_______________General Description

The MAX817/MAX818/MAX819 microprocessor (µP)

supervisory circuits simplify power-supply monitoring,

battery control, and chip-enable gating in µP systems

by reducing the number of components required.

These devices are designed for use in +5V-powered

systems. Low supply current (11µA typical) and small

package size make these devices ideal for portable

applications. The MAX817/MAX818/MAX819 are specifically designed to ignore fast transients on VCC. Other

supervisory functions include active-low reset, backupbattery switchover, watchdog input, battery freshness

seal, and chip-enable gating. The

Selector Guide

below

lists the specific functions available from each device.

These devices offer two pretrimmed reset threshold volt-

ages for ±5% or ±10% power supplies: 4.65V for the L

versions and 4.40V for the M versions. The MAX817/

MAX818/MAX819 are available in space-saving µMAX

packages, as well as 8-pin DIP/SO.

________________________Applications

Battery-Powered Computers and Controllers

Embedded Controllers

Intelligent Instruments

Critical µP Monitoring

Portable Equipment

____________________________Features

♦ Precision Supply-Voltage Monitor:

4.65V (MAX81_L)

4.40V (MAX81_M)

♦ 11µA Quiescent Supply Current

♦ 200ms Reset Time Delay

♦ Watchdog Timer with 1.6sec Timeout

(MAX817/MAX818)

♦ Battery-Backup Power Switching; Battery Voltage

Can Exceed V

CC

♦ Battery Freshness Seal

♦ On-Board, 3ns Gating of Chip-Enable Signals

(MAX818)

♦ Uncommitted Voltage Monitor for Power-Fail or

Low-Battery Warning (MAX817/MAX819)

♦ Manual Reset Input (MAX819)

MAX817L/M, MAX818L/M, MAX819L/M*

+5V Microprocessor Supervisory Circuits

________________________________________________________________

Maxim Integrated Products

1

WDI

GND

PFO

PFI

1

2

8

7

BATT

RESET

V

CC

OUT

MAX817

DIP/SO/µMAX

TOP VIEW

3

4

6

5

_________________Pin Configurations

19-0494; Rev 1; 3/96

PART

†

MAX817_CPA

MAX817_CSA

MAX817_CUA 0°C to +70°C

0°C to +70°C

0°C to +70°C

TEMP. RANGE PIN-PACKAGE

8 Plastic DIP

8 SO

8 µMAX

______________Ordering Information

_____________________Selector Guide

Ordering Information continued on last page.

†

These parts offer a choice of reset threshold voltage. From the

table below, select the suffix corresponding to the desired

threshold and insert it into the blank to complete the part number.

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800

SUFFIX RESET THRESHOLD (V)

L 4.65

M 4.40

FEATURE

MAX817

L/M

Active-Low Reset

✔

Backup-Battery Switchover

✔

MAX818

L/M

✔

✔

MAX819

L/M

✔

✔

Power-Fail Comparator

✔

—

Watchdog Input

✔ ✔

✔

—

Battery Freshness Seal

✔ ✔

Manual Reset Input — —

✔

✔

Chip-Enable Gating —

✔

Pin-Package

8-DIP/SO/

µMAX

8-DIP/SO/

µMAX

—

8-DIP/SO/

µMAX

Low-Power, PinCompatible Upgrades for:

MAX690A/

MAX692A

—

MAX703/

MAX704

Typical Operating Circuit appears at end of data sheet.

Pin Configurations continued at end of data sheet.

*Patents Pending

MAX817L/M, MAX818L/M, MAX819L/M*

+5V Microprocessor Supervisory Circuits

2 _______________________________________________________________________________________

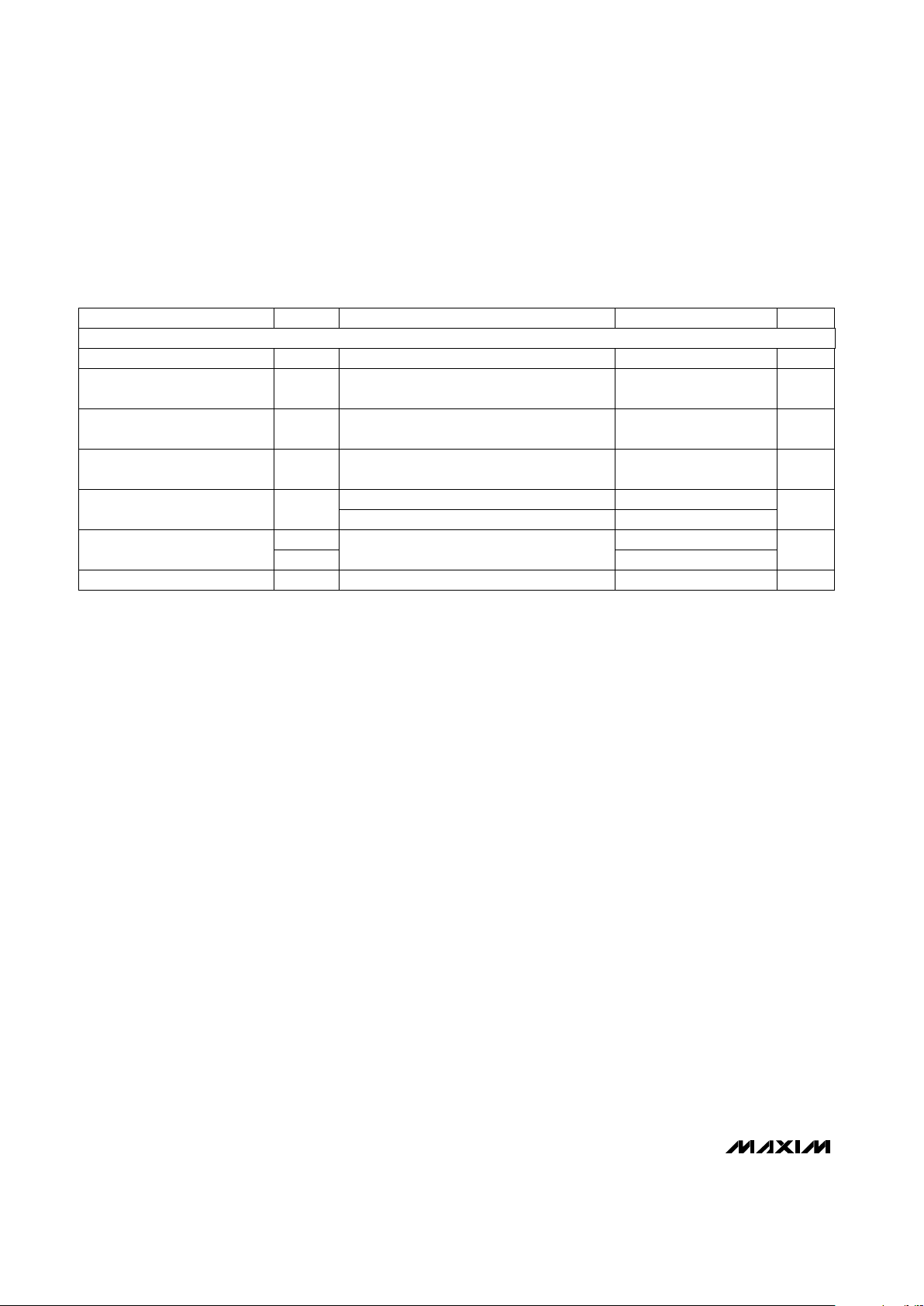

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VCC= +4.75V to +5.5V for MAX81_L, VCC= +4.5V to +5.5V for MAX81_M, V

BATT

= 2.8V, TA= T

MIN

to T

MAX

, unless otherwise

noted. Typical values are at T

A

= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Note 1: The input voltage limits on PFI and WDI may be exceeded (up to 12V VIN) if the current into these pins is limited to less

than 10mA.

