Page 1

General Description

The MAX8543/MAX8544 current-mode, constant-frequency PWM buck controllers operate from a 3V to

13.2V input supply and generate adjustable 0.8V to 0.9

x VINoutput voltages at loads up to 25A. They feature

adjustable switching frequency and synchronization for

noise-sensitive applications.

The MAX8543/MAX8544 can start with (or without) a preexisting bias on the output, without discharging the output. This feature simplifies tracking supply designs for

core and I/O applications and redundant supply designs.

The MAX8543/MAX8544 use the DC resistance of the

output inductor as the current-sense element for lossless, low-cost current sensing. The current-sense

threshold can be set to four discrete levels to accommodate inductors with different DC resistance values.

The MAX8544 features a power-OK monitor and two

MAX8544 controllers that can operate at 180° out-ofphase for dual-output applications.

Applications

Base Stations

Networks and Telecom

Storage

Servers

Features

♦ Prebias Startup/Monotonic

♦ 1% Output Accuracy

♦ Ceramic, Polymer, or Electrolytic Capacitors

♦ 200kHz to 1MHz Adjustable Frequency

♦ 160kHz to 1.2MHz Synchronization

♦ Lossless, Foldback Current Limit

♦ Overvoltage Protection

♦ Enable (On/Off)

♦ Adjustable Soft-Start

♦ MAX8544

Latch-Off/Autorecovery

Power-OK Monitor

Out-of-Phase Clock Output

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

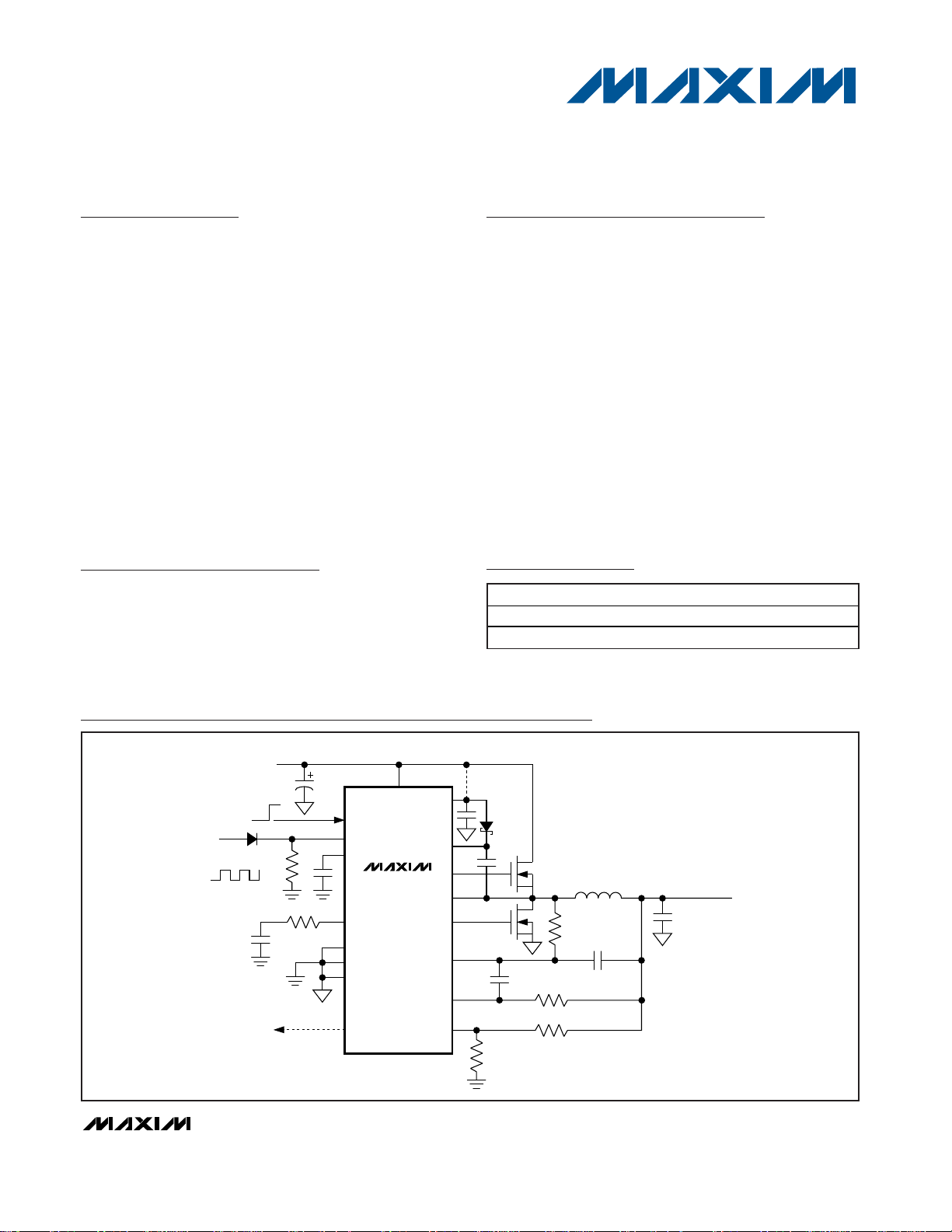

MAX8543

ON

OPTIONAL

SYNCHRONIZATION

OFF

BST

VL

V

IN

= 3V

TO 5.5V

COMP

ILIM

FSYNC

EN

SS

PGND

GND

IN

DH

LX

DL

CS+

CS-

FB

INPUT 3V TO 13.2V

OUTPUT

0.8V TO 0.9 x V

IN

UP TO 25A

POK (MAX8544)

Typical Operating Circuit

19-3155; Rev 0; 5/04

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

PART TEMP RANGE

PIN-PACKAGE

MAX8543EEE -40°C to +85°C 16 QSOP

MAX8544EEP -40°C to +85°C 20 QSOP

Pin Configurations appear at end of data sheet.

Page 2

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

2 _______________________________________________________________________________________

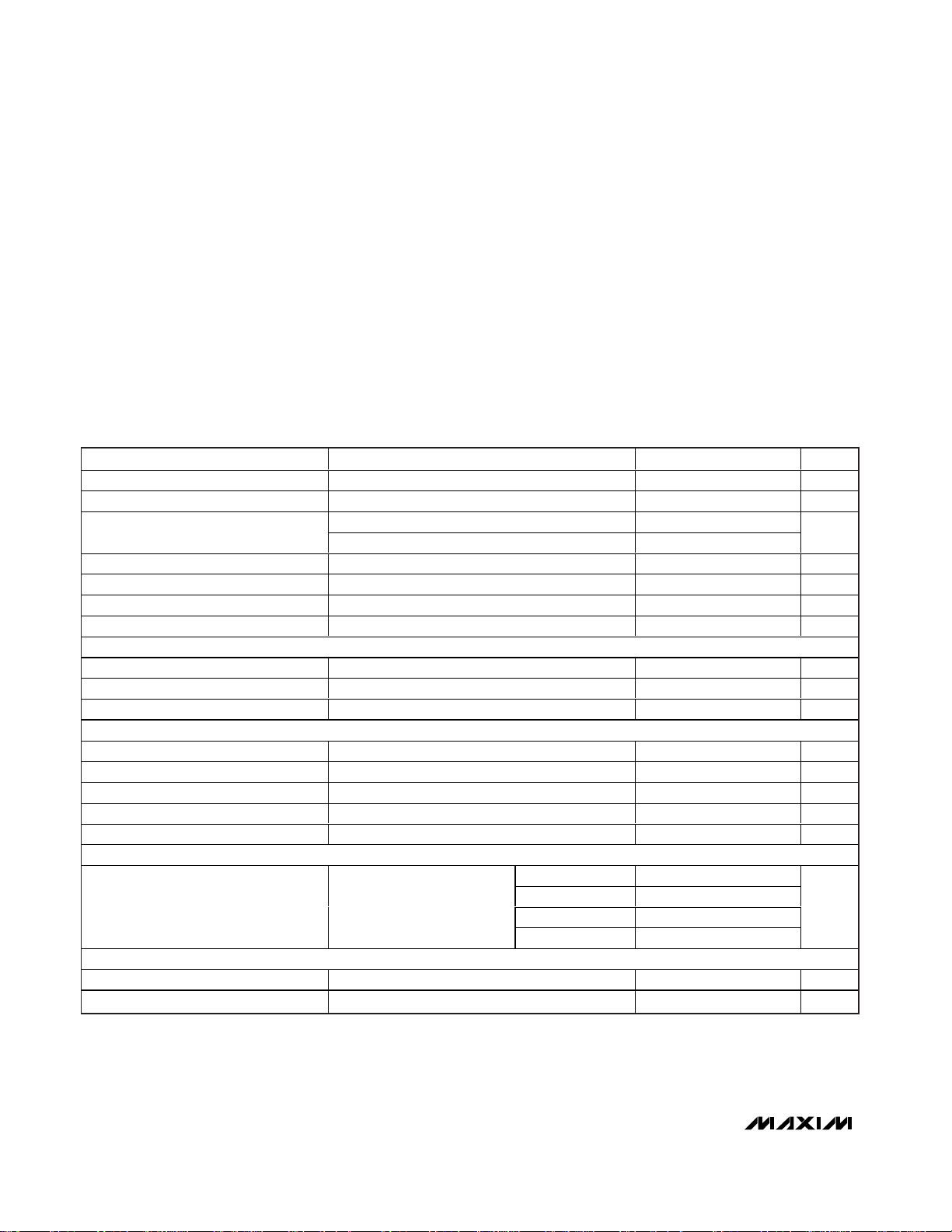

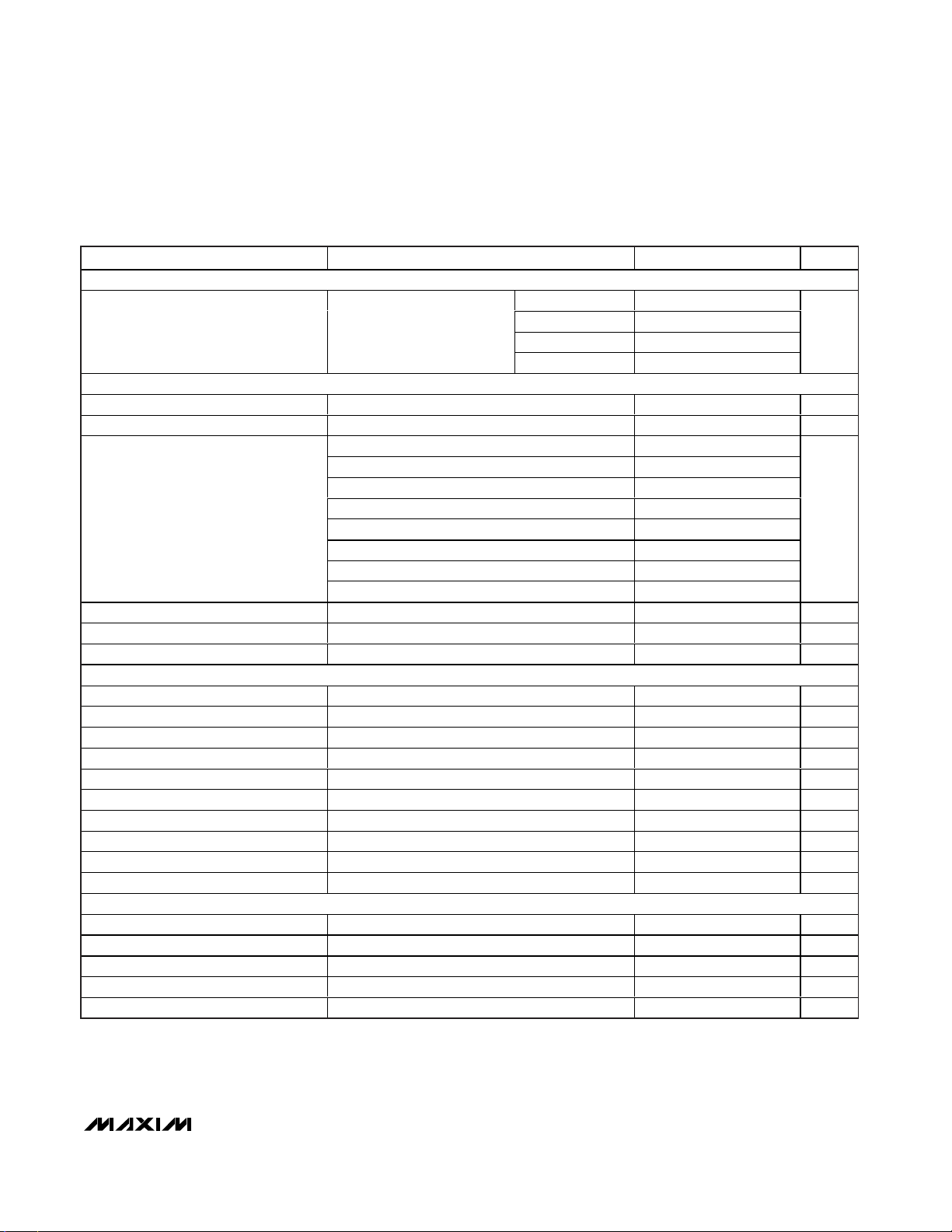

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VIN= 13.2V, V

BST

- VLX= 5V, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

IN, EN, CS+, CS- to GND .......................................-0.3V to +14V

BST, DH to LX ..........................................................-0.3V to +6V

