Page 1

19-5949; Rev 1; 3/12

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

General Description

The MAX7304 consists of 16 port GPIOs, with 12 pushpull GPIOs and four open-drain GPIOs configurable as

PWM-controlled LED drivers. The device supports a

1.62V to 3.6V separate power supply for level translation.

An address-select input (AD0) allows up to four unique

slave addresses for the device.

Each GPIO can be programmed to one of the two

externally applied logic voltage levels. PORT15–PORT12

can also be configured as LED drivers that feature

constant-current sinks and PWM intensity control with the

internal oscillator. The maximum constant-current level for

each open-drain LED port is 20mA. The intensity of the

LED on each open-drain port can be individually adjusted

through a 256-step PWM control. The port also features

LED fading.

The same index rows and columns in the device can be

used as a direct logic-level translator.

The device is offered in a 24-pin (3.5mm x 3.5mm) TQFN

package with an exposed pad, and a small 25-bump

(2.159mm x 2.159mm) wafer-level package (WLP) for

cell phones, pocket PCs, and other portable consumer

electronic applications.

The device operates over the -40NC to +85NC extended

temperature range.

Applications

Cell Phones

Notebooks

PDAs

Handheld Games

Portable Consumer Electronics

Features

S Four LED Driver Pins on PORT15–PORT12

S Integrated High-ESD Protection

±8kV IEC 61000-4-2 Contact Discharge

±15kV IEC 61000-4-2 Air-Gap Discharge

S 5V Tolerant, Open-Drain I/O Ports Capable of

Constant-Current LED Drive

S 256-Step PWM Individual LED Intensity-Control

Accuracy

S Individual LED Blink Rates and Common LED

Fade-In /Out Rates from 256ms to 4096ms

S User-Configurable Debounce Time (1ms to 32ms)

S Configurable Edge-Triggered Port Interrupt (INT)

S 1.62V to 3.6V Operating Supply Voltage

S Individually Programmable GPIOs to Two Logic

Levels

S 8-Channel Individual Programmable Level

Translators

S Supports Hot Insertion

S 400kbps, 5.5V Tolerant I2C Serial Interface with

Selectable Bus Timeout

Ordering Information appears at end of data sheet.

For related parts and recommended products to use with this part,

refer to www.maxim-ic.com/MAX7304.related.

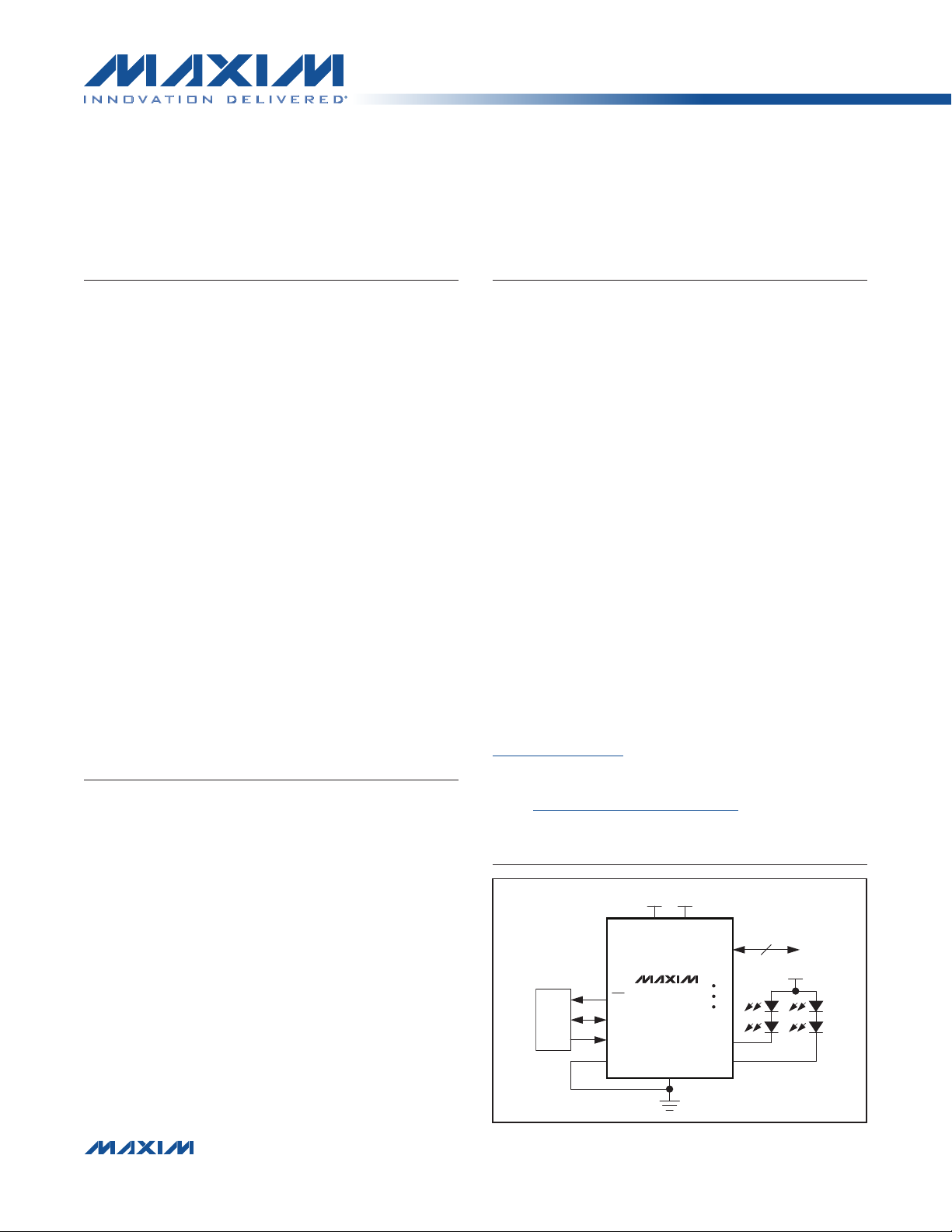

Typical Operating Circuit

+1.8V

+2.6V

V

V

CC

LA

PORT0

PORT1

MAX7304

INT

MCU

_________________________________________________________________ Maxim Integrated Products 1

SDA

SCL

AD0

GND

PORT13

PORT14

PORT15

14

GPIO

+5V

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

Page 2

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

ABSOLUTE MAXIMUM RATINGS

V

CC, VLA

PORT11–PORT0 to GND .......................... -0.3V to (VCC + 0.3V)

PORT15–PORT12 to GND ....................................... -0.3V to +6V

SDA, SCL, AD0, INT to GND ..................................-0.3V to +6V

VLA to VCC ...........................................................-0.3V to +2.3V

DC Current on PORT15–PORT12 to GND .........................25mA

DC Current on PORT11–PORT0 to GND .............................7mA

VCC, VLA, GND Current .....................................................80mA

DC Current VCC, VLA to PORT11–PORT0 ...........................5mA

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

PACKAGE THERMAL CHARACTERISTICS (Note 1)

TQFN

Note 1: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a four-

to GND ....................................................-0.3V to +4V

Junction-to-Ambient Thermal Resistance (BJA) ....65.1NC/W

Junction-to-Case Thermal Resistance (BJC) ...........5.4NC/W

layer board. For detailed information on package thermal considerations, refer to www.maxim-ic.com/thermal-tutorial.

Continuous Power Dissipation (TA = +70NC)

TQFN (derate 15.4mW/NC above +70NC)..................1229mW

WLP (derate 19.2mW/NC above +70NC)......................850mW

Operating Temperature Range .......................... -40NC to +85NC

Junction Temperature .....................................................+150NC

Storage Temperature Range ............................ -65NC to +150NC

Lead Temperature (TQFN) (soldering, 10s) ....................+300NC

Soldering Temperature (reflow) ......................................+260NC

WLP

Junction-to-Ambient Thermal Resistance (BJA) .......52NC/W

ELECTRICAL CHARACTERISTICS

(VCC = 1.62V to 3.6V, TA = -40NC to +85NC, unless otherwise noted. Typical values are at VCC = 3.3V, TA = +25NC.) (Notes 2, 3)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Operating Supply Voltage V

Second Logic Supply V

Operating Supply Current I

Sleep-Mode Supply Current I

POR Threshold V

GPIO SPECIFICATIONS

External Supply Voltage

PORT15–PORT12 (LED Drivers)

LED Port-to-Port Sink Current

Variation

10mA Port Sink Current

PORT15–PORT12

20mA Port Sink Current

PORT15–PORT12

Input High Voltage PORT_ V

Input Low Voltage PORT_ V

Input Leakage Current

PORT11–PORT0

Input Leakage Current

PORT15–PORT12

V

I

LEAKAGE

I

LEAKAGE

CC

LA

CC

SL

POR

LED

I

OL

I

OL

IH

IL

Oscillator running 50 65

Not using GPO or LED configuration 1.8 3

VCC = 3.3V, VOL = 1V, TA = +25NC,

10mA output mode

VOL = 1V

VOL = 0.5V

VOL = 1V

VOL = 0.5V

VS = V CC or VLA depending on

reference logic level setting

Input voltage = VCC or V

Input voltage = 5V -1 +1

TA = +25NC

VCC = 3.6V, TA = +25NC

TA = +25NC

VCC = 3.6V, TA = +25NC

GND

1.62 3.3 3.6 V

V

CC

8.6 11.4

18.13 21.52

0.7 O V

-2 +2

3.3 3.6 V

1.2 V

5 V

Q1.5 Q2.4

9.5

19.05

S

0.3 O V

S

FA

FA

%

mAVCC = 3.3V 9.04 10 10.96

mAVCC = 3.3V 18.47 20 21.34

V

V

FA

FA

_________________________________________________________________ Maxim Integrated Products 2

Page 3

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

ELECTRICAL CHARACTERISTICS (continued)

(VCC = 1.62V to 3.6V, TA = -40NC to +85NC, unless otherwise noted. Typical values are at VCC = 3.3V, TA = +25NC.) (Notes 2, 3)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Input Capacitance PORT_ C

Output Low Voltage PORT_ V

Output High Voltage

COL3–COL0, ROW_

Output Logic-Low Voltage

(INT)

PWM Frequency f

SERIAL-INTERFACE SPECIFICATIONS

Input High Voltage

SDA, SCL, AD0

Input Low Voltage

SDA, SCL, AD0

Input Leakage Current

SDA, SCL, AD0

Output Logic-Low Voltage

SDA

Input Capacitance

SDA, SCL, AD0

I2C TIMING SPECIFICATIONS

SCL Serial-Clock Frequency f

Bus Free Time Between a STOP

and START Condition

Hold Time (Repeated) START

Condition

Repeated START Condition

Setup Time

STOP Condition Setup Time t

Data Hold Time t

Data Setup Time t

SCL Clock Low Period t

SCL Clock High Period t

Rise Time of Both SDA and SCL

Signals, Receiving

Fall Time of Both SDA and SCL

Signals, Receiving

Fall Time of SDA Signal,

Transmitting

I

LEAKAGE

t

HD, STA

t

SU, STA

SU, STO

HD, DAT

SU, DAT

t

IN

OL

V

OH

V

OL

PWM

V

IH

V

IL

V

OL

C

IN

SCL

t

BUF

LOW

HIGH

t

R

t

F

F, TX

VCC = 1.62V and I

VCC = 1.62V and I

VCC = 1.62V and I

VCC = 1.62V and I

I

= 6mA 0.6 V

SINK

Derived from oscillator clock 500 Hz

Input voltage = 5.5V or V

I

= 6mA 0.6 V

SINK

(Notes 4, 5) 10 pF

Bus timeout enabled 0.05 400

Bus timeout disabled 0 400

(Note 6) 0.9

(Notes 4, 5)

(Notes 4, 5)

(Notes 4, 7)

= 2.5mA 50 100

SINK

= 5mA 80 250

SINK

SOURCE

SOURCE

= 2.5mA

= 5mA

GND

VCC -

120

VCC -

250

0.7 O V

-1 +1

1.3

0.6

0.6

0.6

100 ns

1.3

0.7

20 pF

VCC -

40

VCC -

70

CC

0.3 O V

20 +

0.1C

20 +

0.1C

20 +

0.1C

B

B

B

300 ns

300 ns

250 ns

CC

mV

mV

V

V

FA

kHz

Fs

Fs

Fs

Fs

Fs

Fs

Fs

_________________________________________________________________ Maxim Integrated Products 3

Page 4

MAX7304

02

02

02

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

ELECTRICAL CHARACTERISTICS (continued)

(VCC = 1.62V to 3.6V, TA = -40NC to +85NC, unless otherwise noted. Typical values are at VCC = 3.3V, TA = +25NC.) (Notes 2, 3)

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Pulse Width of Spike Suppressed t

Capacitive Load for Each Bus Line C

Bus Timeout t

SP

B

TIMEOUT

ESD PROTECTION

PORT_

All Other Pins Human Body Model

Note 2: All parameters are tested at TA = +25NC. Specifications over temperature are guaranteed by design.

