MAX745

Switch-Mode Lithium-Ion

Battery-Charger

________________________________________________________________

Maxim Integrated Products

1

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 1-800-835-8769.

General Description

The MAX745 provides all functions necessary for

charging lithium-ion battery packs. It provides a regulated charging current of up to 4A without getting hot,

and a regulated voltage with only ±0.75% total error at

the battery terminals. It uses low-cost, 1% resistors to

set the output voltage, and a low-cost N-channel MOSFET as the power switch.

The MAX745 regulates the voltage set point and charging current using two loops that work together to transition smoothly between voltage and current regulation.

The per-cell battery voltage regulation limit is set

between 4.0V and 4.4V using standard 1% resistors,

and then the number of cells is set from 1 to 4 by pinstrapping. Total output voltage error is less than ±0.75%.

For a similar device with an SMBus™ microcontroller

interface and the ability to charge NiCd and NiMH cells,

refer to the MAX1647 and MAX1648. For a low-cost

lithium-ion charger using a linear-regulator control

scheme, refer to the MAX846A.

____________________________Features

♦ Charges 1 to 4 Lithium-Ion Battery Cells

♦ ±0.75% Voltage-Regulation Accuracy

Using 1% Resistors

♦ Provides up to 4A without Excessive Heating

♦ 90% Efficient

♦ Uses Low-Cost Set Resistors and

N-Channel Switch

♦ Up to 24V Input

♦ Up to 18V Maximum Battery Voltage

♦ 300kHz PWM Operation: Low-Noise,

Small Components

♦ Stand-Alone Operation; No Microcontroller

Needed

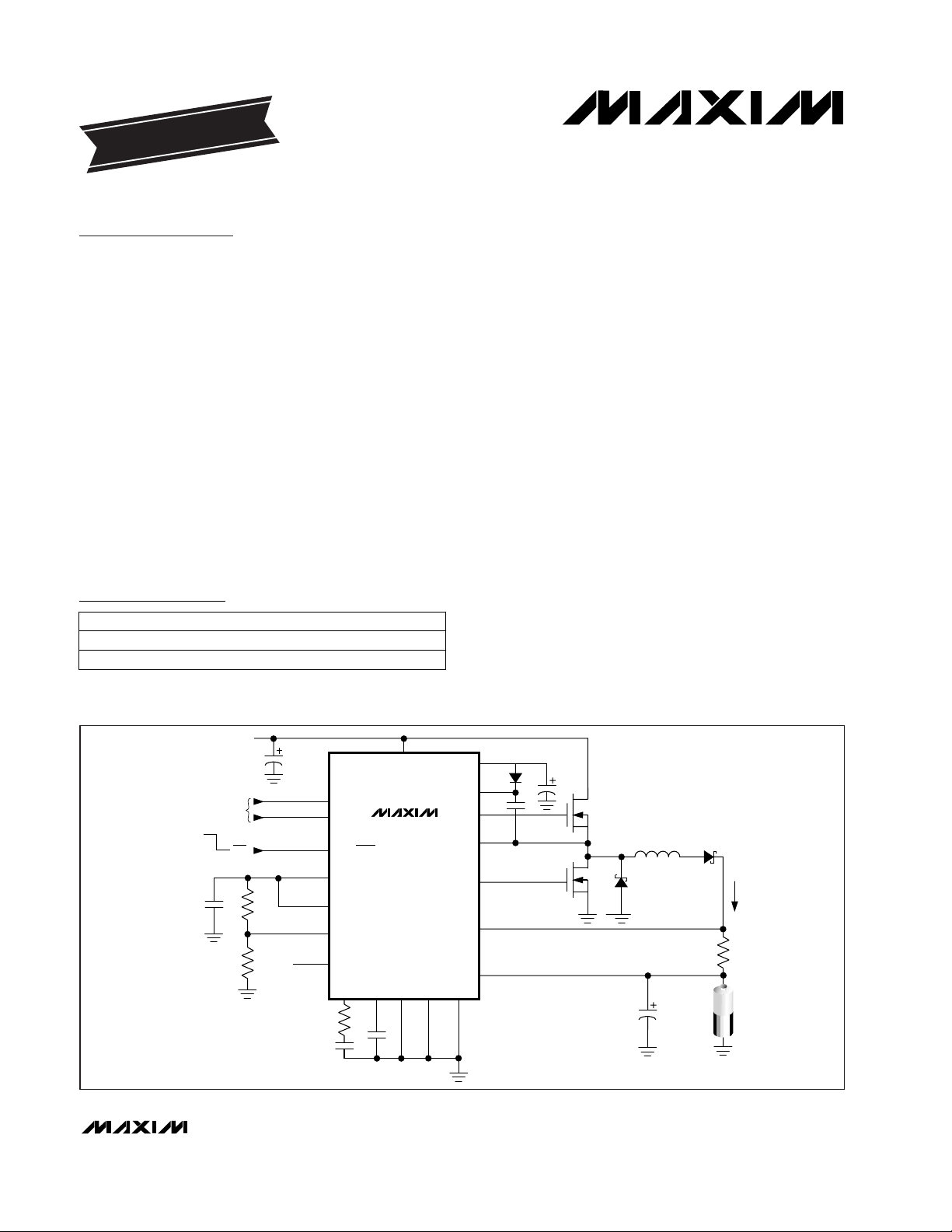

___________________________________________________Typical Operating Circuit

19-1182; Rev 2; 12/98

PART

MAX745EAP -40°C to +85°C

TEMP. RANGE PIN-PACKAGE

20 SSOP

EVALUATION KIT MANUAL

FOLLOWS DATA SHEET

Ordering Information

Pin Configuration appears on last page.

________________________Applications

Lithium-Ion Battery Packs

Desktop Cradle Chargers

Cellular Phones

Notebook Computers

Hand-Held Instruments

MAX745C/D 0°C to +70°C Dice*

*

Dice are tested at TA= +25°C.

SMBus is a trademark of Intel Corp.

(UP TO 24V)

REF

DCIN

V

IN

BST

VL

DHI

DLO

LX

CS

BATT

CELL

COUNT

SELECT

SET PER

CELL VOLTAGE

WITH 1% RESISTORS

ON

OFF

VADJ

STATUS

SETI

CELL0

CELL1

CCI PGNDGND

IBAT

CCV

N

N

I

CHARGE

R

SENSE

VOUT

1–4 Li+ CELLS

(UP TO 18V)

MAX745

THM/SHDN

MAX745

Switch-Mode Lithium-Ion

Battery Charger

2 _______________________________________________________________________________________

