Page 1

General Description

The MAX8529 dual, synchronized, step-down controller

generates two outputs from input supplies ranging from

4.75V to 23V. Each output is adjustable from sub-1V

to 18V. Input voltage ripple and total RMS input ripple

current are reduced by synchronized 180-degree out-ofphase operation.

The switching frequency is adjustable from 600kHz to

1.5MHz with an external resistor. Alternatively, the controller can be synchronized to an external clock generated to another MAX8529 or a system clock. One

MAX8529 can be set to generate an in-phase, or 90degree out-of-phase, clock signal for synchronization

with additional controllers. This allows two controllers to

operate either as an interleaved two- or four-phase system with each output shifted by 90 degrees. These

devices also feature soft-start and soft-stop.

The MAX8529 eliminates the need for current-sense

resistors by utilizing the low-side MOSFET’s on-resistance as a current-sense element. This protects the

DC-to-DC components from damage during output

overload conditions or when output short circuit faults

without requiring a current-sense resistor. Adjustable

foldback current limit reduces power dissipation during

short-circuit conditions. The MAX8529 includes a

power-on reset output to signal the system when both

outputs reach regulation.

The MAX8529 is available in a 24-pin QSOP package. An

evaluation kit is available to speed designs.

Applications

xDSL Modems and Routers

DSP, ASIC, and FPGA Power Supplies

Set-Top Boxes

Broadband Routers

Features

♦ Low Output Noise in DSL Band

♦ Ceramic Input/Output Capacitors

♦ Step-Down or Step-Up/Step-Down Operation

♦ Four Output, 90-Degree Out-of-Phase Operation

(Using Two MAX8529s)

♦ Foldback Current Limit

♦ 4.75V to 23V Input Supply Range

♦ 0 to 18V Output Voltage Range (Up to 6A)

♦ > 90% Efficiency

♦ Fixed-Frequency PWM Operation

♦ Adjustable 600kHz to 1.5MHz Switching

Frequency

♦ External SYNC Input

♦ Clock Output for Master/Slave Synchronization

♦ Soft-Start and Soft-Stop

♦ RST Output with 140ms Minimum Delay

♦ Lossless Current Limit (No Sense Resistor)

MAX8529

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

________________________________________________________________ Maxim Integrated Products 1

Pin Configuration

Ordering Information

19-2696; Rev 1; 4/07

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

PART TEMP RANGE PIN-PACKAGE

MAX8529EEG -40°C to +85°C 24 QSOP

TOP VIEW

COMP2

FB2

ILIM2

REF

GND

SYNC

ILIM1

FB1

COMP1

1

2

3

4

5

V+

6

7

8

9

10

11

12

24

EN

23

DH2

22

LX2

21

BST2OSC

20

DL2

19

MAX8529

QSOP

V

L

18

PGND

17

DL1CKO

16

BST1

15

LX1

14

DH1

13

RST

Page 2

MAX8529

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

V+ to GND ..............................................................-0.3V to +25V

PGND to GND .......................................................-0.3V to +0.3V

V

L

to GND ..................-0.3V to the lower of +6V and (V+ + 0.3V)

BST1, BST2 to GND ...............................................-0.3V to +30V

LX1 to BST1..............................................................-6V to +0.3V

LX2 to BST2..............................................................-6V to +0.3V

DH1 to LX1 ..............................................-0.3V to (V

BST1

+ 0.3V)

DH2 to LX2 ..............................................-0.3V to (V

BST2

+ 0.3V)

DL1, DL2 to PGND........................................-0.3V to (V

L

+ 0.3V)

CKO, REF, OSC, ILIM1, ILIM2,

COMP1, COMP2 to GND ..........................-0.3V to (V

L

+ 0.3V)

FB1, FB2, RST, SYNC, EN to GND...........................-0.3V to +6V

V

L

to GND Short Circuit..............................................Continuous

REF to GND Short Circuit ...........................................Continuous

Continuous Power Dissipation (T

A

= +70°C)

24-Pin QSOP (derate 9.4mW/°C above +70°C)...........762mW

Operating Temperature Range ...........................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

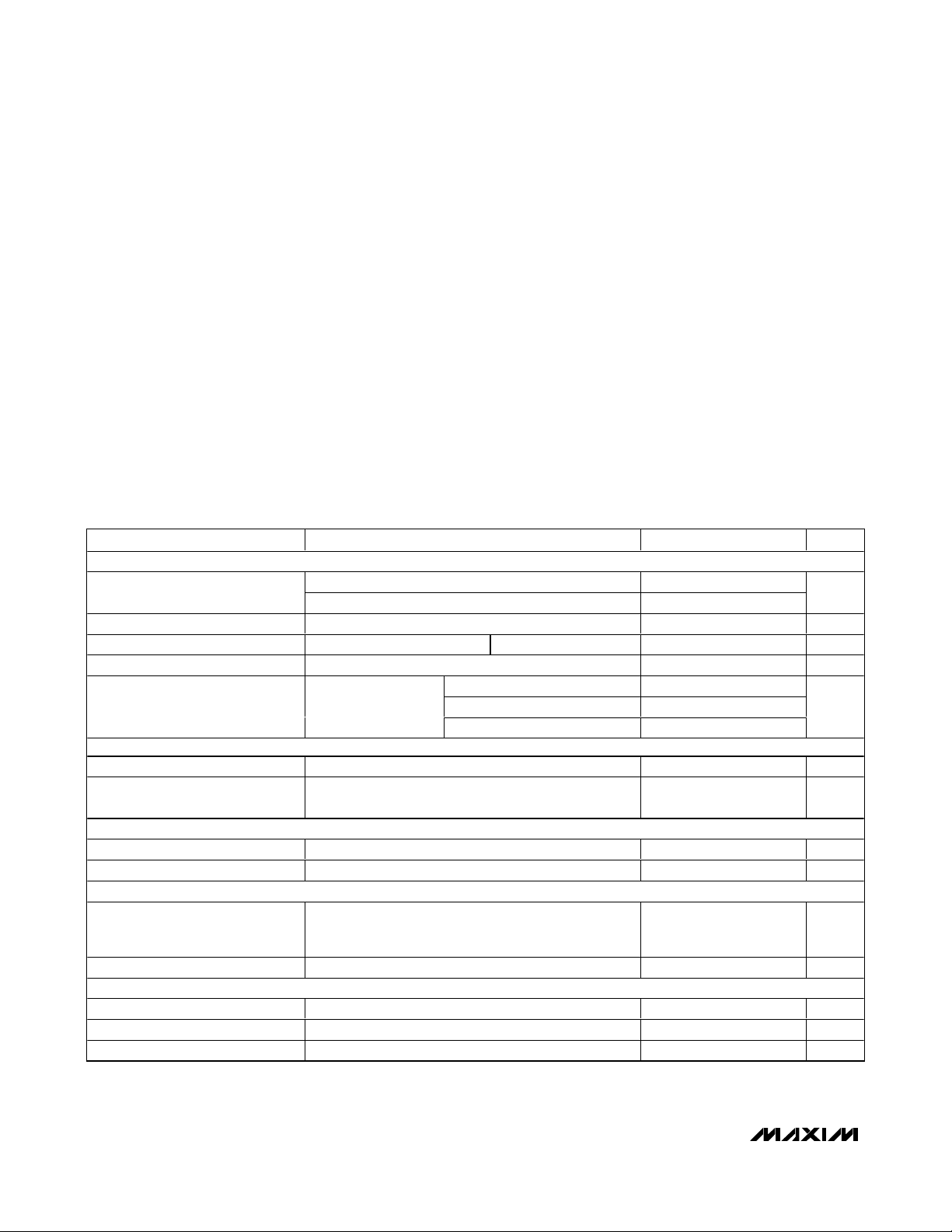

ELECTRICAL CHARACTERISTICS

(V+ = 12V, EN = ILIM_ = VL, SYNC = GND, IVL= 0mA, PGND = GND, C

REF

= 0.22µF, CVL= 4.7µF (ceramic), R

OSC

= 10kΩ,

compensation components for COMP_ are from Figure 1, T

A

= -40°C to +85°C (Note 1), unless otherwise noted.)

PARAMETER CONDITIONS MIN TYP MAX UNITS

GENERAL

V+ Operating Range

V+ Operating Supply Current V

(Note 2) 4.75 23.00

V

= V+ (Note 2) 4.75 5.50

L

unloaded, no MOSFETs connected 4.0 4.8 7.0 mA

L

V+ Standby Supply Current EN = LX_ = FB_ = 0V R

Thermal Shutdown Rising temperature, typical hysteresis = 10°C 160 °C

Current-Limit Threshold PGND - LX_

V

REGULATOR

L

Output Voltage 5.5V < V+ < 23V, 1mA < I

V

Undervoltage Lockout

L

Trip Level

4.4 4.55 4.7 V

REFERENCE

Output Voltage I

Reference Load Regulation 0µA < I

= 0µA 1.98 2.00 2.02 V

REF

< 50µA 0 4 10 mV

REF

SOFT-START

Digital Ramp Period

Internal 6-bit DAC for one converter to ramp from 0V to

full scale (Note 3)

Soft-Start Steps 64 Steps

FREQUENCY

Low End of Range R

High End of Range R

DH_ Minimum Off-Time R

= 10kΩ 540 600 600 kHz

OSC

= 5kΩ 1020 1200 1380 kHz

OSC

= 5kΩ 110 160 ns

OSC

= 10kΩ 0.50 0.65 1.00 mA

OSC

ILIM_ = V

R

R

L

= 100kΩ 32 50 62

ILIM_

= 600kΩ 225 300 375

ILIM_

< 50mA 4.75 5 5.25 V

LOAD

75 100 125

1024

V

mV

DC-to-

DC

Clocks

Page 3

MAX8529

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

_______________________________________________________________________________________ 3

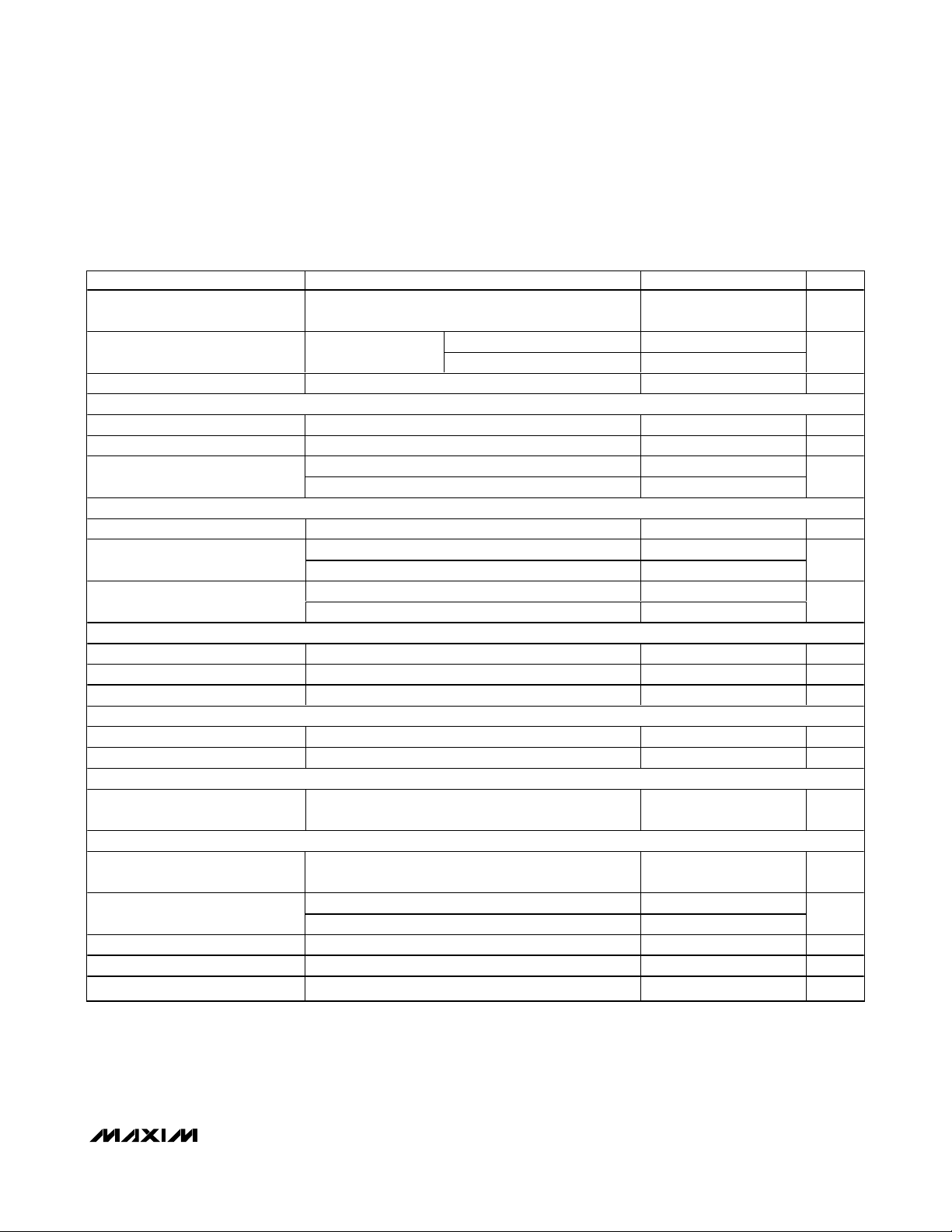

ELECTRICAL CHARACTERISTICS (continued)

(V+ = 12V, EN = ILIM_ = VL, SYNC = GND, IVL= 0mA, PGND = GND, C

REF

= 0.22µF, CVL= 4.7µF (ceramic), R

OSC

= 10kΩ,

compensation components for COMP_ are from Figure 1, T

A

= -40°C to +85°C (Note 1), unless otherwise noted.)