Input Voltage

V

CC

, BATT..........................................................-0.3V to +6.0V

All Other Pins (Note 1).............................-0.3V to (V

CC

+ 0.3V)

Input Current

V

CC

Peak ..............................................................................1A

V

CC

Continuous .............................................................250mA

BATT Peak .....................................................................250mA

BATT Continuous.............................................................50mA

GND.................................................................................25mA

Output Current

OUT................................................................................250mA

All Other Outputs .............................................................25mA

OUT Short-Circuit Duration.................................................10sec

Continuous Power Dissipation (T

A

= +70°C)

Plastic DIP (derate 9.09mW/°C above +70°C) .............727mW

SO (derate 5.88mW/°C above +70°C)..........................471mW

µMAX (derate 4.10mW/°C above +70°C) .....................330mW

Operating Temperature Ranges

MAX81_ _C_A......................................................0°C to +70°C

MAX81_ _E_A ...................................................-40°C to +85°C

Storage Temperature Range.............................-65°C to +160°C

Lead Temperature (soldering, 10sec).............................+300°C

As applicable; CE IN = 0V,

WDI and MR unconnected

VCC< V

RST

I

OUT

= 50mA

I

OUT

= 5mA

VCC= 0V, V

OUT

= 0V

I

OUT

= 250µA, VCC< (V

BATT

- 0.2V)

CONDITIONS

mV40Battery Switchover Hysteresis

mV

-20

Battery Switch Threshold

(V

CC

- V

BATT

)

20

V

V

BATT -VBATT -

0.1 0.02

V

OUT

in Battery-Backup Mode

µA

11 60

I

SUPPLY

Supply Current (excluding I

OUT

)

11 45

V0 5.5

Operating Voltage Range, VCC,

V

BATT

(Note 2)

Ω100BATT to OUT On-Resistance

Ω510VCCto OUT On-Resistance

V

VCC- VCC-

0.5 0.25

V

OUT

Output

VCC- VCC-

0.05 0.025

µA

5.0

µA1

BATT Leakage Current,

Freshness Seal Enabled

UNITSMIN TYP MAXSYMBOLPARAMETER

VCC= 0V

Supply Current in BatteryBackup Mode (excluding I

OUT

)

0.05 1.0

MAX81_ _C

MAX81_ _E

TA= +25°C

TA= T

MIN

to

T

MAX

Power-up

Power-down

TA= +25°C

TA= T

MIN

to

T

MAX

5.5V > VCC> (V

BATT

+ 0.2V)BATT Standby Current (Note 3)

-0.10 0.02

µA

-1.00 0.02

ELECTRICAL CHARACTERISTICS (continued)

(VCC= +4.75V to +5.5V for MAX81_L, VCC= +4.5V to +5.5V for MAX81_M, V

BATT

= 2.8V, TA= T

MIN

to T

MAX

, unless otherwise

noted. Typical values are at T

A

= +25°C.)

MAX817L/M, MAX818L/M, MAX819L/M*

+5V Microprocessor Supervisory Circuits

_______________________________________________________________________________________ 3

V

PFO

= 0V

V

PFI

> 1.30V, I

SOURCE

= 40µA, VCC> 4.5V

MAX81_M

V

PFI

< 1.20V, I

SINK

= 3.2mA, VCC> 4.50V

MAX81_L

WDI = GND, time average

From V

RST

, VCCfalling at 10V/ms

WDI = VCC, time average

VCC= 5V

MAX81_ _C, VCC= 1V, VCCfalling,

V

BATT

= 0V, I

SINK

= 50µA

VCC> V

RST(MAX), ISOURCE

= 800µA

VCC< V

RST(MIN), ISINK

= 3.2mA

VIL= 0.4V, VIH= 0.8V

CC

CONDITIONS

µA250 500

PFO Short-Circuit Current

VCC- 1.5V

OH

PFO Output Voltage

V

0.4V

OL

nA-25 0.01 25I

PFI

PFI Input Current

mV4PFI Input Hysteresis

V1.20 1.25 1.30V

PFT

PFI Input Threshold

µA

-20 -15

WDI Input Current (Note 5)

120 160

V

3.5V

IH

WDI Input Threshold (Note 4)

0.8V

IL

ns50t

WDI

WDI Pulse Width

V

4.25 4.40 4.50

V

RST

Reset Threshold

4.50 4.65 4.75

sec1.00 1.60 2.25t

WD

Watchdog Timeout Period

µs100

VCCto RESET Delay

0.3

mV25Reset Threshold Hysteresis

ms140 200 280t

RP

Reset Timeout Period

VCC- 1.5V

OH

0.4

V

OL

UNITSMIN TYP MAXSYMBOLPARAMETER

MAX81_ _E, VCC= 1.2V, VCCfalling,

V

BATT

= 0V, I

SINK

= 100µA

V

0.3

RESET Output Voltage

0.8

V

2.0

V

IL

MR Input Threshold

µs1

MR Pulse Width

V

IH

ns100

MR Pulse that Would Not Cause

a Reset

ns120

MR to Reset Delay

kΩ45 63 85

MR Pull-Up Resistance

RESET AND WATCHDOG TIMER

POWER-FAIL COMPARATOR (MAX817/MAX819 only)

MANUAL RESET INPUT (MAX819 only)

MAX817L/M, MAX818L/M, MAX819L/M*

+5V Microprocessor Supervisory Circuits

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VCC= +4.75V to +5.5V for MAX81_L, VCC= +4.5V to +5.5V for MAX81_M, V

BATT

= 2.8V, TA= T

MIN

to T

MAX

, unless otherwise

noted. Typical values are at T

A

= +25°C.)

Power-down

VCC= 5V

I

OUT

= -1µA, VCC= 0V, V

BATT

= 2.8V

I

OUT

= -100µA, VCC= 0V

Enable mode

Disable mode

CONDITIONS

µs15

RESET to CE OUT Delay

3.5V

IL

CE OUT Input Threshold

V

0.8V

IH

V

2.7

V

OH

CE OUT Output

VCC- 1V

Ω40 150

CE IN to CE OUT Resistance

(Note 6)

µA±0.005 ±1

CE IN Leakage Current

UNITSMIN TYP MAXSYMBOLPARAMETER

Note 2: Either VCCor V

BATT

can go to 0V if the other is greater than 2.0V.

