General Description

The MAX8819_ is a complete power solution for MP3

players and other handheld applications. The IC

includes a battery charger, step-down converters, and

WLED power. It features an input current-limit switch to

power the IC from an AC-to-DC adapter or USB port, a

1-cell lithium ion (Li+) or lithium polymer (Li-Poly) charger, three step-down converters, and a step-up converter

with serial step dimming for powering two to six white

LEDs. All power switches for charging and switching the

system load between battery and external power are

included on-chip. No external MOSFETs are required.

The MAX8819C/MAX8819D offer a sequenced powerup/power-down of OUT1, OUT2, and then OUT3.

Maxim’s Smart Power Selector™ makes the best use of

AC-to-DC adapter power or limited USB power. Battery

charge current and input current limit are independently set. Input power not used by the system charges the

battery. Charge current is resistor programmable and

the input current limit can be selected as 100mA,

500mA, or 1A. Automatic input selection switches the

system load from battery to external power. In addition,

on-chip thermal limiting reduces the battery charge rate

to prevent charger overheating.

Applications

MP3 Players

Portable GPS Devices

Low-Power Handheld Products

Cellular Telephones

Digital Cameras

Handheld Instrumentation

PDAs

Features

♦ Smart Power Selector

♦ Operates with No Battery Present

♦ USB/AC Adapter One-Cell Li+ Charger

♦ Three 2MHz Step-Down Converters

95% Peak Efficiency

100% Duty Cycle

±3% Output Accuracy over Load/Line/

Temperature

♦ 2 to 6 Series WLED Driver with Dimming Control

♦ RST1 Output

♦ Short-Circuit/Thermal-Overload/Input

Undervoltage/Overvoltage Protection

♦ Power-Up Sequencing (MAX8819C/MAX8819D)

♦ Total Solution Size: Less Than 90mm

2

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

________________________________________________________________

Maxim Integrated Products

1

19-4166; Rev 0; 6/08

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Pin Configuration appears at end of data sheet.

Smart Power Selector is a trademark of Maxim Integrated

Products, Inc.

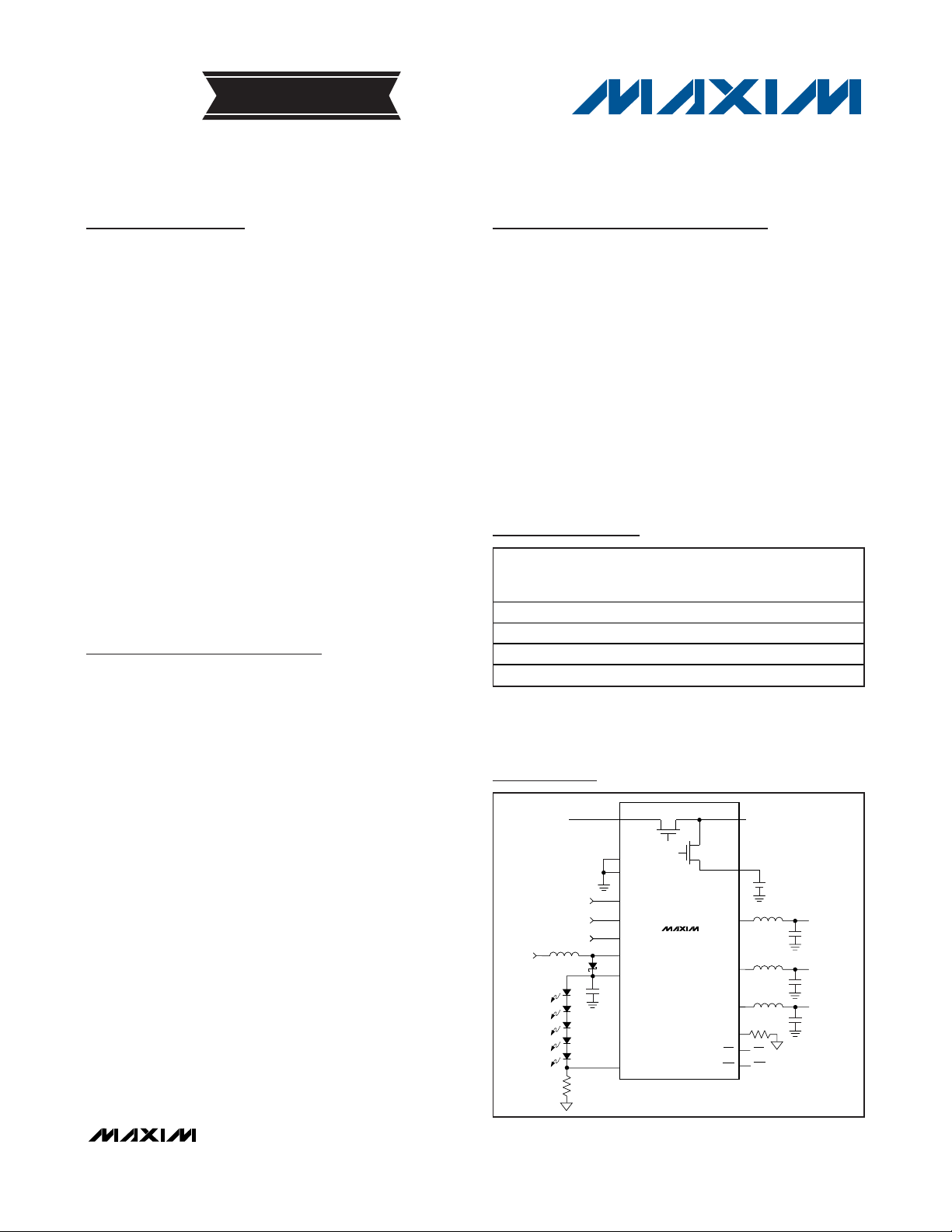

USB/AC-TO-DC

ADAPTER

ENABLE SYSTEM

ENABLE CHARGER

ENABLE BACKLIGHT

SYS

DC

DLIM1

DLIM2

EN123

CEN

EN4

LX4

OVP4

FB4

LX3

LX2

CISET

BAT

SYS

Li+/Li-Poly

BATTERY

OUT1

I/O

OUT2

MEMORY

OUT3

CORE

CHG CHG

LX1

RST1

RST1

MAX8819_

+

Typical Operating Circuit

Ordering Information

+

Denotes a lead-free/RoHS-compliant package.

*

Future product—contact factory for availability.

**

EP = Exposed pad.

PART

TEMP RANGE

PINPACKAGE

SYS

VOLTAGE

(V)

MAX8819AETI+

4.35

MAX8819BETI+

5.3

MAX8819CETI+

4.35

MAX8819DETI+

5.3

EVALUATION KIT

AVAILABLE

-40°C to +85°C 28 TQFN-EP**

-40°C to +85°C 28 TQFN-EP**

-40°C to +85°C 28 TQFN-EP**

-40°C to +85°C 28 TQFN-EP**

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

2 _______________________________________________________________________________________

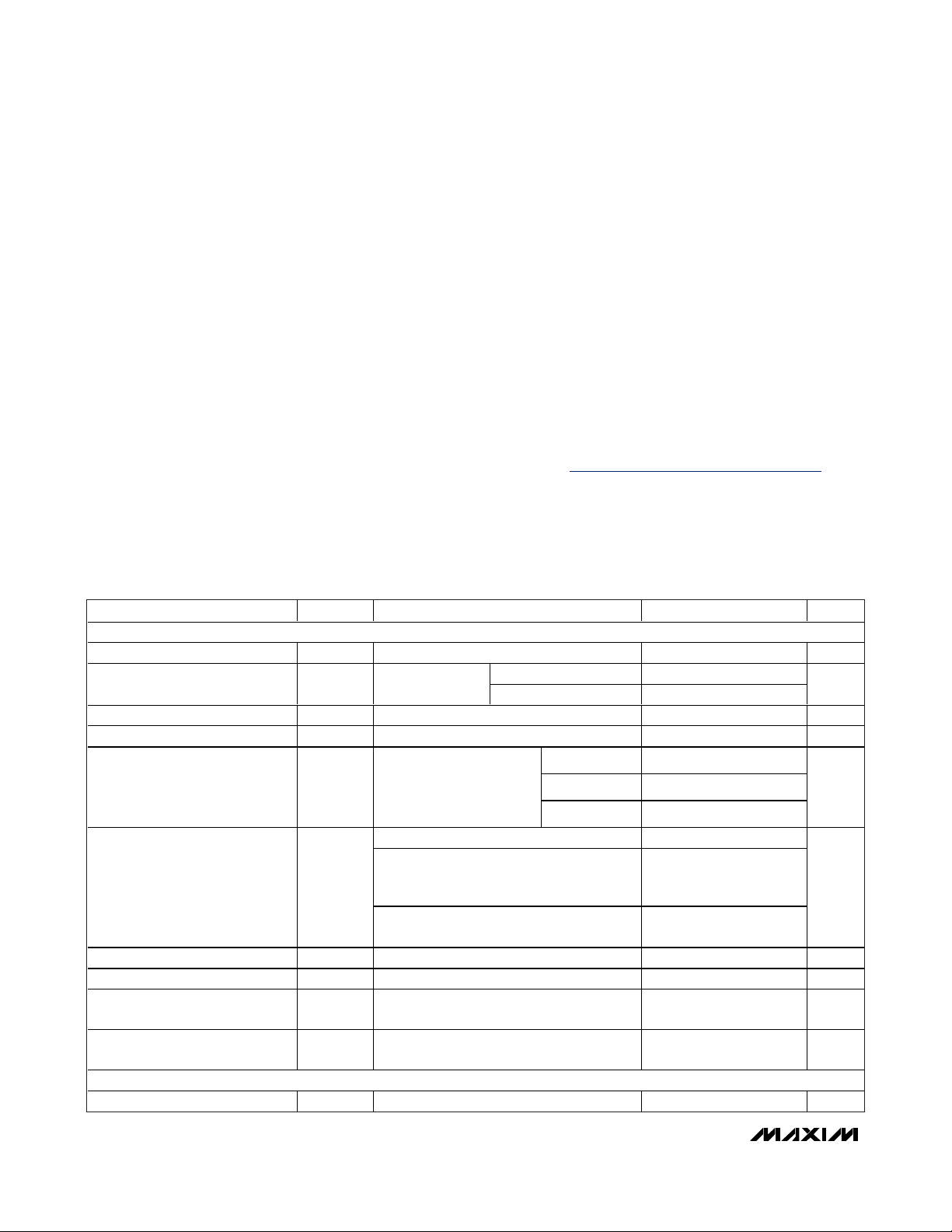

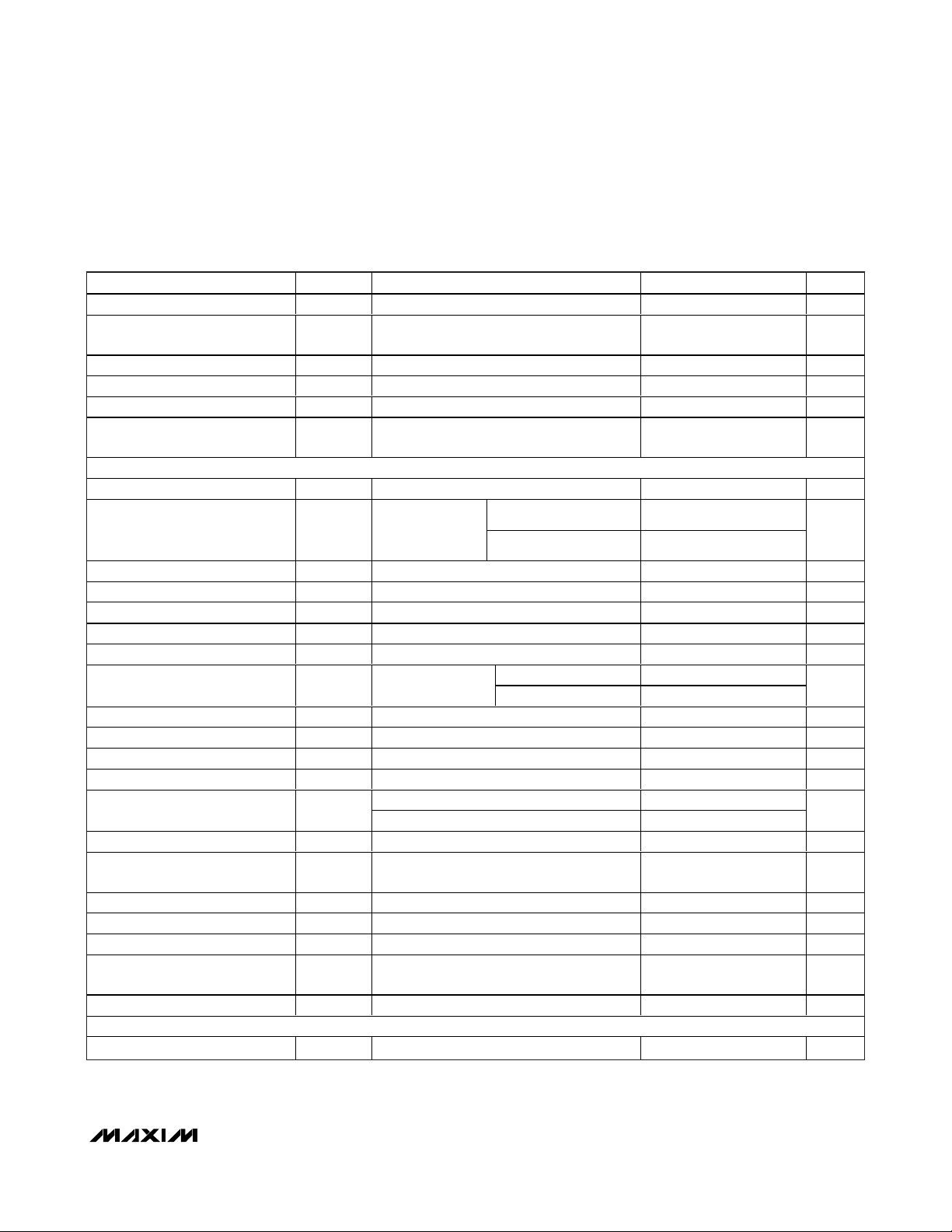

ELECTRICAL CHARACTERISTICS

(DC, LX_ unconnected; VEP= V

GND

= 0V, V

BAT

= 4V, DLIM[1:2] = 00, EN123 = EN4 = low, V

FB1

= V

FB2

= V

FB3

= 1.1V, V

FB4

= 0.6V,

PV13 = PV2 = SYS, T

A

= -40°C to +85°C, capacitors as shown in Figure 1, R

CISET

= 3kΩ, unless otherwise noted.) (Note 3)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

ABSOLUTE MAXIMUM RATINGS

DC, SYS, BAT, CISET, DLIM1, DLIM2, EN123

CEN, EN4, CHG, RST1, FB1, FB2, FB3 to GND....-0.3V to +6V

PV2 to GND...............................................-0.3V to (V

SYS

+ 0.3V)

PV13 to SYS...........................................................-0.3V to +0.3V

PG1, PG2, PG3, PG4 to GND................................-0.3V to +0.3V

COMP4, FB4 to GND ................................-0.3V to (V

SYS

+ 0.3V)

LX4 to PG4 .............................................................-0.3V to +33V

OVP4 to GND .........................................................-0.3V to +33V

LX1, LX2, LX3 Continuous Current (Note 1) .........................1.5A

LX4 Current ................................................................750mA

RMS

Output Short-Circuit Duration.....................................Continuous

Continuous Power Dissipation (T

A

= +70°C)

28-Pin Thin QFN Single-Layer Board (derate 20.8mW/°C

above +70°C)...........................................................1666.7mW

28-Pin Thin QFN Multilayer Board (derate 28.6mW/°C

above +70°C)...........................................................2285.7mW

Junction-to-Case Thermal Resistance (θ

JC

) (Note 2)

28-Lead Thin QFN...........................................................3°C/W

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature........................................-40°C to +125°C

Storage Temperature.........................................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

Note 1: LX1, LX2, LX3 have clamp diodes to their respective PG_ and PV_. Applications that forward bias these diodes must take

care not to exceed the package power dissipation limits.

