)

♦ Program and Data Memory

8kWords EEPROM

200,000 EEPROM Write/Erase Cycles

512 Words of Internal Data RAM

JTAG-Compatible Debug Port Bootloader for

Programming

♦ Peripheral Features

Up to 27 General-Purpose I/O Pins, Most 5V

Tolerant

160-Segment LCD Driver

Up to 4 COM and 40 Segments

Static, 1/2, and 1/3 LCD Bias Supported

No External Resistors Required

Two Analog Comparators with Internal +1.25V

Precision Reference

Two Serial USARTs, One with Infrared PWM

Support

Digital Temperature Sensor

Three 16-Bit Programmable Timers/Counters

8-Bit, Subsecond, System Timer/Alarm

Battery-Backed, 32-Bit RTC with

Time-of-Day Alarm and Digital Trim

Programmable Watchdog Timer

♦ Flexible Programming Interface

Bootloader Simplifies Programming

In-System Programming Through Debug Port

Supports In-Application Programming of EEPROM

♦ Power Consumption

1.9mA at 4.194MHz, 3.6V Operation

1.9µA Standby Current in Sleep Mode

Low-Power Divide-by-256 Mode

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

________________________________________________________________

Maxim Integrated Products

1

Rev 0; 6/07

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

Typical Application Circuits and Pin Configuration appear

at end of data sheet.

Note: Some revisions of this device may incorporate deviations

from published specifications known as errata. Multiple revisions of any device may be simultaneously available through

various sales channels. For information about device errata, go

to:

www.maxim-ic.com/errata

.

MAXQ is a registered trademark of Maxim Integrated Products, Inc.

+

Denotes a Pb-free/RoHS-compliant device.

Ordering Information

Utility Meters

Battery-Powered and

Portable Devices

Electrochemical and

Optical Sensors

Industrial Control

Data-Acquisition

Systems and Data

Loggers

Home Appliances

Consumer Electronics

Thermostats/Humidity

Sensors

Security Sensors

Gas and Chemical

Sensors

HVAC

Smart Transmitters

Applications

PART TEMP RANGE PIN-PACKAGE

MAXQ3100-EMN+ -40°C to +85°C 80 MQFP

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

2 _______________________________________________________________________________________

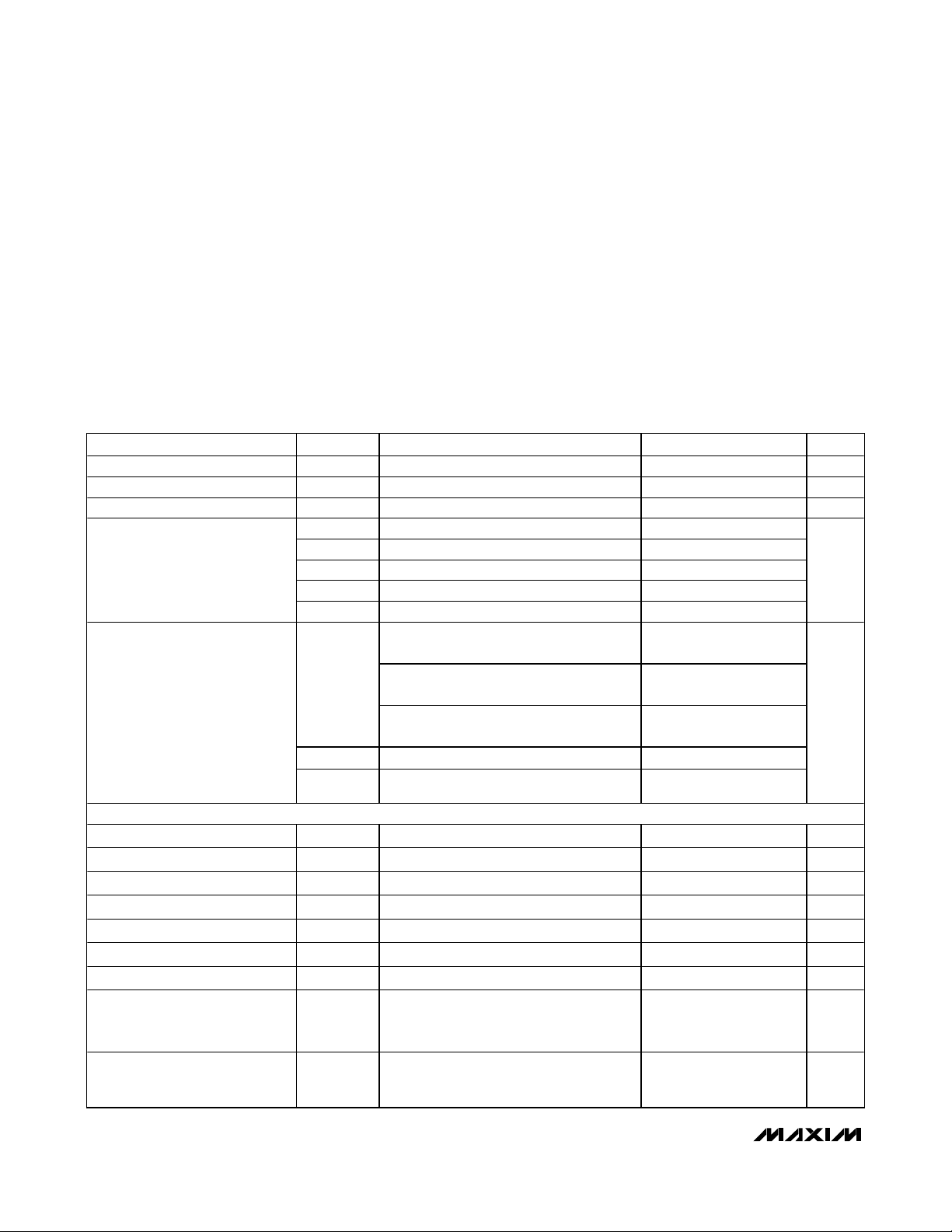

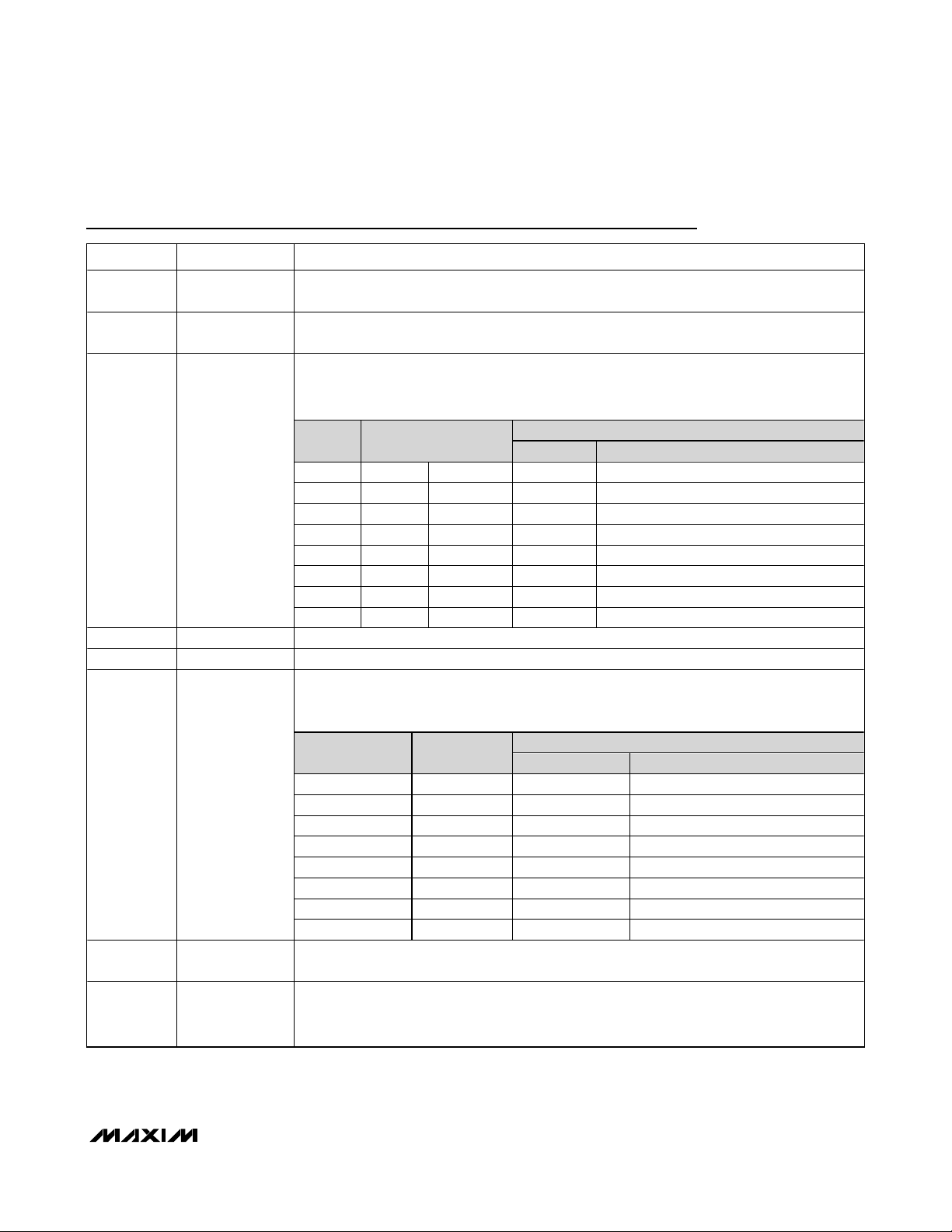

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(DVDD= V

RST

to 3.6V, f

32KIN

= 32.768kHz, TA= -40°C to +85°C, unless otherwise noted.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Voltage Range on DVDDRelative to DGND ..........-0.5V to +6.0V

Voltage Range on Any Pin Relative to DGND

(3V Tolerant) .........................................-0.5V to (DV

DD

+ 0.5V)

Continuous Output Current

(Any Single I/O Pin)..........................................................25mA

(All I/O Pins Combined) ...................................................25mA

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Soldering Temperature .......................................See IPC/JEDEC

J-STD-020 Specification

Digital Supply Voltage DVDD V

Digital Power-Fail Reset V

Battery Supply Voltage V

Active Current

(Note 2)

Stop-Mode Current

ANALOG VOLTAGE COMPARATOR

Comparator Input-Voltage Range V

Internal Voltage Reference V

Input Offset Voltage VOS (Note 4) -10 +10 mV

Input Common-Mode Voltage V

Common-Mode Rejection Ratio CMMR (Note 4) 55 dB

DC Input-Leakage Current TA = +25°C, CMPx pin in tri-state mode -50 +50 nA

Comparator Setup Time t

Response T ime (CMPx Change

to CMO Valid)

Current Consumed By

Comparator

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

2.34 2.5 2.71 V

RST

2.0 3.8 V

BAT

I

/1 mode 1.9 2.6

DD1

I

/2 mode 1.3 1.8

DD2

I

/4 mode 1.0 1.4

DD3

I

/8 mode 0.8 1.2

DD4

I

PMM1 mode 0.7 1.0

DD5

Brownout detector disab led

(Note 3), T

I

STOP1

I

STOP2

I

STOP3

INPUT

REF

CMR

CMP_SETUP fSYS

t

CMP_RES P

I

DD_CMP

Brownout detector disab led

(Note 3), T

Brownout detector disab led

(Note 3), T

Brownout detector enabled (Note 3) 16.3 63.0

Brownout detector enabled, RTC enabled

(Note 3)

GND DVDD V

1.15 1.25 1.35 V

(Note 4) 1 DVDD V

= 4.194MHz, V = 20mV (Note 4) 0.8 1.6 μs

f

= 4.194MHz, transition CMPx from

SYS

DGND to DV

(Note 4)

Per enabled comparator, CMONx = 1,

brownout detector enabled, CMPx pins in

tri-state mode

3.3 3.6 V

RST

= +25°C

A

= +60°C

A

= +85°C

A

in ~2ns, t

DD

SYS

= 1/f

SYS

1.9 5.0

2.1 10.0

3.3 35.0

16.4 64.0

140 +

(2 x

t

SYS)

