Page 1

General Description

The MAX8520/MAX8521 are designed to drive thermoelectric coolers (TECs) in space-constrained optical

modules. Both devices deliver ±1.5A output current

and control the TEC current to eliminate harmful current

surges. On-chip FETs minimize external components and

high switching frequency reduces the size of external

components.

The MAX8520 and MAX8521 operate from a single supply

and bias the TEC between the outputs of two synchronous buck regulators. This operation allows for temperature control without “dead zones” or other nonlinearities

at low current. This arrangement ensures that the control

system does not hunt when the set point is very close to

the natural operating point, requiring a small amount of

heating or cooling. An analog control signal precisely

sets the TEC current.

Both devices feature accurate, individually adjustable

heating current limit and cooling current limit, along

with maximum TEC voltage limit to improve the reliability

of optical modules. An analog output signal monitors

the TEC current. A unique ripple cancellation scheme

helps reduce noise.

The MAX8520 is available in a 5mm x 5mm thin QFN

package and its switching frequency is adjustable up to

1MHz through an external resistor. The MAX8521 is also

available in a 5mm x 5mm thin QFN, as well as a spacesaving 3mm x 3mm UCSP™, with a pin-selectable

switching frequency of 500kHz or 1MHz.

Applications

SFF/SFP Modules

Fiber-Optic Laser Modules

Fiber-Optic Network Equipment

ATE

Biotech Lab Equipment

Features

♦ Circuit Footprint of 0.31in

2

♦ Low-Profile Design

♦ On-Chip Power MOSFETs

♦ High-Efficiency Switch-Mode Design

♦ Ripple Cancellation for Low Noise

♦ Direct Current Control Prevents TEC Current

Surges

♦ 5% Accurate Adjustable Heating/Cooling Current

Limits

♦ 2% Accurate TEC Voltage Limit

♦ No Dead Zone or Hunting at Low Output Current

♦ ITEC Monitors TEC Current

♦ 1% Accurate Voltage Reference

♦ Switching Frequency Up to 1MHz

♦ Synchronization (MAX8521)

MAX8520/MAX8521

Smallest TEC Power Drivers for

Optical Modules

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

19-2586; Rev 0; 10/02

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

EVALUATION KIT

AVAILABLE

PART TEMP RANGE PIN-PACKAGE

MAX8520ETP

20 Thin QFN 5mm x 5mm

MAX8521EBX

36 UCSP 3mm x 3mm

MAX8521ETP

20 Thin QFN 5mm x 5mm

UCSP is a trademark of Maxim Integrated Products, Inc.

INPUT

3V TO 5.5V

V

DD

PV

DD

COMP

GND

SHDN

ITEC

ON

OFF

TEC CURRENT

MONITOR

CTLI

LX1

PGND1

CS

OS1

OS2

LX2

PGND2

TEC

I

TEC

= ± 1.5A

REF

CURRENT-

CONTROL

SIGNAL

FREQ

ANALOG /DIGITAL

TEMPERATURE CONTROL

OUTPUT

MAX8521

Typical Operating Circuit

Pin Configurations appear at end of data sheet.

3mm x 3mm

CSP

5mm x 5mm

QFN

-40°C to +85°C

-40°C to +85°C

-40°C to +85°C

Page 2

MAX8520/MAX8521

Smallest TEC Power Drivers for

Optical Modules

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

VDDto GND..............................................................-0.3V to +6V

SHDN, MAXV, MAXIP, MAXIN,

CTLI to GND .........................................................-0.3V to +6V

COMP, FREQ, OS1, OS2, CS, REF,

ITEC to GND...........................................-0.3V to (V

DD

+ 0.3V)

PV

DD

1, PVDD2 to GND...............................-0.3V to (VDD+ 0.3V)

PV

DD

1, PVDD2 to VDD...........................................-0.3V to +0.3V

PGND1, PGND2 to GND .......................................-0.3V to +0.3V

COMP, REF, ITEC Short to GND ...................................Indefinite

LX Current (Note 1) ........................................±2.25A LX Current

Continuous Power Dissipation (T

A

= +70°C)

20-Pin 5mm x 5mm x 0.9mm QFN (derate 20.8mW/°C

above +70°C) (Note 2)...................................................1.67W

3mm x 3mm UCSP (derate 22mW/°C

above +70°C).................................................................1.75W

Maximum Junction Temperature .....................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering 10s) ..................................+300°C

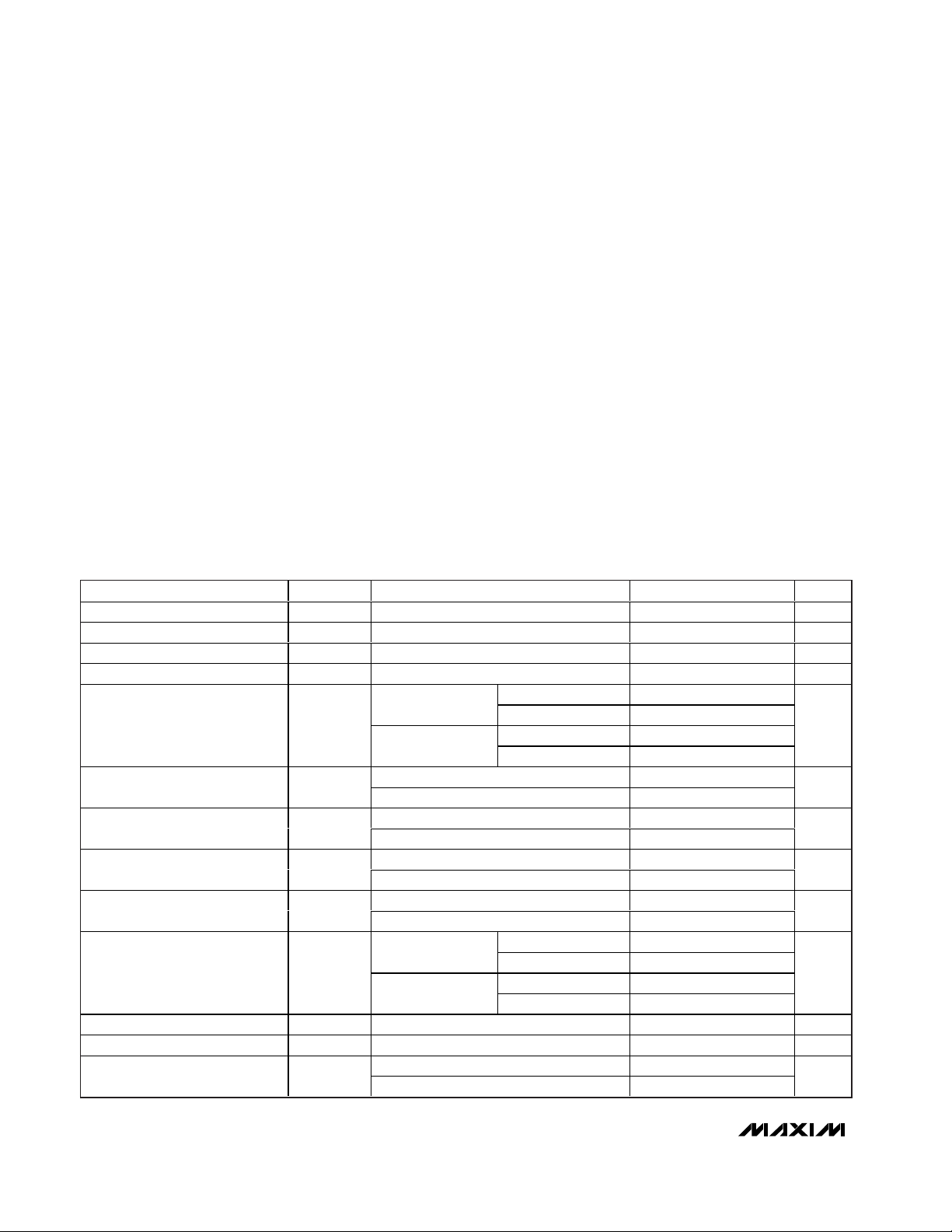

ELECTRICAL CHARACTERISTICS

(VDD= PVDD1 = PVDD2 = SHDN = 5V, 1MHz mode (Note 3). PGND1 = PGND2 = GND, CTLI = MAXV = MAXIP = MAXIN = REF,

T

A

= 0°C to +85°C, unless otherwise noted. Typical values at TA= +25°C.)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

Input Supply Range V

DD

3.0 5.5 V

Maximum TEC Current

A

Reference Voltage V

REF

V

DD

= 3V to 5.5V, I

REF

= 150µA

1.5

V

Reference Load Regulation ∆V

REF

V

DD

= 3V to 5V, I

REF

= 10µA to 1mA 1.2 5.0 mV

V

MAXI_

= V

REF

160

V

DD

= 5V

V

MAXI_

= V

REF

/3 40 50 60

V

MAXI_

= V

REF

155

MAXIP/MAXIN Threshold

Accuracy

V

DD

= 3V

V

MAXI_

= V

REF

/3 45 50 55

mV

V

DD

= 5V, I = 0.2A

NFET On-Resistance

)

V

DD

= 3V, I = 0.2A

Ω

V

DD

= 5V, I = 0.2A

PFET On-Resistance

)

V

DD

= 3V, I = 0.2A

Ω

VLX = V

DD

= 5V, TA = +25°C

4

NFET Leakage I

LEAK(N)

VLX = V

DD

= 5V, TA = +85°C 0.3

µA

VLX = 0, TA = +25°C

4

PFET Leakage I

LEAK(P)

VLX = 0, TA = +85°C 0.3

µA

500kHz mode 11 14

V

COMP

= V

REF

=

1.500V, V

DD

= 5V

1MHz mode 16 21

500kHz mode 8 11

No-Load Supply Current

I

DD(NO

LOAD)

V

COMP

= V

REF

=

1MHz mode 11 14

mA

Shutdown Supply Current I

DD-SD

SHDN = GND, V

DD

= 5V (Note 4) 2 3 mA

Thermal Shutdown

Hysteresis = 15°C

°C

VDD rising

UVLO Threshold V

UVLO

VDD falling

V

Note 1: LX has internal clamp diodes to PGND and PVDD. Applications that forward bias these diodes should take care not to exceed

the IC’s package power dissipation limits.