Note 3: “-” = battery-charging current, “+” = battery-discharging current.

Note 4: WDI is internally serviced within the watchdog timeout period if WDI is left unconnected.

Note 5: WDI input is designed to be driven by a three-stated output device. To float WDI, the “high-impedance mode” of the output

device must have a maximum leakage current of 10µA and a maximum output capacitance of 200pF. The output device

must also be able to source and sink at least 200µA when active.

Note 6: The chip-enable resistance is tested with V

CC

= +4.75V for the MAX818L and VCC= +4.5V for the MAX818M.

V

CE IN

= V

CE OUT

= VCC/2.

Note 7: The chip-enable propagation delay is measured from the 50% point at CE IN to the 50% point at CE OUT.

Disable mode, CE OUT = 0V

mA0.1 0.75 2.0

CE OUT Short-Circuit Current

(Reset Active)

50Ω source impedance driver, C

LOAD

= 50pF ns38

CE IN to CE OUT Propagation

Delay (Note 7)

CHIP-ENABLE GATING (MAX818 only)

MAX817L/M, MAX818L/M, MAX819L/M*

+5V Microprocessor Supervisory Circuits

_______________________________________________________________________________________

5

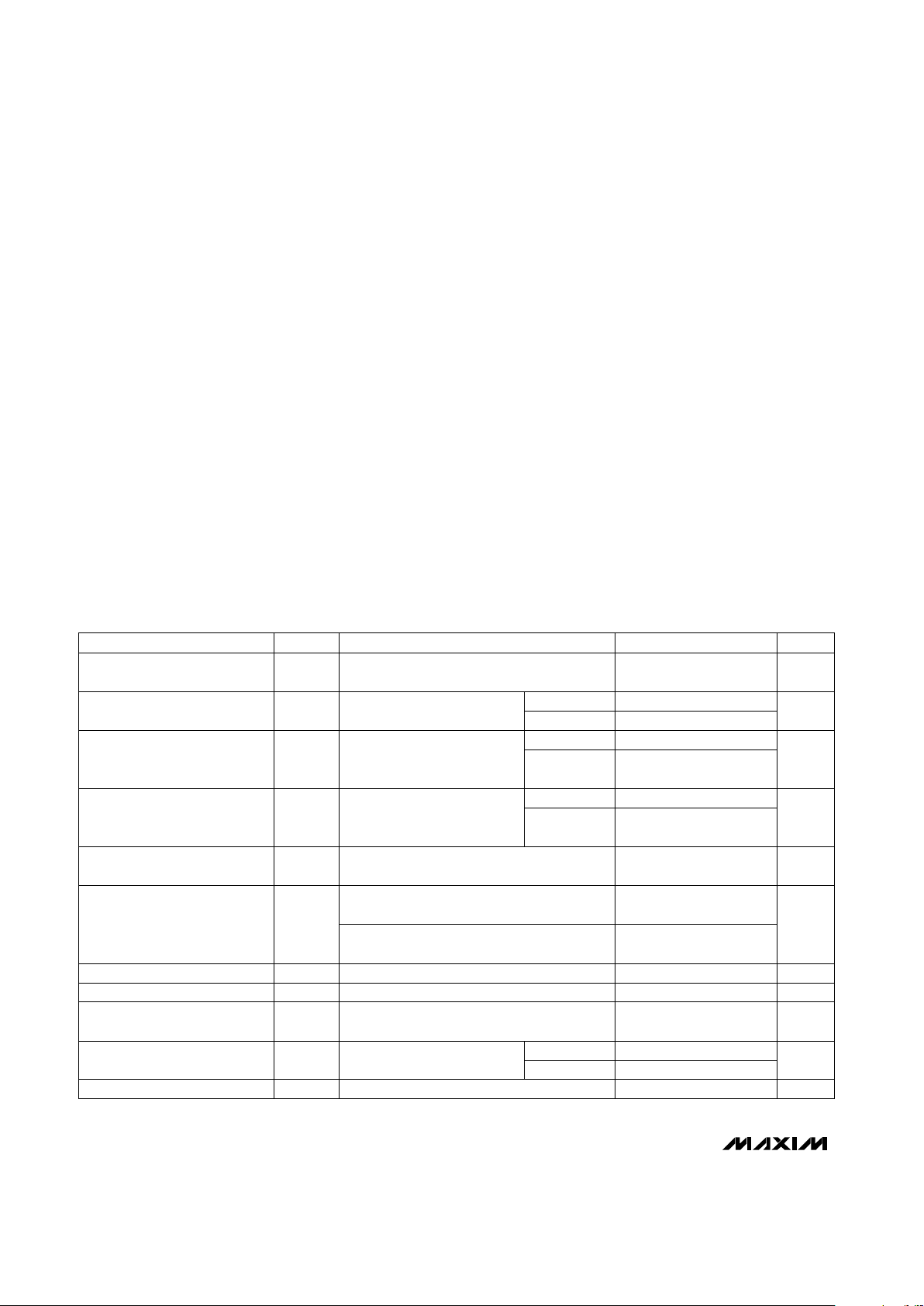

8

-40 40

SUPPLY CURRENT

vs. TEMPERATURE (NO LOAD)

12

MAX817/18/19-01

TEMPERATURE (°C)

SUPPLY CURRENT (µA)

-20 0

20

80 10060

16

14

10

0

-40 40

BATTERY SUPPLY CURRENT

(BACKUP MODE) vs. TEMPERATURE

20

80

100

120

140

160

MAX817/18/19-02

TEMPERATURE (°C)

BATTERY SUPPLY CURRENT (nA)

-20 0 20 80 10060

60

40

VCC = 0V

V

BATT

= 5.0V

V

BATT

= 2.8V

V

BATT

= 2.0V

0

-40 40

CE IN TO CE OUT ON-RESISTANCE

vs. TEMPERATURE

20

80

MAX817/18/19-03

TEMPERATURE (°C)

CE IN TO CE OUT ON-RESISTANCE (Ω)

-20 0 20 80 10060

60

40

90

100

10

70

50

30

V

CE IN

= 4V

V

CE IN

= 3V

V

CE IN

= 2V

0

-40 40

BATT TO OUT ON-RESISTANCE

vs. TEMPERATURE

MAX817/18/19-04

TEMPERATURE (°C)

BATT TO OUT ON-RESISTANCE (Ω)

-20 0 20 80 10060

50

100

150

200

250

300

V

BATT

= 2.0V

V

BATT

= 2.8V

V

BATT

= 5.0V

V

CC

= 0V

0

-40 40

VCC TO RESET PROPAGATION DELAY

vs. TEMPERATURE

200

MAX817/18/19-07

TEMPERATURE (°C)

V

CC

TO RESET PROPAGATION DELAY (ms)

-20 0 20 80 10060

300

400

500

100

VCC FALLING AT:

0.25V/ms

1V/ms

10V/ms

3

-40 40

V

CC

TO OUT ON-RESISTANCE

vs. TEMPERATURE

MAX817/18/19-05

TEMPERATURE (°C)

V

CC

TO OUT ON-RESISTANCE (Ω)

-20 0 20 80 10060

4

5

6

7

180

-40 40

RESET TIMEOUT PERIOD

vs. TEMPERATURE

MAX817/18/19-06

TEMPERATURE (°C)

RESET TIMEOUT PERIOD (ms)

-20 0 20 80 10060

190

200

210

220

1.50

-40 40

WATCHDOG TIMEOUT PERIOD

vs. TEMPERATURE

1.60

MAX817/18/19-08

TEMPERATURE (°C)

WATCHDOG TIMEOUT PERIOD (sec)

-20 0 20 80 10060

1.65

1.70

1.55

0

-40 40

BATTERY FRESHNESS SEAL

LEAKAGE CURRENT vs. TEMPERATURE

10

MAX817/18/19-09

TEMPERATURE (°C)

LEAKAGE CURRENT (nA)

-20 0 20 80 10060

15

20

5

__________________________________________Typical Operating Characteristics

(VCC= +5V, V

BATT

= 3.0V, TA= +25°C, unless otherwise noted.)

MAX817L/M, MAX818L/M, MAX819L/M*

+5V Microprocessor Supervisory Circuits

6 _______________________________________________________________________________________

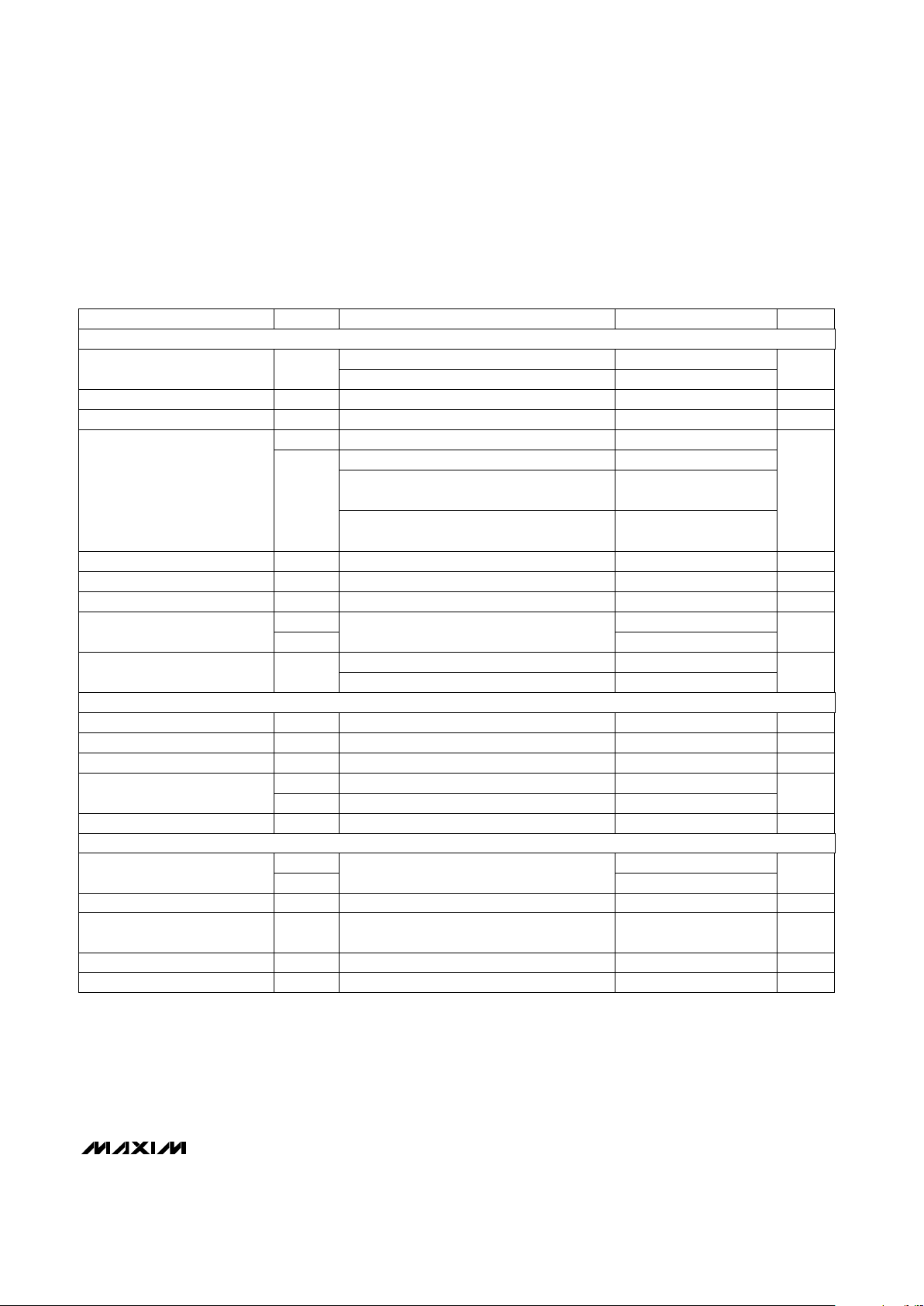

0

04

BATTERY SUPPLY CURRENT

vs. SUPPLY VOLTAGE

MAX817/18/19-12

VCC (V)

BATTERY SUPPLY CURRENT (µA)

123 56

1

2

3

4

5

6

7

8

0

-40 40

CE IN TO CE OUT PROPAGATION DELAY

vs. TEMPERATURE

MAX817/18/19-13

TEMPERATURE (°C)

CE IN TO CE OUT PROPAGATION DELAY (ns)

-20 0 20

t

PD

-

tPD+

80 10060

1

2

3

4

5

6

7

20

MAX817/MAX819 PFI THRESHOLD

vs. TEMPERATURE

MAX817/18/19-14

TEMPERATURE (°C)

THRESHOLD (V)

-40 -20 0 60 80 10040

1.244

1.242

1.240

1.246

1.248

1.250

1.252

1.254

4.3

-40 40

RESET THRESHOLD

vs. TEMPERATURE

4.5

MAX817/18/19-10

TEMPERATURE (°C)

RESET THRESHOLD (V)

-20 0 20 8060

4.6

4.7

4.4

MAX81_L

MAX81_M

1000

1200

1400

1600

0

1 10 100 1000 10,000

MAXIMUM TRANSIENT DURATION

vs. RESET THRESHOLD OVERDRIVE

200

MAX817/18/19-11

RESET COMPARATOR OVERDRIVE, VTH-VCC (mV)

MAXIMUM TRANSIENT DURATION (µs)

400

600

800

RESET OCCURS

ABOVE CURVE

20

MAX817/MAX819 PFI TO PFO PROPAGATION

DELAY vs. TEMPERATURE

MAX817/18/19-15

TEMPERATURE (°C)

PROPAGATION DELAY (µs)

-40 -20 0 60 80 10040

28

29

30

31

32

33

____________________________Typical Operating Characteristics (continued)

(VCC= +5V, V

BATT

= 3.0V, TA= +25°C, unless otherwise noted.)