Note 1: Specifications to -40°C are guaranteed by design and not production tested.

Note 2: Operating supply range is guaranteed by V

L

line regulation test. Connect V+ to VLfor 5V operation.

Note 3: Guaranteed by design and not production tested.

SYNC Range

SYNC Input Pulse Width (Note 3)

SYNC Rise/Fall Time (Note 3) 100 ns

PARAMETER

Internal oscillator nominal frequency must be set to half

of the SYNC frequency

CONDITIONS

High 100

Low 100

MIN TYP MAX UNITS

1000 2800 kHz

ERROR AMPLIFIER

FB_ Input Bias Current 250 nA

FB_ Input Voltage Set Point 0.99 1.00 1.01 V

FB_ to COMP_ Transconductance

DRIVERS

DL_, DH_ Break-Before-Make Time C

DH_ On-Resistance

DL_ On-Resistance

0°C to +85°C 1.25 1.8 2.70

-40°C to +85°C 1.2 1.8 2.9

= 5nF 30 ns

LOAD

Low 1.5 2.5

High 3 5

Low 0.6 1.5

High 3 5

LOGIC INPUTS (EN, SYNC)

Input Low Level Typical 15% hysteresis, V

Input High Level V

Input High/Low Bias Current V

= 5.5V 2.4 V

L

= 0 or 5.5V -1 +0.1 +1 µA

EN

= 4.75V 0.8 V

L

LOGIC OUTPUTS (CKO)

Output Low Level V

Output High Level V

= 5V, sinking 5mA 0.4 V

L

= 5V, sourcing 5mA 4.0 V

L

COMP_

Pulldown Resistance During

Shutdown and Current Limit

17 Ω

RST OUTPUT

Output-Voltage Trip Level

Output Low Level

Output Leakage V+ = V

Reset Timeout Period V

Both FBs must be over this to allow the reset timer to

start; there is no hysteresis

V

= 5V, sinking 3.2mA 0.4

L

V

= 1V, sinking 0.4mA 0.3

L

= 5V, V

L

= 1V 140 315 560 ms

FB_

RST

= 5.5V, V

= 1V 1 µA

FB

0.87 0.9 0.93 V

FB_ to Reset Delay FB_ overdrive from 1V to 0.85V 4 µs

ns

mS

Ω

Ω

V

Page 4

MAX8529

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

4 _______________________________________________________________________________________

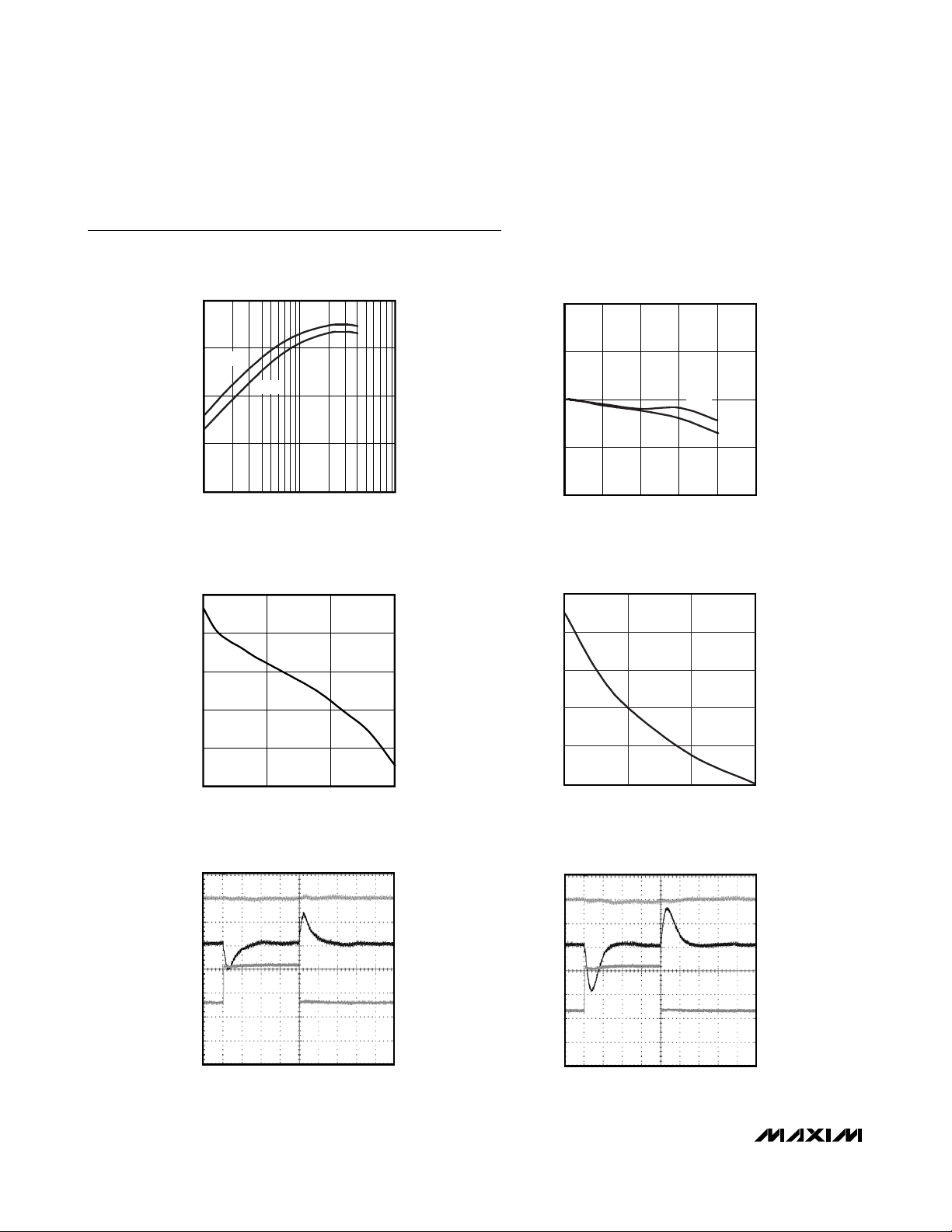

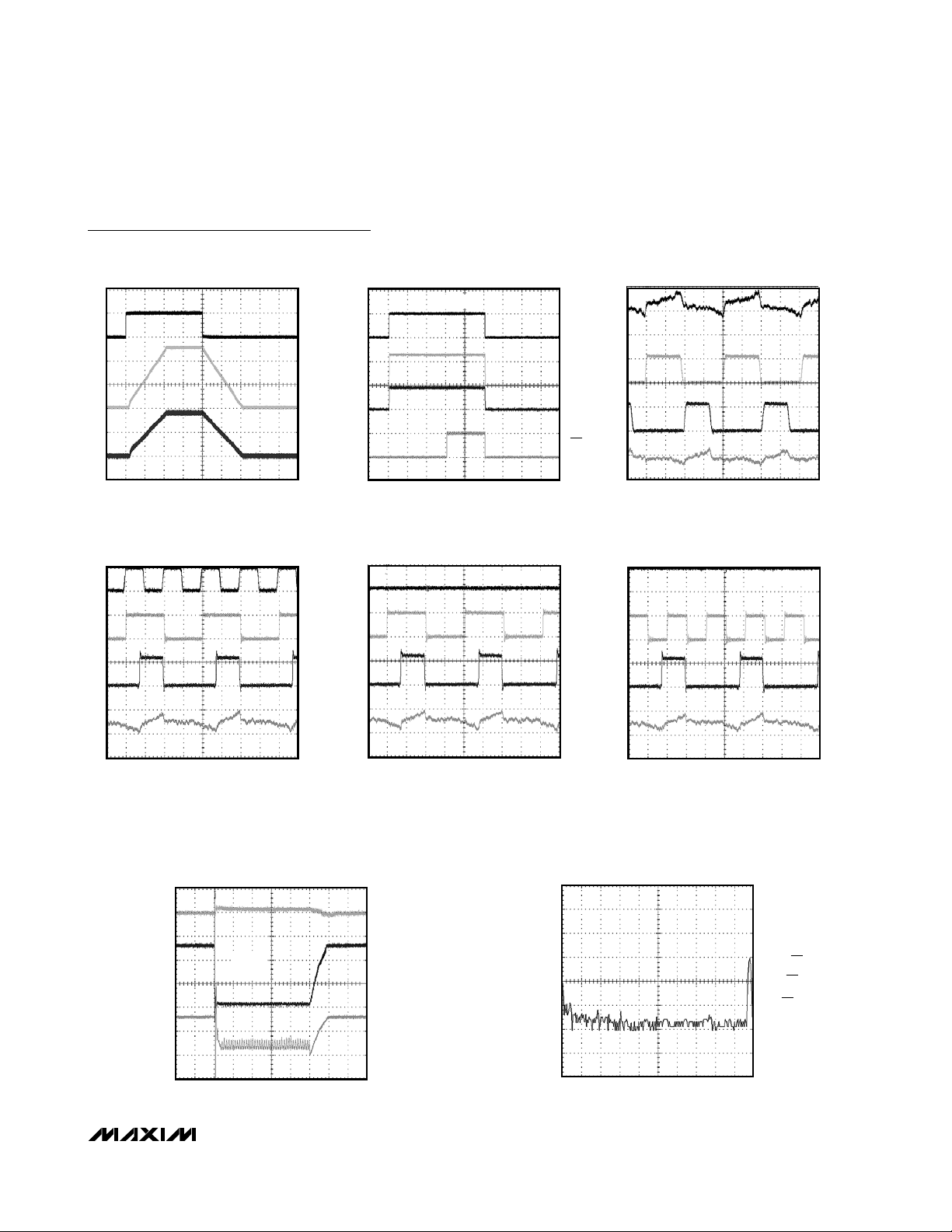

Typical Operating Characteristics

(Circuit of Figure 1, VIN= 6V, TA = +25°C, unless otherwise noted.)

