General Description

The MAX9921 provides a single chip solution to interface

two 2-wire Hall-effect sensors to a low-voltage microprocessor (µP). This device supplies and monitors the current drawn by two Hall-effect sensors, filters the sensed

current level, and outputs the corresponding logic level.

The MAX9921 includes input diagnostics and fault protection. These features allow the device to determine fault

conditions such as open inputs, inputs shorted to the battery, and inputs shorted to ground. If the MAX9921

detects any of these conditions at either IN1 or IN2, the

device shuts off the current to the corresponding input.

The MAX9921 protects the Hall sensors from supply transients up to 60V at the BAT supply. Normal operating

supply voltage ranges from 6V to 18V. If the battery voltage is out of range, the MAX9921 shuts off the current to

the Hall sensors.

The MAX9921 provides an 80µs blanking time following

Hall sensor power-up or restart. The open-drain logic

outputs are compatible with logic levels up to 5.5V.

The MAX9921 is available in a small 10-pin µMAX

®

package and is specified over the -40°C to +125°C

automotive temperature range.

Applications

Features

♦ Withstands 60V at BAT Supply and Hall Inputs

♦ 6V to 18V Operating Voltage Range

♦ Provides Supply Current and Interfaces to Two

2-Wire Hall Sensors

♦ Error Output with Diagnostics of Hall Inputs and

BAT Voltage

♦ Protects Hall Sensors from Overvoltage by

Isolating them from Supply Transients

♦ Hall Inputs Protected from Short to Ground

♦ Ramps Current to Hall Sensors at 4mA/µs

♦ Output Enable Input Allows Multiplexing of

Outputs from Multiple MAX9921s

♦ Hall Output Filtering

♦ Hall Sensor Blanking Following Hall Sensor

Power-Up and Restart

♦ Low-Power Shutdown, Controlled with OE and

DIAG Inputs

♦ Operates with ±2V Ground Shifts Between Hall

Sensor and MAX9921

MAX9921

Dual, 2-Wire Hall-Effect Sensor Interface

with Diagnostics

________________________________________________________________

Maxim Integrated Products

1

Ordering Information

N

REMOTE

GROUND

ISET

BATTERY

OE

ERR

DIAG

OUT1

OUT2

BAT

R

ISET

= 63.4kΩ, 1%

V

BAT

: 6V TO 18V OPERATING,

WITHSTANDS 60V

3.3V TO 5V

IN1

0.1μF

10kΩ

IN2

REF

GENERATION,

DIAGNOSTICS

AND

OVERVOLTAGE

DETECT

S

N

REMOTE

GROUND

S

0.01μF

CONTROL

FILTER

FILTER

μP/LOGIC

CIRCUIT

GND

V

CC

0.01μF

GND

MAX9921

E

C

U

C

O

N

N

E

C

T

O

R

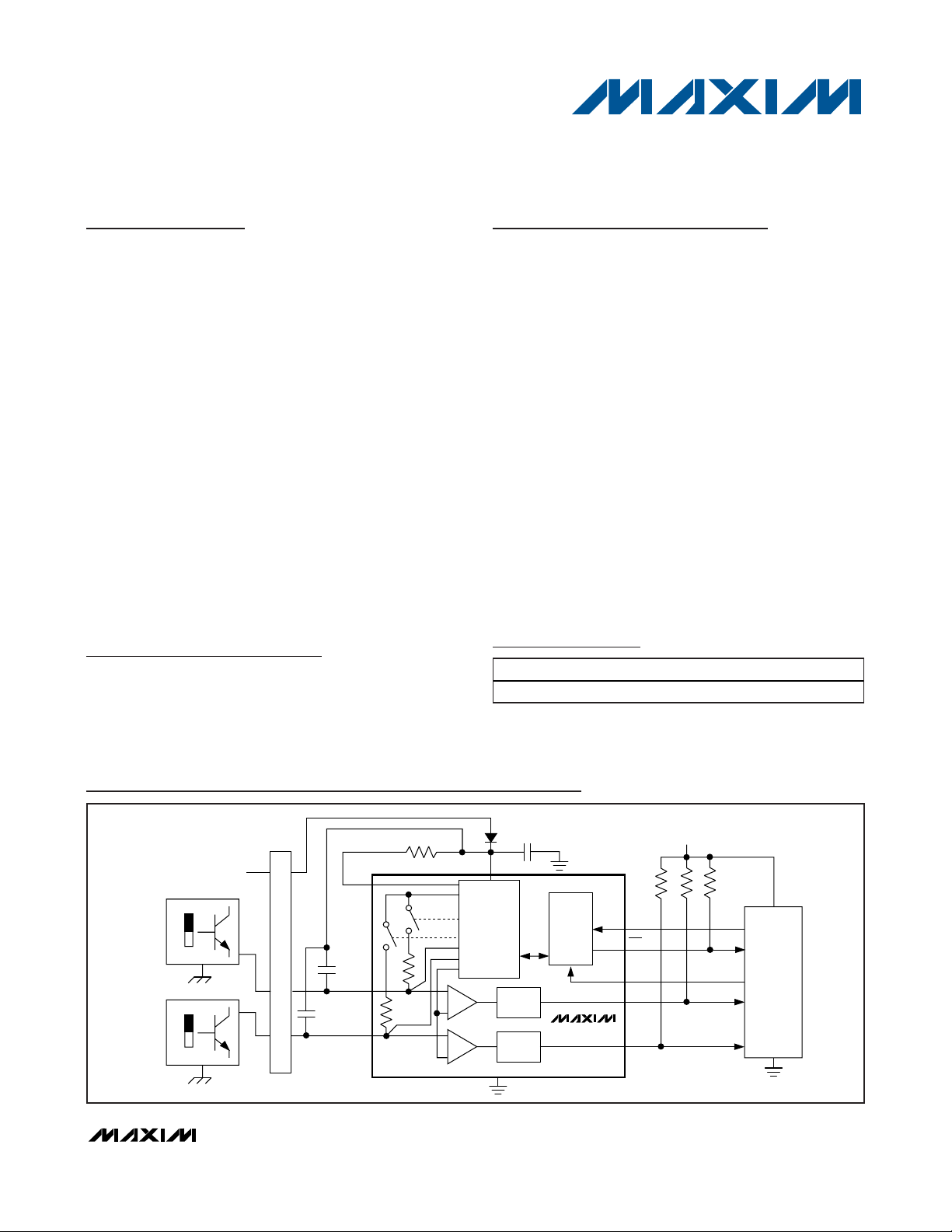

Typical Application Circuit

19-4119; Rev 0; 6/08

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

+

Denotes a lead-free package.

T = Tape and reel.

µMAX is a registered trademark of Maxim Integrated Products, Inc.

Pin Configuration appears at end of data sheet.