BST to GND ............................................................-0.3V to +20V

DL, COMP, ILIM2, SS, SYNCO,

FSYNC to GND .......................................-0.3V to (V

VL

+ 0.3V)

VL, FB, POK, ILIM1, ILIM, MODE to GND ................-0.3V to +6V

PGND to GND .......................................................-0.3V to +0.3V

Continuous Power Dissipation (T

A

= +70°C)

16-Pin QSOP (derate 8.3mW/°C above +70°C) .......666.7mW

20-Pin QSOP (derate 9.1mW/°C above +70°C) .......727.3mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

PARAMETER CONDITIONS

UNITS

Operating Input Voltage Range VL connected to IN for V

IN

< 5.5V 3.0

V

Quiescent Supply Current V

FB

= 0.9V, no switching 2 3 mA

10

Shutdown Supply Current

EN = GND, VL = IN, MODE = GND 20

µA

VL Undervoltage-Lockout Trip Level V

VL

rising, typical hysteresis is 80mV

2.7

V

Output Voltage Adjust Range (V

OUT

) (Note 1) 0.8 V

VL Output Voltage 5.5V < V

IN

< 13.2V, 1mA < IVL < 75mA 4.5 5 5.5 V

VL Output Current 75 mA

VOLTAGE REFERENCE

SS Shutdown Resistance From SS to GND, V

EN

= 0V 20

Ω

SS Soft-Start Current V

REF

= 0.625V 14 24 34 µA

Soft-Start Ramp Time Output from 0% to 100%, C

REF

= 0.01µF to 1µF 33

ms/µF

ERROR AMPLIFIER

FB Regulation Voltage

0.8

V

Transconductance 70

µS

COMP Shutdown Resistance From COMP to GND, V

EN

= 0V 20

Ω

FB Input Leakage Current V

FB

= 0.9V 5

nA

FB Input Common-Mode Range

V

CURRENT-SENSE AMPLIFIER

V

ILIM1

= 0V 8.8 11

4.8 6 7.2

3.2 4 4.8

Voltage Gain V

OUT

= 0 to 13V

V

ILIM1

= V

VL

2.4 3 3.6

V / V

CURRENT LIMIT

ILIM2 Output Current (MAX8544 Only) R

ILIM2

= 50kΩ to 200kΩ 4.5 5 5.5 µA

ILIM1 Input Current V

ILIM1

= 0V or V

VL

-1 +1 µA

MIN TYP MAX

13.2

EN = GND, MODE = GND, IN not connected to VL

2.52

0.792

-0.1

110 160

V

V

ILIM1

ILIM1

= (1/3)V

= (2/3)V

VL

VL

2.88

100

0.808

100

100

+0.9

13.2

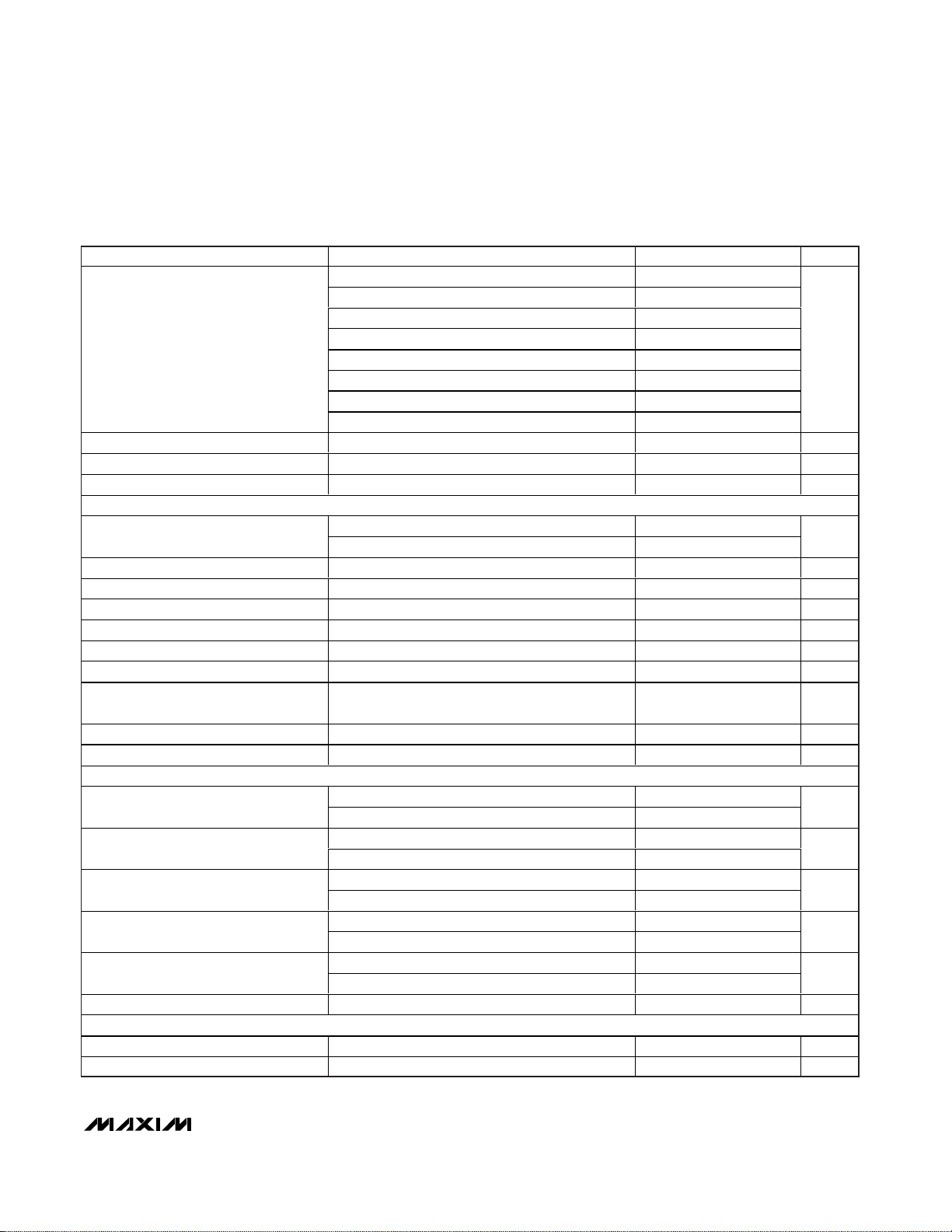

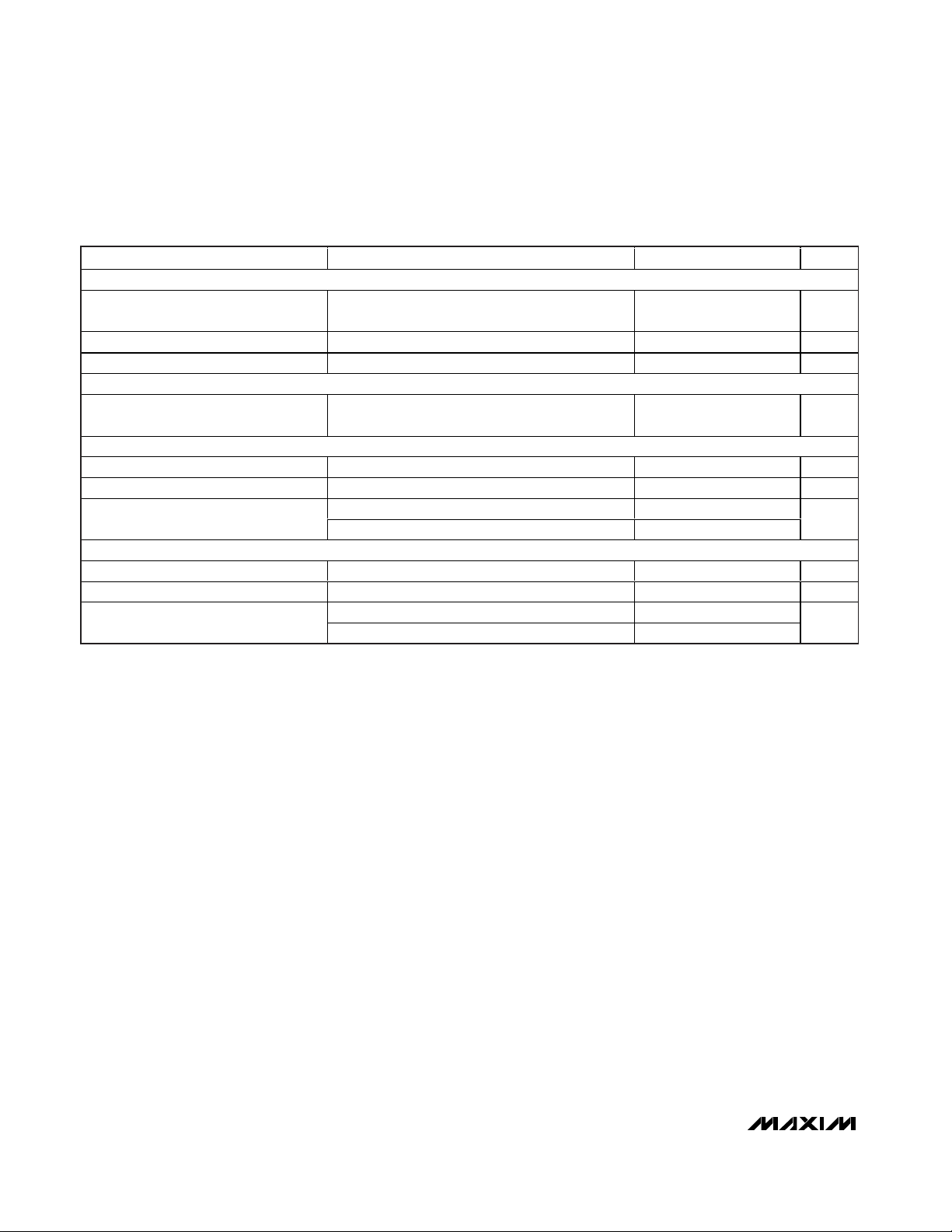

Page 3

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(VIN= 13.2V, V

BST

- VLX= 5V, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

PARAMETER CONDITIONS

MIN

TYP

MAX

UNITS

V

CS+

- V

CS-, VILIM1

= 0V

50

V

CS+

- V

CS-, VILIM1

= (1/3)V

VL

85

V

CS+

- V

CS-

, V

ILIM1

= (2/3)V

VL

V

CS+

- V

CS-

, V

ILIM1

= V

VL

V

LX

- V

PGND

, R

ILIM2

= 50kΩ (MAX8544 only)

-50

V

LX

- V

PGND

, R

ILIM2

= 200kΩ (MAX8544 only)

V

LX

- V

PGND

, VFB = 0.8V (MAX8543 only)