MAX817L/M, MAX818L/M, MAX819L/M*

+5V Microprocessor Supervisory Circuits

_______________________________________________________________________________________ 7

______________________________________________________________Pin Description

Ground. 0V reference for all signals.33

Input Supply Voltage, +5V input.22

Supply Output for CMOS RAM. When VCCrises above the reset threshold

or above V

BATT

, OUT is connected to VCCthrough an internal P-channel

MOSFET switch. When VCCfalls below V

BATT

, BATT connects to OUT.

11

GND3

V

CC

2

OUT1

Power-Fail Comparator Output. When PFI is less than V

PFT

or when VCCis

below V

BATT

, PFO goes low; otherwise PFO remains high. PFO is also used to

enable the battery freshness seal (see

Battery Freshness Seal

and

Power-Fail

Comparator

sections).

—5

Chip-Enable Input. The input to the chip-enable gating circuit. Connect to

ground if unused.

4—

Power-Fail Comparator Input. When V

PFI

is below V

PFT

or when VCCis below

V

BATT

, PFO goes low; otherwise, PFO remains high (see

Power-Fail Comparator

section). Connect to ground if unused.

—4

PFO

5

CE IN

—

PFI4

Backup-Battery Input. When VCCfalls below V

BATT

, OUT switches from VCCto

BATT. When VCCrises above V

BATT

, OUT reconnects to VCC.

88

Active-Low Reset Output. Pulses low for 200ms when triggered and remains

low whenever V

CC

is below the reset threshold or when MR is a logic low. It

remains low for 200ms after V

CC

rises above the reset threshold, the watchdog

triggers a reset, or MR goes low to high.

77

BATT8

RESET

7

Manual Reset Input. A logic low on MR asserts reset. Reset remains asserted

for as long as MR is held low and for 200ms after MR returns high. The activelow input has an internal 63kΩ pull-up resistor. It can be driven from a TTL- or

CMOS-logic line or shorted to ground with a switch. Leave open, or connect to

V

CC

if unused.

——

Watchdog Input. If WDI remains either high or low for longer than the watchdog timeout period, the internal watchdog timer runs out and a reset is triggered. If WDI is left unconnected or is connected to a high-impedance

three-state buffer, the watchdog feature is disabled. The internal watchdog

timer clears whenever reset is asserted, WDI is three-stated, or WDI sees a rising or falling edge. The WDI input is designed to be driven by a three-statedoutput device with a maximum high-impedance leakage current of 10µA and a

maximum output capacitance of 200pF. The output device must also be capable of sinking and sourcing 200µA when active.

66

Chip-Enable Output. CE OUT goes low only if CE IN is low while reset is not

asserted. If CE IN is low when reset is asserted, CE OUT will remain low for

15µs or until CE IN goes high, whichever occurs first. CE OUT is pulled up to

OUT in battery-backup mode. CE OUT is also used to enable the battery

freshness seal (see

Battery Freshness Seal

section).

5—

MR

6

WDI—

CE OUT

—

FUNCTIONNAME

MAX817 MAX818 MAX819

PIN

MAX817L/M, MAX818L/M, MAX819L/M*

+5V Microprocessor Supervisory Circuits

8 _______________________________________________________________________________________

MAX817

MAX818

MAX819

V

CC

BATT

WDI

PFI

CE IN

1.25V

CE OUT

GND

OUT

RESET

THIS PIN

FOR MAX819

ONLY.

THIS SECTION

FOR MAX817/

MAX818 ONLY.

THIS SECTION

FOR MAX817/

MAX819 ONLY.

THIS SECTION

FOR MAX818

ONLY.

MR

PFO

CHIP-ENABLE

OUTPUT

CONTROL

1.25V

RESET

GENERATOR

BATTERY

FRESHNESS

SEAL CIRCUITRY

BATTERY SWITCHOVER

CIRCUITRY

WATCHDOG

TIMER

Figure 1. Functional Diagram

MAX817L/M, MAX818L/M, MAX819L/M*

+5V Microprocessor Supervisory Circuits

_______________________________________________________________________________________ 9

_______________Detailed Description

General Timing Characteristics

Designed for 5V systems, the MAX817/MAX818/

MAX819 provide a number of microprocessor (µP)

supervisory functions (see the

Selector Guide

on the

first page). Figure 2 shows the typical timing relationships of the various outputs during power-up and

power-down with typical VCCrise and fall times.

RESET Output

A µP’s reset input starts the µP in a known state. The

MAX817/MAX818/MAX819 µP supervisory circuits

assert a reset to prevent code-execution errors during

power-up, power-down, and brownout conditions.

RESET is guaranteed to be a logic low for 0V < VCC<

V

RST

if V

BATT

is greater than 1V. Without a backup bat-

tery (V

BATT

= GND) RESET is guaranteed valid for

VCC≥ 1V. Once VCCexceeds the reset threshold an

internal timer keeps RESET low for the reset timeout

period, tRP. After this interval RESET returns high

(Figure 2).

If a brownout condition occurs (VCCdrops below the

reset threshold), RESET goes low. Each time RESET is

asserted it stays low for at least the reset timeout period. Any time VCCgoes below the reset threshold the

internal timer clears. The reset timer starts when V

CC

returns above the reset threshold. RESET both sources

and sinks current.

Manual Reset Input (MAX819)

Many µP-based products require manual reset capability, allowing the operator, a test technician, or external

logic circuitry to initiate a reset. On the MAX819, a logic

low on MR asserts reset. Reset remains asserted while

MR is low, and for tRP(200ms) after it returns high.

During the reset timeout period (tRP), MR’s state is

ignored if the battery freshness seal is enabled. MR has

an internal 63kΩ pull-up resistor, so it can be left open

if not used. This input can be driven with TTL/CMOSlogic levels or with open-drain/collector outputs.

Connect a normally open momentary switch from MR to

GND to create a manual reset function; external

debounce circuitry is not required. If MR is driven from

long cables or the device is used in a noisy environment, connect a 0.1µF capacitor from MR to GND to

provide additional noise immunity.

Note that MR must be high or open to enable the battery freshness seal. Once the battery freshness seal is

enabled its operation is unaffected by MR.

Battery Freshness Seal

The MAX817/MAX818/MAX819 battery freshness seal

disconnects the backup battery from internal circuitry

and OUT until it is needed. This allows an OEM to

ensure that the backup battery connected to BATT will

be fresh when the final product is put to use. To enable

the freshness seal on the MAX817 and MAX819:

1) Connect a battery to BATT.

2) Ground PFO.

3) Bring VCCabove the reset threshold and hold it

there until reset is deasserted following the reset

timeout period.

4) Bring VCCdown again (Figure 3).

Use the same procedure for the MAX818, but ground

CE OUT instead of PFO. Once the battery freshness

seal is enabled (disconnecting the backup battery from

internal circuitry and anything connected to OUT), it

remains enabled until VCCis brought above V

RST

.