18.0 39.0 μA

600 +

t

(2 x

SYS)

mA

μA

ns

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

_______________________________________________________________________________________ 3

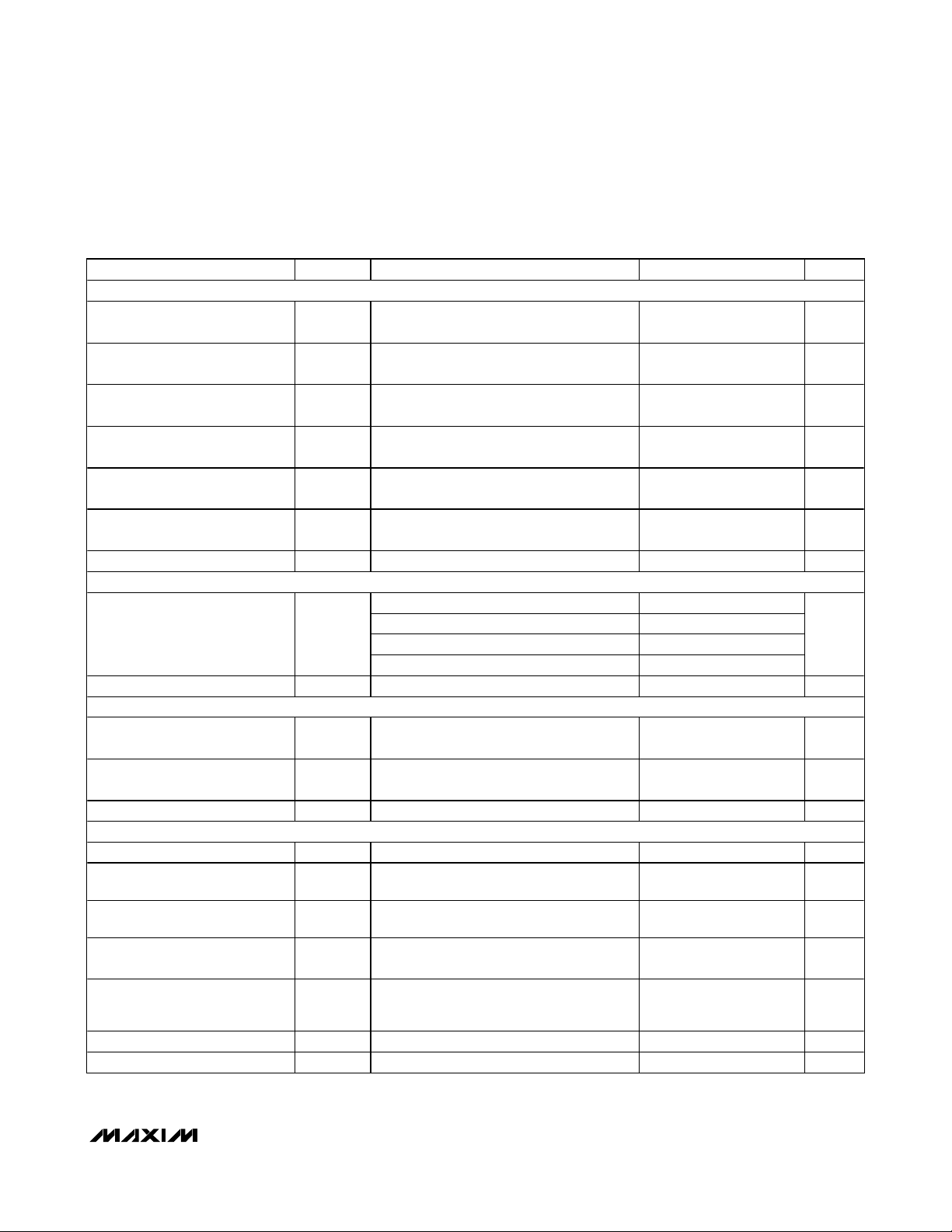

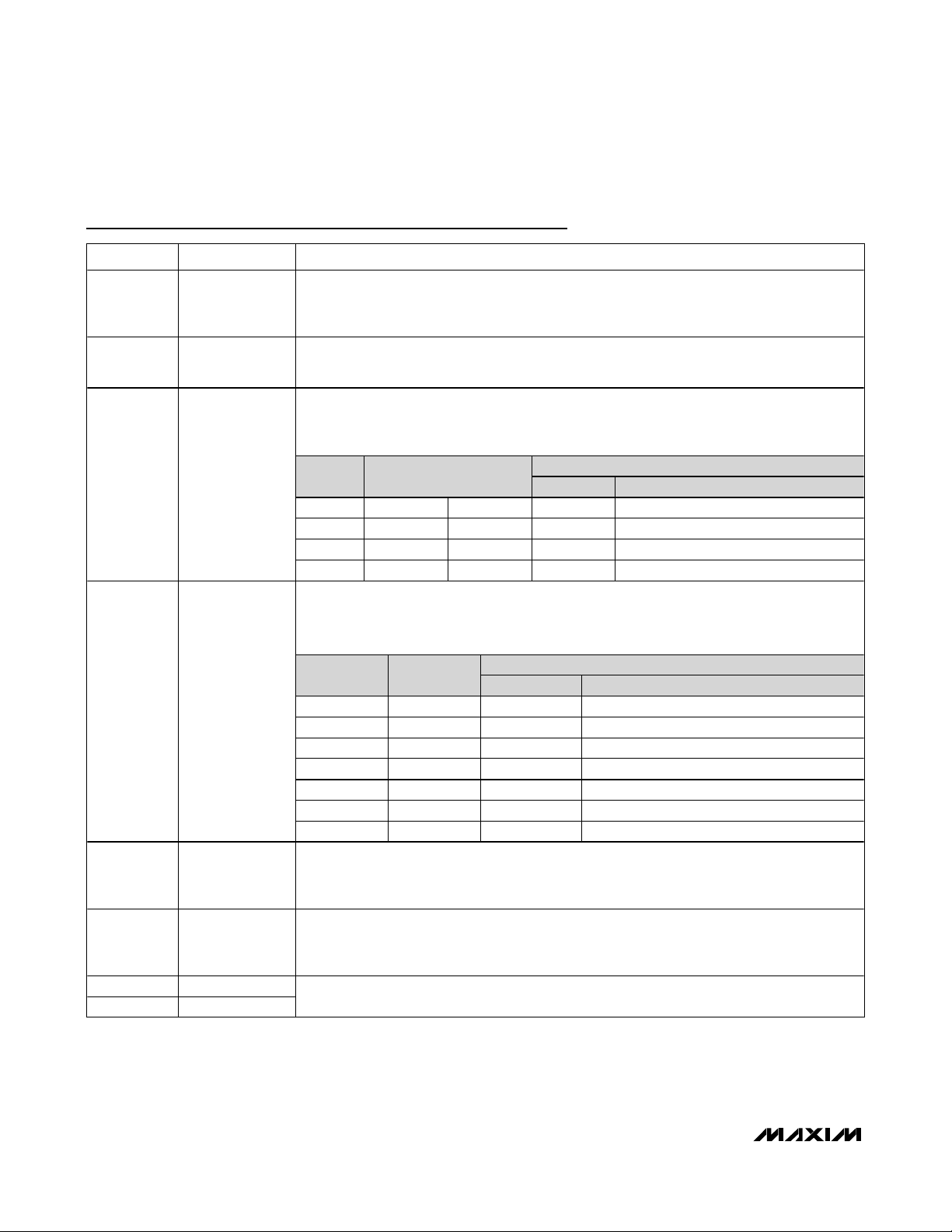

ELECTRICAL CHARACTERISTICS (continued)

(DVDD= V

RST

to 3.6V, f

32KIN

= 32.768kHz, TA= -40°C to +85°C, unless otherwise noted.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DIGITAL I/O

Input High Voltage (Port 0, 1, 3,

RESET)

Input High Voltage (Port 2) V

V

IH1

IH2

Input Low Voltage VIL

Output High Voltage (Al l Ports) VOH I

Output Low Voltage (Al l Ports,

RESET)

Input Pullup Current I

V

OL

PULLUP

I

DVDD = 3.6V, input mode with weak pullup

enabled

= 3mA

SOURCE

= 4mA 0.4 V

SINK

0.8 x

DV

0.8 x

DV

DV

0.4

DD

DD

DD

5.5 V

DV

DD

+ 0.3

0.2 x

DV

DD

DV

DD

V

V

V

40 120 250 μA

Input Leakage (All Ports) IL Input mode with wea k pullup disabled -50 +50 nA

TEMPERATURE SENSOR

Temperature Conversion Time T

CONV

10-bit resolution, f

11-bit resolution, f

12-bit resolution, f

13-bit resolution, f

= 4.194MH z

SYS

= 4.194MH z

SYS

= 4.194MH z

SYS

= 4.194MH z

SYS

12.5

25

50

100

ms

Temperature Sensor Accuracy ±2 °C

RTC

Battery Supply Current, BatteryBacked Mode

Battery Supply Leakage Current I

I

BAT

BATL

Measured on V

DV

= 0V, RTC enab led

DD

Measured on V

= 3.6V, RTC enabled

DV

DD

BAT

BAT

pin, V

pin, V

BAT

BAT

= 3.6V,

= 3.6V,

1.76 3.1 μA

4 200 nA

Trimm ing Resolut ion One 32.768kHz cloc k per 10s (Note 4) 3.05 ppm

LCD

LCD Supply Voltage V

LCD Bias Voltage 1 V

LCD Bias Voltage 2 V

LCD Adjustment Voltage V

2.4 DVDD V

LCD

V

+ 2/3

(Note 4)

LCD1

(Note 4)

LCD2

(Note 4) 0

ADJ

(V

V

(V

ADJ

LCD

ADJ

LCD

- V

ADJ

+ 1/3

- V

ADJ

)

)

0.4 x

V

LCD

V

V

V

Measured on DVDD pin; LCFG = 0xF7,

LCD Digital Operating Current

I

LCD

LCRA = 0x1B20, LCDx = 0xFF; LCD pins

0.1 μA

are unconnected

LCD Bia s Re sistor R

LCD Adjust Resistor R

40 k

LCD

LRA3:LRA0 = 1111 80 k

LADJ

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

4 _______________________________________________________________________________________

Note 1: Specifications to -40°C are guaranteed by design and are not production tested.

Note 2: Measured on the DV

DD

pin with DVDD= 3.6V, V

BAT

= 3.8V, f

32KIN

= 32.768kHz, executing from EEPROM.

Note 3: Measured on the DV

DD

pin with DVDD= 3.6V, V

BAT

= 3.8V, f

32KIN

= 32.768kHz, all I/O pins disconnected, and not in reset.

Note 4: Specification guaranteed by design but not production tested.

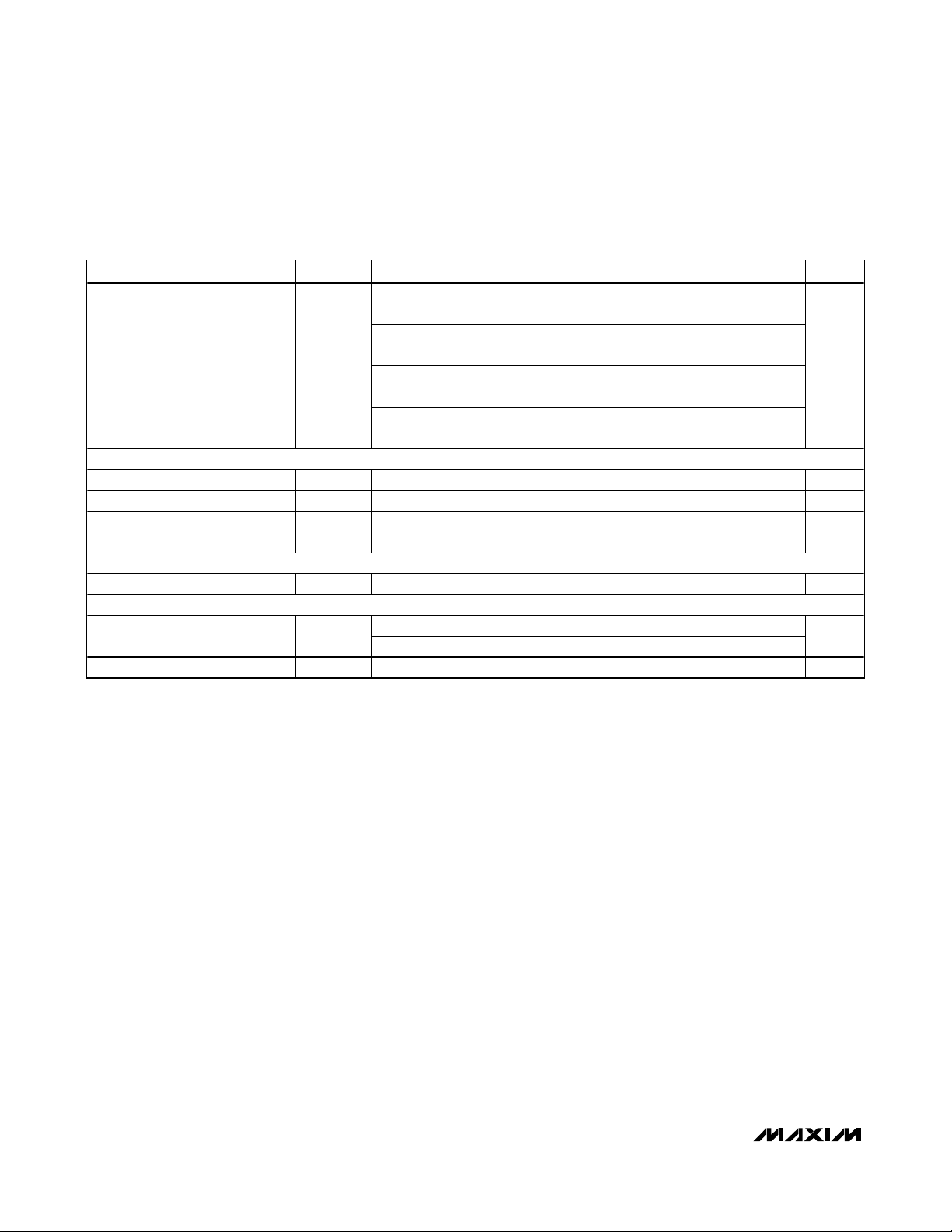

ELECTRICAL CHARACTERISTICS (continued)

(DVDD= V

RST

to 3.6V, f

32KIN

= 32.768kHz, TA= -40°C to +85°C, unless otherwise noted.) (Note 1)

LCD Segment Voltage V

CLOCK SOURCES

External Cry stal Frequency f

Internal Clock Frequency f

System Clock Frequency f

JTAG-COMPATIBLE PROGRAMMING

TCK Frequency f

MEMORY CHARACTERISTICS

EEPROM Write/Era se Cyc les

EEPROM Data Retention Theta-JA = +85°C 50 Years

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Segment is driven at V

= -3μA, guaranteed by design

I

SEGxx

Segment is driven at V

= -3μA, guaranteed by design

I

SEGxx

SEGxx

Segment is driven at V

I

= -3μA, guaranteed by design

SEGxx

Segment is driven at V

I

= +3μA, guaranteed by design

SEGxx

32.768 kHz

32KIN

f

CLK

f

SYS

JTAG programming (Note 4) 0 f

TCK

= 32.768kHz, DVDD = 3.6V 4.110 4.194 4.278 MH z

32KIN

= f

SYS

/ system clock divisor

CLK

LCD

LCD1

LCD2

ADJ

; V

; V

; V

; V

LCD

LCD1

LCD2

ADJ

= 3V,

= 2V,

= 1V,

= 0V,

Theta- JA = +25°C 200,000

Theta- JA = +85°C 50,000

V

-

LCD

0.06

V

LCD1

0.04

V

LCD2

0.02

V

f

CLK /

256

ADJ

V

V

V

0.1

f

LCD

LCD1

LCD2

CLK

/ 8 MHz

SYS

V

Cycles

MAXQ3100

Pin Description

PIN NAME FUNCTION

1, 11, 52,

58, 75

DGND

Digital Ground

6, 53, 59,

76

DV

DD

Digital Supply Voltage (+3.3V)

General-Purpose, Digital, I/O, Type D Port; External Edge-Selectable Interrupt. These port

pins function as bidirectional I/O pins only. All port pins default to input mode with weak

pullups enabled after a reset. All port pins can be configured as external interrupt inputs. All

alternate function s must be enabled from software.

