Page 1

General Description

The MAX6955 is a compact display driver that interfaces

microprocessors to a mix of 7-segment, 14-segment,

and 16-segment LED displays through an I2C-compatible 2-wire serial interface. The MAX6955 drives up to 16

digits 7-segment, 8 digits 14-segment, 8 digits 16-segment, or 128 discrete LEDs, while functioning from a

supply voltage as low as 2.7V. The driver includes five

I/O expander or general-purpose I/O (GPIO) lines, some

or all of which can be configured as a key-switch reader.

The key-switch reader automatically scans and

debounces a matrix of up to 32 switches.

Included on chip are full 14- and 16-segment ASCII

104-character fonts, a hexadecimal font for 7-segment

displays, multiplex scan circuitry, anode and cathode

drivers, and static RAM that stores each digit. The maximum segment current for the display digits is set using

a single external resistor. Digit intensity can be independently adjusted using the 16-step internal digital

brightness control. The MAX6955 includes a low-power

shutdown mode, a scan-limit register that allows the

user to display from 1 to 16 digits, segment blinking

(synchronized across multiple drivers, if desired), and a

test mode, which forces all LEDs on. The LED drivers

are slew-rate limited to reduce EMI.

For an SPI™-compatible version, refer to the MAX6954

data sheet. An evaluation kit (EV kit) for the MAX6955 is

available.

Applications

Set-Top Boxes Automotive

Panel Meters Bar Graph Displays

White Goods Audio/Video Equipment

Features

♦ 400kbps 2-Wire I2C-Compatible Interface

♦ 2.7V to 5.5V Operation

♦ Drives Up to 16 Digits 7-Segment, 8 Digits

14-Segment, 8 Digits 16-Segment, 128 Discrete

LEDs, or a Combination of Digit Types

♦ Drives Common-Cathode Monocolor and Bicolor

LED Displays

♦ Built-In ASCII 104-Character Font for 14-Segment

and 16-Segment Digits and Hexadecimal Font for

7-Segment Digits

♦ Automatic Blinking Control for Each Segment

♦ 10µA (typ) Low-Power Shutdown (Data Retained)

♦ 16-Step Digit-by-Digit Digital Brightness Control

♦ Display Blanked on Power-Up

♦ Slew-Rate-Limited Segment Drivers for Lower EMI

♦ Five GPIO Port Pins Can Be Configured as Key-

Switch Reader to Scan and Debounce Up to 32

Switches with n-Key Rollover

♦ IRQ Output when a Key Input is Debounced

♦ 36-Pin SSOP and 40-Pin TQFN Packages

♦ Automotive Temperature Range Standard

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

19-2548; Rev 2; 12/06

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

PART

TEMP RANGE

PINPACKAGE

PKG

CODE

MAX6955AAX

36 SSOP A36-2

MAX6955ATL+

T4066- 5

Pin Configurations and Typical Operating Circuits appear

at end of data sheet.

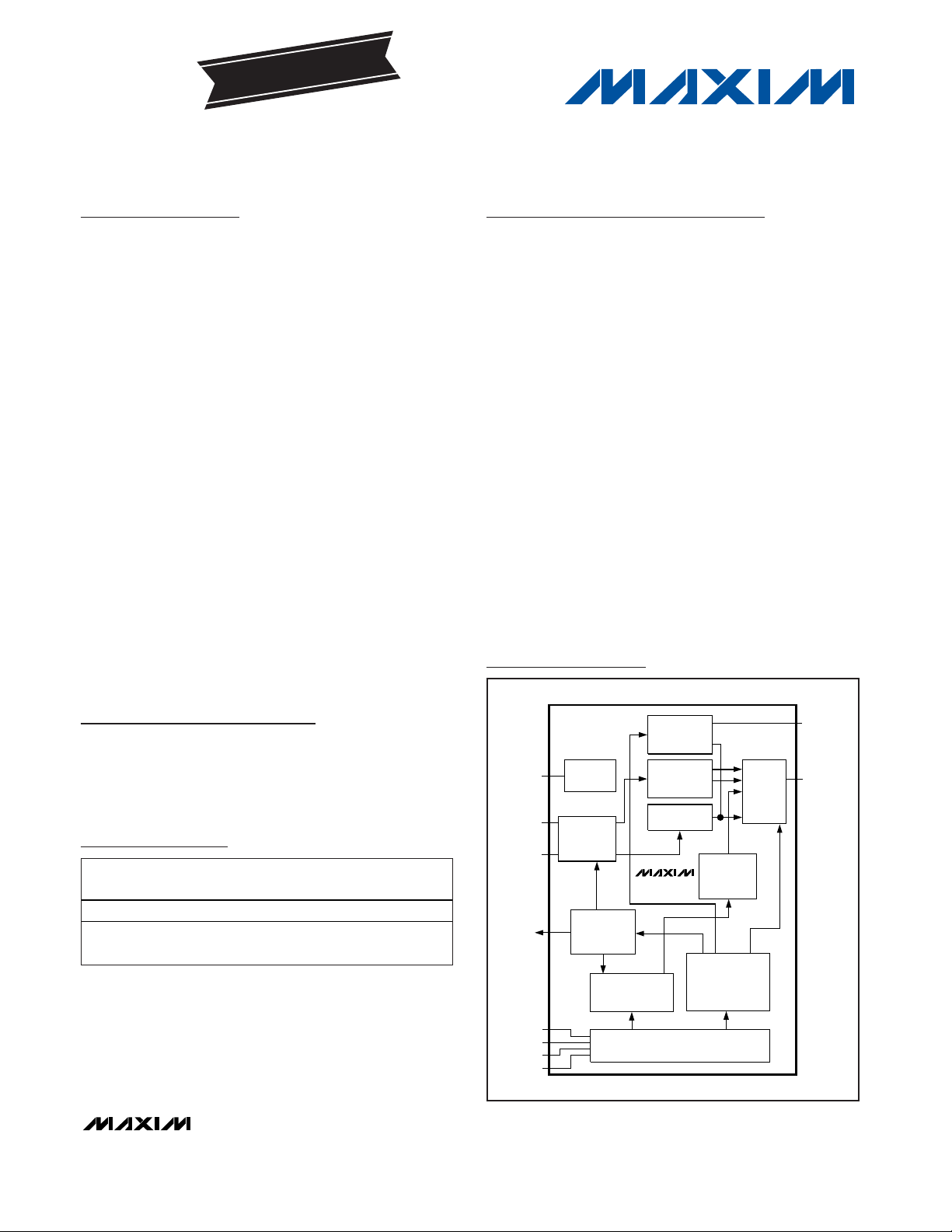

ISET

OSC

OSC_OUT

BLINK

SCL

AD0

AD1

SDA

2-WIRE SERIAL INTERFACE

RAM

BLINK

CONTROL

CONFIGURATION

REGISTER

CHARACTER

GENERATOR

ROM

CURRENT

SOURCE

DIVIDER/

COUNTER

NETWORK

DIGIT

MULTIPLEXER

PWM

BRIGHTNESS

CONTROL

GPIO

AND KEY-SCAN

CONTROL

LED

DRIVERS

O0 TO O18

P0 TO P4

MAX6955

Functional Diagram

EVALUATION KIT

AVAILABLE

SPI is a trademark of Motorola, Inc.

*EP = Exposed paddle.

+Denotes lead-free package.

-40°C to +125°C

-40°C to +125°C

40 TQFN-EP*

(6mm x 6mm)

Page 2

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Voltage (with Respect to GND)

V+ .........................................................................-0.3V to +6V

SCL, SDA, AD0, AD1 ...........................................-0.3V to +6V

All Other Pins............................................-0.3V to (V+ + 0.3V)

Current

O0–O7 Sink Current ......................................................935mA

O0–O18 Source Current .................................................55mA

SCL, SDA, AD0, AD1, BLINK, OSC, OSC_OUT, ISET ....20mA

P0, P1, P2, P3, P4 ...........................................................40mA

GND .....................................................................................1A

Continuous Power Dissipation (T

A

= +70°C)

36-Pin SSOP (derate at 11.8mW/°C above +70°C) .....941mW

40-Pin TQFN (derate at 25.6mW/°C above +70°C)....2051.3mW

Operating Temperature Range

(T

MIN

to T

MAX

) ...............................................-40°C to +125°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

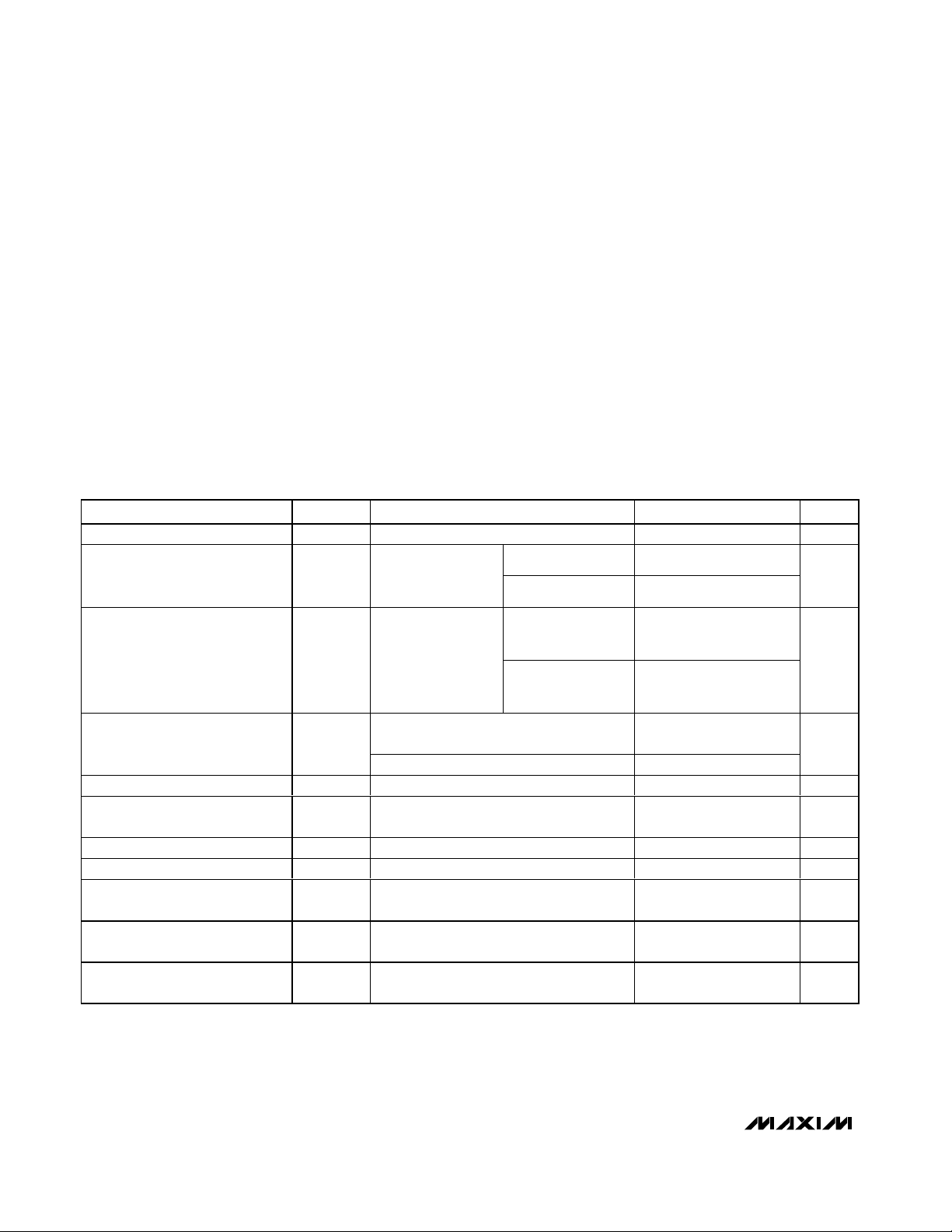

DC ELECTRICAL CHARACTERISTICS

(Typical Operating Circuit, V+ = 2.7V to 5.5V, TA= T

MIN

to T

MAX

, unless otherwise noted.) (Note 1)

