19-0100; Rev 3; 1/97

EVALUATION KIT MANUALS

FOLLOW DATA SHEET

NiCd/NiMH Battery

Fast-Charge Controllers

_______________General Description

The MAX712/MAX713 fast charge Nickel Metal Hydride

(NiMH) and Nickel Cadmium (NiCd) batteries from a DC

source at least 1.5V higher than the maximum battery

voltage. 1 to 16 series cells can be charged at rates up

to 4C. A voltage-slope detecting analog-to-digital converter, timer, and temperature window comparator determine

charge completion. The MAX712/MAX713 are powered

by the DC source via an on-board +5V shunt regulator.

They draw a maximum of 5µA from the battery when not

charging. A low-side current-sense resistor allows the

battery charge current to be regulated while still

supplying power to the battery’s load.

The MAX712 terminates fast charge by detecting zero

voltage slope, while the MAX713 uses a negative

voltage-slope detection scheme. Both parts come in 16pin DIP and SO packages. An external power PNP transistor, blocking diode, three resistors, and three

capacitors are the only required external components.

For high-power charging requirements, the MAX712/

MAX713 can be configured as a switch-mode battery

charger that minimizes power dissipation. Two evaluation

kits are available: Order the MAX712EVKIT-DIP for quick

evaluation of the linear charger, and the MAX713EVKITSO to evaluate the switch-mode charger.

________________________Applications

Battery-Powered Equipment

Laptop, Notebook, and Palmtop Computers

Handy-Terminals

Cellular Phones

Portable Consumer Products

Portable Stereos

Cordless Phones

____________________________Features

♦ Fast Charge NiMH or NiCd Batteries

♦ Voltage Slope, Temperature, and Timer

Fast-Charge Cutoff

♦ Charge 1 to 16 Series Cells

♦ Supply Battery’s Load while Charging (Linear Mode)