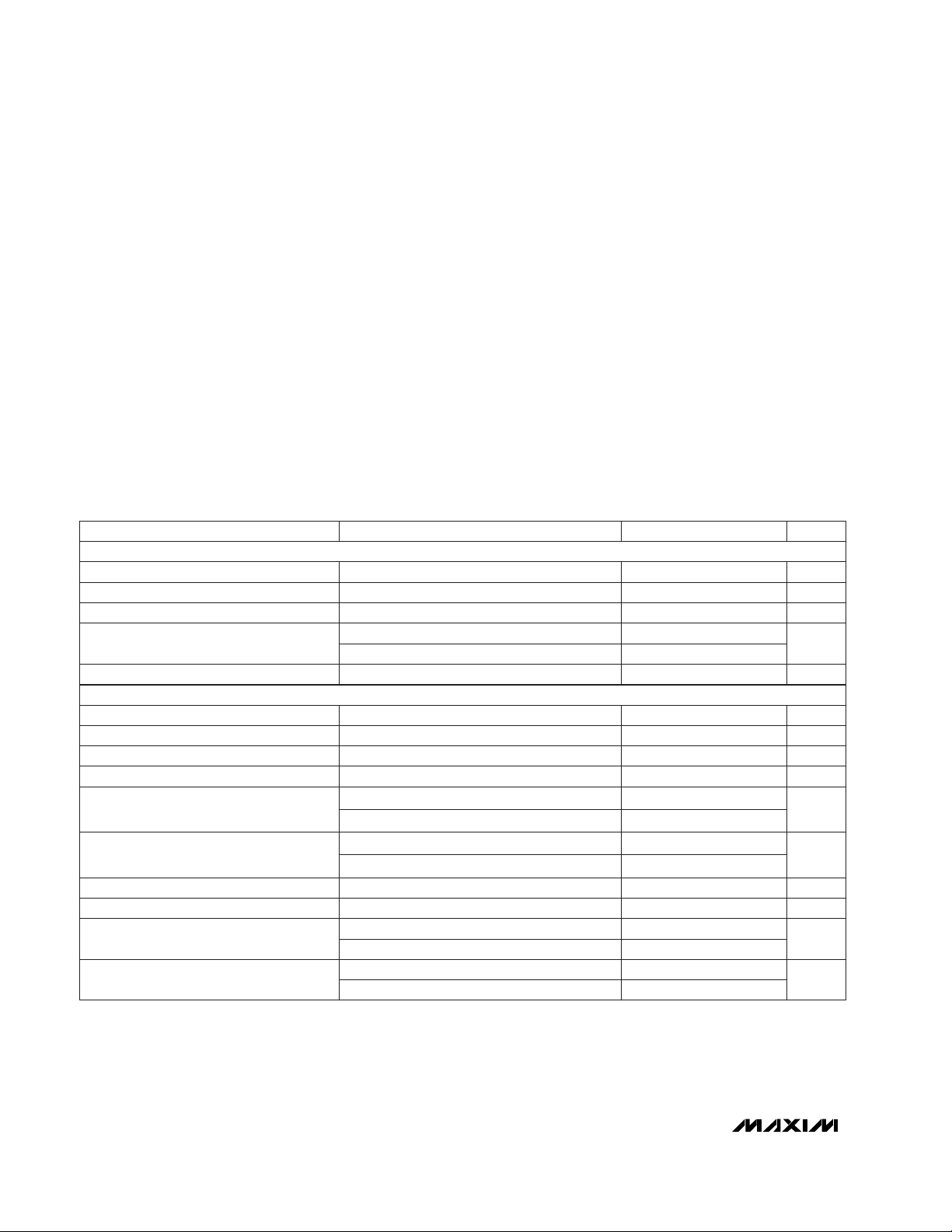

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(V

DCIN

= 18V, V

BATT

= 8.4V, TA= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

DCIN to GND............................................................-0.3V to 26V

BST, DHI to GND......................................................-0.3V to 30V

BST to LX....................................................................-0.3V to 6V

DHI to LX............................................(LX - 0.3V) to (BST + 0.3V)

LX to GND................................................-0.3V to (DCIN + 0.3V)

VL to GND...................................................................-0.3V to 6V

CELL0, CELL1, IBAT, STATUS, CCI, CCV,

REF, SETI, VADJ, DLO, THM/

SHDN to GND ..-0.3V to (VL + 0.3V)

BATT, CS to GND .....................................................-0.3V to 20V

PGND to GND..........................................................-0.3V to 0.3V

VL Current...........................................................................50mA

Continuous Power Dissipation (T

A

= +70°C)

SSOP (derate 8.00mW/°C above +70°C) ......................640mW

Operating Temperature Range ...........................-40°C to +85°C

Storage Temperature.........................................-60°C to +150°C

Lead Temperature (soldering, 10sec).............................+300°C

6.0V < V

DCIN

< 24V, logic inputs = VL

VL < 3.2V, VCS= 12V

VL < 3.2V, V

BATT

= 12V

Output high or low

0 < I

REF

< 1mA

6.0V < V

DCIN

< 24V, no load

TA= +25°C

Output high or low

CONDITIONS

V019BATT, CS Input Voltage Range

µA

5

CS Input Current

µA

5

BATT Input Current

Ω

614DLO On-Resistance

Ω

47DHI On-Resistance

mA46DCIN Quiescent Supply Current

V624DCIN Input Voltage Range

% 89 93DHI Maximum Duty Cycle

kHz270 300 330Oscillator Frequency

mV/mA10 20REF Output Load Regulation

V5.15 5.40 5.65VL Output Voltage

V

4.17 4.2 4.23

REF Output Voltage

UNITSMIN TYP MAXPARAMETER

4V < V

BATT

< 16V

6.0V < V

DCIN

< 24V

mV±1.5CS to BATT Offset Voltage (Note 1)

SETI = V

REF

(full scale)

