Page 1

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

General Description

The MAX8744A/MAX8745A are dual step-down, switchmode, power-supply (SMPS) controllers with synchronous rectification, intended for main 5V/3.3V power

generation in battery-powered systems. Fixed-frequency

operation with optimal interleaving minimizes input ripple current from the lowest input voltages up to the 26V

maximum input. Optimal 40/60 interleaving allows the

input voltage to go down to 8.3V before duty-cycle

overlap occurs, compared to 180° out-of-phase regulators where the duty-cycle overlap occurs when the

input drops below 10V.

Output current sensing provides peak current-limit protection, using either an accurate sense resistor or using

lossless inductor DCR current sensing. A low-noise

mode maintains high light-load efficiency while keeping

the switching frequency out of the audible range.

An internal, fixed 5V, 100mA linear regulator powers up

the MAX8744A/MAX8745A and their gate drivers, as

well as external keep-alive loads. When the main PWM

regulator is in regulation, an automatic bootstrap switch

bypasses the internal linear regulator, providing current

up to 200mA. An additional adjustable linear-regulator

driver with an external pnp transistor can be used with

a secondary winding to provide a 12V supply, or powered directly from the main outputs to generate lowvoltage outputs as low as 1V.

Independent enable controls and power-good signals

allow flexible power sequencing. Voltage soft-start

gradually ramps up the output voltage and reduces

inrush current, while soft-shutdown gradually ramps the

output voltage down, preventing negative voltage dips.

The MAX8744A/MAX8745A feature output undervoltage

and thermal-fault protection. The MAX8744A also

includes output overvoltage-fault protection.

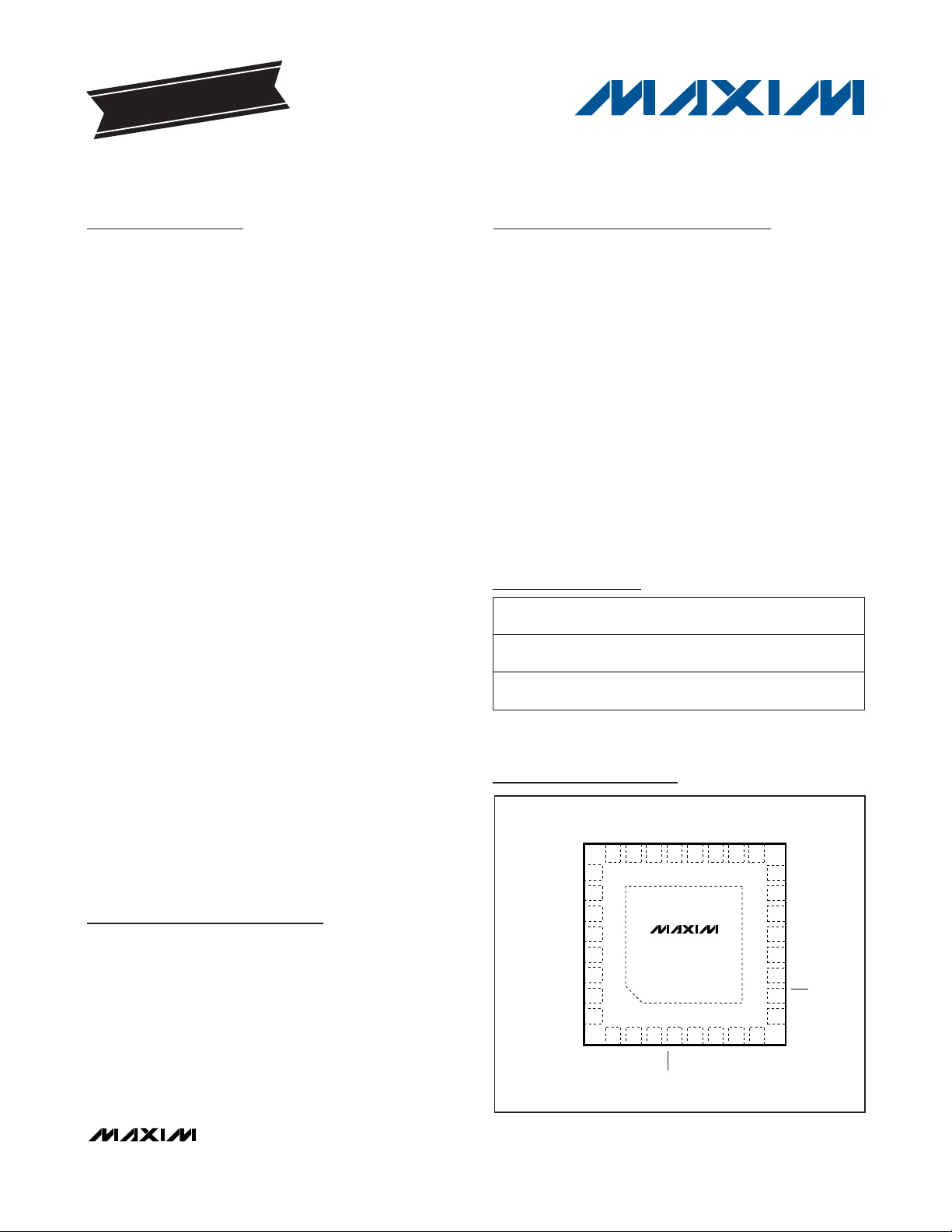

The MAX8744A/MAX8745A are available in a 32-pin,

5mm x 5mm, thin QFN package. The exposed backside pad improves thermal characteristics for demanding linear keep-alive applications.

Applications

Main Power Supplies

2 to 4 Li+ Cell Battery-Powered Devices

Notebook and Subnotebook Computers

PDAs and Mobile Communicators

Features

o Fixed-Frequency, Current-Mode Control

o 40/60 Optimal Interleaving

o Internal BST Switches

o Internal 5V, 100mA Linear Regulator

o Auxiliary Linear-Regulator Driver (12V or

Adjustable Down to 1V)

o Dual Mode™ Feedback—3.3V/5V Fixed or

Adjustable Output Voltages

o 200kHz/300kHz/500kHz Switching Frequency

o Undervoltage and Thermal-Fault Protection

o Overvoltage-Fault Protection (MAX8744A Only)

o 6V to 26V Input Range

o 2V ±0.75% Reference Output

o Independent Enable Inputs and Power-Good

Outputs

o Soft-Start and Soft-Shutdown (Voltage Ramp)

o 8μA (typ) Shutdown Current

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main Power-

Supply Controllers for Notebook Computers

________________________________________________________________

Maxim Integrated Products

1

19-0839; Rev 0; 6/07

+

Denotes a lead-free package.

*

Future product—contact factory for availability.

MAX8744A

MAX8745A

THIN QFN

5mm x 5mm

TOP VIEW

29

30

28

27

12

11

13

DRVA

SHDN

ON3

ON5

REF

14

ONA

DL3

IN

LDO5

LX3

PGND

DL5

12

+

CSL3

4567

2324 22 20 19 18

CSH3

FB3

PGOOD5

CSL5

CSH5

FB5

ILIM

PGOODA

3

21

31

10

FBA

SKIP

32

9

OUTA

FSEL

PGOOD3

26

15

BST5

BST3

25

16

DH5

GND

LX5

8

17

DH3

Pin Configuration

Ordering Information

Dual Mode is a trademark of Maxim Integrated Products, Inc.

EVALUATION KIT

AVAILABLE

PART TEMP RANGE

MAX8744AETJ+ -40°C to +85°C

MAX8745AETJ+* -40°C to +85°C

PINPACKAGE

32 Thin QFN

(5mm x 5mm)

32 Thin QFN

(5mm x 5mm)

PKG

CODE

T3255-4

T3255-4

Page 2

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main PowerSupply Controllers for Notebook Computers

2 _______________________________________________________________________________________

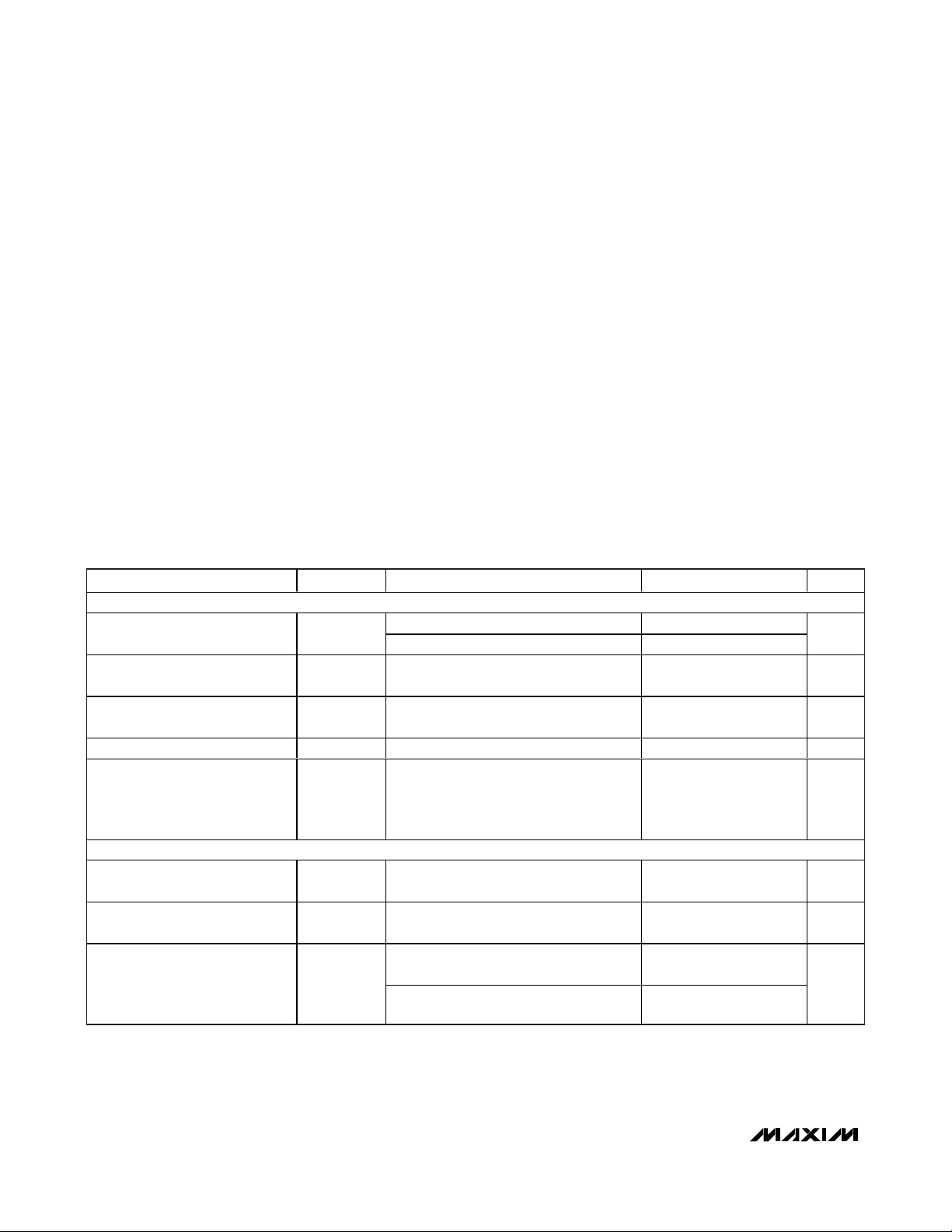

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

IN, SHDN, DRVA, OUTA to GND............................-0.3V to +28V

LDO5, ON3, ON5, ONA to GND ..............................-0.3V to +6V

PGOODA, PGOOD3, PGOOD5 to GND...................-0.3V to +6V

CSL3, CSH3, CSL5, CSH5 to GND ..........................-0.3V to +6V

REF, FB3, FB5, FBA to GND...................-0.3V to (V

LDO5

+ 0.3V)

SKIP, FSEL, ILIM to GND........................-0.3V to (V

LDO5

+ 0.3V)

DL3, DL5 to PGND..................................-0.3V to (V

LDO5

+ 0.3V)

BST3, BST5 to PGND .............................................-0.3V to +34V

BST3 to LX3..............................................................-0.3V to +6V

DH3 to LX3 ..............................................-0.3V to (V

BST3

+ 0.3V)

BST5 to LX5..............................................................-0.3V to +6V

DH5 to LX5 ..............................................-0.3V to (V

BST5

+ 0.3V)

GND to PGND .......................................................-0.3V to +0.3V

BST3, BST5 to LDO5 .............................................-0.3V to +0.3V

LDO Short Circuit to GND ..........................................Momentary

REF Short Circuit to GND ...........................................Momentary

DRVA Current (Sinking) ......................................................30mA

OUTA Shunt Current ...........................................................30mA

Continuous Power Dissipation (T

A

= +70°C)

Multilayer PCB

32-Pin, 5mm x 5mm TQFN

(derated 34.5mW/°C above +70°C) .........................2459mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) ................................+300°C