Figure 2. Power-Up and Power-Down Timing

V

CC

CE OUT FOLLOWS CE IN

*MAX817/MAX819 ONLY.

V

OUT

t

RP

V

RST

V

BATT

V

BATT

V

BATT

V

BATT

V

RST

V

RESET

V

CE OUT**

V

PFO*

RESET TO

CE OUT

DELAY**

PFO FOLLOWS PFI

** MAX818 ONLY.

Figure 3. Battery Freshness Seal Timing

V

CC

RESET

t

RP

V

RST

V

RST

CE OUT

(MAX818)

(EXTERNALLY HELD AT 0V)

CE OUT STATE LATCHED

AT 1/2 t

RP

AND 3/4 tRP,

FRESHNESS SEAL ENABLED

PFO

(MAX817/MAX819)

(EXTERNALLY HELD AT 0V)

PFO STATE LATCHED

AT 1/2 t

RP

AND 3/4 tRP,

FRESHNESS SEAL ENABLED

MAX817L/M, MAX818L/M, MAX819L/M*

+5V Microprocessor Supervisory Circuits

10 ______________________________________________________________________________________

On the MAX819, MR must be high or open to enable

the battery freshness seal. Once the battery freshness

seal is enabled its operation is unaffected by MR.

Watchdog Input (MAX817/MAX818)

In the MAX817/MAX818, the watchdog circuit monitors

the µP’s activity. If the µP does not toggle the watchdog

input (WDI) within tWD(1.6sec), reset asserts. The internal 1.6sec timer is cleared by either a reset pulse or by

toggling WDI, which can detect pulses as short as

50ns. The timer remains cleared and does not count for

as long as reset is asserted. As soon as reset is

released, the timer starts counting (Figure 4).

To disable the watchdog function, leave WDI unconnected or three-state the driver connected to WDI. The

watchdog input is internally driven low during the first

7/8 of the watchdog timeout period, then momentarily

pulses high, resetting the watchdog counter. When

WDI is left open-circuited, this internal driver clears the

1.6sec timer every 1.4sec. When WDI is three-stated or

left unconnected, the maximum allowable leakage current is 10µA and the maximum allowable load capacitance is 200pF.

Chip-Enable Gating (MAX818)

Internal gating of the chip-enable (CE) signal prevents

erroneous data from corrupting CMOS RAM in the

event of an undervoltage condition. The MAX818 uses

a series transmission gate from CE IN to CE OUT

(Figure 5). During normal operation (reset not asserted), the CE transmission gate is enabled and passes

all CE transitions. When reset is asserted, this path

becomes disabled, preventing erroneous data from

corrupting the CMOS RAM. The short CE propagation

delay from CE IN to CE OUT enables the MAX818 to be

used with most µPs. If CE IN is low when reset asserts,

CE OUT remains low for typically 15 µs to permit the

current write cycle to complete.

Chip-Enable Input (MAX818)

The CE transmission gate is disabled and CE IN is high

impedance (disabled mode) while reset is asserted.

During a power-down sequence when VCCpasses the

reset threshold, the CE transmission gate disables and

CE IN immediately becomes high impedance if the voltage at CE IN is high. If CE IN is low when reset asserts,

the CE transmission gate will disable 15µs after reset

asserts (Figure 6). This permits the current write cycle

to complete during power-down.

Figure 4. Watchdog Timing

V

CC

t

RP

t

WD

RESET

WDI

Figure 6. Chip-Enable Timing

V

BATT

V

BATT

V

CC

t

RP

t

RP

15µs

V

RST

V

RST

V

RST

V

RST

V

RESET

V

CE IN

V

CE OUT

Figure 5. Chip-Enable Transmission Gate

CE IN

CE OUT

P

N

OUT

CHIP-ENABLE

OUTPUT

CONTROL

RESET

GENERATOR

BATTERY

SWITCHOVER

CIRCUITRY

BATTERY

FRESHNESS

SEAL CIRCUITRY

MAX817

MAX818

MAX817L/M, MAX818L/M, MAX819L/M*

+5V Microprocessor Supervisory Circuits

______________________________________________________________________________________ 11

Any time a reset is generated, the CE transmission gate

remains disabled and CE IN remains high impedance

(regardless of CE IN activity) for the reset timeout period. When the CE transmission gate is enabled, the

impedance of CE IN appears as a 40Ω resistor in series

with the load at CE OUT. The propagation delay

through the CE transmission gate depends on VCC, the

source impedance of the drive connected to CE IN,

and the loading on CE OUT (see

Typical Operating

Characteristics

). The CE propagation delay is production tested from the 50% point on CE IN to the 50%

point on CE OUT using a 50Ω driver and a 50pF load

capacitance (Figure 7). For minimum propagation

delay, minimize the capacitive load at CE OUT and use

a low-output-impedance driver.

Chip-Enable Output (MAX818)

When the CE transmission gate is enabled, the impedance of CE OUT is equivalent to a 40Ω resistor in series

with the source driving CE IN. In the disabled mode,

the transmission gate is off and an active pull-up connects CE OUT to OUT (Figure 5). This pull-up turns off

when the transmission gate is enabled.

Power-Fail Comparator

(MAX817/MAX819)

The MAX817/MAX819 PFI input is compared to an internal reference. If PFI is less than the power-fail threshold

(V

PFT

), PFO goes low. The power-fail comparator is

intended for use as an undervoltage detector to signal a

failing power supply (Figure 8). However, the comparator

does not need to be dedicated to this function because it

is completely separate from the rest of the circuitry.

The power-fail comparator turns off and PFO goes low

when VCCfalls below V

BATT

. During the reset timeout

period (tRP), PFO is forced high, regardless of the state

of V

PFI

(see

Battery Freshness Seal

section). If the comparator is unused, connect PFI to ground and leave PFO

unconnected. PFO can be connected to MR on the

MAX819 so that a low voltage on PFI will generate a

reset (Figure 9). In this configuration, when the monitored

voltage causes PFI to fall below V

PFT

, PFO pulls MR low,

causing a reset to be asserted. Reset remains asserted

as long as PFO holds MR low, and for tRP(200ms) after

PFO pulls MR high when the monitored supply is above

the programmed threshold. When PFO is connected to

MR, it is not possible to enable the battery freshness

seal. Enabling the battery freshness seal requires MR to

be high or open. Once the battery freshness seal is

enabled, it is no longer affected by PFO’s connection to

MR.

Figure 7. CE Propagation Delay Test Circuit

CE IN

BATT

CE OUT

GND

MAX818

CL*

* C

L

INCLUDES LOAD CAPACITANCE, STRAY CAPACITANCE,

AND SCOPE-PROBE CAPACITANCE.

