Page 1

19-3170; Rev 4; 4/05

EVALUATION KIT

AVAILABLE

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

General Description

The MAX7314 I2C-compatible serial interfaced peripheral provides microprocessors with 16 I/O ports plus one

output-only port and one input-only port. Each I/O port

can be individually configured as either an open-drain

current-sinking output rated at 50mA and 5.5V, or a logic

input with transition detection. The output-only port can

be assigned as an interrupt output for transition detection. The outputs are capable of driving LEDs, or providing logic outputs with external resistive pullup up to 5.5V.

Eight-bit PWM current control is built in for all 17 output

ports. A 4-bit global control applies to all LED outputs

and provides coarse adjustment of current from fully off

to fully on with 14 intensity steps in between. Each output has an individual 4-bit control, which further divides

the globally set current into 16 more steps.

Alternatively, the current control can be configured as a

single 8-bit control that sets all outputs at once.

Each output has independent blink timing with two blink

phases. All LEDs can be individually set to be on or off

during either blink phase, or to ignore the blink control.

The blink period is controlled by a clock input (up to 1kHz)

on BLINK or by a register. The BLINK input can also be

used as a logic control to turn the LEDs on and off, or as a

general-purpose input.

The MAX7314 supports hot insertion. All port pins, the

INT output, SDA, SCL, RST, BLINK, and the slave

address input ADO remain high impedance in powerdown (V+ = 0V) with up to 6V asserted upon them.

The MAX7314 is controlled through a 2-wire serial interface, and uses four-level logic to allow four I

addresses from only one select pin.

2

♦ 400kbps, 2-Wire Serial Interface, 5.5V Tolerant

♦ 2V to 3.6V Operation

♦ Overall 8-Bit PWM LED Intensity Control

Global 16-Step Intensity Control

Individual 16-Step Intensity Controls

♦ 2-Phase LED Blinking

♦ 50mA Maximum Port Output Current

♦ Supports Hot Insertion

♦ Outputs are 5.5V-Rated Open Drain

♦ Inputs are Overvoltage Protected to 5.5V

♦ Transition Detection with Interrupt Output

♦ 1.2µA (typ), 3.6µA (max) Operating Current

♦ Small 4mm x 4mm, Thin QFN Package

♦ -40°C to +125°C Temperature Range

Ordering Information

PART TEMP RANGE

MAX7314ATG -40°C to +125°C

MAX7314AEG -40°C to +125°C 24 QSOP —

PINPACKAGE

24 Thin QFN

4mm x 4mm

x 0.8mm

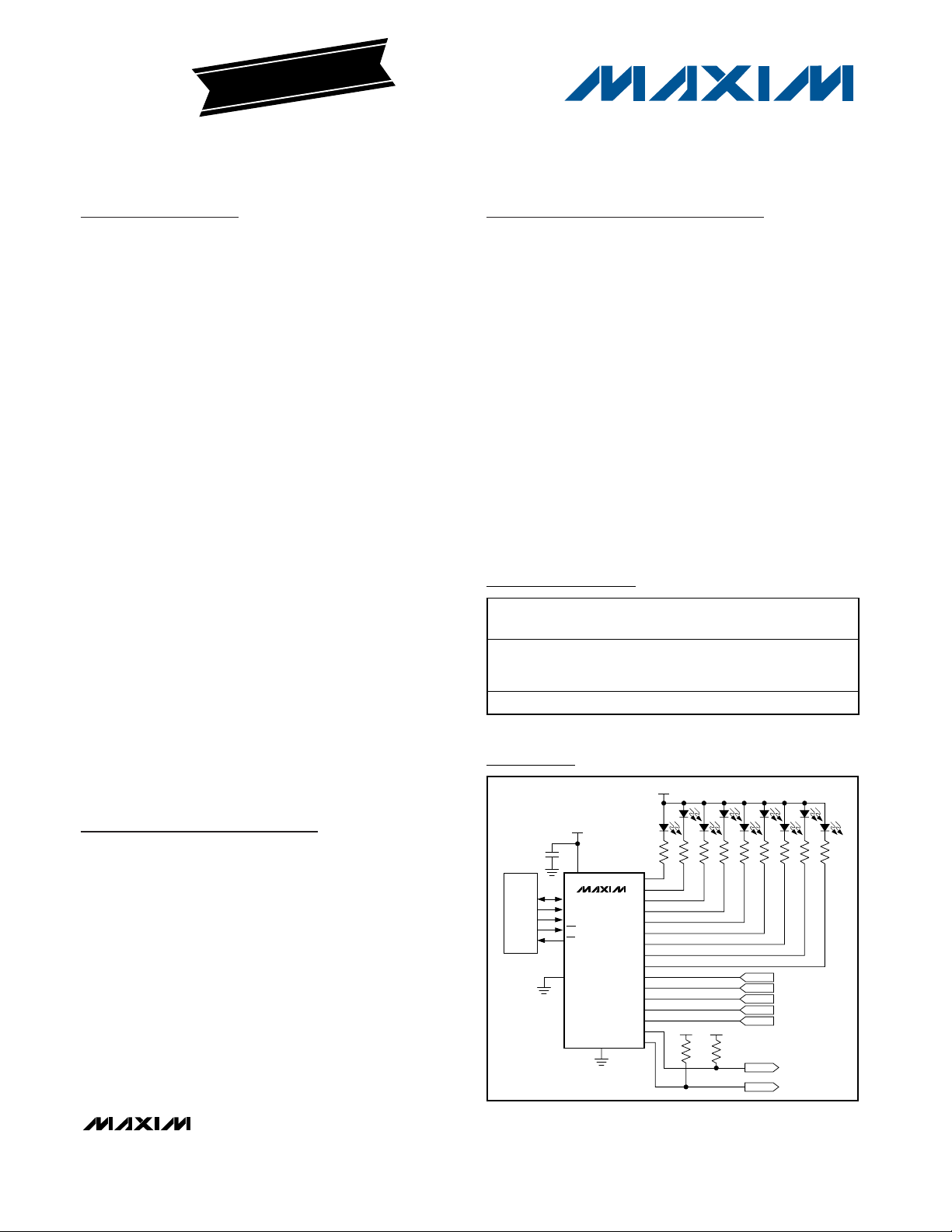

Typical Application Circuit

C

5V

Features

PKG

CODE

T2444-4

MAX7314

Applications

LCD Backlights

LED Status Indication

Relay Drivers

Keypad Backlights

RGB LED Drivers

System I/O Ports

Pin Configurations continued at end of data sheet.

μC

0.047μF

SDA

SCL

3.3V

V+

SDA

MAX7314

SCL

I/O

BLINK

I/O

RST

INT

INT/O16

AD0

P0

P1

P2

P3

P4

P5

P6

P7

P8

P9

P10

P11

P12

P13

P14

P15

GND

3.3V 5V

INPUT 1

INPUT 2

INPUT 3

INPUT 4

INPUT 5

OUTPUT

OUTPUT

________________________________________________________________ Maxim Integrated Products 1

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

Page 2

MAX7314

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Voltage (with respect to GND)

V+ .............................................................................-0.3V to +4V

SCL, SDA, AD0, BLINK, RST, P0–P15 .....................-0.3V to +6V

INT/O16 ...................................................................-0.3V to +8V

DC Current on P0–P15, INT/O16 ........................................55mA

DC Current on SDA.............................................................10mA

Maximum GND Current ....................................................350mA

Continuous Power Dissipation (T

A

= +70°C)

24-Pin QSOP (derate 9.5mW/°C over +70°C)..............761mW

24-Pin QFN (derate 20.8mW/°C over +70°C) ............1666mW

Operating Temperature Range

(T

MIN

to T

MAX

) .............................................-40°C to +125°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

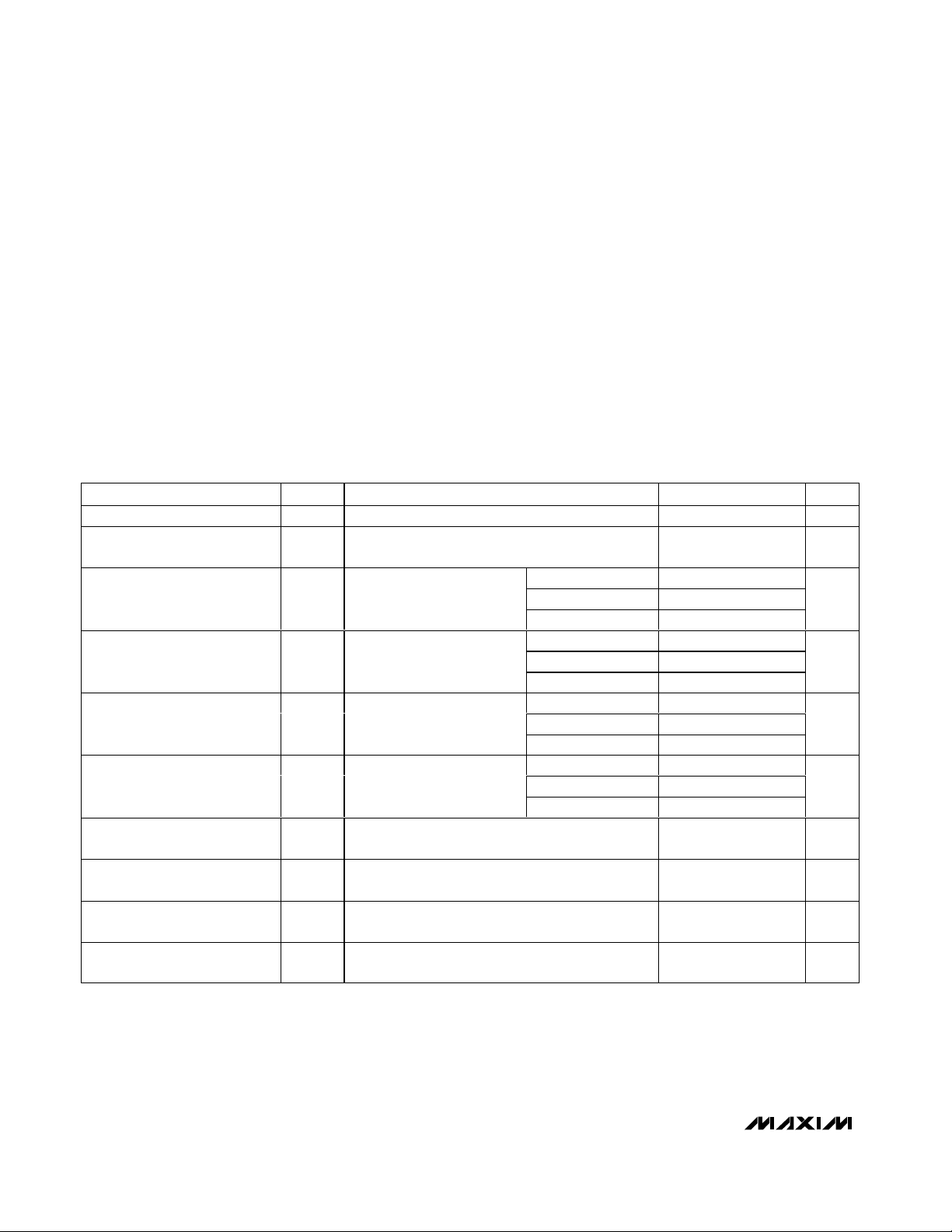

ELECTRICAL CHARACTERISTICS

(Typical Operating Circuit, V+ = 2V to 3.6V, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at V+ = 3.3V, TA = +25°C.)