Note 2: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-layer

board. For detailed information on package thermal considerations, refer to http://www.maxim-ic.com/thermal-tutorial

.

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

DC POWER INPUT

DC Voltage Range V

SYS Regulation Voltage V

DC Undervoltage Threshold V

DC Overvoltage Threshold V

DC Current Limit

(Note 4)

DC Quiescent Current I

DC-to-SYS Dropout Resistance R

DC-to-SYS Soft-Start Time t

DC Thermal-Limit Temperature

DC Thermal-Limit Gain

SYSTEM

System Operating Voltage Range V

DC

SYS_REGVDC

UVLO_DCVDC

OVLO_DCVDC

VDC = 5.75V, V

I

DCLIM

DCIQ

SS-D-S

SYS

for MAX8819B/MAX8819D

or V

MAX8819A/MAX8819C

DLIM[1:2] = 11 (suspend) 0.02 0.035

DLIM[1:2] ≠ 11, I

EN123 = low, EN4 = low, CEN = high,

V

DC

DLIM[1:2] ≠ 11, I

EN4 = low, CEN = low, V

VDC = 4V, I

DS

Die temperature where current limit is

reduced

Amount of input current reduction above

thermal-limit temperature

= 5.75V

rising, 500mV typical hysteresis 3.95 4.00 4.05 V

rising, 300mV typical hysteresis 5.811 5.9 6.000 V

= 4V for

SYS

= 5.5V

MAX8819A/MAX8819C 4.3 4.35 4.4

MAX8819B/MAX8819D 5.1 5.3 5.5

= 5V

SYS

= 0mA, I

SYS

= 0mA, EN123 = low,

SYS

= 400mA, DLIM[1:2] = 01 0.330 0.700 Ω

SYS

DLIM[1:2] = 10 90 95 100

DLIM[1:2] = 01 450 475 500

DLIM[1:2] = 00 900 1000 1100

= 0mA,

BAT

= 5.5V

DC

4.1 5.5 V

2.6 5.5 V

1.33

0.95

1.5 ms

100 °C

5%/°C

V

mA

mA

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

_______________________________________________________________________________________ 3

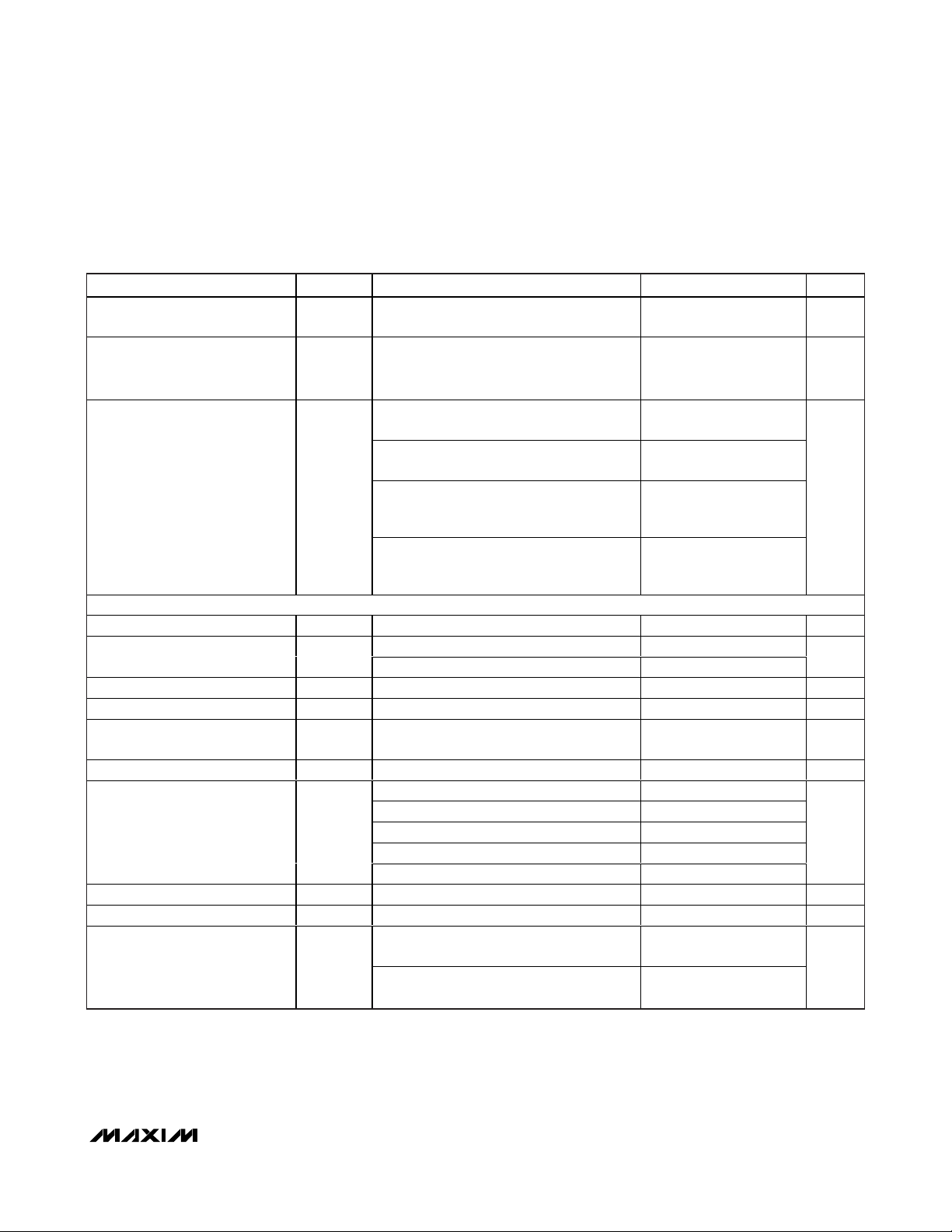

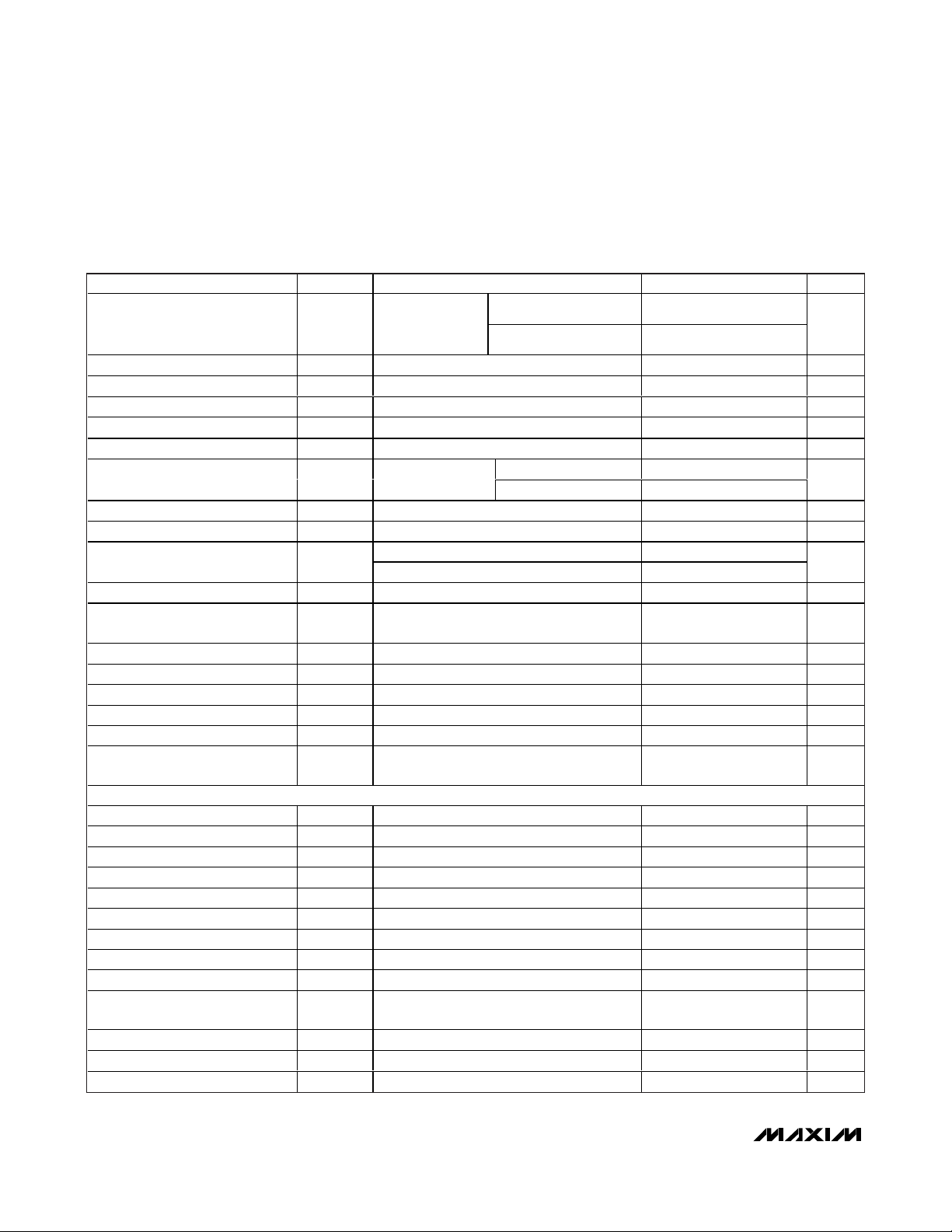

ELECTRICAL CHARACTERISTICS (continued)

(DC, LX_ unconnected; VEP= V

GND

= 0V, V

BAT

= 4V, DLIM[1:2] = 00, EN123 = EN4 = low, V

FB1

= V

FB2

= V

FB3

= 1.1V, V

FB4

= 0.6V,

PV13 = PV2 = SYS, T

A

= -40°C to +85°C, capacitors as shown in Figure 1, R

CISET

= 3kΩ, unless otherwise noted.) (Note 3)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

System Undervoltage Lockout

Threshold

BAT-to-SYS Reverse Regulation

Voltage

Quiescent Current IPV+I

BATTERY CHARGER (VDC = 5.0V)

BAT-to-SYS On-Resistance R

BAT Regulation Voltage

(Figure 2)

BAT Recharge Threshold (Note 4) -135 -100 -65 mV

BAT Prequalification Threshold V

R

Resistance Range

CISET

CISET Voltage V

BAT Fast-Charge Current Limit

BAT Prequalification Current V

Top-Off Threshold (Note 5) TA = +25°C, R

BAT Leakage Current

V

V

UVLO_SYSVSYS

DC and BAT are delivering current to SYS;

V

BSRED

I

BAT

MAX8819A/MAX8819C (only)

VDC = 0V, EN123 = low, EN4 = low,

V

BAT

VDC = 5V, DLIM[1:2] = 11, EN123 = low,

EN4 = low, V

VDC = 0V, EN123 = high, EN4 = low,

SYS

V

BAT

dropout)

VDC = 0V, EN123 = high, EN4 = high,

V

BAT

dropout)

BS

BATREG

BATPRQVBAT

VDC = 0V, V

TA = +25°C 4.174 4.200 4.221

TA = -40°C to +85°C 4.158 4.200 4.242

Guaranteed by BAT fast-charge current

limit

CISET

R

CISET

DLIM[1:2] = 10, R

DLIM[1:2] = 01, R

DLIM[1:2] = 00, R

DLIM[1:2] = 00, R

DLIM[1:2] = 00, R

BAT

VDC = 0V, EN123 = low, EN4 = low,

CEN = low, V

V

DC

EN4 = low, V

falling, 100mV hysteresis 2.45 2.5 2.55 V

= 95mA; V

= 4V

= 4V (step-down converters are not in

= 4V (step-down converters are not in

DC

BAT

BAT

= 4.3V,

= 4V

= 4.2V, I

50 66 90 mV

10 20

010

128 290

362 730

= 0.9A 0.073 0.165 Ω

SYS

rising, 180mV hysteresis, Figure 2 2.9 3.0 3.1 V

315kΩ

= 7.5kΩ, I

= 2.5V, R

= 5V, DLIM[1:2] = 11, EN123 = low,

= 267mA 0.9 1.0 1.1 V

BAT

= 3kΩ 87 92 100

CISET

= 3kΩ 450 472 500

CISET

= 15kΩ 170 200 230

CISET

= 7.5kΩ 375 400 425

CISET

= 3.74kΩ 740 802 860

CISET

= 3.74kΩ 60 82 105 mA

CISET

= 3.74kΩ 60 82 105 mA

CISET

BAT

BAT

= 4V

= 4V

10 20

0

μA

V

mA

μA

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

4 _______________________________________________________________________________________

