Page 1

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

________________________________________________________________

Maxim Integrated Products

1

Ordering Information

19-0732; Rev 0; 2/07

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

♦

♦

♦

♦

♦

General Description

The MAX8662/MAX8663 power-management ICs

(PMICs) are efficient, compact devices suitable for

smart cellular phones, PDAs, Internet appliances, and

other portable devices. They integrate two synchronous

buck regulators, a boost regulator driving two to seven

white LEDs, four low-dropout linear regulators (LDOs),

and a linear charger for a single-cell Li-ion (Li+) battery.

Maxim’s Smart Power Selector™ (SPS) safely distributes power between an external power source (AC

adapter, auto adapter, or USB source), battery, and the

system load. When system load peaks exceed the

external source capability, the battery supplies supplemental current. When system load requirements are

small, residual power from the external power source

charges the battery. A thermal-limiting circuit limits battery-charge rate and external power-source current to

prevent overheating. The PMIC also allows the system

to operate with no battery or a discharged battery.

The MAX8662 is available in a 6mm x 6mm, 48-pin thin

QFN package, while the MAX8663, without the LED driver,

is available in a 5mm x 5mm, 40-pin thin QFN package.

Features

Applications

+

Denotes a lead-free package.

*

EP = Exposed paddle.

PART

TEMP

PIN-PACKAGE

PKG

CODE

MAX8662ETM+

-40°C to

48 Thin QFN-EP*

T4866-1

MAX8663ETL+

-40°C to

40 Thin QFN-EP*

T4055-1

Two 95%-Efficient 1MHz Buck Regulators

Main Regulator: 0.98V to V

IN

at 1200mA

Core Regulator: 0.98V to V

IN

at 900mA

1MHz Boost WLED Driver

Drives Up to 7 White LEDs at 30mA (max)

PWM and Analog Dimming Control

Four Low-Dropout Linear Regulators

1.7V to 5.5V Input Range

15µA Quiescent Current

Single-Cell Li+ Charger

Adapter or USB Input

Thermal-Overload Protection

Smart Power Selector (SPS)

AC Adapter/USB or Battery Source

Charger-Current and System-Load Sharing

Smart Phones and PDAs

MP3 and Portable Media Players

Palmtop and Wireless Handhelds

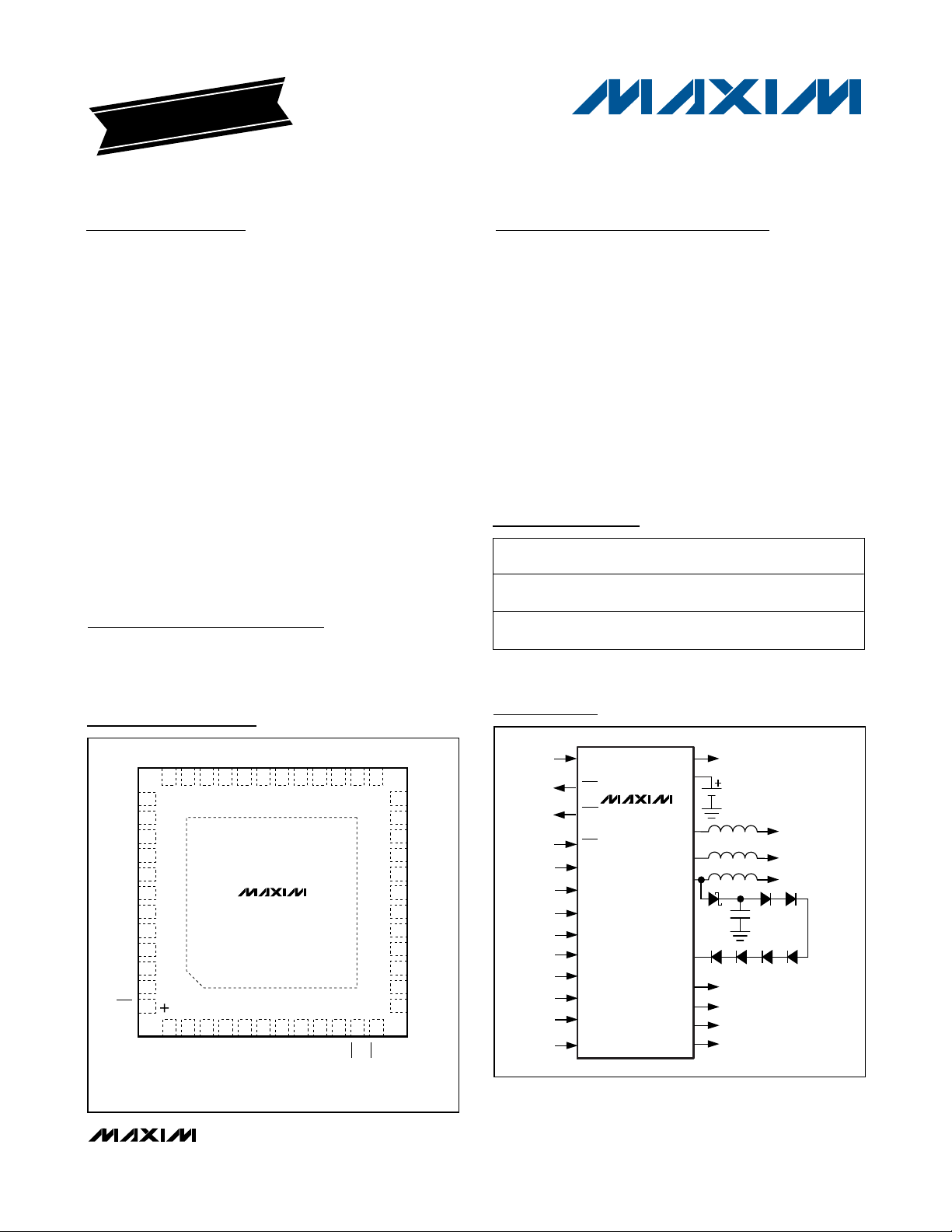

TOP VIEW

MAX8662

THIN QFN

(6mm x 6mm)

13

14

15

16

17

18

19

20

21

22

23

24

THM

ISET

CT

REF

GND

OUT4

IN45

OUT5

EN4

EN5

PWM

FB1

48

47

46

45

44

43

42

41

40

39

38

37

1

2

345678910

11

12

POK

PSET

SL2

SL1

VL

OUT7

IN67

OUT6

PG3

LX3

EN7

EN6

CEN

CHG

BRT

BAT2

BAT1

SYS2

SYS1

DC2

DC1

EN3

PEN2

PEN1

36

35

34 33 32 31 30 29 28 27

26

25

EN1

PG1

LX1

PV1

OVP

CS

CC3

FB2

PV2

LX2

PG2

EN2

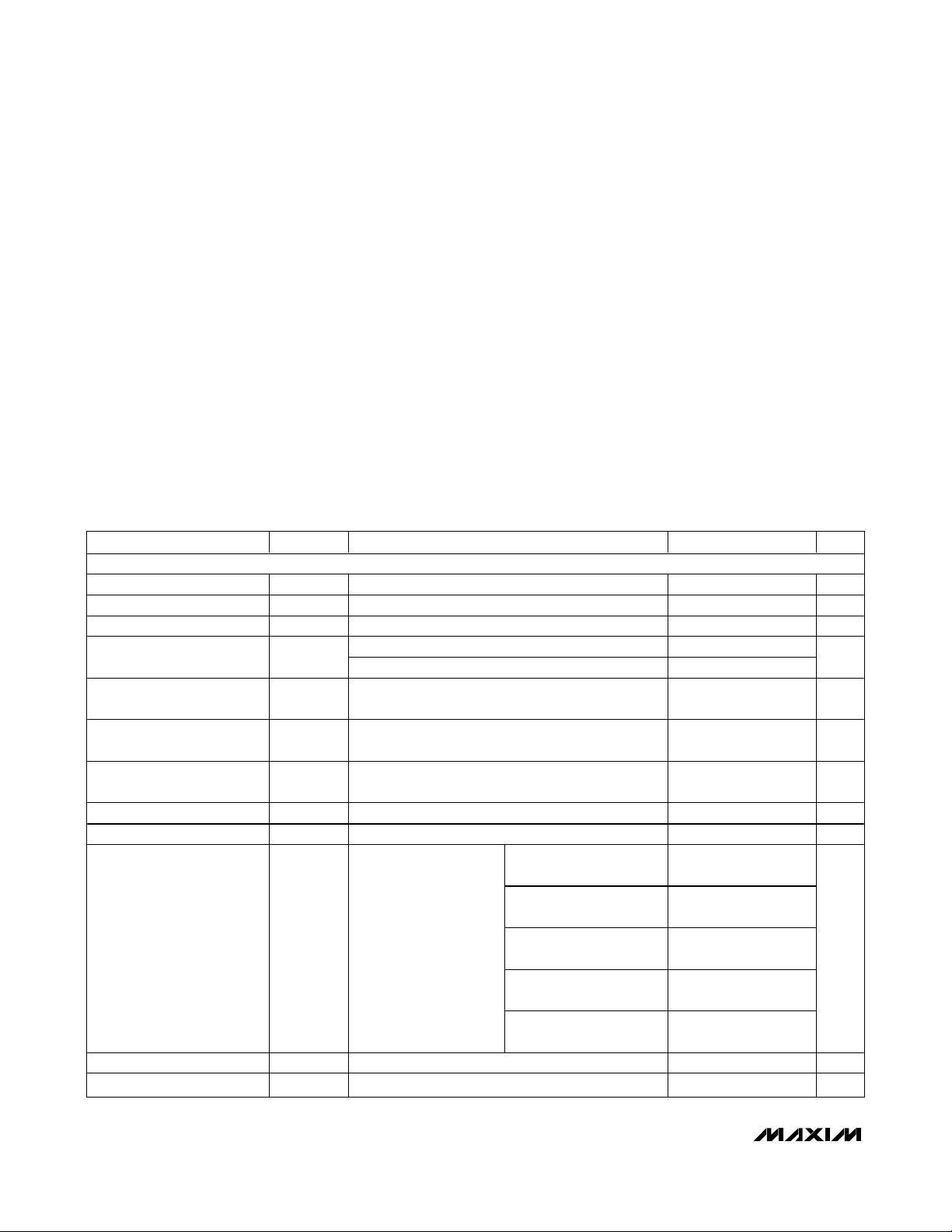

Pin Configurations

OUT1

0.98V TO V

IN

/ 1.2A

OUT2

0.98V TO V

IN

/ 0.9A

OUT3

30mA

WLED

DC SYS

OUT7

EN1

500mA

150mA

300mA

150mA

Li+

BATTERY

DC/USB

INPUT

TO SYSTEM

POWER

BAT

LX1

LX2

LX3

(MAX8662 ONLY)

OUT6

OUT5

OUT4

CS

TO SYS

EN2

EN3

EN4

EN5

EN6

EN7

PWR OK

CHARGE

STATUS

CHARGE

ENABLE

SL1

SL2

OUT4–OUT7

VOLTAGE

SELECT

MAX8662

MAX8663

POK

CHG

CEN

Typical Operating Circuit

Smart Power Selector is a trademark of Maxim Integrated

Products, Inc.

Pin Configurations continued at end of data sheet.

EVALUATION KIT

AVAILABLE

RANGE

+85°C

+85°C

6mm x 6mm x 0.8mm

5mm x 5mm x 0.8mm

Page 2

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

2 _______________________________________________________________________________________