Current-Limit Threshold

V

LX

- V

PGND

, VFB = 0V (MAX8543 only) -20 -30 -40

mV

Negative Current-Limit Threshold % of positive-direction current limit V

LX

- V

PGND

-25 -50 -85 %

CS+, CS- Input Current V

CS+

= V

CS-

= 0 or 5V -40

µA

CS+, CS- Input Common-Mode Range 0

V

OSCILLATOR

R

FSYNC

= 18.2kΩ

Switching Frequency

R

FSYNC

= 158kΩ

kHz

Minimum Off-Time Measured at DH

ns

Minimum On-Time Measured at DH 90

ns

FSYNC Synchronization Range

kHz

FSYNC Input High Pulse Width

ns

FSYNC Input Low Pulse Width

ns

FSYNC Rise/Fall Time

ns

SYNCO Phase Shift from DH Rising

R

FSYNC

= 18.2kΩ, free-running mode,

at maximum duty cycle

Degrees

SYNCO Output Low Level I

SYNCO

= 5mA 0.4 V

SYNCO Output High Level I

SYNCO

= 5mA

V

MOSFET DRIVERS

(V

BST

- VLX) = 5V 1 2.5

DH On-Resistance, High State

(V

BST

- VLX) = 3V 1.2

Ω

(V

BST

- VLX) = 5V 1 2.5

DH On-Resistance, Low State

(V

BST

- VLX) = 3V 1.2

Ω

V

VL

= 5V 1 2.5

DL On-Resistance, High State

V

VL

= 3V 1.2

Ω

V

VL

= 5V 0.6 1.7

DL On-Resistance, Low State

V

VL

= 3V 0.8

Ω

Low-side off to high-side on 55

Break-Before-Make Dead Time

High-side off to low-side on 40

ns

LX, BST, IN Leakage Current V

BST

= 18.7V, VLX = 13.2V, VIN = 13.2V 5 µA

THERMAL PROTECTION

Thermal Shutdown Rising temperature

°C

Thermal-Shutdown Hysteresis 15 °C

38.5

56.5

100 115

127.5 150 172.5

170 200 230

-42.5

-57.5

-160 -200 -240

-110 -130 -150

800 1000 1200

200

150 220 270

160

100

100

165 180 195

V

- 1V

VL

+40

13.2

145

1200

100

+160

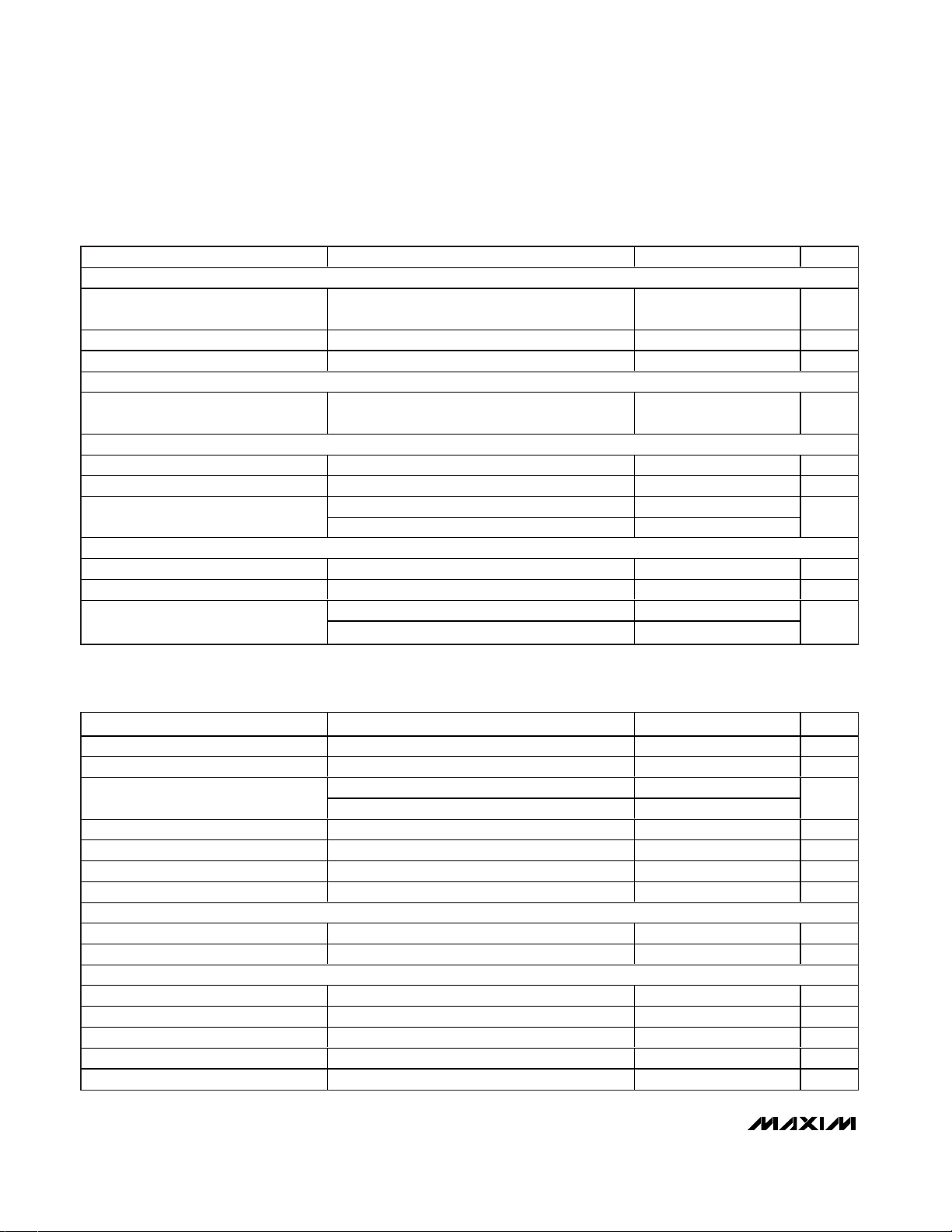

Page 4

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VIN= 13.2V, V

BST

- VLX= 5V, TA= 0°C to +85°C, unless otherwise noted. Typical values are at TA= +25°C.)

PARAMETER CONDITIONS

MIN

TYP

MAX

UNITS

POK

Power-OK Threshold

V

FB

rising, percent of V

OUT

,

typical hysteresis is 3%

88 91 94 %

POK Output Voltage, Low V

FB

= 0.6V, I

POK

= 2mA 25

mV

POK Leakage Current, High V

POK

= 5.5V

1 µA

OVERVOLTAGE PROTECTION (OVP)

Output Overvoltage Fault-Trip level

Rising edge compared to regulation set point;

triggers after one or two clock cycles

%

MODE CONTROL

MODE Logic-Level Low 3V ≤ V

VL

≤ 5.5V 0.4 V

MODE Logic-Level High 3V ≤ V

VL

≤ 5.5V

1.8 V

V

MODE

= 0V -1 +1

MODE Input Current

MODE = VL 5 10

µA

SHUTDOWN CONTROL

EN Logic-Level Low 3V ≤ V

VL

≤ 5.5V

V

EN Logic-Level High 3V ≤ V

VL

≤ 5.5V 2 V

V

EN

= 0 or 5.5V -1 +4

EN Input Current

V

EN

= 13.2V 1.5 6

µA

ELECTRICAL CHARACTERISTICS

(VIN= 13.2V, V

BST

- VLX= 5V, TA= -40°C to +85°C, unless otherwise noted.) (Note 2)

PARAMETER CONDITIONS

UNITS

Operating Input Voltage Range VL connected to IN for V

IN

< 5.5V 3.0

V

Quiescent Supply Current V

FB

= 0.9V, no switching 3 mA

10

Shutdown Supply Current

EN = GND, VL = IN, MODE = GND 20

µA

VL Undervoltage-Lockout Trip Level V

VL

rising, typical hysteresis is 80mV

V

Output Voltage Adjust Range (V

OUT

) (Note 1) 0.8 V

VL Output Voltage 5.5V < V

IN

< 13.2V, 1mA < IVL < 75mA 4.5 5.5 V

VL Output Current 75 mA

VOLTAGE REFERENCE

SS Shutdown Resistance From SS to GND, V

EN

= 0V 100 Ω

SS Soft-Start Current V

REF

= 0.625V 14 34 µA

ERROR AMPLIFIER

FB Regulation Voltage

V

Transconductance 70 160 µS

COMP Shutdown Resistance From COMP to GND, V

EN

= 0V 100 Ω

FB Input Leakage Current V

FB

= 0.9V 100 nA

FB Input Common-Mode Range

V

0.001

+110 +115 +120

200

0.45

MIN

EN = GND, MODE = GND, IN not connected to VL

2.52

0.788

-0.1

MAX

13.2

2.88

0.808

+0.9

Page 5

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(VIN= 13.2V, V

BST

- VLX= 5V, TA= -40°C to +85°C, unless otherwise noted.) (Note 2)

PARAMETER CONDITIONS

UNITS

CURRENT-SENSE AMPLIFIER

V

ILIM1

= 0V 8.8

4.8 7.2

3.2 4.8

Voltage Gain V

OUT

= 0 to 13V

V

ILIM1

= V

VL

2.4 3.6

V / V

CURRENT LIMIT

ILIM2 Output Current (MAX8544 Only) R

ILIM2

= 50kΩ to 200kΩ 4.2 5.5 µA

ILIM1 Input Current V

ILIM1

= 0V or V

VL

-1 +1 µA

V

CS+

- V

CS-, VILIM1

= 0V

V

CS+

- V

CS-, VILIM1

= (1/3)V

VL

85 115

V

CS+

- V

CS-

, V

ILIM1

= (2/3)V

VL

V

CS+

- V

CS-, VILIM1

= V

VL

230

V

LX

- V

PGND

, R

ILIM2

= 50kΩ (MAX8544 only) -40 -60

V

LX

- V

PGND

, R

ILIM2

= 200kΩ (MAX8544 only)

V

LX

- V

PGND

, VFB = 0.8V (MAX8543 only)

Current-Limit Threshold

V

LX

- V

PGND

, VFB = 0V (MAX8543 only) -20 -40

mV

Negative Current-Limit Threshold % of positive-direction current limit V

LX

- V

PGND

-25 -85 %

CS+, CS- Input Current V

CS+

= V

CS-

= 0V or 5V -40

µA

CS+, CS- Input Common-Mode Range 0

V

OSCILLATOR

Switching Frequency R

FSYNC

= 18.2kΩ

kHz

Minimum Off-Time Measured at DH

270 ns

Minimum On-Time Measured at DH 140 ns

FSYNC Synchronization Range

kHz

FSYNC Input High Pulse Width

ns

FSYNC Input Low Pulse Width

ns

FSYNC Rise/Fall Time 100 ns

SYNCO Phase Shift from DH Rising R

FSYNC

= 18.2kΩ

195

Degrees

SYNCO Output Low Level I

SYNCO

= 5mA 0.4 V

SYNCO Output High Level I

SYNCO

= 5mA

V

MOSFET DRIVERS

DH On-Resistance, High State (V

BST

- VLX) = 5V 2.5 Ω

DH On-Resistance, Low State (V

BST

- VLX) = 5V 2.5 Ω

DL On-Resistance, High State V

VL

= 5V 2.5 Ω

DL On-Resistance, Low State V

VL

= 5V 1.7 Ω

LX, BST, IN Leakage Current V

BST

= 18.7V, VLX = 13.2V, VIN = 13.2V 5 µA

V

V

ILIM1

ILIM1

= (1/3)V

= (2/3)V

MIN

VL

VL

38.5

127.5

170

-160

-110

800

150

160

100

100

165

V

- 1V

VL

MAX

13.2

56.5

172.5

-240

-150

+40

13.2

1200

1200

Page 6

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

6 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VIN= 13.2V, V

BST

- VLX= 5V, TA= -40°C to +85°C, unless otherwise noted.) (Note 2)

PARAMETER CONDITIONS

UNITS

POK

Power-OK Threshold

V

FB

rising, percent of V

OUT

,

typical hysteresis is 3%

88 94 %

POK Output Voltage, Low V

FB

= 0.6V, I

POK

= 2mA 200 mV

POK Leakage Current, High V

POK

= 5.5V 1 µA

OVERVOLTAGE PROTECTION (OVP)

Output Overvoltage Fault-Trip level

Rising edge compared to regulation set point;

triggers after one or two clock cycles

%

MODE CONTROL

MODE Logic-Level Low 3V ≤ V

VL

≤ 5.5V

0.4 V

MODE Logic-Level High 3V ≤ V

VL

≤ 5.5V

1.8 V

V

MODE

= 0V -1 +1

MODE Input Current

MODE = VL 10

µA

SHUTDOWN CONTROL

EN Logic-Level Low 3V ≤ V

VL

≤ 5.5V

V

EN Logic-Level High 3V ≤ V

VL

≤ 5.5V

2 V

V

EN

= 0V or 5.5V -1 +4

EN Input Current

V

EN

= 13.2V 6

µA

Note 1: Maximum output voltage is limited by maximum duty cycle and external components.

Note 2: Specifications to -40°C are guaranteed by design and not production tested.

MIN

MAX

+110

+120

0.45

Page 7

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

_______________________________________________________________________________________ 7

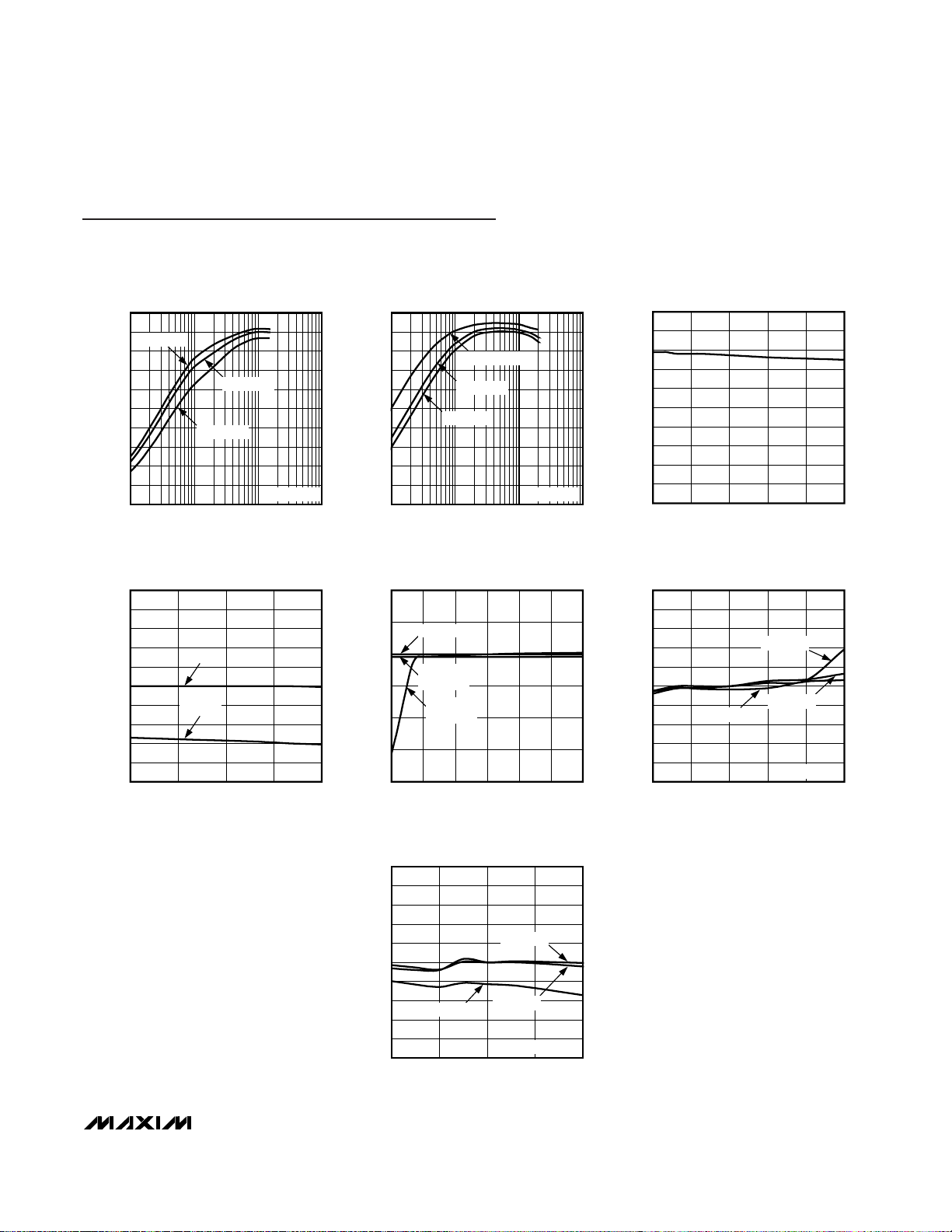

EFFICIENCY vs. LOAD CURRENT

WITH 12V INPUT

MAX8543 toc01

LOAD CURRENT (A)