EFFICIENCY vs. LOAD

MAX8529 toc01

LOAD (A)

EFFICIENCY (%)

10.1

10

20

30

40

50

60

70

80

90

100

0

10

OUT2

OUT1

OUTPUT VOLTAGE ACCURACY

vs. LOAD

MAX8529 toc02

LOAD (A)

OUTPUT VOLTAGE ACCURACY (%)

43

12

-0.5

0.5

0

1.0

-1.0

05

OUT2

OUT1

VL VOLTAGE ACCURACY

vs. LOAD CURRENT

MAX8529 toc03

LOAD CURRENT (mA)

V

L

VOLTAGE ACCURACY

10050

-1.5

-1.0

-0.5

0

0.5

-2.0

0150

SWITCHING FREQUENCY vs. R

OSC

MAX8529 toc04

R

OSC

(kΩ)

SWITCHING FREQUENCY (kHz)

86

800

1000

1200

1400

1600

600

410

LOAD TRANSIENT RESPONSE (OUTPUT 1)

MAX8529 toc05

10μs/div

0A

I

OUT1

1A/div

V

OUT1

50mV/div

AC-COUPLED

V

OUT2

50mV/div

AC-COUPLED

LOAD TRANSIENT RESPONSE (OUTPUT 2)

MAX8529 toc06

10μs/div

0A

I

OUT2

1A/div

V

OUT1

50mV/div

AC-COUPLED

V

OUT2

50mV/div

AC-COUPLED

Page 5

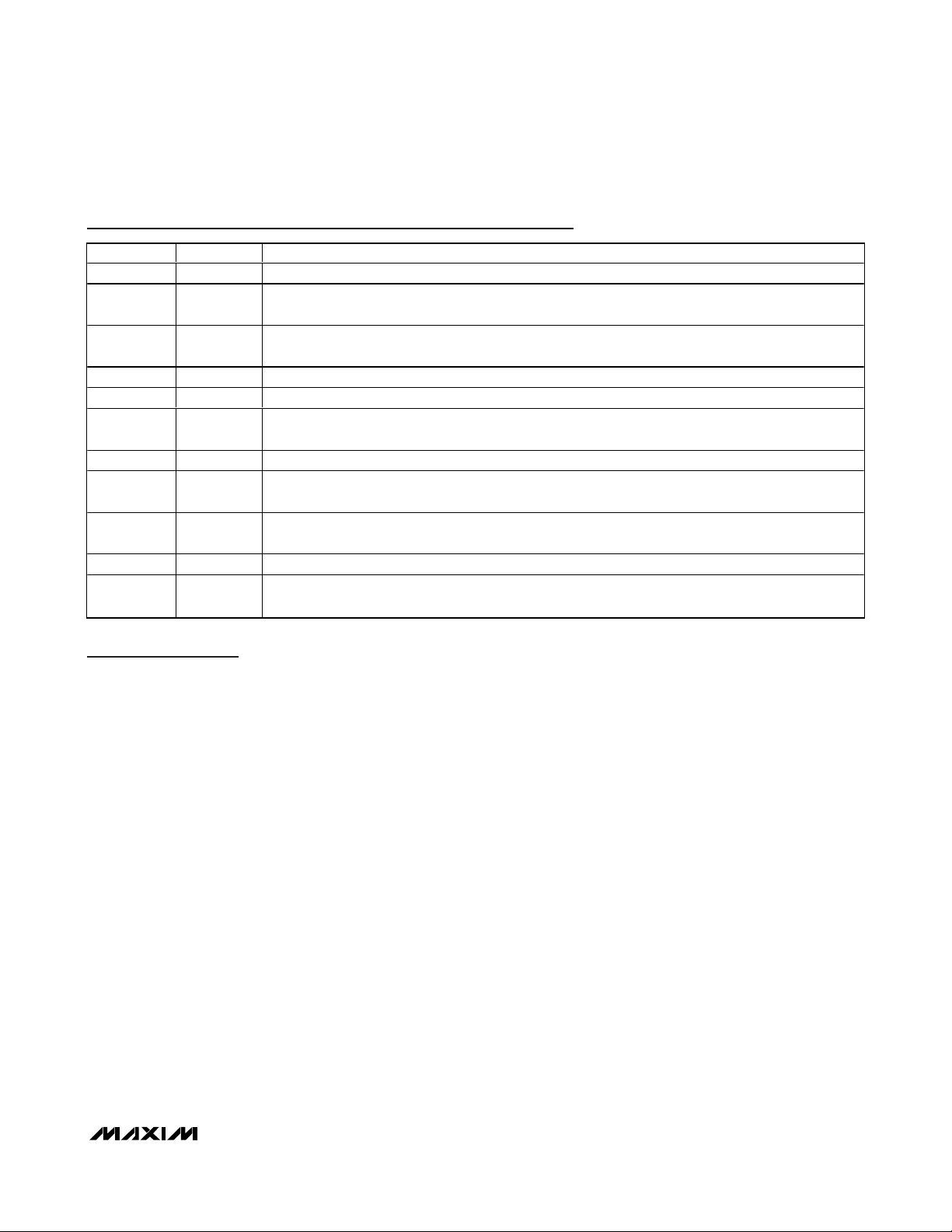

SOFT-START AND SOFT-STOP WAVEFORM

MAX8529 toc07

400μs/div

0V

0V

V

OUT2

1V/div

V

OUT1

1V/div

5V

0V

EN

RESET TIMEOUT

MAX8529 toc08

100ms/div

V

OUT1

2V/div

0V

0V

0V

V

OUT2

2V/div

0V

EN

5V

V

RST

5V/div

OUT-OF-PHASE WAVEFORM

MAX8529 toc09

200ns/div

V

OUT2

10mV/div

AC-COUPLED

V

OUT1

10mV/div

AC-COUPLED

V

LX2

5V/div

V

LX1

5V/div

0V

0V

MAX8529

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

_______________________________________________________________________________________ 5

Typical Operating Characteristics (continued)

(Circuit of Figure 1, VIN= 6V, TA = +25°C, unless otherwise noted.)

EXTERNALLY SYNCHRONIZED

SWITCHING WAVEFORM

200ns/div

MAX8529 toc10

5V

V

SYNC

0V

5V

V

CKO

0V

V

LX1

5V/div

0V

V

OUT1

10mV/div

AC-COUPLED

CKO OUTPUT WAVEFORM

200ns/div

MAX8529 toc11

SYNC = GND

5V

V

CK0

0V

V

LX1

5V/div

0V

V

OUT1

10mV/div

AC-COUPLED

CKO OUTPUT WAVEFORM

SYNC = V

200ns/div

MAX8529 toc12

L

5V

V

CK0

0V

V

LX1

5V/div

0V

V

OUT1

10mV/div

AC-COUPLED

SHORT-CIRCUIT CURRENT FOLDBACK

AND RECOVERY

SHORT

V

OUT2

200μs/div

MAX8529 toc13

V

OUT1

50mV/div

AC-COUPLED

V

OUT2

1V/div

0V

I

OUT2

2A/div

0A

OUTPUT2 NOISE SPECTRUM

0

250

500

FREQUENCY (kHz)

MAX8529 toc14

400nV/√Hz

40nV/√Hz

4nV/√Hz

750 1000 1250

Page 6

MAX8529

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

6 _______________________________________________________________________________________

Pin Description

PIN NAME FUNCTION

1 COMP2 Compensation Pin for Regulator 2 (REG2). Compensate REG2’s control loop as shown in Figure 1.

Feedback Input for Regulator 2 (REG2). Connect FB2 to a resistive-divider between REG2’s output

2 FB2

3 ILIM2

4 OSC

5 V+ Input Supply Voltage (4.75V to 23V)

6 REF 2V Reference Output. Bypass to GND with a 0.22µF or greater ceramic capacitor.

7 GND Analog Ground

8 CKO

9 SYNC

10 ILIM1

and GND to adjust the output voltage between 1V and 18V. To set the output voltage below 1V,

connect FB2 to a resistive voltage-divider from REF to REG2’s output (see the Setting the Output

Voltage section).

Current-Limit Adjustment for Regulator 2 (REG2). The PGND–LX2 current-limit threshold defaults to

100mV if ILIM2 is connected to V

REG2’s current-limit threshold (V

the Setting the Valley Current Limit section).

Oscillator Frequency Set Input. The controller generates the clock signal by dividing down the

oscillator, so the switching frequency equals half the synchronization frequency (f

Connect a resistor from OSC to GND (R

10kΩ) to 1500kHz (R

connected to SYNC. When using SYNC, set R

Clock Output. Clock Output for external 2- or 4-phase synchronization (see the Clock Synchronization

(SYNC, CKO) section).

Synchronization Input or Clock Output Selection Input. SYNC has three operating modes. Connect

SYNC to a 1200kHz to 2800kHz clock for external synchronization. Connect SYNC to GND for 2phase operation as a master controller. Connect SYNC to V

controller (see the Clock Synchronization (SYNC, CKO) section).

Current-Limit Adjustment for Regulator 1 (REG1). The PGND–LX1 current-limit threshold defaults to

100mV if ILIM1 is connected to V

current-limit threshold (V

Setting the Valley Current Limit section).

= 4kΩ). The controller still requires R

OSC

ITH1

. Connect a resistor (R

L

) from 50mV (R

ITH2

OSC

. Connect a resistor (R

L

) from 50mV (R

ILIM2

= 100kΩ) to 300mV (R

ILIM2

) to set the switching frequency from 600kHz (R

for one half of the SYNC input.

OSC

for 4-phase operation as a master

L

ILIM1

= 100kΩ) to 300mV (R

ILIM1

) from ILIM2 to GND to adjust the

= 600kΩ) (see

ILIM2

= f

OSC

/ 2).

OSC

=

SW

when an external clock is

OSC

) from ILIM1 to GND to adjust REG1’s

= 600kΩ) (see the

ILIM1

Feedback Input for Regulator 1 (REG1). Connect FB1 to a resistive-divider between REG1’s output

11 FB1

12 COMP1 Compensation Pin for Regulator 1 (REG1). Compensate REG1’s control loop as shown in Figure 1.

13 RST

and GND to adjust the output voltage between 1V and 18V. To set the output voltage below 1V,

connect FB1 to a resistive voltage-divider from REF and REG1’s output (see the Setting the Output

Voltage section).

Open-Drain Reset Output. RST is low when either output voltage is more than 10% below its

regulation point. After soft-start is completed and both outputs exceed 90% of their nominal output

voltage (VFB_ > 0.9V), RST becomes high impedance after a 140ms delay and remains high

impedance as long as both outputs maintain regulation. Connect a resistor between RST and the

logic supply for logic-level voltages.