mV

170 185 205

CS to BATT

Current-Sense Voltage

Not including VADJ resistor tolerance

%

-0.65 0.65

Absolute Voltage Accuracy

With 1% tolerance VADJ resistors

4.16 4.2 4.24

-0.75 0.75

SWITCHING REGULATOR

SUPPLY AND REFERENCE

VL > 5.15V, V

BATT

= 12V

VL > 5.15V, VCS= 12V 400

500

SETI = 400mV 14 18 22

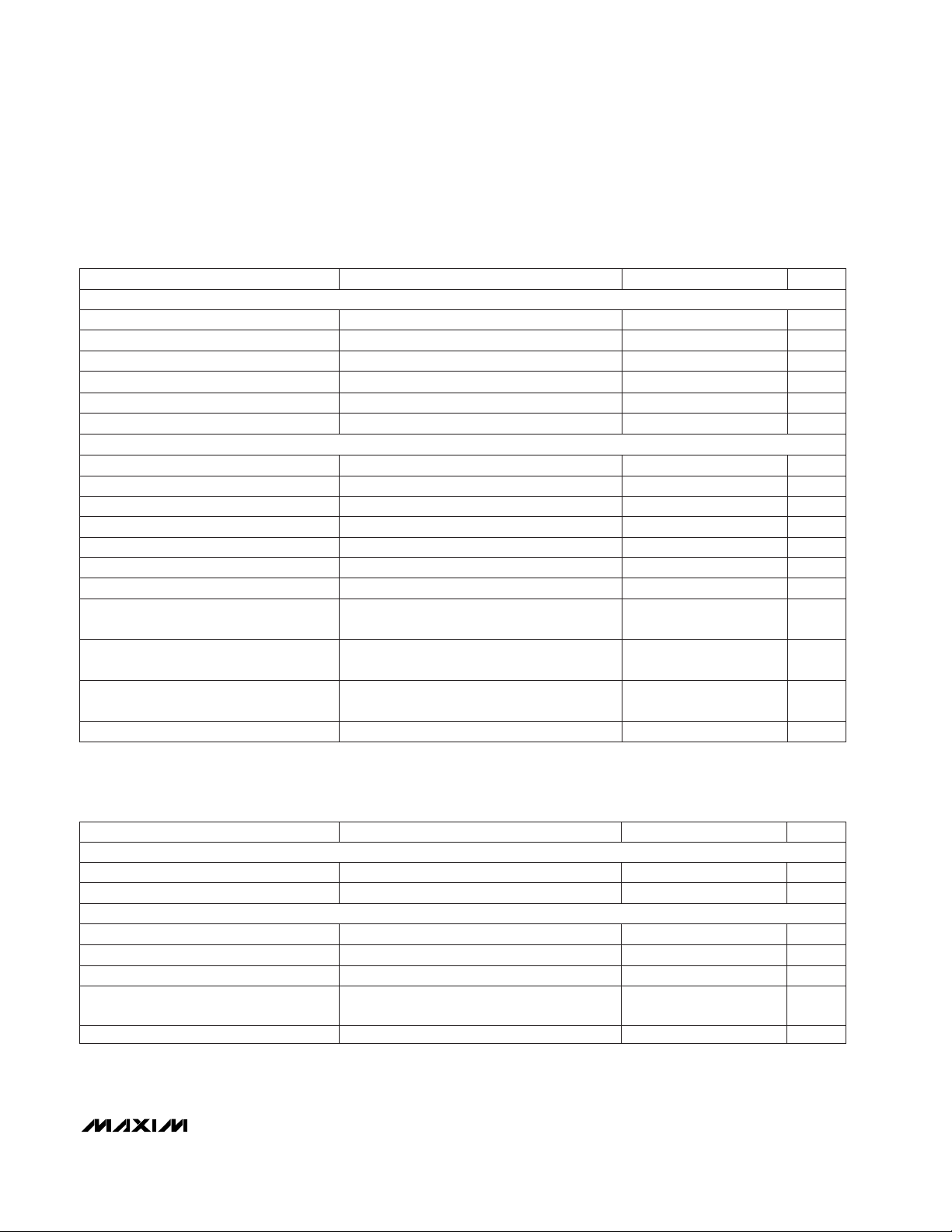

MAX745

_______________________________________________________________________________________

3

Switch-Mode Lithium-Ion

Battery Charger

Note 1: When V

SETI

= 0V, the battery charger turns off.

ELECTRICAL CHARACTERISTICS (continued)

(V

DCIN

= 18V, V

BATT

= 8.4V, TA= 0°C to +85°C. Typical values are at TA= +25°C, unless otherwise noted.)

ELECTRICAL CHARACTERISTICS

(V

DCIN

= 18V, V

BATT

= 8.4V, TA= -40°C to +85°C, unless otherwise noted. Limits over temperature are guaranteed by design.)

