Page 1

General Description

The MAX9507 amplifies and filters standard-definition

video signals and only consumes 5.8mW quiescent

power and 11.7mW average power. The MAX9507

leverages Maxim’s DirectDrive™ technology to generate a clean, internal negative supply. Combining the

internal negative power supply with the external positive 1.8V supply, the MAX9507 is able to drive a 2V

P-P

video signal into a 150Ω load.

The MAX9507 provides an I2C interface for easy configuration and access to the load status. The MAX9507 can

detect, report, and act upon the change of a video load.

This feature helps reduce overall power consumption by

allowing the system to turn on the video encoder and driver only when a video load is connected to the MAX9507.

With a high power-supply rejection ratio (47dB at

100kHz), the MAX9507 can be powered directly from a

1.8V digital supply. The two integrated single-pole/single-throw (SPST) analog switches are ideal for routing

audio, video, or digital signals.

The input of the MAX9507 can be directly connected to

the output of a video DAC. The MAX9507 also features

a transparent input sync-tip clamp, allowing AC-coupling of input signals with different DC biases.

The MAX9507 has an internal fixed gain of 8. The input

full-scale video signal is nominally 0.25V

P-P

, and the

output full-scale video signal is nominally 2V

P-P

.

Features

♦ 1.8V or 2.5V Single-Supply Operation

♦ Low Power Consumption (5.8mW Quiescent,

11.7mW Average)

♦ Video Load Detection

♦ DirectDrive Sets Video Output Black Level Near

Ground

♦ Dual SPST Analog Switches

♦ Transparent Input Sync-Tip Clamp

♦ I2C Control

Applications

Mobile Phones

Portable Media Players (PMP)

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

________________________________________________________________

Maxim Integrated Products

1

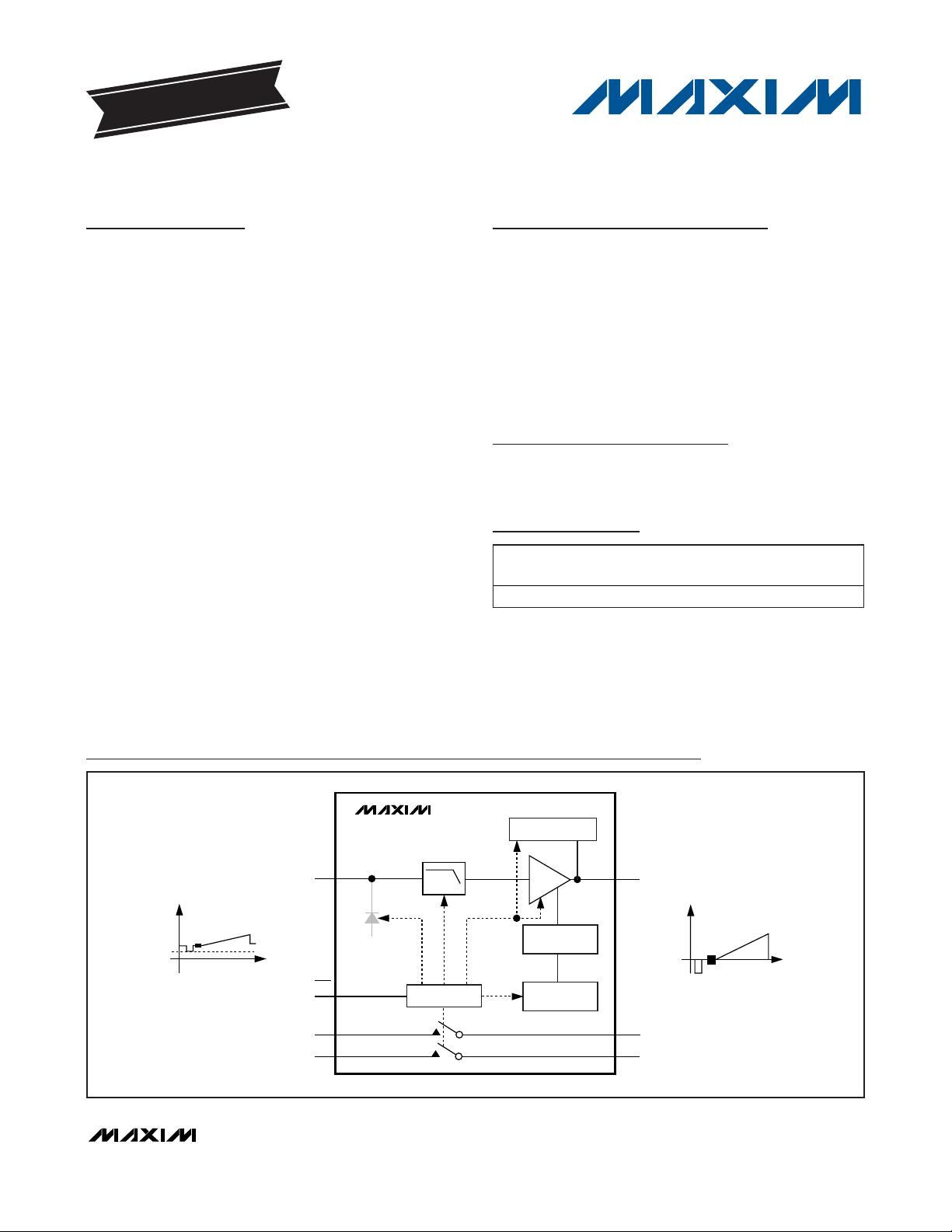

Block Diagram

Ordering Information

PART

PIN-PACKAGE

PKG CODE

TOP

MARK

MAX9507ATE+

16 TQFN-EP* T1633+4 AFH

19-1028; Rev 0; 11/07

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Pin Configuration appears at end of data sheet.

Note: This device is specified over the -40°C to +125°C operat-

ing temperature range.

+

Denotes a lead-free package.

*

EP = Exposed pad.

EVALUATION KIT

AVAILABLE

0V

2V

P-P

VIDEO

MAX9507

AV =

8V/V

LINEAR

REGULATOR

CHARGE

PUMP

LOAD DETECT

I2C

TRANSPARENT

CLAMP

OUT

COM1

COM2

IN

LCF

NO1

NO2

250mV

P-P

VIDEO

LPF

Page 2

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

2 _______________________________________________________________________________________

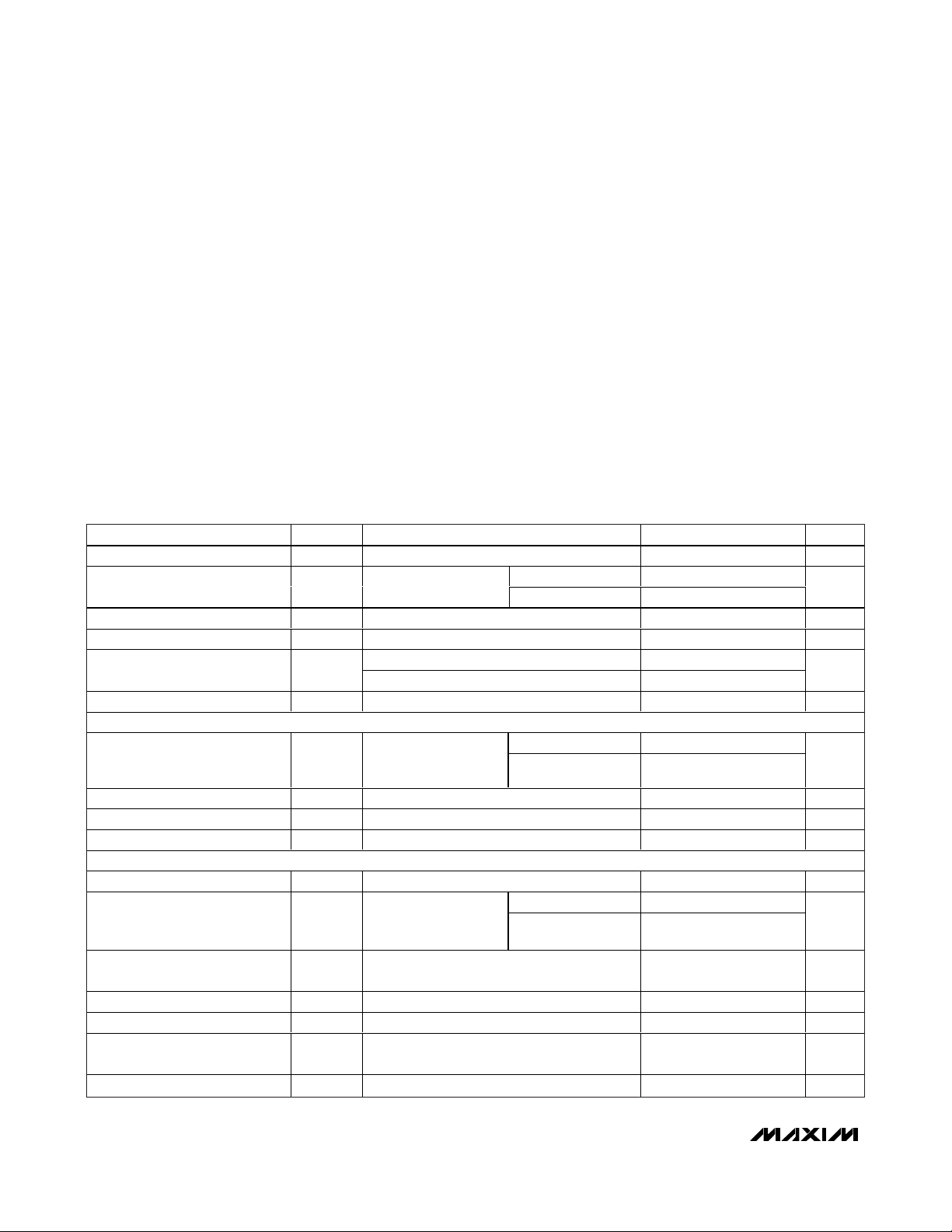

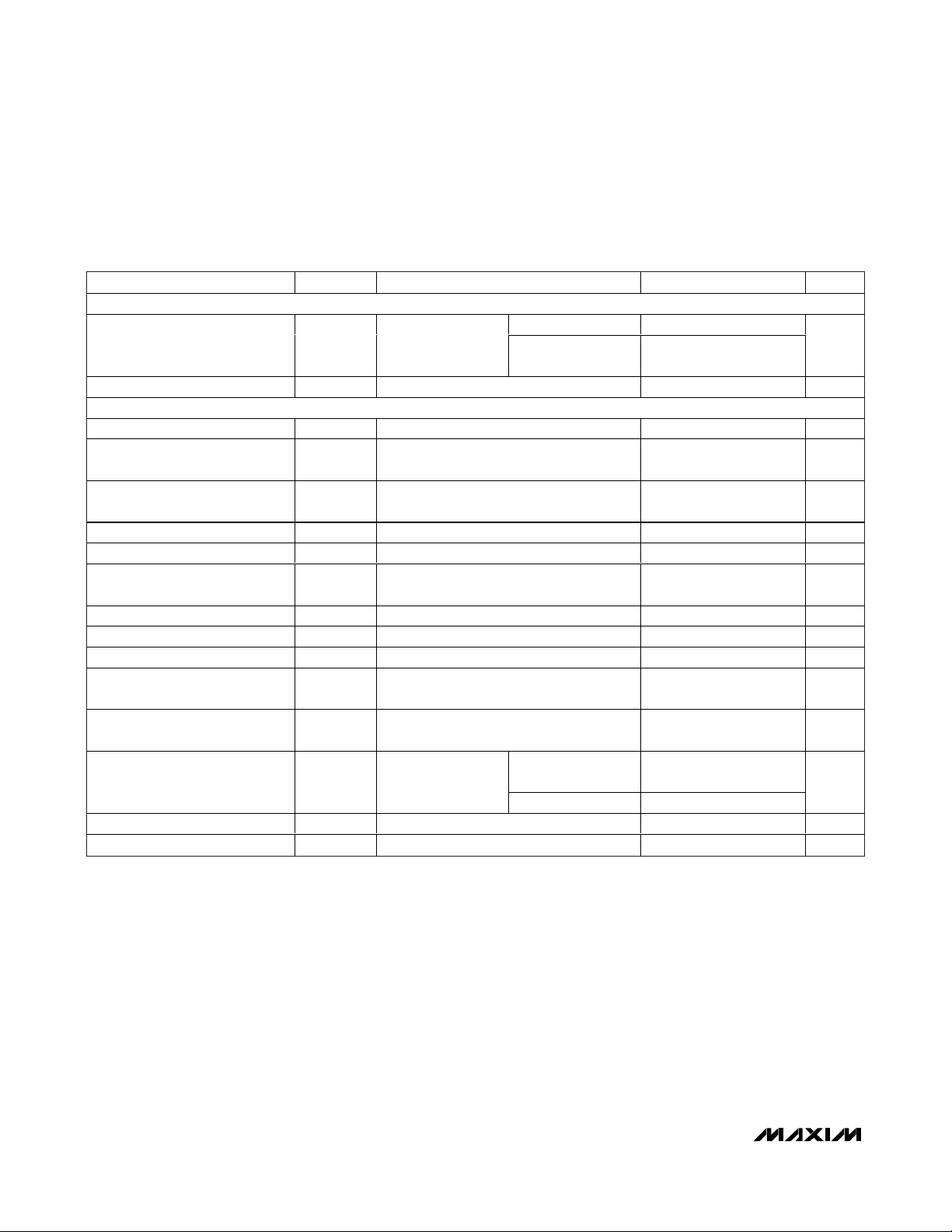

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VDD= +1.8V, GND = 0V, OUT has RL= 150Ω connected to GND, transparent sync-tip clamp enabled, C1= C2= 1µF, TA= T

MIN

to

T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

(Voltages with respect to GND.)