PARAMETER

CONDITIONS

UNITS

Operating Supply Voltage V+ 2.7 5.5 V

TA = +25°C 10 35

Shutdown Supply Current I

SHDN

Shutdown mode, all

digital inputs at V+

or GND

T

A

= T

MIN

to T

MAX

40

µA

TA = +25°C 22 30

Operating Supply Current I+

All segments on, all

digits scanned,

intensity set to full,

internal oscillator, no

display or OSC_OUT

load connected

T

A

= T

MIN

to T

MAX

35

mA

OSC = RC oscillator, R

SET

= 56kΩ,

C

SET

= 22pF, V+ = 3.3V

4

Master Clock Frequency f

OSC

OSC driven externally 1 8

MHz

Dead Clock Protection Frequency

f

OSC

95 kHz

OSC Internal/External Detection

Threshold

V

OSC

1.7 V

OSC High Time t

CH

50 ns

OSC Low Time t

CL

50 ns

Slow Segment Blink Period

OSC = RC oscillator, R

SET

= 56kΩ,

C

SET

= 22pF, V+ = 3.3V

1s

Fast Segment Blink Period

OSC = RC oscillator, R

SET

= 56kΩ,

C

SET

= 22pF, V+ = 3.3V

0.5 s

Fast or Slow Segment Blink Duty

Cycle

%

SYMBOL

MIN TYP MAX

f

SLOWBLINK

f

FASTBLINK

49.5 50.5

Page 3

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

_______________________________________________________________________________________ 3

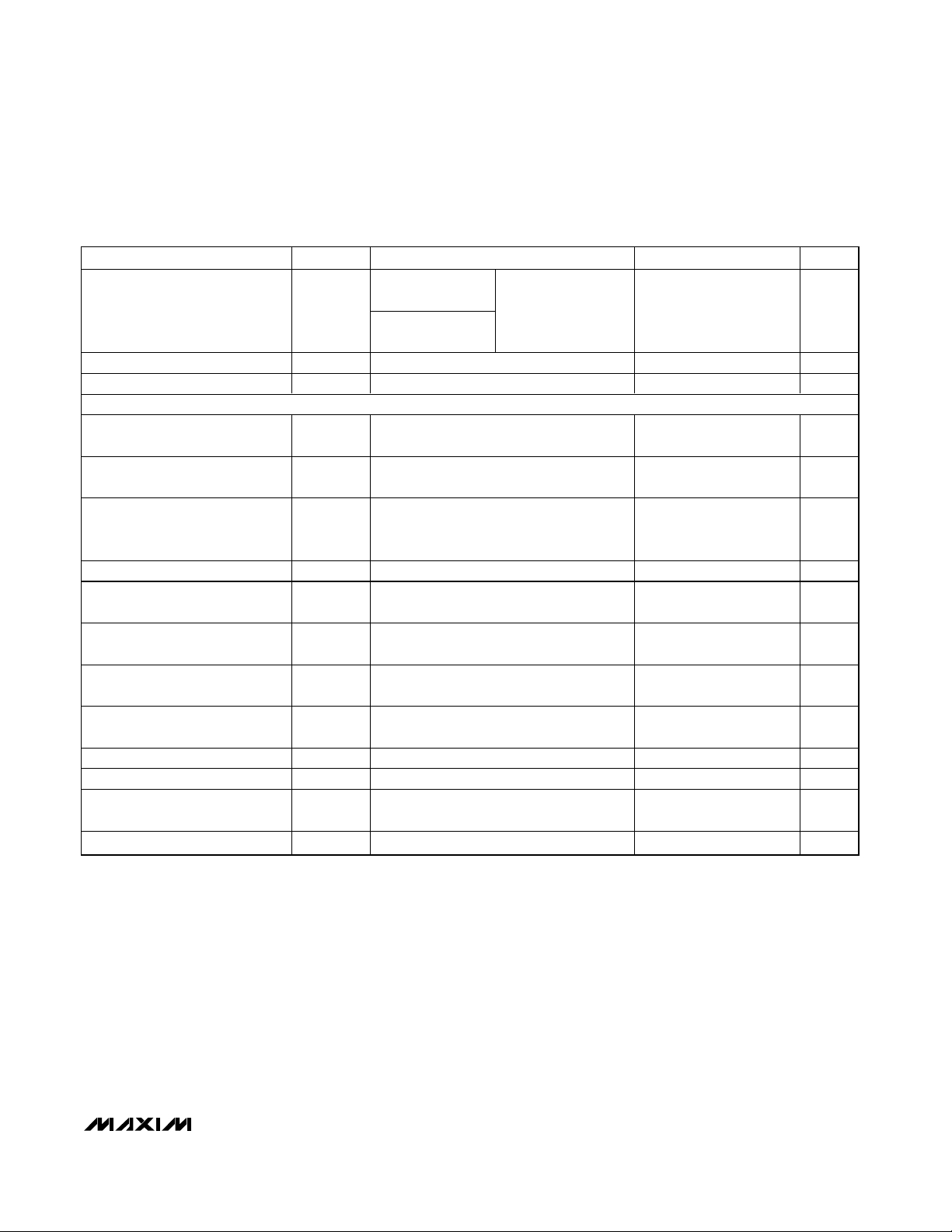

DC ELECTRICAL CHARACTERISTICS (continued)

(Typical Operating Circuit, V+ = 2.7V to 5.5V, TA= T

MIN

to T

MAX

, unless otherwise noted.) (Note 1)

PARAMETER

CONDITIONS

UNITS

V

LED

= 2.2V,

V+

= 3.3V

Segment Drive Source Current I

SEG

V

LED

= 2.2V,

V+

= 2.7V

T

A

= +25°C -32 -40 -48 mA

Segment Current Slew Rate

TA = +25°C, V+ = 3.3V 11

mA/µs

Segment Drive Current Matching

∆I

SEG

TA = +25°C, V+ = 3.3V 5 %

LOGIC INPUTS AND OUTPUTS

Input High Voltage

SDA, SCL, AD0, AD1

V

IH

0.7 x

V+

V

Input Low Voltage

SDA, SCL, AD0, AD1

V

IL

0.3 x

V+

V

Input Leakage Current

SDA, SCL, AD0, AD1, OSC, P0,

P1, P2, P3, P4

I

IH

, I

IL

-1 +1 µA

SDA Output Low Voltage V

OLSDAISINK

= 6mA 0.4 V

Port Logic-High Input Voltage

P0, P1, P2, P3, P4

V

IHP

0.7 x

V+

V

Port Logic-Low Input Voltage

P0, P1, P2, P3, P4

V

ILP

0.3 x

V+

V

Port Hysteresis Voltage

P0, P1, P2, P3, P4

∆V

IP

0.03 x

V+

V

Port Input Pullup Current from V+

I

IPU

P0 to P3 configured as key-scan inputs,

V+ = 3.3V

75 µA

Port Output Low Voltage V

OLP

I

SINK

= 8mA 0.3 0.5 V

Blink Output Low Voltage V

OLBKISINK

= 0.6mA 0.1 0.3 V

OSC_OUT Output High Voltage

I

SOURCE

= 1.6mA

V+ -

0.4

V

OSC_OUT Output Low Voltage

I

SINK

= 1.6mA 0.4 V

SYMBOL

∆I

SEG

/∆t

MIN TYP MAX

V

OHOSC

V

OLOSC

Page 4

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

4 _______________________________________________________________________________________

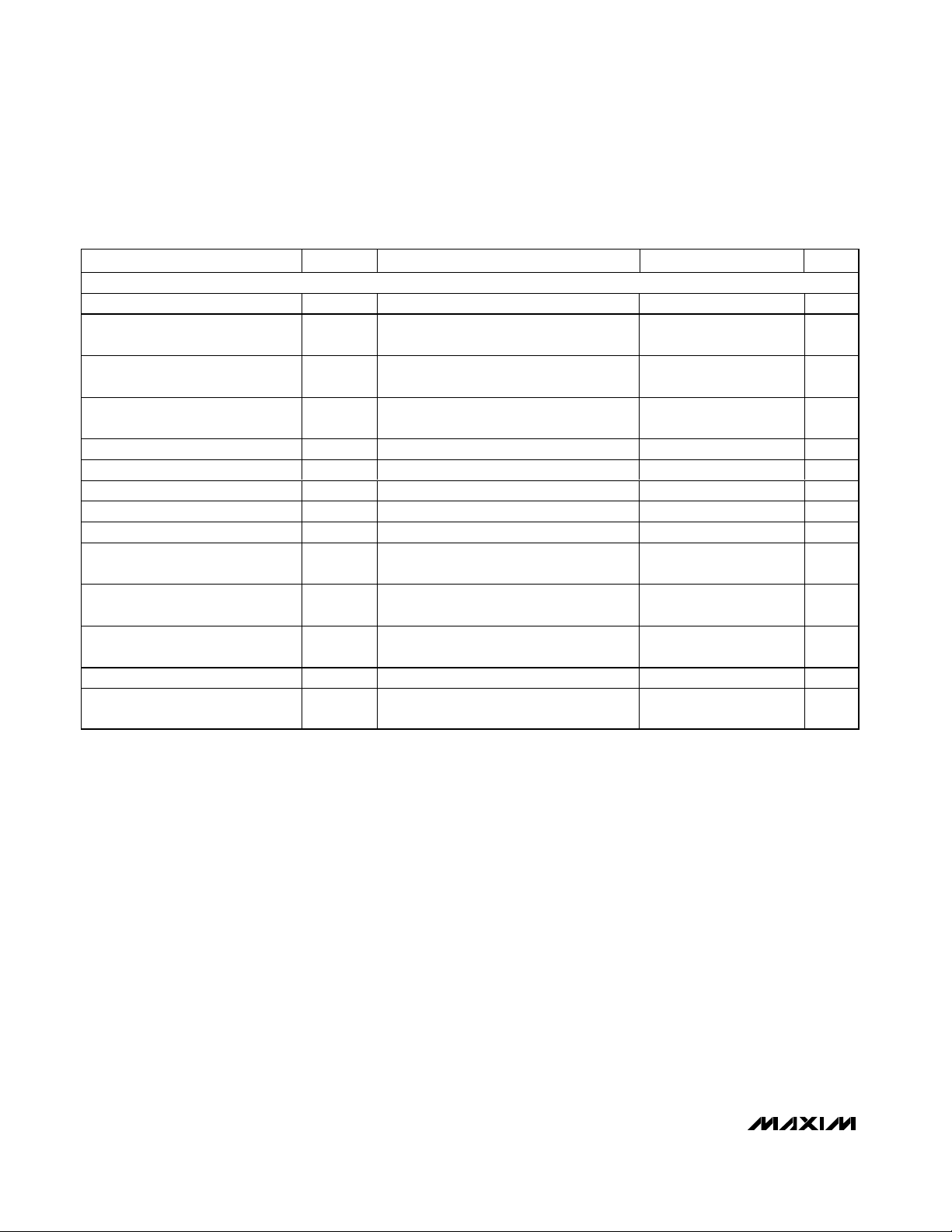

TIMING CHARACTERISTICS

(Typical Operating Circuit, V+ = 2.7V to 5.5V, TA= T

MIN

to T

MAX

, unless otherwise noted.) (Note 1)

PARAMETER

CONDITIONS

UNITS

TIMING CHARACTERISTICS

Serial Clock Frequency f

SCL

kHz

Bus Free Time Between a STOP

and a START Condition

t

BUF

1.3 µs

Hold Time (Repeated) START

Condition

,

0.6 µs

Repeated START Condition Setup

Time

0.6 µs

STOP Condition Setup Time

0.6 µs

Data Hold Time

(Note 3) 0.9 µs

Data Setup Time

ns

SCL Clock Low Period t

LOW

1.3 µs

SCL Clock High Period t

HIGH

0.6 µs

Rise Time of Both SDA and SCL

Signals, Receiving

t

R

(Notes 2, 4)

20 +

ns

Fall Time of Both SDA and SCL

Signals, Receiving

t

F

(Notes 2, 4)

20 +

ns

Fall Time of SDA Transmitting tF, t

X

(Notes 2, 5)

20 +

ns

Pulse Width of Spike Suppressed t

SP

(Notes 2, 6) 0 50 ns

Capacitive Load for Each

Bus Line

C

B

(Note 2)

pF

Note 1: All parameters tested at TA= +25°C. Specifications over temperature are guaranteed by design.

Note 2: Guaranteed by design.

Note 3: A master device must provide a hold time of at least 300ns for the SDA signal (referred to V

IL

- of the SCL signal) in order to

bridge the undefined region of SCL’s falling edge.

Note 4: C

B

= total capacitance of one bus line in pF. tRand tFmeasured between 0.3V+ and 0.7V+.

Note 5: I

SINK

≤ 6mA. CB= total capacitance of one bus line in pF. tRand tFmeasured between 0.3V+ and 0.7V+.

Note 6: Input filters on the SDA and SCL inputs suppress noise spikes less than 50ns.

SYMBOL

MIN TYP MAX

400

t

t

HD

STA

tSU, t

STA

t

SU:STO

tHD, t

DAT

tSU, t

DAT

100

B

B

B

300

300

300

0.1C

0.1C

0.1C

400

Page 5

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

_______________________________________________________________________________________ 5

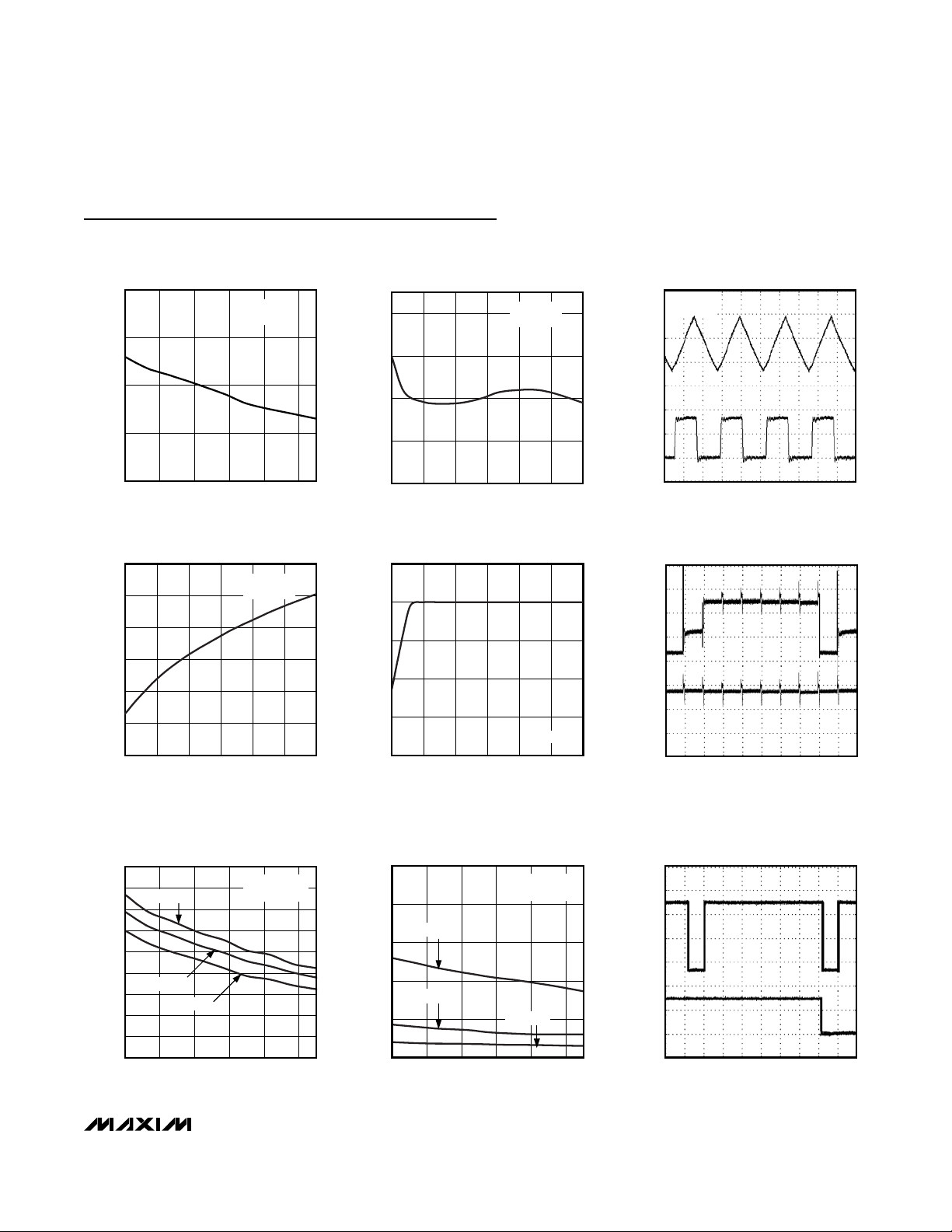

Typical Operating Characteristics

(V+ = 3.3V, LED forward voltage = 2.4V, Typical Application Circuit, TA= +25°C, unless otherwise noted.)