SPECIAL/ALTERNATE FUNCTION

PIN NAME

NAME FUNCTION

77 P0.0 INT0 TXD0 Serial Port 0 Tran sm it

78 P0.1 INT1 RXD0 Serial Port 0 Receive

79 P0.2 INT2 T0G Timer 0 Gate Input

80 P0.3 INT3 T0 Timer 0 Input

2 P0.4 INT4 T1 Timer 1 Input/Output

3 P0.5 INT5 T1EX Timer 1 External Capture/Reload Input

4 P0.6 INT6 — —

2–5, 77–80

P0.0–P0.7;

INT0–INT7;

TXD0, RXD0,

T0G, T0, T1, EX

5 P0.7 INT7 — —

7–10 COM0–COM3

Dedicated LCD Common-Voltage Outputs

12–43 SEG1–SEG31

Dedicated LCD Drive Outputs

General-Purpose, Digital, I/O, Type C Port; LCD Segment-Driver Output. These port pins

function as bidirectional I/O pins and LCD segment-driver outputs. All alternate functions

must be enabled from software.

SPECIAL/ALTERNATE FUNCTION

PIN NAME

NAME FUNCTION

44 P2.0 SEG32 LCD Segment 32

45 P2.1 SEG33 LCD Segment 33

46 P2.2 SEG34 LCD Segment 34

47 P2.3 SEG35 LCD Segment 35

48 P2.4 SEG36 LCD Segment 36

49 P2.5 SEG37 LCD Segment 37

50 P2.6 SEG38 LCD Segment 38

44–51

P2.0–P2.7;

SEG32–SEG39

51 P2.7 SEG39 LCD Segment 39

54

V

LCD

LCD Bias-Control Voltage. Highest LCD drive voltage used in all bias modes. This pin

must be connected to an external supply when using the LCD display controller.

55

V

LCD1

LCD Bias, Voltage 1. Next highest LCD drive voltage, used in 1/2 and 1/3 LCD bias modes.

An internal resistor-divider sets the voltage at this pin. External resistor s and capacitors

can be used to change LCD voltage or drive capability at this pin. This pin must be shunted

externally to V

LCD2

when using 1/2 bias mode.

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

_______________________________________________________________________________________ 5

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

6 _______________________________________________________________________________________

Pin Description (continued)

PIN NAME FUNCTION

56

V

LCD2

LCD Bias, Voltage 2. Third highest LCD drive voltage, used in 1/3 LCD bias mode only. An

internal resistor-divider sets the voltage at this pin. External resistor s and capacitors can be

used to change LCD voltage or drive capability at this pin. This pin must be shunted

externally to V

LCD1

when using 1/2 bias mode.

57

V

ADJ

LCD Adjustment Voltag e. Lowest LCD drive voltage, u sed in al l bias modes . Connect to

DGND through an external resistor to provide external control of the LCD contrast. Leave

disconnected for internal contrast adjustment.

General-Purpose, Digital, I/O, Type D Port; External Edge-Selectable Interrupt. These port

pins function as bidirectional I/O pins only. All port pins default to input mode with weak

pullups enabled after a reset. Port pins P1.0–P1.3 can be configured as external interrupt

inputs. Al l alternate funct ions must be enabled from software.

SPECIAL/ALTERNATE FUNCTION

PIN NAME

NAME FUNCTION

60 P1.0 INT8 T2B Timer 2 Secondary I/O

61 P1.1 INT9 T2A Timer 2 Primary I/O

62 P1.2 INT10 TXD1 Serial Port 1 Transmit

60–63

P1.0–P1.3;

INT8–INT11;

T2B, T2A, TXD1,

RXD1

63 P1.3 INT11 RXD1 Serial Port 1 Receive

General-Purpose, Digital, I/O, Type C Port; External Edge-Selectable Interrupt. These port

pins function as bidirectional I/O pins only. All port pins default to input mode with weak

pullups enabled after a reset. All alternate functions must be enab led from software, except

for the JTAG-compatible functions that are enabled by default fo llowing reset.

SPECIAL/ALTERNATE FUNCTION

PIN NAME

NAME FUNCTION

64 P3.0 TDI JT AG TAP Data Input

65 P3.1 TDO JTAG TAP Data Output

66 P3.2 TCK JT AG TAP Clock Input

67 P3.3 TMS JTAG TAP Mode-Select Input

68 P3.4 SQW RTC Square-Wave Output

69 P3.5 CMP0 Analog Comparator Input 0

64–70

P3.0–P3.6;

TDI, TDO, TCK,

TMS, SWQ,

CMP0, CMP1

70 P3.6 CMP1 Analog Comarator Input 1

71

RESET

Active-Low, Digital Reset Input/Output. The CPU i s held in reset when thi s pin is low and

begins executing from the reset vector when released. The pin must be pulled high by an

external 50k resistor. This pin is driven low as an output when an internal reset condition

occurs.

72

V

BAT

Digital Battery-Backup Supply. This supply provides an optional battery backup for the

RTC when DV

DD

power is removed. If this pin is connected to a nominal 3.3V battery then

the RTC will operate and battery-backed register contents will be preserved when DV

DD

is

removed. If battery backup is not required this pin should be connected directly to DV

DD

.

73 32KIN

74 32KOUT

32kHz Crystal Input/Output. Connect an external, 6pF 32kHz watch crystal between 32KIN

and 32KOUT to generate the system clock.

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

_______________________________________________________________________________________ 7

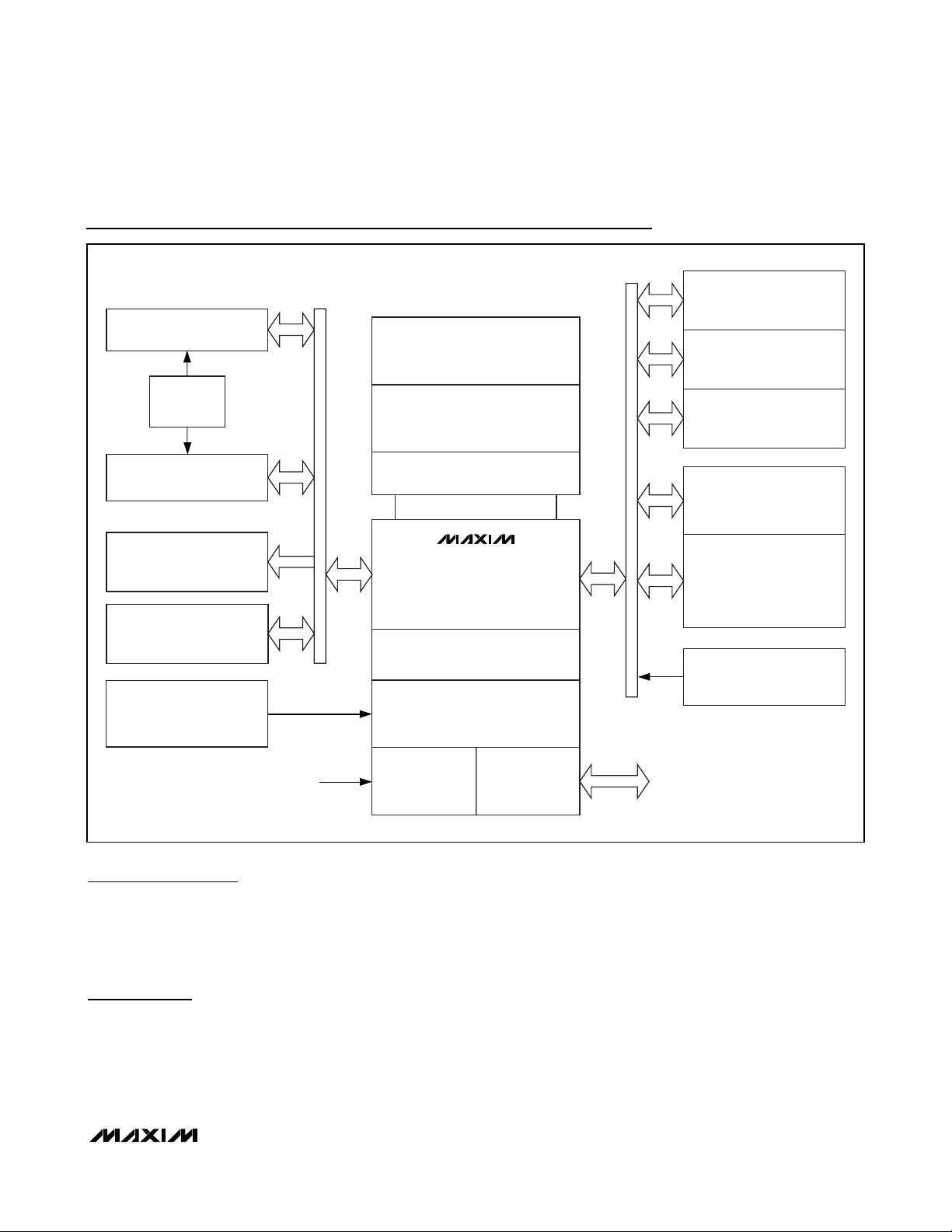

Detailed Description

The following is an introduction to the primary features

of the microcontroller. More detailed descriptions of the

device features can be found in the data sheets, errata

sheets, and user’s guides described later in the

Additional Documentation

section.

MAXQ Core Architecture

The MAXQ3100 is a high-performance, CMOS, 16-bit

RISC microcontroller with EEPROM and an integrated

160-segment LCD controller. It is structured on a highly

advanced, accumulator-based, 16-bit RISC architecture. Fetch and execution operations are completed in

one cycle without pipelining, because the instruction

contains both the op code and data. The result is a

streamlined 4.194 million instructions-per-second

(MIPS) microcontroller.

The highly efficient core is supported by a 16-level

hardware stack, enabling fast subroutine calling and

task switching. Data can be quickly and efficiently

manipulated with three internal data pointers. Multiple

data pointers allow more than one function to access

data memory without having to save and restore data

pointers each time. The data pointers can automatically

increment or decrement following an operation, eliminating the need for software intervention. As a result,

the application speed is greatly increased.

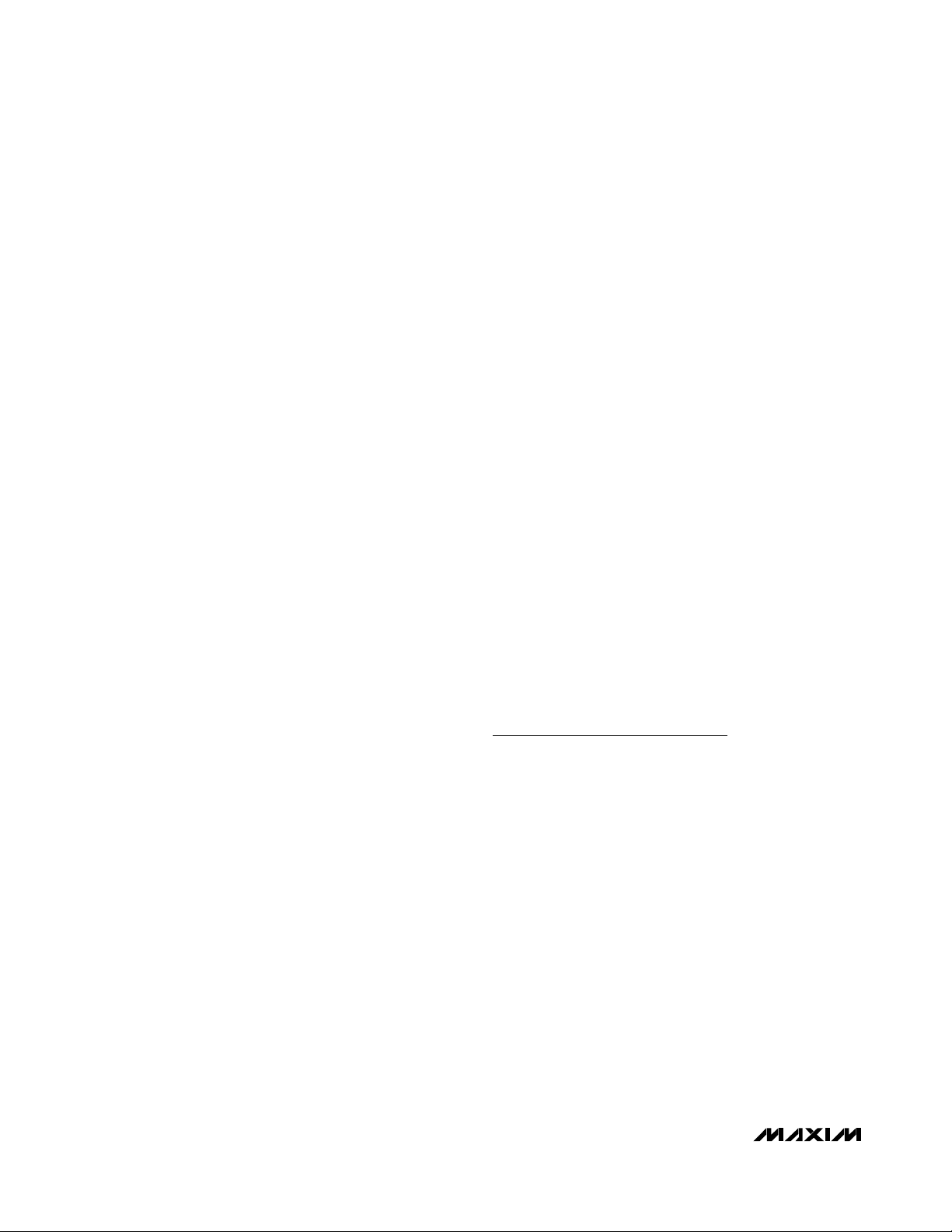

Functional Diagram

ANALOG COMPARATOR

8kW EEPROM

(PROGRAM)

TIMER 0-TYPE

16-BIT TIMER/COUNTER

TIMER 1-TYPE

16-BIT TIMER/COUNTER

TIMER 2-TYPE

16-BIT TIMER/COUNTER

SERIAL USART

SERIAL USART WITH

INFRARED PWM

SUPPORT

DIGITAL TEMPERATURE

SENSOR

512W SRAM

(D ATA)

(16 x 16-BIT ACCUMULATORS)

WATCHDOG TIMER

POWER REDUCTION/

CLOCK GENERATION

POR

JTAG

TMS

TDI

TDO

TCK

2kW UTILITY ROM

+1.25V

REFERENCE

ANALOG COMPARATOR

3.3V

160-SEGMENT LCD

DRIVER

REAL-TIME CLOCK

EXTERNAL 32.768kHz

CRYSTAL

MAXQ20 RISC CORE

MAXQ3100

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

8 _______________________________________________________________________________________

Instruction Set

The instruction set is composed of fixed-length, 16-bit

instructions that operate on registers and memory locations. The instruction set is highly orthogonal, allowing

arithmetic and logical operations to use any register

along with the accumulator. Special-function registers

control the peripherals and are subdivided into register

modules. The family architecture is modular, so that

new devices and modules can reuse code developed

for existing products.