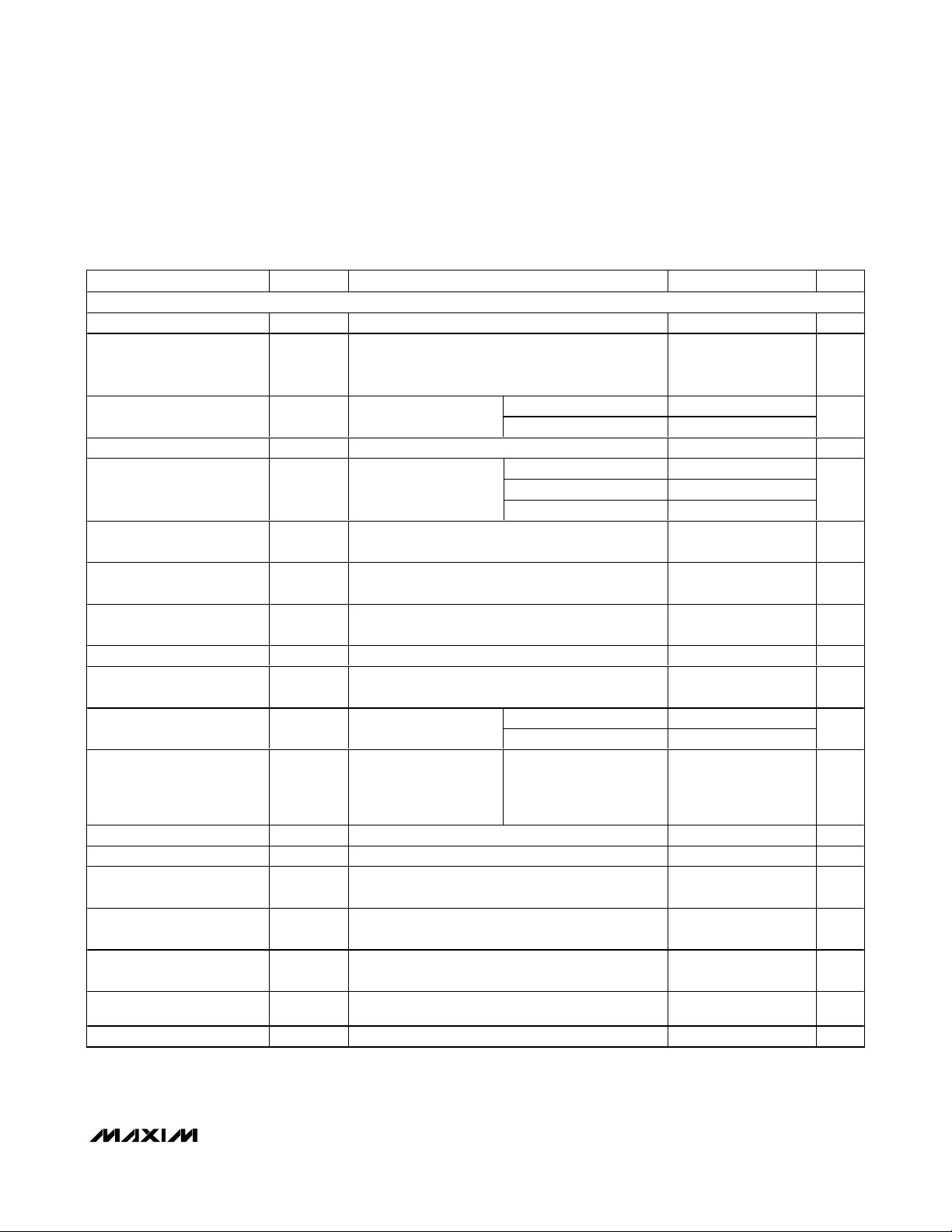

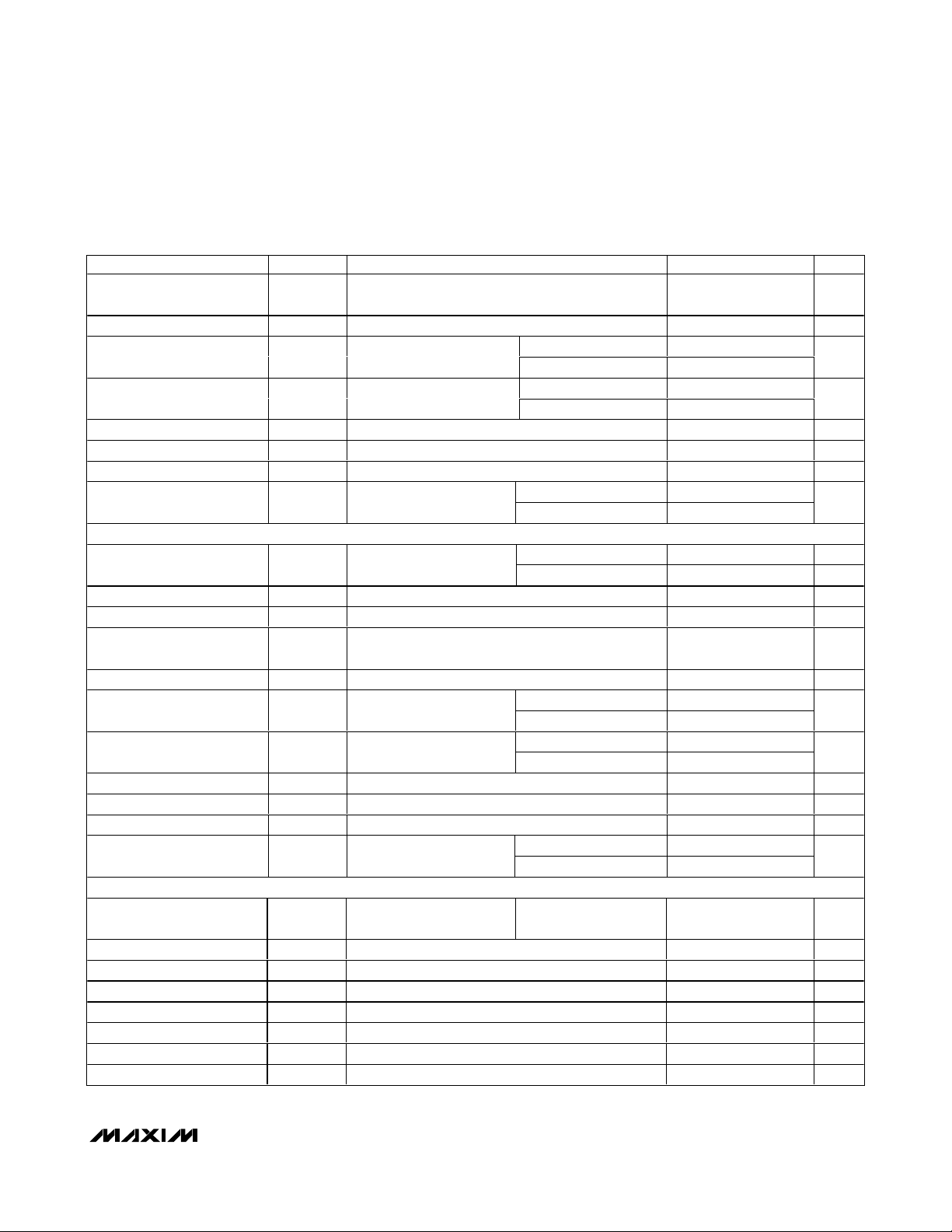

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS (Input Limiter and Battery Charger)

(VDC= 5V, V

BAT

= 4V, V

CEN

= 0V, V

PEN_

= 5V, R

PSET

= 3kΩ, R

ISET

= 3.15kΩ, CCT= 0.068µF, TA= -40°C to +85°C, unless otherwise

noted.) (Note 1)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

LX3 to GND ............................................................-0.3V to +33V

DC_ to GND..............................................................-0.3V to +9V

BAT_ CEN, CHG, EN_, PEN_, POK, PV_, PWM,

SYS_, LX1, CS, LX2 to GND .................................-0.3V to +6V

VL to GND ................................................................-0.3V to +4V

BRT, CC3, FB_, IN45, IN67, OVP, REF,

SL_ to GND ...........................................-0.3V to (V

S

YS

+ 0.3V)

CT, ISET, PSET, THM to GND .....................-0.3V to (V

VL

+ 0.3V)

OUT4, OUT5 to GND................................-0.3V to (V

IN45

+ 0.3V)

OUT6, OUT7 to GND................................-0.3V to (V

IN67

+ 0.3V)

PG_ to GND...........................................................-0.3V to +0.3V

BAT1 + BAT2 Continuous Current ...........................................3A

SYS1 + SYS2 Continuous Current (2 pins) ..............................3A

LX_ Continuous Current ........................................................1.5A

Continuous Power Dissipation (T

A

= +70°C)

40-Pin 5mm x 5mm Thin QFN

(derate 35.7mW/°C above +70°C)

(multilayer board) .......................................................2857mW

48-Pin 6mm x 6mm Thin QFN

(derate 37mW/°C above +70°C) (multilayer board)...2963mW

Operating Temperature Range ..........................-40°C to +85°C

Junction Temperature Range ............................-40°C to +125°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

PARAMETER

CONDITIONS

UNITS

INPUT LIMITER

DC Operating Range V

DC

(Note 2)

V

V

DC_L

VDC rising, 500mV hysteresis

V

DC Overvoltage Threshold V

DC_H

VDC rising, 100mV hysteresis

V

I

SYS = IBAT =

0mA, V

CEN =

0V

DC Supply Current

I

SYS = IBAT =

0mA, V

CEN =

5V

mA

DC Shutdown Current

V

DC

= 5V, V

CEN =

5V, V

PEN1

= V

PEN2 =

0V (USB

suspend mode)

µA

DC-to-SYS Dropout

On-Resistance

V

DC

= 5V, I

SYS =

400mA, V

CEN =

5V

Ω

DC-to-BAT Dropout

Threshold

When V

SYS

regulation and charging stops, V

DC

falling, 150mV hysteresis

50 85

mV

VL Voltage V

VL

I

VL =

0 to 10mA

V

SYS Regulation Voltage

VDC = 5.8V, I

SYS =

1mA, V

CEN =

5V

V

R

PSET =

1.5kΩ

R

PSET

= 3kΩ

R

PSET

= 6kΩ

(500mA USB mode)

DC Input Current Limit I

DC_LIM

VDC = 5V, V

SYS

= 4.0V

V

PEN1

= V

PEN2 =

0V

(100mA USB mode)

90

mA

PSET Resistance Range R

PSET

Guaranteed by SYS current limit

kΩ

Inp ut Li m i ter S oft- S tar t Ti m e

Current-limit ramp time

ms

DC Undervoltage Threshold

SYMBOL

R

DC_SYS

V

DR_DC_BAT

V

SYS_REG

T

S S _ D C _S Y S

MIN TYP MAX

4.1 8.0

3.9 4.0 4.1

6.6 6.9 7.2

1.5

0.9

110 180

0.1 0.2

20

V

PEN1 =

V

PEN1 =

V

PEN1 =

V

PEN1 =

5V, V

5V, V

5V, V

0V, V

PEN2

PEN2 =

PEN2 =

PEN2 =

= 5V,

5V,

5V,

5V

3.1 3.3 3.5

5.2 5.3 5.4

1800 2000 2200

900 1000 1100

450 500 550

450 475 500

80

100

1.5 6.0

1.5

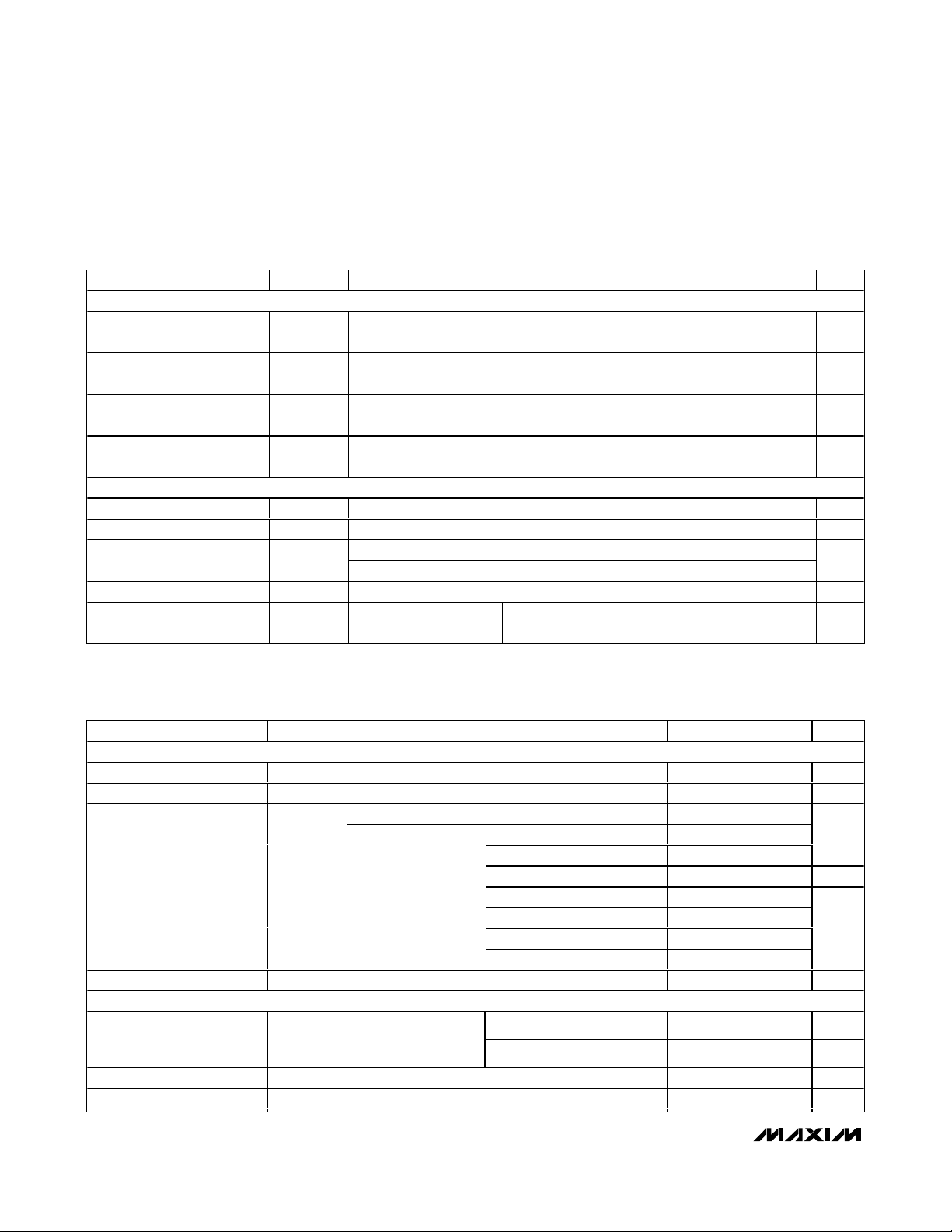

Page 3

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

_______________________________________________________________________________________ 3

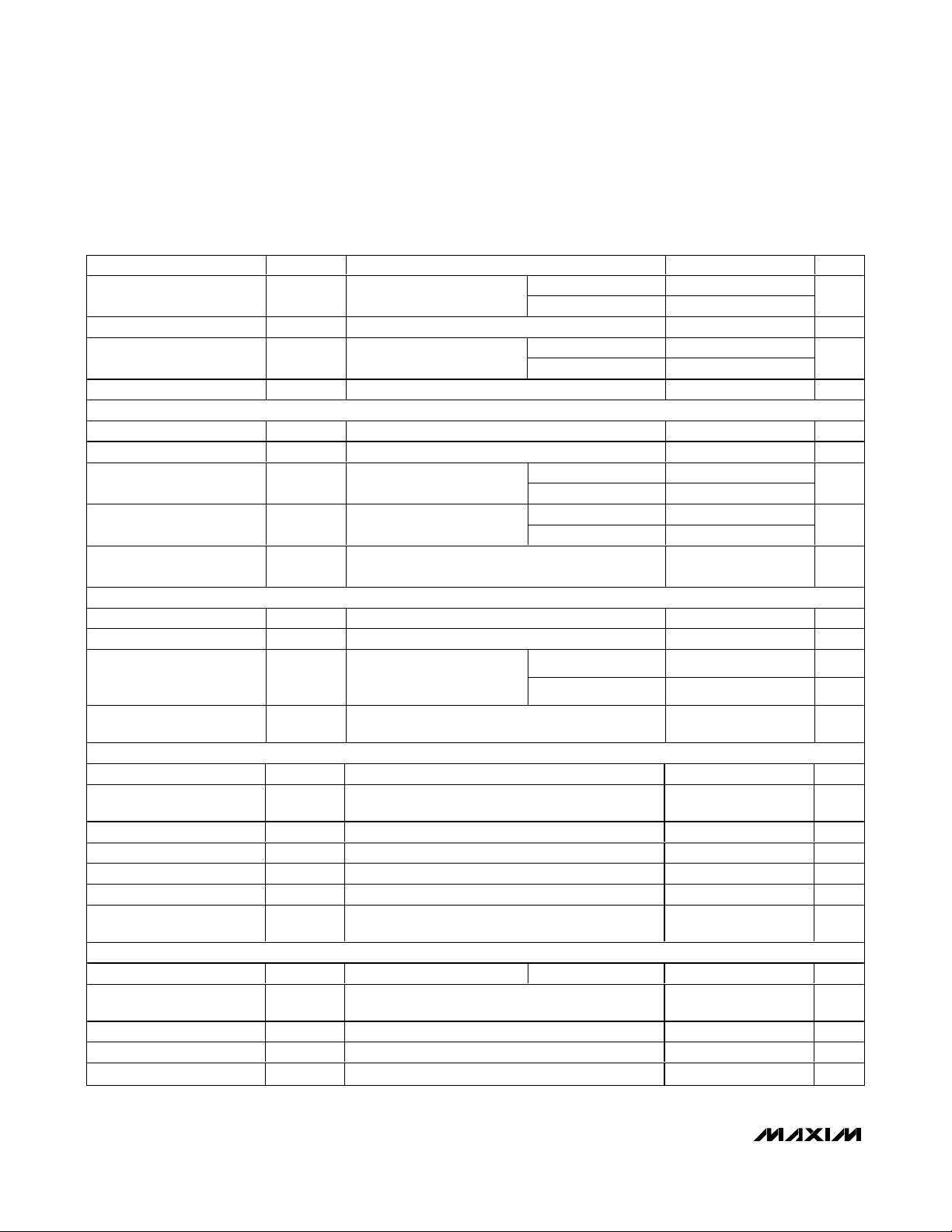

ELECTRICAL CHARACTERISTICS (Input Limiter and Battery Charger) (continued)