♦ Fast Charge from C/4 to 4C Rate

♦ C/16 Trickle-Charge Rate

♦ Automatically Switch from Fast to Trickle Charge

♦ Linear or Switch-Mode Power Control

♦ 5µA Max Drain on Battery when Not Charging

♦ 5V Shunt Regulator Powers External Logic

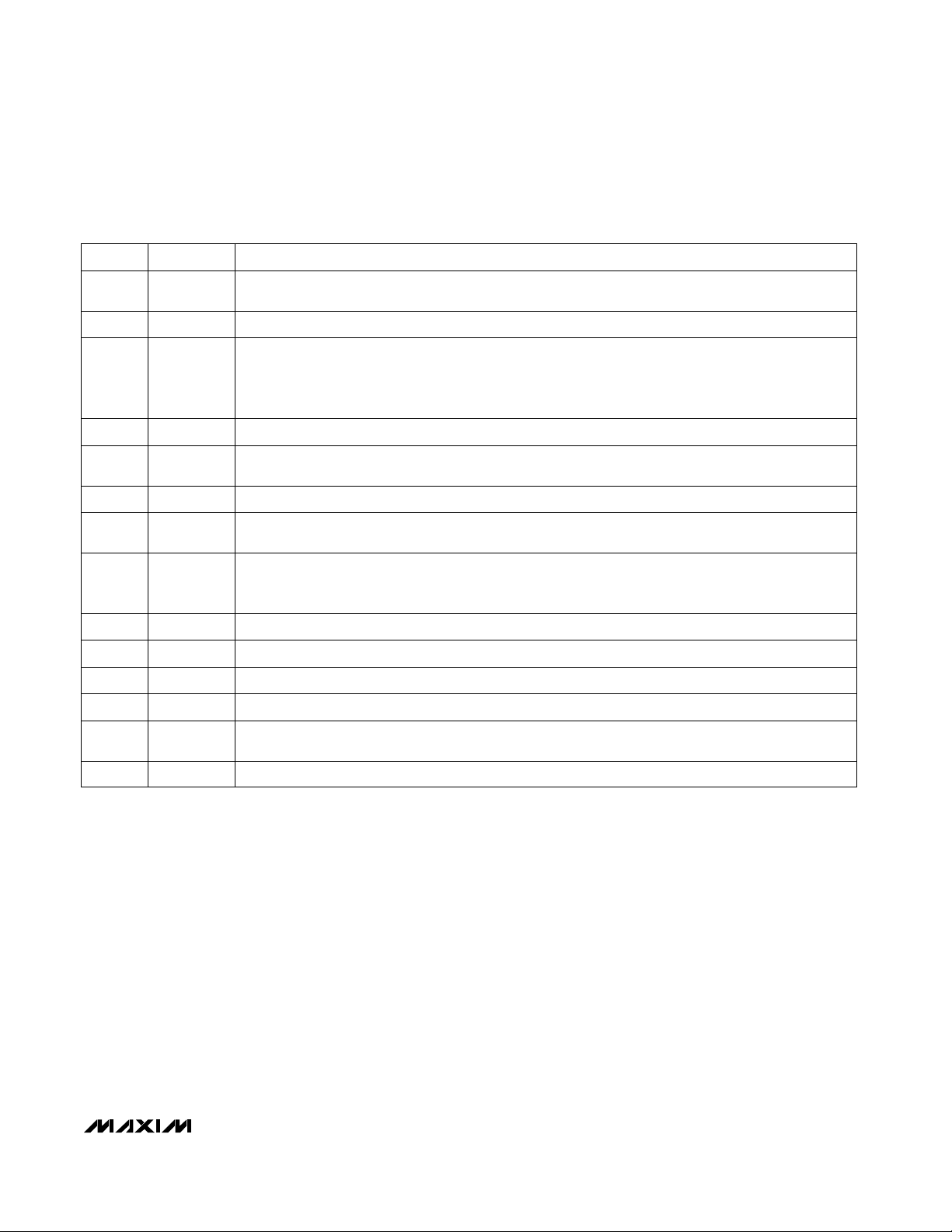

______________Ordering Information

PART

MAX712CPE

MAX712CSE

MAX712C/D 0°C to +70°C

MAX712EPE

MAX712ESE

MAX712MJE -55°C to +125°C

Ordering Information continued at end of data sheet.

*

Contact factory for dice specifications.

**

Contact factory for availability and processing to MIL-STD-883.