The architecture is transport-triggered. This means that

writes or reads from certain register locations can also

cause side effects to occur. These side effects form the

basis for the higher-level op codes defined by the

assembler, such as ADDC, OR, JUMP, etc. The op

codes are actually implemented as MOVE instructions

between certain system register locations, while the

assembler handles the encoding, which need not be a

concern to the programmer.

The 16-bit instruction word is designed for efficient execution. Bit 15 indicates the format for the source field of

the instruction. Bits 0 to 7 of the instruction represent the

source for the transfer. Depending on the value of the

format field, this can either be an immediate value or a

source register. If this field represents a register, the

lower four bits contain the module specifier and the

upper four bits contain the register index in that module.

Bits 8 to 14 represent the destination for the transfer. This

value always represents a destination register, with the

lower four bits containing the module specifier and the

upper three bits containing the register subindex within

that module.

Anytime that it is necessary to directly select one of the

upper 24 index locations in a destination module, the

prefix register PFX is needed to supply the extra destination bits. This prefix register write is inserted automatically by the assembler and requires only one

additional execution cycle.

Memory Organization

The device incorporates several memory areas:

• 2kWords utility ROM

• 8kWords of EEPROM for program storage

• 512 words of SRAM for storage of temporary

variables

• 16-level, 16-bit-wide stack memory for storage of

program return addresses and general-purpose use

The memory is arranged by default in a Harvard architecture, with separate address spaces for program and

data memory. The configuration of program and data

space depends on the current execution location.

• When executing code from EEPROM memory, the

SRAM and utility ROM are accessible in data space.

• When executing code from SRAM, the EEPROM and

utility ROM are accessible in data space.

• When executing code from the utility ROM, the

EEPROM memory and SRAM are accessible in data

space.

Refer to the

MAXQ Family User’s Guide: MAXQ3100

Supplement

for more details.

In all cases, whichever memory segment is currently

being executed from cannot be accessed in data space.

To allow the use of lookup tables and similar constructs

in the memory, the utility ROM contains a set of lookup

and block copy routines (refer to the user’s guide supplement for more details).

The incorporation of EEPROM allows the device to be

reprogrammed, eliminating the expense of throwing

away one-time programmable devices during development and field upgrades. Program memory can be

password protected with a 16-word key, denying

access to program memory by unauthorized individuals.

Stack Memory

A 16-bit-wide internal stack provides storage for program return addresses and general-purpose use. The

stack is used automatically by the processor when the

CALL, RET, and RETI instructions are executed and

interrupts serviced. The stack can also be used explicitly to store and retrieve data by using the PUSH, POP,

and POPI instructions.

On reset, the stack pointer, SP, initializes to the top of

the stack (0Fh). The CALL, PUSH, and interrupt-vectoring operations increment SP, then store a value at the

stack location pointed to by SP. The RET, RETI, POP,

and POPI operations retrieve the value at the stack

location pointed to by SP, and then decrement SP.

Utility ROM

The utility ROM is a 2kWord block of internal ROM

memory that defaults to a starting address of 8000h.

The utility ROM consists of subroutines that can be

called from application software. These include:

• In-system programming (bootloader) over the JTAGcompatible debug port

• In-circuit debug routines

• User-callable routines for in-application flash programming and code space table lookup

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

_______________________________________________________________________________________ 9

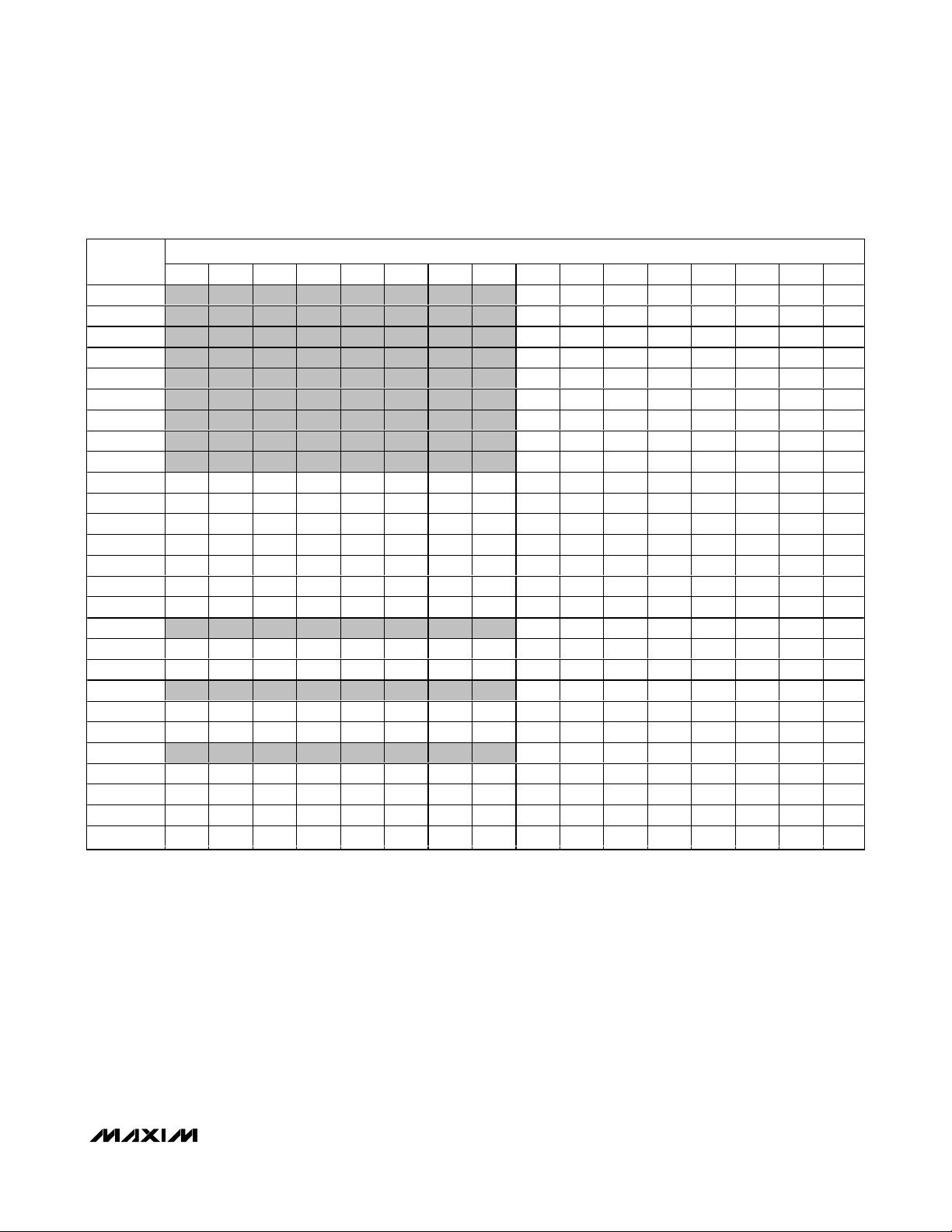

Figure 1. Memory Map When Executing from EEPROM

PROGRAM

SPACE

DATA SPACE

(BYTE MODE)

DATA SPACE

(WORD MODE)

EXECUTING FROM

512 x 16

DATA SRAM

2k x 16

UTILITY ROM

8k x 16

PROGRAM EEPROM

A1FFh

A000h

87FFh

8000h

1FFFh

0000h

4k x 8

UTILITY ROM

1k x 8

DATA SRAM

8FFFh

8000h

03FFh

0000h

2k x 16

UTILITY ROM

512 x 16

DATA SRAM

87FFh

8000h

01FFh

0000h

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

10 ______________________________________________________________________________________

Following any reset, execution begins in the utility

ROM. The ROM software determines whether the program execution should immediately jump to the start of

user-application code (located at address 0000h), or to

the bootloader. Routines within the utility ROM are useraccessible and can be called as subroutines by the

application software. More information on the utility

ROM contents is contained in the user’s guide supplement for this device.

Some applications require protection against unauthorized viewing of program code memory. For these

applications, access to in-system programming, inapplication programming, or in-circuit debugging functions is prohibited until a password has been supplied.

A single password-lock (PWL) bit is implemented in the

SC register. When the PWL is set to one (power-on

reset default), the password is required to access the

utility ROM, including in-circuit debug and in-system

programming routines that allow reading or writing of

internal memory. When PWL is cleared to zero, these

utilities are fully accessible without the password. The

password is automatically set to all ones following a

mass erase.

Programming

The microcontroller’s EEPROM can be programmed by

two different methods: in-system programming and inapplication programming. Both methods afford great flexibility in system design as well as reduce the life-cycle

cost of the embedded system. In-system programming

can be password protected to prevent unauthorized

access to code memory.

In-System Programming

An internal bootloader allows the device to be reloaded

over a simple JTAG-compatible debug port. As a result,

system software can be upgraded in-system, eliminating

the need for a costly hardware retrofit when software

updates are required. Remote software uploads are possible that enable physically inaccessible applications to

be frequently updated. The interface hardware can be a

JTAG connection to another microcontroller, or a connection to a PC serial port using a serial-to-JTAG converter such as the one included in the MAXQ3100

evaluation kit. If in-system programmability is not

required, a commercial gang programmer can be used

for mass programming.

Activating the debug port and loading the test access

port (TAP) with the system programming instruction

invokes the bootloader. Setting the SPE bit to 1 during

reset through the debug port executes the bootloadermode program that resides in the utility ROM. When programming is complete, the bootloader can clear the

SPE bit and reset the device, allowing the device to

bypass the utility ROM and begin execution of the application software.

The following bootloader functions are supported:

•Load

• Dump

• CRC

• Verify

• Erase

In-Application Programming

The in-application programming feature allows the

microcontroller to modify its own program memory from

its application software. This allows on-the-fly software

updates in mission-critical applications that cannot

afford downtime. Alternatively, it allows the application

to develop custom loader software that can operate

under the control of the application software. The utility

ROM contains user-accessible programming functions

that erase and program memory. These functions are

described in detail in the user’s guide supplement for

this device.

Register Set

Most functions of the device are controlled by sets of

registers. These registers provide a working space for

memory operations as well as configuring and addressing peripheral registers on the device. Registers are

divided into two major types: system registers and

peripheral registers. The common register set, also

known as the system registers, includes the ALU, accumulator registers, data pointers, interrupt vectors and

control, and stack pointer. The peripheral registers

define additional functionality that may be included by

different products based on the MAXQ architecture.

This functionality is broken up into discrete modules so

that only the features required for a given product need

to be included. Tables 1 and 4 show the MAXQ3100

register set.

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

______________________________________________________________________________________ 11

Table 1. System Register Map

Note: Names that appear in italics indicate that all bits of a register are read-only. Names that appear in bold indicate that a register

is 16 bits wide. Registers in module AP are bit addressable.

REGISTER

INDEX

0h AP A[0] PFX IP — — —

1h APC A[1] — — SP — —

2h — A[2] — — IV — —

3h — A[3] — — — Offs DP[0]

4h PSF A[4] — — — DPC —

5h IC A[5] — — — GR —

6h IMR A[6] — — LC[0] GRL —

7h — A[7] — — LC[1] BP DP[1]

8h SC A[8] — — — GRS —

9h — A[9] — — — GRH —

Ah — A[10] — — — GRXL —

Bh IIR A[11] — — — BP[offs] —

Ch — A[12] — — — — —

Dh — A[13] — — — — —

Eh CKCN A[14] — — — — —

Fh WDCN A[15] — — — — —

AP

(8h)

A

(9h)

MODULE NAME (BASE SPECIFIER)

PFX

(Bh)

IP

(Ch)

SP

(Dh)

DPC

(Eh)

DP

(Fh)

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

12 ______________________________________________________________________________________

Table 2. System Register Bit Functions

REGISTER

AP — — — — AP (4 bits)

APC CLR IDS — — — MOD2 MOD1 MOD0

PSF Z S — GPF1 GPF0 OV C E

IC — — CGDS — — — INS IGE

IMR IMS — — — IM3 — IM1 IM0

SC TAP — — — — — PWL —

IIR IIS — — — II3 — II1 II0

CKCN — — — STOP SWB PMME CD1 CD0

WDCN POR EWDI WD1 WD0 WDIF WTRF EWT RWT

A[0..15] A[n] (16 bits)

PFX PFX (16 bits)

IP IP (16 bits)

SP — — — — — — — — — — — — SP (4 bits)

IV IV (16 bits)

LC[0] LC[0] (16 bits)

LC[1] LC[1] (16 bits)

Offs Offs (8 bits)

DPC — — — — — — — — — — — WBS2 WBS1 WBS0 SDPS1 SDPS0

GR GR (16 bits)

GRL GR.7 GR.6 GR.5 GR.4 GR.3 GR.2 GR.1 GR.0

BP BP (16 bits)

GRS GR.7 GR.6 GR.5 GR.4 GR.3 GR.2 GR.1 GR.0 GR.15 GR.14 GR.13 GR.12 GR.11 GR.10 GR.9 GR.8

GRH GR.15 GR.14 GR.13 GR.12 GR.11 GR.10 GR.9 GR.8

GRXL GR.7 GR.7 GR.7 GR.7 GR.7 GR.7 GR.7 GR.7 GR.7 GR.6 GR.5 GR.4 GR.3 GR.2 GR.1 GR.0

BP[offs] BP[offs] (16 bits)

DP[0] DP[0] (16 bits)

DP[1] DP[1] (16 bits)

1514131211109876543210

REGISTER BIT

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

______________________________________________________________________________________ 13

Table 3. System Register Reset Values

Note: Bits marked with an “s” have special behavior upon reset. Refer to the user’s guide supplement for this device for more

details.