(VDC= 5V, V

BAT

= 4V, V

CEN

= 0V, V

PEN_

= 5V, R

PSET

= 3kΩ, R

ISET

= 3.15kΩ, CCT= 0.068µF, TA= -40°C to +85°C, unless otherwise

noted.) (Note 1)

PARAMETER

CONDITIONS

UNITS

BATTERY CHARGER

BAT-to-SYS On-Resistance

V

DC =

0V, V

BAT =

4.2V, I

SYS =

1A 40 80

mΩ

BAT-to-SYS Reverse

Regulation Voltage

V

D C

= 5V , V

P E N 1

= V

P E N 2

= 0V ( U S B 100m A m od e) ,

I

SYS

= 200mA (BAT to SYS voltage drop during SYS

overload)

mV

TA = +25°C

BAT Regulation Voltage

I

BAT =

0mA

T

A

= -40°C to +85°C

V

BAT Recharge Threshold BAT voltage drop to restart charging

mV

R

ISET =

1.89kΩ

R

ISET =

3.15kΩ

BAT Fast-Charge Current

I

SYS =

0mA,

R

PSET

= 1.5kΩ,

V

PEN1

= V

PEN2

= 5V

R

ISET =

7.87kΩ

mA

V

BAT =

2.5V, R

ISET =

3.15kΩ (prequalification

current is 10% of fast-charge current)

75

mA

ISET Resistance Range R

ISET

Guaranteed by BAT charging current

(1.5A to 300mA)

kΩ

V

ISET

-to-I

BAT

Ratio

R

ISET

= 3.15kΩ (ISET output voltage to actual

charge-current ratio)

2

V/A

Charger Soft-Start Time

Charge-current ramp time

ms

BAT Prequalification

Threshold

V

BAT

rising, 180mV hysteresis

V

VDC = 0V

5

BAT Leakage Current

V

BAT =

4.2V,

outputs disabled

V

DC = VCEN =

5V

5

µA

I

BAT

where CHG goes

high, and top-off timer;

I

BAT

falling (7.5% of

fast-charge current)

R

ISET =

3.15kΩ

mA

Timer-Suspend Threshold I

BAT

falling (Note 3)

mV

Timer Accuracy C

CT =

0.068µF

%

Prequalification Time

From CEN high to end of prequalification charge,

V

BAT =

2.5V, C

CT =

0.068µF

30

Min

Charge Time

From CEN high to end of fast charge,

C

CT =

0.068µF

Min

Top-Off Time

From CHG high to end of fast charge,

C

CT =

0.068µF

30

Min

Charger Thermal-Limit

Temperature

(Note 4)

°C

R

PSET

= 3kΩ 50

m A/°C

BAT Prequalification Current

CHG and Top-Off Threshold

Charger Thermal-Limit Gain

SYMBOL

R

BAT_REG

V

BAT_REG

t

SS_CHG

t

PREQUAL

t

FST-CHG

t

TOP-OFF

MIN TYP MAX

50 100 150

4.179 4.200 4.221

4.158 4.200 4.242

-140 -100 -60

1250

675 750 825

300

1.57 7.87

1.5

2.9 3.0 3.1

0.01

0.01

56.25

250 300 350

-20 +20

300

100

Page 4

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (Input Limiter and Battery Charger) (continued)

(VDC= 5V, V

BAT

= 4V, V

CEN

= 0V, V

PEN_

= 5V, R

PSET

= 3kΩ, R

ISET

= 3.15kΩ, CCT= 0.068µF, TA= -40°C to +85°C, unless otherwise

noted.) (Note 1)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

THERMISTOR INPUT (THM)

THM Internal Pullup

Resistance

10

kΩ

THM Resistance Threshold,

Hot

Resistance falling (1% hysteresis)

kΩ

THM Resistance Threshold,

Cold

Resistance rising (1% hysteresis)

kΩ

THM Resistance Threshold,

Disabled

Resistance falling

Ω

LOGIC I/O (POK, CHG, PEN_, EN_, PWM, CEN)

Input Logic-High Level

V

Input Logic-Low Level

V

V

LOGIC

= 0V to 5.5V, TA = +25°C

V

LOGIC

= 5.5V, TA = +85°C

µA

Logic Output-Voltage Low I

SINK

= 1mA 10

mV

TA = +25°C

1

Logic Output-High Leakage

Current

V

LOGIC =

5.5V

T

A

= +85°C

µA

ELECTRICAL CHARACTERISTICS (Output Regulator)

(V

SYS_

= V

PV_

= V

IN45

= V

IN67

= 4.0V, V

BRT

= 1.25V, circuit of Figure 1, TA= -40°C to +85°C, unless otherwise noted.) (Note 1)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

SYSTEM

SYS Operating Range V

SYS

V

V

SYS

rising, 100mV hysteresis

V

Extra supply current when at least one output is on 35

OUT1 on, V

PWM

= 0V 16

OUT2 on, V

PWM =

0V 16

µA

OUT3 on 1 2 mA

20

16

17

SYS Bias Current Additional

Regulator Supply Current

Not including

SYS bias current

OUT7 on (current in IN67) 16

µA

Inter nal Osci l l ator Fr eq uency PWM frequency of OUT1, OUT2, and OUT3

MHz

BUCK REGULATOR 1

V

PWM =

0V 16 35 µA

Supply Current

not including SYS

bias current

V

PWM =

5V

mA

Output Voltage Range V

OUT1

Guaranteed by FB accuracy

V

Maximum Output Current I

OUT1

mA

3.73 3.97 4.21

26.98 28.7 30.42

270 300 330

1.3

Logic Input-Leakage Current

-1 +0.001 +1

0.01

0.001

0.01

0.4

100

S Y S U nd er vol tag e Thr eshol d V

UVLO_SYS

OUT4 on (current into IN45)

I

+ I

, no load,

PV1

SYS

OUT5 on (current into IN45)

OUT6 on (current into IN67)

2.6 5.5

2.4 2.5 2.6

70

35

35

30

25

27

25

0.9 1.0 1.1

2.9

0.98 3.30

1200

Page 5

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

_______________________________________________________________________________________ 5

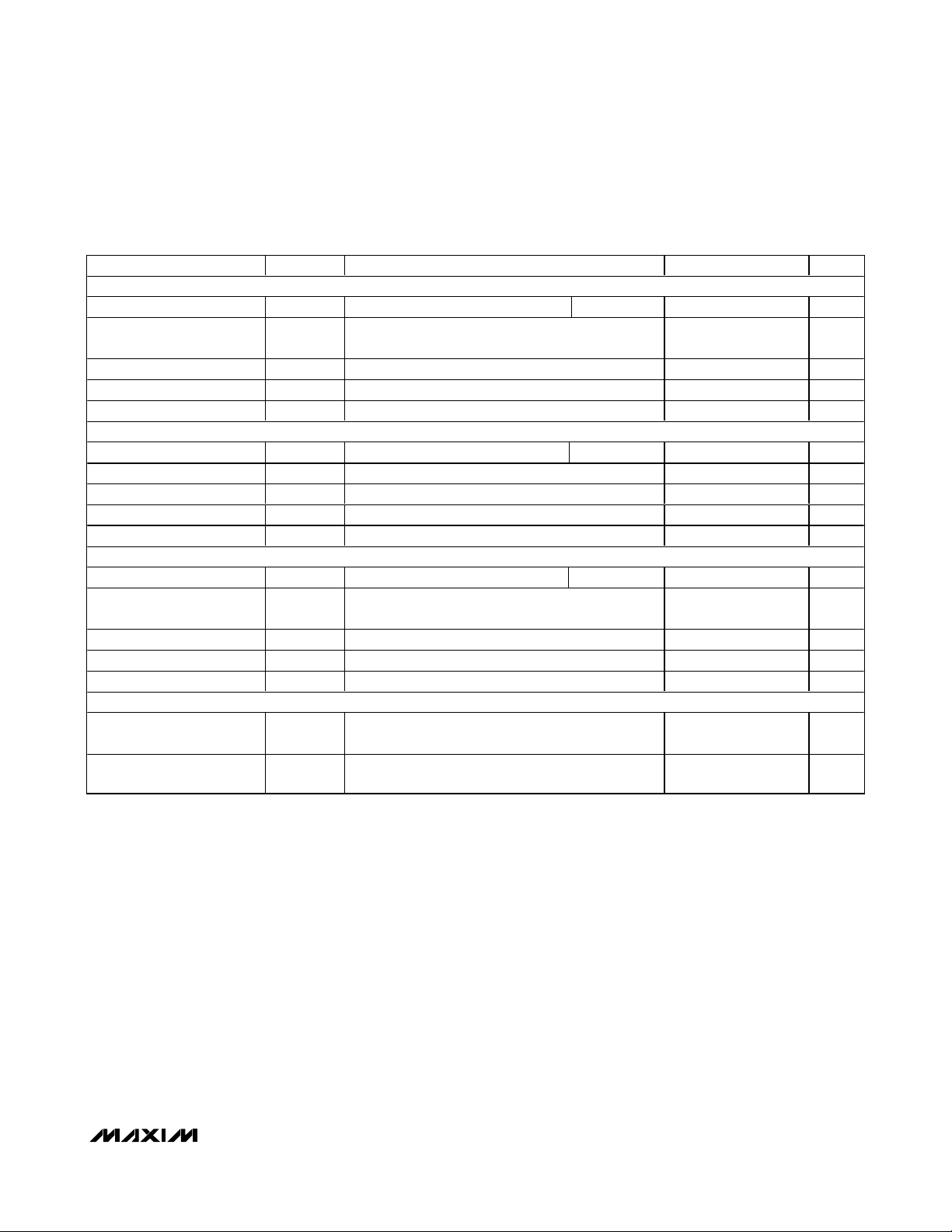

ELECTRICAL CHARACTERISTICS (Output Regulator) (continued)

(V

SYS_

= V

PV_

= V

IN45

= V

IN67

= 4.0V, V

BRT

= 1.25V, circuit of Figure 1, TA= -40°C to +85°C, unless otherwise noted.) (Note 1)

PARAMETER

CONDITIONS

UNITS

FB Regulation Accuracy

From V

FB1

= 0.98V, I

OUT1 =

0 to 1200mA,

V

OUT1 =

0.98V to 3.3V

-3 +3 %

FB1 Input Leakage Current

µA

V

PV1 =

3.3V

pMOS On-Resistance I

LX1 =

100mA

V

PV1 =

2.6V

Ω

V

PV1 =

3.3V

nMOS On-Resistance I

LX1 =

100mA

V

PV1 =

2.6V

Ω

pMOS Current Limit

A

S ki p M od e Transi ti on C ur r ent 90

mA

nMOS Zero-Cross Current 25

mA

V

LX1

= V

PV1 =

5.5V

LX Leakage

V

EN1 =

0V, V

SYS

= 5.5V,

T

A =

+25°C

µA

BUCK REGULATOR 2

V

PWM

= 0V 16 35 µA

Supply Current

I

SYS

+ I

PV2

, no l oad , not

i ncl ud i ng S Y S b i as cur r ent

V

PWM

= 5V

mA

Output Voltage Range Guaranteed by FB accuracy

V

Maximum Output Current

mA

FB Regulation Accuracy

From V

FB2 =

0.98V, I

OUT2 =

0 to 600mA,

V

OUT2

= 0.98V to 3.3V

-3 +3 %

FB2 Input Leakage Current

µA

V

PV2 =

3.3V

pMOS On-Resistance I

LX2

= 100mA

V

PV2 =

2.6V

Ω

V

PV2 =

3.3V

nMOS On- Resistance I

LX2 =

100mA

V

PV2 =

2.6V

Ω

pMOS Current Limit

A

S ki p M od e Transi ti on C ur r ent 90

mA

nMOS Zero-Cross Current 25

mA

V

LX2

= V

PV2

= 5.5V

LX Leakage

V

EN2 =

0V, V

SYS

= 5.5V,

T

A =

+25°C

µA

BOOST REGULATOR FOR LED DRIVER

Supply Current

At S Y S , no l oad , not

i ncl ud i ng S Y S b i as cur r ent

Switching 1

mA

Output Range V

OUT3

30 V

Minimum Duty Cycle D

MIN

10 %

Maximum Duty Cycle D

MAX

92 %

CS Regulation Voltage V

CS

V

OVP Regulation Voltage Duty = 90%, I

LX3 =

0mA

V

OVP Sink Current

µA

OVP Soft-Start Period Time for I

OVP

to ramp from 0 to 20µA

ms

SYMBOL

V

LX1

V

LX2

= 0V, V

= 0V, V

= 5.5V -5.00 -0.01

PV1

= 5.5V -5.00 -0.01

PV2

MIN TYP MAX

0.01 0.10

0.12 0.24

0.15

0.2 0.4

0.3

1.4 1.8 2.2

0.01 1.00

2.1

0.98 3.30

900

0.01 0.10

0.2 0.4

0.3

0.2 0.4

0.3

1.07 1.30 1.55

0.01 1.00

V

SYS

90

0.29 0.32 0.35

1.225 1.250 1.275

19.2 20.0 20.8

1.25

Page 6

ELECTRICAL CHARACTERISTICS (Output Regulator) (continued)

(V

SYS_

= V

PV_

= V

IN45

= V

IN67

= 4.0V, V

BRT

= 1.25V, circuit of Figure 1, TA= -40°C to +85°C, unless otherwise noted.) (Note 1)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

