19-1121; Rev 0; 9/96

EVALUATION KIT

AVAILABLE

Cost-Saving Multichemistry

Battery-Charger System

_______________General Description

The MAX846A is a cost-saving multichemistry batterycharger system that comes in a space-saving 16-pin

QSOP. This integrated system allows different battery

chemistries (Li-Ion, NiMH or NiCd cells) to be charged

using one circuit.

In its simplest application, the MAX846A is a standalone, current-limited float voltage source that charges

Li-Ion cells. It can also be paired up with a low-cost

microcontroller (µC) to build a universal charger capable of charging Li-Ion, NiMH, and NiCd cells.

An internal 0.5%-accurate reference allows safe charging of Li-Ion cells that require tight voltage accuracy.

The voltage- and current-regulation loops used to control a low-cost external PNP transistor (or P-channel

MOSFET) are independent of each other, allowing more

flexibility in the charging algorithms.

The MAX846A has a built-in 1%, 3.3V, 20mA linear regulator capable of powering the µC and providing a reference for the µC’s analog-to-digital converters. An

on-board reset notifies the controller upon any unexpected loss of power. The µC can be inexpensive, since

its only functions are to monitor the voltage and current

and to change the charging algorithms.

________________________Applications

Li-Ion Battery Packs

Desktop Cradle Chargers

Li-Ion/NiMH/NiCd Multichemistry Battery

Chargers

Cellular Phones

Notebook Computers

Hand-Held Instruments

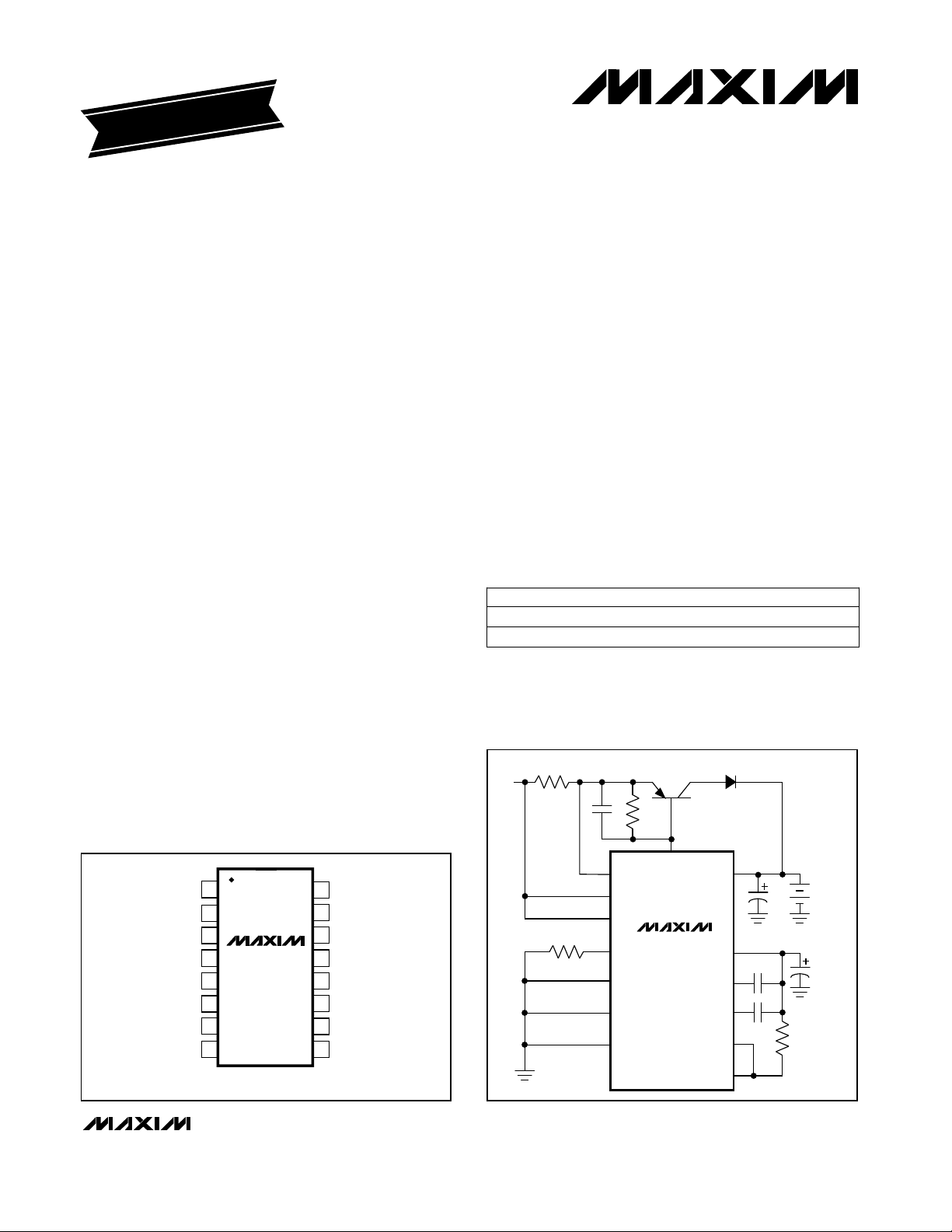

__________________Pin Configuration

TOP VIEW

DCIN

CCI

GND

CCV

VSET

ISET

OFFV

1

VL

2

3

MAX846A

4

5

6

7

8

QSOP

DRV

16

PGND

15

14

CS-

CS+

13

12

BATT

11

ON

10

CELL2

9

PWROK

____________________________Features

♦ Multichemistry Charger System (Li-Ion, NiMH, NiCd)

♦ Independent Voltage and Current Loops

♦ ±0.5% Internal Reference for Li-Ion Cells

♦ Lowers Cost:

—Stands Alone or Uses Low-Cost µC

—Built-In 1% Linear Regulator Powers µC

—Linear Regulator Provides Reference to µC ADCs

—Built-In µC Reset

—Controls Low-Cost External PNP Transistor or

P-Channel MOSFET

♦ Space-Saving 16-Pin QSOP

♦ Charging-Current-Monitor Output

♦ <1µA Battery Drain when Off

______________Ordering Information

PART

MAX846AC/D

MAX846AEEE -40°C to +85°C

*Dice are tested at TA= +25°C only. Contact factory for details.