REGISTER

AP 00000000

APC 00000000

PSF 10000000

IC 00000000

IMR 00000000

SC 100000s 0

IIR 00000000

CKCN 10000000

WDCN ss000ss0

A[0..15] 0000000000000000

PFX 0000000000000000

IP 1000000000000000

SP 0000000000001111

IV 0000000000000000

LC[0] 0000000000000000

LC[1] 0000000000000000

Offs 00000000

DPC 0000000000011100

GR 0000000000000000

GRL 00000000

BP 0000000000000000

GRS 0000000000000000

GRH 00000000

GRXL 0000000000000000

BP[offs] 0000000000000000

DP[0] 0000000000000000

DP[1] 0000000000000000

1514131211109876543210

REGISTER BIT

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

14 ______________________________________________________________________________________

Table 4. Peripheral Register Map

Note: Names that appear in italics indicate that all bits of a register are read-only. Names that appear in bold indicate that a register

is 16 bits wide.

REGISTER INDEX

0h PO0 PO1 PO2 PO3

1h SCON0 SCON1 LCFG RTRM

2h SBUF0 SBUF1 LCRA RCNT

3h T0CN T2CNB LCD0 CCN0

4h T0L T2H LCD1 CCN1

5h T1CN T2RH LCD2 —

6h T1MD T2CH LCD3 TEMPR

7h EIF0 EIF1 LCD4 TPCFG

8h PI0 PI1 PI2 PI3

9h SMD0 SMD1 LCD5 RTSS

Ah PR0 PR1 LCD6 RTSH

Bh T0H T2CNA LCD7 RTSL

Ch T1L T2CFG LCD8 RSSA

Dh T1H T2V LCD9 RASH

Eh T1CL T2C LCD10 RASL

Fh T1CH IRCN LCD11 PWCN

10h PD0 PD1 PD2 PD3

11h

12h

13h

14h

15h

16h

17h

18h

19h

1Ah

1Bh

1Ch

1Dh

1Eh EIE0 EIE1 — —

1Fh EIES0 EIES1 — —

M0

(0h)

—

—

—

—

—

—

—

—

—

—

—

—

—

M1

(1h)

T2R LCD12 —

— LCD13 —

— LCD14 —

— LCD15 —

— LCD16 —

— LCD17 —

— LCD18 —

— LCD19 —

———

———

———

———

———

M2

(2h)

M3

(3h)

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

______________________________________________________________________________________ 15

Table 5. Peripheral Register Bit Functions

REGISTER BIT

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

T0H.6 T0H.5 T0H.4 T0H.3 T0H.2 T0H.1 T0H.0

PR1.6 PR1.5 PR1.4 PR1.3 PR1.2 PR1.1 PR1.0

PO0 PO0.7 PO0.6 PO0.5 PO0.4 PO0.3 PO0.2 PO0.1 PO0.0

REGISTER

SCON0 SM0/FE SM1 SM2 REN TB8 RB8 TI RI

T0CN ET0 T0M TF0 TR0 GATE C/T M1 M0

SBUF0 SBUF0.7 SBUF0.6 SBUF0.5 SBUF0.4 SBUF0.3 SBUF0.2 SBUF0.1 SBUF0.0

T0L T0L.7 T0L.6 T0L.5 T0L.4 T0L.3 T0L.2 T0L.1 T0L.0

T1CN TF1 EXF1 T1OE DCEN EXEN1 TR1 C/T1 CP/RL1

T1MD — ——— — —ET1T1M

EIF0 IE7 IE6 IE5 IE4 IE3 IE2 IE1 IE0

PI0 PI0.7 PI0.6 PI0.5 PI0.4 PI0.3 PI0.2 PI0.1 PI0.0

SMD0 EIR OFS — — — ESI SMOD FEDE

PR0 PR0.15 PR0.14 PR0.13 PR0.12 PR0.11 PR0.10 PR0.9 PR0.8 PR0.7 PR0.6 PR0.5 PR0.4 PR0.3 PR0.2 PR0.1 PR0.0

T0H T0H.7

T1L T1L.7 T1L.6 T1L.5 T1L.4 T1L.3 T1L.2 T1L.1 T1L.0

T1H T1H.7 T1H.6 T1H.5 T1H.4 T1H.3 T1H.2 T1H.1 T1H.0

PD0 PD0.7 PD0.6 PD0.5 PD0.4 PD0.3 PD0.2 PD0.1 PD0.0

T1CL T1CL.7 T1CL.6 T1CL.5 T1CL.4 T1CL.3 T1CL.2 T1CL.1 T1CL.0

EIE0 EX7 EX6 EX5 EX4 EX3 EX2 EX1 EX0

EIES0 IT7 IT6 IT5 IT4 IT3 IT2 IT1 IT0

PO1 — — — — PO1.3 PO1.2 PO1.1 PO1.0

SCON1 SM0/FE SM1 SM2 REN TB8 RB8 TI RI

SBUF1 SBUF1.7 SBUF1.6 SBUF1.5 SBUF1.4 SBUF1.3 SBUF1.2 SBUF1.1 SBUF1.0

T2CNB ET2L T2OE1 T2POL1 — TF2 TF2L TCC2 TC2L

T2H T2V.15 T2V.14 T2V.13 T2V.12 T2V.11 T2V.10 T2V.9 T2V.8

T2RH T2R.15 T2R.14 T2R.13 T2R.12 T2R.11 T2R.10 T2R.9 T2R.8

T2CH T2C.15 T2C.14 T2C.13 T2C.12 T2C.11 T2C.10 T2C.9 T2C.8

EIF1 — — — — IE11 IE10 IE9 IE8

PI1 — — — — PI1.3 PI1.2 PI1.1 PI1.0

SMD1 — — — — — ESI SMOD FEDE

PR1 PR1.15 PR1.14 PR1.13 PR1.12 PR1.11 PR1.10 PR1.9 PR1.8 PR1.7

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

16 ______________________________________________________________________________________

Table 5. Peripheral Register Bit Functions (continued)

PO2.6 PO2.5 PO2.4 PO2.3 PO2.2 PO2.1 PO2.0

REGISTER BIT

T2V.14 T2V.13 T2V.12 T2V.11 T2V.10 T2V.9 T2V.8 T2V.7 T2V.6 T2V.5 T2V.4 T2V.3 T2V.2 T2V.1 T2V.0

T2C.14 T2C.13 T2C.12 T2C.11 T2C.10 T2C.9 T2C.8 T2C.7 T2C.6 TCV.5 TCV.4 TCV.3 TCV.2 TCV.1 TCV.0

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

T2V T2V.15

T2CNA ET2 T2OE0 T2POL0 TR2L TR2 CPRL2 SS2 G2EN

REGISTER

T2CFG T2CI DIV2 DIV1 DIV0 T2MD CCF1 CCF0 C/T2

T2C T2C.15

IRCN — — — — — IREN IRTX IRBB

PD1 — — — — PD1.3 PD1.2 PD1.1 PD1.0

T2R T2R.15 T2R.14 T2R.13 T2R.12 T2R.11 T2R.10 T2R.9 T2R.8 T2R.7 T2R.6 T2R.5 T2R.4 T2R.3 T2R.2 T2R.1 T2R.0

EIE1 — — — — EX11 EX10 EX9 EX8

EIES1 — — — — IT11 IT10 IT9 IT8

PO2 PO2.7

LCFG PCF3 PCF2 PCF1 PCF0 — SMO OPM DPE

LCRA — — — DUTY1 DUTY0 FRM3 FRM2 FRM1 FRM0 — LRIG — LRA3 LRA2 LRA1 LRA0

LCD0 LCD0.7 LCD0.6 LCD0.5 LCD0.4 LCD0.3 LCD0.2 LCD0.1 LCD0.0

LCD1 LCD1.7 LCD1.6 LCD1.5 LCD1.4 LCD1.3 LCD1.2 LCD1.1 LCD1.0

LCD2 LCD2.7 LCD2.6 LCD2.5 LCD2.4 LCD2.3 LCD2.2 LCD2.1 LCD2.0

LCD3 LCD3.7 LCD3.6 LCD3.5 LCD3.4 LCD3.3 LCD3.2 LCD3.1 LCD3.0

LCD4 LCD4.7 LCD4.6 LCD4.5 LCD4.4 LCD4.3 LCD4.2 LCD4.1 LCD4.0

PI2 PI2.7 PI2.6 PI2.5 PI2.4 PI2.3 PI2.2 PI2.1 PI2.0

LCD5 LCD5.7 LCD5.6 LCD5.5 LCD5.4 LCD5.3 LCD5.2 LCD5.1 LCD5.0

LCD6 LCD6.7 LCD6.6 LCD6.5 LCD6.4 LCD6.3 LCD6.2 LCD6.1 LCD6.0

LCD7 LCD7.7 LCD7.6 LCD7.5 LCD7.4 LCD7.3 LCD7.2 LCD7.1 LCD7.0

LCD8 LCD8.7 LCD8.6 LCD8.5 LCD8.4 LCD8.3 LCD8.2 LCD8.1 LCD8.0

LCD9 LCD9.7 LCD9.6 LCD9.5 LCD9.4 LCD9.3 LCD9.2 LCD9.1 LCD9.0

LCD10 LCD10.7 LCD10.6 LCD10.5 LCD10.4 LCD10.3 LCD10.2 LCD10.1 LCD10.0

PD2 PD2.7 PD2.6 PD2.5 PD2.4 PD2.3 PD2.2 PD2.1 PD2.0

LCD11 LCD11.7 LCD11.6 LCD11.5 LCD11.4 LCD11.3 LCD11.2 LCD11.1 LCD11.0

LCD12 LCD12.7 LCD12.6 LCD12.5 LCD12.4 LCD12.3 LCD12.2 LCD12.1 LCD12.0

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

______________________________________________________________________________________ 17

Table 5. Peripheral Register Bit Functions (continued)

— — BOD

CCN1 CMON CMIE CMF CMM — CMO CMPOL —

TEMPR.7 TEMPR.5 TEMPR.5 TEMPR.4 TEMPR.3 TEMPR.2 TEMPR.1 TEMPR.0

.8

TEMPR

.9

TEMPR

.10

TEMPR

.11

TEMPR

.12

TEMPR

.13

TEMPR

.14

TEMPR

.15

TEMPR

TEMPR

TPCFG TPIF TPIE — — — RES1 RES0 START

REGISTER BIT

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

LCD13 LCD13.7 LCD13.6 LCD13.5 LCD13.4 LCD13.3 LCD13.2 LCD13.1 LCD13.0

REGISTER

LCD14 LCD14.7 LCD14.6 LCD14.5 LCD14.4 LCD14.3 LCD14.2 LCD14.1 LCD14.0

LCD15 LCD15.7 LCD15.6 LCD15.5 LCD15.4 LCD15.3 LCD15.2 LCD15.1 LCD15.0

LCD16 LCD16.7 LCD16.6 LCD16.5 LCD16.4 LCD16.3 LCD16.2 LCD16.1 LCD16.0

LCD17 LCD17.7 LCD17.6 LCD17.5 LCD17.4 LCD17.3 LCD17.2 LCD17.1 LCD17.0

LCD18 LCD18.7 LCD18.6 LCD18.5 LCD18.4 LCD18.3 LCD18.2 LCD18.1 LCD18.0

PO3 — PO3.6 PO3.5 PO3.4 PO3.3 PO3.2 PO3.1 PO3.0

LCD19 LCD19.7 LCD19.6 LCD19.5 LCD19.4 LCD19.3 LCD19.2 LCD19.1 LCD19.0

RTRM TSGN TRM6 TRM5 TRM4 TRM3 TRM2 TRM1 TRM0

RCNT WE — — — — — FT SQE ALSF ALDF RDYE RDY BUSY ASE ADE RTCE

CCN0 CMON CMIE CMF CMM — CMO CMPOL —

PI3 — PI3.6 PI3.5 PI3.4 PI3.3 PI3.2 PI3.1 PI3.0

RTSH.

RTSH.

RTSH.

RTSH.

RTSH.

RTSH.

RTSH.

RTSH.

RTSS RTSS.7 RTSS.6 RTSS.5 RTSS.4 RTSS.3 RTSS.2 RTSS.1 RTSS.0

RTSH.7 RTSH.6 RTSH.5 RTSH.4 RTSH.3 RTSH.2 RTSH.1 RTSH.0

8

RTSL.

9

RTSL.

10

RTSL.

11

RTSL.

12

RTSL.

13

RTSL.

14

RSTL.

15

RTSL.

RTSH

RSTL.7 RTSL.6 RTSL.5 RTSL.4 RTSL.3 RTSL.2 RTSL.1 RTSL.0

8

RSSA.

9

RSSA.

10

RSSA.

11

RSSA.

12

RSSA.

13

RSSA.

14

RSSA.

15

RSSA.

RTSL

RSSA.7 RSSA.6 RSSA.5 RSSA.4 RSSA.3 RSSA.2 RSSA.1 RSSA.0

8

9

10

11

12

13

14

15

RSSA

RASL.7 RASL.6 RASL.5 RASL.4 RASL.3 RASL.2 RASL.1 RASL.0

RASL.

RASL.

RASL.

RASL.

RASL.

RASL.

RASL.

RASL.

RASL

RASH — — — — RASH.3 RASH.2 RASH.1 RASH.0

8

9

10

11

12

13

14

15

———— —

PD3 — PD3.6 PD3.5 PD3.4 PD3.3 PD3.2 PD3.1 PD3.0

PWCN

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

18 ______________________________________________________________________________________

Note: Bits marked with an “s” have special behavior upon reset. Refer to the user’s guide supplement for this device for more details.