Note 3: All digital inputs at VCC or GND.

Note 4: Guaranteed by design.

Note 5: CB = total capacitance of one bus line in pF. tR and tF measured between 0.8V and 2.1V.

Note 6: A master device must provide a hold time of at least 300ns for the SDA signal (referred to VIL of the SCL signal) to bridge

the undefined region of SCL’s falling edge.

Note 7: I

= 6mA. CB = total capacitance of one bus line in pF. tR and tF measured between 0.8V and 2.1V.

SINK

Note 8: Input filters on the SDA, SCL, and AD0 inputs suppress noise spikes less than 50ns.

(Notes 4, 8) 50 ns

(Note 4) 400 pF

14 19 27 ms

IEC 61000-4-2 Air-Gap Discharge

IEC 61000-4-2 Contact Discharge

Q15

Q8

Q2.5

kV

kV

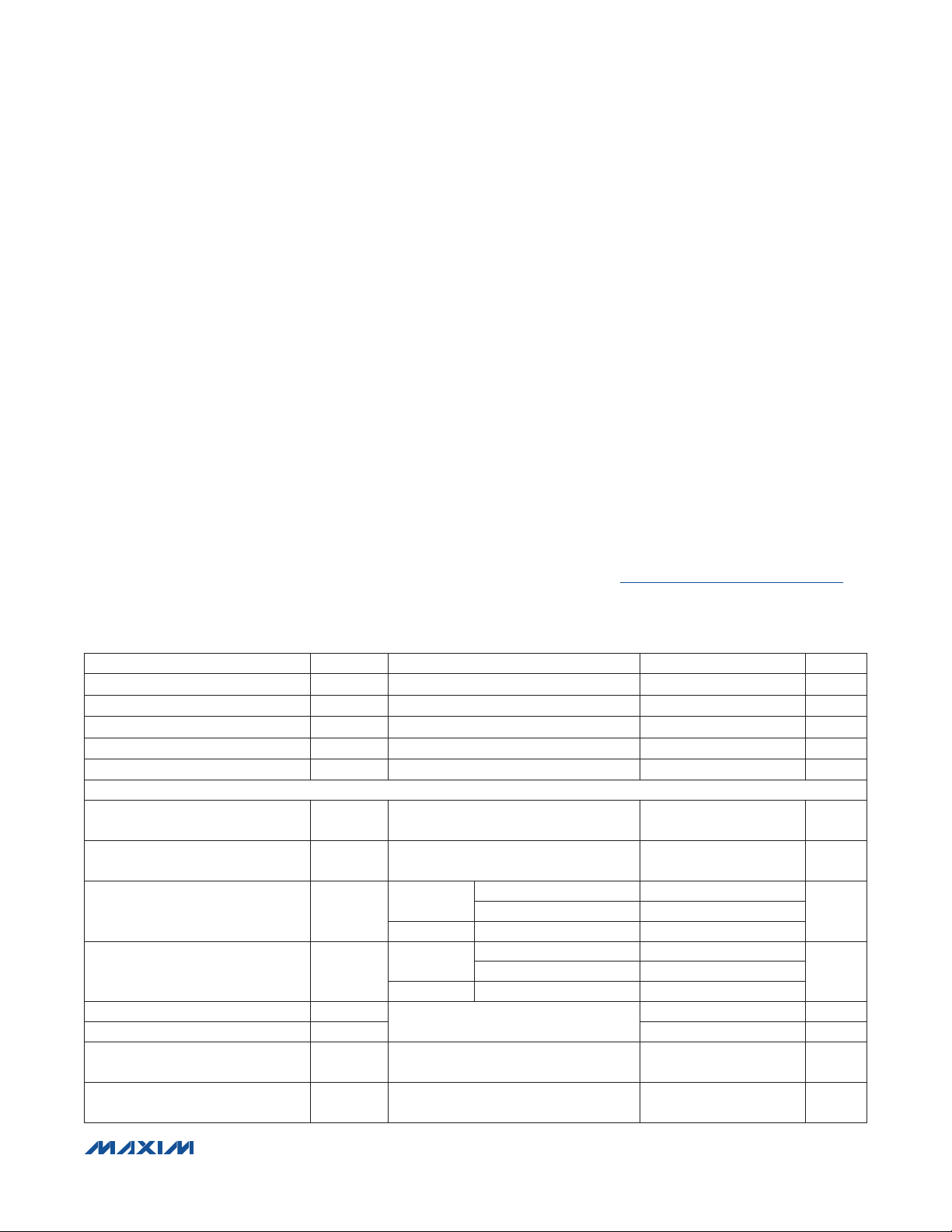

(VCC = 2.5V, VLA = 2.5V, TA = +25NC, unless otherwise noted.)

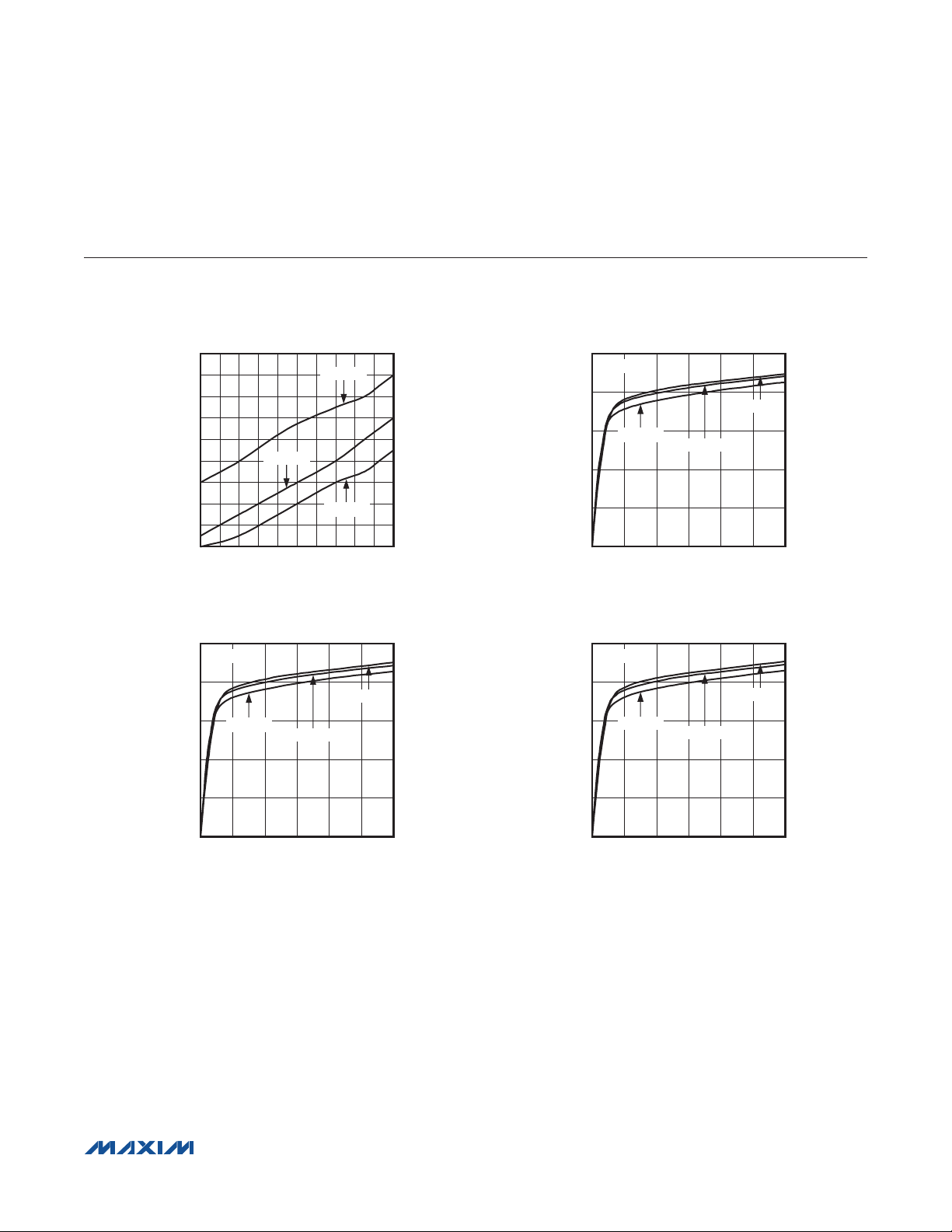

GPO OUTPUT LOW VOLTAGE

vs. SINK CURRENT (PORT15–PORT12)

120

VCC = 2.4V

100

80

60

40

GPO OUTPUT LOW VOLTAGE (mV)

20

0

TA = +25°C

SINK CURRENT (mA)

TA = +85°C

TA = -40°C

120

100

MAX7304 toc01

80

60

40

GPO OUTPUT LOW VOLTAGE (mV)

20

18161412108642

0

GPO OUTPUT LOW VOLTAGE

vs. SINK CURRENT (PORT15–PORT12)

VCC = 3.0V

0

Typical Operating Characteristics

TA = +85°C

TA = +25°C

SINK CURRENT (mA)

TA = -40°C

GPO OUTPUT LOW VOLTAGE

vs. SINK CURRENT (PORT15–PORT12)

120

VCC = 3.6V

100

MAX7304 toc02

80

60

40

GPO OUTPUT LOW VOLTAGE (mV)

20

18161412108642

0

0

TA = +25°C

SINK CURRENT (mA)