TEMP. RANGE PIN-PACKAGE

0°C to +70°C

Dice*

16 QSOP

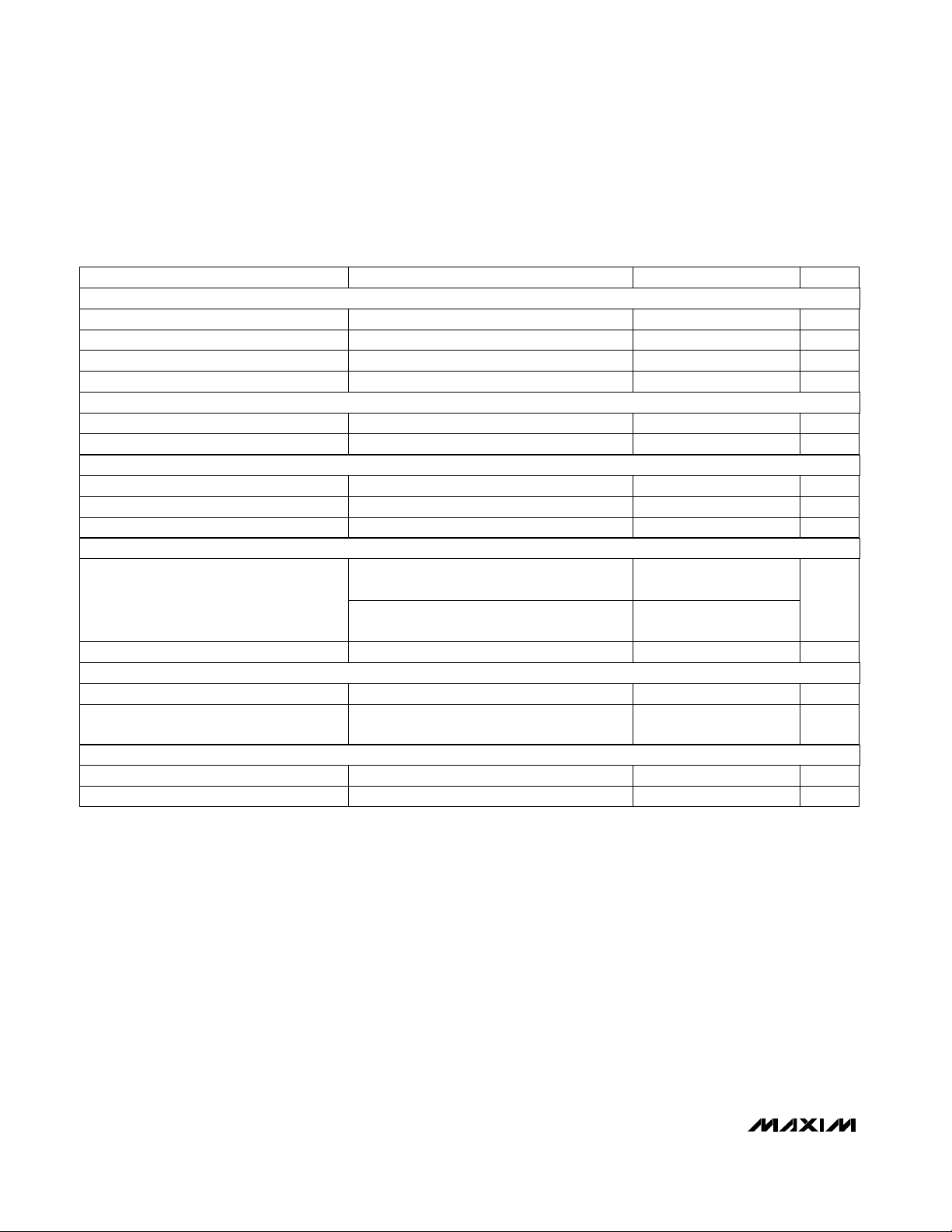

__________Typical Operating Circuit

3.5V

TO

20V

DRV

CSCS+

DCIN

ISET

CELL2

GND

PGND

MAX846A

BATT

CCV

CCI

PWROK

Li-ION

BATTERY

VL

ON

MAX846A

________________________________________________________________

Maxim Integrated Products

1

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800

Cost-Saving Multichemistry

Battery-Charger System

ABSOLUTE MAXIMUM RATINGS

DCIN, DRV, CS+, CS-, BATT to GND........................-0.3V, +21V

PGND to GND.....................................................................±0.3V

VL to GND......................................................................-0.3V, 7V

................................................................................10mA

I

PWROK

PWROK, ISET, CCI, CCV, OFFV, VSET,

CELL2, ON to GND............................................-0.3V, VL + 0.3V

CS+ to CS-..........................................................................±0.3V

VL Short to GND.........................................................Continuous

...................................................................................100mA

I

DRV

MAX846A

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

ELECTRICAL CHARACTERISTICS

(V

= 10V, ON = VL, IVL= I

DCIN