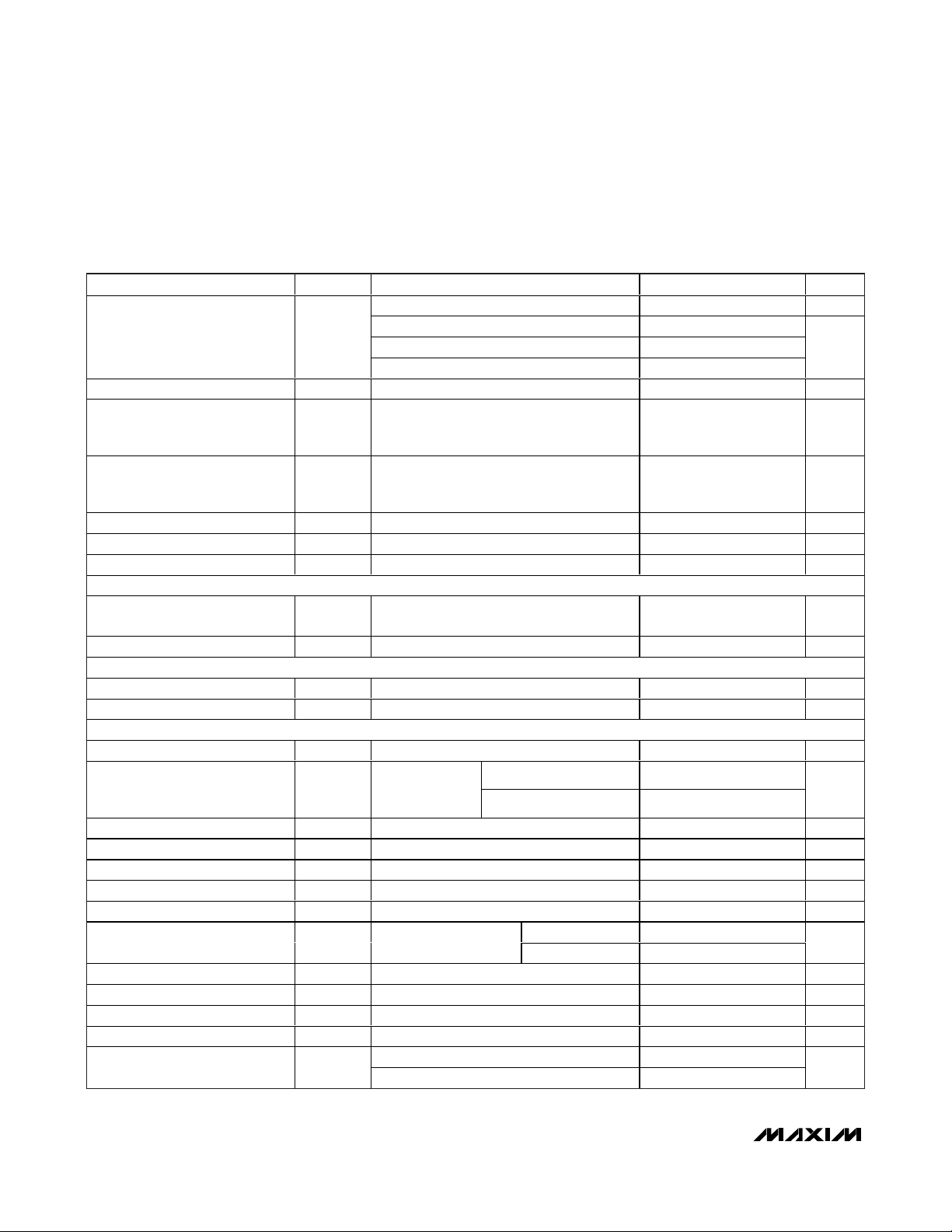

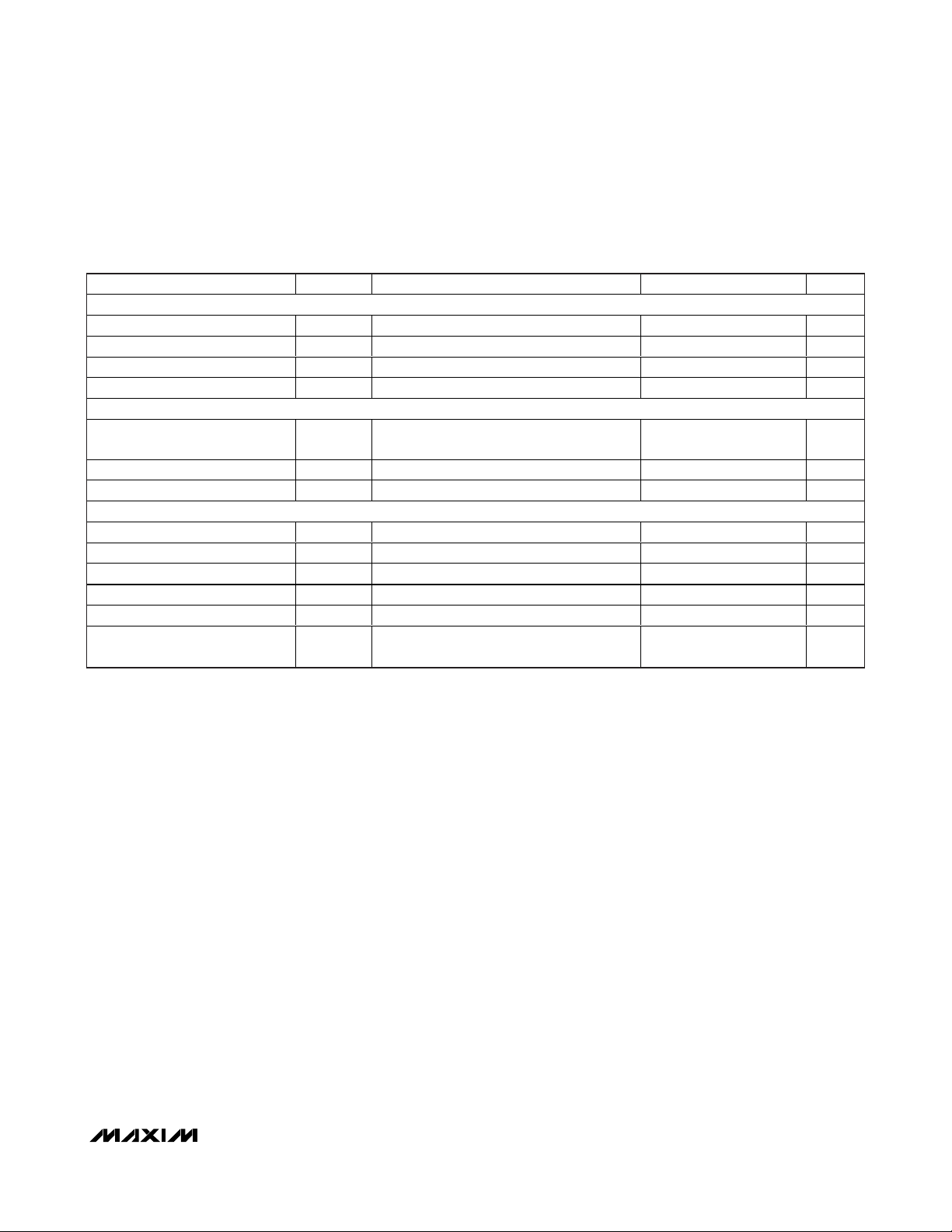

ELECTRICAL CHARACTERISTICS (continued)

(DC, LX_ unconnected; VEP= V

GND

= 0V, V

BAT

= 4V, DLIM[1:2] = 00, EN123 = EN4 = low, V

FB1

= V

FB2

= V

FB3

= 1.1V, V

FB4

= 0.6V,

PV13 = PV2 = SYS, T

A

= -40°C to +85°C, capacitors as shown in Figure 1, R

CISET

= 3kΩ, unless otherwise noted.) (Note 3)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Charger Soft-Start Time t

Timer Accuracy +15 %

Timer Suspend Threshold

Timer Extend Threshold

Prequalification Time t

Fast-Charge Time t

Top-Off Time t

POWER SEQUENCING (Figures 6 and 7)

REG1, REG2, REG3 Soft-Start

Time

REG4 Soft-Start Time t

REGULATOR THERMAL SHUTDOWN

Thermal Shutdown Temperature TJ rising +165 °C

Thermal Shutdown Hysteresis 15 °C

REG1–SYNCHRONOUS STEP-DOWN CONVERTER

Input Voltage PV13 supplied from SYS V

Maximum Output Current

Short-Circuit Current L = 4.7μH, R

Short-Circuit Detection Threshold 230 mV

Short-Circuit Foldback Frequency f

FB1 Voltage (Note 7) 0.997 1.01 1.028 V

Output Voltage Range 1V

FB1 Leakage Current V

Load Regulation I

Line Regulation (Note 9) 1 %/D

p-Channel On-Resistance V

n-Channel On-Resistance V

p-Channel Current-Limit

Threshold

SS_CHG

t

SS1

t

SS3

SS4

PQ

FC

TO

, t

Slew rate 333 mA/ms

Time from 0 to 500mA 1.5

Time from 0 to 100mA 0.3

Time from 100mA to 500mA 1.2

CISET voltage when the fast-charge timer

suspends; 300mV translates to 20% of the

maximum fast-charge current limit

CISET voltage when the fast-charge timer

extends; 750mV translates to 50% of the

maximum fast-charge current limit

,

SS2

C

L = 4.7μH,

R

(Note 6)

MAX8819A/MAX8819B 0.565 0.600 0.640

MAX8819C/MAX8819D 0.615 0.650 0.750

= 0.022μF to GND 5 ms

COMP4

= 0.13Ω

LSR

= 0.13Ω 600 mA

LSR

= 1.01V

FB1

= 100mA to 300mA 1 %

OUT1

= 4.0V, I

PV13

PV13

= 4.0V, I

LX1

LX1

MAX8819A/MAX8819B 400

MAX8819C/MAX8819D 550

TA = +25°C -50 -5 +50

T

A

= 180mA 190 mΩ

= 180mA 250 mΩ

250 300 350 mV

700 750 800 mV

33 min

660 min

33 min

2.6 ms

SYS

/3 Hz

OSC

= +85°C -10

SYS

ms

V

mA

V

nA

A

MAX8819A–MAX8819D

ELECTRICAL CHARACTERISTICS (continued)

(DC, LX_ unconnected; VEP= V

GND

= 0V, V

BAT

= 4V, DLIM[1:2] = 00, EN123 = EN4 = low, V

FB1

= V

FB2

= V

FB3

= 1.1V, V

FB4

= 0.6V,

PV13 = PV2 = SYS, T

A

= -40°C to +85°C, capacitors as shown in Figure 1, R

CISET

= 3kΩ, unless otherwise noted.) (Note 3)

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

_______________________________________________________________________________________ 5

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Skip-Mode Transition Current (Note 8) 80 mA

n-Channel Zero-Crossing

Threshold

Maximum Duty Cycle 100 %

Minimum Duty Cycle 12.5 %

PWM Frequency f

Internal Discharge Resistance in

Shutdown

REG2–SYNCHRONOUS STEP-DOWN CONVERTER

Input Voltage PV2 supplied from SYS V

Maximum Output Current

Short-Circuit Current L = 4.7μH, R

Short-Circuit Detection Threshold 230 mV

Short-Circuit Foldback Frequency f

FB2 Voltage (Note 7) 0.997 1.012 1.028 V

Output Voltage Range 1V

FB2 Leakage Current V

Load Regulation I

Line Regulation (Note 9) 1 %/D

p-Channel On-Resistance V

n-Channel On-Resistance V

p-Channel Current-Limit

Threshold

Skip-Mode Transition Current (Note 8) 80 mA

n-Channel Zero-Crossing

Threshold

Maximum Duty Cycle 100 %

Minimum Duty Cycle 12.5 %

PWM Frequency f

Internal Discharge Resistance in

Shutdown

REG2 Disable ΔI

REG3–SYNCHRONOUS STEP-DOWN CONVERTER

Input Voltage PV13 supplied from SYS V

OSC

OSC

SYS

EN123 = low, resistance from LX1 to PG1 1.0 kΩ

L = 4.7μH,

= 0.13Ω

R

LSR

(Note 6)

= 0.13Ω 600 mA

LSR

= 1.01V

FB2

= 100mA to 300mA 1 %

OUT2

= 4.0V, I

PV2

= 4.0V, I

PV2

MAX8819A/MAX8819B 0.512 0.550 0.595

MAX8819C/MAX8819D 0.565 0.600 0.700

EN123 = low, resistance from LX2 to PG2 1.0 kΩ

V

= 0V, REG2 disabled (Note 10) -25 μA

PV2

= 180mA 290 mΩ

LX2

= 180mA 200 mΩ

LX2

MAX8819A/MAX8819B 300

MAX8819C/MAX8819D 500

TA = +25°C -50 -5 +50

= +85°C -50

T

A

1.8 2.0 2.2 MHz

1.8 2.0 2.2 MHz

10 mA

SYS

/3 Hz

OSC

SYS

10 mA

SYS

mA

nA

V

V

A

V

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(DC, LX_ unconnected; VEP= V

GND

= 0V, V

BAT

= 4V, DLIM[1:2] = 00, EN123 = EN4 = low, V

FB1

= V

FB2

= V

FB3

= 1.1V, V

FB4

= 0.6V,

PV13 = PV2 = SYS, T

A

= -40°C to +85°C, capacitors as shown in Figure 1, R

CISET

= 3kΩ, unless otherwise noted.) (Note 3)

Maximum Output Current

Short-Circuit Current L = 4.7μH, R

Short-Circuit Detection Threshold 230 mV

Short-Circuit Foldback Frequency f

FB3 Voltage (Note 7) 0.997 1.01 1.028 V

Output Voltage Range 1V

FB3 Leakage Current V

Load Regulation I

Line Regulation (Note 9) 1 %/D

p-Channel Current-Limit

Threshold

Skip-Mode Transition Current (Note 8) 80 mA

n-Channel Zero-Crossing

Threshold

p-Channel On-Resistance V

n-Channel On-Resistance V

Maximum Duty Cycle 100 %

Minimum Duty Cycle 12.5 %

PWM Frequency f

Internal Discharge Resistance in

Shutdown

REG4–STEP-UP CONVERTER

Input Voltage Power supplied from SYS (see Figure 1) 2.4 5.5 V

Output Voltage Range V

FB4 Regulation Voltage V

FB4 Leakage REG4 disabled (EN4 = low) -0.050 +0.005 +0.050 μA

Switching Frequency 0.9 1 1.1 MHz

Minimum Duty Cycle 5%

Maximum Duty Cycle 90 94 %

OVP4 Overvoltage Detection

OVP4 Input Current OVP4 = SYS, EN4 = high 4 μA

OVP4 Leakage Current

n-Channel On-Resistance V

n-Channel Off-Leakage Current V

n-Channel Current Limit 555 695 950 mA

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

OSC

OUT4

V

FB4

OVP

L = 4.7μH,

= 0.13Ω

R

LSR

(Note 6)

= 0.13Ω 600 mA

LSR

= 1.01V

FB3

= 100mA to 300mA 1.3 %

OUT3

MAX8819A/MAX8819B 0.512 0.550 0.595

MAX8819C/MAX8819D 0.565 0.600 0.700

= 4.0V, I

PV13

= 4.0V, I

PV13

EN123 = low, resistance from LX3 to PG3 1.0 kΩ

No dimming 475 500 525 mV

REG4 disabled (EN4 = low),

OVP4 = SYS

= 4.0V, I

SYS

= 28V -1 +0.001 +1 μA

LX4

LX3

LX3

= 200mA 395 mΩ

LX4

MAX8819A/MAX8819B 300

MAX8819C/MAX8819D 500

TA = +25°C -50 -5 +50

T

= +85°C -50

A

= 180mA 290 mΩ

= 180mA 120 mΩ

1.8 2.0 2.2 MHz

V

SYS

24 25 26 V

-1 +0.001 +1 μA

/3 Hz

OSC

SYS

10 mA

24 V

mA

V

nA

A

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

_______________________________________________________________________________________ 7

ELECTRICAL CHARACTERISTICS (continued)

(DC, LX_ unconnected; VEP= V

GND

= 0V, V

BAT

= 4V, DLIM[1:2] = 00, EN123 = EN4 = low, V

FB1

= V

FB2

= V

FB3

= 1.1V, V

FB4

= 0.6V,

PV13 = PV2 = SYS, T

A

= -40°C to +85°C, capacitors as shown in Figure 1, R

CISET

= 3kΩ, unless otherwise noted.) (Note 3)

Note 3: Limits are 100% production tested at TA= +25°C. Limits over the operating temperature range are guaranteed through cor-

relation using statistical quality control (SQC) methods.