TEMP. RANGE PIN-PACKAGE

0°C to +70°C

0°C to +70°C

-40°C to +85°C 16 Plastic DIP

-40°C to +85°C

16 Plastic DIP

16 Narrow SO

Dice*

16 Narrow SO

16 CERDIP**

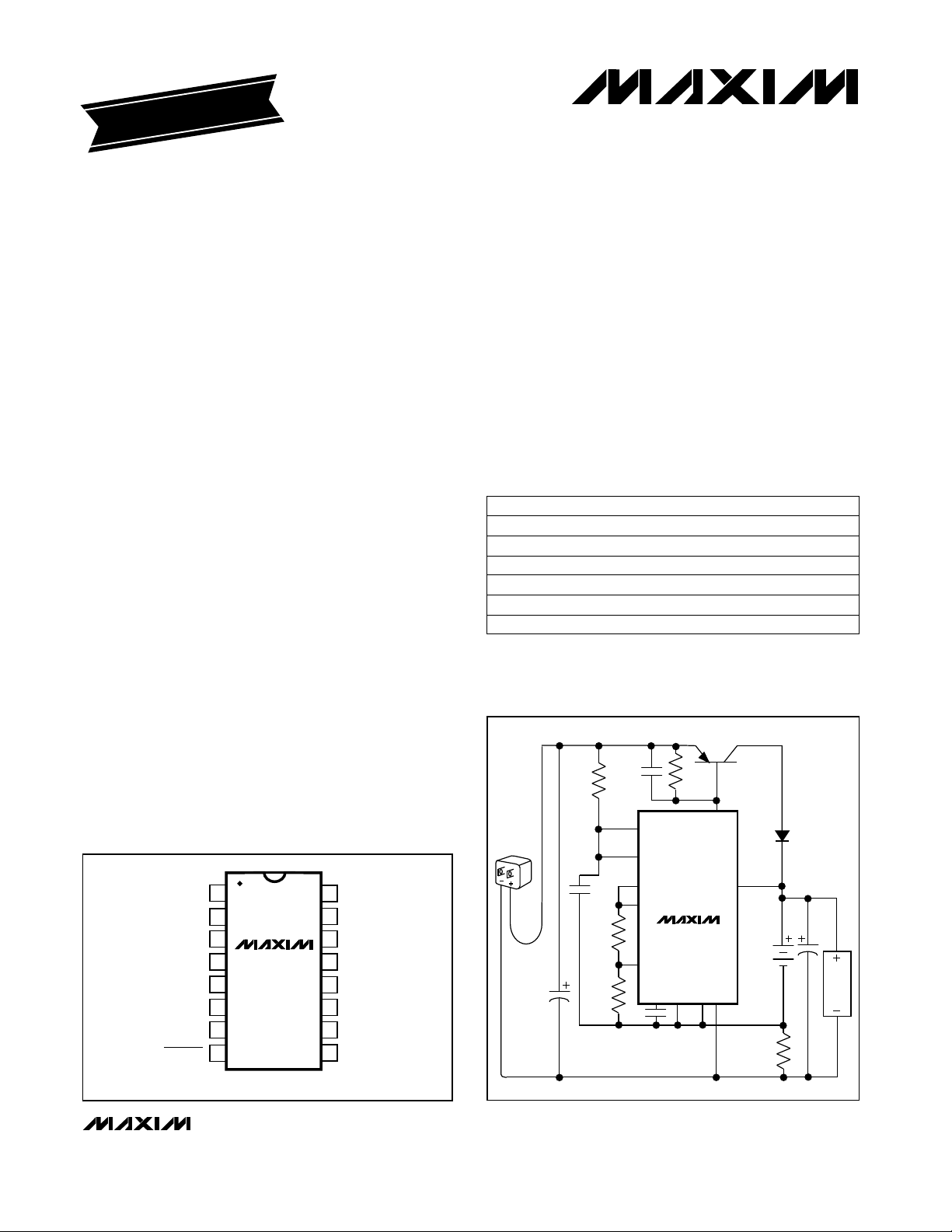

__________Typical Operating Circuit

R2

150Ω

Q1

2N6109

DC IN

R1

C4

0.01µF

MAX712/MAX713

__________________Pin Configuration

TOP VIEW

VLIMIT

1

BATT+

2

PGM0

3

PGM1

THI

TLO

TEMP

FASTCHG

________________________________________________________________

MAX712

4

MAX713

5

6

7

8

DIP/SO

REF

16

V+

15

DRV

14

GND

13

BATT-

12

11

CC

10

PGM3

PGM2

9

WALL

CUBE

C1

1µF

R3

68kΩ

10µF

SEE FIGURE 19 FOR SWITCH-MODE CHARGER CIRCUIT.

R4

22kΩ

THI

V+

VLIMIT

REF

TEMP

C2

0.01µF

DRV

BATT+

MAX712

MAX713

BATT- TLO GNDCC

Maxim Integrated Products

BATTERY

R

D1

1N4001

C3

10µF

SENSE

LOAD

1

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800

NiCd/NiMH Battery

Fast-Charge Controllers

ABSOLUTE MAXIMUM RATINGS

V+ to BATT-.................................................................-0.3V, +7V

BATT- to GND........................................................................±1V

BATT+ to BATT-

Power Not Applied............................................................±20V

With Power Applied................................The higher of ±20V or

DRV to GND ..............................................................-0.3V, +20V

FASTCHG to BATT-...................................................-0.3V, +12V

All Other Pins to GND......................................-0.3V, (V+ + 0.3V)

V+ Current.........................................................................100mA

DRV Current......................................................................100mA

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

MAX712/MAX713

ELECTRICAL CHARACTERISTICS

(IV+= 10mA, TA= T

BATT-, not GND.)

Trickle-Charge VSENSE

Voltage-Slope Sensitivity (Note 3)

Battery-Voltage to Cell-Voltage

Divider Accuracy

MIN

to T