V

DD

...........................................................................-0.3V to +3V

CPGND..................................................................-0.1V to +0.1V

IN................................................................-0.3V to (V

DD

+ 0.3V)

OUT, NO_,

COM_ .................(The greater of V

SS

and -1V) to (VDD+ 0.3V)

SDA, SCL, DEV_ADDR, LCF ....................................-0.3V to +4V

C1P.............................................................-0.3V to (V

DD

+ 0.3V)

C1N .............................................................(V

SS

- 0.3V) to +0.3V

V

SS

............................................................................-3V to +0.3V

Duration of OUT Short Circuit

to V

DD

, GND, and VSS.............................................Continuous

Continuous Current

IN, SDA, SCL, DEV_ADDR, LCF....................................±20mA

NO_, COM_ .................................................................±100mA

Continuous Power Dissipation (T

A

= +70°C)

16-Pin TQFN (derate 15.6mW/°C above +70°C) ........1250mW

Operating Temperature Range .........................-40°C to +125°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

Supply Voltage Range V

Supply Current I

Sleep-Mode Supply Current No load 3 µA

Shutdown Supply Current I

Switch-Only Supply Current

Output Load Detect Threshold RL to GND, V

DC-COUPLED INPUT

Input Voltage Range

Input Current I

Input Resistance R

Output Level IN = 80mV -75 +5 +75 mV

AC-COUPLED INPUT

Sync-Tip Clamp Level V

Input-Voltage Swing

Sync Crush

Input Clamping Current IN = 130mV 2 3.2 µA

Line-Time Distortion CIN = 0.1µF 0.2 %

Minimum Input Source

Resistance

Output Level IN = 80mV -75 +5 +75 mV

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Guaranteed by PSRR 1.700 2.625 V

DD

DD

SHDN

CLP

No load, full operation

mode

Shutdown mode 0.2

Charge-pump-only mode 520

Guaranteed by outputvoltage swing

IN = 130mV 2 3.2 µA

B

10mV ≤ IN ≤ 250mV 280 kΩ

IN

CIN = 0.1µF -8 0 +11 mV

Guaranteed by outputvoltage swing

Percentage reduction in sync pulse at output,

R

= 37.5Ω, CIN = 0.1µF

SOURCE

SYNC-TIP

Filter enabled 3.1 5.4

Filter disabled 2.9 5.1

< 13mV 200 Ω

1.7V ≤ VDD ≤ 2.625V 0 262.5

2.375V ≤ V

2.625V

1.7V ≤ VDD ≤ 2.625V 252.5

2.375V ≤ V

2.625V

DD

DD

≤

≤

0.2 10 µA

0 325

1.6 %

25 Ω

325

mV

mA

µA

mV

P-P

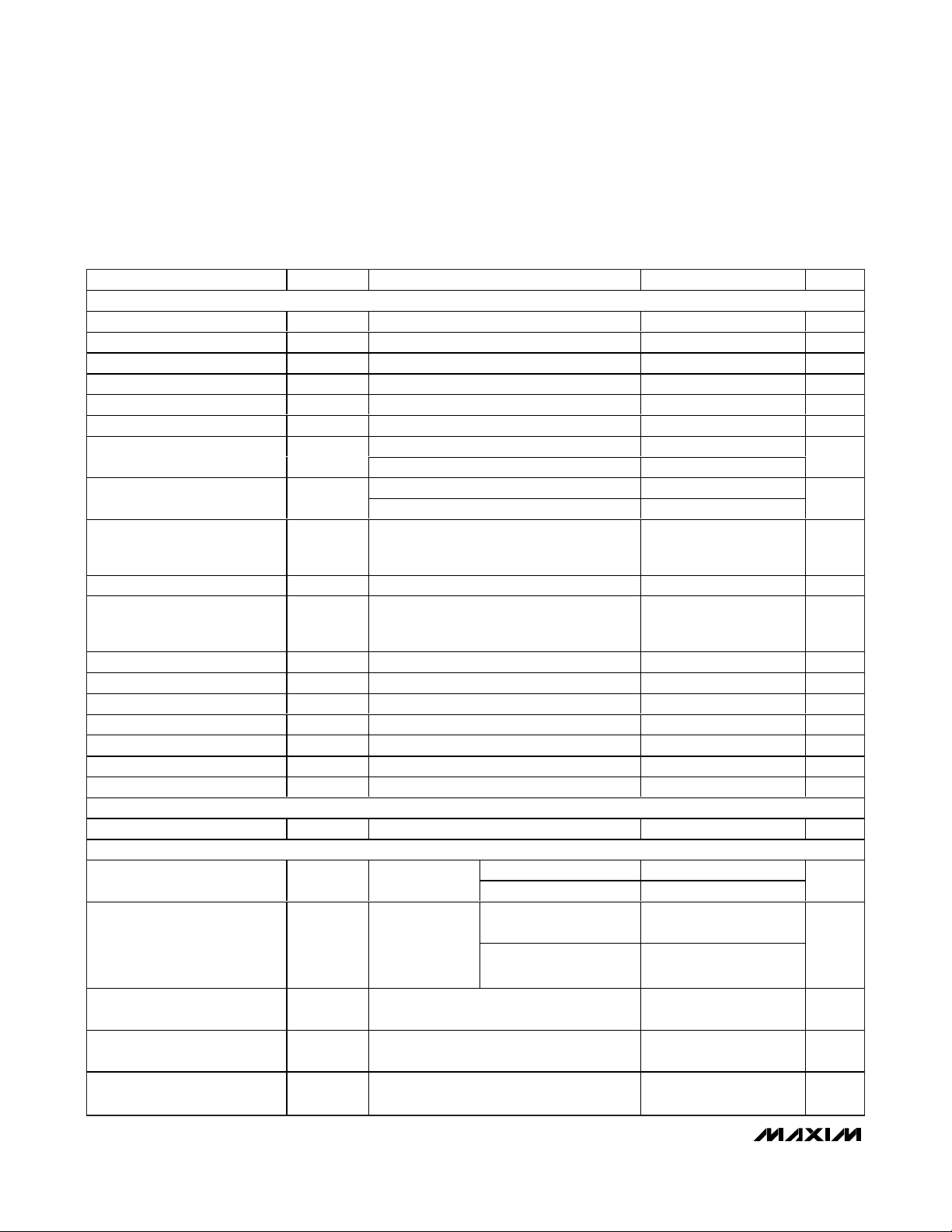

Page 3

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(VDD= +1.8V, GND = 0V, OUT has RL= 150Ω connected to GND, transparent sync-tip clamp enabled, C1= C2= 1µF, TA= T

MIN

to

T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

DC CHARACTERISTICS

DC Voltage Gain A

Output-Voltage Swing

Power-Supply Rejection Ratio PSRR

Shutdown Input Resistance 0V ≤ IN ≤ V

Output Resistance R

Shutdown Output Resistance 0V ≤ OUT ≤ V

Shutdown OUT Leakage Current 1µA

Output Short-Circuit Current

AC CHARACTERISTICS (FILTER ENABLED)

Standard-Definition

Reconstruction Filter

Differential Gain DG

Differential Phase DP

2T Pulse-to-Bar K Rating

2T Pulse Response 2T = 200ns 0.3 K%

2T Bar Response

Nonlinearity 5-step staircase 0.1 %

Group-Delay Distortion 100kHz ≤ f ≤ 5MHz, OUT = 2V

Peak Signal to RMS Noise 100kHz ≤ f ≤ 5MHz 65 dB

Power-Supply Rejection Ratio PSRR f = 100kHz, 100mV

Output Impedance f = 5MHz, IN = 80mV 7.5 Ω

Shutdown OUT-to-IN Isolation f < 5.5MHz 102 dB

Shutdown IN-to-OUT Isolation f < 5.5MHz 98 dB

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Guaranteed by output-voltage swing (Note 2) 7.84 8 8.16 V/V