EFFICIENCY (%)

101

10

20

30

40

50

60

70

80

90

100

0

0.1 100

V

OUT

= 3.3V

V

OUT

= 2.5V

V

OUT

= 1.8V

fS = 600kHz

EFFICIENCY vs. LOAD CURRENT

WITH 3.3V INPUT

MAX8543 toc02

LOAD CURRENT (A)

EFFICIENCY (%)

101

10

20

30

40

50

60

70

80

90

100

0

0.1 100

V

OUT

= 2.5V

V

OUT

= 1.8V

fS = 500kHz

V

OUT

= 1.5V

LOAD REGULATION WITH 12V INPUT

MAX8543 toc03

LOAD CURRENT (A)

OUTPUT VOLTAGE (V)

12963

2.46

2.47

2.48

2.49

2.50

2.51

2.52

2.53

2.54

2.55

2.45

015

LINE REGULATION WITH 12V INPUT

AND 2.5V OUTPUT

MAX8543 toc04

INPUT VOLTAGE (V)

OUTPUT VOLTAGE (V)

12.612.011.4

2.492

2.494

2.496

2.498

2.500

2.502

2.504

2.506

2.508

2.510

2.490

10.8 13.2

NO LOAD

15A LOAD

LINE REGULATION

3.0V TO 3.6V INPUT

MAX8543 toc05

INPUT VOLTAGE (V)

OUTPUT VOLTAGE (V)

3.53.43.33.23.1

2.44

2.46

2.48

2.50

2.52

2.54

2.42

3.0 3.6

NO LOAD

15A LOAD

f

S

= 350kHz

15A LOAD

f

S

= 500kHz

OSCILLATOR FREQUENCY

vs. INPUT VOLTAGE

MAX8543 toc06

INPUT VOLTAGE (V)

OSCILLATOR FREQUENCY (kHz)

5.04.54.03.5

420

440

460

480

500

520

540

560

580

600

400

3.0 5.5

TA = +85°C

TA = +25°C

TA = -40°C

R6 = 53.6k

Ω

OSCILLATOR FREQUENCY

vs. INPUT VOLTAGE

MAX8543 toc07

INPUT VOLTAGE (V)

OSCILLATOR FREQUENCY (kHz)

11.59.57.5

520

540

560

580

600

620

640

660

680

700

500

5.5 13.5

R6 = 42.2kΩ

TA = +85°C

TA = -40°C

TA = +25°C

Typical Operating Characteristics

(TA = +25°C, unless otherwise noted.)

Page 8

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

8 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

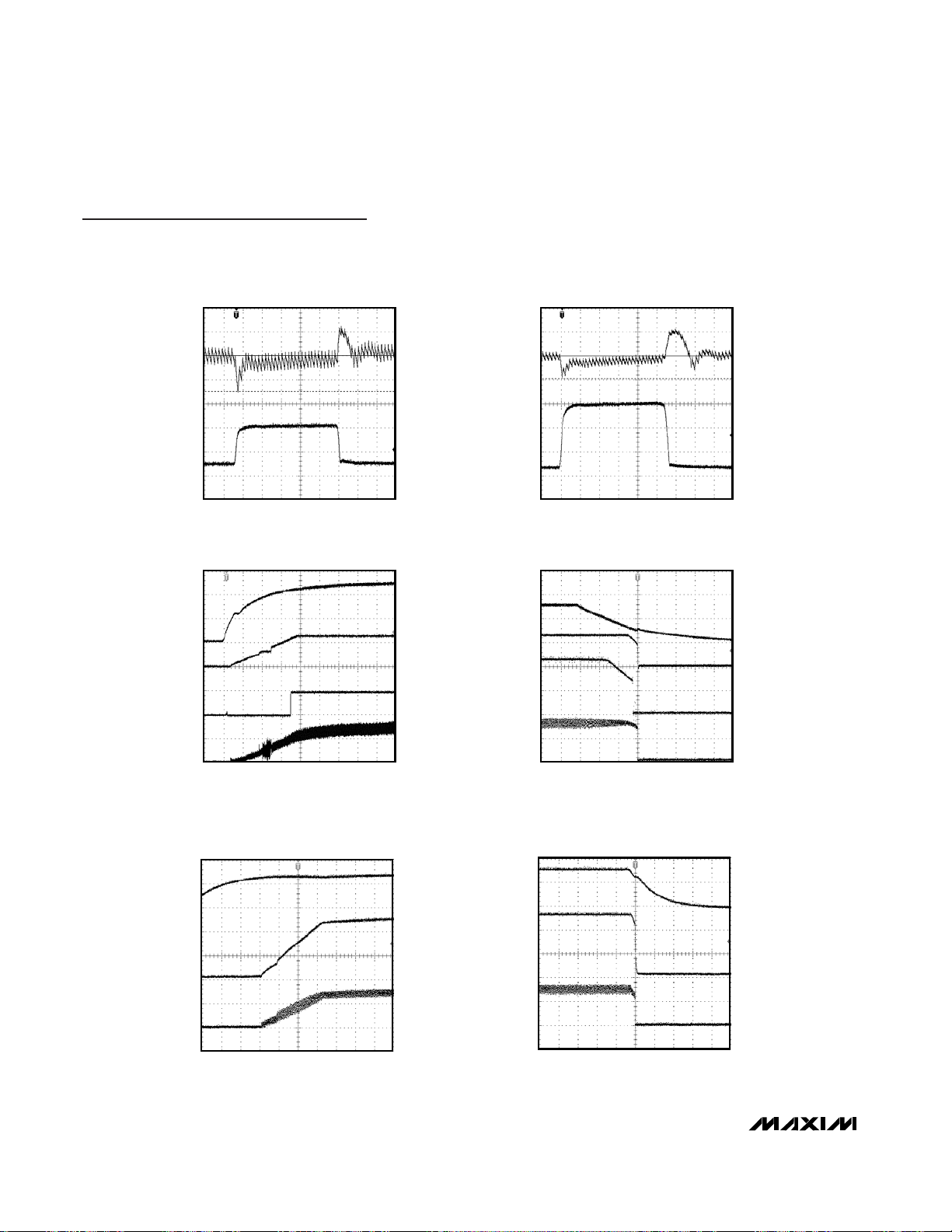

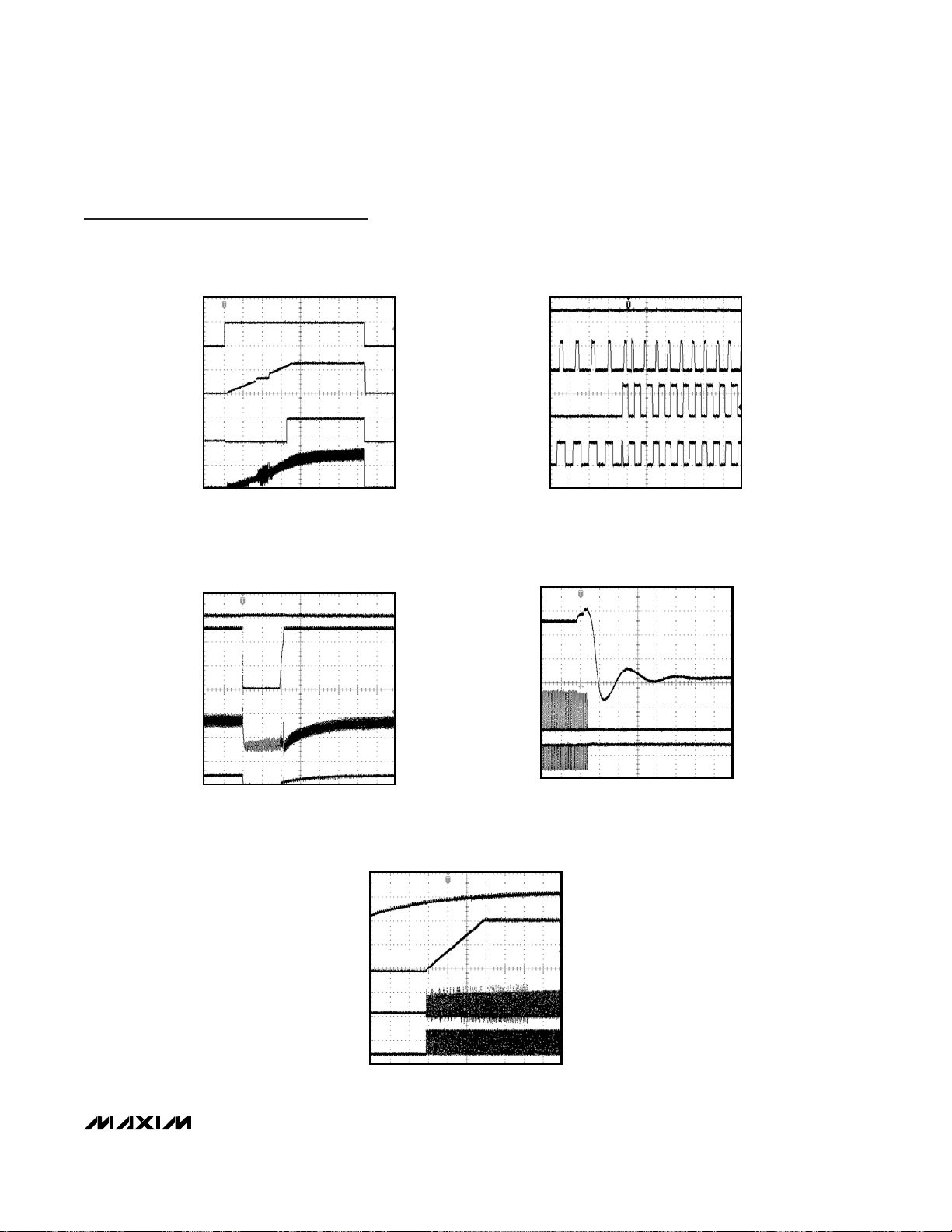

MAX8544 STEP-LOAD RESPONSE

7.5A TO 15A TO 7.5A (5A/μs)

MAX8543 toc08

V

OUT

I

OUT

50mV/div

AC-COUPLED

0

5A/div

10μs/div

MAX8544 STEP-LOAD RESPONSE

1.5A TO 15A TO 1.5A (5A/μs)

MAX8543 toc09

V

OUT

I

OUT

100mV/div

AC-COUPLED

0

5A/div

10μs/div

MAX8544 POWER-UP WAVEFORMS

MAX8543 toc10

V

IN

V

POK

5V/div

0

10A/div

2ms/div

V

OUT

I

L

2V/div

5V/div

MAX8544 POWER-DOWN WAVEFORMS

MAX8543 toc11

V

IN

V

POK

5V/div

0

10A/div

2ms/div

V

OUT

I

L

2V/div

2V/div

MAX8543 POWER-UP WAVEFORMS

MAX8543 toc12

V

IN

2V/div

0

10A/div

2ms/div

V

OUT

I

L

1V/div

MAX8543 POWER-DOWN WAVEFORMS

MAX8543 toc13

V

IN

2V/div

0

10A/div

2ms/div

V

OUT

I

L

1V/div

Page 9

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

_______________________________________________________________________________________ 9

MAX8544 ENABLE WAVEFORMS

MAX8543 toc14

V

EN

5V/div

0

10A/div

2ms/div

V

OUT

I

L

2V/div

V

POK

5V/div

FSYNC AND SYNCO WAVEFORMS

MAX8543 toc15

V

OUT

1V/div

5V/div

2μs/div

V

LX

V

SYNCO

10V/div

V

FSYNC

5V/div

SHORT CIRCUIT AND RECOVERY

MAX8543 toc16

V

IN

10V/div

12V

0

1ms/div

V

OUT

I

IN

1V/div

I

L

10A/div

0

10A/div

OVERVOLTAGE PROTECTION

WITH 15A LOAD

MAX8543 toc17

V

OUT

5V/div

40μs/div

V

DH

V

DL

1V/div

10V/div

0V

0V

5V

5V

PREBIASED STARTUP

(OUTPUT PREBIASED AT 1.5V)

MAX8543 toc18

V

IN

5V/div

1ms/div

V

LX

V

DL

2.5V

10V/div

V

OUT

5V/div

500mV/div

1.5V

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

Page 10

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

10 ______________________________________________________________________________________

Pin Description

PIN

MAX8543

NAME FUNCTION

1 2 GND Ground. Connect to the analog ground plane.