Note 2: Solder underside metal slug to PC board ground plane.

R

DS(ON-N

R

DS(ON-P

T

SHUTDOWN

1.500V, V

DD

= 3.3V

±1.5

1.485

1.515

140 150

143 150

0.09 0.14

0.11 0.16

0.14 0.23

0.17 0.30

0.03

0.03

+165

2.50 2.65 2.80

2.40 2.55 2.70

Page 3

MAX8520/MAX8521

Smallest TEC Power Drivers for

Optical Modules

_______________________________________________________________________________________ 3

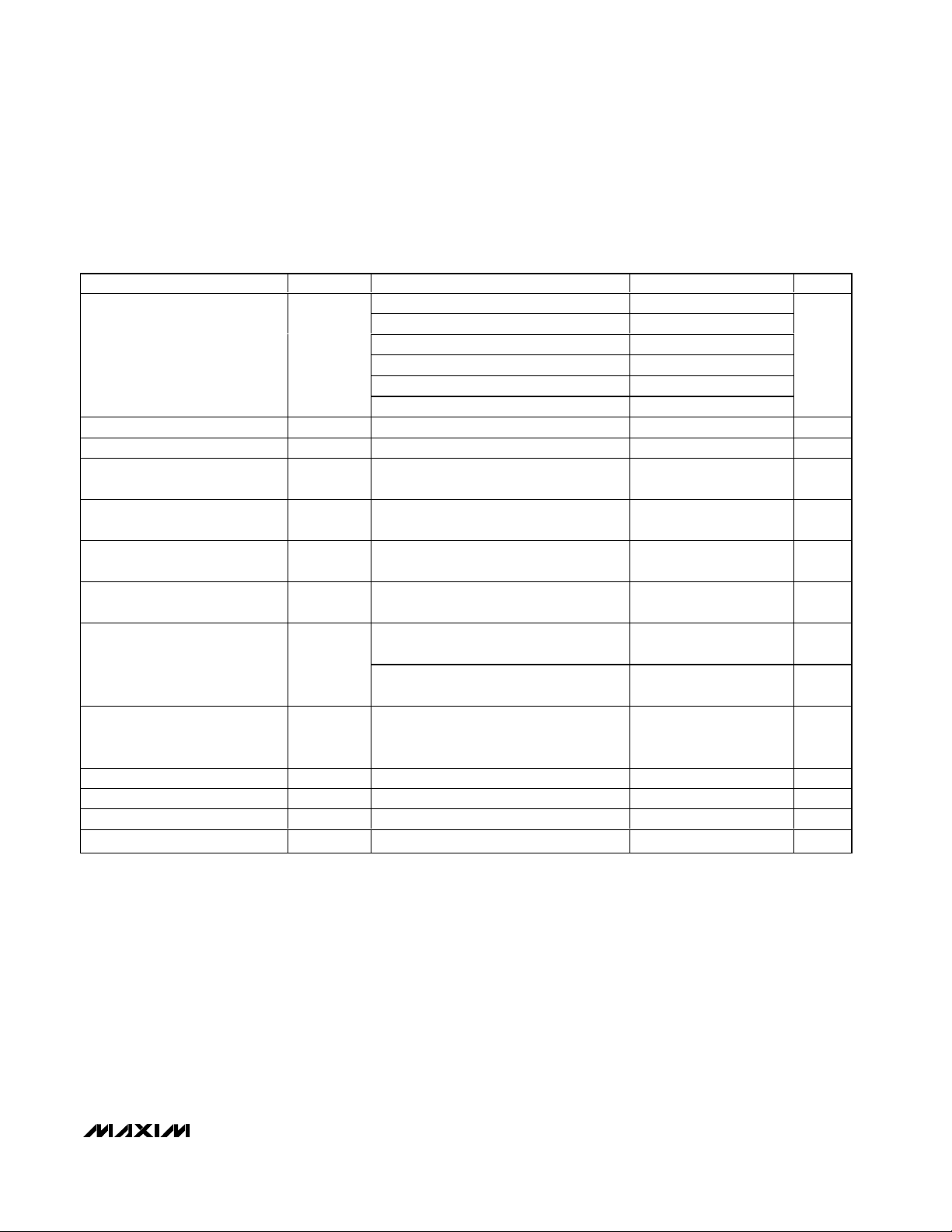

ELECTRICAL CHARACTERISTICS (continued)

(VDD= PVDD1 = PVDD2 = SHDN = 5V, 1MHz mode (Note 3). PGND1 = PGND2 = GND, CTLI = MAXV = MAXIP = MAXIN = REF,

T

A

= 0°C to +85°C, unless otherwise noted. Typical values at TA= +25°C.)

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

MAX8521, FREQ= VDD, V

DD

= 3V to 5V 0.8 1 1.2

MAX8521, FREQ= 0, V

DD

= 3V to 5V 0.4 0.5 0.6

MAX8520, R

EXT

= 60kΩ, V

DD

= 5V 0.8 1 1.2

MAX8520, R

EXT

= 60kΩ, V

DD

= 3V

MAX8520, R

EXT

= 150kΩ, V

DD

= 5V 0.4 0.5 0.6

Internal Oscillator Switching

Frequency

f

SW-INT

MAX8520, R

EXT

= 150kΩ, V

DD

= 3V

MHz

External Sync Frequency Range

25% < duty cycle <75% (MAX8521 only) 0.7 1.2

MHz

LX_ Duty Cycle (Note 5) 0 100 %

OS1, OS2, CS Input Current

I

OS1

, I

OS2

,

I

CS

0 or V

DD

µA

SHDN, FREQ Input Current

I

SHDN

,

I

FREQ

0 or VDD, FREQ applicable for the

MAX8521 only

-5 +5 µA

SHDN, FREQ Input Low Voltage V

IL

V

DD

= 3V to 5.5V, FREQ applicable for the

MAX8521 only

V

SHDN, FREQ Input High Voltage

V

IH

V

DD

= 3V to 5.5V, FREQ applicable for the

MAX8521 only

VDD x

V

V

MAXV

= V

REF

x 0.67, V

OS1

to V

OS2

= ±4V,

V

DD

= 5V

-2 +2 %

MAXV Threshold Accuracy

V

MAXV

= V

REF

x 0.33, V

OS1

to V

OS2

= ±2V,

V

DD

= 3V

-3 +3 %

MAXV, MAXI_ Input Bias Current

I

MAXV-BIAS

,

V

MAXV

= V

MAXI_

= 0.1V or 1.5V

µA

CTLI Gain A

CTLI

V

CTLI

= 0.5V to 2.5V (Note 6) 9.5 10

V/V

CTLI Input Resistance R

CTLI

1MΩ terminated at REF 0.5 1 2.0 MΩ

Error-Amp Transconductance g

m

50

160 µS

V

ITEC

Accuracy V

OS1

to VCS = ±100mV, V

OS1

= VDD/2 -10

%

0.76 0.93 1.10

0.36 0.46 0.56

-100 +100

0.75

I

MAXI_-BIAS

-0.1 +0.1

100

VDD x

0.25

10.5

+10

Page 4

MAX8520/MAX8521

Smallest TEC Power Drivers for

Optical Modules

4 _______________________________________________________________________________________

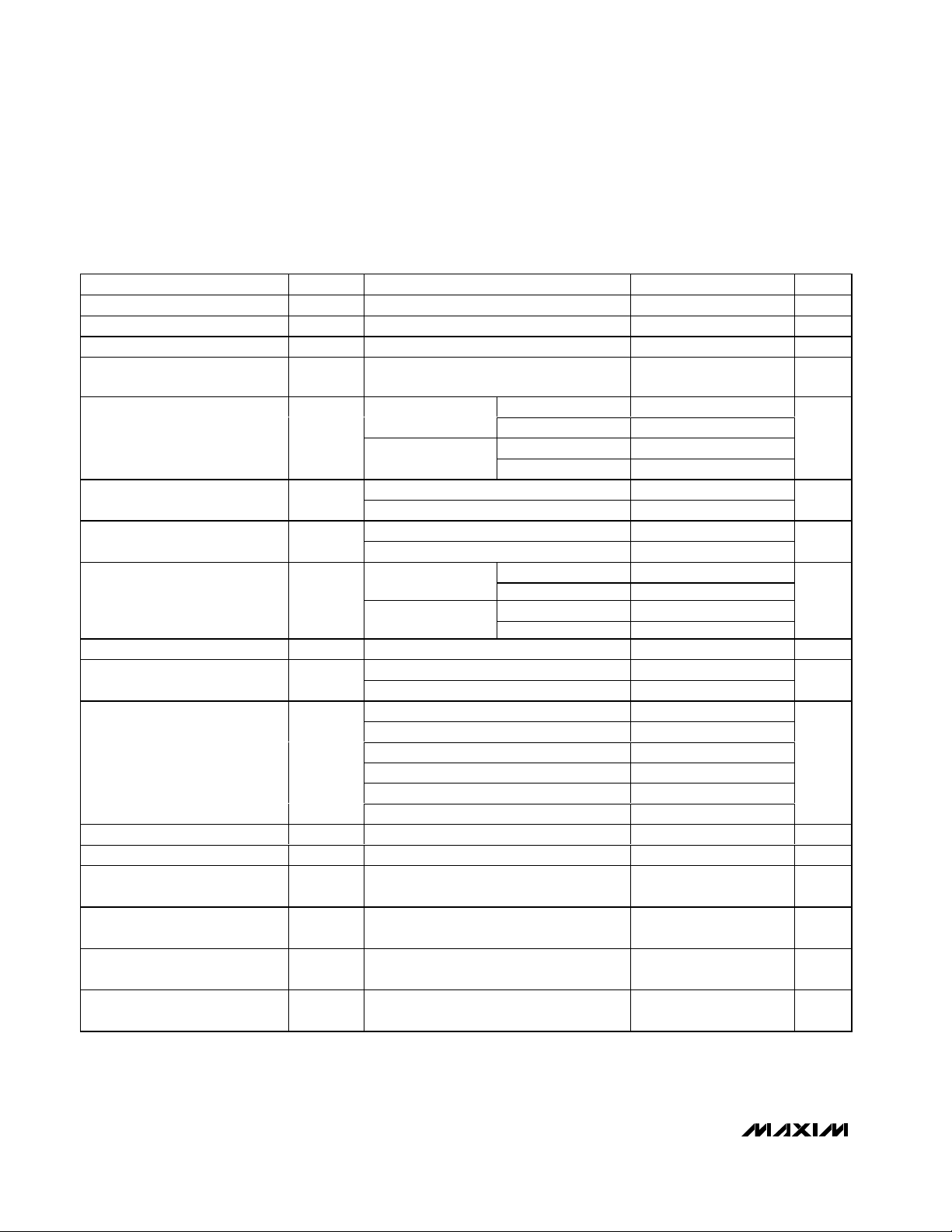

ELECTRICAL CHARACTERISTICS

(VDD= PVDD1 = PVDD2 = SHDN = 5V, 1MHz mode (Note 2). PGND1 = PGND2 = GND, CTLI = MAXV = MAXIP = MAXIN = REF, TA=

-40°C to +85°C, unless otherwise noted.) (Note 7)