6.0V < V

DCIN

< 24V

6.0V < V

DCIN

< 24V, no load

Output high or low

Output high or low

CONDITIONS

mV165 205

CS to BATT Full-Scale

Current-Sense Voltage

Not including VADJ resistors %-1.0 1.0Absolute Voltage Accuracy

V4.14 4.26REF Output Voltage

V5.10 5.70VL Output Voltage

Ω

14DLO On-Resistance

Ω

7DHI On-Resistance

kHz260 340Oscillator Frequency

UNITS

MIN TYP MAX

PARAMETER

IBAT Compliance Voltage Range 02V

V

IBAT

= 2V

IBAT Output Current vs.

Current-Sense Voltage

0.9

µA/mV

Charger in voltage-regulation mode,

V

STATUS

= 5V

STATUS Output Leakage Current 1

µA

Charger in current-regulation mode,

STATUS sinking 1mA

STATUS Output Low Voltage 0.2 V

THM/SHDN Falling Threshold

2.01 2.1 2.19 V

THM/SHDN Rising Threshold

2.20 2.3 2.34 V

1.1V < V

CCI

< 3.5VCCV Clamp Voltage with Respect to CCI

PARAMETER MIN TYP MAX UNITS

GMV Amplifier Output Current ±130

µA

GMI Amplifier Transconductance 200

µA/V

GMI Amplifier Output Current ±320

µA

CCI Clamp Voltage with Respect to CCV 25 80 200 mV

25 80 200 mV

CELL0, CELL1 Input Bias Current -1 1

µA

SETI Input Voltage Range (Note 1) 0V

REF

V

SETI, VADJ Input Bias Current -10 10 nA

VADJ Adjustment Range 10 %

CONDITIONS

VADJ Input Voltage Range 0 V

REF

1.1V < V

CCV

< 3.5V

V

SWITCHING REGULATOR (Note 1)

SUPPLY AND REFERENCE

GMV Amplifier Transconductance 800

µA/V

CONTROL INPUTS/OUTPUTS

ERROR AMPLIFIERS

MAX745

Switch-Mode Lithium-Ion

Battery Charger

4 _______________________________________________________________________________________

4.5

0

0 0.1 0.2 0.4 1.0

BATTERY VOLTAGE

vs. CHARGING CURRENT

1.0

4.0

MAX745/TOC-01

CHARGING CURRENT (A)

BATTERY VOLTAGE (V)

0.3 0.5 0.6 0.7 0.8 0.9

3.0

2.0

0.5

3.5

2.5

1.5

R1 = 0.2Ω

R16 = SHORT

R12 = OPEN CIRCUIT

200

0

0 0.5 1.5 4.0

CURRENT-SENSE VOLTAGE

vs. SETI VOLTAGE

40

160

MAX745/TOC-02

SETI VOLTAGE (V)

CURRENT-SENSE VOLTAGE (mV)

1.0 2.0 2.5 3.0 3.5

120

80

180

20

140

100

60

R1 = 0.2Ω

4.45

3.95

0 0.5 1.0 2.0 4.5

VOLTAGE LIMIT

vs. VADJ VOLTAGE

4.05

4.35

MAX745/TOC-03

VADJ VOLTAGE (V)

PER-CELL VOLTAGE LIMIT (V)

1.5 2.5 3.0 3.5 4.0

4.25

4.15

4.40

4.00

4.30

4.20

4.10

4.205

4.195

02550

REFERENCE VOLTAGE

vs. TEMPERATURE

4.197

4.203

MAX745/TOC-06

TEMPERATURE (°C)

REFERENCE VOLTAGE (V)

75 100

4.201

4.199

4.204

4.196

4.202

4.200

4.198

__________________________________________Typical Operating Characteristics

(TA= +25°C, V

DCIN

= 18V, V

BATT

= 4.2V, CELL0 = CELL1 = GND, CVL= 4.7µF, C

REF

= 0.1µF. Circuit of Figure 1, unless

otherwise noted.)

5.50

0

0 5 10 25

VL LOAD REGULATION

5.10

5.40

MAX745/TOC-04

VL OUTPUT CURRENT (mA)

VL OUTPUT VOLTAGE (V)

15 20

5.30

5.20

5.45

5.05

5.35

5.25

5.15

4.25

4.15

0 500 1000 3000

REFERENCE LOAD REGULATION

4.17

4.23

MAX745/TOC-05

REFERENCE CURRENT (µA)

REFERENCE VOLTAGE (V)

1500 2000 2500

4.21

4.19

4.24

4.16

4.22

4.20

4.18

_______________Detailed Description

The MAX745 is a switch-mode, lithium-ion battery

charger that can achieve 90% efficiency. The charge

voltage and current are set independently by external

resistor-dividers at SETI and VADJ, and at pin connections at CELL0 and CELL1. VADJ is connected to a

resistor-divider to set the charging voltage. The output

voltage-adjustment range is ±5%, eliminating the need

for 0.1% resistors while still achieving 0.75% set accuracy using 1% resistors.