INTERNAL OSCILLATOR FREQUENCY

vs. TEMPERATURE

MAX6955 toc01

TEMPERATURE (°C)

OSCILLATOR FREQUENCY (MHz)

110805020-10

3.8

4.0

4.2

4.4

3.6

-40

R

SET

= 56kΩ

C

SET

= 22pF

SUPPLY VOLTAGE (V)

5.04.54.03.53.02.5 5.5

INTERNAL OSCILLATOR FREQUENCY

vs. SUPPLY VOLTAGE

MAX6955 toc02

OSCILLATOR FREQUENCY (MHz)

3.8

4.0

4.2

4.4

3.6

R

SET

= 56kΩ

C

SET

= 22pF

100ns/div

OSC: 500mV/div

OSC_OUT: 2V/div

MAX6954 toc03

OSC

0V

0V

OSC_OUT

INTERNAL OSCILLATOR WAVEFORM

AT OSC AND OSC_OUT PINS

R

SET

= 56kΩ

C

SET

= 22pF

DEAD CLOCK OSCILLATOR FREQUENCY

vs. SUPPLY VOLTAGE

85

90

95

100

105

110

80

SUPPLY VOLTAGE (V)

5.04.54.03.53.02.5 5.5

MAX6955 toc04

OSCILLATOR FREQUENCY (MHz)

R

SET

= 56kΩ

C

SET

= GND

CURRENT NORMALIZED TO 40mA

0.94

0.96

0.98

1.00

1.02

0.92

SEGMENT SOURCE CURRENT

vs. SUPPLY VOLTAGE

SUPPLY VOLTAGE (V)

5.04.54.03.53.02.5 5.5

MAX6955 toc05

V

LED

= 1.8V

1V/div

200µs/div

MAX6954 toc06

O0

O18

WAVEFORM AT PINS O0 AND O18,

MAXIMUM INTENSITY

0V

0V

GPIO SINK CURRENT

vs. TEMPERATURE

MAX 6955 toc07

TEMPERATURE (°C)

GPIO SINK CURRENT (mA)

110805020-10

5

10

15

20

25

30

35

40

45

0

-40

VCC = 5.5V

VCC = 3.3V

VCC = 2.5V

OUTPUT = LOW

V

PORT

= 0.6V

PORT INPUT PULLUP CURRENT

vs. TEMPERATURE

MAX6955 toc08

TEMPERATURE (°C)

KEY-SCAN SOURCE CURRENT (mA)

110805020-10

0.1

0.2

0.3

0.4

0.5

0

-40

VCC = 5.5V

VCC = 3.3V

VCC = 2.5V

OUTPUT = HIGH

V

PORT

= 1.4V

400µs/div

KEY_A: 1V/div

IRQ: 2V/div

MAX6954 toc09

KEY_A

0V

0V

IRQ

KEY-SCAN OPERATION

(KEY_A AND IRQ)

Page 6

MAX6955

Detailed Description

The MAX6955 is a serially interfaced display driver that

can drive up to 16 digits 7-segment, 8 digits 14-segment, 8 digits 16-segment, 128 discrete LEDs, or a

combination of these display types. Table 1 shows the

drive capability of the MAX6955 for monocolor and

bicolor displays.

The MAX6955 includes 104-character ASCII font maps

for 14-segment and 16-segment displays, as well as

the hexadecimal font map for 7-segment displays. The

characters follow the standard ASCII font, with the addition of the following common symbols: £, A€ , ¥, °, µ, ±,

↑, and ↓. Seven bits represent the 104-character font

map; an 8th bit is used to select whether the decimal

point (DP) is lit. Seven-segment LED digits can be controlled directly or use the hexadecimal font. Direct segment control allows the MAX6955 to be used to drive

bar graphs and discrete LED indicators.

Tables 2, 3, and 4 list the connection schemes for 16-,

14-, and 7-segment digits, respectively. The letters in

Tables 2, 3, and 4 correspond to the segment labels

shown in Figure 1. (For applications that require mixed

display types, see Tables 38–41.)

Serial Interface

Serial Addressing

The MAX6955 operates as a slave that sends and

receives data through an I2C-compatible 2-wire interface. The interface uses a serial data line (SDA) and a

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

6 _______________________________________________________________________________________

Pin Description

PIN

SSOP

NAME FUNCTION

1, 2,

34, 35, 36

36, 37,

P0–P4

General-Purpose I/O Ports (GPIOs). GPIO can be configured as logic inputs or open-drain

outputs. Enabling key scanning configures some or all ports P0–P3 as key-switch matrix inputs

with internal pullup and port P4 as IRQ output.

3 38 AD0

Address Input 0. Sets device slave address. Connect to GND, V+, SCL, or SDA to give four

logic combinations. See Table 5.

4 39 SDA I2C-Compatible Serial Data I/O

5 40 SCL I2C-Compatible Serial Clock Input

6 1 AD1

Address Input 1. Sets device slave address. Connect to GND, V+, SCL, or SDA to give four

logic combinations. See Table 5.

7–15,

22–31

2–10,

21–30

Digit/Segment Drivers. When acting as digit drivers, outputs O0 to O7 sink current from the

display common cathodes. When acting as segment drivers, O0 to O18 source current to the

display anodes. O0 to O18 are high impedance when not being used as digit or segment

drivers.

16, 18

GND Ground

17 14 ISET

Segment Current Setting. Connect ISET to GND through series resistor R

SET

to set the peak

current.

19, 21

V+

Positive Supply Voltage. Bypass V+ to GND with a 47µF bulk capacitor and a 0.1µF ceramic

capacitor.

20 17 OSC

Multiplex Clock Input. To use internal oscillator, connect capacitor C

SET

from OSC to GND.

To use external clock, drive OSC with a 1MHz to 8MHz CMOS clock.

32 31 BLINK Blink Clock Output. Output is open drain.

33 32

Clock Output. OSC_OUT is a buffered clock output to allow easy blink synchronization of

multiple MAX6955s. Output is push-pull.

—

N.C. Not Internally Connected

—EP EP

Exposed Paddle. Internally connected to GND. Connect to a large ground plane to improve

thermal performance.

TQFN

33, 34, 35

O0–O18

12, 13, 15

16, 18, 19

11, 20

OSC_OUT

Page 7

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

_______________________________________________________________________________________ 7

serial clock line (SCL) to achieve bidirectional communication between master(s) and slave(s). A master (typically a microcontroller) initiates all data transfers to and

from the MAX6955, and generates the SCL clock that

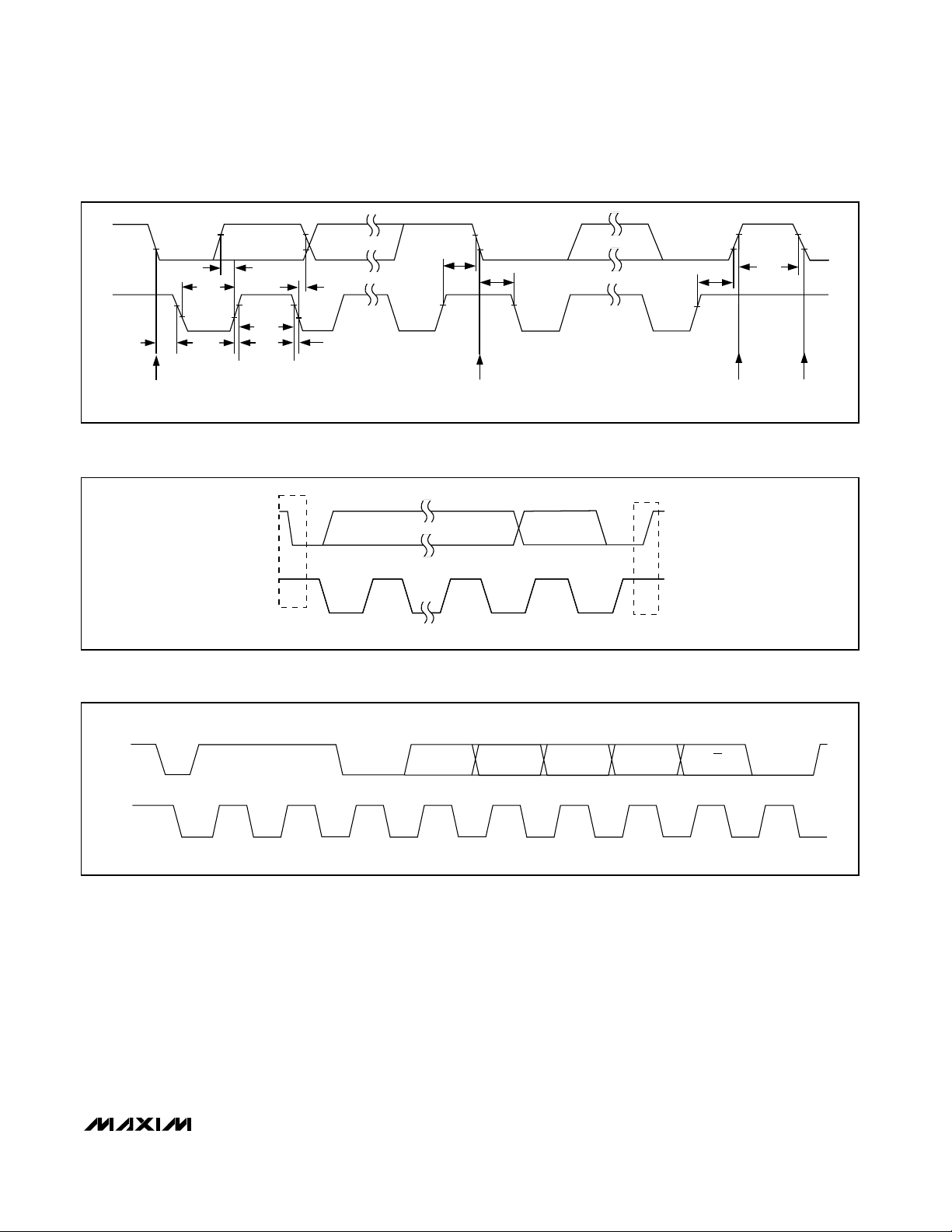

synchronizes the data transfer (Figure 2).

The MAX6955 SDA line operates as both an input and

an open-drain output. A pullup resistor, typically 4.7kΩ,

is required on the SDA. The MAX6955 SCL line operates only as an input. A pullup resistor, typically 4.7kΩ,

is required on SCL if there are multiple masters on the

2-wire interface, or if the master in a single-master system has an open-drain SCL output.

Each transmission consists of a START condition

(Figure 3) sent by a master, followed by the MAX6955

7-bit slave address plus R/W bit (Figure 4), a register

address byte, 1 or more data bytes, and finally a STOP

condition (Figure 3).

Start and Stop Conditions

Both SCL and SDA remain high when the interface is

not busy. A master signals the beginning of a transmission with a START (S) condition by transitioning SDA

from high to low while SCL is high. When the master

has finished communicating with the slave, it issues a

STOP (P) condition by transitioning the SDA from low to

high while SCL is high. The bus is then free for another

transmission (Figure 3).

Bit Transfer

One data bit is transferred during each clock pulse.

The data on the SDA line must remain stable while SCL

is high (Figure 5).

Acknowledge

The acknowledge bit is a clocked 9th bit that the recipient

uses to handshake receipt of each byte of data (Figure 6).

Thus, each byte transferred effectively requires 9 bits. The

master generates the 9th clock pulse, and the recipient

pulls down SDA during the acknowledge clock pulse, such

that the SDA line is stable low during the high period of the

clock pulse. When the master is transmitting to the

MAX6955, the MAX6955 generates the acknowledge bit

because the MAX6955 is the recipient. When the MAX6955

is transmitting to the master, the master generates the

acknowledge bit because the master is the recipient.

Slave Address

The MAX6955 has a 7-bit-long slave address (Figure

4). The eighth bit following the 7-bit slave address is the

R/W bit. It is low for a write command, high for a read

command.