TA = +85°C

TA = -40°C

MAX7304 toc03

18161412108642

0

_________________________________________________________________ Maxim Integrated Products 4

Page 5

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

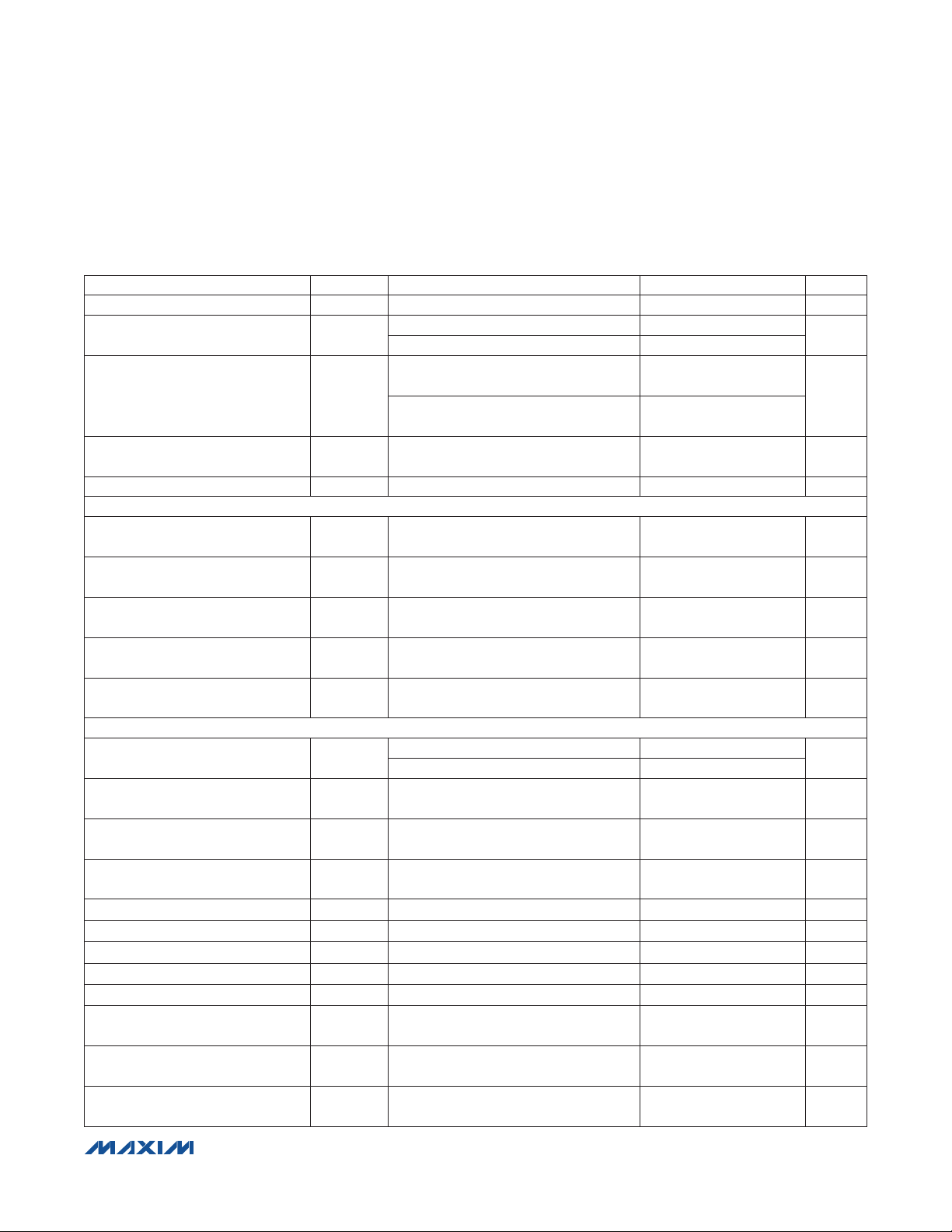

Typical Operating Characteristics (continued)

(VCC = 2.5V, VLA = 2.5V, TA = +25NC, unless otherwise noted.)

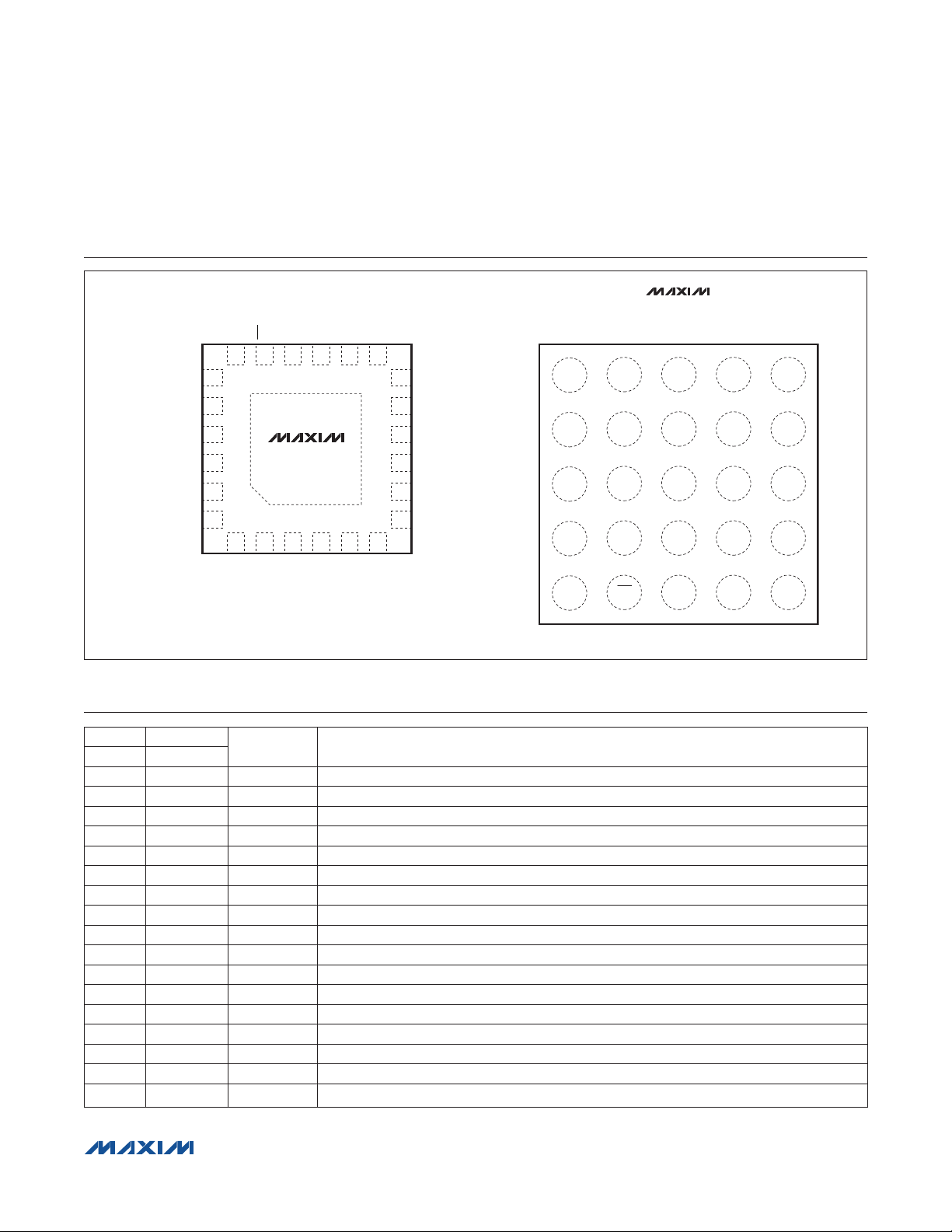

SLEEP-MODE SUPPLY CURRENT

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

SLEEP-MODE SUPPLY CURRENT (µA)

0.2

0

1.6 3.6

vs. OUTPUT VOLTAGE (PORT15– PORT12)

25

20

15

10

vs. SUPPLY VOLTAGE

TA = +25°C

SUPPLY VOLTAGE (V)

CONSTANT-CURRENT GPIO

OUTPUT SINK CURRENT

VCC = 3.0V

TA = -40°C

TA = +25°C

TA = +85°C

MAX7304 toc04

TA = -40°C

3.43.22.8 3.02.0 2.2 2.4 2.61.8

MAX7304 toc06

TA = +85°C

MAX7304

I2C-Interfaced 16-Port,

CONSTANT-CURRENT GPIO OUTPUT

SINK CURRENT vs. OUTPUT VOLTAGE

25

20

15

10

5

0

CONSTANT-CURRENT GPIO OUTPUT SINK CURRENT (mA)

0 3.0

vs. OUTPUT VOLTAGE (PORT15–PORT12)

25

20

15

10

(PORT15–PORT12)

VCC = 2.4V

TA = -40°C

TA = +25°C

OUTPUT VOLTAGE (V)

CONSTANT-CURRENT GPIO

OUTPUT SINK CURRENT

VCC = 3.6V

TA = -40°C

TA = +25°C

MAX7304 toc05

TA = +85°C

2.52.01.51.00.5

MAX7304 toc07

TA = +85°C

5

0

CONSTANT-CURRENT GPIO OUTPUT SINK CURRENT (mA)

0 3.0

OUTPUT VOLTAGE (V)

2.52.01.51.00.5

5

0

CONSTANT-CURRENT GPIO OUTPUT SINK CURRENT (mA)

0 3.0

OUTPUT VOLTAGE (V)

2.52.01.51.00.5

_________________________________________________________________ Maxim Integrated Products 5

Page 6

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

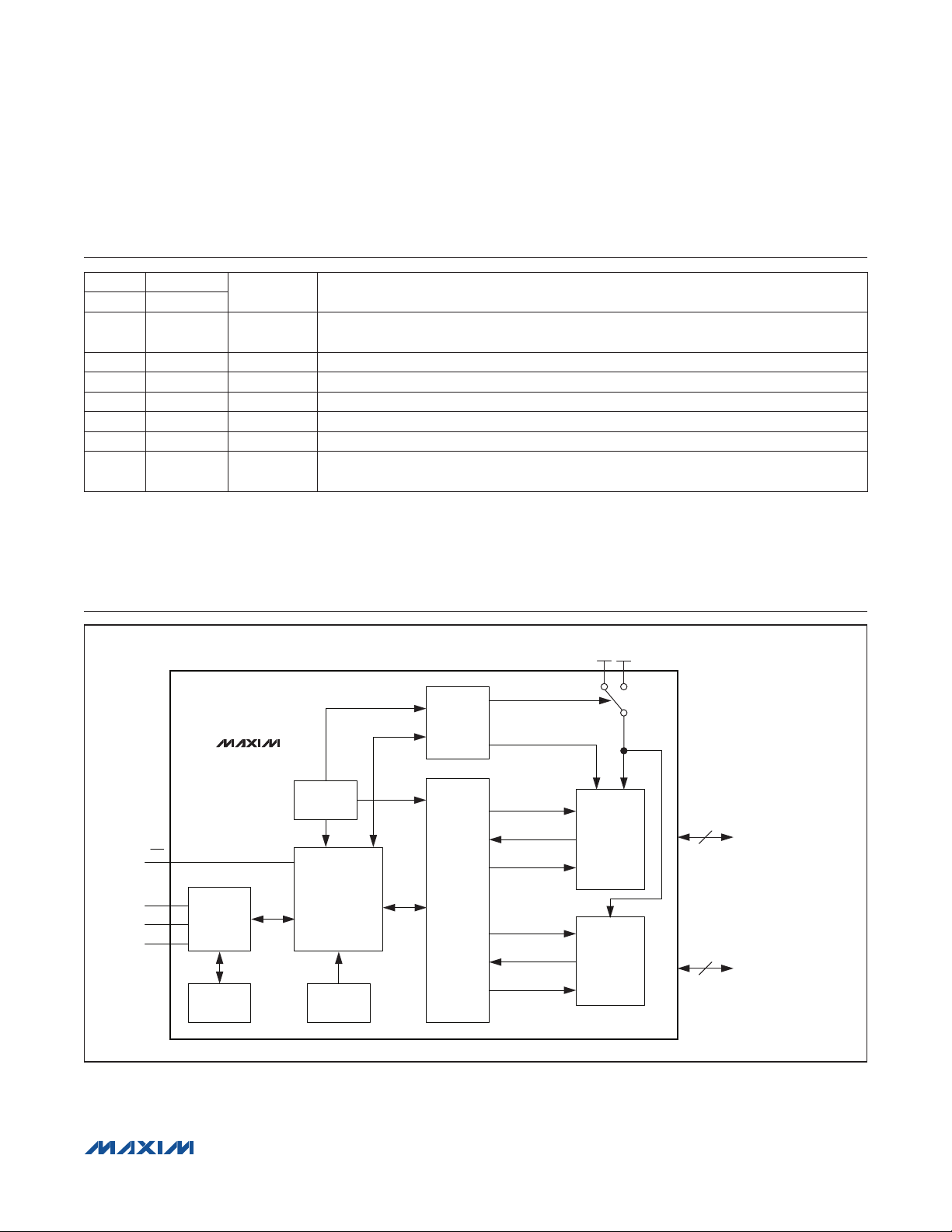

Pin/Bump Configurations

TOP VIEW

TOP VIEW

PORT0

PORT1

PORT2

PORT3

GND

PORT4

19

20

21

22

23

24

CC

INT

V

SCL

1718 16 14 13

15

MAX7304

+

12

3

456

SDA

*EP

AD0

(BUMPS SIDE DOWN)

LA

V

1234

+

A

12

PORT8

PORT9

11

PORT10

10

9

PORT11

GND

8

PORT12

7

PORT4

B

GND

C

PORT3

D

PORT1

PORT5 PORT7 PORT14 PORT13

PORT6 PORT15 PORT12 GND

PORT2 GND PORT10 PORT11

MAX7304

V

CC

SDA

V

LA

5

PORT9

PORT6

PORT5

*CONNECT EP TO GROUND.