Table 6. Peripheral Register Bit Reset Values

REGISTER

PO0 11111111

SCON0 00000000

SBUF0 00000000

T0CN 00000000

T0L 00000000

T1CN 00000000

T1MD 00000000

EIF0 00000000

PI0 ssssssss

SMD0 00000000

PR0 0000000000000000

T0H 00000000

T1L 00000000

T1H 00000000

T1CL 00000000

T1CH 00000000

PD0 00000000

EIE0 00000000

EIES0 00000000

PO1 00001111

SCON1 00000000

SBUF1 00000000

T2CNB 00000000

T2H 00000000

T2RH 00000000

T2CH 00000000

EIF1 00000000

PI1 0000ssss

SMD1 00000000

PR1 0000000000000000

T2CNA 00000000

T2CFG 00000000

T2V 0

T2C 0

IRCN

PD1

T2R 0

EIE1

EIES1 00000000

PO2 11111111

LCFG 00000000

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

0000000

0000000

000000000000000

REGISTER BIT

00000000

0

00000000

00000000

00000000

0000000

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

______________________________________________________________________________________ 19

Table 6. Peripheral Register Bit Reset Values (continued)

Note: Bits marked with an “s” have special behavior upon reset. Refer to the user’s guide supplement for this device for more details.

REGISTER

LCRA

LCD0

LCD1

LCD2

LCD3

LCD4

PI2 ssssssss

LCD5

LCD6

LCD7

LCD8

LCD9

LCD10

LCD11

PD2

LCD12

LCD13

LCD14

LCD15

LCD16

LCD17

LCD18

LCD19

PO3

RTRM

RCNT 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 s

CCN0 00000000

CCN1 00000000

TEMPR s s s s s s s s s s s s s s s s

TPCFG 00000000

PI3 0sssssss

RTSS ssssssss

RTSH s

RTSL s

RSSA 0

RASH 00000000

RASL 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

PWCN 0000000s

PD3 00000000

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

00000000

sssssssssssssss

sssssssssssssss

000000000000000

REGISTER BIT

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

01111111

00ssssss

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

20 ______________________________________________________________________________________

System Timing

The MAXQ3100 generates its internal system clock from

the external 32.768kHz crystal. This serves as the timebase for the RTC and is multiplied internally by a frequency-locked loop (FLL) to provide a system clock of

4.194MHz. Best performance is achieved when mated

with a 32.768kHz crystal rated for a 6pF load. No external load capacitors are required. The frequency accuracy of a crystal-based oscillator circuit is dependent upon

crystal accuracy, the match between the crystal and the

oscillator capacitor load, ambient temperature, etc.

A crystal warmup counter enhances operational reliability. Each time the external crystal oscillation must restart,

including a power-on reset, the device initiates a crystal

warmup period of approximately 2 seconds. This warmup

period allows time for the crystal amplitude and frequency to stabilize before using it as a clock source.

Power Management

Advanced power-management features minimize power

consumption by dynamically matching the processing

speed of the device to the required performance level.

This means device operation can be slowed and power

consumption minimized during periods of reduced

activity. When more processing power is required, the

microcontroller can increase its operating frequency.

Software-selectable clock-divide operations allow flexibility, selecting whether a system clock cycle (SYSCLK)

is 1, 2, 4, or 8 of the 4.194MHz oscillator cycles. By performing this function in software, a lower power state

can be entered without the cost of additional hardware.

For extremely power-sensitive applications, two additional low-power modes are available.

• Divide-by-256 power-management mode (PMM1)

(PMME = 1, CD1:0 = 00b)

• Stop mode (STOP = 1)

In PMM1, one system clock is 256 oscillator cycles, significantly reducing power consumption while the microcontroller functions at reduced speed. The optional

switchback feature allows enabled interrupt sources,

such as the external interrupts, to cause the processor to

quickly exit PMM1 mode and return to a faster internal

clock rate.

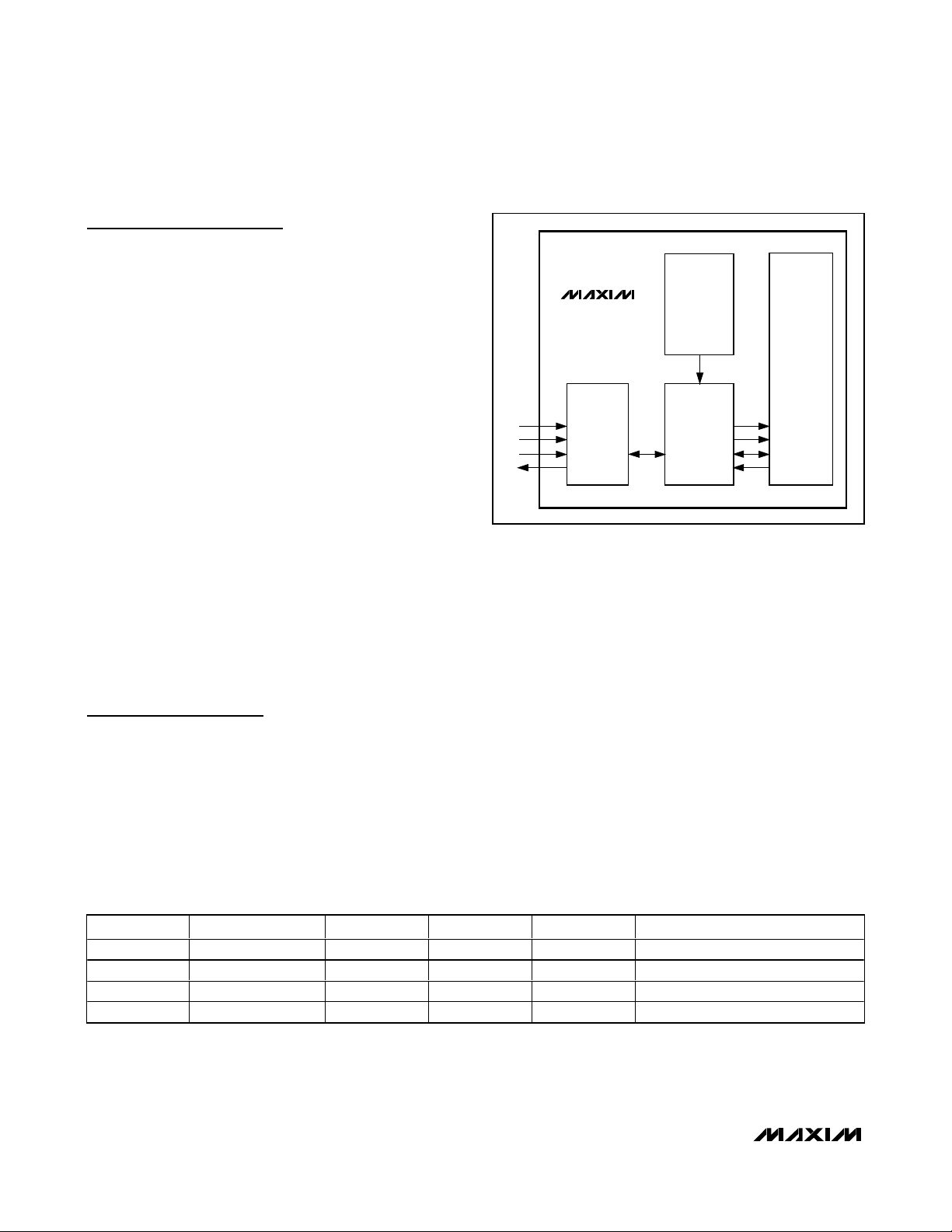

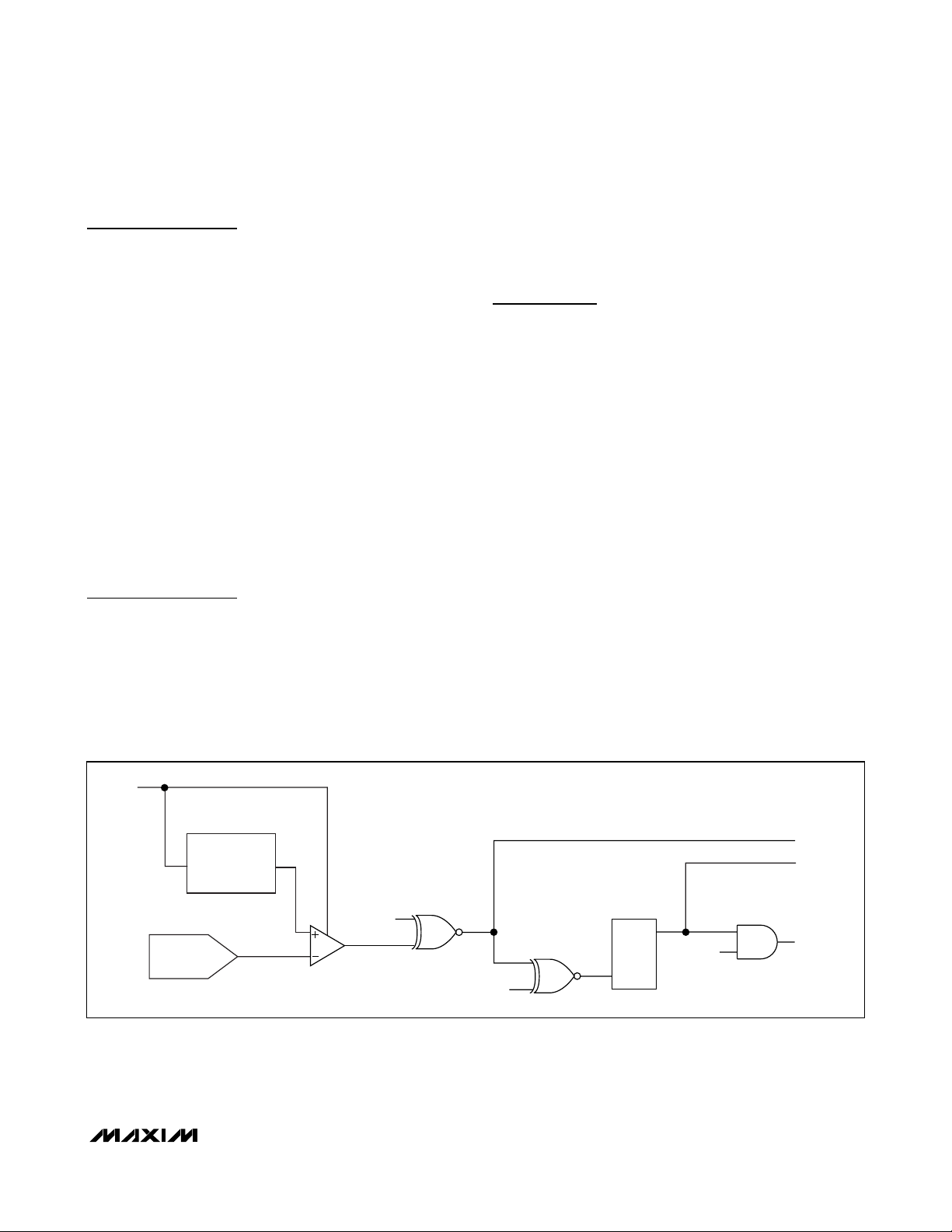

Figure 2. Clock Sources

POWER-ON

RESET

STOP

RESET

XDOG

STARTUP

TIMER

CLK INPUT

XDOG DONE

RESET DOG

WATCHDOG

TIMER

RWT

RESET

WATCHDOG RESET

WATCHDOG INTERRUPT

MAXQ3100

CLOCK

DIVIDER

DIV 1

DIV 2

SELECTOR

MUX

GLITCH-FREE

DIV 4

DIV 8

PWM1

DEFAULT

32kHz

CRYSTAL

OSCILLATOR

INPUT

FREQUENCY-

LOCKED LOOP

ENABLE

X32RY

FLLRY

4-CYCLE

DELAY

ENABLE

CLOCK

GENERATION

WATCHDOG DONE

STOP

POWER-ON

RESET

SYSTEM CLOCK

SWB

SWITCHBACK SOURCE

RESET

STOP

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

______________________________________________________________________________________ 21

Power consumption reaches its minimum in stop mode.

In this mode, the system clock and all code execution

is halted. Upon receiving one of the following enabled

events, the device executes a 250ms warmup delay

and then begins normal operation from the point in the

code following the setting of the STOP bit:

• An enabled external interrupt pin is triggered.

• An enabled comparator interrupt is triggered.

• An external reset signal is applied to the RESET pin.

• The RTC time-of-day or subsecond alarms are

activated.

The following peripherals can be enabled during stop

mode:

• Analog comparators

• RTC

• LCD controller

Interrupts

Multiple interrupt sources are available for quick

response to internal and external events. The MAXQ

architecture uses a single interrupt vector (IV), single

interrupt-service routine (ISR) design. For maximum

flexibility, interrupts can be enabled globally, individually, or by module. When an interrupt condition occurs,

its individual flag is set, even if the interrupt source is

disabled at the local, module, or global level. Interrupt

flags must be cleared within the user-interrupt routine

to avoid repeated interrupts from the same source.

Application software must ensure a delay between the

write to the flag and the RETI instruction to allow time

for the interrupt hardware to remove the internal interrupt condition. Asynchronous interrupt flags require a

one-instruction delay, and synchronous interrupt flags

require a two-instruction delay.

When an enabled interrupt is detected, software jumps

to a user-programmable interrupt vector location. The

IV register defaults to 0000h on reset or power-up, so if

it is not changed to a different address, the user program must determine whether a jump to 0000h came

from a reset or interrupt source.

Once software control has been transferred to the ISR,

the interrupt identification register (IIR) can determine if

a system register or peripheral register was the source

of the interrupt. The specified module can then be interrogated for the specific interrupt source and software

can take appropriate action. Because the interrupts are

evaluated by user software, the user can define a

unique interrupt priority scheme for each application.

The following interrupt sources are available.

• Watchdog Interrupt

• External Interrupts 0 to 11

• Analog Comparator 0 and 1 Interrupts

• Temperature Sensor Interrupt

• RTC Time-of-Day and Subsecond Alarms

• Serial Port 0 Receive and Transmit Interrupts

• Serial Port 1 Receive and Transmit Interrupts

• Timer 0 Overflow Interrupt

• Timer 1 Overflow and External Trigger Interrupts

• Timer 2 Low Compare, Low Overflow, Capture/

Compare, and Overflow Interrupts

Reset Sources

Several reset sources are provided for microcontroller

control. Although code execution is halted in the reset

state, the high-frequency oscillator continues to oscillate.