V

OUT

0V ≤ VIN ≤ 262.5mV,

DC-coupled input

1.7V ≤ VDD ≤ 2.625V

2.375V ≤ V

1.7V ≤ V

load resistors

OUT = 0V, -5mA ≤ I

Sourcing 82

Sinking 32

OUT = 2V

reference frequency is

100kHz

f = 3.58MHz 0.63

f = 4.43MHz 0.93

f = 3.58MHz 0.50

f = 4.43MHz 0.63

2T = 200ns, bar time is 18µs, the beginning

2.5% and the ending 2.5% of the bar time is

ignored

2T = 200ns, bar time is 18µs, the beginning

2.5% and the ending 2.5% of the bar time is

ignored

≤ 2.625V, 0V ≤ VIN ≤ 325mV 2.548 2.6 2.652

DD

≤ 2.625V, measured between 75Ω

DD

DD

DD

,

P-P

0V ≤ V

252.5mV

AC-coupled input

≤ +5mA 0.1 Ω

LOAD

+ 1dB passband

f = 5.5MHz 0

f = 9.3MHz -3

f = 27MHz -49

P-P

P-P

≤

IN

,

P-P

2.058 2.1 2.142

1.979 2.02 2.061

46 60 dB

2.8 MΩ

32 MΩ

7.5 MHz

0.1 K%

0.2 K%

21 ns

47 dB

V

P-P

mA

dB

%

Degrees

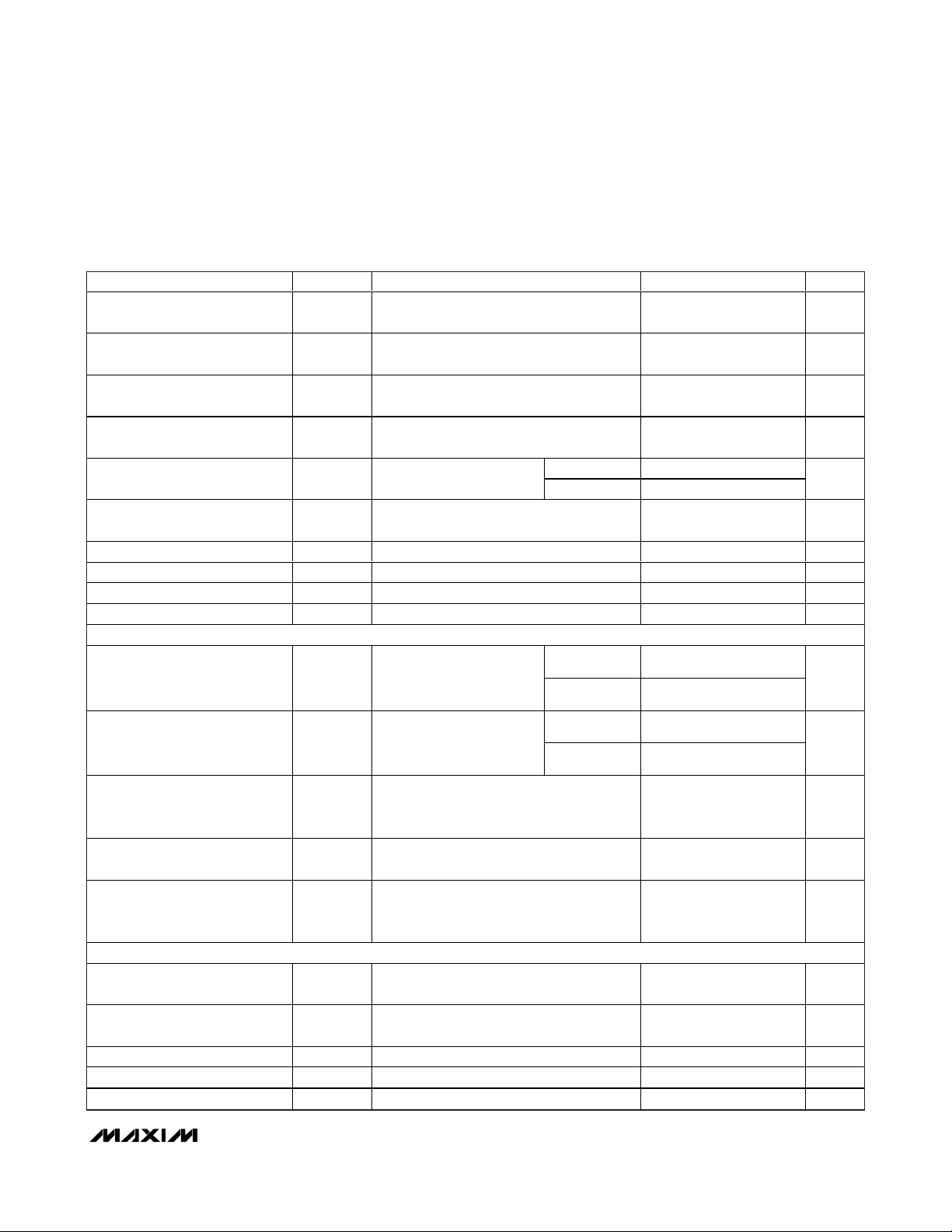

Page 4

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VDD= +1.8V, GND = 0V, OUT has RL= 150Ω connected to GND, transparent sync-tip clamp enabled, C1= C2= 1µF, TA= T

MIN

to

T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

)

AC CHARACTERISTICS (FILTER DISABLED)

Small-Signal -3dB Bandwidth OUT = 100mV

Large-Signal -3dB Bandwidth OUT = 2V

Small-Signal 1dB Flatness OUT = 100mV

Large-Signal 1dB Flatness OUT = 2V

Slew Rate OUT = 2V step 35 V/µs

Settling Time to 0.1% OUT = 2V step 230 ns

Differential Gain DG

Differential Phase DP

2T Pulse-to-Bar K Rating

2T Pulse Response 2T = 200ns 0.2 K%

2T Bar Response

Nonlinearity 5-step staircase 0.1 %

Group-Delay Distortion 100kHz ≤ f ≤ 5MHz, OUT = 2V

Peak Signal to RMS Noise 100kHz ≤ f ≤ 5MHz 69 dB

Power-Supply Rejection Ratio PSRR f = 100kHz, 100mV

Output Impedance f = 5MHz, IN = 80mV 7.5 Ω

Shutdown OUT-to-IN Isolation f < 5.5MHz 102 dB

Shutdown IN-to-OUT Isolation f < 5.5MHz 98 dB

CHARGE PUMP

Switching Frequency 325 625 1150 kHz

ANALOG SWITCHES

On-Resistance (Note 3) R

On-Resistance Flatness

(Notes 3, 4)

NO_ Off-Leakage Current

Normal Range

COM_ On-Leakage Current

Normal Range

NO_ Off-Leakage Current,

Extended Range

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

40.7 MHz

9.8 MHz

32.8 MHz

7.2 MHz

0.1 K%

0.2 K%

15 ns

42 dB

2.3

0.3 1.1

ON

R

FLAT(ON

I

NO_(OFF)N

I

COM_(ON)N

I

NO_(OFF)E

P-P

P-P

P-P

P-P

f = 3.58MHz 0.63

f = 4.43MHz 0.94

f = 3.58MHz 0.50

f = 4.43MHz 0.64

2T = 200ns, bar time is 18µs, the beginning

2.5% and the ending 2.5% of the bar time is

ignored

2T = 200ns, bar time is 18µs, the beginning

2.5% and the ending 2.5% of the bar time is

ignored

P-P

P-P

I

= 10mA,

COM_

V

= 0V

NO_

I

= 10mA

COM_

VDD = 2.625V, V

= 2.3V, 0.3V; TA = +25°C (Notes 3, 5)

V

NO_

V

= 2.625V , V

D D

V

= 0.3V , 2.3V ; TA = + 25° C ( N otes 3, 5)

C OM _

V

= 2.625V , V

D D

V

= + 2.3V , - 0.6V ; TA = + 25° C ( N otes 3, 5)

N O_

Normal range 1.2 2.2

Extended range 1.2 2.2

Normal range,

V

= 0V, 1V, V

NO_

Extended range, V

-0.9V, 0V, +1.2V, V

= 0.3V, 2.3V;

COM_

= hi g h- Z ,

N O_

= - 0.6V , + 2.3V ;

C OM _

DD

NO_

DD

=

-100 +100 nA

-100 +100 nA

-100 +100 nA

%

Degrees

Ω

Ω

Page 5

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(VDD= +1.8V, GND = 0V, OUT has RL= 150Ω connected to GND, transparent sync-tip clamp enabled, C1= C2= 1µF, TA= T

MIN

to

T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

COM_ On-Leakage Current,

Extended Range

Turn-On Time t

Turn-Off Time t

Charge Injection Q

Off-Isolation V

On-Channel -3dB Bandwidth BW

Total Harmonic Distortion THD V

Charge-Pump Noise Extended range, RL = 50Ω 1.2 mV

NO_ Off-Capacitance C

Switch On-Capacitance C

CROSSTALK

Switch to Switch

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

I

COM_(ON)E

ON

OFF

ISO

OFF

ON

= 2.625V , V

D D

V

= - 0.6V , + 2.3V ; TA = + 25°C ( N otes 3, 5)

C OM _

V

= 0.9V, RL = 300Ω, CL = 35pF,

NO_

Figure 1 (Note 6)

V

= 0.9V, RL = 300Ω, CL = 35pF,

NO_

Figure 1 (Note 6)

V

= 0.9V, R

GEN

Figure 2

V

= 1V

NO_

C

= 5pF, Figure 1

L

V

NO_

= 5pF, Figure 1

C

L

COM_

P-P

= 0dBm, R

= 1V

f = 1MHz 21 pF

f = 1MHz 53 pF

Switch 1, 2 closed;

V

= 1V

NO_

= 5pF, Figure 1

C

L

P-P

= hi g h- Z ,

N O_

-100 +100 nA

310 ns

372 ns

= 0Ω, CL = 1nF,

GEN

, RL = 50Ω,

f = 10MHz 49

60 pC

f = 1MHz 69

SOURCE

, RL = 600Ω 0.037 %

P-P

= 50Ω, RL = 50Ω,

280 MHz

f = 10MHz -71

, RL = 50Ω,

f = 1MHz -88

dB

dB

P-P

NO_ to OUT

Switch 1, 2 open; video

circuitry enabled,

= 1V

V

NO_

P-P

f = 10MHz -44

dB

f = 1MHz -78

Switch 1, 2 closed; video circuitry enabled,

OUT to NO_

IN to COM_

f = 20kHz, OUT = 2V

C

= 5pF

L

S w i tch 1, 2 cl osed ; vi d eo ci r cui tr y d i sab l ed ,

f = 20kHz, IN = 0.25V

, RL = 50Ω,

P-P

, RL = 600Ω

P-P

-94 dB

-89 dB

Switch 1, 2 closed; video circuitry enabled,

OUT to COM_

f = 20kHz, OUT = 2V

= 5pF

C

L

, RL = 50Ω,

P-P

-94 dB

CMOS DIGITAL INPUTS (SDA, SCL, DEV_ADDR)

Input Low Voltage V

Input High Voltage V

IL

IH

0.7 x

V

DD

0.3 x

V

DD

V

V

Input Hysteresis 275 mV

Input Leakage Current IIL, I

Input Capacitance C

IH

IN

-10 +10 µA

15 pF

Page 6

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

6 _______________________________________________________________________________________

Note 1: All devices are 100% production tested at TA = +25°C. Specifications over temperature are guaranteed by design.

Note 2: Voltage gain (A

V

) is a two-point measurement in which the output-voltage swing is divided by the input-voltage swing.

Note 3: Normal range: charge pump disabled. Extended range: charge pump enabled. In extended range mode, the switch input

can swing from -0.9V to V

DD

.

Note 4: Flatness is defined as the difference between the maximum and minimum values of on-resistance as measured at the speci-

fied voltages.

Note 5: Not production tested, guaranteed by design.

Note 6: t

ON

and t

OFF

are measured from the end of the writing of register 0x00 until COM reaches 90% of the output voltage. See

Figure 1.

Note 7: C

B

is in picofarads.

ELECTRICAL CHARACTERISTICS (continued)

(VDD= +1.8V, GND = 0V, OUT has RL= 150Ω connected to GND, transparent sync-tip clamp enabled, C1= C2= 1µF, TA= T

MIN

to

T

MAX

, unless otherwise noted. Typical values are at TA= +25°C.) (Note 1)

DIGITAL OUTPUTS (SDA, LCF)

Output Low Voltage V

Output High Leakage Current I

SERIAL INTERFACE TIMING (Figure 3)

Serial Clock Frequency f

Bus Free Time Between STOP

and START Conditions

Hold Time (Repeated) START

Condition

SCL Pulse-Width Low t

SCL Pulse-Width High t

Setup Time for a Repeated

START Condition

Data Hold Time t

Data Setup Time t

Bus Capacitance C

SDA and SCL Receiving Rise

Time

SDA and SCL Receiving Fall

Time

SDA Transmitting Fall Time t

Setup Time for STOP Condition t

Pulse Width of Suppressed Spike t

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

VDD > 2V 0.4

B

IOL = 3mA

V

= V

OUT

(Note 7)

(Note 7)

(Note 7)