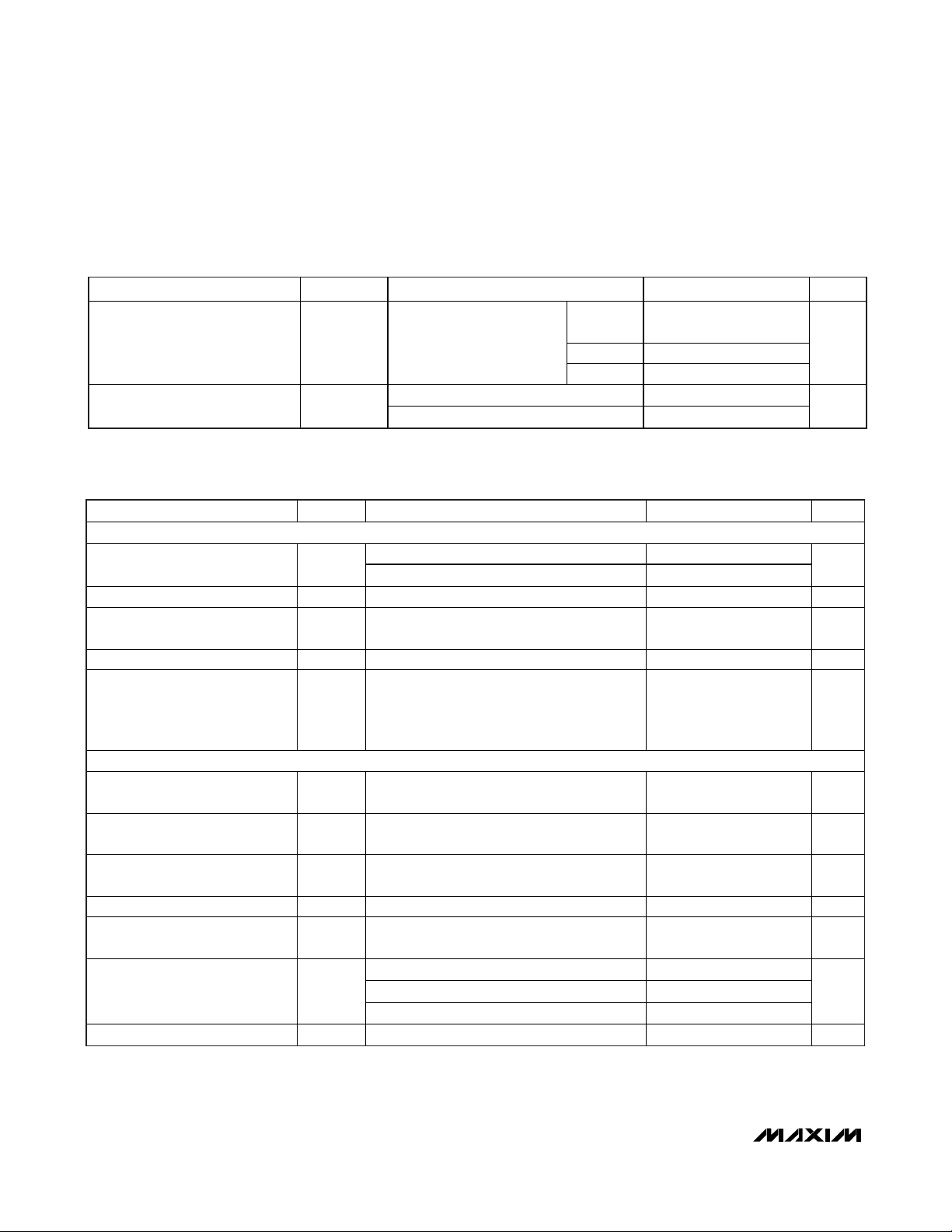

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, VIN= 12V, both SMPS enabled, FSEL = REF, SKIP = GND, ILIM = LDO5, FBA = LDO5, I

REF

= I

LDO5

= I

OUTA

=

no load, T

A

= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

INPUT SUPPLIES (Note 1)

VIN Input Voltage Range V

VIN Operating Supply Current I

VIN Standby Supply Current I

VIN Shutdown Supply Current I

Quiescent Power Consumption P

MAIN SMPS CONTROLLERS

3.3V Output Voltage in Fixed

Mode

5V Output Voltage in Fixed Mode V

Feedback Voltage in Adjustable

Mode (Note 2)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

IN

IN

IN(STBY)

IN(SHDN)VIN

Q

V

OUT3

OUT5

V

FB_

LDO5 in regulation 5.4 26.0

IN = LDO5, V

LDO5 switched over to CSL5, either

SMPS on

VIN = 6V to 26V, both SMPS off, includes

I

SHDN

= 6V to 26V 8 20 µA

Both S M P S on, FB3 = FB5 = LD O5,

SKIP = GN D , V

= 15V ,

V

OU T A

P

+ P

IN

C S L 3

VIN = 6V to 26V, SKIP = FB3 = LDO5,

0 < V

CSH3

VIN = 6V to 26V, SKIP = FB5 = LDO5,

0 < V

CSH5

VIN = 6V to 26V, FB3 or FB5

duty factor = 20% to 80%

VIN = 6V to 26V, FB3 or FB5

duty factor = 50%

< 4.4V 4.5 5.5

CSL5

20 36 µA

65 120 µA

+ P

- V

- V

C S L 3

C S L 5

CSL3

CSL5

= 3.5V , V

+ P

OU T A

< 50mV (Note 2)

< 50mV (Note 2)

C S L 5

= 5.3V ,

3.5 4.5 mW

3.265 3.315 3.365 V

4.94 5.015 5.09 V

1.980 2.010 2.040

1.990 2.010 2.030

V

V

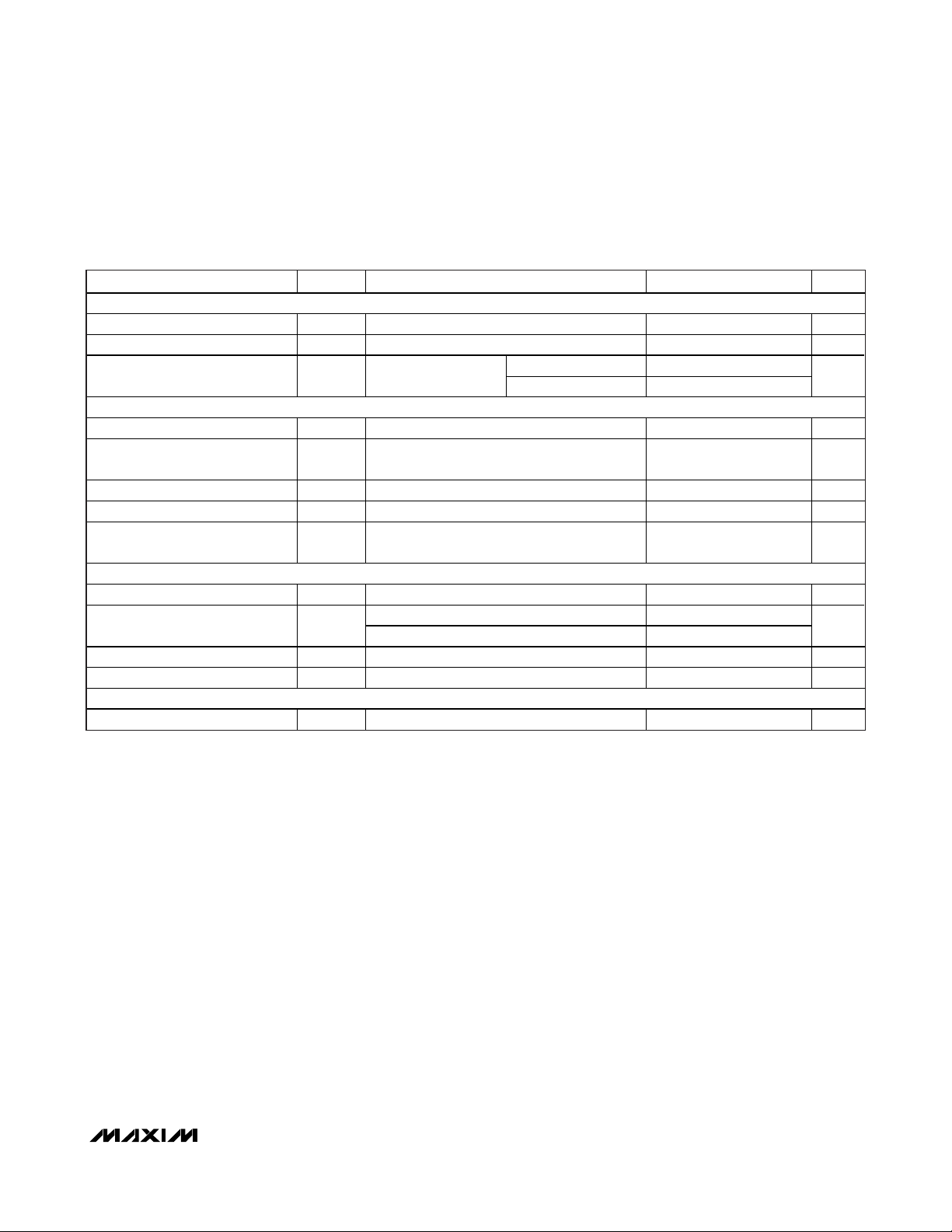

Page 3

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main Power-

Supply Controllers for Notebook Computers

_______________________________________________________________________________________ 3

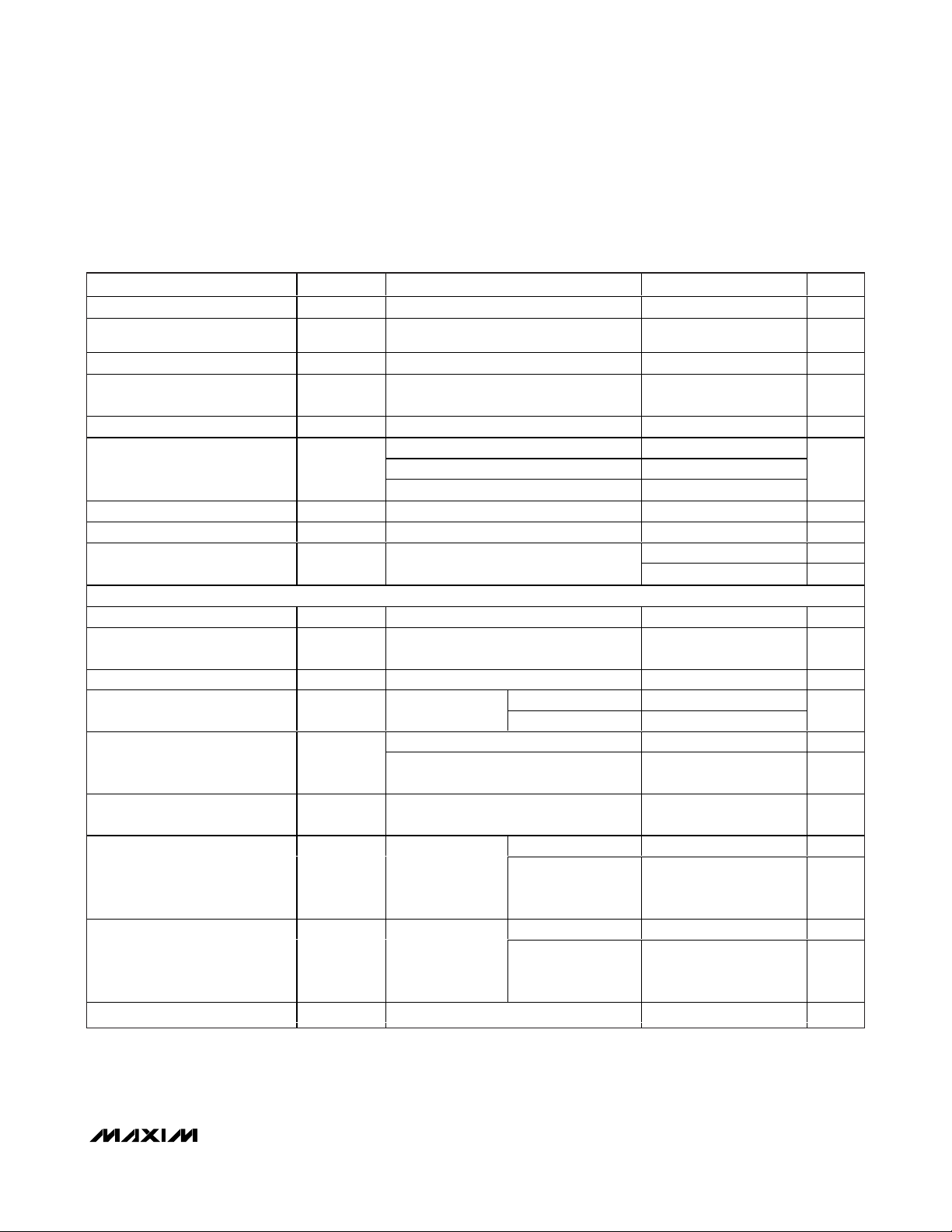

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, VIN= 12V, both SMPS enabled, FSEL = REF, SKIP = GND, ILIM = LDO5, FBA = LDO5, I

REF

= I

LDO5

= I

OUTA

=

no load, T

A

= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

Idle Mode is a trademark of Maxim Integrated Products, Inc.

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Output Voltage Adjust Range Either SMPS 2.0 5.5 V

FB3, FB5 Dual Mode Threshold 3.0

Feedback Input Leakage Current V

DC Load Regulation

= V

FB3

= 2.1V -0.1 +0.1 µA

FB5

Either SMPS, SKIP = LDO5,

- V

0 < V

CSH_

CSL_

< 50mV

Line Regulation Error Either SMPS, 6V < VIN < 26V 0.03 %/V

FSEL = GND 170 200 230

Operating Frequency (Note 1) f

OSC

FSEL = REF 270 300 330

FSEL = LDO5 425 500 575

Maximum Duty Factor D

Minimum On-Time t

MAX

ONMIN

(Note 1) 97.5 99 %

SMPS3-to-SMPS5 Phase Shift SMPS5 starts after SMPS3

CURRENT LIMIT

ILIM Adjustment Range 0.5 V

Current-Sense Input Leakage

Current

Current-Limit Threshold (Fixed) V

Current-Limit Threshold

(Adjustable)

Current-Limit Threshold

(Negative)

Current-Limit Threshold

(Zero Crossing)

V

V

LIMIT

LIMIT

NEG

V

ZX

CSH3 = CSH5 = GND or LDO5 -1 +1 µA

V

V

V

V

CSH

CSH

CSH

CSH

_ - V

_ - V

_ - V

_ - V

_, ILIM = LDO5 45 50 55 mV

CSL

V

= 2.00V 185 200 215

_

CSL

_, SKIP = ILIM = LDO5 -67 -60 -53 mV

CSL

_, SKIP = LDO5, adjustable

CSL

ILIM

= 1.00V 94 100 106

V

ILIM

mode, percent of current limit

V

_ - V

CSH

ILIM = LDO5

_, SKIP = GND,

CSL

036mV

ILIM = LDO5 6 10 14 mV

Idle Mode™ Threshold V

IDLE

_ - V

CSH

SKIP = GND

CSL

_,

With respect to

current-limit

threshold (V

LIMIT

)

V

ILIM = LDO5 2.5 5 7.5 mV

Idle Mode Threshold

(Low Audible-Noise Mode)

V

IDLE

V

_ - V

CSH

SKIP = REF

CSL

_,

With respect to

current-limit

threshold (V

LIMIT

)