TA = +25°C

1

OVP Leakage Current

V

EN3

= 0V,

V

OVP

= V

SYS

= 5.5V

T

A =

+85°C

µA

nMOS On-Resistance I

LX3

= 100mA

1.2 Ω

TA = +25°C

V

LX3

= 30V

T

A =

+85°C

µA

nMOS Current Limit

mA

LED DRIVER

BRT Input Range V

BRT

I

CS =

0 to 30mA 0 1.5 V

REF Voltage V

REF

I

REF =

0mA

V

TA = +25°C -1

+1

BRT Input Current V

BRT

= 0 to 1.5V

T

A =

+85°C

µA

V

BRT

= 1.5V

30 32

CS Sink Current VCS = 0.2V

V

BRT

= 50mV

1.2

mA

CS Current-Source

Line Regulation

V

SYS

= 2.7V to 5.5V

%/V

PWM DIMMING

EN3 DC Turn-On Delay From V

EN3

= high to LED on

2.5 ms

EN3 Shutdown Delay From V

EN3

= low to LED off

2.5 ms

Maximum

ms

PWM Dimming Capture

Period

Time between rising edges

on EN3 for PWM dimming to

become active

Minimum 8 10 µs

PWM Dimming Pulse-Width

Resolution

Resolution of high or low-pulse width on EN3 for

dimming change

µs

LINEAR REGULATORS

V

IN45

5.5 V

IN45, IN67 Undervoltage

Threshold

V

IN45

rising, 100mV hysteresis

1.7 V

Output Noise f = 100Hz to 100kHz

µV

RMS

PSRR f = 100kHz 30 dB

Shutdown Supply Current V

EN4

= V

EN5

= 0V, TA = +25°C

1µA

Soft-Start Ramp Time V

OUT4

to 90% of final value 10

V/ms

Output Discharge

Resistance in Shutdown

V

EN4

= 0V

2.0 kΩ

LINEAR REGULATOR 4 (LDO4)

Supply Current At IN45, V

EN5

= 0V I

OUT4

= 0A 20 30 µA

Voltage Accuracy

I

OUT4

= 0 to 500mA,

V

IN45

= V

OUT4

+ 0.3V to 5.5V with 1.7V (min)

%

M i ni m um O utp ut C ap aci tor C

OUT4

Guaranteed stability, ESR < 0.05Ω

µF

Dropout Resistance IN45 to OUT4

0.4 Ω

Current Limit V

OUT4

= 0V

mA

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

6 _______________________________________________________________________________________

nMOS Off-Leakage Current

IN 45, IN 67 O p er ati ng Rang e

V

UVLO-IN45

0.01

0.1

0.6

0.01 5.00

0.1

500 620 900

1.45 1.50 1.55

-0.01

0.1

28

0.4 0.8

0.1

1.5 2.0

1.5 2.0

1.5 2.0

0.5

1.7

1.5 1.6

200

0.001

0.5 1.0

-1.5 +1.5

3.76

0.2

500 700

Page 7

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

_______________________________________________________________________________________ 7

ELECTRICAL CHARACTERISTICS (OUTPUT REGULATOR) (continued)

(V

SYS_

= V

PV_

= V

IN45

= V

IN67

= 4.0V, V

BRT

= 1.25V, circuit of Figure 1, TA= -40°C to +85°C, unless otherwise noted.) (Note 1)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

LINEAR REGULATOR 5 (LDO5)

Supply Current At IN45, V

EN4

= 0V I

OUT5

= 0A

25 µA

Voltage Accuracy

I

OUT5 =

0 to 150mA,

V

IN45

= V

OUT5

+ 0.3V to 5.5V with 1.7V (min)

%

M i ni m um O utp ut C ap aci tor C

OUT5

Guaranteed stability, ESR < 0.05Ω

µF

Dropout Resistance IN45 to OUT5

Ω

Current Limit V

OUT5

= 0V

mA

LINEAR REGULATOR 6 (LDO6)

Supply Current At IN67, V

EN6

= V

SYS

, V

EN7

= 0V I

OUT6

= 0A

27 µA

Voltage Accuracy I

OUT6 =

0 to 300mA, V

IN67

= V

OUT6

+ 0.3V to 5.5V

%

M i ni m um O utp ut C ap aci tor C

OUT6

Guaranteed stability, ESR < 0.05Ω

µF

Dropout Resistance IN67 to OUT6

Ω

Current Limit V

OUT6

= 0V

mA

LINEAR REGULATOR 7 (LDO7)

Supply Current At IN67, V

EN6

= 0V, V

EN7

= V

SYS

I

OUT7

= 0A

25 µA

Voltage Accuracy

I

OUT7

= 0 to 150mA,

V

IN67

= V

OUT7

+ 0.3V to 5.5V with 1.7V (min)

%

M i ni m um O utp ut C ap aci tor C

OUT7

Guaranteed stability, ESR < 0.05Ω

µF

Dropout Resistance IN67 to OUT6

Ω

Current Limit V

OUT7

= 0V

mA

THERMAL SHUTDOWN

Thermal-Shutdown

Temperature

T

J

rising

°C

Thermal-Shutdown

Hysteresis

°C

Note 1: Limits are 100% production tested at TA= +25°C. Limits over the operating temperature range are guaranteed through

correlation using statistical quality control (SQC) methods.

Note 2: Input withstand voltage. Not designed to operate above V

DC

= 6.5V due to thermal-dissipation issues.

Note 3: ISET voltage when CT timer stops. Occurs only when in constant-current mode. Translates to 20% of fast-charge current.

Note 4: Temperature at which the input current limit begins to reduce.

16

-1.5 +1.5

0.8

0.6 1.2

150 210

17

-1.5 +1.5

1.76

0.35 0.60

300 420

16

-1.5 +1.5

0.8

0.6 1.2

150 210

165

15

Page 8

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

8 _______________________________________________________________________________________

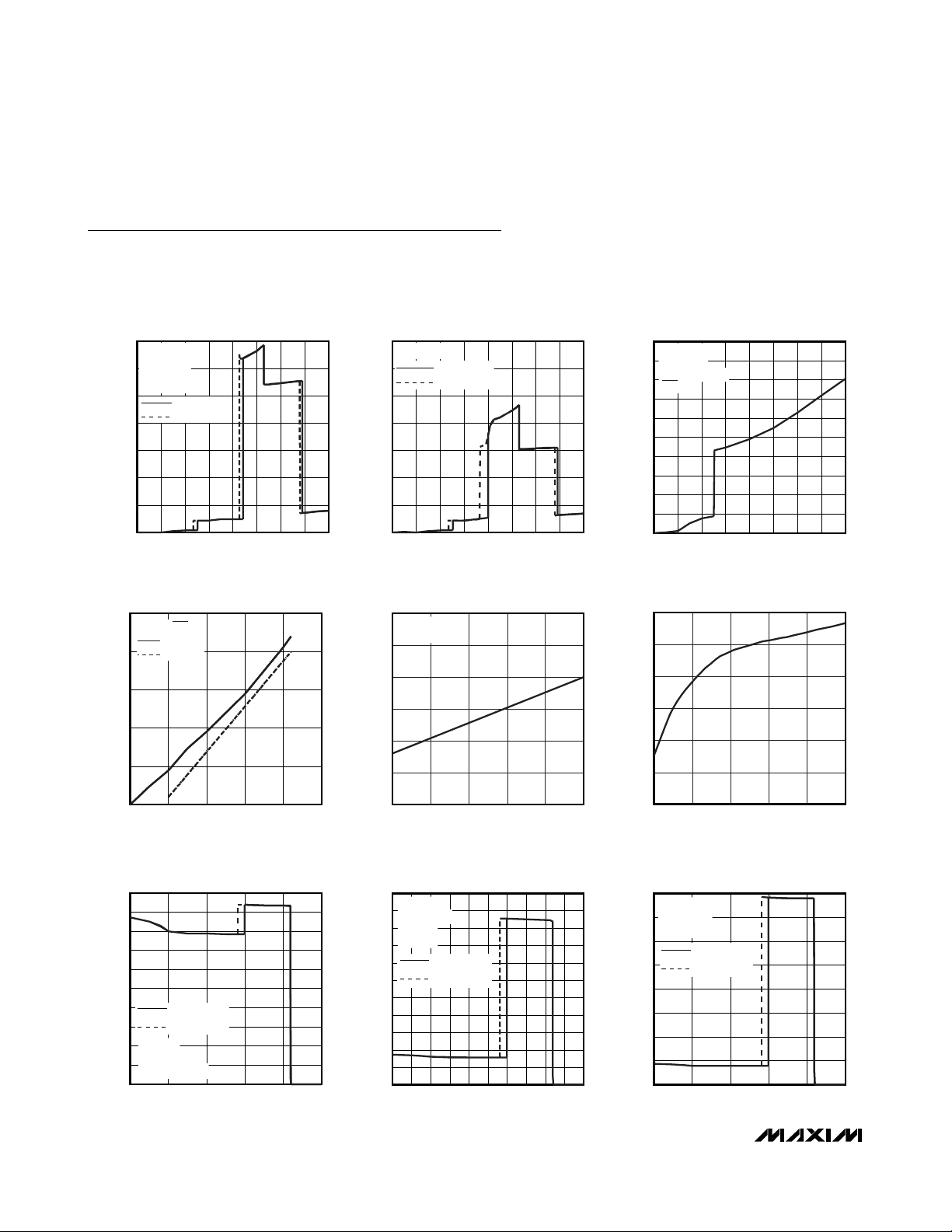

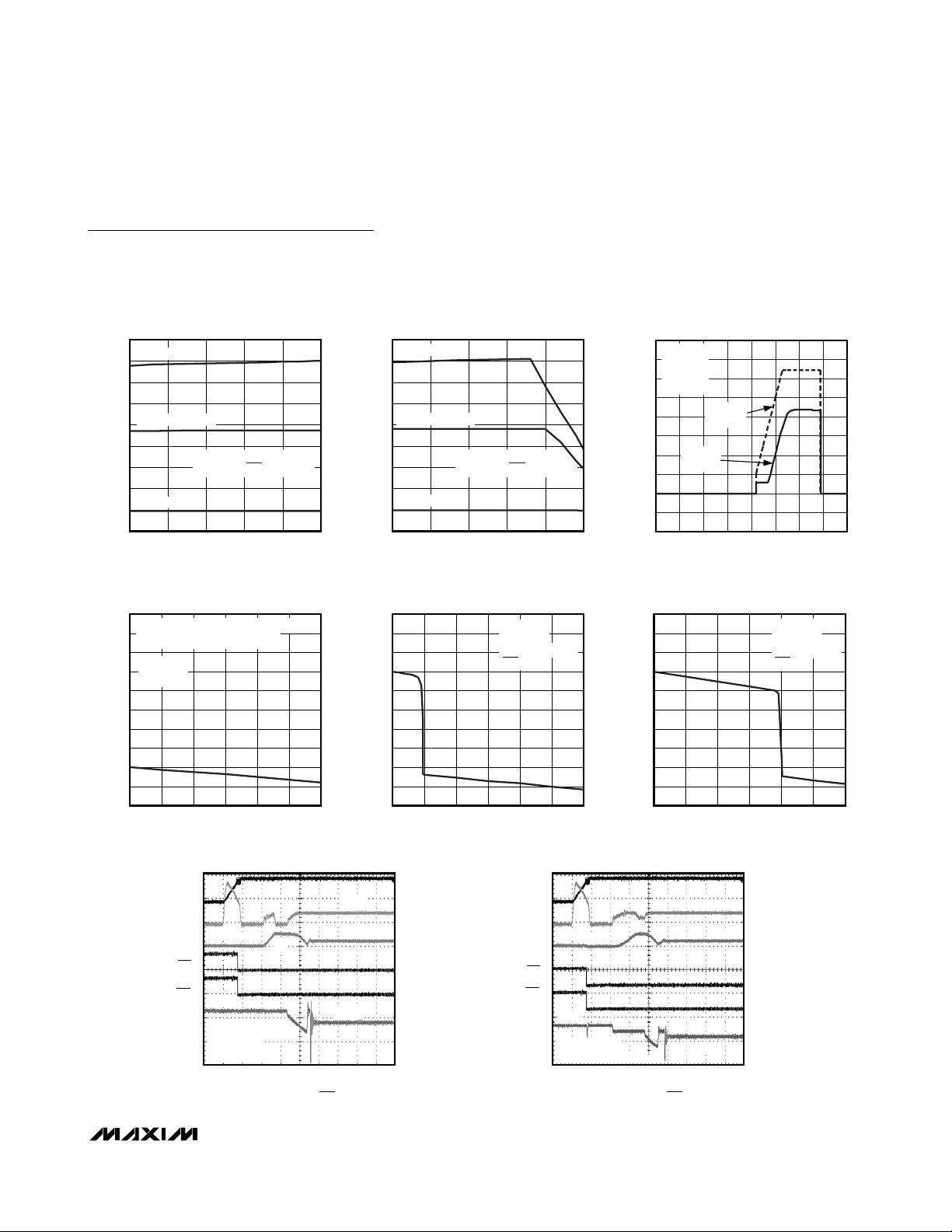

Typical Operating Characteristics

(Circuit of Figure 1, V

DC

= 5V, R

PSET

= 1.5kΩ, R

ISET

= 3kΩ, V

OUT1

= 3.3V, V

OUT2

= 1.3V, SL1 = SL2 = open, V

CEN

= 0V, V

PEN1

=

V

PEN2

= 5V, C

OUT1

= 2 x 10µF, C

OUT2

= 2 x 10µF, C

OUT3

= 0.1µF, C

OUT4

= 4.7µF, C

OUT5

= 1µF, C

OUT6

= 2.2µF, C

OUT7

= 1µF, CT =

0.068µF, C

REF

= CVL= 0.1µF, R

THM

= 10kΩ, L1 = 3.3µH, L2 = 4.7µH, L3 = 22µH, GND = PG1 = PG2 = PG3 = 0, TA= +25°C, unless

otherwise noted.)