DD

V

< 2V

DD

0 400 kHz

1.3 µs

0.6 µs

1.3 µs

0.6 µs

0.6 µs

0 900 ns

100 ns

20 +

0.1C

B

20 +

0.1C

B

VDD = 1.7V

= 2.625V 0 250

V

DD

20 +

0.1C

B

0.6 µs

050ns

0.2 x

V

DD

1µA

400 pF

300 ns

300 ns

250

OL

OH

SCL

t

BUF

t

HD,STA

LOW

HIGH

t

SU,STA

HD,DAT

SU,DAT

t

R

t

F

F

SU,STO

SP

V

ns

Page 7

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

_______________________________________________________________________________________ 7

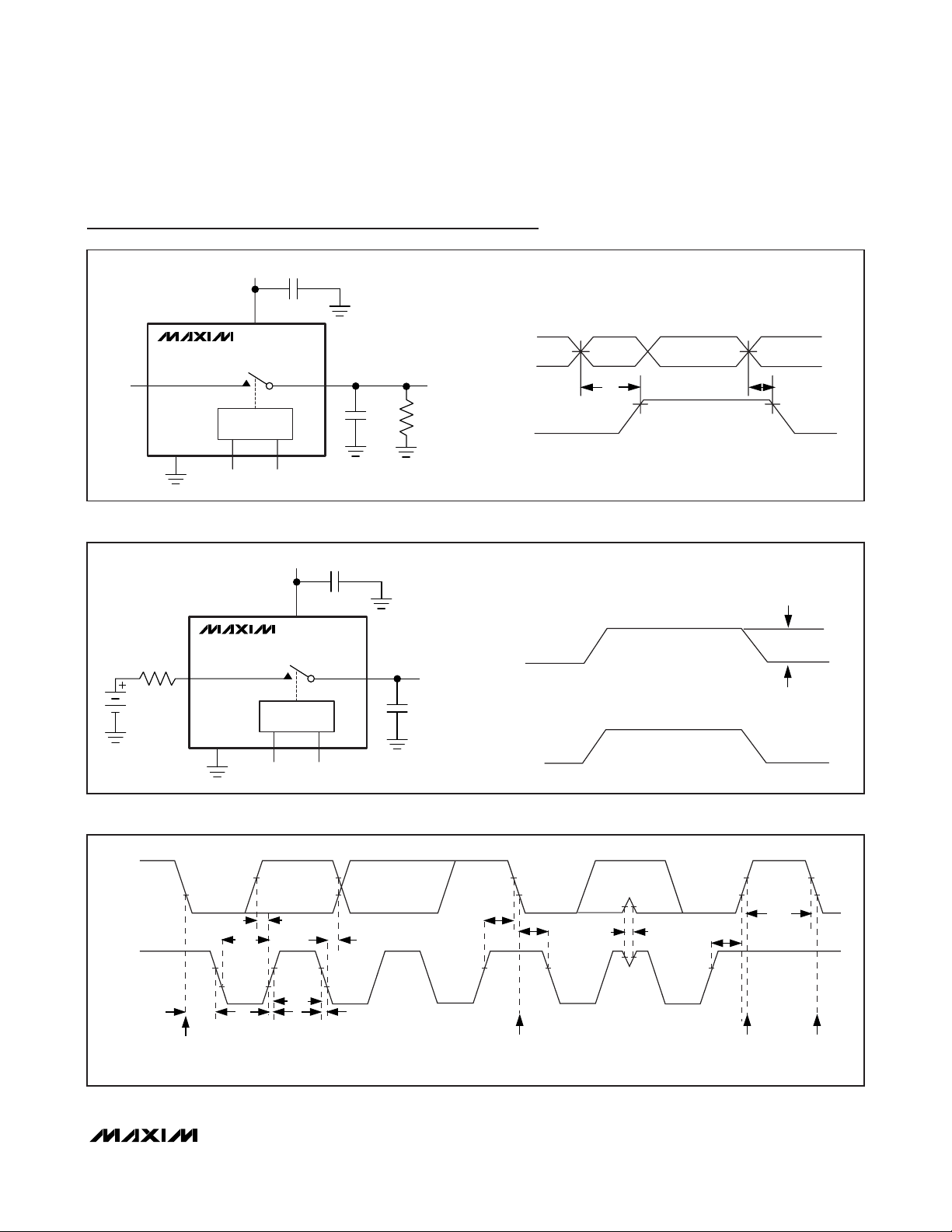

Test Circuits/Timing Diagrams

Figure 1. Analog Switch Test Circuit

Figure 2. Analog Switch Charge Injection

Figure 3. I2C Serial-Interface Timing Diagram

V

DD

V

DD

MAX9507

NO_

V

NO_

2

C

I

GND

SCL

SDA

MAX9507

R

GEN

NO_

V

GEN

GND

SDA

COM_

V

DD

V

DD

2

I

WRITE

SDA

REGISTER 00H

V

COM_

C

COM_

C

SCL

R

L

L

V

C

L

COM_

V

COM_

V

COM_

SWITCH

STATE

0V

OFF

50%

t

ON

90%

Q = CL x ΔV

WRITE

REGISTER 00H

COM_

ON

t

OFF

90%

ΔV

COM_

OFF

SDA

t

SU,DAT

t

LOW

SCL

t

t

HD,STA

START

CONDITION

HIGH

t

R

t

F

t

HD,DAT

t

SU,STA

START CONDITION

REPEATED

t

HD,STA

t

BUF

t

SP

t

SU,STO

STOP

CONDITION

START

CONDITION

Page 8

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

8 _______________________________________________________________________________________

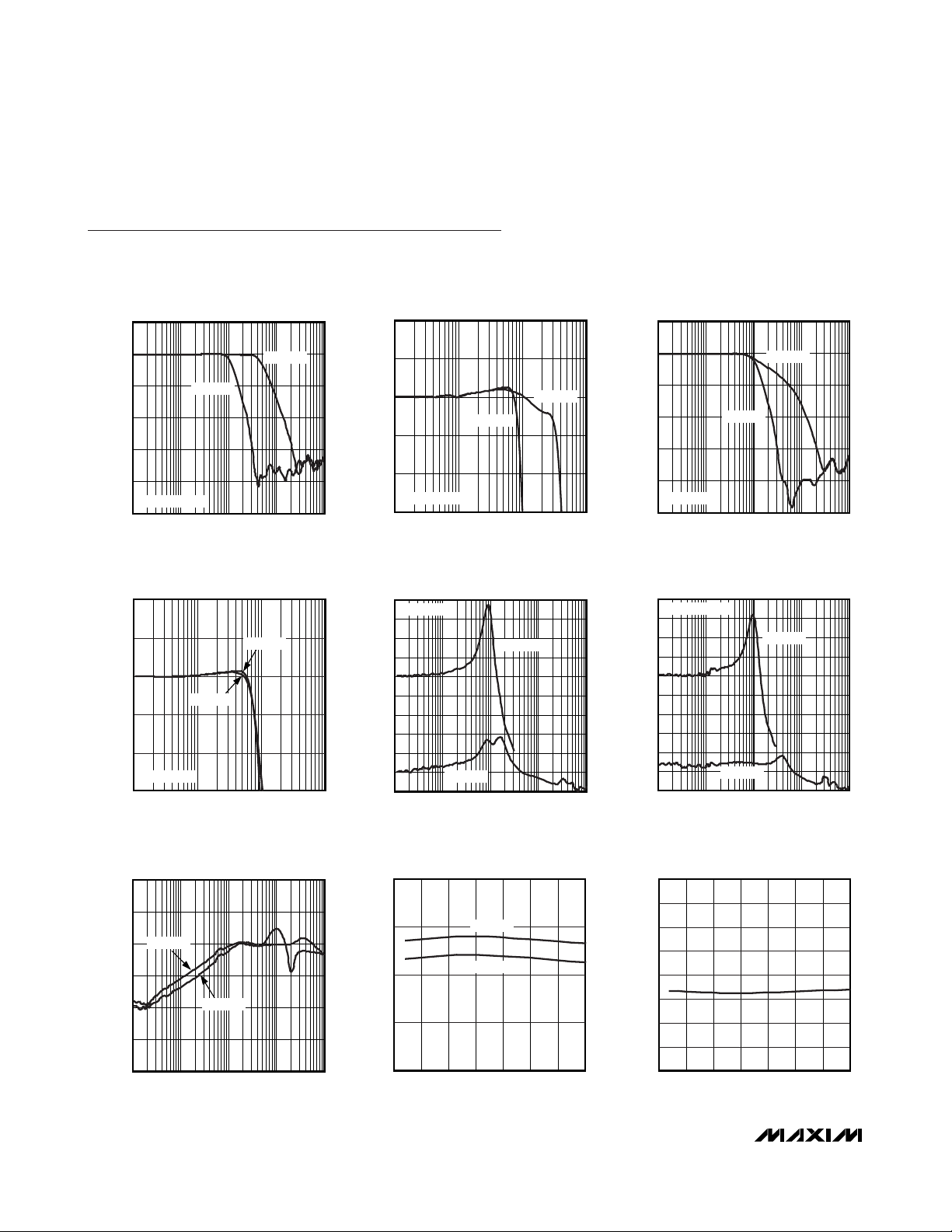

Typical Operating Characteristics

(VDD= +1.8V, GND = 0V, mode 2 (Table 6), video output has RL= 150Ω connected to GND, video filter enabled, TA= +25°C,

unless otherwise noted.)

SMALL-SIGNAL GAIN

vs. FREQUENCY

MAX9507 toc01

FREQUENCY (Hz)

GAIN (dB)

100M10M1M

-80

-60

-40

-20

0

20

-100

100k 1G

FLTEN = 0

FLTEN = 1

V

OUT

= 100mV

P-P

SMALL-SIGNAL GAIN FLATNESS

vs. FREQUENCY

MAX9507 toc02

FREQUENCY (Hz)

GAIN (dB)

10M1M

-2

-1

0

1

2

-3

100k 100M

FLTEN = 0

FLTEN = 1

V

OUT

= 100mV

P-P

LARGE-SIGNAL GAIN

vs. FREQUENCY

MAX9507 toc03

FREQUENCY (Hz)

GAIN (dB)

100M10M1M

-80

-60

-40

-20

0

20

-100

100k 1G

FLTEN = 0

FLTEN = 1

V

OUT

= 2V

P-P

LARGE-SIGNAL GAIN FLATNESS

vs. FREQUENCY

MAX9507 toc04

FREQUENCY (Hz)

GAIN (dB)

10M1M

-2

1

0

-1

2

-3

100k 100M

V

OUT

= 2V

P-P

FLTEN = 1

FLTEN = 0

LARGE-SIGNAL

GROUP DELAY vs. FREQUENCY

MAX9507 toc05

FREQUENCY (Hz)

DELAY (ns)

100M10M1M

10

20

30

40

50

60

70

80

90

100

0

100k 1G

FLTEN = 0

FLTEN = 1

V

OUT

= 2V

P-P

SMALL-SIGNAL

GROUP DELAY vs. FREQUENCY

MAX9507 toc06

FREQUENCY (Hz)

DELAY (ns)

100M10M1M

10

20

30

40

50

60

70

80

90

100

0

100k 1G

FLTEN = 0

FLTEN = 1

V

OUT

= 100mV

P-P

POWER-SUPPLY REJECTION RATIO

vs. FREQUENCY

MAX9507 toc07

FREQUENCY (Hz)

GAIN (dB)

10M1M100k

-80

-60

-40

-20

0

20

-100

10k 100M

FLTEN = 0

FLTEN = 1

QUIESCENT SUPPLY CURRENT

vs. TEMPERATURE

MAX9507 toc08

TEMPERATURE (°C)

QUIESCENT SUPPLY CURRENT (mA)

1007550250-25

3.0

2.5

3.5

4.0

2.0

-50 125

FLTEN = 1

FLTEN = 0

VOLTAGE GAIN

vs. TEMPERATURE

MAX9507 toc09

TEMPERATURE (°C)

VOLTAGE GAIN (V/V)