ILIM Leakage Current ILIM = GND or REF -1 +1 µA

V

LOO5

- 1.0

V

LOO5

- 0.4

-0.1 %

100 ns

40 %

144 Deg

REF

-120 %

20 %

10 %

V

kHz

V

mV

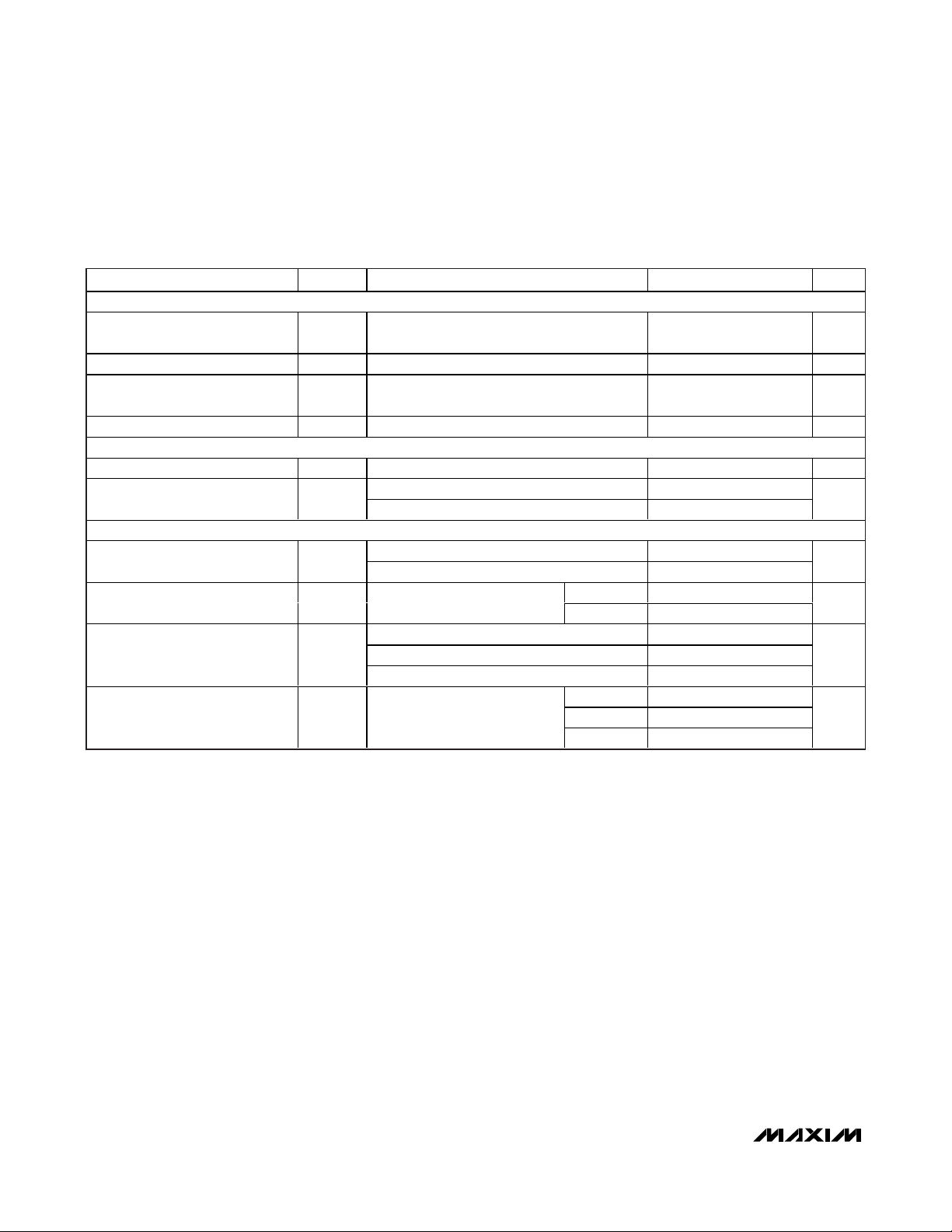

Page 4

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main PowerSupply Controllers for Notebook Computers

4 _______________________________________________________________________________________

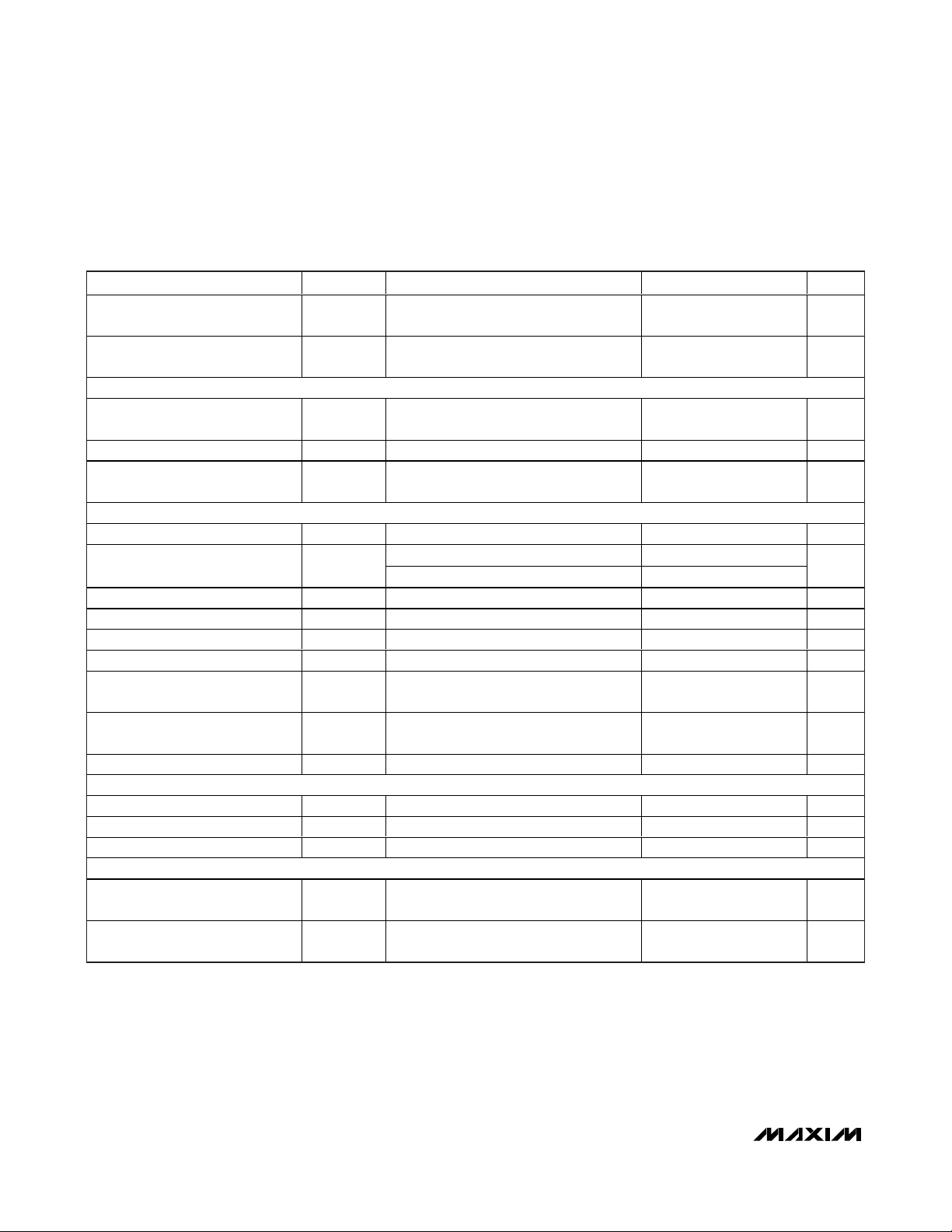

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, VIN= 12V, both SMPS enabled, FSEL = REF, SKIP = GND, ILIM = LDO5, FBA = LDO5, I

REF

= I

LDO5

= I

OUTA

=

no load, T

A

= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Soft-Start Ramp Time t

Soft-Stop Ramp Time t

SSTART

SSTOP

Measured from the rising edge of ON_ to

full scale

Measured from the falling edge of ON_ to

full scale

INTERNAL FIXED LINEAR REGULATORS

LDO5 Output Voltage V

LDO5

ON5 = GND, 6V < VIN < 26V,

0 < I

LDO5

< 100mA

LDO5 Undervoltage-Lockout Fault Rising edge, hysteresis = 1%

Short-Circuit Current (Switched

Over to CSL5)

LDO5 = GND, V

> 4.7V 200 425 mA

CSL5

4.85 4.95 5.10 V

3.7 4.0 4.1 V

AUXILIARY LINEAR REGULATOR

DRVA Voltage Range V

DRVA Drive Current

FBA Regulation Threshold V

FBA Load Regulation V

DRVA

FBA

V

= 1.05V, V

FBA

= 0.965V, V

V

FBA

V

DRVA

DRA

= 5V, I

= 5V, I

= 5V 0.4

DRVA

= 5V 10

DRVA

= 1mA (sink) 0.98 1.00 1.02 V

DRVA

= 0.5mA to 5mA -1.2 -2.2 %

DRVA

0.5 26.0 V

OUTA Shunt Trip Level Rising edge 25 26 27 V

FBA Leakage Current V

Secondary Feedback Regulation

Threshold

= 1.035V -0.1 +0.1 µA

FBA

V

- V

DRVA

OUTA

DL5 Pulse Width

OUTA Leakage Current I

OUTA

V

DRVA

= V

= 25V 50 µA

OUTA

REFERENCE (REF)

Reference Voltage V

Reference Load-Regulation Error ΔV

REF Lockout Voltage V

REF(UVLO

REF

REF

LDO5 in regulation, I

I

= -5µA to +50µA -10 +10 mV

REF

= 0 1.985 2.00 2.015 V

REF

Rising edge 1.8 V

FAULT DETECTION

Output Overvoltage Trip Threshold

(MAX8744A Only)

Outp ut Over vol tag e Faul t

P r op ag ati on D elay (M AX 8744A Only)

t

OVP

With respect to error-comparator

threshold

81114%

50mV overdrive 10 µs

2ms

4ms

0V

1/

3f

OSC

mA

µs

Page 5

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main Power-

Supply Controllers for Notebook Computers

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, VIN= 12V, both SMPS enabled, FSEL = REF, SKIP = GND, ILIM = LDO5, FBA = LDO5, I

REF

= I

LDO5

= I

OUTA

=

no load, T

A

= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

)

Output Undervoltage Protection

Trip Threshold

Output Undevoltage Fault

Propagation Delay

Output Undervoltage Protection

Blanking Time

PGOOD_ Lower Trip Threshold

PGOOD_ Propagation Delay t

PGOOD_ Output Low Voltage I

PGOOD_ Leakage Current I

Thermal-Shutdown Threshold t

GATE DRIVERS

DH_ Gate-Driver On-Resistance R

DL_ Gate-Driver On-Resistance R

DH_ Gate-Driver Source/Sink

Current

DL_ Gate-Driver Source Current

DL_ Gate-Driver Sink Current I

Dead Time t

Internal BST_ Switch

On-Resistance

BST_ Leakage Current V

INPUTS AND OUTPUTS

SHDN Input Trip Level

ONA Logic Input Voltage Hysteresis = 600mV (typ)

ON3, ON5 Input Voltage

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

With respect to error-comparator

threshold

t

UVP

t

BLANK

PGOOD

PGOOD

SHDN

DH

DL

I

DH

I

DL

DL (SINK

DEAD

R

BST

50mV overdrive 10 µs

From rising edge of ON_ with respect to

f

SW

With respect to error-comparator

threshold, hysteresis = 1% (typ)

Falling edge, 50mV overdrive 10

_

Rising edge, 50mV overdrive 1

= 1mA 0.4 V

SINK

_ High state, PGOOD_ forced to 5.5V 1 µA

Hysteresis = 15°C +160 °C

BST_ – LX_ forced to 5V 1.3 5 Ω

DL_, high state 1.7 5

DL_, low state 0.6 3

DH_ forced to 2.5V, BST_ – LX_ forced to

5V

DL_ forced to 2.5V 1.7 A

DL_ forced to 2.5V 3.3 A

DH_low to DL_high 15 45

DL_low to DH_high 15 44

I

= 10mA 5 Ω

BST

_ = 26V 2 20 µA

BST

Rising trip level 1.1 1.6 2.2

Falling trip level 0.96 1 1.04

High 2.4

Low 0.8

SMPS off level/clear fault level 0.8

Delay start level 1.9 2.1

SMPS on level 2.4

65 70 75 %

5000 6144 7000 1/f

-12 -10 -8 %

2A

OSC

µs

Ω

ns

V

V

V

Page 6

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main PowerSupply Controllers for Notebook Computers

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS

(Circuit of Figure 1, VIN= 12V, both SMPS enabled, FSEL = REF, SKIP = GND, ILIM = LDO5, FBA = LDO5, I

REF

= I

LDO5

= I

OUTA

=

no load, T

A

= -40°C to +85°C, unless otherwise noted.) (Note 3)

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, VIN= 12V, both SMPS enabled, FSEL = REF, SKIP = GND, ILIM = LDO5, FBA = LDO5, I

REF

= I

LDO5

= I

OUTA

=

no load, T

A

= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

LDO5

- 0.4

Tri-Level Input Logic SKIP, FSEL

High

REF 1.65 2.35

GND 0.5

Input Leakage Current

SKIP, FSEL forced to GND or LDO5 -1 +1

SHDN forced to GND or 26V -1 +1

INPUT SUPPLIES (Note 1)

VIN Input Voltage Range VIN

VIN Operating Supply Current I

VIN Standby Supply Current I

VIN Shutdown Supply Current I

Quiescent Power Consumption P

MAIN SMPS CONTROLLERS

3.3V Output Voltage in Fixed

Mode

5V Output Voltage in Fixed Mode V

Feedback Voltage in Adjustable

Mode

Output Voltage Adjust Range

FB3, FB5 Dual Mode Threshold

Operating Frequency (Note 1) f

Maximum Duty Factor D

PARAMETER SYMBOL CONDITIONS MIN MAX UNITS

LDO5 in regulat ion 5.4 26.0

IN = LDO5, V

LDO5 switched over to CSL5, either SMPS on 40 μA

IN

IN(STBY)

IN(SHDN) VIN

VIN = 6V to 26V, both SMPS off, includes

I

SHDN

= 6V to 26V 20 μA

< 4.4V 4.5 5.5

CSL5

Both SMPS on, FB3 = FB5 = LDO5; SKIP =

GND, V

Q

V

OUTA

P

+ P

IN

V

OUT3

OUT5

V

VIN = 6V to 26V, SKIP = FB3 = LDO5,

0 < V

VIN = 6V to 26V, SKIP = FB5 = LDO5,

0 < V

VIN = 6V to 26V, FB3 or FB5

FB_

duty factor = 20% to 80% (Note 2)

Either SMPS 2.0 5.5 V

3V

CSL3

= 15V,

CSL3

- V

CSH3

- V

CSH5

= 3.5V, V

+ P

+ P

CSL5

< 50mV (Note 2)

CSL3

< 50mV (Note 2)