PARAMETER

SYMBOL

CONDITIONS

MIN

MAX

UNITS

Input Supply Range V

DD

3.0 5.5 V

Maximum TEC Current

A

Reference Voltage V

REF

V

DD

= 3V to 5.5V, I

REF

= 150µA

V

Reference Load Regulation ∆V

REF

V

DD

= 3V to 5V, I

REF

= 10µA to 1mA 5 mV

V

MAXI_

= V

REF

140 160

V

DD

= 5V

V

MAXI_

= V

REF

/3 40 60

V

MAXI_

= V

REF

143 155

MAXIP/MAXIN Threshold

Accuracy

V

DD

= 3V

V

MAXI_

= V

REF

/3 45 55

mV

V

DD

= 5V, I = 0.2A

NFET On-Resistance

)

V

DD

= 3V, I = 0.2A

Ω

V

DD

= 5V, I = 0.2A

PFET On-Resistance

)

V

DD

= 3V, I = 0.2A

Ω

500kHz mode 14

V

COMP

= V

REF

=

1.500V, V

DD

= 5V

1MHz mode 21

500kHz mode 11

No-Load Supply Current

I

DD(NO

LOAD)

V

COMP

= V

REF

=

1MHz mode 14

mA

Shutdown Supply Current I

DD-SD

SHDN = GND, V

DD

= 5V (Note 4) 3 mA

VDD rising

UVLO Threshold V

UVLO

VDD falling

V

MAX8521, FREQ = VDD, V

DD

= 3V to 5V 0.8 1.2

MAX8521, FREQ = 0, V

DD

= 3V to 5V 0.4 0.6

MAX8520, R

EXT

= 60kΩ, V

DD

= 5V 0.8 1.2

MAX8520, R

EXT

= 60kΩ, V

DD

= 3V

MAX8520, R

EXT

= 150kΩ, V

DD

= 5V 0.4 0.6

Internal Oscillator Switching

Frequency

f

SW-INT

MAX8520, R

EXT

= 150kΩ, V

DD

= 3V

MHz

25% < duty cycle <75% (MAX8521 only) 0.7 1.2

MHz

LX_ Duty Cycle (Note 5) 0 100 %

OS1, OS2, CS Input Current

I

OS1

, I

OS2

,

I

CS

0 or V

DD

µA

SHDN, FREQ Input Current

I

SHDN

,

I

FREQ

0 or VDD, FREQ applicable for the MAX8521

only

-5 +5 µA

SHDN, FREQ Input Low Voltage V

IL

V

DD

= 3V to 5.5V, FREQ applicable for the

MAX8521 only

VDD x

V

V

IH

V

DD

= 3V to 5.5V, FREQ applicable for the

MAX8521 only

VDD x

V

±1.5

1.480 1.515

R

DS(ON-N

External Sync Frequency Range

SHDN, FREQ Input High Voltage

R

DS(ON-P

1.500V, V

DD

= 3.3V

2.50 2.80

2.40 2.70

0.76 1.10

0.36 0.56

-100 +100

0.75

0.14

0.16

0.23

0.30

0.25

Page 5

MAX8520/MAX8521

Smallest TEC Power Drivers for

Optical Modules

_______________________________________________________________________________________ 5

ELECTRICAL CHARACTERISTICS (continued)

(VDD= PVDD1 = PVDD2 = SHDN = 5V, 1MHz mode (Note 2). PGND1 = PGND2 = GND, CTLI = MAXV = MAXIP = MAXIN = REF, TA=

-40°C to +85°C, unless otherwise noted.) (Note 7)

PARAMETER

CONDITIONS

UNITS

V

MAXV

= V

REF

x 0.67, V

OS1

to V

OS2

= ±4V,

V

DD

= 5V

-2 +2 %

MAXV Threshold Accuracy

V

MAXV

= V

REF

x 0.33, V

OS1

to V

OS2

= ±2V,

V

DD

= 3V

-3 +3 %

I

MAXV-

BIAS

,

V

MAXV

= V

MAXI_

= 0.1V or 1.5V

µA

CTLI Gain A

CTLI

V

CTLI

= 0.5V to 2.5V (Note 6) 9.5

V/V

CTLI Input Resistance R

CTLI

1MΩ terminated at REF 0.5 2.0 MΩ

Error-Amp Transconductance g

m

50 160 µS

V

ITEC

Accuracy V

OS1

to VCS = ±100mV, V

OS1

= VDD/2 -10

%

Note 3: Enter 1MHz mode by tying a 60kΩ resistor from FREQ to ground for the MAX8520, and tying FREQ to VDDfor the MAX8521.

Note 4: Includes PFET leakage.

Note 5: Duty-cycle specification is guaranteed by design and not production tested.

Note 6: CTLI Gain is defined as:

Note 7: Specifications to -40°C are guaranteed by design and not production tested.

A

V

VV

CTLI

CTLI

OS CS

=

−

()

∆

∆

1

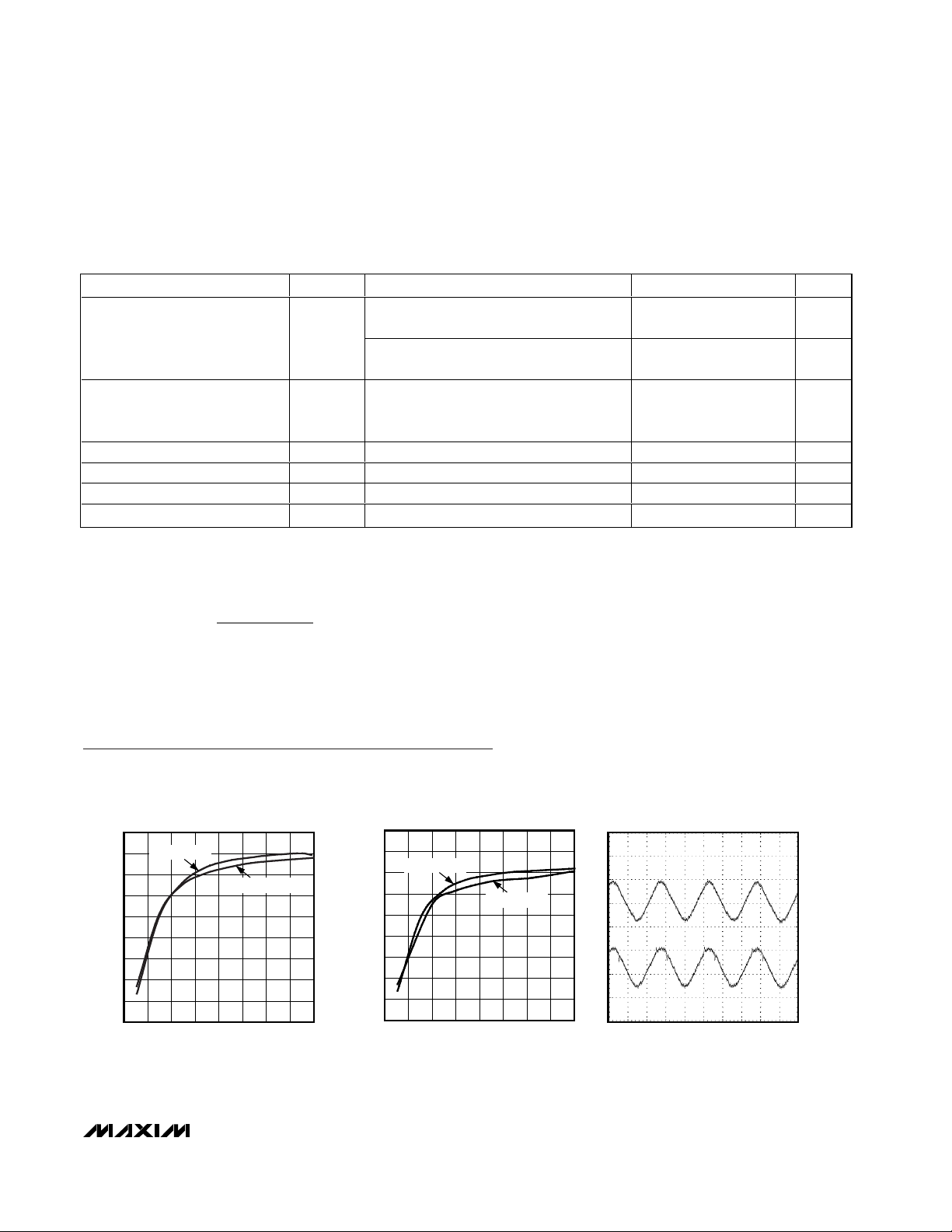

Typical Operating Characteristics

(VDD= 5V, circuit of Figure 1, TA= +25°C, unless otherwise noted)

EFFICIENCY vs. TEC CURRENT

(V

DD

= 5V, R

TEC

= 2Ω)

MAX8520/21 toc01

TEC CURENT (A)

EFFICIENCY (%)

1.41.20.8 1.00.4 0.60.2

10

20

30

40

50

60

70

80

90

0

0 1.6

FREQ = 500kHz

FREQ = 1MHz

EFFICIENCY vs. TEC CURRENT

(V

DD

= 3.3V, R

TEC

= 1.3Ω)

MAX8520/21 toc02

TEC CURRENT (A)

EFFICIENCY (%)