PORT7

TQFN

PORT15

PORT14

PORT13

E

PORT0

INT

SCL AD0 PORT8

WLP

Pin/Bump Description

PIN BUMP

TQFN WLP

1 A2 PORT5 GPIO Port 5. Push-pull I/O.

2 B2 PORT6 GPIO Port 6. Push-pull I/O.

3 A3 PORT7 GPIO Port 7. Push-pull I/O.

4 B3 PORT15 GPIO Port 15. Open-drain I/O. PORT15 can be configured as a constant-current sink.

5 A4 PORT14 GPIO Port 14. Open-drain I/O. PORT14 can be configured as a constant-current sink.

6 A5 PORT13 GPIO Port 13. Open-drain I/O. PORT13 can be configured as a constant-current sink.

7 B4 PORT12 GPIO Port 12. Open-drain I/O. PORT12 can be configured as a constant-current sink.

8, 23 B1, B5, C3 GND Ground

9 C5 PORT11 GPIO Port 11. Push-pull I/O.

10 C4 PORT10 GPIO Port 10. Push-pull I/O.

11 D5 PORT9 GPIO Port 9. Push-pull I/O.

12 E5 PORT8 GPIO Port 8. Push-pull I/O.

13 D4 V

14 E4 AD0 Address Input. Selects up to four device slave addresses (Table 2).

15 D3 SDA I2C-Compatible, Serial-Data I/O

16 E3 SCL I2C-Compatible Serial-Clock Input

17 E2

NAME FUNCTION

LA

Second Logic Level for GPIO Level Shifting (where VCC P VLA P 3.6V)

INT Active-Low Key-Switch Interrupt Output. INT is open-drain and requires a pullup resistor.

_________________________________________________________________ Maxim Integrated Products 6

Page 7

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Pin Description (continued)

PIN BUMP

TQFN WLP

18 D2 V

NAME FUNCTION

CC

Positive Supply Voltage. Bypass to GND with a 0.1FF capacitor as close as possible to

the device.

19 E1 PORT0 GPIO Port 0. Push-pull I/O.

20 D1 PORT1 GPIO Port 1. Push-pull I/O.

21 C2 PORT2 GPIO Port 2. Push-pull I/O.

22 C1 PORT3

GPIO Port 3. Push-pull I/

24 A1 PORT4 GPIO Port 4. Push-pull I/O.

— — EP

MAX7304

Exposed Pad (TQFN Only). Internally connected to GND. Connect to a large ground plane

to maximize thermal performance. Not intended as an electrical connection point.

PWM

LOGIC

O.

I/0 SUPPLY CONTROL

LED ENABLE

PWM SIGNAL

VCCV

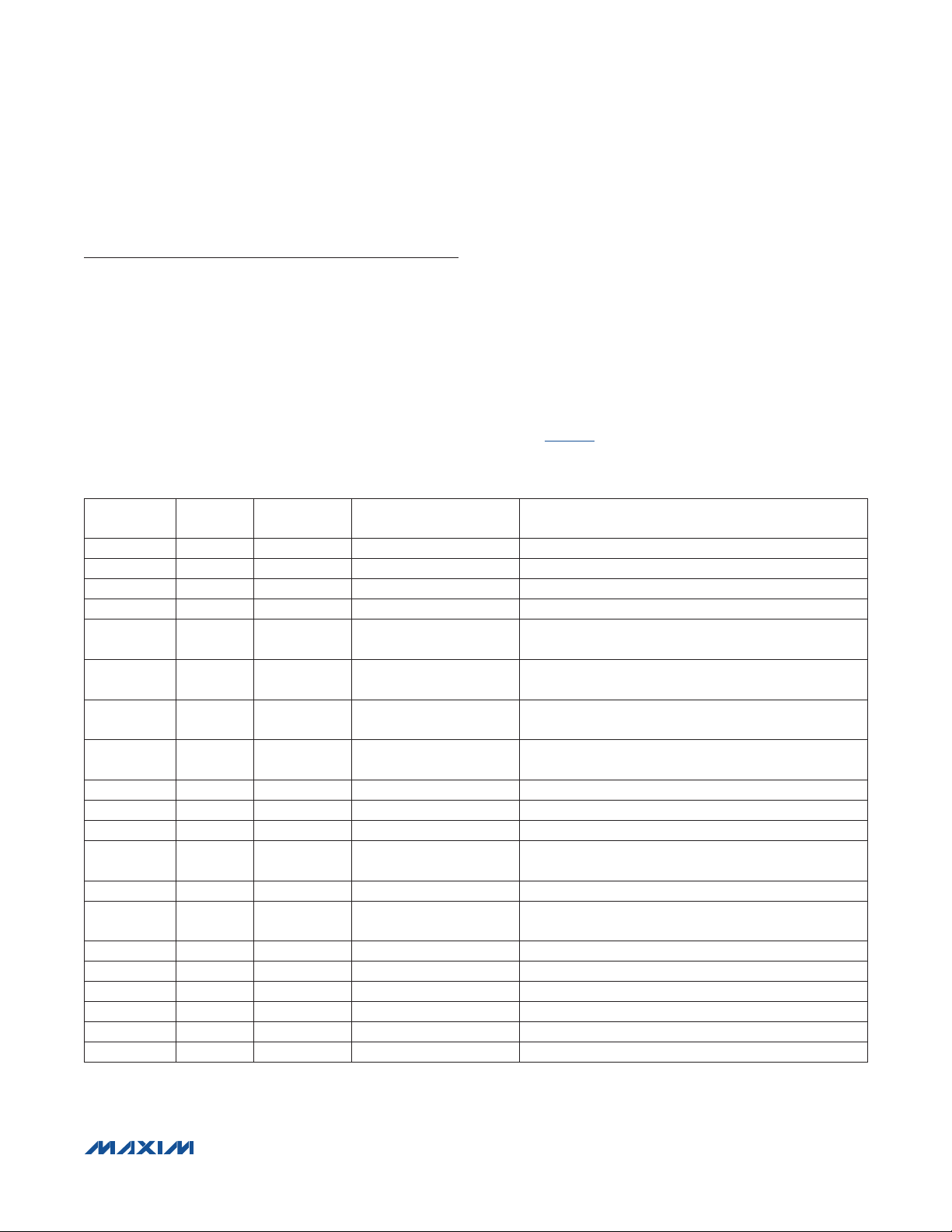

Functional Diagram

LA

INT

SDA

SCL

AD0

I2C

INTERFACE

BUS

TIMEOUT

128kHz

OSCILLATOR

CONTROL

REGISTERS

FIFO

POR

I/O

LOGIC

GPIO ENABLE

GPIO INPUT

GPIO OUTPUT

GPIO ENABLE

GPIO INPUT

GPIO OUTPUT

OPEN-DRAIN

GPIO/LED

DRIVERS

PUSH-PULL

GPIO

4

12

PORT15–PORT12

PORT11–PORT10

_________________________________________________________________ Maxim Integrated Products 7

Page 8

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Detailed Description

constant-current and PWM intensity control. The maximum

constant-current level for each open-drain LED port is

The MAX7304 is an I2C-interfaced 16-port GPIO expander. The device features 12 push-pull GPIOs configured

for digital I/O and four open-drain GPIOs configurable

as constant-current outputs for LED applications up to

5V. The device supports a second 1.62V to 3.6V power

supply for level translation. The second logic supply

20mA. The intensity of the LED on each open-drain port

can be individually adjusted through a 256-step PWM

control. The port also features LED fading.

The device meets ESD requirements for Q8kV contact

discharge and Q15kV air-gap discharge on all port pins

(configured as GPIO and/or LED drivers).

voltage (VLA) must be set equal to or higher than VCC.

Each GPIO can be programmed to one of the two externally applied logic voltage levels. PORT15–PORT12

can also be configured as LED drivers that feature

On power-up, all control registers reset to power-up

values (Table 1) and the device is in sleep mode.

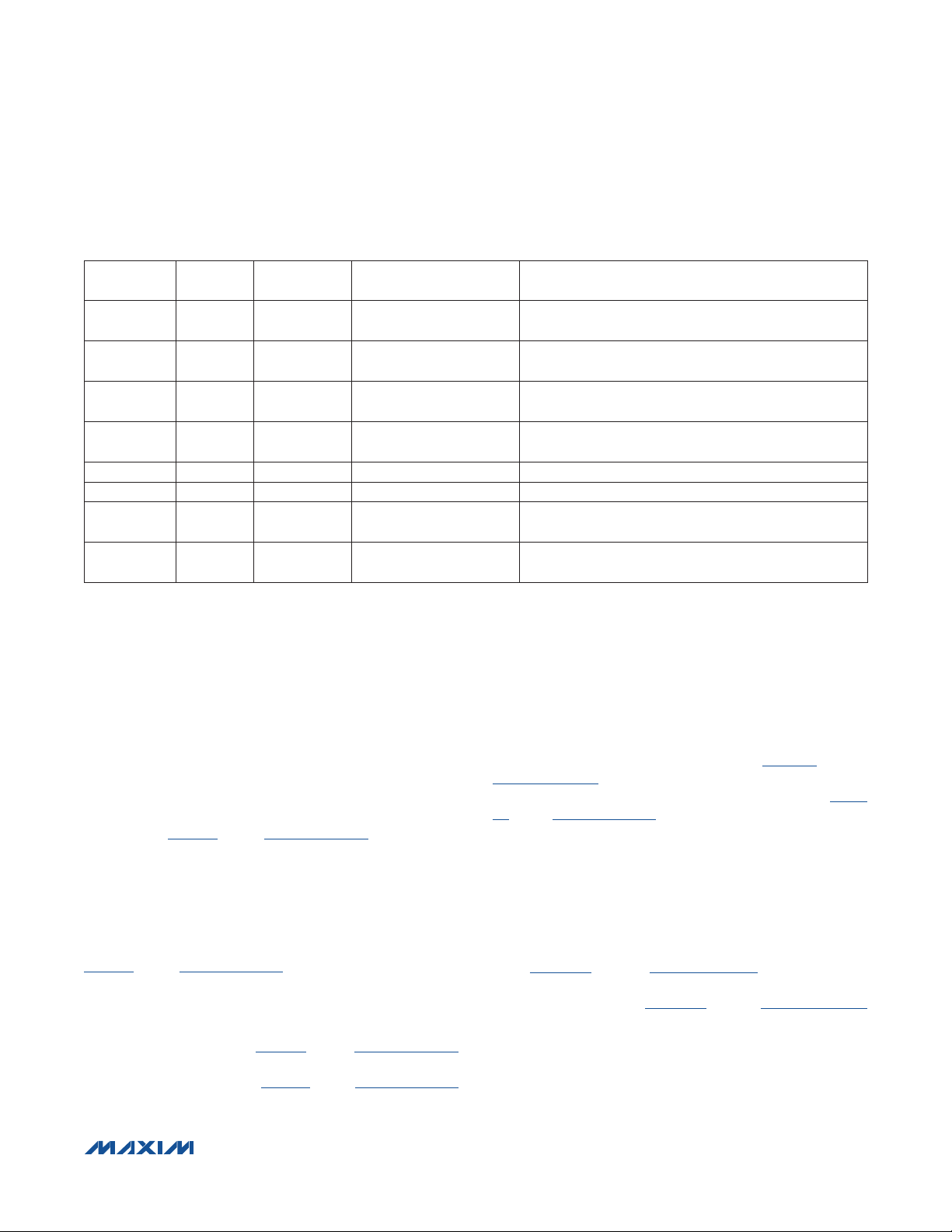

Table 1. Register Address Map and Power-Up Conditions

ADDRESS

CODE (hex)