The MAX745 consists of a current-mode, pulse-widthmodulated (PWM) controller and two transconductance

error amplifiers: one for regulating current (GMI) and

the other for regulating voltage (GMV) (Figure 2). The

error amplifiers are controlled via the SETI and VADJ

pins. Whether the MAX745 is controlling voltage or current at any time depends on the battery state. If the battery is discharged, the MAX745 output reaches the

current-regulation limit before the voltage limit, causing

the system to regulate current. As the battery charges,

the voltage rises to the point where the voltage limit is

reached and the charger switches to regulating voltage. The STATUS pin indicates whether the charger is

regulating current or voltage.

Voltage Control

To set the voltage limit on the battery, tie a resistordivider to VADJ from REF. A 0V to V

REF

change at

VADJ sets a ±5% change in the battery limit voltage

around 4.2V. Since the 0 to 4.2V range on VADJ results

in only a 10% change on the voltage limit, the resistordivider’s accuracy does not need to be as high as the

output voltage accuracy. Using 1% resistors for the

voltage dividers typically results in no more than 0.1%

degradation in output voltage accuracy. VADJ is internally buffered so that high-value resistors can be used

to set the output voltage. When the voltage at VADJ is

MAX745

Switch-Mode Lithium-Ion

Battery Charger

_______________________________________________________________________________________ 5

______________________________________________________________Pin Description

IBAT

Current-Sense Amplifier’s Analog Current-Source Output. See

Monitoring Charge Current

section for

detailed description.

2 DCIN Charger Input Voltage. Bypass DCIN with a 0.1µF capacitor.

3 VL Chip Power Supply. Output of the 5.4V linear regulator from DCIN. Bypass VL with a 4.7µF capacitor.

1

4 CCV Voltage-Regulation-Loop Compensation Point

5 CCI Current-Regulation-Loop Compensation Point

8 VADJ

Voltage-Adjustment Pin. VADJ is tied to a 1% tolerance external resistor-divider to adjust the voltage set

point by 10%, eliminating the need for precision 0.1% resistors. The input voltage range is 0V to V

REF

.

7 REF 4.2V Reference Voltage Output. Bypass REF with a 0.1µF or greater capacitor.

6

THM/

SHDN

Thermistor Sense-Voltage Input. THM/SHDN also performs the shutdown function. If pulled low,

the charger turns off.

13 STATUS

An open-drain MOSFET sinks current when in current-regulation mode, and is high impedance when in volt-

age-regulation mode. Connect STATUS to VL through a 1kΩ to 100kΩ pull-up resistor. STATUS may also drive

an LED for visual indication of regulation mode (see MAX745 evaluation kit). Leave STATUS floating if not used.

11, 12

CELL1,

CELL0

Logic Inputs to Select Cell Count. See Table 1 for cell-count programming.

10 GND Analog Ground

9 SETI SETI is externally tied to the resistor-divider between REF and GND to set the charging current.

14 BATT Battery-Voltage-Sense Input and Current-Sense Negative Input

15 CS Current-Sense Positive Input

16 PGND Power Ground

17 DLO Low-Side Power MOSFET Driver Output

18 DHI High-Side Power MOSFET Driver Output

19 LX Power Connection for the High-Side Power MOSFET Source

20 BST Power Input for the High-Side Power MOSFET Driver

NAME FUNCTIONPIN

MAX745

Switch-Mode Lithium-Ion

Battery Charger

6 _______________________________________________________________________________________

V

REF

/ 2, the voltage limit is 4.2V. Table 1 defines the

battery cell count.

The battery limit voltage is set by the following:

Solving for V

ADJ

, we get:

Set V

ADJ

by choosing a value for R11 (typically 100k),

and determine R3 by:

R3 = [1 - (V

ADJ

/ V

REF

)] x R11 (Figure 1)

where V

REF

= 4.2V and cell count is 1, 2, 3, or 4

(Table 1).