CSL5

CSL5

= 5.3V,

OUTA

3.255 3.375 V

4.925 5.105 V

1.974 2.046 V

FSEL = GND 170 230

OSC

FSEL = REF 270 330

FSEL = LDO5 425 575

97 %

MAX

120 μA

4.5 mW

V

LDO5

0.4

-

µA

kHz

V

V

V

Page 7

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main Power-

Supply Controllers for Notebook Computers

_______________________________________________________________________________________ 7

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, VIN= 12V, both SMPS enabled, FSEL = REF, SKIP = GND, ILIM = LDO5, FBA = LDO5, I

REF

= I

LDO5

= I

OUTA

=

no load, T

A

= -40°C to +85°C, unless otherwise noted.) (Note 3)

CURRENT LIMIT

ILIM Adjustment Range

Current-Limit Threshold (Fixed) V

Current-Limit Thresho ld

(Adjustable)

PARAMETER SYMBOL CONDITIONS MIN MAX UNITS

0.5 V

LIMIT VCSH

V

LIMIT VCSH

_ - V

_ - V

_, ILIM = LDO5 44 56 mV

CSL

V

= 2.00V 185 215

CSL

_

ILIM

= 1.00V 93 107

V

ILIM

INTERNAL FIXED LINEAR REGULATORS

LDO5 Output Voltage V

LDO5 Undervoltage-Lockout

Fault Threshold

LDO5 Bootstrap Switch

LDO5

ON5 = GND, 6V < VIN < 26V,

Risi ng edge, hysteresi s = 1% (typ) 3.7 4.1 V

Risi ng edge of CSL5, hysteres is = 1% (typ) 4.30 4.75 V

4.85 5.10 V

Short-Circuit Current LDO5 = GND, ON5 = GND 450 mA

Short-Circuit Current (Switched

over to CSL5)

AUXILIARY LINEAR REGULATOR

DRVA Voltage Range V

DRVA

DRVA Dri ve Current

FBA Regulation Threshold V

LDO5 = GND, V

0.5 26.0 V

V

= 1.05V, V

FBA

= 0.965V, V

V

FBA

V

FBA

DRVA

= 5V, I

> 4.7V 200 mA

CSL5

= 5V 0.4

DRVA

= 5V 10

DRVA

= 1mA (sink) 0.98 1.02 V

DRVA

OUTA Shunt Trip Level 25 27 V

REFERENCE (REF)

Reference Voltage V

LDO5 in regulation, I

REF

= 0 1.980 2.020 V

REF

V

REF

mV

mA

Page 8

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main PowerSupply Controllers for Notebook Computers

8 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(Circuit of Figure 1, VIN= 12V, both SMPS enabled, FSEL = REF, SKIP = GND, ILIM = LDO5, FBA = LDO5, I

REF

= I

LDO5

= I

OUTA

=

no load, T

A

= -40°C to +85°C, unless otherwise noted.) (Note 3)

Note 1: The MAX8744A/MAX8745A cannot operate over all combinations of frequency, input voltage (VIN), and output voltage. For

large input-to-output differentials and high switching-frequency settings, the required on-time may be too short to maintain

the regulation specifications. Under these conditions, a lower operating frequency must be selected. The minimum on-time

must be greater than 150ns, regardless of the selected switching frequency. On-time and off-time specifications are measured from 50% point to 50% point at the DH_ pin with LX_ = GND, V

BST_

= 5V, and a 250pF capacitor connected from

DH_ to LX_. Actual in-circuit times may differ due to MOSFET switching speeds.

Note 2: When the inductor is in continuous conduction, the output voltage has a DC-regulation level lower than the error-comparator

threshold by 50% of the ripple. In discontinuous conduction (SKIP = GND, light load), the output voltage has a DC regulation level higher than the trip level by approximately 1.1% due to slope compensation.

Note 3: Specifications from -40°C to +85°C are guaranteed by design, not production tested.

FAULT DETECTION

Output Overvoltage Trip

Threshold (MAX8744A Only)

Output Undervoltage Protection

PGOOD_ Lower Trip Threshold

PGOOD_ Output Low Voltage I

GATE DRIVERS

DH_ Gate-Driver On-Resistance R

DL_ Gate-Driver On-Resistance R

INPUTS AND OUTPUTS

SHDN Input Trip Level

ONA Logic Input Voltage Hysteresis = 600mV

Tri-Level Input Logic SKIP, FSEL

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

With respect to error comparator threshold 8 14 %

With respect to error comparator threshold 65 75 %

With respect to error comparator threshold,

hysteresis = 1%

= 1mA 0.4 V

SINK

BST_ – LX_ forced to 5V 5 Ω

DH

DL_, high state 5

DL

DL_, low state 3

Rising trip level 1.0 2.3

Falling trip level 0.96 1.04

High 2.4

Low 0.8

SMPS off level/clear fault level 0.8

Delay start level 1.9 2.1ON3, ON5 Input Voltage

SMPS on level 2.4

High V

REF 1.65 2.35

GND 0.5

-12 -8 %

LDO5

- 0.4

Ω

V

V

V

V

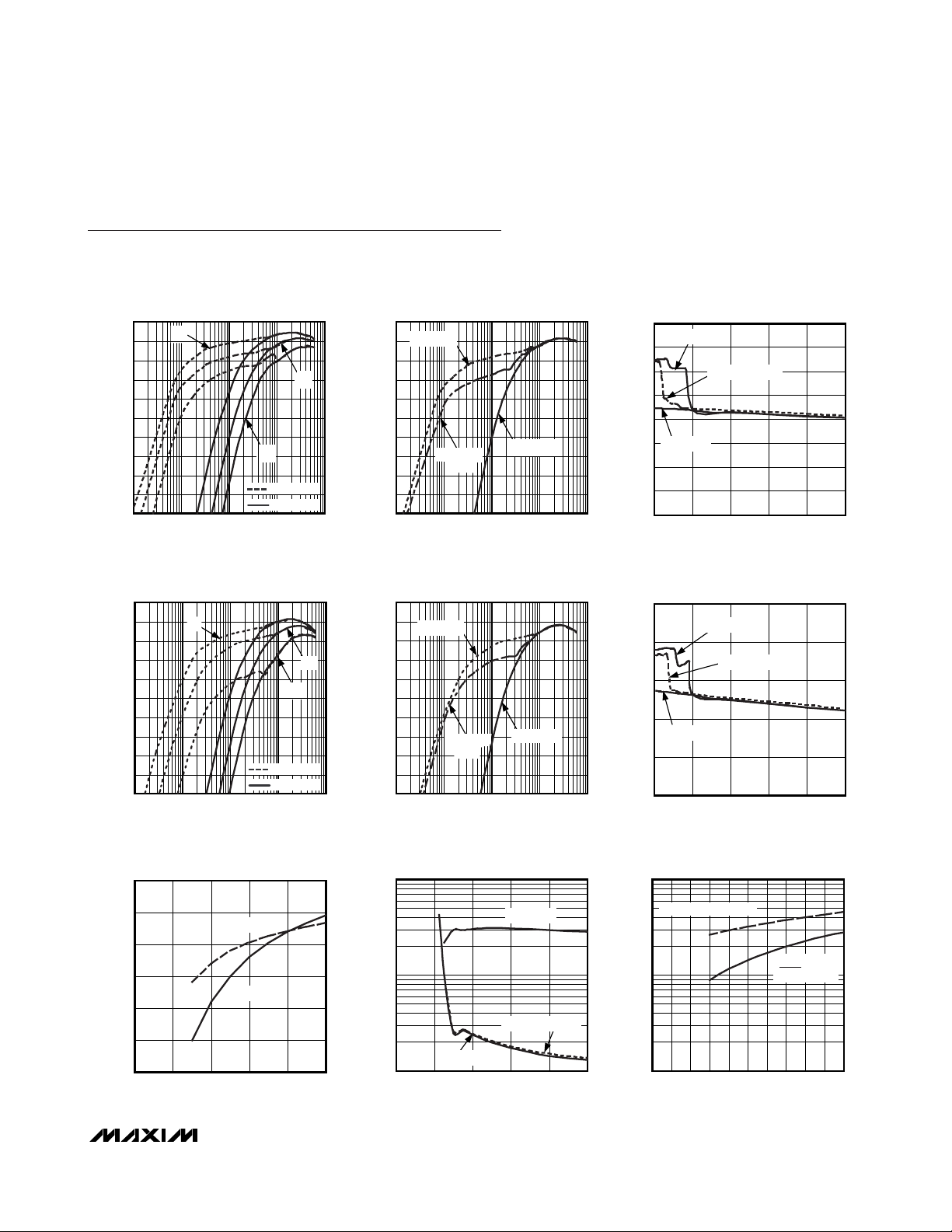

Page 9

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main Power-

Supply Controllers for Notebook Computers

_______________________________________________________________________________________

9

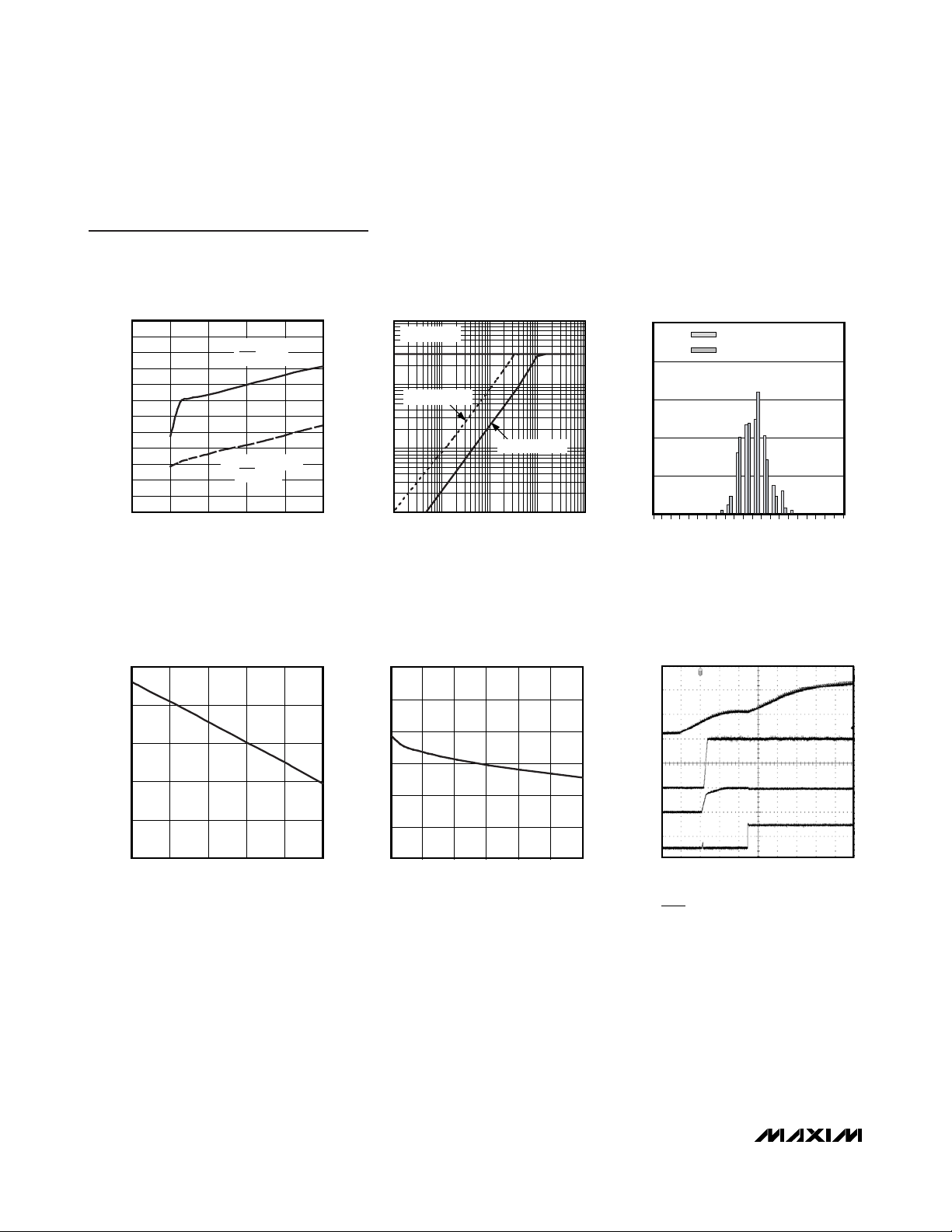

Typical Operating Characteristics

(Circuit of Figure 1, VIN= 12V, SKIP = GND, FSEL = REF, TA= +25°C, unless otherwise noted.)