1.41.20.8 1.00.4 0.60.2

10

20

30

40

50

60

70

80

90

0

0 1.6

FREQ = 500kHz

FREQ = 1MHz

COMMON-MODE

OUTPUT VOLTAGE RIPPLE

MAX8520/21 toc03

400ns/div

V

OS2

20mV/div

AC-COUPLED

V

OS1

20mV/div

AC-COUPLED

I

TEC

= 1A

C

2

= C7 = 1µF

MAXV, MAXI_ Input Bias Current

SYMBOL

I

MAXI_-BIAS

MIN MAX

-0.1 +0.1

10.5

+10

Page 6

MAX8520/MAX8521

Smallest TEC Power Drivers for

Optical Modules

6 _______________________________________________________________________________________

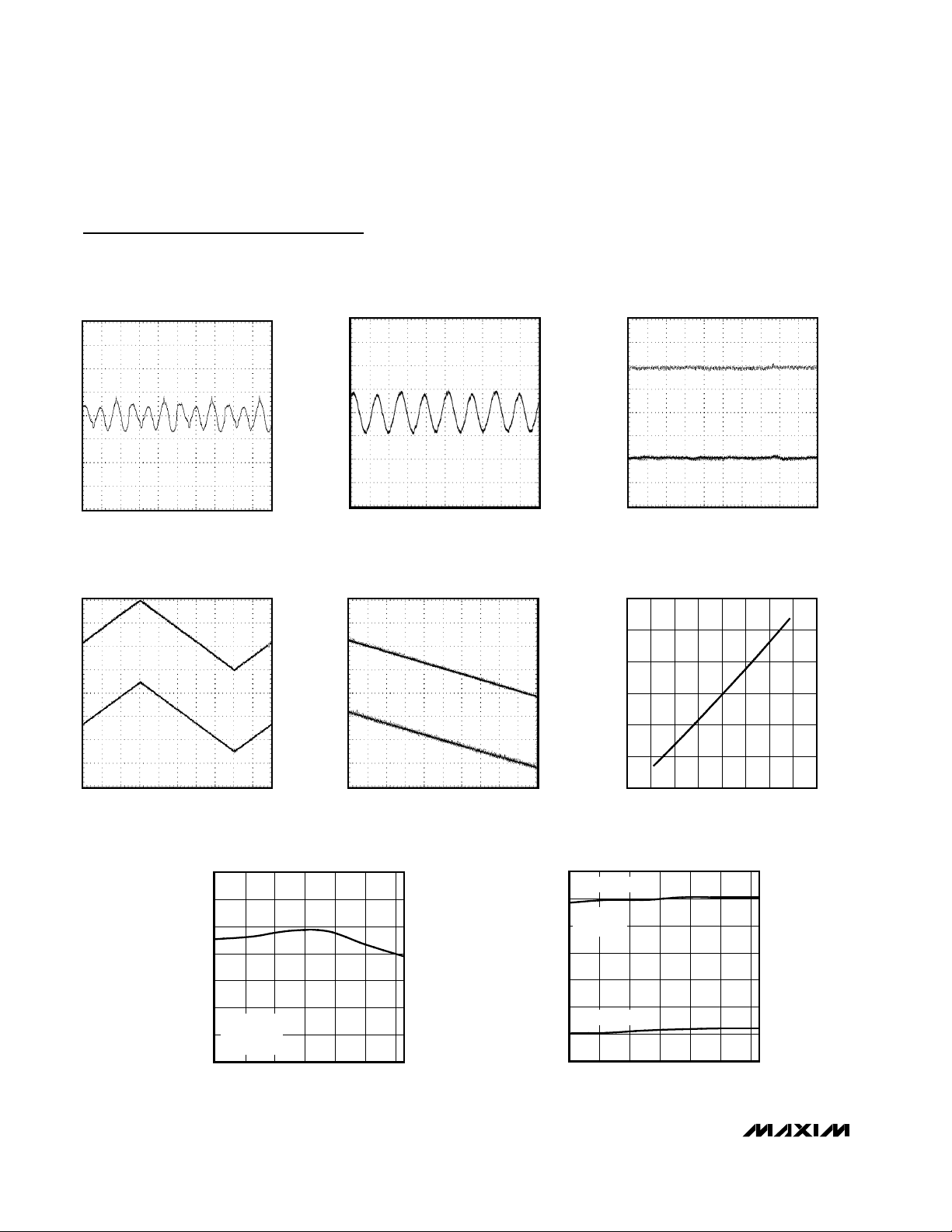

DIFFERENTIAL

OUTPUT VOLTAGE RIPPLE

MAX8520/21 toc04

400ns/div

V

OS2

- V

OS1

1mV/div

AC-COUPLED

C

2

= C7 = 1µF

I

TEC

= 1A

VDD RIPPLE

MAX8520/21 toc05

400ns/div

V

DD

20mV/div

AC-COUPLED

I

TEC

= 1A

TEC CURRENT RIPPLE

MAX8520/21 toc06

400ns/div

10mA/div

AC-COUPLED

0A

1.5A

TEC CURRENT vs. CTLI VOLTAGE

MAX8520/21 toc07

20ms/div

V

CTLI

1V/div

I

TEC

1A/div

0A

0V

ZERO-CROSSING TEC CURRENT

MAX8520/21 toc08

1ms/div

V

CTLI

I00mV/div

I

TEC

100mA/div

0A

1.5V

V

ITEC

vs. TEC CURRENT

MAX8520/21 toc09

TEC CURRENT (A)

V

ITEC

(V)

1.51.00.50-0.5-1.0-1.5

0.5

1.0

1.5

2.0

2.5

3.0

0

-2.0 2.0

Typical Operating Characteristics (continued)

(VDD= 5V, circuit of Figure 1, TA= +25°C, unless otherwise noted)

I

TEC

vs. AMBIENT TEMPERATURE

MAX8520/21 toc10

AMBIENT TEMPERATURE (°C)

TEC CURRENT (A)

6040200-20

0.460

0.470

0.480

0.490

0.500

0.510

0.520

0.450

-40 80

FREQ = 1MHz

V

CTLI

= 2V

R

TEC

= 1Ω

SWITCHING FREQUENCY

vs. TEMPERATURE

MAX8520/21 toc11

TEMPERATURE (°C)

SWITCHING FREQUENCY (kHz)

806040200-20

500

600

700

800

900

1000

1100

400

-40

FREQ = 1MHz

V

CTLI

= 1.5V

R

TEC

= 1Ω

FREQ = 500kHz

Page 7

MAX8520/MAX8521

Smallest TEC Power Drivers for

Optical Modules

_______________________________________________________________________________________ 7

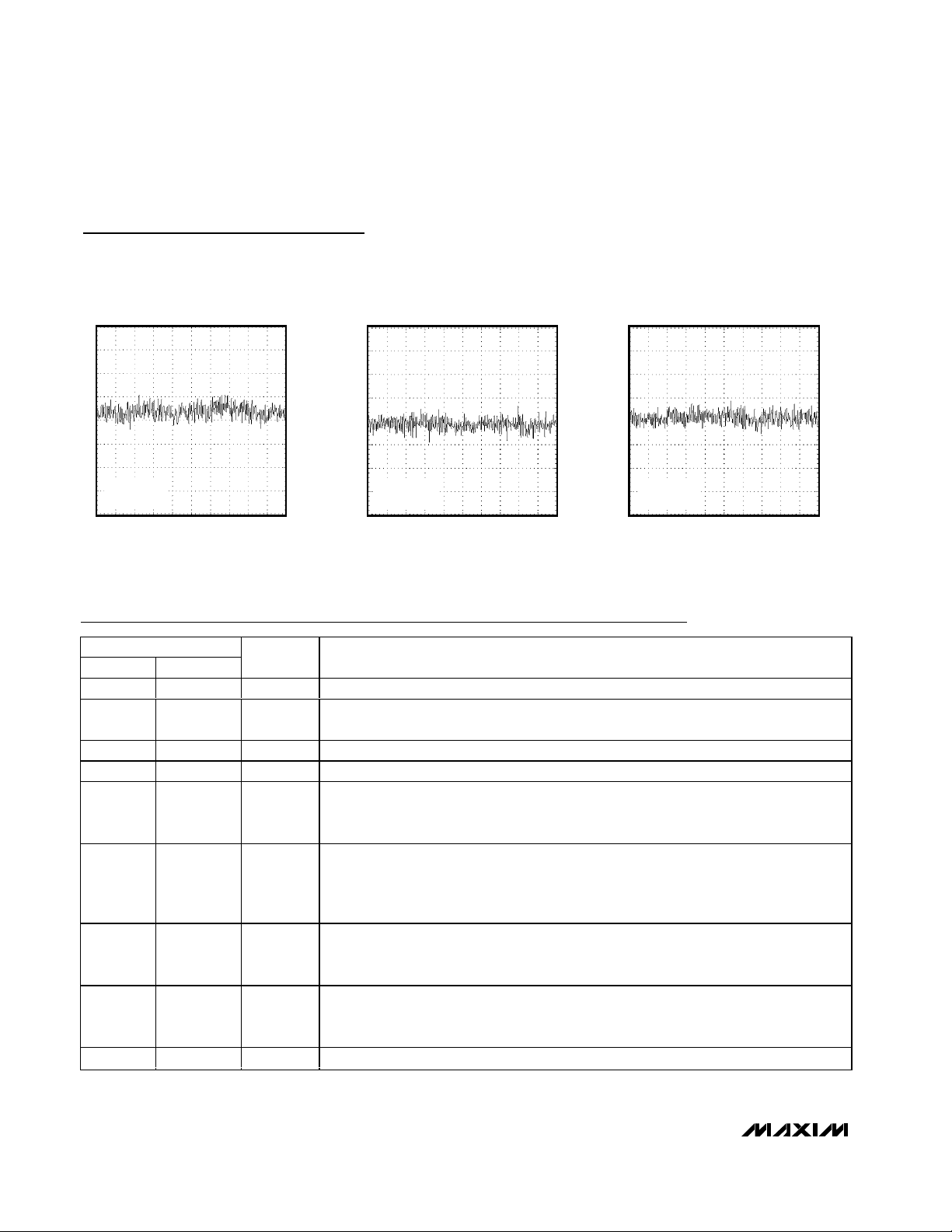

SWITCHING FREQUENCY CHANGE vs. V

DD

MAX8520/21 toc12

VDD (V)