50pF

V

CC

+5V

50Ω

50Ω

Figure 8. Using the Power-Fail Comparator to Generate a

Power-Fail Warning

MAX817

MAX819

V

WARN

= 1.25

POWER-FAIL-WARNING TRIP VOLTAGE

R1 + R2

R2

PFI

PFO

R1

R2

µP

V

CC

V

IN

NMI

RESET

1.25V

RESET

+5V

REGULATOR

( )

MAX817L/M, MAX818L/M, MAX819L/M*

+5V Microprocessor Supervisory Circuits

12 ______________________________________________________________________________________

Backup-Battery Switchover

In a brownout or power failure, it may be necessary to

preserve the contents of RAM. With a backup battery

installed at BATT, the MAX817/MAX818/MAX819 automatically switch RAM to backup power when VCCfalls.

These devices require two conditions before switching

to battery-backup mode: 1) VCCmust be below the

reset threshold, and 2) VCCmust be below V

BATT

.

Table 1 lists the status of the inputs and outputs in battery-backup mode.

As long as VCCexceeds the reset threshold, OUT connects to VCCthrough a 5Ω PMOS power switch. Once

VCCfalls below the reset threshold, VCCor V

BATT

(whichever is higher) switches to OUT. When VCCfalls

below V

RST

and V

BATT

, BATT switches to OUT through

an 80Ω switch.

When VCCexceeds the reset threshold, it is connected to

the substrate, regardless of the voltage applied to BATT

(Figure 10). During this time, the diode (D1) between

BATT and the substrate will conduct current from BATT

to VCCif V

BATT

is 0.6V greater than VCC. When BATT

connects to OUT, backup mode is activated and the

internal circuitry is powered from the battery (Table 1).

When VCCis just below V

BATT

, the current draw from

BATT is typically 6µA. When VCCdrops to more than 1V

below V

BATT

, the internal switchover comparator shuts

off and the supply current falls to less than 1µA.

__________Applications Information

The MAX817/MAX818/MAX819 are protected for typical

short-circuit conditions of 10sec or less. Shorting OUT

to ground for longer than 10sec destroys the device.

Decouple VCC, OUT, and BATT to ground by placing

0.1µF capacitors as close to the device as possible.

Connected to V

OUT

. Current drawn from

the battery is less than 1µA, as long as

VCC< V

BATT

- 0.2V.

V

BATT

Logic low

Disconnected from V

OUT

.V

CC

V

RESET

Logic high. The open-circuit voltage is equal

to V

OUT

.

V

CEOUT

High impedanceV

CEIN

Watchdog timer is disabled.V

WDI

Connected to V

BATT

through an internal 80Ω

PMOS switch.

V

OUT

STATUSSIGNAL

Table 1. Input and Output Status in

Battery-Backup Mode

Figure 9. Monitoring an Additional Supply by Connecting

PFO to MR.

MAX819

V2

(RESET)

= 1.25

ADDITIONAL SUPPLY RESET VOLTAGE

R1 + R2

R2

R1

R2

µP

V

CC

V1

V2

RESET

PFI

RESET

MR

PFO

( )

Figure 10. Backup-Battery-Switchover Block Diagram

SW1/SW2

SW3/SW4CONDITION

V

CC

> Reset Threshold Open

Closed

Closed

Open

Open

Closed

V

CC

< Reset Threshold and

V

CC

> V

BATT

VCC < Reset Threshold and

V

CC

< V

BATT

RESET THRESHOLD = 4.65V IN MAX81_L

RESET THRESHOLD = 4.4V IN MAX81_M

OUT

D3

SUBSTRATE

D1

D2

SW2

SW1

SW4

SW3

BATT

V

CC

MAX817

MAX818

MAX819

MAX817L/M, MAX818L/M, MAX819L/M*

+5V Microprocessor Supervisory Circuits

______________________________________________________________________________________ 13

Watchdog Input Current

The MAX817/MAX818 WDI inputs are internally driven

through a buffer and series resistor from the watchdog

counter (Figure 1). When WDI is left unconnected, the

watchdog timer is serviced within the watchdog timeout

period by a low-high-low pulse from the counter chain.

For minimum watchdog input current (minimum overall

power consumption), leave WDI low for the majority of the

watchdog timeout period, pulsing it low-high-low once

within 7/8 of the watchdog timeout period to reset the

watchdog timer. If instead WDI is externally driven high for

the majority of the timeout period, up to 150µA can flow

into WDI.

Using a SuperCap™ as a

Backup Power Source

SuperCaps are capacitors with extremely high capacitance values (on the order of 0.47F) for their size. Since

BATT has the same operating voltage range as VCC, and

the battery switchover threshold voltages are typically

±30mV centered at V

BATT

, a SuperCap and simple

charging circuit can be used as a backup power source.

Figure 11 shows a SuperCap used as a backup source.

If VCCis above the reset threshold and V

BATT

is 0.5V

above VCC, current flows to OUT and VCCfrom BATT

until the voltage at BATT is less than 0.5V above VCC.

For example, if a SuperCap is connected to BATT

through a diode to VCC, and VCCquickly changes from

5.4V to 4.9V, the capacitor discharges through OUT

and VCCuntil V

BATT

reaches 5.1V typical. Leakage current through the SuperCap charging diode and the

internal power diode eventually discharges the

SuperCap to VCC. Also, if VCCand V

BATT

start from

0.1V above the reset threshold and power is lost at

VCC, the SuperCap on BATT discharges through V

CC

until V

BATT

reaches the reset threshold. Battery-backup

mode is then initiated and the current through V

CC

goes to zero.

Operation Without a

Backup Power Source

The MAX817/MAX818/MAX819 were designed for battery-backed applications. If a backup battery is not

used, connect VCCto OUT, and connect BATT to

ground.

Replacing the Backup Battery

The backup power source can be removed while V

CC

remains valid, without danger of triggering a reset

pulse, if BATT is decoupled with a 0.1µF capacitor to

ground. As long as VCCstays above the reset threshold, battery-backup mode cannot be entered.

Adding Hysteresis to the Power-Fail

Comparator (MAX817/MAX819)

The power-fail comparator has a typical input hysteresis of 4mV. This is sufficient for most applications where

a power-supply line is being monitored through an

external voltage divider (see

Monitoring an Additional

Supply

).

For additional noise margin, connect a resistor between

PFO and PFI, as shown in Figure 12. Select the ratio of

R1 and R2 such that PFI sees V

PFT

when VINfalls to the

Figure 11. Using a SuperCap™ as a Backup Power Source

with a +5V ±10% Supply

SuperCap is a trademark of Baknor Industries.

BATT

V

CC

OUT

RESET

GND

TO STATIC RAM

TO µP

0.1F

MAX817

MAX818

MAX819

+5V

100k

Figure 12. Adding Hysteresis to the Power-Fail Comparator

V

CC

GND

TO µP

PFI

PFO

R1

R2

R3

*OPTIONAL

C1*

V

IN

+5V

R1

+ R2

R2

V

H

= 1.25V

V

TRIP

= 1.25V

++||

||

R2 R3

R1 R2 R3

MAX817

MAX819

PFO

0V

+5V

V

H

V

L

0V

V

TRIP

V

IN

( )

R1

V

L

- 1.25

R3

5

- 1.25

=

R2

1.25

( )

MAX817L/M, MAX818L/M, MAX819L/M*

+5V Microprocessor Supervisory Circuits

14 ______________________________________________________________________________________

desired trip point (V

TRIP

). Resistor R3 adds hysteresis.