INPUT QUIESCENT CURRENT

vs. INPUT VOLTAGE (CHARGER ENABLED)

MAX8662/63 toc01

INPUT VOLTAGE (V)

INPUT QUIESCENT CURRENT (mA)

7654321

0.2

0.4

0.6

0.8

1.0

1.2

1.4

0

08

V

BAT

= 4.2V

I

SYS

= 0

CHARGER IN

DONE MODE

V

BAT

RISING

V

BAT

FALLING

INPUT QUIESCENT CURRENT

vs. INPUT VOLTAGE (CHARGER DISABLED)

MAX8662/63 toc02

INPUT VOLTAGE (V)

INPUT QUIESCENT CURRENT (mA)

7654321

0.2

0.4

0.6

0.8

1.0

1.2

1.4

0

08

V

BAT

= 3.6V

V

BAT

RISING

V

BAT

FALLING

INPUT QUIESCENT CURRENT

vs. INPUT VOLTAGE (SUSPEND)

MAX8662/63 toc03

INPUT VOLTAGE (V)

INPUT QUIESCENT CURRENT (mA)

764 52 31

0.02

0.04

0.06

0.08

0.10

0.12

0.14

0.16

0.18

0.20

0

08

V

BAT

= 4.2V

I

SYS

= 0mA

PEN1 = PEN2 = 0

CEN = 1

BATTERY-LEAKAGE CURRENT

vs. BATTERY VOLTAGE

MAX8662/63 toc04

BATTERY VOLTAGE (V)

BATTERY-LEAKAGE CURRENT (μA)

4321

0.1

0.2

0.3

0.4

0.5

0

05

EN_ = 0, CEN = 1

V

DC

OPEN

V

DC

= 5V

BATTERY-LEAKAGE CURRENT

vs. TEMPERATURE (INPUT DISCONNECTED)

MAX8662/63 toc05

AMBIENT TEMPERATURE (°C)

BATTERY-LEAKAGE CURRENT (μA)

603510-15

0.3

0.5

0.4

0.6

0.7

0.8

0.2

-40 85

V

BAT

= 4.0V

EN_ = 0

BATTERY-REGULATION VOLTAGE

vs. TEMPERATURE

MAX8662/63 toc06

AMBIENT TEMPERATURE (°C)

BATTERY-REGULATION VOLTAGE (V)

603510-15

4.180

4.175

4.185

4.195

4.190

4.200

4.170

-40 85

EN_ = 0

CHARGE CURRENT

vs. BATTERY VOLTAGE (100mA USB)

MAX8662/63 toc07

BATTERY VOLTAGE (V)

CHARGE CURRENT (mA)

4321

10

20

30

40

50

60

70

80

90

100

0

05

VDC = 5V

R

ISET

= 3kΩ

PEN1 = PEN2 = 0

V

BAT

FALLING

V

BAT

RISING

CHARGE CURRENT

vs. BATTERY VOLTAGE (500mA USB)

MAX8662/63 toc08

BATTERY VOLTAGE (V)

CHARGE CURRENT (mA)

4.54.03.0 3.51.0 1.5 2.0 2.50.5

50

100

150

200

250

300

350

400

450

500

550

0

05.0

VDC = 5V

R

ISET

= 3k

Ω

PEN1 = 0

PEN2 = 1

V

BAT

FALLING

V

BAT

RISING

CHARGE CURRENT

vs. BATTERY VOLTAGE (AC ADAPTER)

MAX8662/63 toc09

BATTERY VOLTAGE (V)

CHARGE CURRENT (mA)

431 2

100

200

300

400

600

500

700

800

0

05

VDC = 5V

R

ISET

= 3k

Ω

PEN1 = PEN2 = 1

V

BAT

FALLING

V

BAT

RISING

Page 9

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

_______________________________________________________________________________________

9

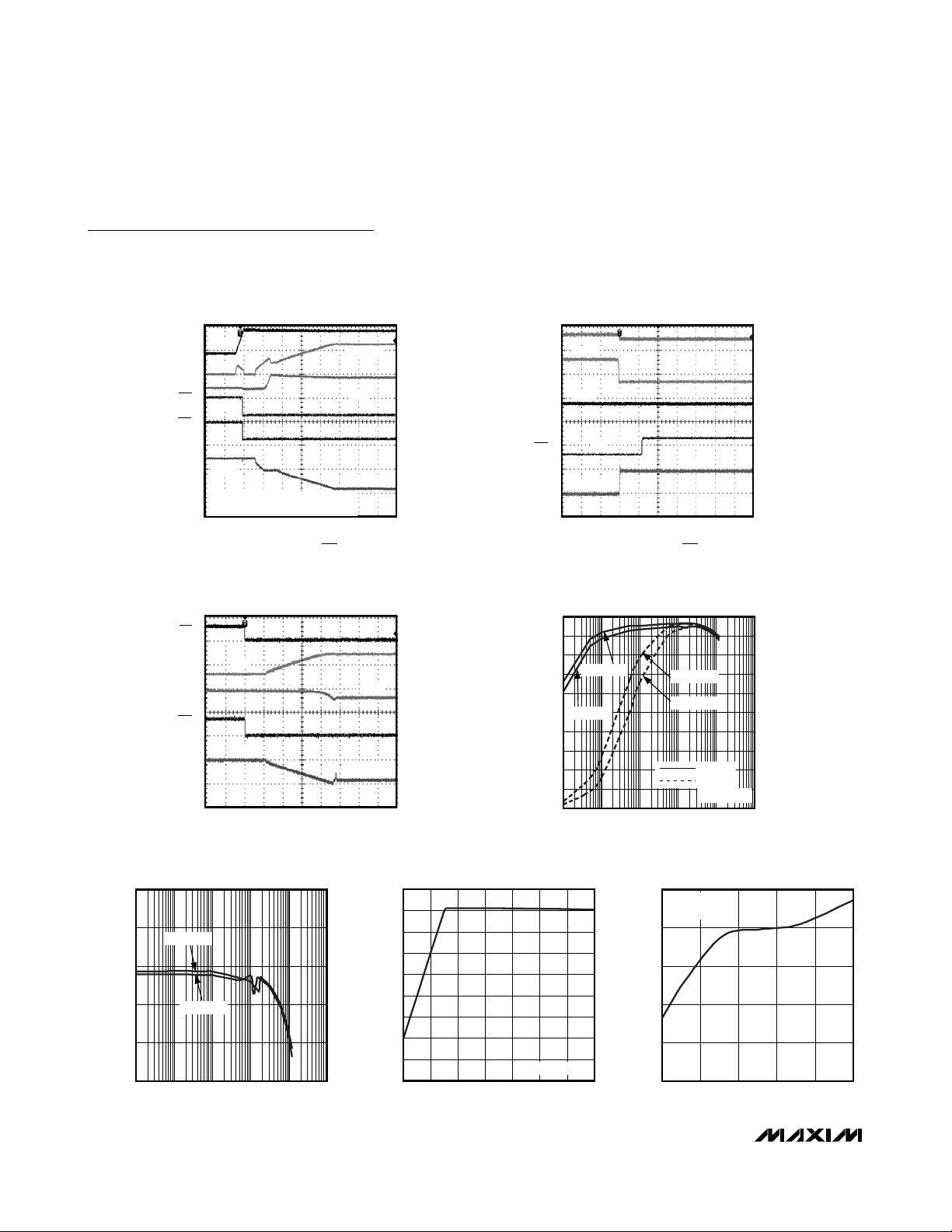

CHARGE CURRENT vs. AMBIENT TEMPERATURE

(LOW IC POWER DISSIPATION)

MAX8662/63 toc10

AMBIENT TEMPERATURE (°C)

CHARGE CURRENT (mA)

603510-15

100

200

300

400

500

600

700

800

900

0

-40 85

PEN1 = PEN2 = 1

PEN1 = PEN2 = 0

PEN1 = 0, PEN2 = 1

VDC = 5.0V, V

BAT

= 4.0V

R

ISET

= 3kΩ, CEN = 0, EN_ = 0

CHARGE CURRENT vs. AMBIENT TEMPERATURE

(HIGH IC POWER DISSIPATION)

MAX8662/63 toc11

AMBIENT TEMPERATURE (°C)

CHARGE CURRENT (mA)

603510-15

100

200

300

400

500

600

700

800

900

0

-40 85

PEN1 = PEN2 = 1

PEN1 = PEN2 = 0

PEN1 = 0, PEN2 = 1

VDC = 6.5V, V

BAT

= 3.1V

R

ISET

= 3kΩ, CEN = 0, EN_ = 0

SYS OUTPUT VOLTAGE

vs. INPUT VOLTAGE

MAX8662/63 toc12

INPUT VOLTAGE (V)

V

SYS

(V)

76

53412

3.8

4.2

4.0

4.6

4.4

5.2

5.0

4.8

5.4

5.6

3.6

08

V

BAT

= 4.0V

I

SYS

= 0mA

PEN1 = 0

PEN2 = 1

CHARGER

DISABLED

CHARGER

ENABLED

SYS OUTPUT VOLTAGE

vs. SYS OUTPUT CURRENT (DC DISCONNECTED)

MAX8662/63 toc13

I

SYS

(A)

V

SYS

(V)

2.52.01.51.00.5

3.8

4.0

4.2

4.4

4.6

4.8

5.0

5.2

5.4

5.6

3.6

03.0

V

BAT

= 4.0V

V

DC

= 0V

THE SLOPE OF THIS LINE SHOWS THAT THE

BAT-TO-SYS RESISTANCE IS 49mΩ.

SYS OUTPUT VOLTAGE

vs. SYS OUTPUT CURRENT (500mA USB)

MAX8662/63 toc14

I

SYS

(A)

V

SYS

(V)

2.52.01.51.00.5

3.8

4.0

4.2

4.4

4.6

4.8

5.0

5.2

5.4

5.6

3.6

03.0

VDC = 5.0V

V

BAT

= 4.0V

PEN1 = 0, PEN2 = 1

CEN = 1

SYS OUTPUT VOLTAGE

vs. SYS OUTPUT CURRENT (AC ADAPTER)

MAX8662/63 toc15

I

SYS

(A)

V

SYS

(V)

2.52.01.51.00.5

3.8

4.0

4.2

4.4

4.6

4.8

5.0

5.2

5.4

5.6

3.6

03.0

VDC = 5.0V

V

BAT

= 4.0V

PEN1 = PEN2 = 1

CEN = 1

USB CONNECT (I

SYS

= 0mA)

MAX8662/63 toc16

200μs/div

PEN1 = PEN2 = 0, CEN = 0,

V

BAT

= 4.0V, I

SYS

= 0mA, EN_ = 1

V

DC

I

IN

V

SYS

V

POK

V

CHG

I

BAT

0V

0V

0mA

0mA

4.0V

5V

4.4V

5V

+95mA

+95mA

5V/div

5V/div

5V/div

2V/div

200mA/div

200mA/div

NEGATIVE BATTERY

CURRENT FLOWS INTO

THE BATTERY

(CHARGING).

USB CONNECT (I

SYS

= 50mA)

MAX8662/63 toc17

200μs/div

PEN1 = PEN2 = 0, CEN = 0,

V

BAT

= 4.0V, I

SYS

= 50mA, EN_ = 1

V

DC

I

IN

V

SYS

V

POK

V

CHG

I

BAT

NEGATIVE BATTERY

CURRENT FLOWS

INTO THE BATTERY (CHARGING).

0V

0V

0V

0mA

50mA

4.0V

4.4V

5V/div

5V/div

5V/div

2V/div

200mA/div

200mA/div

5V

5V

+95mA

-45mA

Typical Operating Characteristics (continued)

(Circuit of Figure 1, V

DC

= 5V, R

PSET

= 1.5kΩ, R

ISET

= 3kΩ, V

OUT1

= 3.3V, V

OUT2

= 1.3V, SL1 = SL2 = open, V

CEN

= 0V, V

PEN1

=

V

PEN2

= 5V, C

OUT1

= 2 x 10µF, C

OUT2

= 2 x 10µF, C

OUT3

= 0.1µF, C

OUT4

= 4.7µF, C

OUT5

= 1µF, C

OUT6

= 2.2µF, C

OUT7

= 1µF, CT =

0.068µF, C

REF

= CVL= 0.1µF, R

THM

= 10kΩ, L1 = 3.3µH, L2 = 4.7µH, L3 = 22µH, GND = PG1 = PG2 = PG3 = 0, TA= +25°C, unless

otherwise noted.)

Page 10

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

10 ______________________________________________________________________________________

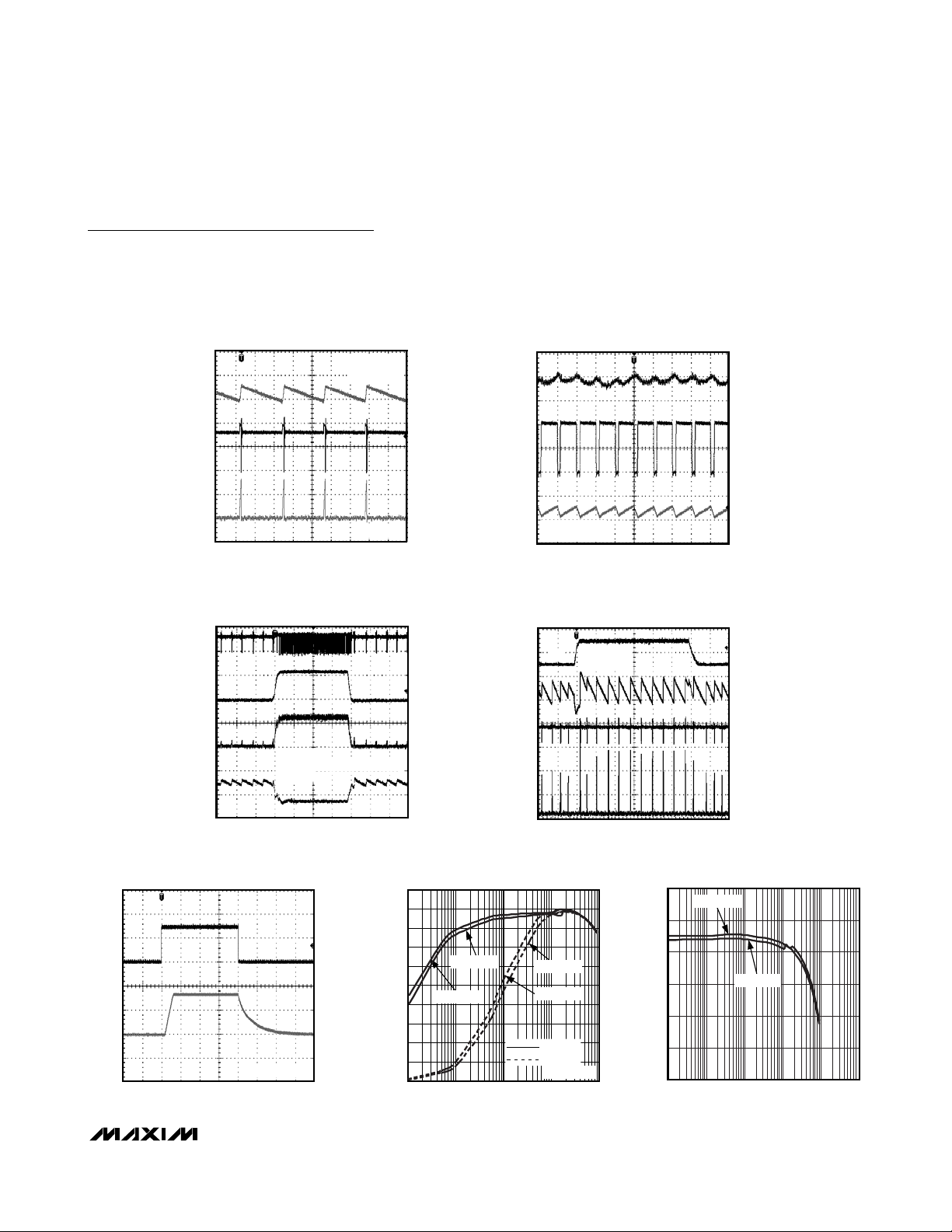

AC ADAPTER CONNECT (I

SYS

= 500mA)

MAX8662/63 toc18

400μs/div

PEN1 = PEN2 = 1, CEN = 0,

V

BAT

= 4.0V, I

SYS

= 500mA, EN_ = 1

V

DC

I

IN

V

SYS

V

POK

V

CHG

I

BAT

NEGATIVE BATTERY CURRENT FLOWS

INTO THE BATTERY (CHARGING).