23SS

Soft-Start. Connect a 0.1µF to 1µF ceramic capacitor from SS to GND. This capacitor

sets the soft-start period during startup. See the Startup and Soft-Start section. SS is

internally pulled to GND in shutdown.

3 4 COMP

Compensation. Connect to an external RC network to compensate the feedback loop.

See the Compensation Design section. COMP is internally pulled to GND in shutdown.

45FB

Output Feedback. Connect to the center of a voltage-divider connected between OUT

and GND to set the output voltage. The FB threshold voltage is 0.8V.

56EN

Enable. Drive EN logic high to enable the output, or drive logic low for shutdown.

Connect EN to IN for always-on operation.

6 7 CS- Negative Differential Current-Sensing Input

7 8 CS+ Positive Differential Current-Sensing Input

— 9 ILIM1

8 — ILIM

Digital Programmable Current-Limit Input for Inductor Current Sensing (V

CS+

- V

CS-

).

See Table 3.

9 12 PGND

Power Ground. Connect to the power ground plane and to the source of the low-side

external MOSFETs. Connect PGND to GND at a single point.

10 13 DL

Low-Side MOSFET Gate-Driver Output. Connect to the gate of the low-side external

MOSFETs. DL is pulled low in shutdown.

11 14 VL

Internal 5V Linear-Regulator Output. Connect a 1µF to 10µF ceramic capacitor from

VL to PGND. Connect VL to IN for VIN less than 5.5V. VL provides power for bias and

gate drive.

12 15 IN

Input Supply Voltage. IN is the input to the internal linear regulator. Connect VL to IN for

V

IN

less than 5.5V.

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

BODE PLOT, 600kHz, 15A LOAD

SWEEP TIME

10.000s

MAX8543 toc19

BODE PLOT, 600kHz, NO LOAD

SWEEP TIME

10.000s

MAX8543 toc20

0dB

10dB/div

1kHz 1MHz100kHz10kHz

°

90

30°/div

MAX8544

0dB

10dB/div

1kHz 1MHz100kHz10kHz

°

90

30°/div

Page 11

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

______________________________________________________________________________________ 11

Pin Description (continued)

PIN

MAX8543

NAME FUNCTION

13 16 LX Inductor Connection

14 17 DH

High-Side MOSFET Gate-Driver Output. Connect DH to the gate of the high-side

external MOSFETs. DH is pulled low in shutdown.

15 18 BST

Boost Capacitor Connection. Connect a 0.1µF or larger ceramic capacitor from BST to

LX. BST provides power for the high-side MOSFET gate drive.

16 19 FSYNC

Frequency Set and Synchronization. Connect a resistor from FSYNC to GND to set the

switching frequency or drive with a clock signal to synchronize between 160kHz and

1.2MHz. See the Switching Frequency and Synchronization section.

— 1 ILIM2

Analog Programmable Current-Limit Input for Low-Side MOSFET (V

LX

- V

PGND

).

Connect a resistor from ILIM2 to ground to set the overcurrent threshold. See the

Setting the Current Limits section.

— 10 MODE

Current-Limit Operating-Mode Selection. Connect MODE to VL for latch-off current limit

or connect to GND for automatic-recovery current limit with the MAX8544. The MAX8543

always uses automatic-recovery current limit.

—11POK

Power-OK. POK is an open-drain output that is high impedance when the output is

above 91% of its nominal regulation voltage. POK is pulled low when the output is out

of regulation and when the part is in shutdown. To use POK as a logic-level signal,

connect a pullup resistor from POK to the logic supply.

— 20 SYNCO

Synchronization Output. Provides a clock output that is 180° out of phase with the rising

edge of DH for out-of-phase synchronization of another MAX8544.

MAX8544

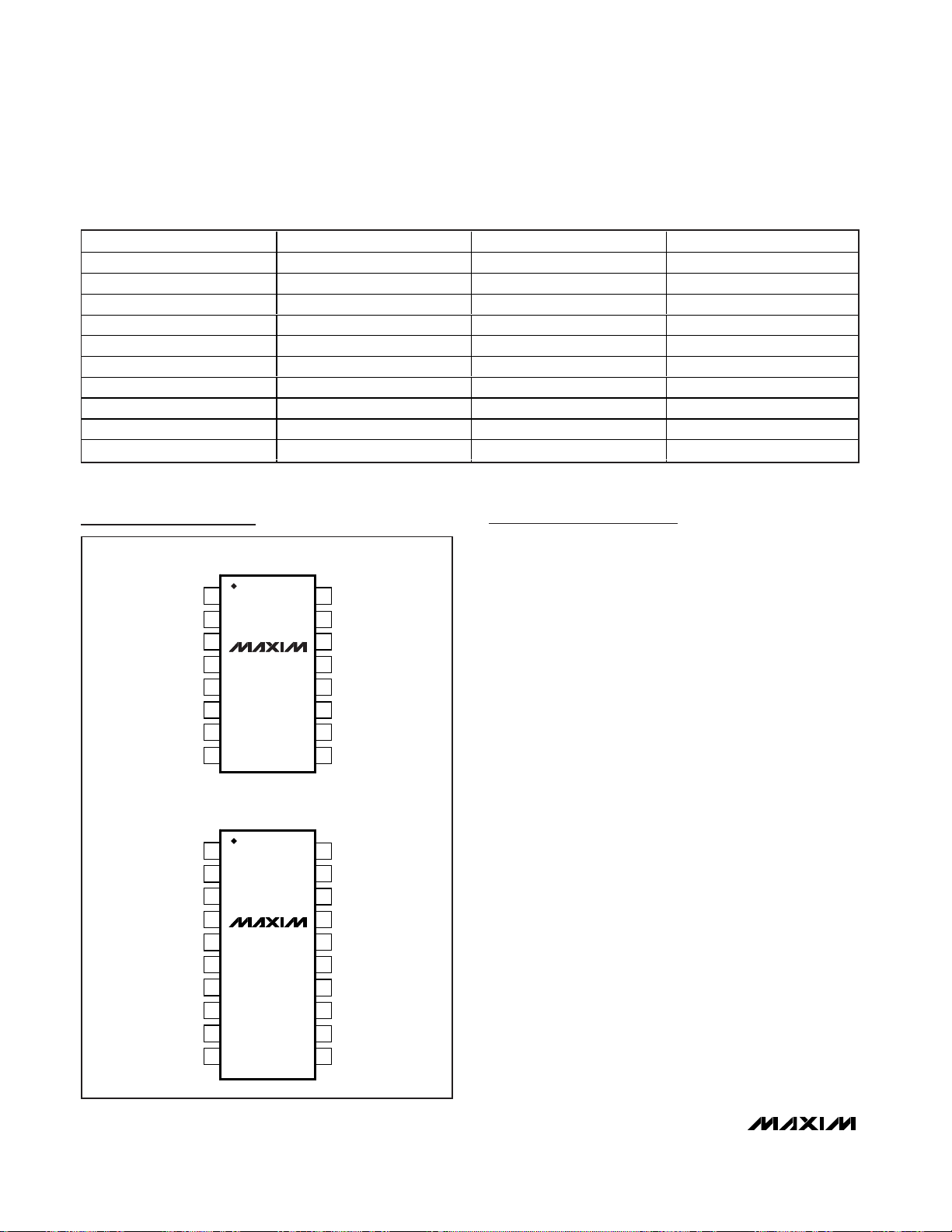

Page 12

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

12 ______________________________________________________________________________________

MAX8544EEP

SS

COMP

MODE

SYNCO

POK

VL

GND

VL

EN

LX

ILIM2

CS-

CS+

PGND

DL

BST

DH

IN

ILIM1

FSYNC

FB

9

19

6

2

3

4

5

10

1

11

20

7

8

12

13

18

D1

C1

C2

C4A C4B C4C

VL

VL

17

16

14

15

C3

C6A C6B

SYNC OUT

R6

R3

R1

R7

R9

POK

R2

R8

D2

C5

C9

N3

N4

L1

V

OUT

= 2.5V

UP TO 15A

V

IN

= (10.8V TO 13.2V)

N2

N1

C7

C8

ON

OFF

SYNC IN

R4

R5

C11

C10

C12

Figure 1. Typical Applications Circuit with 12V (±10%) Input, 2.5V Output at Up to 15A, and 600kHz Switching Frequency

Page 13

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

______________________________________________________________________________________ 13

Table 1. Suggested Components for Figure 1

DESIGNATION QTY DESCRIPTION

C1 1

1µF ±20%, 16V X5R ceramic capacitor (0603)

Panasonic ECJ1VB1C105M or equivalent

C2 1

10µF ±20%, 6.3V X5R ceramic capacitor (0805)

Panasonic ECJ2FB0J106M or Taiyo Yuden JMK212BJ106MG

C3 1

0.1µF ±10%, 50V X7R ceramic capacitor (0603)

TDK C1608X7R1H104KT or equivalent

C4A, C4B, C4C 2

10µF ±20%, 16V X5R ceramic capacitors (1206)

Panasonic ECJ3YB1C106M or equivalent

C5 1

0.22µF ±10%, 10V X7R ceramic capacitor (0603)

Taiyo Yuden LMK107BJ224KA or equivalent

C6A, C6B 2

180µF, 4V aluminum poly SPCAPs

Panasonic EEFUE0G181XR

C7 1 10pF, 50V C0G ceramic capacitor (0603)

C8 1 220pF ±10%, 50V X7R ceramic capacitor (0603)

C9, C10 2 0.47µF ±10% X7R ceramic capacitors (0603)

C11 1 100pF, 50V C0G ceramic capacitor (0603)

C12 1

470µF ±20%, 16V aluminum electrolytic capacitor

Rubycon 16MBZ470M

D1 1

100mA, 30V Schottky diode (SOT-323)

Central CMSSH-3

D2 1

250mA, 100V switching diode (SOT23)

Central CMPD914

L1 1

0.82µH, 33A, 1.6mΩ inductor

Vishay IHLP-5050FD-01 0.82µH

N1, N2 2

N-channel MOSFETs

IRF IRF7821

N3, N4 2

N-channel MOSFETs

IRF IRF7832

R1 1 17.4kΩ ±1% resistor (0603)

R2 1 8.06kΩ ±1% resistor (0603)

R3 1 220kΩ ±5% resistor (0603)

R4, R5 2 1.3kΩ ±5% resistors (0603)

R6 1 42.2kΩ ±1% resistor (0603)

R7 1 90.9kΩ ±1% resistor (0603)

R8 1 9.31kΩ ±1% resistor (0603)

R9 1 100kΩ ±5% resistor (0603)

Page 14

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

14 ______________________________________________________________________________________

MAX8543

SS

COMP

CS-

GND

VL

EN

LX

FB

CS+

PGND

DL

BST

DH

IN

ILIM

FSYNC

8

16

5

1

2

3

4

6

7

9

10

15

D1

C1

C2

C4A C4B C4D

IN

14

13

11

12

C3

C6A C6B

R6

R3

R1

R2

D2

C5

C9

R4

R5

N3

N4

L1

V

OUT

= 2.5V

UP TO 15A

V

IN

= (3V TO 3.6V)

N2

N1

C7

C8

C4C

ON

OFF

SYNC IN

C12

C11

C10

Figure 2. Typical Applications Circuit with 3.3V (±10%) Input, 2.5V Output at Up to 15A, and 500kHz Switching Frequency

Page 15

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

______________________________________________________________________________________ 15

Table 2. Suggested Components for Figure 2

DESIGNATION QTY DESCRIPTION

C1 1

1µF ±10%, 16V X5R ceramic capacitor (0603)

Panasonic ECJ1VB1C105K or equivalent

C2 1

10µF ±20%, 6.3V X5R ceramic capacitor (0805)

Panasonic ECJ2FB0J106M or Taiyo Yuden JMK212BJ106MG

C3 1

0.1µF ±10%, 50V X7R ceramic capacitor (0603)

TDK C1608X7R1H104KT or equivalent

C4A, C4B, C4C,

C4D

4

10µF ±20%, 16V X5R ceramic capacitors (1206)

Panasonic ECJ3YB1C106M or equivalent

C5 1

0.22µF ±10%, 10V X7R ceramic capacitor (0603)

Taiyo Yuden LMK107BJ224KA or equivalent

C6A, C6B 2

180µF, 4V, 10mΩ aluminum poly SPCAPs

Panasonic EEFUE0G181XR

C7 1 12pF, 50V C0G ceramic capacitor (0603)

C8 1 220pF ±10%, 50V X7R ceramic capacitor (0603)

C9, C10 2 0.47µF ±10% X7R ceramic capacitors (0603)

C11 1 100pF, 50V C0G ceramic capacitor (0603)

C12 1

470µF ±20%, 6.3V POSCAP

Sanyo 6PB470M

D1 1

100mA, 30V Schottky diode (SOT-323)

Central CMSSH-3

D2 1

250mA, 100V switching diode (SOT23)

Central CMPD914

L1 1

0.33µH, 16A, 2mΩ inductor (13 x 10 x 6.35)

Coilcraft DO3316P-331HC

N1, N2 2

N-channel MOSFETs

Vishay Si4866DY

N3, N4 2

N-channel MOSFETs

Vishay Si4866DY

R1 1 17.4kΩ ±1% resistor (0603)

R2 1 8.06kΩ ±1% resistor (0603)

R3 1 150kΩ ±5% resistor (0603)

R4, R5 2 680Ω ±5% resistors (0603)

R6 1 53.6kΩ ±1% resistor (0603)

Page 16

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

16 ______________________________________________________________________________________

Detailed Description

DC-DC Converter Control Architecture

The MAX8543/MAX8544 step-down controllers use a

PWM, current-mode control scheme. An internal

transconductance amplifier establishes an integrated

error voltage. The heart of the PWM controller is an

open-loop comparator that compares the integrated

voltage-feedback signal against the amplified currentsense signal plus the slope-compensation ramp, which

are summed into the main PWM comparator to preserve inner-loop stability and eliminate inductor staircasing. At each rising edge of the internal clock, the

high-side MOSFET turns on until the PWM comparator

trips or the maximum duty cycle is reached or the peak

current limit is reached. During this on-time, current

ramps up through the inductor, storing energy in a

magnetic field and sourcing current to the output. The

current-mode feedback system regulates the peak

inductor current as a function of the output-voltageerror signal. The circuit acts as a switch-mode

transconductance amplifier and pushes the output LC

filter pole normally found in a voltage-mode PWM to a

higher frequency.