Note 4: The charger transitions from done to fast-charge mode at this BAT recharge threshold.

Note 5: The charger transitions from fast-charge to top-off mode at this top-off threshold (Figure 2).

Note 6: The maximum output current is guaranteed by correlation to the p-channel current-limit threshold, p-channel on-resistance,

n-channel on-resistance, oscillator frequency, input voltage range, and output voltage range. The parameter is stated for

a 4.7μH inductor with 0.13Ω series resistance. See the

Step-Down Converter Maximum Output Current

section for more

information.

Note 7: The step-down output voltages are 1% high with no load due to the load-line architecture.

Note 8: The skip-mode current threshold is the transition point between fixed-frequency PWM operation and skip-mode operation.

The specification is given in terms of output load current for inductor values shown in the typical application circuit (Figure 1).

Note 9: Line regulation for the step-down converters is measured as ΔV

OUT

/ΔD, where D is the duty cycle (approximately

V

OUT/VIN

).

Note 10: REG2 is disabled by connecting PV2 to ground, decreasing the quiescent current.

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

LED DIMMING CONTROL (EN4)

EN4 Low Shutdown Delay t

EN4 High Enable Delay (Figure 8) t

EN4 Low Time t

EN4 High Time t

RESET (RST)

Reset Trip Threshold V

Reset Deassert Delay Time t

Reset Glitch Filter t

LOGIC (DLIM1, DLIM2, EN123, EN4, CHG, RST1)

Logic Input-Voltage Low VDC = 4.1V to 5.5V, V

Logic Input-Voltage High VDC = 4.1V to 5.5V, V

Logic Input Pulldown Resistance V

Logic Leakage Current V

Logic Output Voltage Low I

Logic Output-High Leakage

Current

SHDN

H_INIT

THRST

DRST

GLRST

LO

HI

Voltage from FB1 to GND, V

50mV hysteresis

= 0.4V to 5.5V, CEN, EN123, EN4 400 760 1200 kΩ

LOGIC

= 0 to 5.5V, DLIM1, DLIM2 -1.0 +0.001 +1.0 μA

LOGIC

= 1mA 7 15 mV

SINK

V

= 5.5V -1.0 +0.001 +1.0 μA

LOGIC

falling,

FB1

= 2.6V to 5.5V 0.4 V

SYS

= 2.6V to 5.5V 1.2 V

SYS

100 μs

0.5 500 μs

0.5 μs

0.765 0.858 0.945 V

180 200 220 ms

2 3.2 ms

50 μs

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

8 _______________________________________________________________________________________

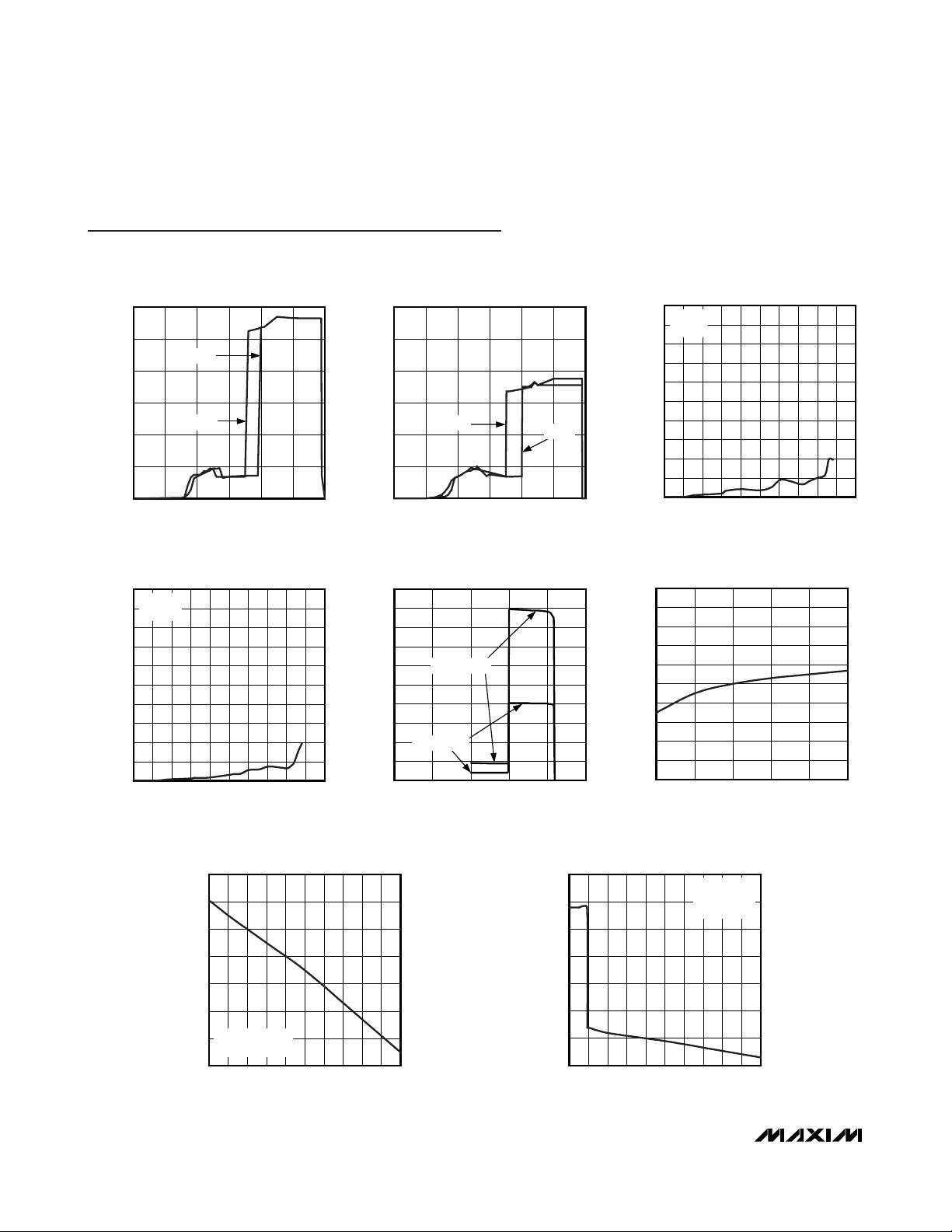

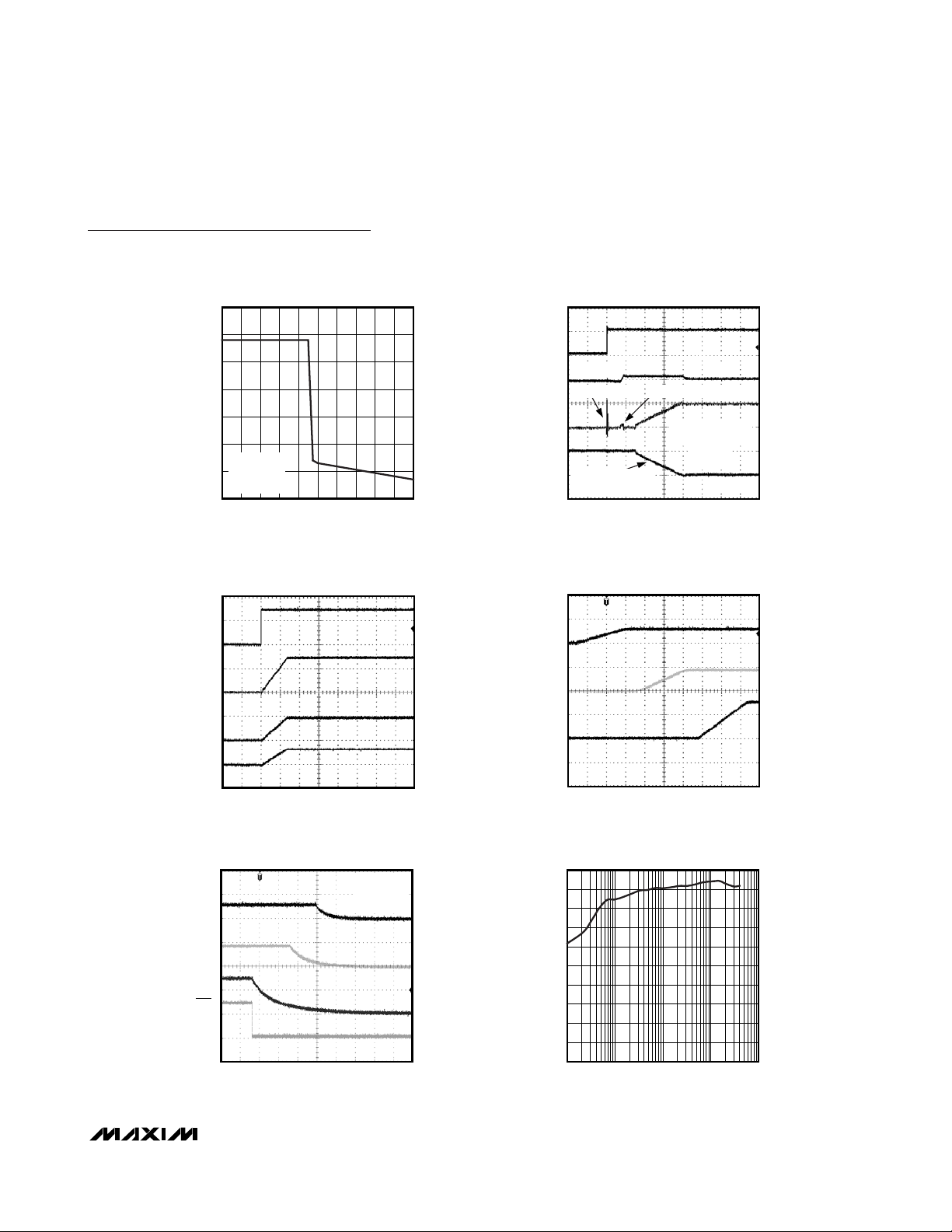

Typical Operating Characteristics

(TA = +25°C, unless otherwise noted.)

BATTERY LEAKAGE CURRENT

vs. BATTERY VOLTAGE

BATTERY VOLTAGE (V)

BATTERY LEAKAGE CURRENT (nA)

MAX8819A toc04

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

0

100

200

300

400

500

600

700

800

900

1000

VDC = 0V

EN123 = 1

CHARGE CURRENT

vs. BATTERY VOLTAGE

BATTERY VOLTAGE (V)

CHARGE CURRENT (mA)

MAX8819A toc05

034215

0

50

100

150

200

250

300

350

400

450

500

R

CISET

= 6.8kΩ

R

CISET

= 15kΩ

BATTERY REGULATION VOLTAGE

vs. TEMPERATURE

TEMPERATURE (°C)

BATTERY REGULATION VOLTAGE (V)

MAX8819A toc06

-40 -15 10 35 60 85

4.15

4.16

4.17

4.18

4.19

4.20

4.21

4.22

4.23

4.24

4.25

SYSTEM VOLTAGE

vs. SYSTEM CURRENT

OUTPUT CURRENT (mA)

SYSTEM VOLTAGE (V)

MAX8819A toc07

0 100 200 300 400 500 600 700 800 900 1000

3.88

3.90

3.92

3.94

3.96

3.98

4.00

4.02

DC UNCONNECTED

V

BATT

= 4V

SYSTEM VOLTAGE

vs. SYSTEM CURRENT

OUTPUT CURRENT (mA)

SYSTEM VOLTAGE (V)

MAX8819A toc08

0 100 200 300 400 500 600 700 800 900 1000

3.8

3.9

4.0

4.1

4.2

4.3

4.4

4.5

VDC = 5.1V

V

BATT

= 4V

DLIM[1:2] = 10

QUIESCENT CURRENT vs.