0V

0V

0mA

500mA

4.0V

4.4V

5V

5V/div

5V/div

5V/div

2V/div

1A/div

1A/div

5V

+1280mA

-780mA

USB DISCONNECTED (500mA USB)

MAX8662/63 toc19

200μs/div

PEN1 = 0, PEN2 = 1, CEN = 0,

V

BAT

= 4.0V, I

SYS

= 0mA

V

DC

I

IN

V

SYS

V

CHG

I

BAT

0V

0mA

4.4V

5V

5V/div

5V/div

500mA/div

500mA/div

1V/div

475mA

-475mA

CHARGER ENABLE (I

SYS

= 0mA)

MAX8662/63 toc20

200μs/div

PEN1 = 0, PEN2 = 1, V

BAT

= 4.0V, I

SYS

= 0mA, EN_ = 1

V

CEN

I

IN

V

SYS

V

CHG

I

BAT

2.8V

0V

0mA

0mA

5V

4.4V

0V

475mA

-475mA

5V/div

5V/div

500mA/div

2V/div

1A/div

OUT1 REGULATOR EFFICIENCY

vs. LOAD CURRENT

MAX8662/63 toc21

LOAD CURRENT (mA)

OUT1 REGULATOR EFFICIENCY (%)

1000100101

10

20

30

40

50

60

70

80

90

100

0

0.1 10,000

V

BAT

= 4.2V

V

BAT

= 3.6V

PWM = 0

PWM = 1

V

BAT

= 4.2V

V

BAT

= 3.6V

V

OUT1

= 3.3V

Typical Operating Characteristics (continued)

(Circuit of Figure 1, V

DC

= 5V, R

PSET

= 1.5kΩ, R

ISET

= 3kΩ, V

OUT1

= 3.3V, V

OUT2

= 1.3V, SL1 = SL2 = open, V

CEN

= 0V, V

PEN1

=

V

PEN2

= 5V, C

OUT1

= 2 x 10µF, C

OUT2

= 2 x 10µF, C

OUT3

= 0.1µF, C

OUT4

= 4.7µF, C

OUT5

= 1µF, C

OUT6

= 2.2µF, C

OUT7

= 1µF, CT =

0.068µF, C

REF

= CVL= 0.1µF, R

THM

= 10kΩ, L1 = 3.3µH, L2 = 4.7µH, L3 = 22µH, GND = PG1 = PG2 = PG3 = 0, TA= +25°C, unless

otherwise noted.)

OUT1 REGULATOR LINE REGULATION

MAX8662/63 toc23

V

SYS

(V)

OUTPUT VOLTAGE (V)

5.14.73.9 4.33.53.1

2.6

2.7

2.8

2.9

3.0

3.1

3.2

3.3

3.4

2.5

2.7 5.5

R

LOAD

= 330Ω

OUT1 VOLTAGE vs. TEMPERATURE

MAX8662/63 toc24

AMBIENT TEMPERATURE (°C)

OUTPUT VOLTAGE (V)

603510-15

3.294

3.298

3.302

3.306

3.310

3.290

-40 85

V

BAT

= 4.0V

R

LOAD

= 330Ω

OUT1 REGULATOR LOAD REGULATION

MAX8662/63 toc22

LOAD CURRENT (mA)

OUTPUT VOLTAGE (V)

1000100101

3.24

3.28

3.32

3.36

3.40

3.20

0.1 10,000

V

BAT

= 4.2V

V

BAT

= 3.6V

Page 11

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

______________________________________________________________________________________

11

OUT1 REGULATOR LIGHT-LOAD

SWITCHING WAVEFORMS

MAX8662/63 toc25

20μs/div

V

OUT1

AC-COUPLED

V

LX

I

L

50mV/div

2V/div

200mA/div

V

BAT

= 4.0V

I

OUT1

= 10mA

PWM = 0

OUT1 REGULATOR HEAVY-LOAD

SWITCHING WAVEFORMS

MAX8662/63 toc26

1μs/div

V

OUT1

AC-COUPLED

V

LX

I

L

10mV/div

2V/div

500mA/div

V

BAT

= 4.2V

I

OUT1

= 1200mA

OUT1 REGULATOR LOAD-

TRANSIENT RESPONSE

MAX8662/63 toc27

40μs/div

V

OUT1

V

LX

I

OUT1

I

L

100mV/div

5V/div

1A/div

1A/div

V

BAT

= 4.0V

I

OUT1

= 10mA TO 1200mA TO 10mA

PWM = 0

OUT1 REGULATOR LINE-

TRANSIENT RESPONSE

MAX8662/63 toc28

100μs/div

V

OUT1

V

SYS

V

LX

I

L

200mA/div

5V/div

50mV/div

1V/div

I

OUT1

= 10mA

PWM = 0

5V

4V

OUT1 ENABLE AND DISABLE RESPONSE

MAX8662/63 toc29

1ms/div

V

OUT1

V

EN1

2V/div

2V/div

I

OUT1

= 10mA

Typical Operating Characteristics (continued)

(Circuit of Figure 1, V

DC

= 5V, R

PSET

= 1.5kΩ, R

ISET

= 3kΩ, V

OUT1

= 3.3V, V

OUT2

= 1.3V, SL1 = SL2 = open, V

CEN

= 0V, V

PEN1

=

V

PEN2

= 5V, C

OUT1

= 2 x 10µF, C

OUT2

= 2 x 10µF, C

OUT3

= 0.1µF, C

OUT4

= 4.7µF, C

OUT5

= 1µF, C

OUT6

= 2.2µF, C

OUT7

= 1µF, CT =

0.068µF, C

REF

= CVL= 0.1µF, R

THM

= 10kΩ, L1 = 3.3µH, L2 = 4.7µH, L3 = 22µH, GND = PG1 = PG2 = PG3 = 0, TA= +25°C, unless

otherwise noted.)

OUT2 REGULATOR EFFICIENCY

vs. LOAD CURRENT

MAX8662/63 toc30

LOAD CURRENT (mA)

OUT2 REGULATOR EFFICIENCY (%)

100101

10

20

30

40

50

60

70

80

90

100

0

0.1 1000

V

BAT

= 4.2V

V

BAT

= 4.2V

V

BAT

= 3.6V

V

BAT

= 3.6V

PWM = 0

PWM = 1

V

OUT1

= 3.3V

MAX8662/63 toc31

LOAD CURRENT (mA)

OUTPUT VOLTAGE (V)

1000100101

1.27

1.28

1.29

1.30

1.31

1.32

1.26

0.1 10,000

OUT2 REGULATOR LOAD REGULATION

V

BAT

= 3.6V

V

BAT

= 4.2V

Page 12

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

12 ______________________________________________________________________________________

OUT2 REGULATOR LINE-

TRANSIENT RESPONSE

MAX8662/63 toc37

100μs/div

V

OUT1

I

L

V

SYS

V

LX

200mA/div

1V/div

5V/div

20mV/div

I

OUT1

= 10mA

PWM = 0

4V

5V

OUT2 REGULATOR LINE REGULATION

MAX8662/63 toc32

V

SYS

(V)

OUTPUT VOLTAGE (V)

5.14.3 4.73.93.1 3.5

1.304

1.302

1.306

1.308

1.310

1.300

2.7 5.5

R

LOAD

= 130Ω

OUT2 VOLTAGE vs. TEMPERATURE

MAX8662/63 toc33

AMBIENT TEMPERATURE (°C)

OUTPUT VOLTAGE (V)

603510-15

1.3035

1.3040

1.3045

1.3050

1.3030

-40 85

V

BAT

= 4.0V

R

LOAD

= 130Ω

OUT2 REGULATOR LIGHT-LOAD

SWITCHING WAVEFORMS

MAX8662/63 toc34

10μs/div

V

OUT2

AC-COUPLED

I

L

V

LX

20mV/div

100mA/div

2V/div

V

BAT

= 4.0V

I

OUT2

= 10mA

PWM = 0

OUT2 REGULATOR HEAVY-LOAD

SWITCHING WAVEFORMS

MAX8662/63 toc35

1μs/div

V

OUT2

AC-COUPLED

I

L

V

L

10mV/div

500mA/div

2V/div

V

BAT

= 4.0V

I

OUT2

= 900mA

OUT2 REGULATOR LOAD-

TRANSIENT RESPONSE

MAX8662/63 toc36

40μs/div

I

OUT2

V

OUT2

AC-COUPLED

I

L

V

LX

50mV/div

500mA/div

5V/div

1A/div

V

BAT

= 4.0V

I

OUT2

= 10mA TO 900mA TO 10mA

PWM = 0

Typical Operating Characteristics (continued)

(Circuit of Figure 1, V

DC

= 5V, R

PSET

= 1.5kΩ, R

ISET

= 3kΩ, V

OUT1

= 3.3V, V

OUT2

= 1.3V, SL1 = SL2 = open, V

CEN

= 0V, V

PEN1

=

V

PEN2

= 5V, C

OUT1

= 2 x 10µF, C

OUT2

= 2 x 10µF, C

OUT3

= 0.1µF, C

OUT4

= 4.7µF, C

OUT5

= 1µF, C

OUT6

= 2.2µF, C

OUT7

= 1µF, CT =

0.068µF, C

REF

= CVL= 0.1µF, R

THM

= 10kΩ, L1 = 3.3µH, L2 = 4.7µH, L3 = 22µH, GND = PG1 = PG2 = PG3 = 0, TA= +25°C, unless

otherwise noted.)

Page 13

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

_____________________________________________________________________________________

13

OUT2 ENABLE AND DISABLE RESPONSE

MAX8662/63 toc38

1μs/div

V

OUT2

V

EN2

2V/div

1V/div

I

OUT2

= 10mA

0V

0V

LED CURRENT

vs. PWM DIMMING DUTY CYCLE

MAX8662/63 toc39

DUTY CYCLE (%)

LED CURRENT (mA)

80604020

1.0

0.5

2.0

1.5

2.5

3.5

3.0

4.5

4.0

5.0

0

09070503010 100

V

BAT

= 3.6V

V

BRT

= 0.25V

f = 1kHz

LED CURRENT vs. BRT VOLTAGE

MAX8662/63 toc40

BRT VOLTAGE (V)

LED CURRENT (mA)

1.20.90.60.3

5

10

15

20

25

30

0

01.5

V

BAT

= 3.6V

OUT4 REGULATOR LOAD REGULATION

MAX8662/63 toc44

LOAD CURRENT (mA)

OUTPUT VOLTAGE (V)

400300200100

3.285

3.290

3.295

3.300

3.305

3.310

3.315

3.280

0 500

VIN = 5.5V

VIN = 3.6V

OUT4 REGULATOR LINE REGULATION

MAX8662/63 toc45

V

IN_OUT4

(V)

OUTPUT VOLTAGE (V)

5432

1.8

2.2

3.0

2.6

3.4

1.4

16

R

LOAD

= 330Ω

Typical Operating Characteristics (continued)

(Circuit of Figure 1, V

DC

= 5V, R

PSET

= 1.5kΩ, R

ISET

= 3kΩ, V

OUT1

= 3.3V, V

OUT2

= 1.3V, SL1 = SL2 = open, V

CEN

= 0V, V

PEN1

=

V

PEN2

= 5V, C

OUT1

= 2 x 10µF, C

OUT2

= 2 x 10µF, C

OUT3

= 0.1µF, C

OUT4

= 4.7µF, C

OUT5

= 1µF, C

OUT6

= 2.2µF, C

OUT7

= 1µF, CT =

0.068µF, C

REF

= CVL= 0.1µF, R

THM

= 10kΩ, L1 = 3.3µH, L2 = 4.7µH, L3 = 22µH, GND = PG1 = PG2 = PG3 = 0, TA= +25°C, unless

otherwise noted.)

OUT4 VOLTAGE vs. TEMPERATURE

MAX8662/63 toc46

AMBIENT TEMPERATURE (°C)

OUTPUT VOLTAGE (V)

603510-15

3.309

3.311

3.313

3.315

3.305

3.307

-40 85

V

BAT

= 4.0V

R

LOAD

= 330Ω

OUT3 SWITCHING WAVEFORMS

MAX8662/63 toc41

1μs/div

V

OUT3

AC-COUPLED

I

L

V

LX

100mA/div

200mV/div

10V/div

I

OUT3

= 1mA

OUT3 ENABLE AND DISABLE RESPONSE

MAX8662/63 toc42

40ms/div

V

OUT3

V

EN3

2V/div

10V/div

0V

0V

OUT3 REGULATOR EFFICIENCY

vs. LOAD CURRENT

MAX8662/63 toc43

LOAD CURRENT (mA)

OUT2 REGULATOR EFFICIENCY (%)

20

10

40

30

50

70

60

90

80

100

0

0.1 101100

V

SYS

= 4.2V

V

SYS

= 3.6V

V

SYS

= 5.5V

Page 14

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

14 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(Circuit of Figure 1, V

DC

= 5V, R

PSET

= 1.5kΩ, R

ISET

= 3kΩ, V

OUT1

= 3.3V, V

OUT2

= 1.3V, SL1 = SL2 = open, V

CEN

= 0V, V

PEN1

=

V

PEN2

= 5V, C

OUT1

= 2 x 10µF, C

OUT2

= 2 x 10µF, C

OUT3

= 0.1µF, C

OUT4

= 4.7µF, C

OUT5

= 1µF, C

OUT6

= 2.2µF, C

OUT7

= 1µF, CT =

0.068µF, C

REF

= CVL= 0.1µF, R

THM

= 10kΩ, L1 = 3.3µH, L2 = 4.7µH, L3 = 22µH, GND = PG1 = PG2 = PG3 = 0, TA= +25°C, unless

otherwise noted.)