(Note 1)

Operating Supply Voltage V+ 2 3.6 V

Output Load External Supply

Voltage

Standby Current

(Interface Idle, PWM Disabled)

Supply Current

(Interface Idle, PWM Enabled)

Supply Current

(Interface Running, PWM

Disabled)

Supply Current

(Interface Running, PWM

Enabled)

Input High Voltage

SDA, SCL, AD0, BLINK, P0–P15

Input Low Voltage

SDA, SCL, AD0, BLINK, P0–P15

Input Leakage Current

SDA, SCL, AD0, BLINK, P0–P15

Input Capacitance

SDA, SCL, AD0, BLINK, P0–P15

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V

EXT

S C L and S D A at V + ; other

d i g i tal i np uts at V + or GN D ;

I

+

P WM i ntensi ty contr ol d i sab l ed

S C L and S D A at V + ; other

I

d i g i tal i np uts at V + or GN D ;

+

P WM i ntensi ty contr ol d i sab l ed

f

I

inputs at V+ or GND; PWM

+

intensity control enabled

f

I

inputs at V+ or GND; PWM

+

intensity control enabled

V

IH

V

IL

I

, IIL0 ≤ input voltage ≤ 5.5V -0.2 +0.2 µA

IH

= 400kHz; other digital

SCL

= 400kHz; other digital

SCL

TA = +25°C 1.2 2.3

TA = -40°C to +85°C 2.8

T

= T

= T

= T

= T

MIN

MIN

MIN

MIN

to T

to T

to T

to T

MAX

MAX

MAX

MAX

A

TA = +25°C 8.5 15.1

TA = -40°C to +85°C 16.5

T

A

TA = +25°C 50 95.3

TA = -40°C to +85°C 99.2

T

A

TA = +25°C 57 110.2

TA = -40°C to +85°C 117.4

T

A

0 5.5 V

3.6

17.2

102.4

122.1

0.7 x

V+

0.3 x

V+

8pF

µA

µA

µA

µA

V

V

Page 3

MAX7314

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

_______________________________________________________________________________________ 3

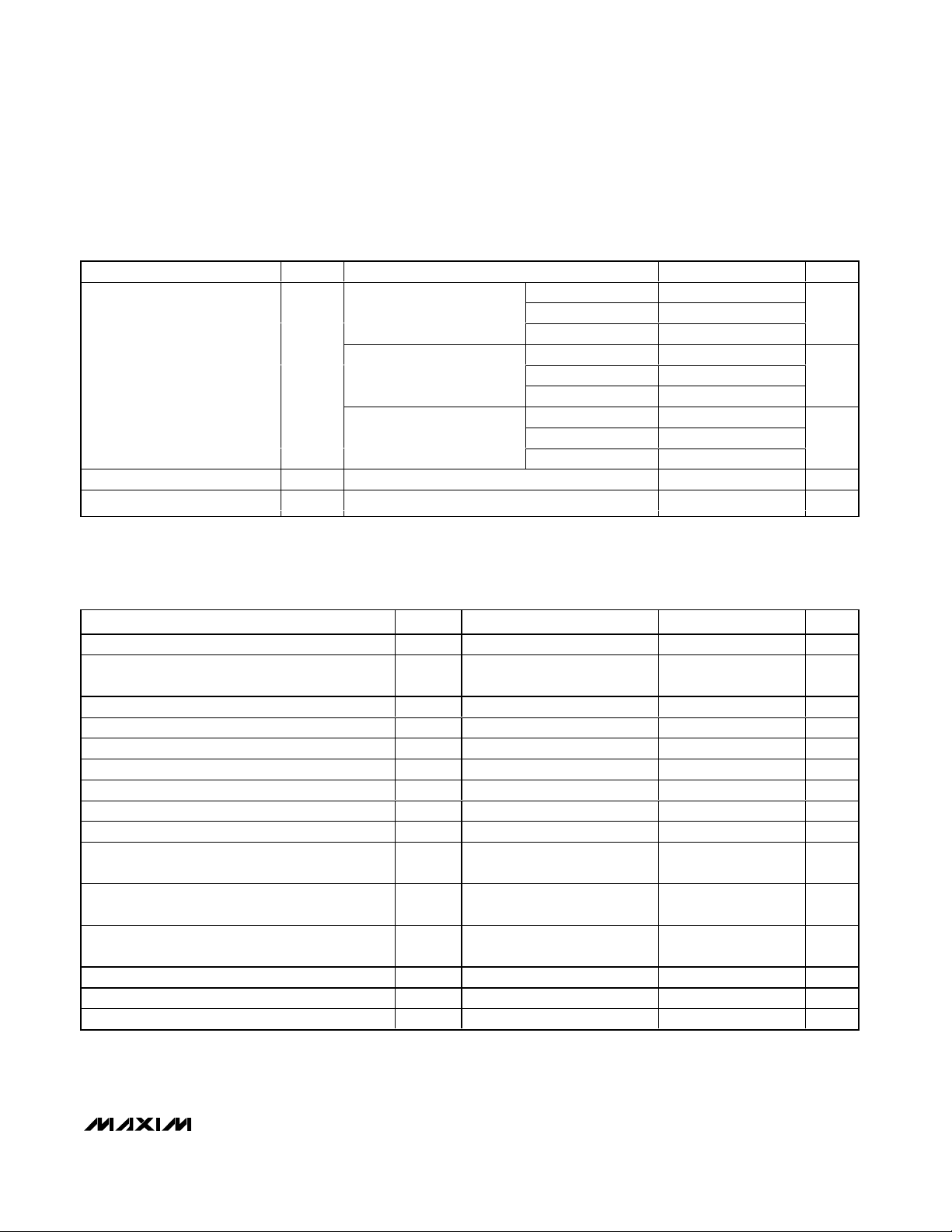

ELECTRICAL CHARACTERISTICS (continued)

(Typical Operating Circuit, V+ = 2V to 3.6V, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at V+ = 3.3V, TA= + 25°C.)

(Note 1)

TIMING CHARACTERISTICS

(Typical Operating Circuit, V+ = 2V to 3.6V, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at V+ = 3.3V, TA = +25°C.)

(Note 1)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

V+ = 2V, I

Output Low Voltage

P0–P15, INT/O16

V

OL

V+ = 3.3V, I

Output Low-Voltage SDA V

PWM Clock Frequency f

OLSDAISINK

PWM

= 20mA

SINK

= 20mA

SINK

= 20mA

SINK

= 6mA 0.4 V

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Serial Clock Frequency f

Bus Free Time Between a STOP and a START

Condition

Hold Time, Repeated START Condition t

Repeated START Condition Setup Time t

STOP Condition Setup Time t

Data Hold Time t

Data Setup Time t

SCL Clock Low Period t

SCL Clock High Period t

Rise Time of Both SDA and SCL Signals, Receiving t

Fall Time of Both SDA and SCL Signals, Receiving t

Fall Time of SDA Transmitting t

Pulse Width of Spike Suppressed t

Capacitive Load for Each Bus Line C

RST Pulse Width t

SCL

t

BUF

HD, STA

SU, STA

SU, STO

HD, DAT

SU, DAT

LOW

HIGH

F.TX

(Note 2) 0.9 µs

(Notes 3, 4)

R

(Notes 3, 4)

F

(Notes 3, 5)

(Note 6) 50 ns

SP

(Note 3) 400 pF

b

W

TA = +25°C 0.15 0.26

TA = -40°C to +85°C 0.3

= T

MIN

to T

MAX

T

A

0.32

TA = +25°C 0.13 0.23

TA = -40°C to +85°C 0.26V+ = 2.5V, I

= T

MIN

to T

MAX

T

A

0.28

TA = +25°C 0.12 0.23

TA = -40°C to +85°C 0.24

= T

MIN

to T

MAX

T

A

0.26

32 kHz

400 kHz

1.3 µs

0.6 µs

0.6 µs

0.6 µs

180 ns

1.3 µs

0.7 µs

20 +

0.1C

20 +

0.1C

20 +

0.1C

b

b

b

300 ns

300 ns

250 ns

1µs

V

V

V

Page 4

MAX7314

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

4 _______________________________________________________________________________________

TIMING CHARACTERISTICS (continued)

(Typical Operating Circuit, V+ = 2V to 3.6V, TA= T

MIN

to T

MAX

, unless otherwise noted. Typical values are at V+ = 3.3V, TA = +25°C.)

(Note 1)

Note 1: All parameters tested at TA= +25°C. Specifications over temperature are guaranteed by design.

Note 2: A master device must provide a hold time of at least 300ns for the SDA signal (referred to V

IL

of the SCL signal) to bridge

the undefined region of SCL’s falling edge.

Note 3: Guaranteed by design.

Note 4: C

b

= total capacitance of one bus line in pF. tRand tFmeasured between 0.3 x VDDand 0.7 x VDD.

Note 5: I

SINK

≤ 6mA. Cb= total capacitance of one bus line in pF. tRand tFmeasured between 0.3 x VDDand 0.7 x VDD.

Note 6: Input filters on the SDA and SCL inputs suppress noise spikes less than 50ns.