SUPPLY VOLTAGE (CHARGER ENABLED)

1.2

1.0

0.8

0.6

0.4

QUIESCENT CURRENT (mA)

0.2

0

0123456

RISING

FALLING

SUPPLY VOLTAGE (V)

1.2

1.0

MAX8819A toc01

0.8

0.6

0.4

QUIESCENT CURRENT (mA)

0.2

0

0123456

QUIESCENT CURRENT vs. VDC

CHARGER DISABLED

FALLING

DC VOLTAGE, VDC (V)

RISING

1000

900

MAX8819A toc02

800

700

600

500

400

300

200

BATTERY LEAKAGE CURRENT (nA)

100

BATTERY LEAKAGE CURRENT

vs. BATTERY VOLTAGE

VDC = 5V

EN123 = 1

0

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

MAX8819A toc03

BATTERY VOLTAGE (V)

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

_______________________________________________________________________________________ 9

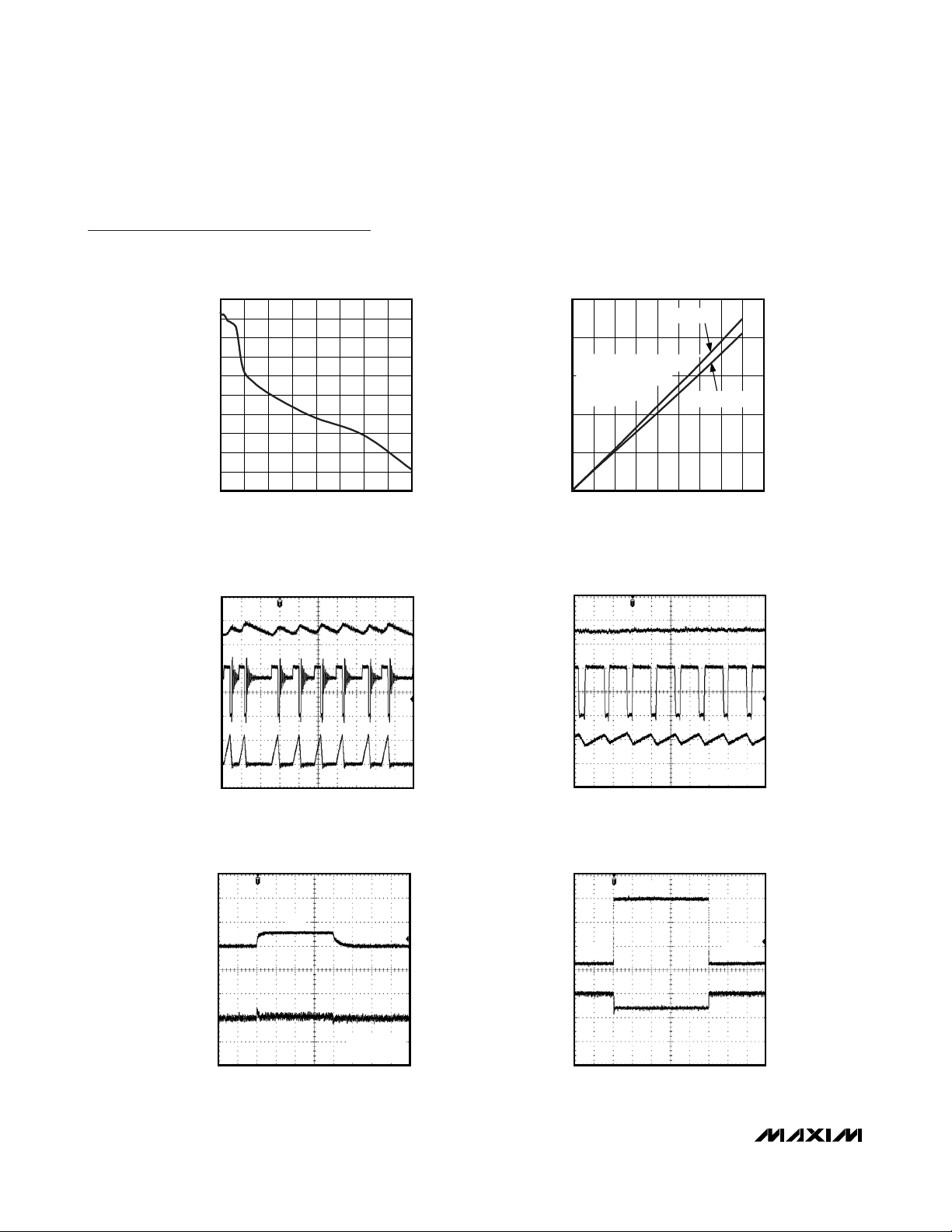

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

SYSTEM VOLTAGE

vs. SYSTEM CURRENT

4.5

4.4

4.3

4.2

4.1

SYSTEM VOLTAGE (V)

4.0

VDC = 5.1V

3.9

3.8

= 4V

V

BATT

DLIM[1:2] = 01

0 100 200 300 400 500 600 700 800 900 1000

OUTPUT CURRENT (mA)

POWER-UP SEQUENCING

(MAX8819A/MAX8819B)

V

EN123

V

V1

MAX8819A toc11

MAX8819A toc09

2V/div

0V

2V/div

0V

V

DC

V

SYS

I

DC

I

BAT

V

V3

V

V2

AC-TO-DC ADAPTER CONNECT

CHARGING

4.3V

C

SYS

400μs/div

3.84V

C

DC

BATTERY CHARGER

SOFT-START

POWER-UP SEQUENCING

(MAX8819C/MAX8819D)

MAX8819A toc10

4V

CHARGING

NEGATIVE BATTERY

CURRENT FLOWS

INTO THE

BATTERY

1A

-1A

MAX8819A toc12

5V/div

2V/div

1A/div

1A/div

2V/div

0V

2V/div

0V

V

V2

V

V3

2ms/div

POWER-DOWN SEQUENCING

(MAX8819C/MAX8819D)

V

V3

V

V2

V

V1

V

RST1

100μs/div

MAX8819A toc13

IV3 = 200mA

= 180mA

I

V2

= 220mA

I

V1

2V/div

0V

2V/div

0V

2V/div

0V

2V/div

0V

2V/div

0V

2V/div

0V

V

V1

1ms/div

REG1 EFFICIENCY

vs. LOAD CURRENT (V

100

90

80

70

60

50

40

30

REG1 EFFICIENCY (%)

20

10

0

0.1 1 10 100 1000

LOAD CURRENT (mA)

REG1

= 3.01V)

2V/div

0V

MAX8819A toc14

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

10 ______________________________________________________________________________________

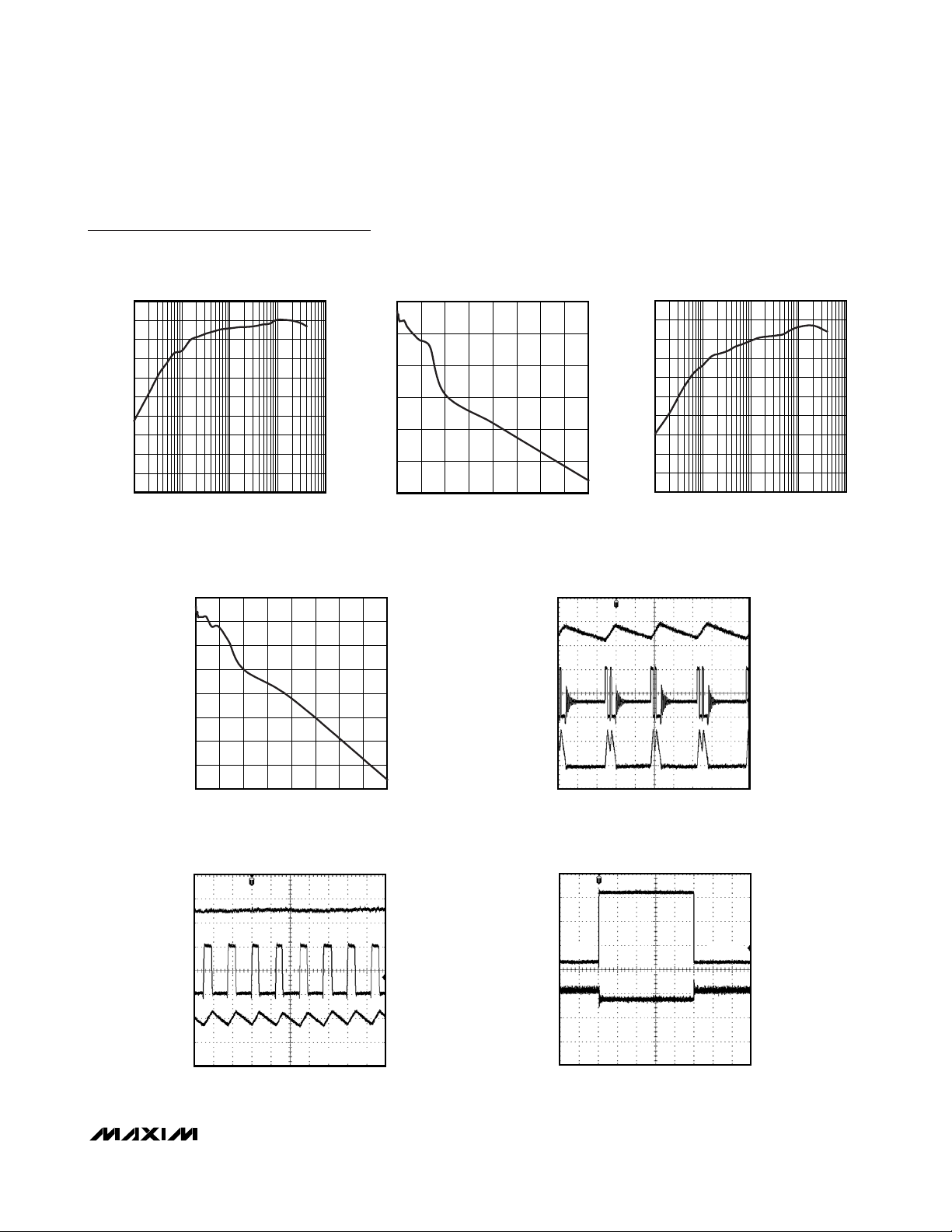

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

REG1 LIGHT-LOAD SWITCHING

WAVEFORMS

MAX8819A toc17

2μs/div

20mV/div

AC-COUPLED

0V

0mA

2V/div

100mA/div

I

LX1

V

LX1

V

OUT1

20mA LOAD

REG1 HEAVY-LOAD SWITCHING

WAVEFORMS

MAX8819A toc18

400ns/div

20mV/div

AC-COUPLED

0V

0mA

2V/div

200mA/div

I

LX1

V

LX1

V

OUT1

200mA LOAD

LINE TRANSIENT

MAX8819A toc19

100μs/div

4V 4V

5V

2V/div

50mV/div

AC-COUPLED

V

OUT1

V

SYS

V

OUT1

= 3V

I

OUT1

= 30mA

REG1 LOAD TRANSIENT (V

OUT

= 3V)

MAX8819A toc20

200μs/div

30mA

300mA

30mA

100mA/div

100mV/div

3V DC OFFSET

V

OUT1

I

OUT1

REG1 LOAD REGULATION

3.09

3.08

3.07

3.06

3.05

3.04

3.03

3.02

REG1 OUTPUT VOLTAGE (V)

3.01

3.00

2.99

0 50 100 150 200 250 300 350 400

REG1 LOAD CURRENT (mA)

MAX8819A toc15

250

200

150

100

DROPOUT VOLTAGE (mV)

50

0

REG1 DROPOUT VOLTAGE

vs. LOAD CURRENT

V

= 3V

OUT1

SYS IS 100mV BELOW THE

REG1 NOMINAL

REGULATION

VOLTAGE

0 50 100 150 200 250 300 350 400 450

OUTPUT CURRENT (mA)

V

OUT1

MAX8819A toc16

= 3.3V

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

______________________________________________________________________________________ 11

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

REG2 EFFICIENCY

vs. LOAD CURRENT (V

REG2

= 1.82V)

LOAD CURRENT (mA)

REG2 EFFICIENCY (%)

MAX8819A toc21

0

10

20

30

40

50

60

70

80

90

100

0.1 1 10 100 1000

REG2 LOAD REGULATION

REG2 LOAD CURRENT (mA)

REG2 OUTPUT VOLTAGE (V)

MAX8819A toc22

0 50 100 150 200 250 300 350 400

1.80

1.81

1.82

1.83

1.84

1.85

1.86

REG3 EFFICIENCY

vs. LOAD CURRENT (V

REG3

= 1.21V)

LOAD CURRENT (mA)

REG3 EFFICIENCY (%)

MAX8819A toc23

0

10

20

30

40

50

60

70

80

90

100

0.1 1 10 100 1000

REG3 LOAD REGULATION

REG3 LOAD CURRENT (mA)

REG3 OUTPUT VOLTAGE (V)

MAX8819A toc24

0 50 100 150 200 250 300 350 400

1.185

1.190

1.195

1.200

1.205

1.210

1.215

1.220

1.225

REG3 HEAVY-LOAD SWITCHING

WAVEFORMS

MAX8819A toc26

400ns/div

20mV/div

AC-COUPLED

2V/div

0V

0mA

200mA/div

V

OUT3

V

LX3

I

LX3

200mA LOAD

REG3 LIGHT-LOAD SWITCHING

WAVEFORMS

MAX8819A toc25

2μs/div

20mV/div

AC-COUPLED

2V/div

0V

0mA

100mA/div

V

OUT3

V

LX3

I

LX3

20mA LOAD

REG3 LOAD TRANSIENT

MAX8819A toc27

200μs/div

100mA/div

100mV/div

1.2V DC OFFSET

30mA 30mA

320mA

I

OUT3

V

OUT3

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

12 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

LED EFFICIENCY vs. SYS VOLTAGE

SYS VOLTAGE (V)

LED EFFICIENCY (%)

MAX8819A toc28

2.5 3.0 3.5 4.0 4.5 5.0 5.5

50

55

60

65

70

75

80

85

90

95

100

6 LEDS

4 LEDS

I

LED

= 25mA

INDUCTOR: TOKO 1096AS-100M

DIODE: NXP PMEG3005EB

LED EFFICIENCY

vs. LED CURRENT (6 LEDS)

LED CURRENT (mA)

LED EFFICIENCY (%)

MAX8819A toc29

0 5 10 15 20 25

0

10

20

30

40

50

60

70

80

90

100

V

SYS

= 3.6V

LED EFFICIENCY

vs. LED CURRENT (4 LEDS)

LED CURRENT (mA)

LED EFFICIENCY (%)

MAX8819A toc30

0 5 10 15 20 25

0

10

20

30

40

50

60

70

80

90

100

V

SYS

= 3.6V

LED AND BOOST EFFICIENCY

vs. SYS VOLTAGE

SYS VOLTAGE (V)

EFFICIENCY (%)

MAX8819A toc31

2.5 3.0 3.5 4.0 4.5 5.0 5.5

50

55

60

65

70

75

80

85

90

95

100

I

LED

= 25mA

6 LEDS

INDUCTOR: TOKO 1096AS-100M

DIODE: NXP PMEG3005EB

BOOST

LED

REG4 INPUT CURRENT

vs. SYS VOLTAGE

SYS VOLTAGE (V)

REG4 INPUT CURRENT (mA)

MAX8819A toc32

2.5 3.0 3.5 4.0 4.5 5.0 5.5

0

50

100

150

200

250

300

6 LEDS, 100% BRIGHTNESS

REG4 STARTUP AND SHUTDOWN

RESPONSE

MAX8819A toc33

2ms/div

2V/div

10V/div

0V

0mA

10mA/div

V

EN

V

OVP4

I

LED

FB4 VOLTAGE vs. LED CURRENT

LED CURRENT (mA)

FB4 VOLTAGE (mV)

MAX8819A toc34

0 5 10 15 20 25

0

50

100

150

200

250

300

350

400

450

500

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

______________________________________________________________________________________

13

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

MAXIMUM LED CURRENT

vs. TEMPERATURE

TEMPERATURE (°C)

LED CURRENT (mA)

MAX8819A toc35

-40 -15 10 35 60 85

24.5

24.6

24.7

24.8

24.9

25.0

25.1

25.2

25.3

25.4

25.5

MINIMUM LED CURRENT

vs. TEMPERATURE

TEMPERATURE (°C)

LED CURRENT (mA)

MAX8819A toc36

-40 -15 10 35 60 85

0.730

0.735

0.740

0.745

0.750

Pin Description

PIN NAME FUNCTION

1 COMP4 External Compensation Capacitor for REG4

2 FB4 REG4 Feedback Input

3 OVP4 Overvoltage Protection Node for REG4

4 PG4 REG4 Power Ground

5 LX4 Inductor Switching Node for REG4

6 GND Analog Ground

7 EN4 REG4 Enable Input and Dimming Control Digital Input

8 RST1

9 BAT

10 SYS

11 DC

12 CEN Battery Charger Enable Input

13 FB1

Active-Low, Open-Drain Reset Output. RST1 pulls low to indicate that FB1 is below its regulation

threshold. RST1 goes high 200ms after FB1 reaches its regulation threshold. RST1 is high-impedance

when EN123 is low, and DC is unconnected.