otherwise noted. Typical values are at T

VL REGULATOR

REFERENCE

Output Voltage

CURRENT-SENSE AMPLIFIER

Transconductance V

Output Offset Current V

Input Common-Mode Range Measured at V

Maximum Differential Input Voltage

CS- Lockout Voltage

CS+, CS- Input Current V

CS+, CS- Off Input Current DCIN = VL = ON = GND 0.01 10

= 0mA, VCS- = V

VSET

A

= 10V, V

= +25°C.)

CS+

V

= 20V, I

DCIN

0mA < IVL< 20mA, 3.7V < V

VL = GND

Rising VL edge, 2% hysteresis

Measured at VSET, I

= 1.7V, V

ISET

= 4V 3

CS+

V

= V

CS-

CSA transconductance >0.9mA/V

When V

disabled.

CS+

= 2.1V,

ISET

is less than this voltage, DRV is

CS-

= 20V, V

Continuous Power Dissipation (T

QSOP (derate 8.3mW/°C above +70°C)........................667mW

Operating Temperature Range

MAX846AEEE ....................................................-40°C to +85°C

Junction Temperature......................................................+150°C

Storage Temperature Range.............................-65°C to +160°C

Lead Temperature (soldering, 10sec).............................+300°C

= 4.5V, V

BATT

CONDITIONS

= IVL= 0mA mA5DCIN Supply Current

DRV

VSET

- V

CS+

CS-

, V

- V

CS+

CS-

CS+-VCS-

= 165mV 250

DCIN

= 0mA, VON= 0V

= 165mV 0.95 1 1.05 mA/V

CS-

= V

OFFV

< 20V

= 165mV 2.1 20.0 V

= 0V, TA= 0°C to +85°C, unless

CELL2

= +70°C)