During the second half of the cycle, the high-side

MOSFET turns off and the low-side MOSFET turns on.

The inductor releases the stored energy as the current

ramps down, providing current to the output. The output capacitor stores charge when the inductor current

exceeds the required load current and discharges

when the inductor current is lower, smoothing the voltage across the load. Under soft-overload conditions,

when the peak inductor current exceeds the selected

current limit (see the Current-Limit Circuit section), the

high-side MOSFET is turned off immediately and the

low-side MOSFET is turned on and remains on to let the

inductor current ramp down until the next clock cycle.

Under heavy-overload or short-circuit conditions, the

valley foldback current limit is enabled to reduce power

dissipation of external components.

The MAX8543/MAX8544 operate in a forced-PWM

mode. As a result, the controller maintains a constant

switching frequency, regardless of load, to allow for

easier filtering of the switching noise.

Internal 5V Linear Regulator (VL)

All MAX8543/MAX8544 functions are powered from the

on-chip, low-dropout, 5V linear regulator. Connect a

1µF to 10µF ceramic capacitor from VL to PGND. In

applications where the input voltage is less than 5.5V,

bypass the linear regulator by connecting VL to IN.

Undervoltage Lockout

When VL drops below 2.62V, the MAX8543/MAX8544

assume that the supply voltage is too low for proper operation, so the undervoltage-lockout (UVLO) circuitry

inhibits switching and forces the DL and DH gate drivers

low. When VL rises above 2.7V, the controller enters the

startup sequence and then resumes normal operation.

Startup and Soft-Start

The soft-start circuitry gradually ramps up the reference

voltage to control the rate of rise of the step-down controller output and reduce input surge currents during

startup. The soft-start period is determined by the value

of the capacitor from SS to GND. The soft-start time is

approximately (33ms/µF) x CSS. The MAX8543/MAX8544

also feature prebias startup; therefore, both external

power MOSFETs are kept off if the voltage at FB is higher

than that at SS. This allows the MAX8543/MAX8544 to

start up into a prebiased output without pulling the output

voltage down.

Before the MAX8543/MAX8544 can begin the soft-start

and power-up sequence, the following conditions must

be met:

1) VVLexceeds the 2.7V undervoltage-lockout threshold.

2) EN is at logic high.

3) The thermal limit is not exceeded.

Enable

The MAX8543/MAX8544 feature a low-power shutdown

mode. A logic low at EN shuts down the controller.

During shutdown, the output is high impedance, and

both DH and DL are low. Shutdown reduces the quiescent current (IQ) to less than 10µA. A logic high at EN

enables the controller.

Synchronous-Rectifier Driver (DL)

Synchronous rectification reduces conduction losses in

the rectifier by replacing the normal Schottky catch

diode with a low-resistance MOSFET switch. The

MAX8543/MAX8544 also use the synchronous rectifier

to ensure proper startup of the boost gate-driver circuit

and to provide the current-limit signal. The DL low-side

gate-drive waveform is always the complement of the

DH high-side gate-drive waveform (with controlled

dead time to prevent cross-conduction or shootthrough). An adaptive dead-time circuit monitors the DL

voltage and prevents the high-side MOSFET from turning on until DL is fully off. For the dead-time circuit to

work properly, there must be a low-resistance, lowinductance path from the DL driver to the MOSFET

gate. Otherwise, the sense circuitry in the MAX8543/

MAX8544 can interpret the MOSFET gate as off when

gate charge actually remains.

Page 17

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

______________________________________________________________________________________ 17

Use very short, wide traces, about 10 to 20 squares

(50 mils to 100 mils wide if the MOSFET is 1in from the

device) for the gate drive. The dead time at the other

edge (DH turning off) also has an adaptive dead-time

circuit operating in a similar manner. For both edges,

there is an additional fixed dead time after the adaptive

dead time expires.

High-Side Gate-Drive Supply (BST)

A flying capacitor boost circuit (Figure 3) generates the

gate-drive voltage for the high-side n-channel MOSFET.

The capacitor between BST and LX is charged from VL

up to VVLminus the diode forward-voltage drop while the

low-side MOSFET is on. When the low-side MOSFET is

switched off, the stored voltage of the capacitor is

stacked above LX to provide the necessary turn-on

voltage (VGS) for the high-side MOSFET. The controller

then closes an internal switch between BST and DH to

turn the high-side MOSFET on.

Current-Sense Amplifier

The MAX8543/MAX8544 current-sense circuit amplifies

the differential current-sense voltage (V

CS+

- V

CS-

). The

gain of the current-sense amplifier is determined by the

states of ILIM and ILIM1. This amplified current-sense

signal and the internal slope-compensation signal are

summed (V

SUM

) together and fed into the PWM comparator’s inverting input. The PWM comparator shuts

off the high-side MOSFET when V

SUM

exceeds the

integrated feedback voltage (V

COMP

).

The differential current sense is also used to provide

peak inductor current limiting. This current limit is more

accurate than the valley current limit, which is measured

across the low-side MOSFET’s on-resistance.

Current-Limit Circuit

The MAX8543/MAX8544 use both valley foldback current

limiting and peak constant current limiting, simultaneously

(Figure 4). The valley foldback current limit is used to

reduce power dissipation of external components, mainly

inductor and power MOSFETs, and upstream power

source, when output is severely overloaded or short

circuited. Thus the circuit can withstand short-circuit

conditions indefinitely without causing overheating of any

component. The peak constant current limit sets the current-limit point more accurately since it does not have to

suffer the wide variation of the low-side power MOSFET’s

on-resistance due to tolerance and temperature.

The valley current is sensed across the on-resistance of

the low-side MOSFET (V

PGND

- VLX). The valley current

limit trips when the sensed current exceeds the valley

current-limit threshold. The valley current limit recovers

when the sensed current drops below the valley currentlimit threshold (except when using the latch-off option

with the MAX8544).

Set the minimum valley current-limit threshold, when the

output voltage is at a nominal regulated value, higher

than the maximum peak current-limit setting. With this

method, the current-limit point accuracy is controlled by

the peak current limit and is not interfered with by the

wide variation of MOSFET on-resistance. See the Setting

the Current Limits section for how to set these limits.

The MAX8543 has a fixed valley current-limit threshold

and fixed foldback ratio. The MAX8544 can select

between an adjustable valley current-limit threshold

with adjustable foldback ratio and a fixed valley current

limit without foldback for latch-off. When latch-off is

used (MODE is connected to VL), set the current-limit

threshold by only one resistor from ILIM2 to GND and

make sure this threshold is higher than the maximum

output current required by at least a 20% margin. Cycle

EN or input power to reset the current-limit latch.

The peak current limit is used to sense the inductor

current, and is more accurate than the valley current limit

since it does not depend upon the on-resistance of the

low-side MOSFET. The peak current can be measured

across the resistance of the inductor for the highest

efficiency, or alternatively, a current-sense resistor can

be used for more accurate current sensing. The

MAX8543/MAX8544 have four selectable peak currentlimit thresholds that are selected using ILIM (MAX8543)

or ILIM1 (MAX8544). See Table 3 for the current-limit

settings.

For more information on the current limit, see the

Setting the Current Limits section.

MAX8543/

MAX8544

BST

IN

DH

LX

DL

N

N

Figure 3. The boost circuit provides voltage for the high-side

MOSFET gate drive.

Page 18

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

18 ______________________________________________________________________________________

Switching Frequency and

Synchronization

The MAX8543/MAX8544 have an adjustable internal

oscillator that can be set to any frequency from 200kHz

to 1MHz. To set the switching frequency, connect a

resistor from FSYNC to GND. Calculate the resistor

value from the following equation:

The MAX8543/MAX8544 can also be synchronized to an

external clock by connecting the clock signal to FSYNC.

When using an external clock, select R

FSYNC

such that

the free-running frequency is within ±30% of the clock frequency. In addition, the MAX8544 has a synchronization

output (SYNCO) that provides a clock signal that is 180°

out-of-phase with the MAX8544 switching. SYNCO is

used to synchronize a second controller 180° out-ofphase with the first by connecting SYNCO of the first controller to FSYNC of the second when the first controller

operates in free-running mode. When the first controller is

synchronized to an external clock, the external clock is

inverted to generate SYNCO.

Power-Good Signal (POK)

POK is an open-drain output on the MAX8544 that monitors the output voltage. When the output is above 91% of

its nominal regulation voltage, POK is high impedance.

When the output drops below 91% of its nominal regulation voltage, POK is pulled low. POK is also pulled low

when the MAX8544 is shut down. To use POK as a logiclevel signal, connect a pullup resistor from POK to the

logic-supply rail.

Thermal-Overload Protection

Thermal-overload protection limits total power dissipation

in the MAX8543/MAX8544. When the junction temperature exceeds TJ= +160°C, an internal thermal sensor

shuts down the device, allowing the IC to cool. The thermal sensor turns the IC on again after the junction temperature cools by 15°C, resulting in a pulsed output

during continuous thermal-overload conditions.

Design Procedure

Setting the Output Voltage

To set the output voltage for the MAX8543/MAX8544,

connect FB to the center of an external resistor-divider

from the output to GND (Figure 5). Select R2 between

8kΩ and 24kΩ; then calculate R1 with the following

equation:

where VFB= 0.8V. R1 and R2 should be placed as

close to the IC as possible.

Inductor Selection

There are several parameters that must be examined

when determining which inductor is to be used: input voltage, output voltage, load current, switching frequency,

and LIR. LIR is the ratio of peak-to peak inductor current

ripple to maximum DC load current. A higher LIR value

allows for a smaller inductor, but results in higher losses

and higher output ripple.

RR

V

V

OUT

FB

12 1=× −

⎛

⎝

⎜

⎞

⎠

⎟

R

f

ns

k

ns

FSYNC

S

=−

⎛

⎝

⎜

⎞

⎠

⎟

⎛

⎝

⎜

⎞

⎠

⎟

1

2

240

1

14 18Ω.