Page 7

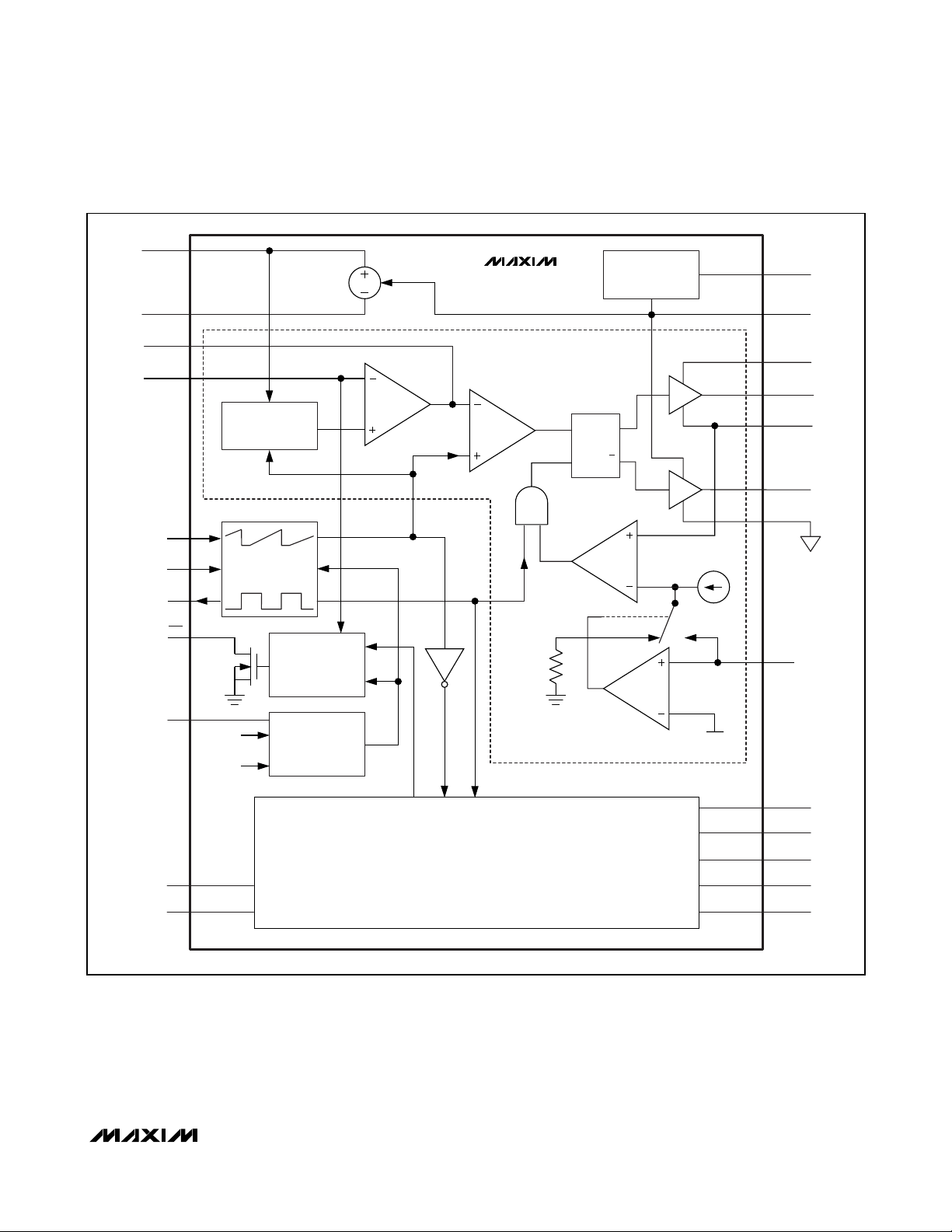

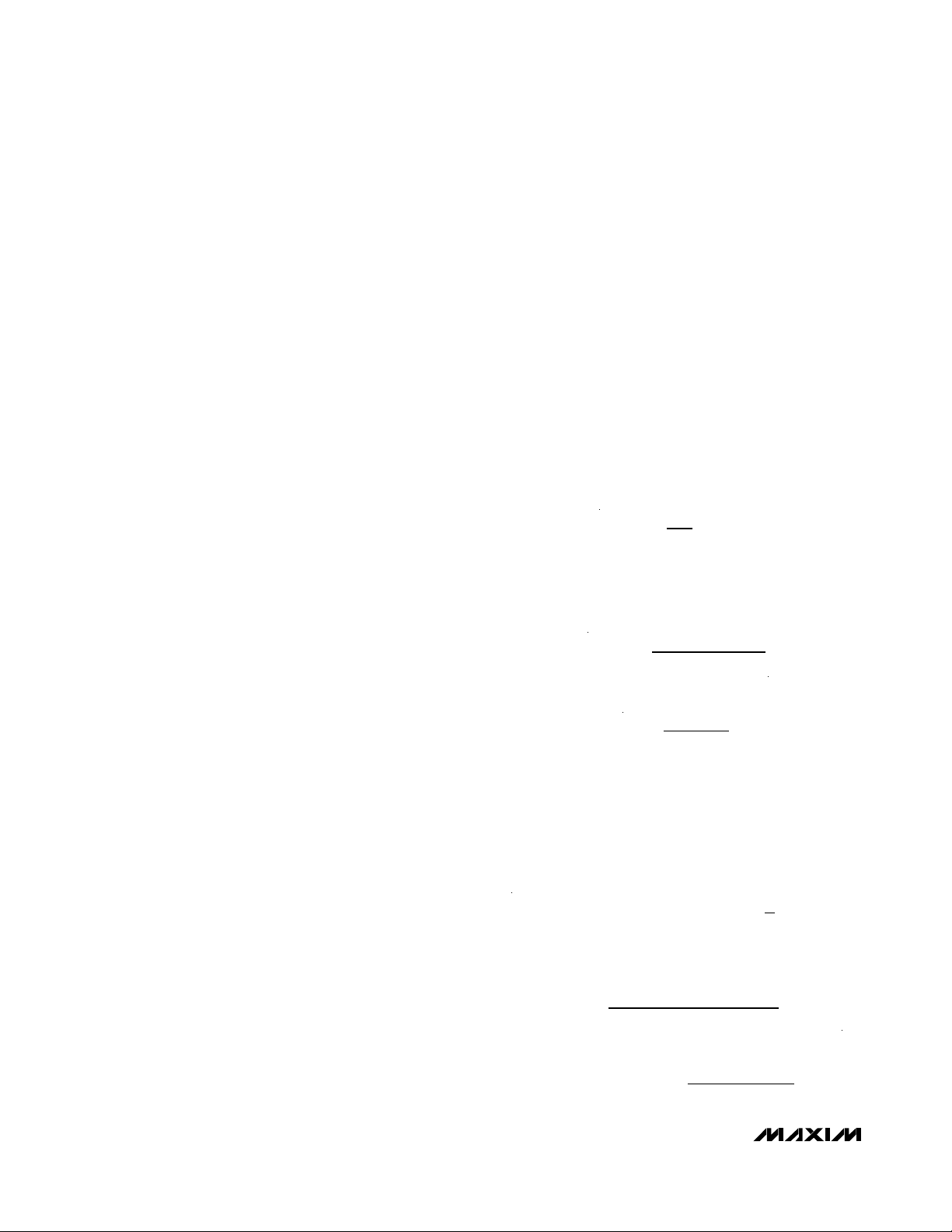

Detailed Description

DC-to-DC PWM Controller

The MAX8529 step-down converter uses a PWM voltage-mode control scheme (Figure 2) for each out-ofphase controller. The controller generates the clock

signal by dividing down the internal oscillator or SYNC

input when driven by an external clock, so each controller’s switching frequency equals half the oscillator frequency (fSW= f

OSC

/ 2). An internal transconductance

error amplifier produces an integrated error voltage at

the COMP pin, providing high DC accuracy. The voltage

at COMP sets the duty cycle using a PWM comparator

and a ramp generator. At each rising edge of the clock,

REG1’s high-side n-channel MOSFET turns on and

remains on until either the appropriate duty cycle or until

the maximum duty cycle is reached. REG2 operates outof-phase, so the second high-side MOSFET turns on at

each falling edge of the clock. During each high-side

MOSFET’s on-time, the associated inductor current

ramps up.

During the second-half of the switching cycle, the highside MOSFET turns off and the low-side n-channel

MOSFET turns on. Now the inductor releases the stored

energy as its current ramps down, providing current to

the output. Under overload conditions, when the inductor current exceeds the selected valley current limit

(see the Current-Limit Circuit (ILIM_) section), the highside MOSFET does not turn on at the appropriate clock

edge and the low-side MOSFET remains on to let the

inductor current ramp down.

Synchronized Out-of-Phase Operation

The two independent regulators in the MAX8529 operate

180 degrees out-of-phase to reduce input filtering

requirements, reduce electromagnetic interference (EMI),

and improve efficiency. This effectively lowers component

cost and saves board space, making the MAX8529 ideal

for cost-sensitive applications.

Dual-switching regulators typically operate both

controllers in-phase, and turn on both high-side MOSFETs

at the same time. The input capacitor must then support

the instantaneous current requirements of both controllers

simultaneously, resulting in increased ripple voltage and

current when compared to a single switching regulator.

The higher RMS ripple current lowers efficiency due to

power loss associated with the input capacitor’s effective

series resistance (ESR). This typically requires more lowESR input capacitors in parallel to minimize input voltage

ripple and ESR-related losses, or to meet the necessary

ripple-current rating.

MAX8529

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

_______________________________________________________________________________________ 7

Pin Description (continued)

PIN NAME FUNCTION

14 DH1 High-Side Gate Driver Output for Regulator 1 (REG1). DH1 swings from LX1 to BST1.

15 LX1

16 BST1

17 DL1 Low-Side Gate-Driver Output for Regulator 1 (REG1). DL1 swings from PGND to VL.

18 PGND Power Ground

19 V

20 DL2 Low-Side Gate-Driver Output for Regulator 2 (REG2). DL2 swings from PGND to VL.

21 BST2

22 LX2

23 DH2 High-Side Gate-Driver Output for Regulator 2 (REG2). DH2 swings from LX2 to BST2.

24 EN

L

External Inductor Connection for Regulator 1 (REG1). Connect LX1 to the switched side of the

inductor. LX1 serves as the lower supply rail for the DH1 high-side gate driver.

Boost Flying-Capacitor Connection for Regulator 1 (REG1). Connect BST1 to an external ceramic

capacitor and diode according to Figure 1.

Internal 5V Linear-Regulator Output. Supplies the regulators and powers the low-side gate drivers

and external boost circuitry for the high-side gate drivers.

Boost Flying-Capacitor Connection for Regulator 2 (REG2). Connect BST2 to an external ceramic

capacitor and diode according to Figure 1.

External Inductor Connection for Regulator 2 (REG2). Connect LX2 to the switched side of the

inductor. LX2 serves as the lower supply rail for the DH2 high-side gate driver.

Active-High Enable Input. A logic low shuts down both controllers. Connect to V

operation.

for always-on

L

Page 8

MAX8529

With dual synchronized out-of-phase operation, the

MAX8529’s high-side MOSFETs turn on 180 degrees outof-phase. The instantaneous input current peaks of both

regulators no longer overlap, resulting in reduced RMS

ripple current and input voltage ripple. This reduces the

required input capacitor ripple-current rating, allowing

fewer or less expensive capacitors, and reduces shielding requirements for EMI. The out-of-phase waveforms in

the Typical Operating Characteristics demonstrate syn-

chronized 180-degree out-of-phase operation.

Internal 5V Linear Regulator (VL)

All MAX8529 functions are internally powered from an

on-chip, low-dropout 5V regulator. The maximum regulator input voltage (V+) is 23V. Bypass the regulator’s

output (V

L

) with a 4.7µF ceramic capacitor to PGND.

The VLdropout voltage is typically 500mV, so when V+

is greater than 5.5V, VLis typically 5V. The MAX8529

also employs an undervoltage lockout circuit that disables both regulators when VLfalls below 4.5V.

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

8 _______________________________________________________________________________________

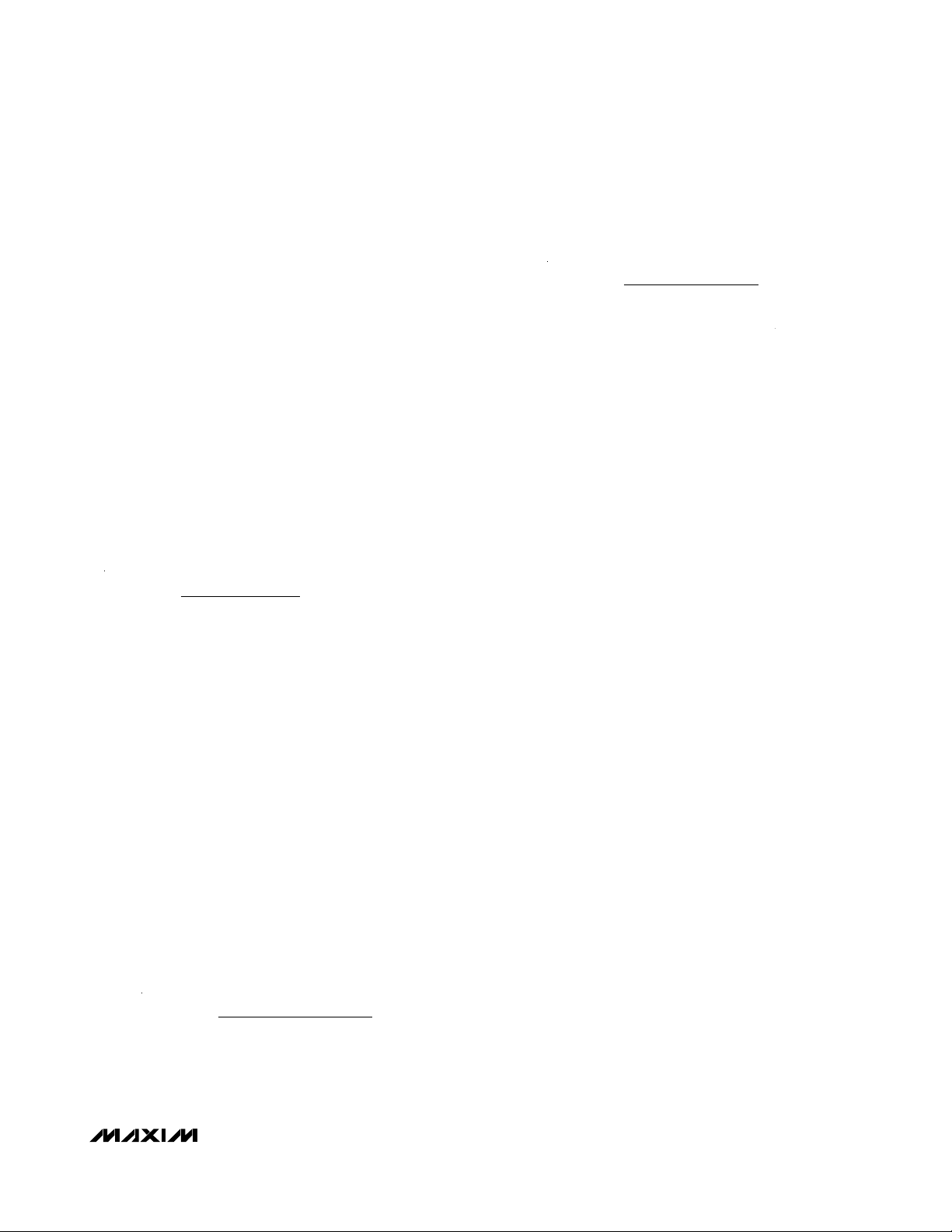

Figure 1. Standard Application Circuit

5.4V TO 6.6V

V

IN

D1A, B

CMPSH-3A

C2

10μF

10V

X5R

(2x)

1.8V AT

3A

V

OUT1

C1

22μF

6V

X5R

(2x)

C4

390pF

L1

1.0μH

DO3316P

-102HC

R3

16.5kΩ

R5

560Ω

N1A, B

FDS

6912A

C5

1nF

R6

10kΩ

3.3Ω

3.3Ω

20.5kΩ

C6

27pF

R1

R2

R4

0.22μF

10V

C3

0.1μF

C8

5

19

16

14

15

17

18

11

12

IN

BST1

DH1

LX1

DL1

PGND

FB1

COMP1

U1

MAX8529

V

L

COMP2

BST2

DH2

LX2

DL2

FB2

C9

4.7μF

10V

X5R

21

C10

0.1μF

23

22

20

2

1

R10

3.3Ω

R11

3.3Ω

R13

11.0kΩ

C14

10pF

R15

10kΩ

N2A, B

FDS

6912A

16.5kΩ

C5

1nF

L2

1.5μH

DO3316P

-152HC

22μF

R12

R14

560Ω

C12

X5R

(2x)

C11

10μF

10V

X5R

(2x)

6V

C13

390pF

2.5V AT

3A

V

OUT2

R7

RESET

100kΩ

22kΩ

R8

68kΩ

R9

V

L

0.22μF

V

C7

10

ILIM1

24

L

EN

13

RST

6

REF

GND

7

R16

R18

4.99kΩ

68kΩ

R17

68kΩ

ILIM2

SYNC

CKO

OSC

3

9

8

4

Page 9

The internal VLlinear regulator can source over 50mA to

supply the IC, power the low-side gate driver, charge the

external boost capacitor, and supply small external

loads. When driving large FETs, little or no regulator current may be available for external loads.