Power-On Reset/Brownout Reset

An internal power-on reset circuit enhances system reliability. This circuit forces the device to perform a

power-on reset whenever a rising voltage on DV

DD

climbs above approximately V

RST

. Additionally, the

device performs a brownout reset whenever DV

DD

drops below V

RST

, a feature that can be optionally disabled in stop mode. The following events occur during

a power-on reset:

• All registers and circuits enter their power-on reset

state.

• I/O pins revert to their reset state, with logic one

states tracking DVDD.

• The power-on reset flag is set to indicate the source

of the reset.

• Code execution begins at location 8000h following a

2-second 32.768kHz warmup.

Watchdog Timer Reset

The watchdog timer functions are described in the

MAXQ Family User’s Guide

. Software can determine if

a reset was caused by a watchdog timeout by checking the watchdog timer reset flag (WTRF) in the WDCN

register. Execution resumes at location 8000h following

a watchdog timer reset.

External System Reset

Asserting the external RESET pin low causes the

device to enter the reset state. The external reset functions as described in the

MAXQ Family User’s Guide

.

Execution resumes at location 8000h after the RESET

pin is released.

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

22 ______________________________________________________________________________________

I/O Ports

The microcontroller uses the Type C and Type D bidirectional I/O ports described in the

MAXQ Family

User’s Guide

. The use of two port types allows for maximum flexibility when interfacing to external peripherals.

Each port has independent, general-purpose I/O pins

and three configure/control registers. Many pins support alternate functions such as timers or interrupts,

which are enabled, controlled, and monitored by dedicated peripheral registers. Using the alternate function

automatically converts the pin to that function.

Type C port pins have Schmitt Trigger receivers and

full CMOS output drivers, and can support alternate

functions. The pin is either tri-stated or a weak pullup

when defined as an input, dependent on the state of

the corresponding bit in the output register.

Type D port pins have Schmitt Trigger receivers and

full CMOS output drivers, and can support alternate

functions. The pin is either tri-stated or a weak pullup

when defined as an input, dependent on the state of

the corresponding bit in the output register. All Type D

pins also have interrupt capability.

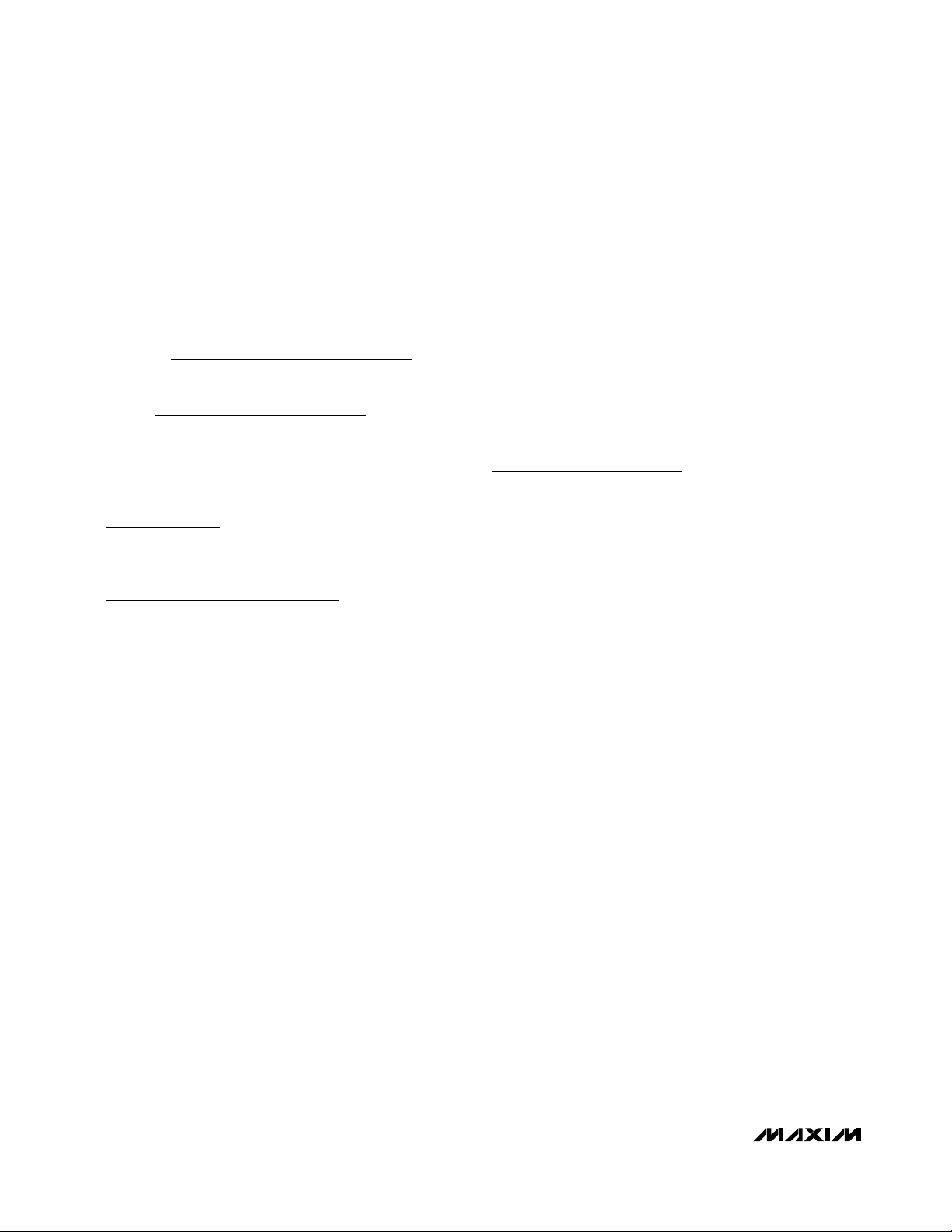

Figure 3. Type C/D Port Pin Schematic

PD.x

SF DIRECTION

SF ENABLE

PO.x

SF OUTPUT

MUXMUX

DV

DD

WEAK

DV

DD

MAXQ3100

I/O PAD

PORT PIN

PI.x OR SF INPUT

INTERRUPT

FLAG

FLAG

DETECT

CIRCUIT

EIES.x

TYPE D PORT ONLY

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

______________________________________________________________________________________ 23

Real-Time Clock

A binary real-time clock keeps the time of day in

absolute seconds with 1/256-second resolution. The

32-bit second counter can count up to approximately

136 years and be translated to calendar format by the

application software. A time-of-day alarm and independent subsecond alarm can cause an interrupt or wake

the device from stop mode.

The independent subsecond alarm runs from the same

RTC, and allows the application to perform periodic

interrupts up to 8 seconds with a granularity of approximately 3.9ms. This creates an additional timer that can

be used to measure long periods without performance

degradations. Traditionally, long time periods have

been measured using multiple interrupts from shorter

programmable timers. Each timer interrupt required

servicing, with each accompanying interruption slowing

system operation. By using the RTC subsecond timer

as a long-period timer, only one interrupt is needed,

eliminating the performance hit associated with using a

shorter timer.

Higher accuracy can be obtained by using the useraccessible digital RTC trim function. This feature allows

the designer to fine tune the RTC timing to compensate

for crystal inaccuracies and any unintended boardlevel effects that could cause crystal-frequency drift.

The user can enable a 1Hz or 512Hz square-wave output on P3.4. Frequency measurements of these signals

can show if there is any deviation from the expected

frequency, and writes to the RTC trim register can compensate in increments of 1 to 127 steps, with each step

approximately 3.05ppm (30.5µs).

If the V

BAT

pin is not directly tied to the DVDDpin, then

there may be a short increase in IDDwhile the device is

switching between V

BAT

and DVDDas the RTC power

source. IDDcan temporarily increase up to 300µA while

DVDDis rising and in the range 1.05 x V

BAT

< DVDD<

[(1.05 x V

BAT

) + 200mV]. A similar effect may be

observed while V

BAT

is falling and in the range [(0.95 x

DVDD) - 200mV] < V

BAT

< 0.95 x DVDD.

Programmable Timers

The MAXQ3100 incorporates one instance each of the

timer 0, timer 1, and timer 2 peripherals. These timers

can be used in counter/timer/capture/compare/PWM

functions, allowing precise control of internal and external events. Timer 2 supports optional single-shot, external gating, and polarity control options as well as

carrier generation support for infrared transmit/receive

functions using serial port 0.

Timer 0

The timer 0 peripheral includes the following:

• 8-bit autoreload timer/counter

• 13-bit or 16-bit timer/counter

• Dual 8-bit timer/counter

• External pulse counter

Timer 1

The timer 1 peripheral includes the following:

• 16-bit autoreload timer/counter

• 16-bit capture

• 16-bit counter

• Clock generation output

Timer 2

The timer 2 peripheral includes the following:

• 16-bit autoreload timer/counter

• 16-bit capture

• 16-bit counter

• 8-bit capture and 8-bit timer

• 8-bit counter and 8-bit timer

• Infrared carrier generation support

Watchdog Timer

An internal watchdog timer greatly increases system

reliability. The timer resets the processor if software

execution is disturbed. The watchdog timer is a freerunning counter designed to be periodically reset by

the application software. If software is operating correctly, the counter is periodically reset and never

reaches its maximum count. However, if software operation is interrupted, the timer does not reset, triggering

a system reset and optionally a watchdog timer interrupt. This protects the system against electrical noise

or electrostatic discharge (ESD) upsets that could

cause uncontrolled processor operation. The internal

watchdog timer is an upgrade to older designs with

external watchdog devices, reducing system cost and

simultaneously increasing reliability.

The watchdog timer is controlled through bits in the

WDCN register. Its timeout period can be set to one of

four programmable intervals ranging from 212to 2

21

system clocks in its default mode, allowing flexibility to

support different types of applications. The interrupt

occurs 512 system clocks before the reset, allowing the

system to execute an interrupt and place the system in

a known, safe state before the device performs a total

system reset. At 4.194MHz, watchdog timeout periods

can be programmed from 976µs to 128s, depending on

the system clock mode.

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

24 ______________________________________________________________________________________

In-Circuit Debug

Embedded debugging capability is available through

the debug port TAP. Embedded debug hardware and

embedded ROM firmware provide in-circuit debugging

capability to the user application, eliminating the need

for an expensive in-circuit emulator. Figure 4 shows a

block diagram of the in-circuit debugger. The in-circuit

debug features include:

• Hardware debug engine

• Set of registers able to set breakpoints on register,

code, or data accesses

• Set of debug service routines stored in the utility

ROM

The embedded hardware debug engine is an independent hardware block in the microcontroller. The debug

engine can monitor internal activities and interact with

selected internal registers while the CPU is executing

user code. Collectively, the hardware and software features allow two basic modes of in-circuit debugging:

• Background mode allows the host to configure and set

up the in-circuit debugger while the CPU continues to

execute the application software at full speed. Debug

mode can be invoked from background mode.

• Debug mode allows the debug engine to take control

of the CPU, providing read/write access to internal registers and memory, and single-step trace operation.

Serial Peripherals

The MAXQ3100 incorporates two 8051-style universal

synchronous/asynchronous receiver/transmitters. The

USARTs allow the device to conveniently communicate

with other RS-232 interface-enabled devices, as well as

PCs and serial modems when paired with an external

RS-232 line driver/receiver. The dual independent

USARTs can communicate simultaneously at different

baud rates with two separate peripherals. The USART

can detect framing errors and indicate the condition

through a user-accessible software bit.

The time base of the serial ports is derived from either a

division of the system clock or the dedicated baud

clock generator. The following table summarizes the

operating characteristics as well as the maximum baud

rate of each mode.

Serial port 0 contains additional functionality to support

low-speed infrared transmission in combination with the

PWM function of timer 2. When enabled in this mode,

the serial port automatically outputs a waveform generated by combining the normal serial port output waveform with the PWM carrier waveform output by timer 2,

using a logical OR or logical NOR function. The output

of serial port 0 in this mode can be used to drive an

infrared LED to communicate using a fixed-frequency

carrier modulated signal. Depending on the drive

strength required, the output may require a buffer when

used for this purpose.

Figure 4. In-Circuit Debugger

MAXQ3100

TMS

TCK

TDI

TDO

TAP

CONTROLLER

DEBUG

SERVICE

ROUTINES

(UTILITY ROM)

DEBUG

ENGINE

CONTROL

BREAKPOINT

ADDRESS

CPU

DATA

MODE TYPE START BITS DATA BITS STOP BIT MAX BAUD RATE AT 4.194MHz

Mode 0 Synchronous — 8 — 1.05Mbps

Mode 1 Asynchronous 1 8 1 131kbps

Mode 2 Asynchronous 1 8 + 1 1 131kbps

Mode 3 Asynchronous 1 8 + 1 1 131kbps

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

______________________________________________________________________________________ 25

Analog Comparators

The MAXQ3100 incorporates a pair of 1-bit analog-todigital comparators. The comparator inputs can be

connected to a wide range of peripherals, including

chemical, motion, or proximity detectors; voltage-supply monitoring; or any other appropriate analog input.

The comparator measures the analog inputs against

the internal +1.25V reference. The polarity of the internal comparator-output signal can be selected to indicate a value above or below the internal reference. The

comparators can be configured to generate an optional

interrupt in addition to setting an internal flag when the

input is out of range. A combination of the two comparators along with appropriate biasing of an input

allows the two comparators to be used as a window

comparator. When not in use, the pins associated with

the comparator are usable as general-purpose I/O. A

useful feature of the comparators is that they can be

used to wake the device from stop mode, allowing the

device to monitor external voltages while in an ultralow-power mode and only wake when necessary.

Temperature Sensor

The internal temperature sensor has a user-selectable

resolution of 10 (0.5°C), 11 (0.25°C), 12 (0.125°C), or

13 (0.0625°C) bits. Higher resolutions require longer

conversion times.

Setting the START bit initiates the temperature conversion, and the temperature sensor hardware clears the

bit when the conversion is complete. This bit can be

polled by software, or, optionally, the temperature conversion complete interrupt can be used to alert the system that the results are ready to be read from the

temperature results register (TEMPR).

Applications Information

Grounds and Bypassing

Careful PC-board layout significantly minimizes

crosstalk among the comparator inputs and other digital

signals. Keep digital and analog lines separate, and use

ground traces as shields between them where possible.