A

225 mV

1.9 2.1 V

UNITSMIN TYP MAXPARAMETER

V3.7 20.0Operating Range

V3.267 3.305 3.333Output Voltage

mA50Short-Circuit Current Limit

V2.9 3.0 3.1PWROK Trip Level

V2.5 2.9VL Undervoltage-Lockout Level

V-0.5% 1.650 +0.5%

kΩ-2% 20 +2%Output Resistance

µA

µA

µA

2 _______________________________________________________________________________________

Cost-Saving Multichemistry

Battery-Charger System

ELECTRICAL CHARACTERISTICS (continued)

(V

= 10V, ON = VL, IVL= I

DCIN

otherwise noted. Typical values are at T

VOLTAGE LOOP

Voltage-Loop Set Point

BATT Input Current

CURRENT LOOP

Current-Loop Set Point I

CA Voltage Gain 5

CCI Output Impedance 50 kΩ

Overcurrent Trip Level

DRIVER

DRV Sink Current V

DRV Off Current V

LOGIC INPUTS AND OUTPUTS

Input High Level CELL2, ON, OFFV 2.4 VL V

Input Low Level CELL2, ON, OFFV 0 0.8 V

Input Current CELL2, ON, OFFV 0.01 1

PWROK Output Low Level I

PWROK Output High Leakage V

= 0mA, VCS- = V

VSET

A

= +25°C.)

V

VSET

V

DRV

V

VSET

V

DRV

1mA < I

V

BATT

V

BATT

DRV

When V

is disabled.

DRV

DRV

PWROK

PWROK

= 10V, V

CS+

= 1.650V, V

= 10V

= 1.650V, V

= 10V

< 5mA

DRV

= 10V, CELL2 = GND or VL

= 10V, ON = GND, CELL2 = GND or VL

= 5mA, V

= 3V 20 mA

= 20V, VON= 0V 0.1 100

DRV

exceeds this voltage, DRV current

ISET

= 1mA, V

= 3.3V 0.01 1

= 4.5V, V

BATT

CONDITIONS

= 0V, I

CELL2

CELL2

= 10V

DCIN

DRV

= VL, I

DRV

= VVL= 2.5V 0.4 V

= V

OFFV

= 1mA,

= 1mA,

MAX846A

= 0V, TA= 0°C to +85°C, unless

CELL2

-0.25% 4.2 +0.25%

-0.25% 8.4 +0.25%

0.05Voltage-Loop Load Regulation

0.01 1BATT Off Input Current

1.634 1.650 1.666 V

1.90 2.1 V

225

MAX846A

UNITSMIN TYP MAXPARAMETER

V

V1.25 2.0VSET Common-Mode Input Range

kΩ150CCV Output Impedance

%

µA

µA

V/V

µA

µA

µA

_______________________________________________________________________________________ 3

Cost-Saving Multichemistry

Battery-Charger System

ELECTRICAL CHARACTERISTICS (Note 1)

(V

= 10V, ON = VL, IVL= I

DCIN

otherwise noted.)

= 0mA, VCS- = V

VSET

CS+

= 10V, V

BATT

= 4.5V, V

OFFV

= V

= 0V, TA= -40°C to +85°C, unless

CELL2

CONDITIONS

VL REGULATOR

V

DCIN

= 20V, I

DRV

= IVL= 0mA mA5DCIN Supply Current

0mA < IVL< 20mA, 3.7V < V

MAX846A

Rising VL edge, 2% hysteresis

REFERENCE

Measured at VSET, I

= 0mA, VON= 0V

VSET

CURRENT-SENSE AMPLIFIER

Transconductance V

Output Offset Current V

CS+, CS- Off Input Current V

ISET

CS+

ON

= 1.7V, V

= 4V

= 0V, V

CS+

CS+

= V

- V

= 165mV

CS-

= 10V 10

CS-

VOLTAGE LOOP

V

Voltage-Loop Set Point

BATT Off Input Current V

= 1.650V, V

VSET

V

= 10V

DRV

V

= 1.650V, V

VSET

V

= 10V

DRV

= 10V, ON = GND, CELL2 = GND or VL 1

BATT

CELL2

CELL2

= 0V, I

= VL, I

CURRENT LOOP

Current-Loop Set Point I

Overcurrent Trip Level

= 5mA, V

DRV

When V

ISET

is disabled.