5V OUTPUT EFFICIENCY

vs. LOAD CURRENT

100

90

80

70

EFFICIENCY (%)

60

50

0.001 0.01 0.1 1 10

7V

20V

LOAD CURRENT (A)

3.3V OUTPUT EFFICIENCY

vs. LOAD CURRENT

100

7V

90

80

12V

SKIP MODE

PWM MODE

12V

20V

MAX8744A toc01

MAX8744A toc04

100

90

80

70

EFFICIENCY (%)

60

50

100

90

80

5V OUTPUT EFFICIENCY

vs. LOAD CURRENT

SKIP MODE

LOW-NOISE

MODE

0.001 0.01 0.1 1 10

LOAD CURRENT (A)

PWM MODE

3.3V OUTPUT EFFICIENCY

vs. LOAD CURRENT

SKIP MODE

MAX8744A toc02

OUTPUT VOLTAGE (V)

MAX8744A toc05

5V OUTPUT VOLTAGE

vs. LOAD CURRENT

5.10

SKIP MODE

5.05

5.00

PWM MODE

4.95

4.90

0.0 1.0 2.0 3.0 4.0 5.0

LOW-NOISE MODE

LOAD CURRENT (A)

3.3V OUTPUT VOLTAGE

vs. LOAD CURRENT

3.39

SKIP MODE

3.36

LOW-NOISE MODE

3.33

MAX8744A toc03

MAX8744A toc06

70

EFFICIENCY (%)

60

50

0.001 0.01 0.1 1 10

LOAD CURRENT (A)

OUTPUT VOLTAGE DEVIATION

vs. INPUT VOLTAGE

3

2

1

0

-1

OUTPUT VOLTAGE DEVIATION (%)

-2

-3

0 4 8 12 16 20

3.3V OUTPUT

5.0V OUTPUT

INPUT VOLTAGE (V)

SKIP MODE

PWM MODE

70

EFFICIENCY (%)

60

50

100

MAX8744A toc07

10

SUPPLY CURRENT (mA)

1

LOW-NOISE

MODE

0.001 0.01 0.1 1 10

LOAD CURRENT (A)

PWM MODE

NO-LOAD INPUT SUPPLY CURRENT

vs. INPUT VOLTAGE

PWM MODE

LOW-NOISE MODE

SKIP MODE

0 4 8 12 16 20

INPUT VOLTAGE (V)

3.30

PWM MODE

OUTPUT VOLTAGE (V)

3.27

3.24

012345

LOAD CURRENT (A)

STANDBY AND SHUTDOWN INPUT CURRENT

vs. INPUT VOLTAGE

100

MAX8744A toc08

STANDBY (ONx = GND)

10

SUPPLY CURRENT (μA)

1

0 4 8 12 16 20

INPUT VOLTAGE (V)

SHUTDOWN

(SHDN = GND)

MAX8744A toc09

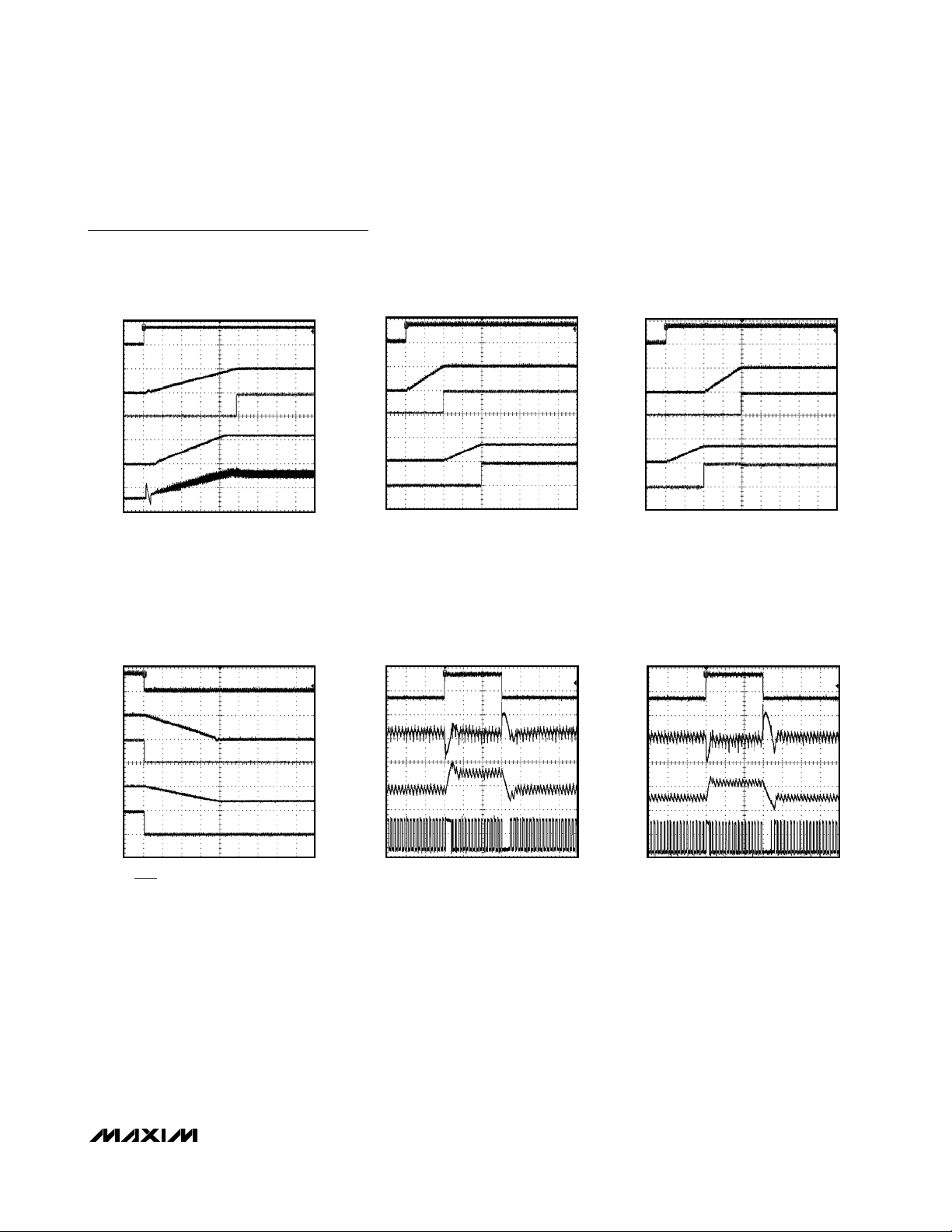

Page 10

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main PowerSupply Controllers for Notebook Computers

10 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VIN= 12V, SKIP = GND, FSEL = REF, TA= +25°C, unless otherwise noted.)

3.3V IDLE MODE CURRENT

vs. INPUT VOLTAGE

3

SKIP MODE

SKIP = GND

2

1

IDLE MODE CURRENT (A)

0

0 4 8 12 16 20

LOW-NOISE MODE

SKIP = REF

INPUT VOLTAGE (V)

1000

FORCED-PWM

MAX8744A toc10

100

LOW-NOISE SKIP

10

SWITCHING FREQUENCY (kHz)

1

0.001 10

LDO5 OUTPUT VOLTAGE

5.0

vs. LOAD CURRENT

4.9

4.8

4.7

OUTPUT VOLTAGE (V)

4.6

4.5

0 20406080100

LOAD CURRENT (mA)

12.2

MAX8744A toc13

12.1

12.0

OUTPUT VOLTAGE (V)

11.9

0 50 100 150

3.3V SWITCHING FREQUENCY

vs. LOAD CURRENT

PULSE SKIPPING

10.10.01

LOAD CURRENT (A)

OUTA OUTPUT VOLTAGE

vs. LOAD CURRENT

LOAD CURRENT (mA)

50

MAX8744A toc11

40

30

20

SAMPLE PERCENTAGE (%)

10

0

-10 -6 -2 2 6 10

12V

MAX8744A toc14

5V

2V

1V

5V

0

5V

0

REFERENCE OFFSET VOLTAGE

DISTRIBUTION

+85°C

+25°C

2V REF OFFSET VOLTAGE (mV)

SAMPLE SIZE = 125

LDO5 POWER-UP

1ms/div

A. INPUT SUPPLY, 5V/div

B. REF, 2V/div

SHDN = IN

C. LDO5, 5V/div

D. PGOOD5, 5V/div

MAX8744A toc12

MAX8744A toc15

A

B

C

D

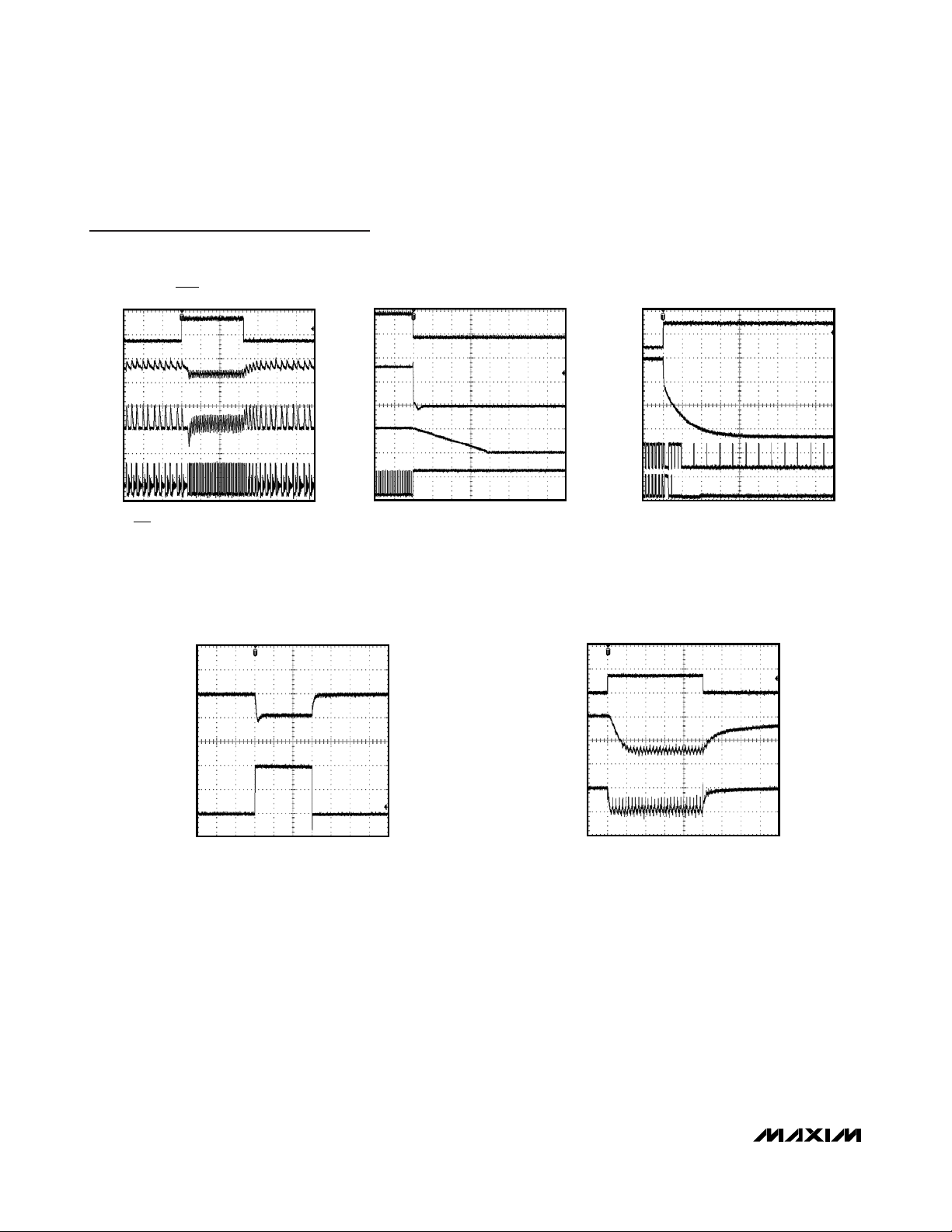

Page 11

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main Power-

Supply Controllers for Notebook Computers

______________________________________________________________________________________

11

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VIN= 12V, SKIP = GND, FSEL = REF, TA= +25°C, unless otherwise noted.)

SOFT-START WAVEFORM

MAX8744A toc16

B

A

400μs/div

C

D

E

3.3V

0

5V

0

0

0

12V

5A

0

A. ON3 AND ON5, 5V/div

B. 5V OUTPUT (V

OUT5

), 5V/div

C. PGOOD5, 5V/div

D. AUX LDO OUTPUT

(V

OUTA

), 10V/div

E. L5 INDUCTOR CURRENT,

5A/div

SMPS DELAYED STARTUP SEQUENCE

(ON3 = REF)

MAX8744A toc17

B

A

1ms/div

C

D

E

3.3V

0

5V

0

0

0

3.3V

0

A. ON5, 5V/div

B. 5V OUTPUT (V

OUT5

), 5V/div

C. PGOOD5, 5V/div

ON3 = REF

D. 3.3V OUTPUT (V

OUT3

),

5V/div

E. PGOOD3, 5V/div

SMPS DELAYED STARTUP SEQUENCE

(ON5 = REF)

MAX8744A toc18

B

A

1ms/div

C

D

E

3.3V

0

5V

0

0

0

3.3V

0

A. ON3, 5V/div

B. 5V OUTPUT (V

OUT5

), 5V/div

C. PGOOD5, 5V/div

ON5 = REF

D. 3.3V OUTPUT (V

OUT3

),

5V/div

E. PGOOD3, 5V/div

SMPS SHUTDOWN WAVEFORM

MAX8744A toc19

B

A

1ms/div

C

D

E

3.3V

5V

3.3V

5V

0

0

0

0

A. SHDN, 5V/div

B. 5V OUTPUT (V

OUT5

), 5V/div

C. PGOOD5, 5V/div

NO LOAD

D. 3.3V OUTPUT (V

OUT3

),

5V/div

E. PGOOD3, 5V/div

OUT5 LOAD TRANSIENT

MAX8744A toc20

B

A

20μs/div

C

D

5A

5.1V

1A

5A

12V

5.0V

4.9V

0

1A

A. I

OUT5

= 1A TO 5A, 5A/div

B. V

OUT5

, 50mV/div

C. INDUCTOR CURRENT,

5A/div

D. LX5, 10V/div

OUT3 LOAD TRANSIENT

MAX8744A toc21

B

A

20μs/div

C

D

3A

3.35V

1A

3A

12V

3.30V

3.25V

0

1A

A. I

OUT3

= 1A TO 3A, 5A/div

B. V

OUT3

, 50mV/div

C. INDUCTOR CURRENT,

5A/div

D. LX3, 10V/div

Page 12

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main PowerSupply Controllers for Notebook Computers

12 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VIN= 12V, SKIP = GND, FSEL = REF, TA= +25°C, unless otherwise noted.)

3.3V

0

3.35V

3.25V

2A

0

12V

0

SKIP TRANSITION

5V/div

A. SKIP,

B. 3.3V OUTPUT (V

100mV/div

0.5A LOAD

40μs/div

C. INDUCTOR CURRENT,

),

2A/div

OUT3

D. LX3, 10V/div

MAX8744A toc22

OUTPUT OVERVOLTAGE

FAULT PROTECTION (MAX8744A ONLY)

5V

A

0

3.3

B

0

5V

C

0

5V

D

0

1ms/div

A. PGOOD3, 5V/div

B. 3.3V OUTPUT (V

2V/div

OUT3

),

MAX8744A toc23

C. 5V OUTPUT (V

5V/div

D. DL3, 5V/div

OUT5

5V

A

0

3.3V

B

0

5V

C

0

12V

D

),

0

OUTPUT UNDERVOLTAGE

(SHORT-CIRCUIT) FAULT PROTECTION

20μs/div

A. LOAD FET GATE, 5V/div

B. 3.3V OUTPUT (V

30mΩ MOSFET

OUT3

), 1V/div

MAX8744A toc24

C. DL3, 5V/div

D. DH3, 10V/div

A

B

C

D

5.00V

4.95V

100mA

0

A. LDO5 OUTPUT, 50mV/div

B. LOAD CURRENT, 50mA/div

LDOH5 LOAD TRANSIENT

20μs/div

MAX8744A toc25

LDOHA LOAD TRANSIENT

5V

A

B

0

15.0V

14.5V

12.0V

11.9V

A. LOAD FET GATE, 5V/div

B. AUX LDO INPUT, 0.5V/div

0 TO 150mA LOAD TRANSIENT

20μs/div

MAX8744A toc26

C. AUX LDO OUTPUT (V

0.1V/div

A

B

C

),

OUTA

Page 13

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main Power-

Supply Controllers for Notebook Computers

______________________________________________________________________________________ 13

Pin Description

PIN NAME FUNCTION

1 ONA

2 DRVA

3 ILIM

4 SHDN

5 ON3

6 ON5

7 REF

8 GND Analog Ground. Connect the exposed backside pad to GND.

9 FSEL

Auxiliary LDO Enable Input. When ONA is pulled low, OUTA is high impedance and the secondary

feedback control is disabled. When ONA is driven high, the controller enables the auxiliary LDO.