1007550250-25

8.05

7.95

7.90

7.85

8.00

8.10

8.15

8.20

7.80

-50 125

Page 9

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

_______________________________________________________________________________________

9

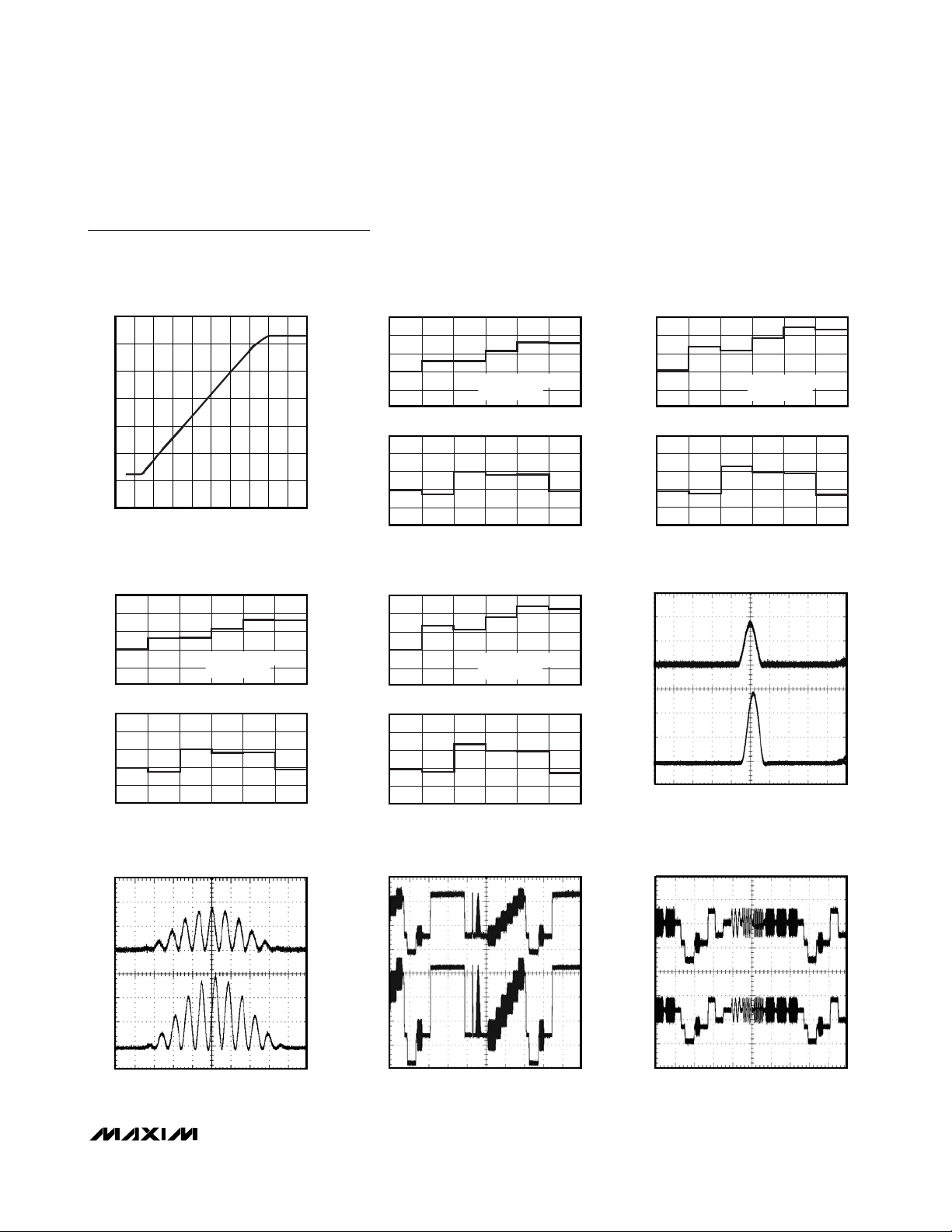

Typical Operating Characteristics (continued)

(VDD= +1.8V, GND = 0V, mode 2 (Table 6), video output has RL= 150Ω connected to GND, video filter enabled, TA= +25°C,

unless otherwise noted.)

OUTPUT VOLTAGE

vs. INPUT VOLTAGE

2.0

1.5

1.0

0.5

0

OUTPUT VOLTAGE (V)

-0.5

-1.0

-1.5

-100 400

INPUT VOLTAGE (mV)

DIFFERENTIAL GAIN AND PHASE

1.2

0.8

0.4

0

-0.4

DIFFERENTIAL GAIN (%)DIFFERENTIAL PHASE (deg)

-0.8

1.2

0.8

0.4

0

-0.4

-0.8

(FLTEN = 0)

FREQUENCY = 3.58MHz

= 71mV

V

IN

13610471 232

DC INPUT LEVEL (mV)

DC INPUT LEVEL (mV)

P-P

200168

20016813610471 232

DIFFERENTIAL GAIN AND PHASE

1.2

0.8

MAX9507 toc10

350300250200150100500-50

0.4

0

-0.4

DIFFERENTIAL GAIN (%)DIFFERENTIAL PHASE (deg)

-0.8

1.2

0.8

0.4

0

-0.4

-0.8

(FLTEN = 1)

FREQUENCY = 3.58MHz

= 71mV

V

IN

13610471 232

DC INPUT LEVEL (mV)

DC INPUT LEVEL (mV)

P-P

200168

20016813610471 232

MAX9507 toc11

DIFFERENTIAL GAIN (%)DIFFERENTIAL PHASE (deg)

DIFFERENTIAL GAIN AND PHASE

(FLTEN = 0)

FREQUENCY = 4.43MHz

= 71mV

V

IN

13610471 232

DC INPUT LEVEL (mV)

DC INPUT LEVEL (mV)

MAX9507 toc14

P-P

200168

20016813610471 232

MAX9507 toc13

-0.4

DIFFERENTIAL GAIN (%)DIFFERENTIAL PHASE (deg)

-0.8

-0.4

-0.8

1.2

0.8

0.4

0

1.2

0.8

0.4

0

DIFFERENTIAL GAIN AND PHASE

1.2

0.8

0.4

0

-0.4

-0.8

1.2

0.8

0.4

0

-0.4

-0.8

(FLTEN = 1)

13610471 232

DC INPUT LEVEL (mV)

DC INPUT LEVEL (mV)

2T RESPONSE

400ns/div

FREQUENCY = 4.43MHz

= 71mV

V

IN

P-P

200168

20016813610471 232

MAX9507 toc15

MAX9507 toc12

IN

100mV/div

0V

OUT

500mV/div

0V

12.5T RESPONSE

400ns/div

MAX9507 toc16

IN

100mV/div

0V

OUT

500mV/div

0V

NTC-7 RESPONSE

10μs/div

MAX9507 toc17

IN

100mV/div

0V

OUT

500mV/div

0V

PAL MULTIBURST

10μs/div

MAX9507 toc18

IN

100mV/div

0V

OUT

1V/div

0V

Page 10

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

10 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(VDD= +1.8V, GND = 0V, mode 2 (Table 6), video output has RL= 150Ω connected to GND, video filter enabled, TA= +25°C,

unless otherwise noted.)

PAL COLOR BARS

10μs/div

LARGE-SIGNAL PULSE RESPONSE

INPUT (125mV/div)

OUTPUT (1V/div)

ON-RESISTANCE vs. COM_ VOLTAGE

7

6

5

4

3

ON-RESISTANCE (Ω)

2

1

0

0 2.0

(FLTEN = 0)

100ns/div

(NORMAL RANGE)

TA = +125°C

COM_ VOLTAGE (V)

TA = -40°C

TA = +25°C

MAX9507 toc19

MAX9507 toc22

1.81.61.41.21.00.80.60.40.2

IN

100mV/div

0V

OUT

1V/div

0V

MAX9507 toc25

FIELD SQUARE-WAVE RESPONSE

(AC-COUPLED INPUT)

10μs/div

ON-RESISTANCE vs. COM_ VOLTAGE

(NORMAL RANGE)

4.0

3.5

3.0

2.5

2.0

1.5

ON-RESISTANCE (Ω)

1.0

0.5

0

0 3.0

VDD = 1.8V

VDD = 2.5V

COM_ VOLTAGE (V)

ON-RESISTANCE vs. COM_ VOLTAGE

(EXTENDED RANGE)

1.8

1.6

1.4

1.2

1.0

0.8

0.6

ON-RESISTANCE (Ω)

0.4

0.2

0

-1.0 2.0

TA = +125°C

TA = +25°C

TA = -40°C

COM_ VOLTAGE (V)

MAX9507 toc20

2.52.00.5 1.0 1.5

1.51.00.50-0.5

IN

100mV/div

0V

OUT

500mV/div

0V

MAX9507 toc23

MAX9507 toc26

SMALL-SIGNAL PULSE RESPONSE

(FLTEN = 0)

INPUT (6.25mV/div)

OUTPUT (50mV/div)

100ns/div

ON-RESISTANCE vs. COM_ VOLTAGE

(EXTENDED RANGE)

1.6

1.4

1.2

1.0

0.8

0.6

ON-RESISTANCE (Ω)

0.4

0.2

0

-1.0 3.0

VDD = 1.8V

VDD = 2.5V

COM_ VOLTAGE (V)

ANALOG SWITCH LEAKAGE CURRENT

vs. TEMPERATURE (NORMAL RANGE)

6

V

= 2.625V

DD

5

4

3

2

LEAKAGE CURRENT (nA)

1

0

-1

-50 125

TEMPERATURE (°C)

COM

COM

MAX9507 toc21

MAX9507 toc24

2.52.0-0.5 0 0.5 1.0 1.5

MAX9507 toc27

ON

OFF

1007550250-25

Page 11

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

______________________________________________________________________________________

11

Typical Operating Characteristics (continued)

(VDD= +1.8V, GND = 0V, mode 2 (Table 6), video output has RL= 150Ω connected to GND, video filter enabled, TA= +25°C,

unless otherwise noted.)

ANALOG SWITCH LEAKAGE CURRENT

vs. TEMPERATURE (EXTENDED RANGE)

6

V

= 2.625V

DD

5

4

3

2

LEAKAGE CURRENT (nA)

1

0

-1

-50 125

TEMPERATURE (°C)

COM

COM

SWITCH FREQUENCY RESPONSE

5

0

-5

-10

GAIN (dB)

-15

-20

-25

RL = 50Ω

= 5pF

C

L

-30

100k 1G

ON

OFF

1007550250-25

FREQUENCY (Hz)

500

MAX9507 toc28

400

300

200

100

SWITCH CHARGE INJECTION (pC)

0

-1.0 2.0

MAX9507 toc31

100M10M1M

SWITCH CHARGE INJECTION

vs. VOLTAGE

C

LOAD

OPEN = 1

OPEN = 0

SWITCH INPUT VOLTAGE (V)

= 1nF

MAX9507 toc29

SUPPLY CURRENT (nA)

1.51.00 0.5-0.5

SWITCH OFF-ISOLATION

0

-10

-20

-30

-40

-50

GAIN (dB)

-60

-70

-80

-90

-100

100k 1G

SWITCH-ONLY SUPPLY CURRENT

vs. TEMPERATURE (NORMAL RANGE)

300

250

200

150

100

50

0

-50 125

TEMPERATURE (°C)

SPEN = 0

CPEN = 0

vs. FREQUENCY

MAX9507 toc32

100M10M1M

FREQUENCY (Hz)

MAX9507 toc30

1007550250-25

SWITCH-TO-SWITCH CROSSTALK

vs. FREQUENCY

0

-20

-40

-60

ISOLATION (dB)

-80

-100

-120

100k 100M

FREQUENCY (Hz)

10M1M

MAX9507 toc33

TOTAL HARMONIC DISTORTION PLUS NOISE

vs. FREQUENCY

0.1

V

= 2V

IN

P-P

R

= 600Ω

LOAD

THD+N (%)

0.01

FREQUENCY (Hz)

10k1k10010 100k

MAX9507 toc34

Page 12

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

12 ______________________________________________________________________________________

Pin Description

Detailed Description

The MAX9507 represents Maxim’s second-generation

of DirectDrive video amplifiers that meet the requirements of current and future portable equipment:

• 1.8V Operation: Eliminate the need for 3.3V supply in

favor of lower supply voltages.

• Lower Power Consumption: The MAX9507 reduces

average power consumption by up to 75% compared to the 3.3V first generation (MAX9503/

MAX9505).

• Internal Fixed Gain of 8: As the supply voltages drop

for system chips on deep submicron processes, the

video DAC can no longer create a 1V

P-P

signal at its

output, and the gain of 2 found in the previous generation of video filter amplifiers is not enough.

• Load Reporting: The MAX9507 senses the presence

of a video load. For portable devices, a video load is

not connected most of the time, and turning off the

video encoder saves power. Another benefit of load

reporting is a simpler user interface, eliminating the

need to browse through menus to activate the video

output. Instead, the equipment will automatically

enable this feature.

• Dual SPST Analog Switches: The two analog switches are ideal for routing additional audio, video, or

digital signals.

DirectDrive technology is necessary for a voltage-mode

amplifier to output a 2V

P-P

video signal from a 1.8V

supply. The integrated inverting charge pump creates

a negative supply that increases the output range and

gives the video amplifier enough headroom to drive a

2V

P-P

video signal into a 150Ω load.

DirectDrive

Background

Integrated video filter amplifier circuits operate from a

single supply. The positive power supply usually creates video output signals that are level-shifted above

ground to keep the signal within the linear range of the

output amplifier. For applications where the positive DC

level is not acceptable, a series capacitor can be

inserted in the output connection in an attempt to eliminate the positive DC level shift. The series capacitor

cannot truly level shift a video signal because the average level of the video varies with picture content. The

series capacitor biases the video output signal around

ground, but the actual level of the video signal can vary

significantly depending upon the RC time constant and

the picture content.