The first 3 bits (MSBs) of the MAX6955 slave address

are always 110. Slave address bits A3, A2, A1, and A0

are selected by the address input pins AD1 and AD0.

These two input pins can be connected to GND, V+,

SDA, or SCL. The MAX6955 has 16 possible slave

addresses (Table 5) and therefore a maximum of 16

MAX6955 devices can share the same interface.

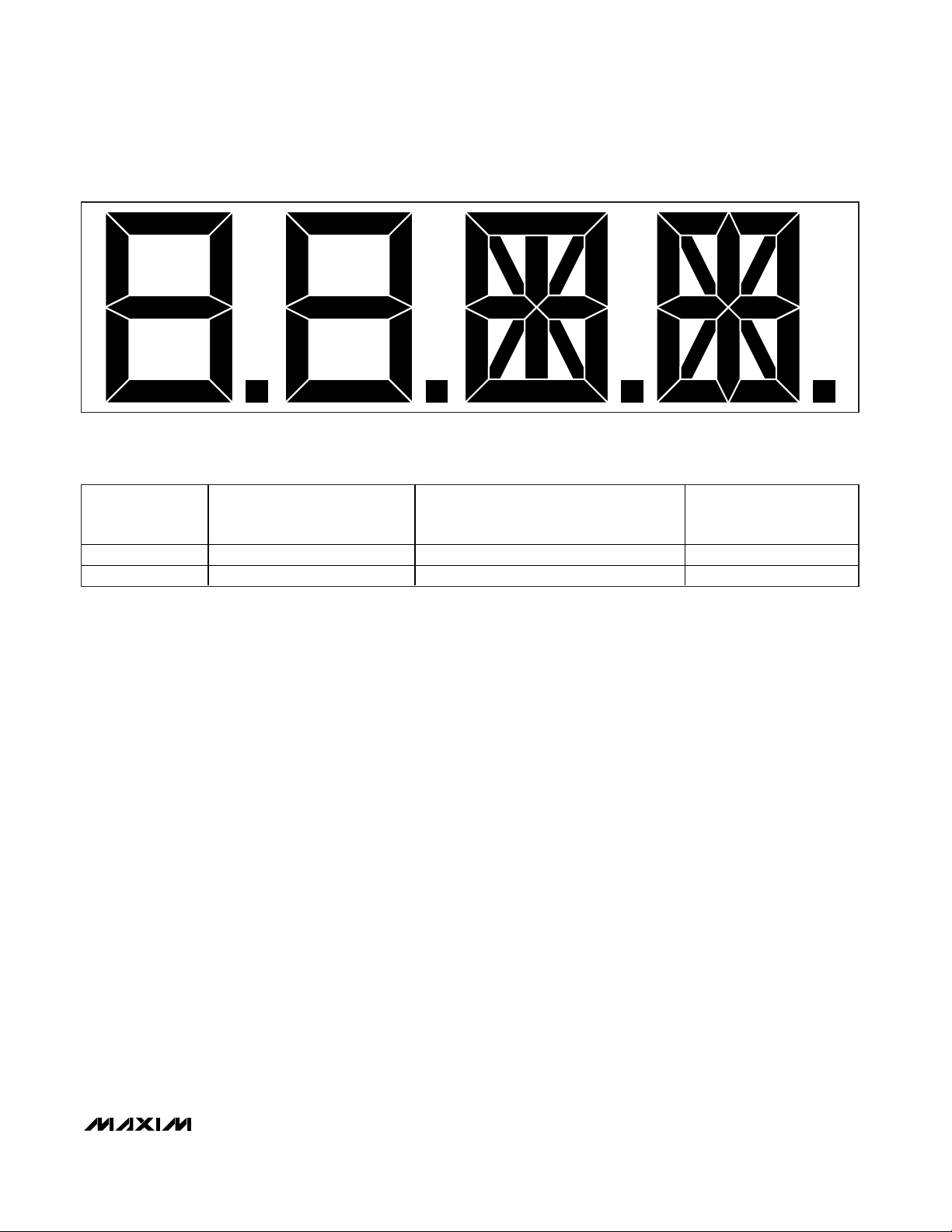

DISPLAY TYPE

7 SEGMENT

(16-CHARACTER

HEXADECIMAL FONT)

14 SEGMENT/

16 SEGMENT

(104-CHARACTER ASCII FONT MAP)

DISCRETE LEDs

(DIRECT CONTROL)

Monocolor 16 8 128

Bicolor 8 4 64

Table 1. MAX6955 Drive Capability

1dp

2dp

fb

ec

d2

a1

i

l

g1 g2

hj

mk

a2

d1

dp dp

1a

1g

1f

1b

1e 1c

1d

2a

2g

2f 2b

2e 2c

2d

fb

ec

d

a

i

l

g1 g2

hj

mk

Figure 1. Segment Labeling for 7-Segment Display, 14-Segment Display, and 16-Segment Display

Page 8

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

8 _______________________________________________________________________________________

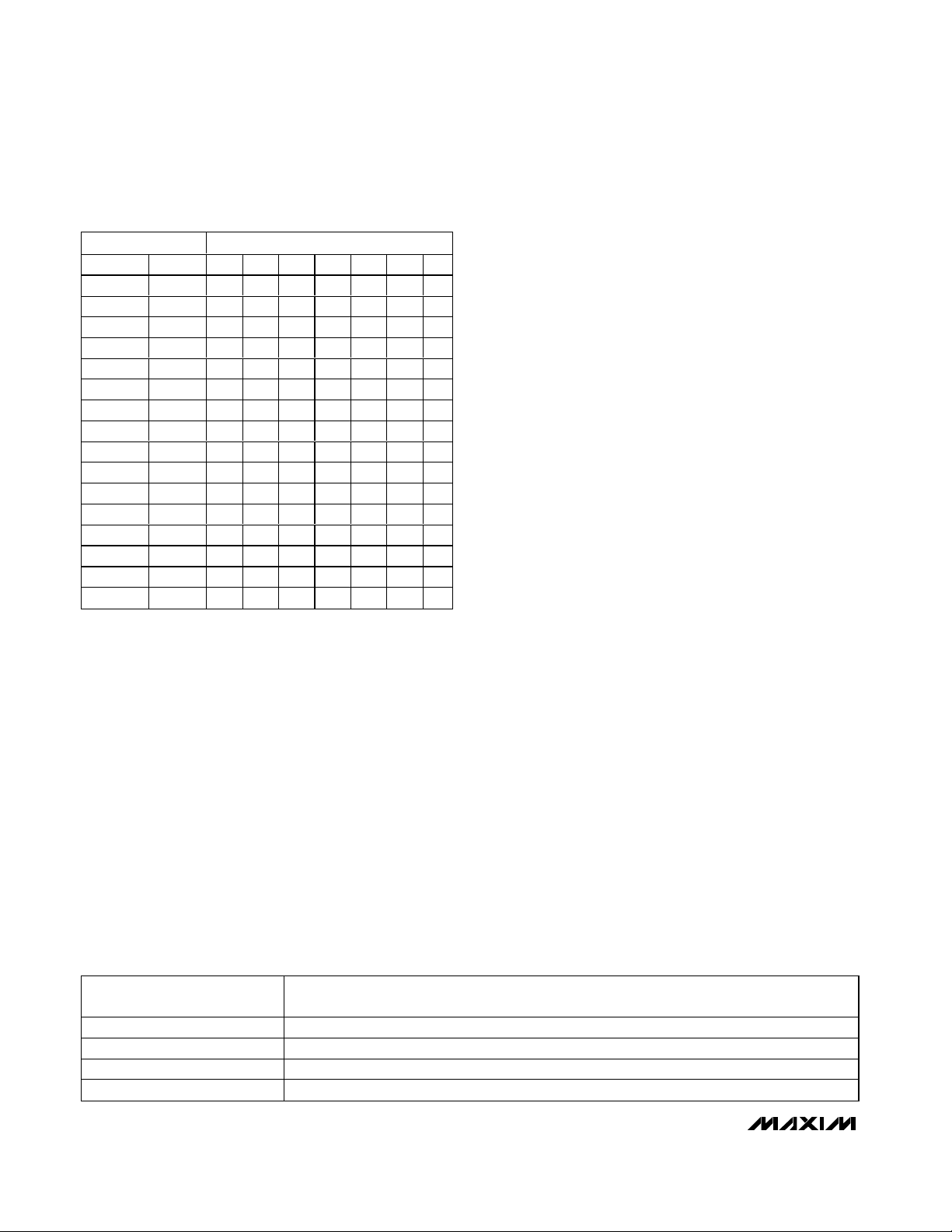

Message Format for Writing

A write to the MAX6955 comprises the transmission of

the MAX6955’s slave address with the R/W bit set to

zero, followed by at least 1 byte of information. The first

byte of information is the command byte, which determines which register of the MAX6955 is to be written by

the next byte, if received. If a STOP condition is detected after the command byte is received, then the

MAX6955 takes no further action (Figure 7) beyond

storing the command byte.

Any bytes received after the command byte are data

bytes. The first data byte goes into the internal register of

the MAX6955 selected by the command byte (Figure 8).

If multiple data bytes are transmitted before a STOP

condition is detected, these bytes are generally stored

in subsequent MAX6955 internal registers because the

command byte address generally autoincrements

(Table 6) (Figure 9).