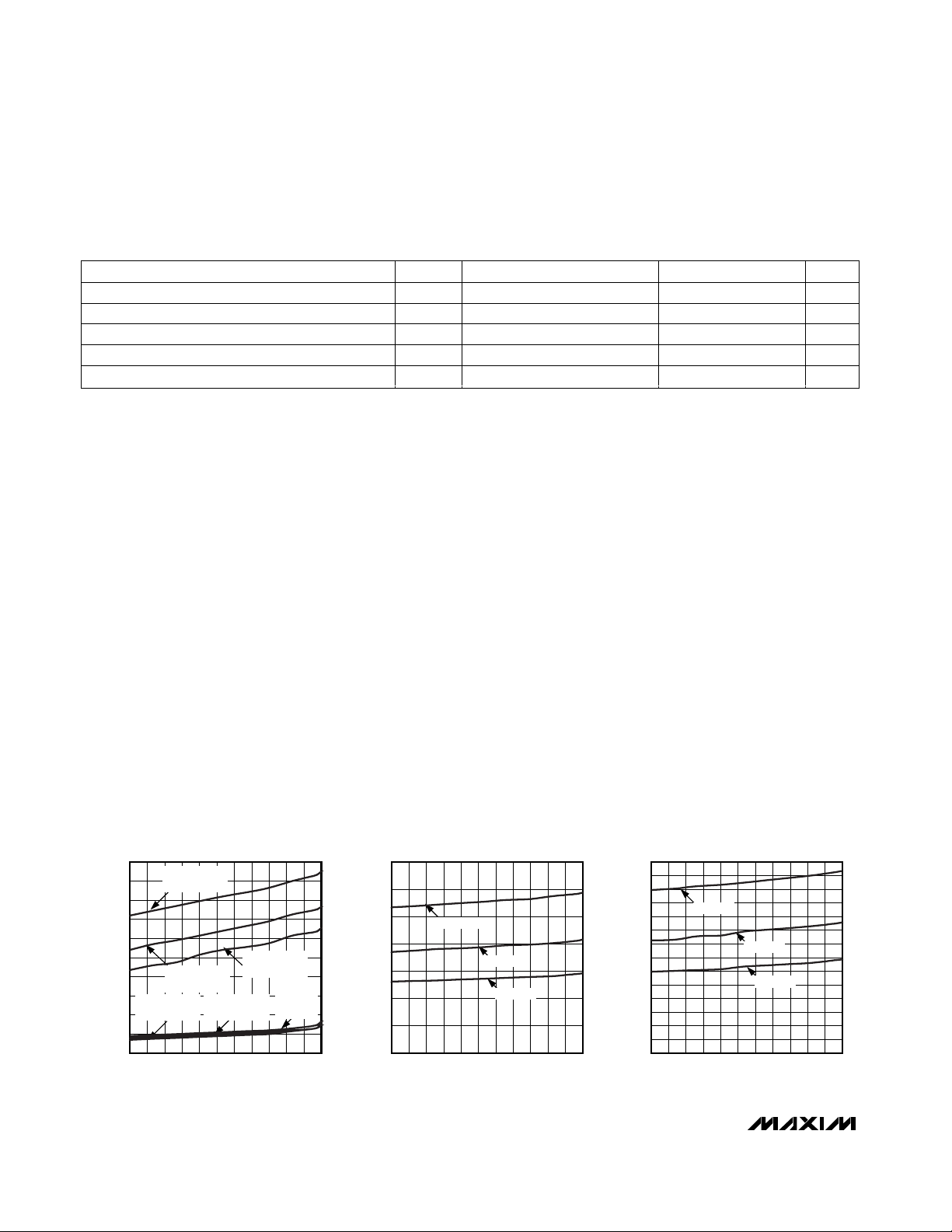

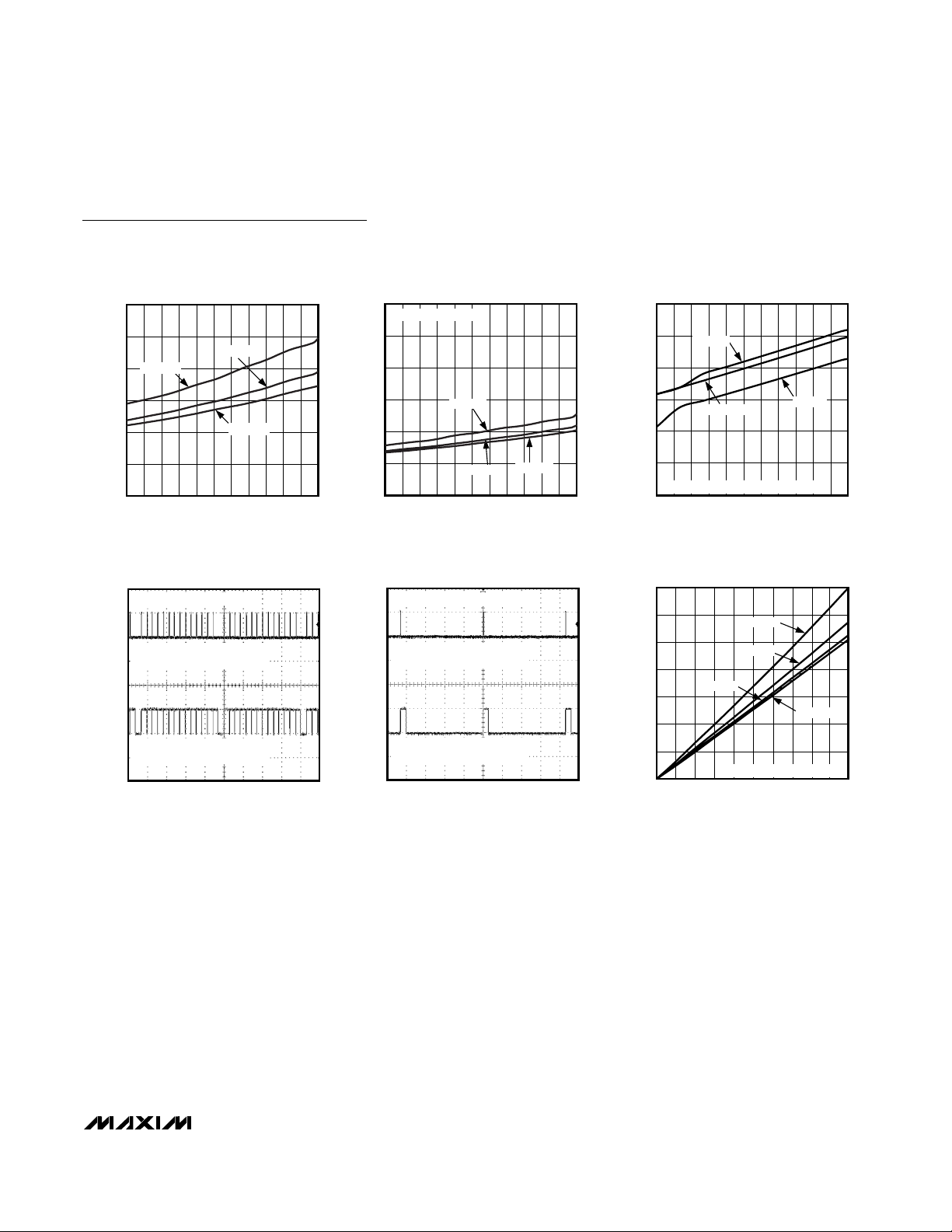

STANDBY CURRENT vs. TEMPERATURE

MAX7314 toc01

TEMPERATURE (°C)

STANDBY CURRENT (μA)

1109565 80-10 5 20 35 50-25

1

2

3

4

5

6

7

8

9

10

0

-40 125

V+ = 3.6V

PWM ENABLED

V+ = 2.7V

PWM ENABLED

V+ = 2V

PWM DISABLED

V+ = 2.7V

PWM DISABLED

V+ = 3.6V

PWM

DISABLED

V+ = 2V

PWM ENABLED

SUPPLY CURRENT vs. TEMPERATURE

(PWM DISABLED; f

SCL

= 400kHz)

MAX7314 toc02

TEMPERATURE (°C)

SUPPLY CURRENT (μA)

1109565 80-10 5 20 35 50-25

10

20

30

40

50

60

70

0

-40 125

V+ = 3.6V

V+ = 2.7V

V+ = 2V

5

10

15

20

25

30

35

40

45

50

55

60

65

70

0

SUPPLY CURRENT vs. TEMPERATURE

(PWM ENABLED; f

SCL

= 400kHz)

MAX7314 toc03

TEMPERATURE (°C)

SUPPLY CURRENT (μA)

1109565 80-10 5 20 35 50-25-40 125

V+ = 3.6V

V+ = 2.7V

V+ = 2V

__________________________________________Typical Operating Characteristics

(TA = +25°C, unless otherwise noted.)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Interrupt Valid t

Interrupt Reset t

Output Data Valid t

Input Data Set-Up Time t

Input Data Hold Time t

Figure 10 6.5 µs

IV

Figure 10 1 µs

IR

Figure 10 5 µs

DV

Figure 10 100 ns

DS

Figure 10 1 µs

DH

Page 5

MAX7314

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

_______________________________________________________________________________________ 5

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

PORT OUTPUT LOW VOLTAGE WITH 50mA

LOAD CURRENT vs. TEMPERATURE

0.6

(V)

0.5

OL

V+ = 2V

0.4

0.3

0.2

0.1

PORT OUTPUT LOW VOLTAGE V

0

SCOPE SHOT OF 2 OUTPUT PORTS

MASTER INTENSITY SET TO 1/15

OUTPUT 1 INDIVIDUAL INTENSITY

SET TO 1/16

OUTPUT 2 INDIVIDUAL INTENSITY

SET TO 15/16

V+ = 2.7V

V+ = 3.6V

TEMPERATURE (°C)

MAX7314 toc07

2ms/div

1109565 80-10 5 20 35 50-25-40 125

PORT OUTPUT LOW VOLTAGE WITH 20mA

LOAD CURRENT vs. TEMPERATURE

0.6

ALL OUTPUTS LOADED

(V)

0.5

MAX7314 toc04

OL

0.4

0.3

0.2

0.1

PORT OUTPUT LOW VOLTAGE V

0

-40 125

SCOPE SHOT OF 2 OUTPUT PORTS

MASTER INTENSITY SET TO 14/15

OUTPUT 1,

2V/div

OUTPUT 1 INDIVIDUAL INTENSITY

SET TO 1/16

OUTPUT 2,

2V/div

OUTPUT 2 INDIVIDUAL INTENSITY

SET TO 14/15

V+ = 2V

V+ = 2.7V

TEMPERATURE (°C)

2ms/div

V+ = 3.6V

MAX7314 toc08

1.050

1.025

MAX7314 toc05

1.000

0.975

0.950

PWM CLOCK FREQUENCY (kHz)

0.925

OUTPUT 1

2V/div

OUTPUT 2

2V/div

0.900

(V)

OL

V

0.35

0.30

0.25

0.20

0.15

0.10

0.05

1109580655035205-10-25

PWM CLOCK FREQUENCY

vs. TEMPERATURE

V+ = 3.6V

V+ = 2.7V

NORMALIZED TO V+ = 3.3V, TA = +25°C

-40 125

TEMPERATURE (°C)

SINK CURRENT vs. V

V+ = 2V

V+ = 2.7V

V+ = 3.3V

0

0453525155

ONLY ONE OUTPUT LOADED

SINK CURRENT (mA)

MAX7314 toc06

V+ = 2V

1109580655035205-10-25

OL

MAX7314 toc09

V+ = 3.6V

5040302010

Page 6

MAX7314

Functional Overview

The MAX7314 is a general-purpose input/output (GPIO)

peripheral that provides 16 I/O ports, P0–P15, controlled through an I2C-compatible serial interface. A

17th output-only port, INT/O16, can be configured as

an interrupt output or as a general-purpose output port.

All output ports sink loads up to 50mA connected to

external supplies up to 5.5V, independent of the

MAX7314’s supply voltage. The MAX7314 is rated for a

ground current of 350mA, allowing all 17 outputs to sink

20mA at the same time. Figure 1 shows the output

structure of the MAX7314. The ports default to inputs on

power-up.