It will typically be an order of magnitude greater than R1

or R2. The current through R1 and R2 should be at least

1µA to ensure that the 25nA (max) PFI input leakage

current does not shift the trip point. R3 should be larger

than 200kΩ to prevent it from loading down the PFO pin.

Capacitor C1 adds additional noise rejection.

Monitoring an Additional Supply

(MAX817/MAX819)

The MAX817/MAX819 µP supervisors can monitor either

positive or negative supplies using a resistor voltage

divider to PFI. PFO can be used to generate an interrupt

to the µP or to trigger a reset (Figures 9 and 13).

Interfacing to µPs with

Bidirectional Reset Pins

µPs with bidirectional reset pins, such as the Motorola

68HC11 series, can contend with the MAX817/MAX818/

MAX819 RESET output. If, for example, the RESET output is driven high and the µP wants to pull it low, indeterminate logic levels may result. To correct this,

connect a 4.7kΩ resistor between the RESET output

and the µP reset I/O, as in Figure 14. Buffer the RESET

output to other system components.

Negative-Going VCCTransients

These supervisors are relatively immune to short-duration, negative-going VCCtransients (glitches) while

issuing a reset to the µP during power-up, power-down,

and brownout conditions. Therefore, resetting the µP

when VCCexperiences only small glitches is usually not

desirable.

The

Typical Operating Characteristics

show a graph of

Maximum Transient Duration vs. Reset Threshold

Overdrive for which reset pulses are not generated. The

graph was produced using negative-going VCCpulses,

starting at 3.3V and ending below the reset threshold by

the magnitude indicated (reset threshold overdrive). The

graph shows the maximum pulse width that a negativegoing VCCtransient can typically have without triggering

a reset pulse. As the amplitude of the transient increases

(i.e., goes farther below the reset threshold), the maximum allowable pulse width decreases. Typically, a V

CC

transient that goes 100mV below the reset threshold and

lasts for 135µs will not trigger a reset pulse.

A 0.1µF bypass capacitor mounted close to the V

CC

pin provides additional transient immunity.

Figure 13. Monitoring a Negative Voltage

MAX817

MAX819

V

CC

GND

PFI PFO

R1

R2

V-

NOTE: V

TRIP

IS NEGATIVE

0V

PFO

0V

V

TRIP

V-

+5V

+5V

R1

5

- 1.25R21.25 - V

TRIP

=

Figure 14. Interfacing to µPs with Bidirectional Reset I/O

MAX817

MAX818

MAX819

BUFFERED RESET TO OTHER SYSTEM COMPONENTS

4.7k

V

CC

GND

V

CC

GND

RESET

RESET

MAX817L/M, MAX818L/M, MAX819L/M*

+5V Microprocessor Supervisory Circuits

______________________________________________________________________________________ 15

____Pin Configurations (continued)

__________Typical Operating Circuit

WDI

GND

CE OUT

CE IN

1

2

8

7

BATT

RESET

V

CC

OUT

MAX818

DIP/SO/µMAX

TOP VIEW

3

4

6

5

MR

GND

PFO

PFI

1

2

8

7

BATT

RESET

V

CC

OUT

MAX819

DIP/SO/µMAX

3

4

6

5

CE IN*

*CE IN AND CE OUT APPLY TO MAX818 ONLY.

**WDI APPLIES TO MAX817/MAX818 ONLY.

BATT

RESET

I/O

OUT

CMOS

RAM

RESET

WDI**

CE OUT*

0.1µF

0.1µF

0.1µF

GND

MAX817

MAX818

MAX819

V

CC

ADDRESS

DECODE

REAL-

TIME

CLOCK

A0–A15

µP

+5V

Watchdog Software Considerations

(MAX817/MAX818)

To help the watchdog timer monitor software execution

more closely, set and reset the watchdog input at different

points in the program, rather than “pulsing” the watchdog

input high-low-high or low-high-low. This technique avoids

a “stuck” loop, in which the watchdog timer would continue to be reset within the loop, keeping the watchdog from

timing out. Figure 15 shows an example of a flow diagram

where the I/O driving the watchdog input is set high at the

beginning of the program, set low at the beginning of

every subroutine or loop, then set high again when the

program returns to the beginning. If the program should

“hang” in any subroutine, the problem would quickly be

corrected, since the I/O is continually set low and the

watchdog timer is allowed to time out, triggering a reset or

an interrupt. As described in the

Watchdog Input Current

section, this scheme results in higher average WDI input

current than does the method of leaving WDI low for the

majority of the timeout period and periodically pulsing it

low-high-low.

Figure 15. Watchdog Flow Diagram

START

SET

WDI

LOW

SUBROUTINE

OR PROGRAM LOOP,

SET WDI

HIGH

RETURN

END

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

16

__________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 (408) 737-7600

© 1996 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

MAX817L/M, MAX818L/M, MAX819L/M*

+5V Microprocessor Supervisory Circuits

_Ordering Information (continued) ___________________Chip Information

________________________________________________________Package Information

TRANSISTOR COUNT: 719

†

These parts offer a choice of reset threshold voltage. From the

table below, select the suffix corresponding to the desired

threshold and insert it into the blank to complete the part number.

PART

†

MAX817_EPA

MAX817_ESA

MAX818_CPA

0°C to +70°C

-40°C to +85°C

-40°C to +85°C

TEMP. RANGE PIN-PACKAGE

8 Plastic DIP

8 SO

8 Plastic DIP

MAX818_CSA

MAX818_CUA

MAX818_EPA -40°C to +85°C

0°C to +70°C

0°C to +70°C 8 SO

8 µMAX

8 Plastic DIP

MAX818_ESA -40°C to +85°C 8 SO

MAX819_CPA

MAX819_CSA

MAX819_CUA 0°C to +70°C

0°C to +70°C

0°C to +70°C 8 Plastic DIP

8 SO

8 µMAX

MAX819_EPA

MAX819_ESA -40°C to +85°C

-40°C to +85°C 8 Plastic DIP

8 SO

SUFFIX RESET THRESHOLD (V)

L 4.65

M 4.40

L

α

C

A1B

DIM

A

A1

B

C

D

E

e

H

L

α

MIN

0.036

0.004

0.010

0.005

0.116

0.116

0.188

0.016

0°

MAX

0.044

0.008

0.014

0.007

0.120

0.120

0.198

0.026

6°

MIN

0.91

0.10

0.25

0.13

2.95

2.95

4.78

0.41

0°

MAX

1.11

0.20

0.36

0.18

3.05

3.05

5.03

0.66

6°

INCHES MILLIMETERS

8-PIN µMAX

MICROMAX SMALL-OUTLINE

PACKAGE

0.650.0256

A

e

E H

D

0.101mm

0.004 in

21-0036D

Loading...

Loading...