DIGIT

O18

0

f

ij

l

dp

1

f

ij

l

dp

2

f

ij

l

dp

3

f

ij

l

dp

4

f

ij

l

dp

5

f

ij

l

dp

6

f

ij

l

dp

7

f

ij

l

dp

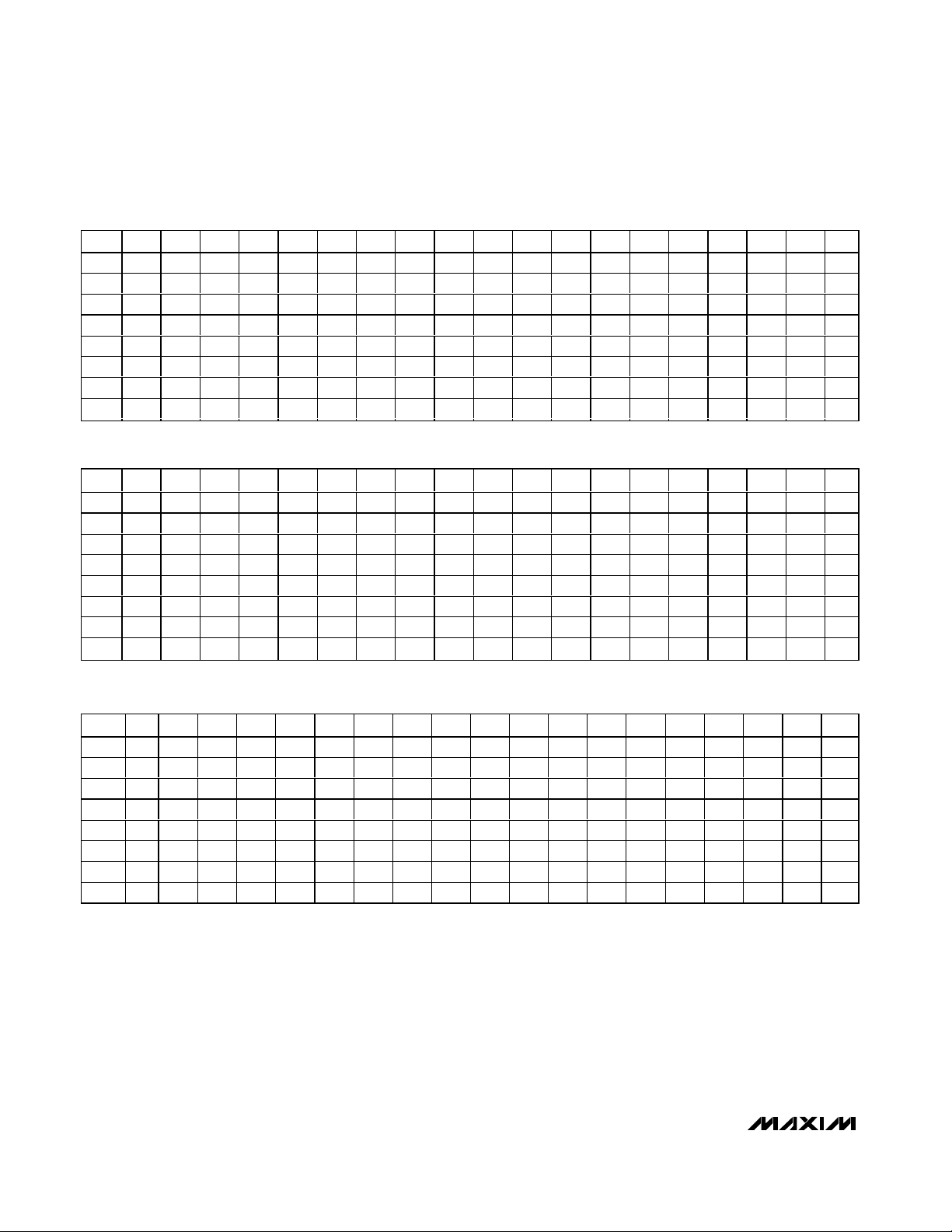

Table 2. Connection Scheme for Eight 16-Segment Digits

Table 3. Connection Scheme for Eight 14-Segment Digits

DIGIT

O18

0, 0a

2dp

1, 1a

2dp

2, 2a

2dp

3, 3a

2dp

4, 4a

2dp

5, 5a

2dp

6, 6a

2dp

7, 7a

2dp

Table 4. Connection Scheme for Sixteen 7-Segment Digits

O0 O1 O2 O3 O4 O5 O6 O7 O8 O9 O10 O11 O12 O13 O14 O15 O16 O17

CCO — a1 a2 b c d1 d2 e

— CC1 a1 a2 b c d1 d2 e

a1 a2 CC2 — b c d1 d2 e

a1 a2 — CC3 b c d1 d2 e

a1 a2 b c CC4 — d1 d2 e

a1 a2 b c — CC5 d1 d2 e

a1 a2 b c d1 d2 CC6 — e

a1 a2 b c d1 d2 — CC7 e

DIGIT O0 O1 O2 O3 O4 O5 O6 O7 O8 O9 O10 O11 O12 O13 O14 O15 O16 O17 O18

0 CCO — a — b c d — e f g1 g2 h i j k l m dp

1 — CC1 a — b c d — e f g1 g2 h i j k l m dp

2 a — CC2 — b c d — e f g1 g2 h i j k l m dp

3 a — — CC3 b c d — e f g1 g2 h i j k l m dp

4 a—b cCC4—d—e fg1g2h i j k l mdp

5 a — b c — CC5 d — e f g1 g2 h i j k l m dp

6 a—b c d—CC6—e fg1g2h i j k l mdp

7 a — b c d — — CC7 e f g1 g2 h i j k l m dp

g1 g2 h

g1 g2 h

g1 g2 h

g1 g2 h

g1 g2 h

g1 g2 h

g1 g2 h

g1 g2 h

k

k

k

k

k

k

k

k

m

m

m

m

m

m

m

m

O0 O1 O2 O3 O4 O5 O6 O7 O8 O9 O10 O11 O12 O13 O14 O15 O16 O17

CC0 — 1a — 1b 1c 1d 1dp 1e 1f 1g 2a 2b 2c 2d 2e 2f 2g

— CC1 1a — 1b 1c 1d 1dp 1e 1f 1g 2a 2b 2c 2d 2e 2f 2g

1a — CC2 — 1b 1c 1d 1dp 1e 1f 1g 2a 2b 2c 2d 2e 2f 2g

1a — — CC3 1b 1c 1d 1dp 1e 1f 1g 2a 2b 2c 2d 2e 2f 2g

1a — 1b 1c CC4 — 1d 1dp 1e 1f 1g 2a 2b 2c 2d 2e 2f 2g

1a — 1b 1c — CC5 1d 1dp 1e 1f 1g 2a 2b 2c 2d 2e 2f 2g

1a—1b1c1d1dpCC6— 1e 1f 1g2a2b2c2d2e2f 2g

1a — 1b 1c 1d 1dp — CC7 1e 1f 1g 2a 2b 2c 2d 2e 2f 2g

Page 9

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

_______________________________________________________________________________________ 9

SDA

START CONDITION STOP CONDITION

SCL

S

P

Figure 3. Start and Stop Conditions

Figure 4. Slave Address

SDA

t

LOW

t

BUF

t

SU, DAT

t

SU, STA

t

HD, STA

t

SU, STO

t

HD, DAT

t

HIGH

t

R

t

F

SCL

START

CONDITION

START

CONDITION

STOP

CONDITION

REPEATED START

CONDITION

t

HD, STA

Figure 2. 2-Wire Serial Interface Timing Details

SDA

SCL

1

MSBSTART

1

0

A3

A2

A1 A0

LSB

R/W

ACK

Page 10

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

10 ______________________________________________________________________________________

Message Format for Reading

The MAX6955 is read using the MAX6955’s internally

stored command byte as address pointer, the same

way the stored command byte is used as address

pointer for a write. The pointer generally autoincrements after each data byte is read using the same rules

as for a write (Table 6). Thus, a read is initiated by first

configuring the MAX6955’s command byte by performing a write (Figure 7). The master can now read n consecutive bytes from the MAX6955, with the first data

byte being read from the register addressed by the initialized command byte (Figure 9). When performing

read-after-write verification, reset the command byte’s

address because the stored byte address generally is

autoincremented after the write (Table 6).

Operation with Multiple Masters

If the MAX6955 is operated on a 2-wire interface with

multiple masters, a master reading the MAX6955

should use a repeated start between the write, which

sets the MAX6955’s address pointer, and the read(s)

that takes the data from the location(s). This is because

it is possible for master 2 to take over the bus after

master 1 has set up the MAX6955’s address pointer but

before master 1 has read the data. If master 2 subsequently changes the MAX6955’s address pointer, then

master 1’s delayed read may be from an unexpected

location.

Command Address Autoincrementing

Address autoincrementing allows the MAX6955 to be

configured with the shortest number of transmissions by

minimizing the number of times the command byte

needs to be sent. The command address or the font

pointer address stored in the MAX6955 generally increments after each data byte is written or read (Table 6).

To utilize the autoincrement read cycle feature, the master clocks SCL after the first data byte is read, and the

MAX6955 continues sending data, incrementing the

pointer after each byte is sent. A not-acknowledge or

stop condition halts autoincrement.

Digit Type Registers

The MAX6955 uses 32 digit registers to store the characters that the user wishes to display. These digit registers are implemented with two planes, P0 and P1. Each

digit is represented by 2 bytes of memory, 1 byte in

plane P0 and the other in plane P1. The digit registers

are mapped so that a digit’s data can be updated in

plane P0, plane P1, or both planes at the same time

(Table 7).

If the blink function is disabled through the Blink Enable

Bit E (Table 20) in the configuration register, then the

digit register data in plane P0 is used to multiplex the

display. The digit register data in P1 is not used. If the

blink function is enabled, then the digit register data in

both plane P0 and plane P1 are alternately used to multiplex the display. Blinking is achieved by multiplexing

the LED display using data plane P0 and plane P1 on

alternate phases of the blink clock (Table 21).

COMMAND BYTE

ADDRESS RANGE

AUTOINCREMENT BEHAVIOR

x0000000 to x0001100 Command byte address autoincrements after byte read or written.

x0001101 Factory reserved; do not write this register.

x0001111 to x1111110 Command byte address autoincrements after byte read or written.

x1111111 Command byte address remains at x1111111 after byte read or written.

Table 5. MAX6955 Address Map

Table 6. Command Address Autoincrement Rules

PIN CONNECTION

DEVICE ADDRESS

AD1

A0

GND

0

GND V+

1

GND

0

GND

1

V+

0

V+ V+

1

V+

0

V+

1

SDA

0

SDA V+

1

SDA

0

SDA

1

SCL

0

SCL V+

1

SCL

0

SCL

1

AD0 A6A5A4A3A2A1

GND110000

110000

SDA110001

SCL 110001

GND110010

110010

SDA110011

SCL 110011

GND110100

110100

SDA110101

SCL 110101

GND110110

110110

SDA110111

SCL 110111

Page 11

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

______________________________________________________________________________________ 11

The data in the digit registers does not control the digit

segments directly for 14- and 16-segment displays.

Instead, the register data is used to address a character generator that stores the data for the 14- and 16segment fonts (Tables 8 and 9). The lower 7 bits of the

digit data (D6 to D0) select the character from the font.

The most significant bit of the register data (D7) controls the DP segment of the digits; it is set to 1 to light

DP, and to zero to leave DP unlit (Table 10).

For 7-segment displays, the digit plane data register

can be used to address a character generator, which

contains the data of a 16-character font containing the

hexadecimal font. The decode mode register can be

used to disable the character generator and allow the

segments to be controlled directly. Table 11 shows the

one-to-one pairing of each data bit to the appropriate

segment line in the digit plane data registers. The hexadecimal font is decoded according to Table 12.

The digit-type register configures the display driver for

various combinations of 14-segment digits, 16-segment

digits, and/or pairs, or 7-segment digits. The function of

this register is to select the appropriate font for each

digit and route the output of the font to the appropriate

MAX6955 driver output pins. The MAX6955 has four

digit drive slots. A slot can be filled with various combinations of monocolor and bicolor 16-segment displays,

14-segment displays, or two 7-segment displays. Each

pair of bits in the register corresponds to one of the four

digit drive slots, as shown in Table 13. Each bit also corresponds to one of the eight common-cathode digit

drive outputs, CC0 to CC7. When using bicolor digits,

the anode connections for the two digits within a slot are

always the same. This means that a slot correctly drives

two monocolor or one bicolor 14- or 16-segment digit.

The digit type register can be written, but cannot be

read. Examples of configuration settings required for

some display digit combinations are shown in Table 14.

7-Segment Decode-Mode Register

In 7-segment mode, the hexadecimal font can be disabled (Table 15). The decode-mode register selects

between hexadecimal code or direct control for each of

eight possible pairs of 7-segment digits. Each bit in the

register corresponds to one pair of digits. The digit

pairs are {digit 0, digit 0a} through {digit 7, digit 7a}.

Disabling decode mode allows direct control of the 16

LEDs of a dual 7-segment display. Direct control mode

can also be used to drive a matrix of 128 discrete LEDs.

A logic high selects hexadecimal decoding, while a

logic low bypasses the decoder. When direct control is

selected, the data bits D7 to D0 correspond to the segment lines of the MAX6955. Write x0010000 to blank all

segments in hexadecimal decode mode.

Display Blink Mode

The display blinking facility, when enabled, makes the

driver flip automatically between displaying the digit

register data in planes P0 and P1. If the digit register

data for any digit is different in the two planes, then that

digit appears to flip between two characters. To make a

character appear to blink on or off, write the character

to one plane, and use the blank character (0x20) for the

other plane. Once blinking has been configured, it continues automatically without further intervention.

Blink Speed

The blink speed is determined by the frequency of the

multiplex clock, OSC, and by the setting of the Blink

Rate Selection Bit B (Table 19) in the configuration register. The Blink Rate Selection Bit B sets either fast or

slow blink speed for the whole display.

Initial Power-Up

On initial power-up, all control registers are reset, the

display is blanked, intensities are set to minimum, and

shutdown is enabled (Table 16).

Configuration Register

The configuration register is used to enter and exit shutdown, select the blink rate, globally enable and disable

the blink function, globally clear the digit data, select

between global or digit-by-digit control of intensity, and

reset the blink timing (Tables 17–20 and 22–25).

The configuration register contains 7 bits:

• S bit selects shutdown or normal operation

(read/write).

• B bit selects the blink rate (read/write).

• E bit globally enables or disables the blink function

(read/write).

• T bit resets the blink timing (data is not stored—transient bit).

• R bit globally clears the digit data for both planes P0

and P1 for ALL digits (data is not stored—transient bit).

• I bit selects between global or digit-by-digit control

of intensity (read/write).

• P bit returns the current phase of the blink timing

(read only—a write to this bit is ignored).

Character Generator Font Mapping

The font is composed of 104 characters in ROM. The

lower 7 bits of the 8-bit digit register represent the character selection. The most significant bit, shown as x in

the ROM map of Tables 8 and 9, is 1 to light the DP

segment and zero to leave the DP segment unlit.

The character map follows the standard ASCII font for

96 characters in the x0101000 through x1111111

Page 12

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

12 ______________________________________________________________________________________

range. The first 16 characters of the 16-segment ROM

map cover 7-segment displays. These 16 characters

are numeric 0 to 9 and characters A to F (i.e., the hexadecimal set).

Multiplex Clock and Blink Timing

The OSC pin can be fitted with capacitor C

SET

to GND to

use the internal RC multiplex oscillator, or driven by an

external clock to set the multiplex clock frequency and

blink rate. The multiplex clock frequency determines the

frequency that the complete display is updated. With

OSC at 4MHz, each display digit is enabled for 200µs.

The internal RC oscillator uses an external resistor,

R

SET

, and an external capacitor, C

SET

, to set the oscil-

lator frequency. The suggested values of R

SET

(56kΩ)

and C

SET

(22pF) set the oscillator at 4MHz, which

makes the blink frequency 0.5Hz or 1Hz.

The external clock is not required to have a 50:50 duty

cycle, but the minimum time between transitions must

be 50ns or greater and the maximum time between

transitions must be 750ns.