Door Modules

Window Lifters

Seat Movers

Electric Sunroofs

Powered Lift Gate

Controllers

Powered Running Boards

Seatbelt Buckles

PART TEMP RANGE PIN-PACKAGE

MAX9921AUB+T -40°C to +125°C 10 µMAX

MAX9921

Dual, 2-Wire Hall-Effect Sensor Interface

with Diagnostics

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

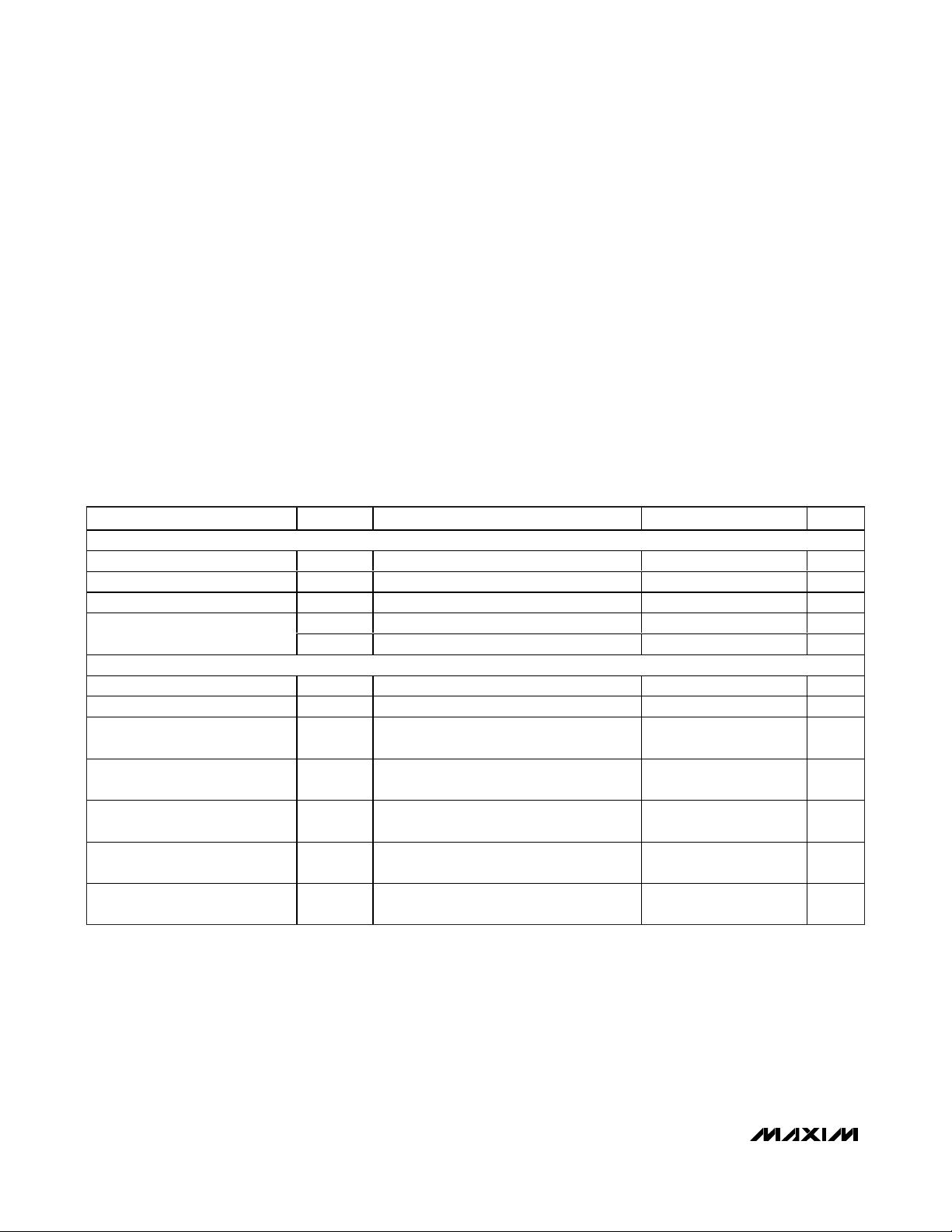

DC ELECTRICAL CHARACTERISTICS

(V

BAT

= 13.6V, V

DIAG

= 0V, VOE= 5V, IN1 = IN2 = no connection, R

ISET

= 63.4kΩ, RPU= 10kΩ at ERR, OUT1 and OUT2, TA= -40°C

to +125°C, unless otherwise noted. Typical values are at T

A

= +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

BAT to GND............................................................-0.3V to +60V

ISET to BAT ...........................................................-2.0V to +0.3V

IN1, IN2 to GND..........-5.0V to the lower of +60V or (V

BAT

+ 1V)

DIAG, OE to GND..................................................-0.3V to +6.0V

OUT1, OUT2, ERR to GND....................................-0.3V to +6.0V

Short-Circuit Duration of OUT1, OUT2, ERR to GND

or to 5.5V (individually)............................................Continuous

Current into Any Pin Except IN1, IN2 ...............................±20mA

Current into IN1, IN2.......................................................±100mA

Continuous Power Dissipation (T

A

= +70°C)

10-Pin µMAX (derate 5.6mW/°C above +70°C) .........444.4mW

Operating Temperature Range .........................-40°C to +125°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

GENERAL

BAT Supply Range V

V

Low for ERR Output Active V

BAT

V

High for ERR Output Active V

BAT

BAT Supply Current

HALL INPUTS (IN1 and IN2)

Input Current for Output High I

Input Current for Output Low I

Input Current Hysteresis for

High/Low Detection

Input Pullup Impedance R

Input Voltage Interpreted as

Shorted to Battery

Current Range Interpreted as

Open Circuit

Current Level Interpreted as

Shorted Sensor to Ground

BAT

BL

BH

I

BAT

I

SD

I

IN,HYS

V

I

OC

I

SC

Normal mode 1 1.3 mA

Shutdown mode, VOE = V

IH

IL

V

PU

SB

BAT

I

= -14mA

IN

Measured with respect to V

Not a sustained condition, reverts to -50µA

when detected

= 6V, inputs IN1, IN2 with

= 0V 1 µA

DIAG

BAT

618V

5.2 V

22 V

-11.5 mA

-7.2 mA

0.76 mA

50 Ω

100 mV

-2 +0.02 mA

-23 mA

MAX9921

Dual, 2-Wire Hall-Effect Sensor Interface

with Diagnostics

_______________________________________________________________________________________ 3

Note 1: All DC specifications are 100% tested at TA= +25°C. AC specifications and specifications over -40°C to +125°C are guar-

anteed by design.

Note 2: C

L

is external load capacitance on the outputs for test only.

Note 3: These blanking times apply when the MAX9921 is operating in normal mode. Blanking times following power-up or startup

from shutdown mode are 20µs longer.

AC TIMING CHARACTERISTICS

(V

BAT

= 13.6V, V

DIAG

= 0V, VOE= 5V, IN1 = IN2 = no connection, R

ISET

= 63.4kΩ, R

PU

= 10kΩ at ERR, OUT1 and OUT2, TA= -40°C

to +125°C, unless otherwise noted. Typical values are at T

A

= +25°C.) (Notes 1 and 2)

DC ELECTRICAL CHARACTERISTICS (continued)

(V

BAT

= 13.6V, V

DIAG

= 0V, VOE= 5V, IN1 = IN2 = no connection, R

ISET

= 63.4kΩ, RPU= 10kΩ at ERR, OUT1 and OUT2, TA= -40°C

to +125°C, unless otherwise noted. Typical values are at T

A

= +25°C.) (Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

LOGIC I/O (OUT1, OUT2, ERR, DIAG, and OE)

Output Voltage Low (ERR, OUT1,

OUT2)

Three-State Output Current (ERR,

OUT1, OUT2)

Input-Voltage High (DIAG, OE) V

Input-Voltage Low (DIAG, OE) V

Input Resistance to GND (DIAG,

OE)

V

I

OZ

R

Sink current = 1mA 0.4 V

OL

VOE = 0V, 0 ≤ V

IH

IL

IN

≤ 5V ±1 µA

OUT_

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

IN1, IN2 Blanking Time at Hall

Switch Power-Up

IN1, IN2 Current Ramp Rate

After Turn-On

Delay from IN_ to OUT_ (Filter

Delay)

Delay from IN_ Fault to ERR t

Delay from DIAG High to

OUT_ and ERR

Delay from DIAG Low to OUT_

and ERR

Delay Difference Between

Rising and Falling Edges for

Both Channels

t

BL

t

RAMP

t

DEL

ERR

t

DLH

t

DHL

t

DM

IIH = -11.5mA to GND, time from V

500mV until OUT_ high, C

VIN = GND 3.8 mA/µs

From IIH to IIL or from IIL to IIH, CL = 20pF,

Figure 1

From IIL to ISC or from IIH to I

only, C

Rising edge of DIAG to falling or rising edge

of outputs, C

Falling edge of DIAG to falling or rising edge

of outputs, C

C

HALL-BYPASS

= -7.2mA, CL = 20pF

I

IL

= 20pF, Figure 1

L

= 20pF, Figure 1

L

= 20pF, Figure 1

L

= 0.01µF, IIH = -11.5mA and

=

IN_

= 20pF (Note 3)