±2V x (programmed cells)

, unless otherwise noted. Refer to

MAX

5mA < IV+< 20mA

V+ = 0V, BATT+ = 17V

PGM0 = PGM1 = BATT-, BATT+ = 30V

0mA < I

REF

Per cell

0V < TEMP < 2V, TEMP voltage rising

1.2V < V

PGM0 = PGM1 = V+

V

PGM3 = V+

PGM3 = open

PGM3 = REF

PGM3 = BATTMAX713

MAX712

V

LIMIT

DRV

LIMIT

= V+

= 10V

< 1mA

REF Current.........................................................................10mA

Continuous Power Dissipation (T

Plastic DIP (derate 10.53mW/°C above +70°C............842mW

Narrow SO (derate 8.70mW/°C above +70°C .............696mW

CERDIP (derate 10.00mW/°C above +70°C................800mW

Operating Temperature Ranges

MAX71_C_E .......................................................0°C to +70°C

MAX71_E_E .................................................... -40°C to +85°C

MAX71_MJE ................................................. -55°C to +125°C

Storage Temperature Range.............................-65°C to +150°C

Lead Temperature (soldering, 10sec).............................+300°C

Typical Operating Circuit

CONDITIONS

< 2.5V, 5mA < I

DRV

< 20mA,

. All measurements are with respect to

= +70°C)

A

1.5 3.9 7.0

4.5 7.8 12.0

12.0 15.6 20.0

26.0 31.3 38.0

-2.5

0

UNITSMIN TYP MAXPARAMETER

mV/t

per cell

V4.5 5.5V+ Voltage

mA5IV+(Note 1)

µA5BATT+ Leakage

kΩ30BATT+ Resistance with Power On

µF0.5C1 Capacitance

nF5C2 Capacitance

V1.96 2.04REF Voltage

V0.35 0.50Undervoltage Lockout

V1.25 2.50External VLIMIT Input Range

V02THI, TLO, TEMP Input Range

mV-10 10THI, TLO Offset Voltage (Note 2)

µA-1 1THI, TLO, TEMP, VLIMIT Input Bias Current

mV-30 30VLIMIT Accuracy

V1.6 1.65 1.7Internal Cell Voltage Limit

mV225 250 275Fast-Charge VSENSE

mV

A

%-15 15Timer Accuracy

%-1.5 1.5

mA30DRV Sink Current

2 _______________________________________________________________________________________

NiCd/NiMH Battery

Fast-Charge Controllers

ELECTRICAL CHARACTERISTICS (continued)

(IV+ = 10mA, TA= T

BATT-, not GND.)