0x01

0x31

0x34

0x35

0x36

0x37

0x38

0x39

0x3A

0x3B

0x3C

0x40

0x42

0x43

0x45

0x48 Read only 0x00 I2C timeout flag I2C timeout since last POR

0x50

0x51

0x52

0x53

READ/

WRITE

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

POWER-UP

VALUE (hex)

0x0B Configuration Power-down and I2C timeout enable

0x00 LED driver enable LED driver enable register

0x00 GPIO direction 1 GPIO input/output control register 1 for PORT7–PORT0

0x00 GPIO direction 2 GPIO input/output control register 2 for PORT15–PORT8

0xFF GPO output mode 1

0x0F GPO output mode 2

0x00 GPIO supply voltage 1

0x00 GPIO supply voltage 2

0xFF GPIO values 1 Debounced input or output values of PORT7–PORT0

0xFF GPIO values 2 Debounced input or output values of PORT15–PORT8

0x00 GPIO level-shifter enable GPIO level-shifter pair enable

0x00

0x00 GPIO debounce PORT7–PORT0 debounce time setting

0xC0

0x00 Common PWM Common PWM duty-cycle setting

0x00 PORT12 PWM ratio PORT12 individual duty-cycle setting

0x00 PORT13 PWM ratio PORT13 individual duty-cycle setting

0x00 PORT14 PWM ratio PORT14 individual duty-cycle setting

0x00 PORT15 PWM ratio PORT15 individual duty-cycle setting

REGISTER

FUNCTION

GPIO global

configuration

LED constant-current

setting

GPO open-drain/push-pull output setting for

PORT7–PORT0

GPO open-drain/push-pull output setting for

PORT15–PORT8

GPIO voltages supplied by VCC or VLA for

PORT7–PORT0

GPIO voltages supplied by VCC or VLA for

PORT15–PORT8

GPIO standby, GPIO reset, LED fade

PORT15–PORT12 constant-current output setting

Initial Power-Up

DESCRIPTION

_________________________________________________________________ Maxim Integrated Products 8

Page 9

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Table 1. Register Address Map and Power-Up Conditions (continued)

MAX7304

ADDRESS

CODE (hex)

0x54

0x55

0x56

0x57

0x58

0x59

0x5A

0x5B

READ/

WRITE

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

POWER-UP

VALUE (hex)

0x00

0x00

0x00

0x00

0xFF Interrupt mask 1 Interrupt mask for PORT7–PORT0

0xFF Interrupt mask 2 Interrupt mask for PORT15–PORT8

0x00 GPI trigger mode 1

0x00 GPI trigger mode 2

REGISTER

FUNCTION

PORT12 LED

configuration

PORT13 LED

configuration

PORT14 LED

configuration

PORT15 LED

configuration

GPIOs

The device has 16 GPIO ports, of which four have

LED control functions. The ports can be used as logic

inputs and logic outputs. PORT15–PORT12 are also

configurable as constant-current PWM LED drivers. Each

ports’ logic level is referenced to VCC or VLA. The GPIO

port’s inputs can also be debounced. When in PWM

mode, the ports are set up to start their PWM cycle in

45N phase increments. This prevents large current spikes

on the LED supply voltage when driving multiple LEDs.

Configuration Register (0x01)

The configuration register controls the I2C bus timeout

feature (see Table 5 in the Register Tables section). The

bus timeout feature prevents the SDA being held low

when the SCL line hangs.

LED Driver Enable Register (0x31)

Bits D[3:0] correspond to PORT15–PORT12 on the

device. Set the corresponding bit to 1 for enabling the

LED driver circuitry and 0 for normal GPIO function (see

Table 6 in the Register Tables section).

GPIO Direction 1 and 2 Registers (0x34, 0x35)

These registers configure the pin as an input or an

output. GPIO direction 1 register bits D[7:0] correspond

with PORT7–PORT0 (see Table 7 in the Register Tables

section). GPIO direction 2 register bits D[7:0] correspond

with PORT15–PORT8 (see Table 8 in the Register Tables

section). Set the corresponding bit to 0 to configure as

input and 1 to configure as output.

DESCRIPTION

PORT12 interrupt, PWM mode control, and blinkperiod settings

PORT13 interrupt, PWM mode control, and blinkperiod settings

PORT14 interrupt, PWM mode control, and blinkperiod settings

PORT15 interrupt, PWM mode control, and blinkperiod settings

GPI edge-triggered detection setting for

PORT7–PORT0

GPI edge-triggered detection setting for

PORT15–PORT8

When the port is initially programmed as an input, there

is a delay of one debounce period prior to detecting

a transition on the input port. This is to prevent a false

interrupt from occurring when changing a port from an

output to an input.

GPO Output Mode 1 and 2 Registers (0x36, 0x37)

These registers configure the pins as an open-drain or

push-pull output. GPO output mode 1 register bits D[7:0]

correspond with PORT7–PORT0 (see Table 9 in the

Register Tables section). GPO output mode 2 register

bits D[7:0] correspond with PORT15–PORT8 (see Table

10 in the Register Tables section). Set the corresponding

bit to 0 to configure the output mode as open-drain and

1 to configure the output mode as push-pull.

GPIO Supply Voltage 1 and 2

Registers (0x38, 0x39)

These registers configure input and output voltages

to be referenced to VCC or VLA. GPIO supply voltage

1 register bits D[7:0] correspond with PORT7–PORT0

(see Table 11 in the Register Tables section). GPIO

supply voltage 2 register bits D[7:0] correspond with

PORT15–PORT8 (see Table 12 in the Register Tables

section). Set the bit to 0 for input/output voltages

referenced to VCC and set the bit to 1 for the input/output

voltage referenced to VLA.

_________________________________________________________________ Maxim Integrated Products 9

Page 10

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

GPIO Values 1 and 2 Registers (0x3A, 0x3B)

The GPIO values 1 and 2 registers contain the debounced

input data for all the GPIOs for PORT7–PORT0 and

PORT15–PORT8, respectively (see Tables 13 and 14

in the Register Tables section). There is one debounce

period delay prior to detecting a transition on the input

port. This prevents a false interrupt from occurring when

changing a port from an output to an input. The GPIO

values 1 and 2 registers reports the state of all input ports

regardless of any interrupt mask settings.

When writing to the GPIO values 1 and 2 registers, the

corresponding PORT_ voltage is set high when written 1

or cleared when written 0. Reading the port when configured as an output always returns the value 0 for the corresponding port regardless of the output value.

GPIO Level-Shifter Enable Register (0x3C)

Enabling bit D_ in this register enables the direct

level shifter between GPIO pins PORT15–PORT8 and

PORT7–PORT0 (see Table 15 in the Register Tables section). The level-shifting pairs are PORT0/PORT8, PORT1/

PORT9, etc. The direction of the level shifter is controlled by the GPIO direction 2 register (0x35). When the

corresponding bit in the GPIO direction 2 register is set

to 0, PORT15–PORT8 are inputs, while PORT7–PORT0

are outputs. When the bit is set to 1, PORT7–PORT0 are

inputs, while PORT15–PORT8 are outputs.

GPIO Global Configuration Register (0x40)

The GPIO global configuration register controls the main

settings for the GPIO ports (see Table 16 in the Register

Tables section).

Bit D5 enables interrupt generation for I2C timeouts. D4

is the main enable/shutdown bit for the GPIOs. Bit D3

functions as a software reset for the GPIO registers

(0x31 to 0x5B). Bits D[2:0] set the fade-in/out time for the

GPIOs configured as constant-current sinks.

GPIO Debounce Configuration Register (0x42)

The GPIO debounce configuration register sets the

amount of time a GPIO must be held in order for the

device to register a logic transition (see Table 17 in

the Register Tables section). Five bits (D[4:0]) set 32

possible debounce times from 9ms up to 40ms.

LED Constant-Current Setting Register (0x43)

The LED constant-current setting register sets the global

constant-current level (see Table 18 in the Register

Tables section). Bit D0 selects the global current values

between 10mA and 20mA. This setting only applies to the

LED driver enabled pins, PORT15–PORT12.

Common PWM Ratio Register (0x45)

The common PWM ratio register stores the common con-

stant-current output PWM duty cycle (see Table 19 in the

Register Tables section). The values stored in this register

translate over to a PWM ratio in the same manner as the

individual PWM ratio registers (0x50 to 0x53). Ports can use

their own individual PWM value or the common PWM value.

Write to this register to change the PWM ratio of several

ports at once.

2

I

C Timeout Flag Register (0x48) (Read Only)

The I2C timeout flag register contains a single bit (D0),

which indicates if an I2C timeout has occurred (see Table

20 in the Register Tables section). Read this register to

clear an I2C timeout initiated interrupt.

PORT12–PORT15 Individual PWM Ratio

Registers (0x50 to 0x53)

Each LED driver port has an individual PWM ratio reg-

ister, 0x50 to 0x53 (see Table 21 in the Register Tables

section). Use values 0x00 to 0xFE in these registers to

configure the number of cycles out of 256 the output

sinks current (LED is on), from 0 cycles to 254 cycles.

Use 0xFF to have an output continuously sink current

(always on). For applications requiring multiple ports

to have the same intensity, program a particular port’s

configuration register (0x54 to 0x57) to use the common

PWM ratio register (0x45). New PWM settings take place

at the beginning of a PWM cycle, to allow changes from

common intensity to individual intensity with no interrup-

tion in the PWM cycle.

PORT12–PORT15 LED Configuration

Registers (0x54 to 0x57)

Registers 0x54 to 0x57 set individual configurations for

each port (see Table 22 in the Register Tables section).

D5 sets the port’s PWM setting to either the common or

individual PWM setting. Bits D[4:2] enable and set the

port’s individual blink period from 0 to 4096ms. Bits D1

and D0 set a port’s blink duty cycle.

Interrupt Mask 1 and 2 Registers (0x58, 0x59)

The interrupt mask 1 and 2 registers control which ports

trigger an interrupt for PORT7–PORT0 and PORT15–

PORT8, respectively (see Tables 23 and 24 in the

Register Tables section). Set the bit to 0 to enable the

interrupt. Set the bit to 1 to mask the interrupt.