SWITCHING FREQUENCY CHANGE (kHz)

5.04.54.03.5

200

400

600

800

1000

1200

0

3.0 5.5

FREQ = 500kHz

FREQ = 1MHz

SWITCHING FREQUENCY vs. R

EXT

MAX8520/21 toc13

R

EXT

(kΩ)

SWITCHING FREQUENCY (kHz)

14012010080

500

600

700

800

900

1000

1100

400

60 160

VDD = 3.3V

VDD = 5V

VDD STEP RESPONSE

MAX8520/21 toc19

10ms/div

V

DD

2V/div

I

TEC

10mA/div

1A

0V

REFERENCE VOLTAGE CHANGE vs. V

DD

MAX8520/21 toc14

VDD (V)

REFERENCE VOLTAGE CHANGE (mV)

5.04.54.03.5

-1.2

-1.0

-0.8

-0.6

-0.4

-0.2

0.0

0.2

0.4

0.6

-1.4

3.0 5.5

REF SOURCING 150µA

REFERENCE VOLTAGE CHANGE

vs. TEMPERATURE

MAX8520/21 toc15

TEMPERATURE (°C)

REFERENCE VOLTAGE CHANGE (mV)

8040 600 20-20

-4

-3

-2

-1

0

1

2

3

4

5

-5

-40

REF SOURCING 150µA

REFERENCE VOLTAGE CHANGE

vs. LOAD CURRENT

MAX8520/21 toc16

LOAD CURRENT (mA)

REFERENCE VOLTAGE CHANGE (mV)

0.80.60.40.2

-10

-8

-6

-4

-2

0

-12

0 1.0

STARTUP AND SHUTDOWN WAVEFORMS

MAX8520/21 toc17

200µs/div

V

SHDN

5V/div

I

TEC

500mA/div

I

DD

200mA/div

0mA

0mA

0V

CTLI STEP RESPONSE

MAX8520/21 toc18

1ms

V

CTLI

1V/div

I

TEC

1A/div

0A

1.5V

Typical Operating Characteristics (continued)

(VDD= 5V, circuit of Figure 1, TA= +25°C unless otherwise noted)

Page 8

MAX8520/MAX8521

Smallest TEC Power Drivers for

Optical Modules

8 _______________________________________________________________________________________

Typical Operating Characteristics (continued)

(VDD= 5V, circuit of Figure 1, TA= +25°C unless otherwise noted)

THERMAL STABILITY,

COOLING MODE

MAX8520/21 toc20

4s/div

TEMPERATURE

0.001°C/div

T

TEC

= +25°C

T

A

= +45°C

THERMAL STABILITY,

ROOM TEMPERATURE

MAX8520/21 toc21

4s/div

TEMPERATURE

0.001°C/div

T

TEC

= +25°C

T

A

= +25°C

THERMAL STABILITY,

HEATING MODE

MAX8520/21 toc22

4s/div

TEMPERATURE

0.001°C/div

T

TEC

= +25°C

T

A

= +5°C

Pin Description

PIN

QFN UCSP

NAME FUNCTION

1 E1, E2 LX1 Inductor Connection. LX1 is high-impedance in shutdown.

2

PGND1

Power Ground 1. Internal synchronous-rectifier ground connection. Connect all PGND

pins together at power ground plane.

3C1SHDN Shutdown Control Input. Pull SHDN low to turn off PWM control and ITEC output.

4 C2 COMP Current-Control Loop Compensation. Refer to the Compensation Capacitor section.

5 B1 ITEC

TEC Current-Monitor Output. The ITEC output voltage is a function of the voltage across

the TEC current-sense resistor. V

ITEC

= V

REF

+ 8 (V

OS

- VCS). Keep capacitance on ITEC

<150pF.

6 A1 MAXIN

Maximum Negative TEC Current. Connect MAXIN to REF to set default negative current

limit to -150mV/R

SENSE

. To lower this current limit, connect MAXIN to a resistor divider

network from REF to GND. The current limit will then be equal to -(V

MAXIN/VREF

) x

(150mV/R

SENSE

).

7 A2 MAXIP

Maximum Positive TEC Current. Connect MAXIP to REF to set default positive current limit

to 150mV/R

SENSE

. To lower this current limit, connect MAXIP to a resistor divider network

from REF to GND. The current limit will then be equal to (V

MAXIP/VREF

) x (150mV/R

SENSE

).

8 A3 MAXV

Maximum Bipolar TEC Voltage. Connect MAXV to REF to set default maximum TEC

voltage to VDD. To lower this limit, connect MAXV to a resistor-divider network from REF to

GND. The maximum TEC voltage is equal to 4 x V

MAXV

or VDD, whichever is lower.

9 A4 REF 1.50V Reference Output. Bypass REF to GND with a 0. 1µF ceramic capacitor.

D1, D2, D3

Page 9

MAX8520/MAX8521

Smallest TEC Power Drivers for

Optical Modules

_______________________________________________________________________________________ 9

PIN

QFN UCSP

NAME FUNCTION

10 A5 CTLI

TEC Current-Control Input. Sets TEC current. Center point is 1.50V (no TEC current). The

current is given by:

I

TEC

= (V

OS1

- VCS) / R

SENSE

= (V

CTLI

- 1.50) / (10 x R

SENSE

). When (V

CTLI

- V

REF

) > 0,

then V

OS2

> V

OS1

> VCS.

11 A6 GND Analog Ground. Start connect to PGND at underside exposed pad for QFN package.

12 B6 V

DD

Analog Supply Voltage Input. Bypass VDD to GND with a 1µF ceramic capacitor.

For MAX8520: Analog FREQ Set Pin (see the Switching Frequency section).

13 C5 FREQ

For MAX8521: Digital FREQ Selection Pin. Tie to V

DD

for 1MHz operation, tie to GND for

500kHz operation. The PWM oscillator can synchronize to FREQ by switching at FREQ

between 700kHz and 1.2MHz.

14

PGND2

Power Ground 2. Internal synchronous rectifier ground connection. Connect all PGND

pins together at the power ground plane.

15 E5, E6 LX2 Inductor Connection. LX2 is high impedance in shutdown.

16 F5, F6 PVDD2 Power Input 2. Connect all PVDD inputs together at the VDD power plane.

17 F4 CS

Current-Sense Input. The current through the TEC is monitored between CS and OS1. The

maximum TEC current is given by 150mV/R

SENSE

and is bipolar.

18 C6 OS2

Output Sense 2. OS2 senses one side of the differential TEC voltage. OS2 is a sense

point, not a power output. OS2 discharges to ground in shutdown.

19 F3 OS1

Output Sense 1. OS1 senses one side of the differential TEC voltage. OS1 is a sense

point, not a power output. OS1 discharges to ground in shutdown.

20 F1, F2 PVDD1 Power Input 1. Connect all PVDD inputs together at the VDD power plane.

B2, B5,

C3, C4

GND2

Ground. Additional ground pads aid in heat dissipation. Short to either GND or PGND

plane.

B3, B4

E3, E4

N.C. No Connect. Connect no-connect pads to GND2 to aid in heat dissipation.

Pin Description (continued)

D4, D5, D6

Page 10

MAX8520/MAX8521

Smallest TEC Power Drivers for

Optical Modules

10 ______________________________________________________________________________________

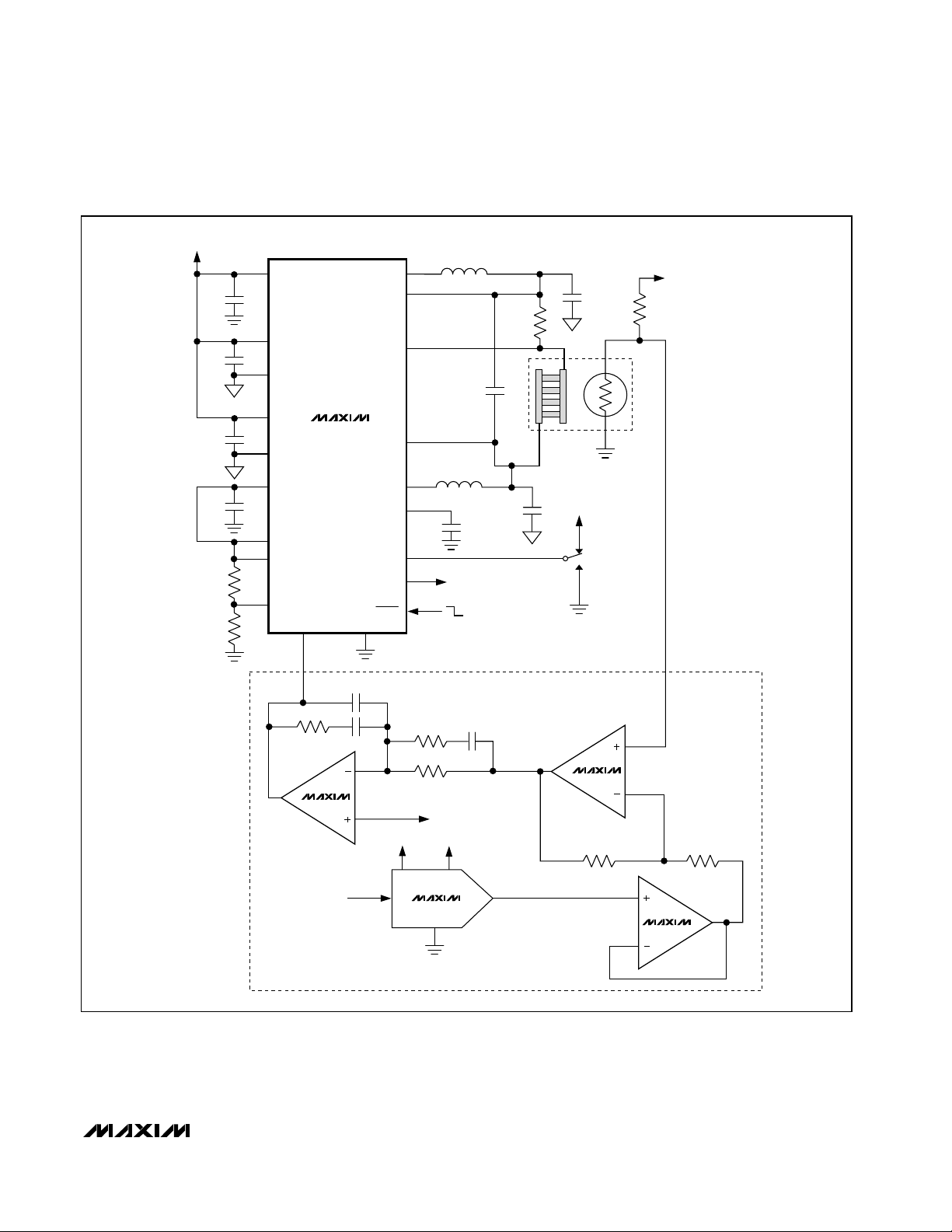

Detailed Description

The MAX8520/MAX8521 TEC drivers consist of two

switching buck regulators that operate together to directly

control the TEC current. This configuration creates a

differential voltage across the TEC, allowing bidirectional

TEC current for controlled cooling and heating. Controlled

cooling and heating allow accurate TEC temperature control to within ±0.01°C. The voltage at CTLI directly sets

the TEC current. An external thermal- control loop is typically used to drive CTLI. Figures 1 and 2 show examples

of the thermal control-loop circuit.