For example, when switched at 600kHz, a single large

FET with 18nC total gate charge requires 18nC ✕600kHz

= 11mA. To drive larger MOSFETs, or deliver larger

loads, connect VLto an external power supply from

4.75V to 5.5V.

MAX8529

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

_______________________________________________________________________________________ 9

REF

Figure 2. Functional Diagram

GND

COMP1

FB1

OSC

V+

V

L

BST1

DH1

LX1

DL1

PGND

SOFT-START

DAC

V

2.0V

Q

Q

5V LINEAR

REGULATOR

REF

g

m

MAX8529

CONVERTER 1

R

S

SYNC

CK0

RST

EN

V

REF

V

L

COMP2

OSCILLATOR

RESET

UVLO

AND

SHUTDOWN

CONVERTER 2

V

5μA

- 0.5V

L

ILIM1

BST2

DH2

LX2

DL2

ILIM2FB2

Page 10

MAX8529

High-Side Gate-Drive Supply (BST_)

Gate-drive voltages for the high-side n-channel switches are generated by the flying-capacitor boost circuits

(Figure 3). A boost capacitor (connected from BST_ to

LX_) provides power to the high-side MOSFET driver.

On startup, the synchronous rectifier (low-side MOSFET)

forces LX_ to ground and charges the boost capacitor to

5V. On the second half-cycle, after the low-side MOSFET

turns off, the high-side MOSFET is turned on by closing

an internal switch between BST_ and DH_. This provides

the necessary gate-to-source voltage to turn on the highside switch, an action that boosts the 5V gate-drive

signal above V

IN

. The current required to drive the high-

side MOSFET gates (f

SWITCH

✕

QG) is ultimately drawn

from V

L

.

MOSFET Gate Drivers (DH_, DL_)

The DH and DL drivers are optimized for driving

moderate-size n-channel high-side and larger low-side

power MOSFETs. This is consistent with the low duty

factor seen with a large V

IN

- V

OUT

differential. The DL_

low-side drive waveform is always the complement of

the DH_ high-side drive waveform (with controlled dead

time to prevent cross-conduction or “shoot-through”).

An adaptive dead-time circuit monitors the DL_ output

and prevents the high-side FET from turning on until

DL_ is fully off. There must be a low-resistance, lowinductance path from the DL_ driver to the MOSFET

gate in order for the adaptive dead-time circuit to work

properly. Otherwise, the sense circuitry in the MAX8529

interprets the MOSFET gate as “off” while there is actually charge still left on the gate. Use very short, wide

traces (50mils to 100mils wide if the MOSFET is 1in

from the device). The dead time at the DH off edge is

determined by a fixed 30ns internal delay.

Synchronous rectification reduces conduction losses in

the rectifier by replacing the normal low-side Schottky

catch diode with a low-resistance MOSFET switch.

Additionally, the MAX8529 uses the synchronous rectifier to ensure proper startup of the boost gate-driver circuit and to provide the current-limit signal.

The internal pulldown transistor that drives DL_ low is

robust, with a 0.5Ω (typ) on-resistance. This low onresistance helps prevent DL_ from being pulled up during the fast rise-time of the LX_ node, due to capacitive

coupling from the drain to the gate of the low-side synchronous-rectifier MOSFET. However, for high-current

applications, some combinations of high- and low-side

FETs can cause excessive gate-drain coupling, leading

to poor efficiency, EMI, and shoot-through currents.

This can be remedied by adding a resistor (typically

less than 5Ω) in series with BST_, which increases the

turn-on time of the high-side FET without degrading the

turn-off time (Figure 3).

Current-Limit Circuit (ILIM_)

The current-limit circuit employs a “valley” current-sensing algorithm that uses the on-resistance of the low-side

MOSFET as a current-sensing element. If the currentsense signal is above the current-limit threshold, the

MAX8529 does not initiate a new cycle (Figure 4). Since

valley current sensing is employed, the actual peak current is greater than the current-limit threshold by an

amount equal to the inductor ripple current. Therefore,

the exact current-limit characteristic and maximum load

capability are a function of the low-side MOSFET’s onresistance, current-limit threshold, inductor value, and

input voltage. The reward for this uncertainty is robust,

lossless overcurrent sensing that does not require costly

sense resistors.

The adjustable current limit accommodates MOSFETs

with a wide range of on-resistance characteristics (see

the Design Procedure section). The current-limit

threshold is adjusted with an external resistor at ILIM_

(Figure 1). The adjustment range is from 50mV to

300mV, corresponding to resistor values of 100kΩ to

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

10 ______________________________________________________________________________________

Figure 3. Reducing the Switching-Node Rise Time

Figure 4. “Valley” Current-Limit Threshold Point

INPUT

)

(V

V

L

BST_

DH_

LX_

MAX8529

INDUCTOR CURRENT

0 TIME

5Ω

IN

I

PEAK

I

LOAD

I

LIMIT

Page 11

600kΩ. In adjustable mode, the current-limit threshold

across the low-side MOSFET is precisely 1/10th the

voltage seen at ILIM_. However, the current-limit

threshold defaults to 100mV when ILIM is connected to

V

L

. The logic threshold for switchover to this 100mV

default value is approximately V

L

- 0.5V.

Adjustable foldback current limit reduces power dissipation during short-circuit conditions (see the Design

Procedure section).

Carefully observe the PC board layout guidelines to

ensure that noise and DC errors do not corrupt the current-sense signals seen by LX_ and PGND. The IC

must be mounted close to the low-side MOSFET with

short direct traces making a Kelvin sense connection

so that trace resistance does not add to the intended

sense resistance of the low-side MOSFET.

Undervoltage Lockout and Startup

If VLdrops below 4.5V, the MAX8529 assumes that the

supply and reference voltages are too low to make valid

decisions and activates the undervoltage lockout (UVLO)

circuitry, which forces DH low and DL high to inhibit

switching. RST is also forced low during UVLO. After V

L

rises above 4.5V, the controller powers up the outputs.

Enable (EN), Soft-Start, and Soft-Stop

Pull EN high to enable or low to shut down both regulators. During shutdown the supply current drops to 1mA

(max), LX enters a high-impedance state (DH_ connected to LX_, and DL_ connected to PGND), and

COMP_ is discharged to GND through a 17Ω resistor.

V

L

and REF remain active in shutdown. For “always-on”

operation, connect EN to V

L

.

On the rising edge of EN both controllers enter softstart. Soft-start gradually ramps up to the reference

voltage seen by the error amplifier in order to control

the outputs’ rate of rise and reduce input surge currents during startup. The soft-start period is 1024 clock

cycles (1024/fSW), and the internal soft-start DAC

ramps up the voltage in 64 steps. The output reaches

regulation when soft-start is completed. On the falling

edge of EN both controllers simultaneously enter softstop, which reverses the soft-start ramp. The part

enters shutdown after soft-stop is complete.

Reset Output

RST is an open-drain output. RST pulls low when either

output falls below 90% of its nominal regulation voltage.

Once both outputs exceed 90% of their nominal regulation

voltages and both soft-start cycles are completed, RST

goes high impedance. To obtain a logic-voltage output,

connect a pullup resistor from RST to the logic supply

voltage. A 100kΩ resistor works well for most applications.

If unused, leave RST grounded or unconnected.

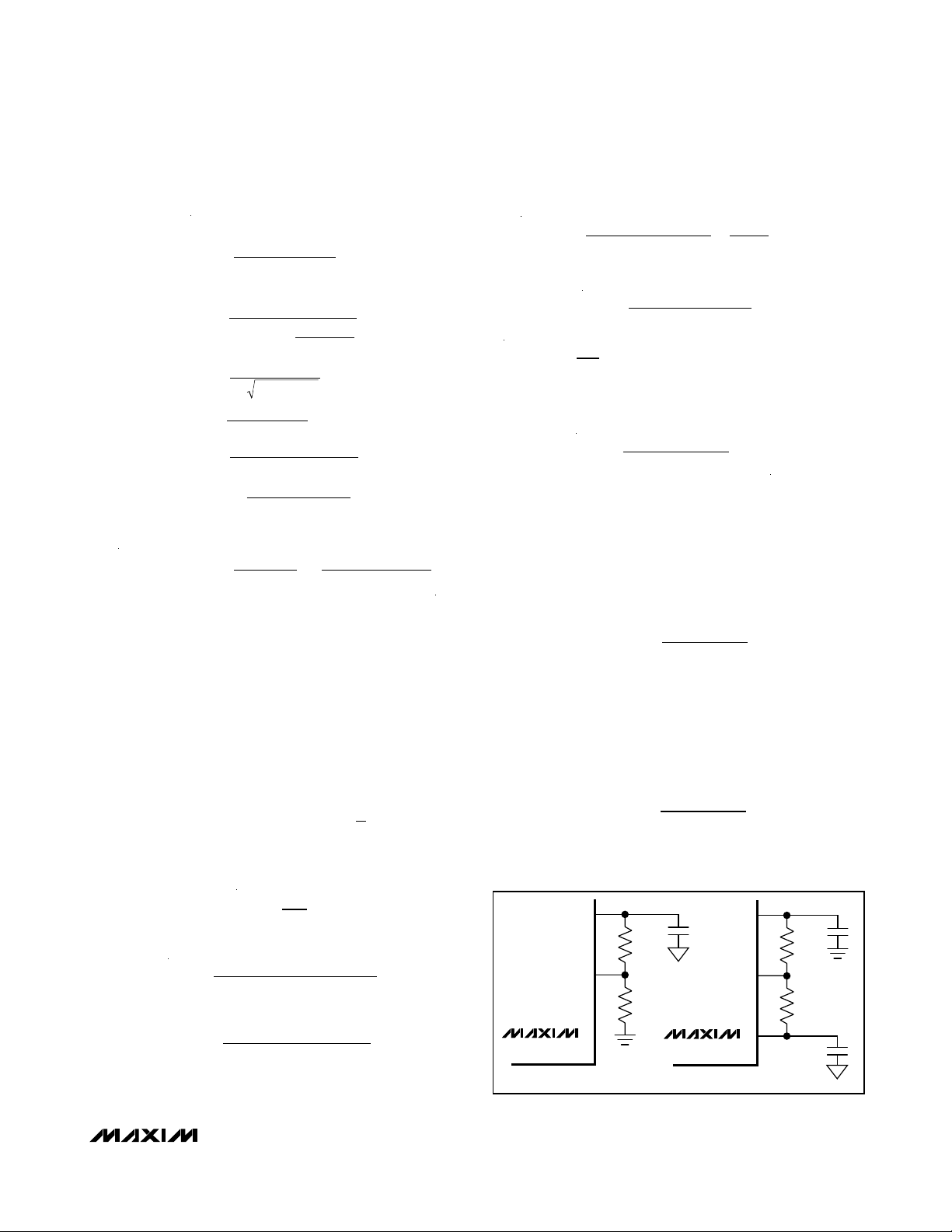

Clock Synchronization (SYNC, CKO)

SYNC serves two functions: SYNC selects the clock

output (CKO) type used to synchronize slave controllers, or it serves as a clock input so the MAX8529

can be synchronized with an external clock signal. This

allows the MAX8529 to function as either a master or

slave. CKO provides a clock signal synchronized to the

MAX8529’s switching frequency, allowing either inphase (SYNC = GND) or 90-degrees out-of-phase

(SYNC = VL) synchronization of additional DC-to-DC

controllers (Figure 5). The MAX8529 supports the following three operating modes:

• SYNC = GND: The CKO output frequency equals

REG1’s switching frequency (f

CKO

= f

DH1

) and the

CKO signal is in phase with REG1’s switching frequency. This provides 2-phase operation when synchronized with a second slave controller.