L

falling edge

OC,

2.1 V

0.8 V

50 80 kΩ

50 140 µs

6.5 µs

31 ns

350 ns

1.6 µs

20 ns

Delay Difference Between

Channels

Maximum Frequency on Hall

Inputs

IN_ Pulse Length Rejected by

Filter to OUT_

t

CC

f

MAX

P

R

C

HALL-BYPASS

I

= -7.2mA, CL = 20pF

IL

C

HALL-BYPASS

I

= -7.2mA, CL = 20pF

IL

= 0.01µF, IIH = -11.5mA and

= 0.01µF, IIH = -11.5mA and

100 ns

50 kHz

Figure 2 5.5 µs

MAX9921

Dual, 2-Wire Hall-Effect Sensor Interface

with Diagnostics

4 _______________________________________________________________________________________

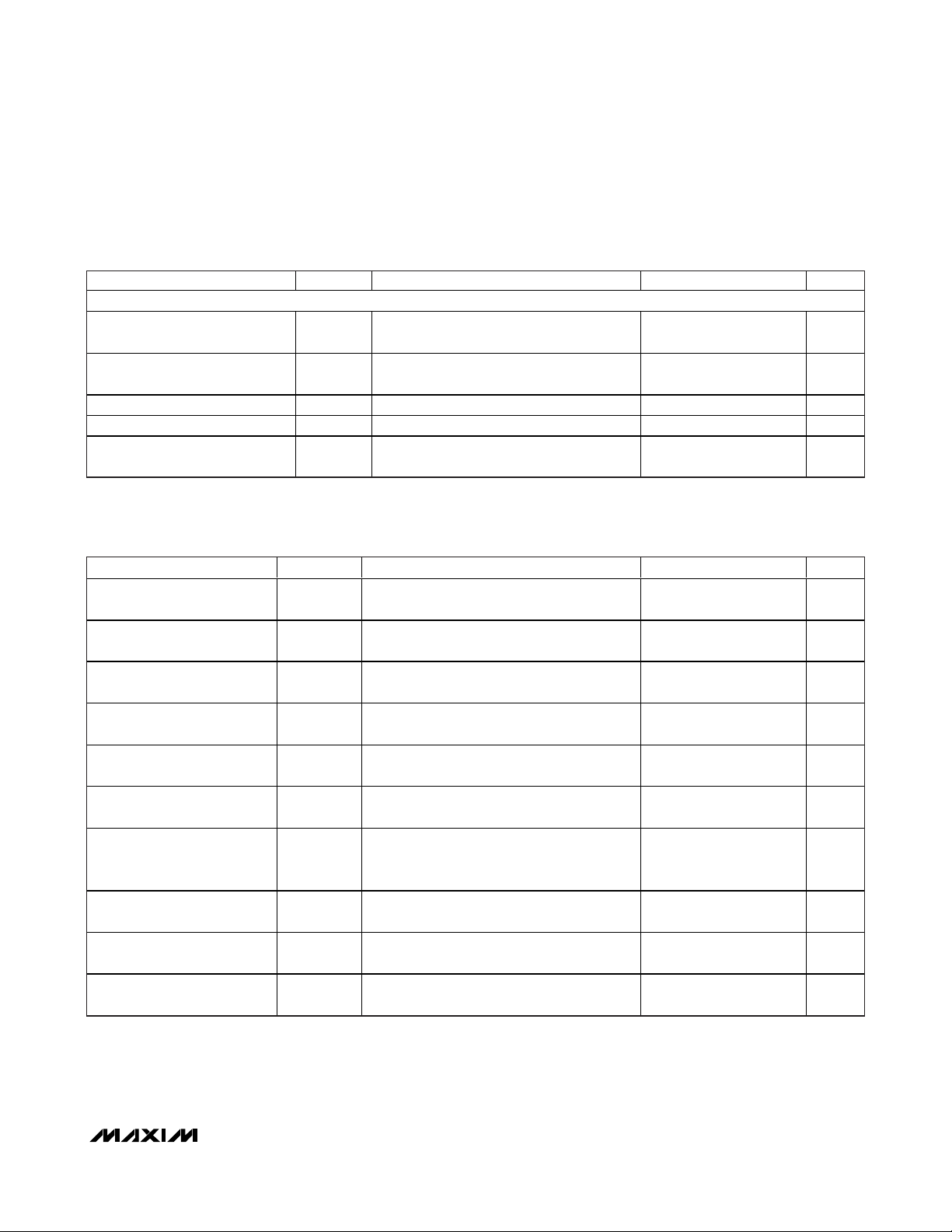

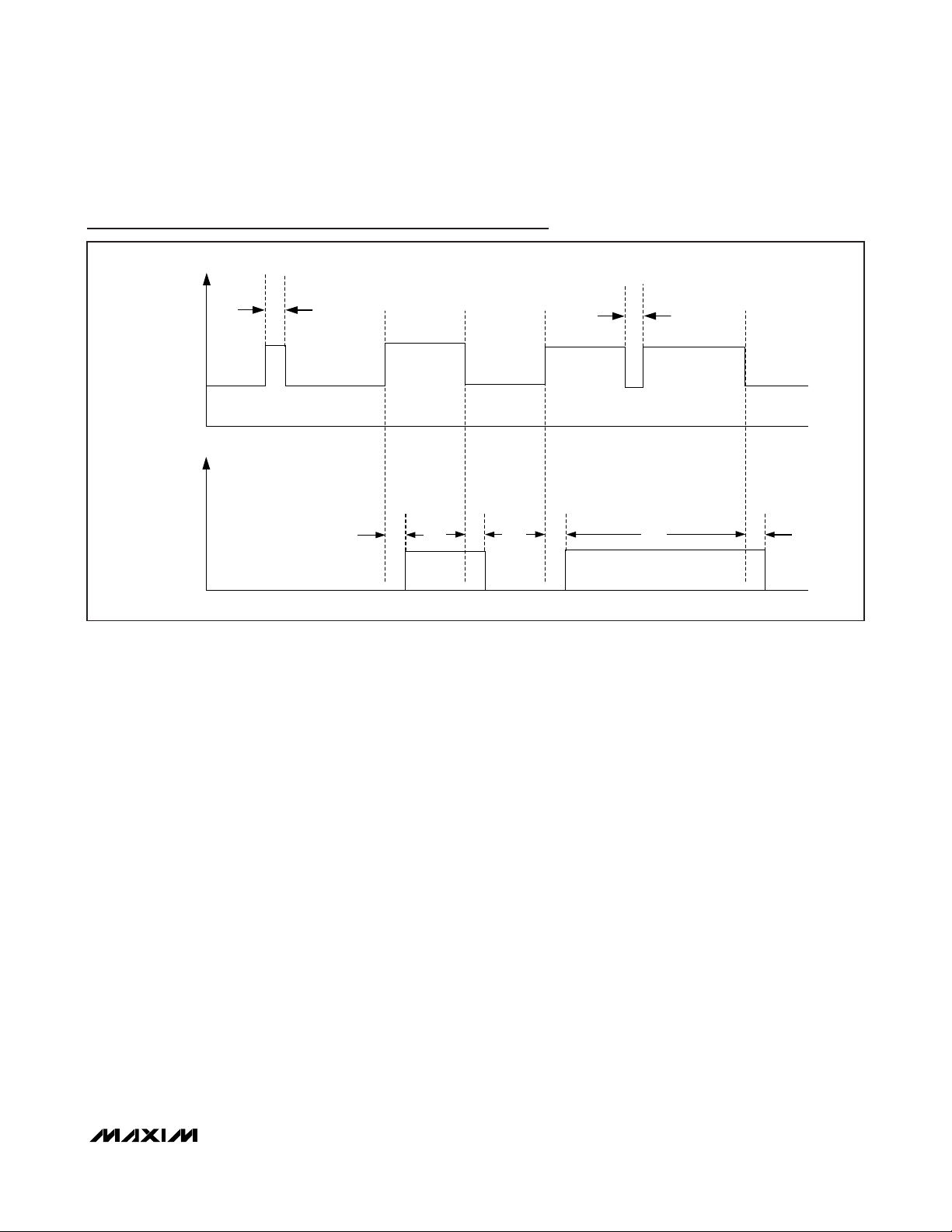

Timing Diagrams

Figure 1. Timing Diagram

APPROX. 50 mA

SHORT CIRCUIT

14mA

IN 1

7mA