= 10V 1.625 1.675 V

DRV

exceeds this voltage, DRV current

DRIVER

DRV Sink Current V

DRV Off Current

= 3V 20 mA

DRV

V

= 20V, ON = GND 100

DRV

Note 1: Specifications to -40°C are guaranteed by design and not production tested.

< 20V

DCIN

= 1mA,

DRV

MAX846A

= 1mA,

DRV

UNITSMIN TYP MAXPARAMETER

-2% 20 +2%Output Resistance

kΩ

0.93 1.07 mA/V

5

µA

µA

-0.35% 4.2 +0.35%

-0.35% 8.4 +0.35%

µA

1.86 2.14 V

µA

V3.259 3.341Output Voltage

V2.9 3.1PWROK Trip Level

V2.5 3.0VL Undervoltage-Lockout Level

V-0.7% 1.650 +0.7%Output Voltage

V

4 _______________________________________________________________________________________

Cost-Saving Multichemistry

Battery-Charger System

__________________________________________Typical Operating Characteristics

(TA = +25°C, unless otherwise noted.)

CURRENT-SENSE AMPLIFIER

TRANSCONDUCTANCE vs. ISET VOLTAGE

1.035

∆V = V

1.030

1.025

1.020

1.015

1.010

CSA GM (mA/V)

1.005

1.000

0.995

0.990

0 0.4 1.2 2.0

- V

CS+

∆V = 100mV

∆V = 200mV

CS-

∆V = 165mV

∆V = 250mV

0.8 1.60.2 1.0 1.80.6 1.4

ISET VOLTAGE (V)

CURRENT-LOOP GAIN

80

C

= 10nF

CCI

70

60

50

40

30

GAIN (dB)

20

10

0

-10

-20

10 10k 100k1k100 1M

GAIN

PHASE

FREQUENCY (Hz)

MAX846-01

MAX846-03

180

150

120

90

60

30

0

PHASE (DEGREES)

-30

-60

-90

-120

Li-ION CHARGING PROFILE

900

800

700

600

500

400

300

CHARGING CURRENT (mA)

200

100

0

0 180 24012060

TIME (MINUTES)

80

70

60

50

40

30

20

BATT INPUT CURRENT (µA)

10

40

30

20

10

-10

GAIN (dB)

-20

-30

-40

-50

-60

MAX846-04

BATTERY VOLTAGE

CHARGING CURRENT

0

0

BATTERY INPUT CURRENT

vs. BATTERY VOLTAGE

CELL2 = VL

CELL2 = GND

82kΩ

ON

02 6 10

4815 937

BATT VOLTAGE (V)

128kΩ

OFF

MAX846-02

VOLTAGE-LOOP GAIN

GAIN

= - Charging at 100mA

= -Charging at 200mA

2 Li-Ion Cells

C

= 10nF

CCV

C

= 4.7µF

OUT

TIP2955 PNP PASS TRANSISTOR

10 10k 100k1k100 1M

FREQUENCY (Hz)

9.0

8.8

8.6

8.4

8.2

8.0

7.8

7.6

BATTERY VOLTAGE (V)

7.4

7.2

7.0

PHASE

MAX846-04

180

150

120

90

60

30

0

-30

-60

-90

--120

PHASE (DEGREES)

MAX846A

_______________________________________________________________________________________

5

Cost-Saving Multichemistry

Battery-Charger System

______________________________________________________________Pin Description

PIN FUNCTION

1 Supply Input from External DC Source. 3.7V ≤ V

2

MAX846A

3

4 Ground

5

6

7 ISET

8 OFFV Logic Input that disables the voltage-regulation loop. Set OFFV high for NiCd or NiMH batteries.

9 PWROK

10 CELL2

11 ON

12 BATT Battery Input. Connect BATT to positive battery terminal.

13 CS+

14 CS- Current-Sense Amplifier Low-Side Input. Connect CS- to the sense resistor’s battery side.

15 PGND Power Ground

16 DRV External Pass Transistor (P-channel MOSFET or PNP) Base/Gate Drive Output. DRV sinks current only.

NAME

DCIN

VL

CCI

GND

CCV

VSET

3.3V, 20mA, 1% Linear-Regulator Output. VL powers the system µC and other components. Bypass to

GND with a 4.7µF tantalum or ceramic capacitor.