If the port that has generated the interrupt is not masked,

the interrupt causes the INT signal to assert. A read of the

GPIO values 1 and 2 registers (0x3A, 0x3B) is required

to deassert the INT pin. Note that transitions that occur

while the INT signal is asserted, but before the read of

________________________________________________________________ Maxim Integrated Products 10

Page 11

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

the values 1 and 2 registers, sets the appropriate bit of

the values 1 and 2 registers only, but has no effect on

the INT pin as it is already asserted. However, transitions

that occur when the I2C is active cannot be latched into

the values 1 and 2 registers until after the read has taken

place. If there are transitions that cause the INT signal to

assert, during the time of an I2C read, they cause the INT

signal to reassert once the read transaction has taken

place. Note that the interrupt configurations only apply

when a port is configured as an input.

GPI Trigger Mode 1 and 2 Registers (0x5A, 0x5B)

The GPI trigger mode 1 and 2 registers control how

ports can trigger an interrupt for PORT7–PORT0 and

PORT15–PORT8, respectively (see Tables 25 and 26 in

the Register Tables section). Set the bit to 0 for risingedge triggering. Set the bit to 1 for rising- and fallingedge triggering.

The inputs are debounced (if enabled) by taking a snapshot of the port state when the transition occurs, and

another after the debounce time has elapsed—ensuring that the state of the port is stable prior to triggering

the interrupt. After the debounce cycle, an interrupt is

generated and the INT pin asserts if it is not masked for

that particular port. Regardless of whether or not the INT

signal is masked, the GPIO values 1 and 2 registers

(0x3A, 0x3B) report the state of all input ports.

Sleep Mode

The device is put into sleep mode by clearing bit D4 in

the GPIO global configuration register (0x40). In sleep

mode, the device draws minimal current. The device is

taken out of sleep mode and put into operating mode by

setting bit D4 in the GPIO configuration register. When

the GPIOs are enabled, the part is in operating mode.

In sleep mode, the internal oscillator and I2C timeout

features are disabled.

LED Fade

Set the fade cycle time in the GPIO global configuration

register (0x40) to a non-zero value to enable fade in/out

(see Table 16 in the Register Tables section). Fade in

increases an LED’s PWM intensity in 16 even steps, from

zero to its stored value. Fade out decreases an LED’s

PWM intensity in 16 even steps, from its current value to

zero. Fading occurs automatically in any of the following

scenarios:

1) Change the common PWM register value from any

value to zero to cause all ports using the common

PWM register settings to fade out. No ports using

individual PWM settings are affected.

2) Change the common PWM register value to any value

from zero to cause all ports using the common PWM

register settings to fade in. No ports using individual

PWM settings are affected.

3) Take the part out of sleep mode to cause all ports

to fade in. Changing an individual PWM intensity during fade in automatically cancels that port’s fade and

immediately outputs at its newly programmed intensity.

4) Put the part into sleep mode to cause all ports to fade

out. Changing an individual PWM intensity during

fade out automatically cancels that port’s fade and

immediately turns off.

LED PWM

Each port has an individual PWM ratio register. The value

stored in this register configures the number of cycles

out of 255 that the output is sinking current (LED is on).

Setting a value of 0xFF in an individual intensity register

sets the output to continuously sink current (always on).

Conversely, setting a value of 0x00 in an individual intensity register sets the output in a high-impedance state

(always off).

For applications requiring multiple ports to have the same

intensity, the common PWM ratio intensity setting can be

used in lieu of the individual intensity setting. To use the

common intensity setting, program bit D5 of the

corresponding port’s configuration register to logic-high.

Setting a port to use the common PWM ratio setting

copies the value of the common intensity register into

the individual intensity register at the beginning of each

PWM cycle. This allows an output port to be seamlessly

changed from common intensity to individual intensity

with no interruption in the PWM cycle.

Outputs are configured to sink a constant current of either

10mA or 20mA during the period when the output is on.

The setting in the individual constant-current setting

register (0x43) controls the value of the current.

________________________________________________________________ Maxim Integrated Products 11

Page 12

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

LED Blink

Each LED driver-supported port has its own blink-control

settings through registers 0x54 to 0x57 (see Table 22

in the Register Tables section). The blink period ranges

from 0 (blink disabled) to 4.096s. Settable blink duty

cycles range from 6.25% to 50%. All blink periods start at

the same PWM cycle for synchronized blinking between

multiple ports.

Each port has its own counter to generate blink

timing. The blink counter can be programmed to cause

the output to gate off and on at a programmable rate. The

blink period can be set to 256ms, 512ms, 1.024s, 2.048s,

or 4.096s using D[4:2] of the port’s individual configuration register. The percentage of time that the LED is on

for one blink cycle is set to 50%, 25%, 12.5%, or 6.25%

by D[1:0] of the individual configuration register.

Interrupt

Two possible sources generate INT: I2C timeout or

GPIOs configured as inputs (registers 0x48, 0x5A, and

0x5B). Read the respective data/status registers for each

type of interrupt in order to clear INT. If multiple sources

generate the interrupt, all the related status registers

must be read to clear INT.

Serial Interface

Figure 1 shows the 2-wire serial interface timing details.

Serial Addressing

The device operates as a slave that sends and receives

data through an I2C-compatible 2-wire interface. The

interface uses a serial-data line (SDA) and a serialclock line (SCL) to achieve bidirectional communication

between master(s) and slave(s). A master (typically a

microcontroller) initiates all data transfers to and from the

device and generates the SCL clock that synchronizes

the data transfer.

The device’s SDA line operates as both an input and an

open-drain output. A pullup resistor, typically 4.7kI, is

required on SDA. The device’s SCL line operates only as

an input. A pullup resistor is required on SCL if there are

multiple masters on the 2-wire interface, or if the master

in a single-master system has an open-drain SCL output.

Each transmission consists of a START (S) condition

(Figure 2) sent by a master, followed by the device’s 7-bit

slave address plus R/W bit, a register address byte, one

or more data bytes, and finally, a STOP (P) condition.

START and STOP Conditions

Both SCL and SDA remain high when the interface is not

busy. A master signals the beginning of a transmission

with a START condition by transitioning SDA from high

to low while SCL is high. When the master has finished

communicating with the slave, it issues a STOP condition

by transitioning SDA from low to high while SCL is high.

The bus is then free for another transmission.

SDA

t

t

LOW

SCL

t

HD, STA

START

CONDITION

Figure 1. Two-Wire Serial Interface Timing Details

________________________________________________________________ Maxim Integrated Products 12

SU, DAT

t

HIGH

t

t

R

F

t

HD, DAT

t

SU, STA

START CONDITION

REPEATED

t

R

t

HD, STA

t

SU, STO

t

t

F

F, TX

STOP

CONDITION

t

BUF

START

CONDITION

Page 13

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Bit Transfer

One data bit is transferred during each clock pulse

(Figure 3). The data on SDA must remain stable while

SCL is high.

Acknowledge

The acknowledge bit is a clocked 9th bit (Figure 4), which

the recipient uses to handshake receipt of each byte of

data. Thus, each byte transferred effectively requires 9 bits.

SDA

SCL

S

START

CONDITION

Figure 2. START and STOP Conditions

SDA

The master generates the 9th clock pulse, and the recipient pulls down SDA during the acknowledge clock pulse;

therefore, the SDA line is stable low during the high

period of the clock pulse. When the master is transmitting to the device, the device generates the acknowledge

bit because the device is the recipient. When the device

is transmitting to the master, the master generates the

acknowledge bit because the master is the recipient.

P

STOP

CONDITION

SCL

Figure 3. Bit Transfer

SCL

SDA BY

TRANSMITTER

SDA BY

RECEIVER

Figure 4. Acknowledge

________________________________________________________________ Maxim Integrated Products 13

START

CONDITION

S

DATA LINE STABLE;

DATA VALID

CHANGE OF DATA

ALLOWED

CLOCK PULSE FOR

ACKNOWLEDGE

1 2 8 9

Page 14

MAX7304

AA

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Slave Addresses

The device has two 7-bit long slave addresses. The bit

following a 7-bit slave address is the R/W bit, which is

low for a write command and high for a read command.

The first 4 bits (MSBs) of the device slave addresses

are always 0111. Slave address bits A[3:1] correspond,

by the matrix in Table 2, to the states of the device

address input pin AD0, and A0 corresponds to the R/W

bit (Figure 5). The AD0 input can be connected to any of

four signals: GND, VCC, SDA, or SCL, giving four possible slave-address pairs, allowing up to four devices to

share the same bus. Because SDA and SCL are dynamic

signals, care must be taken to ensure that AD0 transitions

no sooner than the signals on SDA and SCL.

The device monitors the bus continuously, waiting for a

START condition followed by its slave address. When the

device recognizes its slave address, it acknowledges

and is then ready for continued communication.

Table 2. 2-Wire Interface Address Map

PIN AD0

GND

V

CC

SDA 1 0

SCL 1 1

A7 A6 A5 A4 A3 A2 A1 A0

0 1 1 1

DEVICE ADDRESS

0 0

0 1

0

R/W

Bus Timeout

The device features a 20ms (min) bus timeout on the

2-wire serial interface, largely to prevent the device from

holding the SDA I/O low during a read transaction, should

the SCL lock up for any reason before a serial transaction is completed. Bus timeout operates by causing the

device to internally terminate a serial transaction, either

read or write, if the time between adjacent edges on SCL

exceeds 20ms. After a bus timeout, the device waits for a

valid START condition before responding to a consecutive transmission. This feature can be enabled or disabled

under user control by writing to the configuration register.

Message Format for Writing

A write to the device comprises the transmission of the

slave address with the R/W bit set to zero, followed by at

least one byte of information. The first byte of information

is the command byte. The command byte determines

which register of the device is to be written by the next

byte, if received. If a STOP condition is detected after the

command byte is received, the device takes no further

action (Figure 6) beyond storing the command byte.

Any bytes received after the command byte are data

bytes. The first data byte goes into the internal register

of the device selected by the command byte (Figure 7).

If multiple data bytes are transmitted before a STOP

condition is detected, these bytes are generally stored

in subsequent device internal registers, because the

command byte address generally autoincrements.

SDA

SCL

Figure 5. Slave Address

S

Figure 6. Command Byte Received

01 1A3A2A11

MSB

COMMAND BYTE IS STORED ON RECEIPT OF

ACKNOWLEDGE FROM MAX7304

SLAVE ADDRESS COMMAND BYTE

________________________________________________________________ Maxim Integrated Products 14

ACKR/W

LSB

ACKNOWLEDGE CONDITION

R/W

D7 D6 D5 D4 D3 D2 D1 D0

P0

ACKNOWLEDGE FROM MAX7304

Page 15

MAX7304

AA

AA

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Message Format for Reading

The device is read using the internally stored command

byte as an address pointer, the same way the stored command byte is used as an address pointer for a write. The

pointer generally autoincrements after each data byte is

read using the same rules as for a write. Thus, a read is

initiated by first configuring the device’s command byte

by performing a write (Figure 6). The master can now

read N consecutive bytes from the device, with the first

data byte being read from the register addressed by the

initialized command byte. When performing read-afterwrite verification, remember to reset the command byte’s

address because the stored command byte address is

generally autoincremented after the write (Figure 8).

Operation with Multiple Masters

When the device is operated on a 2-wire interface with

multiple masters, a master reading the device uses a

repeated START between the write that sets the device’s

address pointer, and the read(s) that takes the data from

the location(s). This is because it is possible for master 2

to take over the bus after master 1 has set up the device’s

address pointer but before master 1 has read the data. If

master 2 subsequently resets the device’s address pointer,

master 1’s read can be from an unexpected location.

Command Address Autoincrementing

Address autoincrementing allows the device to be

configured with fewer transmissions by minimizing the

number of times the command address needs to be

sent. The command address (0x31 to 0x5B) stored in the

device increments after each data byte is written or read.