OUT4 REGULATOR LOAD-

TRANSIENT RESPONSE

MAX8662/63 toc47

40μs/div

V

OUT4

AC-COUPLED

I

OUT4

500mA/div

50mV/div

V

BAT

= 4.0V

I

OUT4

= 10mA TO 500mA TO 10mA

OUT4 REGULATOR LINETRANSIENT RESPONSE

MAX8662/63 toc48

100μs/div

V

OUT4

AC-COUPLED

V

IN45

2V/div

20mV/div

I

OUT4

= 10mA

3.6V

5V

OUT4 ENABLE AND DISABLE RESPONSE

MAX8662/63 toc49

200μs/div

V

OUT4

V

EN4

2V/div

2V/div

0V

0V

OUT4 REGULATOR DROPOUT VOLTAGE

vs. LOAD CURRENT

MAX8662/63 toc50

LOAD CURRENT (mA)

DROPOUT VOLTAGE (mV)

400300200100

10

40

50

30

20

60

70

90

80

100

0

0 500

THE SLOPE OF THIS LINE SHOWS THAT

THE DROPOUT RESISTANCE OF AN

AVERAGE PART AND BOARD

COMBINATION IS 181mΩ.

OUT5 REGULATOR LOAD REGULATION

MAX8662/63 toc51

LOAD CURRENT (mA)

OUTPUT VOLTAGE (V)

120906030

3.302

3.304

3.308

3.306

3.310

3.300

0150

VIN = 3.6V

VIN = 5.5V

OUT5 REGULATOR LINE REGULATION

MAX8662/63 toc52

V

IN_OUT5

(V)

OUTPUT VOLTAGE (V)

5432

1.8

2.2

3.0

2.6

3.4

1.4

16

R

LOAD

= 330Ω

OUT5 VOLTAGE vs. TEMPERATURE

MAX8662/63 toc53

AMBIENT TEMPERATURE (°C)

OUTPUT VOLTAGE (V)

603510-15

3.305

3.307

3.306

3.309

3.308

3.310

3.304

-40 85

V

BAT

= 4.0V

R

LOAD

= 330Ω

Page 15

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

______________________________________________________________________________________

15

OUT5 REGULATOR LOAD-

TRANSIENT RESPONSE

MAX8662/63 toc54

40μs/div

V

OUT5

AC-COUPLED

I

OUT5

100mA/div

50mV/div

V

BAT

= 4.0V

I

OUT5

= 10mA TO 150mA TO 10mA

OUT5 REGULATOR LINE-

TRANSIENT RESPONSE

MAX8662/63 toc55

100μs/div

V

OUT5

AC-COUPLED

V

IN45

2V/div

20mV/div

I

OUT5

= 10mA

3.6V

5V

OUT5 ENABLE AND DISABLE RESPONSE

MAX8662/63 toc56

200μs/div

V

OUT5

V

EN5

2V/div

2V/div

0V

0V

OUT5 REGULATOR DROPOUT VOLTAGE

vs. LOAD CURRENT

MAX8662/63 toc57

I

OUT

(mA)

DROPOUT VOLTAGE (V)

120906030

10

30

20

40

50

60

70

0

0 150

THE SLOPE OF THIS LINE SHOWS THAT

THE DROPOUT RESISTANCE OF AN

AVERAGE PART AND BOARD

COMBINATION IS 384mΩ.

OUT6 REGULATOR LOAD REGULATION

MAX8662/63 toc58

LOAD CURRENT (mA)

OUTPUT VOLTAGE (V)

250150 20010050

3.294

3.298

3.302

3.306

3.310

3.290

0 300

VIN = 5.5V

VIN = 3.6V

OUT6 REGULATOR LINE REGULATION

MAX8662/63 toc59

V

IN_OUT6

(V)

OUTPUT VOLTAGE (V)

5432

1.8

1.6

2.0

2.4

2.2

3.2

3.0

2.8

2.6

3.4

1.4

16

R

LOAD

= 330Ω

OUT6 VOLTAGE vs. TEMPERATURE

MAX8662/63 toc60

AMBIENT TEMPERATURE (°C)

OUTPUT VOLTAGE (V)

603510-15

3.303

3.305

3.307

3.309

3.301

-40 85

V

BAT

= 4.0V

R

LOAD

= 330Ω

Typical Operating Characteristics (continued)

(Circuit of Figure 1, V

DC

= 5V, R

PSET

= 1.5kΩ, R

ISET

= 3kΩ, V

OUT1

= 3.3V, V

OUT2

= 1.3V, SL1 = SL2 = open, V

CEN

= 0V, V

PEN1

=

V

PEN2

= 5V, C

OUT1

= 2 x 10µF, C

OUT2

= 2 x 10µF, C

OUT3

= 0.1µF, C

OUT4

= 4.7µF, C

OUT5

= 1µF, C

OUT6

= 2.2µF, C

OUT7

= 1µF, CT =

0.068µF, C

REF

= CVL= 0.1µF, R

THM

= 10kΩ, L1 = 3.3µH, L2 = 4.7µH, L3 = 22µH, GND = PG1 = PG2 = PG3 = 0, TA= +25°C, unless

otherwise noted.)

Page 16

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

16 ______________________________________________________________________________________

Typical Operating Characteristics (continued)

(Circuit of Figure 1, V

DC

= 5V, R

PSET

= 1.5kΩ, R

ISET

= 3kΩ, V

OUT1

= 3.3V, V

OUT2

= 1.3V, SL1 = SL2 = open, V

CEN

= 0V, V

PEN1

=

V

PEN2

= 5V, C

OUT1

= 2 x 10µF, C

OUT2

= 2 x 10µF, C

OUT3

= 0.1µF, C

OUT4

= 4.7µF, C

OUT5

= 1µF, C

OUT6

= 2.2µF, C

OUT7

= 1µF, CT =

0.068µF, C

REF

= CVL= 0.1µF, R

THM

= 10kΩ, L1 = 3.3µH, L2 = 4.7µH, L3 = 22µH, GND = PG1 = PG2 = PG3 = 0, TA= +25°C, unless

otherwise noted.)

OUT6 REGULATOR LOAD-

TRANSIENT RESPONSE

MAX8662/63 toc61

40μs/div

V

OUT6

AC-COUPLED

I

OUT6

200mA/div

50mV/div

V

BAT

= 4.0V

I

OUT6

= 10mA TO 300mA TO 10mA

OUT6 REGULATOR LINE-

TRANSIENT RESPONSE

MAX8662/63 toc62

100μs/div

V

OUT6

AC-COUPLED

V

IN67

2V/div

20mV/div

I

OUT6

= 10mA

3.6V

5V

OUT6 ENABLE AND DISABLE RESPONSE

MAX8662/63 toc63

200μs/div

V

OUT6

V

EN6

2V/div

2V/div

0V

0V

OUT6 REGULATOR DROPOUT VOLTAGE

vs. LOAD CURRENT

MAX8662/63 toc64

I

OUT

(mA)

DROPOUT VOLTAGE (mV)

25020015010050

10

30

40

20

50

60

70

80

0

0300

THE SLOPE OF THIS LINE SHOWS THAT

THE DROPOUT RESISTANCE OF AN

AVERAGE PART AND BOARD

COMBINATION IS 238mΩ.

OUT7 REGULATOR LOAD REGULATION

MAX8662/63 toc65

LOAD CURRENT (mA)

OUTPUT VOLTAGE (V)

120906030

3.296

3.300

3.298

3.302

3.304

3.294

0 150

VIN = 5.5V

VIN = 3.6V

OUT7 REGULATOR LINE REGULATION

MAX8662/63 toc66

V

IN_OUT7

(V)

OUTPUT VOLTAGE (V)

5432

1.8

1.6

2.0

2.4

2.2

3.2

3.0

2.8

2.6

3.4

1.4

16

R

LOAD

= 330Ω

OUT7 VOLTAGE vs. TEMPERATURE

MAX8662/63 toc67

AMBIENT TEMPERATURE (°C)

OUTPUT VOLTAGE (V)

603510-15

3.299

3.301

3.300

3.302

3.303

3.298

-40 85

V

BAT

= 4.0V

R

LOAD

= 330Ω

Page 17

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

______________________________________________________________________________________

17

OUT7 REGULATOR LOAD-

TRANSIENT RESPONSE

MAX8662/63 toc68

40μs/div

V

OUT7

AC-COUPLED

I

OUT7

100mA/div

50mV/div

V

BAT

= 4.0V

I

OUT7

= 10mA TO 150mA TO 10mA

OUT7 REGULATOR LINE-

TRANSIENT RESPONSE

MAX8662/63 toc69

100μs/div

V

OUT7

AC-COUPLED

V

IN67

2V/div

20mV/div

I

OUT7

= 10mA

3.6V

5V

OUT7 ENABLE AND DISABLE RESPONSE

MAX8662/63 toc70

200μs/div

V

OUT7

V

EN7

2V/div

2V/div

0V

0V

OUT7 REGULATOR DROPOUT VOLTAGE

vs. LOAD CURRENT

MAX8662/63 toc71

I

OUT

(mA)

DROPOUT VOLTAGE (V)

125100755025

10

30

20

40

50

60

70

0

0 150

THE SLOPE OF THIS LINE SHOWS THAT

THE DROPOUT RESISTANCE OF AN

AVERAGE PART AND BOARD

COMBINATION IS 391mΩ.

MAX8662/63 toc72

LOAD CURRENT (mA)

OUTPUT VOLTAGE (V)

86429753

3.25

3.27

3.28

3.26

3.29

3.30

3.31

3.24

01 10

VL REGULATOR LOAD REGULATION

VIN = 5.5V

VIN = 4.35V

MAX8662/63 toc73

VIN (V)

OUTPUT VOLTAGE (V)

7654

3.10

3.05

3.20

3.30

3.15

3.25

3.35

3.40

3.45

3.50

3.00

38

VL REGULATOR LINE REGULATION

R

LOAD

= 3.3kΩ

MAX8662/63 toc74

I

SINK

(mA)

OUTPUT LOW VOLTAGE (V)

3530252015105

0.1

0.2

0.3

0.4

0.5

0

040

VIN = 5.0V

V

BAT

= 4.0V

THE SLOPE OF THIS LINE SHOWS THAT

THE PULLDOWN RESISTANCE IS 11Ω.

PULLDOWN DEVICE HAS A

20mA STEADY-STATE RATING

OPEN-DRAIN OUTPUT VOLTAGE LOW

vs. SINK CURRENT

Typical Operating Characteristics (continued)

(Circuit of Figure 1, V

DC

= 5V, R

PSET

= 1.5kΩ, R

ISET

= 3kΩ, V

OUT1

= 3.3V, V

OUT2

= 1.3V, SL1 = SL2 = open, V

CEN

= 0V, V

PEN1

=

V

PEN2

= 5V, C

OUT1

= 2 x 10µF, C

OUT2

= 2 x 10µF, C

OUT3

= 0.1µF, C

OUT4

= 4.7µF, C

OUT5

= 1µF, C

OUT6

= 2.2µF, C

OUT7

= 1µF, CT =

0.068µF, C

REF

= CVL= 0.1µF, R

THM

= 10kΩ, L1 = 3.3µH, L2 = 4.7µH, L3 = 22µH, GND = PG1 = PG2 = PG3 = 0, TA= +25°C, unless

otherwise noted.)

Page 18

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

18 ______________________________________________________________________________________

Pin Description

PIN

FUNCTION

1 1 PEN1

Inp ut Li m i ter - C ontr ol Inp ut 1. U sed w i th CE N and P E N 2 to set the D C cur r ent l i m i t to 95m A,

475m A, a r esi st or p r og r am m ab l e l evel up to 2A, or to tur n off the i np ut l i m i ter ( see Tab l e 1) .

2 2 PEN2

Inp ut Li m i ter - C ontr ol Inp ut 2. U sed w i th CE N and P E N 1 to set the D C cur r ent l i m i t to 95m A,

475m A, a r esi st or p r og r am m ab l e l evel up to 2A, or to tur n off the i np ut l i m i ter ( see Tab l e 1) .

3 — EN3

Enable Input and PWM Dimming Input for Regulator 3 White LED Boost. Drive high to

enable. Drive low for more than 2ms to turn off. For PWM-controlled dimming, drive EN3

with a PWM switching input with a frequency of 1kHz to 100kHz.

4, 5 3, 4

DC1,

DC2

DC Input Source. Connect to an AC adapter or USB source. DC1 and DC2 are internally

connected.

6, 7 5, 6

SYS1,

SYS2

System Supply Voltage. The SYS output supplies power to all regulators. With no external

power, SYS1 and SYS2 connect to BAT through an internal 40mΩ switch. When a valid

voltage is present at DC_, SYS_ connects to DC_ but is limited to 5.3V. SYS1 and SYS2 are

internally connected.

8, 9 7, 8

BAT1,

BAT2

Battery Connections. Connect to a single-cell Li+ battery. The battery is charged from SYS_

when a valid source is present at DC. BAT_ drives SYS_ when DC is not valid. BAT1 and

BAT2 are internally connected.

10 — BRT

LED Analog Brightness Control Input. Connect BRT to a voltage from 50mV to 1.5V to set

I

CS

from 1mA to 30mA. Connect BRT to the center of a resistor-divider connected between

REF and GND to set a fixed brightness when analog dimming is not required.

11 9 CHG

Charger Status Output. CHG is an open-drain nMOS that pulls low when the charger is in

fast charge or prequalification modes. CHG goes high impedance when the charger is in

top-off mode or disabled.

12 10 CEN

Charger Enable Input. Drive CEN low to enable the charger when a valid source is

connected at DC. Drive CEN high to disable charging. Drive CEN high and PEN2 low to

enter USB suspend mode.

13 11 THM

Thermistor Input. Connect a 10kΩ negative temperature coefficient (NTC) thermistor from

THM to GND. Charging is suspended when the temperature is beyond the hot or cold

limits. Connect THM to GND to disable the thermistor functionality.

14 12 ISET

Charge Rate-Set Input. Connect a resistor from ISET to GND to set the fast-charge current

from 300mA to 1.25A. The prequalification charge current and top-off threshold are set to

10% and 7.5% of fast-charge current, respectively.