Positive Battery Terminal Connection. Connect BAT to the positive terminal of a single-cell Li+/Li-Poly

battery. Bypass BAT to GND with a 4.7μF ceramic capacitor.

System Supply Output. Bypass SYS to GND with a 10μF ceramic capacitor. When a valid voltage is

present at DC and DLIM[1:2] ≠ 11, V

(MAX8819B/MAX8819D). When the system load (I

75mV (V

BSREG

) below V

, allowing both the external power source and the battery to service SYS.

BAT

SYS is connected to BAT through an internal 70mΩ system load switch when a valid source is not

present at DC.

DC Power Input. DC is capable of delivering 1A to SYS. DC supports both AC adapters and USB

inputs. As shown in Table 1, the DC current limit is controlled by DLIM1 and DLIM2.

Feedback Input for REG1. Connect FB1 to the center of a resistor voltage-divider from the REG1

output capacitors to GND to set the output voltage from 1V to V

is limited to 4.35V (MAX8819A/MAX8819C) or 5.3V

SYS

) exceeds the input current limit, V

SYS

.

SYS

SYS

drops

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

14 ______________________________________________________________________________________

Pin Description (continued)

PIN NAME FUNCTION

14 CISET

15 CHG

16 PG1 REG1 Power Ground

17 LX1

18 PV13

19 LX3

20 PG3 REG3 Power Ground

21 DLIM1

22 FB2

23 FB3

24 EN123

25 PV2 Power Input for REG2. Connect PV2 to SYS. Bypass PV2 to PG2 with a 4.7μF ceramic capacitor.

26 LX2

27 PG2 REG2 Power Ground

28 DLIM2

— EP Exposed Pad

Charge Rate Select Input. Connect a resistor from CISET to GND (R

current limit, prequalification-charge current limit, and top-off threshold.

Active-Low, Open-Drain Charge Status Output. CHG pulls low to indicate that the battery is charging.

See Figure 3 for more information.

Inductor Switching Node for REG1. When enabled, LX1 switches between PV13 and PG1 to regulate

the FB1 voltage to 1.0V. When disabled, LX1 is pulled to PG1 by 1kΩ in shutdown.

Power Input for the REG1 and REG3 Converters. Connect PV13 to SYS. Bypass PV13 to PG1 with a

4.7μF ceramic capacitor.

Inductor Switching Node for REG3. When enabled, LX3 switches between PV13 and PG3 to regulate

the FB3 voltage to 1.0V. When disabled, LX3 is pulled to PG3 by a 1kΩ internal resistor.

Input Current-Limit Selection Digital Input 1. Drive high or low according to Table 1 to set the DC input

current limit.

Feedback Input for REG2. Connect FB2 to the center of a resistor voltage-divider from the REG2

output capacitors to GND to set the output voltage from 1V to V

Feedback Input for REG3. Connect FB3 to the center of a resistor voltage-divider from the REG3

output capacitors to GND to set the output voltage from 1V to V

RE G1, RE G2, and RE G3 E nab l e Inp ut. D r i ve E N 123 hi g h to enab l e RE G1, RE G 2, and RE G3. D r i ve E N 123

l ow to d i sab l e RE G 1, RE G2, and RE G 3. The enab l e/d i sab l e seq uenci ng i s show n i n Fi g ur es 6 and 7.

Inductor Switching Node for REG2. When enabled, LX2 switches between PV2 and PG2 to regulate

the FB2 voltage to 1.0V. When disabled, LX2 is pulled to PG2 by a 1kΩ internal resistor.

Input Current-Limit Selection Digital Input 2. Drive high or low according to Table 1 to set the DC input

current limit.

SYS

SYS

) to set the fast-charge

CISET

.

.

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

______________________________________________________________________________________ 15

Detailed Description

The MAX8819_ is a complete power solution that

includes a battery charger, step-down converters, and

WLED power. As shown in Figure 1, the IC integrates a

DC power input, Li+/Li-Poly battery charger, three stepdown converters, and one step-up converter for powering

white LEDs. All three step-down converters feature

adjustable output voltages set with external resistors.

The MAX8819_ has one external power input that connects to either an AC-to-DC adapter or USB port. Logic

inputs DLIM1 and DLIM2 select the desired input current limit.

Figure 1. Functional Diagram/Typical Applications Circuit

AC-TO-DC

ADAPTER

DLIM1

DLIM2

00

0

195

1

ON

L4

0.1μF

C2

0.1μF

50V

X7R

C3

PG4

UP TO 6

WLED

10μH

PG4

(25mA)

SYS

OUT4

BATTERY

DESIRED

CAPACITY

(mAh)

300

400

600

800

900

Li+/LiPo

BATTERY

OUT1

R6

470kΩ

C8*

10μF

PG1

OUT1

R10

470kΩ

CHARGE

RATE (C)

0.7

0.7

0.7

0.7

0.7

ON

CHG

3.0V

400mA

OUT1

RST1

1.8V

200mA

C10*

10μF

PG2

300mA

OUT3

C11*

10μF

PG3

DC

C1

4.7μF

SMART

POWER

REG4

STEP-UP

DC-DC

PULSE

DIMMING

SELECTOR

GLITCH FILTER

MAX8819A

MAX8819B

MAX8819C

MAX8819D

AGND

BIAS

DC I

(mA)

LIM

DLIM1

1000

1

475

D1

D2

D3

D4

D5

D6

OFF

0.022μF

DLIM2

EN123

LX4

OVP4

PG4

PG4

COMP4

C4

FB4

EN4

OFF

0

SUSPEND

1

D7

R1

20

ON

EP

Li+/Li-Poly

BATTERY

CHARGER AND

SYSTEM LOAD

SWITCH

PV13

EN

PWM

EN

PWM

PV13

EN

PWM

REG1

STEP-DOWN

DC-DC

REG1/RESET

87% FALLING

50us BLANKING

92% RISING

80ms DELAY

REG2

STEP-DOWN

DC-DC

REG3

STEP-DOWN

DC-DC

SYS

BAT

CEN

CISET

CHG

PV13

LX1

FB1

PG1

RST1

PV2

LX2

FB2

PG2

LX3

FB3

PG3

SYS

C5

10μF

L1

R8

200kΩ

R9

100kΩ

4.7μH

80.6kΩ

4.7

20.0kΩ

100kΩ

L2

R12

R13

100kΩ

L3

R14

R15

+

SYS

SYS

μH

C6

4.7μF

R2

C7

4.7μF

PG1

4.7μH

PG1

C9

4.7μF

PG2

PG2

PG3

R7 (kΩ)

OUT2

1.2V

CHARGE

CURRENT

14.3 210

10.7

7.15

5.36

4.75

OFF

FAST-

(mA)

280

420

560

632

*22μF FOR MAX8819C/MAX8819D IS RECOMMENDED.

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

16 ______________________________________________________________________________________

In addition to charging the battery, the IC supplies

power to the system through the SYS output. The

charging current is provided from SYS so that the set

input current limit controls the total SYS current, this is

the sum of the system load current and the batterycharging current.

In some instances, there may not be enough DC input

current to supply peak system loads. The Smart Power

Selector circuitry offers flexible power distribution from

an AC-to-DC adapter or USB source to the battery and

system load. The battery is charged with any available

power not used by the system load. If a system load

peak exceeds the input current limit, supplemental current is taken from the battery. Thermal limiting prevents

overheating by reducing power drawn from the input

source. In the past, it might have been necessary to

reduce system functionality to limit current drain when a

USB source is connected. However, with the

MAX8819_, this is no longer the case. When the DC or

USB source hits its limit, the battery supplies supplemental current to maintain the load.

The IC features overvoltage protection. Part of this protection is a 4.35V (MAX8819A/MAX8819C) or 5.3V

(MAX8819B/MAX8819D) voltage limiter at SYS. If DC

exceeds the overvoltage threshold of 5.88V (V

OVLO_DC

),

the input limiter disconnects SYS from DC, but batterypowered operation of all regulators is still allowed.

Input Limiter

The Smart Power Selector seamlessly distributes power

between the current-limited external input (DC), the battery (BAT), and the system load (SYS). The basic functions performed are:

With both an external power supply (DC) and battery

(BAT) connected:

• When the system load requirements are less than

the input current limit, the battery is charged with

residual power from the input.

• When the system load requirements exceed the

input current limit, the battery supplies supplemental current to the load through the internal system load switch.

• When the battery is connected and there is no

external power input, the system (SYS) is powered

from the battery.

• When an external power input is connected and

there is no battery, the system (SYS) is powered

from the external power input.

A thermal-limiting circuit reduces the battery charge

rate and external power source current to prevent the

MAX8819_ from overheating.

System Load Switch

An internal 70mΩ MOSFET connects SYS to BAT when

no voltage source is available at DC. When an external

source is detected at DC, this switch opens and SYS is

powered from the valid input source through the Smart

Power Selector.

When the system load requirements exceed the input

current limit, the battery supplies supplemental current

to the load through the internal system load switch. If

the system load continuously exceeds the input current

limit, the battery does not charge, even though external

power is connected. This is not expected to occur in

most cases because high loads usually occur only in

short peaks. During these peaks, battery energy is

used, but at all other times the battery charges.

DC Power Input (DC, DLIM1, DLIM2)

DC is a current-limited power input that supplies the

system (SYS) up to 1A. The DC to SYS switch is a linear

regulator designed to operate in dropout. This linear

regulator prevents the SYS voltage from exceeding

5.3V for the MAX8819B/MAX8819D or 4.35V for the

MAX8819A/MAX8819C. As shown in Table 1, DC supports four different current limits that are set with the

DLIM1 and DLIM2 digital inputs. These current limits

are ideally suited for use with AC-to-DC wall adapters

and USB power. The operating voltage range for DC is

4.1V to 5.5V, but it can tolerate up to 6V without damage. When the DC input voltage is below the undervoltage threshold (4V), it is considered invalid. When the

DC voltage is below the battery voltage it is considered

invalid. The DC power input is disconnected when the

DC voltage is invalid. Bypass DC to ground with at least

a 4.7μF capacitor.

Four current settings are provided based upon the settings of DLIM1 and DLIM2, see Table 1. DLIM1 and

DLIM2 are deglitched. This deglitching prevents the

problem of major carry transitions momentarily entering

the suspend state.

Table 1. DC Current-Limit Settings

DLIM1 DLIM2 DC I

0 0 1000

0 1 475

10 95

1 1 Suspend

LIM

(mA)