The on-chip oscillator may be accurate enough for

applications using a single device. If an exact blink rate

is required, use an external clock ranging between

1MHz and 8MHz to drive OSC. The OSC inputs of multiple MAX6955s can be connected to a common external

clock to make the devices blink at the same rate. The

relative blink phasing of multiple MAX6955s can be synchronized by setting the T bit in the control register for

all the devices in quick succession. If the serial interfaces of multiple MAX6955s are daisy-chained by connecting the DOUT of one device to the DIN of the next,

then synchronization is achieved automatically by

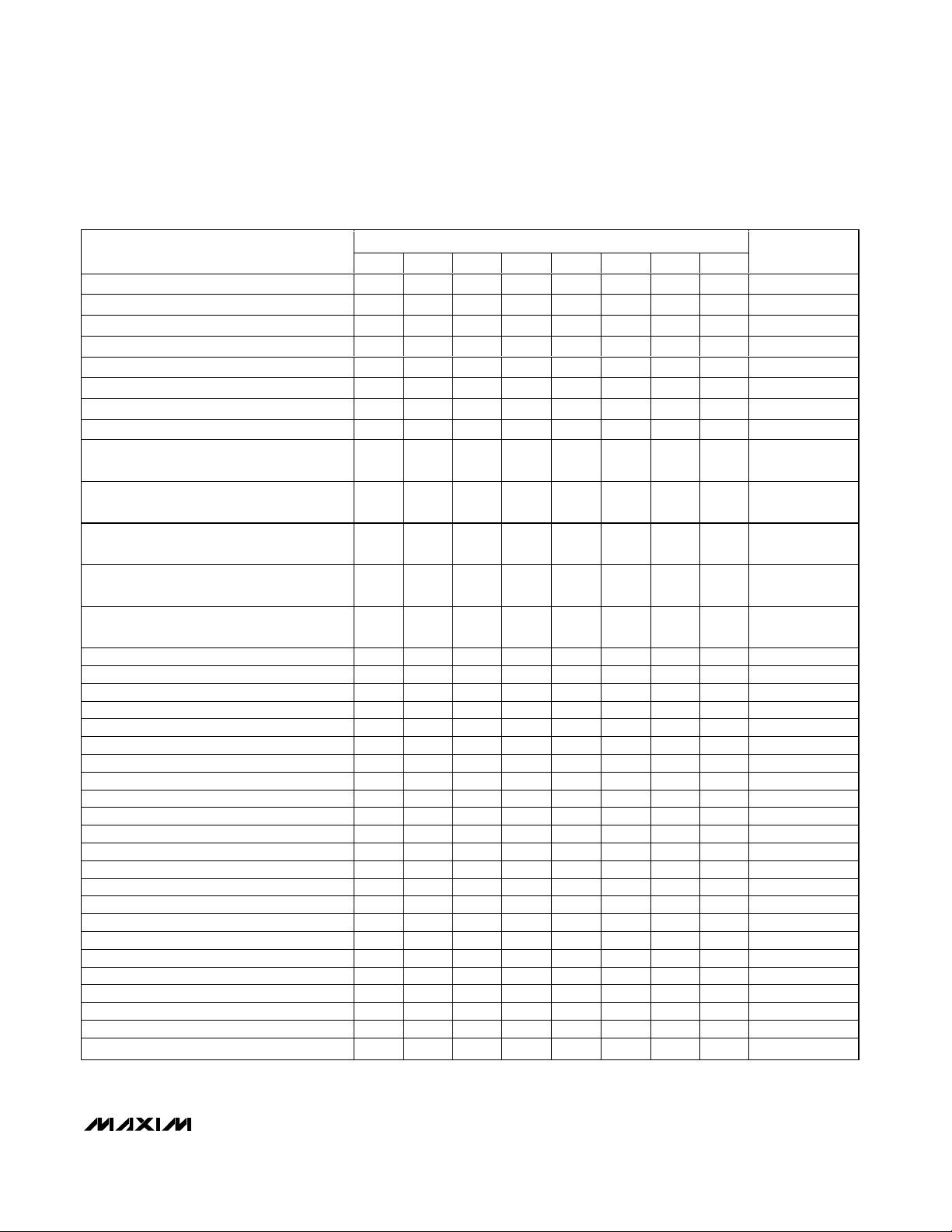

updating the configuration register for all devices simultaneously. Figure 10 is the multiplex timing diagram.

OSC_OUT Output

The OSC_OUT output is a buffered copy of either the

internal oscillator clock or the clock driven into the OSC

pin if the external clock has been selected. The feature

is useful if the internal oscillator is used, and the user

wishes to synchronize other MAX6955s to the same

blink frequency. The oscillator is disabled while the

MAX6955 is in shutdown.

Scan-Limit Register

The scan-limit register sets how many 14-segment digits or 16-segment digits or pairs of 7-segment digits are

displayed, from 1 to 8. A bicolor digit is connected as

two monocolor digits. The scan register also limits the

number of keys that can be scanned.

Since the number of scanned digits affects the display

brightness, the scan-limit register should not be used to

blank portions of the display (such as leading-zero suppression). Table 26 shows the scan-limit register format.

Intensity Registers

Digital control of display brightness is provided and

can be managed in one of two ways: globally or individually. Global control adjusts all digits together.

Individual control adjusts the digits separately.

The default method is global brightness control, which

is selected by clearing the global intensity bit (I data bit

D6) in the configuration register. This brightness setting

applies to all display digits. The pulse-width modulator

is then set by the lower nibble of the global intensity

register, address 0x02. The modulator scales the average segment current in 16 steps from a maximum of

15/16 down to 1/16 of the peak current. The minimum

interdigit blanking time is set to 1/16 of a cycle. When

using bicolor digits, 256 color/brightness combinations

are available.

Individual brightness control is selected by setting the

global intensity bit (I data bit D6) in the configuration

register. The pulse-width modulator is now no longer

set by the lower nibble of the global intensity register,

address 0x02, and the data is ignored. Individual digital control of display brightness is now provided by a

separate pulse-width modulator setting for each digit.

Each digit is controlled by a nibble of one of the four

intensity registers: intensity10, intensity32, intensity54,

and intensity76 for all display types, plus intensity10a,

intensity32a, intensity54a, and intensity76a for the extra

eight digits possible when 7-segment displays are

used. The data from the relevant register is used for

each digit as it is multiplexed. The modulator scales the

average segment current in 16 steps in exactly the

same way as global intensity adjustment.

Table 27 shows the global intensity register format. Table

28 shows individual segment intensity registers. Table 29

shows the even individual segment intensity format. Table

30 shows the odd individual segment intensity format.

GPIO and Key Scanning

The MAX6955 features five general-purpose input/output (GPIO) ports: P0 to P4. These ports can be individually enabled as logic inputs or open-drain logic

outputs. The GPIO ports are not debounced when configured as inputs. The ports can be read and the outputs set using the 2-wire interface.

Some or all of the five ports can be configured to perform key scanning of up to 32 keys. Ports P0 to P4 are

renamed Key_A, Key_B, Key_C, Key_D, and IRQ,

respectively, when used for key scanning. The full keyscanning configuration is shown in Figure 11. Table 31

is the GPIO data register.

Page 13

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

______________________________________________________________________________________ 13

ADDRESS (COMMAND BYTE)

REGISTER

HEX CODE

No-Op X 0 0 0 0 0 0 0 0x00

Decode Mode X 0 0 0 0 0 0 1 0x01

Global Intensity X 0 0 0 0 0 1 0 0x02

Scan Limit X 0 0 0 0 0 1 1 0x03

Configuration X 0 0 0 0 1 0 0 0x04

GPIO Data X 0 0 0 0 1 0 1 0x05

Port Configuration X 0 0 0 0 1 1 0 0x06

Display Test X 0 0 0 0 1 1 1 0x07

Write KEY_A Mask

Read KEY_A Debounce

X 0 0 0 1 0 0 0 0x08

Write KEY_B Mask

Read KEY_B Debounce

X 0 0 0 1 0 0 1 0x09

Write KEY_C Mask

Read KEY_C Debounce

X 0 0 0 1 0 1 0 0x0A

Write KEY_D Mask

Read KEY_D Debounce

X 0 0 0 1 0 1 1 0x0B

Write Digit Type

Read KEY_A Pressed

X 0 0 0 1 1 0 0 0x0C

Read KEY_B Pressed* X 0 0 0 1 1 0 1 0x0D

Read KEY_C Pressed* X 0 0 0 1 1 1 0 0x0E

Read KEY_D Pressed* X 0 0 0 1 1 1 1 0x0F

Intensity 10 X 0 0 1 0 0 0 0 0x10

Intensity 32 X 0 0 1 0 0 0 1 0x11

Intensity 54 X 0 0 1 0 0 1 0 0x12

Intensity 76 X 0 0 1 0 0 1 1 0x13

Intensity 10a (7 Segment Only) X 0 0 1 0 1 0 0 0x14

Intensity 32a (7 Segment Only) X 0 0 1 0 1 0 1 0x15

Intensity 54a (7 Segment Only) X 0 0 1 0 1 1 0 0x16

Intensity 76a (7 Segment Only) X 0 0 1 0 1 1 1 0x17

Digit 0 Plane P0 X 0 1 0 0 0 0 0 0x20

Digit 1 Plane P0 X 0 1 0 0 0 0 1 0x21

Digit 2 Plane P0 X 0 1 0 0 0 1 0 0x22

Digit 3 Plane P0 X 0 1 0 0 0 1 1 0x23

Digit 4 Plane P0 X 0 1 0 0 1 0 0 0x24

Digit 5 Plane P0 X 0 1 0 0 1 0 1 0x25

Digit 6 Plane P0 X 0 1 0 0 1 1 0 0x26

Digit 7 Plane P0 X 0 1 0 0 1 1 1 0x27

Digit 0a Plane P0 (7 Segment Only) X 0 1 0 1 0 0 0 0x28

Digit 1a Plane P0 (7 Segment Only) X 0 1 0 1 0 0 1 0x29

Digit 2a Plane P0 (7 Segment Only) X 0 1 0 1 0 1 0 0x2A

Digit 3a Plane P0 (7 Segment Only) X 0 1 0 1 0 1 1 0x2B

Table 7. Register Address Map

*Do NOT write to register.

D15 D14 D13 D12 D11 D10 D9 D8

Page 14

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

14 ______________________________________________________________________________________

ADDRESS (COMMAND BYTE)

REGISTER

HEX CODE

Digit 4a Plane P0 (7 Segment Only) X 0 1 0 1 1 0 0 0x2C

Digit 5a Plane P0 (7 Segment Only) X 0 1 0 1 1 0 1 0x2D

Digit 6a Plane P0 (7 Segment Only) X 0 1 0 1 1 1 0 0x2E

Digit 7a Plane P0 (7 Segment Only) X 0 1 0 1 1 1 1 0x2F

Digit 0 Plane P1 X 1 0 0 0 0 0 0 0x40

Digit 1 Plane P1 X 1 0 0 0 0 0 1 0x41

Digit 2 Plane P1 X 1 0 0 0 0 1 0 0x42

Digit 3 Plane P1 X 1 0 0 0 0 1 1 0x43

Digit 4 Plane P1 X 1 0 0 0 1 0 0 0x44

Digit 5 Plane P1 X 1 0 0 0 1 0 1 0x45

Digit 6 Plane P1 X 1 0 0 0 1 1 0 0x46

Digit 7 Plane P1 X 1 0 0 0 1 1 1 0x47

Digit 0a Plane P1 (7 Segment Only) X 1 0 0 1 0 0 0 0x48

Digit 1a Plane P1 (7 Segment Only) X 1 0 0 1 0 0 1 0x49

Digit 2a Plane P1 (7 Segment Only) X 1 0 0 1 0 1 0 0x4A

Digit 3a Plane P1 (7 Segment Only) X 1 0 0 1 0 1 1 0x4B

Digit 4a Plane P1 (7 Segment Only) X 1 0 0 1 1 0 0 0x4C

Digit 5a Plane P1 (7 Segment Only) X 1 0 0 1 1 0 1 0x4D

Digit 6a Plane P1 (7 Segment Only) X 1 0 0 1 1 1 0 0x4E

Digit 7a Plane P1 (7 Segment Only) X 1 0 0 1 1 1 1 0x4F

Write Digit 0 Planes P0 and P1 with Same

Data, Reads as 0x00

X 1 1 0 0 0 0 0 0x60

Write Digit 1 Planes P0 and P1 with Same

Data, Reads as 0x00

X 1 1 0 0 0 0 1 0x61

Write Digit 2 Planes P0 and P1 with Same

Data, Reads as 0x00

X 1 1 0 0 0 1 0 0x62

Write Digit 3 Planes P0 and P1 with Same

Data, Reads as 0x00

X 1 1 0 0 0 1 1 0x63

Write Digit 4 Planes P0 and P1 with Same

Data, Reads as 0x00

X 1 1 0 0 1 0 0 0x64

Write Digit 5 Planes P0 and P1 with Same

Data, Reads as 0x00

X 1 1 0 0 1 0 1 0x65

Write Digit 6 Planes P0 and P1 with Same

Data, Reads as 0x00

X 1 1 0 0 1 1 0 0x66

Write Digit 7 Planes P0 and P1 with Same

Data, Reads as 0x00

X 1 1 0 0 1 1 1 0x67

Write Digit 0a Planes P0 and P1 with Same

Data (7 Segment Only), Reads as 0x00

X 1 1 0 1 0 0 0 0x68

Write Digit 1a Planes P0 and P1 with Same

Data (7 Segment Only), Reads as 0x00

X 1 1 0 1 0 0 1 0x69

Table 7. Register Address Map (continued)

D15 D14 D13 D12 D11 D10 D9 D8

Page 15

One diode is required per key switch. These diodes

can be common-anode dual diodes in SOT23 packages, such as the BAW56. Sixteen diodes would be

required for the maximum 32-key configuration.

The MAX6955 can only scan the maximum 32 keys if

the scan-limit register is set to scan the maximum eight

digits. If the MAX6955 is driving fewer digits, then a

maximum of (4 x n) switches can be scanned, where n

is the number of digits set in the scan-limit register. For

example, if the MAX6955 is driving four 14-segment

digits, cathode drivers O0 to O3 are used. Only 16 keys

can be scanned in this configuration; the switches

shown connected to O4 through O7 are not read.

If the user wishes to scan fewer than 32 keys, then

fewer scan lines can be configured for key scanning.

The unused Key_x ports are released back to their original GPIO functionality. If key scanning is enabled,

regardless of the number of keys being scanned, P4 is

always configured as IRQ (Table 32).

The key-scanning circuit utilizes the LEDs’ commoncathode driver outputs as the key-scan drivers. O0 to

O7 go low for nominally 200µs (with OSC = 4MHz) in

turn as the displays are multiplexed. By varying the

oscillator frequency, the debounce time changes,

though key scanning still functions. Key_x inputs have

internal pullup resistors that allow the key condition to

be tested. The Key_x input is low during the appropriate digit multiplex period when the key is pressed. The

timing diagram of Figure 12 shows the normal situation

where all eight LED cathode drivers are used.