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

6 _______________________________________________________________________________________

Pin Description

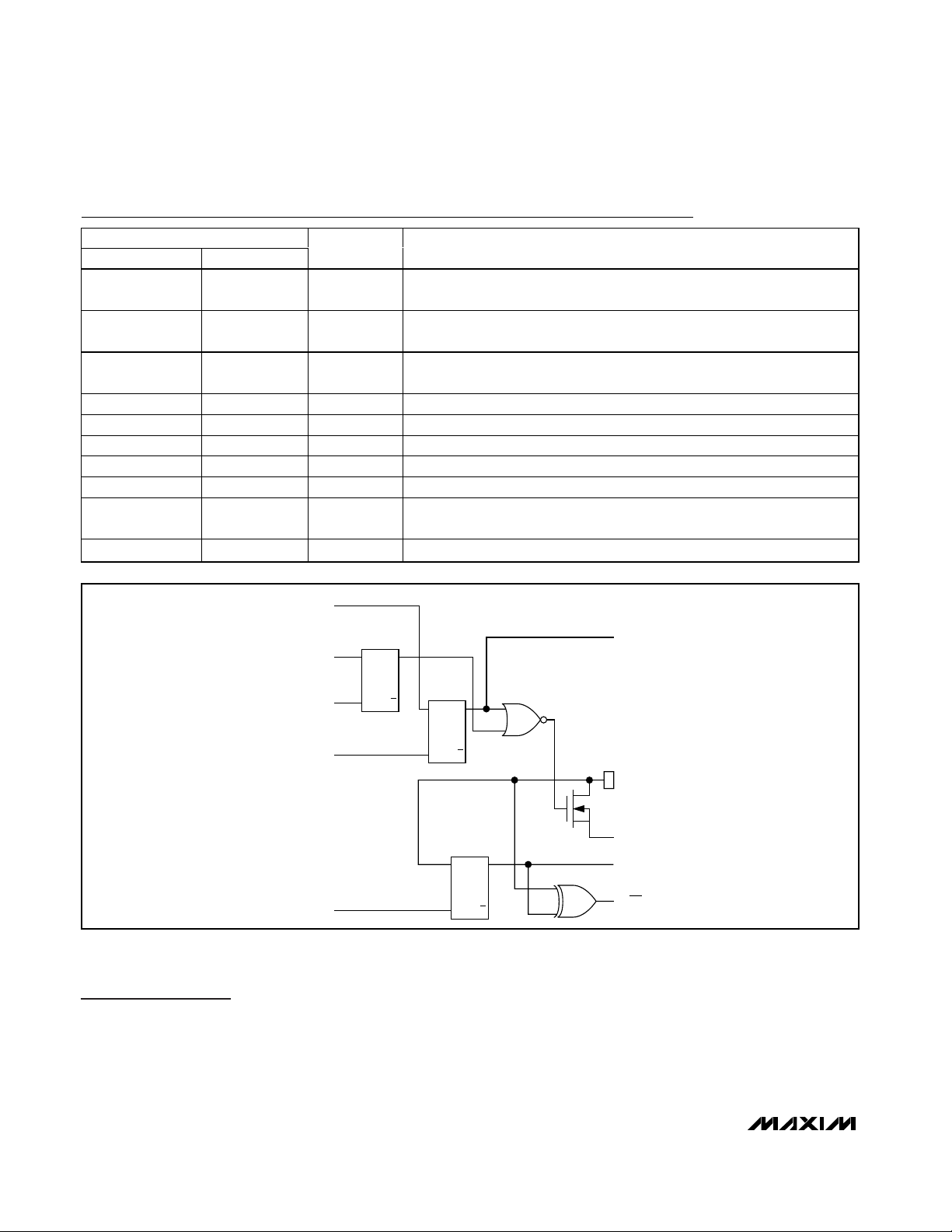

Figure 1. Simplified Schematic of I/O Ports

PIN

QSOP QFN

122INT/O16

223RST

3 24 AD0

4–11, 13–20 1–8, 10–17 P0–P15 Input/Output Ports. P0–P15 are open-drain I/Os rated at 5.5V, 50mA.

12 9 GND Ground. Do not sink more than 350mA into the GND pin.

21 18 BLINK Input Port Configurable as Blink Control or General-Purpose Input

22 19 SCL I2C-Compatible Serial Clock Input

23 20 SDA I2C-Compatible Serial Data I/O

24 21 V+

— PAD Exposed Pad Exposed Pad on Package Underside. Connect to GND.

DATA FROM

SHIFT REGISTER

DATA FROM

SHIFT REGISTER

WRITE

CONFIGURATION

PULSE

WRITE PULSE

NAME FUNCTION

Output Port. Open-drain output rated at 7V, 50mA. Configurable as interrupt

output or general-purpose output.

Reset Input. Active low clears the 2-wire interface and puts the device in the

same condition as power-up reset.

Address Input. Sets device slave address. Connect to either GND, V+, SCL,

or SDA to give four logic combinations. See Table 1.

Positive Supply Voltage. Bypass V+ to GND with a 0.047µF ceramic

capacitor.

CONFIGURATION

REGISTER

D

Q

FF

C

Q

K

OUTPUT

PORT

REGISTER

D

FF

C

K

Q

Q

OUTPUT PORT

REGISTER DATA

I/O PIN

Q2

READ PULSE

INPUT PORT

REGISTER

D

Q

FF

C

Q

K

GND

INPUT PORT

REGISTER DATA

TO INT

Page 7

Port Inputs and Transition Detection

Input ports registers reflect the incoming logic levels of

the port pins, regardless of whether the pin is defined

as an input or an output. Reading an input ports register latches the current-input logic level of the affected

eight ports. Transition detection allows all ports configured as inputs to be monitored for changes in their

logic status. The action of reading an input ports register samples the corresponding 8 port bits’ input condition. This sample is continuously compared with the

actual input conditions. A detected change in input

condition causes the INT/O16 interrupt output to go

low, if configured as an interrupt output. The interrupt is

cleared either automatically if the changed input

returns to its original state, or when the appropriate

input ports register is read.

The INT/O16 pin can be configured as either an interrupt output or as a 17th output port with the same static

or blink controls as the other 16 ports (Table 4).

Port Output Control and LED Blinking

The two blink phase 0 registers set the output logic levels of the 16 ports P0–P15 (Table 8). These registers

control the port outputs if the blink function is disabled.

A duplicate pair of registers, the blink phase 1 registers,

are also used if the blink function is enabled (Table 9).

In blink mode, the port outputs can be flipped between

using the blink phase 0 registers and the blink phase 1

registers using hardware control (the BLINK input)

and/or software control (the blink flip flag in the configuration register) (Table 4). The logic level of the BLINK

input can be read back through the blink status bit in

the configuration register (Table 4). The BLINK input,

therefore, can be used as a general-purpose logic input

(GPI port) if the blink function is not required.

PWM Intensity Control

The MAX7314 includes an internal oscillator, nominally

32kHz, to generate PWM timing for LED intensity control.

PWM intensity control can be enabled on an output-byoutput basis, allowing the MAX7314 to provide any mix

of PWM LED drives and glitch-free logic outputs (Table

10). PWM can be disabled entirely, in which case all output ports are static and the MAX7314 operating current

is lowest because the internal oscillator is turned off.

PWM intensity control uses a 4-bit master control and 4

bits of individual control per output (Tables 13, 14). The

4-bit master control provides 16 levels of overall intensity control, which applies to all PWM-enabled output

ports. The master control sets the maximum pulse

width from 1/15 to 15/15 of the PWM time period. The

individual settings comprise a 4-bit number, further

reducing the duty cycle to be from 1/16 to 15/16 of the

time window set by the master control.

For applications requiring the same PWM setting for all

output ports, a single global PWM control can be used

instead of all the individual controls to simplify the control software and provide 240 steps of intensity control

(Tables 10 and 13).

Standby Mode

When the serial interface is idle and the PWM intensity

control is unused, the MAX7314 automatically enters

standby mode. If the PWM intensity control is used, the

operating current is slightly higher because the internal

PWM oscillator is running. When the serial interface is

active, the operating current also increases because

the MAX7314, like all I2C slaves, has to monitor every

transmission.

MAX7314

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

_______________________________________________________________________________________ 7

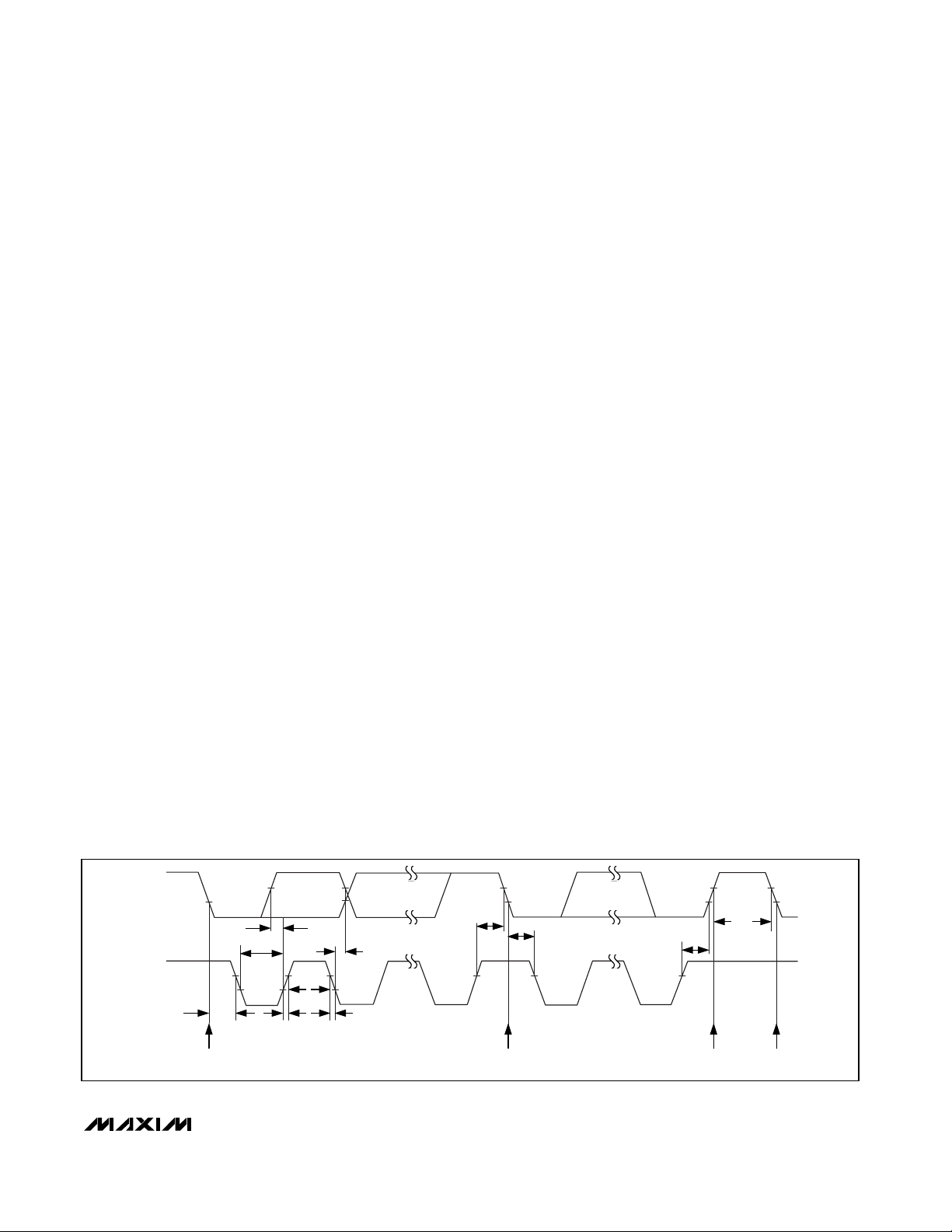

Figure 2. 2-Wire Serial Interface Timing Details

SDA

t

SU,DAT

t

LOW

SCL

t

HD,STA

START CONDITION

t

HIGH

t

t

R

F

t

HD,DAT

t

SU,STA

REPEATED START CONDITION

t

HD,STA

t

SU,STO

STOP

CONDITION

t

BUF

START

CONDITION

Page 8

MAX7314

Serial Interface

Serial Addressing

The MAX7314 operates as a slave that sends and

receives data through an I

2

C-compatible 2-wire interface. The interface uses a serial data line (SDA) and a

serial clock line (SCL) to achieve bidirectional communication between master(s) and slave(s). A master (typically a microcontroller) initiates all data transfers to and

from the MAX7314 and generates the SCL clock that

synchronizes the data transfer (Figure 2).

The MAX7314 SDA line operates as both an input and

an open-drain output. A pullup resistor, typically 4.7kΩ,

is required on the SDA. The MAX7314 SCL line operates only as an input. A pullup resistor, typically 4.7kΩ,

is required on SCL if there are multiple masters on the

2-wire interface, or if the master in a single-master system has an open-drain SCL output.