Autoincrement only functions when doing a multiburst

read or write.

Applications Information

Reset from I2C

After a catastrophic event such as ESD discharge or

microcontroller reset, use bit D4 of the GPIO global

configuration register (0x40) as a software reset.

Hot Insertion

The INT, SCL, and AD0 inputs and SDA remain high

impedance with up to 5.5V asserted on them when the

device powers down (VCC = 0V). I/O ports remain high

impedance with up to 5.5V asserted on them when not

powered. Use the device in hot-swap applications.

ACKNOWLEDGE FROM MAX7304

D7 D6 D5 D4 D3 D2 D1 D0 D1 D0D3 D2D5 D4D7 D6

ACKNOWLEDGE FROM MAX7304

SA

R/W

Figure 7. Command and Single Data Byte Received

ACKNOWLEDGE FROM MAX7304

ACKNOWLEDGE FROM MAX7304

SA

R/W

Figure 8. N Data Bytes Received

________________________________________________________________ Maxim Integrated Products 15

D7 D6 D5 D4 D3 D2 D1 D0 D1 D0D3 D2D5 D4D7 D6

ACKNOWLEDGE FROM MAX7304

P0SLAVE ADDRESS COMMAND BYTE DATA BYTE

N BYTES

AUTOINCREMENT

COMMAND BYTE ADDRESS

ACKNOWLEDGE FROM MAX7304

P0SLAVE ADDRESS COMMAND BYTE DATA BYTE

N BYTES

AUTOINCREMENT

COMMAND BYTE ADDRESS

Page 16

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Staggered PWM

The LED’s on-time in each PWM cycle is phase delayed

by 45N into four evenly spaced start positions. Optimize

phasing when using fewer than four ports as constantcurrent outputs by allocating the ports with the most

appropriate start positions. For example, if using two

constant-current outputs, choose PORT12 and PORT14

because their PWM start positions are evenly spaced.

In general, choose the ports that spread the current

demand from the ports’ load supply.

Power-Supply Considerations

The device operates with a 1.62V to 3.6V power-supply

voltage. Bypass the power supply VCC to GND with a

0.1FF or higher ceramic capacitor as close as possible

to the device. Bypass the logic power supply (VLA) to

GND with a 0.1FF or higher ceramic capacitor as close

as possible to the device.

Table 3. ESD Test Levels

1A—CONTACT DISCHARGE 1B—AIR DISCHARGE

LEVEL TEST VOLTAGE (kV) LEVEL TEST VOLTAGE (kV)

1 2 1 2

2 4 2 4

3 6 3 8

4 8 4 15

X Special X Special

ESD Protection

All device pins meet the Q2.5kV Human Body Model ESD

tolerances. The GPIOs meet IEC 61000-4-2 ESD protection. The IEC test stresses consist of 10 consecutive ESD

discharges per polarity at the maximum specified level

and below (per IEC 61000-4-2). Test criteria include:

1) The powered device does not latch up during the ESD

discharge event.

2) The device subsequently passes the final test used for

prescreening.

Tables 3 and 4 are from the IEC 61000-4-2: Edition 1.1

1999-05: Electromagnetic compatibility (EMC) Testing

and measurement techniques—Electrostatic discharge

immunity test.

X = Open level. The level has to be specified in the dedicated equipment specification. If higher voltages than those shown are

specified, special test equipment could be needed.

Table 4. ESD Waveform Parameters

INDICATED

LEVEL

1 2 7.5 0.7 to 1 4 2

2 4 15 0.7 to 1 8 4

3 6 22.5 0.7 to 1 12 6

4 8 30 0.7 to 1 16 8

VOLTAGE

(kV)

________________________________________________________________ Maxim Integrated Products 16

FIRST PEAK OF CURRENT

DISCHARGE Q10%

(A)

RISE TIME (tR) WITH

DISCHARGE SWITCH

(ns)

CURRENT (Q30%)

AT 30ns

(A)

CURRENT (Q30%)

AT 60ns

(A)

Page 17

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Register Tables

Table 5. Configuration Register (0x01)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

D[7:1] Reserved — — 0000101

D0 Timeout disable

Table 6. LED Driver Enable Register (0x31)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

D[7:4] Reserved 0000 — 0000

D3 PORT15

D2 PORT14

D1 PORT13

D0 PORT12

0 I2C timeout enabled

1 I2C timeout disabled

0 GPIO function

1 LED driver enable

0 GPIO function

1 LED driver enable

0 GPIO function

1 LED driver enable

0 GPIO function

1 LED driver enable

1

0

0

0

0

Table 7. GPIO Direction 1 Register (0x34)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

D7 PORT7

D6 PORT6

D5 PORT5

D4 PORT4

D3 PORT3

D2 PORT2

D1 PORT1

D0 PORT0

0 Set as input pin

1 Set as output pin

0 Set as input pin

1 Set as output pin

0 Set as input pin

1 Set as output pin

0 Set as input pin

1 Set as output pin

0 Set as input pin

1 Set as output pin

0 Set as input pin

1 Set as output pin

0 Set as input pin

1 Set as output pin

0 Set as input pin

1 Set as output pin

0

0

0

0

0

0

0

0

________________________________________________________________ Maxim Integrated Products 17

Page 18

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Table 8. GPIO Direction 2 Register (0x35)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

D7 PORT15

D6 PORT14

D5 PORT13

D4 PORT12

D3 PORT11

D2 PORT10

D1 PORT9

D0 PORT8

0 Set as input pin

1 Set as output pin

0 Set as input pin

1 Set as output pin

0 Set as input pin

1 Set as output pin

0 Set as input pin

1 Set as output pin

0 Set as input pin

1 Set as output pin

0 Set as input pin

1 Set as output pin

0 Set as input pin

1 Set as output pin

0 Set as input pin

1 Set as output pin

0

0

0

0

0

0

0

0

Table 9. GPO Output Mode 1 Register (0x36)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

D7 PORT7

D6 PORT6

D5 PORT5

D4 PORT4

D3 PORT3

D2 PORT2

D1 PORT1

D0 PORT0

0 Port is an open-drain output

1 Port is a push-pull output

0 Port is an open-drain output

1 Port is a push-pull output

0 Port is an open-drain output

1 Port is a push-pull output

0 Port is an open-drain output

1 Port is a push-pull output

0 Port is an open-drain output

1 Port is a push-pull output

0 Port is an open-drain output

1 Port is a push-pull output

0 Port is an open-drain output

1 Port is a push-pull output

0 Port is an open-drain output

1 Port is a push-pull output

1

1

1

1

1

1

1

1

________________________________________________________________ Maxim Integrated Products 18

Page 19

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Table 10. GPO Output Mode 2 Register (0x37)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

D7 PORT15 0 Port is an open-drain output 0

D6 PORT14 0 Port is an open-drain output 0

D5 PORT13 0 Port is an open-drain output 0

D4 PORT12 0 Port is an open-drain output 0

D3 PORT11

D2 PORT10

D1 PORT9

D0 PORT8

Note: When programmed as GPO, PORT15–PORT12 are always open-drain and bits D[7:4] are not writable.

0 Port is an open-drain output

1 Port is a push-pull output

0 Port is an open-drain output

1 Port is a push-pull output

0 Port is an open-drain output

1 Port is a push-pull output

0 Port is an open-drain output

1 Port is a push-pull output

1

1

1

1

Table 11. GPIO Supply Voltage 1 Register (0x38)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

D7 PORT7

D6 PORT6

D5 PORT5

D4 PORT4

D3 PORT3

D2 PORT2

D1 PORT1

D0 PORT0

0 PORT7 supplied by V

1 PORT7 supplied by V

0 PORT6 supplied by V

1 PORT6 supplied by V

0 PORT5 supplied by V

1 PORT5 supplied by V

0 PORT4 supplied by V

1 PORT4 supplied by V

0 PORT3 supplied by V

1 PORT3 supplied by V

0 PORT2 supplied by V

1 PORT2 supplied by V

0 PORT1 supplied by V

1 PORT1 supplied by V

0 PORT0 supplied by V

1 PORT0 supplied by V

CC

LA

CC

LA

CC

LA

CC

LA

CC

LA

CC

LA

CC

LA

CC

LA

0

0

0

0

0

0

0

0

________________________________________________________________ Maxim Integrated Products 19

Page 20

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Table 12. GPIO Supply Voltage 2 Register (0x39)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

D7 PORT15

D6 PORT14

D5 PORT13

D4 PORT12

D3 PORT11

D2 PORT10

D1 PORT9

D0 PORT8

0 PORT15 supplied by V

1 PORT15 supplied by V

0 PORT14 supplied by V

1 PORT14 supplied by V

0 PORT13 supplied by V

1 PORT13 supplied by V

0 PORT12 supplied by V

1 PORT12 supplied by V

0 PORT11 supplied by V

1 PORT11 supplied by V

0 PORT10 supplied by V

1 PORT10 supplied by V

0 PORT9 supplied by V

1 PORT9 supplied by V

0 PORT8 supplied by V

1 PORT8 supplied by V

CC

LA

CC

LA

CC

LA

CC

LA

CC

LA

CC

LA

CC

LA

CC

LA

0

0

0

0

0

0

0

0

Table 13. GPIO Values 1 Register (0x3A)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

D7 PORT7

D6 PORT6

D5 PORT5

D4 PORT4

D3 PORT3

D2 PORT2

D1 PORT1

D0 PORT0

0 Clear PORT7 low

1 Set PORT7 high

0 Clear PORT6 low

1 Set PORT6 high

0 Clear PORT5 low

1 Set PORT5 high

0 Clear PORT4 low

1 Set PORT4 high

0 Clear PORT3 low

1 Set PORT3 high

0 Clear PORT2 low

1 Set PORT2 high

0 Clear PORT1 low

1 Set PORT1 high

0 Clear PORT0 low

1 Set PORT0 high

1

1

1

1

1

1

1

1

________________________________________________________________ Maxim Integrated Products 20

Page 21

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Table 14. GPIO Values 2 Register (0x3B)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

D7 PORT15

D6 PORT14

D5 PORT13

D4 PORT12

D3 PORT11

D2 PORT10

D1 PORT9

D0 PORT8

*Open-drain output, pullup resistor required.

0 Clear PORT15 low

1 Set PORT15 high*

0 Clear PORT14 low

1 Set PORT14 high*

0 Clear PORT13 low

1 Set PORT13 high*

0 Clear PORT12 low

1 Set PORT12 high*

0 Clear PORT11 low

1 Set PORT11 high

0 Clear PORT10 low

1 Set PORT10 high

0 Clear PORT9 low

1 Set PORT9 high

0 Clear PORT8 low

1 Set PORT8 high

1

1

1

1

1

1

1

1

Table 15. GPIO Level-Shifter Enable (0x3C)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

0 Level shifting disabled

D7 PORT7/PORT15

D6 PORT6/PORT14

D5 PORT5/PORT13

D4 PORT4/PORT12

D3 PORT3/PORT11

D2 PORT2/PORT10

1

0 Level shifting disabled

1

0 Level shifting disabled

1

0 Level shifting disabled

1

0 Level shifting disabled

1

0 Level shifting disabled

1

Level shift between PORT7 and PORT15 enabled;

direction controlled by GPIO direction 2 register (0x35)

Level shift between PORT6 and PORT14 enabled;

direction controlled by GPIO direction 2 register (0x35)

Level shift between PORT5 and PORT13 enabled;

direction controlled by GPIO direction 2 register (0x35)

Level shift between PORT4 and PORT12 enabled;

direction controlled by GPIO direction 2 register (0x35)

Level shift between PORT3 and PORT11 enabled;

direction controlled by GPIO direction 2 register (0x35)

Level shift between PORT2 and PORT10 enabled;

direction controlled by GPIO direction 2 register (0x35)

0

0

0

0

0

0

________________________________________________________________ Maxim Integrated Products 21

Page 22

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Table 15. GPIO Level-Shifter Enable (0x3C) (continued)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

0 Level shifting disabled

D1 PORT1/PORT9

D0 PORT0/PORT8

1

0 Level shifting disabled

1

Level shift between PORT1 and PORT9 enabled;

direction controlled by GPIO direction 2 register (0x35)

Level shift between PORT0 and PORT8 enabled;

direction controlled by GPIO direction 2 register (0x35)

Table 16. GPIO Global Configuration Register (0x40)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

D[7:6] Reserved 0 — 00

0 Disabled

D5

I2C timeout

interrupt enable

1

INT is asserted when I2C bus times out.