Bypass DV

DD

with a capacitor as low as 1µF and keep

bypass capacitor leads short for best noise rejection.

This device incorporates both analog and digital components, straddling both the analog and digital ground

planes. For increased accuracy, an LC filter can be

used to isolate pin 59. This pin powers the analog circuitry, and the additional filtering reduces the noise

entering the analog block.

Device Applications

The low-power, high-performance RISC architecture of

the MAXQ3100 makes it an excellent fit for many applications that require analog measurements combined

with the intelligence of a full-featured microcontroller.

Simple voltage-dividers can be used to scale any input

into a value in the range of the +1.25V reference. The

dual comparators allow the device to function as a simple limit comparator or window comparator in a wide

range of analog applications.

Figure 5. Analog Comparator Functional Diagram

CMON

INTERNAL

1.25V

REFERENCE

CMPOL

CMPx

CMM

SET

CMO

CMF

Q

CMM

INTERRUPT

REQUEST

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

26 ______________________________________________________________________________________

Additional Documentation

Designers must have four documents to fully use all the

features of this device. This data sheet contains pin

descriptions, feature overviews, and electrical specifications. Errata sheets contain deviations from published specifications. The user’s guides offer detailed

information about programming, device features, and

operation. The following documents can be downloaded from www.maxim-ic.com/microcontrollers.

• The MAXQ3100 data sheet, which contains electrical/timing specifications and pin descriptions, available at www.maxim-ic.com/MAXQ3100

.

• The MAXQ3100 errata sheet, available at

www.maxim-ic.com/errata.

• The

MAXQ Family User’s Guide

, which contains

detailed information on core features and operation,

including programming, avaliable at www.maximic.com/MAXQUG.

• The

MAXQ Family User’s Guide: MAXQ3100

Supplement

, which contains detailed information on

features specific to the MAXQ3100, available at

www.maxim-ic.com/MAXQ3100UG.

Development and Technical Support

A variety of highly versatile, affordably priced development tools for this microcontroller are available from

Maxim/Dallas Semiconductor and third-party suppliers,

including:

• Compilers

• In-circuit emulators

• Integrated development environments (IDEs)

• JTAG-to-serial converters for programming and

debugging

A partial list of development tool vendors can be found

on our website at www.maxim-ic.com/microcontrollers

.

Technical support is available through email at

maxq.support@dalsemi.com.

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

______________________________________________________________________________________ 27

Typical Application Circuits

Typical Application Circuit #1

Typical Application Circuit #1

shows a general-purpose

implementation using a MAXQ3100 that reads two sensor inputs, displays result and status information on an

LCD display, and also interfaces simultaneously with

an RS-232 and RS-485 networks. I/O pins that are not

dedicated to special functions are available to control

other system functions.

3.3V

DIRECT INPUT

FROM USER-

DEFINED SENSOR

SCALED

COMPARATOR

INPUT

R

1

R

2

DV

CMP0

CMP1

BACKUP BATTERY

VBAT

DD

V

REF

MAXQ3100

TXD0

RXD0

TXD1

RXD1

Px.x

SEG[39:0]

COM[3:0]

RS-232

Tx/Rx

RS-485

Tx/Rx

RTS

LCD MODULE

NOTE THAT UP TO 160 LCD SEGMENTS

CAN BE DRIVEN IF OTHER MUXED PIN

FUNCTIONS ARE NOT USED.

2

C FRAM

I

OR EEPROM

JTAG DOWNLOAD/

DEBUG

CONNECTOR

P2.3

P2.2

TDO

TDI

TCK

TMS

32KIN

32KOUT

GENERAL-

PURPOSE I/O

INT7

INT6

BUTTON 1

BUTTON 2

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

28 ______________________________________________________________________________________

Typical Application Circuits (continued)

Typical Application Circuit #2

Another target application of the MAXQ3100 is in the

electricity metering market. When coupled with an analog front-end, the microcontroller becomes the core of

an affordable electricity metering solution. Such an

application can accurately keep time, incorporate a

versatile display, and allow for multiple modes of communication. See

Typical Application Circuit #2

.

UNREGULATED

SUPPLY

ENERGY

METERING IC

CALIBRATION

EQUIPMENT

REGULATOR

3.3V

BACKUP BATTERY

ISOLATION

DV

CMP0

V

BAT

CMP1

T0

SQW

DD

MAXQ3100

V

REF

IR Tx/Rx

CIRCUIT

TXD0

RXD0

TXD1

RXD1

RS-232

Tx/Rx

IR Rx

MODULE

2

C FRAM

I

OR EEPROM

JTAG DOWNLOAD/

DEBUG

CONNECTOR

P2.3

P2.2

TDO

TDI

TCK

TMS

32KIN

32KOUT

SEG[39:0]

COM[3:0]

INT7

INT6

LCD MODULE

NOTE THAT UP TO 160 LCD SEGMENTS

CAN BE DRIVEN IF OTHER MUXED PIN

FUNCTIONS ARE NOT USED.

BUTTON 1

BUTTON 2

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

______________________________________________________________________________________ 29

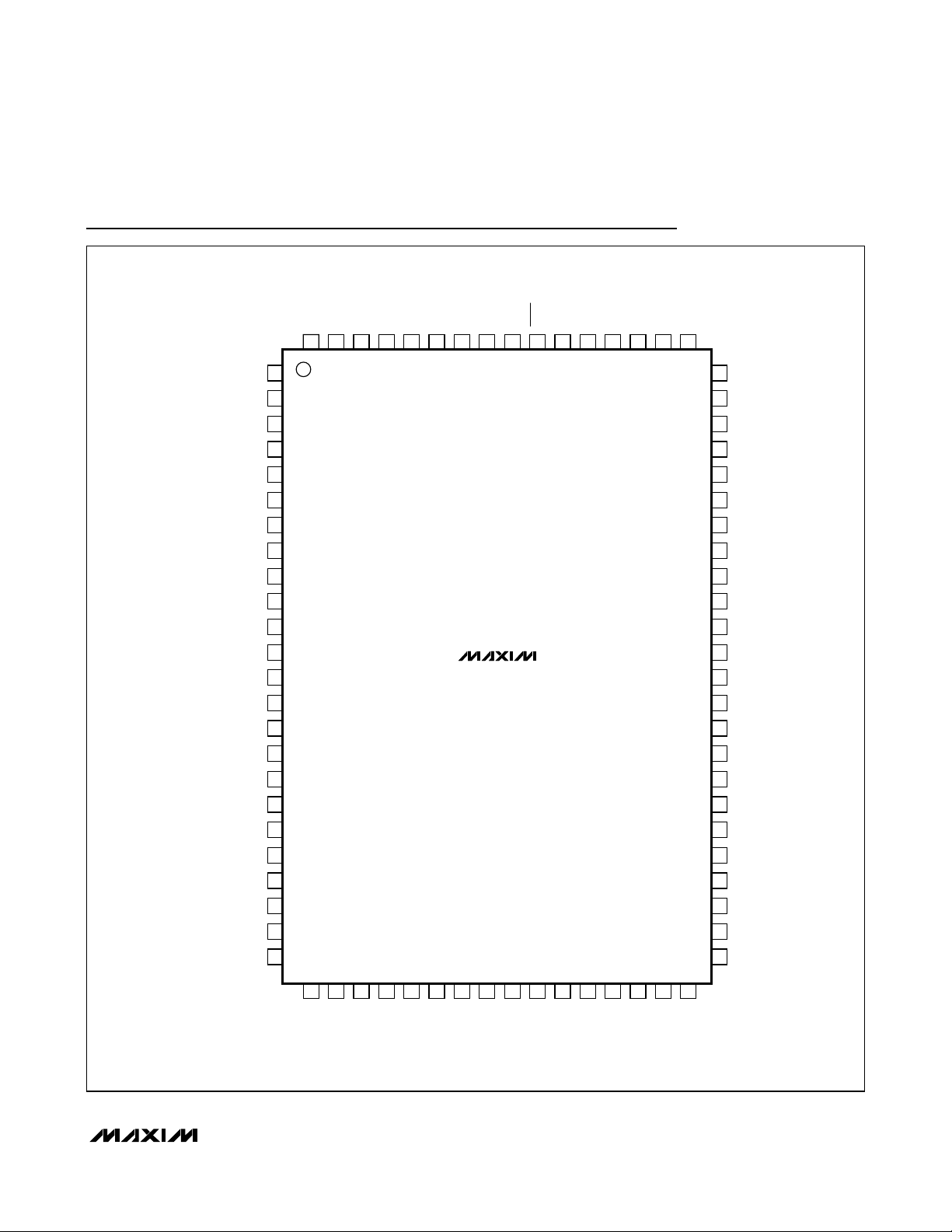

Pin Configuration

TOP VIEW

DGND

P0.4/INT4/T1

P0.5/INT5/T1EX

P0.6/INT6

P0.7/INT7

DV

COM0

COM1

COM2

COM3

DGND

SEG0

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

SEG8

SEG9

SEG10

SEG11

SEG12

DD

DGND

P0.3/INT3/T0

P0.2/INT2/T0G

P0.1/INT1/RXD0

P0.0/INT0/TXD0

DV

77

80

1

2

3

4

5

6

DD

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

78

79

76

32KOUT

74

75

32KIN

73

MAXQ3100

BAT

V

72

RESET

71

P3.6/CMP1

P3.5/CMP0

70

69

P3.4/SQW

P3.3/TMS

68

67

P3.1/TDO

P3.2/TCK

65

66

64

P3.0/TDI

63

P1.3/INT11/RXD1

P1.2/INT10/TXD1

62

61

P1.1/INTP/T2A

P1.0/INT8/T2B

60

DV

59

DD

DGND

58

V

57

ADJ

56

V

LCD2

V

55

LCD1

54

V

LCD

DV

53

DD

DGND

52

51

P2.7/SEG39

P2.6/SEG38

50

49

P2.5/SEG37

48

P2.4/SEG36

P2.3/SEG35

47

P2.2/SEG34

46

P2.1/SEG33

45

44

P2.0/SEG32

SEG31

43

SEG30

42

SEG29

41

25

SEG13

26

SEG14

27

SEG15

28

SEG16

29

SEG17

30

SEG18

SEG19

32

SEG20

33

SEG21

34

SEG22

35

SEG23

36

SEG24

37

SEG25

38

SEG26

39

SEG27

40

SEG28

31

MQFP

MAXQ3100

Mixed-Signal Microcontroller with Analog

Comparators, LCD, and RTC

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

30

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2007 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

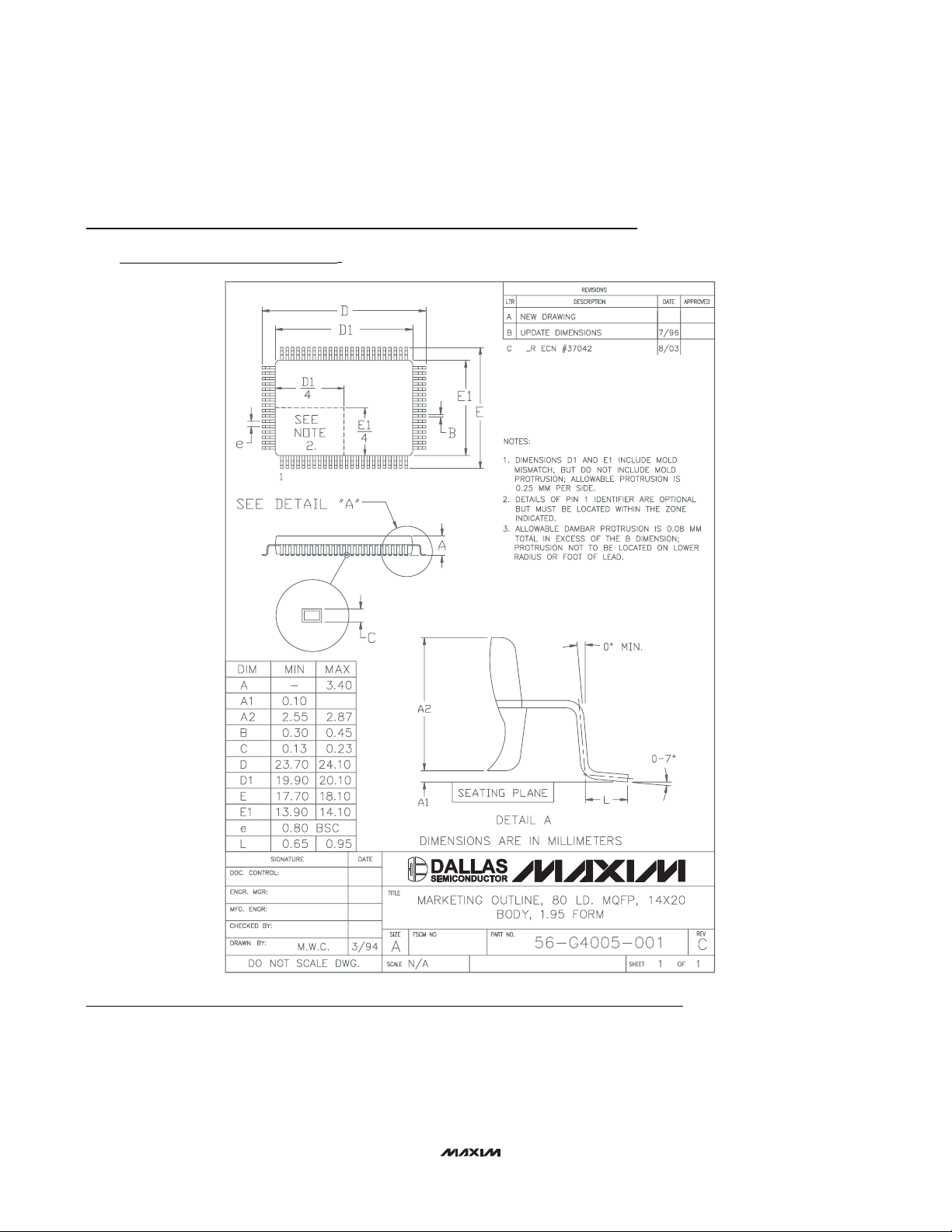

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/DallasPackInfo

)

.

Revision History

Rev 0; 6/07: Original release.

Loading...

Loading...