RETRY

4mA/μs

0mA

5V

OUT1

0V

5V

OUT2

0V

5V

ERR

0V

5V

DIAG

0V

HALL SENSOR OPEN CIRCUIT

t

DEL

t

ERR

t

ERR

MAX9921

Dual, 2-Wire Hall-Effect Sensor Interface

with Diagnostics

_______________________________________________________________________________________ 5

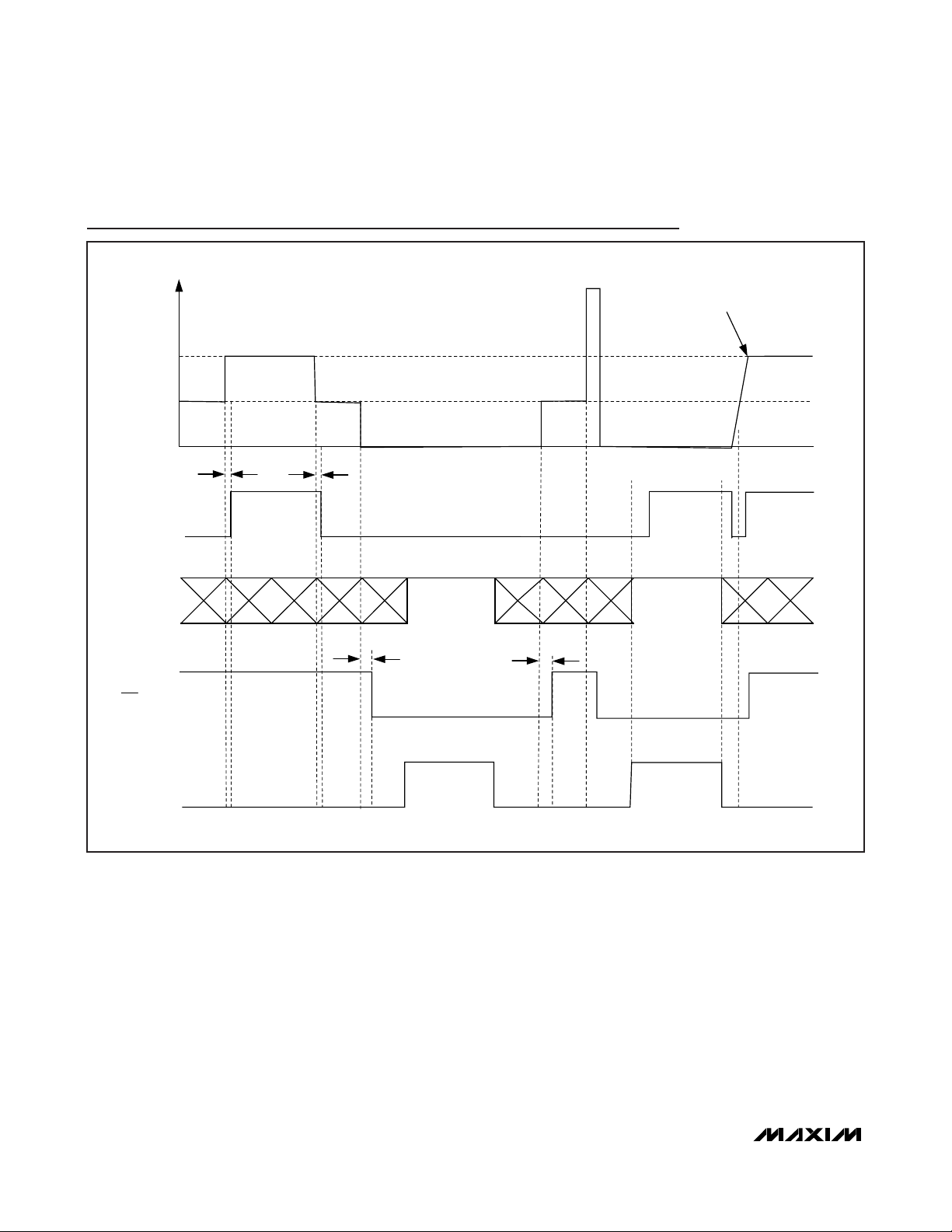

Timing Diagrams (continued)

Figure 2. Hall Input Pulse Rejection

P

R

14mA

IN_

7mA

0mA

5V

OUT_

0V

P

R

t

DEL

t

DEL

MAX9921

Dual, 2-Wire Hall-Effect Sensor Interface

with Diagnostics

6 _______________________________________________________________________________________

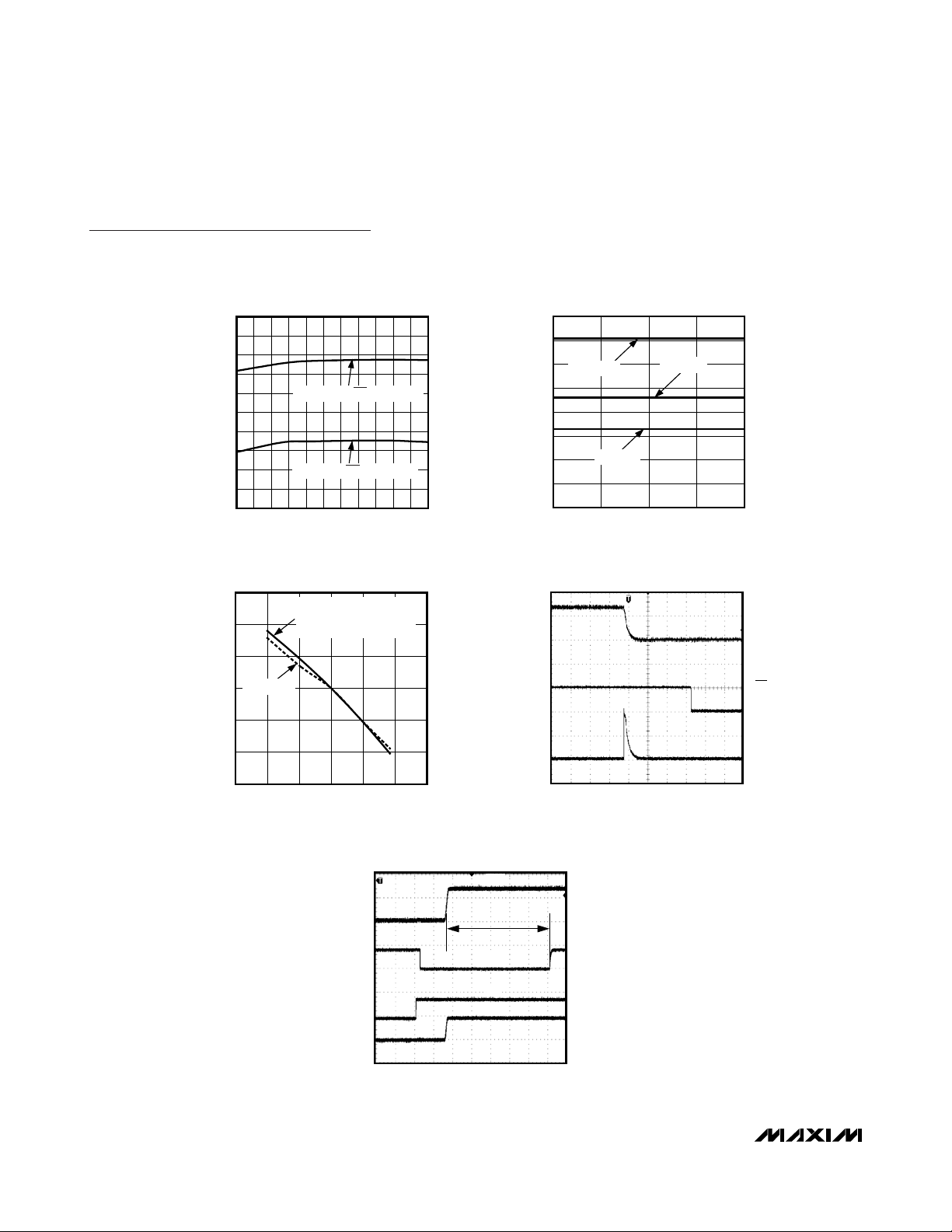

Typical Operating Characteristics

(V

BAT

= 14V, TA= +25°C, unless otherwise noted.)