The voltage-regulation loop is compensated at the CCV

pin. Typically, a series-resistor-capacitor combination

can be used to form a pole-zero doublet. The pole

introduced rolls off the gain starting at low frequencies.

The zero of the doublet provides sufficient AC gain at

mid-frequencies. The output capacitor (C1) rolls off the

mid-frequency gain to below unity. This guarantees stability before encountering the zero introduced by the

C1’s equivalent series resistance (ESR). The GMV

amplifier’s output is internally clamped to between onefourth and three-fourths of the voltage at REF.

Current Control

The charging current is set by a combination of the current-sense resistor value and the SETI pin voltage. The

current-sense amplifier measures the voltage across

the current-sense resistor, between CS and BATT. The

current-sense amplifier’s gain is 6. The voltage on SETI

is buffered and then divided by 4. This voltage is compared to the current-sense amplifier’s output.

Therefore, full-scale current is accomplished by connecting SETI to REF. The full-scale charging current

(I

FS)

is set by the following:

IFS= 185mV / R1 (Figure 1)

V =

9.523 V

cell count

9.023V

ADJ

BATT

REF

()

−

V = cell count x V

V

1

2

V

9.523

BATT REF

ADJ REF

()

+

−

CELL0 CELL1

GND GND 1

VL GND 2

GND VL 3

VL VL 4

CELL COUNT

Figure 1. Standard Application Circuit

Table 1. Cell-Count Programming Table

4.7µF

R16

THM 1

R12

C2, 0.1µF

0.1µF

C4

R3

100k

1%

R11

100k

1%

V

IN

C5

R15

10k

(UP TO 24V)

R2

10k

C3

47nF

REF

THM/SHDN

SETI

VADJ

CCV

CCI

VL

D2

C7

0.1µF

1/2 IRF7303

M1B

C6

0.1µF

M1A

1/2 IRF7303

D1

MBRS

340T3

L1

22µH

BATTERY

MAX745

GND

IN4148

DCIN

BST

DHI

LX

DLO

PGND

CS

BATT

STATUS

IBAT

D6

MBRS

340T3

0.2Ω

R1

C1

68µF

MAX745

Switch-Mode Lithium-Ion

Battery Charger

_______________________________________________________________________________________ 7

BATT

1

/

4

IBAT DCIN

CURRENT

SENSE

A

V

= 6

ON

CS

SETI

CCI

VADJ

CCV

CELL0

VL

BST

VL

STATUS

REF

DHI

LX

DLO

PGND

GND

GMV

GMI

CELL1

PWM

LOGIC

5.4V

REG

4.2

REF

CELL

LOGIC

CLAMP

REF

2

THM/SHDN

Figure 2. Functional Diagram

To set currents below full scale without changing

R1, adjust the voltage at SETI according to the following formula:

I

CHG

= IFS(V

SETI

/ V

REF

)

A capacitor at CCI sets the current-feedback loop’s

dominant pole. While the current is in regulation, CCV

voltage is clamped to within 80mV of the CCI voltage.

This prevents the battery voltage from overshooting

when the voltage setting is changed. The converse is

true when the voltage is in regulation and the current

setting is changed. Since the linear range of CCI or

CCV is about 2V (1.5V to 3.5V), the 80mV clamp results

in negligible overshoot when the loop switches from

voltage regulation to current regulation, or vice versa.

Monitoring Charge Current

The battery-charging current can be externally monitored by placing a scaling resistor (R

IBAT

) between

IBAT and GND. IBAT is the output of a voltage-controlled current source, with output current given by:

I

BAT

= 0.9µA/V

SENSE

where V

SENSE

is the voltage across the current-sense

resistor (in millivolts) given by:

V

SENSE

= VCS- V

BATT

= I

CHG

x R1

The voltage across R

IBAT

is then given by:

R

IBAT

must be chosen to limit V

IBAT

to voltages below

2V for the maximum charging current. Connect IBAT to

GND if unused.

PWM Controller

The battery voltage or current is controlled by a

current-mode, PWM DC/DC converter controller. This

controller drives two external N-channel MOSFETs,

which control power from the input source. The controller sets the switched voltage’s pulse width so that it

supplies the desired voltage or current to the battery.

Total component cost is reduced by using a dual,

N-channel MOSFET.

The heart of the PWM controller is a multi-input comparator. This comparator sums three input signals to

determine the switched signal’s pulse width, setting the

battery voltage or current. The three signals are the

current-sense amplifier’s output, the GMV or GMI error

amplifier’s output, and a slope-compensation signal

that ensures that the current-control loop is stable.