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

______________________________________________________________________________________ 17

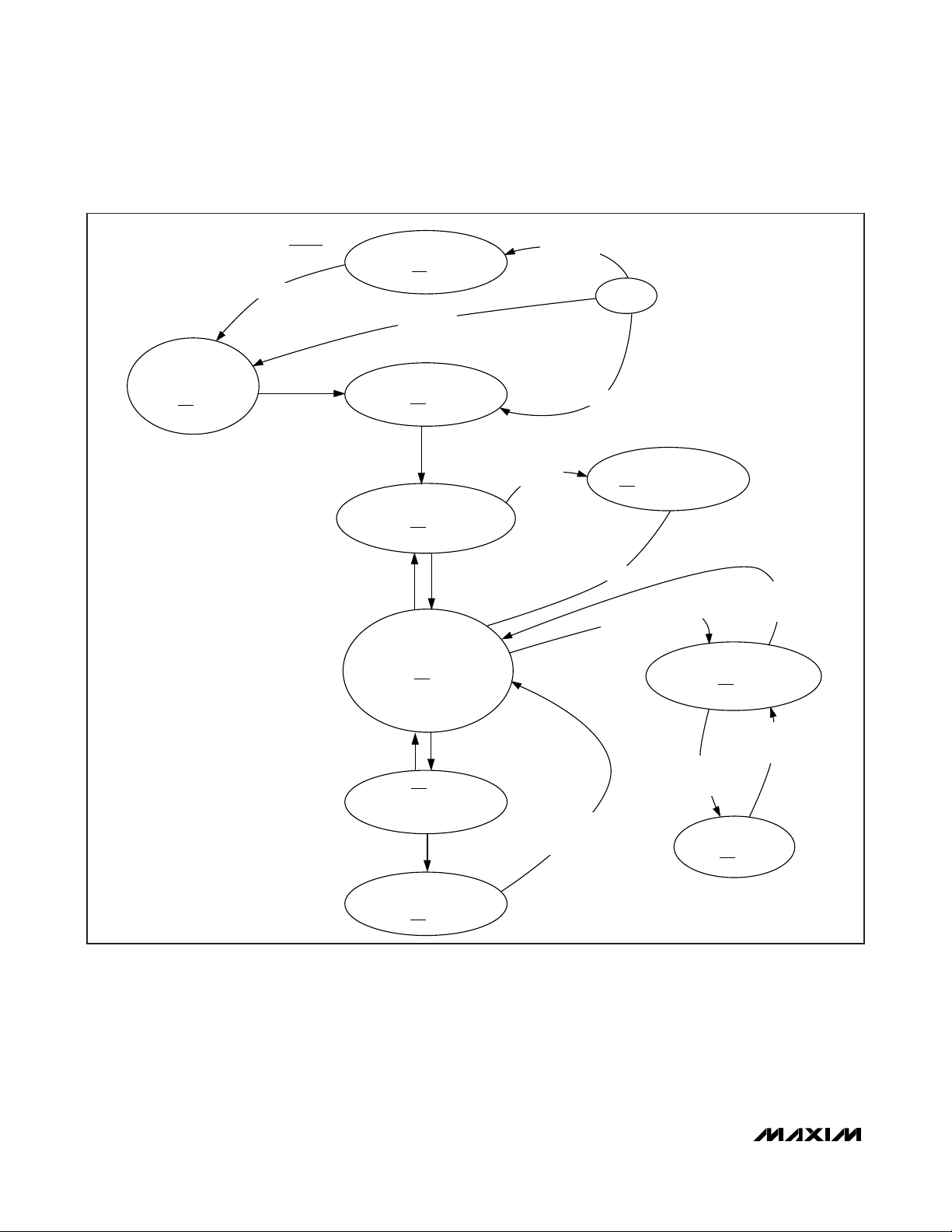

Battery Charger

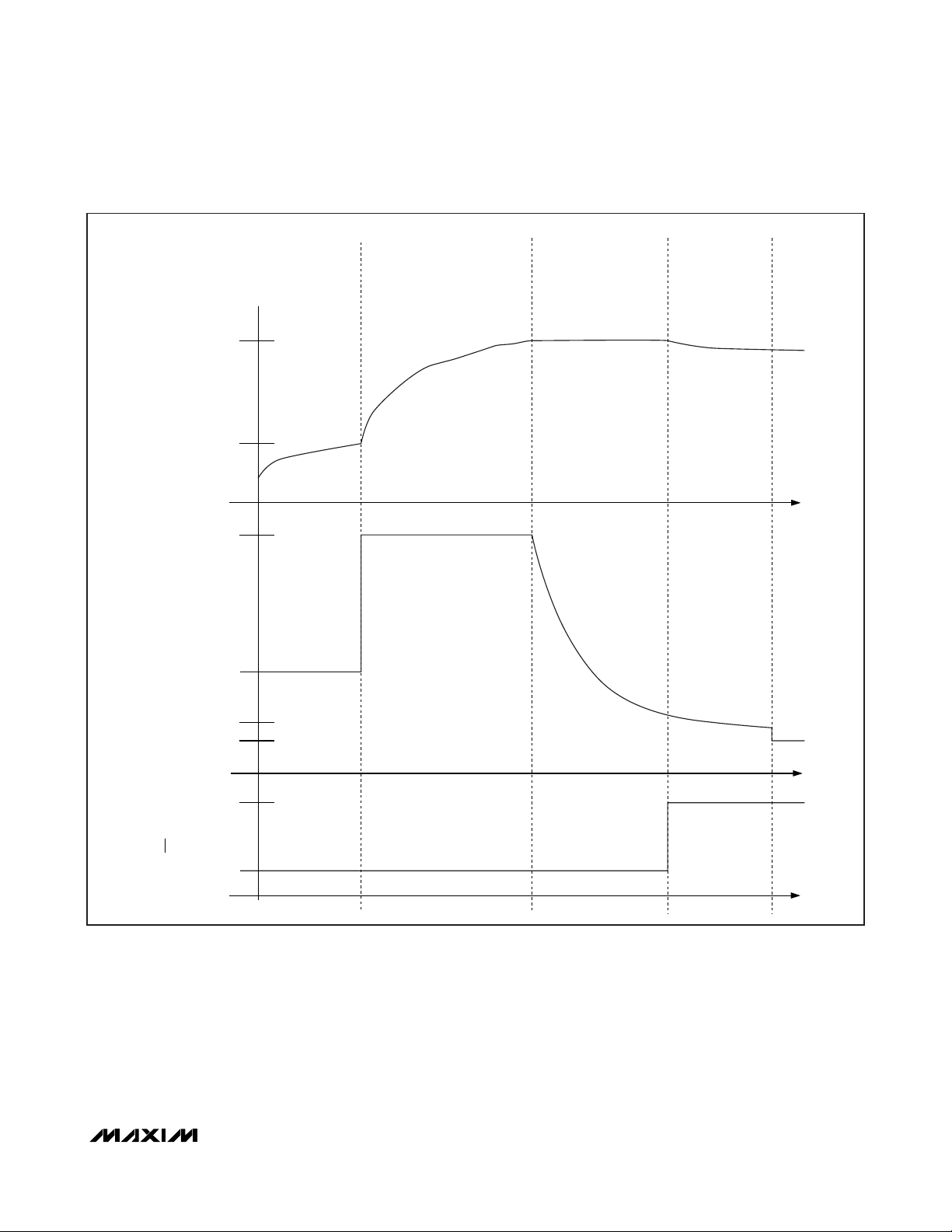

Figure 2 shows the typical Li+/Li-Poly charge profile for

the MAX8819_, and Figure 3 shows the battery charger

state diagram.

With a valid DC input that is not suspended, the battery

charger initiates a charge cycle once CEN is driven

high. It first detects the battery voltage. If the battery

voltage is less than the prequalification threshold

(3.0V), the charger enters prequalification mode and

charges the battery at 10% of the maximum fast-charge

current while deeply discharged. Once the battery voltage rises to 3.0V, the charger transitions to fast-charge

mode and applies the maximum charge current. As

charging continues, the battery voltage rises until it

Figure 2. Li+/Li-Poly Charge Profile

BATTERY VOLTAGEBATTERY CHARGE CURRENTCHG

V

BATREG

V

BATPRQ

I

CHGMAX

PREQUALIFICATION

I

PQ

FAST-CHARGE

(CONSTANT CURRENT)

FAST-CHARGE

(CONSTANT VOLTAGE)

TOP-OFF

DONE

I

TO

0

HIGH

IMPEDANCE

LOW

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

18 ______________________________________________________________________________________

approaches the battery regulation voltage (4.2V typ)

where charge current starts tapering down. When

charge current decreases to 10% of the maximum fastcharge current, the charger enters a 33min top-off state

and then charging stops. If the battery voltage subsequently drops 100mV below the battery regulation voltage, charging restarts and the timers reset.

The battery charge rate is set by several factors:

• Battery voltage

• DC input current limit

• The charge-setting resistor, R

CISET

• The system load (I

SYS

)

Figure 3. Li+/Li-Poly Charger State Diagram

I

= 2000 x

CHGMAX

DC = VALID

INPUT SUSPENDED

DLIM[1:2] = 11

I

= 0mA

CHG

CHG = 1

1.5V

R

CISET

DLIM[1:2] ≠ 11

NO INPUT POWER

CHARGER DISABLED

PREQUALIFICATION

I

CHG

V

< 2.82V

BAT

IC SETS TIMER = 0

I

CHG

CHG = 1

DLIM[1:2] = 11

I

CHG

CHG = 1

≤ I

CHGMAX

CHG = 0

FAST-CHARGE

I

≤ I

CHG

CHG = 0

= 0mA

= 0mA

CEN = 1

IC SETS TIMER = 0

/10

V

> 3V,

BAT

IC SETS TIMER = 0

CHGMAX

t > t

PREQUAL

DC = INVALID

CEN = 0

ANY STATE

TIMER FAULT

I

= 0mA

CHG

CHG = 2Hz SQUAREWAVE

t > t

FSTCHG

I

< I

CHGMAX

< V

BAT

(I

x 50%

BATREG

CHGMAX

CHG

AND V

IC EXTENDS TIMER BY 2x

TIMER EXTEND

x 20%) < I

CHG = 0

I

< I

CHG

CHGMAX

OR V

BAT

IC RESUMES TIMER

< (I

CHG

CHGMAX

= V

x 50%)

x 53%

BATREG

< I

I

CHG

x 20%

CHGMAX

IC SETS TIMER = 0

t

TOP-OFF

(V

BATREG

TOP-OFF

CHG = 1

V

= V

BAT

I

≤ I

CHG

CHGMAX

>

DONE

-100mV) ≤ V

I

= 0mA

CHG

CHG = 1

< I

I

CHG

CHGMAX

IC SETS TIMER = 0

BATREG

/10

33min

≤ V

BAT

BATREG

x 10% AND V

BAT

V

< (V

BAT

BATREG

100mV)

IC SETS TIMER = 0

I

< I

CHG

AND V

IC SUSPENDS

x 20%

CHGMAX

BAT<VBATREG

TIMER

TIMER SUSPEND

I

< (I

CHG

CHGMAX

CHG = 0

I

< I

x 23%

CHG

SET

OR V

= V

BAT

IC RESUMES TIMER

BATREG

x 20%)

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

______________________________________________________________________________________ 19

• The die temperature

• The battery charger is enabled by the processor driving the CEN input high. A valid input must be available at DC. The battery charger is disabled without

a valid input at DC or by driving CEN low.

• The system current has priority over the battery

charger; the battery charger automatically reduces

its charge current to maintain the input current limit

while still providing the system current (I

SYS

).

• The input current limit is tapered down from full current to zero current when the die temperature transitions from +100°C to +120°C. Since I

SYS

has priority

over the battery charge current, the battery charge

current tapers down before I

SYS

. The overall result is

self-regulation of die temperature (see the

Thermal

Limiting and Overload Protection

section for more

information).

• The battery charger stops charging in done mode

as shown in Figures 2 and 3.

Charge Status Output (CHG)

CHG is an open-drain, active-low output that indicates

charger status. As shown in Figures 2 and 3, CHG is

low when the charger is in its prequalification or fastcharge states. When a timer count is exceeded in

either state, CHG indicates the fault by blinking at a

2Hz rate and remains in that state until the charger is

reset by CEN going low, removal of DC or setting

DLIM[1:2] = 11.

When the MAX8819_ is used with a microprocessor

(μP), connect a pullup resistor between CHG and the

system logic voltage to indicate charge status to the

μP. Alternatively, CHG sinks up to 20mA for an LED

charge indicator.

If the charge status output feature is not required, connect CHG to ground or leave unconnected.

Charge Timer

As shown in Figure 3, a fault timer prevents the battery

from charging indefinitely. In prequalification mode, the

charge time is internally fixed to 33min.

t

PREQUAL

= 33min

In fast-charge mode, the charge timer is internally fixed

to 660min.

t

FSTCHG

= 660min

When the charger exits fast-charge mode, a fixed

33min top-off mode is entered:

t

TOP-OFF

= 33min

While in the constant-current fast-charge mode (Figure

2), if the MAX8819_ reduces the battery charge current

due to its internal die temperature or large system

loads, it slows down the charge timer. This feature eliminates nuisance charge timer faults. When the battery

charge current is between 100% and 50% of its programmed fast-charge level, the fast-charge timer runs

at full speed. When the battery charge current is

between 50% and 20% programmed fast-charge level,

the fast-charge timer is slowed by 2x. Similarly, when

the battery charge current is below 20% of the programmed fast-charge level, the fast-charge timer is

Figure 4. Calculated Charge Currents vs. R

CISET

Table 2. Calculated Charge Currents vs.

R

CISET

FAST-CHARGE, PREQUALIFICATION, AND TOP-OFF

CURRENT vs. CHARGE-SETTING RESISTOR

10,000

I

1000

100

CURRENT (mA)

10

1

0 5 10 15 20

CHGMAX

I

PREQUAL, ITOP-OFF

R

CISET

(kΩ)

I

R

(kΩ)

CISET

3.01 1000 100 100

4.02 746 75 75

4.99 601 60 60

6.04 497 50 50

6.98 430 43 43

8.06 372 37 37

9.09 330 33 33

10 300 30 30

11 273 27 27

12.1 248 25 25

13 231 23 23

14 214 21 21

15 200 20 20

CHGMAX

(mA)

I

(mA) I

PQ

TO

(mA)

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

20 ______________________________________________________________________________________

paused. The fast-charge timer is not slowed or paused

when the charger is in the constant voltage portion of

its fast-charge mode (Figure 2) where the charge current reduces normally.

Charge Current (CISET)

As shown in Table 2 and Figure 4, a resistor from CISET

to ground (R

CISET

) sets the maximum fast-charge cur-

rent (I

CHGMAX

), the charge current in prequalification

mode (I

PREQUAL

), and the top-off threshold (I

TOP-OFF

).

The MAX8819_ supports values of I

CHGMAX

from 200mA

to 1000mA. Select the R

CISET

as follows:

Determine I

CHGMAX

by considering the characteristics

of the battery. It is not necessary to limit the charge current based on the capabilities of the expected AC-toDC adapter or USB/DC input current limit, the system

load, or thermal limitations of the PCB. The IC automatically lowers the charging current as necessary to

accommodate for these factors.

For the selected value of R

CISET

, calculate I

CHGMAX

,

I

PREQUAL

, and I

TOP-OFF

as follows:

Step-Down Converters

(REG1, REG2, REG3)

REG1, REG2, and REG3 are high-efficiency, 2MHz current-mode step-down converters with adjustable outputs.

REG1 is designed to deliver 400mA for the MAX8819A/

MAX8819B and 550mA for the MAX8819C/MAX8819D.

REG2 and REG3 are designed to deliver 300mA for the

MAX8819A/MAX8819B and 500mA for the MAX8819C/

MAX8819D.

The step-down regulator power inputs (PV_) must be

connected to SYS. The step-down regulators operate

with V

SYS

from 2.6V to 5.5V. Undervoltage lockout

ensures that the step-down regulators do not operate

with SYS below 2.55V (max).

See the

Step-Down Converter Enable/Disable (EN123)

and Sequencing

section for how to enable and disable

the step-down converters. When enabled, the

MAX8819_ gradually ramps each output up during a

2.6ms soft-start time. When enabled, the MAX8819C/

MAX8819D sequentially ramps up each output. Softstart eliminates input current surges when regulators

are enabled.

See the

Step-Down Control Scheme

section for informa-

tion about the step-down converters control scheme.

The IC uses external resistor-dividers to set the stepdown output voltages between 1V and V

SYS

. Use at

least 10μA of bias current in these dividers to ensure no

change in the stability of the closed-loop system. To set

the output voltage, select a value for the resistor connected between FB_ and GND (R

FBL

). The recommended value is 100kΩ. Next, calculate the value of the

resistor connected from FB_ to the output (R

FBH

):

REG1, REG2, and REG3 are optimized for high, medium, and low output voltages, respectively. The highest

overall efficiency occurs with V1 set to the highest output voltage and V3 set to the lowest output voltage.

REG2 can be disabled by connecting PV2 to GND.

Step-Down Control Scheme

At light load, the step-down converter switches only as

needed to supply the load. This improves light-load efficiency. At higher load currents (~80mA), the step-down

converter transitions to fixed 2MHz switching.

Step-Down Dropout and Minimum Duty Cycle

All of the step-down regulators are capable of operating in 100% duty-cycle dropout, however, REG1 has

been optimized for this mode of operation. During

100% duty-cycle operation, the high-side p-channel

MOSFET turns on constantly, connecting the input to

the output through the inductor. The dropout voltage

(VDO) is calculated as follows:

where:

R

P

= p-channel power switch R

DS(ON)

R

LSR

= external inductor ESR

The minimum duty cycle for all step-down regulators is

12.5% (typ), allowing a regulation voltage as low as 1V

over the full SYS operating range. REG3 is optimized

for low duty-cycle operation.

Step-Down Input Capacitor

The input capacitor in a step-down converter reduces

current peaks drawn from the power source and

reduces switching noise in the controller. The impedance of the input capacitor at the switching frequency

must be less than that of the source impedance of the

II

PREQ UAL TOP OF F

2000

15.

I

CHGMAX

R

R

CISET

I

CHGMAX

=×2000

=×

==

−

V

V

1510.

CISET

%% × I

CHGMAX

RR

=× −

FBH FBL

V

⎛

OUT

⎜

⎝

101.

⎞

⎟

⎠

V

VI RR

=+

DO LOAD P L

()

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

______________________________________________________________________________________ 21

supply so that high-frequency switching currents do not

pass through the input source.