BAT SUPPLY CURRENT

vs. V

BAT

IN OPERATING MODE

BAT VOLTAGE (V)

BAT CURRENT (mA)

MAX9921 toc01

19.0 19.5 20.0 20.5 21.0

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

TA = -40°C

BAT SUPPLY CURRENT

vs. V

BAT

IN OPERATING MODE

BAT VOLTAGE (V)

BAT CURRENT (mA)

MAX9921 toc02

19.0 19.5 20.0 20.5 21.0

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

TA = +25°C

BAT SUPPLY CURRENT

vs. V

BAT

IN OPERATING MODE

BAT VOLTAGE (V)

BAT CURRENT (mA)

MAX9921 toc03

19.0 19.5 20.0 20.5 21.0

0.8

0.9

1.0

1.1

1.2

1.3

1.4

1.5

1.6

TA = +125°C

BAT SUPPLY CURRENT

vs. V

BAT

IN OPERATING MODE

BAT VOLTAGE (V)

BAT CURRENT (mA)

MAX9921 toc04

5 1015202530354045505560

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

TA = -40°C

HALL INPUTS DISABLED

OPERATING MODE

BAT SUPPLY CURRENT

vs. V

BAT

IN OPERATING MODE

BAT VOLTAGE (V)

BAT CURRENT (mA)

MAX9921 toc05

5 1015202530354045505560

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

TA = +25°C

HALL INPUTS DISABLED

OPERATING MODE

BAT SUPPLY CURRENT

vs. V

BAT

IN OPERATING MODE

BAT VOLTAGE (V)

BAT CURRENT (mA)

MAX9921 toc06

5 1015202530354045505560

0.6

0.8

1.0

1.2

1.4

1.6

HALL INPUTS DISABLED

OPERATING MODE

TA = +125°C

BAT SUPPLY CURRENT

vs. V

BAT

IN SHUTDOWN MODE

BAT VOLTAGE (V)

BAT CURRENT (nA)

MAX9921 toc07

0 10203040

0

5

10

15

20

25

30

35

40

45

50

TA = +25°C

TA = +125°C

TA= -40°C

HALL INPUT CURRENT HYSTERESIS FOR

HIGH/LOW THRESHOLDS

vs. TEMPERATURE

HALL INPUT CURRENT (mA)

MAX9921 toc08

-40 -25 -10 5 20 35 50 65 80 95 110 125

8.4

8.6

8.8

9.0

9.2

9.4

9.6

9.8

10.0

LOW THRESHOLD

HIGH THRESHOLD

HALL INPUT CURRENT HYSTERESIS FOR

HIGH/LOW THRESHOLD vs. V

BAT

BAT VOLTAGE (V)

HALL INPUT CURRENT (mA)

MAX9921 toc09

6 8 10 12 14 16 18

8.6

8.8

9.0

9.2

9.4

9.6

9.8

LOW THRESHOLD

HIGH THRESHOLD

MAX9921

Dual, 2-Wire Hall-Effect Sensor Interface

with Diagnostics

_______________________________________________________________________________________

7

Typical Operating Characteristics (continued)

(V

BAT

= 14V, TA= +25°C, unless otherwise noted.)

IN_ BLANKING TIME AT HALL SWITCH

POWER-UP vs. TEMPERATURE

TEMPERATURE (°C)

IN_ BLANKING TIME (μs)

MAX9921 toc10

-40 -25 -10 5 20 35 50 65 80 95 110 125

60

65

70

75

80

85

90

95

100

IN_ CURRENT RAMP RATE AFTER

TURN-ON vs. TEMPERATURE

TEMPERATURE (°C)

IN_ CURRENT RAMP RATE (mA/μs)

MAX9921 toc11

-40 -25 -10 5 20 35 50 65 80 95 110 125

0

1

2

3

4

5

DELAY FROM IN_ TO OUT_ (FILTER DELAY)

vs. TEMPERATURE

TEMPERATURE (°C)

DELAY (μs)

MAX9921 toc12

-40 -25 -10 5 20 35 50 65 80 95 110 125

5

6

7

8

9

10

DELAY FROM IN_ FAULT TO ERR

(FILTER DELAY) vs. TEMPERATURE

TEMPERATURE (°C)

DELAY (μs)

MAX9921 toc13

-40 -25 -10 5 20 35 50 65 80 95 110 125

0

10

20

30

40

50

DELAY DIFFERENCE BETWEEN RISING

AND FALLING EDGES FOR BOTH CHANNELS

vs. TEMPERATURE

TEMPERATURE (°C)

DELAY DIFFERENCE (ns)

MAX9921 toc14

-40 -25 -10 5 20 35 50 65 80 95 110 125

0

20

40

60

80

100

120

140

160

180

IN1 AND IN2

DELAY DIFFERENCE BETWEEN

CHANNELS vs. TEMPERATURE

TEMPERATURE (°C)

DELAY DIFFERENCE (ns)

MAX9921 toc15

-40 -25 -10 5 20 35 50 65 80 95 110 125

0

50

100

150

200

250

MAXIMUM FREQUENCY ON HALL INPUTS

vs. TEMPERATURE

TEMPERATURE (°C)

FREQUENCY (kHz)

MAX9921 toc16

-40 -25 -10 5 20 35 50 65 80 95 110 125

50

55

60

65

70

75

80

85

90

95

100

IN1 AND IN2, 50% DUTY CYCLE

IN_ PULSE LENGTH REJECTED BY FILTER

TO OUT_ vs. TEMPERATURE

TEMPERATURE (°C)

PULSE LENGTH (μs)

MAX9921 toc17

-40 -25 -10 5 20 35 50 65 80 95 110 125

0

1

2

3

4

5

6

7

IN1 AND IN2 WITH

NEGATIVE PULSE

IN1 AND IN2 WITH

POSITIVE PULSE

V

BAT

UNDERVOLTAGE THRESHOLD

vs. TEMPERATURE

TEMPERATURE (°C)

V

BAT

THRESHOLD (V)

MAX9921 toc18

-40 -25 -10 5 20 35 50 65 80 95 110 125

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

6.0

6.1

6.2

V

BAT

RISING, ERR GOES HIGH

V

BAT

FALLING, ERR GOES LOW

MAX9921

Dual, 2-Wire Hall-Effect Sensor Interface

with Diagnostics

8 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(V

BAT

= 14V, TA= +25°C, unless otherwise noted.)

V

BAT

OVERVOLTAGE THRESHOLD

vs. TEMPERATURE

TEMPERATURE (°C)

V

BAT

THRESHOLD (V)

MAX9921 toc19

-40 -25 -10 5 20 35 50 65 80 95 110 125

19.5

19.6

19.7

19.8

19.9

20.0

20.1

20.2

20.3

20.4

20.5

V

BAT

FALLING, ERR GOES LOW

V

BAT

RISING, ERR GOES HIGH

INPUT PULLUP RESISTANCE

vs. V

BAT

V

BAT

(V)

INPUT PULLUP RESISTANCE (Ω)

MAX9921 toc20

6 9 12 15 18

0

10

20

30

40

50

60

70

80

TA = +125°C

TA = +25°C

TA = -40°C

THRESHOLD CURRENT vs. ISET RESISTOR

CHANGE IN ISET RESISTOR (%)

CHANGE IN THRESHOLD CURRENT (%)

MAX9921 toc21

-15 -10 -5 0 5 10 15

-15

-10

-5

0

5

10

15

HYSTERESIS

INPUT CURRENT FOR OUTPUT

HIGH AND INPUT CURRENT

FOR OUTPUT LOW

RESPONSE OF INPUT TO SHORT TO GROUND

MAX9921 toc22

10μs/div

V

IN1

10V/div

I

IN1

25mA/div

0V

0V

0A

V

ERR

5V/div

STARTUP OF HALL INPUT FROM SHUTDOWN

MAX9921 toc23

20μs/div

10V/div

5V/div

5V/div

10mA/div

BLANKING PERIOD

V

IN_

V

OUT_

V

OE_

I

IN_

MAX9921

Dual, 2-Wire Hall-Effect Sensor Interface

with Diagnostics

_______________________________________________________________________________________ 9

Pin Description

PIN NAME FUNCTION

1 BAT

2 ISET

3 IN1

4 IN2

5 GND Ground

6 OUT2

7 OUT1

8 ERR

9OE

10 DIAG

Battery Power Supply. Connect BAT to the positive supply through an external reverse-polarity diode. Bypass BAT

to ground with a 0.1µF capacitor.