FASTCHG Low Current

FASTCHG High Current

Note 1: The MAX712/MAX713 are powered from the V+ pin. Since V+ shunt regulates to +5V, R1 must be small enough to allow at

least 5mA of current into the V+ pin.

Note 2: Offset voltage of THI and TLO comparators referred to TEMP.

Note 3: t

is the A/D sampling interval (Table 3).

A

Note 4: This specification can be violated when attempting to charge more or fewer cells than the number programmed. To ensure

proper voltage-slope fast-charge termination, the (maximum battery voltage) ÷ (number of cells programmed) must fall

within the A/D input range.

MIN

to T

, unless otherwise noted. Refer to

MAX

V

FASTCHG

V

FASTCHG

Battery voltage ÷ number of cells programmed

CONDITIONS

= 0.4V

= 10V

Typical Operating Circuit

. All measurements are with respect to

UNITSMIN TYP MAXPARAMETER

mA2

µA10

V1.4 1.9A/D Input Range (Note 4)

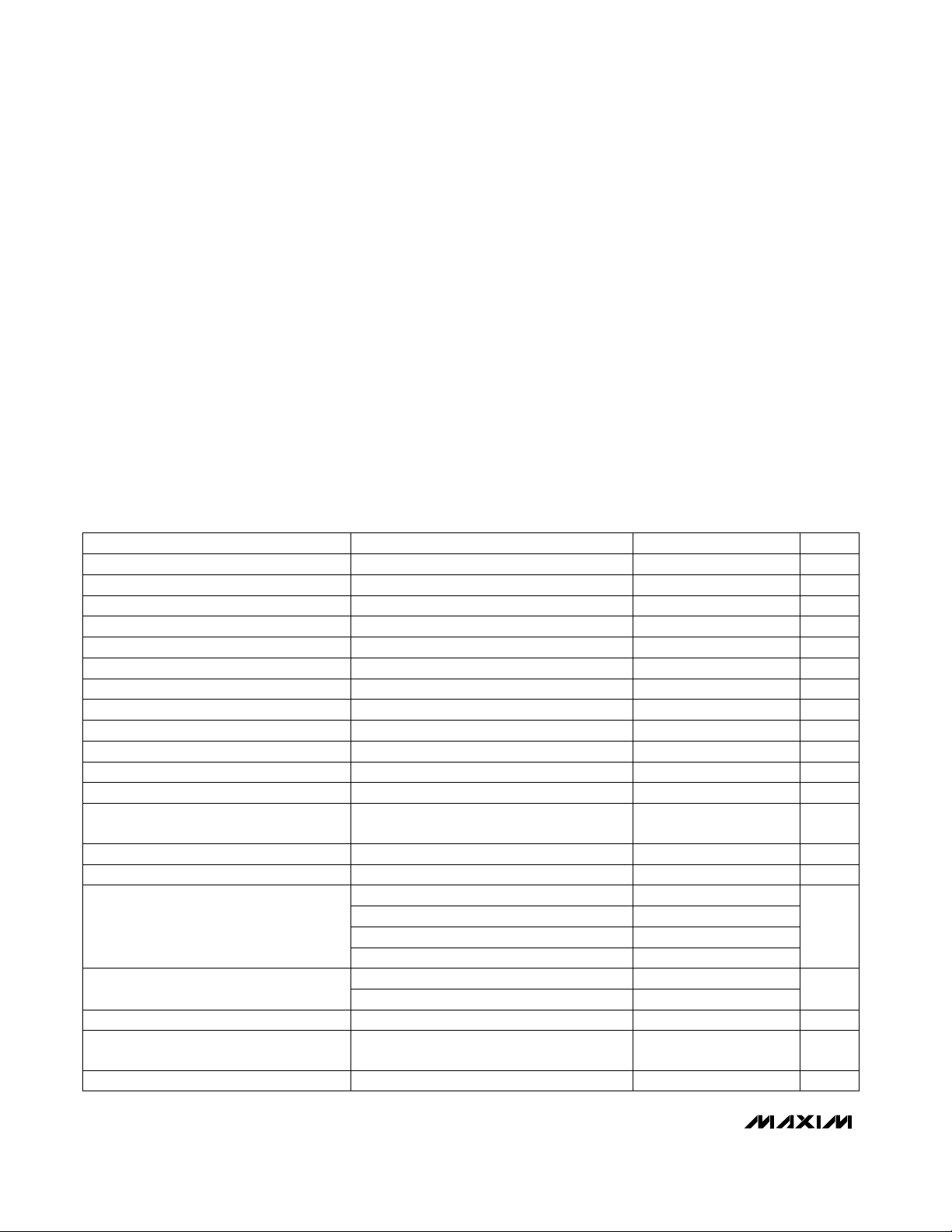

__________________________________________Typical Operating Characteristics

(TA = +25°C, unless otherwise noted.)

20

10

0

GAIN (dB)

-10

-20

CURRENT-SENSE AMPLIFIER

FREQUENCY RESPONSE (with 15pF)

C2 = 15pF

FASTCHG = 0V

A

Φ

BATT-

+

V

IN

-

GND

1k

CURRENT-

SENSE

AMP

FREQUENCY (Hz)

CC

BATT-

100k

V

OUT

+

-

1M10k 10M

40

MAX712/13 LOG1

0

V

-40

PHASE (DEGREES)

-80

-120

20

10

GAIN (dB)

-10

-20

CURRENT-SENSE AMPLIFIER

FREQUENCY RESPONSE (with 10nF)

0

Φ

10 1k

100 10k

FREQUENCY (Hz)

C2 = 10nF

FASTCHG = 0V

A

V

40

MAX712/13 LOG2

0

-40

PHASE (DEGREES)

-80

-120

MAX712/MAX713

CURRENT ERROR-AMPLIFIER

TRANSCONDUCTANCE

100

FASTCHG = 0V, V+ = 5V

10

1

DRV PIN SINK CURRENT(mA)

0.1

1.95 1.97 2.01 2.05

1.99 2.03

VOLTAGE ON CC PIN (V)

_______________________________________________________________________________________ 3

MAX712/13 LOG3

V+ VOLTAGE (V)

SHUNT-REGULATOR VOLTAGE

vs. CURRENT

5.8

DRV NOT SINKING CURRENT

5.6

5.4

5.2

5.0

4.8

4.6

4.4

4.2

4.0

10 20 50

060

DRV SINKING CURRENT

30

40

CURRENT INTO V+ PIN (mA)

MAX712/13 LOG4

ALPHA THERMISTOR PART No. 13A1002

STEINHART-HART INTERPOLATION

1.6

1.4

1.2

1.0

0.8

0.6

TEMP PIN VOLTAGE (V)

0.4

0.2

10 20 50

060

BATTERY TEMPERATURE(°C)

35

30

25

20

15

10

5

BATTERY THERMISTOR RESISTANCE (kΩ)