Ripple Cancellation

Switching regulators like those used in the MAX8520/

MAX8521 inherently create ripple voltage on the output.

The dual regulators in the MAX8520/MAX8521 switch in

phase and provide complementary in-phase duty

cycles so ripple waveforms at the TEC are greatly

reduced. This feature suppresses ripple currents and

electrical noise at the TEC to prevent interference with

the laser diode.

Switching Frequency

For the MAX8521, FREQ sets the switching frequency of

the internal oscillator. With FREQ = GND, the oscillator

frequency is set to 500kHz. The oscillator frequency is

1MHz when FREQ = VDD.

For the MAX8520, connect a resistor (R

EXT

in Figure 2)

from FREQ to GND. Choose R

EXT

= 60kΩ for 1MHz

operation, and R

EXT

= 150kΩ for 500kHz operation. For

any intermediary frequency between 500kHz and

1MHz, use the following equation to find the value of

R

EXT

value needed for VDD= 5V:

where R

EXT

is the resistance given in kΩ, and fs is the

desired frequency given in MHz. Note that for VDD<

5V, the frequency is reduced slightly, to the extent of

about 7% when VDDreaches 3V. This should be taken

into consideration when selecting the value for R

EXT

at

a known supply voltage.

Voltage and Current-Limit Setting

Both the MAX8520 and MAX8521 provide control of the

maximum differential TEC voltage. Applying a voltage

to MAXV limits the maximum voltage across the TEC.

The voltage at MAXIP and MAXIN sets the maximum

positive and negative current through the TEC. These

current limits can be independently controlled.

Current Monitor Output

ITEC provides a voltage output proportional to the TEC

current (I

TEC

). See the Functional Diagram for more

details:

V

ITEC

= 1.5V +(8 ✕ (VOS1-VCS))

Reference Output

The MAX8520/MAX8521 include an on-chip voltage reference. The 1.50V reference is accurate to 1% over

temperature. Bypass REF with 0.1µF to GND. REF can

be used to bias an external thermistor for temperature

sensing as shown in Figures 1 and 2.

Thermal and Fault-Current Protection

The MAX8520/MAX8521 provide fault-current protection

in either FET by turning off both high-side and low-side

FETs when the peak current exceeds 3A in either FET. In

addition, thermal-overload protection limits the total

power dissipation in the chip. When the device’s die junction temperature exceeds +165°C, an on-chip thermal

sensor shuts down the device. The thermal sensor turns

the device on again after the junction temperature cools

down by 15°C.

Design Procedures

Duty-Cycle Range Selection

By design, the MAX8520/MAX8521 are capable of operating from 0% to 100% duty cycle, allowing both LX outputs to enter dropout. However, as the LX pulse width

narrows, accurate duty-cycle control becomes difficult.

This can result in a low-frequency noise appearing at the

TEC output (typically in the 20kHz to 50kHz range). While

this noise is typically filtered out by the low thermal-loop

bandwidth, for best results, operate the PWM with a pulse

width greater than 200ns. For a 500kHz application, the

recommended duty-cycle range is from 10% to 90%. For

a 1MHz application, it is from 20% to 80%.

R

fs

EXT

=× −

90

11

3

TEC CONNECTION THERMISTOR

Heating mode PTC

Cooling mode NTC

Table 1. TEC Connection for Figure 1

TEC CONNECTION THERMISTOR

Heating mode NTC

Cooling mode PTC

Table 2. TEC Connection for Figure 2

Page 11

MAX8520/MAX8521

Smallest TEC Power Drivers for

Optical Modules

______________________________________________________________________________________ 11

V

DD

R

SENSE

0.09Ω

C2

1µF

C5

10µF

L2

4.7µF

R2

REF

R

THER

LX1

V

DD

L1

4.7µF

CS

OS1

OS2

PV

DD

1

C1

1µF

C3

1µF

C4

1µF

C6

0.1µF

49.9kΩ

100kΩ

PGND1

PGND2

REF

MAXIP

MAXIN

MAXV

PV

DD

2

MAX8521

LX2

COMP

FREQ

ITEC

ON

OFF

SHDN

CTLI GND

0.022µF

10µF

243kΩ

10kΩ

1µF

510kΩ

100kΩ

10kΩ

TO

U3B

OUTPUT

DAC

INPUTS

V

DD

V

DD

REF

C7

1µF

C8

0.1µF

MAX4477

MAX4477

MAX4475

MAX5144

U1

U2

U4

U3A

U3B

Figure 1. MAX8521 Typical Application Circuit

Page 12

MAX8520/MAX8521

Smallest TEC Power Drivers for

Optical Modules

12 ______________________________________________________________________________________

V

DD

R

SENSE

0.09Ω

C2

1µF

C5

10µF

L2

4.7µF

R2

REF

LX1

V

DD

L1

4.7µF

CS

OS1

OS2

PV

DD

1

C1

1µF

C3

1µF

C4

1µF

C6

0.1µF

49.9kΩ

100kΩ

PGND1

PGND2

REF

MAXIP

MAXIN

MAXV

PV

DD

2

MAX8520

LX2

COMP

FREQ

ITEC

ON

OFF

SHDN

CTLI GND

0.022µF

10µF

243kΩ

1kΩ

10µF

50kΩ

0.01µF

REF

DAC

INPUTS

V

DD

C7

1µF

C8

0.1µF

R

EXT

60kΩ

R

THER

MAX5144

U1

MAX4238

U2

U4

Figure 2. Typical Application Circuit for the MAX8520 with Reduced Op-Amp Count Configuration

Page 13

MAX8520/MAX8521

Smallest TEC Power Drivers for

Optical Modules

______________________________________________________________________________________ 13

Inductor Selection

The MAX8520/MAX8521 dual buck converters operate

in phase and in complementary mode to drive the TEC

differentially in a current-mode control scheme. At zero

TEC current, the differential voltage is zero; hence, the

outputs with respect to GND are equal to half of VDD.

As the TEC current demand increases, one output goes

up and the other goes down from the initial point of

0.5VDDby an amount equal to 0.5 ✕ V

TEC(VTEC

= I

TEC

✕ R

TEC

). Therefore, the operating duty cycle of each

buck converter depends on the operating I

TEC

and

R

TEC

. Since inductor current calculations for heating

and cooling are identical, but reverse in polarity, the

calculations only need to be carried out for either one.

For a given inductor and input voltage, the maximum

inductor ripple current happens when the duty cycle is

at 50%. Therefore, the inductor should be calculated at

50% duty cycle to find the maximum ripple current. The

maximum desired ripple current of a typical standard

buck converter is in the range of 20% to 40% of the

maximum load. The higher the value of the inductor, the

lower the ripple current. However, the size is physically

larger. For the TEC driver, the thermal loop is inherently

slow, so the inductor can be larger for lower ripple

current for better noise and EMI performance. Picking

an inductor to yield ripple current of 10% to 20% of the

maximum TEC current is a good starting point.

Calculate the inductor value as follows:

where LIR is the selected inductor ripple-current ratio,

I

TEC(MAX)

is the maximum TEC current, and fs is the

switching frequency.

As an example, for VDD= 3.3V, LIR = 12%, and fs =

1MHz, L = 4.58µH.

Even though each inductor ripple current is at its maximum at 50% duty cycle (zero TEC current), the ripple

cancels differentially because each is equal and in

phase.

Output Filter Capacitor

Selection

Common-Mode Filter Capacitors

The common-mode filter capacitors (C2 and C7 of Figure

1) are used as filter capacitors to ground for each output.

The output ripple voltage depends on the capacitance,

the ESR of these capacitors, and the inductor ripple

current. Ceramic capacitors are recommended for their

low ESR and impedance at high frequency.

L

V

LIR I fs

DD

TEC MAX

=

×

()

××

025.

()

CTLI

R

SENSE

CS

REF

OS1

C

COMP

R

R

0.5X

REF

1.2X

COMP

PWM

4X

LX2

3/4 V

DD

1/4 V

DD

LX1

-1.2

+1.2

10X

1

gm

Figure 3. Functional Diagram of the Current-Control Loop

Page 14

MAX8520/MAX8521

The output common-mode ripple voltage can be calculated as follows:

V

RIPPLE(P-P)

= LIR x I

TEC(MAX)

(ESR + 1/8 x C x fs)

A 1µF ceramic capacitor with ESR of 10mΩ with LIR =

12% and I

TEC(MAX)

= 1.5A results in V

RIPPLE(P-P)

of

24.3mV. For size-constraint applications, the capacitor

can be made smaller at the expense of higher ripple

voltage. However, the capacitance must be high

enough so that the LC resonant frequency is less than

1/5 the switching frequency:

where f is the resonant frequency of the output filter.

Differential Mode Filter Capacitor

The differential-mode filter capacitor (C5 in Figure 1) is

used to bypass differential ripple current through the

TEC as the result of unequal duty cycle of each output.