Each transmission consists of a START condition

(Figure 3) sent by a master, followed by the MAX7314

7-bit slave address plus R/W bit, a register address

byte, one or more data bytes, and finally a STOP condition (Figure 3).

Start and Stop Conditions

Both SCL and SDA remain high when the interface is

not busy. A master signals the beginning of a transmission with a START (S) condition by transitioning SDA

from high to low while SCL is high. When the master

has finished communicating with the slave, it issues a

STOP (P) condition by transitioning SDA from low to

high while SCL is high. The bus is then free for another

transmission (Figure 3).

Bit Transfer

One data bit is transferred during each clock pulse.

The data on SDA must remain stable while SCL is high

(Figure 4).

Acknowledge

The acknowledge bit is a clocked 9th bit that the recipient uses to handshake receipt of each byte of data

(Figure 5). Thus, each byte transferred effectively

requires 9 bits. The master generates the 9th clock

pulse, and the recipient pulls down SDA during the

acknowledge clock pulse so the SDA line is stable low

during the high period of the clock pulse. When the

master is transmitting to the MAX7314, the device generates the acknowledge bit because the MAX7314 is

the recipient. When the MAX7314 is transmitting to the

master, the master generates the acknowledge bit

because the master is the recipient.

Slave Address

The MAX7314 has a 7-bit long slave address (Figure 6).

The eighth bit following the 7-bit slave address is the

R/W bit. The R/W bit is low for a write command, high

for a read command.

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

8 _______________________________________________________________________________________

Figure 3. Start and Stop Conditions

Figure 4. Bit Transfer

Figure 5. Acknowledge

Figure 6. Slave Address

SDA

SCL

SP

START

CONDITION

SDA

SCL

DATA LINE STABLE;

DATA VALID

START

CONDITION

SCL

SDA BY

TRANSMITTER

SDA BY

RECEIVER

S

12 89

CHANGE OF DATA

ALLOWED

CLOCK PULSE

FOR ACKNOWLEDGE

STOP

CONDITION

SDA

MSB

SCL

1

LSB

ACK00A6 0 0A2 R/W

Page 9

The second (A5), third (A4), fourth (A3), sixth (A1), and

last (A0) bits of the MAX7314 slave address are always

1, 0, 0, 0, and 0. Slave address bits A6 and A2 are

selected by the address input AD0. AD0 can be connected to GND, V+, SDA, or SCL. The MAX7314 has four

possible slave addresses (Table 1), and therefore a

maximum of four MAX7314 devices can be controlled

independently from the same interface.

Message Format for Writing the MAX7314

A write to the MAX7314 comprises the transmission of

the MAX7314’s slave address with the R/W bit set to

zero, followed by at least 1 byte of information. The first

byte of information is the command byte. The command byte determines which register of the MAX7314

is to be written to by the next byte, if received (Table 2).

If a STOP condition is detected after the command byte

is received, then the MAX7314 takes no further action

beyond storing the command byte.

Any bytes received after the command byte are data

bytes. The first data byte goes into the internal register

of the MAX7314 selected by the command byte (Figure

8). If multiple data bytes are transmitted before a STOP

condition is detected, these bytes are generally stored

in subsequent MAX7314 internal registers because the

command byte address autoincrements (Table 2). A

diagram of a write to the output ports registers (blink

phase 0 registers or blink phase 1 registers) is given in

Figure 10.

MAX7314

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

_______________________________________________________________________________________ 9

Table 1. MAX7314 Address Map

Figure 8. Command and Single Data Byte Received

Figure 9. n Data Bytes Received

Figure 7. Command Byte Received

PIN AD0

SCL1100000

SDA1100100

GND0100000

V+ 0100100

A6 A5 A4 A3 A2 A1 A0

SAAP0SLAVE ADDRESS COMMAND BYTE

DEVICE ADDRESS

COMMAND BYTE IS STORED ON RECEIPT OF

STOP CONDITION

ACKNOWLEDGE FROM MAX7314

D15 D14 D13 D12 D11 D10 D9 D8

R/W

HOW COMMAND BYTE AND DATA BYTE MAP INTO

MAX7314's REGISTERS

ACKNOWLEDGE FROM MAX7314

SAAAP0SLAVE ADDRESS COMMAND BYTE DATA BYTE

R/W

HOW COMMAND BYTE AND DATA BYTE MAP INTO

MAX7314's REGISTERS

ACKNOWLEDGE FROM MAX7314

SAAAP0SLAVE ADDRESS COMMAND BYTE DATA BYTE

R/W

D15 D14 D13 D12 D11 D10 D9 D8 D1 D0D3 D2D5 D4D7 D6

D15 D14 D13 D12 D11 D10 D9 D8 D1 D0D3 D2D5 D4D7 D6

ACKNOWLEDGE FROM MAX7314 ACKNOWLEDGE FROM MAX7314

ACKNOWLEDGE FROM MAX7314 ACKNOWLEDGE FROM MAX7314

ACKNOWLEDGE FROM MAX7314

AUTOINCREMENT MEMORY ADDRESS

AUTOINCREMENT MEMORY ADDRESS

1

BYTE

N

BYTES

Page 10

MAX7314

Message Format for Reading

The MAX7314 is read using the MAX7314’s internally

stored command byte as an address pointer the same

way the stored command byte is used as an address

pointer for a write. The pointer autoincrements after

each data byte is read using the same rules as for a

write (Table 2). Thus, a read is initiated by first configuring the MAX7314’s command byte by performing a

write (Figure 7). The master can now read n consecutive bytes from the MAX7314 with the first data byte

being read from the register addressed by the initialized command byte. When performing read-after-write

verification, remember to reset the command byte’s

address because the stored command byte address

has been autoincremented after the write (Table 2). A

diagram of a read from the input ports registers is

shown in Figure 10 reflecting the states of the ports.

Operation with Multiple Masters

If the MAX7314 is operated on a 2-wire interface with

multiple masters, a master reading the MAX7314 should

use a repeated start between the write, which sets the

MAX7314’s address pointer, and the read(s) that takes

the data from the location(s) (Table 2). This is because it

is possible for master 2 to take over the bus after master

1 has set up the MAX7314’s address pointer but before

master 1 has read the data. If master 2 subsequently

changes the MAX7314’s address pointer, then master

1’s delayed read can be from an unexpected location.

Command Address Autoincrementing

The command address stored in the MAX7314 circulates around grouped register functions after each data

byte is written or read (Table 2).

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

10 ______________________________________________________________________________________

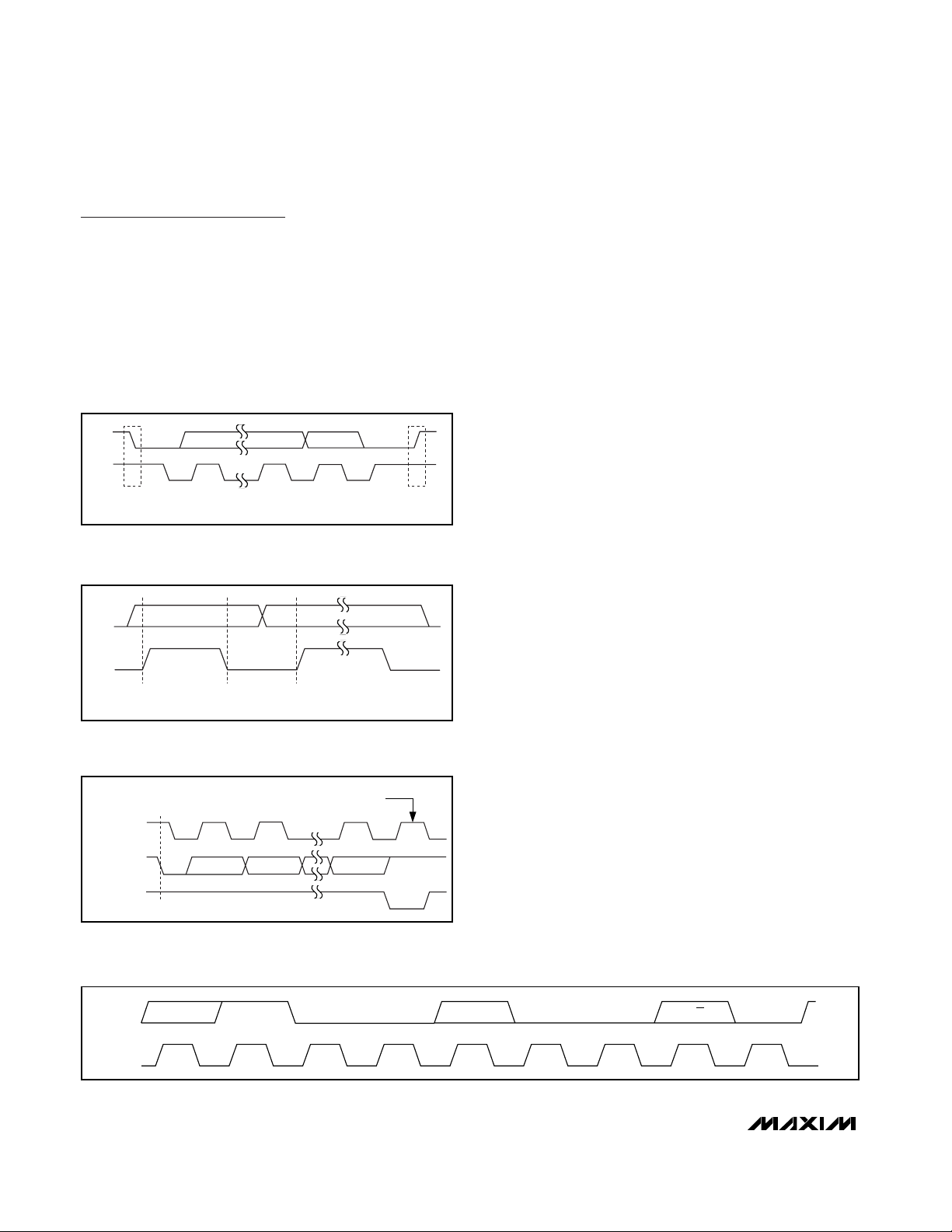

Figure 10. Read, Write, and Interrupt Timing Diagrams

WRITE TO OUTPUT PORTS REGISTERS (BLINK PHASE 0 REGISTERS/BLINK PHASE 1 REGISTERS)

123456789

SCL

SLAVE ADDRESS

SA6A5A4A3A2A1A00 A0 000000

SDA

COMMAND BYTE

1A A AP

MSB LSBDATA 1

MSB LSBDATA 2

START CONDITION

P7–P0

P15– P8

READ FROM INPUT PORTS REGISTERS

123456789

SCL

SA6A5A4A3A2A1A0 1 A

SDA

START CONDITION

P7–P0

P15–P8

INTERRUPT VALID/RESET

SCL

123456789

SDA

S A6A5A4A3A2A1A0 1 A

START CONDITION

P7–P0

P15–P8

INT

ACKNOWLEDGE FROM SLAVE

R/W

SLAVE ADDRESS

R/W

DATA 1 DATA2 DATA3 DATA 4

SLAVE ADDRESS

R/W

DATA1

t

IV

COMMAND BYTE

MSB LSBDATA 1

ACKNOWLEDGE FROM SLAVE

t

DH

COMMAND BYTE

MSB LSBDATA 2 MSB LSBDATA 4

ACKNOWLEDGE FROM SLAVE

DATA2

t

t

IV

IR

ACKNOWLEDGE FROM SLAVE ACKNOWLEDGE FROM SLAVE STOP

ANA

ACKNOWLEDGE FROM MASTER

ANA

ACKNOWLEDGE FROM MASTER

MSB LSBDATA6

DATA 6DATA 5

t

DS

DATA4DATA3

t

IR

DATA1 VALID

t

DV

P

STOP CONDITION

NO ACKNOWLEDGE FROM

MASTER

P

STOP CONDITION

NO ACKNOWLEDGE FROM

MASTER

CONDITION

t

DATA2 VALID

DV

Page 11

Device Reset

The reset input RST is an active-low input. When taken

low, RST clears any transaction to or from the MAX7314

on the serial interface and configures the internal registers to the same state as a power-up reset (Table 3),

which resets all ports as inputs. The MAX7314 then

waits for a START condition on the serial interface.