30

40

0

NiCd/NiMH Battery

Fast-Charge Controllers

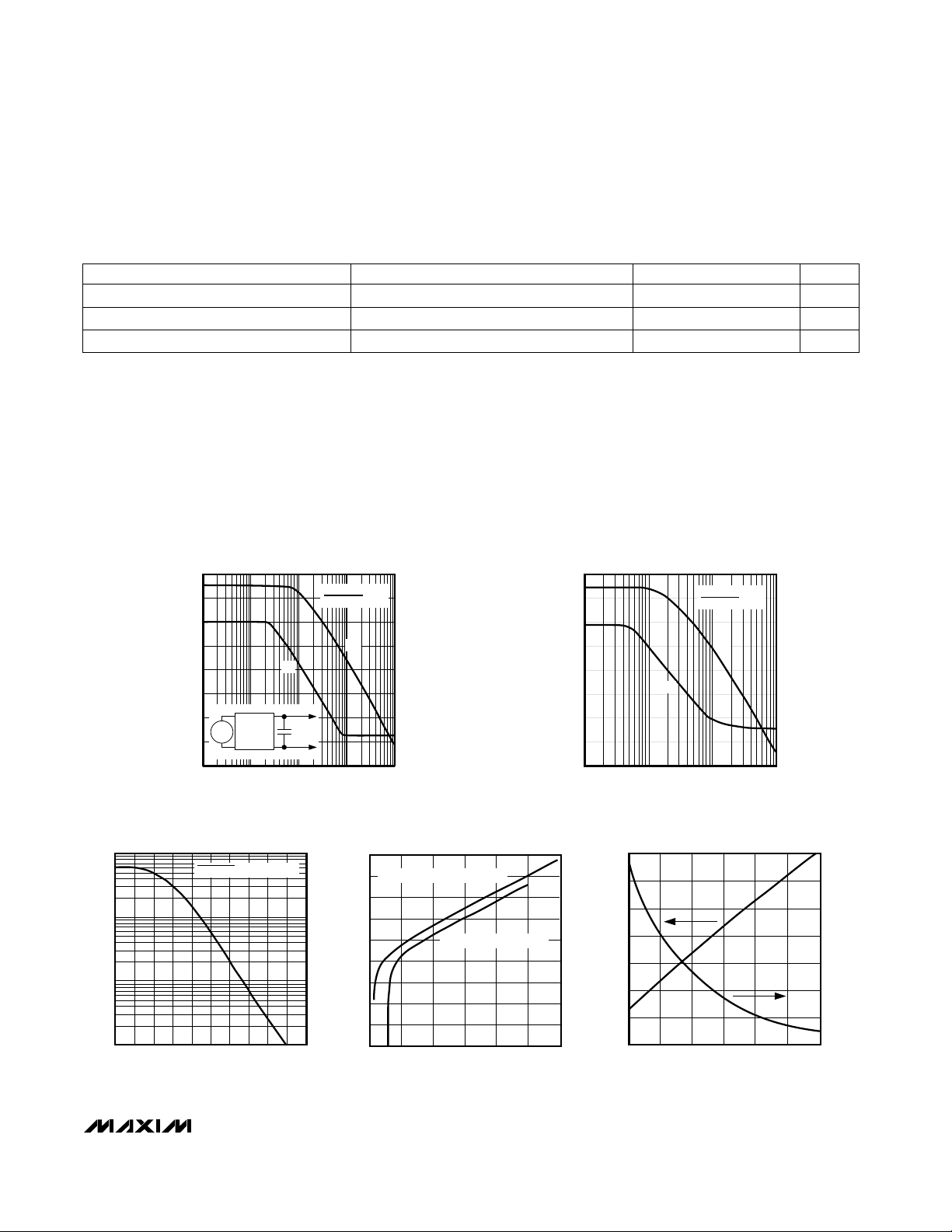

____________________________Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

MAX713

NiCd BATTERY-CHARGING

CHARACTERISTICS AT C RATE

CHARACTERISTICS AT C RATE

MAX713

NiMH BATTERY-CHARGING

1.55

1.50

1.45

CELL VOLTAGE (V)

1.40

∆V

V

CUTOFF

∆t

T

MAX712/MAX713

0

CHARACTERISTICS AT C/2 RATE

1.50

1.45

CELL VOLTAGE (V)

1.40

30 9060

CHARGE TIME (MINUTES)

MAX713

NiCd BATTERY-CHARGING

∆V

CUTOFF

∆t

V

T

MAX712/713

40

35

30

25

MAX712/713

35

30

25

MAX712/713

1.60

1.55

1.50

CELL VOLTAGE (V)

CELL TEMPERATURE (°C)

1.45

0

30 9060

CHARGE TIME (MINUTES)

∆V

V

T

∆t

CUTOFF

40

35

30

CELL TEMPERATURE (°C)

25

MAX713

NiMH BATTERY-CHARGING

CHARACTERISTICS AT C/2 RATE

MAX712/713

1.55

1.50

1.45

CELL VOLTAGE (V)

CELL TEMPERATURE (°C)

1.40

∆V

CUTOFF

∆t

V

T

40

35

30

CELL TEMPERATURE (°C)

25

0

50 150100

CHARGE TIME (MINUTES)

MAX713

CHARGING CHARACTERISTICS OF A

FULLY CHARGED NiMH BATTERY

1.65

1.60

1.55

1.50

CELL VOLTAGE (V)

1.45

V

T

0

CHARGE TIME (MINUTES)

BETWEEN CHARGES

∆V

5152010

5-MINUTE REST

∆t

CUTOFF

MAX712/713

40

35

30

25

0

CHARGING CHARACTERISTICS OF A

1.65

1.60

1.55

1.50

CELL TEMPERATURE (°C)

CELL VOLTAGE (V)

1.45

0

50 150100

CHARGE TIME (MINUTES)

MAX713

FULLY CHARGED NiMH BATTERY

V

∆V

CUTOFF

∆t

5-HOUR REST

BETWEEN CHARGES

T

51510

CHARGE TIME (MINUTES)

4 _______________________________________________________________________________________

MAX712/713

40

35

30

CELL TEMPERATURE (°C)

25

20

NiCd/NiMH Battery

Fast-Charge Controllers

______________________________________________________________Pin Description

PIN

3, 4

8

9, 10

VLIMIT1

PGM0,

PGM1

TLO6

FASTCHG

PGM2,

PGM3

Sets the maximum cell voltage. The battery terminal voltage (BATT+ - BATT-) will not exceed VLIMIT x

(number of cells). Do not allow VLIMIT to exceed 2.5V. Tie VLIMIT to VREF for normal operation.