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

______________________________________________________________________________________ 15

ADDRESS (COMMAND BYTE)

REGISTER

HEX CODE

Write Digit 2a Planes P0 and P1 with Same

Data (7 Segment Only), Reads as 0x00

X 1 1 0 1 0 1 0 0x6A

Write Digit 3a Planes P0 and P1 with Same

Data (7 Segment Only), Reads as 0x00

X 1 1 0 1 0 1 1 0x6B

Write Digit 4a Planes P0 and P1 with Same

Data (7 Segment Only), Reads as 0x00

X 1 1 0 1 1 0 0 0x6C

Write Digit 5a Planes P0 and P1 with Same

Data (7 Segment Only), Reads as 0x00

X 1 1 0 1 1 0 1 0x6D

Write Digit 6a Planes P0 and P1 with Same

Data (7 Segment Only), Reads as 0x00

X 1 1 0 1 1 1 0 0x6E

Write Digit 7a Planes P0 and P1 with Same

Data (7 Segment Only), Reads as 0x00

X 1 1 0 1 1 1 1 0x6F

Table 7. Register Address Map (continued)

Note: Unused register bits read as zero.

SDA

DATA LINE STABLE,

DATA VALID

CHANGE OF DATA

ALLOWED

SCL

Figure 5. Bit Transfer

1

SCL

START CONDITION

SDA

BY TRANSMITTER

SDA

BY RECEIVER

S

28 9

CLOCK PULSE FOR ACKNOWLEDGMENT

Figure 6. Acknowledge

D15 D14 D13 D12 D11 D10 D9 D8

Page 16

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

16 ______________________________________________________________________________________

The timing in Figure 12 loops over time, with 32 keys

experiencing a full key-scanning debounce over typically 25.6ms. Four keys are sampled every 1.6ms, or

every multiplex cycle. If at least one key that was not

previously pressed is found to have been pressed during both sampling periods, then that key press is

debounced, and an interrupt is issued. The key-scan

circuit detects any combination of keys being pressed

during each debounce cycle (n-key rollover).

Port Configuration Register

The port configuration register selects how the five port

pins are used. The port configuration register format is

described in Table 33.

Key Mask Registers

The Key_A Mask, Key_B Mask, Key_C Mask, and

Key_D Mask write-only registers (Table 34) configure

the key-scanning circuit to cause an interrupt only when

selected (masked) keys have been debounced. Each

bit in the register corresponds to one key switch. The bit

is clear to disable interrupt for the switch, and set to

enable interrupt. Keys are always scanned (if enabled

through the port configuration register), regardless of

the setting of these interrupt bits, and the key status is

stored in the appropriate Key_x pressed register.

S

A0

SLAVE ADDRESS

COMMAND BYTE

ACKNOWLEDGE FROM MAX6955

R/W

ACKNOWLEDGE FROM MAX6955

D15 D14 D13 D12 D11 D10 D 9 D 8

COMMAND BYTE IS STORED ON RECEIPT OF STOP CONDITION

A P

Figure 7. Command Byte Received

AP0SLAVE ADDRESS

COMMAND BYTE

DATA BYTE

ACKNOWLEDGE FROM MAX6955

R/W

1 BYTE

AUTOINCREMENT MEMORY WORD ADDRESS

ACKNOWLEDGE FROM MAX6955

ACKNOWLEDGE FROM MAX6955

D15 D14 D13 D12 D11 D10 D9 D8 D1 D0D3 D2D5 D4D7 D6

HOW CONTROL BYTE AND DATA BYTE MAP INTO

MAX6955's REGISTERS

S

AA

Figure 8. Command and Single Data Byte Received

AP0SLAVE ADDRESS

COMMAND BYTE

DATA BYTE

ACKNOWLEDGE FROM MAX6955

R/W

n BYTE

AUTOINCREMENT MEMORY WORD ADDRESS

ACKNOWLEDGE FROM MAX6955

ACKNOWLEDGE FROM MAX6955

D15 D14 D13 D12 D11 D10 D9 D8 D1 D0D3 D2D5 D4D7 D6

HOW CONTROL BYTE AND DATA BYTE MAP INTO

MAX6955's REGISTERS

S

AA

Figure 9. n Data Bytes Received

Page 17

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

______________________________________________________________________________________ 17

DIGIT 1

ONE COMPLETE 1.6ms MULTIPLEX CYCLE AROUND 8 DIGITS

DIGIT 0's 200µs MULTIPLEX TIMESLOT

DIGIT 0

200µs

DIGIT 2 DIGIT 3 DIGIT 4 DIGIT 5 DIGIT 6 DIGIT 7

START OF

NEXT CYCLE

LOW

2/16TH

1/16TH

(MIN ON)

HIGH-Z

HIGH-Z

LOW

3/16TH

HIGH-Z

LOW

4/16TH

HIGH-Z

LOW

5/16TH

HIGH-Z

LOW

6/16TH

HIGH-Z

LOW

7/16TH

HIGH-Z

LOW

8/16TH

HIGH-Z

LOW

9/16TH

HIGH-Z

LOW

10/16TH

HIGH-Z

LOW

11/16TH

HIGH-Z

LOW

12/16TH

HIGH-Z

LOW

13/16TH

HIGH-Z

LOW

14/16TH

HIGH-Z

LOW

15/16TH

HIGH-Z

LOW

15/16TH

HIGH-Z

(MAX ON)

HIGH-Z

HIGH-Z

CURRENT SOURCE ENABLED

MINIMUM 12.5µs INTERDIGIT BLANKING INTERVAL

HIGH-Z

ANODE (LIT)

DIGIT 0 CATHODE

DRIVER INTENSITY

SETTINGS

ANODE (UNLIT)

Figure 10. Multiplex Timing Diagram (OSC = 4MHz)

Page 18

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

18 ______________________________________________________________________________________

LED OUTPUT O0

LED OUTPUT O1

LED OUTPUT O2

LED OUTPUT O3

LED OUTPUT O4

LED OUTPUT O5

LED OUTPUT O6

LED OUTPUT O7

12.5µs TO 187.5µs DIGIT PERIOD

1.6ms MULTIPLEX CYCLE 1 1.6ms MULTIPLEX CYCLE 2 1.6ms MULTIPLEX CYCLE 8

THE FIRST HALF OF A 25.6ms KEY-SCAN CYCLE

1.6ms MULTIPLEX CYCLE 8

THE SECOND HALF OF A 25.6ms KEY-SCAN CYCLE

1.6ms MULTIPLEX CYCLE 1

START OF NEXT KEY-SCAN CYCLE

FIRST TEST OF KEY SWITCHES SECOND TEST OF KEY SWITCHES

INTERRUPT ASSERTED IF REQUIRED

DEBOUNCE REGISTER UPDATED

C

A

A

B

DE

Figure 11. Key-Scanning Configuration

SW A0

SW A1

SW A2

SW A3

SW A4

SW A5

SW A6

SW A7

KEY_A

V

CC

LED OUTPUT O0

LED OUTPUT O1

LED OUTPUT O2

LED OUTPUT O3

LED OUTPUT O4

LED OUTPUT O5

LED OUTPUT O6

LED OUTPUT O7

KEY_B

KEY_C

KEY_D

IRQ

MICROCONTROLLER INTERRUPT

SW B0

SW B1

SW B2

SW B3

SW B4

SW B5

SW B6

SW B7

SW C0

SW C1

SW C2

SW C3

SW C4

SW C5

SW C6

SW C7

SW D0

SW D1

SW D2

SW D3

SW D4

SW D5

SW D6

SW D7

Figure 12. Key-Scan Timing Diagram

Page 19

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

______________________________________________________________________________________ 19

Key Debounced Registers

The Key_A debounced, Key_B debounced, Key_C

debounced, and Key_D debounced read-only registers

(Table 35) show which keys have been detected as

debounced by the key-scanning circuit.

Each bit in the register corresponds to one key switch.

The bit is set if the switch has been correctly

debounced since the register was read last. Reading a

debounced register clears that register (after the data

has been read) so that future keys pressed can be

identified. If the debounced registers are not read, the

key-scan data accumulates. However, as there is no

FIFO in the MAX6955, the user is not able to determine

key order, or whether a key has been pressed more

than once, unless the debounced key status registers

are read after each interrupt, and before the next keyscan cycle.

Reading any of the four debounced registers clears the

IRQ output. If a key is pressed and held down, the key is

reported as debounced (and IRQ issued) only once. The

key must be detected as released by the key-scanning

circuit, before it debounces again. If the debounced registers are being read in response to the IRQ being

asserted, then the user should generally read all four

registers to ensure that all the keys that were detected by

the key-scanning circuit are discovered.

Key Pressed Registers

The Key_A pressed, Key_B pressed, Key_C pressed,

and Key_D pressed read-only registers (Table 36)

show which keys have been detected as pressed by

the key-scanning circuit during the last test.

Each bit in the register corresponds to one key switch.

The bit is set if the switch has been detected as

pressed by the key-scanning circuit during the last test.

The bit is cleared if the switch has not been detected

as pressed by the key-scanning circuit during the last

test. Reading a pressed register does not clear that

register or clear the IRQ output.

Display Test Register

The display test register (Table 37) operates in two

modes: normal and display test. Display test mode

turns all LEDs on (including DPs) by overriding, but not

altering, all controls and digit registers (including the

shutdown register), except for the digit-type register

and the GPIO configuration register. The duty cycle,

while in display test mode, is 7/16 (see the Choosing

Supply Voltage to Minimize Power Dissipation section).

Selecting External Components R

SET

and

C

SET

to Set Oscillator Frequency and

Peak Segment Current

The RC oscillator uses an external resistor, R

SET

, and

an external capacitor, C

SET

, to set the frequency, f

OSC

.

The allowed range of f

OSC

is 1MHz to 8MHz. R

SET

also

sets the peak segment current. The recommended values of R

SET

and C

SET

set the oscillator to 4MHz, which

makes the blink frequencies selectable between 0.5Hz

and 1Hz. The recommended value of R

SET

also sets the

peak current to 40mA, which makes the segment current adjustable from 2.5mA to 37.5mA in 2.5mA steps.

I

SEG

= KL/ R

SET

mA

f

OSC

= KF/ (R

SET

x C

SET

) MHz

where:

KL= 2240

KF= 5376

R

SET

= external resistor in kΩ

C

SET

= external capacitor in pF

C

STRAY

= stray capacitance from OSC pin to GND in

pF, typically 2pF

The recommended value of R

SET

is 56kΩ and the rec-

ommended value of C

SET

is 22pF.

The recommended value of R

SET

is the minimum

allowed value, since it sets the display driver to the

maximum allowed peak segment current. R

SET

can be

set to a higher value to set the segment current to a

lower peak value where desired. The user must also

ensure that the peak current specifications of the LEDs

connected to the driver are not exceeded.

The effective value of C

SET

includes not only the actual

external capacitor used, but also the stray capacitance

from OSC to GND. This capacitance is usually in the

1pF to 5pF range, depending on the layout used.

Applications Information

Driving Bicolor LEDs

Bicolor digits group a red and a green die together for

each display element, so that the element can be lit red

or green (or orange), depending on which die (or both)

is lit. The MAX6955 allows each segment’s current to

be set individually from the 1/16th (minimum current

and LED intensity) to 15/16th (maximum current and

LED intensity), as well as off (zero current). Thus, a

bicolor (red-green) segment pair can be set to 256

color/intensity combinations.

Page 20

MAX6955

Choosing Supply Voltage to Minimize

Power Dissipation

The MAX6955 drives a peak current of 40mA into LEDs

with a 2.2V forward-voltage drop when operated from a

supply voltage of at least 3.0V. The minimum voltage

drop across the internal LED drivers is therefore (3.0V -

2.2V) = 0.8V. If a higher supply voltage is used, the driver absorbs a higher voltage, and the driver’s power

dissipation increases accordingly. However, if the LEDs

used have a higher forward-voltage drop than 2.2V, the

supply voltage must be raised accordingly to ensure

that the driver always has at least 0.6V of headroom.

The voltage drop across the drivers with a nominal 5V

supply (5.0V - 2.2V) = 2.8V is nearly 3 times the drop

across the drivers with a nominal 3.3V supply (3.3V -

2.2V) = 1.1V. In most systems, consumption is an

important design criterion, and the MAX6955 should be

operated from the system’s 3.3V nominal supply. In

other designs, the lowest supply voltage may be 5V.

The issue now is to ensure the dissipation limit for the

MAX6955 is not exceeded. This can be achieved by

inserting a series resistor in the supply to the MAX6955,

ensuring that the supply decoupling capacitors are still

on the MAX6955 side of the resistor. For example, consider the requirement that the minimum supply voltage

to a MAX6955 must be 3.0V, and the input supply

range is 5V ±5%. Maximum supply current is 35mA +

(40mA x 17) = 715mA. Minimum input supply voltage is

4.75V. Maximum series resistor value is (4.75V -

3.0V)/0.715A = 2.44Ω. We choose 2.2Ω ±5%. Worstcase resistor dissipation is at maximum toleranced

resistance, i.e., (0.715A) 2 x (2.2Ω x 1.05) = 1.18W. The

maximum MAX6955 supply voltage is at maximum

input supply voltage and minimum toleranced resistance, i.e., 5.25V - (0.715A x 2.2Ω x 0.95) = 3.76V.

Low-Voltage Operation

The MAX6955 works over the 2.7V to 5.5V supply

range. The minimum useful supply voltage is determined by the forward-voltage drop of the LEDs at the

peak current I

SEG

, plus the 0.8V headroom required by

the driver output stages. The MAX6955 correctly regulates I

SEG

with a supply voltage above this minimum

voltage. If the supply drops below this minimum volt-

age, the driver output stages can brown out, and be

unable to regulate the current correctly. As the supply

voltage drops further, the LED segment drive current

becomes effectively limited by the output driver's onresistance, and the LED drive current drops. The characteristics of each individual LED in a display digit are

well matched, so the result is that the display intensity

dims uniformly as supply voltage drops out of regulation and beyond.