Current-Setting Input. Connect a 63.4kΩ, 1% resistor (R

thresholds for Hall current sensing. Make no other connections to ISET. All routing must have low parasitic

capacitance.

Hall-Effect Sensor Input 1. Bypass IN1 to BAT or GND with a 0.01µF capacitor. Terminate an unused input with a

1.5kΩ resistor from IN1 to GND to prevent false error diagnostics.

Hall-Effect Sensor Input 2. Bypass IN2 to BAT or GND with a 0.01µF capacitor. Terminate an unused input with a

1.5kΩ resistor from IN2 to GND to prevent false error diagnostics.

Open-Drain Output Signal 2. OUT2 is the signal translated from Hall Sensor 2. Connect a 10kΩ or larger pullup

resistor to logic supply.

Open-Drain Output Signal 1. OUT1 is the signal translated from Hall Sensor 1. Connect a 10kΩ or larger pullup

resistor to logic supply.

Open-Drain Diagnostic and Error Output. Connect a 10kΩ or larger pullup resistor to logic supply. If DIAG is

asserted low, a high on ERR indicates that there is no fault while a low on ERR indicates that either the battery

voltage is out of range or there is a fault condition. If DIAG is high, ERR provides diagnostic information in

conjunction with OUT1 and OUT2. See Tables 1 and 2. If OE is low or while in shutdown, ERR is high impedance.

Output Enable Input. OE has an internal 80kΩ resistor to GND. Drive OE high to enable the outputs ERR, OUT1,

and OUT2. Drive OE low to place the outputs in high impedance. If OE and DIAG are both low for more than 40µs,

the device enters shutdown and all outputs are in high impedance. While in shutdown, if either OE or DIAG

transitions low to high, the device exits shutdown mode.

Diagnostic Enable Input. DIAG has an internal 80kΩ resistor to GND. Drive DIAG low for normal operation. In this

mode, ERR, OUT1, and OUT2 provide Hall sensor information. Drive DIAG high for diagnostic operation. A high-tolow transition initiates an attempt to restart, with a blanking cycle any Hall input that has been shut down. See

Tables 1 and 2 (diagnostic truth tables). If OE and DIAG are both low for more than 40µs, the device enters

shutdown mode with all outputs in high impedance. While in the shutdown mode, if either OE or DIAG transitions

low to high, the device exits shutdown mode.

) between BAT and ISET to set the standard current

ISET

Detailed Description

The MAX9921 connects two 2-wire Hall-effect sensors to

a low-voltage µP. This device supplies current through

IN1 and IN2 to Hall sensors and monitors the current

level drawn by the Hall sensors. The MAX9921 outputs a

high or low logic-level to the corresponding open-drain

output (OUT1 or OUT2). If the current flowing out of

either IN1 or IN2 exceeds the high input current threshold, the corresponding output goes high. If the current

flowing out of either IN1 or IN2 is lower than the low input

current threshold, the corresponding output goes low.

Hall Input Diagnostic

Normal Mode

In normal mode, DIAG is driven low. In this case, if ERR

is high, the outputs (OUT1 and OUT2) indicate the high

or low state of the corresponding Hall sensors (IN1 and

IN2). In normal mode, a low ERR indicates a fault. If

ERR is low, the outputs may be pulled low and may not

indicate the high or low state of the Hall sensors. This

can happen during the power-up, restart, or blanking

cycles of the Hall inputs, or due to a fault on one or

both of the Hall inputs, or when V

BAT

is out of range,

while the error output is low. If one output continues

signaling and the other output is low, the output with

the low logic-level indicates a fault or a restart and

blanking cycle on the corresponding Hall input. Table 1

summarizes normal mode operation.

Diagnostic Mode

When DIAG is driven high, the MAX9921 enters diagnostic mode. In this mode, OUT1 and OUT2 output diagnostic information. IN1 takes precedence over IN2. IN2’s

diagnostics remain masked until a fault on IN1 is cleared.

For diagnostics and troubleshooting, when IN1 or IN2

shuts off due to an input short to ground, it continues to

source 50µA. A falling edge at DIAG restarts a Hall input

that has been shut off due to a short to ground.

Diagnostic indications are never latched internally and

they indicate the real-time state of IN1 or IN2. Table 2

summarizes diagnostic mode operation.

Hall Input Fault Detection

If a fault is detected, the ERR output is asserted low to

notify the µP. This condition can occur due to the Hall

input being shorted to ground, shorted to battery,

or open.

MAX9921

Dual, 2-Wire Hall-Effect Sensor Interface

with Diagnostics

10 ______________________________________________________________________________________

Functional Diagram

Table 1. Diagnostic Truth Table (Normal Mode)

BAT

ISET

REF

GENERATION,

DIAGNOSTICS,

IN1

IN2

AND

OVERVOLTAGE

DETECT

FILTER

FILTER

GND

CONTROL

MAX9921

DIAG

ERR

OE

OUT1

OUT2

INPUT OUTPUT

DIAG ERR OUT1 OUT2

0 1 0 or 1 0 or 1

00 0 0

0 0 0 0 or 1 Fault on IN1 or restart blanking of IN1

0 0 0 or 1 0 Fault on IN2 or restart blanking of IN2

OUT1 and OUT2 indicate state of IN1

and IN2, respectively

Fault on IN1 and/or IN2, or V

of range, or power-up or restart

blanking (unknown current level of

IN1 and IN2)

DIAGNOSIS COMMENT

Normal mode: No fault indication (outputs

indicate Hall sensor high or low status)

out

BAT

Normal mode: ERR asserted low indicates

fault (outputs may no longer indicate the

high or low state of the Hall sensors)

Normal mode: ERR asserted low indicates

fault; Hall output 2 continues signaling

Normal mode: ERR asserted low indicates

fault; Hall output 1 continues signaling

MAX9921

Dual, 2-Wire Hall-Effect Sensor Interface

with Diagnostics

______________________________________________________________________________________ 11

Hall Sensor Protection from Supply Transients

If the V

BAT

voltage is lower than 6V or exceeds 18V,

IN1 and IN2 shut off current to both Hall sensors and

ERR, OUT1, and OUT2 go low. When V

BAT

returns to

the proper range, both IN1 and IN2 restart, following a

blanking cycle.

Hall Inputs Open Condition

If either IN1 or IN2 is open (IIN< 2mA), the corresponding input shuts off current to the Hall sensor. If IN1 or

IN2 is loaded, it exits the open input fault condition and

restarts the corresponding Hall input, following a blanking cycle.

Hall Input Shorted to Battery

If either IN1 or IN2 is shorted to the battery (VIN> V

BAT

+ 100mV), the MAX9921 shuts off current to the corresponding Hall sensor. In this case, if IN1 or IN2 is more

than 1V above V

BAT

, it may back-drive current into

BAT. In such a condition, the current level in the Hall

input should not exceed 100mA. Therefore, all the

MAX9921s together can share a separate reversepolarity protection diode to avoid powering up other circuitry sharing a common diode (Figure 4).