Auxiliary LDO Transistor Base Driver. Connect DRVA to the base of a pnp power transistor. Add a

680Ω pullup resistor between the base and emitter.

Peak Current-Limit Threshold Adjustment. The current-limit threshold defaults to 50mV if ILIM is pulled

up to LDO5. In adjustable mode, the current-limit threshold across CSH_ and CSL_ is precisely 1/10

the voltage seen at ILIM over a 0.5V to 2.0V range. The logic threshold for switchover to the 50mV

default value is approximately V

Shutdown Control Input. The device enters its 8µA supply-current shutdown mode if V

than the SHDN input falling edge trip level and does not restart until V

input rising-edge trip level. Connect SHDN to V

through a resistive voltage-divider to implement a programmable undervoltage lockout.

V

IN

3.3V SMPS Enable Input. Driving ON3 high enables the 3.3V SMPS, while pulling ON3 low disables

the 3.3V SMPS. If ON3 is connected to REF, the 3.3V SMPS starts after the 5V SMPS reaches

regulation (delayed start). Drive ON3 below the clear fault level to reset the fault latch.

5V SMPS Enable Input. Driving ON5 high enables the 5V SMPS, while pulling ON5 low disables the

5V SMPS. If ON5 is connected to REF, the 5V SMPS starts after the 3.3V SMPS reaches regulation

(delayed start). Drive ON5 below the clear fault level to reset the fault latch.

2.0V Reference Voltage Output. Bypass REF to analog ground with a 0.1µF or greater ceramic

capacitor. The reference sources up to 50µA for external loads. Loading REF degrades outputvoltage accuracy according to the REF load-regulation error. The reference shuts down when the

system pulls SHDN low.

Frequency Select Input. This three-level logic input sets the controllers’ switching frequency. Connect

to LDO5, REF, or GND to select the following typical switching frequencies:

LDO5 = 500kHz, REF = 300kHz, GND = 200kHz.

LDO5

- 1V.

for automatic startup. SHDN can be connected to

IN

is less

is greater than the SHDN

SHDN

SHDN

10 SKIP

11 FB5

12 CSH5

13 CSL5

14 PGOOD5

Pulse-Skipping Control Input. Connect to LDO5 for low-noise, forced-PWM operation. Connect to REF

for automatic, low-noise, pulse-skipping operation at light loads. Connect to GND for automatic, highefficiency, pulse-skipping operation at light loads.

Feedback Input for the 5V SMPS. Connect to LDO5 for the preset 5V output. In adjustable mode, FB5

regulates to 2V.

P osi ti ve C ur r ent- S ense Inp ut for the 5V S M P S . C onnect to the p osi ti ve ter m i nal of the cur r ent- sense

el em ent. Fi g ur e 7 d escr i b es tw o d i ffer ent cur r ent- sensi ng op ti ons— usi ng accur ate sense r esi stor s or

l ossl ess i nd uctor D C R sensi ng .

Output-Sense and Negative Current-Sense Input for the 5V SMPS. When using the internal preset 5V

feedback-divider (FB5 = LDO5), the controller uses CSL5 to sense the output voltage. Connect to the

negative terminal of the current-sense element. CSL5 also serves as the bootstrap input for LDO5.

Open-Drain, Power-Good Output for the 5V SMPS. PGOOD5 is pulled low if CSL5 drops more than

10% (typ) below the normal regulation point. PGOOD5 is held low during soft-start and shutdown.

PGOOD5 becomes high impedance when CSL5 is in regulation.

Page 14

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main PowerSupply Controllers for Notebook Computers

14 ______________________________________________________________________________________

Pin Description (continued)

PIN NAME FUNCTION

Boost Flying Capacitor Connection for the 5V SMPS. The MAX8744A/MAX8745A include an internal

15 BST5

16 DH5 High-Side Gate-Driver Output for the 5V SMPS. DH5 swings from LX5 to BST5.

17 LX5

18 DL5 Low-Side Gate-Driver Output for the 5V SMPS. DL5 swings from PGND to LDO5.

19 PGND Power Ground

20 LDO5

21 IN

22 PGOODA

23 DL3 Low-Side Gate-Driver Output for the 3.3V SMPS. DL3 swings from PGND to LDO5.

24 LX3

25 DH3 High-Side Gate-Driver Output for the 3.3V SMPS. DH3 swings from LX3 to BST3.

26 BST3

boost switch connected between LDO5 and BST5. Connect to an external capacitor as shown in

Figure 1.

Inductor Connection for the 5V SMPS. Connect LX5 to the switched side of the inductor. LX5 serves

as the lower supply rail for the DH5 high-side gate driver.

5V Internal Linear-Regulator Output. Bypass with 4.7µF minimum (1µF/25mA). Provides at least

100mA for the DL_ low-side gate drivers, the DH_ high-side drivers through the BST switches, the

PWM controller, logic, reference, and external loads. If CSL5 is greater than 4.5V and soft-start is

complete, the linear regulator shuts down, and LDO5 connects to CSL5 through a 1Ω switch rated for

loads up to 200mA.

Input of the Startup Circuitry and the LDO5 Internal 5V Linear Regulator. Bypass to PGND with a

0.22µF or greater ceramic capacitor close to the IC.

Open-Drain, Power-Good Output for the Auxiliary LDO. PGOODA is pulled low if FBA drops more

than 10% (typ) below the normal regulation point, and when the auxiliary LDO is shut down. PGOODA

becomes high impedance when FBA is in regulation.

Inductor Connection for the 3.3V SMPS. Connect LX3 to the switched side of the inductor. LX3 serves

as the lower supply rail for the DH3 high-side gate driver.

Boost Flying Capacitor Connection for the 3.3V SMPS. The MAX8744A/MAX8745A include an internal

boost switch connected between LDO5 and BST3. Connect to an external capacitor as shown in

Figure 1.

Open-Drain, Power-Good Output for the 3.3V SMPS. PGOOD3 is pulled low if CSL3 drops more than

27 PGOOD3

28 CSL3

29 CSH3

30 FB3

31 FBA

10% (typ) below the normal regulation point. PGOOD3 is held low during soft-start and shutdown.

PGOOD3 becomes high impedance when CSL3 is in regulation.

Output Sense and Negative Current Sense for the 3.3V SMPS. When using the internal preset 3.3V

feedback divider (FB3 = LDO5), the controller uses CSL3 to sense the output voltage. Connect to the

negative terminal of the current-sense element.

Positive Current-Sense Input for the 3.3V SMPS. Connect to the positive terminal of the current-sense

element. Figure 7 describes two different current-sensing options—using accurate sense resistors or

lossless inductor DCR sensing.

Feedback Input for the 3.3V SMPS. Connect to LDO5 for fixed 3.3V output. In adjustable mode, FB3

regulates to 2V.

Auxiliary LDO Feedback Input. Connect a resistive voltage-divider from OUTA to analog ground to

adjust the auxiliary linear-regulator output voltage. FBA regulates at 1V.

Page 15

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main Power-

Supply Controllers for Notebook Computers

______________________________________________________________________________________ 15

Pin Description (continued)

Table 1. Component Selection for Standard Applications

Pin Description (continued)

PIN NAME FUNCTION

PIN NAME FUNCTION

Adjustable Auxiliary Linear-Regulator Output. Bypass OUTA to GND with 1µF or greater capacitor

Boost Flying Capacitor Connection for the 5V SMPS. The MAX8744A/MAX8745A include an internal

(1µF/25mA). When DRVA < OUTA, the secondary feedback control triggers the DL5 for 1µs forcing

15 BST5

32 OUTA

16 DH5 High-Side Gate-Driver Output for the 5V SMPS. DH5 swings from LX5 to BST5.

17 LX5

EP EP Exposed Pad. Connect the exposed backside pad to analog ground.

18 DL5 Low-Side Gate-Driver Output for the 5V SMPS. DL5 swings from PGND to LDO5.

19 PGND Power Ground

20 LDO5

COMPONENT

INPUT VOLTAGE VIN = 7V TO 24V VIN = 7V TO 24V

21 IN

C

, Input Capacitor

IN_

5V OUTPUT

22 PGOODA

C

, Output Capacitor

OUT5

23 DL3 Low-Side Gate-Driver Output for the 3.3V SMPS. DL3 swings from PGND to LDO5.

L5/T5 Inductor/Transformer

24 LX3

25 DH3 High-Side Gate-Driver Output for the 3.3V SMPS. DH3 swings from LX3 to BST3.

NH5 High-Side MOSFET

26 BST3

27 PGOOD3

NL5 Low-Side MOSFET

3V OUTPUT

28 CSL3

, Output Capacitor

C

OUT3

29 CSH3

L3, Inductor

30 FB3

NH3 High-Side MOSFET

31 FBA

boost switch connected between LDO5 and BST5. Connect to an external capacitor as shown in

the controller to recharge the auxiliary storage capacitor. When DRVA exceeds 25V, the

Figure 1.

MAX8744A/MAX8745A enable a 10mA shunt on OUTA, preventing the storage capacitor from rising

to unsafe levels due to the transformer’s leakage inductance. Pulling ONA high enables the linear-

Inductor Connection for the 5V SMPS. Connect LX5 to the switched side of the inductor. LX5 serves

regulator driver and the secondary feedback control.

as the lower supply rail for the DH5 high-side gate driver.

5V Internal Linear-Regulator Output. Bypass with 4.7µF minimum (1µF/25mA). Provides at least

100mA for the DL_ low-side gate drivers, the DH_ high-side drivers through the BST switches, the

PWM controller, logic, reference, and external loads. If CSL5 is greater than 4.5V and soft-start is

complete, the linear regulator shuts down, and LDO5 connects to CSL5 through a 1Ω switch rated for

loads up to 200mA.

Input of the Startup Circuitry and the LDO5 Internal 5V Linear Regulator. Bypass to PGND with a

(3) 10µF, 25V

0.22µF or greater ceramic capacitor close to the IC.

Taiyo Yuden TMK432BJ106KM

Open-Drain, Power-Good Output for the Auxiliary LDO. PGOODA is pulled low if FBA drops more

than 10% (typ) below the normal regulation point, and when the auxiliary LDO is shut down. PGOODA

2x 100µF, 6V, 35mΩ

becomes high impedance when FBA is in regulation.

SANYO 6TPE100MAZB

6.8µH, 6.4A, 18mΩ (max) 1:2

Inductor Connection for the 3.3V SMPS. Connect LX3 to the switched side of the inductor. LX3 serves

Sumida 4749-T132

as the lower supply rail for the DH3 high-side gate driver.

Fairchild Semiconductor

FDS6612A

Boost Flying Capacitor Connection for the 3.3V SMPS. The MAX8744A/MAX8745A include an internal

International Rectifier

boost switch connected between LDO5 and BST3. Connect to an external capacitor as shown in

IRF7807V

Figure 1.

Fairchild Semiconductor

Open-Drain, Power-Good Output for the 3.3V SMPS. PGOOD3 is pulled low if CSL3 drops more than

FDS6670S

10% (typ) below the normal regulation point. PGOOD3 is held low during soft-start and shutdown.

International Rectifier

PGOOD3 becomes high impedance when CSL3 is in regulation.

IRF7807VD1

Output Sense and Negative Current Sense for the 3.3V SMPS. When using the internal preset 3.3V

feedback divider (FB3 = LDO5), the controller uses CSL3 to sense the output voltage. Connect to the

2x 150µF, 4V, 35mΩ

negative terminal of the current-sense element.

SANYO 4TPE150MAZB

Positive Current-Sense Input for the 3.3V SMPS. Connect to the positive terminal of the current-sense

5.8µH, 8.6A, 16.2mΩ

element. Figure 7 describes two different current-sensing options—using accurate sense resistors or

Sumida

lossless inductor DCR sensing.

CDRH127/LD-5R8NC

Feedback Input for the 3.3V SMPS. Connect to LDO5 for fixed 3.3V output. In adjustable mode, FB3

Fairchild Semiconductor

regulates to 2V.

FDS6612A

Auxiliary LDO Feedback Input. Connect a resistive voltage-divider from OUTA to analog ground to

International Rectifier

adjust the auxiliary linear-regulator output voltage. FBA regulates at 1V.

IRF7807V

300kHz

5V AT 5A

3.3V AT 5A

(3) 10µF, 25V

Taiyo Yuden TMK432BJ106KM

2x 100µF, 6V, 35mΩ

SANYO 6TPE100MAZB

—

Fairchild Semiconductor

FDS6612A

International Rectifier

IRF7807V

Fairchild Semiconductor

FDS6670S

International Rectifier

IRF7807VD1

2x 100µF, 6V, 35mΩ

SANYO 6TPE100MAZB

3.9µH, 6.5A, 15mΩ

Sumida CDRH124-3R9NC

Fairchild Semiconductor

FDS6612A

International Rectifier

IRF7807V

500kHz

5V AT 3A

3.3V AT 5A

NL3 Low-Side MOSFET

Fairchild Semiconductor

FDS6670S

International Rectifier

IRF7807VD1

Fairchild Semiconductor

FDS6670S

International Rectifier

IRF7807VD1

Page 16

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main PowerSupply Controllers for Notebook Computers

16 ______________________________________________________________________________________

Figure 1. Standard Application Circuit

)

INPUT (V

C

IN

21

IN

C

IN

IN

N

H1

25

DH3

26

N

L1

C

REF

0.22μF

24

23

29

28

9

7

2

32

31

4

5

6

1

BST3

LX3

DL3

CSH3

CSL3

FSEL

REF

MAX8744A

MAX8745A

DRVA

OUTA

FBA

SHDN

ON3

ON5

ONA

C

3.3V PWM

OUTPUT

C

OUT3

L3

6.96kΩ

R2

3.48kΩ

C1

0.22μF

1000pF

R1

C3

SECONDARY

OUTPUT

12V LDO

OUTPUT

C

LDOA

4.7μF

BST1

0.1μF

D

L1

REF

(300kHz)

R10

680Ω

R5

110kΩ

R6

10kΩ

OFFON

DH5

BST5

LX5

DL5

PGND

GND

CSH5

CSL5

ILIM

FB5

FB3

LDO5

SKIP

PGOODA

PGOOD3

PGOOD5

T5

R3

10.5kΩ

R4

4.02kΩ

C2

0.22μF

C4

1000pF

R9

100kΩ

D1

CONNECT

TO 5V OR 3.3V

N

H2

16

15

C

BST2

0.1μF

17

18

N

L2

19

8

12

13

3

11

30

20

10

R7

100kΩ

22

27

14

C

LDO5

4.7μF

D

L2

5V LDO OUTPUT

R8

100kΩ

SECONDARY

OUTPUT

C

AUX

4.7μF

5V PWM

OUTPUT

C

OUT5

POWER-GOOD

POWER GROUND

ANALOG GROUND

SEE TABLE 1 FOR COMPONENT SPECIFICATIONS.