Detailed Description

Initial Power-Up

On power-up, and whenever the RST input is pulled

low, all control registers are reset and the MAX7314

enters standby mode (Table 3). Power-up status makes

all ports into inputs and disables both the PWM oscillator and blink functionality. RST can be used as a hardware shutdown input, which effectively turns off any

LED (or other) loads and puts the device into its lowest

power condition.

Configuration Register

The configuration register is used to configure the PWM

intensity mode, interrupt, and blink behavior, operate

the INT/O16 output, and read back the interrupt status

(Table 4).

Ports Configuration

The 16 I/O ports P0 through P15 can be configured to

any combination of inputs and outputs using the ports

configuration registers (Table 5). The INT/O16 output

can also be configured as an extra general-purpose

output, and the BLINK input can be configured as an

extra general-purpose input using the configuration

register (Table 4).

Input Ports

The input ports registers are read only (Table 6). They

reflect the incoming logic levels of the ports, regardless of

whether the port is defined as an input or an output by the

ports configuration registers. Reading an input ports register latches the current-input logic level of the affected

eight ports. A write to an input ports register is ignored.

MAX7314

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

______________________________________________________________________________________ 11

Table 2. Register Address Map

REGISTER

Read input ports P7–P0 0x00 0x01

Read input ports P15–P8 0x01 0x00

Blink phase 0 outputs P7–P0 0x02 0x03

Blink phase 0 outputs P15–P8 0x03 0x02

Ports configuration P7–P0 0x06 0x07

Ports configuration P15–P8 0x07 0x06

Blink phase 1 outputs P7–P0 0x0A 0x0B

Blink phase 1 outputs P15–P8 0x0B 0x0A

Master, O16 intensity 0x0E 0x0E (no change)

Configuration 0x0F 0x0F (no change)

Outputs intensity P1, P0 0x10 0x11

Outputs intensity P3, P2 0x11 0x12

Outputs intensity P5, P4 0x12 0x13

Outputs intensity P7, P6 0x13 0x14

Outputs intensity P9, P8 0x14 0x15

Outputs intensity P11, P10 0x15 0x16

Outputs intensity P13, P12 0x16 0x17

Outputs intensity P15, P14 0x17 0x10

ADDRESS CODE

(hex)

AUTOINCREMENT

ADDRESS

Page 12

MAX7314

Transition Detection

All ports configured as inputs are always monitored for

changes in their logic status. The action of reading an

input ports register or writing to the configuration register samples the corresponding 8 port bits’ input condition (Tables 4, 6). This sample is continuously

compared with the actual input conditions. A detected

change in input condition causes an interrupt condition.

The interrupt is cleared either automatically if the

changed input returns to its original state, or when the

appropriate input ports register is read, updating the

compared data (Figure 10). Randomly changing a port

from an output to an input may cause a false interrupt

to occur if the state of the input does not match the

content of the appropriate input ports register. The

interrupt status is available as the interrupt flag INT in

the configuration register (Table 4).

The input status of all ports is sampled immediately

after power-up as part of the MAX7314’s internal initialization, so if all the ports are pulled to valid logic levels

at that time, an interrupt does not occur at power-up.

INT

/O16 Output

The INT/O16 output pin can be configured as either the

INT output that reflects the interrupt flag logic state or as

a general-purpose output O16. When used as a generalpurpose output, the INT/O16 pin has the same blink and

PWM intensity control capabilities as the other ports.

Set the interrupt enable I bit in the configuration register

to configure INT/O16 as the INT output (Table 4). Clear

interrupt enable to configure INT/O16 as the O16. The

O16 logic state is set by the 2 bits O1 and O0 in the

configuration register. O16 follows the rules for blinking

selected by the blink enable flag E in the configuration

register. If blinking is disabled, then interrupt output

control O0 alone sets the logic state of the INT/O16 pin.

If blinking is enabled, then both interrupt output controls O0 and O1 set the logic state of the INT/O16 pin

according to the blink phase. PWM intensity control for

O16 is set by the 4 global intensity bits in the master

and O16 intensity register (Table 13).

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

12 ______________________________________________________________________________________

Table 3. Power-Up Configuration

REGISTER FUNCTION POWER-UP CONDITION

Blink phase 0 outputs P7–P0 High-impedance outputs 0x02 1 1 1 1 1 1 1 1

Blink phase 0 outputs P15–P8 High-impedance outputs 0x03 1 1 1 1 1 1 1 1

Ports configuration P7–P0 Ports P7–P0 are inputs 0x06 1 1 1 1 1 1 1 1

Ports configuration P15–P8 Ports P15–P8 are inputs 0x07 1 1 1 1 1 1 1 1

Blink phase 1 outputs P7–P0 High-impedance outputs 0x0A 1 1 1 1 1 1 1 1

Blink phase 1 outputs P15–P8 High-impedance outputs 0x0B 1 1 1 1 1 1 1 1

Master, O16 intensity

Configuration

Outputs intensity P1, P0 P1, P0 are static logic outputs 0x10 1 1 1 1 1 1 1 1

Outputs Intensity P3, P2 P3, P2 are static logic outputs 0x11 1 1 1 1 1 1 1 1

Outputs intensity P5, P4 P5, P4 are static logic outputs 0x12 1 1 1 1 1 1 1 1

Outputs intensity P7, P6 P7, P6 are static logic outputs 0x13 1 1 1 1 1 1 1 1

Outputs intensity P9, P8 P9, P8 are static logic outputs 0x14 1 1 1 1 1 1 1 1

Outputs intensity P11, P10 P11, P10 are static logic outputs 0x15 1 1 1 1 1 1 1 1

Outputs intensity P13, P12 P13, P12 are static logic outputs 0x16 1 1 1 1 1 1 1 1

Outputs intensity P15, P14 P15, P14 are static logic outputs 0x17 1 1 1 1 1 1 1 1

PWM oscillator is disabled;

O16 is static logic output

INT/O16 is interrupt output;

blink is disabled;

global intensity is enabled

ADDRESS

CODE

(hex)

0x0E 0 0 0 0 1 1 1 1

0x0F 0 0 0 0 1 1 0 0

D7 D6 D5 D4 D3 D2 D1 D0

REGISTER DATA

Page 13

MAX7314

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

______________________________________________________________________________________ 13

Table 4. Configuration Register

REGISTER DATA

REGISTER

ADDRESS

CODE

(hex)

D7 D6 D5 D4 D3 D2 D1 D0

CONFIGURATION

R/W

0x0F

INTERRUPT

STATUS

BLINK

STATUS

INTERRUPT

OUTPUT

CONTROL

AS GPO

INTERRUPT

ENABLE

GLOBAL

INTENSITY

BLINK FLIP

BLINK

ENABLE

Write device configuration

Read back device configuration

O0 I G B E

Disable blink

XXXXXXX0

Enable blink

XXXXXXX1

XXXXXX01

Flip blink register (see text)

XXXXXX11

Disable global intensity control—intensity

is set by registers 0x10–0x17 for ports P0

through P15 when configured as outputs,

and by D3–D0 of register 0x0E for

INT/O16 when INT/O16 pin is configured

as an output port

XXXXX0 XX

Enable global intensity control—intensity

for all ports configured as outputs is set

by D3–D0 of register 0x0E

XXXXX1 XX

Disable data change interrupt—INT/O16

output is controlled by the O0 and O1 bits

XXXX0 XXX

Enable data change interrupt—INT/O16

output is controlled by port input data

change

XXXX1 XXX

INT/O16 output is low (blink is disabled)

XXX00XX0

INT/O16 output is high impedance (blink

is disabled)

XXX10XX0

INT/O16 outp ut i s l ow d ur i ng b l i nk p hase 0

XXX00XX1

INT/O16 output is high impedance during

blink phase 0

XXX10XX1

INT/O16 outp ut i s l ow d ur i ng b l i nk p hase 1

XX0 X 0 XX1

INT/O16 output is high impedance during

blink phase 1

XX1 X 0 XX1

X = Don’t care.

0

1

—

—

—

—

—

—

—

—

—

—

—

INT BLINK O1

—

—

—

Page 14

MAX7314

Blink Mode

In blink mode, the output ports can be flipped between

using either the blink phase 0 registers or the blink

phase 1 registers. Flip control is both hardware (the

BLINK input) and software control (the blink flip flag B

in the configuration register) (Table 4).

The blink function can be used for LED effects by programming different display patterns in the two sets of

output port registers, and using the software or hardware controls to flip between the patterns.

If the blink phase 1 registers are written with 0xFF, then

the BLINK input can be used as a hardware disable to,

for example, instantly turn off an LED pattern programmed into the blink phase 0 registers. This technique can be further extended by driving the BLINK

input with a PWM signal to modulate the LED current to

provide fading effects.

The blink mode is enabled by setting the blink enable flag

E in the configuration register (Table 4). When blink mode

is enabled, the states of the blink flip flag and the BLINK

input are EXOR’ed to set the phase, and the output ports

are set by either the blink phase 0 registers or the blink

phase 1 registers (Figure 11) (Table 7).

The blink mode is disabled by clearing the blink enable

flag E in the configuration register (Table 4). When blink

mode is disabled, the state of the blink flip flag is

ignored, and the blink phase 0 registers alone control

the output ports.

Blink Phase Registers

When the blink function is disabled, the two blink phase

0 registers set the logic levels of the 16 ports (P0

through P15) when configured as outputs (Table 8). A

duplicate pair of registers called the blink phase 1 registers are also used if the blink function is enabled (Table

9). A logic high sets the appropriate output port high

impedance, while a logic low makes the port go low.

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

14 ______________________________________________________________________________________

Table 4. Configuration Register (continued)

REGISTER DATA

REGISTER

ADDRESS

CODE

(hex)

D7 D6 D5 D4 D3 D2 D1 D0

CONFIGURATION

R/W

INTERRUPT

STATUS

BLINK

STATUS

INTERRUPT

OUTPUT

CONTROL

AS GPO

INTERRUPT

ENABLE

GLOBAL

INTENSITY

BLINK FLIP

BLINK

ENABLE

Write device configuration

Read back device configuration

IGBE

Read back BLINK input pin status—

input is low

X 0 XXXXXX

Read back BLINK input pin status—

input is high

X 1 XXXXXX

Read b ack d ata chang e i nter r up t status

— d ata chang e i s not d etected , and

INT/O16 outp ut i s hi g h w hen i nter r up t

enab l e ( I b i t) i s set

0 XXXXXXX

Read b ack d ata chang e i nter r up t status

—d ata chang e i s d etected , and INT/O16

outp ut i s l ow w hen i nter r up t enab l e ( I b i t) i s set

0x0F

1 XXXXXXX

X = Don’t care.