• SYNC = VL: The CKO output frequency equals two

times REG1’s switching frequency (f

CKO

= 2f

DH1

)

and the CKO signal is phase shifted by 90 degrees

with respect to REG1’s switching frequency. This

provides 4-phase operation when synchronized with

a second MAX8529 (slave controller).

• SYNC Driven by External Oscillator: The controller

generates the clock signal by dividing down the

SYNC input signal, so that the switching frequency

equals half the synchronization frequency (fSW=

f

SYNC

/ 2). REG1’s conversion cycles initiate on the

rising edge of the internal clock signal. The CKO output frequency and phase match REG1’s switching

frequency (f

CKO

= f

DH1

) and the CKO signal is in

phase. Note that the MAX8529 still requires R

OSC

when SYNC is externally clocked and the internal

oscillator frequency should be set to 50% of the synchronization frequency (f

OSC

= 0.5 f

SYNC

).

Thermal-Overload Protection

Thermal-overload protection limits total power dissipation

in the MAX8529. When the device’s die junction temperature exceeds TJ= +160°C, an on-chip thermal sensor

shuts down the device, forcing DL_ and DH_ low, allowing the IC to cool. The thermal sensor turns the part on

again after the junction temperature cools by 10°C.

During thermal shutdown, the regulators shut down, RST

goes low, and soft-start is reset. If the VLlinear-regulator

output is short-circuited, thermal-overload protection is

triggered.

MAX8529

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

______________________________________________________________________________________ 11

Page 12

MAX8529

Design Procedure

Effective Input Voltage Range

Although the MAX8529 controllers can operate from

input supplies ranging from 4.75V to 23V, the input

voltage range can be effectively limited by the

MAX8529’s duty-cycle limitations. The maximum input

voltage is limited by the minimum on-time (t

ON(MIN)

):

where t

ON(MIN)

is 100ns. The minimum input voltage is

limited by the maximum duty cycle (D

MAX

= 0.875):

where V

DROP1

is the sum of the parasitic voltage drops in

the inductor discharge path, including synchronous rectifier, inductor, and PCB resistances. V

DROP2

is the sum of

the resistances in the charging path, including high-side

switch, inductor, and PCB resistances.

Setting the Switching Frequency

The controller generates the clock signal by dividing

down the internal oscillator or SYNC input signal when

driven by an external oscillator, so the switching

frequency equals half the oscillator frequency (fSW=

f

OSC

/2). The internal oscillator frequency is set by a

resistor (R

OSC

) connected from OSC to GND. The rela-

tionship between fSWand R

OSC

is:

where fSWis in Hz, f

OSC

is in Hz, and R

OSC

is in Ω. For

example, a 600kHz switching frequency is set with

R

OSC

= 10kΩ. Higher frequencies allow designs with

lower inductor values and less output capacitance.

Consequently, peak currents and I2R losses are lower

at higher switching frequencies, but core losses, gatecharge currents, and switching losses increase.

A rising clock edge on SYNC is interpreted as a synchronization input. If the SYNC signal is lost, the internal

oscillator takes control of the switching rate, returning

the switching frequency to that set by R

OSC

. This maintains output regulation even with intermittent SYNC signals. When an external synchronization signal is used,

R

OSC

should set the switching frequency to one half

SYNC rate (f

SYNC

).

R

Hz

S

f

OSC

SW

=×

610

9

Ω -

V

VV

VV

IN MIN

OUT DROP

DROP DROP()

.

=

+

⎡

⎣

⎢

⎤

⎦

⎥

+

1

21

0 875

-

V

V

tf

IN MAX

OUT

ON MIN SW

()

()

≤

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

12 ______________________________________________________________________________________

Figure 5. Synchronized Controllers

MAX8529 MAX8529

OSC

MASTER

180° PHASE SHIFT 90° PHASE SHIFT

SLAVE

DH1

DH2

DH1

DH2

MASTER

CK0

SYNC

V

L

SYNC

SLAVE

MAX8529 MAX8529

OSC OSC

MASTER

MASTER

SLAVE

DH1

DH2

DH1

DH2

CK0

SYNC

V

L

4-PHASE SYSTEM2-PHASE SYSTEM

SYNC

SLAVE

Page 13

Inductor Selection

Three key inductor parameters must be specified for

operation with the MAX8529: inductance value (L),

peak-inductor current (I

PEAK

), and DC resistance (RDC).

The following equation assumes a constant ratio of

inductor peak-to-peak AC current to DC average current

(LIR). For LIR values too high, the RMS currents are

high, and therefore I2R losses are high. Large inductances must be used to achieve very low LIR values.

Typically inductance is proportional to resistance (for a

given package type), which again makes I

2

R losses

high for very low LIR values. A good compromise

between size and loss is a 30% peak-to-peak ripple current to average-current ratio (LIR = 0.3). The switching

frequency, input voltage, output voltage, and selected

LIR determine the inductor value as follows:

where VIN, V

OUT

, and I

OUT

are typical values (so that efficiency is optimum for typical conditions). The switching

frequency is set by R

OSC

(see the Setting the Switching

Frequency section). The exact inductor value is not

critical and can be adjusted in order to make trade-offs

among size, cost, and efficiency. Lower inductor values

minimize size and cost, but also improve transient

response and reduce efficiency due to higher peak currents. On the other hand, higher inductance increases

efficiency by reducing the RMS current. However, resistive losses due to extra wire turns can exceed the benefit

gained from lower AC current levels, especially when the

inductance is increased without also allowing larger

inductor dimensions.

Find a low-loss inductor having the lowest possible DC

resistance that fits in the allotted dimensions. The

inductor’s saturation rating must exceed the peakinductor current at the maximum defined load current

(I

LOAD(MAX)

):

Setting the Valley Current Limit

The minimum current-limit threshold must be high

enough to support the maximum expected load current

with the worst-case low-side MOSFET on-resistance

value since the low-side MOSFET’s on-resistance is used

as the current-sense element. The inductor’s valley current occurs at I

LOAD(MAX)

minus half of the ripple cur-

rent. The current-sense threshold voltage (V

ITH

) should

be greater than the voltage on the low-side MOSFET

during the ripple-current valley:

where R

DS(ON)

is the on-resistance of the low-side

MOSFET (N

L

). Use the maximum value for R

DS(ON)

from the low-side MOSFET’s data sheet, an additional

margin to account for R

DS(ON)

rise with temperature is

also recommended. A good general rule is to allow

0.5% additional resistance for each °C of the MOSFET

junction temperature rise.

Connect ILIM_ to VLfor the default 100mV (typ) currentlimit threshold. For an adjustable threshold, connect a

resistor (R

ILIM

_) from ILIM_ to GND. The relationship

between the current-limit threshold (V

ITH

_) and R

ILIM

_ is:

where R

ILIM

_ is in Ω and V

ITH

_ is in V.

An R

ILIM

resistance range of 100kΩ to 600kΩ corre-

sponds to a current-limit threshold of 50mV to 300mV.

When adjusting the current limit, 1% tolerance resistors

minimize error in the current-limit threshold.

For foldback current limit, a resistor (R

FBI

) is added

from ILIM pin to output. The value of R

ILIM

and R

FBI

can then be calculated as follows:

First select the percentage of foldback, PFB, from 15%

to 30%, then:

Input Capacitor

The input filter capacitor reduces peak currents drawn

from the power source and reduces noise and voltage

ripple on the input caused by the circuit’s switching.

The input capacitor must meet the ripple current

requirement (I

RMS

) imposed by the switching currents

as defined by the following equation:

I

RMS

has a maximum value when the input voltage equals

twice the output voltage (VIN= 2V

OUT

), so I

RMS(MAX)

=

I

LOAD

/ 2. For most applications, nontantalum capacitors

II

VVV

V

RMS LOAD

OUT IN OUT

IN

=

() -

R

PV

P

and

R

VPR

VVP

FBI

FB OUT

FB

ILIM

ITH FB FBI

OUT ITH FB

=

×

×

=

××

×

[]

( )

( )

( )

5101

10 1

10 1

6-

-

-

- -

R

V

A

ILIM

ITH__

.=

μ05

VR I

LIR

ITH DS ON MAX LOAD MAX

>××

⎛

⎝

⎜

⎞

⎠

⎟

(, ) ( )

12-

II

LIR

I

PEAK LOAD MAX LOAD MAX

=+

⎛

⎝

⎜

⎞

⎠

⎟

() ()

2

L

VVV

V f I LIR

OUT IN OUT

IN SW OUT

()

=

-

MAX8529

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

______________________________________________________________________________________ 13

Page 14

MAX8529

(ceramic, aluminum, polymer, or OS-CON) are preferred

at the input due to their robustness with high inrush currents typical of systems that can be powered from very

low impedance sources. Additionally, two (or more)

smaller-value low-ESR capacitors can be connected in

parallel for lower cost. Choose an input capacitor that

exhibits less than 10°C temperature rise at the RMS input

current for optimal long-term reliability.

Output Capacitor

The key selection parameters for the output capacitor

are capacitance value, ESR, and voltage rating. These

parameters affect the overall stability, output ripple voltage, and transient response. The output ripple has two

components: variations in the charge stored in the output capacitor, and the voltage drop across the capacitor’s ESR caused by the current flowing into and out of

the capacitor:

The output voltage ripple as a consequence of the ESR

and output capacitance is:

where I

P-P

is the peak-to-peak inductor current (see the

Inductor Selection section). These equations are suitable

for initial capacitor selection, but final values should be

verified by testing in a prototype or evaluation circuit.

As a general rule, a smaller inductor ripple current results

in less output ripple voltage. Since inductor ripple current

depends on the inductor value and input voltage, the output ripple voltage decreases with larger inductance and

increases with higher input voltages. However, the inductor ripple current also impacts transient-response performance, especially at low VIN- V

OUT

differentials. Low

inductor values allow the inductor current to slew faster,

replenishing charge removed from the output filter capacitors by a sudden load step. The amount of output-voltage sag is also a function of the maximum duty factor,

which can be calculated from the minimum off-time and

switching frequency:

where t

OFF(MIN)

is the minimum off-time (see the

Electrical Characteristics), and fSWis set by R

OSC

(see

the Setting the Switching Frequency section).

Compensation

The high switching frequency range of the MAX8529

allows the use of ceramic output capacitors. Since the

ESR of ceramic capacitors is typically very low, the frequency of the associated transfer function zero is higher

than the unity-gain crossover frequency and the zero cannot be used to compensate for the double pole created

by the output inductor and capacitor. The solution is Type

3 compensation which takes advantage of local feedback

to create two zeros and three poles (Figure 6). The frequency of the poles and zeros are described below:

V

LI I

V

Vf

t

CV

VV

Vf

t

SAG

LOAD LOAD

OUT

IN SW

OFF MIN

OUT OUT

IN OUT

IN SW

OFF MIN

=

⎛

⎝

⎜

⎞

⎠

⎟

+

⎡

⎣

⎢

⎢

⎤

⎦

⎥

⎥

⎛

⎝

⎜

⎞

⎠

⎟

⎡

⎣

⎢

⎢

⎤

⎦

⎥

⎥

()

()

()

12

2

2

-

-

-

VIR

V

I

Cf

I

VV

fLVV

RIPPLE ESR P P ESR

RIPPLE C

PP

OUT SW

PP

IN OUTSWOUT

IN

()

()

=

=

=

⎛

⎝

⎜

⎞

⎠

⎟

⎛

⎝

⎜

⎞

⎠

⎟

-

-

-

-

8

VV V

RIPPLE RIPPLE ESR RIPPLE C

() ()

≅+

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

14 ______________________________________________________________________________________

Figure 6. Compensation Network and Asymptotic Transfer Function

V

IN

DH

LX

L

O

GAIN (dB)

V

OUT

DL

MAX8529

FB

COMP

R4

C2

C

O

R3

C3

R2

R1

C1

fp1

fz1 fz2 fp2

fp3

FREQUENCY

Page 15

Unity-gain crossover frequency:

where:

V

IN,MAX

= Maximum input voltage

V

OSC

= Oscillator ramp voltage = 1V

LO= Output inductance

CO= Output capacitance

The goal is to place the two zeros below crossover and

the two poles above crossover so that crossover

occurs with a single-pole slope. The compensation procedure is as follows:

1) Select the crossover frequency such that:

2) Select R1 such that:

3) Place the first zero before the double pole:

4) Place the third pole at 1/2 the switching frequency:

C2 < 10pF can be omitted.