Current-Regulation-Loop Compensation Pin. Connect a compensation capacitor (typically 10nF) from

CCI to VL.

Voltage-Regulation-Loop Compensation Pin. Connect a compensation capacitor (typically 10nF) from

CCV to VL.

Float-Voltage Reference-Adjust Input. Leave VSET open for a 4.2V default. See the

Information

Current-Set Input/Current-Monitor Output. ISET sets the current-regulation point. Connect a resistor

from ISET to GND to monitor the charging current. ISET voltage is regulated at 1.65V by the currentregulation loop. To adjust the current-regulation point, either modify the resistance from ISET to ground

or connect a fixed resistor and adjust the voltage on the other side of the resistor (Figure 5). The

transconductance of the current-sense amplifier is 1mA/V.

Open-Drain, Power-Good Output to µC. PWROK is low when VL is less than 3V. The reset timeout period can be set externally using an RC circuit (Figure 3).

Digital Input. CELL2 programs the number of Li-Ion cells to be charged. A high level equals two cells; a

low level equals one cell.

Charger ON/OFF Input. When low, the driver section is turned off and I

always active.

Current-Sense Amplifier High-Side Input. Connect CS+ to the sense resistor’s power-source side. The

sense resistor may be placed on either side of the pass transistor.

section for adjustment information.

DCIN

≤ 20V.

Applications

<1µA. The VL regulator is

BATT

_______________Detailed Description

The MAX846A battery-charging controller combines

three functional blocks: a 3.3V precision, low-dropout

linear regulator (LDO), a precision voltage reference,

and a voltage/current regulator (Figure 1).

Linear Regulator

The LDO regulator output voltage (VL) is two times the

internal reference voltage; therefore, the reference and

LDO track. VL delivers up to 20mA to an external load

and is short-circuit protected. The power-good output

The precision internal reference provides a voltage to

accurately set the float voltage for lithium-ion (Li-Ion)

battery charging. The reference output connects in

series with an internal, 2%-accurate, 20kΩ resistor. This

allows the float voltage to be adjusted using one external 1% resistor (R

VSET

(Figure 4). The float-voltage accuracy is important for

battery life and to ensure full capacity in Li-Ion batteries. Table 1 shows the accuracies attainable using the

MAX846A.

Voltage Reference

) to form a voltage divider

(PWROK) provides microcontroller (µC) reset and

charge-current inhibition.

6 _______________________________________________________________________________________

Cost-Saving Multichemistry

Battery-Charger System

Voltage/Current Regulator

The voltage/current regulator consists of a precision

attenuator, voltage loop, current-sense amplifier, and

current loop. The attenuator can be pin programmed to

set the regulation voltage for one or two Li-Ion cells

(4.2V and 8.4V, respectively). The current-sense amplifier is configured to sense the battery current on the

high side. It is, in essence, a transconductance amplifier converting the voltage across an external sense

resistor (RCS) to a current, and applying this current to

an external load resistor (R

by selecting RCSand R

also be adjusted by varying the voltage at the low side

of R

ISET node (Figure 5). The voltage and current loops are

individually compensated using external capacitors at

CCV and CCI, respectively. The outputs of these two

loops are OR’ed together and drive an open-drain,

internal N-channel MOSFET transistor sinking current to

ground. An external P-channel MOSFET or PNP transistor pass element completes the loop.

or by summing/subtracting current from the

ISET

). Set the charge current

ISET

. The charge current can

ISET

Stability

The

Typical Operating Characteristics

gains for the current loop and voltage loop. The dominant pole for each loop is set by the compensation

capacitor connected to each capacitive compensation

pin (CCI, CCV). The DC loop gains are about 50dB for

the current loop and about 33dB for the voltage loop,

for a battery impedance of 250mΩ.

The CCI output impedance (50kΩ) and the CCI capacitor determine the current-loop dominant pole. In Figure

2, the recommended C

dominant pole at 300Hz. There is a high-frequency

pole, due to the external PNP, at approximately fT/ß.