This happens when the TEC current is not at zero. As

TEC current increases from zero, both outputs move

away from the 50% duty-cycle point complementarily.

The common-mode ripple decreases, but the differential

ripple does not cancel perfectly, and there is a resulting

differential ripple. The maximum value happens when

one output is at 75% duty cycle and the other is at 25%

duty cycle. At this operating point, the differential ripple

is equal to 1/2 of the maximum common-mode ripple.

The TEC ripple current determines the TEC performance, because the maximum temperature differential

that can be created between the terminals of the TEC

depends on the ratio of ripple current and DC current.

The lower the ripple current, the closer to the ideal

maximum. The differential-mode capacitor provides a

low-impedance path for the ripple current to flow, so that

the TEC ripple current is greatly reduced. The TEC ripple

current can then be calculated as follows:

I

TEC(RIPPLE)

= (0.5 x LIR x I

TEC(MAX)

) x (ZC5)/(R

TEC

+ R

SENSE

+ ZC5)

where ZC5is the impedance of C5 at twice the switching

frequency, R

TEC

is the TEC equivalent resistance, and

R

SENSE

is the current-sense resistor.

Decoupling Capacitor Selection

Decouple each power-supply input (VDD, PVDD1,

PVDD2) with a 1µF ceramic capacitor close to the supply

pins. In applications with long distances between the

source supply and the MAX8520/MAX8521, additional

bypassing may be needed to stabilize the input supply.

In such cases, a low-ESR electrolytic or ceramic capacitor of 100µF or more at V

DD

is sufficient.

Compensation Capacitor

A compensation capacitor is needed to ensure currentcontrol-loop stability (see Figure 3). Select the capacitor

so that the unity-gain bandwidth of the current-control

loop is less than or equal to 10% the resonant frequency

of the output filter:

where:

fBW= unity-gain bandwidth frequency, less than or

equal to 10% the output filter resonant frequency

g

m

= loop transconductance, typically 100µA/V

C

COMP

= value of the compensation capacitor

R

TEC

= TEC series resistance; use the minimum resis-

tance value

R

SENSE

= sense resistor

Setting Voltage and Current Limits

Certain TEC parameters must be considered to guarantee

a robust design. These include maximum positive current,

maximum negative current, and the maximum voltage

allowed across the TEC. These limits should be used to

set the MAXIP, MAXIN, and MAXV voltages.

Setting Max Positive and Negative TEC Current

MAXIP and MAXIN set the maximum positive and negative TEC currents, respectively. The default current limit

is ±150mV/R

SENSE

when MAXIP and MAXIN are connected to REF. To set maximum limits other than the

defaults, connect a resistor-divider from REF to GND to

set V

MAXI_

. Use resistors in the 10kΩ to 100kΩ range.

V

MAXI_

is related to ITEC by the following equations:

V

MAXIP

= 10(I

TECP(MAX)

✕ R

SENSE

)

V

MAXIN

= 10(I

TECN(MAX)

✕ R

SENSE

)

where I

TECP(MAX)

is the maximum positive TEC current

and I

TECN(MAX)

is the negative maximum TEC current.

Positive TEC current occurs when CS is less than OS1:

I

TEC

x R

SENSE

= OS1 - CS

when I

TEC

> 0.

I

TEC

✕ R

SENSE

= CS - OS1

when I

TEC

< 0.

C

g

f

R

RR

COMP

m

BW

SENSE

SENSE TEC

≥

×

×

×

24

2π()

fLC=

1

2π

Smallest TEC Power Drivers for

Optical Modules

14 ______________________________________________________________________________________

Page 15

Take care not to exceed the positive or negative current limit on the TEC. Refer to the manufacturer’s data

sheet for these limits.

Setting Max TEC Voltage

Apply a voltage to the MAXV pin to control the maximum

differential TEC voltage. MAXV can vary from 0 to REF.

The voltage across the TEC is four times V

MAXV

and

can be positive or negative:

|V

OS1

- V

OS2

| = 4 x V

MAXV

or VDD, whichever is lower

Set V

MAXV

with a resistor-divider between REF and

GND using resistors from 10kΩ to 100kΩ. V

MAXV

can

vary from 0 to REF.

Control Inputs/Outputs

Output Current Control

The voltage at CTLI directly sets the TEC current. CTLI

is typically driven from the output of a temperature control loop. The transfer function relating current through

the TEC (I

TEC

) and V

CTLI

is given by:

I

TEC

= (V

CTLI

- V

REF

) / (10 ✕ R

SENSE

)

where V

REF

is 1.50V and:

ITEC = (V

OS1

- VCS) / R

SENSE

CTLI is centered around REF (1.50V). I

TEC

is zero when

CTLI = 1.50V. When V

CTLI

> 1.50V, the current flow is

from OS2 to OS1. The voltages on the pins relate as

follows:

V

OS2

> V

OS1

> V

CS

The opposite applies when V

CTLI

< 1.50V current flows

from OS1 to OS2:

V

OS2

< V

OS1

< V

CS

Shutdown Control

The MAX8520/MAX8521 can be placed in a power-saving

shutdown mode by driving SHDN low. When the

MAX8520/MAX8521 are shut down, the TEC is off (OS1

and OS2 decay to GND) and supply current is reduced to

2mA (typ).

ITEC Output

ITEC is a status output that provides a voltage proportional

to the actual TEC current. V

ITEC

= REF when TEC current

is zero. The transfer function for the ITEC output is:

V

ITEC

= 1.50 + 8 ✕ (V

OS1

– VCS)

Use ITEC to monitor the cooling or heating current

through the TEC. For stability, keep the load capacitance on ITEC to less than 150pF.

Applications Information

The MAX8520/MAX8521 typically drive a TEC inside a

thermal-control loop. TEC drive polarity and power are

regulated based on temperature information read from a

thermistor or other temperature-measuring device to

maintain a stable control temperature. Temperature stability of ±0.01°C can be achieved with carefully selected

external components.

There are numerous ways to implement the thermal loop.

Figures 1 and 2 show designs that employ precision op

amps, along with a DAC or potentiometer to set the control temperature. The loop may also be implemented digitally, using a precision A/D to read the thermistor or

other temperature sensor, a microcontroller to implement

the control algorithm, and a DAC (or filtered-PWM signal)

to send the appropriate signal to the MAX8520/MAX8521

CTLI input. Regardless of the form taken by the thermalcontrol circuitry, all designs are similar in that they read

temperature, compare it to a set-point signal, and then

send an error-correcting signal to the MAX8520/

MAX8521 that moves the temperature in the appropriate

direction.

PC Board Layout and Routing

High switching frequencies and large peak currents

make PC board layout a very important part of design.

Good design minimizes excessive EMI and voltage

gradients in the ground plane, both of which can result

in instability or regulation errors. Follow these guidelines for good PC board layout:

1) Place decoupling capacitors as close to the IC pins

as possible.

2) Keep a separate power ground plane, which is connected to PGND1 and PGND2. PVDD1, PVDD2,

PGND1, and PGND2 are noisy points. Connect

decoupling capacitors from PV

DD

s to PGNDs as

directly as possible. Output capacitors C2 and C7

returns are connected to PGND plane.

3) Connect a decoupling capacitor from V

DD

to GND.

Connect GND to a signal ground plane (separate

from the power ground plane above). Other V

DD

decoupling capacitors (such as the input capacitor)

need to be connected to the PGND plane.

4) Connect GND and PGND_ pins together at a single

point, as close as possible to the chip.

5) Keep the power loop, which consists of input

capacitors, output inductors, and capacitors, as

compact and small as possible.

MAX8520/MAX8521

Smallest TEC Power Drivers for

Optical Modules

______________________________________________________________________________________ 15

Page 16

MAX8520/MAX8521

6) To ensure high DC loop gain and minimum loop

error, keep the board layout adjacent to the negative

input pin of the integrator (U2 in Figure1) clean and

free of moisture. Any contamination or leakage

current into this node can act to lower the DC gain of

the integrator, which can degrade the accuracy of

the thermal loop. If space is available, it can also be

helpful to surround the negative input node of the

integrator with a grounded guard ring.

Refer to the MAX8520/MAX8521 evaluation kit for a PC

board layout example.

Chip Information

TRANSISTOR COUNT: 3007

PROCESS: BiCMOS

Smallest TEC Power Drivers for

Optical Modules

16 ______________________________________________________________________________________