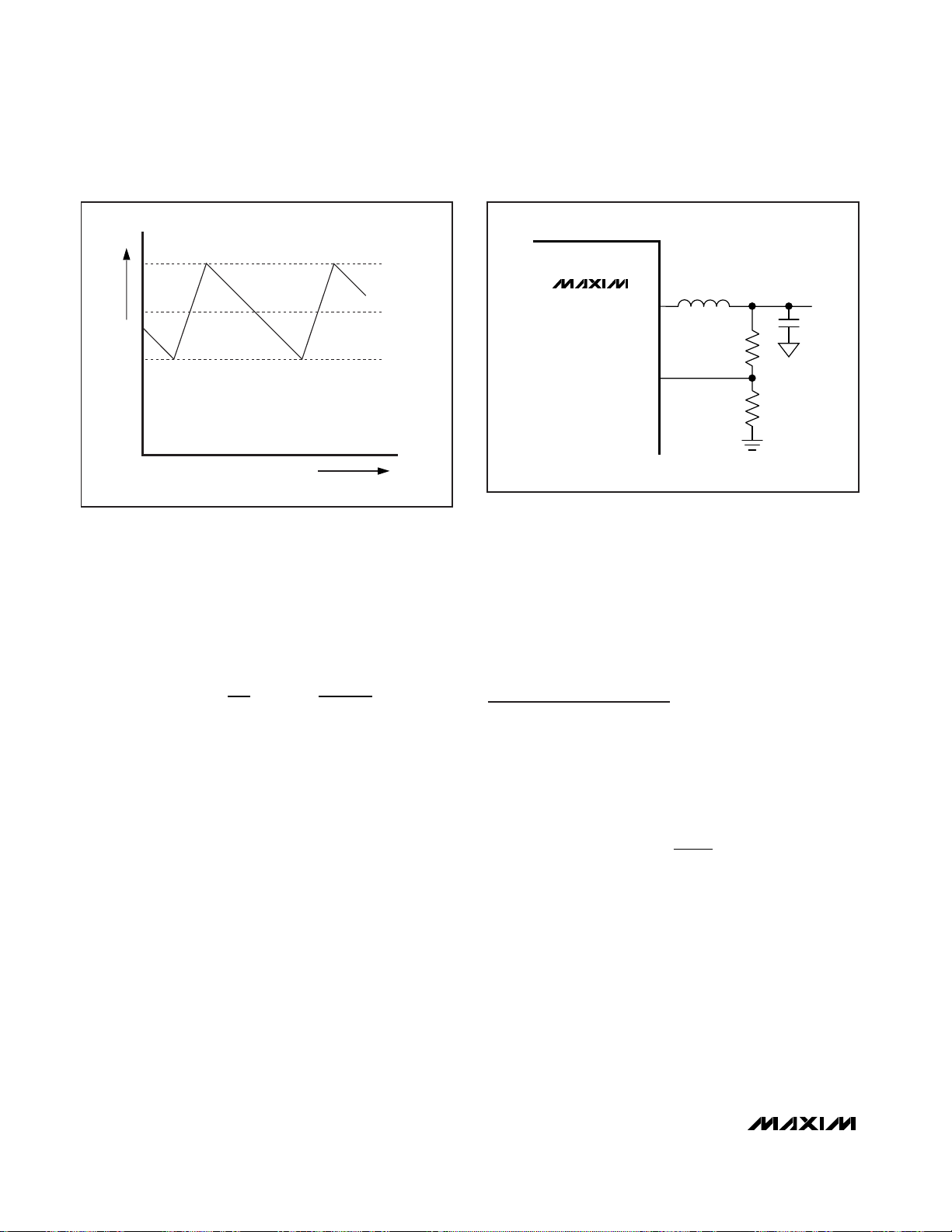

TIME

INDUCTOR CURRENT

I

VALLEY

I

LOAD

I

PEAK

Figure 4. Inductor-Current Waveform

MAX8543/

MAX8544

R1

R2

LX

FB

Figure 5. Setting the Output Voltage with a Resistor VoltageDivider

Page 19

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

______________________________________________________________________________________ 19

A good compromise between size and efficiency is an

LIR of 0.3. Once all the parameters are chosen, the

inductor value is determined as follows:

where fS is the switching frequency. Choose a standardvalue inductor close to the calculated value. The exact

inductor value is not critical and can be adjusted to

make trade-offs among size, cost, and efficiency. Lower

inductor values minimize size and cost, but they also

increase the output ripple and reduce the efficiency due

to higher peak currents. On the other hand, higher inductor values increase efficiency, but eventually resistive

losses due to extra turns of wire exceed the benefit

gained from lower AC current levels. This is especially

true if the inductance is increased without also increasing the physical size of the inductor. Find a low-loss

inductor with the lowest possible DC resistance that fits

the allotted dimensions. Ferrite cores are often the best

choice, although powdered iron is inexpensive and can

work well at 300kHz. The chosen inductor’s saturation

current rating must exceed the peak inductor current

determined as:

Setting the Current Limits

Valley Current Limit

The valley current limit employs a current foldback

scheme. The MAX8543 has a fixed valley current-limit

threshold of 130mV, and a fixed foldback ratio (P

FB

) of

23%. The foldback ratio is the current-limit threshold

when the output is at 0V (output shorted to ground),

divided by the threshold when the output is at its nominal

regulated value. Thus, the minimum output current limit

(I

LIM

) and maximum short-circuit current (ISC) is calculat-

ed as:

where R

DS(ON)

is the maximum on-resistance of the

low-side MOSFET at the highest expected operating

junction temperature, and I

P-P

is the inductor ripple cur-

rent, calculated as:

Ensure that I

LIM

is equal to or greater than the maximum load current at peak current limit (see the Peak

Current Limit section):

where 40mV is the maximum current-limit threshold

when the output is shorted (V

OUT

= 0V).

The MAX8544 has an adjustable valley current limit and

can be selected for foldback with automatic recovery,

or constant current with latch-up. To set the current limit

for foldback mode, connect a resistor from ILIM2 to the

output (R

FOBK

), and another resistor from ILIM2 to

GND (R

ILIM

). See Figure 6. The values of R

FOBK

and

R

ILIM

are calculated as follows:

1) First, select the percentage of foldback (PFB). This

percentage corresponds to the current limit when

V

OUT

equals zero, divided by the current limit when

V

OUT

equals a nominal voltage. A typical value of

P

FB

is in the range of 15% to 40%. A lower value of

PFByields lower short-circuit current. The following

equations are used to calculate R

FOBK

and R

ILIM:

where I

VALLEY

is the value of the inductor valley

current at maximum load (I

LOAD(MAX)

- 1/2 I

P-P

),

and R

DS(ON)

is the maximum on-resistance of the

low-side MOSFET at the highest operating junction

temperature.

R

RI PR

VRI P

ILIM

DS ON VALLEY FB FOBK

OUT DS ON VALLEY FB

=

×××−

()

×

−× × ×−

()

[]

51

51

()

()

R

PV

AP

FOBK

FB OUT

FB

=

×

×−

()

51μ

I

V

R

I

SC

DS ON

PP

=+

−

0042.

()

I

VV V

fLV

PP

IN OUT OUT

SIN

−

=

−

()

×

××

I

V

R

I

LIM

DS ON

PP

=+

−

0112.

()

II

LIR

I

PEAK LOAD MAX LOAD MAX

=+×

() ()

2

L

VVV

V f I LIR

OUT IN OUT

IN S LOAD MAX

=

×−

×× ×

()

()

MAX8544

R

FOBK

R

ILIM

LX

OUT

ILIM2

Figure 6. ILIM2 Resistor Connections

Page 20

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

20 ______________________________________________________________________________________

2) If the resulting value of R

ILIM

is negative, either

increase P

FB

or choose a low-side MOSFET with a

lower R

DS(ON)

. The latter is preferred as it increases the efficiency and results in a lower short-circuit

current.

To set the constant current limit for the latch-up mode,

only R

ILIM

is used. The equation for R

ILIM

below sets

the current-limit threshold at 1.2 times the maximumrated output current:

Similarly, I

VALLEY

is the value of the inductor valley

current at maximum load, R

DS(ON)

is the maximum onresistance of the low-side MOSFET at the highest operating junction temperature.

Peak Current Limit

Peak inductor current-limit threshold (VTH) has four

possible settings through ILIM (MAX8543) or ILIM1

(MAX8544) as shown in Table 3 below. The resulting

current limit is calculated as:

where RDCis either the DC resistance of the inductor or

the value of the optional current-sense resistor.

Note that V

ILIM

is a logic-level setting, and can allow a

variation of ±0.1 x VVLwithout affecting VTH. To ensure

maximum output current, use the minimum value of V

TH

from each setting, and the maximum RDCvalues at the

highest expected operating temperature. The DC resistance of the inductor’s copper wire has a +0.22%/°C

temperature coefficient.

To use the DC resistance of the output inductor for current sensing, an RC circuit is added (see Figure 7). The

RC time constant is set to be twice the inductor (L / RDC)

time constant. Pick the value of R4 in the range of 470Ω

to 2kΩ, and then calculate the capacitor value from: C9

= 2L / (R

DC

× R4). Add a resistor (R5) equal in value to

R4 to the CS- connection to minimize input-offset error.

The equivalent current-sense resistance is equal to the

DC resistance of the inductor (RDC).

To use a current-sense resistor, connect the resistor as

shown in Figure 8. Since most current-sense resistors

have inductance, the RC circuit is also required

and is calculated in the same manner as inductor

current sensing. Place C11 close to CS+ and CS- pins

to decouple the high-frequency noise pickup. Place

C10 (same value as C9) across R5 to aid in shortcircuit recovery.

I

V

R

I

LIM

THDCPP

=−

−

2

R

IR

A

ILIM

VALLEY DS ON

=

××121.

()

μ

Table 3. ILIM Current-Limit Threshold

Settings

V

ILIM

RECOMMENDED

ILIM CONNECTION

V

TH

MIN

V

TH

TYP

V

TH

MAX

(mV)

0 GND

56.5

1/3 V

VL

Voltage-divider:

200kΩ from ILIM/ILIM1 to VL

115.0

2/3 V

VL

Voltage-divider:

100kΩ from ILIM/ILIM1 to VL

172.5

V

VL

VL

230.0

Figure 8. Using a Current-Sense Resistor

MAX8543/

MAX8544

C9

V

OUT

R4

R5

L1

LX

CS-

CS+

C11

C10

Figure 7. Inductor RDCCurrent Sensing

LX

(mV)

(mV)

38.5 50

100kΩ from ILIM/ILIM1 to GND

200kΩ from ILIM/ILIM1 to GND

85.0 100

127.5 150

170.0 200

MAX8543/

MAX8544

CS+

CS-

L1

C11

R3

R4

C9

V

OUT

C10

R5

Page 21

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

______________________________________________________________________________________ 21

MOSFET Selection

The MAX8543/MAX8544 drive two or four external,

logic-level, n-channel MOSFETs as the circuit switch

elements. The key selection parameters are:

1) On-resistance (R

DS(ON)

): the lower, the better.

2) Maximum drain-to-source voltage (V

DSS

): should

be at least 20% higher than the input supply rail at

the high-side MOSFET’s drain.

3) Gate charges (QG, QGD, QGS): the lower, the better.

For a 3.3V input application, choose a MOSFET with a

rated R

DS(ON)

at VGS= 2.5V. For a 5V input application,

choose the MOSFETs with rated R

DS(ON)

at VGS≤ 4.5V.

For a good compromise between efficiency and cost,

choose the high-side MOSFET (N1, N2) that has conduction losses equal to the switching loss at nominal input

voltage and output current. The selected low-side

MOSFET (N3, N4) must have an R

DS(ON)

that satisfies the

current-limit-setting condition above. Ensure that the lowside MOSFET does not spuriously turn on due to dV/dt

caused by the high-side MOSFET turning on as this

would result in shoot-through current and degrade the

efficiency. MOSFETs with a lower QGD/ Q

GS

ratio have

higher immunity to dV/dt. For high-current applications, it

is often preferable to parallel two MOSFETs rather than to

use a single large MOSFET.

For proper thermal-management design, the power dissipation must be calculated at the desired maximum

operating junction temperature, maximum output current,

and worst-case input voltage (for the low-side MOSFET,

worst case is at V

IN(MAX)

; for the high-side MOSFET, it

could be either at V

IN(MAX)

or V

IN(MIN)

). The high-side

and low-side MOSFETs have different loss components

due to the circuit operation. The low-side MOSFET operates as a zero-voltage switch; therefore, major losses

are the channel-conduction loss (P

LSCC

) and the body-

diode conduction loss (P

LSDC

):

Use R

DS(ON)

at T

J(MAX)

:

where VFis the body-diode forward-voltage drop, tDTis

the dead time between high-side and low-side switching

transitions, and fSis the switching frequency.

The high-side MOSFET operates as a duty-cycle control

switch and has the following major losses: the channelconduction loss (P

HSCC

), the VI overlapping switching

loss (P

HSSW

), and the drive loss (P

HSDR

). The high-side

MOSFET does not have body-diode conduction loss

because the diode never conducts current:

Use R

DS(ON)

at T

J(MAX)

:

where I

GATE

is the average DH-driver output current

capability determined by:

where R

DS(ON)(HS)

is the high-side MOSFET driver’s

on-resistance (1Ω, typ) and R

GATE

is the internal gate

resistance of the MOSFET (≈0.5Ω to 3Ω):

where V

GS

≈ V

VL.

In addition to the losses above, allow about 20% more for

additional losses due to MOSFET output capacitances

and low-side MOSFET body-diode reverse-recovery

charge dissipated in the high-side MOSFET, but it is not

well defined in the MOSFET data sheet. Refer to the

MOSFET data sheet for thermal resistance specifications

to calculate the PC board area needed to maintain the

desired maximum operating junction temperature with the

above calculated power dissipations.

To reduce EMI caused by switching noise, add a 0.1µF

ceramic capacitor from the high-side switch drain to

the low-side switch source or add resistors in series

with DH and DL to slow down the switching transitions.

However, adding series resistors increases the power

dissipation of the MOSFET, so be sure this does not

overheat the MOSFET.

PQVf

R

RR

HSDR G GS S

GATE

GATE DS ON HS

=× ××

+

()()

I

V

RR

GATE

VL

DS ON HS GATE

≅

×

+

05.

()()

PVI

QQ

I

f

HSSW IN LOAD

GS GD

GATE

S

=× ×

+

×

P

V

V

IR

HSCC

OUT

IN

LOAD

DS ON

=× ×

()

2

PIVtf

LSDC LOAD F DT S

=× × × ×2

P

V

V

IR

LSCC

OUT

IN

LOAD

DS ON

=−

⎛

⎝

⎜

⎞

⎠

⎟

××1

2

()

Page 22

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

22 ______________________________________________________________________________________

MOSFET Snubber Circuit

Fast switching transitions cause ringing because of resonating circuit parasitic inductance and capacitance at

the switching nodes. This high-frequency ringing

occurs at LX’s rising and falling transitions and can

interfere with circuit performance and generate EMI. To

dampen this ringing, a series RC snubber circuit is

added across each switch. Below is the procedure for

selecting the value of the series RC circuit.