This pole frequency (on the order of a few hundred kilohertz) will vary with the type of PNP used. Connect a

10nF capacitor between the base and emitter of the

is 10nF, which places a

CCV

show the loop

PNP to prevent self-oscillation (due to the high-impedance base drive).

Similarly, the CCV output impedance (150kΩ) and the

CCV capacitor set the voltage-loop dominant pole. In

Figure 2, the compensation capacitance is 10nF, which

places a dominant pole at 200Hz.

The battery impedance directly affects the voltage-loop

DC and high-frequency gain. At DC, the loop gain is

proportional to the battery resistance. At higher frequencies, the AC impedance of the battery and its connections introduces an additional high-frequency zero.

A 4.7µF output capacitor in parallel with the battery,

mounted close to BATT, minimizes the impact of this

impedance. The effect of the battery impedance on DC

gain is noticeable in the Voltage-Loop-Gain graph (see

Typical Operating Characteristics

sents voltage-loop gain versus frequency for a fully

charged battery, when the battery energy level is high

and the ESR is low. The charging current is 100mA. The

dashed line shows the loop gain with a 200mA charging current, a lower amount of stored energy in the battery, and a higher battery ESR.

). The solid line repre-

__________Applications Information

Stand-Alone Li-Ion Charger

Figure 2 shows the stand-alone configuration of the

MAX846A. Select the external components and pin

configurations as follows:

• Program the number of cells: Connect CELL2 to GND

for one-cell operation, or to VL for two-cell operation.

• Program the float voltage: Connect a 1% resistor from

VSET to GND to adjust the float voltage down, or to

VL to adjust it up. If VSET is unconnected, the float

voltage will be 4.2V per cell. Let the desired float voltage per cell be VF, and calculate the resistor value

as follows:

MAX846A

Table 1. Float-Voltage Accuracy

ERROR SOURCE ERROR

VSET error due to external divider. Calculated from a 2% internal 20kΩ resistor tolerance and

a 1% external R

adjustment range of 5%.

resistor tolerance. The total error is 3% x (adjustment). Assume max

VSET

_______________________________________________________________________________________ 7

±0.5%Internal-reference accuracy

±0.15%

±0.25%VSET amplifier and divider accuracy

±0.9%TOTAL

Cost-Saving Multichemistry

Battery-Charger System

DC INPUT (OR P-CHANNEL)

3.5V TO 20V

0.01µF

R

DRV

660Ω

MAX846A

3.3V

GND

DAC

ADC

OPEN

DAC

µC

OR

OR

TO

TO

4.7µF

VL

VL

1 Li

ON

(±5% ADJ)

10k

2 Li

OFF

R

VSET

400k, 1%

5nF

5nF

VL

PGND

ISET

CCI

CCV

CELL2

OFFV

VSET

GND

DCIN DRV

3.3V, 1%

LDO

20k, 2%

1.65V, 0.5%

REF

BST

BST

N

REFOK

CS- > 2V

CS+

4.7µF

R

CS

165mΩ

I

BATT

Li

OR

Ni

VL

1k

CSA

VL

2V

CL

1.65V

CA

VA

VA

N

N

CS-

BATT

DRV ENABLE

MAX846A

VL > 3V

OFF

ON

ON

PWROK

Figure 1. Functional Diagram

8 _______________________________________________________________________________________

TO µC

DCIN

3.7V TO 20V

0.165V

( )

I

BATT

RCS

Cost-Saving Multichemistry

Battery-Charger System

EXTERNAL PASS TRANSISTOR

CAN BE EITHER PNP OR PMOS FET.

10nF

R

DRV

660Ω

4.7µF

MAX846A

DCIN

VL

100k

PWROK

0.01µF

0.01µF

4.7µF

ON

CCI

CCV

OFFV

Figure 2. Stand-Alone Li-Ion Charger

CS+

GND

MAX846A

DRV BATTCS-

VSET

ISET

CELL2

PGND

VL

R

VSET

10k

R

ISET

ADJUST

(UP)

(DOWN)

VL

(2 CELLS)

(1 CELL)

−

XF

R = 20k

VSET

4.2

1.65

Ω

V V

V 4.2

−

F

where VX is either GND or VL, and VFis the per-cell

float voltage. In the circuit of Figure 1, R

400kΩ. R

and the internal 20kΩ resistor form a

VSET

VSET

divider, resulting in an adjustment range of approximately ±5%.