Figure 11. Blink Logic

0

1

1

1

1

INT BLINK O1 O0

1

BLINK ENABLE FLAG E

BLINK FLIP FLAG B

BLINK INPUT

BLINK PHASE REGISTERS

Page 15

Reading a blink phase register reads the value stored

in the register, not the actual port condition. The port

output itself may or may not be at a valid logic level,

depending on the external load connected.

The 17th output, O16, is controlled through 2 bits in the

configuration register, which provide the same static or

blink control as the other 16 output ports.

PWM Intensity Control

The MAX7314 includes an internal oscillator, nominally

32kHz, to generate PWM timing for LED intensity control or other applications such as PWM trim DACs.

PWM can be disabled entirely for all the outputs. In this

case, all outputs are static and the MAX7314 operating

current is lowest because the internal PWM oscillator is

turned off.

The MAX7314 can be configured to provide any combination of PWM outputs and glitch-free logic outputs.

Each PWM output has an individual 4-bit intensity control (Table 14). When all outputs are to be used with the

same PWM setting, the outputs can be controlled

together instead using the global intensity control

(Table 13). Table 10 shows how to set up the MAX7314

to suit a particular application.

PWM Timing

The PWM control uses a 240-step PWM period, divided

into 15 master intensity timeslots. Each master intensity

timeslot is divided further into 16 PWM cycles (Figure 12).

The master intensity operates as a gate, allowing the individual output settings to be enabled from 1 to 15 timeslots

per PWM period (Figures 13, 14, 15) (Table 13).

MAX7314

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

______________________________________________________________________________________ 15

Table 5. Ports Configuration Registers

Table 6. Input Ports Registers

Table 7. Blink Logic

REGISTER R/W

Ports configuration P7–P0

(1 = input, 0 = output)

Read back ports configuration P7–P0 1

Ports configuration P15–P8

(1 = input, 0 = output)

Read back ports configuration P15–P8 1

REGISTER R/W

Read input ports P7–P0 1 0x00 IP7 IP6 IP5 IP4 IP3 IP2 IP1 IP0

Read input ports P15–P8 1 0x01 IP15 IP14 IP13 IP12 IP11 IP10 IP9 IP8

0

0

ADDRESS

CODE

(hex)

0x06 OP7 OP6 OP5 OP4 OP3 OP2 OP1 OP0

0x07 OP15 OP14 OP13 OP12 OP11 OP10 OP9 OP8

ADDRESS

CODE

(hex)

BLINK ENABLE

FLAG E

0 X X X Disabled Blink phase 0 registers

1

BLINK FLIP

FLAG B

0 0 0 Blink phase 0 registers

0 1 1 Blink phase 1 registers

1 0 1 Blink phase 1 registers

11 0

BLINK INPUT

PIN

D7 D6 D5 D4 D3 D2 D1 D0

D7 D6 D5 D4 D3 D2 D1 D0

BLINK FLIP FLAG

EXOR

BLINK INPUT PIN

REGISTER DATA

REGISTER DATA

BLINK FUNCTION OUTPUT REGISTERS USED

Enabled

Blink phase 0 registers

Page 16

MAX7314

Each output’s individual 4-bit intensity control only

operates during the number of timeslots gated by the

master intensity. The individual controls provide 16

intensity settings from 1/16 through 16/16 (Table 14).

Figures 16, 17, and 18 show examples of individual

intensity control settings. The highest value an individual or global setting can be set to is 16/16. This setting

forces the output to ignore the master control, and follow the logic level set by the appropriate blink phase

register bit. The output becomes a glitch-free static output with no PWM.

Using PWM Intensity Controls with Blink Disabled

When blink is disabled (Table 7), the blink phase 0 registers specify each output’s logic level during the PWM

on-time (Table 8). The effect of setting an output’s blink

phase 0 register bit to zero or 1 is shown in Table 11.

With its output bit set to zero, an LED can be controlled

with 16 intensity settings from 1/16th duty through fully

on, but cannot be turned fully off using the PWM intensity control. With its output bit set to 1, an LED can be

controlled with 16 intensity settings from fully off

through 15/16th duty.

Using PWM Intensity Controls with Blink Enabled

When blink is enabled (Table 7), the blink phase 0 registers and blink phase 1 registers specify each output’s

logic level during the PWM on-time during the respective

blink phases (Tables 8 and 9). The effect of setting an

output’s blink phase x register bit to zero or 1 is shown in

Table 12. LEDs can be flipped between either directly on

and off, or between a variety of high/low PWM intensities.

Global/O16 Intensity Control

The 4 bits used for output O16’s PWM individual intensity setting also double as the global intensity control

(Table 13). Global intensity simplifies the PWM settings

when the application requires them all to be the same,

such as for backlight applications, by replacing the 17

individual settings with 1 setting. Global intensity is

enabled with the global intensity flag G in the configuration register (Table 4). When global PWM control is

used, the 4 bits of master intensity and 4 bits of global

intensity effectively combine to provide an 8-bit, 240step intensity control applying to all outputs.

It is not possible to apply global PWM control to a subset of the ports, and use the others as logic outputs. To

mix static logic outputs and PWM outputs, individual

PWM control must be selected (Table 10).

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

16 ______________________________________________________________________________________

Table 8. Blink Phase 0 Registers

Table 9. Blink Phase 1 Registers

REGISTER R/W

Write outputs P7–P0 phase 0 0

Read back outputs P7–P0 phase 0 1

Write outputs P15–P8 phase 0 0

Read back outputs P15–P8 phase 0 1

REGISTER R/W

Write outputs P7–P0 phase 1 0

Read back outputs P7–P0 phase 1 1

Write outputs P15–P8 phase 1 0

Read back outputs P15–P8 phase 1 1

ADDRESS

ADDRESS

CODE

(hex)

0x02 OP7 OP6 OP5 OP4 OP3 OP2 OP1 OP0

0x03 OP15 OP14 OP13 OP12 OP11 OP10 OP9 OP8

CODE

(hex)

0x0A OP7 OP6 OP5 OP4 OP3 OP2 OP1 OP0

0x0B OP15 OP14 OP13 OP12 OP11 OP10 OP9 OP8

D7 D6 D5 D4 D3 D2 D1 D0

D7 D6 D5 D4 D3 D2 D1 D0

REGISTER DATA

REGISTER DATA

Page 17

MAX7314

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

______________________________________________________________________________________ 17

Table 10. PWM Application Scenarios

Figure 12. PWM Timing

Figure 13. Master Set to 1/15

Figure 15. Master Set to 15/15

Figure 14. Master Set to 14/15

APPLICATION RECOMMENDED CONFIGURATION

Set the master, O16 intensity register 0x0E to any value 0x00 to 0xOF.

All outputs static without PWM

The global intensity G bit in the configuration register is don't care.

The output intensity registers 0x10 through 0x17 are don't care.

Set the master and global intensity register 0x0E to any value from 0x10 to 0xFF.

A mix of static and PWM outputs, with PWM

outputs using different PWM settings

Clear global intensity G bit to zero in the configuration register to disable global

intensity control.

For the static outputs, set the output intensity value to 0xF.

For the PWM outputs, set the output intensity value in the 0x0 to 0xE range.

A mix of static and PWM outputs, with PWM

outputs all using the same PWM setting

As above. Global intensity control cannot be used with a mix of static and PWM

outputs, so write the individual intensity registers with the same PWM value.

Set the master, O16 intensity register 0x0E to any value from 0x10 to 0xFF.

All outputs PWM using the same PWM

setting

Set global intensity G bit to 1 in the configuration register to enable global intensity

control.

The master, O16 intensity register 0x0E is the only intensity register used.

The output intensity registers 0x10 through 0x17 are don't care.

ONE PWM PERIOD IS 240 CYCLES OF THE 32kHz PWM

OSCILLATOR. A PWM PERIOD CONTAINS 15 MASTER

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 14 15 1 2

INTENSITY TIMESLOTS

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 15 16 1 2

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 14 15 2 1

.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 14 15 2 1

EACH MASTER INTENSITY

TIMESLOT CONTAINS 16

PWM CYCLES

.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 14 15 2 1

.

.

.

Page 18

MAX7314

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

18 ______________________________________________________________________________________

Figure 17. Individual (or Global) Set to 15/16

Figure 16. Individual (or Global) Set to 1/16

Figure 18. Individual (or Global) Set to 16/16

Table 11. PWM Intensity Settings (Blink Disabled)

MASTER INTENSITY TIMESLOT

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

MASTER INTENSITY TIMESLOT

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

MASTER INTENSITY TIMESLOT CONTROL IS IGNORED

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

OUTPUT

(OR

GLOBAL)

INTENSITY

SETTING

0x0 1/16 15/16 Lowest PWM intensity 15/16 1/16 Highest PWM intensity

0x1 2/16 14/16 14/16 2/16

0x2 3/16 13/16 13/16 3/16

0x3 4/16 12/16 12/16 4/16

0x4 5/16 11/16 11/16 5/16

0x5 6/16 10/16 10/16 6/16

0x6 7/16 9/16 9/16 7/16

0x7 8/16 8/16 8/16 8/16

0x8 9/16 7/16 7/16 9/16

0x9 10/16 6/16 6/16 10/16

0xA 11/16 5/16 5/16 11/16

0xB 12/16 4/16 4/16 12/16

0xC 13/16 3/16 3/16 13/16

0xD 14/16 2/16

0xE 15/16 1/16 Highest PWM intensity 1/16 15/16 Lowest PWM intensity

0xF Static low Static low

PWM DUTY CYCLE

OUTPUT BLINK PHASE 0

REGISTER BIT = 0

LOW TIME HIGH TIME

LED BEHAVIOR WHEN

OUTPUT BLINK PHASE 0

REGISTER BIT = 0

(LED IS ON WHEN

OUTPUT IS LOW)

Increasing PWM intensity

Full intensity, no PWM

(LED on continuously)

NEXT MASTER INTENSITY TIMESLOT

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

NEXT MASTER INTENSITY TIMESLOT

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

PWM DUTY CYCLE

OUTPUT BLINK PHASE 0

REGISTER = 1

LOW TIME HIGH TIME

2/16 14/16

Static high

impedance

Static high

impedance

LED BEHAVIOR WHEN

OUTPUT BLINK PHASE 0

REGISTER BIT = 1

(LED IS ON WHEN

OUTPUT IS LOW)

LED off continuously

Increasing PWM intensity

Page 19

Applications Information

Hot Insertion

I/O ports P0–P15, interrupt output INT/O16, RST input,

BLINK input, and serial interface SDA, SCL, AD0 remain

high impedance with up to 6V asserted on them when

the MAX7314 is powered down (V+ = 0V). The MAX7314

can therefore be used in hot-swap applications.

Output Level Translation

The open-drain output architecture allows the ports to

level translate the outputs to higher or lower voltages

than the MAX7314 supply. An external pullup resistor

can be used on any output to convert the high-impedance logic-high condition to a positive voltage level.

The resistor can be connected to any voltage up to

5.5V. For interfacing CMOS inputs, a pullup resistor

value of 220kΩ is a good starting point. Use a lower

resistance to improve noise immunity, in applications

where power consumption is less critical, or where a

faster rise time is needed for a given capacitive load.