PIN NAME FUNCTION

1 IN Video Input

2 SDA I2C-Compatible Serial-Data Input/Output

3 SCL I2C-Compatible Serial-Clock Input

4 DEV_ADDR I2C Device Address Input. Connect DEV_ADDR to GND, VDD, SCL, or SDA. See Table 4.

5VDDPositive Power Supply. Bypass with a 0.1µF capacitor to GND.

6 C1P Charge-Pump Flying Capacitor Positive Terminal. Connect a 1µF capacitor from C1P to C1N.

7 CPGND Charge-Pump Ground

8 C1N Charge-Pump Flying Capacitor Negative Terminal. Connect a 1µF capacitor from C1P to C1N.

9VSSCharge-Pump Negative Power Supply. Bypass with a 1µF capacitor to GND.

10 OUT Video Output

11 GND Ground

12 LCF Load Change Flag. Open-drain, active-low signal indicates when a video load change occurs.

13 NO1 Normally Open Terminal 1

14 COM1 Common Terminal 1

15 COM2 Common Terminal 2

16 NO2 Normally Open Terminal 2

— EP Exposed Pad. EP is internally connected to GND. Connect EP to GND.

Page 13

The series capacitor creates a highpass filter. Since the

lowest frequency in video is the frame rate, which can be

between 24Hz and 30Hz, the pole of the highpass filter

should ideally be an order of magnitude lower in frequency than the frame rate. Therefore, the series capacitor must be very large, typically from 220µF to 3000µF.

For space-constrained equipment, the series capacitor

is unacceptable. Changing from a single series capacitor to a SAG network that requires two smaller capacitors

can only reduce space and cost slightly.

The series capacitor in the usual output connection

also prevents damage to the output amplifier if the connector is shorted to a supply or to ground. While the

output connection of the MAX9507 does not have a

series capacitor, the MAX9507 will not be damaged if

the connector is shorted to a supply or to ground (see

the

Short-Circuit Protection

section).

Video Amplifier

If the full-scale video signal from a video DAC is

250mV, the black level of the video signal created by

the video DAC is around 75mV. The MAX9507 shifts the

black level to near ground at the output so that the

active video is above ground and the sync is below

ground. The amplifier needs a negative supply for its

output stage to remain in its linear region when driving

sync below ground.

The MAX9507 has an integrated charge pump and linear regulator to create a low-noise negative supply

from the positive supply voltage. The charge pump

inverts the positive supply to create a raw negative voltage that is then fed into the linear regulator filtering out

the charge-pump noise.

Comparison Between DirectDrive Output

and AC-Coupled Output

The actual level of the video signal varies less with a

DirectDrive output than an AC-coupled output. The

average video signal level can change greatly depending upon the picture content. With an AC-coupled output, the average level will change according to the time

constant formed by the series capacitor and series

resistance (usually 150Ω). For example, Figure 4 shows

an AC-coupled video signal alternating between a

completely black screen and a completely white

screen. Notice the excursion of the video signal as the

screen changes.

With the DirectDrive amplifier, the black level is held at

ground. The video signal is constrained between -0.3V

to +0.7V. Figure 5 shows the video signal from a

DirectDrive amplifier with the same input signal as the

AC-coupled system.

Video Reconstruction Filter

The MAX9507 includes an internal five-pole,

Butterworth lowpass filter to condition the video signal.

The reconstruction filter smoothes the steps and

reduces the spikes created whenever the DAC output

changes value. In the frequency domain, the steps and

spikes cause images of the video signal to appear at

multiples of the sampling clock frequency. The reconstruction filter typically has ±1dB passband flatness of

7.3MHz and 48dB attenuation at 27MHz.

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

______________________________________________________________________________________ 13

Figure 4. AC-Coupled Output

Figure 5. DirectDrive Output

0V

0V

INPUT

OUTPUT

2ms/div

INPUT

OUTPUT

2ms/div

Page 14

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

14 ______________________________________________________________________________________

Transparent Sync-Tip Clamp

The MAX9507 contains an integrated, transparent

sync-tip clamp. When using a DC-coupled input, the

sync-tip clamp does not affect the input signal, as long

as it remains above ground. When using an AC-coupled input, the sync-tip clamp automatically clamps the

input signal to ground, preventing it from going lower. A

small current of 2µA pulls down on the input to prevent

an AC-coupled signal from drifting outside the input

range of the device.

Using an AC-coupled input results in some additional

variation of the black level at the output. Applying a

voltage above ground to the input pin of the device

always produces the same output voltage, regardless

of whether the input is DC- or AC-coupled. However,

since the sync-tip clamp level (V

CLP

) can vary over a

small range, the video black level at the output of the

device when using an AC-coupled input can vary by an

additional amount equal to the V

CLP

multiplied by the

DC voltage gain (AV).

Dual SPST Analog Switches

The MAX9507 has dual SPST analog switches for routing additional audio, video, digital, and other signals.

The switches are selected through the I2C interface.

SW1EN (register 0x00, bit B6) and SW2EN (register

0x00, bit B7) control the analog switches. See the

I2C

Registers and Bit Descriptions

section. The dual analog

switches operate in either normal or extended range. In

normal range, the part is in shutdown and the analog

switches can handle signals between GND and V

DD

. In

extended range, the charge pump and linear regulator

are on and the analog switches can handle signals

between -0.9V and V

DD

.

Short-Circuit Protection

The MAX9507 typical operating circuit includes a 75Ω

back-termination resistor that limits short-circuit current

if an external short is applied to the video output. The

MAX9507 also features internal output short-circuit protection to prevent device damage in prototyping and

applications where the amplifier output can be directly

shorted.

Powering On/Off the MAX9507

The MAX9507 powers on in a low-power shutdown

mode with the analog switches open and the video signal path, charge pump, and load detection circuitry

disabled. It is good practice to configure the operating

mode of the signal path before enabling it. This may

include selecting the sync-tip clamp and video filter.

Setting CPEN = 1 (register 0x00, bit B0) enables the

charge pump. The charge pump must be fully operational before the signal path will be functional. Setting

SPEN = 1 (register 0x00, bit B1) enables the signal

path. Both SPEN and CPEN may be set at the same

time and internal control circuitry will monitor the

charge pump and enable the signal path at the appropriate time.

The analog switches can be turned on or off at any

time, regardless of the state of the charge pump or signal path. However, the signal range is limited from GND

to VDDwhen the charge pump is disabled.

The MAX9507 can be placed in a low-power shutdown

mode by setting SPEN = 0 and CPEN = 0.

Video Load Detection Circuitry

The MAX9507 contains video load detection circuitry at

the video output, enabling efficient power consumption

based on the actual presence of a video load. Setting

the automatic signal path enable bit, ASPEN = 1 (register 0x01, bit B1) or the automatic charge-pump enable

bit, ACPEN = 1 (register 0x01, bit B0) enables the load

detection feature. The LOAD bit (register 0x01, bit B7)

indicates the load status.

To enable complete, automatic control of the part, set

ASPEN = ACPEN = 1 and SPEN = CPEN = 0. In this

state, when an output load is connected to the amplifier, the signal path and charge pump fully turn on and

stay on until the output load is disconnected. If an output load is not connected to the amplifier, then the signal path and charge pump remain in a low-power sleep

mode while continuing to check if a load is connected.

Setting SPEN = 1 or CPEN = 1 overrides the corresponding ASPEN or ACPEN bits, enabling the block

regardless of the detected video load status.

The LOAD bit indicates the latest video load status. All

changes to the video load status are debounced typically 128ms to eliminate false load-detect events.

Setting the load change flag enable bit, LCFEN = 1 (register 0x01, bit B3), and enabling the load detection feature (ASPEN = 1 or ACPEN = 1) enables the open-drain

LCF output. LCF asserts low whenever the LOAD bit

changes state. It remains low until the LOAD bit (register

0x01) is read. LCF can be used as an interrupt to notify

the system that the load status has changed.

Page 15

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

______________________________________________________________________________________ 15

Sleep Mode

If a video load is not connected to the amplifier, the

MAX9507 remains in a low-power sleep mode. The

load-sense circuitry checks for a load eight times per

second by connecting an internal 7.5kΩ pullup resistor

to the output for 1ms. If the output is pulled up, no load

is present. If the output stays low, a load is connected,

and the automatic control circuitry enables the appro-

priate blocks. When the amplifier is on, it continually

checks if the load has been disconnected by detecting

if the amplifier is sinking current during a horizontal line

time. Therefore, a black-burst signal (or input signal

< 13mV) is required to maintain the detected load status. If the load is disconnected, the device returns to

the low-power sleep mode.

Common Modes of Operation

X = Don’t care.

I2C Registers and Bit Descriptions

Table 1. Register Map

NO. MODE ASPEN ACPEN SPEN CPEN

Shutdown mode.

1

Switches in normal range.

Load-detect function disabled.

Full operation mode.

Video, charge pump, and regulator on.

2

Switches in extended range.

Charge-pump-only mode.

3

Charge pump and regulator on, video off.

Switches in extended range.

Sleep mode.

Video, charge pump, and regulator automatic.

4

Switches in extended range only when the charge

pump is on.

Load-detect function enabled.

Charge pump and regulator on, video automatic.

Switches in extended range.

5

Load-detect function enabled.

0000

XX11

XX01

1100

1001

REGISTER

ADDRESS

0x00 Configuration SW2EN SW1EN 0 STEN FLTEN 0 SPEN CPEN 0x00

0x01

REGISTER B7 B6 B5 B4 B3 B2 B1 B0

Video Load

Detect

LOAD 0 0 0 LCFEN 0 ASPEN ACPEN 0x00

POWER-ON

RESET

STATE

Page 16

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

16 ______________________________________________________________________________________

I2C Serial Interface

The MAX9507 features an I2C/SMBus™-compatible, 2wire serial interface consisting of a serial-data line (SDA)

and a serial-clock line (SCL). SDA and SCL facilitate

communication between the MAX9507 and the master at

clock rates up to 400kHz. Figure 3 shows the 2-wire interface timing diagram. The master generates SCL and initiates data transfer on the bus. A master device writes data

to the MAX9507 by transmitting a START (S) condition,

the proper slave address with the R/W bit set to 0, followed by the register address and then the data word.

Each transmit sequence is framed by a START and a

STOP (P) condition. Each word transmitted to the

MAX9507 is 8 bits long and is followed by an acknowledge clock pulse. A master reads from the MAX9507 by

transmitting the slave address with the R/W bit set to 0,

the register address of the register to be read, a REPEATED START (Sr) condition, the slave address with the R/W

bit set to 1, followed by a series of SCL pulses. The

MAX9507 transmits data on SDA in sync with the mastergenerated SCL pulses. The master acknowledges receipt

of each byte of data. Each read sequence is framed by a

START or REPEATED START condition, an acknowledge

or a not acknowledge, and a STOP condition. SDA operates as both an input and an open-drain output. A pullup

resistor, typically greater than 500Ω, is required on the

SDA bus. SCL operates as only an input. A pullup resistor, typically greater than 500Ω, is required on SCL if

there are multiple masters on the bus, or if the master in a

single-master system has an open-drain SCL output.

Table 2. Configuration Register (0x00)

*

Internal control circuitry prevents the signal path from turning on until the charge pump has been enabled and has settled.

Table 3. Video Load-Detect Register (0x01)

*

Read-only bit indicating the load status when the video load-detect circuitry is enabled (ASPEN = 1 or ACPEN = 1). When LCFEN = 1,

reading this bit will clear the LCF flag.

**

If SPEN = 0, then the signal path will be automatically enabled when a video load is detected and the charge pump has been

enabled and has settled.

***

If CPEN = 0, then the charge pump will be automatically enabled when a video load is detected.

SMBus is a trademark of Intel Corp.

BIT NAME FUNCTION

B7 SW2EN

B6 SW1EN

B4 STEN

B3 FLTEN

B1 SPEN

B0 CPEN

BIT NAME FUNCTION

B7 LOAD*

B3 LCFEN

B1 ASPEN

B0 ACPEN

1 = Analog switch 2 closed.