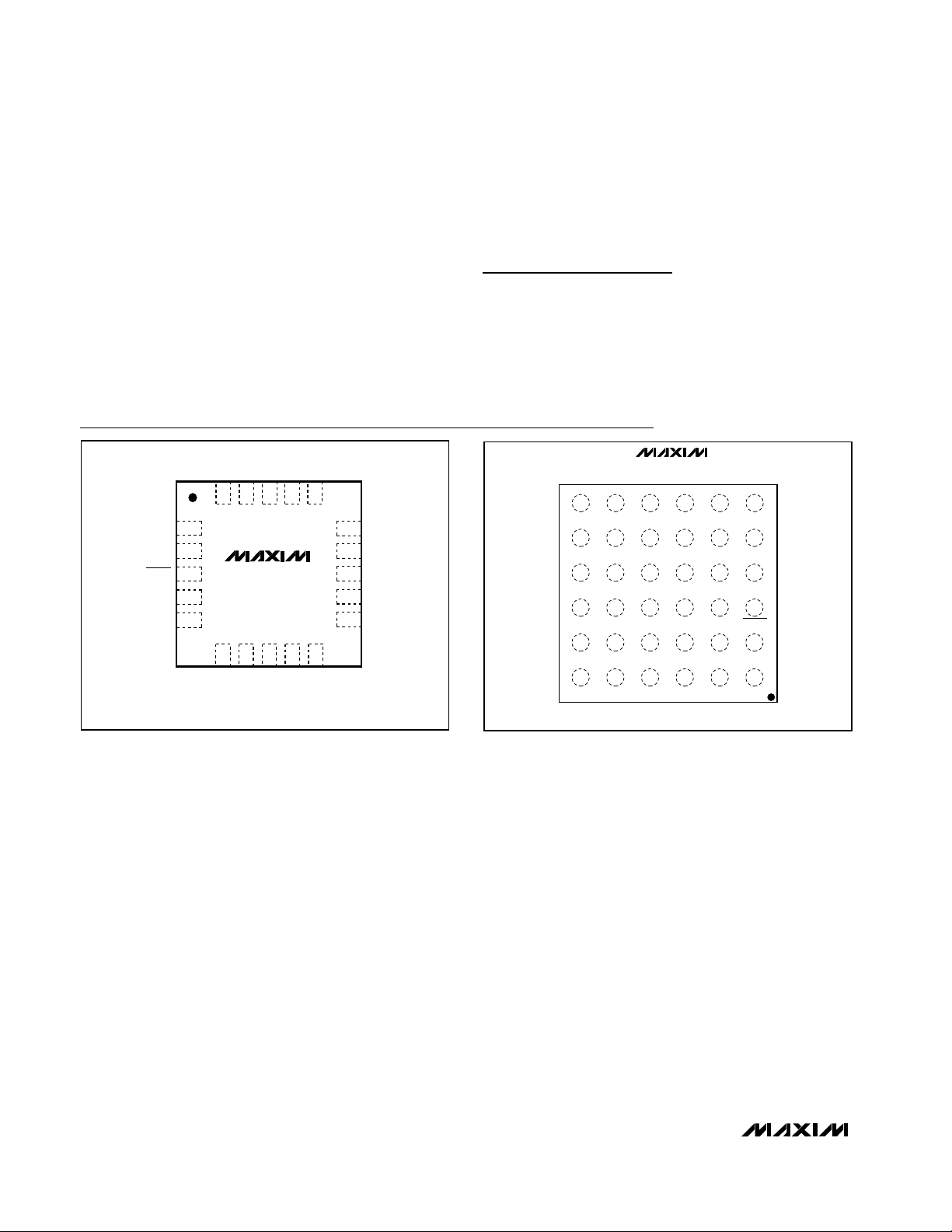

20

19

18

17

PV

DD

1

OS1

OS2

CS

16 PV

DD

2

13

12

11

14

15

V

DD

FREQ

PGND2

LX2

GND

4

3

2

1

COMP

SHDN

PGND1

LX1

5ITEC

6

7

8

9

MAXIN

MAXIP

MAXV

REF

10CTLI

MAX8520/

MAX8521

TOP VIEW

THIN QFN

Pin Configurations

MAX8521

F5 F4 F3 F2 F1

F6

2

PV

E6 E5 E4 E3 E2 E1

LX2 LX2 N.C. N.C. LX1 LX1

D6 D5 D4 D3 D2 D1

PGND2 PGND2 PGND2 PGND1 PGND1 PGND1

C6 C5 C4 C3 C2 C1

OS2 FREQ GND2 GND2 COMP

B6 B5 B4 B3 B2 B1

VDD GND2 N.C. N.C. GND2 ITEC

A6 A5 A4 A3 A2 A1

GND CTLI REF MAXV MAXIP MAXIN

2 CS OS1 PVDD1PVDD1

PV

DD

DD

SHDN

UCSP

Page 17

MAX8520/MAX8521

Smallest TEC Power Drivers for

Optical Modules

______________________________________________________________________________________ 17

GND

FREQ

(MAX8520)

COMP

CTLI

ITEC

MAXIP

FREQ (MAX8521)

PWM CONTROL

AND

GATE CONTROL

MAXIN

R

SENSE

PGND1

PGND2

MAXV

REF

SHDN

REF

OS1

OS2

CS

LX1

LX2

ON

OFF

3V TO

5.5V

OS1

REF

CS

MAX V

TEC

=

V

MAXV

× 4

OR V

DD

MAX I

TEC

=

(V

MAXIP/VREF

) ×

(0.15V/R

SENSE

)

MAX I

TEC

=

(V

MAXIN/VREF

) ×

(0.15V/R

SENSE

)

PV

DD

1

PV

DD

2

V

DD

V

DD

MAX8520/

MAX8521

Functional Diagram

Page 18

MAX8520/MAX8521

Smallest TEC Power Drivers for

Optical Modules

18 ______________________________________________________________________________________

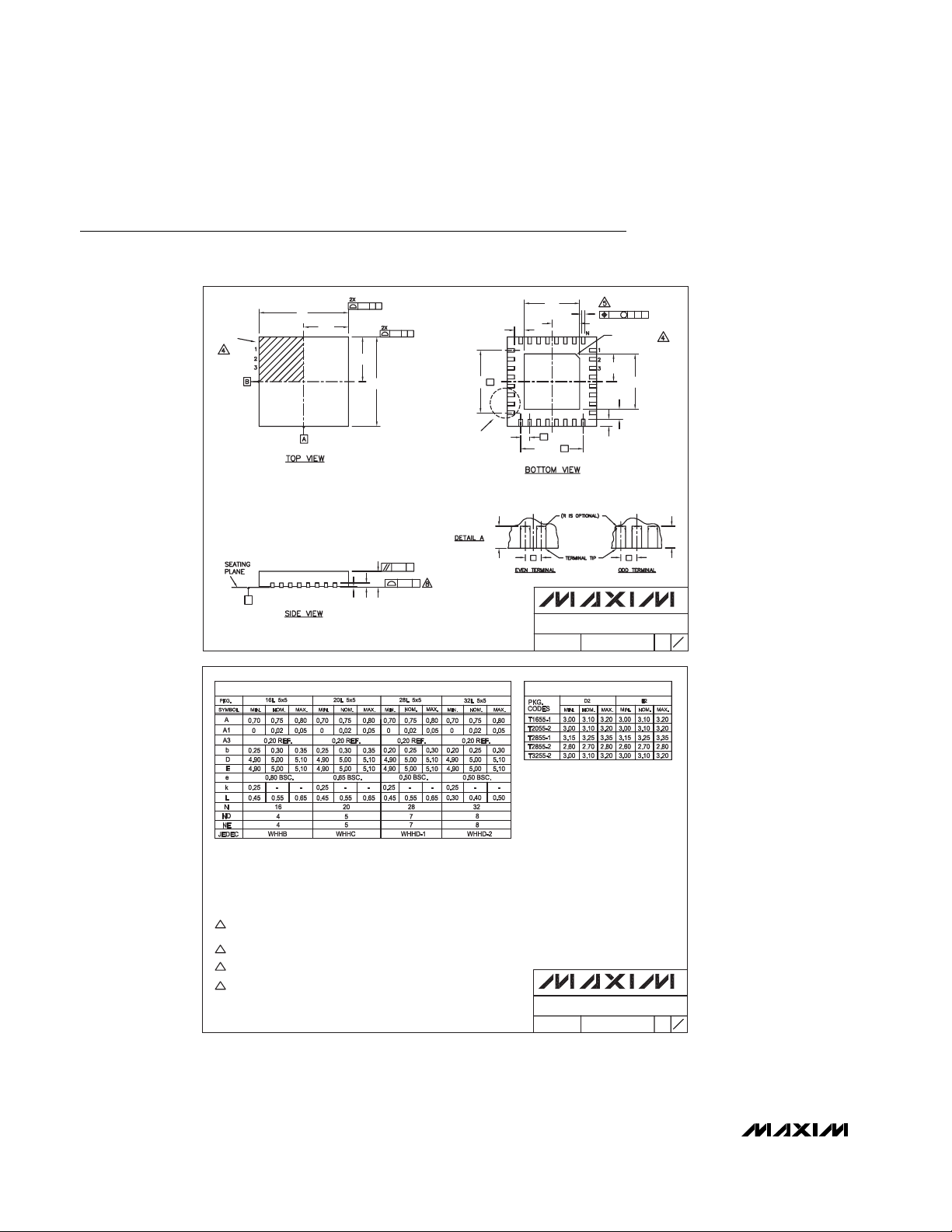

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages.)

QFN THIN.EPS

D2

(ND-1) X e

e

D

C

PIN # 1

I.D.

(NE-1) X e

E/2

E

0.08 C

0.10

C

A

A1

A3

DETAIL A

0.15

C B

0.15 C A

DOCUMENT CONTROL NO.

21-0140

PACKAGE OUTLINE

16, 20, 28, 32L, QFN THIN, 5x5x0.8 mm

PROPRIETARY INFORMATION

APPROVAL

TITLE:

C

REV.

2

1

E2/2

E2

0.10 M

C A B

PIN # 1 I.D.

b

0.35x45

L

D/2

D2/2

L

C

L

C

e e

L

CC

L

k

k

L

L

2

2

21-0140

REV.DOCUMENT CONTROL NO.APPROVAL

PROPRIETARY INFORMATION

TITLE:

COMMON DIMENSIONS

EXPOSED PAD VARIATIONS

1. DIMENSIONING & TOLERANCING CONFORM TO ASME Y14.5M-1994.

2. ALL DIMENSIONS ARE IN MILLIMETERS. ANGLES ARE IN DEGREES.

3. N IS THE TOTAL NUMBER OF TERMINALS.

4. THE TERMINAL #1 IDENTIFIER AND TERMINAL NUMBERING CONVENTION SHALL CONFORM TO JESD 95-1

SPP-012. DETAILS OF TERMINAL #1 IDENTIFIER ARE OPTIONAL, BUT MUST BE LOCATED WITHIN THE

ZONE INDICATED. THE TERMINAL #1 IDENTIFIER MAY BE EITHER A MOLD OR MARKED FEATURE.

5. DIMENSION b APPLIES TO METALLIZED TERMINAL AND IS MEASURED BETWEEN 0.25 mm AND 0.30 mm

FROM TERMINAL TIP.

6. ND AND NE REFER TO THE NUMBER OF TERMINALS ON EACH D AND E SIDE RESPECTIVELY.

7. DEPOPULATION IS POSSIBLE IN A SYMMETRICAL FASHION.

8. COPLANARITY APPLIES TO THE EXPOSED HEAT SINK SLUG AS WELL AS THE TERMINALS.

9. DRAWING CONFORMS TO JEDEC MO220.

NOTES:

10. WARPAGE SHALL NOT EXCEED 0.10 mm.

C

PACKAGE OUTLINE

16, 20, 28, 32L, QFN THIN, 5x5x0.8 mm

Page 19

MAX8520/MAX8521

Smallest TEC Power Drivers for

Optical Modules

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________ 19

© 2002 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages.)

36L,UCSP.EPS

Loading...

Loading...