The step-down regulator power inputs are critical discontinuous current paths that require careful bypassing. In the PCB layout, place the step-down converter

input bypass capacitors as close as possible to each

pair of switching converter power input pins (PV_ to

PG_) to minimize parasitic inductance. If making connections to these capacitors through vias, be sure to

use multiple vias to ensure that the layout does not

insert excess inductance or resistance between the

bypass capacitor and the power pins.

The input capacitor must meet the input ripple current

requirement imposed by the step-down converter.

Ceramic capacitors are preferred due to their low ESR

and resilience to power-up surge currents. Choose the

input capacitor so that its temperature rise due to input

ripple-current does not exceed approximately +10°C.

For a step-down DC-DC converter, the maximum input

ripple current is half of the output current. This maximum input ripple current occurs when the step-down

converter operates at 50% duty factor (VIN= 2 x V

OUT

).

Bypass each step-down converter input with a 4.7μF

ceramic capacitor from PV_ to PG_. Use capacitors that

maintain their capacitance over temperature and DC

bias. Ceramic capacitors with an X7R or X5R temperature characteristic generally perform well. The capacitor

voltage rating should be 6.3V or greater.

Step-Down Output Capacitors

The output capacitance keeps output ripple small and

ensures control-loop stability. The output capacitor

must have low impedance at the switching frequency.

Ceramic, polymer, and tantalum capacitors are suitable

with ceramic exhibiting the lowest ESR and lowest highfrequency impedance. The MAX8819A/MAX8819B

require at least 10μF of output capacitance. The

MAX8819C/MAX8819D require ar least 22μF of output

capacitance.

As the case sizes of ceramic surface-mount capacitors

decreases, their capacitance vs. DC bias voltage characteristic becomes poor. Due to this characteristic, it is

possible for 0805 capacitors to perform well while 0603

capacitors of the same value may not. The MAX8819A/

MAX8819B require a nominal output capacitance of

10μF, however, after their DC bias voltage derating, the

output capacitance must be at least 7.5μF.

Step-Down Inductor

Choose the step-down converter inductance to be

4.7μH. The minimum recommended saturation current

requirement is 700mA. In PWM mode, the peak inductor currents are equal to the load current plus one half

of the inductor ripple current. See Table 3 for suggested

inductors.

Table 3. Suggested Inductors

MANUFACTURER SERIES

Sumida

Taiyo Yuden

TDK

TOKO DE2812C 4.7 130 880 3.0 x 2.8 x 1.2 = (10.8mm)

FDK

CDRH2D11HP 4.7 190 750 3.0 x 3.0 x 1.2 = (10.8mm)

CDH2D09 4.7 218 700 3.0 x 3.0 x 1.0= (9.0mm)

NR3012 4.7 130 770 3.0 x 3.0 x 1.2 = (10.8mm)

NR3010 4.7 190 750 3.0 x 3.0 x 1.0 = (9.0mm)

VLF3012 4.7 160 740 2.8 x 2.6 x 1.2 = (8.7mm)

VLF3010 4.7 240 700 2.8 x 2.6 x 1.0 = (7.3mm)

MIPF2520 4.7 110 1100 2.5 x 2.0 x 1.0 = (5mm)

MIPF2016 4.7 160 900 2.0 x 1.6 x 1.0 = (3.2mm)

INDUCTANCE

(µH)

ESR

(mΩ)

CURRENT RATING

(mA)

DIMENSIONS

(mm)

3

3

3

3

3

3

3

3

3

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

22 ______________________________________________________________________________________

The peak-to-peak inductor ripple current during PWM

operation is calculated as follows:

where f

S

is the 2MHz switching frequency.

The peak inductor current during PWM operation is calculated as follows:

Step-Down Converter Maximum Output Current

The maximum regulated output current from a step-down

converter is ultimately determined by the p-channel peak

current limit (IPK). The calculation follows:

I

OUT,MAX

= IPK– (I

P-P

/2)

For example, if V

SYS

= 5.3V, V

OUT

= 3V, fS= 2MHz,

L = 4.7μH, and IPK= 0.6A:

I

P-P

= 3V x (5.3V - 3V)/(5.3V x 2MHz x 4.7μH) = 0.138A

then I

OUT_MAX

= 0.6A - (0.138A/2) = 0.531A.

Figure 5a. MAX8819A/MAX8819B Enable/Disable Logic

SYS

2.5V RISING

100mV HYST.

DIE TEMP

+165°C

DC

6.0V RISING

400mV HYST.

4.0V RISING

500mV HYST.

+

SYSOK

-

+

DT165

-

+

DCOVLO

-

DCUVLO

+

EN123

EN4

2MHz

OSC

BIAS

AND

REF

64 CYCLE

DELAY

(32μs)

READY

REGON

READY

DCPOK

REGON

MAX8819A

MAX8819B

SOFT-START

REG1

EN

SOFT-START

REG2

EN

SOFT-START

REG3

EN

SOFT-START

REG4

EN OK

OK

OK

OK

REG1OK

REG2OK

REG3OK

REG4OK

VV V

I

PP

OUT SYS OUT

=

−

VfL

−

()

××

SYS S

I

PP

II

L PEA K LOAD

=+

_

−

2

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

______________________________________________________________________________________ 23

As the load current is increased beyond this point, the

output voltage sags and the converter goes out of regulation because the inductor current cannot increase

above the p-channel peak current limit.

Step-Down Converter Short-Circuit Protection

The step-down converter implements short-circuit protection by monitoring the feedback voltage, V

FB_

. After soft-

start, if V

FB_

drops below 0.23V, the converter reduces its

switching frequency to fS/3. The inductor current still

reaches the p-channel peak current limit, however, at

one-third the frequency. Therefore, the output and input

currents are reduced to approximately one-third of the

maximum value in response to an output short circuit to

ground. When the short is removed, the inductor current

raises the voltage on the output capacitor and the stepdown converter resumes normal operation.

REG1 Reset (RST1)

RST1 is an active-low, open-drain output that pulls low

to indicate that FB1 is below its regulation threshold.

RST1 goes high 200ms after FB1 reaches its regulation

threshold. RST1 is high-impedance when EN123 is

high. See Figures 6 and 7.

A 50μs blanking delay is provided when FB1 is falling,

so that RST1 does not glitch if the REG1 output voltage

is dynamically adjusted by altering the resistors in its

feedback network.

Figure 5b. MAX8819C/MAX8819D Enable Logic

SYS

EN123

EN4

+

SYSOK

2.5V RISING

100mV HYST.

DIE TEMP

+165°C

DC

6.0V RISING

400mV HYST.

4.0V RISING

500mV HYST.

-

READY

+

+

-

-

+

DT165

-

DCOVLO

DCPOK

DCUVLO

2MHz

OSC

BIAS

AND

REF

64 CYCLE

DELAY

(32μs)

READY

REGON

REGON

MAX8819C

MAX8819D

SOFT-START

REG1

EN

SOFT-START

REG2

EN

SOFT-START

REG3

EN

SOFT-START

REG4

EN OK

OK

OK

OK

REG1OK

REG2OK

REG3OK

REG4OK

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

24 ______________________________________________________________________________________

Step-Down Converter Active Discharge

in Shutdown

Each MAX8819_ step-down converter (REG1, REG2,

REG3) has an internal 1kΩ resistor that discharges the

output capacitor when the converter is off. The discharge resistors ensure that the load circuitry powers

down completely. The internal discharge resistors are

connected when a converter is disabled and when the

device is in UVLO with an input voltage greater than

1.0V. With an input voltage less than 1.0V the internal

discharge resistors are not activated.

Step-Down Converter Enable/Disable (EN123)

and Sequencing

Figure 5a shows the MAX8819A/MAX8819B enable and

disable logic. Figure 5b shows MAX8819C/MAX8819D

enable/disable logic. Figure 6 shows an example of

enable and disable waveforms for the MAX8819A/

MAX8819B.

Figure 6 notes:

1) The device is off with no external power applied to

DC. The system voltage (V

SYS

) is equal to the bat-

tery voltage (V

BAT

).

2) An external supply is applied to DC that causes the

step-down converter to power up after the DC-toSYS soft-start time (t

SS-D-S

). When the DC input is

valid and DLIM[1:2] ≠ 11, V

SYS

increases.

3) When V1 reaches the reset trip threshold (V

THRST

),

the reset deassert delay timer starts. When the reset

deassert delay timer expires (t

DRST1

), RST1 goes

high-impedance. If RST1 is connected to the RESET

Figure 6. MAX8819A/MAX8819B Enable/Disable Waveforms Example

NOTES

V

V

V

V

V

V

V

SYS

EN123

OUT1

OUT2

OUT3

RST1

DC

12

V

BAT

t

SS-D-S

34

V

BAT

t

SS1

t

SS2

t

SS3

V

EN4

V

V

OUT4

SYS

- V

D

5

6

< V

< V

SYS

DC

HIGH

IMPEDANCE

t

DRST1

t

SS4

78

V

BAT

V

SYS

- V

D

V

CEN

V

CHG

t

SS_CHG

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

______________________________________________________________________________________ 25

input of the system μP, the processor can begin its

boot-up sequence up at this time.

4) During the μP’s boot-up sequence, it asserts EN123

to keep the step-down converters enabled, even if

DC is removed.

5) After the μP has booted, it asserts EN4 to turn on the

display’s backlight.

6) CEN is asserted by the μP to start a charge cycle.

7) The external supply is removed from DC and V

SYS

falls. The converters remain enabled because the μP

has asserted EN123 and EN4, but the battery charging current drops to zero even though CEN is still

asserted. CHG goes high impedance.

8) System is turned off by deasserting EN123, EN4, and

CEN; RST1 goes low to reset the μP.

Figure 7 notes:

1) The MAX8819C/MAX8819D are off with no external

power applied to DC. The system voltage (V

SYS

) is

equal to the battery voltage (V

BAT

).

2) An external supply is applied to DC that causes the

step-down regulator to power up after the DC-toSYS soft-start time (t

SS-D-S

). When the DC input is

valid and DC is not suspended, V

SYS

rises.

3) EN123 is pulled high to start the OUT3, OUT2, and

OUT1 power-up sequence. When OUT1 reaches the

reset trip threshold (V

THRST

), the reset deassert

delay timer starts. When the reset deassert delay

timer expires (t

DRST1

200ms typ.), RST1 goes high-

impedance. If RST1 is connected to the RESET input

of the system μP, the processor can begin its bootup sequence at this time.

Figure 7. MAX8819C/MAX8819D Enable/Disable Waveforms Example

NOTES

V

V

V

V

V

V

V

V

EN123

OUT3

OUT2

OUT1

RST1

V

OUT4

DC

SYS

EN4

12

V

BAT

t

SS-D-S

34

V

< V

< V

BAT

SYS

DC

2.6ms

2.6ms

2.6ms

V

- V

SYS

D

5

HIGH IMPEDANCE

200ms

t

SS4

6

V

BAT

7

V

- V

SYS

D

V

CEN

V

CHG

t

SS_CHG

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

26 ______________________________________________________________________________________

4) EN4 to turn on the display’s backlight.

5) CEN is asserted by the μP to start a charge cycle.

6) The external supply is removed from DC and V

SYS

falls. The regulators remain enabled because EN123

and EN4 are asserted, but the battery charging current drops to zero even though CEN is still asserted.

CHG goes high-impedance.

7) System is turned off by deasserting EN123, EN4,

and CEN. OUT1, OUT2, and OUT3 power down in

the opposite order of power-up. RST1 goes low to

reset the μP.

Step-Up Converter (REG4)

The step-up converter (REG4) operates by regulating

the voltage at FB4 to 0.5V. REG4 operates from the

system voltage (V

SYS

); this voltage can vary from 2.6V to

4.35V (MAX8819A/MAX8819C) or 5.3V (MAX8819B/

MAX8819D). The 1MHz switching frequency allows for

tiny external components. The step-up converter control

scheme optimizes the efficiency while achieving low EMI

and low input ripple.

REG4 WLED Driver Configuration

Figure 1 shows that REG4 is configured as a white light

emitting diodes (WLED) driver, typically used to drive

up to six devices with an output voltage up to 24V. The

full-scale current is set by resistor R1, according to the

following relationship:

Figure 8. Dimming Control Timing Diagram

Table 4. REG4 Recommended Inductors

Table 5. REG4 Recommended Diodes

t

HI_INIT

> 100μs

t

SOFT-START

SHUTDOWN

0

STEP

EN4

I

LED

1 3332313029285432

FULL

31/32

30/32

29/32

500ns TO 500μs

28/32

27/32

t

t

6/32

HI

> 500ns

5/32

LO

V

FB

I

FS

IV mA

FS

4/32

4

==

<=

3/32

, . min

where V V no ally

1

R

0 5 16 30 9

./ .Ω

FULL

2/32

1/32

FB

4

31/32

05

t

SHDN

2ms (typ)

SHUTDOWN

MANUFACTURER SERIES

TOKO

FDK MIP3226 10 160 900 3.2 x 2.6 x 1 = (8.32mm)

DE2812C 10 290 580 3.0 x 2.8 x 1.2 = (10.8mm)

DB3018C 10 240 630 3.2 x 3.2 x 1.8 = (18.4mm)

INDUCTANCE

(µH)

ESR (mΩ)

CURRENT

RATING (mA)

DIMENSIONS (mm)

CONTINUOUS

MANUFACTURER PART NUMBER

Central Semiconductor

NXP PMEG3005EB 500 500 30 SOD-523

ON Semiconductor MBR0530L 500 430 30 SOD-123

CMDSH05-4 500 470 40 SOD-323

CMHSH5-4 500 510 40 SOD-123

CURRENT

(mA)

FORWARD VOLTAGE

(mV)

BREAKDOWN

VOLTAGE

(V)

PACKAGE

3

3

3

MAX8819A–MAX8819D

PMIC with Integrated Chargers and Smart

Power Selector in a 4mm x 4mm TQFN

______________________________________________________________________________________ 27

EN4 enables REG4, disables REG4, and adjusts the voltage on FB4 in 32 linear steps. If current adjustment is not

required, EN4 acts as a simple enable/disable controller.

Driving EN4 high for at least 100μs powers up REG4 and

sets V

FB4

to 0.5V. Pulling EN4 low for at least 2ms dis-

ables REG4. To adjust V

FB4

, apply pulses as shown in

Figure 8. Dim the WLEDs by pulsing EN4 low (500ns to

500μs pulse width). Each pulse reduces the LED current

by 1/32. Note: When REG4 is disabled, OUT4 is equal to

V

SYS

minus the drop from the catch diode.

In the event that the load (typically WLEDs) opens,

V

OUT4

rises quickly until it reaches the overvoltage protection threshold (typically 25V). When this occurs,

REG4 stops switching and latches off until EN4 is reset

low for at least 2ms.

Step-Up Converter Inductor Selection

The WLED boost converter switches at 1MHz, allowing