6) Place the second pole afer the ESR zero:

7) Place the second zero at the double pole frequency:

8) See the Setting the Output Voltage section for

selecting R4.

Setting the Output Voltage

For 1V or greater output voltages, set the MAX8529 output voltage by connecting a voltage-divider from the

output to FB_ to GND (Figure 7). Calculate R4 (OUT_ to

FB_ resistor) with the following equation:

where VSET = 1V (see the Electrical Characteristics)

and VOUT can range from VSET to 18V.

For output voltages below 1V, set the MAX8529 output

voltage by connecting a voltage-divider from the output

to FB_ to REF (Figure 7). Calculate R4 (FB_ to REF

resistor) with the following equation:

where VSET = 1V, VREF = 2V (see the Electrical

Characteristics), and VOUT can range from 0 to VSET.

RR

VV

VV

REF SET

SET OUT

43=

−

−

[]

R

fC

R

LC

3

1

23

2

≥

××π

-

If R

g

increase R and go back

to step

m

,

.

2

1

550 1

2

<=

()

Ω

R

fC

ZESR

2

1

23

≤

××π

53

2

1

0

)

C

fL CRV

V

O O OSC

IN

≤

×× ×

×

π

C

fR

S

2

1

205 1

.

≤

×

()

××π

C

fR

LC

1

1

2 0 75 1

.

≥

×

()

××π

R

g

m

12 >

f f and f f

f switching frequency

ZESR S

S

00

1

5

<<×

=

fRC

V

VLC

VINMAX

OO

OSC

0

13

1

2

=× × ×

××

,

π

f

f

RC

f

f

f

f

P

P

P

R

CC

CC

LC

LC

Z

RC

Z

RR

OO

1

2

3

1

21

12

12

1

2

1

1

211

2

1

223

0

1

223

=

=

××

=

××

×

()

+

()

=

×

=

××

=

×+

()

π

π

π

π

π

××

=

××

C

ZESR

RC

f

ESR O

3

1

2π

MAX8529

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

______________________________________________________________________________________ 15

Figure 7. Adjustable Output Voltage

V

RR

43=

SET

[]

−

VV

OUT SET

OUT_

R3

FB_

R4

MAX8529

V

> 1V

OUT_

MAX8529

REF

FB_

V

OUT_

R4

R3

OUT_

< 1V

Page 16

MAX8529

MOSFET Selection

The MAX8529’s step-down controller drives two external logic-level n-channel MOSFETs as the circuit switch

elements. The key selection parameters are:

• On-resistance (R

DS(ON)

)

• Maximum drain-to-source voltage (V

DS(MAX)

)

• Minimum threshold voltage (V

TH(MIN)

)

• Total gate charge (Q

g

)

• Reverse transfer capacitance (C

RSS

)

• Power dissipation

All four n-channel MOSFETs must be a logic-level type

with guaranteed on-resistance specifications at VGS≥

4.5V. For maximum efficiency, choose a high-side

MOSFET (NH_) that has conduction losses equal to the

switching losses at the optimum input voltage. Check to

ensure that the conduction losses at minimum input

voltage do not exceed MOSFET package thermal limits,

or violate the overall thermal budget. Also, check to

ensure that the conduction losses plus switching losses

at the maximum input voltage do not exceed package

ratings or violate the overall thermal budget.

Ensure that the MAX8529 DL_ gate drivers can drive

N

L

_. In particular, check that the dv/dt caused by NH_

turning on does not pull up the NL_ gate through NL_’s

drain-to-gate capacitance. This is the most frequent

cause of cross-conduction problems.

Gate-charge losses are dissipated by the driver and do

not heat the MOSFET. All MOSFETs must be selected

so that their total gate charge is low enough that VLcan

power all four drivers without overheating the IC:

MOSFET package power dissipation often becomes a

dominant design factor. I2R power losses are the greatest heat contributor for both high-side and low-side

MOSFETs. I2R losses are distributed between NH_ and

NL_ according to duty factor as shown in the equations

below. Switching losses affect only the high-side

MOSFET, since the low-side MOSFET is a zero-voltage

switched device when used in the buck topology.

Calculate MOSFET temperature rise according to package thermal-resistance specifications to ensure that

both MOSFETs are within their maximum junction temperature at high ambient temperature. The worst-case

dissipation for the high-side MOSFET (P

NH

) occurs at

both extremes of input voltage, and the worst-case dissipation for the low-side MOSFET (P

NL

) occurs at maxi-

mum input voltage:

I

GATE

is the average DH driver output current capability

determined by:

where R

DS(ON)DH

is the high-side MOSFET driver’s on-

resistance (5Ω max), and R

GATE

is any series resis-

tance between DH and BST (Figure 3).

where P

NH(CONDUCTION)

is the conduction power loss

in the high-side MOSFET, and PNLis the total low-side

power loss.

To reduce EMI caused by switching noise, add a 0.1µF

ceramic capacitor from the high-side switch drain to

the low-side switch source or add resistors in series

with DL_ and DH_ to increase the MOSFETs’ turn-on

and turn-off times.

Applications Information

Independent Shutdown

The two controllers in the MAX8529 can be shut down

independently by pulling COMP to ground. DH is

forced low and DL is forced high to inhibit switching.

Digital soft-stop is not active when using this method

for shutdown and the output voltage can go negative.

Use a Schottky clamp diode to limit the negative swing

of the output voltage.

When COMP is released, DH and DL resume switching.

In this mode, digital soft-start is not active and the

inrush current is limited by the foldback current limit.

Dropout Performance

When working with low input voltages, the output voltage

adjustable range for continuous-conduction operation is

restricted by the minimum off-time (t

OFF(MIN)

). For best

dropout performance, use the lowest (600kHz) switchingfrequency setting. Manufacturing tolerances and internal

propagation delays introduce an error to the switching

frequency and minimum off-time specifications. This error

is more significant at higher frequencies. Also, keep in

PIR

V

V

PP P

PI R

V

V

NH CONDUCTION LOAD DS ON NH

OUT

IN

NH TOTAL NH SWITCHING NH CONDUCTION

NL LOAD DS ON NL

OUT

IN

() ()

() ( )( )

()

=

⎛

⎝

⎜

⎞

⎠

⎟

=+

=

⎛

⎝

⎜

⎞

⎠

⎟

⎛

⎝

⎜

⎞

⎠

⎟

2

2

1-

I

V

RR

GATE

L

DS ON DH GATE

=

+

()

()

2

P

VI f Q Q

I

NH SWITCHING

IN LOAD OSC GS GD

GATE

()

=+

⎛

⎝

⎜

⎞

⎠

⎟

2

PV Q f

VL IN G TOTAL SW

=× ×

_

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

16 ______________________________________________________________________________________

Page 17

mind that transient response performance of buck regulators operated close to dropout is poor, and bulk output

capacitance must often be added (see the V

SAG

equa-

tion in the Design Procedure section).

The absolute point of dropout is when the inductor current ramps down during the minimum off-time (ΔI

DOWN

)

as much as it ramps up during the maximum on-time

(ΔIUP). The ratio h = ΔI

UP

/ ΔI

DOWN

is an indicator of

the ability to slew the inductor current higher in

response to increased load, and must always be

greater than 1. As h approaches 1, the absolute minimum dropout point, the inductor current cannot

increase as much during each switching cycle and

V

SAG

greatly increases unless additional output capac-

itance is used.

A reasonable minimum value for h is 1.5, but adjusting

this up or down allows tradeoffs between V

SAG

, output

capacitance, and minimum operating voltage.

For a given value of h, the minimum operating voltage

can be calculated as:

where V

DROP1

is the sum of the parasitic voltage drops

in the inductor discharge path, including synchronous

rectifier, inductor, and PCB resistances; V

DROP2

is the

sum of the resistances in the charging path, including

high-side switch, inductor, and PCB resistances; and

t

OFF(MIN)

is from the Electrical Characteristics. The

absolute minimum input voltage is calculated with h = 1.

If the calculated V+

(MIN)

is greater than the required minimum input voltage, then reduce the operating frequency

or add output capacitance to obtain an acceptable

V

SAG

. If operation near dropout is anticipated, calculate

V

SAG

to be sure of adequate transient response.

Dropout Design Example:

V

OUT

= 5V

fSW= 600kHz

t

OFF(MIN)

= 250ns

V

DROP1

= V

DROP2

= 100mV

h = 1.5

Calculating again with h = 1 gives the absolute limit of

dropout:

Therefore, VINmust be greater than 6V, even with very

large output capacitance, and a practical input voltage

with reasonable output capacitance would be 6.58V.

Improving Noise Immunity

Applications where the MAX8529 must operate in noisy

environments can typically adjust their controller’s compensation to improve the system’s noise immunity. In particular, high-frequency noise coupled into the feedback

loop causes jittery duty cycles. One solution is to lower

the crossover frequency (see the Compensation section).

PCB Layout Guidelines

Careful PCB layout is critical to achieve low switching

losses and clean, stable operation. This is especially

true for dual converters where one channel can affect

the other. Refer to the MAX8529 EV kit data sheet for a

specific layout example.

If possible, mount all of the power components on the

top side of the board with their ground terminals flush

against one another. Follow these guidelines for good

PCB layout:

1) Isolate the power components on the top side from

the analog components on the bottom side with a

ground shield. Use a separate PGND plane under

the OUT1 and OUT2 sides (referred to as PGND1

and PGND2). Avoid the introduction of AC currents

into the PGND1 and PGND2 ground planes. Run the

power-plane ground currents on the top side only.

2) Use a star ground connection on the power plane to

minimize the crosstalk between OUT1 and OUT2.

3) Keep the high-current paths short, especially at the

ground terminals. This practice is essential for stable, jitter-free operation.

4) Connect GND and PGND together close to the IC.

Do not connect them together anywhere else.

Carefully follow the grounding instructions under

step 4 of the Layout Procedure section.

5) Keep the power traces and load connections short.

This practice is essential for high efficiency. Use

thick copper PCBs (2oz vs. 1oz) to enhance fullload efficiency by 1% or more.

V

VmV

kHz ns

mV mV V

IN MIN()

()()

=

+

⎡

⎣

⎢

⎤

⎦

⎥

+=

−

5 100

1 600 250

100 100 6

-

V

VmV

kHz ns

mV mV V

IN MIN()

. ( )( )

.

=

+

⎡

⎣

⎢

⎤

⎦

⎥

+=

−

5 100

1 1 5 600 250

100 100 6 58

-

V

VV

hf t

VV

IN MIN

OUT DROP

SW OFF MIN

DROP DROP()

()

=

+

⎡

⎣

⎢

⎢

⎤

⎦

⎥

⎥

+

1

21

1-

-

MAX8529

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

______________________________________________________________________________________ 17

Page 18

MAX8529

6) LX_ and PGND connections to the synchronous

rectifiers for current limiting must be made using

Kelvin sense connections to guarantee the currentlimit accuracy. With 8-pin SO MOSFETs, this is best

done by routing power to the MOSFETs from outside using the top copper layer, while connecting

PGND and LX_ underneath the 8-pin SO package.

7) When trade-offs in trace lengths must be made,

allow the inductor-charging path to be made longer

than the discharge path. Since the average input

current is lower than the average output current in

step-down converters, this minimizes the power

dissipation and voltage drops caused by board

resistance. For example, allow some extra distance

between the input capacitors and the high-side

MOSFET rather than to allow distance between the

inductor and the low-side MOSFET or between the

inductor and the output filter capacitor.

8) Ensure that the feedback connection to C

OUT_

is

short and direct.

9) Route high-speed switching nodes (BST_, LX_, DH_,

and DL_) away from the sensitive analog areas (REF,

COMP_, ILIM_, and FB_). Use PGND1 and PGND2

as EMI shields to keep radiated noise away from the

IC, feedback dividers, and analog bypass capacitors.

10) Make all pin-strap control input connections (ILIM_,

SYNC, and EN) to analog ground (GND) rather

than power ground (PGND).

Layout Procedure

1) Place the power components first, with ground termi-

nals adjacent (NL_ source, CIN_, and C

OUT

_). Make

all these connections on the top layer with wide, copper-filled areas (2oz copper recommended).