Computing Power Dissipation

The upper limit for power dissipation (PD) for the

MAX6955 is determined from the following equation:

PD= (V+ x 35mA) + (V+ - V

LED

) (DUTY x I

SEG

x N)

where:

V+ = supply voltage

DUTY = duty cycle set by intensity register

N = number of segments driven (worst case is 17)

V

LED

= LED forward voltage at I

SEG

I

SEG

= segment current set by R

SET

PD= Power dissipation, in mW if currents are in mA

Dissipation example:

I

SEG

= 30mA, N = 17, DUTY = 15/16,

V

LED

= 2.4V at 30mA, V+ = 3.6V

P

D

= 3.6V (35mA) + (3.6V - 2.4V)(15/16 x

30mA x 17) = 0.700W

Thus, for a 36-pin SSOP package (T

JA

= 1 / 0.0118 =

+85°C/W from Operating Ratings), the maximum

allowed ambient temperature T

A

is given by:

T

J(MAX)

= TA+ (PDx TJA) = +150°C

= TA+ (0.700 x +85°C/W)

So TA= +90.5°C. Thus, the part can be operated safely

at a maximum package temperature of +85°C.

Power Supplies

The MAX6955 operates from a single 2.7V to 5.5V

power supply. Bypass the power supply to GND with a

0.1µF capacitor as close to the device as possible. Add

a 47µF capacitor if the MAX6955 is not close to the

board’s input bulk decoupling capacitor.

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

20 ______________________________________________________________________________________

Page 21

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

______________________________________________________________________________________ 21

x000 x010 x011 x100 x101 x110 x111x001

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

1100

1101

1110

1111

MSB

LSB

Table 8. 16-Segment Display Font Map

x000 x010 x011 x100 x101 x110 x111x001

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

1100

1101

1110

1111

MSB

LSB

Table 9. 14-Segment Display Font Map

Page 22

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

22 ______________________________________________________________________________________

REGISTER DATA

MODE

ADDRESS

CODE

(HEX)

D0

14-segment or 16-segment mode, writing digit data

to use font map data with decimal place unlit

0 Bits D6 to D0 select font characters 0 to 127

14-segment or 16-segment mode, writing digit data

to use font map data with decimal place lit

1 Bits D6 to D0 select font characters 0 to 127

7-segment decode mode, DP unlit

0 0 0 0 D3 to D0

7-segment decode mode, DP lit

1 0 0 0 D3 to D0

7-segment no-decode mode

Direct control of 8 segments

Table 10. Digit Plane Data Register Format

REGISTER DATA

MODE

ADDRESS CODE

(HEX)

D7 D6 D5 D4 D3 D2 D1 D0

Segment Line

0x20 to 0x2F

0x40 to 0x4F

0x60 to 0x6F

dp a b c d e f g

Table 11. Segment Decoding for 7-Segment Displays

D7 D6 D5 D4 D3 D2 D1

0x20 to 0x2F

0x40 to 0x4F

0x60 to 0x6F

0x20 to 0x2F

0x40 to 0x4F

0x60 to 0x6F

0x20 to 0x2F

0x40 to 0x4F

0x60 to 0x6F

0x20 to 0x2F

0x40 to 0x4F

0x60 to 0x6F

0x20 to 0x2F

0x40 to 0x4F

0x60 to 0x6F

Page 23

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

______________________________________________________________________________________ 23

REGISTER

DATA

ON SEGMENTS = 1

7-SEGMENT

CHARACTER

D7*

D6, D5,

D4

DP*

G

0 — X 0000—

0

1 — X 0001—

0

2 — X 0010—

1

3 — X 0011—

1

4 — X 0100—

1

5 — X 0101—

1

6 — X 0110—

1

7 — X 0111—

0

8 — X 1000—

1

9 — X 1001—

1

A — X 1010—

1

B — X 1011—

1

C — X 1100—

0

D — X 1101—

1

E — X 1110—

1

F — X 1111—

1

Table 12. 7-Segment Segment Mapping Decoder for Hexadecimal Font

REGISTER DATA

DIGIT-TYPE

REGISTER

ADDRESS

CODE (HEX)

D7 D6 D5 D4 D3 D2 D1 D0

Output Drive Line

CC0

Slot Identification

0x0C

Slot 4 Slot 3 Slot 2 Slot 1

Table 13. Digit-Type Register

*The decimal point is set by bit D7 = 1.

D3 D2 D1 D0

ABC D E F

111 111

011 000

110 110

111 100

011 001

101 101

101 111

111 000

111 111

111 101

111 011

001 111

100 111

011 110

100 111

100 011

CC7 CC6 CC5 CC4 CC3 CC2 CC1

Page 24

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

24 ______________________________________________________________________________________

REGISTER DATA

DECODE

MODE

ADDRESS

CODE

(HEX)

HEX

CODE

No decode for digit pairs 7 to 0. 0x01 00000000 0x00

Hexadecimal decode for digit pair 0,

no decode for digit pairs 7 to 1.

0x01 00000001 0x01

Hexadecimal decode for digit pairs 2 to 0,

no decode for digit pairs 7 to 3.

0x01 00000111 0x07

Hexadecimal decode for digit pairs 7 to 0.

0x01 11111111 0xFF

Table 15. Decode-Mode Register Examples

REGISTER DATA

DIGIT-TYPE

REGISTER SETTING

ADDRESS

CODE (HEX)

D7 D6 D5 D4 D3 D2 D1 D0

Digits 7 to 0 are 16-segment or 7segment digits.

0x0C 00000000

Digit 0 is a 14-segment digit,

digits 7 to 1 are 16-segment or 7segment digits.

0x0C 00000001

Digits 2 to 0 are 14-segment

digits, digits 7 to 3 are 16segment or 7-segment digits.

0x0C 00000111

Digits 7 to 0 are 14-segment

digits.

0x0C 11111111

Table 14. Example Configurations for Display Digit Combinations

D7 D6 D5 D4 D3 D2 D1 D0

Page 25

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

______________________________________________________________________________________ 25

REGISTER DATA

REGISTER

POWER-UP

CONDITION

CODE

(HEX)

D0

Decode Mode Decode mode enabled 0x01

1

Global Intensity 1/16 (min on) 0x02

0

Scan Limit Display 8 digits: 0, 1, 2, 3, 4, 5, 6, 7 0x03

1

Control Register

Shutdown enabled, blink speed is

slow, blink disabled

0x04

0

GPIO Data Outputs are low 0x05

0

Port Configuration

No key scanning, P0 to P4 are all

inputs

0x06

1

Display Test Normal operation 0x07

0

Key_A Mask None of the keys cause interrupt 0x08

0

Key_B Mask None of the keys cause interrupt 0x09

0

Key_C Mask None of the keys cause interrupt 0x0A

0

Key_D Mask None of the keys cause interrupt 0x0B

0

Digit Type All are 16 segment or 7 segment 0x0C

0

Intensity10 1/16 (min on) 0x10

0

Intensity32 1/16 (min on) 0x11

0

Intensity54 1/16 (min on) 0x12

0

Intensity76 1/16 (min on) 0x13

0

Intensity10a 1/16 (min on) 0x14

0

Intensity32a 1/16 (min on) 0x15

0

Intensity54a 1/16 (min on) 0x16

0

Intensity76a 1/16 (min on) 0x17

0

Digit 0 Blank digit, both planes 0x60

0

Digit 1 Blank digit, both planes 0x61

0

Digit 2 Blank digit, both planes 0x62

0

Digit 3 Blank digit, both planes 0x63

0

Digit 4 Blank digit, both planes 0x64

0

Digit 5 Blank digit, both planes 0x65

0

Digit 6 Blank digit, both planes 0x66

0

Digit 7 Blank digit, both planes 0x67

0

Digit 0a Blank digit, both planes 0x68

0

Digit 1a Blank digit, both planes 0x69

0

Digit 2a Blank digit, both planes 0x6A

0

Digit 3a Blank digit, both planes 0x6B

0

Digit 4a Blank digit, both planes 0x6C

0

Digit 5a Blank digit, both planes 0x6D

0

Digit 6a Blank digit, both planes 0x6E

0

Digit 7a Blank digit, both planes 0x6F

0

Key_A Debounced No key presses have been detected 0x08

0

Key_B Debounced No key presses have been detected 0x09

0

Key_C Debounced

No key presses have been detected 0x0A

0

Key_D Debounced

No key presses have been detected 0x0B

0

Key_A Pressed Keys are not pressed 0x0C

0

Key_B Pressed Keys are not pressed 0x0D

0

Key_C Pressed Keys are not pressed 0x0E

0

Key_D Pressed Keys are not pressed 0x0F

0

Table 16. Initial Power-Up Register Status

ADDRESS

D7 D6 D5 D4 D3 D2 D1

1111111

XXXX000

XXXXX11

00XX000

XXX0000

0001111

XXXXXXX

0000000

0000000

0000000

0000000

0000000

0000000

0000000

0000000

0000000

0000000

0000000

0000000

0000000

0010000

0010000

0010000

0010000

0010000

0010000

0010000

0010000

0000000

0000000

0000000

0000000

0000000

0000000

0000000

0000000

0000000

0000000

0000000

0000000

0000000

0000000

0000000

0000000

Page 26

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

26 ______________________________________________________________________________________

REGISTER DATA

MODE

Configuration

Register

Table 17. Configuration Register Format

REGISTER DATA

MODE

D0

Shutdown

0

Normal

Operation

1

Table 18. Shutdown Control (S Data Bit DO)

Format

REGISTER DATA

MODE

D0

Slow blinking. Segments blink on for 1s, off for 1s with f

OSC

= 4MHz.

I

S

Fast blinking. Segments blink on for 0.5s, off for 0.5s with f

OSC

= 4MHz.

I

S

Table 19. Blink Rate Selection (B Data Bit D2) Format

REGISTER DATA

MODE

D7 D6 D5 D4 D3 D2 D1 D0

Blink function is disabled. P I R T 0 B X S

Blink function is enabled. P I R T 1 B X S

Table 20. Global Blink Enable/Disable (E Data Bit D3) Format

SEGMENT’S BIT SETTING

IN PLANE P1

SEGMENT’S BIT SETTING

IN PLANE P0

SEGMENT

BEHAVIOR

0 0 Segment off.

01

Segment on only during the 1st half of each

blink period.

10

Segment on only during the 2nd half of each

blink period.

1 1 Segment on.

Table 21. Digit Register Mapping with Blink Globally Enabled

REGISTER DATA

MODE

D0

Blink timing counters are unaffected. P I R 0 E B X S

Blink timing counters are reset during the I2C acknowledge. P I R 1 E B X S

Table 22. Global Blink Timing Synchronization (T Data Bit D4) Format

REGISTER DATA

MODE

D0

Digit data for both planes P0 and P1 are unaffected.

I

S

D i g i t d ata for b oth p l anes P 0 and P 1 ar e cl ear ed d ur i ng the I2 C acknow l ed g e.

I

S

Table 23. Global Clear Digit Data (R Data Bit D5) Format

D7 D6 D5 D4 D3 D2 D1 D0

P I RTEBXS

D7 D6 D5 D4 D3 D2 D1

PIRTEBX

PIRTEBX

D7 D6 D5 D4 D3 D2 D1

P

P

RTE0X

RTE1X

D7 D6 D5 D4 D3 D2 D1

D7 D6 D5 D4 D3 D2 D1

P

P

0TEBX

1TEBX

Page 27

MAX6955

2-Wire Interfaced, 2.7V to 5.5V LED Display

Driver with I/O Expander and Key Scan

______________________________________________________________________________________ 27

REGISTER DATA

MODE

D0

Intensity for all digits is controlled by one setting in the global intensity register.

S

Intensity for digits is controlled by the individual settings in the intensity10 and

intensity76 registers.

S

Table 24. Global Intensity (I Data Bit D6) Format

REGISTER DATA

MODE

D7 D6 D5 D4 D3 D2 D1 D0

P1 Blink Phase 0 I R T E B X S

P0 Blink Phase 1 I R T E B X S

Table 25. Blink Phase Readback (P Data Bit D7) Format

REGISTER DATA

SCAN

LIMIT

ADDRESS CODE

(HEX)

HEX

CODE

Display Digit 0 only 0x03 X X X X X 0 0 0 0x00

Display Digits 0 and 1 0x03 X X X X X 0 0 1 0x01

Display Digits 0 1 2 0x03 X X X X X 0 1 0 0x02

Display Digits 0 1 2 3 0x03 X X X X X 0 1 1 0x03

Display Digits 0 1 2 3 4 0x03 X X X X X 1 0 0 0x04

Display Digits 0 1 2 3 4 5 0x03 X X X X X 1 0 1 0x05

Display Digits 0 1 2 3 4 5 6 0x03 X X X X X 1 1 0 0x06

Display Digits 0 1 2 3 4 5 6 7 0x03 X X X X X 1 1 1 0x07

Table 26. Scan-Limit Register Format

REGISTER DATA

DUTY

CYCLE

TYPICAL

SEGMENT

ADDRESS

D7

HEX

CODE

1/16 (min on) 2.5 0x02 X X X X 0 0 0 0 0xX0

2/16 5 0x02 X X X X 0 0 0 1 0xX1

3/16 7.5 0x02 X X X X 0 0 1 0 0xX2

4/16 10 0x02 X X X X 0 0 1 1 0xX3

5/16 12.5 0x02 X X X X 0 1 0 0 0xX4

6/16 15 0x02 X X X X 0 1 0 1 0xX5

7/16 17.5 0x02 X X X X 0 1 1 0 0xX6