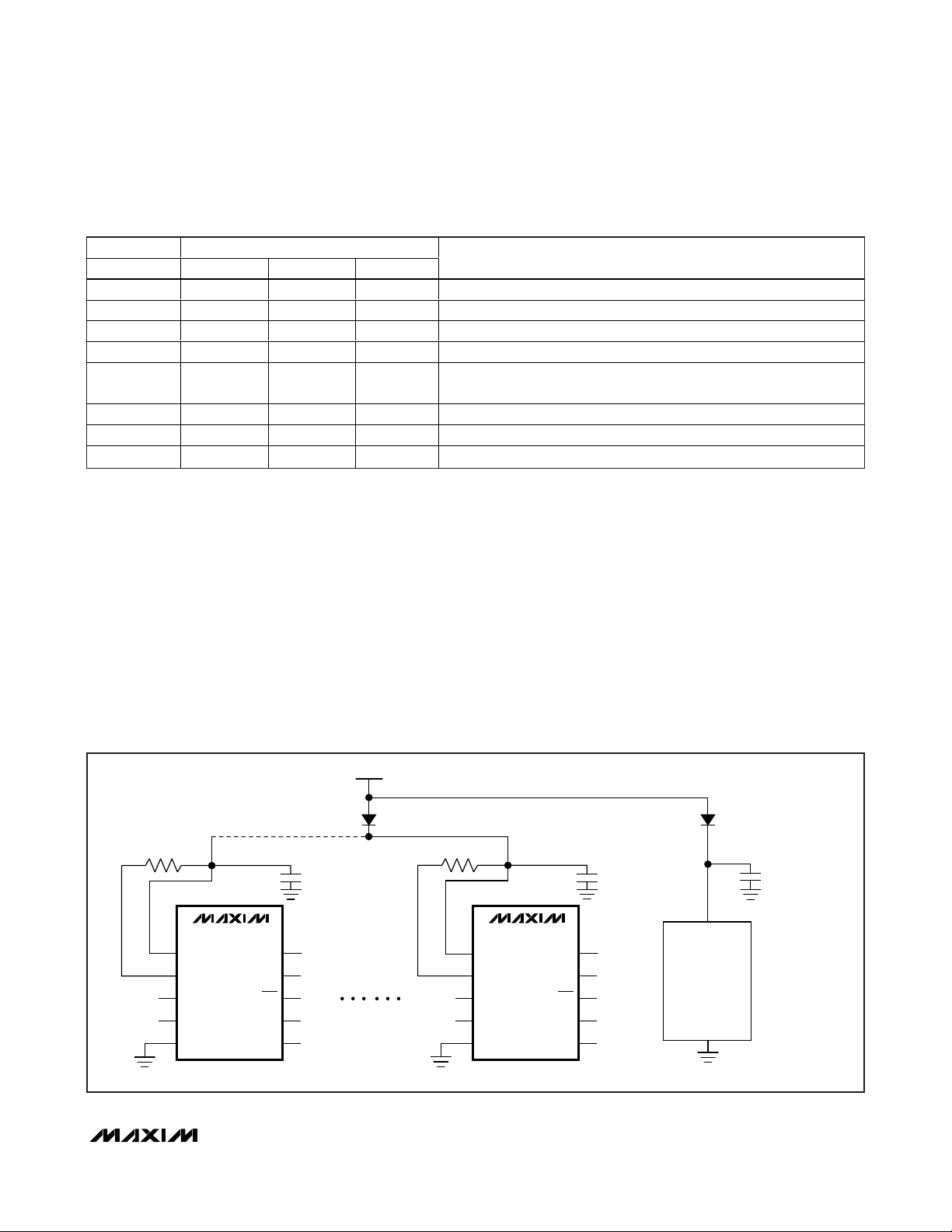

Table 2. Diagnostic Truth Table (Diagnostic Mode)

Figure 4. Several MAX9921s Connected to a Common Reverse-Polarity Diode

INPUT OUTPUT

DIAG ERR OUT1 OUT2

1 0 0 0 No fault

1 0 0 1 IN1 open circuit, or IN1 open circuit and fault on IN2

1 0 1 0 IN1 shorted to battery, or IN1 shorted to battery and fault on IN2

1 0 1 1 IN1 shorted to ground, or IN1 shorted to ground and fault on IN2

V

out of range, or power-up or restart and blanking cycle (dominant

1100

1 1 0 1 IN2 open circuit

1 1 1 0 IN2 shorted to battery

1 1 1 1 IN2 shorted to ground

BAT

fault masks all other faults)

DIAGNOSIS

BATTERY

REVERSE-POLARITY DIODE

R

ISET

MAX9921

BAT

ISET

IN1

IN2

GND

DIAG

OE

ERR

OUT1

OUT2

FOR MAX9921s

R

ISET

MAX9921

BAT

ISET

IN1

IN2

GND

DIAG

ERR

OUT1

OUT2

REVERSE-POLARITY DIODE

FOR OTHER CIRCUITRY

BAT

OE

OTHER

CIRCUITRY

GND

MAX9921

Hall Input Short-to-Ground

The Hall input shorted-to-ground fault is effectively a

latched condition if the input remains loaded by the Hall

switch when the shorting condition is removed. The current required to power the Hall switch is shut off and only

a 50µA pullup current remains. The Hall input can be

manually re-energized or it can be re-energized by the

ECU. A falling edge at DIAG initiates a restart with a

blanking cycle of any Hall input that has been shut down

due to the shorted-to-ground condition. During startup or

restart, it is possible for a Hall input to charge up an external capacitance of 0.02µF without tripping into a shortedto-ground latched state. All other fault conditions are not

latched and when these other faults are removed, ERR

goes high and the Hall input is again functional.

Manual Method for Re-Energizing Hall Sensor

and Means for Diagnosing an Intermittent

Hall Sensor Connection

Figure 5 shows the behavior of the MAX9921 when a

Hall input is open. Figure 6 shows the behavior of the

MAX9921 when the open input is reconnected to a Hall

sensor. Figures 5 and 6 demonstrate how a shorted-toground Hall input can be reset.

Resetting a shorted-to-ground Hall input involves

three steps:

1) Relieve the short to ground at the Hall sensor.

2) Disconnect the Hall input from the Hall sensor (open

input fault condition).

3) Reconnect the Hall input to the Hall sensor.

The MAX9921 restarts the Hall input with a blanking

cycle. If the Hall input is disconnected from the Hall

sensor for 10ms, it allows the Hall input to be pulled up

by the 50µA pullup current to register the open-input

fault condition. Then, reconnecting the Hall input to the

Hall sensor restarts the Hall input with a blanking cycle.

This provides a manual means of re-energizing a Hall

input without having to resort to the ECU to reset it. This

also demonstrates that an intermittent connection to a

Hall sensor can recover without intervention of the ECU.

This gives the ECU a means of diagnosing an intermittent connection to a Hall sensor by using the diagnostic

mode to detect a diagnostic sequence of “open-circuit”

to “blanking cycle” to “no fault.”

Dual, 2-Wire Hall-Effect Sensor Interface

with Diagnostics

12 ______________________________________________________________________________________

Figure 5. Hall Input Ramps to Open-Circuit Fault When Short to Ground is Relieved

14V

V

IN_

DISCONNECTED

0V

I

IN_

50μA

0A

HALL INPUT

SHORT TO

GROUND FAULT

INDICATED

5mV/ms

HALL INPUT

FROM SENSOR

HALL INPUT

OPEN-CIRCUIT

FAULT INDICATED

V

BAT

- 25mV

TIME

TIME

MAX9921

Dual, 2-Wire Hall-Effect Sensor Interface

with Diagnostics

______________________________________________________________________________________ 13

V

Figure 6. Hall Input Re-Energized When Open Input is Reconnected to Hall Sensor

Table 3. Summary of Fault Protection and Recovery

IN_

11.5mA

I

IN_

14V

V

- 500mV

8V

HALL INPUT

RECONNECTED

TO HALL SENSOR

0V

4mA/μs

BAT

TIME

0A

FAULT

DESCRIPTION

V

< 6V — Asserted low

BAT

V

> 18V — Asserted low

BAT

Hall input open IIN < 2mA Asserted low

Hall input shorted

to battery

Hall input shorted

to ground

CRITERION

V

> V

IN

to external

reverse-battery

protection

I

IN

due

BAT

Asserted low

diode

> 23mA Asserted low

OUTPUT

MAX9921 ACTIONS

ERR

Shutoff current to both Hall

sensors

Shutoff current to both Hall

sensors

Shutoff current to

corresponding Hall sensor

Shutoff current to

corresponding Hall sensor

Shutoff current to

corresponding Hall sensor.