2) Mount the controller IC adjacent to the synchronous

rectifier MOSFETs (NL_), preferably on the back

side in order to keep LX_, PGND_, and DL_ traces

short and wide. The DL_ gate trace must be short

and wide, measuring 50 mils to 100 mils wide if the

low-side MOSFET is 1in from the controller IC.

3) Group the gate-drive components (BST_ diodes and

capacitors, and VLbypass capacitor) together near

the controller IC.

4) Make the DC-to-DC controller ground connections

as follows:

a) Create a small analog ground plane near the IC.

b) Connect this plane to GND and use this plane for

the ground connection for the reference (REF) V+

bypass capacitor, compensation components,

feedback dividers, OSC resistor, and ILIM_ resistors (if any).

c) Connect GND and PGND together under the IC

(this is the only connection between GND and

PGND).

5) On the board’s top side (power planes), make a star

ground to minimize crosstalk between the two sides.

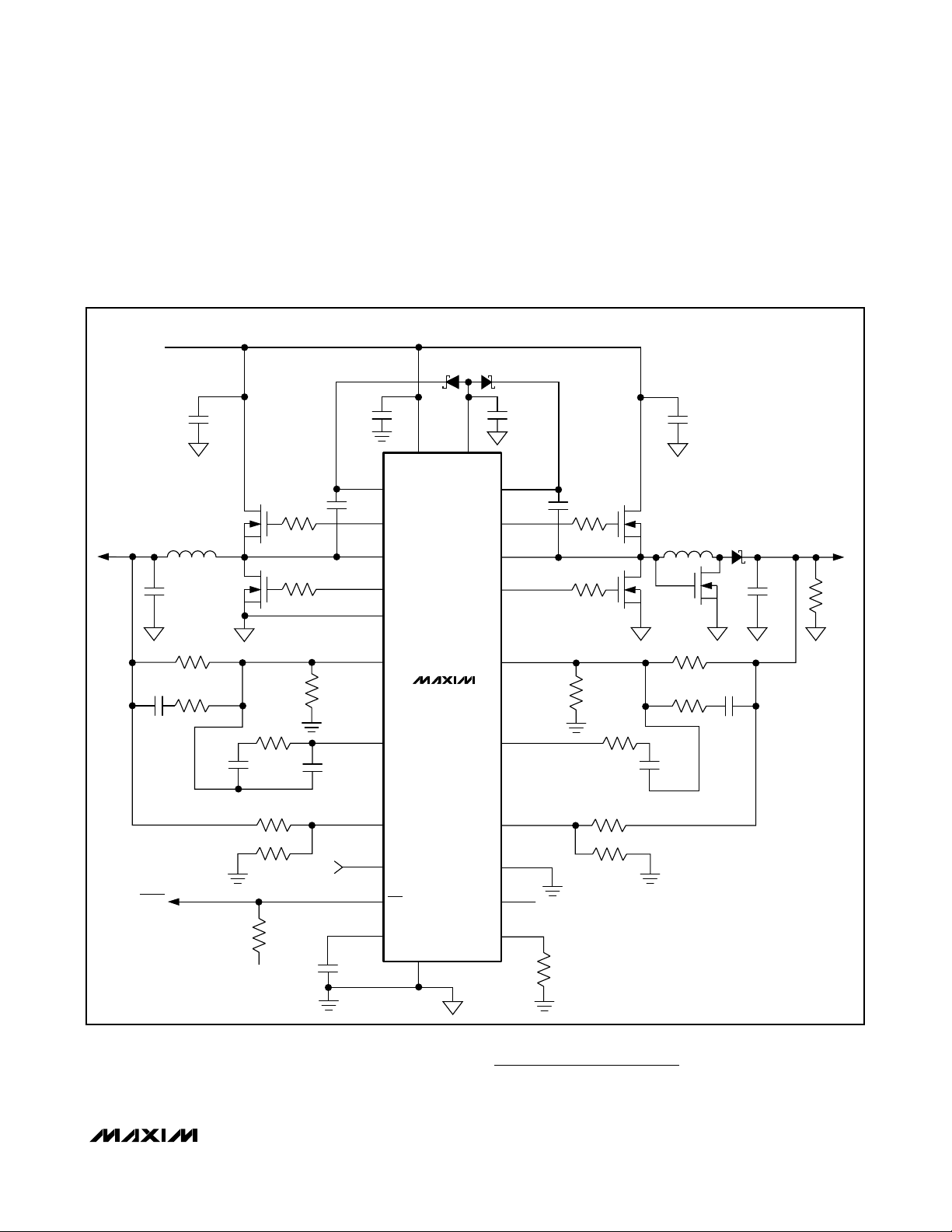

Buck-Boost

The MAX8529 step-down regulator can be configured as

a buck-boost (step-up) regulator with the addition of a

MOSFET switch and an output diode (Figure 8). When LX

is high, the inductor current increases with a slope of V

IN

/ L. When LX is low, the inductor current decreases with a

slope of (V

OUT

+ VD) / L. The input and output currents

are discontinuous, which allows the output voltage to be

greater or less than the input voltage.

The output voltage is a function of the input voltage and

the duty cycle:

Notice that the output voltage is increased by a factor of

1 / (1 - D) compared with a normal step-down regulator.

The additional loop gain must be considered when

designing the compensation circuit. Solving for D:

and the maximum additional gain is:

The open-loop gain must be reduced by a factor of G for

stability at a given bandwidth compared with a normal

step-down regulator. Alternatively, the unity-gain

crossover frequency can be reduced by a factor of G

when applying the compensation equations.

The output current is a fraction of the peak switch current and depends on the DC current in the inductor:

where fSWis the switching frequency:

Choose C

ID

Vf

OUT

OUT MAX

RIPPLE SW

>

×

×

.

,,

,,

IDII

and

II I

Choose L

VDD

If

OUT L DC L RIPPLE

PK L DC L RIPPLE

IN MAX MAX

OUT SW

=

()

×+

⎛

⎝

⎜

⎞

⎠

⎟

=+

≈

×

()

×

××

1

1

2

1

04

-

-

G

D

MAX

=

1

1-

D

V

VV

MAX

OUT

IN MIN OUT

=+

,

V

D

D

V

OUT IN

=×

1-

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

18 ______________________________________________________________________________________

Page 19

where V

RIPPLE

is the maximum output ripple voltage

and C

OUT

is a ceramic capacitor. Choose the output

Schottky diode to be rated for IPKand V

OUT

. Similarly,

choose the extra MOSFET to be rated for IPK, V

GS,BR

>

VIN, and fast switching (< 50ns).

The buck-boost portion of the circuit shown in Figure 8

delivers 24V at 50mA with 70% efficiency. A preload

resistor is used to ensure constant frequency operation

over the entire load range.

MAX8529

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

______________________________________________________________________________________ 19

Chip Information

TRANSISTOR COUNT: 6688

PROCESS: BiCMOS

Figure 8. Buck-Boost Application

5.4V TO 6.6V

V

IN

3.3V AT

2A

V

OUT1

C4

150pF

10μF

10V

X5R

C1

10μF

6V

X5R

C2

2.5μH

CDRH

5D28

34kΩ

620Ω

R6

27kΩ

10Ω

10Ω

14.7kΩ

10pF

R1

R2

R4

C6

L2

N1A, B

FDS

6930A

R3

R5

C5

270pF

0.22μF

10V

C3

0.1μF

C8

16

BST1

14

DH1

15

LX1

17

DL1

18

PGND

11

FB1

12

COMP1

5

IN

MAX8529

CMPSH-3A

19

U1

D1A, B

V

L

COMP2

BST2

DH2

LX2

DL2

FB2

21

23

22

20

2

1

C9

4.7μF

10V

X5R

C10

0.1μF

R10

10Ω

R11

10Ω

R13

14kΩ

N2A, B

NDS

9956A

R15

100kΩ

324kΩ

C14

180pF

L3

33μH

CDRH

5D28

R12

R14

1kΩ

C11

4.7μF

10V

X5R

EC10

QS03L

N3

FDN

359AN

C13

39pF

D2

C12

4.7μF

25V

X5R

24V AT

50mA

V

OUT2

R19

5.6kΩ

150kΩ

68kΩ

RESET

R9

100kΩ

V

L

R18

4.99kΩ

R16

750kΩ

R17

22kΩ

R7

10

ILIM1

24

L

EN

13

RST

6

REF

GND

7

0.22μF

V

C7

R8

ILIM2

SYNC

CKO

OSC

3

9

8

4

Page 20

MAX8529

1.5MHz Dual 180° Out-of-Phase

PWM Step-Down Controller with POR

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

20 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2007 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

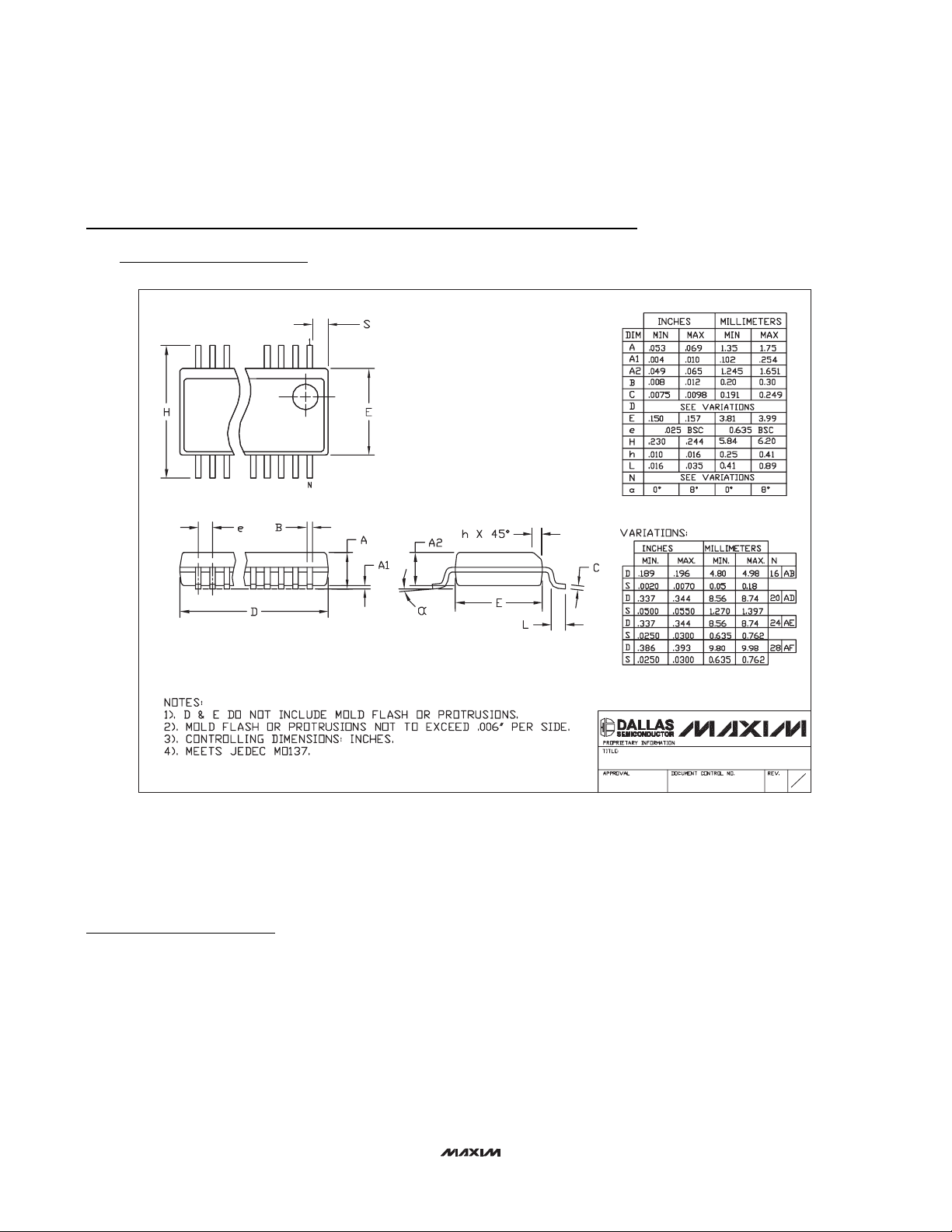

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.

)

Revision History

Pages changes at Rev 1: 1, 12–20

QSOP.EPS

PACKAGE OUTLINE, QSOP .150", .025" LEAD PITCH

21-0055

1

F

1

Loading...

Loading...