Page 17

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main Power-

Supply Controllers for Notebook Computers

______________________________________________________________________________________ 17

Detailed Description

The MAX8744A/MAX8745A standard application circuit

(Figure 1) generates the 5V/5A and 3.3V/5A typical of the

main supplies in a notebook computer. The input supply

range is 7V to 24V. See Table 1 for component selections, while Table 2 lists the component manufacturers.

The MAX8744A/MAX8745A contain two interleaved,

fixed-frequency, step-down controllers designed for lowvoltage power supplies. The optimal interleaved architecture guarantees out-of-phase operation, reducing the

input capacitor ripple. One internal LDO generates the

keep-alive 5V power. The MAX8744A/MAX8745A have

an auxiliary LDO with an adjustable output for generating either the 3.3V keep-alive supply or regulating the

low-power 12V system supply.

Fixed 5V Linear Regulator (LDO5)

An internal linear regulator produces a preset 5V lowcurrent output. LDO5 powers the gate drivers for the

external MOSFETs, and provides the bias supply

required for the SMPS analog controller, reference, and

logic blocks. LDO5 supplies at least 100mA for external and internal loads, including the MOSFET gate

drive, which typically varies from 5mA to 50mA,

depending on the switching frequency and external

MOSFETs selected. Bypass LDO5 with a 4.7µF or

greater ceramic capacitor (1µF per 25mA of load) to

guarantee stability under the full-load conditions.

The MAX8744A/MAX8745A switch-mode power supplies

(SMPS) require a 5V bias supply in addition to the highpower input supply (battery or AC adapter). This 5V bias

supply is generated by the controller’s internal 5V linear

regulator (LDO5). This bootstrapped LDO allows the

controller to power up independently. The gate-driver

input supply is connected to the fixed 5V linear-regulator

output (LDO5). Therefore, the 5V LDO supply must provide LDO5 (PWM controller) and the gate-drive power,

so the maximum supply current required is:

I

BIAS

= ICC+ fSW(Q

G(LOW)

+ Q

G(HIGH)

)

= 5mA to 50mA (typ)

where ICCis 0.7mA (typ), fSWis the switching frequency,

and Q

G(LOW)

and Q

G(HIGH)

are the MOSFET data

sheet’s total gate-charge specification limits at VGS= 5V.

SMPS to LDO Bootstrap Switchover

When the 5V main output voltage is above the LDO5

bootstrap-switchover threshold and has completed

soft-start, an internal 1Ω (typ) p-channel MOSFET

shorts CSL5 to LDO5, while simultaneously shutting

down the LDO5 linear regulator. This bootstraps the

device, powering the internal circuitry and external

loads from the 5V SMPS output (CSL5), rather than

through the linear regulator from the battery. Bootstrapping reduces power dissipation due to gate

charge and quiescent losses by providing power from

a 90%-efficient switch-mode source, rather than from a

much-less-efficient linear regulator. The current capability increases from 100mA to 200mA when the LDO5

output is switched over to CSL5. When ON5 is pulled

low, the controller immediately disables the bootstrap

switch and reenables the 5V LDO.

Reference (REF)

The 2V reference is accurate to ±1% over temperature

and load, making REF useful as a precision system reference. Bypass REF to GND with a 0.1µF or greater

ceramic capacitor. The reference sources up to 50µA

and sinks 5µA to support external loads. If highly accurate specifications are required for the main SMPS output voltages, the reference should not be loaded.

Loading the reference reduces the LDO5, CSL5

(OUT5), CSL3 (OUT3), and OUTA output voltages

slightly because of the reference load-regulation error.

System Enable/Shutdown (

SHDN

)

Drive SHDN below the precise SHDN input falling-edge

trip level to place the MAX8744A/MAX8745A in its lowpower shutdown state. The controller consumes only

8µA of quiescent current while in shutdown mode.

When shutdown mode activates, the reference turns off

after the controller completes the shutdown sequence

Table 2. Component Suppliers

SUPPLIER WEBSITE

AVX www.avx.com

Central Semiconductor www.centralsemi.com

Fairchild

International Rectifier www.irf.com

KEMET www.kemet.com

NEC/Tokin www.nec-tokin.com

Panasonic www.panasonic.com/industrial

Philips www.philips.com

Pulse www.pulseeng.com

Renesas www.renesas.com

SANYO www.edc.sanyo.com

Sumida www.sumida.com

Taiyo Yuden www.t-yuden.com

TDK www.component.tdk.com

TOKO www.tokoam.com

Vishay (Dale, Siliconix) www.vishay.com

www.fairchildsemi.com

Page 18

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main PowerSupply Controllers for Notebook Computers

18 ______________________________________________________________________________________

making the threshold to exit shutdown less accurate. To

guarantee startup, drive SHDN above 2V (SHDN input

rising-edge trip level). For automatic shutdown and

startup, connect SHDN to VIN. The accurate 1V fallingedge threshold on SHDN can be used to detect a specific input voltage level and shut the device down. Once

in shutdown, the 1.6V rising-edge threshold activates,

providing sufficient hysteresis for most applications.

SMPS POR, UVLO, and Soft-Start

Power-on reset (POR) occurs when LDO5 rises above

approximately 1V, resetting the undervoltage, overvoltage, and thermal-shutdown fault latches. The POR circuit also ensures that the low-side drivers are pulled

high until the SMPS controllers are activated. Figure 2 is

the MAX8744A/MAX8745A block diagram.

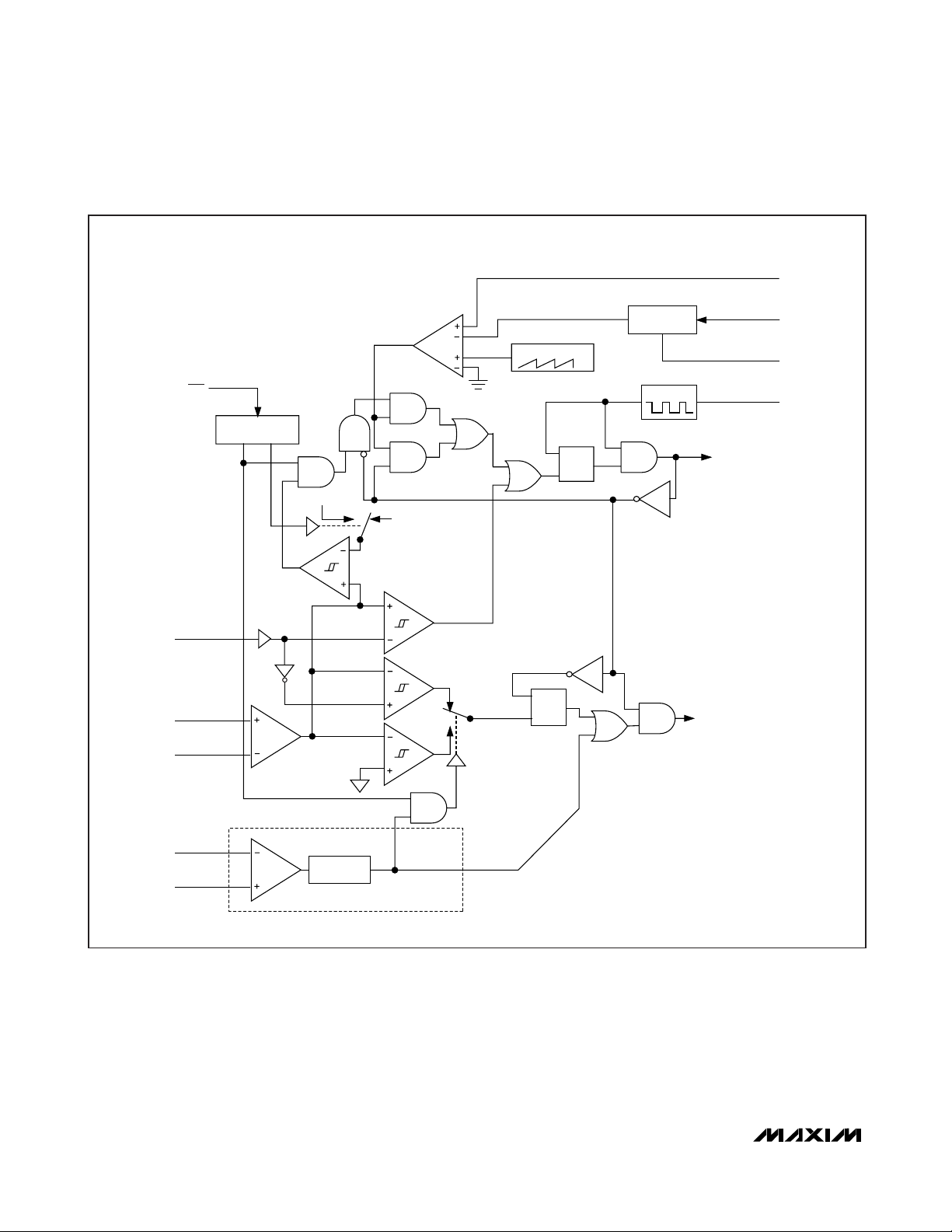

Figure 2. Block Diagram

FSEL

ILIM

SKIP

CSH3

CSL3

BST3

DH3

LX3

DL3

PGND

FB3

ON3

PGOOD5

PGOOD3

PGOODA

OSC

LDO5

LDO5

CONTROLLER

FB

DECODE

(FIGURE 5)

PWM3

(FIGURE 3)

INTERNAL

FB

POWER-GOOD AND FAULT

PROTECTION

(FIGURE 6)

MAX8744A

MAX8745A

IN

FAULT

5V LINEAR

REGULATOR

LDO BYPASS

CIRCUITRY

PWM5

CONTROLLER

(FIGURE 3)

DECODE

(FIGURE 5)

SECONDARY

FEEDBACK

LINEAR REGULATOR

LDO5

FB

2.0V

R

AUXILIARY

REF

R

SHDN

LDO5

CSH5

CSL5

BST5

DH5

LX5

DL5

ON5

FB5

REF

GND

DRVA

OUTA

FBA

ONA

Page 19

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main Power-

Supply Controllers for Notebook Computers

______________________________________________________________________________________ 19

The LDO5 input undervoltage-lockout (UVLO) circuitry

inhibits switching if the 5V bias supply (LDO5) is below

its 4V UVLO threshold. Once the 5V bias supply

(LDO5) rises above this input UVLO threshold and the

SMPS controllers are enabled (ON_ driven high), the

SMPS controllers start switching, and the output voltages begin to ramp up using soft-start. If the LDO5

voltage drops below the UVLO threshold, the controller

stops switching and pulls the low-side gate drivers low

until the LDO5 voltage recovers or drops below the

POR threshold.

The internal soft-start gradually increases the feedback

voltage with a 1V/ms slew rate. Therefore, the outputs

reach their nominal regulation voltage 2ms after the

SMPS controllers are enabled (see the SMPS Shutdown

Waveform in the

Typical Operating Characteristics

).

This gradual slew rate effectively reduces the input

surge current by minimizing the current required to

charge the output capacitors (I

OUT

= I

LOAD

+ C

OUT

x

V

OUT(NOM)

/ t

SLEW

).

SMPS Enable Controls (ON3, ON5)

ON3 and ON5 control SMPS power-up sequencing.

ON3 or ON5 rising above 2.4V enables the respective

outputs. ON3 or ON5 falling below 1.6V disables the

respective outputs. Driving ON_ below 0.8V clears the

overvoltage, undervoltage, and thermal fault latches.

SMPS Power-Up Sequencing

Connecting ON3 or ON5 to REF forces the respective

outputs off while the other output is below regulation

and starts after that output regulates. The second

SMPS remains on until the first SMPS turns off, the

device shuts down, a fault occurs, or LDO5 goes into

UVLO. Both supplies begin their power-down

sequence immediately when the first supply turns off.

Output Discharge (Soft-Shutdown)

When the switching regulators are disabled—when ON_

or SHDN is pulled low, or when an output undervoltage

fault occurs—the internal soft-shutdown gradually

decreases the feedback voltage with a 0.5V/ms slew rate.

Therefore, the regulation voltage drops to 0V within 4ms

after the SMPS controllers are disabled (see the SMPS

Shutdown Waveform in the

Typical Operating

Characteristics

). This slowly discharges the output

capacitance, eliminating the negative output voltages

caused by quickly discharging the output through the

inductor and low-side MOSFET. When an SMPS target

voltage discharges to 0.1V, its low-side driver (DL_) is

forced high, clamping the respective SMPS output to

GND. The reference remains active to provide an accurate threshold and to provide overvoltage protection. Both

SMPS controllers contain separate soft-shutdown circuits.

Table 3. Operating Mode Truth Table

*

SHDN is an accurate, low-voltage logic input with 1V falling-edge threshold voltage and 1.6V rising-edge threshold voltage. ON3

and ON5 are tri-level CMOS logic inputs, a logic-low voltage is less than 0.8V, a logic-high voltage is greater than 2.4V, and the middle-logic level is between 1.7V and 2.3V (see the

Electrical Characteristics

table).

MODE

Shutdown Mode Low X X OFF OFF OFF

Standby Mode High Low Low ON OFF OFF

Normal Operation High High High ON ON ON

3.3V SMPS Active High Low High ON OFF ON

5V SMPS Active High High Low

Normal Operation

(Delayed 5V SMPS

Startup)

Normal Operation

(Delayed 3.3V SMPS

Startup)

SHDN ON5 ON3 LDO5 5V SMPS 3V SMPS

High Ref High

High High Ref

INPUTS* OUTPUTS

OFF

LDO5 to CSL5 bypass

switch enabled

OFF

LDO5 to CSL5 bypass

switch enabled

OFF

LDO5 to CSL5 bypass

switch enabled

ON OFF

ON

Power-up after 3.3V

SMPS is in regulation

ON

ON

ON

Power-up after 5V

SMPS is in regulation

Page 20

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main PowerSupply Controllers for Notebook Computers

20 ______________________________________________________________________________________

Fixed-Frequency, Current-Mode

PWM Controller

The heart of each current-mode PWM controller is a

multi-input, open-loop comparator that sums two signals: the output-voltage error signal with respect to the

reference voltage and the slope-compensation ramp

(Figure 3). The MAX8744A/MAX8745A use a directsumming configuration, approaching ideal cycle-tocycle control over the output voltage without a

traditional error amplifier and the phase shift associated

with it.