50µA of pullup current is

sourced to IN1 or IN2 to

aid in troubleshooting.

HALL INPUT RESPONSE

TIME

COMMENT/RECOVERY

Both IN1 and IN2 are restarted with blanking

cycle when V

Both IN1 and IN2 are restarted with blanking

cycle when V

When a Hall input is again loaded, terminating

open input condition, the Hall input are restarted

with blanking cycle.

If a Hall input is pulled more than 1V above

V

, the input may back drive current into the

BAT

BAT supply and pull V

condition, current levels in the Hall inputs should

never exceed 100mA. For this reason, it is

recommended that one or more MAX9921s be

powered together and share a reverse-polarity

diode separate from other circuitry.

A falling edge at DIAG initiates a restart with a

blanking cycle of any Hall input that has been

shut off due to a short to ground. See Hall input

short-to-ground description.

returns to proper range.

BAT

returns to proper range.

BAT

up with it. In this

BAT

MAX9921

Dual, 2-Wire Hall-Effect Sensor Interface

with Diagnostics

14 ______________________________________________________________________________________

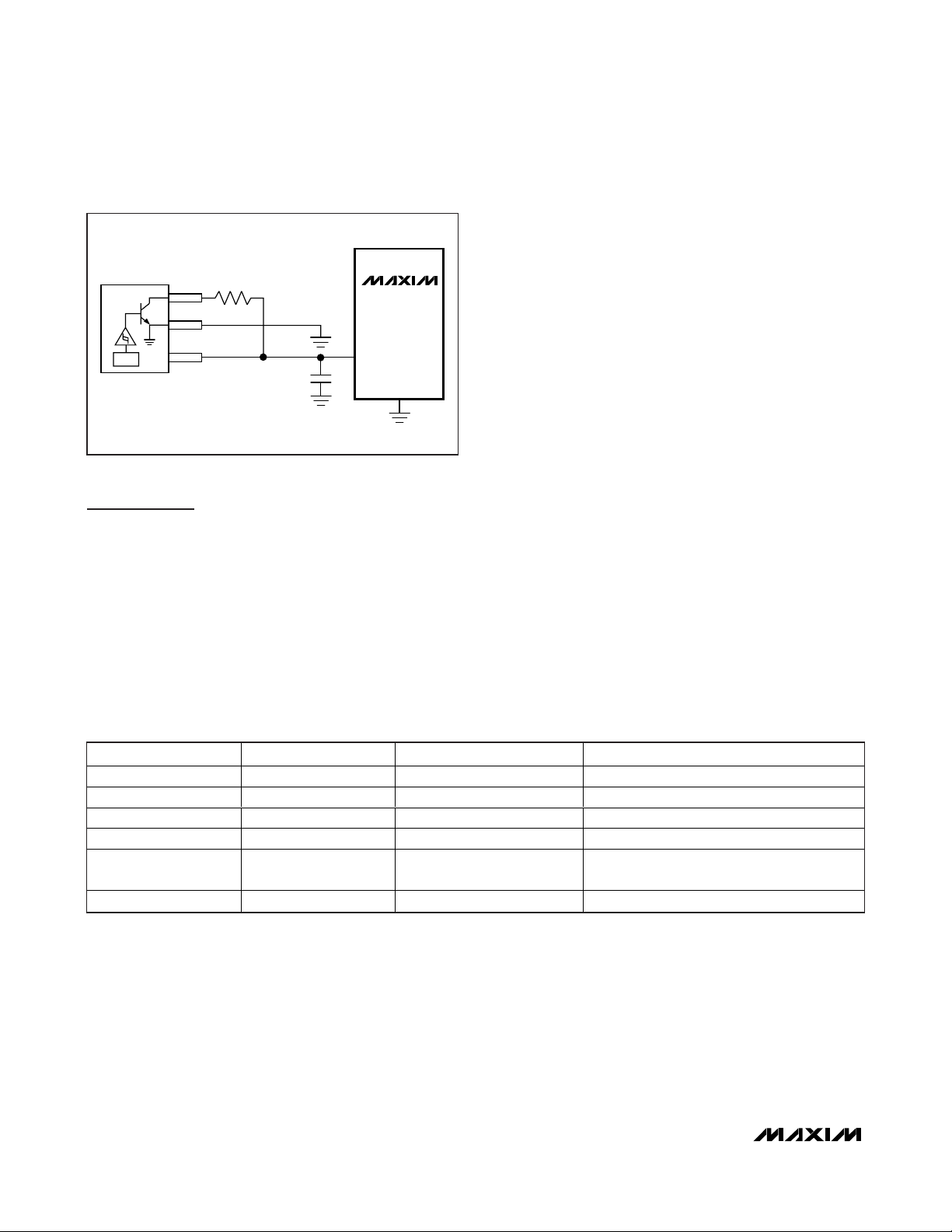

Applications Information

Hall-Effect Sensor Selection

The MAX9921 is optimized for use with 2-wire Halleffect switches or with 3-wire Hall-effect switches connected as 2-wire (Figure 7). When using a 3-wire Hall

sensor, the resistor R is chosen so that the current

drawn by the Hall sensor crosses the MAX9921 current

threshold when the magnetic threshold of the Hall sensor is exceeded.

Table 4 shows a partial list of mostly 2-wire Hall switches, which can be used with the MAX9921.

Hall Input Bypass Capacitor

The MAX9921 is optimized for use with external protection 0.01µF capacitors from both IN1 and IN2 to BAT.

These are essential to ensure robustness against automotive transients. These capacitors may be tied to

GND instead of to BAT, but the connection to BAT is

recommended.

Low-Voltage Operation

To ensure correct operation of the Hall sensor at low

input voltages, it is important to consider the voltage

drop of the MAX9921 with low battery voltages. This

dropout voltage can be calculated using the formula:

V

DROPOUT

= I

HALL

x R

PU

I

HALL

is the maximum current which must be supplied to

the Hall sensor and RPUis the internal resistance of the

MAX9921, nominally 50Ω (see the Input Pullup

Resistance vs. V

BAT

graph in the

Typical Operating

Characteristics

). As an example, assume the use of a

HAL573 sensor, which draws a maximum current of

17mA. The dropout voltage is then 850mV and the

approximate minimum voltage supplied to the Hall sensor

is 6V - 0.85V = 5.15V, which is higher than the minimum

operating voltage of 3.75V specified for the HAL573.

Figure 7. 3-Wire Hall-Effect Switches Configured as 2-Wire

Table 4. Partial List of Compatible Hall Switches

R

V

CC

x_

MAX9921

IN_

GND

PART MANUFACTURER WEBSITE COMMENT

HAL573-6 Micronas www.micronas.com 2-wire

HAL556/560/566 Micronas www.micronas.com 2-wire

HAL581/584 Micronas www.micronas.com 2-wire

A1140/1/2/3 Allegro www.allegromicro.com 2-wire

3161 Allegro www.allegromicro.com

TLE4941/C Infineon www.infineon.com 2-wire

3-wire, optimized for 2-wire use without added

resistor

MAX9921

Dual, 2-Wire Hall-Effect Sensor Interface

with Diagnostics

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________

15

© 2008 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Chip Information

PROCESS: BiCMOS

Pin Configuration

PACKAGE TYPE PACKAGE CODE DOCUMENT NO.

10 µMAX U10+2

21-0061

Package Information

For the latest package outline information and land patterns, go

to www.maxim-ic.com/packages

.

TOP VIEW

BAT

ISET

IN1

DIAG

1

2

3

MAX9921

4

5

μMAX

10

OE

9

ERR

8

OUT1IN2

7

6

OUT2GND

Loading...

Loading...