15 13 CT

Charge Timer-Programming Pin. Connect a capacitor from CT to GND to set the length of

time required to trigger a fault condition in fast-charge or prequalification mode and to

determine the time the charger remains in top-off mode. Connect CT to GND to disable

timers.

16 — REF

Reference Voltage. Provides 1.5V output when EN3 is high. An internal discharge

resistance pulls REF to 0V when EN3 is low.

17 14 GND Ground. Low-noise ground connection.

18 15

Linear Regulator 4 Output. Delivers up to 500mA at an output voltage determined by SL1

and SL2. Connect a 4.7µF ceramic capacitor from OUT4 to GND. Increase the value to

10µF if V

OUT4

< 1.5V.

MAX8662 MAX8663

NAME

OUT4

Page 19

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

______________________________________________________________________________________ 19

Pin Description (continued)

PIN

NAME

FUNCTION

19 16 IN45

Input Supply for Linear Regulators 4 and 5. Connect IN45 to a supply voltage between 1.7V

and V

SYS

. Connect at least a 1µF ceramic capacitor from IN45 to GND.

20 17

Linear Regulator 5 Output. Delivers up to 150mA at an output voltage determined by SL1

and SL2. Connect a 1µF ceramic capacitor from OUT5 to GND. Increase the value to 2.2µF

if V

OUT5

< 1.5V.

21 18 EN4 Enable Input for Linear Regulator 4. Drive high to enable.

22 19 EN5 Enable Input for Linear Regulator 5. Drive high to enable.

23 20 PWM

PWM/Skip-Mode Selector. Drive PWM high to force step-down regulators 1 and 2 to

operate in 1MHz forced-PWM mode. Drive PWM low, or connect to GND to allow regulators

1 and 2 to enter skip mode at light loads.

24 21 FB1

Feedback Input for Buck Regulator 1. Connect FB1 to the center of a resistor-divider

connected between OUT1 and GND to set the output voltage between 0.98V and 3.3V.

25 22 EN1 Enable Input for Buck Regulator 1. Drive high to enable.

26 23 PG1

Power Ground for Buck Regulator 1. GND, PG1, PG2, and PG3 must be connected

together externally.

27 24 LX1

Buck Regulator 1 Inductor Connection Node. Connect an inductor from LX1 to the output of

regulator 1.

28 25 PV1

P ow er Inp ut for Buck Reg ul ator 1. C onnect P V 1 to S Y S and d ecoup l e w i th a 10µF or g r eater l ow E S R cap aci tor to GN D . P V 1, P V 2, and S Y S m ust b e connected tog ether exter nal l y.

29 — OVP

LED Boost Overvoltage Input. Connect a resistor from OVP to the boost output to set the

maximum output voltage and to initiate soft-start when EN3 goes high. An internal 20µA

pulldown current from OVP to GND determines the maximum boost voltage. The internal

current is disconnected when EN3 is low. OVP is diode clamped to SYS_.

30 — CS

LED Current Source. Sinks from 1mA to 30mA depending on the voltage at BRT and the

PWM signal at EN3. Driving EN3 low for more than 2ms turns off the current source. V

CS

is

regulated to 0.32V.

31 — CC3

C om p ensati on Inp ut for LE D Boost Regul ator 3. S ee the Boost C onverter w i th Whi te LE D D r i ver

( OU T3, M AX 8662 Onl y) secti on.

32 26 FB2

Feedback Input for Buck Regulator 2. Connect FB2 to the center of a resistor-divider

connected between OUT2 and GND to set the output voltage between 0.98V and 3.3V.

33 27 PV2

Power Input for Buck Regulator 2. Connect PV2 to SYS and decouple with a 10µF or

greater low-ESR capacitor to GND. PV1, PV2, and SYS must be connected together

externally.

34 28 LX2

Buck Regulator 2 Inductor Connection Node. Connect an inductor from LX2 to the output of

regulator 2.

35 29 PG2

P ower Gr ound for Buck Reg ulator 2. GN D , P G1, P G2, and PG3 must b e connected together

exter nal l y.

36 30 EN2 Enable Input for Buck Regulator 2. Drive high to enable.

37 31 EN6 Enable Input for Linear Regulator 6. Drive high to enable.

38 32 EN7 Enable Input for Linear Regulator 7. Drive high to enable.

39 — LX3 Boost Regulator 3 Inductor Connection Node. Connect an inductor from LX3 to SYS_.

MAX8662 MAX8663

OUT5

Page 20

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

20 ______________________________________________________________________________________

Pin Description (continued)

PIN

NAME

FUNCTION

40 — PG3

Power Ground for Boost Regulator 3. GND, PG1, PG2, and PG3 must be connected

together externally.

41 33 OUT6

Linear Regulator 6 Output. Delivers up to 300mA at an output voltage determined by SL1

and SL2. Connect a 2.2µF ceramic capacitor from OUT6 to GND. Increase the value to

4.7µF if V

OUT6

< 1.5V.

42 34 IN67

Input Supply for Linear Regulators 6 and 7. Connect IN67 to a supply voltage of 1.7V to

V

SYS

. Connect at least a 1µF ceramic capacitor from IN67 to GND.

43 35 OUT7

Linear Regulator 7 Output. Delivers up to 150mA at an output voltage determined by SL1

and SL2. Connect a 1µF ceramic capacitor from OUT7 to GND. Increase the value to 2.2µF

if V

OUT7

< 1.5V.

44 36 VL

Input Limiter and Charger Logic Supply. Provides 3.3V when a valid input voltage is

present at DC. Connect a 0.1µF capacitor from VL to GND. VL is capable of providing up to

10mA to an external load when DC is valid.

45 37 SL1

46 38 SL2

Output-Voltage Select Inputs 1 and 2 for Linear Regulators. Leave disconnected, or

connect to GND or SYS to set to one of three states. SL1 and SL2 set the output voltage of

OUT4, OUT5, OUT6, and OUT7 to one of nine combinations. See Table 3.

47 39 PSET

Input Current-Limit Set Input. Connect a resistor (R

PSET

) from PSET to ground to program

the DC input current limit from 500mA to 2A.

48 40 POK

Power-Ok Output. POK is an open-drain nMOS output that pulls low when a valid input is

detected at DC. This output is not affected by the states of PEN1, PEN2, or CEN.

——EP

Exposed Paddle. Connect the exposed paddle to ground. Connecting the exposed paddle

to ground does not remove the requirement for proper ground connections to GND, PG1,

PG2, and PG3. The exposed paddle is attached with epoxy to the substrate of the die,

making it an excellent path to remove heat from the IC.

MAX8662 MAX8663

Page 21

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

______________________________________________________________________________________ 21

Figure 1. Block Diagram and Application Circuit

INPUT FROM AC

ADAPTER/USB

4.1V TO 8V

VLOGIC

R1

SYS

OUT1

0.98V TO 3.3V AT 1.2A

MAIN

R3

OFF

SKIP

SYS

OUT2

0.98V TO 3.3V AT 0.9A

CORE

R5

OFF

SYS

TRI-STATE MODE

INPUTS; SEE TABLE 2

SYS

DC1

DC2

C1

100mV

BATTERY-TO-SYS

SWITCH (ALLOWS

CURRENT TO SYS)

INPUT LIMITER

AND

THERMAL

PROTECTION

MAX8662

MAX8663

+

-

+

-

BATTERY

CHARGER

STEP-UP

LED

DRIVER

1.5V

INPUT-

VOLTAGE

POK

MONITOR

INPUT-TO-SYS

MAIN

STEP-DOWN

REGULATOR

CORE

STEP-DOWN

REGULATOR

LDO OUTPUT-

VOLTAGE

SETTING

CURRENT-

LIMITING

SWITCH

BAT AND DC TO SUPPLY

GND

VL

C2

C4

L1

C5

R2

ON

PWM

C6

L2

C7

R4

ON

C8

{

C9

3.3V

PV1

LX1

PG1

FB1

EN1

PWM

PV2

LX2

PG2

FB2

EN2

IN45

SL1

SL2

IN67

SYS1

SYS2

BAT1

BAT2

THM

BATTERY THERMISTOR

R7

CHG

PEN2

PEN1

ADAPTER

CEN

CT

PSET

ISET

LX3

D1

PG3

OVP

CC3

CS

ANALOG DIMMING

BRT

(0 TO 1.5V)

EN3

PWM BRIGHTNESS

CONTROL AND ENABLE

REF

C3

OUT4

EN4 ON

OUT5

EN5

OUT6

EN6

OUT7

EN7

DONE

500mA

L3

MAIN

BATTERY

VLOGIC

TIMEOUT

CHARGING

100mA

USB

ON

C13

OUT3 AT 30mA

OFF

OFF

OFF

OFF

SYS

SYS

D2

D3

D4

D5

D6

D7

D8

D9 TO SYS

C16

C17

C18

C19

ONLY AVAILABLE

FOR THE MAX8662

OUT4

500mA

OUT5

150mA

OUT6

300mA

OUT7

150mA

C10

C11

R6

OK

OFF

C12

R8

R9

C14

R10

C15

ON

ON

ON

E P

Page 22

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

22 ______________________________________________________________________________________

Detailed Description

The MAX8662/MAX8663 highly integrated PMICs are

designed for use in smart cellular phones, PDAs,

Internet appliances, and other portable devices. They

integrate two synchronous buck regulators, a boost

regulator driving two to seven white LEDs (MAX8662

only), four low dropout (LDO) linear regulators, and a

linear charger for a single-cell Li+ battery. Figure 1 is

the block diagram and application circuit.

SPS circuitry offers flexible power distribution between

an AC adapter or USB source, battery, and system

load, and makes the best use of available power from

the AC adapter/USB input. The battery is charged with

any available power not used by the system load. If a

system load peak exceeds the current limit, supplemental current is taken from the battery. Thermal limiting prevents overheating by reducing power drawn

from the input source.

Two step-down DC-DC converters achieve excellent

light-load efficiency and have on-chip soft-start circuitry; 1MHz switching frequency allows for small external

components. Four LDO linear regulators feature low

quiescent current and operate from inputs as low as

1.7V. This allows the LDOs to operate from the stepdown output voltage to improve efficiency. The white

LED driver features easy adjustment of LED brightness

and open-LED overvoltage protection. A 1-cell Li+

charger has programmable charge current up to 1.25A

and a charge timer.

Smart Power Selector (SPS)

SPS seamlessly distributes power between the external

input, the battery, and the system load (Figure 2). The

basic functions of SPS are:

• With both the external power supply and battery

connected:

a) When the system load requirements exceed the

capacity of the external power input, the battery

supplies supplemental current to the load.

b) When the system load requirements are less than

the capacity of the external power input, the bat-

tery is charged with residual power from the input.

• When the battery is connected and there is no

external power input, the system is powered from

the battery.

• When an external power input is connected and

there is no battery, the system is powered from the

external power input.

A thermal-limiting circuit reduces battery-charge rate and

external power-source current to prevent overheating.

Input Limiter

All regulated outputs (OUT1–OUT7) derive their power

from the SYS output. With an AC adapter or USB source

connected at DC, the input limiter distributes power

from the external power source to the system load and

battery charger. In addition to the input limiter’s primary

function of passing the DC power source to the system

and charger loads at SYS, it performs several additional

functions to optimize use of available power:

• Input Voltage Limiting: If the voltage at DC rises,

SYS limits to 5.3V, preventing an overvoltage of the

system load. A DC voltage greater than 6.9V is considered invalid and the input limiter disconnects the

DC input entirely. The withstand voltage at DC is

guaranteed to be at least 9V. A DC input is also

invalid if it is less than BAT, or less than the DC

undervoltage threshold of 3.5V (falling). With an

invalid DC input voltage, SYS connects to BAT

through a 30mΩ switch.

• Input Overcurrent Protection: The current at DC is

limited to prevent input overload. This current limit

is automatically adjusted to match the capabilities

of source, whether it is a 100mA or 500mA USB

source, or an AC adapter. When the load exceeds

the input current limit, SYS drops to 100mV below

BAT and supplemental load current is provided by

the battery.

Q1 INPUT-TO-SYS

SWITCH

Q2

BATTERY-TO-SYS

SWITCH

(DISCHARGE PATH)

Q3

(CHARGE

PATH)

DC

SYS

BAT

AC ADAPTER

OR

USB INPUT

SYSTEM

LOAD

BATTERY

THM

GND

R

THM

MAX8662

MAX8663

Figure 2. Smart Power Selector Block Diagram

Page 23

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices

______________________________________________________________________________________ 23

• Thermal Limiting: The input limiter includes a ther-

mal-limiting circuit that reduces the current drawn

from DC when the IC junction temperature increases

beyond +100°C in an attempt to prevent further

heating. The current limit is be reduced by 5%/°C for

temperatures above +100°C, dropping to 0mA at

+120°C. Due to the adaptive nature of the charging

circuitry, the charger current reduces to 0mA before

the system load is affected by thermal limiting.

• Adaptive Battery Charging: While the system is

powered from DC, the charger can also draw

power from SYS to charge the battery. If the charger load plus system load exceeds the current capability of the input source, an adaptive charger

control loop reduces charge current to prevent the

SYS voltage from collapsing. Maintaining a higher

SYS voltage improves efficiency and reduces

power dissipation in the input limiter by running the

switching regulators at lower current.

Figure 3 shows the SYS voltage and its relationship to

DC and BAT under three conditions:

a) Charger is off and SYS is driven from DC.

b) Charger is on and adaptive charger control is limiting

charge current.

c) The load at SYS is greater than the available input current.

The adaptive battery-charger circuit reduces charging

current when the SYS voltage drops 550mV below DC.

For example, if DC is at 5V, the charge current reduces

to prevent SYS from dropping below 4.45V. When DC is

greater than 5.55V, the adaptive charging circuitry

reduces charging current when SYS drops 300mV

below the 5.3V SYS regulation point (5.0V). Finally, the

circuit prevents itself from pulling SYS down to within

100mV of BAT.

BAT

DC

SYS

(CHARGER OFF)

SYS

(CHARGER ON)

550mV

SYS

(SYS OVERLOAD)

5.3V

100mV

100mV

5.0V

INPUT: 500mA USB

CHARGER: RISET = 4Ω (750mA)

I(SYS) x 30mΩ

I(SYS) x 150mAΩ

475mA

0mA

BAT CHARGE

CURRENT

(CHARGE ON)

4.0V

3.9V

Figure 3. SYS Voltage and Charge Current vs. DC and BAT Voltage

Page 24

MAX8662/MAX8663

Power-Management ICs for

Single-Cell, Li+ Battery-Operated Devices