Positive terminal of batteryBATT+2

PGM0 and PGM1 set the number of series cells to be charged. The number of cells can be set from

1 to 16 by connecting PGM0 and PGM1 to any of V+, REF, or BATT-, or by leaving the pin open (Table

2). For cell counts greater than 11, see the

or fewer cells than the number programmed may inhibit ∆V fast-charge termination.

Trip point for the over-temperature comparator. If the voltage-on TEMP rises above THI, fast charge ends.THI5

Trip point for the under-temperature comparator. If the MAX712/MAX713 power on with the voltage-on

TEMP less than TLO, fast charge is inhibited and will not start until TEMP rises above TLO.

Sense input for temperature-dependent voltage from thermistors.TEMP7

Open-drain, fast-charge status output. While the MAX712/MAX713 fast charge the battery, FASTCHG

sinks current. When charge ends and trickle charge begins, FASTCHG stops sinking current.

PGM2 and PGM3 set the maximum time allowed for fast charging. Timeouts from 33 minutes to 264

minutes can be set by connecting to any of V+, REF, or BATT-, or by leaving the pin open (Table 3).

PGM3 also sets the fast-charge to trickle-charge current ratio (Table 5).

Compensation input for constant current regulation loopCC11

FUNCTIONNAME

Linear-Mode, High Series Cell Count

section. Charging more

MAX712/MAX713

Negative terminal of batteryBATT-12

System ground. The resistor placed between BATT- and GND monitors the current into the battery.GND13

Current sink for driving the external PNP current sourceDRV14

V+15

Shunt regulator. The voltage on V+ is regulated to +5V with respect to BATT-, and the shunt current

powers the MAX712/MAX713.

2V reference outputREF16

_______________________________________________________________________________________ 5

NiCd/NiMH Battery

Fast-Charge Controllers

____________________Getting Started

The MAX712/MAX713 are simple to use. A complete

linear-mode or switch-mode fast-charge circuit can be

designed in a few easy steps. A linear-mode design

uses the fewest components and supplies a load while

charging, while a switch-mode design may be necessary if lower heat dissipation is desired.

1) Follow the battery manufacturer’s recommendations

on maximum charge currents and charge-termination

methods for the specific batteries in your application.

Table 1 provides general guidelines.