INT is deasserted when a read is performed on the

I2C timeout flag register (0x48).

0

0

0

D4 GPIO enable

D3 GPIO reset

D[2:0] Fade-in/out time

PWM, constant-current circuits, and GPIs are shut

0

1

0 Normal operation.

1

000 No fading.

XXX

down. GPO values depend on their setting. Register

0x31 to 0x5B values are stored and cannot be

changed. The entire part is shut down.

Normal GPIO operation. PWM, constant-current circuits,

and GPIOs are enabled.

Return all GPIO registers (registers 0x31 to 0x5B) to

their POR value. This bit is momentary and resets itself

to 0 after the write cycle.

PWM intensity ramps up (down) between the common

PWM value and 0% duty cycle in 16 steps over the

following time period:

D[2:0] = 001 = 256ms

D[2:0] = 010 = 512ms

D[2:0] = 011 = 1024ms

D[2:0] = 100 = 2048ms

D[2:0] = 101 = 4096ms

D[2:0] = 110/111 = Undefined

0

0

000

________________________________________________________________ Maxim Integrated Products 22

Page 23

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Table 17. GPIO Debounce Configuration Register (0x42)

REGISTER DATA

REGISTER DESCRIPTION

Power-up default setting

Debounce time is 9ms

Debounce time is 10ms 0 0 0 0 0 0 0 1

Debounce time is 11ms 0 0 0 0 0 0 1 0

Debounce time is 12ms 0 0 0 0 0 0 1 1

Debounce time is 37ms 0 0 0 1 1 1 0 0

Debounce time is 38ms 0 0 0 1 1 1 0 1

Debounce time is 39ms 0 0 0 1 1 1 1 0

Debounce time is 40ms 0 0 0 1 1 1 1 1

Table 18. LED Constant-Current Setting Register (0x43)

D7 D6 D5 D4 D3 D2 D1 D0

RESERVED DEBOUNCE TIME

0 0 0 0 0 0 0 0

⋮

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

D[7:6] Reserved 11 Set always as 11 11

D[5:1] Reserved 00000 — 00000

D0

Constant-

current setting

0 Constant current is 20mA

1 Constant current is 10mA

0

Table 19. Common PWM Ratio Register (0x45)

REGISTER DATA

REGISTER DESCRIPTION

Power-up default setting

Common PWM ratio is 0/256

Common PWM ratio is 1/256 0 0 0 0 0 0 0 1

Common PWM ratio is 2/256 0 0 0 0 0 0 1 0

Common PWM ratio is 3/256 0 0 0 0 0 0 1 1

Common PWM ratio is 252/256 1 1 1 1 1 1 0 0

Common PWM ratio is 253/256 1 1 1 1 1 1 0 1

Common PWM ratio is 254/256 1 1 1 1 1 1 1 0

Common PWM ratio is 256/256

(100% duty cycle)

D7 D6 D5 D4 D3 D2 D1 D0

COMMON PWM

0 0 0 0 0 0 0 0

⋮

1 1 1 1 1 1 1 1

________________________________________________________________ Maxim Integrated Products 23

Page 24

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Table 20. I2C Timeout Flag Register (0x48) (Read Only)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

D[7:1] Reserved 0000000 — 0000000

0 No I2C timeout has occurred since last read or POR.

I2C timeout has occurred since last read or POR. This

D0 I2C timeout flag

1

bit is reset to zero when a read is performed on this

register. I2C timeouts must be enabled for this function

to work (see Table 5).

Table 21. PORT12–PORT15 Individual PWM Ratio Registers (0x50 to 0x53)

REGISTER DATA

REGISTER DESCRIPTION

Power-up default setting

PORT PWM ratio is 0/256

PORT PWM ratio is 1/256 0 0 0 0 0 0 0 1

PORT PWM ratio is 2/256 0 0 0 0 0 0 1 0

PORT PWM ratio is 3/256 0 0 0 0 0 0 1 1

PORT PWM ratio is 252/256 1 1 1 1 1 1 0 0

PORT PWM ratio is 253/256 1 1 1 1 1 1 0 1

PORT PWM ratio is 254/256 1 1 1 1 1 1 1 0

PORT PWM ratio is 256/256

(100% duty cycle)

D7 D6 D5 D4 D3 D2 D1 D0

PORT PWM

0 0 0 0 0 0 0 0

⋮

1 1 1 1 1 1 1 1

0

Table 22. PORT12–PORT15 LED Configuration Registers (0x54 to 0x57)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

D[7:6] Don’t care 00 — 00

Port uses individual PWM intensity register to set the

PWM ratio

Port uses common PWM intensity register to set the

PWM ratio

0

000

00

D5 Common PWM

D[4:2] Blink period

D[1:0] Blink-on time

________________________________________________________________ Maxim Integrated Products 24

0

1

000 Port does not blink

001 Port blink period is 256ms

010 Port blink period is 512ms

011 Port blink period is 1024ms

100 Port blink period is 2048ms

101 Port blink period is 4096ms

110/111 Undefined

00 LED is on for 50% of the blink period

01 LED is on for 25% of the blink period

10 LED is on for 12.5% of the blink period

11 LED is on for 6.25% of the blink period

Page 25

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Table 23. Interrupt Mask 1 Register (0x58)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

D7 PORT7

D6 PORT6

D5 PORT5

D4 PORT4

D3 PORT3

D2 PORT2

D1 PORT1

D0 PORT0

0 Interrupt is not masked

1 Interrupt is masked

0 Interrupt is not masked

1 Interrupt is masked

0 Interrupt is not masked

1 Interrupt is masked

0 Interrupt is not masked

1 Interrupt is masked

0 Interrupt is not masked

1 Interrupt is masked

0 Interrupt is not masked

1 Interrupt is masked

0 Interrupt is not masked

1 Interrupt is masked

0 Interrupt is not masked

1 Interrupt is masked

1

1

1

1

1

1

1

1

Table 24. Interrupt Mask 2 Register (0x59)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

D7 PORT15

D6 PORT14

D5 PORT13

D4 PORT12

D3 PORT11

D2 PORT10

D1 PORT9

D0 PORT8

0 Interrupt is not masked

1 Interrupt is masked

0 Interrupt is not masked

1 Interrupt is masked

0 Interrupt is not masked

1 Interrupt is masked

0 Interrupt is not masked

1 Interrupt is masked

0 Interrupt is not masked

1 Interrupt is masked

0 Interrupt is not masked

1 Interrupt is masked

0 Interrupt is not masked

1 Interrupt is masked

0 Interrupt is not masked

1 Interrupt is masked

1

1

1

1

1

1

1

1

________________________________________________________________ Maxim Integrated Products 25

Page 26

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Table 25. GPI Trigger Mode 1 Register (0x5A)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

D7 PORT15

D6 PORT14

D5 PORT13

D4 PORT12

D3 PORT11

D2 PORT10

D1 PORT9

D0 PORT8

0 Rising-edge-triggered interrupts

1 Rising- and falling-edge-triggered interrupts

0 Rising-edge-triggered interrupts

1 Rising- and falling-edge-triggered interrupts

0 Rising-edge-triggered interrupts

1 Rising- and falling-edge-triggered interrupts

0 Rising-edge-triggered interrupts

1 Rising- and falling-edge-triggered interrupts

0 Rising-edge-triggered interrupts

1 Rising- and falling-edge-triggered interrupts

0 Rising-edge-triggered interrupts

1 Rising- and falling-edge-triggered interrupts

0 Rising-edge-triggered interrupts

1 Rising- and falling-edge-triggered interrupts

0 Rising-edge-triggered interrupts

1 Rising- and falling-edge-triggered interrupts

0

0

0

0

0

0

0

0

Table 26. GPI Trigger Mode 2 Register (0x5B)

REGISTER BIT DESCRIPTION VALUE FUNCTION DEFAULT VALUE

D7 PORT15

D6 PORT14

D5 PORT13

D4 PORT12

D3 PORT11

D2 PORT10

D1 PORT9

D0 PORT8

0 Rising-edge-triggered interrupts

1 Rising- and falling-edge-triggered interrupts

0 Rising-edge-triggered interrupts

1 Rising- and falling-edge-triggered interrupts

0 Rising-edge-triggered interrupts

1 Rising- and falling-edge-triggered interrupts

0 Rising-edge-triggered interrupts

1 Rising- and falling-edge-triggered interrupts

0 Rising-edge-triggered interrupts

1 Rising- and falling-edge-triggered interrupts

0 Rising-edge-triggered interrupts

1 Rising- and falling-edge-triggered interrupts

0 Rising-edge-triggered interrupts

1 Rising- and falling-edge-triggered interrupts

0 Rising-edge-triggered interrupts

1 Rising- and falling-edge-triggered interrupts

0

0

0

0

0

0

0

0

________________________________________________________________ Maxim Integrated Products 26

Page 27

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Wafer-Level Packaging (WLP)

Applications Information

For the latest application details on WLP construction,

dimensions, tape-carrier information, PCB techniques,

bump-pad layout, and recommended reflow temperature profile, as well as the latest information on reliability

testing results, refer to Application Note 1891: Wafer-

Level Packaging (WLP) and Its Applications, available at

www.maxim-ic.com.

PROCESS: BiCMOS

PART TEMP RANGE PIN-PACKAGE

MAX7304ETG+

MAX7304EWA+**

+Denotes a lead(Pb)-free/RoHS-compliant package.

*EP = Exposed pad.

**Future product—contact factory for availability.

-40NC to +85NC

-40NC to +85NC

Chip Information

Ordering Information

24 TQFN-EP*

25 WLP

Package Information

For the latest package outline information and land patterns (footprints), go to www.maxim-ic.com/packages. Note that a “+”, “#”, or

“-” in the package code indicates RoHS status only. Package drawings may show a different suffix character, but the drawing pertains

to the package regardless of RoHS status.

PACKAGE TYPE PACKAGE CODE OUTLINE NO. LAND PATTERN NO.

24 TQFN-EP T243A3+1

25 WLP W252F2+1

21-0188 90-0122

21-0453

Refer to Application Note 1891

________________________________________________________________ Maxim Integrated Products 27

Page 28

MAX7304

I2C-Interfaced 16-Port,

Level-Translating GPIO and LED Driver

with High Level of Integrated ESD Protection

Revision History

REVISION

NUMBER

0 6/11 Initial release —

1 3/12 Updated ESD protection specifications 1, 4, 8, 16

REVISION

DATE

DESCRIPTION

PAGES

CHANGED

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are implied.

Maxim reserves the right to change the circuitry and specifications without notice at any time. The parametric values (min and max limits) shown in the Electrical

Characteristics table are guaranteed. Other parametric values quoted in this data sheet are provided for guidance.

Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600 28

©

2012 Maxim Integrated Products Maxim is a registered trademark of Maxim Integrated Products, Inc.

Loading...

Loading...