The current-regulation loop attempts to maintain the

voltage on ISET at 1.65V. Selecting resistor R

ISET

determines the reflected voltage required at the currentsense amplifier input.

_______________________________________________________________________________________ 9

• Calculate R

RCS= VCS/ I

R

(in kΩ) = 1.65V / V

ISET

CS

and R

BATT

ISET

CS

as follows:

where the recommended value for VCSis 165mV.

• Connect ON to PWROK to prevent the charge current

is

from turning on until the voltages have settled.

Minimize power dissipation in the external pass transistor. Power dissipation can be controlled by setting the

DCIN input supply as low as possible, or by making

V

track the battery voltage.

DCIN

Microprocessor-Controlled

Multichemistry Operation

The MAX846A is highly adjustable, allowing for simple

interfacing with a low-cost µC to charge Ni-based and

Li-Ion batteries using one application circuit (Figure 3).

Cost-Saving Multichemistry

Battery-Charger System

P

DCIN

3.7V TO 20V

Li OR Ni

MAX846A

DCIN

CCI

CCV

GND

PGND

Figure 3. Desktop Multichemistry Charger Concept

CS-CS+

MAX846A

DRV

BATT

CELL2

OFFV

VSET

ISET

PWROK

ON

ADC (MEASURE V(BATT))

I/O (LOW = TURN OFF CHARGE)

I/O (HIGH = 2 Li CELLS)

I/O (HIGH = DISABLE FLOAT V)

PWM/DAC (CONTROL FLOAT V)

PWM/DAC (CONTROL CHARGE I)

ADC (MEASURE I

VL

V

RST

DD

)

BATT

MICROCONTROLLER

Component selection is similar to that of stand-alone

operation. By using DACs or µC PWM outputs, the float

voltage and charging current can be adjusted by the

µC. When a Ni-based battery is being charged, disable

the float-voltage regulation using the OFFV input. The

µC can also monitor the charge current through the

battery by reading the ISET output’s voltage using its

Float-voltage accuracy is important for battery life and

for reaching full capacity for Li-Ion batteries. Table 1

shows the accuracy attainable using the MAX846A.

For best float-voltage accuracy, set the DRV current to

1mA (R

= 660Ω for a PNP pass transistor).

DRV

High-Power Multichemistry

ADC. Similarly, the battery voltage can be measured

using a voltage divider from the battery.

Note that the µC only needs to configure the system for

correct voltage and current levels for the battery being

charged, and for Ni-based batteries to detect end-ofcharge and adjust the current level to trickle. The controller is not burdened with the regulation task.

10 ______________________________________________________________________________________

The circuit in Figure 6 minimizes power dissipation in

the pass transistor by providing optical feedback to the

input power source. The offline AC/DC converter maintains 1.2V across the PNP. This allows much higher

charging currents than can be used with conventional

power sources.

Offline Charger

1.65V

MAX846A

20k

2%

Cost-Saving Multichemistry

Battery-Charger System

MAX846A

0 TO V

VSET

400k

1%

L

DAC

n

1.65V

MAX846A

20k

2%

VSET

400k

1%

0 100%

µC

PWM

OUTPUT

WITH VOLTAGE OUTPUT DAC

Figure 4. VSET Adjustment Methods

MAX846A

ISET

20k

WITH VOLTAGE OUTPUT DAC

Figure 5. ISET Adjustment Methods

20k

DAC

n

OPTO-COUPLER

MAX846A

WITH PWM FROM MICROCONTROLLER

0 100%

ISET

20k

WITH PWM FROM MICROCONTROLLER

10k10k

µC

PWM

OUTPUT

FEEDBACK

AC/DC

CONVERTER

Figure 6. Low-Cost Desktop Multichemistry Charger Concept

______________________________________________________________________________________ 11

MAX846

MICRO

CONTROLLER

Cost-Saving Multichemistry

Battery-Charger System

___________________Chip Topography

DCINVL DRV PGND

CCI

MAX846A

GND

CCV

VSET

0.085"

(2.165mm)

SUBSTRATE CONNECTED TO GND

TRANSISTOR COUNT: 349

CS-

CS+

0.105"

(2.67mm)

BATT

ON

CELL2PWROKOFFVISET

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

12

__________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 (408) 737-7600

© 1996 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Loading...

Loading...