Connect a scope probe to measure VLXto GND and

observe the ringing frequency, fR.

Find the capacitor value (connected from LX to GND)

that reduces the ringing frequency by half.

The circuit parasitic capacitance (C

PAR

) at LX is then

equal to 1/3rd the value of the added capacitance above.

The circuit parasitic inductance (L

PAR

) is calculated by:

The resistor for critical dampening (R

SNUB

) is equal to

2π x fRx L

PAR

. Adjust the resistor value up or down

to tailor the desired damping and the peak voltage

excursion.

The capacitor (C

SNUB

) should be at least 2 to 4 times the

value of the C

PAR

to be effective. The power loss of the

snubber circuit (P

RSNUB

) is dissipated in the resistor and

can be calculated as:

where VINis the input voltage and fSWis the switching

frequency. Choose an R

SNUB

power rating that meets

the specific application’s derating rule for the power

dissipation calculated.

Input Capacitor

The input filter capacitor reduces peak currents drawn

from the power source and reduces noise and voltage

ripple on the input caused by the circuit’s switching.

The input capacitor must meet the ripple-current

requirement (I

RMS

) imposed by the switching currents

defined by the following equation:

I

RMS

has a maximum value when the input voltage equals

twice the output voltage (VIN= 2 x V

OUT

), so I

RMS(MAX)

=

I

LOAD

/ 2. Ceramic capacitors are recommended due to

their low ESR and ESL at high frequency with relatively

low cost. Choose a capacitor that exhibits less than 10°C

temperature rise at the maximum operating RMS current

for optimum long-term reliability. Ceramic capacitors with

an X5R or better temperature characteristic are recommended. When operating from a soft input source, an

additional input capacitor (bulk bypass capacitor) may

be required to prevent input from sagging.

Output Capacitor

The key selection parameters for the output capacitor

are the actual capacitance value, the equivalent series

resistance (ESR), the equivalent series inductance

(ESL), and the voltage-rating requirements. These

parameters affect the overall stability, output voltage

ripple, and transient response. The output ripple has

three components: variations in the charge stored in

the output capacitor, the voltage drop across the

capacitor’s ESR, and ESL caused by the current into

and out of the capacitor. The maximum output voltage

ripple is estimated as follows:

V

RIPPLE

= V

RIPPLE(ESR)

+ V

RIPPLE(C)

+ V

RIPPLE(ESL)

The output voltage ripple as a consequence of the

ESR, ESL, and output capacitance is:

where I

P-P

is the peak-to-peak inductor current:

These equations are suitable for initial capacitor selection, but final values should be chosen based on a prototype or evaluation circuit. As a general rule, a smaller

current ripple results in less output voltage ripple. Since

the inductor ripple current is a factor of the inductor value

and input voltage, the output voltage ripple decreases

with larger inductance, and increases with higher input

voltages. Polymer, tantalum, or aluminum electrolytic

capacitors are recommended.

I

VV

fLVV

PP

IN OUTSOUT

IN

−

=

−

×

×

V

I

Cf

RIPPLE C

PP

OUT S

()

=

××

−

8

V

V

L

ESL

RIPPLE ESLIN()

=×

V I ESR

RIPPLE ESR P P()

=×

−

I

IVVV

V

RMS

LOAD OUT IN OUT

IN

=

×−

()

PCVf

RSNUB SNUB IN SW

=×

()

×

2

L

fC

PAR

R PAR

=

()

×

1

22π

Page 23

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

______________________________________________________________________________________ 23

The aluminum electrolytic capacitor is the least expensive; however, it has higher ESR. To compensate for this,

use a ceramic capacitor in parallel to reduce the switching ripple and noise. For reliable and safe operation,

ensure that the capacitor’s voltage and ripple-current ratings exceed the calculated values.

The response to a load transient depends on the

selected output capacitors. After a load transient, the

output voltage instantly changes by ESR x ΔI

LOAD

.

Before the controller can respond, the output voltage

deviates further depending on the inductor and output

capacitor values. After a short period of time (see the

Typical Operating Characteristics), the controller

responds by regulating the output voltage back to its

nominal state. The controller response time depends on

its closed-loop bandwidth. With a higher bandwidth,

the response time is faster, thus preventing the output

voltage from further deviation from its regulation value.

Compensation Design

The MAX8543/MAX8544 use an internal transconductance error amplifier whose output compensates the

control loop. The external inductor, output capacitor,

compensation resistor, and compensation capacitors

determine the loop stability. The inductor and output

capacitor are chosen based on performance, size, and

cost. Additionally, the compensation resistor and capacitors are selected to optimize control-loop stability. The

component values, shown in the Typical Application

Circuits (Figures 1 and 2), yield stable operation over the

given range of input-to-output voltages.

The controller uses a current-mode control scheme that

regulates the output voltage by forcing the required current through the external inductor, so the MAX8543/

MAX8544 use the voltage drop across the DC resistance

of the inductor or the alternate series current-sense resistor to measure the inductor current. Current-mode control

eliminates the double pole in the feedback loop caused

by the inductor and output capacitor resulting in a smaller

phase shift and requiring a less elaborate error-amplifier

compensation than voltage-mode control. A simple single

series RCand CCis all that is needed to have a stable,

high-bandwidth loop in applications where ceramic

capacitors are used for output filtering. For other types of

capacitors, due to the higher capacitance and ESR, the

frequency of the zero created by the capacitance and

ESR is lower than the desired closed-loop crossover frequency. To stabilize a nonceramic output-capacitor loop,

add another compensation capacitor (C

F

) from COMP to

GND to cancel this ESR zero.

The basic regulator loop is modeled as a power modulator, output feedback divider, and an error amplifier.

The power modulator has DC gain set by g

mc

x R

LOAD

,

with a pole and zero pair set by R

LOAD

, the output

capacitor (C

OUT

), and its ESR. Below are equations

that define the power modulator:

where R

LOAD

= V

OUT

/ I

OUT(MAX)

, fSis the switching

frequency, L is the output inductance, and gmc=

1 / (A

VCS

× RDC), where A

VCS

is the gain of the current-sense amplifier and RDCis the DC resistance of

the inductor (or current-sense resistor). A

VCS

is

dependent on the current-limit selection at ILIM, and

ranges from 3 to 11 (see Current-Sense Amplifier

Voltage Gain in the Electrical Characteristics table).

The frequencies at which the pole and zero created by

the power modulator are determined as follows:

When C

OUT

is composed of “n” identical capacitors in

parallel, the resulting C

OUT

= n x C

OUT(EACH)

, and ESR

= ESR

(EACH)

/ n. Note that the capacitor zero for a parallel combination of like capacitors is the same as for an

individual capacitor.

The feedback voltage-divider has a gain of GFB= VFB/

V

OUT

, where VFBis equal to 0.8V.

The transconductance error amplifier has a DC gain,

G

EA(DC)

= g

mEA

x RO, where g

mEA

is the error-amplifier

transconductance, which is equal to 110µS, ROis the

output resistance of the error amplifier, which is 10MΩ.

A dominant pole is set by the compensation capacitor

(CC), the amplifier output resistance (RO), and a zero is

set by the compensation resistor (RC) and the compensation capacitor (CC). There is an optional pole set by

CFand RCto cancel the output-capacitor ESR zero if it

occurs near the crossover frequency (fC). Thus:

f

CRR

pdEA

COC

=

×× +

1

2π ()

f

C ESR

zMOD

OUT

=

××

1

2π

f

C

RfL

RfL

ESR

pMOD

OUT

LOAD S

LOAD S

=

××

××

+×

+

⎛

⎝

⎜

⎞

⎠

⎟

1

2π

()

Gg

RfL

RfL

MOD dc mc

LOAD S

LOAD S

()

()

=×

××

+×

Page 24

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

24 ______________________________________________________________________________________

The crossover frequency, fC, should be much higher

than the power-modulator pole f

PMOD

. Also, fCshould

be less than or equal to 1/5th the switching frequency.

Select a value for fCin the range:

At the crossover frequency, the total loop gain must

equal 1, and is expressed as:

For the case where f

zMOD

is greater than fC:

then R

C

can be calculated as:

where g

mEA

= 110µS.

The error-amplifier compensation zero formed by R

C

and CCshould be set at the modulator pole f

PMOD

. C

C

is calculated by:

If f

zMOD

is less than 5 x fC, add a second capacitor C

F

from COMP to GND. The value of CFis calculated as

follows:

As the load current decreases, the modulator pole also

decreases; however, the modulator gain increases

accordingly and the crossover frequency remains

the same.

For the case where f

zMOD

is less than fC:

The power-modulator gain at fCis:

The error-amplifier gain at fCis:

RCis calculated as:

where g

mEA

= 110µS.

CCis calculated from:

CFis calculated from:

Below is a numerical example to calculate RCand C

C

values of the typical operating circuit of Figure 1

(MAX8544):

A

VCS

= 11 (for ILIM1 = GND)

RDC= 2.5mΩ

gmc= 1 / (A

VCS

x RDC) = 1 / (11 x 0.0025) = 36.7S

V

OUT

= 2.5V

I

OUT(MAX)

= 15A

R

LOAD

= V

OUT

/ I

OUT(MAX)

= 2.5 / 15 = 0.167Ω

C

OUT

= 360µF

ESR = 5mΩ

Gg

RfL

RfL

MOD dc mc

LOAD S

LOAD S

()

()

.

.( ).

.( ).

.

=×

××

+×

=

××××

()

+×××

()

=

−

−

36 36

0 167 600 10 0 8 10

0 167 600 10 0 8 10

450

36

36

C

Rf

F

C zMOD

=

××

1

2π

C

RfLC

RfLR

C

LOAD S OUT

LOAD S C

=

×××

+×

()

×()

R

V

V

f

gG f

C

OUT

FB

C

mEA MOD fc zMOD

=×

××

()

GgR

f

f

EA fc mEA C

zMOD

C

()

=××

GG

f

f

MOD fc MOD dc

pMOD

zMOD

() ( )

=×

C

Rf

F

C zMOD

=

××

1

2π

C

RfLC

RfLR

C

LOAD S OUT

LOAD S C

=

×××

+×

()

×()

R

V

gVG

C

OUT

mEA FB MOD fc

=

××

()

GG

f

f

MOD fc MOD dc

pMOD

C

() ( )

=×

GgR

EA fc mEA C()

=×

GG

V

V

EA fc MOD fc

FB

OUT

() ()

××=1

ff

f

pMOD C

S

<< ≤

5

f

CR

pEA

FC

=

××

1

2πfCR

zEA

CC

=

××

1

2π

Page 25

MAX8543/MAX8544

Step-Down Controllers with Prebias Startup,

Lossless Sensing, Synchronization, and OVP

______________________________________________________________________________________ 25

3.43kHz << fC< 120kHz; select fC= 120kHz.

Since f

zMOD

< fC:

Select the nearest standard value: CC= 220pF

Select the nearest standard value: CF= 10pF:

R3 = RC = 220kΩ

C8 = C

C

= 220pF

C7 = CF= 10pF

Applications Information

PC Board Layout Guidelines

Careful PC board layout is critical to achieve low

switching losses and clean, stable operation. The

switching power stage requires particular attention.

Follow these guidelines for good PC board layout:

1) Place IC decoupling capacitors as close to IC pins

as possible. Keep separate the power ground

plane and the signal ground plane. Place the input

ceramic decoupling capacitor directly across and

as close as possible to the high-side MOSFET’s

drain and the low-side MOSFET’s source. This is to

help contain the high switching current within this

small loop.

2) For output current greater than 10A, a four-layer PC

board is recommended. Pour a signal ground

plane in the second layer underneath the IC to minimize noise coupling.

3) Connect input, output, snubber, and VL capacitors

to the power ground plane; connect all other

capacitors to the signal ground plane.

4) Place the inductor current-sense resistor and capacitor as close to the inductor as possible. Make a

Kelvin connection to minimize the effect of PC board

trace resistance. Place the input bias balance resistor

and bypass capacitor (R5 and C10 in Figures 7 and

8) near CS-. Run two closely parallel traces from

across the capacitor (C9 in Figures 7 and 8) to CS+

and CS-. Place the decoupling capacitor C11 close

to CS+ and CS- pins.

5) Place the MOSFET as close as possible to the IC to

minimize trace inductance of the gate-drive loop. If

parallel MOSFETs are used, keep the trace lengths

to both gates equal.

6) Connect the drain leads of the power MOSFET to a

large copper area to help cool the device. Refer to

the power MOSFET data sheet for recommended

copper area.

7) Place the feedback and compensation components

as close to the IC pins as possible. Connect the

feedback-divider resistor from FB to the output as

close as possible to the farthest output capacitor.

Refer to the MAX8544 evaluation kit for an example layout.

C

Rf

pF

F

C zMOD

=

××

=

××× ×

=

1

2

1

2 220 10 88 4 10

82

33

π

π

()(.)

.

C

RfLC

RfLR

pF

C

LOAD S OUT

LOAD S C

=

×××

+×

()

×

=

×× ×

+× ×

⎛

⎝

⎞

⎠

×

=

−−

−

.( )(. )( )

.( )(. )( )

0 167 600 10 0 8 10 360 10

0 167 600 10 0 8 10 220 10

202

36 6

36 3

R

V

V

f

gG f

k

C

OUT

FB

C

mEA MOD fc zMOD

=×

××

=×

×

××××