Driving LED Loads

When driving LEDs, a resistor in series with the LED

must be used to limit the LED current to no more than

50mA. Choose the resistor value according to the following formula:

R

LED

= (V

SUPPLY

- V

LED

- VOL) / I

LED

where:

R

LED

is the resistance of the resistor in series with the

LED (Ω).

V

SUPPLY

is the supply voltage used to drive the LED (V).

V

LED

is the forward voltage of the LED (V).

VOLis the output low voltage of the MAX7314 when

sinking I

LED

(V).

I

LED

is the desired operating current of the LED (A).

For example, to operate a 2.2V red LED at 14mA from a

5V supply, R

LED

= (5 - 2.2 - 0.25) / 0.014 = 182Ω.

MAX7314

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

______________________________________________________________________________________ 19

Table 12. PWM Intensity Settings (Blink Enabled)

OUTPUT

(OR

GLOBAL)

INTENSITY

SETTING

0x0 1/16 15/16 15/16 1/16

0x1 2/16 14/16 14/16 2/16

0x2 3/16 13/16 13/16 3/16

0x3 4/16 12/16 12/16 4/16

0x4 5/16 11/16 11/16 5/16

0x5 6/16 10/16 10/16 6/16

0x6 7/16 9/16 9/16 7/16

0x7 8/16 8/16 8/16 8/16 Output is half intensity during both blink phases

0x8 9/16 7/16 7/16 9/16

0x9 10/16 6/16 6/16 10/16

0xA 11/16 5/16 5/16 11/16

0xB 12/16 4/16 4/16 12/16

0xC 13/16 3/16 3/16 13/16

0xD 14/16 2/16 2/16 14/16

0xE 15/16 1/16 1/16 15/16

0xF Static low Static low

PWM DUTY CYCLE

OUTPUT BLINK

PHASE X

REGISTER BIT = 0

LOW

TIME

HIGH

TIME

PWM DUTY CYCLE

OUTPUT BLINK

PHASE X

REGISTER = 1

LOW

TIME

Static high

impedance

HIGH

TIME

Static high

impedance

P hase 0: LE D on at l ow i ntensi ty

P hase 1: LE D on at hi g h i ntensi ty

P hase 0: LE D on at hi g h i ntensi ty

P hase 1: LE D on at l ow i ntensi ty

Phase 0: LED on continuously

Phase 1: LED off continuously

EXAMPLES OF LED BLINK BEHAVIOR

(LED IS ON WHEN OUTPUT IS LOW)

BLINK PHASE 0

REGISTER BIT = 0

BLINK PHASE 1

REGISTER BIT = 1

P hase 0: LE D on at hi g h i ntensi ty

P hase 1: LE D on at l ow i ntensi ty

P hase 0: LE D on at l ow i ntensi ty

P hase 1: LE D on at hi g h i ntensi ty

Phase 0: LED off continuously

Phase 1: LED on continuously

BLINK PHASE 0

REGISTER BIT = 1

BLINK PHASE 1

REGISTER BIT = 0

Page 20

MAX7314

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

20 ______________________________________________________________________________________

Table 13. Master, O16 Intensity Register

REGISTER

MASTER AND GLOBAL INTENSITY

Write master and global intensity 0

Read back master and global intensity 1

Master intensity duty cycle is 0/15 (off);

internal oscillator is disabled;

all outputs will be static with no PWM

Master intensity duty cycle is 1/15 — 0001————

Master intensity duty cycle is 2/15 — 0010————

Master intensity duty cycle is 3/15 — 0011————

— — ————————

Master intensity duty cycle is 13/15 — 1101————

Master intensity duty cycle is 14/15 — 1110————

Master intensity duty cycle is 15/15 (full) — 1111————

O16 intensity duty cycle is 1/16 — — — — — 0 0 0 0

O16 intensity duty cycle is 2/16 — — — — — 0 0 0 1

O16 intensity duty cycle is 3/16 — — — — — 0 0 1 0

— — ————————

O16 intensity duty cycle is 14/16 — — — — — 1 1 0 1

O16 intensity duty cycle is 15/16 — — — — — 1 1 1 0

O16 intensity duty cycle is 16/16

(static output, no PWM)

ADDRESS

CODE

R/W

— 0000————

—

(hex)

0X0E

D7 D6 D5 D4 D3 D2 D1 D0

MSB LSB MSB LSB

MASTER INTENSITY O16 INTENSITY

M3 M2 M1 M0 G3 G2 G1 G0

———— 1 1 1 1

REGISTER DATA

Page 21

MAX7314

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

______________________________________________________________________________________________________ 21

Table 14. Output Intensity Registers

REGISTER DATA

REGISTER

ADDRESS

CODE

(hex)

D7 D6 D5 D4 D3 D2 D1 D0

LSB

OUTPUTS P1, P0 INTENSITY

OUTPUT P1 INTENSITY OUTPUT P0 INTENSITY

Write output P1, P0 intensity

Read back output P1, P0 intensity

P0I0

Output P1 intensity duty cycle is 1/16

0000————

Output P1 intensity duty cycle is 2/16

0001————

Output P1 intensity duty cycle is 3/16

0010————

—

————————

Output P1 intensity duty cycle is 14/16

1101————

Output P1 intensity duty cycle is 15/16

1110————

Output P1 intensity duty cycle is 16/16

(static logic level, no PWM)

1111————

Output P0 intensity duty cycle is 1/16

———— 0 0 0 0

Output P0 intensity duty cycle is 2/16

———— 0 0 0 1

Output P0 intensity duty cycle is 3/16

———— 0 0 1 0

—

————————

Output P0 intensity duty cycle is 14/16

———— 1 1 0 1

Output P0 intensity duty cycle is 15/16

———— 1 1 1 0

Output P0 intensity duty cycle is 16/16

(static logic level, no PWM)

0X10

———— 1 1 1 1

LSB

OUTPUTS P3, P2 INTENSITY

OUTPUT P3 INTENSITY OUTPUT P2 INTENSITY

Write output P3, P2 intensity

Read back output P3, P2 intensity

0x11

P2I0

LSB

OUTPUTS P5, P4 INTENSITY

OUTPUT P5 INTENSITY OUTPUT P4 INTENSITY

Write output P5, P4 intensity

Read back output P5, P4 intensity

0x12

P4I0

LSB

OUTPUTS P7, P6 INTENSITY

OUTPUT P7 INTENSITY OUTPUT P6 INTENSITY

Write output P7, P6 intensity

Read back output P7, P6 intensity

0x13

P6I0

R/W

MSB LSB MSB

0

1

—

—

—

—

—

—

—

—

—

—

—

—

—

—

P1I3 P1I2 P1I1 P1I0 P0I3 P0I2 P0I1

0

1

0

1

0

1

MSB LSB MSB

P3I3 P3I2 P3I1 P3I0 P2I3 P2I2 P2I1

MSB LSB MSB

P5I3 P5I2 P5I1 P5I0 P4I3 P4I2 P4I1

MSB LSB MSB

P7I3 P7I2 P7I1 P7I0 P6I3 P6I2 P6I1

Page 22

MAX7314

Driving Load Currents Higher than 50mA

The MAX7314 can be used to drive loads drawing more

than 50mA, like relays and high-current white LEDs, by

paralleling outputs. Use at least one output per 50mA of

load current; for example, a 5V 330mW relay draws

66mA and needs two paralleled outputs to drive it.

Ensure that the paralleled outputs chosen are controlled

by the same blink phase register, i.e., select outputs

from the P0 through P7 range, or the P8 through P15

range. This way, the paralleled outputs are turned on

and off together. Do not use output O16 as part of a

load-sharing design. O16 cannot be switched at the

same time as any of the other outputs because it is controlled by a different register.

The MAX7314 must be protected from the negative

voltage transient generated when switching off inductive loads, such as relays, by connecting a reversebiased diode across the inductive load (Figure 19). The

peak current through the diode is the inductive load’s

operating current.

Power-Supply Considerations

The MAX7314 operates with a power-supply voltage of

2V to 3.6V. Bypass the power supply to GND with at

least 0.047µF as close to the device as possible. For

the QFN version, connect the underside exposed pad

to GND.

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

22 ______________________________________________________________________________________

Table 14. Output Intensity Registers (continued)

REGISTER DATA

REGISTER

ADDRESS

CODE

(hex)

D7 D6 D5 D4 D3 D2 D1 D0

LSB

OUTPUTS P9, P8 INTENSITY

R/W

OUTPUT P9 INTENSITY OUTPUT P8 INTENSITY

Write output P9, P8 intensity

Read back output P9, P8 intensity

0x14

P8I0

LSB

OUTPUTS P11, P10 INTENSITY

OUTPUT P11 INTENSITY OUTPUT P10 INTENSITY

Write output P11, P10 intensity

Read back output P11, P10 intensity

0x15

P10I0

LSB

OUTPUTS P13, P12 INTENSITY

OUTPUT P13 INTENSITY OUTPUT P12 INTENSITY

Write output P13, P12 intensity

Read back output P13, P12 intensity

0x16

P12I0

LSB

OUTPUTS P15, P14 INTENSITY

OUTPUT P15 INTENSITY OUTPUT P14 INTENSITY

Write output P15, P14 intensity

Read back output P15, P14 intensity

0x17

P14I0

OUTPUT O16 INTENSITY See master, O16 intensity register (Table 13).

MSB LSB MSB

0

1

0

1

0

1

0

1

P9I3 P9I2 P9I1 P9I0 P8I3 P8I2 P8I1

MSB LSB MSB

P11I3 P11I2 P11I1 P11I0 P10I3 P10I2 P10I1

MSB LSB MSB

P13I3 P13I2 P13I1 P13I0 P12I3 P12I2 P12I1

MSB LSB MSB

P15I3 P15I2 P15I1 P15I0 P14I3 P14I2 P14I1

Page 23

MAX7314

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

______________________________________________________________________________________ 23

Figure 19. Diode-Protected Switching Inductive Load

Chip Information

TRANSISTOR COUNT: 25,991

PROCESS: BiCMOS

TOP VIEW

THIN QFN

MAX7314ATG

19

20

21

22

12 3456

18 17 16 15 14 13

23

24

12

11

10

9

8

7

SCL

V+

SDA

INT/O16

AD0

P0

P1

P2

P3

P4

P5

BLINK

P15

P13

P12

P11

RST

P10

P8

P9

GND

P6

P7

P14

Pin Configurations

0.047μF

2V TO 3.6V

TOP VIEW

INT/O16

RST

AD0

P1

P2

P3

P5

P6

P7

1

2

3

4

5

6

7

8

9

10

11

12

MAX7314AEG

24

V+

23

SDA

22

SCL

21

BLINKP0

20

P15

19

P14

18

P13

17

P12P4

16

P11

15

P10

14

P9

13

P8GND

QSOP

5V

μC

SDA

SCL

I/O

I/O

INT

V+

SDA

MAX7314

SCL

BLINK

RST

INT/O16

AD0

GND

P0

P1

P2

P3

P4

P5

P6

P7

P8

P9

P10

P11

P12

P13

P14

P15

BAS16

Page 24

MAX7314

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

24 ______________________________________________________________________________________

QSOP EPS

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

Page 25

MAX7314

18-Port GPIO with LED Intensity Control,

Interrupt, and Hot-Insertion Protection

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 ____________________ 25

© 2005 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products, Inc.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

24L QFN THIN.EPS

Loading...

Loading...