Figure 3. PWM Controller Functional Diagram

FROM FB

(SEE FIGURE 5)

SKIP

TRI-LEVEL

DECODE

0.2 x V

LIMIT

0.1 x V

LIMIT

IDLE MODE

ILIM

CSH_

CSL_

A = 1/10

A = 1.2

CURRENT

PEAK CURRENT

LIMIT

NEG CURRENT

LIMIT

ZERO

CROSSING

AGND

SLOPE COMP

S

Q

R

SOFT-

START/STOP

OSC

R

Q

S

DH DRIVER

DL DRIVER

REF

ON_

FSEL

PGND

DRVA

OUTA

ONE-SHOT

5V SMPS ONLY

Page 21

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main Power-

Supply Controllers for Notebook Computers

_______________________________________

Frequency Selection (FSEL)

The FSEL input selects the PWM mode switching frequency. Table 4 shows the switching frequency based

on FSEL connection. High-frequency (500kHz) operation

optimizes the application for the smallest component

size, trading off efficiency due to higher switching losses.

This may be acceptable in ultraportable devices where

the load currents are lower. Low-frequency (200kHz)

operation offers the best overall efficiency at the expense

of component size and board space.

Forced-PWM Mode

The low-noise forced-PWM mode (SKIP = LDO5) disables the zero-crossing comparator, which controls the

low-side switch on-time. This forces the low-side gatedrive waveform to be constantly the complement of the

high-side gate-drive waveform, so the inductor current

reverses at light loads while DH_ maintains a duty factor

of V

OUT/VIN

. The benefit of forced-PWM mode is to keep

the switching frequency fairly constant. However, forcedPWM operation comes at a cost: the no-load 5V supply

current remains between 20mA to 50mA, depending on

the external MOSFETs and switching frequency.

Forced-PWM mode is most useful for avoiding audiofrequency noise and improving load-transient

response. Since forced-PWM operation disables the

zero-crossing comparator, the inductor current reverses under light loads.

Light-Load Operation Control (

SKIP

)

The MAX8744A/MAX8745A include a light-load operating mode control input (SKIP) used to enable or disable the zero-crossing comparator for both switching

regulators. When the zero-crossing comparator is

enabled, the regulator forces DL_ low when the current-sense inputs detect zero inductor current. This

keeps the inductor from discharging the output capacitors and forces the regulator to skip pulses under lightload conditions to avoid overcharging the output. When

the zero-crossing comparator is disabled, the regulator

is forced to maintain PWM operation under light-load

conditions (forced PWM).

Idle Mode Current-Sense Threshold

When pulse-skipping mode is enabled, the on-time of the

step-down controller terminates when the output voltage

exceeds the feedback threshold and when the current-

sense voltage exceeds the idle mode current-sense

threshold. Under light-load conditions, the on-time duration depends solely on the idle mode current-sense

threshold, which is 20% (SKIP = GND) of the full-load

current-limit threshold set by ILIM, or the low-noise current-sense threshold, which is 10% (SKIP = REF) of the

full-load current-limit threshold set by ILIM. This forces

the controller to source a minimum amount of power with

each cycle. To avoid overcharging the output, another

on-time cannot begin until the output voltage drops

below the feedback threshold. Since the zero-crossing

comparator prevents the switching regulator from sinking

current, the controller must skip pulses. Therefore, the

controller regulates the valley of the output ripple under

light-load conditions.

Automatic Pulse-Skipping Crossover

In skip mode, an inherent automatic switchover to PFM

takes place at light loads (Figure 4). This switchover is

affected by a comparator that truncates the low-side

switch on-time at the inductor current’s zero crossing.

The zero-crossing comparator senses the inductor current across CSH_ to CSL_. Once V

CSH

_ - V

CSL

_ drops

below the 3mV zero-crossing, current-sense threshold,

the comparator forces DL_ low (Figure 3). This mechanism causes the threshold between pulse-skipping

PFM and nonskipping PWM operation to coincide with

the boundary between continuous and discontinuous

inductor-current operation (also known as the “critical

conduction” point). The load-current level at which

PFM/PWM crossover occurs, I

LOAD(SKIP)

, is given by:

Table 4. FSEL Configuration Table

Figure 4. Pulse-Skipping/Discontinuous Crossover Point

FSEL SWITCHING FREQUENCY (kHz)

LDO5 500

REF 300

GND 200

VV V

I

LOAD SKIP

()

()

=

−

IN OUT OUT

Vf L

2

IN OSC

V

t

ON(SKIP)

INDUCTOR CURRENT

0

ON-TIME

OUT

=

VINf

OSC

TIME

I

PK

I

LOAD

= IPK / 2

Page 22

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main PowerSupply Controllers for Notebook Computers

22 ______________________________________________________________________________________

The switching waveforms may appear noisy and asynchronous when light loading causes pulse-skipping

operation, but this is a normal operating condition that

results in high light-load efficiency. Trade-offs in PFM

noise vs. light-load efficiency are made by varying the

inductor value. Generally, low inductor values produce

a broader efficiency vs. load curve, while higher values

result in higher full-load efficiency (assuming that the

coil resistance remains fixed) and less output-voltage

ripple. Penalties for using higher inductor values

include larger physical size and degraded load-transient response (especially at low input-voltage levels).

Output Voltage

DC output accuracy specifications in the

Electrical

Characteristics

table refer to the error comparator’s

threshold. When the inductor continuously conducts,

the MAX8744A/MAX8745A regulate the peak of the output ripple, so the actual DC output voltage is lower than

the slope-compensated trip level by 50% of the output

ripple voltage. For PWM operation (continuous conduction), the output voltage is accurately defined by the following equation:

where V

NOM

is the nominal output voltage, A

SLOPE

equals 1.1%, and V

RIPPLE

is the output ripple voltage

(V

RIPPLE

= ESR x ΔI

INDUCTOR

, as described in the

Output Capacitor Selection

section).

In discontinuous conduction (I

OUT

< I

LOAD(SKIP)

), the

MAX8744A/MAX8745A regulate the valley of the output

ripple, so the output voltage has a DC regulation level

higher than the error-comparator threshold. For PFM

operation (discontinuous conduction), the output voltage is approximately defined by the following equation:

where V

NOM

is the nominal output voltage, f

OSC

is the

maximum switching frequency set by the internal oscillator, fSWis the actual switching frequency, and I

IDLE

is

the idle mode inductor current when pulse skipping.

Connect FB3 and FB5 to LDO5 to enable the fixed

SMPS output voltages (3.3V and 5V, respectively), set

by a preset, internal resistive voltage-divider connected

between the output (CSL_) and analog ground.

Connect a resistive voltage-divider at FB_ between the

output (CSL_) and GND to adjust the respective output

voltage between 2V and 5.5V (Figure 5). Choose R

FBLO

(resistance from FB to AGND) to be approximately

10kΩ and solve for R

FBHI

(resistance from the output to

FB) using the equation:

where V

FB_

= 2V nominal.

When adjusting both output voltages, set the 3.3V

SMPS lower than the 5V SMPS. LDO5 connects to the

5V output (CSL5) through an internal switch only when

CSL5 is above the LDO5 bootstrap threshold (4.5V)

and the soft-start sequence for the CSL5 side has completed. Bootstrapping works most effectively when the

fixed output voltages are used. Once LDO5 is bootstrapped from CSL5, the internal 5V linear regulator

turns off. This reduces the internal power dissipation

and improves efficiency at higher input voltages.

Current-Limit Protection (ILIM)

The current-limit circuit uses differential current-sense

inputs (CSH_ and CSL_) to limit the peak inductor current. If the magnitude of the current-sense signal

exceeds the current-limit threshold, the PWM controller

turns off the high-side MOSFET (Figure 3). The actual

maximum load current is less than the peak currentlimit threshold by an amount equal to half of the inductor ripple current. Therefore, the maximum load

capability is a function of the current-sense resistance,

inductor value, switching frequency, and duty cycle

(V

OUT/VIN

).

Figure 5. Dual Mode Feedback Decoder

⎛

AVVV

VV

OUT PWM NOM

=−

()

SLOPE RIPPLE

1

⎜

⎝

IN

⎛

⎞

f

1

VV

OUT PFM NOM

=+

SW

⎜

⎟

f

2

⎝

⎠

OSC

⎞

⎛

RIPPLE

−

⎜

⎟

⎝

⎠

I ESR

IDLE()

2

TO ERROR

AMPLIFIER

ADJUSTABLE

OUTPUT

FIXED OUTPUT

FB = LDO5

⎛

V

OUT

_

FB

1

_

⎜

V

⎝

LDO5

OUT

⎞

⎟

⎠

FB

9R

RR

R

=−

FBHI FBLO

⎞

⎟

⎠

Page 23

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main Power-

Supply Controllers for Notebook Computers

______________________________________________________________________________________ 23

In forced-PWM mode, the MAX8744A/MAX8745A also

implement a negative current limit to prevent excessive

reverse inductor currents when V

OUT

is sinking current.

The negative current-limit threshold is set to approximately 120% of the positive current limit and tracks the

positive current limit when ILIM is adjusted.

Connect ILIM to LDO5 for the 50mV default threshold,

or adjust the current-limit threshold with an external

resistor-divider at ILIM. Use a 2µA to 20µA divider current for accuracy and noise immunity. The current-limit

threshold adjustment range is from 50mV to 200mV. In

the adjustable mode, the current-limit threshold voltage

equals precisely 1/10 the voltage seen at ILIM. The

logic threshold for switchover to the default value is

approximately V

LDO5

- 1V.

Carefully observe the PCB layout guidelines to ensure

that noise and DC errors do not corrupt the differential

current-sense signals seen by CSH_ and CSL_. Place

the IC close to the sense resistor with short, direct

traces, making a Kelvin-sense connection to the current-sense resistor.

MOSFET Gate Drivers (DH_, DL_)

The DH_ and DL_ drivers are optimized for driving

moderate-sized high-side and larger low-side power

MOSFETs. This is consistent with the low duty factor

seen in notebook applications, where a large VINV

OUT

differential exists. The high-side gate drivers

(DH_) source and sink 2A, and the low-side gate drivers (DL_) source 1.7A and sink 3.3A. This ensures

robust gate drive for high-current applications. The

DH_ floating high-side MOSFET drivers are powered by

charge pumps at BST_ while the DL_ synchronous-rectifier drivers are powered directly by the fixed 5V linear

regulator (LDO5).

Adaptive dead-time circuits monitor the DL_ and DH_

drivers and prevent either FET from turning on until the

other is fully off. The adaptive driver dead-time allows

operation without shoot-through with a wide range of

MOSFETs, minimizing delays and maintaining efficiency.

There must be a low-resistance, low-inductance path

from the DL_ and DH_ drivers to the MOSFET gates for

the adaptive dead-time circuits to work properly; otherwise, the sense circuitry in the MAX8744A/MAX8745A

interprets the MOSFET gates as “off” while charge actually remains. Use very short, wide traces (50 mils to 100

mils wide if the MOSFET is 1in from the driver).

The internal pulldown transistor that drives DL_ low is

robust, with a 0.6Ω (typ) on-resistance. This helps prevent

DL_ from being pulled up due to capacitive coupling from

the drain to the gate of the low-side MOSFETs when the

inductor node (LX_) quickly switches from ground to V

IN

.

Applications with high input voltages and long inductive

driver traces may require additional gate-to-source

capacitance to ensure fast-rising LX_ edges do not pull

up the low-side MOSFETs gate, causing shoot-through

currents. The capacitive coupling between LX_ and DL_

created by the MOSFET’s gate-to-drain capacitance

(C

GD

= C

RSS

), gate-to-source capacitance (CGS= C

ISS

- CGD), and additional board parasitics should not

exceed the following minimum threshold:

Lot-to-lot variation of the threshold voltage may cause

problems in marginal designs.

Power-Good Output (PGOOD_)

PGOOD_ is the open-drain output of a comparator that

continuously monitors both SMPS output voltages and

the auxiliary LDO output for undervoltage conditions.

PGOOD_ is actively held low in shutdown (SHDN =

GND), standby (ON3 = ON5 = ONA = GND), soft-start,

and soft-shutdown. Once the soft-start sequence terminates, PGOOD_ becomes high impedance as long as

the outputs are above 90% of the nominal regulation voltage set by FB_. PGOOD_ goes low once the respective

output drops 10% below its nominal regulation point, an

SMPS output overvoltage fault occurs, or ON_ or SHDN

is low. For a logic-level PGOOD_ output voltage, connect

an external pullup resistor between PGOOD_ and LDO5.

A 100kΩ pullup resistor works well in most applications.

Figure 6. Power-Good and Fault Protection

VV

GS TH IN

()

⎛

>

⎜

⎝

C

C

RSS

ISS

⎞

⎟

⎠

POWER GOOD

0.9 x INT REF_

0.7 x INT REF_ 1.11 x INT REF_

6144

CLK

POR

FAULT

PROTECTION

FAULT

LATCH

INTERNAL FB

ENABLE OVP

ENABLE UVP

FAULT

POWER-GOOD

Page 24

MAX8744A/MAX8745A

High-Efficiency, Quad Output, Main PowerSupply Controllers for Notebook Computers

24 ______________________________________________________________________________________

Fault Protection

Output Overvoltage Protection (OVP)—

MAX8744A Only

If the output voltage of either SMPS rises above 111% of

its nominal regulation voltage and the OVP protection is

enabled, the controller sets the fault latch, pulls PGOOD

low, shuts down the SMPS controllers that tripped the

fault, and immediately pulls DH_ low and forces DL_

high. This turns on the synchronous-rectifier MOSFETs

with 100% duty, rapidly discharging the output capacitors and clamping both outputs to ground. However,

immediately latching DL_ high typically causes slightly

negative output voltages due to the energy stored in the

output LC at the instant the OVP occurs. If the load cannot tolerate a negative voltage, place a power Schottky

diode across the output to act as a reverse-polarity

clamp. If the condition that caused the overvoltage persists (such as a shorted high-side MOSFET), the battery

blows. The other output is shut down using the soft-shutdown sequence. Cycle LDO5 below 1V or toggle either

ON3, ON5, or SHDN to clear the fault latch and restart

the SMPS controllers.

Output Undervoltage Protection (UVP)