0 = Analog switch 2 open.

1 = Analog switch 1 closed.

0 = Analog switch 1 open.

1 = Transparent sync-tip clamp enabled, the input can be DC- or AC-coupled.

0 = Transparent sync-tip clamp disabled, the input must be DC-coupled.

1 = Video filter enabled.

0 = Video filter disabled (bypassed).

1 = Signal path enabled* (SPEN overrides the ASPEN setting).

0 = Signal path disabled.

1 = Charge pump enabled (CPEN overrides the ACPEN setting).

0 = Charge pump disabled.

1 = Load detected.

0 = No load detected.

1 = Changes to the video load will trigger LCF to pull low.

0 = Changes to the video load are not reported.

1 = Enable automatic control of the video signal path**.

0 = Disable automatic control of the video signal path.

1 = Enable automatic control of the charge pump***.

0 = Disable automatic control of the charge pump.

Page 17

Series resistors in line with SDA and SCL are optional.

Series resistors protect the digital inputs of the MAX9507

from high-voltage spikes on the bus lines, and minimize

crosstalk and undershoot of the bus signals.

Bit Transfer

One data bit is transferred during each SCL cycle. The

data on SDA must remain stable during the high period

of the SCL pulse. Changes in SDA while SCL is high

are control signals (see the

START and STOP

Conditions

section). SDA and SCL idle high when the

I2C bus is not busy.

START and STOP Conditions

SDA and SCL idle high when the bus is not in use. A

master initiates communication by issuing a START condition. A START condition is a high-to-low transition on

SDA with SCL high. A STOP condition is a low-to-high

transition on SDA while SCL is high (Figure 6). A START

condition from the master signals the beginning of a

transmission to the MAX9507. The master terminates

transmission, and frees the bus, by issuing a STOP condition. The bus remains active if a REPEATED START

condition is generated instead of a STOP condition.

Early STOP Conditions

The MAX9507 recognizes a STOP condition at any point

during data transmission except if the STOP condition

occurs in the same high pulse as a START condition. For

proper operation, do not send a STOP condition during

the same SCL high pulse as the START condition.

Slave Address

The slave address is defined as the 7 most significant

bits (MSBs) followed by the read/write (R/W) bit. Set the

R/W bit to 1 to configure the MAX9507 to read mode.

Set the R/W bit to 0 to configure the MAX9507 to write

mode. The slave address is always the first byte of

information sent to the MAX9507 after a START or a

REPEATED START condition. The MAX9507 slave

address is configurable with DEV_ADDR. Table 4

shows the possible slave addresses for the MAX9507.

Acknowledge

The acknowledge bit (ACK) is a clocked 9th bit that the

MAX9507 uses to handshake receipt of each byte of data

when in write mode (see Figure 7). The MAX9507 pulls

down SDA during the entire master-generated ninth clock

pulse if the previous byte is successfully received.

Monitoring ACK allows for detection of unsuccessful data

transfers. An unsuccessful data transfer occurs if a

receiving device is busy or if a system fault has occurred.

In the event of an unsuccessful data transfer, the bus

master may retry communication. The master pulls down

SDA during the ninth clock cycle to acknowledge receipt

of data when the MAX9507 is in read mode. An acknowledge is sent by the master after each read byte to allow

data transfer to continue. A not acknowledge is sent

when the master reads the final byte of data from the

MAX9507, followed by a STOP condition.

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

______________________________________________________________________________________ 17

Figure 6. START, STOP, and REPEATED START Conditions

Figure 7. Acknowledge

Table 4. Slave Address

DEV_ADDR B7 B6 B5 B4 B3 B2 B1 B0

GND 1001100R/W 0x98 0x99

V

DD

SCL 1001110R/W 0x9C 0x9D

SDA 1001111R/W 0x9E 0x9F

SCL

SDA

1001101R/W 0x9A 0x9B

SSrP

START

CONDITION

SCL

SDA

WRITE ADDRESS

(hex)

1

289

NOT ACKNOWLEDGE

READ ADDRESS

(hex)

CLOCK PULSE FOR

ACKNOWLEDGMENT

ACKNOWLEDGE

Page 18

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

18 ______________________________________________________________________________________

Write Data Format

A write to the MAX9507 consists of transmitting a

START condition, the slave address with the R/W bit set

to 0, one data byte to configure the internal register

address pointer, one or more data bytes, and a STOP

condition. Figure 8 illustrates the proper frame format

for writing one byte of data to the MAX9507. Figure 9

illustrates the frame format for writing n-bytes of data to

the MAX9507.

The slave address with the R/W bit set to 0 indicates

that the master intends to write data to the MAX9507.

The MAX9507 acknowledges receipt of the address

byte during the master-generated ninth SCL pulse.

The second byte transmitted from the master configures the MAX9507’s internal register address pointer.

The pointer tells the MAX9507 where to write the next

byte of data. An acknowledge pulse is sent by the

MAX9507 upon receipt of the address pointer data.

The third byte sent to the MAX9507 contains the data

that will be written to the chosen register. An acknowledge pulse from the MAX9507 signals receipt of the

data byte. The address pointer autoincrements to the

next register address after each received data byte.

This autoincrement feature allows a master to write to

sequential register address locations within one continuous frame. The master signals the end of transmission

by issuing a STOP condition.

Read Data Format

The master presets the address pointer by first sending

the MAX9507’s slave address with the R/W bit set to 0

followed by the register address after a START condition. The MAX9507 acknowledges receipt of its slave

address and the register address by pulling SDA low

during the ninth SCL clock pulse. A REPEATED START

condition is then sent followed by the slave address

with the R/W bit set to 1. The MAX9507 transmits the

contents of the specified register. Transmitted data is

valid on the rising edge of the master-generated serial

clock (SCL). The address pointer autoincrements after

each read data byte. This autoincrement feature allows

all registers to be read sequentially within one continuous frame. A STOP condition can be issued after any

number of read data bytes. If a STOP condition is

issued followed by another read operation, the first

Figure 8. Writing a Byte of Data to the MAX9507

Figure 9. Writing n-Bytes of Data to the MAX9507

ACKNOWLEDGE FROM MAX9507

ACKNOWLEDGE FROM MAX9507

S AA

ACKNOWLEDGE FROM MAX9507

S

SLAVE ADDRESS

R/W

0SLAVE ADDRESS REGISTER ADDRESS DATA BYTE

R/W

ACKNOWLEDGE FROM MAX9507

A

REGISTER ADDRESS

ACKNOWLEDGE FROM MAX9507

ACKNOWLEDGE FROM MAX9507

A

DATA BYTE 1

1 BYTE

AUTOINCREMENT INTERNAL

REGISTER ADDRESS POINTER

B1 B0B3 B2B5 B4B7 B6

A

P

1 BYTE

AUTOINCREMENT INTERNAL

REGISTER ADDRESS POINTER

ACKNOWLEDGE FROM MAX9507

B1 B0B3 B2B5 B4B7 B6

A0

DATA BYTE n

1 BYTE

B1 B0B3 B2B5 B4B7 B6

A

P

Page 19

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

______________________________________________________________________________________ 19

data byte to be read will be from the register address

location set by the previous transaction and not 0x00,

and subsequent reads will autoincrement the address

pointer until the next STOP condition. Attempting to

read from register addresses higher than 0x01 results

in repeated reads from a dummy register containing

0xFF data. The master acknowledges receipt of each

read byte during the acknowledge clock pulse. The

master must acknowledge all correctly received bytes

except the last byte. The final byte must be followed by

a not acknowledge from the master and then a STOP

condition. Figures 10 and 11 illustrate the frame format

for reading data from the MAX9507.

Applications Information

Power Consumption

The quiescent power consumption and average power

consumption of the MAX9507 is remarkably low

because of 1.8V operation and DirectDrive technology.

Quiescent power consumption is defined when the

MAX9507 is operating without load. In this case, the

MAX9507 consumes about 5.8mW. Average power

consumption, which is defined when the MAX9507 drives a 150Ω load to ground with a 50% flat field, is

about 11.7mW. Table 5 shows the power consumption

with different video signals. The supply voltage is 1.8V

and OUT drives a 150Ω load to ground.

Notice that the two extremes in power consumption occur

with a video signal that is all black and a video signal that

is all white. The power consumption with 75% color bars

and 50% flat field lies in between the extremes.

Figure 11. Reading n-Bytes of Indexed Data from the MAX9507

Figure 10. Reading One Indexed Byte of Data from the MAX9507

Table 5. MAX9507 Power Consumption with Different Video Signals

ACKNOWLEDGE FROM MAX9507

SA

R/W

ACKNOWLEDGE FROM MAX9507

0

ACKNOWLEDGE FROM MAX9507

Sr 1SLAVE ADDRESS REGISTER ADDRESS SLAVE ADDRESS DATA BYTE

NOT ACKNOWLEDGE FROM MASTER

AA

R/WREPEATED START

A

1 BYTE

AUTOINCREMENT INTERNAL

REGISTER ADDRESS POINTER

P

ACKNOWLEDGE FROM MAX9507

SA

R/W

ACKNOWLEDGE FROM MAX9507

0

REPEATED START

ACKNOWLEDGE FROM MAX9507

Sr 1SLAVE ADDRESS REGISTER ADDRESS SLAVE ADDRESS DATA BYTE

AA

R/W

VIDEO SIGNAL

All Black Screen 6.7 6.2

All White Screen 18.2 17.9

75% Color Bars 11.6 11.0

50% Flat Field 11.7 11.3

MAX9507 POWER CONSUMPTION WITH

FILTER ENABLED (mW)

MAX9507 POWER CONSUMPTION WITH

FILTER DISABLED (mW)

A

1 BYTE

AUTOINCREMENT INTERNAL

REGISTER ADDRESS POINTER

Page 20

MAX9507

Interfacing to Video DACs that Produce

Video Signals Larger than 0.25V

P-P

Devices designed to generate 1V

P-P

video signals at

the output of the video DAC can still work with the

MAX9507. Most video DACs source current into a

ground-referenced resistor, which converts the current

into a voltage. Figure 12 shows a video DAC that creates a video signal from 0 to 1V across a 150Ω resistor.

The following video filter amplifier has a 2V/V gain so

that the output is 2V

P-P

.

The MAX9507 expects input signals that are 0.25V

P-P

nominally. The same video DAC can be made to work

with the MAX9507 by scaling down the 150Ω resistor to

a 37.5Ω resistor, as shown in Figure 13. The 37.5Ω resistor is one-quarter the size of the 150Ω resistor, resulting

in a video signal that is one-quarter the amplitude.

Changing Between Video Output and

Microphone Input on a Single Connector

Figure 14 shows how a single pole on a mobile phone

jack can be used for transmitting a video signal to a

television or receiving the signal from the microphone

of a headset. To transmit a video signal, open SW1 and

enable the video circuitry. To receive a signal from a

microphone, close SW1 and disable the video circuitry.

Switching Between Video

and Digital Signals

Figure 15 shows how the dual SPST analog switches

and the high-impedance output of the video amplifier

enable video transmission, digital transmission, and

digital reception all on a single pole of a connector. To

transmit a video signal, open SW1 and SW2 and enable

the video circuitry. To receive a digital signal, close

SW1, open SW2, and disable the video circuitry. To

transmit a digital signal, open SW1, close SW2, and

disable the video circuitry.

Selecting Between Two Video Sources

The analog switches can multiplex between two video

sources. For example, a mobile phone might have an

application processor with an integrated video encoder

and a mobile graphics processor with an integrated

video encoder, each creating a composite video signal

that is between 0 and 0.25V. Figure 16 shows this application in which the MAX9507 chooses between two internal video sources. The two analog switches can be used

as a 2:1 multiplexer to select which video DAC output is

filtered, amplified, and driven out to the connector.

If the analog switches are in extended mode, then they

can also be used to select between two external video

signals, as shown in Figure 17. The external video signals are usually between -2V and +2V. The resistor network divides the external signal by a factor of four,

thereby reducing the signal to between -0.5V and +0.5V

(see the

Anti-Alias Filter

section for an explanation on

why the resistor-divider network is necessary). In extended mode, the analog switch can easily handle this bipolar input signal, even if the supply voltage is 1.8V.