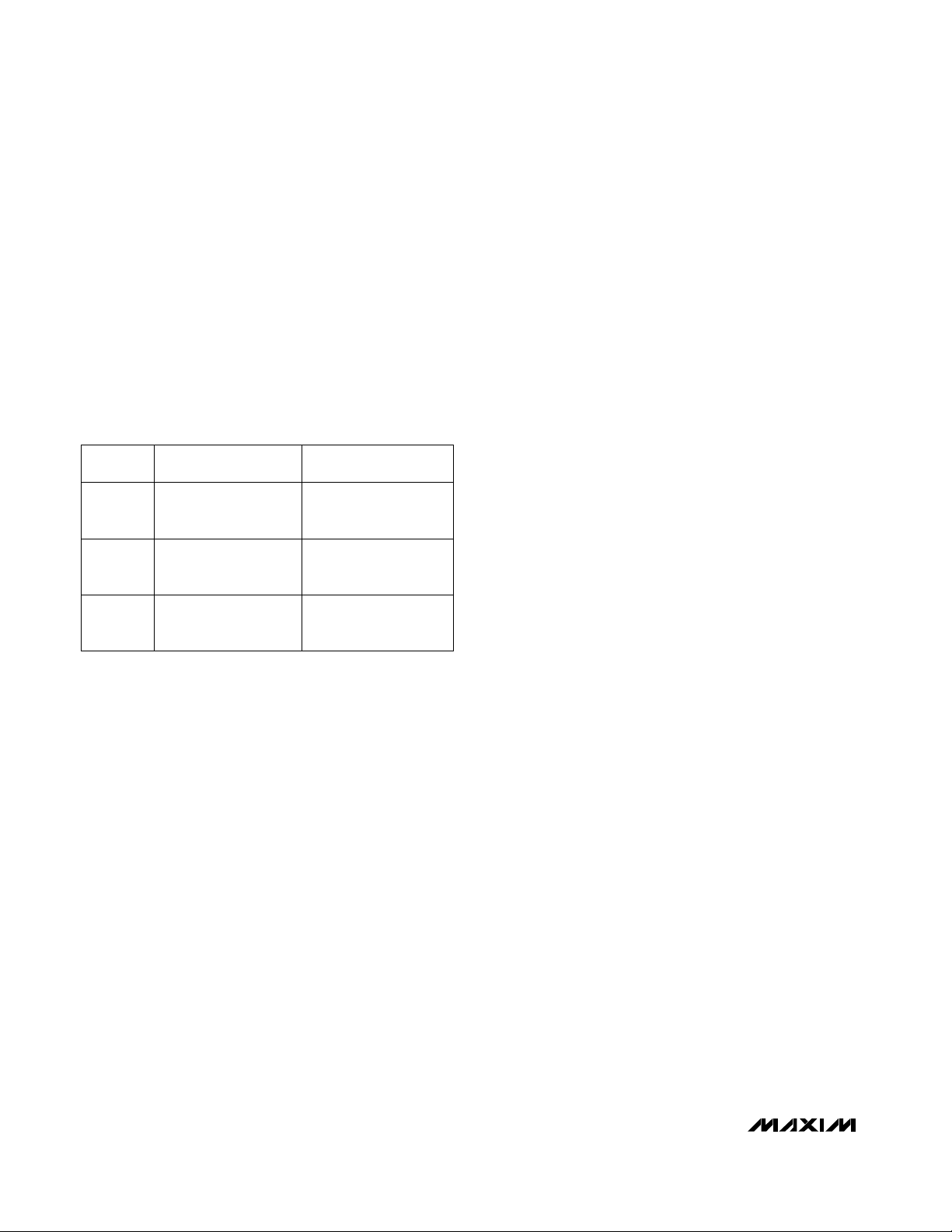

Table 1. Fast-Charge Termination Methods

Charge

MAX712/MAX713

Rate

> 2C

2C to C/2

< C/2

2) Decide on a charge rate (Tables 3 and 5). The slowest fast-charge rate for the MAX712/MAX713 is C/4,

because the maximum fast-charge timeout period is

264 minutes. A C/3 rate charges the battery in about

three hours. The current in mA required to charge at

this rate is calculated as follows:

Depending on the battery, charging efficiency can be

as low as 80%, so a C/3 fast charge could take 3 hours

and 45 minutes. This reflects the efficiency with which

electrical energy is converted to chemical energy within

the battery, and is not the same as the powerconversion efficiency of the MAX712/MAX713.

3) Decide on the number of cells to be charged (Table 2).

If your battery stack exceeds 11 cells, see the

Mode High Series Cell Count

changing the number of cells to be charged, PGM0

NiMH Batteries NiCd Batteries

∆V/∆t and

temperature,

MAX712 or MAX713

∆V/∆t and/or

temperature,

MAX712 or MAX713

∆V/∆t and/or

temperature, MAX712

I

= (capacity of battery in mAh)

FAST

–––––––––––––––––––––––

(charge time in hours)

∆V/∆t and/or

temperature, MAX713

∆V/∆t and/or

temperature, MAX713

∆V/∆t and/or

temperature, MAX713

section. Whenever

––

Linear-

and PGM1 must be adjusted accordingly. Attempting

to charge more or fewer cells than the number programmed can disable the voltage-slope fast-charge

termination circuitry. The internal ADC’s input voltage range is limited to between 1.4V and 1.9V (see

Electrical Characteristics

the

voltage across the battery divided by the number of

cells programmed (using PGM0 and PGM1, as in

Table 2). When the ADC’s input voltage falls out of

its specified range, the voltage-slope termination circuitry can be disabled.

4) Choose an external DC power source (e.g., wall

cube). Its minimum output voltage (including ripple)

must be greater than 6V and at least 1.5V higher (2V

for switch mode) than the maximum battery voltage

while charging. This specification is critical because

normal fast-charge termination is ensured only if this

requirement is maintained (see

MAX712/MAX713

5) For linear-mode designs, calculate the worst-case

power dissipation of the power PNP and diode (Q1

and D1 in the

using the following formula:

PD

load - minimum battery voltage) x (charge current

in amps)

If the maximum power dissipation is not tolerable for

your application, refer to the

use a switch-mode design (see

= (maximum wall-cube voltage under

PNP

Operation

and see the MAX713 EV kit manual).

6) For both linear and switch-mode designs, limit current into V+ to between 5mA and 20mA. For a fixed

or narrow-range input voltage, choose R1 in the

section for more details).

Typical Operating Circuit

in the

Applications Information

Typical Operation Circuit

R1 = (minimum wall-cube voltage - 5V) / 5mA

For designs requiring a large input voltage variation,

choose the current-limiting diode D4 in Figure 19.

7) Choose R

8) Consult Tables 2 and 3 to set pin-straps before

applying power. For example, to fast charge at a

rate of C/2, set the timeout to between 1.5x or 2x the

charge period, three or four hours, respectively.

using the following formula:

SENSE

RSENSE = 0.25V / (I

), and is equal to the

Powering the

) in watts,

Detailed Description

or

Switch-Mode

section,

using the following formula:

)

FAST

6 _______________________________________________________________________________________

Loading...

Loading...