The PWM comparator compares the current-sense

amplifier’s output to the lower output voltage of either

the GMV or GMI amplifiers (the error voltage). This current-mode feedback reduces the effect of the inductor

on the output filter LC formed by the output inductor

(L1) and C1 (Figure 1). This makes stabilizing the circuit much easier, since the output filter changes to a

first-order RC from a complex, second-order RLC.

V =

0.9 A

I

x

R

R

IBAT

CHG

IBAT

1

µ

MAX745

Switch-Mode Lithium-Ion

Battery Charger

8 _______________________________________________________________________________________

MOSFET Drivers

The MAX745 drives external N-channel MOSFETs to

switch the input source generating the battery voltage or

current. Since the high-side N-channel MOSFET’s gate

must be driven to a voltage higher than the input source

voltage, a charge pump is used to generate such a voltage. The capacitor (C7) charges through D2 to approximately 5V when the synchronous rectifier (M1B) turns on

(Figure 1). Since one side of C7 is connected to LX (the

source of M1A), the high-side driver (DHI) drives the gate

up to the voltage at BST, which is greater than the input

voltage while the high-side MOSFET is on.

The synchronous rectifier (M1B) behaves like a diode

but has a smaller voltage drop, improving efficiency. A

small dead time is added between the time when the

high-side MOSFET is turned off and when the synchronous rectifier is turned on, and vice versa. This

prevents crowbar currents during switching transitions.

Place a Schottky rectifier from LX to ground (D1, across

M1B’s drain and source) to prevent the synchronous

rectifier’s body diode from conducting during the dead

time. The body diode typically has slower switchingrecovery times, so allowing it to conduct degrades

efficiency. D1 can be omitted if efficiency is not a

concern, but the resulting increased power dissipation

in the synchronous rectifier must be considered.

Since the BST capacitor is charged while the synchronous rectifier is on, the synchronous rectifier may not be

replaced by a rectifier. The BST capacitor will not fully

charge without the synchronous rectifier, leaving the highside MOSFET with insufficient gate drive to turn on.

However, the synchronous rectifier can be replaced with

a small MOSFET (such as a 2N7002) to guarantee that

the BST capacitor is allowed to charge. In this case, the

majority of the high charging currents are carried by D1,

and not by the synchronous rectifier.

Internal Regulator and Reference

The MAX745 uses an internal low-dropout linear regulator to create a 5.4V power supply (VL), which powers its

internal circuitry. The VL regulator can supply up to

25mA. Since 4mA of this current powers the internal circuitry, the remaining 21mA can be used for external circuitry. MOSFET gate-drive current comes from VL,

which must be considered when drawing current for

other functions. To estimate the current required to drive

the MOSFETs, multiply the sum of the MOSFET gate

charges by the switching frequency (typically 300kHz).

Bypass VL with a 4.7µF capacitor to ensure stability.

The MAX745 internal 4.2V reference voltage must be

bypassed with a 0.1µF or greater capacitor.

Minimum Input Voltage

The input voltage to the charger circuit must be greater

than the maximum battery voltage by approximately 2V

so the charger can regulate the voltage properly. The

input voltage can have a large AC-ripple component

when operating from a wall cube. The voltage at the low

point of the ripple waveform must still be approximately

2V greater than the maximum battery voltage.

Using components as indicated in Figure 1, the minimum

input voltage can be determined by the following formula:

V

IN

x

[V

BATT

+ VD6+ I

CHG

(

R

DS(ON)

+ RL+ R1)]

0.89

where: VINis the input voltage;

VD6is the voltage drop across D6

(typically 0.4V to 0.5V);

I

CHG

is the charging current;

R

DS(ON)

is the high-side

MOSFET M1A’s on-resistance;

RLis the the inductor’s series resistance;

R1 is the current-sense resistor R1’s value.

18

17

16

15

14

13

19

201

2

3

4

5

6

7

8

TOP VIEW

12

11

9

10

BST

LX

DHI

DLO

PGND

CS

BATT

STATUS

CELL0

CELL1

CCV

VL

DCIN

IBAT

VADJ

REF

THM/SHDN

CCI

GND

SETI

SSOP

MAX745

__________________Pin Configuration

___________________Chip Information

TRANSISTOR COUNT: 1695

SUBSTRATE CONNECTED TO GND

Loading...

Loading...