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

20 ______________________________________________________________________________________

Figure 12. Video DAC Generates a 1V

P-P

Signal Across a

150

Ω

Resistor Connected to Ground

Figure 13. Video DAC Generates a 0.25V

P-P

Signal Across a

37.5

Ω

Resistor Connected to Ground

IMAGE

PROCESSOR

ASIC

DAC

IMAGE

PROCESSOR

ASIC

DAC

0 TO 1V

LPF

150Ω

MAX9507

0 TO 0.25V

LPF

37.5Ω

2V

2V/V

2V

8V/V

75Ω

P-P

75Ω

P-P

Page 21

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

______________________________________________________________________________________ 21

Figure 14. Video Output Configuration

V

CC

V

CC

MIC

BASEBAND

IC

BIAS

MIC

AMP

MAX9507

V

CC

SDA

SCL

LCF

2

C INTERFACE

I

SW1 COM1NO1

SW2 COM2NO2

LOAD

DETECT

V

DD

DAC

VIDEO

ASIC

1.8V

0.1μF

IN

TRANSPARENT

CLAMP

V

DD

C3

LPF

LEVEL SHIFT

CHARGE PUMP

CPGND C1P C1N V

C1

1μF

AV = 8V/V

DC

LINEAR

REGULATOR

SS

C2

1μF

OUT

GND

75Ω

TO JACK

Page 22

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

22 ______________________________________________________________________________________

Figure 15. Video Output Configuration

V

CC

V

CC

MAX9507

SW1 COM1NO1

BASEBAND

IC

DAC

VIDEO

ASIC

1.8V

0.1μF

SW2 COM2NO2

V

CC

SDA

SCL

LCF

IN

TRANSPARENT

CLAMP

V

DD

C3

CPGND C1P C1N V

2

C INTERFACE

I

LPF

CHARGE PUMP

1μF

DC

LEVEL SHIFT

REGULATOR

C1

AV = 8V/V

LINEAR

SS

C2

1μF

LOAD

DETECT

V

DD

75Ω

OUT

GND

TO JACK

Page 23

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

______________________________________________________________________________________ 23

Figure 16. Selecting Between Two Internal Video Sources

APPLICATION

PROCESSOR

MICROCONTROLLER

MAX9507

SW1 COM1NO1

SW2 COM2NO2

V

CC

SDA

SCL

LCF

2

I

C INTERFACE

LOAD

DETECT

V

DD

DAC

DAC

MOBILE

GPU

IN

TRANSPARENT

V

1.8V

C3

0.1μF

DD

LPF

CLAMP

CHARGE PUMP

CPGND C1P C1N V

DC

LEVEL SHIFT

C1

1μF

AV = 8V/V

LINEAR

REGULATOR

SS

C2

1μF

OUT

GND

75Ω

Page 24

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

24 ______________________________________________________________________________________

Figure 17. Selecting Between Two External Video Sources

VIDIN1

56Ω

MICROCONTROLLER

0.1μF

1.8V

18Ω

MAX9507

SW1 COM1NO1

SW2 COM2NO2

V

CC

SDA

SCL

LCF

V

DD

IN

TRANSPARENT

CLAMP

2

I

C INTERFACE

LPF

CHARGE PUMP

DC

LEVEL SHIFT

REGULATOR

AV = 8V/V

LINEAR

LOAD

DETECT

V

DD

OUT

GND

VIDIN2

56Ω

18Ω

75Ω10Ω

C3

0.1μF

CPGND C1P C1N V

1μF

SS

C2

1μF

C1

Page 25

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

______________________________________________________________________________________ 25

Anti-Alias Filter

The MAX9507 can also provide anti-alias filtering with a

buffer before an analog-to-digital converter (ADC),

which would be present in an NTSC/PAL video decoder,

for example. Figure 18 shows the application circuit. An

external composite video signal is applied to VIDIN,

which is terminated with a total of 74Ω (56Ω and 18Ω

resistors) to ground. The signal is attenuated by four,

and then AC-coupled to IN. The normal 1V

P-P

video signal must be attenuated because with a 1.8V supply, the

MAX9507 can only handle a video signal of approxi-

mately 0.25V

P-P

at IN. AC-couple the video signal to IN

because the DC level of an external video signal is usually not well specified, although it is reasonable to

expect that the signal is between -2V and +2V. The 10Ω

series resistor increases the equivalent source resistance to about 25Ω, which is the minimum necessary for

a video source to drive the internal sync-tip clamp.

For external video signals larger than 1V

P-P

, then operate the MAX9507 from a 2.5V supply so that IN can

accommodate a 0.325V

P-P

video signal, which is equiv-

alent to a 1.3V

P-P

video signal at VIDIN.

Figure 18. MAX9507 Used as an Anti-Alias Filter with Buffer

V

CC

MICROCONTROLLER

SDA

SCL

LCF

MAX9507

2

C INTERFACE

I

SW1 COM1NO1

SW2 COM2NO2

LOAD

DETECT

VIDIN

0.1μF

56Ω

18Ω

1.8V

C3

0.1μF

IN

V

DD

TRANSPARENT

CLAMP

CPGND C1P C1N V

LPF

CHARGE PUMP

1μF

DC

LEVEL SHIFT

REGULATOR

C1

AV = 8V/V

LINEAR

SS

C2

1μF

V

DD

75Ω10Ω

OUT

GND

Page 26

MAX9507

Power-Supply Bypassing and

Ground Management

The MAX9507 operates from a 1.7V to 2.625V single

supply and requires proper layout and bypassing. For

the best performance, place the components as close

to the device as possible.

Proper grounding improves performance and prevents

any switching noise from coupling into the video signal.

Bypass the analog supply (V

DD

) with a 0.1µF capacitor

to GND, placed as close to the device as possible.

Bypass CPV

SS

with a 1µF capacitor to GND as close to

the device as possible. The total system bypass capacitance on V

DD

should be at least 10µF, or ten times the

capacitance between C1P and C1N.

Using a Digital Supply

The MAX9507 is designed to operate from noisy digital

supplies. The high power-supply rejection ratio (47dB

at 100kHz) allows the MAX9507 to reject the noise from

the digital power supplies (see the

Typical Operating

Characteristics

). If the digital power supply is very

noisy and stripes appear on the television screen,

increase the supply bypass capacitance. An additional,

smaller capacitor in parallel with the main bypass

capacitor can reduce digital supply noise because the

smaller capacitor has lower equivalent series resistance (ESR) and equivalent series inductance (ESL).

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

26 ______________________________________________________________________________________

Chip Information

PROCESS: BiCMOS

Pin Configuration

TOP VIEW

NO1

COM1

COM2

LCF

12 10 9

13

14

15

11

MAX9507

OUT

SS

V

C1N

8

CPGND

7

C1P

6

16

NO2

+

13

2

IN

SDA GND

*EXPOSED PAD CONNECTED TO GND.

THIN QFN

(3mm x 3mm)

*EP

4

SCL

5

DEV_ADDR

V

DD

Page 27

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

______________________________________________________________________________________ 27

Functional Diagram/Typical Operating Circuit

V

CC

V

CC

MICROCONTROLLER

DAC

VIDEO

ASIC

MAX9507

SW1 COM1NO1

SW2 COM2NO2

V

CC

SDA

SCL

LCF

IN

TRANSPARENT

CLAMP

2

C INTERFACE

I

LPF

DC

LEVEL SHIFT

V

DD

AV = 8V/V

LOAD

DETECT

OUT

75Ω

TO JACK

LINEAR

REGULATOR

GND

SS

C2

1μF

C1

1μF

1.8V

0.1μF

V

DD

CHARGE PUMP

C3

CPGND C1P C1N V

Page 28

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

28 ______________________________________________________________________________________

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

MARKING

E/2

D/2

D

AAAA

0.10 C 0.08 C

L

(NE - 1) X e

E2/2

E2

D2/2

D2

b

0.10 M C A B

C

L

L

e

12x16L QFN THIN.EPS

E

(ND - 1) X e

C

L

C

L

A

A2

A1

L

e

k

C

L

e

PACKAGE OUTLINE

8, 12, 16L THIN QFN, 3x3x0.8mm

21-0136

1

I

2

Page 29

MAX9507

1.8V DirectDrive Video Filter Amplifier with

Load Detection and Dual SPST Analog Switches

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________

29

© 2007 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

PKG

REF. MIN.

8L 3x3

MIN.

NOM. MAX.

0.70 0.75 0.80

A

b

0.25 0.30 0.35

D

2.90

3.00 3.10

E

2.90 3.00 3.10

e

0.65 BSC.

L

0.35

0.55 0.75

ND

NE

0

A1

A2

NOTES:

0.02

0.20 REF

k

0.25

1. DIMENSIONING & TOLERANCING CONFORM TO ASME Y14.5M-1994 .

2. ALL DIMENSIONS ARE IN MILLIMETERS. ANGLES ARE IN DEGREES.

3. N IS THE TOTAL NUMBER OF TERMINALS.

4. THE TERMINAL #1 IDENTIFIER AND TERMINAL NUMBERING CONVENTION SHALL CONFORM TO

JESD 95-1 SPP-012. DETAILS OF TERMINAL #1 IDENTIFIER ARE OPTIONAL, BUT MUST BE LOCATED

WITHIN THE ZONE INDICATED. THE TERMINAL #1 IDENTIFIER MAY BE EITHER A MOLD OR

MARKED FEATURE.

5. DIMENSION b APPLIES TO METALLIZED TERMINAL AND IS MEASURED BETWEEN 0.20 mm AND 0.25 mm

FROM TERMINAL TIP.

6. ND AND NE REFER TO THE NUMBER OF TERMINALS ON EACH D AND E SIDE RESPECTIVELY.

7. DEPOPULATION IS POSSIBLE IN A SYMMETRICAL FASHION.

8. COPLANARITY APPLIES TO THE EXPOSED HEAT SINK SLUG AS WELL AS THE TERMINALS .

9. DRAWING CONFORMS TO JEDEC MO220 REVISION C.

10. MARKING IS FOR PACKAGE ORIENTATION REFERENCE ONLY.

11. NUMBER OF LEADS SHOWN ARE FOR REFERENCE ONLY.

12. WARPAGE NOT TO EXCEED 0.10mm.

0.70

0.20

2.90

2.90

0.45

8

2

2

0.05

0

-

-

0.25

12L 3x3

NOM. MAX. NOM.

0.75

0.25

3.00

3.00

0.50 BSC.

0.55

12N

0.0230.05

0.20 REF

3

-

0.80

0.30

3.10

3.10

0.65

-

MIN. MAX.

0.70

0.20

2.90

2.90

0.30

040.02

0.25

16L 3x3

0.75

0.25

3.00

3.00

0.50 BSC.

0.40

16

4

0.20 REF

-

0.80

0.30

3.10

3.10

0.50

0.05

EXPOSED PAD VARIATIONS

PKG.

CODES

TQ833-1 1.250.25 0.70 0.35 x 45° WEEC1.250.700.25

T1233-1

T1233-3

T1233-4

T1633-2 0.95

T1633F-3

T1633FH-3 0.65 0.80 0.95

T1633-4 0.95

T1633-5 0.95

-

D2

MIN.

NOM.

MAX.

0.95

0.95

0.65

1.25

1.10

1.25

1.10

1.251.10

1.25

1.10

0.95

0.80

1.10 1.25 0.95 1.10

1.25

1.10

NOM.

MIN.

1.10

0.95

0.95 1.10 0.35 x 45°1.25 WEED-10.95

1.100.95

1.10

0.95

0.80

0.65

0.65 0.80

1.10 1.25

0.95

E2

PACKAGE OUTLINE

8, 12, 16L THIN QFN, 3x3x0.8mm

MAX.

0.35 x 45°

1.25

0.35 x 45°

1.25

0.35 x 45°

0.95

0.225 x 45°

0.95

0.225 x 45°

1.25

0.35 x 45°

0.35 x 45° WEED-2

PIN ID

WEED-1

WEED-11.25

WEED-2

WEED-2

WEED-2

WEED-2

21-0136

JEDEC

2

I

2

Loading...

Loading...